Preparation method of reinforced jade-based porcelain and product made of reinforced jade-based porcelain

A jade and product technology, applied in the field of inorganic non-metallic materials (ceramics), can solve the problems of not very good light transmission performance and poor permeability, so as to solve the problems of poor light transmission performance, good transparency and production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

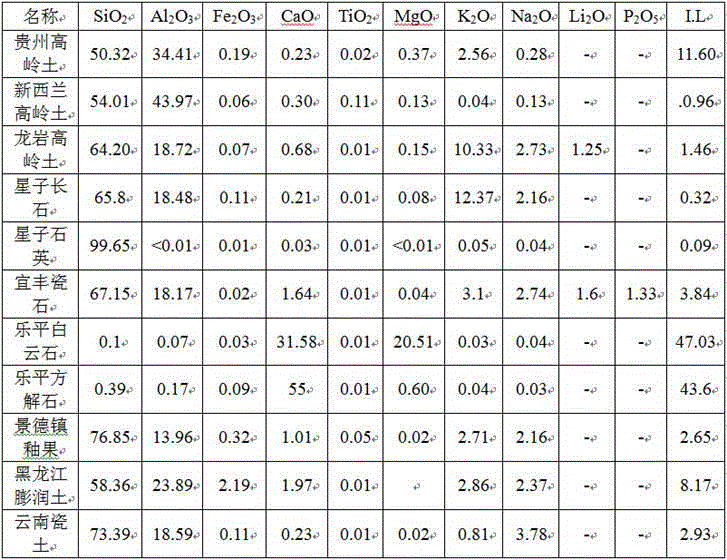

[0021] The weight percentage of the strengthened jade porcelain body formula is 11% of Longyan kaolin, 12% of Guizhou kaolin, 6% of New Zealand kaolin, 12% of Xingzi feldspar, 40% of Xingzi quartz, 6% of Yifeng low-temperature porcelain stone, 5% of Jingdezhen glaze fruit, Heilongjiang bentonite 4%, Yunnan china clay 4%.

[0022] The weight percentage of strengthened jade porcelain glaze is Longyan kaolin 9%, New Zealand kaolin 3%, Xingzi feldspar 11%, Xingzi quartz 30%, Yifeng low temperature porcelain stone 9%, Leping dolomite 15%, Le square calcite 6%, Jingdezhen glaze Fruit 9%, Yunnan porcelain clay 8%.

[0023] Weigh and mix the raw materials according to the billet formula requirements. After crushing, put them into the ball mill according to the weight ratio of material: ball: water = 1:1.5:1. The ball milling time is 36 hours. Less than 0.1%, to obtain a slurry with a solid particle fineness of less than 6 microns reaching 62%. After the slurry is iron-removed and sie...

Embodiment 2

[0030] The weight percentage of the strengthened jade porcelain body formula is 14% Longyan kaolin, 8% Guizhou kaolin, 5% New Zealand kaolin, 14% Xingzi feldspar, 45% Xingzi quartz, 5% Yifeng low-temperature porcelain stone, 3% Jingdezhen glaze fruit, Heilongjiang bentonite 3%, Yunnan porcelain clay 3%.

[0031] The weight percentage of strengthened jade porcelain glaze is Longyan kaolin 11%, New Zealand kaolin 4%, Xingzi feldspar 14%, Xingzi quartz 30%, Yifeng low temperature porcelain stone 8%, Leping dolomite 15%, Le square calcite 5%, Jingdezhen glaze Fruit 8%, Yunnan china clay 5%.

[0032] Weigh and mix the raw materials according to the billet formula requirements. After crushing, put them into the ball mill according to the weight ratio of material: ball: water = 1:1.6:1. The ball milling time is 38 hours. Less than 0.3%, to obtain a slurry with a solid particle fineness of less than 6 microns reaching 65%. After the slurry is sieved by iron removal, the specific grav...

Embodiment 3

[0039] The weight percentage of the strengthened jade porcelain body formula is 10% Longyan kaolin, 9% Guizhou kaolin, 9% New Zealand kaolin, 10% Xingzi feldspar, 48% Xingzi quartz, 5% Yifeng low-temperature porcelain stone, 3% Jingdezhen glaze fruit, Heilongjiang bentonite 3%, Yunnan porcelain clay 3%.

[0040] The weight percentage of strengthened jade porcelain glaze is 8% Longyan kaolin, 3% New Zealand kaolin, 10% Xingzi feldspar, 36% Xingzi quartz, 8% Yifeng low-temperature porcelain stone, 19% Leping dolomite, 5% Leping calcite, Jingdezhen glaze Fruit 8%, Yunnan china clay 8%.

[0041] Weigh and mix the raw materials according to the billet formula requirements. After crushing, put them into the ball mill according to the weight ratio of material: ball: water = 1:1.7:1. The ball milling time is 36 hours. It is less than 0.3%, obtains the slurry that solid particle fineness is less than 6 microns and reaches 69%, after described slurry is sieved through deironing, after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com