Ethanol fuel oil resistance rubber

A technology of resistance to ethanol and fuel oil, which is applied in the field of rubber combination, can solve the problems of poor resistance to ethanol fuel and other problems, and achieve the effect of solving the effect of intolerant ethanol fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The invention will be further described below in conjunction with specific embodiments.

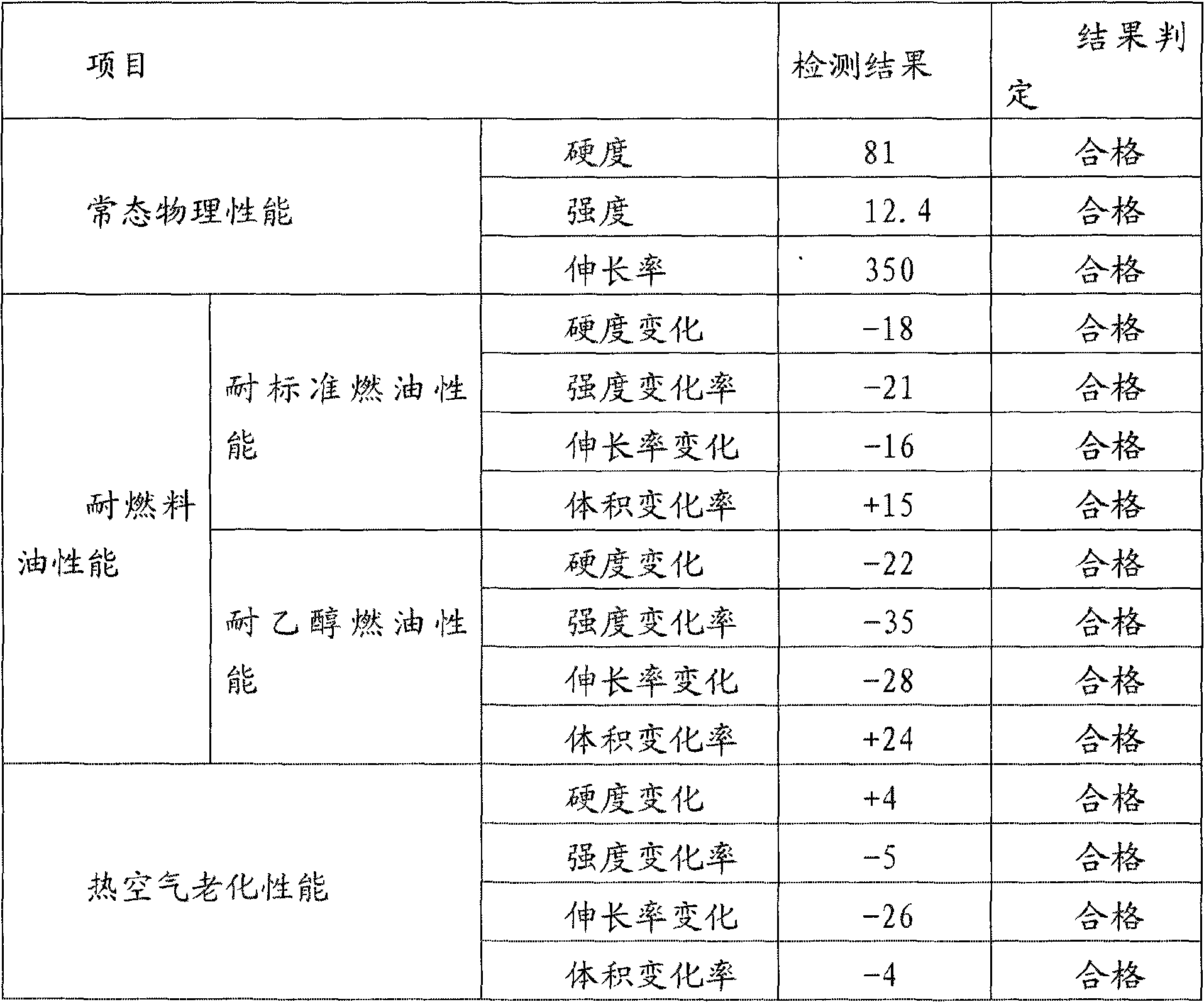

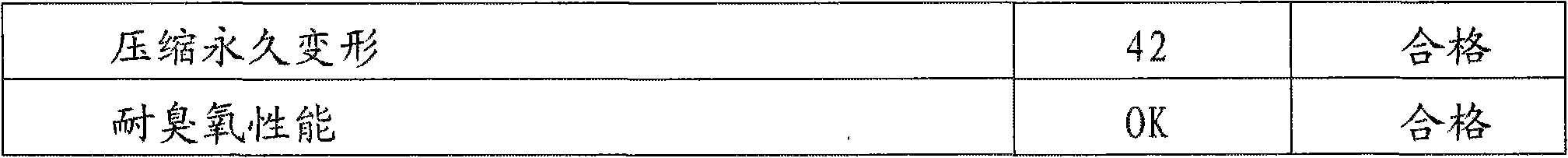

[0009] An ethanol-resistant fuel-fuel rubber composition, in parts by weight, containing nitrile rubber 60-70 with an acrylonitrile content of 40-50%, polyvinyl chloride 30-40, plasticizer 26-36, and stearic acid 1.5 -3.5, reinforcing filler 67-90, antioxidant 5-13.5.

[0010] As the aforementioned plasticizer, it is required that it does not chemically react with polyvinyl chloride, and has low volatility, compatibility, solvent resistance and non-migration. For example, dibutyl phthalate, followed by dioctyl phthalate, and the plasticizer is less than 67 parts by weight or more than 90 parts by weight, and the composition tends to not satisfy the performance. In parts by weight, dibutyl phthalate 18-24 and dioctyl phthalate 8-12 are preferred.

[0011] Properly increasing the amount of reinforcing filler can reduce swelling. Examples of the aforementioned reinforcing filler include c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com