Patents

Literature

162 results about "Underglaze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Underglaze is a method of decorating pottery in which painted decoration is applied to the surface before it is covered with a transparent ceramic glaze and fired in a kiln. Because the glaze subsequently covers it, such decoration is completely durable, and it also allows the production of pottery with a surface that has a uniform sheen. Underglaze decoration uses pigments derived from oxides which fuse with the glaze when the piece is fired in a kiln. It is also a cheaper method, as only a single firing is needed, whereas overglaze decoration requires a second firing at a lower temperature.

Enamel glaze and preparation process thereof

The invention discloses an enamel glaze which belongs to the technical field of ceramic materials, and the enamel glaze comprises a colored glaze basic glaze, an enamel glaze basic glaze and coloring pigments. The invention further discloses a preparation process of the enamel glaze and an application of the enamel glaze. The preparation process can improve the firing temperature of the enamel colored glaze, expand the firing range of the glaze, improve the viscosity of the enamel colored glaze and ensure that coloring metal oxides can not be diffused or the color can not be dimmed due to the flowing of the glaze by optimizing the formula of the enamel colored glaze, adopting an appropriate amount of zinc oxide for replacing heavy metal flux materials, such as lead oxide and the like, integrating the applicable color development performances of a variety of coloring materials and introducing a rare earth compound of yttrium oxide. The preparation process can further ensure that the coloring metal oxides in the enamel glaze can not be oxidized by oxygen or water vapor in the air through the way of underglaze color, thereby further ensuring that a product can not change the color or fade forever, closing heavy metals contained in the coloring oxides for avoiding solventing-out and solving the problem of heavy metal pollution.

Owner:SHENZHEN YONG FENG YUAN IND

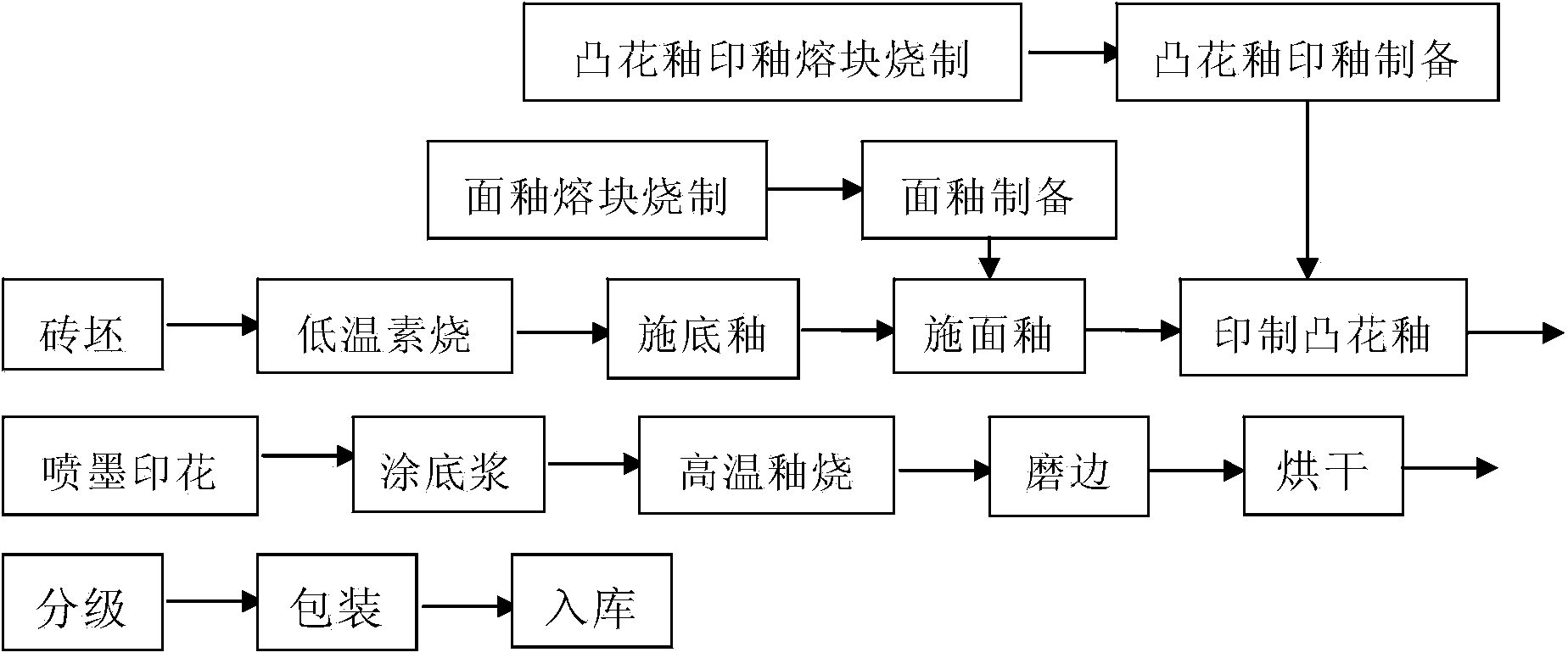

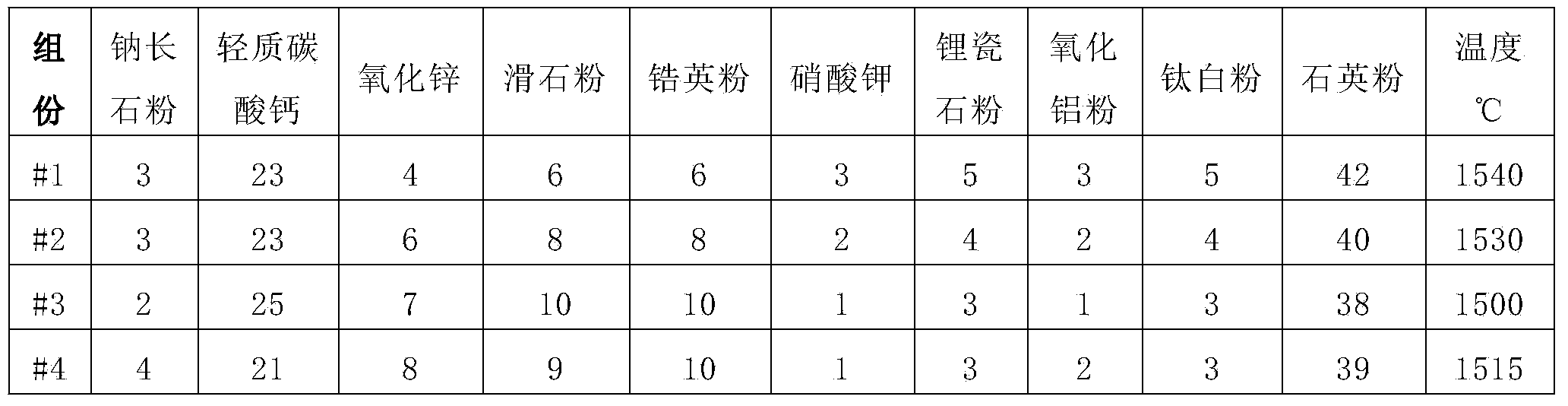

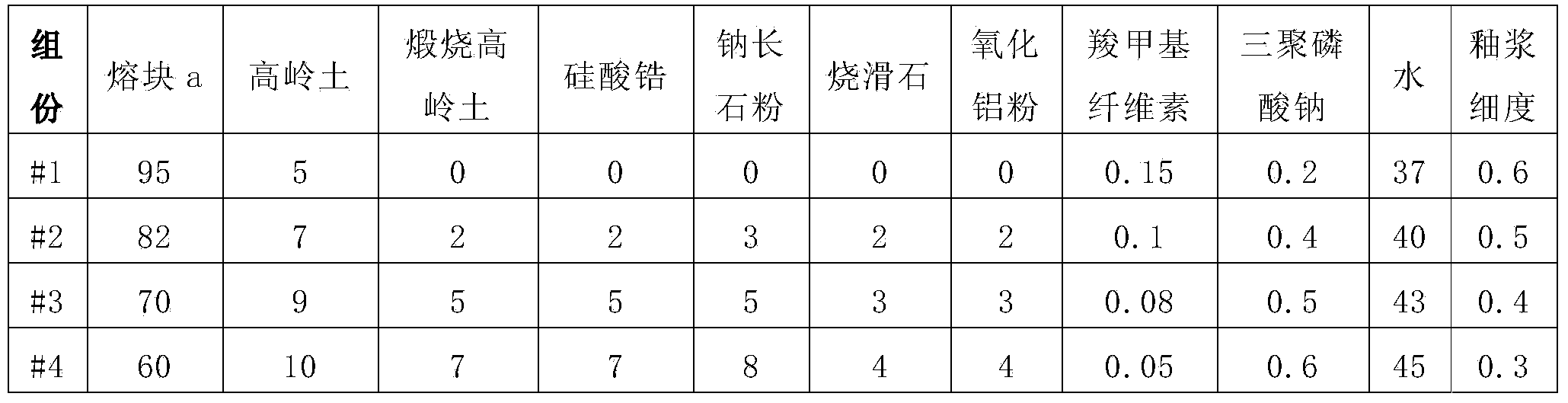

Glazed tile with wallpaper or bark-shaped surface and concave and convex effect and preparation method

The invention discloses glazed tile with wallpaper or bark-shaped surface and concave and convex effect and a preparation method. According to the invention, a product which is a glazed tile with wallpaper or bark-shaped surface and concave and convex effect is obtained by optimizing the composition of an overglaze frit and an overglaze formula, as well as the composition of a convex fancy glaze printed glaze frit and a convex fancy glaze printed glaze formula, printing the convex fancy glaze printed glaze on a green body coated with underglaze and overglaze through a special rubber roller or screen printing plate, and then enabling patterns of convex fancy glaze to keep original printing appearance after being fired at a high temperature and protrude on the surface of inkjet patterns through inkjet printing and high-temperature firing. Further, by mixing with optimized ceramic rubber roller printing ink, through the special rubber roller with optimized design or the screen printing plate with optimized mesh count, the surface gloss of the obtained glazed tile with wallpaper or bark-shaped surface and concave and convex effect is 15-40, the convex fancy glaze has good performance, the protruding height is greater than or equal to 0.8mm, and the convex fancy glaze does not adsorb pollution, so that the decorative patterns formed by inkjet printing are not damaged, and the disadvantage of single decoration style of an existing glazed tile is overcome.

Owner:GUANGDONG WINTO CERAMICS +3

Ceramic carving process

InactiveCN101088777AEasy to useGood collection valueDecorative surface effectsOrnamental structuresChina clayCarving

The present invention relates to ceramic carving making process. The ceramic carving making process includes the steps of forming biscuit with high quality china clay, carving patterns with sharp tools, blowing special color glaze and baking. The ceramic carving may be made through porcelain carving, underglaze carving or mold carving. The novel ceramic carving has strong stereo sensation, clear pattern, and high use and collection value.

Owner:谢开强

Complex Tang-dynasty jun glaze with blue spots in white and process for preparing jun porcelain by use of complex Tang-dynasty jun glaze

The invention discloses a complex tang-dynasty jun glaze with blue spots in white and a process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze. The process comprises: firstly crushing and molding carcass raw materials, and firing the carcass raw materials into plain carcass; then, immersing the plain carcass into slurry of glaze in white for glazing; applying slurry of the glaze with blue spots in surface points of the plain carcass after the slurry of the glaze in white adhered on the surface of the plain carcass is dried in air; and putting the plain carcass into a kiln for firing after the slurry of the glaze with blue spots is dried, thereby obtaining the complex Tang-dynasty jun glaze with blue spots in white. According to the Tang-dynasty jun glaze with blue spots in white and the process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze disclosed by the invention, milky white glaze is presented in the process of firing by adding zircon into a formula of the glaze in white; and the position of the glaze with blue spots is fixed by use of a secondary glazing mode. A coloring process of overglaze color or underglaze color adopted by general piebald porcelains is broken through; economic value of the jun porcelain is increased through innovation in glazing color and coating; and the jun porcelain, which is a Chinese characteristic, also represents advanced level of the production process in China, thereby increasing the social value of the jun porcelain.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

Manufacturing technique of stereoscopic underglaze multicolor ceramic

The invention relates to a manufacturing technique of stereoscopic underglaze multicolor ceramic, which comprises the following steps: carrying out ball milling on a selected ceramic raw material, screening, slurrying, carrying out injection forming on a mold to obtain a required shape, preparing a blank, and carrying out bisque firing to obtain a biscuit; carving out a stereoscopic multilayer plain color picture on the biscuit with a carving tool; dipping a drawing tool into underglaze multicolor pigments, and drawing and decorating on the stereoscopic picture of the biscuit to obtain a colored biscuit; carrying out color depth gradation treatment on the picture of the colored biscuit by using a special brush; and covering a glaze layer on the surface of the colored biscuit subjected to color treatment; and firing the glaze-covered colored biscuit in a kiln again to obtain the finished product. The technique adopts the two modes of biscuit carving and mold carving. The ceramic article prepared by the technique has the advantages of strong stereoscopic effect, abundant colors, high color layering effect and glossy and bright glaze.

Owner:HUNAN NEW CENTURY CERAMICS

Manufacturing method of underglaze white double crystal fancy glaze

The invention relates to a manufacturing method of an underglaze white double crystal fancy glaze. The method comprises the steps of preparing materials according to a formula, manufacturing a frit, sieving by using a ball mill and modulating, wherein the frit is made from borax, potash feldspar and quartz; a ground glaze is made from potash feldspar, zinc oxide, calcite, quartz and frit; and an overglaze is made from frit, barium carbonate, iron red, potash feldspar, titanium oxide, zinc oxide, bentonite, quartz, iron oxide red and zirconium silicate; dry grinding frit materials, burning the frit materials at 1250 DEG C, and cooling fast to obtain the frit; sieving ground glaze and overglaze materials by using the ball mill; wet ball milling, and sieving by using a 250 mesh sieve; modulating the ground glaze and the overglaze: mixing the crushed frit respectively with the ground glaze and overglaze materials which are sieved and wet ball milling mixtures so as to modulate the mixtures into slurries at 45-50 baume degree; burning: spraying glaze on a green body, wherein the thickness of the ground glaze is 0.4-0.7mm, the thickness of the overglaze is 0.3 mm, and feeding the green body into a roller way to be burnt into the underglaze white double crystal fancy glaze in an oxidizing atmosphere; after burning, natural, smooth and crystal clear decorative patterns can be generated.

Owner:湖南泉湘陶瓷有限公司

White-ground red-spot composite tangjun glaze and process of preparing jun porcelain with same

The invention discloses white-ground red-spot composite tang jun glaze and a process of preparing jun porcelain with the same. The preparing process comprises the steps that a porcelain body material is smashed and molded firstly, plain porcelain body firing is conducted, then a plain porcelain body is dipped in white-ground glaze slurry for glazing, local spot application of red-spot glaze slurry is conducted on the surface of the plain porcelain body after the white-ground glaze slurry attached to the surface of the plain porcelain body is dried in the air, the plain porcelain body is placed in a kiln to be fired after the red-spot glaze slurry is dried in the air, and then the white-ground red-spot composite tang jun glaze jun porcelain is obtained. According to the white-ground red-spot composite tang jun glaze and the process of preparing the jun porcelain with the same, by adding a certain proportion of zirconite to white-ground glaze and adopting secondary glazing, the position of red-spot glaze is fixed, and a glaze layer is cracked evenly and not prone to rupture; the coloring technology of overglaze or underglaze adopted for general piebald porcelain is replaced, the economic value of the jun porcelain is increased through innovation in glazing color and coatings, the jun porcelain represents the advanced manufacturing technology of China, and the social value of the jun porcelain is increased.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

Underglaze engraving and filling technology for purple pottery of Jianshui

InactiveCN105272165AImprove yieldLabor savingDecorative surface effectsOrnamental structuresEngravingMaterials science

The invention particularly discloses an underglaze engraving and filling technology for purple pottery of Jianshui. The technology comprises steps as follows: clay production, throwing molding, painting and calligraphy decoration, engraving, filling and scraping, fine blank repairing, glazing, blank cooling and firing. After adoption of the technology, the technology has the advantages as follows: pottery produced with the technology reserves the traditional engraving and clay filling technology of the purple pottery of Jianshui and shows simplicity, variety and gentle nature of glaze, polishing is not required after firing, the yield can be increased, the labor force can be greatly reduced, the cost can be reduced, and underglaze engraving and filling has greater innovative value and significance for follow-up inheritance and development of the purple pottery of Jianshui.

Owner:李 俊荣

White-ground piebald composite tang jun glaze and process of preparing jun porcelain with same

The invention discloses white-ground piebald composite tang jun glaze and a process of preparing jun porcelain with the same. A porcelain body material is smashed and molded firstly, plain porcelain body firing is conducted, then a plain porcelain body is dipped in white-ground glaze slurry for glazing, local spot application of piebald glaze slurry is conducted on the surface of the plain porcelain body after the white-ground glaze slurry attached to the surface of the plain porcelain body is dried in the air, the plain porcelain body is placed in a kiln to be fired after the piebald glaze slurry is dried in the air, and then the white-ground piebald composite tang jun glaze jun porcelain is obtained. According to the white-ground piebald composite tang jun glaze and the process of preparing the jun porcelain with the same, by adding zirconite to the formula of white-ground glaze, opacified white glaze is generated during firing; furthermore, secondary glazing is adopted to fix the position of piebald glaze; the coloring technology of overglaze or underglaze adopted for general piebald porcelain is replaced, and the economic value of the jun porcelain is increased through innovation in glazing color and coatings; furthermore, as a characteristic of China, the jun porcelain represents the advanced manufacturing technology of China, and the social value of the jun porcelain is increased.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

Pigment pencil for underglaze painting of ceramics and application method of pigment pencil

The invention relates to a pigment pencil for underglaze painting of ceramics and an application method of the pigment pencil. The pigment pencil for the underglaze painting of the ceramics is made up of a penholder and a refill, wherein the refill is prepared from the materials in percentage by weight: 70% to 90% of high-temperature underglaze painting pigment for ceramics, 5% to 30% of paraffin and 2% to 8% of clay. According to the pigment pencil for the underglaze painting of the ceramics, provided by the invention, the traditional underglaze painting pigment for ceramics is processed into a pencil refill structure which is convenient to operate, and a writing-brush underglaze painting mode, which is hard to master, is improved into a pencil painting mode which is common in daily lives, so that the material category and mode of expression of the underglaze painting of the ceramics are enriched. According to the pigment pencil for the underglaze painting of the ceramics, provided by the invention, the use in basic instruction of the ceramics is better facilitated, the popularization rate is high, the pigment pencil is simple and convenient in operation, is smooth and clear, is not prone to falling and is durable in stability, and the transition of a ceramics underglaze painting process to the pigment-pencil-for-the-underglaze-painting-of-the-ceramics, i.e., hard-pen convenient operating process from a writing-brush-dipping-pigment soft-pen tedious operating process is achieved.

Owner:上海满意文化传播有限公司

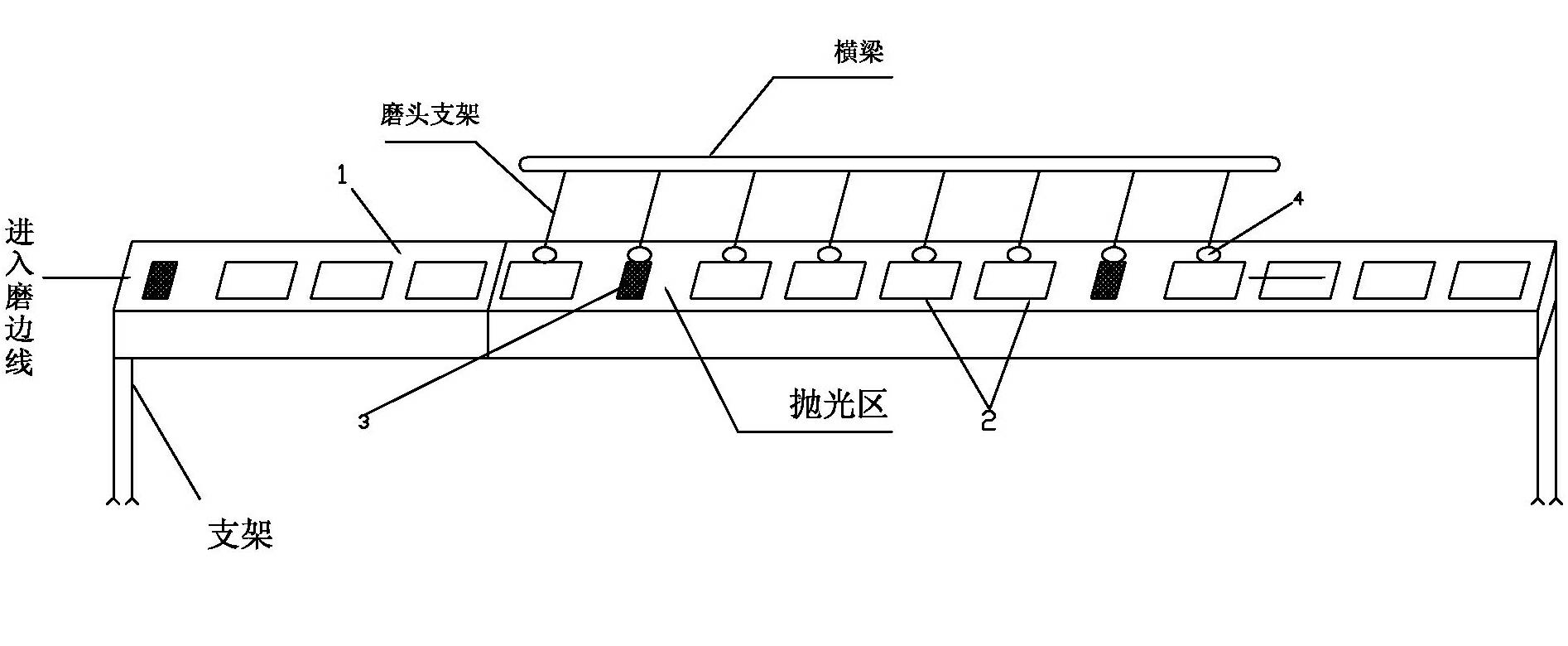

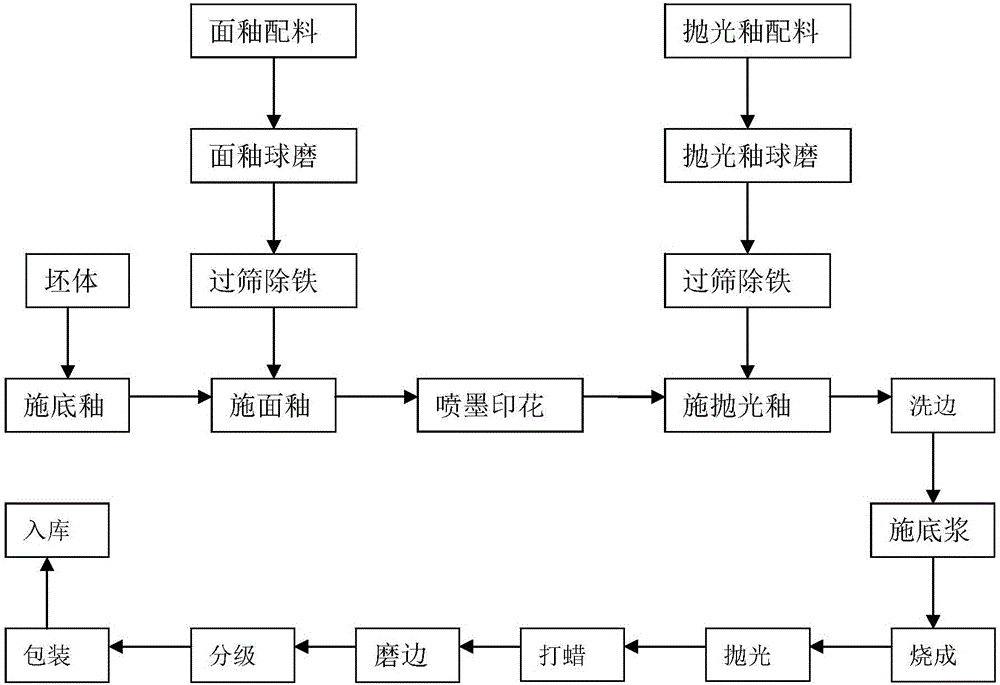

Manufacture method of non-aqueous printing ink wet underglaze colour self-sharpening polishing ceramic glazed tile

The invention relates to a manufacture method of a non-aqueous printing ink wet underglaze colour self-sharpening polishing ceramic glazed tile. The manufacture method is characterized by comprising the following steps of proportioning raw materials, ball milling, iron removal, spraying pulverizing, compacting for moulding, biscuiting, wet underglaze colour decoration, glaze firing, self-sharpening polishing and edging. The self-polishing is as below: in order to prevent passivation of a resin polishing grinding head on a smooth glaze, during normal polishing operation, a ceramic glazed tile product to be polished is added with a rough surface body to be polished; the rough surface body to be polished rubs the polishing grinding head to keep the grinding head sharp. The method has advantages that produced polishing ceramic glazed tile has high strength, brilliant color, rich pattern texture of a ceramic tile as well as high surface flatness and good glossiness of a polishing product. Meanwhile, a production technology has advantages of simple process, low production cost, short sintering period, low energy consumption and simple polishing technology, and is suitable for large-scale production and demand of common consumers.

Owner:FOSHAN SANSHUI NEW PEARL CONSTR CERAMICS IND +2

Black background-white spot composite Tang jun glaze, and method used for producing jun porcelain with black background white spot composite Tang jun glaze

The invention discloses a black background-white spot composite Tang jun glaze, and a method used for producing jun porcelain with the black background white spot composite Tang jun glaze. According to the method, a ceramic body raw material is subjected to smashing, moulding, and sintering so as to obtain unglazed porcelain bodies; the unglazed porcelain bodies are immersed into a black background glaze slurry for glazing; after airing of the black background glaze slurry on the surfaces of the unglazed porcelain bodies, the surfaces of the unglazed porcelain bodies are coated with a white spot glaze slurry via spot application; after airing, the obtained unglazed porcelain bodies are delivered into a kiln for sintering so as to obtain the black background-white spot composite Tang jun glaze jun porcelain. According to the black background-white spot composite Tang jun glaze and the method, iron element is added into a black priming glaze at a certain ratio; secondary glazing is adopted; the positions of white sport glaze are immobilized; talc powder and bone meal are added into the black background-white spot composite Tang jun glaze at a certain ratio, so that glaze layer crackles are uniform, and cracking is not easily caused. Overglaze color or underglaze color generally adopted in conventional speckle porcelain production is not adopted in the method, so that economic value of jun porcelain is increased via innovation on glazing color and coating; jun porcelain is a featured product of our country, so that the method is used for reflecting advanced technology of China, and social value of jun porcelain is increased.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

High temperature resistant pearlescent pigment and preparation method thereof

ActiveCN104327552AChemically activeSmall thermal expansionInorganic pigment treatmentColor ScaleHot Temperature

The invention relates to a high temperature resistant pearlescent pigment including a synthetic mica substrate, one layer or multi layers of metal oxide layer coating the synthetic mica substrate, and a zirconia high temperature resistant layer coating the metal oxide layer. The high temperature resistant pearlescent pigment using high temperature is up to 1150 DEG C, the high temperature resistant pearlescent pigment can be stably and well dispersed at high temperature, and can be widely used in underglaze color, in-glaze color, overglaze color, enamel, enamel paper transfers, architectural enamel plates, permanent color scales, high temperature resistant paints and other industries, and the usage amount is 0.5 ~ 50% of that of a glaze or a coating.

Owner:GUANGXI CHESIR PEARL MATERIAL CO LTD

Bright red underglaze color, overglaze and their prepn process

The present invention discloses one kind of bright red underglaze color, one kind of overglaze and their preparation process. The bright red underglaze color consists of stabilizer, 0.02-34 wt%, silica 11.3-56 wt%, lead oxide 2.4-27 wt%, cadmium sulfoselenide 2-20 wt%, Al2O3 1.7-27 wt%, B2O3 1.5-27 wt%, CrO2 0.3-32 wt%, GeO2 0.08-33 wt%, MgO 1.4-13 wt%, CaO 0.7-15 wt%, Li2O 0.7-13.2 wt%, K2O 1-7 wt% and NaO 1-5.3 wt%; and the overglaze consists of clinker 5-55 wt%, ZnO 3-12 wt%, albite 5-30 wt%, potash feldspar 7-35 wt%, baked talc 2-16 wt%, silica 2-18 wt%, and kaolin 2-26 wt%. The bright red underglaze color and the overglaze have pure color and very low Pb and Cd leaching amount.

Owner:胡天霏 +2

Kiln-variable underglaze color material and manufacturing process of ceramics with kiln-variable underglaze color material

InactiveCN108706879AImprove protectionEasy to save energyClaywaresManufacturing technologyEconomic benefits

The invention relates to the technical field of manufacturing of ceramics, in particular to kiln-variable underglaze color material and a manufacturing process of ceramics with the kiln-variable underglaze color material. The kiln-variable underglaze color material comprises raw mineral material and water, the raw mineral material is composed of feldspar, quartz, kaolin, titanium dioxide, iron trioxide and inorganic colors, and the ratio of the raw mineral material to the water is 3-4:1. In the manufacturing process of the ceramics made from the kiln-variable underglaze color material, the kiln-variable underglaze color material containing multiple coloring elements undergoes oxidation and reduction to react through temperature variable of a furnace in firing, colorful kiln-variable effectis formed under the transparent glaze layer, and the ceramics decorated with the kiln-variable material are quite unique and wonderful; by the arrangement, a brand-new ceramic variety is provided, and positive significance and economic benefits are achieved for promoting the development of ceramic products.

Owner:福建省德化县恒昇陶瓷有限公司

Preparation method of ceramic clay body and method for preparing ceramic product from ceramic clay body

The invention discloses a preparation method of a ceramic clay body and a method for preparing a ceramic product from the ceramic clay body. The preparation method of the high-strength ceramic clay body comprises the following production steps: (1) preparing a blank; (2) carrying out molding; (3) repairing the blank; and (4) drying the blank. According to the method for preparing the ceramic product, the clay body prepared by the method is printed by a printing material; a ceramic transparent glaze is utilized; and an under-glaze daily ceramic product is finally prepared through conventional sintering. The prepared high-strength ceramic clay body is suitable for direct printing on the clay body by a transfer printing machine; the clay body is smooth in surface and high in strength; in the process of preparing the ceramic product, the clay body is not damaged when the printing material is adopted for printing; and the printed pattern is clear and complete.

Owner:广东皓明陶瓷科技有限公司

Complex Tang-dynasty jun glaze with blue spots in black and process for preparing jun porcelain by use of complex Tang-dynasty jun glaze

The invention discloses a complex tang-dynasty jun glaze with blue spots in black and a process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze. The process comprises: firstly crushing and molding carcass raw materials, and firing the carcass raw materials into plain carcass; then, immersing the plain carcass into slurry of glaze in black for glazing; applying slurry of the glaze with blue spots in surface points of the plain carcass after the slurry of the glaze in black adhered on the surface of the plain carcass is dried in air; and putting the plain carcass into a kiln for firing after the slurry of the glaze with blue spots is dried, thereby obtaining the complex Tang-dynasty jun glaze with blue spots in black. According to the Tang-dynasty jun glaze with blue spots in black and the process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze disclosed by the invention, an iron element, a copper element and a cobalt element in special proportion are added into glaze in black, are fired at a high temperature to form black glaze which is stable in color generation, uniform in color and luster and full of a jade texture, and the position of the glaze with blue spots is fixed by use of a secondary glazing mode. A coloring process of overglaze color or underglaze color adopted by general piebald porcelains is broken through; economic value of the jun porcelain is increased through innovation in glazing color and coating; and the jun porcelain, which is a Chinese characteristic, also represents advanced level of the production process in China, thereby increasing the social value of the jun porcelain.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

Black-base mottled composite Tang jun glaze and process for preparing jun porcelain through black-base mottled composite Tang jun glaze

The invention provides black-base mottled composite Tang jun glaze and a process for preparing jun porcelain through the black-base mottled composite Tang jun glaze. Firstly, base raw materials are smashed and molded, a plain base is fired, the plain base is immersed in slurry of black-base glaze for glazing, after the slurry of the black-base glaze is attached to the surface of the plain base and the plaint base is aired, slurry of mottled glaze is arranged on part of the surface of the plain base in a spot application mode, the plain base is placed in a kiln to be fired after being aired, and then the black-base mottled composite Tang jun glaze jun porcelain is obtained. According to the black-base mottled composite Tang jun glaze and the process for preparing the jun porcelain through the black-base mottled composite Tang jun glaze, an iron element at a specific ratio is added to the black-base glaze, black glaze which is stable in color generation, uniform in color and luster and rich in jade texture feeling is obtained through high-temperature firing, the mottled glaze is fixed in a secondary glazing mode, an overglaze color or underglaze color coloring process adopted by ordinary mottled porcelain is broken through, the economic value of the jun porcelain is increased through innovation in glaze colors and coatings, the jun porcelain stands for the feature of China and also represents the advanced level of the craftsmanship in China, and the social value of the jun porcelain is increased.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

Ceramic boneless painting and manufacturing method thereof

The invention discloses a manufacturing method of a ceramic boneless painting. The manufacturing method comprises the following steps that firstly, tools and a ceramic plate are prepared, wherein the tools comprise a writing brush, an oil painting brush, silks, sponge, cotton swabs, a shovel, paper and the like; pigments are prepared and tertiary colors are made, and then the painting is drawn on a technical ceramic disk or the ceramic plate by adopting the following drawing techniques of color splashing, flowing, homogenizing through paper, stamping, beating, plane coating, coloring, pigment frying and shoveling. The method is boldly innovated based on traditional techniques, underglaze colours are used as foundation, a primary color method is used for realization, the ceramic boneless painting is different from fine brushwork and freehand brushwork in traditional Chinese painting, the boneless means submerged and has an implicit mean, the method is characterized in that pen writing and coloring are organically combined, drafts are not needed, outlines do not need to be drawn, and a ground pattern for tracing is not needed.

Owner:操驰

Method for preparing underglaze bone china

The invention discloses a method for preparing underglaze bone china, which comprises the following production steps: preparing a bone china material into a blank; performing high temperature biscuit firing on the blank, wherein the temperature of the biscuit firing is between 1,250 and 1,280 DEG C; performing color painting on a product after the biscuit firing, wherein the pigment used by the color painting is prepared from the following compositions by weight percentage: 65 to 75 percent of colorradical and 25 to 35 percent of glaze; performing high temperature color firing on the product after the color painting, and the temperature of the color firing is between 1,200 and 1,250 DEG C; and glazing the product after the high temperature color firing with the same glaze in the pigment, and performing medium temperature glaze firing to prepare a finished product, wherein the temperature of the glaze firing is between 1,050 and 1,150 DEG C. The underglaze bone china prepared by the method has clear color painting patterns, strong stereovision, and rich, fresh and bright color of the color painting patterns, smooth, neat and delicate glaze and high firing rate.

Owner:李永生 +1

Process for manufacturing surface decoration layer of ceramic

A manufacturing method for a ceramic surface decoration layer is characterized in that: the method comprises the following steps of: (1) making decorations on a ceramic piece through an underglaze blue and white pigment; (2) drying the underglaze blue and white pigment on the ceramic piece by baking; (3) applying or spraying three-dimensional crystalline art glaze on the underglaze blue and white pigment on the ceramic piece; (4) heating the ceramic piece to 1300 to 1320 DEG C in an oxidative atmosphere, and then quickly reducing the temperature to 1130 DEG C; (5) keeping the ceramic at the temperature of 1130 DEG C for 1.5 to 2 hours and then naturally cooling down the ceramic piece through extinguishing fire. Compared with the prior art, the method has the advantages that: the ceramic surface decoration layer manufactured through the method has the underglaze blue and white pigment blending under the three-dimensional crystalline art glaze; the underglaze blue and white pigment has a blue and smooth color with high clearness and can be used for drafting patterns such as Chinese painting with high requirements on clearness; crystalline patterns on the glaze are three dimensional and give off lofty rays of light with brilliant and rich color, harmony and good appearance.

Owner:吴渭阳

Complex Tang-dynasty jun glaze with white spots in blue and process for preparing jun porcelain by use of complex Tang-dynasty jun glaze

The invention discloses a complex tang-dynasty jun glaze with white spots in blue and a process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze. The process comprises: firstly crushing and molding carcass raw materials, and firing the carcass raw materials into plain carcass; then, immersing the plain carcass into slurry of glaze in blue for glazing; applying slurry of the glaze with white spots in surface points of the plain carcass after the slurry of the glaze in blue adhered on the surface of the plain carcass is dried in air; and putting the plain carcass into a kiln for firing after the slurry of the glaze with white spots is dried, thereby obtaining the complex Tang-dynasty jun glaze with white spots in blue. According to the Tang-dynasty jun glaze with white spots in blue and the process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze disclosed by the invention, an iron element, a copper element and a cobalt element in special proportion are added into a glaze material of glaze in blue, and the position of the glaze with white spots is fixed by use of a secondary glazing mode. A coloring process of overglaze color or underglaze color adopted by general piebald porcelains is broken through; economic value of the jun porcelain is increased through innovation in glazing color and coating; and the jun porcelain, which is a Chinese characteristic, also represents advanced level of the production process in China, thereby increasing the social value of the jun porcelain.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

Double firing manufacturing method of under-glaze decoration ceramic

The invention provides a manufacturing method for an under-glaze decoration pottery and porcelain twice fired, which has the steps that: firstly, an unburnt earthenware body fired by high temperature is made; secondly, low temperature over-glaze decoration paint is used to carry out painting decoration on the unburnt earthenware body, and the paint is adhered on the unburnt earthenware body; thirdly, the unburnt earthenware body after decorated by the painting is sent into a low temperature decorating kiln to carry out low temperature baking, and the paint on the unburnt earthenware body and the unburnt earthenware body are combined together; fourthly, transparent glaze is painted on the unburnt earthenware body after baked by the low temperature; fifthly, the unburnt earthenware body after painted by the transparent glaze is sent into a high temperature kiln to be fired by high temperature, and the under-glaze decoration pottery and porcelain is made. The pottery and porcelain manufactured by the method solves the problem that the picture wears after the under-glaze decoration pottery and porcelain is used for a long time. After fired in high temperature, the paint and glaze are tightly blent, the effect similar to rain drop glaze appears in the place where the paint is thick, artistic quality is strong, decoration effect is good, and esthetics is increased.

Owner:郭春森

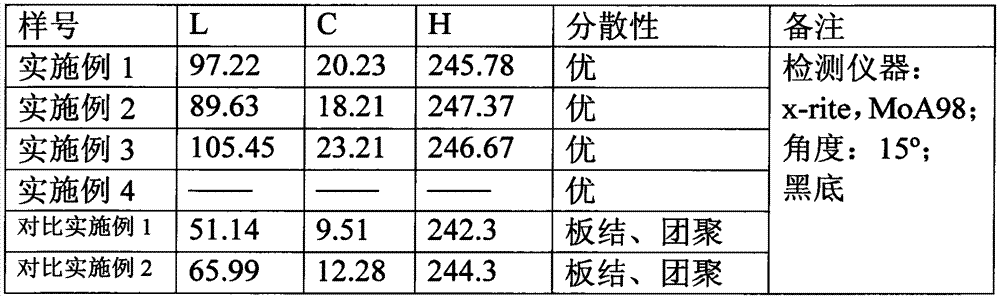

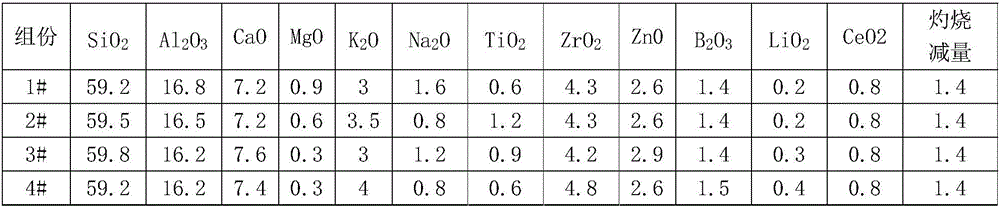

Underglaze five-color polished and glazed tile and preparation method thereof

The invention discloses an underglaze five-color polished and glazed tile which comprises a cover glaze and a polished glaze. On the basis of not making a significant change of the production technology of an existing glazed tile, the underglaze five-color polished and glazed tile product is abundant in pattern and color, clear and natural in texture, vivid in color, high in third dimension and smooth as a mirror, and covers the pattern as transparent glass through optimization of the formulation composition of the cover glaze, the formulation composition of the polished glaze and a melting starting temperature difference of the cover glaze and the polished glaze, optimization and sorting of color variety of inkjet printing ink and adjustment and optimization of a glazing process, so that the worldwide problems that the underglaze color is not vivid enough in comparison with an cover glaze color and not abundant enough in color are broken through; the Chinese culture treasure of a traditional underglaze five-color process is guided to a new height, so that poetries of paintings and porcelain of literators vividly appear on the surface of the ceramic tiles for walls and floors and are delightful to the eye, and the underglaze five-color polished and glazed tile has high decorativeness and artistry; and meanwhile, the technology has relatively high universality and can be easy popularized within the industry.

Owner:GUANGDONG WINTO CERAMICS +3

Method for fabricating blue-and-white peony porcelain

The invention provides a method for fabricating blue-and-white peony porcelain, which comprises calcining from basic material of china clay, raw material of glaze and chromatic china clay, wherein the chromatic china clay includes red china clay, pink china clay, yellow china clay and green china clay. The method for fabricating peony porcelain comprises the following steps: preparing a clay blank; preparing color mud; making enamel frit; making porcelain body; biscuit firing; applying underglaze blue and glazing; dough molding and calcining. The blue-and-white peony porcelain fabricated by the method of the invention comprises overglaze blue and underglaze blue, and can combine porcelain flowers and porcelain during the calcination process.

Owner:李学武

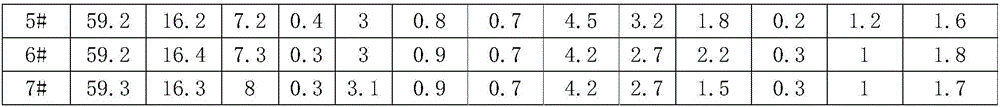

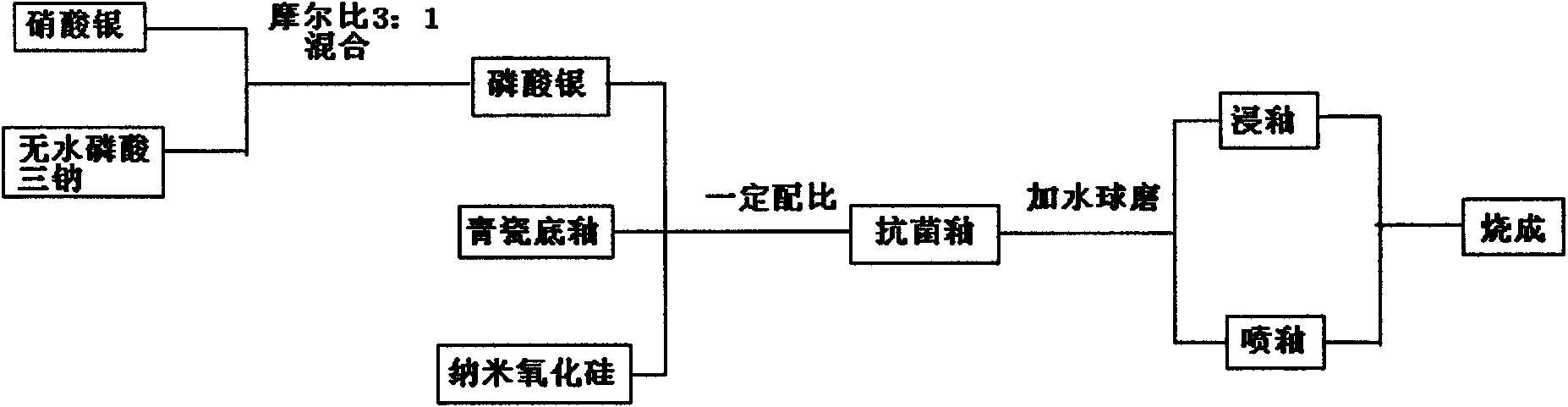

Dragon spring celadon antibacterial agent and application thereof

InactiveCN101611718AImprove antibacterial functionIncrease costBiocideDisinfectantsEscherichia coliNano silicon

The invention discloses a dragon spring celadon antibacterial agent, which comprises the following components according to weight percentage: 45 percent to 65 percent of dragon spring celadon glaze, 15 percent to 35 percent of nano silicon oxide and 15 percent to 30 percent of silver phosphate. The invention also discloses an application of the dragon spring celadon antibacterial agent in preparing the celadon antibacterial glaze, the dragon spring celadon antibacterial agent and celadon underglaze are mixed to prepare the antibacterial glaze dry agent. The antibacterial glaze dry agent is dissolved by adding water, is ball-milled into glaze slurry, is glazed by adopting a mode of dipping glaze or spraying glaze and then is fired into celadon antibacterial glaze; under the premise of keeping the style of the traditional celadon not to be changed, the glazed surface thereof is added with the antibacterial function, the sterilizing rate for escherichia coli and staphylococcus aureus reaches to more than 90 percent.

Owner:ZHEJIANG UNIV

Preparation process of underglaze red nixing pottery

The invention provides a preparation process of underglaze red nixing pottery. The preparation process comprises the steps of blank preparing, blank forming, blank drying, blank decorating and blank burning, wherein, in the blank decorating, a layer of clear glaze is applied on a dry blank body after describing patterns by using an underglaze red pigment and / or writing characters; the underglaze red pigment is prepared from the following raw materials in parts by weight: 12 to 15 parts of copper oxide, 58 to 65 parts of hydrophite, 19 to 25 parts of glass powder and 6 to 9 parts of diabase; the clear glaze comprises the following raw materials in parts by weight: 79 to 81 parts of glaze stone, 21 to 23 parts of glaze ash and 5 to 8 parts of fluorite. According to the invention, the underglaze red pigment can be directly applied on the blank of the nixing pottery without need of ground glaze, the process is simplified, the finished products are bright-colored, and the glaze is bright.

Owner:QINZHOU UNIV

Underglaze red ceramic

InactiveCN104844154AGood colorHigh hardnessCeramic materials productionClaywaresTin dioxideUnderglaze

The invention discloses an underglaze red ceramic. The ceramic body is composed of waste ceramic, natural clay, calcined talcum, feldspar, aluminum oxide micropowder, silicon nitride, black soil and wollastonite. The underglaze red ceramic is composed of cuprous oxide, quartz, limestone, Li-feldspar, ulexite, silicon carbide, silicon nitride, ferric oxide, tin dioxide, zirconium silicate, zinc borate, smectite, hydroxymethyl cellulose sodium and sodium humate. The compositions of the ceramic body and glaze are optimized to enhance the coloration effect, hardness, stability and other physicochemical properties of the ceramic. The product grade completely satisfies the industrial and domestic demands, and has the effect of waste utilization.

Owner:SUZHOU TUOKE INSTR EQUIP

Underglaze blue and underglaze red glaze ceramic

The invention discloses underglaze blue and underglaze red glaze ceramic. A ceramic body comprises the following components: kaolin, natural clay, talcum, feldspar, alumina micro powder, silicon nitride, barium carbonate and wollastonite; the ceramic glaze comprises the following components: cuprous oxide, zinc oxide, cobaltous oxide, quartz, limestone, lithium feldspar, ulexite, silicon carbide, silicon nitride, iron trioxide, stannic oxide, zinc borate, montmorillonite, carboxymethyl cellulose sodium and sodium humate. Through optimizing the components of the ceramic body and the glaze, the physical and chemical properties, such as the coloring effect, the hardness and the stability of the ceramic are improved.

Owner:SUZHOU TUOKE INSTR EQUIP

Production process of underglaze five-color ceramics with fine brushwork traditional Chinese painting carving

ActiveCN103601471AHigh artistic valueImprove economyMould separation apparatusSpecial ornamental structuresCeramicGypsum

The invention discloses a production process of underglaze five-color ceramics with fine brushwork traditional Chinese painting carving, belonging to the production process field of art ceramics. The production process comprises the following steps: (1) design; (2) plaster master stamper manufacturing; (3) painting; (4) carving; (5) mould opening;(6) slip casting; (7) finishing and washing; (8) bisque firing; (9) polishing; (10) colouring: delineating, pigment solution coating and color spraying; (11) roasting; (12) applying transparent glaze; and (13) firing. According to the process provided by the invention, a fine brushwork traditional Chinese painting process, a carving process and a underglaze five-color coloring process are combined organically, so that the picture of the ceramics is relatively delicate, and has sense of space, sense of layering and third dimension, and the artistic value and added value of products of the ceramics are improved.

Owner:景德镇手都陶瓷有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com