Patents

Literature

92results about How to "Tightly fused" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

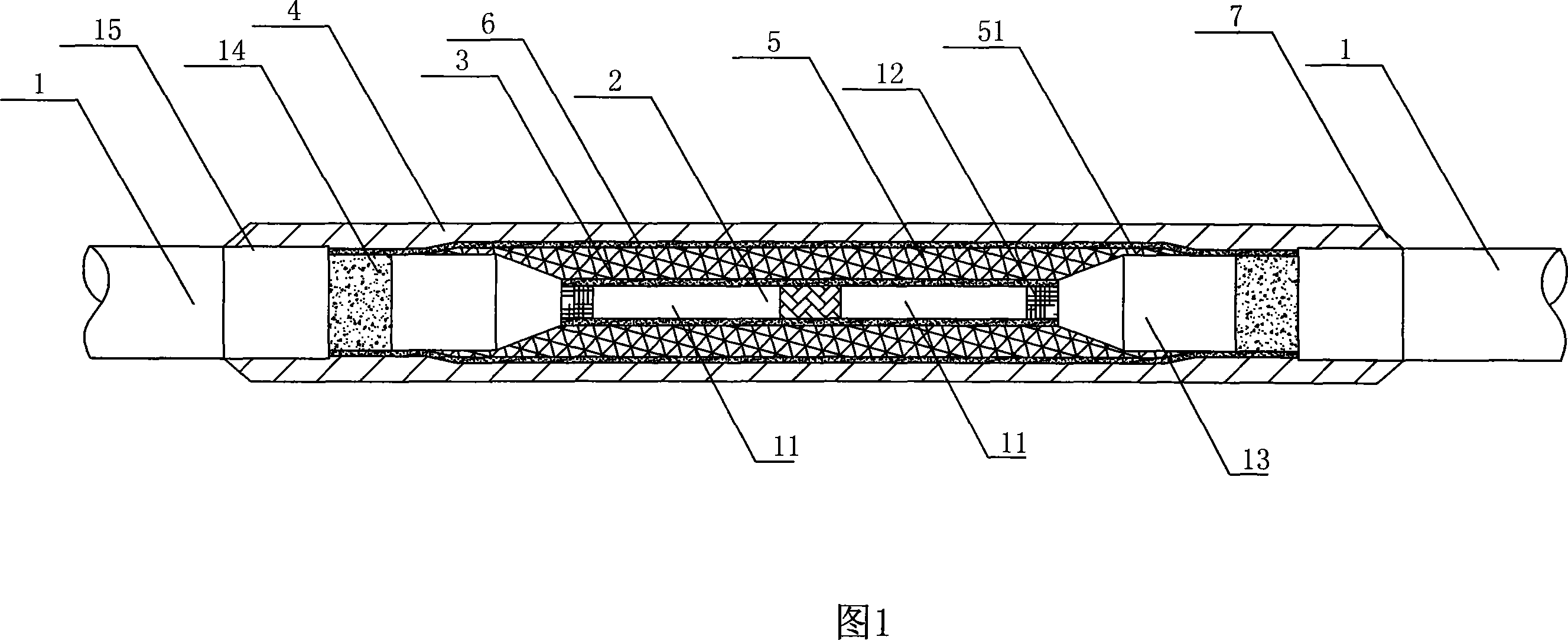

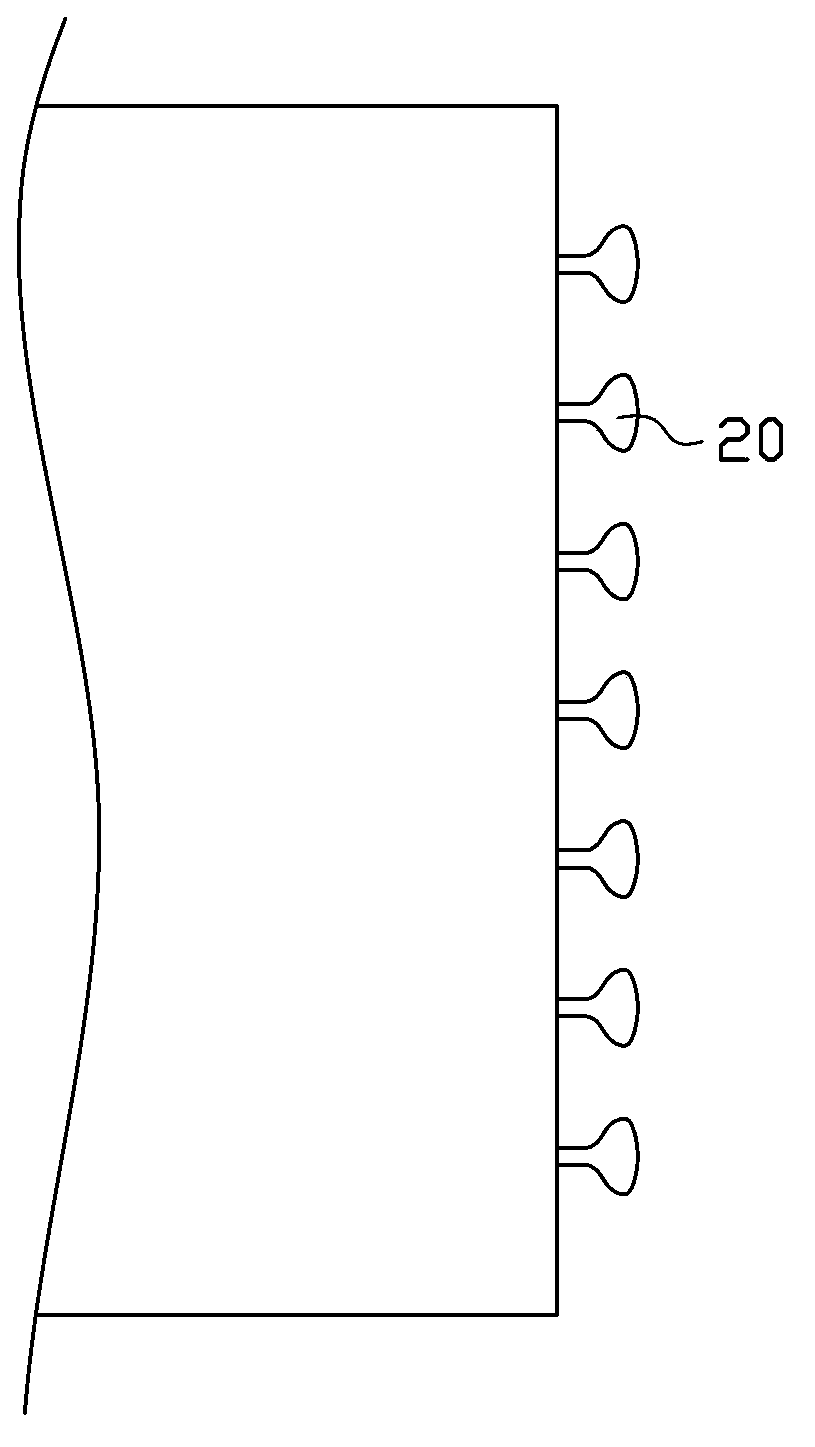

Soft joint for cross-linked polyethylene cable and producing method thereof

ActiveCN101068075AElectrical performance improvements and enhancementsEliminate void defectsCable junctionsApparatus for joining/termination cablesInsulation layerEngineering

This invention discloses a soft joint of a cross-linked polythene cable including an inner semiconductive layer and metal jacket sleeves, in which, two core leads between two cables are welded to form a core connection part, the inner semiconductive layer is combined with a preserved section of the inner screen layer of the cable characterizing in setting a polythene filled vulcanized insulation layer out of the inner semiconductive layer to be fused with the polythene insulation layer of the cable, and wrapping the polythene insulation of the cable with a transition connection section and an outer semiconductive layer combining with the preserved section of the outer screen of the cable is set out of the polythene filled vulcanized insulation layer, two ends of the metal jacket sleeve are welded with the out surfaces of lead protection pipe of the cable and set with slope connection sections.

Owner:宁波东方电缆股份有限公司

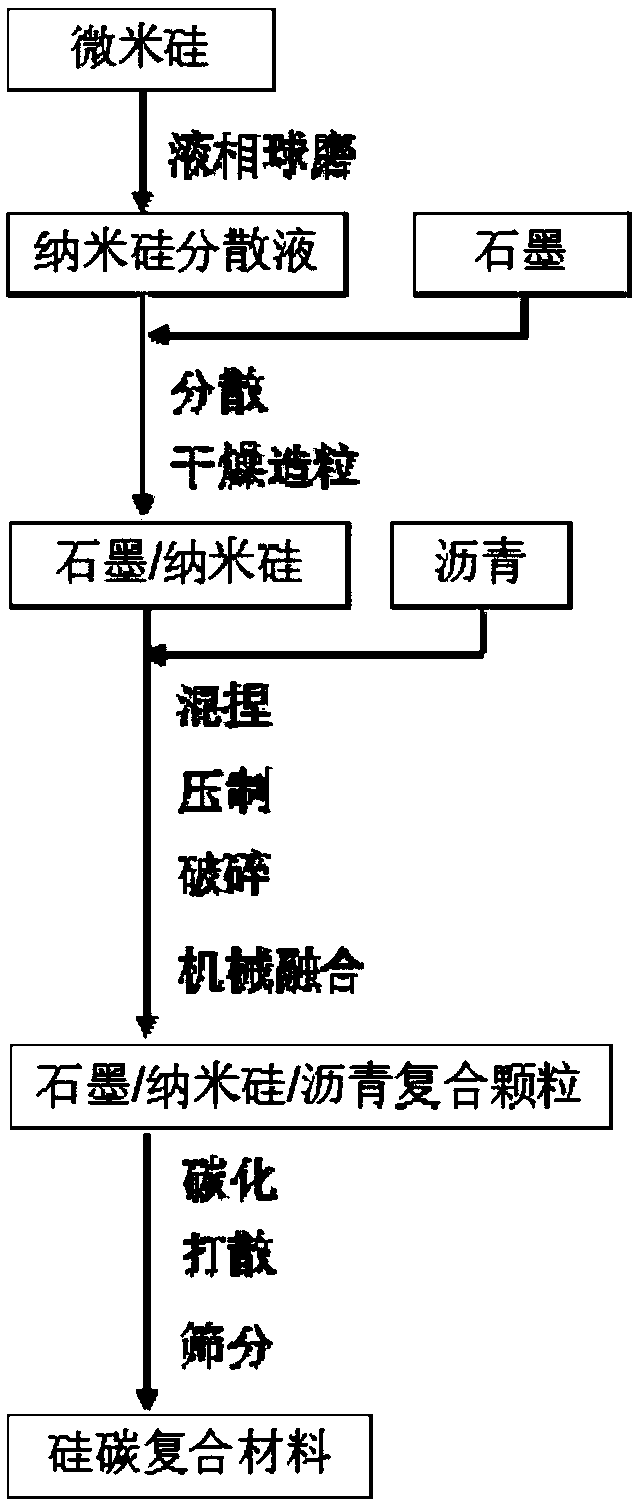

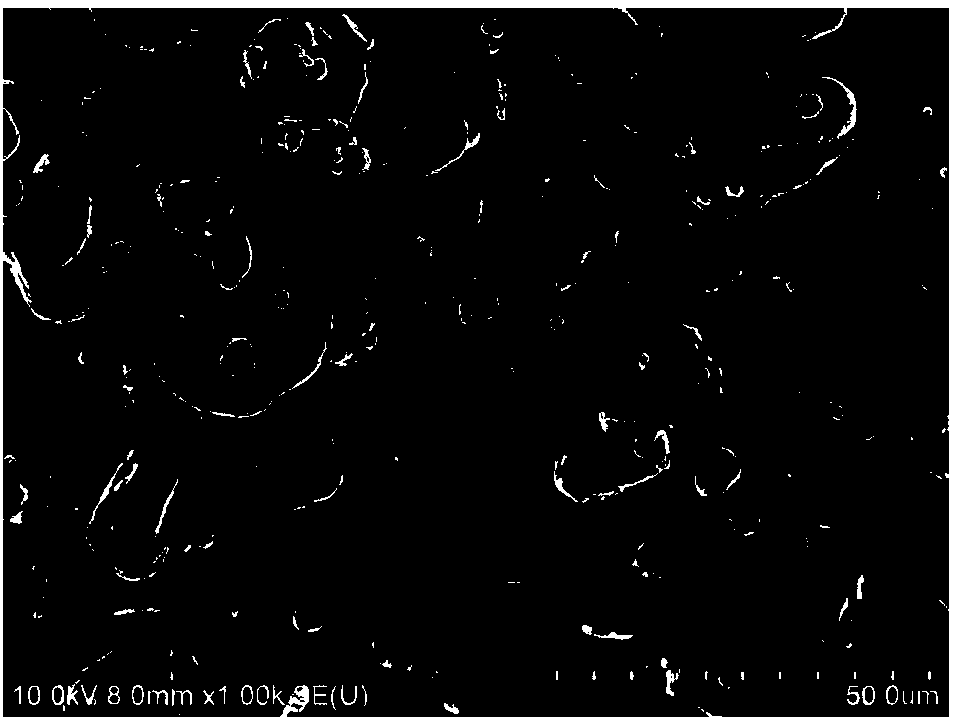

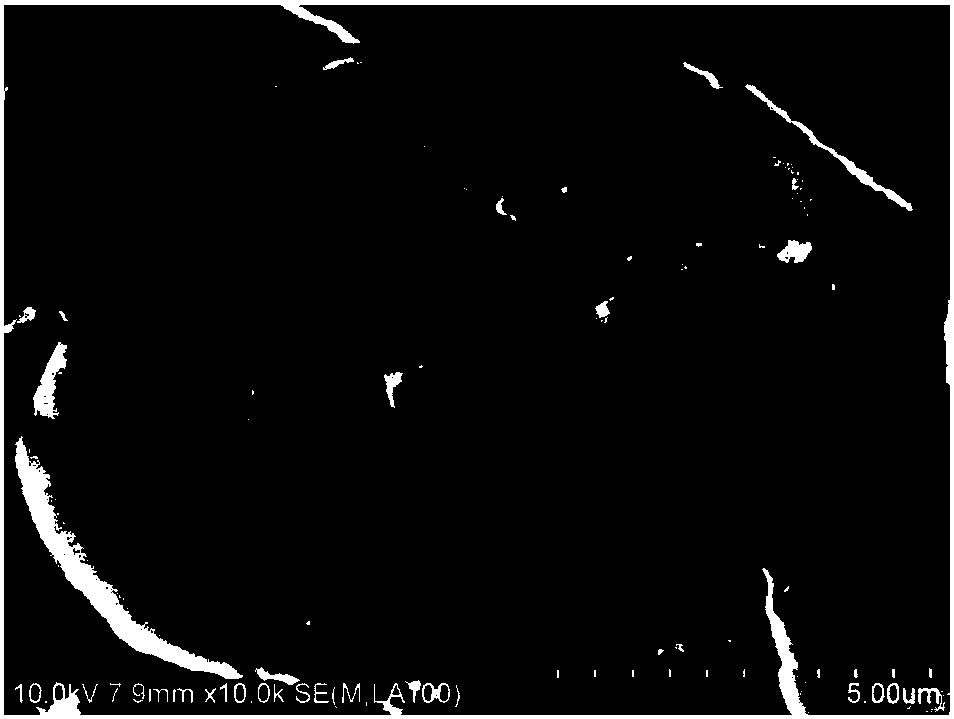

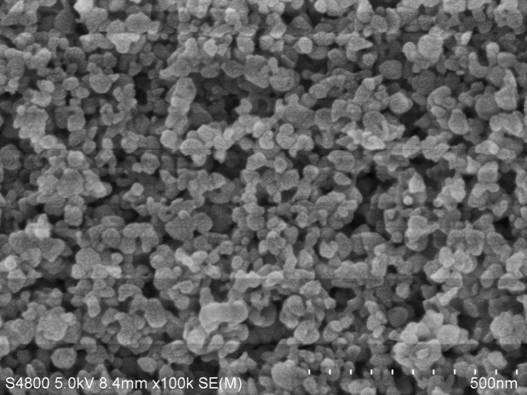

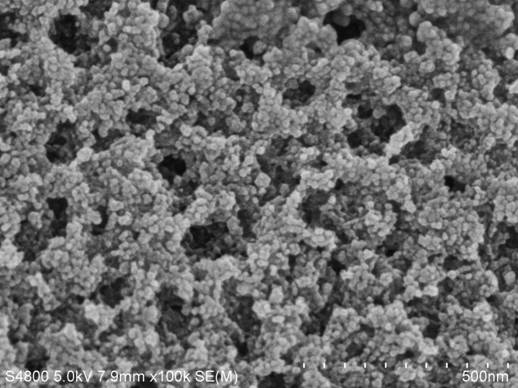

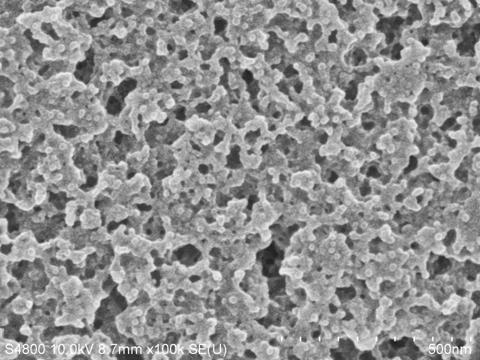

High-performance silicon-carbon cathode material and preparation method thereof

ActiveCN107785560ACover tightlyCoated evenlyNegative electrodesSecondary cellsNano siliconCarbonization

The invention relates to a high-performance silicon-carbon cathode material and a preparation method thereof. The preparation method comprises the following steps: (1) dispersing silicon into a solvent, carrying out liquid-phase ball-milling, so as to obtain nano-silicon dispersion liquid, adding graphite, and carrying out liquid-phase ball milling so as to uniformly mix nano-silicon with graphite; (2) carrying out granulation on slurry obtained the step (1), so as to obtain graphite / nano-silicon composite particles; (3) carrying out granulation on the product of the step (2) and asphalt by virtue of a mixed kneading-pressing-crushing method, so as to obtain graphite / nano-silicon / asphalt composite particles, and carrying out mechanical fusion so as to realize spheroidization and uniform coating of the graphite / nano-silicon / asphalt composite particles in one step; and (4) carrying out carbonization, scattering and sieving, so as to obtain the high-performance silicon-carbon cathode material. The preparation method is simple and low in cost and can be used for easily producing the high-performance silicon-carbon cathode material in large scale.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

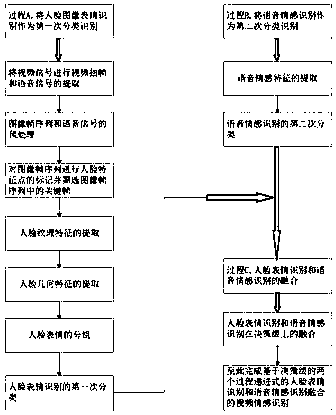

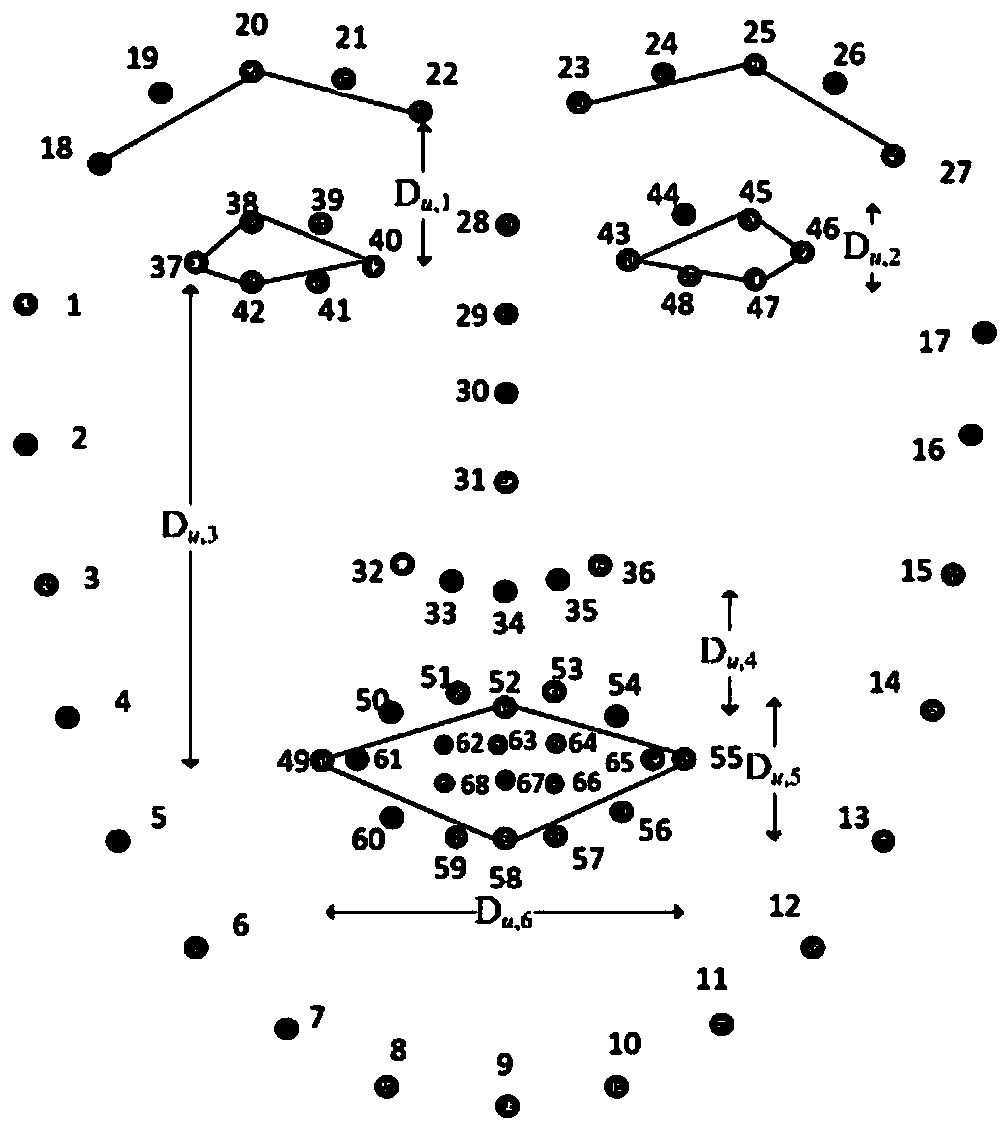

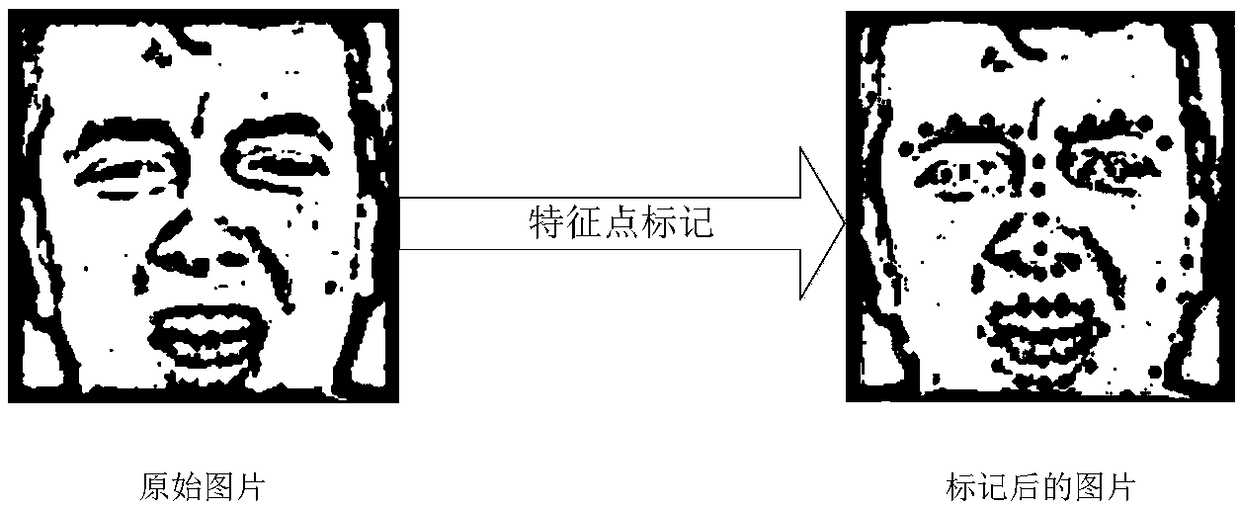

A video emotion recognition method integrating facial expression recognition and voice emotion recognition

ActiveCN109409296ATightly fusedIdeal human emotion recognition effectSpeech analysisAcquiring/recognising facial featuresIdentification rateConditional probability

The invention relates to a video emotion recognition method integrating facial expression recognition and voice emotion recognition. The invention relates to processing of a recording medium for identifying graphics. The method is a decision-level-based two-process progressive audio-visual emotion recognition method, the method separates face expression recognition from voice emotion recognition in a video, the two-process progressive emotion recognition method is adopted, and the technology of voice emotion recognition is carried out on the basis of face expression recognition by calculatingthe conditional probability; the method comprises the steps that A, facial image expression recognition serves as first-time classification recognition; B, voice emotion recognition serves as second-time classification recognition; and C, fusion of facial expression recognition and speech emotion recognition. According to the method, the defects that in the prior art, the internal relation betweenface features and voice features is ignored in human emotion recognition, the recognition speed of video emotion recognition is low, and the recognition rate is low are overcome.

Owner:HEBEI UNIV OF TECH

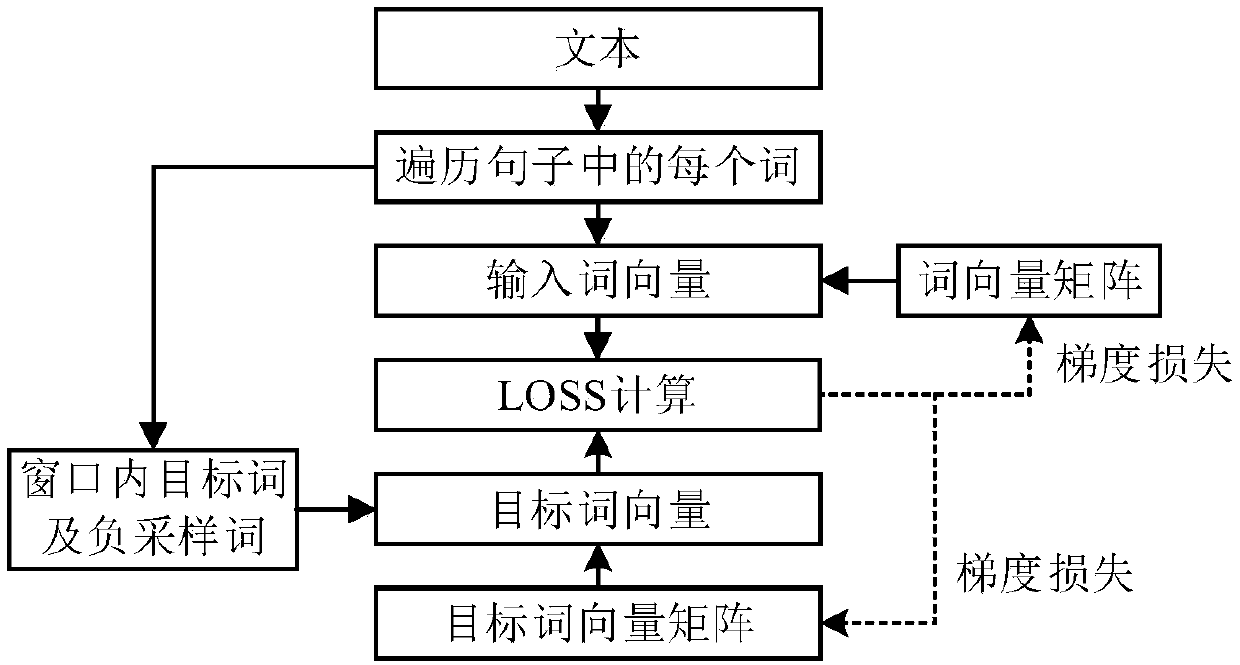

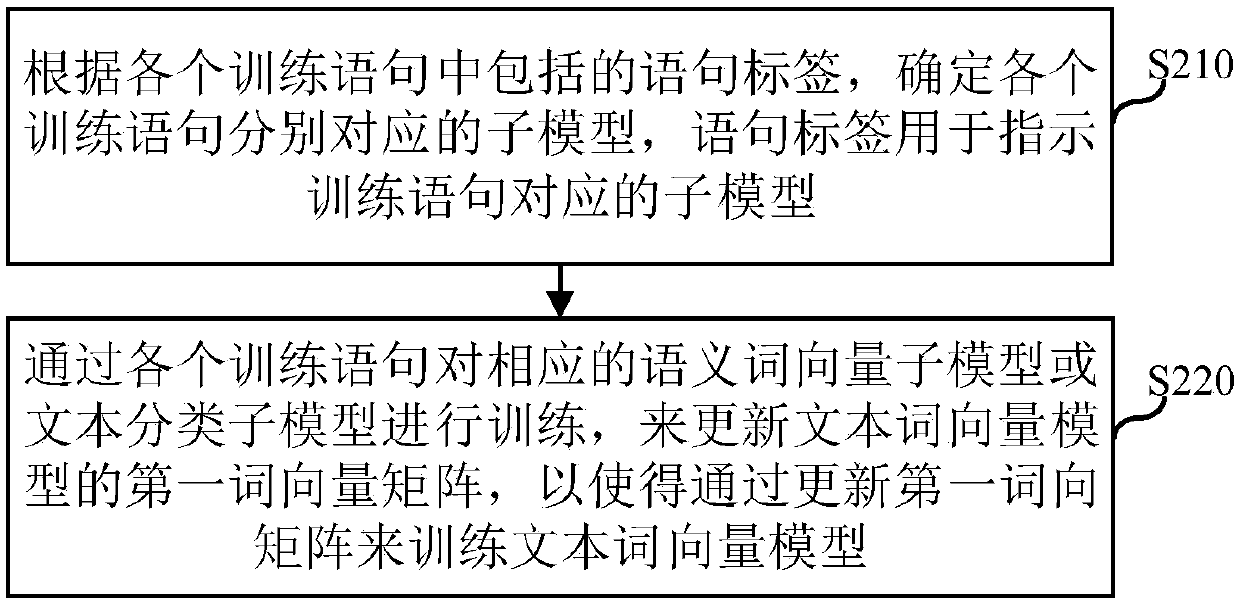

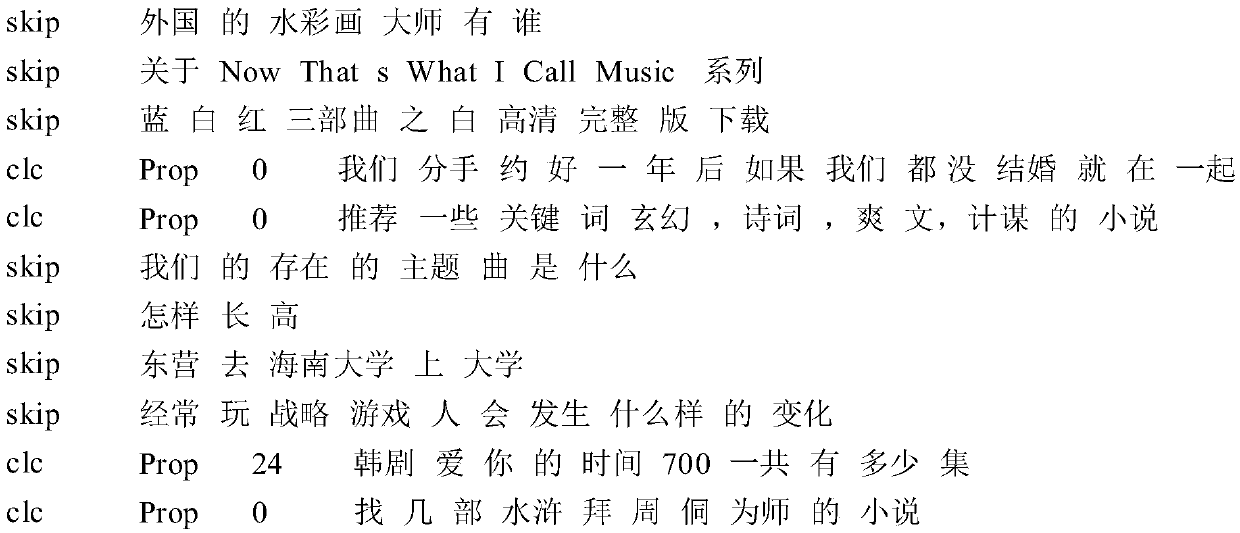

Text word vector model training method, electronic equipment and computer storage medium

ActiveCN109635116AAchieve trainingEnhanced Representational CapabilitiesSemantic analysisSpecial data processing applicationsQuantum modelingText categorization

The invention relates to the technical field of computer processing, and discloses a training method of a text word vector model, electronic equipment and a computer readable storage medium. The training method of the text word vector model comprises the steps: determining a sub-model corresponding to each training statement according to statement tags included in each training statement, the statement tags being used for indicating the sub-models corresponding to the training statements; Respectively training the corresponding semantic word vector quantum model and the text classification sub-model through each training statement to update a first word vector matrix of the text word vector model, so as to train the text word vector model by updating the first word vector matrix. Accordingto the method provided by the embodiment of the invention, through the combination of the semantic word vector quantum model and the text classification sub-model, the close connection and fusion between the word vector training method and the text classification method are realized, and the representation capability of the word vector is enhanced.

Owner:TENCENT TECH (SHENZHEN) CO LTD

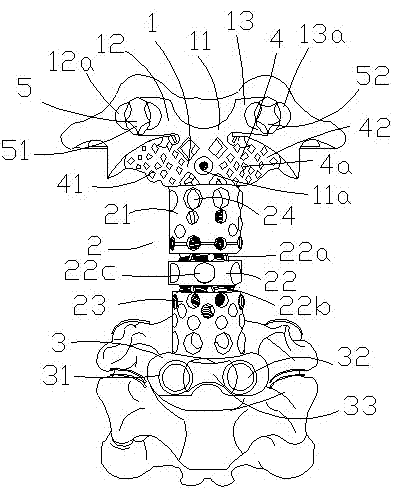

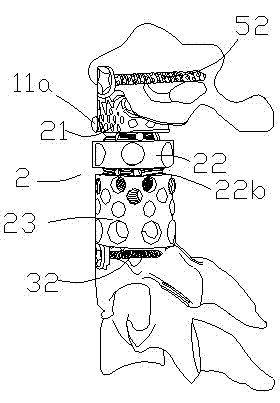

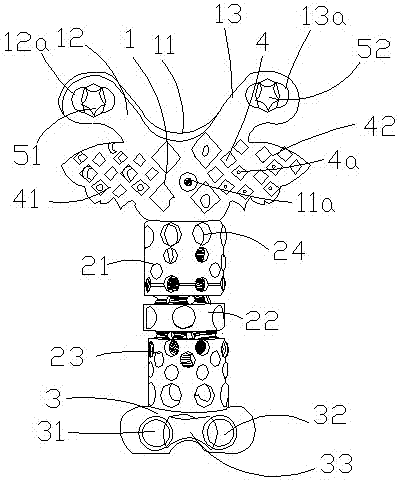

Second cervical vertebra displacer with merging structure

InactiveCN102860864AImprove stabilityReduce loosenessInternal osteosythesisSpinal implantsSpinal cageGynecology

The invention relates to a second cervical vertebra displacer with a merging structure. The second cervical vertebra displacer comprises an atlas connecting part, a fixed connector and a third cervical vertebra connecting part, wherein the atlas connecting part is fixedly connected with the atlas through a hollow atlas bolt, at least one merging hole is arranged on the bolt body of the hollow atlas bolt, the merging hole is internally provided with bone particles, and a support merging device matched with the shape of the lower surface of the atlas is arranged at the lower part of the atlas connecting part. The second cervical vertebra displacer can integrate a vertebral merging device bolt and a vertebral body, and greatly enhance the connecting performance and the fixation performance of the displacer. The second cervical vertebra displacer has the advantages that the displacer is more reliable, and the length of the displacer can be adjusted as required.

Owner:胡勇

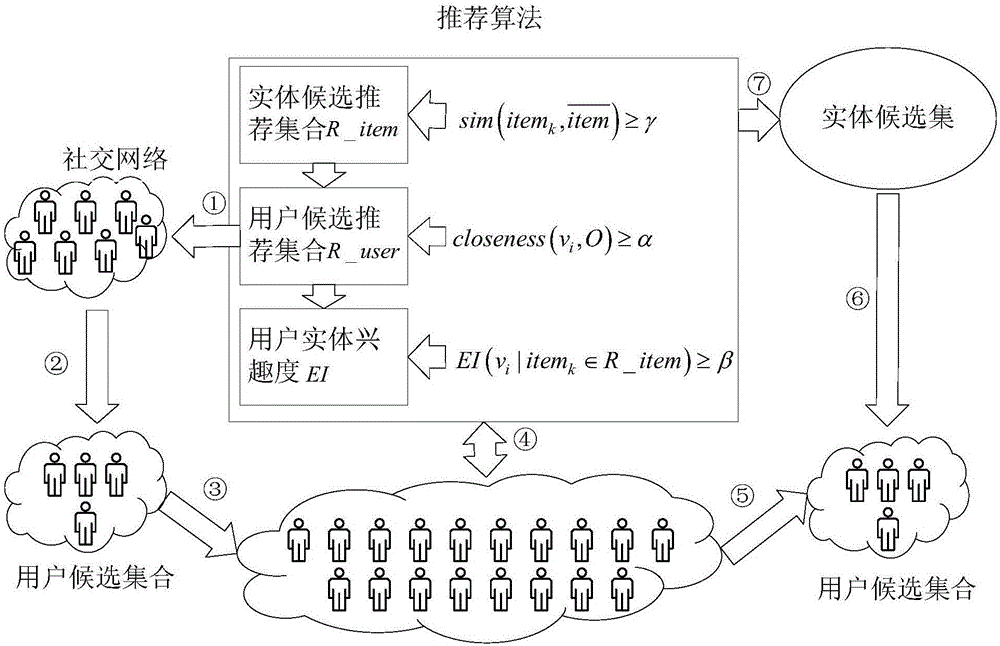

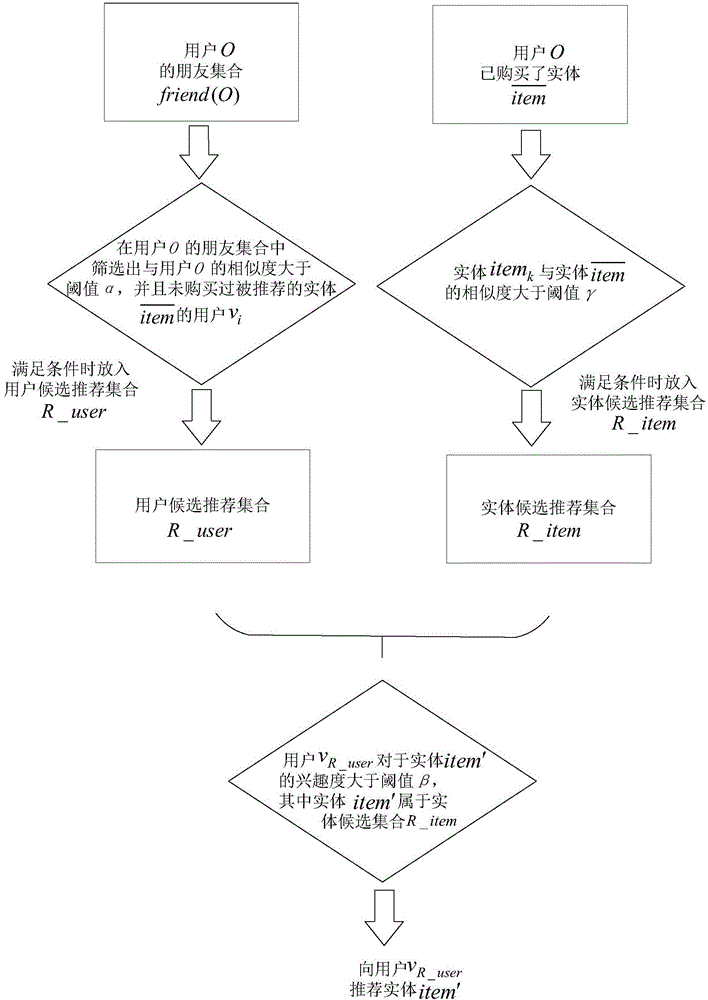

Social network based multi-dimension comprehensive recommending method

ActiveCN106528643ATightly fusedConsider comprehensivelyAdvertisementsSpecial data processing applicationsCommunity modelSocial web

The invention relates to a social network based multi-dimension comprehensive recommending method. The recommending method includes: establishing a social network model and a community model; S2: defining the user compactness, the user entity interest degree, and the entity similarity, wherein the user compactness reflects the compactness of a relation between two users, the user entity interest degree reflects the interest degree of a user in an entity, and the entity similarity reflects the consistent degree of attributes of two entities; and S3: performing multi-dimension entity comprehensive recommending on users in a social network according to the user compactness, the user entity interest degree, and the entity similarity. Compared with the prior art, the method can evaluate the influence of commerce websites of the social network from the user relation dimension, the entity similarity dimension, and the user interest dimension, and can perform relative entity recommending, and has wide actual application prospect.

Owner:SHANGHAI NORMAL UNIVERSITY

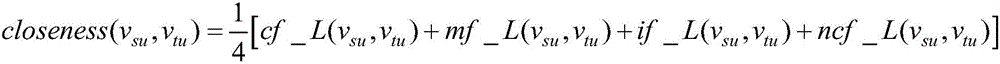

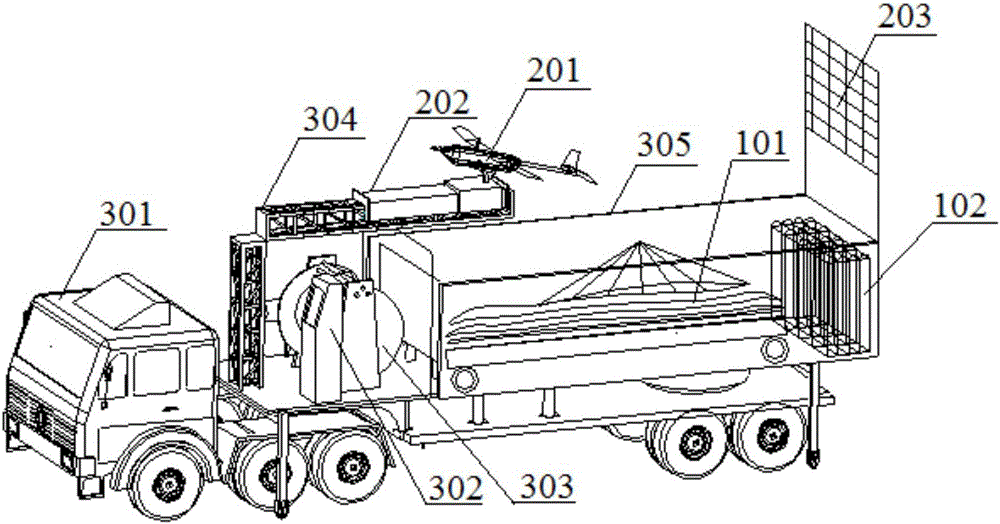

Boat, ground and vehicle combined monitoring method and monitoring system

ActiveCN106274617ALow costEasy to use and maintainLaunching/towing gearItem transportation vehiclesMonitoring systemEngineering

The invention discloses a boat, ground and vehicle combined monitoring method. Searching load equipment on a bag body of a moored boat is used for conducting region searching, tracking and recognizing load equipment on an unmanned aerial vehicle is used for conducting close tracking and recognizing on a target searched by the load searching equipment, and recognition results are sent back to a ground monitoring station. The invention further discloses a boat, ground and vehicle combined monitoring system which comprises the moored boat, the unmanned aerial vehicle, ground equipment and the load equipment. The ground equipment comprises a multifunctional truck and the ground monitoring station. The load equipment comprises the searching load equipment and the tracking and recognizing load equipment. The moored boat carries the searching load equipment for achieving long-term hover and region searching; the unmanned aerial vehicle carries the tracking and recognizing load equipment for achieving rapid departure and close investigation; and the multifunctional truck enables the moored boat, the unmanned aerial vehicle and the load equipment to be integrated, rapid and mobile deployment is achieved, and the ground monitoring station is used for achieving information fusion and commanding and coordinating work, so that a combined monitoring function of the boat, ground and vehicle combined monitoring system is achieved.

Owner:湖南航天远望科技有限公司 +1

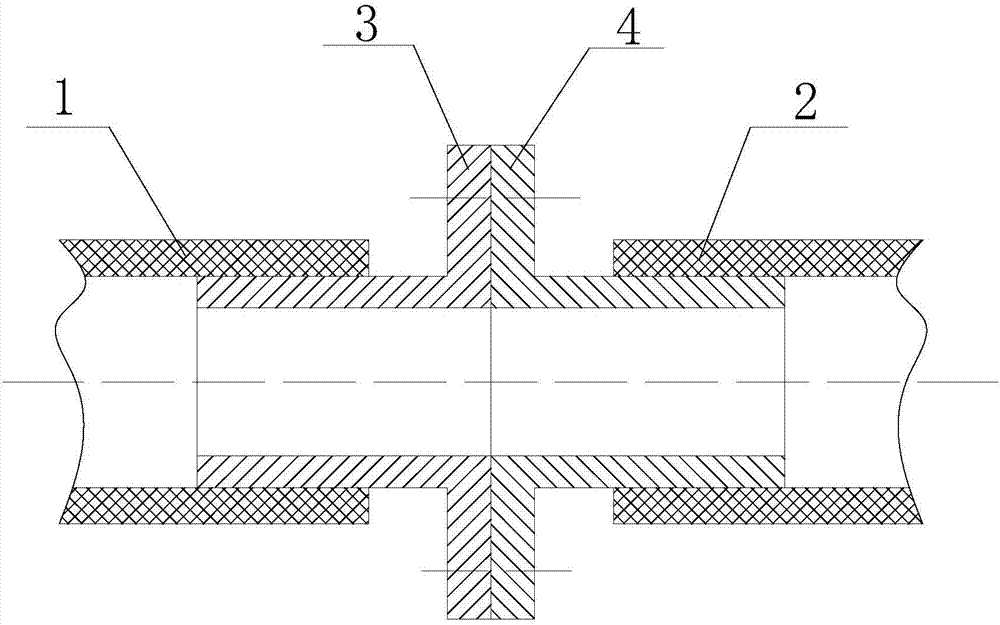

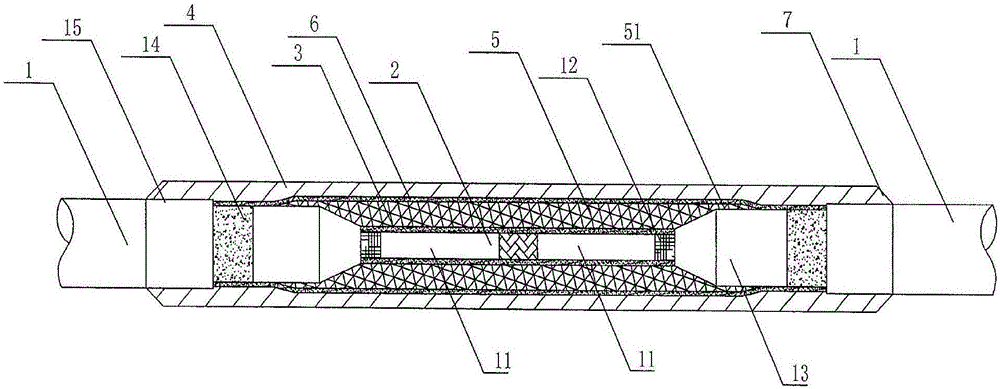

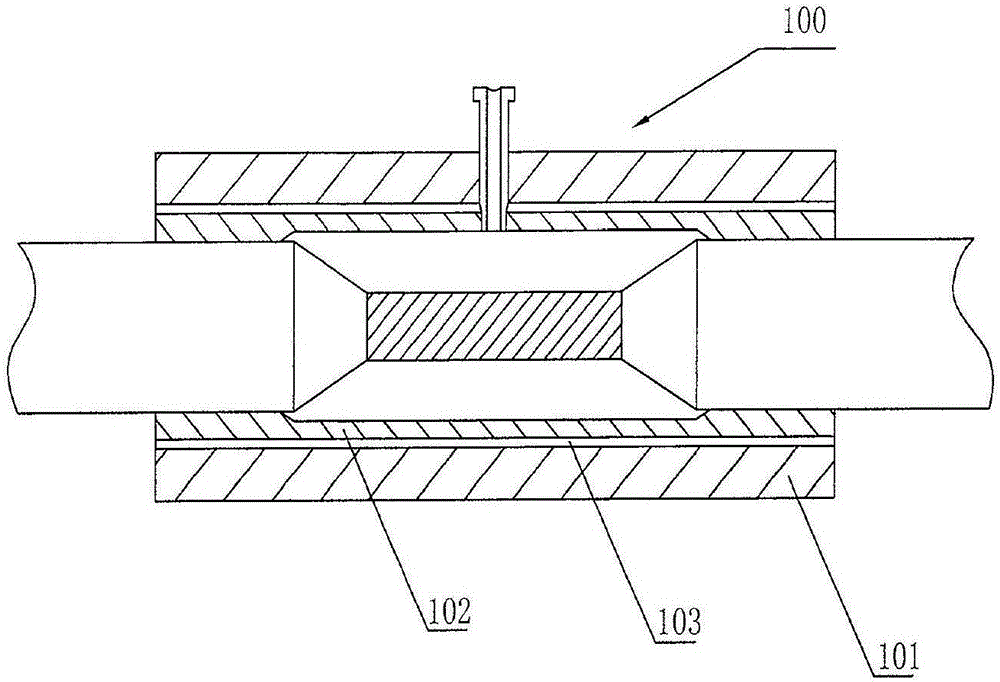

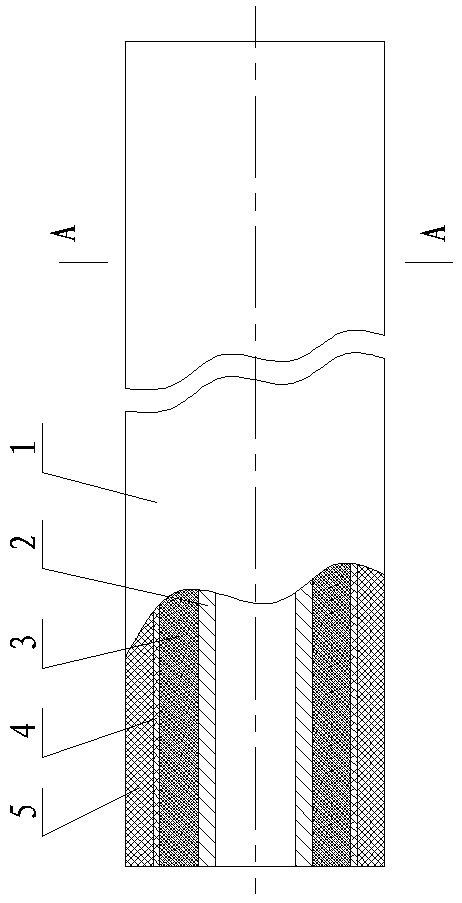

Reinforced thermoplastic pipe (RTP) joint structure and connection method thereof

PendingCN107228248AEffective protectionImprove pressure resistancePipe connection arrangementsButt jointHigh pressure

The invention provides a reinforced thermoplastic pipe (RTP) joint structure and a connection method thereof. The RTP joint structure comprises a first RTP, a second RTP, a PE electric melting joint and a GRE reinforced pipe hoop. The first RTP and the second RTP have the same external diameter, and the butt joint end faces of the first RTP and the second RTP are subjected to thermofusion welding. The internal diameter of the PE electric melting joint is matched with the external diameter of the first RTP, and a heating wire is preset and wound inside the PE electric melting joint. The outer wall of the PE electric melting joint is provided with an external thread. The PE electric melting joint simultaneously sleeves the first RTP and the second RTP and is subjected to electric fusion welding to the first RTP and the second RTP through the heating wire, the inner wall of the GRE reinforced pipe hoop is provided with an internal thread matched with the external thread of the PE electric melting joint, and the GRE reinforced pipe hoop is screwed on the external thread of the PE electric melting joint. According to the RTP joint structure, problems that in the prior art, an RTP connection part corrodes easily, is low in high pressure resistance and is subjected to wax deposition and blockage easily can be effectively solved.

Owner:曹如锋

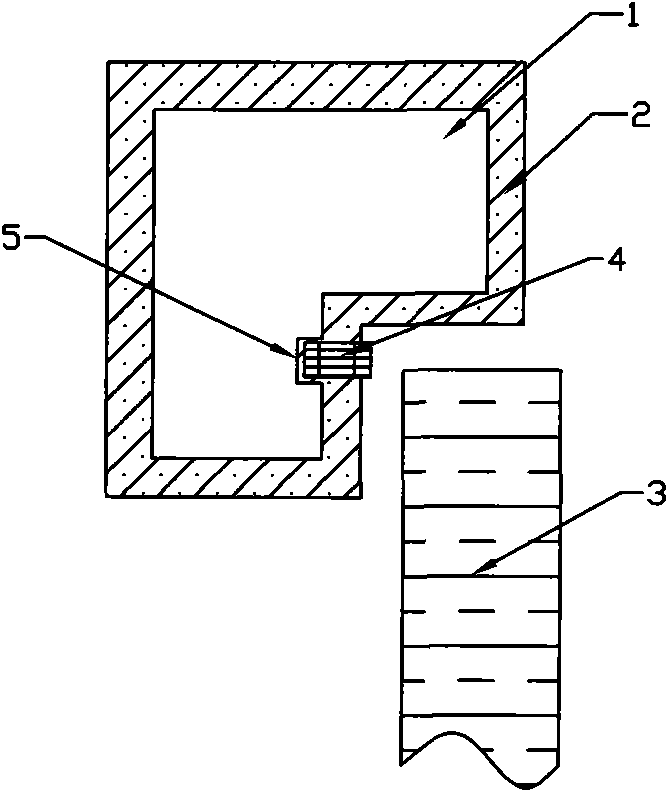

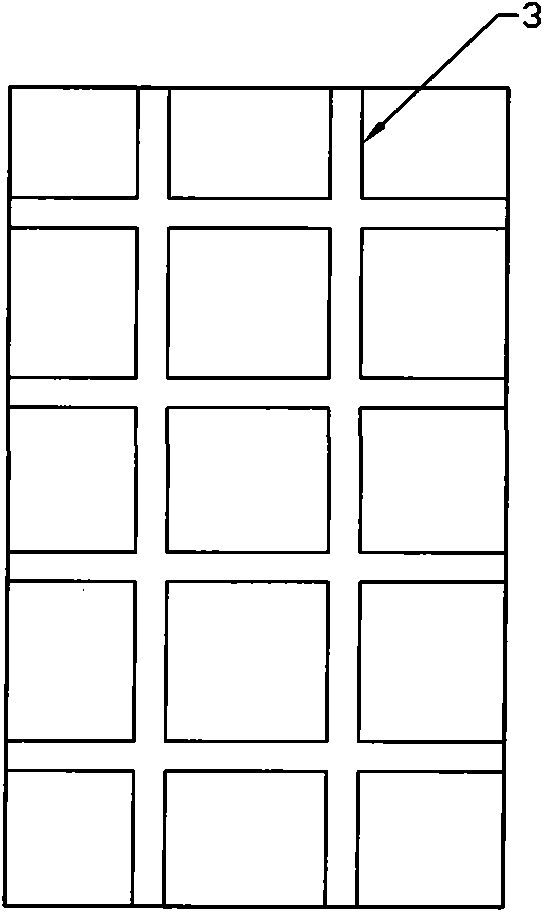

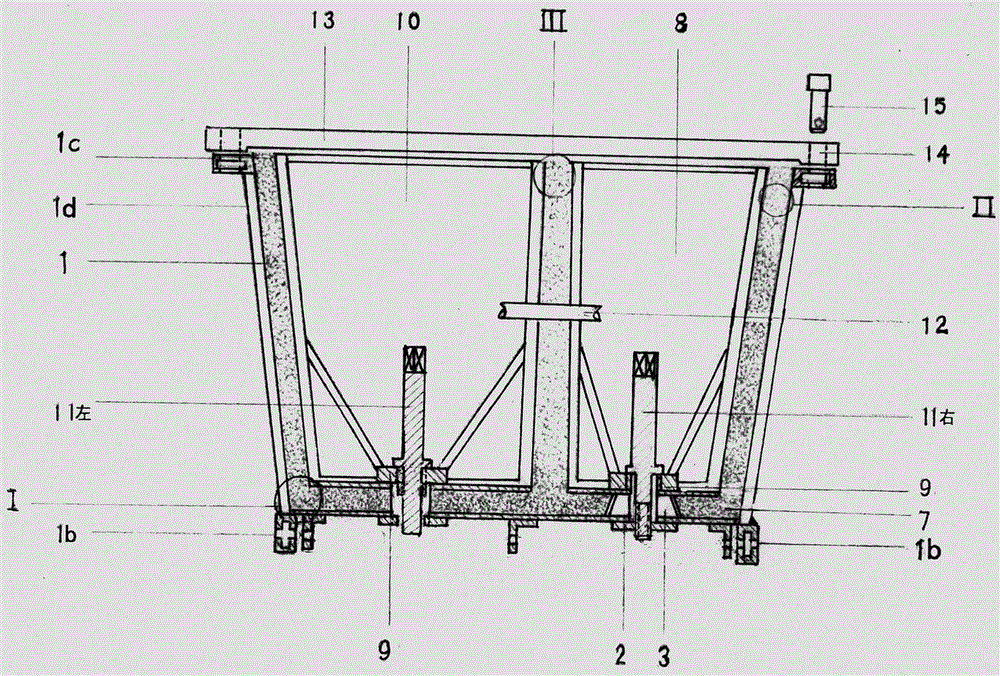

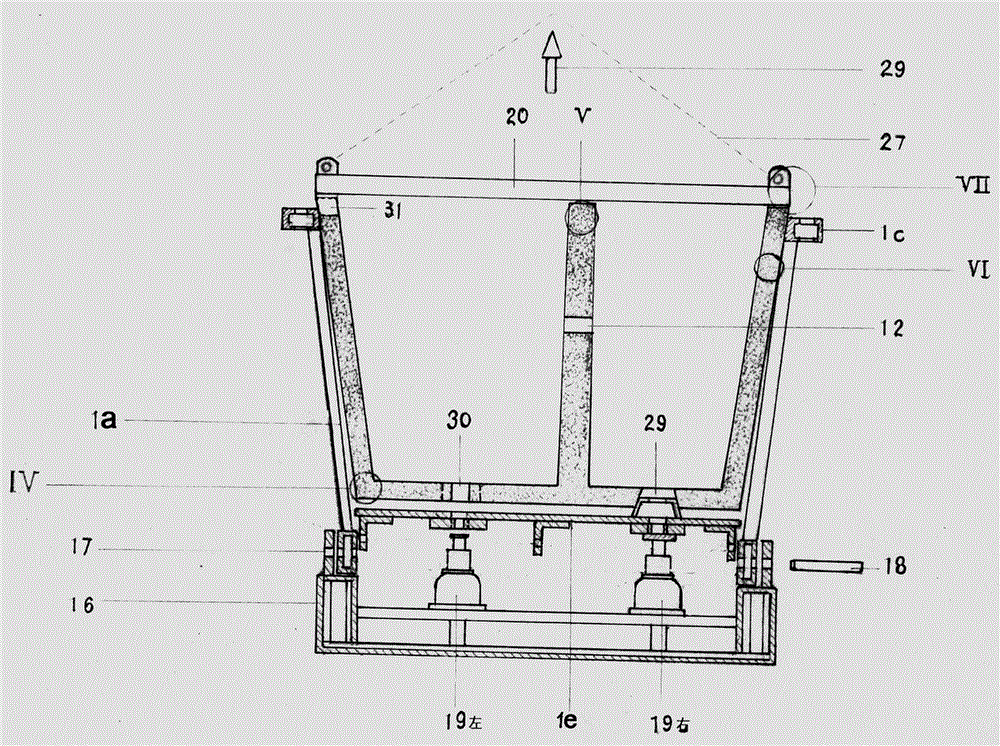

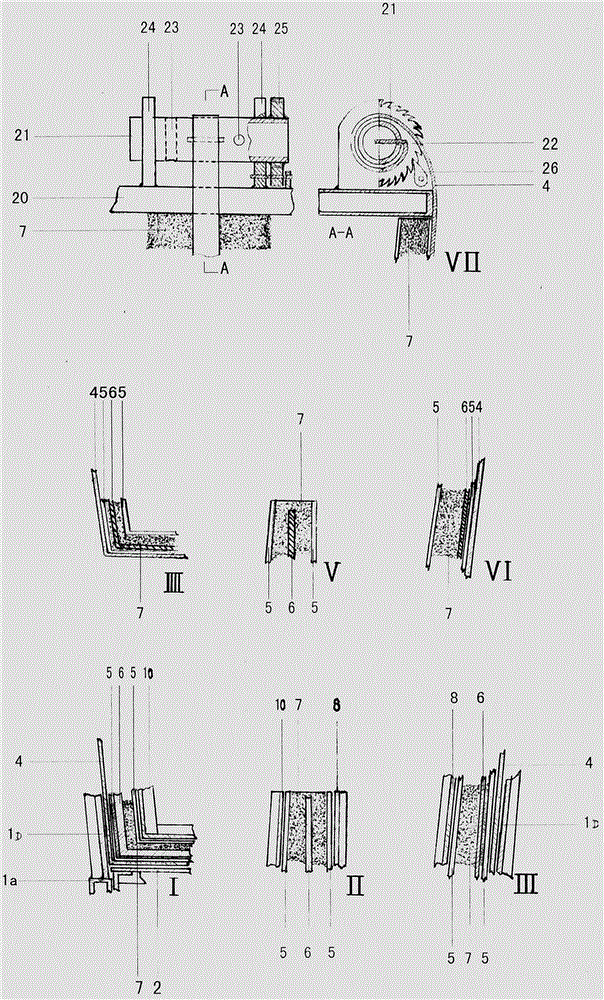

Cast-in-situ fire-proof door and method for manufacturing same

InactiveCN101550799AImprove fire performanceAvoid the problem of reduced fire resistanceFireproof doorsCeramic layered productsKeelFireproofing

The invention relates to a cast-in-situ fire-proof door and a method for manufacturing same, wherein the door comprises: a frame, panels, a keel frame and inorganic cement for filling, outer surface of the frame and one side of the two panels is in-situ cast with fireproofing inorganic cement coatings, the keel frame is installed between the sides cast with inorganic cement of the two panels, blowing agent is added in the liquid inorganic cement, which is cast in-situ in the chamber formed by the keel frame, contact surface of the frame and door leaf has a seal groove for installing sealing strip, and the door leaf and the frame cast-in-suit is pressed and shaped by a pressure device. The fire-proof door leaf and the frame of the invention avoids crack and nonuniform filling and nonuniform mixing of material in prior art because of employing fire-proof material, mass of inorganic cement with bubbles is filled in the keel frame, thereby lightening the fire-proof door, having good heat insulating effect, increasing density of the whole fire-proof door, and greatly strengthening fireproofing performance.

Owner:HUNAN BDF ENERGY SAVING TECH

Double firing manufacturing method of under-glaze decoration ceramic

The invention provides a manufacturing method for an under-glaze decoration pottery and porcelain twice fired, which has the steps that: firstly, an unburnt earthenware body fired by high temperature is made; secondly, low temperature over-glaze decoration paint is used to carry out painting decoration on the unburnt earthenware body, and the paint is adhered on the unburnt earthenware body; thirdly, the unburnt earthenware body after decorated by the painting is sent into a low temperature decorating kiln to carry out low temperature baking, and the paint on the unburnt earthenware body and the unburnt earthenware body are combined together; fourthly, transparent glaze is painted on the unburnt earthenware body after baked by the low temperature; fifthly, the unburnt earthenware body after painted by the transparent glaze is sent into a high temperature kiln to be fired by high temperature, and the under-glaze decoration pottery and porcelain is made. The pottery and porcelain manufactured by the method solves the problem that the picture wears after the under-glaze decoration pottery and porcelain is used for a long time. After fired in high temperature, the paint and glaze are tightly blent, the effect similar to rain drop glaze appears in the place where the paint is thick, artistic quality is strong, decoration effect is good, and esthetics is increased.

Owner:郭春森

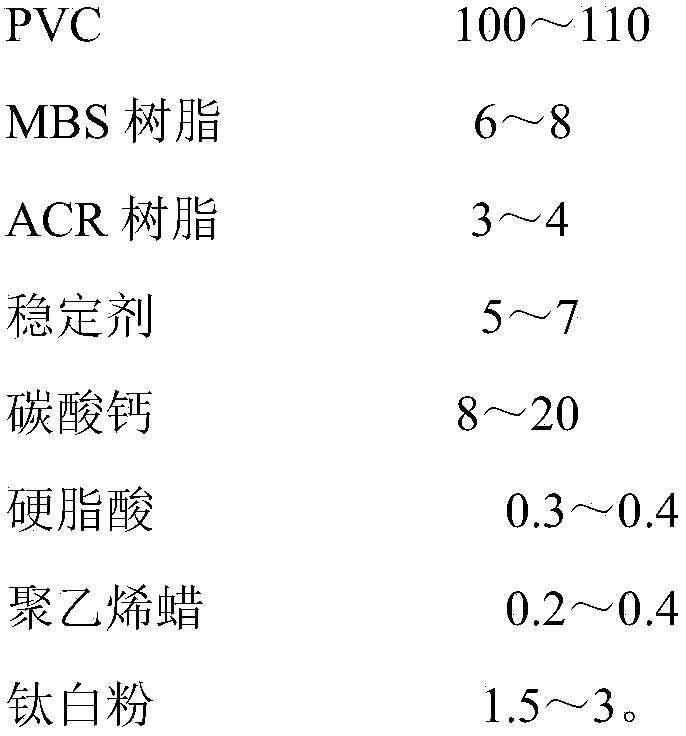

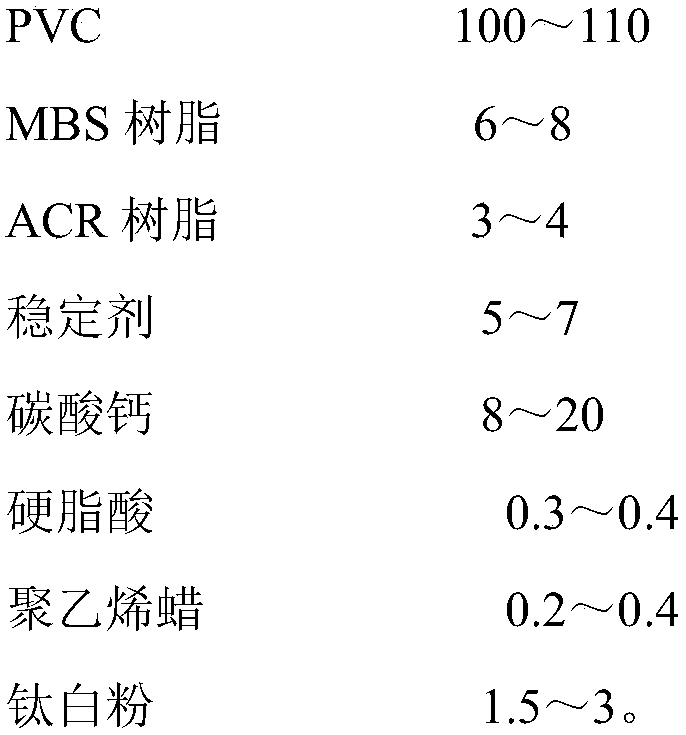

PVC tubular material formula high in impact resistance, and preparation method thereof

The invention discloses a PVC tubular material formula high in impact resistance, and a preparation method thereof, and belongs to the technical field of high molecular material moulding processing. The PVC tubular material formula high in impact resistance is composed of, by weight, 100 to 110 parts of PVC, 6 to 8 parts of MBS resin, 3 to 4 parts of ACR resin, 5 to 7 parts of a stabilizing agent,8 to 20 parts of calcium carbonate, 0.3 to 0.4 part of stearic acid, 0.2 to 0.4 part of polyethylene wax, and 1.5 to 3 parts of titanium dioxide. According to the preparation method, a composite flexibilizer is prepared from MBS resin and ACR resin to modify PVC; a sea-island structure is formed by a dispersion phase the MBS resin and the ACR resin, and a continuous phase polyvinyl chloride, a small amount of MBS and ACR is capable of providing polyvinyl chloride material with relatively high impact strength, the toughening effect is ideal, and technical defect problems of conventional PVC tubular material that the toughness is poor, and rupture is easily caused are solved.

Owner:马鞍山顾地塑胶有限公司

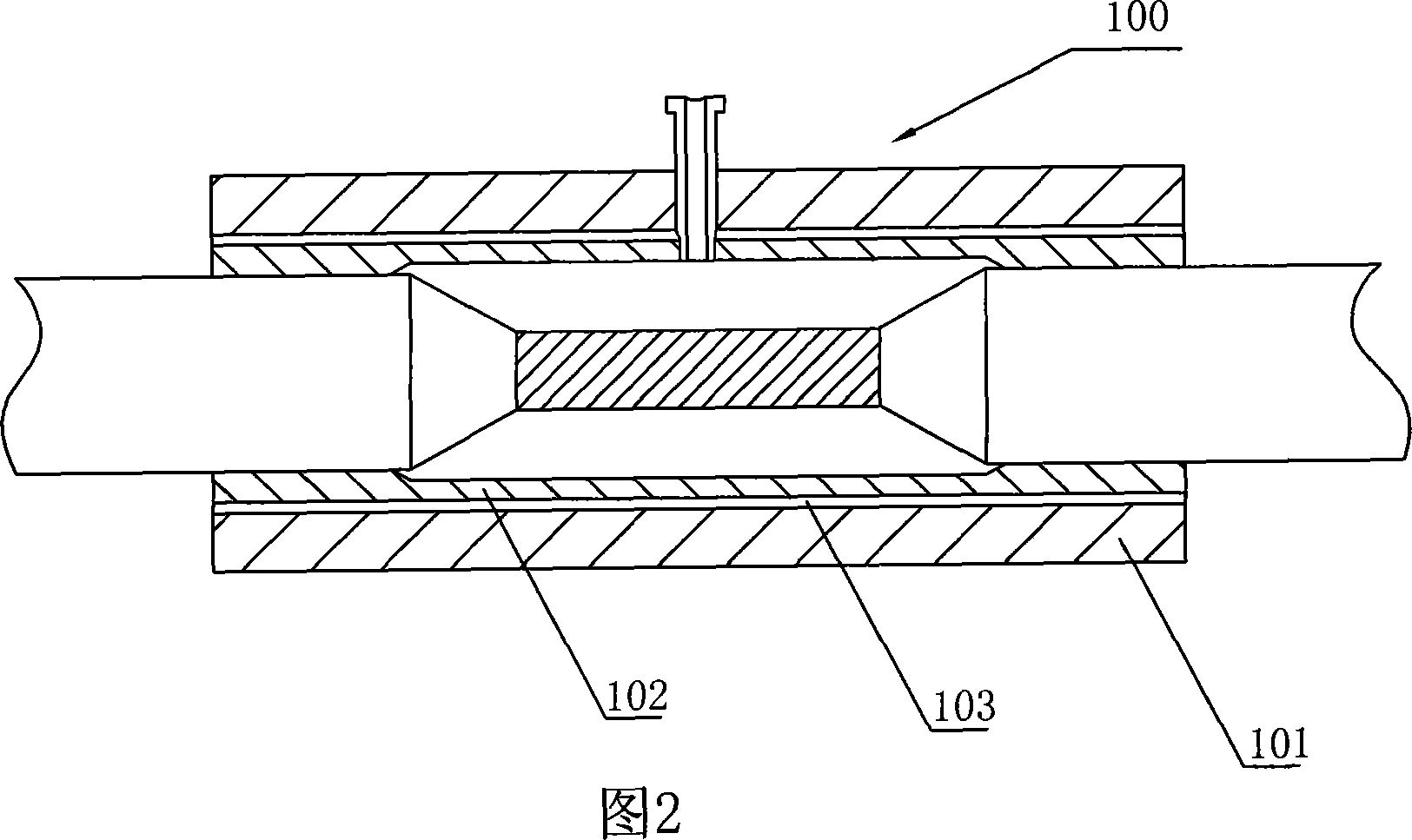

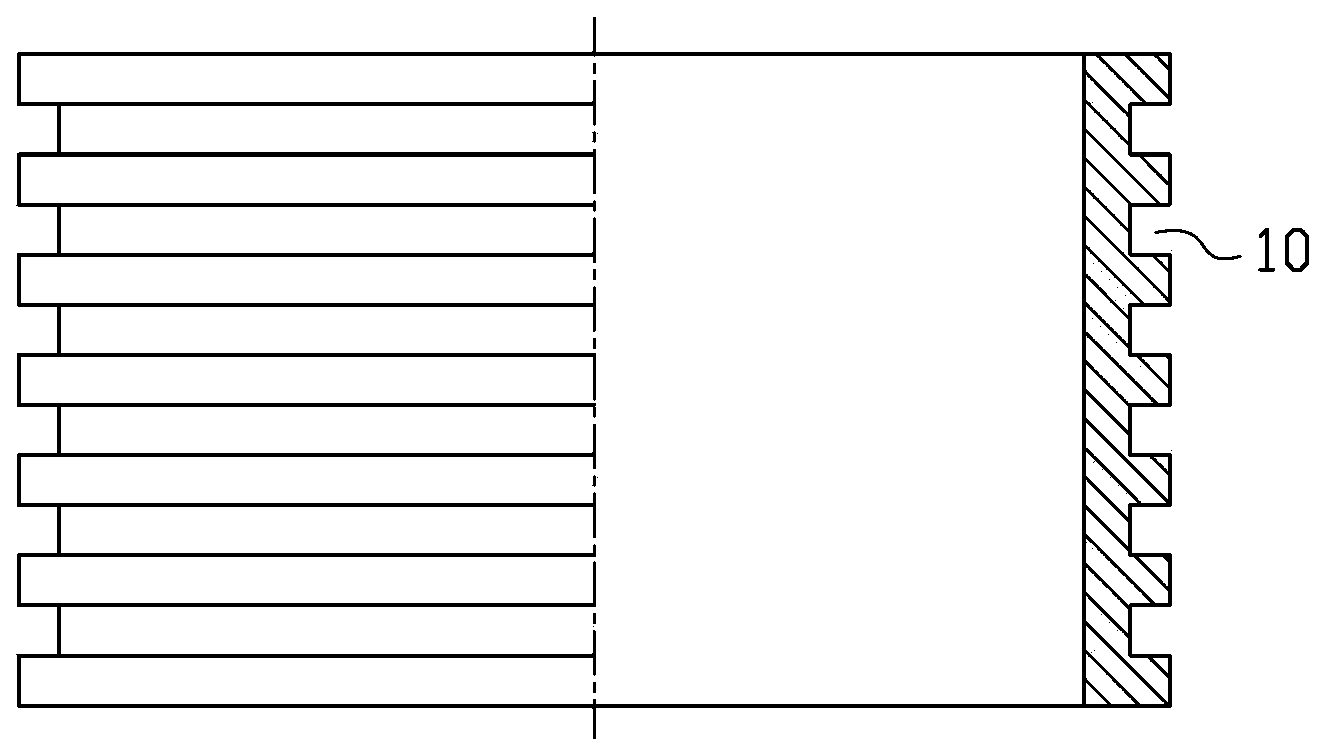

Preparation method of crosslinked polyethylene cable connector

InactiveCN106374397AElectrical performance improvements and enhancementsEliminate void defectsApparatus for joining/termination cablesAnti stressEngineering

The invention relates to a cable connector, in particular to a preparation method of a crosslinked polyethylene cable connector. The preparation method comprises the following steps: firstly, peeling and cutting insulating layers at two ends of a cable so that a core of the cable is exposed; secondly, cutting the crosslinked insulating layers on two sides of the connector to be conical; thirdly, setting an anti-stress cone at the end of the cable, and fixing the treated cable to two ends of an insulating forming die, wherein the insulating forming die comprises a metal outer die and an elastic lining die, an elastic die expansion gap is formed between the metal outer die and the elastic lining die, and the temperature of an inner cavity of the insulating forming die is raised to be 120 DEG C; fourthly, after performing cleaning drying treatment on the surface of the insulating layer, setting an outer semi-conducting layer in combination with an outer shielding layer reserved section of the cable; and fifthly, wrapping a metal belt on the surface of the outer semi-conducting layer in a gap manner, using an oxyhydrogen flame to firmly weld two ends of the metal belt and the outer surface of a lead protective tube so as to form a metal projective sleeve tube, and then using the oxyhydrogen flame to trim welding surfaces at two ends of the metal protective sleeve tube so as to form a slope connecting section.

Owner:重庆三峡电线电缆科技股份有限公司

Cylinder device and manufacturing method thereof

ActiveCN103437896AReduce axial sizeMiniaturizationCylinder headsCylindersWear resistantMiniaturization

The invention relates to a cylinder device manufacturing method, which comprises the steps of a) prefabricating a ceramic cylinder liner with a porous structure; b) sintering or depositing a wear-resistant alloy layer on the inner surface of the ceramic cylinder liner; c) casting molten aluminum on the outer surface of the ceramic cylinder liner to form a cylinder body. The embodiment of the invention additionally provides a cylinder device which is manufactured by adopting the cylinder device manufacturing method. The cylinder device comprises the ceramic cylinder liner with the porous structure, the wear-resistant layer which is formed on the inner surface of the ceramic cylinder liner, and the cylinder body which is formed on the outer surface of the ceramic cylinder liner and is made of cast aluminum, wherein wear-resistant alloy which seeps inwards from the inner surface of the ceramic cylinder liner and the molten aluminum which seeps inwards from the outer surface of the ceramic cylinder liner are mutually interlaced in the ceramic cylinder liner. The cylinder device provided by the embodiment of the invention can be manufactured to be very thin, the axial dimension of an engine can be reduced, the miniaturization of the engine is facilitated and the manufacturing cost is lower.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

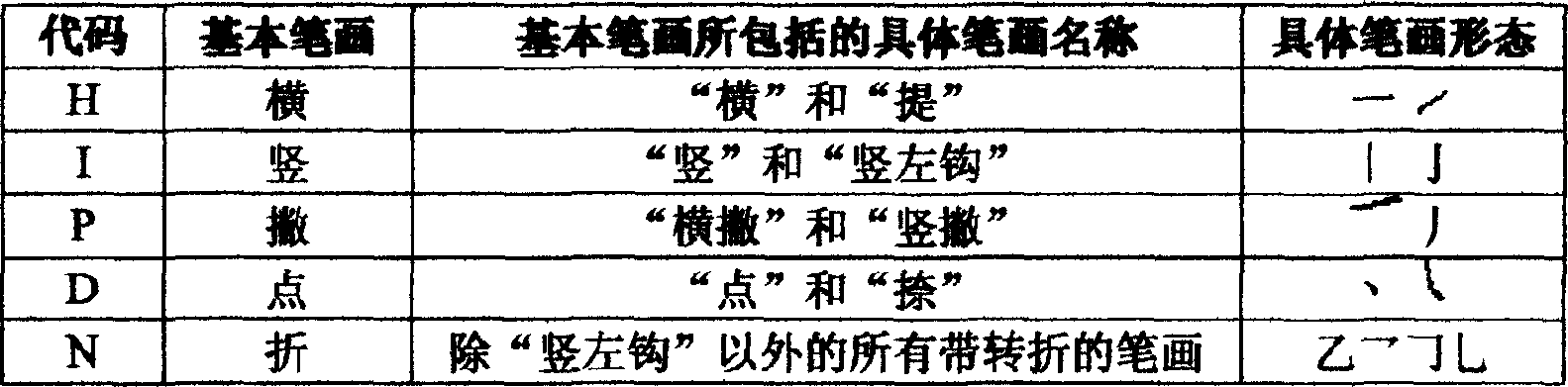

Computer Chinese character inputting method

InactiveCN1564110AIncrease learning difficultyDestroy natureInput/output processes for data processingChinese charactersAlgorithm

The invention considers Chinese character is composed of coded components. Component includes characters, radicals, single strokes, and others. According to definition specified in the invention, a character is split into components, which have their own codes. In inputting a character, the character is split into components, or a character is combination of components. Components are arranged in sequence according to national standard, and each component has own code. Thus, Chinese character is input to computer through code sequence. In the invention, coded component is not limited by forms and quantity.

Owner:张满元

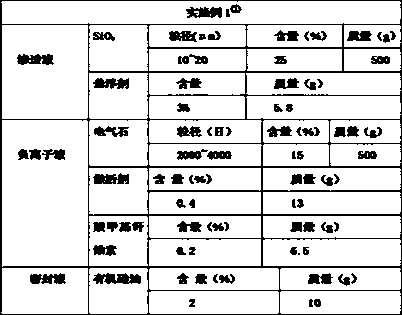

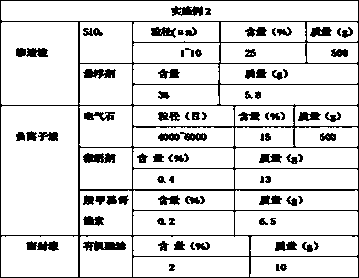

Hollow glass drying agent and preparation method thereof

InactiveCN107115771ALow costLarge specific surface areaDispersed particle separationSURFACTANT BLENDPolyacrylamide

The invention discloses a hollow glass drying agent and a preparation method thereof. The drying agent is prepared from the following raw materials: diatomite, straw powder, foam aluminum, magnesium perchlorate, polyacrylamide, aluminum sulfate, sodium hexametaphosphate, titanium dioxide, polyethylene, a surfactant and de-ionized water. The preparation method comprises the following steps: mixing and combusting the straw powder and the diatomite to obtain mixture ash; mixing and grinding the foam aluminum, the polyacrylamide, the titanium dioxide, the polyethylene and the de-ionized water to obtain a first mixture; adding the magnesium perchlorate, the aluminum sulfate, the sodium hexametaphosphate and the surfactant into a reaction kettle; heating to 120 DEG C to 180 DEG C and adding a first mixture; stirring and raising the temperature to 340 DEG C to 450 DEG C; adding the mixture into a double-screw extruder and extruding to obtain grains. The drying agent disclosed by the invention has the advantages of low cost, large specific surface area and large static water absorption amount, is not easily influenced by temperature and humidity and has a stable absorption capability. A preparation process is simple, and the components are more tightly fused and are not easy to disintegrate.

Owner:JIANGSU JINGDUN ENERGY SAVING TECH CO LTD

Low-cost wall brick

InactiveCN106220143AMaterial selection scienceThe preparation method is simple and easyCeramic materials productionClaywaresIndustrial constructionBrick

The invention discloses a low-cost wall brick, belonging to the technical field of building materials. The low-cost wall brick is prepared from the following raw materials: 20-30 parts by weight of cinder, 35-45 parts by weight of construction waste soil, 25-28 parts by weight of grinding wheel ash, 3-5 parts by weight of straw, 5-10 parts by weight of limestone, 1-2 parts by weight of vermiculite and 80-90 parts by weight of river water; the low-cost wall brick is prepared by the steps of pre-activating, crushing, aging in a sealing way, making adobe, drying and sintering. The low-cost wall brick is scientific in material selection and fully utilizes industrial construction waste, thus reducing the production cost and increasing the enterprise profit; a preparation method of the low-cost wall brick is advanced, and improves the activity and adhesiveness of raw materials through a pre-activating method so as to enable the raw materials to be blended together closely; therefore, the low-cost wall brick is close in texture, non-powdered, high in compressive strength and wear resistance and good in anti-cracking performance, can be used for a long time in a low-temperature environment, and is long in service life, wide in use and strong in adaptability to construction.

Owner:滁州市瑞景园林股份有限公司

Environment-friendly permeable ceramic brick and production method thereof

InactiveCN107793131ARealize resource reuseReduce consumptionCeramic materials productionClaywaresCompression moldingSurface layer

The invention provides an environment-friendly permeable ceramic brick and a production method thereof. The production method is characterized by comprising the following steps: taking particles of awaste unglazed ceramic product as a basic framework, taking waste brick particles with different sizes as bottom layer aggregate and surface layer aggregate according to certain proportions respectively and respectively adding proper amounts of ceramic binder, water and ceramic pigment; carrying out dosing, mixing, secondary cloth compression molding, firing, inspecting and other working procedures, thus obtaining the qualified environment-friendly permeable ceramic brick. The production method disclosed by the invention is suitable for large-batch industrial production of the permeable brick;the produced permeable brick has the characteristics of high permeability, high compressive strength, good skidproof performance, diversified varieties, convenience in maintenance and the like; in addition, waste bricks in a ceramic factory are used as raw materials, so that a novel path is provided for effectively utilizing ceramic waste products.

Owner:佛山绿顺透科技有限公司

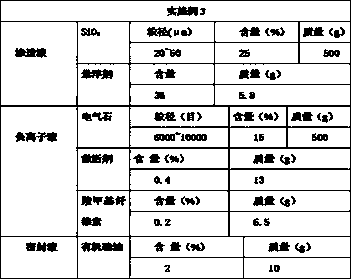

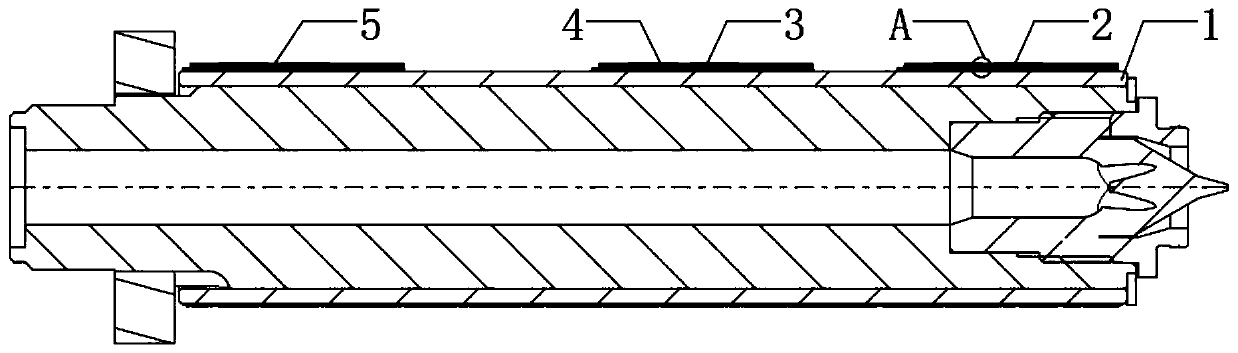

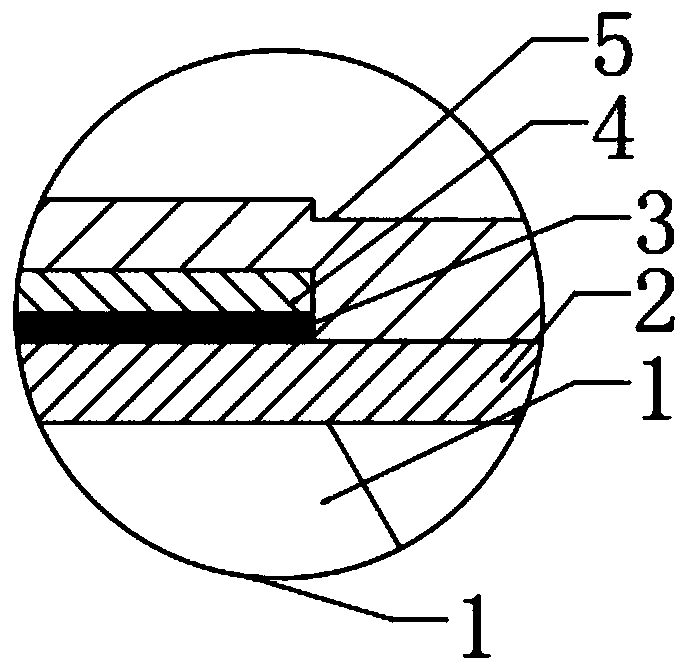

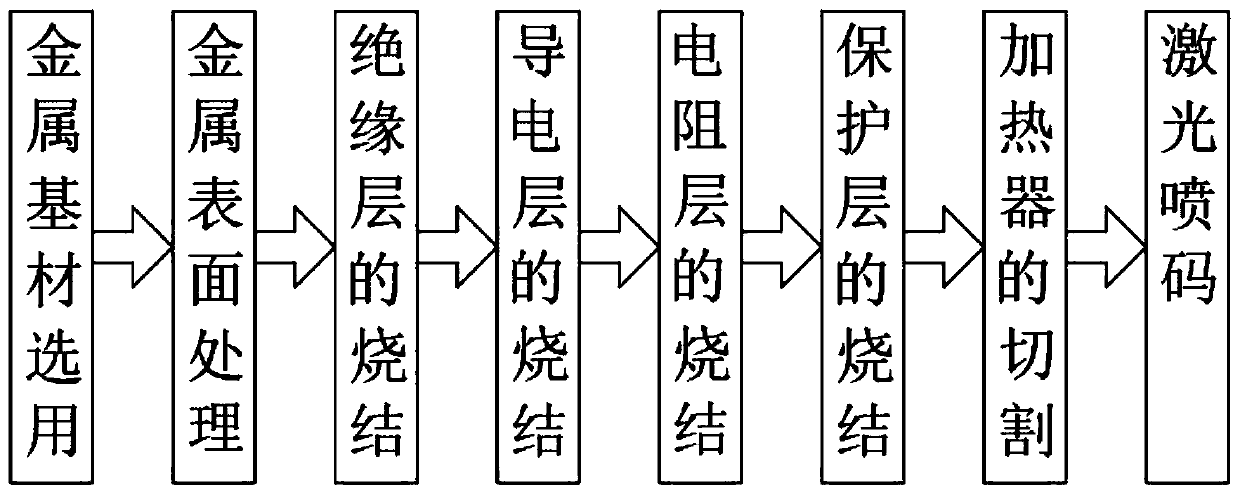

Manufacturing process of metal surface thick-film heater

InactiveCN111491401AAvoid scratchesTightly fusedOhmic-resistance heating detailsHeating element materialsProtection layerLow power dissipation

The invention discloses a manufacturing process of a metal surface thick-film heater. The manufacturing process comprises the following steps of 1, selecting a metal surface thick-film heater base material; 2, treating a metal surface; 3, printing and sintering an insulating layer 2; 4, printing and sintering a conductive layer; 5, printing and sintering a resistance layer 4; 6, printing and sintering a protective layer; 7, cutting the heater; and 8, performing laser code spraying. According to the invention, a metal substrate is coated with the insulating layer; the insulating layer is coatedwith the conductive layer; the conductive layer is coated with the resistance layer to serve as a heating medium, and finally, the resistance layer is coated with the protective layer to prevent accidental collision and the scratching of film layers of the thick-film heater such that all the film layers are closely fused into a whole, all the layers are closely fused into a whole, and the problems of low efficiency, high power consumption, short service life, high cost and the like of the thick-film heater are solved.

Owner:SUZHOU HTS MOLD

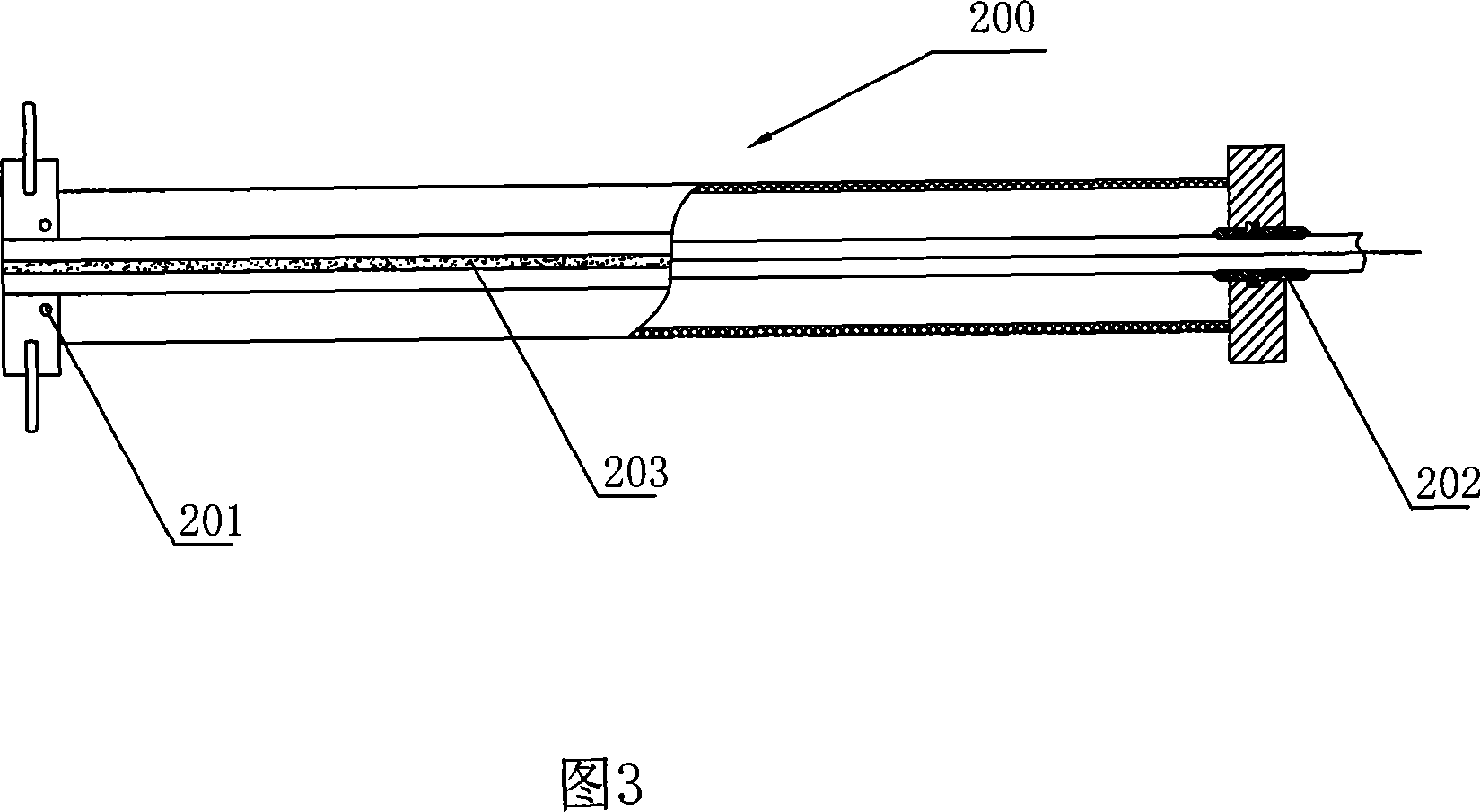

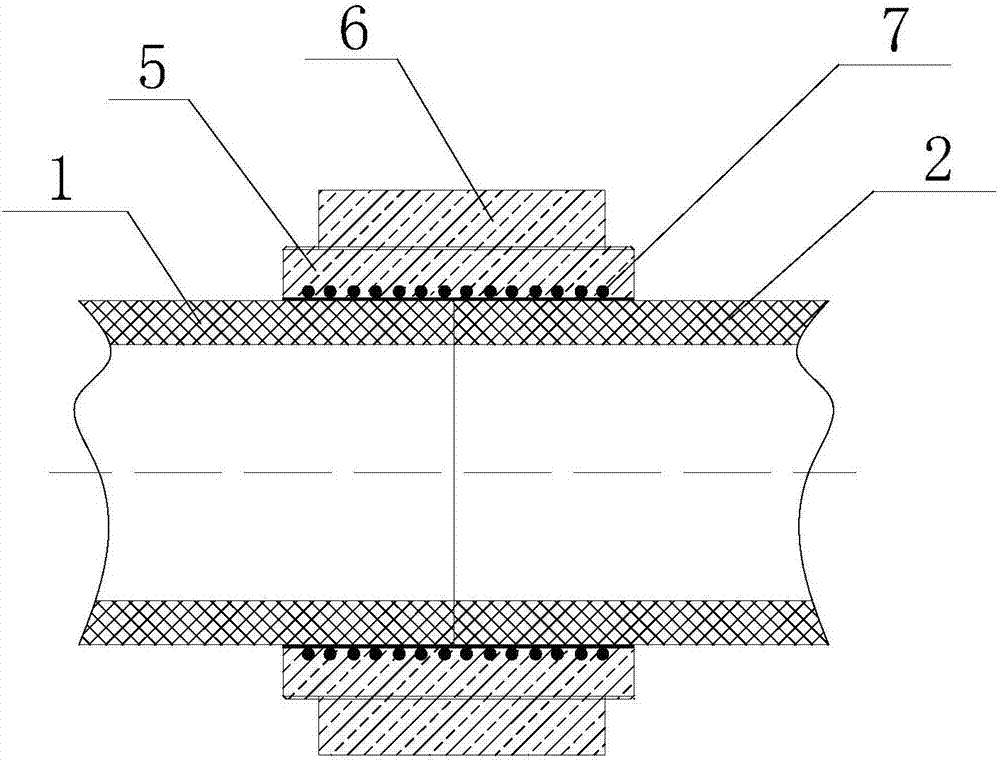

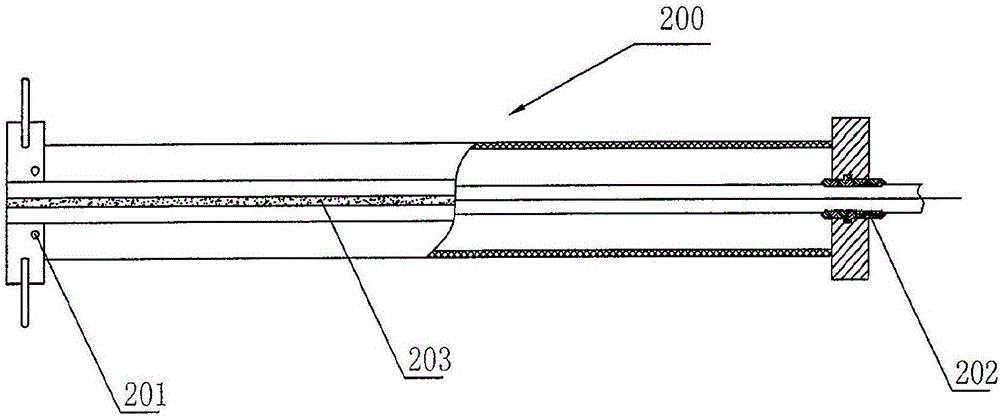

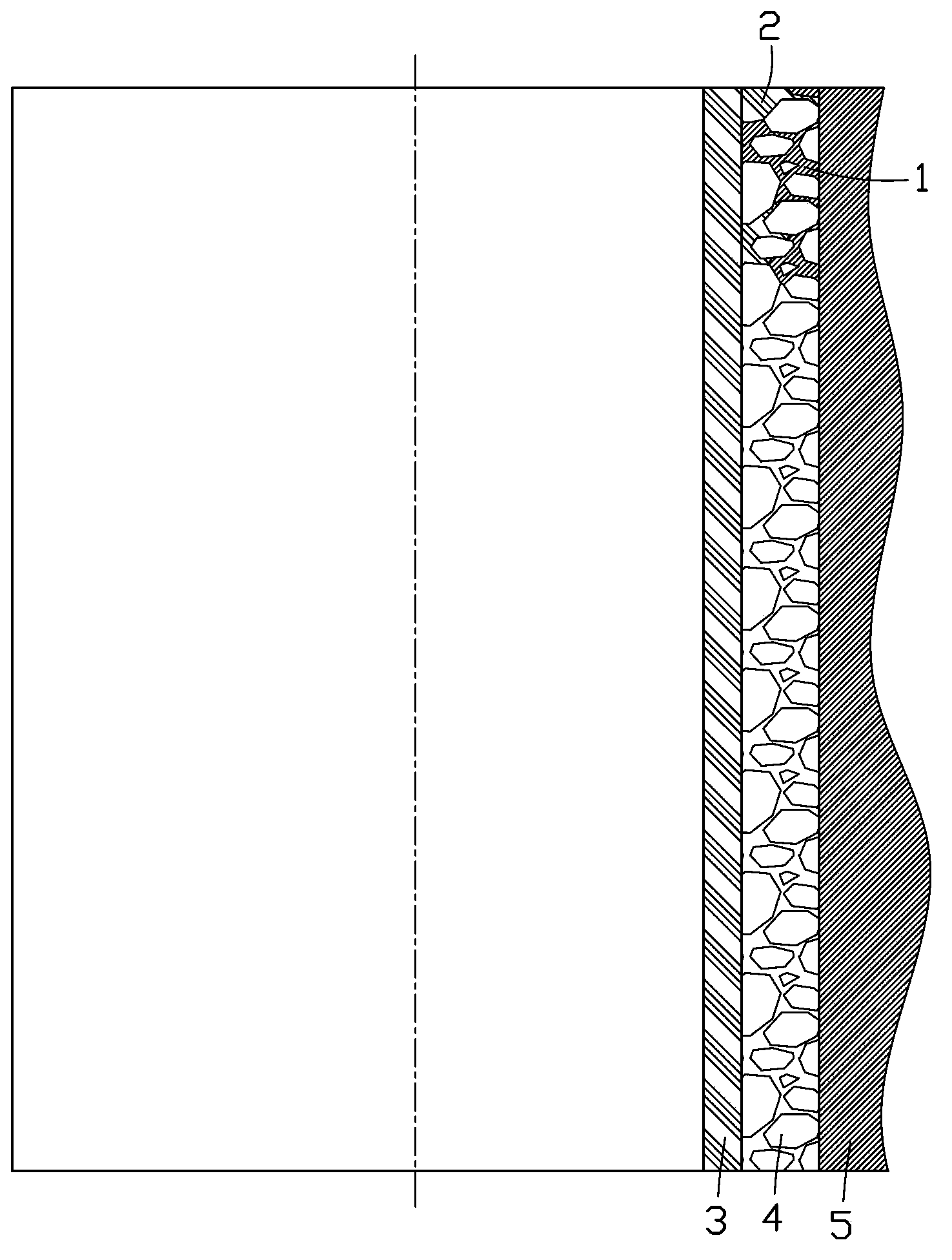

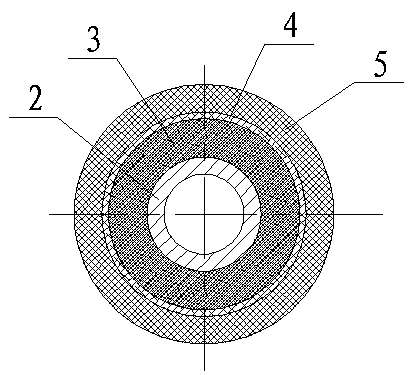

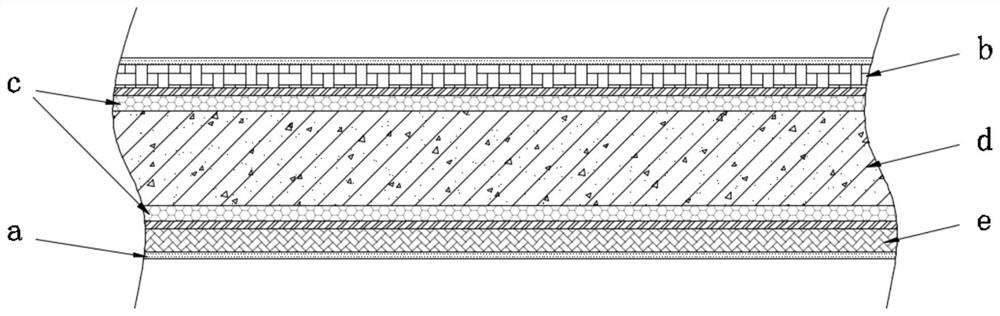

Heat preservation pipe and combination method for combining foamed polyurethane spraying with outer protective pipe winding

PendingCN109630809ASynchronization of Life EffectsAchieve continuityThermal insulationPipe protection by thermal insulationPlastic foamEngineering

The invention provides a heat preservation pipe and a combination method for combining foamed polyurethane spraying with outer protective pipe winding. At present, a pipe-in-pipe technology is used for heat preservation pipe manufacturing, a polyurethane plastic foam heat preservation layer and a pre-manufactured outer protective pipe are independent and cannot be closely combined due to materialand manufacturing difference, the two materials are subjected to phase change independently due to heat expansion and cold contraction caused by temperature change, and accordingly a three-in-one structure needed by the heat preservation pipe technology cannot be realized. The heat preservation pipe comprises a heat preservation pipe body (1), the heat preservation pipe body comprises a working pipe (2), a polyurethane heat preservation layer (3) is arranged on the outer diameter portion of the working pipe, a coating of polyethylene particles (4) is sprayed on the outer side of the polyurethane heat preservation layer through a spraying gun, the polyethylene particles are uniformly embedded in the outer layer of the polyurethane heat preservation layer, the embedding depth is 0.5-1 mm, and a polyethylene outer protective pipe (5) is wound on the outer side of the polyethylene particles. The heat preservation pipe is used for combining foamed polyurethane spraying with outer protectivepipe winding.

Owner:HARBIN LOGSTOR ENERGY SAVING TECH

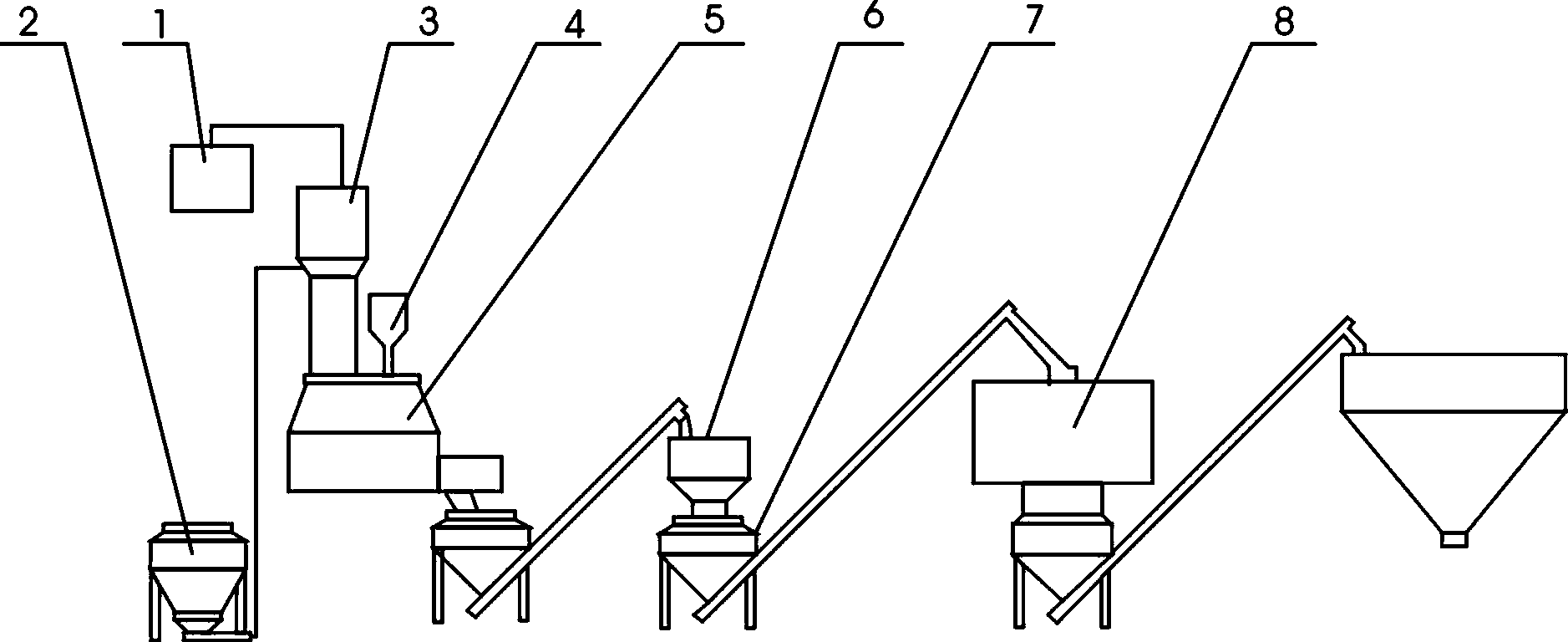

Continuous production equipment and production technology of powdered condiments

The invention relates to production equipment and a method of food condiments, in particular to continuous production equipment and a production technology of powdered condiments. According to the continuous production equipment and the production technology of the powdered condiments, a vacuum pump is connected with the top end of a vacuum feeder, a hopper is connected with a feed port of the vacuum feeder, an outlet of the vacuum feeder is arranged at a feed port of a high-speed mixer, an atomizer is arranged at the top of the high-speed mixer, an outlet of the high-speed mixer is connected with a screw feeder, the discharge tail end of the screw feeder is arranged above a particle screen, the screw feeder is arranged at a bottom outlet of the particle screen, and the discharge tail end of the screw feeder is connected with a trough type mixer. The technology comprises the steps of vacuum pumping, high-speed mixing, atomization, sieving and the like. The equipment and the method have the advantages that the operational pollution is avoided, and the solid-liquid phase mixing efficiency and the production efficiency are improved.

Owner:成都圣恩生物科技股份有限公司

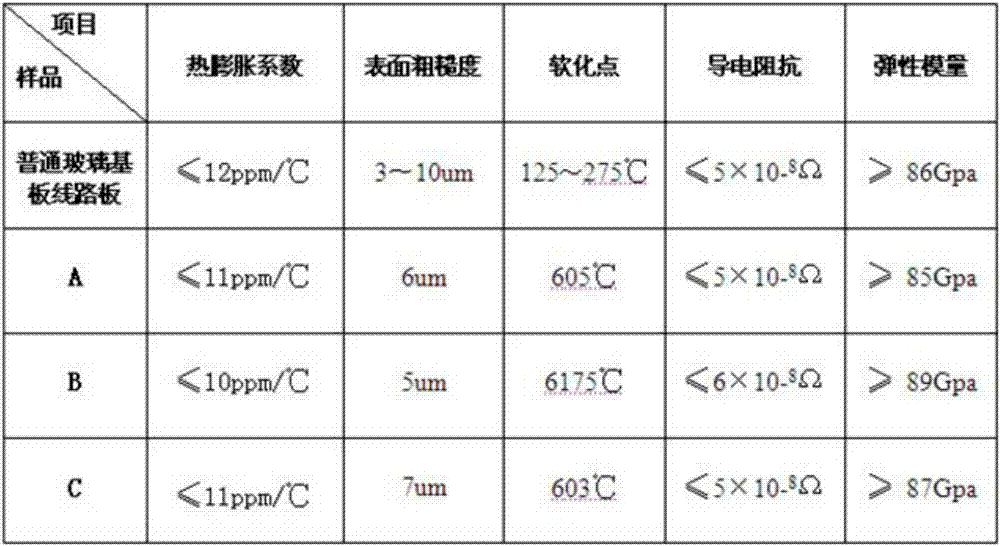

Circuit board glass substrate manufactured from alkali-free glass fiber waste silk and preparation method thereof

ActiveCN107188407ACapable of superconductingReduce conductive resistanceCoatingsCircuit susbtrate materialsOptical transmittanceMaterial technology

The invention discloses a circuit board glass substrate manufactured from alkali-free glass fiber waste silk and a preparation method thereof, and belongs to the technical field of circuit board materials. According to the circuit board glass substrate manufactured from alkali-free glass fiber waste silk, the alkali-free glass fiber waste silk is adopted as a raw material for manufacturing the circuit board glass substrate, the obtained glass substrate and a conducting circuit are in the fusion relation, the relation is compact, the super-conductivity is achieved, and the conductive resistance is lower than 5*10<-8> omega; the glass substrate and the conductive circuit are in dielectric-free combination, the circuit layer has the good heat conductivity during high-power application, the circuit layer and the glass substrate are in molecular tight fusion, and peeling is likely to be achieved; high light transmittance can be ensured, and the light transmittance exceeds 95%; the surface of the glass substrate is flushed with the upper surface of the conducting circuit, the surface of the while glass substrate circuit board is smooth, and the conducting circuit is not likely to be damaged.

Owner:江苏顺德缘文化科技股份有限公司

Integral lining of continuous casting tundish

The invention relates to an integral lining of a continuous casting tundish. The integral lining is not attached to the surface of a permanent layer of the continuous casting tundish, but can hold molten steel for a long time, resists corrosion of molten steel slag liquid and scouring, is provided with a straight arc slag dam with an impact area, a molten steel discharge hole, a molten steel drain hole and a slag liquid drain outlet, and is manufactured in one step. The integral lining has the outstanding advantages that the field assembly is simple and fast, labor and time are saved, and the integral lining is very environment-friendly. The using time is fixed and clear, and the integral lining is definitely safe and reliable. After the using of the integral lining is completed, the continuous casting tundish can be tilted for only once to pour all remaining lining bodies, steel lumps and slag, so that the lining bodies, the steel lumps and the slag are instantaneously and thoroughly separated from the surface of the permanent layer, the surface of the permanent layer is always not damaged, and the service life of the integral lining is effectively prolonged.

Owner:沈光辉

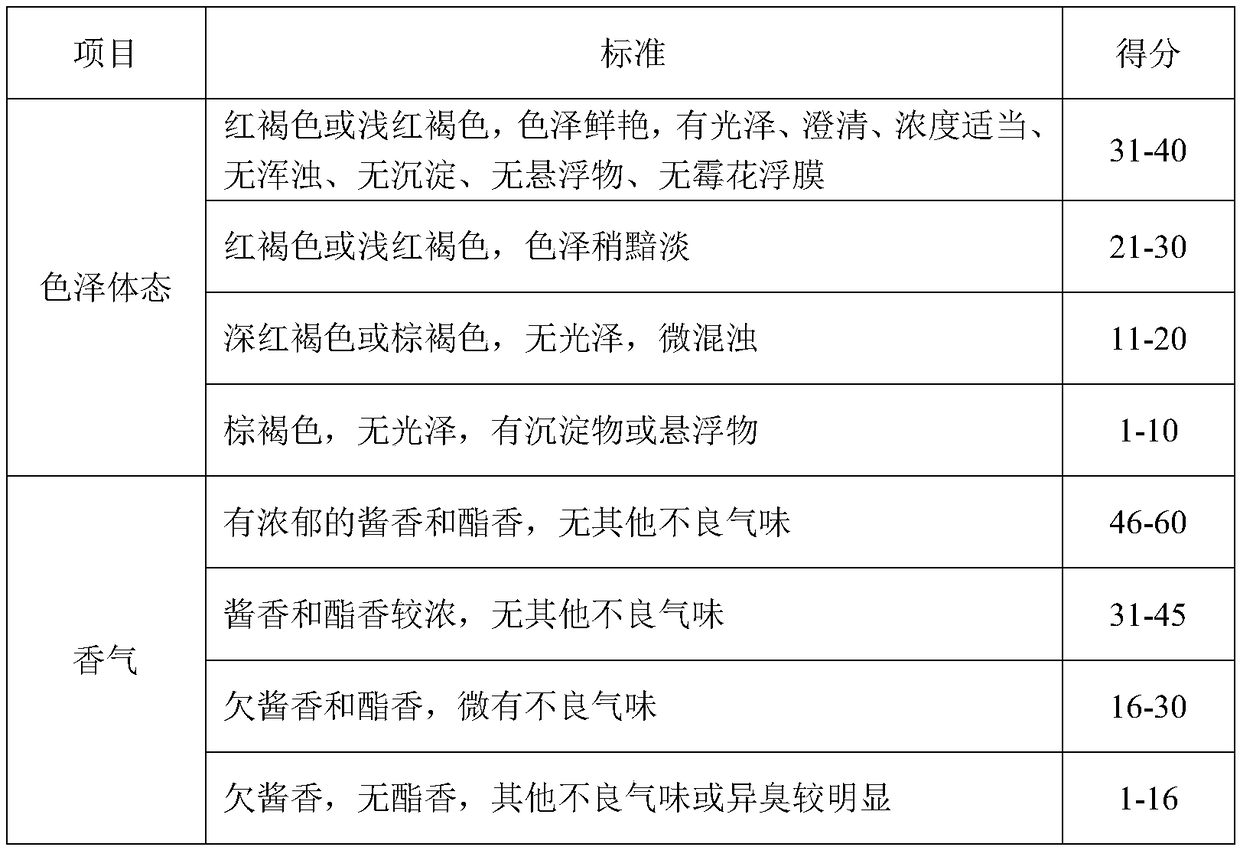

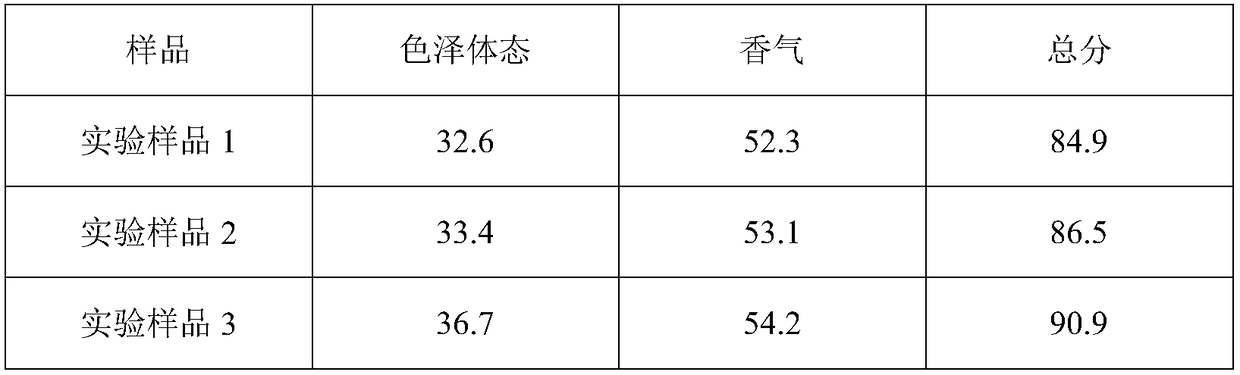

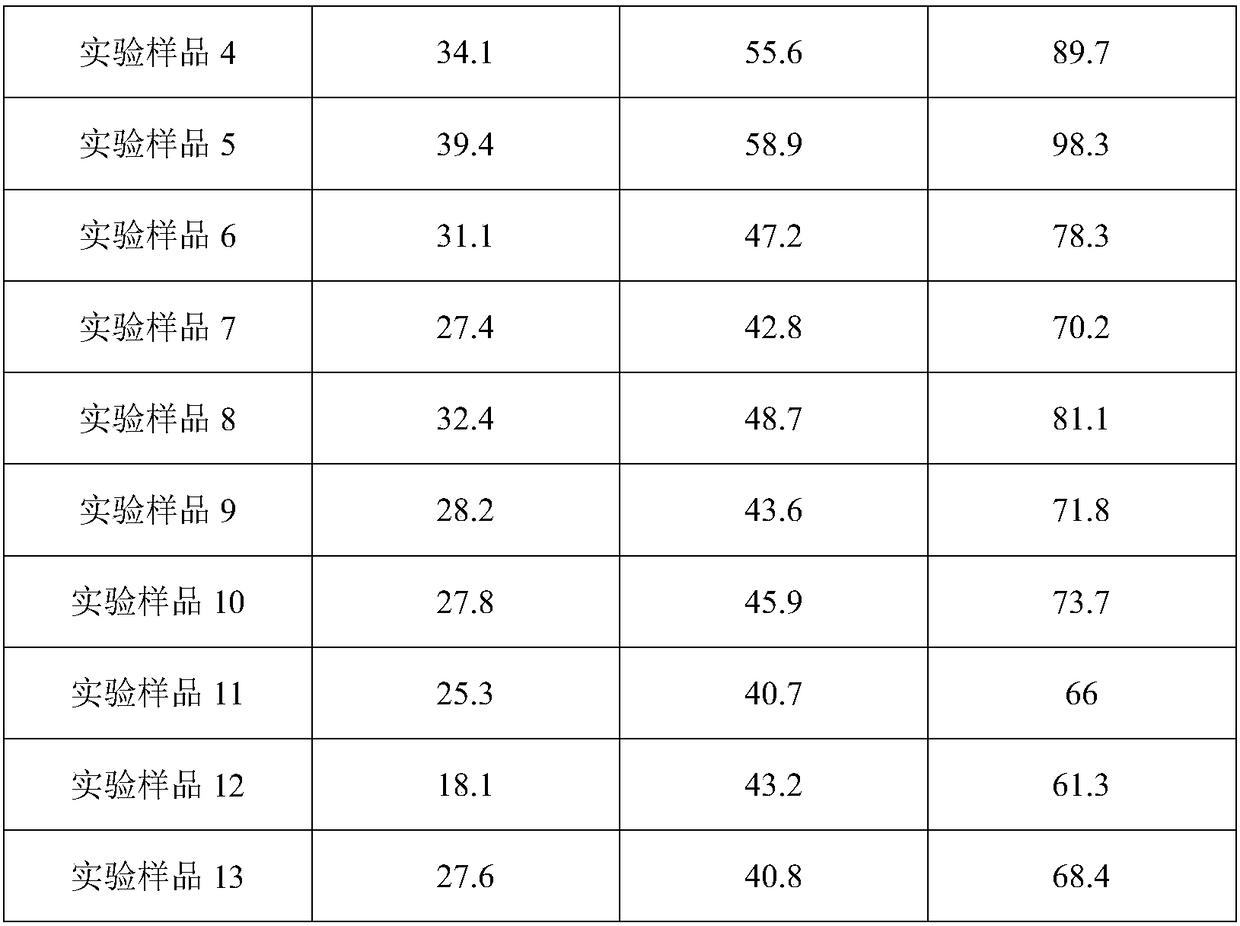

Soybean sauce microbial immobilization fermentation composition, preparation process and use method

ActiveCN108949592AIncrease reproductive rateImprove fermentation capacityFungiBacteriaAnti stressTrehalose

The invention provides a soybean sauce microbial immobilization fermentation composition, a preparation process and a use method and particularly relates to the technical field of production of seasonings. The fermentation composition includes: low-fat pectin, water, zygosaccharomyces rouxii, zygosaccharomyces sojae, torulopsis etchellsii, pediococcus halophilus, tetracoccus sojae, an MgCl2 solution, egg white, azotobacter chroococcum and trehalose. When being used for fermentation of soybean sauce, the fermentation composition is stirred and mixed with soybean sauce mash, then nitrogen is fedfor performing fermentation; finally the fermented product is filtered to obtain a fermented liquid. The fermentation composition is toxic-free and environment-friendly, is anti-stress and anti-corrosion and can be recycled; when being used for fermentation of soybean sauce, the fermentation composition can reduce fermentation period, and the fermented liquid is high in contents of soluble non-salt solids, total nitrogen and amino acid nitrogen.

Owner:广西顶俏食品科技集团有限公司

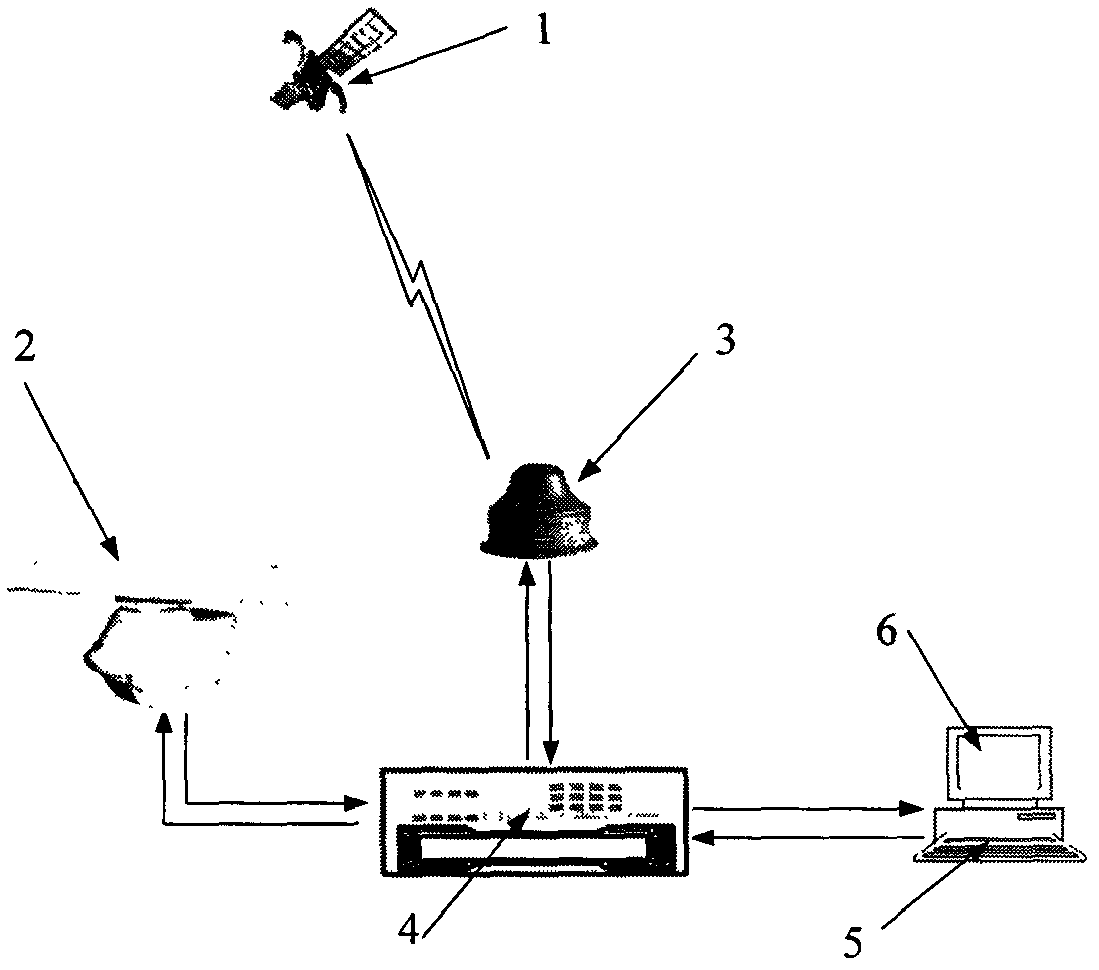

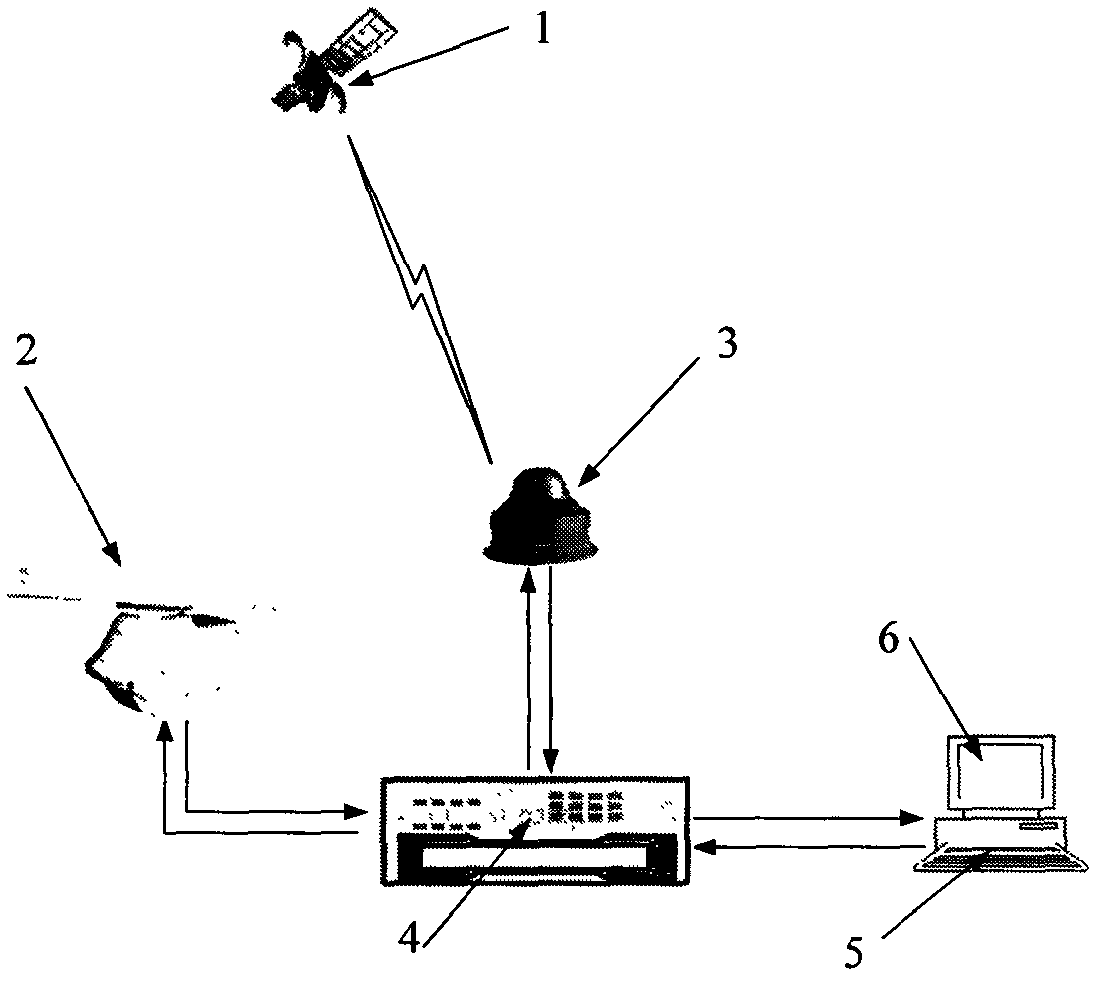

Multifunctional navigation radar based on Beidou satellite

InactiveCN102628932ATightly fusedRealize integrationSatellite radio beaconingCollision preventionNetwork construction

The invention belongs to the field of application of a Beidou satellite navigation system, and belongs to the technical field of radars. Specifically, a Beidou satellite navigation system of China is applied to a navigation radar, and the Beidou satellite navigation system is integrally designed with the navigation radar, so that the functions of time service, positioning, speed measuring, navigation, communication, electronic chart and the like of Beidou are integrated with the target measuring and sea condition measuring functions of the navigation radar, the navigation radar has the multiple functions of accurate positioning of a ship, electronic chart, path planning, automatic path guidance, course replaying, path plotting, collision prevention alarming, target indication, ship network construction, connection with superior units, receiving of monitoring of superior units, inquiry of positions of brother ships, water surface situation monitoring, radar networking, sea condition measurement, information recording and reporting and the like, and the navigation capability of the ship navigation radar is improved greatly.

Owner:BEIJING HUIMEI ELECTRONICS TECH

Glass ceramic and preparation method thereof

ActiveCN113562977AThere is a high possibility of integrationClose contactGlass-ceramicMaterials science

The invention discloses glass ceramic and a preparation method thereof, and belongs to the technical field of glass materials. The glass ceramic comprises the following components in percentage by weight: 40 to 80 percent of SiO2, 5 to 25 percent of Al2O3, 1 to 15 percent of Li2O, 0.5 to 25 percent of Na2O, 0.1 to 1 percent of K2O and 0 to 5 percent of B2O3. The invention also provides a preparation method of the glass ceramic, which comprises the following steps: S1, heating precursor glass to T1 and preserving heat, T1 being 540-580 DEG C; s2, cooling the precursor glass to T2 and preserving heat, T2 being 480-560 DEG C, and T1>T2; s3, repeating the steps S1-S2, heating the precursor glass continuously to T3 and preserving heat, T3 being 560-650 DEG C, and T3>T1>T2; and S4, continuously heating the precursor glass treated in the step S3 to 700-800 DEG C, and carrying out heat preservation to obtain the glass ceramic. The glass ceramic has a microscopic hierarchical structure and excellent mechanical properties.

Owner:WUHAN UNIV OF TECH

Grinding wheel ash hollow brick and production method thereof

InactiveCN106187096AThe preparation method is simple and easyReduce manufacturing costCeramic shaping apparatusCeramic materials productionIndustrial constructionBrick

The invention discloses a grinding wheel ash hollow brick. The grinding wheel ash hollow brick comprises, by weight, 15-20 parts of grinding wheel ash, 30-40 parts of river silt, 25-30 parts of coal cinder, 90-105 parts of water, 20-30 parts of montmorillonite, 35-40 parts of basalt, 2-5 parts of wood chip, 1-3 parts of polystyrene beads and 2-5 parts of quicklime, and is produced through the steps of pre-activating, crushing, sealed aging, green body making, drying, sintering and the like. Industrial construction waste is fully utilized, production cost is lowered, corporate profit is increased, the production method is advanced, raw material activity and adhesiveness are improved by means of pre-activating, the raw materials are closely fused together, and the grinding wheel ash hollow brick is compact in texture, non-chalking, high in compressive strength and wear resistance, good in cracking resistance, long in service life, wide in application, high in construction adaptability and capable of being used for a long time under the condition of low temperature.

Owner:安徽琮玥工程项目管理有限公司

Wind-resistant metal rock wool composite plate for external wall thermal insulation

The invention relates to the technical field of metal rock wool composite plate manufacturing, and discloses a wind-resistant metal rock wool composite plate for external wall thermal insulation. An outer side steel plate and an inner side steel plate are used as inner and outer layers of a base material, magnetite, mica powder, manganese steel and chromium carbide alloy are added into a four-roller centrifugal machine for high-speed solidification processing into a composite plate blank after high-temperature smelting, the composite plate blank is soaked in a composite resin liquid to form apreliminary rock wool layer, the inner and outer layers of the base material and the preliminary rock wool layer are sequentially placed into a composite machine to form a whole, and the wind-resistant metal composite plate is prepared. By means of the combination of the magnetite, the mica powder, the manganese steel and the chromium carbide alloy, the performance requirements of the rock wool composite plate are improved, by means of the combination of polyvinyl chloride, epoxy resin and polystyrene, the compactness among all plate layers is optimal, the internal structure is prevented fromgenerating gaps, damage caused by outside wind is avoided, and the integral structural strength is not affected while the wind resistance of the rock wool composite plate is improved.

Owner:广东万邦模块化建筑有限公司

Environment-friendly bamboo plastic composite floor and manufacturing method thereof

InactiveCN103835474AImprove mechanical propertiesTightly fusedSynthetic resin layered productsWood layered productsSolid woodFiber

The invention discloses an environment-friendly bamboo plastic composite floor and a manufacturing method of the environment-friendly bamboo plastic composite floor. The environment-friendly bamboo plastic composite floor comprises a bamboo plastic board layer, wherein an aluminum foil damp-proof layer is laid below the bamboo plastic board layer; a solid wood veneer gluing layer is laid on the bamboo plastic board layer and is coated with a veneer paint layer; the bamboo plastic board layer comprises, by mass, 60-70 parts of bamboo fiber powder, 30-40 parts of polypropylene, 5-10 parts of 800-mesh calcium carbonate powder, 2-4 parts of maleic anhydride grafting polypropylene and 2-4 parts of carbon black. The environment-friendly bamboo plastic composite floor can have a higher mechanical property, is not prone to deformation, long in service life and low in cost, can be recycled, and facilitates environment and full utilization of resources.

Owner:HUZHOU CITY NANXUN HENGLI WOODEN PROD FACTORY

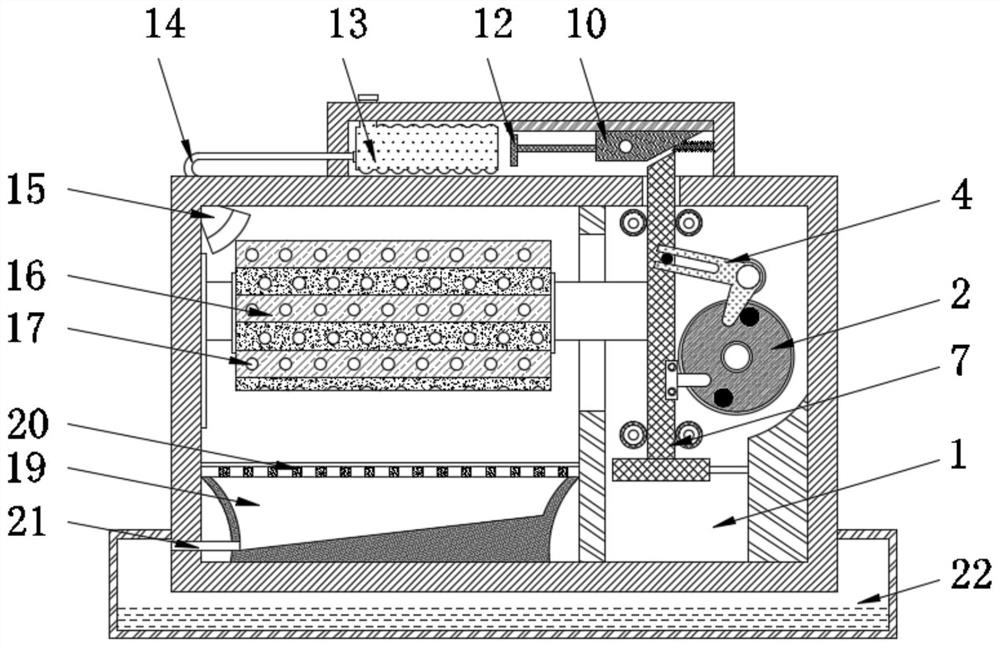

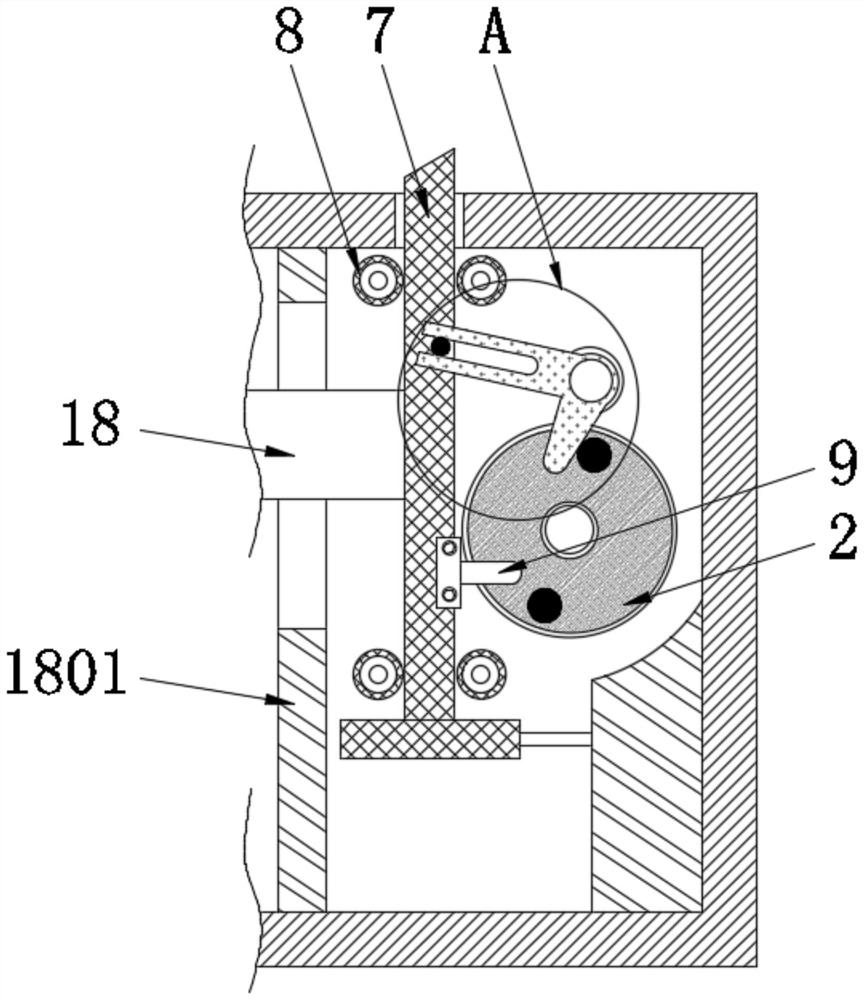

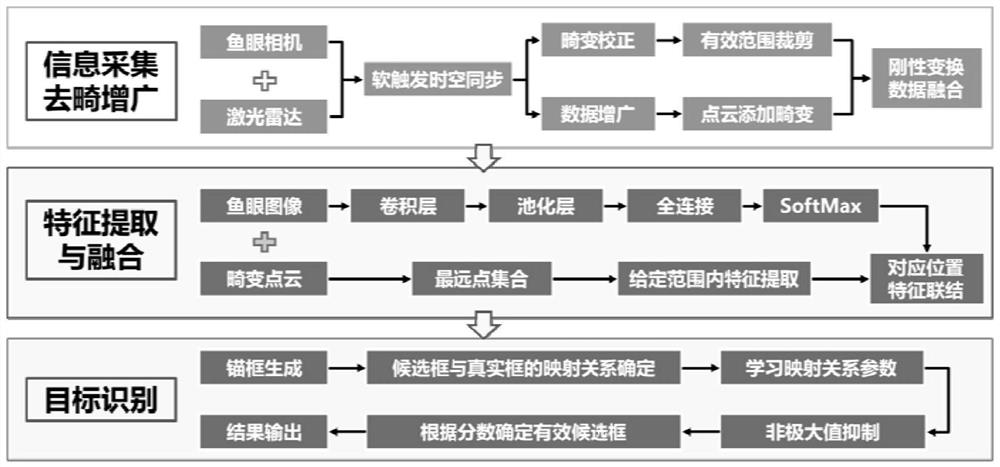

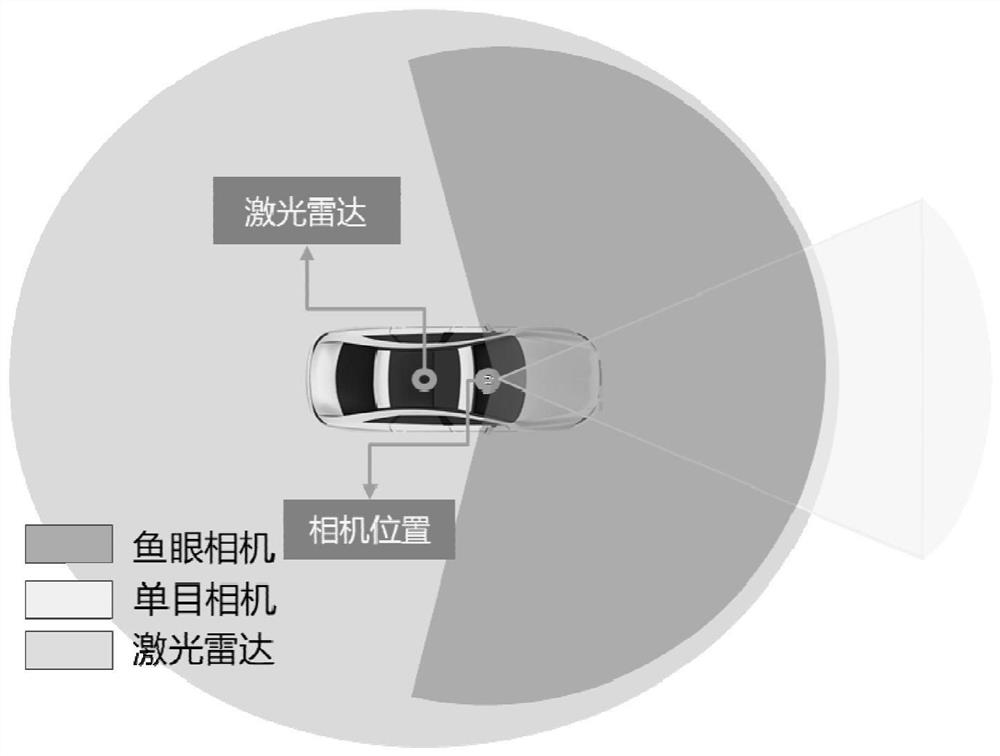

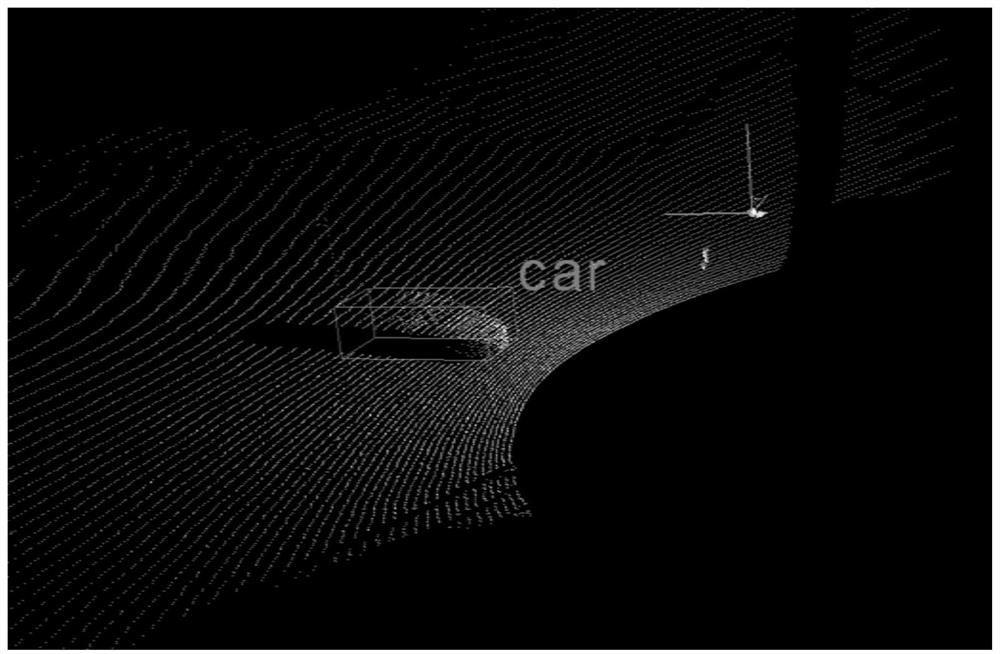

Mining area target identification method based on fusion of fisheye camera and laser radar

PendingCN113743472AKeep intactFeature extraction is completeImage enhancementImage analysisDistortion correctionData subject

The invention provides a mining area target identification method based on fusion of a fisheye camera and a laser radar. The mining area target identification method comprises the following steps: 1) carrying out information acquisition, distortion correction and data augmentation; 2) feature extraction and fusion: performing feature extraction on the data subjected to distortion correction and data augmentation by using different branches, and then performing fusion output on the features of the two kinds of data through a bilinear interpolation-based method; and 3) target identification: using a classic RPN structure, and performing result output through several important steps of generating an anchor frame, determining a mapping relationship between the anchor frame and a real frame, mapping parameter learning, non-maximum suppression and determining an effective candidate frame according to a score. The advantages of the two are integrated, the recognition performance of unmanned driving in a mining area environment is effectively improved by using a fusion mode, rich, real-time and accurate target pose information is provided for a subsequent decision control module, and unmanned driving landing is assisted.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com