PVC tubular material formula high in impact resistance, and preparation method thereof

A PVC pipe and high-impact technology, which is applied in the formulation and preparation of high-impact PVC pipes, can solve the problems of poor toughness and easy occurrence of brittle fracture, and achieve improved hardness, strong permeability, toughness and impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

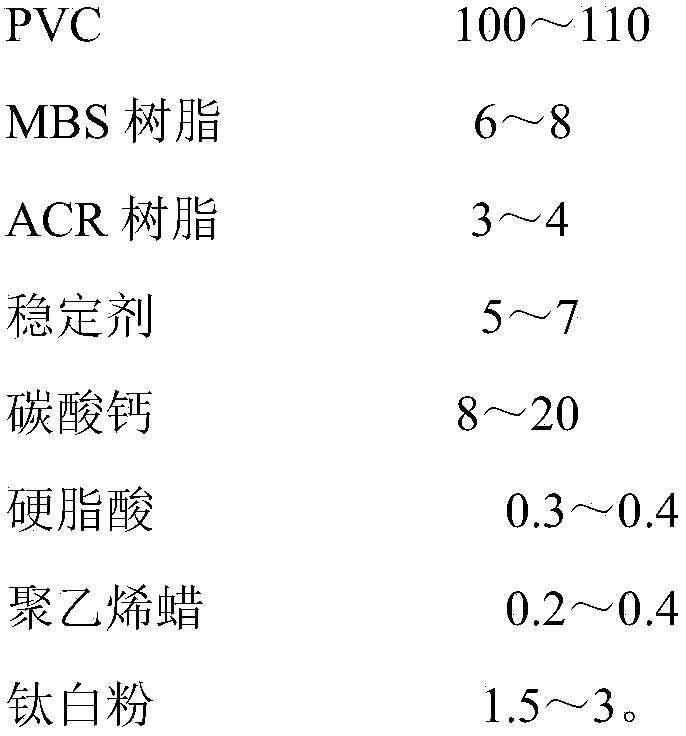

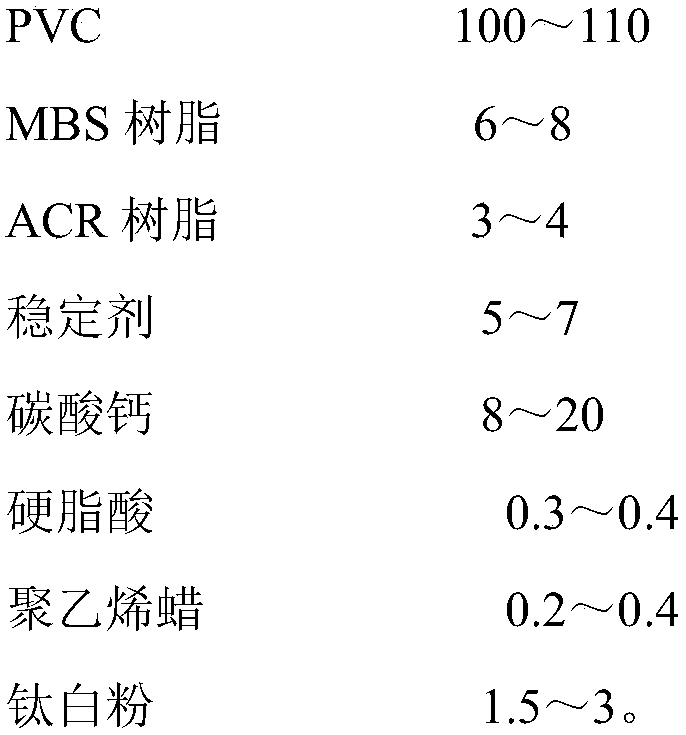

[0038] The high-impact PVC pipe formulation of this embodiment includes the following raw materials by weight: PVC: 100; MBS resin: 6; ACR resin: 3; calcium zinc stabilizer: 5; calcium carbonate: 8; stearic acid: 0.3 ; Polyethylene wax: 0.2; Titanium dioxide: 1.5.

[0039] The preparation method of the high-impact PVC pipe of the present embodiment, the steps are:

[0040] Step 1. Weigh each component according to the formula measurement requirements, add it to a high-speed mixer and stir and mix it. The temperature of the material is raised to 100-120°C through friction, stop stirring, and then cool to 30-35°C and discharge it for later use;

[0041] Step 2. Extrude and cut the material obtained in Step 1 on the pipe forming equipment. The temperature of the barrel of the extruder is controlled at 150-190°C, and the temperature of the die is controlled at 155-195°C.

[0042] According to GB / T 13664-2006, various indicators are tested, and the performance indicators of the pr...

Embodiment 2

[0046] The high-impact PVC pipe formulation of the present embodiment includes the following raw materials by weight: SG-5 type PVC: 110; MBS resin is a core-shell structure obtained by copolymerization of methyl methacrylate, butadiene and styrene Terpolymer: 8; ACR resin is also a core-shell structure acrylate copolymer: 4; calcium zinc stabilizer: 7; calcium carbonate: 8; stearic acid: 0.4; polyethylene wax: 0.4; Ethylene wax is combined into a composite lubricant; titanium dioxide: 3, mainly used as a colorant.

[0047] The preparation method of the high-impact PVC pipe of the present embodiment, the steps are:

[0048] Step 1. Weigh each component according to the formula measurement requirements, add it to a high-speed mixer and stir and mix it. The temperature of the material is raised to 100-120°C through friction, stop stirring, and then cool to 30-35°C and discharge it for later use;

[0049] Step 2. Extrude and cut the material obtained in Step 1 on the pipe formin...

Embodiment 3

[0054] The high-impact PVC pipe material formula of the present embodiment comprises the raw material composition of following parts by weight: SG-5 type PVC: 110; MBS resin is the polymethyl methacrylate of shell structure: 8; ACR resin is also the shell structure Polymethyl methacrylate: 4; rare earth stabilizer: 7; calcium carbonate: 8; stearic acid: 0.4; polyethylene wax: 0.4; stearic acid, polyethylene wax combined into a composite lubricant; titanium dioxide: 3 , mainly used as a coloring agent.

[0055] The steps of the preparation method of the high-impact PVC pipe in this embodiment are the same as those in Embodiment 2.

[0056] After testing, the performance indicators of the prepared PVC pipe and the traditional formula are compared, as shown in Table 3 below:

[0057] Compare items

[0058] It can be seen from the above table that because PMMA has strong polarity, high glass transition temperature, and good compatibility with polyvinyl chloride resin, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com