Patents

Literature

852results about "Refining with oxygen compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Complex comprising oxidative dehydrogenation unit

ActiveUS20140249339A1Consumes lotThermal non-catalytic crackingSequential/parallel process reactionsAlkaneDehydrogenation

Oxidative dehydrogenation of paraffins to olefins provides a lower energy route to produce olefins. Oxidative dehydrogenation processes may be integrated with a number of processes in a chemical plant such as polymerization processes, manufacture of glycols, and carboxylic acids and esters. Additionally, oxidative dehydrogenation processes can be integrated with the back end separation process of a conventional steam cracker to increase capacity at reduced cost.

Owner:NOVA CHEM (INT) SA

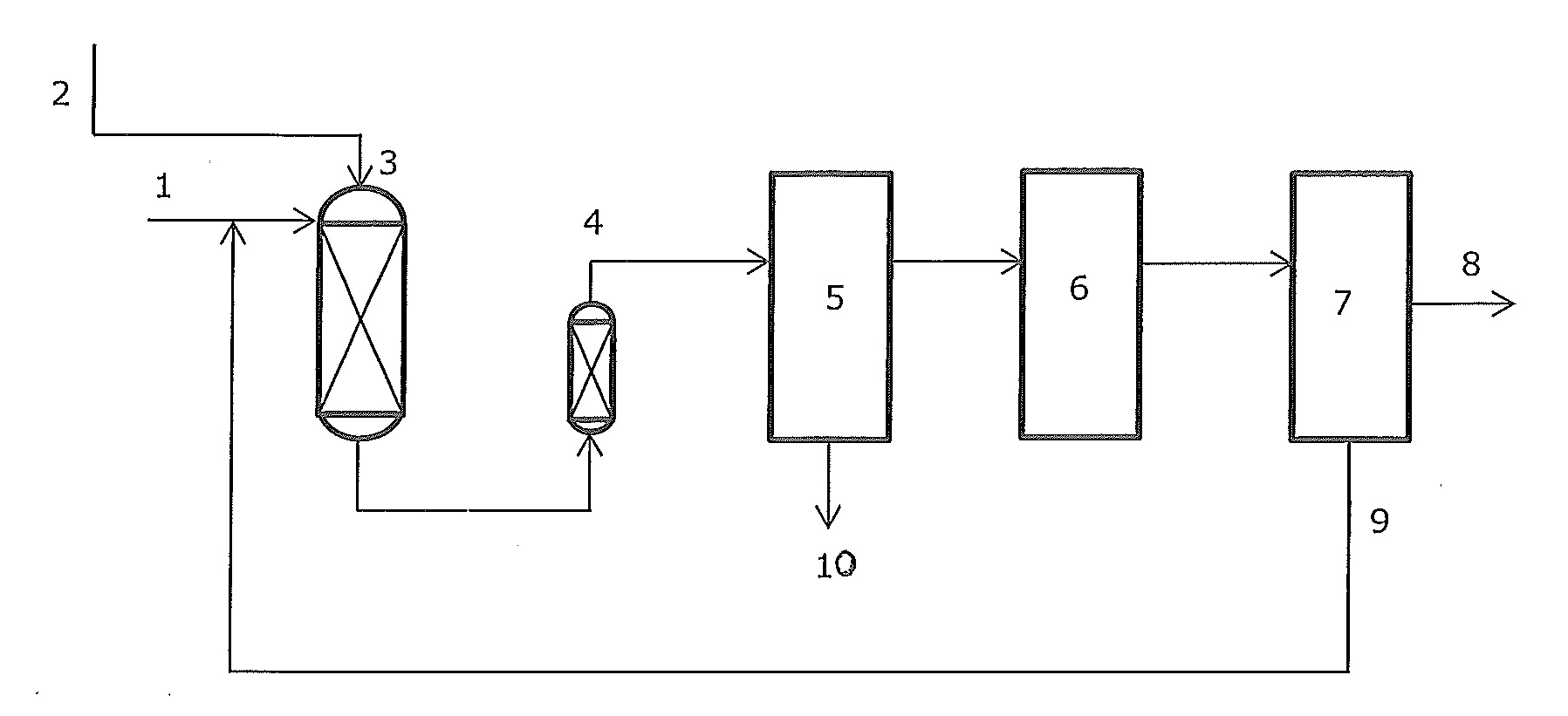

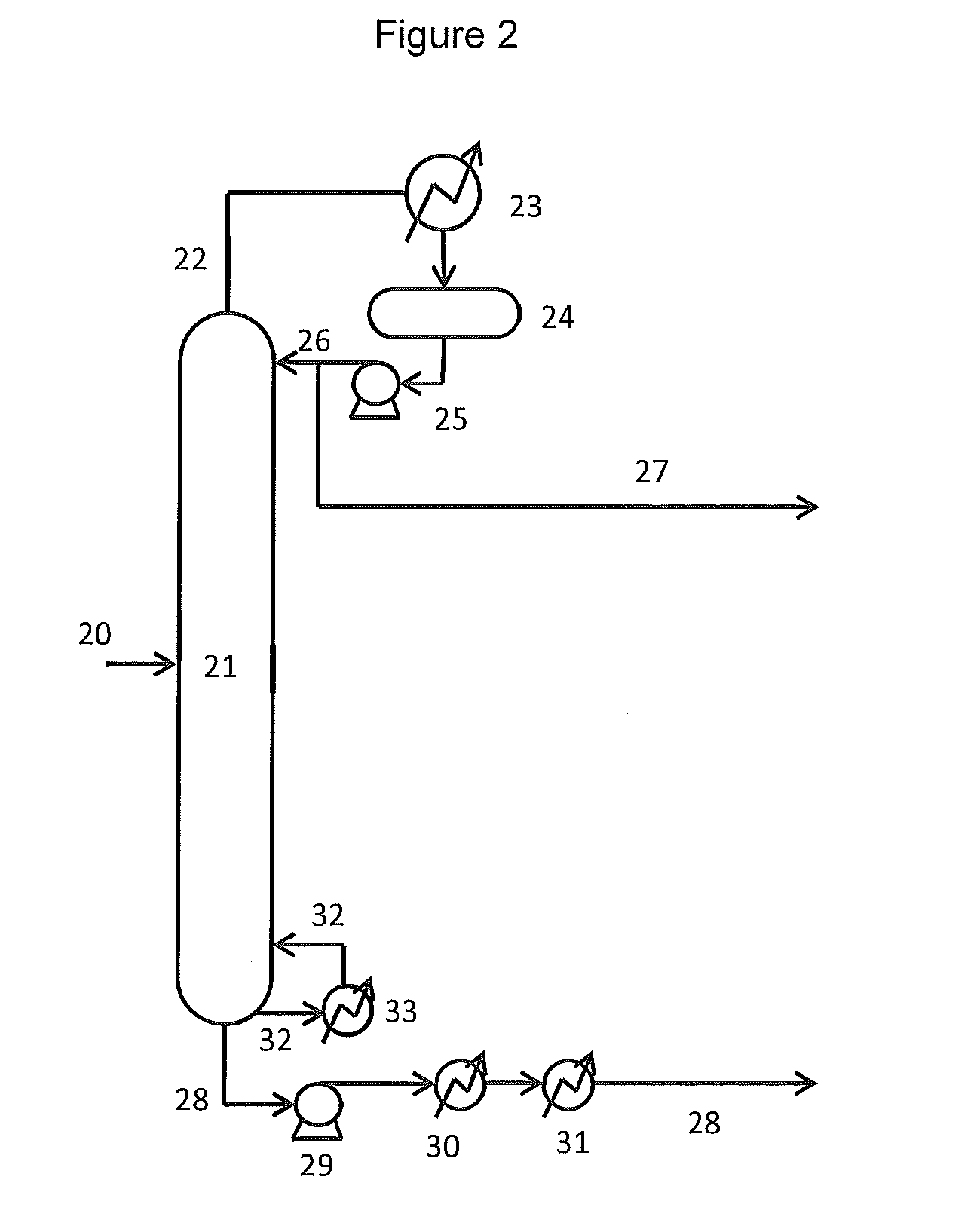

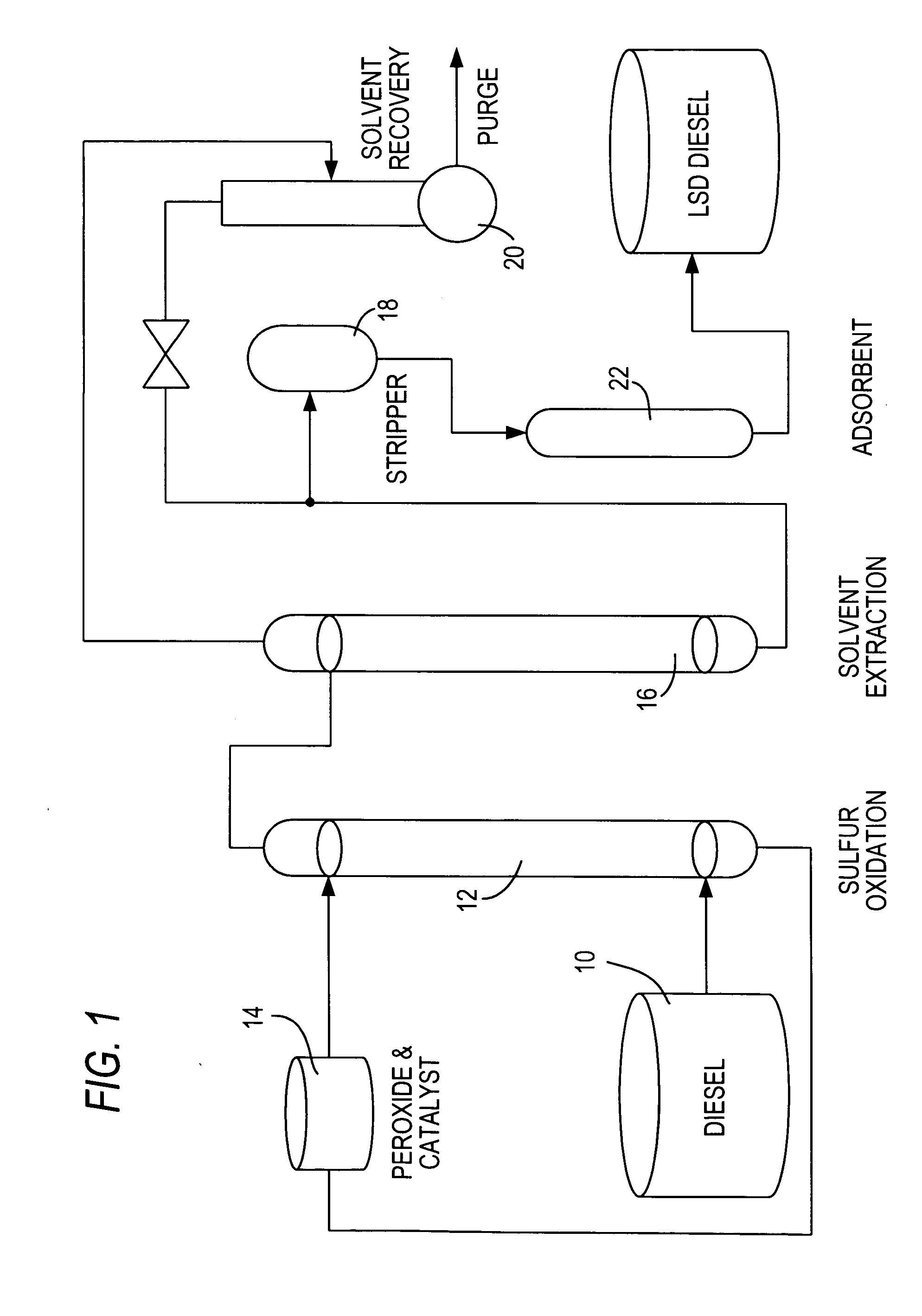

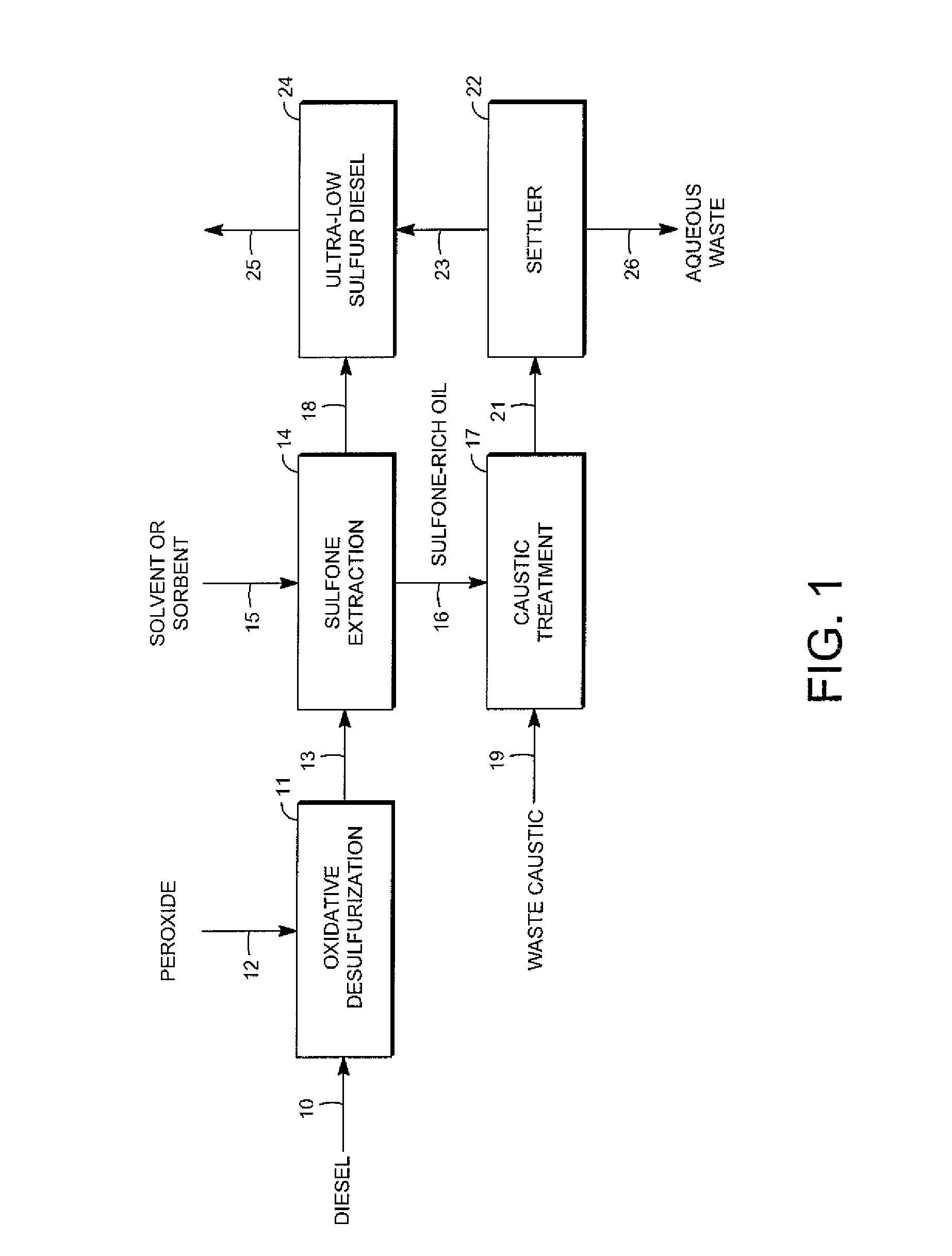

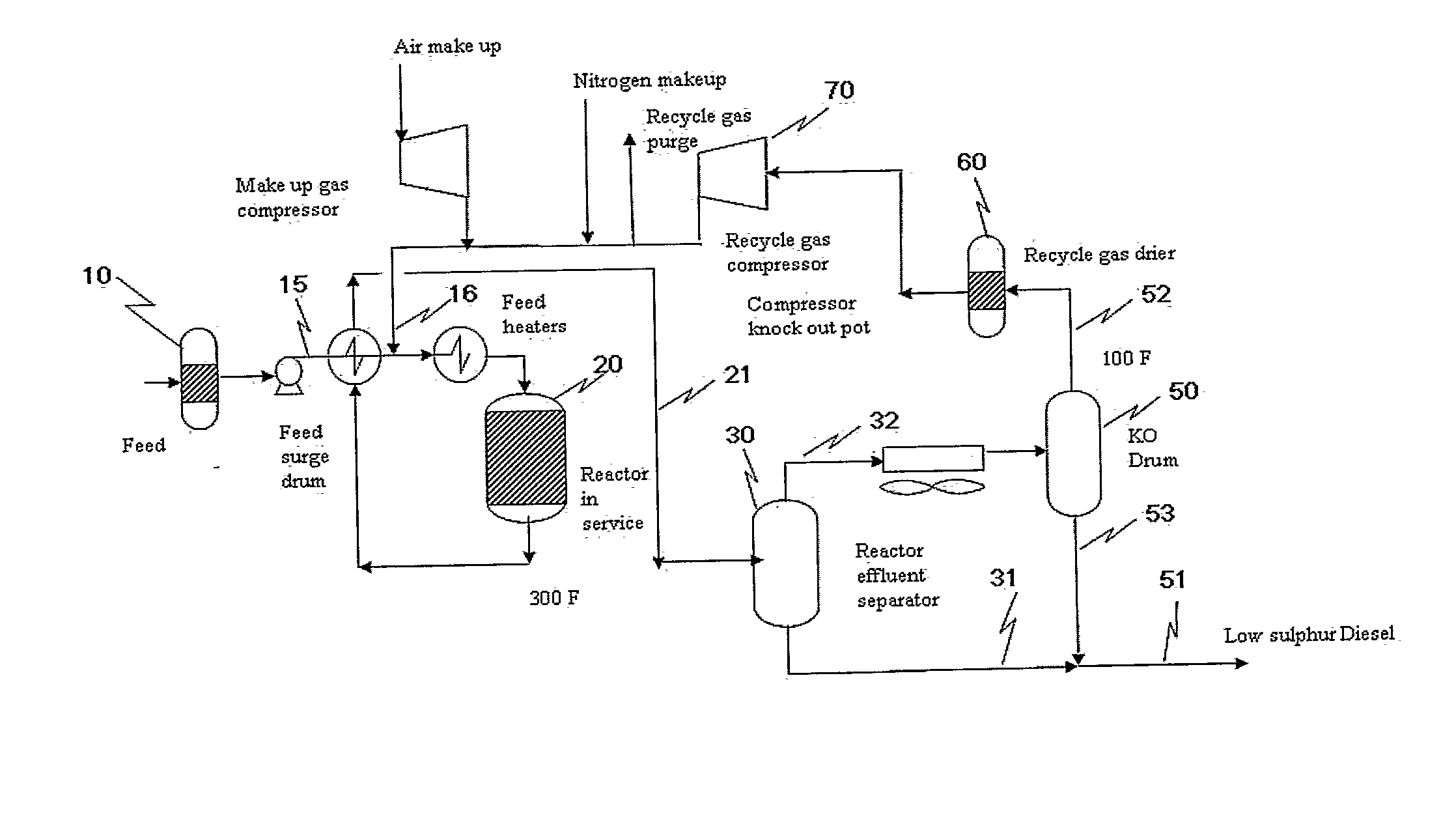

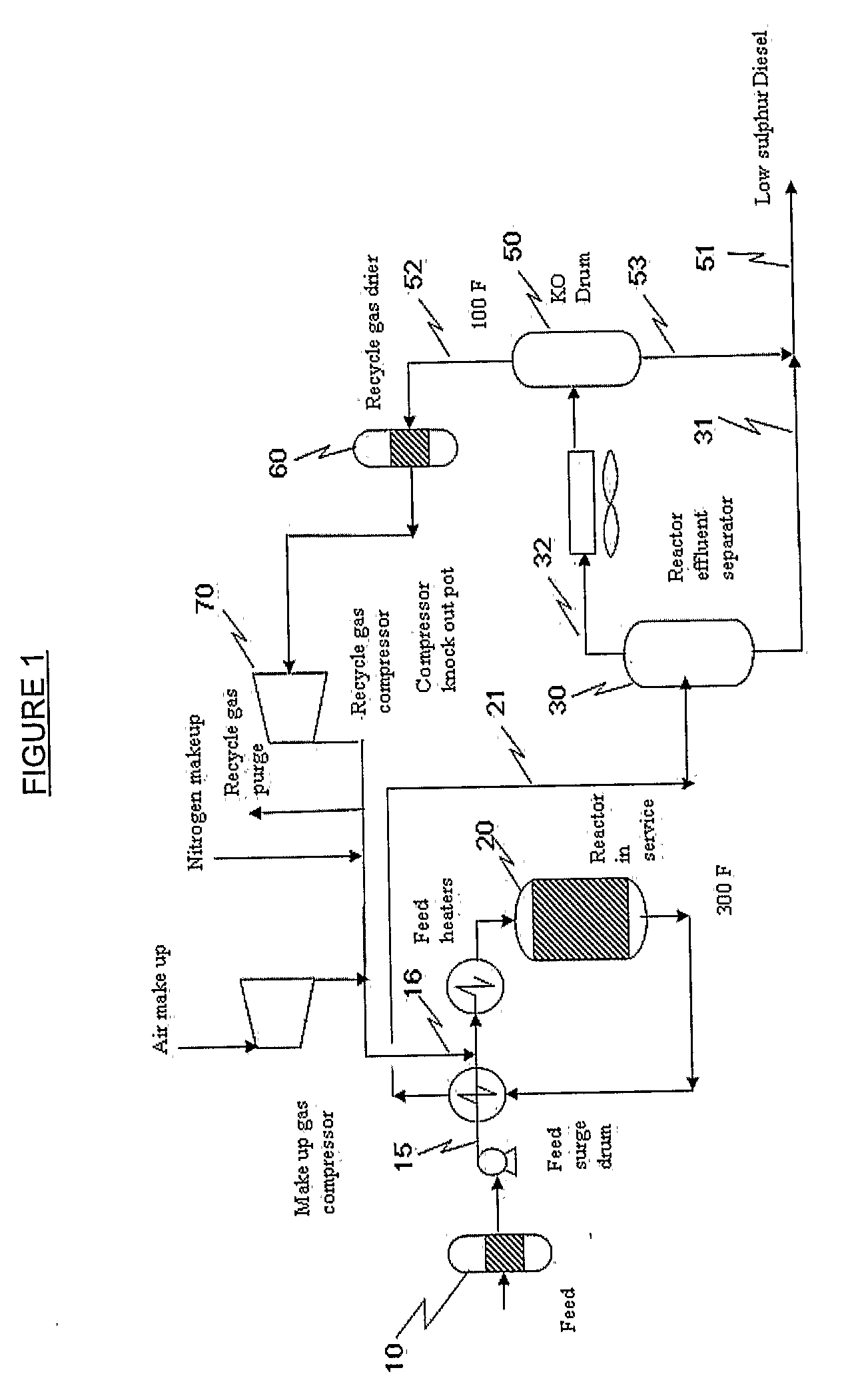

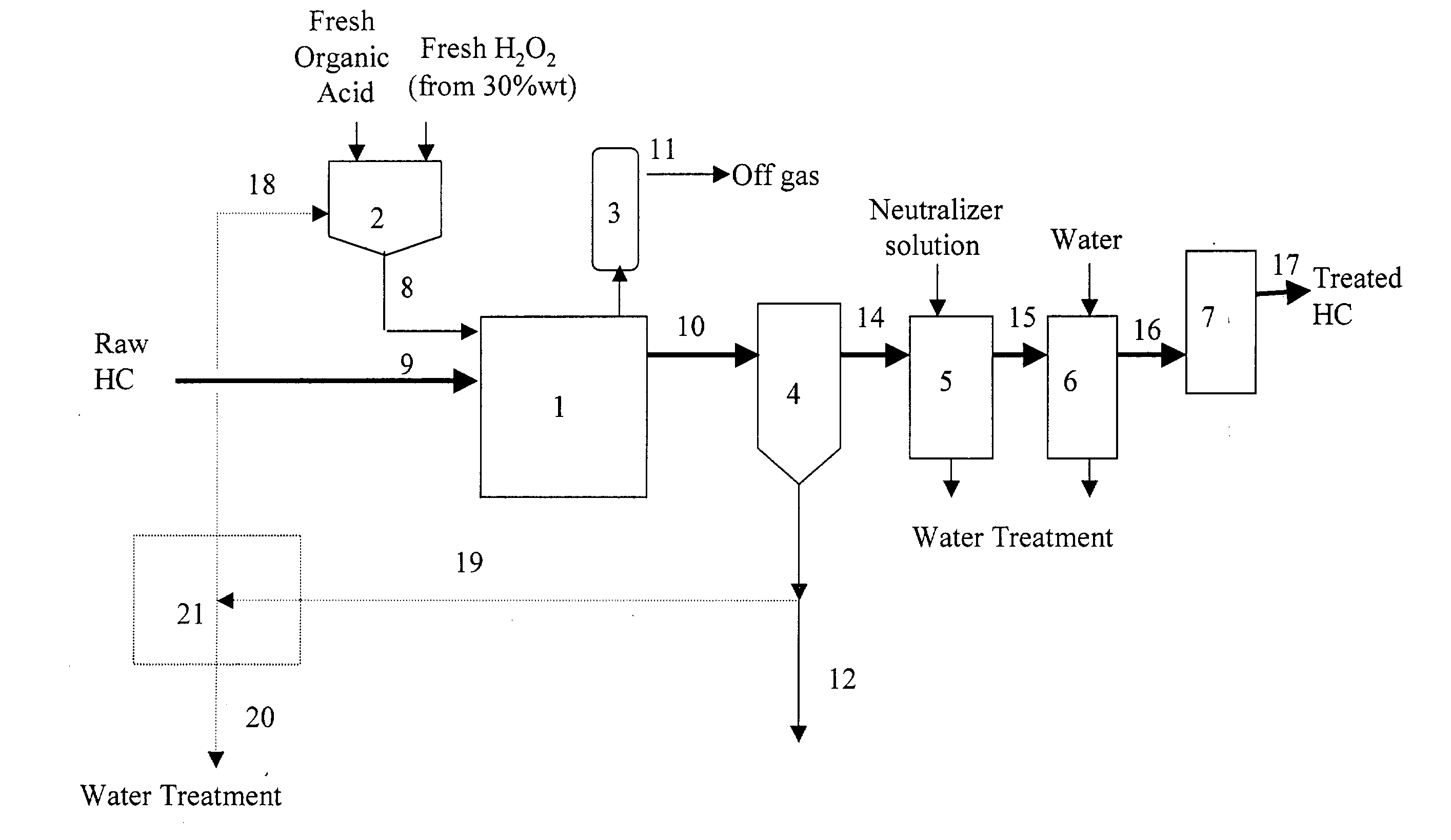

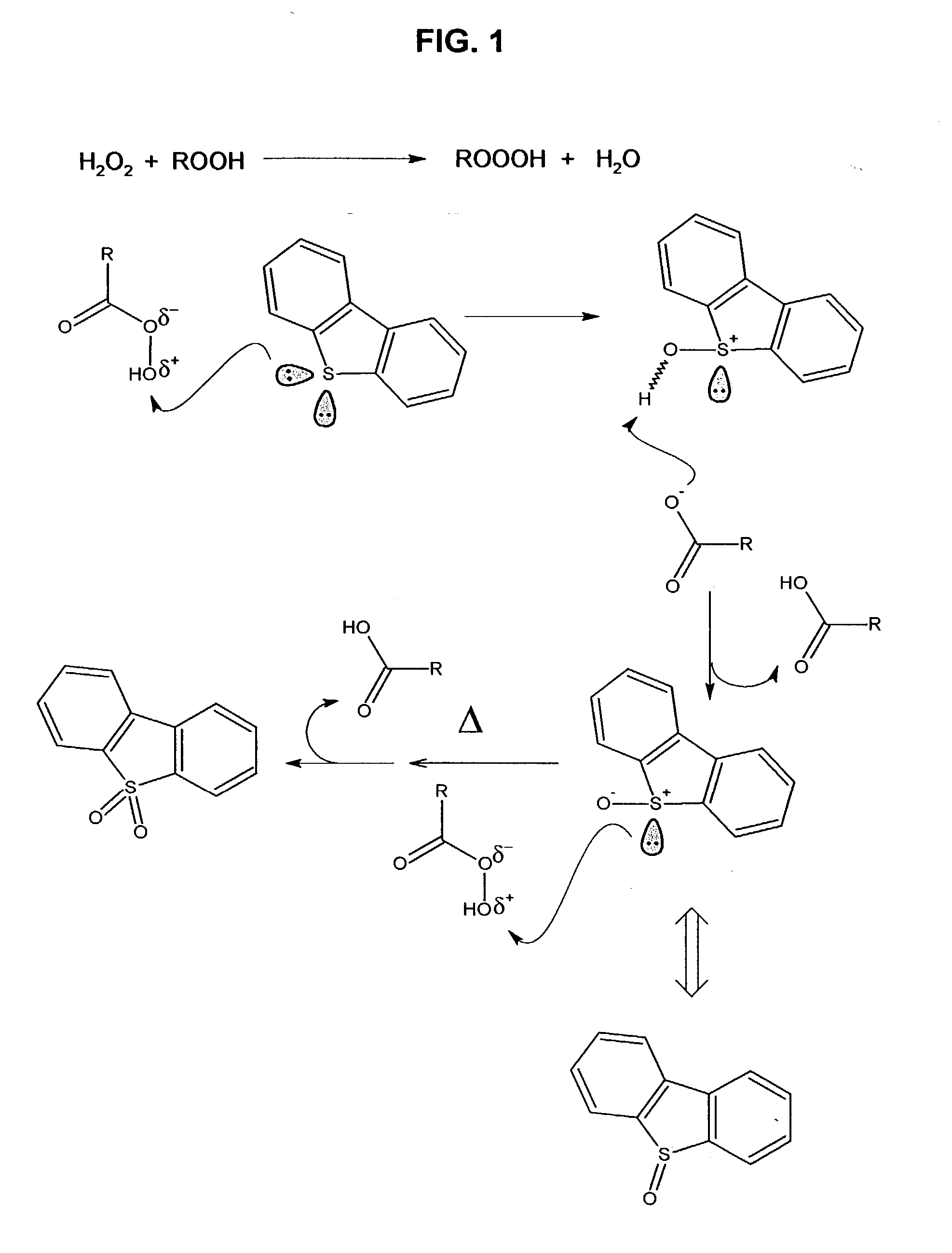

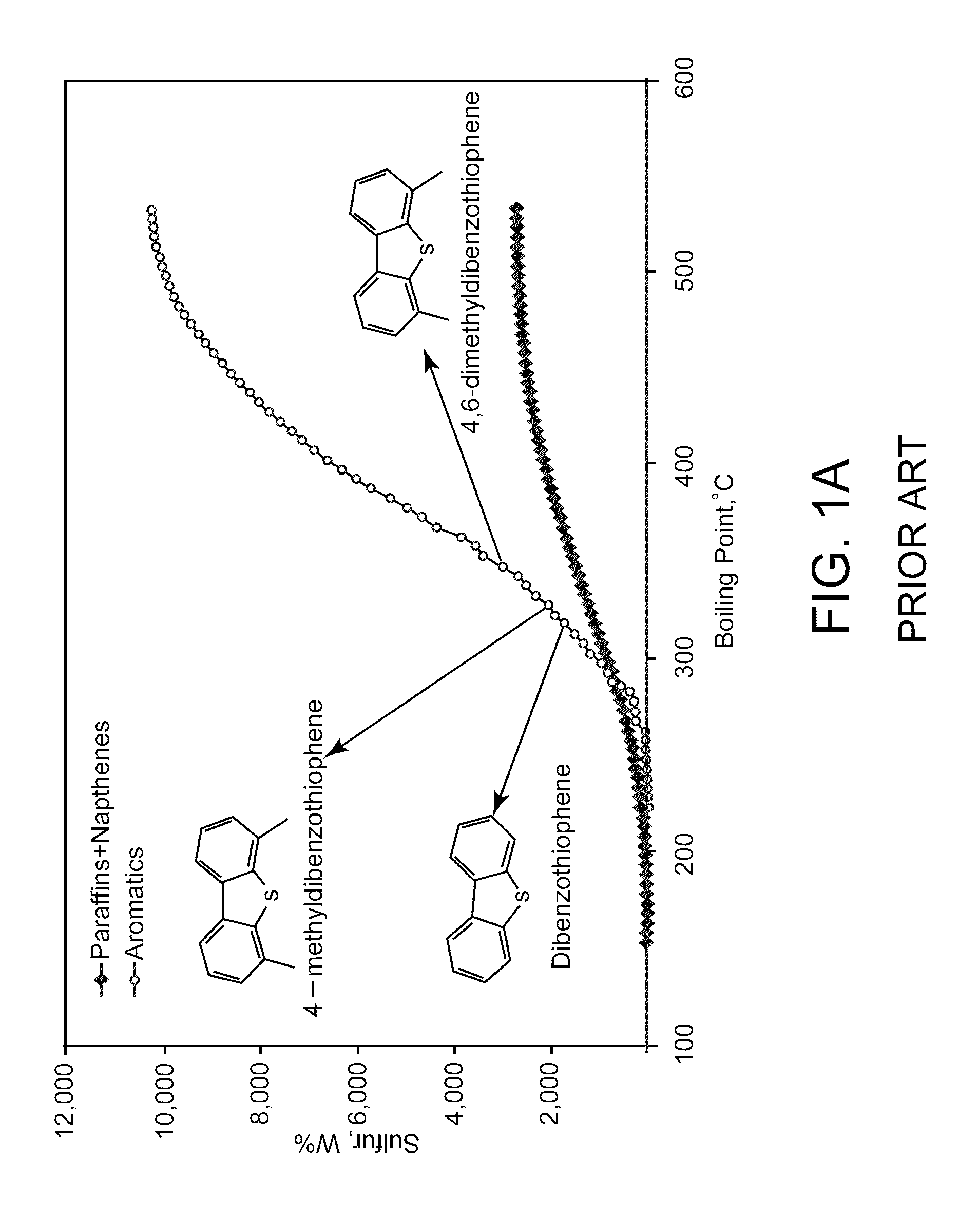

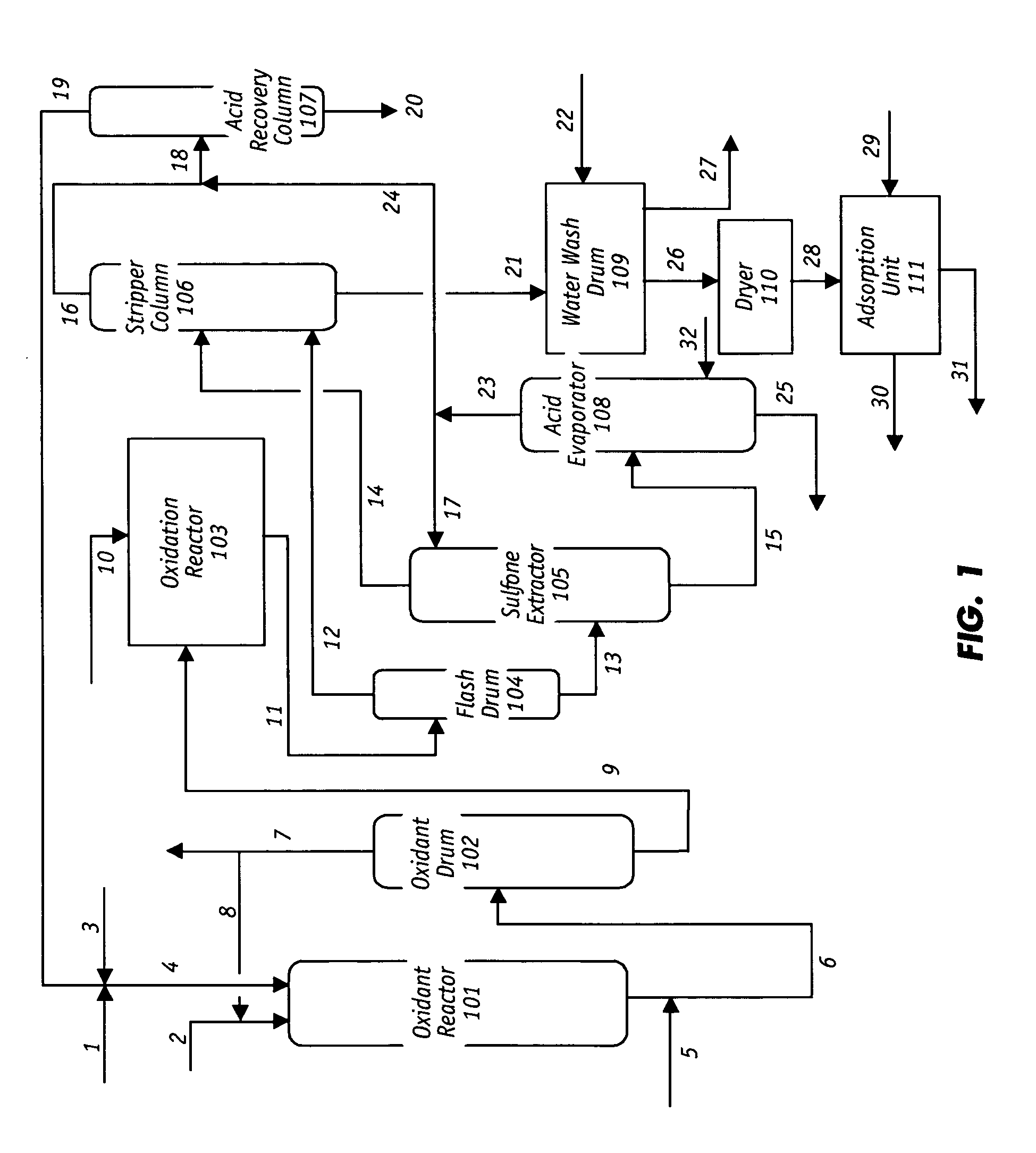

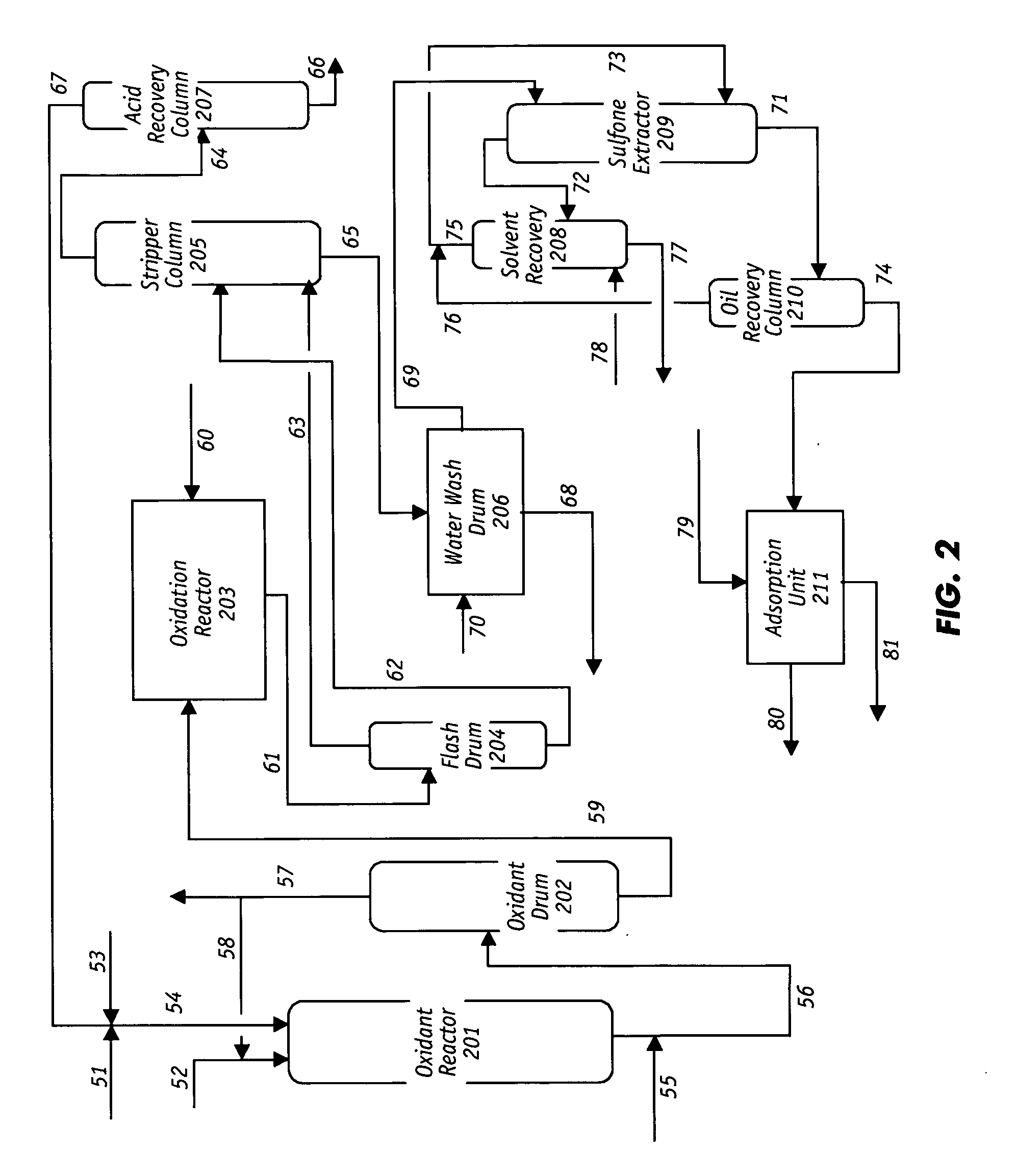

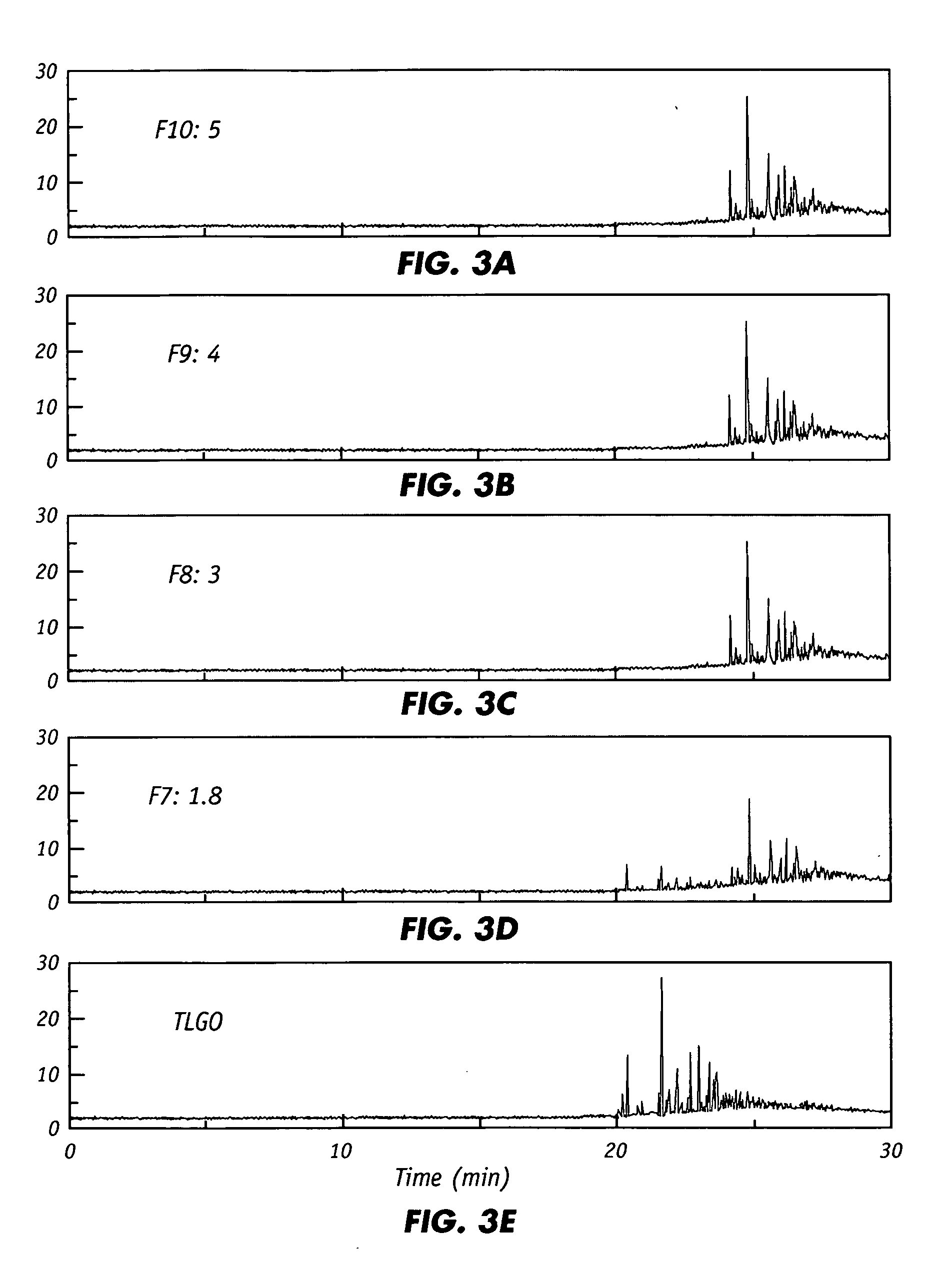

Diesel oil desulfurization by oxidation and extraction

ActiveUS20070051667A1Refining with oxygen compoundsRefining with acid-forming oxidesSulfur containingDiesel fuel

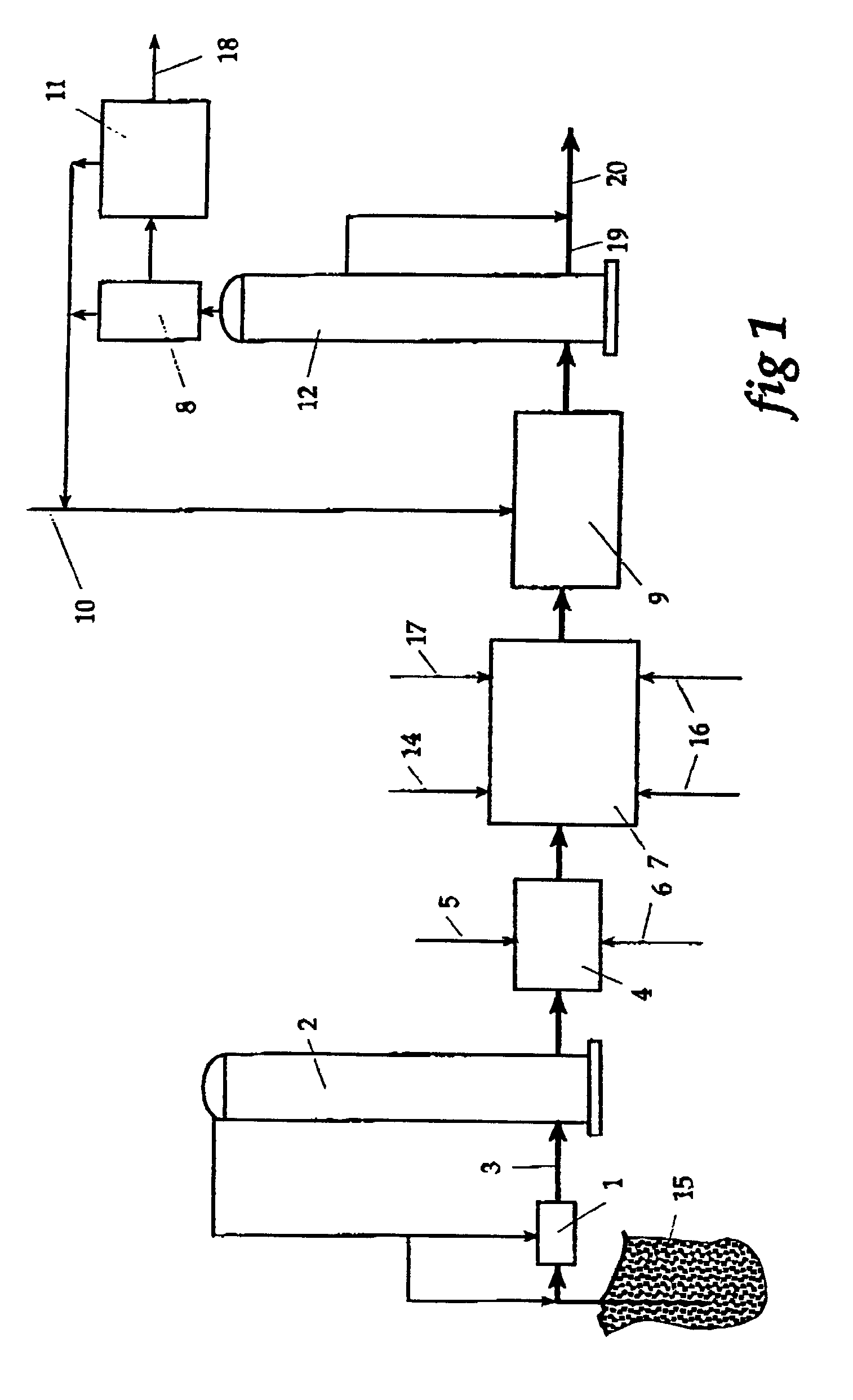

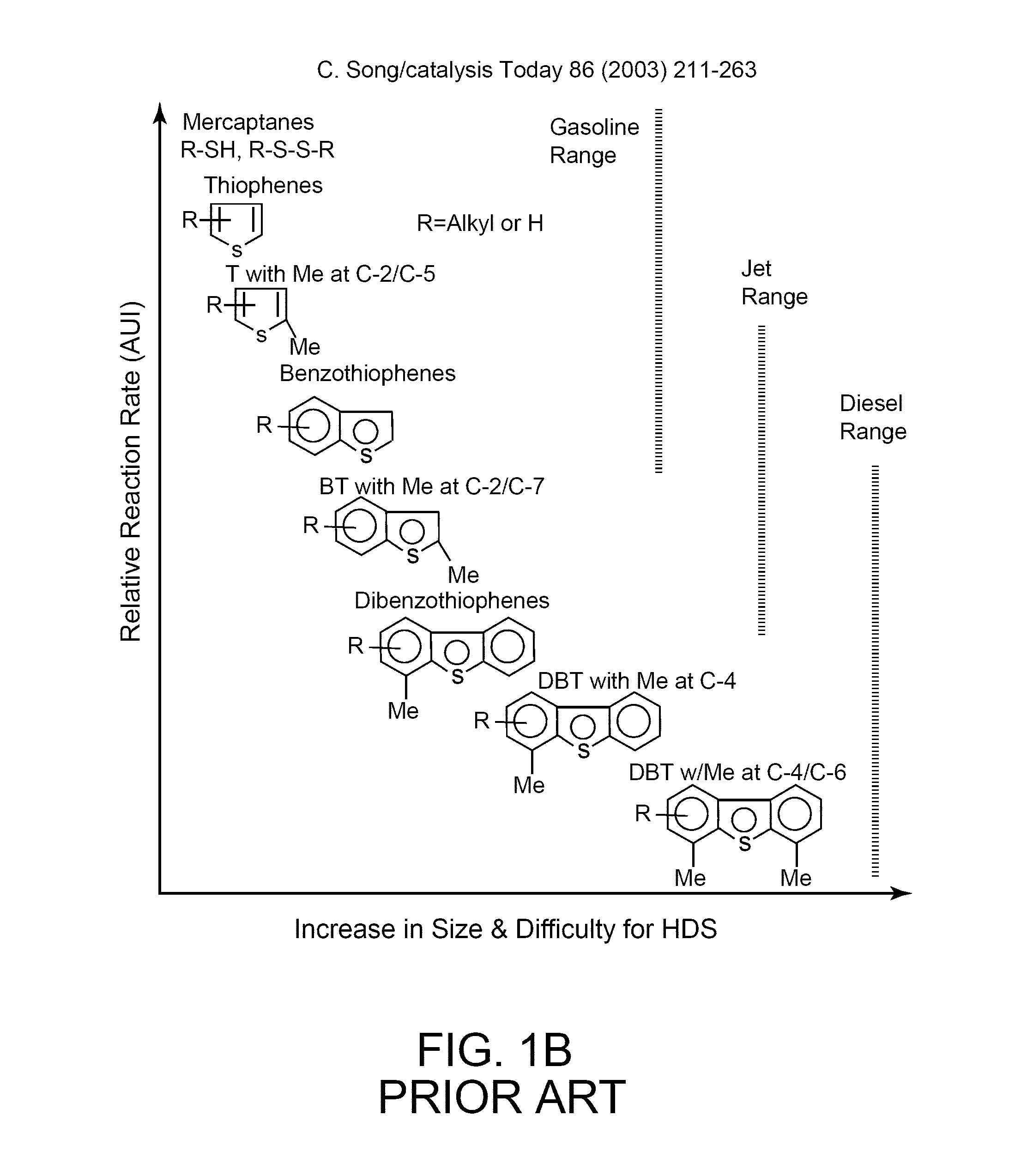

The reduction in the sulfur-containing content of diesel fuel is achieved by oxidation in the presence of a catalyst followed by a liquid-liquid countercurrent extraction.

Owner:SAUDI ARABIAN OIL CO

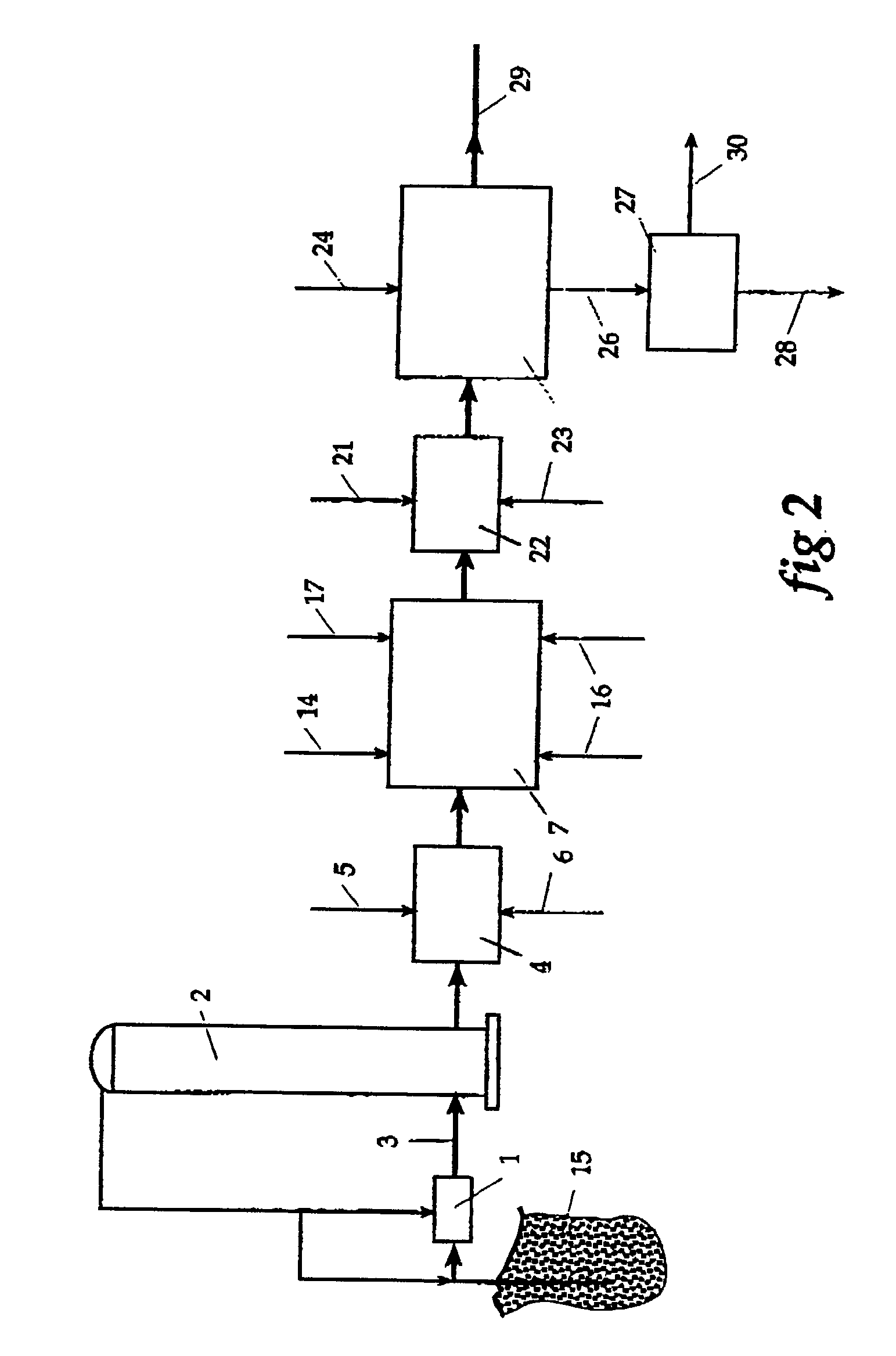

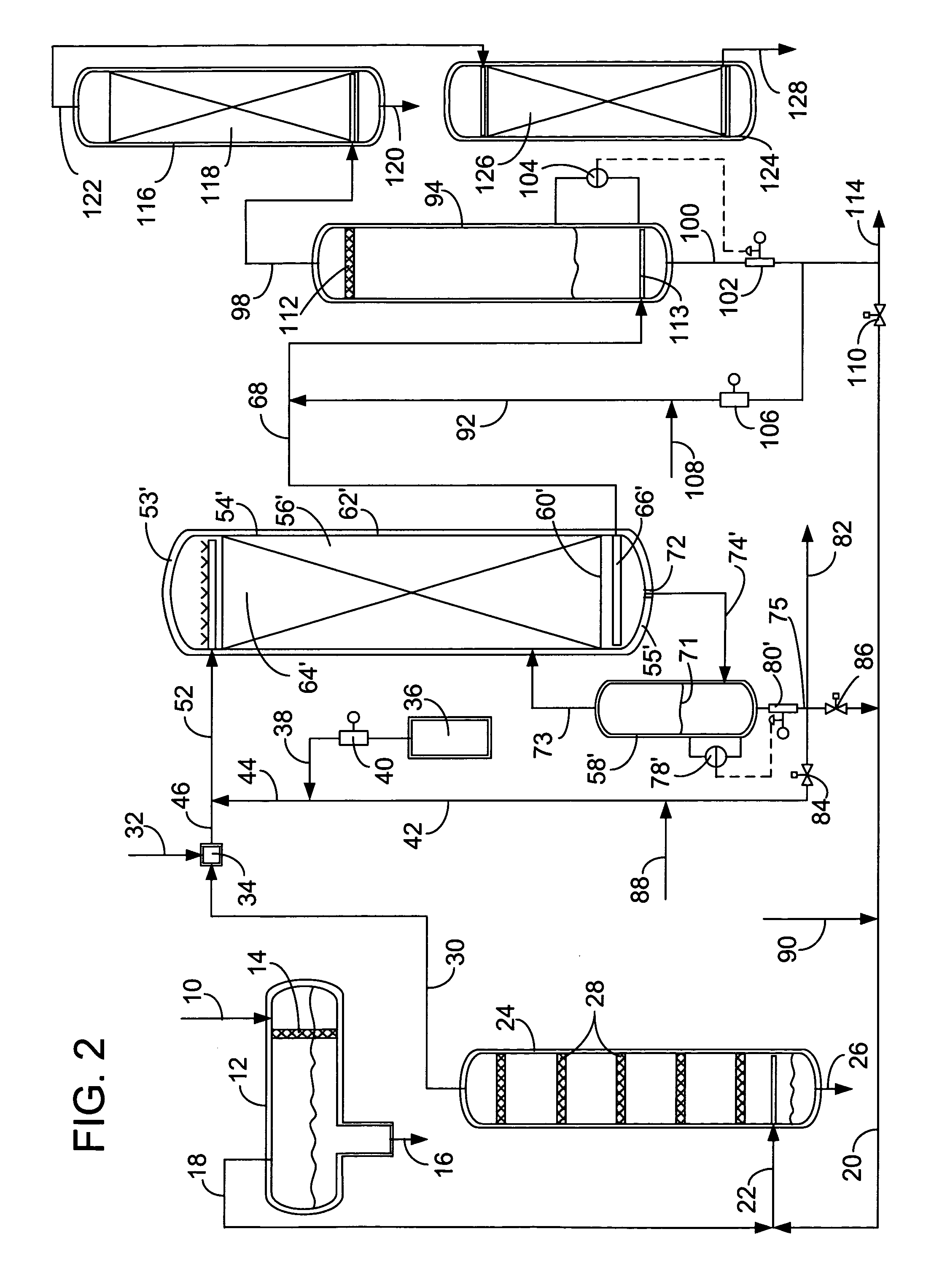

Upgrading of tar using POX/coker

ActiveUS8083931B2Reduce and eliminate needThermal non-catalytic crackingTreatment with plural serial cracking stages onlyNaphthaPartial oxidation

The invention is directed to a process wherein a feedstock or stream comprising steam cracker tar is passed to a vacuum pipestill. A deasphalted cut of tar is obtained as an overhead (or sidestream) and a heavy tar asphaltenic product is obtained as bottoms. In preferred embodiments, at least a portion of the bottoms product is sent to a partial oxidation unit (POX) wherein syn gas may be obtained as a product, and / or at least a portion of the bottoms product is used to produce a light product stream in a coker unit, such as coker naphtha and / or or coker gas oil. In another preferred embodiment at least a portion of the overheads product is added to refinery fuel oil pools and in yet another preferred embodiment at least a portion of the overheads product is mixed with locally combusted materials to lower soot make. Two or more of the aforementioned preferred embodiments may be combined.

Owner:EXXONMOBIL CHEM PAT INC

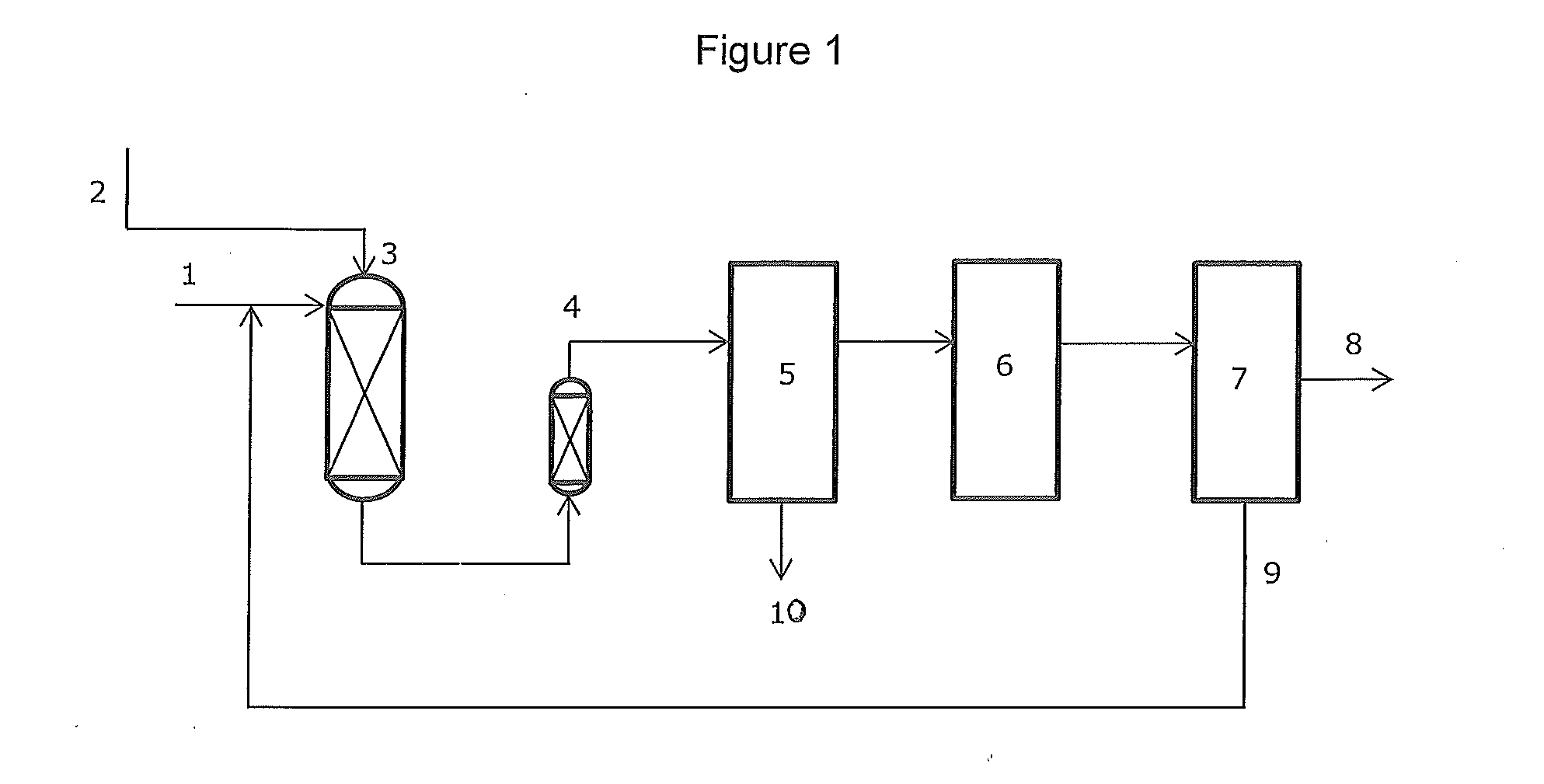

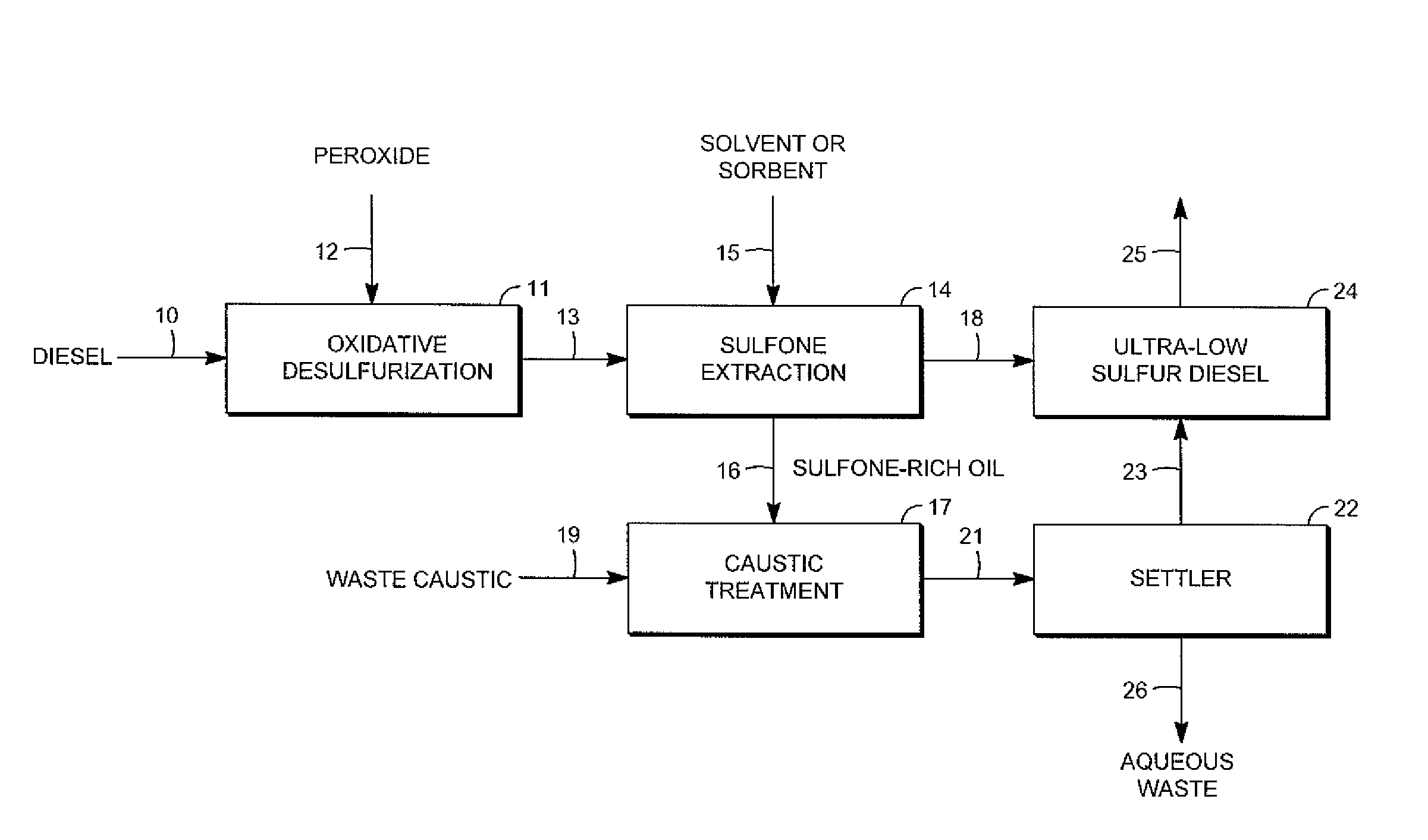

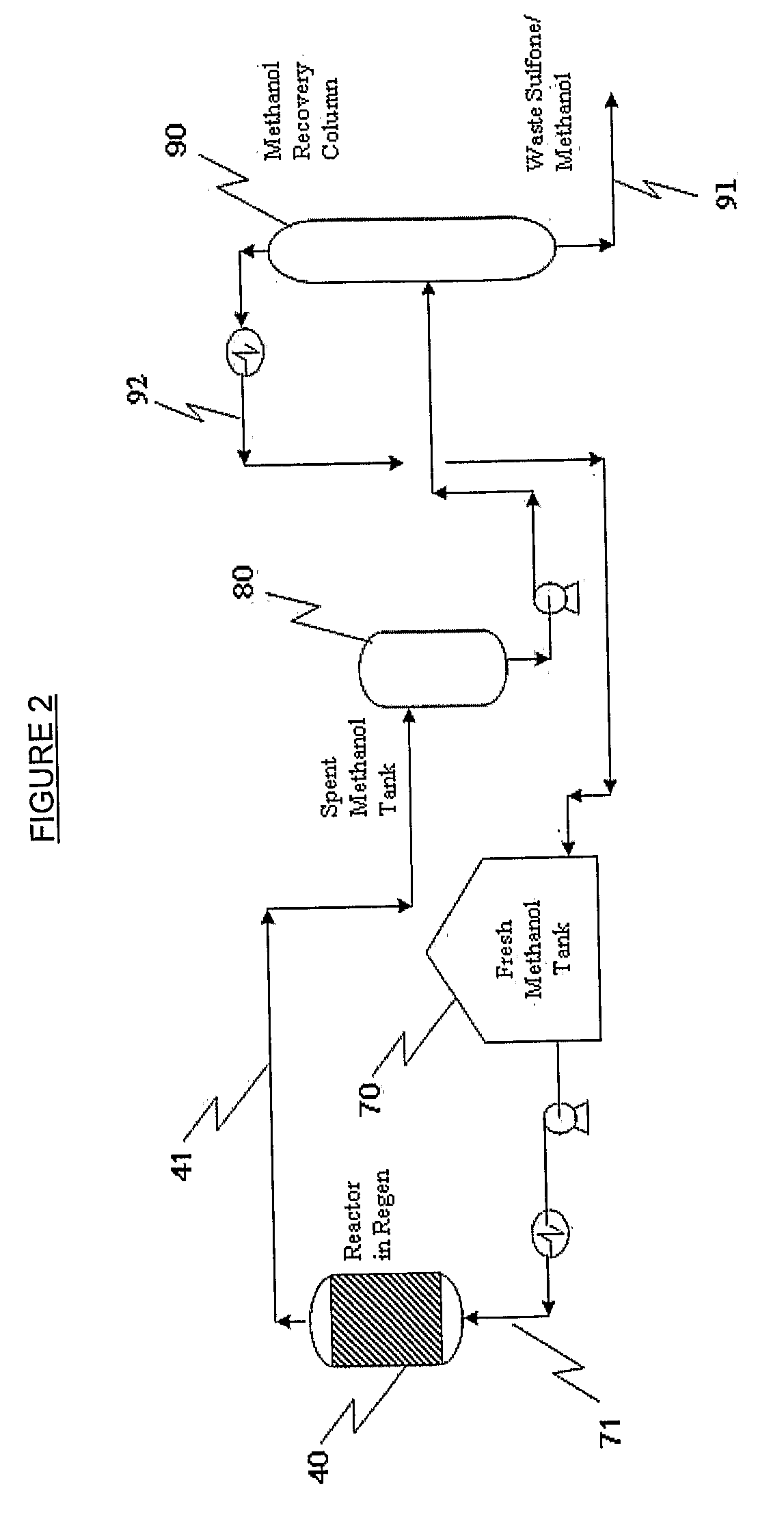

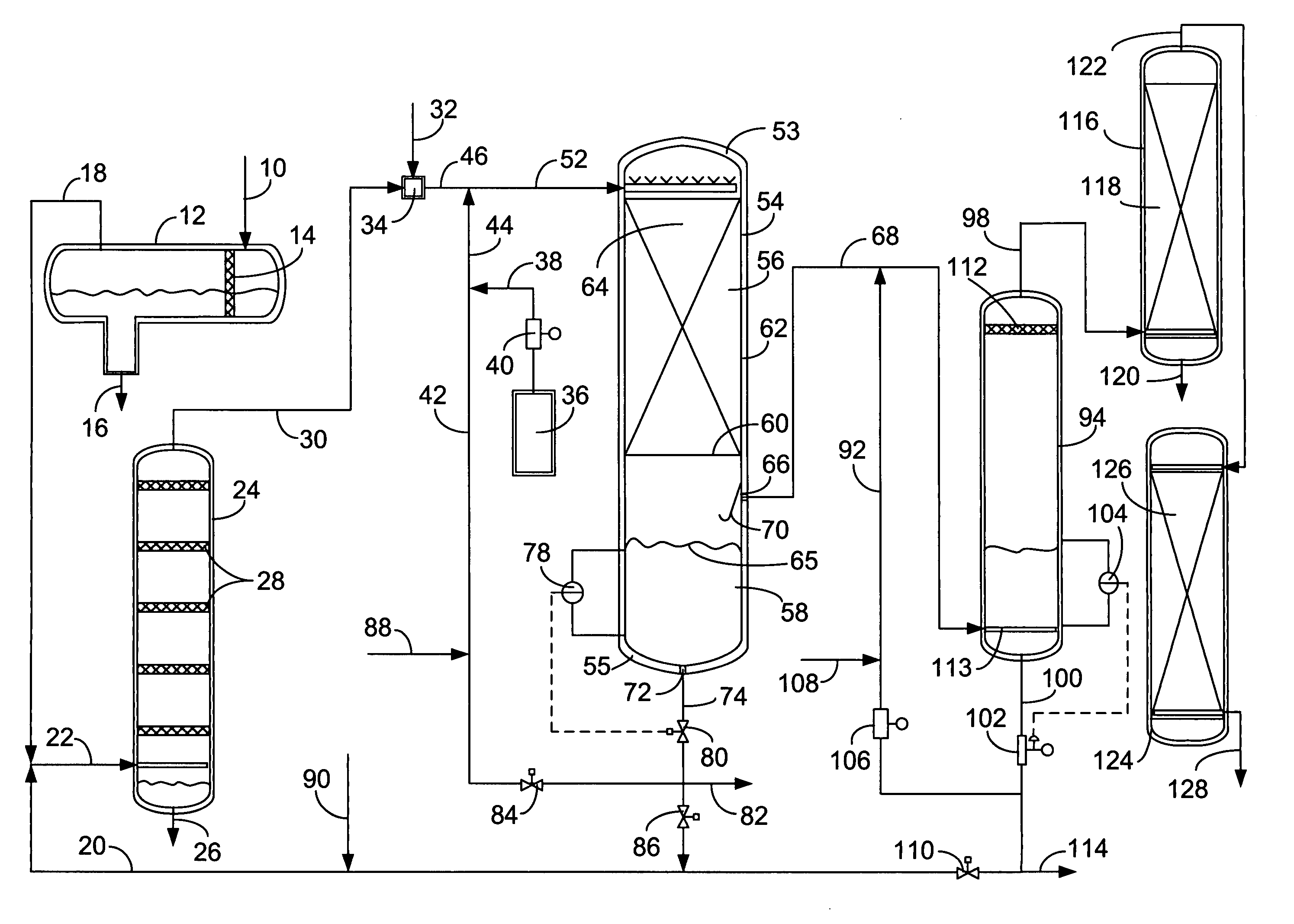

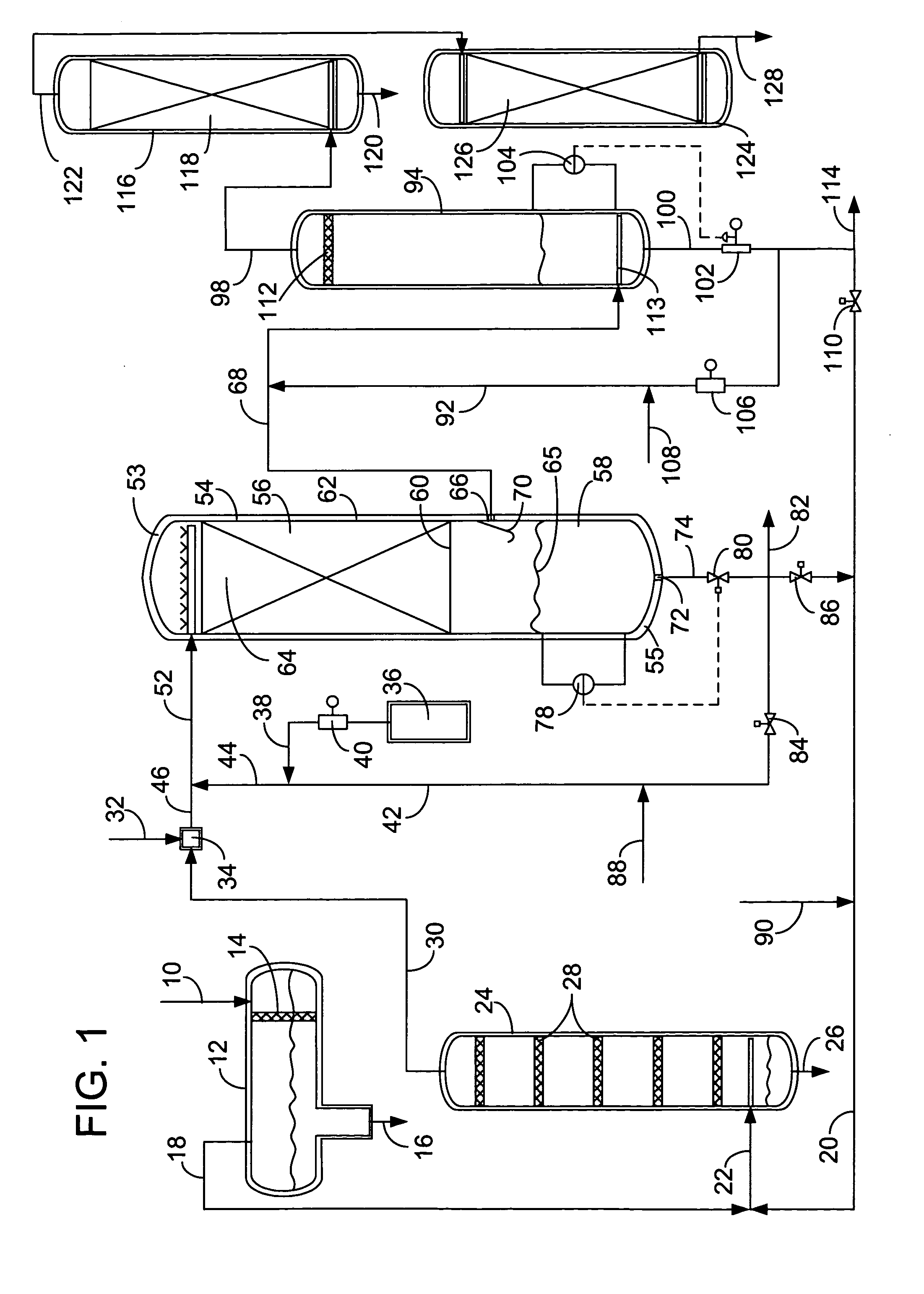

Removal of sulfur-containing compounds from liquid hydrocarbon streams

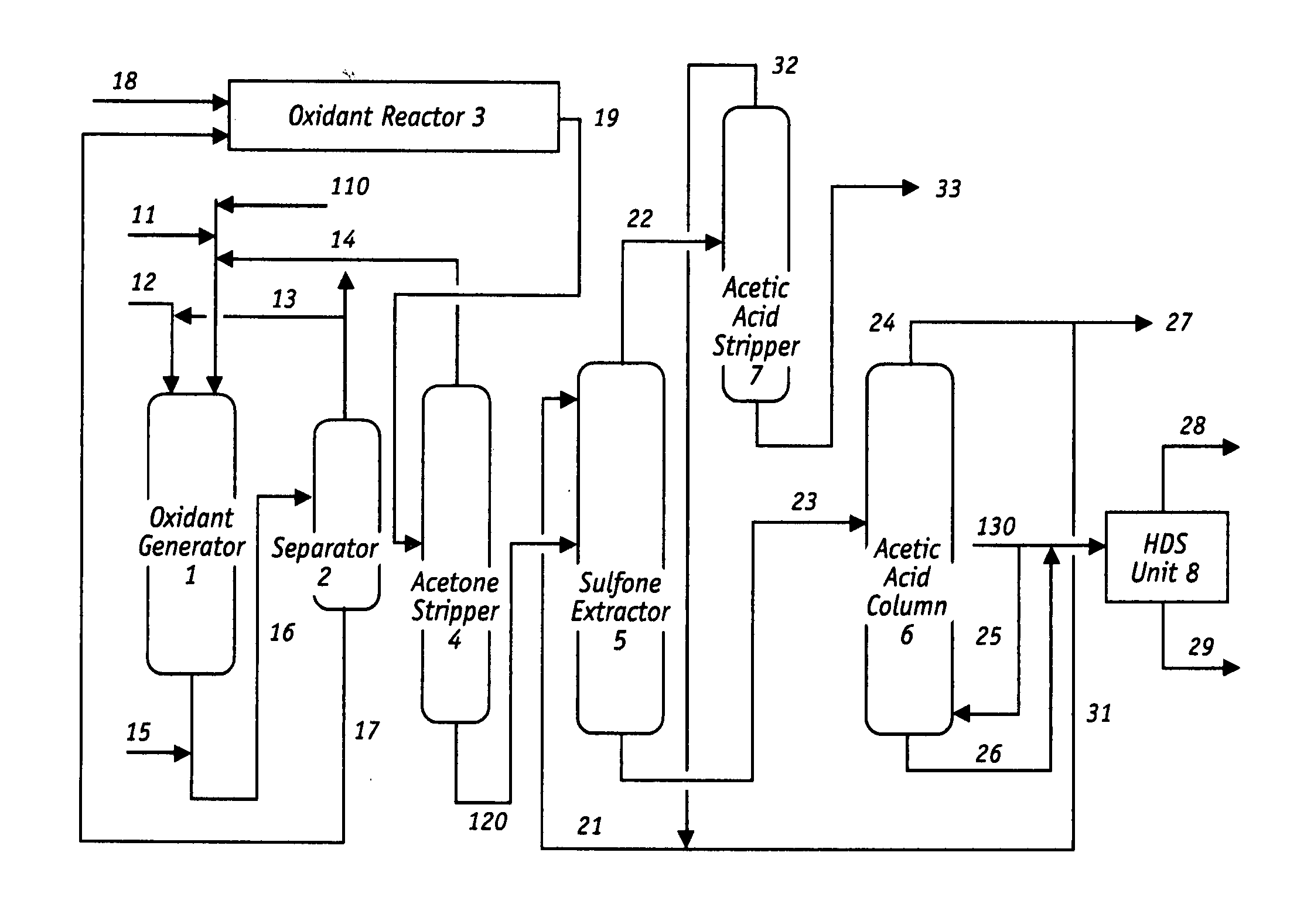

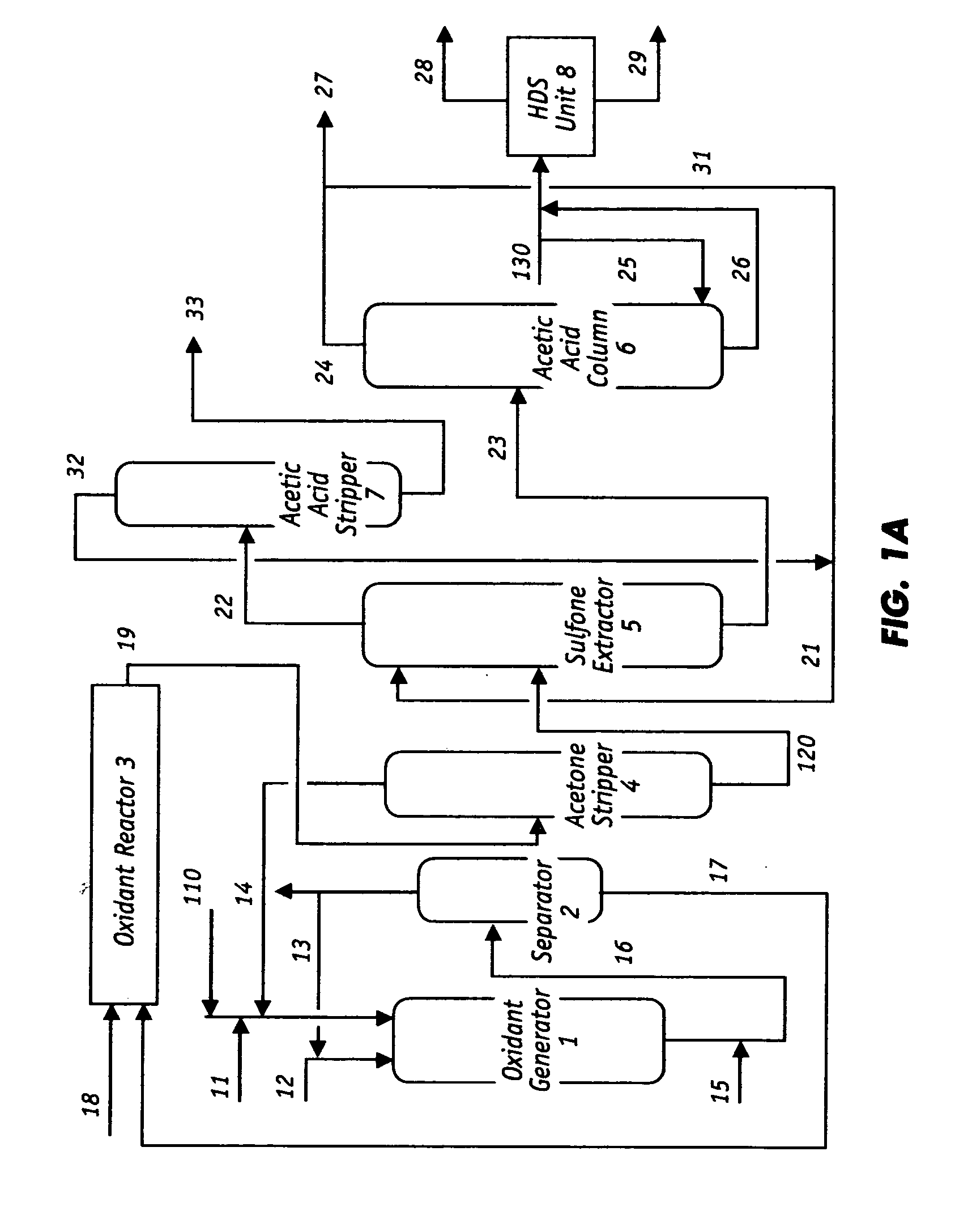

InactiveUS20090065399A1Easy to separateEasy extractionRefining with oxygen compoundsTreatment with plural serial refining stagesLiquid hydrocarbonsImproved method

An improved method for desulfurizing a fuel stream such as a diesel stream is disclosed which includes generation of a sulfone oil, the desulfurization of the sulfone oil and the recycling of the resulting biphenyl-rich stream and ultra-low sulfur diesel streams. The method includes combining a thiophene-rich diesel stream with an oxidant to oxidize the thiophenes to sulfones to provide a sulfone-rich diesel stream. Sulfone oil is extracted from the sulfone-rich diesel stream to provide sulfone oil and a first low-sulfur diesel stream The low-sulfur diesel stream is recycled. The sulfone-rich oil stream is combined with an aqueous oxidant-containing stream, such as caustic stream, which oxidizes the sulfones to biphenyls and forms sulfite to provide a second low-sulfur diesel stream

Owner:UOP LLC

Process for the catalytic oxidation of sulfur, nitrogen and unsaturated compounds from hydrocarbon streams

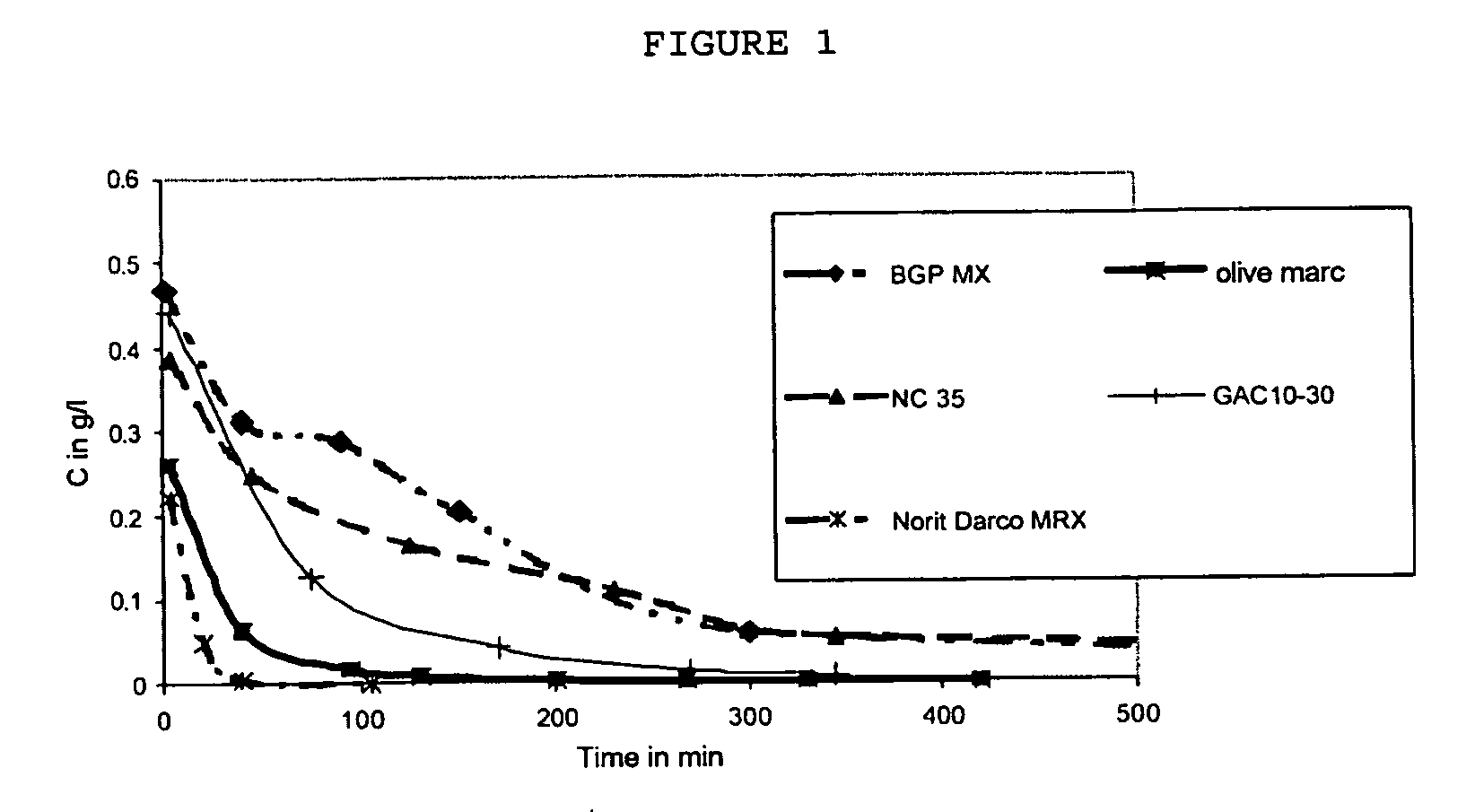

A process for the catalytic oxidation of sulfur and nitrogen contaminants as well as unsaturated compounds present in a hydrocarbon fossil oil medium is described, the process comprising effecting the oxidation in the presence of at least one peroxide, at least one acid and a pulverized raw iron oxide. The process shows an improved oxidation power towards the contaminants typically present in a fossil oil medium, this deriving from the combination of the peroxyacid and the hydroxyl radical generated in the reaction medium due to the presence of an iron oxyhydroxide such as a limonite clay, which bears a particular affinity for the oil medium. The process finds use in various applications, from a feedstock for refining until the preparation of deeply desulfurized and deeply denitrified products.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Oxidative desulfurization of sulfur-containing hydrocarbons

InactiveUS20050150819A1Reduce sulfur contentLow sulfurRefining with oxygen compoundsRefining with metal oxidesGas phaseOxygen

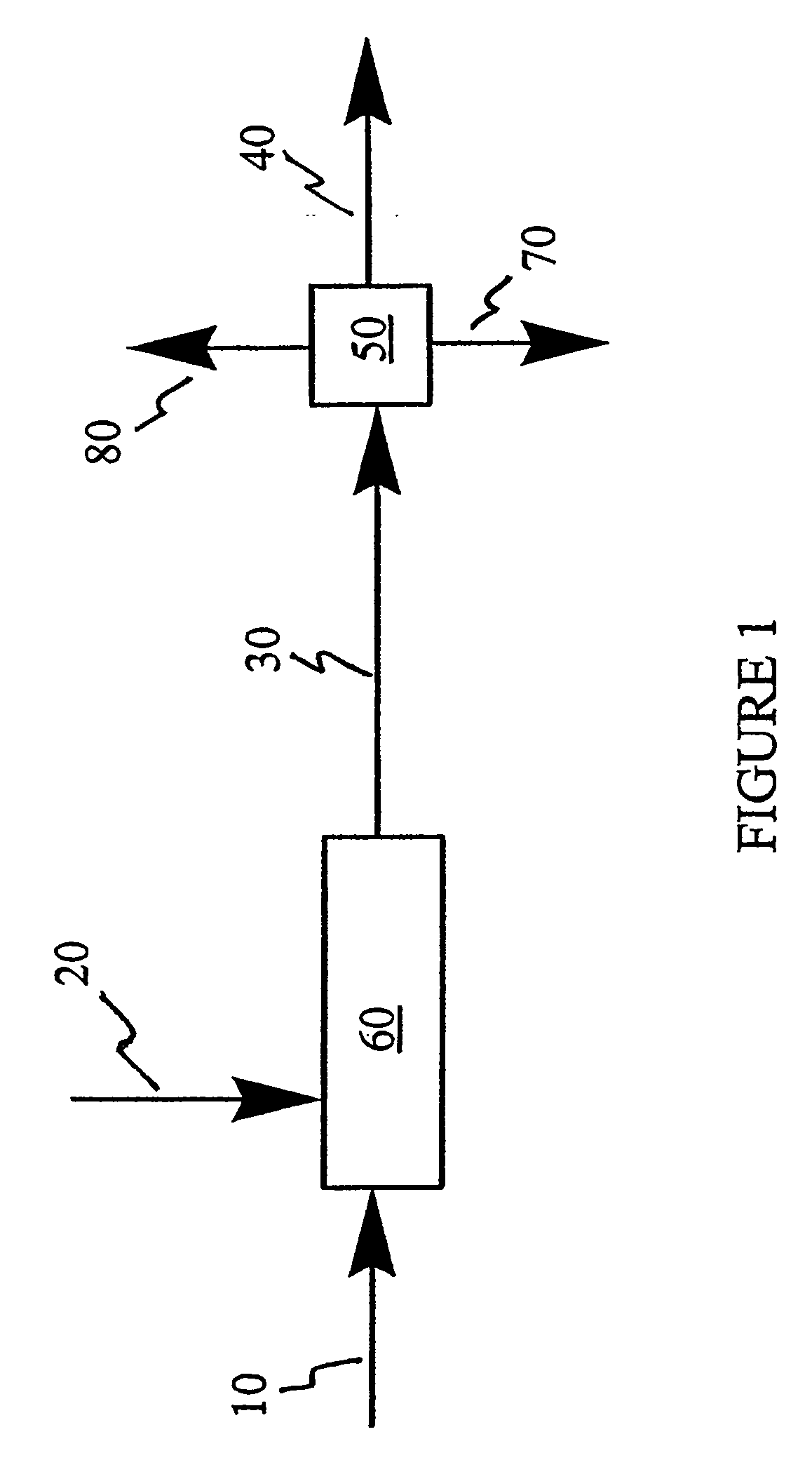

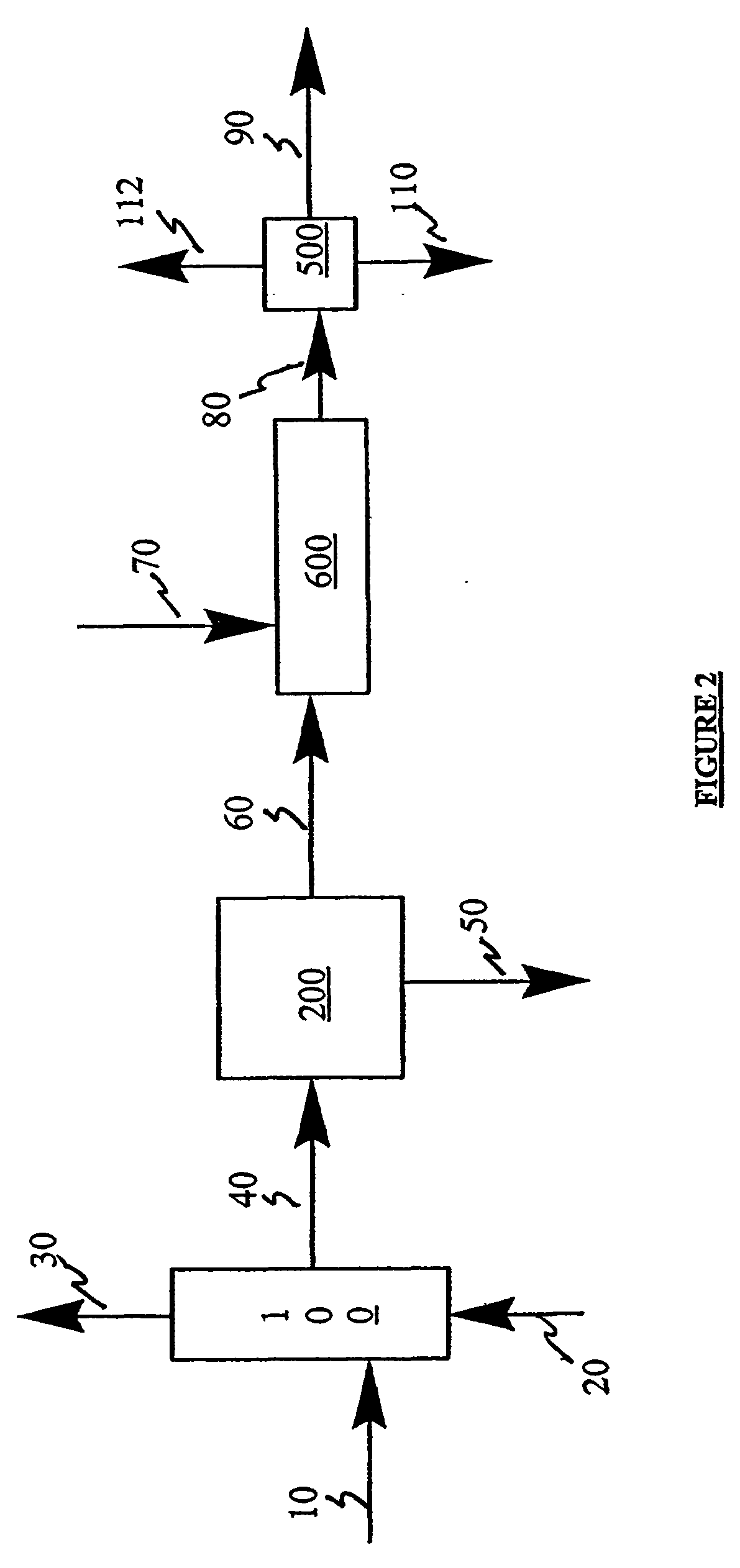

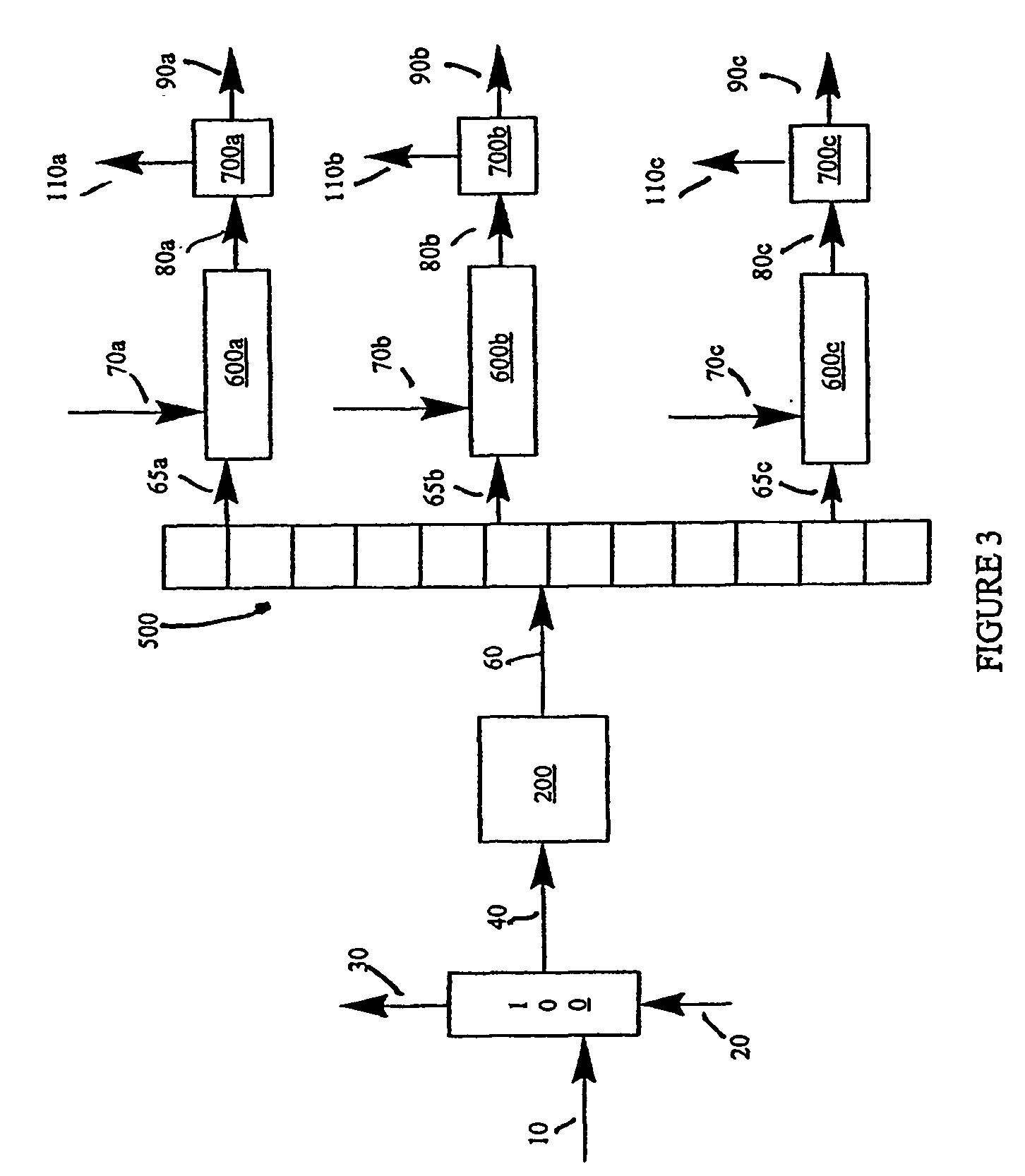

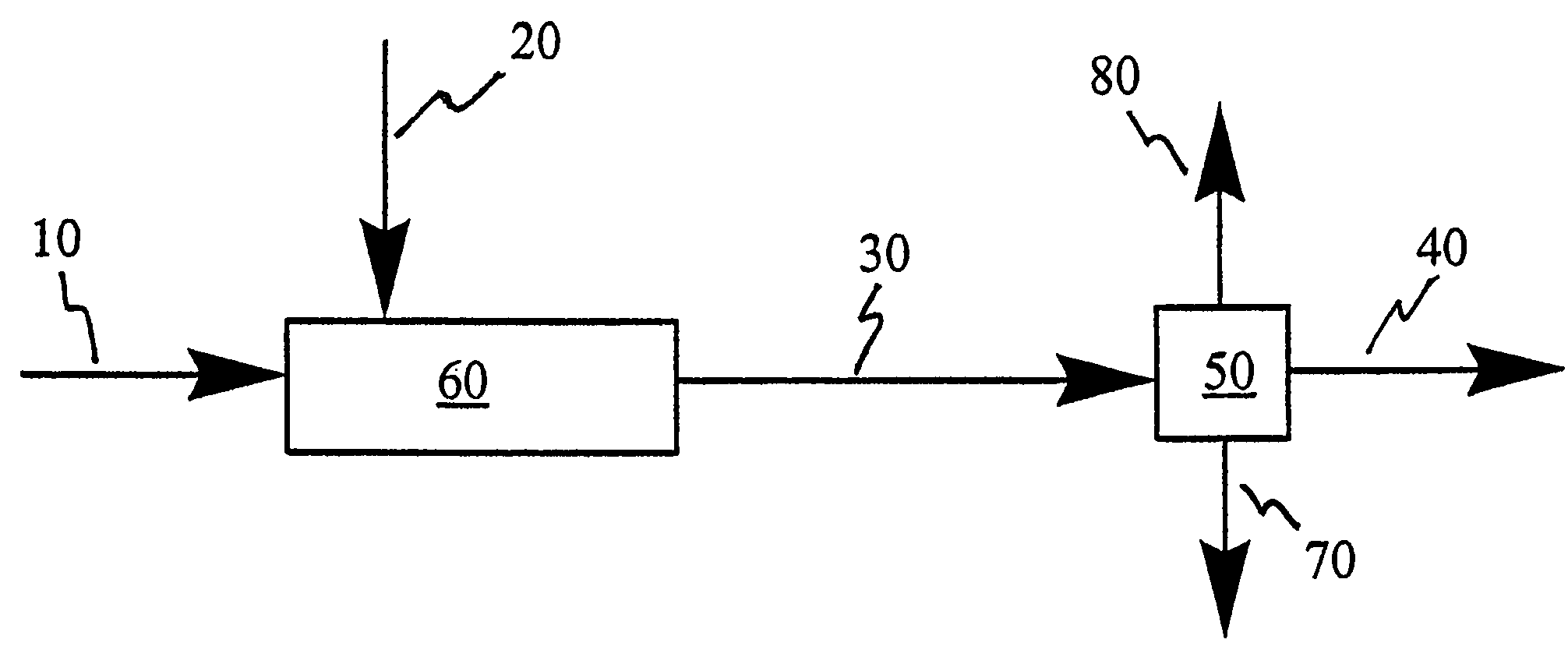

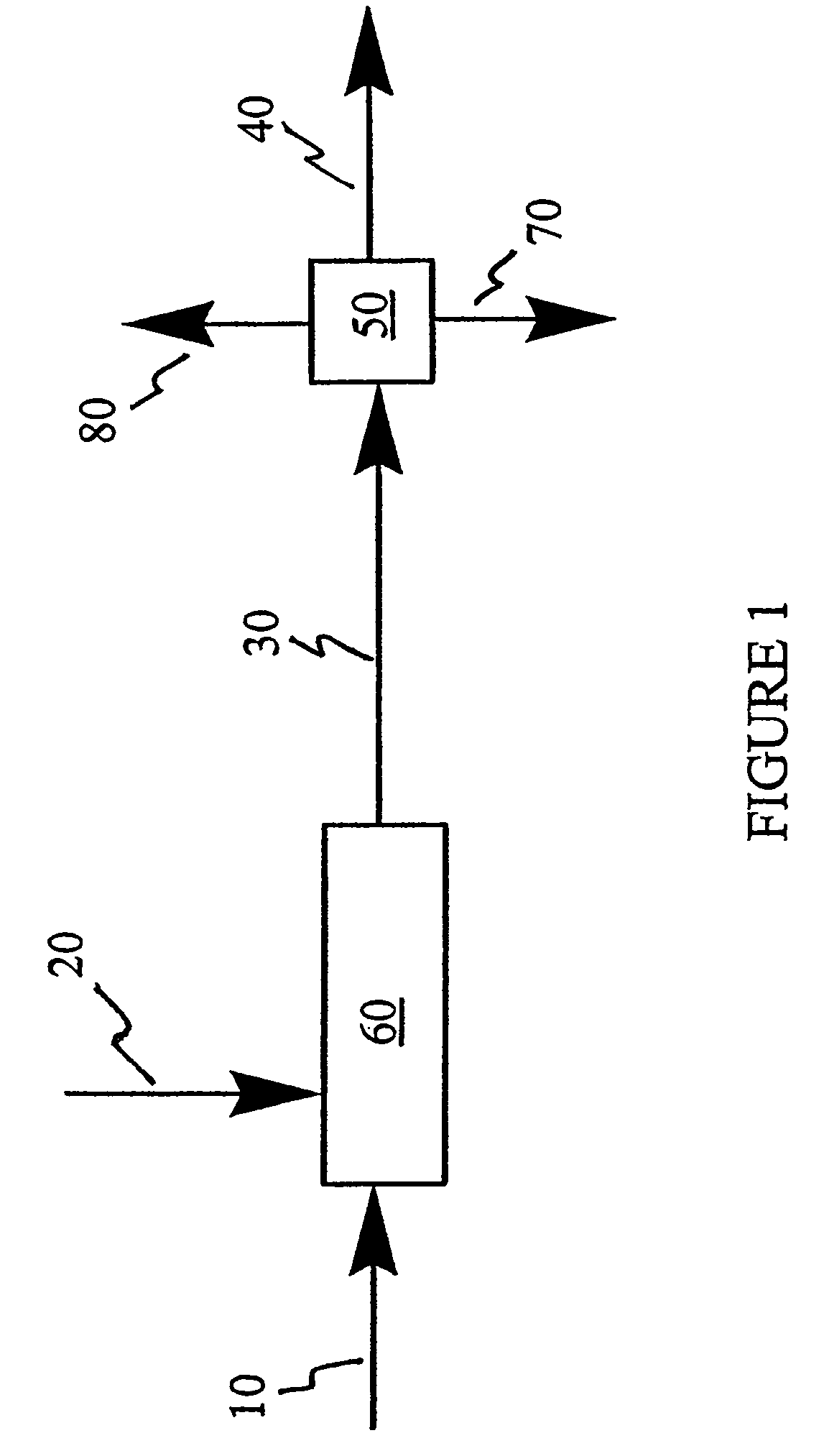

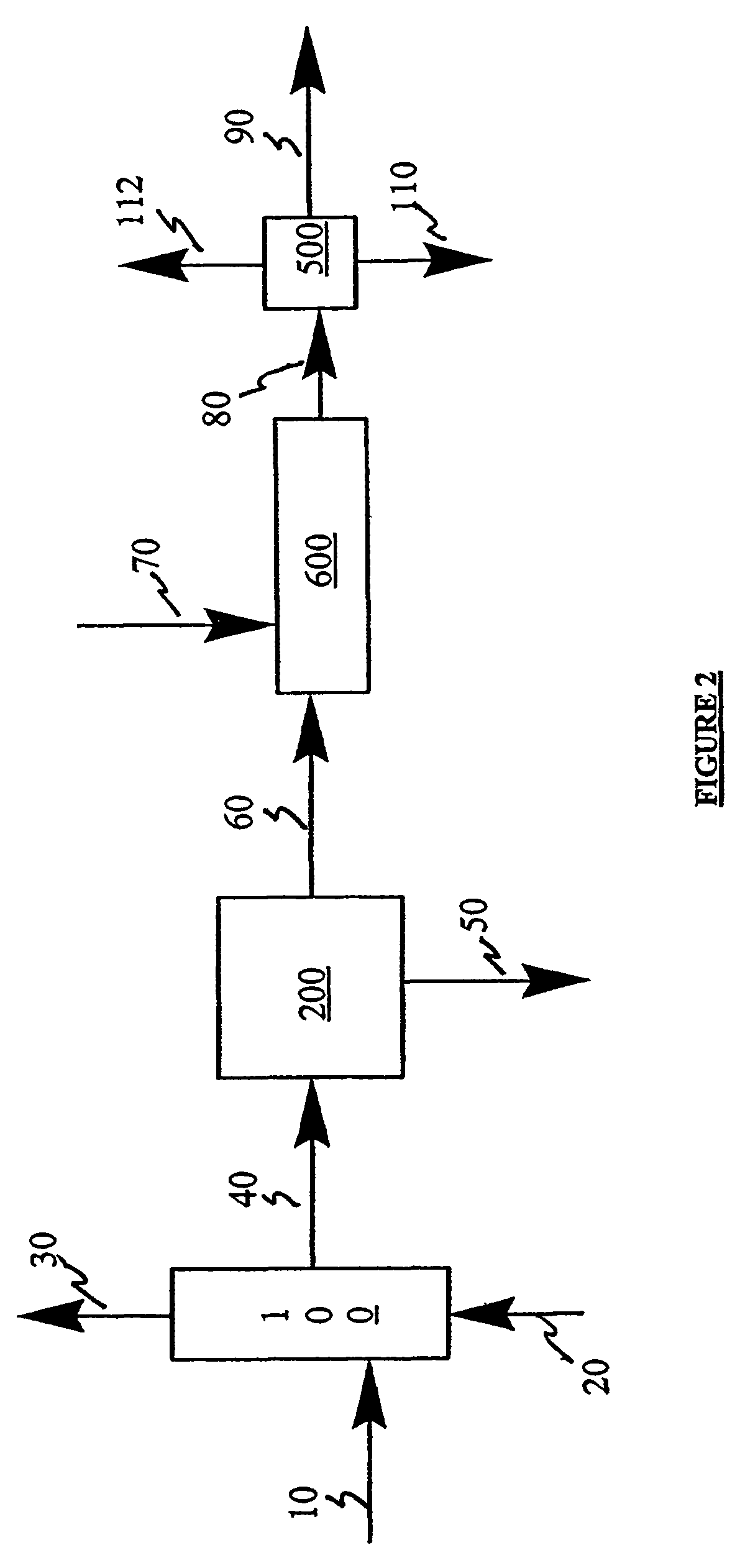

A method for desulfurizing a hydrocarbon stream (10) containing heterocyclic sulfur compounds, which process comprises contacting the heterocyclic sulfur compounds in the gas phase (60) in the presence of oxygen (70) with a supported metal oxide catalyst, or with a bulk metal oxide catalyst (600) to convert at least a portion of the heterocyclic sulfur compounds to oxygenated products as well as sulfur-deficient hydrocarbons and separately recovering the oxygenated products separately from a hydrocarbon stream with substantially reduced sulfur.

Owner:LEHIGH UNIVERSITY

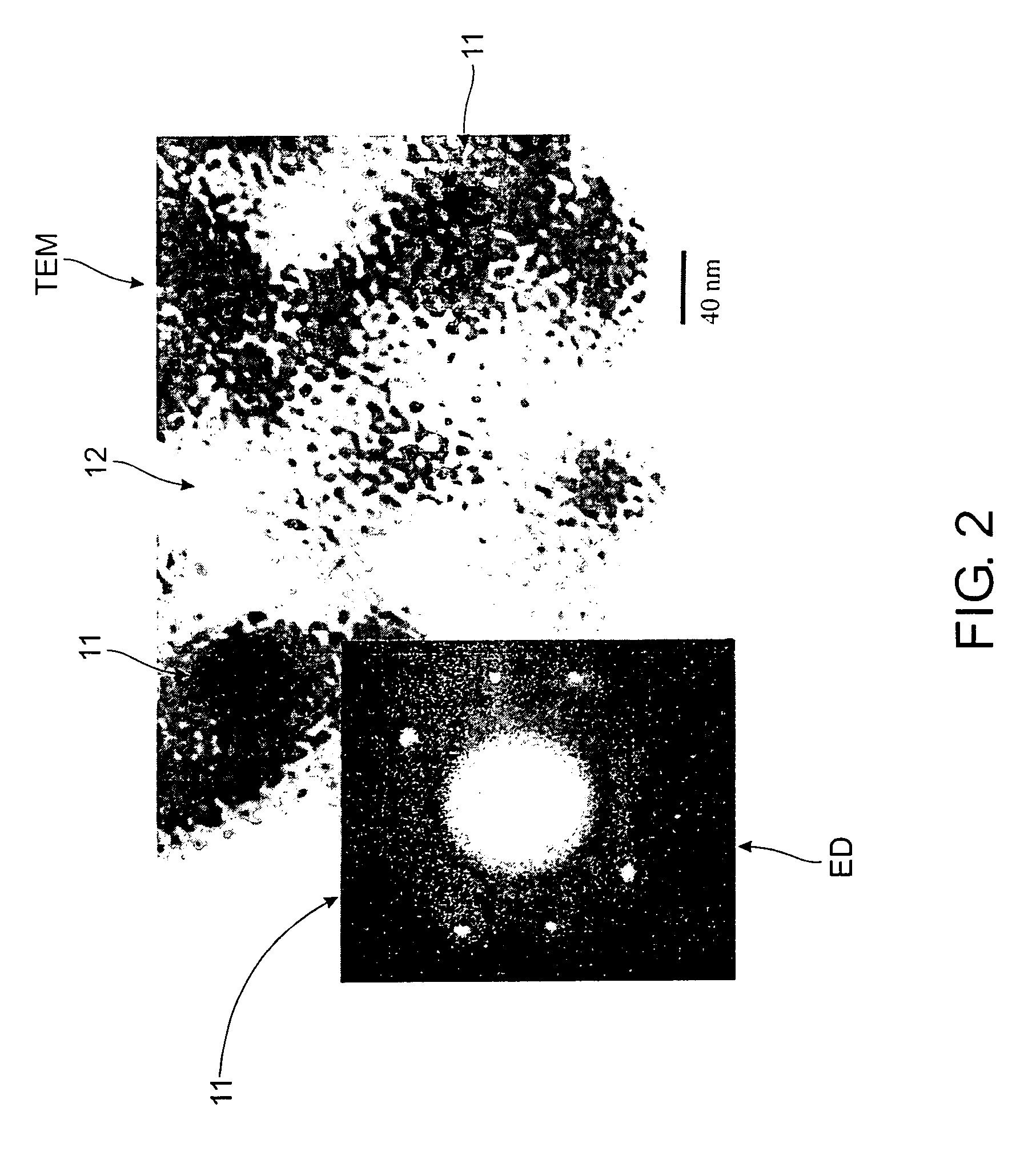

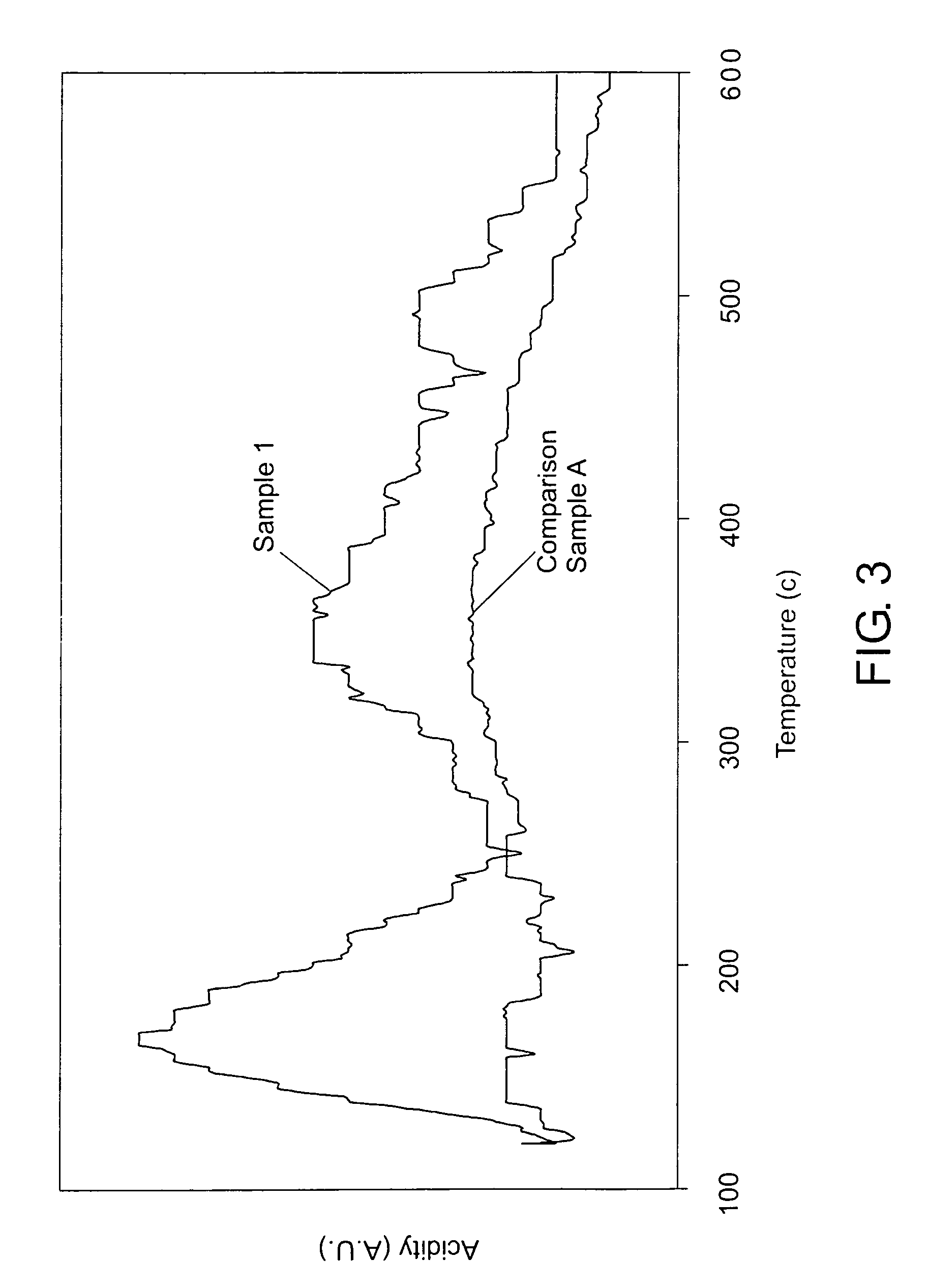

Zeolite composite, method for making and catalytic application thereof

A catalytic material includes microporous zeolites supported on a mesoporous inorganic oxide support. The microporous zeolite can include zeolite Beta, zeolite Y (including “ultra stable Y”—USY), mordenite, Zeolite L, ZSM-5, ZSM-11, ZSM-12, ZSM-20, Theta-1, ZSM-23, ZSM-34, ZSM-35, ZSM-48, SSZ-32, PSH-3, MCM-22, MCM-49, MCM-56, ITQ-1, ITQ-2, ITQ-4, ITQ-21, SAPO-5, SAPO-11, SAPO-37, Breck-6, ALPO4-5, etc. The mesoporous inorganic oxide can be e.g., silica or silicate. The catalytic material can be further modified by introducing some metals e.g. aluminum, titanium, molybdenum, nickel, cobalt, iron, tungsten, palladium and platinum. It can be used as catalysts for acylation, alkylation, dimerization, oligomerization, polymerization, hydrogenation, dehydrogenation, aromatization, isomerization, hydrotreating, catalytic cracking and hydrocracking reactions.

Owner:ABB LUMMUS GLOBAL INC

Oxidative desulfurization and denitrogenation of petroleum oils

InactiveUS20070102323A1Reduce the temperatureShort stayOrganic chemistryRefining with oxygen compoundsHydrocotyle bowlesioidesSolvent

An improved oxidative process that employ a robust, non-aqueous, and oil-soluble organic peroxide oxidant for effective desulfurization and denitrogenation of hydrocarbons including petroleum fuels, hydrotreated vacuum gas oil (VGO), non-hydrotreated VGO, petroleum crude oil, synthetic crude oil from oil sand, and residual oil. Even at low concentrations and without the assistance of catalysts, the non-aqueous organic peroxide oxidant is extremely active and fast in oxidizing the sulfur and nitrogen compounds in the hydrocarbon feedstocks. Furthermore, the process generates a valuable organic acid by-product that is also used internally as the extractive solvent for effective removal of the oxidized sulfur and nitrogen from the hydrocarbons without the need of a final adsorption step. Novel process steps are also disclosed to substantially prevent yield loss in the oxidative process.

Owner:CPC CORPORATION

Process for the desulfurization of hydrocarbonacecus oil

InactiveUS20050040078A1Easily and economically reducing sulfur contentHigh recovery rateRefining with oxygen compoundsTreatment with plural serial refining stagesHydrodesulfurizationSulfur

A process for the desulfurization of hydrocarbonaceous oil wherein the hydrocarbonaceous oil is contacted with a hydrodesulfurization catalyst in a hydrodesulfurization reaction zone to reduce the sulfur level to a relatively low level then contacting the resulting hydrocarbonaceous stream from the hydrodesulfurization zone with an oxidizing agent to convert the residual, low level of sulfur compounds into sulfur-oxidated compounds. The resulting hydrocarbonaceous oil stream containing the sulfur-oxidated compounds is separated after decomposing any residual oxidizing agent by contacting the stream with an adsorbent material to adsorb the sulfur-oxidated compounds to produce a hydrocarbonaceous oil stream having a reduced concentration of sulfur-oxidated compounds. The spent adsorbent is regenerated and subsequently returned to adsorbent service.

Owner:UOP LLC

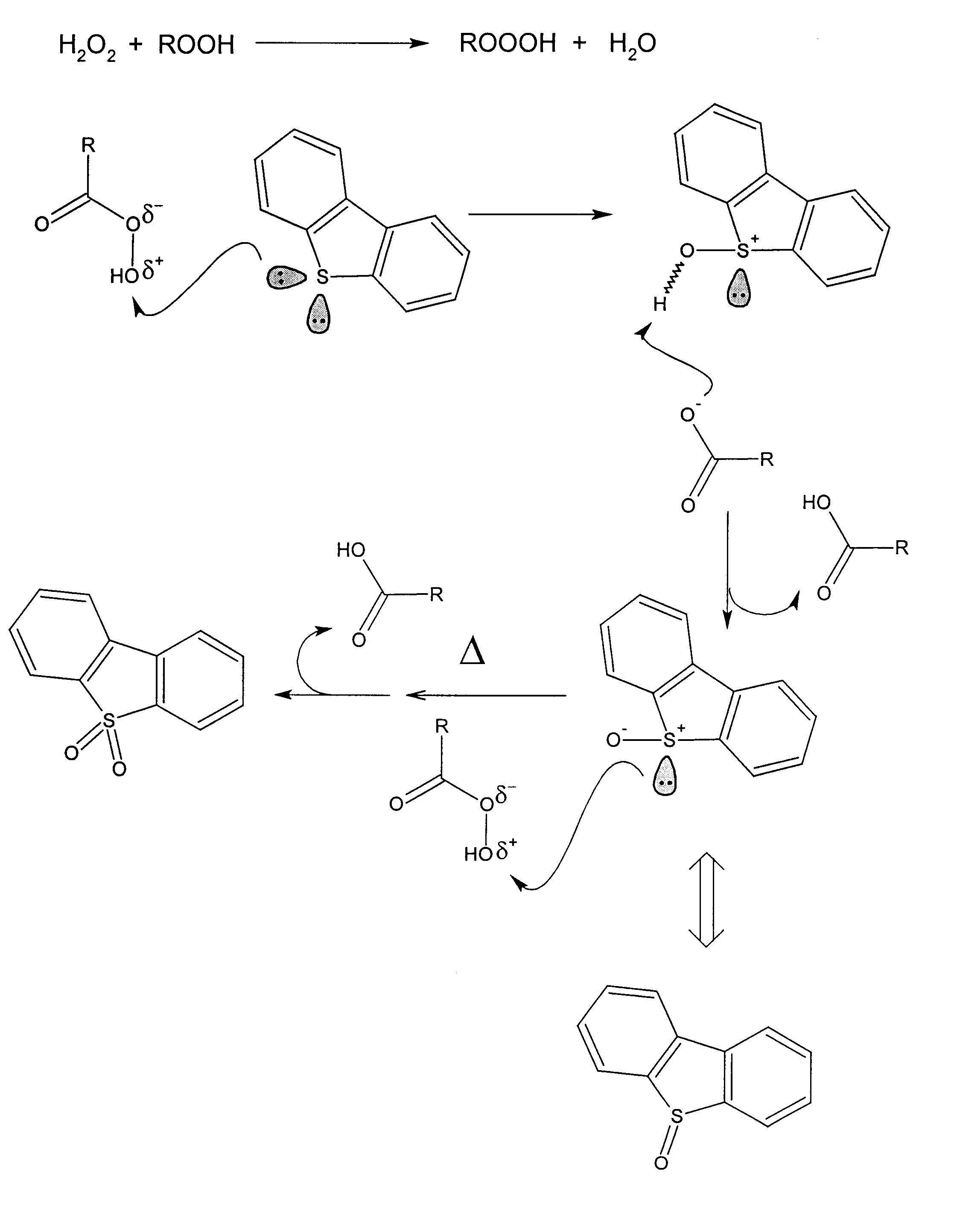

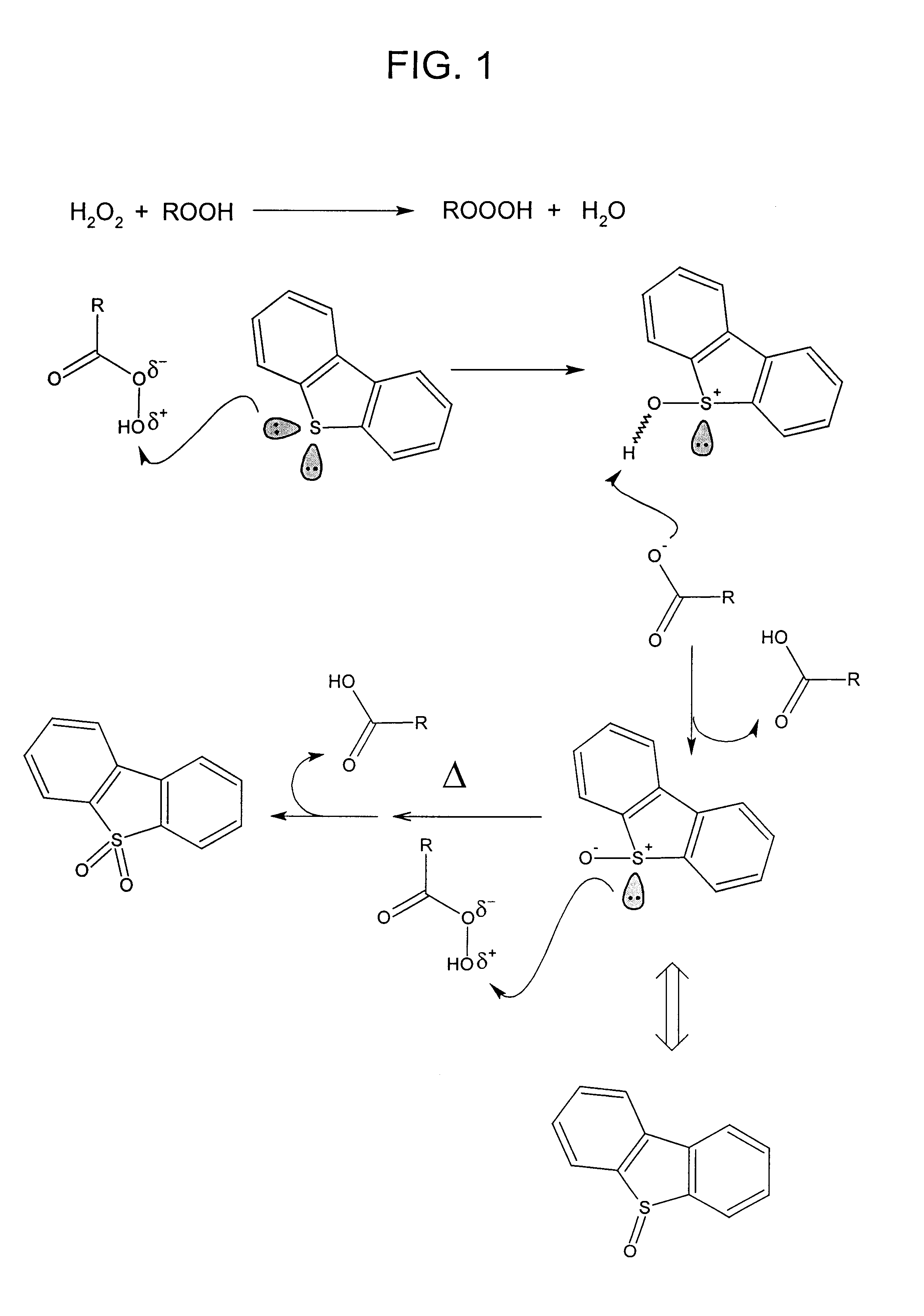

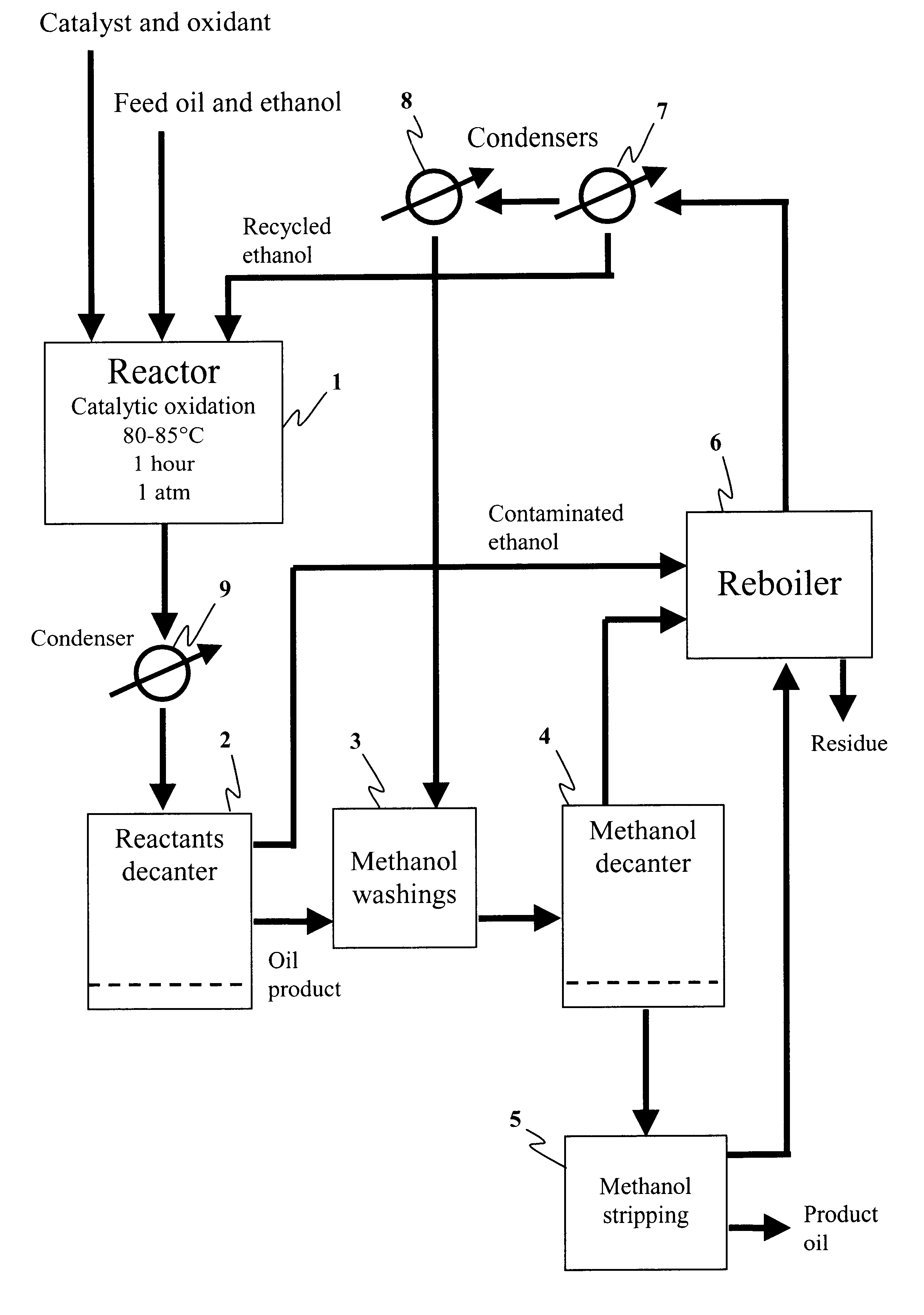

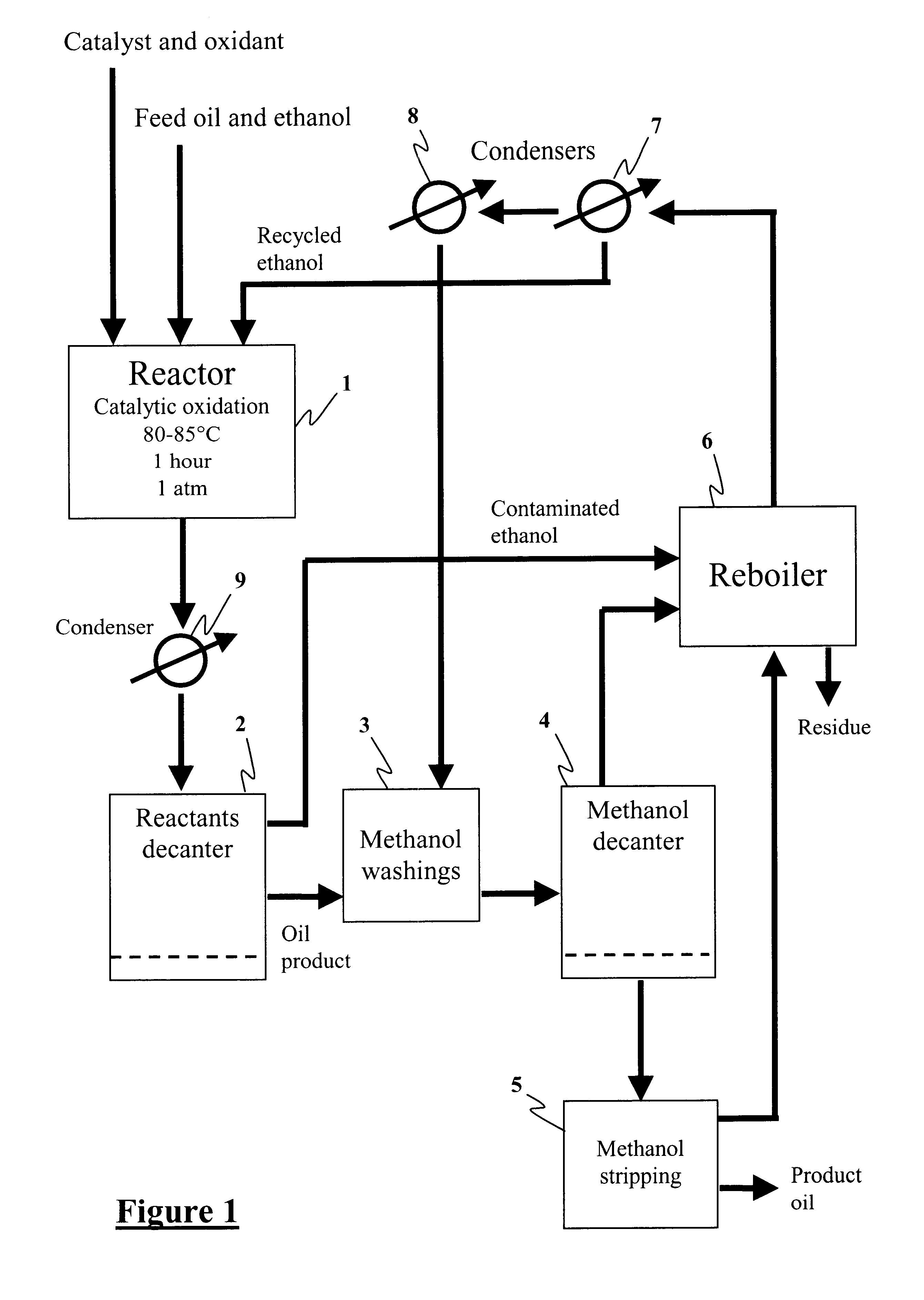

Method for the production of hydrocarbon fuels with ultra-low sulfur content

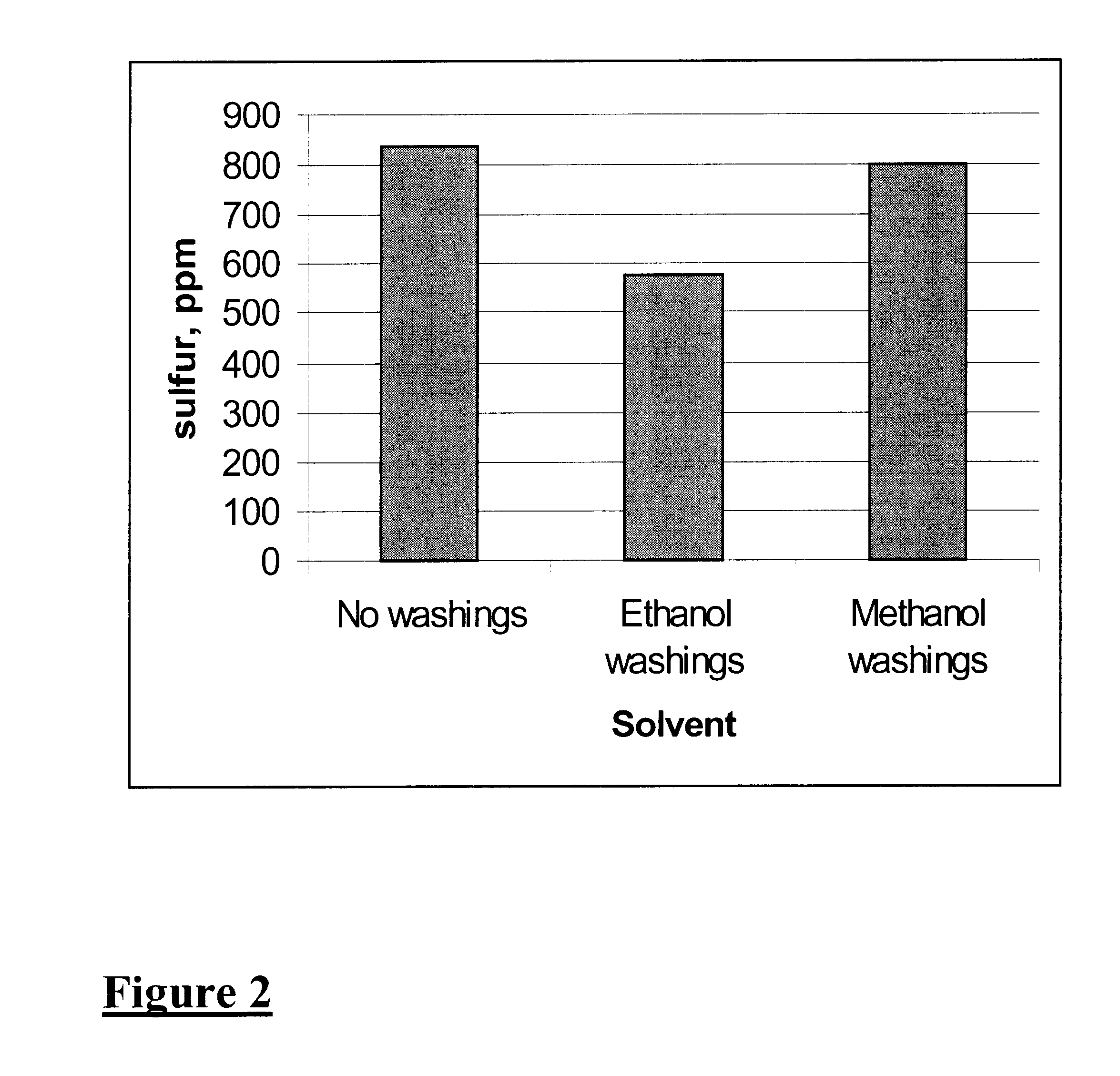

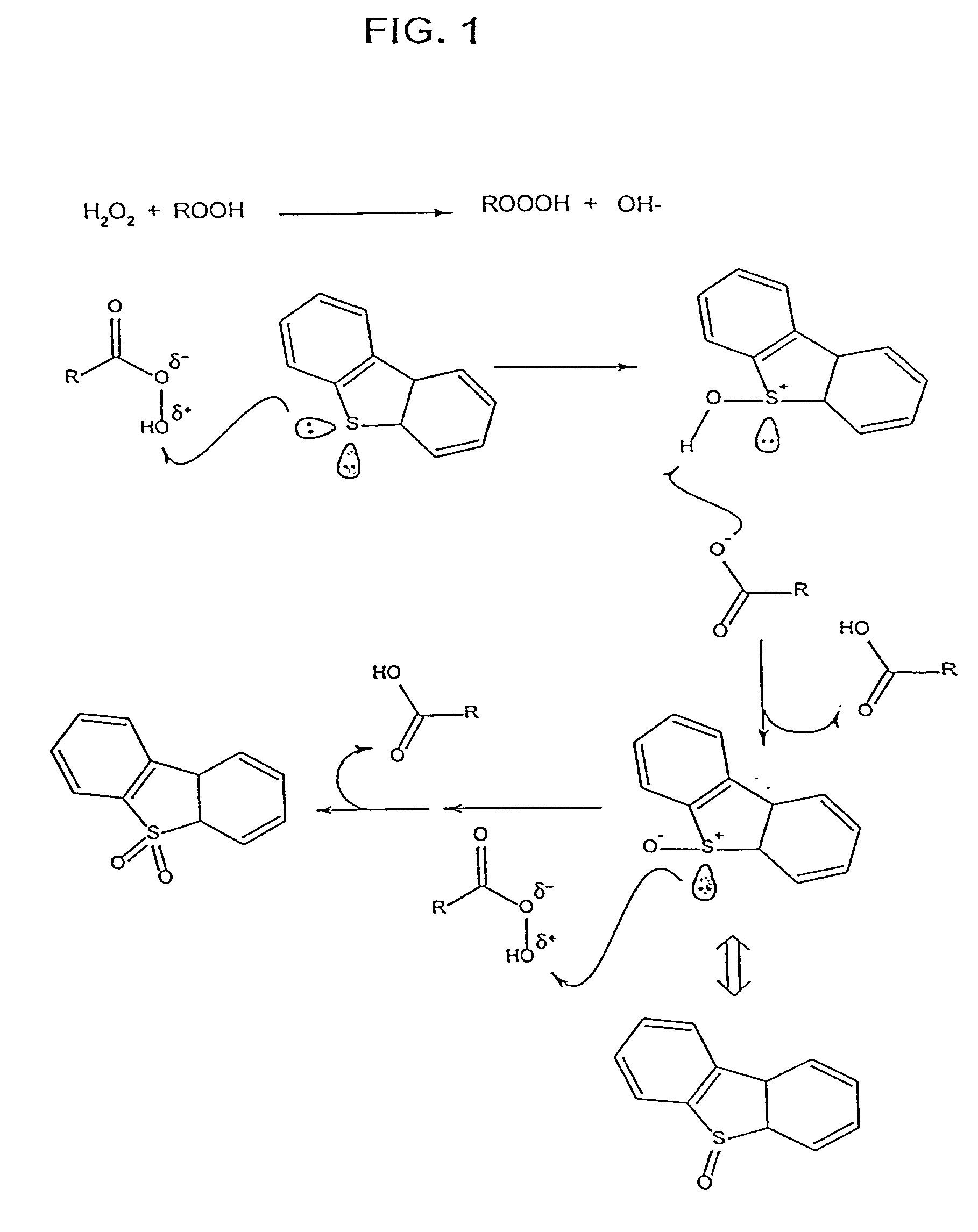

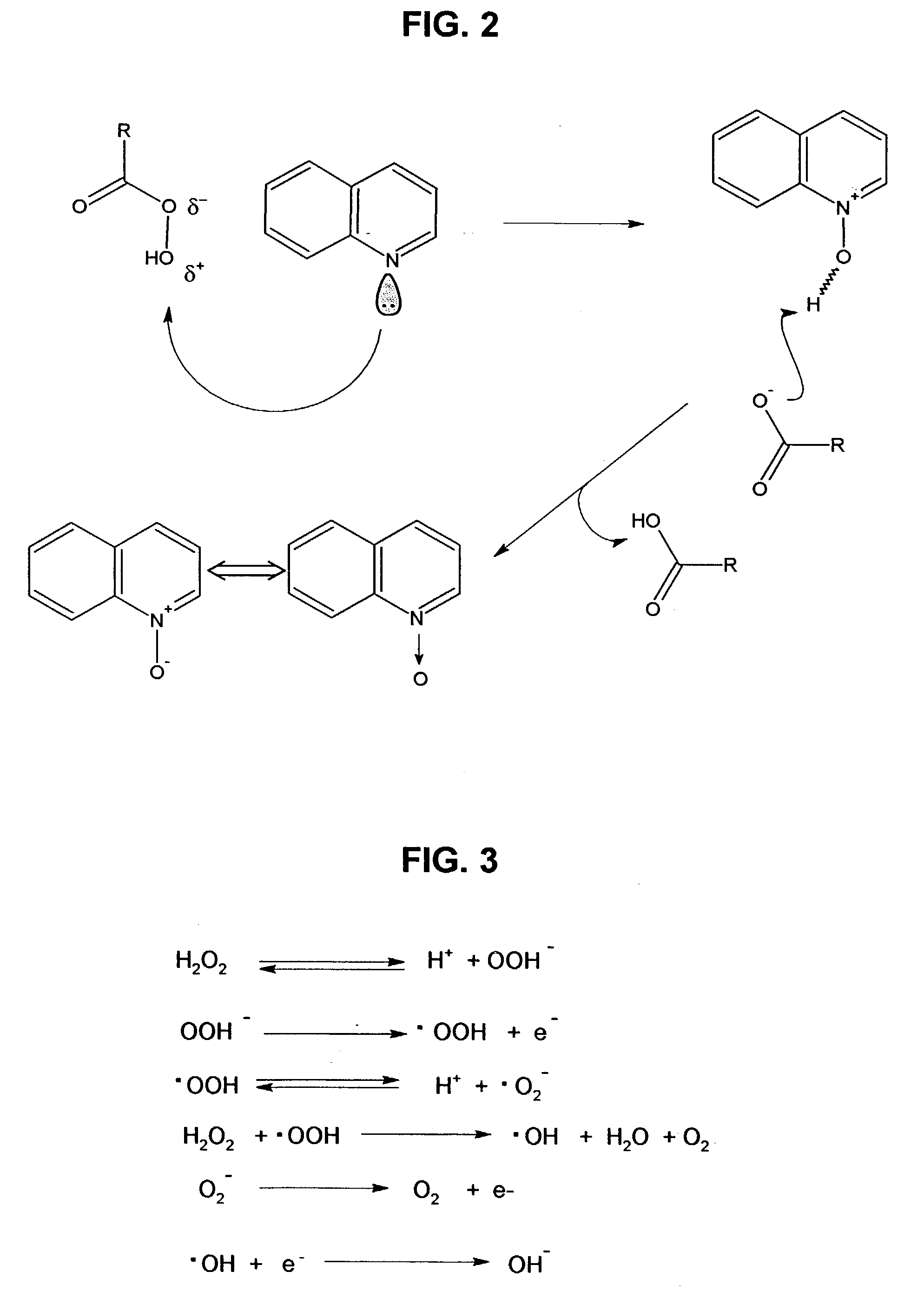

InactiveUS6673236B2Efficient oxidationReduce sulfur contentRefining with oxygen compoundsCatalytic naphtha reformingAlcoholCatalytic oxidation

The present invention provides a method for producing hydrocarbon fuels with ultra-low levels of sulfur. The method involves catalytic oxidation of the sulfurous compounds within the hydrocarbon fuel, followed by extraction of the oxidized (and polarized) sulfurous compounds using a polar solvent. The present invention teaches the involvement of ethanol during catalytic oxidation. In this way, the oxidation catalyst has a dual-role in the oxidation process: firstly the catalyst directly oxidizes the sulfurous compounds, and secondly the oxidation catalyst converts of a small portion of the alcohol to the corresponding peroxy acid, which also helps to drive the oxidation process.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

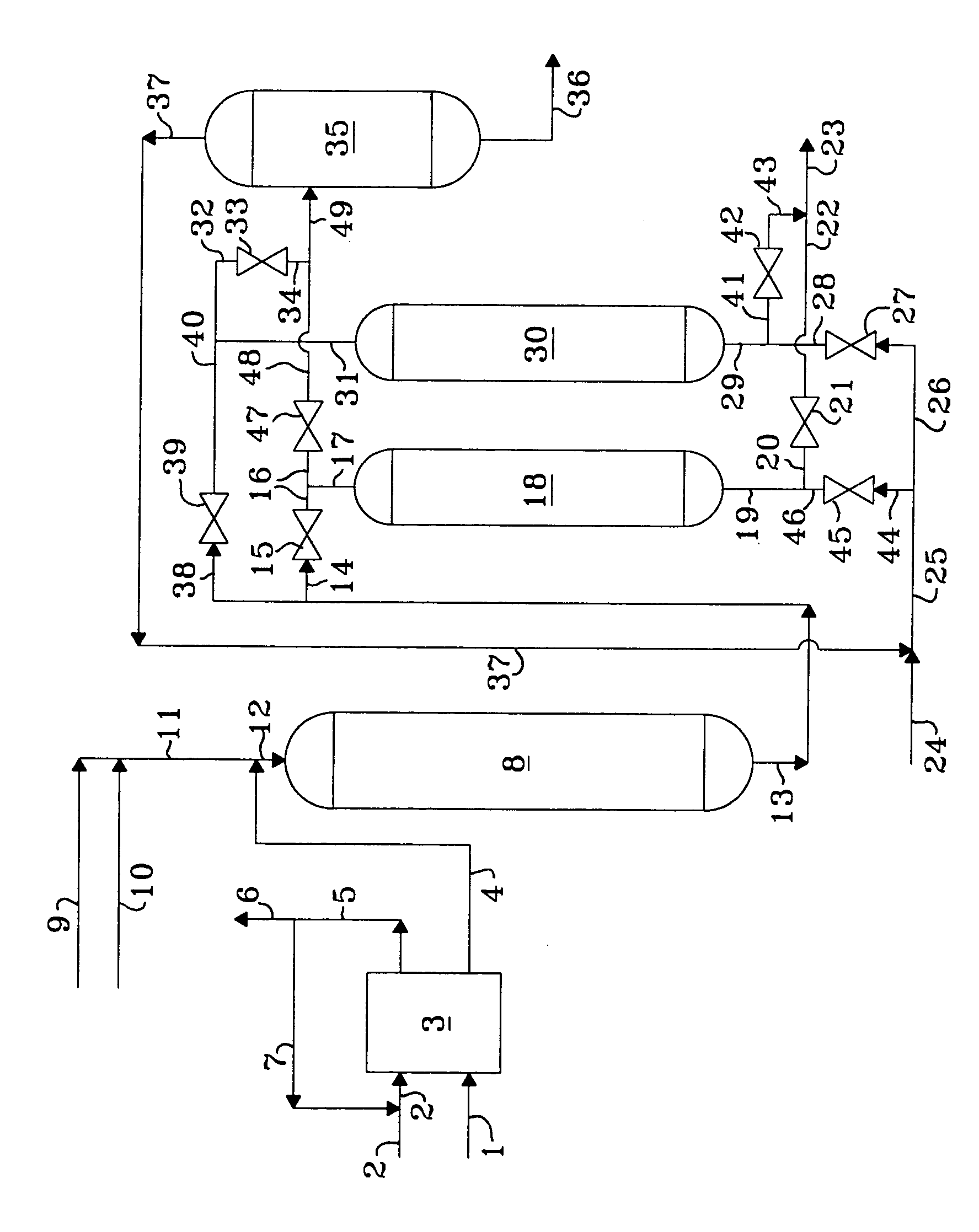

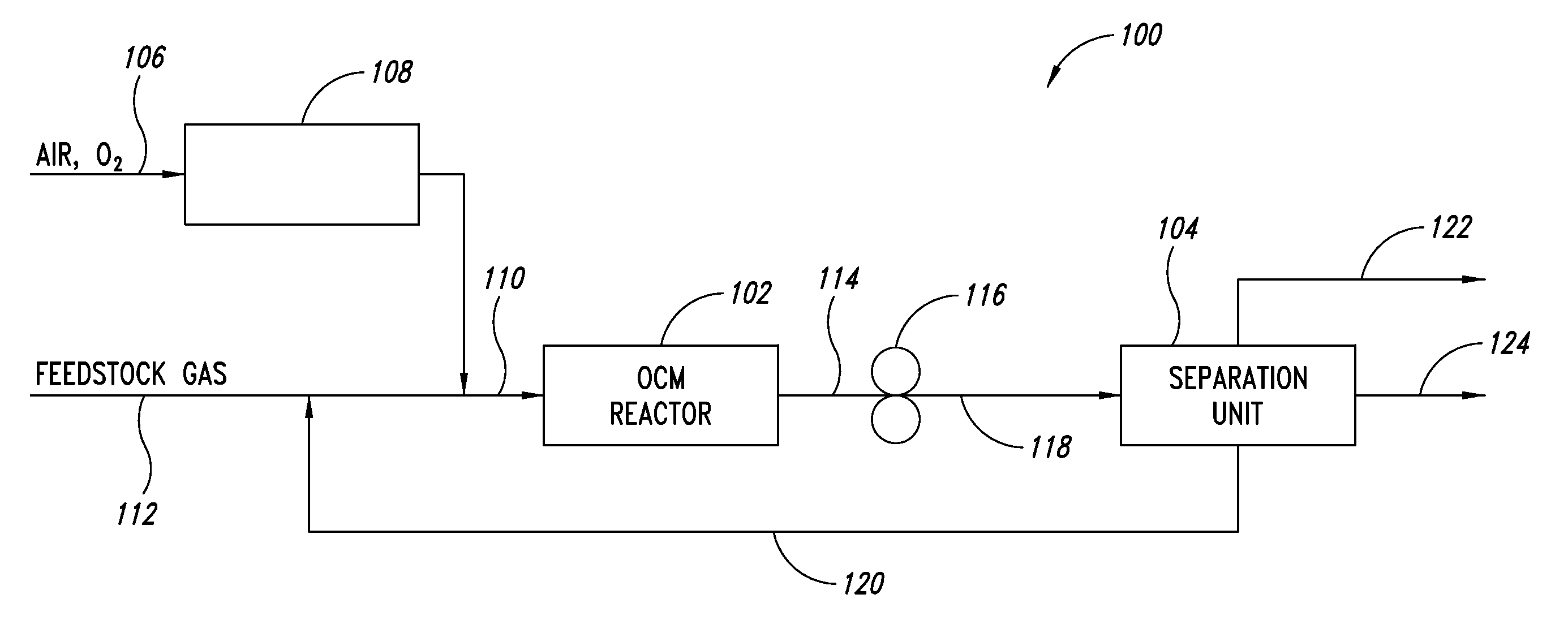

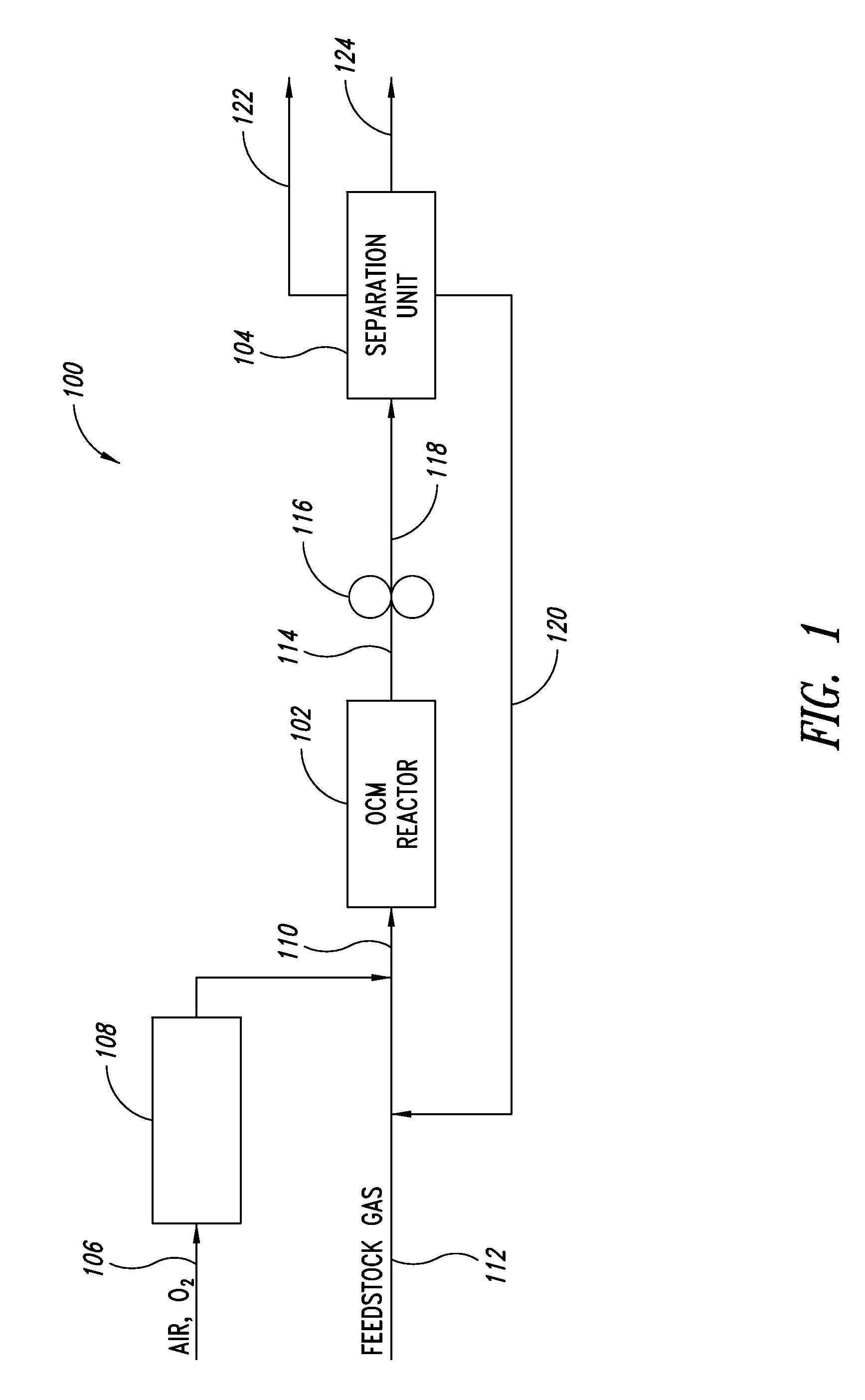

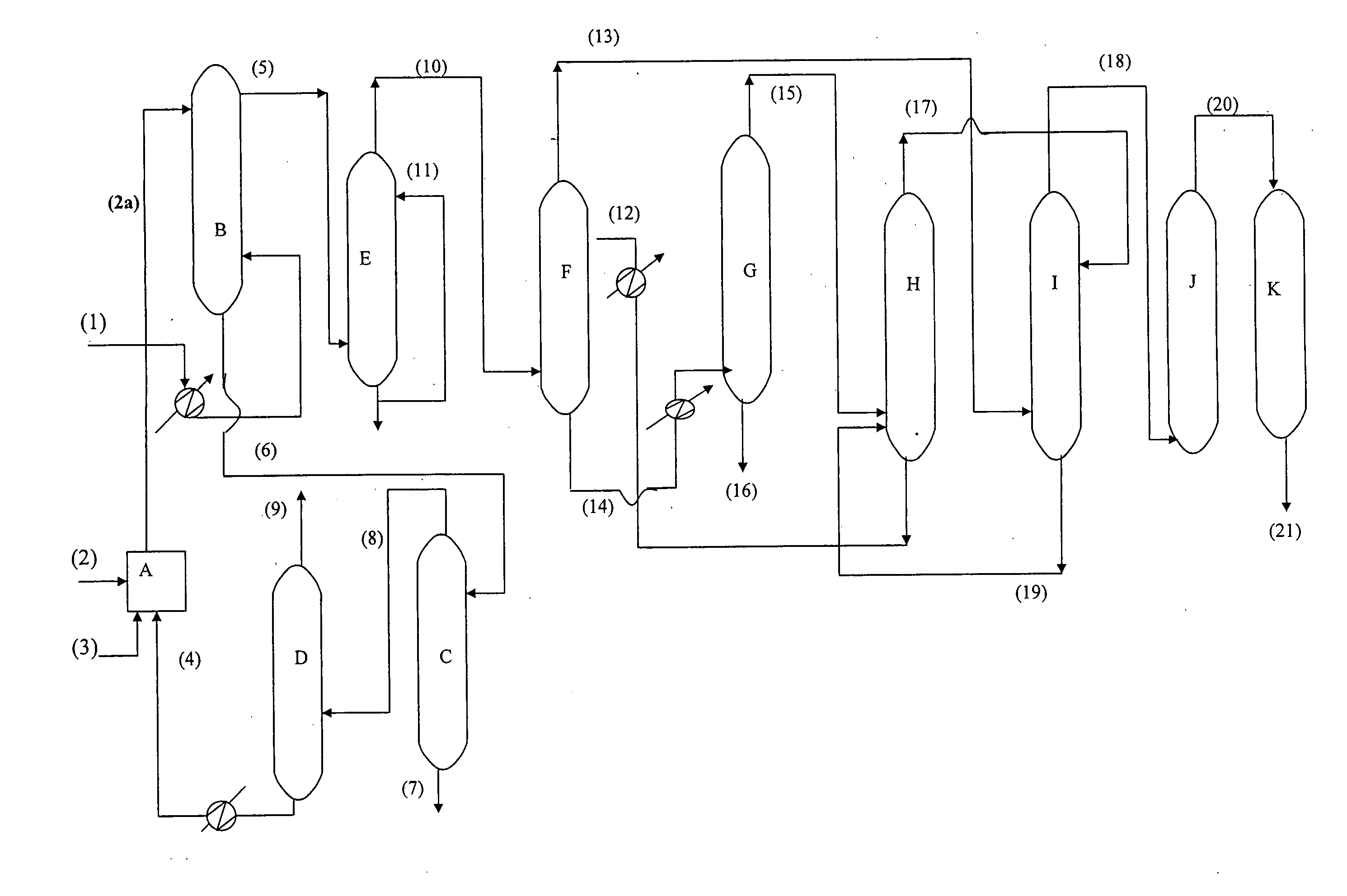

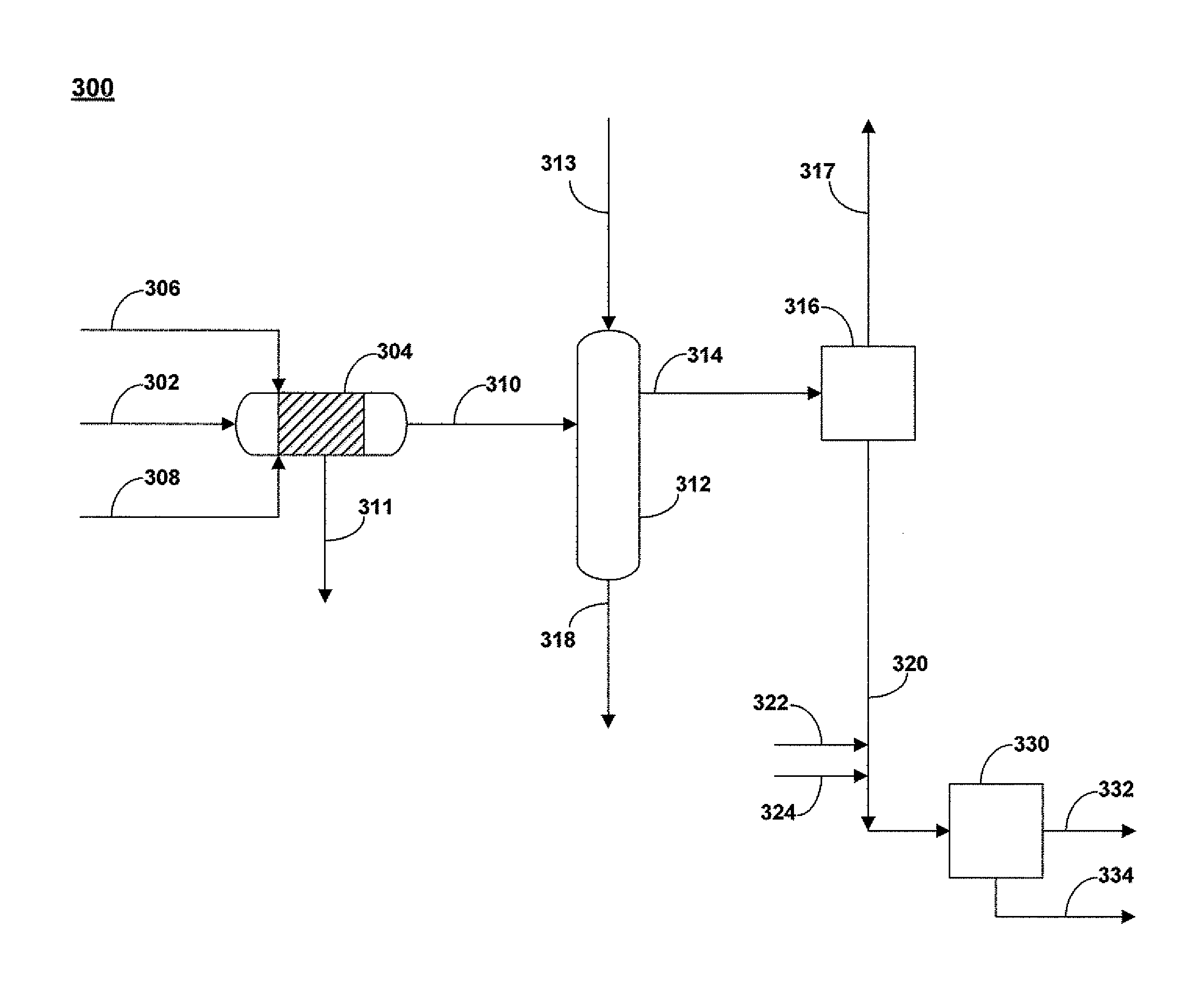

Process for separating hydrocarbon compounds

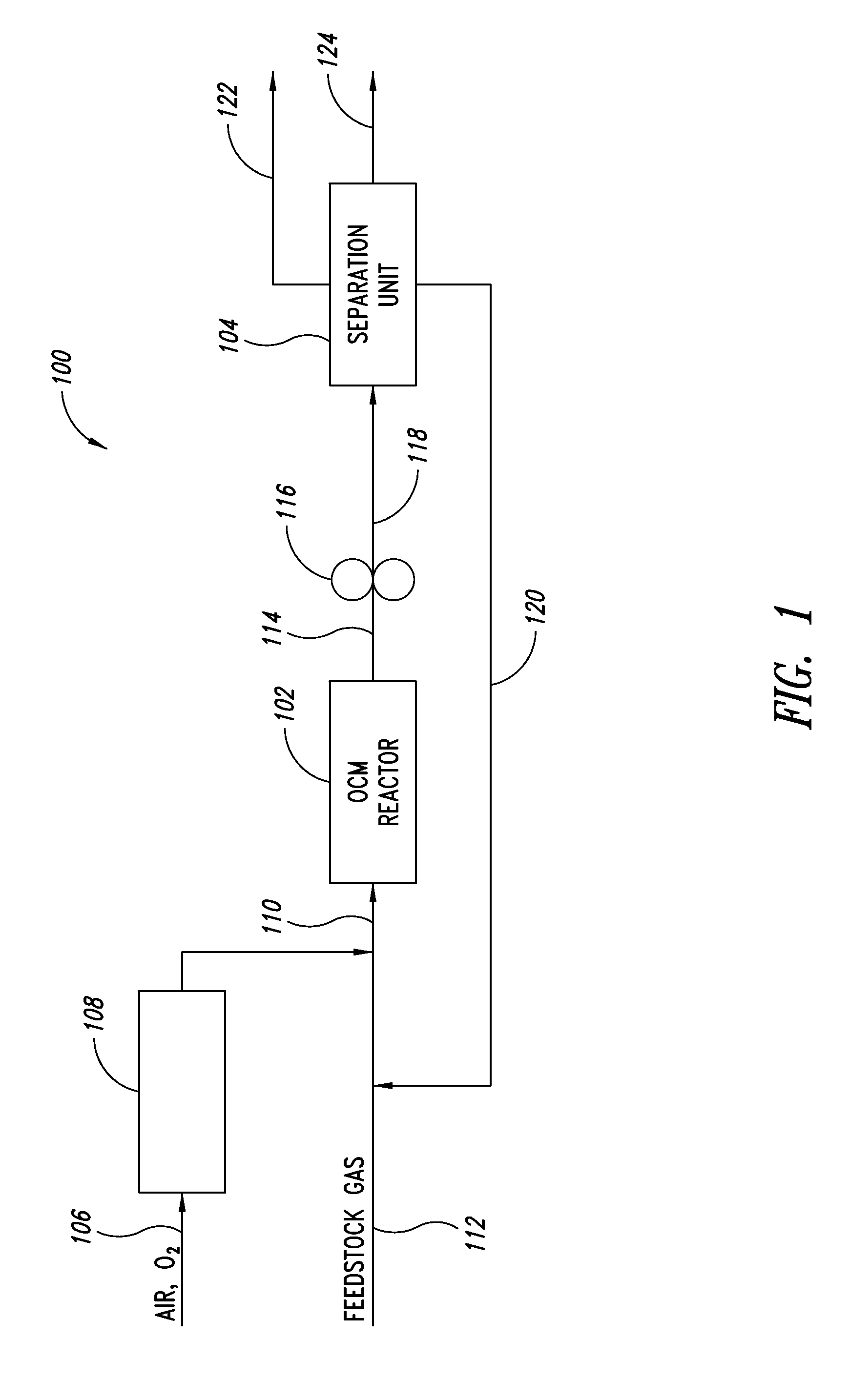

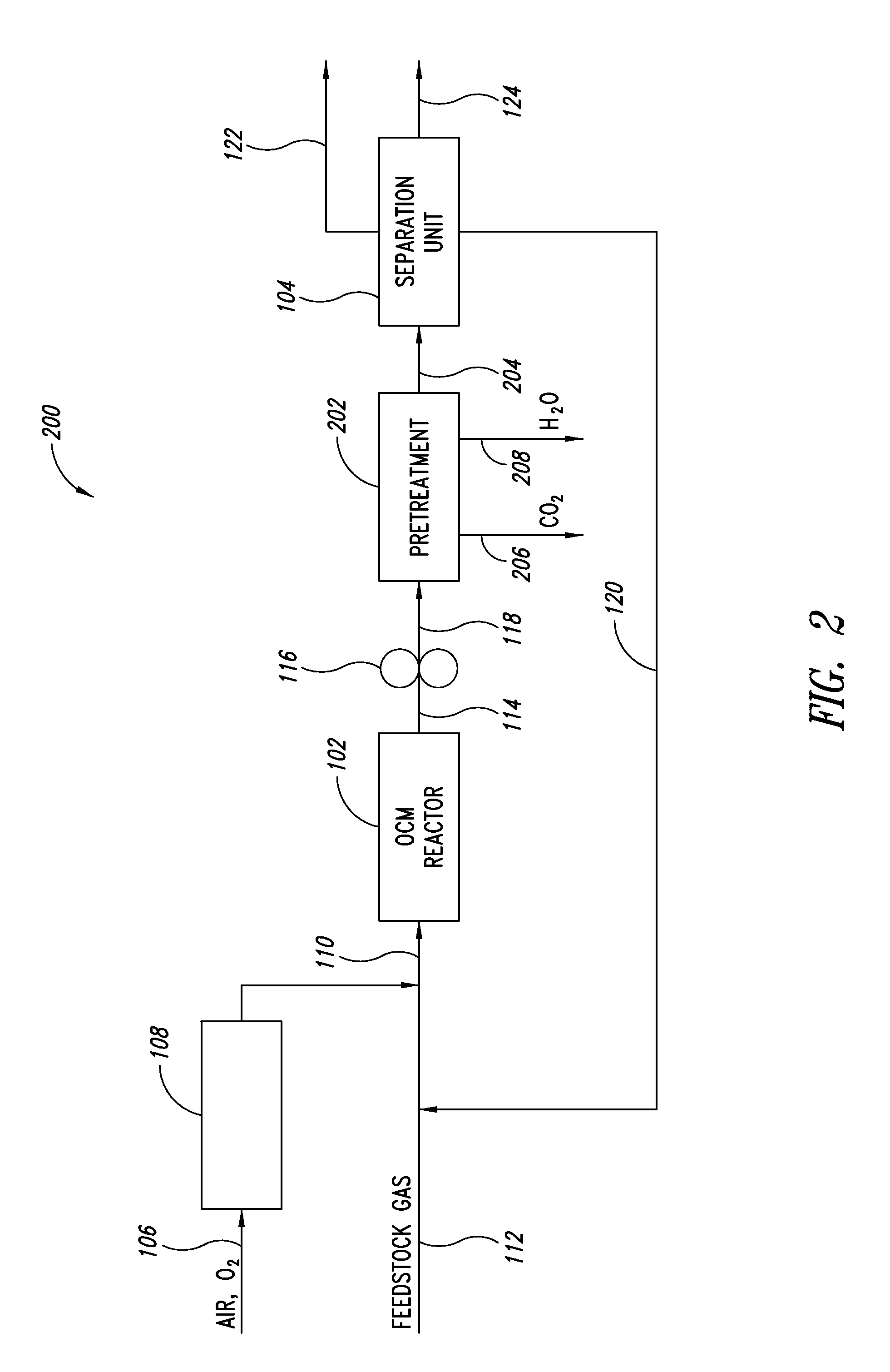

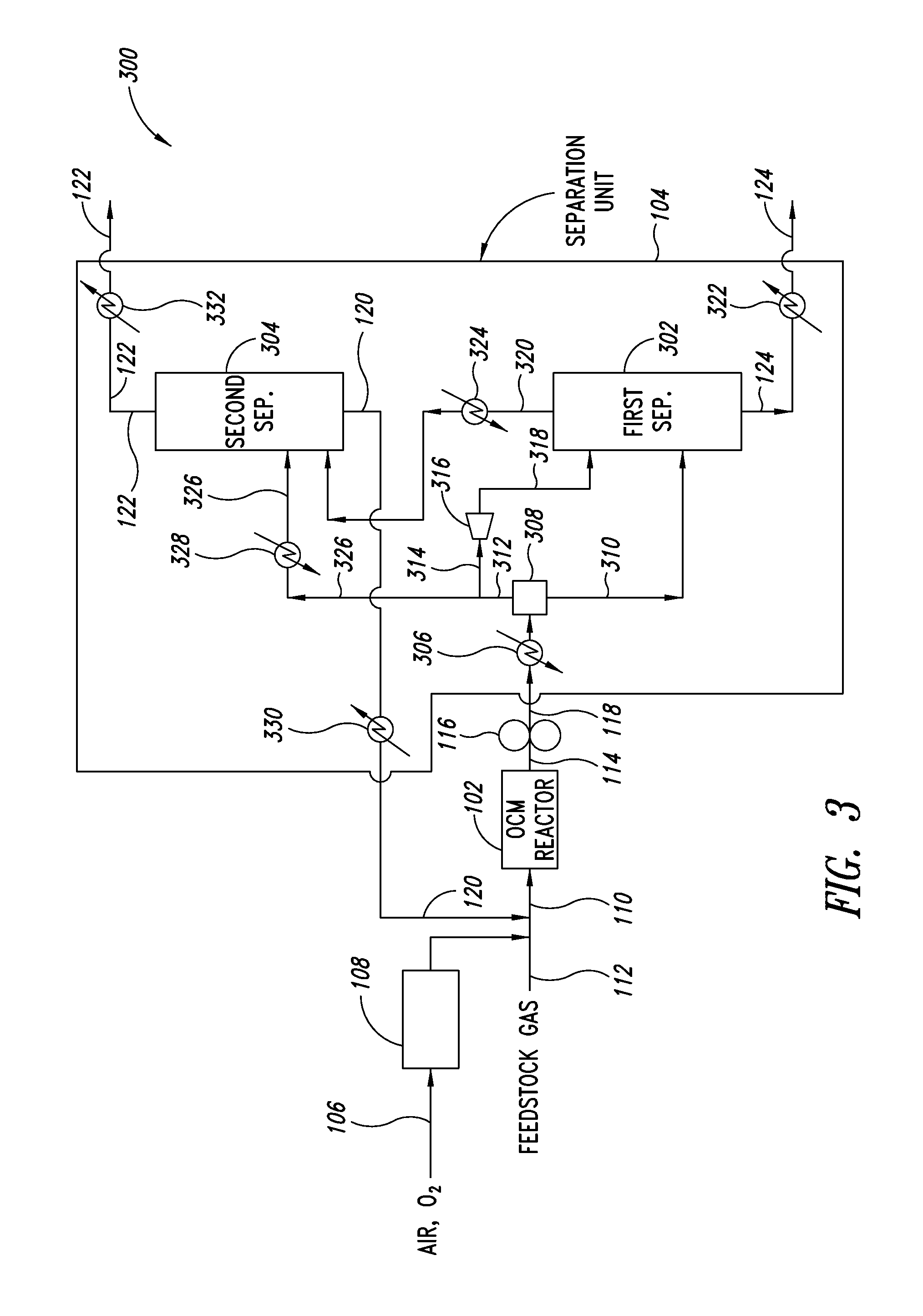

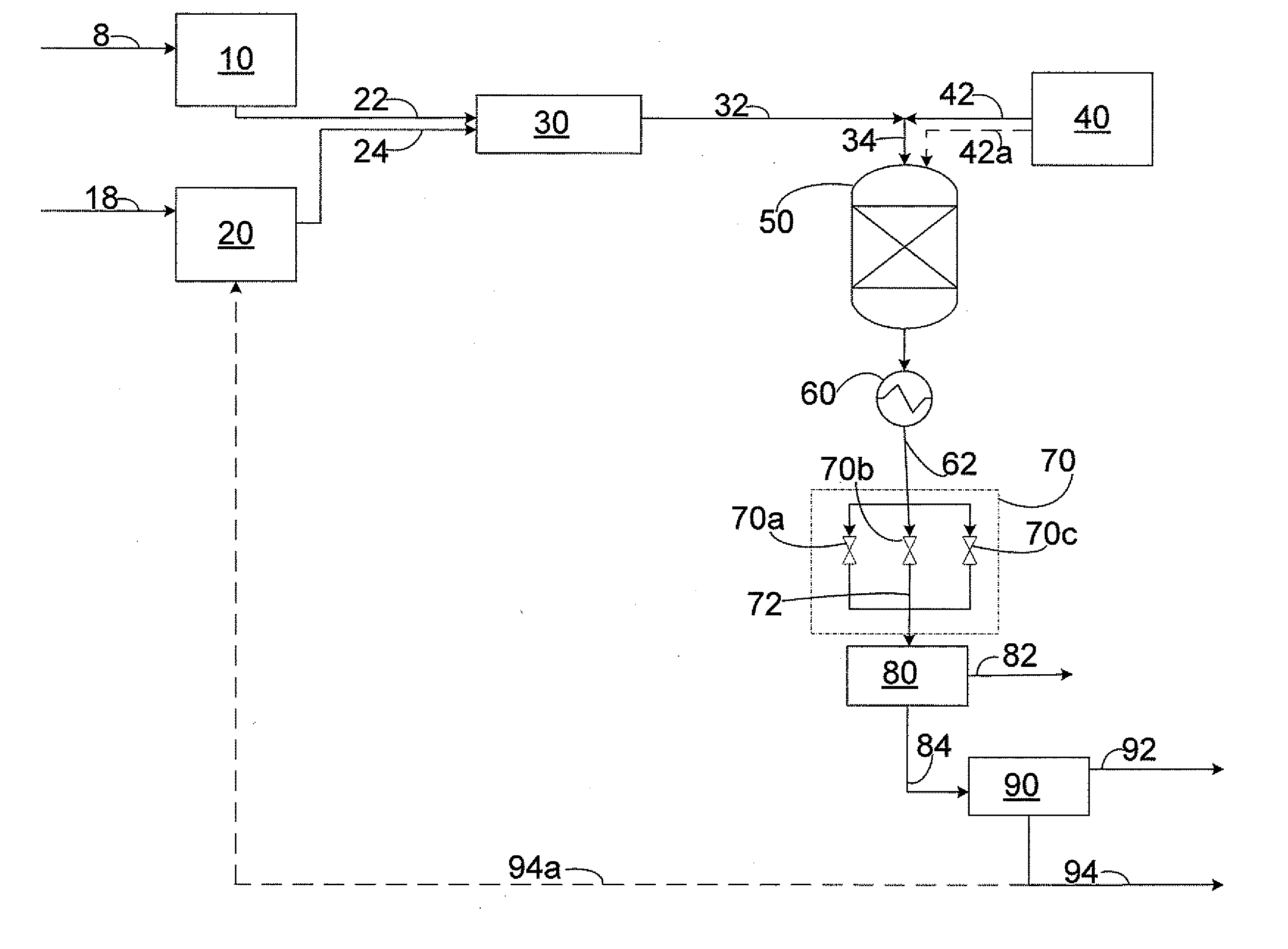

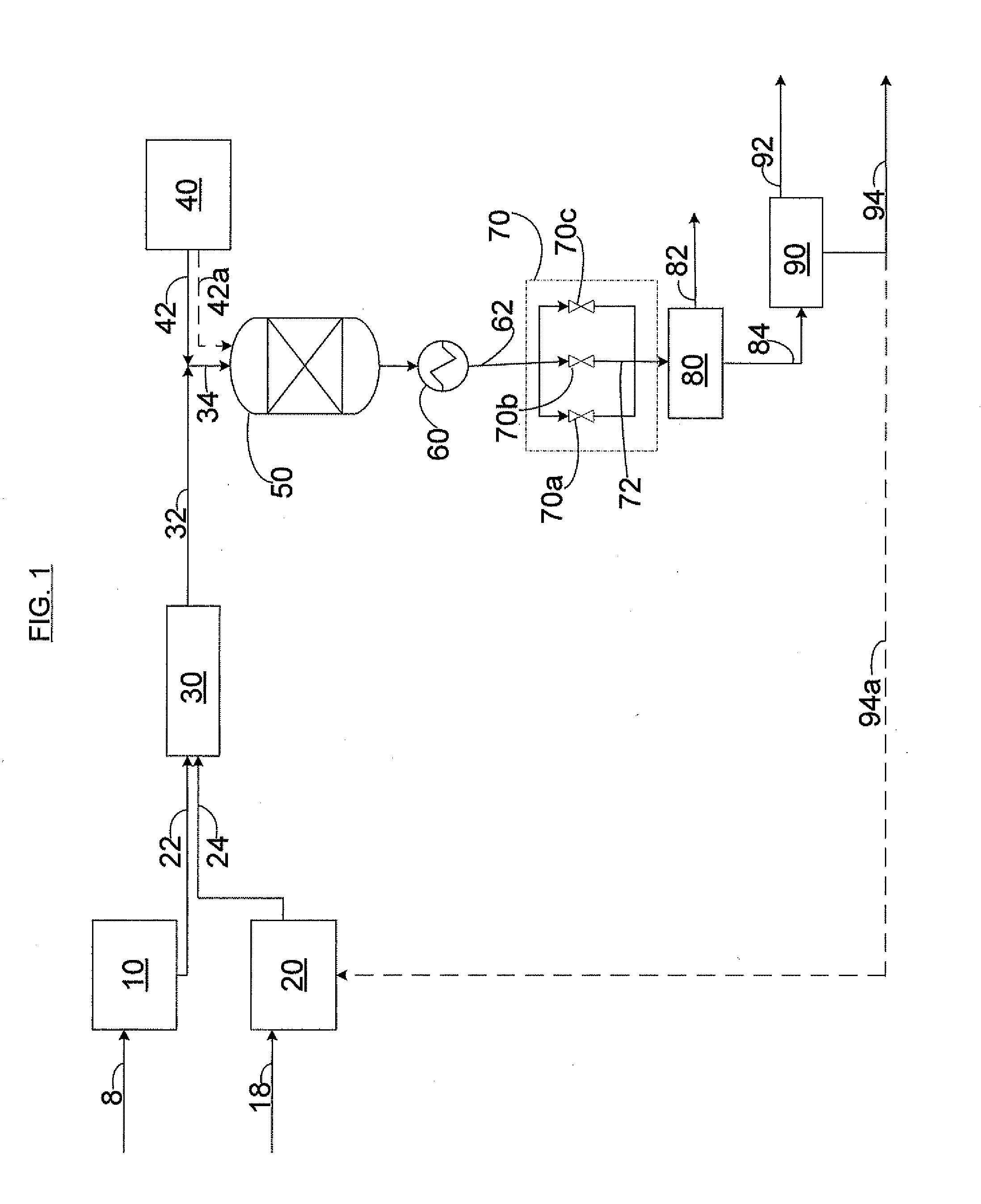

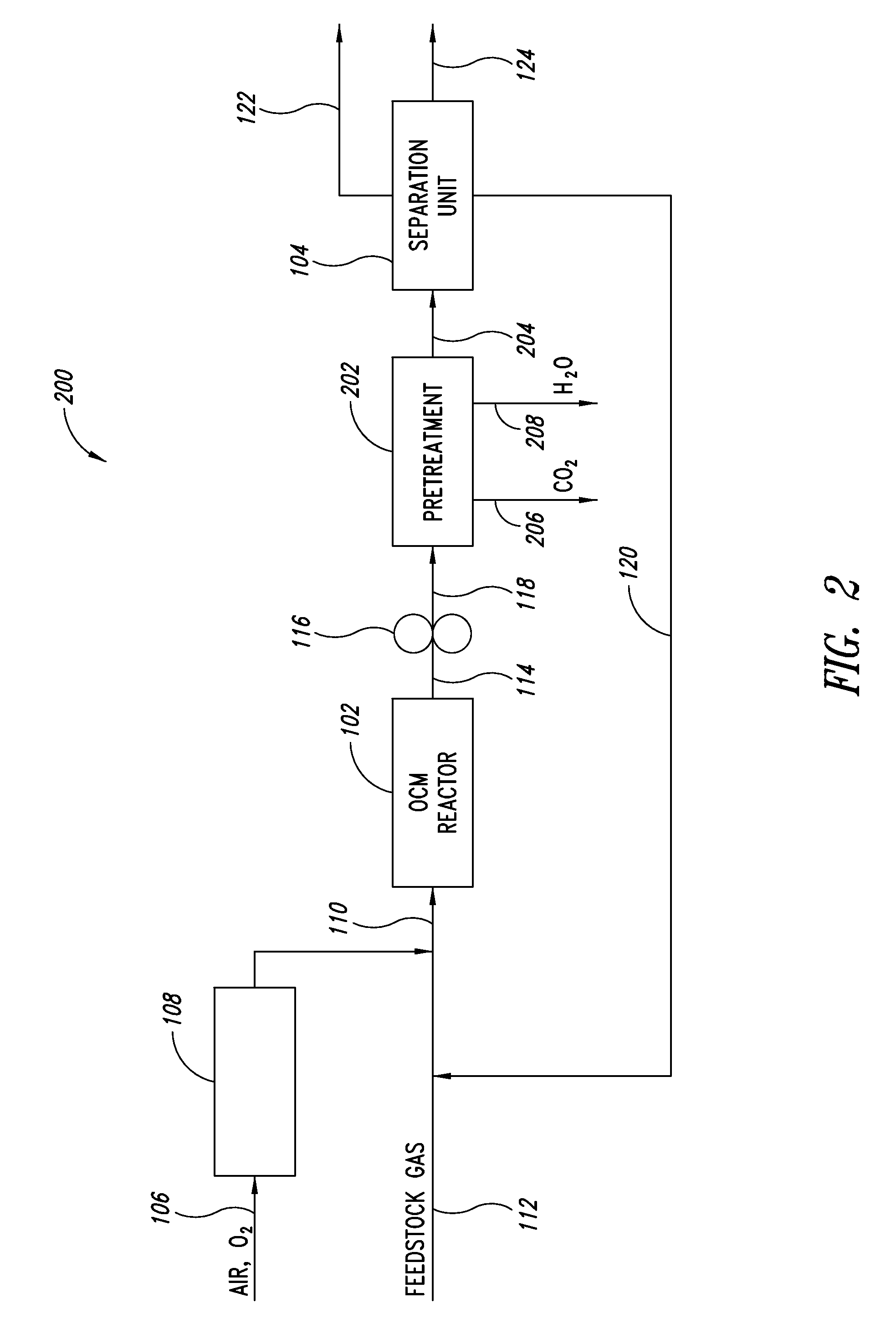

ActiveUS20150368167A1Reduce moistureReduce hydrogen sulfide contentSolidificationLiquefactionHydrocotyle bowlesioidesOxidative coupling of methane

Disclosed herein are processes for producing and separating ethane and ethylene. In some embodiments, an oxidative coupling of methane (OCM) product gas comprising ethane and ethylene is introduced to a separation unit comprising two separators. Within the separation unit, the OCM product gas is separated to provide a C2-rich effluent, a methane-rich effluent, and a nitrogen-rich effluent. Advantageously, in some embodiments the separation is achieved with little or no external refrigeration requirement.

Owner:LUMMUS TECH LLC

Petroleum Upgrading Process

ActiveUS20110147266A1Reduce the amount requiredIncrease gravityThermal non-catalytic crackingCatalytic crackingSulfurLow nitrogen

A process for upgrading a heavy oil stream by completely mixing the heavy oil stream with a water stream prior to the introduction of an oxidant stream. A mixture of the heavy oil stream and the water stream are subjected to operating conditions, in the presence of the oxidant stream, that are at or exceed the supercritical temperature and pressure of water. The resulting product stream is a higher value oil having low sulfur, low nitrogen, and low metallic impurities as compared to the heavy oil stream.

Owner:SAUDI ARABIAN OIL CO

Preparation of components for transportation fuels

InactiveUS6881325B2Environmentally friendlyRefining with oxygen compoundsRefining with acid-containing liquidsPhosphomolybdic acidComponents of crude oil

Economical processes are disclosed for the production of components for refinery blending of transportation fuels by selective oxidation of feedstocks comprising a mixture of hydrocarbons, sulfur-containing and nitrogen-containing organic compounds. Oxidation feedstock is contacted with a soluble quaternary ammonium salt containing halogen, sulfate, or bisulfate anion, and an immiscible aqueous phase comprising a source of hydrogen peroxide, and at least one member of the group consisting of phosphomolybdic acid and phosphotungstic acid, in a liquid reaction mixture under conditions suitable for reaction of one or more of the sulfur-containing and / or nitrogen-containing organic compounds. Blending components containing less sulfur and / or less nitrogen than the oxidation feedstock are recovered from the reaction mixture. Advantageously, at least a portion of the immiscible acid-containing phase is recycled to the oxidation.

Owner:BP CORP NORTH AMERICA INC

Oxidative Desulfurization Process

InactiveUS20080308463A1Reduce sulfur contentRefining with metalsMolecular sieve catalystsSulfurNitrogen

Disclosed is a process which reduces the sulfur and / or nitrogen content of a distillate feedstock to produce a refinery transportation fuel or blending components for refinery transportation fuel, by contacting the feedstock with an oxygen-containing gas in an 5 oxidation / adsorption zone at oxidation conditions in the presence of an oxidation catalyst comprising a titanium-containing composition whereby the sulfur species are converted to sulfones and / or sulfoxides which are adsorbed onto the titanium-containing composition.

Owner:BP CORP NORTH AMERICA INC

Process for separating hydrocarbon compounds

Disclosed herein are processes for producing and separating ethane and ethylene. In some embodiments, an oxidative coupling of methane (OCM) product gas comprising ethane and ethylene is introduced to a separation unit comprising two separators. Within the separation unit, the OCM product gas is separated to provide a C2-rich effluent, a methane-rich effluent, and a nitrogen-rich effluent. Advantageously, in some embodiments the separation is achieved with little or no external refrigeration requirement.

Owner:LUMMUS TECH LLC

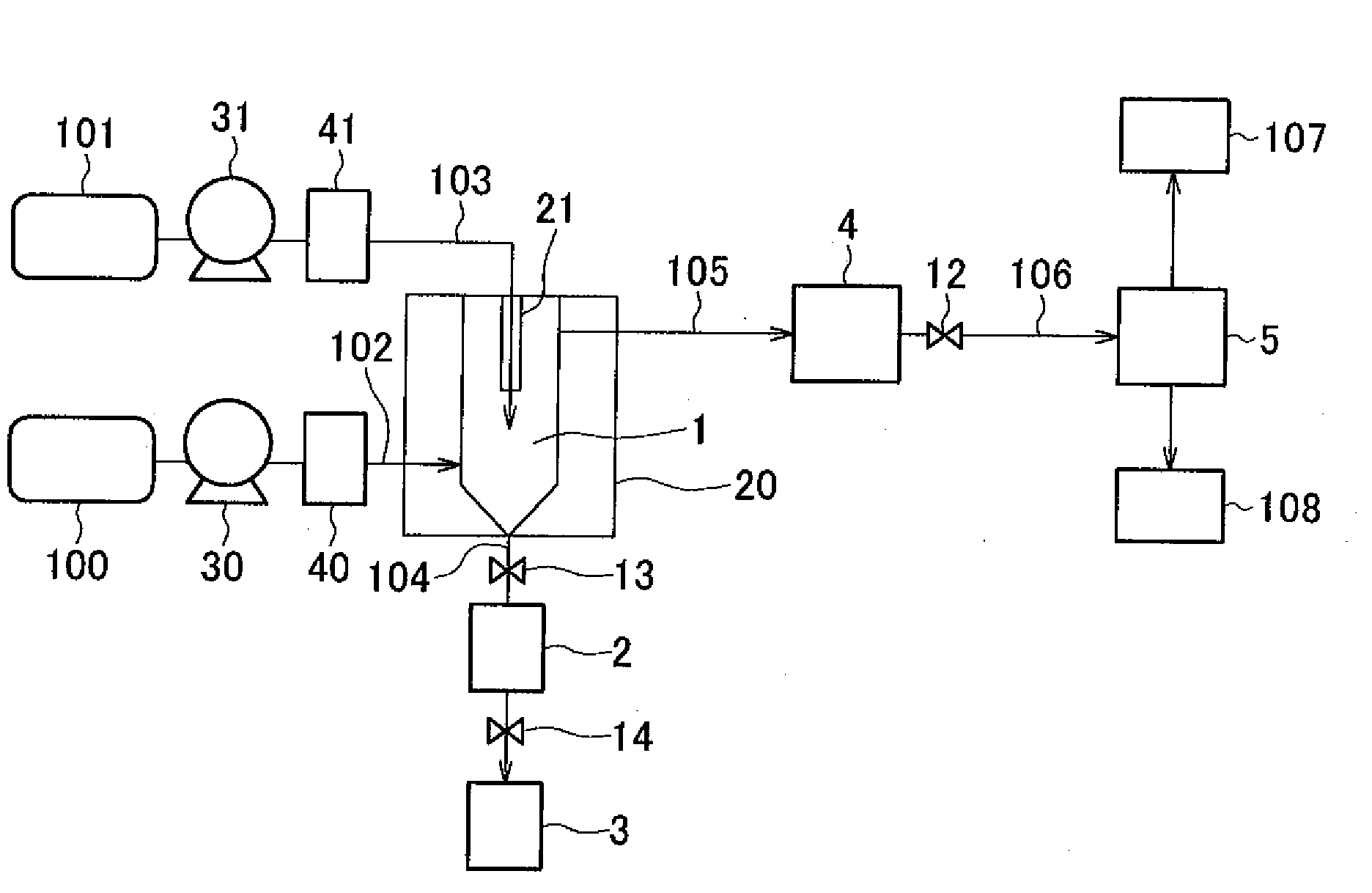

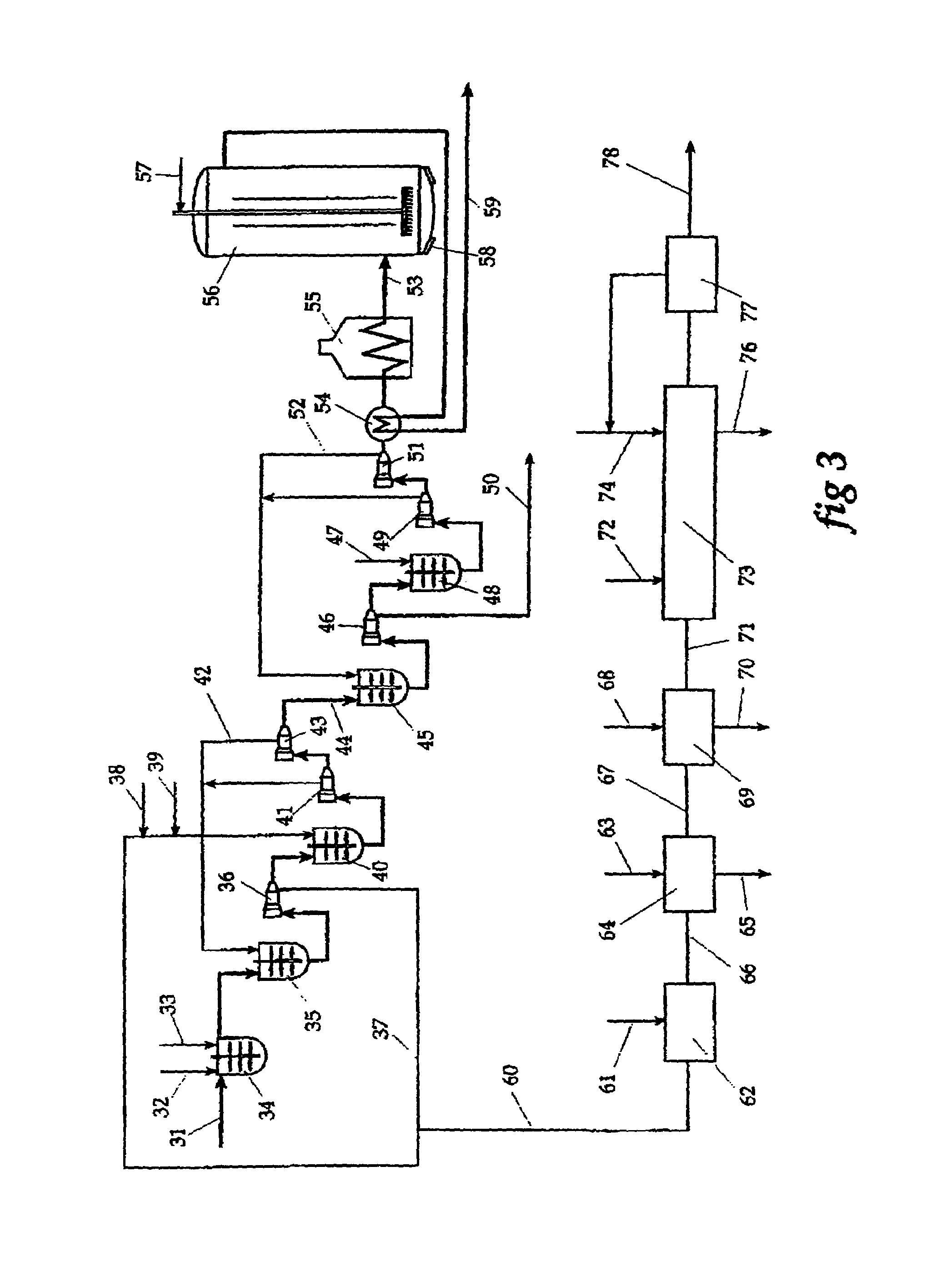

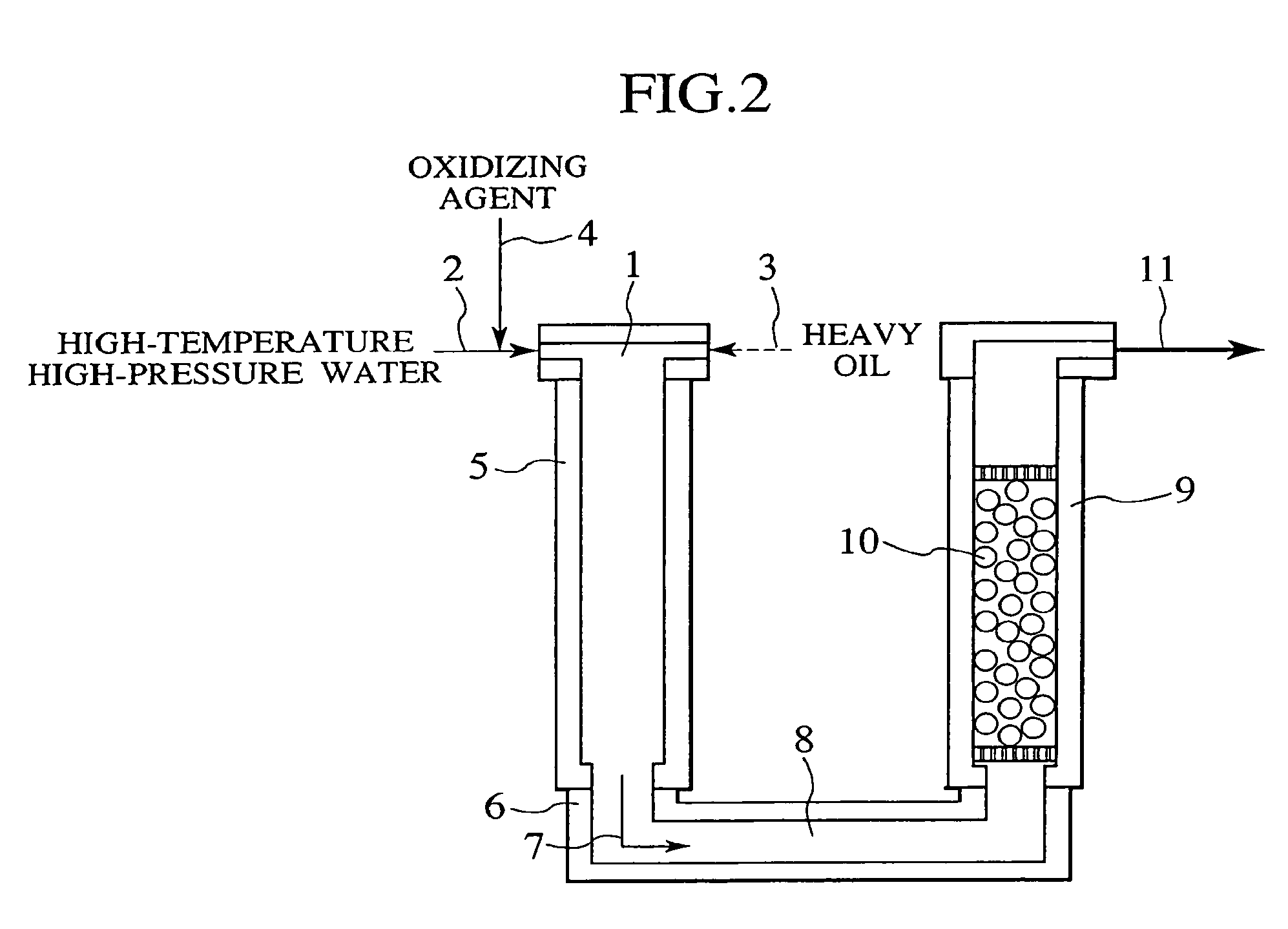

Heavy oil treating method and heavy oil treating system

InactiveUS20090032436A1Eliminate needMolecular sieve catalystsRefining with oxygen compoundsLighter fuelHigh pressure water

The invention is intended to produce high-pressure light fuel gas with good combustibility by contacting and reacting high-temperature, high-pressure water and heavy oil with each other in a contact-reaction unit to extract light oil components from the heavy oil and to remove metals. The high-temperature, high-pressure water and the heavy oil are introduced to the contact-reaction unit for contact and reaction with each other therein. Heavy oil components not dissolved in the high-temperature, high-pressure water are separated by precipitation from hydrocarbon gases and light oil components which are dissolved in the high-temperature, high-pressure water. The separated heavy oil components are burnt or incinerated without any further modification.

Owner:TAKAHASHI HIROKAZU +6

Oxidative desulfurization of sulfur-containing hydrocarbons

A method for desulfurizing a hydrocarbon stream (10) containing heterocyclic sulfur compounds, which process comprises contacting the heterocyclic sulfur compounds in the gas phase (60) in the presence of oxygen (70) with a supported metal oxide catalyst, or with a bulk metal oxide catalyst (600) to convert at least a portion of the heterocyclic sulfur compounds to oxygenated products as well as sulfur-deficient hydrocarbons and separately recovering the oxygenated products separately from a hydrocarbon stream with substantially reduced sulfur.

Owner:LEHIGH UNIVERSITY

Treatment of crude oils

InactiveUS6955753B1Quality improvementImprove efficiencyWorking-up pitch/asphalt/bitumen by selective extractionSolvent extractionHydrogenPetroleum

A process and apparatus to extract and recover heavy metals and sulfur from crude oil or petroleum fuel products including the steps of emulsifying the crude oil with an emulsifying agent, adding a leach solution to the emulsified crude oil and leaching the emulsified crude oil at elevated temperature and pressure to give a leached emulsified crude oil. The leach solution may be acid or alkali. A proportion of the leach solution is extracted for recovering heavy metals. There can also be a microwave hydro-treating step using hydrogen gas at a temperature below 220° C. to ensure there is no quality degradation in the crude feed to produce a desulfurized crude oil and a hydrogen sulphide by-product and recovering sulfur from the hydrogen sulphide by-product.

Owner:RODOLFO ANTONIO M GOMEZ

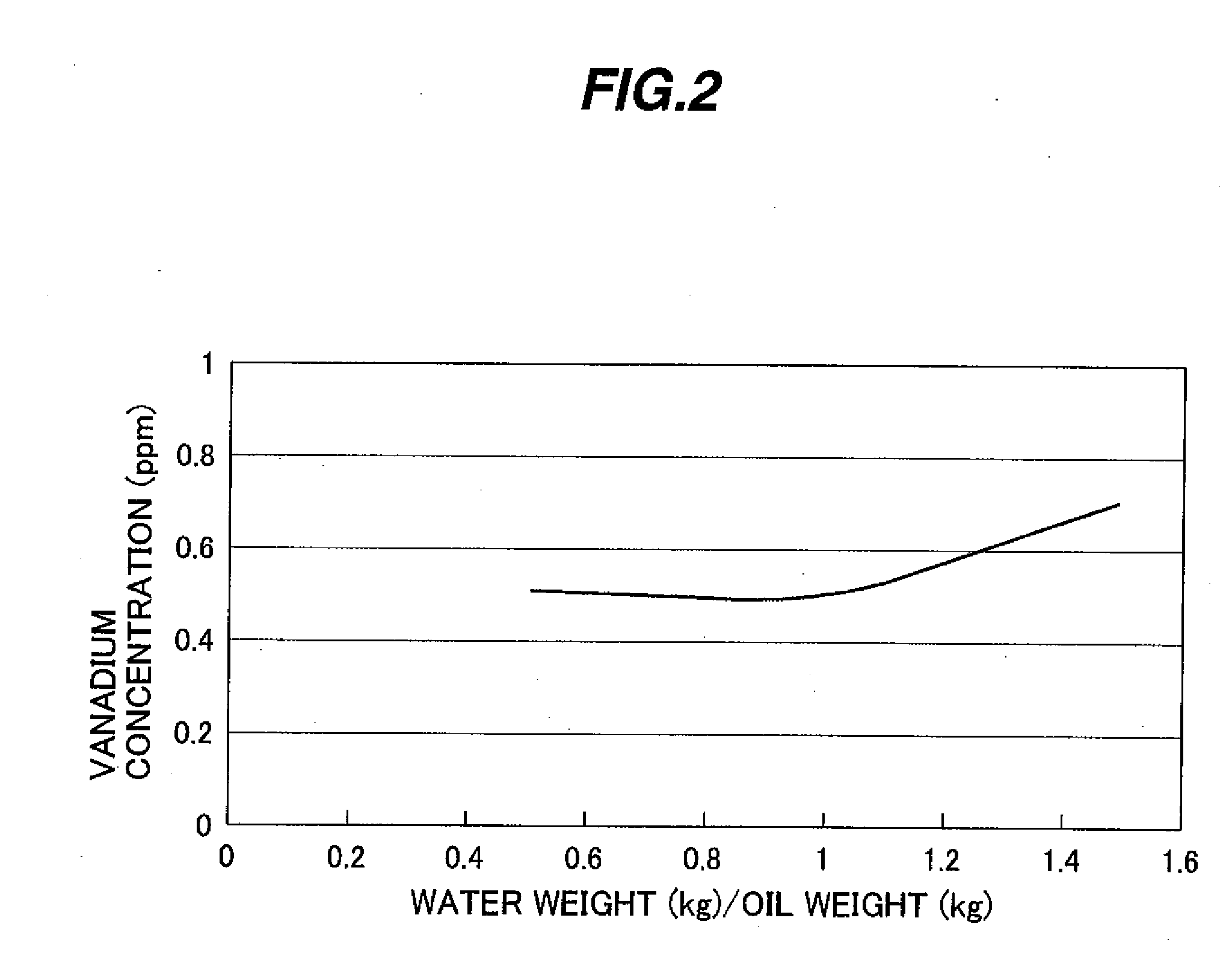

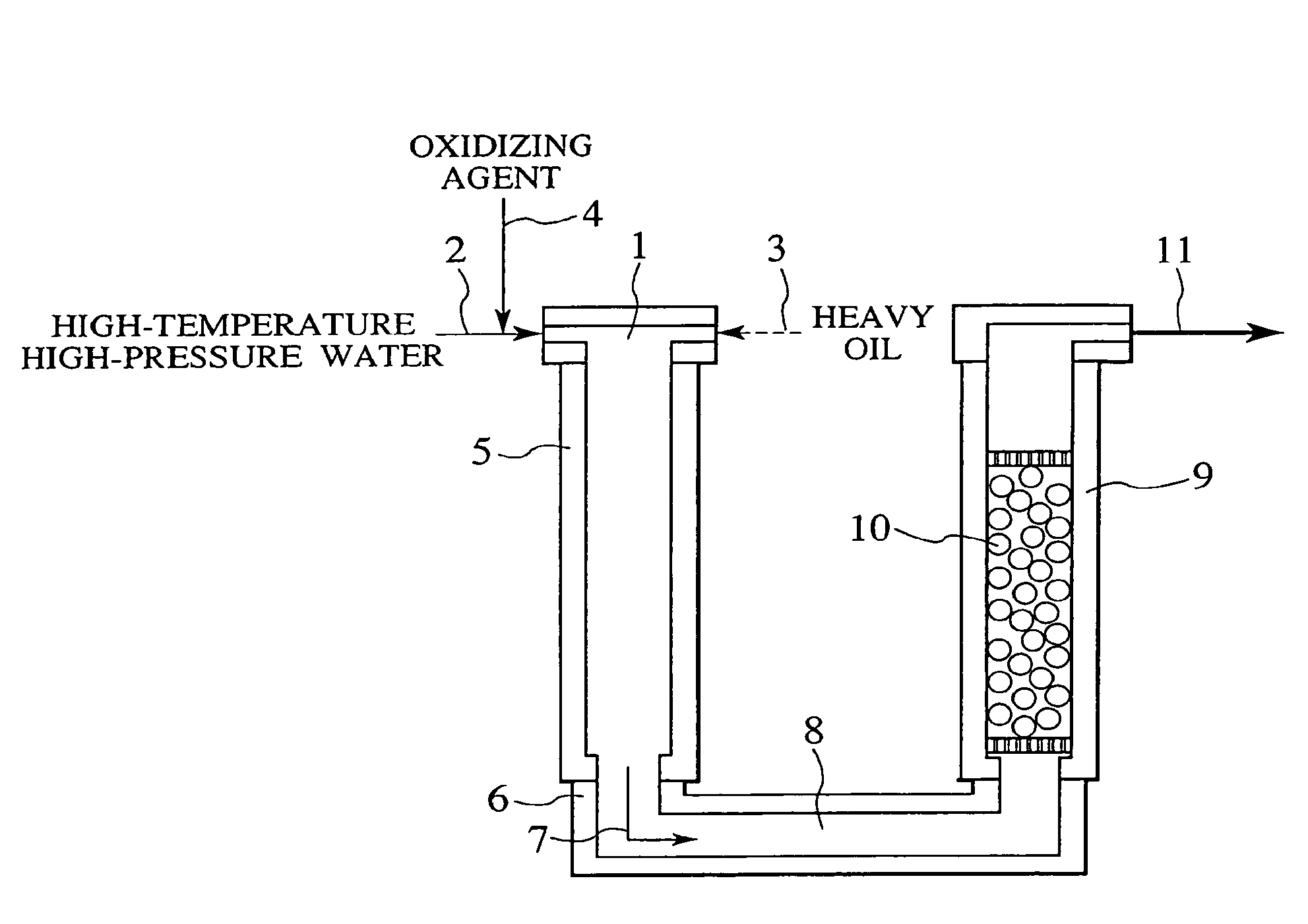

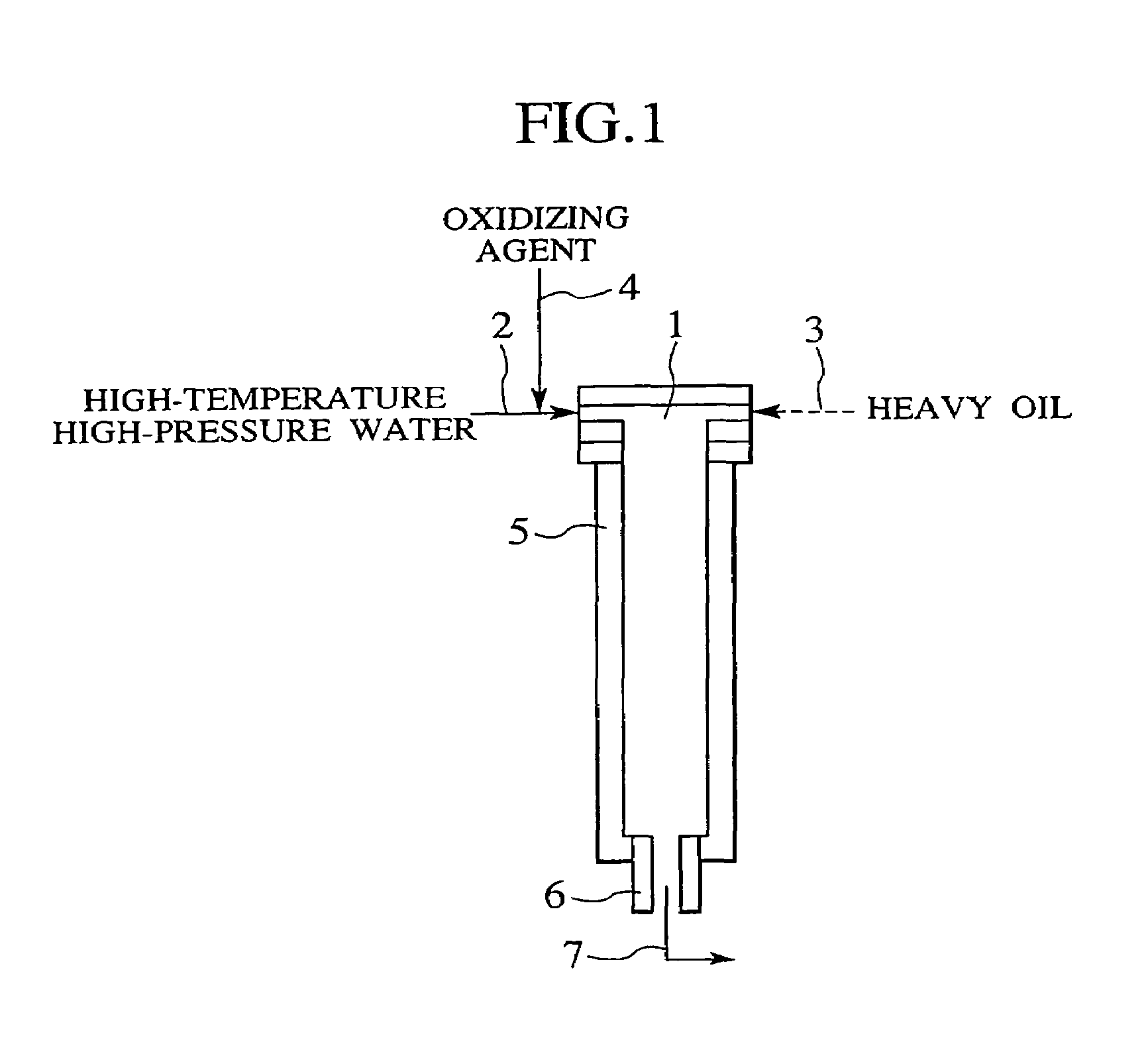

Process and apparatus for treating heavy oil with supercritical water and power generation system equipped with heavy oil treating apparatus

InactiveUS7264710B2Thermal non-catalytic crackingPressurized chemical processScavengerAfter treatment

The reforming of heavy oil with supercritical water or subcritical water is accomplished by mixing together supercriticai water, heavy oil, and oxidizing agent, thereby oxidizing vanadium in heavy oil with the oxidizing agent at the time of treatment with supercritical water and separate vanadium oxide. The separated vanadium oxide is removed by the scavenger after treatment with supercritical water. In this way it is possible to solve the long-standing problem with corrosion of turbine blades by vanadium which arises when heavy oil is used as gas turbine fuel.

Owner:HITACHI LTD

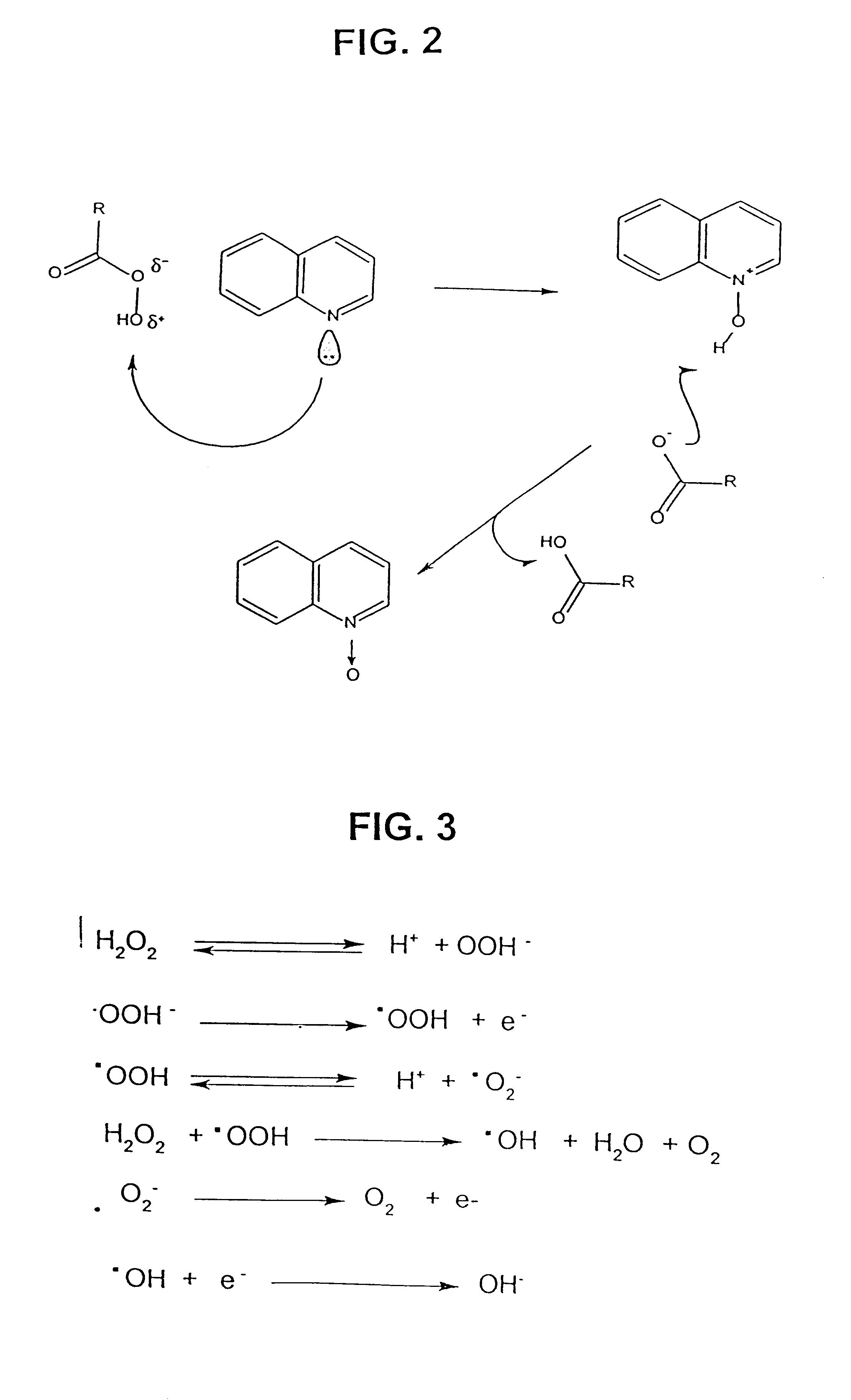

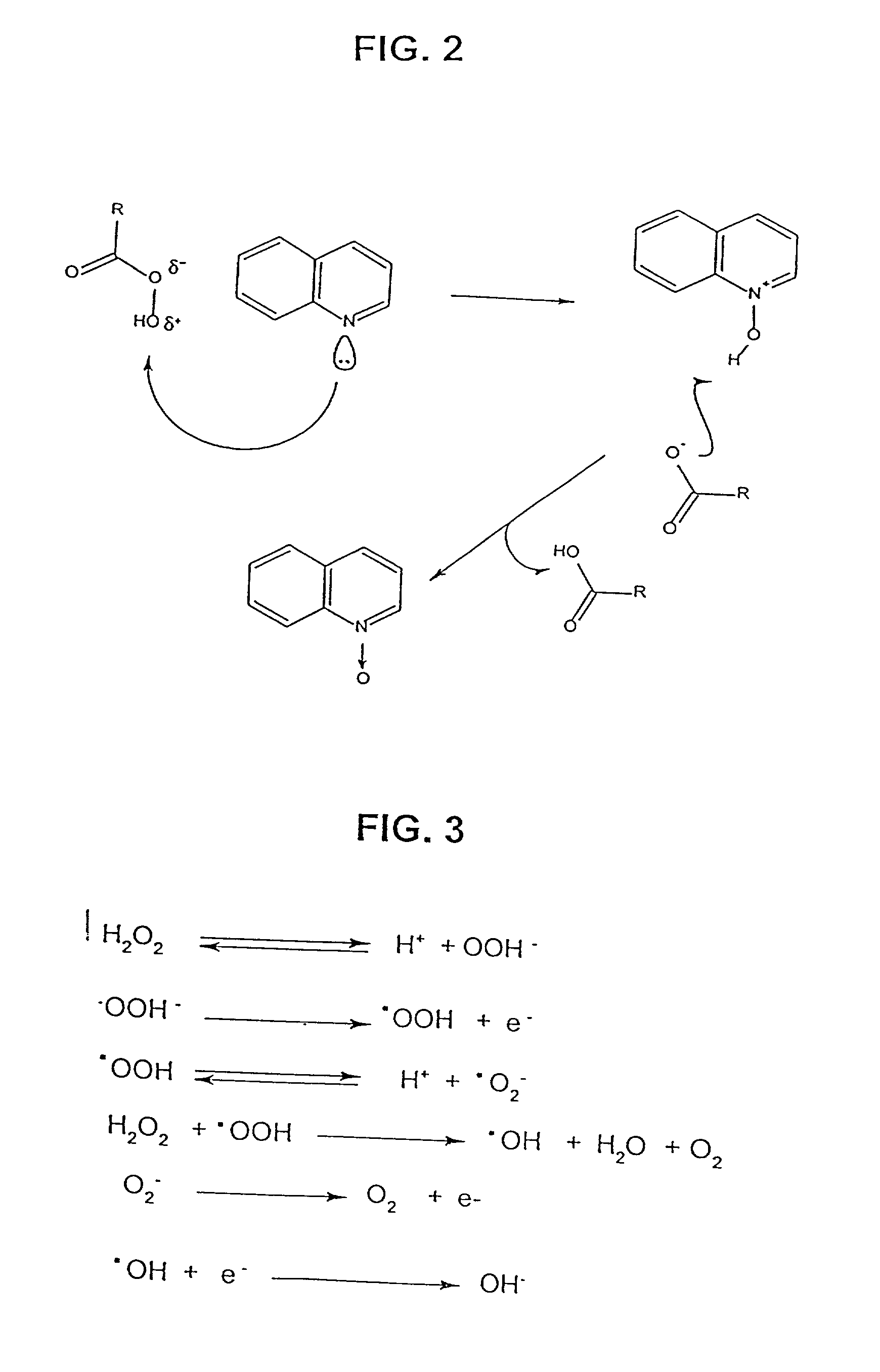

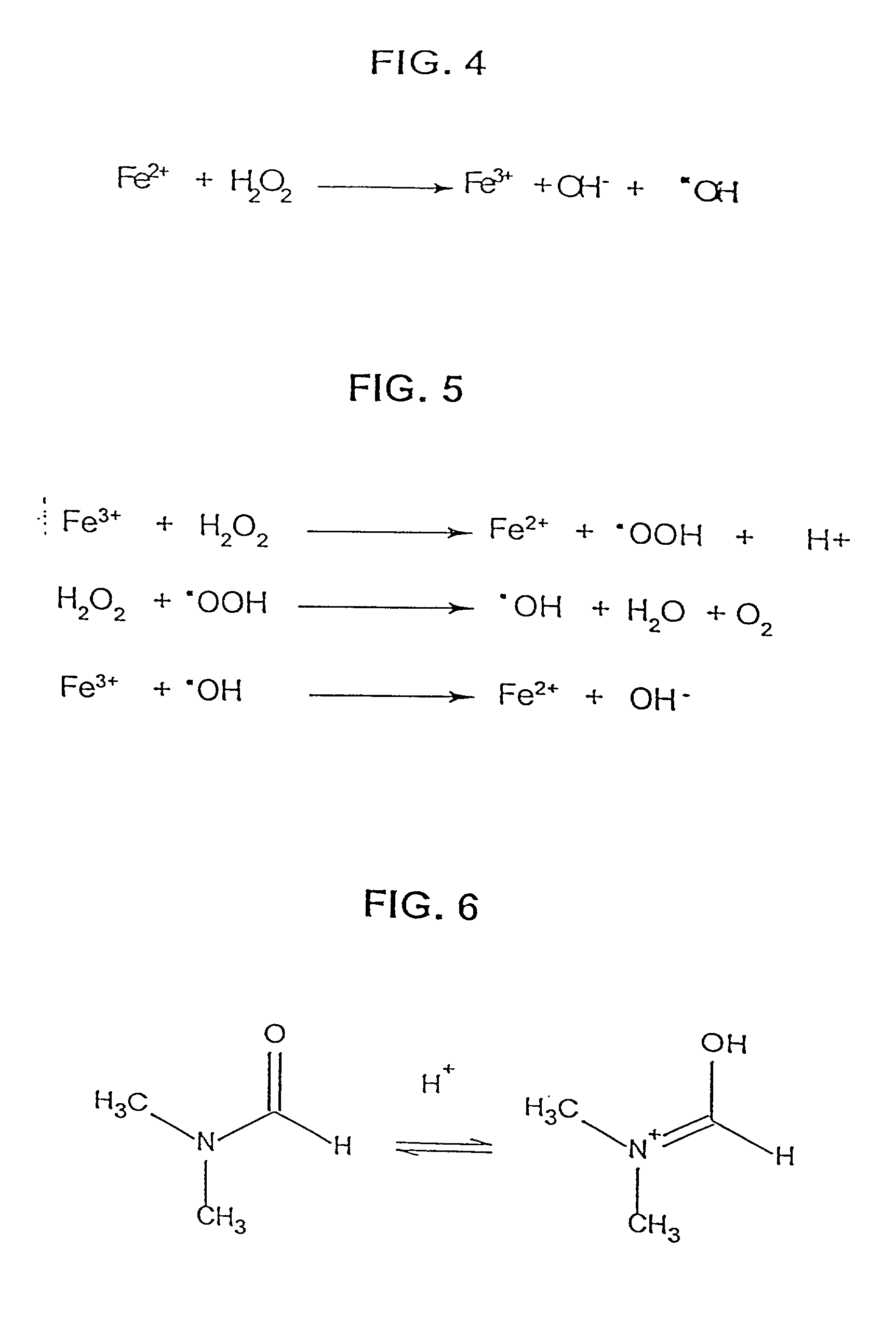

Process for the catalytic oxidation of sulfur, nitrogen and unsaturated compounds from hydrocarbon streams

InactiveUS20020189975A1Refining with metalsRefining with oxygen compoundsCatalytic oxidationPeroxy acid

A process for the catalytic oxidation of sulfur and nitrogen contaminants as well as unsaturated compounds present in a hydrocarbon fossil oil medium is described, the process comprising effecting the oxidation in the presence of at least one peroxide, at least one acid and a pulverized raw iron oxide. The process shows an improved oxidation power towards the contaminants typically present in a fossil oil medium, this deriving from the combination of the peroxy-acid and the hydroxyl radical generated in the reaction medium due to the presence of an iron oxyhydroxide such as a limonite clay, which bears a particular affinity for the oil medium. The process finds use in various applications, from a feedstock for refining until the preparation of deeply desulfurized and deeply denitrified products.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Process for desulphurisation of liquid hydrocarbon fuels

InactiveUS20070151901A1Eliminate needRefining with oxygen compoundsTreatment with plural serial refining stagesPetroleum productSulfur

The present invention provides a process for oxidative desulphurization of liquid hydrocarbon fuels, such as diesel fuel, gasoline, jet fuel, fuel oils, coal liquids and similar petroleum products to ultra low sulphur hydrocarbon fuels with sulphur content less than 10 ppm. In this process, the sulfur compounds present in hydrocarbon fuel are first oxidised to more polar sulphones / sulphoxides and then removed by solvent extraction with NMP containing antisolvent followed by final polishing by passing through adsorption column.

Owner:COUNCIL OF SCI & IND RES +1

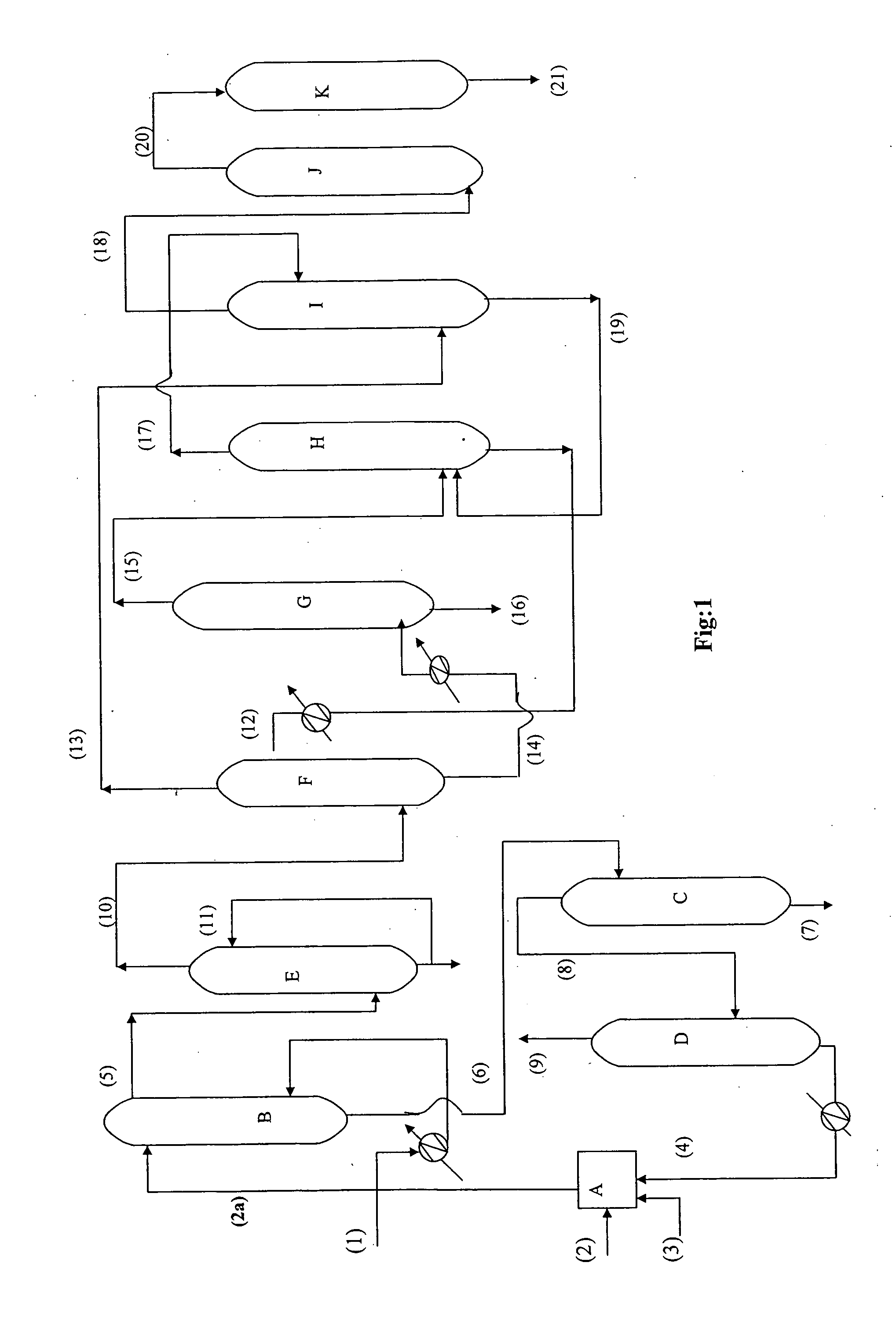

Process for the extractive oxidation of contaminants from raw hydrocarbon streams

A process for the extractive oxidation of contaminants from raw hydrocarbon streams rich in heteroatomic polar compounds is described, the said process involving the extractive oxidation of sulfur and nitrogen compounds from said streams, the said process comprising treating said streams with a peroxide solution / organic acid couple, the weight percent of the peroxide solution and organic acid based on raw hydrocarbon being at least 3 for both the peroxide and organic acid solution, under an acidic pH, atmospheric or higher pressure and ambient or higher temperature. As a result of the reaction, the oxidized heteroatomic compounds, having strong affinity for the aqueous phase, are extracted into said aqueous phase, while the oxidized hydrocarbon is neutralized, water washed and dried, the resulting end product being a hydrocarbon stream from which have been removed 88.1 wt % or more of total nitrogen compounds and basic nitrogen up to 99.1 wt %, both calculated as mass contents, total Sulfur 23.3% removal, and removal of total olefins is limited to 6.5 weight %. The treated product is further directed to any refining process.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

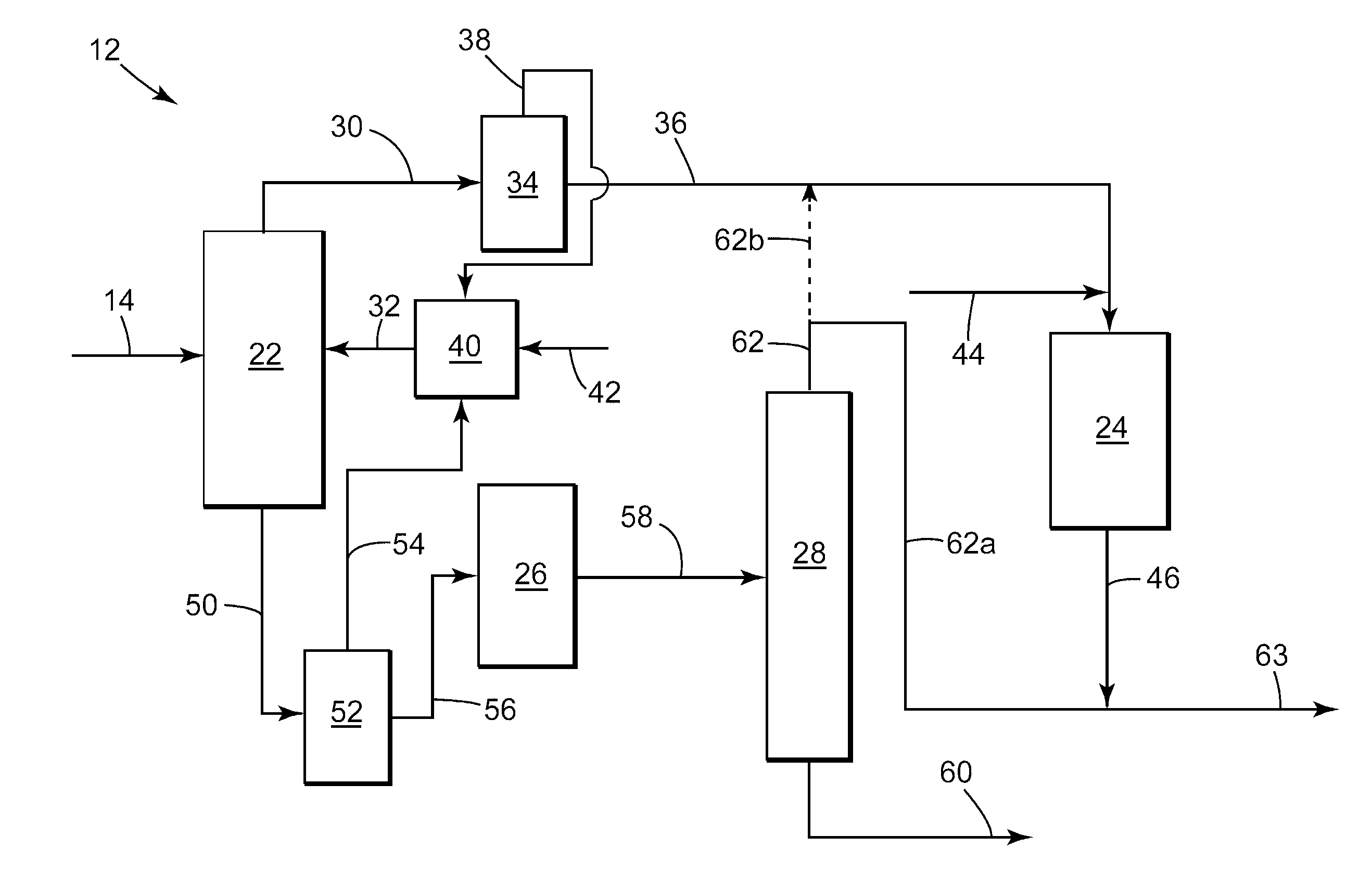

Activated carbon with improved mechanical resistance, and the uses thereof, especially as a catalyst carrier

InactiveUS20070123419A1Strong mechanical propertiesRapidly impregnated with oxidation catalystCarbon compoundsOther chemical processesGas phaseSolvent

The present invention relates to active charcoals with improved mechanical properties. They can advantageously be used in the sweetening of petroleum fractions, as oxidation catalyst support in the conversion of mercaptans to disulphides, but also in any other type of reaction, such as, for example, for the oxidation of cyanide present in water or in the synthesis of glyphosate, and in processes for purification and / or separation by selective adsorption in a liquid phase and / or in a gas phase (decolouration of liquid foodstuffs, water treatment, air treatment, recovery of solvents, and the like).

Owner:LE BEC REMY

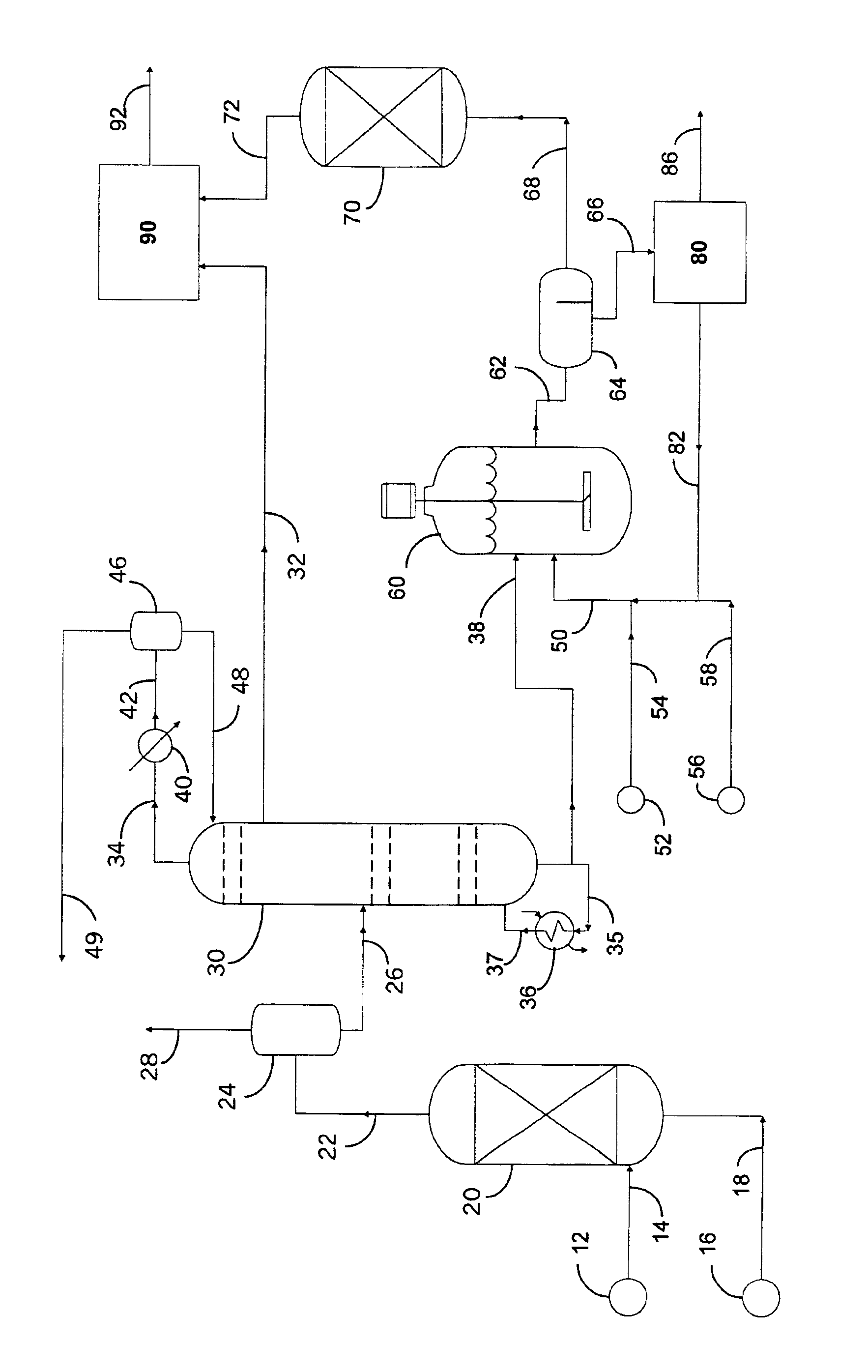

Integrated desulfurization and denitrification process including mild hydrotreating of aromatic-lean fraction and oxidation of aromatic-rich fraction

ActiveUS20120152804A1Improve overall utilizationCost-effective processTreatment with plural parallel cracking stages onlyRefining with oxygen compoundsNitrogenOrganonitrogen compounds

Deep desulfurization of hydrocarbon feeds containing undesired organosulfur and organonitrogen compounds to produce a hydrocarbon product having low levels of sulfur-containing and nitrogen-containing compounds, is achieved by first subjecting the entire feed to an extraction zone to separate an aromatic-rich fraction containing a substantial amount of the refractory organosulfur and organonitrogen compounds and an aromatic-lean fraction containing a substantial amount of the labile organosulfur and organonitrogen compounds. The aromatic-lean fraction is contacted with a hydrotreating catalyst in a hydrotreating reaction zone operating under mild conditions to convert the labile organosulfur and organonitrogen compounds. The aromatic-rich fraction is oxidized to convert the refractory organosulfur and organonitrogen compounds to oxidized organosulfur and organonitrogen compounds. These oxidized organosulfur and organonitrogen compounds are subsequently removed, producing a stream containing reduced levels of organosulfur and organonitrogen compounds.

Owner:SAUDI ARABIAN OIL CO

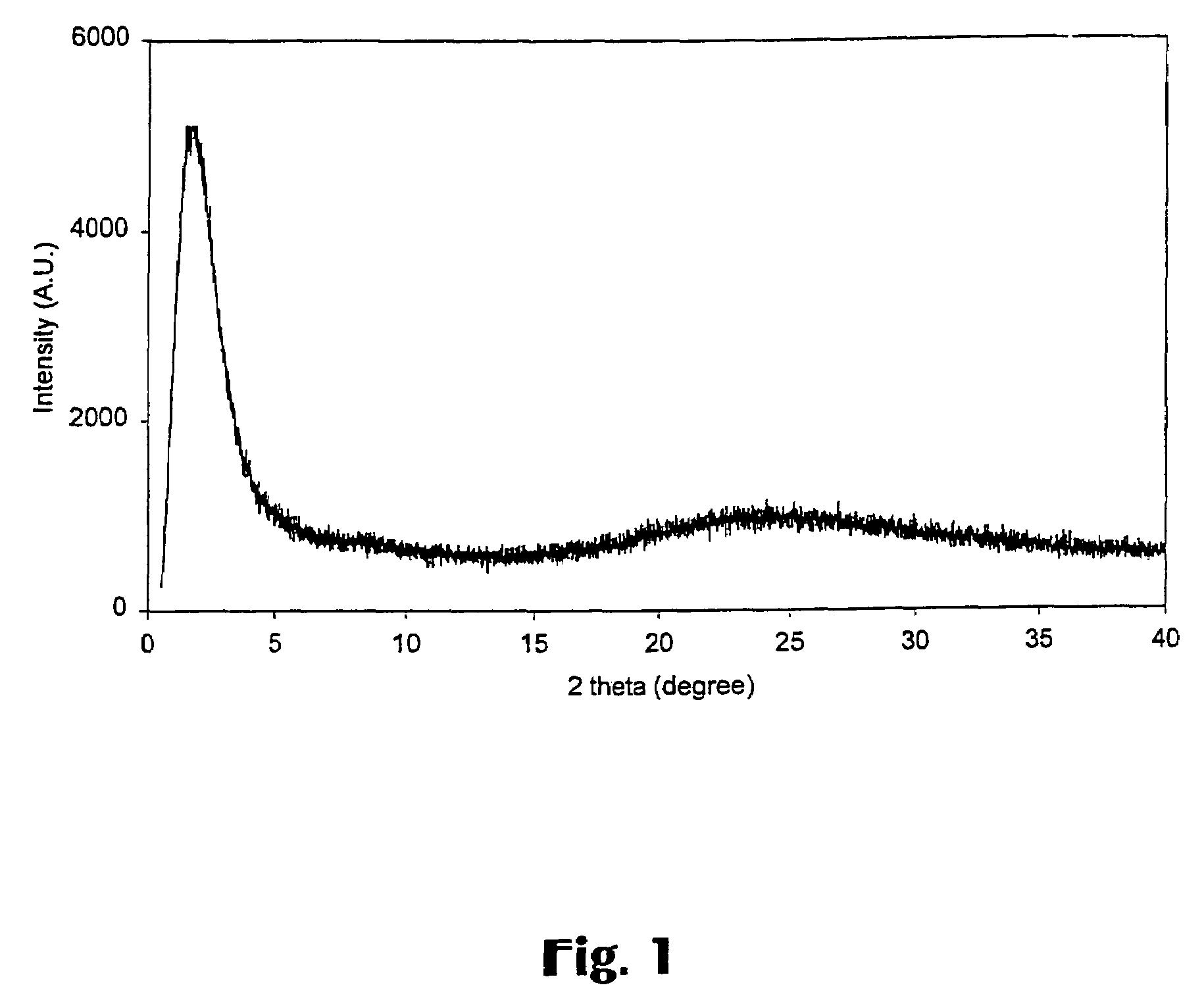

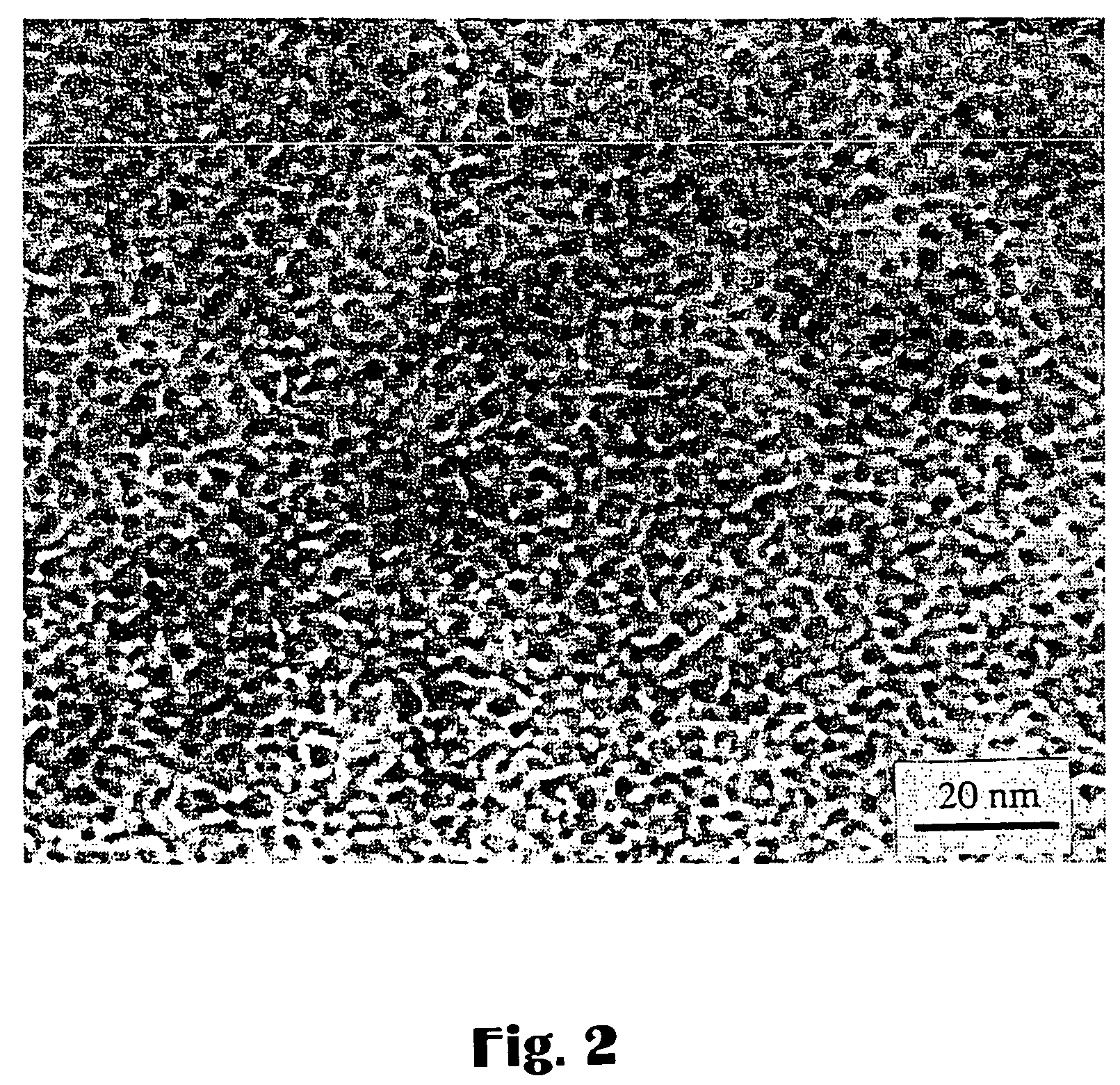

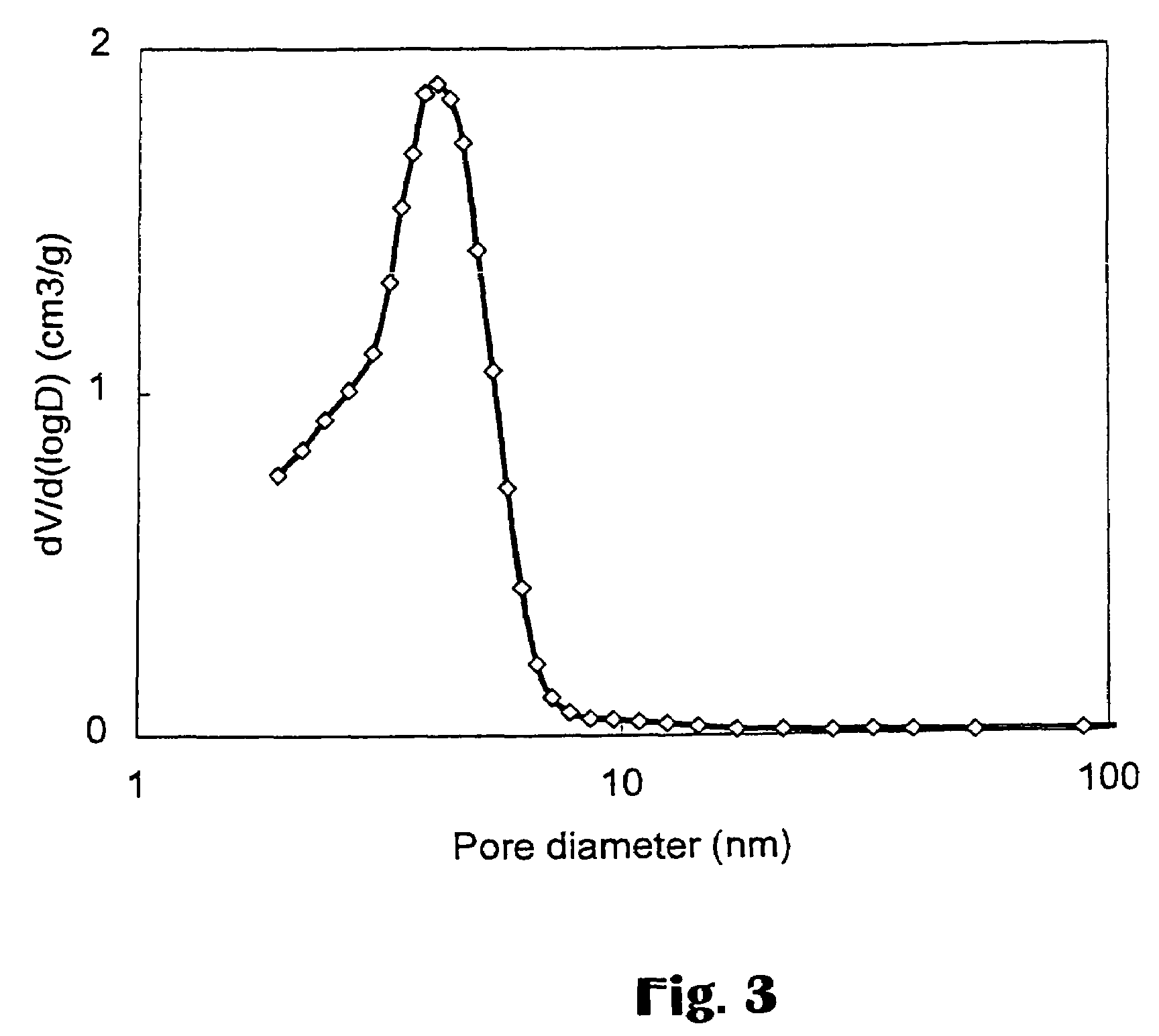

Mesoporous material with active metals

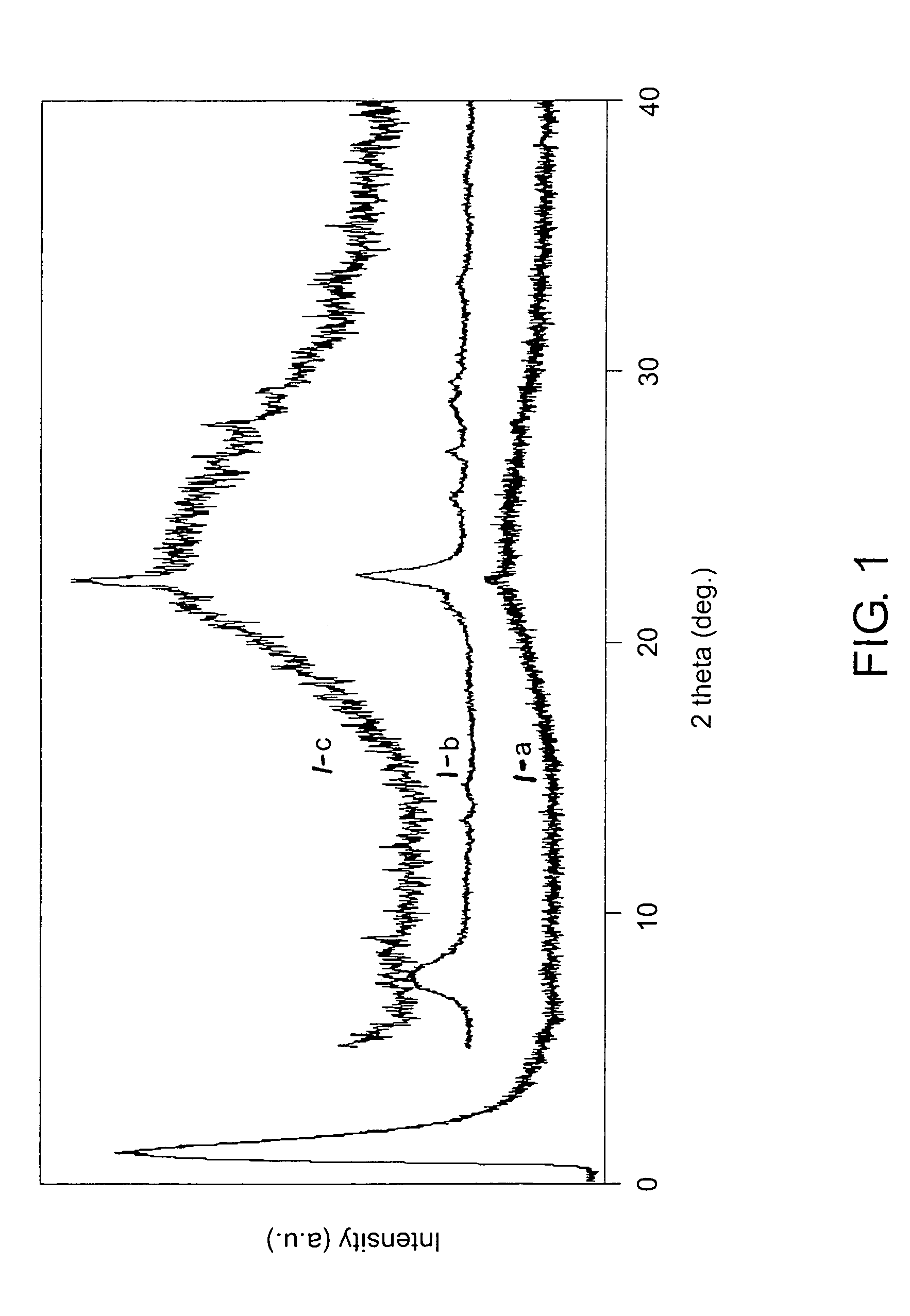

A process for treating organic compounds includes providing a composition which includes a substantially mesoporous structure of refractory oxide containing at least 97% by volume of pores having a pore size ranging from about 15 Å to about 30 Å and having a micropore volume of at least about 0.01 cc / g, wherein the mesoporous structure has incorporated therewith at least about 0.02% by weight of at least one catalytically and / or chemically active heteroatom selected from the group consisting of Al, Ti, V, Cr, Zn, Fe, Sn, Mo, Ga, Ni, Co, In, Zr, Mn, Cu, Mg, Pd, Pt and W, and the catalyst has an X-ray diffraction pattern with one peak at 0.3° to about 3.5° at 2 theta (θ). The catalyst is contacted with an organic feed under reaction conditions wherein the treating process is selected from alkylation, acylation, oligomerization, selective oxidation, hydrotreating, isomerization, demetalation, catalytic dewaxing, hydroxylation, hydrogenation, ammoximation, isomerization, dehydrogenation, cracking and adsorption.

Owner:LUMMUS TECH INC

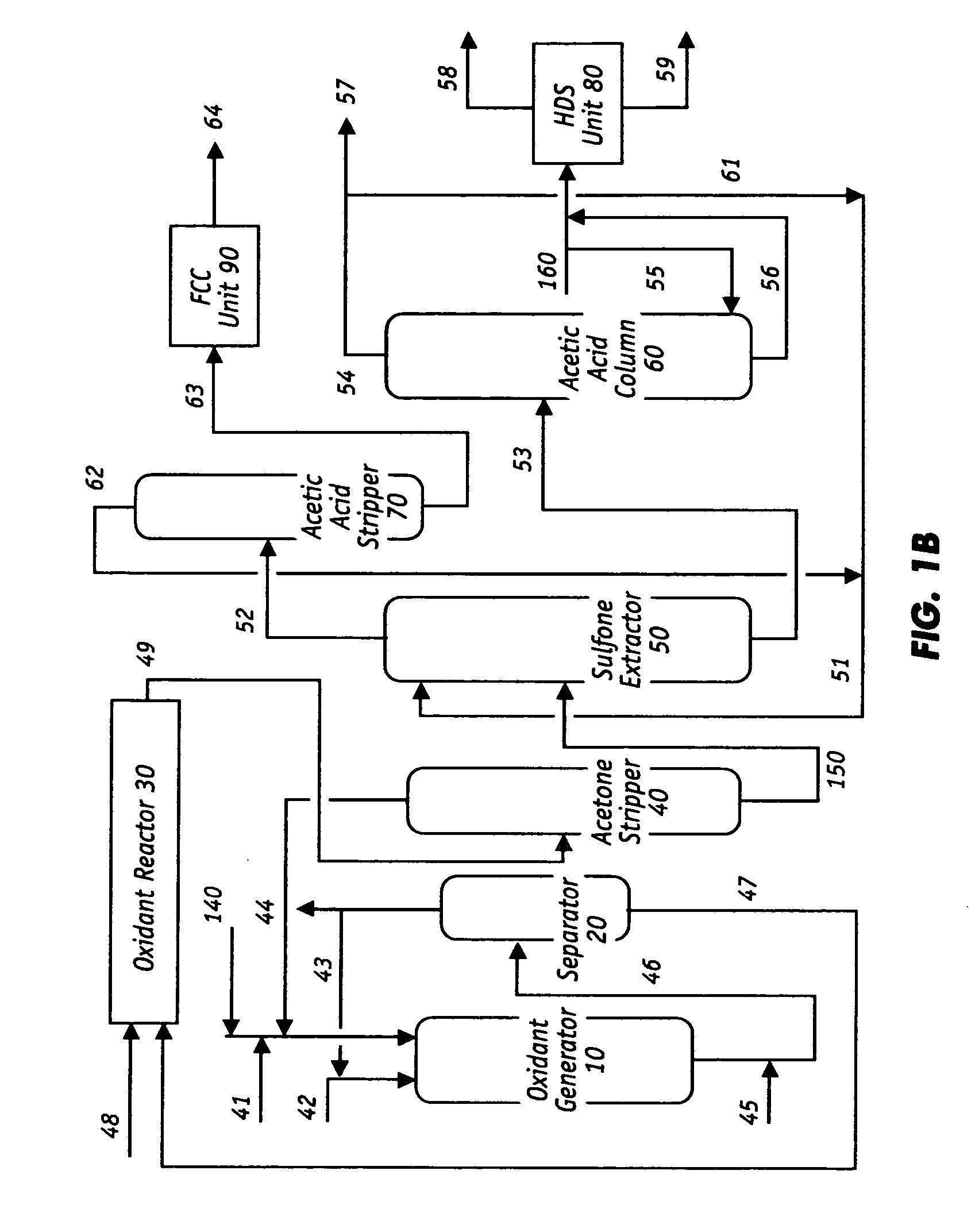

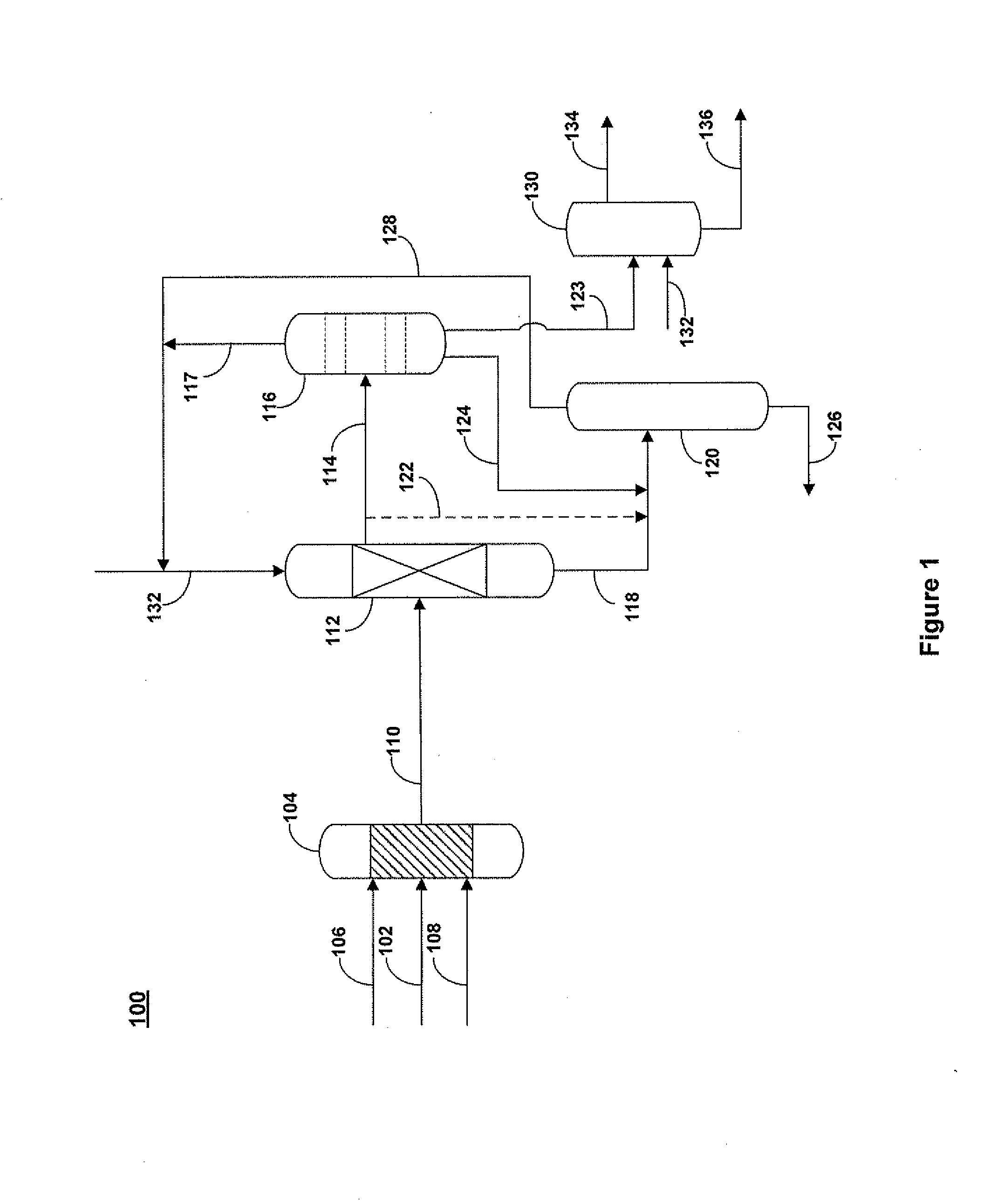

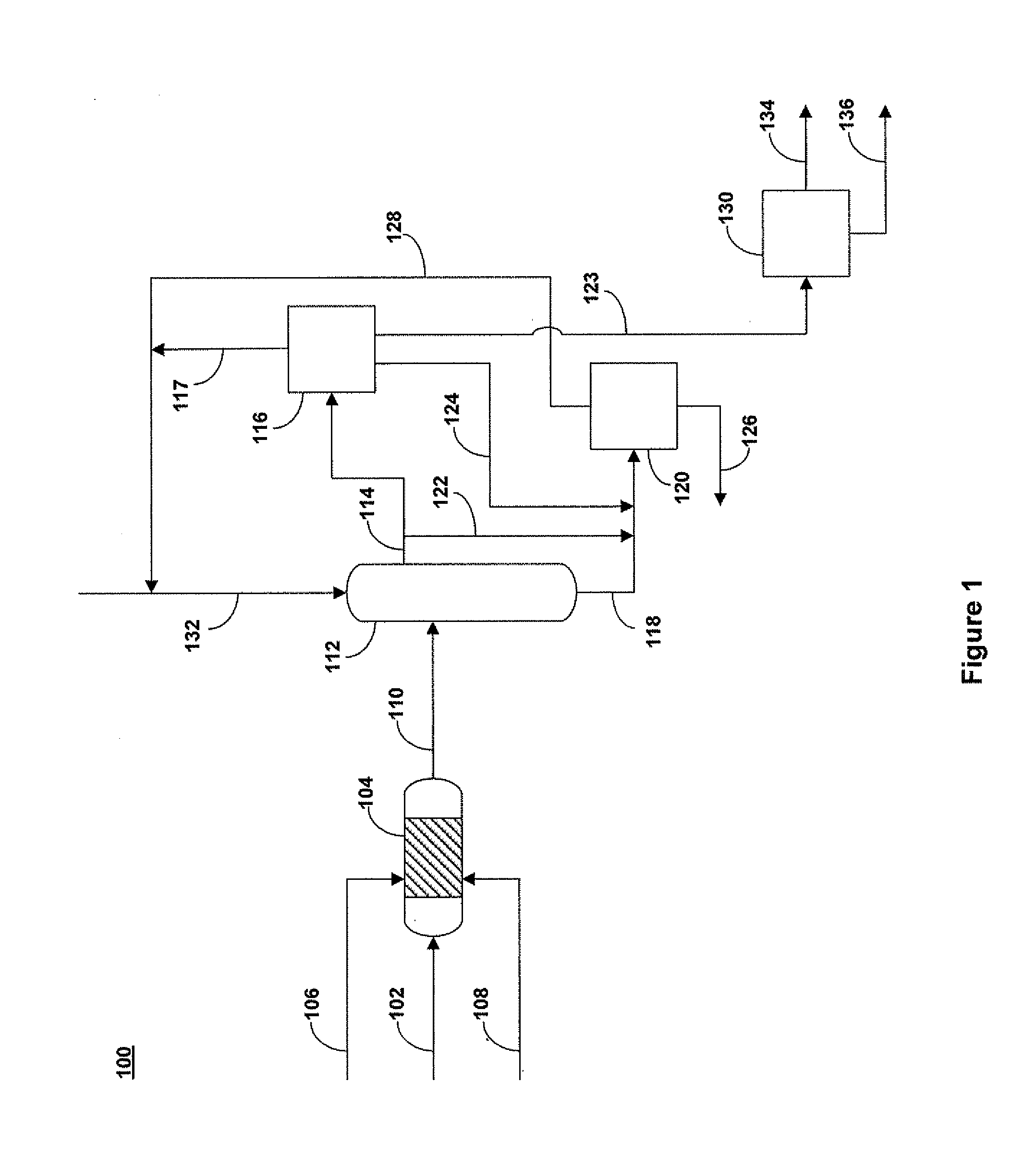

Desulfurization and Sulfone Removal Using A Coker

ActiveUS20120055845A1Refining with oxygen compoundsTreatment with plural serial refining stagesSulfurSolvent

A method and apparatus for upgrading a hydrocarbon feedstock is provided. The method includes the steps of (a) supplying a hydrocarbon feedstock to an oxidation reactor, wherein the hydrocarbon feedstock is oxidized in the presence of a catalyst under conditions sufficient to selectively oxidize sulfur compounds present in the hydrocarbon feedstock; (c) separating the hydrocarbons and the oxidized sulfur compounds by solvent extraction; (d) collecting a residue stream that includes the oxidized sulfur compounds; and (e) supplying the residue stream to a coker to produce coker gases and solid coke.

Owner:SAUDI ARABIAN OIL CO

Oxidative desulfurization and denitrogenation of petroleum oils

InactiveUS20060108263A1Active and fast in oxidizing the sulfurReduce the temperatureOrganic chemistryRefining with oxygen compoundsPtru catalystEnvironmental engineering

A robust, non-aqueous, and oil-soluble organic peroxide oxidant is employed for oxidative desulfurization and denitrogenation of hydrocarbon feedstocks including petroleum fuels. Even at low concentrations, the non-aqueous organic peroxide oxidant is extremely active and fast in oxidizing the sulfur and nitrogen compounds in the hydrocarbon feedstocks without catalyst. Consequently, the oxidation reactions that employ the non-aqueous organic peroxide oxidant take place at substantially lower temperatures and shorter residence times than reactions in other oxidative desulfurization and denitrogenation processes. As a result, a higher percentage of the valuable non-sulfur and non-nitrogen containing components in the hydrocarbon feedstock are more likely preserved with the inventive process. Desulfurization and denitrogenation occur in a single phase non-aqueous environment so that no phase transfer of the oxidant is required.

Owner:CPC CORPORATION

Desulfurization process

InactiveUS7144499B2Refining with oxygen compoundsTreatment with plural serial refining stagesSulfurSorbent

Owner:LYONDELL CHEM TECH LP

Reactor and process for mercaptan oxidation and separation in the same vessel

ActiveUS7223332B1Sweetening hydrocarbon streamSmall volumeRefining with oxygen compoundsLiquid displacementThiolKerosene

The present invention is an apparatus and process for oxidizing mercaptans in a preferably kerosene stream. By using a catalyst promoter, sufficient separation of hydrocarbon and aqueous alkali occurs in the reactor vessel to obviate the need for a settling tank. Hence, the sweetened kerosene can be withdrawn from the reactor vessel and sent directly to a residual alkali removal unit such as a sand filter vessel or to a water wash vessel if jet grade fuel is desired. In an embodiment, the reactor vessel used for this purpose includes a reaction section and a separation section in the same reactor vessel and an aqueous alkali outlet and a sweetened hydrocarbon outlet in the separation section.

Owner:UOP LLC

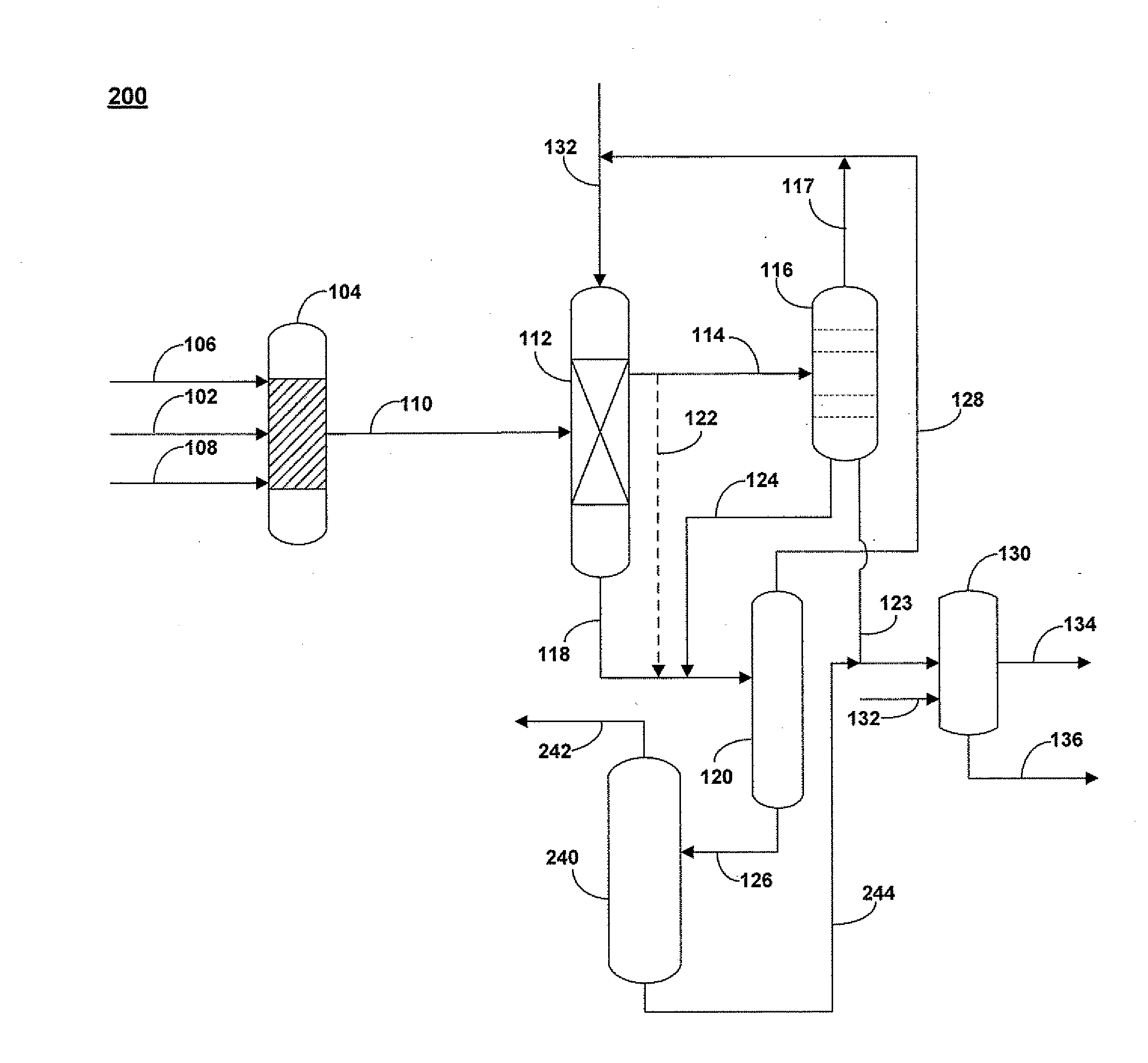

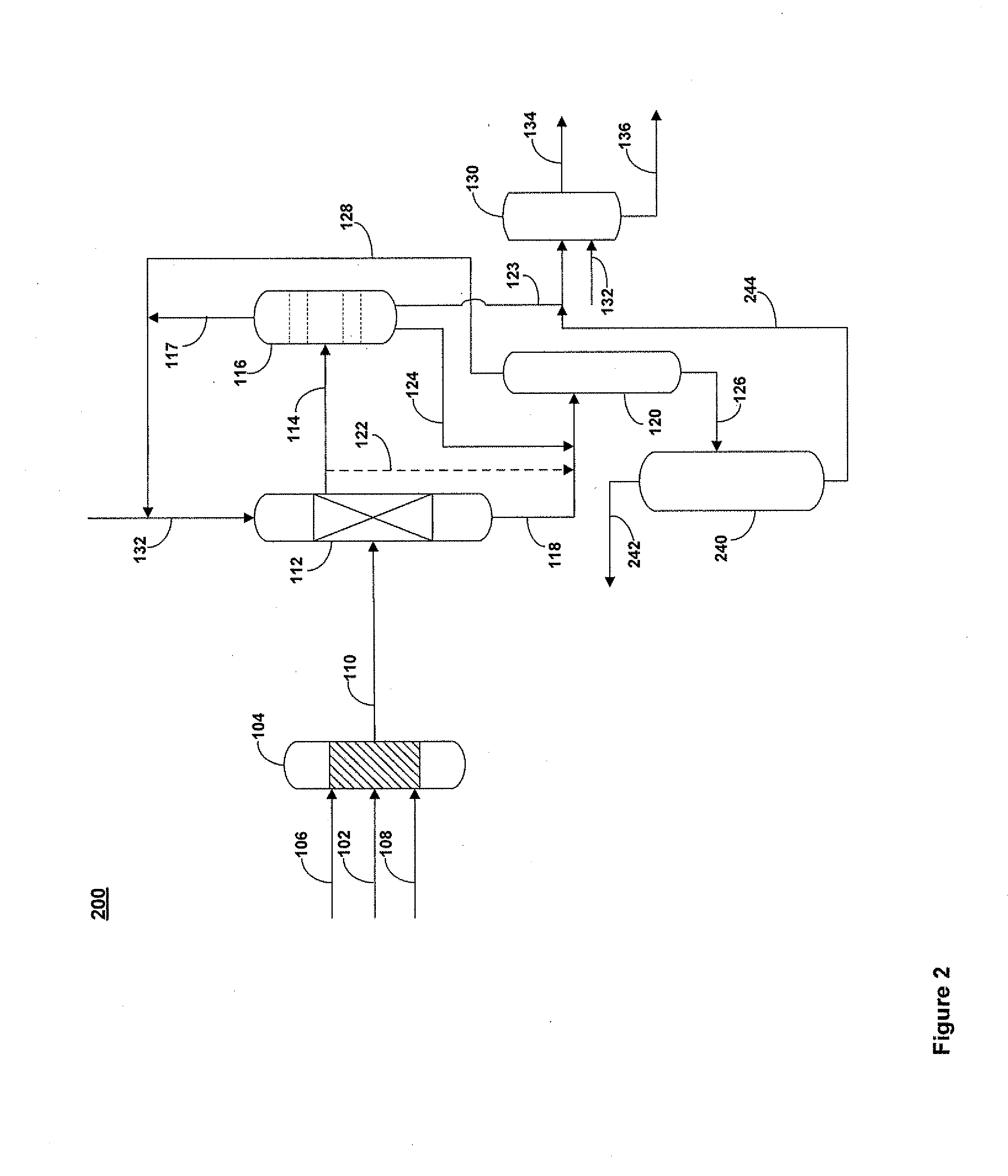

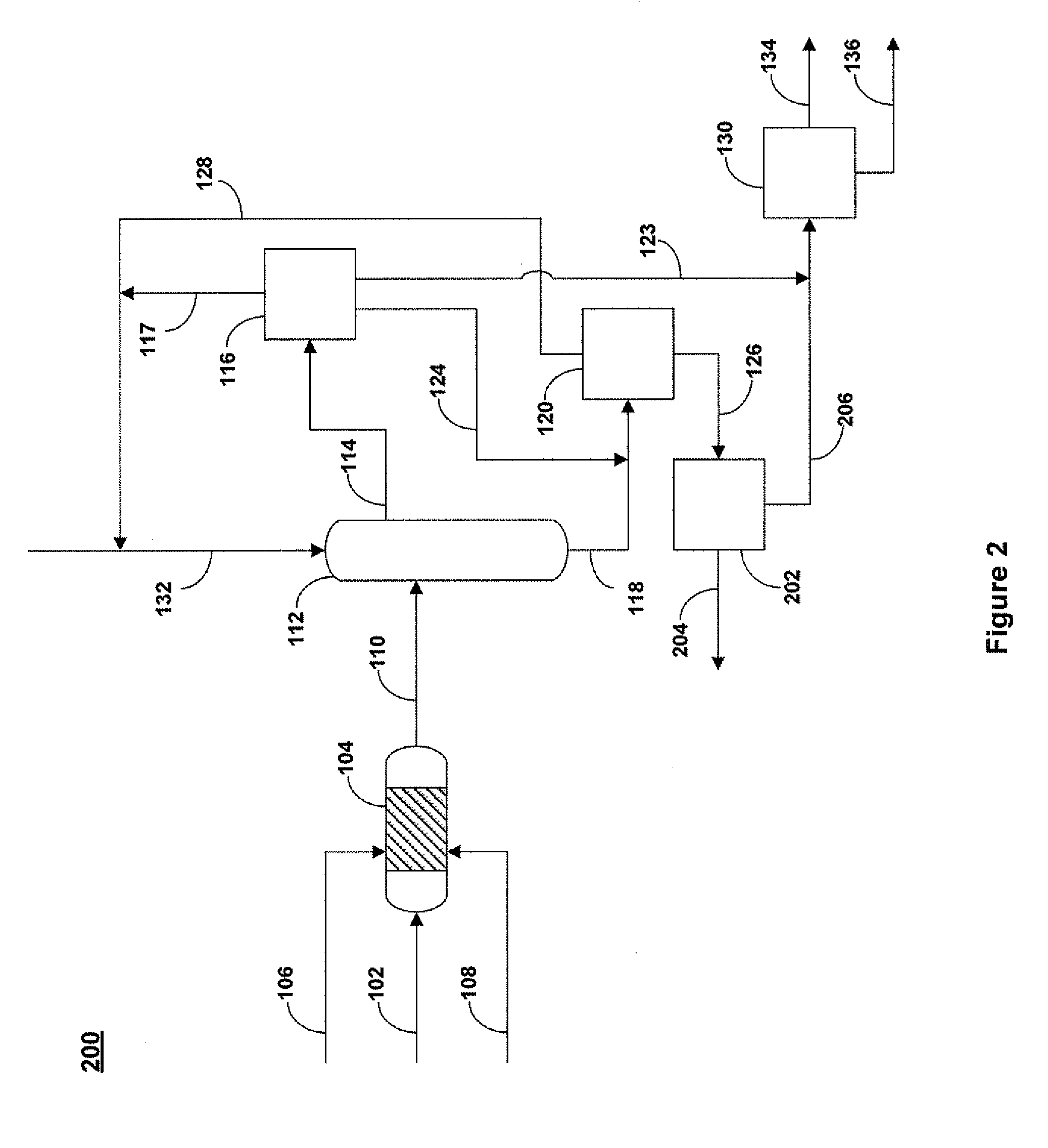

Process for Oxidative Desulfurization and Sulfone Disposal Using Solvent Deasphalting

ActiveUS20120055843A1High purityWorking-up pitch/asphalt/bitumen by selective extractionSulfur-dioxide/sulfurous-acidSulfurSolvent

A method and apparatus for upgrading a hydrocarbon feedstock is provided. The method includes the steps of (a) supplying a hydrocarbon feedstock to an oxidation reactor, wherein the hydrocarbon feedstock is oxidized in the presence of a catalyst under conditions sufficient to selectively oxidize sulfur compounds present in the hydrocarbon feedstock; (c) separating the hydrocarbons and the oxidized sulfur compounds by solvent extraction; (d) collecting a residue stream that includes the oxidized sulfur compounds; and (e) supplying the residue stream to a deasphalting unit.

Owner:SAUDI ARABIAN OIL CO

Popular searches

Carboxylic acid esters preparation Hydrocarbon purification/separation Ethylene production Gaseous mixture working up Refining by selective hydrogenation Bulk chemical production Hydrocarbon oils treatment products Organic compound preparation Treatment with plural serial stages only Organic halogenation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com