Process for the desulfurization of hydrocarbonacecus oil

a hydrocarbonaceous oil and desulfurization technology, applied in the field of desulfurization of hydrocarbonaceous oil, can solve the problems of uneconomic, low yield of sulfur-free material from original hydrocarbonaceous oil, and high cost of hydrotreating known current hydrotreating techniques, so as to reduce the sulfur content of hydrocarbonaceous oil. , the effect of reducing the cost of hydrotreating is easy and economically feasibl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

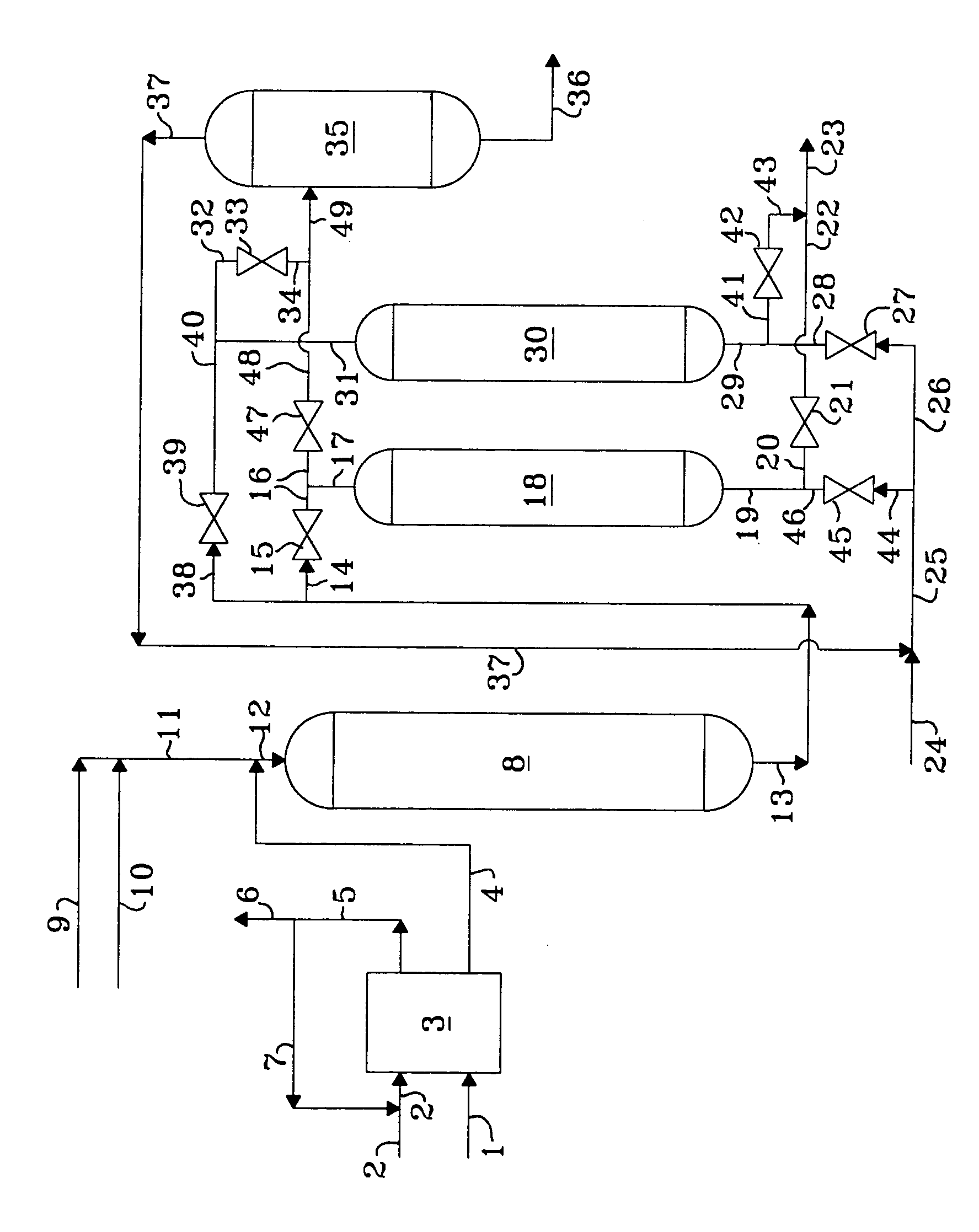

[0014] The present invention provides an improved integrated process for the deep desulfurization of hydrocarbonaceous oil in a two-stage desulfurization process. In accordance with the present invention, a preferred hydrocarbonaceous oil feedstock contains distillable hydrocarbons boiling in the range from about 93° C. (200° F.) to about 565° C. (1050° F.) and more preferably from about 149° C. (300° F.) to about 538° C. (1000° F.). The hydrocarbonaceous oil feedstock is contemplated to contain from about 0.1 to about 5 weight percent sulfur and the process is most advantageously utilized when the feedstock contains high levels of sulfur and the desired desulfurized product contains a very low concentration of sulfur. Preferred product sulfur levels are less than about 100 wppm, more preferably less than about 50 wppm, and even more preferably less than about 30 wppm.

[0015] The hydrocarbonaceous oil containing sulfur compounds is introduced into a catalytic hydrodesulfurization zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com