Patents

Literature

118 results about "Synthetic crude" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthetic crude is the output from a bitumen/extra heavy oil upgrader facility used in connection with oil sand production. It may also refer to shale oil, an output from an oil shale pyrolysis. The properties of the synthetic crude depend on the processes used in the upgrading. Typically, it is low in sulfur and has an API gravity of around 30. It is also known as "upgraded crude".

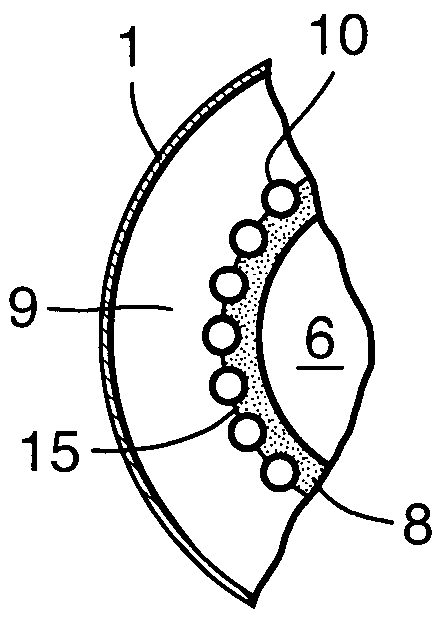

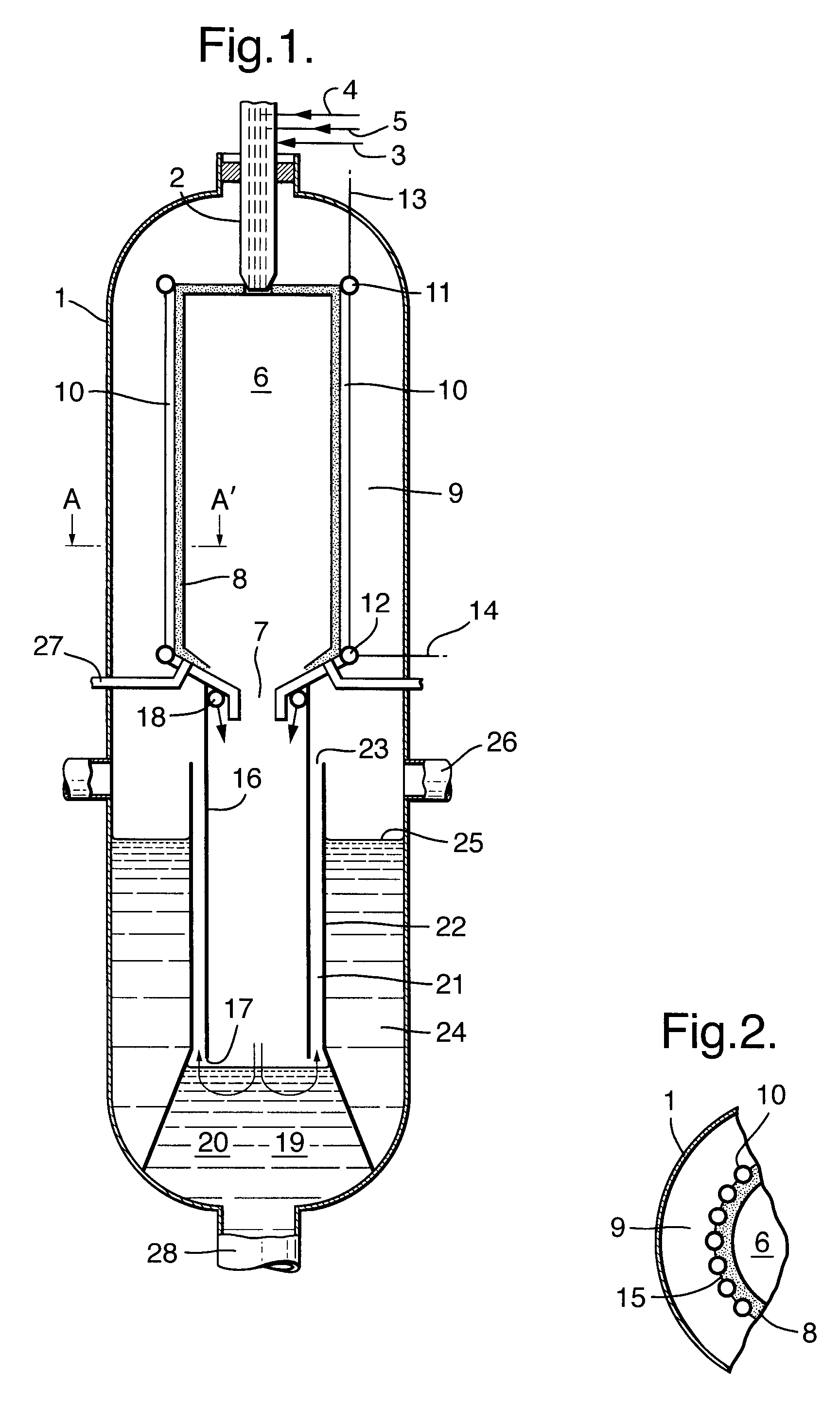

Reactor and process for upgrading heavy hydrocarbon oils

InactiveUS20080099374A1Prevent subsidenceRefining by water treatmentFeed devicesMomentumVolumetric Mass Density

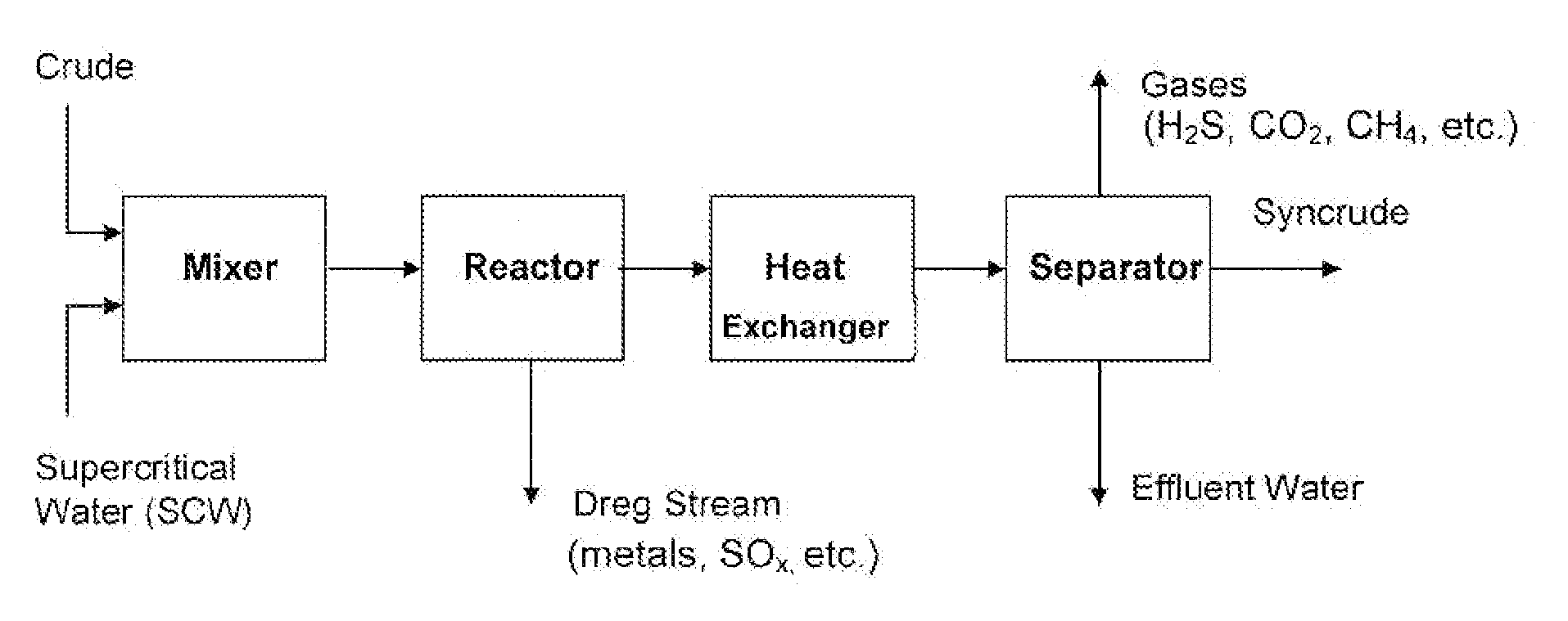

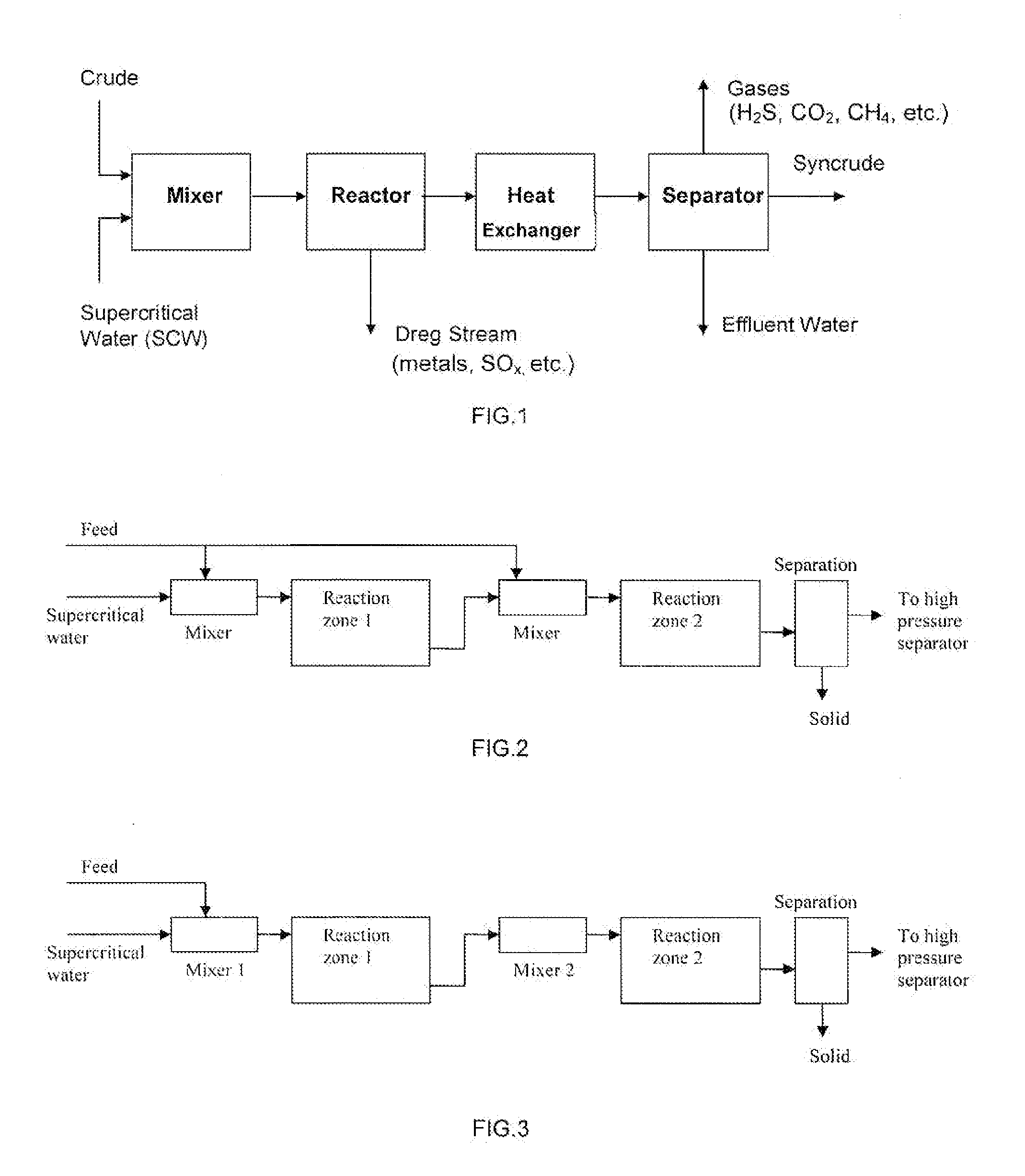

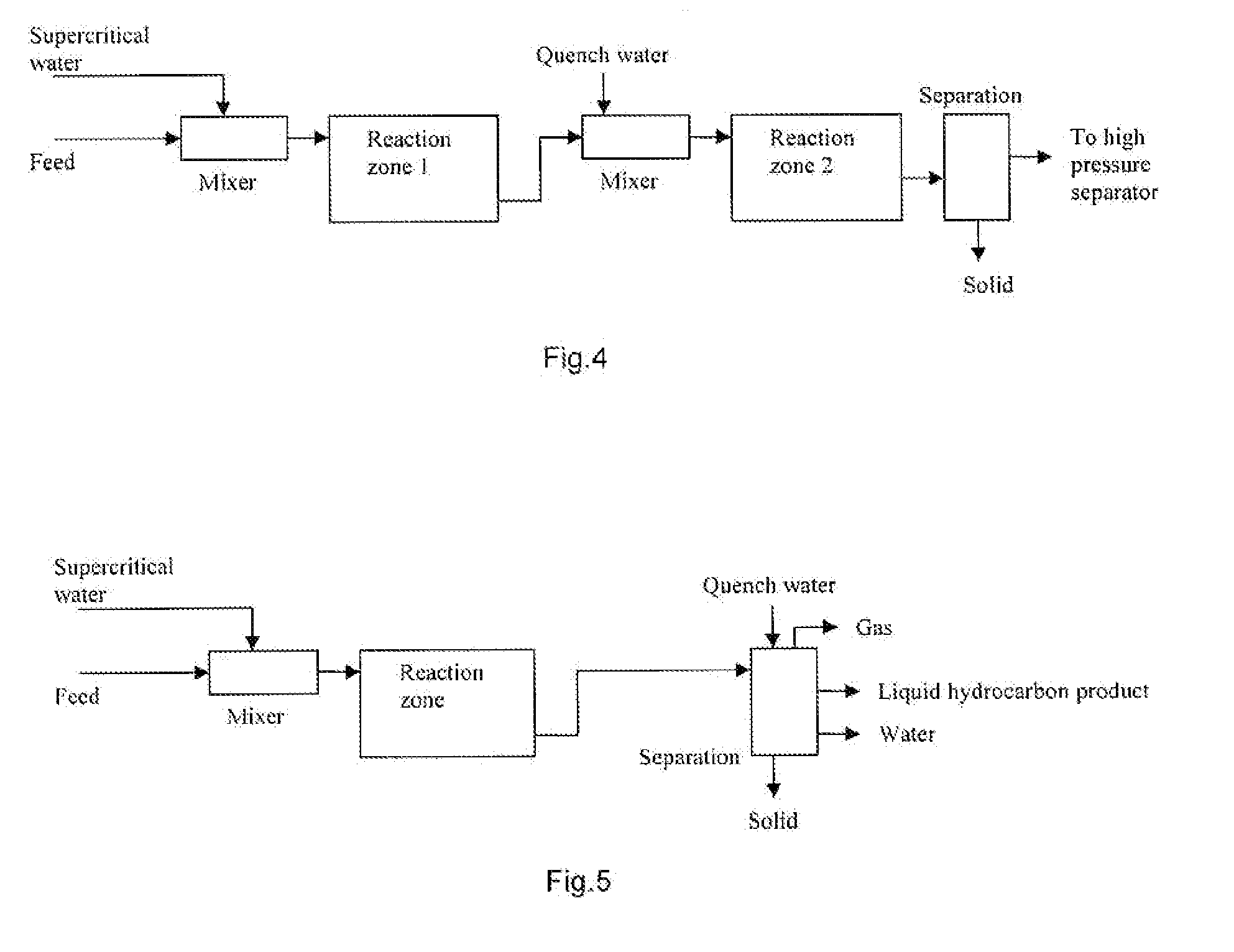

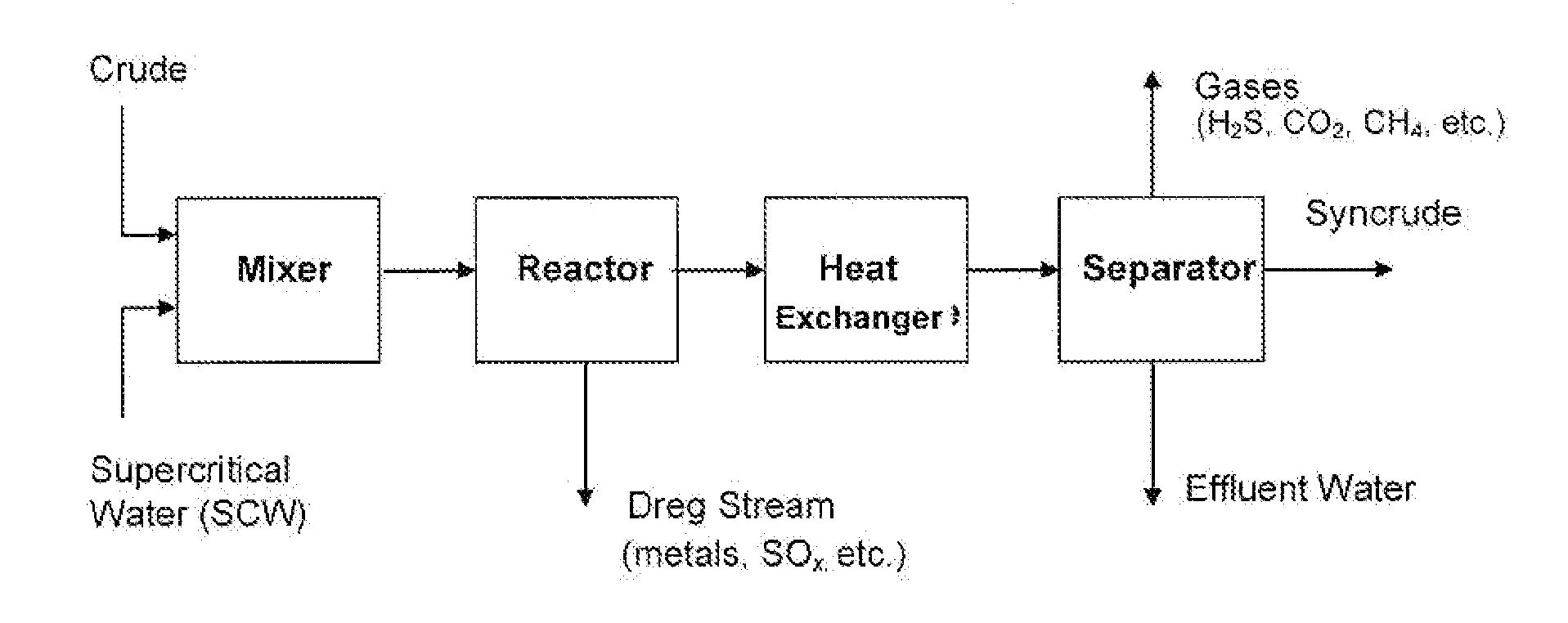

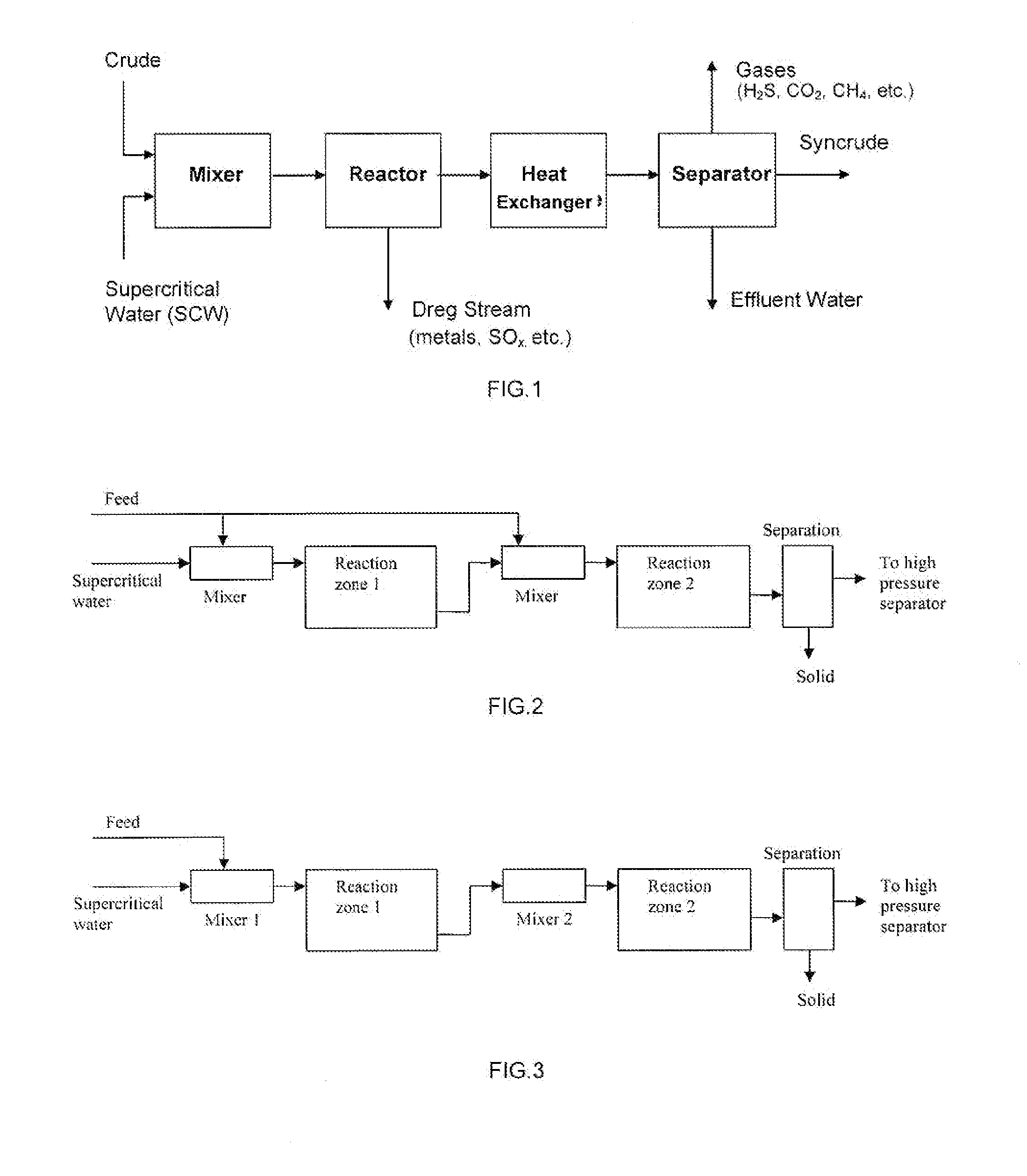

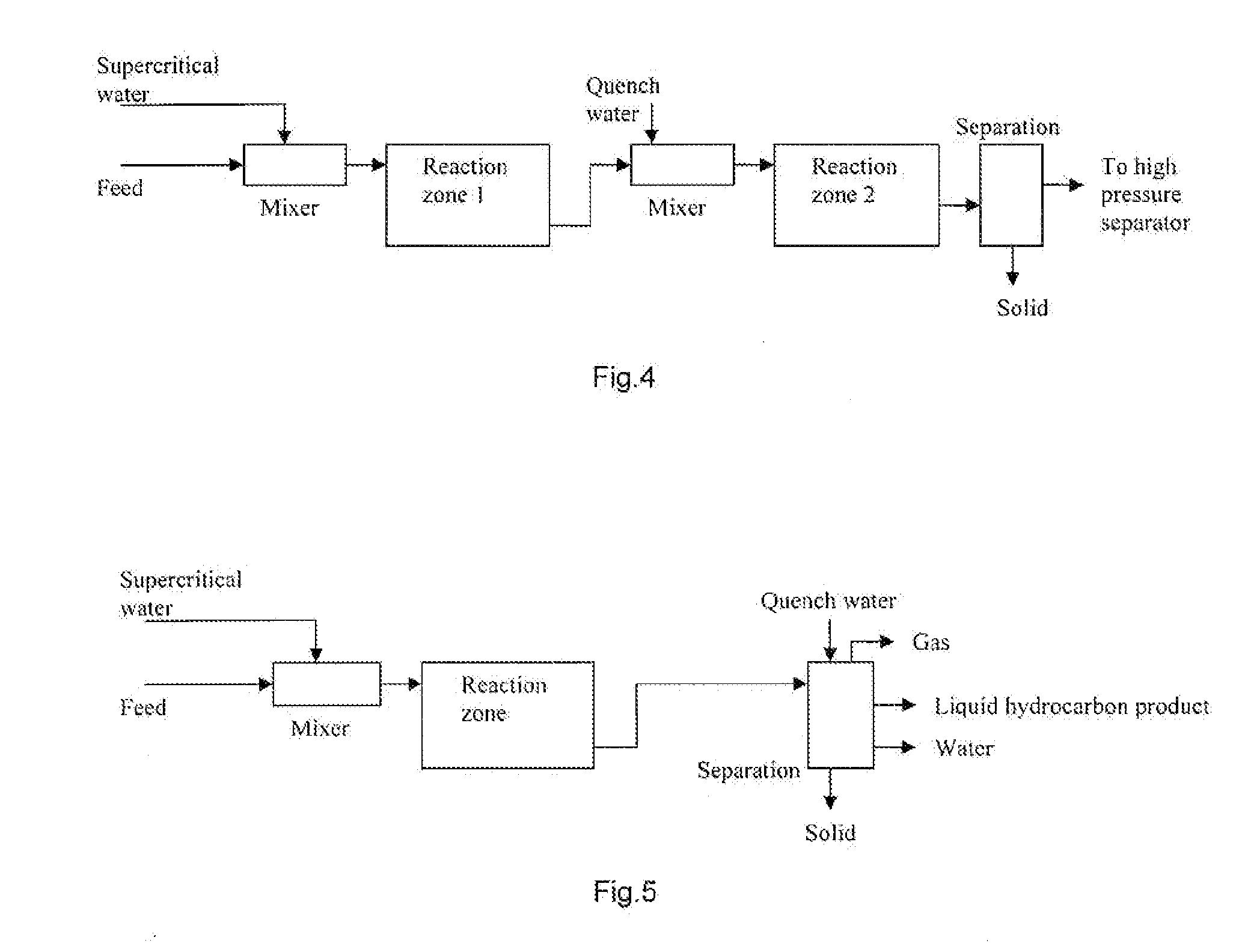

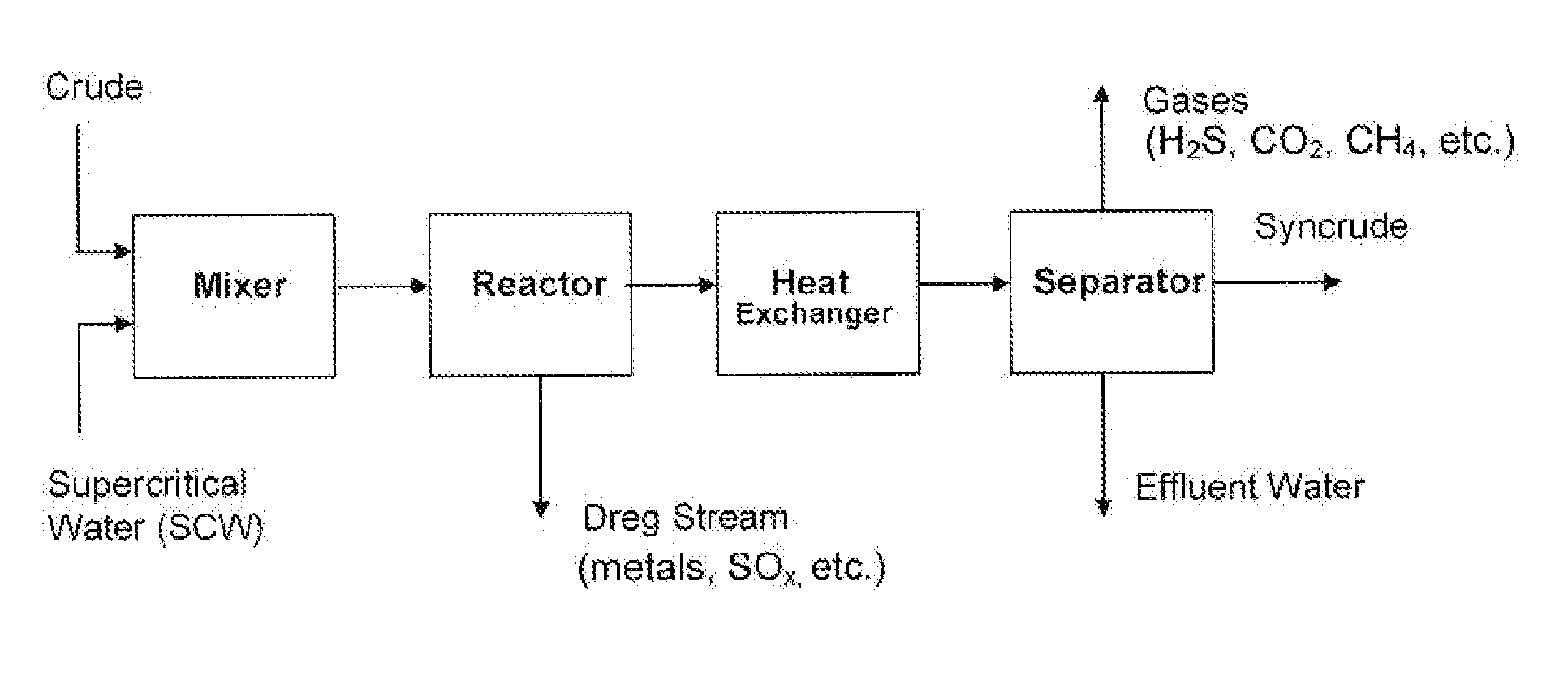

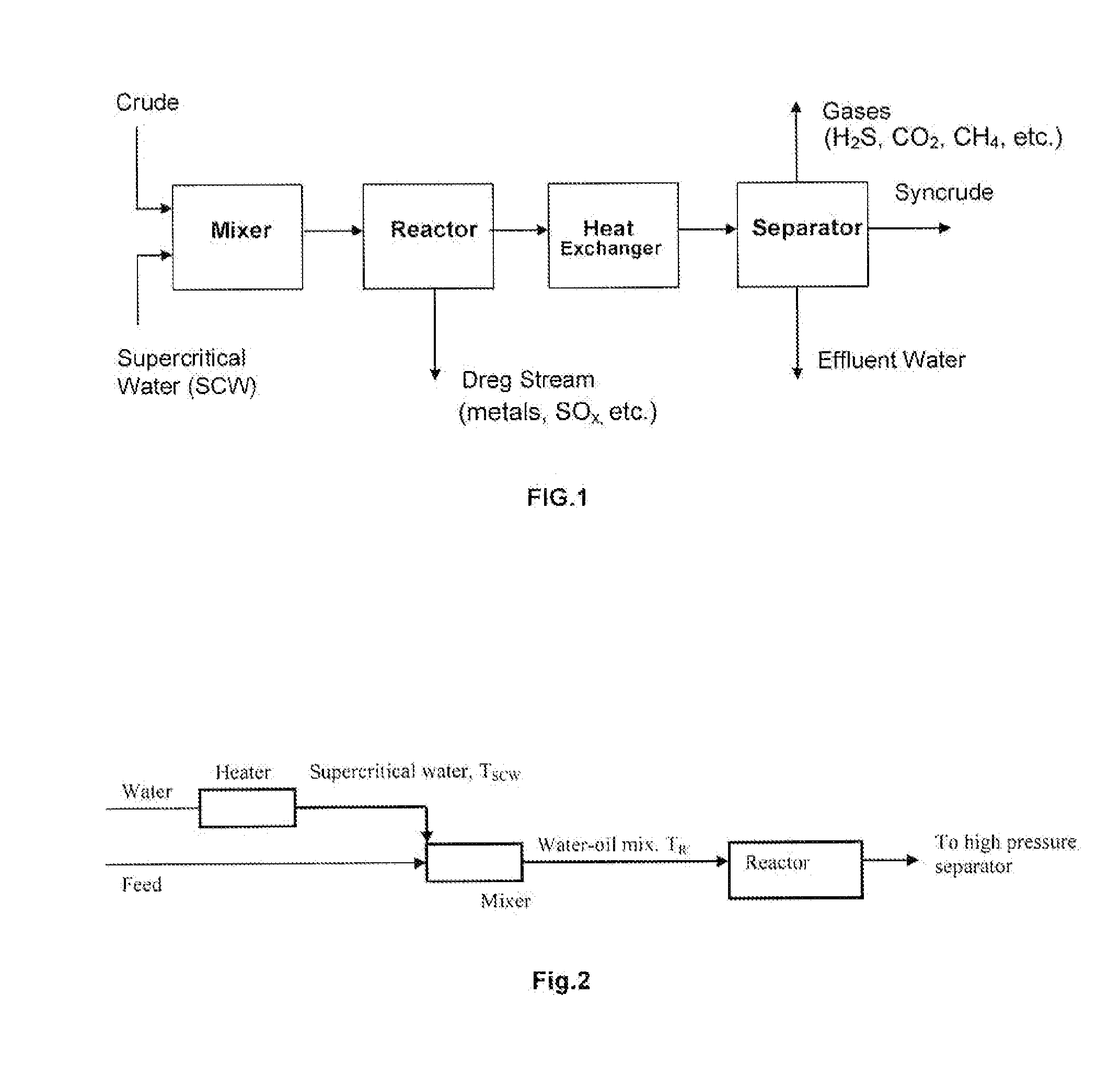

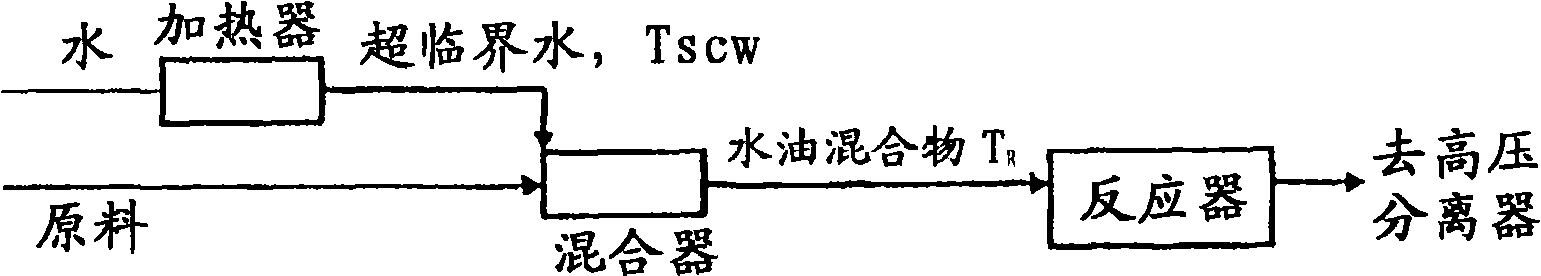

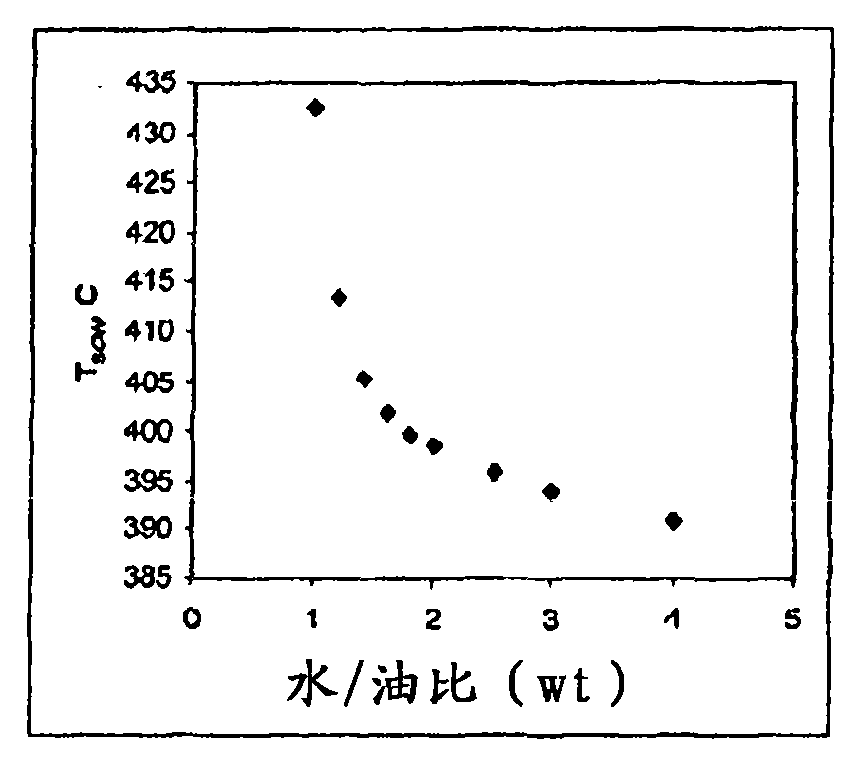

A reactor for conducting a process using supercritical water to upgrade a heavy hydrocarbon feedstock into an upgraded hydrocarbon product or syncrude with highly desirable properties (low sulfur content, low metals content, lower density (higher API), lower viscosity, lower residuum content, etc.) is described. The reactor is operable under continuous) semi-continuous or batch mode and is equipped with means to enable momentum, heat and mass transfer in and out of and within the reactor.

Owner:CHEVROU USA INC

Blended compression-ignition fuel containing light synthetic crude and blending stock

InactiveUS6056793AImprove performanceEmission reductionLiquid carbonaceous fuelsFuel additivesAlcoholIgnition delay

This invention is a composition of matter useful as a compression-ignition fuel. The composition has from about 30 to about 95 mass % of a light synthetic crude or syncrude, preferably from Fischer-Tropsch synthesis or related processes, and from about 5 to about 70 mass % of a blending stock that improves one or more desirable fuel property(s) including but not limited to pour point temperature, viscosity and emissions generated during combustion in a diesel engine. The blend stock preferably has an average molecular weight less than the average molecular weight of the light syncrude. Preferred blending stocks include hydrocarbons and oxygenates, such as alcohols, and ethers, having average molecular weights less than 200, preferably less than 160. The composition may optionally also contain pour point depressants, cetane improvers, carbon-containing compounds which react with water, and / or emulsifiers.

Owner:REG SYNTHETIC FUELS LLC +1

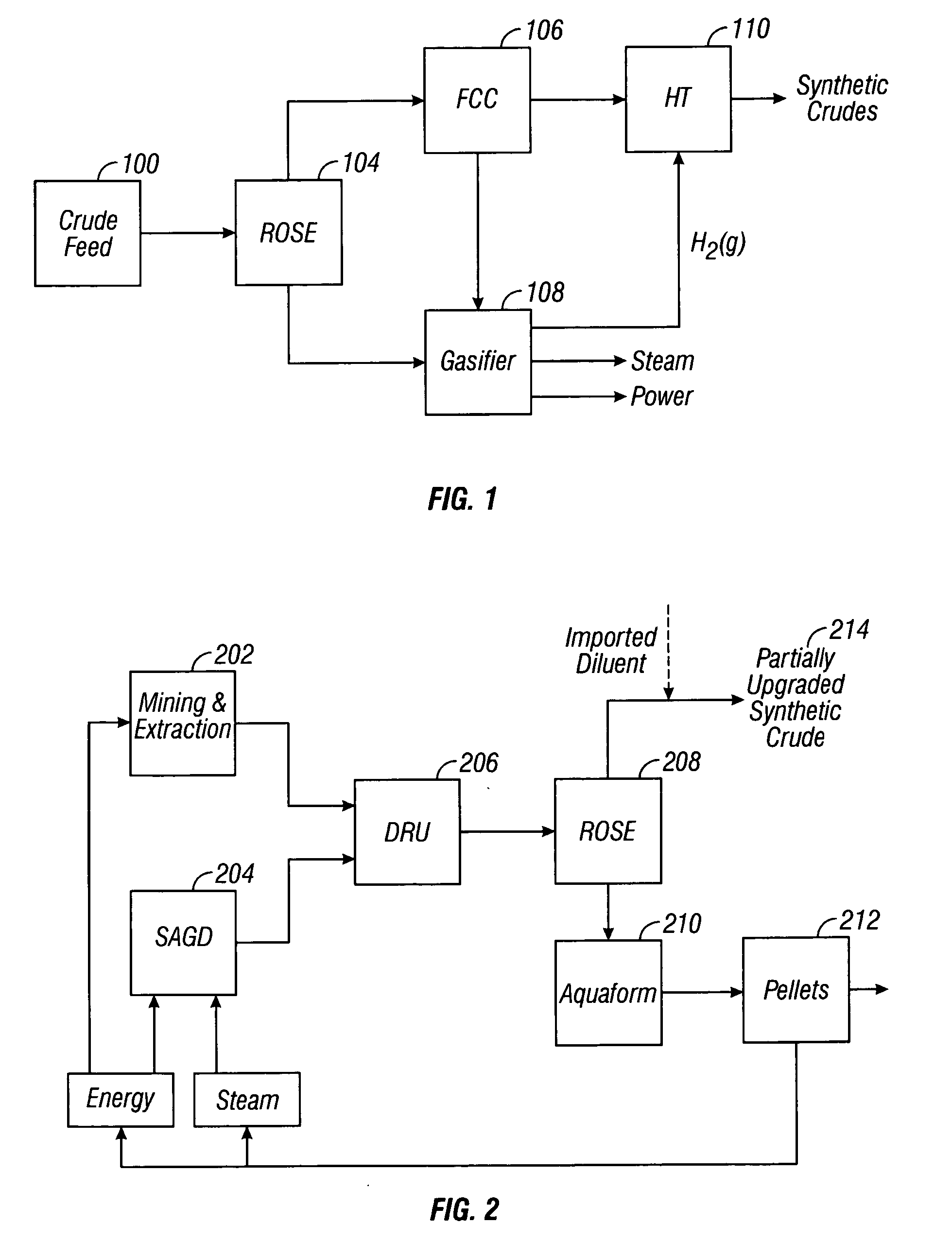

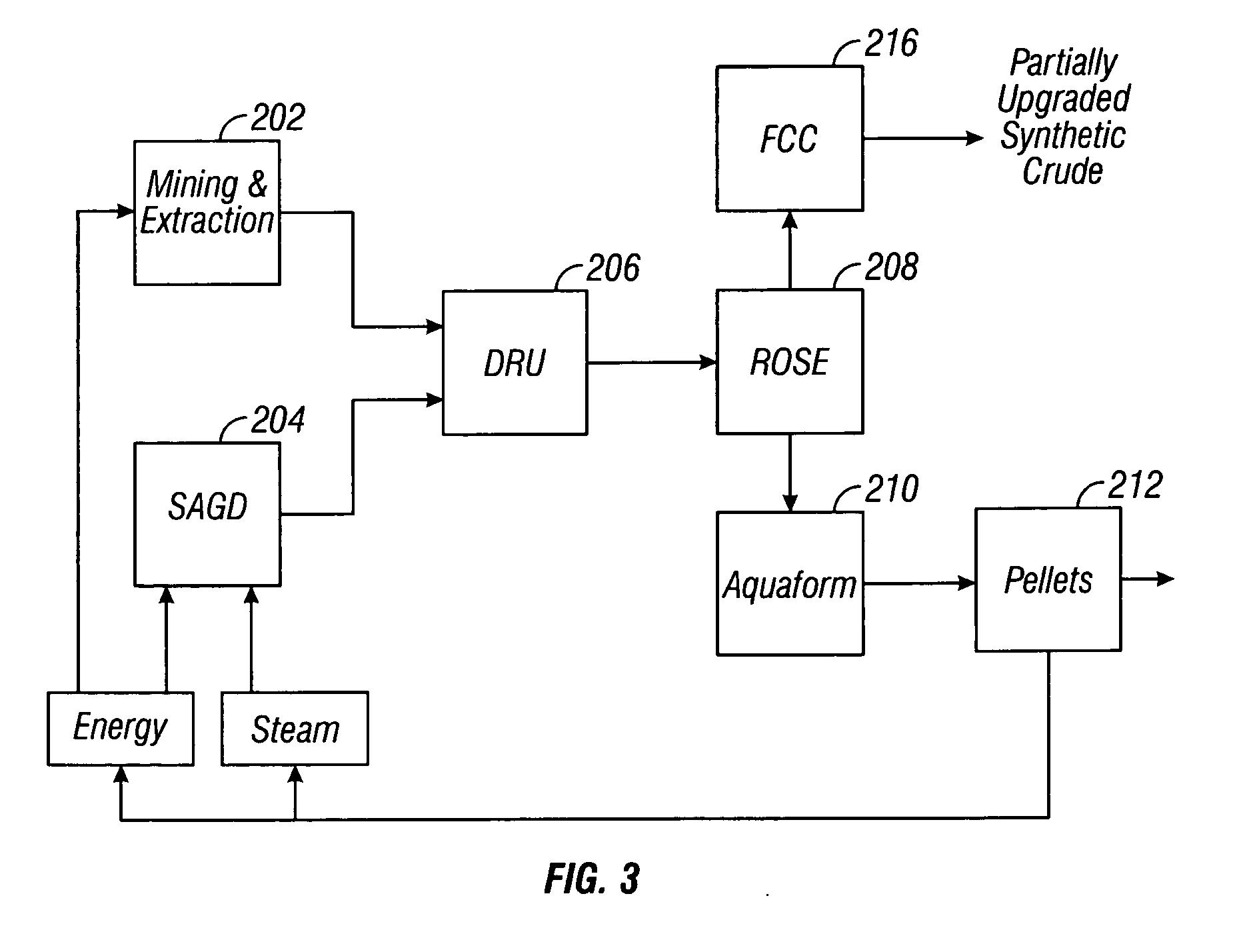

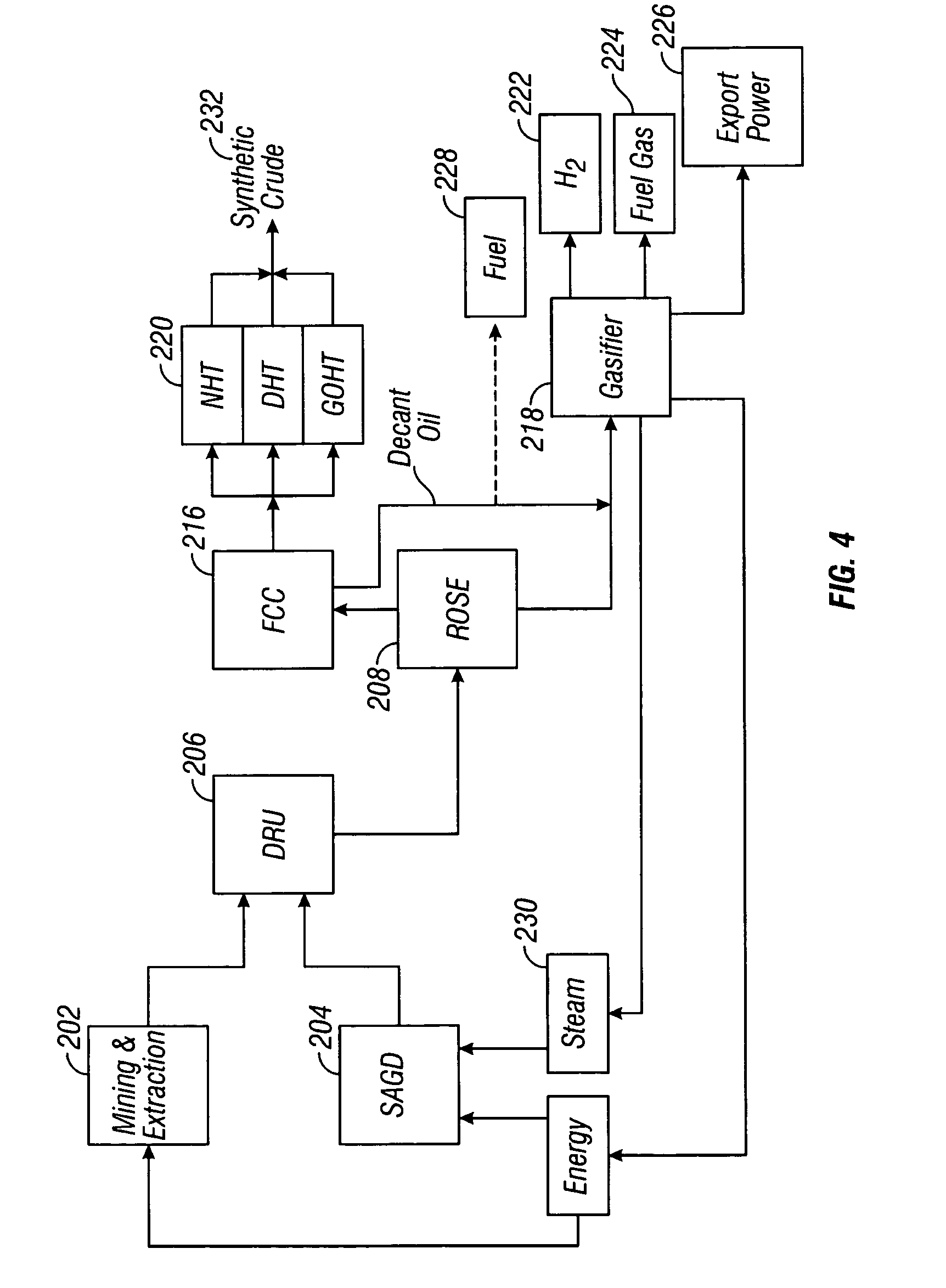

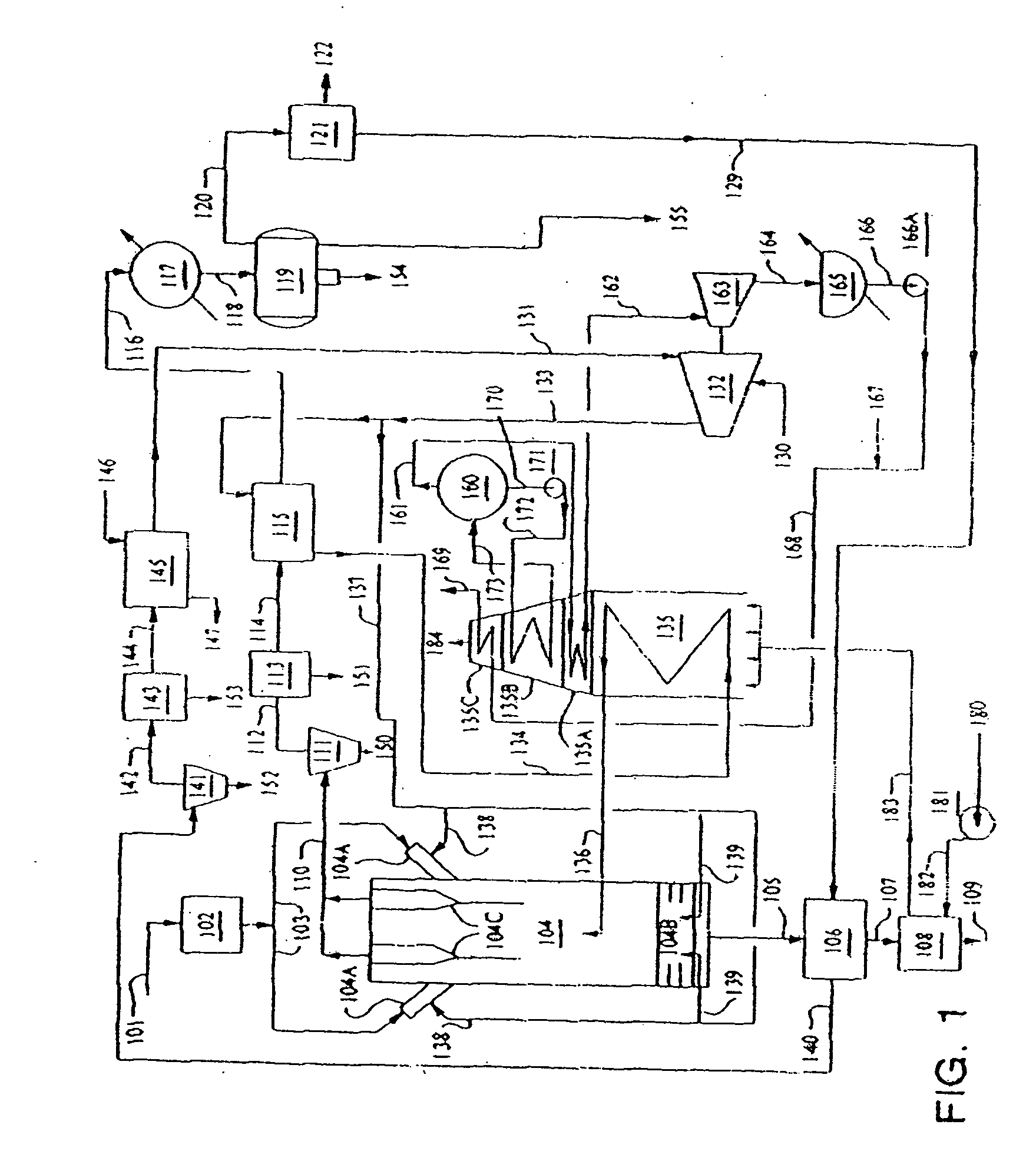

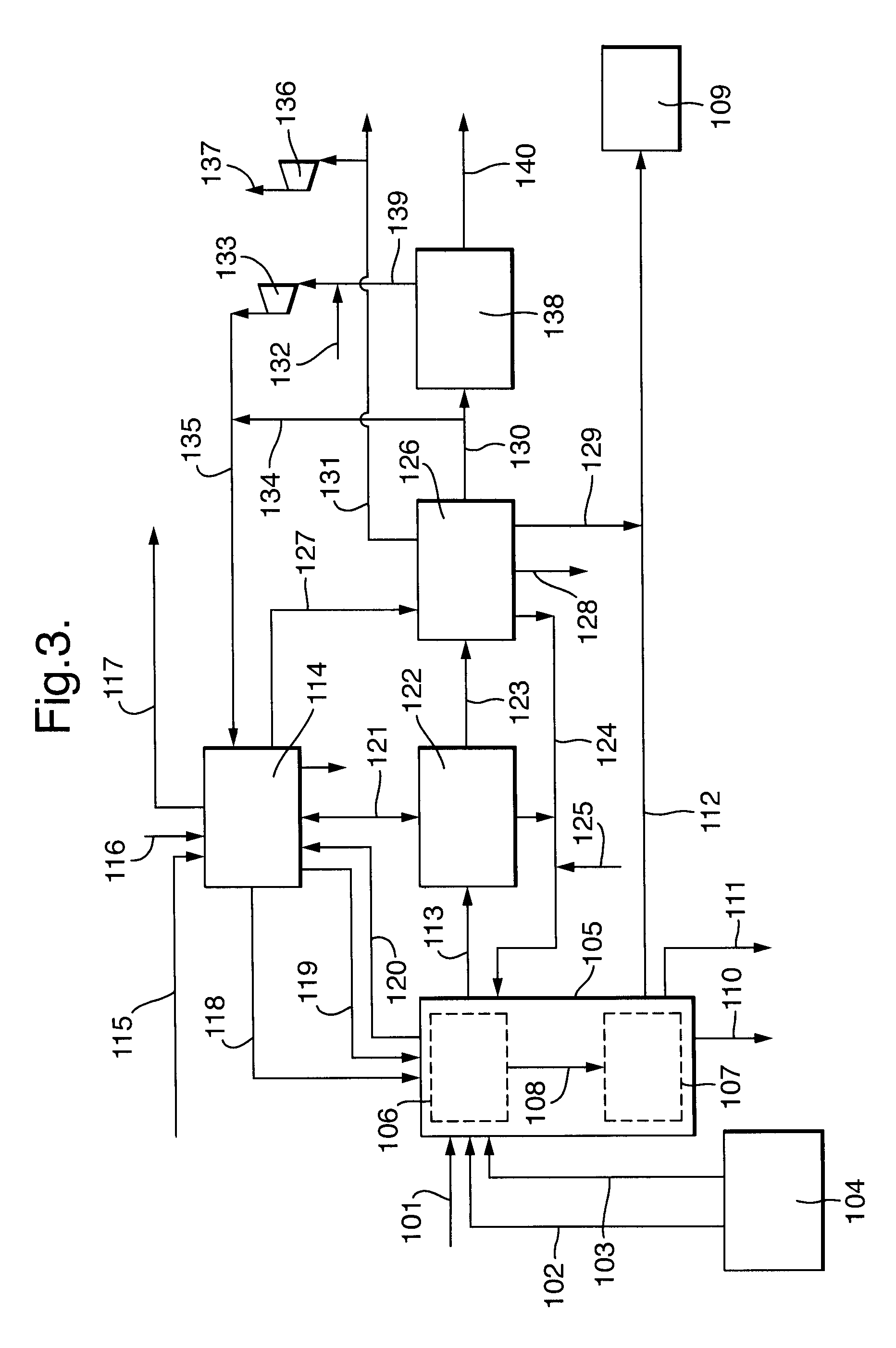

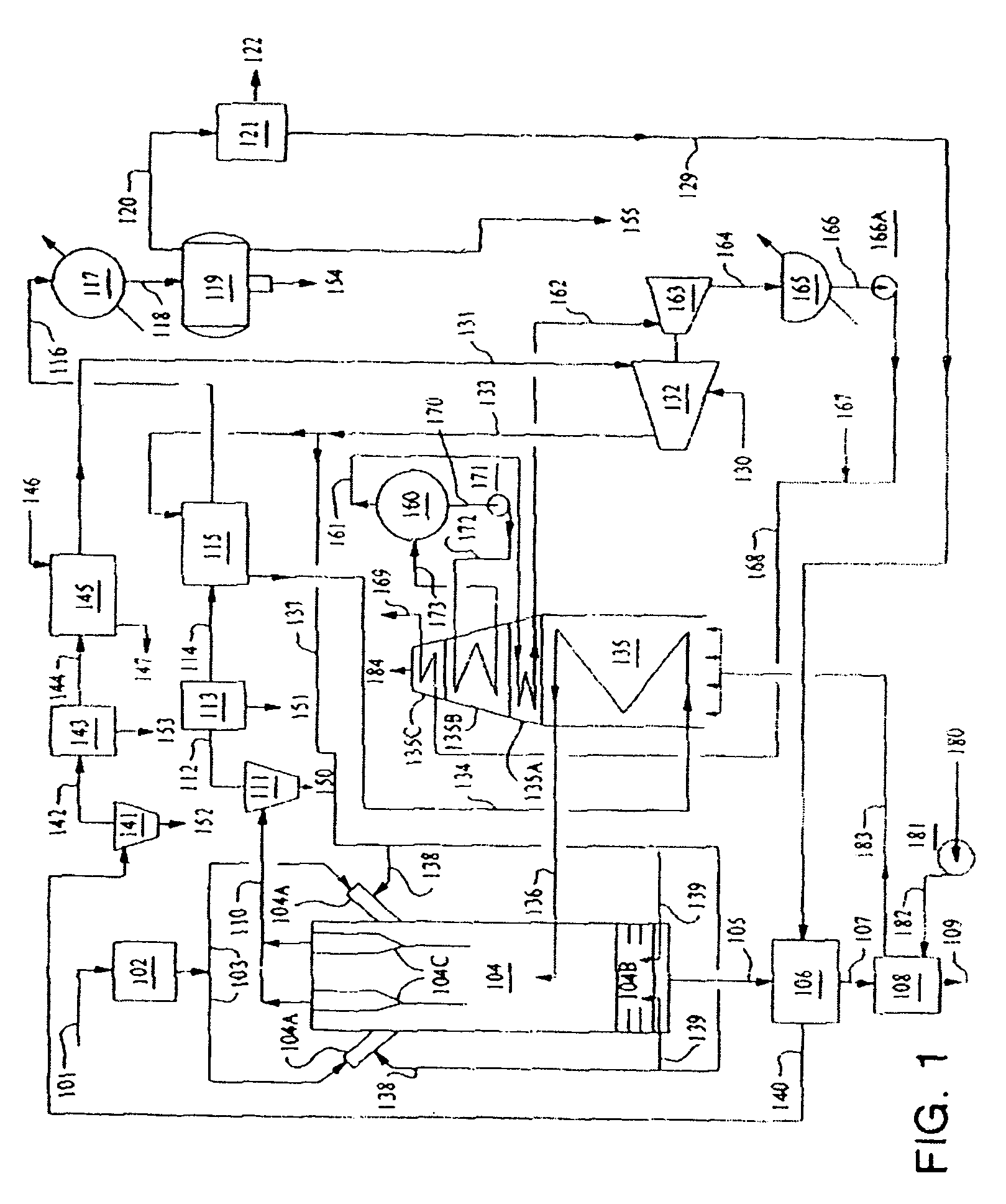

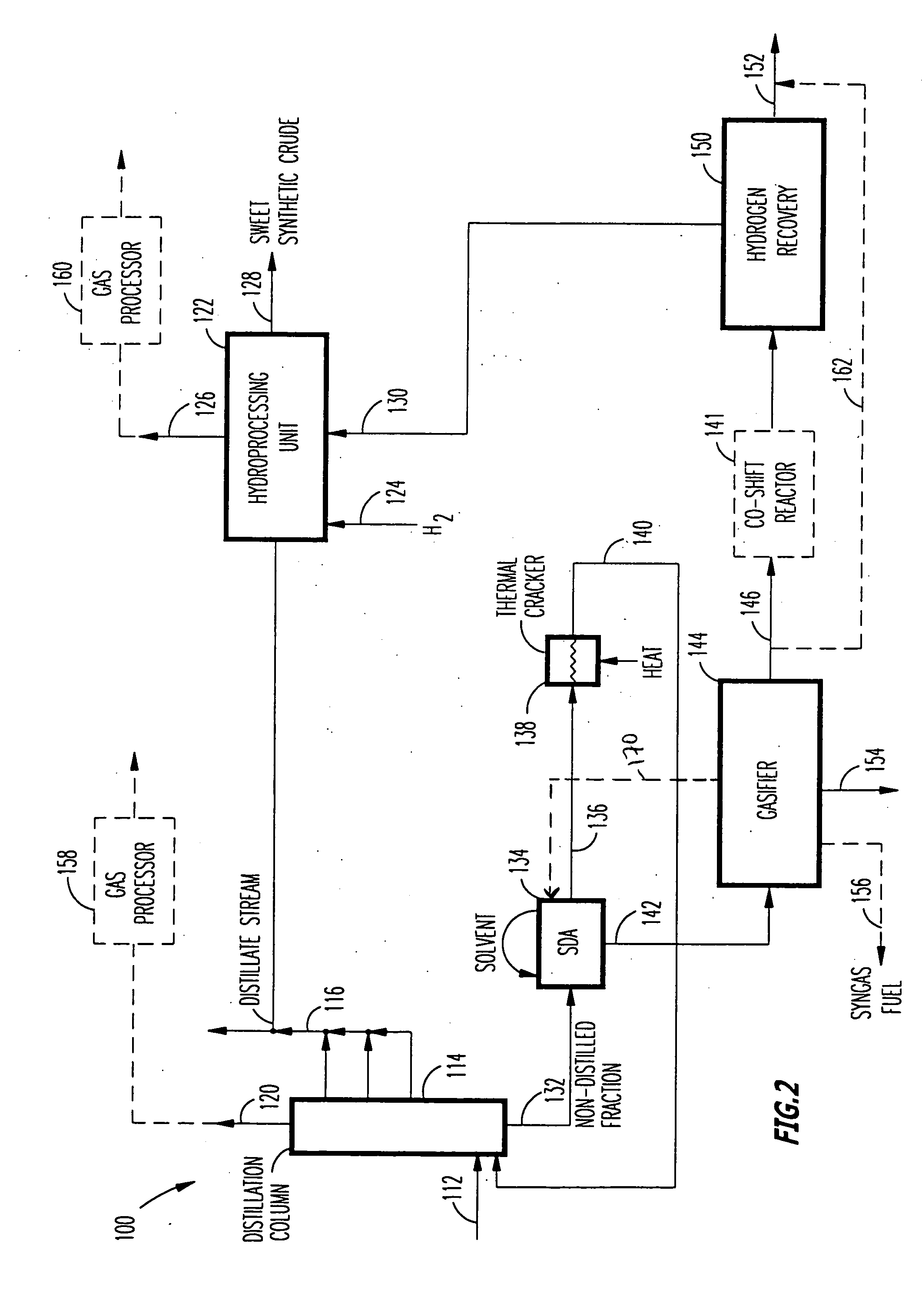

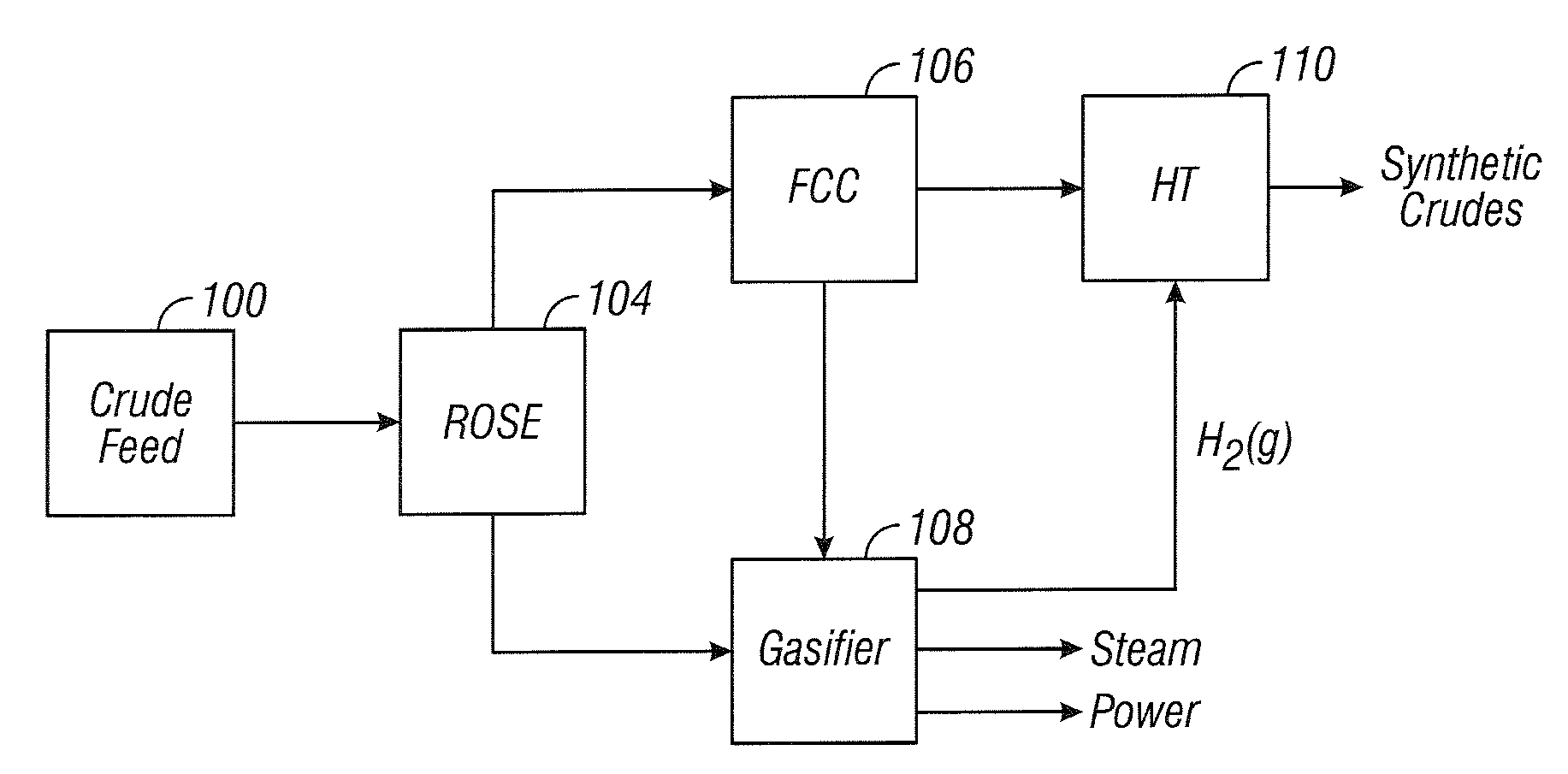

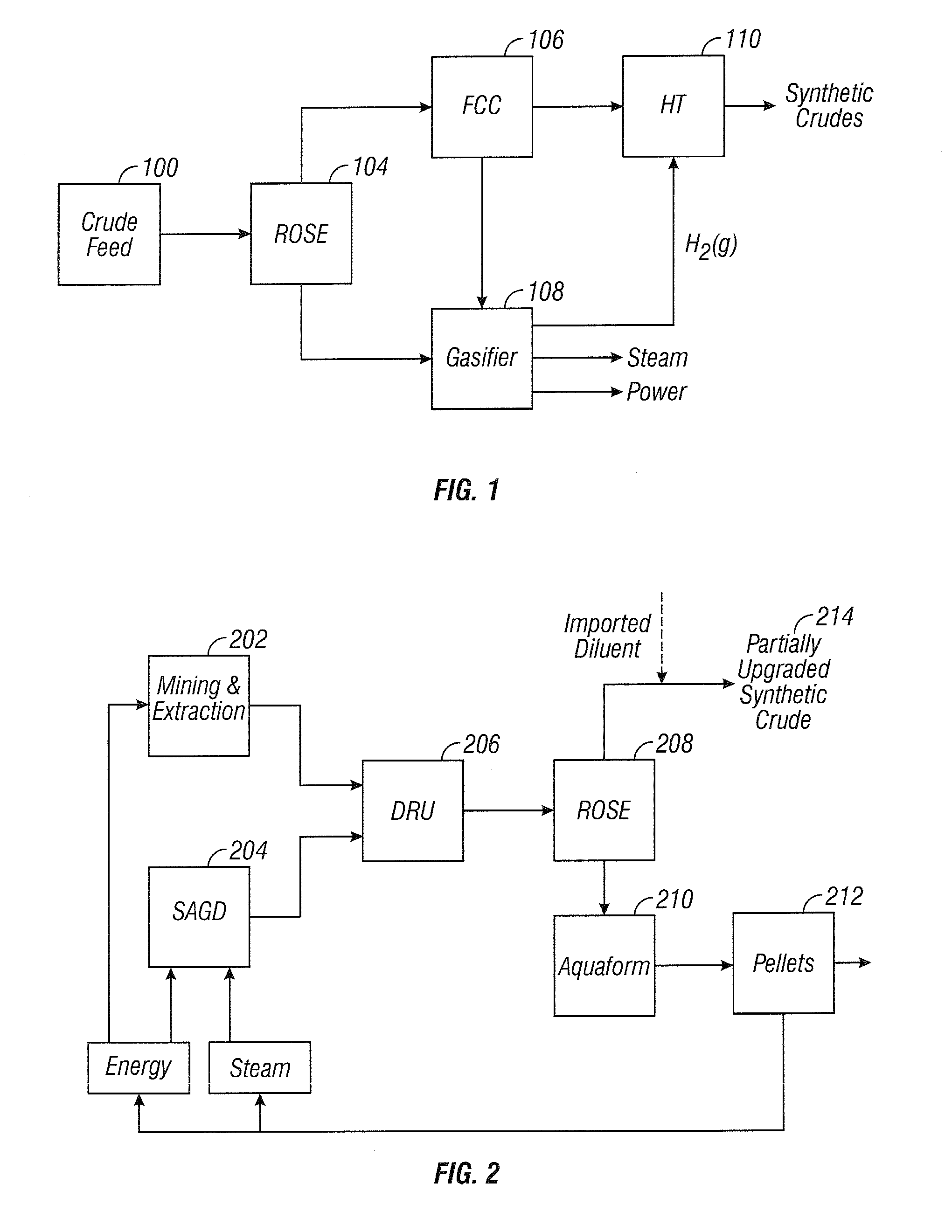

Heavy Oil and Bitumen Upgrading

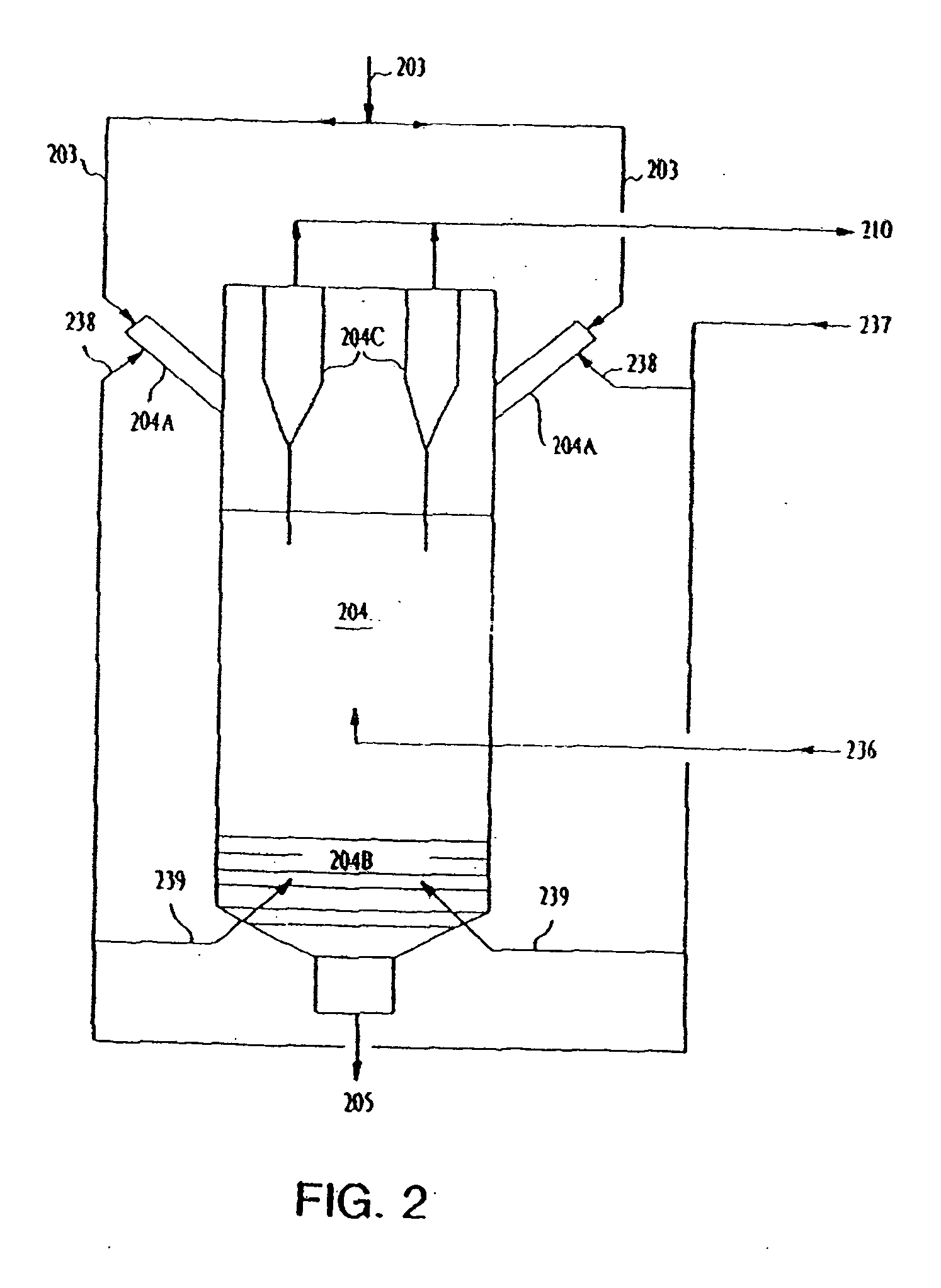

ActiveUS20060042999A1Reduce metal contentEasy to liftThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by selective extractionNaphthaHydrogen

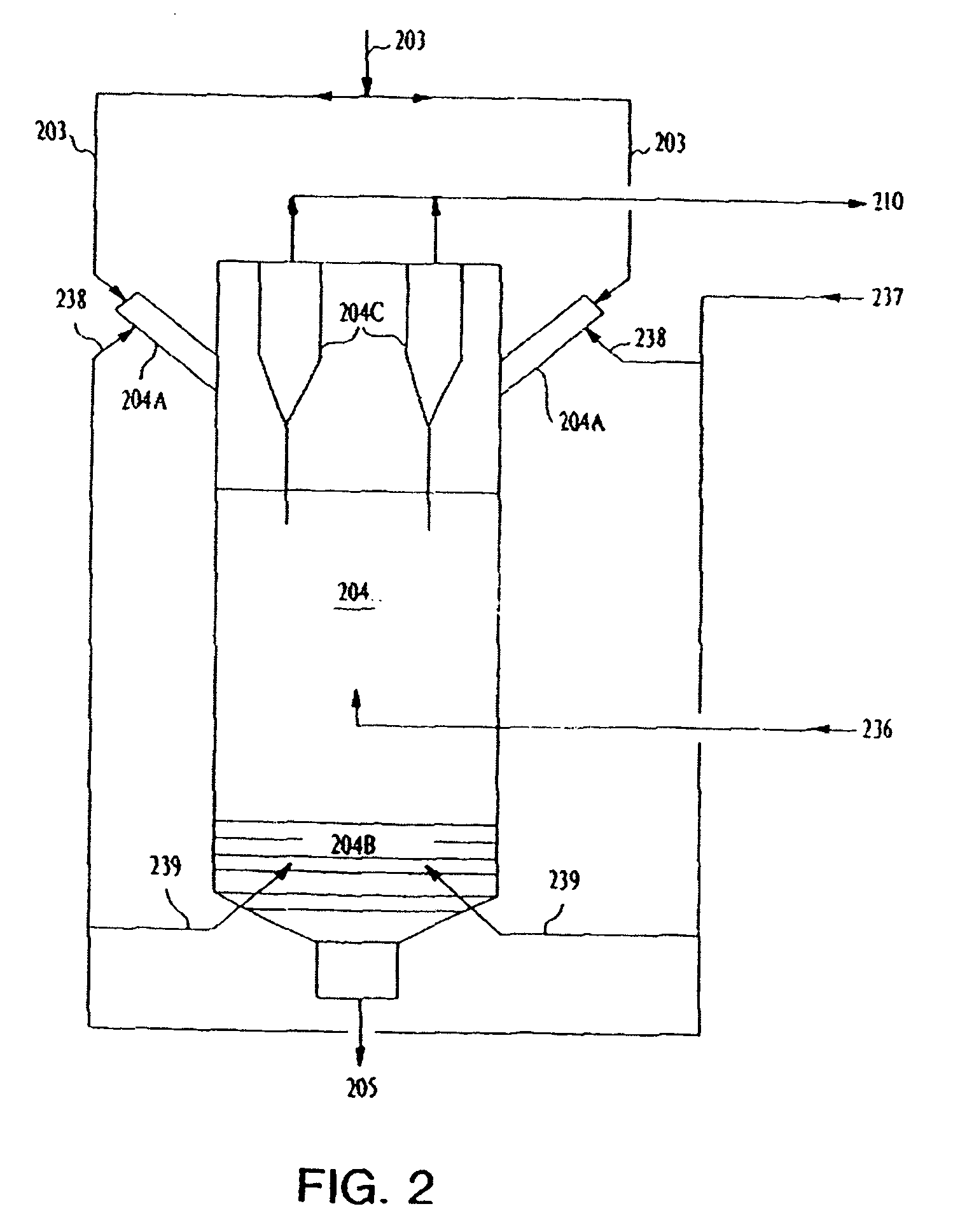

Disclosed is a process for the upgrading and demetallizing of heavy oils and bitumens. A crude heavy oil and / or bitumen feed is supplied to a solvent extraction process 104 wherein DAO and asphaltenes are separated. The DAO is supplied to an FCC unit 106 having a low conversion activity catalyst for the removal of metals contained therein. The demetallized distillate fraction is supplied to a hydrotreater 110 for upgrading and collected as a synthetic crude product stream. The asphaltene fraction can be supplied to a gasifier 108 for the recovery of power, steam and hydrogen, which can be supplied to the hydrotreater 110 or otherwise within the process or exported. An optional coker 234 can be used to convert excess asphaltenes and / or decant oil to naphtha, distillate and gas oil, which can be supplied to the hydrotreater 220.

Owner:KELLOGG BROWN & ROOT LLC

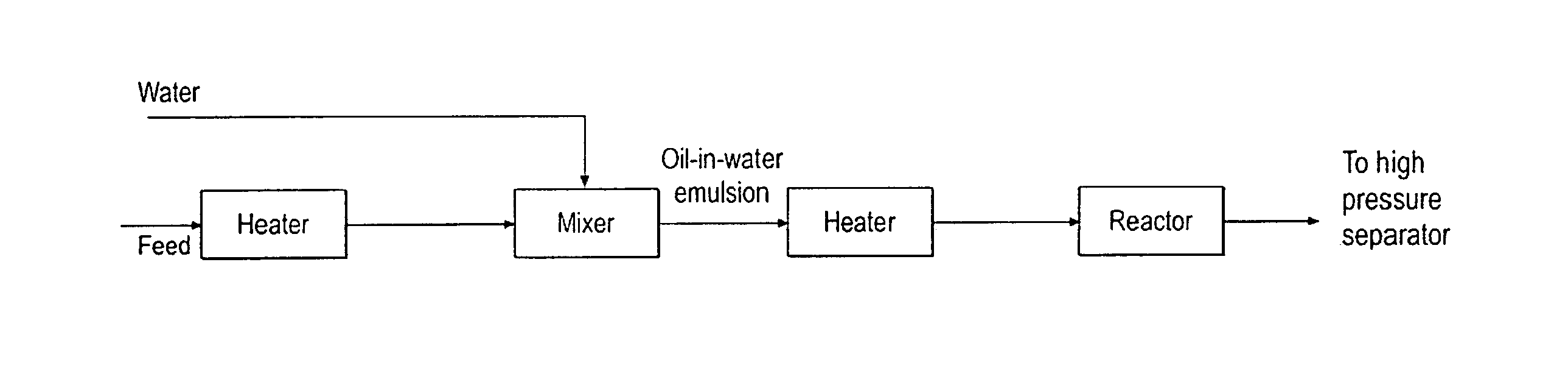

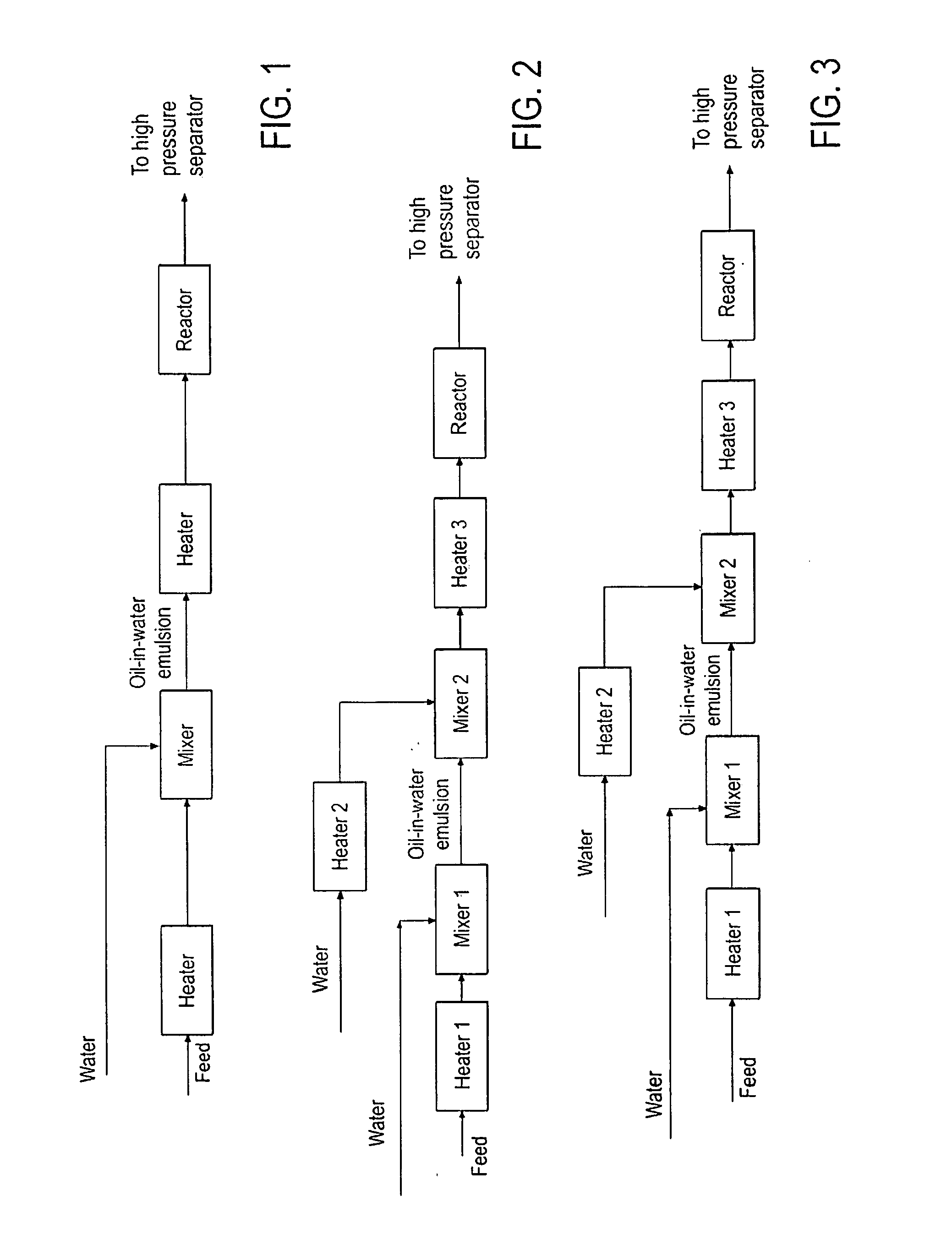

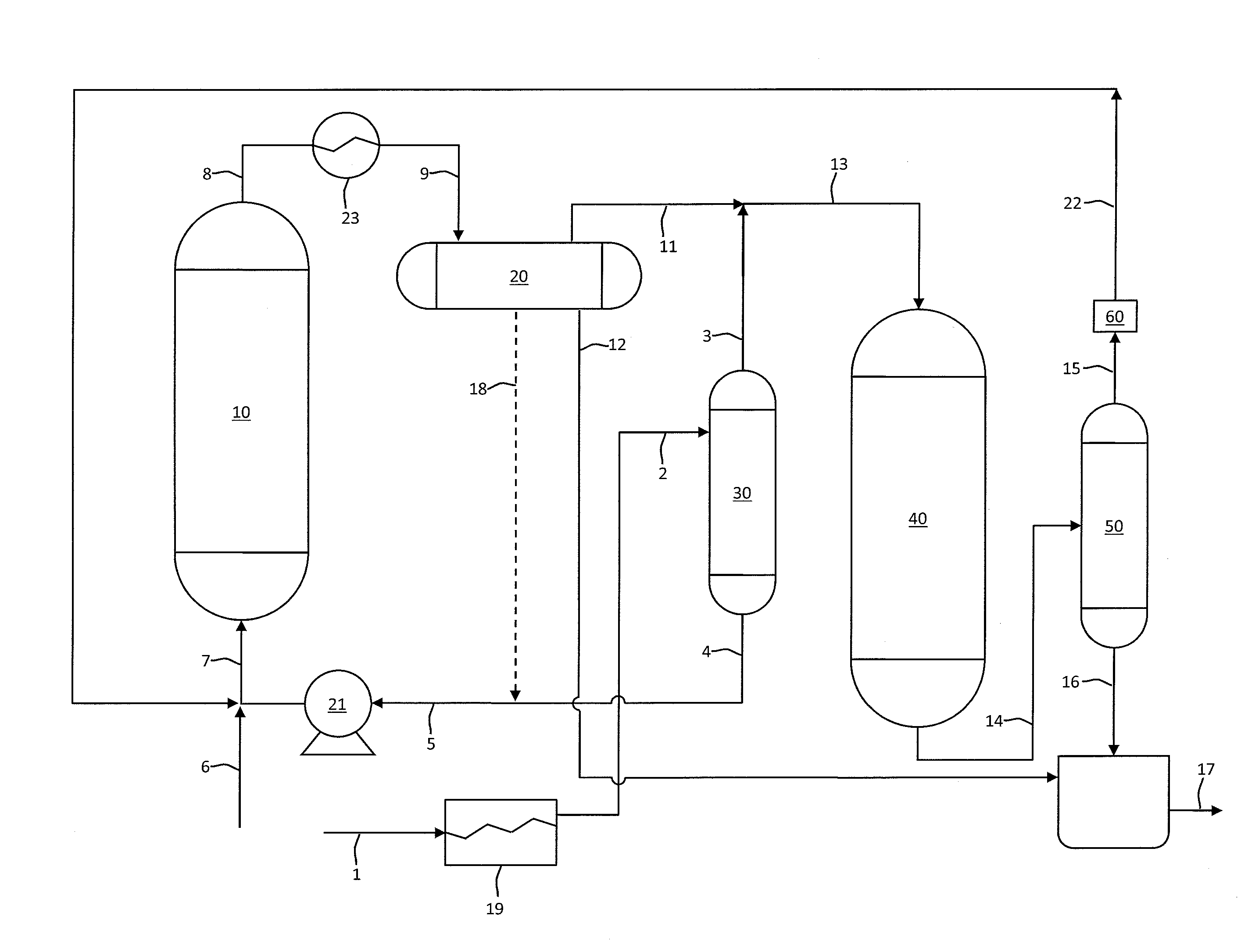

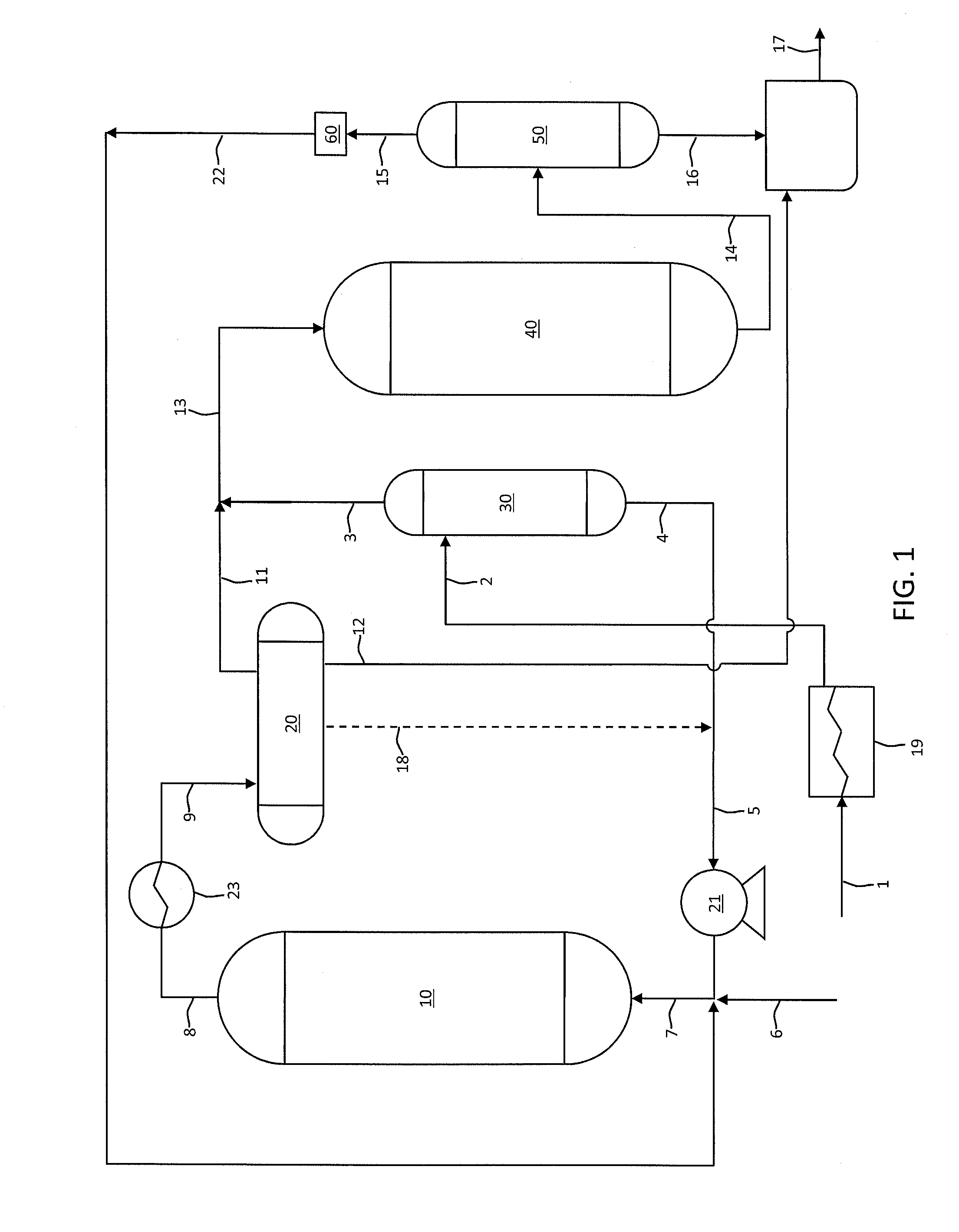

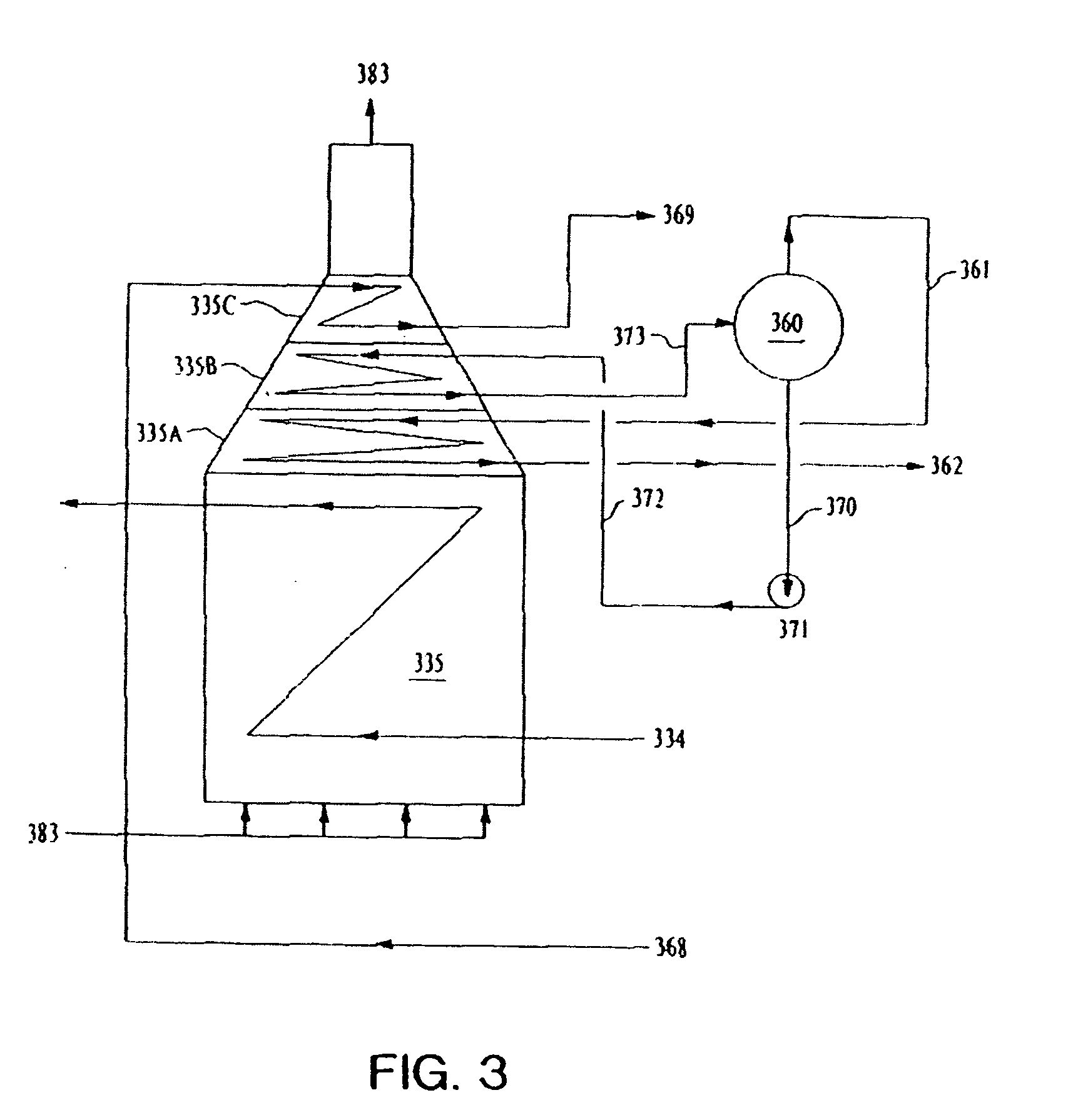

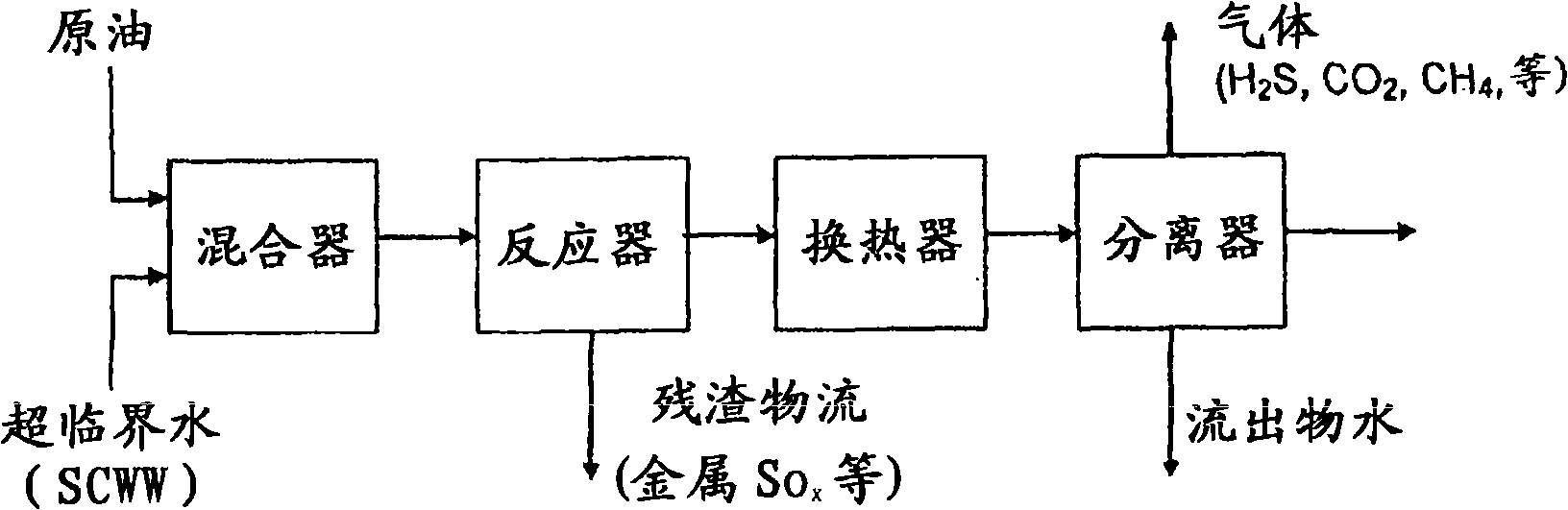

Process and reactor for upgrading heavy hydrocarbon oils

A process using supercritical water to upgrade a heavy hydrocarbon feedstock into an upgraded hydrocarbon product or syncrude with highly desirable properties (low sulfur content, low metals content, lower density (higher API) lower viscosity, lower residuum content, etc.) is described. The process does not require external supply of hydrogen nor does it use externally supplied catalysts. A reactor design to carry out the process is also described,

Owner:CHEVROU USA INC

Process for upgrading heavy hydrocarbon oils

InactiveUS20080099377A1Increase gravityHigh yieldLiquid hydrocarbon mixture productionHydrocarbon oils refiningHydrogenLow density

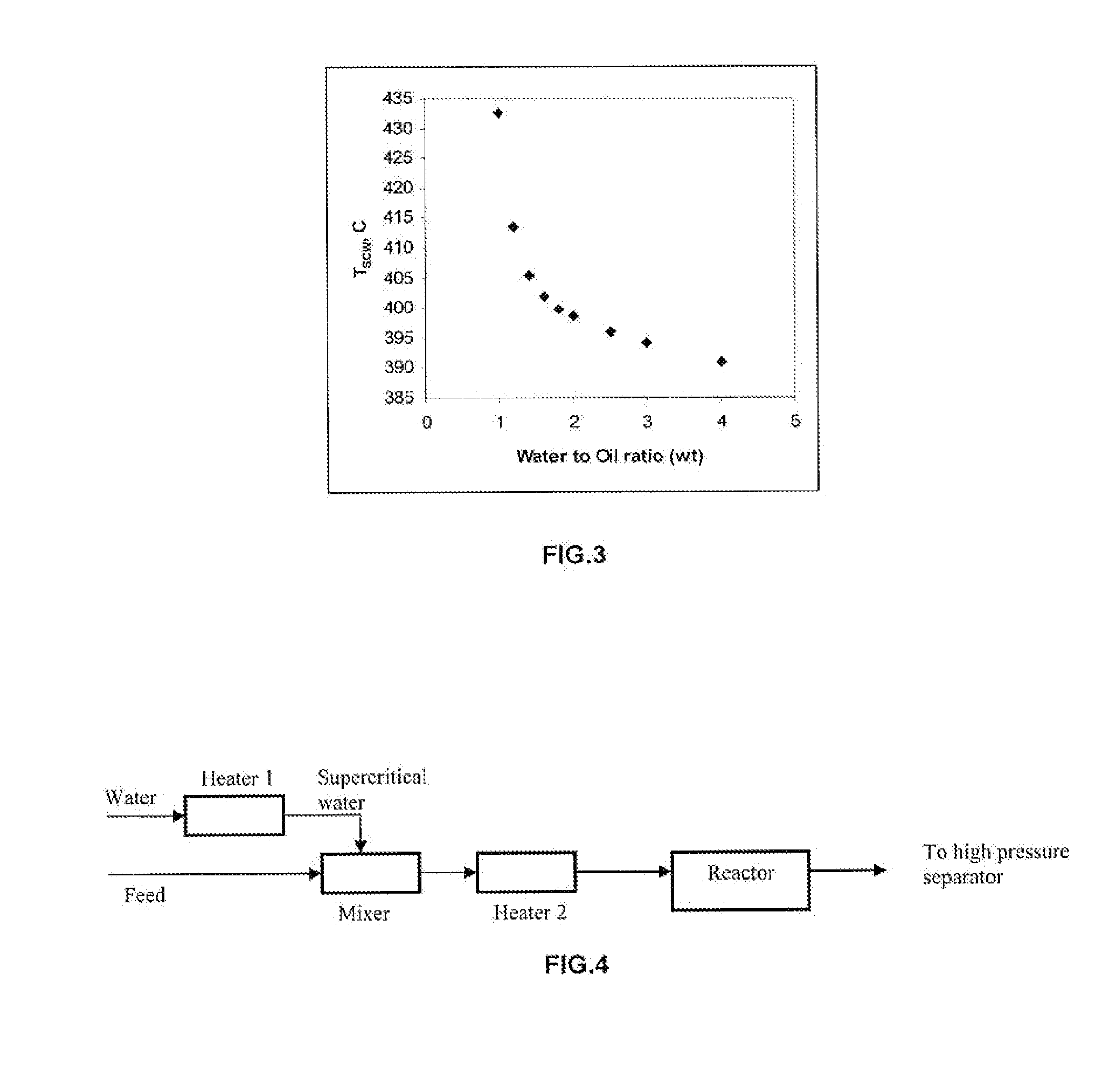

A process using supercritical water to upgrade a heavy hydrocarbon feedstock into an upgraded hydrocarbon product or syncrude with highly desirable properties (low sulfur content, low metals content, lower density (higher API), lower viscosity lower, residuum content, etc.) is disclosed. The process does not require external supply of hydrogen nor does it use externally supplied catalysts. Improved methods of mixing the reactants are also disclosed.

Owner:CHEVROU USA INC

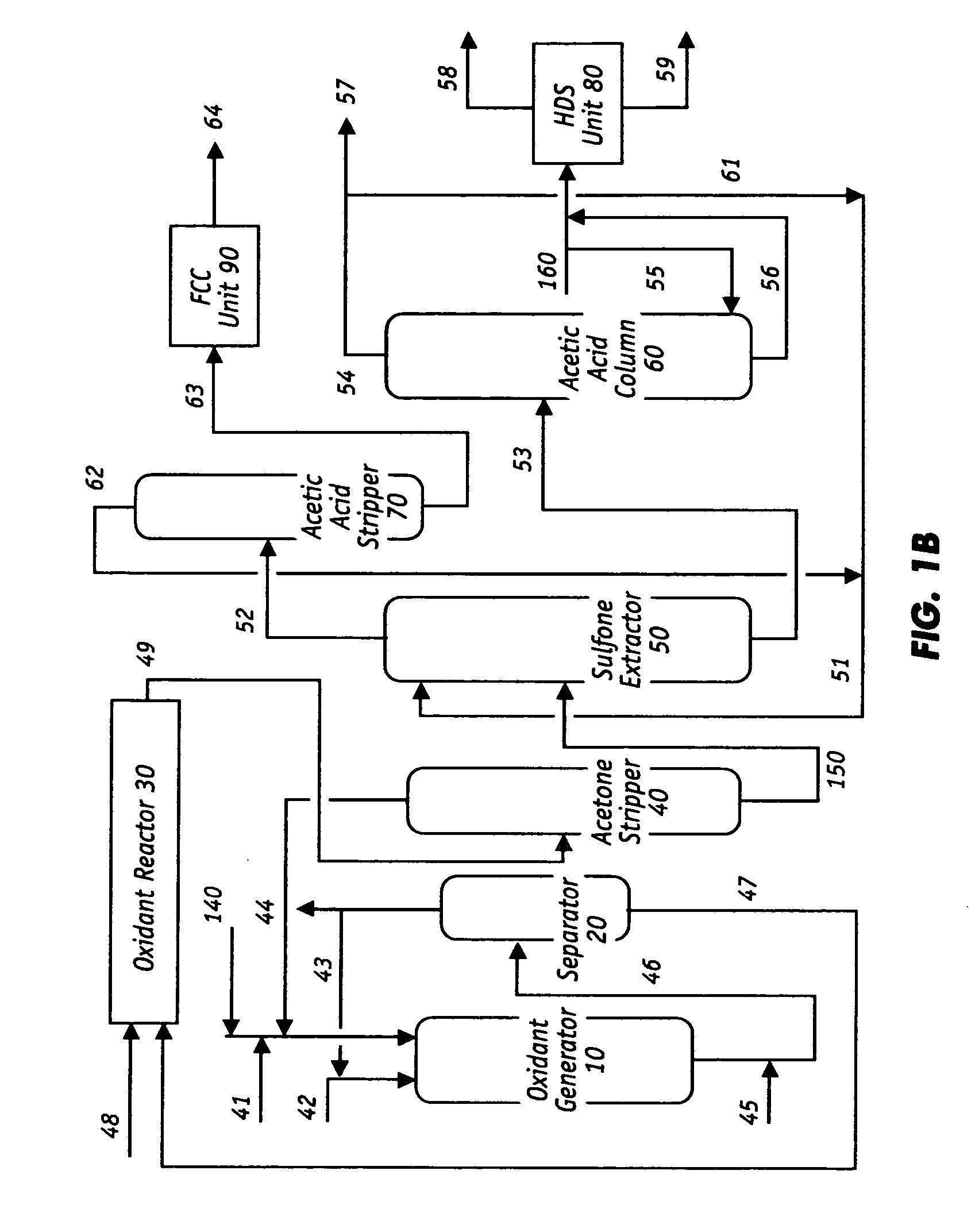

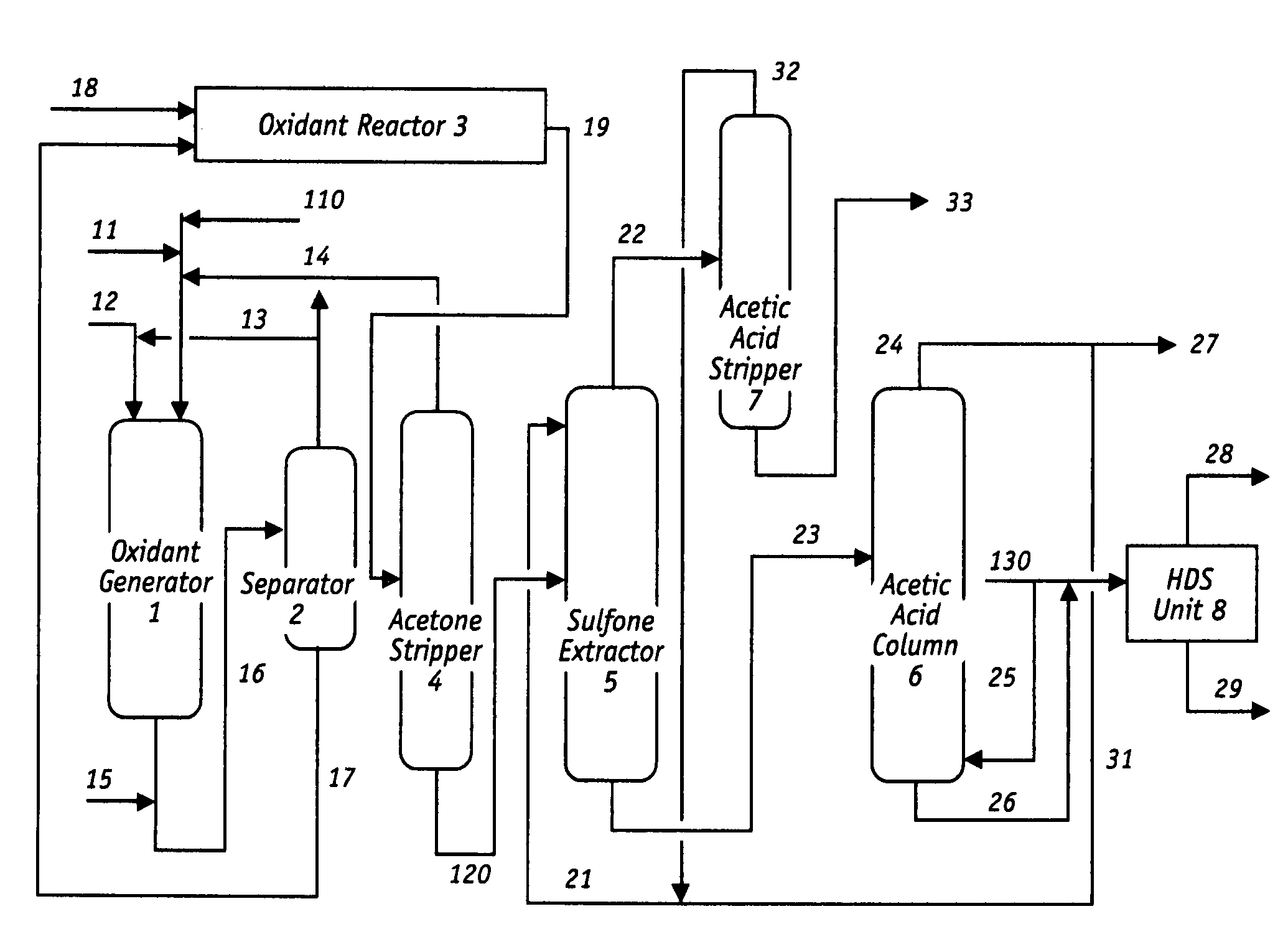

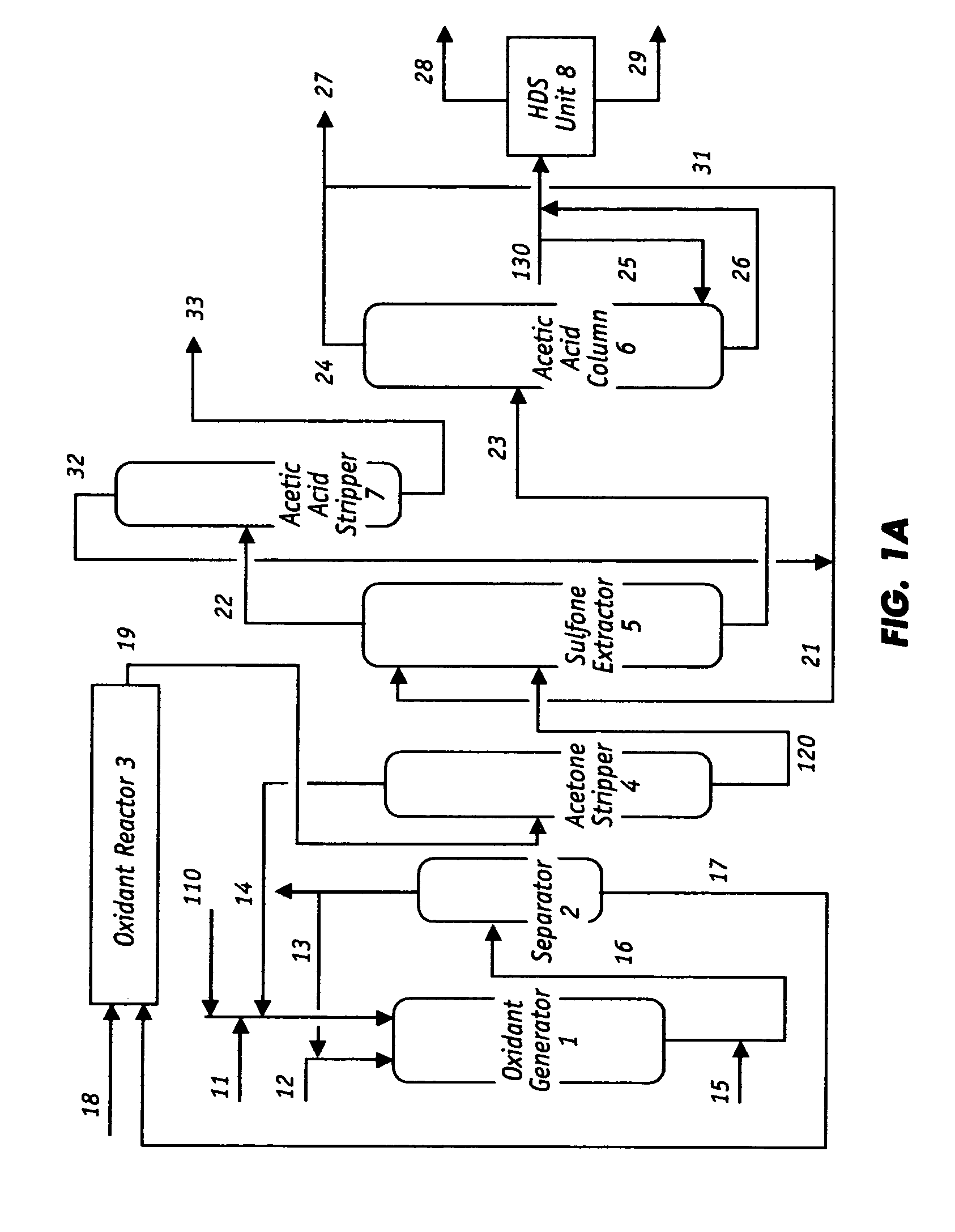

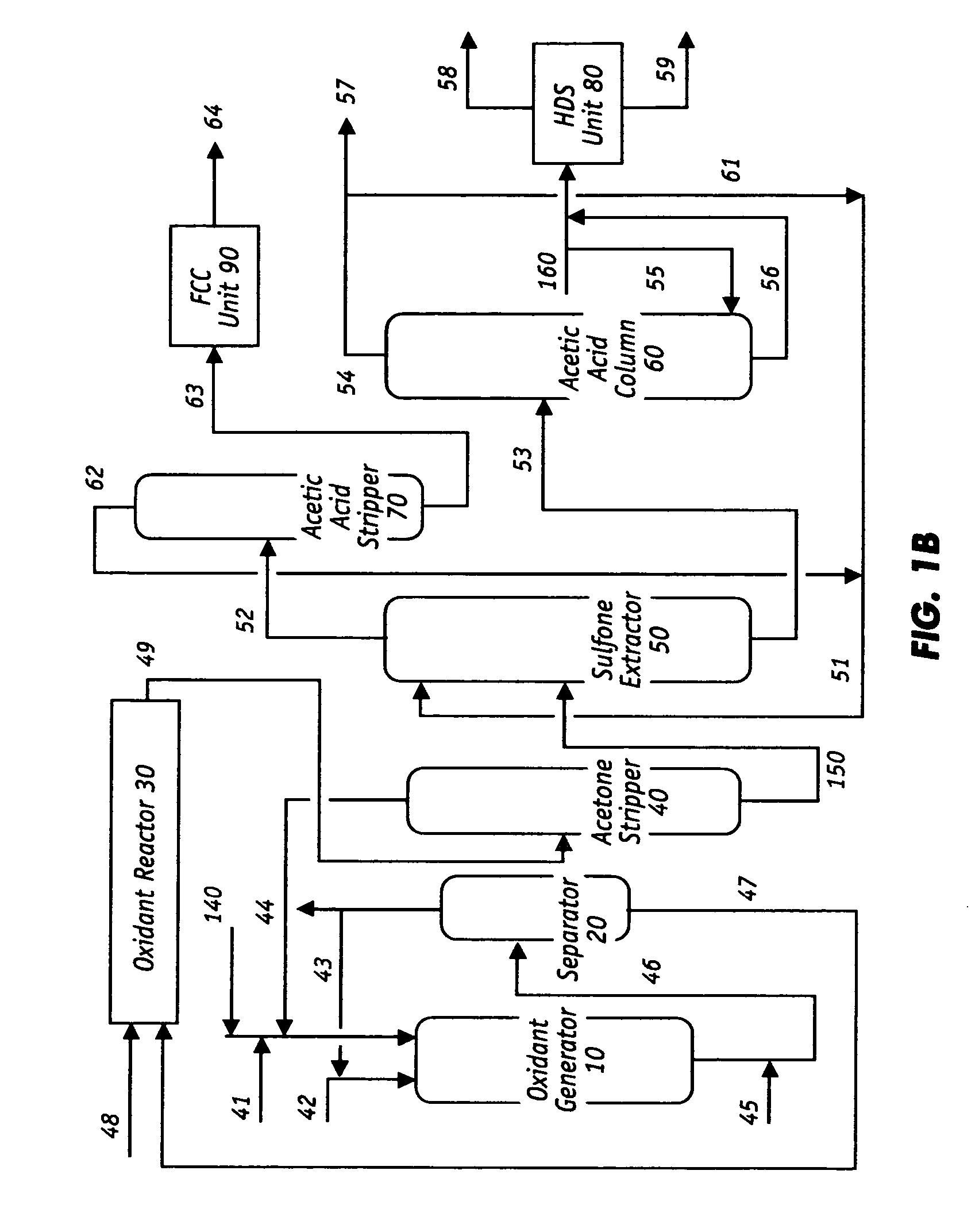

Oxidative desulfurization and denitrogenation of petroleum oils

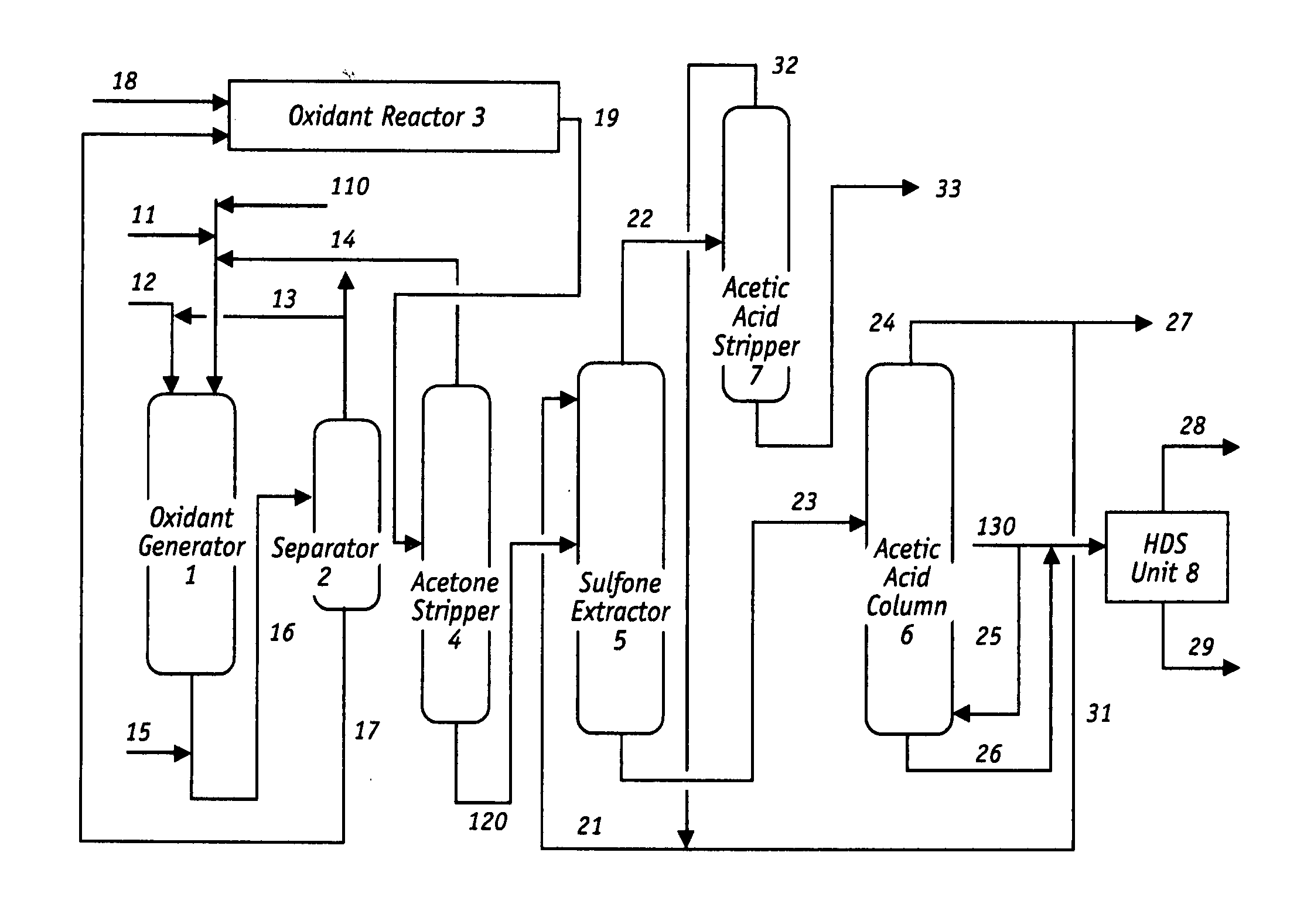

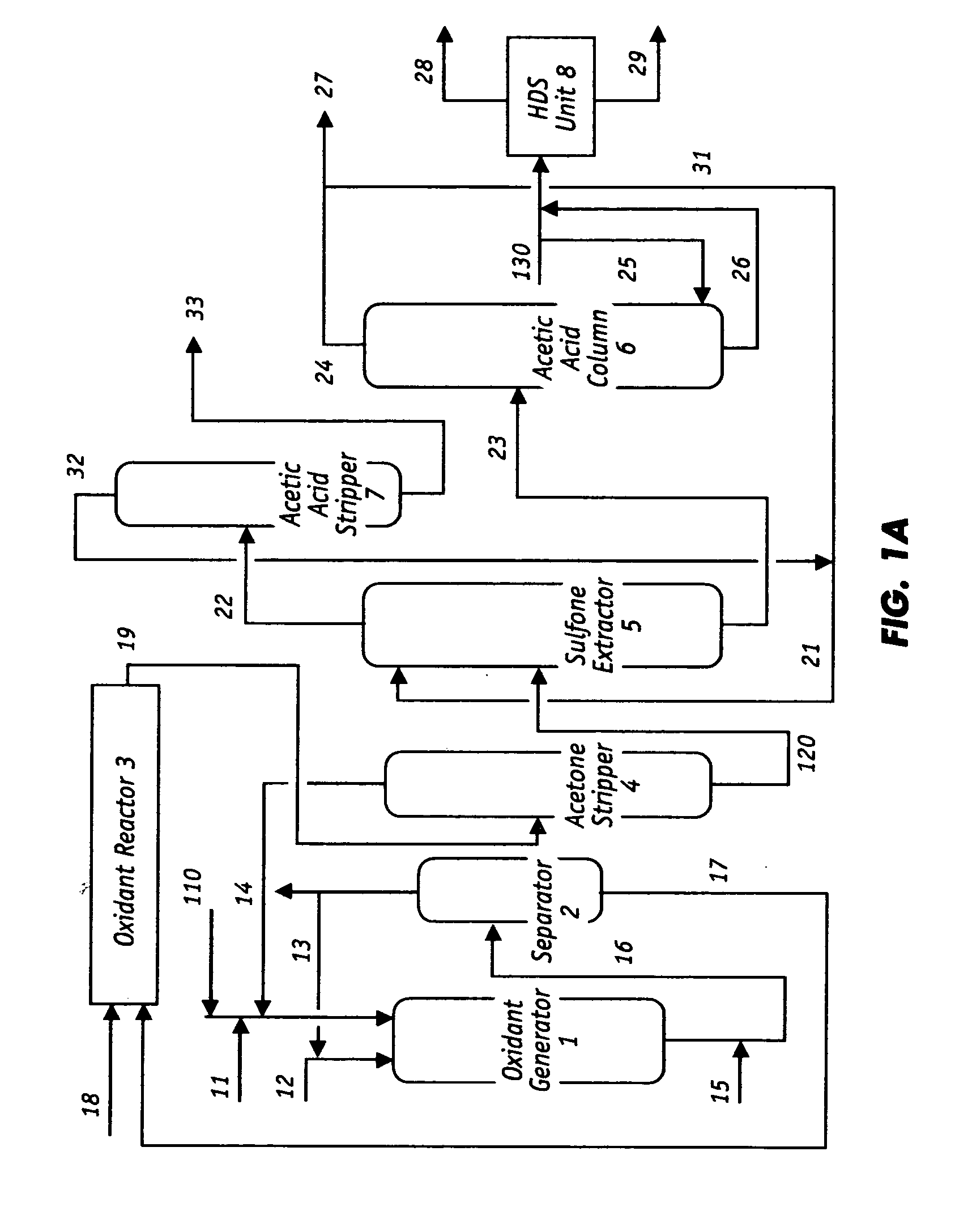

InactiveUS20070102323A1Reduce the temperatureShort stayOrganic chemistryRefining with oxygen compoundsHydrocotyle bowlesioidesSolvent

An improved oxidative process that employ a robust, non-aqueous, and oil-soluble organic peroxide oxidant for effective desulfurization and denitrogenation of hydrocarbons including petroleum fuels, hydrotreated vacuum gas oil (VGO), non-hydrotreated VGO, petroleum crude oil, synthetic crude oil from oil sand, and residual oil. Even at low concentrations and without the assistance of catalysts, the non-aqueous organic peroxide oxidant is extremely active and fast in oxidizing the sulfur and nitrogen compounds in the hydrocarbon feedstocks. Furthermore, the process generates a valuable organic acid by-product that is also used internally as the extractive solvent for effective removal of the oxidized sulfur and nitrogen from the hydrocarbons without the need of a final adsorption step. Novel process steps are also disclosed to substantially prevent yield loss in the oxidative process.

Owner:CPC CORPORATION

Process for cracking synthetic crude oil-containing feedstock

ActiveCN101583697ATreatment with hydrotreatment processesHydrocarbon preparationLiquid hydrocarbonsChemistry

A process for steam cracking liquid hydrocarbon feedstocks containing synthetic crude oil comprises i) hydroprocessing a wide boiling range aliquot containing a) normally liquid hydrocarbon portion substantially free of resids and b) thermally cracked hydrocarbon liquid, boiling in a range from 600 DEG F to 1050 DEG F, to provide a synthetic crude oil substantially free of resids; ii) adding to the synthetic crude oil a normally liquid hydrocarbon component boiling in a range from 100 DEG F to 1050 DEG F; and iii) cracking the mixture resulting from ii) in a cracker furnace comprising a radiantcoil outlet to provide a cracked effluent, wherein the cracking is carried out under conditions sufficient to effect a radiant coil outlet temperature which is greater than the optimum radiant coil outlet temperature for cracking the synthetic crude oil separately. A method for upgrading synthetic crude for use in cracking is also provided, as well as a feedstock for cracking.

Owner:EXXONMOBIL CHEM PAT INC

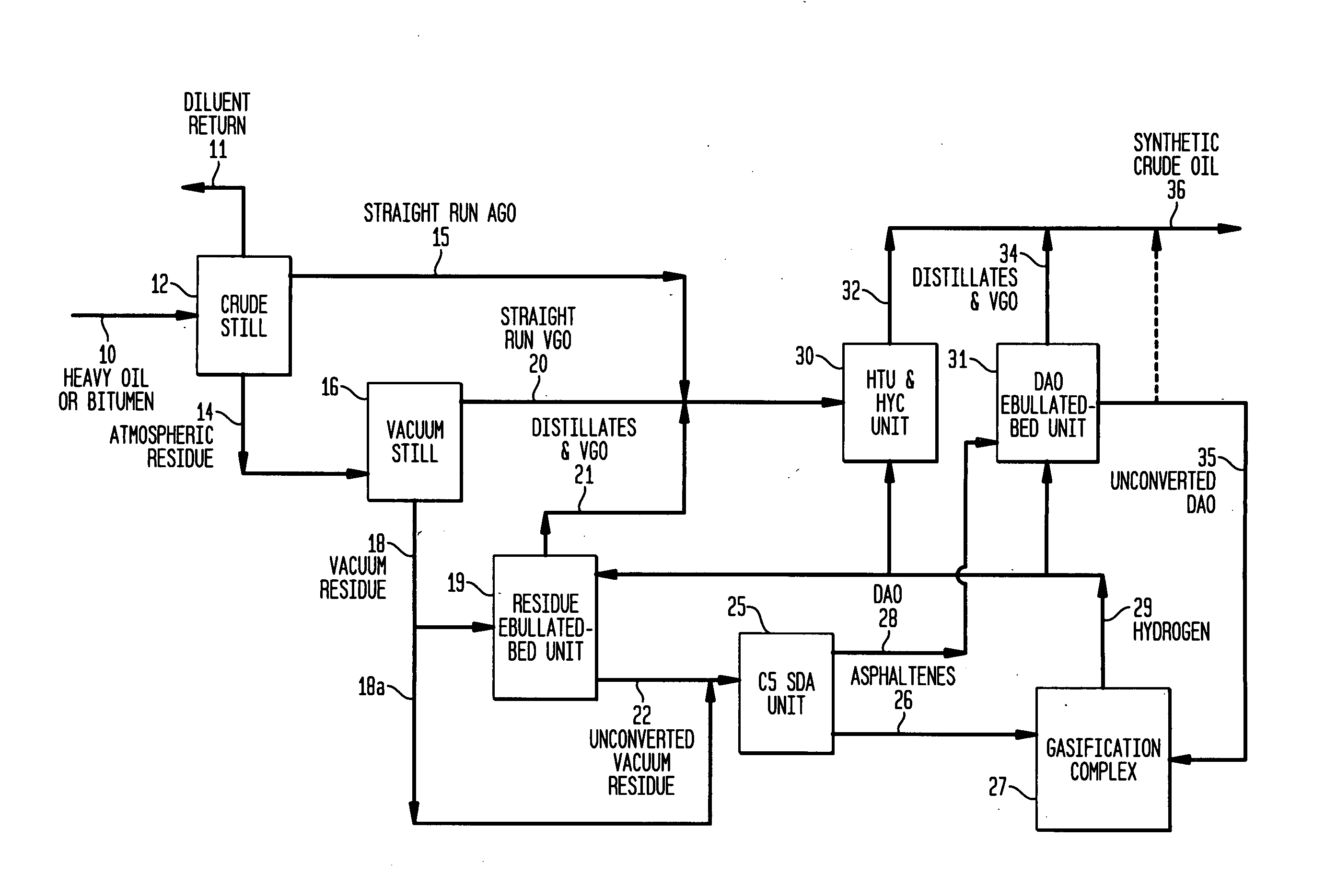

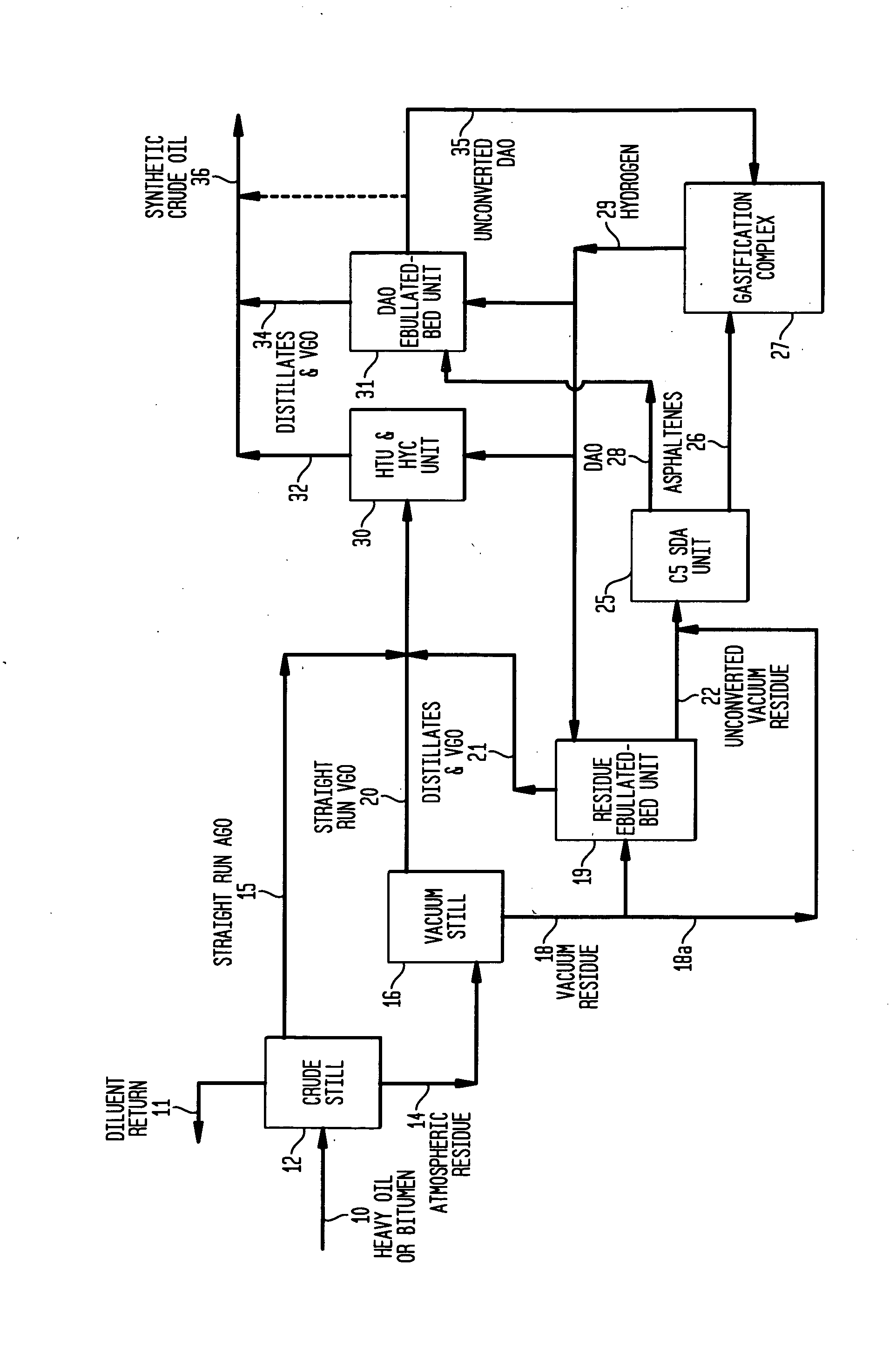

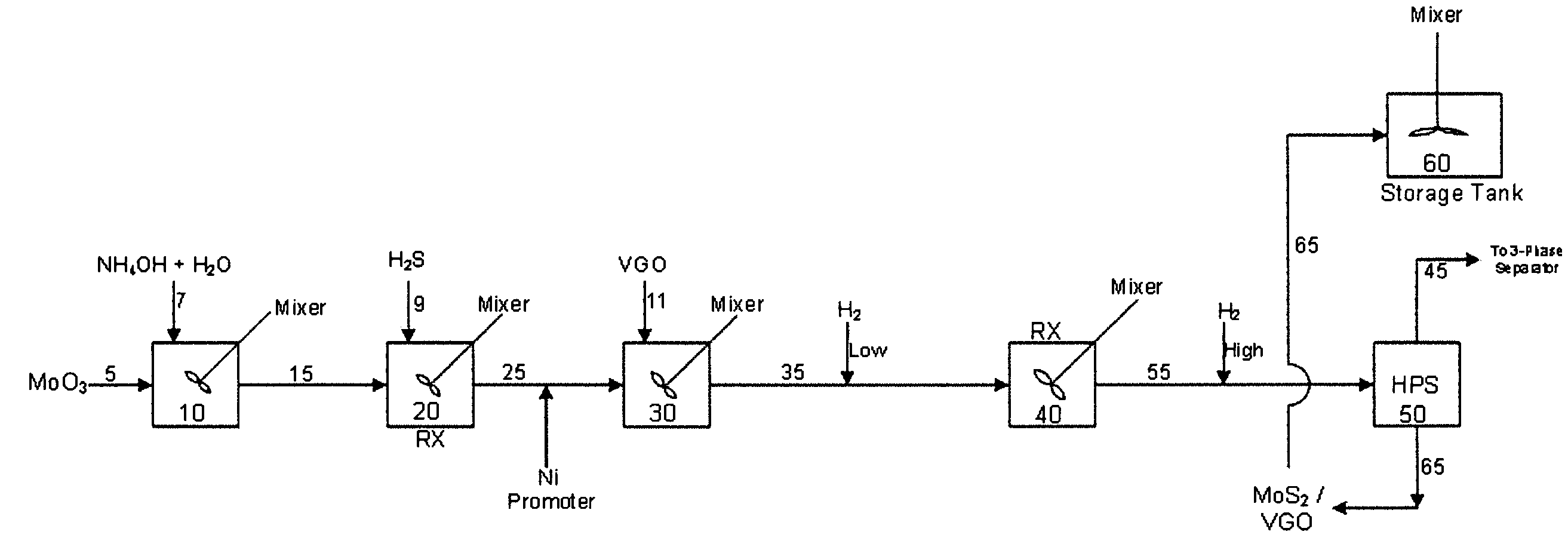

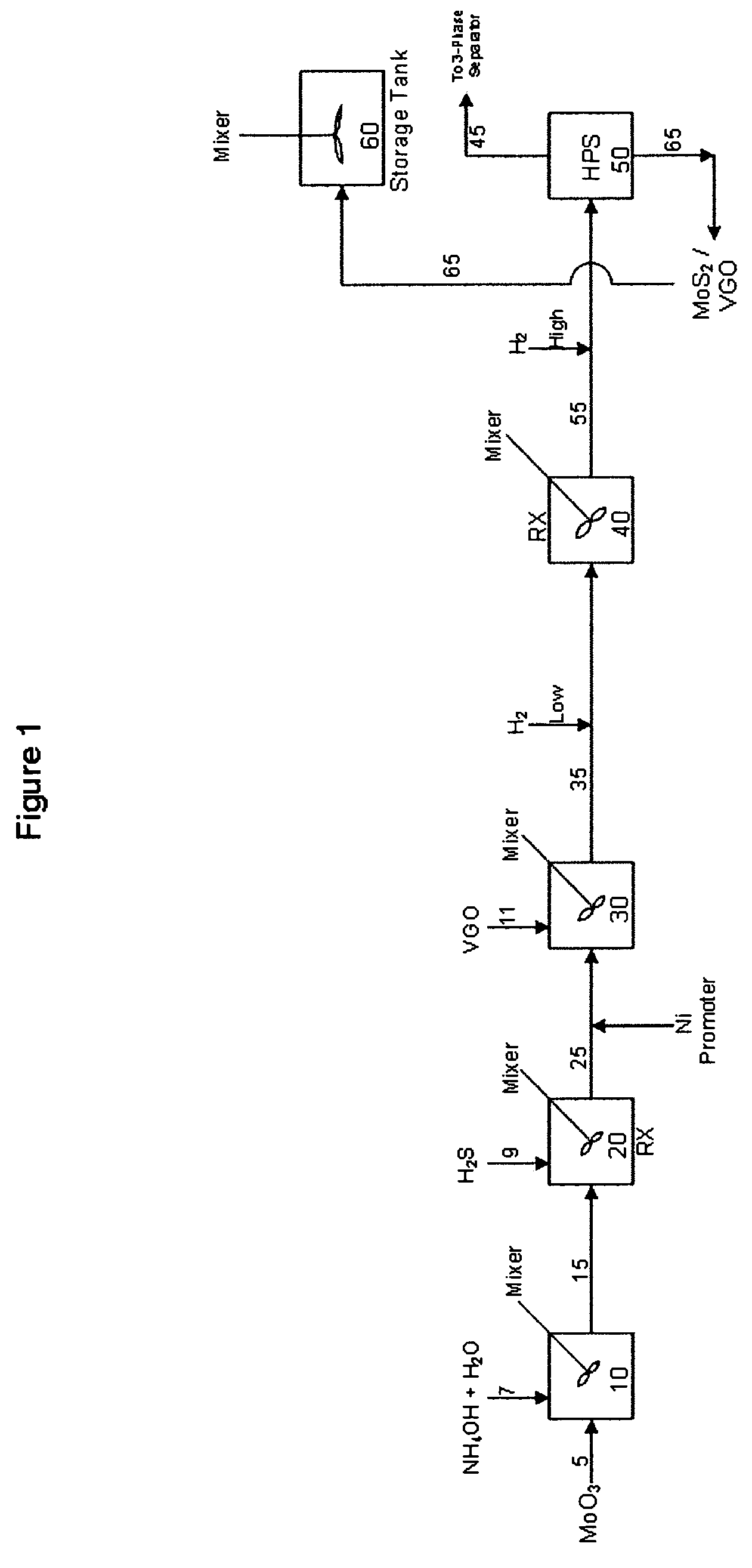

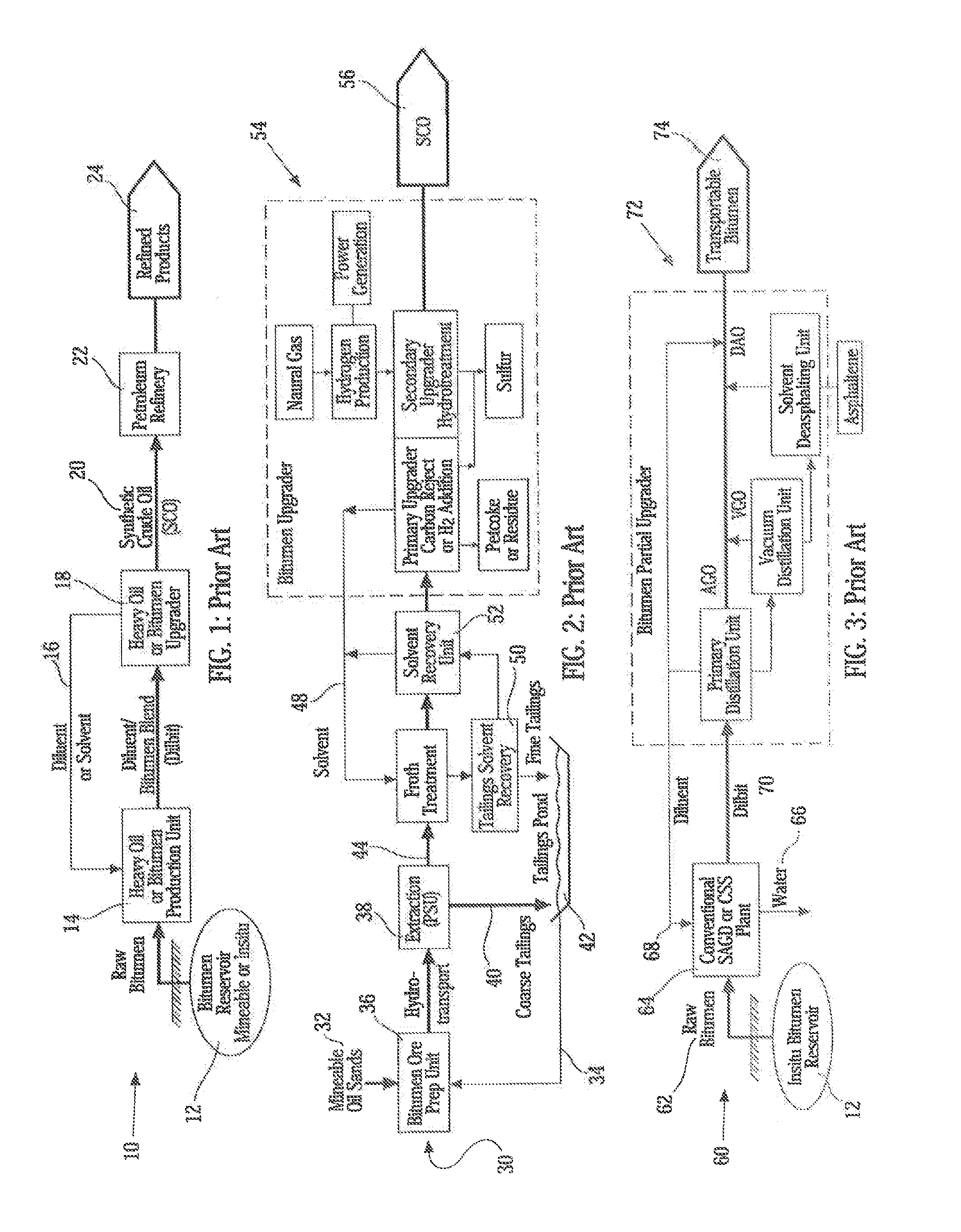

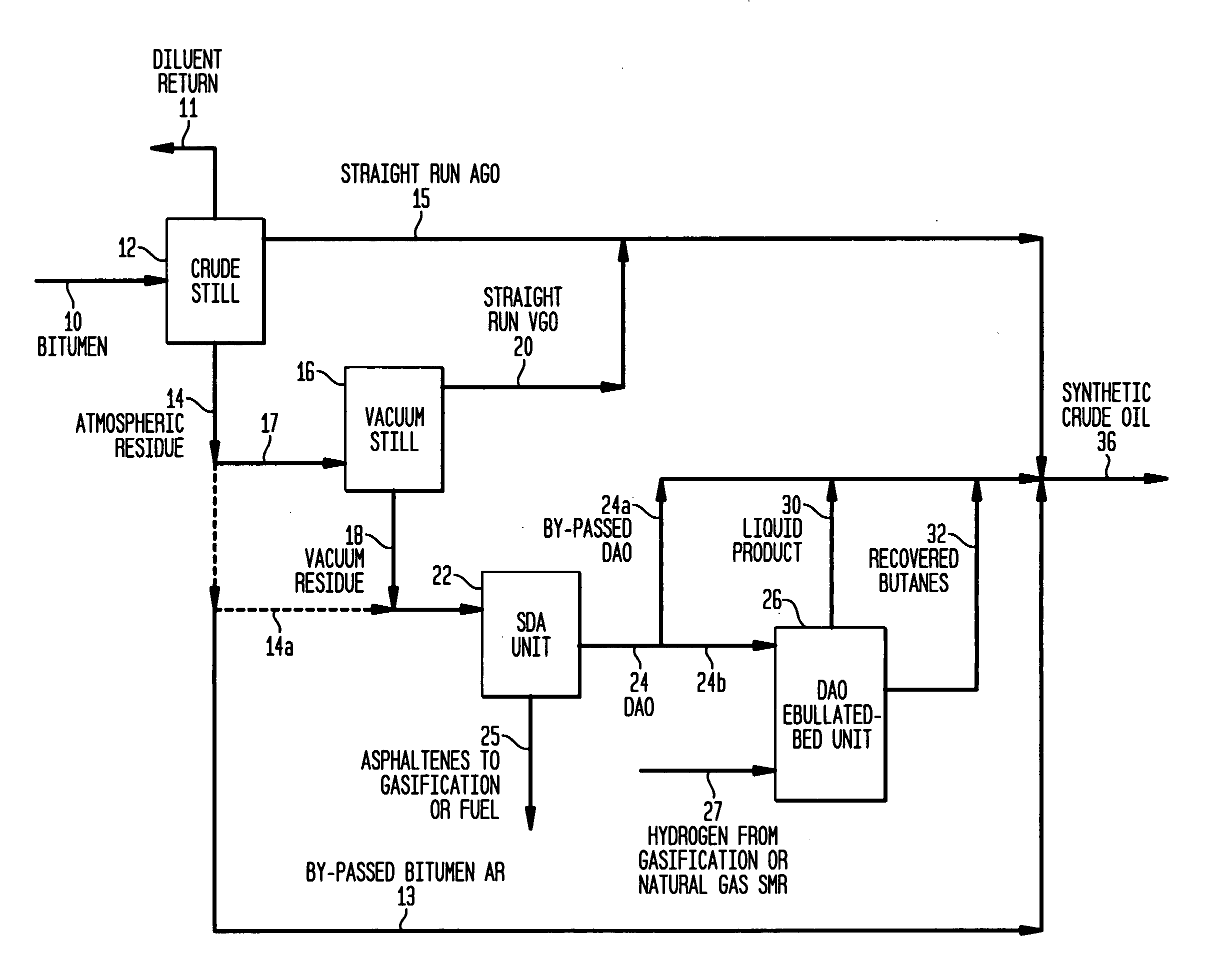

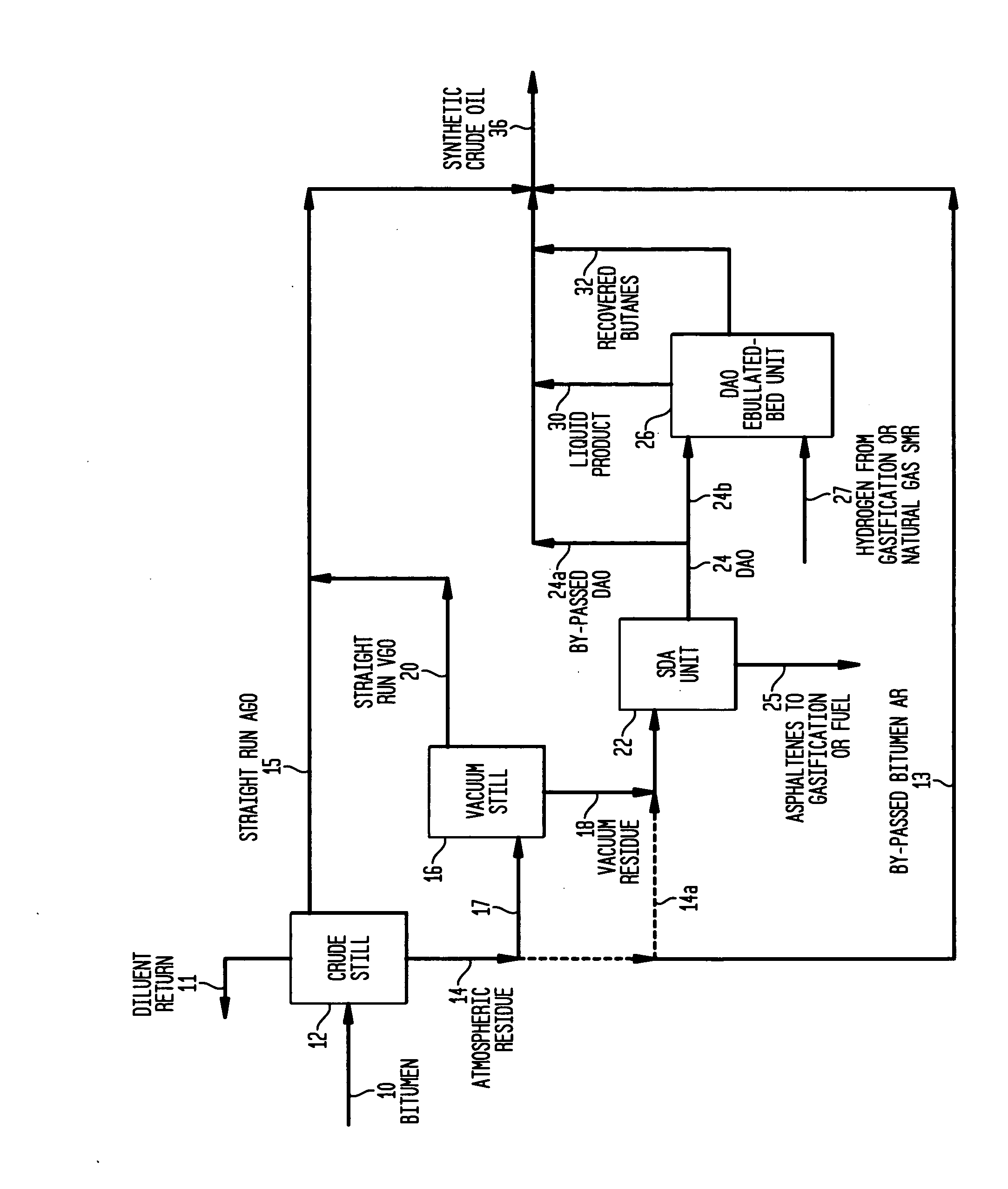

Innovative heavy crude conversion/upgrading process configuration

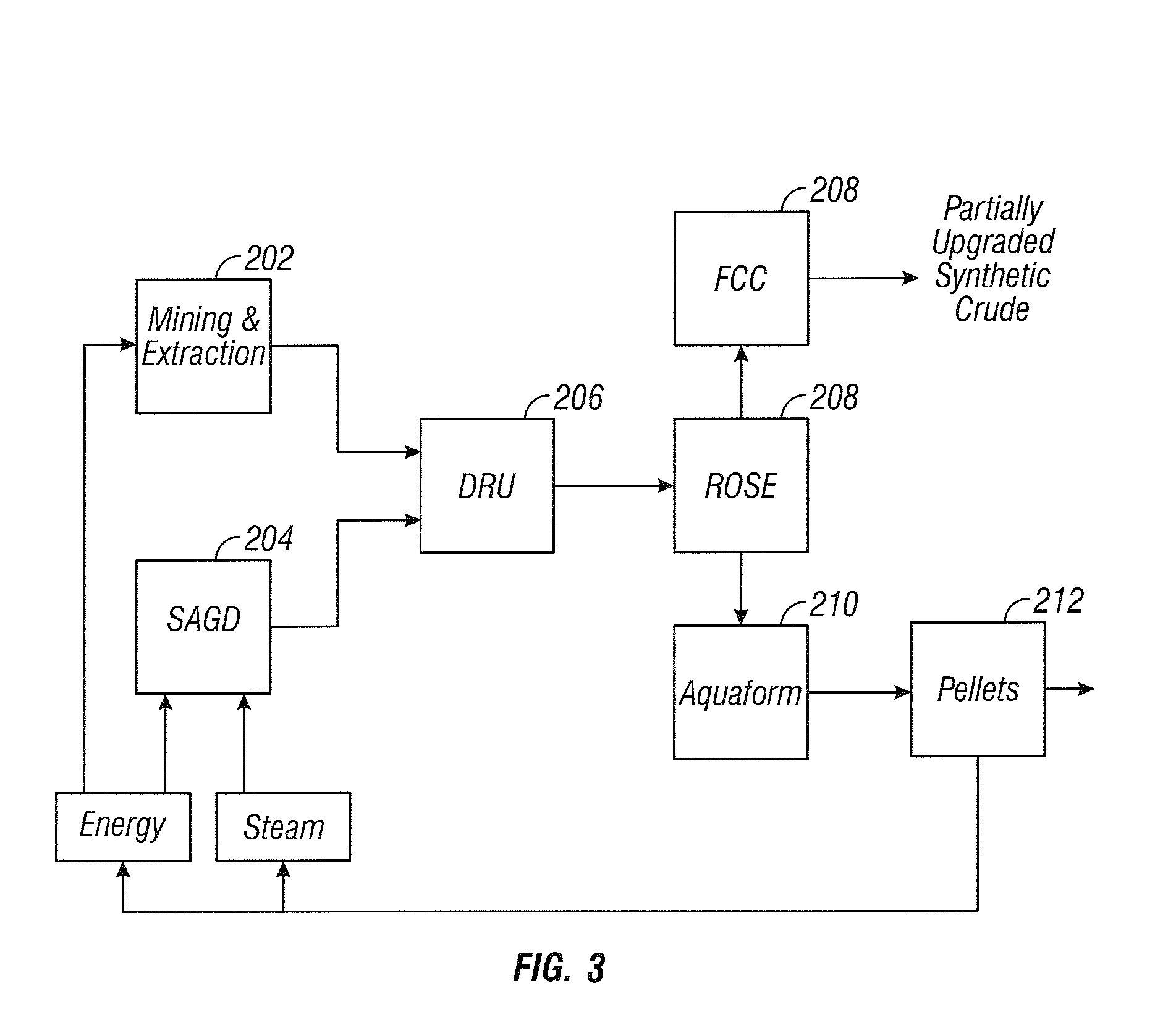

InactiveUS20110198265A1Maximizing liquid SCO yieldYield maximizationHydrocarbon oil crackingTreatment with hydrotreatment processesFuel oilProcess configuration

The described invention discloses an innovative solvent deasphalter and hydroconversion-processing configuration for converting bitumen or heavy oils to produce a transportable synthetic crude oil (SCO). The innovative processing scheme disclosed herein maximizes the synthetic crude oil yield at a minimal investment compared to currently known methods.

Owner:INST FR DU PETROLE

Process for upgrading coal pyrolysis oils

ActiveUS20100147743A1Reduce and eliminate needMinimize feedstock foulingLiquid hydrocarbon mixture productionHydrocarbon oil crackingOxygen contaminationPtru catalyst

This invention utilizes a novel method and set of operating conditions to efficiently and economically process a potentially very fouling hydrocarbon feedstock. A multi-stage catalytic process for the upgrading of coal pyrolysis oils is developed. Coal Pyrolysis Oils are highly aromatic, olefinic, unstable, contain objectionable sulfur, nitrogen, and oxygen contaminants, and,may contain coal solids which will plug fixed-bed reactors. The pyrolysis oil is fed with hydrogen to a multi-stage ebullated-bed hydrotreater and hydrocracker containing a hydrogenation or hydrocracking catalyst to first stabilize the feed at low temperature and is then fed to downstream reactor(s) at higher temperatures to further treat and hydrocrack the pyrolysis oils to a more valuable syncrude or to finished distillate products. The relatively high heat of reaction is used to provide the energy necessary to increase the temperature of the subsequent stage thus eliminating the need for additional external heat input. A refined heavy oil product stream is recycled to the fresh feed to minimize feedstock fouling of heat exchangers and feed heaters.

Owner:MACARTHUR JAMES B +2

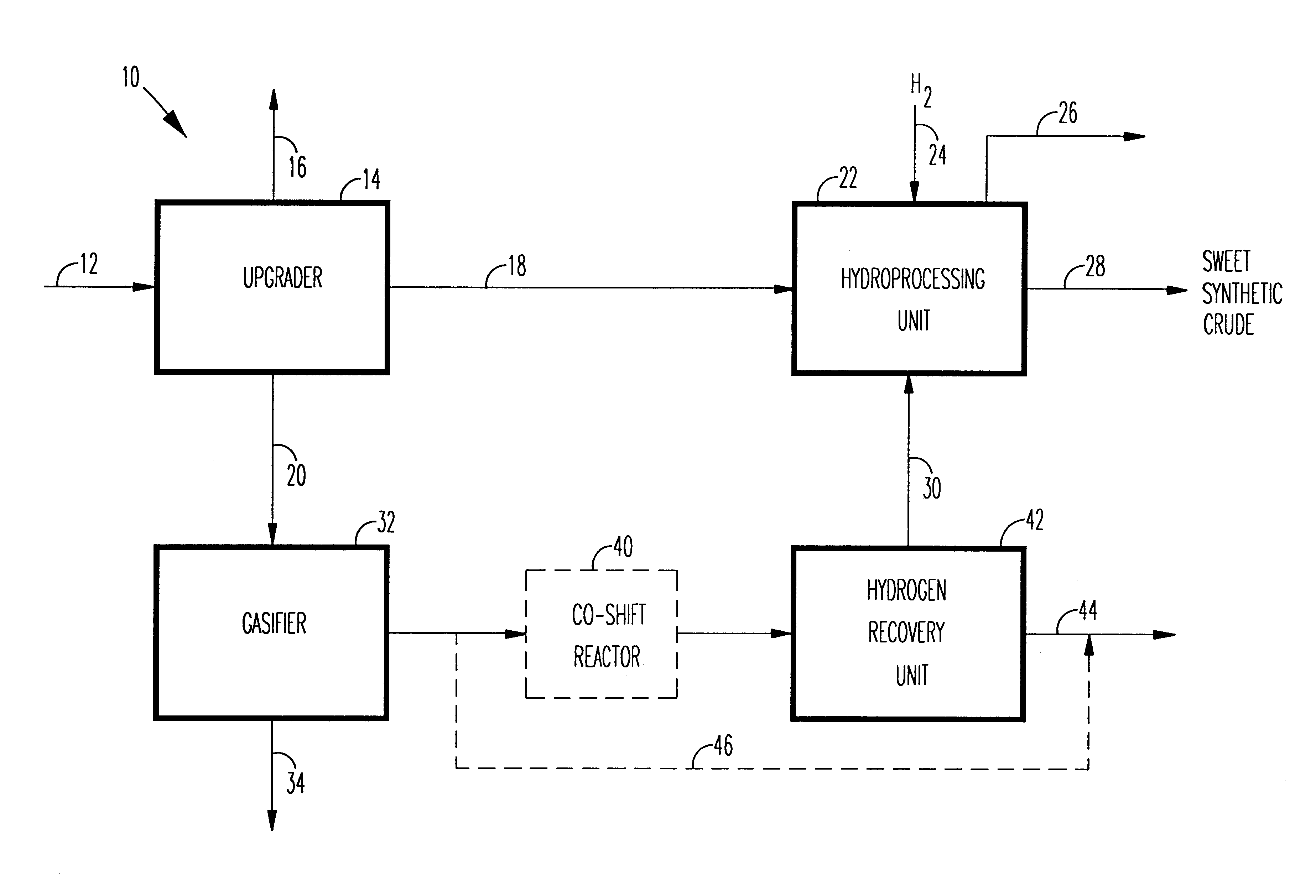

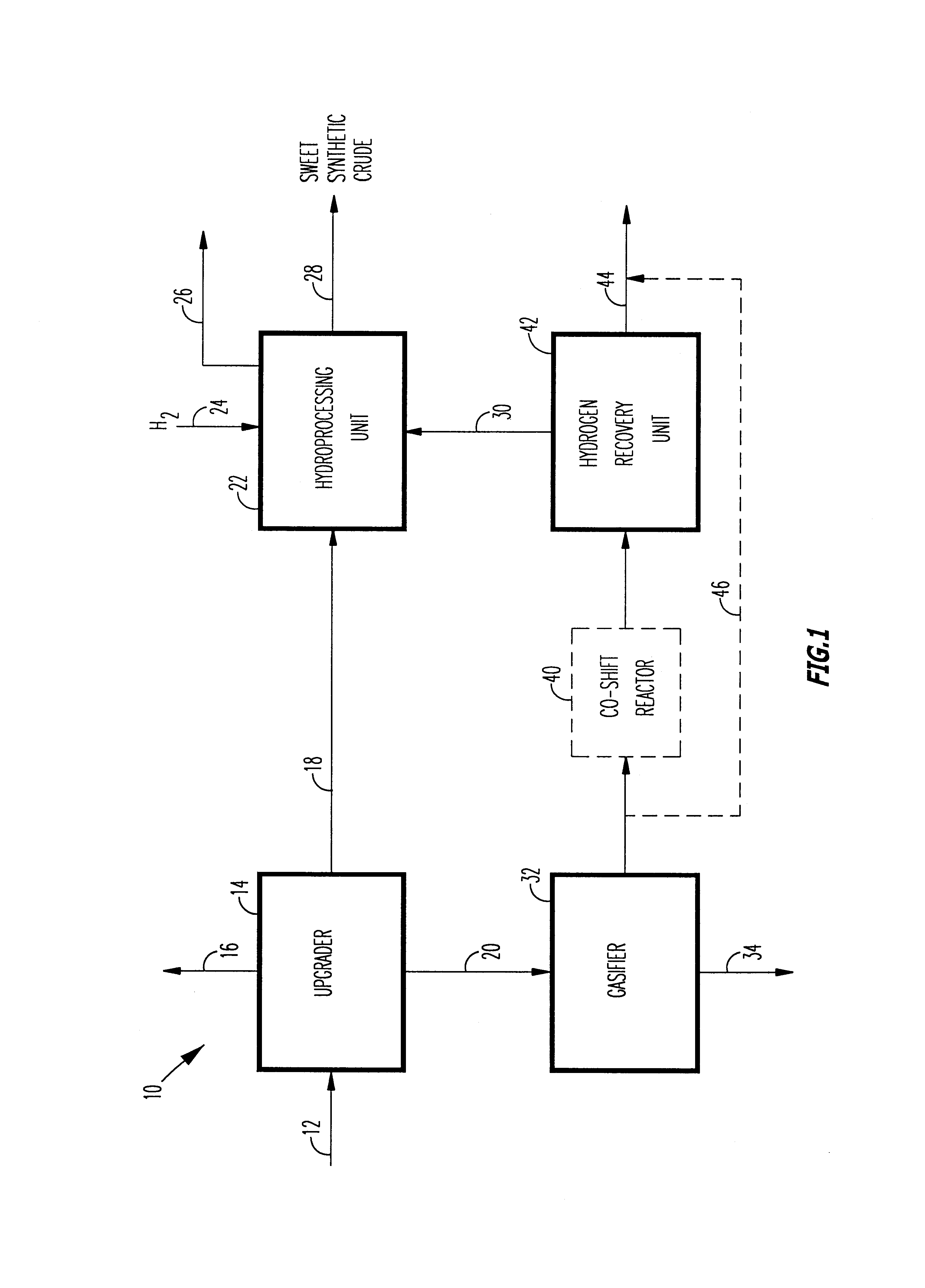

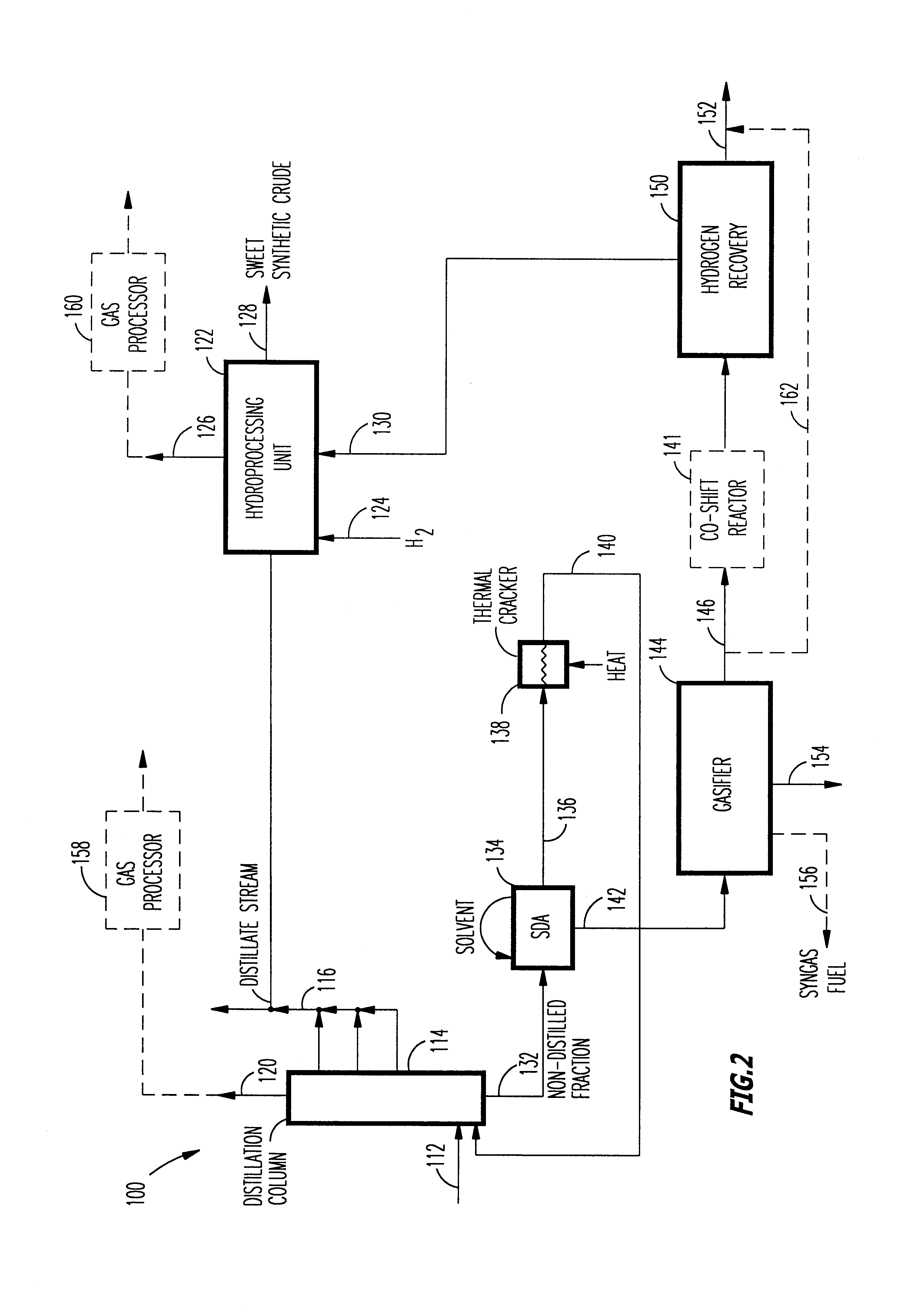

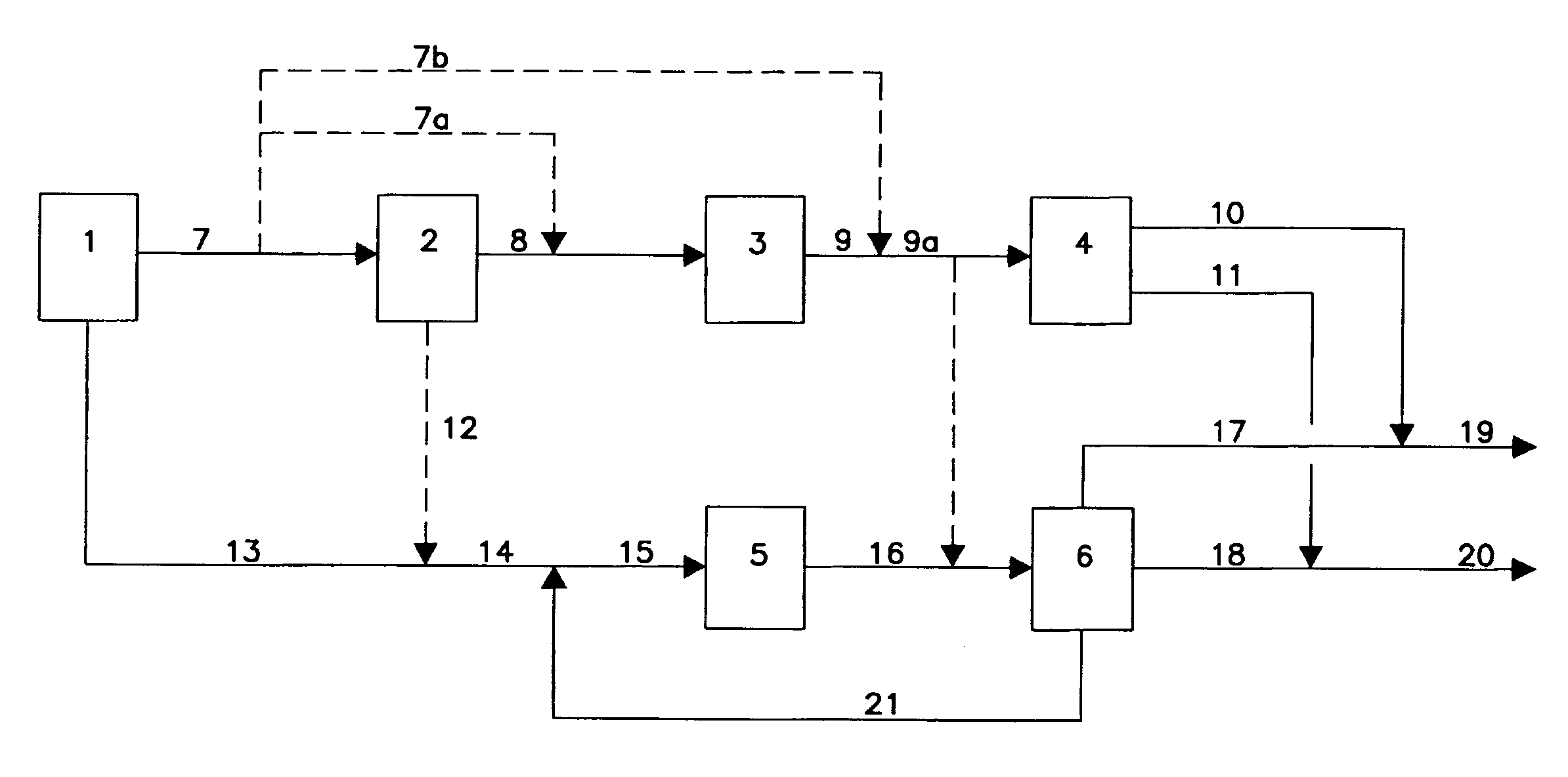

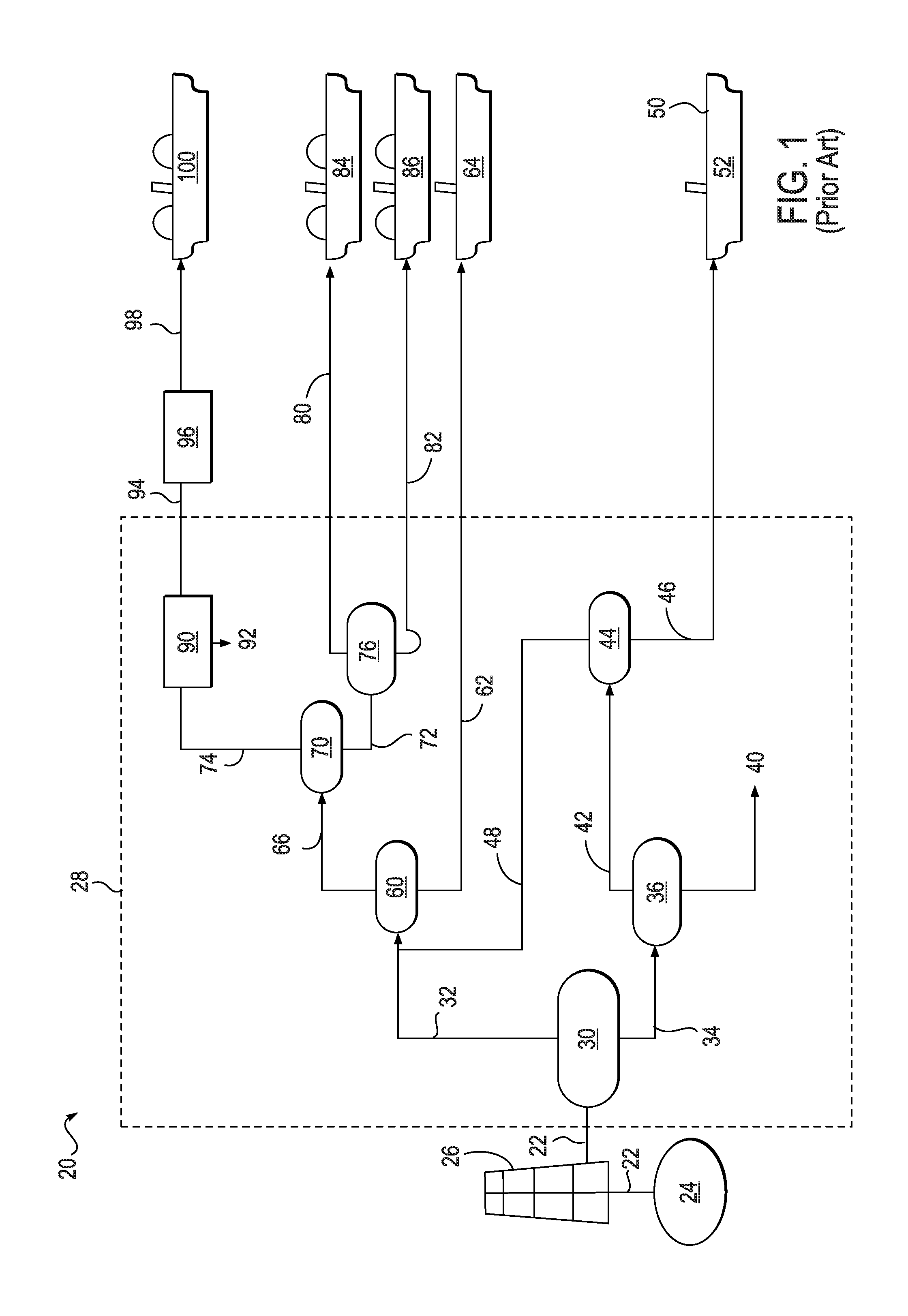

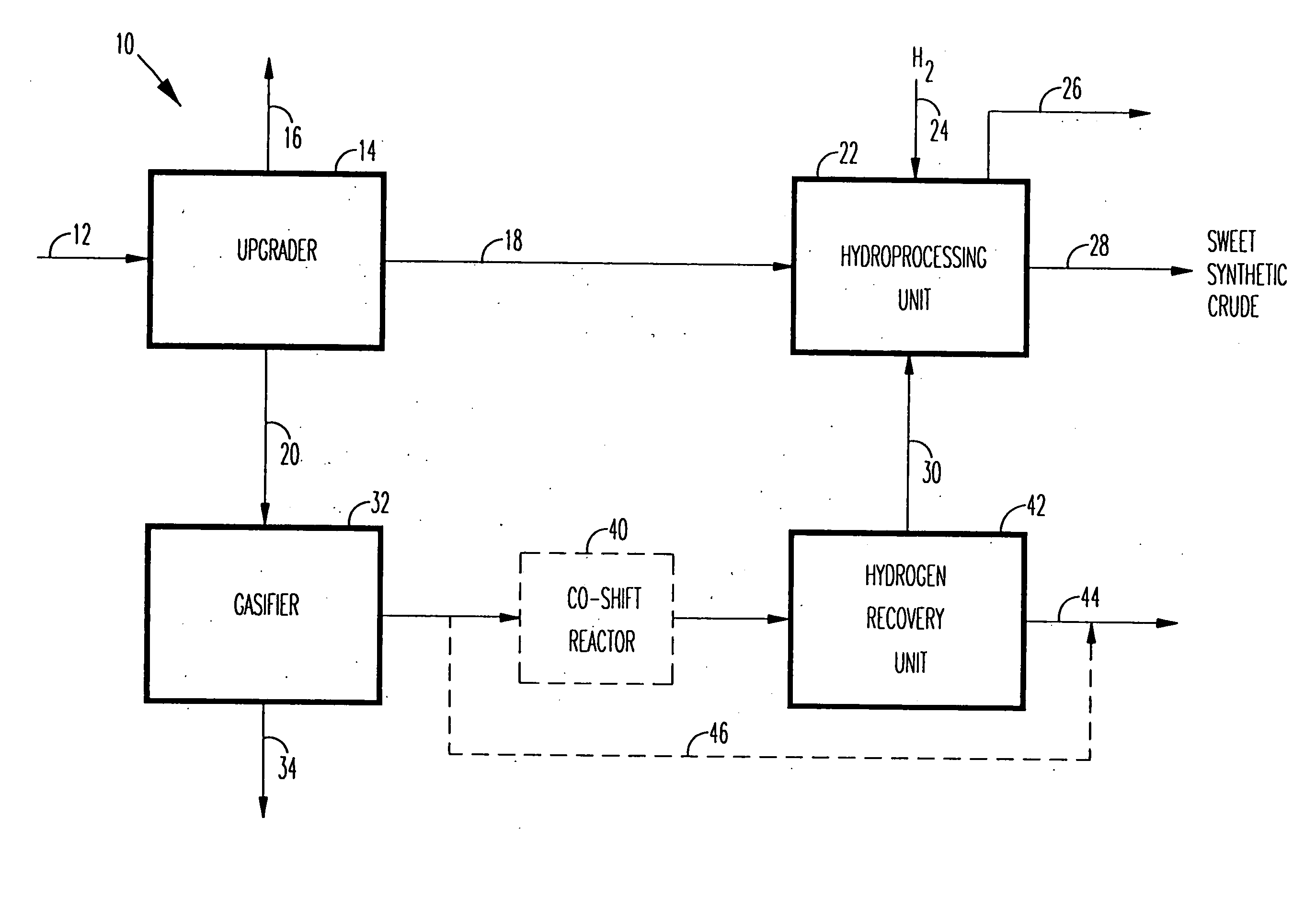

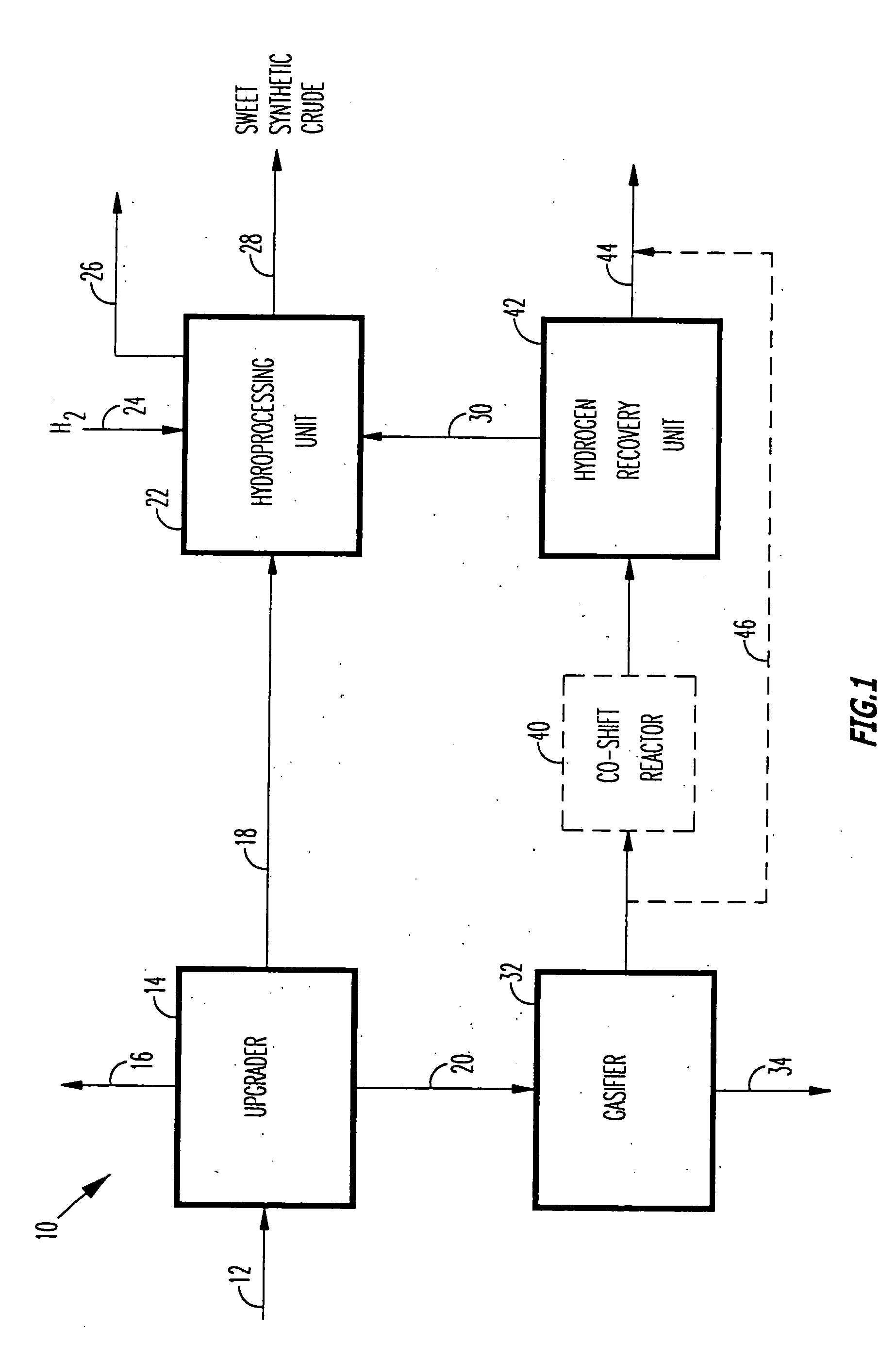

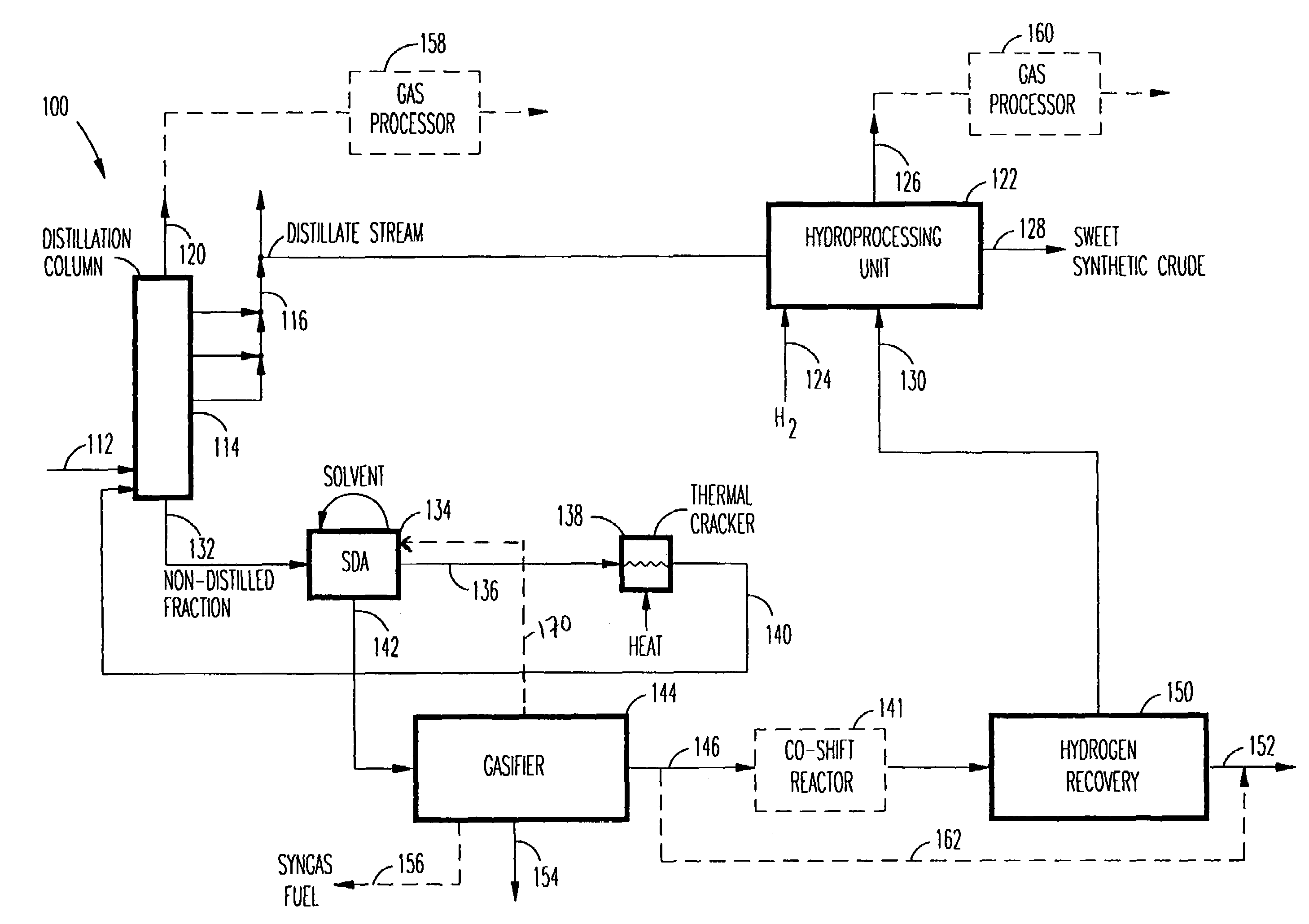

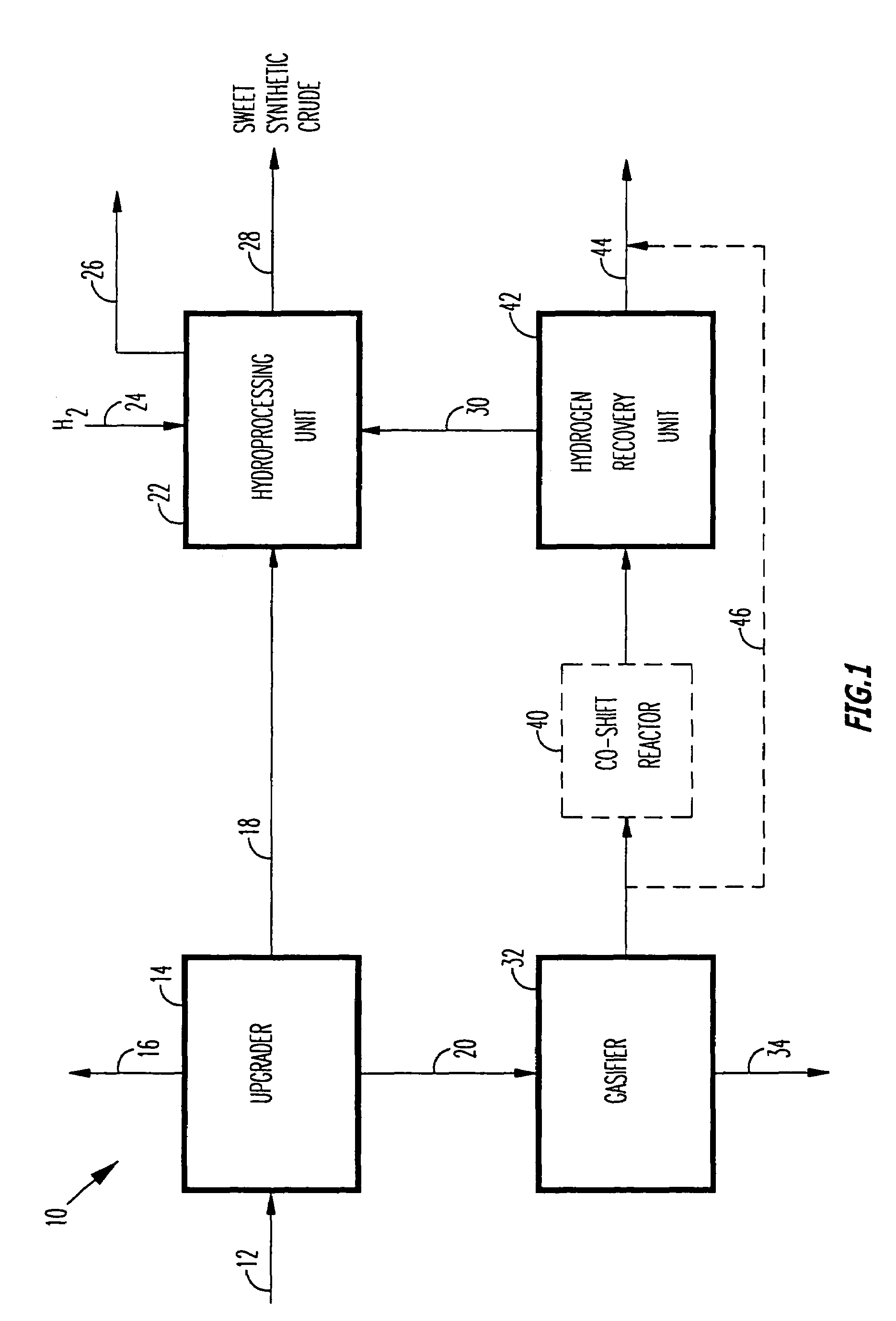

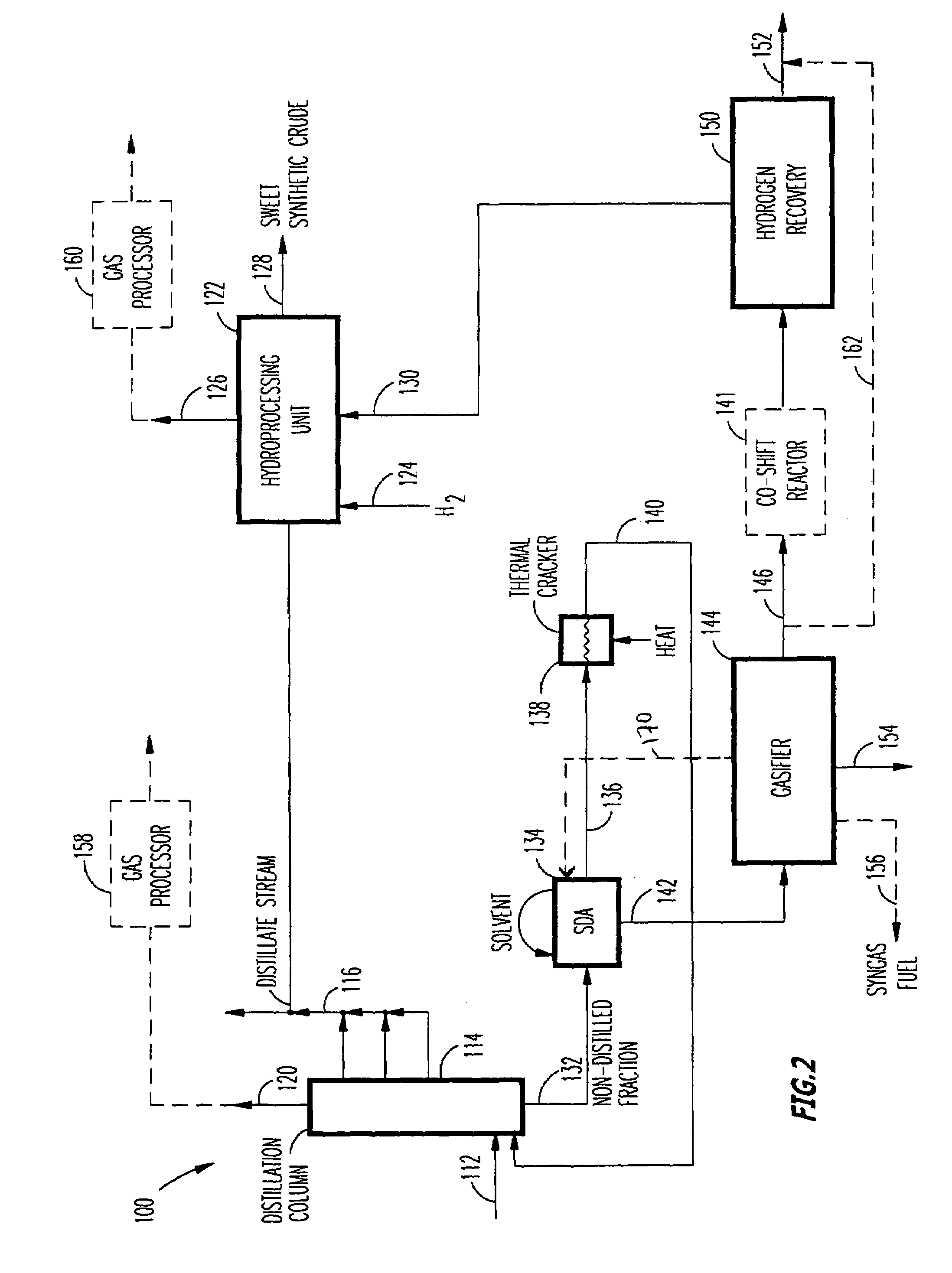

Method of and apparatus for upgrading and gasifying heavy hydrocarbon feeds

A novel apparatus for producing sweet synthetic crude from a heavy hydrocarbon feed comprising: an upgrader for receiving said heavy hydrocarbon feed and producing a distillate fraction including sour products, and high-carbon content by-products; a gasifier for receiving the high-carbon content by-products and producing synthetic fuel gas and sour by-products; a hydroprocessing unit for receiving the sour by-products and hydrogen gas, thereby producing gas and sweet crude; and a hydrogen recovery unit for receiving said synthetic fuel gas and producing further hydrogen gas and hydrogen-depleted synthetic fuel gas, said further hydrogen gas being supplied to said hydroprocessing unit.

Owner:ORMAT IND LTD

Upgrading heavy hydrocarbon oils

A process using supercritical water-oil emulsion to upgrade a heavy hydrocarbon feedstock into an upgraded hydrocarbon product or syncrude with highly desirable properties (low sulfur content, low metals content, lower density (higher API), lower viscosity, lower residuum content, etc.) is disclosed. The process does not require external supply of hydrogen nor does it use externally supplied catalysts.

Owner:CHEVROU USA INC

How to convert carbon dioxide into synthetic hydrocarbon through a process of catalytic hydrogenation called CO2hydrocarbonation

InactiveUS6987134B1Improve actionImprove standardizationOrganic compound preparationOxygen compounds preparation by reductionOxygenChemistry

This process uses two catalysts instead of one, converting CO2 into C8H18. Addition of a NaCl catalyst to a Ni catalyst improves the efficiency of Fischer's process because the salt catalyst retains humidity. Furthermore, chlorine opens chemical chains and sodium prevents crystals of oxygen from covering the Ni catalyst. If we are equipped to produce CO2 from biogas or smoke, we can recycle this CO2 and yield a useful liquid. In fact, recycling CO2 into a synthetic crude hydrocarbon, octane, contributes to clean air and to produce a valuable source of energy. Because CO2 is a renewable resource, this process favors a lasting economic development.

Owner:GAGNON ROBERT

Process and apparatus for converting oil shale or oil sand (tar sand) to oil

InactiveUS20050252833A1Flexibility in processingLiquid hydrocarbon mixture productionHydrocarbon oil crackingOil shale gasPetroleum

Three new embodiments to the Chattanooga Process that convert or upgrade oil bitumen, a combination of oil sands and bitumen, a combination of sand and bitumen, and oil shale to high grade low sulfur (about 0.1 to 0.5 wt. % sulfur, or less) crude oil. The invention relates to a continuous process for producing synthetic crude oil (SCO) from oil sand bitumen which has been extracted from under ground via in situ processes, or strip mined and extracted via hot water extraction processes before upgrading. It can also apply to kerogen extracted in situ from shale underground. The process involves treating the hot bitumen with sand from an extraction process or the hot oil from kerogen with ground shale containing kerogen in a fluid bed reactor where the reactant and fluidizing medium is only hydrogen. The invention also relates to a continuous process for producing synthetic crude oil (SCO) from oil shale kerogen. The invention relates to a continuous process for producing synthetic crude oil from oil bearing material, e.g., oil shale or oil sand (tar sand), through continuous process for producing synthetic crude oil from bituminous oil sand (tar sand) or shale. The process includes treating the oil sand (tar sand) or shale to produce a fluidizable feed, feeding the fluidizable feed to a fluidized bed reactor, and fluidizing and reacting the fluidizable feed in the fluidized bed reactor with a feed of hydrogen provided by a feed stream having a stream containing hydrogen in a concentration greater than 90 vol % (90 vol %-100 vol % H2). In one embodiment, the invention relates to a continuous process which can recover methane and ethane from a recycle hydrogen stream. In one embodiment, the process can recover PSA tail gas as feed to a hydrogen plant. In one embodiment, the process can be operated to reduce or eliminate the requirement for externally provided methane feed to the hydrogen plant.

Owner:DOYLE JAMES A +1

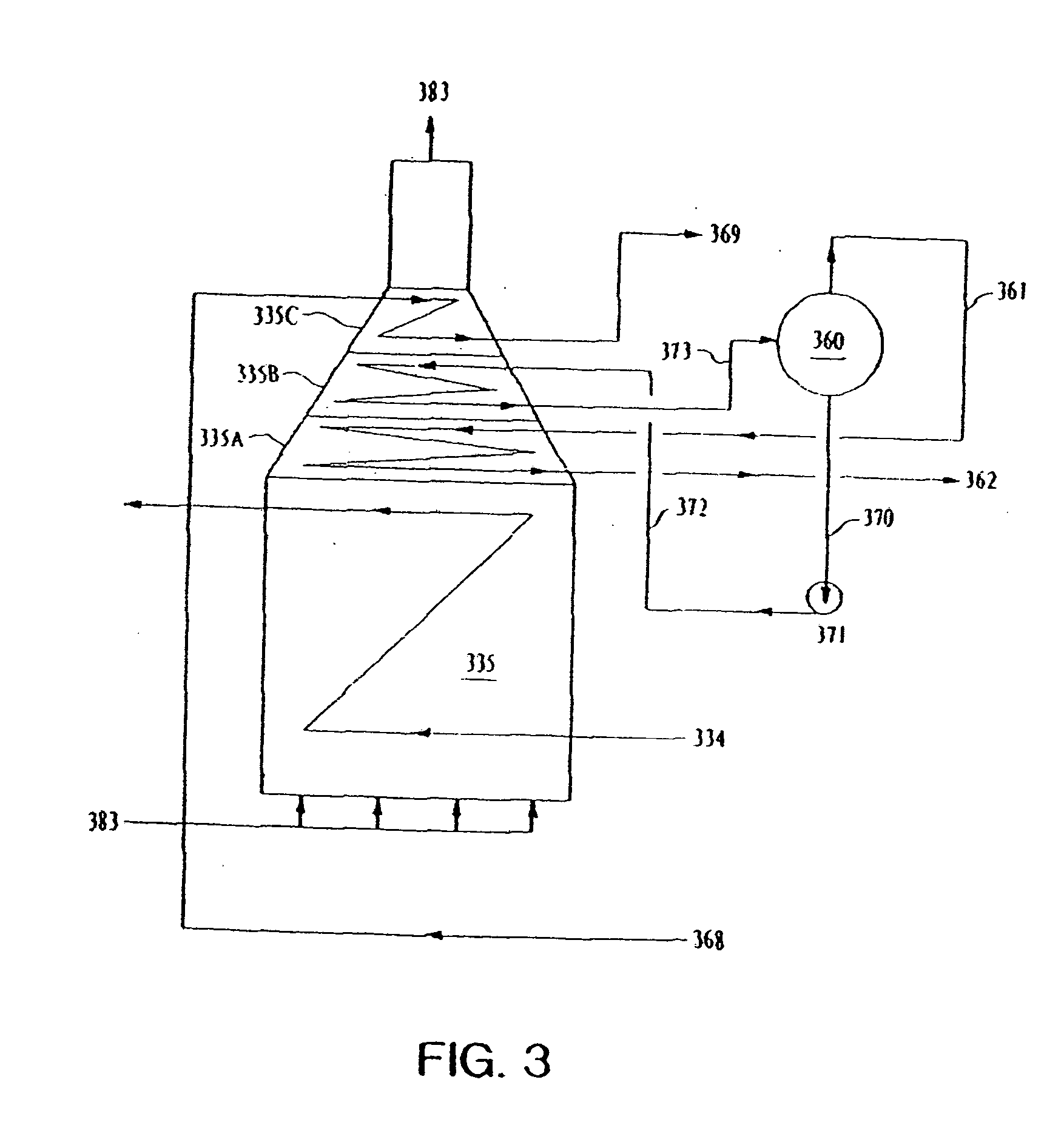

Movable gas-to-liquid system and process

InactiveUS20050106086A1Organic compounds purification/separation/stabilisationWaterborne vesselsProcess equipmentGas to liquids

A system having a movable platform including synthesis gas production, synthetic crude production and product upgrading is provided. The system may include one or more movable platforms on which the various production and / or upgrading facilities are located. A process for converting natural gas to hydrocarbon products is also provided where the process occurs on a movable platform. The process may occur on one or more operationally connected vessels. The movable platform may be any of a number of movable or transportable bases on which process equipment may be placed and / or in which hydrocarbon products may be stored.

Owner:REG SYNTHETIC FUELS LLC

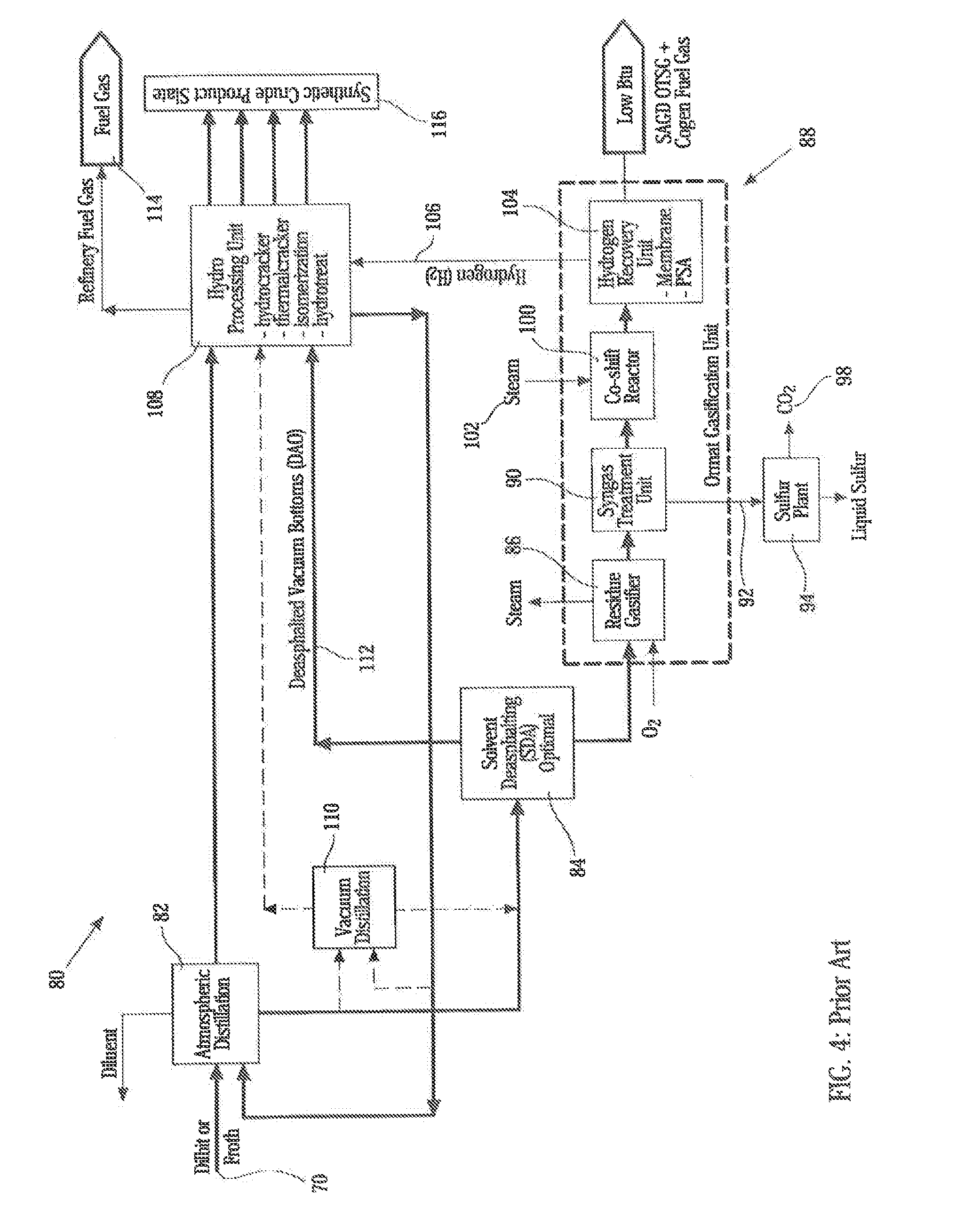

Process to prepare a sweet crude

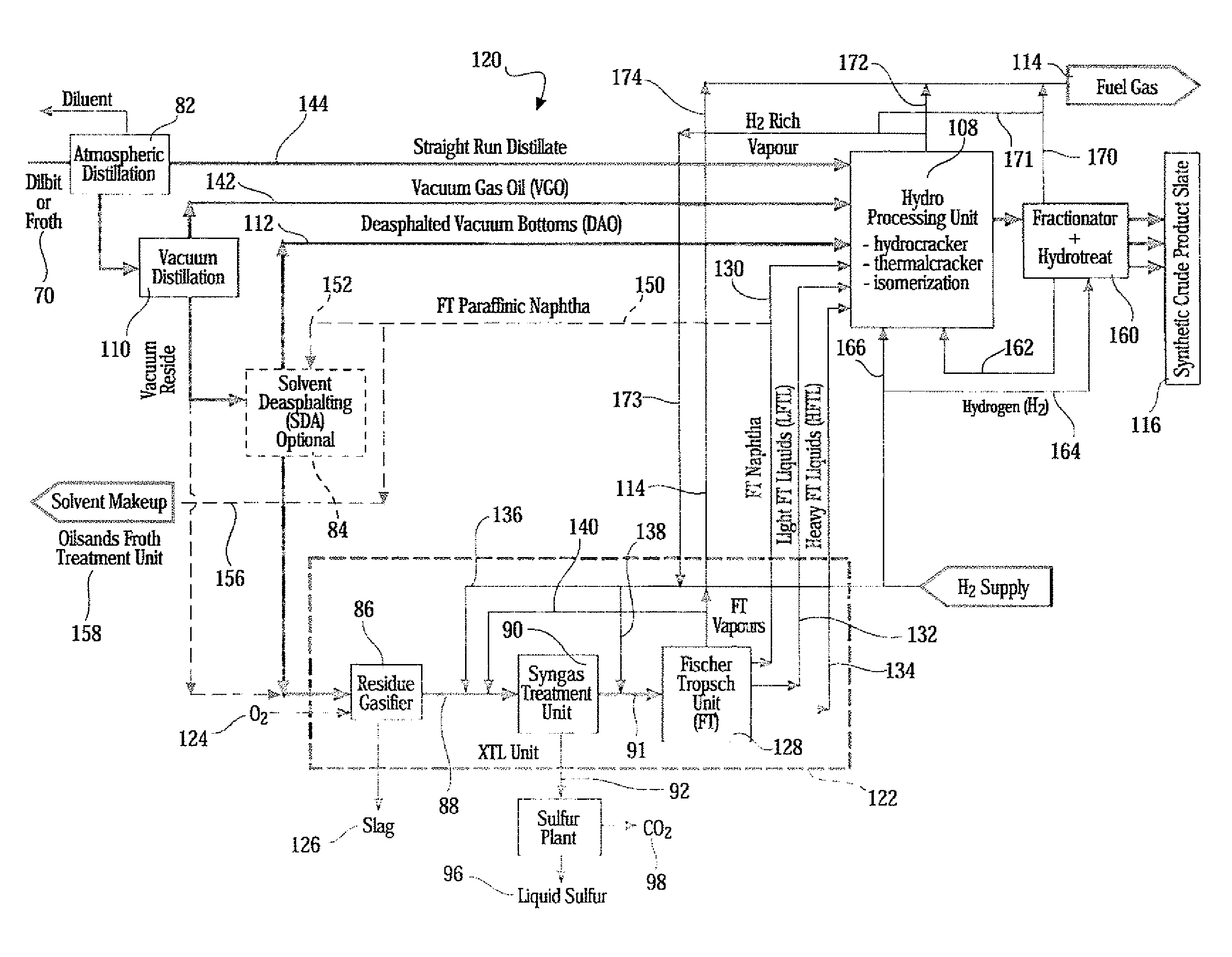

ActiveUS20080142408A1Hydrocarbon distillationCombustible gas catalytic treatmentOil sandsRemoval Units

A process to prepare a sweet crude from an ash containing and heavy fraction of a tar sand oil by:(a) supplying an atmospheric distillation bottoms of a tar sands originated feed to a vacuum distillation to obtain a vacuum gas oil and a vacuum bottoms,(b) contacting the vacuum gas oil with hydrogen in the presence of a suitable hydrocracking catalyst to obtain a sweet synthetic crude(c) separating the vacuum bottoms obtained in step (a) into an asphalt fraction comprising between 0.1 and 4 wt % ash and a de-asphalted oil,(d) feeding said asphalt fraction to a burner of a gasification reactor where the asphalt fraction is partially oxidized in the presence of an oxidizer gas in a burner to obtain a mixture of hydrogen and carbon monoxide,(e) performing a water gas shift reaction on the mixture of hydrogen and carbon monoxide,(f) separating hydrogen sulphide and carbon dioxide from the shifted gas in an acid removal unit thereby obtaining crude hydrogen,(g) purifying the crude hydrogen to obtain pure hydrogen and(h) using part of the pure hydrogen in step (b), wherein in step (d) the asphalt fraction is provided to the burner in a liquid state and wherein in case separation step (c) fails to provide sufficient feed for step (d), step (d) is performed by feeding the vacuum bottoms of step (a) to the burner in a liquid state.

Owner:AIR PROD & CHEM INC

Process for producing tailored synthetic crude oil that optimize crude slates in target refineries

InactiveUS7799207B2Physical/chemical process catalystsHydrocarbon oil crackingFuel oilProcess engineering

The instant invention is directed to a process wherein a heavy oil feedstock upgrader alters its mode of operation of its full conversion hydroprocessing unit to create a custom tailored synthetic crude feedstock based upon data communicated from a target refinery and data communicated from the heavy oil feedstock upgrader. The data from the target refinery is data that represents refining process data and linear program modeling along with analysis by a refining planner to calculate the optimum “synthetic trim crude” that will optimize the effective use of the target refinery's capacity and equipment.

Owner:CHEVROU USA INC

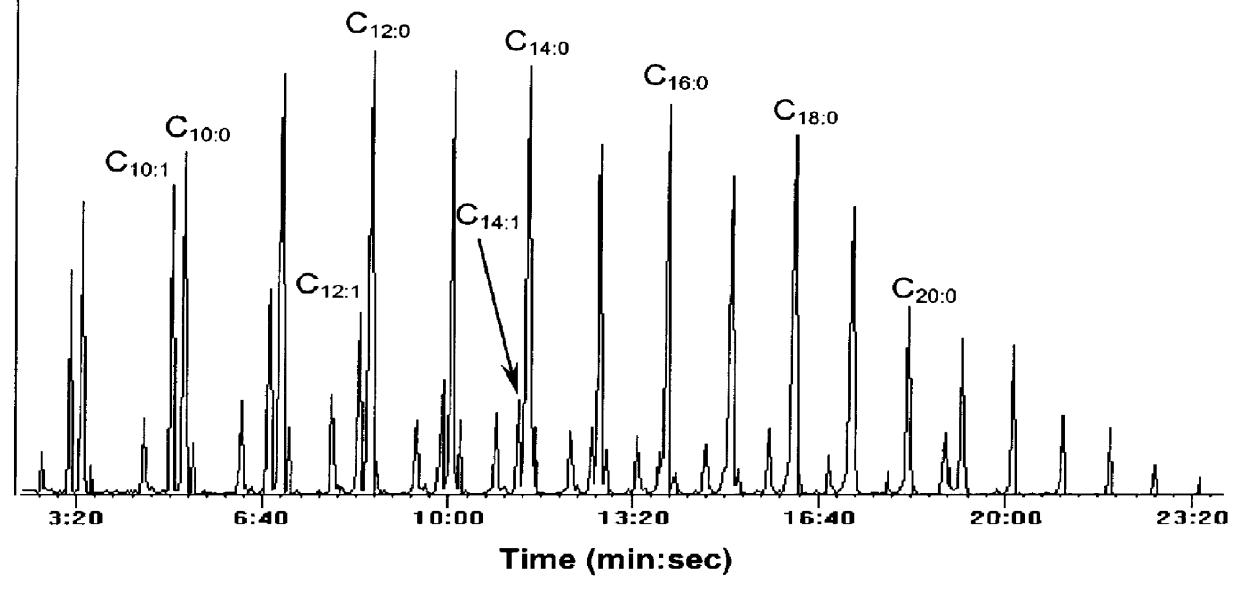

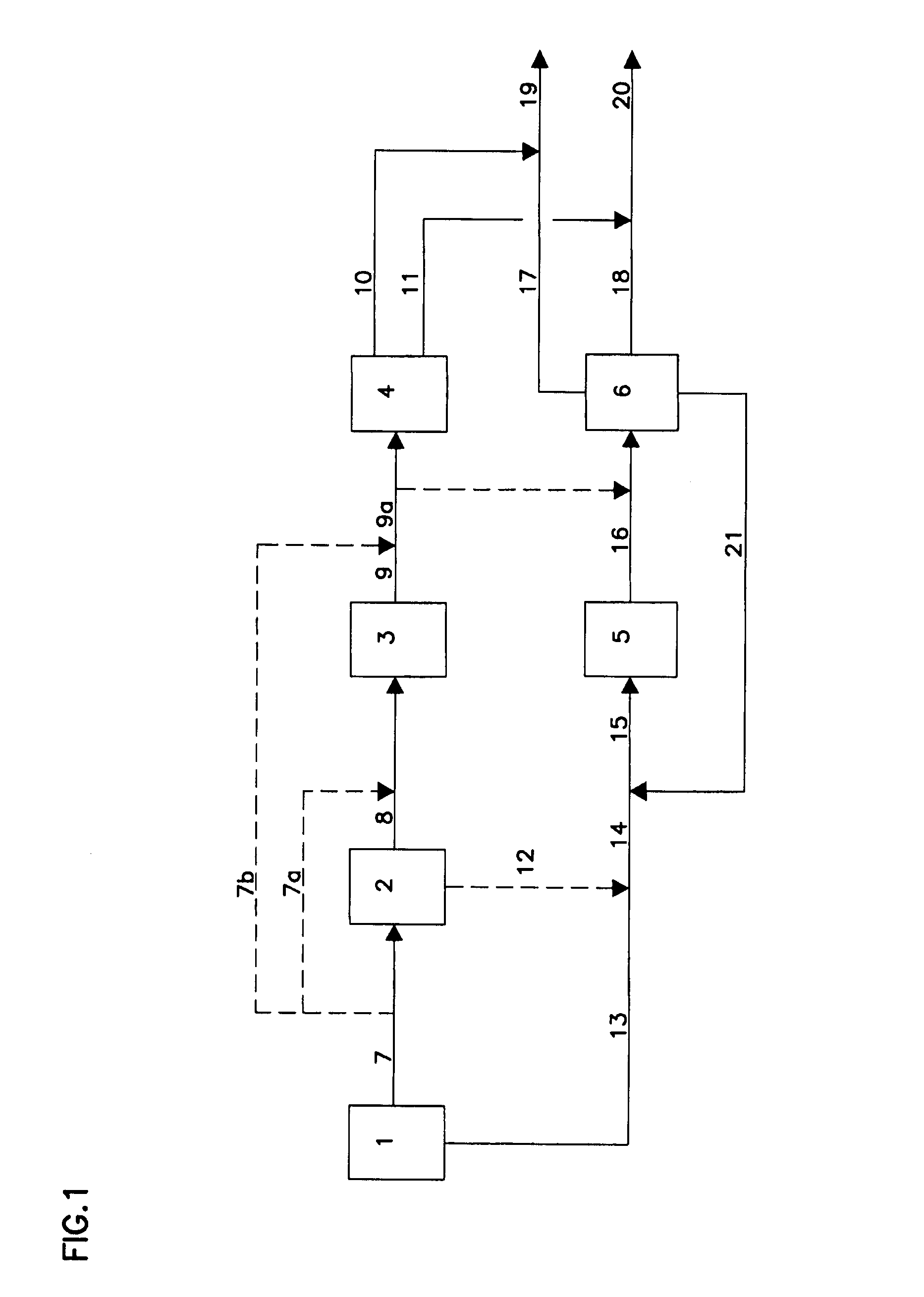

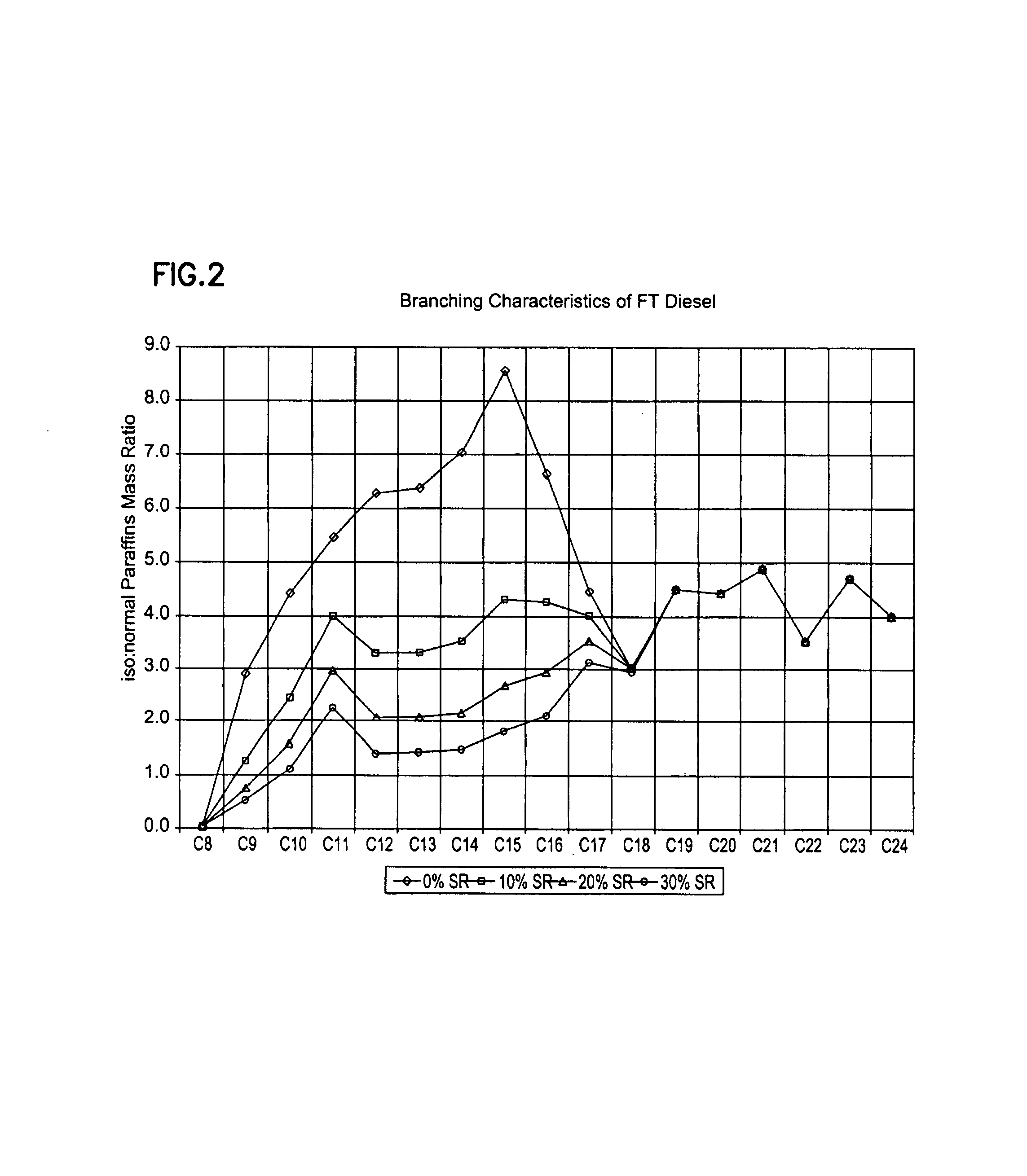

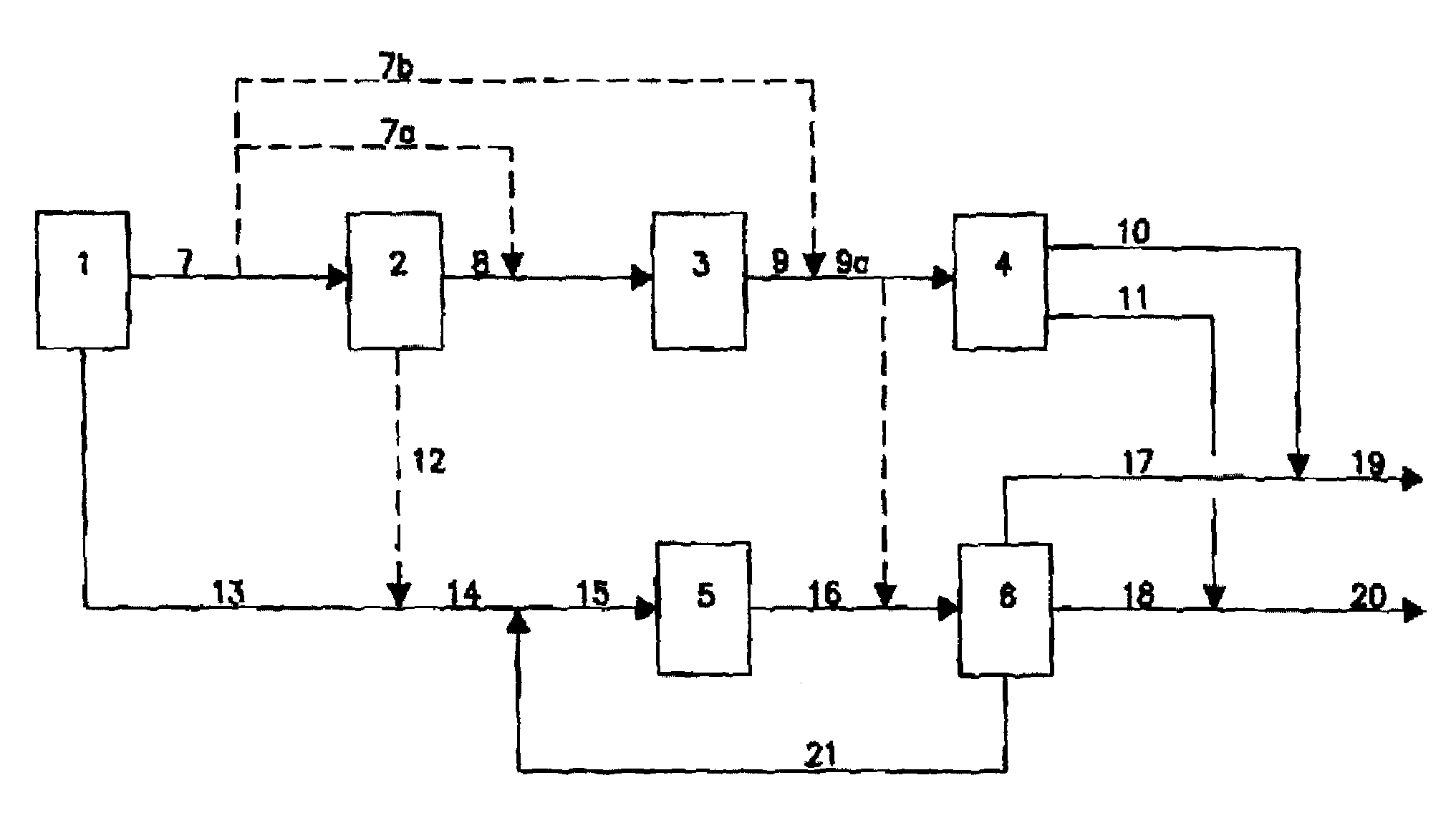

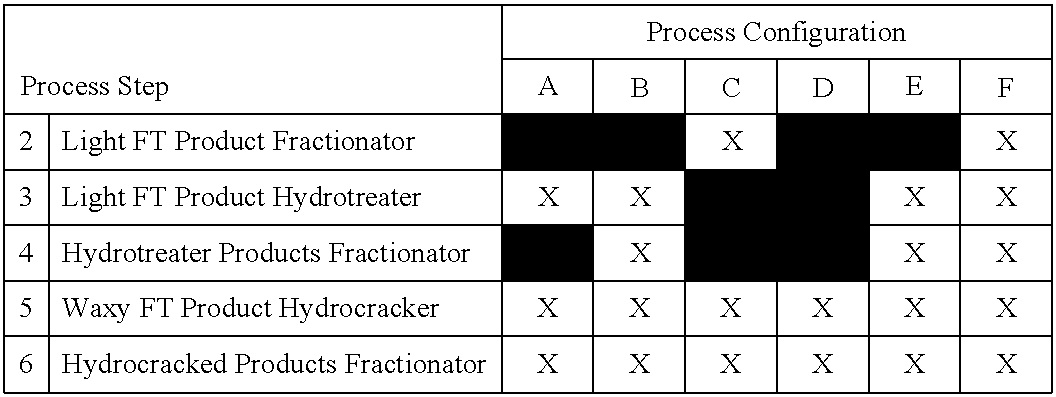

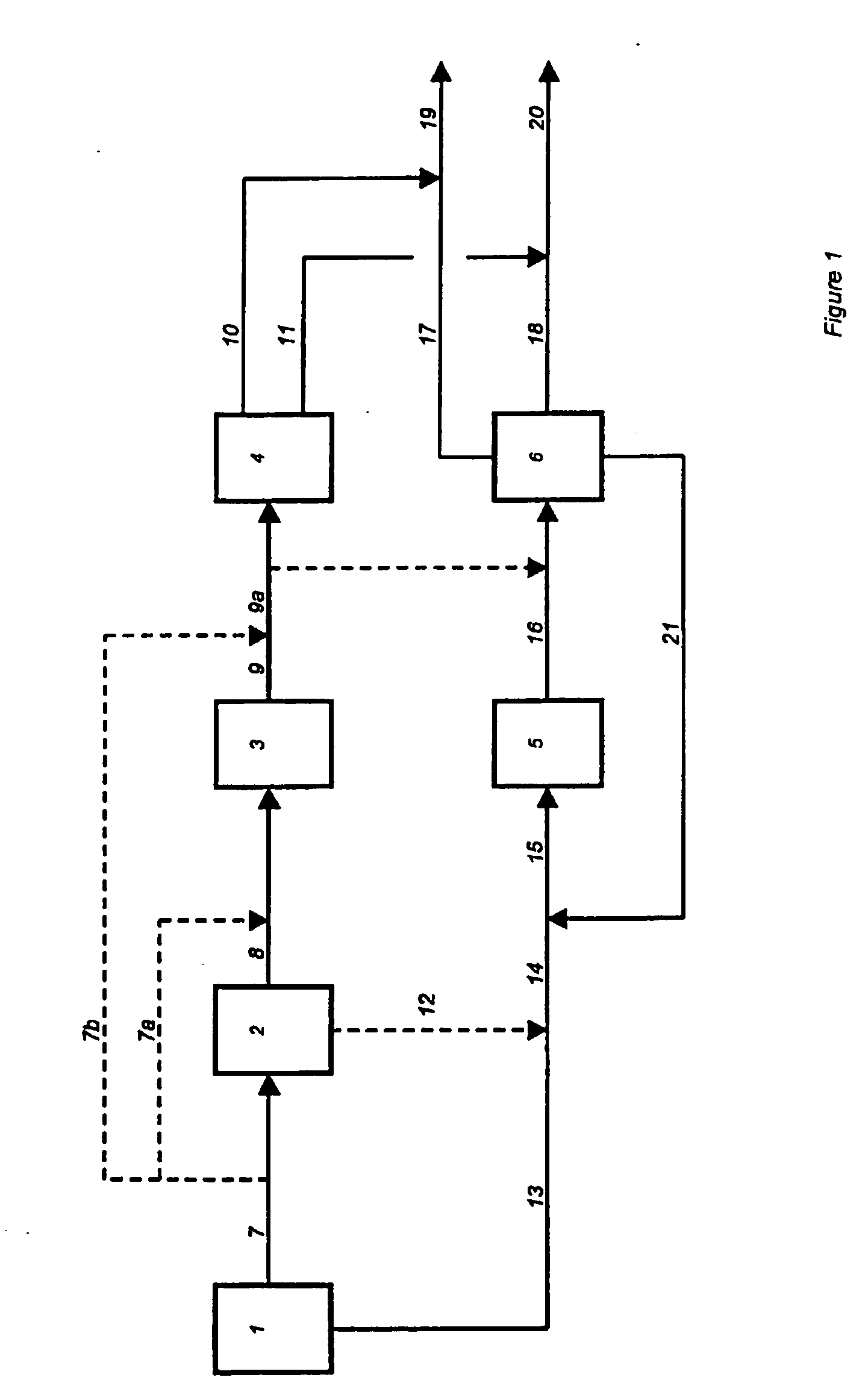

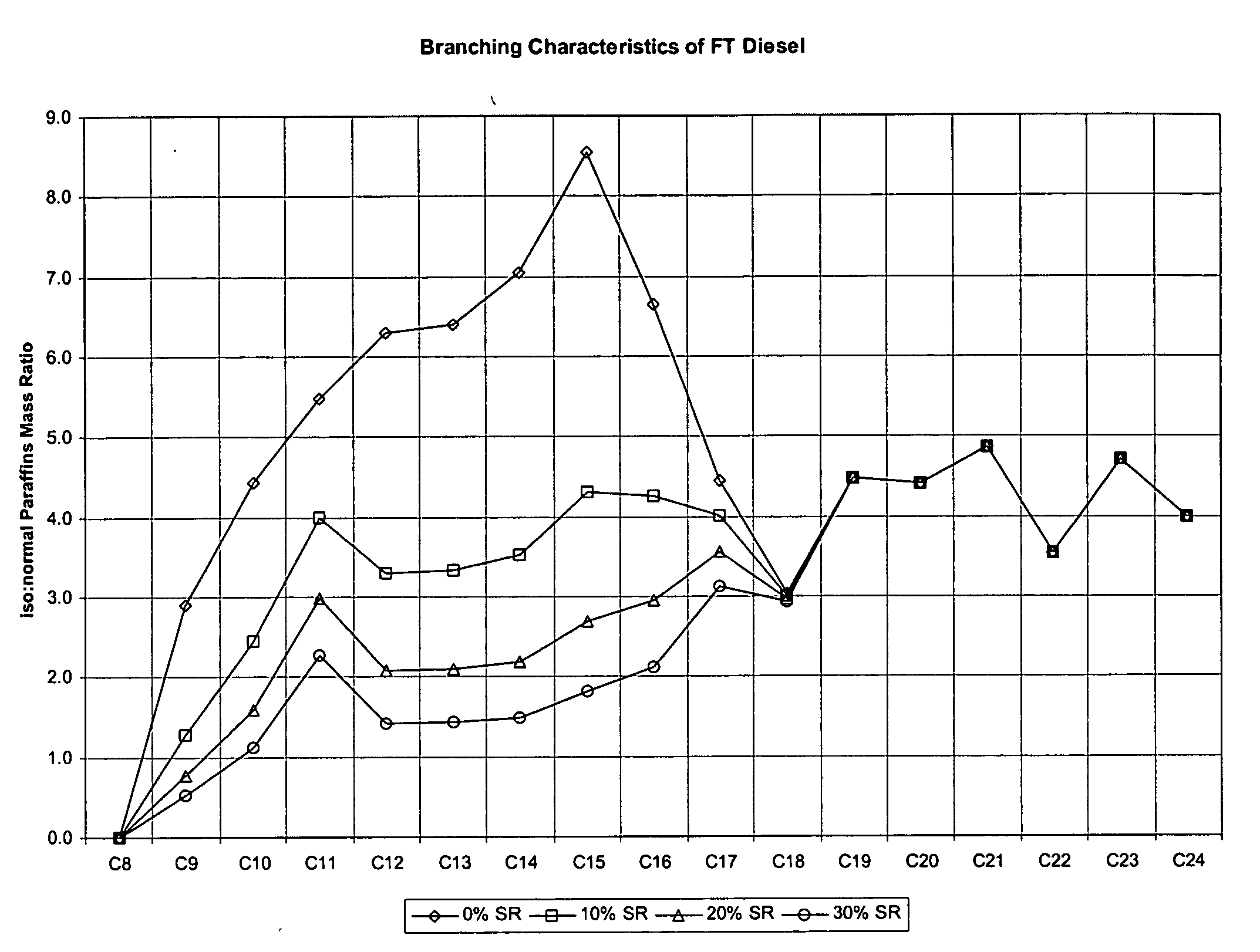

Process for producing middle distillates

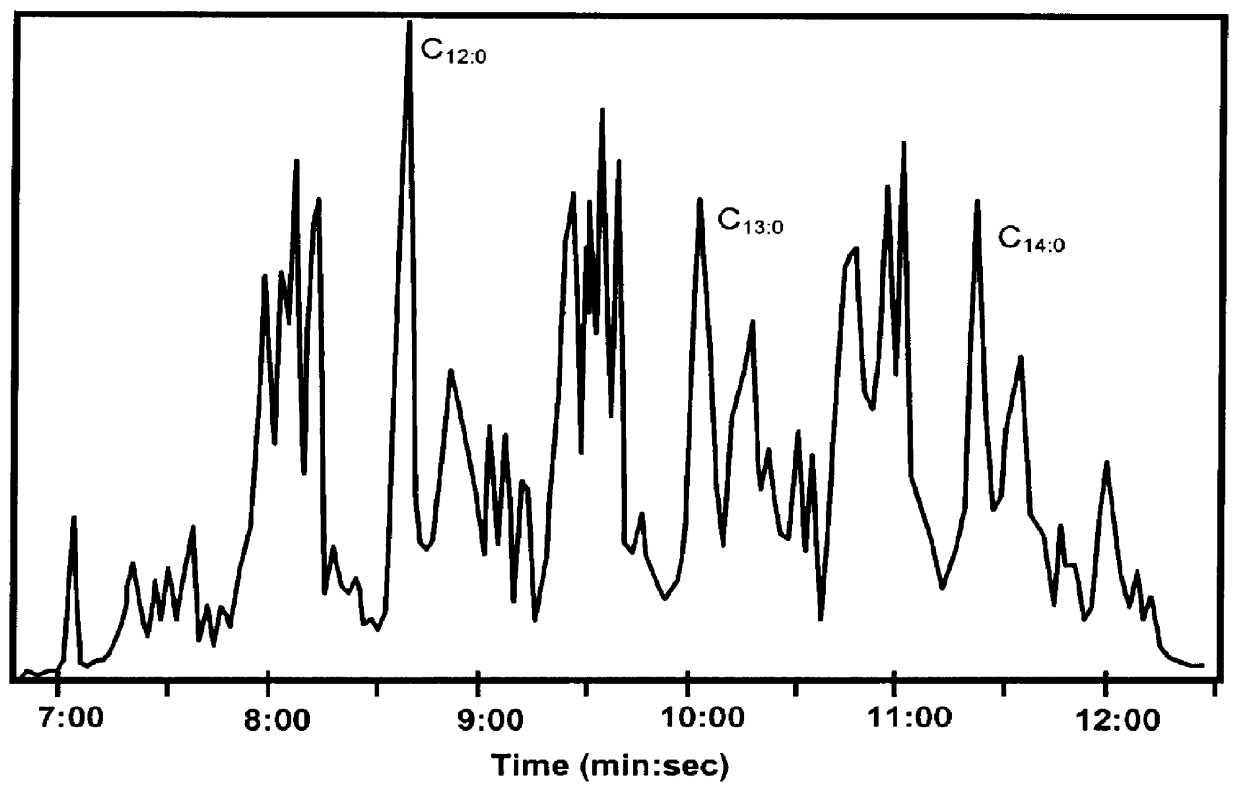

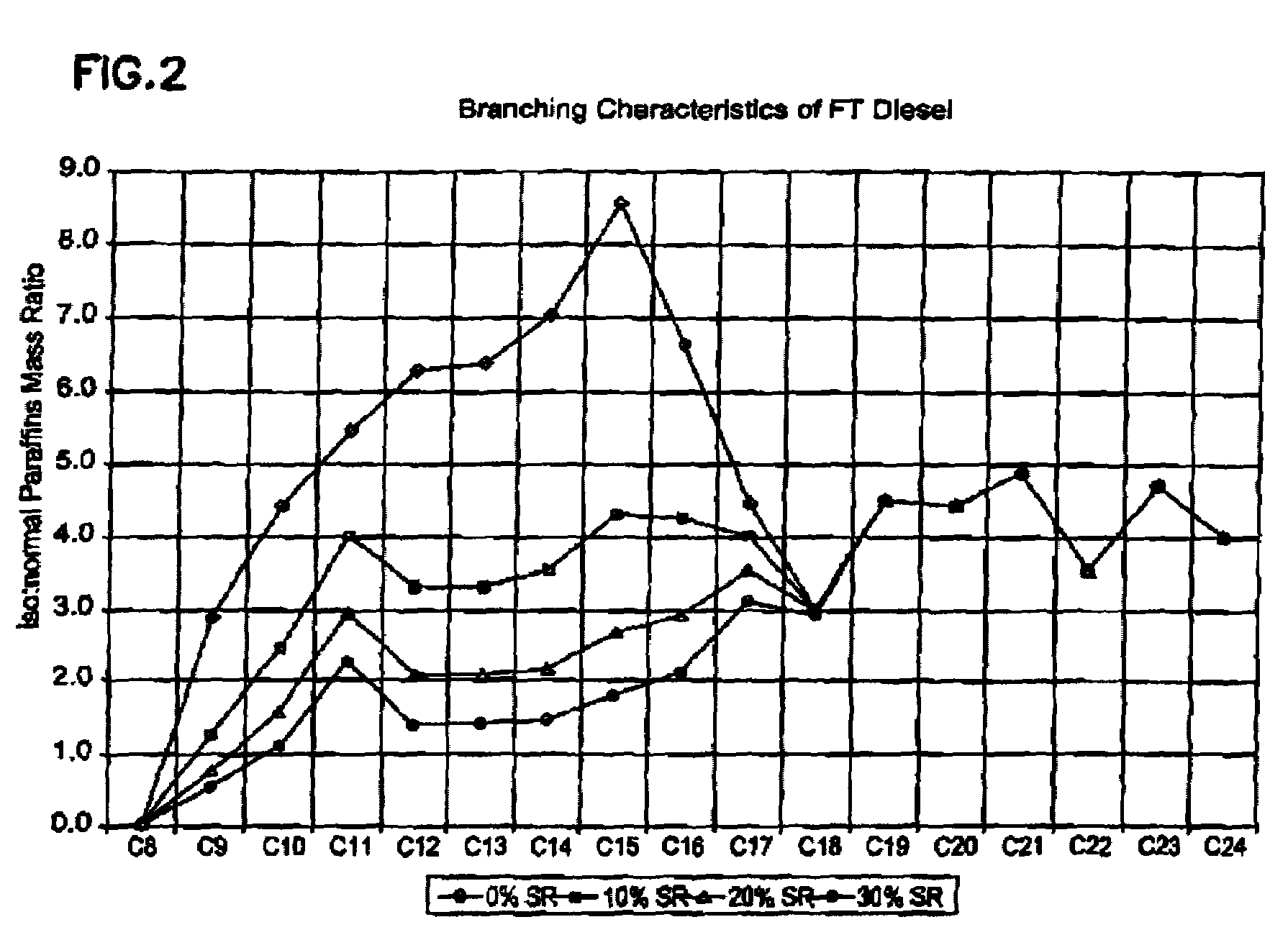

InactiveUS7294253B2Increase cetane numberImprove cold flowOrganic compounds purification/separation/stabilisationOrganic compound preparationAlkanePolymer science

This invention relates to process for producing middle distillates having good cold flow properties, such as the Cold Filter Plugging Point (CFPP) measured in accordance with the IP method 309, and a high Cetane number, as well as to a process for production of such distillates. More particularly, this invention relates to a process in which middle distillates are produced from a mainly paraffinic synthetic crude which is produced by the reaction of CO and H2, typically by the Fischer-Tropsch (FT) process. The middle distillates produced by the process of the invention are predominantly isoparaffinic, the isoparaffins being methyl, ethyl and / or propyl branched.

Owner:SASOL TECHNOLOGY (PTY) LTD

Process for producing middle distillates and middle distillates produced by that process

InactiveUS7217852B1Increase cetane numberImprove cold flowHydrocarbon by hydrogenationHydrocarbon distillationAlkaneCold filter plugging point

This invention relates to middle distillates having good cold flow properties, such as the Cold Filter Plugging Point (CFPP) measured in accordance with the IP method (309), and a high Cetane number, as well as to a process for production of such distillates. More particularly, this invention relates to middle distillates produced from a mainly paraffinic synthetic crude which is produced by the reaction of CO and H2, typically by the Fischer-Tropsch (FT) process. The middle distillates of the invention are predominantly isoparaffinic, the isoparaffins being methyl, ethyl and / or propyl branched. The invention also provides a diesel fuel composition including the middle distillates in accordance with the invention. A process for preparing the middle distillates is also included in the invention.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

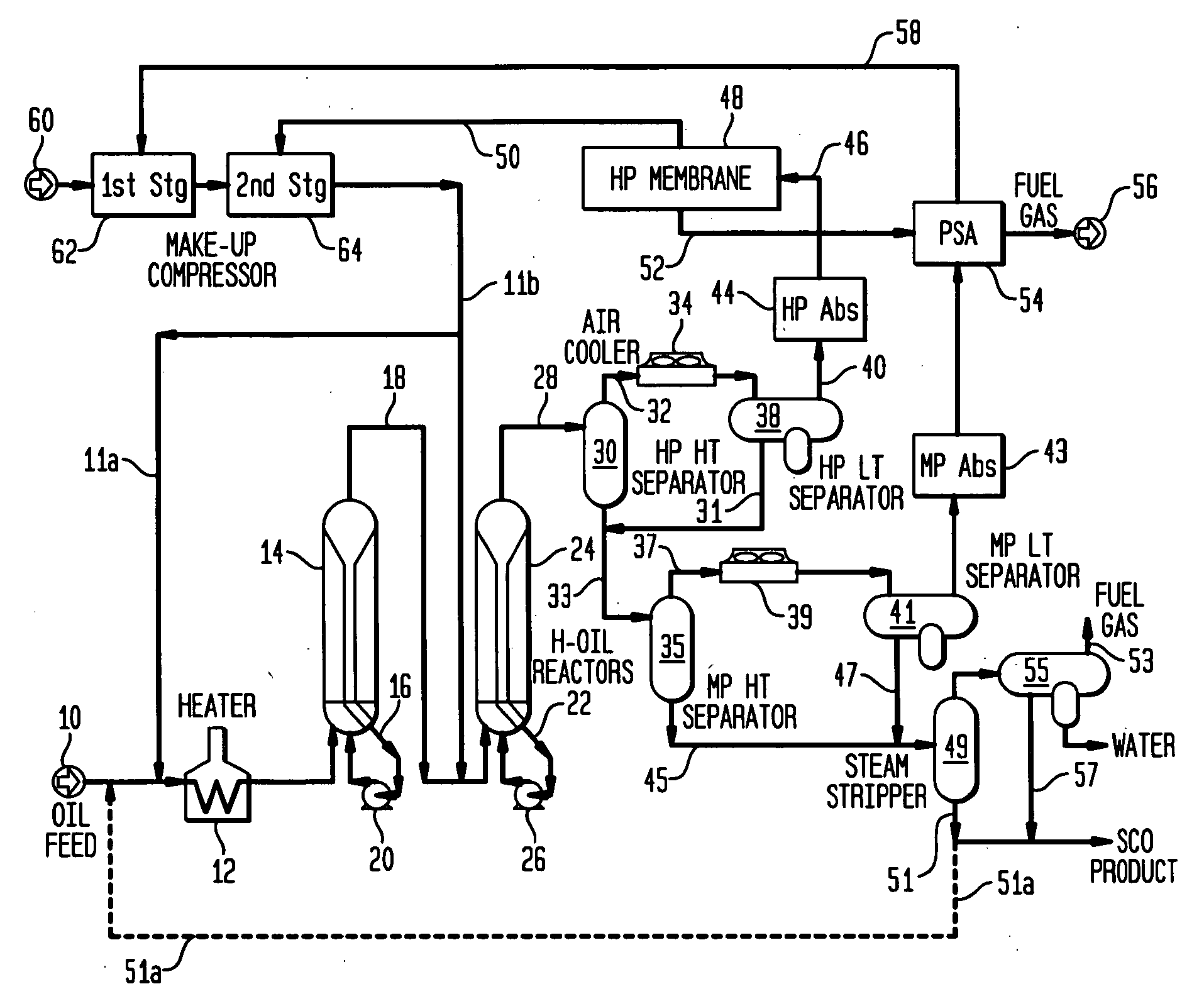

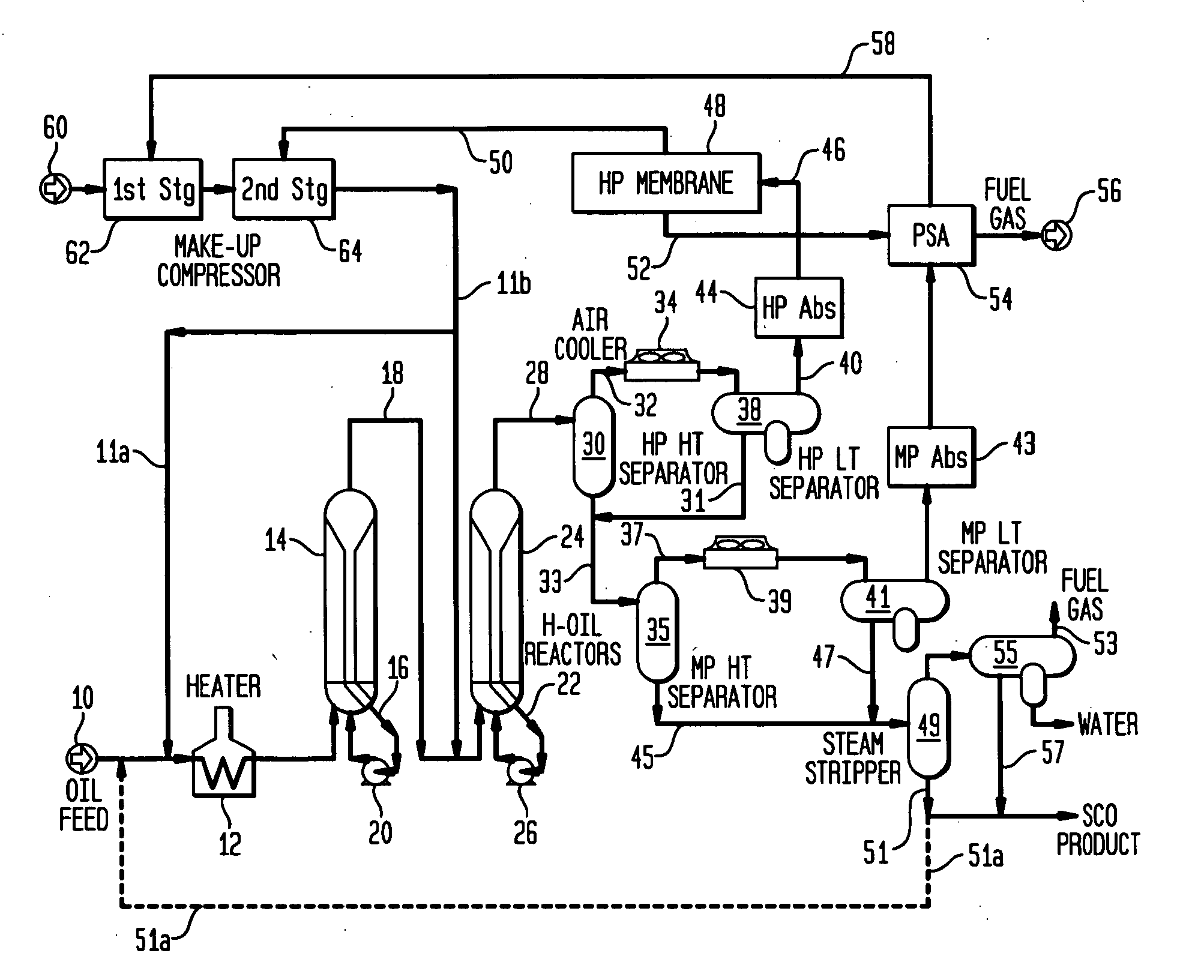

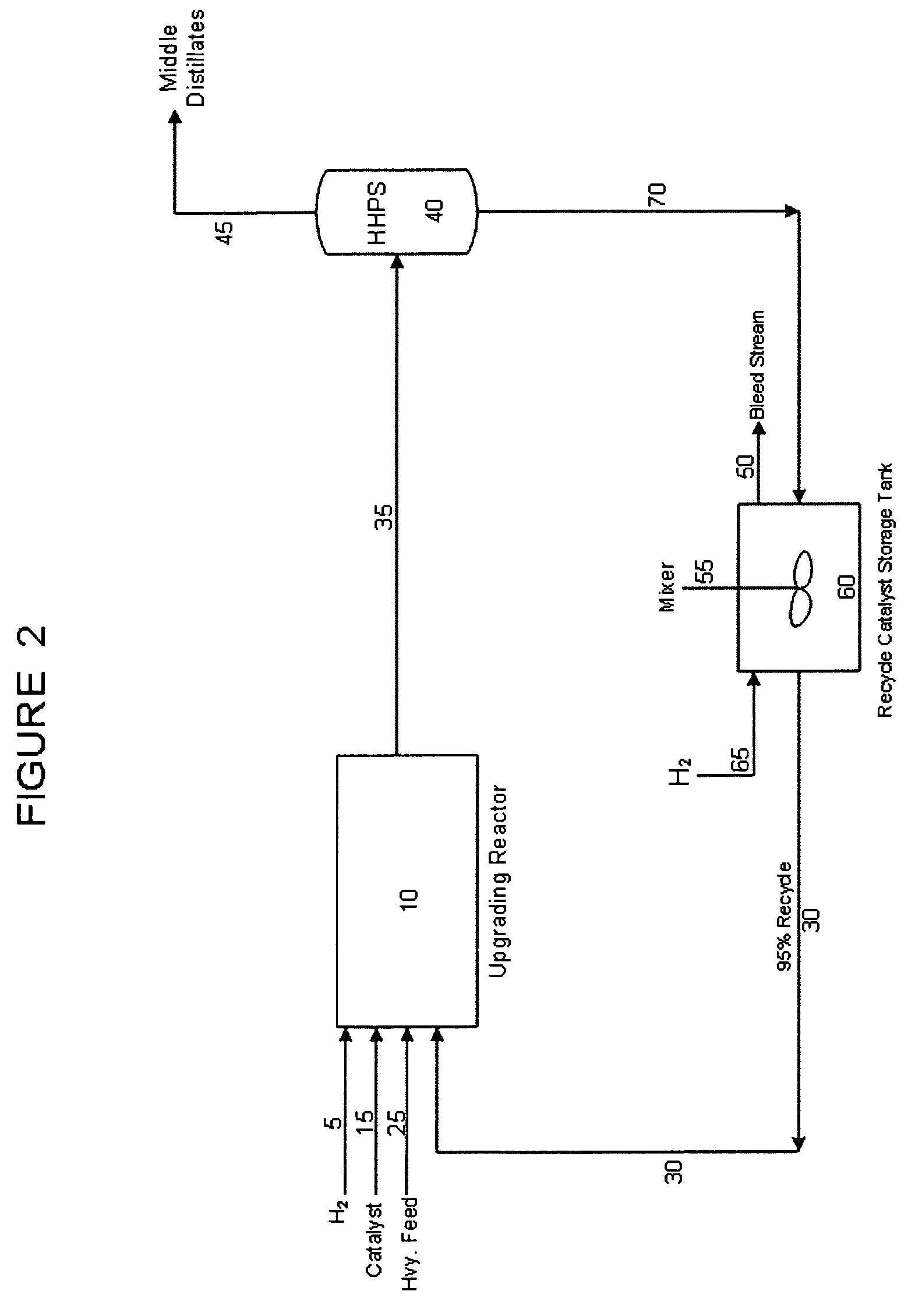

Integrated ebullated-bed process for whole crude oil upgrading

ActiveUS20130292299A1Reduce contentHydrocarbon oil crackingTreatment with hydrotreatment processesFixed bedReaction zone

A system and process for upgrading a whole crude oil feed in an integrated ebullated-bed and hydrotreater is provided in which the whole crude oil is flashed into a flashed straight run distillates fraction and an atmospheric residue fraction. The atmospheric residue fraction is hydroprocessed in an ebullated-bed reaction zone, while the flashed straight run distillates fraction and the products fraction produced from the ebullated-bed reaction zone are hydrotreated in a fixed-bed reaction zone. Distillates from the hydrotreater and the unconverted residue fraction from the ebullated-bed reaction zone can be combined to produce an upgraded synthetic crude oil.

Owner:SAUDI ARABIAN OIL CO

Process and apparatus for converting oil shale or oil sand (tar sand) to oil

InactiveUS20050252832A1Flexibility in processingLiquid hydrocarbon mixture productionHydrocarbon oil crackingKerogenHydrogen

The disclosed invention is a process for producing synthetic crude oil and includes embodiments which convert or upgrade oil bitumen, a combination of oil sands and bitumen, a combination of sand and bitumen, oil shale and kerogen to high grade low sulfur crude oil. In one embodiment it is a continuous process for producing synthetic crude oil from oil sand bitumen. In another it produces synthetic crude oil from oil shale. The process in one embodiment includes a fluid bed reactor where the reactant and fluidizing medium is substantially hydrogen. In other embodiments, the process includes treating the oil sand (tar sand) or shale to produce a fluidizable feed, feeding the fluidizable feed to a fluidized bed reactor, and fluidizing and reacting the fluidizable feed in the fluidized bed reactor with a feed having hydrogen.

Owner:CHATTANOOGA

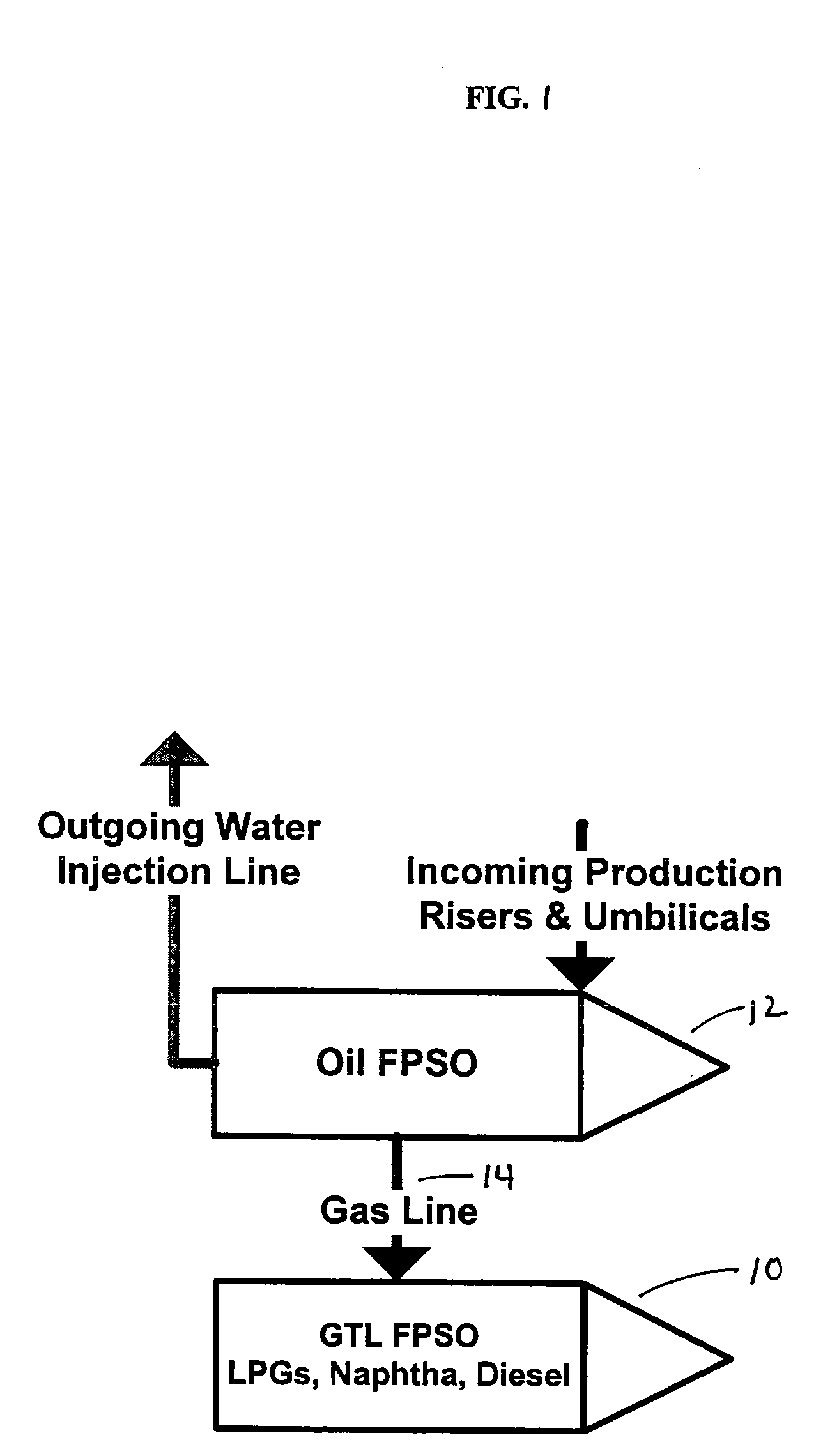

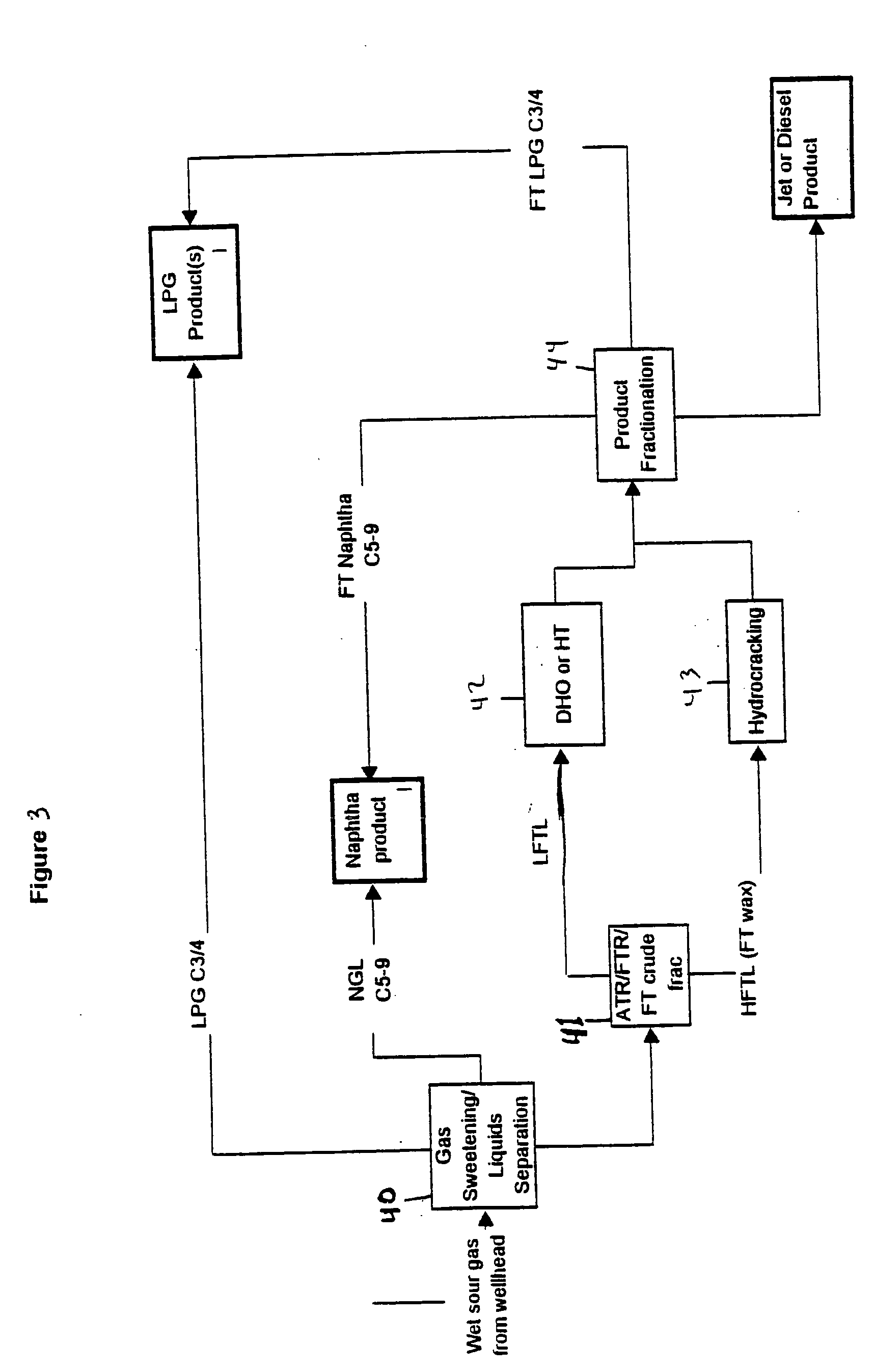

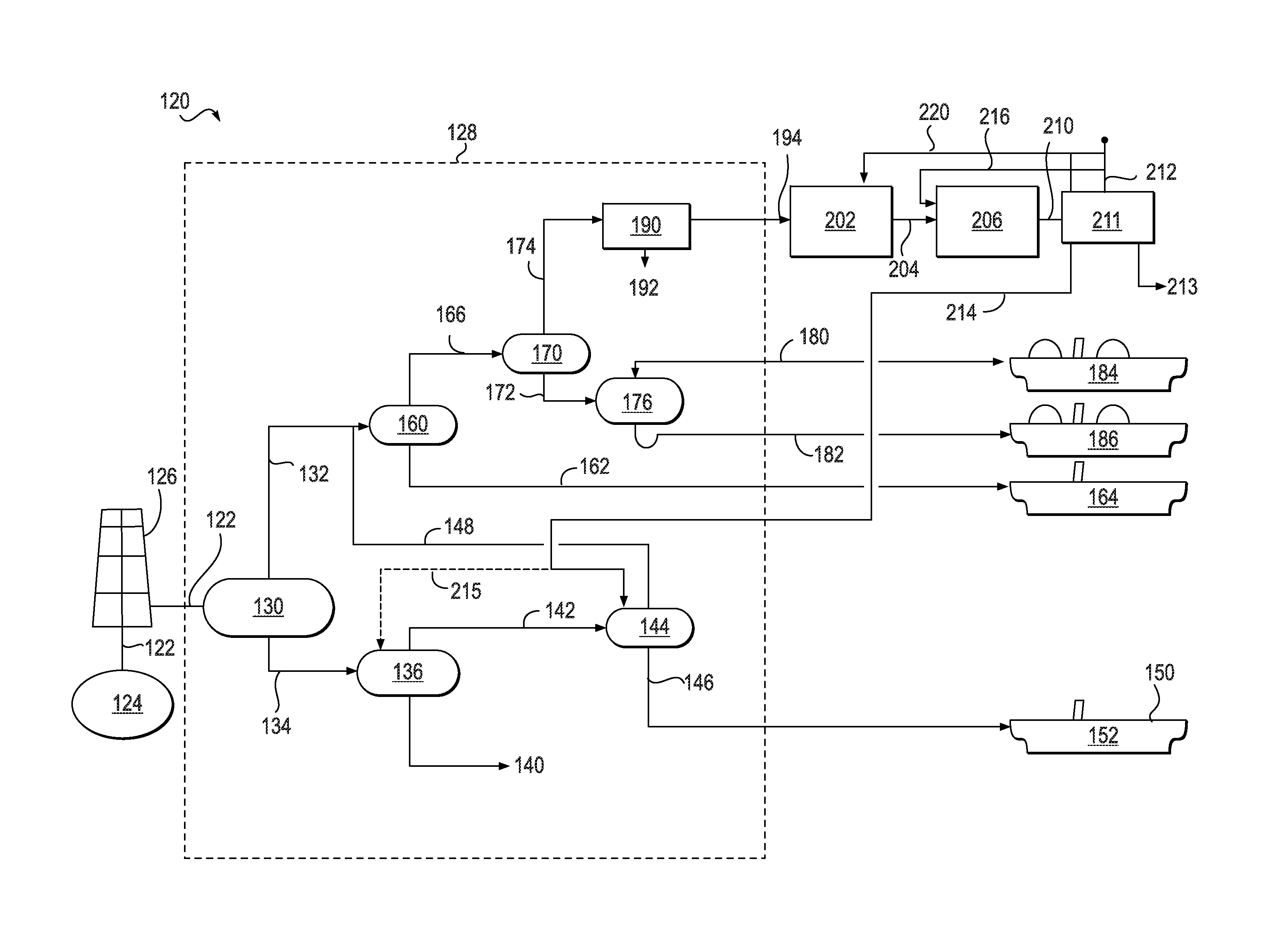

Process and system for blending synthetic and natural crude oils derived from offshore produced fluids

ActiveUS20110240288A1Refining to change hydrocarbon structural skeletonLiquid hydrocarbon mixture recoveryPtru catalystLiquefied petroleum gas

A process and system are described for the processing of gas associated with crude oil production, i.e. associated gas. A separation complex is used to separate produced fluids produced from a hydrocarbon reservoir into crude oil, liquefied petroleum gas, water, and natural gas. At least a portion of the natural gas is converted into synthesis gas in a synthesis gas generator. A combination of a synthesis gas conversion catalysts and hydroconversion catalysts are used in a synthesis gas reactor to convert the synthesis gas into a liquid effluent stream containing liquefied petroleum gas and a synthetic crude oil. The liquefied petroleum gas and synthetic crude oil from the synthesis gas reactor is sent to the separation complex. Liquefied petroleum gas is separated both from the synthetic crude oil and a natural crude oil obtained from the produced fluids. The system and process permits synthetic crude oil to be blended with the natural crude oil producing a blended stabilized crude oil having 2 wt % or more of the synthetic crude oil and with a pour point of 60° C. or less. Use of a common facility for separation operations on the natural crude oil and synthetic crude oil thus reduces capital costs and allows converted associated gases to be shipped with the natural crude oil on a conventional crude oil tanker.

Owner:CHEVROU USA INC

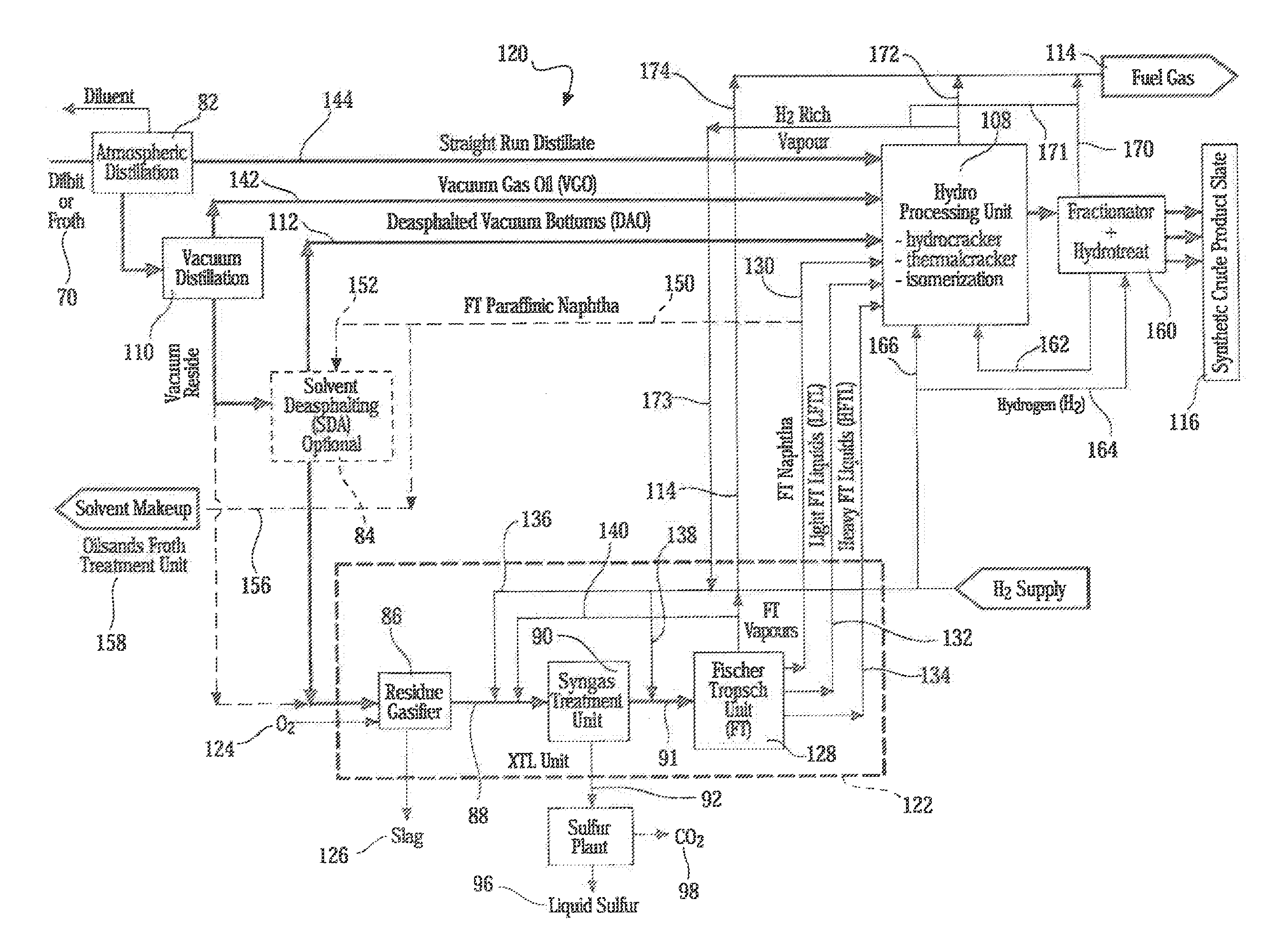

Process for heavy oil and bitumen upgrading

ActiveUS20120270957A1Improved heavy oil and bitumen upgradingIncrease productionHydrogenOrganic compound preparationMethane reformerSyngas

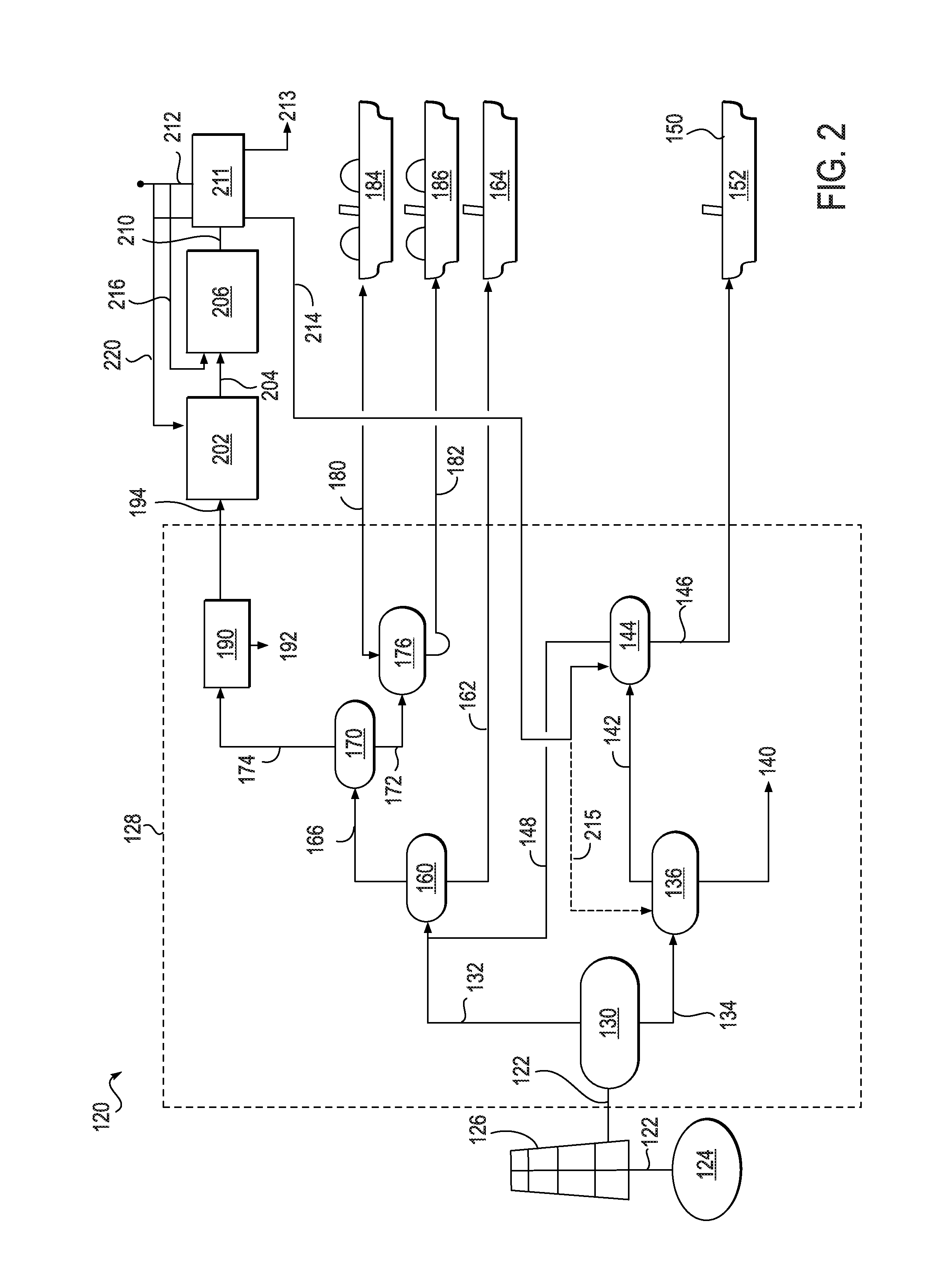

A bitumen and heavy oil upgrading process and system is disclosed for the synthesis of hydrocarbons, an example of which is synthetic crude oil (SCO). The process advantageously avoids the waste attributed to residuum and / or petcoke formation which has a dramatic effect on the yield of hydrocarbon material generated. The process integrates Fischer-Tropsch technology with gasification and hydrogen rich gas stream generation. The hydrogen rich gas generation is conveniently effected using singly or in combination a hydrogen source, a hydrogen rich vapour from hydroprocessing and the Fischer-Tropsch process, a steam methane reformer (SMR) and autothermal reformer (ATR) or a combination of SMR / ATR. The feedstock for upgrading is distilled and the bottoms fraction is gasified and converted in a Fischer-Tropsch reactor. A resultant hydrogen lean syngas is then exposed to the hydrogen rich gas stream to optimize the formation of, for example, the synthetic crude oil. The hydrogen lean gas stream may also be effected by a water gas shift reaction, singly or in combination or in addition with the hydrogen rich gas stream generation. A system for effecting the process is also characterized in the specification.

Owner:EXPANDER ENERGY

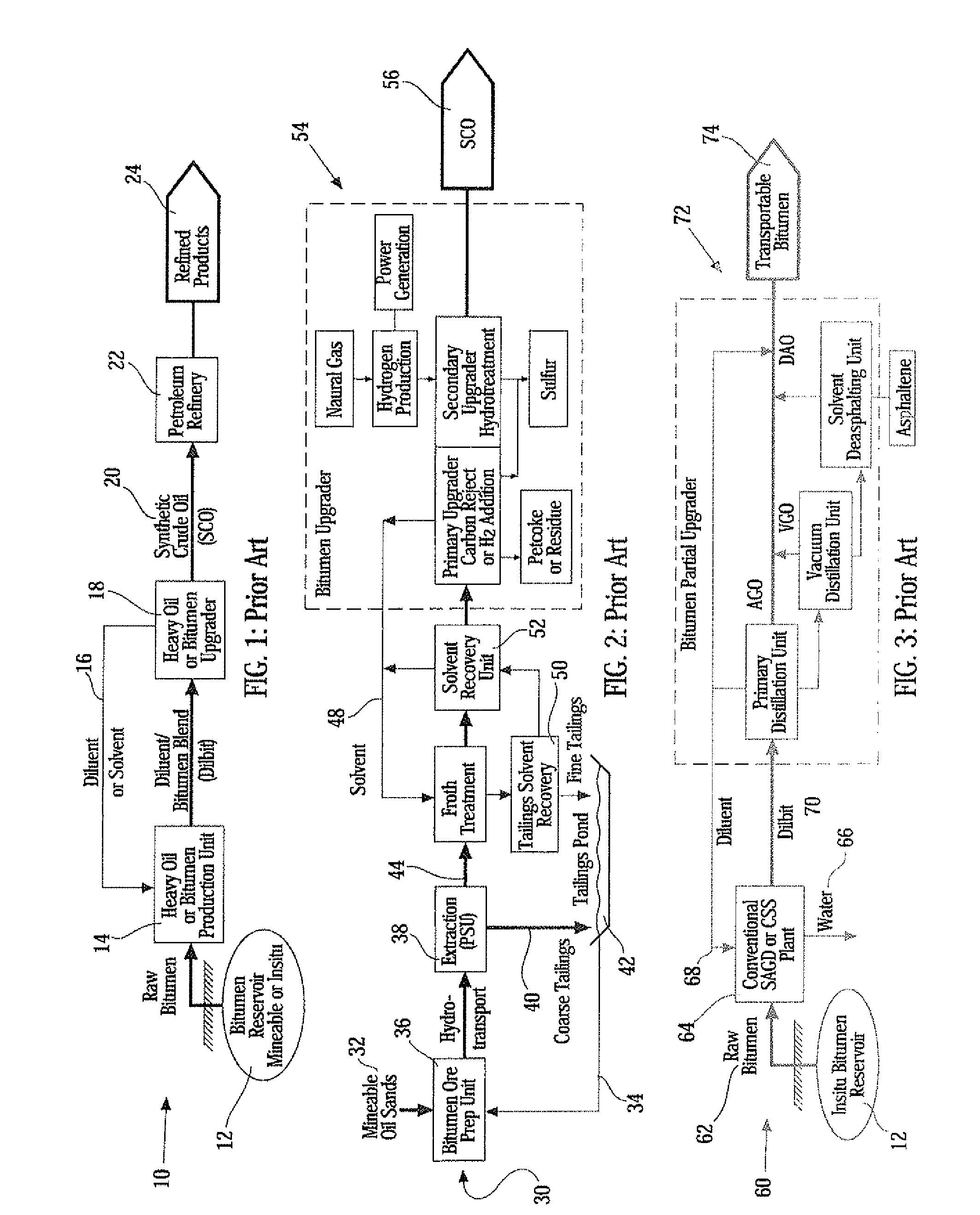

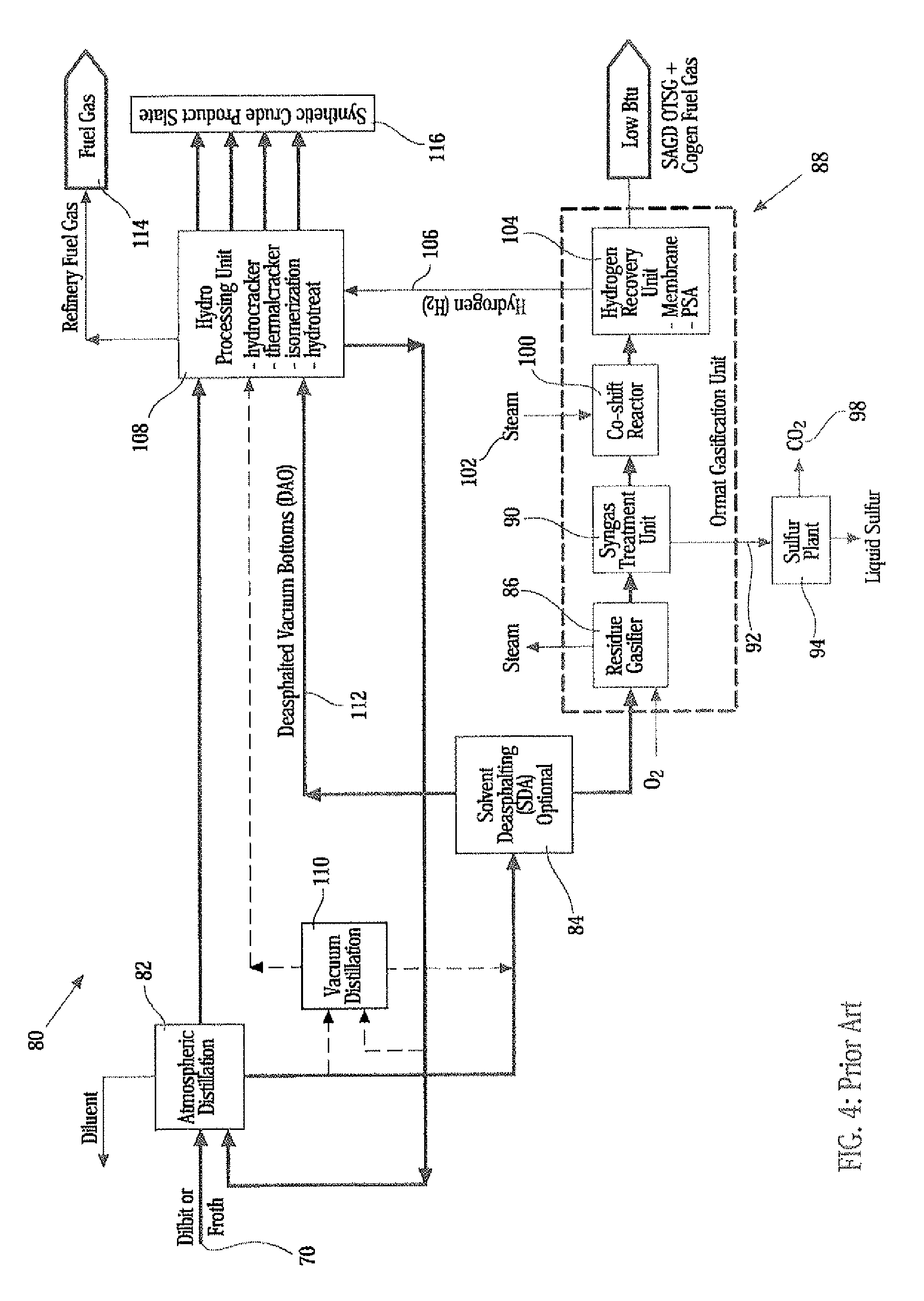

Method of and apparatus for upgrading and gasifying heavy hydrocarbon feeds

InactiveUS20040118745A1Thermal non-catalytic crackingSolvent extractionThermodynamicsProcess engineering

A novel apparatus for producing sweet synthetic crude from a heavy hydrocarbon feed includes: an upgrader for receiving the heavy hydrocarbon feed and producing a distillate fraction including sour products, and high-carbon content by-products; a gasifier for receiving the high-carbon content by-products and producing synthetic fuel gas and sour by-products; a hydroprocessing unit for receiving the sour by-products and hydrogen gas, thereby producing gas and sweet crude; and a hydrogen recovery unit for receiving the synthetic fuel gas and producing further hydrogen gas and hydrogen-depleted synthetic fuel gas, the further hydrogen gas being supplied to the hydroprocessing unit.

Owner:ORMAT IND LTD

Process for upgrading heavy hydrocarbon oils

InactiveCN101553553AHigh yieldIncrease API proportionThermal non-catalytic crackingLiquid hydrocarbon mixture productionHydrogenLow density

A process using supercritical water to upgrade a heavy hydrocarbon feedstock into an upgraded hydrocarbon product or syncrude with highly desirable properties (low sulfur content, low metals content, lower density (higher API), lower viscosity lower, residuum content, etc.) is disclosed. The process does not require external supply of hydrogen nor does it use externally supplied catalysts. Improved methods of mixing the reactants are also disclosed.

Owner:CHEVROU USA INC

Method of and apparatus for upgrading and gasifying heavy hydrocarbon feeds

A novel apparatus for producing sweet synthetic crude from a heavy hydrocarbon feed includes: an upgrader for receiving the heavy hydrocarbon feed and producing a distillate fraction including sour products, and high-carbon content by-products; a gasifier for receiving the high-carbon content by-products and producing synthetic fuel gas and sour by-products; a hydroprocessing unit for receiving the sour by-products and hydrogen gas, thereby producing gas and sweet crude; and a hydrogen recovery unit for receiving the synthetic fuel gas and producing further hydrogen gas and hydrogen-depleted synthetic fuel gas, the further hydrogen gas being supplied to the hydroprocessing unit.

Owner:ORMAT IND LTD

Process for co-producing commercially valuable products from byproducts of heavy oil and bitumen upgrading process

ActiveUS20150038599A1Increase productionImproved heavy oil and bitumen upgradingThermal non-catalytic crackingUrea derivatives preparationFuel oilCo product

The present invention is directed to modifications of bitumen and heavy oil upgrading and refining processes to synthesize synthetic crude oil and other valuable synthesized hydrocarbon products in an efficient manner along with the production of commercially valuable co-products from by-products formed by the upgrading process.

Owner:EXPANDER ENERGY

Production of biodegradable middle distillates

InactiveUS20040173502A1Easy to getHydrocarbon by hydrogenationLiquid carbonaceous fuelsAlkaneDiesel fuel

This invention relates to a process for production of middle distillates having biodegradability properties. More particularly, this invention relates to a process for production of middle distillates produced from a mainly paraffinic synthetic crude which is produced by the reaction of CO and H2, typically by the Fischer-Tropsch (FT) process. The middle distillate produced according to the process of the invention may be a diesel fuel, having an aromatics content of less than 9%, as determined by the ASTM D 5186 or IP 391 test method. The paraffinic chains of the middle distillate may be predominantly isoparaffins.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Process for Upgrading Heavy Oil and Bitumen

Disclosed is a process for the upgrading and demetallizing of heavy oils and bitumens. A crude heavy oil and / or bitumen feed is supplied to a solvent extraction process 104 wherein DAO and asphaltenes are separated. The DAO is supplied to an FCC unit 106 having a low conversion activity catalyst for the removal of metals contained therein. The demetallized distillate fraction is supplied to a hydrotreater 110 for upgrading and collected as a synthetic crude product stream. The asphaltene fraction can be supplied to a gasifier 108 for the recovery of power, steam and hydrogen, which can be supplied to the hydrotreater 110 or otherwise within the process or exported. An optional coker unit 234 can be used to convert excess asphaltenes and / or decant oil to naphtha, distillate and gas oil, which can be supplied to the hydrotreater 220.

Owner:KELLOGG BROWN & ROOT LLC

Oxidative desulfurization and denitrogenation of petroleum oils

InactiveUS7666297B2Fast in oxidizing the sulfurReduce the temperatureOrganic chemistryRefining with oxygen compoundsPtru catalystHydrocotyle bowlesioides

An improved oxidative process that employ a robust, non-aqueous, and oil-soluble organic peroxide oxidant for effective desulfurization and denitrogenation of hydrocarbons including petroleum fuels, hydrotreated vacuum gas oil (VGO), non-hydrotreated VGO, petroleum crude oil, synthetic crude oil from oil sand, and residual oil. Even at low concentrations and without the assistance of catalysts, the non-aqueous organic peroxide oxidant is extremely active and fast in oxidizing the sulfur and nitrogen compounds in the hydrocarbon feedstocks. Furthermore, the process generates a valuable organic acid by-product that is also used internally as the extractive solvent for effective removal of the oxidized sulfur and nitrogen from the hydrocarbons without the need of a final adsorption step. Novel process steps are also disclosed to substantially prevent yield loss in the oxidative process.

Owner:CPC CORPORATION

Partial uprading utilizing solvent deasphalting and DAO hydrocracking

ActiveUS20110198266A1Maximizing feedstock processing capacityMinimal investmentWorking-up pitch/asphalt/bitumen by chemical meansHydrocarbon distillationFuel oilSolvent

The described invention discloses an innovative solvent deasphalter and hydroconversion-processing configuration for converting bitumen or heavy oils to produce a transportable synthetic crude oil (SCO). The innovative processing scheme disclosed herein maximizes the synthetic crude oil yield at a minimal investment compared to currently known methods.

Owner:INST FR DU PETROLE

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com