Process for producing tailored synthetic crude oil that optimize crude slates in target refineries

a synthetic crude oil and refinery technology, applied in hydrocarbon oil treatment products, instruments, physical/chemical process catalysts, etc., can solve the problems of undesirable cost implications of selection and achieve the effects of reducing sulfur content, reducing metal content, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

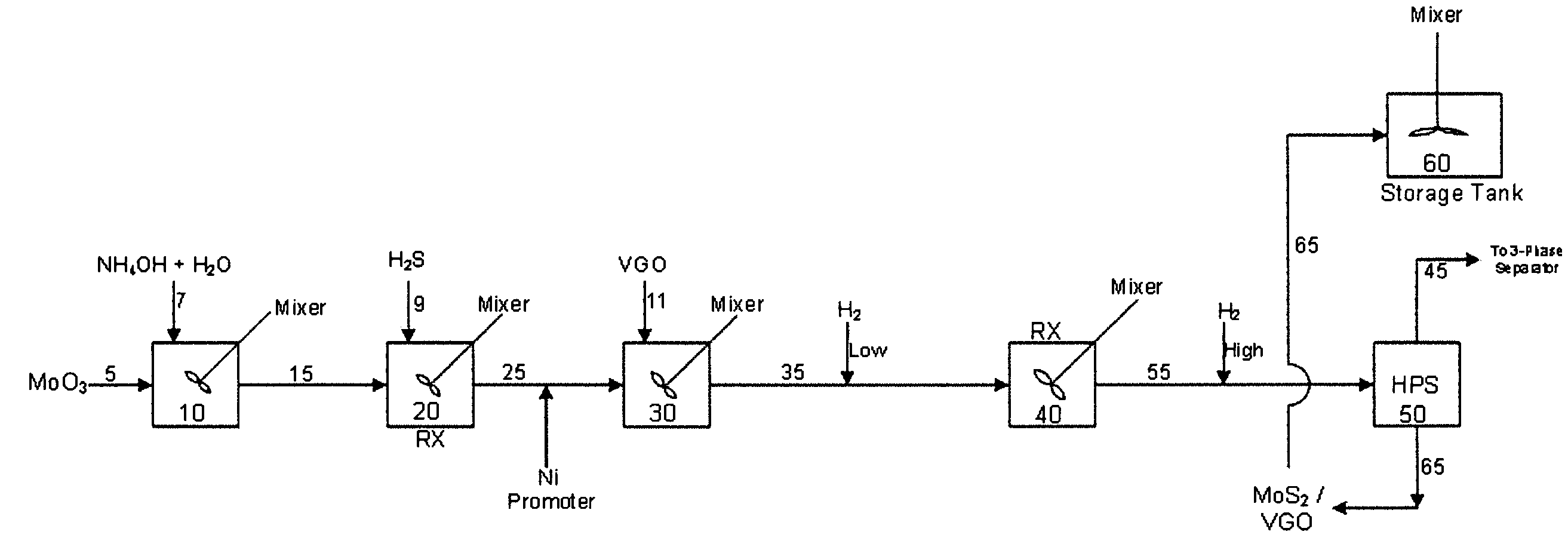

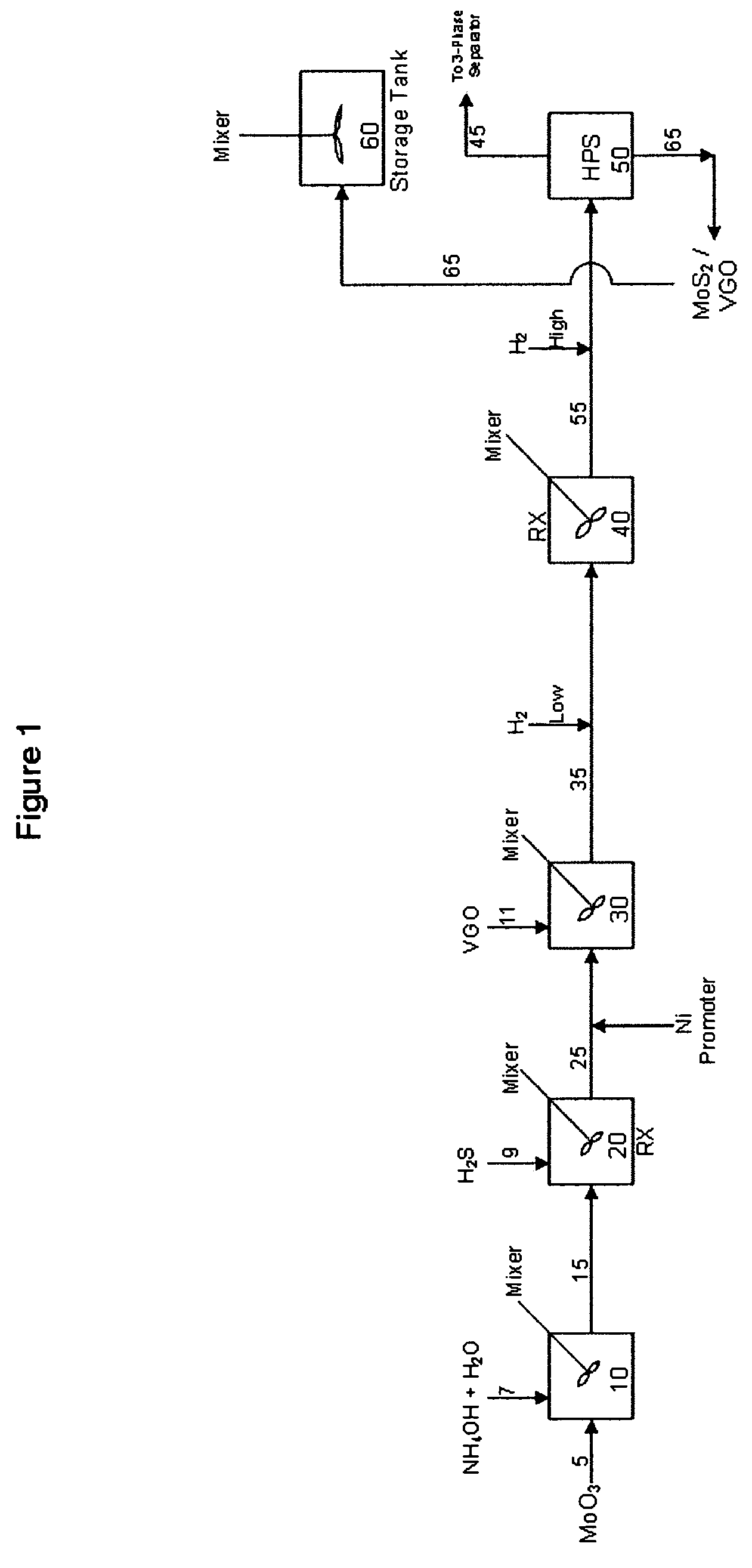

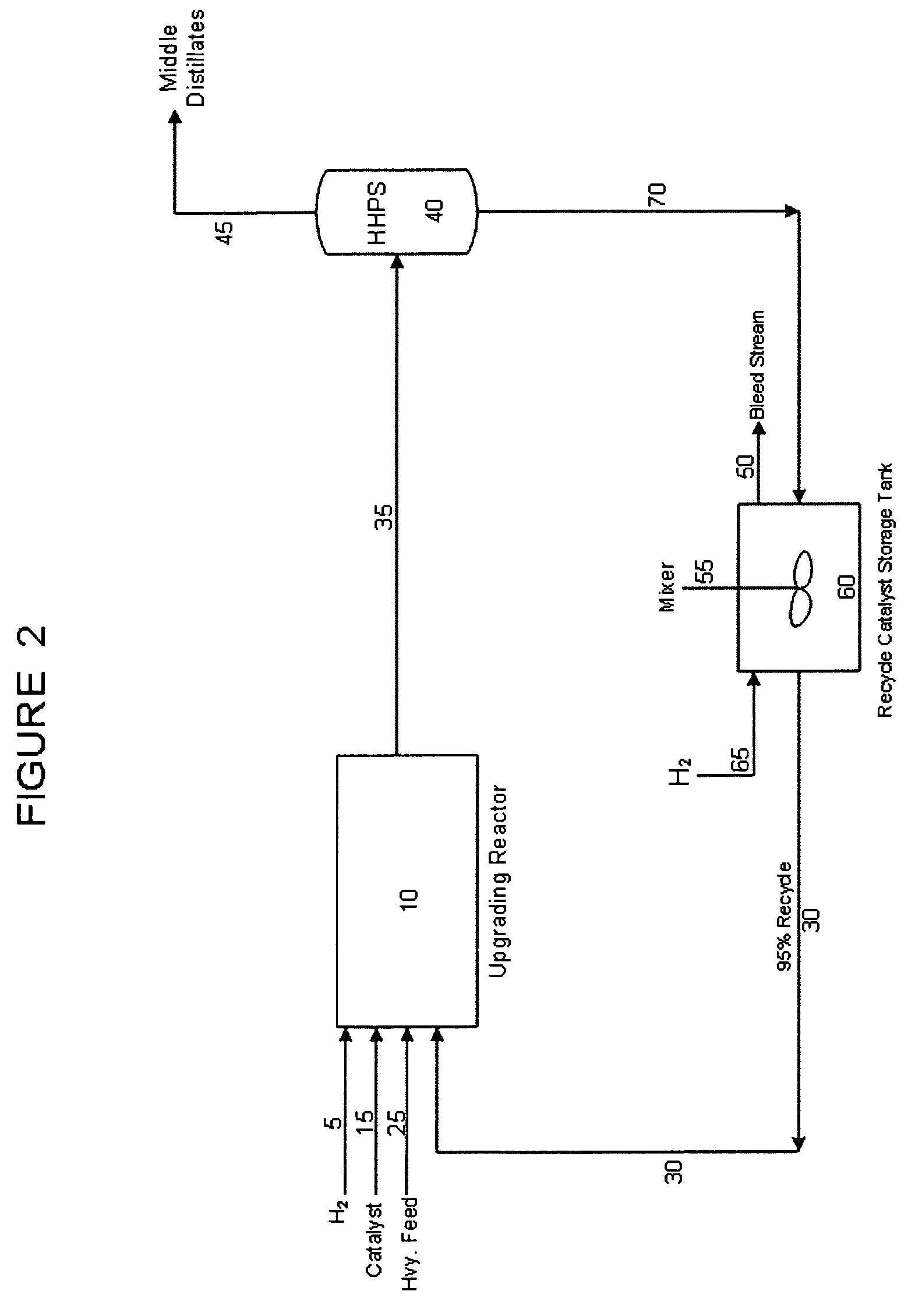

Method used

Image

Examples

example

Example

[0067]Refinery planners at company downstream locations run weekly linear program models to optimize the refinery's crude slate, operation, and utilization, nominally 20 weeks in advance of the actual processing date. The base crude slate is chosen, and the linear program model is run again substituting the tailored synthetic crude for all or some of the base crude slate. The willing-to-pay-price and optimum volume are calculated. For example Refinery “A” may specify a 30 days supply of 100 MBPD 28.6 API syncrude with 10 percent bottoms, 80 percent middle distillates and gas oil, and 10 percent naphtha at $32.12 per bbl. This information would be communicated to the planner at Upgrader “1”. Simultaneously, Refinery “B” may specify a need for similar 30 days supply of 60 MBPD 36 API bottomless Synthetic Precision Crude Oil at $37.16 per bbl, and again the information is communicated to Upgrader “1” planner. Upgrader “1” is capable of producing a nominal 200 MBPD, and would run...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com