Innovative heavy crude conversion/upgrading process configuration

a technology of heavy crude oil and process configuration, which is applied in the direction of hydrotreatment process, hydrocarbon oil cracking, hydrocarbon oil treatment, etc., can solve the problems of unsatisfactory world demand for light crude oil, unsustainable world supply of light crude oil, and use of nature's resources, so as to maximize the yield of liquid sco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

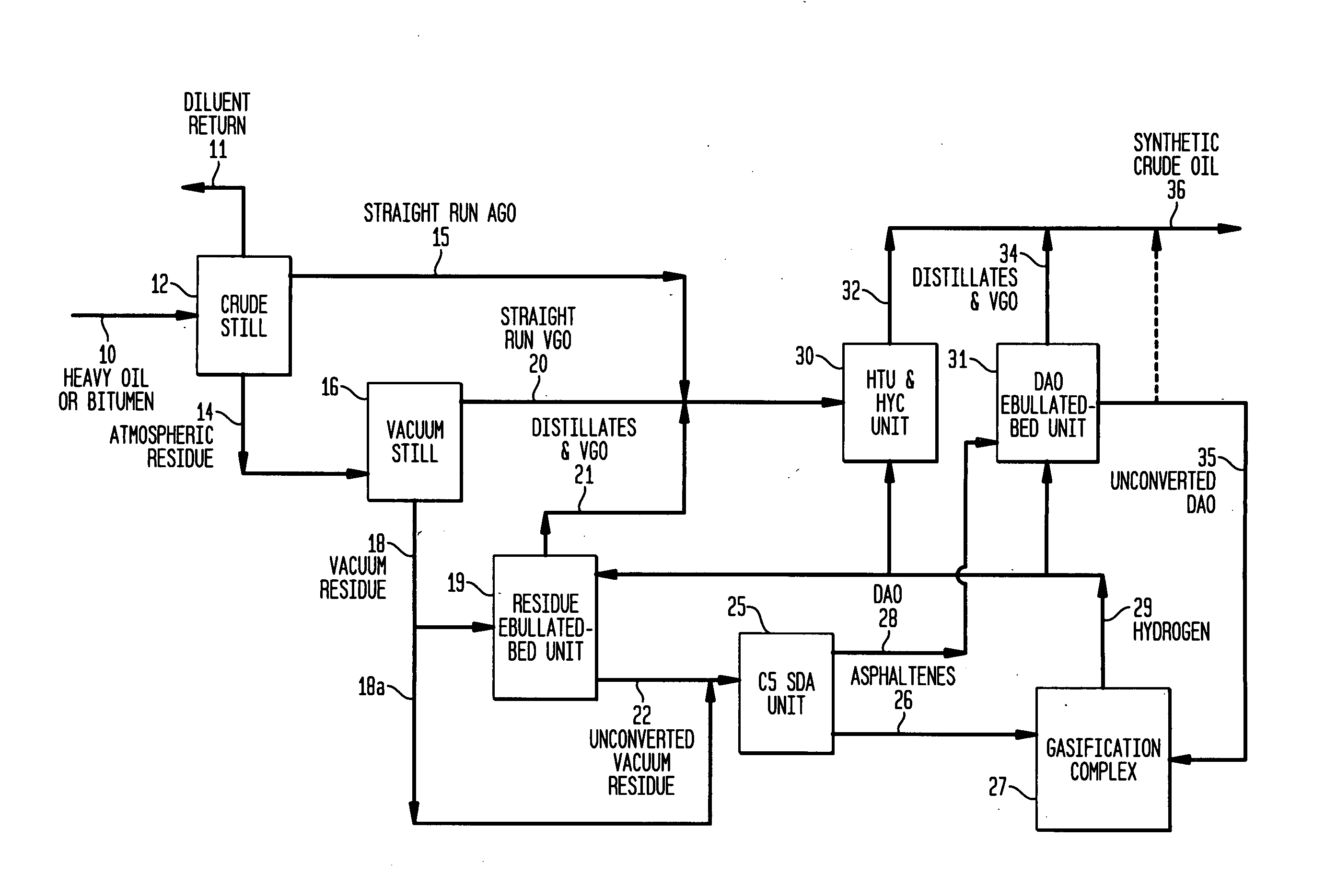

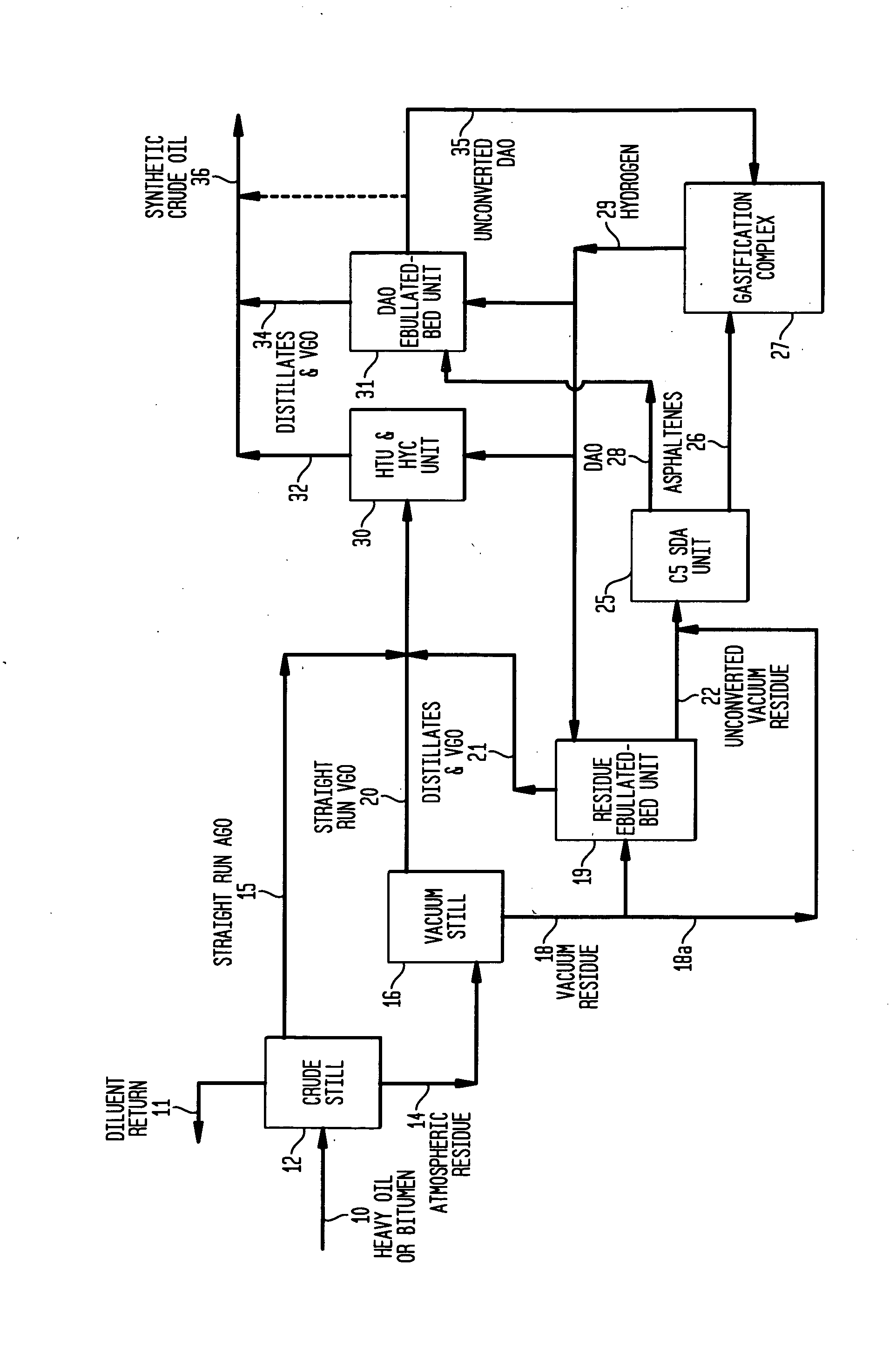

[0053]A flowrate of 300,000 BPSD of bitumen is processed in the example. The rate does not include the light diluent which is used to transport the crude from the field. The bitumen is fed to an atmospheric still which produces the light diluent (returned to the field), 43,400 BPSD of straight run atmospheric gas oil (SRAGO), and 256,600 BPSD of atmospheric residue. The atmospheric residue is sent to the vacuum fractionator to produce a vacuum residue stream (167,500 BPSD) along with 89,100 BPSD straight run vacuum gas oil (SRVGO) stream. The SRAGO and SRVGO are routed to traditional fixed-bed hydrotreating and hydrocracking units, respectively. These values and other flowrates are shown in Table 1.

[0054]The vacuum residue stream from the vacuum fractionator is split between an ebullated-bed hydroconversion unit and a solvent deasphalting unit. The split is determined by attaining a hydrogen-balanced plant. In this example, of the total 167,500 BPSD of straight run vacuum residue, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield rate | aaaaa | aaaaa |

| yield rate | aaaaa | aaaaa |

| volume percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com