Patents

Literature

819results about "Liquid hydrocarbon mixture recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

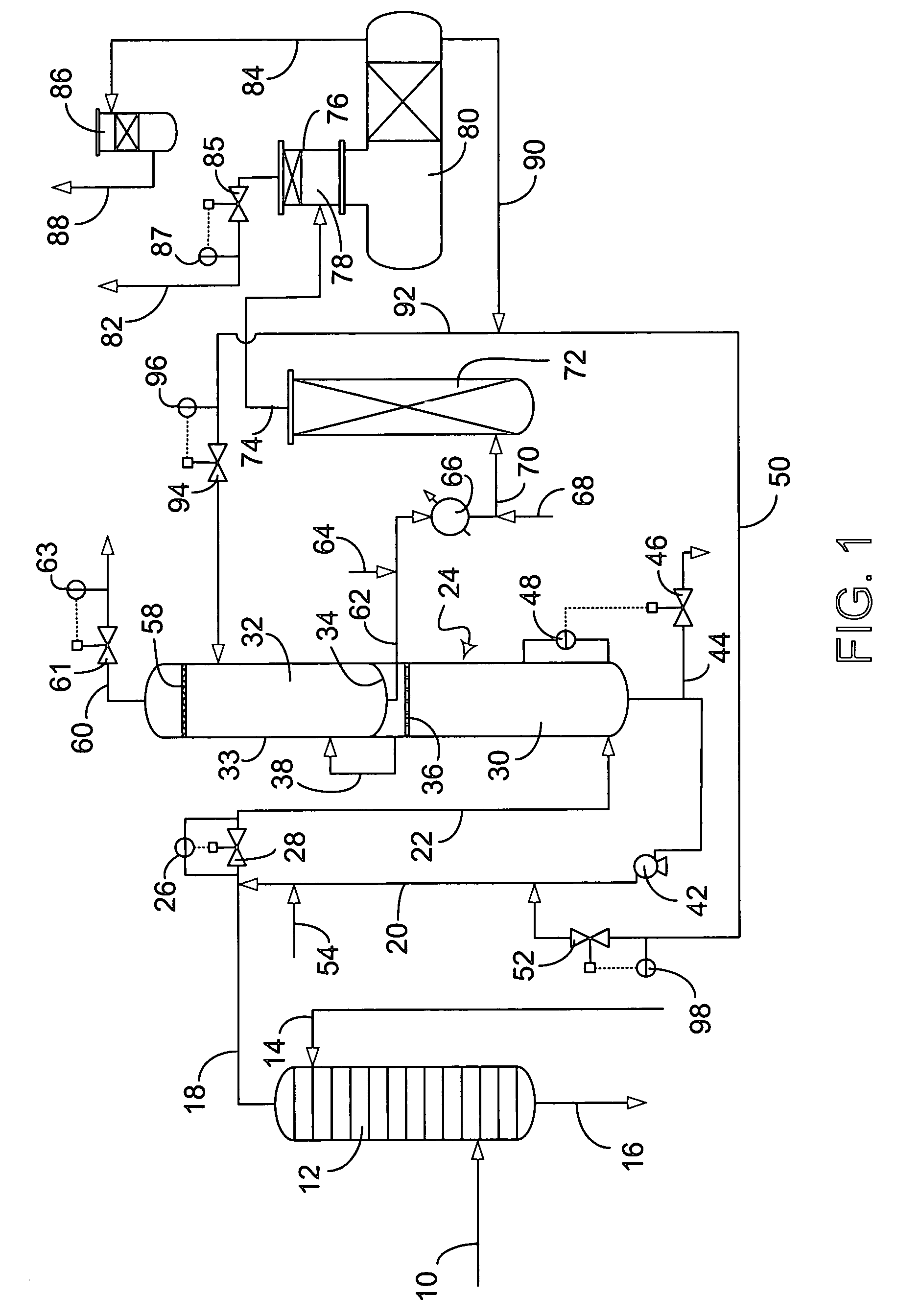

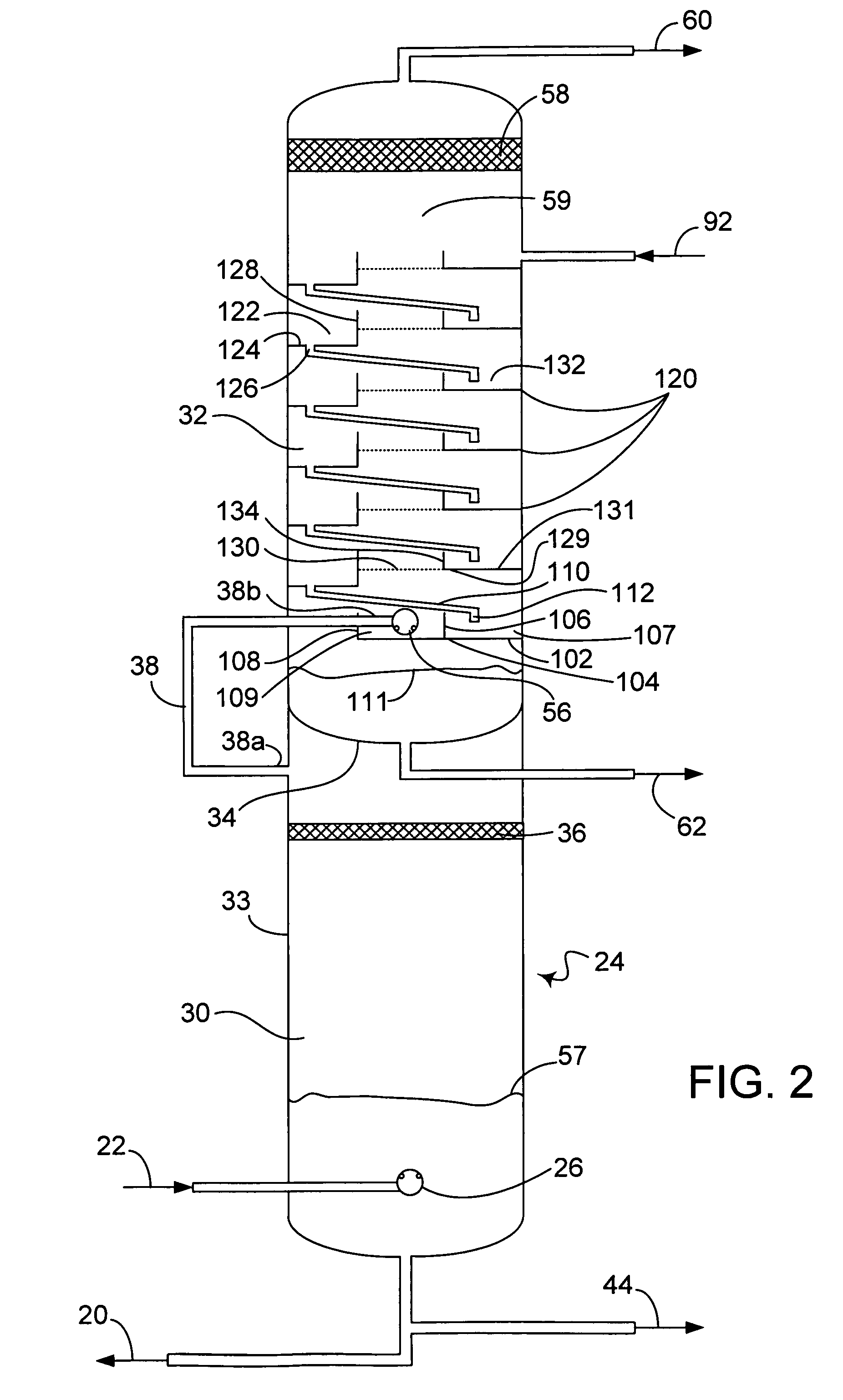

Hydrocarbon gas processing

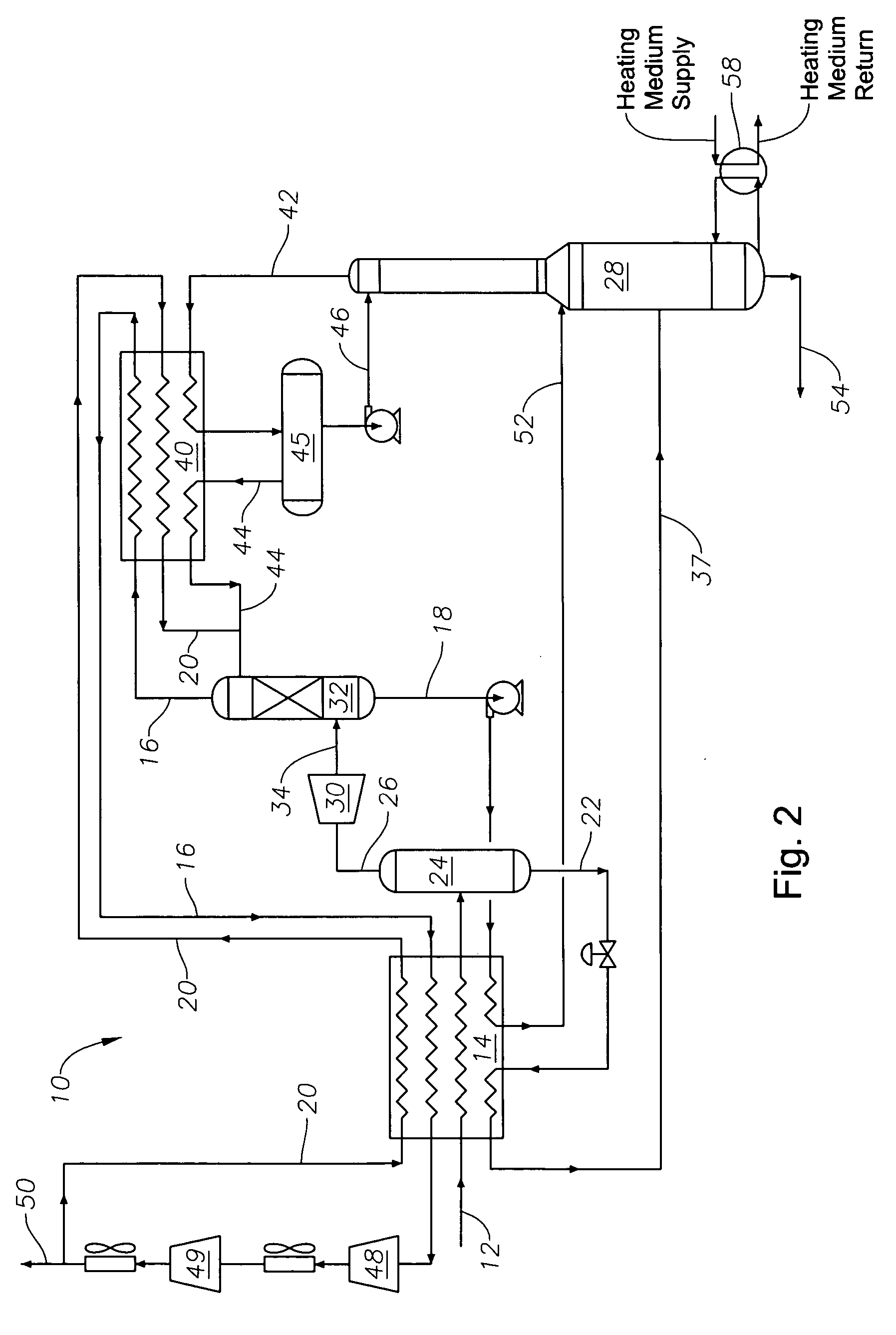

A process for the recovery of ethane, ethylene, propane, propylene and heavier hydrocarbon components from a hydrocarbon gas stream is disclosed. In recent years, the preferred method of separating a hydrocarbon gas stream generally includes supplying at least portions of the gas stream to a fractionation tower having at least one reboiler, and often one or more side reboilers, to supply heat to the column by withdrawing and heating some of the tower liquids to produce stripping vapors that separate the more volatile components from the desired components. The reboiler and side reboilers (if any) are typically integrated into the feed stream cooling scheme to provide at least a portion of the refrigeration needed to condense the desired components for subsequent fractionation in the distillation column. In the process disclosed, the tower reboiling scheme is modified to use one or more tower liquid distillation streams from a point higher in the column than is used in the conventional reboiling scheme, providing colder stream(s) for the reboiler(s) that allow more effective cooling of the feed streams and thereby improve the efficiency with which the desired components are recovered. In addition, the tower liquid streams withdrawn from a higher point in the column contain larger quantities of the more volatile components, which when vaporized provide better stripping of undesirable components like carbon dioxide without reducing the recovery of the desired components. The heated distillation stream is returned to a lower point on the fractionation tower that is separated from the withdrawal point by at least one theoretical stage.

Owner:UOP LLC

Hydrocarbon gas processing

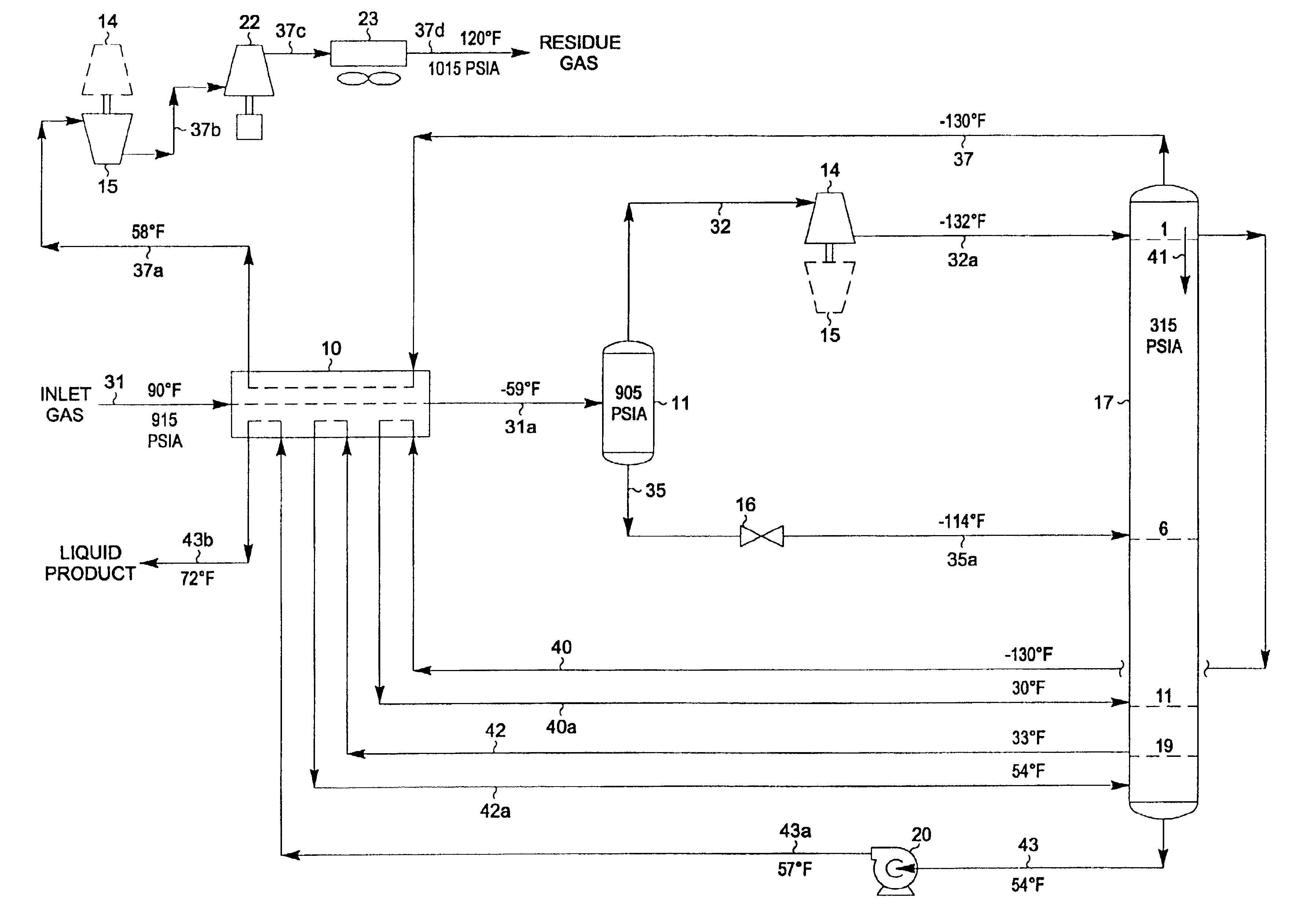

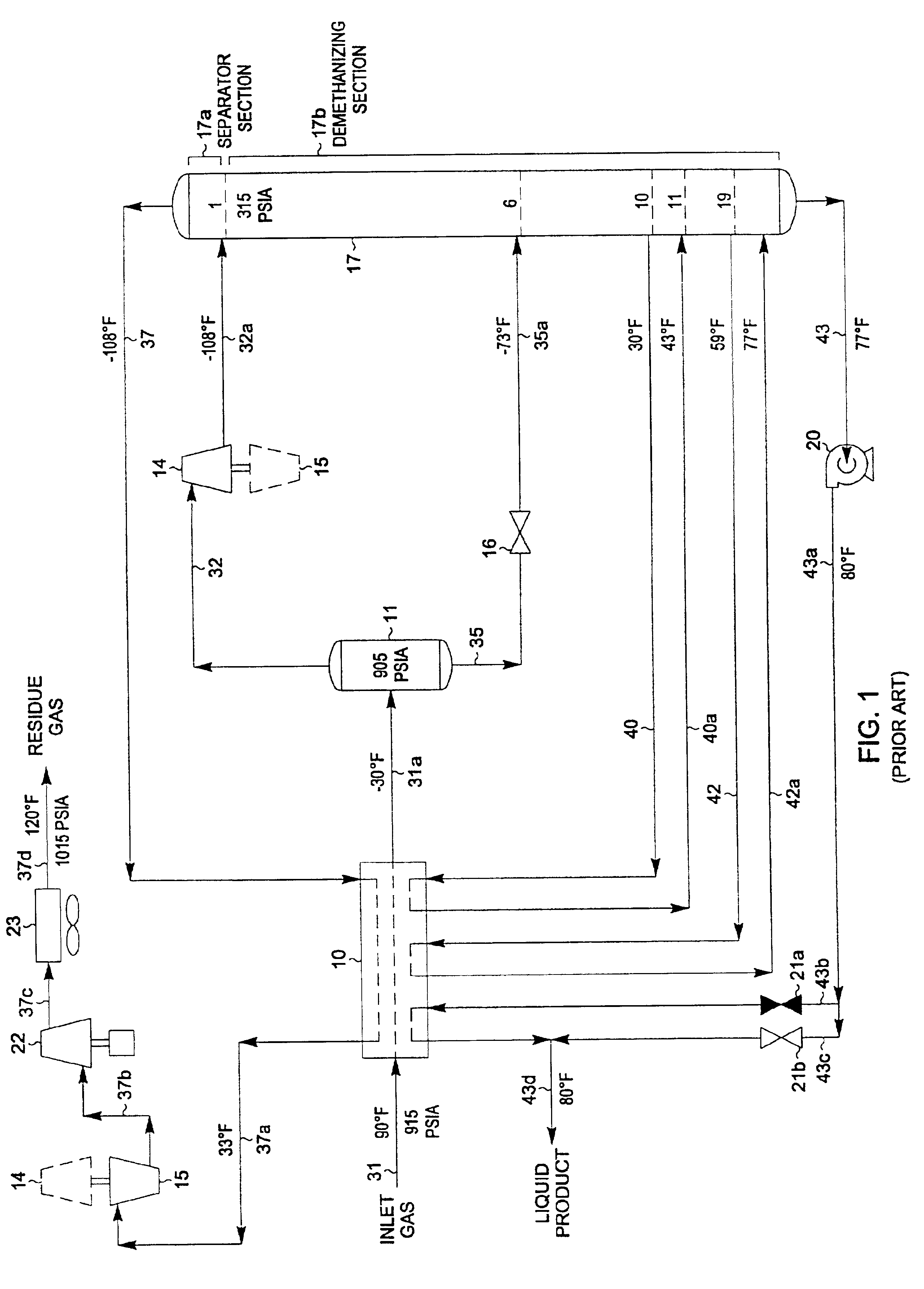

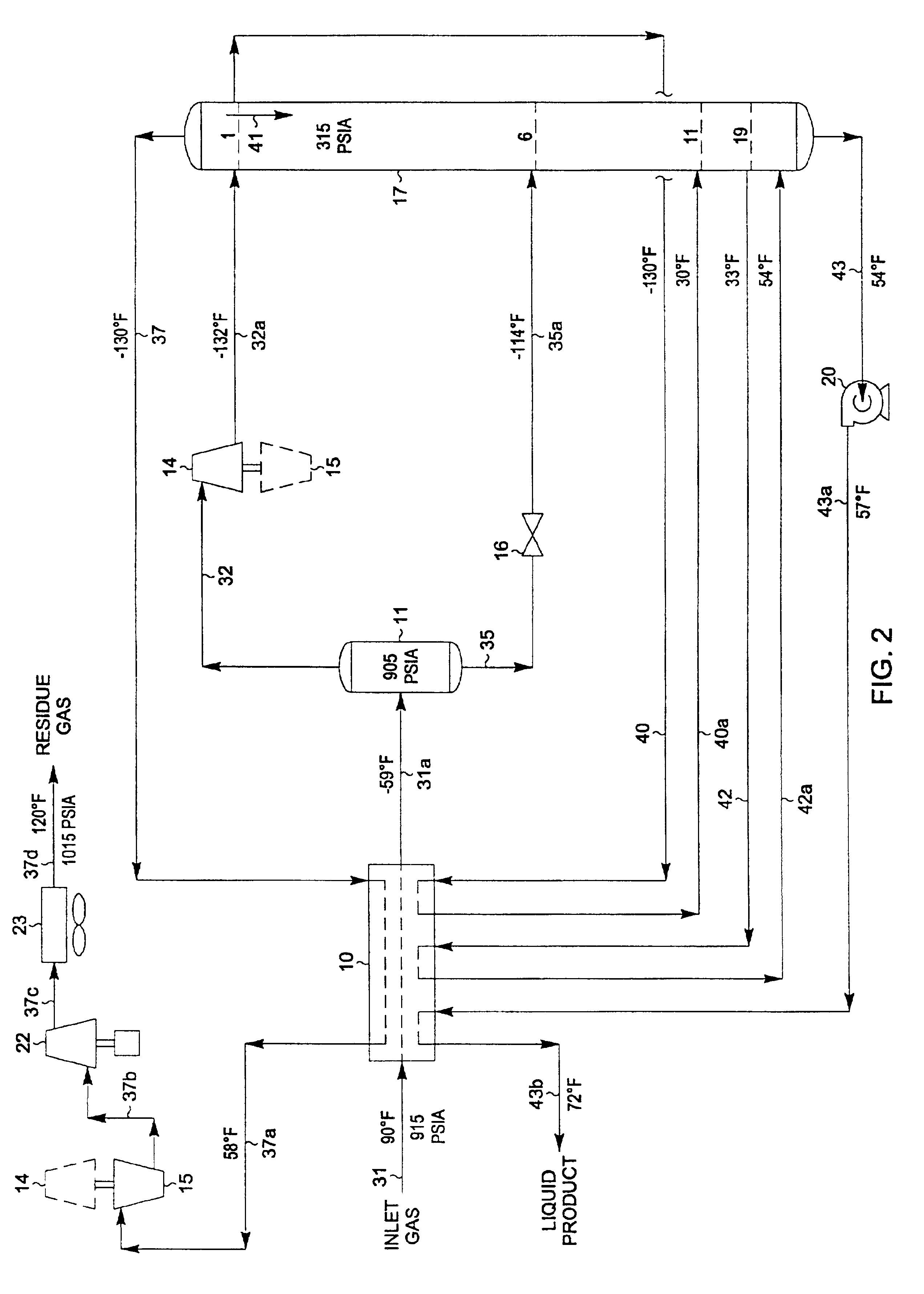

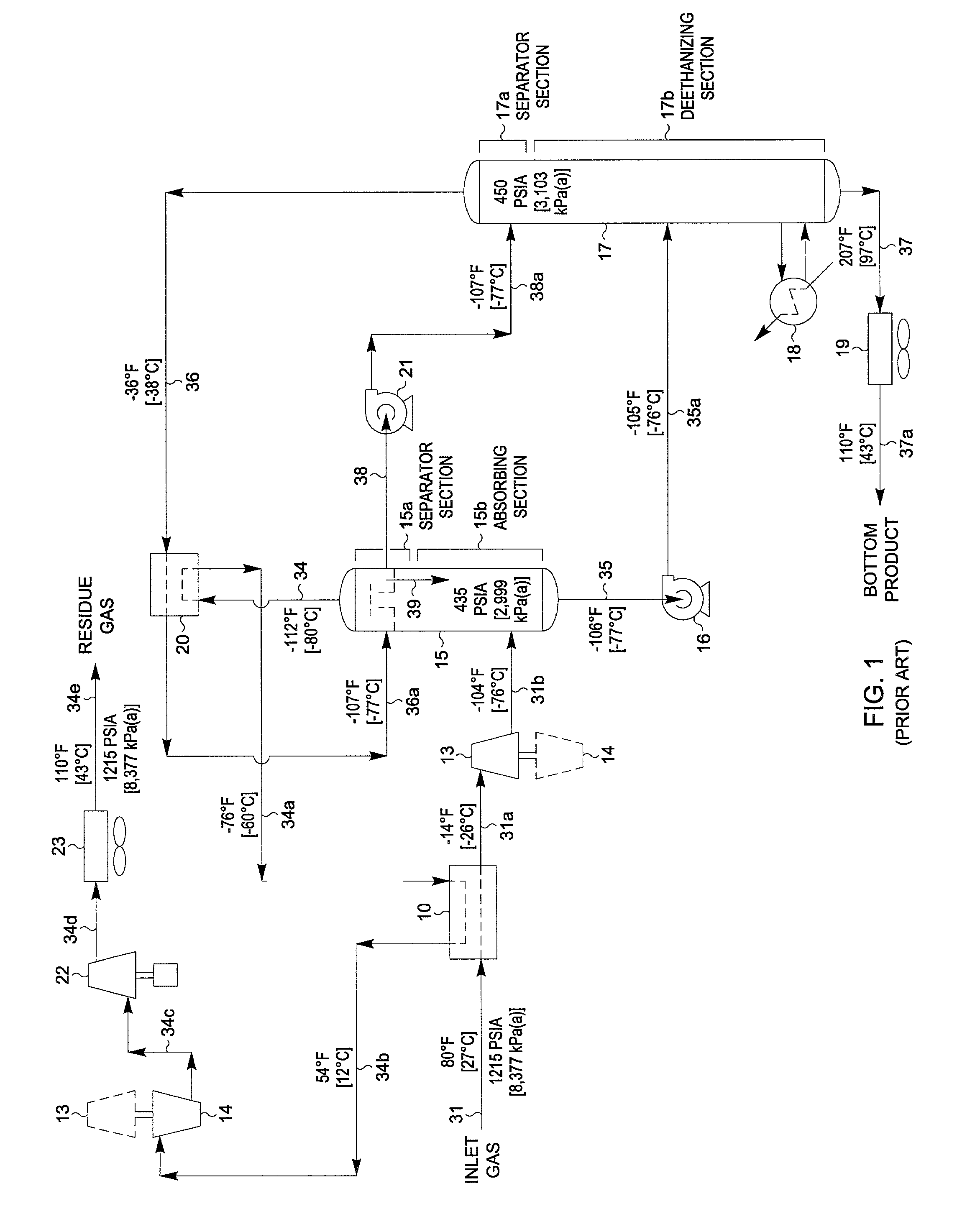

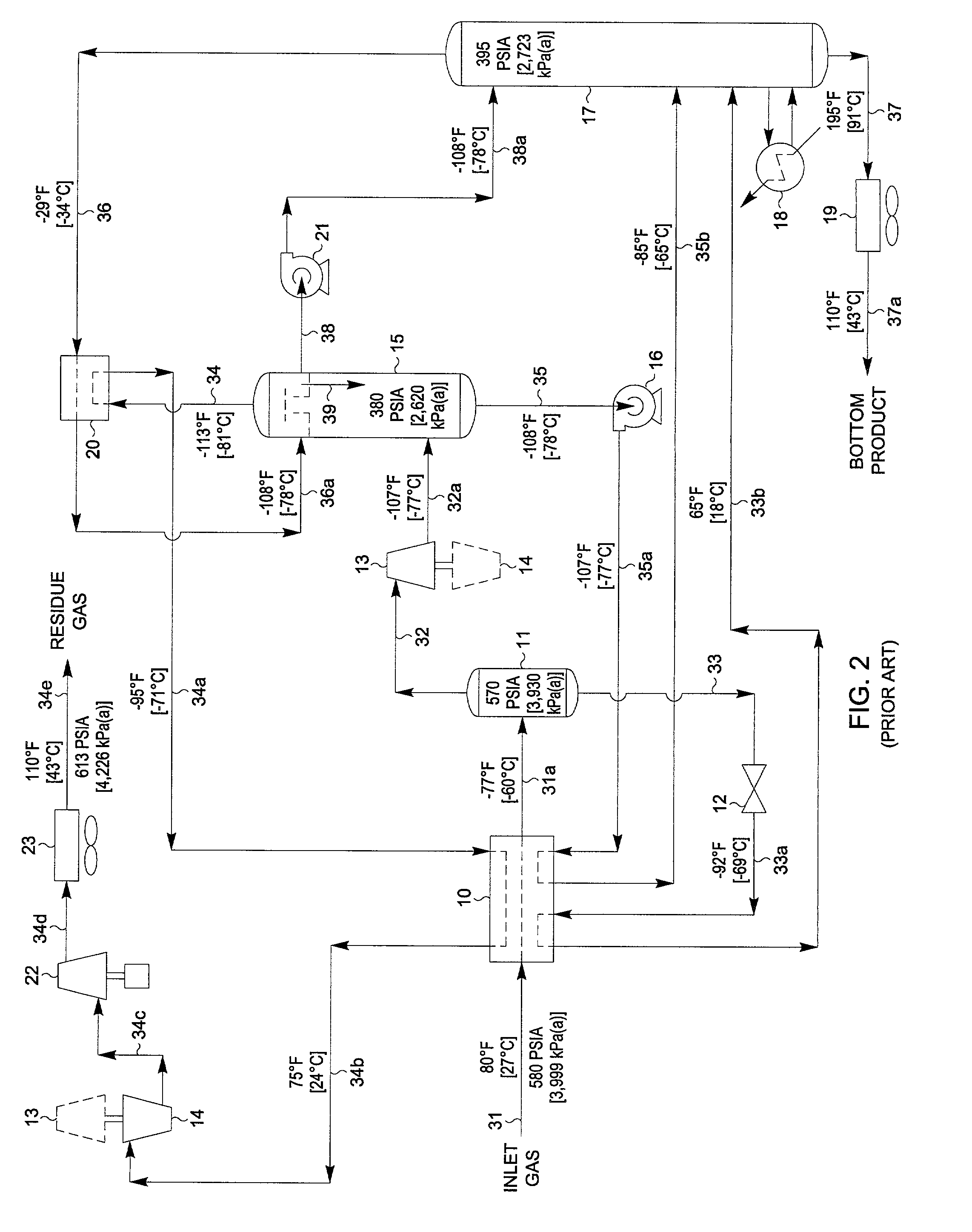

A process for the recovery of propane, propylene and heavier hydrocarbon components from a hydrocarbon gas stream is disclosed. The stream is cooled and / or expanded to partially condense it, then separated to provide a first vapor stream. The first vapor stream is directed into a contacting device whereby vapors and liquids are formed. The liquids are directed to a distillation column operating at lower pressure wherein a second vapor stream is separated to recover a product containing the major portion of the C3 components and heavier hydrocarbon components. The second vapor stream is directed into heat exchange relation with the vapors to cool the second vapor stream and condense at least a part of it, forming a condensed stream. At least a portion of the condensed stream is directed to the contacting device to intimately contact the first vapor stream; the remaining portion (if any) of the condensed stream can be supplied to the distillation column as its top feed. The quantities and temperatures of the feeds to the contacting device and the distillation column are effective to maintain the overhead temperatures of the contacting device and the distillation column at temperatures whereby the major portion of the desired components is recovered.

Owner:ELCOR CORP

Hydrocarbon separation process and apparatus

InactiveUS6363744B2Reduce the temperaturePromote recoverySolidificationLiquefactionPhysical chemistryRefrigeration

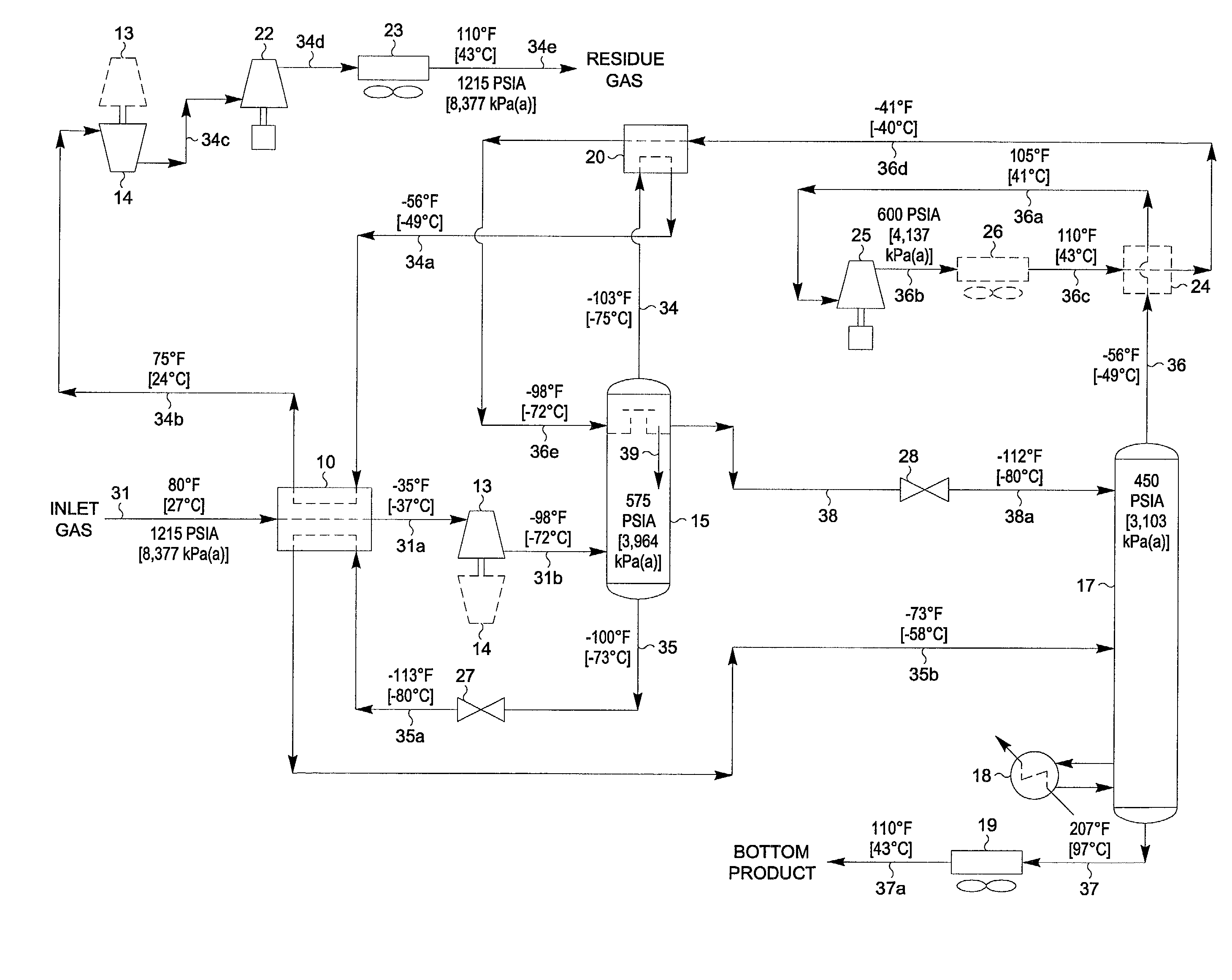

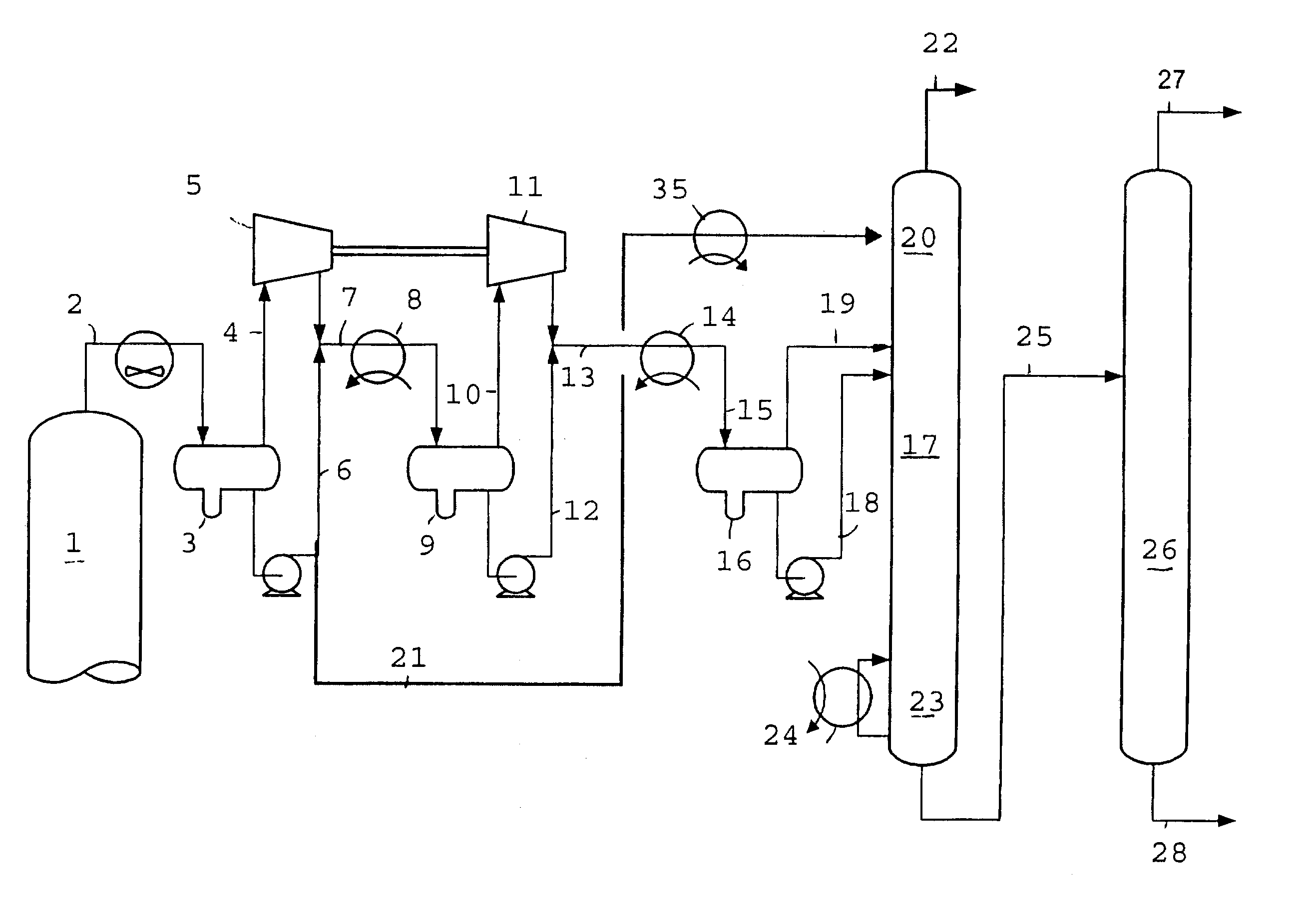

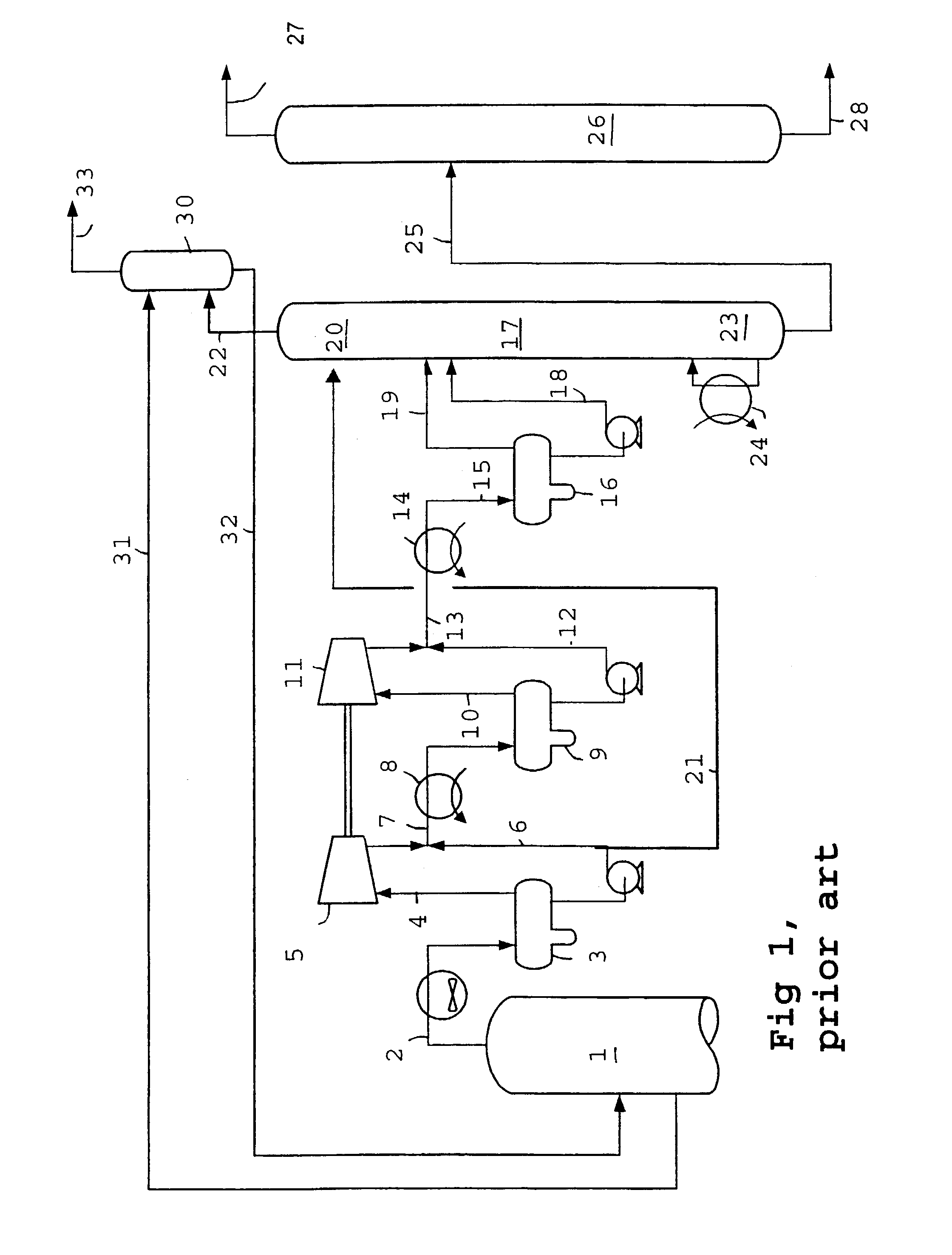

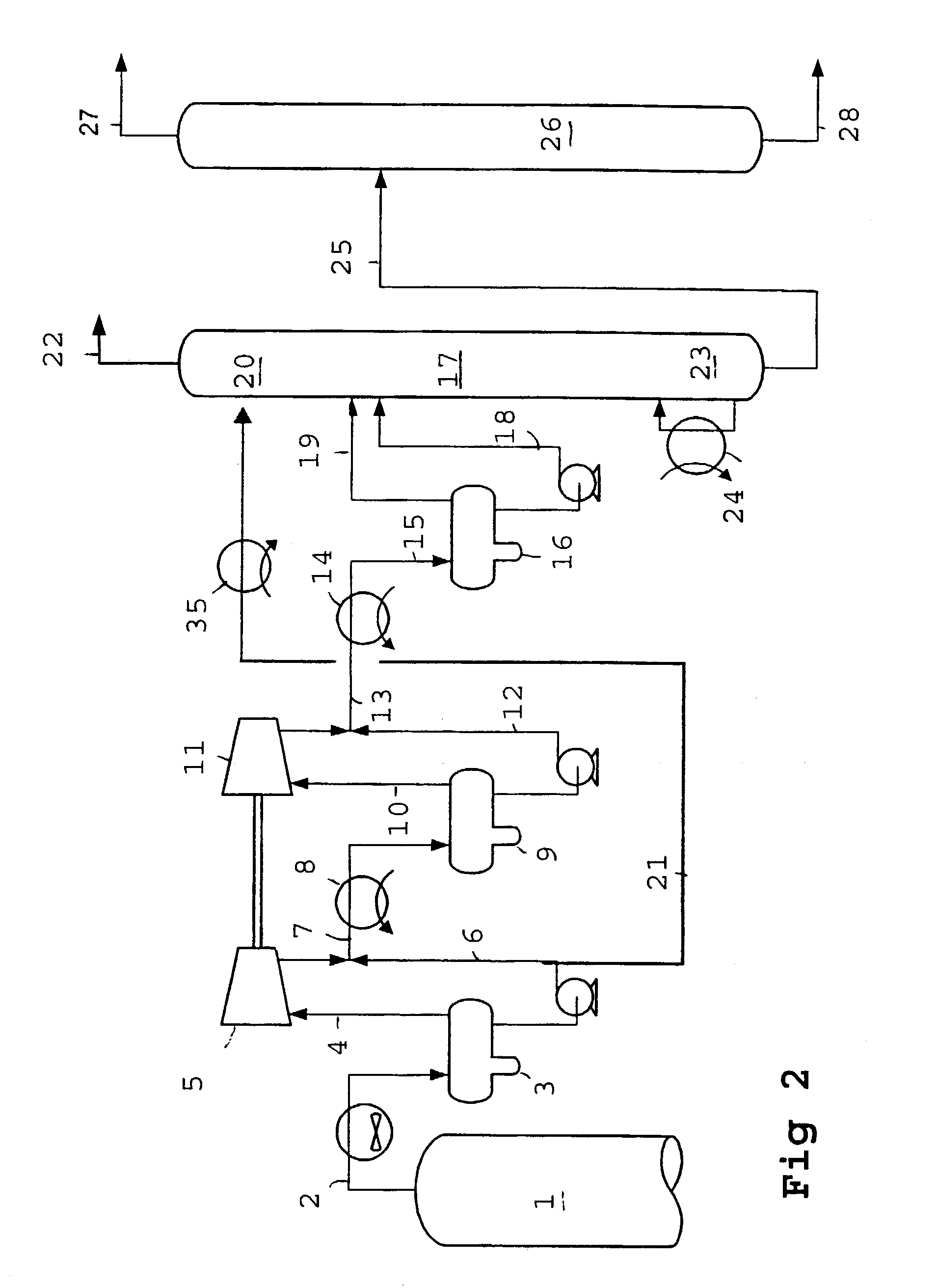

A process is described for separating the heavier hydrocarbons from a gaseous hydrocarbon feed wherein a first separator is employed to separate partially condensed gaseous feed and wherein the vapour portion undergoes work expansion and is fed to a fractionation column. The liquid portion is subcooled in heat exchange with the overhead vapour from the fractionation column, expanded, evaporated to provide refrigeration at a low temperature level, and fed to the fractionation column. The rewarmed residual vapour is subsequently compressed to a pressure suitable for export, with a portion of the compressed gas being cooled, condensed and recycled back to reflux the top section of the fractionation column.Also described is a process wherein a first separator is employed to separate partially condensed gaseous feed and wherein the vapour portion undergoes work expansion and is fed to a high pressure wash column. The liquid portion is expanded and fed to the base of the high pressure wash column. Bottoms liquid from the wash column is subcooled in heat exchange with the overhead vapour from a fractionation column, expanded, evaporated to provide refrigeration at a low temperature level, and fed to the fractionation column. Vapour from the high pressure wash column is partially condensed, with the liquid portion used to provide reflux to the high pressure wash column and the fractionation column.The processes are especially applicable to recovery of ethane and heavier components from natural gas. Overall process power requirements are reduced, recovery of the desired heavy hydrocarbons is increased or both of these effects are realised.

Owner:COSTAIN OIL GAS & PROCESS

Continuous process for converting natural gas to liquid hydrocarbons

InactiveUS20070238909A1Easily toleratedContinuous regenerationMolecular sieve catalystLiquid hydrocarbon mixture recoveryAlkaneOxygen

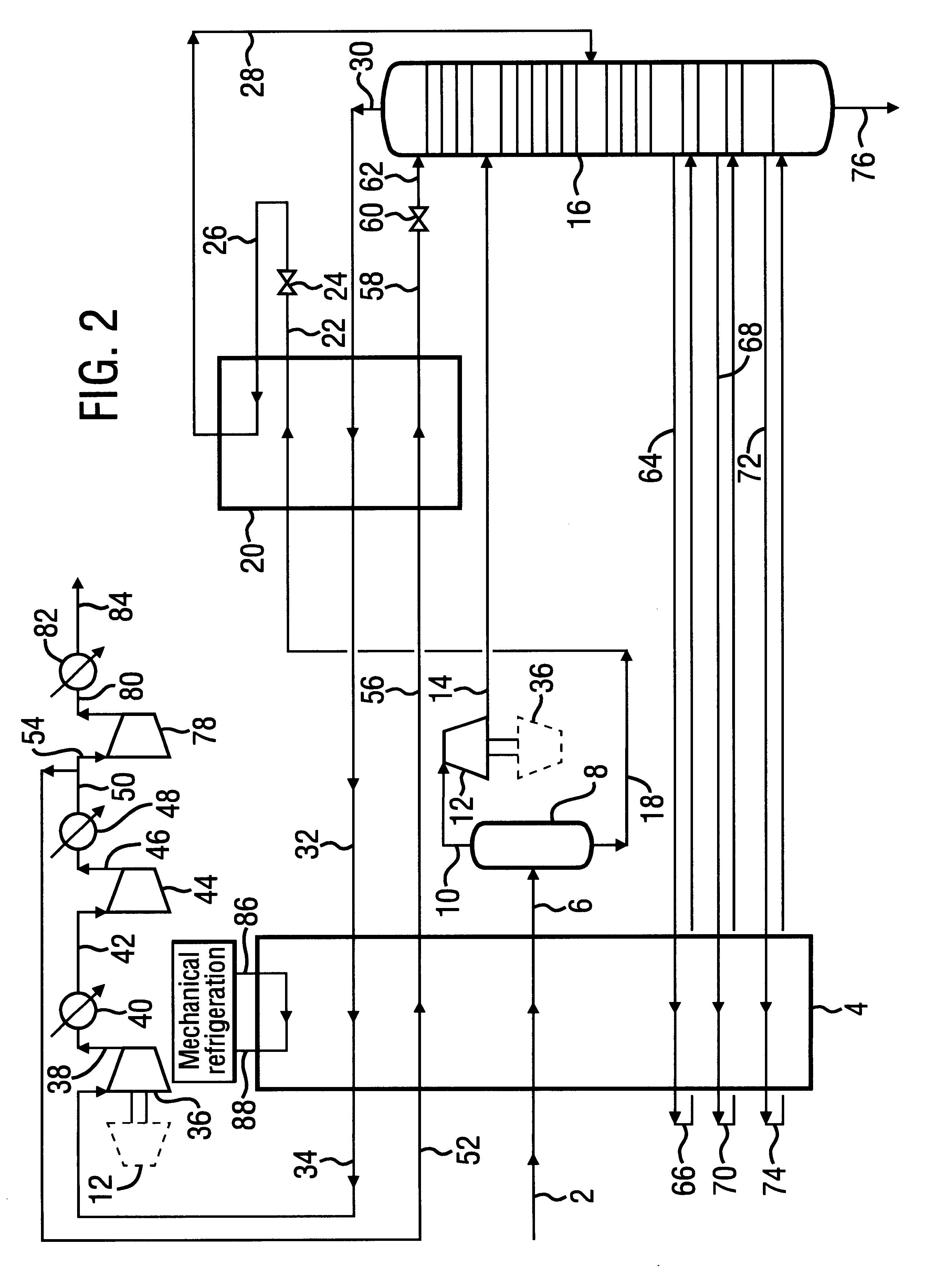

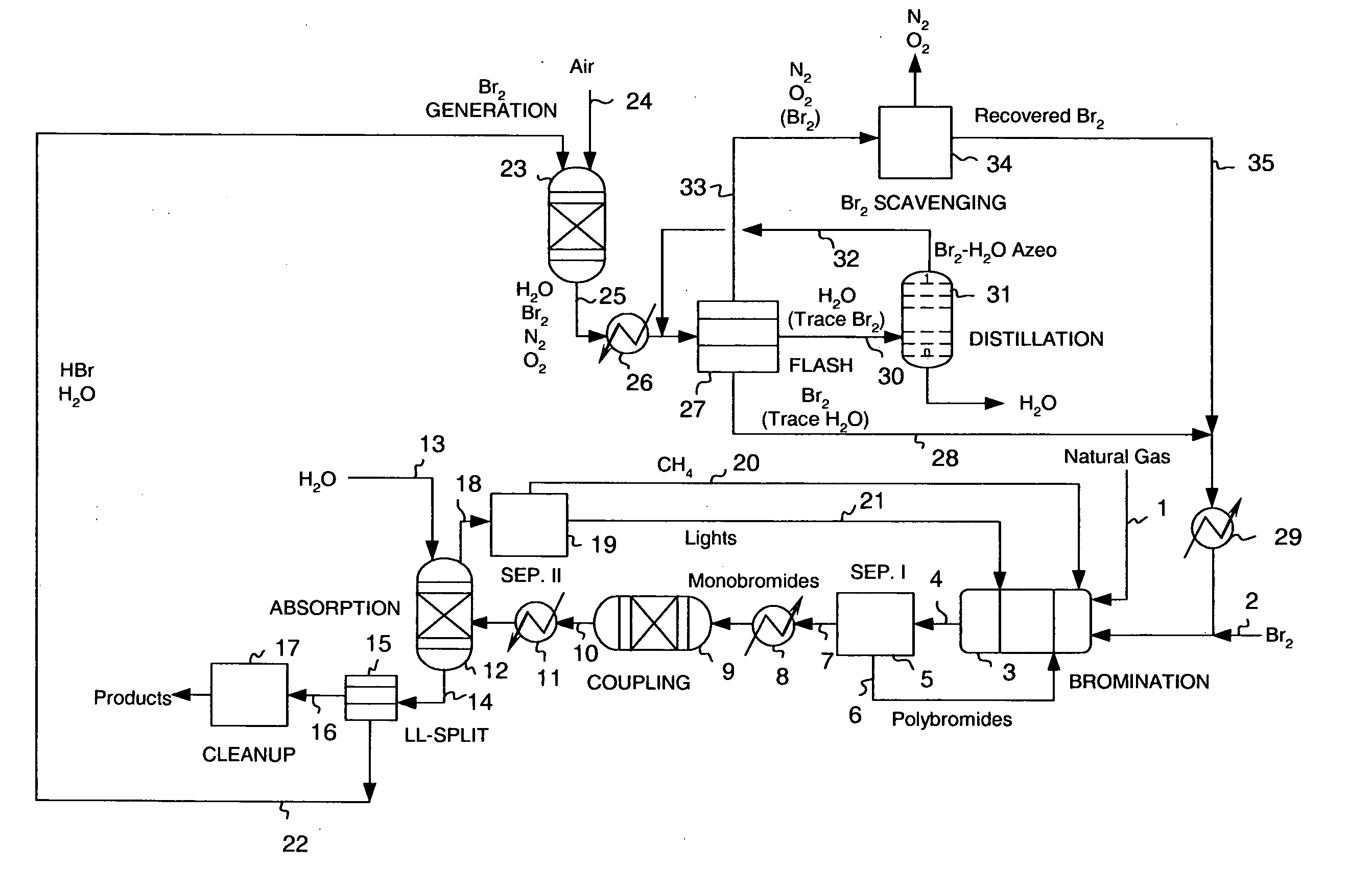

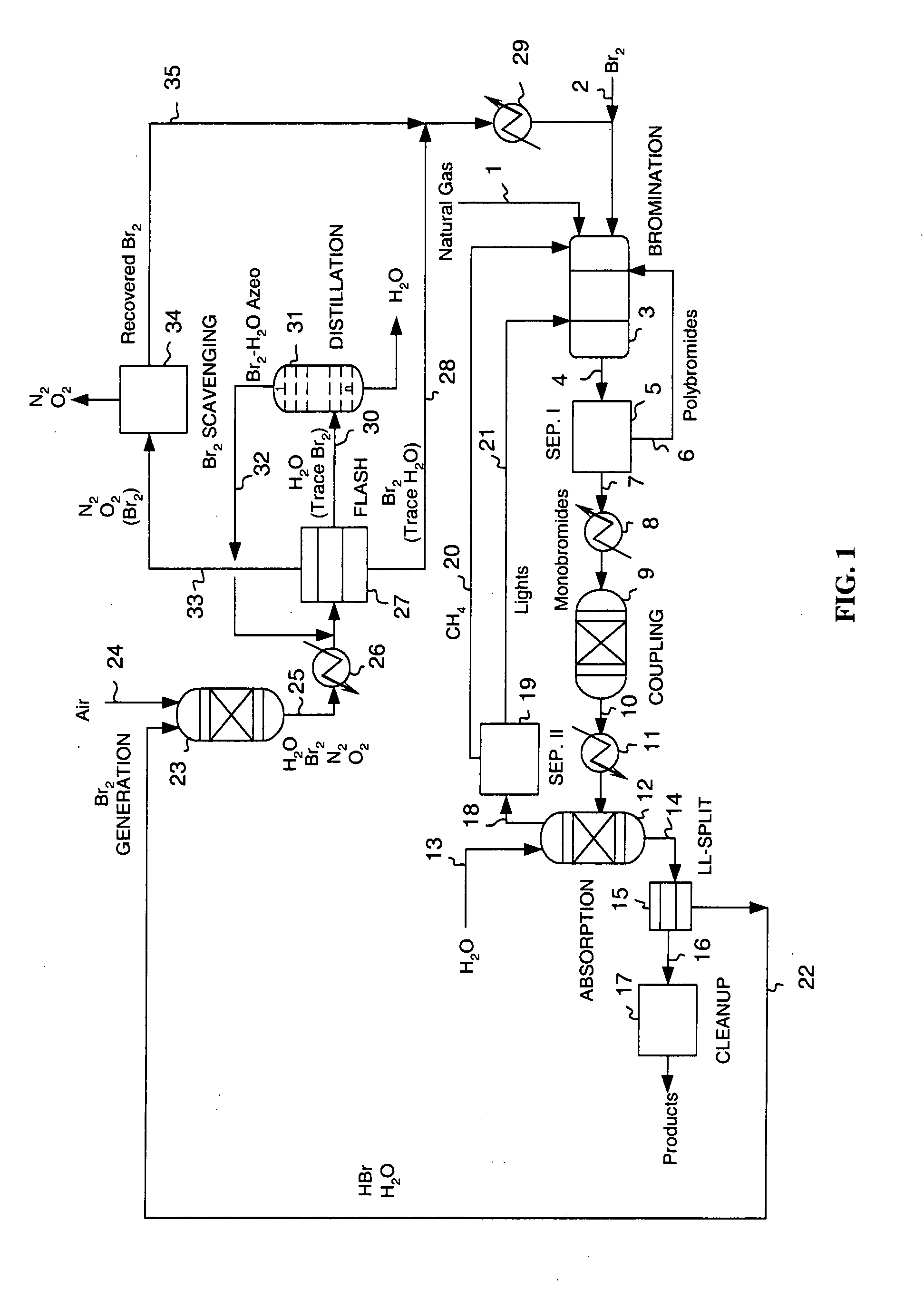

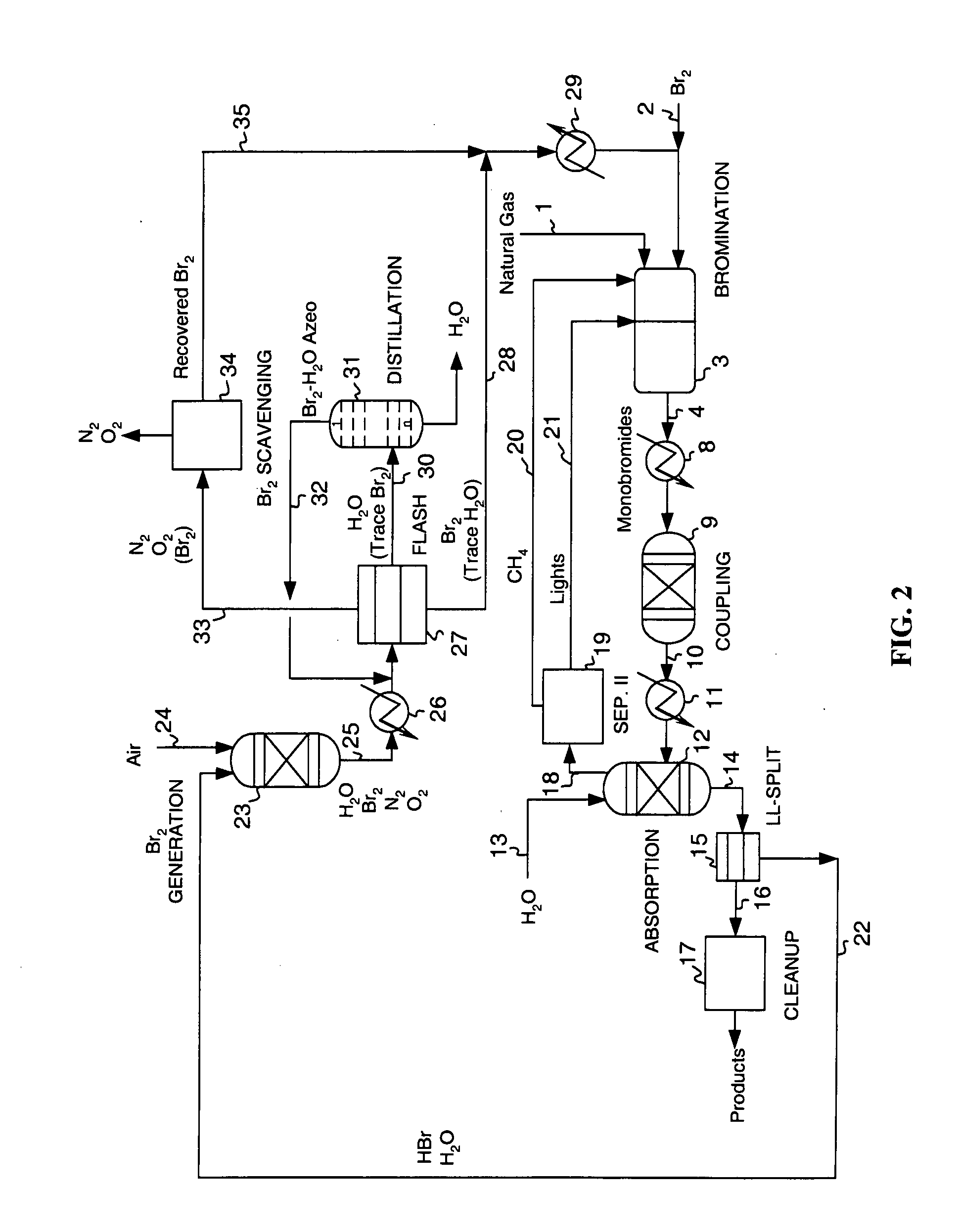

An improved continuous process for converting methane, natural gas, or other hydrocarbon feedstocks into one or more higher hydrocarbons or olefins by continuously cycling through the steps of alkane halogenation, product formation (carbon-carbon coupling), product separation, and regeneration of halogen is provided. Preferably, the halogen is continually recovered by reacting hydrobromic acid with air or oxygen. The invention provides an efficient route to aromatic compounds, aliphatic compounds, mixtures of aliphatic and aromatic compounds, olefins, gasoline grade materials, and other useful products.

Owner:REACTION 35 LLC

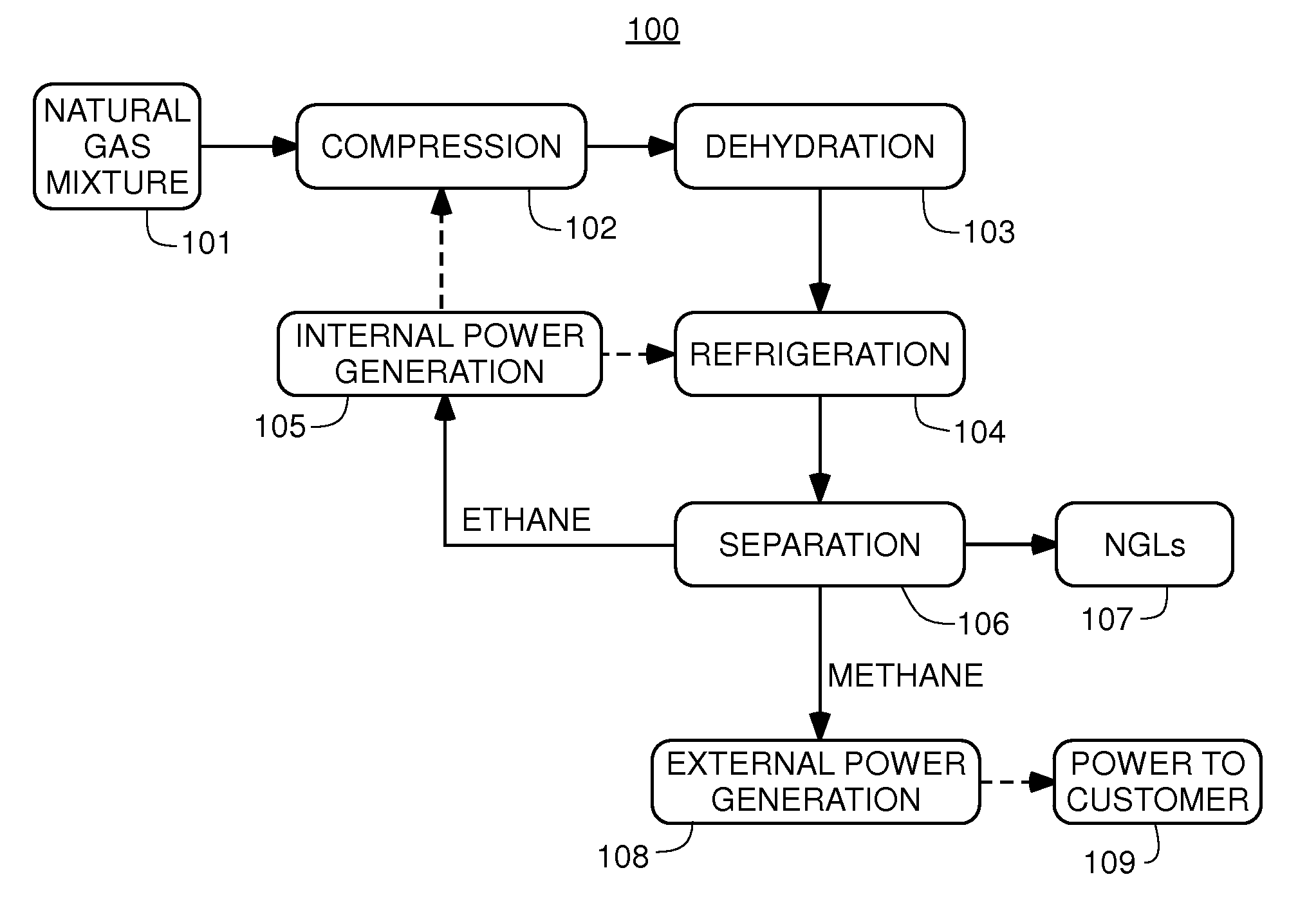

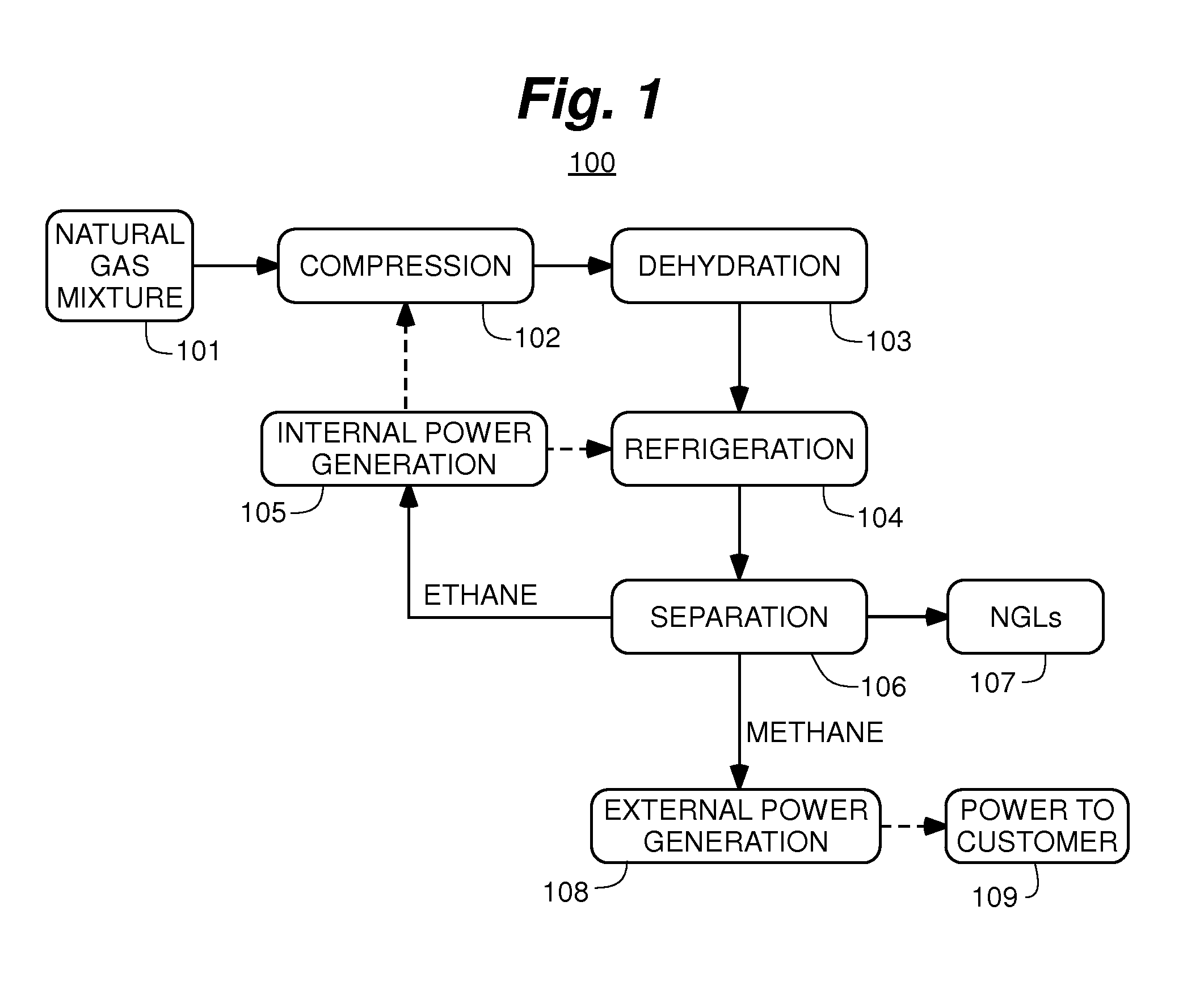

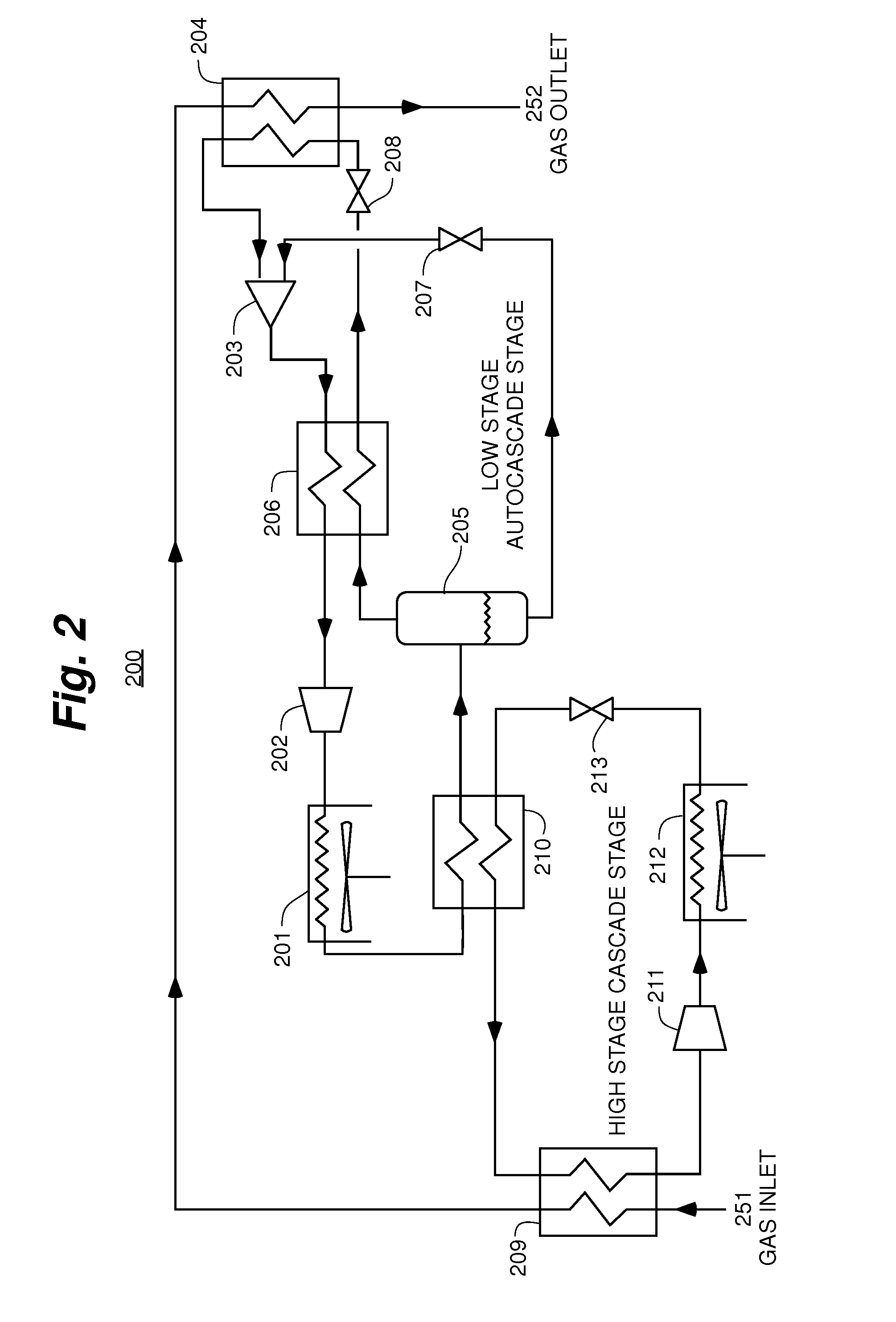

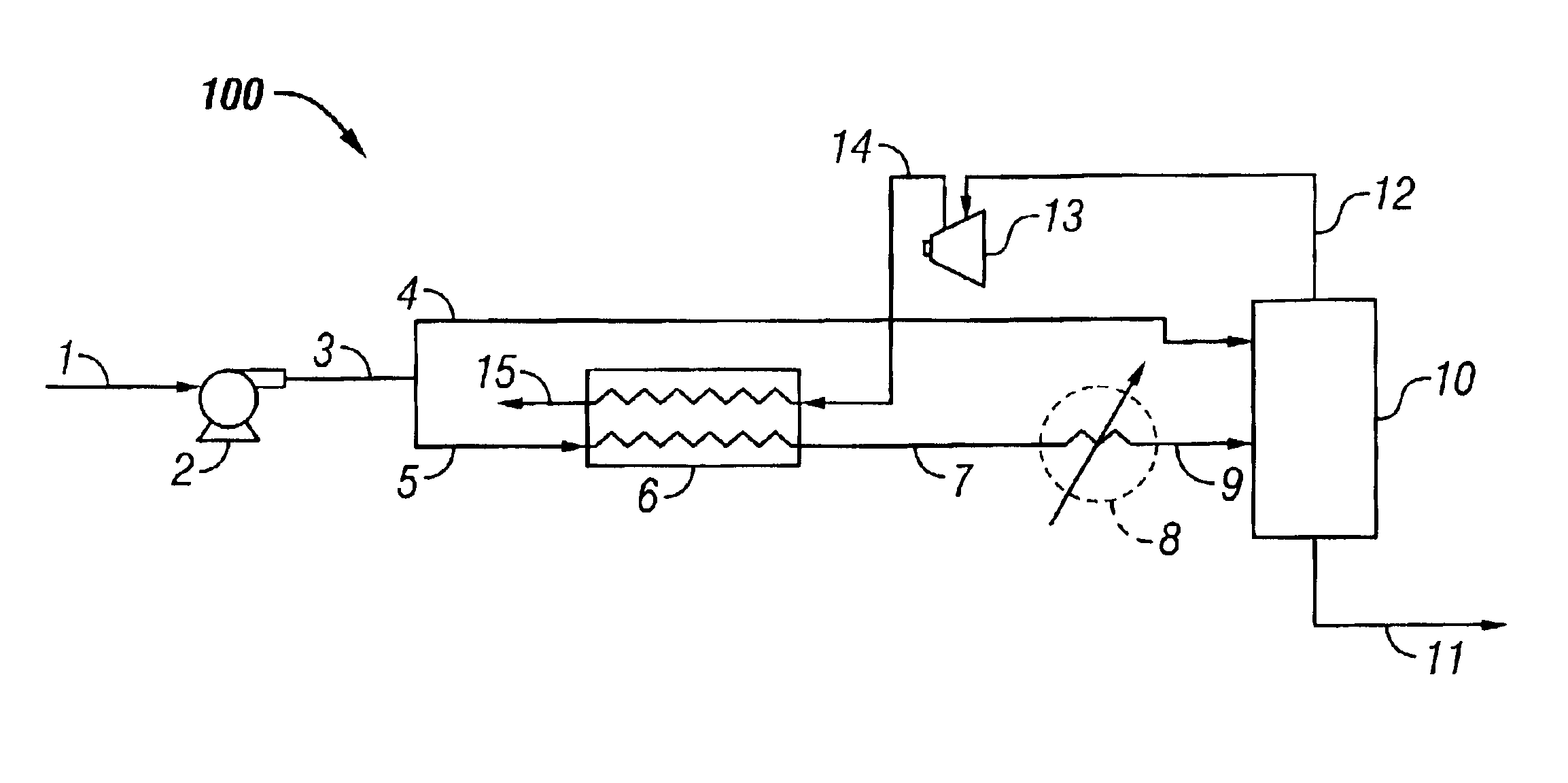

Systems and methods for separating alkane gases with applications to raw natural gas processing and flare gas capture

InactiveUS20140366577A1Reduce stepsHigh quality separationSolidificationLiquefactionAlkaneNatural-gas processing

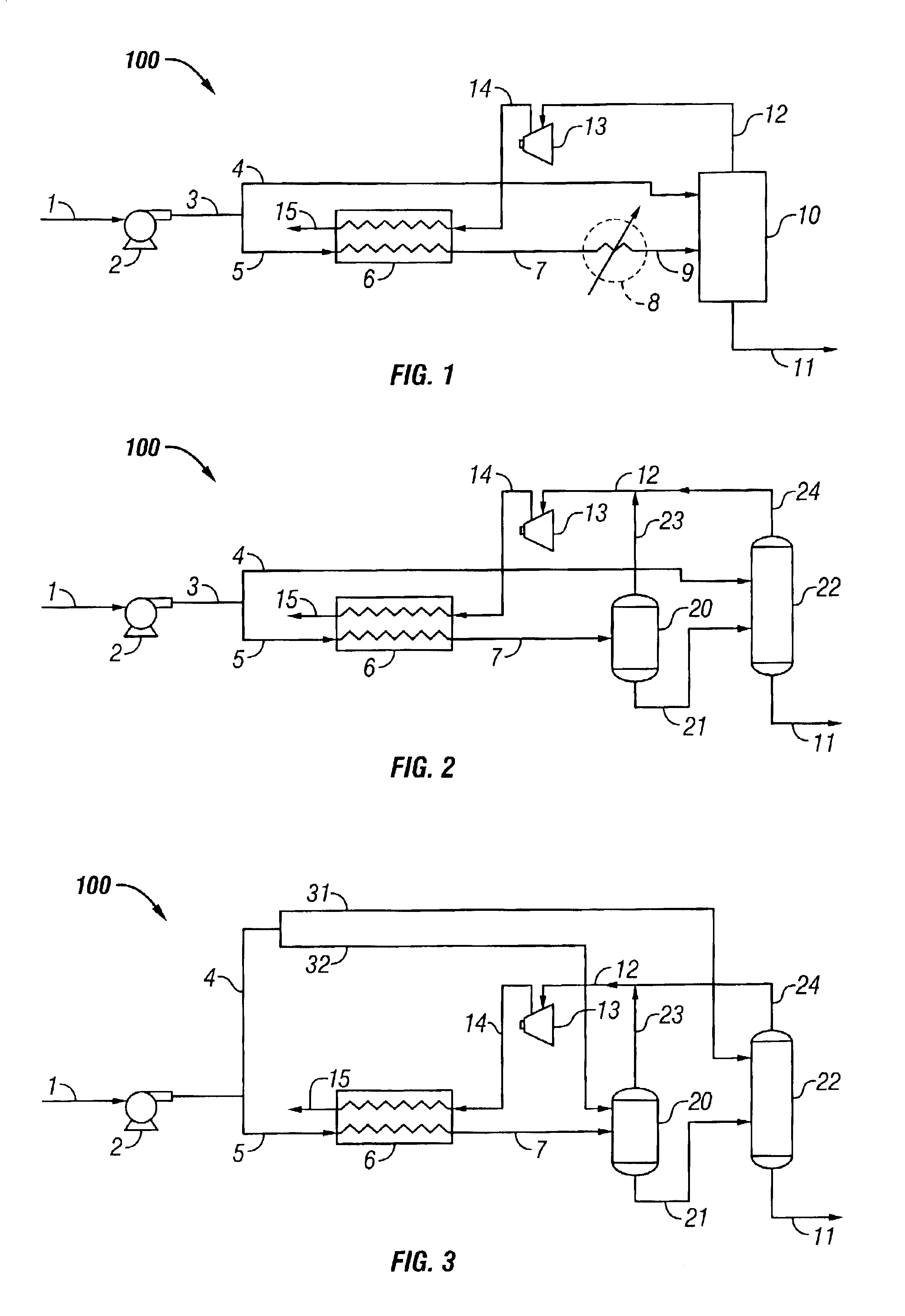

The present invention is a field-deployable system for separating methane and natural gas liquids (NGLs) from a raw gas stream comprising a compressor; a dehydrator; a refrigerator having one or more stages; and a separation subsystem adapted to separate the raw gas stream into three product streams including a methane stream that is at least 80% methane, an ethane-rich stream, and a NGLs stream having a vapor pressure of no more than 250 psia at 38° C. The methane stream is sufficiently lean to be useable in existing natural gas engines without modification. The NGLs stream has a sufficiently low vapor pressure to be transportable in standard propane containers. The ethane-rich stream may be utilized within the system itself to power its own operations. The system can be utilized to reduce flaring from liquids-rich gas production sites to an absolute minimum, produce natural gas liquids for transport, and provide dry methane gas suitable for use in portable field generators.

Owner:PIONEER ENERGY

Catalyst for preparing alkane of diesel oil fraction from synthetic gas and its prepn

InactiveCN1417292AHydrocarbon from carbon oxidesLiquid hydrocarbon mixture recoveryAlkanePore distribution

The catalyst consists of three parts including active component, assistant and carrier. The main active component is metal Co. The first assistant element is group IVB metal element, such as Ti and Zr or group IIIB metal element, such as La and Ce; and the second ssistant element is group VIII metal element, such as Rh, Ru and Pt. The carrier is active carbon of apricot kernel, coconut shell, oilpalm or coal; has specific surface area of 200-2000 sq mg, pore volume of 0.5-2.0 cu cm / g and pore distribution of 4-1000 angstrom. Of the catalyst weight, metal Co accounts for 4-50 %, the first assistant element 0.01-20.0% and the second assistant element 0.01-50 %. The catalyst may be used in the Fischer-Tropsch reaction of synthetic gas to prepare high-quality diesel oil as clean liquid fuel.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Liquid natural gas processing

ActiveUS6941771B2Avoid the needLower energy requirementsSolidificationLiquefactionRefluxNatural-gas processing

A process for the recovery of natural gas liquids (NGL) (ethane, ethylene, propane, propylene and heavier hydrocarbons) from liquefied natural gas (LNG) is disclosed. The LNG feed stream is split with at least one portion used as an external reflux, without prior treatment, to improve the separation and recovery of the natural gas liquids (NGL).

Owner:HOWE BAKER ENGINEERS LTD

Use of low pressure distillate as absorber oil in a FCC recovery section

InactiveUS7074323B2Less equipmentImprove throughputThermal non-catalytic crackingCatalytic crackingNaphthaDistillation

A process for the recovery of gaseous products from the product mixture obtained by contacting a hydrocarbon feed with a catalyst in a fluid catalytic cracking process, wherein the liquid, obtained by separating the top product of main fractionators into gaseous and liquid fraction, when supplied to the absorber has a temperature of between about 8–25 DEG C. This liquid may be pre-saturated with gaseous top product from absorber; or also a high boiling fraction (cat cracker naphtha / light cycle oil) may be first separated from this liquid by distillation.

Owner:SHELL OIL CO

Process and device for production of LNG by removal of freezable solids

ActiveUS7325415B2Reducing and eliminating foulingSolidificationLiquefactionWorking pressureAmount of substance

Novel processes and devices for the removal of freezable species such as carbon dioxide, water and heavy hydrocarbons from a natural gas feed stream during liquefaction to produce LNG are disclosed. The freezable species are able to be removed as a solid, avoiding the costly step of pretreatment to remove the freezable species from the natural gas feed stream prior to the liquefaction stage. The freezable species may be removed on a continuous basis being separated as solids following liquefaction of the natural gas feed stream with subsequent separation of the solids. The solid freezable species may then be liquefied on a continuous basis if required with natural gas recycled to the process. Continuous removal of the freezable species from the natural gas feed stream is achievable by maintaining cooling and separation apparatus at the same working pressure. Advantageously, at least part of the cooling vessel is constructed from a material having a low thermal conductivity which discourages formation of the solids of the freezable species on the walls of the cooling vessel.

Owner:SHELL USA INC

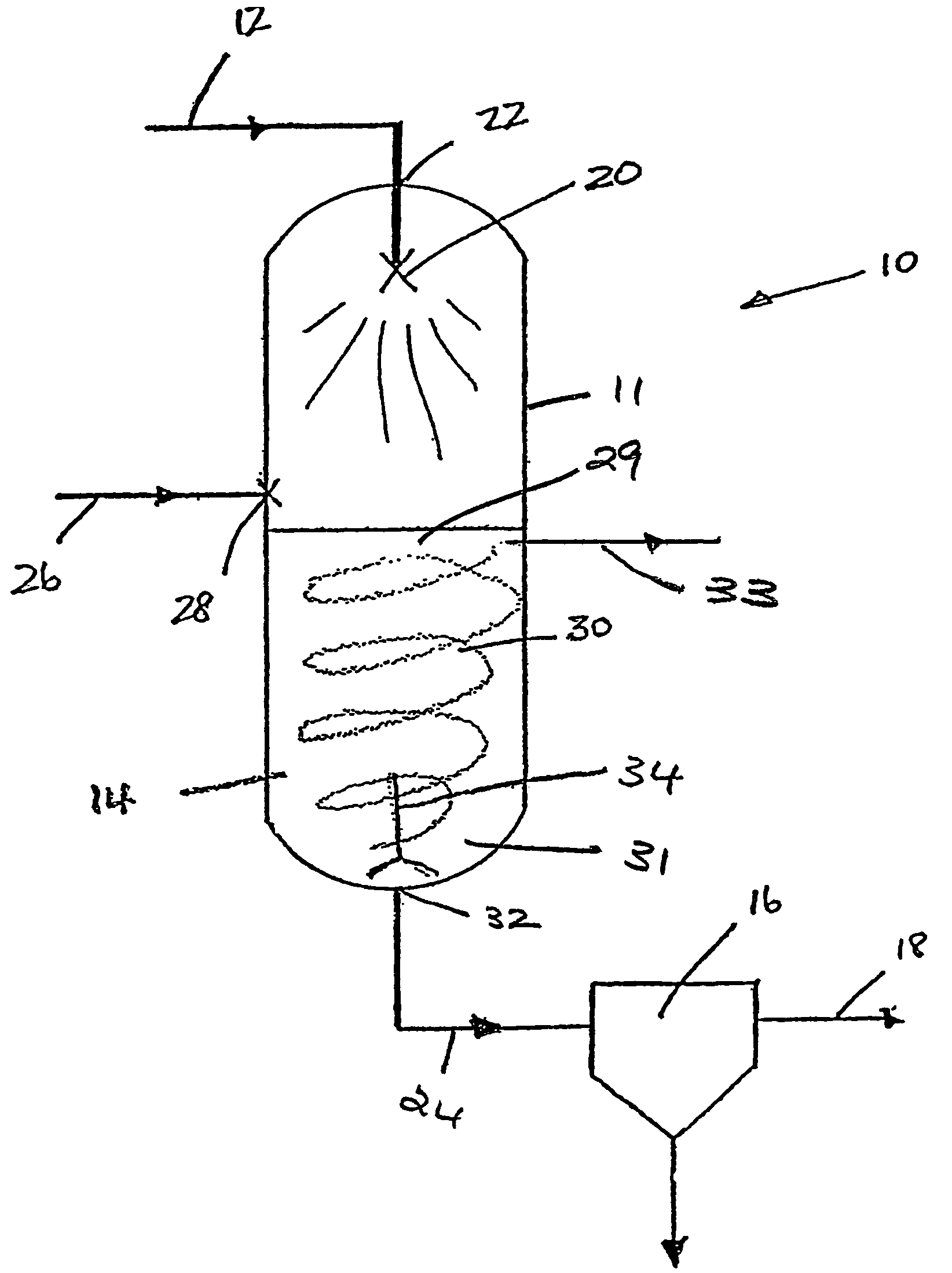

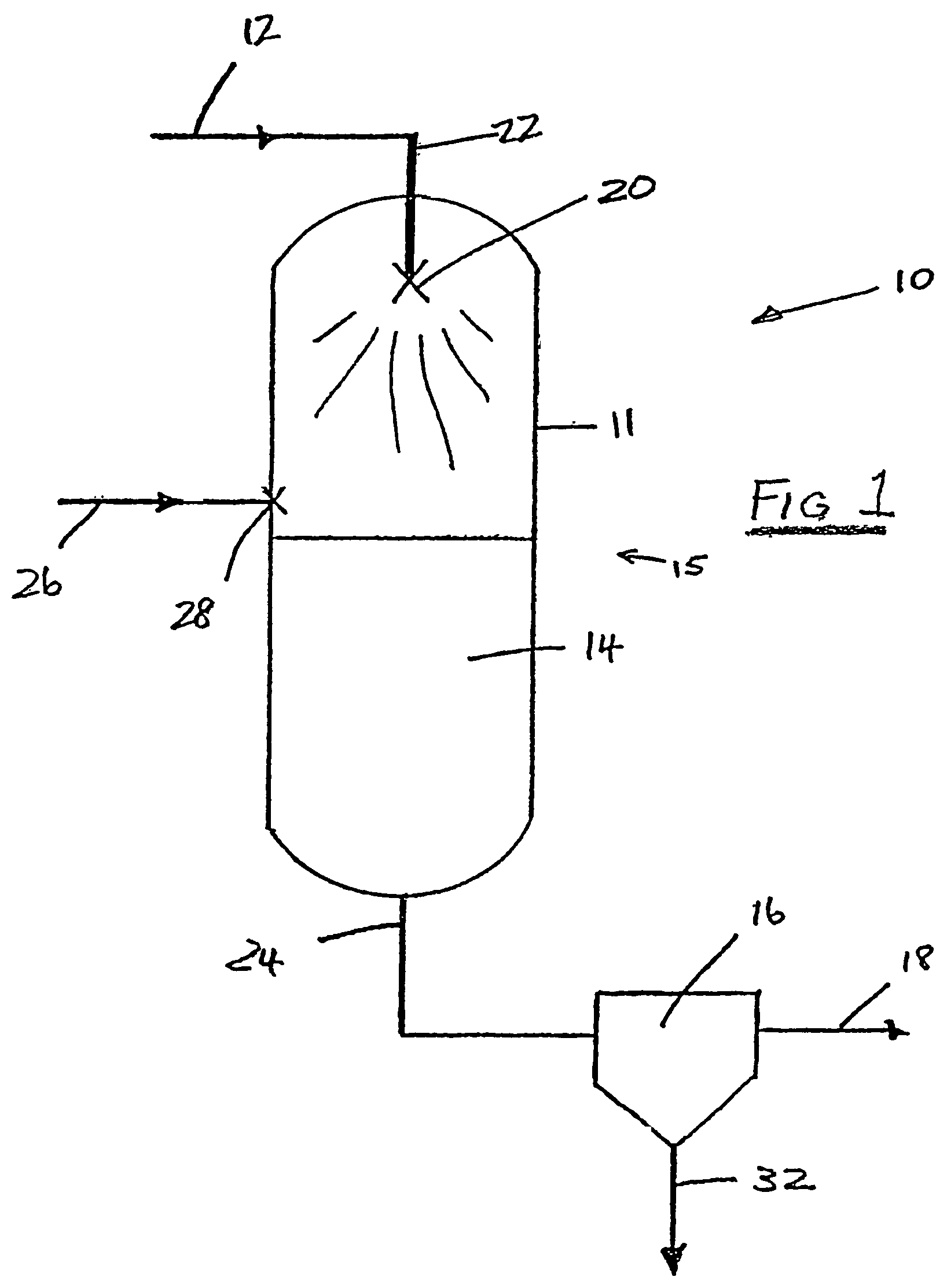

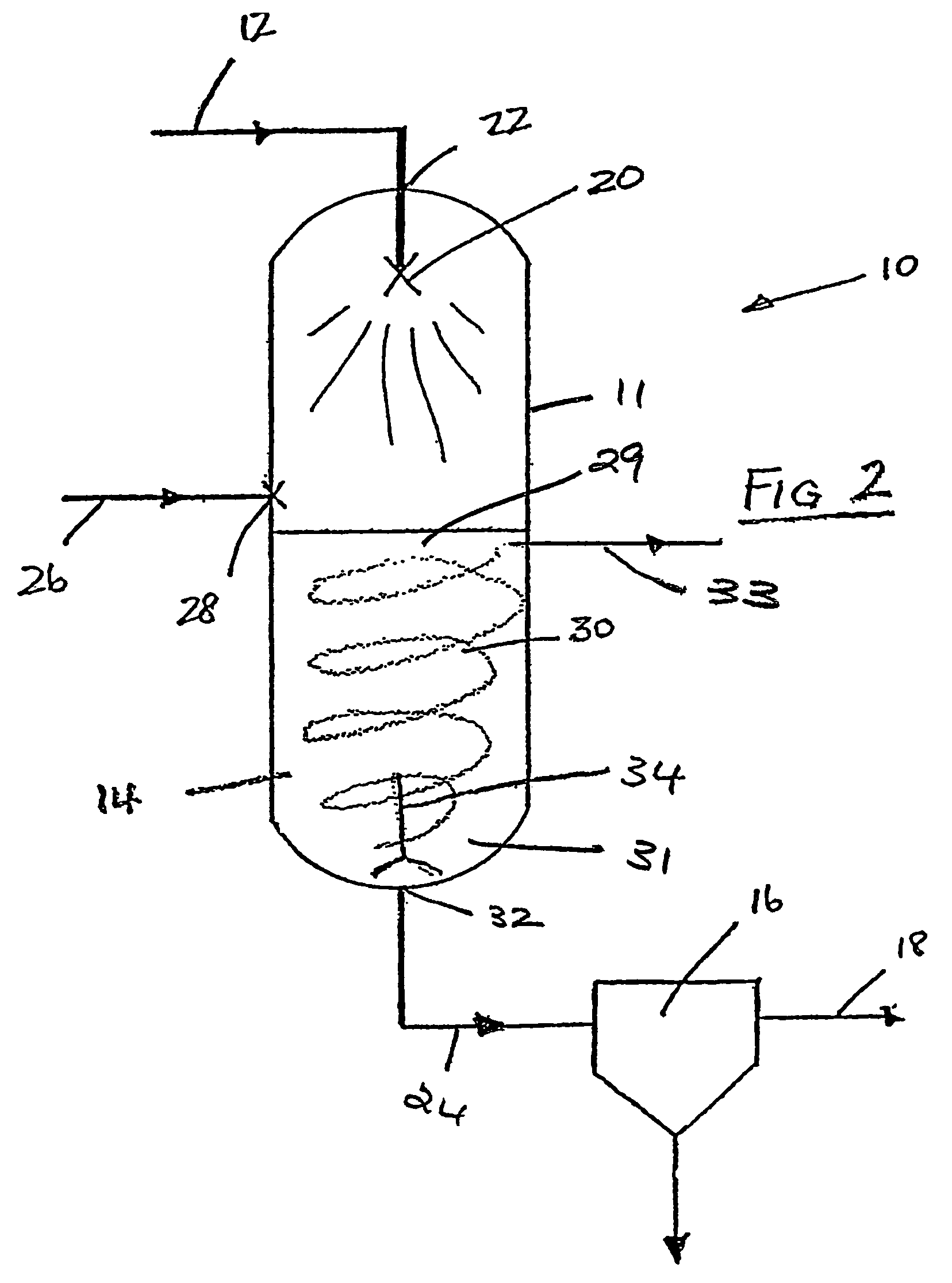

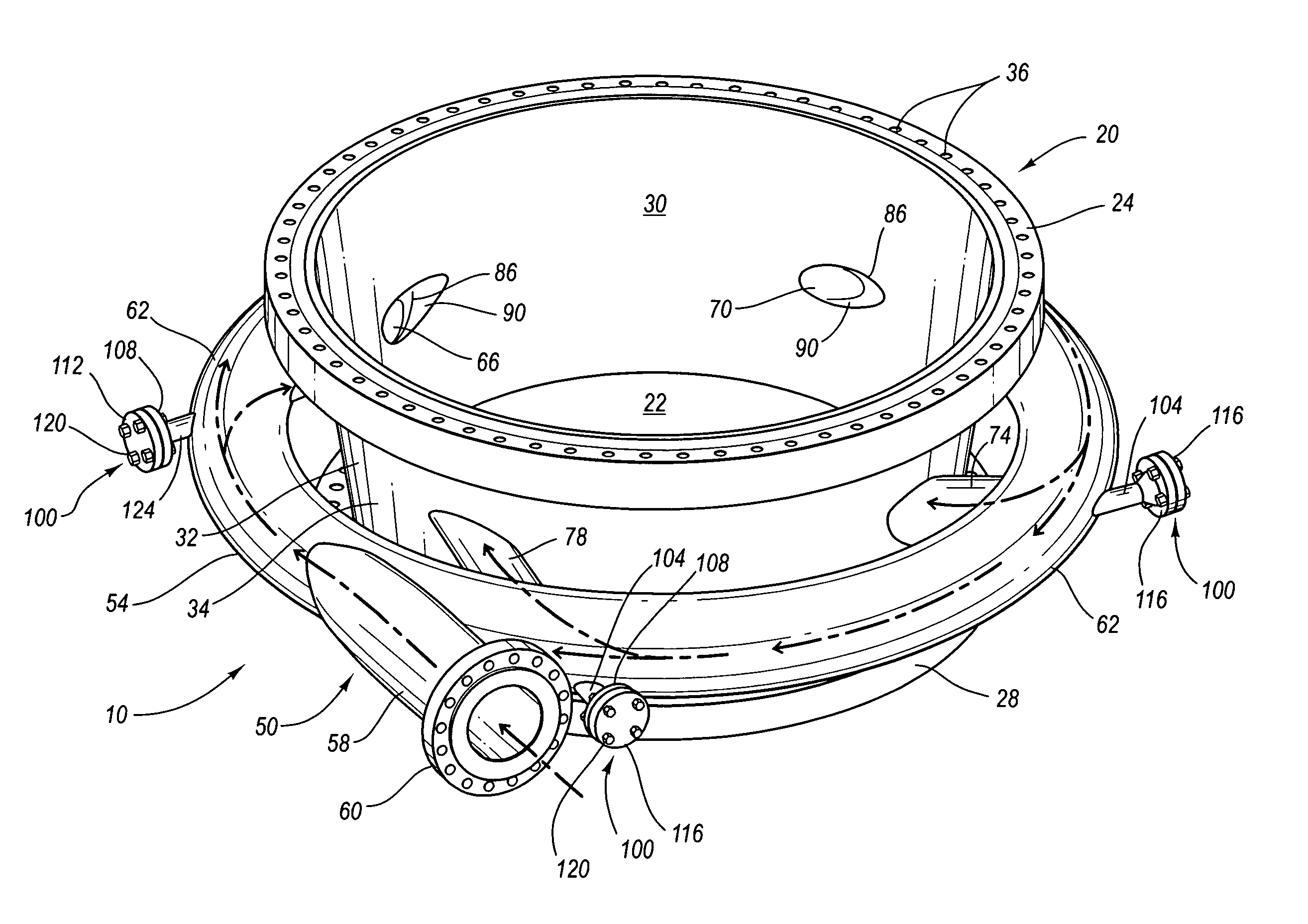

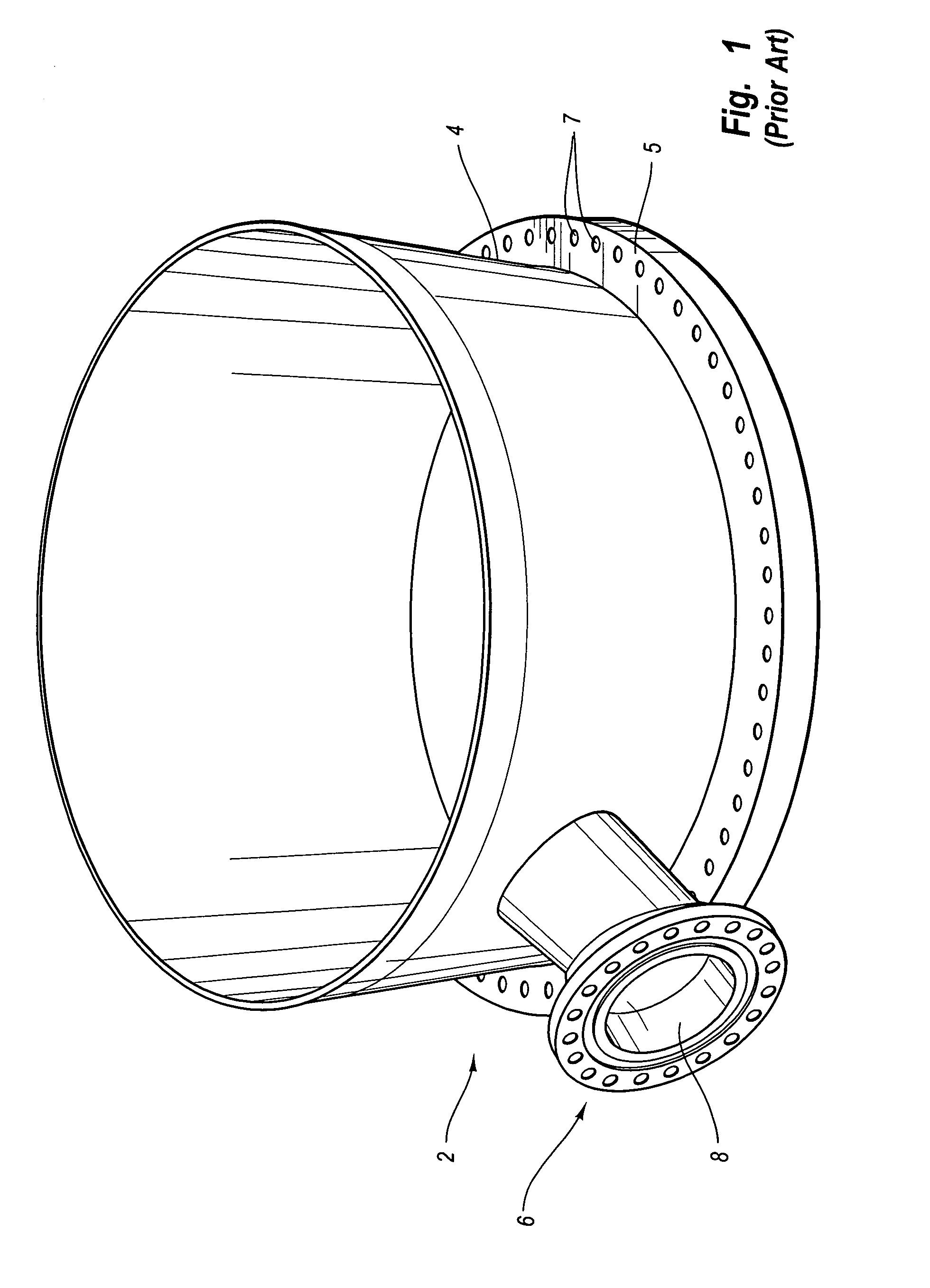

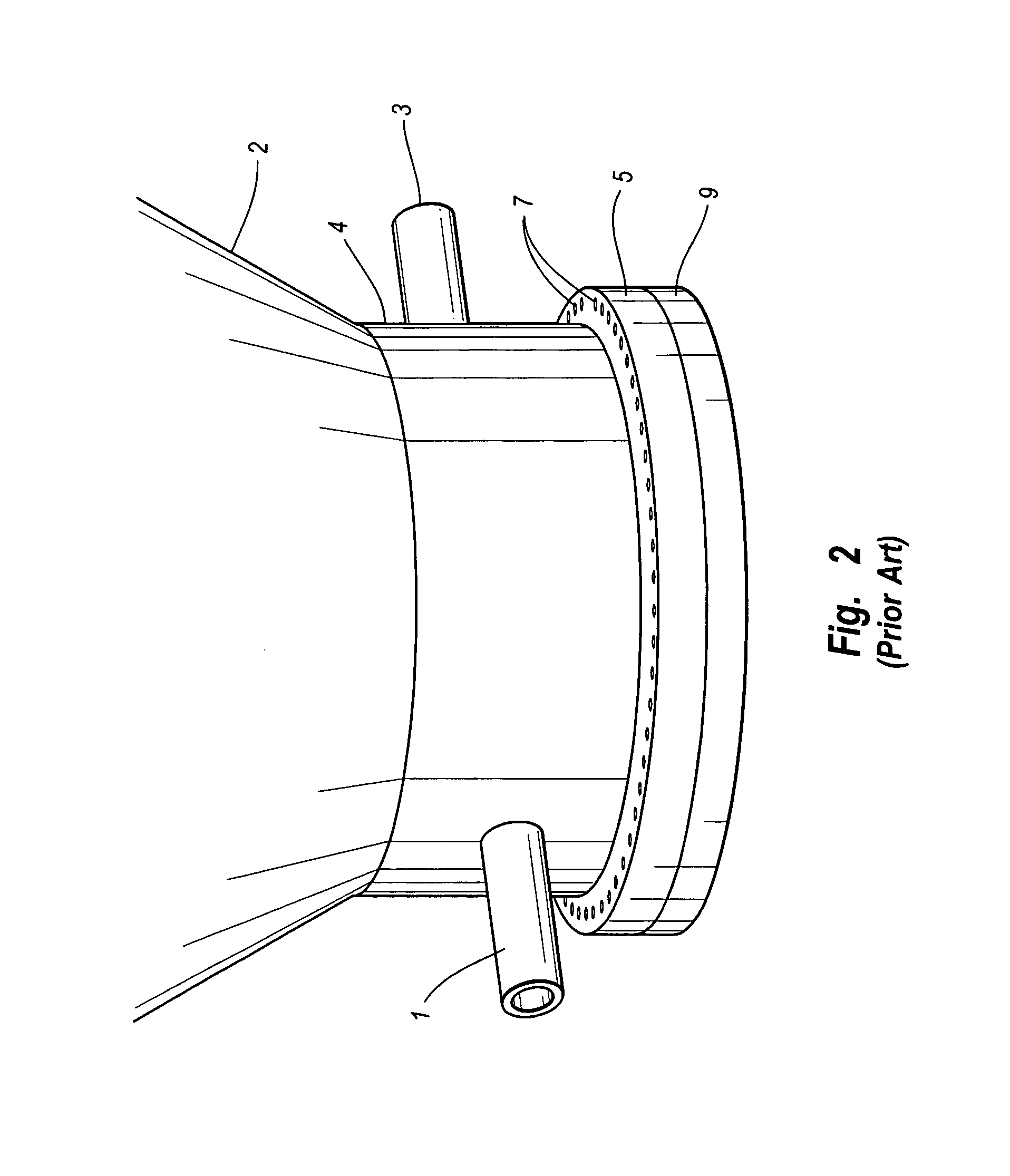

Tangential dispenser and system for use within a delayed coking system

ActiveUS7115190B2Hydrocarbon distillationLiquid hydrocarbon mixture recoveryEngineeringHeat distribution

The present invention features a tangential injection system for use within a delayed coking system, or any other similar system. The tangential injection system comprises a spool, a tangential dispenser, and a hydro blasting system, wherein the tangential dispenser comprises a delivery main surrounding the perimeter of the spool and that functions to deliver a residual byproduct or other material to a plurality of feed lines positioned at a position or at distances around the delivery main for the purpose of providing tangential dispensing of the residual byproduct into the vessel, thus effectuating or inducing even thermal distribution throughout the vessel.

Owner:DELTAVALVE

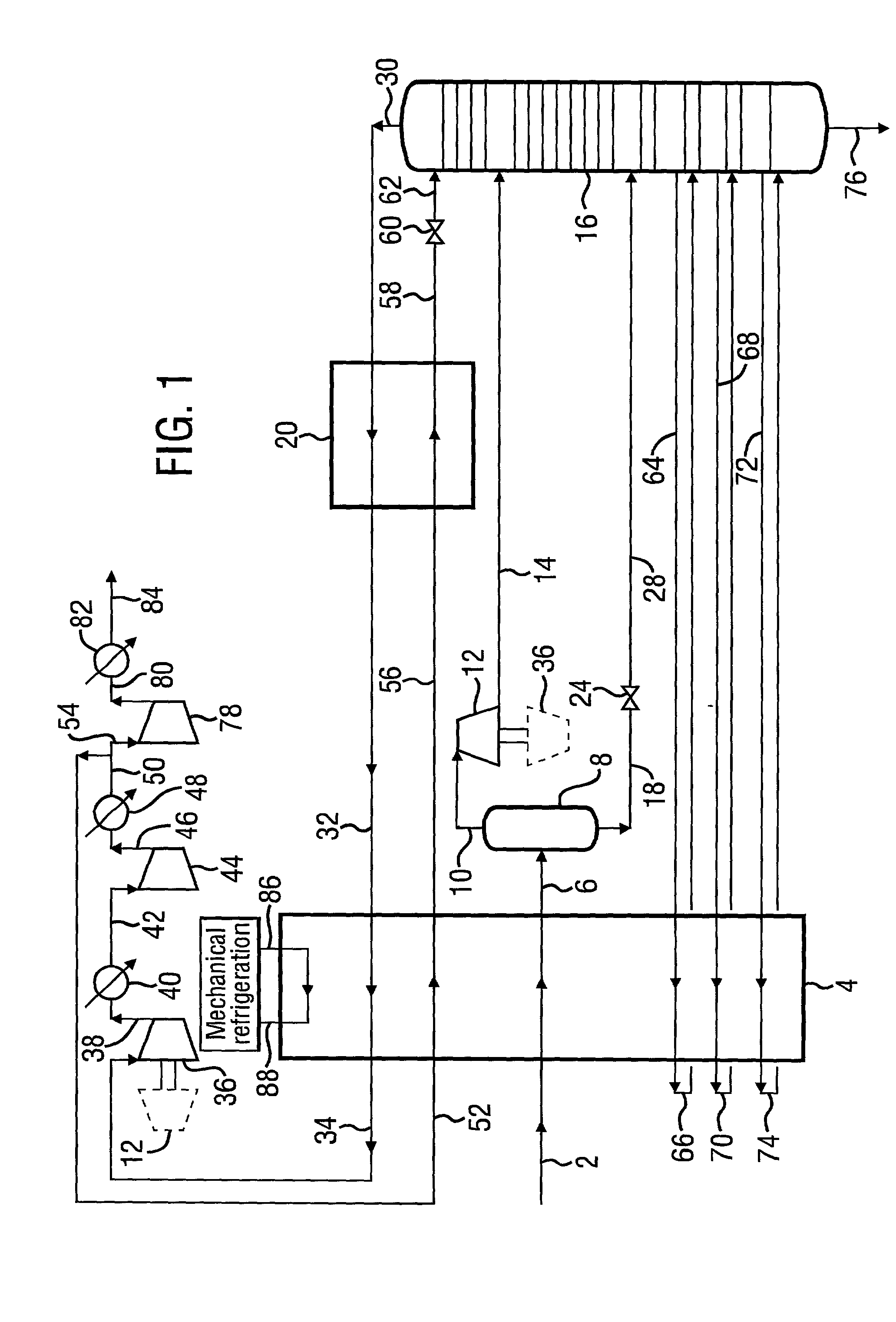

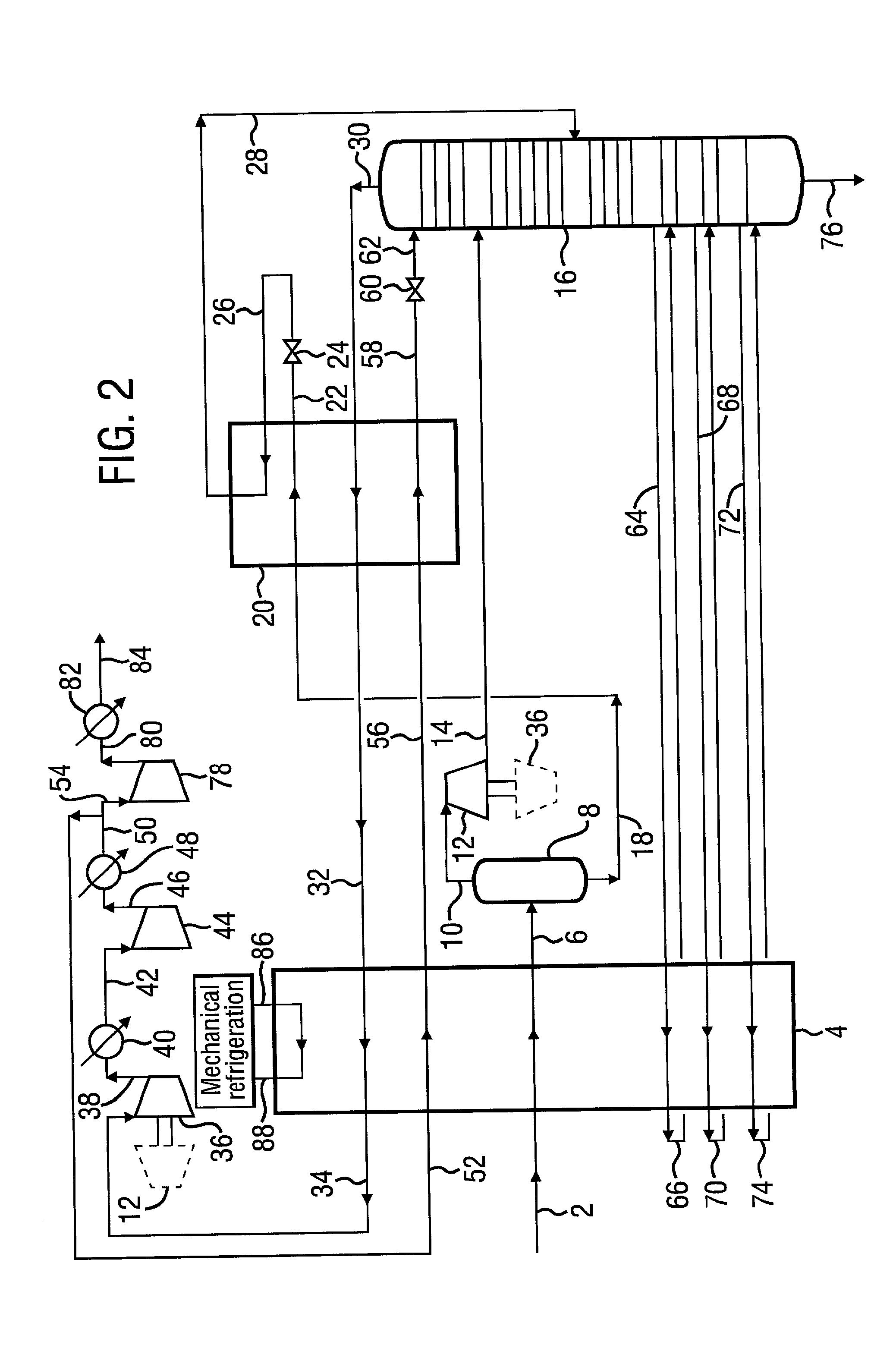

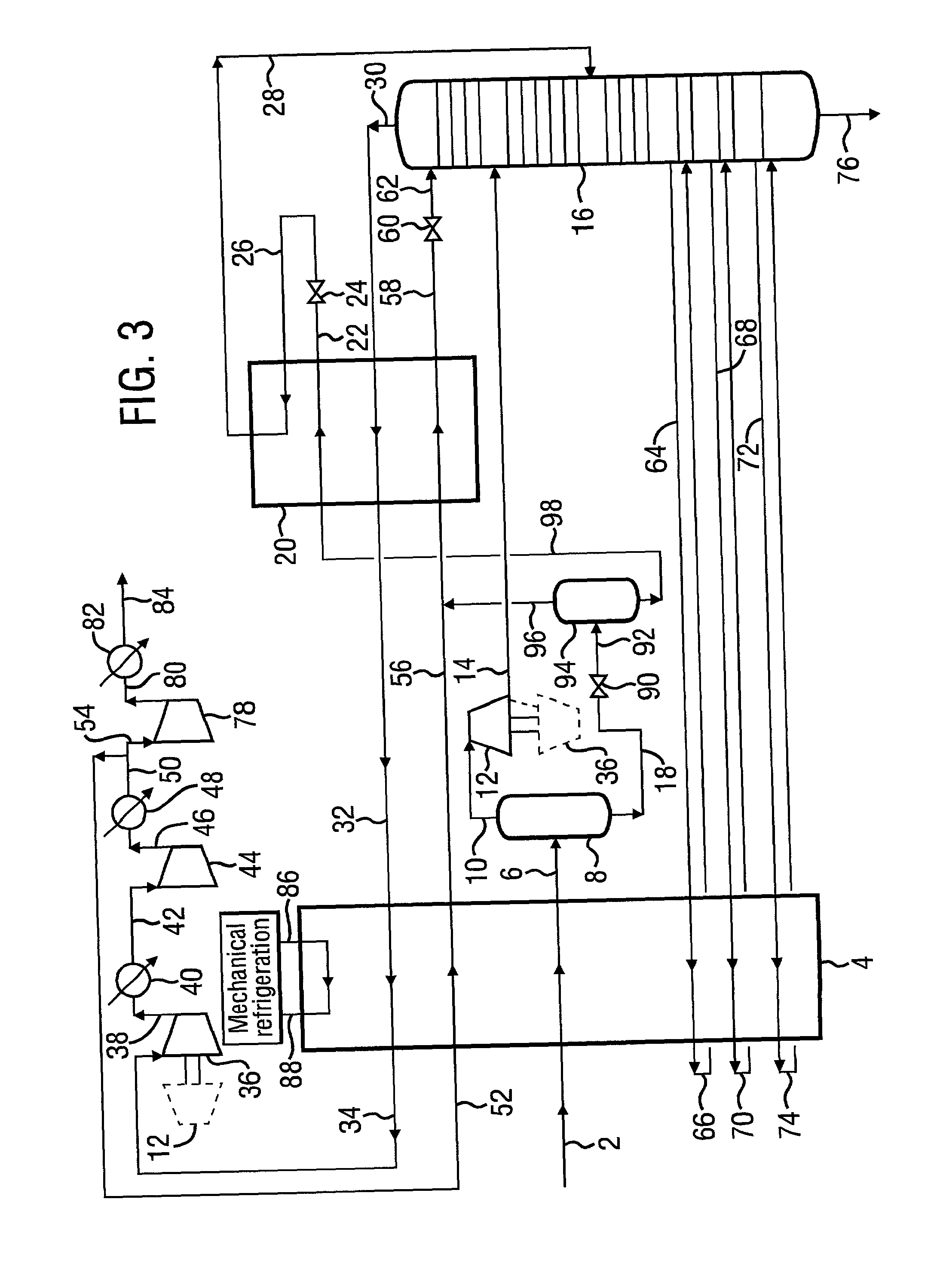

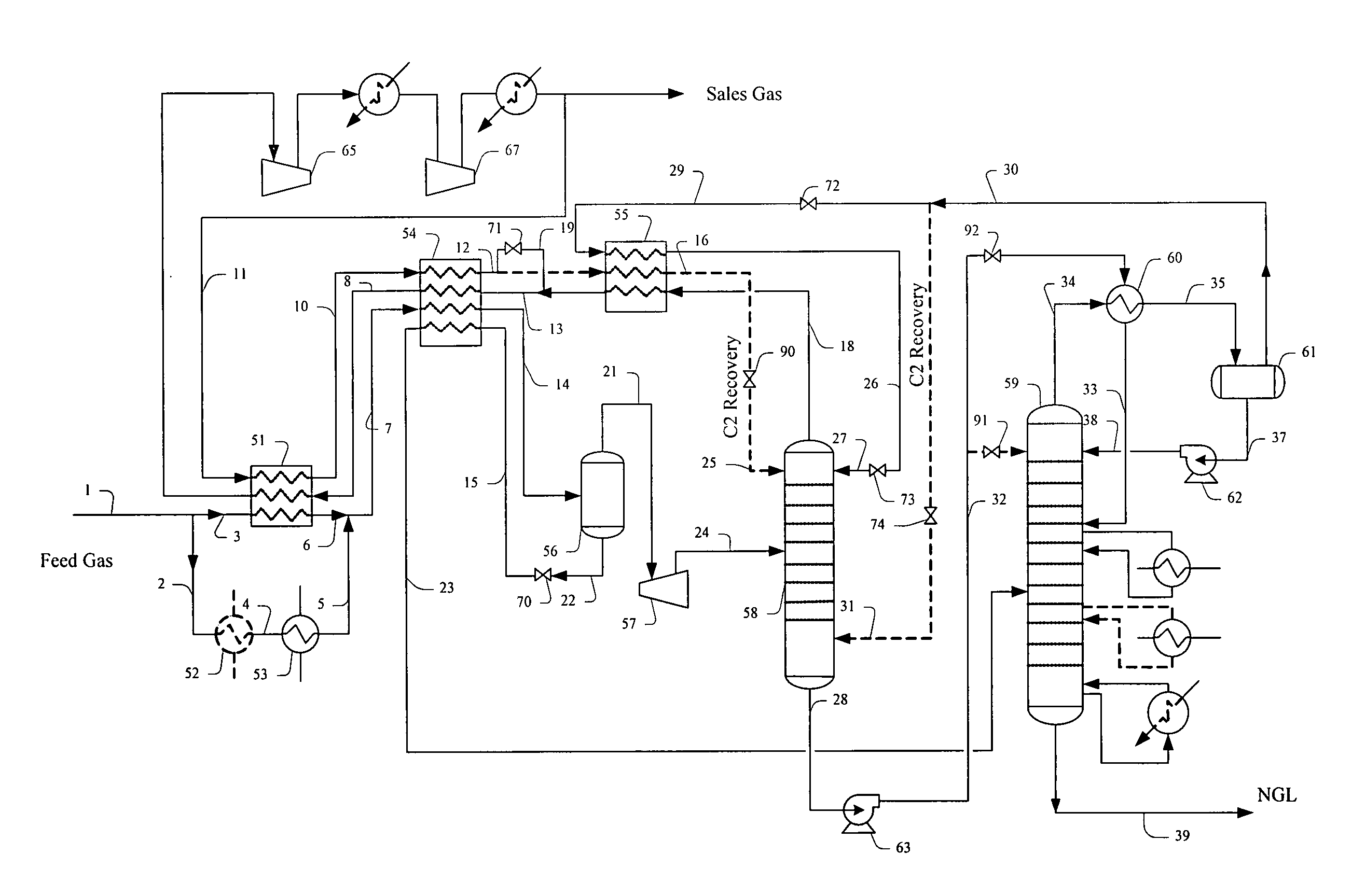

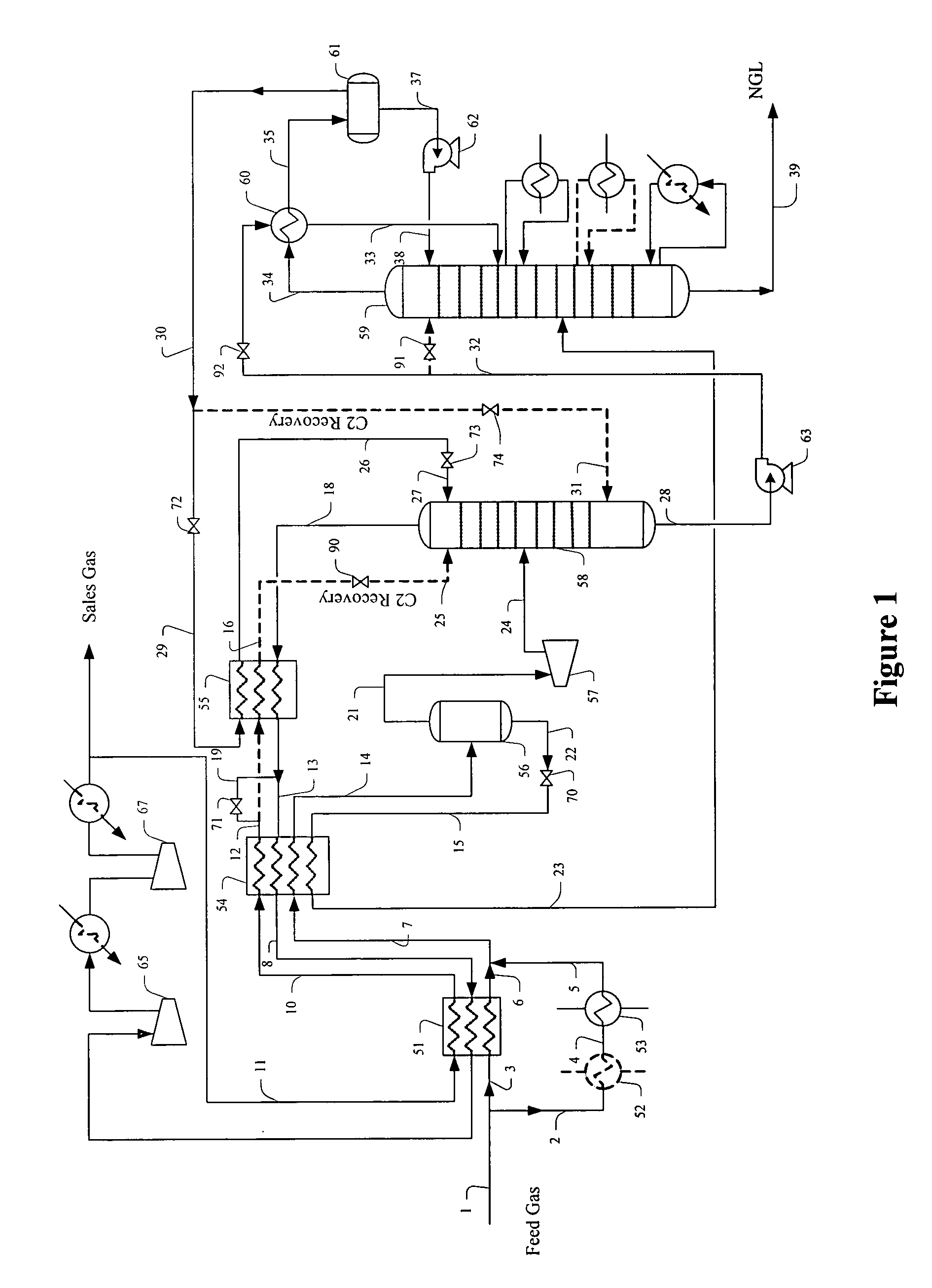

Lean reflux-high hydrocarbon recovery process

A two-tower scheme process for the recovery of propane and heavier components from a hydrocarbon gas stream is provided. Feed gas is cooled, partially condensed, and then separated to give a first liquid stream and a first vapor stream. First liquid stream is sent to a distillation tower that recovers at the bottoms a major portion of propane and heavier components and produces an overhead gas stream. First vapor stream is expanded and sent as bottom feed to the absorber. Absorber produces an absorber overhead stream containing essentially all the ethane and lighter components and an absorber bottoms stream. Absorber bottoms stream is heated and sent to the distillation tower as middle feed. Absorber overhead stream is warmed and optionally compressed. A part of the compressed stream is substantially condensed and sent to absorber as top feed. The process and apparatus can be used to recover ethane and heavier hydrocarbons.

Owner:LUMMUS TECH INC

Hydrocarbon separation process and apparatus

InactiveUS20010008073A1Reduced overhead temperaturePromote recoverySolidificationLiquefactionRefluxFractionation

A process is described for separating the heavier hydrocarbons from a gaseous hydrocarbon feed wherein a first separator is employed to separate partially condensed gaseous feed and wherein the vapour portion undergoes work expansion and is fed to a fractionation column. The liquid portion is subcooled in heat exchange with the overhead vapour from the fractionation column, expanded, evaporated to provide refrigeration at a low temperature level, and fed to the fractionation column. The rewarmed residual vapour is subsequently compressed to a pressure suitable for export, with a portion of the compressed gas being cooled, condensed and recycled back to reflux the top section of the fractionation column. Also described is a process wherein a first separator is employed to separate partially condensed gaseous feed and wherein the vapour portion undergoes work expansion and is fed to a high pressure wash column. The liquid portion is expanded and fed to the base of the high pressure wash column. Bottoms liquid from the wash column is subcooled in heat exchange with the overhead vapour from a fractionation column, expanded, evaporated to provide refrigeration at a low temperature level, and fed to the fractionation column. Vapour from the high pressure wash column is partially condensed, with the liquid portion used to provide reflux to the high pressure wash column and the fractionation column. The processes are especially applicable to recovery of ethane and heavier components from natural gas. Overall process power requirements are reduced, recovery of the desired heavy hydrocarbons is increased or both of these effects are realised.

Owner:COSTAIN OIL GAS & PROCESS

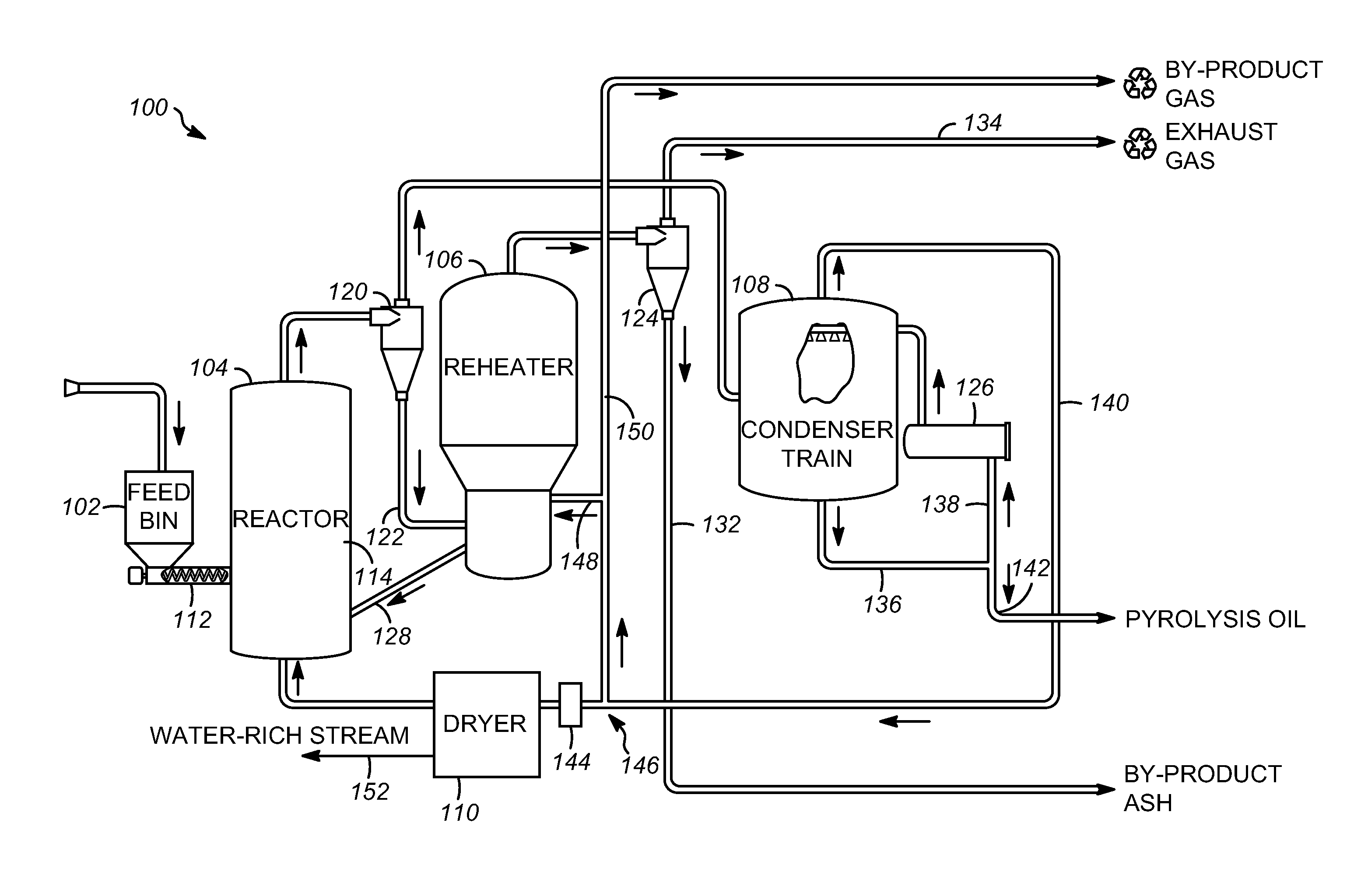

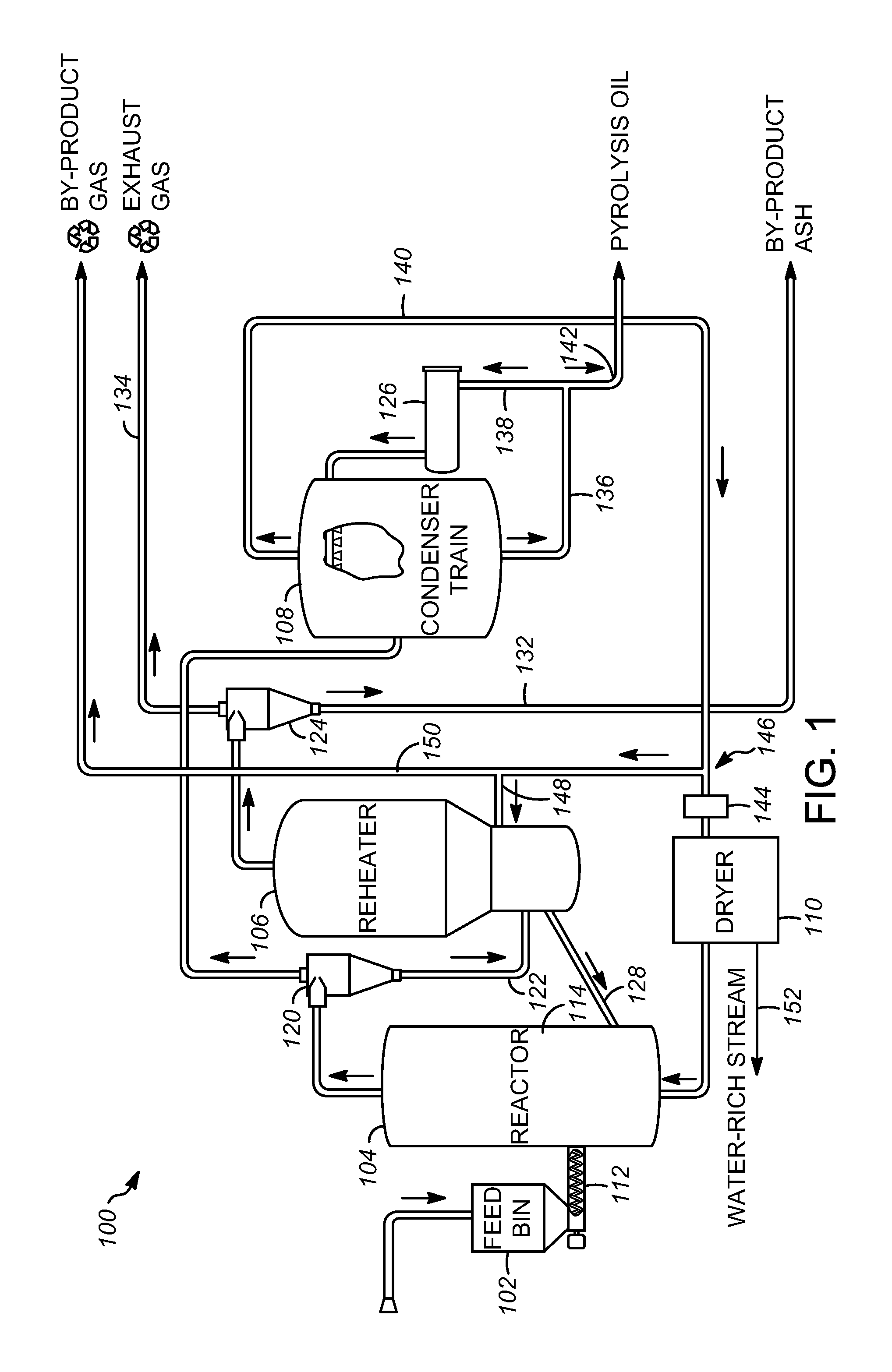

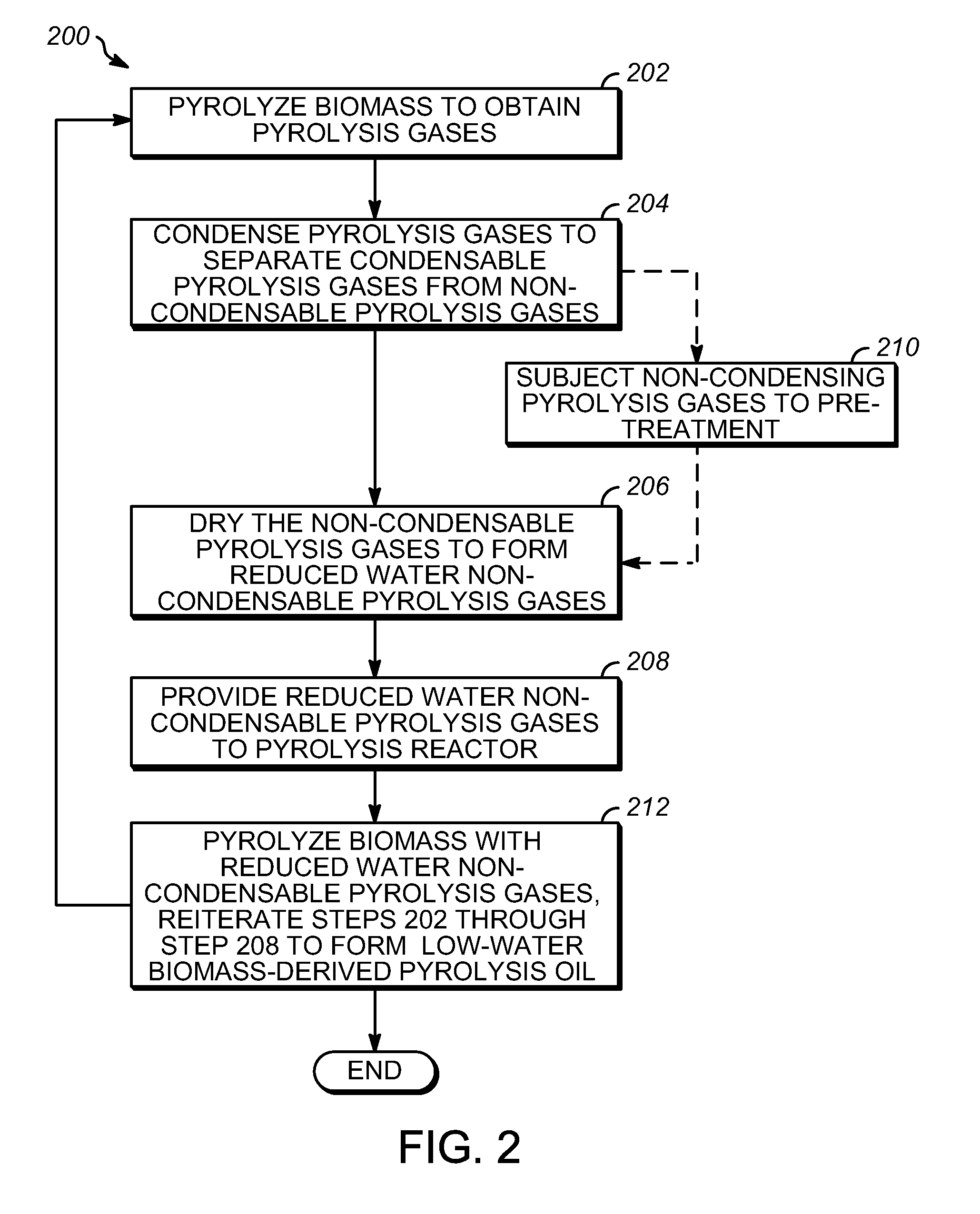

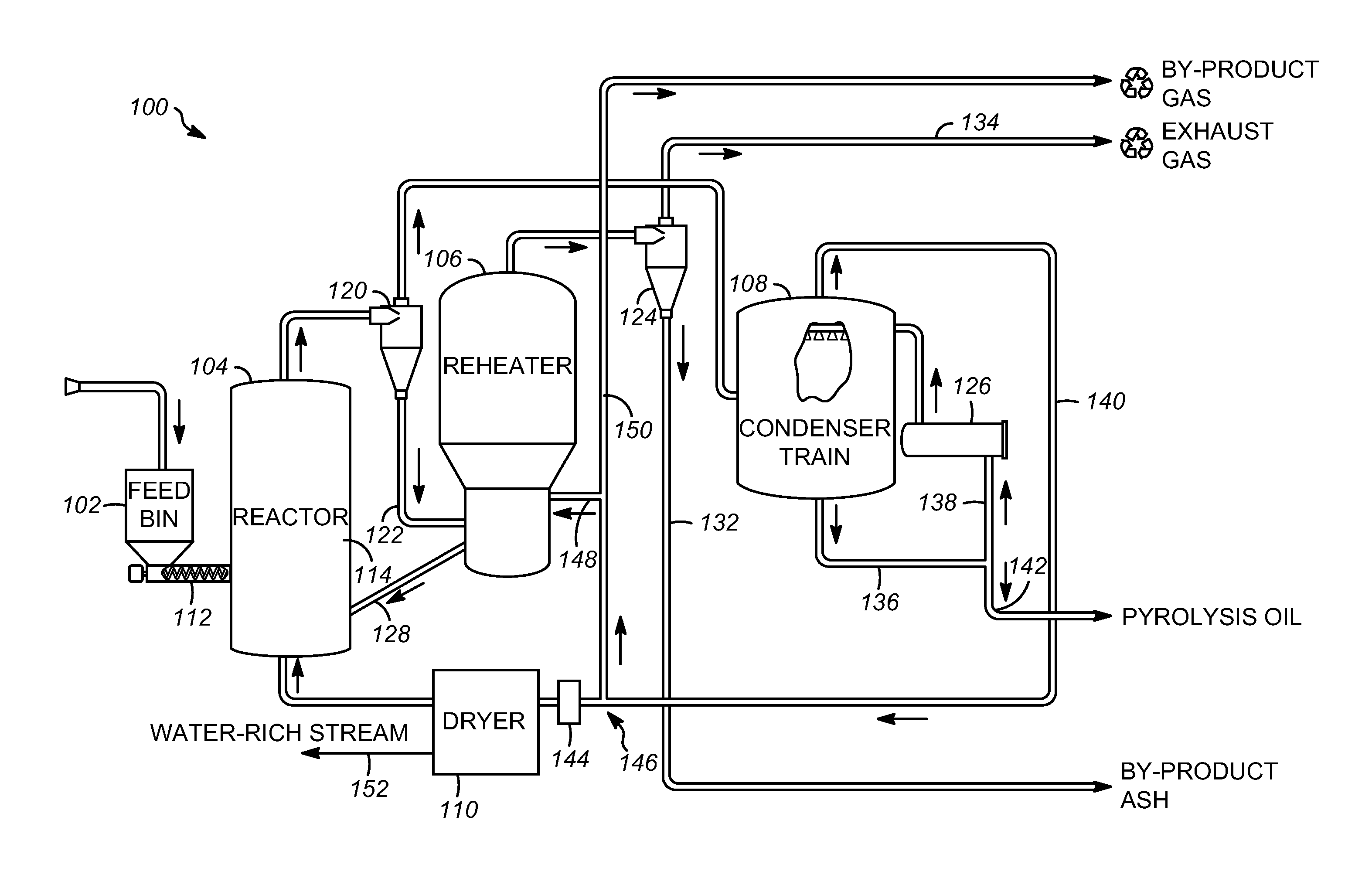

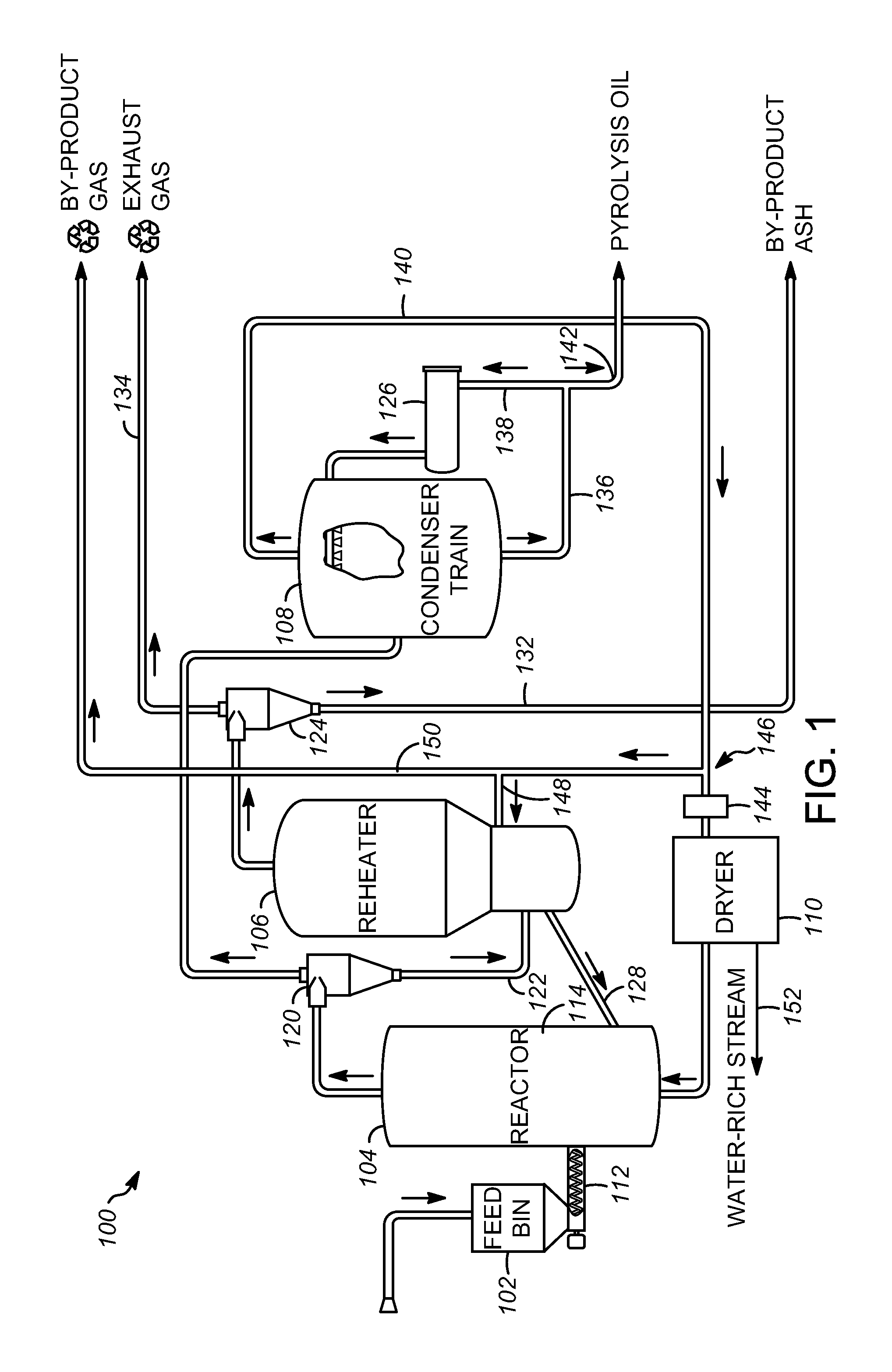

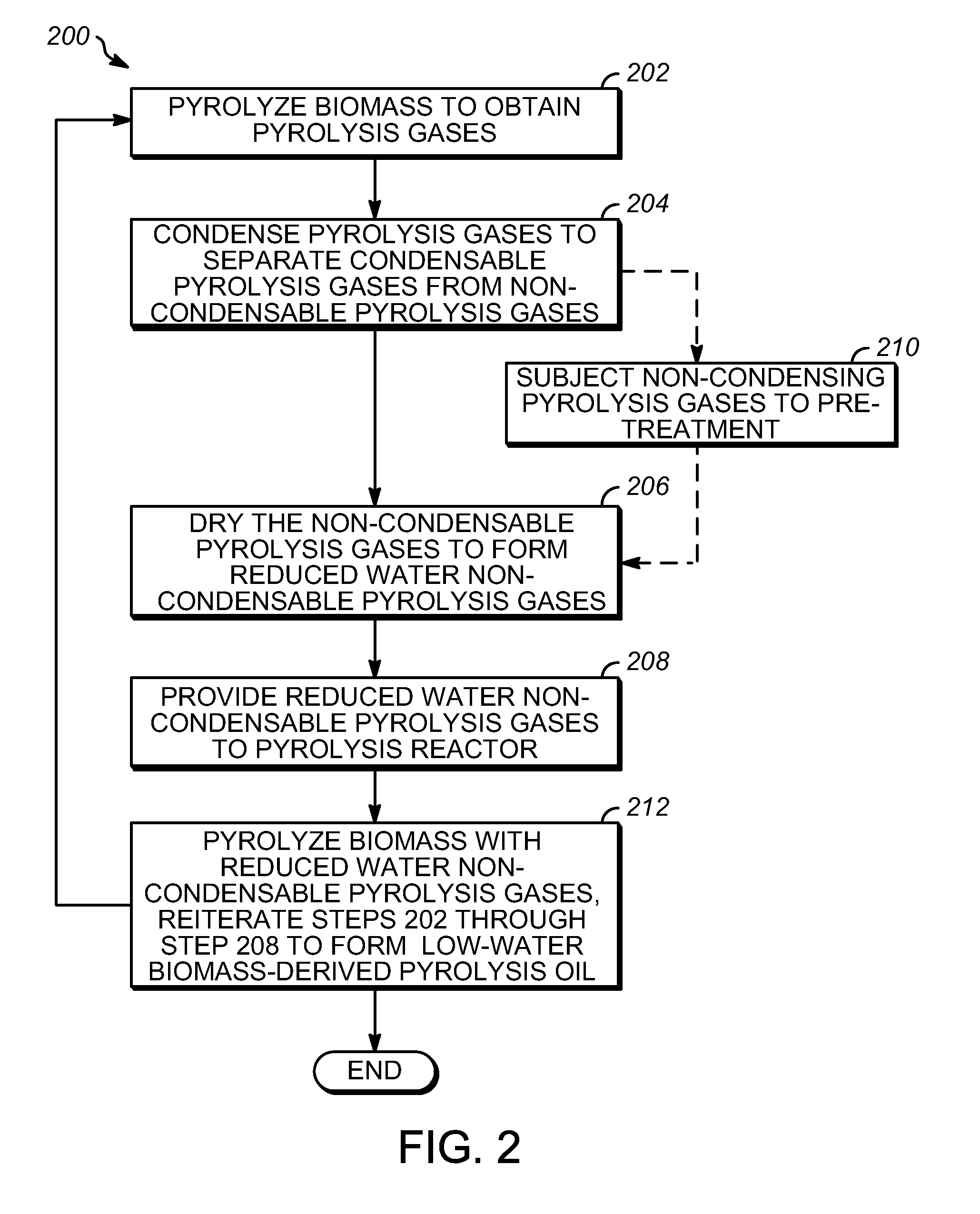

Low water biomass-derived pyrolysis oils and processes for producing the same

ActiveUS8519205B2Extensive contentReduce moistureDirect heating destructive distillationLiquid hydrocarbon mixture recoveryProduct gasWater content

Low water-containing biomass-derived pyrolysis oils and processes for producing them are provided. The process includes condensing pyrolysis gases including condensable pyrolysis gases and non-condensable gases to separate the condensable pyrolysis gases from the non-condensable gases, the non-condensable gases having a water content, drying the non-condensable pyrolysis gases to reduce the water content of the-non-condensable gases to form reduced-water non-condensable pyrolysis gases, and providing the reduced-water non-condensable pyrolysis gases to a pyrolysis reactor for forming the biomass-derived pyrolysis oil.

Owner:ENSYN RENEWABLES

Catalyst for synthesizing gasoline and diesel fraction selected by synthesis gas

InactiveCN1418933AHydrocarbon from carbon oxidesLiquid hydrocarbon mixture recoveryActivated carbonAdjuvant

The catalyst for directly preparing high-grade gasoline and diesel oil clean liquid fuel by using synthetic gas and utilizing Fischer-Tropsch synthesis reaction is formed from three portions of active component, adjuvant and carrier, in which its active component is metal iron, the adjuvant is formed from metal elements of Cu, Ce, K, Co and Ru, etc. and its carrier can use apricot stone activatedcarbon or coconut activated carbon, the specific surface area of active carbon is 200 sq.m / g-2000 sq.m / g, its pore volume is 0.3-1.5 cu.cm / g, pore size distribution is 4-1000 A, the metal iron content is 4-40% of total weight of catalyst, the adjuvant element content is 0.01-20.0% of total weight of the catalyst. The addition of adjuvant element can effectively improve the reaction and stability property of catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

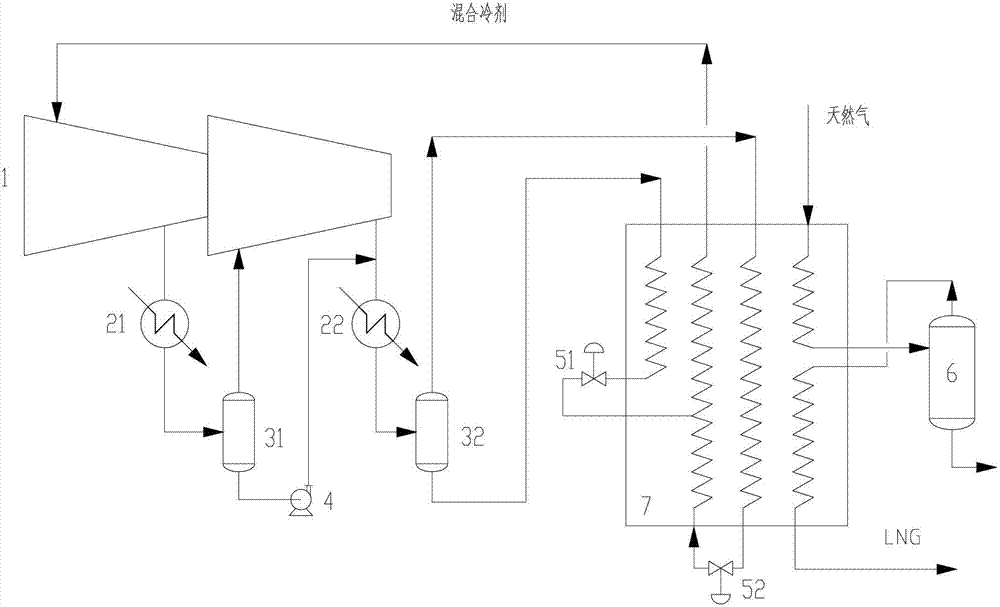

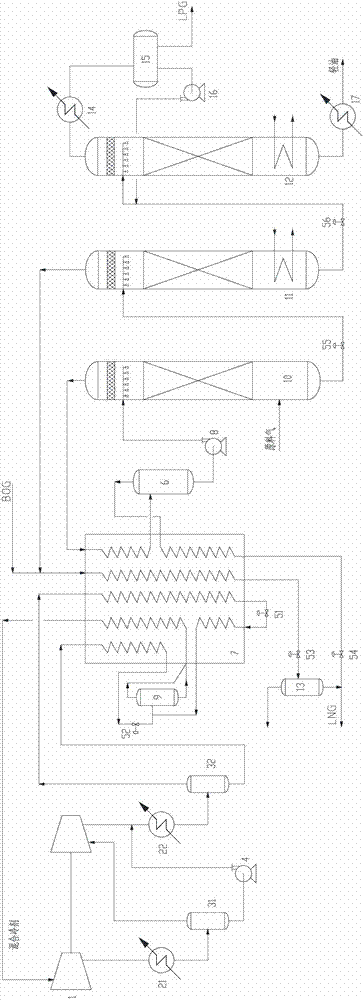

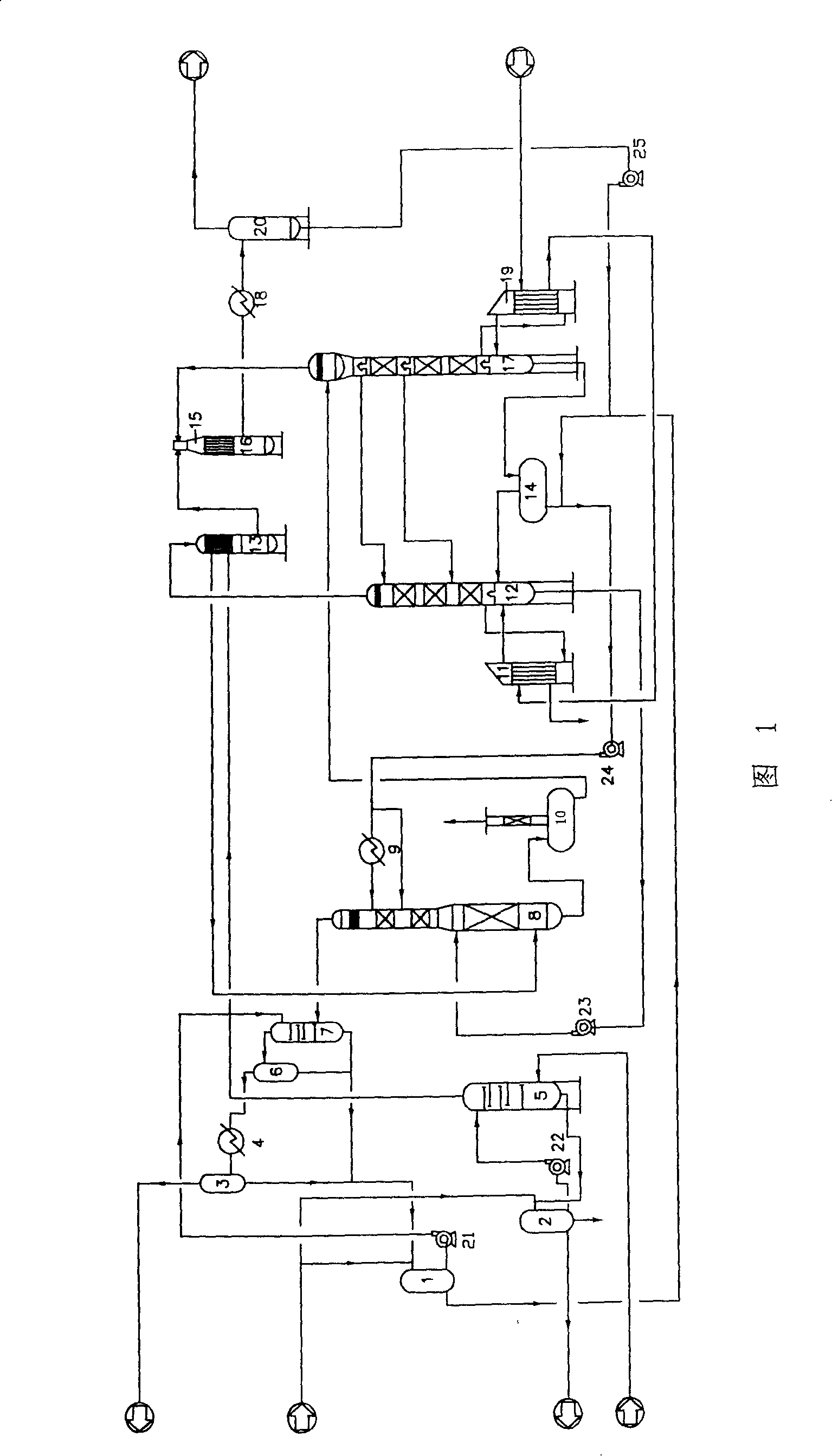

Method and device for carrying out liquefaction and heavy hydrocarbon treatment on natural gas

ActiveCN103031169AEconomical and reliableReasonable designSolidificationLiquefactionGas phaseLarge range

The invention relates to a process for carrying out liquefaction and heavy hydrocarbon treatment on natural gas, which comprises a low temperature liquefaction process and a heavy hydrocarbon treatment process. The low temperature liquefaction process comprises the following step that mixed refrigerant provides refrigerating capacity for the natural gas which is subjected to partial heavy hydrocarbon removal in the heavy hydrocarbon treatment process so as to implement cooling, complete heavy hydrocarbon removal and liquefaction on the natural gas in a cold box to obtain LNG (Liquefied Natural Gas); the heavy hydrocarbon treatment process comprises the following steps that the natural gas rich in heavy hydrocarbon is subjected to partial heavy hydrocarbon in a heavy hydrocarbon washing tower and the removed heavy hydrocarbon sequentially enters a deethanizing column and a rectifying column to be subjected to removal of light components and be separated into LPG (Liquefied Petroleum Gas) and light oil. According to the process disclosed by the invention, by-products, i.e. the LPG and the light oil, are also produced when the LNG is produced, the process route is advanced and the process is economical and reliable; the process can be suitable for the condition that raw material gas comprises aromatic hydrocarbon such as benzene and the like, the aromatic hydrocarbon such as the benzene and the like are removed along with the heavy hydrocarbon component and the cold box is prevented from being frozen and blocked; the process has large operation elasticity and can be suitable for natural gas heavy hydrocarbon content in a large range; the mixed refrigerant is adopted to circulate the flow and provide refrigerating capacity and gas-phase and liquid-phase refrigerants respectively enter the cold box to carry out heat exchange, so that heat exchange curves of cold and hot fluids are further matched; and the adopted refrigerating flow can effectively avoid liquid accumulation at the bottom of the cold box.

Owner:XINDI ENERGY ENG TECH

Low water biomass-derived pyrolysis oils and processes for producing the same

ActiveUS20120022171A1Large water contentReduce moistureDirect heating destructive distillationLiquid hydrocarbon mixture recoveryWater contentChemistry

Low water-containing biomass-derived pyrolysis oils and processes for producing them are provided. The process includes condensing pyrolysis gases including condensable pyrolysis gases and non-condensable gases to separate the condensable pyrolysis gases from the non-condensable gases, the non-condensable gases having a water content, drying the non-condensable pyrolysis gases to reduce the water content of the-non-condensable gases to form reduced-water non-condensable pyrolysis gases, and providing the reduced-water non-condensable pyrolysis gases to a pyrolysis reactor for forming the biomass-derived pyrolysis oil.

Owner:ENSYN RENEWABLES

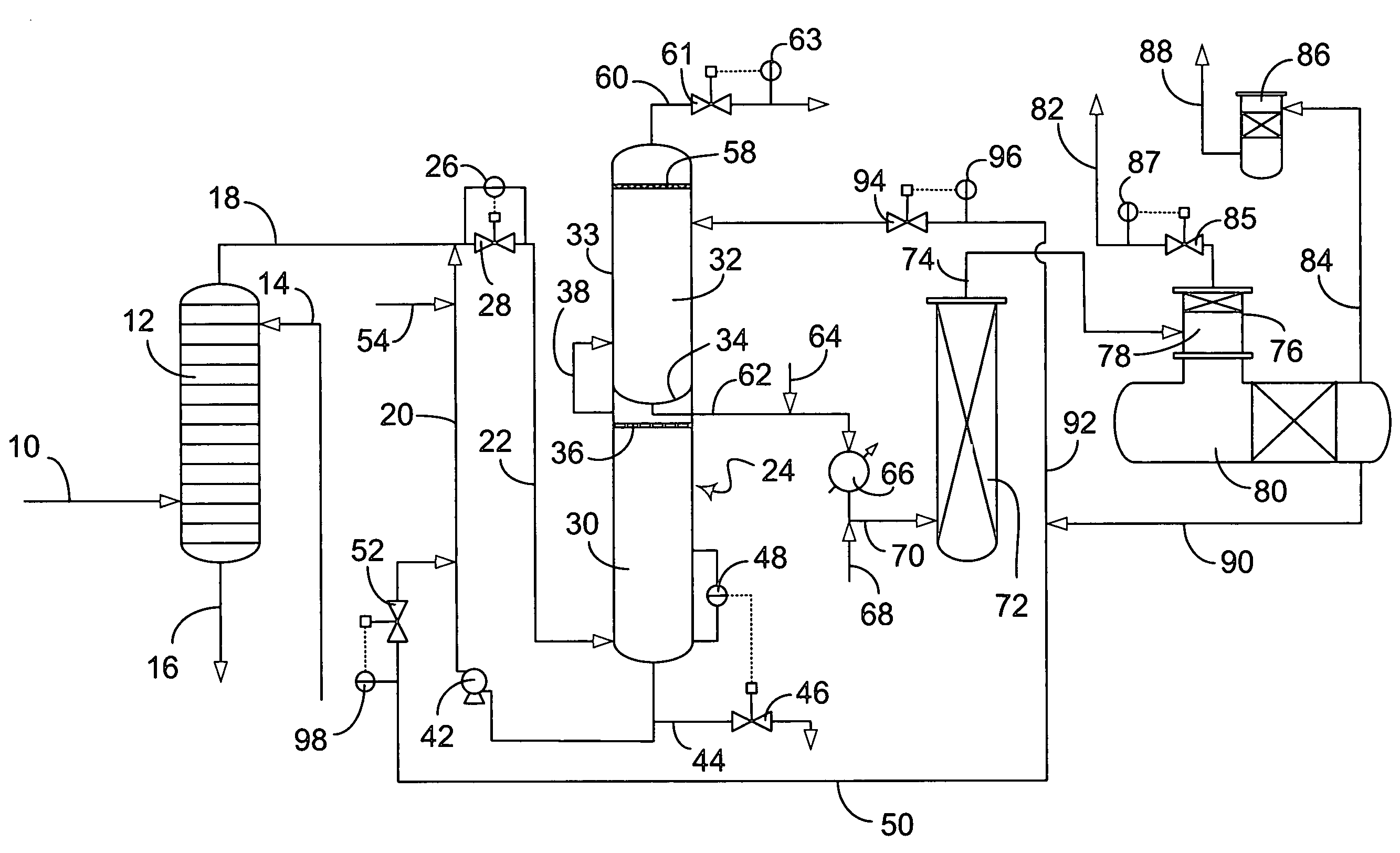

Method of purifying a natural gas by mercaptan adsorption

InactiveUS7211128B2Prolong lifeReduce the amount requiredGas treatmentUsing liquid separation agentThiolSorbent

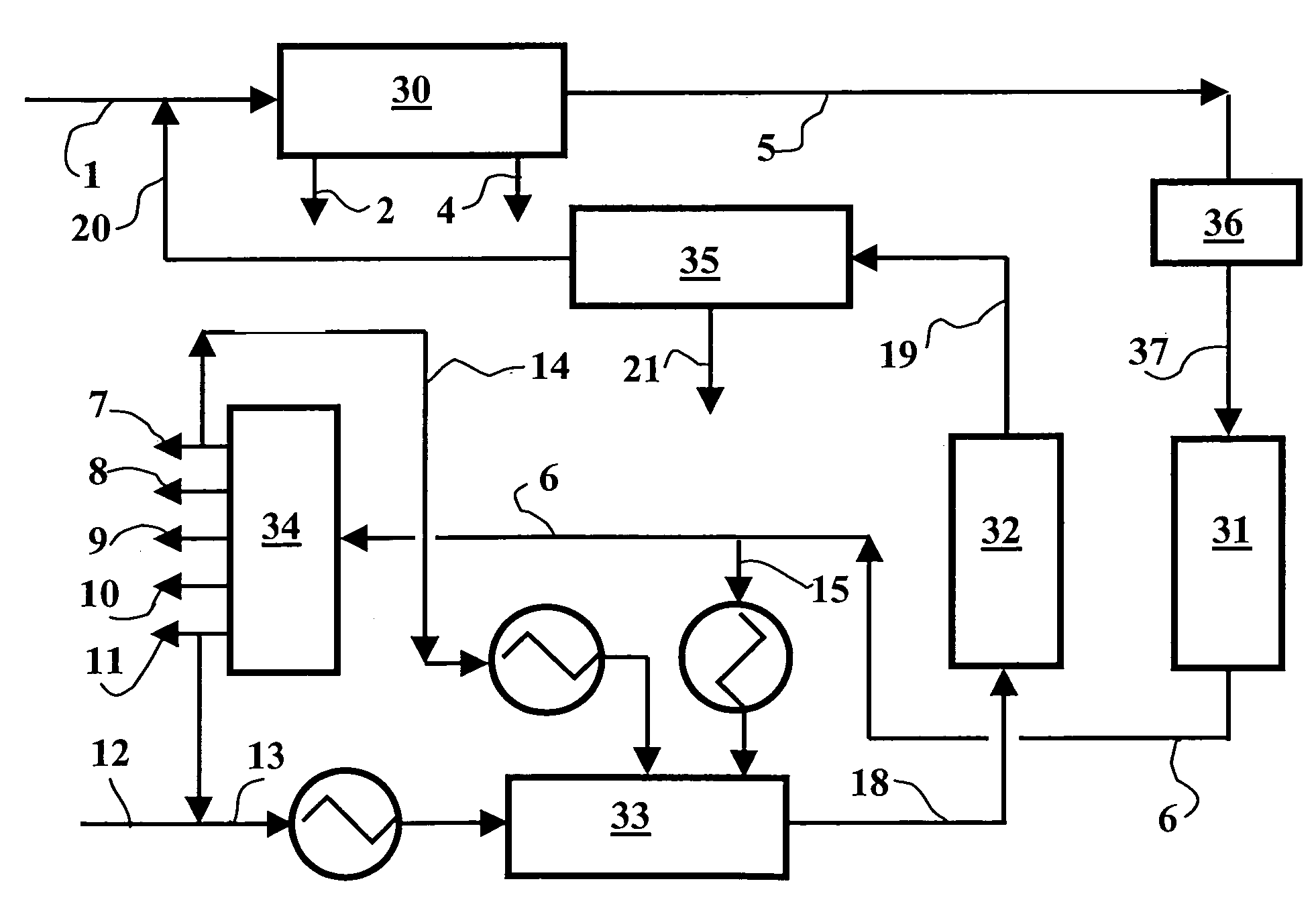

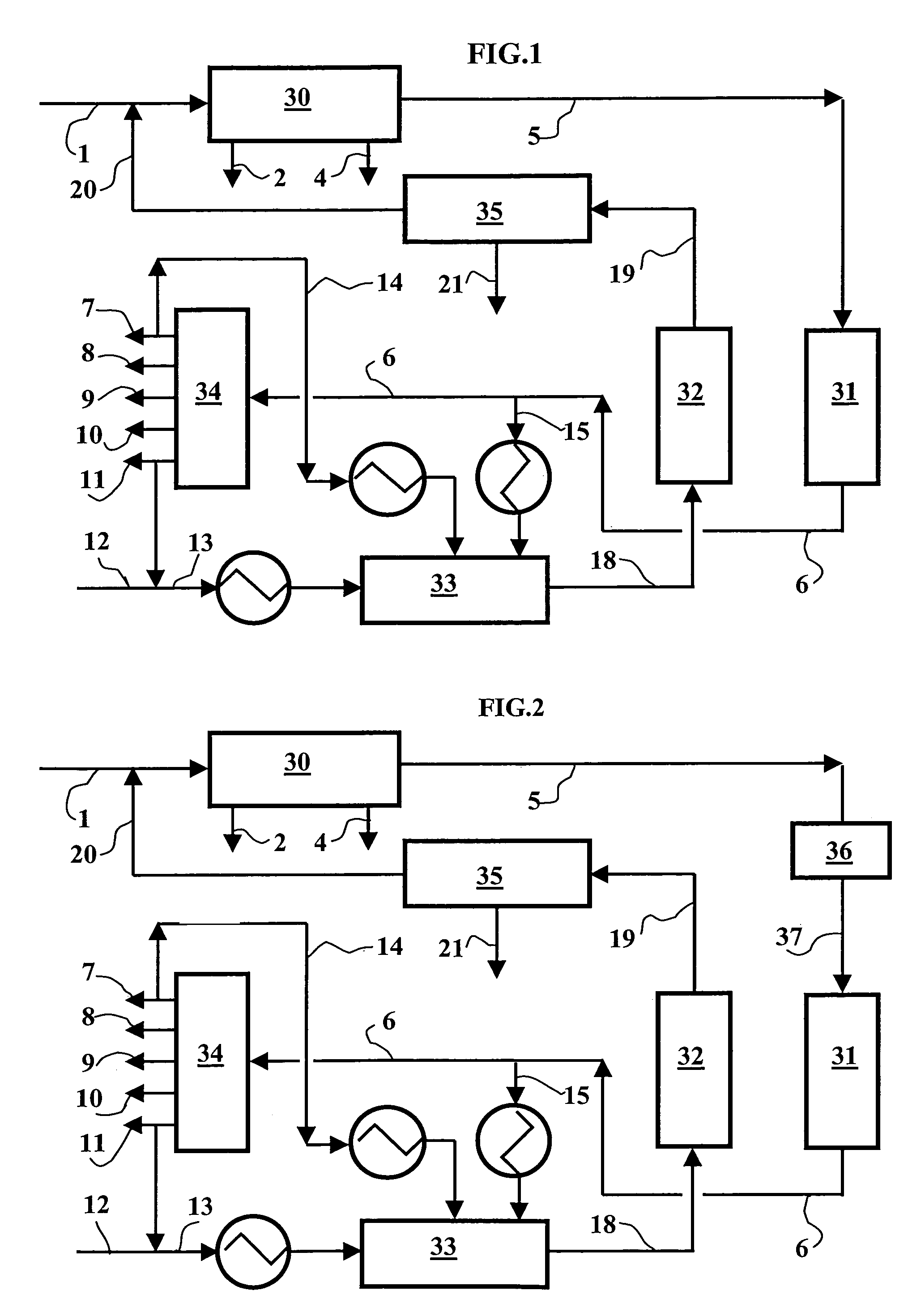

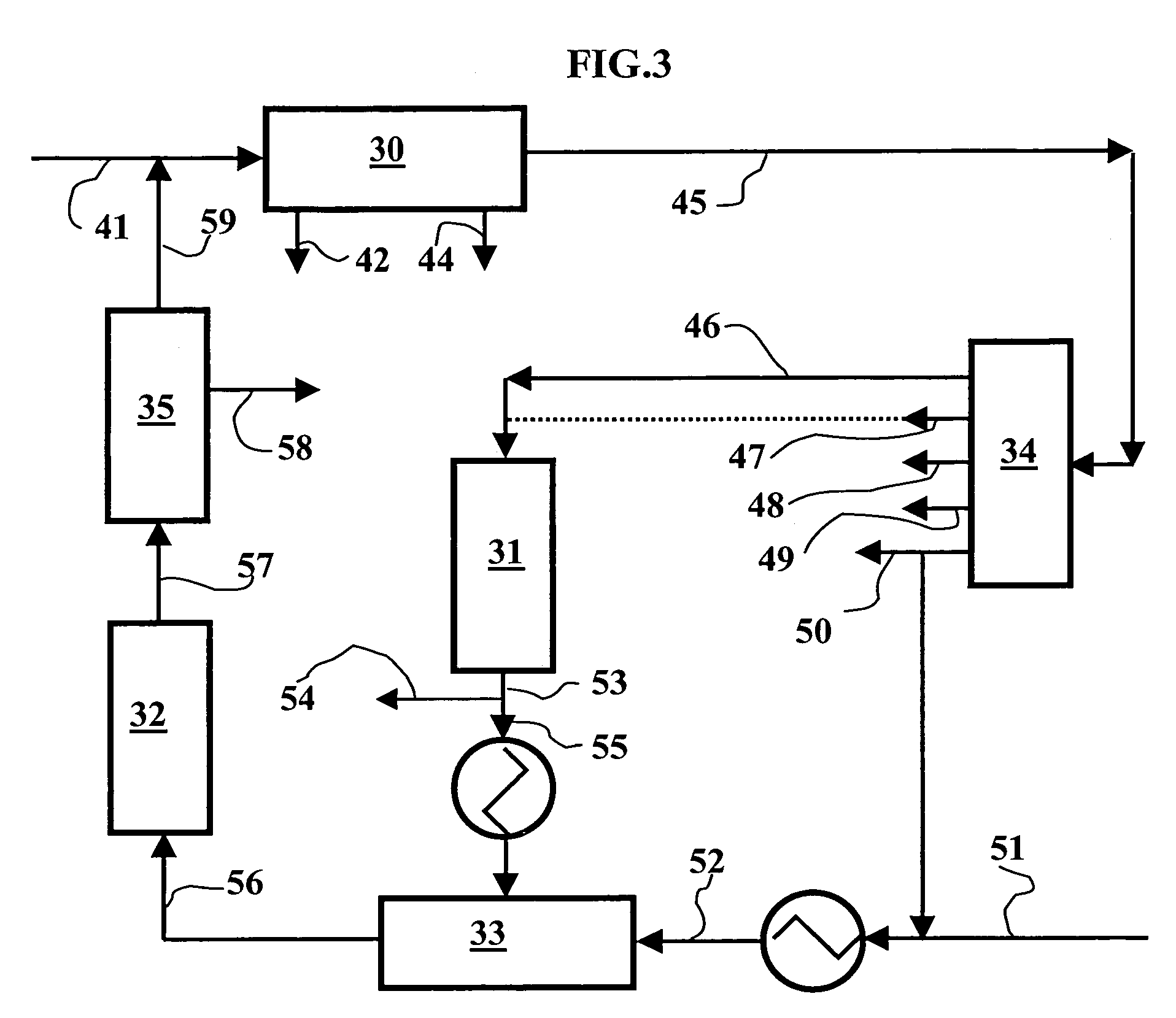

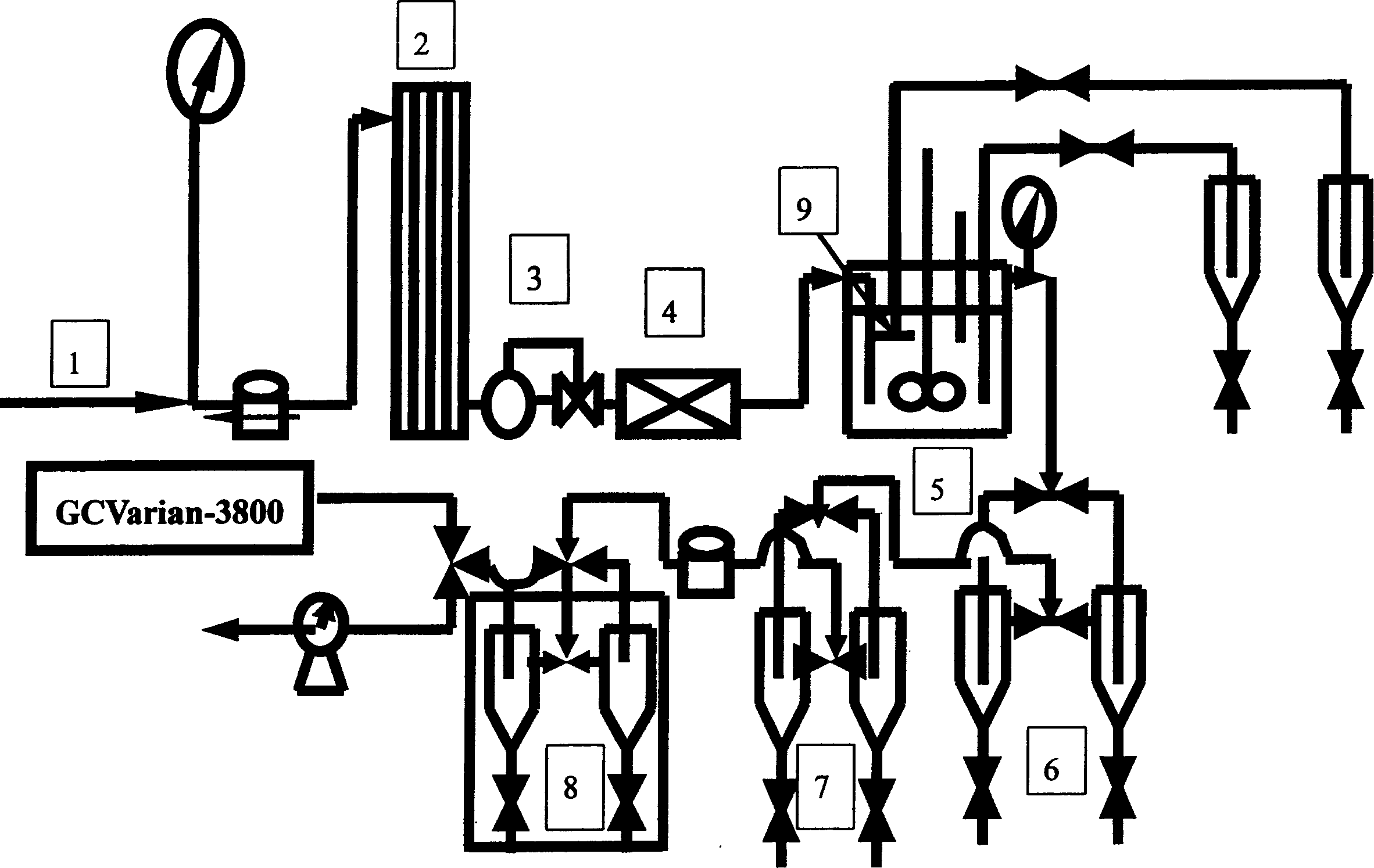

The raw natural gas is pretreated in treating unit 30. The treated gas is then purified by adsorption of the mercaptans in first enclosure 31. The various cuts that make up the purified gas are separated in fractionating unit 34. Part of the methane making up the purified gas is saturated with a C5+ hydrocarbon in contactor 33, then it is fed into second enclosure 32 so as to regenerate the adsorbent material contained in this second enclosure. The gas from the second enclosure is washed in unit 35, then recycled.

Owner:INST FR DU PETROLE

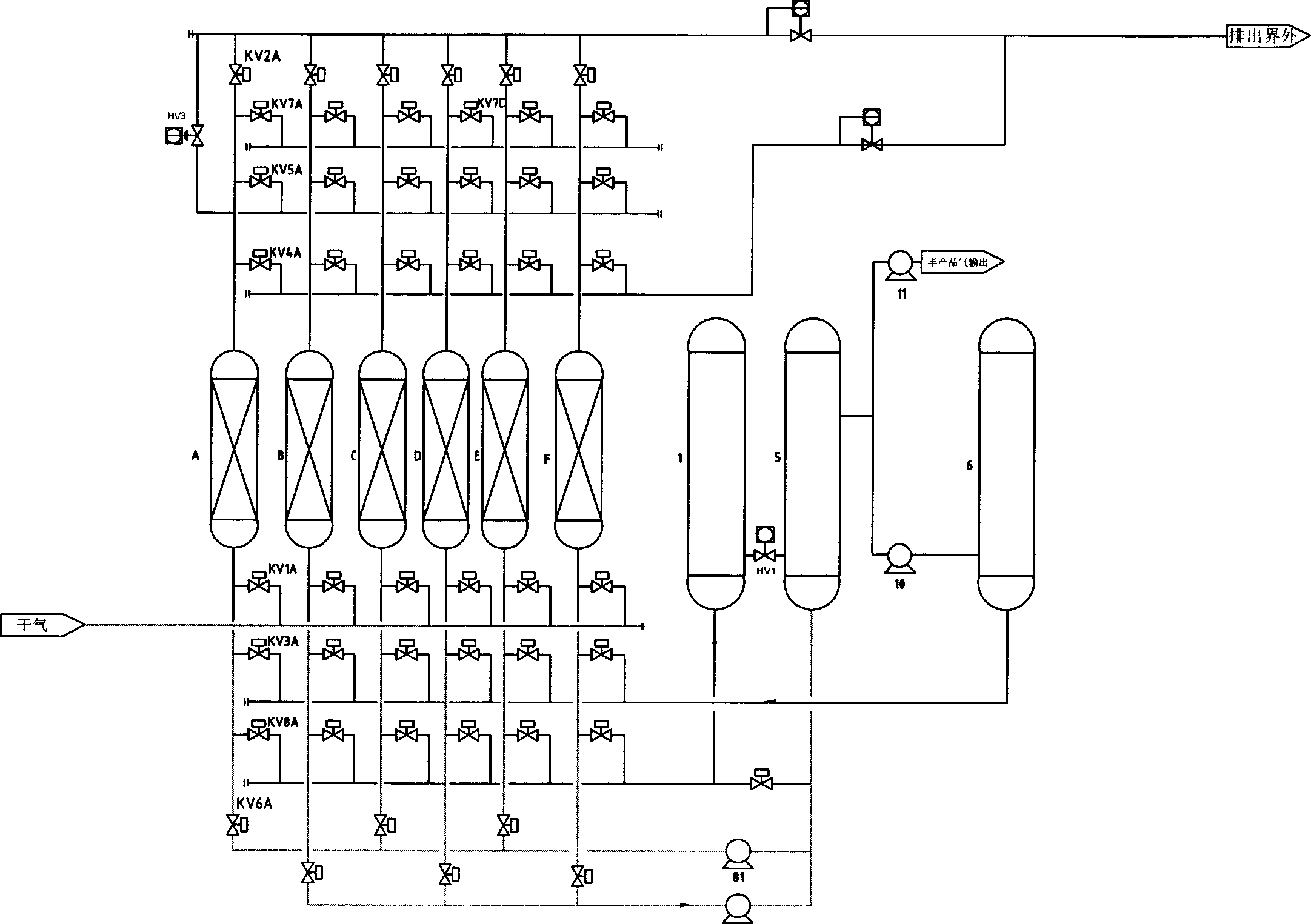

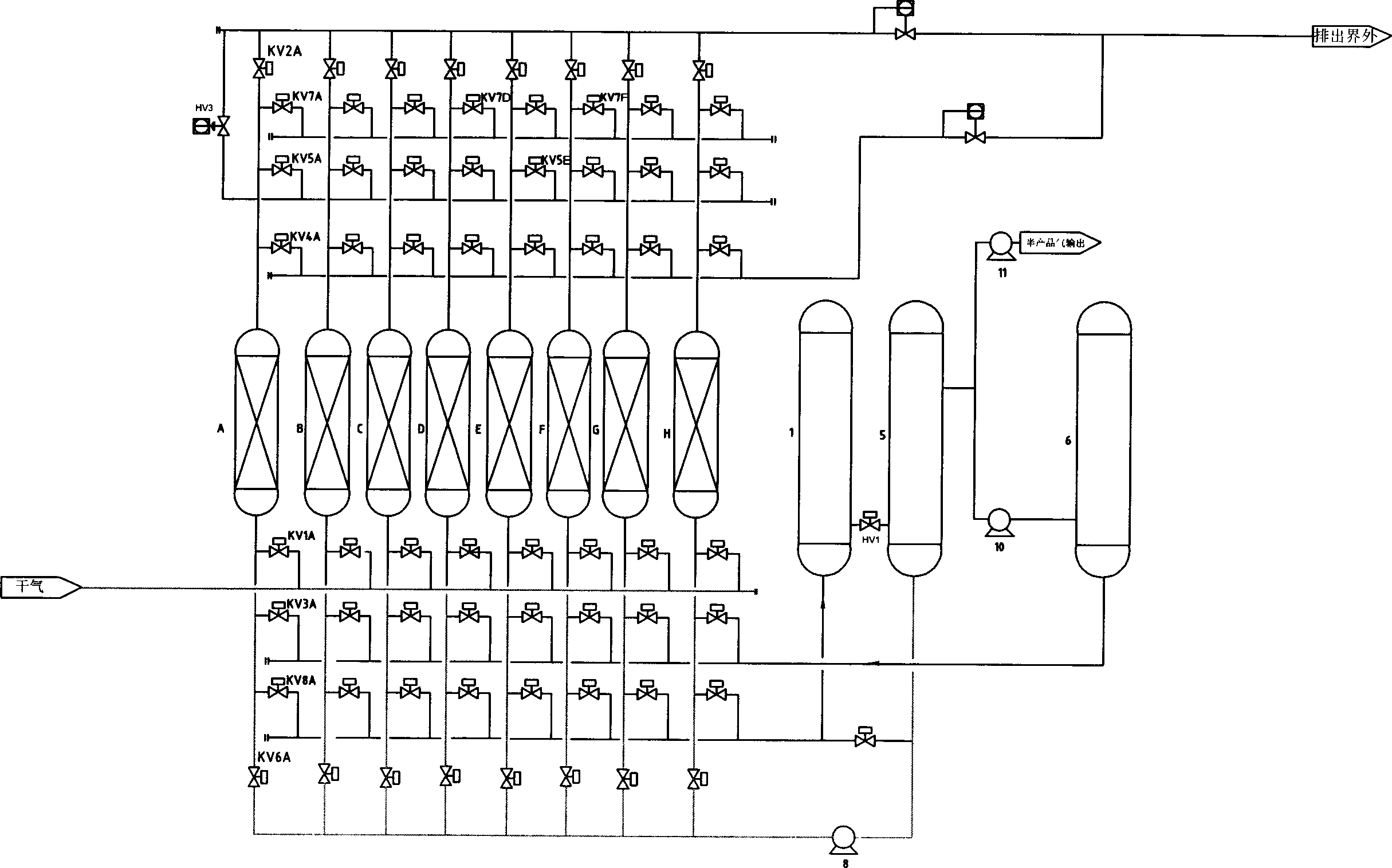

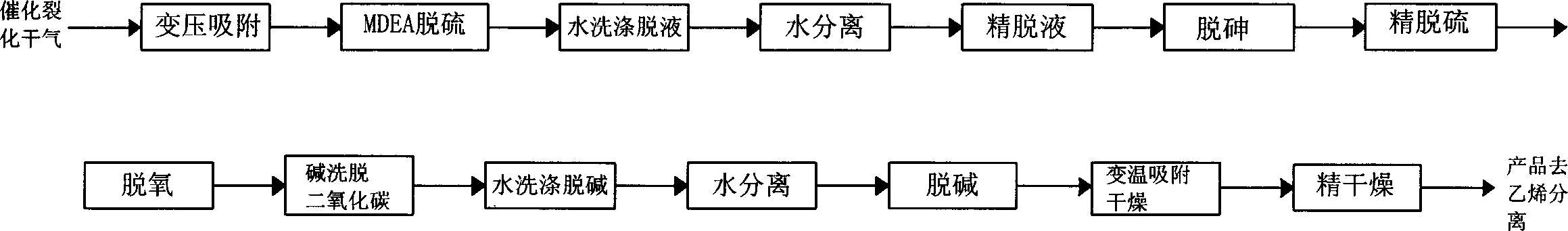

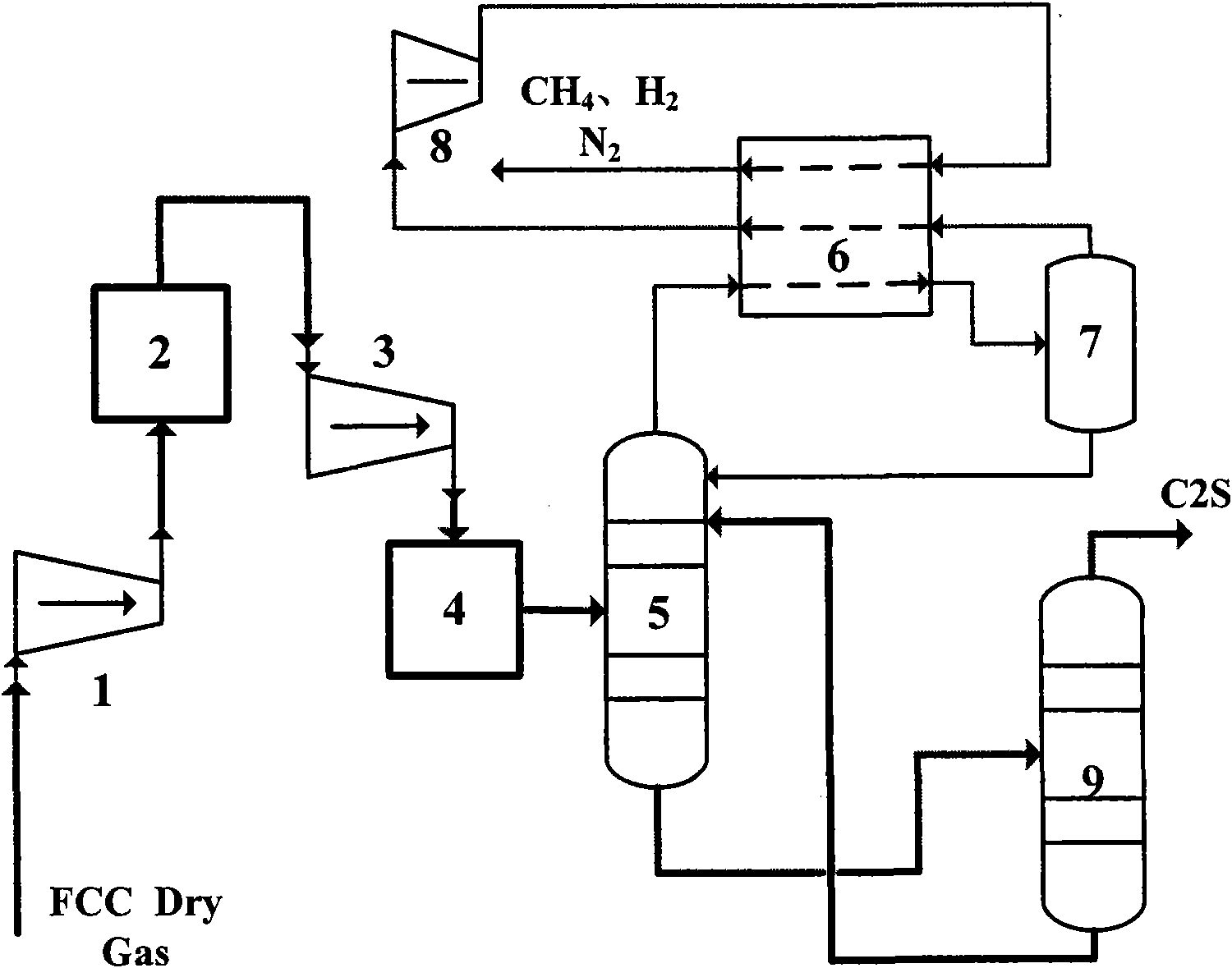

Stripped gas method for recovering C2 and higher carbon content hydrocarbon constituent

ActiveCN1800308AAchieve reasonable handlingUse restrictionsLiquid hydrocarbon mixture recoveryHigh carbonPhysical chemistry

The invention discloses a method for dry gas reclaiming C2 and C2 above hydrocarbon component. The dry gas at least uses the pressure swing adsorbing step which is formed by absorbing, inverse putting, air drafting and swashing to separate the C2 and C2 above hydrocarbon component; the gas after swashing and absorbing at least dose wet desulfurization, extract desulfurization and deoxidation steps to purify it to obtain the mixing gas of C2 and C2 above hydrocarbon component. The (V / V) sulfur content of the reclaiming C2 and C2 above hydrocarbon component is less than 0.1ppm and the oxygen content is less than 1ppm.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

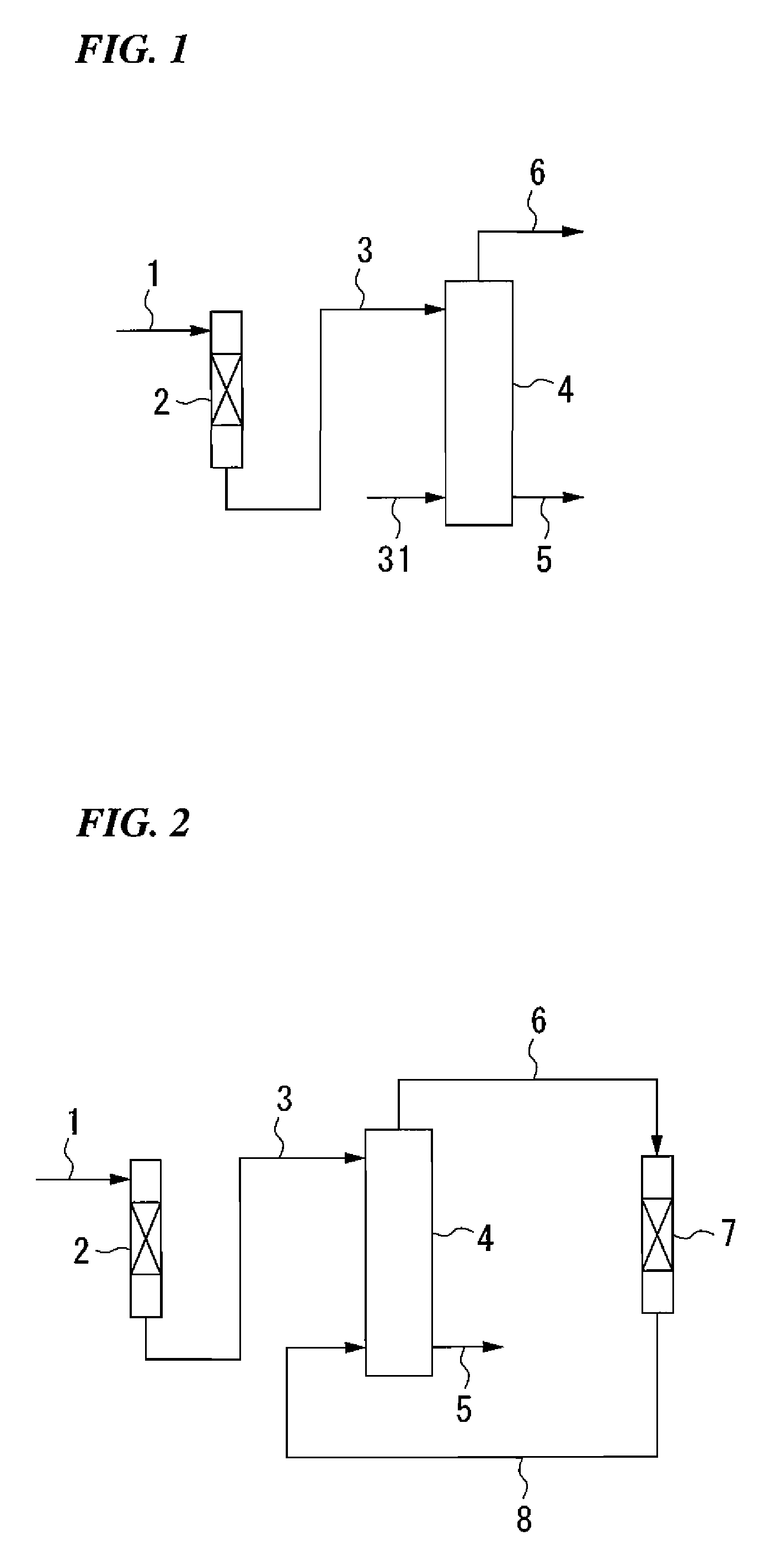

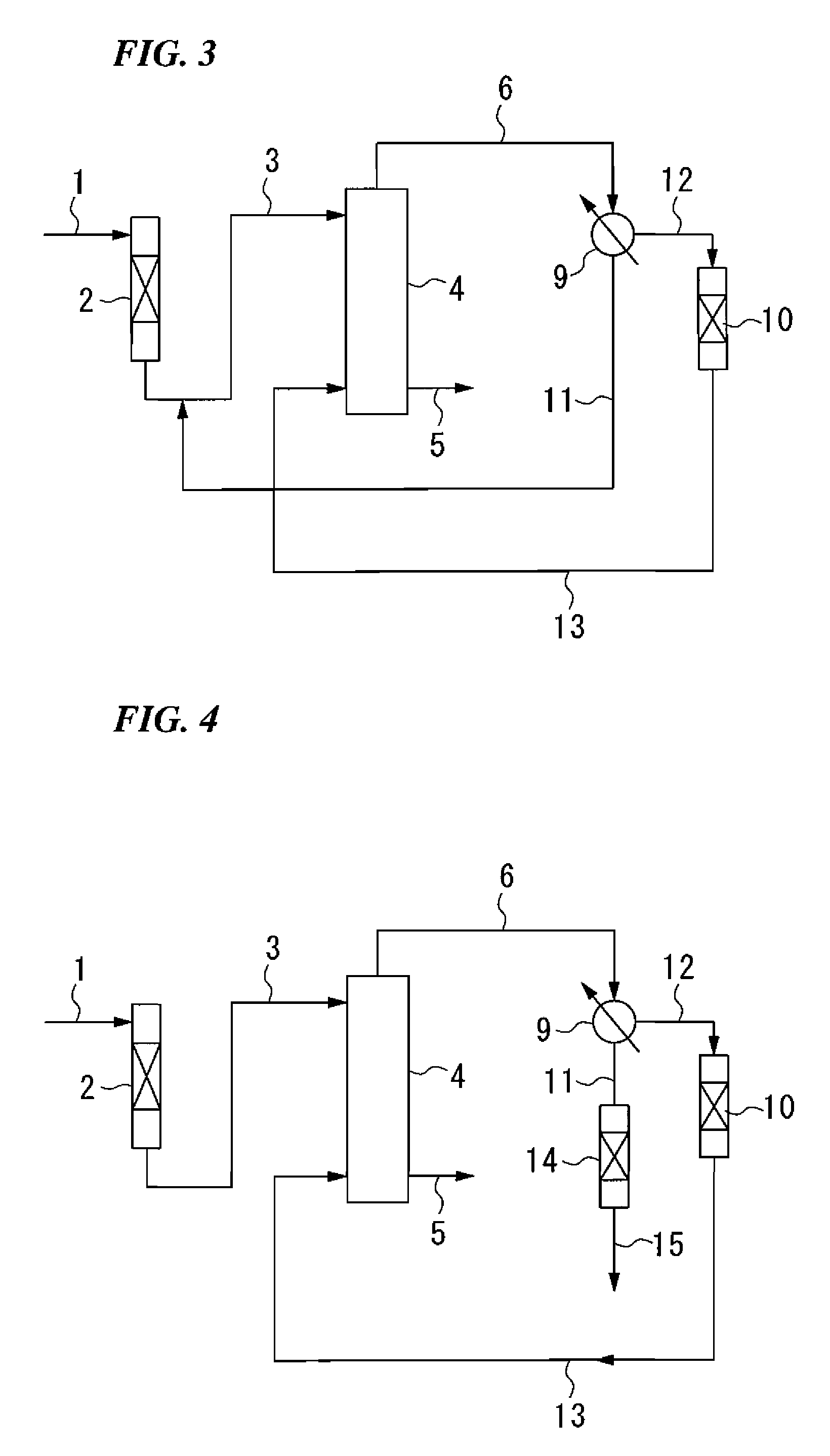

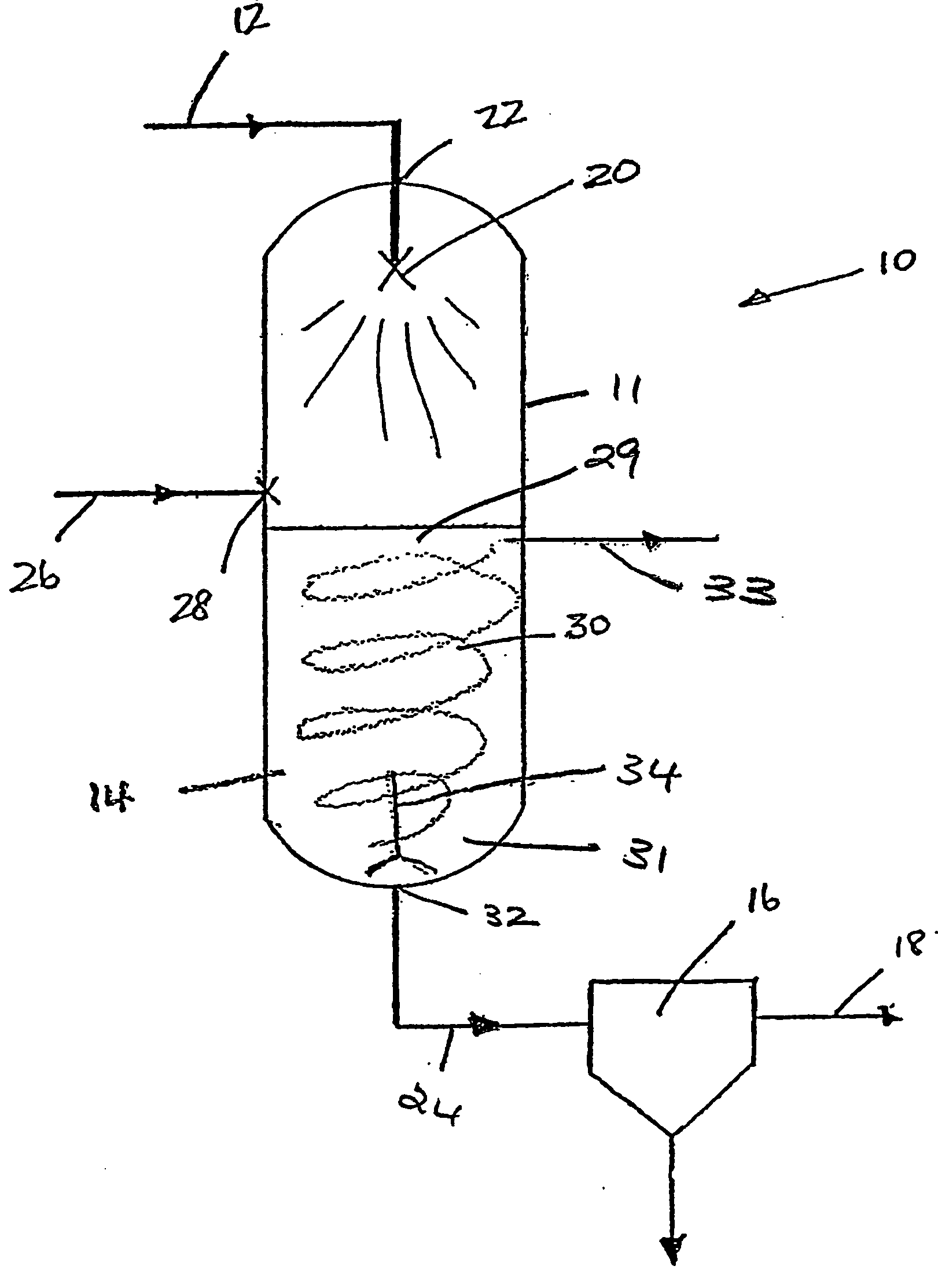

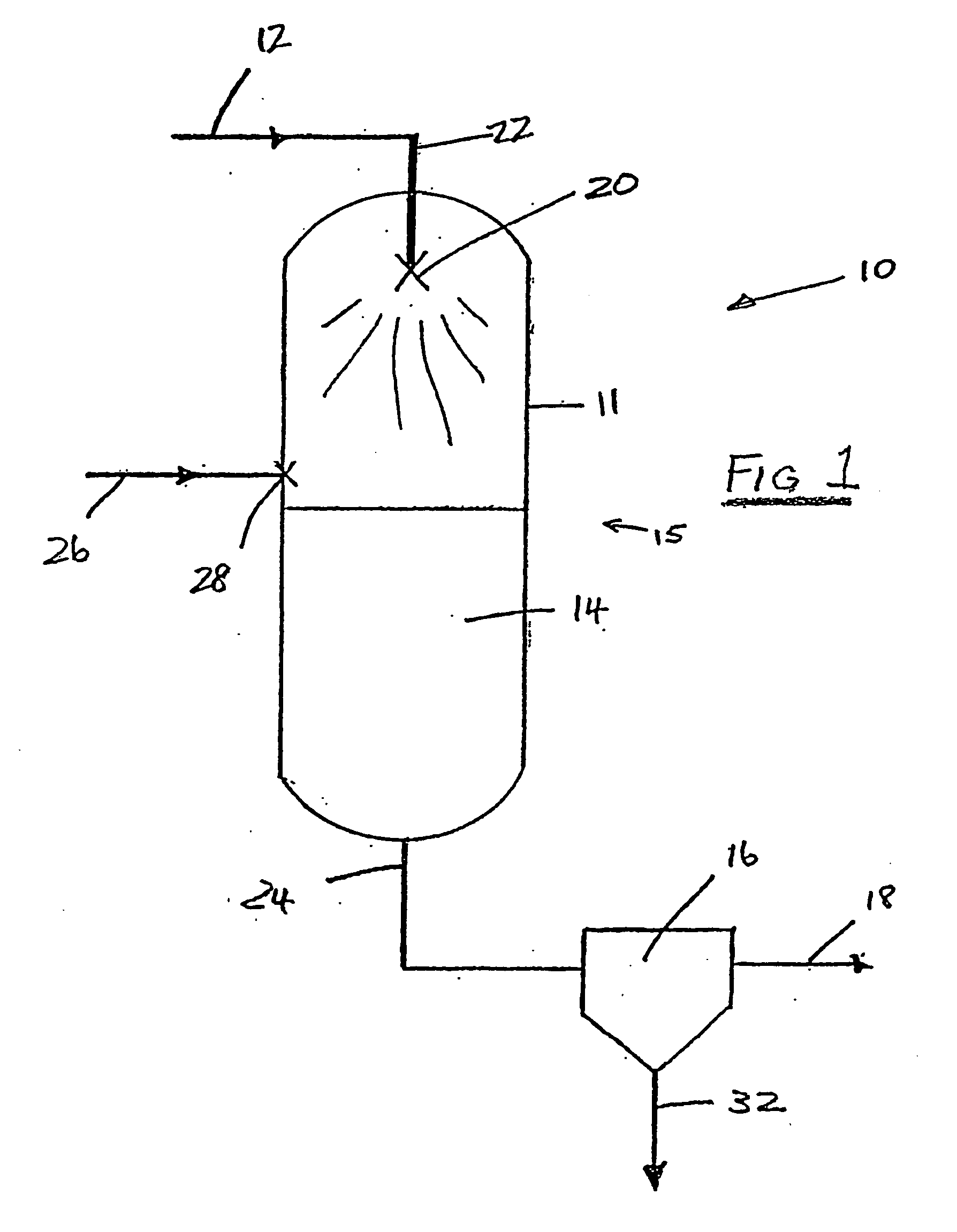

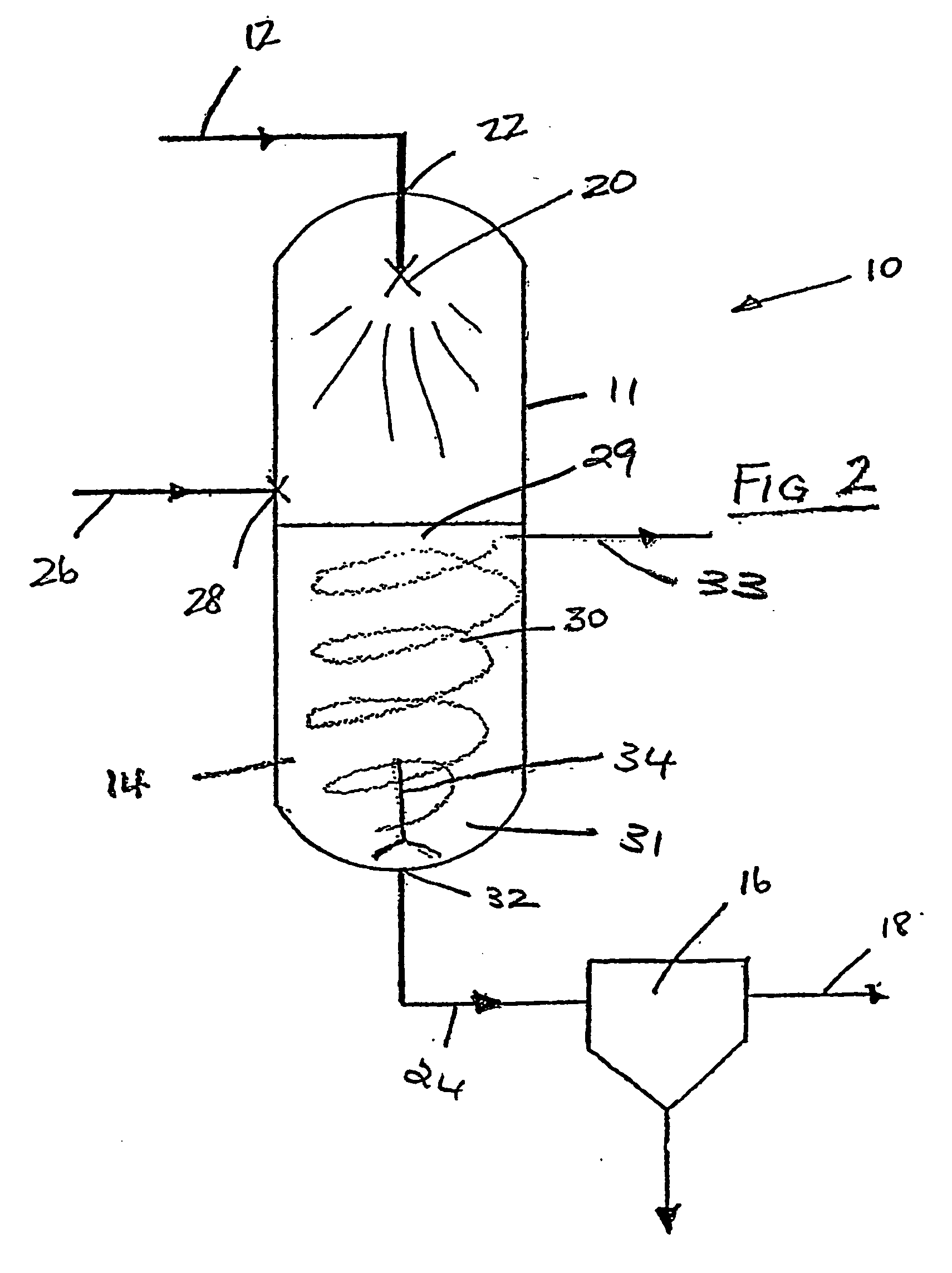

Mercury removal apparatus for liquid hydrocarbon

InactiveUS20100025184A1Easy to useComponent can be removedPhysical/chemical process catalystsUsing liquid separation agentLiquid stateLiquid hydrocarbons

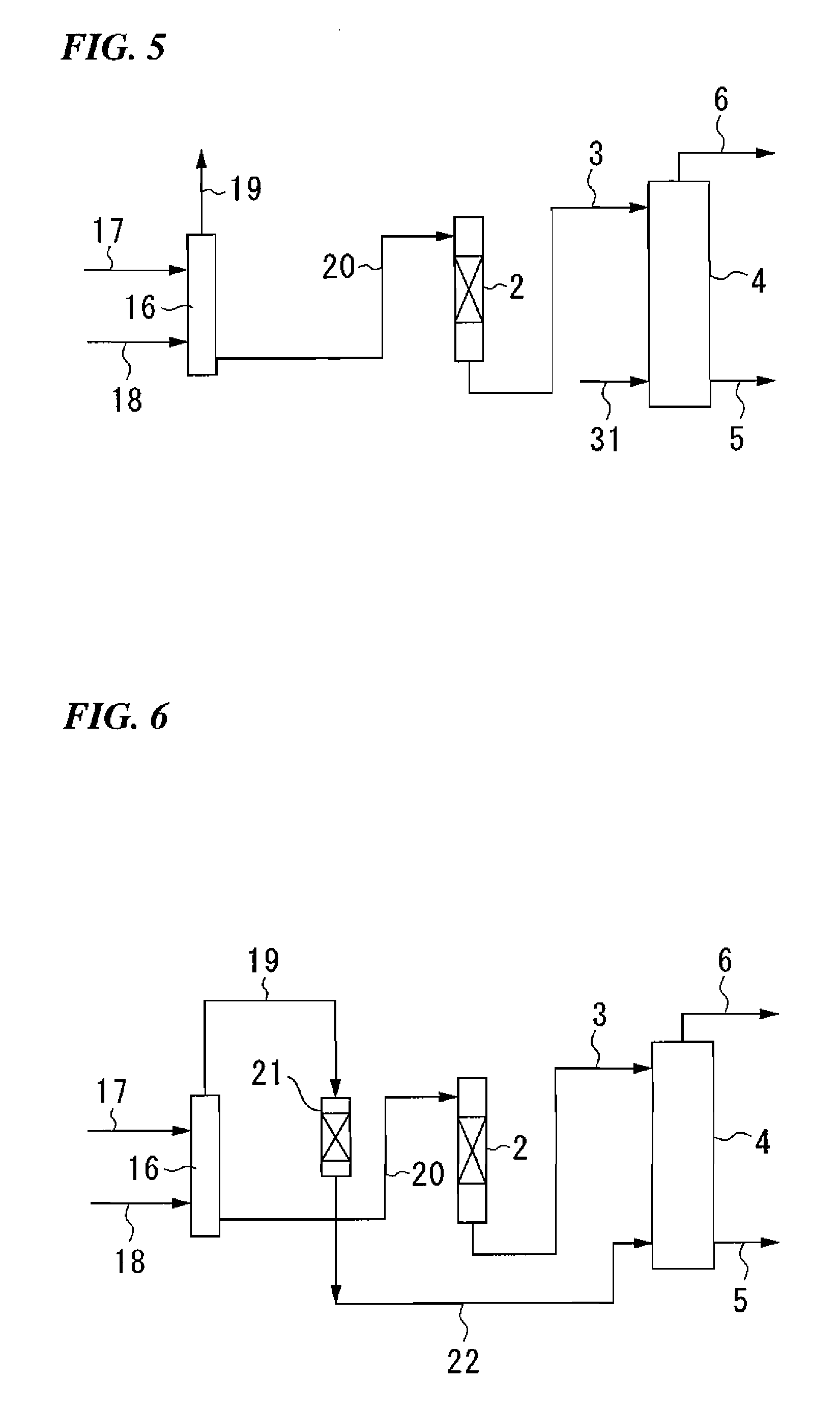

A mercury removal apparatus for a liquid hydrocarbon of the present invention includes a conversion device 2 which converts a mercury component in a raw liquid hydrocarbon into elemental mercury to obtain a first liquid hydrocarbon containing the elemental mercury; and a first stripping device 4 which brings the first liquid hydrocarbon into counter-current contact with a first stripping gas, thereby transferring the elemental mercury in the first liquid hydrocarbon to the first stripping gas to obtain a second liquid hydrocarbon in which the amount of the elemental mercury decreases and a first gaseous hydrocarbon containing the elemental mercury.

Owner:JAPAN PETROLEUM EXPLORATION CO LTD +1

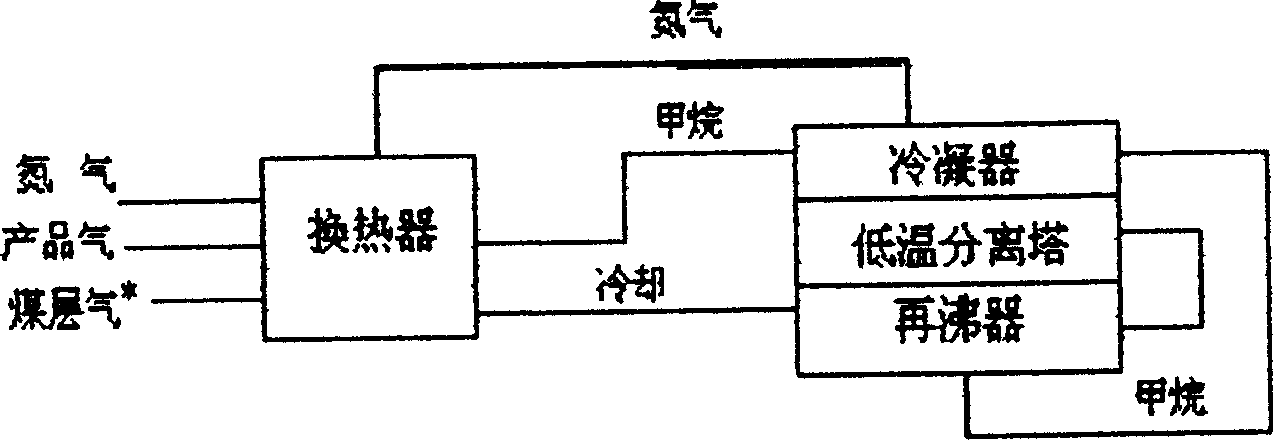

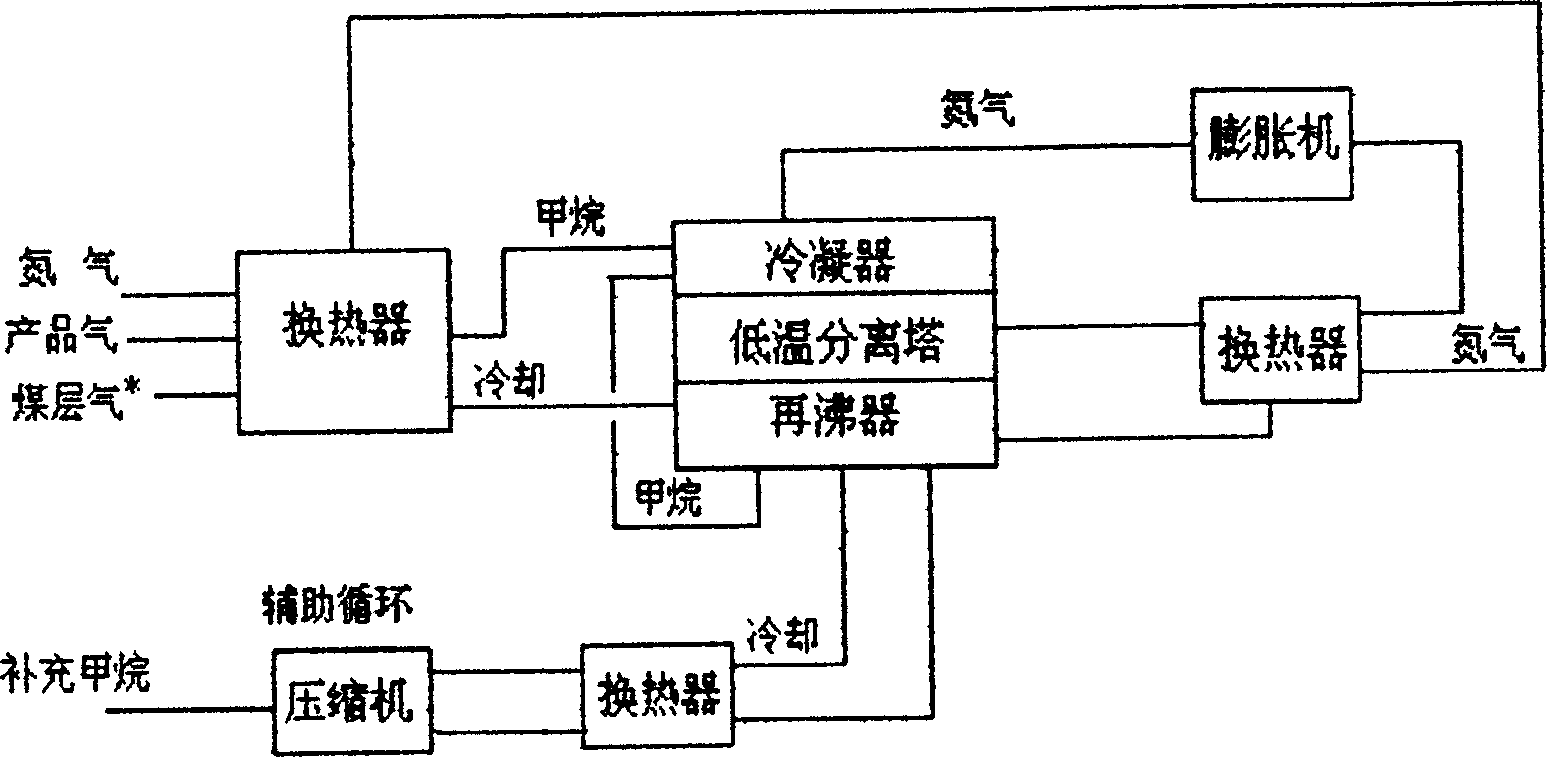

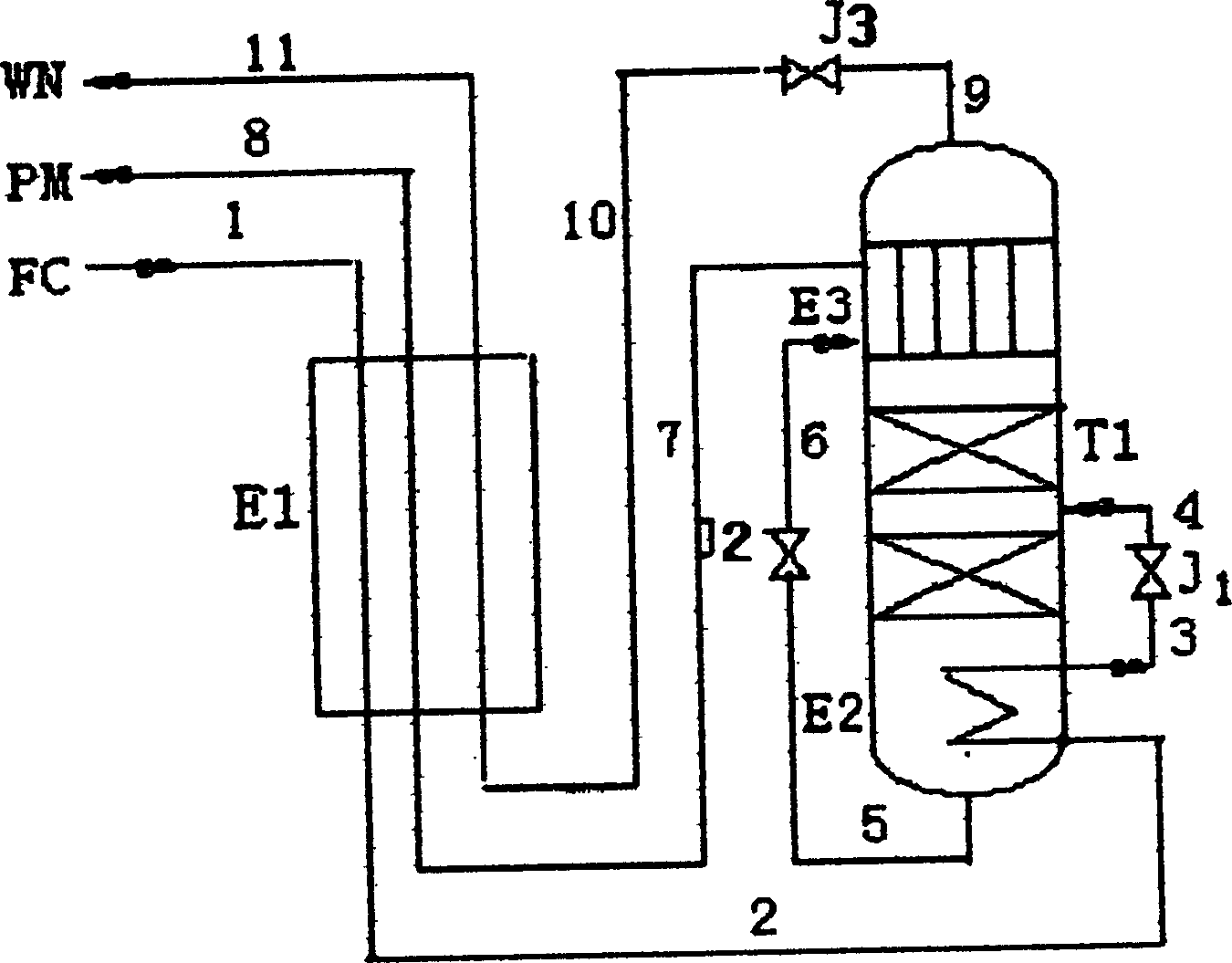

Technology of low temperature separation and concentration coal layer gas to produce methane

A process for low-temp separation of methane from coal seam gas and concentrating it includes such steps as removing O2, pressurizing, desulfurizing, decarbonizing, drying. Low-temp separation to obtain liquid methane, flowing in the condenser on the tower top for using it as the cold source of condensing reflux, and flowing the evaporated methane through heat exchanger to obtain product. Its purity is 95-99%. Its recovery rate is 95-99%.

Owner:HAO HUA CHENGDU TECH

Process and device for production of lng by removal of freezable solids

ActiveUS20050072186A1Reducing and eliminating foulingSolidificationLiquefactionWorking pressureThermal conductivity

Novel processes and devices for the removal of freezable species such as carbon dioxide, water and heavy hydrocarbons from a natural gas feed stream during liquefaction to produce LNG are disclosed. The freezable species are able to be removed as a solid, avoiding the costly step of pretreatment to remove the freezable species from the natural gas feed stream prior to the liquefaction stage. The freezable species may be removed on a continuous basis being separated as solids following liquefaction of the natural gas feed stream with subsequent separation of the solids. The solid freezable species may then be liquefied on a continuous basis if required with natural gas recycled to the process. Continuous removal of the freezable species from the natural gas feed stream is achievable by maintaining cooling and separation apparatus at the same working pressure. Advantageously, at least part of the cooling vessel is constructed from a material having a low thermal conductivity which discourages formation of the solids of the freezable species on the walls of the cooling vessel.

Owner:SHELL USA INC

Apparatus for prewashing a hydrocarbon stream containing hydrogen sulfide

Disclosed is an apparatus for extracting sulfur compounds from a hydrocarbon stream. A prewash section for converting hydrogen sulfide to sodium sulfide by reaction with an alkali such as caustic prepares the hydrocarbon stream for extraction. Spent alkali is continuously withdrawn and regenerated alkali is continuously added to the prewash section.

Owner:UOP LLC

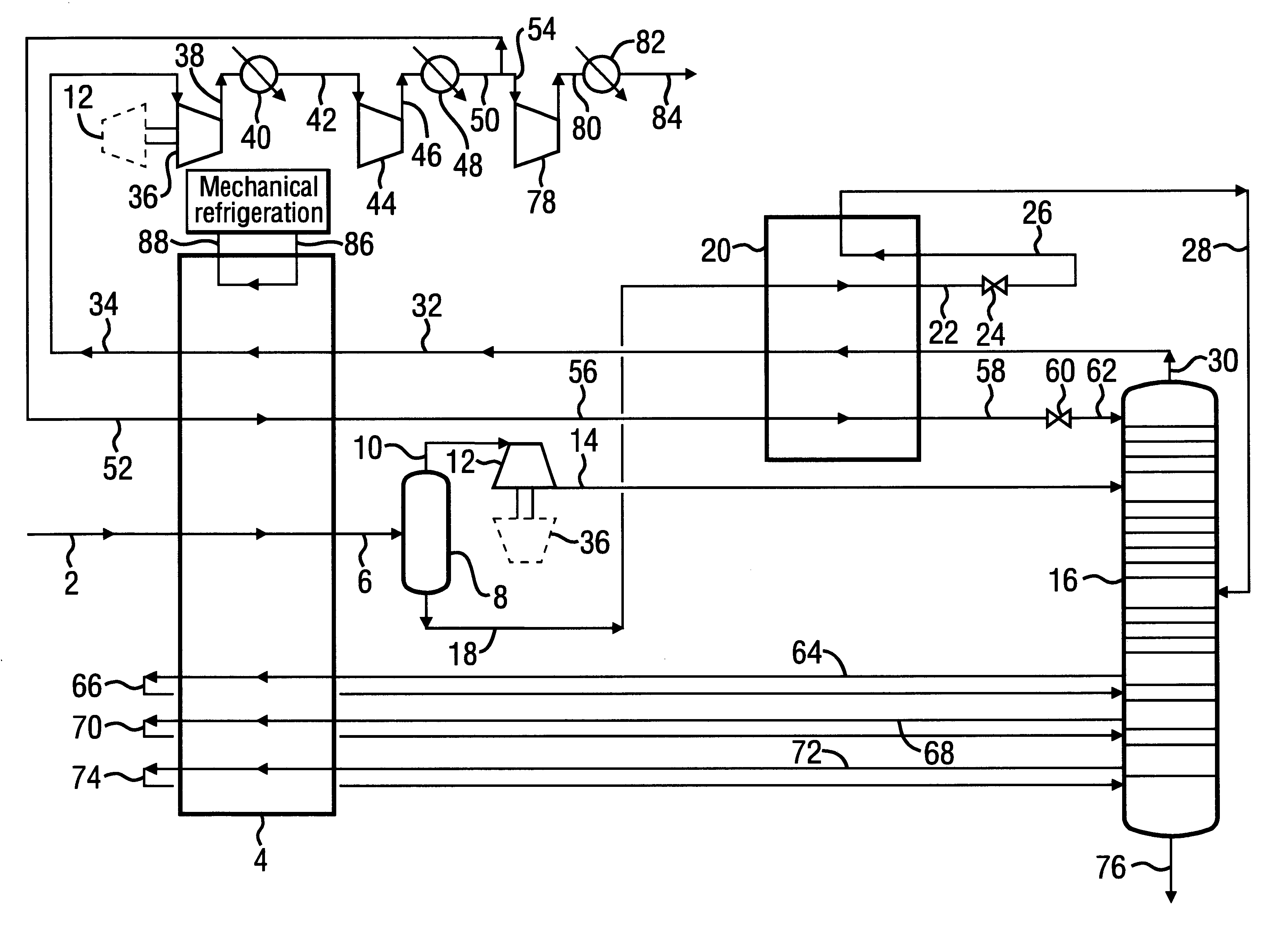

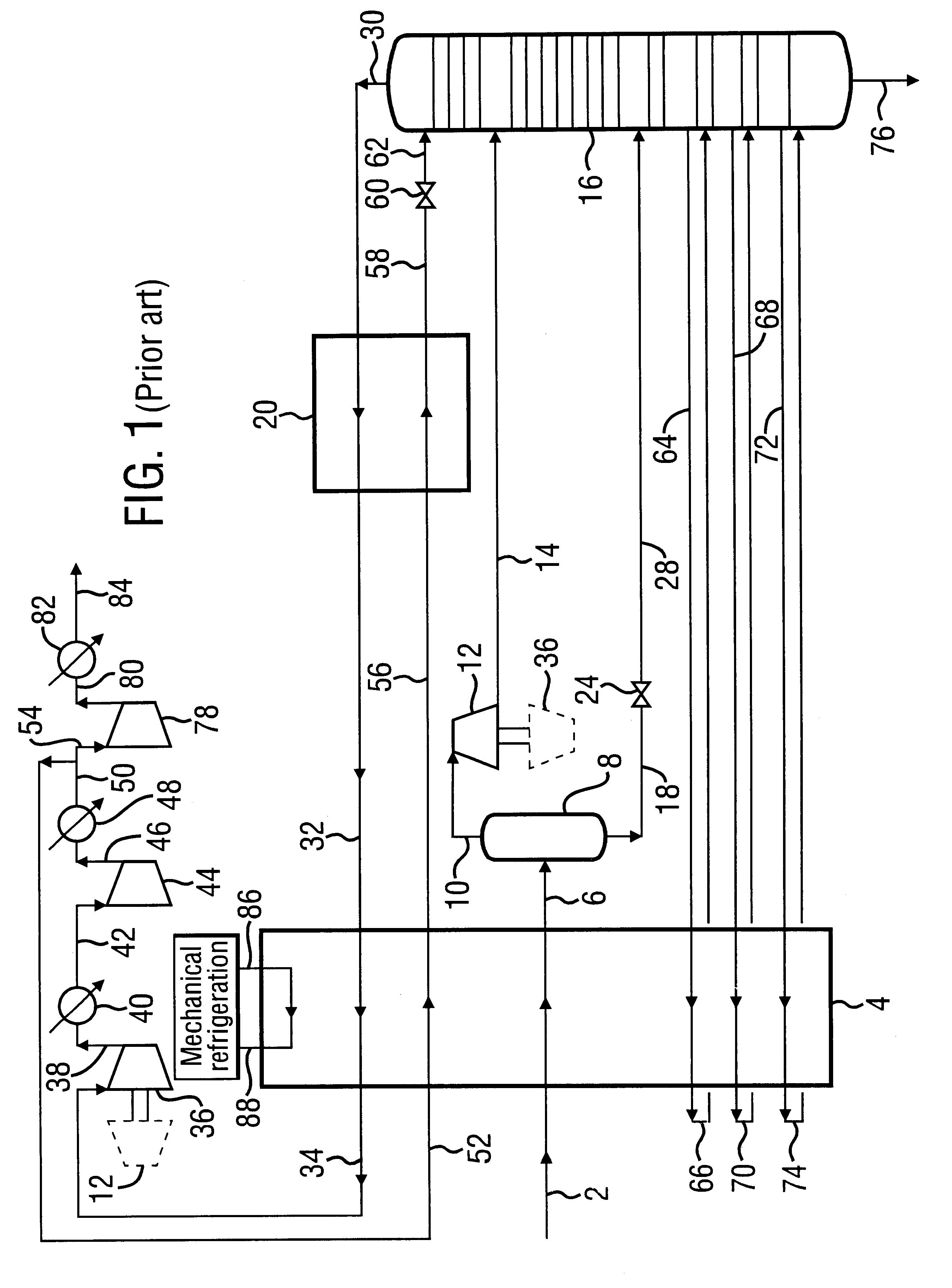

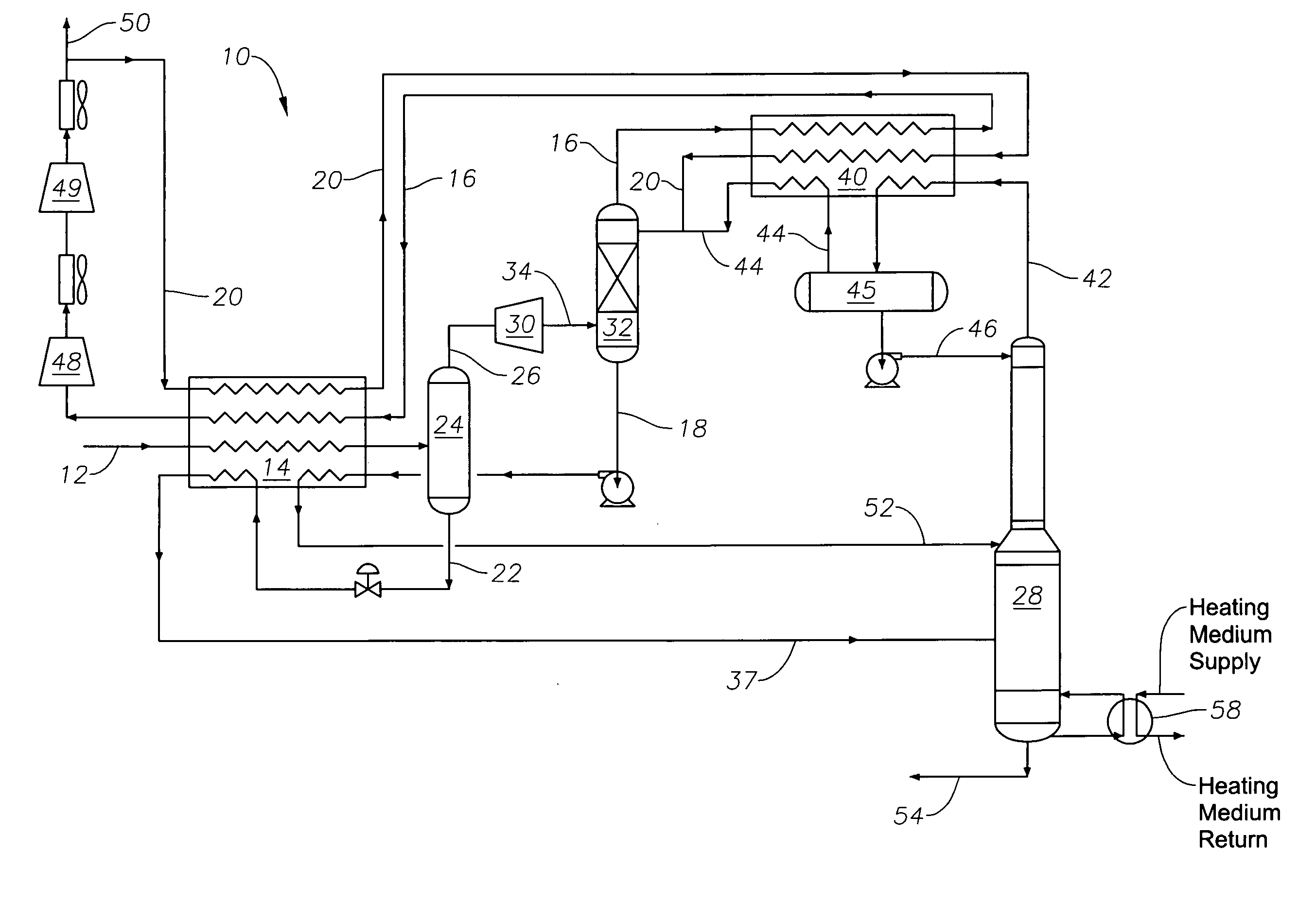

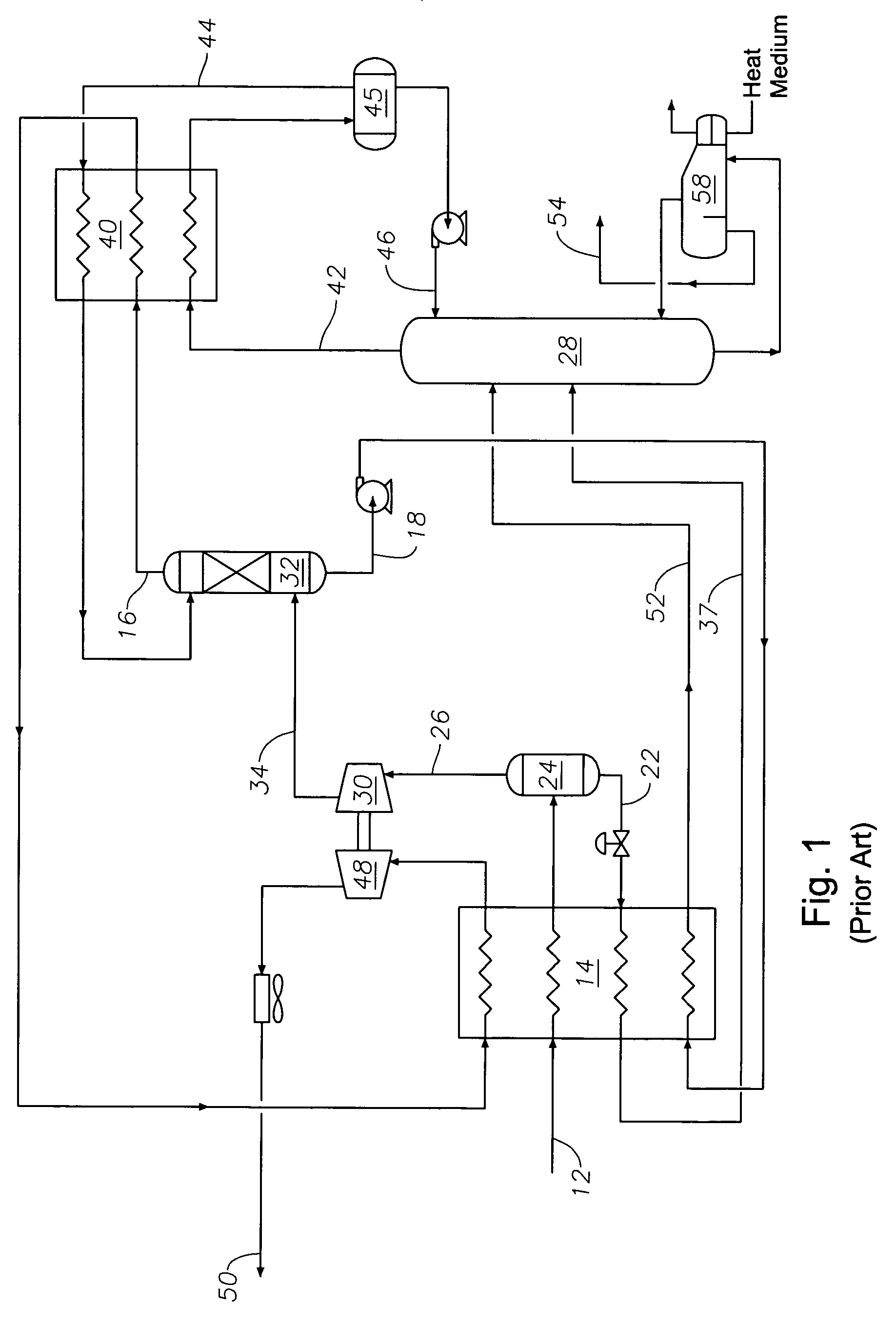

Configurations And Methods For Improved Natural Gas Liquids Recovery

Contemplated plants for recovery of NGL from natural gas employ alternate reflux streams in a first column and a residue gas bypass stream, wherein expansion of various process streams provides substantially all of the refrigeration duty in the plant. Contemplated plants not only have flexible recovery of ethane between 2% and 90% while recovering at least 99% of propane, but also reduce and more typically eliminate the need for external refrigeration.

Owner:FLUOR TECH CORP

Method for separating catalytic dry gas in refinery by using shallow cold oil absorption method

ActiveCN101638584AReduce consumptionReduce energy consumptionLiquid hydrocarbon mixture recoveryAlkaneRefinery

The invention discloses a method for separating catalytic dry gas in a refinery by using a shallow cold oil absorption method, which belongs to the technical field of separation and recovery of olefin and alkane. In order to solve the problems of large investment and high power consumption in the prior process of recovering the olefin and the alkane from the dry gas of the refinery, the inventionprovides a high-efficient method for separating the catalytic dry gas in the refinery by using the shallow cold oil absorption method. The method uses a C5 fraction as an absorbent, maintains an absorption temperature at shallow cold higher than 20 DEG C below zero, and adopts an expansion machine and a cold box to recover cold amount to significantly improve the recovery rate of the olefin and the alkane and simultaneously reduce the cycle amount and the loss amount of the absorbent so as to reduce the power consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

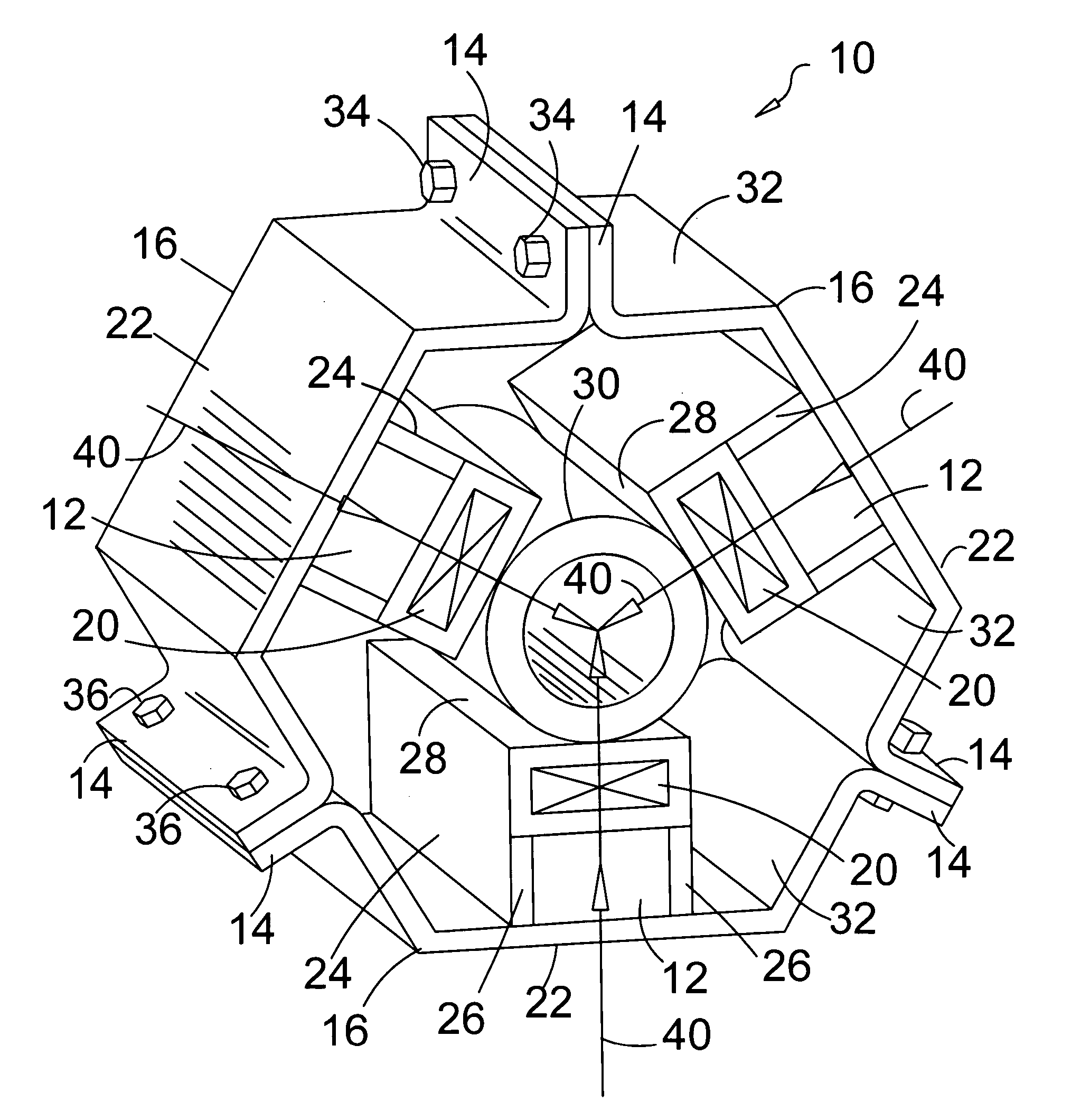

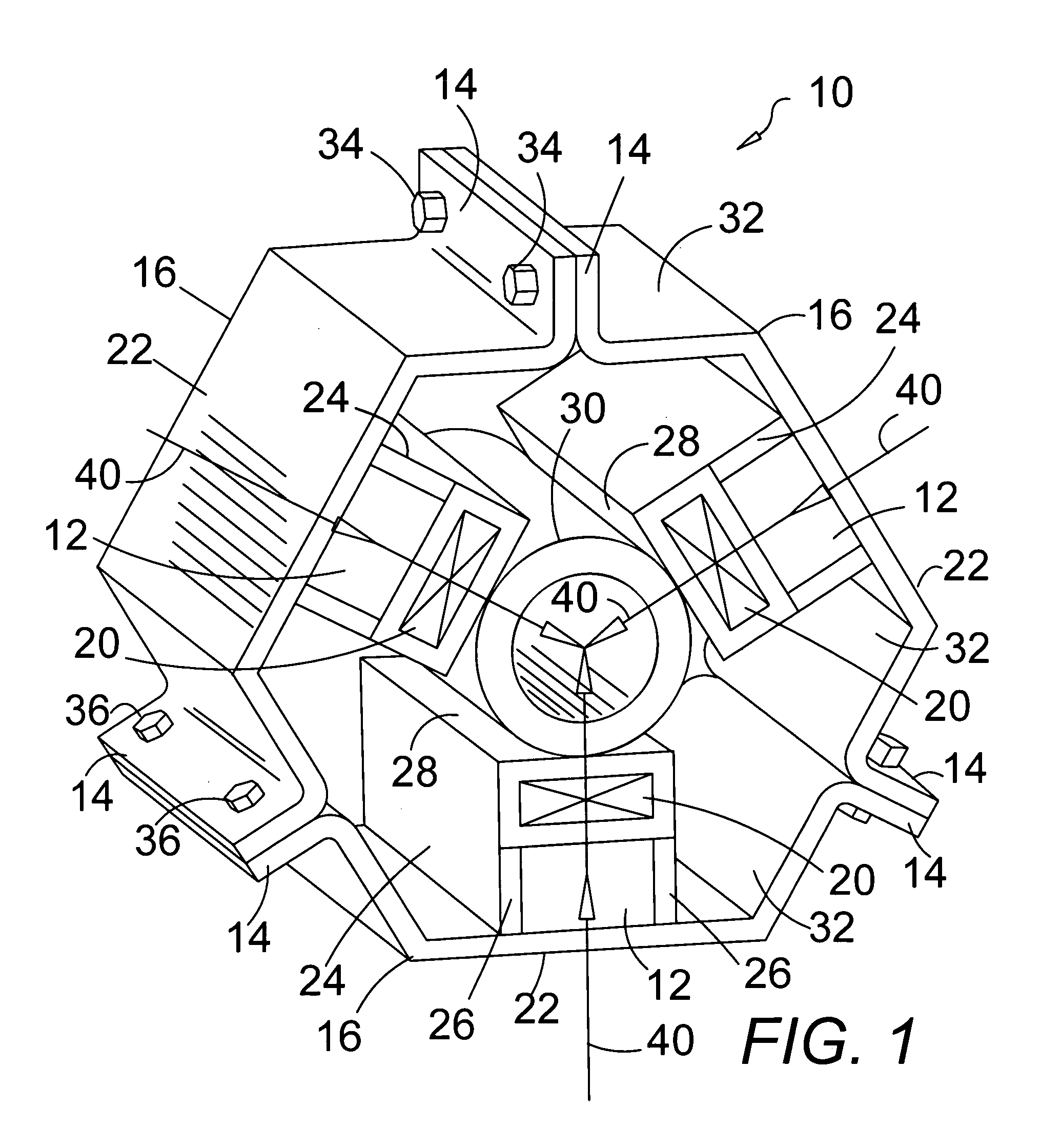

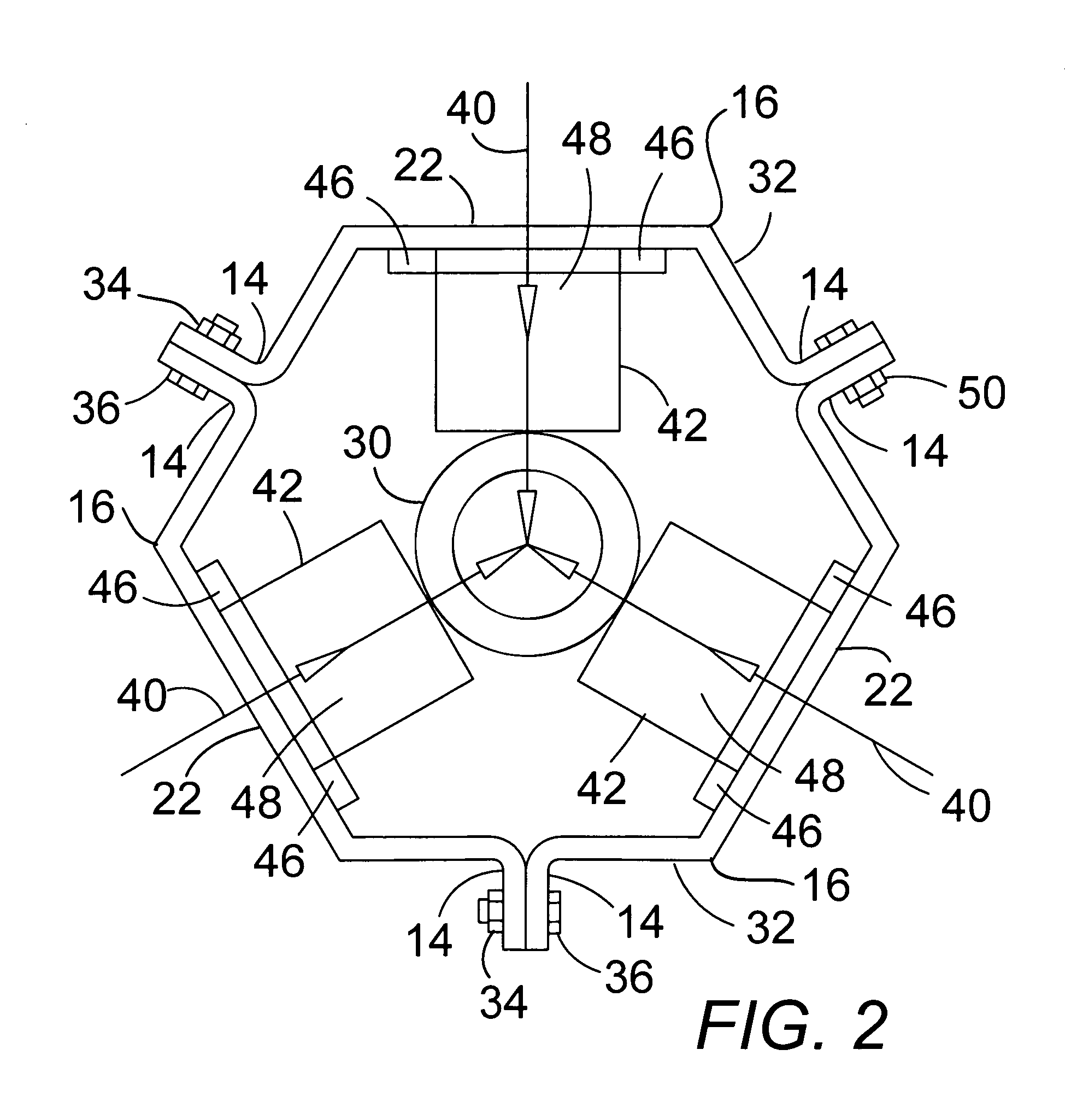

Device for focusing a magnetic field to treat fluids in conduits

ActiveUS20070068862A1Maximize fuel combustionEasy to installCombustion-air/fuel-air treatmentLiquid hydrocarbon mixture recoveryEngineeringCatheter

Three magnet casings are adjustably and removably attached to one another such that the device may snuggly fit about fluid conduits of differing diameters. An outer casing wall of ferrous content stainless steel confines the magnetic field. An inner magnet holder frame attached to the outer casing wall holds a magnet to the conduit and is fabricated of non-ferrous stainless steel to allow maximum trans mission of the magnetic field to the fluid in the non-ferrous section of the conduit around which the casings are attached together.

Owner:TRINITY REFINING & SAFETY SYST LLC +1

Technological process of preparing diesel oil fraction selectively with Fischer-tropsch synthetic gas

The one-stage production process is used to the prepare product with diesel oil fraction as main component from synthetic gas. The synthetic gas consists of H2 and CO in the volume ratio of 1.0-4.0 as main components; and the Fischer-Tropsch synthesis catalyst is a metal Co / active carbon carrier catalyst. The reaction conditions of Fischer-Tropsch synthesis include: reaction temperature of 120-400 deg.c, reaction pressure of 0.05-10 MPa, and space velocity of synthetic gas of 100-5000 / hr. The product of the present inventino is diesel oil fraction in 180-380 deg.c, contains alkane of at least95%, with isomeric hydrocarbon / normal hydrocarbon ratio of 0.03-0.3, S and N2 content lower than 50 ppm, unsaturately hydrocarbon content lower than 2% and oxygen content of 0.001-0.3%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

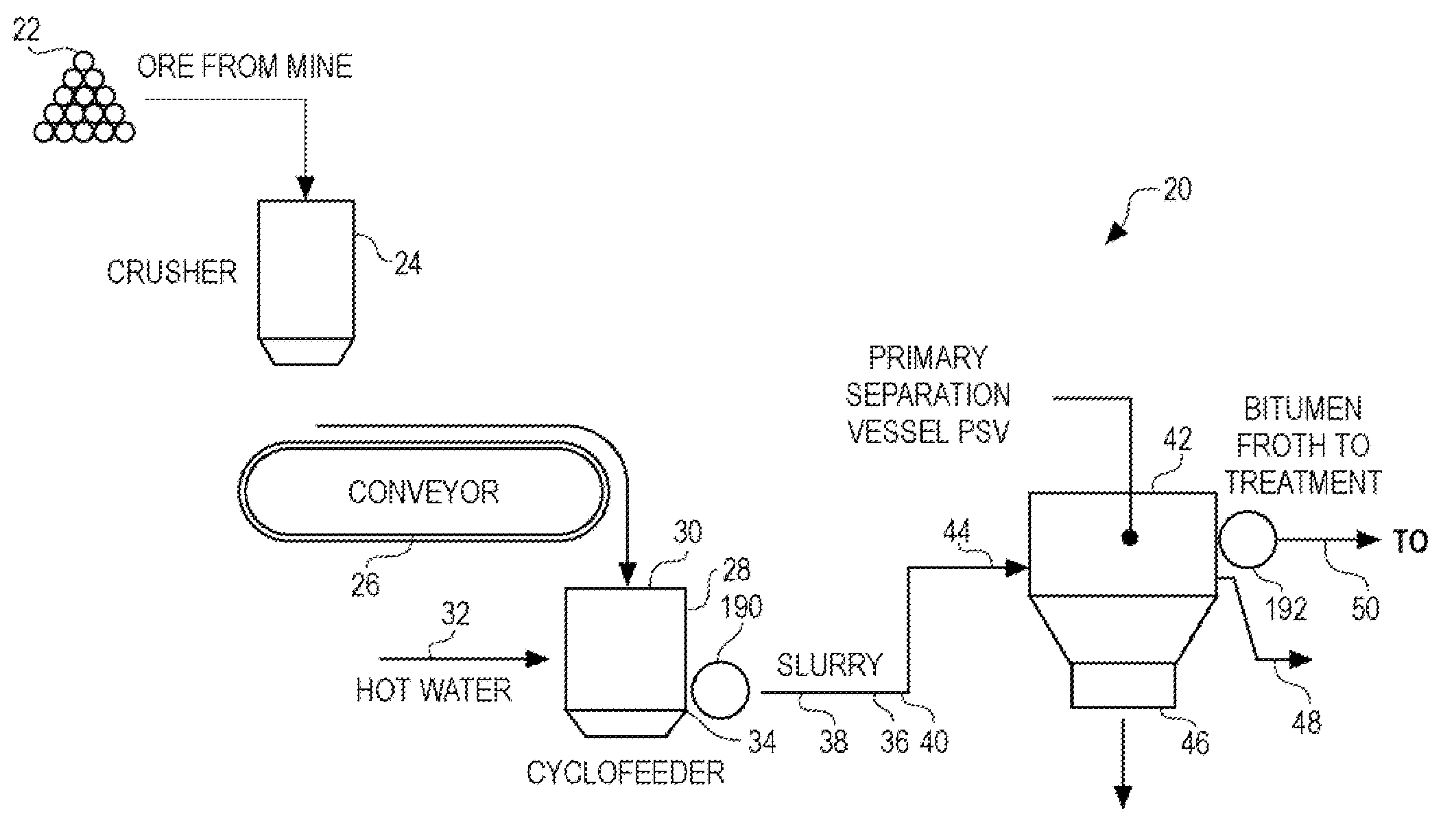

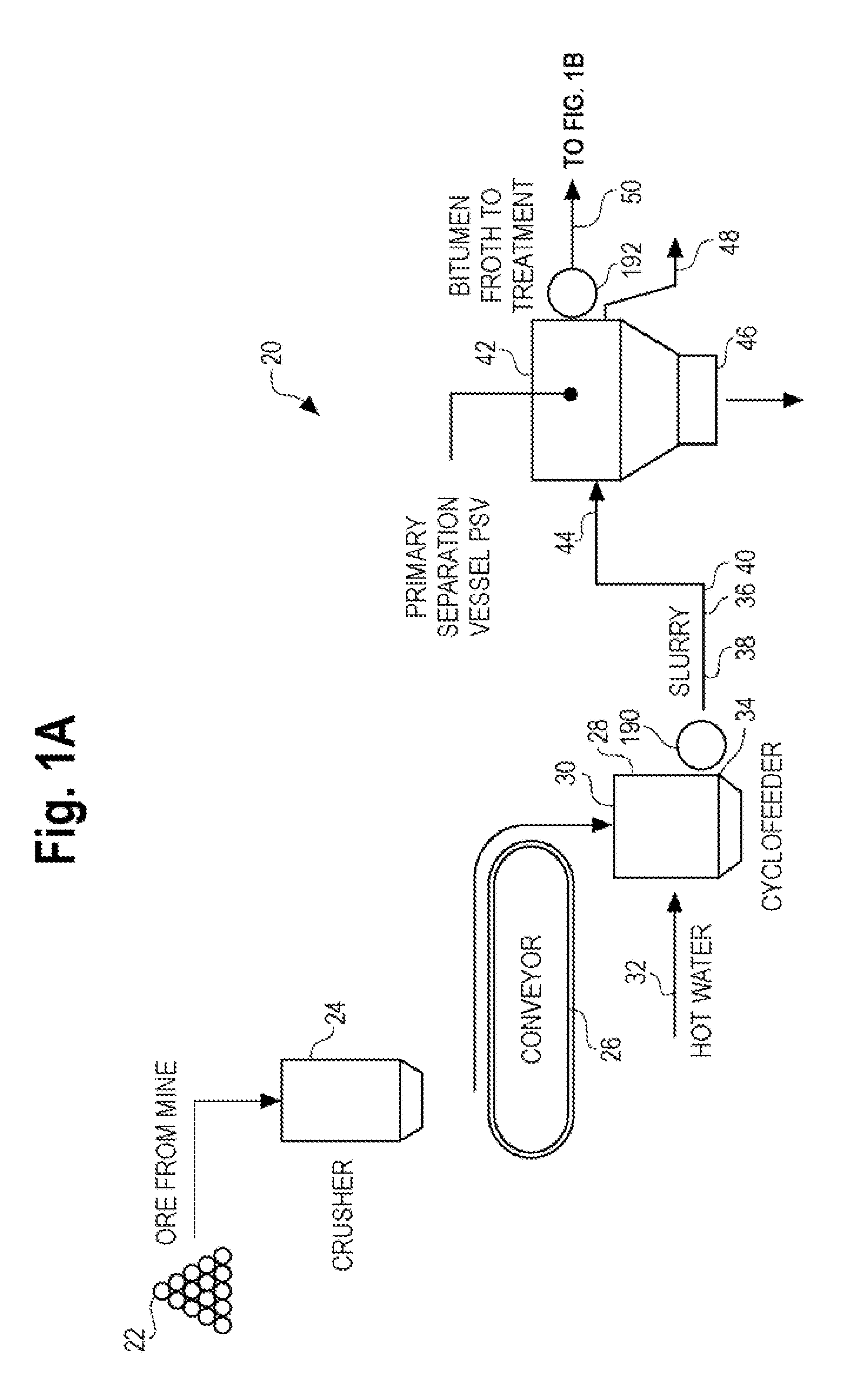

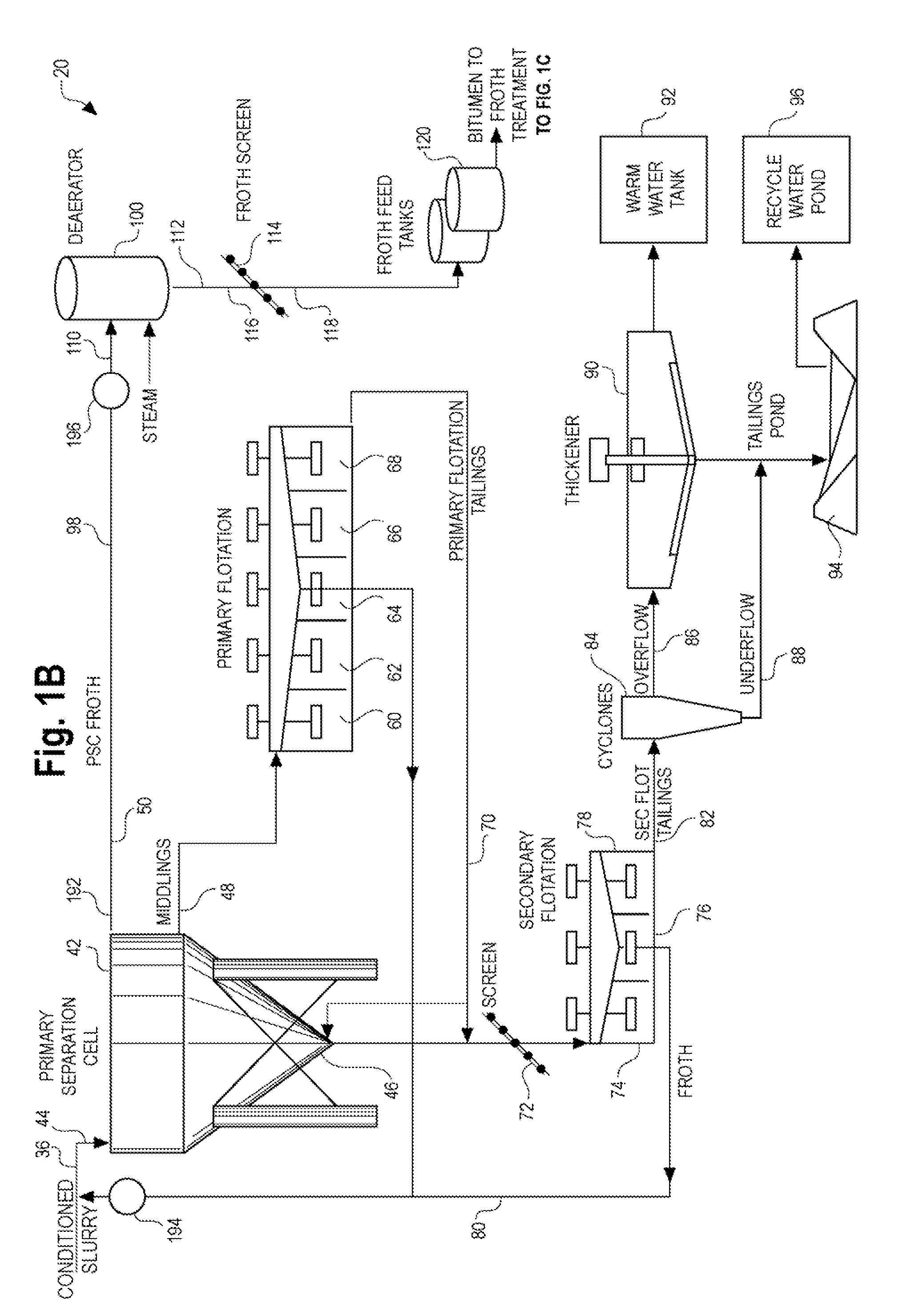

RF heating to reduce the use of supplemental water added in the recovery of unconventional oil

ActiveUS20100219105A1Selective heatingWorking-up pitch/asphalt/bitumen by selective extractionLiquid hydrocarbon mixture recoveryEngineeringSlurry

Equipment and a process for separating bitumen from oil sand in a process stream are disclosed. The equipment includes several processing vessels and one or more local area radio frequency applicators to selectively heat the process stream in local areas of the equipment. The local area can be adjacent to an input or output of a component of the equipment. Also disclosed is equipment for processing an oil sand—water slurry, including a slurrying vessel, a slurry pipe, and a local area radio frequency applicator. The local area radio frequency applicator is located outside of the slurry pipe, and heats the local area without significantly heating the contents of the slurrying vessel or of the downstream portion of the slurry pipe.

Owner:HARRIS CORP

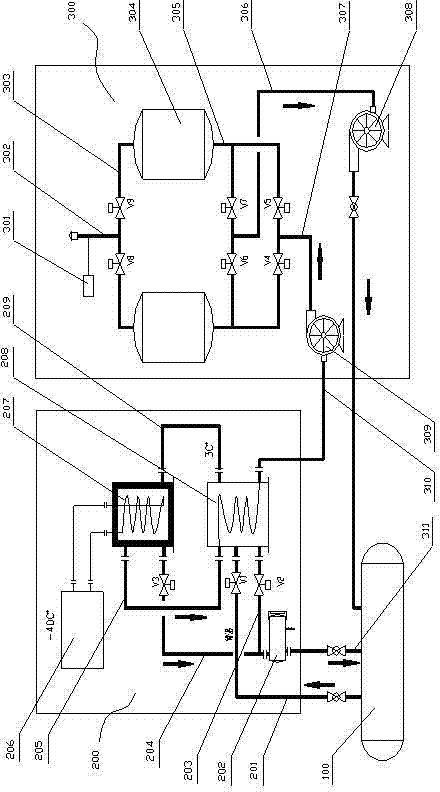

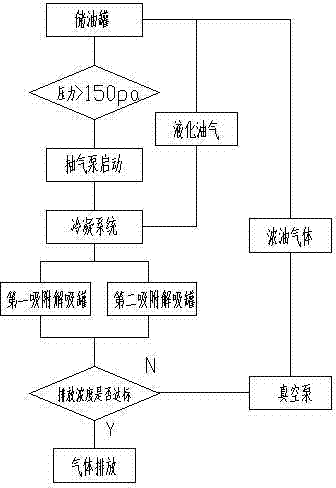

Oil gas recovery system

InactiveCN102899064AReduce oil contentReduce the use effectDispersed particle separationLiquid hydrocarbon mixture recoveryPlate heat exchangerDesorption

The invention relates to an oil gas recovery system. The oil gas recovery system comprises an adsorption unit and a condensing unit, wherein a gas inlet pipe for oil gas to be adsorbed, an exhaust pipe for adsorbed oil gas and a return pipe for desorbed oil gas are arranged on the adsorption unit; a gas inlet pipe for oil gas to be condensed, an exhaust pipe for condensed oil gas and a return pipe for condensate are arranged on the condensing unit; the exhaust pipe for the condensed oil gas of the condensing unit is connected with the gas inlet pipe of the oil gas to be adsorbed of the adsorption unit; a first adsorption / desorption tank and a second adsorption / desorption tank are arranged on the adsorption unit to alternately adsorb and desorb the oil gas; and two condensing plants namely an oil gas heat exchanger and a cold box are arranged on the condensing unit to sequentially condense the oil gas. The oil gas recovery system is high in treatment capacity and recovery efficiency, can continuously work, and is mainly suitable for recovering the oil gas generated during oil injection of a buried oil tank of a gas station and refueling of a fuel tank of an automobile.

Owner:陈玲海

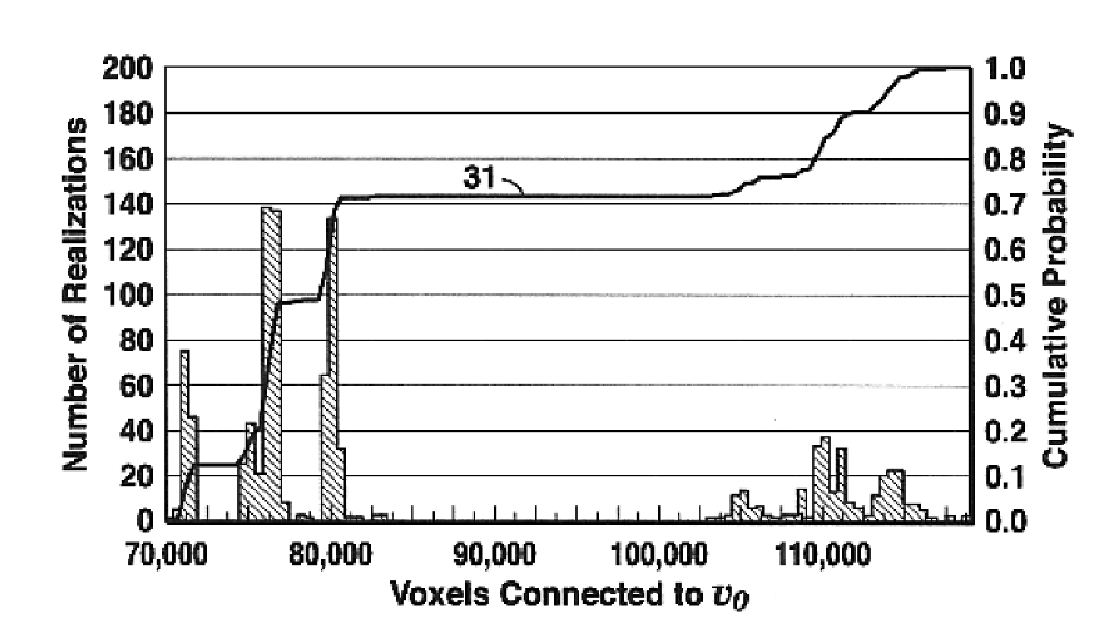

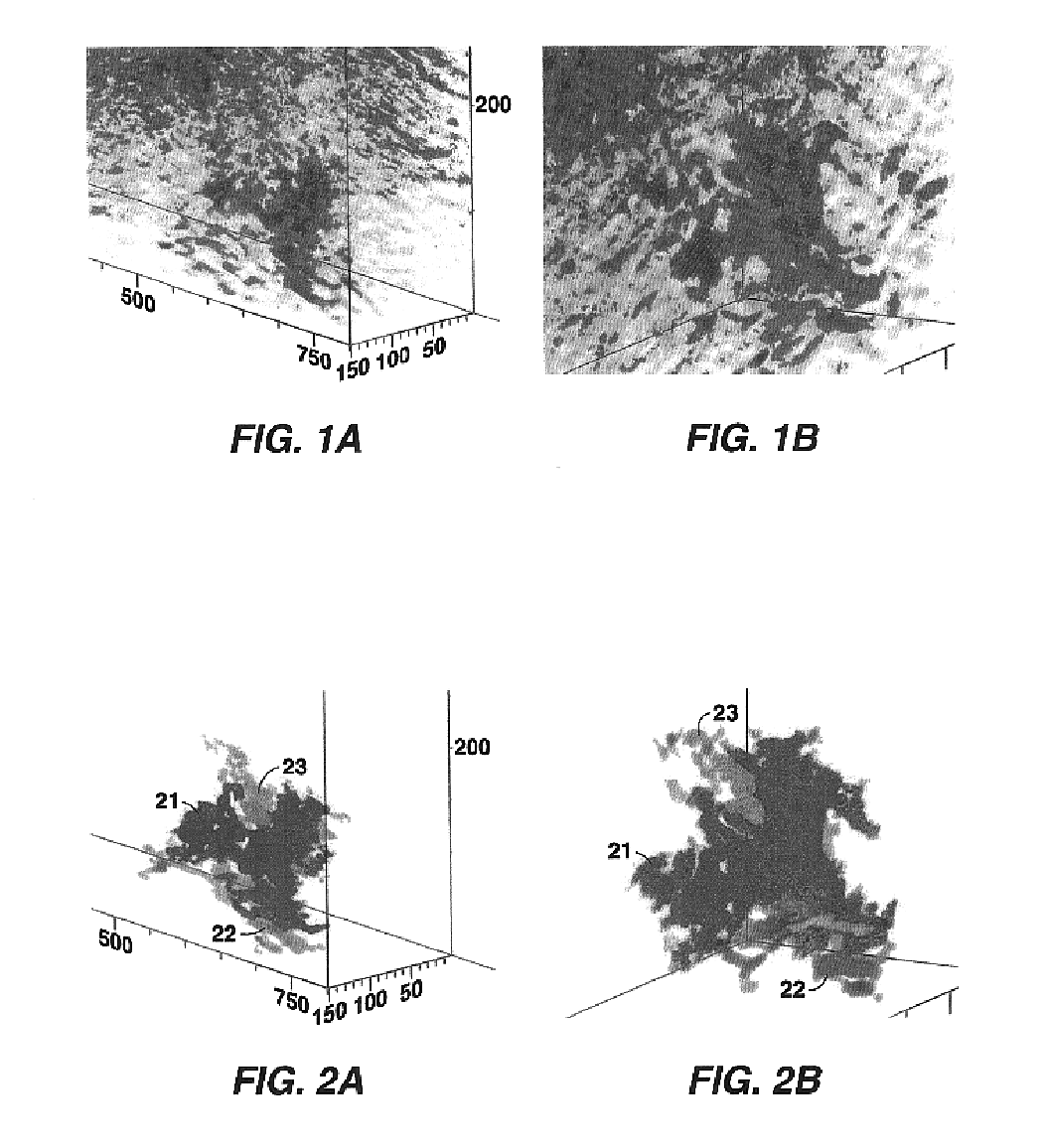

Method for estimation of size and analysis of connectivity of bodies in 2- and 3-dimensional data

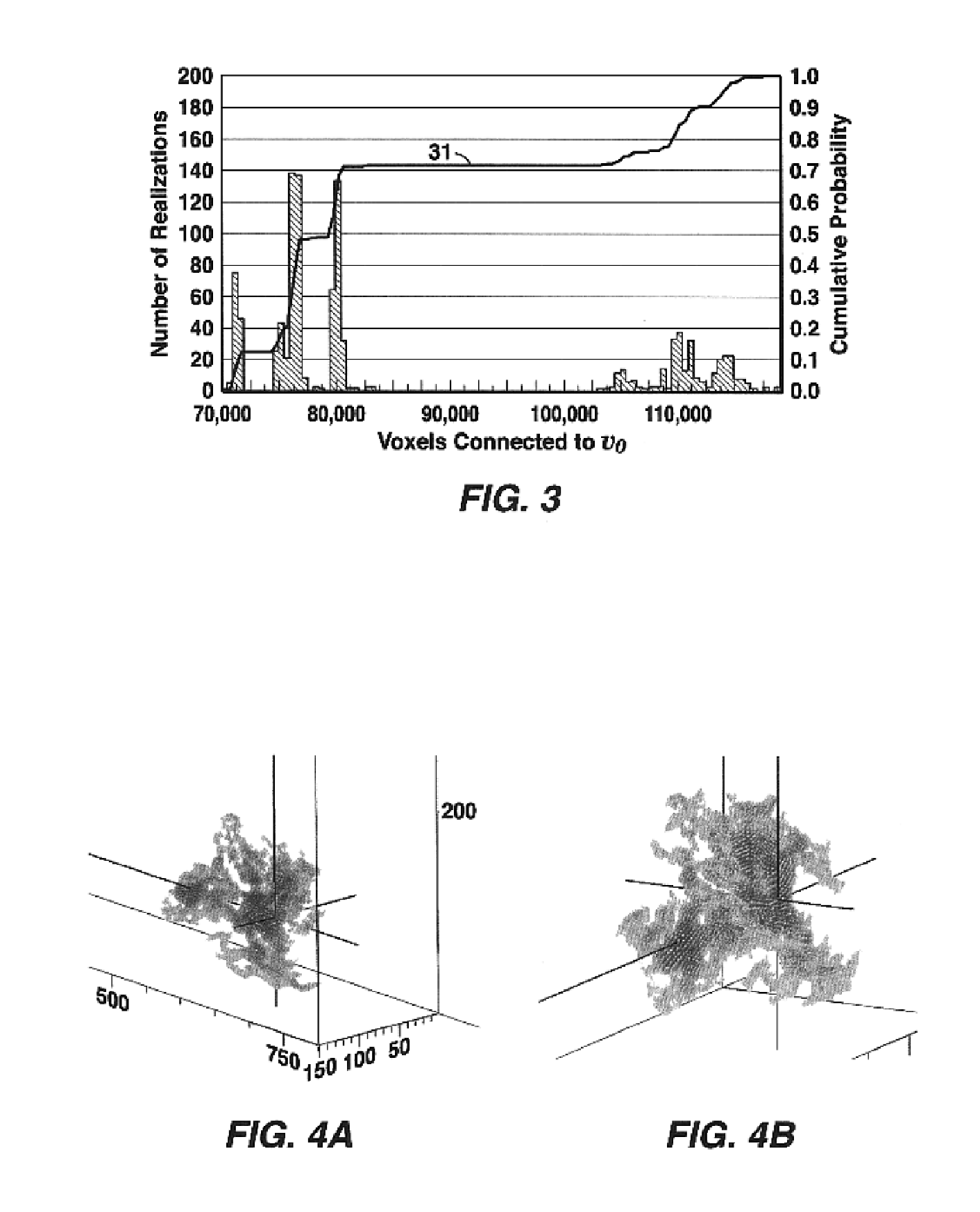

ActiveUS6912467B2Improve automationReadily suitedElectric/magnetic detection for well-loggingLiquid hydrocarbon mixture recoveryData valueComputer science

A method for performing region growing in a data volume that accounts for noise in the data on a probabilistic basis. The data volume is divided into discrete cells, and a probability distribution for each cell's datum value is calculated. Each probability distribution is randomly sampled to generate one probabilistic, noise-free realization for the data volume, and region growing is performed using selected criteria. The process is repeated for different realizations until sufficient statistics are accumulated to estimate the probable size and connectivity of objects discovered.

Owner:EXXONMOBIL UPSTREAM RES CO

Solvent and method for removing carbon dioxide from Fischer-Tropsch synthesis circulation gas

ActiveCN101210186AImprove stability"Low hydrocarbon lossLiquid hydrocarbon mixture recoveryCombustible gas purificationOxygenSolvent

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD

Popular searches

Hydrocarbon purification/separation By rectification and condensation Hydrocarbons Gaseous mixture working up Cold treatment separation Catalysts Preparation by halogenatd hydrocarbon disproportionation Hydrocarbon from halogen organic compounds Treatment with hydrotreatment processes Bulk chemical production

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com