Method for separating catalytic dry gas in refinery by using shallow cold oil absorption method

A shallow cold oil absorption and dry gas technology, applied in the petroleum industry, recovery of liquid hydrocarbon mixtures, etc., can solve the problems of large investment, high energy consumption, reduction of absorbent circulation and loss, and achieve low investment and simple operation , The effect of strong adaptability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The composition of catalytic dry gas in a refinery is listed in Table 1.

[0040] Table 1 Composition of catalytic dry gas in a refinery

[0041]

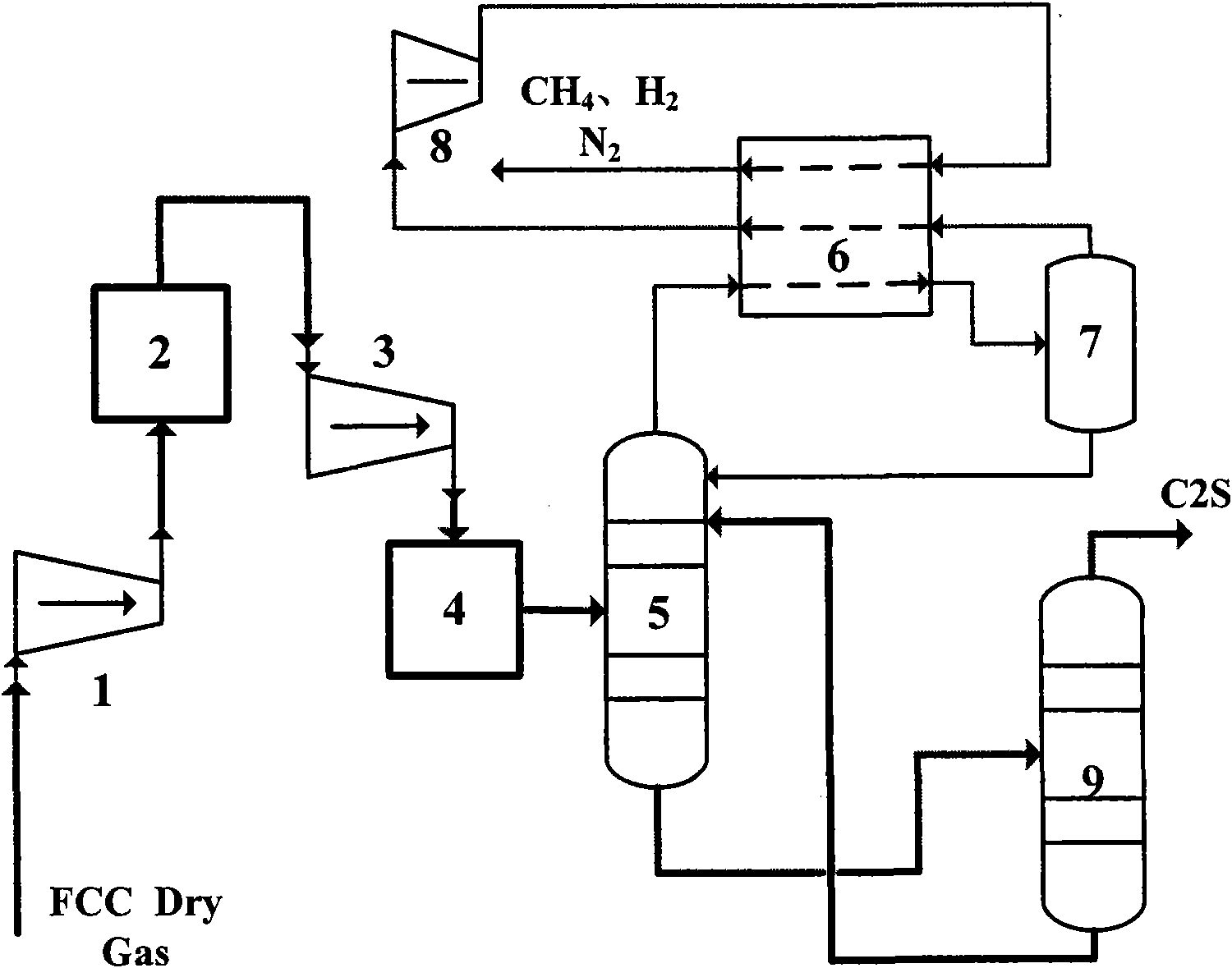

[0042] (1) Compression: After the refinery FCC with a flow rate of 13500kg / h is compressed by the first stage of the compressor, its pressure is increased to 1.4MPa, and the acid gas, NOx and oxygen are removed through the purification system 2, and then the second stage of the compressor After section 3 is compressed, it enters dryer 4 for drying, and finally the pressure of catalytic dry gas is increased to 2.4MPa;

[0043] (2) Cooling: Cool the dried catalytic dry gas to -15°C;

[0044] (3) absorption: flow is 52375kg / h by the C5 that pentane 37wt%, isopentene 23wt%, n-pentene 17wt%, pentene-223wt% are formed as absorbent, sprays into from absorption tower 5 tops, absorbs C2 and components above C2 fraction in catalytic dry gas. The theoretical plate number of the absorption tower is preferably 45, the operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com