Patents

Literature

34results about How to "Continuous regeneration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

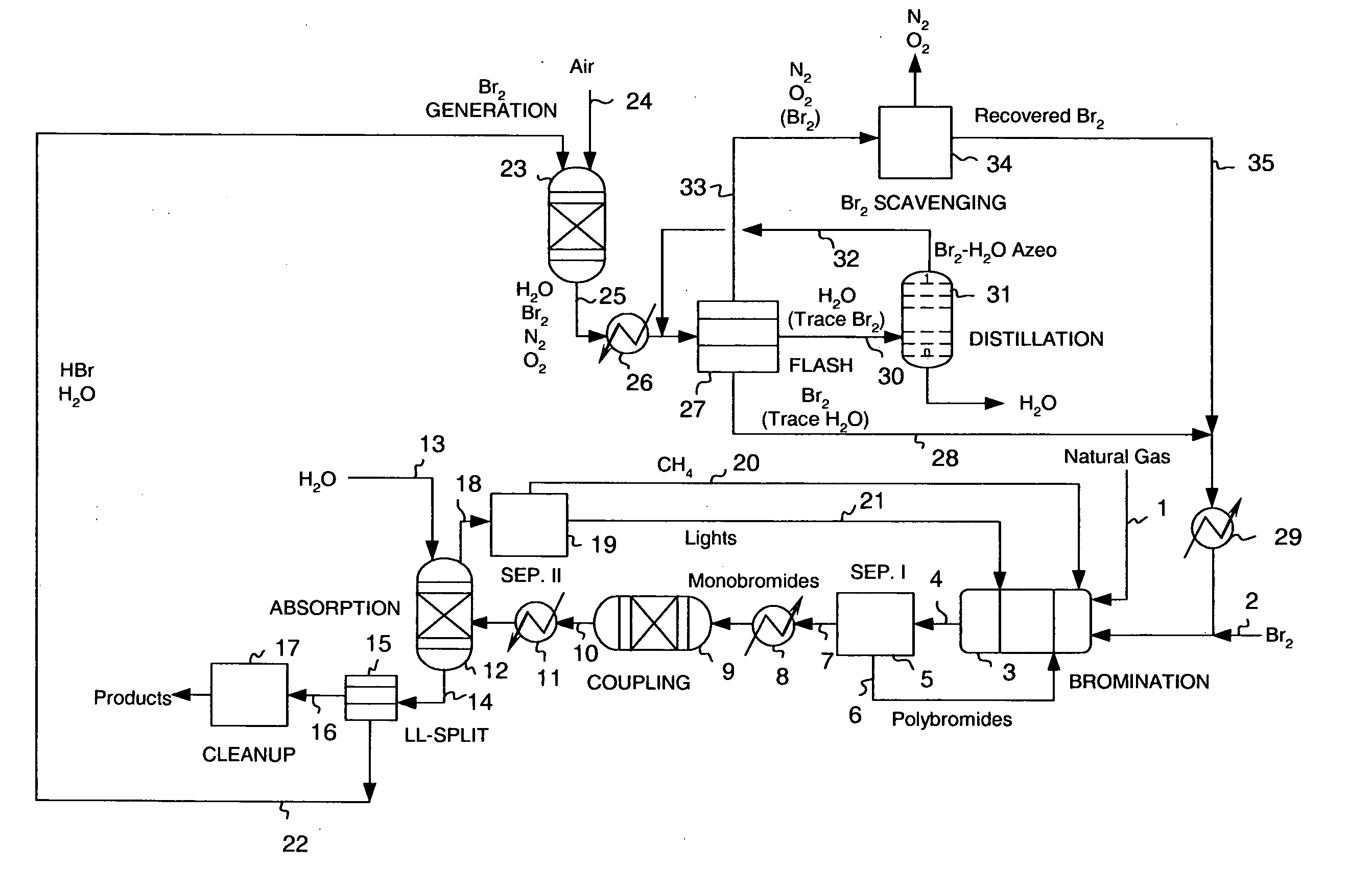

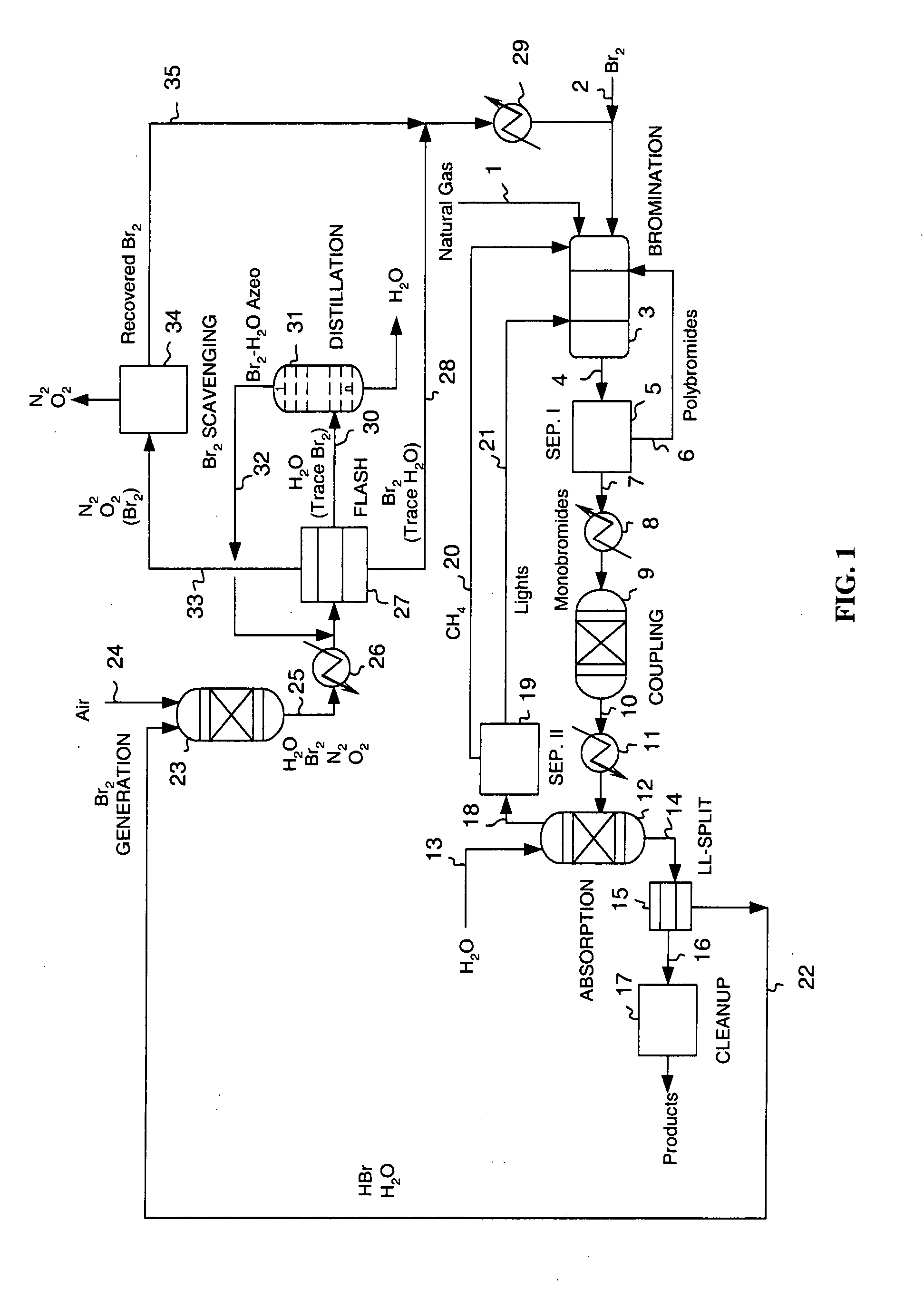

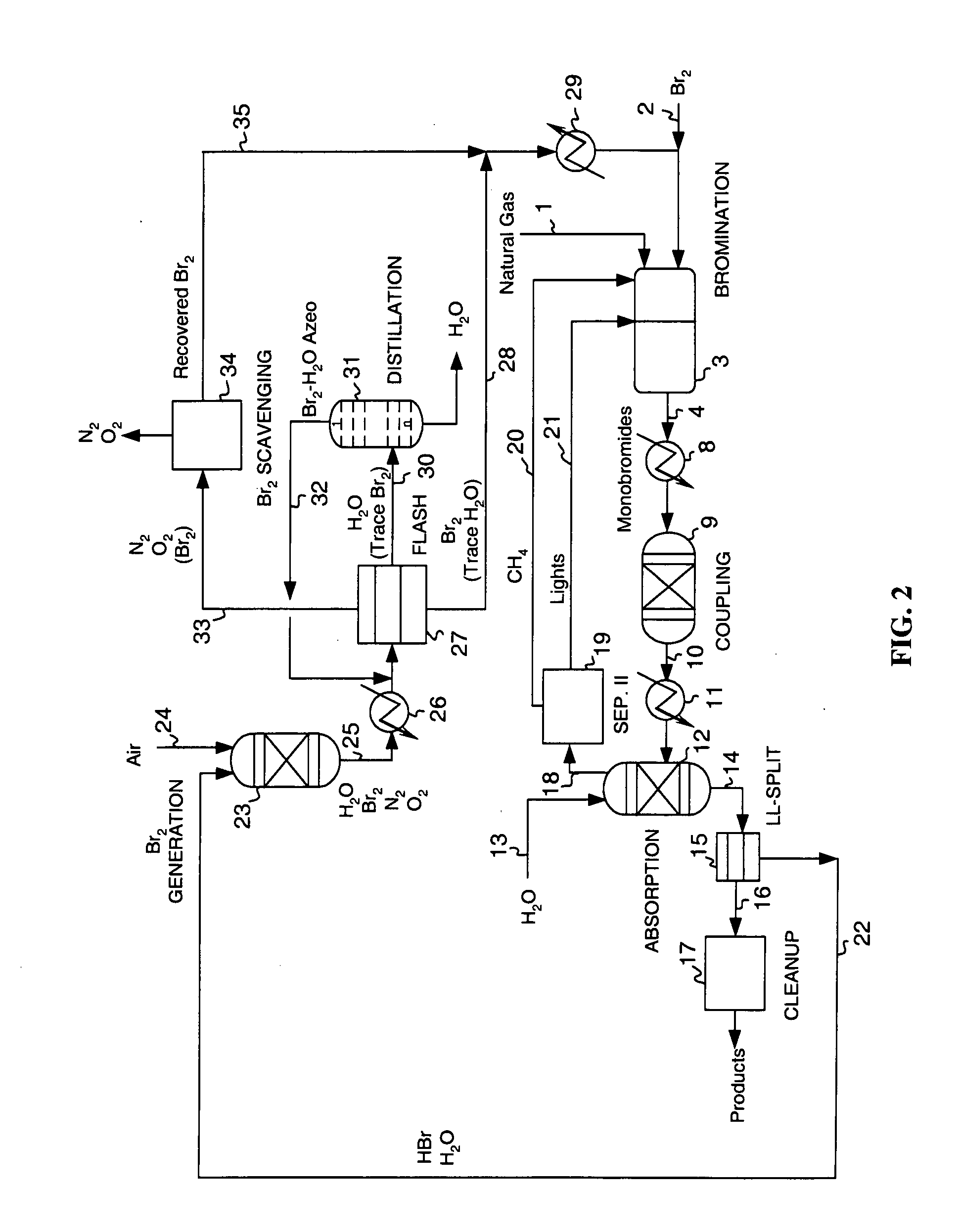

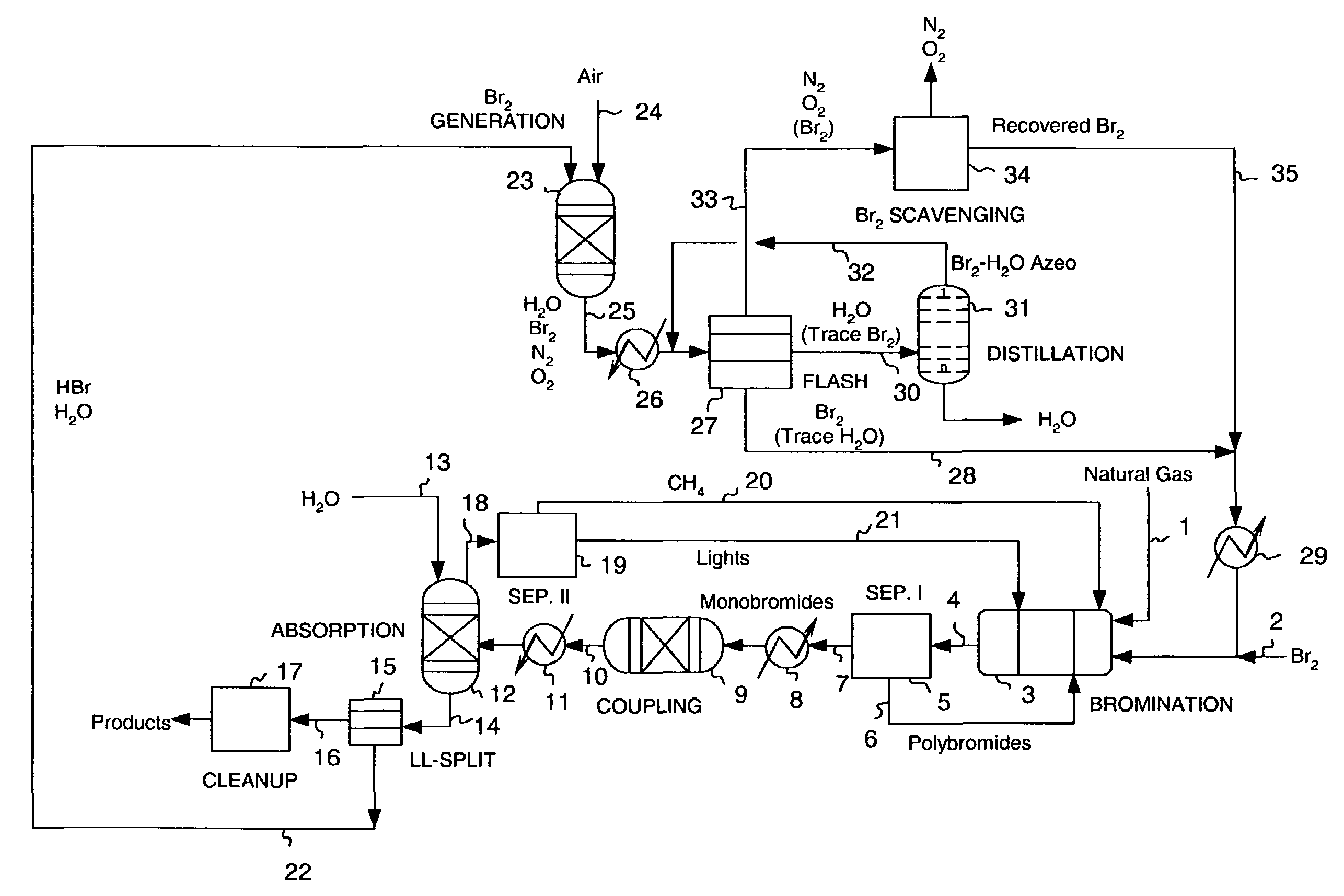

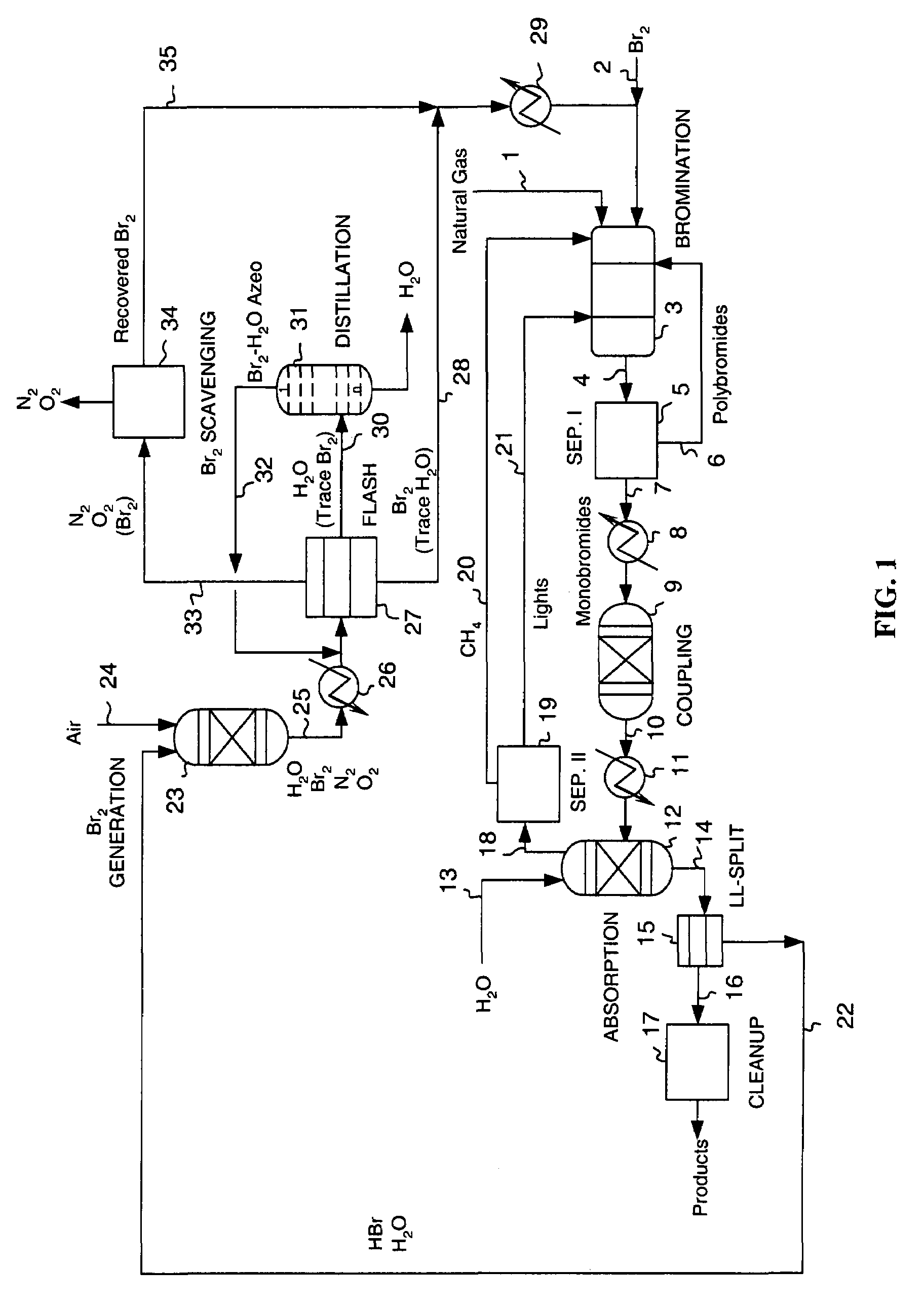

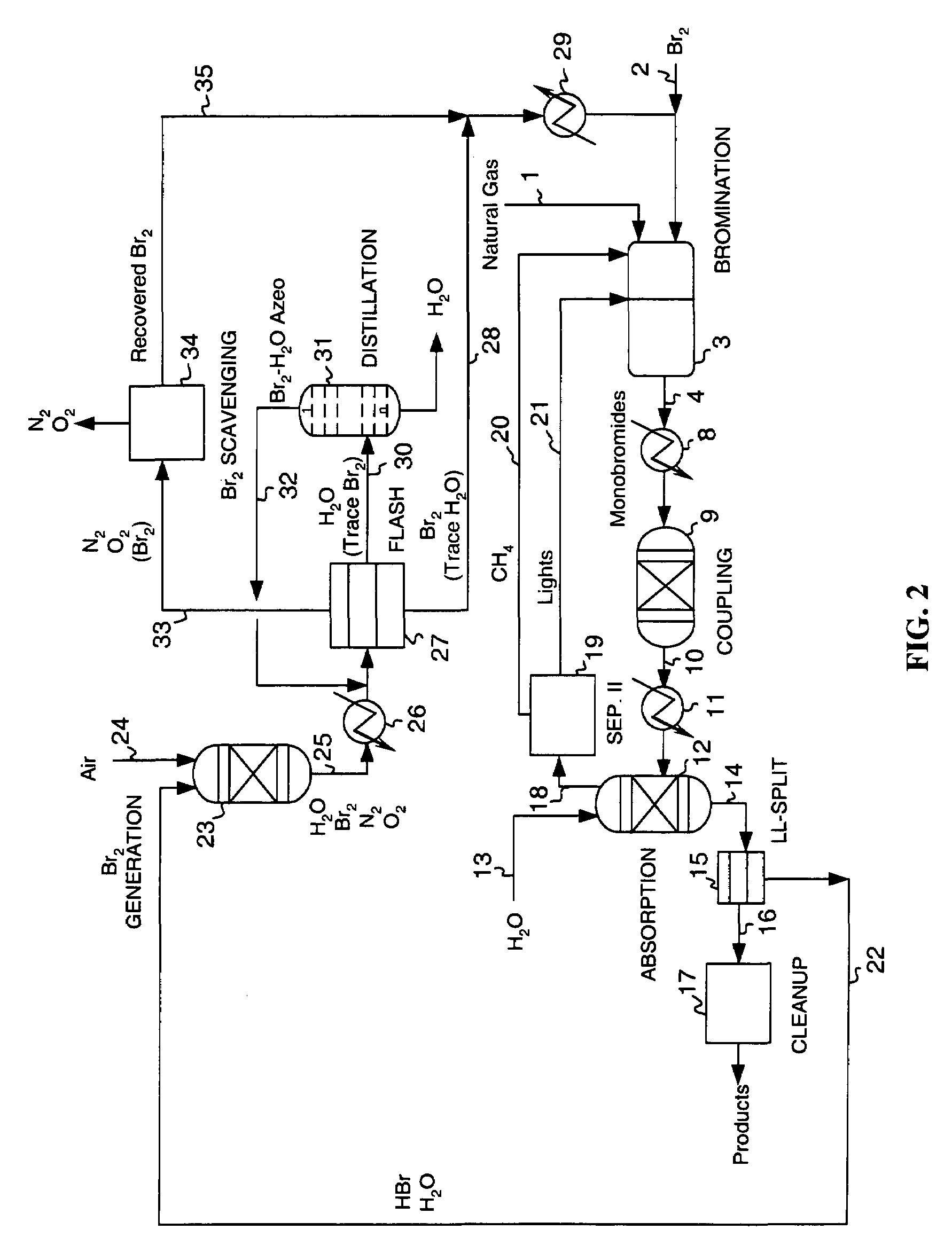

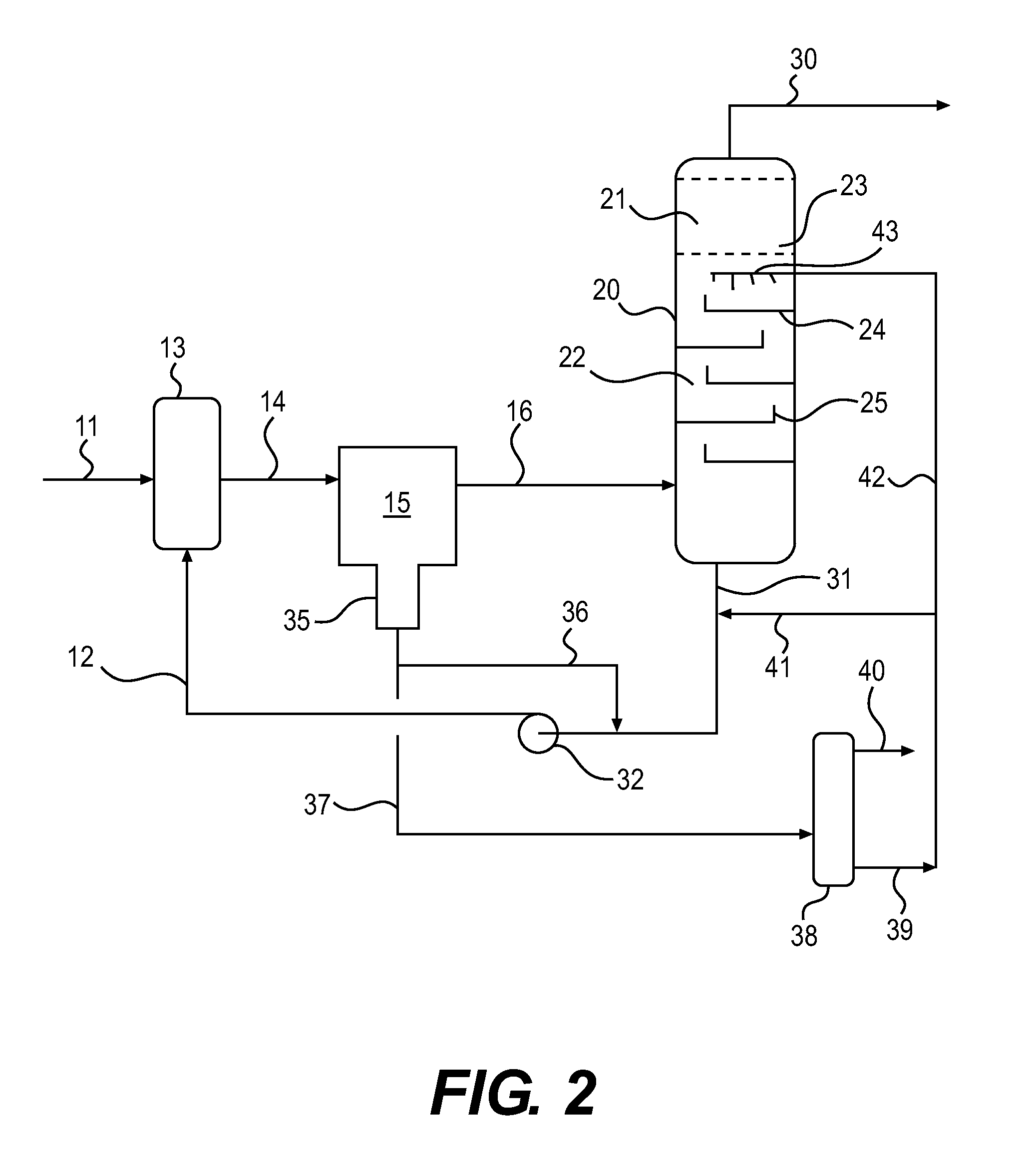

Continuous process for converting natural gas to liquid hydrocarbons

InactiveUS20070238909A1Easily toleratedContinuous regenerationMolecular sieve catalystLiquid hydrocarbon mixture recoveryAlkaneOxygen

An improved continuous process for converting methane, natural gas, or other hydrocarbon feedstocks into one or more higher hydrocarbons or olefins by continuously cycling through the steps of alkane halogenation, product formation (carbon-carbon coupling), product separation, and regeneration of halogen is provided. Preferably, the halogen is continually recovered by reacting hydrobromic acid with air or oxygen. The invention provides an efficient route to aromatic compounds, aliphatic compounds, mixtures of aliphatic and aromatic compounds, olefins, gasoline grade materials, and other useful products.

Owner:REACTION 35 LLC

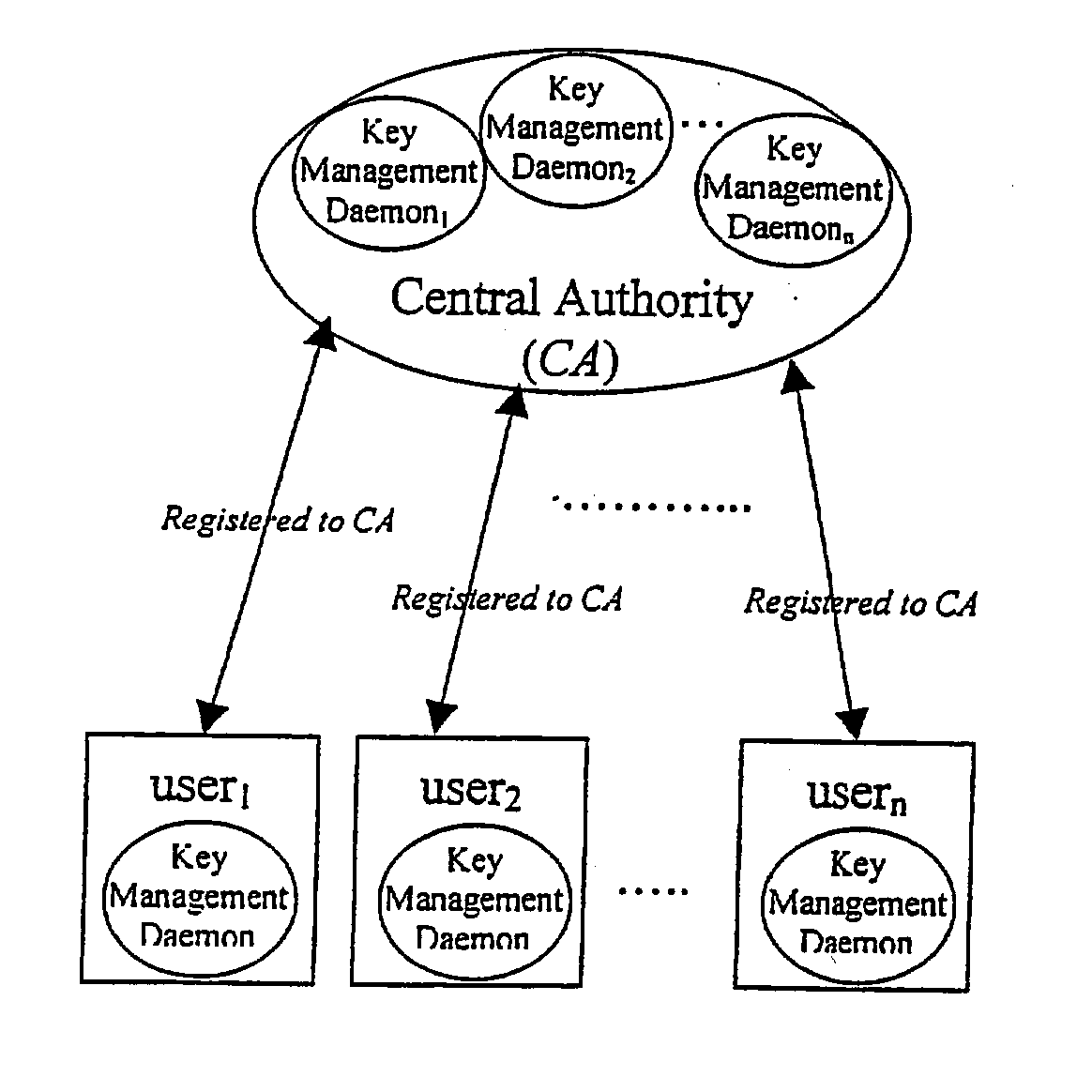

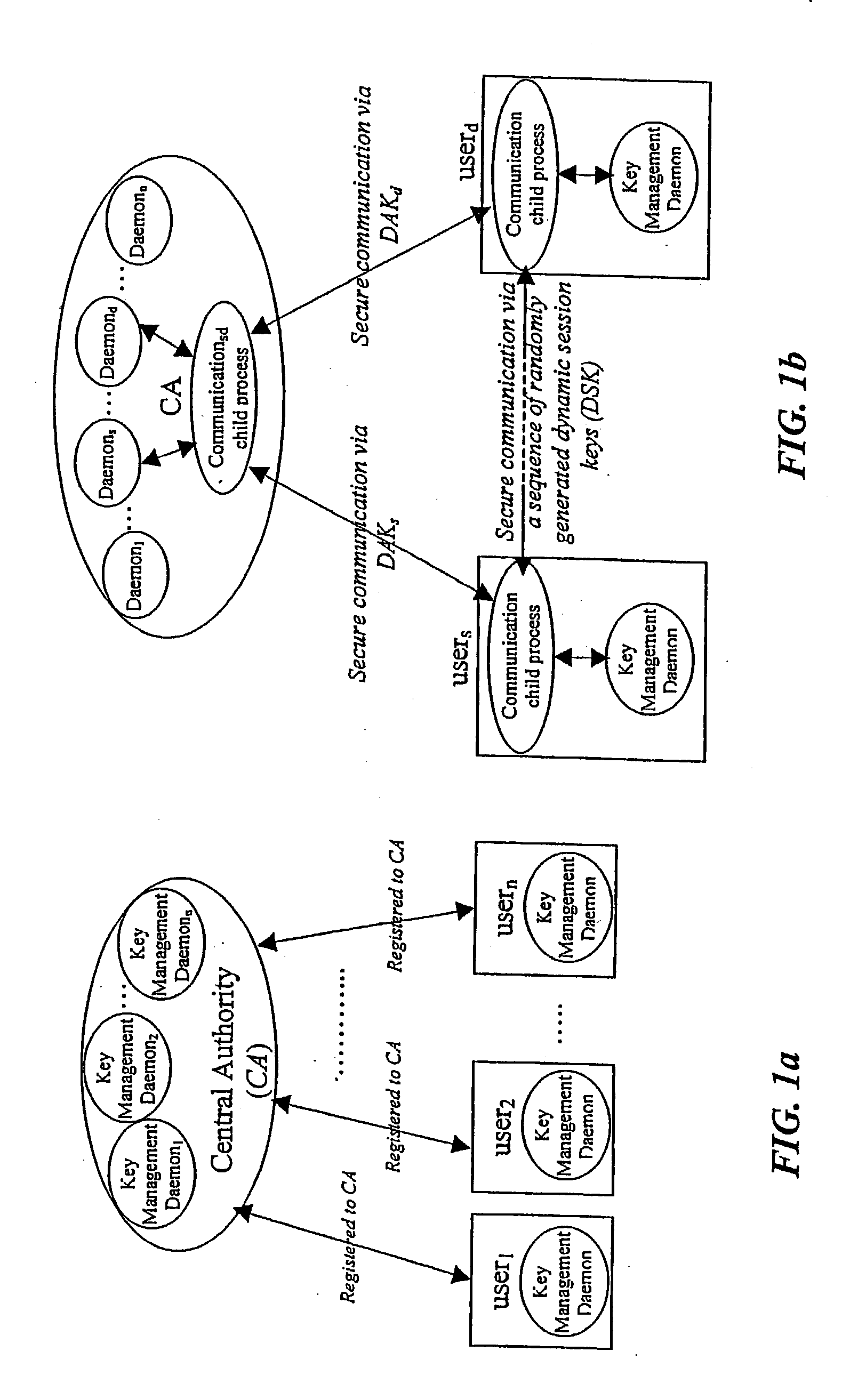

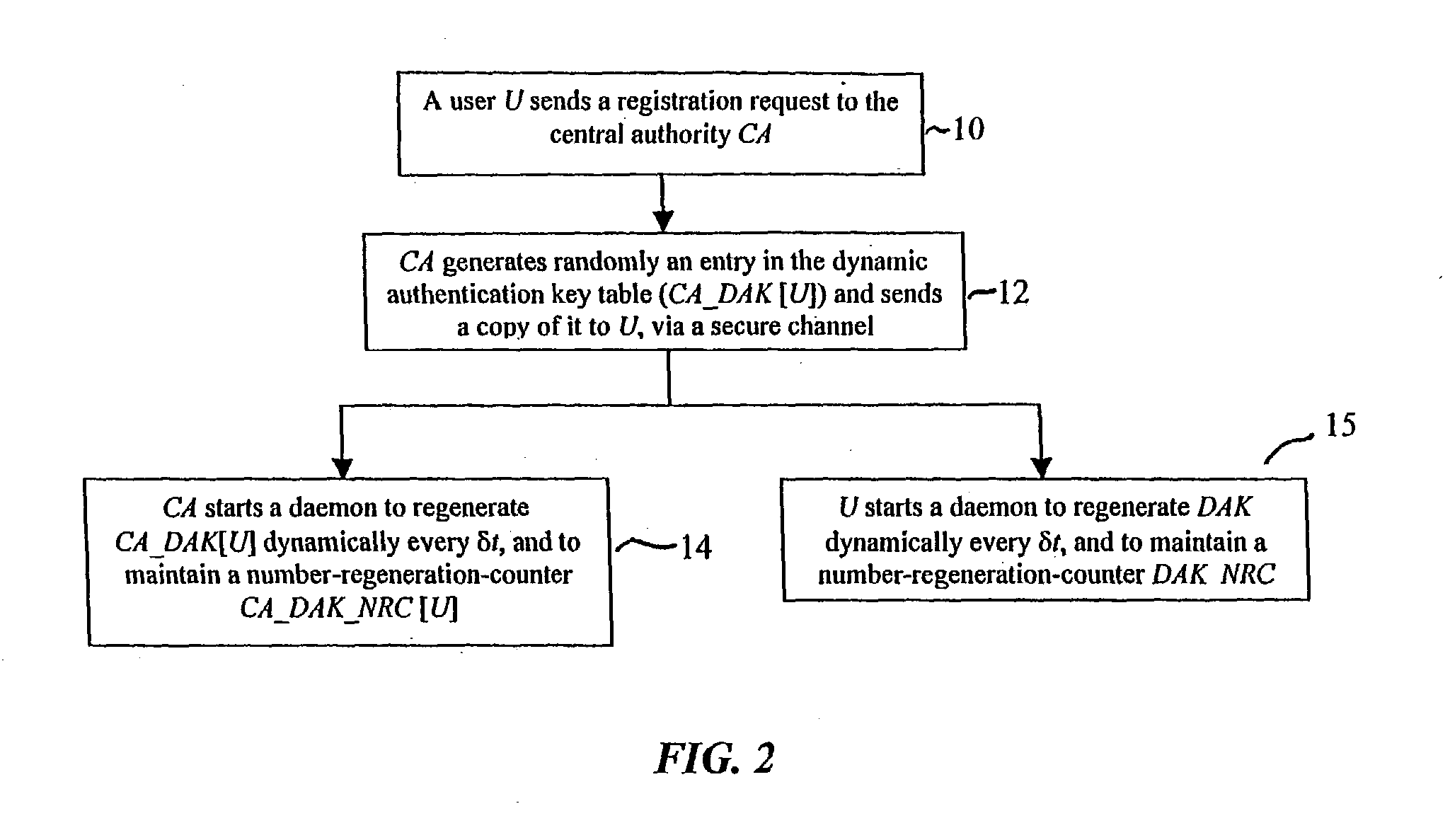

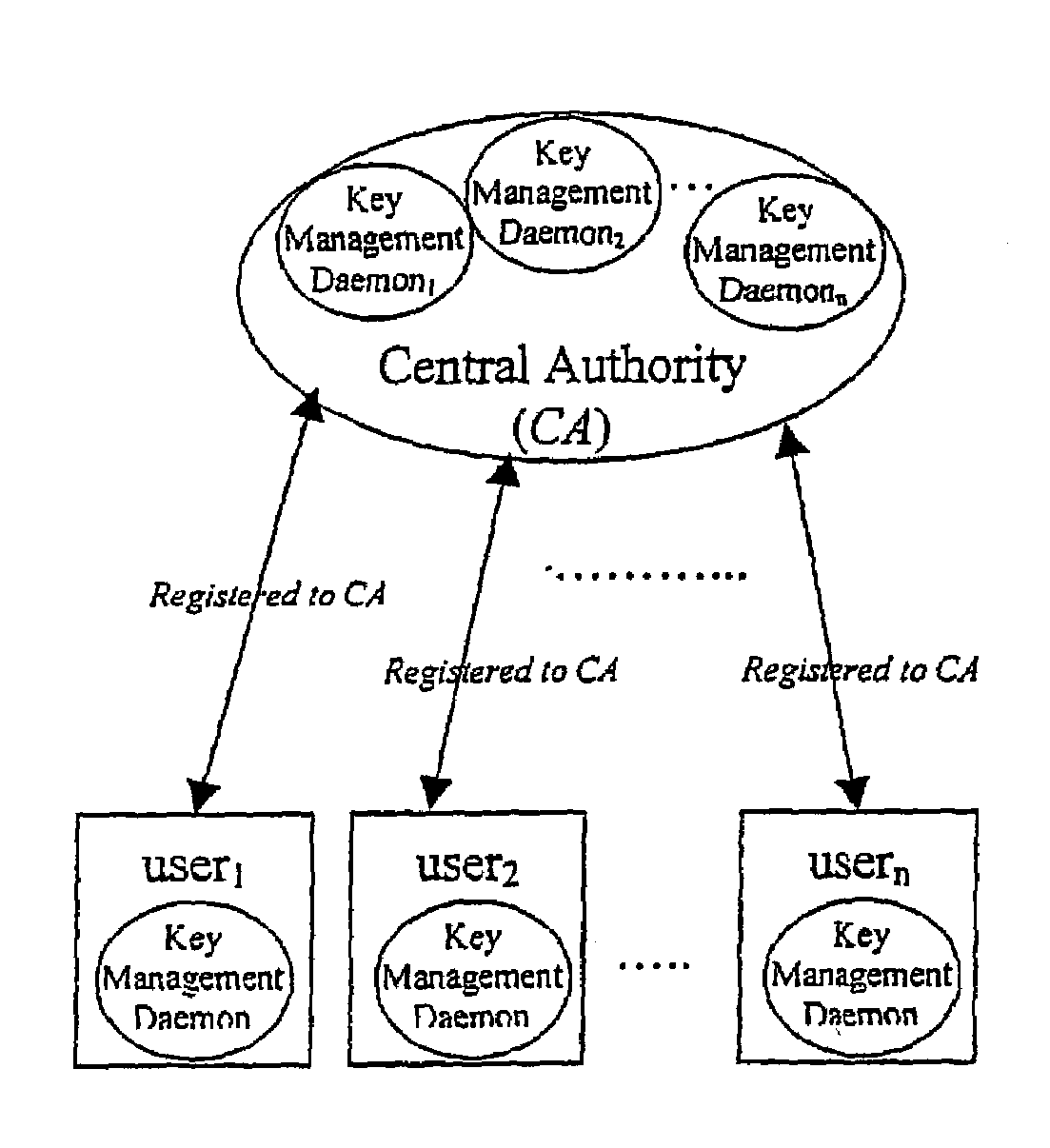

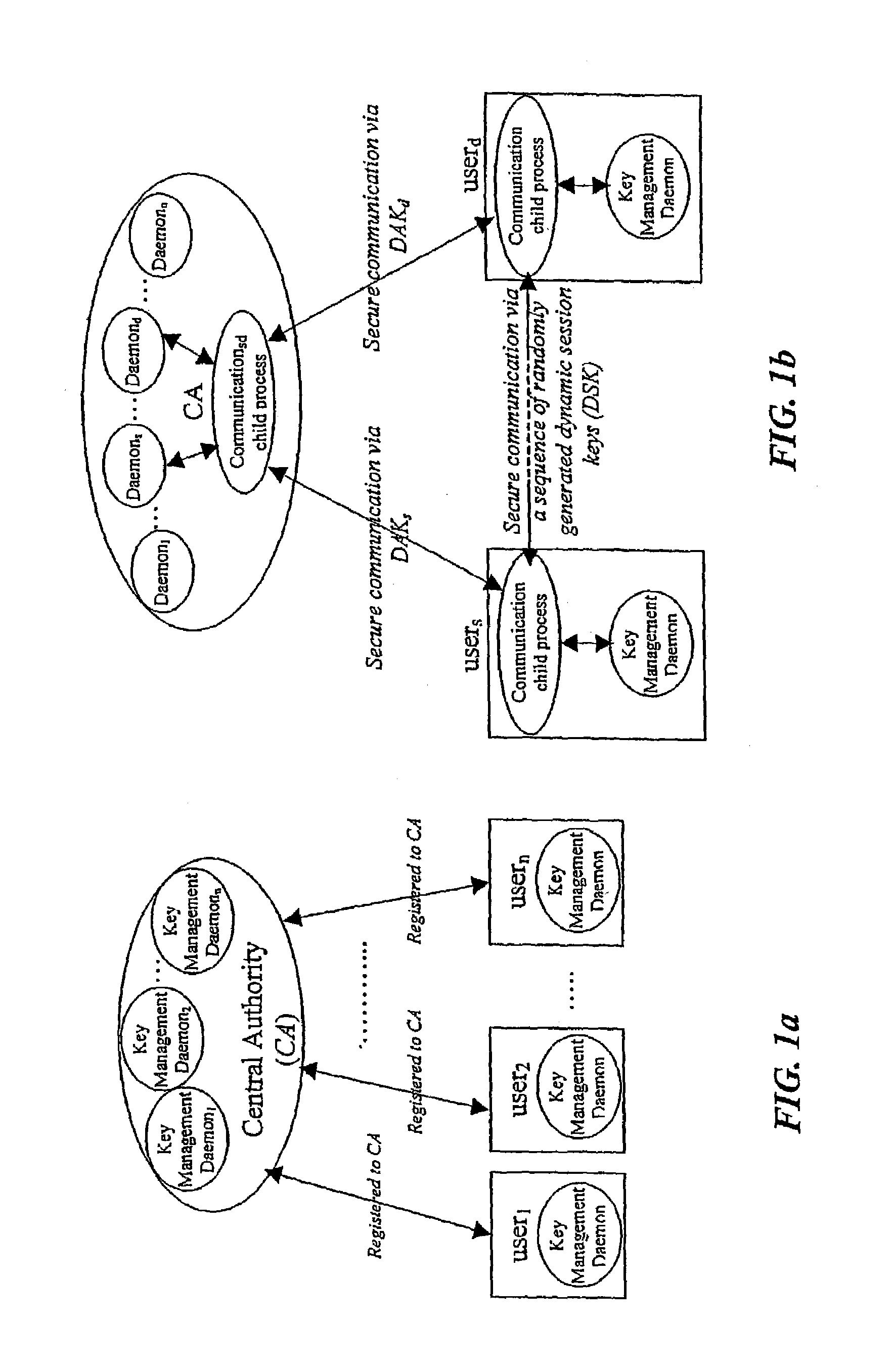

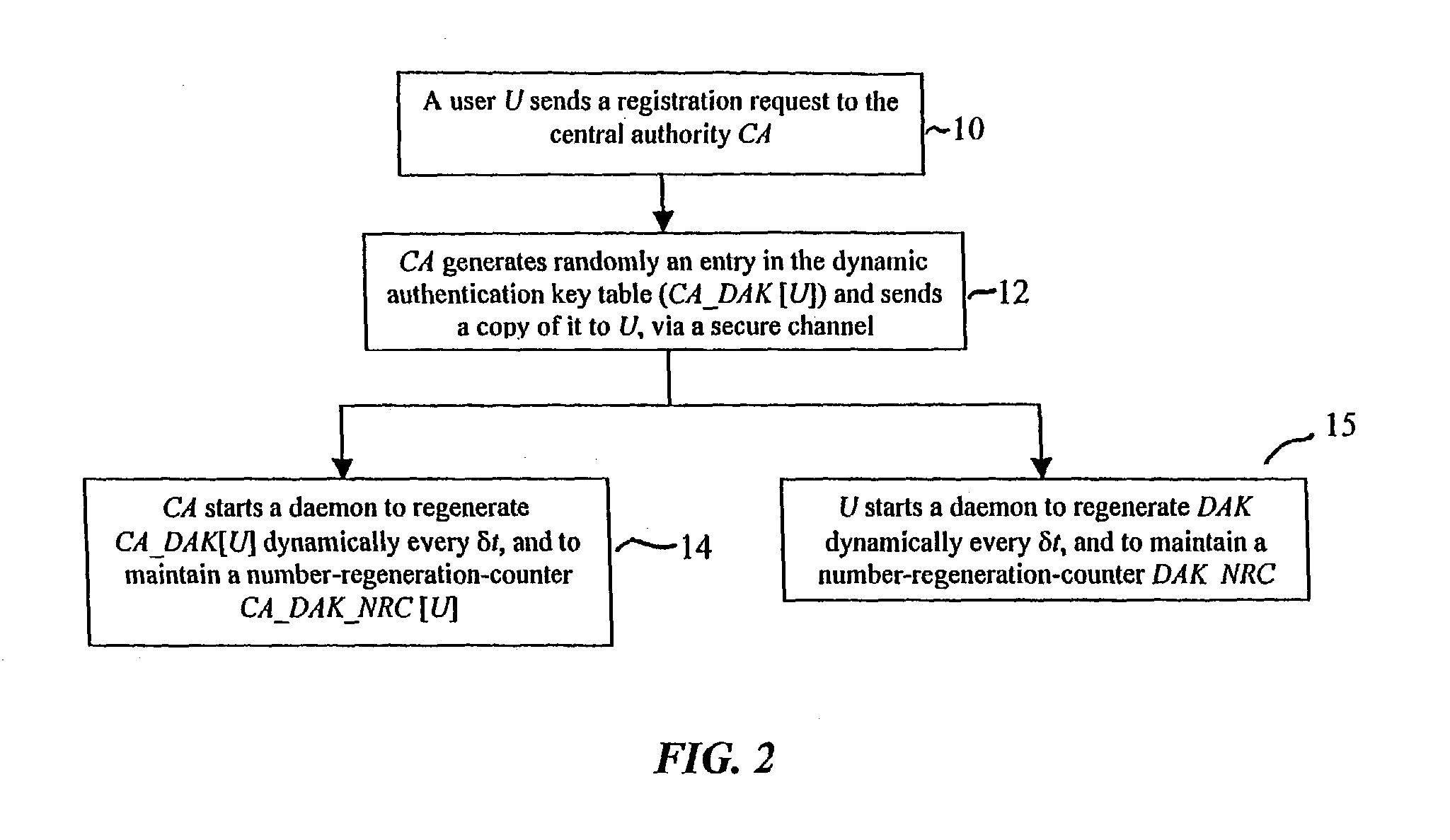

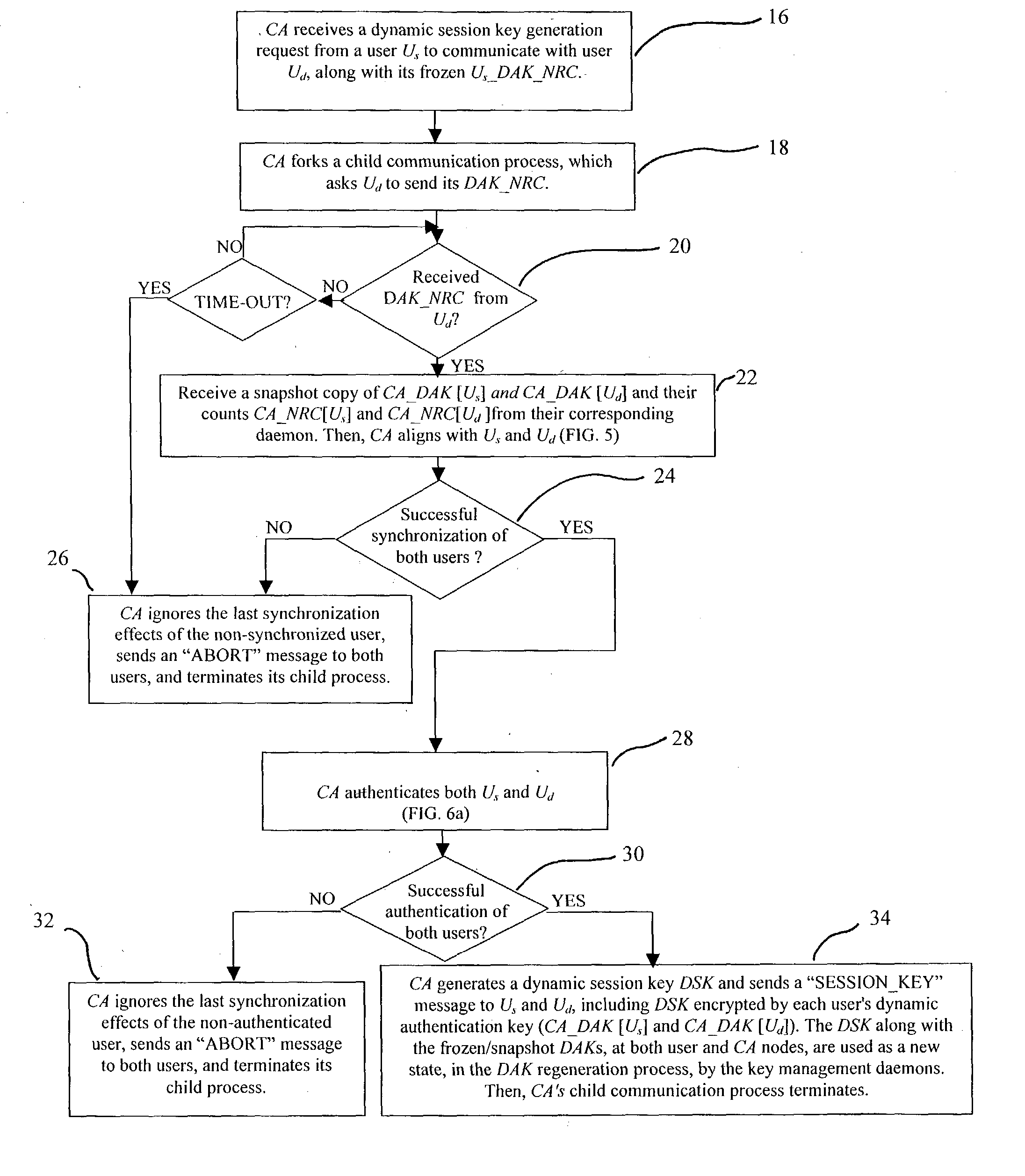

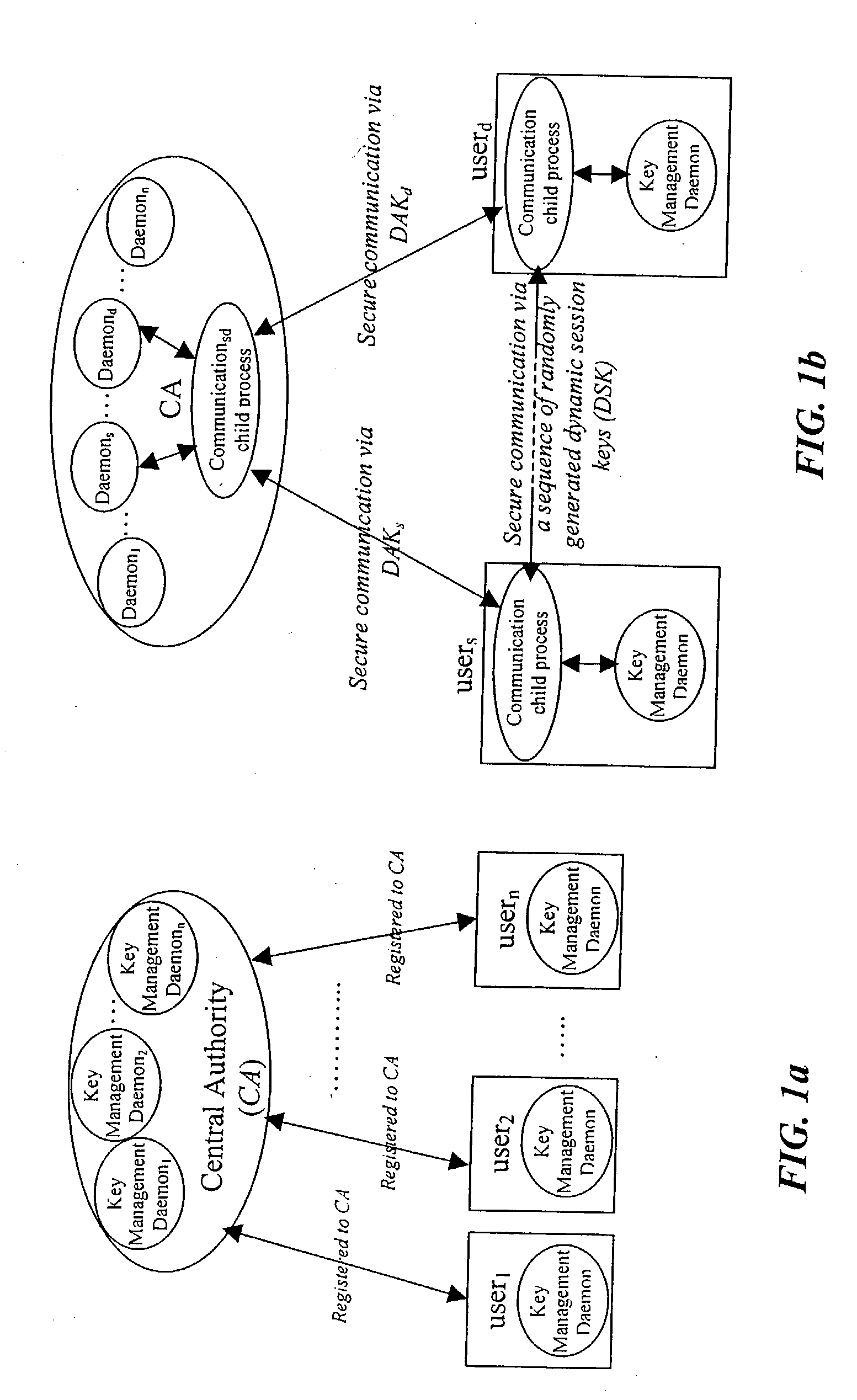

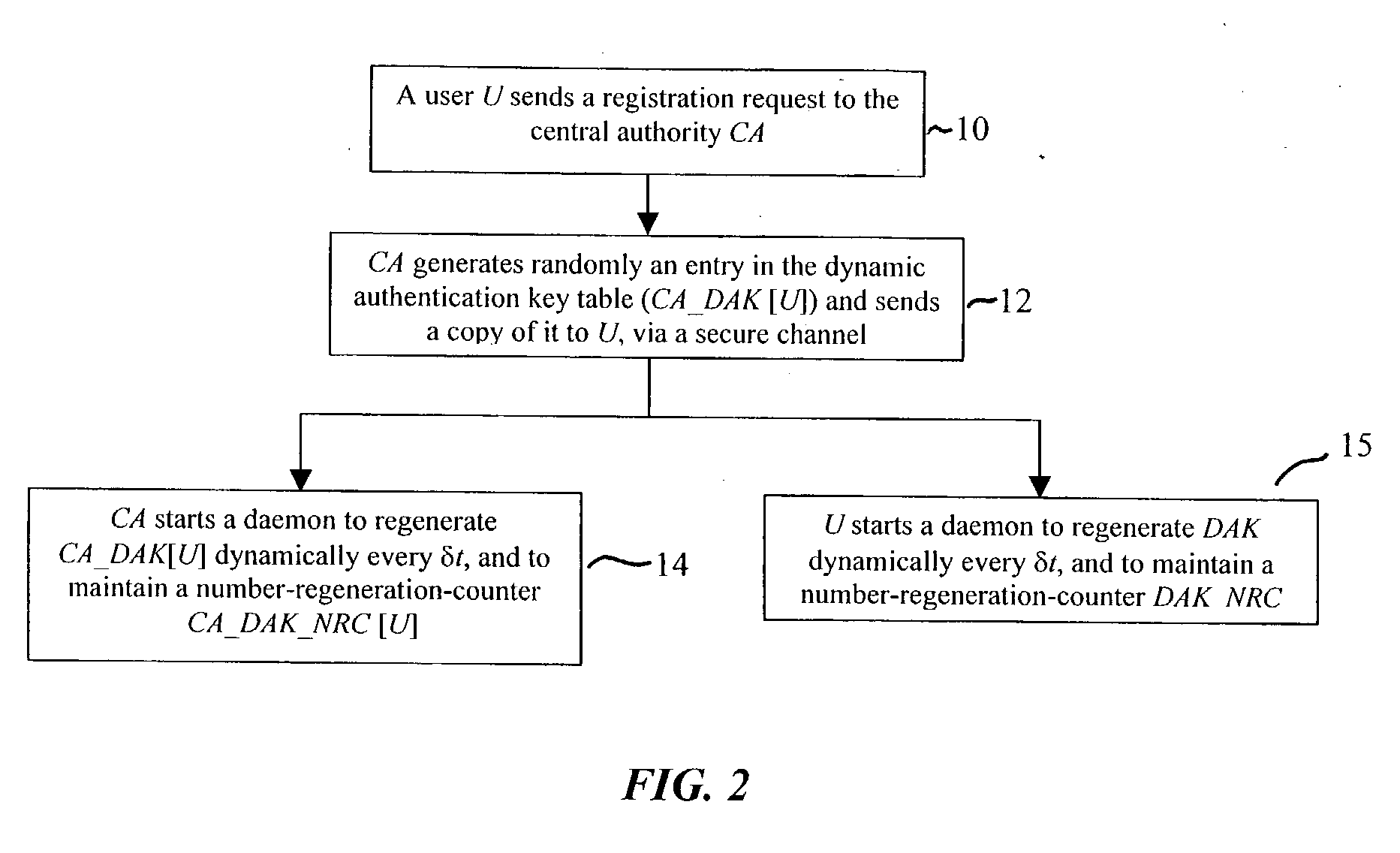

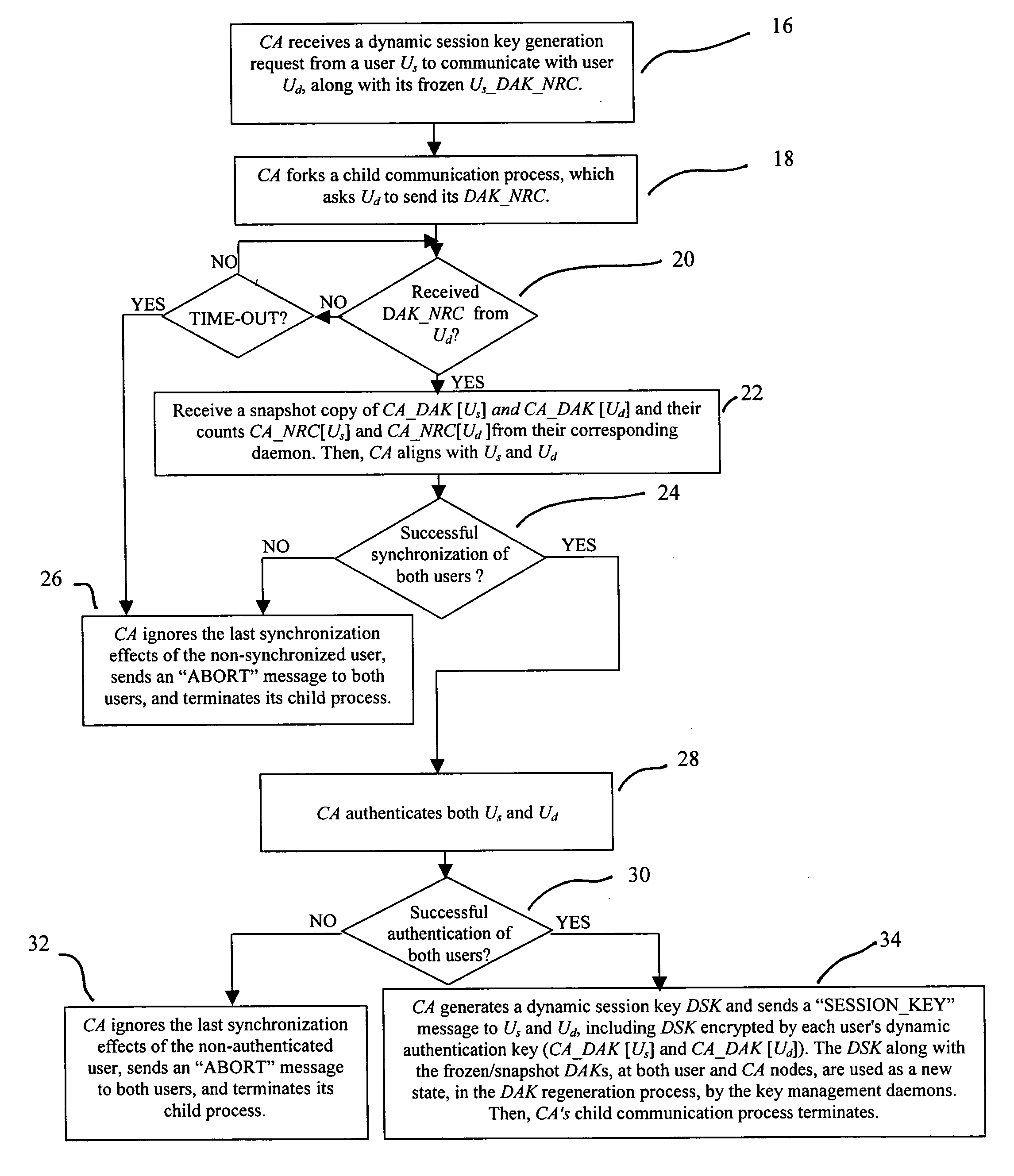

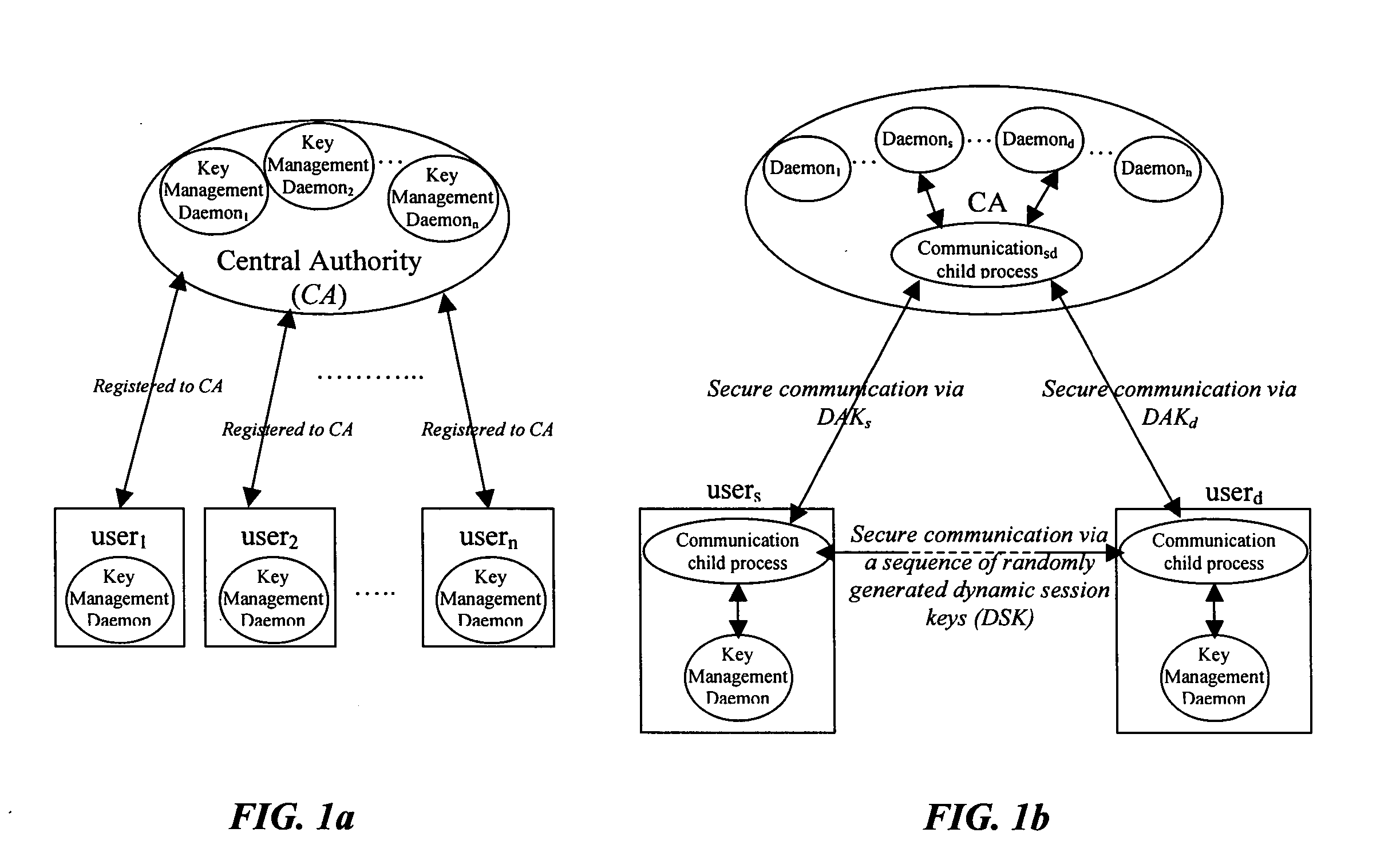

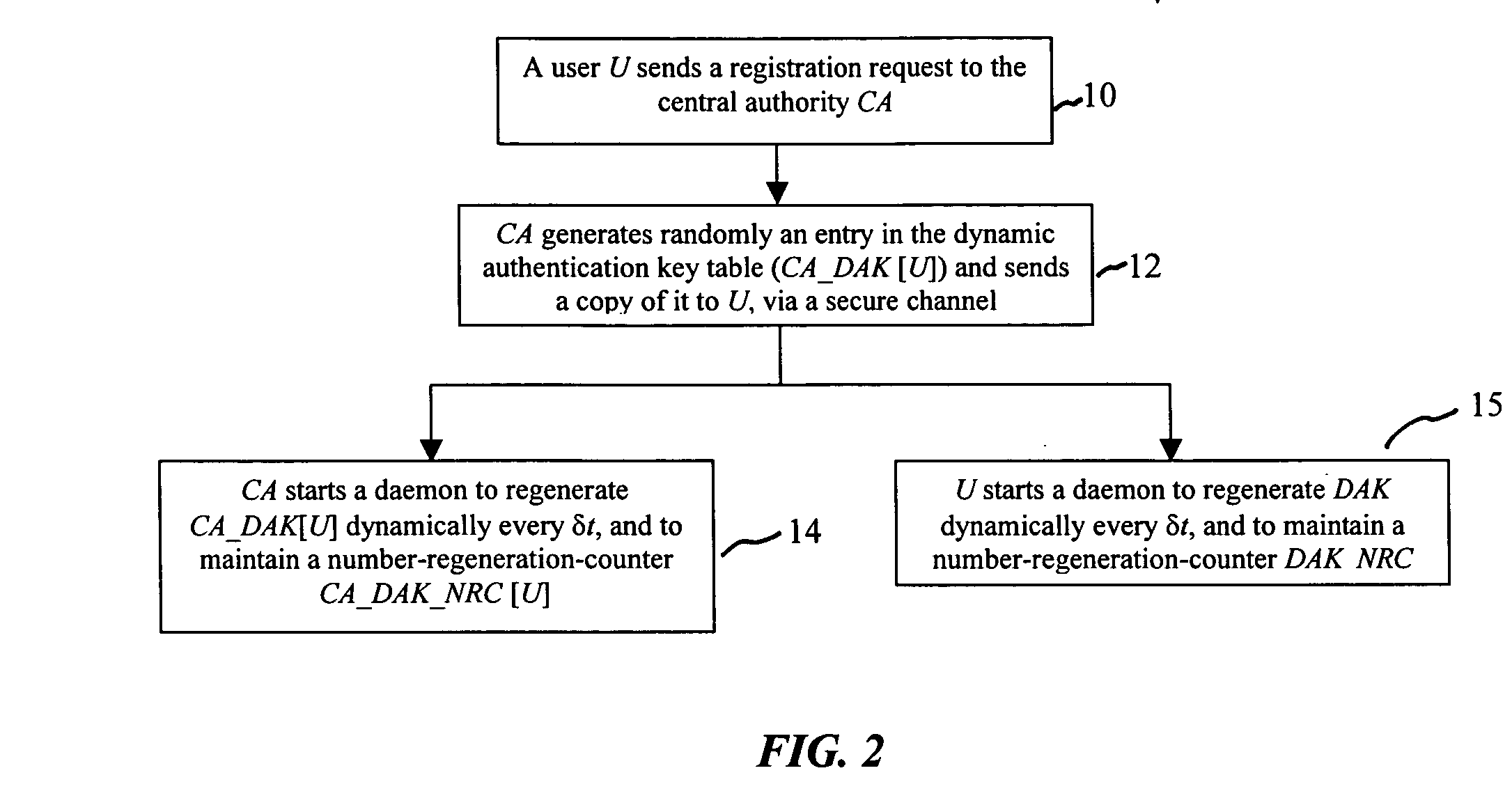

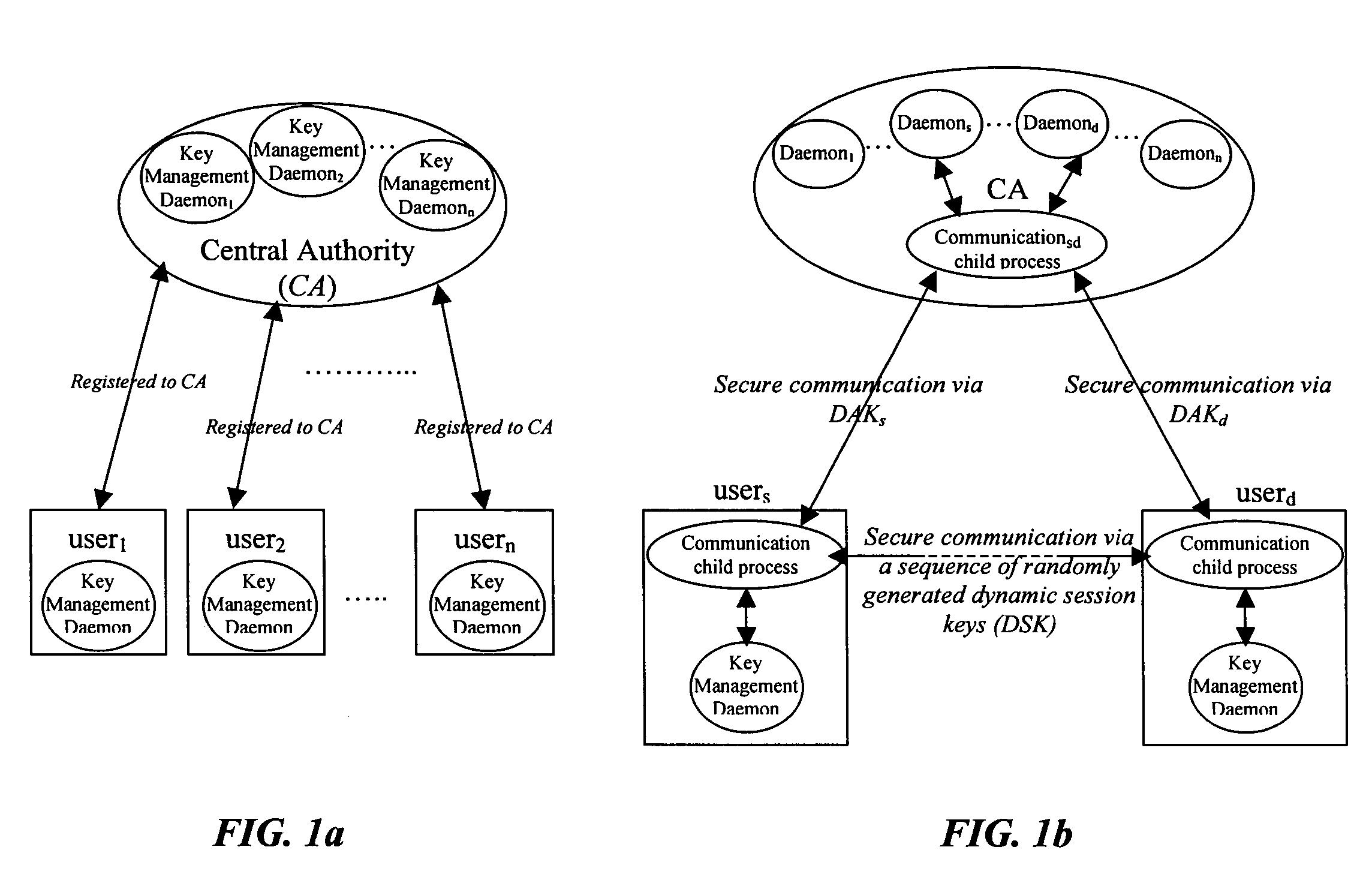

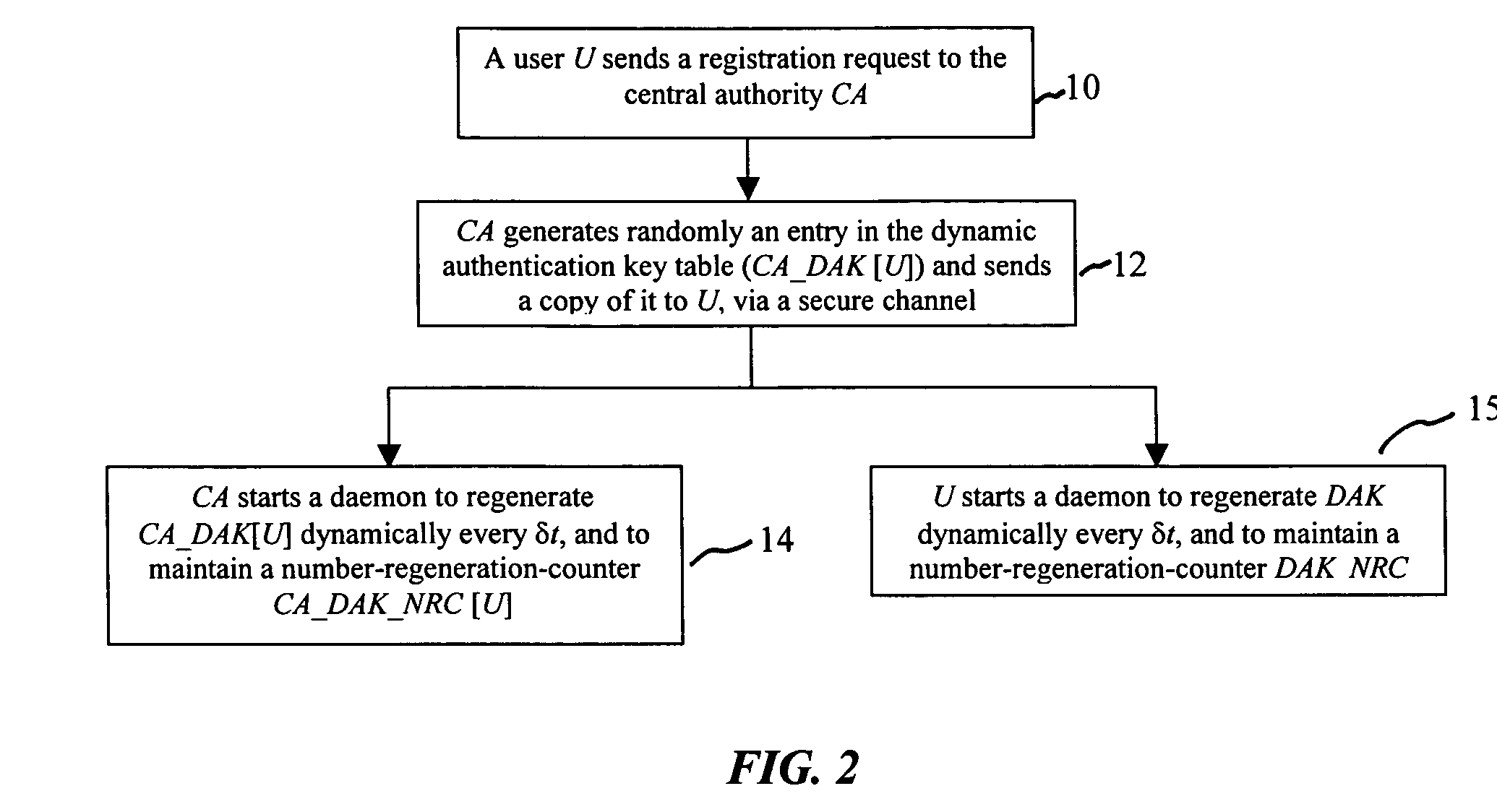

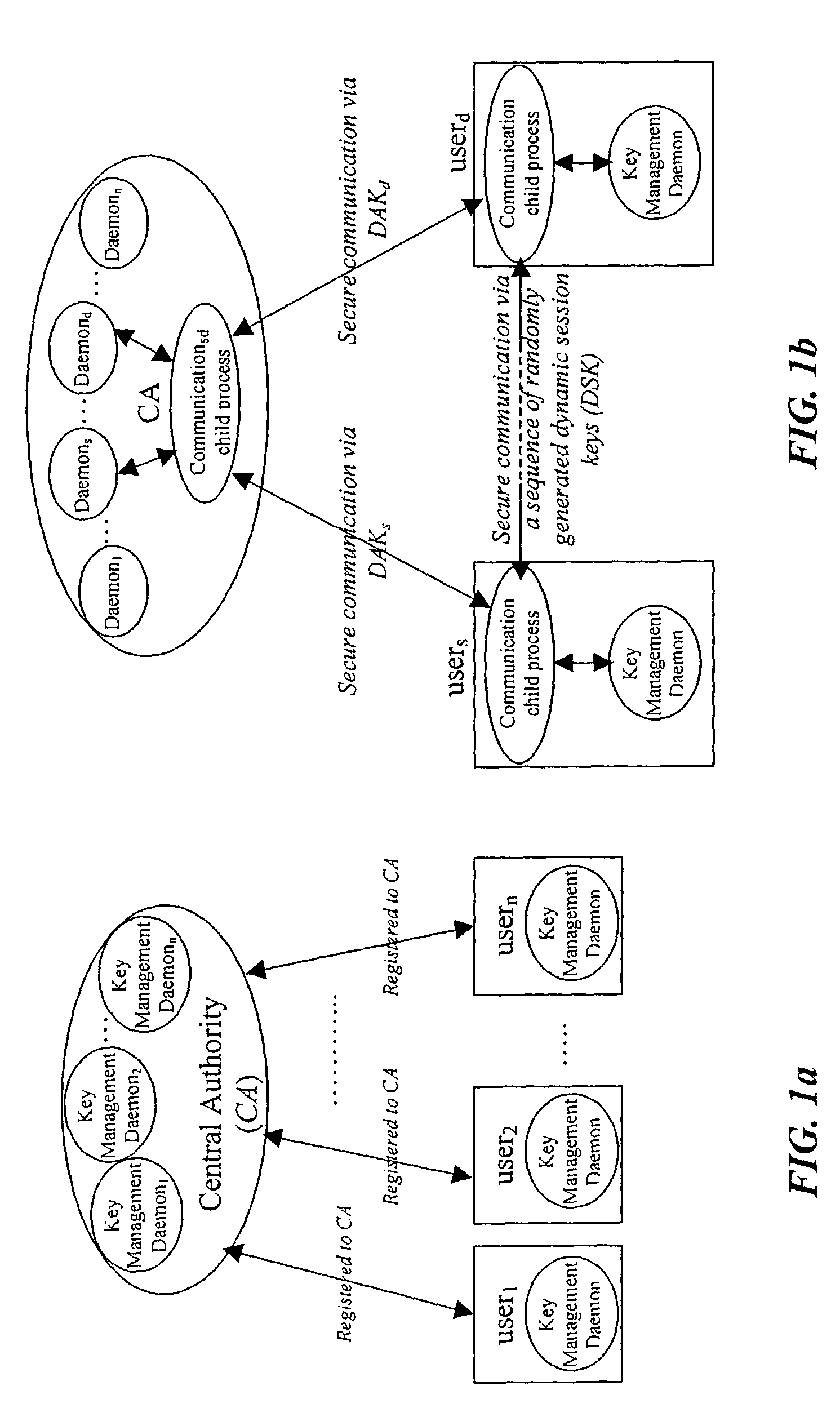

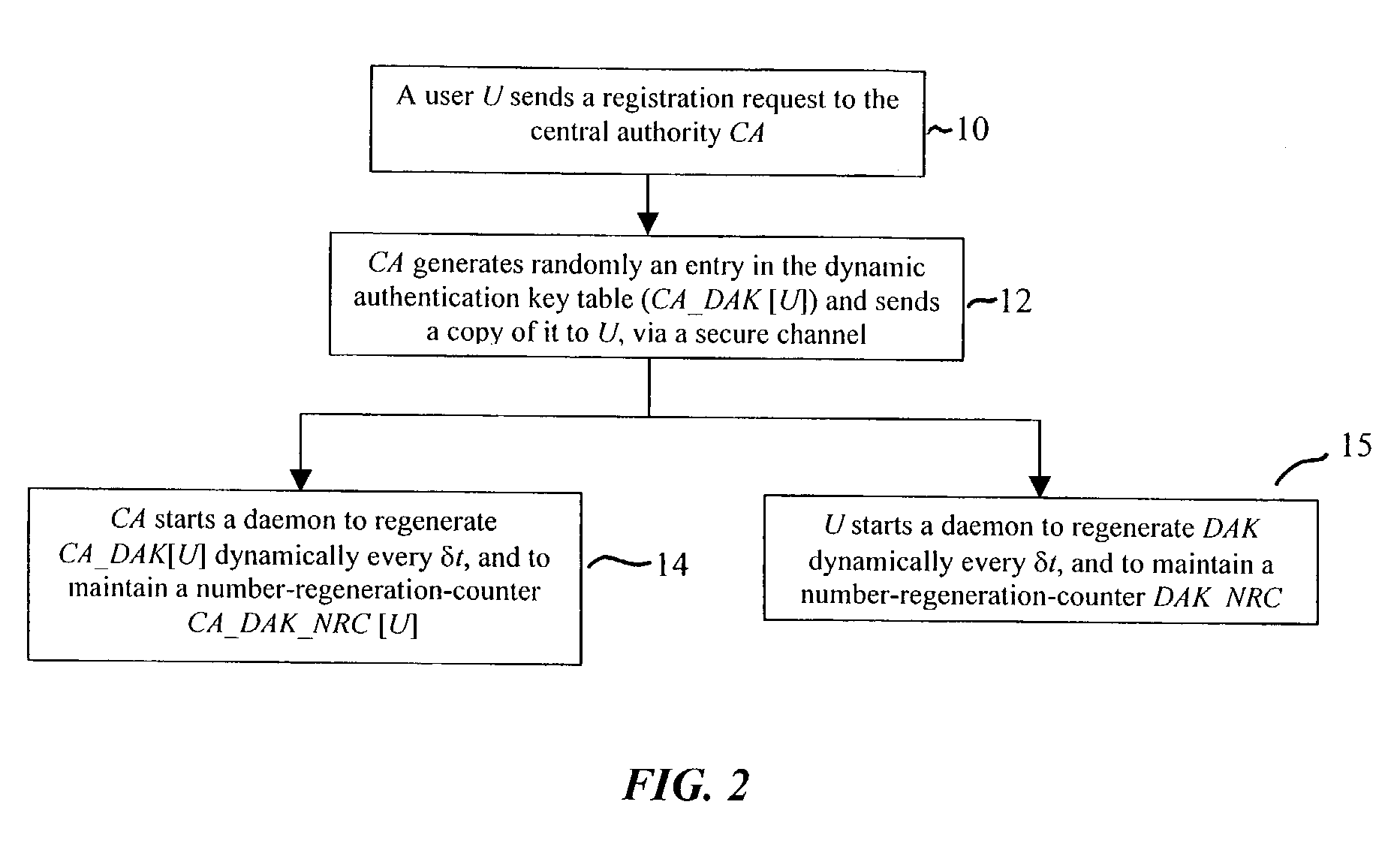

Dynamic security authentication for wireless communication networks

ActiveUS20040179690A1Minimize exchangeMinimization of wasted bandwidthKey distribution for secure communicationSynchronising transmission/receiving encryption devicesSystemic approachAuthentication server

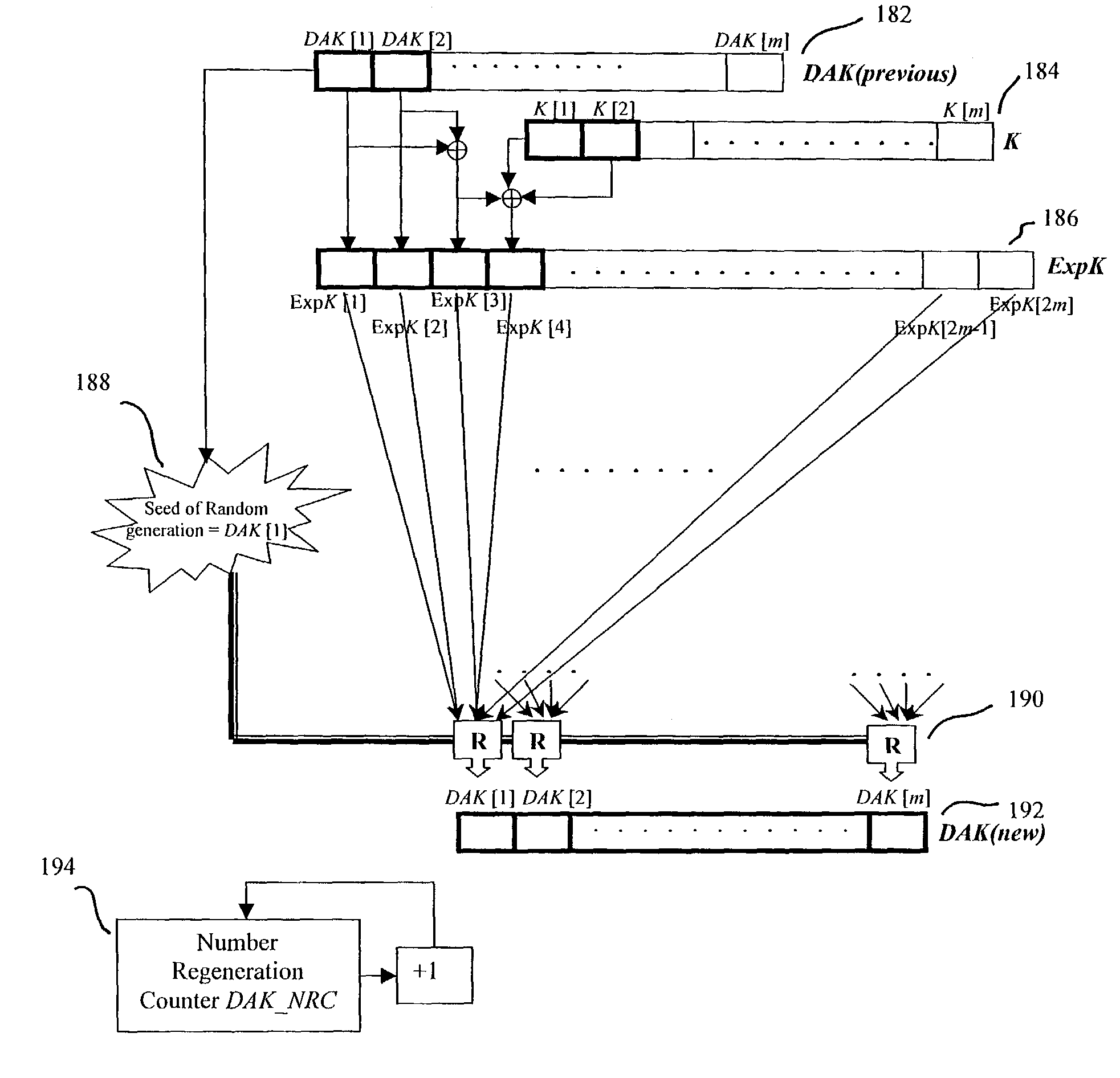

In a first embodiment, a dynamic computer system security method and system using dynamic encryption and full synchronization between system nodes. A data record created by a source user is encrypted with an initial dynamic session key. A new dynamic session key is generated based upon a data record and a previous dynamic session key. A central authority is used to synchronize and authenticate both source and destination users with constantly regenerated dynamic authentication keys. In a second embodiment, a method of providing dynamic security authentication between wireless communication network nodes. An initial authentication key and an address are assigned to certain of the nodes. The address along with information encrypted by the initial authentication key is sent to an authentication server. The authentication server and node or nodes synchronously regenerate authentication keys based upon the initial authentication key. Secure handovers occur between nodes via an authentication key.

Owner:MOXCHANGE LLC

Dynamic security authentication for wireless communication networks

ActiveUS7233664B2Minimize exchangeMinimize wasteKey distribution for secure communicationSynchronising transmission/receiving encryption devicesSystemic approachAuthentication server

In a first embodiment, a dynamic computer system security method and system using dynamic encryption and full synchronization between system nodes. A data record created by a source user is encrypted with an initial dynamic session key. A new dynamic session key is generated based upon a data record and a previous dynamic session key. A central authority is used to synchronize and authenticate both source and destination users with constantly regenerated dynamic authentication keys. In a second embodiment, a method of providing dynamic security authentication between wireless communication network nodes. An initial authentication key and an address are assigned to certain of the nodes. The address along with information encrypted by the initial authentication key is sent to an authentication server. The authentication server and node or nodes synchronously regenerate authentication keys based upon the initial authentication key. Secure handovers occur between nodes via an authentication key.

Owner:MOXCHANGE LLC

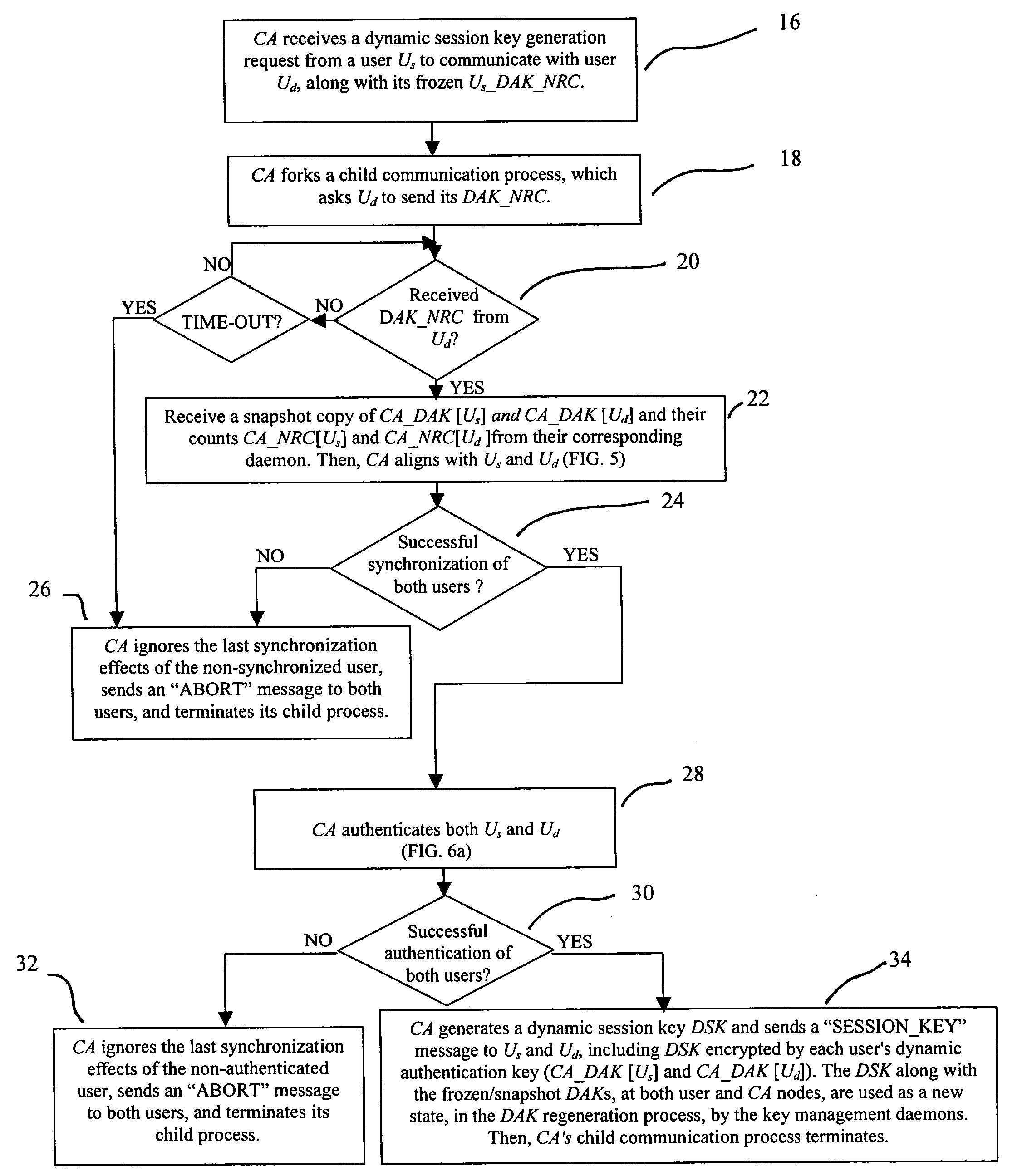

Computer system security via dynamic encryption

InactiveUS20040179682A1Minimize exchangeThe process is simple and fastKey distribution for secure communicationSynchronising transmission/receiving encryption devicesSecure communicationSystemic approach

A dynamic computer system security method and system using dynamic encryption and full synchronization between system nodes. A data record from a data stream created by a source user is encrypted with an initial dynamic session key. A new dynamic session key is generated based upon a data record and a previous dynamic session key. The new dynamic session key is then used to encrypt the next data record. A central authority is used to synchronize and authenticate both source and destination users with dynamic authentication keys. The central authority and users constantly regenerate new dynamic authentication keys. A child process is forked to ensure synchronization and authentication of dynamic authentication keys of each node upon a request for a secure communication establishment from a user. The central authority generates the initial dynamic session key with the current dynamic authentication key to begin a secure communication session.

Owner:MOXCHANGE LLC

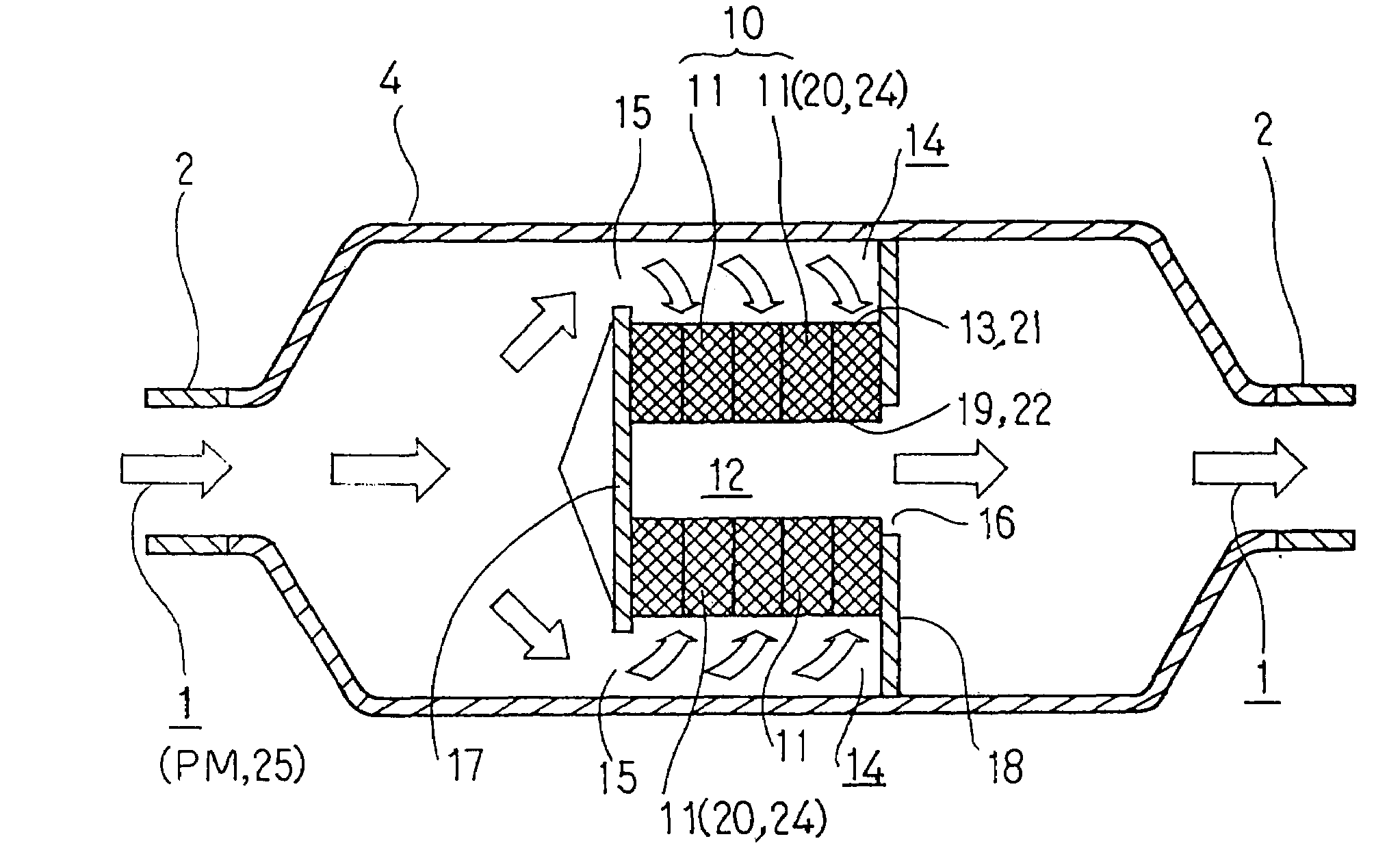

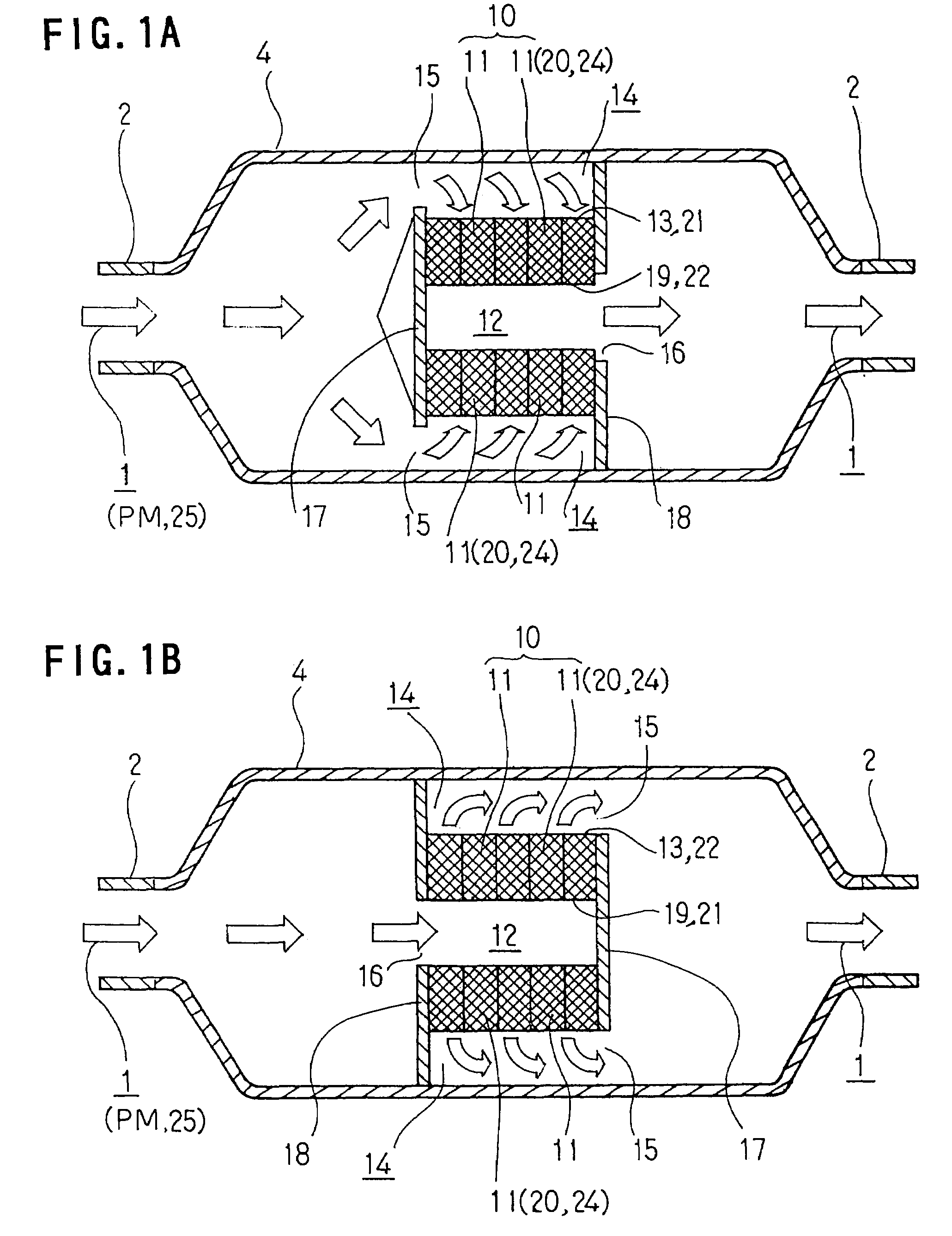

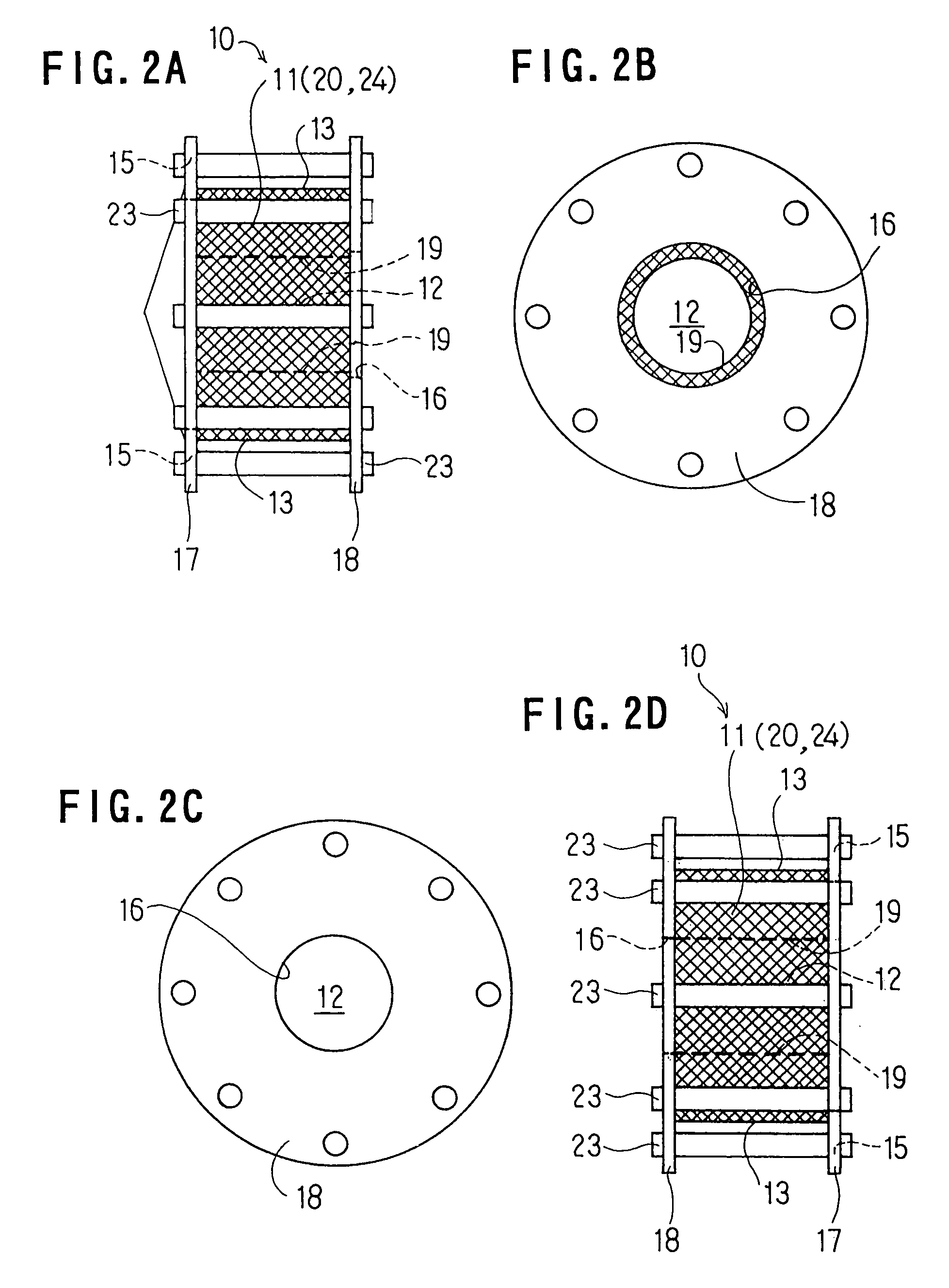

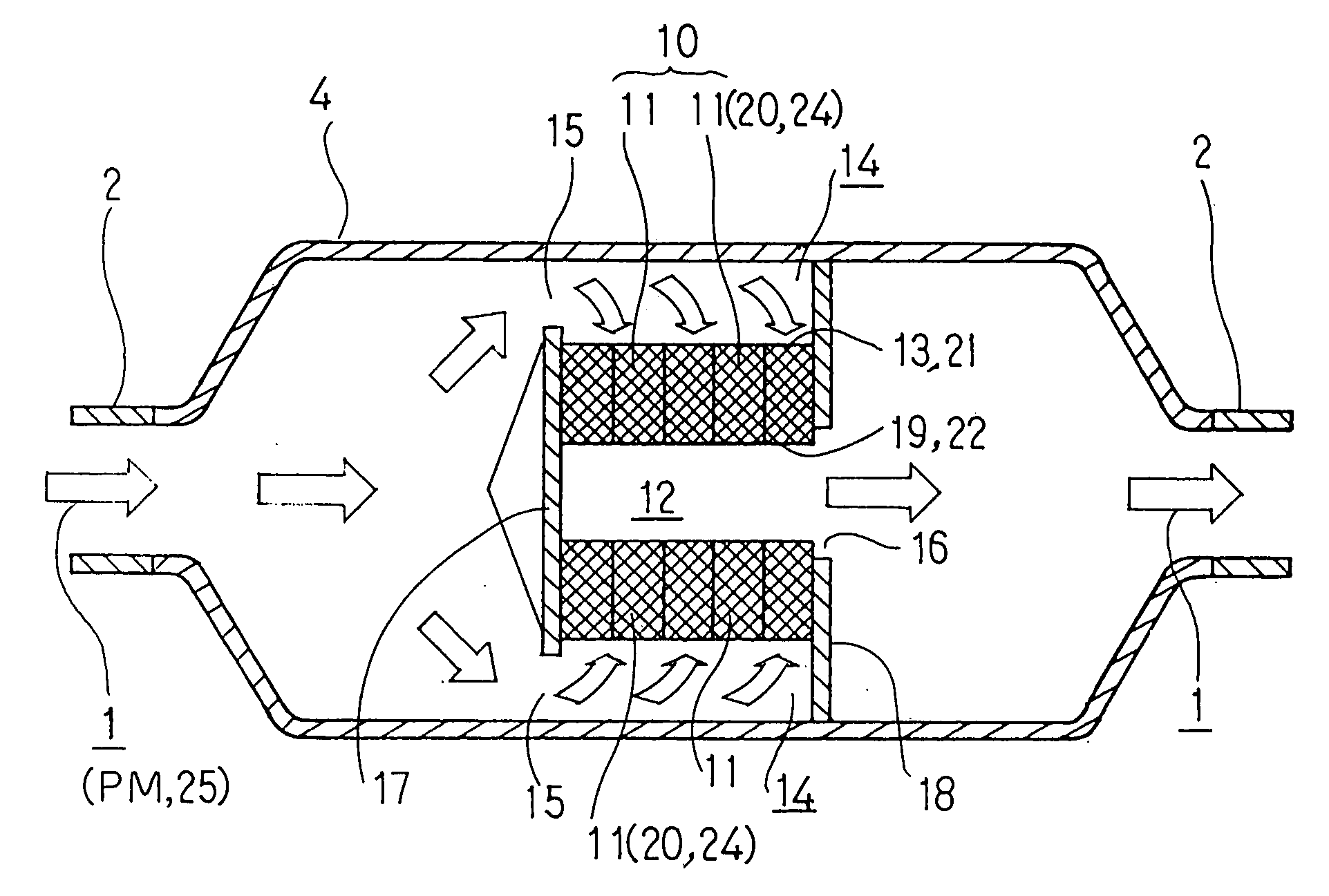

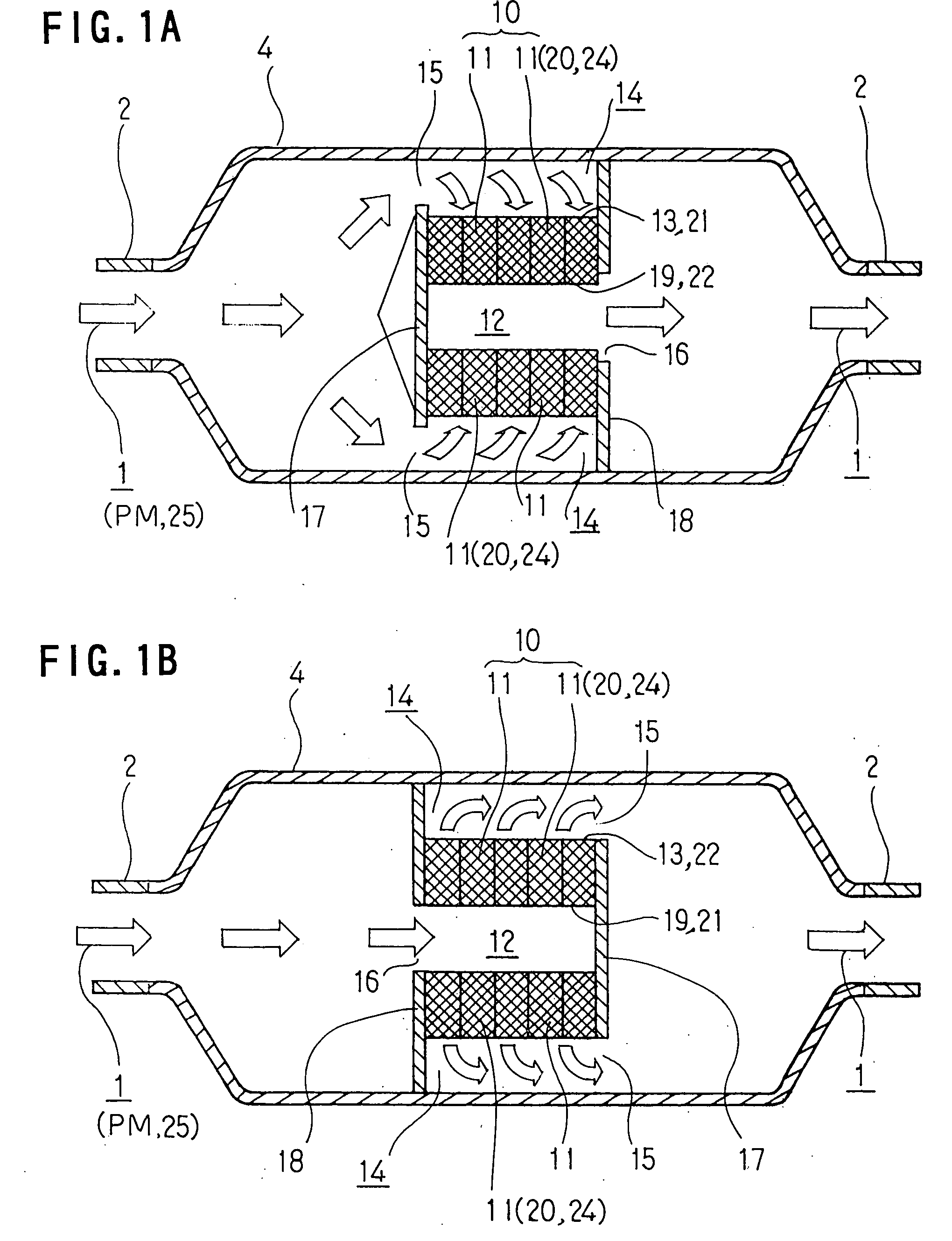

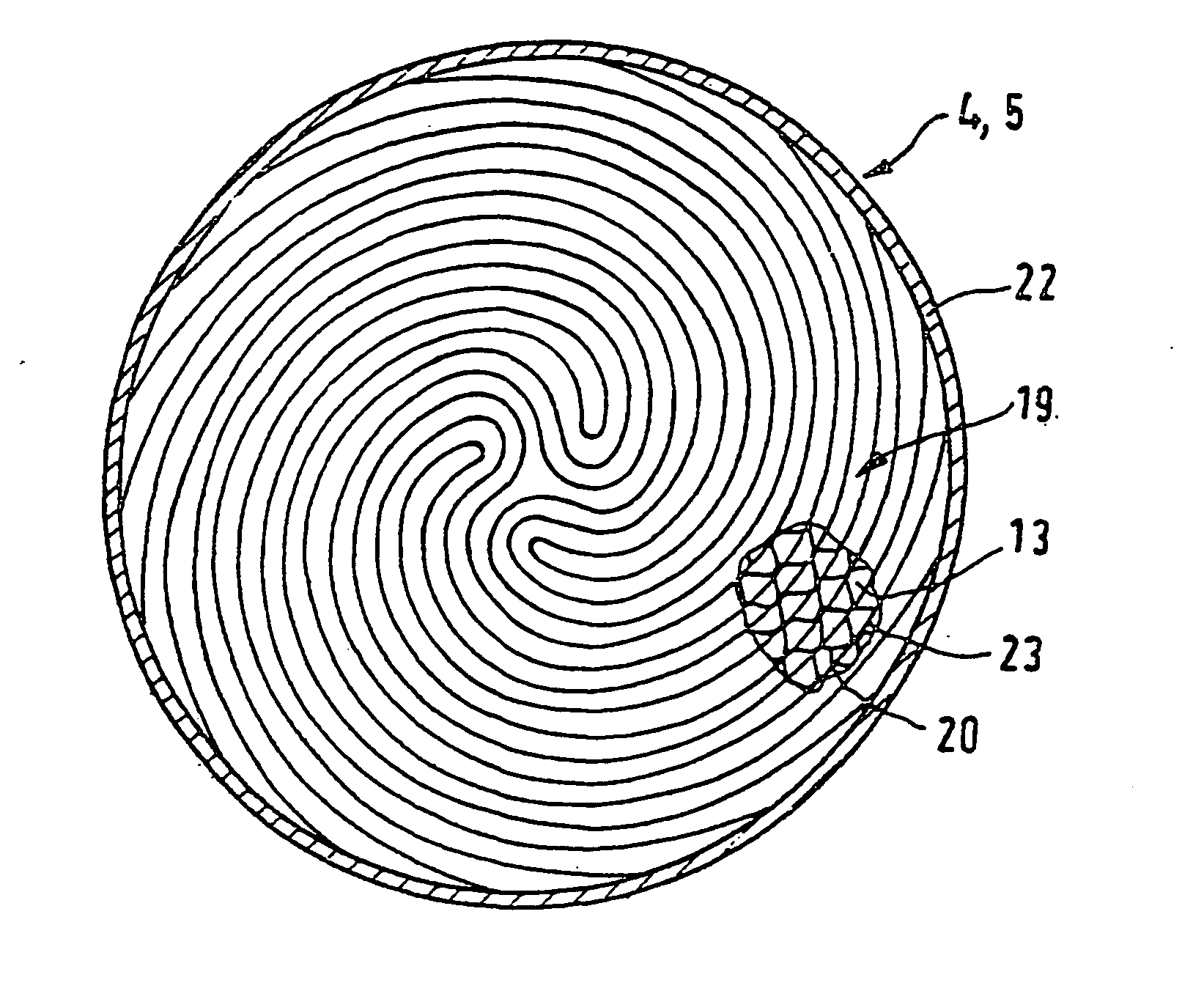

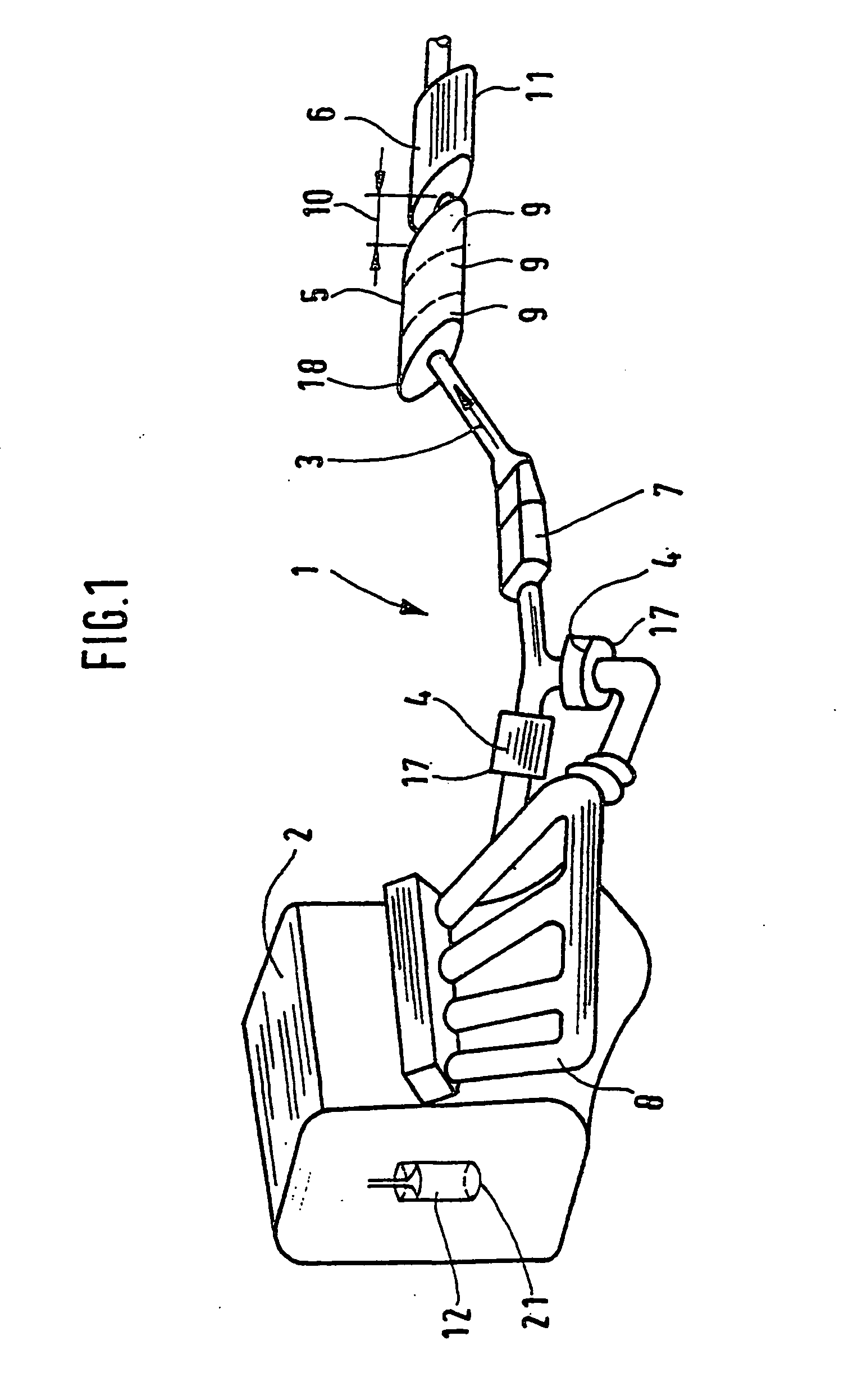

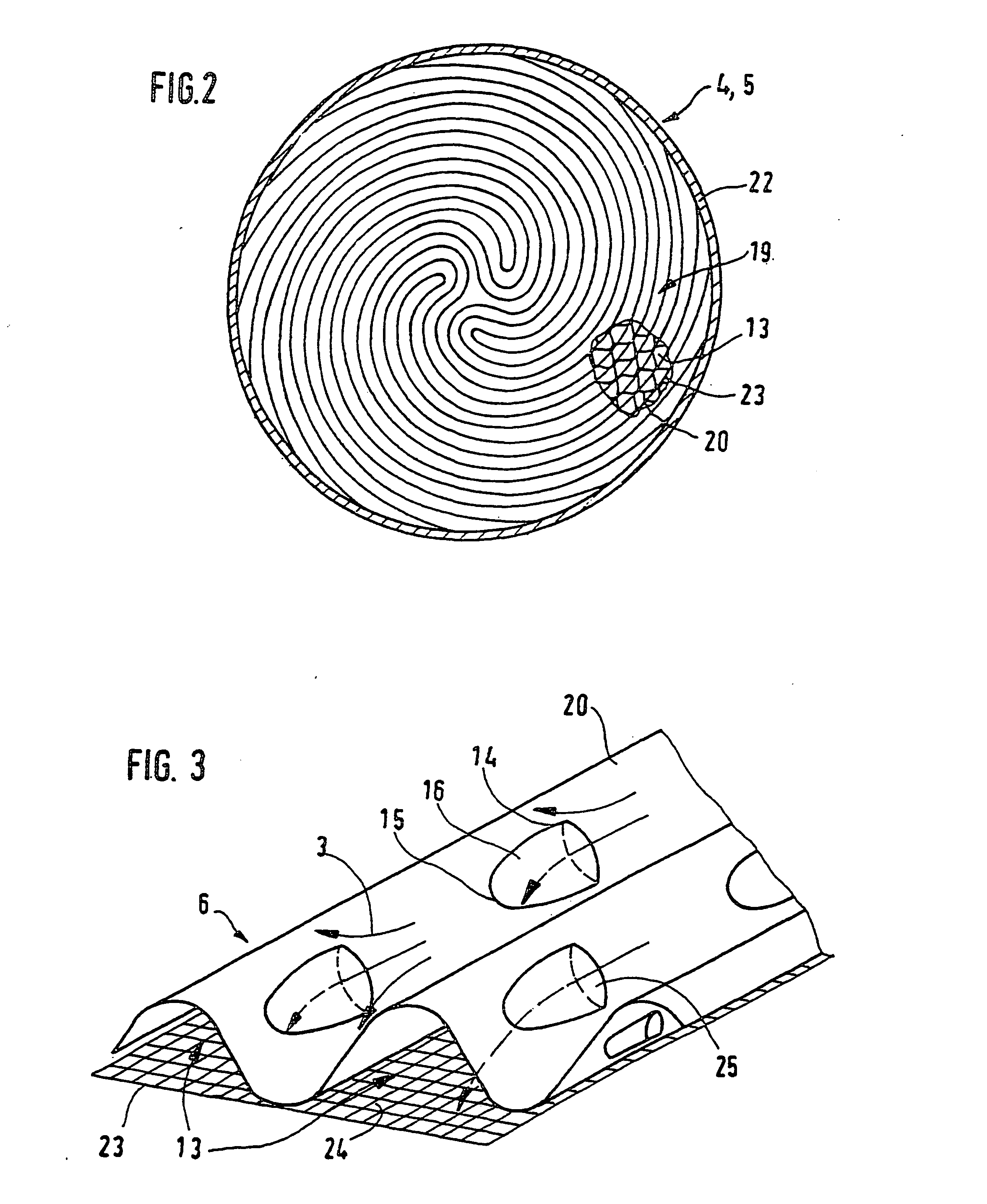

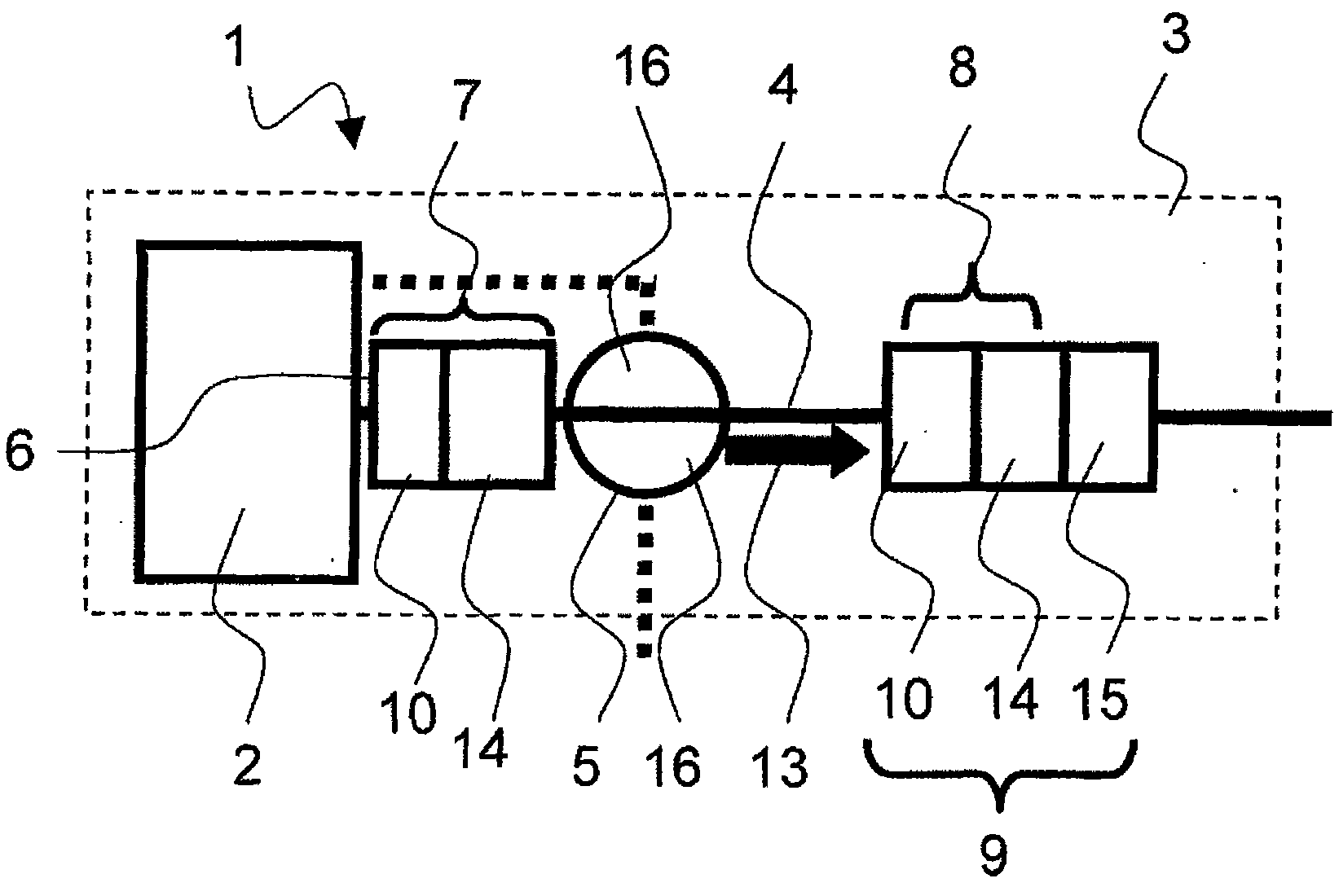

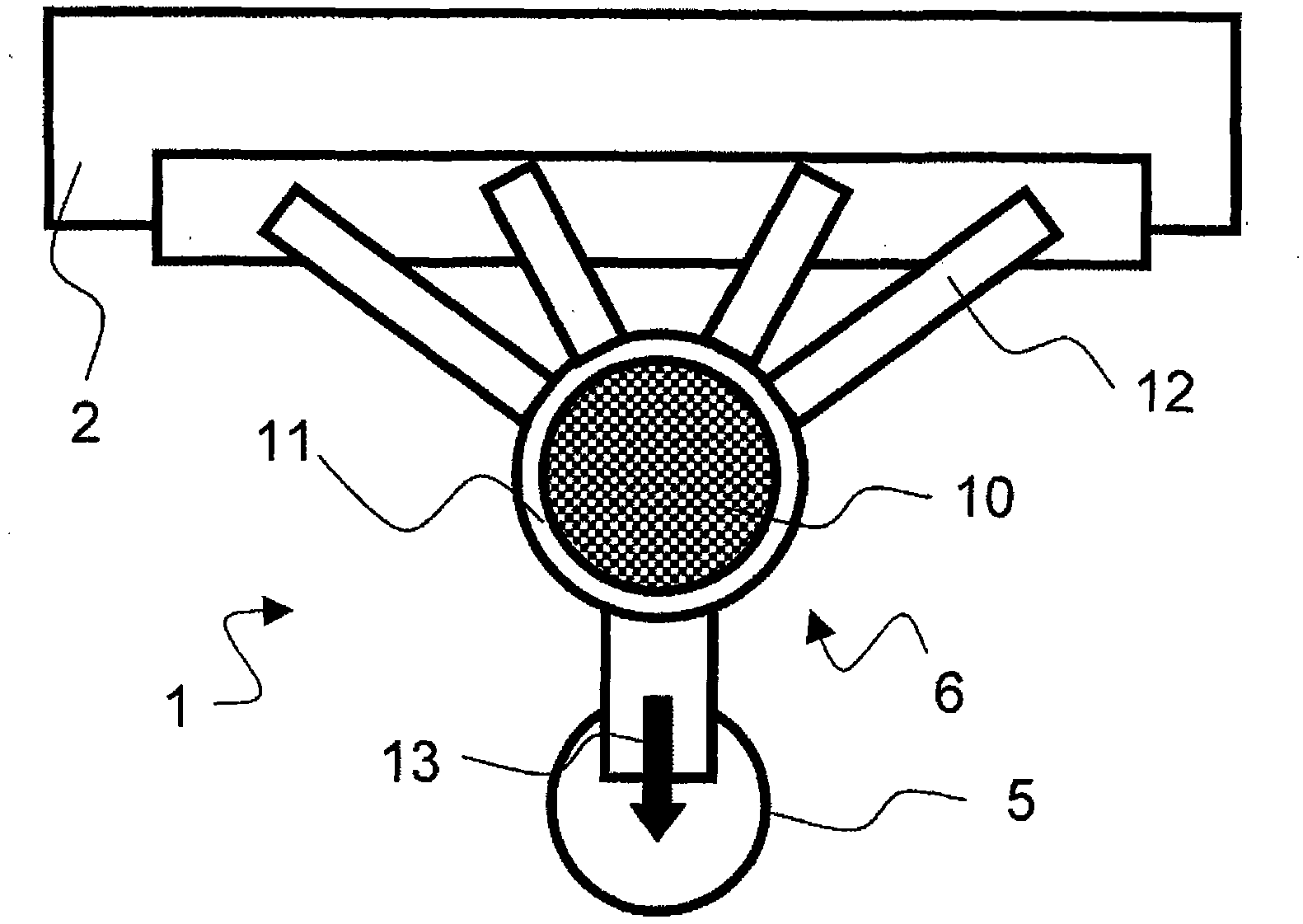

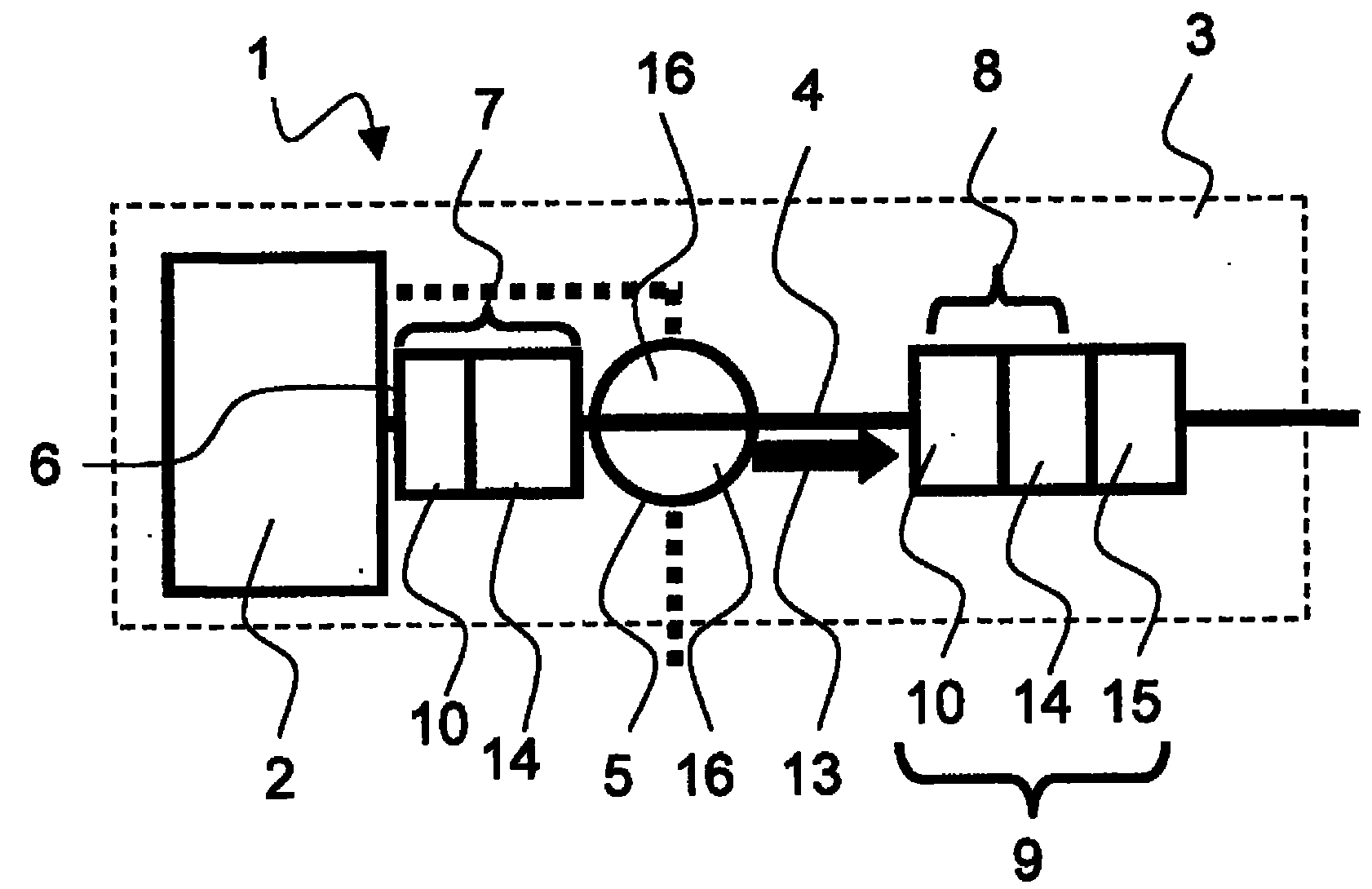

Particulate matter reducing apparatus

InactiveUS7473288B2Collection rate is lowStable collectionCombination devicesAuxillary pretreatmentParticulatesEngineering

This particulate matter reducing apparatus 10 is provided to burn and reduce particulate matter (“PM”) in an exhaust gas 1 of a diesel engine while collecting the PM on each filter 11 at a low collection rate of 50% or less in total. The filter 11 is composed of a wire mesh structure and is formed in a short column shape provided with a central through hole 12. The filter 11 is coaxially housed in an outer cylindrical casing 4 with a gap 14 provided within the casing and is retained by a pair of front and rear shielding plates 17 and 18. The pair of shielding plates 17 and 18 divides the inside of the outer cylindrical casing 4 in front and rear and is provided with one or more air holes 15 and 16 at the outer circumferential section or at the central section.

Owner:CLEAN DIESEL TECHNOLOGIES

Particulate matter reducing apparatus

InactiveUS20050132674A1Minimize any troubleBarely cloggedCombination devicesAuxillary pretreatmentParticulatesEngineering

This particulate matter reducing apparatus 10 is provided to burn and reduce particulate matter (“PM”) in an exhaust gas 1 of a diesel engine while collecting the PM on each filter 11 at a low collection rate of 50% or less in total. The filter 11 is composed of a wire mesh structure and is formed in a short column shape provided with a central through hole 12. The filter 11 is coaxially housed in an outer cylindrical casing 4 with a gap 14 provided within the casing and is retained by a pair of front and rear shielding plates 17 and 18. The pair of shielding plates 17 and 18 divides the inside of the outer cylindrical casing 4 in front and rear and is provided with one or more air holes 15 and 16 at the outer circumferential section or at the central section.

Owner:CLEAN DIESEL TECHNOLOGIES

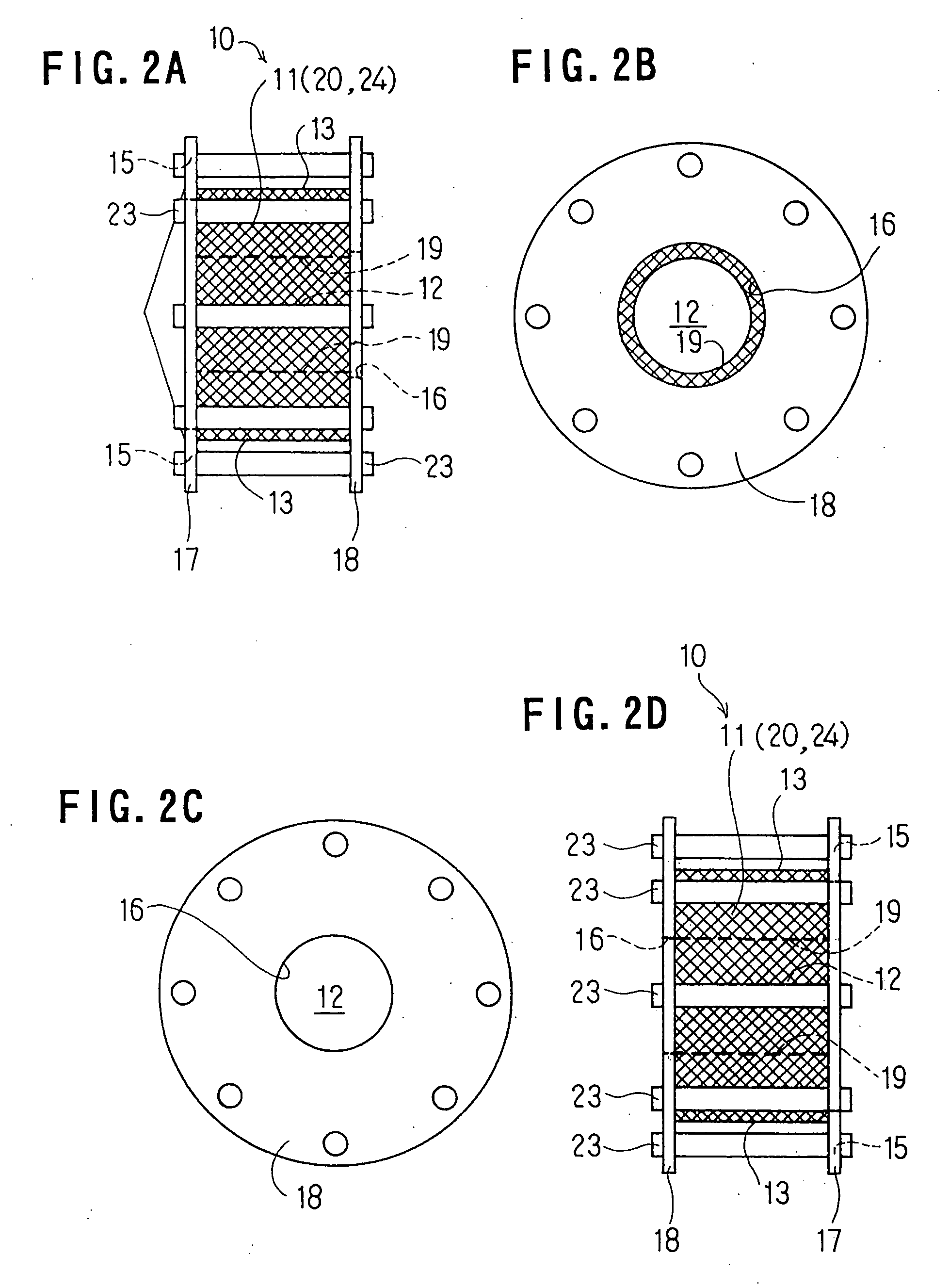

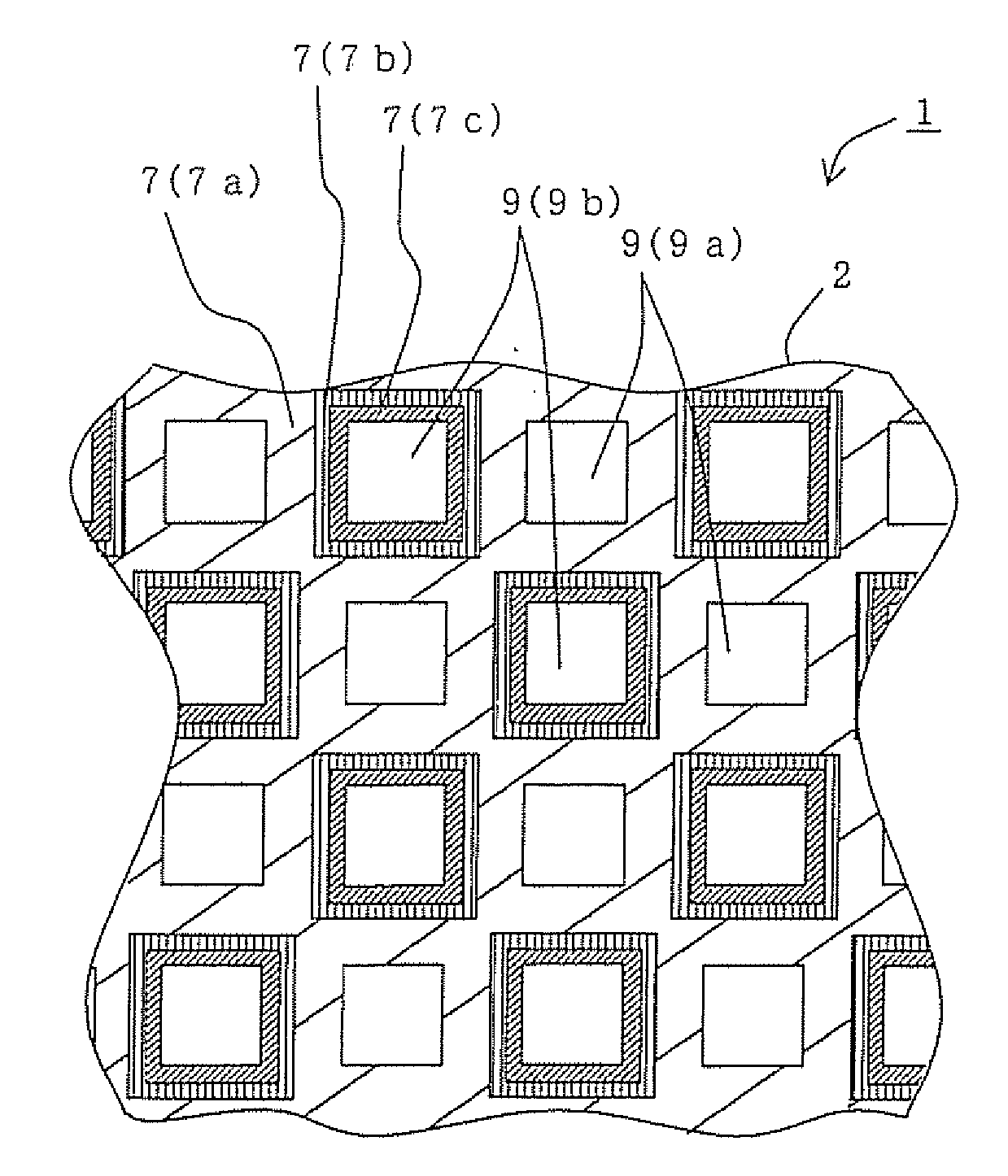

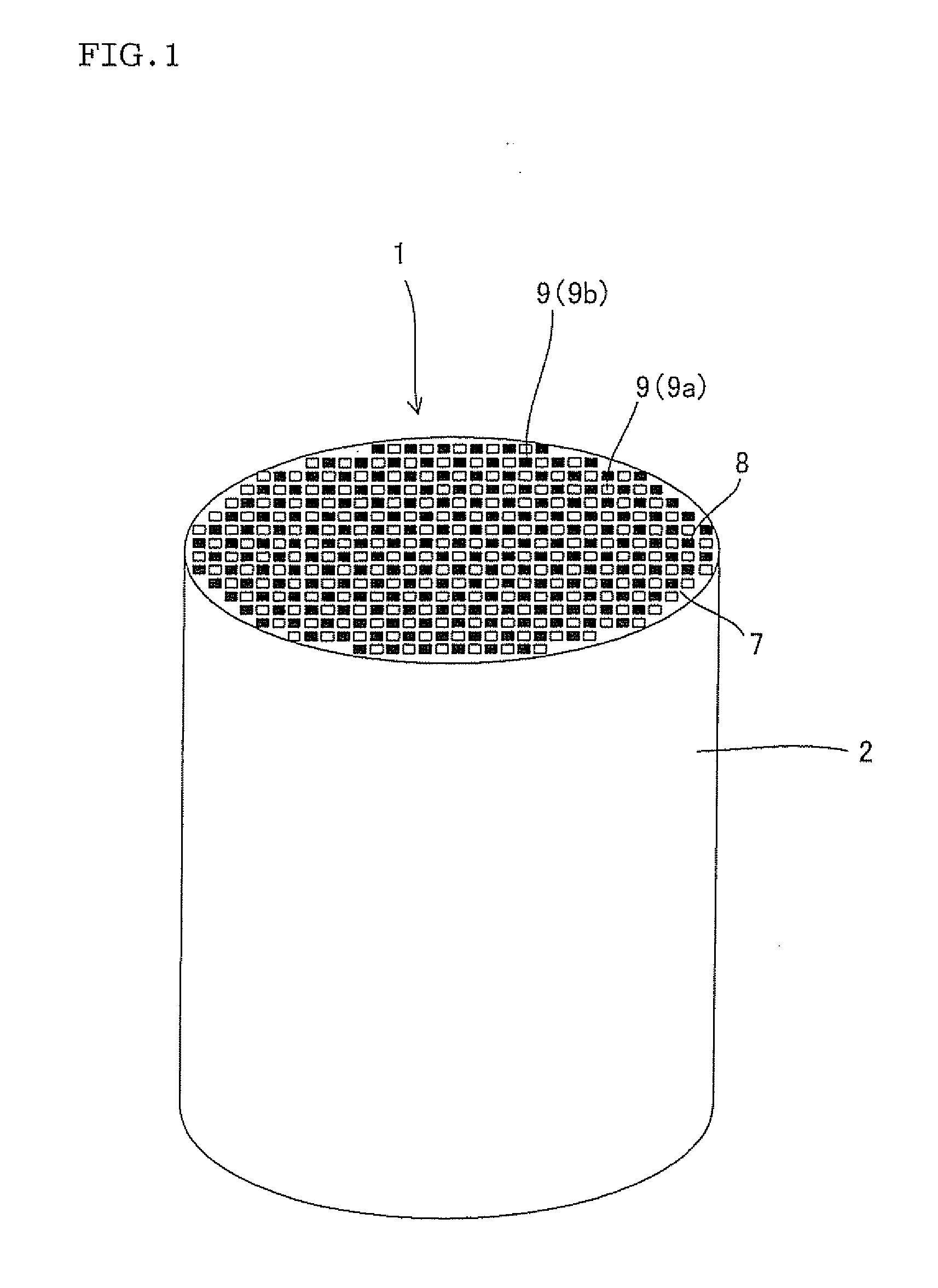

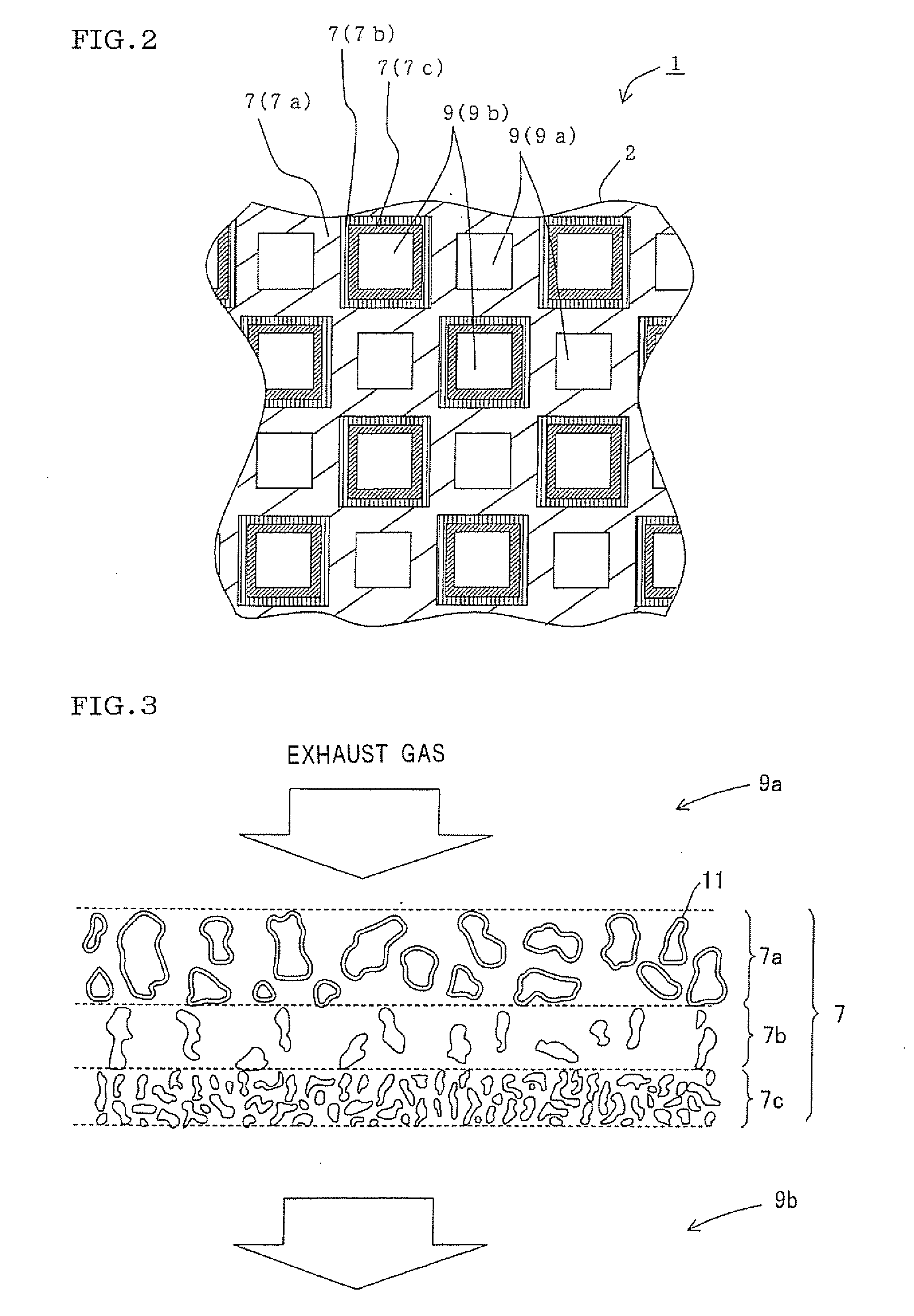

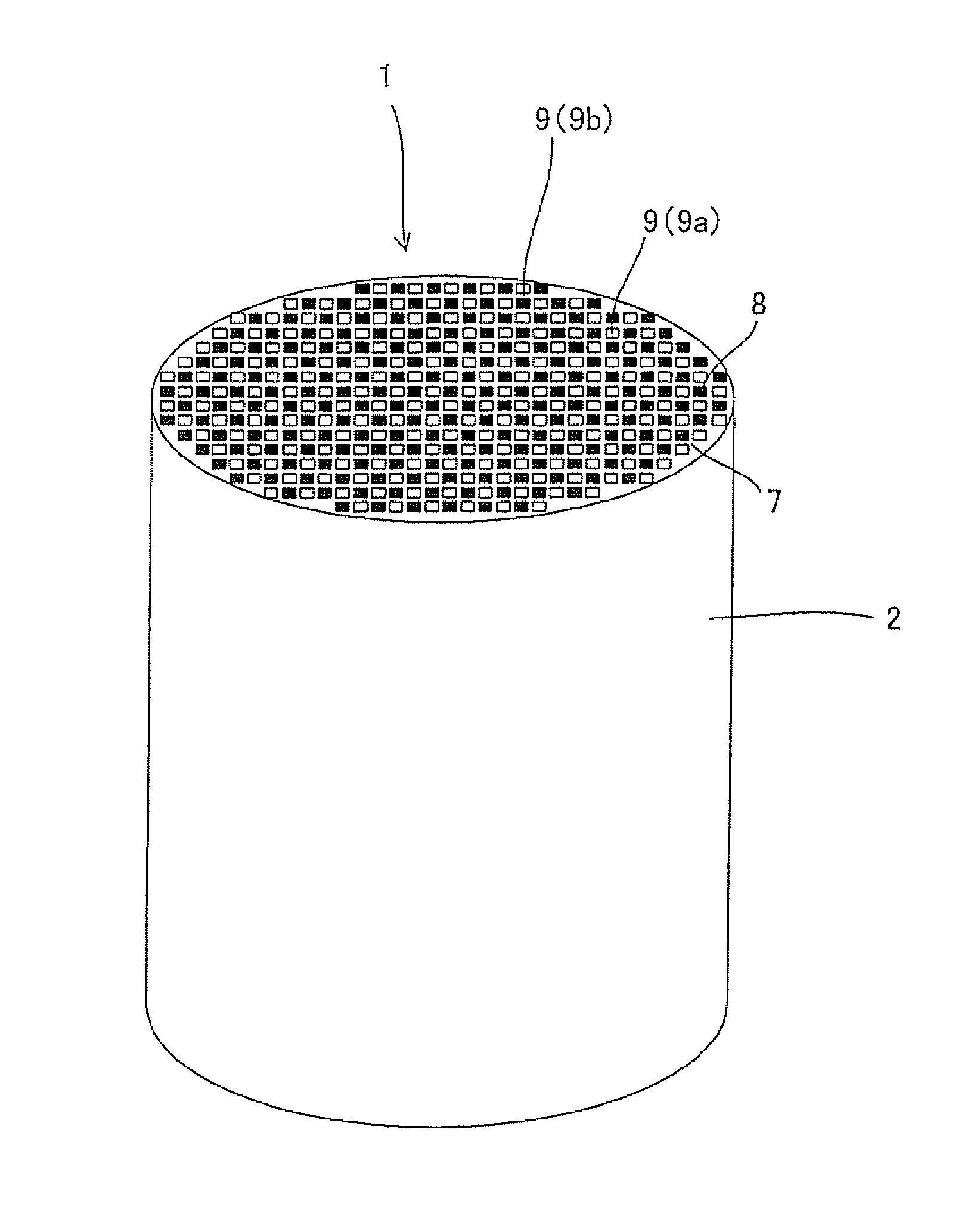

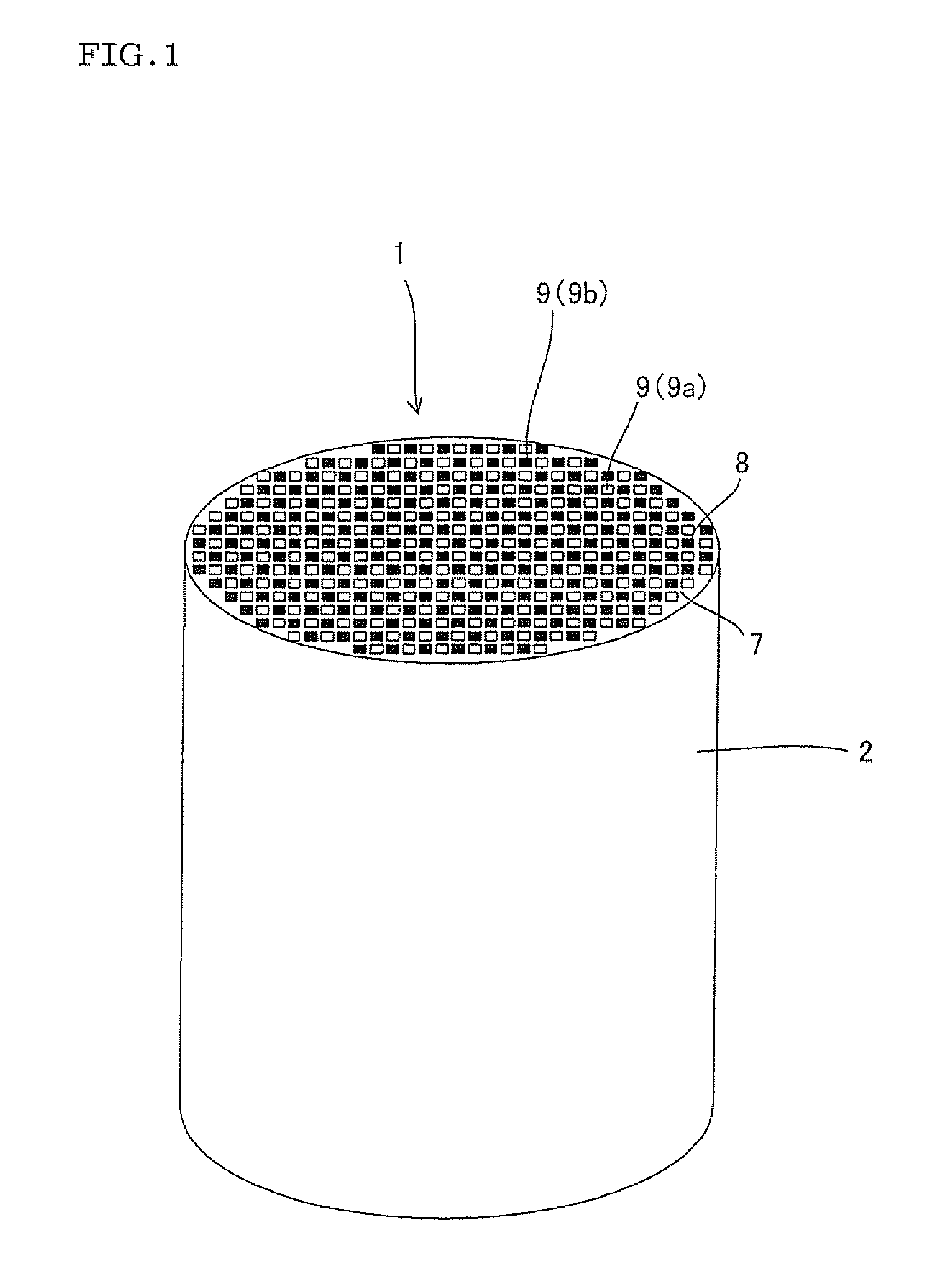

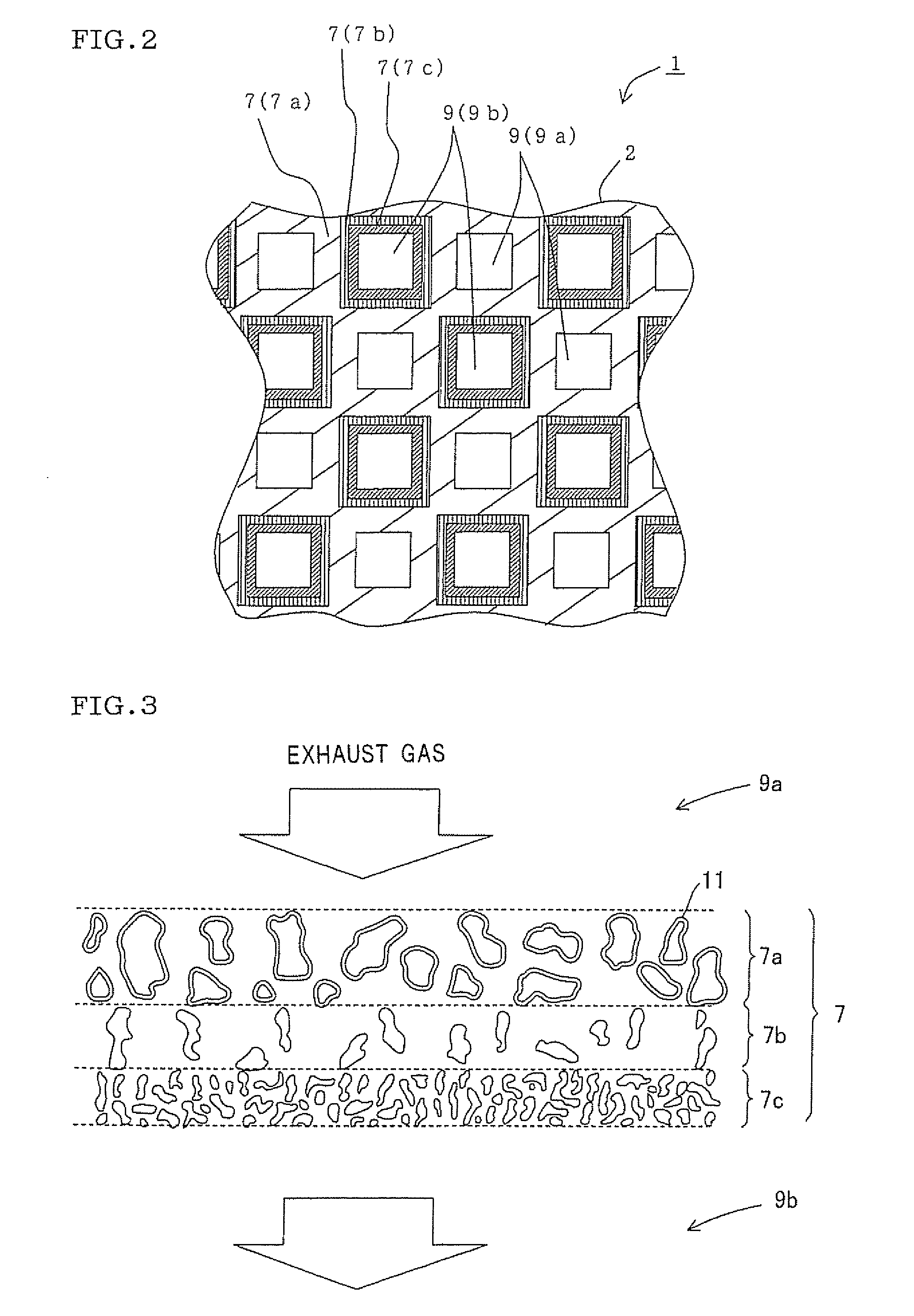

Honeycomb filter

ActiveUS20080295469A1Pressure loss of whole can satisfactorily be suppressUniform pressureCombination devicesDispersed particle filtrationHoneycomb structurePore diameter

A honeycomb filter 1 of the present invention includes a honeycomb structure 2 having partition walls 7 and plugging portions, and the partition walls 7 are constituted of a porous layer in which a first wall portion 7a having an average pore diameter of 20 μm or more and carrying an oxidation catalyst 11 on the inner surfaces of formed pores 8, a second wall portion 7b functioning as a buffer and having a high porosity, and a third wall portion 7c having an average pore diameter of 1 to 15 μm and a porosity of 50 to 90% are laminated in the thickness direction of the partition walls 7 from a surface side where cells 9a having opening end portions opened on an inflow side and opening end portions plugged on an outflow side are defined.

Owner:NGK INSULATORS LTD

Salt drying process

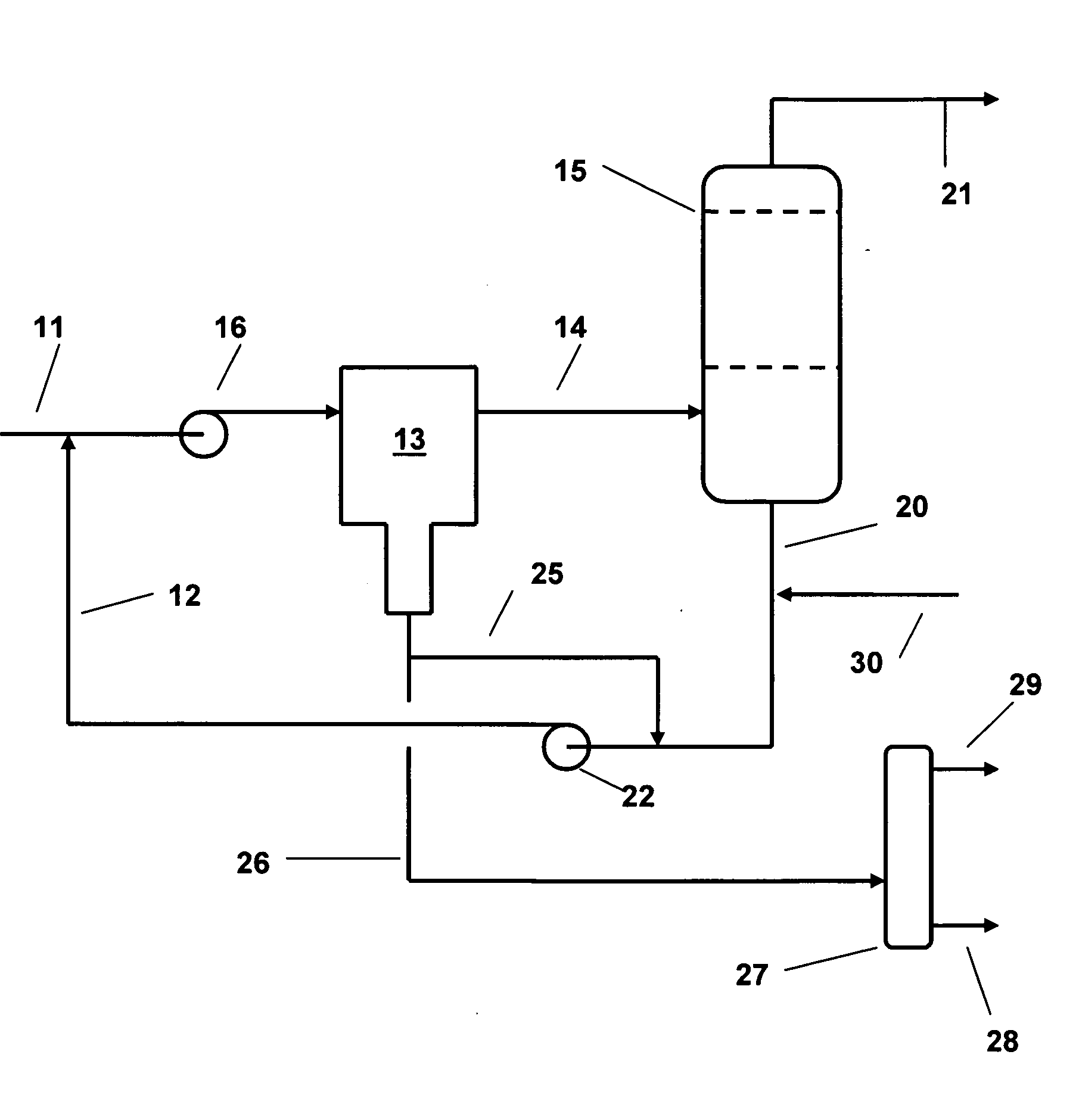

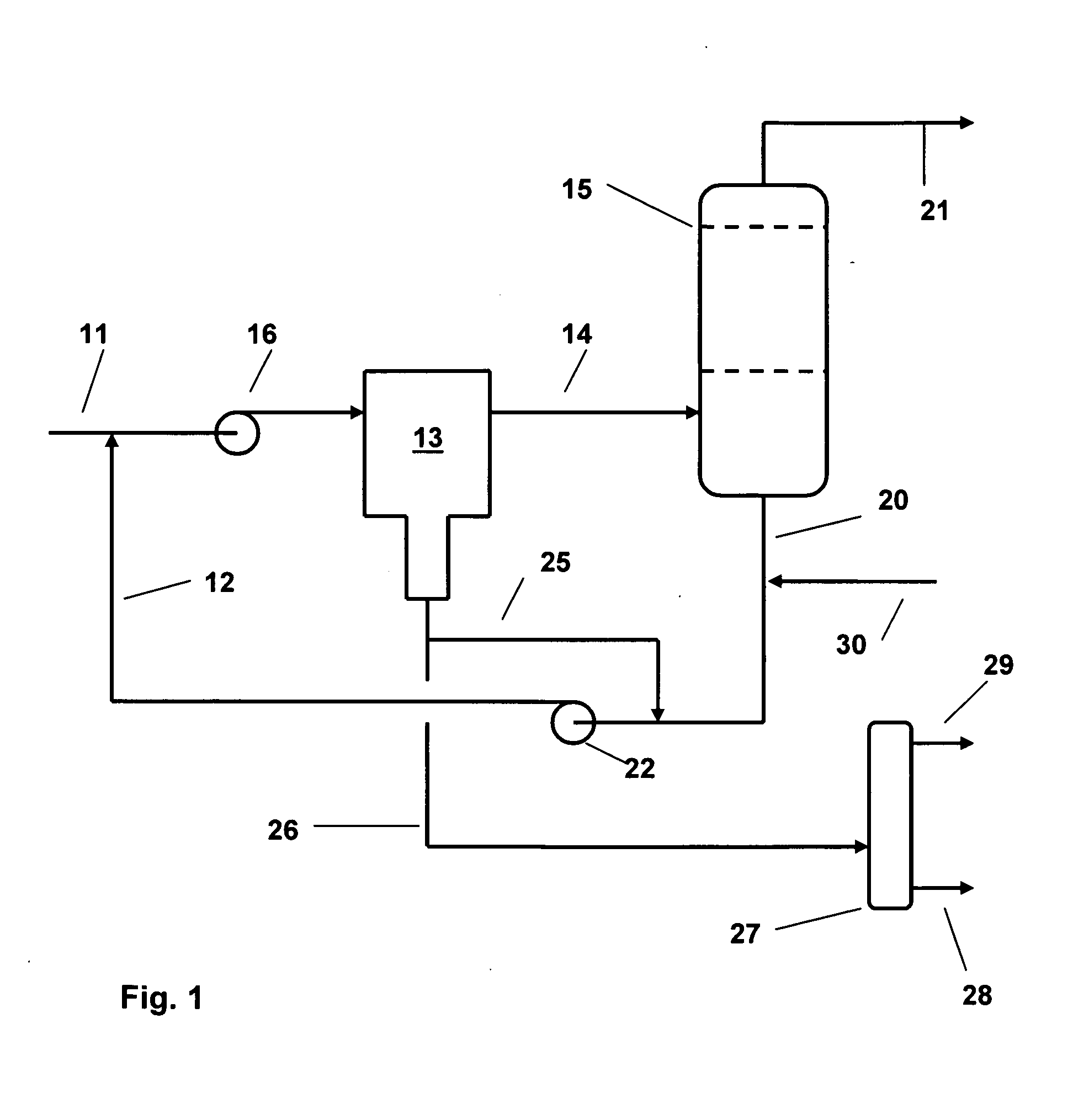

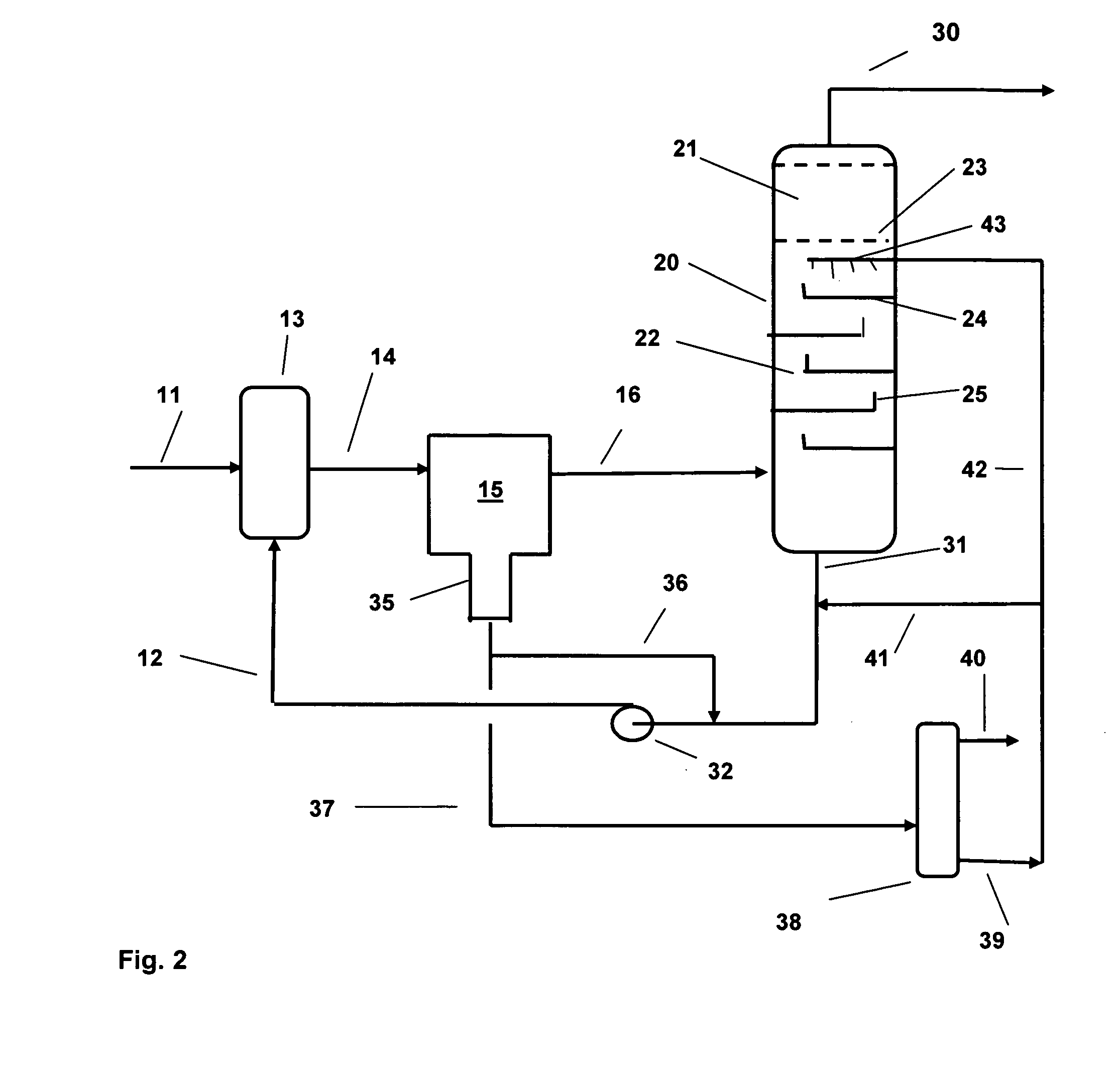

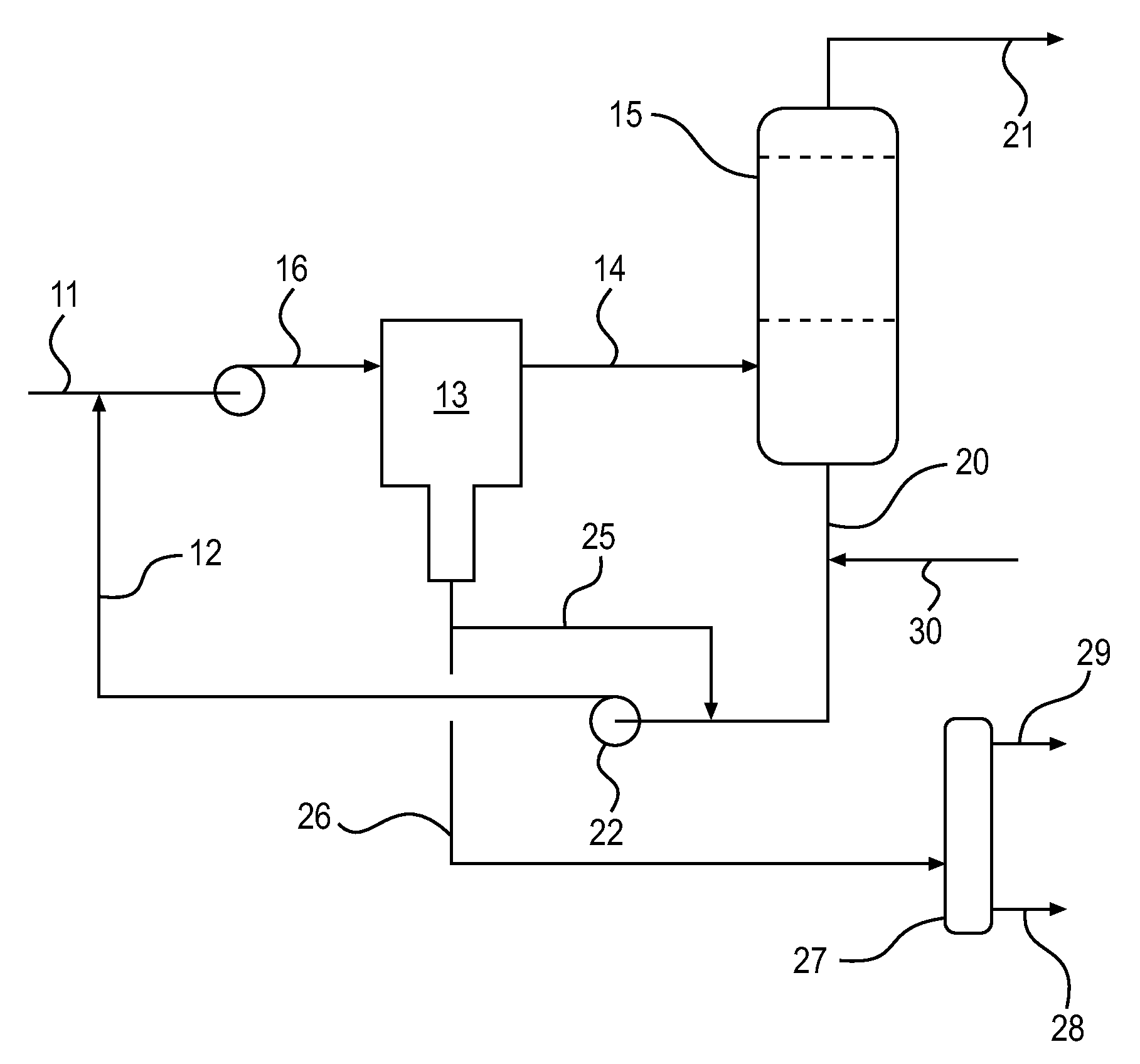

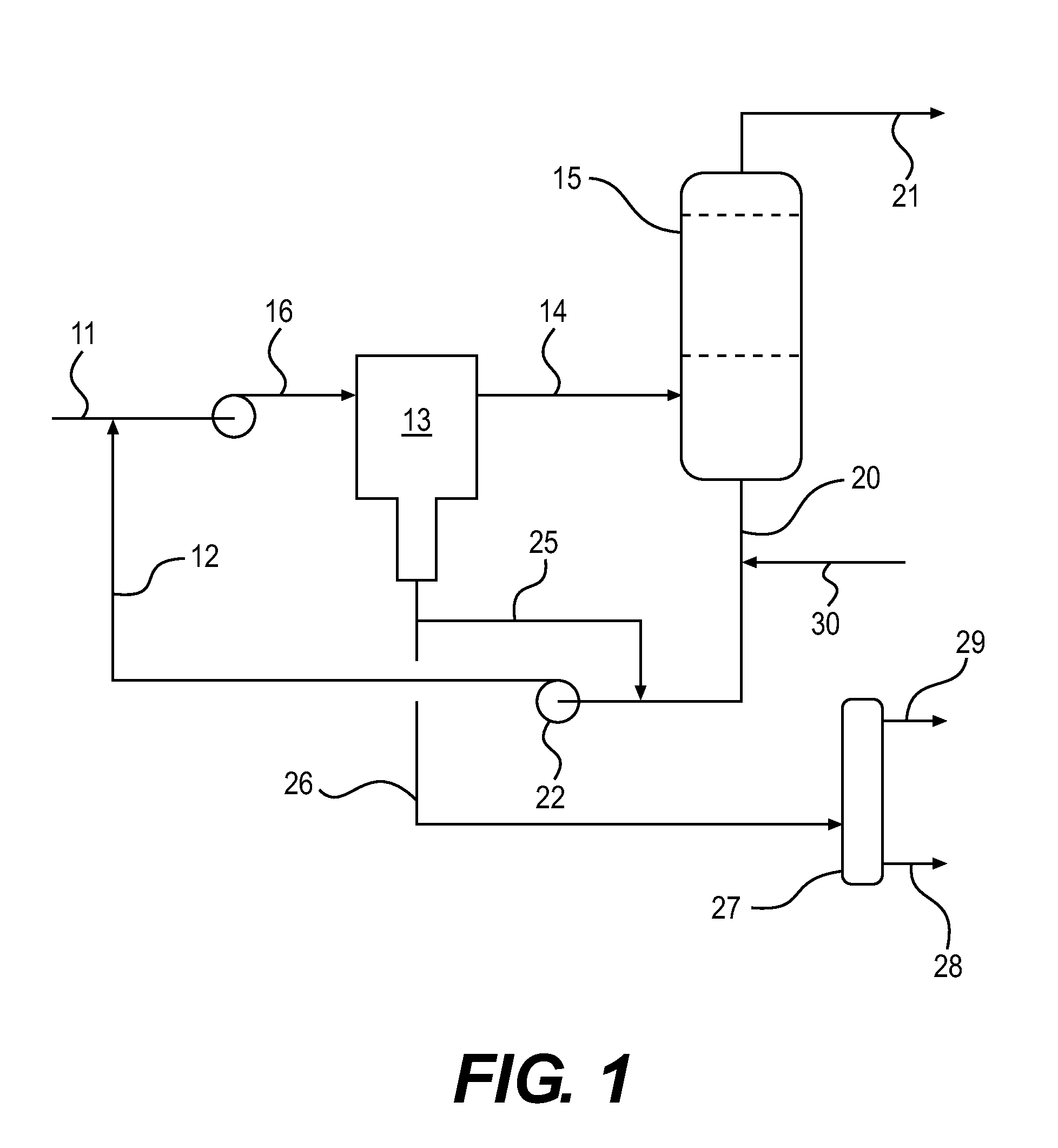

ActiveUS20090133577A1Improve efficiencyReduce consumptionDewatering/demulsification with chemical meansGas treatmentDesiccantAqueous solution

A method of drying liquid and gaseous hydrocarbons by contacting a feed stream of the hydrocarbon with an aqueous solution of a salt drying agent prior to passing the stream through a salt dryer to remove part of the water in the stream. The aqueous solution of the salt drying agent is generated in the salt dryer when the partly dried stream comes into contact with the drying salt and forms the solution. The solution is circulated in a loop from the salt dryer to the incoming feed and then through a liquid / liquid coalescer which removes a portion of the water together with dissolved salt from the mixture before the mixture is passed on to the salt dryer where further removal of water occurs. The salt dryer is off-loaded by a substantial factor by the initial partial dehydration and does not require to remove such a large amount of water; the salt consumption is therefore reduced in proportion to the amount of water removed in the treatment steps which precede the dryer.

Owner:EXXON RES & ENG CO

Computer system security via dynamic encryption

ActiveUS20040179685A1Minimize exchangeThe process is simple and fastKey distribution for secure communicationSynchronising transmission/receiving encryption devicesSecure communicationSystemic approach

A dynamic computer system security method and system using dynamic encryption and full synchronization between system nodes. A data record from a data stream created by a source user is encrypted with an initial dynamic session key. A new dynamic session key is generated based upon a previous dynamic session key and a selected previously encrypted data record. The new dynamic session key is then used to encrypt the next data record. A central authority is used to synchronize and authenticate both source and destination users with dynamic authentication keys. The central authority and users constantly regenerate new dynamic authentication keys. A child process is forked to ensure synchronization and authentication of dynamic authentication keys of each node upon a request for a secure communication establishment from a user. The central authority generates the initial dynamic session key with the current dynamic authentication key to begin a secure communication session.

Owner:MOXCHANGE LLC

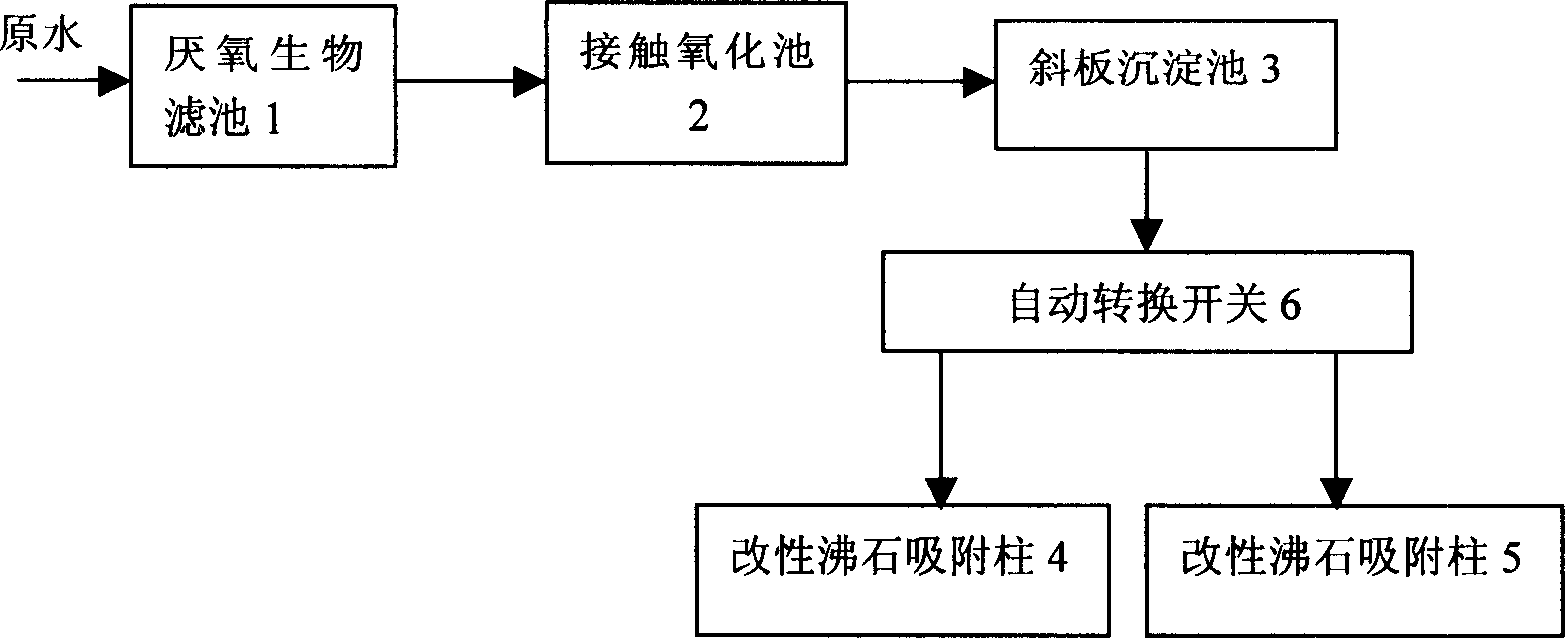

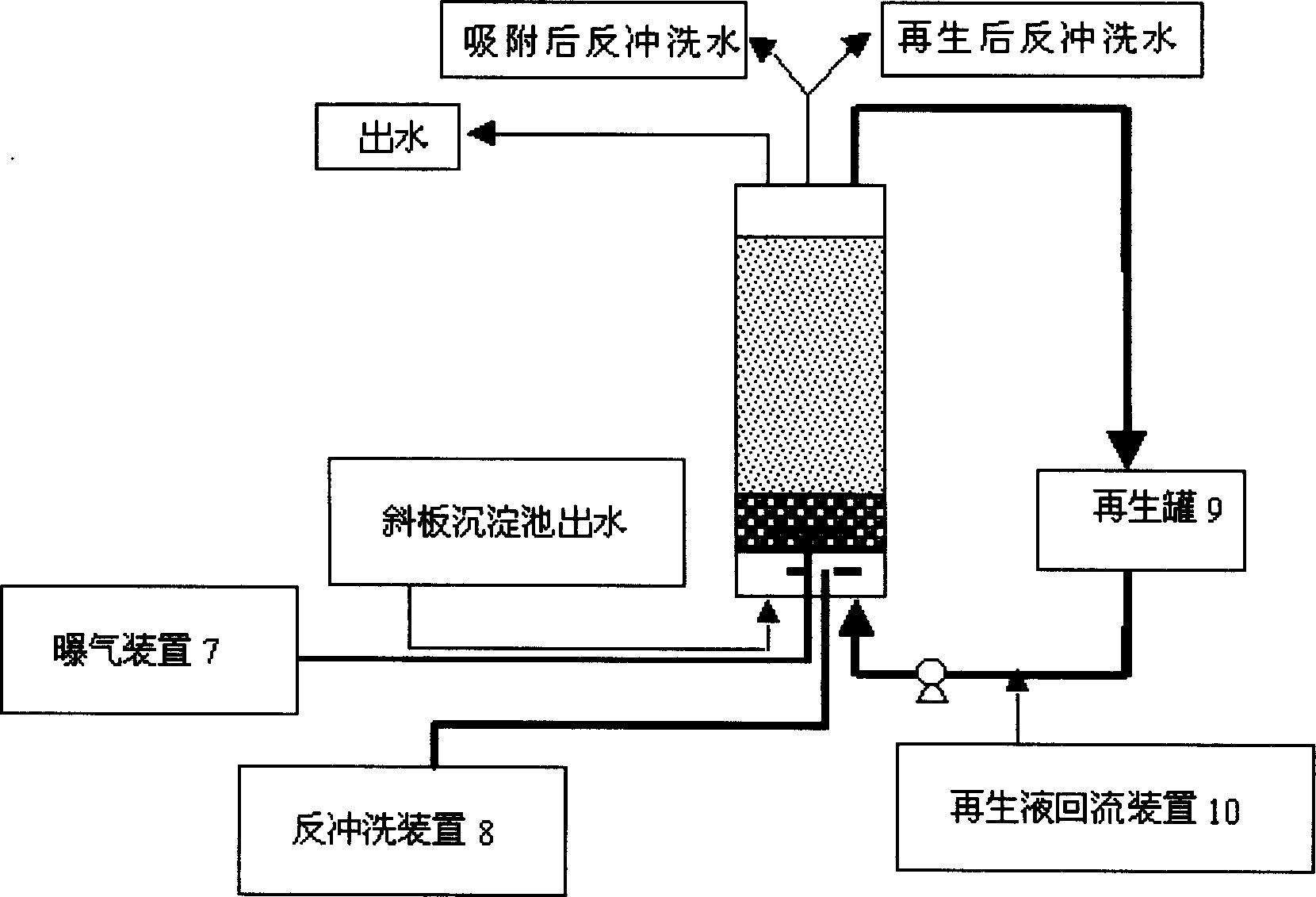

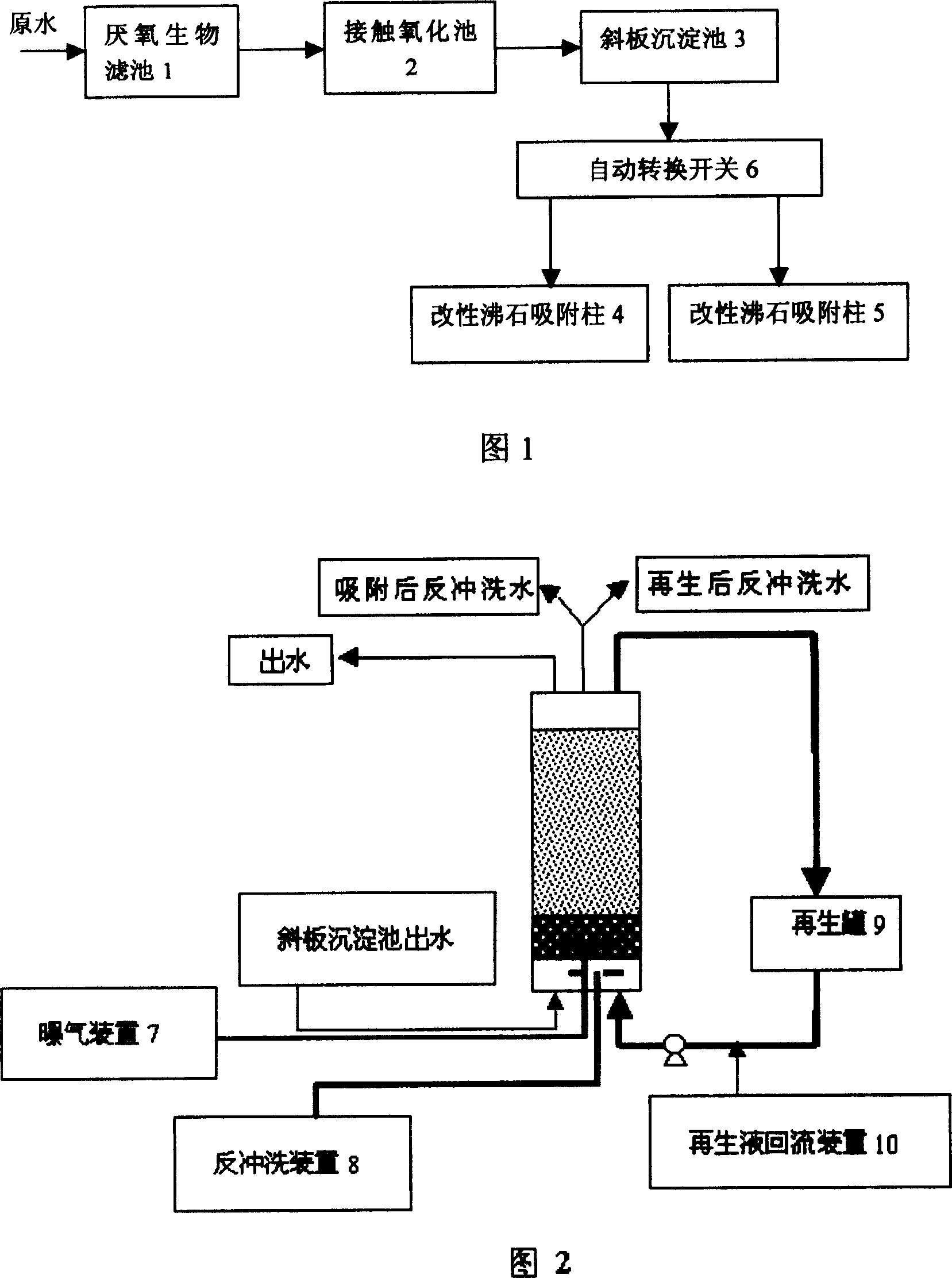

Method for removing ammonia nitrogen from sewage in subzone

InactiveCN1686872AAchieve regenerationContinuous regenerationTreatment with anaerobic digestion processesMultistage water/sewage treatmentAnaerobic filterSewage

The present invention relates to a method for deamination and denitrification of residential quarter sewage, belonging to the field of sewage treatment technology. It is characterized by that after the sewage is passed through anaerobic filter tank, contact oxidation tank and precipitation tank to obtain treatment, then sewage can upwards flow and be fed into two parallel modified zeolite adsorption regeneration columns to implement ammonia and nitrogen adsorption at twice successively, so that said invention can obtain high ammonia and nitrogen treatment efficiency. Said invention also provides the regeneration method of the above-mentioned zeolite adsorption regeneration column by using backflush process.

Owner:HARBIN INST OF TECH

Computer system security via dynamic encryption

ActiveUS7376232B2Minimize exchangeThe process is simple and fastKey distribution for secure communicationSynchronising transmission/receiving encryption devicesSecure communicationData stream

Owner:MOXCHANGE LLC

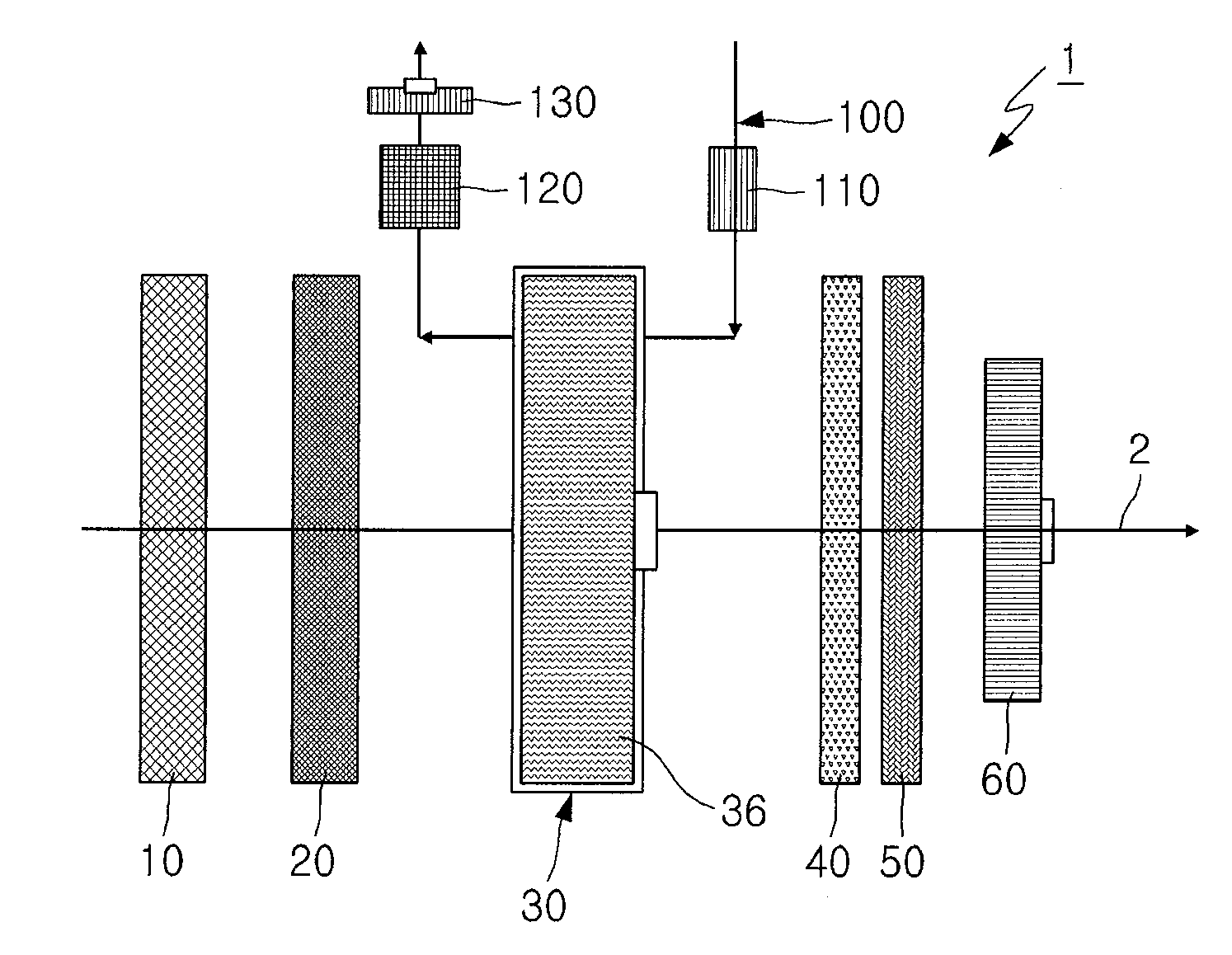

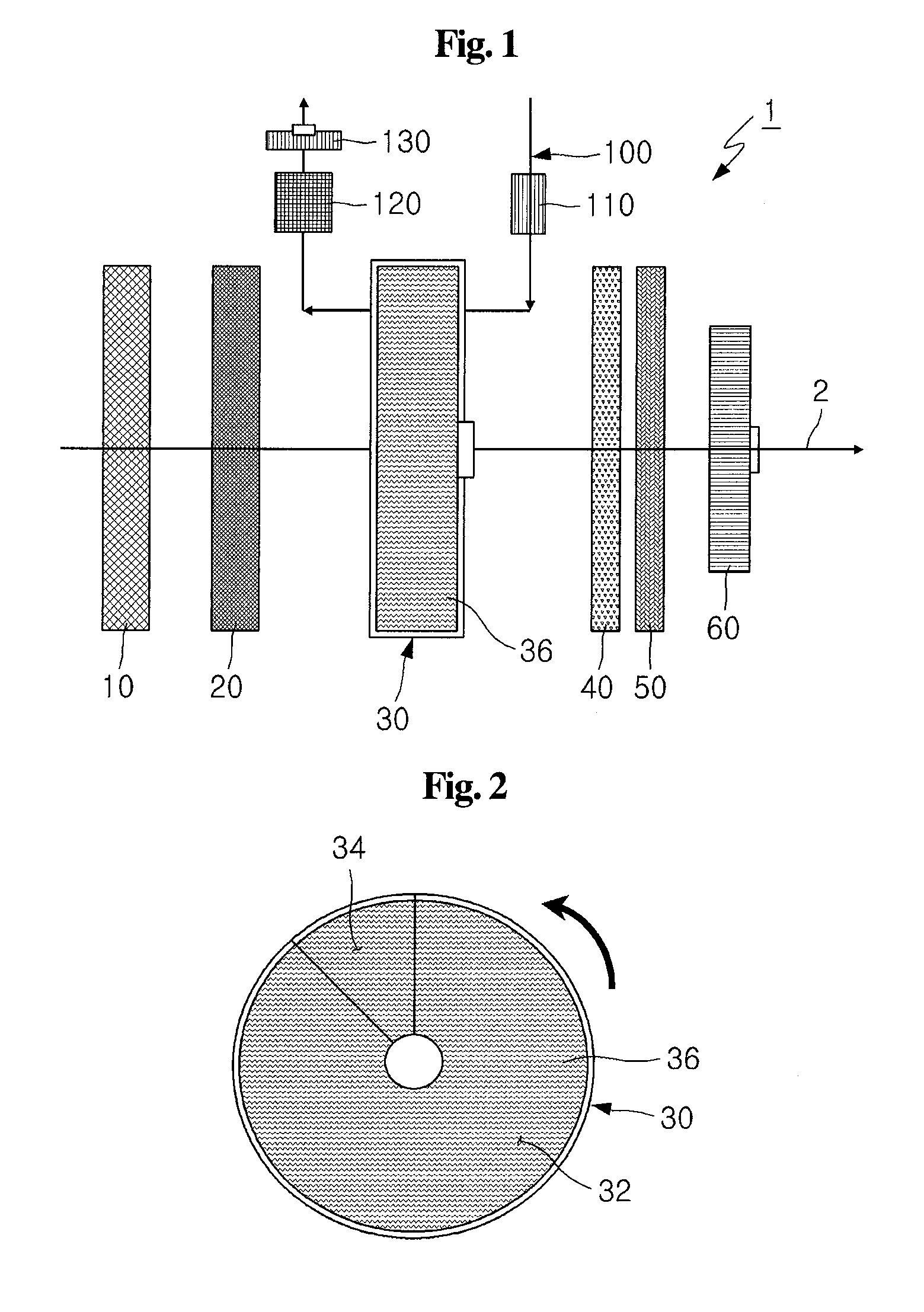

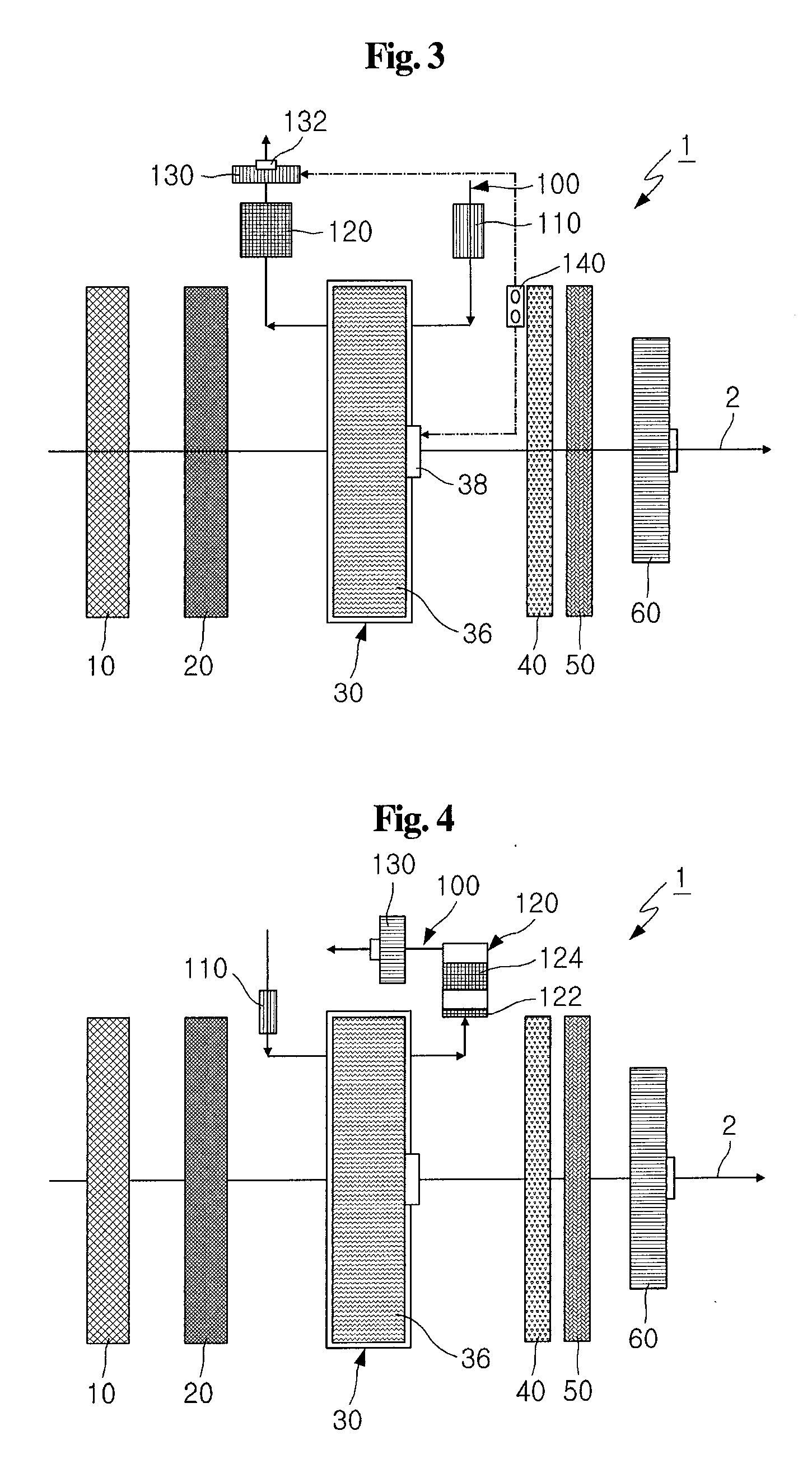

Air Cleaner Having Regenerative Filter, and Method for Regenerative of Air Cleaner Filter

ActiveUS20100180763A1Continuous regenerationCombination devicesGas treatmentAir cleanersGaseous substance

The invention relates to an air cleaner, and more particularly to an air cleaner which includes a regenerative deodorizing filter to purify and treat gaseous substances contained in air, thus enabling efficient regeneration of the regenerative deodorizing filter, and a method of regenerating the filter of the air cleaner.

Owner:ENBION

Honeycomb filter

ActiveUS8361399B2Improve efficiencyReduce total pressure lossCombination devicesDispersed particle filtrationPorous layerEngineering

A honeycomb filter 1 of the present invention includes a honeycomb structure 2 having partition walls 7 and plugging portions, and the partition walls 7 are constituted of a porous layer in which a first wall portion 7a having an average pore diameter of 20 μm or more and carrying an oxidation catalyst 11 on the inner surfaces of formed pores 8, a second wall portion 7b functioning as a buffer and having a high porosity, and a third wall portion 7c having an average pore diameter of 1 to 15 μm and a porosity of 50 to 90% are laminated in the thickness direction of the partition walls 7 from a surface side where cells 9a having opening end portions opened on an inflow side and opening end portions plugged on an outflow side are defined.

Owner:NGK INSULATORS LTD

Continuous process for converting natural gas to liquid hydrocarbons

InactiveUS7579510B2Easily toleratedContinuous regenerationMolecular sieve catalystLiquid hydrocarbon mixture recoveryAlkaneOxygen

An improved continuous process for converting methane, natural gas, or other hydrocarbon feedstocks into one or more higher hydrocarbons or olefins by continuously cycling through the steps of alkane halogenation, product formation (carbon-carbon coupling), product separation, and regeneration of halogen is provided. Preferably, the halogen is continually recovered by reacting hydrobromic acid with air or oxygen. The invention provides an efficient route to aromatic compounds, aliphatic compounds, mixtures of aliphatic and aromatic compounds, olefins, gasoline grade materials, and other useful products.

Owner:REACTION 35 LLC

Salt drying process

ActiveUS8080087B2Improve efficiencyReduce consumptionDewatering/demulsification with chemical meansGas treatmentDesiccantAqueous solution

Owner:EXXON RES & ENG CO

Exhaust system

InactiveUS20050005597A1Efficient conversionOvercome disadvantagesCombination devicesCombustion enginesParticulatesNitrogen monooxide

An exhaust gas system for purifying exhaust gases of an internal combustion engine, particularly a diesel engine in a motor vehicle, conducts the exhaust gas in a specific flow direction. A catalytic converter, particularly for converting hydrocarbons and carbon monoxides contained in the exhaust gas, an oxidation catalytic converter, particularly for converting nitrogen monoxide contained in the exhaust gas and a particulate trap for collecting particulates contained in the exhaust gas, are disposed successively in the flow direction. The exhaust gas system ensures a highly efficient conversion of harmful substances contained in the exhaust gas, and a particularly positive effect with respect to the regeneration of the particulate trap also occurs.

Owner:EMITEC GESELLSCHAFT FUR EMISSIONSTECHNOLOGIE MBH

Waste tire tread regeneration method

InactiveCN106750508AContinuous regenerationHigh quality regenerationProductsReagentsEngineeringMixing effect

The invention discloses a waste tire tread regeneration method. The waste tire tread regeneration method comprises the following steps: preparing materials, wherein the formula comprises 100 parts of waste tire tread rubber particles of 15 to 20 meshes, 6 parts of environmentally-friendly operating oil, 2 parts of a regenerant, 2 parts of an efficient activating agent 580 and 2 parts of an aldehyde amine accelerant; mixing in a first stage: putting the materials in a tandem type internal mixer, and carrying out first-stage shearing and mixing, wherein the time lasts for 10 to 15 min, the temperature is 65 DEG C, and the rotating speed is 50 r / min; mixing in a second stage: directly discharging a sizing material mixed in the first stage into a downstream internal mixer, and carrying out second-stage shearing and kneading, wherein the time lasts for 10 to 15 min, the temperature is 55 to 80 DEG C, and the rotating speed is 60 r / min; refining: discharging a sizing material mixed in the second stage into a refining machine, refining for 10 min for film discharging, and preparing regenerative rubber. The method has the beneficial effects that low-temperature, continuous and high-quality regeneration of waste tire tread rubber is realized through a shearing mixing effect of a first-stage internal mixer rotor and a supplementary shearing and kneading effect of second-stage internal mixer rotor as well as refining forming of the refining machine, so that the problems that a traditional regeneration method is low in efficiency and high in labor intensity and pollutes the environment are solved.

Owner:QINGDAO UNIV OF SCI & TECH

Method for removing ammonia nitrogen from sewage in subzone

InactiveCN1312063CAchieve regenerationContinuous regenerationTreatment with anaerobic digestion processesMultistage water/sewage treatmentAnaerobic filterSewage

The present invention relates to a method for deamination and denitrification of residential quarter sewage, belonging to the field of sewage treatment technology. It is characterized by that after the sewage is passed through anaerobic filter tank, contact oxidation tank and precipitation tank to obtain treatment, then sewage can upwards flow and be fed into two parallel modified zeolite adsorption regeneration columns to implement ammonia and nitrogen adsorption at twice successively, so that said invention can obtain high ammonia and nitrogen treatment efficiency. Said invention also provides the regeneration method of the above-mentioned zeolite adsorption regeneration column by using backflush process.

Owner:HARBIN INST OF TECH

Fluid for carrying out pollution control in heat engines, and methods for preparing said fluids by producing a homogeneous solution

ActiveUS20180345216A1Promotes homogeneous mixingFuel consumptionGas treatmentExhaust apparatusParticulatesNitrogen

The present invention describes a fluid which is suitable for the decontamination of heat engines which can carry out both, at the same time, the catalytic reduction of oxides of nitrogen (NOx) contained in exhaust gases and assist in the regeneration of the particulate filter (PF). The invention also describes several embodiments of said fluid.

Owner:INST FR DU PETROLE

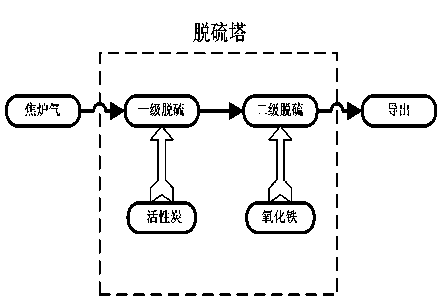

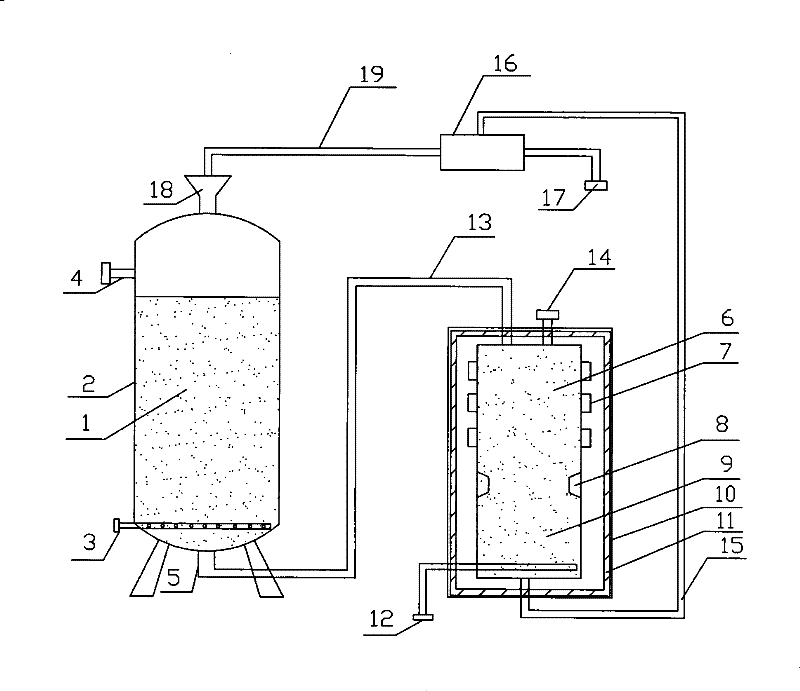

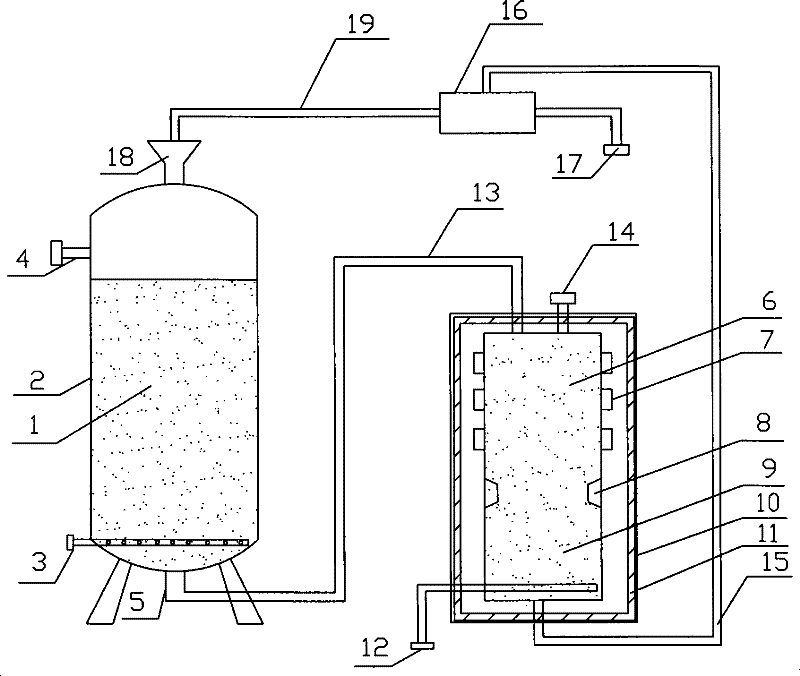

Desulfurization process and device for coke-oven gas automobile gas station

InactiveCN103468329AThe desulfurization process is easy to operatePromote activationGas purification by catalytic conversionGas purification with selectively adsorptive solidsActivated carbonChemical reaction

The invention discloses a desulfurization process for a coke-oven gas automobile gas station. The desulfurization process is characterized by comprising the primary rough desulfurization process and the secondary fine desulfurization process. According to the desulfurization process for the coke-oven gas automobile gas station, coke or activated carbon is used as a rough desulfurization agent for removing a small amount of organic sulfur out of the coke-oven gas and absorbing hydrogen sulfide in a primary desulfurization tower, and a fine desulfurization agent composed of iron oxide hydrates is used for removing the hydrogen sulfide through chemical reactions in the secondary desulfurization tower. The desulfurization process is simple, high in accuracy, capable of achieving continuous regeneration and suitable for desulfurization purification for the large-scale automobile coke-oven gas, the activated carbon resources and the iron oxide resources are abundant and low in price, therefore, the production cost can be greatly saved, and popularization is facilitated.

Owner:GUIZHOU UNIV

Computer system security via dynamic encryption

InactiveUS7860254B2Minimize exchangeThe process is simple and fastKey distribution for secure communicationSynchronising transmission/receiving encryption devicesSecure communicationData stream

A dynamic computer system security method and system using dynamic encryption and full synchronization between system nodes. A data record from a data stream created by a source user is encrypted with an initial dynamic session key. A new dynamic session key is generated based upon a data record and a previous dynamic session key. The new dynamic session key is then used to encrypt the next data record. A central authority is used to synchronize and authenticate both source and destination users with dynamic authentication keys. The central authority and users constantly regenerate new dynamic authentication keys. A child process is forked to ensure synchronization and authentication of dynamic authentication keys of each node upon a request for a secure communication establishment from a user. The central authority generates the initial dynamic session key with the current dynamic authentication key to begin a secure communication session.

Owner:MOXCHANGE LLC

Exhaust-gas secondary treatment preceding a turbocharger

ActiveCN101828010AIncrease temperatureThe first volume is largeInternal combustion piston enginesExhaust apparatusTurbochargerEngineering

The invention relates to an exhaust-gas secondary treatment system (1) for an internal combustion engine (2) of a vehicle (3) having at least one exhaust pipe (4) and at least one turbocharger (5) and at least one exhaust converter (6), wherein the catalytic converter (6) is provided between the internal combustion engine (3) and the minimum of one turbocharger (5) that has an initial volume (7) of at least 0.6 liters.

Owner:EMITEC EMISSIONSTECHNIK +1

Soil-improving organic complex agent and preparation method thereof

InactiveCN105347865ASimple structureIncrease contentBioloigcal waste fertilisersSocial benefitsSoil organic matter

A disclosed soil-improving organic complex agent comprises the following compositions in percent by mass: 25-30% of eichhornia crassipes (Mart.) Solms, 35-41% of bagasse, 4.5-5.5% of a microbial inocula, 8.5-12% of relict soil, 8.5-12% of algae soil, and 8.5-12% of sludge. The organic complex employs waste raw residue, changes waste into valuables, and is capable of effectively improving soil composition, improving soil organic matter content and nutrients, and enabling soil to be sustainably regenerated and virtuously cycled. Also, the preparation method is simple and low in cost, and possesses relatively good economic benefit and social benefit.

Owner:徐天佐 +4

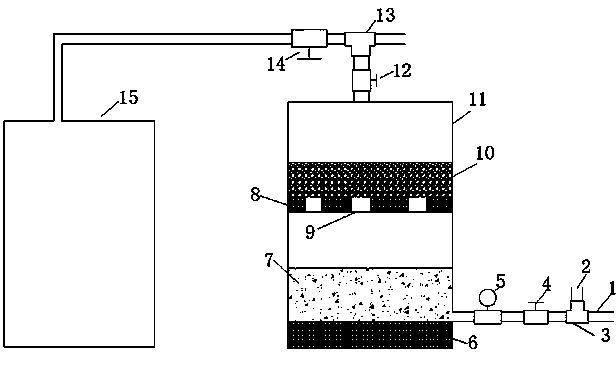

Method for regenerating activated carbon by ultrasound and device thereof

ActiveCN101590398BAchieve the purpose of regenerationReduce energy consumptionCombustible gas purificationEnergy based chemical/physical/physico-chemical processesActivated carbonEngineering

The invention discloses a method for regenerating activated carbon by ultrasound and a device thereof. The device comprises an ultrasound regenerating unit and a corresponding connection delivery system; wherein, the ultrasound regenerating unit is divided into an exterior layer and an interior layer; two side walls corresponding to the outside wall of the interior layer are fixed with a plurality of ultrasonic oscillators with the same frequency while the numbers of ultrasonic oscillators fixed on each side wall are the same and the ultrasonic oscillators are arranged in a pairwise corresponding manner; the lower part of a cavity in the interior layer of the ultrasound regenerating unit is a cleaning section for the activated carbon, while the upper part thereof is a regenerating sectionof the activated carbon; the top part of the ultrasound regenerating unit is provided with a waste stripping liquid outlet and a carbon unloading tube; the lower part of the ultrasound regenerating unit is provided with a cleaning analytical water inlet; the bottom part thereof is connected with an activated carbon delivery pipe after regeneration. The method for regenerating activated carbon by ultrasound uses a plurality of ultrasonic generators with the same frequency to work together, so that the saturated adsorption activated carbon can continuously enter the ultrasound regenerating unitto be regenerated under the effect of ultrasonic oscillators with the same frequency. The invention has the advantages of less energy consumption, small carbon loss, simple regeneration process, short regeneration time, wide application range and the like.

Owner:北京科净源科技股份有限公司

Fluid for purifying heat engines and methods for preparing said fluids by emulsification

ActiveUS20180371974A1Promotes homogeneous mixingContinuous regenerationGas treatmentInternal combustion piston enginesParticulatesNitrogen

The present invention describes a fluid which is suitable for the decontamination of heat engines which can carry out, at the same time, both the catalytic reduction of oxides of nitrogen (NOx) contained in exhaust gases and assist in the regeneration of the particulate filter (PF). The invention also describes several embodiments of said fluid consisting of producing an oil-in-water type emulsion.

Owner:INST FR DU PETROLE

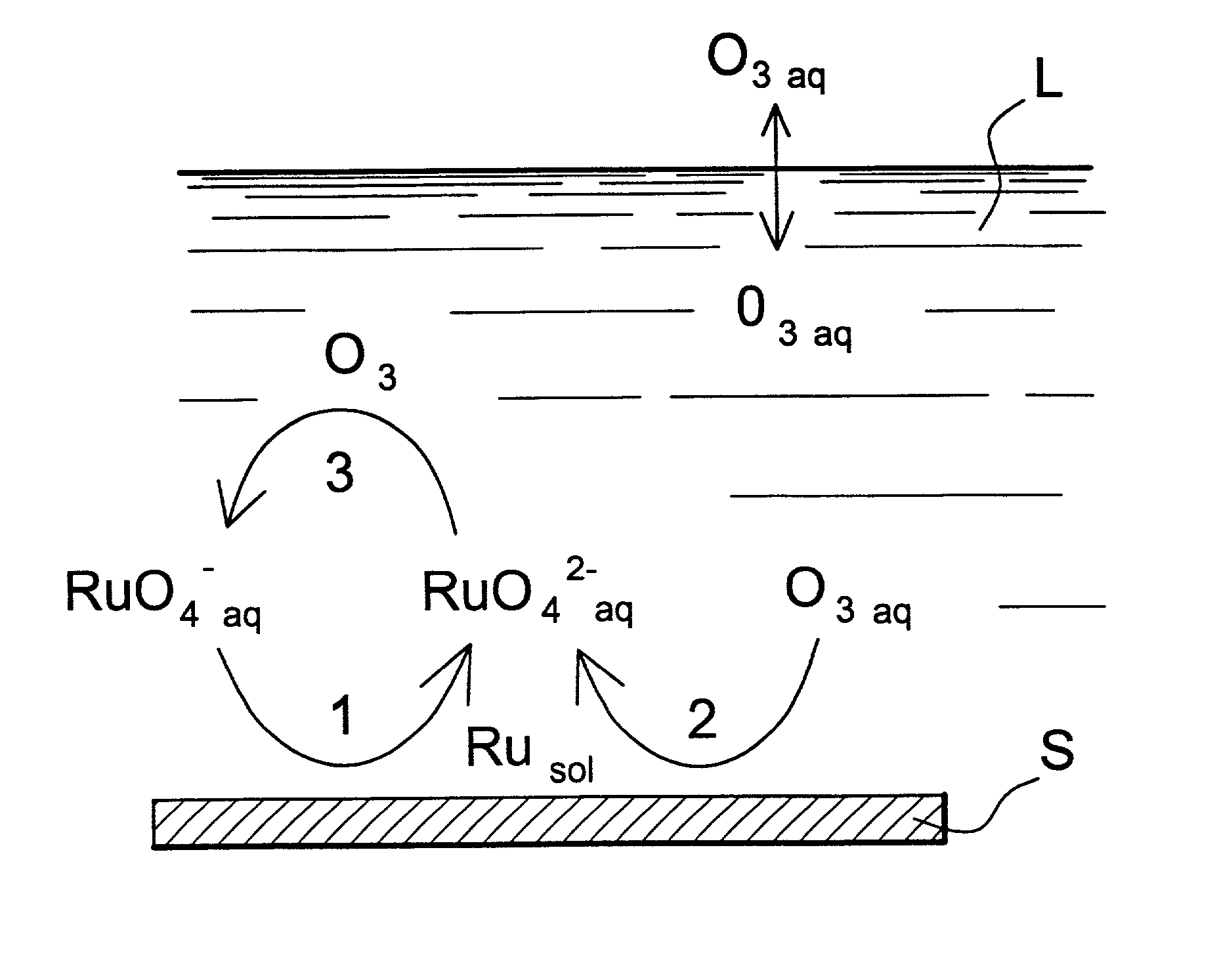

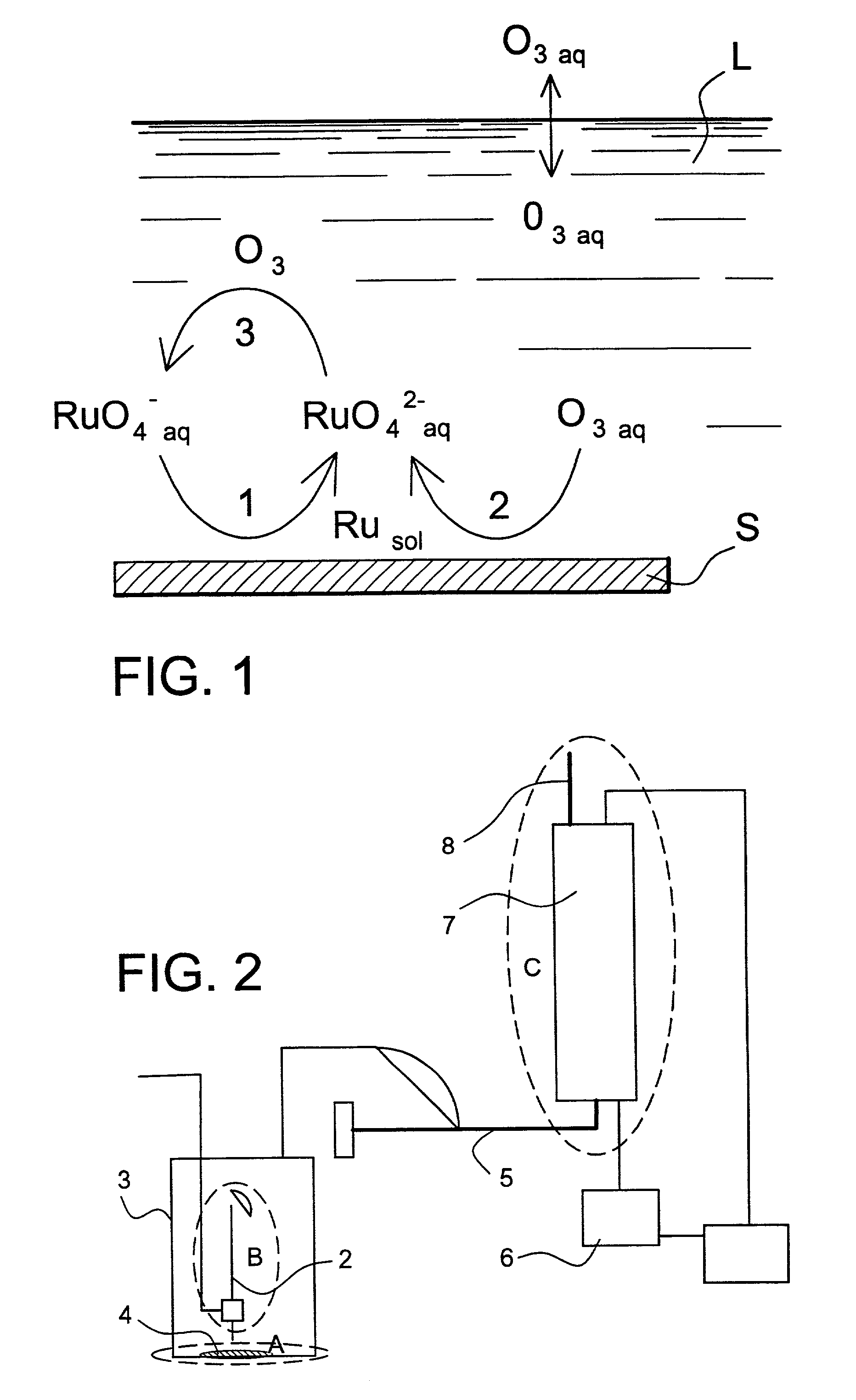

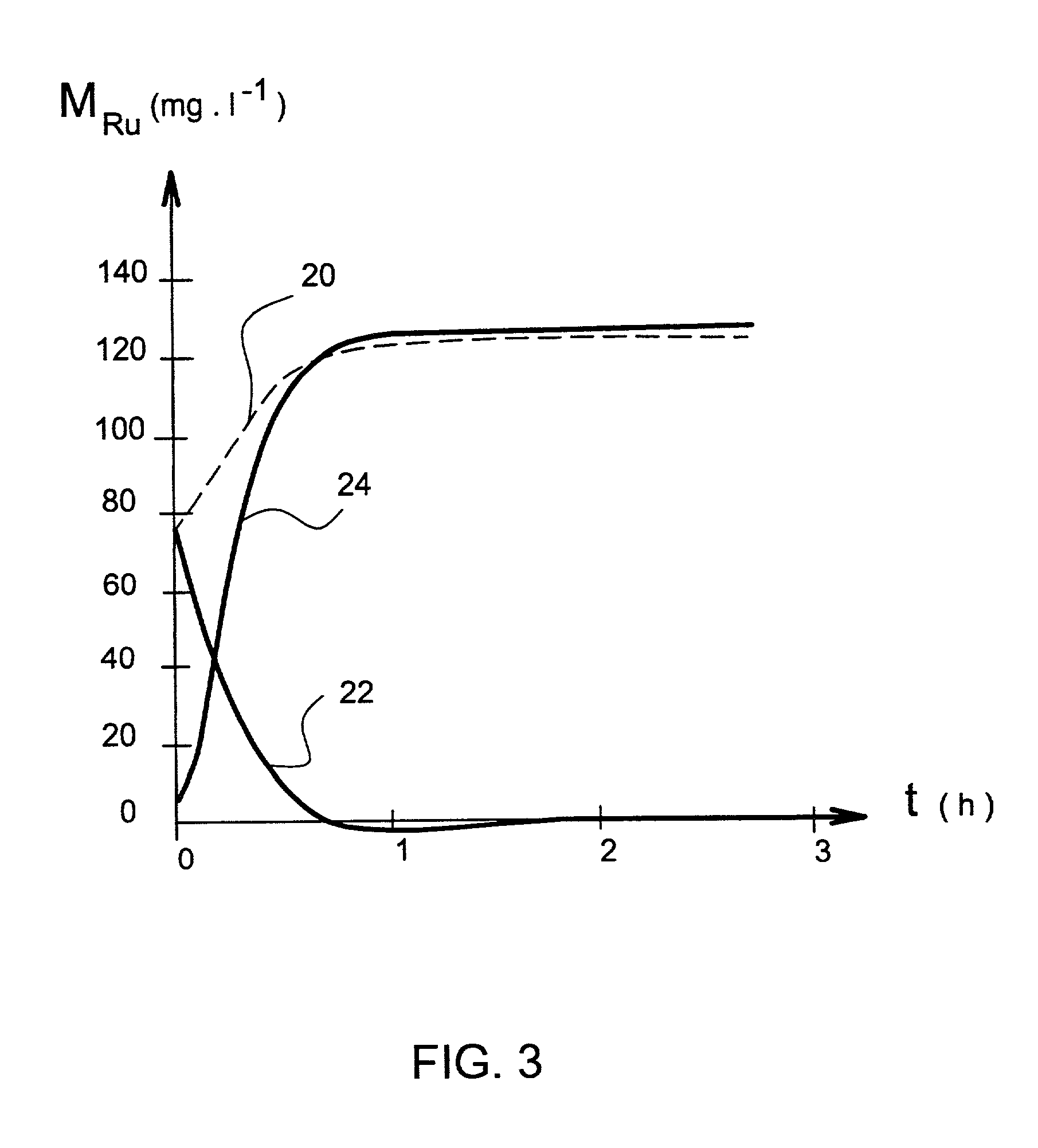

Dissolution and decontamination process

InactiveUS20020150196A1Continuous regenerationImprove responseRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsReactor fuel elementsRutheniumDissolution

The present invention concerns a process for dissolving ruthenium deposits that are present on a surface and a process for decontaminating the internal circuits of nuclear fuel reprocessing plants using the said dissolution process. The process according to the invention comprises bringing the said surface into contact with an aqueous solution of perruthenate, with the said aqueous solution having a pH equal to or greater than 12, so that the ruthenium is oxidised.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Fluid for carrying out pollution control in heat engines, and methods for preparing said fluids by producing a homogeneous solution

ActiveUS11014045B2Fuel consumptionContinuous regenerationGas treatmentExhaust apparatusNitrogen oxidesExhaust fumes

The present invention describes a fluid which is suitable for the decontamination of heat engines which can carry out both, at the same time, the catalytic reduction of oxides of nitrogen (NOx) contained in exhaust gases and assist in the regeneration of the particulate filter (PF). The invention also describes several embodiments of said fluid.

Owner:INST FR DU PETROLE

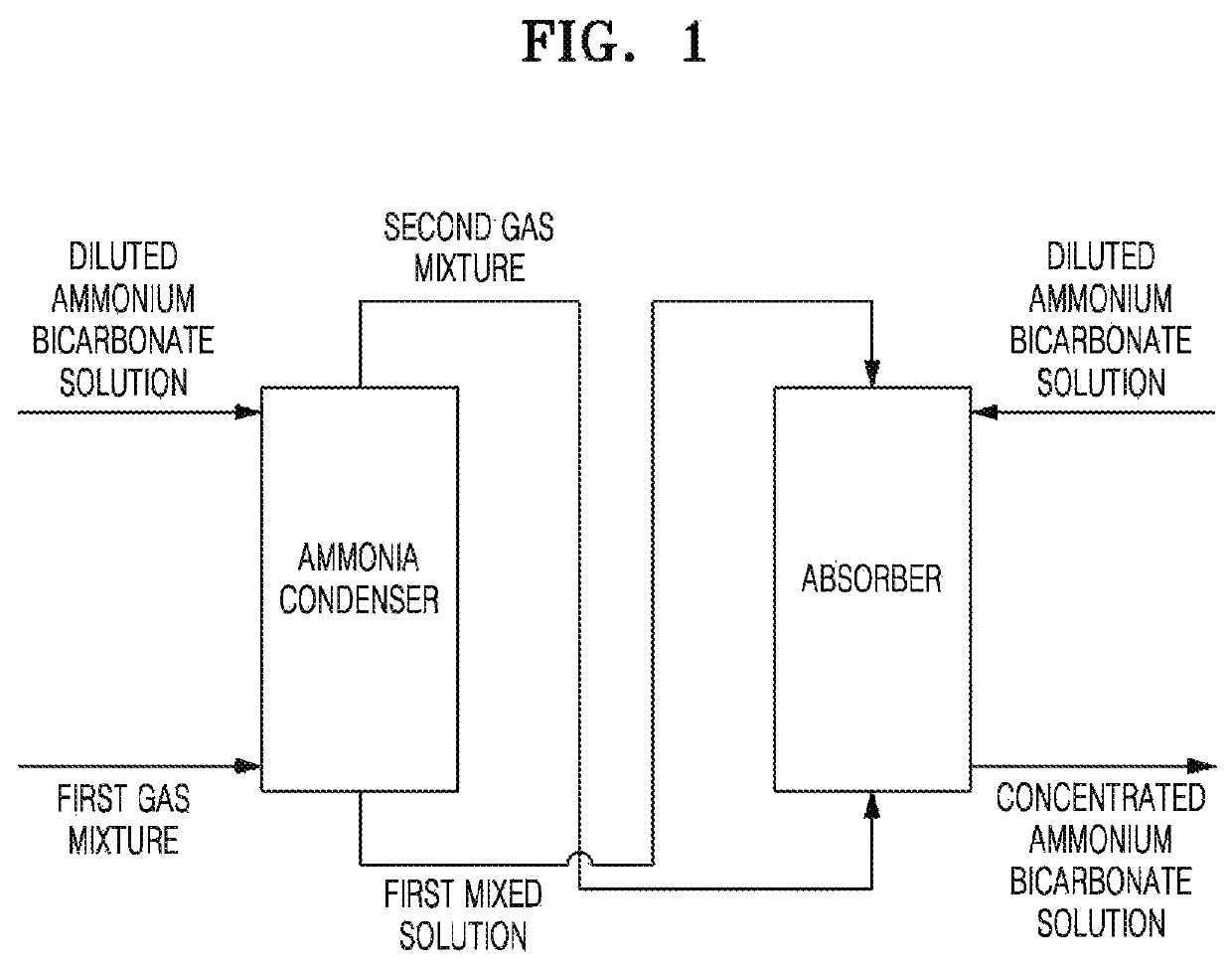

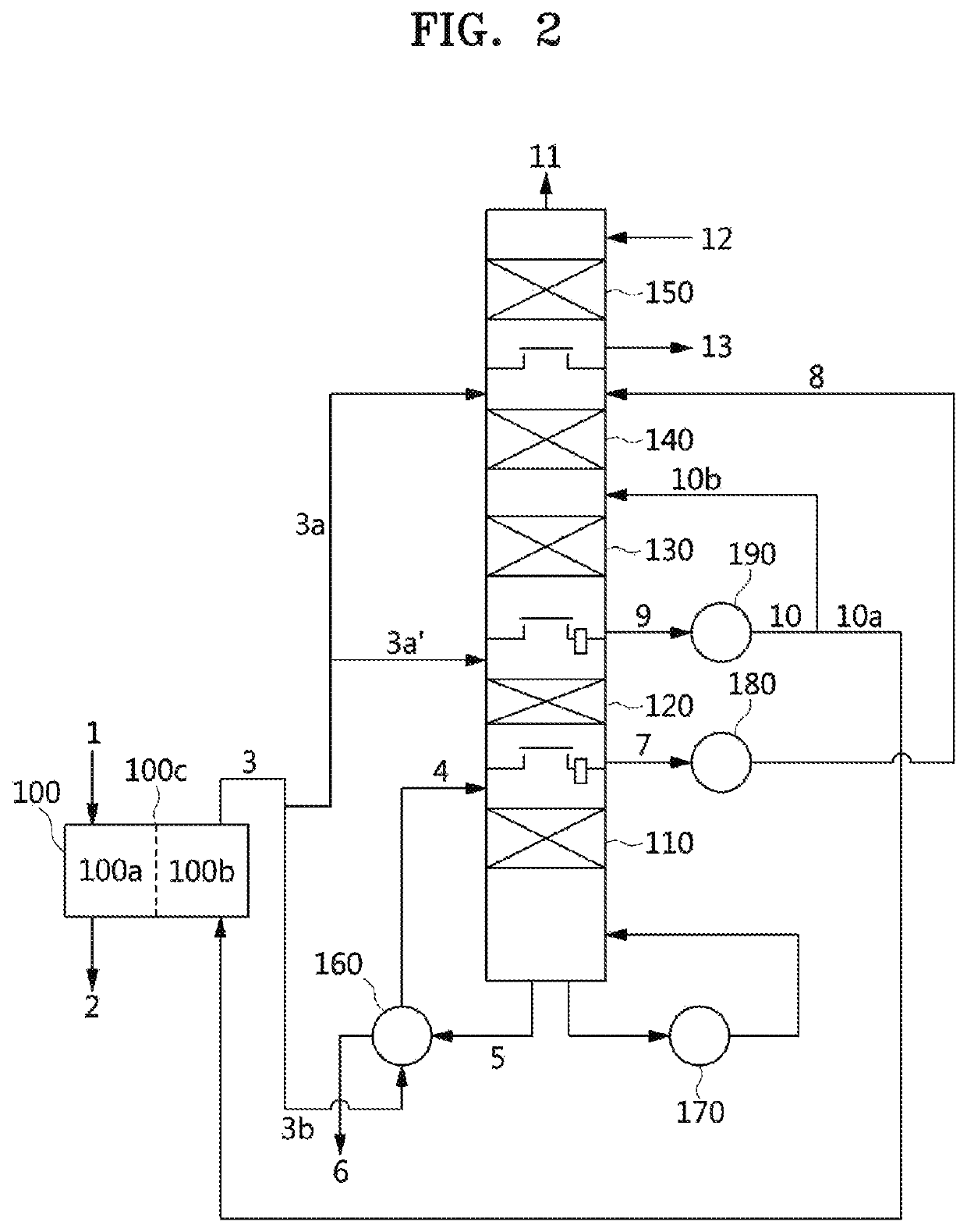

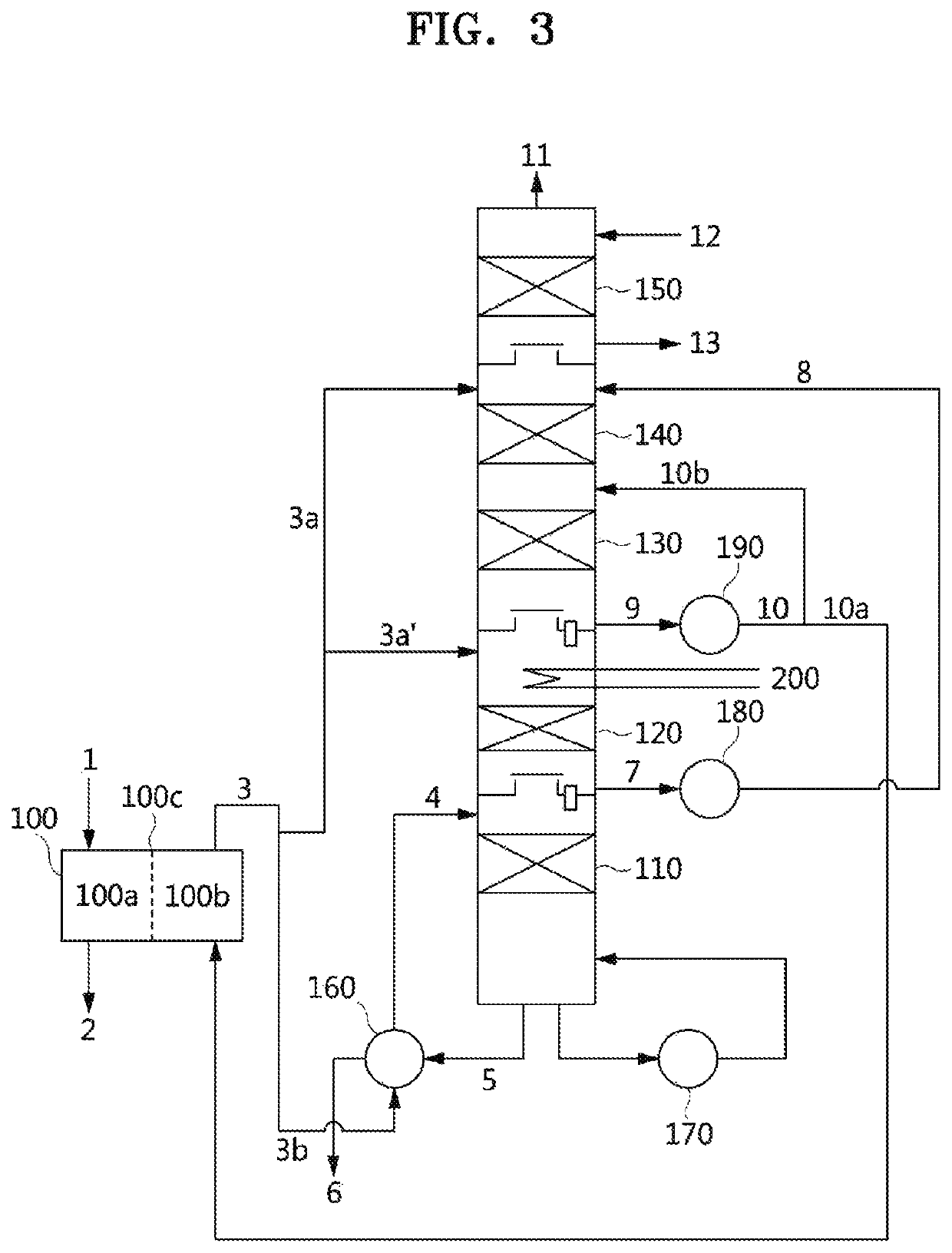

Recovery method for ammonium bicarbonate solution

ActiveUS10682609B2Continuous regenerationQuantity minimizationSemi-permeable membranesGas treatmentDistillationPhysical chemistry

A method of regenerating an ammonium bicarbonate solution includes supplying a diluted ammonium bicarbonate solution to an upper portion of a distillation unit, an upper portion of an ammonia condenser, and an upper portion of an absorber; distilling the diluted solution to discharge a first gas mixture, supplying the first gas mixture to a lower portion of the ammonium condenser; bringing the first gas mixture into contact with the diluted solution to be separated into a first mixed solution and a second gas mixture, supplying the first mixed solution to the upper portion of the absorber, and supplying the second gas mixture to a lower portion of the absorber; and bringing the second gas mixture into contact with the diluted solution supplied to the upper portion of the absorber and the first mixed solution supplied to the upper portion of the absorber to recover a concentrated ammonium bicarbonate solution.

Owner:BENIT M CO LTD

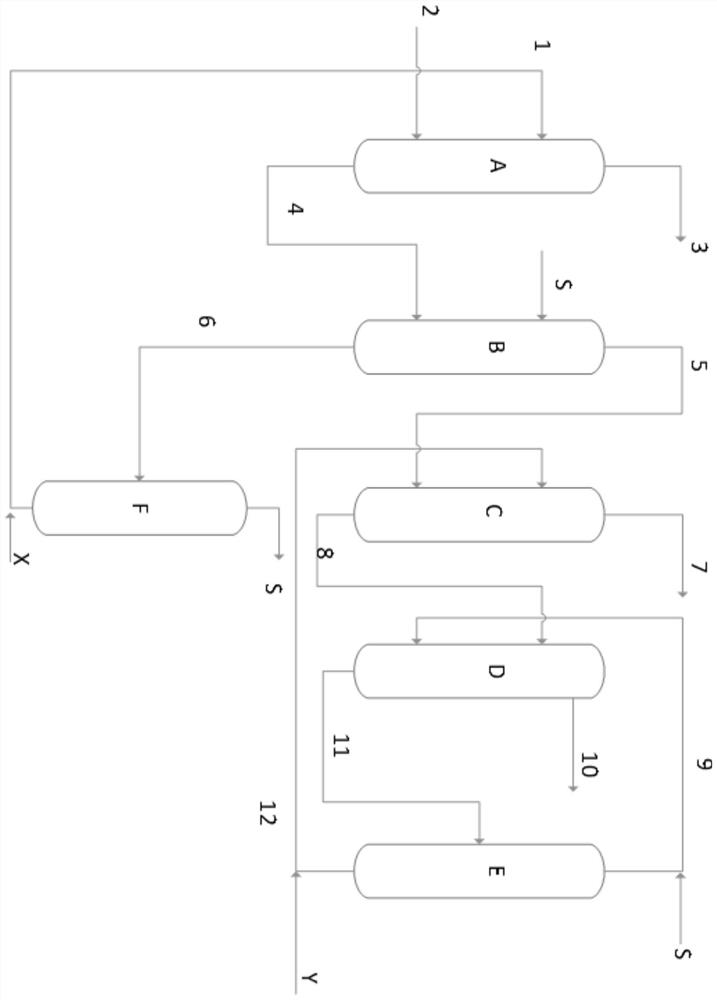

System and method for separating oil product by using deep eutectic solvent

ActiveCN112625731AContinuous regenerationAchieve regenerationHydrocarbon oils refiningHydrocarbon oils treatment productsPolycyclic aromatic hydrocarbonDistillates petroleum

The invention relates to a system and a method for separating an oil product by using a deep eutectic solvent in the field of separation of polycyclic aromatic hydrocarbons in petroleum or petroleum fractions. The system for separating the oil product by the deep eutectic solvent comprises the following units: a non-aromatic removal tower A, an aromatic hydrocarbon separation tower B, a monocyclic aromatic hydrocarbon separation tower C and a polycyclic aromatic hydrocarbon separation tower D; the system can separate an oil product into three major components, namely non-aromatic hydrocarbon, monocyclic aromatic hydrocarbon and polycyclic aromatic hydrocarbon. Moreover, the system can also comprise a regeneration tower E and a regeneration tower F of the deep eutectic solvent of the extraction agent, and continuous separation and regeneration of the extraction agent can also be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthetic method of pharmaceutical intermediate pyrano [2, 3-d] [1, 3] thiazolo [3, 2-a] pyrimidine derivative

PendingCN114478580AHigh yieldGood industrialization and large-scale use valueOrganic chemistryPtru catalystThiazole

The invention relates to the field of pharmaceutical chemical industry, and particularly discloses a synthetic method of a pharmaceutical intermediate pyrano [2, 3-d] [1, 3] thiazolo [3, 2-a] pyrimidine derivative, which comprises the following steps: in a catalytic system consisting of a basic ionic liquid catalyst and a mixed solvent, taking aldehyde, malononitrile and 7-hydroxy-2, 3-dihydro-5H-[1, 3] thiazolo [3, 2-a] pyrimidine-5-ketone as raw materials, and reacting at the temperature of 60-80 DEG C to obtain the pyrano [2, 3-d] [1, 3] thiazolo [3, 2-a] pyrimidine derivative. And reacting at the temperature of between 35 and 50 DEG C for 4 to 8 minutes, and preparing to obtain the pyrano [2, 3-d] [1, 3] thiazolo [3, 2-a] pyrimidine derivative medical intermediate. According to the synthesis method, through selection of a plurality of elements such as catalyst, reaction solvent and catalytic system regeneration, the target product can be obtained at high yield, and the synthesis method has good industrial large-scale use value in the technical field of medical intermediate synthesis.

Owner:南京欣久医药科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthetic method of pharmaceutical intermediate pyrano [2, 3-d] [1, 3] thiazolo [3, 2-a] pyrimidine derivative Synthetic method of pharmaceutical intermediate pyrano [2, 3-d] [1, 3] thiazolo [3, 2-a] pyrimidine derivative](https://images-eureka.patsnap.com/patent_img/b94a75d2-814a-40a4-b140-efe19beba049/RE-FDA0003597781530000011.png)

![Synthetic method of pharmaceutical intermediate pyrano [2, 3-d] [1, 3] thiazolo [3, 2-a] pyrimidine derivative Synthetic method of pharmaceutical intermediate pyrano [2, 3-d] [1, 3] thiazolo [3, 2-a] pyrimidine derivative](https://images-eureka.patsnap.com/patent_img/b94a75d2-814a-40a4-b140-efe19beba049/RE-FDA0003597781530000012.png)

![Synthetic method of pharmaceutical intermediate pyrano [2, 3-d] [1, 3] thiazolo [3, 2-a] pyrimidine derivative Synthetic method of pharmaceutical intermediate pyrano [2, 3-d] [1, 3] thiazolo [3, 2-a] pyrimidine derivative](https://images-eureka.patsnap.com/patent_img/b94a75d2-814a-40a4-b140-efe19beba049/RE-FDA0003597781530000021.png)