Method for regenerating activated carbon by ultrasound and device thereof

A regeneration device and activated carbon technology, applied in separation methods, filter regeneration, filtration separation, etc., can solve problems such as inapplicability and restrictions on the use of activated carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

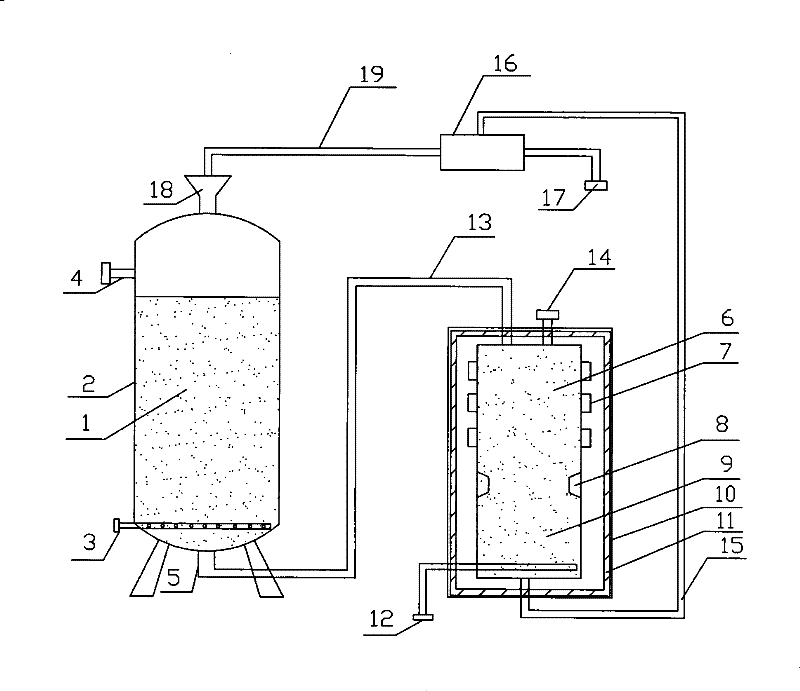

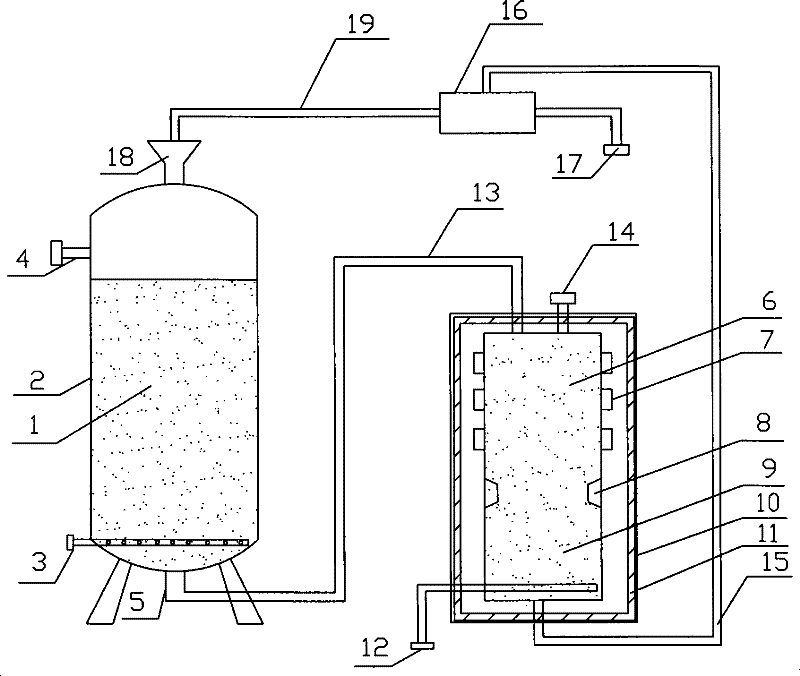

[0019] The ultrasonic regeneration activated carbon device of the present invention is mainly composed of two parts, that is, an activated carbon adsorption tank and a same-frequency ultrasonic regeneration device.

[0020] The first part is activated carbon adsorption tank 2. The tank is made of anti-corrosion materials, such as stainless steel, epoxy fiberglass, plastic, plexiglass, and carbon steel for anti-corrosion. The adsorption tank 2 is equipped with granular activated carbon 1, and the thickness of the carbon layer is several meters to tens of meters. The top of the adsorption tank 2 is provided with a carbon inlet funnel 18, the upper part is provided with a water outlet pipe 4, the lower part is provided with a water inlet distribution pipe 3, and the bottom is provided with a discharge pipe. The charcoal pipe mouth 5, the charcoal inlet funnel 18 is communicated with the outlet pipe of a water injector 16.

[0021] The second part is the same-frequency ultrasonic...

Embodiment 2

[0027]In the drinking water treatment process, after coagulation, sedimentation and filtration, ozone oxidation activated carbon is used for adsorption treatment. The daily water treatment volume is 6000m3. There are 6 activated carbon adsorption tanks 2, the diameter of the tank is 3m, and the thickness of the carbon layer is 8m. A set of ultrasonic regeneration device with the same frequency is used, 10 ultrasonic oscillators with a frequency of 32KHz are fixed on the inner and outer walls of the regeneration device, each with a power of 200W, the activated carbon stays in the ultrasonic regeneration device for 30 minutes, and the water consumption is 12L / kg. Carbon loss is 0.6%, and 160kg of activated carbon can be regenerated per hour. The carbon unloading pipes 13 of the six activated carbon adsorption tanks 2 are respectively connected to the ultrasonic regeneration device, and the six activated carbon tanks are regenerated by one ultrasonic regeneration device in turn....

Embodiment 3

[0029] The phenol-containing wastewater produced by coal-to-gas production has a residual phenol content of 12 mg / L after biological treatment, and the activated carbon adsorption process is used to treat the excess phenol and then discharge it up to the standard. The daily water treatment volume is 600m3. Two activated carbon adsorption tanks are used, each with a diameter of 2m and a carbon layer thickness of 4.5m. A set of same-frequency ultrasonic regeneration device is used to regenerate the saturated activated carbon. The ultrasonic frequency is 39KHz. Four ultrasonic oscillators are symmetrically fixed on the inner layer of the regeneration device. On the outer wall, each power is 150W, the activated carbon stays in the ultrasonic regeneration device for 24 minutes, the water consumption is 9L / kg, the carbon loss is 0.7%, and the activated carbon is regenerated 60kg per hour. connected. The ultrasonic regeneration device regenerates the saturated activated carbon in ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com