Patents

Literature

265results about How to "Short regeneration time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

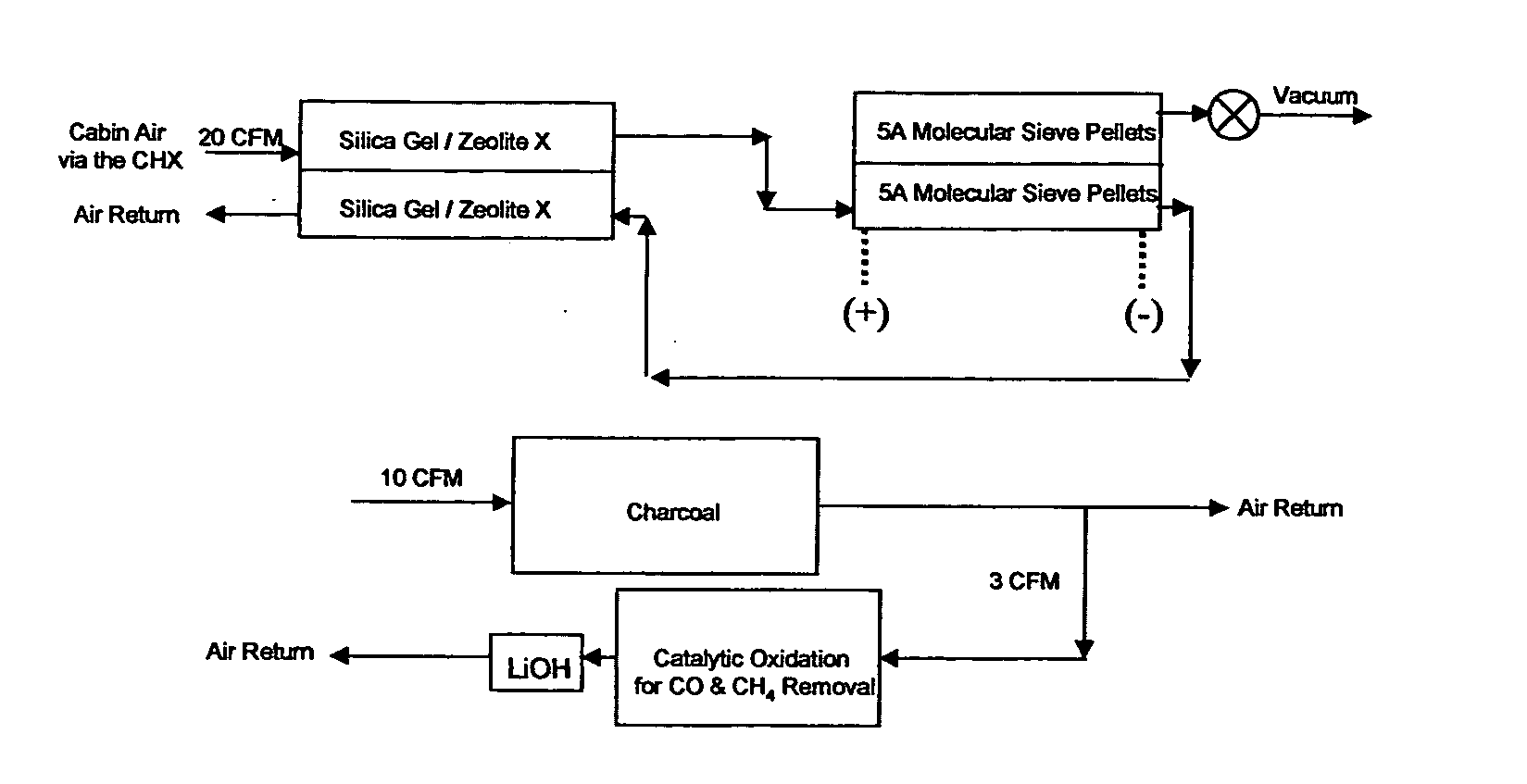

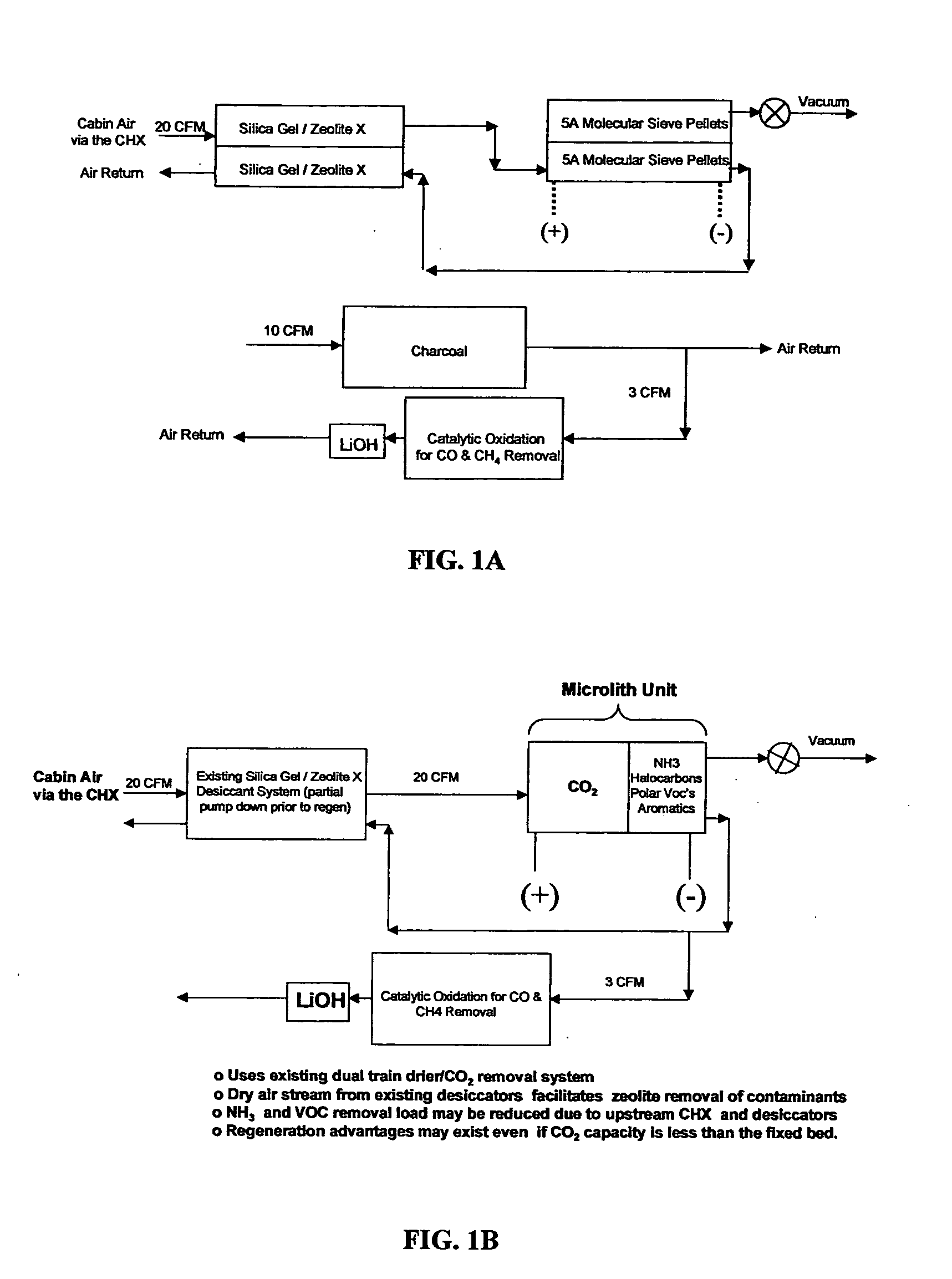

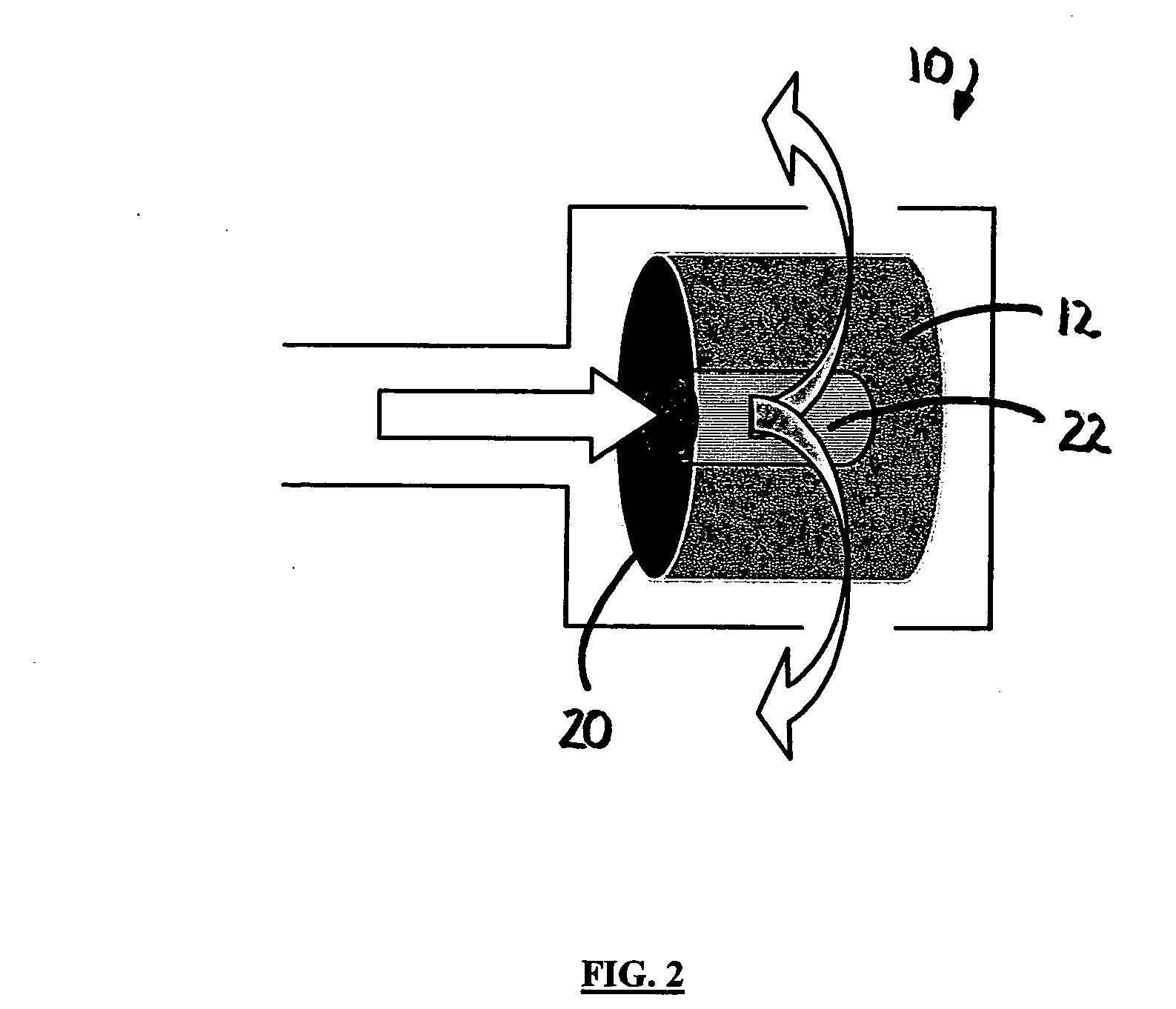

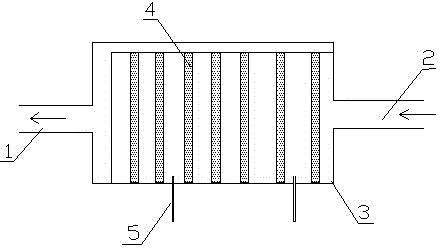

Regenerable adsorption system

ActiveUS20060249019A1Reduced Power RequirementsSignificant weightGas treatmentIsotope separationElectrical resistance and conductanceSorbent

A method for regenerable adsorption includes providing a substrate that defines at least one layer of ultra short channel length mesh capable of conducting an electrical current therethrough, coating at least a portion of the substrate with a desired sorbent for trace contaminant control or CO2 sorption, resistively heating the substrate, and passing a flowstream through the substrate and in contact with the sorbent.

Owner:PRECISION COMBUSTION

Regeneration method of catalyst for dehydrogenation of low-carbon alkanes

ActiveCN101940959AExtend the life cycleExtended service lifeCatalyst regeneration/reactivationHydrocarbonsAir atmosphereAlkane

The invention discloses a regeneration method of a catalyst for dehydrogenation of low-carbon alkanes, which comprises the following steps: firstly regenerating the catalyst in the air atmosphere at a lower temperature, burning out carbon deposits on the surface of the catalyst and most of carbon deposits in holes, and then preferably regenerating the catalyst further in a vapor-air mixed atmosphere at a temperature of 400-500 DEG C, so that the carbon deposits on the surface of the catalyst and in the holes can be completely removed, and simultaneously, the acid value and the acid distribution of the catalyst can be modulated so as to restore the crystal form and crystal phase composition of the deactivated catalyst to the original state of the fresh catalyst. Thus, the catalyst can be regenerated, and simultaneously, the physicochemical properties and the dehydrogenation activity of the regenerated catalyst are similar to those of the fresh catalyst, thereby prolonging the service cycle and life of the catalyst. The method has the advantages of moderate regeneration conditions and short regeneration time, and further lowers the production cost of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

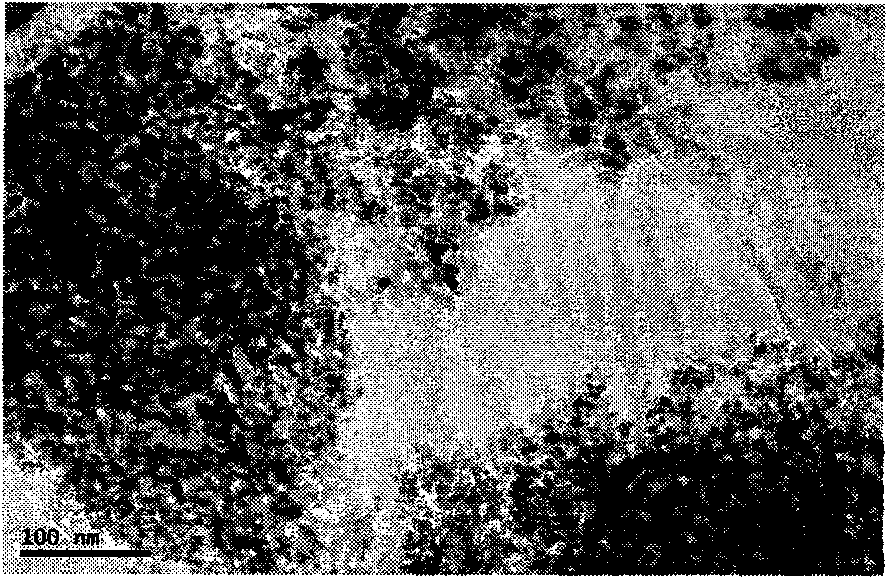

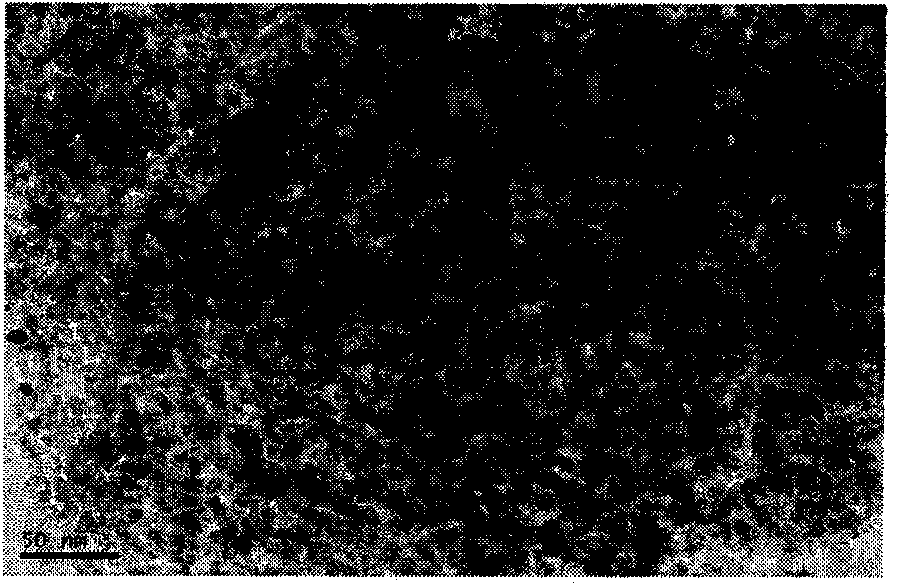

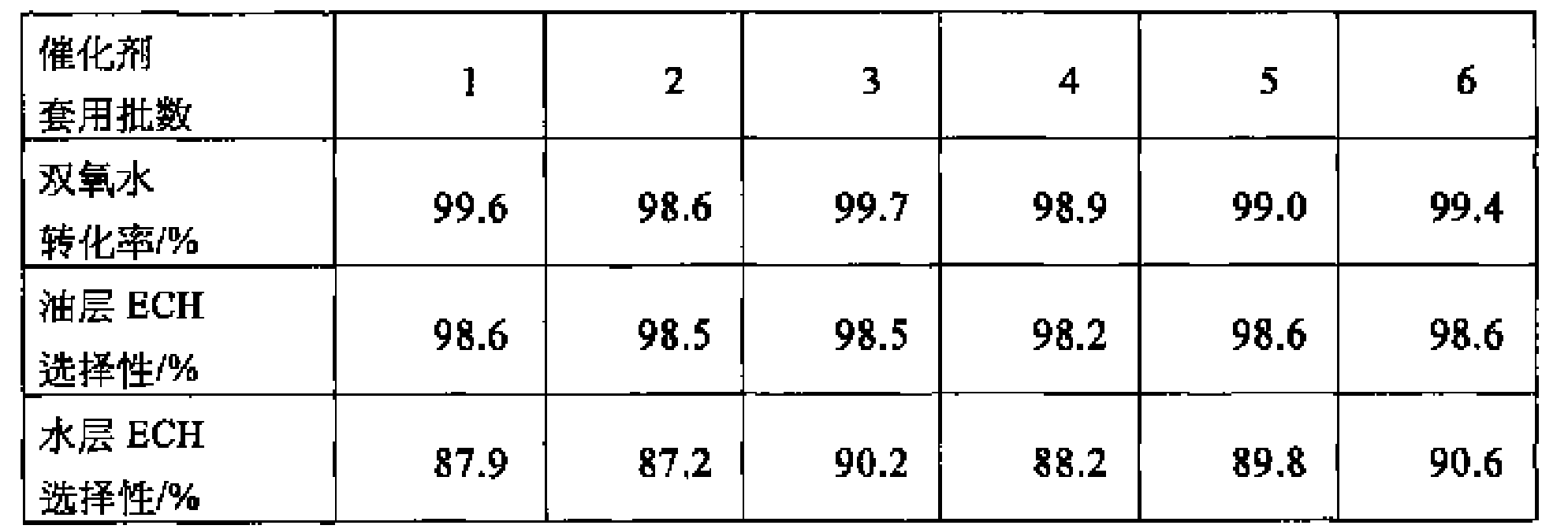

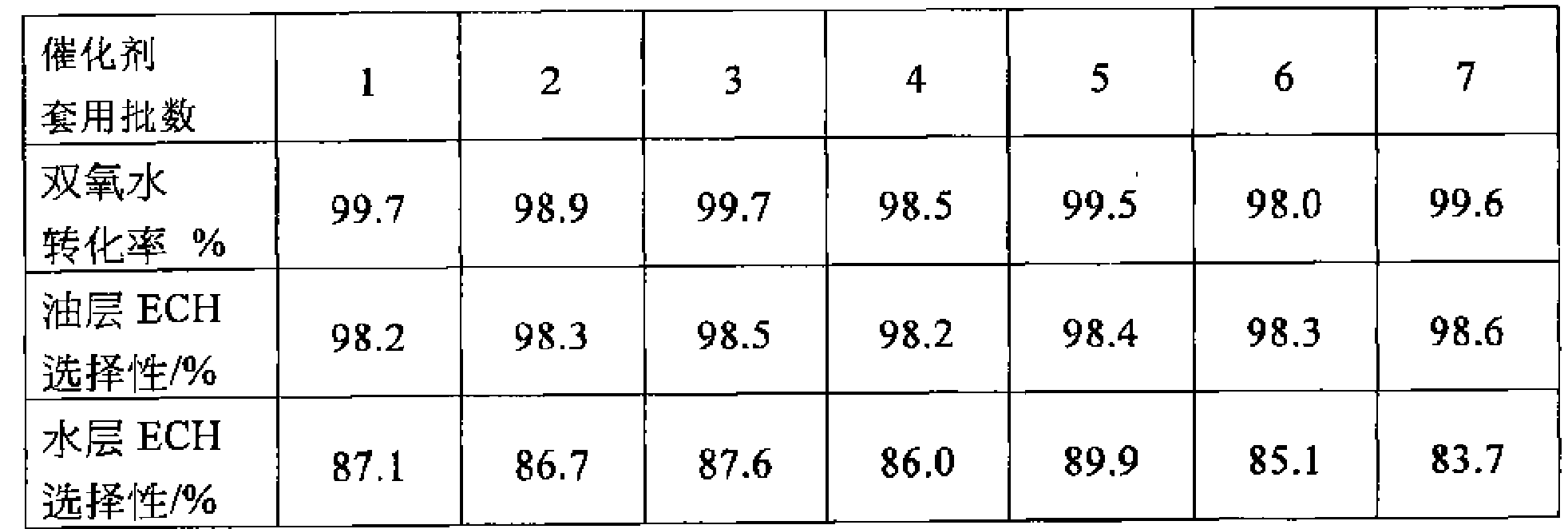

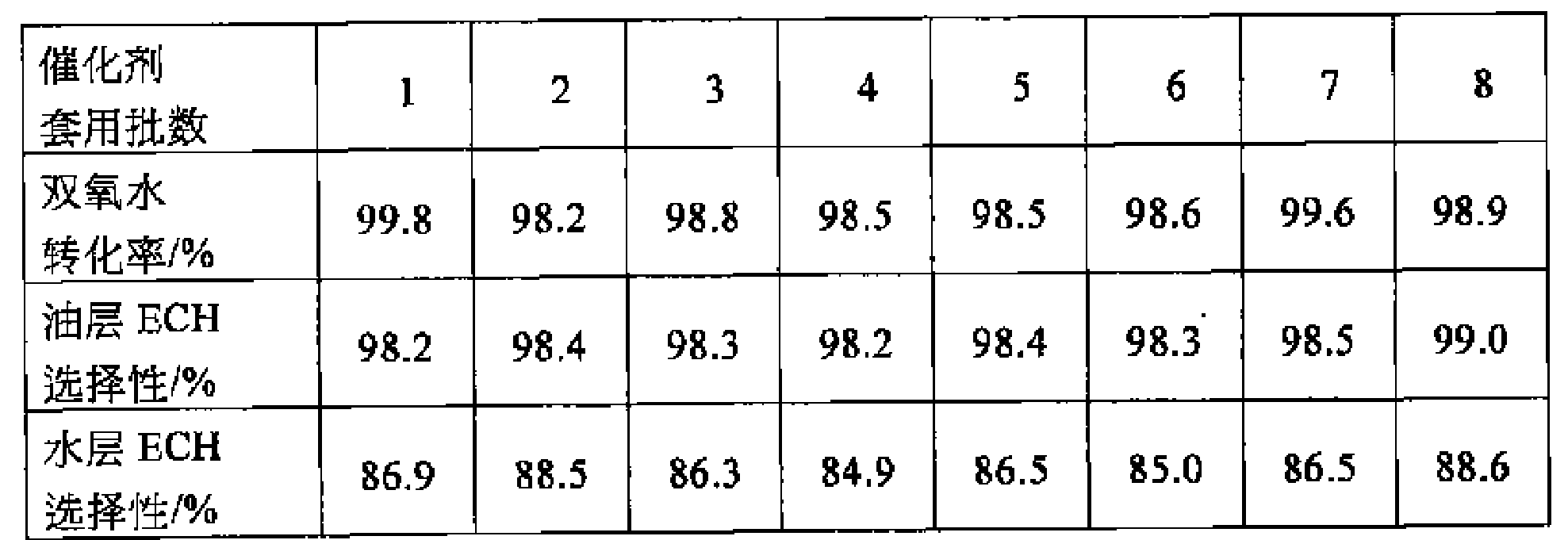

Method for regenerating titanium-silicon molecular sieve catalyst

ActiveCN101480623AGood regeneration performanceImprove securityOrganic chemistryMolecular sieve catalystsDecompositionSolvent

The invention provides a catalyst used as a titanium-silicate molecular sieve in the process of preparing epoxide from olefin and hydrogen peroxide. The invention is characterized by comprising the following steps: washing with or without a small amount of methanol solvent; purging the catalyst cake with steam directly after reaction; extracting few organic matters absorbed in the catalyst; then stirring in a regenerating kettle and dropwise adding H2O2 with a certain concentration simultaneously; removing the organic matters and low polymers absorbed on the catalyst and in a pore path through oxidative decomposition; and finally, washing with a small amount of methanol or deionized water to remove the organic acid generated by oxidation on the surface of the catalyst. The regenerated catalyst can be circularly used for the epoxidation reaction of olefin to stably maintain the activity of the epoxidation reaction.

Owner:JIANGSU YANGNONG CHEM GROUP +2

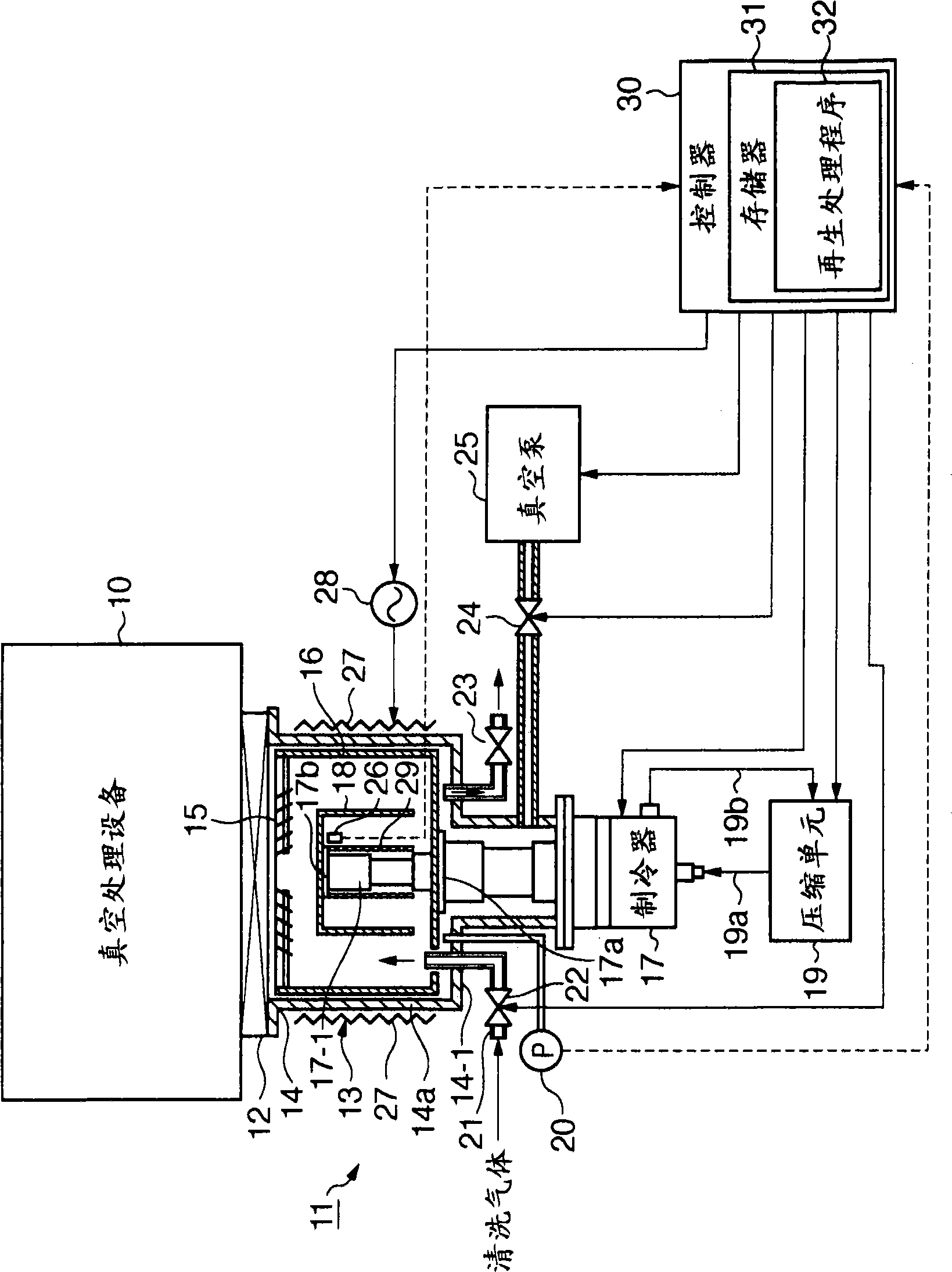

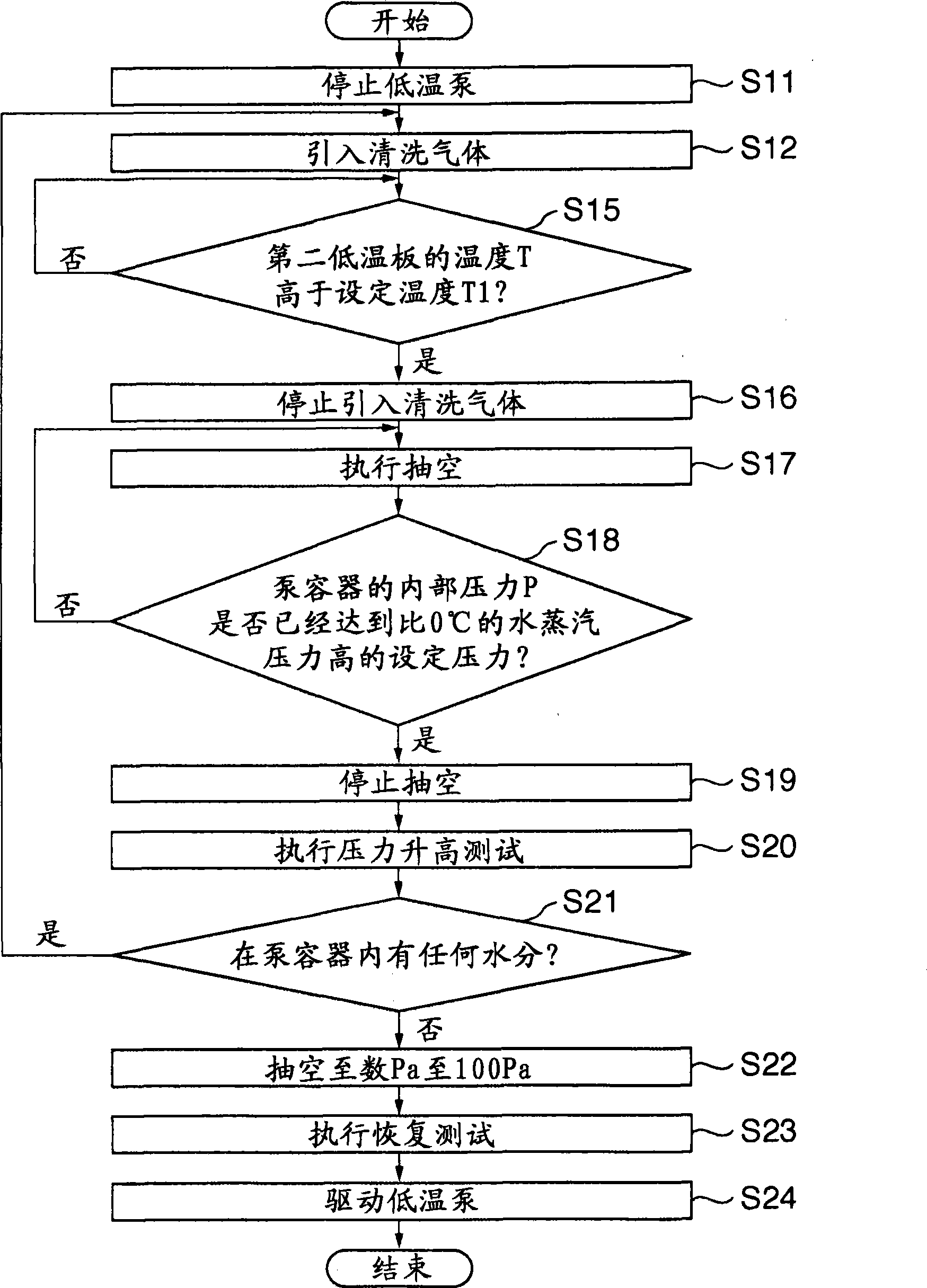

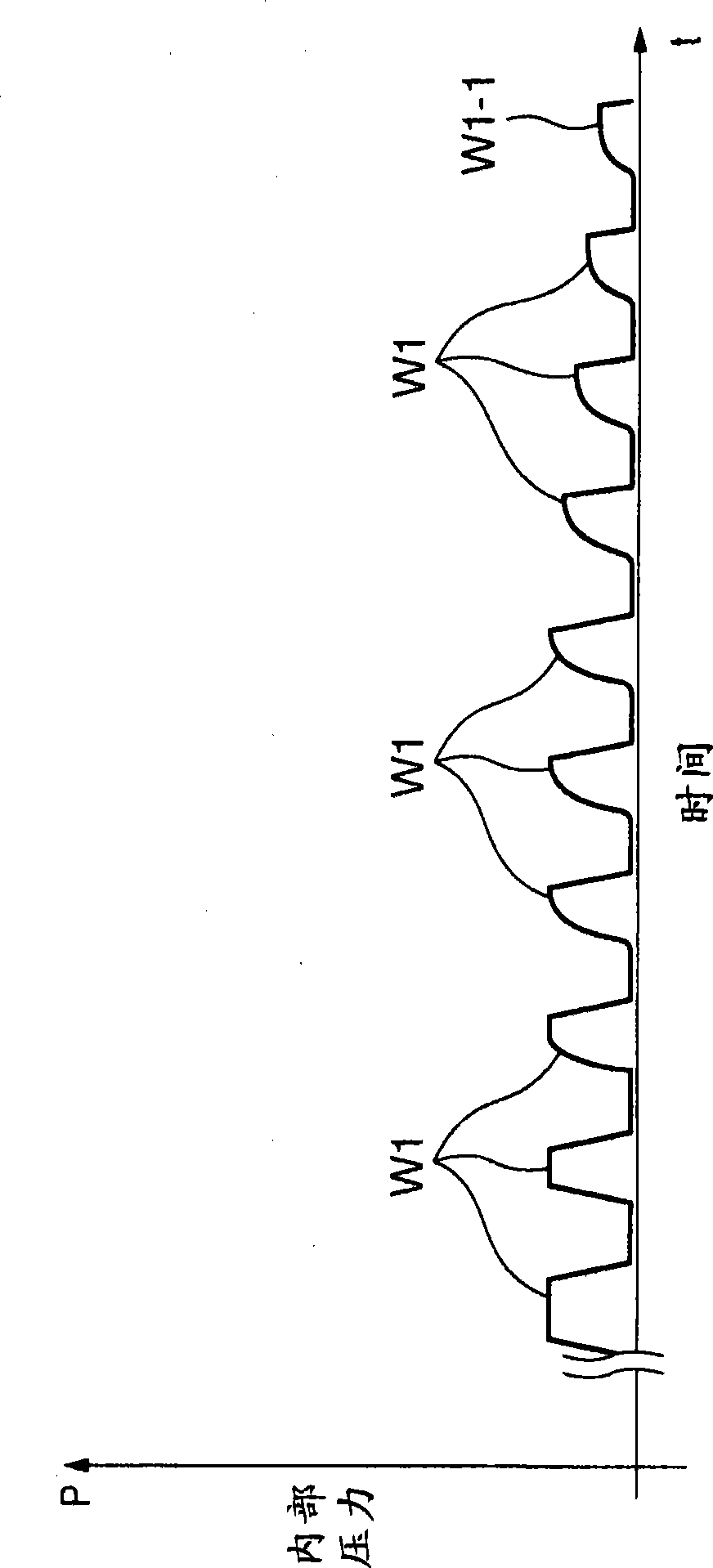

Cryopump, cryopump unit, vacuum processing apparatus including cryopump unit, and cryopump regeneration method

InactiveCN101469689AAccurate observationShort regeneration timePumpsPositive-displacement liquid enginesInternal pressurePressure rise

Owner:CANON ANELVA CORP

Desulfur catalyst

InactiveCN1559680AHigh activityShort regeneration timeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHazardous substanceSulfur

A desulfurizing catalyst for removing sulfide, thiooxide and thioether from natural gas or fume contains ZnO, NiO, CaAlO3, TiO2, CoO, MoO and A2O3.

Owner:四川五色石环保科技有限公司

S-1 full-silicon molecular sieve and preparation method thereof as well as application of S-1 full-silicon molecular sieve in caprolactam preparation

The invention discloses an S-1 full-silicon molecular sieve and a preparation method thereof as well as application of the S-1 full-silicon molecular sieve in caprolactam preparation. The S-1 full-silicon molecular sieve is prepared by the method comprising the following steps: (1) synthesizing a tetrapropylammonium hydroxide template agent; and (2) synthesizing a molecular sieve: carrying out a reaction on tetrapropylammonium hydroxide liquor and tetraethoxysilane and ethanol, filtering, washing with deionized water, drying reaction liquid, roasting, so as to obtain molecular sieve raw powder; adding silica sol, polyethylene glycol 2000, and stronger ammonia water, sesbania powder and activated carbon powder in the molecular sieve raw powder, kneading in a kneader, then carrying out extrusion; roasting, immersing the roasted product in a NH3-NH3NO3 mixing solution and a hydrofluoric acid solution respectively, washing with deionized water, drying, roasting again so as to obtain the S-1 full-silicon molecular sieve. In the invention, the template agent is cheap; the conversion rate of the cyclohexanone and selectivity of the caprolactam are extremely high; a catalyst can be easily and fast regenerated; and the use of concentrated sulphuric acid is avoided, thus the S-1 full-silicon molecular sieve and the preparation method thereof are environment-friendly.

Owner:CHINA TIANCHEN ENG +1

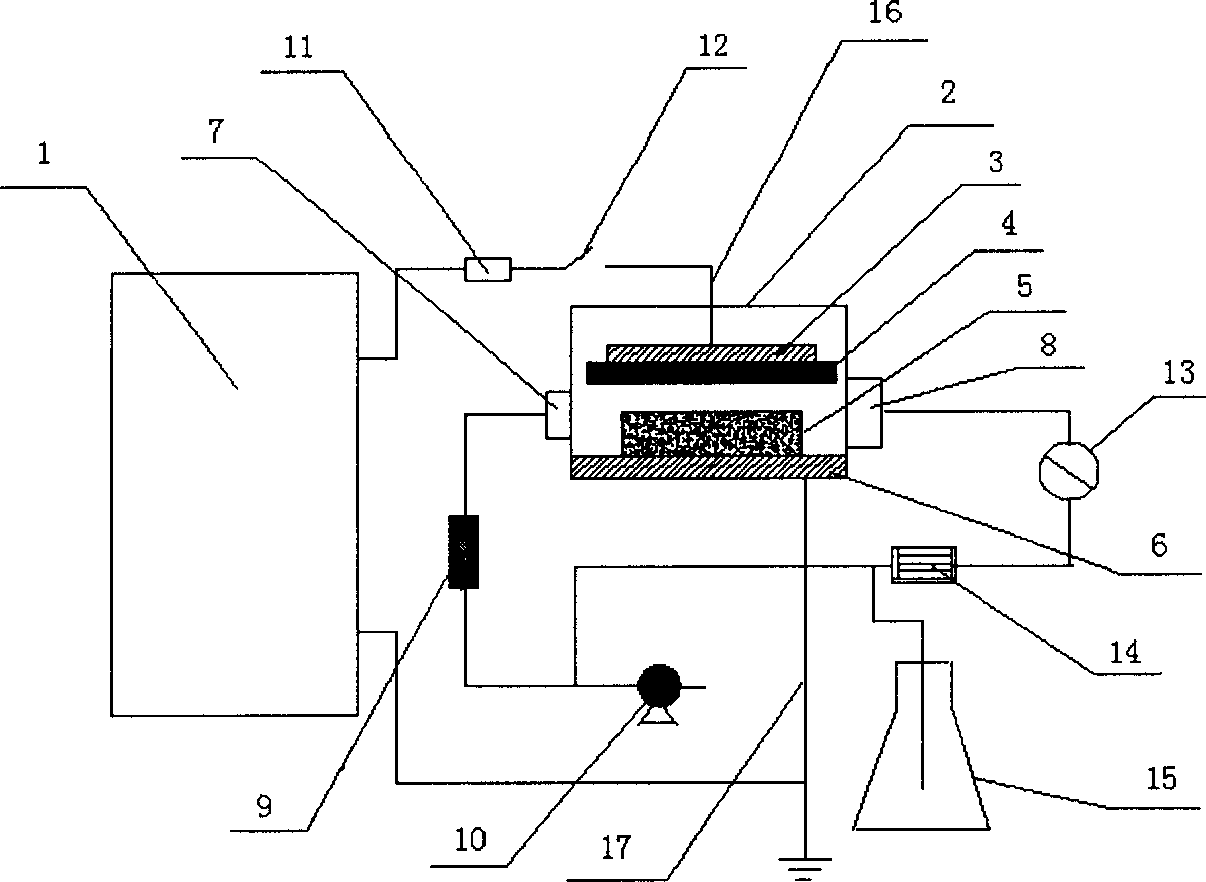

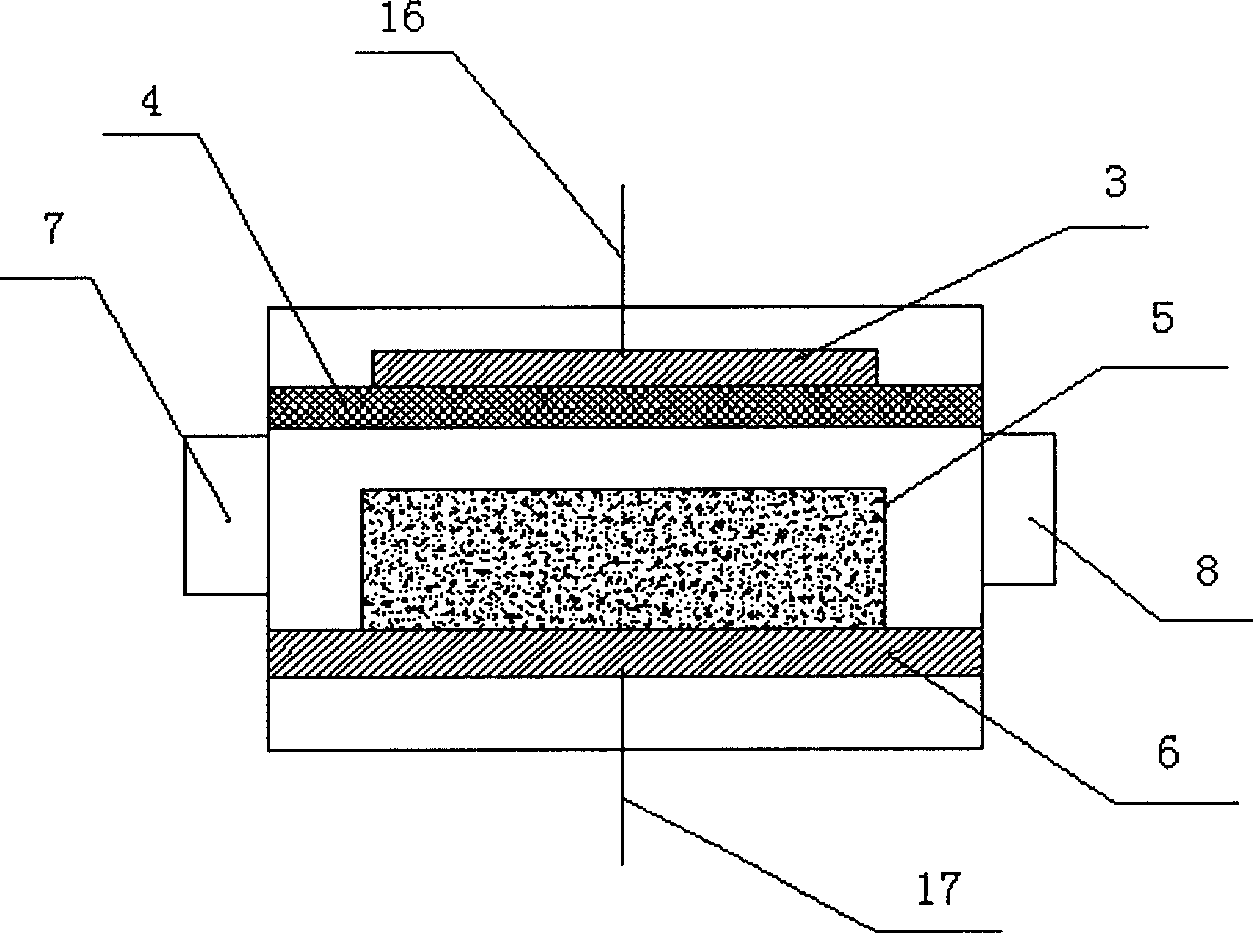

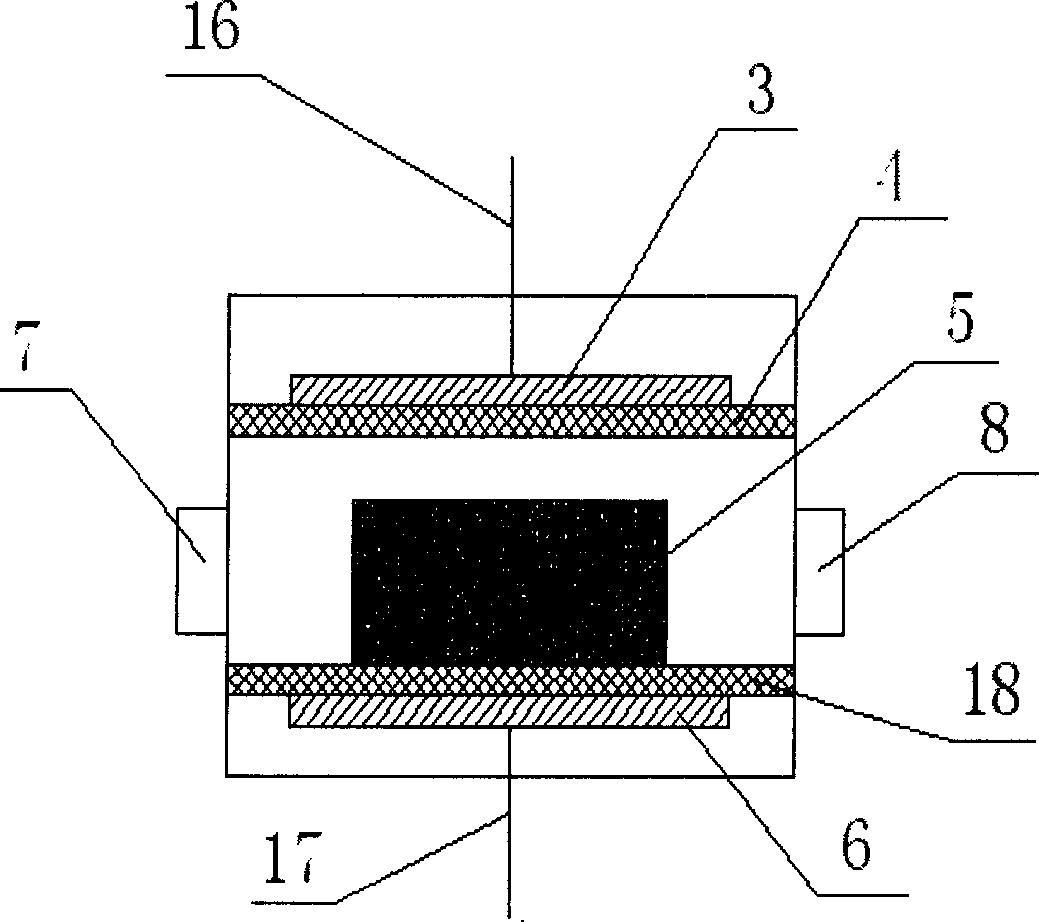

In situ regenerating method and device for medium blocking discharging plasma active carbon

InactiveCN1899685AImprove regeneration efficiencyShort regeneration timeOther chemical processesCombustible gas purificationActivated carbonCompound (substance)

The in situ active carbon regenerating method and apparatus with medium blocking discharge plasma belongs to the field of chemical adsorbing separation and pollutant controlling technology. Under atmospheric pressure, low temperature unbalanced plasma generated through medium blocking discharge is used to in situ regenerate active carbon with adsorbate filled between the discharge electrodes under the action of high activity matter, ultraviolet and high energy electron bombardment, etc. The in situ active carbon regenerating apparatus consists of high voltage AC source, reactor and auxiliary device mainly. The present invention has the advantages of high regeneration efficiency, short regeneration period, no secondary pollution, no need of post-treatment, low active carbon loss, etc; and is suitable for active carbon regeneration mainly.

Owner:DALIAN UNIV OF TECH

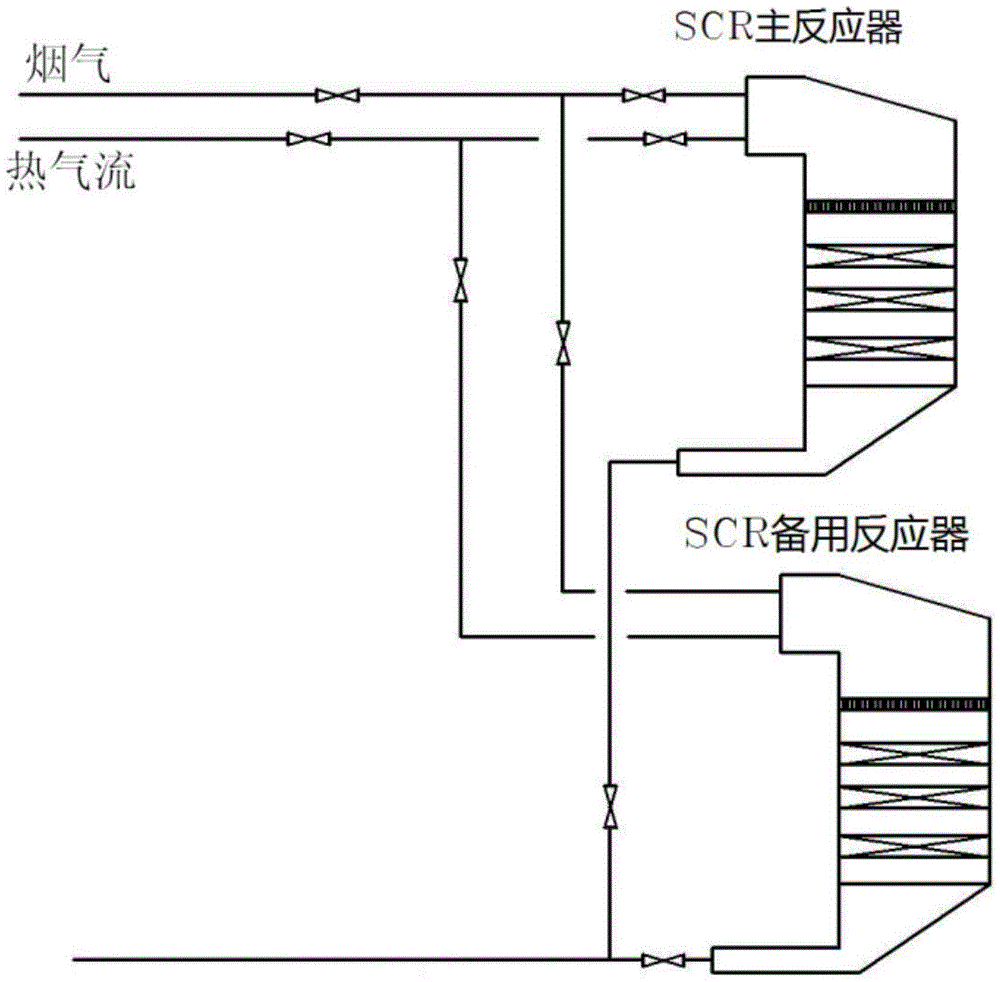

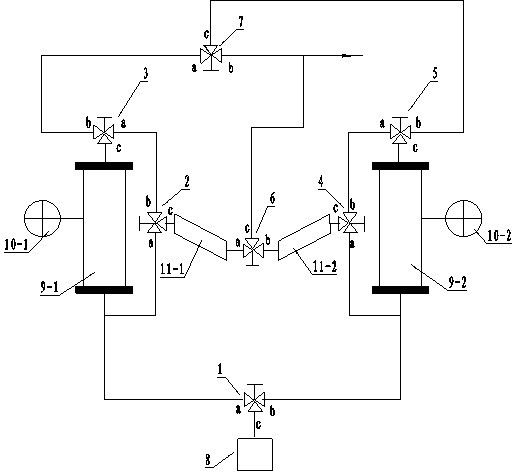

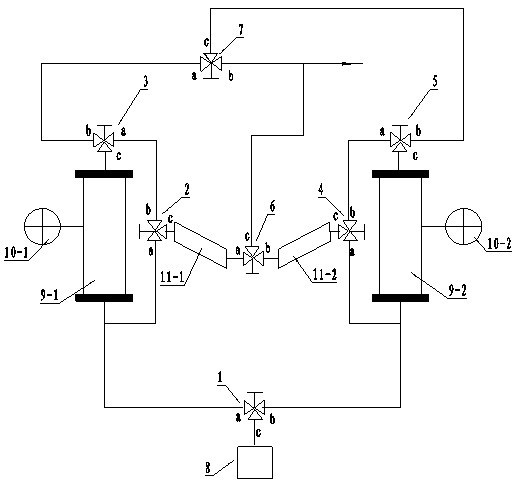

In-situ regeneration method of ammonium sulfate poisoning denitration catalyst

InactiveCN105688936AEasy to operateShort regeneration timeHeterogenous catalyst chemical elementsDispersed particle separationNitrogen oxidesFlue gas

The invention relates to an in-situ regeneration method of an ammonium sulfate poisoning denitration catalyst and belongs to the technical field of an industrial denitration catalyst. The in-situ regeneration method comprises the following steps: (1) when the concentration of nitrogen oxide in outlet flue gas of an SCR (Semiconductor Control Rectifier) main reactor is close to an emission limit value, switching the flue gas to an SCR reserved reactor; (2) introducing hot gas flow into the SCR main reactor and decomposing an ammonium sulfate layer deposited on the surface of the catalyst under the action of the hot gas flow; continuously introducing the hot gas flow for 1 hour to 8 hours to finish regeneration of the denitration catalyst; (3) switching the flue gas back to the SCR main reactor and continually carrying out a denitration reaction. Under the action of the hot gas flow, ammonium sulfate is decomposed into ammonia gas, sulfur trioxide and water steam and is removed along the flowing of the hot gas flow, so that the denitration performance of the catalyst can be recovered. The in-situ regeneration method of the ammonium sulfate poisoning denitration catalyst has the advantages of simplicity in operation, short regeneration time, low regeneration cost, safety and environmental friendliness, high denitration efficiency of the regenerated catalyst, and no changes of the strength and pore structure of the catalyst.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

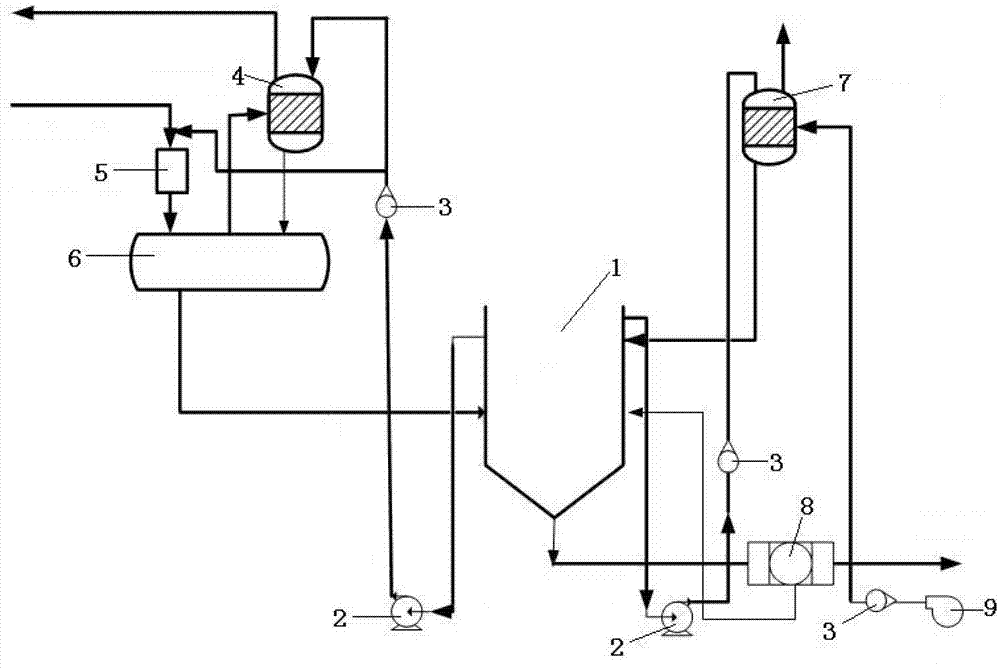

Method and device for removing hydrogen sulfide in gas phase through oxidation

InactiveCN103111177AShort regeneration timeAvoid cloggingDispersed particle separationGas phaseProcess engineering

The invention discloses a method and a device for removing hydrogen sulfide in a gas phase through oxidation. The device comprises a settling tank, an extracting pump, a filtering membrane, an ultra gravity rotary packed bed, a separator, a balanced tank and a regeneration ultra gravity machine, wherein the extracting pump and the filtering membrane are sequentially connected between the settling tank and the ultra gravity rotary packed bed; the balanced tank is connected between the settling tank and the separator; the ultra gravity rotary packed bed is communicated with the balanced tank; the settling tank and the separator are sequentially connected with the extracting pump and the filtering membrane; and the extraction pump and the filtering membrane are sequentially connected between the settling tank and the regeneration ultra gravity machine. A technology flow of pre-oxidation sweetening, ultra oxidation sweetening, sulfur settlement, and regeneration is adopted for the method. According to the method and the device, the ultra gravity machine is adopted to replace the traditional low-mass-transfer-efficiency reactor, and the ultra gravity rotary packed bed reactor is adopted both in hydrogen sulfide oxidation and catalyst regeneration, the process mass transfer efficiency is intensified greatly, and the regeneration time oxidation sulfur removing time and the desulfurizing agent regenerating time are shortened.

Owner:WUHAN GLT ENERGY & ENVIRONMENTAL TECH CO LTD

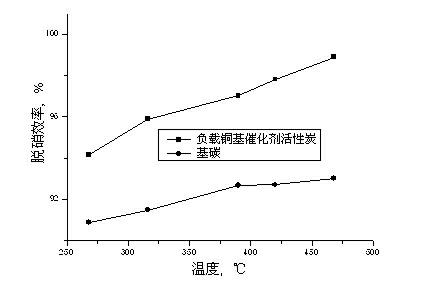

Desulfurization and denitrification process utilizing microwave to intermittently irradiate activated carbon

InactiveCN102489107AReduce lossesAchieve in situ regenerationDispersed particle separationSulfur preparation/purificationActivated carbonPtru catalyst

Disclosed is a desulfurization and denitrification process utilizing microwave to intermittently irradiate activated carbon. Two or more adsorption beds filled with activated carbon particles are used for adsorbing or implementing microwave irradiation to flue gas of boilers alternatively. Flue gas is delivered into one of the adsorption beds by an induced draft fan, then the adsorption bed begins to run, and sulfur and nitric oxides in the flue gas are adsorbed by the activated carbon. After the activated carbon in the adsorption bed in running is saturated, the adsorption bed is in a regenerating state so as to be reused. The flue gas is delivered into the other adsorption bed beginning to run so as to be adsorbed, activated carbon particles of the regenerating adsorption bed are irradiated by microwave, sulfur and nitric oxides adsorbed on the surface of the activated carbon are quickly reduced and decomposed into elemental sulfur and nitrogen gas under high temperature, and the different adsorption beds are switched between the running state and the regenerating stage alternatively. Metal oxide is used as a reduction reaction catalyst so as to reduce reduction and decomposition temperature and loss of carbon. By the desulfurization and denitrification process, energy consumption of microwave irradiation can be reduced greatly, loss of carbon can be decreased, and in-situ regeneration of activated carbon is realized. In addition, the desulfurization and denitrification process has the advantages of fine desulfurization and denitrification effect, short time for regeneration of activated carbon, low cost for desulfurization and denitrification, high recovery rate, easiness in industrialized implementing and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

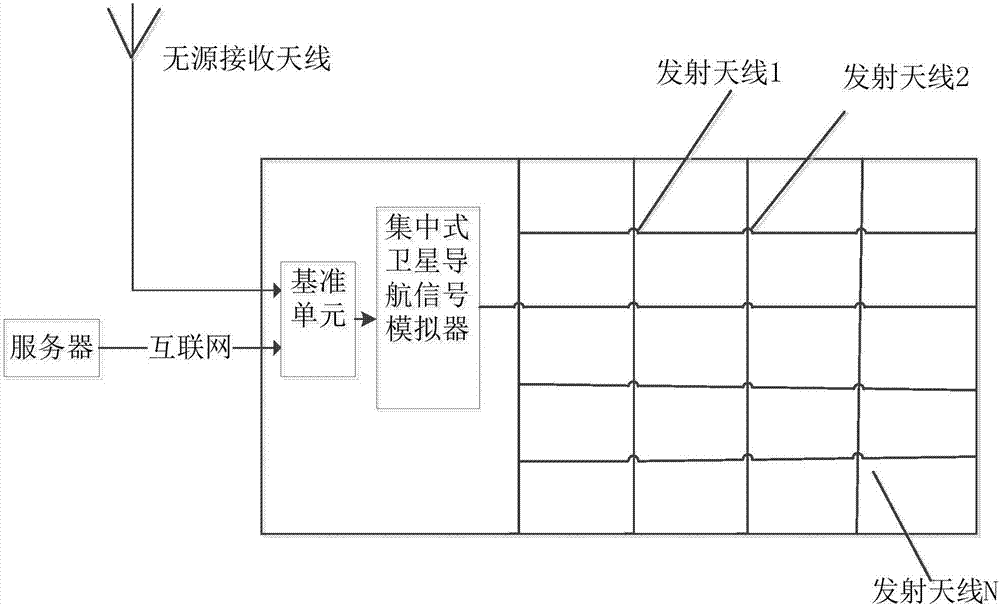

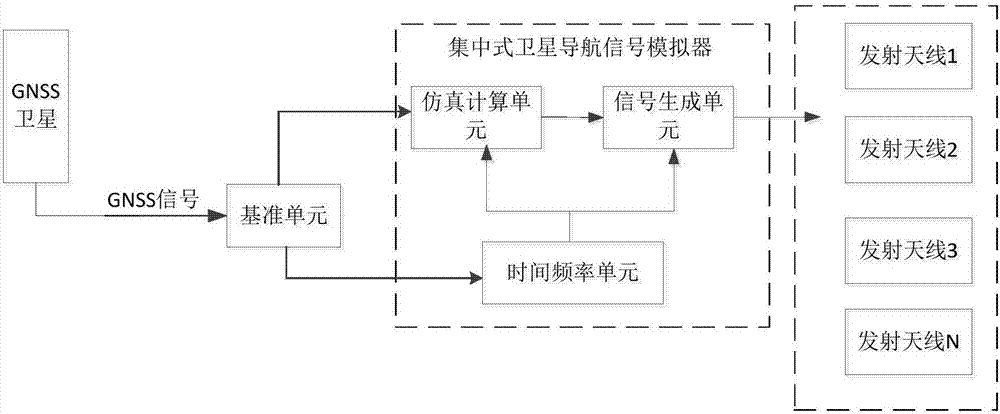

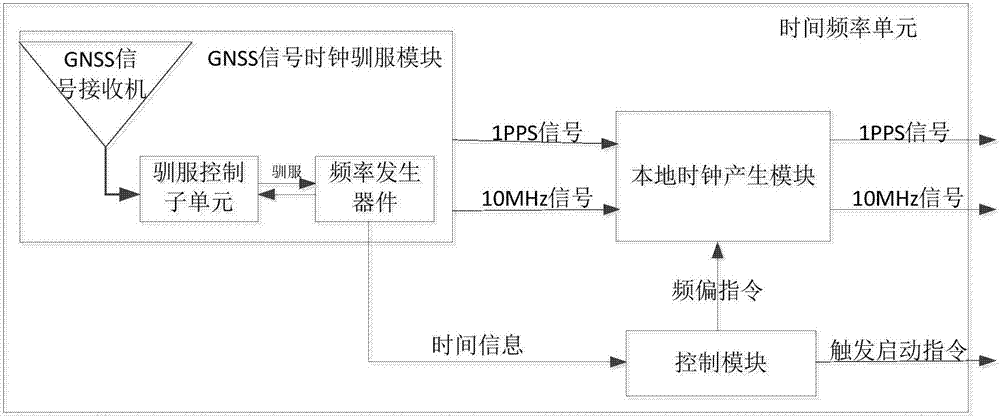

Satellite navigation positioning enhancing system and method in indoor environment

PendingCN106980122AShorten air timeExcellent broadcast speedSatellite radio beaconingThe InternetEngineering

The invention relates to the field of satellite navigation, and discloses a satellite navigation positioning enhancing system in an indoor environment. The system comprises a reference unit, a centralized satellite navigation signal simulator and N transmitting antennas, the reference unit and the centralized satellite navigation signal simulator are connected successively, and the N transmitting antennas are connected with the centralized satellite navigation signal simulator, and emit N regenerated satellite navigation signals synchronously. The invention also discloses a satellite navigation positioning enhancing method in the indoor environment. Satellite navigation signals in an indoor area are received instantly or reference signals are obtained via the Internet, and navigation signals synchronized with signals of a real satellite navigation system in the indoor area are generated and broadcast in real time indoor. Indoor satellite navigation positioning is realized without change of a navigation terminal. The system of the invention is low in construction difficulty, low in cost and general and supports GNSS systems.

Owner:神州天衡科技(深圳)有限公司

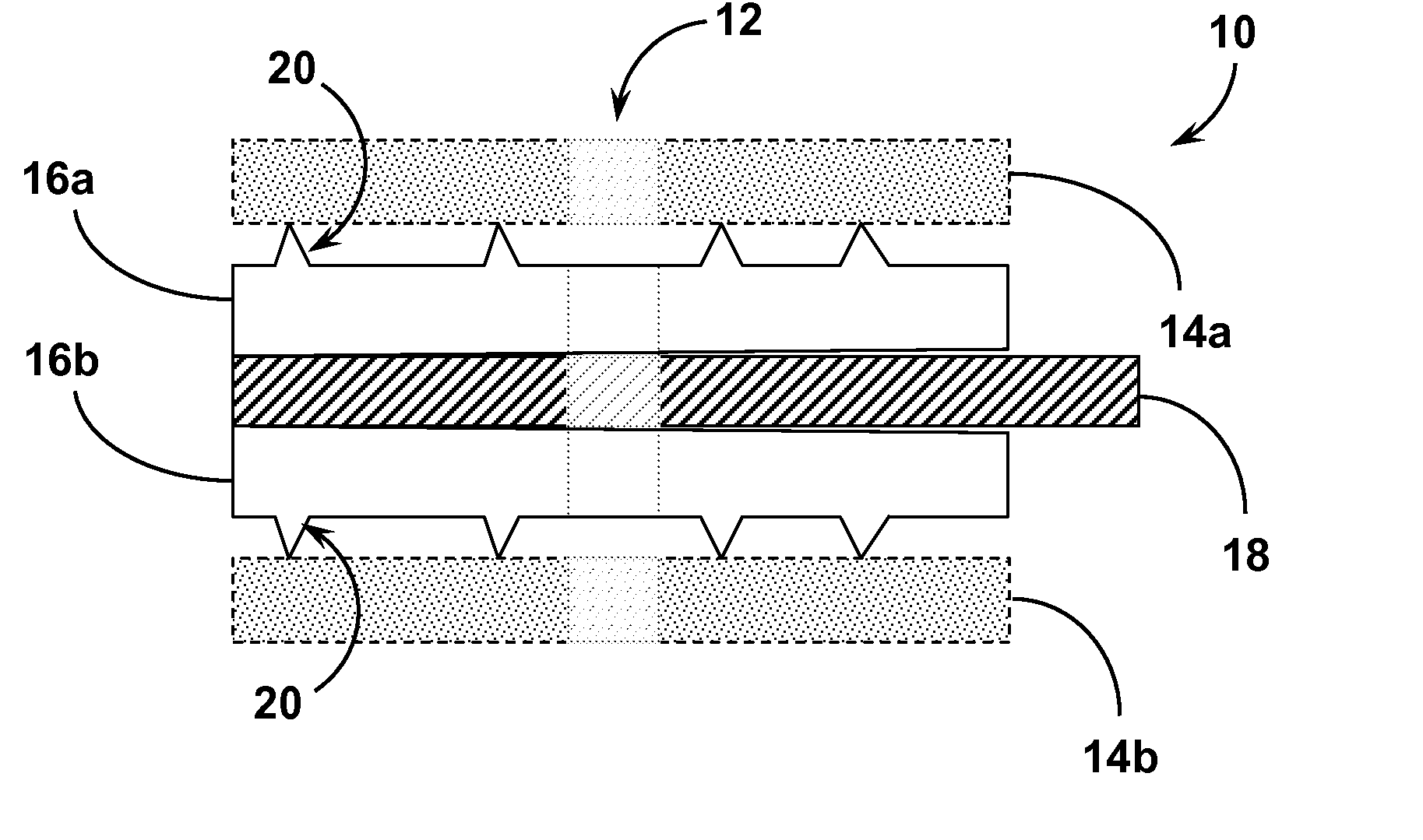

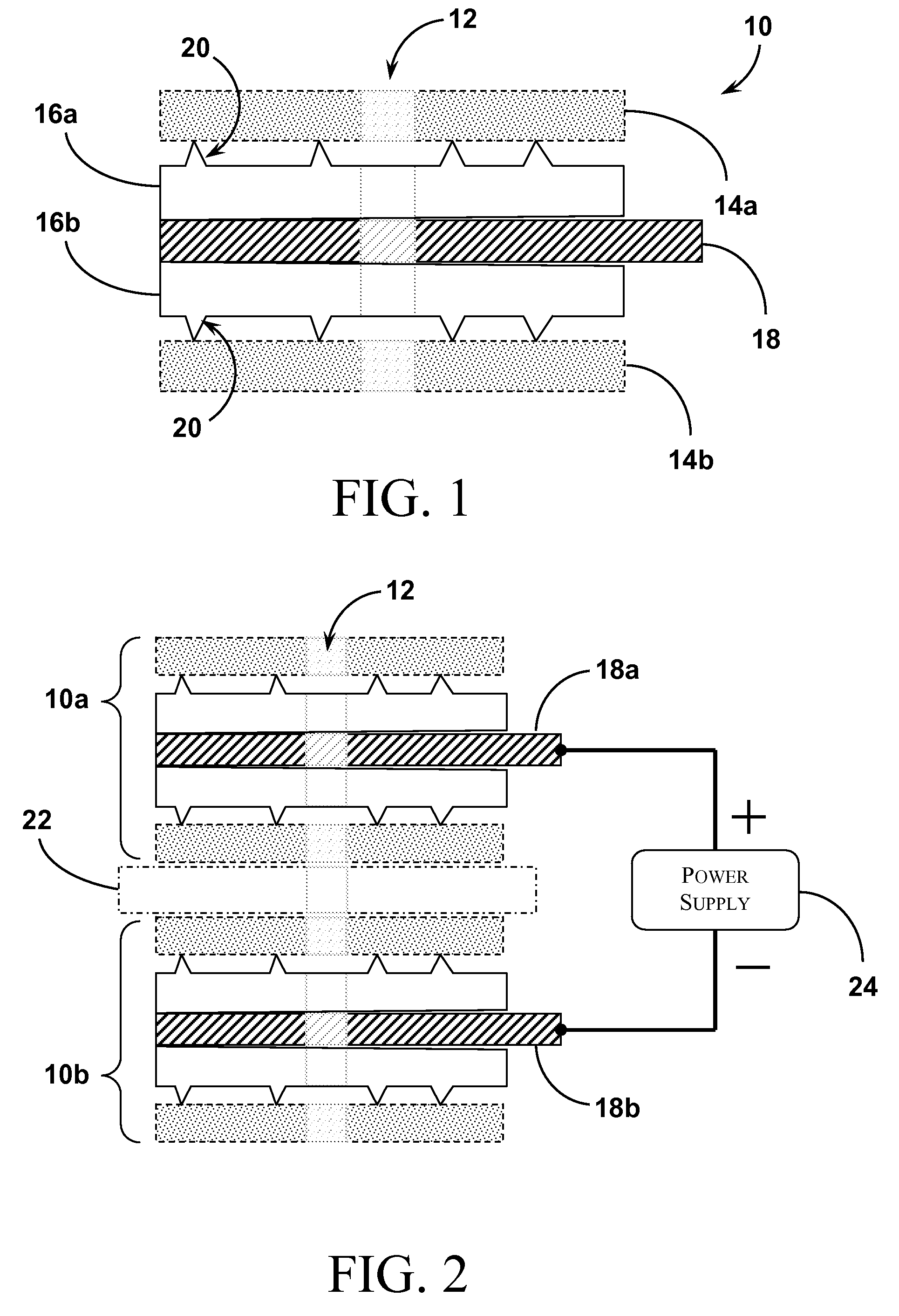

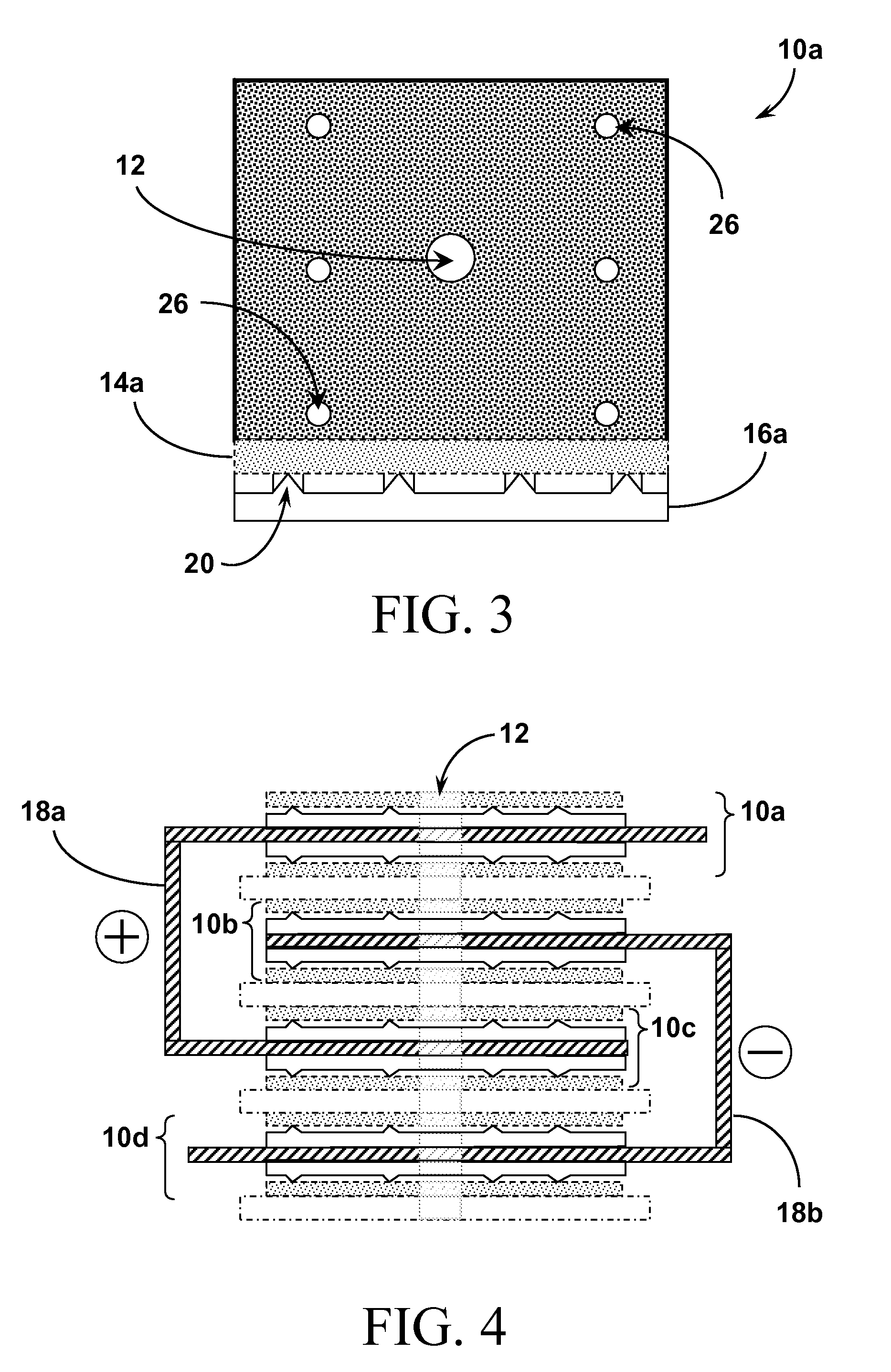

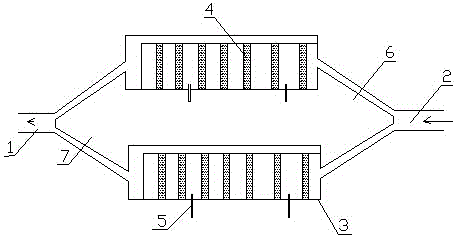

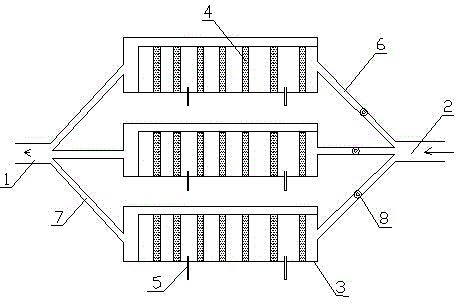

Hybrid Capacitive Deionization and Electro-Deionization (CDI-EDI) Electrochemical Cell for Fluid Purification

InactiveUS20080078672A1Function increaseShort regeneration timeCellsEnergy based chemical/physical/physico-chemical processesCapacitanceCapacitive deionization

Systems and methods are described that combine capacitive deionization (CDI) and electro-deionization (EDI) mechanisms for deionizing aqueous or non-aqueous solutions. The inventive systems and methods modify certain known coatings or films by perforating the films with pin holes and using spacers that separate the coatings from the electrodes. Benefits derived from these improvements include: (a) maintaining a high level of purification; (b) increasing by as much as 25% the rate of expulsion of ions during regeneration; (c) increasing by as much as 50% the rate of electrical discharge of the cell; (d) decreasing the regeneration time (producing as much as 33% more purified water per unit of time); (e) reducing by as much as 25% the power required; and (f) improving the recovery of the system to as much as 85%.

Owner:ATLAS ROBERT D

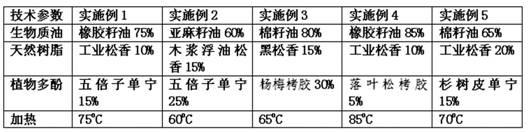

Environmentally-friendly biomass compound rubber regenerant and preparation method thereof

The invention provides an environmentally-friendly biomass compound rubber regenerant. The regenerant is prepared from the following raw materials in mass percentage: 60-85% of bio-oil, 10-20% of natural resin and 5-30% of plant polyphenol. The preparation method of the regenerant comprises the following steps: (1) heating the bio-oil to 60-85 DEG C; (2) respectively adding the natural resins andthe plant polyphenol to the bio-oil and evenly mixing; and (3) naturally cooling the evenly mixed product to room temperature to finally obtain the environmentally-friendly biomass compound rubber regenerant product. In the invention, the bio-oil, the natural resins and the plant polyphenol which are extracted from plants are taken as raw materials, and the raw materials are renewable materials, which realizes maximum resource utilization and reduces dependence on petrochemical resource so as to achieve the purpose of green production of reclaimed rubber. The regenerant has the advantages of good rubber regeneration effect, high product quality, low production cost and no pollution and nuisance during the production process. The environmentally-friendly reclaimed rubber produced by the regenerant can be widely applied to various rubber products and can replace rubber materials, thus saving rubber resources.

Owner:KUNMING PHOENIX RUBBERS

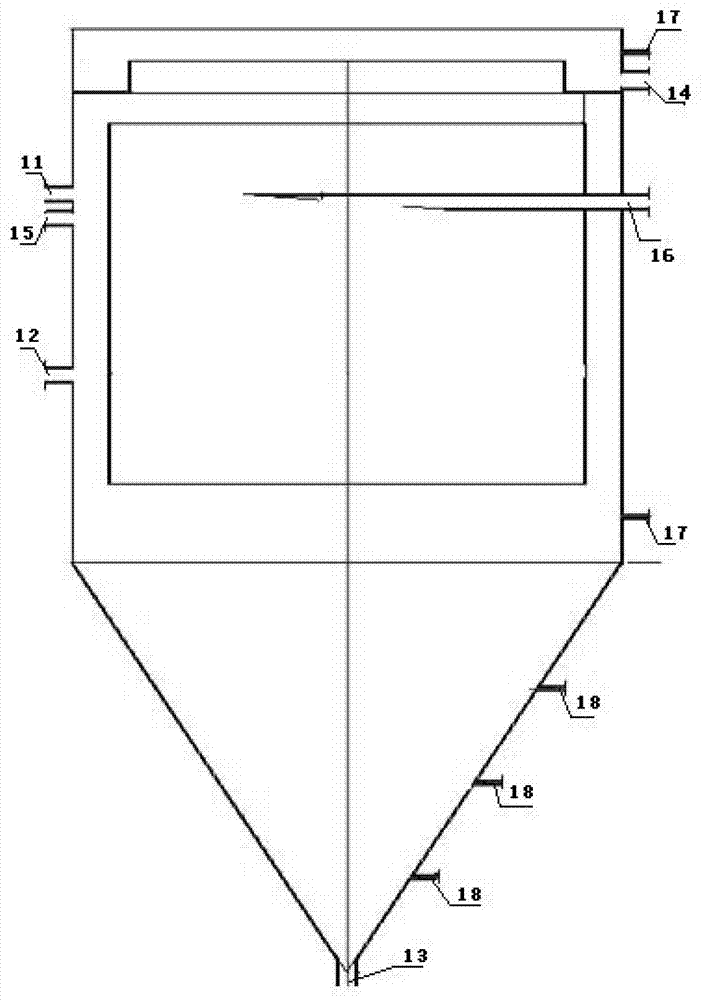

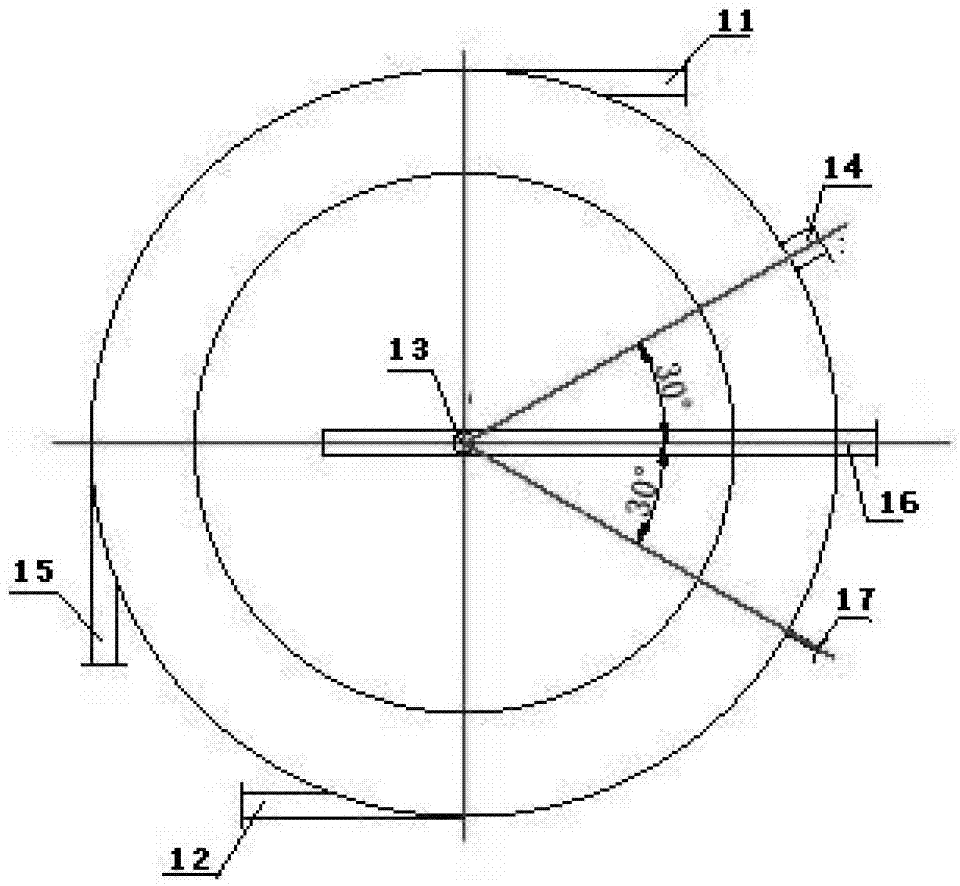

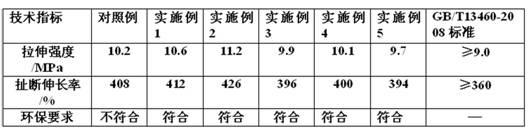

Dust filtration system of mixed gas of high-temperature oil gas, water vapour and carbonaceous easy-precipitation substances

ActiveCN104147862AReduce investmentExtended service lifeDispersed particle filtrationTransportation and packagingTarPulverized fuel ash

The invention discloses a dust filtration system of a mixed gas of high-temperature oil gas, water vapour and carbonaceous easy-precipitation substances. The system comprises a sealed separation chamber communicating a gas inlet pipe and a gas discharge pipe. A filtration mechanism is arranged in the sealed separation chamber. The outer surface of the filtration mechanism communicates with the gas inlet pipe, and the inner surface of the filtration mechanism communicates with the gas discharge pipe. A filtration body regeneration mechanism is arranged in the dust filtration system. According to the invention, the filtration body regeneration mechanism is arranged in the sealed separation chamber communicating the gas inlet pipe and the gas discharge pipe. When the filtration body works for a period of time, the filtration capacity of the filtration body cannot satisfy the requirement of normal working because the filtration capacity is greatly reduced due to tar and coal ash deposits on the surface and pores of the filtration body. The filtration body regeneration mechanism works, and the filtration body is recovered to a desired level. Regeneration is repeated, such that filtration body investment is directly reduced, and filtration body service life is greatly improved.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

Treatment method of high iron manganese and ammonia nitrogen compound pollution low temperature underground water

ActiveCN108706745ASolve the problem of simultaneous purification of compound pollutionImprove adsorption capacityTreatment using aerobic processesWater contaminantsNitrateManganese

The invention discloses a treatment method of high iron manganese and ammonia nitrogen compound pollution low temperature underground water. Natural zeolite is used as a raw material, a zeolite-basedmaterial is loaded with manganite, through impregnation of enrichment culture liquid, the material is loaded with microorganisms of nitrifying bacteria, iron and manganese oxidizing bacteria and the like, so that a multifunctional compound material of the zeolite loaded with the manganite and the microorganisms is obtained, a filter candle is filled with the multifunctional compound material, sequencing batch running is conducted according to four stages of inlet water adsorption, water emptying, air blasting for bio-regeneration and nitrate washing, meanwhile, iron, manganese and ammonia nitrogen in the low temperature underground water are purified, and thus effluent reaches the domestic drinking water quality standards.

Owner:HEFEI UNIV OF TECH

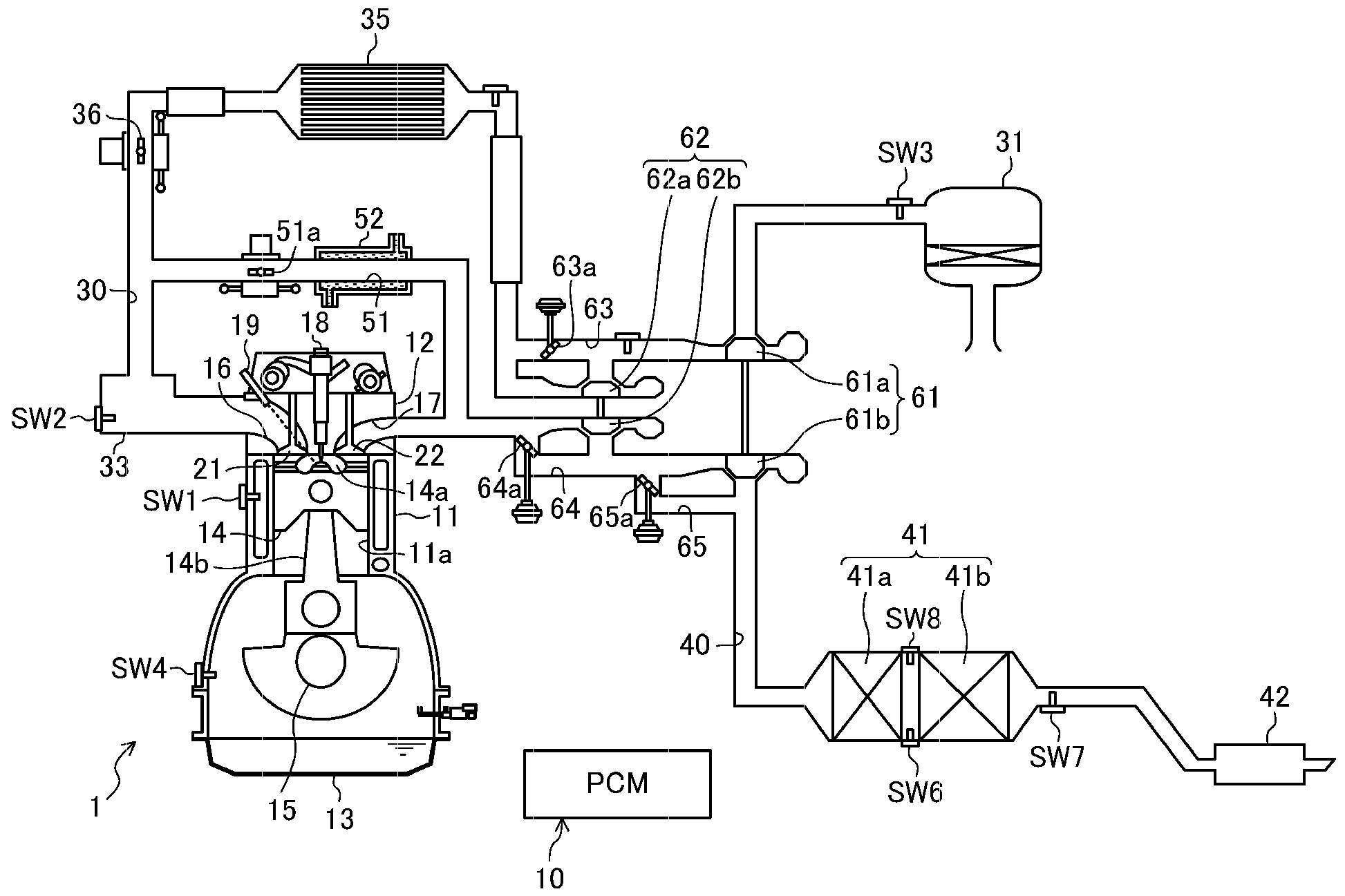

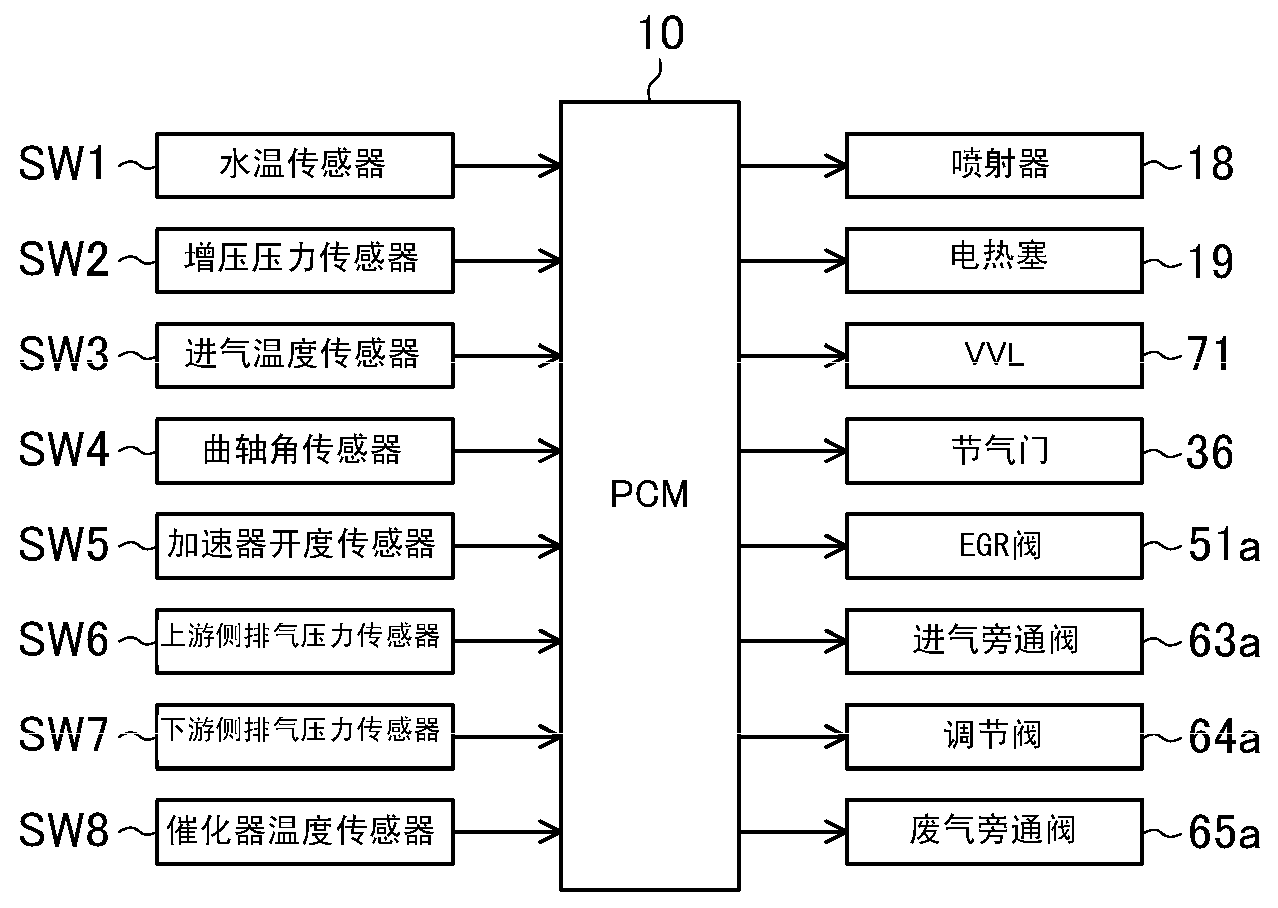

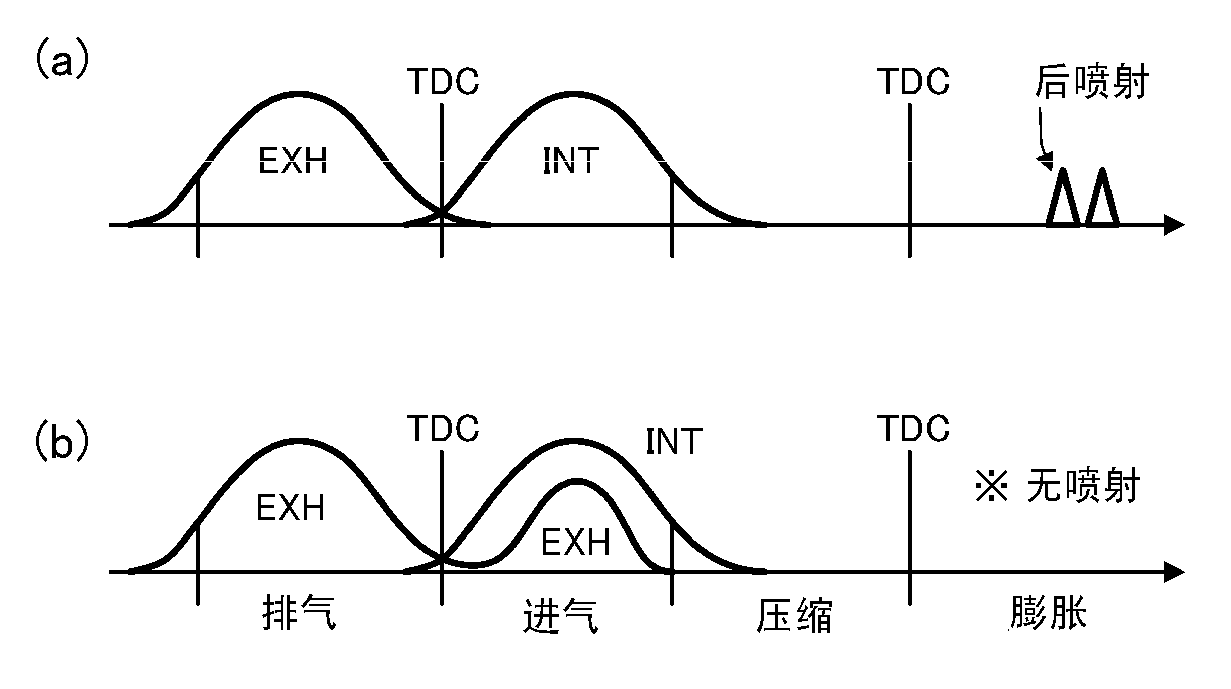

Control device and control method of diesel engine

InactiveCN103184947AShort regeneration timeInhibition of dilutionElectrical controlInternal combustion piston enginesExhaust valveInlet valve

The invention provides a control device and a control method of a diesel engine. When the engine (1) is in a deceleration condition and when a predetermined DPF regeneration condition is satisfied, two opening controls for valve opening of an exhaust valve (22) during an intake stroke is performed (step S13) except for the opening of an intake valve (21) in the intake stroke and the opening of the exhaust valve (22) in the exhaust stroke of a cylinder.

Owner:MAZDA MOTOR CORP

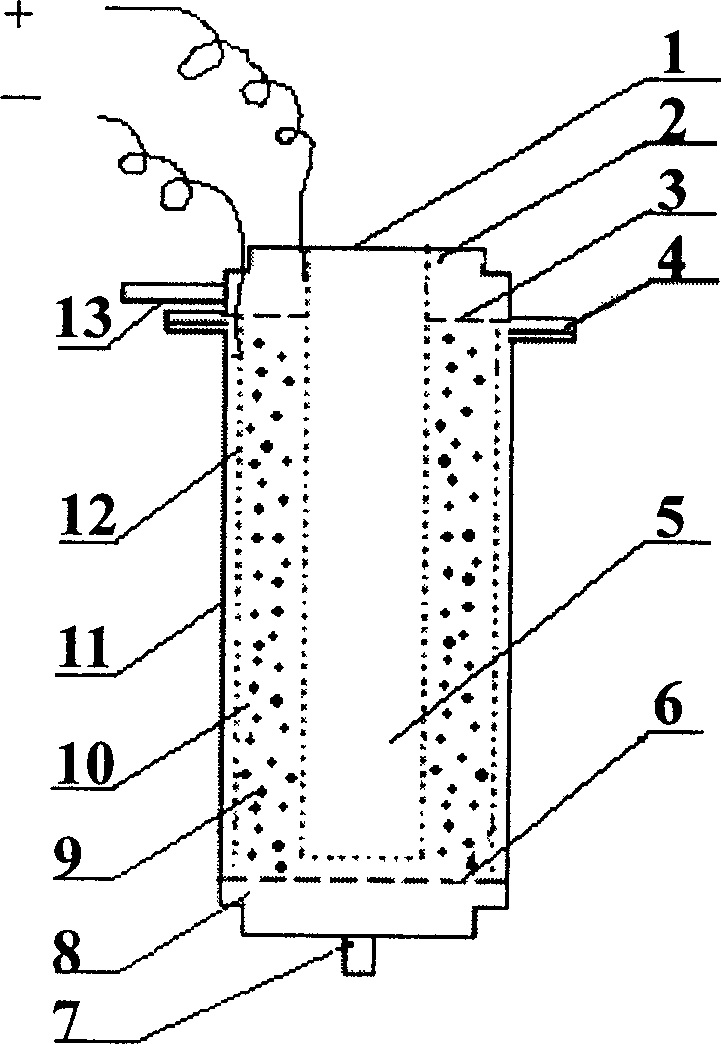

Electrochemical regenerator and regenerating method for activated carbon

InactiveCN1613552AAchieve regenerationEfficient degradationOther chemical processesCombustible gas purificationElectrochemical responseElectricity

An electrochemical device for regenerating activated carbon is composed of a casing, the first and the second hydraulic distribution plates for dividing the internal space of casing into water outlet chamber, electrochemical reaction chamber and water inlet chamber, the cathode on the inner surface of said electrochemical reaction chamber, and the central anode. Its regenerating method includes such steps as filling the activated carbon to be regenerated in the space between said anode and cathode, pumping the electrolyzing liquid into water inlet chamber to force it to flow from bottom to top for degradating the organic pollutant on the surface of activated carbon by the strong oxidizing substance generated by electric catalyzing.

Owner:ZHEJIANG UNIV

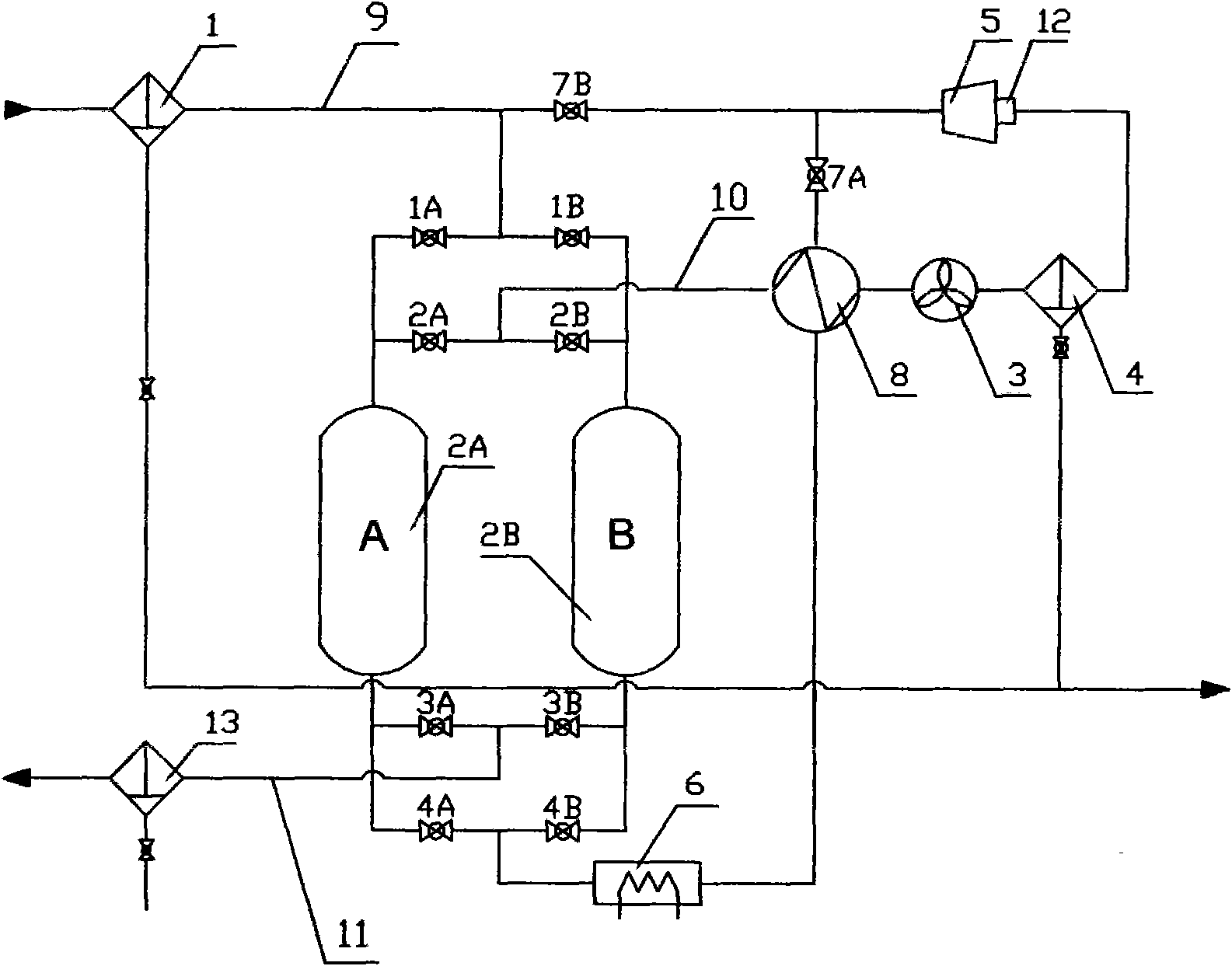

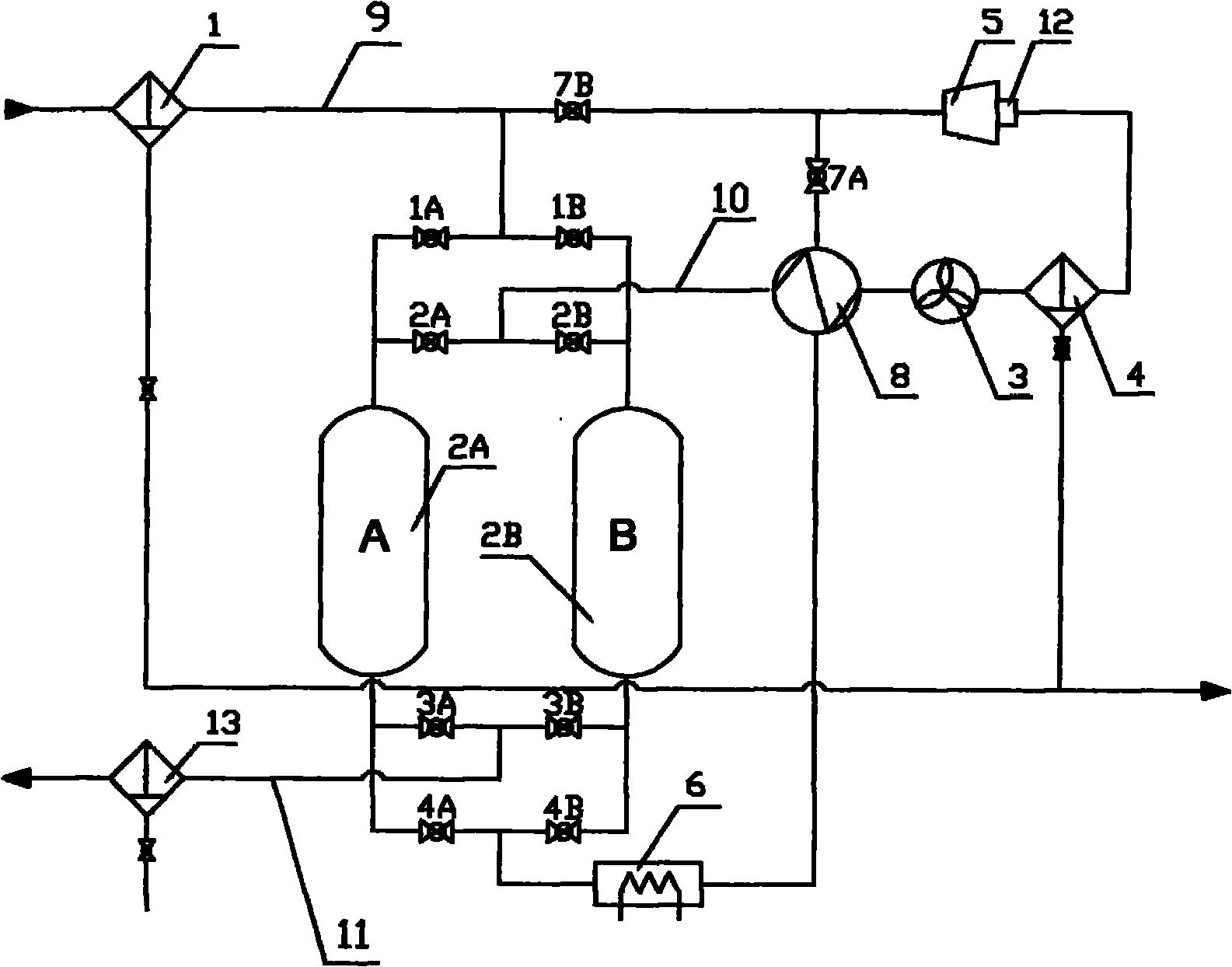

Pressure-reduction zero-emission energy-saving gas dewatering device

ActiveCN101797465AShort lifeExtended service lifeDispersed particle separationMolecular sieveElectricity

The invention relates to a pressure-reduction zero-emission energy-saving gas dewatering device which is adapted to a middle or high pressure (>2.0MPa) double-tower or multi-tower molecular sieve dewatering process and comprises a filter (1), two or a plurality of drying / absorption towers (2A and 2B), an air cooler (3), a gas-water separator (4), a circulating fan (5), an electric heater (6), a gas-gas heat exchanger (8) and a frequency transformer (12). The invention is characterized in that a regeneration discharge branch path is branched at an air outlet of the circulating fan, and the regeneration discharge branch is merged into an adsorption air inlet pipe. Thus, dry gas discharged by a regeneration loop is extracted and discharged into an absorption loop when in regeneration, so that a regeneration tower is depressurized, and the regeneration loop is restored through the switching of a valve after pressure reduction. Thus, not only pressure-reduction regeneration is realized, but also zero emission is realized, and the regeneration time is reduced, thereby reducing the energy consumption and prolonging the service life of a molecular sieve.

Owner:陕西高芯超滤膜科技有限责任公司

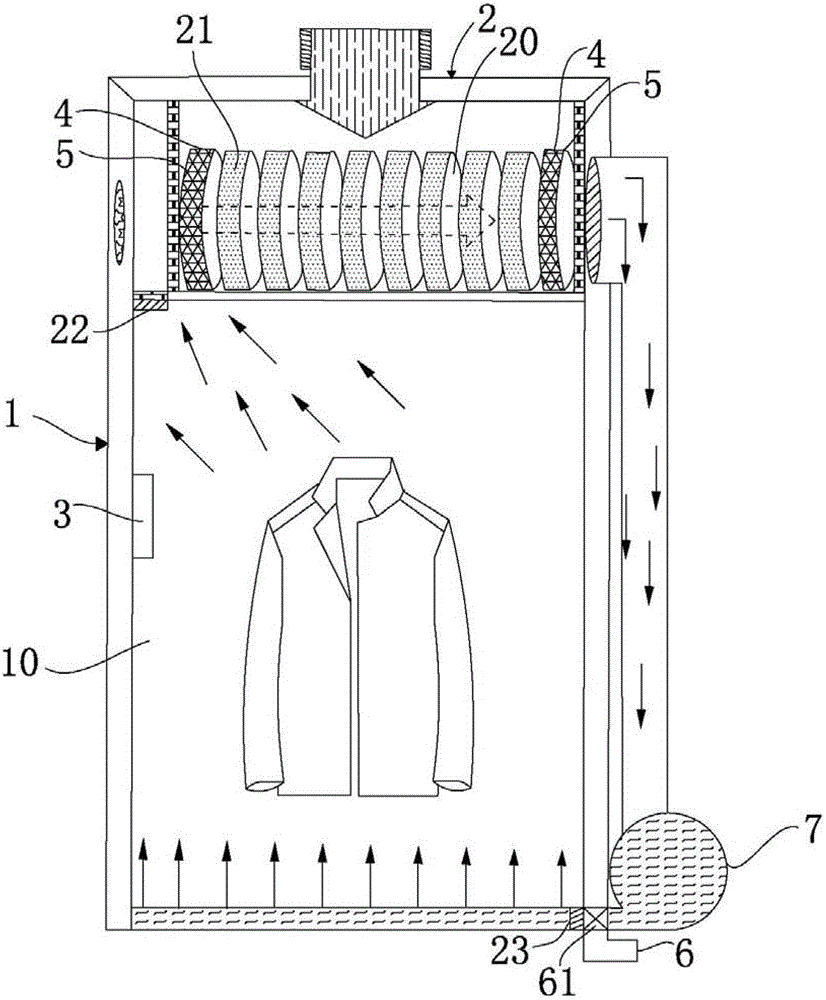

Clothes drying device

InactiveCN102978885AShort regeneration timeSolve the problem of high regeneration energy consumptionTextiles and paperLaundry driersEngineeringShort stay

The invention relates to the technical field of household appliances, in particular to a clothes drying device adopting renewable molecular sieves to dry clothes. The clothes drying device comprises a main body with a cavity capable of containing clothes, and is characterized in that the device also comprises a drying cylinder; molecular sieves are filled in the drying cylinder; a gas hole is arranged in the drying cylinder; the inlet and the outlet of the gas channel are connected with the cavity; a heating device is arranged in the gas channel; and the gas channel is also connected with a power device for enhancing convection. The invention has the other purpose of providing a pull rod type clothes dryer which is convenient to carry during travelling and dries the taken-along clothes by arranging a roller, a pull rod and a solar charging module on the clothes drying device, and solves the problem that a traveler can not rapidly dry clothes because of short stay.

Owner:深圳市佳能宝节能环保科技有限公司 +1

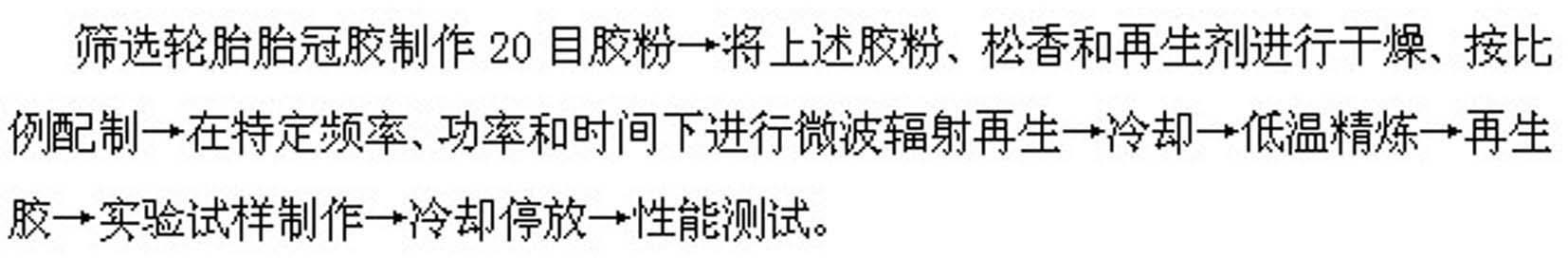

Microwave radiation reclaiming method for environment-friendly high-strength reclaimed rubber

InactiveCN102634056AProtection from destructionSure breakPlastic recyclingRubber materialWaste rubber

The invention discloses a microwave radiation reclaiming method for environment-friendly high-strength reclaimed rubber, and belongs to the technical field of waste rubber reclaiming. The method comprises the following steps of: mixing waste rubber outer tire crown powder with the particle size of 20 meshes, rosin and dipentene according to a certain proportion; uniformly feeding the materials with a certain thickness on a roller way conveying device; determining the length of a roller way according to microwave radiation time; arranging a high-frequency microwave radiation device on the roller way; conveying the materials on the roller way for reclaiming the materials by microwave radiation during conveying; continuously putting the reclaimed rubber materials into a cooling device through the roller way; directly discharging the cooled materials to an open mill for performing refining, wherein the refining temperature is controlled to be 35-50 DEG C; and refining at low temperature on the open mill for 20 minutes to obtain a refined rubber sheet with smooth surface and uniform texture. A test result shows that the tensile strength of the reclaimed rubber is more than 18MPa, the breaking elongation is over 400%, and the Weigert plasticity is 0.35-0.45. The microwave radiation reclaiming method has the advantages of environment friendliness, short reclaiming time, low reclaiming temperature, energy conservation and high production efficiency.

Owner:XUZHOU COLLEGE OF INDAL TECH

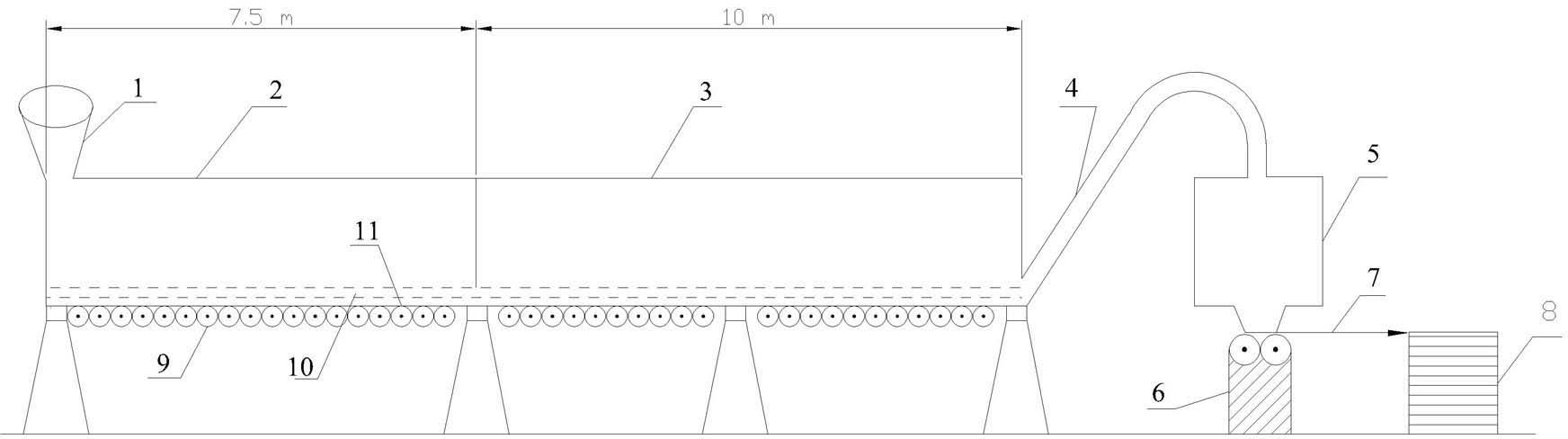

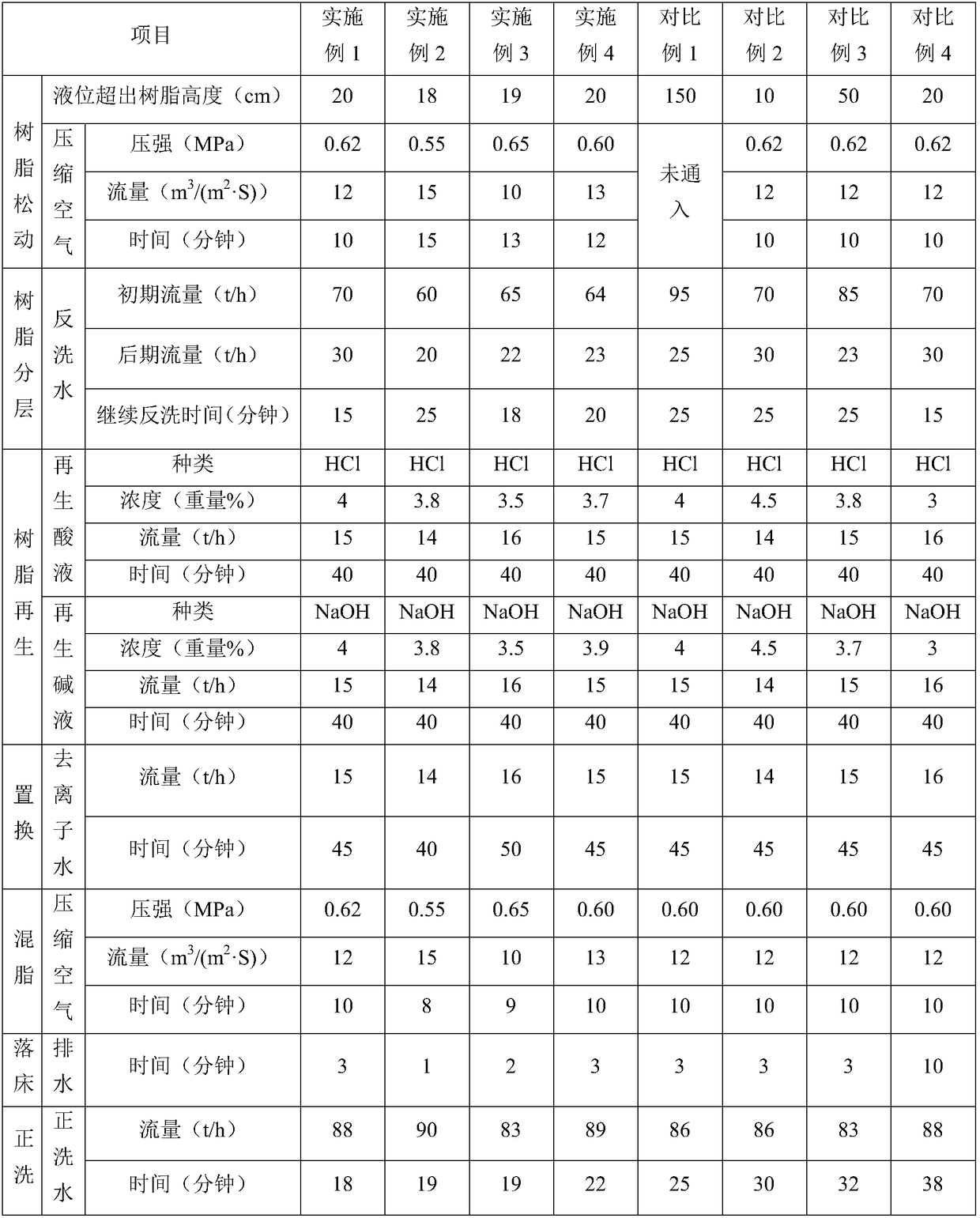

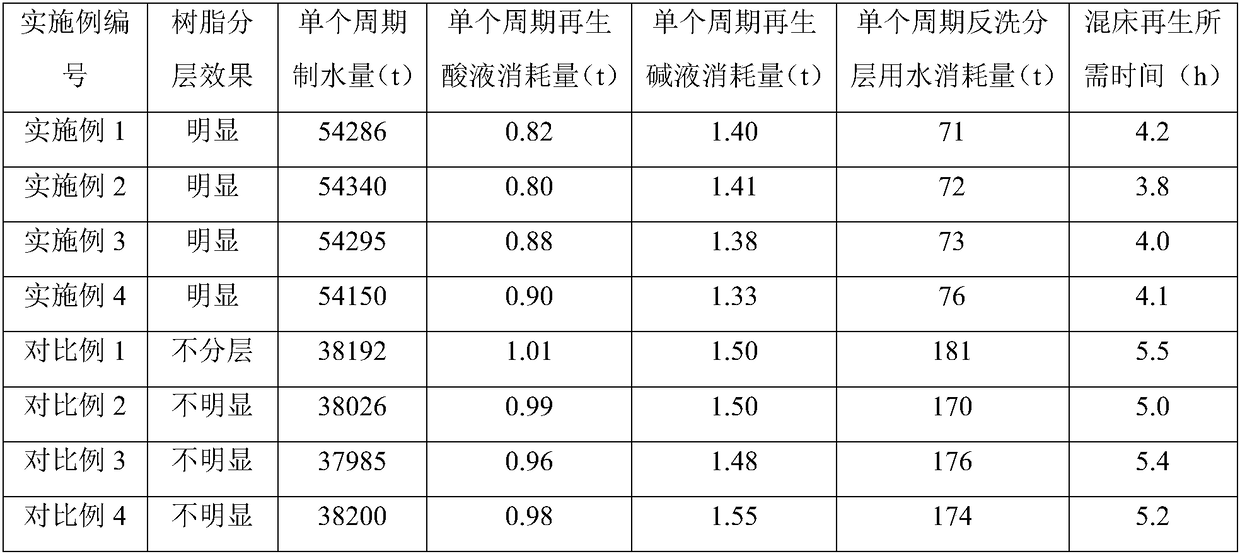

Method for regenerating desalting mixed bed

ActiveCN108178240AShort regeneration timeIncrease water productionSpecific water treatment objectivesWater/sewage treatment by ion-exchangePower stationWater production

The invention relates to the field of chemical water production in power plants, and discloses a method for regenerating a desalting mixed bed. In the method, the liquid level in a mixed bed tank reduces to the top of a resin layer before the resin layer is subjected to hydrodynamic backwashing layering, and compressed air is introduced into the mixed bed tank to perform air washing, so the resinis effectively loosened, the water injection pressure of the subsequent backwashing step is reduced, the backwashing layering effect is enhanced, the backwashing layering time is significantly shortened, and the consumption of backwashing water in the resin backwashing layering process is reduced. After the resin is backwashed with water, the control of the concentrations and the flow amounts of aregeneration alkali solution and a regeneration alkali solution can significantly reduce the consumptions of the regeneration alkali solution and the regeneration alkali solution in the resin regenerating process and greatly shortens the regeneration time of the desalting mixed bed. The water production volume of the desalting mixed bed in a single period is high, and the outlet water of the regenerated desalting mixed bed has excellent quality.

Owner:CHINA SHENHUA ENERGY CO LTD +2

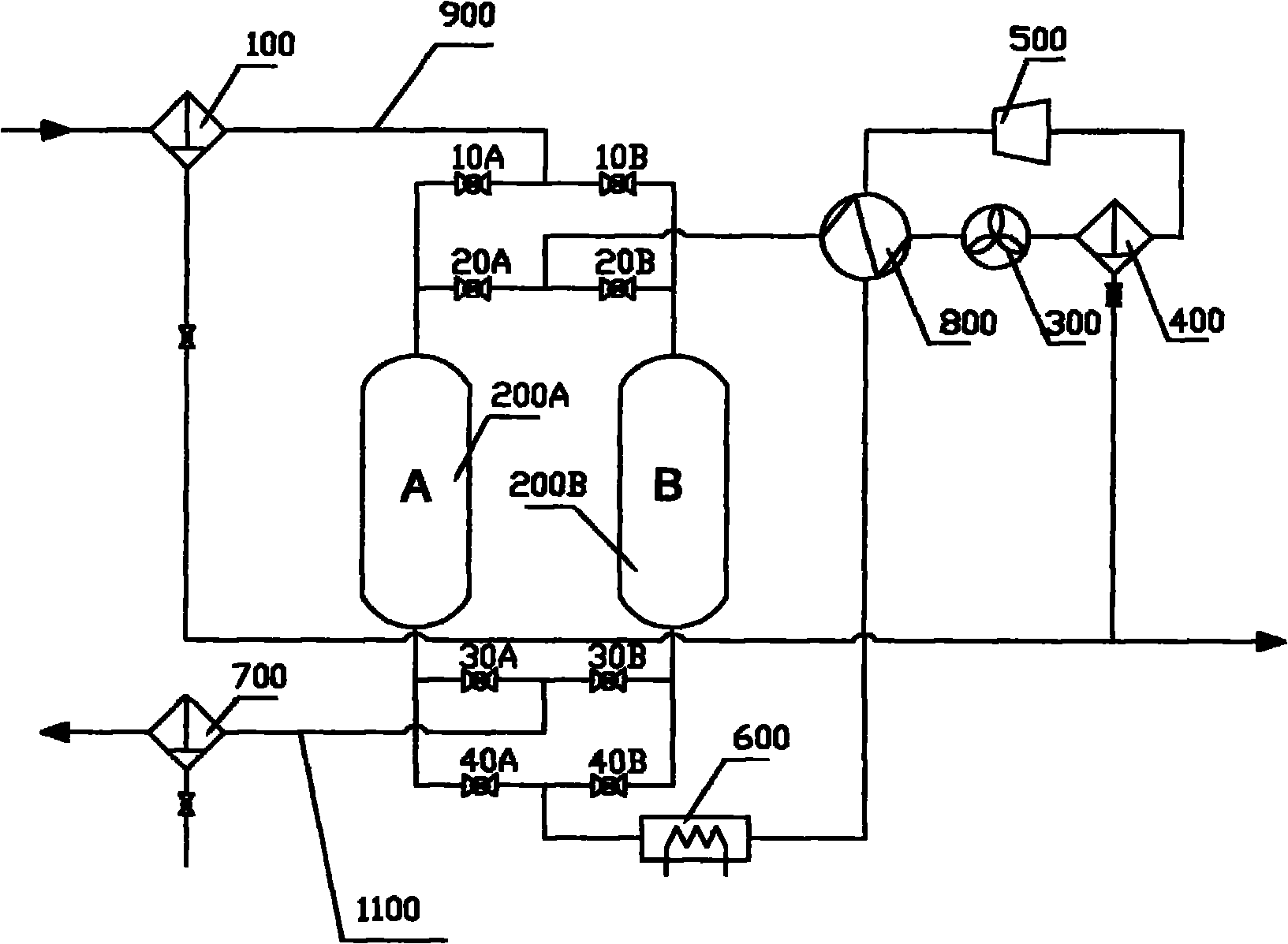

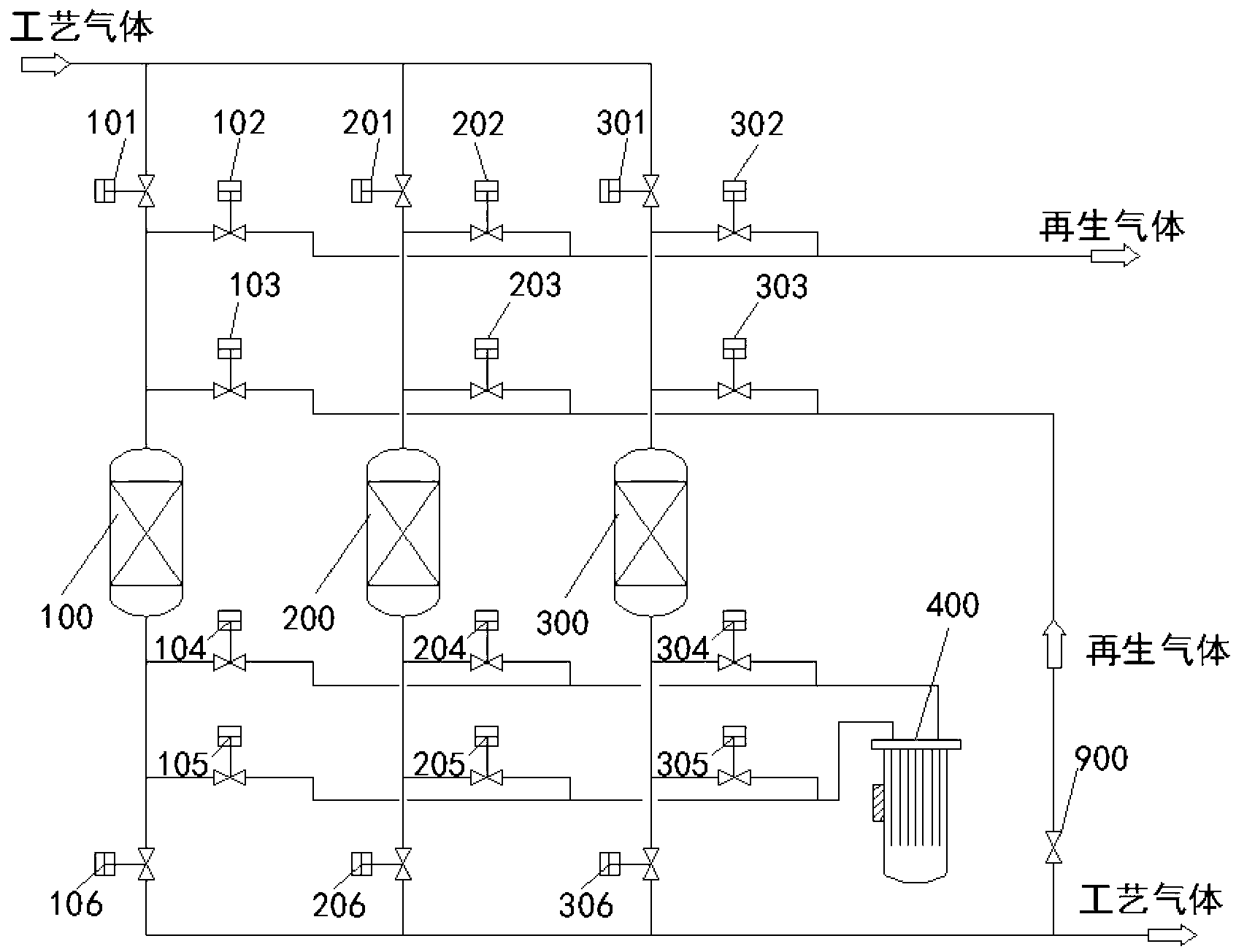

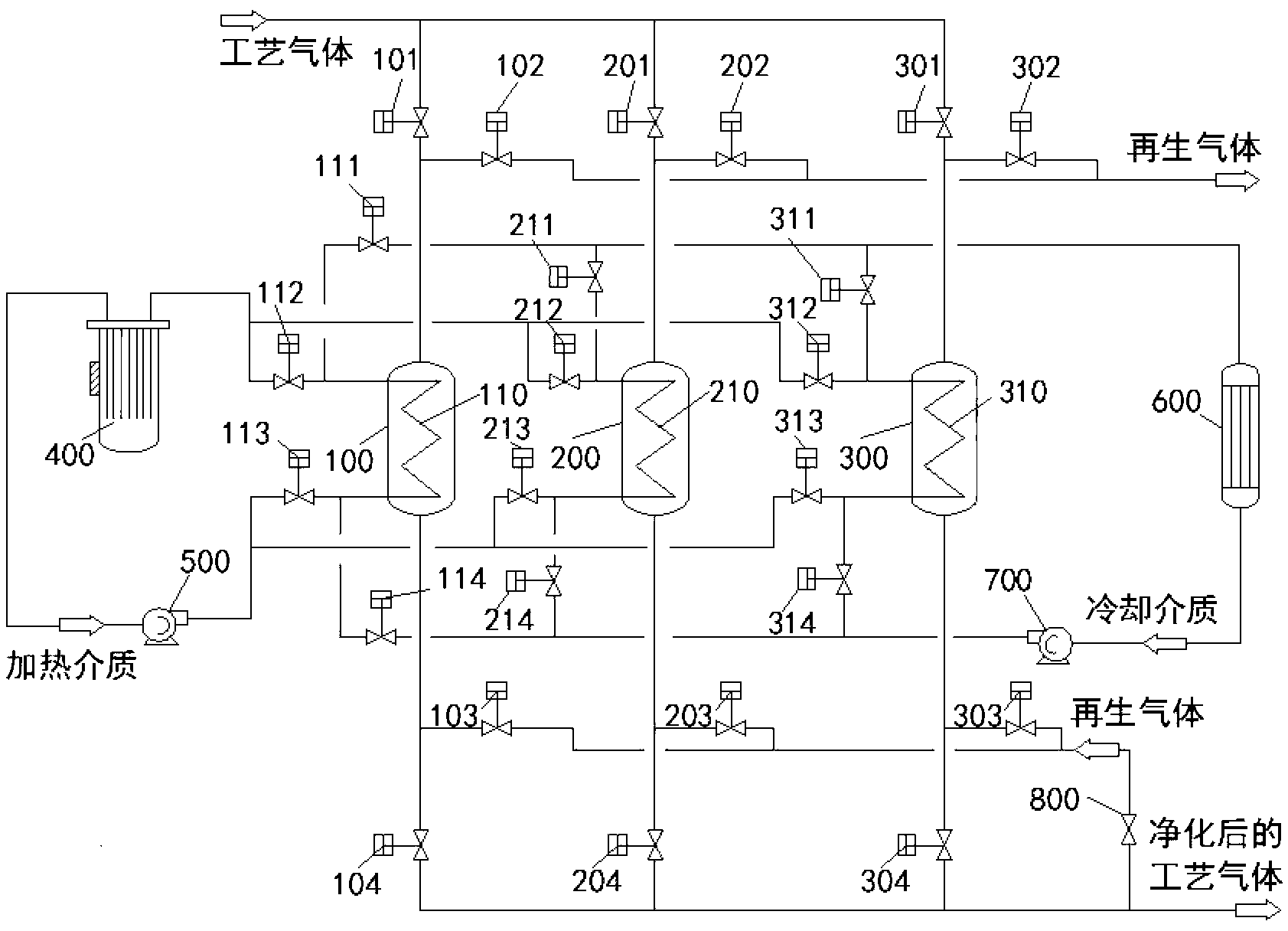

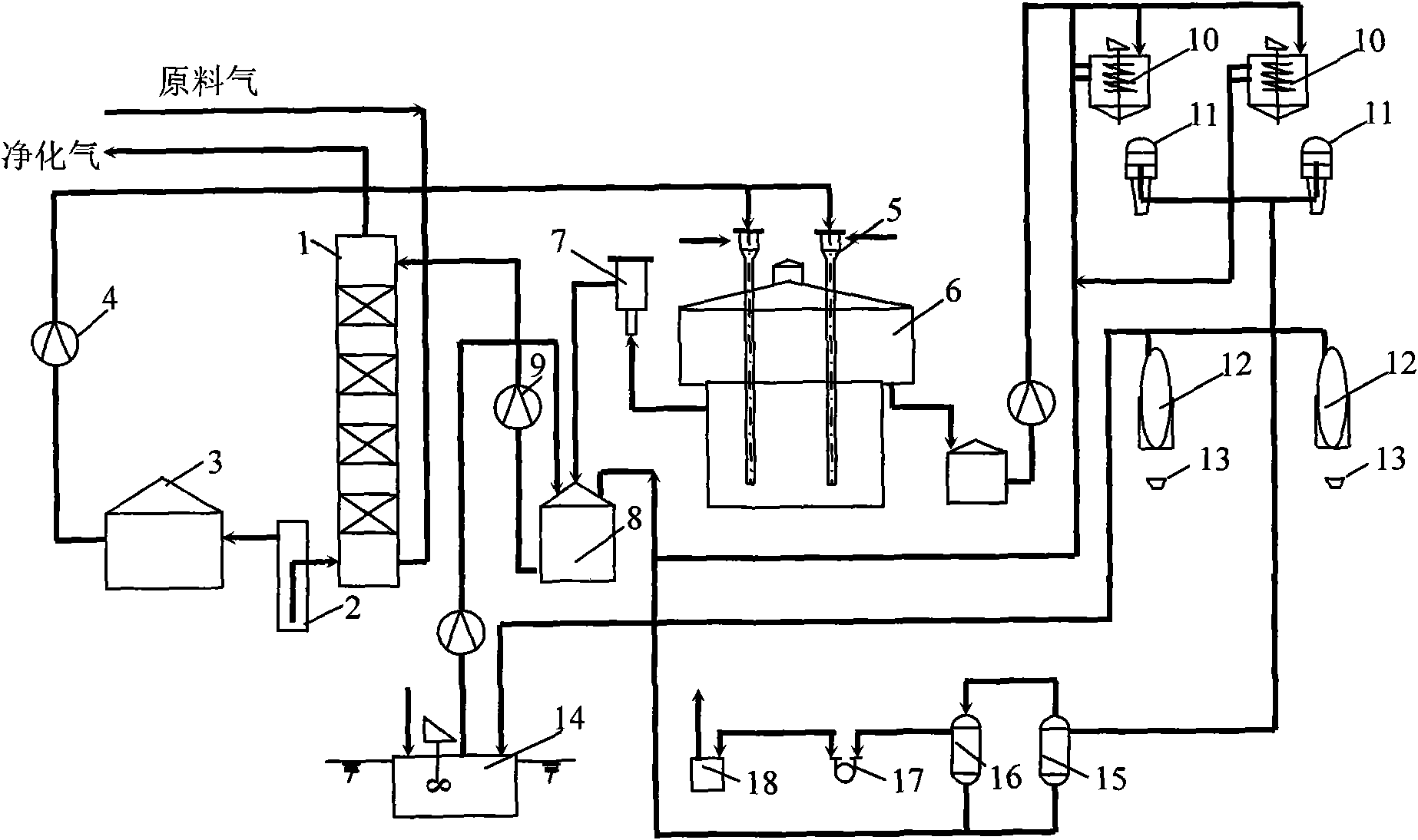

Movable skid-mounted natural/coal bed gas adsorption and purification system with external medium heat exchange function

ActiveCN103007676AFast desorptionRapid coolingGaseous fuelsDispersed particle separationSorbentDesorption

The invention relates to a movable skid-mounted natural / coal bed gas adsorption and purification system with an external medium heat exchange function, which comprises an adsorption tower system and a heat conduction medium heating circulation and cooling circulation system. The adsorption tower system consists of three adsorption towers which are connected in parallel and are switched to be started; one tower is used for adsorption, another tower is used for heating desorption and the third tower is used for cooling; in the heating desorption process, an adsorbent is heated by a high temperature heat conduction medium which is from external circulation so as to be rapidly heated and desorbed, and simultaneously, a small volume of purified process gas is used as regenerated gas to take away impurities generated in the desorption process; and in the cooling process, the adsorbent is cooled by a low temperature heat conduction medium which is from external circulation, so that the temperature of the adsorbent is rapidly reduced and the regeneration process is completed. Regeneration time of the adsorbent can be shortened; consumption of the regenerated gas is reduced; meanwhile, adsorption period is reduced and the heights of the adsorption towers are reduced; and the adsorption and purification system is miniaturized.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

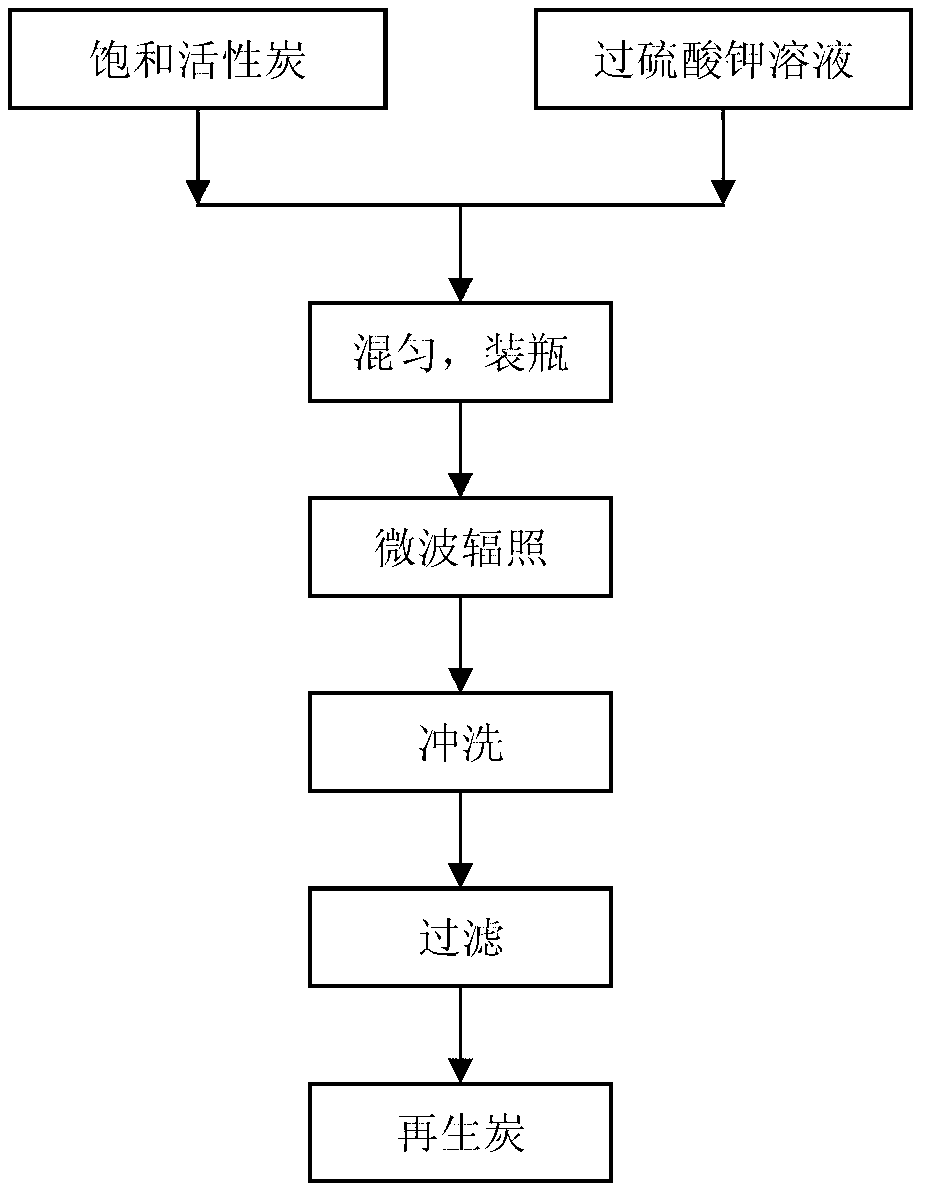

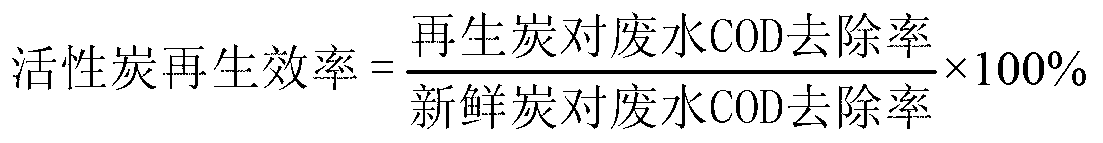

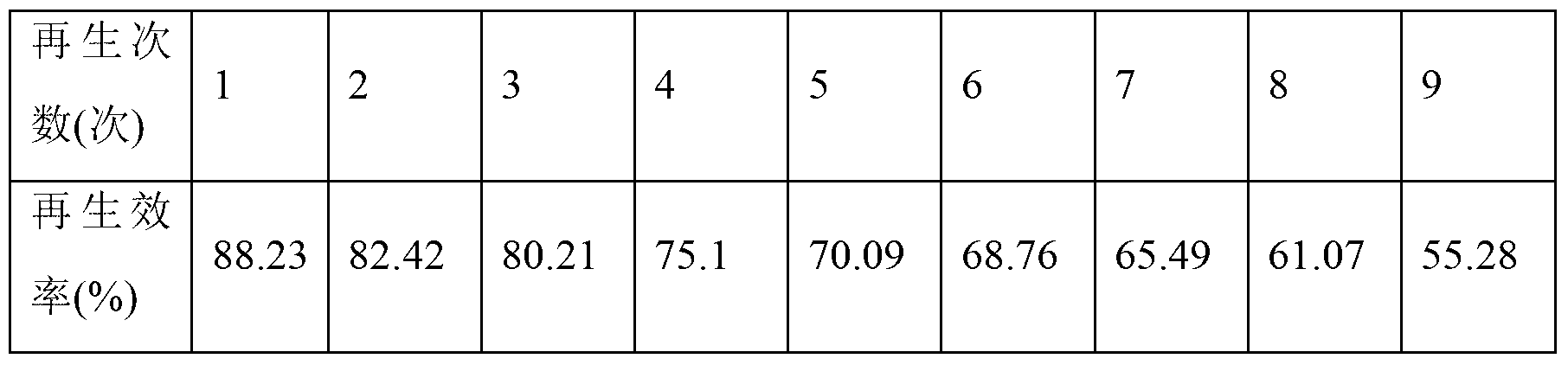

Method for regenerating saturated active carbon adsorbing organic matters through microwave activation of potassium persulfate

InactiveCN103252223AIncrease profitRestore adsorption capacityOther chemical processesCombustible gas purificationPotassium persulfatePersulfate

The invention relates to a method for regenerating saturated active carbon adsorbing organic matters through microwave activation of potassium persulfate. The method comprises the following steps of: adding a potassium persulfate solution into saturated active carbon; performing microwave irradiation for 5 to 30 minutes; cooling to room temperature; and filtering and cleaning to obtain regenerated carbon, wherein the mass ratio of the saturated active carbon to the potassium persulfate is (1-5):1. Compared with the traditional active carbon regeneration method, the method has the advantages that the regeneration cost is reduced and the regeneration efficiency is improved. Advanced oxidation and microwave irradiation of persulfate are organically combined, so the regeneration efficiency of the active carbon is improved. A chemical catalyst is not used, so new pollutants are not introduced. Due to the action of microwave, the oxidation time is short, the regeneration time is shortened, and the regeneration efficiency is improved and can reach about 80 percent. According to the method, regeneration can be performed for times, namely more than eight times, and the mass loss and the strength loss of the active carbon after regeneration are small.

Owner:DONGHUA UNIV

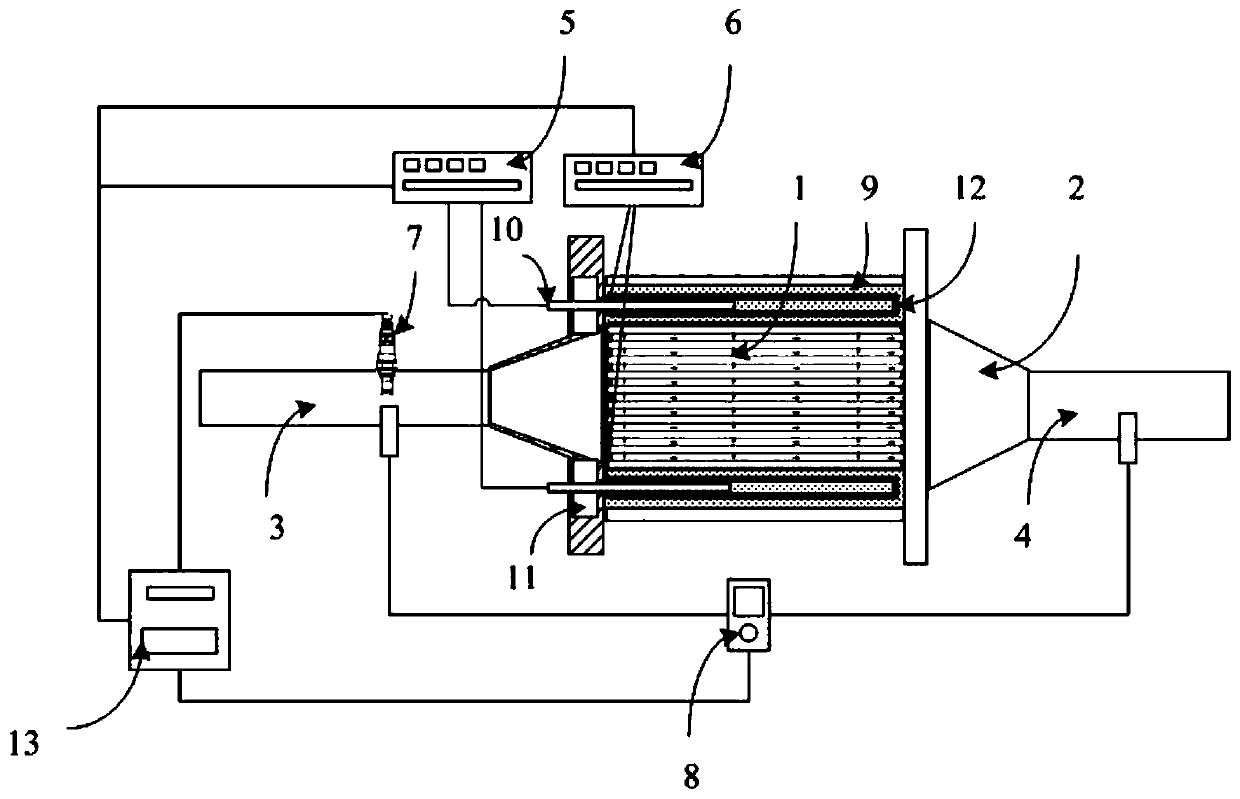

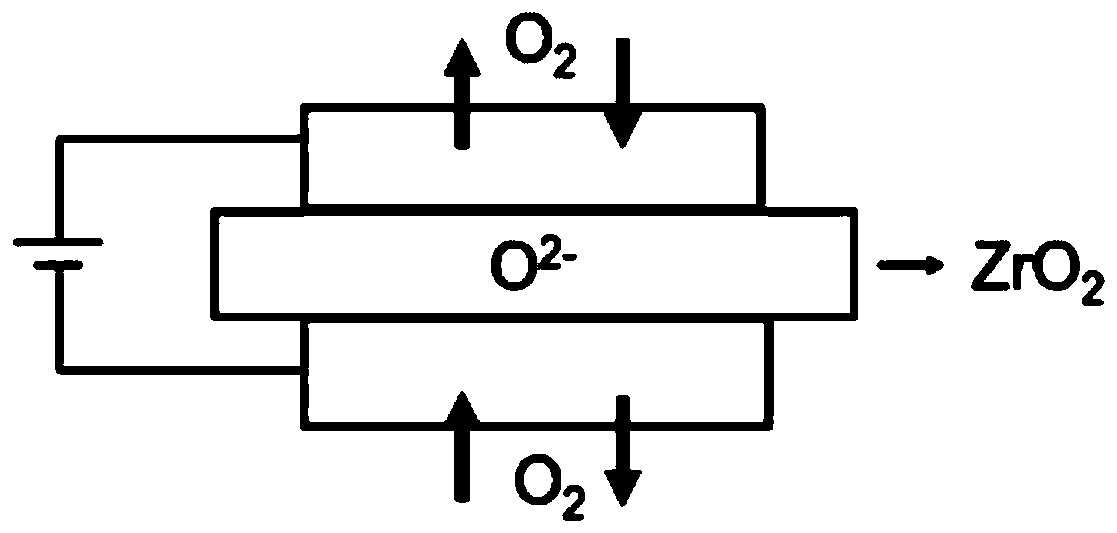

Active regeneration system and method for diesel engine particulate trap

ActiveCN109899134AIncrease oxygen concentrationIncrease temperatureInternal combustion piston enginesExhaust apparatusParticulatesElectricity

The invention discloses an active regeneration system and a method for a diesel engine particulate trap. The active regeneration system comprises a high-frequency ceramic body, an electric heating wire, an oxygen pump electrolyte sheet, and an oxygen guide pipe, wherein the high-frequency ceramic body is filled between a filter body of the particle trap and an outer shell of the particle trap, theelectric heating wire is arranged in the high-frequency ceramic body in a penetrating mode, the oxygen pump electrolyte sheet is arranged in the electric heating wire in a penetrating mode, and the oxygen guide pipe is connected with an inlet chamber of the particle trap. One end of the oxygen pump electrolyte sheet penetrates through the oxygen guide pipe and is electrically connected with an oxygen pump power supply, and the electric heating wire is electrically connected with a heating power supply; the gas inlet end of the particle trap is connected with a tail gas inlet pipe, an oxygen sensor is arranged in the tail gas inlet pipe, and the gas outlet end of the particle trap is connected with a tail gas discharge pipe; and a differential pressure sensor is further arranged in the particle trap, and the heating power supply, the oxygen pump power supply, the oxygen sensor and the differential pressure sensor are electrically connected with a controller respectively. The active regeneration system and method for the diesel particulate trap improve the active regeneration efficiency of the diesel particulate trap.

Owner:JIANGSU UNIV

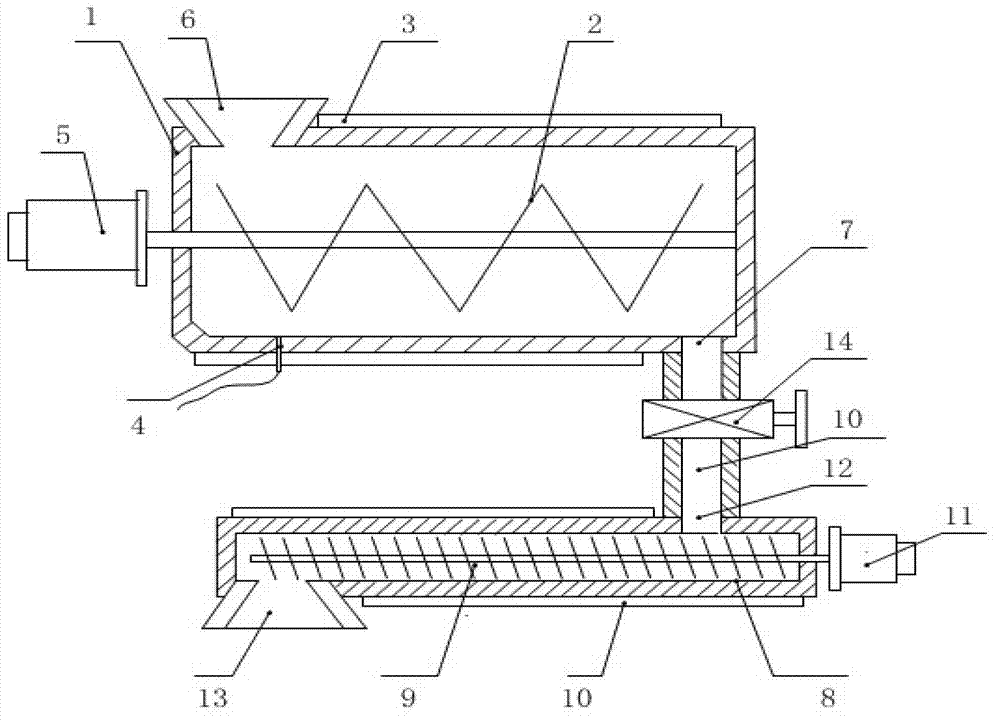

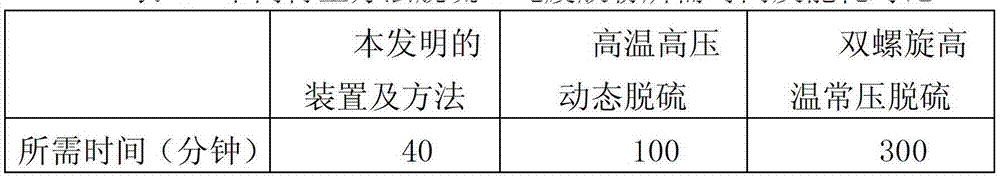

Device and method for regenerating waste rubber at normal pressure, medium temperature and low consumption

InactiveCN103205016ARecycling, environmental protection, energy saving and high efficiencyLow costChemical industryPlastic recyclingWaste rubberDrive motor

The invention relates to a device and a method for regenerating waste rubber at normal pressure, medium temperature and low consumption, and belongs to the field of reutilization of the waste rubber. The device comprises two parts, wherein the first part is a heating reaction kettle which comprises a tank body, a stirring paddle, a heater, a temperature sensor, a paddle driving motor, a first material inlet and a first material outlet; the second part is a cooler which comprises a cylinder body, a spiral, a cooling flow channel, a spiral driving motor, a second material inlet and a second material outlet; and the material outlet of the heating reaction kettle is connected with the material inlet of the cooler. The regeneration process flow which utilizes the device comprises the following steps of: simultaneously adding metered waste rubber, softening agents and activating agents to the heating reaction kettle; reacting at 160-250 DEG C for 15-40 minutes, and then opening a connecting valve to enter the cooler; conveying for 8-15 minutes through the spiral, and cooling materials to be lower than 80 DEG C. The device and method which are disclosed by the invention have the advantages of low manufacturing cost and environmental protection and energy saving in a production process, effectively solve the problem of wall adhesion of rubber powder in a regeneration process and are stable in product quality.

Owner:QINGWEI RUBBER SUQIAN +1

Novel ion exchange fiber and its application

InactiveCN102872833AEasy to prepareHigh adsorption valueOther chemical processesFibre typesChemical treatmentPolystyrene

The invention discloses a novel ion exchange fiber and its application. The ion exchange fiber is directly prepared by directly selecting raw materials having ion exchange functions without obtaining functional groups through a chemical treatment of grafting. The preparation method of the ion exchange fiber is simple, is in favor of the industrialized continuous production of products, and has a low economic cost. The ion exchange fiber prepared in the invention has the advantages of large exchange capacity, fast elution and adsorption speed, and the like. The filament diameter and the exchange capacity of the ion exchange fiber prepared in the invention are 5-100mum and 3.0-5.8mmol / g respectively. The matrix fiber of the ion exchange fiber has good comprehensive performances comprising good mechanical performances, high temperature resistance, acid and alkali resistance and the like. The preparation method of the novel ion exchange fiber comprises the following steps: mixing the raw materials comprising polystyrene (PS) and polyethylene (PE) with a compatilizer according to a certain weight ratio, adjusting an optimum spinning temperature, and carrying out melt spinning to prepare the base material of the ion exchange fiber; and carrying out chemical treatment of the base material to prepare the cation exchange fiber having sulfonic groups. The novel ion exchange fiber can be widely applied to the environmental protection field, the medicine and health field, the metallurgical filed, the water treatment field, the chemical adsorption field, the resource recovery field and the like.

Owner:冯淑芹

Regeneration method for alkali metal poisoned denitration catalyst

InactiveCN106179528AEfficient removalAvoid churnCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsRegenerative processActive component

The invention discloses a regeneration method for an alkali metal poisoned denitration catalyst. After ash removal is carried out, the alkali metal poisoned denitration catalyst is dipped in an ammonium salt aqueous solution; and then a mixed solution is transferred to a microwave reactor to carry out microwave treatment, and filtered, dried and roasted to obtain a regenerated denitration catalyst. The regeneration method for the alkali metal poisoned denitration catalyst disclosed by the invention is simple to operate, short in processing time and better in removal effect for alkali metals on the surface of an inactivated denitration catalyst, and further can remove most of calcium compounds on the catalyst. Furthermore, active components of the denitration catalyst are not lost greatly in the regenerative process.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

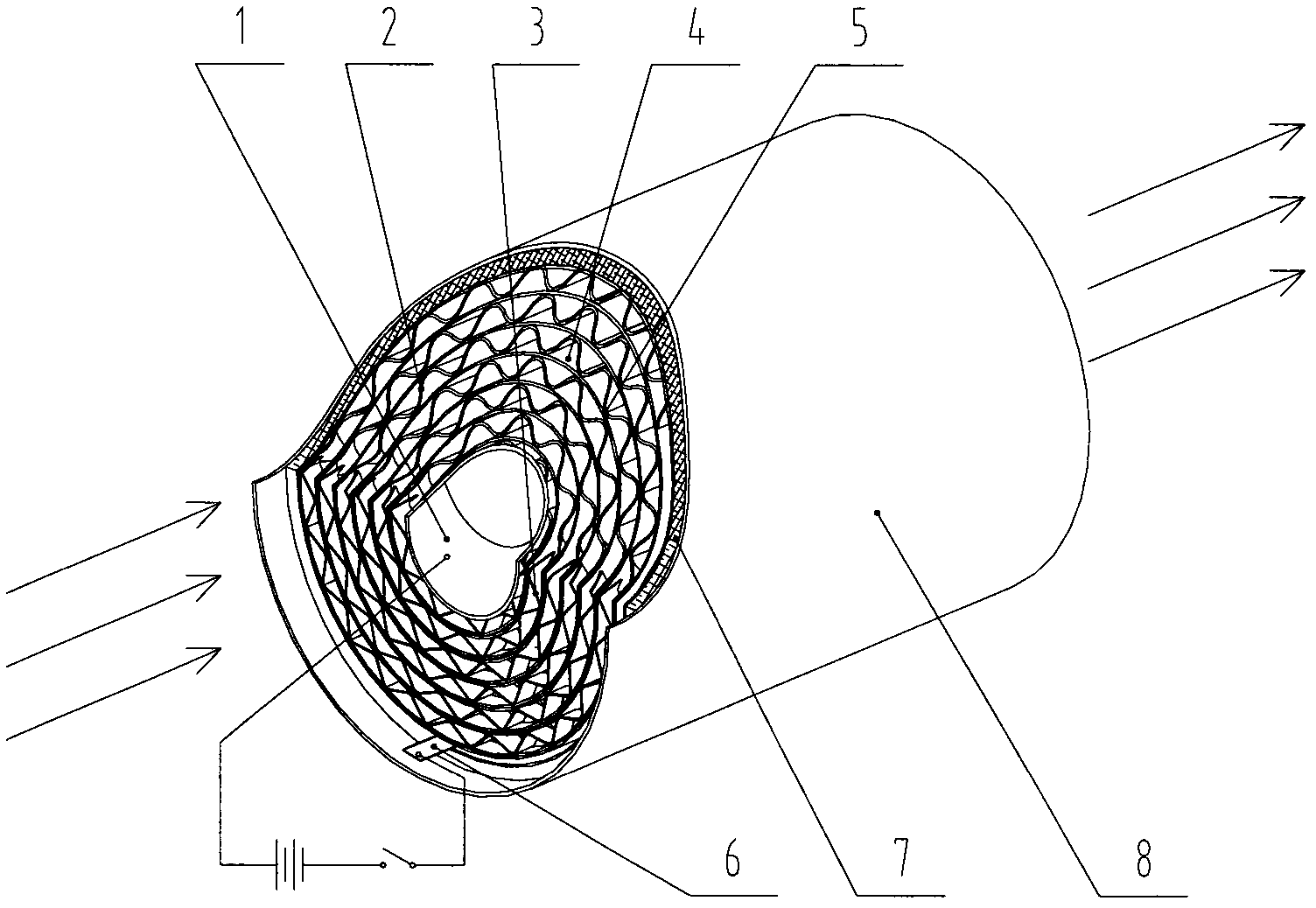

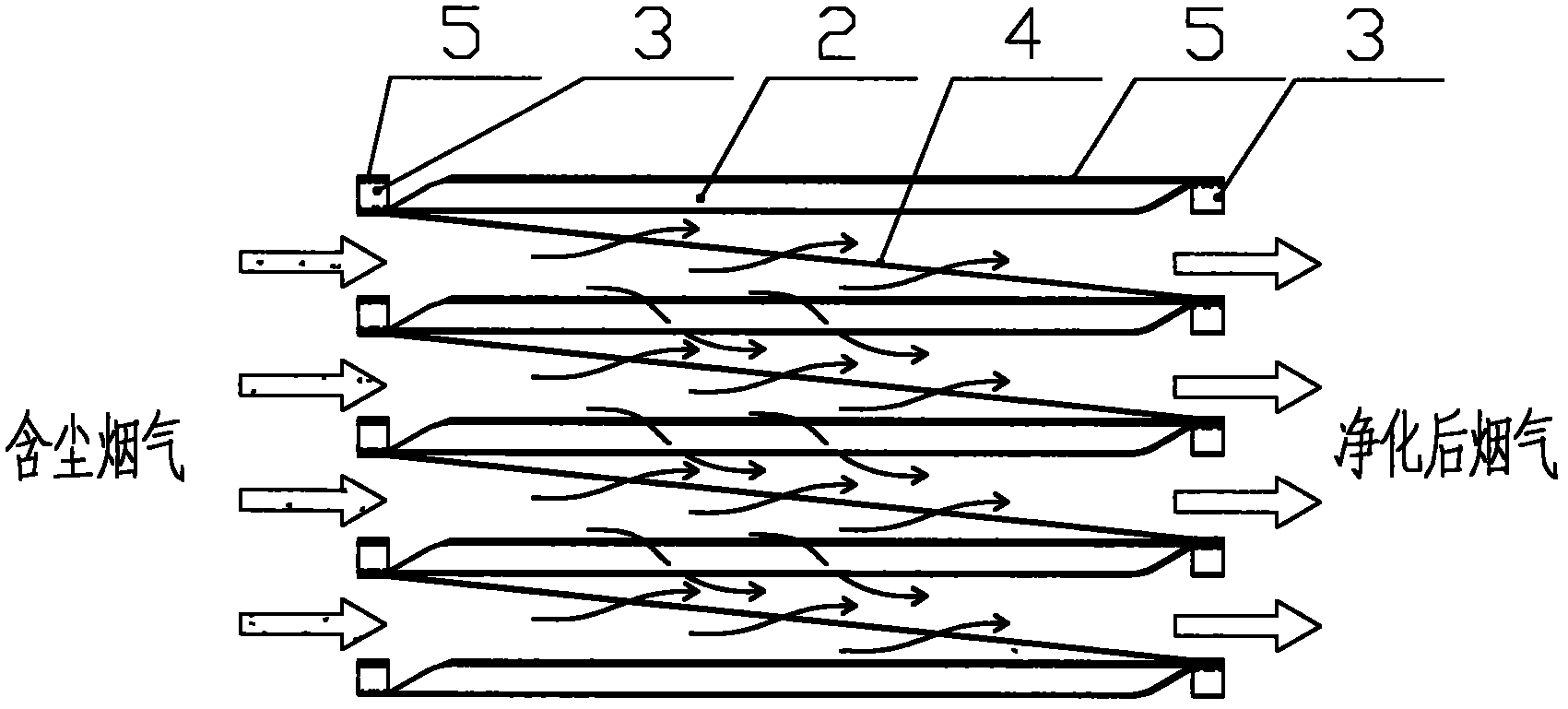

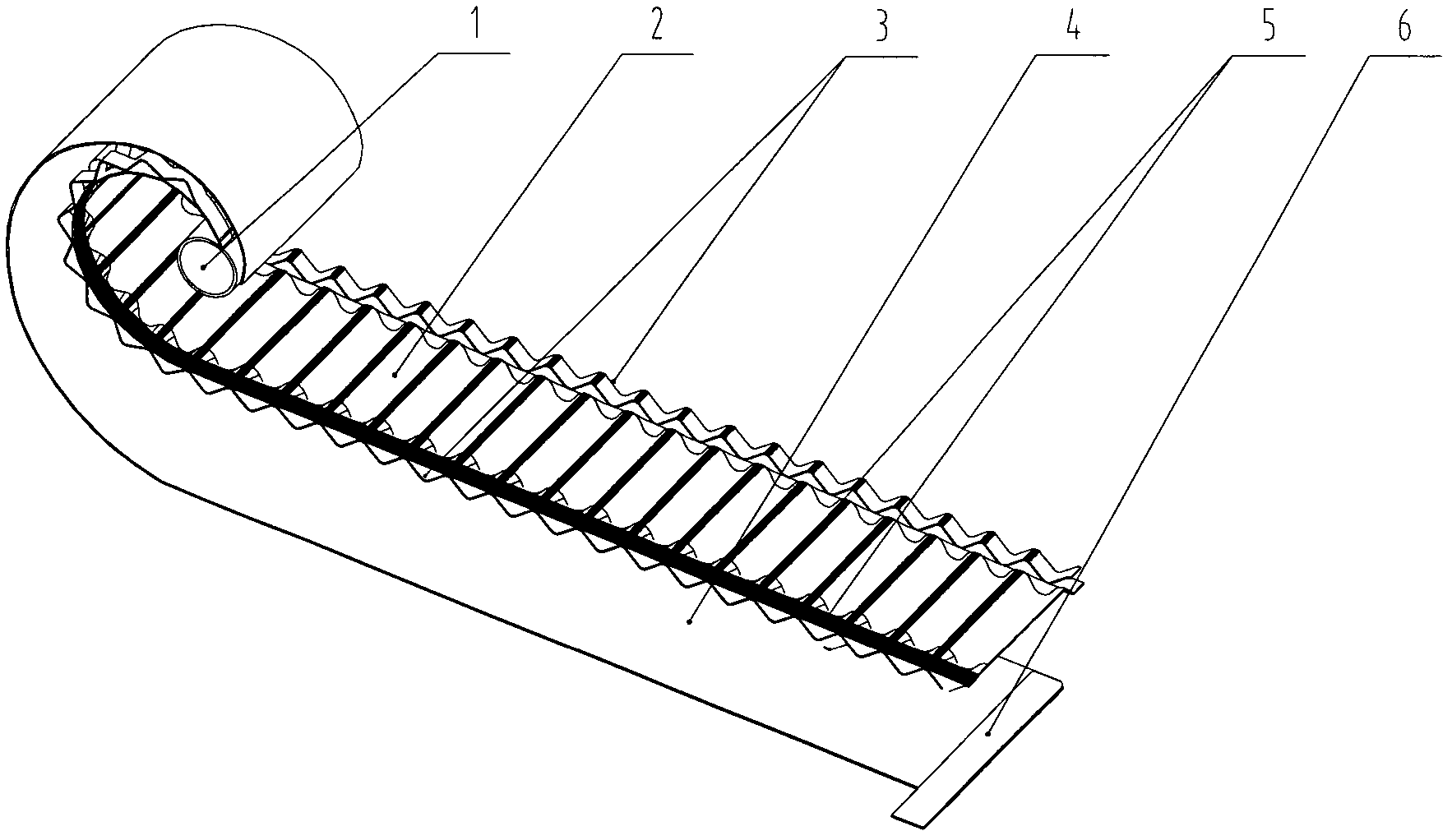

Electrothermic type diesel engine exhaust gas grain catcher

ActiveCN102071991AImprove filtration efficiencyReduce exhaust back pressureExhaust apparatusSilencing apparatusMetal stripsFiltration

The invention provides an electrothermic type diesel engine exhaust gas grain catcher, which comprises a conductive central tube, corrugated sheet filter elements, hold-down strips, flat plate filter elements, insulating coatings, a conductive metal strip, an outer ring insulating layer and a metal shell. The flat plate filter elements with the same width are superposed on a lower layer of the corrugated sheet filter elements to form a filter element, the head end of the filter element is flat and level, and is superposed and welded with a bus of the conductive central tube; the tail end of the filter element is closely welded together with the conductive metal strip; two hold-down strips coated with the insulating coatings are welded on straight edges of two ends of the corrugated sheet filter elements respectively; the filter element is wound into a cylindrical filter element by taking the conductive central tube as an axis, and outer layer of the filter element is bound up with the outer ring insulating layer and then is placed in the metal shell; and the height of the hold-down strips is the same as that of the wave crests of the corrugated sheet filter elements. The electrothermic type diesel engine exhaust gas grain catcher integrates the functions of filtering and heating, and has the characteristics of high filtration rate, low exhaust back pressure, direct and overall energization and heating, small power consumption, short regeneration time and simple and reliable control.

Owner:广东新力金属有限公司

Regeneration method of catalyst for producing diphenylamine with phenylamine continuous condensation

ActiveCN101172262AAvoid lostFlexible switchingMolecular sieve catalystsCatalyst regeneration/reactivationActivity indexNitrogen

The invention relates to a catalyst regeneration method used for preparing diphenylamine by aniline consecutive condensation. The method is a method of coke burning regeneration of nitrogen including oxygen in an adoption device, and comprises the steps of purging the complete system with nitrogen to remove reaction mixture, reducing the temperature of the system and replacing the oxygen gas by nitrogen, wherein, the regenerated temperature and the oxygen content are strictly controlled by adopting a method of multiple step burning regeneration, the operation is simple, the regenerating time is short, and the physicochemical property and the activity index of the regenerated catalyst are basically identical to the fresh catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Absorption liquid for gas desulfurization and desulfurization method thereof

InactiveCN101613089AShort regeneration timeOvercoming the problem of slow real lifeDispersed particle separationSulfur preparation/purificationOrganic sulfide compoundCatalyst degradation

The invention relates to an absorption liquid for gas desulfurization and a desulfurization method thereof, solving the problems that catalysts in the prior art have slow regeneration, absorption tower clogging, high degradation speed of desulfurater and the like. Phenol, quinine, microbial enzyme, vanadium and complex preparation serve as catalysts; under the condition of alkaline compounds, gas is led in to quickly oxidize inorganic sulphide and organic sulphide in absorption liquid to be sulphur. The gas desulfurization method of the invention has the advantages of small amount of catalyst, high regeneration efficiency of catalyst, low degradation speed of catalyst, no absorption tower clogging and the like.

Owner:苏喜太

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com