S-1 full-silicon molecular sieve and preparation method thereof as well as application of S-1 full-silicon molecular sieve in caprolactam preparation

A technology of all-silicon molecular sieve and caprolactam, which is applied in the direction of molecular sieve catalysts, molecular sieve characteristic polycrystalline silicon, chemical instruments and methods, etc., can solve the problems of difficult regeneration, high price, easy deactivation, etc., and achieve easy and fast regeneration, The effect of reducing labor intensity and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

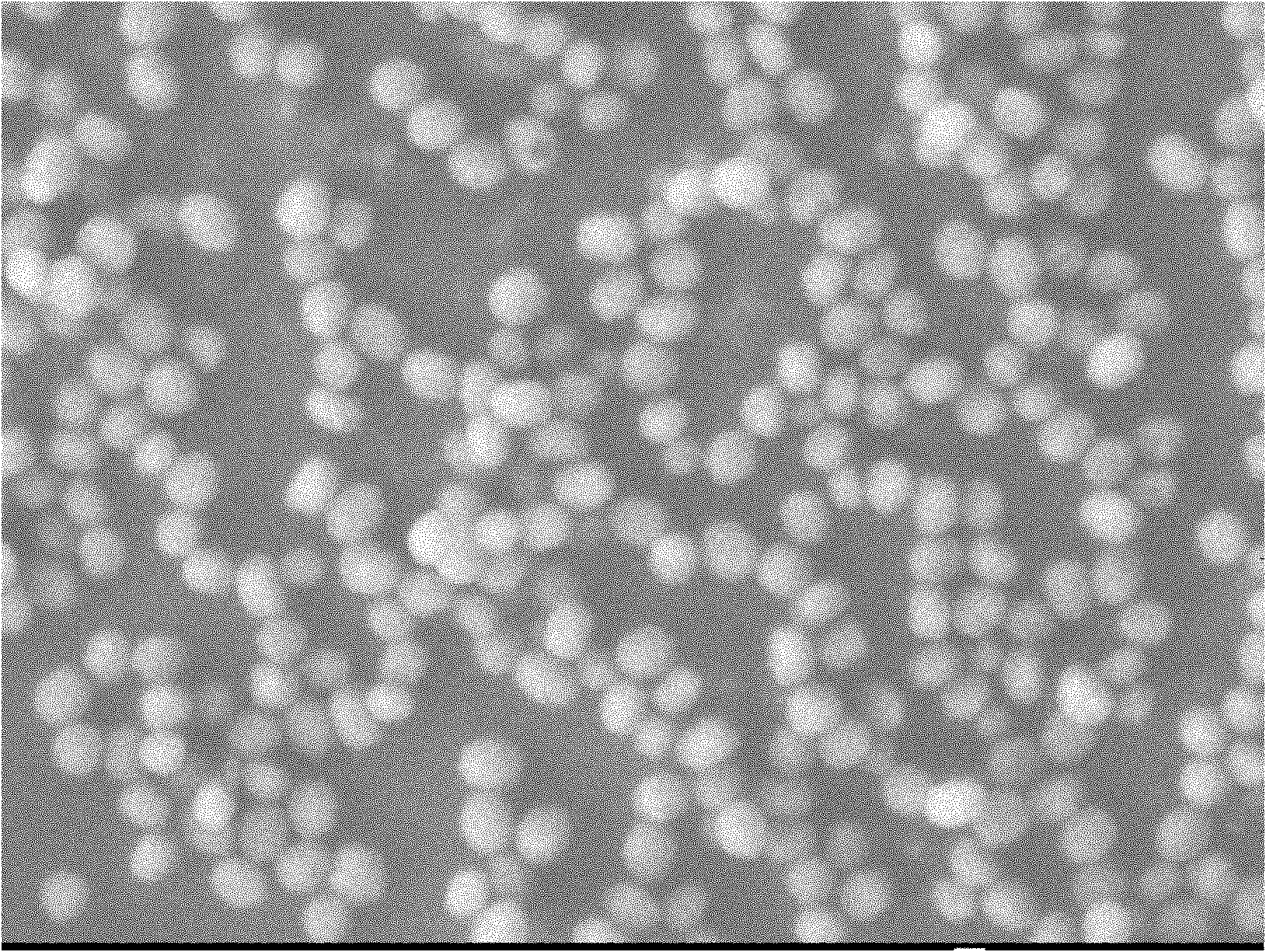

Image

Examples

Embodiment 1

[0030] A. The synthesis of tetrapropyl ammonium hydroxide template:

[0031] 201 * 7 anion resin 100L is packed in the ion-exchange column, is 1m / h with 10L mass fraction successively with the hydrochloric acid of 6% and the sodium hydroxide aqueous solution of 10L mass fraction to carry out pretreatment to described anion resin with 10L mass fraction Treatment, then regenerate the anion resin with a linear speed of 2m / h and 6% sodium hydroxide aqueous solution with a mass fraction of 100L; after regeneration, wash the anion resin with deionized water until the effluent contains Na +The content is below 100ppm; use 100L mass fraction of 5% tetrapropylammonium bromide aqueous solution to pass through the ion exchange column with a linear velocity of 1m / h, and collect the tetrapropylammonium hydroxide aqueous solution obtained after the exchange for subsequent use.

[0032] Synthesis of B.S-1 all silicon molecular sieve

[0033] 160 L of tetrapropylammonium hydroxide aqueous so...

Embodiment 2

[0040] A. Template Synthesis

[0041] 201 * 7 anion resin 100L is packed in the ion-exchange column, be that 4% hydrochloric acid and 100L mass fraction are used successively with 100L mass fraction as 4% sodium hydroxide aqueous solution to the described anion resin with linear velocity 2m / h Treatment, and then regenerate the anion resin with a linear speed of 1m / h and 600L of 6% sodium hydroxide aqueous solution; after regeneration, wash the anion resin with deionized water until the effluent contains Na + The content is below 100ppm; use 100L mass fraction of 8% tetrapropylammonium bromide aqueous solution to pass through the ion exchange column with a linear velocity of 2m / h, and collect the tetrapropylammonium hydroxide aqueous solution obtained after the exchange for subsequent use.

[0042] Synthesis of B.S-1 all silicon molecular sieve

[0043] Put 100 L of tetrapropylammonium hydroxide aqueous solution with a mass fraction of 10% into the reaction kettle, and turn on...

Embodiment 3

[0050] A. Template Synthesis

[0051] 201 * 7 anion resin 100L is packed in the ion-exchange column, be that 3m / h is that 4% hydrochloric acid and 100L mass fraction are used successively with 100L mass fraction to carry out pretreatment to described anion resin with 4% sodium hydroxide aqueous solution with line speed Treatment, then regenerate the anion resin with a linear speed of 3m / h and 5% sodium hydroxide aqueous solution with a mass fraction of 500L; after regeneration, wash the anion resin with deionized water until the effluent contains Na + The content is below 100ppm; use 250L mass fraction of 15% tetrapropylammonium bromide aqueous solution to pass through the ion exchange column with a linear velocity of 3m / h, and collect the tetrapropylammonium hydroxide aqueous solution obtained after the exchange for subsequent use.

[0052] Synthesis of B.S-1 all silicon molecular sieve

[0053] 180 L of tetrapropylammonium hydroxide aqueous solution with a mass fraction of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com