Microwave radiation reclaiming method for environment-friendly high-strength reclaimed rubber

A technology of high-strength reclaimed rubber and microwave radiation, which is applied in the field of waste rubber regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. The formula of waste rubber powder microwave reclaimed rubber:

[0025] Raw material name Mass parts

[0026] 9.00-20 Heavy-duty tire crown preparation 20 mesh rubber powder 100.00

[0027] Softener Rosin 12.00

[0028] Regenerant dipentene 0.40.

[0029] 2. Microwave reclaimed rubber performance testing formula:

[0030] Raw material name Mass parts

[0031] Microwave reclaimed rubber 100.00

[0032] Accelerator NS 2.80

[0033] Zinc oxide (indirect method, primary) 2.50

[0034] Sulfur 1.20

[0035] Stearic acid 0.33.

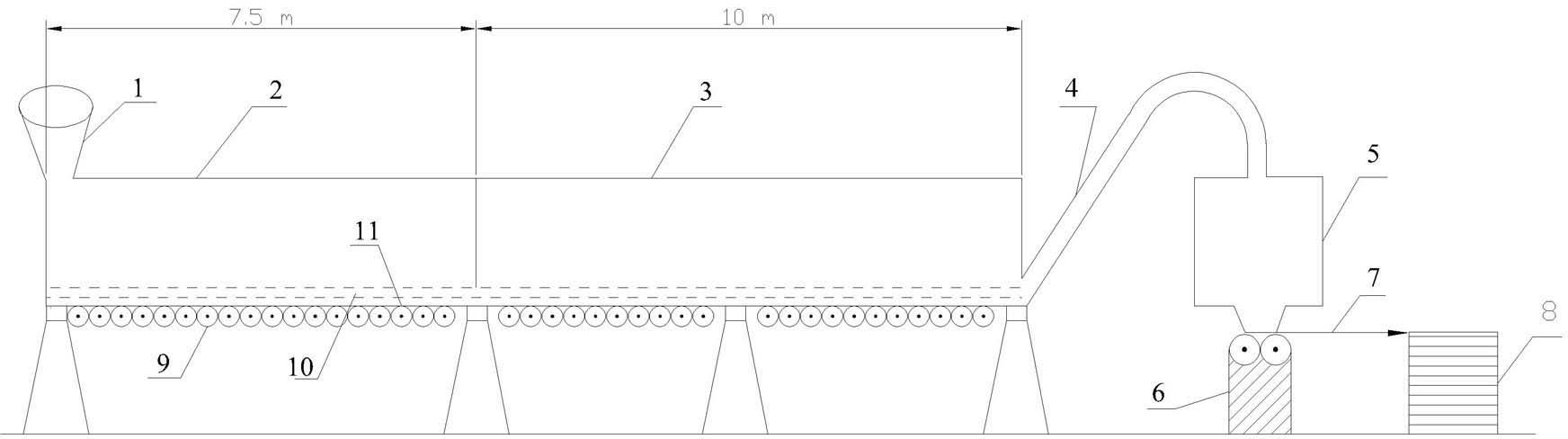

[0036] Preparation :according to figure 1 The process flow diagram shown and figure 2 The flow chart of the microwave regeneration equipment is shown, the raw materials are weighed according to the proportion, and the dried waste rubber tire crown rubber powder with a particle size of 20 mesh, rosin and regeneration agent dipentene are automatically measured and weighed according to the ratio in the following formula Device 1 weighs a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com