Patents

Literature

146results about How to "Low regeneration temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

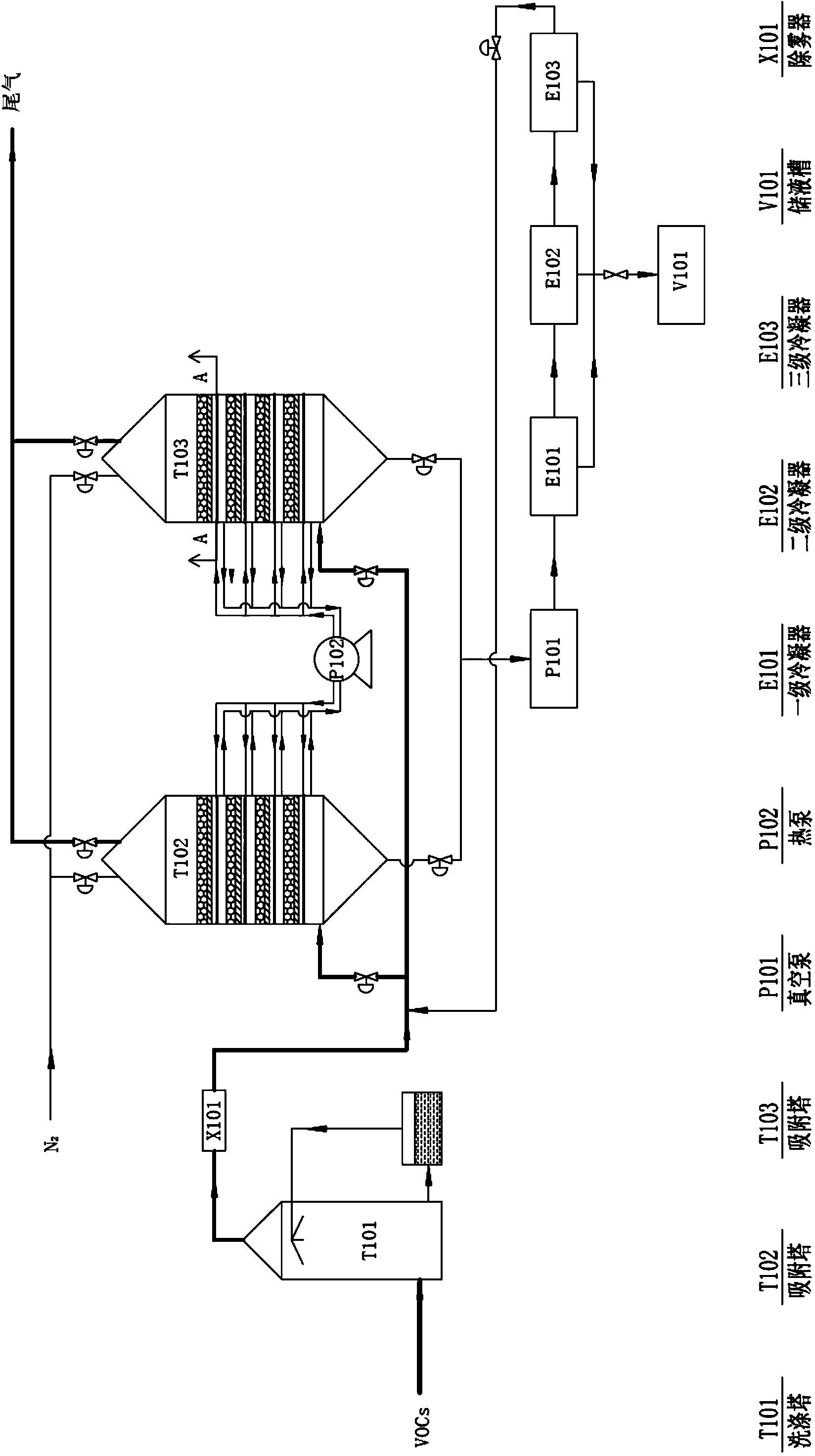

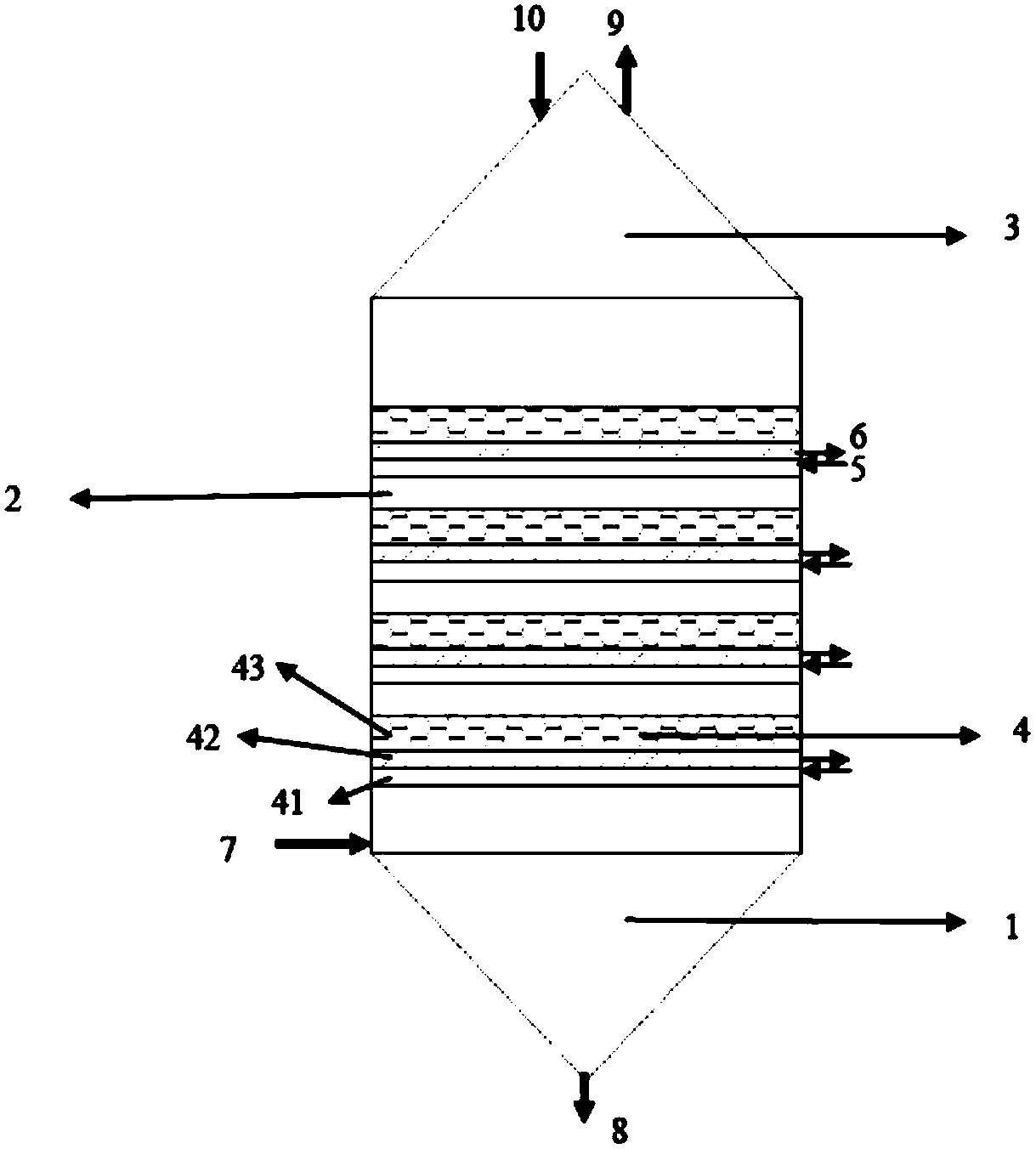

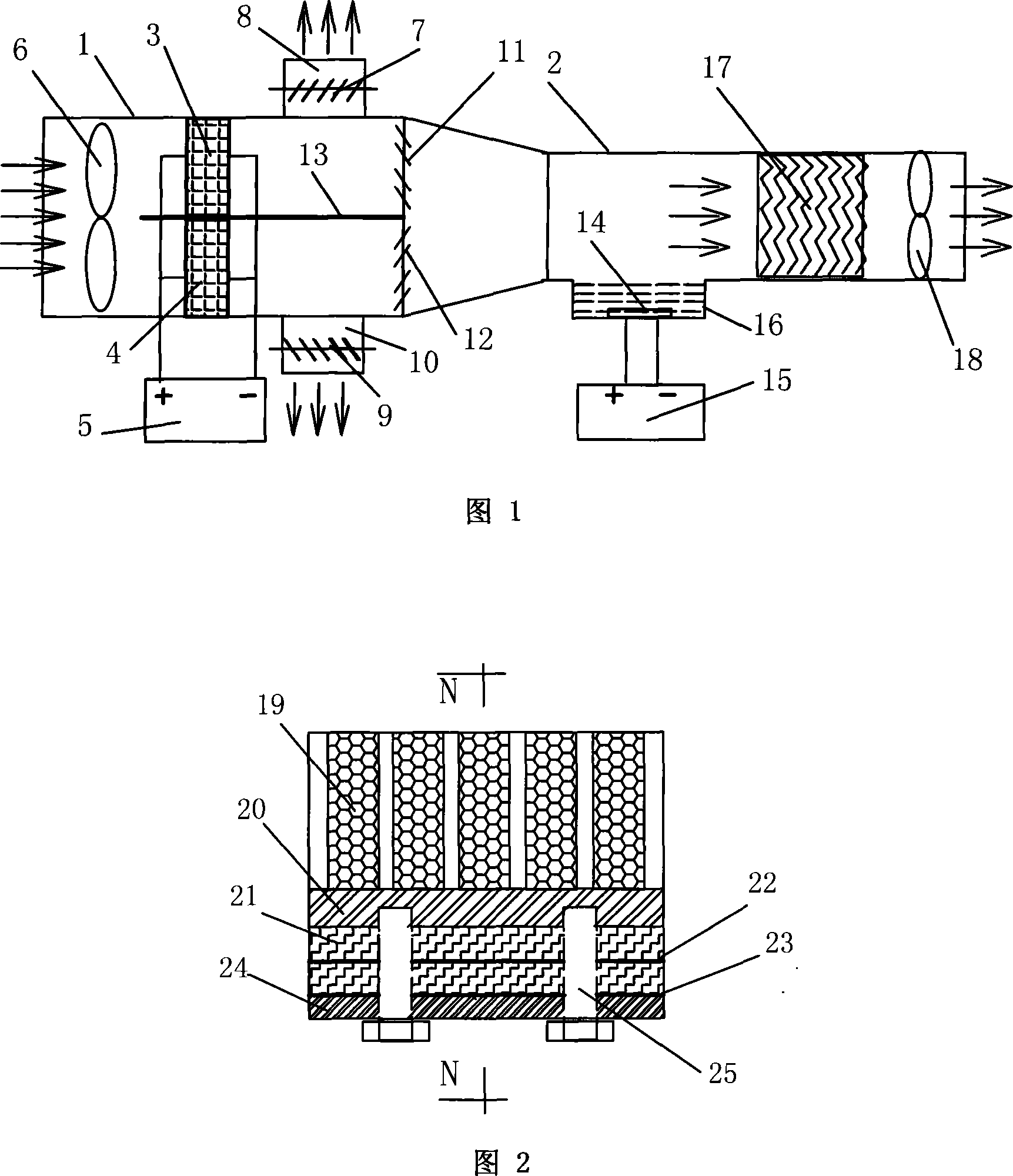

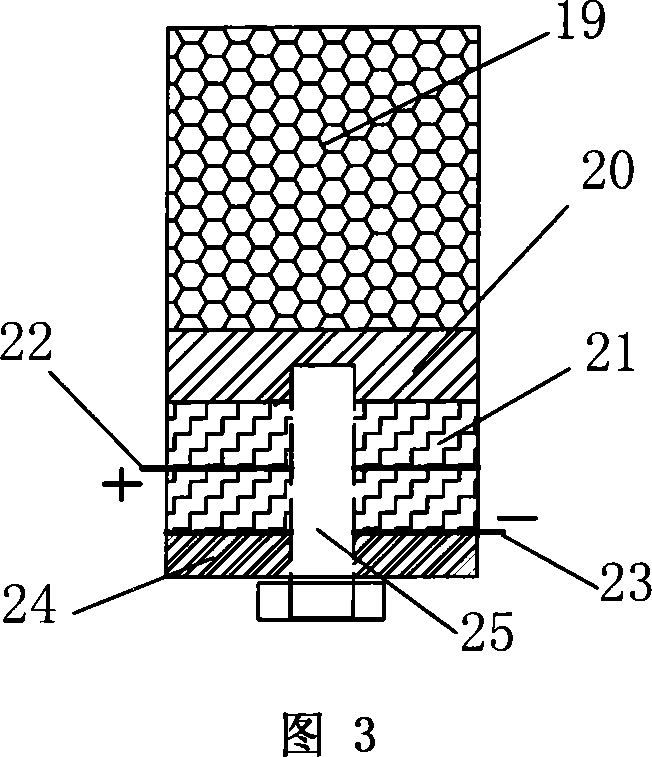

Organic waste gas adsorbing recovery device and process

ActiveCN103877827AHigh recovery rateAvoid cokingDispersed particle separationProduct gasHigh concentration

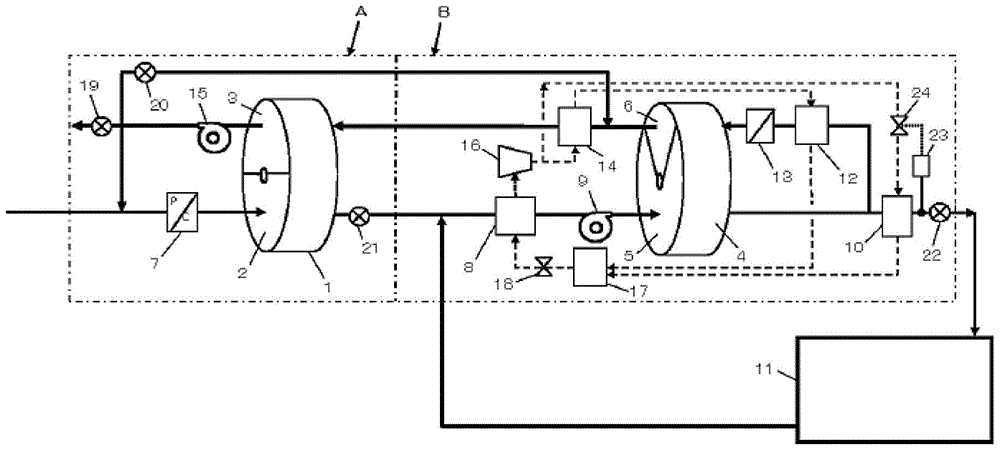

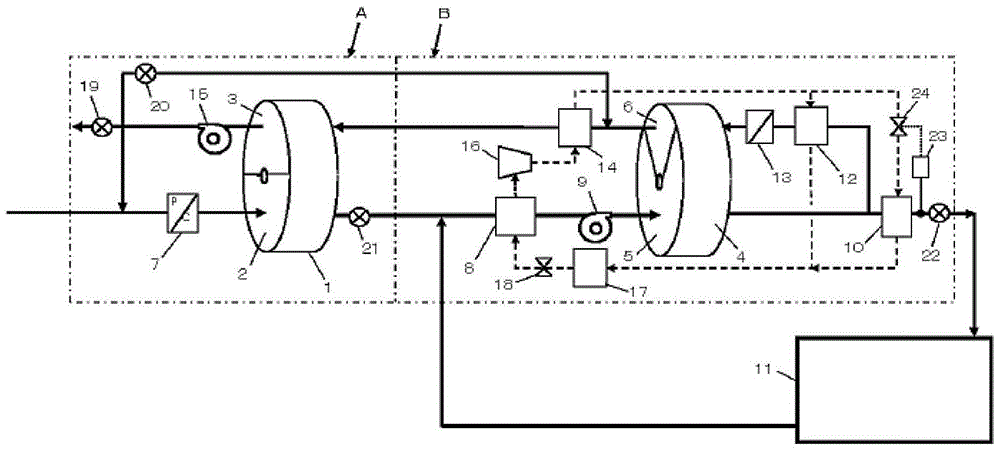

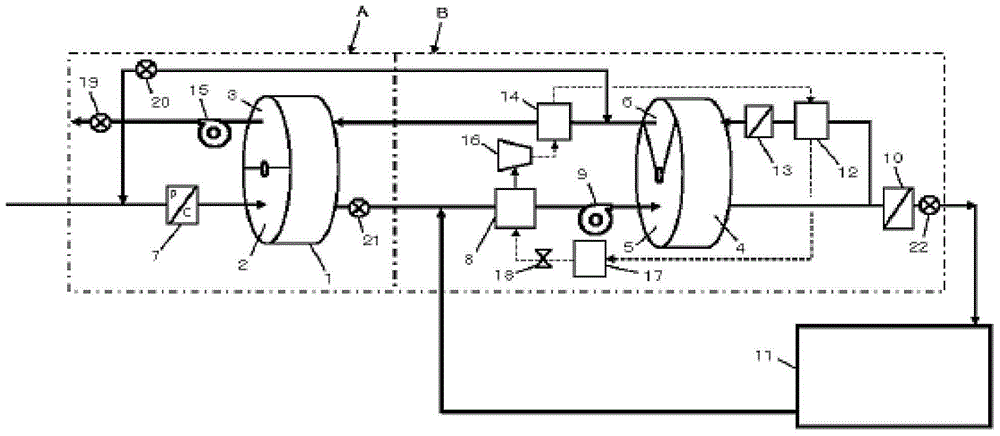

The invention discloses an organic waste gas adsorbing recovery device and a process. The device comprises at least two macromolecule resin adsorbing towers, a heat pump, a vacuum pump, a condenser, a liquid storing tank and the like, wherein the macromolecule resin adsorbing towers are internally provided with waste gas inlet regions, purifying regions for adsorbing and purifying gas and a purifying gas discharging region; the purifying regions are provided with adsorbing layers which are horizontally paved, the adsorbing layers are composed of multi-hole supporting plates fixed on the adsorbing towers, heat exchanging coils paved above the multi-hole supporting plates and macromolecule resin layers which are fully paved on the cross sections of the adsorbing towers above the heat exchanging coils successively in a overlaying manner, and the heat exchanging coils are provided with inlets and outlets communicated with the heat pump arranged outside the adsorbing towers. The organic waste gas adsorbing recovery device and the process provided by the invention have the advantages that a non-flammable macromolecule resin is adopted as an adsorbing material, the removing rate of middle-high concentration organic waste gas is more than 98%, the organic waste gas recovery rate is more than 95%, the resin is fully regenerated, and the organic waste gas can reach the discharge standard.

Owner:杭州润信科技有限公司

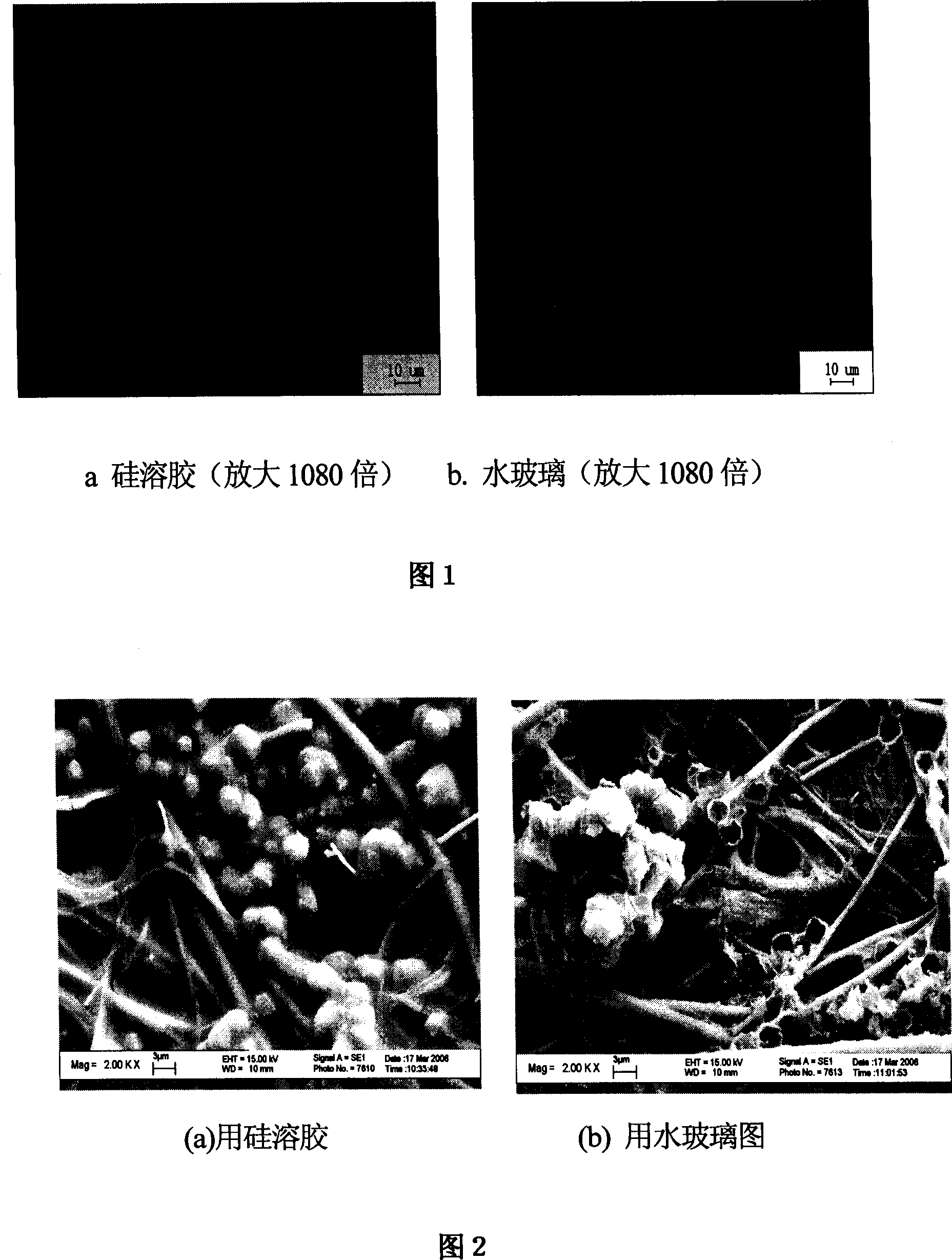

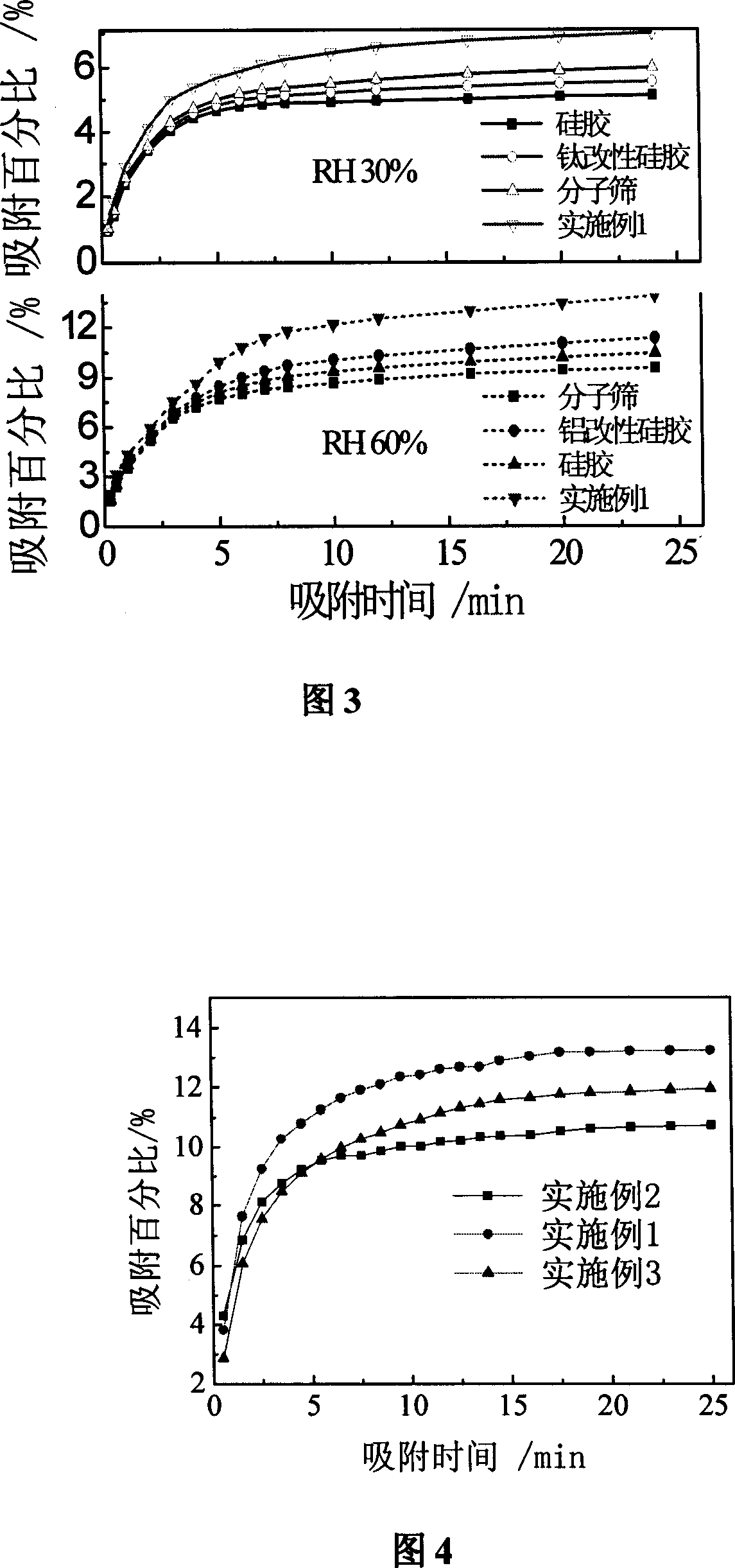

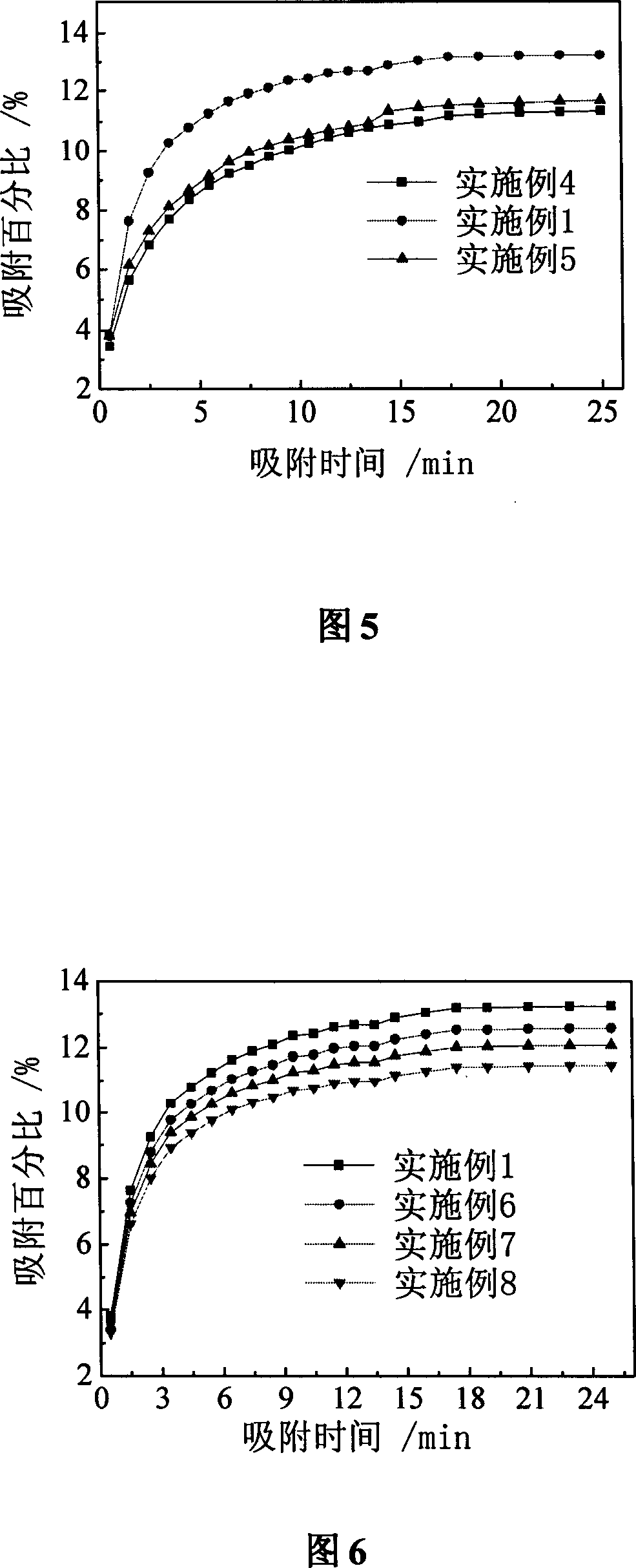

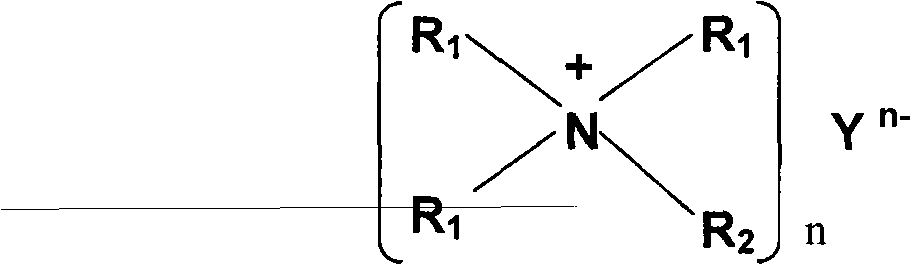

Preparing process of composite block adsorbent of molecular sieve and modified silica gel

InactiveCN1986046AIncrease the areaHigh pore volumeOther chemical processesAlkali metal oxides/hydroxidesFiberSorbent

The preparation process of composite block adsorbent of molecular sieve and modified silica gel includes the following steps: soaking ceramic fiber paper in water glass and hot pressing to form corrugated paper, adhering to flat sheet paper through the soaking at the same condition to form honeycomb block, drying, soaking the block into metal salt solution to react, washing with clear water, soaking the block in mixed liquid comprising silica sol and molecular sieve, taking out, sweeping to eliminate liquid and air drying to obtain the adsorbent. The adsorbent has homogeneous distribution of adsorbent grains on the base material, high adsorption amount, low regeneration temperature and high heat stability, and is suitable for adsorbing dehumidifying and whole heat recovery at different humidity and / or different temperature.

Owner:SOUTH CHINA UNIV OF TECH

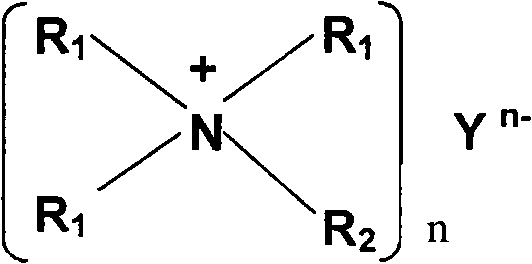

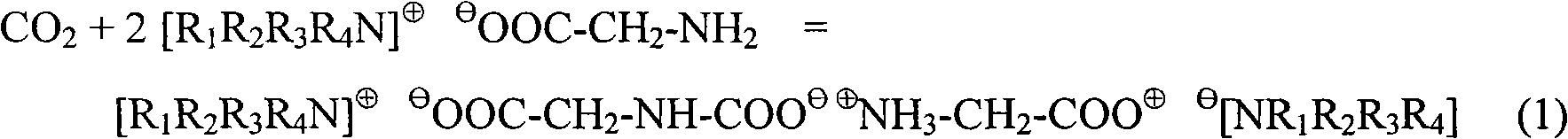

Special MDEA formula solution activated by functional ion liquid for CO2 gas absorption separation

InactiveCN101804292AReduce lossOvercome the disadvantage of high energy consumptionDispersed particle separationBy chemical separationSulfolanePoly(ethylene glycol) dimethyl ether

The invention relates to a special N-methyldiethanolamine formula solution activated by ion liquid for CO2 gas absorption separation, which consists of the following ingredients in mass percent: 35 to 50 percent of N-methyldiethanolamine, 5 to 20 percent of low-viscosity kalescent functional ion liquid, 15 to 30 percent of dimethyl ether of polyethlene glycol and / or sulfolane and 15 to 30 percent of water, wherein cations of the low-viscosity kalescent functional ion liquid are tetraalkylammonium ions, and anions of the low-viscosity kalescent functional ion liquid are amino acid radicals or organic carboxylate anions. The formula solution of the invention has the advantages that the high mass transfer performance of the absorption-desorption process is improved, the material consumption in the use process is low, the defect of high energy consumption because a large amount of water vapor is brought away during the absorbing agent regeneration, and the invention belongs to an energy-saving formula with high green degree. The regeneration temperature of the solution is lower than that of the traditional absorbing liquid, the grade of a heat source required to be provided in the regeneration process is reduced, energy sources can be saved, the stability of the absorbing agent solution in the operation is high, the consumption of each absorption-desorption circulation is low, and in addition, the cost is low.

Owner:NANJING UNIV

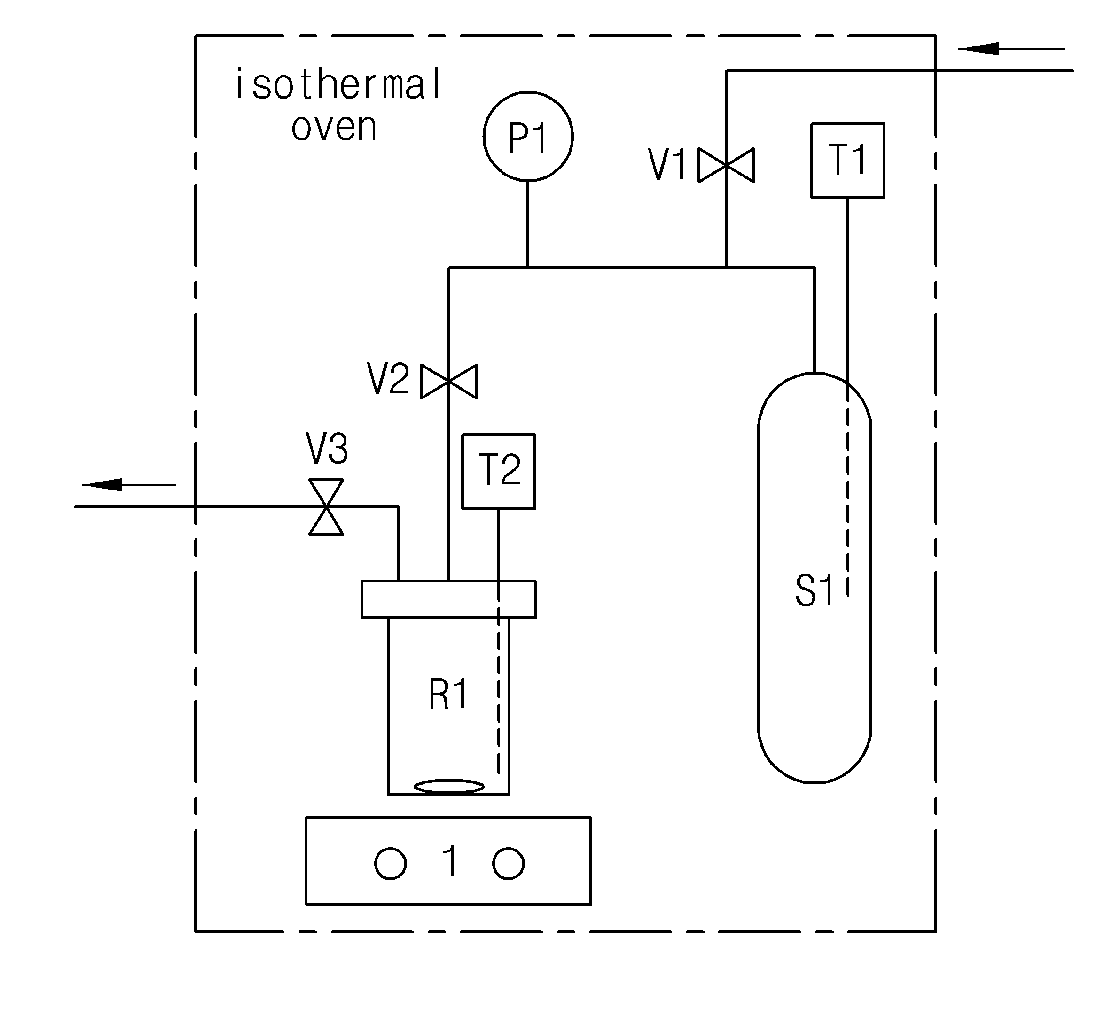

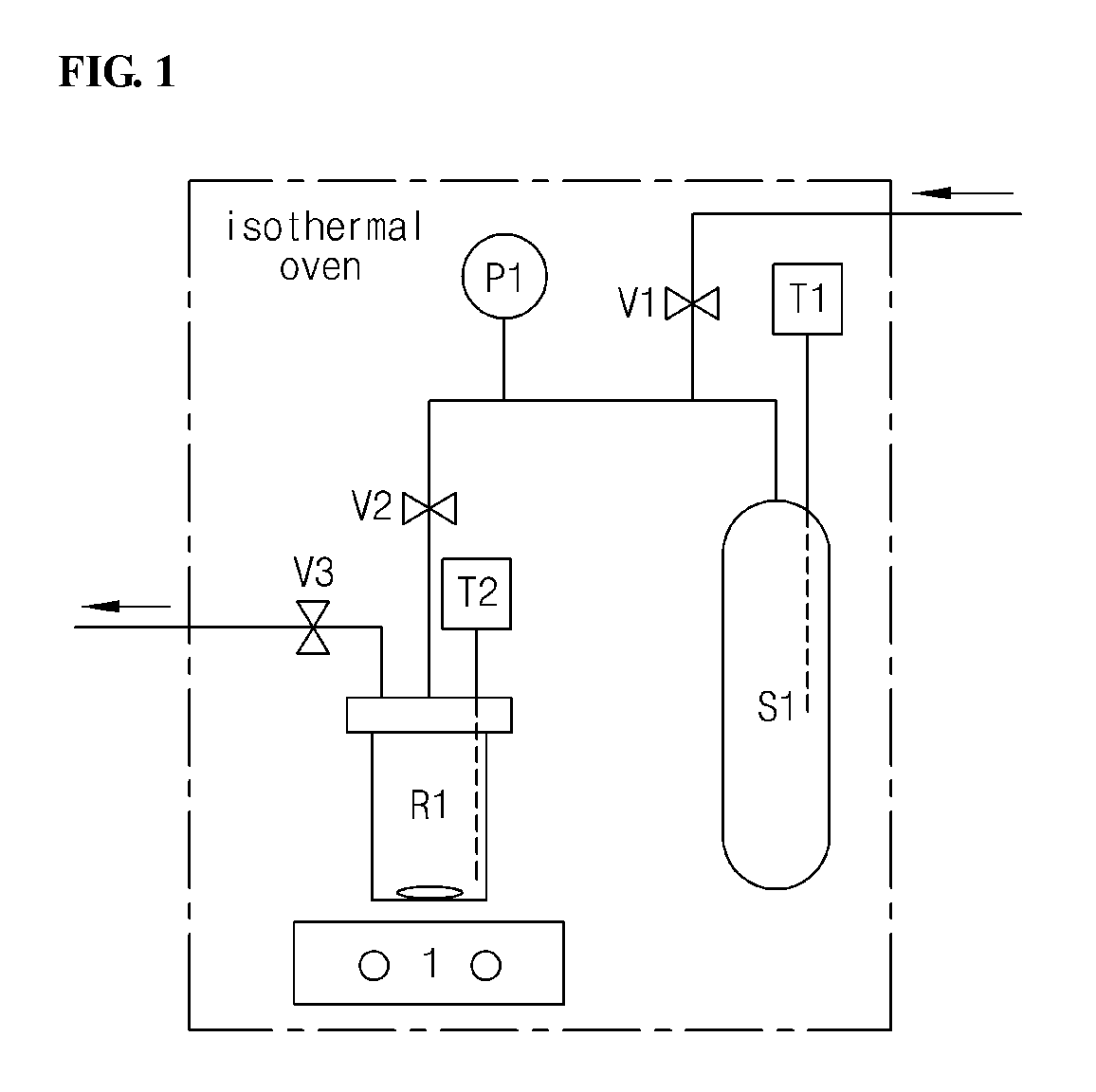

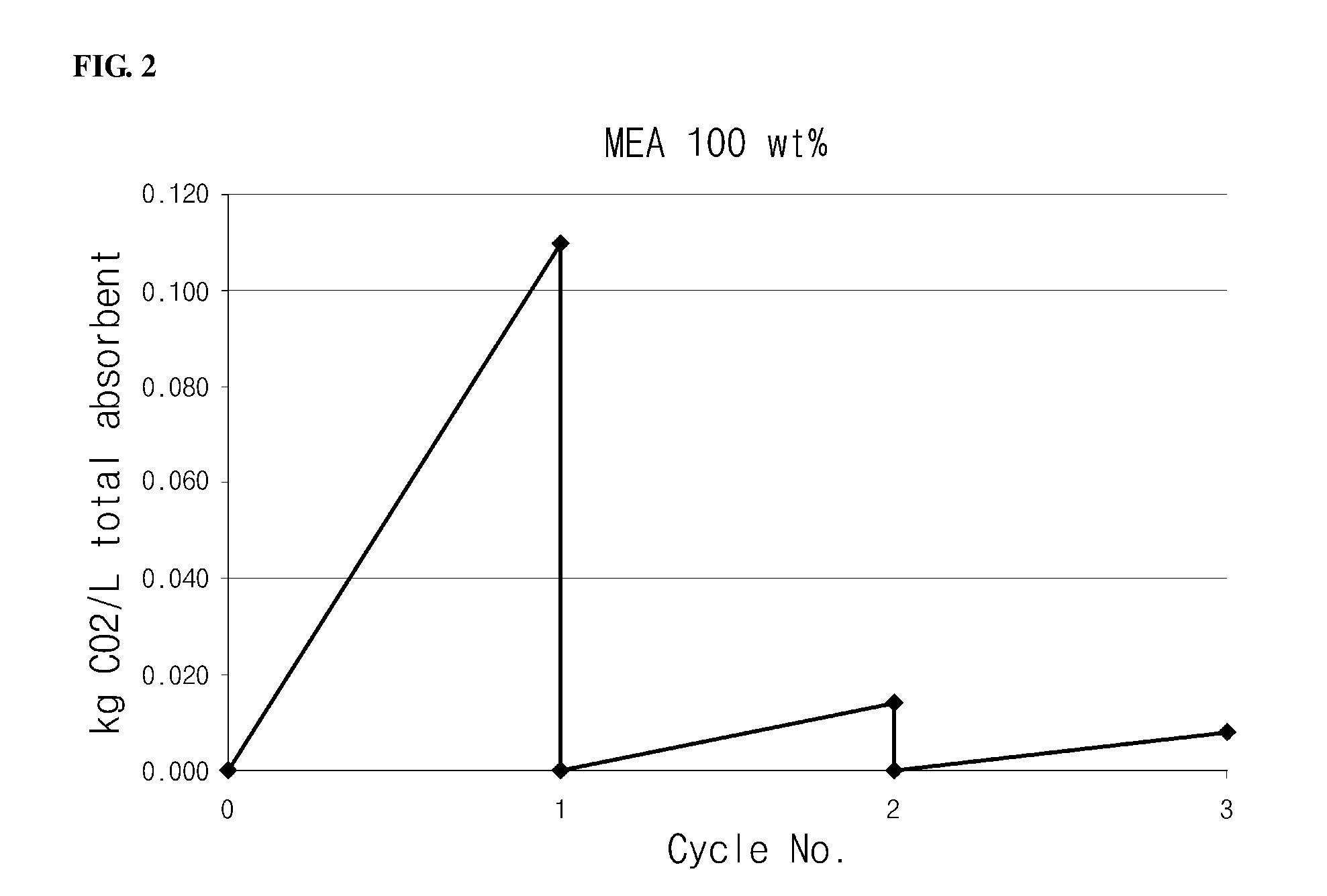

Carbon dioxide absorbents

InactiveUS20110214566A1Improve thermal stabilityExcellent CO absorbing capacityLiquid degasificationOther chemical processesAbsorption capacityIonic liquid

The present invention relates to a carbon dioxide absorbent. In particular, the present invention relates to a carbon dioxide absorbent comprising an ionic liquid, amine and glycol. Since the carbon dioxide absorbent of the present invention can retain excellent CO2 absorption capacity despite repetitive regenerations at low temperature, it can reduce energy consumption and a loss of absorbents used, and therefore, can be effectively used for a process of collecting carbon dioxide from exhaust gas and natural gas and separating the same.

Owner:HYUNDAI MOTOR CO LTD +1

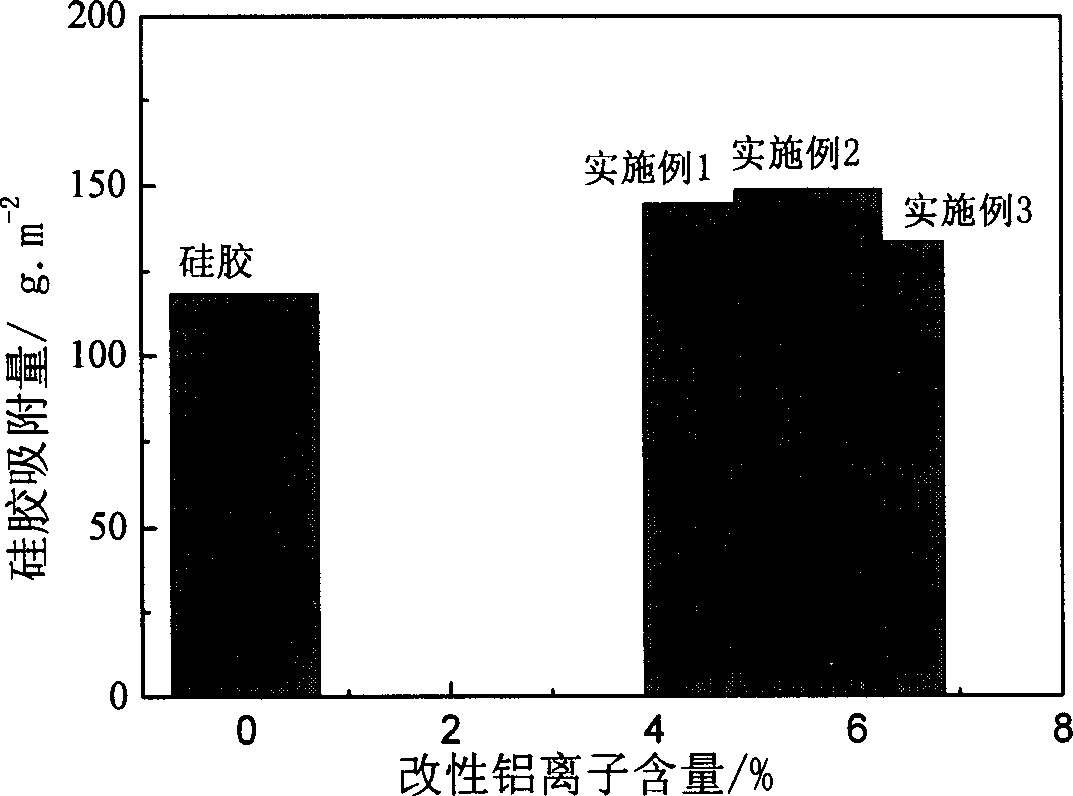

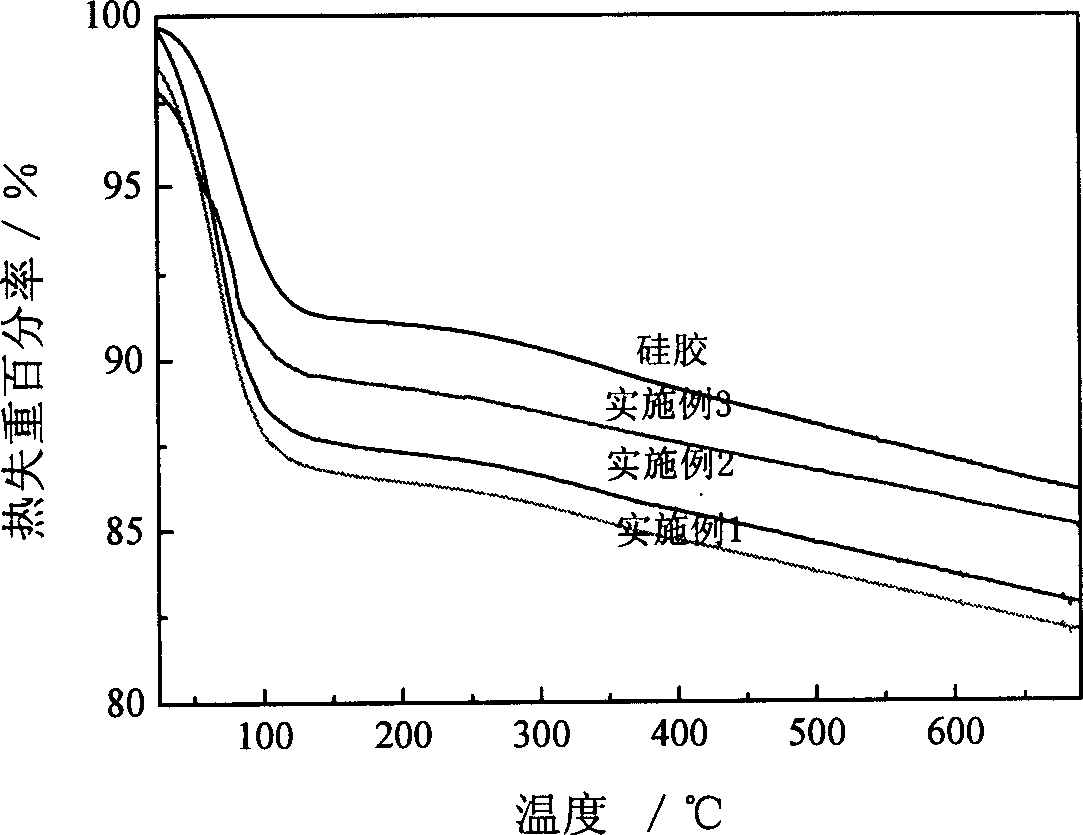

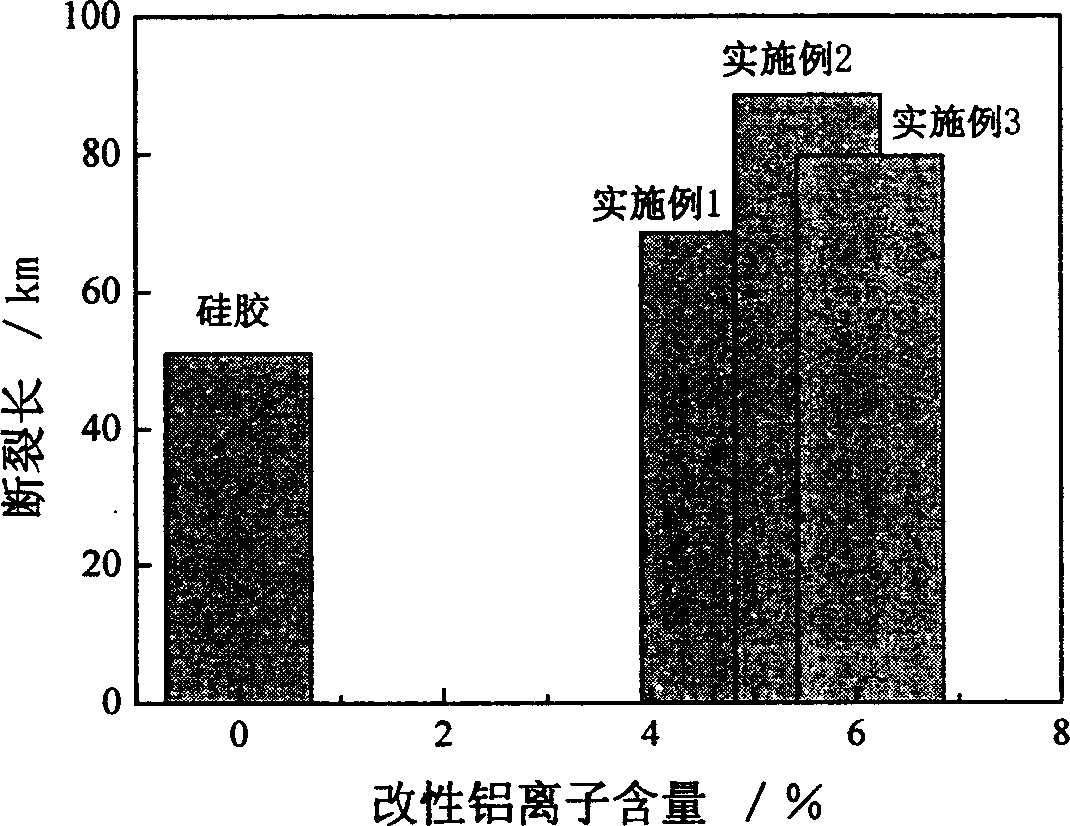

Aluminium modified silica-gel adsorbent material and its preparing process

InactiveCN1586711AHigh mechanical strengthLarge adsorption capacitySilicon compoundsFiberRoom temperature

The preparation process of aluminum modified silica gel adsorbent material includes the following steps: soaking inorganic fiber paper in water glass at room temperature for 2-5 hr and drying for 10-24 hr; compounding water solution of soluble aluminum salt, adding dilute acid solution to regulate pH to 0.5-2, heating to 30-80 deg.c, soaking the inorganic fiber paper under powerful stirring for co-precipitation in the surface and interval of the inorganic fiber paper via full reaction for 12-24 hr; washing the inorganic fiber paper with clear water to pH 7, air drying and programmed heating treatment. The aluminum modified silica gel adsorbent material thus prepared has great adsorption amount, high dehumidifying efficiency, low regeneration temperature, high heat resistance, high mechanical strength and long service life, and may be used widely in producing dehumidifying wheel.

Owner:SOUTH CHINA UNIV OF TECH

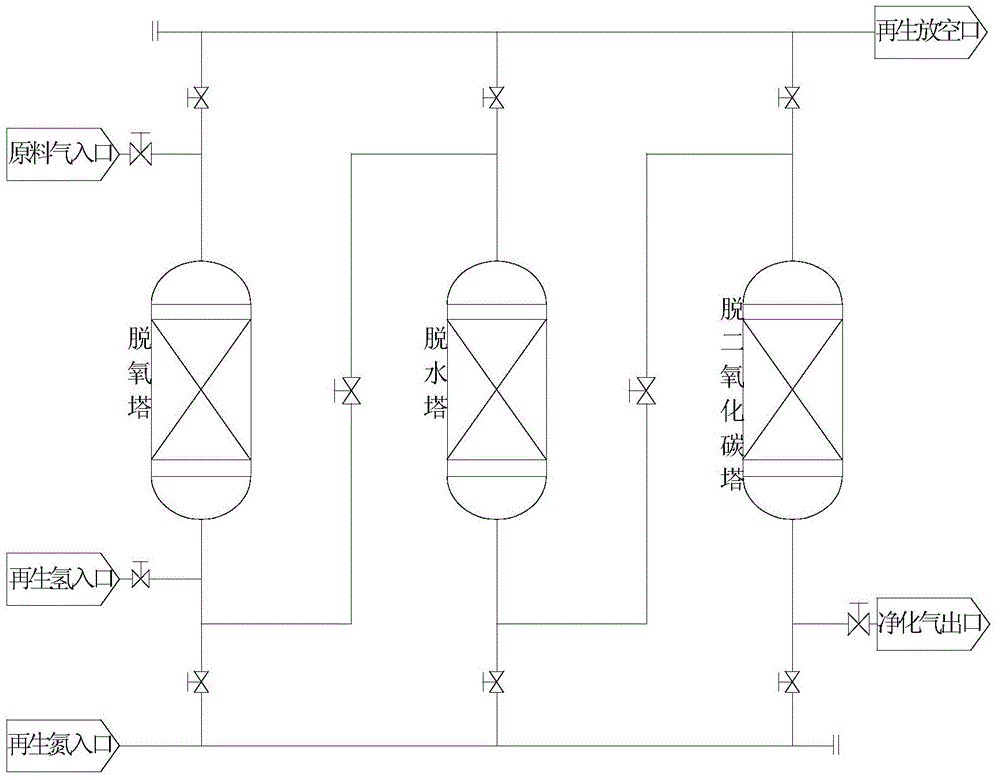

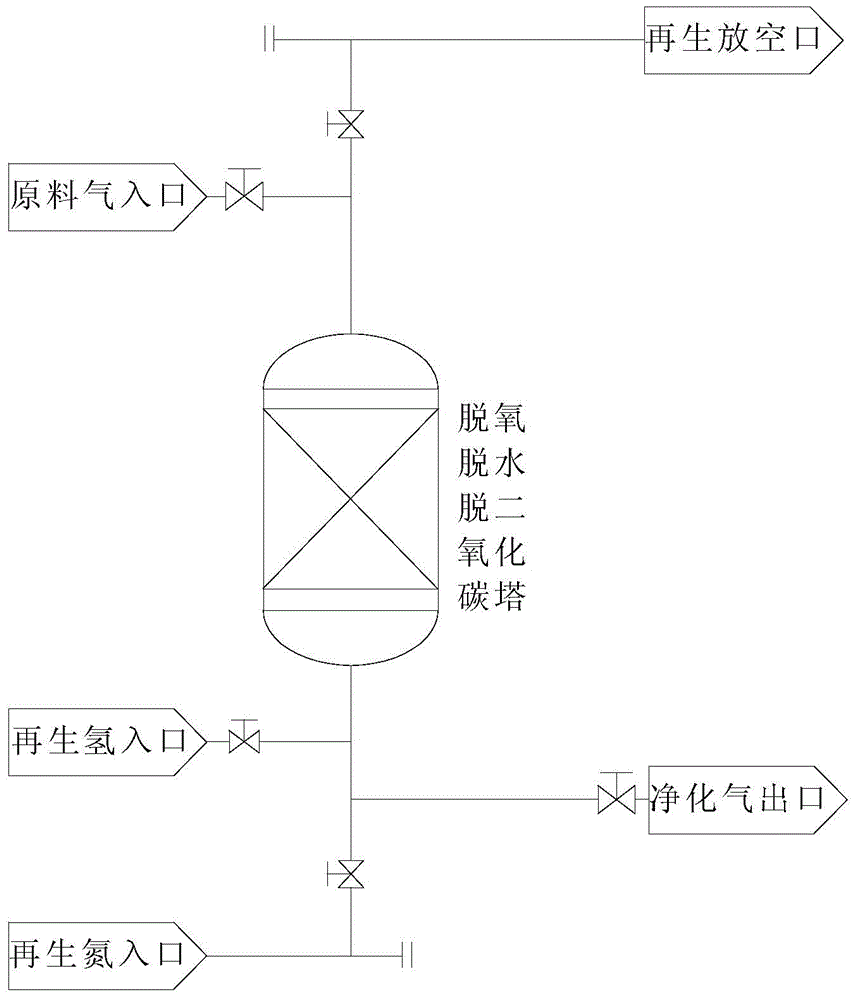

Multifunctional deoxidizer, preparation and applications thereof

InactiveCN105363406AHigh deoxygenation depthLarge capacityOther chemical processesDispersed particle separationActive componentCarbonate

The present invention relates to a multifunctional deoxidizer and a preparation method thereof, wherein the multifunctional deoxidizer comprises a suitable metal carbonate, a proper amount of an activity promoter and a proper amount of a structure support monomer. During a multifunctional deoxidizer production process, a thermal decomposition (calcination) method is used to decompose a metal carbonate to form the active component of the metal oxide deoxidizer while release carbon dioxide gas, such that a large number of uniform adsorption pore sizes having the carbon dioxide molecule size are formed in the multifunctional deoxidizer, and the pore size can deeply adsorb a lot of water and carbon dioxide. According to the present invention, the novel gas purification material is provided, the production process can be simplified, the production energy source and the materials can be saved, and the production cost and the consumption can be reduced; and the energy saving and consumption reducing industrial policy direction in the country new material and new technology application can be met.

Owner:王雅坤

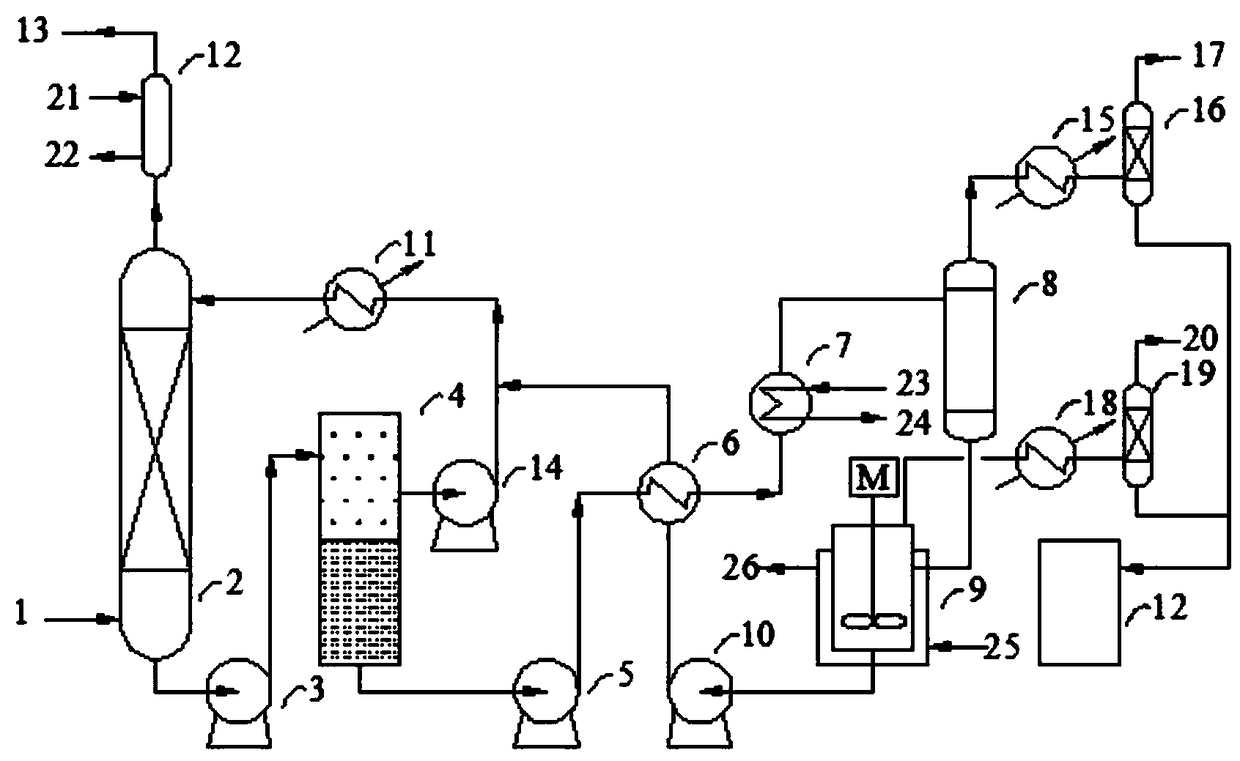

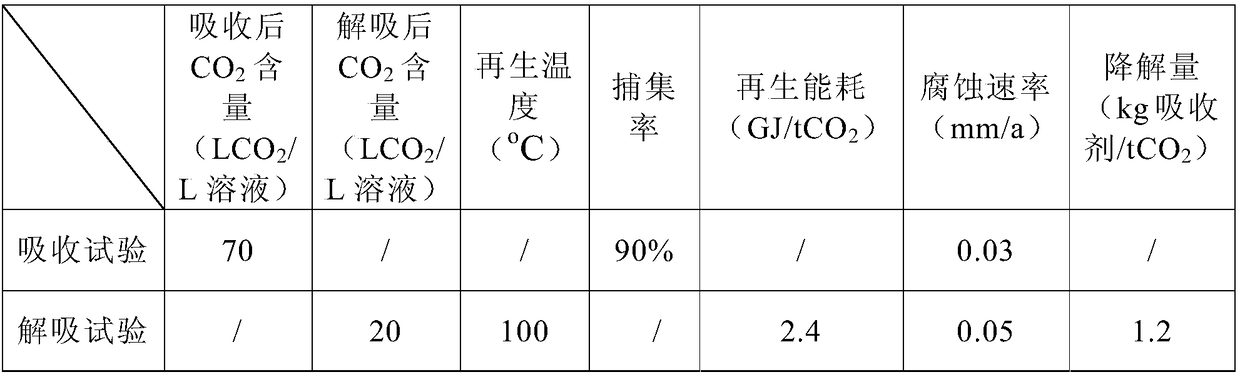

Phase change absorbent for capturing CO2 in waste gas

ActiveCN109331610ALarge absorption capacityIncrease capture rateDispersed particle separationAir quality improvementNanoparticleAntioxidant

The invention provides a phase change absorbent for capturing CO2 in the waste gas. The phase change absorbent for capturing the CO2 in the waste gas comprises an alkylol amine absorbent, an amine absorbent, a nanoparticle, a corrosion inhibitor, an antioxidant, a defoamer and water, the mass ratio of the alkylol amine absorbent to the amine absorbent, to nanoparticles to the corrosion inhibitor to the antioxidant to the defoamer to the water in the phase change absorbent for capturing CO2 in the waste gas is (15%-20%):(5%-10%):(0.01%-0.1%):(0.01%-0.2%):(0.01%-0.2%):(0.01%-0.1%):(70%-80%). Thephase change absorbent for capturing CO2 in the waste gas increases the absorptive capacity of CO2, increases the capturing rate of CO2, reduces the corrosion rate of equipment, improves the self-stability, reduces the regeneration temperature, reduces the energy consumption of regeneration, and improves the degradation effect.

Owner:CHINA PETROCHEMICAL CORP +2

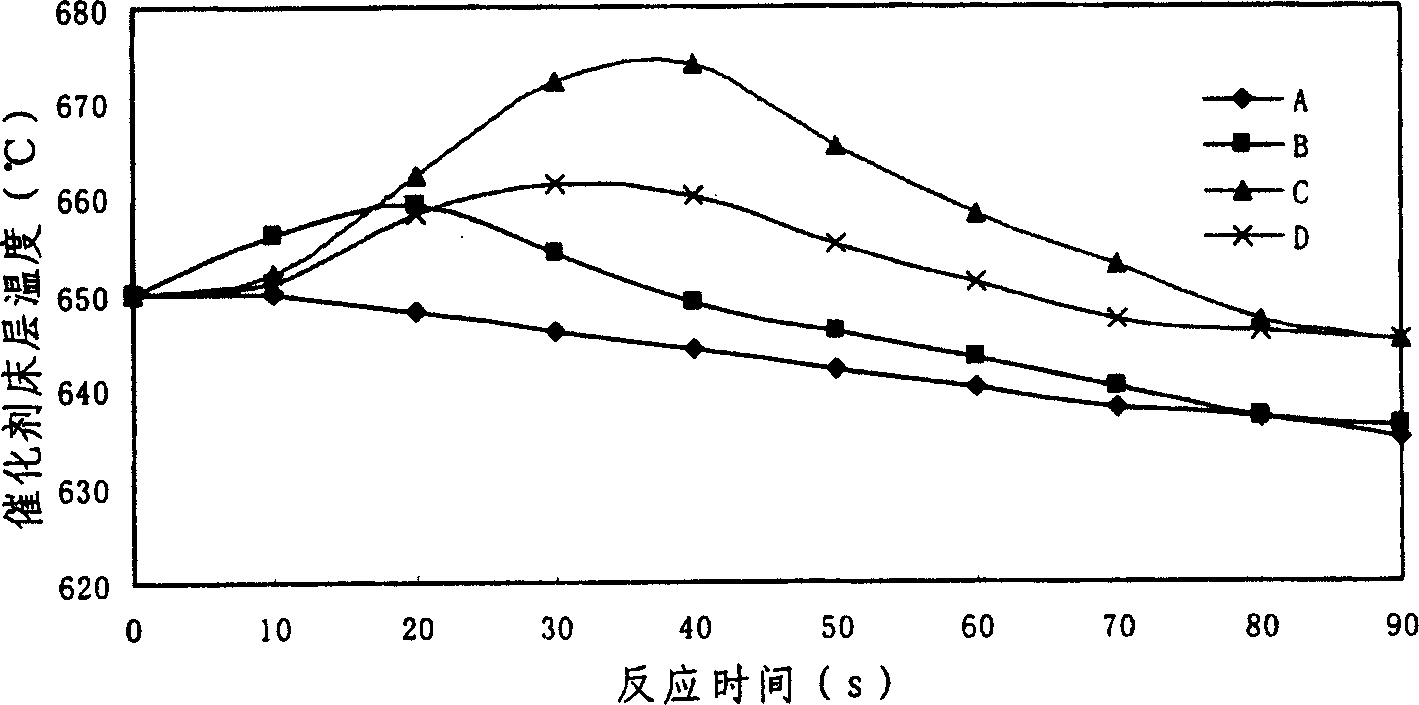

Method for preparing olefin by catalytic oxidation of petroleum hydrocarbon

InactiveCN1876766AReduce regeneration temperature and agent-to-oil ratioThermal balance is easy to achieveCatalytic crackingTreatment with plural serial stages onlyChemistryPetroleum

The invention relates the oil catalytic oxidation cracking method for producing olefin. The invention uses solid acid and metallic oxide as composite catalyst to carry out catalytic oxidation cracking reaction. The method uses solid acid as cracking catalyst, and uses metallic oxide as oxidative catalyst. The catalyst is regenerated. The reaction temperature is 500-720Deg.C, the weight ratio of solid acid and metallic oxide is 2-30:1, and the weight ratio of catalyst and petroleum hydrocarbon is 5-30:1. The petroleum hydrocarbon comprises lower carbon number hydrocarbons, petrol, diesel, vacuum gas oil, benzin naphtha, base oil, residual oil and heavy hydrocarbon. The ratio of water and oil is 0.1-1: 1, when the reaction condition is aqueous vapor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

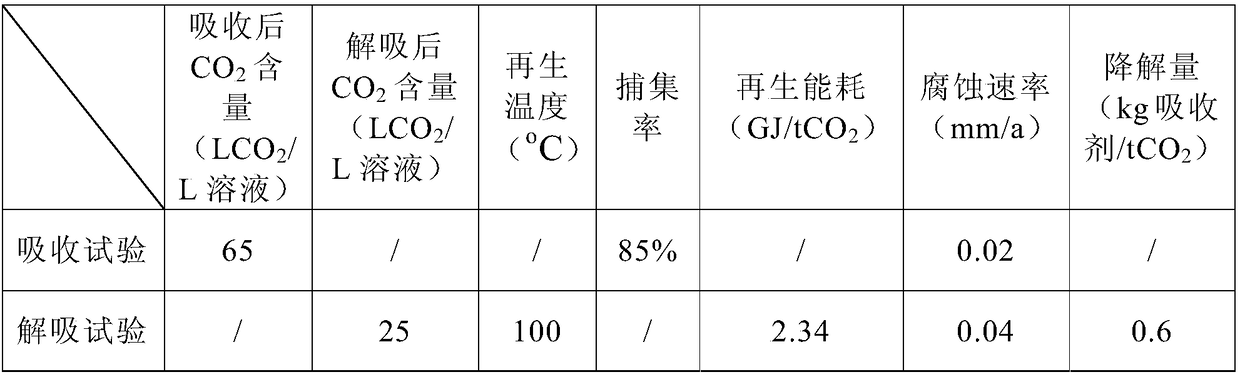

Double phase absorption system for removing CO2 from flue gas

InactiveCN105396447AEffective absorptionEffective implementation of absorptionDispersed particle separationAir quality improvementOrganic solventDouble phase

The invention provides a double phase absorption system for removing CO2 from flue gas. The system is composed of an alkylol amine absorbent, an amine absorbent, an activator, a consumption reduction agent, water and an organic solvent. The double phase absorption system for removing CO2 from flue gas has the advantages of strong absorption capability, fast absorption rate, low regeneration temperature and low energy consumption in the regeneration process.

Owner:SINOPEC ENERGY & ENVIRONMENTAL ENG CO LTD

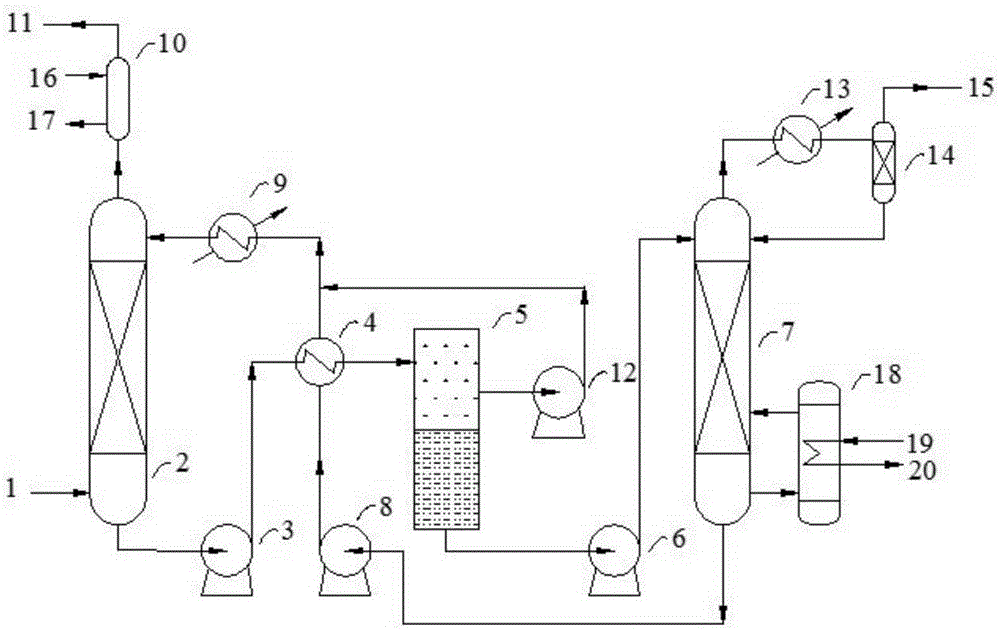

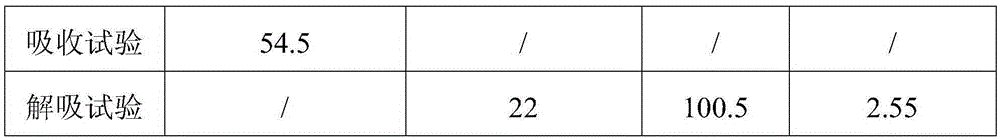

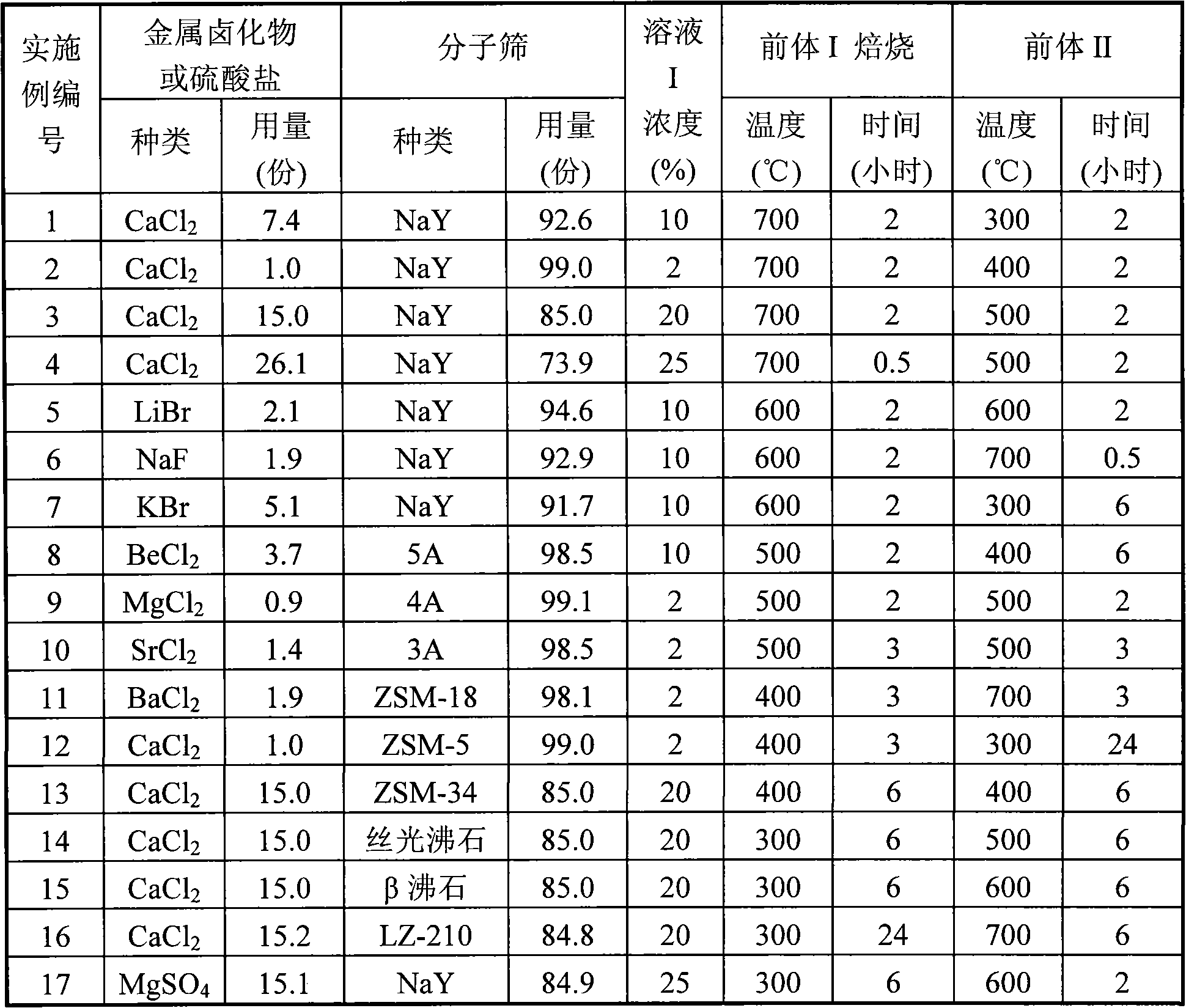

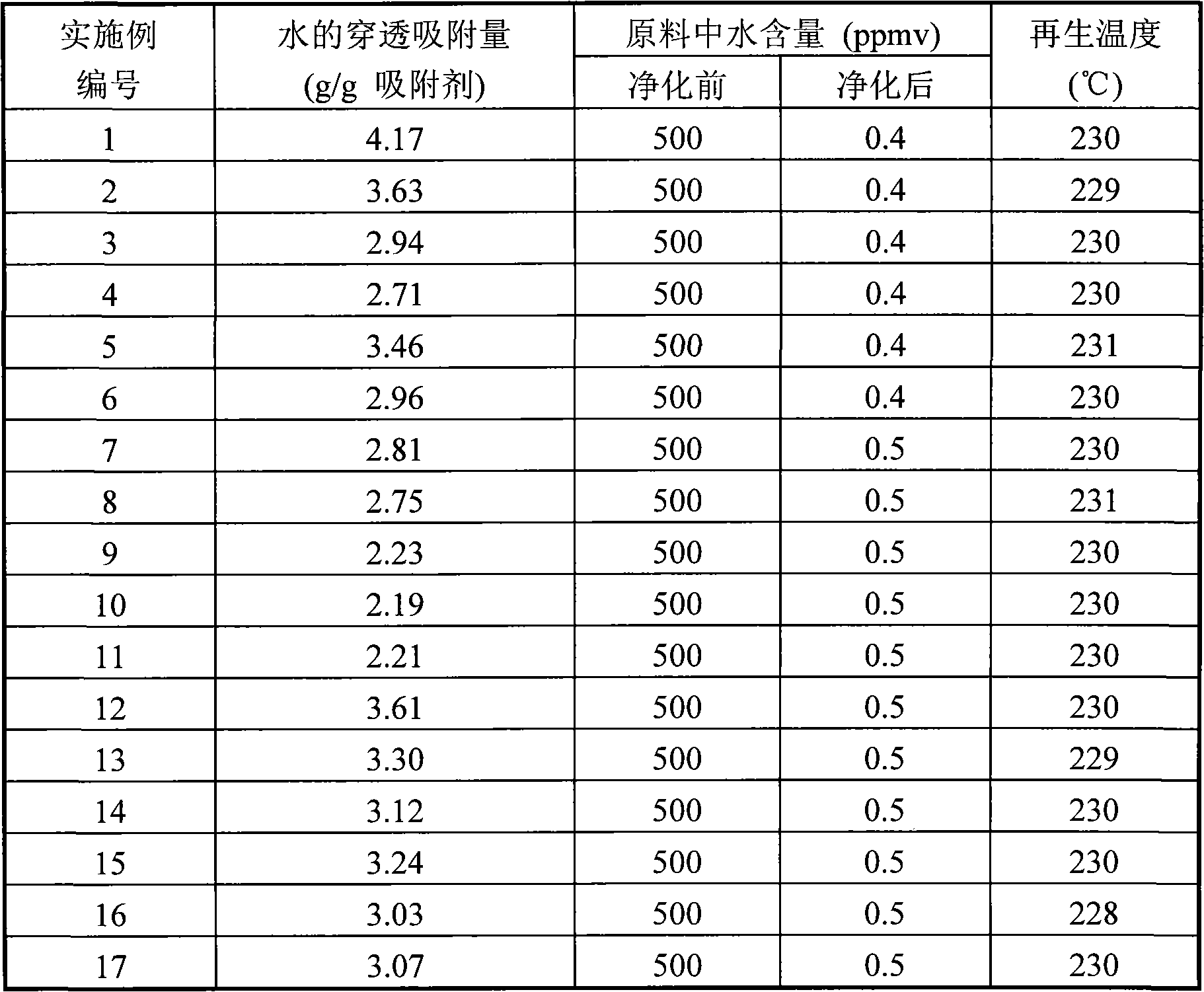

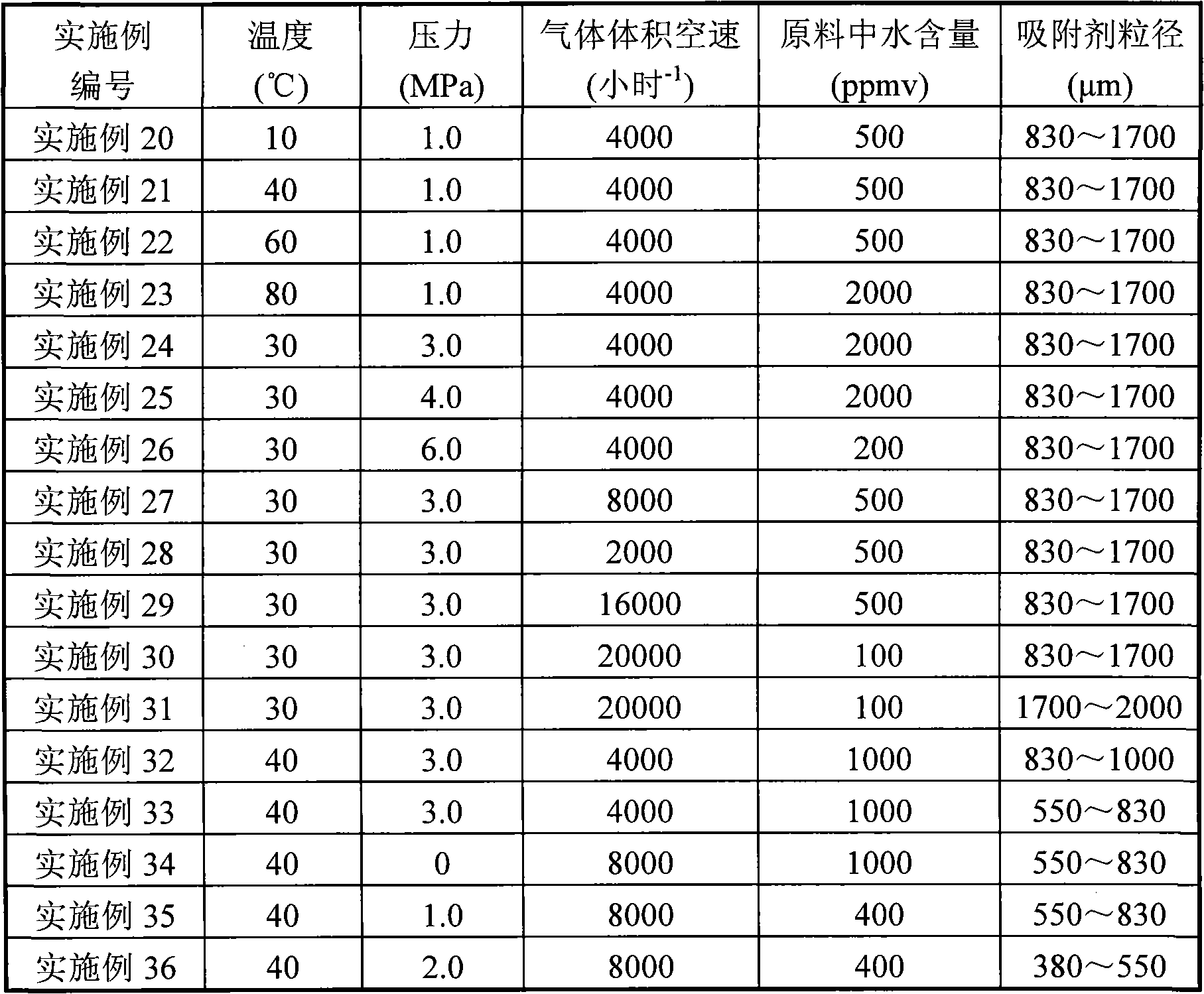

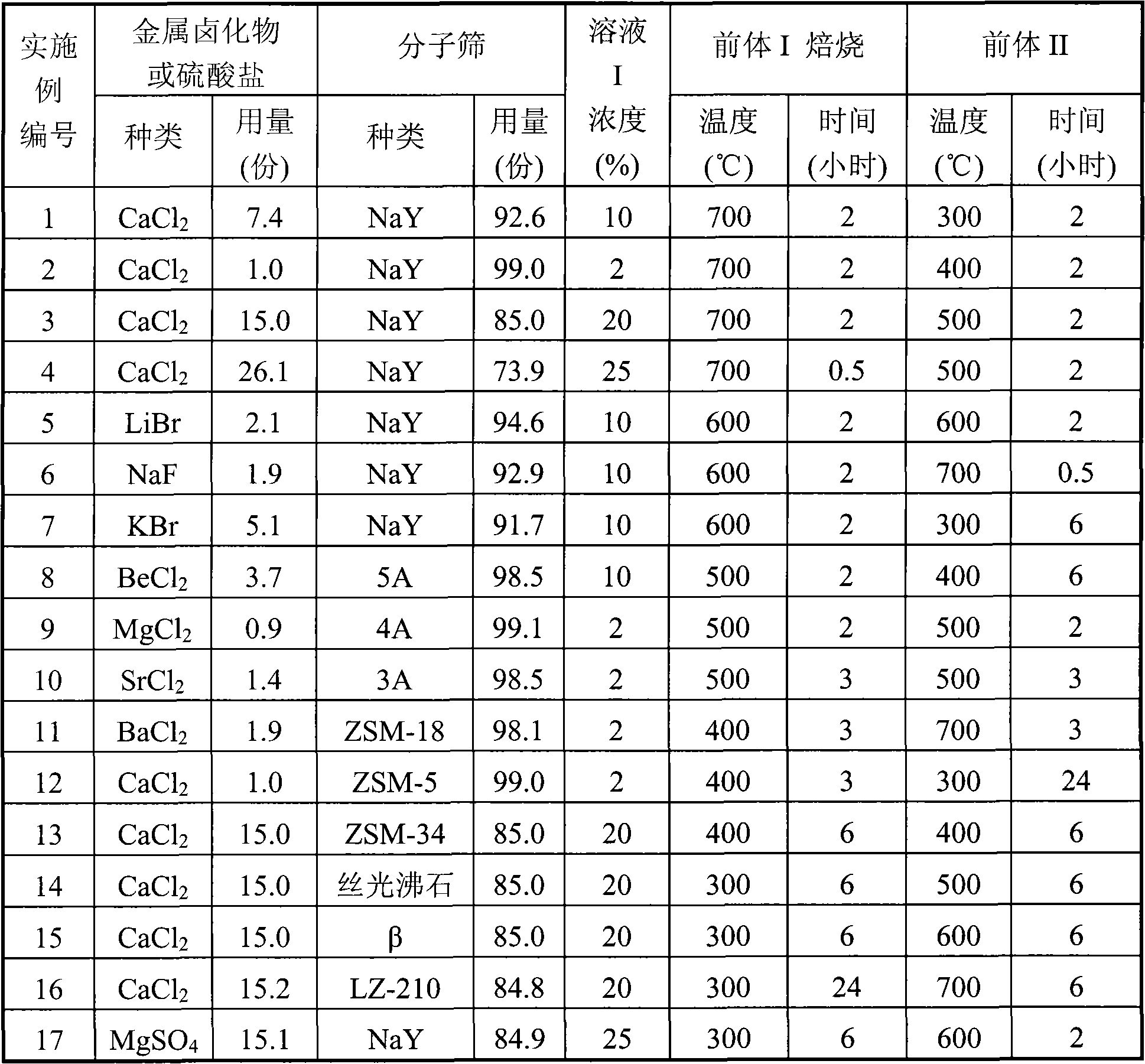

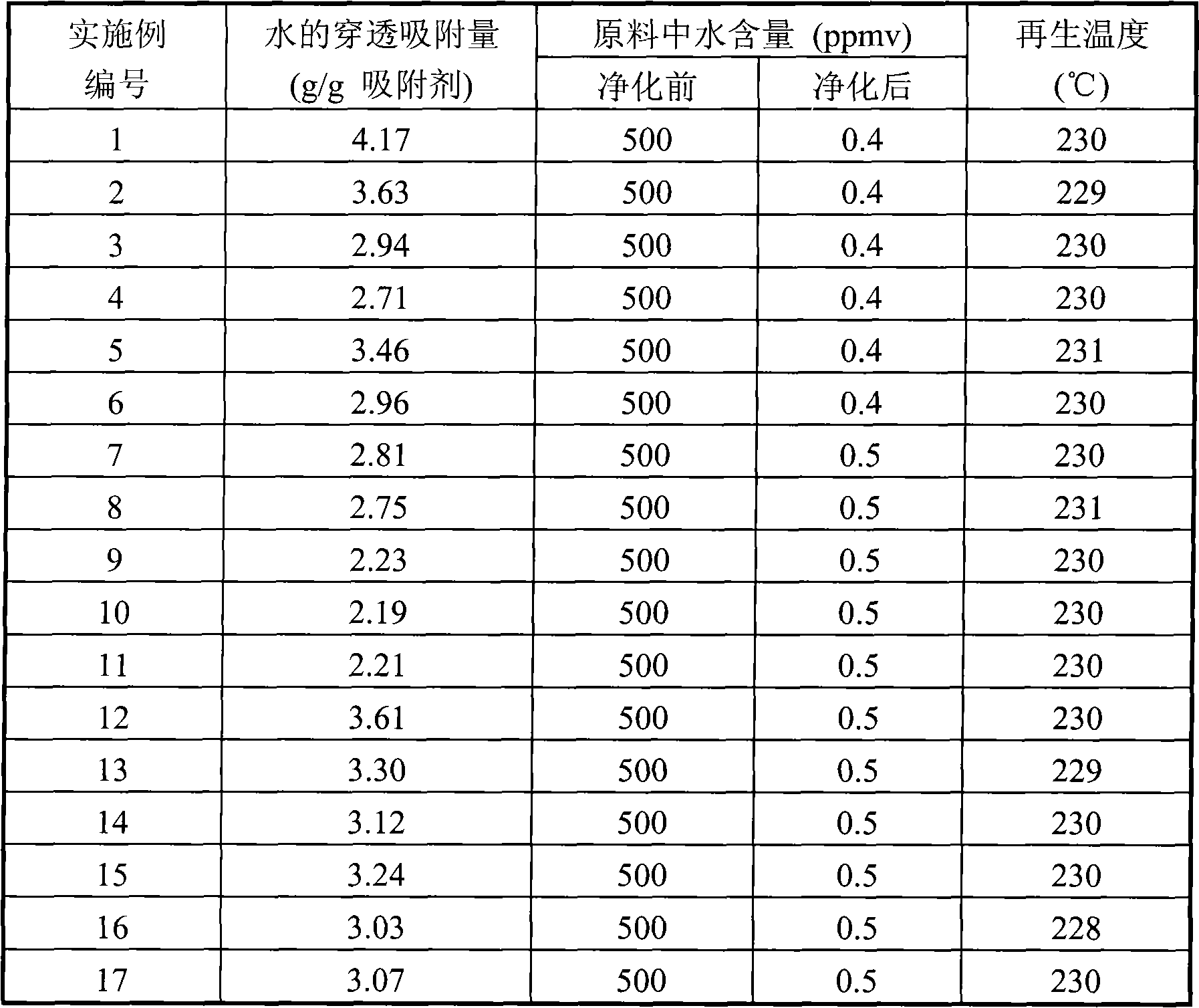

Adsorption purification method for hydrocarbon stream

ActiveCN101885656AHigh adsorption capacityImprove adsorption capacityOther chemical processesAluminium silicatesMolecular sieveAlkaline earth metal

The invention relates to an adsorption purification method for hydrocarbon stream, which is mainly used for solving the problems of low adsorption capacity of adsorbent, need of frequent regeneration and high regeneration temperature in the existing adsorption purification method. The method can better solve the problems by adopting the technical scheme of leading hydrocarbon raw material containing a certain amount of oxygen-containing compound impurities to be in contact with the solid compound adsorbent containing metal halide, wherein the adsorbent comprises halide or sulfate of at least one metal selected from alkali metals or alkaline-earth metals and at least one molecular sieve selected from A type, Y type, L type, mordenite, ZSM type zeolite or beta type molecular sieve, and be used for the adsorption purification industrial production of various types of hydrocarbon stream.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-temperature desulfurization reclaimed rubber production method

The invention discloses a low-temperature desulfurization reclaimed rubber production method and belongs to the technical field of reclaimed rubber production. According to the low-temperature desulfurization reclaimed rubber production method, the raw materials comprises, by weight part, 100 parts of waste rubber powder, 0.2-2 parts of reclaiming active agent and 10-18 parts of swelling agent. Specifically, the method comprises uniformly mixing the waste rubber powder, the reclaiming active agent and the swelling agent in proportion; at 35-85 DEG C, performing desulfurization for 10-60 minutes through rubber desulfurization equipment to obtain reclaimed rubber. The low-temperature desulfurization reclaimed rubber production method has the advantages of being simple in preparation, low in production temperature and energy consumption, free from discharge, energy-saving and environmentally friendly.

Owner:REBORN ENVIRONMENTAL EQUIP MFG CO LTD

Solid adsorbent and preparation method thereof

ActiveCN101884905AHigh adsorption capacityImprove adsorption capacityOther chemical processesMolecular sieveAlkaline earth metal

The invention relates to a solid adsorbent and a preparation method thereof, mainly solving the problems of low adsorption capacity and higher regeneration temperature of the adsorbent in the prior art. By adopting the technical scheme that a compound solid adsorbent is prepared by combining at least one kind of halide of alkali metal, halide of alkaline earth metal or metal sulfates with a molecular sieve, the invention better solves the problems and can be used for industrial production of adsorption and purification of various hydrocarbon raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation and use of nano porous silica gel adsorbent material

InactiveCN1424138AImprove performanceReduce consumptionOther chemical processesSilicon compoundsFiberSorbent

A silica gel absorbent with nano pores is prepared through immersing inorganic fibrous paper in water glass for 10-24 hr, drying for 10-24 hr, immersing in aquous solution of precipitant for 12-24 hr, drying in air, immersing in acid for 12-24 hr, water washing until it become neutral, drying in air, and program heating. It can be used as demoistening core of air conditioner. Its advantages are high adsorptive power, and low energy consumption and regenerating temp.

Owner:SOUTH CHINA UNIV OF TECH

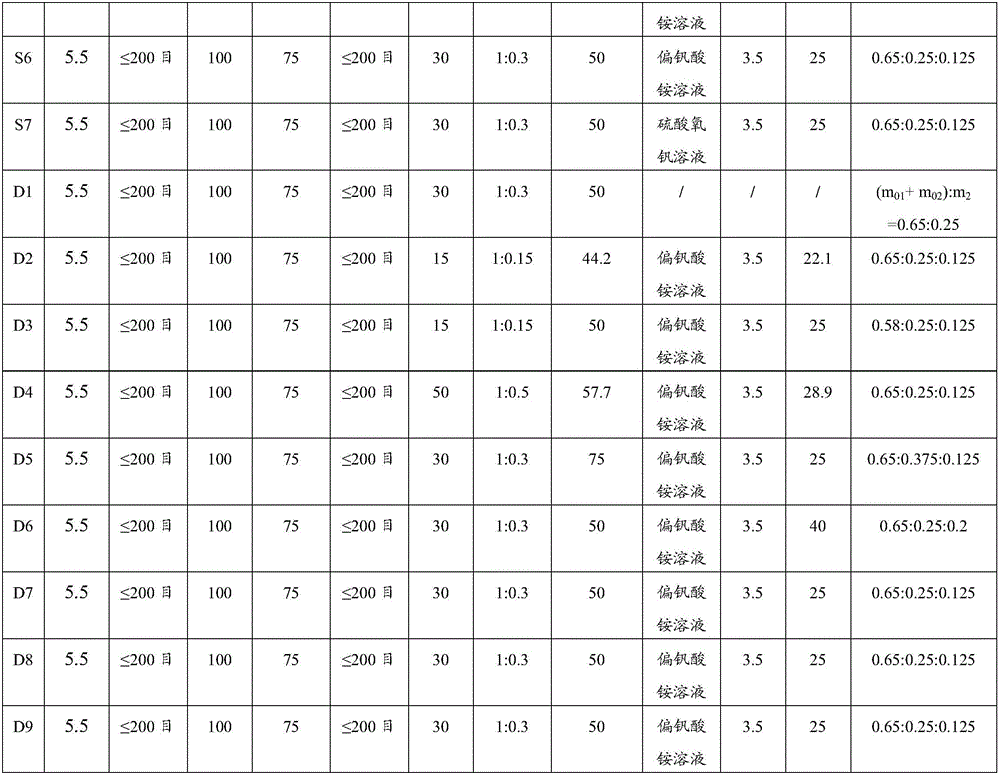

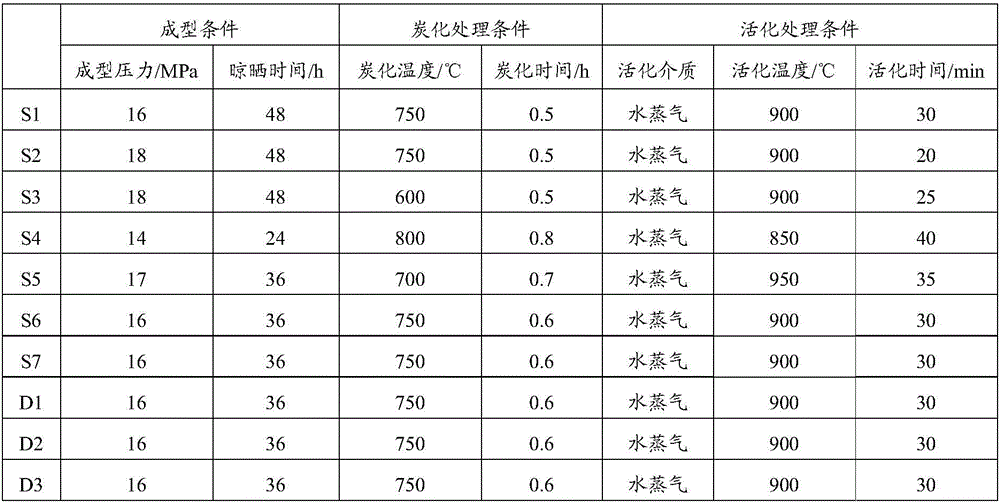

Preparation method for activated carbon for desulfurization and denitrification and activated carbon for desulfurization and denitrification and application

ActiveCN106672967ALow regeneration temperatureImprove regeneration efficiencyGas treatmentCarbon compoundsActivated carbonLow activity

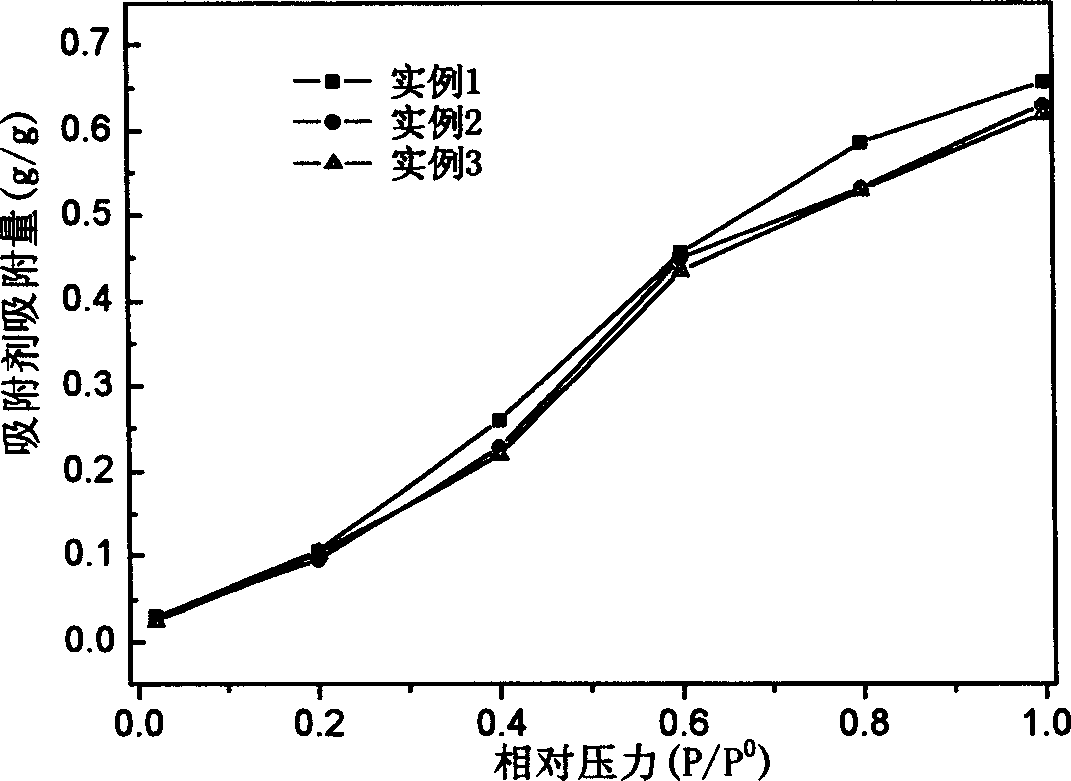

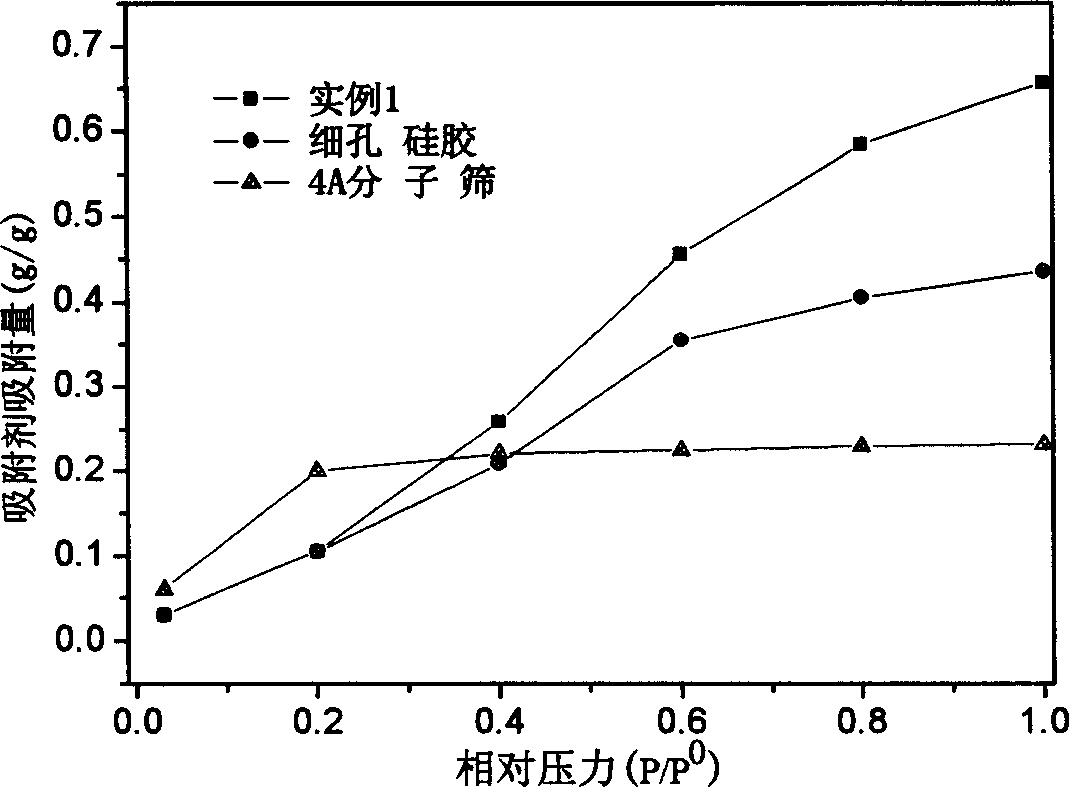

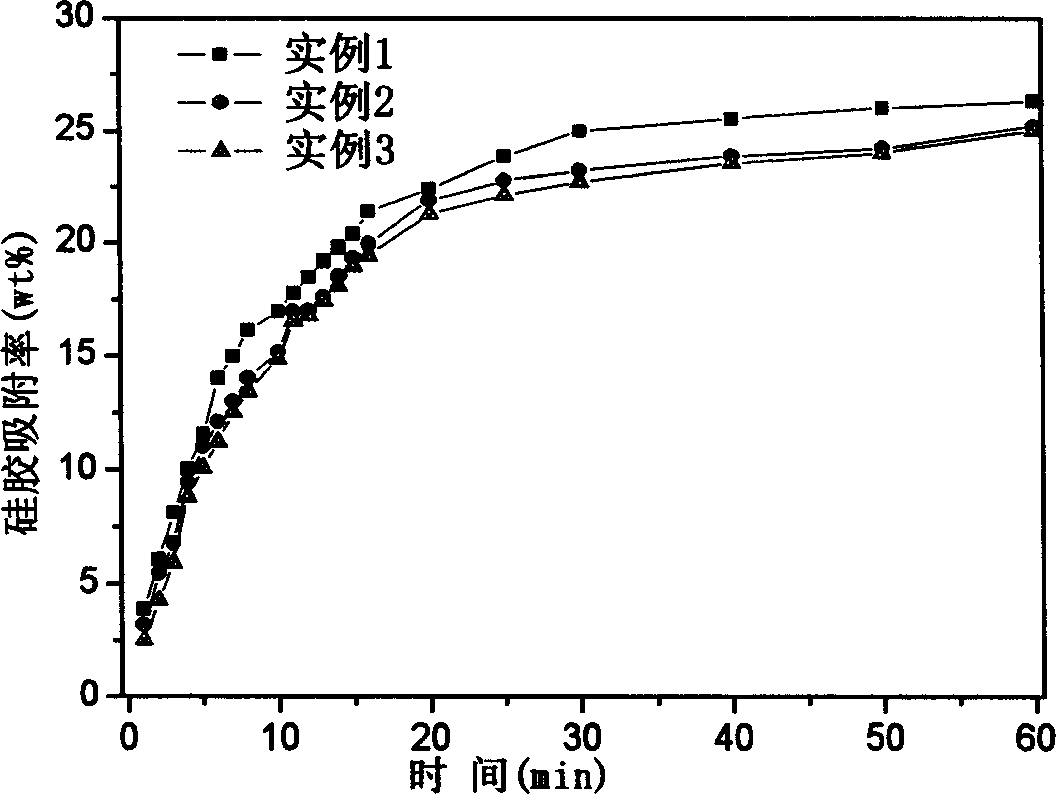

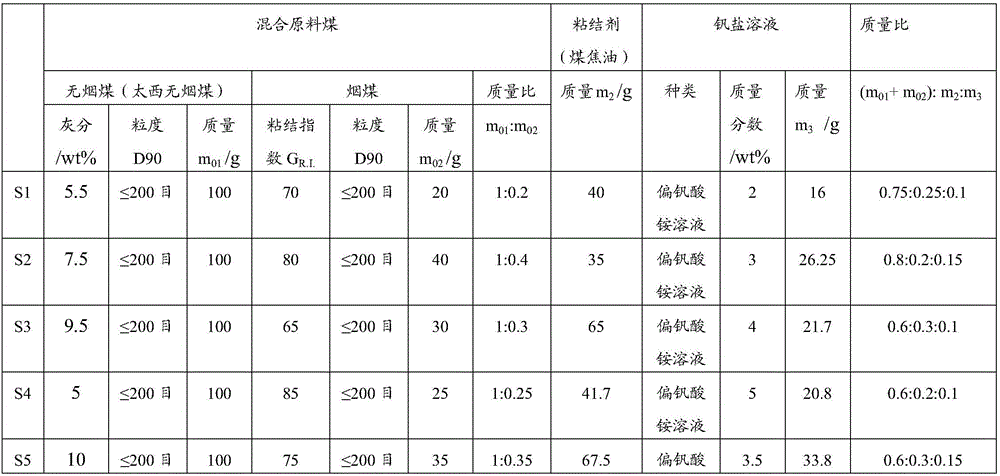

The invention provides a preparation method for activated carbon for desulfurization and denitrification. The method comprises the steps of (1) mixing anthracite and bituminous coal in the mass ratio of 1:(0.2-0.4) to obtain mixed feed coal; (2) preparing a vanadium salt solution; (3) mixing the mixed feed coal, a binder and the vanadium salt solution in the mass ratio of (0.6-0.8):(0.2-0.3):(0.1-0.15) and stirring evenly to obtain coal paste; and (4) sequentially molding, carbonizing and activating the coal paste to obtain the activated carbon for desulfurization and denitrification. The invention further provides the activated carbon for desulfurization and denitrification prepared by the method and application of the activated carbon for desulfurization and denitrification. According to the preparation method, vanadium salt is introduced into the pulverized coal in a liquid form and is evenly distributed; the obtained activated carbon for desulfurization and denitrification is good in effect in desulfurization and denitrification and high in efficiency. The catalyst component is tightly combined with the activated carbon and cannot fall off easily; the activated carbon can be recycled only by regeneration at a relatively low temperature after low-activity sulfate is generated through desulfurization, and the service life is long; and the technological process is simple and the operation is easy.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Vaporizing and cooling air conditioning device based on ultrasonic technology

InactiveCN101196321ALow regeneration temperatureGood regeneration performanceLighting and heating apparatusAir conditioning systemsUltrasonic generatorPotential energy

A steam cooling air conditioning device based on ultrasonic technology is provided, which belongs to the technical field of air conditioner energy saving, and comprises a dehumidify or a regeneration whirl tube, a steam cooling whirl tube, two ultrasonic dehumidifiers, two supersonic generators, two blowers, two exhaust ducts, a clapboard, an ultrasonic atomizer plate, an atomizer sink, a breakwater and a plurality of air valves. The two ultrasonic dehumidifiers dehumidify air and regenerate dehumidizer in alternation and the air after processed by the ultrasonic dehumidifier enters into the steam cooling whirl tube and then is steamed and cooled by the little liquid atomized by the ultrasonic atomizer plate and flow across the breakwater next and finally is led into air conditioning area by the blower. The invention is able to effectively cool the air in high temperature and humidity environment, which has potential energy-saving effect and strong adaptability.

Owner:SHANGHAI JIAO TONG UNIV

Dehumidifier

InactiveCN105890048AAlleviate the problem of electricity shortageReduce consumptionEnergy recovery in ventilation and heatingGas treatmentAmbient airChiller

The invention provides an adsorption type dehumidifier. The adsorption type humidifier employs two dehumidification rotors; ambient air passes a first cooler, a processing zone of a first dehumidification rotor, a second cooler, a processing zone of a second dehumidification rotor, and a first heater in order, the air is adjusted to a required temperature and sent to a drying room. Return air from the drying room and air which passes the processing zone of the first dehumidification rotor are mixed, and the mixed air is sent to a regeneration zone. One part of the air is sent to a regeneration zone of the second dehumidification rotor through a second heater and a third heater. The air passes a fourth heater and is sent to the regeneration zone of the first dehumidification rotor, and the air which passes the regeneration zone of the first dehumidification rotor is branched into two parts, wherein one part turns to an outlet of the regeneration zone of the second dehumidification rotor and is mixed with air from the outlet, and the other part is sent to an inlet of the first cooler and mixed with ambient air, and the mixed air enters a part of the first cooler.

Owner:SEIBU GIKEN CO LTD

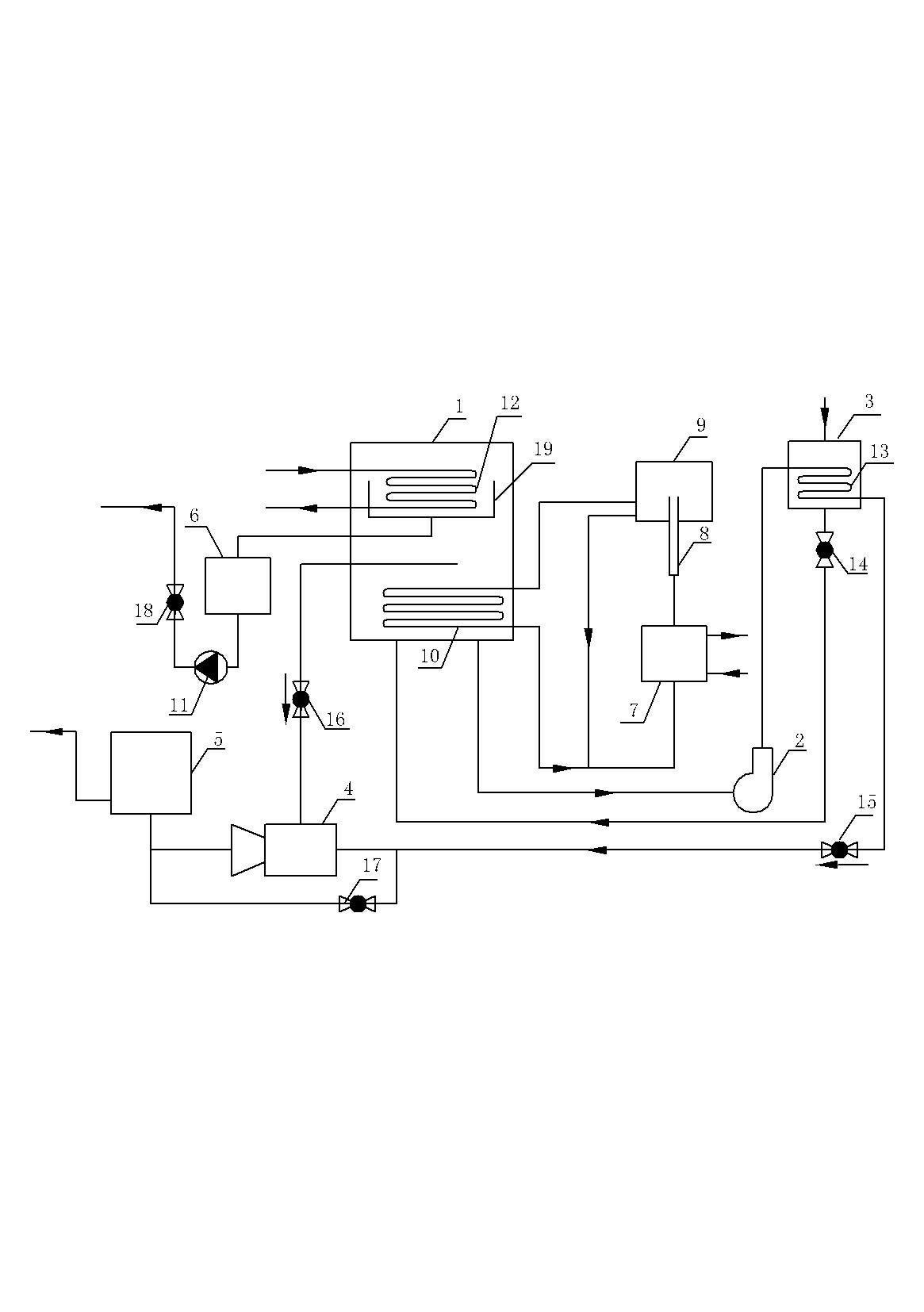

Hollow fiber membrane liquid dehumidifying device driven by gas heat pump

InactiveCN105627464AReduce partial pressureImprove dehumidification effectEnergy industryAir conditioning systemsWater vaporCooling capacity

The invention discloses a hollow fiber membrane liquid dehumidifying device driven by a gas heat pump. The hollow fiber membrane liquid dehumidifying device comprises an air inlet system, an exhaust system, a gas heat pump device, a dehumidifying solution circulating system, a gas engine waste heat recovery device, wherein the air inlet system is used for conveying air into a room, and the exhaust system is used for exhausting the air out of the room. According to the hollow fiber membrane liquid dehumidifying device driven by the gas heat pump, the gas heat pump is adopted for providing the required cooling capacity before air dehumidifying and the required heat before solution regeneration, the steam partial pressure difference between the two sides of a membrane assembly is increased, and good mass transfer efficiency is achieved; at the same time, the gas engine waste heat recovery device and a solution heat-regenerating device are adopted, so that energy consumption is reduced, and the energy utilization rate is increased; the gas heat pump has a good partial load characteristic so that gas combustion season peaks and valleys can be effectively balanced, the peak shaving problem of natural gas reserves is solved, the gas pipe network utilization rate is further increased, and the comprehensive gas supplying cost is further reduced; meanwhile, relieving of the tense power supply situation caused by summer power utilization is facilitated; natural gas is also a clean and efficient energy source, harmful emissions are basically avoided, and it is conducive to environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

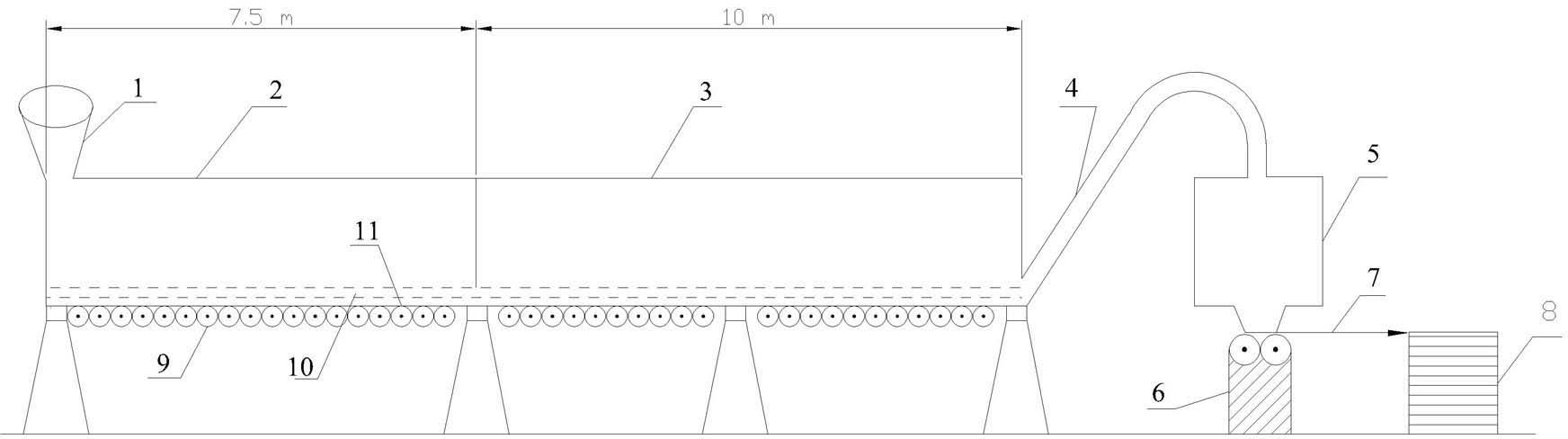

Microwave radiation reclaiming method for environment-friendly high-strength reclaimed rubber

InactiveCN102634056AProtection from destructionSure breakPlastic recyclingRubber materialWaste rubber

The invention discloses a microwave radiation reclaiming method for environment-friendly high-strength reclaimed rubber, and belongs to the technical field of waste rubber reclaiming. The method comprises the following steps of: mixing waste rubber outer tire crown powder with the particle size of 20 meshes, rosin and dipentene according to a certain proportion; uniformly feeding the materials with a certain thickness on a roller way conveying device; determining the length of a roller way according to microwave radiation time; arranging a high-frequency microwave radiation device on the roller way; conveying the materials on the roller way for reclaiming the materials by microwave radiation during conveying; continuously putting the reclaimed rubber materials into a cooling device through the roller way; directly discharging the cooled materials to an open mill for performing refining, wherein the refining temperature is controlled to be 35-50 DEG C; and refining at low temperature on the open mill for 20 minutes to obtain a refined rubber sheet with smooth surface and uniform texture. A test result shows that the tensile strength of the reclaimed rubber is more than 18MPa, the breaking elongation is over 400%, and the Weigert plasticity is 0.35-0.45. The microwave radiation reclaiming method has the advantages of environment friendliness, short reclaiming time, low reclaiming temperature, energy conservation and high production efficiency.

Owner:XUZHOU COLLEGE OF INDAL TECH

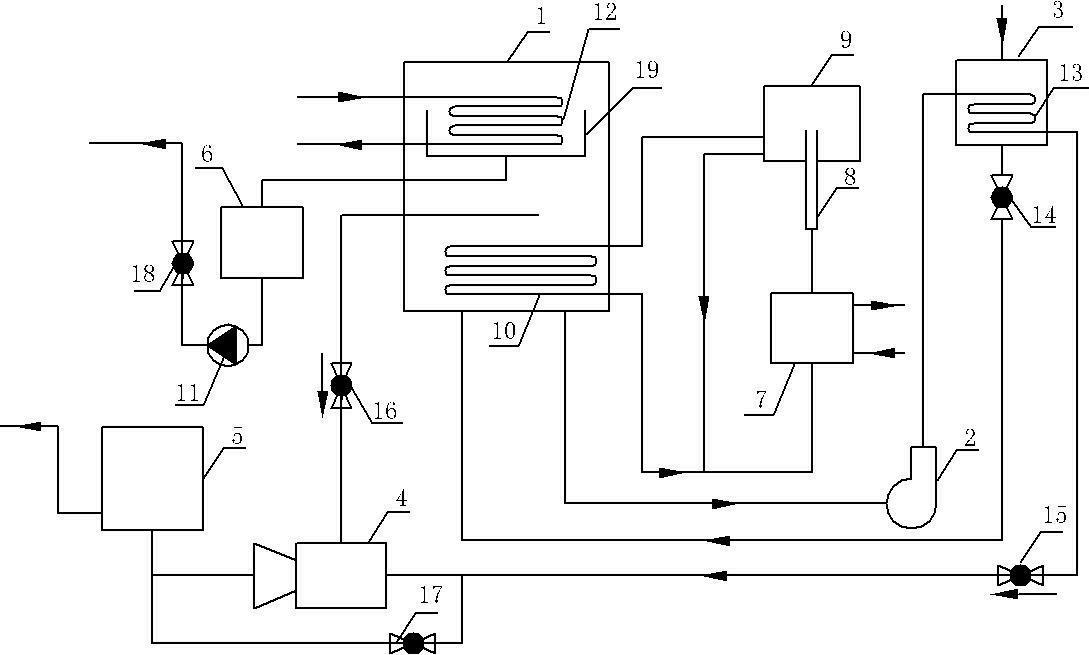

Regeneration system of dehumidifying solution for moist air

InactiveCN102679468AReduce heat transfer areaLow regeneration temperatureLighting and heating apparatusAir conditioning systemsVapor–liquid separatorEngineering

The invention relates to a regeneration system of a dehumidifying solution for moist air, wherein a generator is internally provided with a heating coil and a condensing coil, and the condensing coil is in a condensing disc provided with a condensate outlet. A liquid outlet of a dilute solution storage tank is connected with a liquid inlet of the generator, and a liquid outlet of the generator is connected with an inlet of a solution heat exchange tube through a solution pump. An outlet of the solution heat exchange tube is divided into two paths, and one solution heat exchange tube is connected with a dehumidifying device through a flow adjusting valve while the other solution heat exchange tube is connected with a work liquid inlet of an ejector. A driven fluid inlet of the ejector is communicated with a gas outlet of the generator and an outlet of the ejector is connected with a liquid inlet of the dehumidifying device after being joined with an outlet of the flow adjusting valve. An outlet of the heating coil is connected with an inlet of a heater, an outlet of the heater is connected with a vapor-liquid separator through a bubble pump, a gas outlet of the vapor-liquid separator is connected with an inlet of the heating coil, and a liquid outlet of the vapor-liquid separator is connected with the inlet of the heater after being joined with the outlet of the heating coil.

Owner:HENAN UNIV OF SCI & TECH

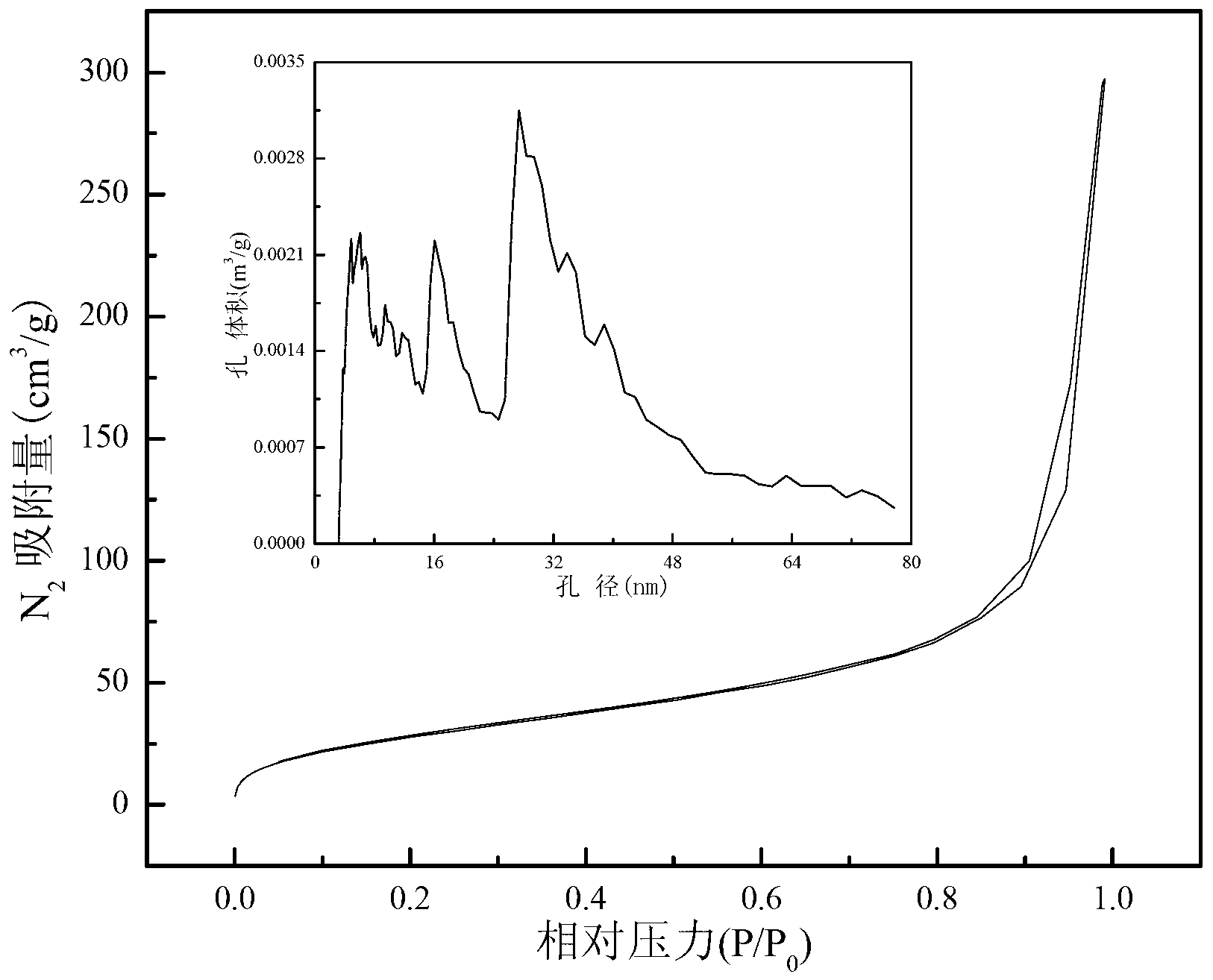

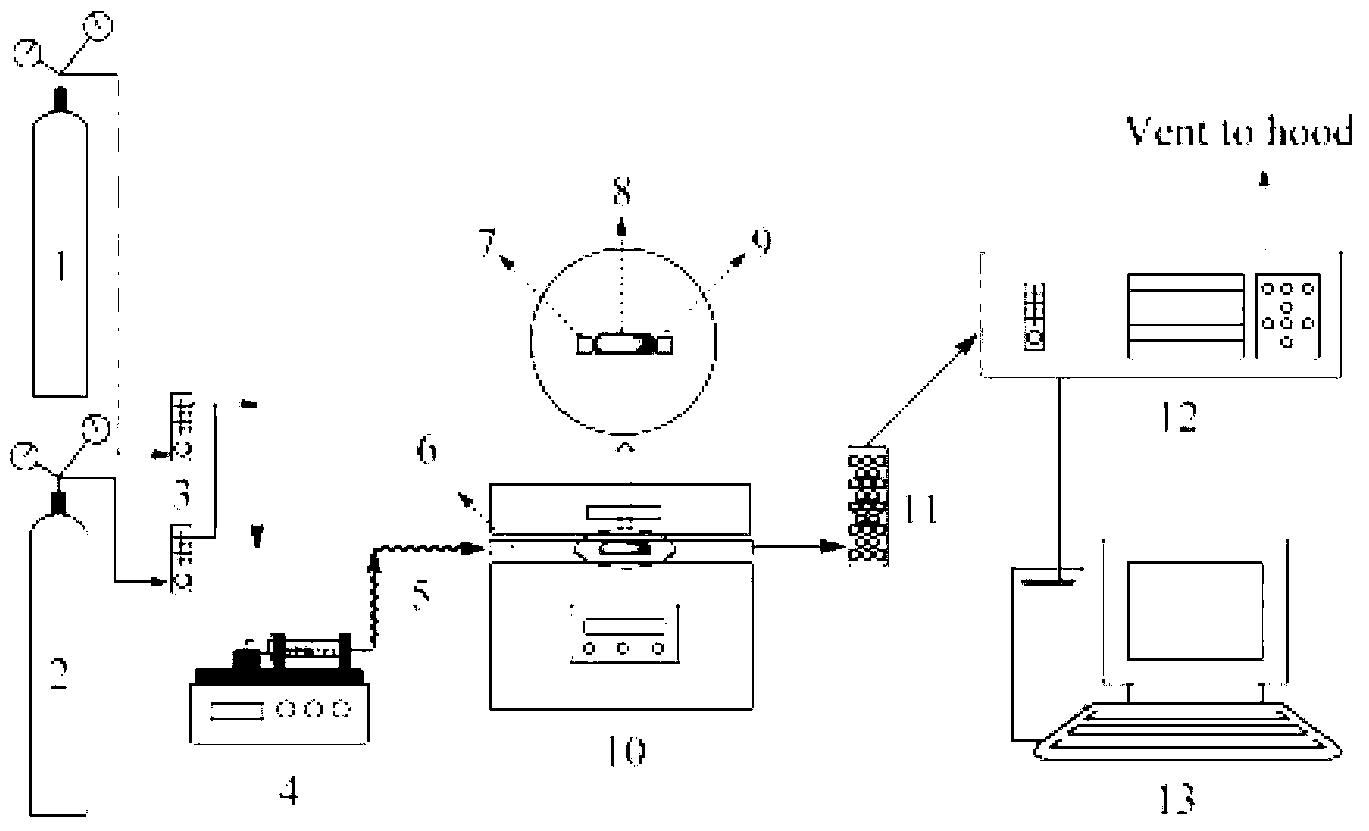

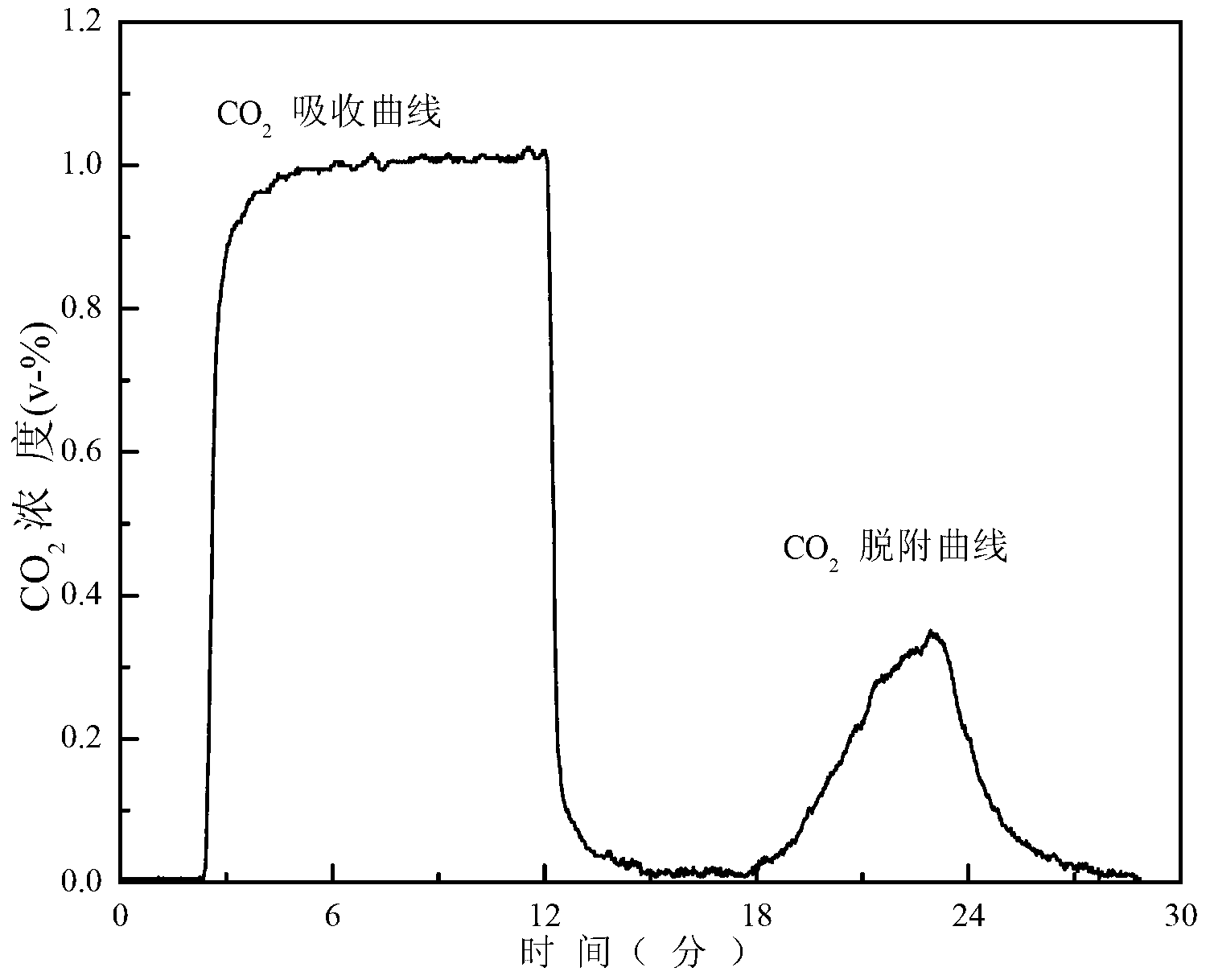

Solid absorbent with high CO2 adsorption capacity and preparation method thereof

InactiveCN103230778AFast decarbonizationFastOther chemical processesDispersed particle separationSupercritical dryingCorrosion

The invention discloses a solid absorbent with high CO2 adsorption capacity and a preparation method thereof. The solid absorbent comprises active components and a carrier; the active components are alkali carbonate and an amino group at the surface of the carrier, and are 15-60% of total quality of the solid absorbent; the molar ratio of the alkali carbonate and the amino group is 1 to (0.5-25); and the carrier is monox, and is 40-85% of total quality of the solid absorbent. The preparation method comprises the following steps of mixing and stirring the materials into emulsion; putting the emulsion into air to form cross-linking gel; putting the gel into a sealed dryer; soaking the gel by ethanol; and drying and screening the gel by a supercritical drying method, so as to prepare the solid absorbent with high CO2 adsorption capacity. The absorbent is low in price, stable in structure, high in carbonic acid conversion ratio, not easy to inactivate, and small in corrosion on equipment, and has certain mechanical strength, and high cyclic utilization rate; and the preparation method of the absorbent is convenient to operate, and low in expenses.

Owner:SOUTHEAST UNIV

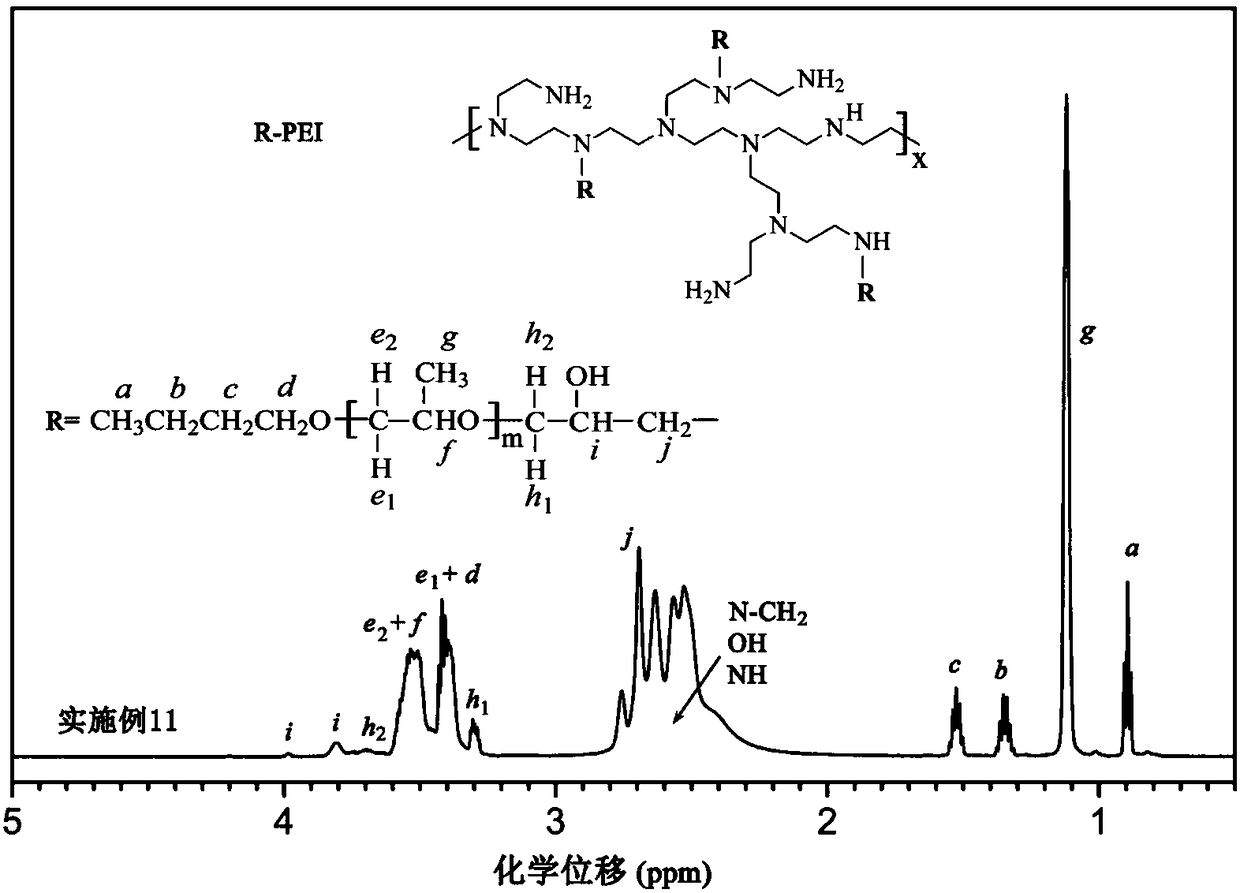

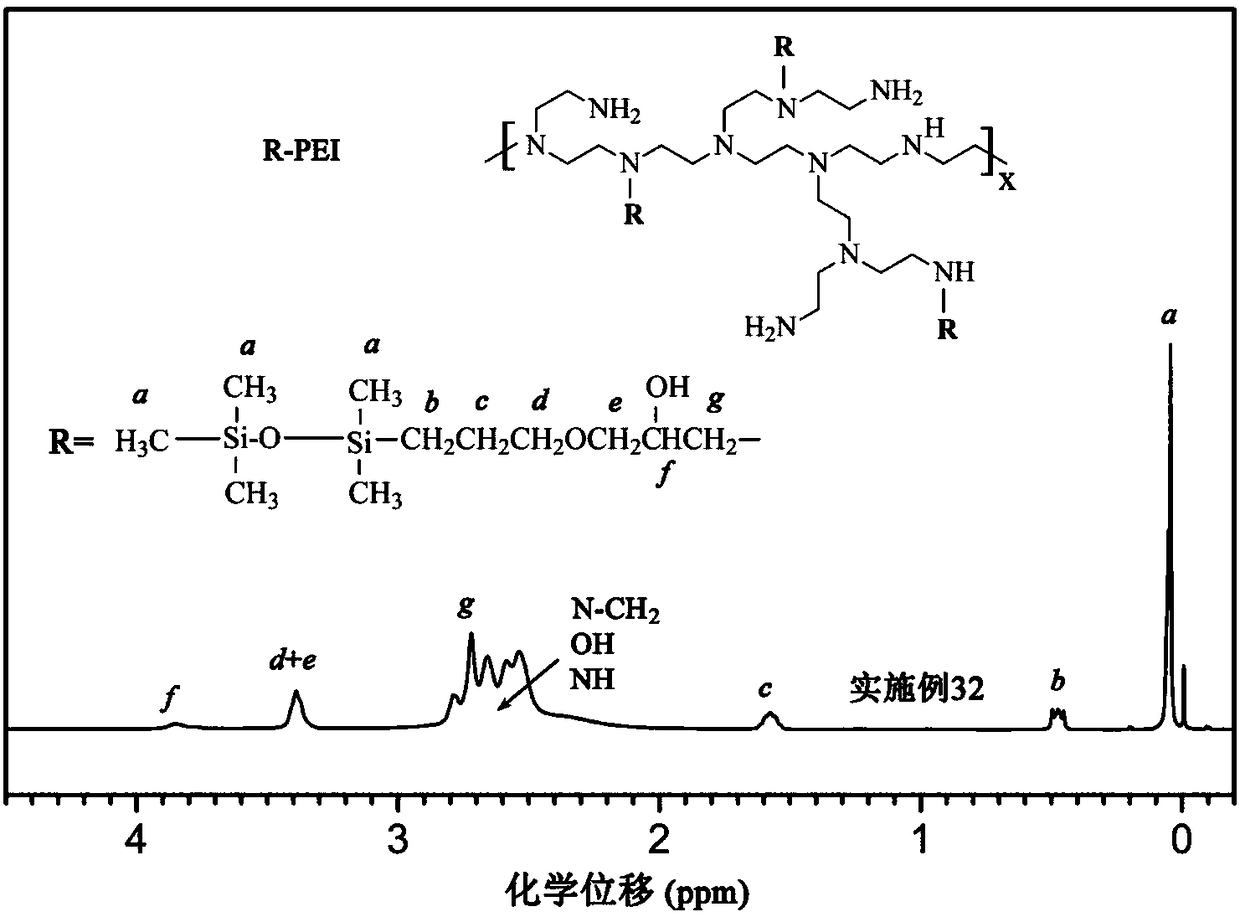

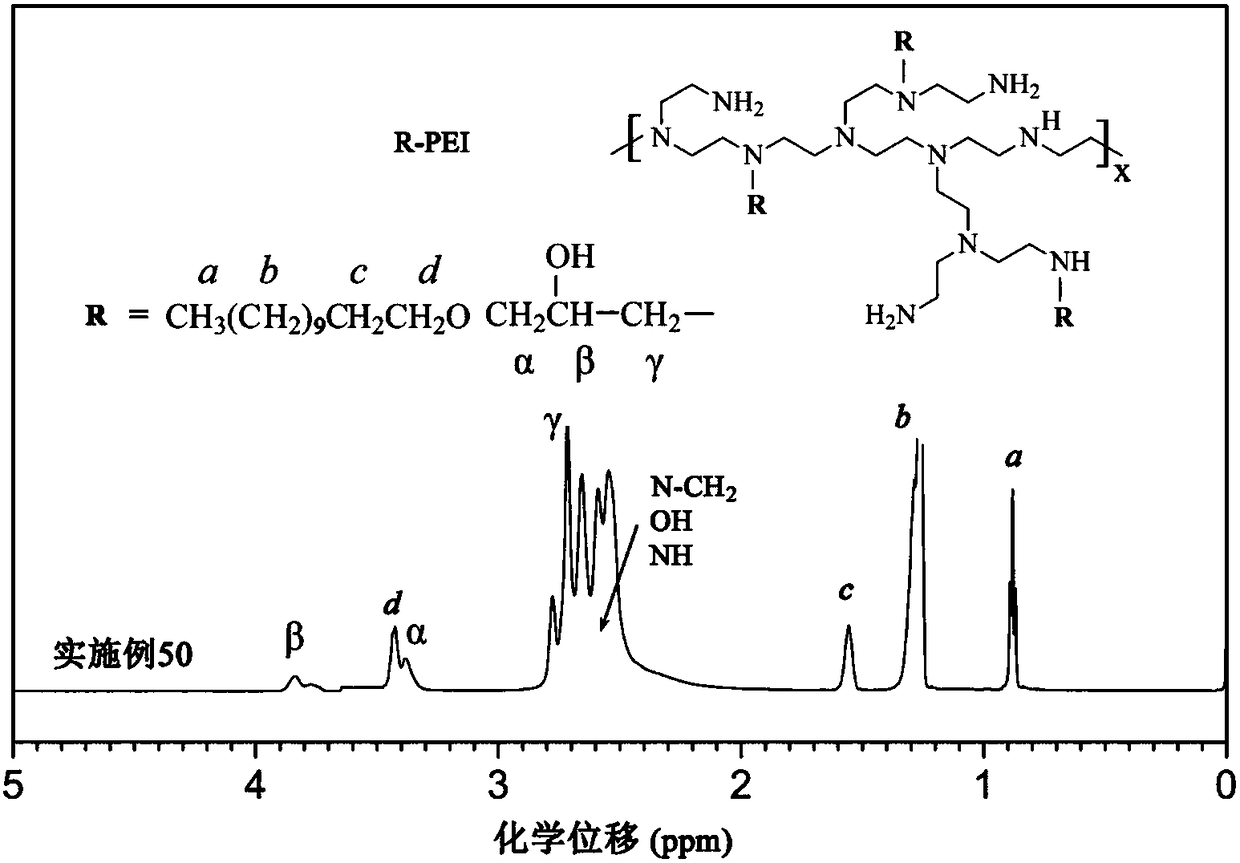

CO2 absorbent of hydrophobic modified polyethyleneimine and application

ActiveCN108355472AEnhanced absorption of CO

<sub>2</sub>

s efficiencyWeaken hydrogen bond interactionsProductsGas treatmentCarbon numberSilanes

The invention provides hydrophobic chain-grafted polyethyleneimine as a CO2 absorbent. The absorbent is used for absorbing CO2 in air at room temperature or absorbing CO2 in combustion emission from afactory at higher temperature, so as to reduce CO2 emission and prevent or alleviate global warming. The content of hydrophobic chain is 3 percent to 70 percent; the hydrophobic chain contains at least one repetitive unit of polypropylene oxide, polyoxetane or polytetrahydrofuran, or contains silane or siloxane, or contains alkyl or fluorine-containing alkyl with the carbon number of 1 to 22. Thehydrophobic chain is thermodynamically incompatible with polyethyleneimine, can generate a microphase separation structure, and a hydrophobic microcell provides an extra CO2 rapid diffusion channel,so that polyethyleneimine chain units in a material body can quickly take part in CO2 absorption. Compared with non-modified polyethyleneimine, the CO2 absorption rate of the hydrophobic chain-graftedpolyethyleneimine is greatly increased.

Owner:SICHUAN UNIV

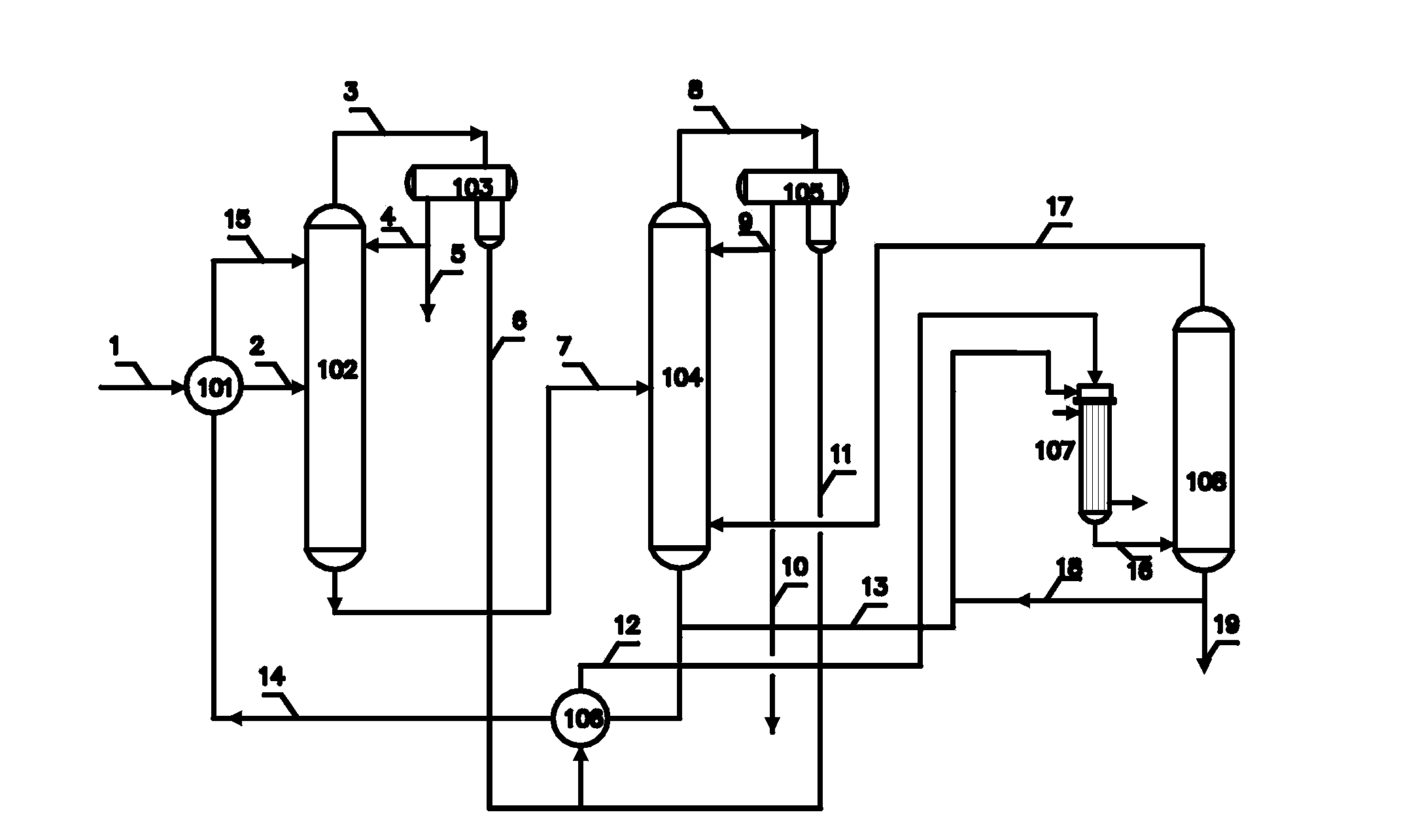

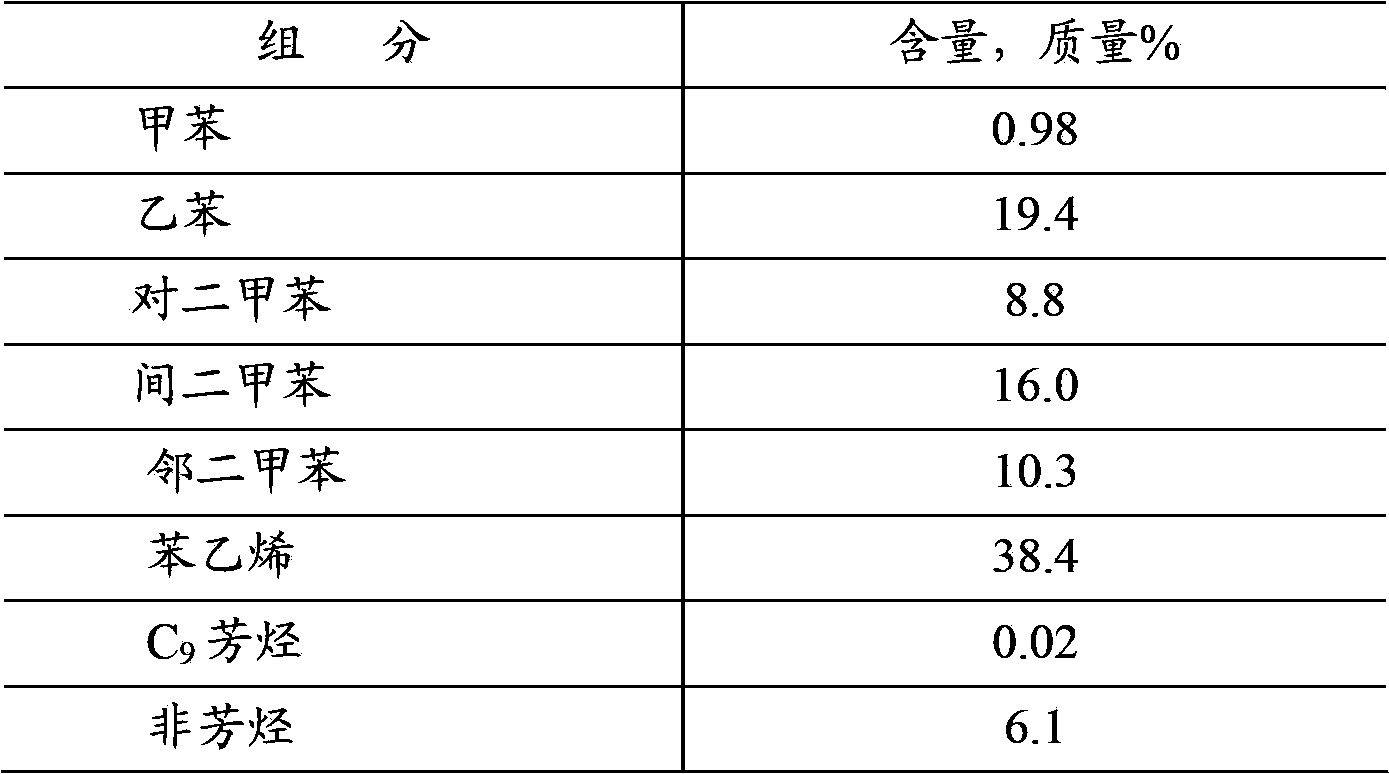

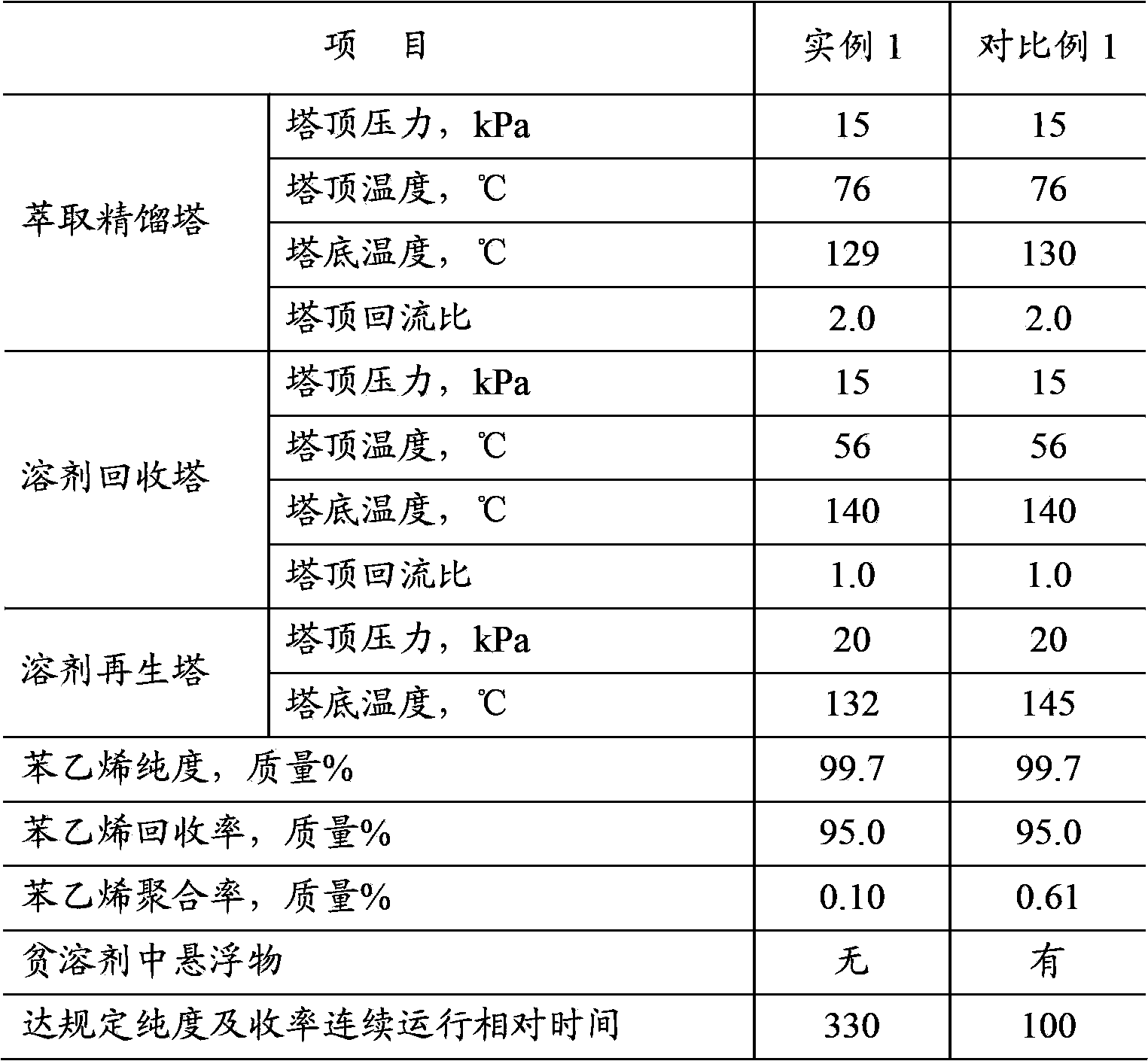

Method for separating styrene from hydrocarbon mixture by extractive distillation

ActiveCN103664498AReduce the probability of aggregationInhibit aggregationDistillation purification/separationHydrocarbon mixturesExtractive distillation

The invention discloses a method for separating styrene from a hydrocarbon mixture by extractive distillation. The method comprises the following steps: performing extractive distillation on the hydrocarbon mixture with a compound solvent in the presence of a polymerization inhibitor; after extractive distillation, feeding a styrene-containing rich solvent into a solvent recovery tower, and separating styrene and a compound lean solvent out; removing high-boiling-point impurities from a part of the compound lean solvent with a falling film evaporation method to regenerate the solvent; feeding the regenerated compound lean solvent into the solvent recovery tower once again, wherein the compound solvent comprises 80-99 mass percent of a major solvent, 0.01-19 mass percent of a cosolvent and 0.1-2.0 mass percent of water; the major solvent is selected from sulfone compounds; the cosolvent is selected from metoxyphenol and / or ethylene glycol monomethyl ether; the polymerization inhibitor contains 10-60 mass percent of free radicals of nitroxide, 30-70 mass percent of nitrophenol and derivatives thereof, and 5-35 mass percent of N,N-diethylhydroxylamine. Through the method, the polymerization of styrene in an extractive distillation process can be reduced to the maximum extent, and the stable running period of an extractive distillation device is effectively prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

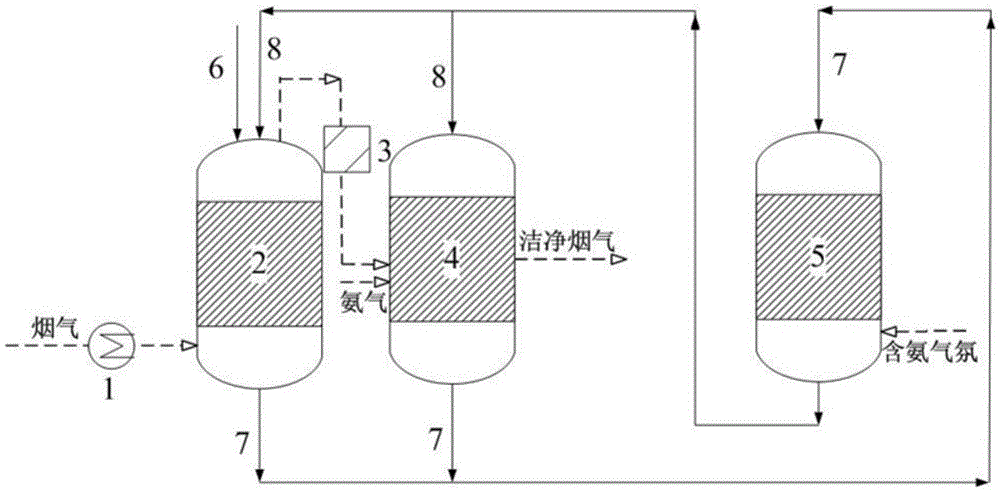

Desulfurization and denitration device and technology used for purifying coke oven smoke

ActiveCN105597531AReduce concentrationReduce inhibitionNitrous oxide captureGas treatmentCoke ovenEnergy consumption

The invention provides a desulfurization and denitration device and technology used for purifying coke oven smoke. The device comprises a smoke waste heat recovery device, a desulfurization reactor and an SCR denitration reactor in a sequential connection mode. The desulfurization reactor is provided with a first smoke inlet, a first smoke outlet and a bearing device, the SCR denitration reactor is provided with a second smoke inlet, a second smoke outlet and a bearing device, the bearing devices can move downwards, the first smoke inlet and the first smoke outlet enable the coke oven smoke to make countercurrent contact with active coke and / active carbon in the desulfurization reactor, and the second smoke inlet and the second smoke outlet enable the smoke which is subjected to desulfurization treatment to make cross-current contact with active coke and / or active carbon in the SCR denitration reactor. By the utilization of the device, the denitration efficiency reaches 80% or more, the desulfurization efficiency reaches 96% or more, the temperature in the regeneration reaction of active coke can be obviously decreased to 50 DEG C-75 DEG C, and therefore energy consumption is lowered.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Novel chemical absorbent for trapping and recovering carbon dioxide

InactiveCN101264415AEasy to makeImprove stabilityDispersed particle separationBy absorptionHigh absorptionSolvent

The invention provides a chemical absorbent for recovery of carbon dioxide, which comprises organo-metallic compound and solvent; wherein, the organo-metallic compound is organo-metallic bismuth oxide or organo-metallic antimony oxide. The chemical absorbent for recovery of carbon dioxide has the advantages of strong absorptive capacity, high absorption and analytic speed, low regeneration temperature and energy consumption, no equipment loss, low cost of absorbent, simple preparation, innocuity and non-pollution, high stability and repeatability, and being applicable to recovery of carbon dioxide of flue gas, synthetic ammonia, natural gas, kiln gas and other industrial gases.

Owner:HUNAN UNIV

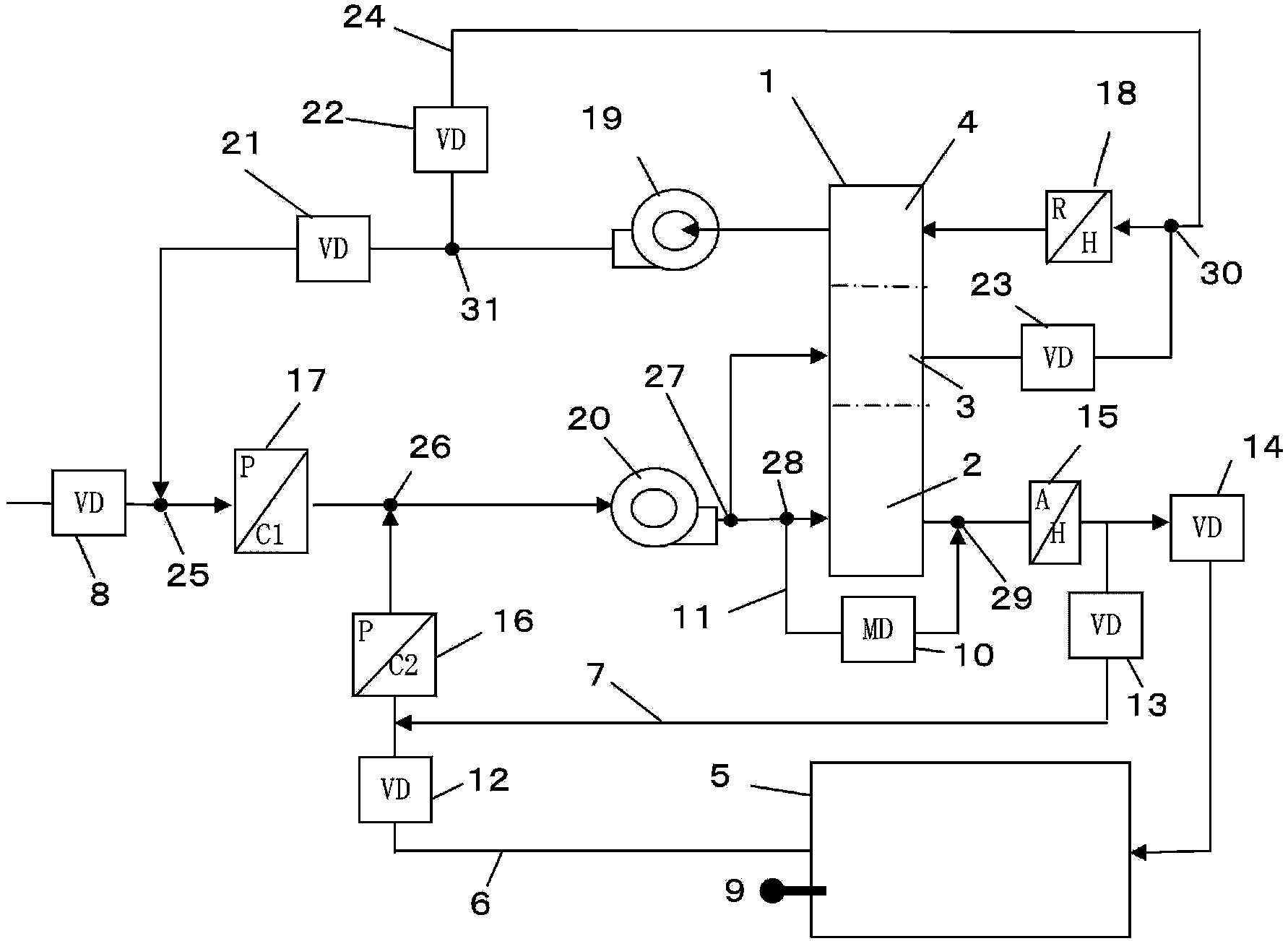

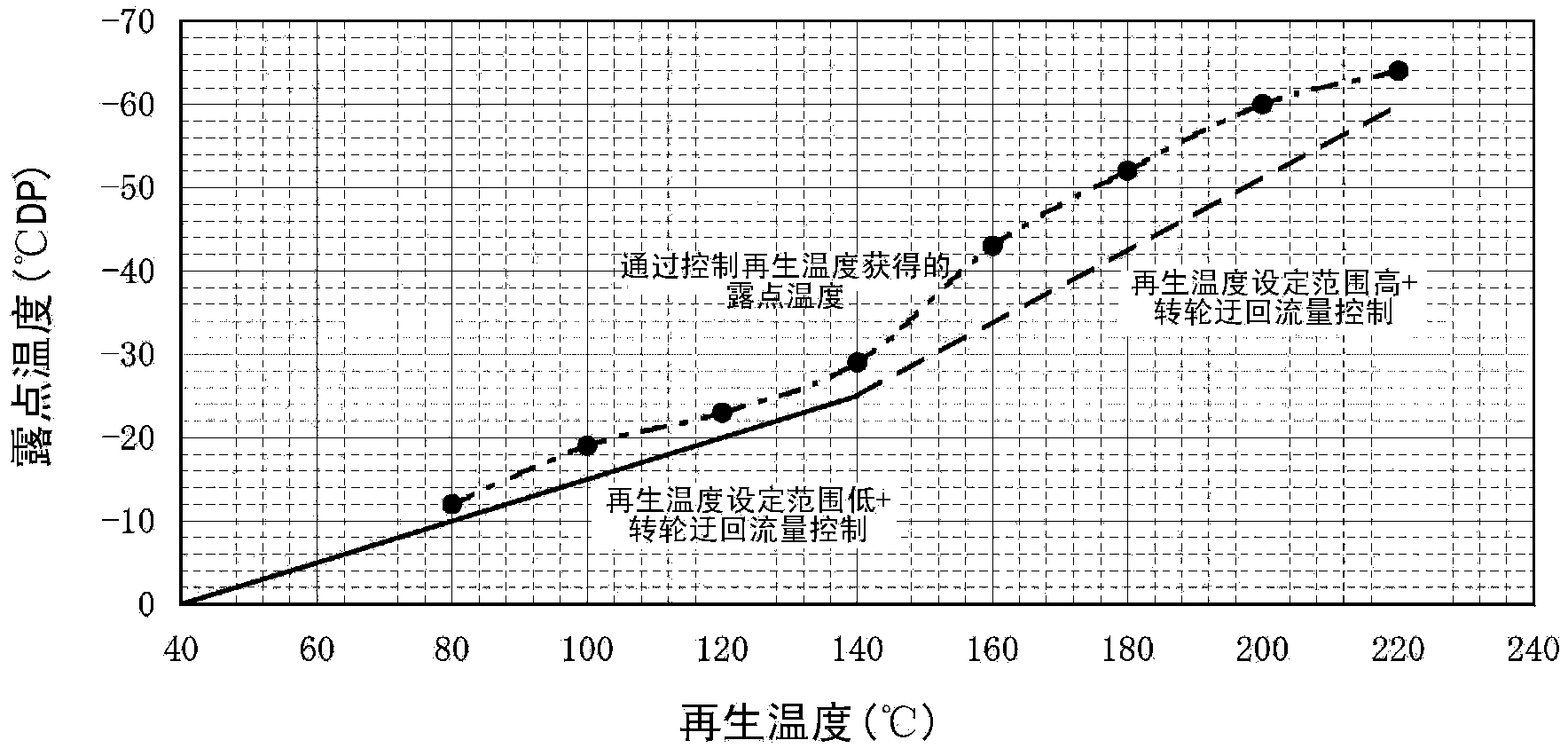

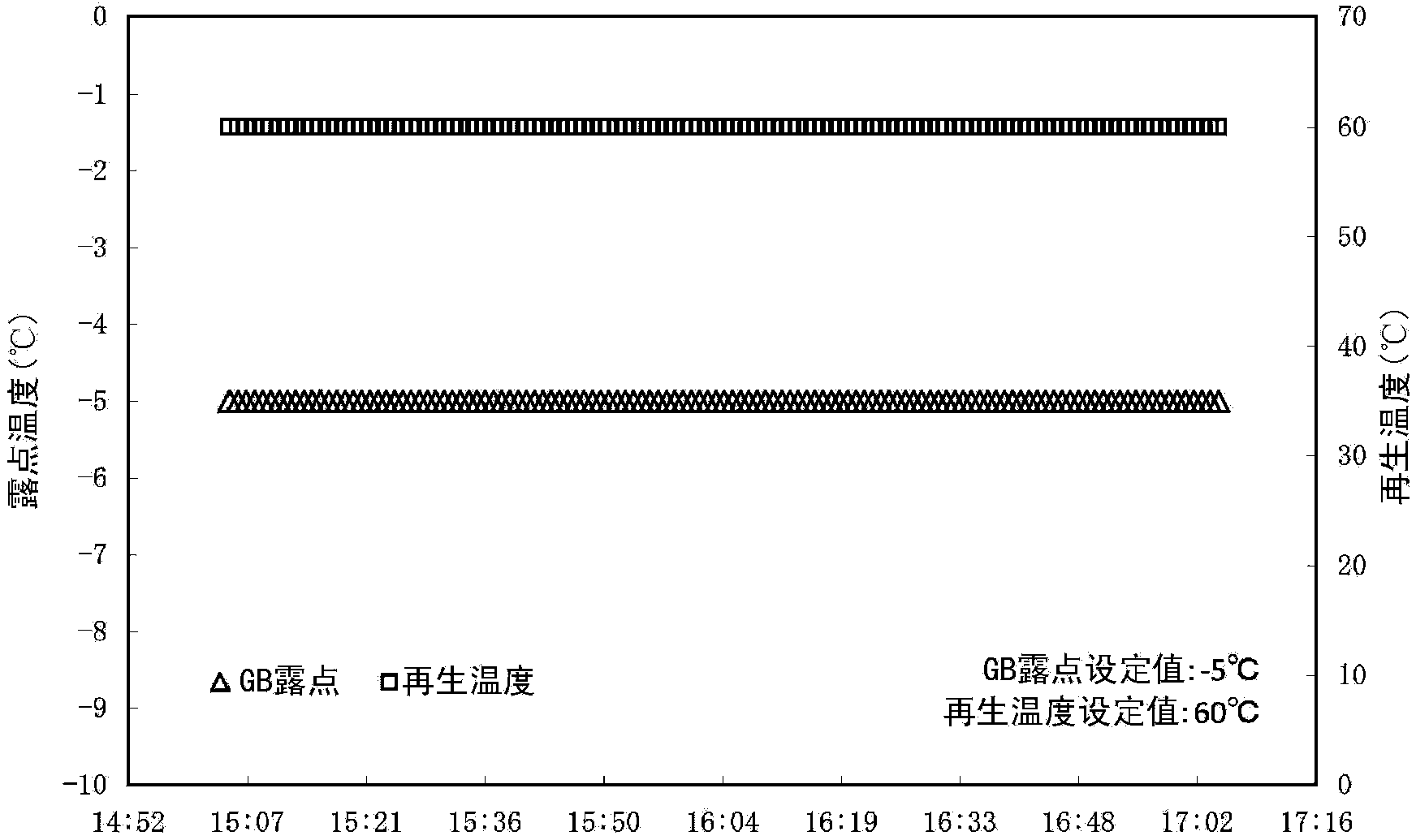

Glove box

ActiveCN103568025ADew point can be fine-tunedReduce consumptionDispersed particle separationShielded cellsTemperature controlProportional control

The present invention aims to provide a glove box which enables the exposure point in the box to be controlled at any exposure point at a high precision and with less energy, and enables a device not to be complicated. The glove box is characterized in that a dehumidify rotating wheel is segmented into an absorption area (2), a purifying area (3) and a regeneration area (4) relative to the rotation direction of the dehumidify rotating wheel, so that a part of or all of an external gas passes the absorption area (2); the rest part of the external gas passes a circuitous channel which enables an upstream side branch point (28) and a downstream side confluence of the absorption area (2)to be communicated and possesses a flow control device, and is supplied to the box (5) as a supply destination. The temperature control of the exposure point in the box (5) is carried out by combining the regeneration temperature proportion control and the above circuitous flow control, and the temperature of the exposure point in the box (5) can be controlled at any exposure point temperature with less energy consumption and at a high precision.

Owner:SEIBU GIKEN CO LTD

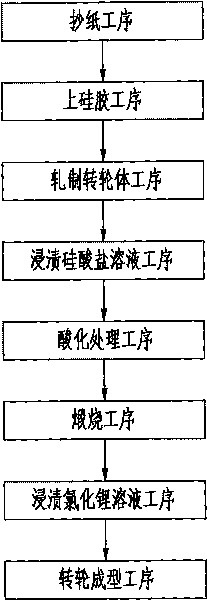

Method for preparing lithium chloride silica gel composite turning wheels

ActiveCN101703918AGood hygroscopicityImprove dehumidification effectOther chemical processesSilicon compoundsLithium chlorideMoisture absorption

The invention relates to a method for preparing lithium chloride silica gel composite turning wheels. No dehumidification turning wheels which are good in dehumidification performance and still have good moisture absorption performance and moisture absorption stability when regeneration temperature is low exist at present. The method sequentially comprises the processes of making paper, supplying silica gel, rolling turning-wheel bodies and molding turning wheels, and is characterized in that the method also comprises the processes of impregnating with silicate solution, acidizing, calcining and impregnating with lithium chloride solution in turn between the process of rolling turning-wheel bodies and the process of molding turning wheels; in the process of impregnating with silicate solution, the turning-wheel bodies are impregnated with silicate aqueous solution in a concentration of 10 to 30 percent; in the acidizing process, the turning-wheel bodies are soaked in acid solution in a concentration of 3 to 30 percent; in the calcining process, the turning-wheel bodies are calcined at a high temperature between 400 and 500 DEG C; and in the process of impregnating with lithium chloride solution, the turning-wheel bodies are impregnated with the lithium chloride solution in a concentration of 15 to 40 percent. The turning wheels prepared by the method have the advantages of good dehumidification performance, low regeneration temperature, convenient manufacture and long lifespan.

Owner:HANGZHOU DRY AIR TREATMENT EQUIP

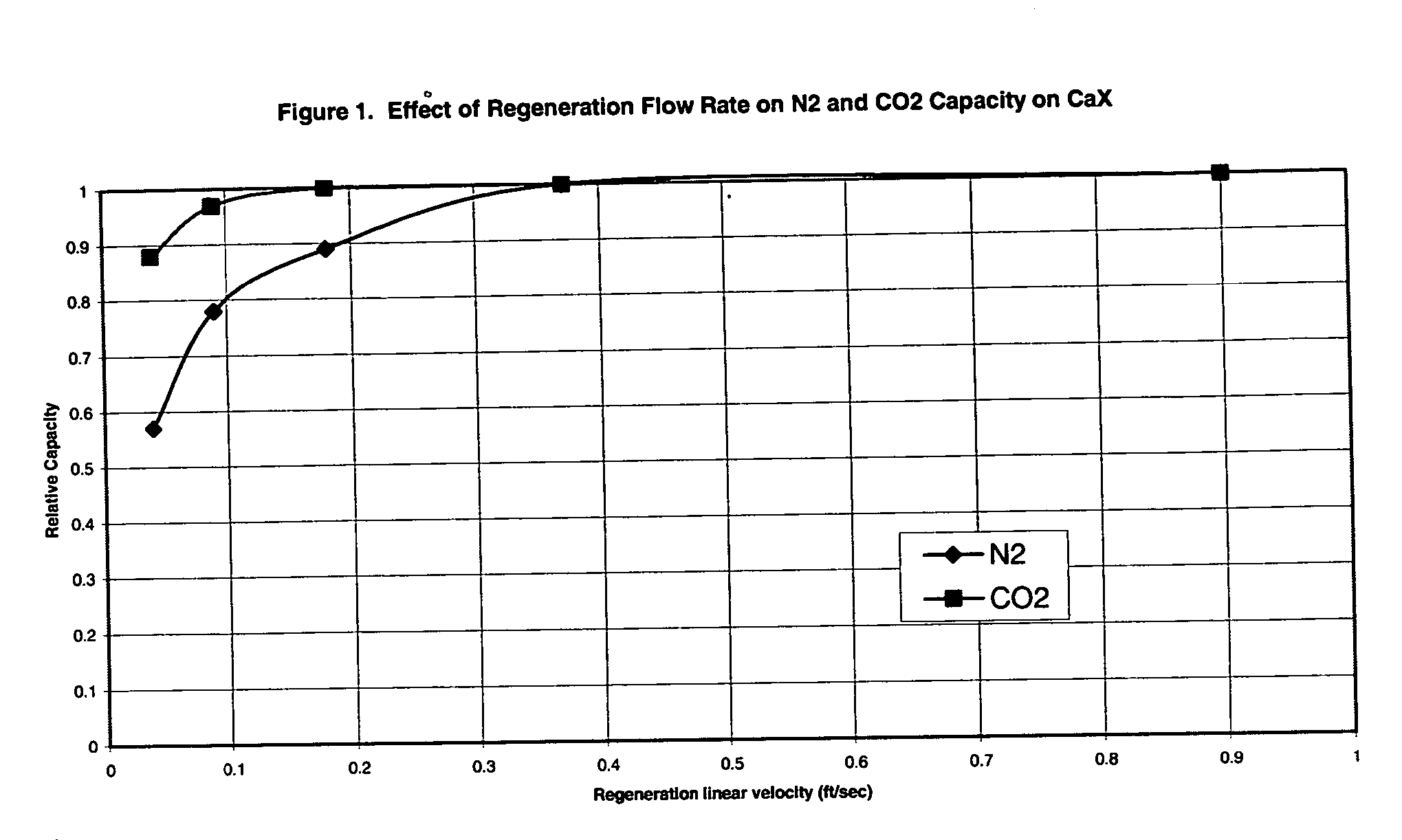

Periodic high temperature regeneration of thermal swing adsorption systems

ActiveUS20050199123A1Reduced Power RequirementsCapacity of systemNitrous oxide captureSolidificationSorbentHigh heat

Owner:AIR PROD & CHEM INC

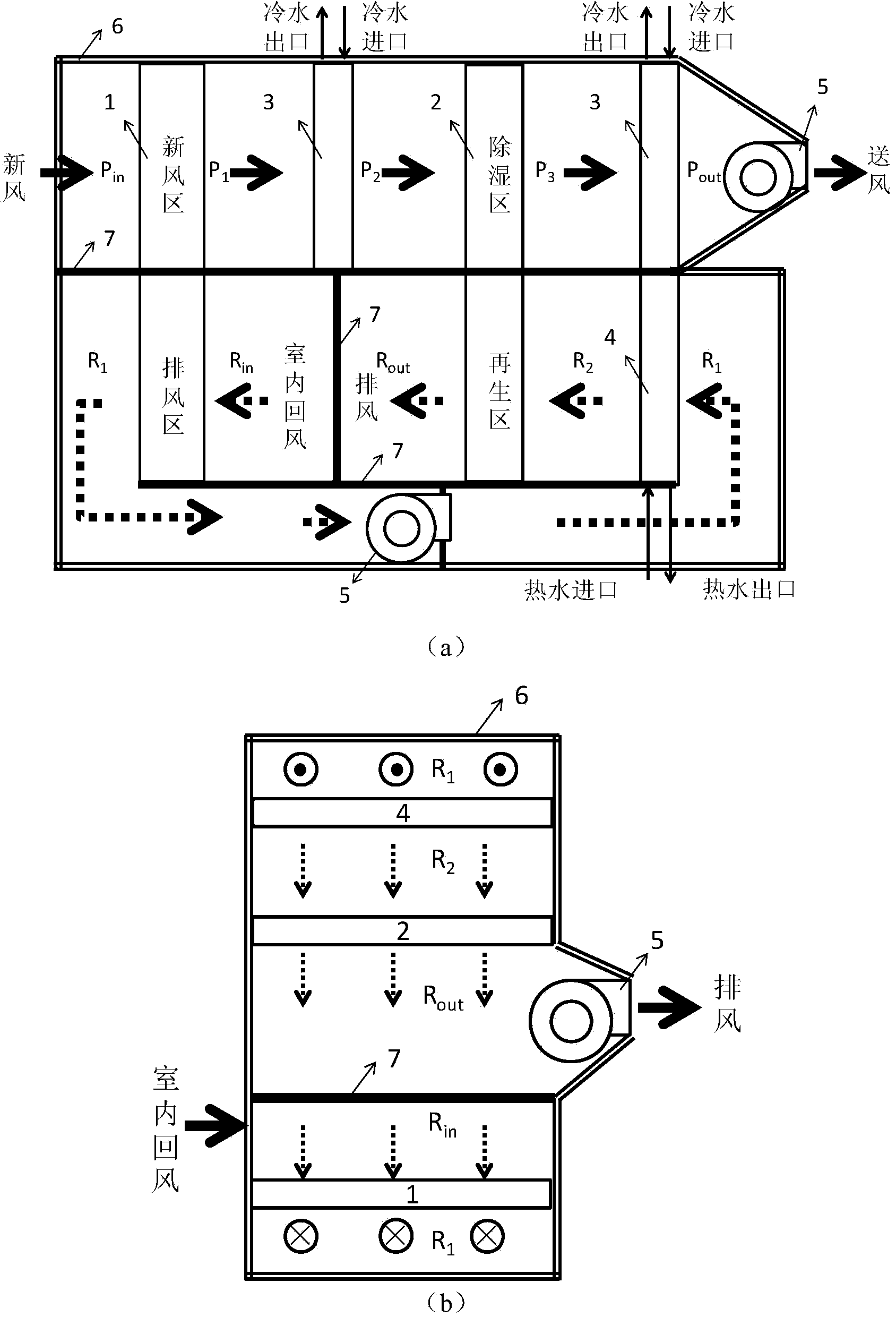

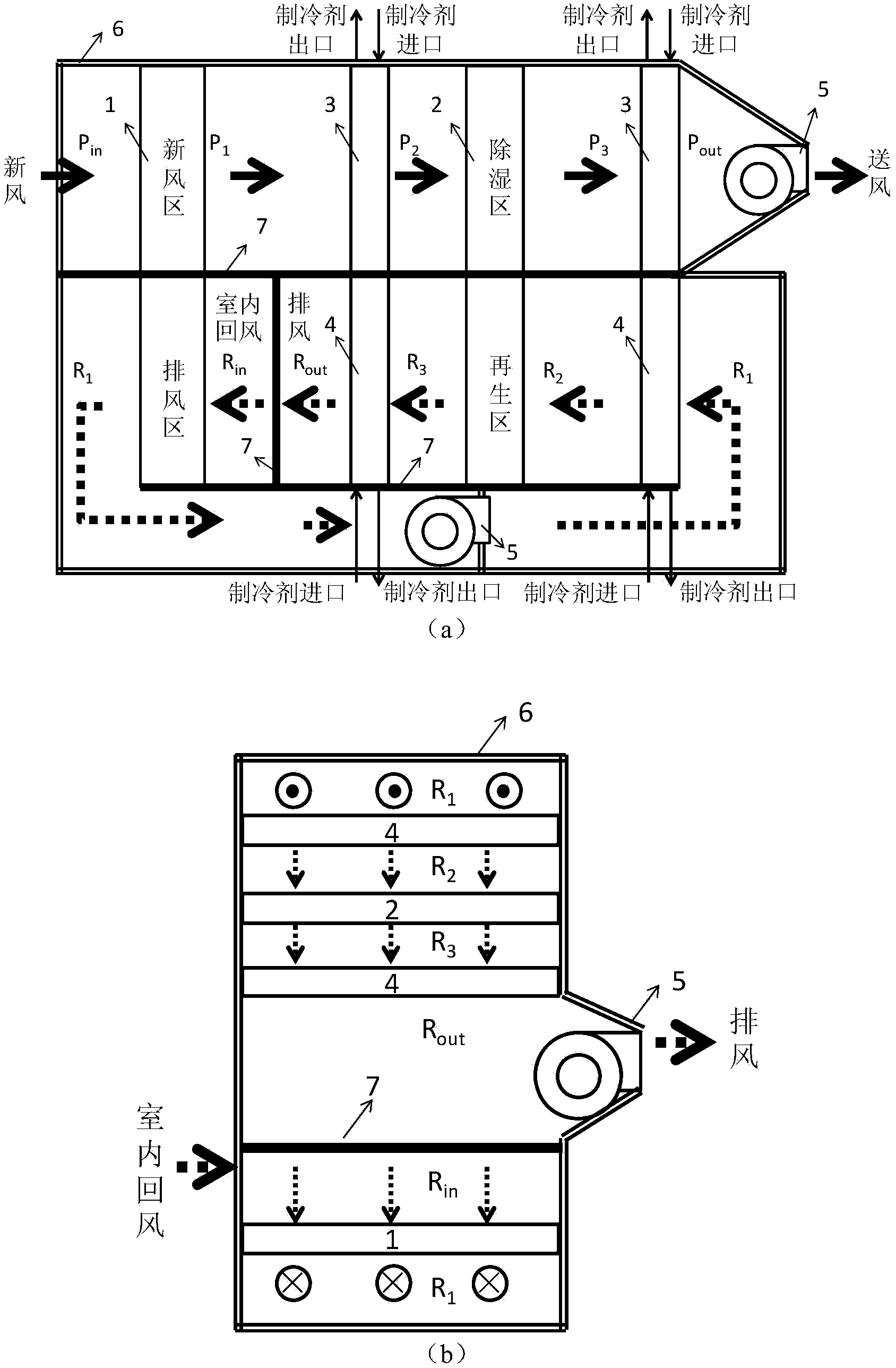

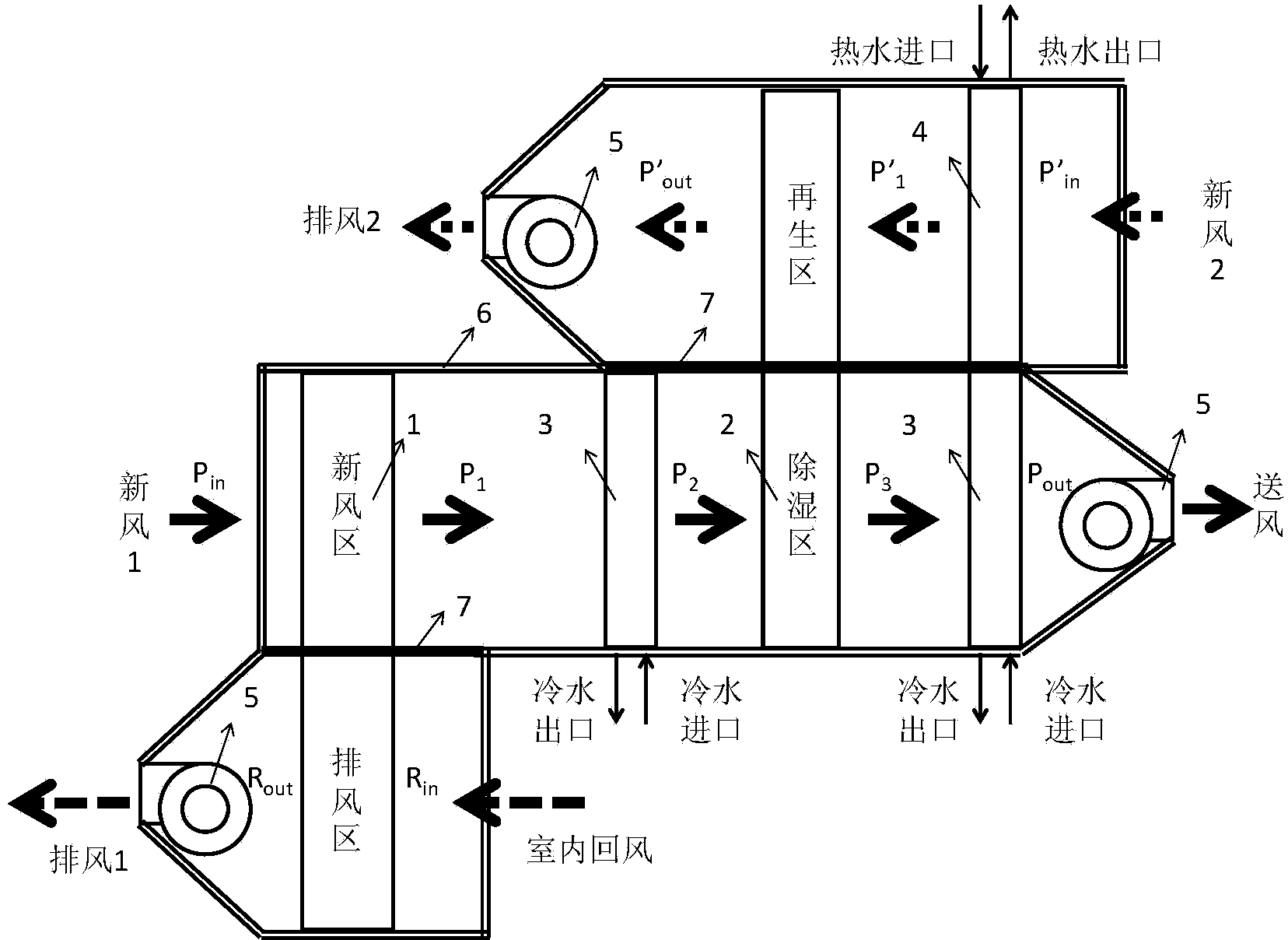

Double-runner fresh air treating unit combining total heat recovery runner and dehumidifying runner

ActiveCN104390288AReduce energy consumptionLarge specific surface areaAir treatment detailsLighting and heating apparatusRecovery performanceHoneycomb

The invention belongs to the field of heating ventilation and air conditioning, and particularly relates to a double-runner fresh air treating unit combining a total heat recovery runner with a dehumidifying runner. The double-runner fresh air treating unit consists of a plurality of layers of channels, and can be used for dehumidifying and cooling fresh air. A solid adsorbent having moisture absorption performance is taken as a dehumidifying medium, and a honeycomb-shaped runner is taken as a carrier for performing total heat recovery and dehumidification on the fresh air. The runner has a large specific surface area, so that the size of the device can be reduced, and superior dehumidification and total heat recovery performance is realized; by using the total heat recovery runner, the cold and hot quantity input of active cold and heat sources can be reduced, so that the energy consumption in a fresh air treating process is lowered. By adopting the device, high-temperature cold source cooling and low-temperature heat source heating can be realized, so that efficient cold and heat source driving of solar energy, heat pump systems, high-temperature cold machine cold water and the like can be adopted. Therefore, an efficient fresh air dehumidifying and cooling process can be realized efficiently in summer by using the system.

Owner:UNIV OF SCI & TECH BEIJING

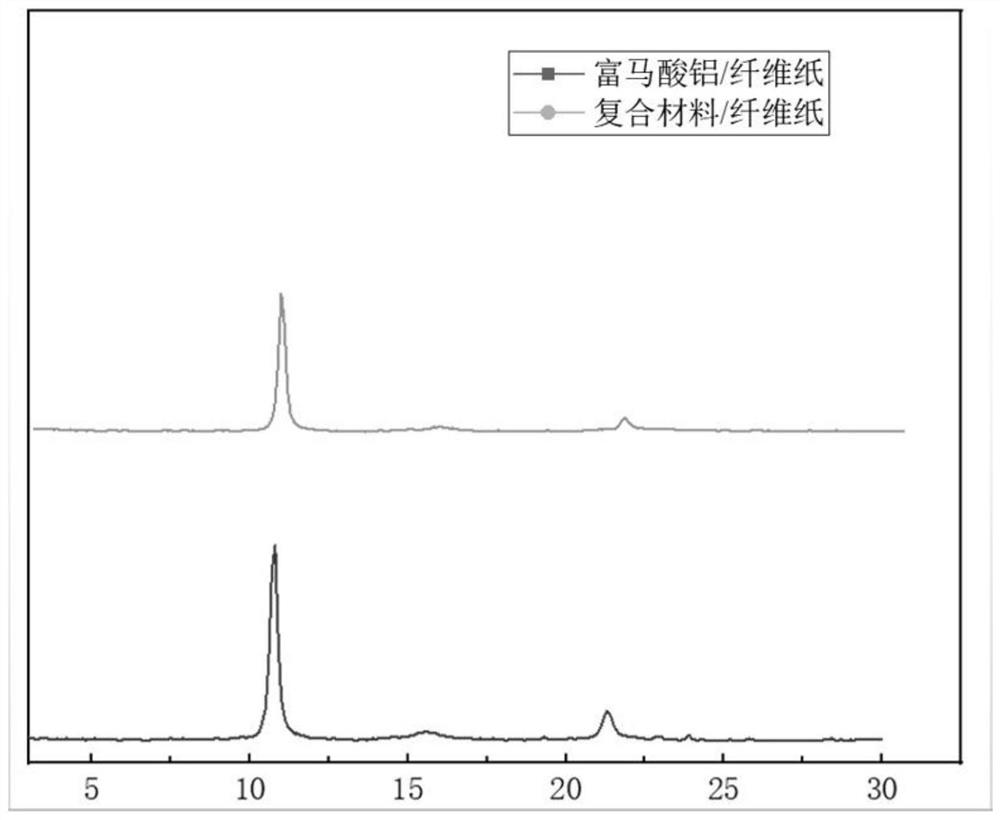

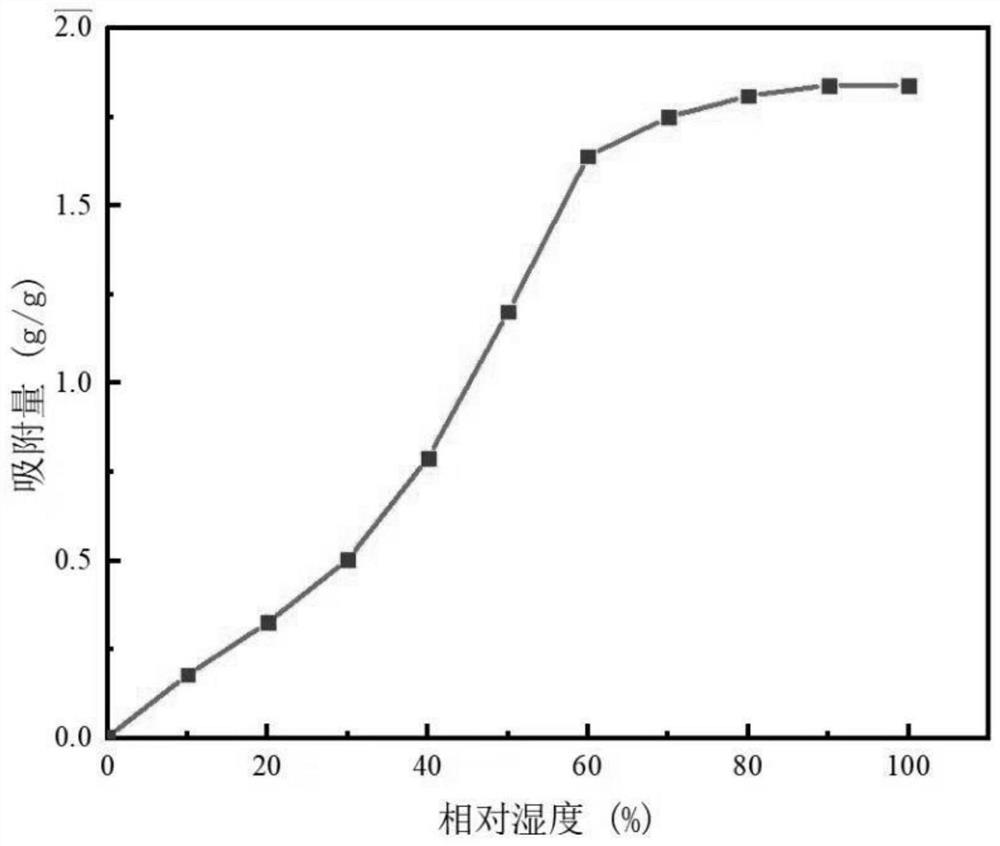

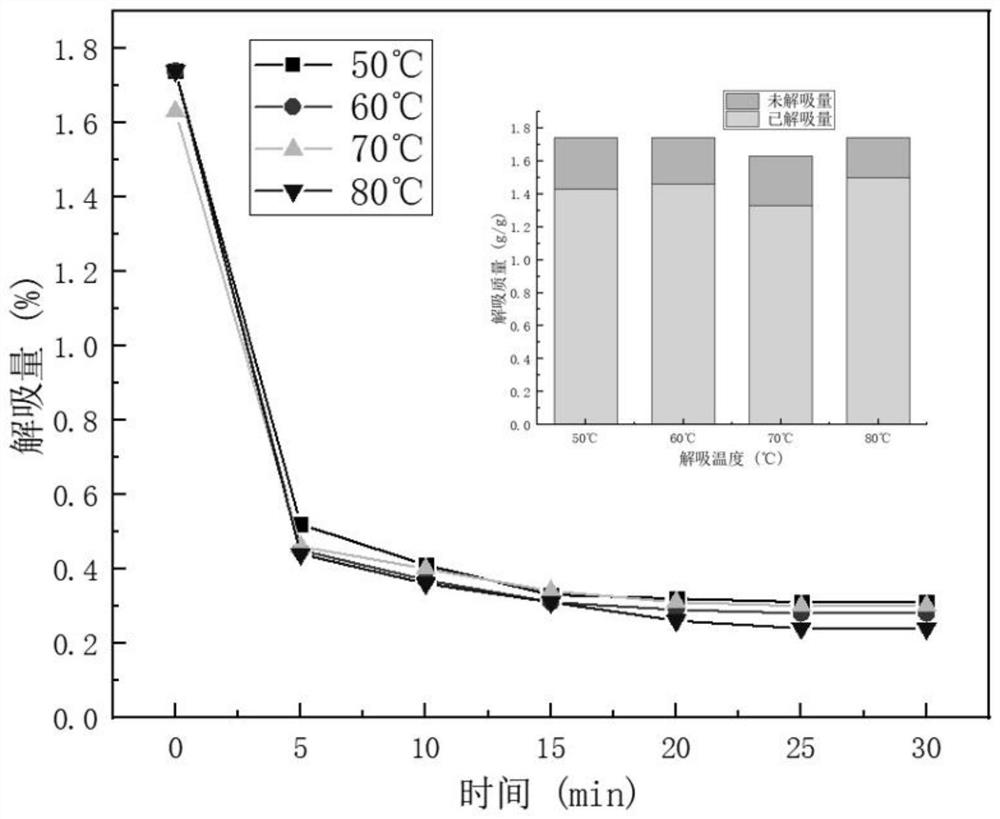

Preparation method of composite dehumidification adsorbent paper sheet prepared from MOF material and lithium chloride

ActiveCN112755965ALow regeneration temperatureShort regeneration timeOther chemical processesDispersed particle separationFiberLithium chloride

The invention discloses a preparation method of a composite dehumidification adsorbent paper sheet prepared from an MOF material and lithium chloride. The method comprises the following steps: 1) synthesizing a large amount of the MOF material; 2) dipping fiber paper in a mixed solution formed by the MOF material and silica sol so as to form an MOF layer, taking out the fiber paper after the fiber paper is completely wetted, and airing and drying the fiber paper; and 3) dipping the fiber paper with the MOF layer material in a mixed solution formed by polyvinyl alcohol and lithium chloride again, taking out the fiber paper after the fiber paper is completely wetted, and airing and drying the fiber paper to form a lithium chloride layer, thereby obtaining the composite material dehumidification adsorbent paper sheet. According to the adsorbent paper sheet provided by the invention, the equilibrium adsorption capacity of the adsorbent paper sheet can reach 1.8 g / g, a regeneration temperature is 50-80 DEG C, film-like substances exist on the surface of the adsorbent paper sheet, and the problem of powder falling can be effectively reduced. The paper sheet can be processed into a honeycomb shape and is suitable for adsorption type rotary wheel dehumidification and heat recovery under the conditions of different humidity and low regeneration temperature.

Owner:BEIJING UNIV OF TECH

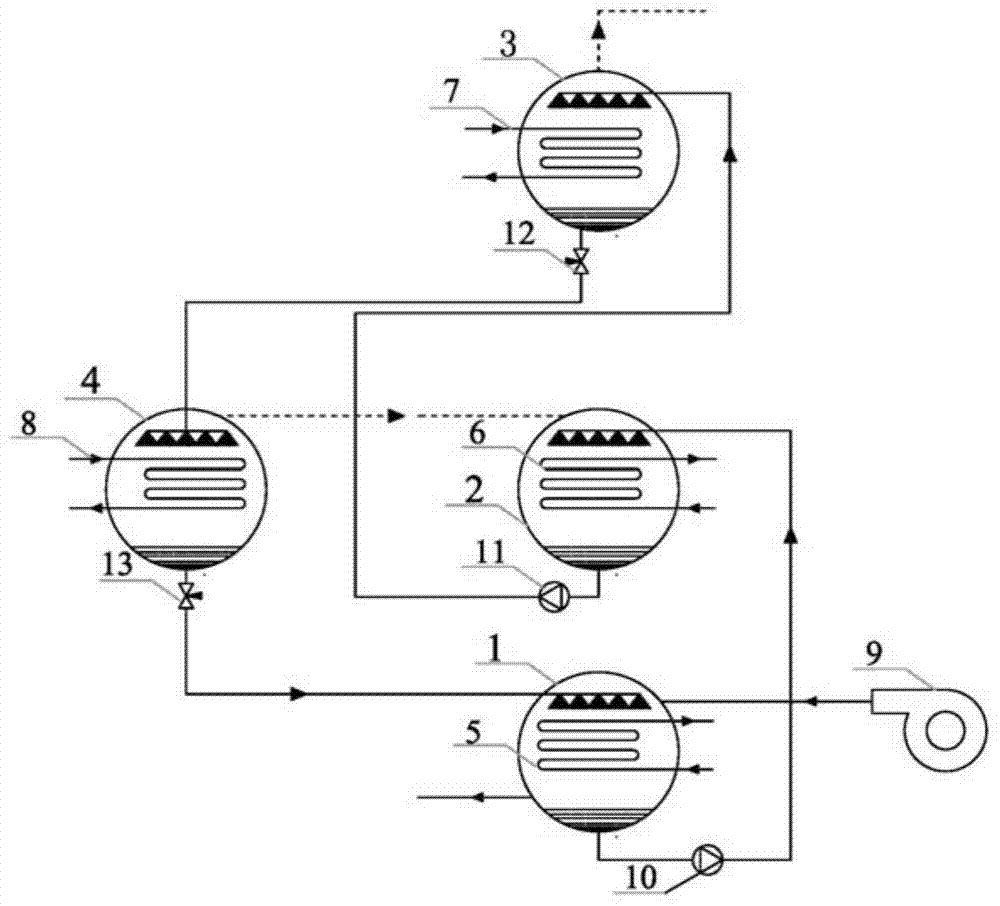

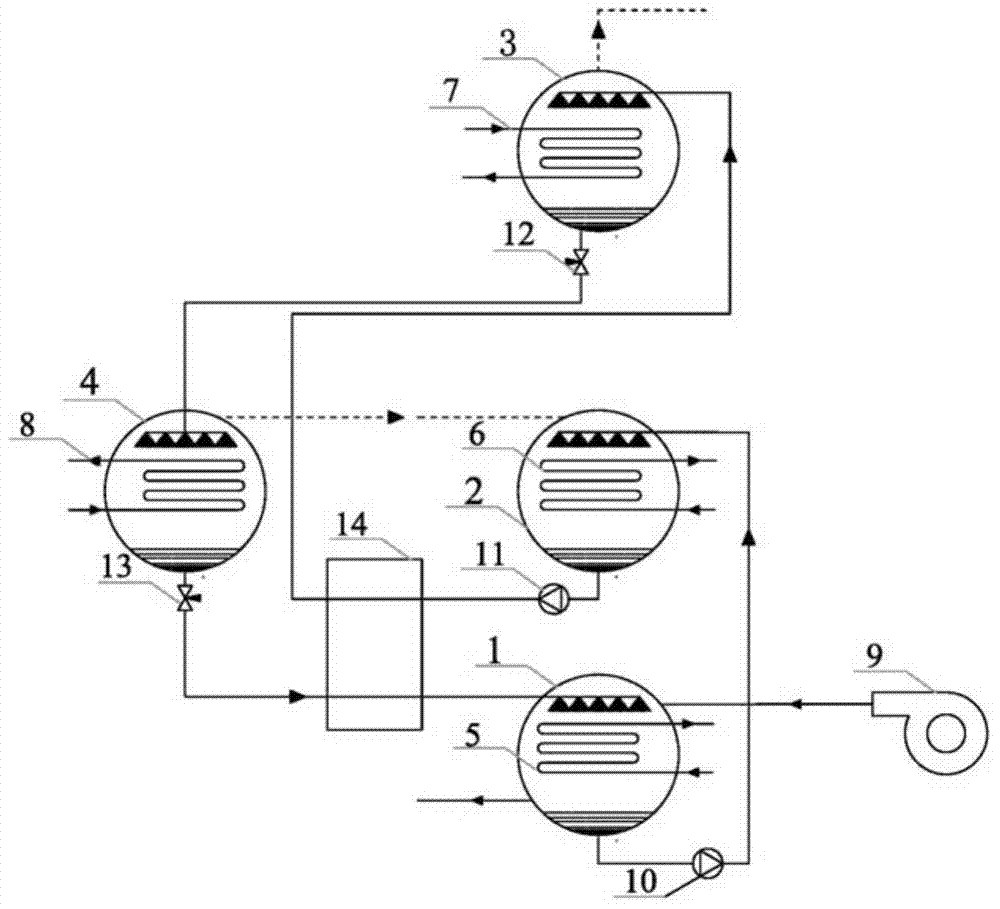

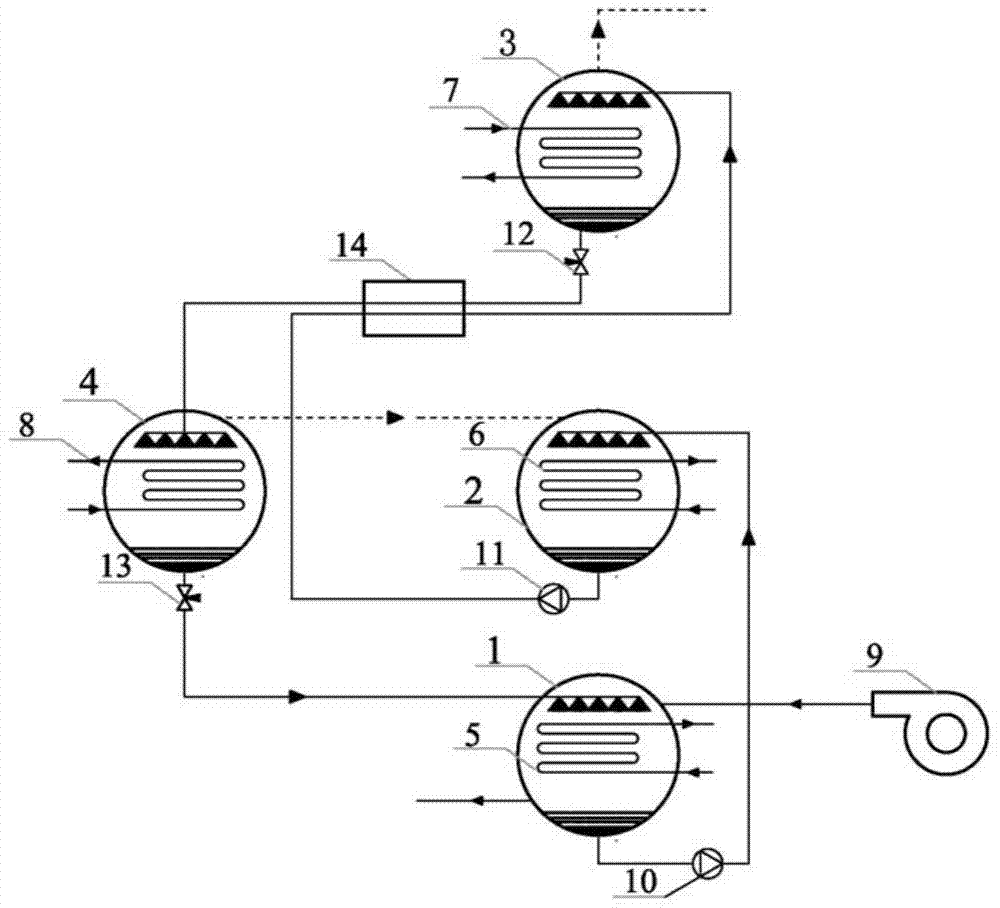

Hot and humid gas energy recovery high-temperature heat production system

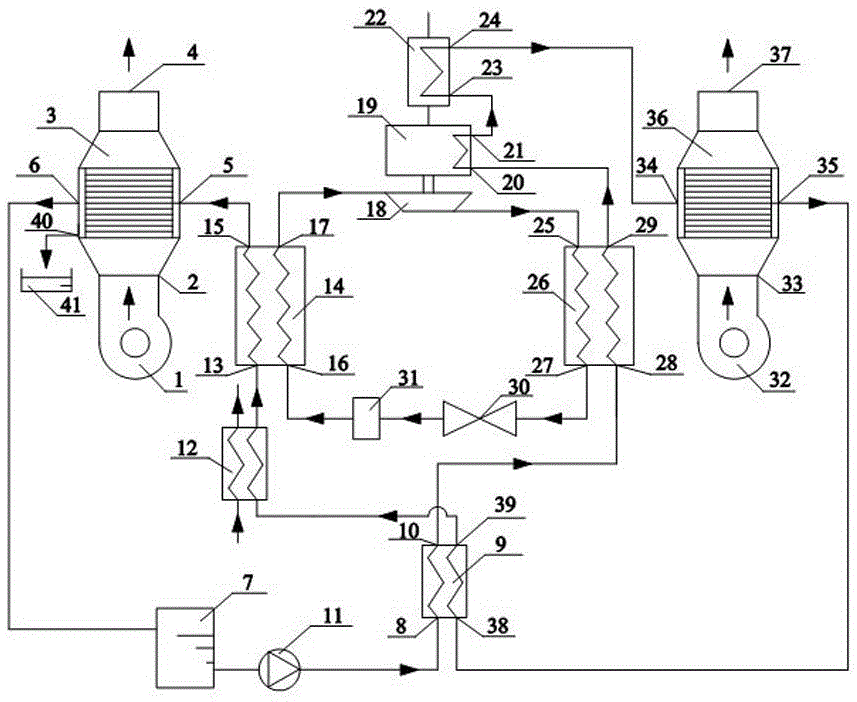

ActiveCN103672835ALow regeneration temperatureSolute saturated vapor pressure is lowEnergy efficient heating/coolingSorption machinesProcess engineeringProduct gas

The invention discloses a hot and humid gas energy recovery high-temperature heat production system. The hot and humid gas energy recovery high-temperature heat production system is characterized by comprising a first-stage absorber, a second-stage absorber, a first-stage generator and a second-stage generator; absorption heat exchange pipes are arranged inside the first-stage absorber and the second-stage absorber; heat supplying pipes are arranged inside the first-stage generator and the second-stage generator; a liquid absorbent outlet of the first-stage absorber is connected with a liquid absorbent inlet of the second-stage absorber, a liquid absorbent outlet of second-stage absorber is connected with a liquid absorbent inlet of the first-stage generator, a liquid absorbent outlet of the first-stage generator is connected with a liquid absorbent inlet of the second-stage generator, and a liquid absorbent outlet of the second-stage generator is connected with a liquid absorbent inlet of the first-stage absorber; besides, the second-stage absorber is communicated with the second-stage generator through a steam pipeline so that the second-stage generator can convey steam to the second-stage absorber; the first-stage generator is provided with a steam outlet which conveys steam outward; the first-stage absorber is provided with a hot and humid gas inlet and a hot and humid gas outlet. According to the hot and humid gas energy recovery high-temperature heat production system, a liquid absorbent is used for absorbing the steam in humid and hot waste gas, and the steam is converted into steam at a high temperature and high pressure to be used in the industrial production process.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com