Multifunctional deoxidizer, preparation and applications thereof

A deoxidizer, multifunctional technology, used in other chemical processes, chemical instruments and methods, filter regeneration, etc., to achieve the effect of easy operation, high deoxidation depth, and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

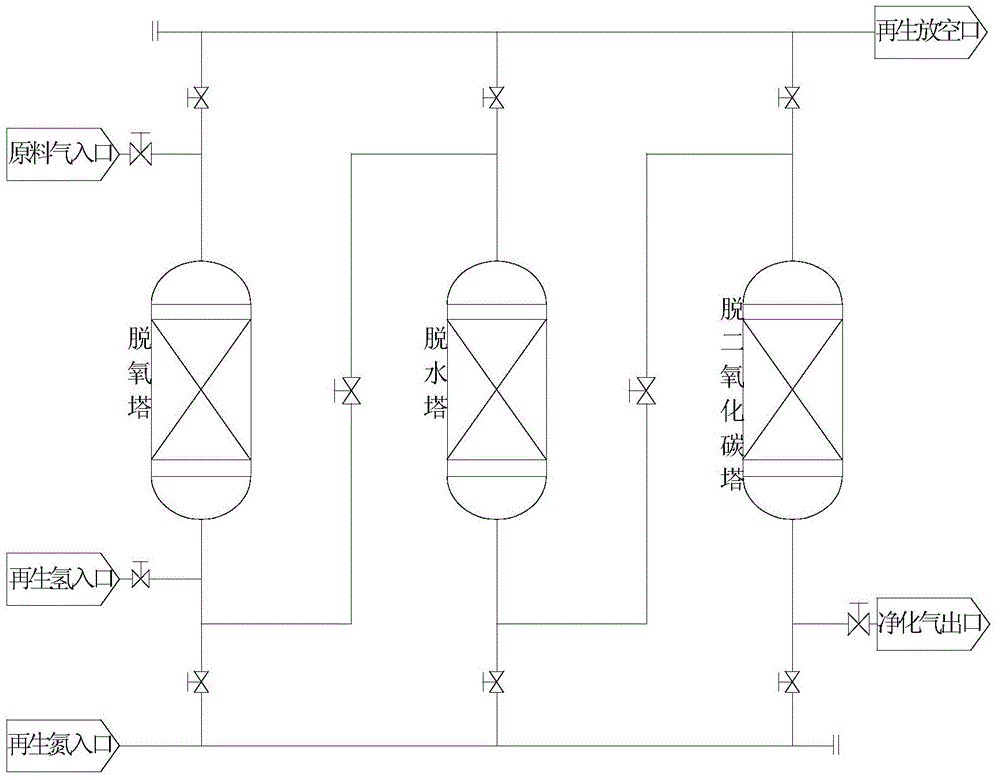

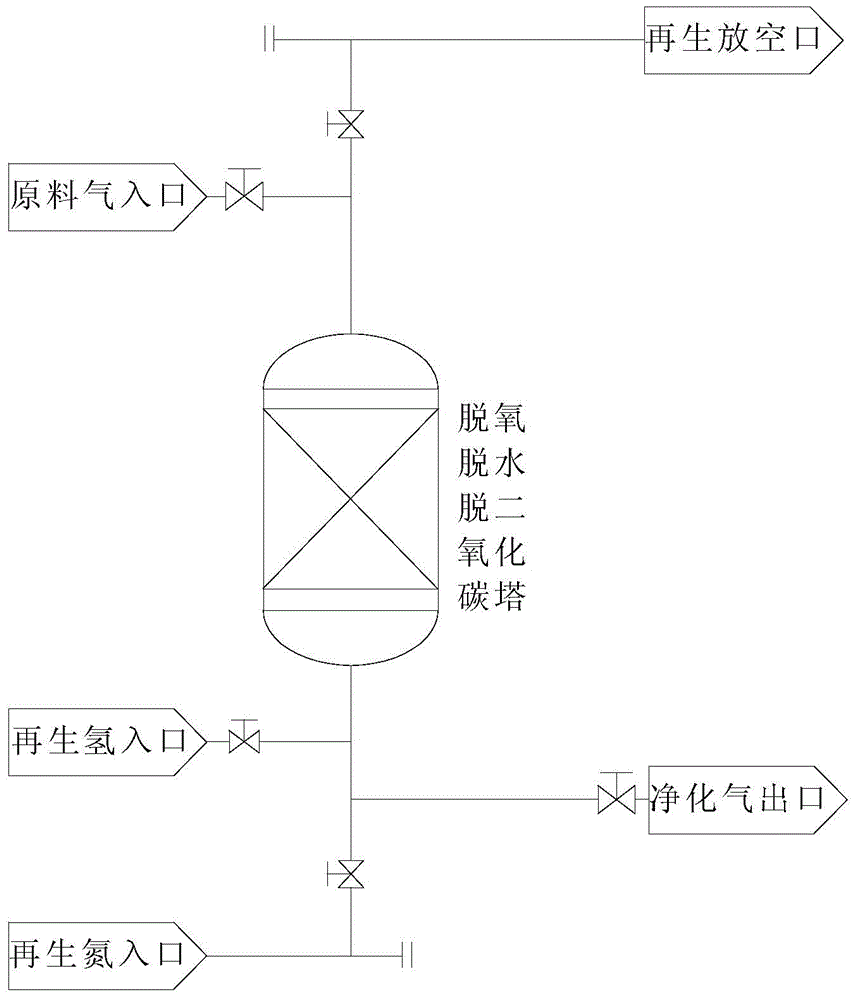

Image

Examples

Embodiment 1

[0061] Embodiment 1, get 140 grams of MnCO 3 , 20 g CuCO 3 , 30 grams of high-alumina cement, 10 grams of CaO are fully mixed evenly, processed into small balls with a particle size of 10-20 mesh using a sugar coating machine; the small balls are placed overnight and dried; roasted at 400-450 ° C for 4-6 hours; After natural cooling, the preparation is completed.

[0062] (1) Weigh 5 grams of the sample of Example 1, put it into an evaluation tube with a diameter of 10mm, and fill it with a height of 5.3mm (the aspect ratio is about 5.3), and pass hydrogen at 300°C (the oxygen content in the hydrogen is less than 0.1×10 -6 v / v) Regeneration for 6 hours, hydrogen space velocity is 300 / h -1 , cooled to room temperature under the condition of flowing hydrogen.

[0063] With oxygen content 1000×10 -6 v / v nitrogen, at 2000 / h -1 The space velocity is passed into the evaluation device, it works at room temperature, and the deoxidation depth is 0.01×10 -6 At v / v, the deoxygenati...

Embodiment 2

[0070] Embodiment 2, get 150 grams of MnCO 3 , 50 g NiCO 3 , 30 g CuCO 3 60 grams of high-alumina cement and 10 grams of CaO are fully mixed and processed into a spherical shape with a particle size of 10-20 meshes, fired at 400-600°C for 4-8 hours, and finished after natural cooling.

[0071] (1) Weigh 5 grams of the sample of Example 2, put it into an evaluation tube with a diameter of 10mm, and fill it with a height of 5.3mm (the aspect ratio is about 5.3), and pass hydrogen at 300°C (the oxygen content in the hydrogen is less than 0.1×10 -6 v / v, water content less than 0.1×10 -6 v / v) Regeneration for 6 hours, hydrogen space velocity is 300 / h -1 , cooled to room temperature under the condition of flowing hydrogen.

[0072] With oxygen content 1000×10 -6 v / v, water content is 3000×10 -6 The v / v nitrogen gas is passed into the evaluation device, it works at normal temperature, and the deoxidation depth is 0.01×10 -6 At v / v, the deoxygenation capacity is 11.6ml / g; the d...

Embodiment 3

[0075] Embodiment 3, get 90 grams of CnCO 3 , 50 g ZnCO 3 , 70 g NiCO 3 , 70 grams of water glass, 20 grams of Al 2 o 3 , the two are fully mixed evenly, processed into a spherical shape, the particle size is selected from 8 to 10 mesh, roasted at 400 to 800 ° C for 4 to 8 hours, and cooled naturally, the production is completed.

[0076] (1) Weigh 5 grams of the sample of Example 2, put it into an evaluation tube with a diameter of 10mm, and fill it with a height of 5.3mm (the aspect ratio is about 5.3), and pass hydrogen at 300°C (the oxygen content in the hydrogen is less than 0.1×10 -6 v / v, water content less than 0.1×10 -6 v / v) Regeneration for 6 hours, hydrogen space velocity is 300 / h -1 , cooled to room temperature under the condition of flowing hydrogen.

[0077] With oxygen content 1000×10 -6 v / v, water content is 3000×10 -6 The v / v nitrogen gas is passed into the evaluation device, it works at normal temperature, and the deoxidation depth is 0.01×10 -6 At v / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com