Nano-deoxidant composition and its synthesis method

A synthesis method and technology of deoxidizer, applied in chemical instruments and methods, manganese compounds, adsorption purification/separation, etc., can solve problems such as increased cost, increased consumption of polymerization catalyst, insufficient deoxidation depth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

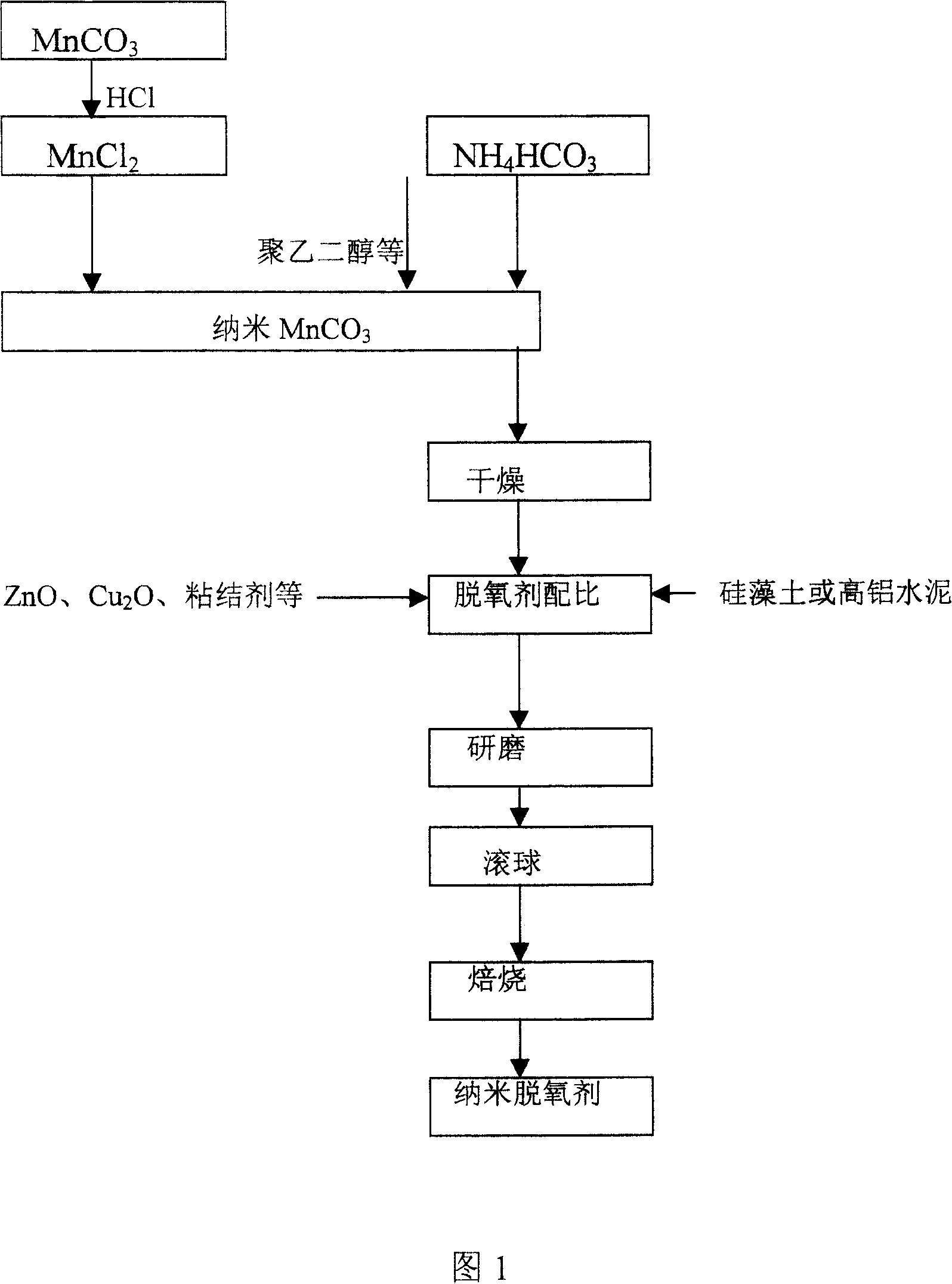

Image

Examples

Embodiment 1

[0026] Step 1: Nano MnCO 3 preparation of

[0027] Reaction formula: MnCO 3 +2HCl→MnCl 2 +CO 2 ↑+H 2 o

[0028] MnCl 2 +2NH 4 HCO 3 → MnCO 3 ↓+2NH 4 Cl+H 2 O+CO 2 ↑

[0029] A: 0.5mol manganese carbonate is added to 30ml water, and hydrochloric acid is added dropwise at a molar ratio of 1:2;

[0030] B: Add 1.0mol ammonium bicarbonate to 250ml water; the molar ratio of manganese carbonate to ammonium bicarbonate is 1:2;

[0031] C: Add 5g polyethylene glycol (surface treatment agent) to 100ml water.

[0032] Put C into a reaction bottle equipped with high-speed stirring (with 2 dropping ports), heat up to 40°C and dissolve completely, add A and B dropwise into C at a constant speed of 1 drop / second, and stir under high speed (100-120 rpm), react at 40°C for 1 hour, filter the resulting white precipitate, wash with deionized water until there is no chloride ion, and spray dry to obtain 30-100 nanometer MnCO 3 .

[0033] Step 2: Synthesis of Nano Deoxidizer

[...

Embodiment 2

[0038] Step 1: Nano MnCO 3 preparation of

[0039] Reaction formula: MnCO 3 +2HCl→MnCl 2 +CO 2 ↑+H 2 o

[0040] MnCl 2 +2NH 4 HCO 3 → MnCO 3 ↓+2NH 4 Cl+H 2 O+CO 2 ↑

[0041]A: 0.5mol manganese carbonate is added to 30ml water, and hydrochloric acid is added dropwise at a molar ratio of 1:2;

[0042] B: Add 1.0mol ammonium bicarbonate to 250ml water; the molar ratio of manganese carbonate to ammonium bicarbonate is 1:2;

[0043] C: Add 3g of polyethylene glycol (surface treatment agent) to 100ml of water.

[0044] Put C into a reaction bottle equipped with high-speed stirring (with 2 dropping ports), heat up to 40°C and dissolve completely, add A and B dropwise into C at a constant speed of 1 drop / second, and stir under high speed (100-120 rpm), react at 40°C for 2 hours, filter the resulting white precipitate, wash with deionized water until there is no chloride ion, and spray dry to obtain 30-100 nanometer MnCO 3 .

[0045] Step 2: Synthesis of Nano Deoxidize...

Embodiment 3

[0050] Step 1: Nano MnCO 3 preparation of

[0051] Reaction formula: MnCO 3 +2HCl→MnCl 2 +CO 2 ↑+H 2 o

[0052] MnCl 2 +2NH 4 HCO 3 → MnCO 3 ↓+2NH 4 Cl+H 2 O+CO 2 ↑

[0053] A: 0.5mol manganese carbonate is added to 30ml water, and hydrochloric acid is added dropwise at a molar ratio of 1:2;

[0054] B: Add 1.0mol ammonium bicarbonate to 250ml water; the molar ratio of manganese carbonate to ammonium bicarbonate is 1:2;

[0055] C: Add 6g of polyethylene glycol (surface treatment agent) to 100ml of water.

[0056] Put C into a reaction bottle equipped with high-speed stirring (with 2 dropping ports), heat up to 40°C and dissolve completely, add A and B dropwise into C at a constant speed of 1 drop / second, and stir under high speed (100-120 rpm), react at 40°C for 3 hours, filter the resulting white precipitate, wash with deionized water until there is no chloride ion, and spray dry to obtain 30-100 nanometer MnCO 3 .

[0057] Step 2: Synthesis of Nano Deoxidiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com