Patents

Literature

30results about How to "Efficient deoxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same

ActiveCN102850159AEfficient deoxidationExtended service lifeChemical modification purification/separationAlkali metal oxideRoom temperature

The invention discloses an olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same. The preparation method includes (by weight parts) (1) mixing manganese source (as Mn3O4) 100 and titania nanoparticle (modified by alkali metal oxide) 58-100 to obtain a mixture; (2) kneading the mixture and a silver compound (as Ag2O) aqueous solution 8-35, and forming; (3) aging and drying; and (4) calcining. The inventive olefin deoxygenation agent has high room-temperature deoxygenation capacity up to 29.3 mL / g, deoxygenation depth smaller than 0.01 ppm, low reduction temperature, and wide applicability in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same

ActiveCN102850162AEfficient deoxidationHigh mechanical crush strengthChemical modification purification/separationMechanical crushingRoom temperature

The invention discloses an olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same. The preparation method includes (by weight parts) (1) mixing manganese source (as Mn3O4) 100, modified titania nanoparticle 58-100 and binder 1.5-25 to obtain a mixture; (2) kneading the mixture and a silver compound (as Ag2O) aqueous solution 8-35, and forming; (3) aging and drying; and (4) calcining. The inventive olefin deoxygenation agent has high room-temperature deoxygenation capacity up to 28.5 mL / g, high mechanical crushing strength up to 88 N / cm, deoxygenation depth smaller than 0.01 ppm, low reduction temperature, and wide applicability in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Waste electromagnetic wire copper refining agent and preparation method and application thereof

ActiveCN106636668ALow costPromote recycling industryProcess efficiency improvementNickelMaterials science

The invention relates to a waste electromagnetic wire copper refining agent and a preparation method and application thereof. The refining agent is preferably composed of, by mass, 1.0-5.0% of V, 1.0-5.0% of Sr, 0.5-2.5% of B, 5.5-7.5% of Mg, 5-10% of Y, 5-10% of Ce and the balance Cu. According to the preparation method of the refining agent, Cu-B-Y-Ce-Mg intermediate alloy and Cu-Sr intermediate alloy are crushed into fragments with the particle size being smaller than 10 mm, and the fragments and vanadium with the particle size being smaller than 10 mm are mixed evenly according to a set proportion and then wrapped with a high-purity oxygen-free copper sheet to obtain the refining agent. The refining agent can be used for refining oxygen-free copper from waste copper electromagnetic wires, and the adding amount is 0.1-0.65 percent of the melt mass. The refining agent of the design has the good effects on deoxidation, desulfurization, dealumination, deferrization, denickelefication and the like, and does not pollute copper liquid secondarily. The refining agent is reasonable in component design and simple in preparation process and can achieve large-scale industrial application conveniently.

Owner:CENT SOUTH UNIV +1

Molten steel composite refining agent

The composite molten steel refining agent consists of deoxidizing alloy and refining agent base material in the weight ratio of 0.75-3 to 1. The deoxidizing alloy consists of Ca 8-18%, Si 35-45%, Ba 7- 17%, Al 10-25% and C 15-35%; and the refining agent base material consists of CaO 50-65%, Al2O3 30-45%, SiO 6-22% and MgO 5-10%. The composite molten steel refining agent of the present invention may be used as the pre-deoxidizing agent or cinder pushing modifier, can avoid the formation of SiO2, AL2O3 and other high smelting point solid deoxidizing products, and is favorable to the formation of low smelting point composite compounds. The present invention has high deoxidizing effect, low deoxidizing cost, and no fluorine content resulting in environment friendship.

Owner:CHONGQING UNIV

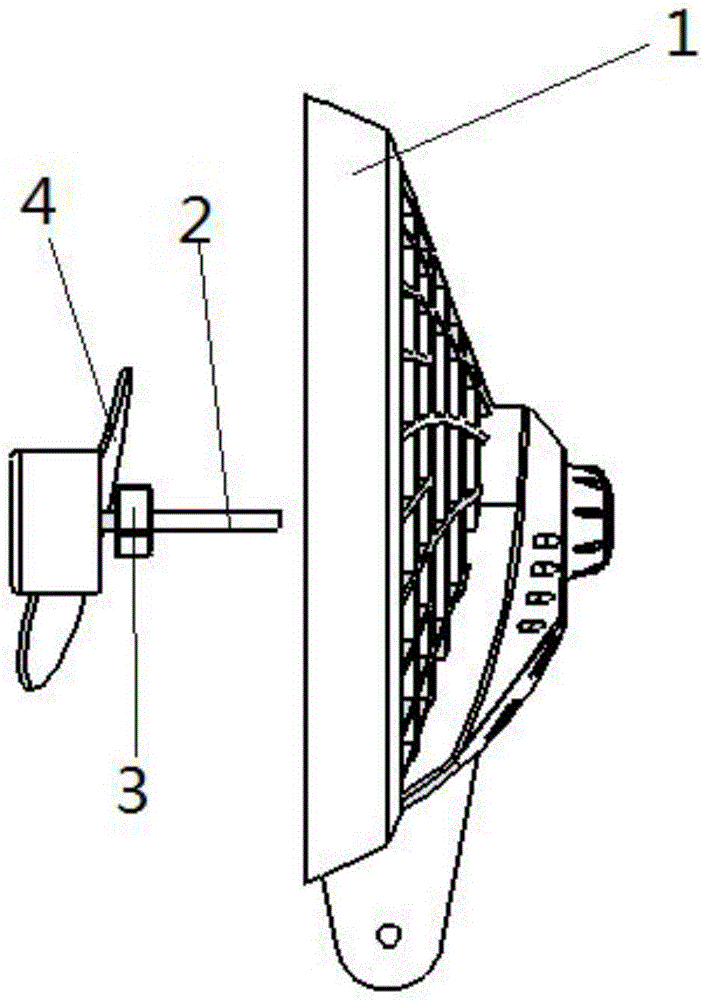

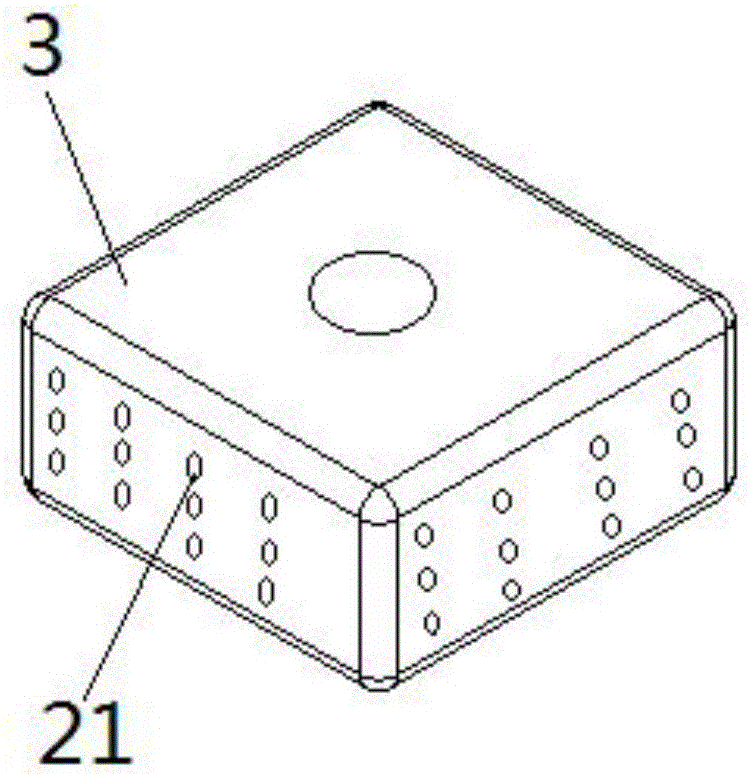

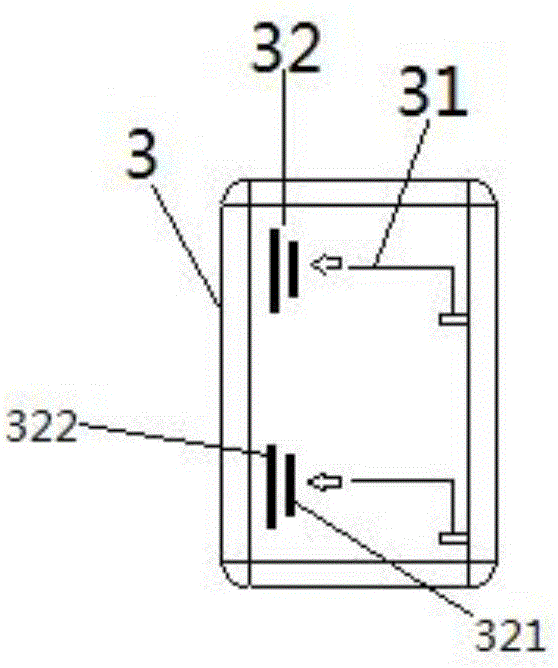

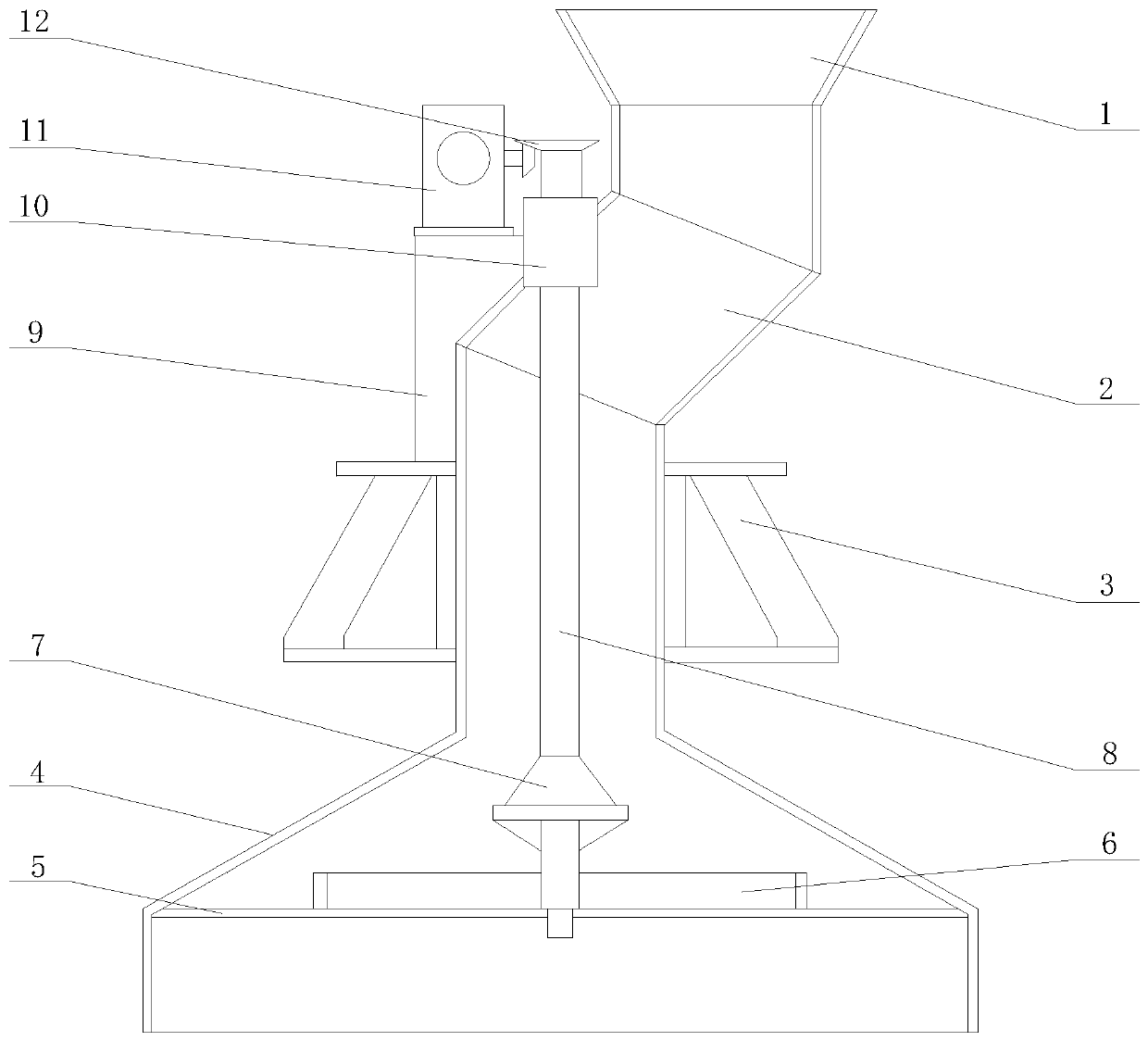

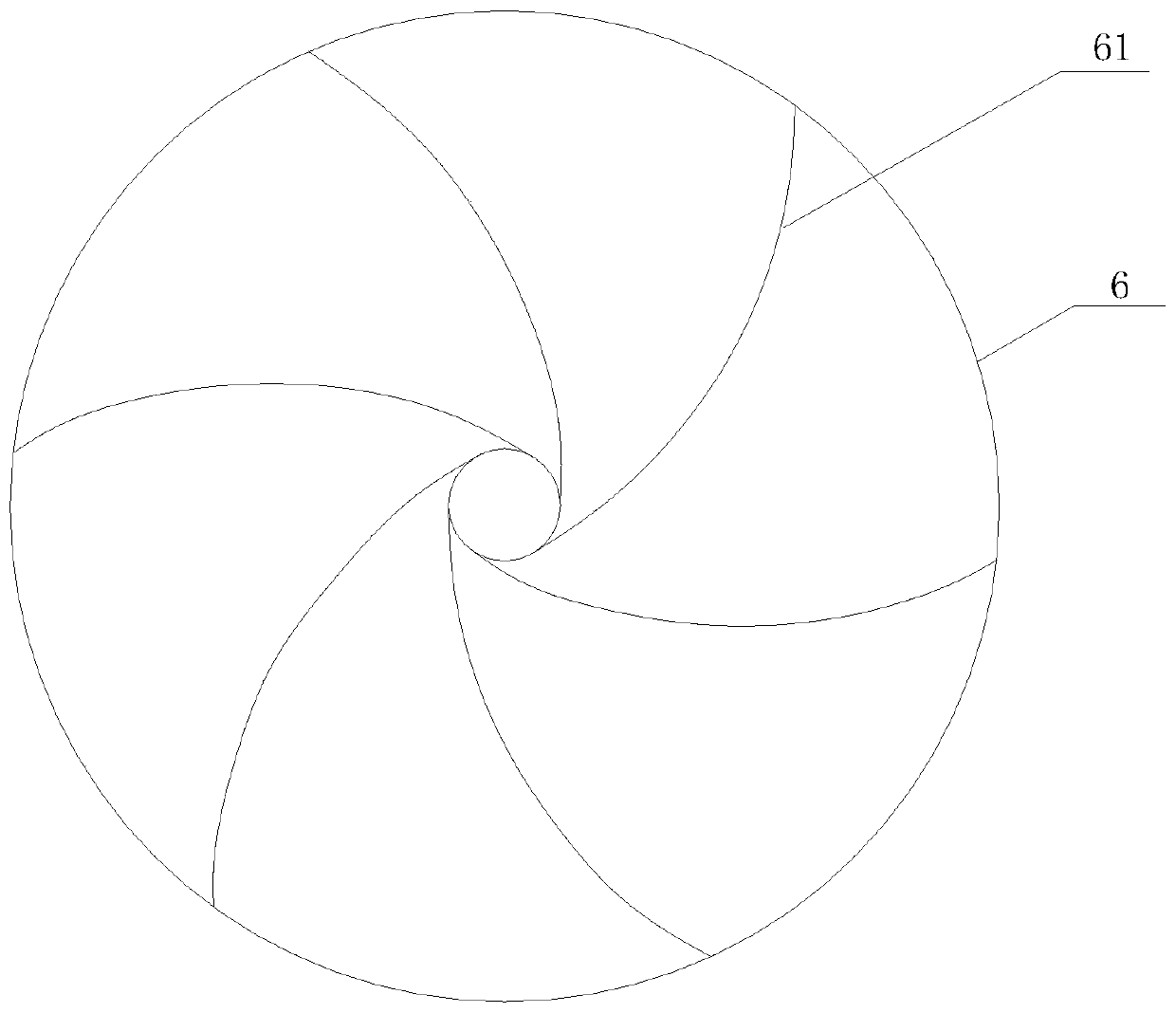

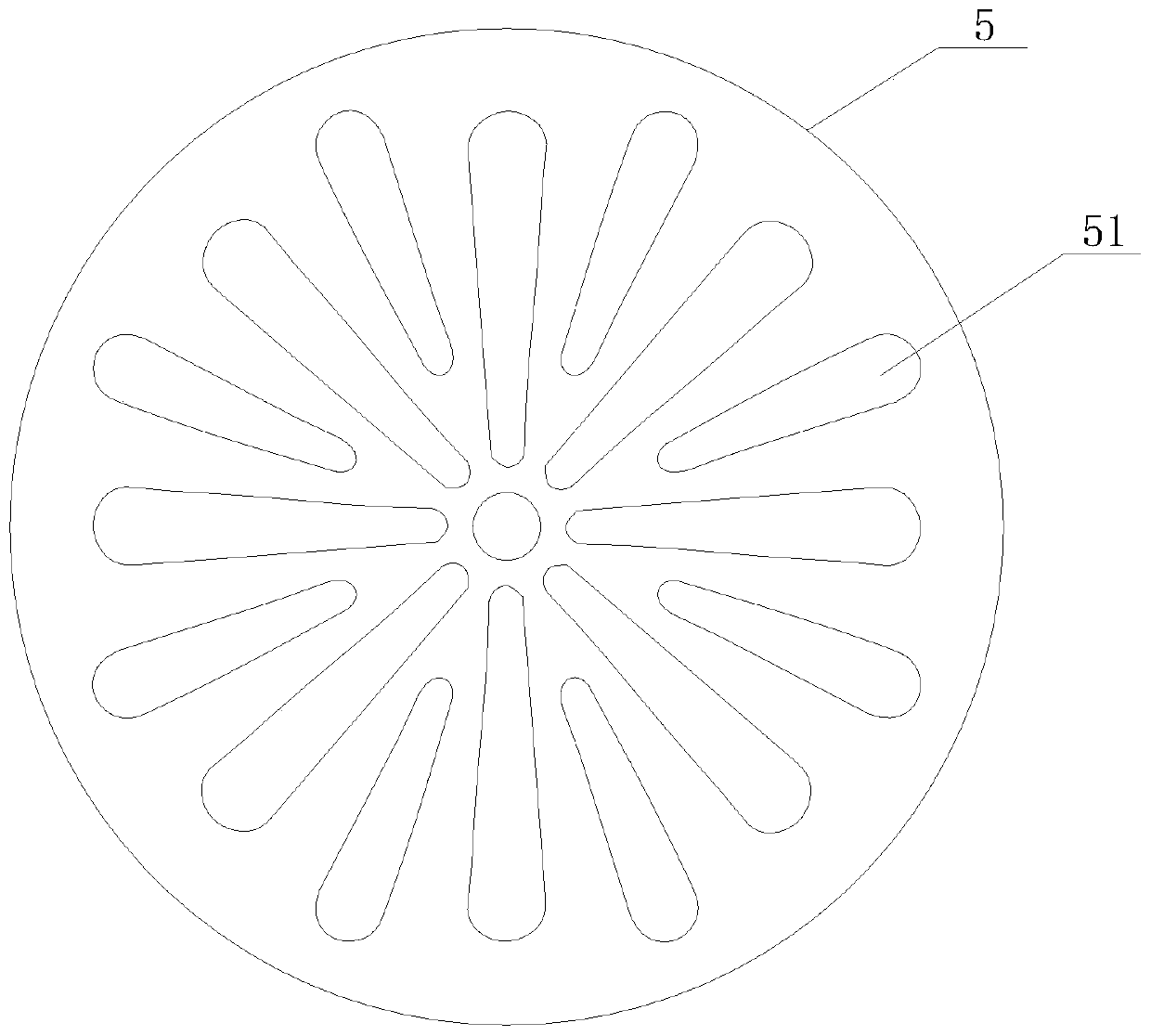

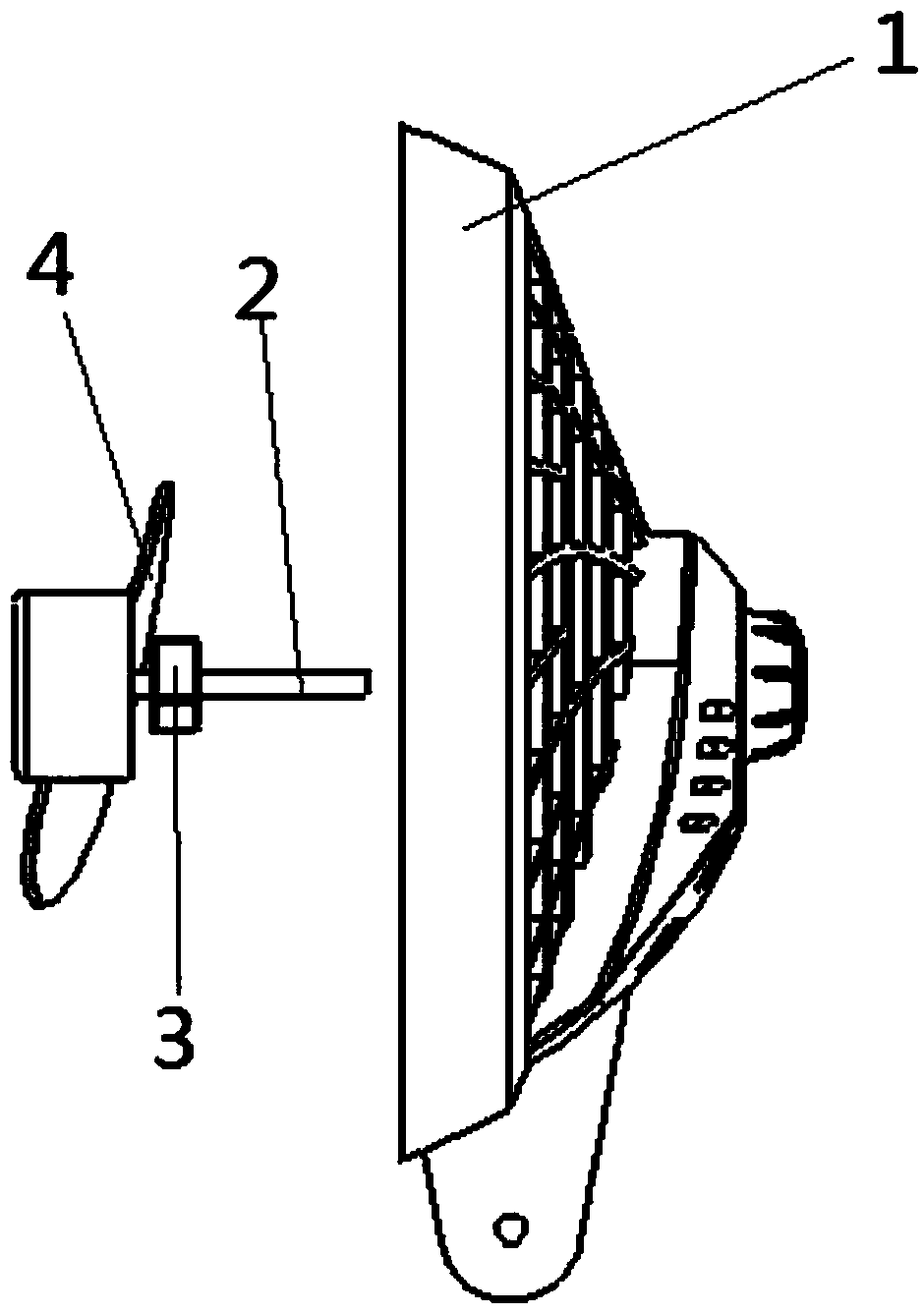

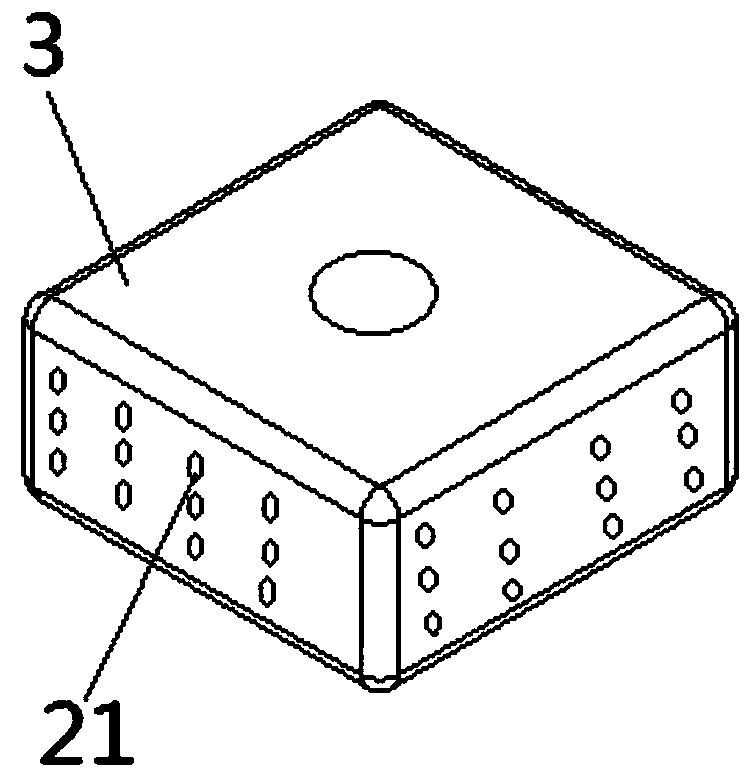

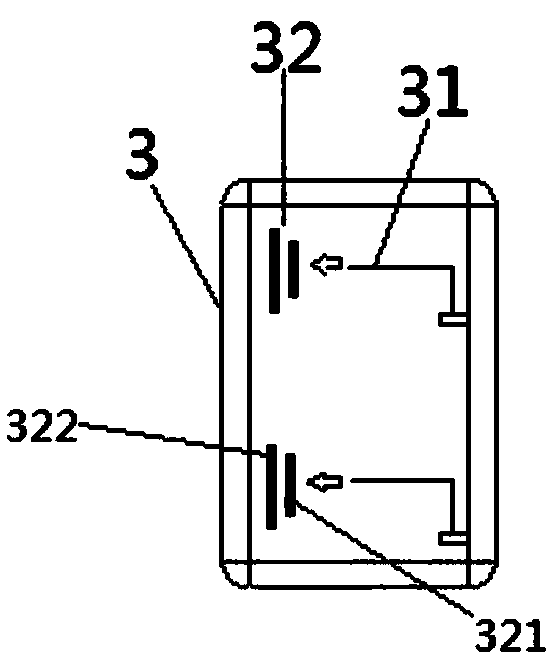

Air purifying fan

InactiveCN106089762AHigh efficiency deoxygenationEfficient deoxidationPump componentsGaseous substancesIonNeedle electrode

The invention belongs to the field of household appliances, and particularly relates to an air purifying fan capable of generating ionic wind for air purification. The air purifying fan comprises a fan shell, a rotating shaft, an air purifying device and fan blades. The rotating shaft is inserted into the fan shell, the fan blades are fixed to one end of the rotating shaft, and the air purifying device is arranged on the periphery of the rotating shaft in a matched mode. The air purifying device comprises needle electrodes, matched electrode sets and ironic wind releasing openings, wherein the matched electrode sets are symmetrically distributed around the central axis of the air purifying device, the needle electrodes are arranged at the sides opposite to the matched electrode sets, and the ionic wind releasing openings are distributed on the left side face and the peripheral side face of the air purifying device. The air purifying device of the structure generates ionic wind through corona discharge, ionic wind containing high-concentration ions can be sent out through the matched electrode sets, and therefore efficient deoxygenation, sterilization and disinfection are achieved.

Owner:深圳市艾美科技开发有限责任公司

Passivation deoxidizer for LF furnace refining and blowing and deoxidizing method thereof

the invention discloses a passive deoxidant of LF furnace refining spraying, which consists of 100-20% passive carbide powder and 0-80% passive lime powder, wherein the passive carbide powder or passive lime powder is blended by 1-15% carbide powder or lime powder and hydroxyl capping methyl-vinyl silicon oil according to proportion.

Owner:INST OF METALLURGICAL TECH DONGBEI UNIV SHENYANG

Olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same

ActiveCN102850164AExtended service lifePrevent sinteringChemical modification purification/separationMechanical crushingRoom temperature

The invention discloses an olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same. The preparation method includes (by weight parts) (1) mixing manganese source (as Mn3O4) 100, modified titania nanoparticle 58-100 and binder 1.5-25 to obtain a mixture; (2) calcining; (3) kneading the calcined mixture and a silver compound (as Ag2O) aqueous solution 8-35, and forming; (4) aging and drying; and (5) calcining. The inventive olefin deoxygenation agent has high room-temperature deoxygenation capacity, high mechanical crushing strength, low deoxygenation depth, low reduction temperature, and wide applicability in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

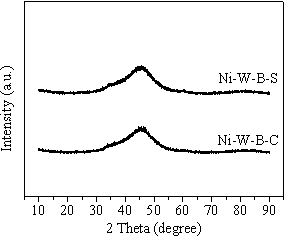

A kind of preparation method for the catalyst of bio-oil hydrodeoxygenation

InactiveCN103638938BHigh activityIncrease profitLiquid hydrocarbon mixture productionBio-feedstockEthylenediamineNickel salt

The invention discloses a preparation method of an amorphous catalyst for catalytic hydrodeoxygenation of phenol, aldehyde, alcohol and ketone oxygenated compounds in biological oil. The catalyst mainly consists of Ni, W and B as active ingredients. The preparation method comprises a step of preparing the catalyst through induced chemical deposition by taking soluble nickel salt and tungstate as raw materials, NaBH4 or KBH4 as a reducing agent and ammonia water or ethidene diamine as a chelating agent. The preparation method has the characteristics of improving utilization rate of the NaBH4 or KBH4 as a reducing agent, reducing coverage of boron oxide in active centers on the surface of the catalyst, and increasing the number of the active centers on the surface of the catalyst; the entire preparation method is simple in process, moderate in preparation condition and free from protective gas; the prepared catalyst is quite high in catalysis activity, and can implement catalytic hydrodeoxygenation of the oxygenated compounds at relatively low reaction temperature and obviously reduce contents of benzene of aromatic hydrocarbon in a reaction product.

Owner:XIANGTAN UNIV

Compounded deoxidized material as well as preparation method and application thereof

InactiveCN103614516AReduce oxidationAvoid secondary oxidationRecycling and recovery technologiesSteelmakingAlloy

The invention belongs to the technical field of steel making, and particularly relates to a compounded deoxidized material for the deoxidization of steel slag or molten steel as well as a preparation method and an application thereof. The compounded deoxidized material is kalzium metal and comprises the following components in percentage by weight: 45-65% of Al, 15-30% of Ca, less than 3% of Si and the balance of aluminium oxide and calcium oxide mixture. The particle size of the kalzium metal is 10-40mm. The kalzium metal is the novel compounded deoxidized material which can be used for realizing the deoxidization and desulfurization of the steel slag and the molten steel and the inclusion adsorption and integrates the functions of deoxidization, purification and refinement; by adopting the compounded deoxidized material, the production cost of steel making is reduced under the condition of ensuring the quality.

Owner:XIXIA COUNTY SHUNFA NEW FURNACE CHARGE CO LTD

Olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same

ActiveCN102850165AExtended service lifeEmission reductionChemical modification purification/separationRoom temperatureAlkene

The invention discloses an olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same. The preparation method includes (by weight parts) (1) mixing manganese source (as Mn3O4) 100 and modified titania nanoparticle 58-100 to obtain a mixture; (2) calcining; (3) kneading the calcined mixture and a silver compound (as Ag2O) aqueous solution 8-35, and forming; (4) aging and drying; and (5) calcining. The second calcining temperature is lower than the first calcining temperature. The inventive olefin deoxygenation agent has high room-temperature deoxygenation capacity up to 31 mL / g, deoxygenation depth lower than 0.01 ppm, low reduction temperature, and wide applicability in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same

ActiveCN102850160AImprove deoxygenation capacityHigh mechanical crush strengthChemical modification purification/separationDeoxygenationMechanical crushing

The invention discloses an olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same. The preparation method includes (by weight parts) (1) mixing manganese source (as Mn3O4) 100, titania nanoparticle 58-100 and binder 1.5-25 to obtain a mixture; (2) kneading the mixture and a silver compound (as Ag2O) aqueous solution 8-35, and forming; (3) aging and drying; and (4) calcining. The inventive olefin deoxygenation agent has high room-temperature deoxygenation capacity up to 24.8 mL / g, high mechanical crushing strength up to 89 N / cm, deoxygenation depth smaller than 0.01 ppm, low reduction temperature, and wide applicability in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same

ActiveCN102850160BEfficient deoxidationImprove deoxygenation capacityChemical modification purification/separationPolymer scienceDeoxygenation

The invention discloses an olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same. The preparation method includes (by weight parts) (1) mixing manganese source (as Mn3O4) 100, titania nanoparticle 58-100 and binder 1.5-25 to obtain a mixture; (2) kneading the mixture and a silver compound (as Ag2O) aqueous solution 8-35, and forming; (3) aging and drying; and (4) calcining. The inventive olefin deoxygenation agent has high room-temperature deoxygenation capacity up to 24.8 mL / g, high mechanical crushing strength up to 89 N / cm, deoxygenation depth smaller than 0.01 ppm, low reduction temperature, and wide applicability in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same

ActiveCN102850163BExtended service lifePrevent sinteringChemical modification purification/separationMechanical crushingRoom temperature

The invention discloses an olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same. The preparation method includes (by weight parts) (1) mixing manganese source (as Mn3O4) 100, titania nanoparticle 58-100 and binder 1.5-25 to obtain a mixture; (2) calcining; (3) kneading the calcined mixture and a silver compound (as Ag2O) aqueous solution 8-35, and forming; (4) aging and drying; and (5) calcining. The second calcining temperature is lower than the first calcining temperature. The inventive olefin deoxygenation agent has high room-temperature deoxygenation capacity, high mechanical crushing strength, low deoxygenation depth, low reduction temperature, and wide applicability in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing high-conductivity oxygen-free copper and smelting device

InactiveCN102994786BIncrease contact areaLess soluble than oxygenStirring devicesIngotElectric conductance

Owner:JINZHOU NEW CENTURY QUARTZ GROUP CO LTD

A kind of method that prepares beryllium-containing silicon carbide ceramic fiber by gallium bath

ActiveCN109516808BEfficient deoxidationNon-uniform dopingInorganic material artificial filamentsCarbide siliconSic fiber

The invention relates to a method for preparing beryllium-containing silicon carbide ceramic fibers through a gallium bath, and belongs to the technical field of silicon carbide fiber preparation. The present invention uses beryllium-containing SiC ceramic precursors as raw materials; through melt spinning, PBCS precursors are obtained; the PBCS precursors are subjected to non-melting treatment; the precursors after non-melting treatment are obtained; the precursors after non-melting treatment are processed gallium bath to obtain deoxidized precursors; the temperature of the gallium bath is 29.76-100° C.; the obtained deoxidized precursors are subjected to high temperature treatment to obtain finished products. The preparation process of the invention is reasonable, the obtained product has excellent performance, and is convenient for large-scale industrial application.

Owner:湖南泽睿新材料有限公司

Olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same

ActiveCN102850164BExtended service lifePrevent sinteringChemical modification purification/separationMechanical crushingRoom temperature

The invention discloses an olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same. The preparation method includes (by weight parts) (1) mixing manganese source (as Mn3O4) 100, modified titania nanoparticle 58-100 and binder 1.5-25 to obtain a mixture; (2) calcining; (3) kneading the calcined mixture and a silver compound (as Ag2O) aqueous solution 8-35, and forming; (4) aging and drying; and (5) calcining. The inventive olefin deoxygenation agent has high room-temperature deoxygenation capacity, high mechanical crushing strength, low deoxygenation depth, low reduction temperature, and wide applicability in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same

ActiveCN102850166BExtended service lifeEmission reductionChemical modification purification/separationRoom temperatureAlkene

The invention discloses an olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same. The preparation method includes (by weight parts) (1) mixing manganese source (as Mn3O4) 100 and titania nanoparticle 58-100 to obtain a mixture; (2) calcining; (3) kneading the calcined mixture and a silver compound (as Ag2O) aqueous solution 8-35, and forming; (4) aging and drying; and (5) calcining. The second calcining temperature is lower than the first calcining temperature. The inventive olefin deoxygenation agent has high room-temperature deoxygenation capacity up to 27.1 mL / g, deoxygenation depth lower than 0.01 ppm, low reduction temperature, and wide applicability in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same

ActiveCN102850165BExtended service lifeEmission reductionChemical modification purification/separationRoom temperatureDeoxygenation

The invention discloses an olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same. The preparation method includes (by weight parts) (1) mixing manganese source (as Mn3O4) 100 and modified titania nanoparticle 58-100 to obtain a mixture; (2) calcining; (3) kneading the calcined mixture and a silver compound (as Ag2O) aqueous solution 8-35, and forming; (4) aging and drying; and (5) calcining. The second calcining temperature is lower than the first calcining temperature. The inventive olefin deoxygenation agent has high room-temperature deoxygenation capacity up to 31 mL / g, deoxygenation depth lower than 0.01 ppm, low reduction temperature, and wide applicability in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for preparing beryllium-containing silicon carbide ceramic fibers using gallium as a deoxidizer

ActiveCN109574708BEfficient deoxidationInorganic material artificial filamentsCarbide siliconMetallurgy

Owner:湖南泽睿新材料有限公司

A fluorine-free, carbon-free, high-alkalinity submerged arc foaming refining agent and its preparation method

The invention discloses a fluorine-free carbon-free high-alkalinity submerged arc foaming refining agent for an LF (ladle furnace) and a preparation method thereof. The refining agent comprises the following components in percentage by weight: 20 to 60 percent of calcium oxide, 4 to 10 percent of magnesium oxide, 10 to 20 percent of aluminum oxide, 6 to 20 percent of barium oxide, and 6 to 12 percent of plant cellulose. According to the method, the raw materials are reasonably assorted, foundational slag can release gas through a high temperature decomposition reaction, and the compound with a plurality of fine pores in a polymer is of a foaming shape, the thickness of the slag layer is increased, the performance is constant and stable, the radiation of electric arc to a flame retardant material can be reduced, and the electric arc heating effect is improved. Furthermore, a proper deoxidation and desulfurization promoting agent is added in the foundational slag, so that the content of oxide in steel is reduced, carbon and silicon are not increased, the adsorption and inclusion effect is good, the refining time is shortened, and the service life of steel ladles is improved.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

A kind of copper refining agent for waste electromagnetic wire and its preparation method and application

ActiveCN106636668BImprove refining effectLow costProcess efficiency improvementAlloyMaterials science

The invention relates to a waste electromagnetic wire copper refining agent and a preparation method and application thereof. The refining agent is preferably composed of, by mass, 1.0-5.0% of V, 1.0-5.0% of Sr, 0.5-2.5% of B, 5.5-7.5% of Mg, 5-10% of Y, 5-10% of Ce and the balance Cu. According to the preparation method of the refining agent, Cu-B-Y-Ce-Mg intermediate alloy and Cu-Sr intermediate alloy are crushed into fragments with the particle size being smaller than 10 mm, and the fragments and vanadium with the particle size being smaller than 10 mm are mixed evenly according to a set proportion and then wrapped with a high-purity oxygen-free copper sheet to obtain the refining agent. The refining agent can be used for refining oxygen-free copper from waste copper electromagnetic wires, and the adding amount is 0.1-0.65 percent of the melt mass. The refining agent of the design has the good effects on deoxidation, desulfurization, dealumination, deferrization, denickelefication and the like, and does not pollute copper liquid secondarily. The refining agent is reasonable in component design and simple in preparation process and can achieve large-scale industrial application conveniently.

Owner:CENT SOUTH UNIV +1

Submerged arc foaming refining agent and preparation method thereof

The invention discloses a submerged arc foaming refining agent and a preparation method thereof. The submerged arc foaming refining agent comprises the following raw materials by weight: 10 to 30 of high calcium white ash, 30 to 60 of calcium carbonate, 10 to 20 AD powder, 10 to 30 of barium carbonate, 4 to 10 of fused magnesite, 10 to 30 of dolomite, 4 to 8 of sodium lignosulfonate, 2 to 4 of paper pulp waste liquid and 3 to 6 of water. According to the invention, a basic slag system having capability of storing bubbles is employed and is compounded with surface active substances capable of adjusting slag viscosity, surface tension and solid phase particles; raw materials are reasonably collocated, the basic slag system is guaranteed to release gas and form compounds with a plurality of fine pores in polymers so as to obtain a foaming state through a pyrolysis reaction, the thickness of a slag layer is increased, and continuous stabilization of the slag layer is realized, thereby reducing radiation of arc to refractory materials and improving the heating effect of arc; further, a proper amount of a deoxidation and desulphurization promoter is added into the basic slag system, andtherefore, the content of oxides in steel is reduced, there is no increase of carbon and silicon, a good adsorption and inclusion effect is obtained, time for refining is shortened, and the service life of steel ladles is prolonged.

Owner:ZHENGZHOU DONGSHENG METALLURGY NEW MATERIAL

Olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same

ActiveCN102850162BEfficient deoxidationHigh mechanical crush strengthChemical modification purification/separationMechanical crushingRoom temperature

The invention discloses an olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same. The preparation method includes (by weight parts) (1) mixing manganese source (as Mn3O4) 100, modified titania nanoparticle 58-100 and binder 1.5-25 to obtain a mixture; (2) kneading the mixture and a silver compound (as Ag2O) aqueous solution 8-35, and forming; (3) aging and drying; and (4) calcining. The inventive olefin deoxygenation agent has high room-temperature deoxygenation capacity up to 28.5 mL / g, high mechanical crushing strength up to 88 N / cm, deoxygenation depth smaller than 0.01 ppm, low reduction temperature, and wide applicability in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

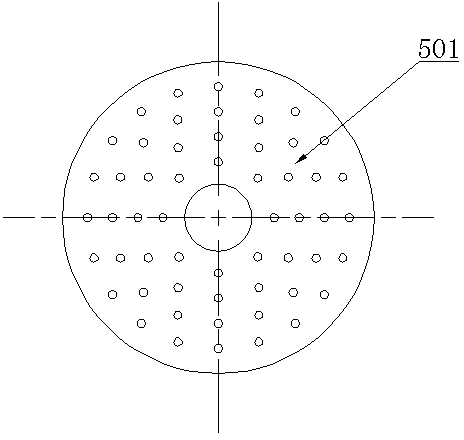

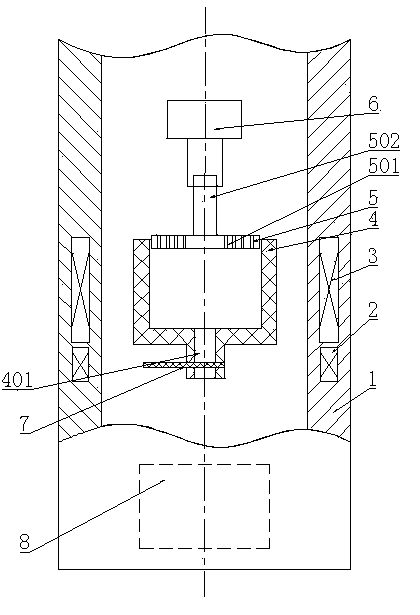

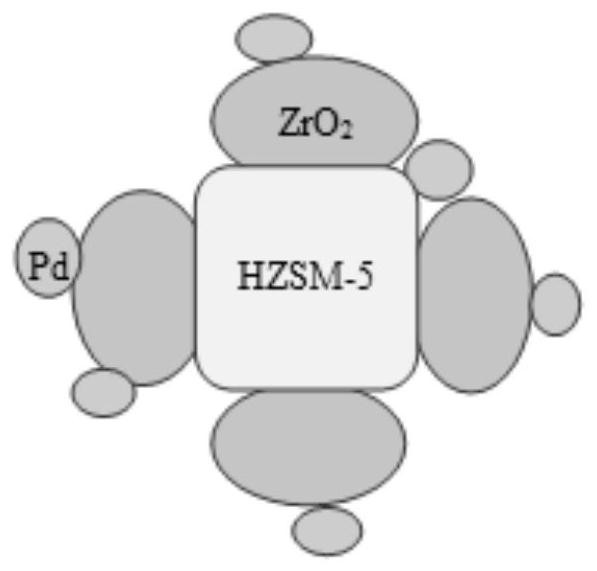

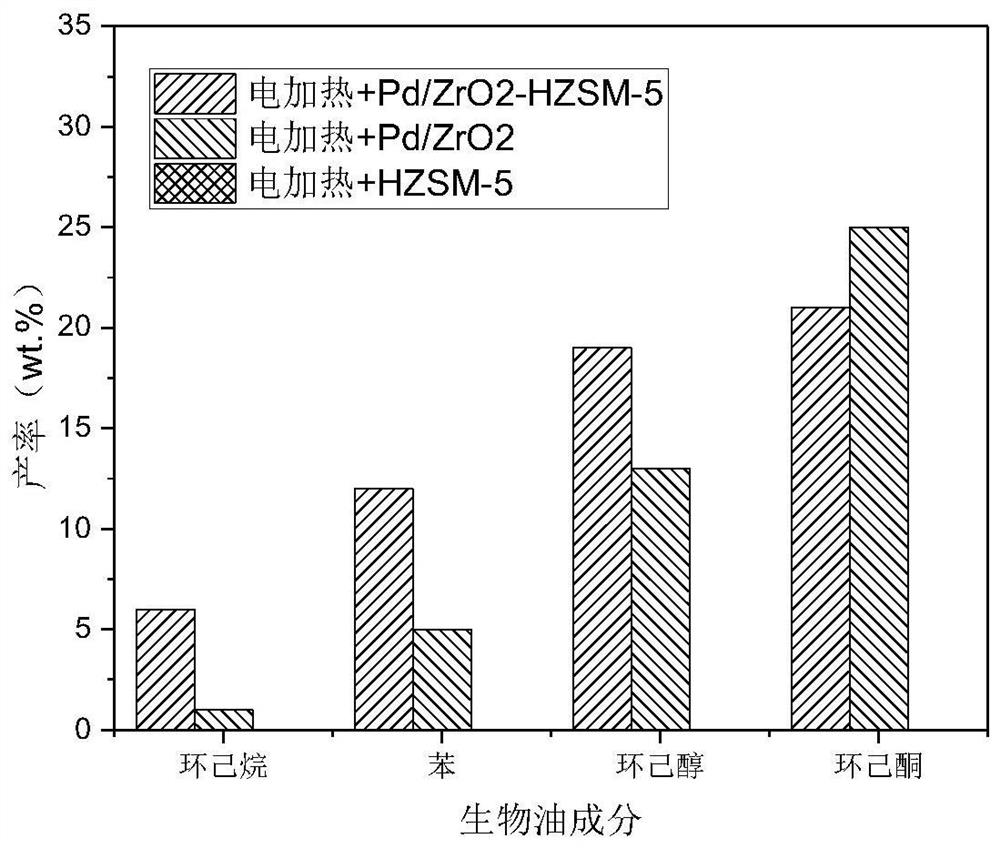

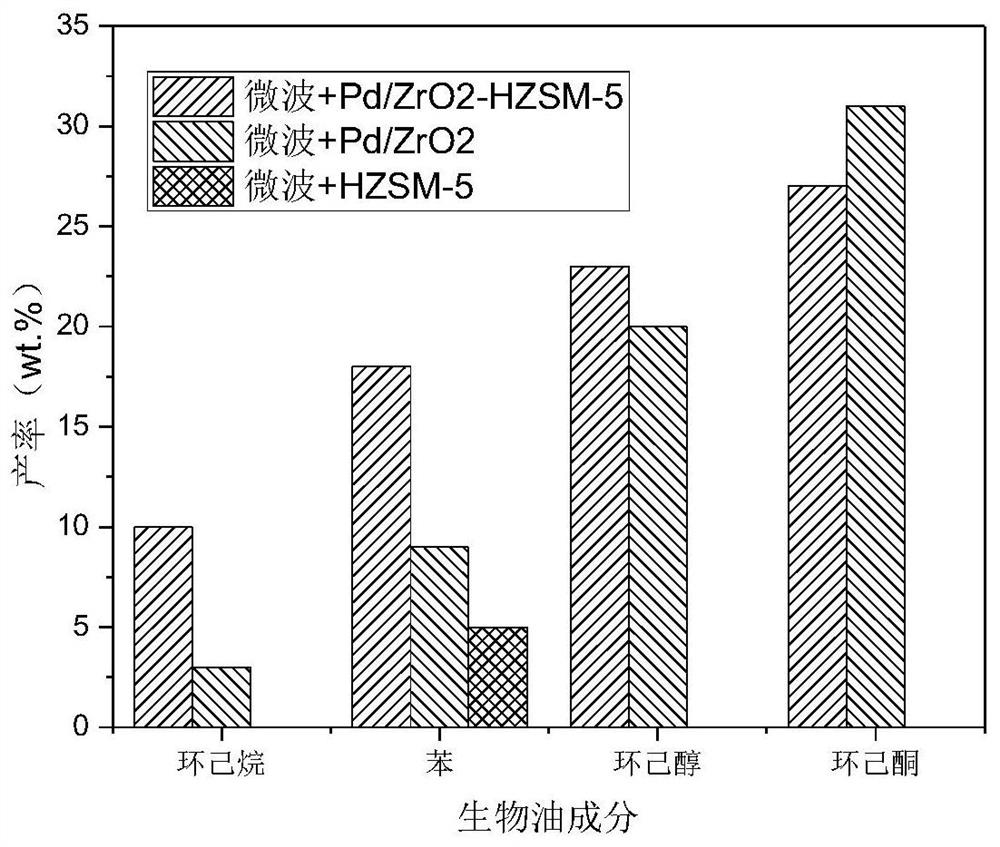

Pd/ZrO2-HZSM-5 bifunctional catalyst and preparation method of Pd/ZrO2-HZSM-5 bifunctional catalyst

PendingCN111659460AIncrease acidic sitesHigh catalytic activityMolecular sieve catalystsLiquid hydrocarbon mixture productionPtru catalystHydrodeoxygenation

The invention discloses a Pd / ZrO2-HZSM-5 bifunctional catalyst and a preparation method thereof. A carrier of the Pd / ZrO2-HZSM-5 bifunctional catalyst is ZrO2-HZSM-5, and the mass ratio of ZrO2 to HZSM-5 is 1: 1; an active component of the Pd / ZrO2-HZSM-5 bifunctional catalyst is Pd, and the loading capacity of the Pd is 1%-3% of the mass of the carrier. According to the Pd / ZrO2-HZSM-5 bifunctionalcatalyst and the preparation methodthereof, ZrO2 and HZSM-5 are compounded as a carrier to increase the acidic sites of the catalyst, the diameter range of adsorption molecules is widened; the loadedmetal Pd reduces the activation energy of the C-O bond, and the hydrodeoxygenation catalytic activity of the catalyst is enhanced; the prepared catalyst integrates the respective deoxygenation and hydrogenation advantages of HZSM-5 and ZrO2 so as to form the advantage complementation, and the catalyst has the potential of catalyzing bio-oil to prepare high quality fuels or high added value products, and has strong application prospects.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

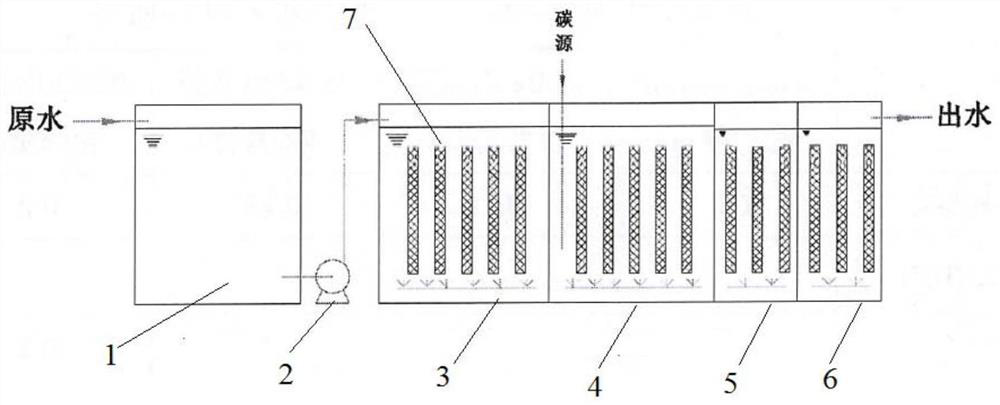

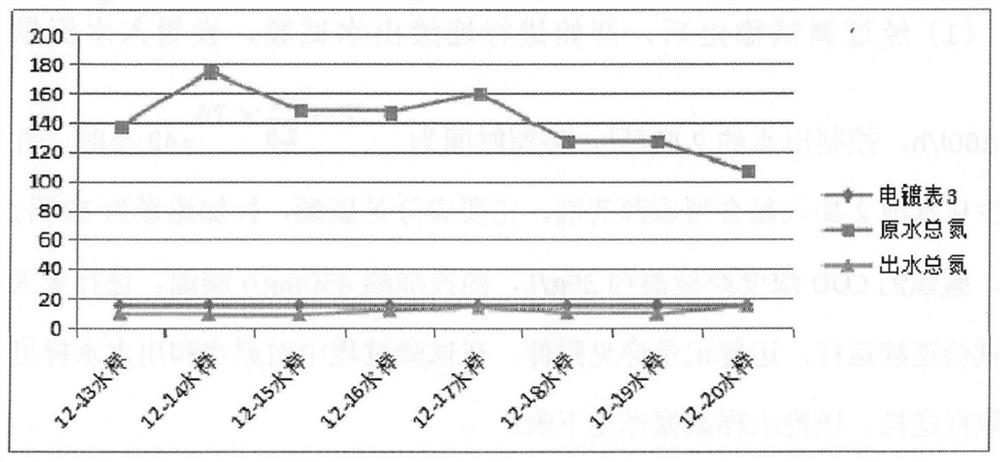

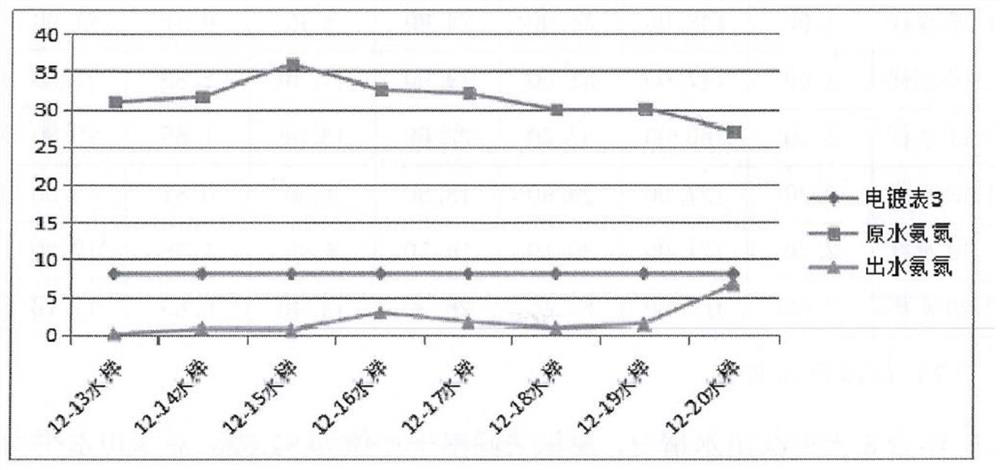

Electroplating wastewater biochemical treatment device and application thereof

InactiveCN111995050ASimple processLess operating pointsWaste water treatment from metallurgical processTreatment with aerobic and anaerobic processesFiberBiofilm

The invention discloses an electroplating wastewater biochemical treatment device. The biochemical treatment device comprises a raw water bucket and biochemical pools, and the raw water bucket is connected with the biochemical pools through a lifting pump; the number of the biochemical pools is not less than 4; biofilm culturing biochemistry is conducted in the biochemical pools through biochemical filler, the biochemical filler is composed of a nylon net and chemical fiber cotton, the chemical fiber cotton is fixed to the nylon net through nylon net clamps, and the use amount of the chemicalfiber cotton is 150-500g / m<2>; in the same biochemical pool, the distance between every two adjacent nylon net clamps is 15-25mm, and the distance between every two adjacent mycoderm is 100-200mm; themounting direction of the mycoderm is parallel to the water inlet direction in the biochemical pools, the distance between the top of the mycoderm and the water surface is 100-150mm, and the distancebetween the bottom of the mycoderm and an aeration head of each biochemical pool is 150-100mm; and the distances from the mycoderm to the four side surfaces of the biochemical pools are respectively100-150mm. The invention also discloses application of the biochemical treatment device.

Owner:董英良 +1

A method for rapid slag formation in the tapping process of high-quality steel

The invention discloses a method for rapid slag formation in the tapping process of high-quality steel. During production, the tapping temperature of an electric furnace or a converter is controlled at 1630°C-1680°C to meet the needs of refining slag melting and deoxidation in the tapping process; , when the tapping amount reaches 30-80%, add pre-deoxidizer and alloy to the molten steel casting stream through the alloy chute to realize the initial precipitation deoxidation of molten steel; Blow the flow of argon to keep the diameter of the exposed surface of the molten steel at 200-600mm, and at the same time spread aluminum particles evenly on the slag surface. In the tapping process of the converter or electric furnace, the invention quickly forms a low-oxidation and high-fluidity refining slag system through deoxidation alloying of molten steel and evenly spreading aluminum particles on the slag surface, which not only improves the refining efficiency of the LF refining process, but also improves the Improve the refining effect of molten steel and improve the quality of molten steel to solve the problem that the deoxidation and rapid slagging of refining slag cannot be effectively realized in the current tapping process of electric furnace or converter.

Owner:MAANSHAN IRON & STEEL CO LTD

Molten steel composite refining agent

The composite molten steel refining agent consists of deoxidizing alloy and refining agent base material in the weight ratio of 0.75-3 to 1. The deoxidizing alloy consists of Ca 8-18%, Si 35-45%, Ba 7- 17%, Al 10-25% and C 15-35%; and the refining agent base material consists of CaO 50-65%, Al2O3 30-45%, SiO 6-22% and MgO 5-10%. The composite molten steel refining agent of the present invention may be used as the pre-deoxidizing agent or cinder pushing modifier, can avoid the formation of SiO2, AL2O3 and other high smelting point solid deoxidizing products, and is favorable to the formation of low smelting point composite compounds. The present invention has high deoxidizing effect, low deoxidizing cost, and no fluorine content resulting in environment friendship.

Owner:CHONGQING UNIV

Olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same

ActiveCN102850159BEfficient deoxidationExtended service lifeChemical modification purification/separationAlkali metal oxideRoom temperature

The invention discloses an olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same. The preparation method includes (by weight parts) (1) mixing manganese source (as Mn3O4) 100 and titania nanoparticle (modified by alkali metal oxide) 58-100 to obtain a mixture; (2) kneading the mixture and a silver compound (as Ag2O) aqueous solution 8-35, and forming; (3) aging and drying; and (4) calcining. The inventive olefin deoxygenation agent has high room-temperature deoxygenation capacity up to 29.3 mL / g, deoxygenation depth smaller than 0.01 ppm, low reduction temperature, and wide applicability in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

air purifying fan

InactiveCN106089762BEfficient deoxidationPump componentsGaseous substancesHigh concentrationCorona discharge

Owner:深圳市艾美科技开发有限责任公司

Olefin deoxygenation agent, its preparation method, and olefin deoxygenation method using the same

ActiveCN102850161BEfficient deoxidationImprove deoxygenation capacityChemical modification purification/separationRoom temperatureAqueous solution

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com