A kind of preparation method for the catalyst of bio-oil hydrodeoxygenation

A hydrodeoxygenation and catalyst technology, which is used in metal/metal oxide/metal hydroxide catalysts, preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, etc., can solve the problem that bio-oil cannot meet clean fuel quality standards, metal The problems of low content of nickel and tungsten trioxide, reducing the activity of amorphous catalysts, etc., can achieve the effect of excellent catalytic activity, high-quality deoxidation, and reducing the content of benzene or aromatics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

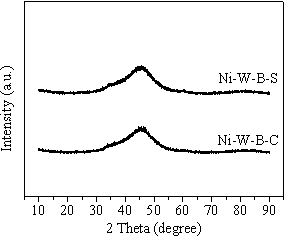

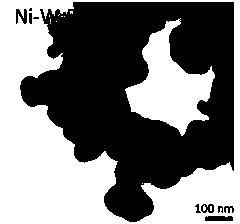

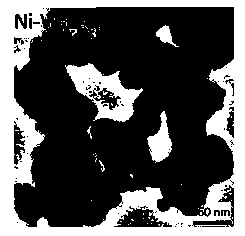

[0026] 1.31 g NiSO 4 ·6H 2 O was dissolved in 25 mL of water, and 2.5 g of 25% NH 3 ·H 2 O, add 1.65 g Na 2 WO 4 2H 2 O, stirred and dissolved, transferred to a 250 mL three-necked flask, and then added 25 mL of 1.0 mol / mL NaBH 4 solution, at 30°C under vigorous stirring, add 1 mL of 0.001 mol / / mL of Ag + solution, the reaction occurred immediately, and a black precipitate was obtained after the reaction, washed with water and alcohol, and dried in a vacuum oven at 40°C for 5 hours.

[0027] Add 88.24 g of n-dodecane, 11.76 g of phenol and 0.20 g of the catalyst prepared above in the autoclave, install the device, remove the air in the autoclave, then rise from room temperature to 225 °C at a rate of 10 °C / min, adjust The rotation speed was 900 r / min, the hydrogen pressure was 4.0 MPa, and the reaction was continued for 3 h. The product was analyzed by Agilent 6890 / 5973N GC / MS. The conversion rate of phenol reaches 100%, and the selectivity of cyclohexane reaches 79.6%...

Embodiment 2

[0029] 1.18 g NiCl 2 ·6H 2 O was dissolved in 25 mL of water, and 2.5 g of 25% NH 3 ·H 2 O, add 1.65 g Na 2 WO 4 2H 2 O, stirred and dissolved, transferred to a 250 mL three-necked flask, and then added 25 mL of 1.0 mol / mL NaBH 4 solution, at 30°C under vigorous stirring, add 1 mL of 0.001 mol / / mL of Ag + solution, the reaction occurred immediately, and a black precipitate was obtained after the reaction, washed with water and alcohol, and dried in a vacuum oven at 40°C for 5 hours.

[0030] Add 88.24g of n-dodecane, 11.76g of phenol and 0.20g of the catalyst prepared above in the autoclave, install the device, remove the air in the kettle, then rise from room temperature to 225°C at a rate of 10°C / min, adjust The rotation speed was 900 r / min, the hydrogen pressure was 4.0 MPa, and the reaction was continued for 3 hours. The product was analyzed by Agilent 6890 / 5973N GC / MS. The conversion rate of phenol was 100%, and the selectivity of cyclohexane was 71.8%.

Embodiment 3

[0032] 0.59 g NiCl 2 ·6H 2 O was dissolved in 25 mL of water, and 2.5 g of 25% NH 3 ·H 2 O, add 1.65 g Na 2 WO 4 2H 2 O, stirred and dissolved, transferred to a 250 mL three-necked flask, and then added 25 mL of 1.0 mol / mL NaBH 4 solution, at 30 ℃ and vigorously stirred, add 1 mL of 0.001 mol / / mL of Ag + solution, the reaction occurred immediately, and a black precipitate was obtained after the reaction, washed with water and alcohol, and dried in a vacuum oven at 40°C for 5 hours.

[0033] Add 88.24 g of n-dodecane, 11.76 g of phenol and 0.20 g of the catalyst prepared above in the autoclave, install the device, remove the air in the autoclave, then rise from room temperature to 225 °C at a rate of 10 °C / min, adjust The rotation speed was 900 r / min, the hydrogen pressure was 4.0 MPa, and the reaction was continued for 3 hours. The product was analyzed by Agilent 6890 / 5973N GC / MS. The conversion rate of phenol reaches 100%, and the selectivity of cyclohexane reaches 86...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com