Electroplating wastewater biochemical treatment device and application thereof

A biochemical treatment device and electroplating wastewater technology, which is applied in metallurgical wastewater treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of unstable removal of total nitrogen and low efficiency of nitrogen-containing compounds , to achieve the effect of short commissioning cycle, high bacterial concentration and few operating points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

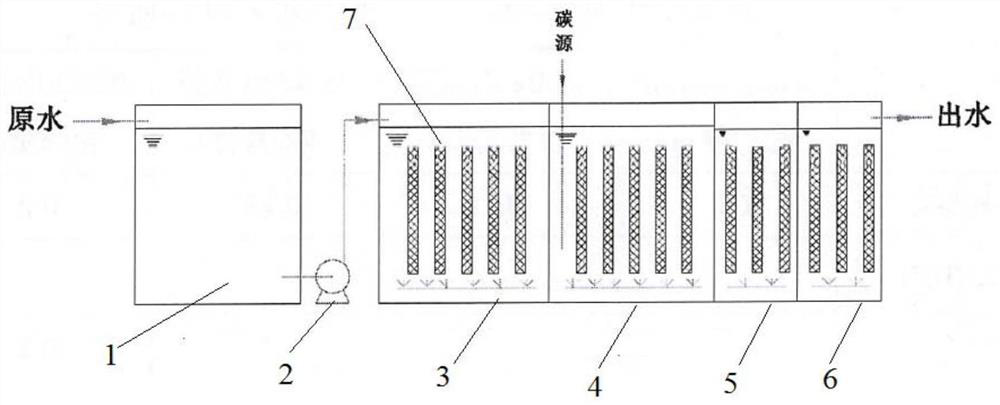

[0032] An embodiment of the electroplating wastewater biochemical treatment device of the present application, the structural schematic diagram of the biochemical treatment device of this embodiment is as attached figure 1 As shown, it includes raw water tank 1 and biochemical pools 1 to 4. Raw water tank 1 and biochemical pools 1 to 4 are connected by lift pump 2; the outlet of biochemical pool 1 is connected to the entrance of biochemical pool 2, and the outlet of biochemical pool 2 is connected to The inlet of the biochemical pool 3 is connected, and the outlet of the biochemical pool 3 is connected with the entrance of the biochemical pool 4; in the biochemical pools 1 to 4, the film-hanging biochemical is carried out through the biochemic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com