Patents

Literature

55results about How to "Short commissioning cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

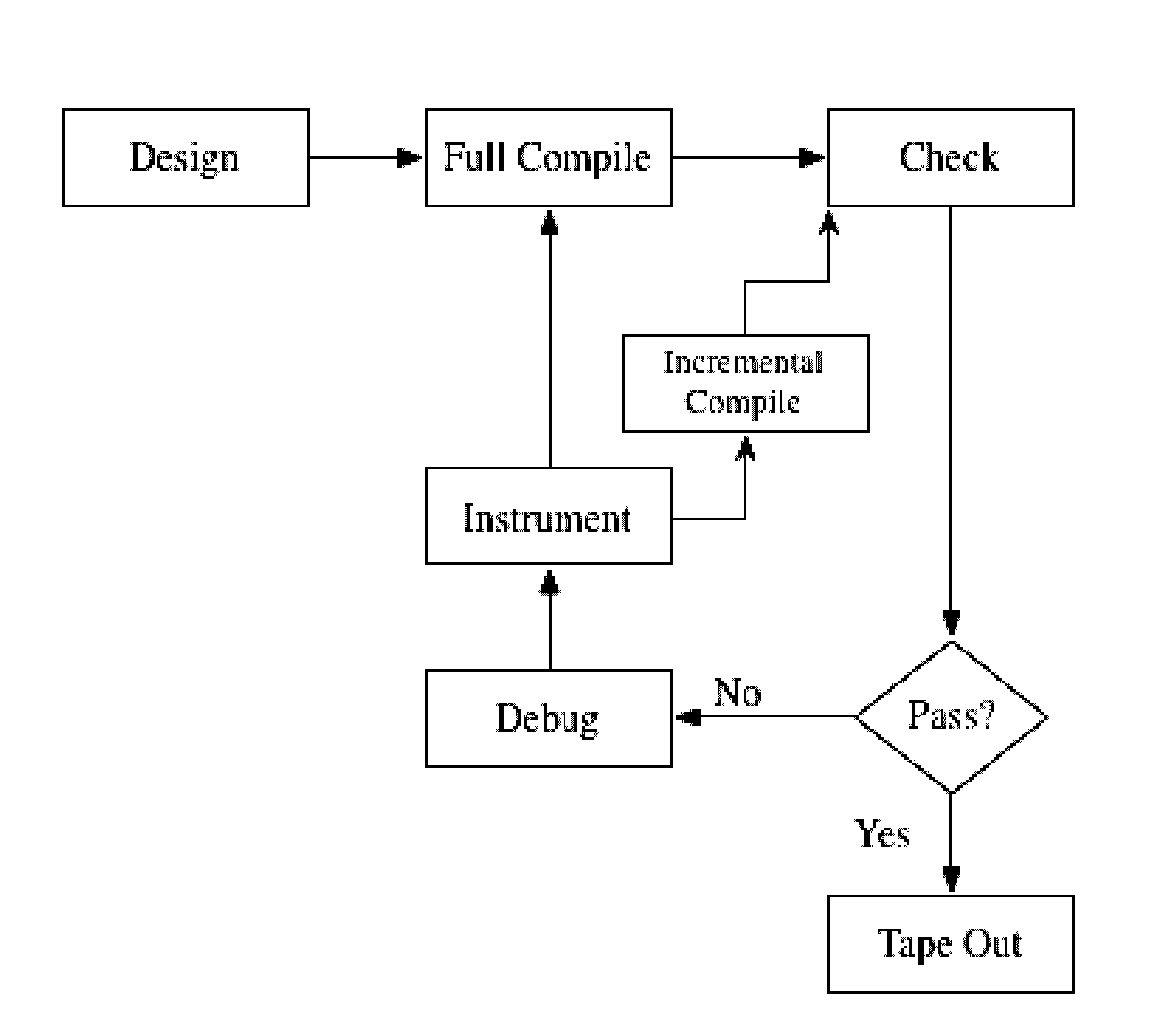

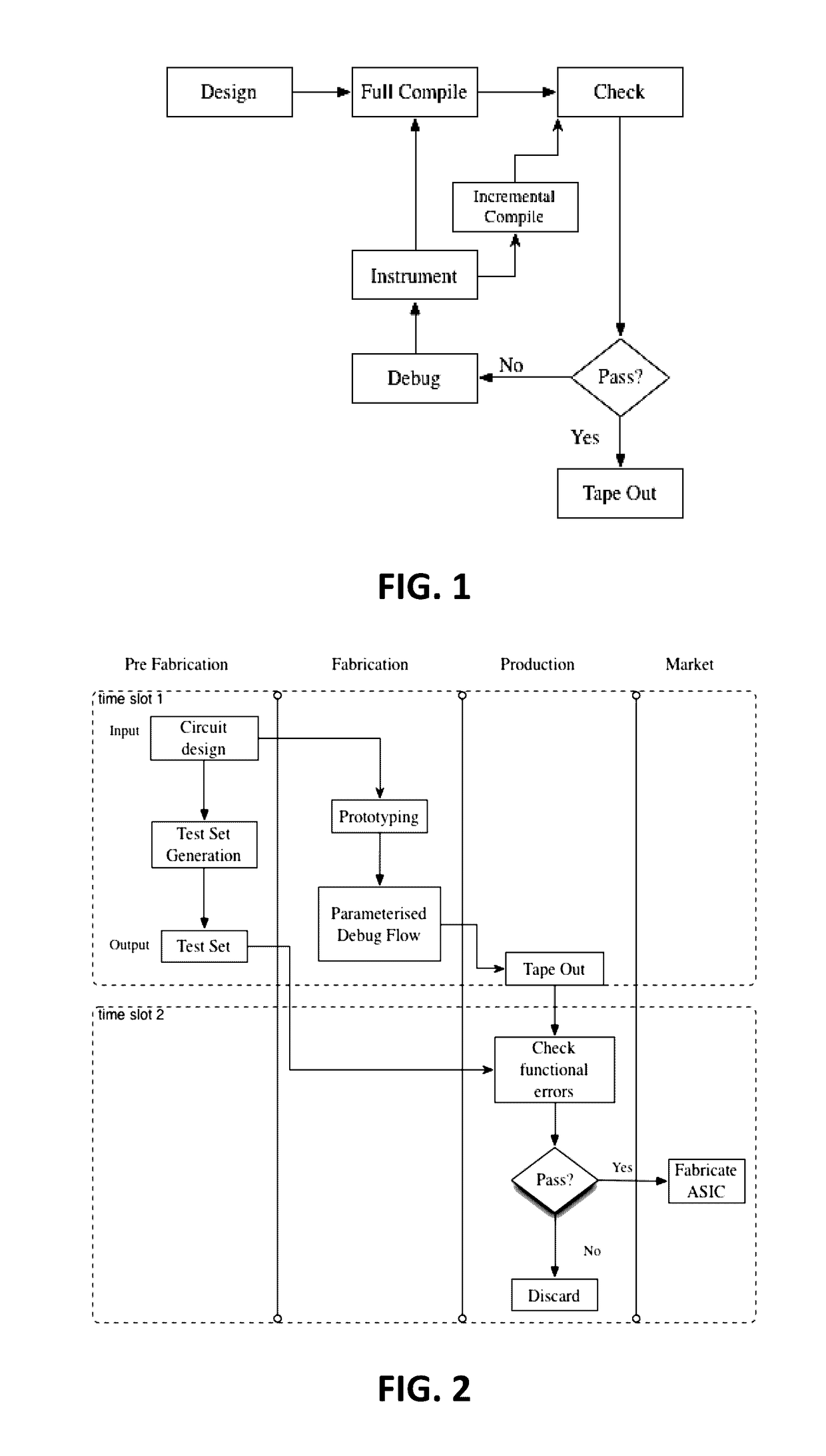

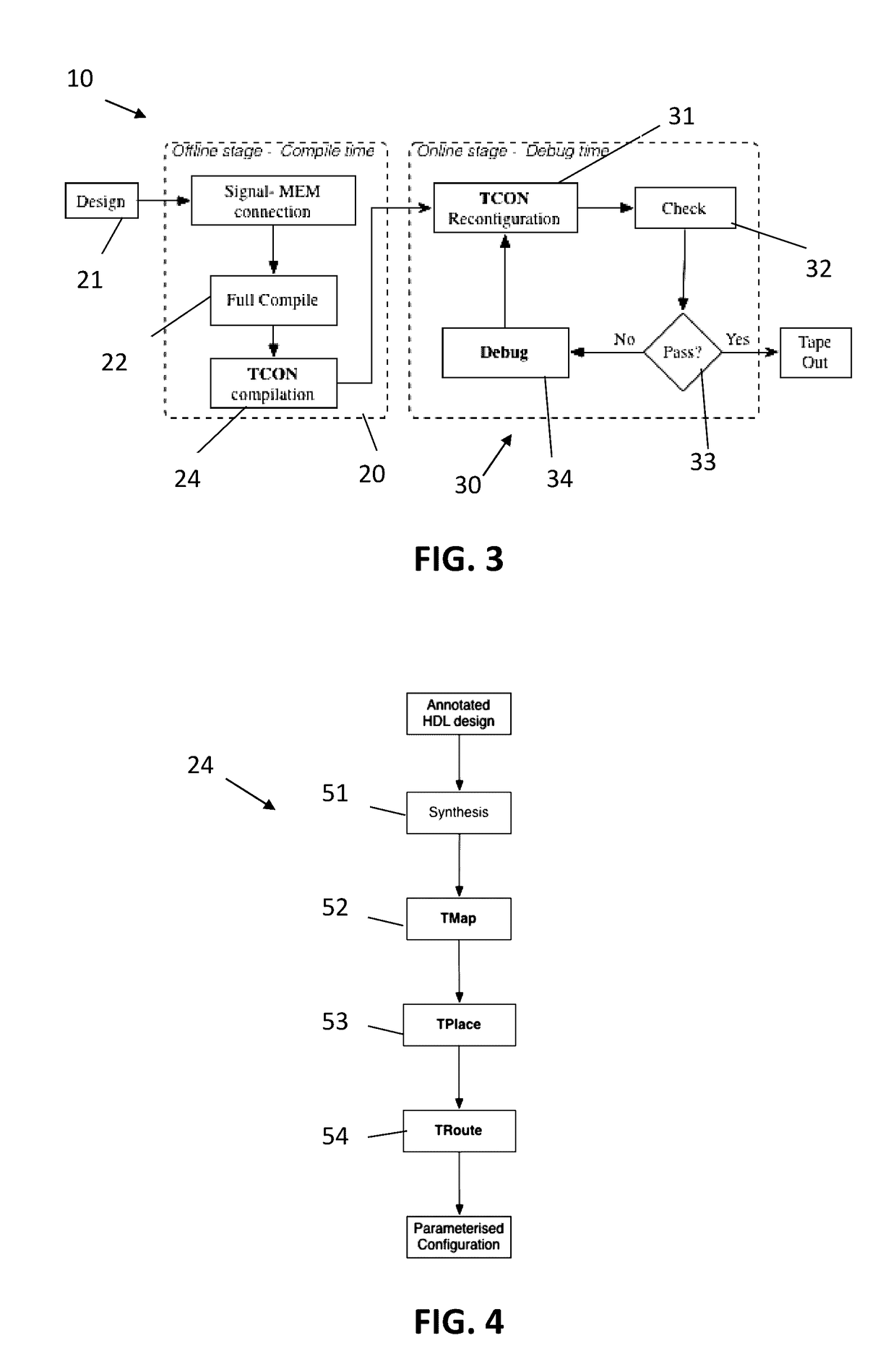

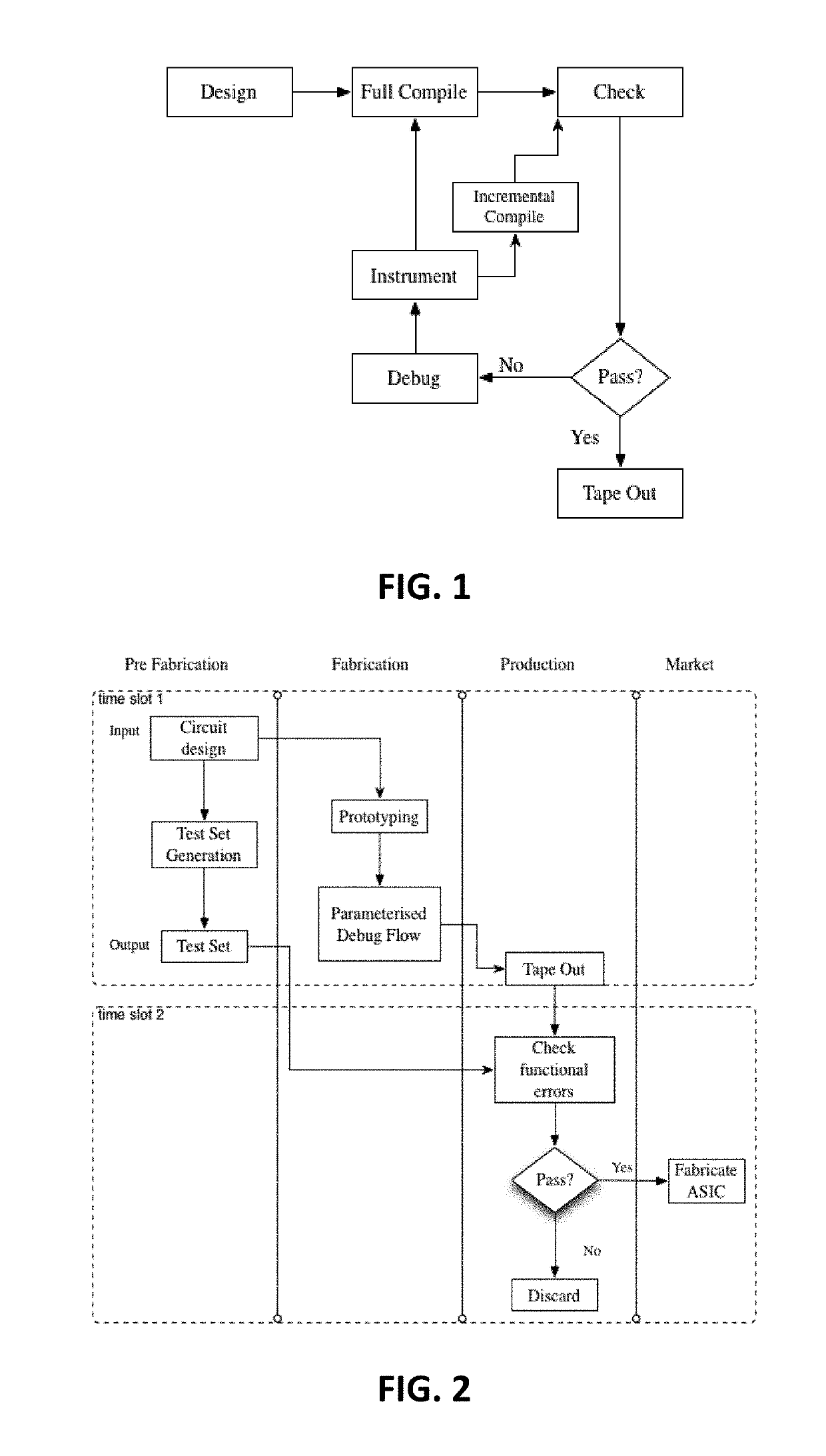

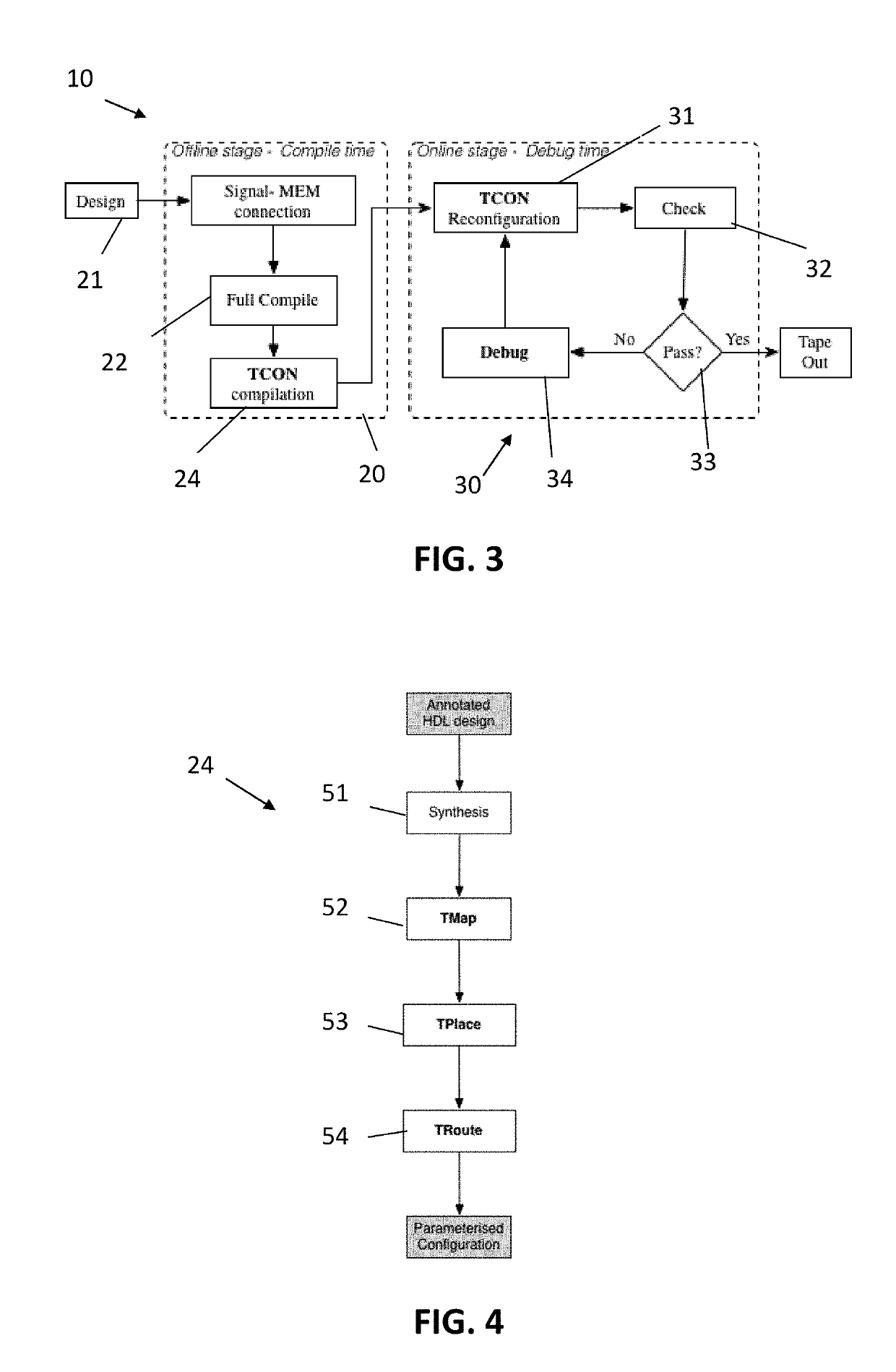

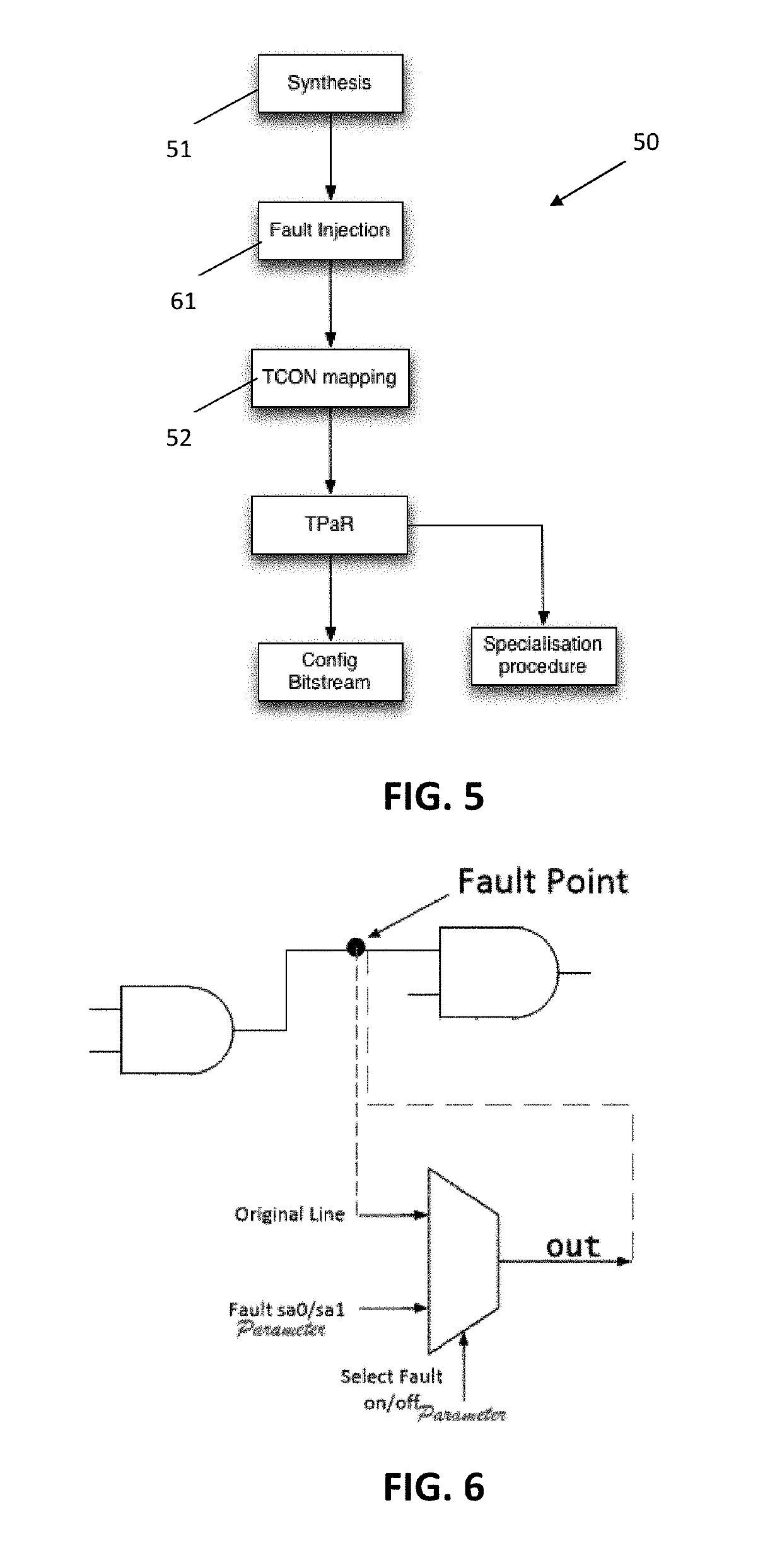

Integrated circuit verification using parameterized configuration

InactiveUS20170074932A1Short commissioning cycleDigital circuit testingComputer aided designProgrammable logic deviceCircuit design

A method for debugging and a method for testing a circuit design on a programmable logic device is disclosed, making use of a parameterized configuration. A corresponding system also is disclosed.

Owner:UNIV GENT

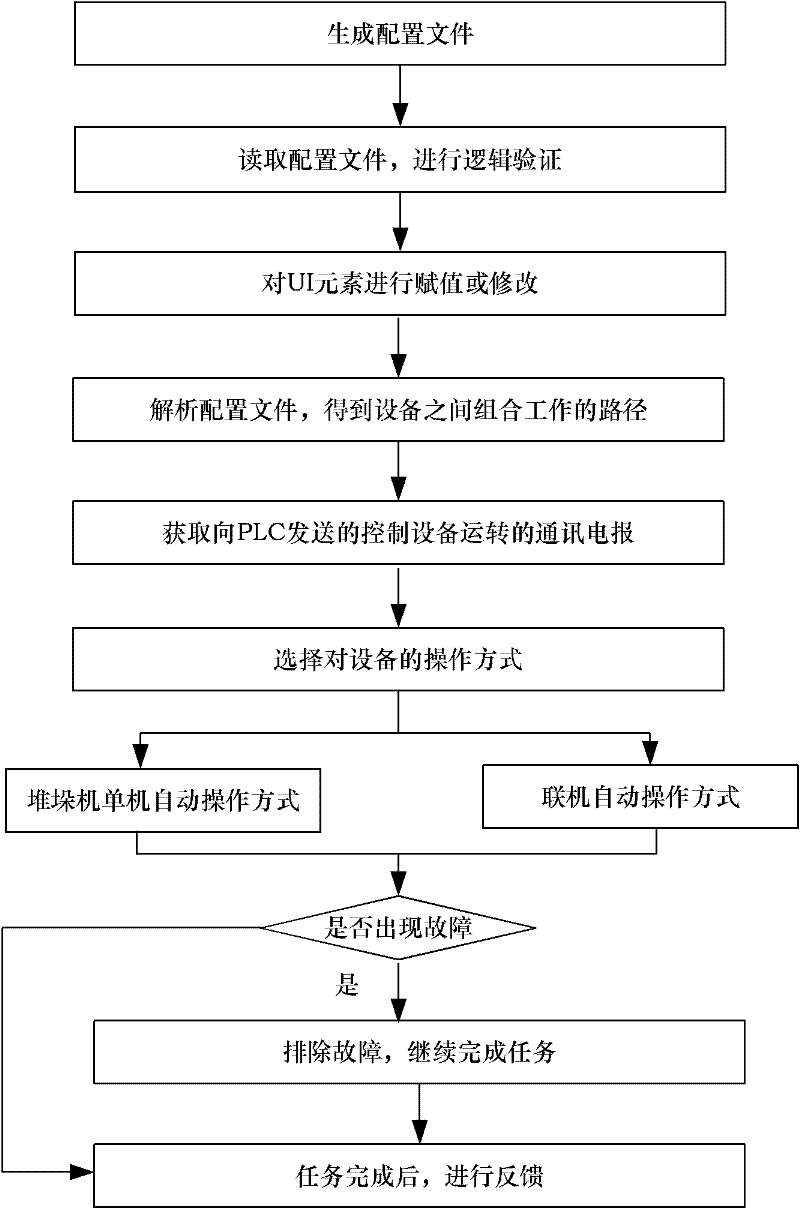

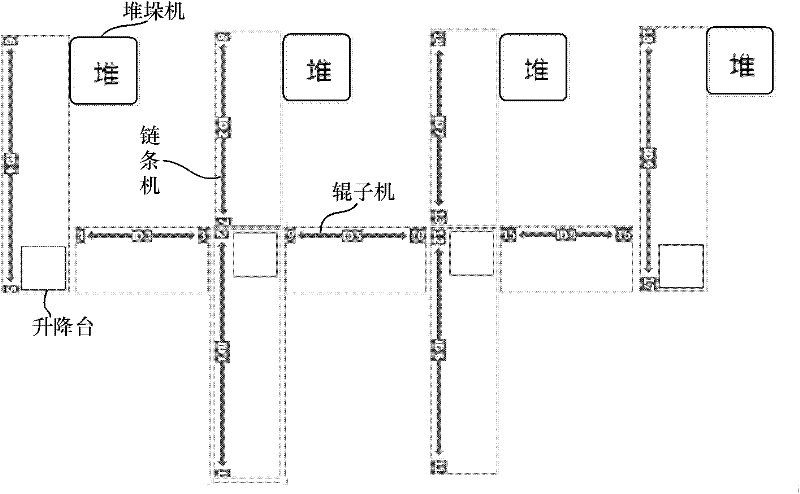

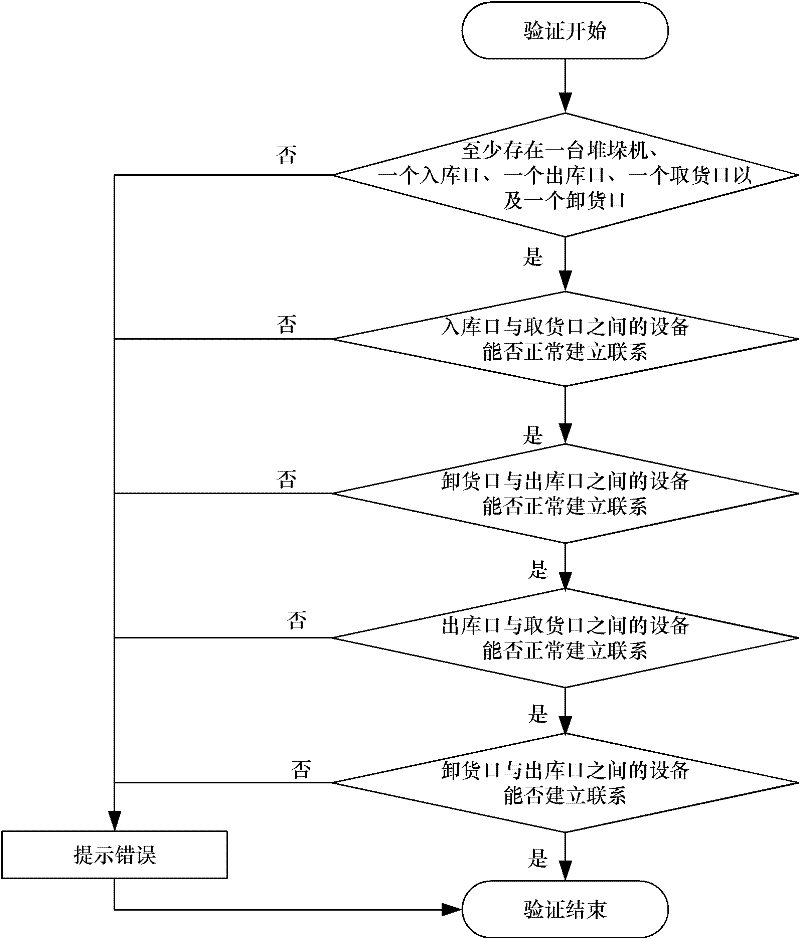

Monitoring method and monitoring system of programmable logic controller (PLC)

InactiveCN102298373AImprove reusabilityShort development cycleProgramme total factory controlProgrammable logic controllerIp address

The invention provides a monitoring method and monitoring system of a programmable logic controller (PLC). The monitoring method is characterized by comprising the following steps: firstly generating a configuration file for a project, then verifying the configuration file, setting a user interface (UI) element and obtaining paths for equipment to carry out combined working; then obtaining equipment telegraphs corresponding to the paths; and finally selecting the stacker single automatic or combined automatic operation mode to complete the task. The monitoring system comprises a configurationmodule, a logic processing module, a main interface module and a system configuration module, wherein the configuration module is used for managing the configuration file; the logic processing moduleis used for verifying and analyzing the configuration file and generating the equipment telegraphs corresponding to the working paths; the main interface module is used for modifying the UI element and selecting the working mode; and the system configuration module is used for setting a database and the IP address of a camera. The monitoring method and the monitoring system have the following advantages: the reuseability is strong; the developing and debugging cycles are shorter; and the difficulty in electrical program development is reduced.

Owner:BEIJING CTROWELL INFRARED TECHN

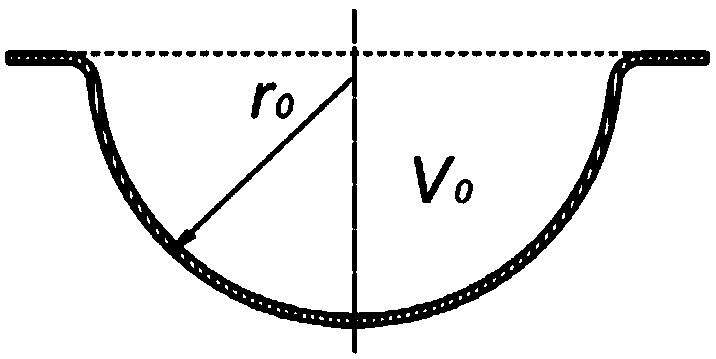

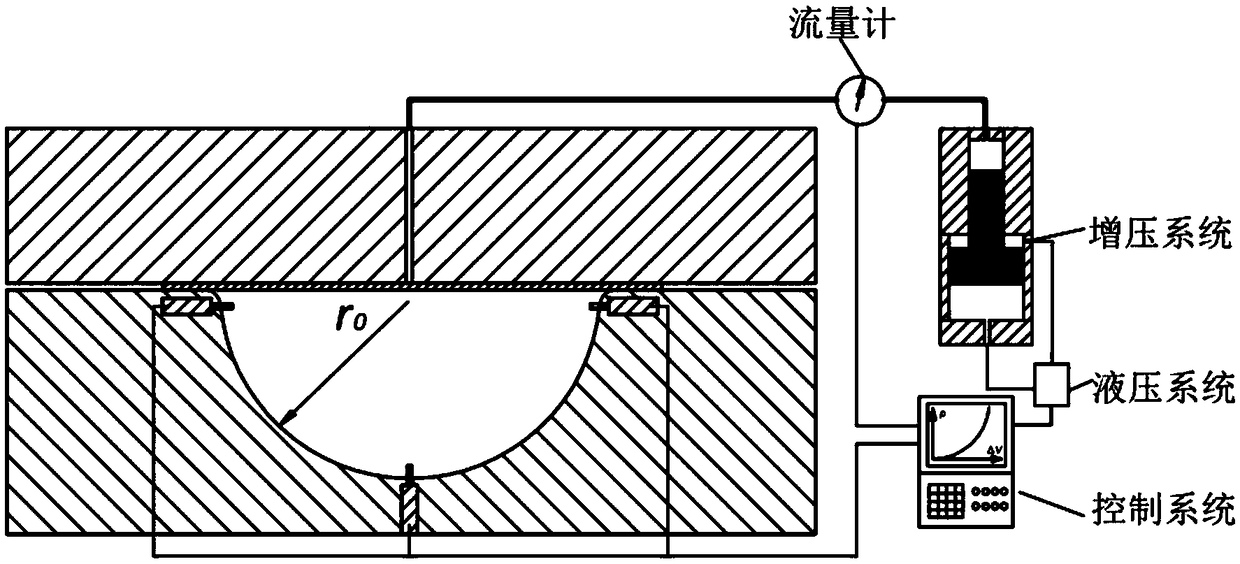

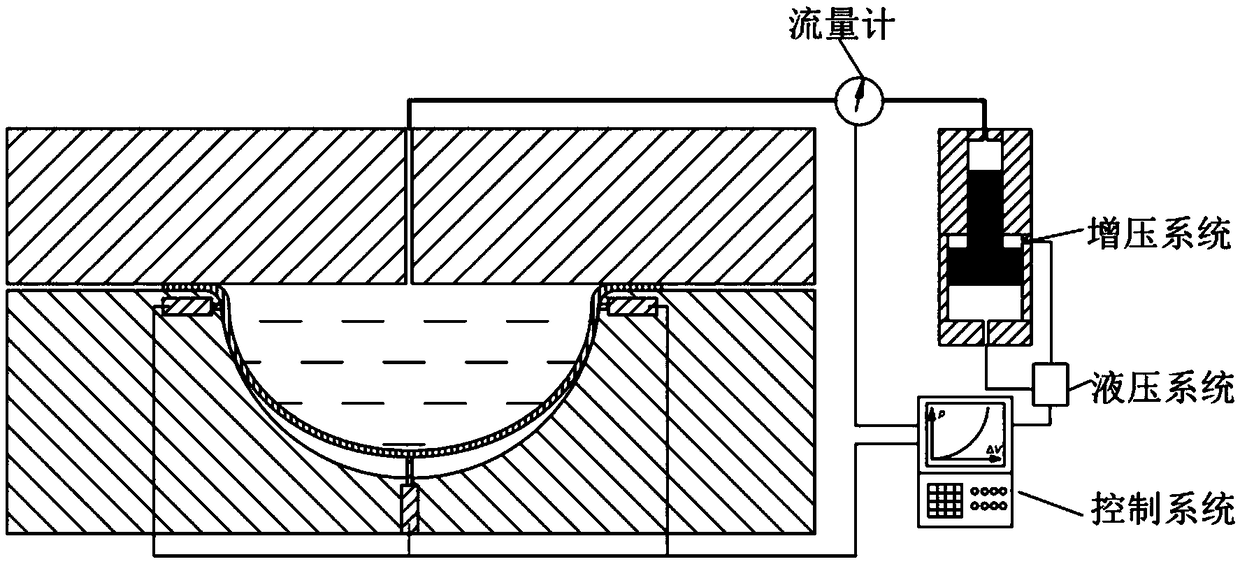

Component hydroforming springback accurate compensation method based on liquid volume control

ActiveCN108994141AShorten the debugging cycleAccurate springback compensationVolume variationEngineering

The invention discloses a component hydroforming springback accurate compensation method based on liquid volume control, and relates to a metal curved plate forming manufacturing method. According tothe component hydroforming springback accurate compensation method, a plate liquid male die deep drawing forming method is utilized, the difference between the theoretical volume of a target part andthe volume of an actual part after springback is calculated, a die is elastically deformed by adjusting and controlling the volume of injected liquid, the elastic deformation and the springback amountof the die are controlled to be equal, the springback of a curved plate is accurately compensated, and the size of a component meets the design requirement. According to the component hydroforming springback accurate compensation method, a die does not need to be repaired, and springback caused by plate batch changes and die machining errors can be accurately compensated on line in place. According to the component hydroforming springback accurate compensation method, the springback amount compensation is realized by adopting measurable and numerically-controlled liquid volume variation, theadvantages of high compensation precision, simple process, high efficiency, short period and low production cost are achieved, and the requirements of precise springback compensation and high profileprecision control of curved plates in different batches can be met.

Owner:HARBIN INST OF TECH

Method for machining key part on semiconductor encapsulation equipment

The invention relates to a method for machining a key part on semiconductor encapsulation equipment. A rectangular Peek plate is located and clamped on a bench clamp of a vertical milling machine, andthe lower surface, the upper surface and the side faces are subjected to rough machining; the lower surface and the upper surface are subjected to rough machining on a grinding machine; the upper surface is machined through a stainless steel four-blade milling cutter, and bottom holes of threaded holes are drilled in the upper surface through a twist drill; bottom holes of bolt holes and stainless steel locating holes are subjected to rough machining through a four-blade tungsten steel milling cutter; bottom holes of black light sensing original points are drilled in the upper surface throughthe twist drill, and assembly holes of the black light sensing original points are machined through a drill bit; the lower surface is subjected to finish machining through the stainless steel four-blade milling cutter; stainless steel bushes are mounted on the bottom holes of the stainless steel locating holes; black PEEK cylinders are mounted on the bottom holes of the black light sensing original points; the stainless steel bushes of the stainless steel locating holes are subjected to rough machining through the four-blade tungsten steel milling cutter, the stainless steel locating holes are subjected to finish machining through the four-blade tungsten steel milling cutter, and the stainless steel locating holes are formed; the upper surface and the lower surface are subjected to finishmachining through a tungsten steel grinding wheel; and an encapsulation position groove is subjected to rough machining through the four-blade tungsten steel milling cutter.

Owner:KERUI AUTOMATION TECH SUZHOU

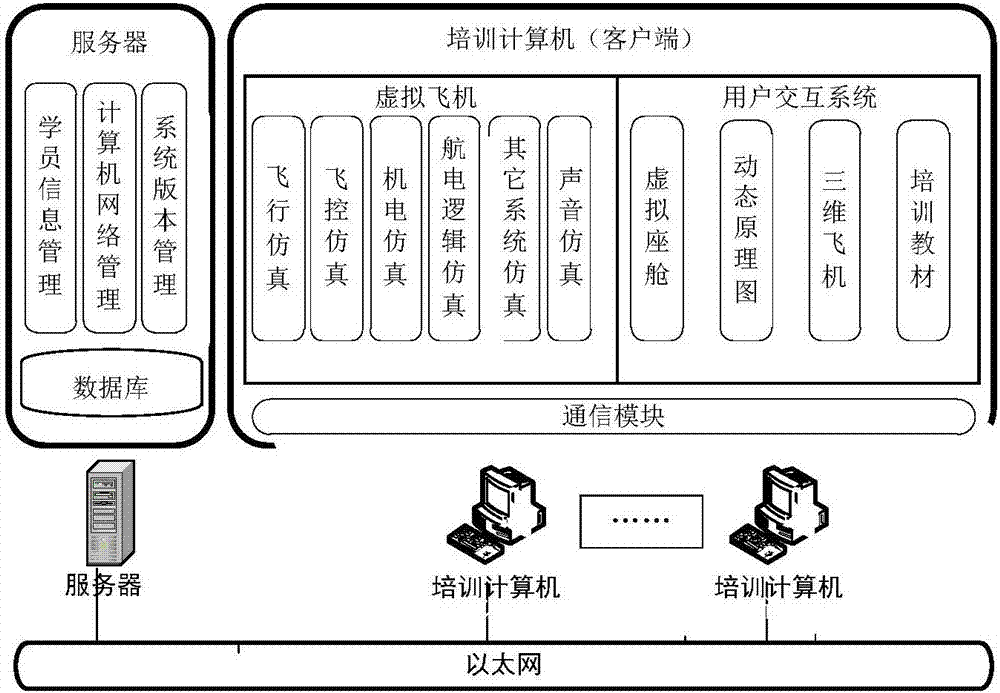

Ground crew virtual teaching system based on aircraft model driving

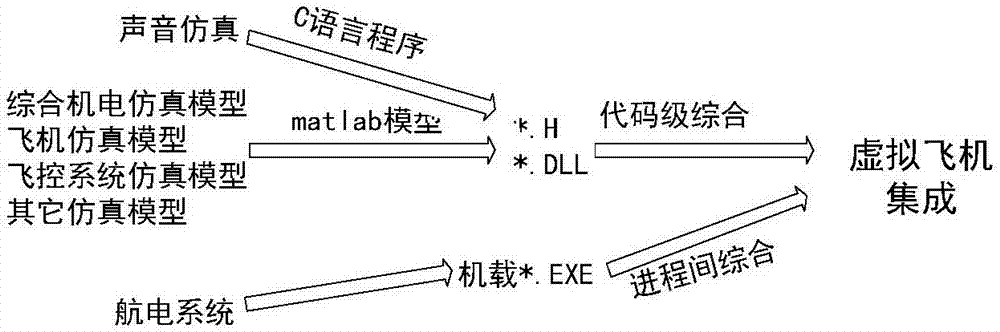

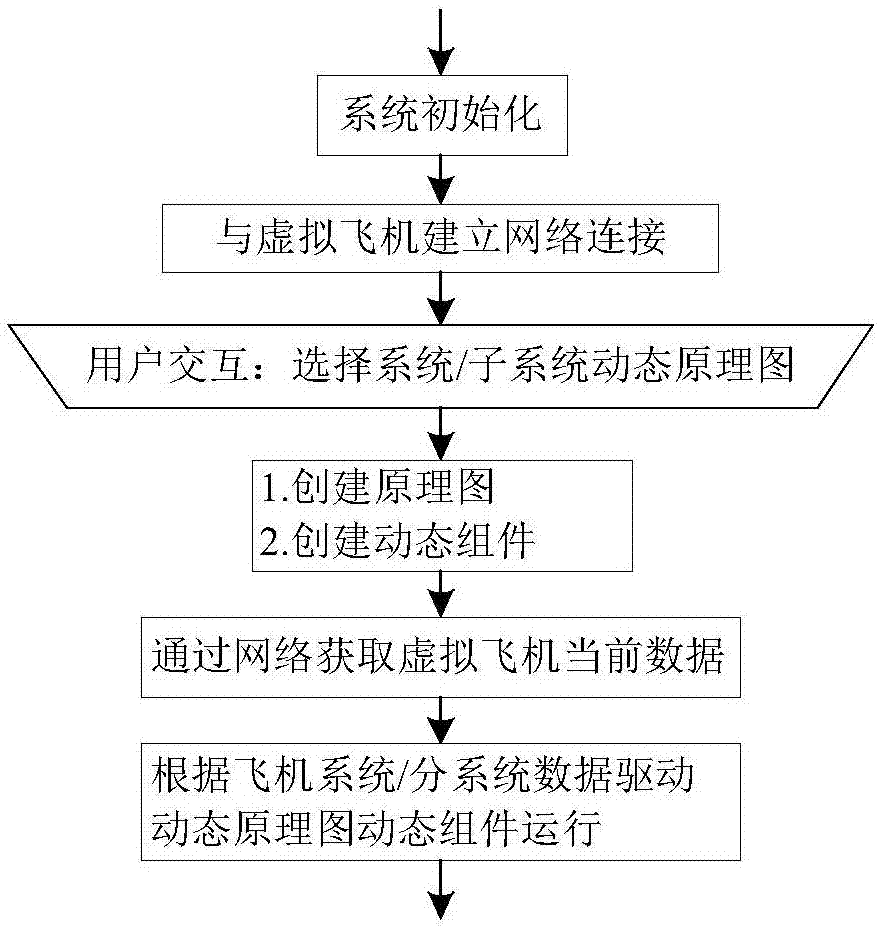

InactiveCN107274741AFunction increaseEasy to expand and upgradeCosmonautic condition simulationsSimulatorsAviationInteraction systems

The invention discloses a ground crew virtual teaching system based on aircraft model driving, and belongs to the technical field of aviation virtual training. The ground crew virtual teaching system includes virtual aircraft integration and a user interaction system. The virtual aircraft integration is used to reflect the actual operation status of an aircraft. The user interaction system includes a virtual cockpit, a dynamic schematic diagram module, a three-dimensional aircraft module and training teaching materials. The virtual cockpit simulates all the control and display devices in a cockpit by modeling, and sends input signals to the virtual aircraft integration. The virtual aircraft integration responds and generates output signals. The dynamic schematic diagram module displays a relationship among various components in an aircraft system according to the output signals. In the invention, the real system model of the aircraft is used for driving, the interface state of the aircraft system is in real accord with that of the aircraft, new subjects can be successfully added only by simple connection to the system model interface, the ground crew training effect is greatly improved and the cost is low.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

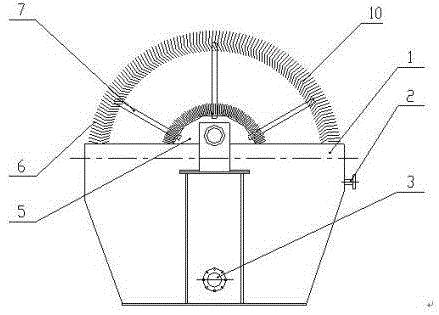

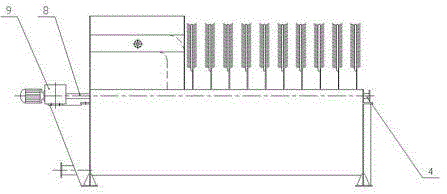

Self cleaning type ammonia-nitrogen wastewater treatment set device

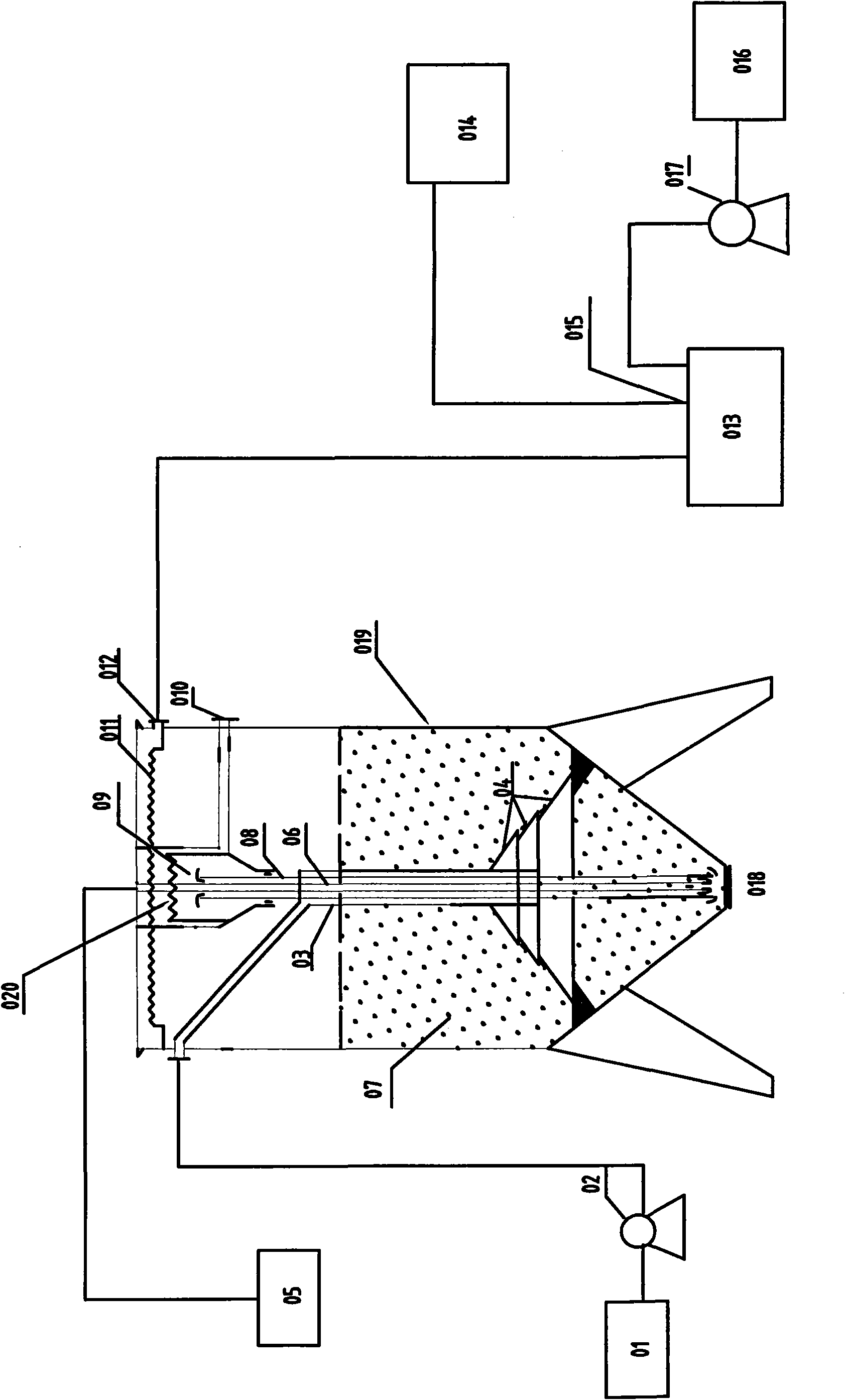

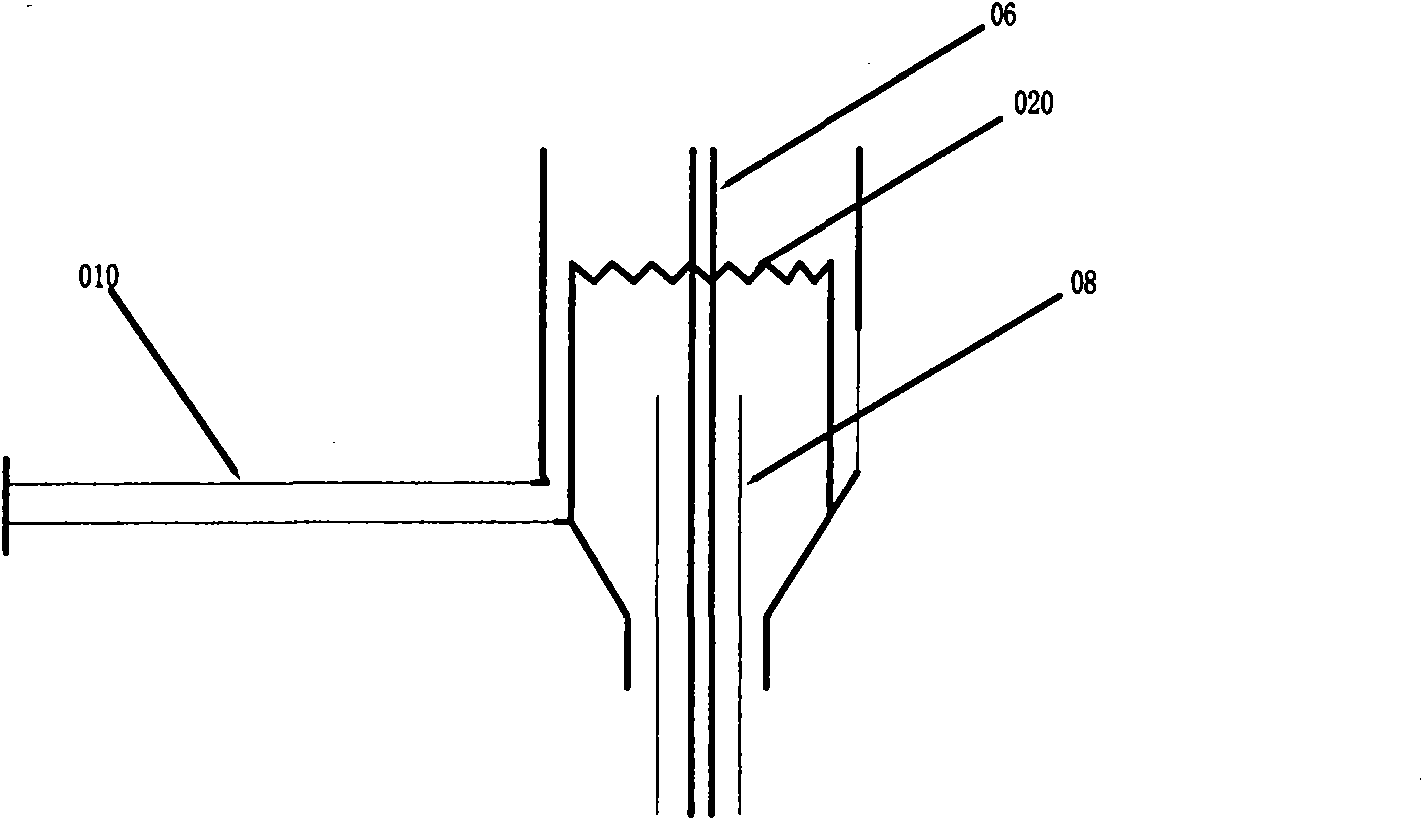

InactiveCN101823817AIngenious ideaInnovative designWater/sewage treatment by ion-exchangeTreatment with aerobic and anaerobic processesHigh concentrationAutomatic control

The invention relates to a high-concentration ammonia-nitrogen wastewater treatment set device, which comprises a dissolved medicine dissolution box, a wastewater flow stabilizing and flow guiding tube, a sand and stone exchange cleaner, filter materials, a sand blocking water distributor, sand and stone air stripping pipe, an air compressor output pipe, an air input pipe, a monitoring probe, an automatic control system and the like. The invention can treat the high-concentration ammonia-nitrogen wastewater which can not be treated by a physical chemical and biochemical method, at the same time, the defect that alkali addition, acid addition or temperature raising is needed during the high-concentration ammonia-nitrogen wastewater treatment by other methods for reaching the treatment effect can be avoided, the operation cost is reduced, and the area of the occupied ground is saved. The saturated filtering materials can be used as slow-release fertilizers for plants after being pulverized, and no secondary pollution is caused after the whole equipment operates to the filter material recovery.

Owner:宜兴市芳惠子环保设备厂

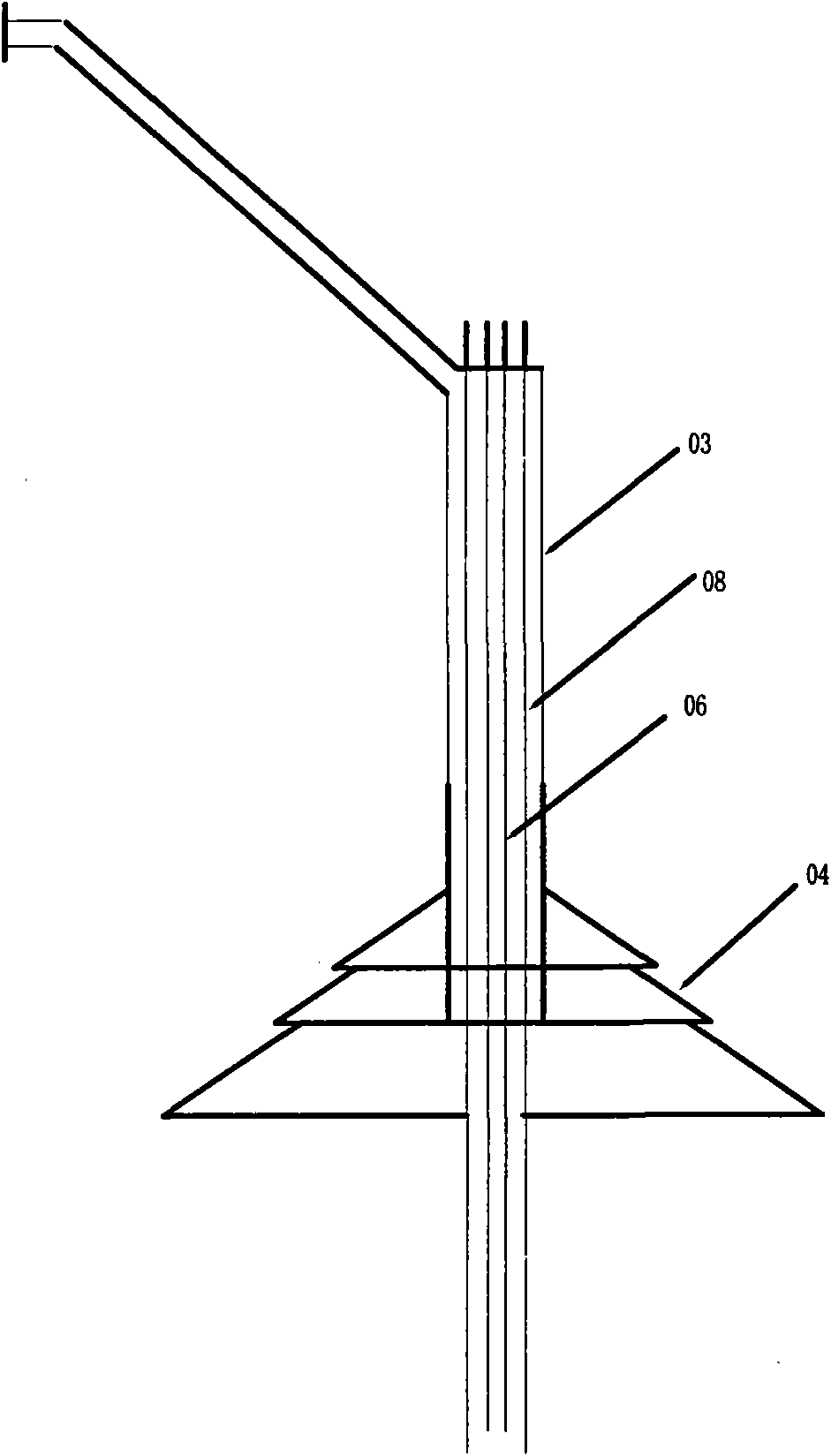

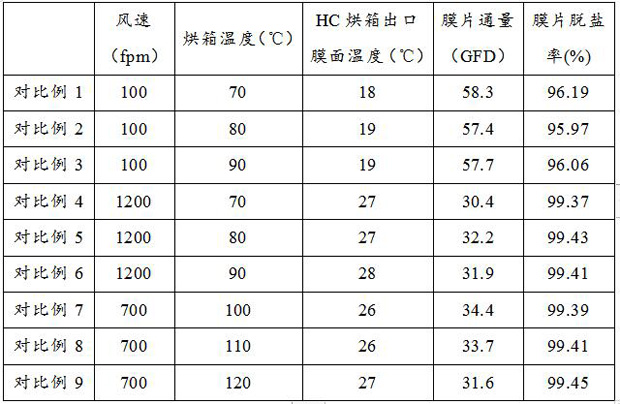

Preparation process of nanofiltration composite membrane

ActiveCN113368713AIncrease water fluxImprove performanceSemi-permeable membranesAir velocityWoven fabric composite

The invention provides a preparation process of a nanofiltration composite membrane, wherein the preparation process comprises the steps: firstly, compounding an aqueous phase solution on a non-woven fabric composite bottom membrane, and then compounding an oil phase solution to obtain a semi-finished product; performing heat treatment on the semi-finished product obtained in the step 1 through a drying oven, and controlling the membrane surface temperature of an outlet of the drying oven after heat treatment by adjusting the air speed and temperature of the drying oven to obtain the nanofiltration composite membrane, wherein the temperature of the membrane surface at the outlet of the drying oven is 20-30 DEG C. According to the preparation process, the membrane flux can be remarkably improved under the condition that the desalination rate of the composite nanofiltration membrane is not greatly reduced, and the problems that the water flux is generally low and the separation efficiency cannot be effectively improved in an existing NF membrane are effectively solved. Meanwhile, according to the preparation process provided by the invention, a reaction system is not greatly changed as much as possible, the variation of related matching parameters is small, the debugging period is short, the process application prospect is good, and the preparation process is more suitable for industrial production and application.

Owner:HUNAN KEENSEN TECH CO LTD

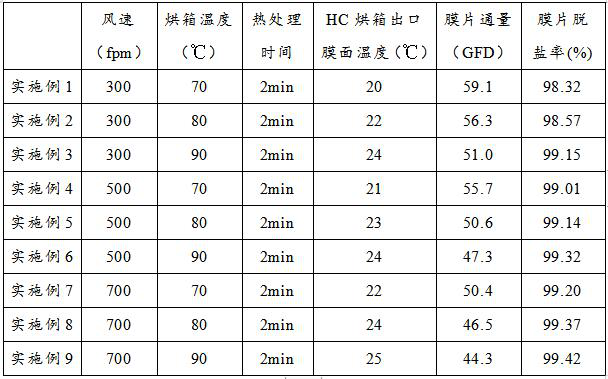

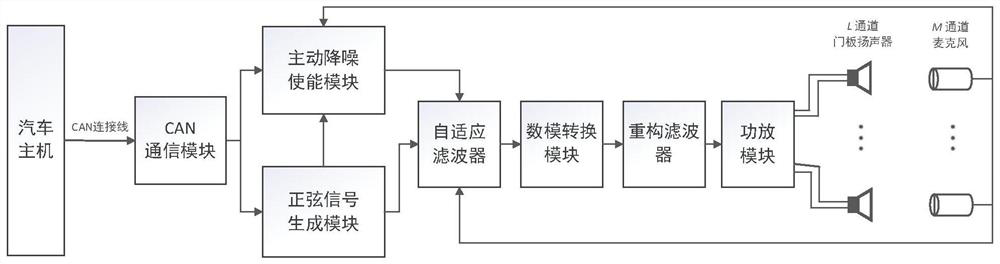

Wind noise control method and device for vehicle

PendingCN111754968AReduce wind noiseMinor changes requiredSound producing devicesElectric/fluid circuitNoise fieldNoise

The invention discloses a wind noise control method and device for a vehicle.The wind noise control method comprises the following steps of: S1, sampling vehicle window opening degree information in real time or regularly; S2, calculating the inherent frequency of a Helmholtz resonator formed by the carriage and the vehicle window according to the vehicle window opening degree information; S3, determining whether a wind vibration noise modal mark signal is generated or not according to the inherent frequency, and executing the following step S4 when the wind vibration noise modal mark signal is generated; S4, generating a reference signal according to the inherent frequency, updating filter parameters according to the reference signal and a noise signal in the vehicle, and outputting a stable control signal; and S5, driving a loudspeaker to generate an active control sound field according to the stable control signal, and coherently superposing the active control sound field with a noise field. The active noise reduction mode is adopted to solve the problem of wind vibration noise, and the vehicle structure does not need to be changed excessively.

Owner:COLSONIC SUZHOU ELECTRONICS CO LTD

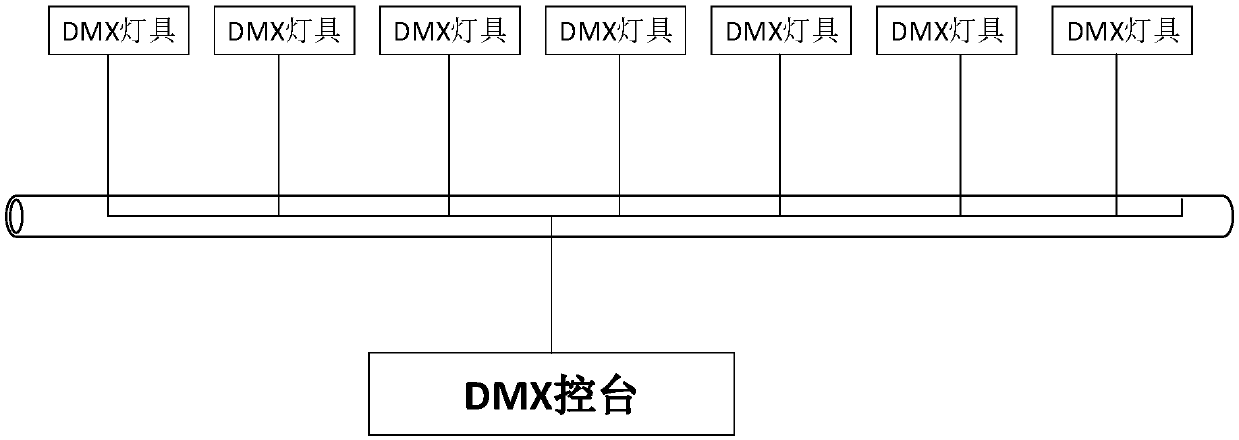

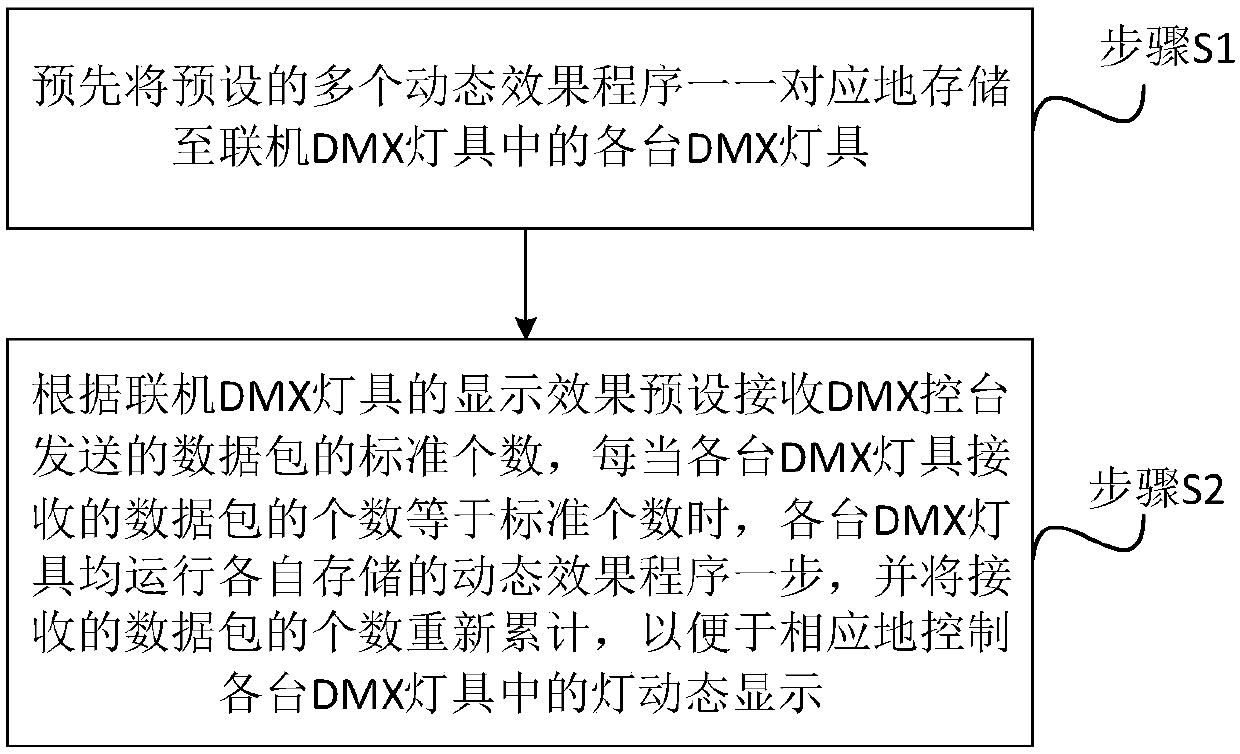

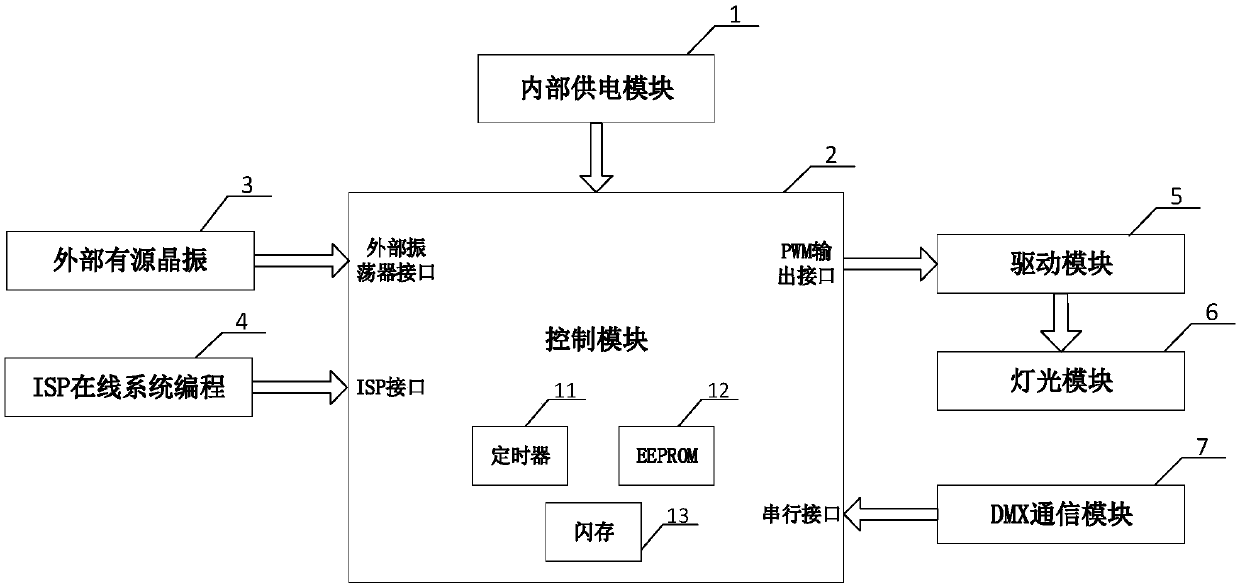

Method and system for synchronizing dynamic effect of online DMX lamp and DMX lamp

ActiveCN108040389AAchieving dynamismControl dynamic displayElectrical apparatusElectroluminescent light sourcesNetwork packetWorkload

The invention discloses a method and a system for synchronizing the dynamic effect of an online DMX lamp and a DMX lamp. The method includes the following steps: multiple preset dynamic effect programs are stored in DMX lamps of an online DMX lamp in advance in a one-to-one correspondence manner; the standard number of received data packets sent by a DMX console is preset according to the displayeffect of the online DMX lamp; and when the number of data packets received by each DMX lamp is equal to the standard number, each DMX lamp runs the dynamic effect program stored therein once, and thenumber of received data packets is re-calculated, so that the dynamic display of light in each DMX lamp can be correspondingly controlled. The performance quality of performers and the visual effectof the audience are improved. The workload is small, the difficulty is low, the debugging period is short, there is no need to change the hardware, and the purchasing cycle and the product cost are reduced. For an online DMX lamp running at high speed or for a long time, the probability of dynamic effect asynchronization is reduced.

Owner:LETARON ELECTRONICS

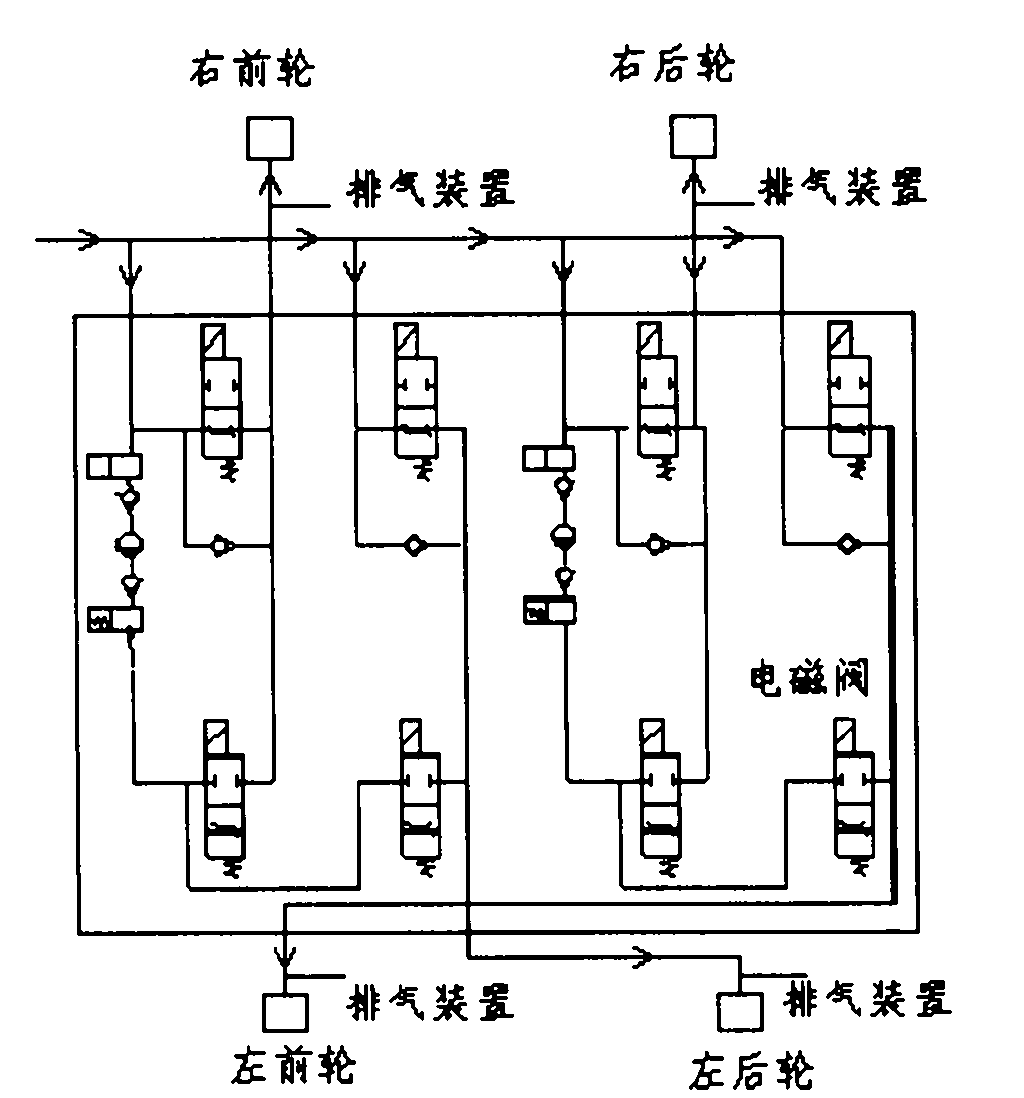

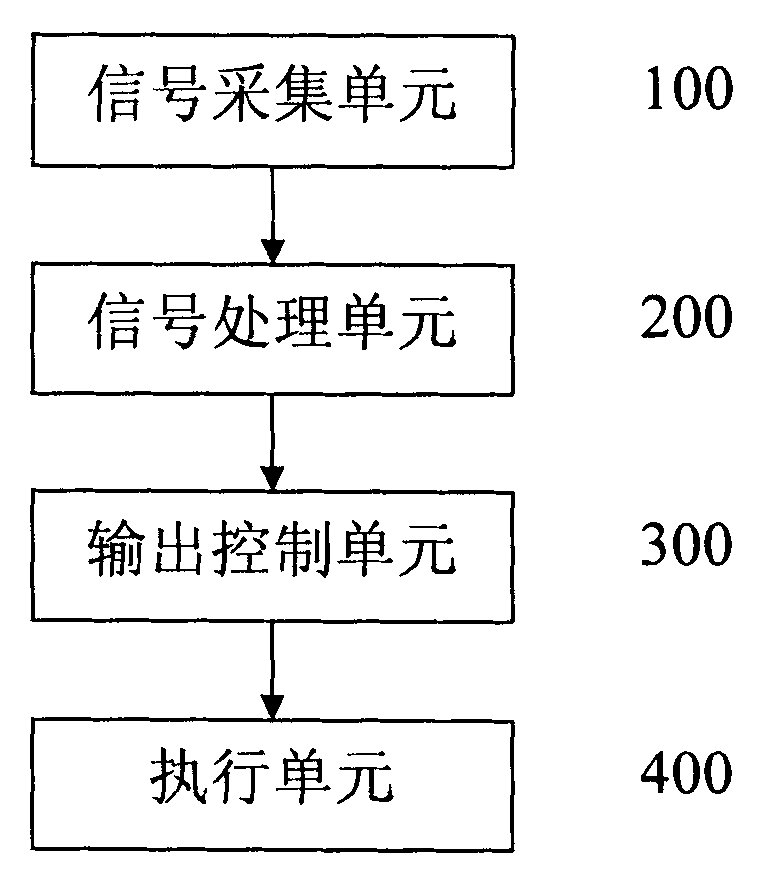

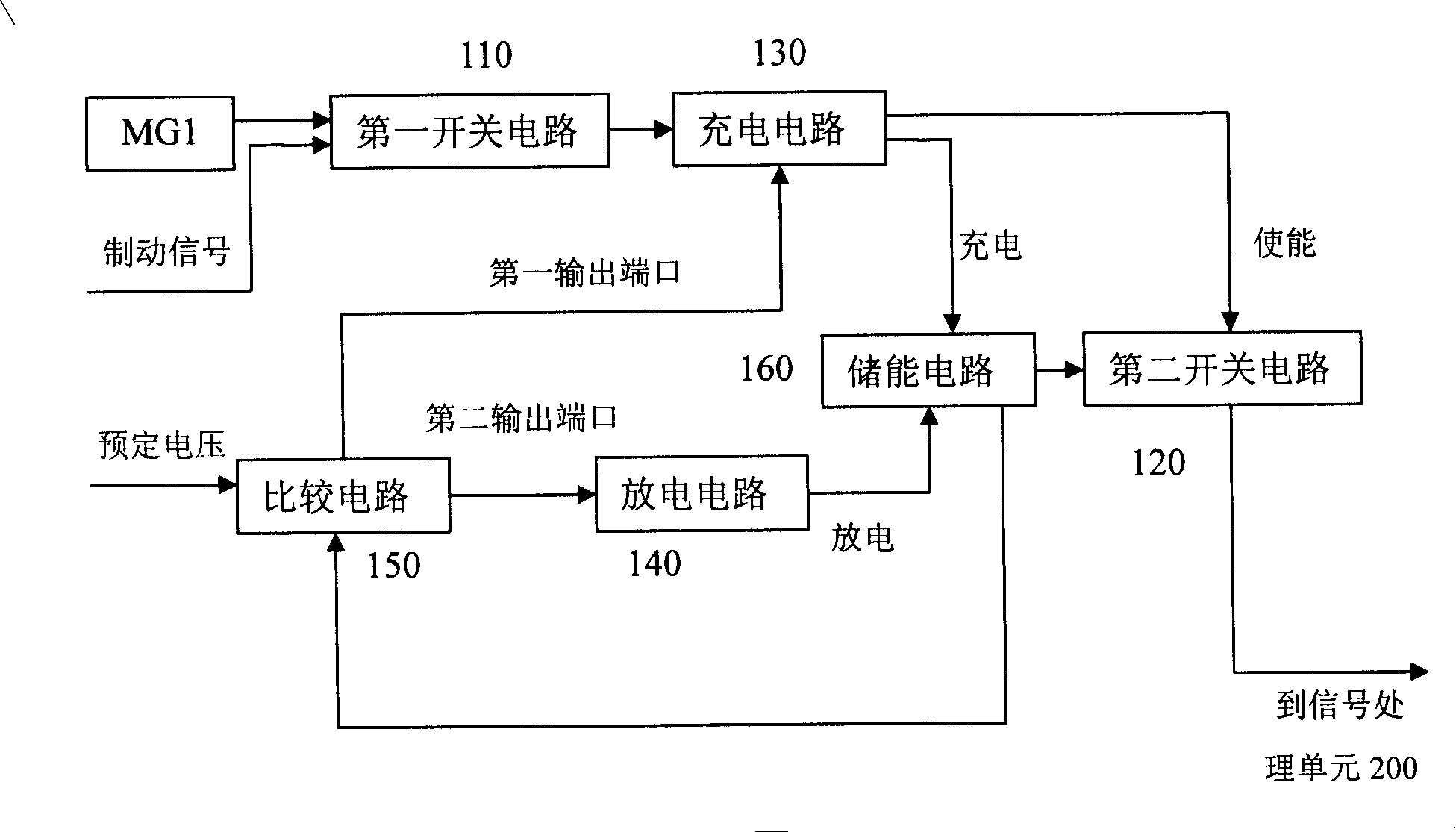

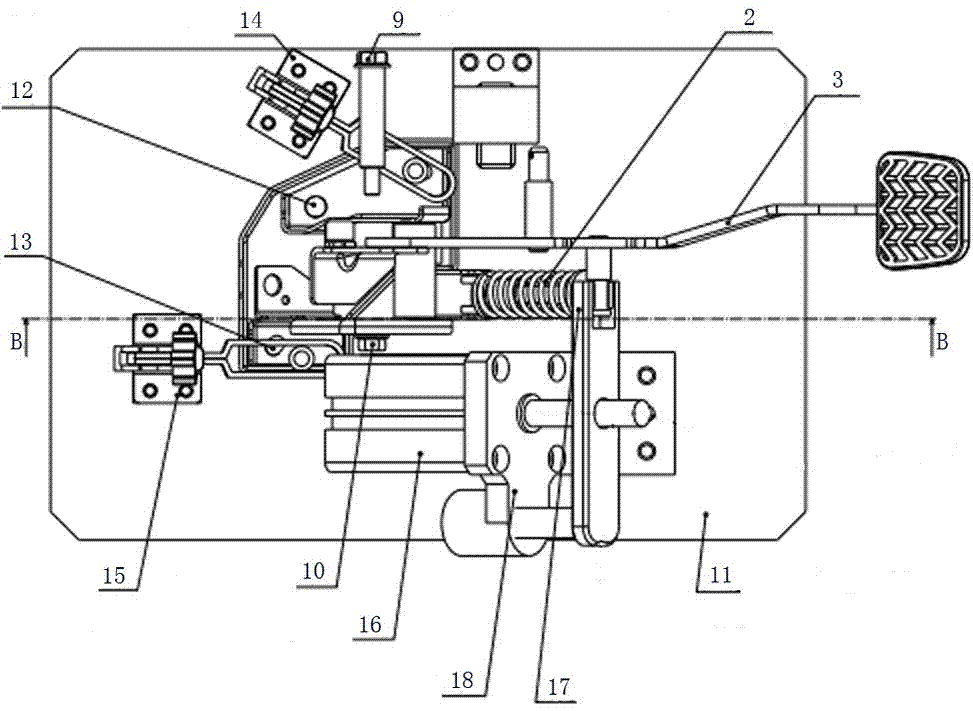

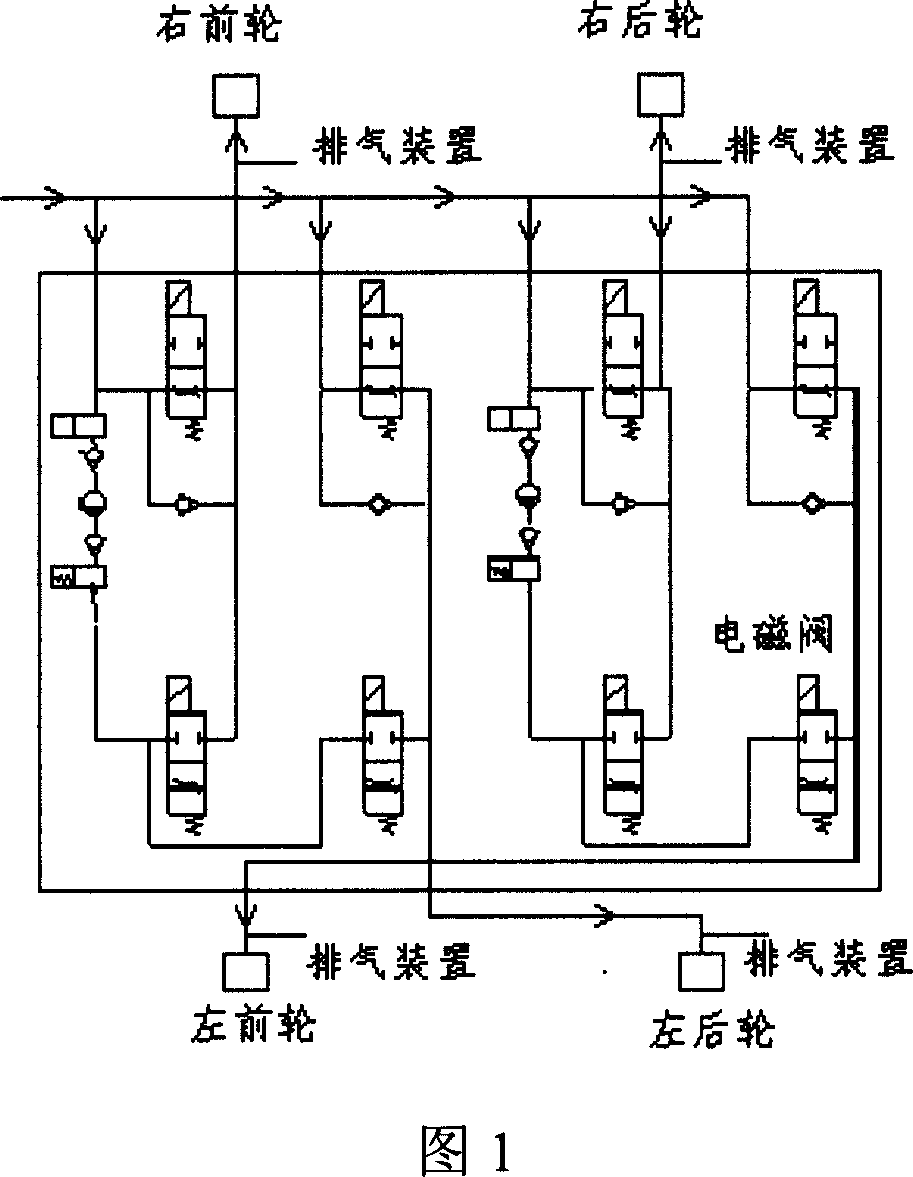

ABS locking proof system controlling means

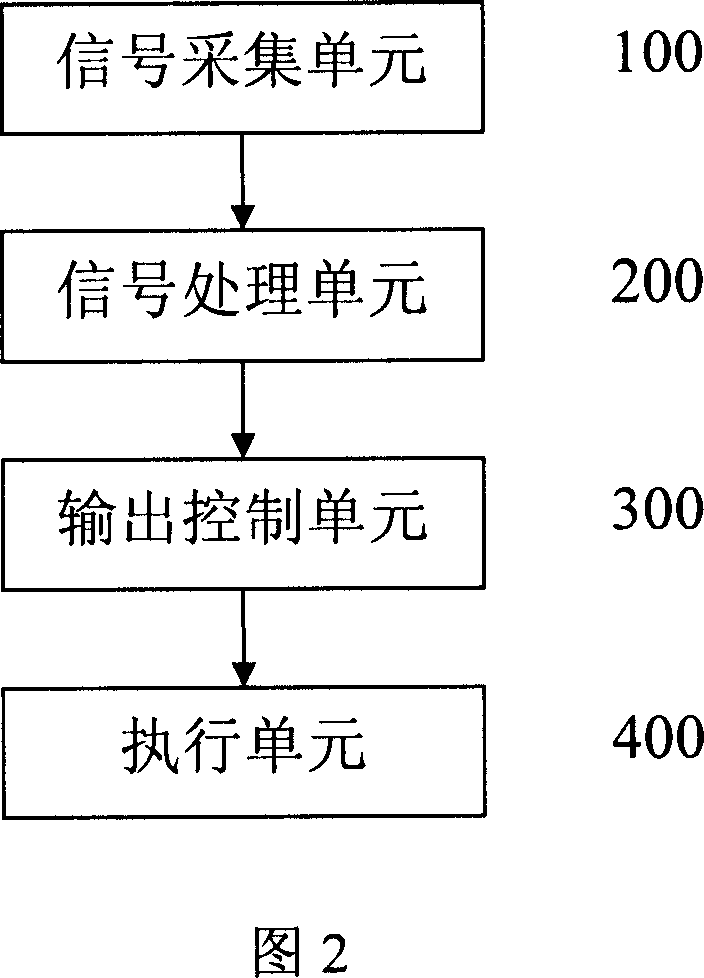

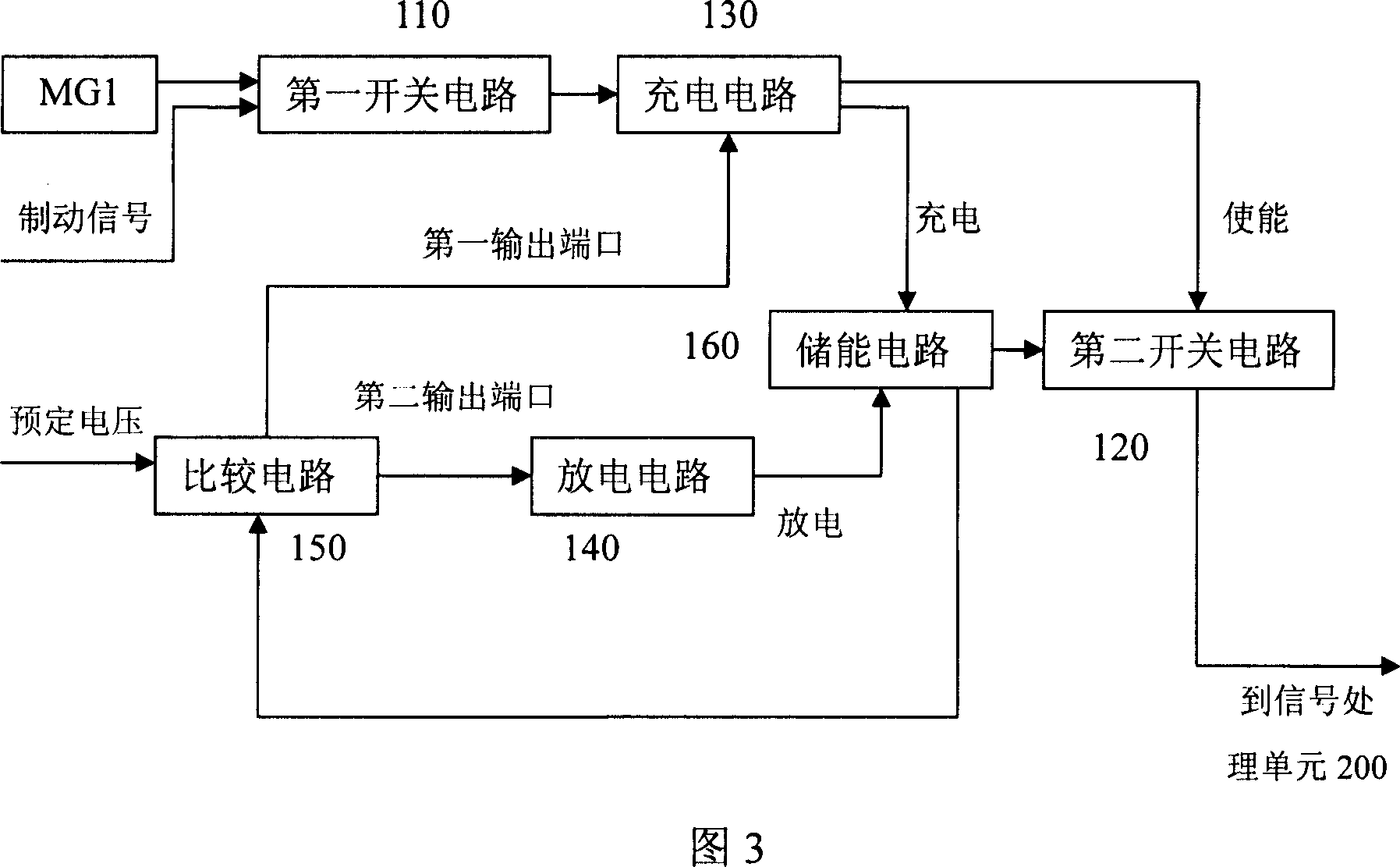

ActiveCN1990318BSimple methodShort commissioning cycleBraking systemsControl engineeringControl cell

The invention discloses a control device of ABS locking-proof system, which comprises the following parts: signal gathering unit (100), signal processing unit (200), output control unit (300) and executing unit (400), wherein the signal gathering unit (100) gathers wheel speed signal, which generates signal according to changing line of wheel speed; the signal processing unit (200) receives the signal of signal gathering unit (100), which switches the signal into acceleration signal of wheel; the output control unit (300) receives the acceleration signal, which generates decompressing output and / or pressurized output; the executing unit (400) receives decompressing output and / or pressurized output, which adjusts braking force of wheel.

Owner:BYD CO LTD

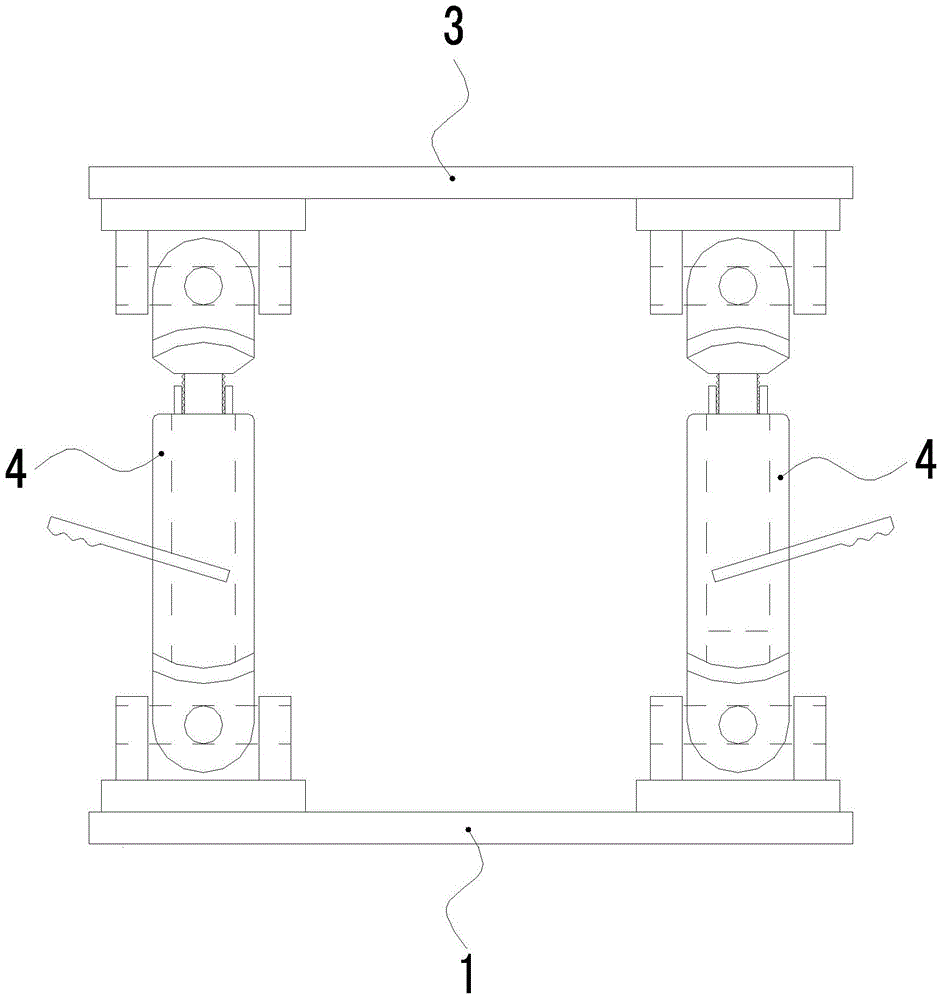

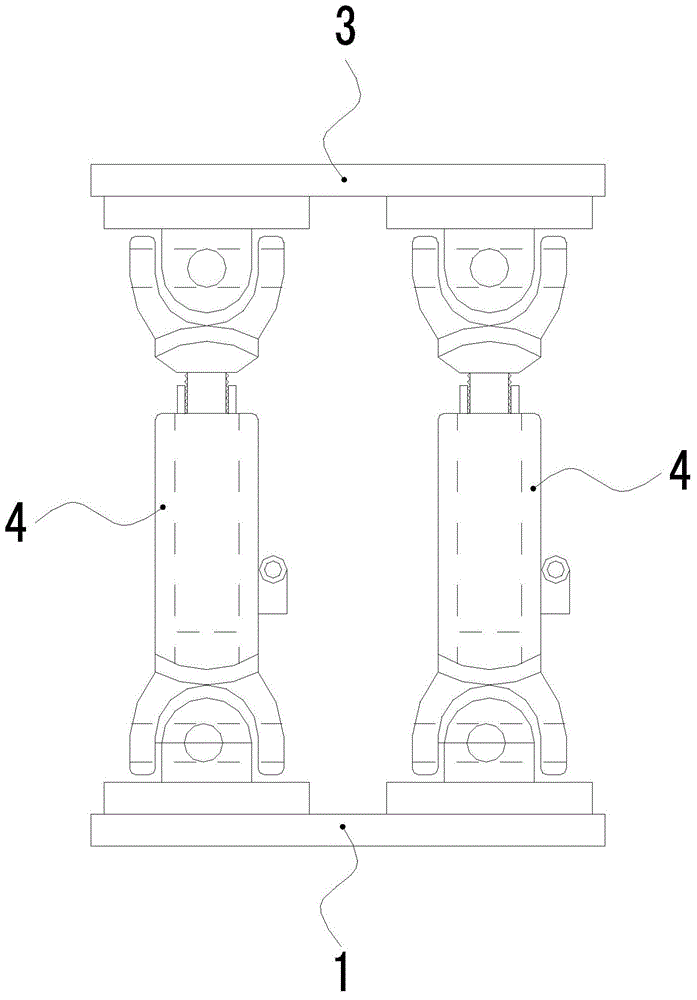

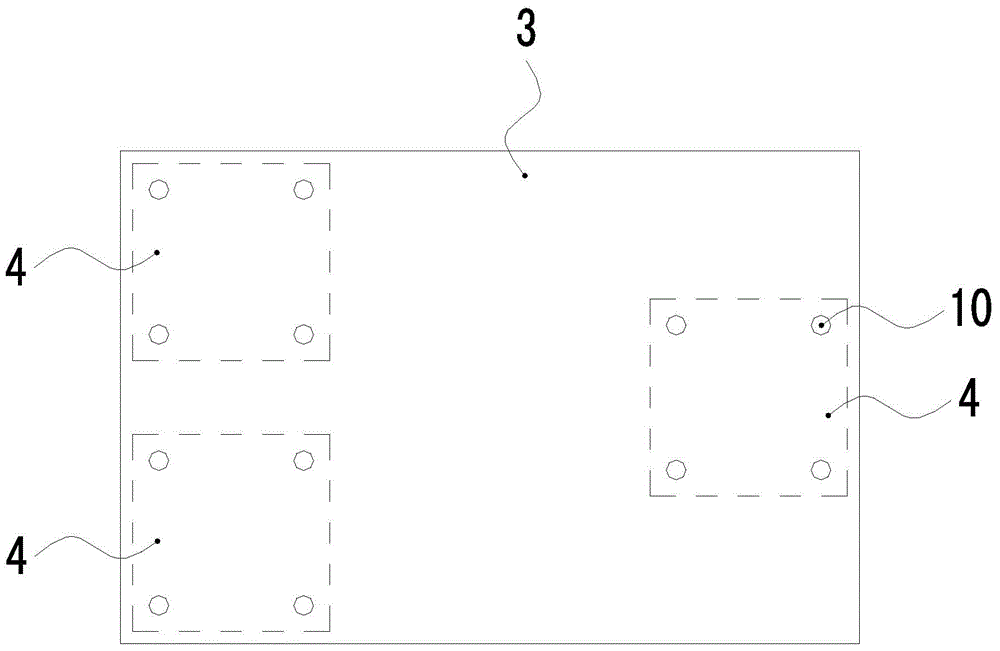

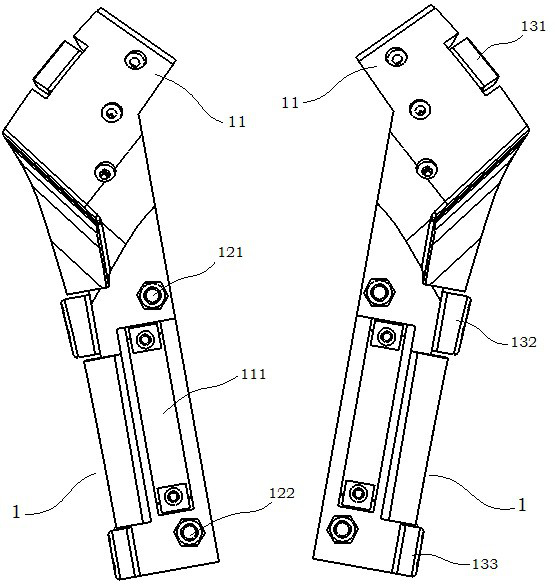

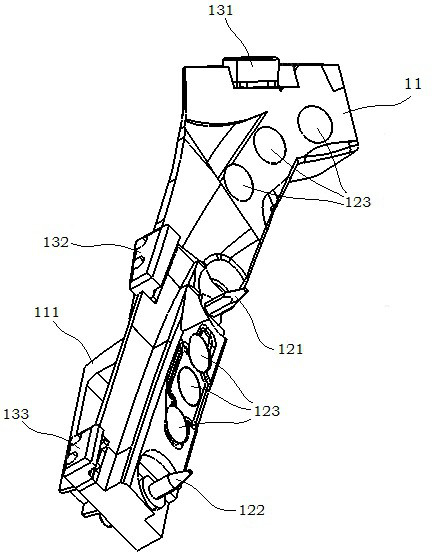

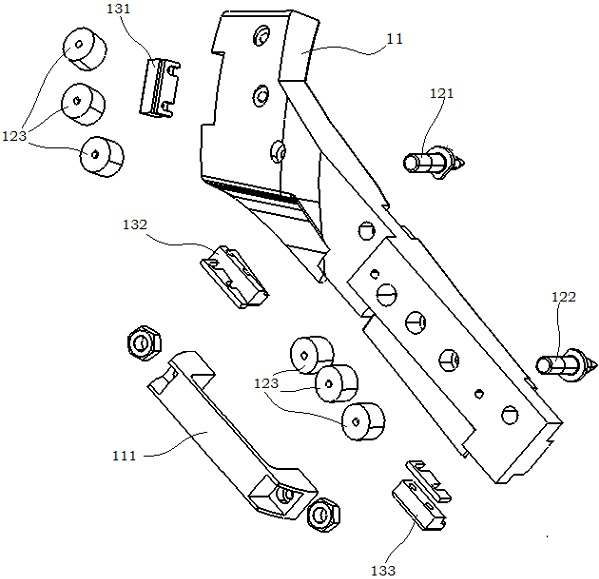

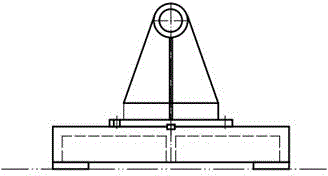

Mounting base for adjusting anchor chain stopper

ActiveCN105216970AReduce workloadShort commissioning cycleWaterborne vesselsUniversal jointEngineering

The invention relates to a mounting base for adjusting an anchor chain stopper. The mounting base comprises a base bottom plate which can be fixedly mounted on a ship deck, and a base panel for mounting the anchor chain stopper, wherein a position adjusting device which can adjust the three-dimensional position of the base panel is arranged between the base panel and the base bottom plate. The position adjusting device comprises three telescopic devices which can realize telescopic adjustment, wherein the three telescopic devices are respectively arranged at three peaks of a triangle; the lower end of each telescopic device is connected with the base bottom plate through a first universal joint; the upper end of each telescopic device is connected with the base panel through a second universal joint. According to the mounting base disclosed by the invention, through the manual adjustment of the position adjusting device, the three-dimensional position (including height and angle) of the base panel, namely the three-dimensional position of the anchor chain stopper, is adjusted, so that when an anchor chain is pulled and reeled back, the anchor chain does not rub an anchor mouth (namely an up-and-down opening of an anchor chain cylinder) anymore, and does not drop off the base panel anymore; the mounting base does not need to be trimmed, so that the workload of operation for cutting and welding the mounting base for in-situ adjustment is reduced; the mounting base is simple in structure and easy to make adjustment.

Owner:GUANGXIN SHIPBUILDING & HEAVY IND

Multi-laser system lap joint correction method for additive manufacturing equipment

ActiveCN114211003AFacilitate lap debugging and verificationEasy to install and debugAdditive manufacturing apparatusIncreasing energy efficiencyGalvanometerLap joint

The invention discloses a multi-laser system lap joint correction method for additive manufacturing equipment. The multi-laser system lap joint correction method comprises the steps that a detection plate with at least one film is placed on a substrate of the additive manufacturing equipment; controlling the multi-laser system to emit laser, and printing a graph with at least a plurality of cross points or a plurality of central points on the film according to a set program; taking out the detection plate, and placing the detection plate on a support plate of the correction device; a light source of the correction device emits light to the front side or the back side of the film, so that at least one camera of the correction device shoots a graph on at least one film; and the to-be-processed graph is processed to obtain the deviation angle, the expansion and shrinkage ratio and the offset of the galvanometers which are overlapped in pairs in the multi-laser system. According to the multi-laser system lap joint correction method for the additive manufacturing equipment, installation and debugging are convenient, installation and carrying are convenient, and lap joint debugging verification can be conveniently conducted on a client site; and the cost is low, the debugging period is short and the correction precision is high.

Owner:HUNAN FARSOON HIGH TECH CO LTD

Centering method for rod crash test

ActiveCN102645311AHigh debugging accuracyReduce cumulative errorVehicle testingShock testingClassical mechanicsCrash test

The invention discloses a centering method for rod crash test, which comprises the following steps that: A, two laser instruments are symmetrically arranged at positions which are close to the rear side of the two sides of a collision rod; B, the directions of beams which are emitted by the laser instruments are respectively adjusted to make the beams be tangent to the cambered surface of the collision rod of the corresponding side; C, the intersection point position of the beams is determined; and D, the position of a test car is adjusted, so that the mass center of a dummy head part in the car is superposed with the intersection point of the beams. The invention aims to provide the centering method for rod crash test, which is more intuitive and accurate and has higher efficiency.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Fire control system for bulging testing of containment of nuclear power plant and configuration method of fire control system

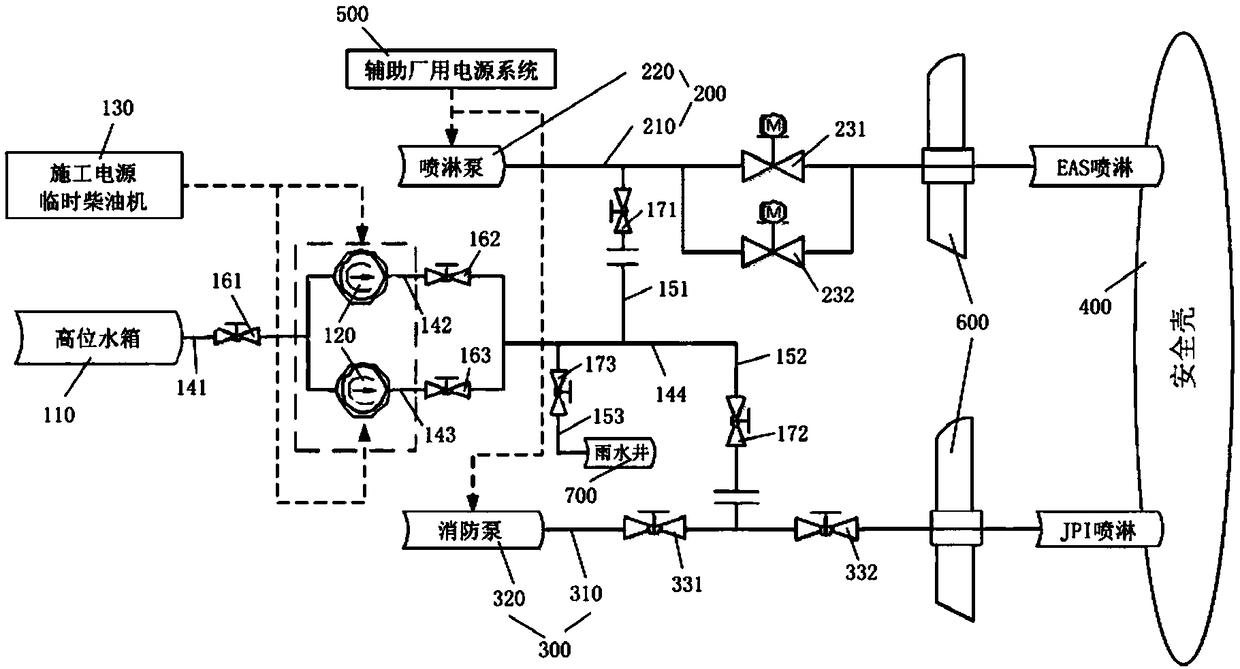

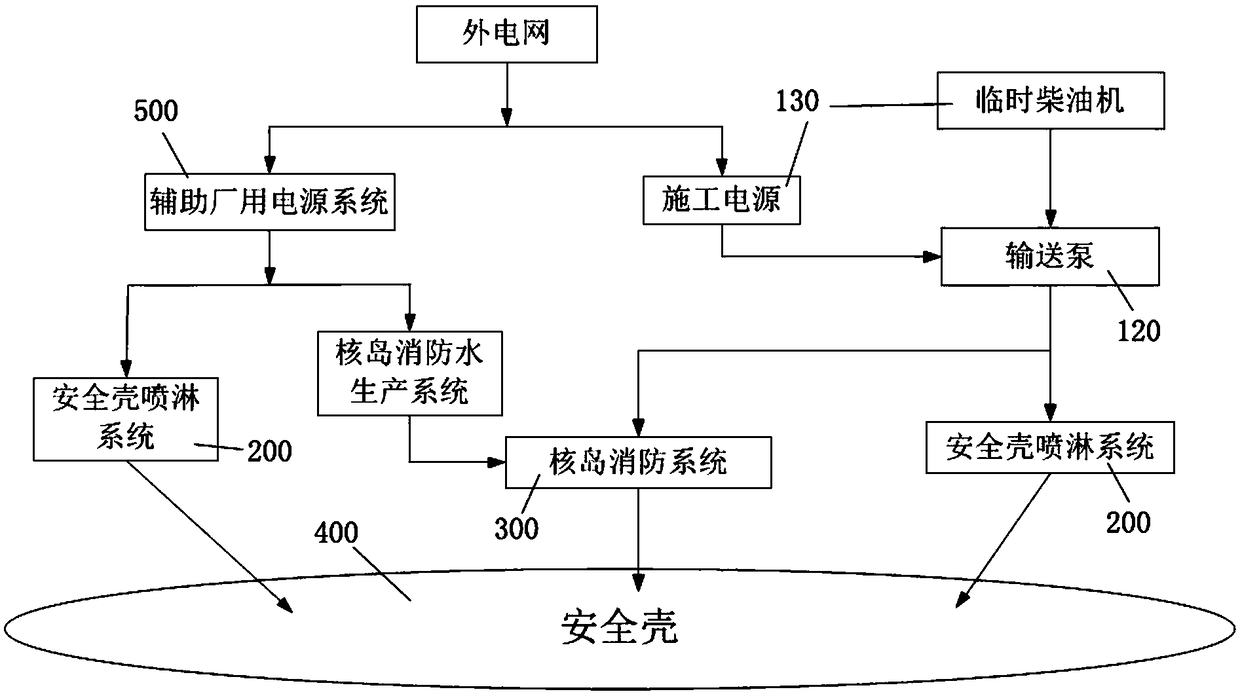

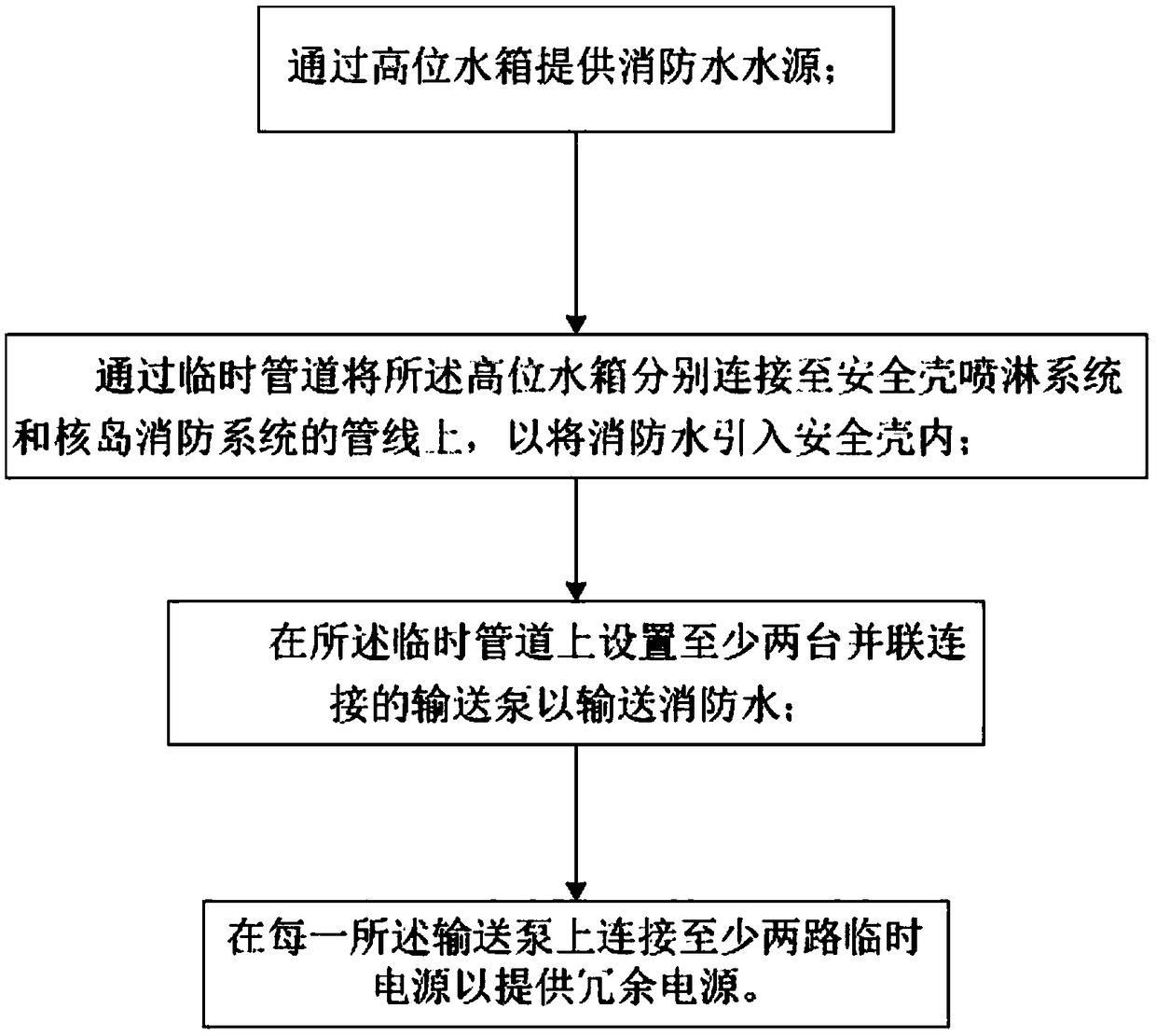

InactiveCN109273110AMeet the redundancyFulfil requirementsNuclear energy generationEmergency protection arrangementsNuclear plantFire-control system

The invention provides a fire control system for bulging testing of a containment of a nuclear power plant and a configuration method of the fire control system. The fire control system comprises a containment spray system, a nuclear island fire extinguishing system and a standby fire extinguishing system, wherein the standby fire extinguishing system comprises an overhead tank, a temporary pipeline, at least two conveying pumps and at least two temporary power supplies, wherein the overhead tank is used for providing a fire water source; one end of the temporary pipeline is connected with theoverhead tank, and the other end of the temporary pipeline is connected with pipelines of the containment spray system and the nuclear island fire extinguishing system separately so as to introduce fire water into the containment; the at least two conveying pumps are connected in parallel and are arranged on the temporary pipeline so as to convey the fire water; each temporary power supply is simultaneously connected with the at least two conveying pumps so as to provide a redundant power supply. According to the fire control system for bulging testing of the containment of the nuclear powerplant and the configuration method of the fire control system, provided by the invention, available resources of the nuclear power plant are utilized, the equipment debugging cycle is short, the costis low, and thus, the fire control system and the configuration method thereof have relatively high economical efficiency and practicability.

Owner:中广核工程有限公司 +2

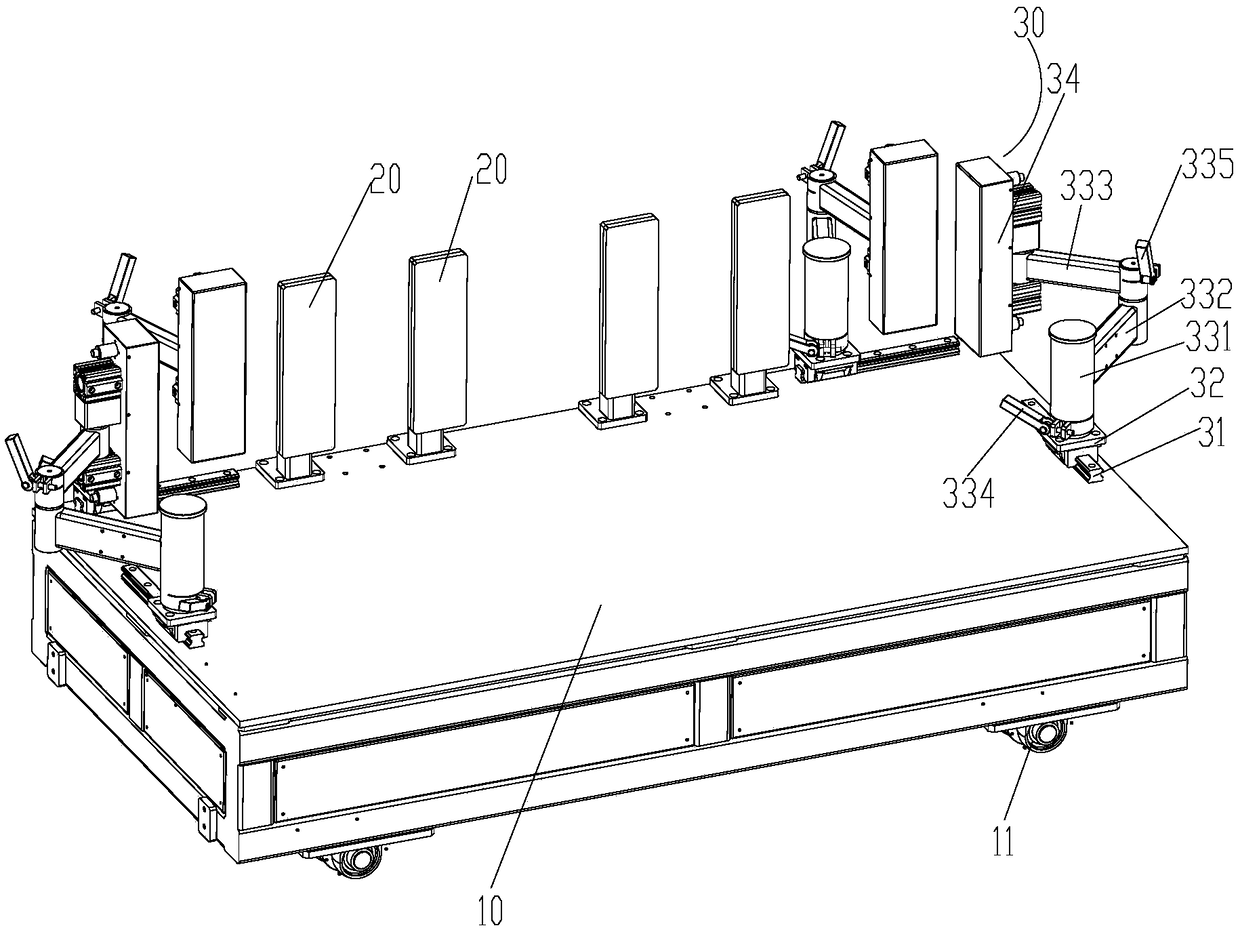

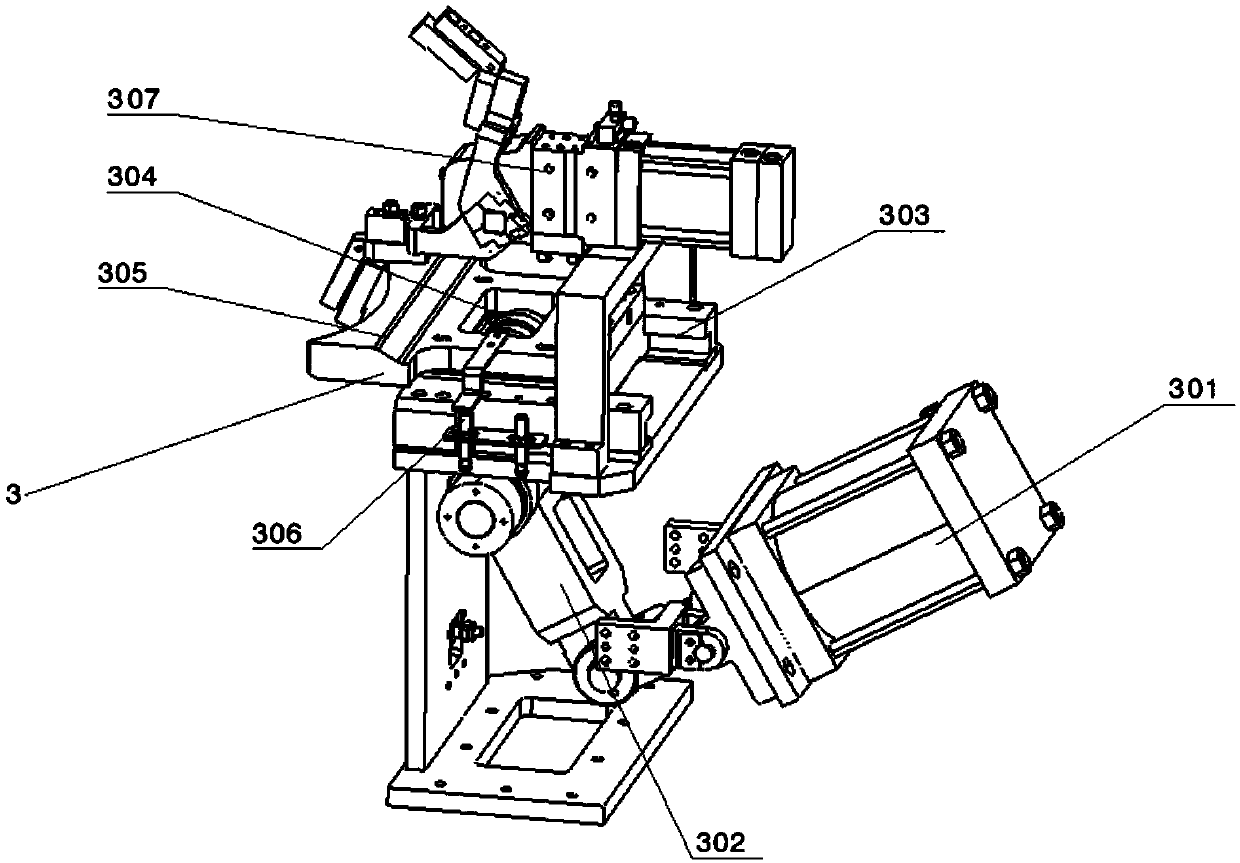

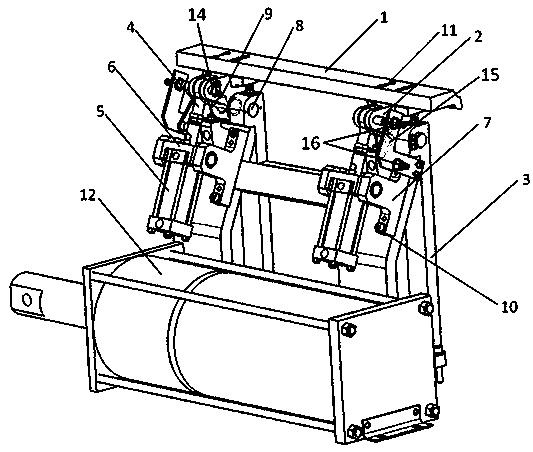

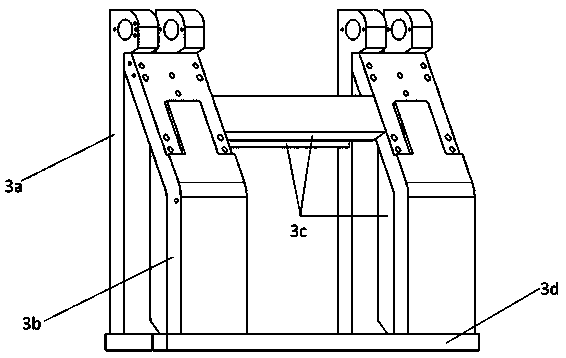

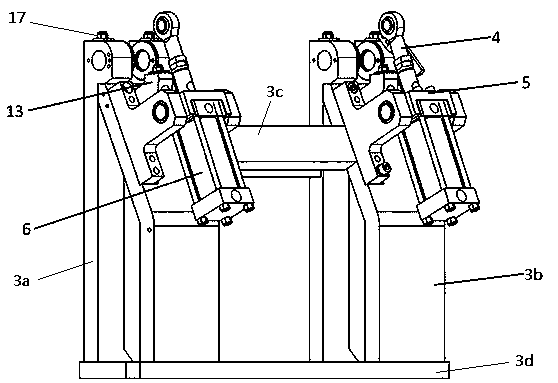

Sheet metal part distributing device

InactiveCN109230448AImprove compatibilityShort commissioning cycleConveyorsConveyor partsEngineeringMechanical engineering

The invention provides a sheet metal part distributing device which comprises a workbench, used for containing sheet metal parts, a positioning base arranged at one side of the workbench, and a distributing assembly. The distributing assembly comprises a first distributing mechanism and a second distributing mechanism, the first distributing mechanism is movably arranged at the first side of the workbench, and the second distributing mechanism is movably arranged at the second side perpendicular to the first side. Due to the fact that the first distributing mechanism and the second distributing mechanism are movably arranged on the workbench, by moving the positions of the first distributing mechanism and the second distributing mechanism, the device can adapt to sheet metal parts of different sizes, the compatibility of the sheet metal part distributing device can be improved, the adjusting period for the sheet metal part distributing device is short when sheet metal parts of different sizes are switched, operation is easy and rapid, and the automatic product production efficiency can be improved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

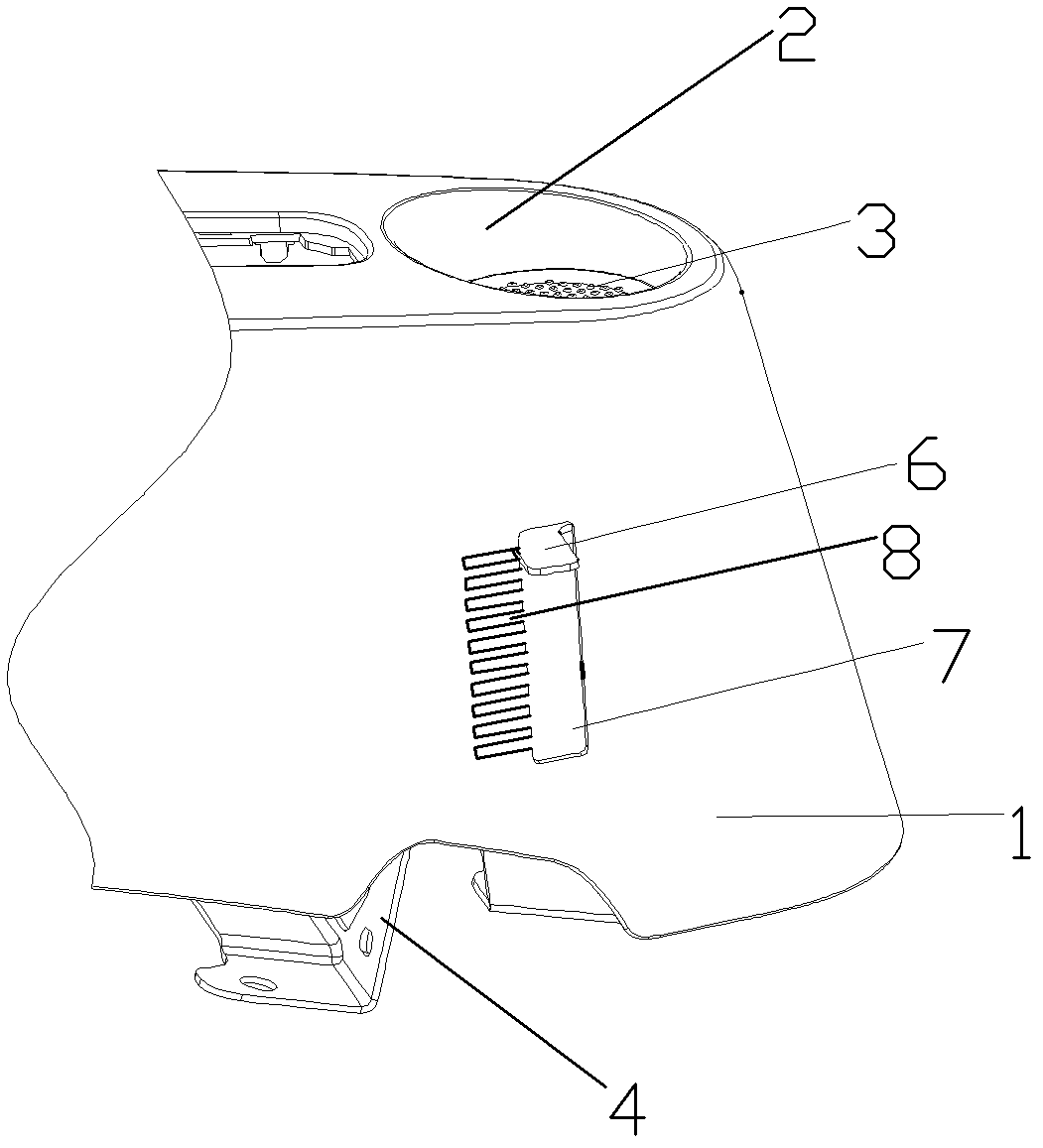

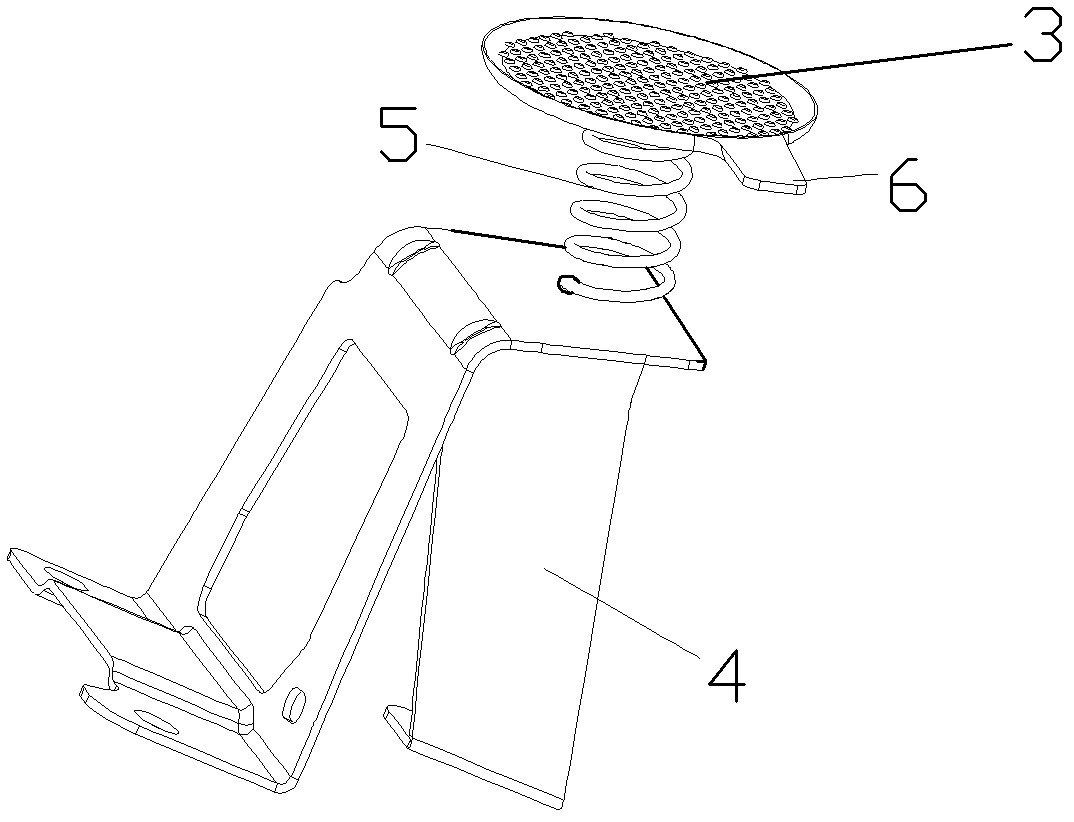

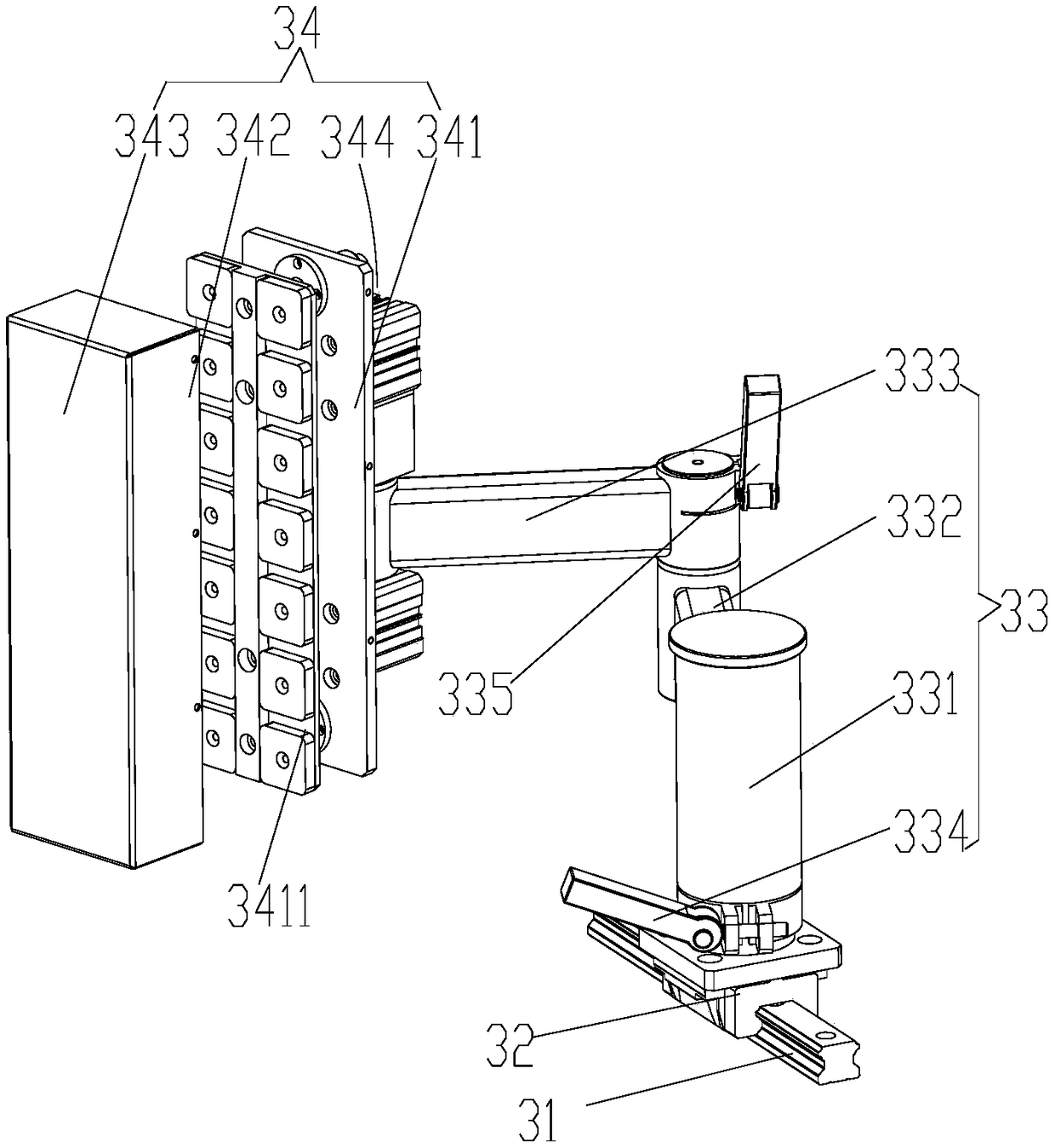

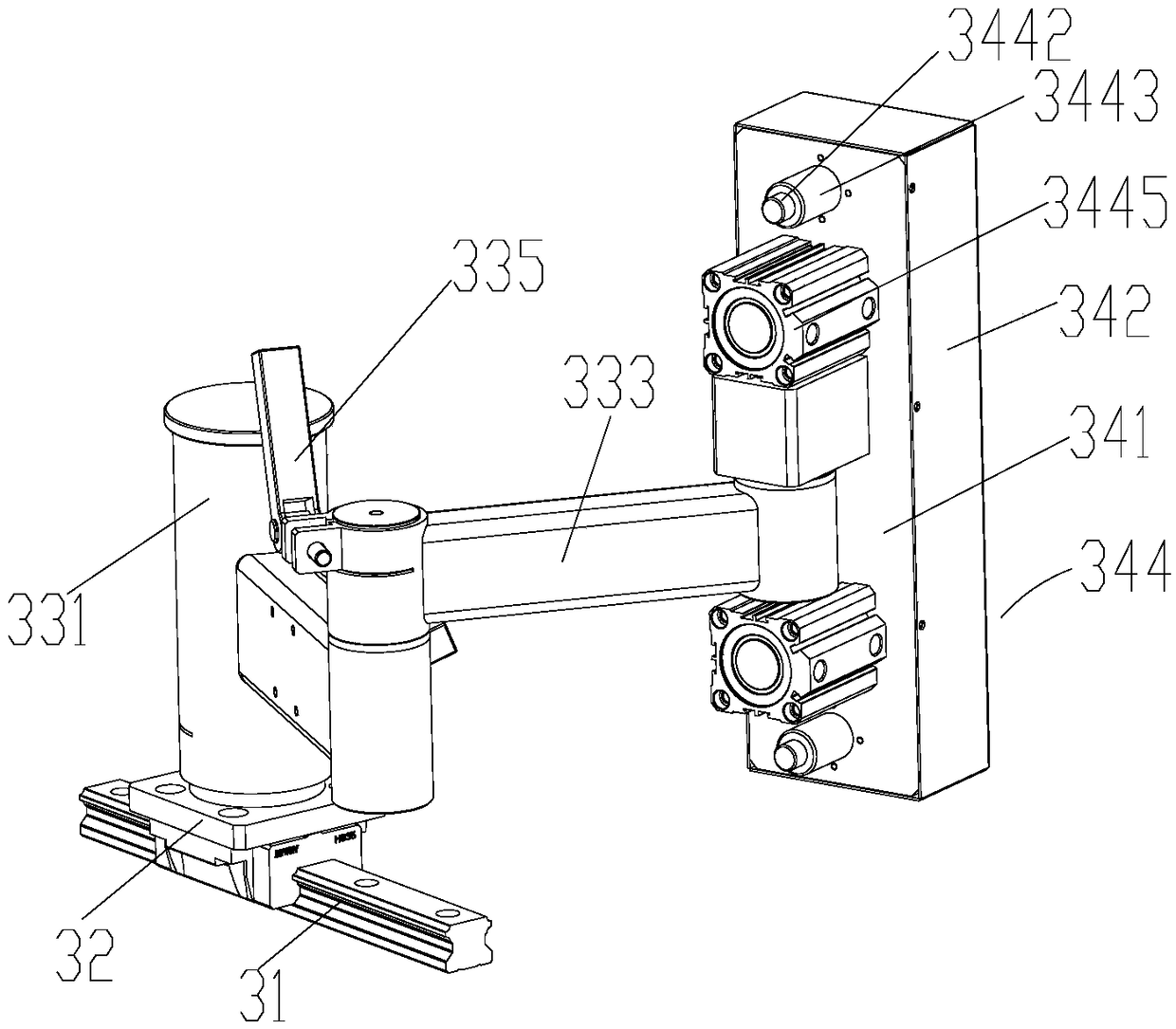

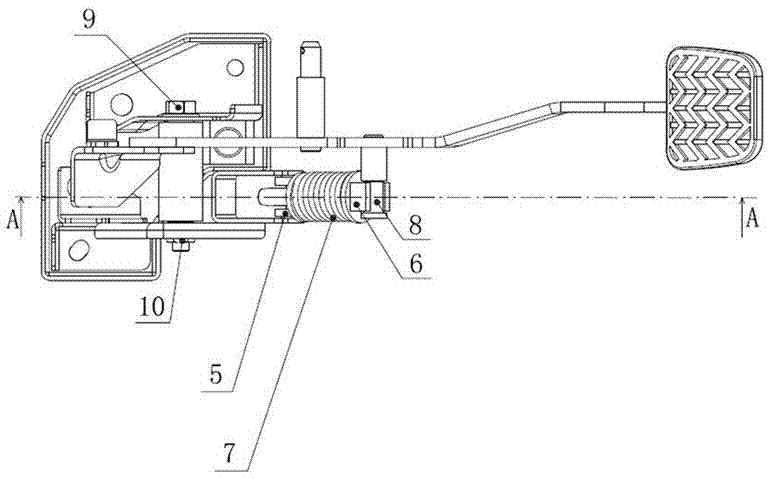

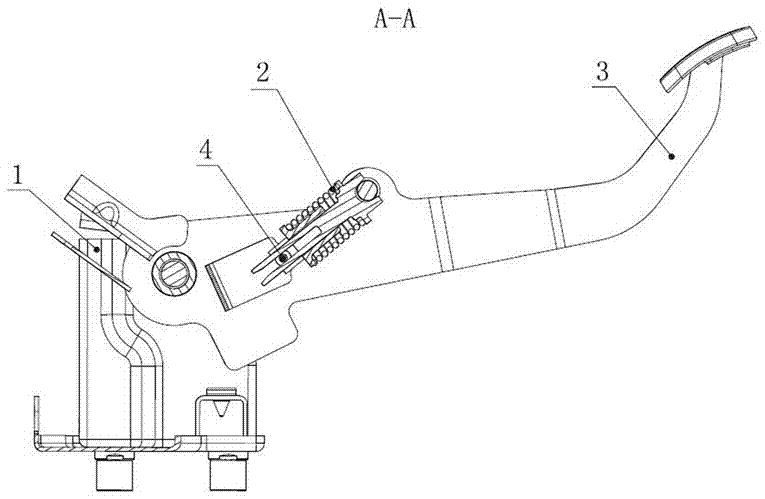

Press-fitting fixture for spring of pedal

InactiveCN107127718AImprove assembly efficiencyReduce labor intensityMetal-working hand toolsEngineeringPiston rod

The invention provides a press-fitting fixture for a spring of a pedal. The fixture comprises a fixture body; the fixture body comprises a base; a limiting mechanism for limiting a pedal support component assembly and a pressing mechanism for pressing a boosting spring component assembly are arranged on the base; the limiting mechanism comprises a first positioning pin, a second positioning pin, a first pressing plate and a second pressing plate; the pressing mechanism is correspondingly arranged in front of the limiting mechanism and comprises an air cylinder arranged vertically upwards; a pressing head is fixedly connected onto a piston rod of the air cylinder; a clamping groove corresponding to a guide rod in the boosting spring component assembly is arranged at one end of the pressing head; the pressing head is clamped at the upper part of the guide rod during use; and a limiting plate is arranged on an end cover of the air cylinder. The fixture is simple in structure, easy to manufacture, short in adjustment period, low in cost, beneficial to increase of the enterprise benefit and capable of being popularized for use.

Owner:DONGFENG SHIYAN BODY PART CO LTD

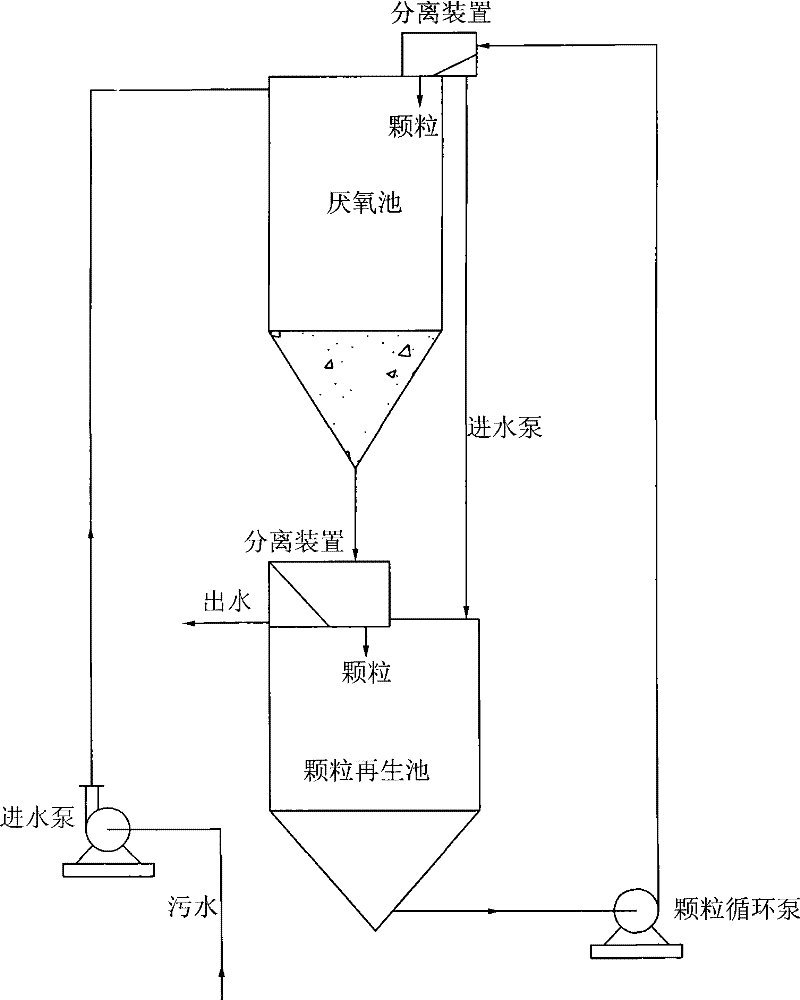

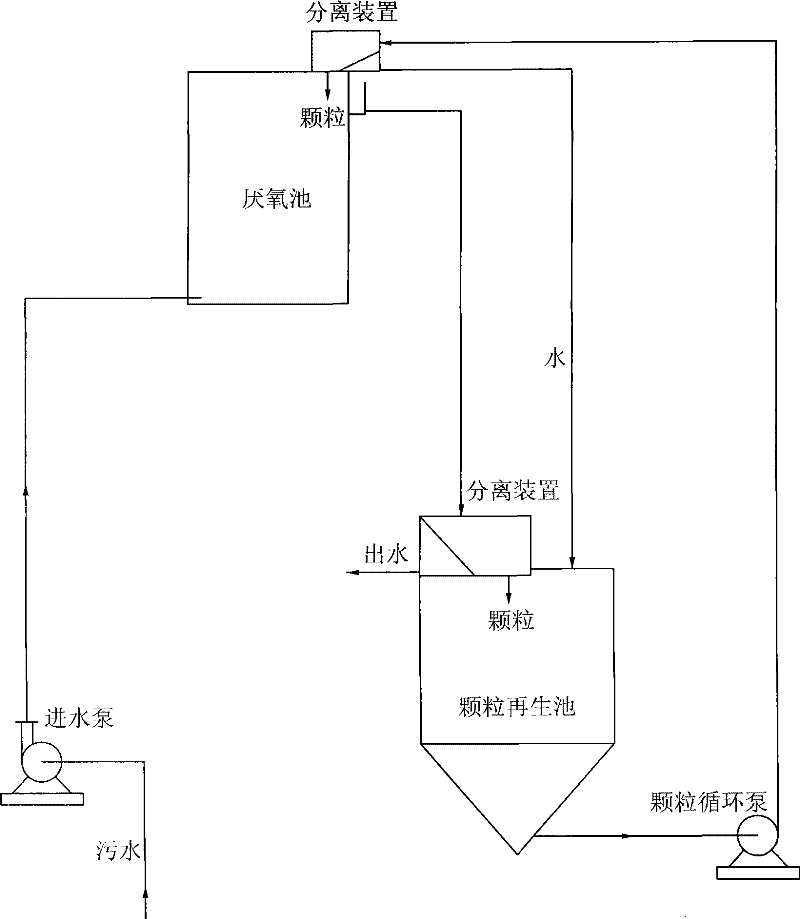

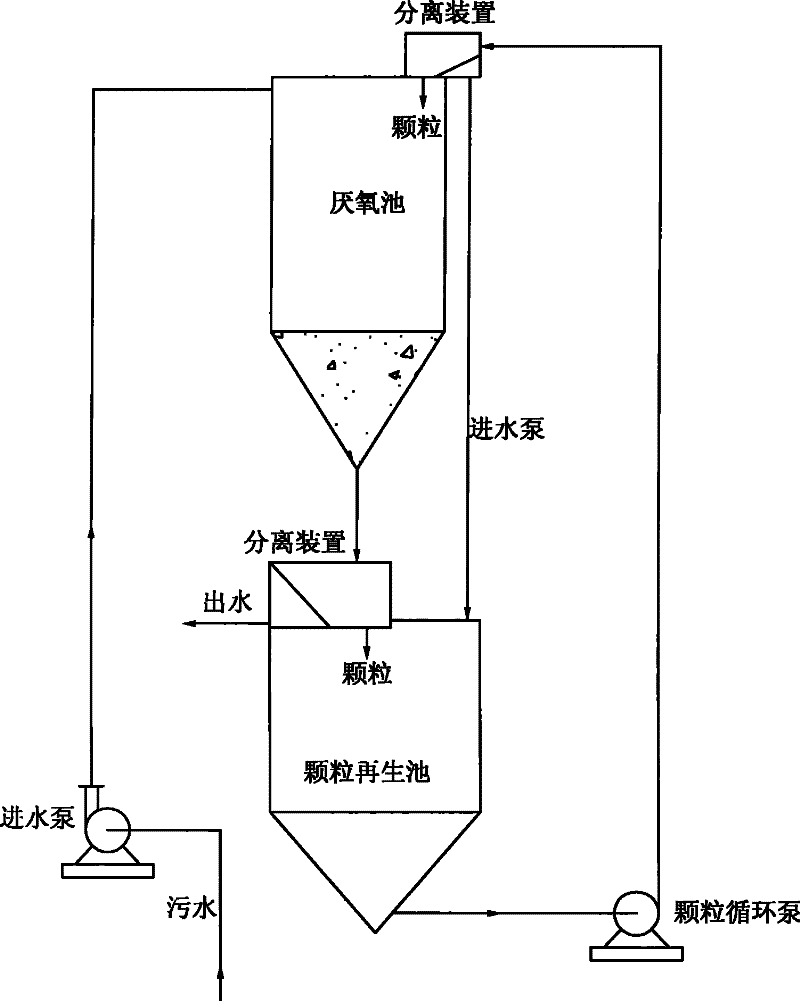

Sewage disposal method using embedding immobilization microorganism grain fluidized bed

ActiveCN101381151BNo bloating issuesTo achieve the treatment effectSustainable biological treatmentOn/in organic carrierMicroorganismSludge

The invention discloses a method for treating sewage of an embedded immobilized microorganism particle fluidized bed, wherein spherical filler particles which are embedded with microorganism flora are filled into a sewage disposal device at first and then the sewage is led into the sewage disposal device, so as to make the filler particles which are embedded with the microorganism flora roll up and down when stirred by an aerator to become fluid state; organic substances in water are transformed and degraded by enzymes which are generated by microorganisms, and mixture which flows out from the sewage disposal device enters into a solid-liquid separator for solid-liquid separation; the filler particles flow into a regenerative device for regeneration, and the spherical filler particles after regeneration are sent into the solid-liquid separator on the upper part of the sewage disposal device; and a liquid inversely flows into a mother liquor device, and the filler particles are returned back to the sewage disposal device. The method not only overcomes the defects of the prior sewage disposal method but also has the characteristics of high efficiency, strong adaptability, short adjusting period, low sludge amount, convenient assembly and maintenance, compact structure, convenient operation and so on.

Owner:ZHONGSHAN ENVIRONMENTAL PROTECTION IND CO LTD

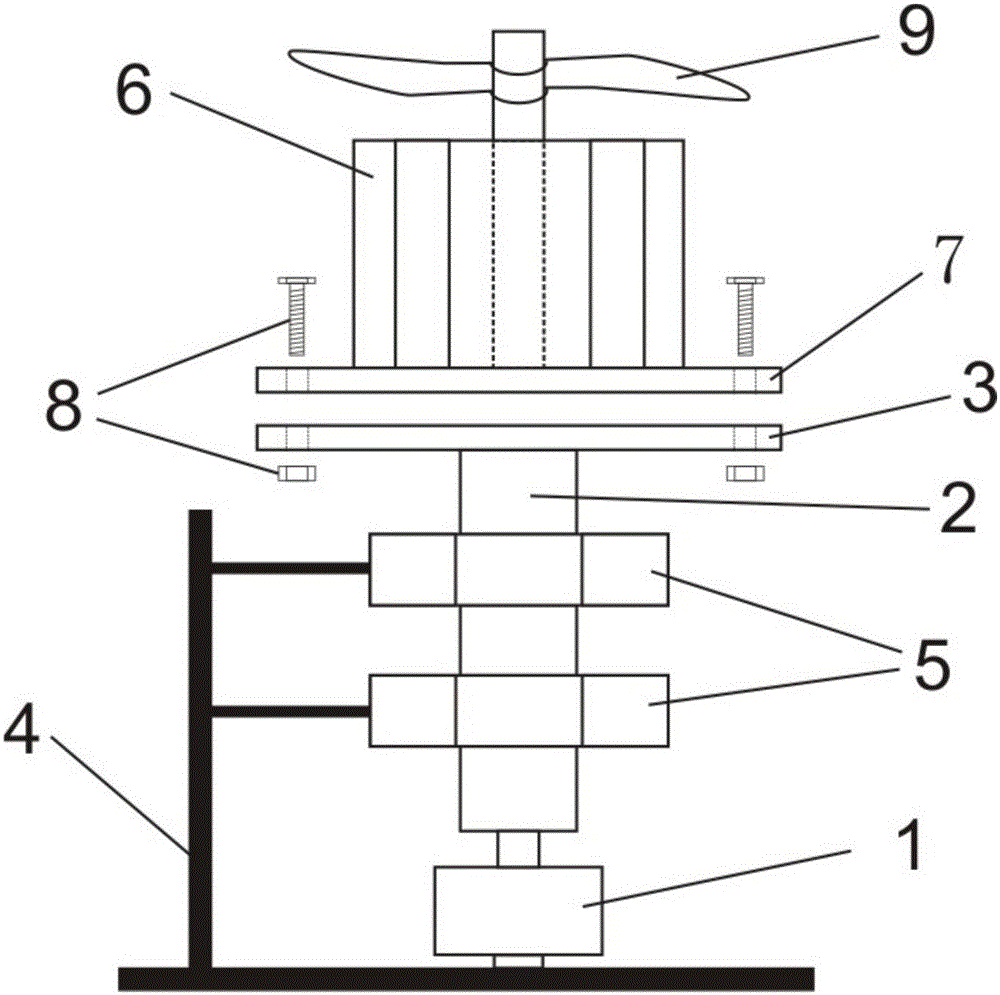

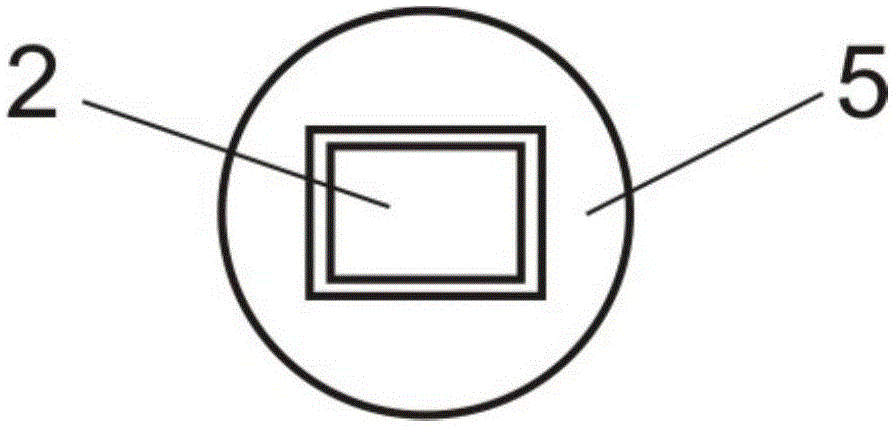

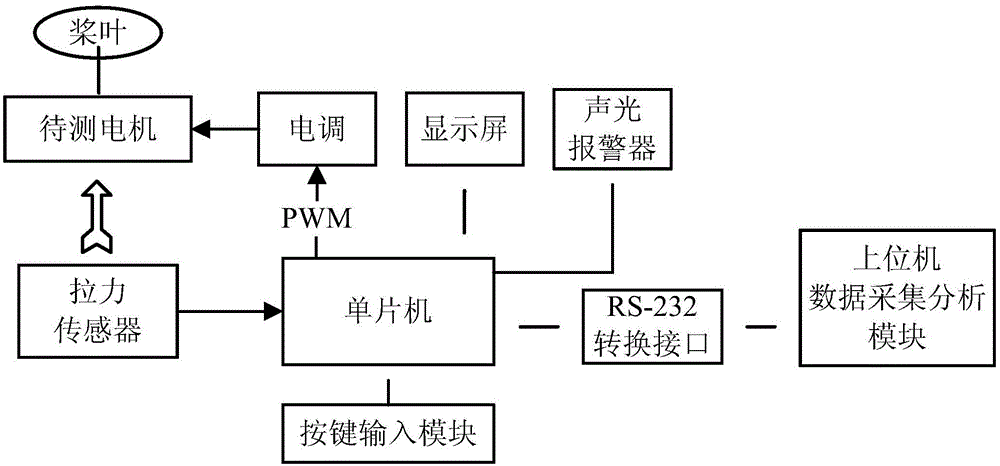

Measuring apparatus for motor tension linearity of multi-rotor type aircraft, and control system and method thereof

ActiveCN105116333ASimple structureLow costDynamo-electric machine testingPull forceMeasurement device

The present invention discloses a measuring apparatus for a motor tension linearity of a multi-rotor type aircraft, and a control system and method thereof. The measuring apparatus provided by the invention comprises a tension sensor, a light pull bar, a motor to be detected and a support. The bottom end of the light pull bar is connected with a tension end of the tension sensor, the top end of the light pull bar is connected with a mounting base, and fixed collars sleeve the light pull bar; a motor base is arranged at the bottom of the motor to be detected, and a paddle is installed at the top of the motor to be detected; and the motor base may be fixed on the mounting base. According to the invention, the measurement and the analysis of the motor tension linearity are performed to form an analytical curve of the linearity; programming developers may perform linearity compensations of each point according to the analytical curve of the linearity to allow the motor tension linearity to approximate to be linear so as to facilitate the post control of the aircraft; and random PWM (pulse width modulated signal) values are given to the motor for observing the tension of the point in such a manner to contribute to the stable hovering regulation of the aircraft. The measuring apparatus for the motor tension linearity of the multi-rotor type aircraft, and the control system and the method thereof have the advantages of simple structure, low cost, short debugging period and high accuracy of debugging parameters, thereby bringing users convenience.

Owner:南京天际航空科技发展有限公司

Electromagnetic dehumidification biochemical treatment system and method for wet garbage

InactiveCN111348944ALower operating temperatureImprove working environmentClimate change adaptationChemical industryThermodynamicsProcess engineering

The invention discloses an electromagnetic dehumidification biochemical treatment system and a method for wet garbage, and relates to the technical field of wet garbage treatment. The device comprisesa fermentation bin, a power distribution cabinet and deodorization equipment, an elevator is fixedly mounted at the outer side part of the fermentation bin; a crusher is arranged at the outer top ofthe fermentation bin; gas generated at the top of the fermentation bin is communicated with a tubular condenser through a pipeline; condensed water generated in the tubular condenser is separated fromdry gas, the dried gas is blown into an electromagnetic heating coil at the top of the fermentation bin through a pipeline under the action of a vortex blower to be subjected to electromagnetic heating and then returns to the fermentation bin, and a radiator is connected to the tubular condenser. The problems that in an existing wet garbage treatment system, the water loss energy efficiency is low, the time is long, the speed is low, the drying time of kitchen garbage is prolonged, no gas circulation process exists in the prior art, a hot air drying technology adopts a dry filament hot burning technology, the heat loss is large, the service life is short, and the maintenance amount is large are solved.

Owner:上海统净环保科技有限公司

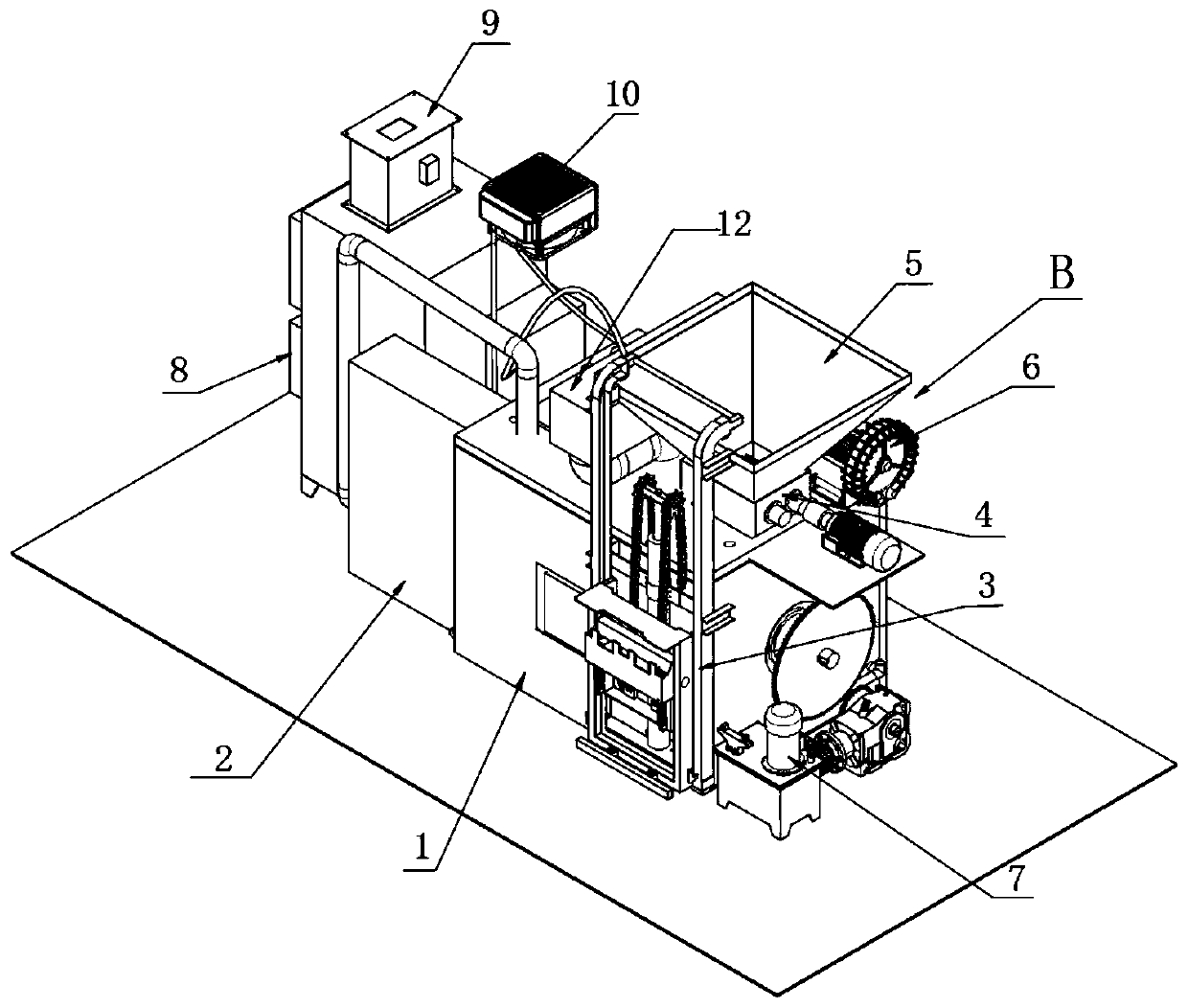

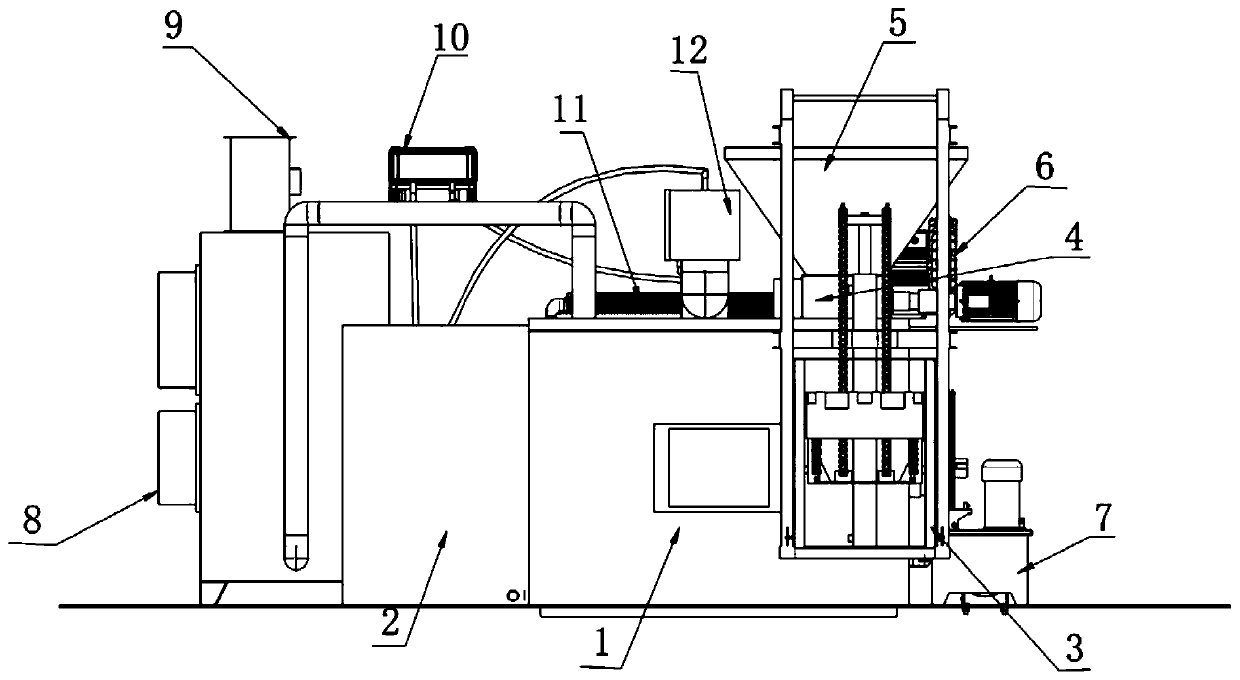

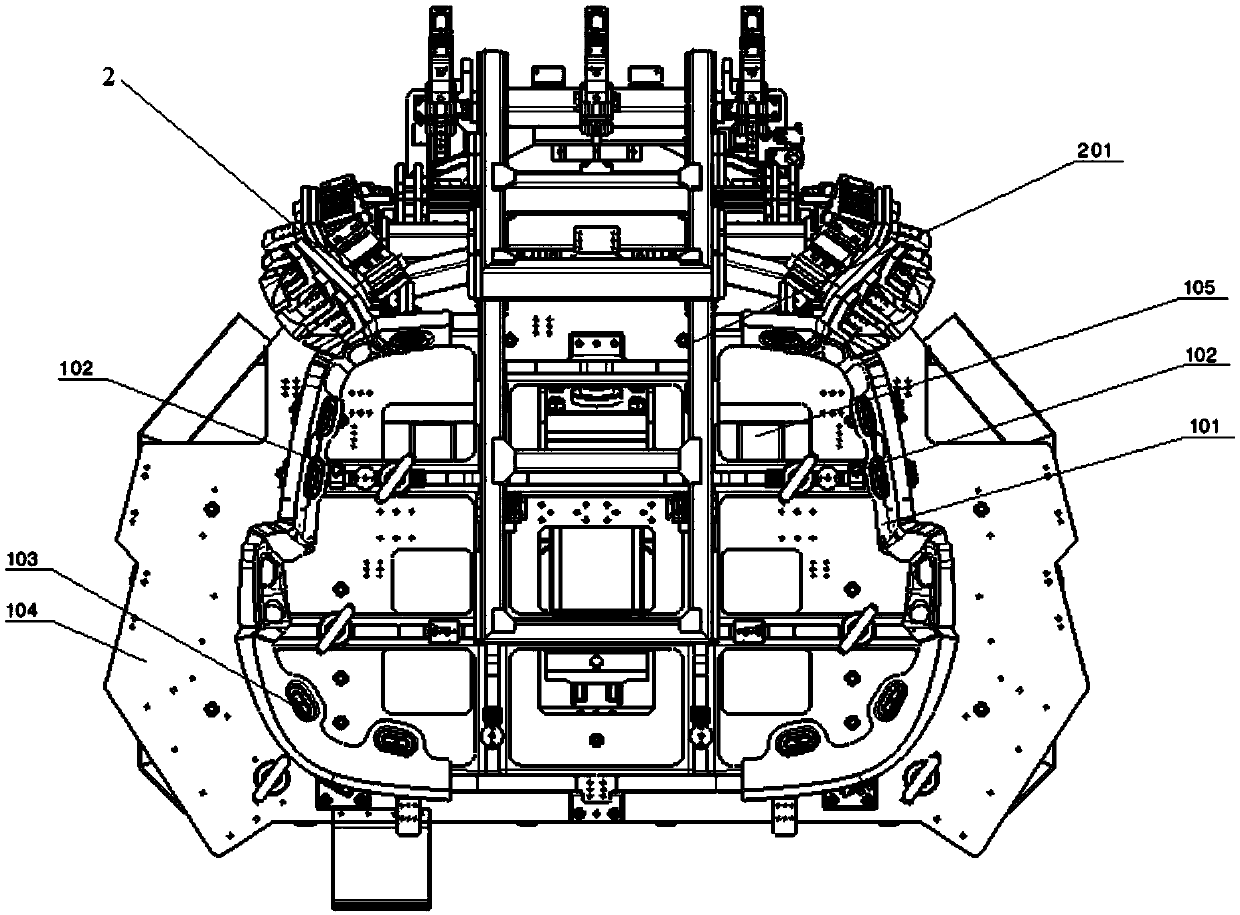

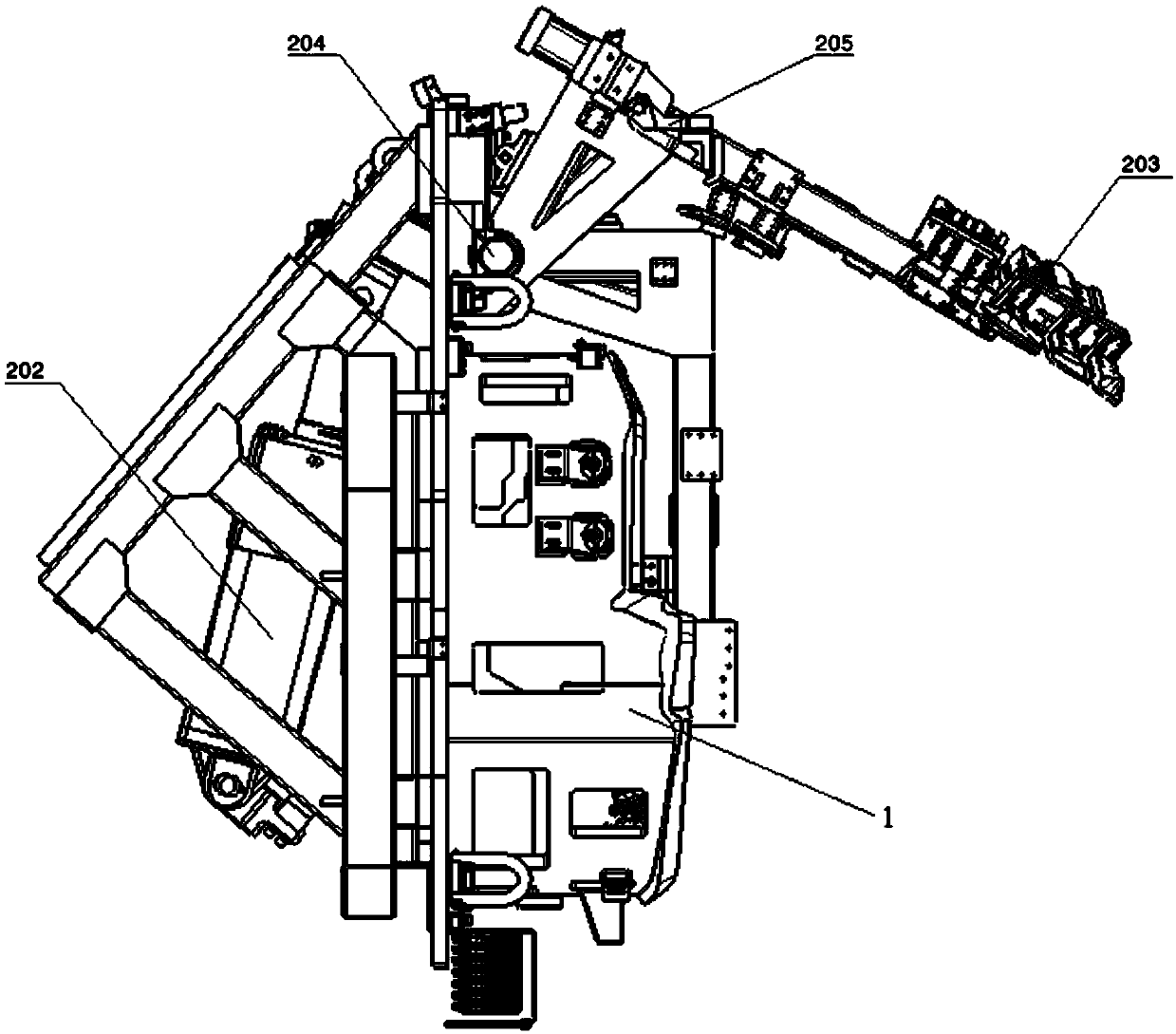

Pre-edge-rolling device

The invention relates to a pre-edge-rolling device. The pre-edge-rolling device comprises a rotary table mechanism (4) provided with a plurality of pre-edge-rolling stations, wherein each pre-edge-rolling station is provided with a positioning mechanism and an angle pushing mechanism (3); each positioning mechanism comprises a moulding bed clamp (1) fixed to the corresponding pre-edge-rolling station and a pressing mould assembly (2) arranged above the moulding bed clamp (1); the moulding bed clamps (1) are connected with the pressing mould assemblies (2) through rotary shafts (204); and eachangle pushing mechanism (3) comprises a support fixed to the corresponding pre-edge-rolling station, an angle pushing assembly arranged on the support and a driving assembly for driving the angle pushing assembly to conduct pre-edge-rolling operation. Compared with the prior art, the pre-edge-rolling speed is greatly increased, and the equipment cost is reduced.

Owner:FFT PRODION SYST SHANGHAI

Integrated circuit verification using parameterized configuration

InactiveUS10295594B2Short commissioning cycleDigital circuit testingComputer aided designProgrammable logic deviceCircuit design

A method for debugging and a method for testing a circuit design on a programmable logic device is disclosed, making use of a parameterized configuration. A corresponding system also is disclosed.

Owner:UNIV GENT

Back door assembly assistive device

InactiveCN113579610AImprove stabilityImprove assembly qualityWelding/cutting auxillary devicesWork holdersControl engineeringEngineering

The invention relates to a back door assembly assistive device which is characterized in by comprising two auxiliary assembly modules, wherein the two auxiliary assembly modules are arranged and used in a bilateral symmetry mode about the longitudinal center line of a vehicle; each of the auxiliary assembly modules comprises a profiling positioning block, a positioning mechanism and an assembly reference block, wherein the positioning mechanism and the assembly reference block are arranged on the profiling positioning block, and the auxiliary assembly module is accurately and stably positioned on the back door through the positioning mechanism; an assembly reference block controls the position of the back door relative to an automobile framework, so that the assembled position of the back door can be located at the theoretical design position of the back door. The device is simple in structure, low in cost, high in space utilization rate and easy, convenient and flexible to operate, and the assembling precision and consistency of the back door are effectively improved.

Owner:CHERY AUTOMOBILE CO LTD

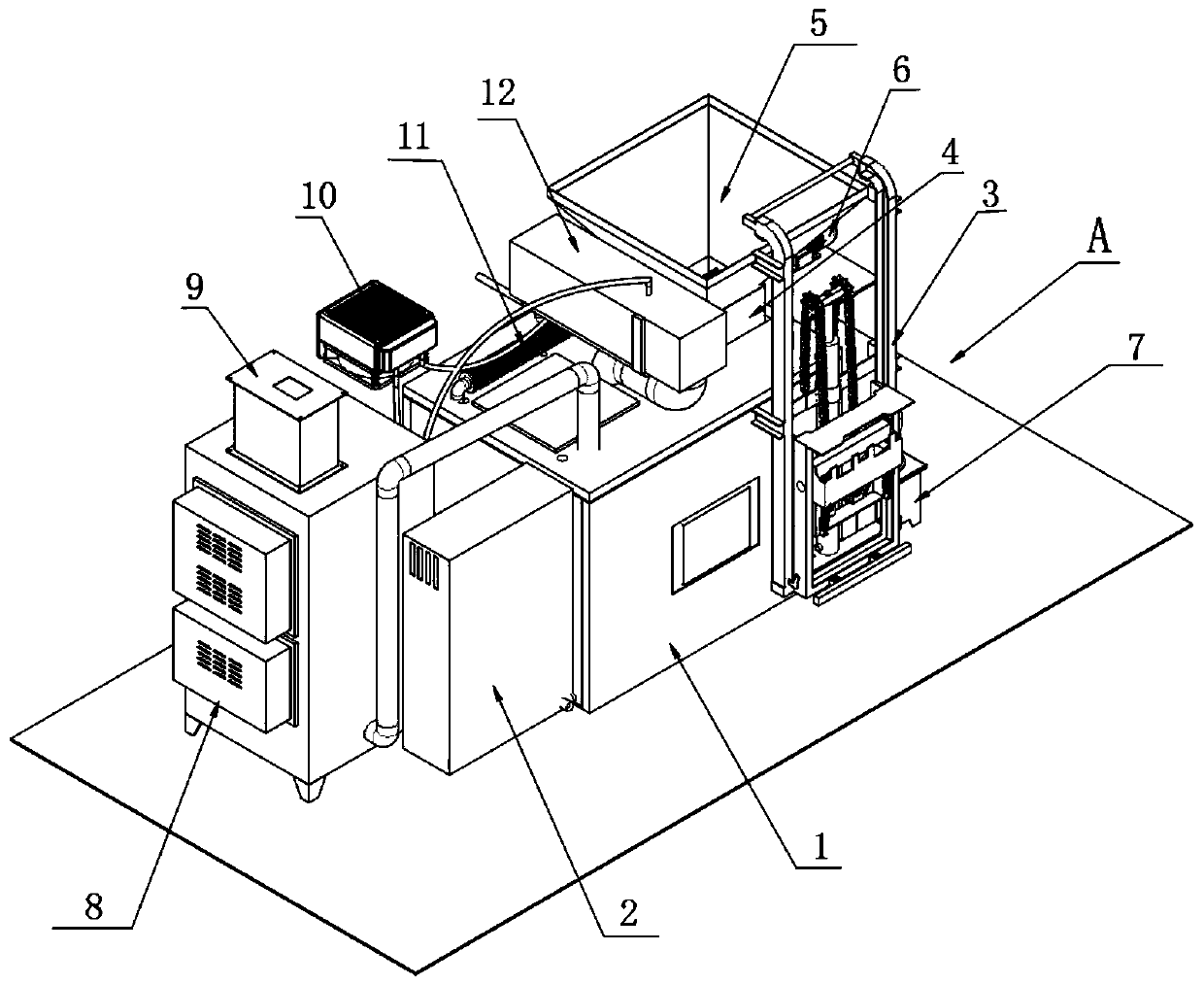

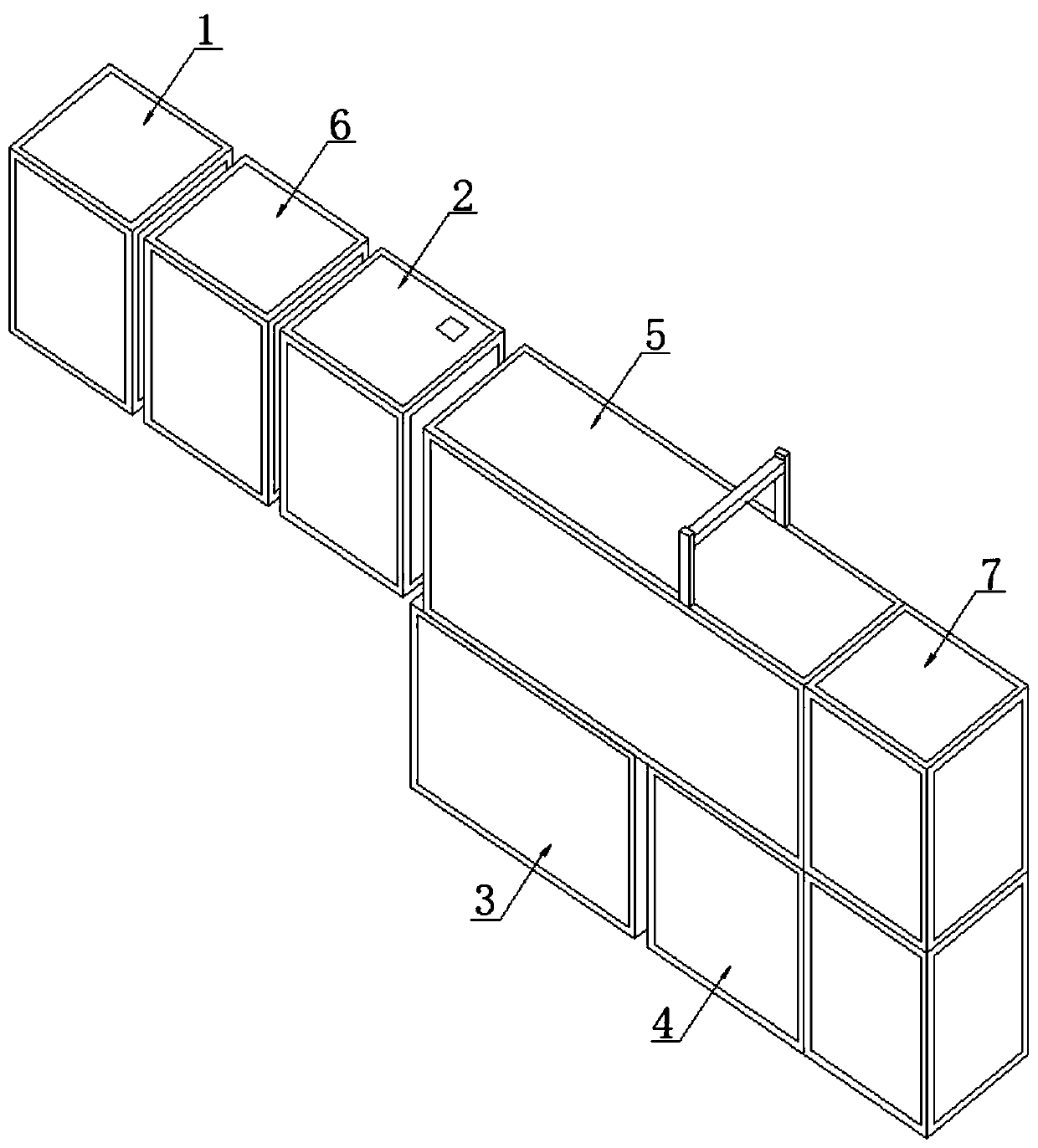

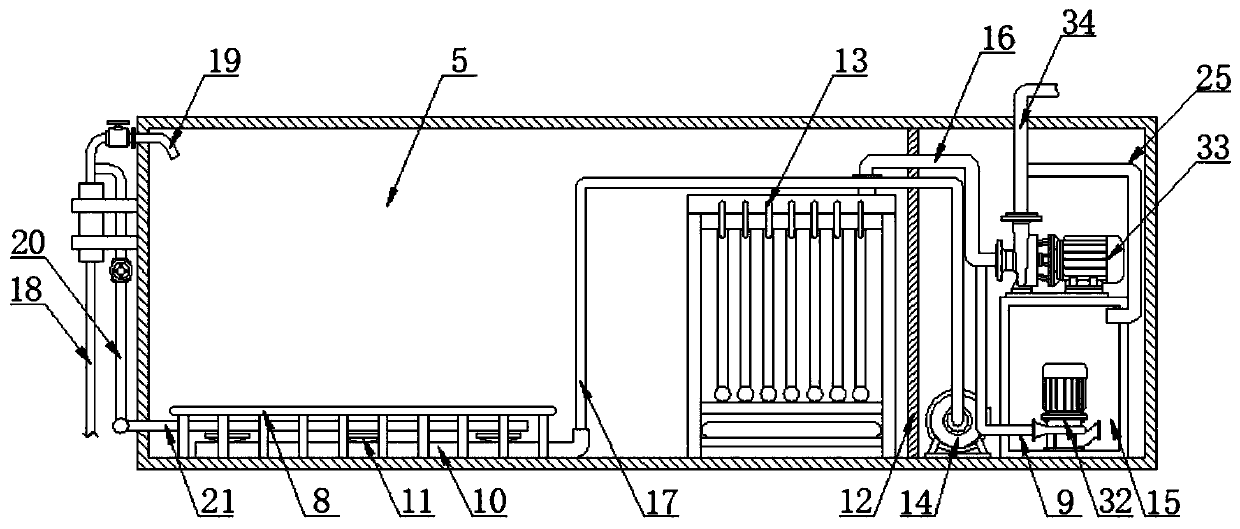

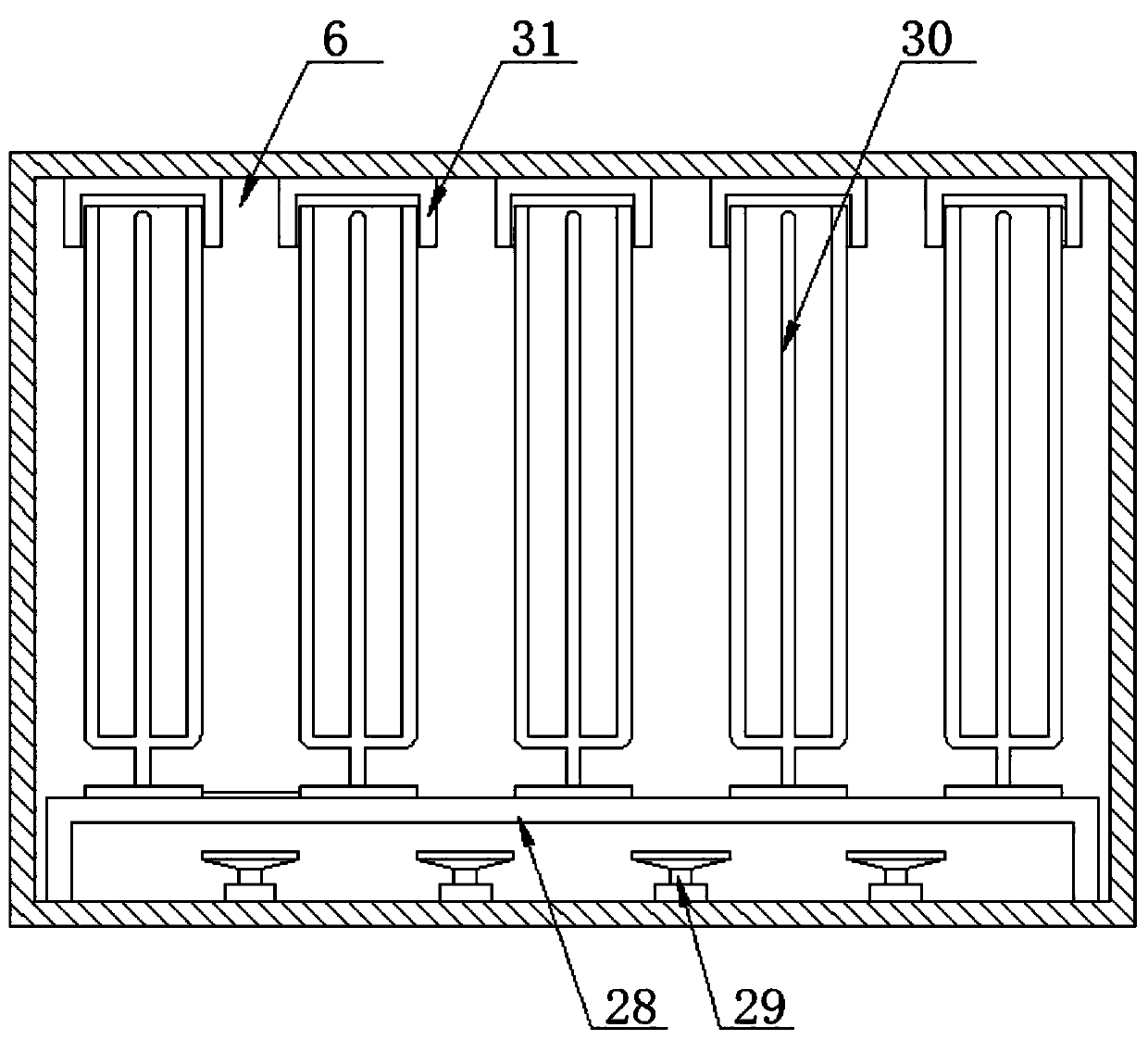

Intelligent modular novel sewage integrated equipment

PendingCN110372152AHigh degree of automationImprove impact resistanceWater/sewage treatment by irradiationWater treatment compoundsWater treatment systemWater quality

The invention discloses intelligent modular novel sewage integrated equipment and relates to the technical field of sewage treatment systems. The intelligent modular novel sewage integrated equipmentcomprises a sediment tank, an A treatment tank, an O treatment tank, an MBR treatment tank, an O+MBR treatment tank, a UV-Cu-Fenton advanced oxidation pond and an equipment room. According to the intelligent modular novel sewage integrated equipment, by freely assembling and combining all independent treatment equipment, various technical routes and schemes can be easily combined into tens of different techniques at will, compared with similar products or other technical treaters, the more energy-saving effect is realized, the operation cost is low, the requirements for a site are low, the intelligent modular novel sewage integrated equipment can be built on the deserted flat ground, investment is low, the comprehensive construction cost is lower than the comprehensive construction cost ofother technical sewage treatment stations, meanwhile, the equipment room is provided with a plurality of remote transmission device equipment and automatic PLC modules, thus full-automatic operationand remote monitoring of a mobile phone client can be conducted, the automation degree is high, the anti-impact ability is high, and the intelligent modular novel sewage integrated equipment can copewith different water quality changes by adjusting the front-rear position of the modular equipment.

Owner:宁夏环保集团有限责任公司 +2

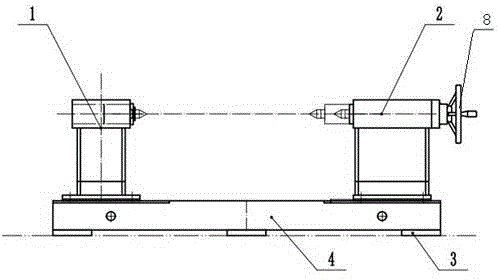

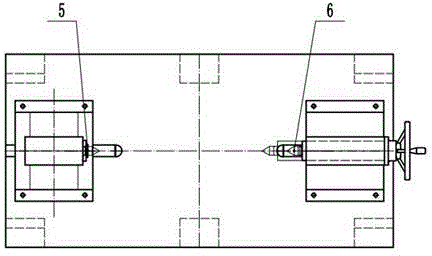

Boring tool for axle suspension bush of traction motor

InactiveCN104439305AFast boringGuaranteed positioning sizeTailstocks/centresLarge fixed membersTailstockMachining

The invention belongs to the technical field of machining and provides a boring tool for an axle suspension bush of a traction motor. The boring tool for the axle suspension bush of the traction motor comprises a working table (4), a movable tailstock I (1) and a movable tailstock II (2). The movable tailstock I (1) and the movable tailstock II (2) are matched with corresponding guide rails on the working table (4) respectively through slide blocks arranged on the bottoms of the movable tailstock I (1) and the movable tailstock II (2). A fixed center (5) used for being matched with a central hole in one end of a rotor shaft of the traction motor is installed on the movable tailstock I (1), and a movable center (6) used for being matched with a central hole in the other end of the rotor shaft of the traction motor is installed on the movable tailstock II (2). The boring tool achieves quick boring of the axle suspension bush of the traction motor under the condition of guaranteeing machining accuracy.

Owner:CRRC LUOYANG CO LTD

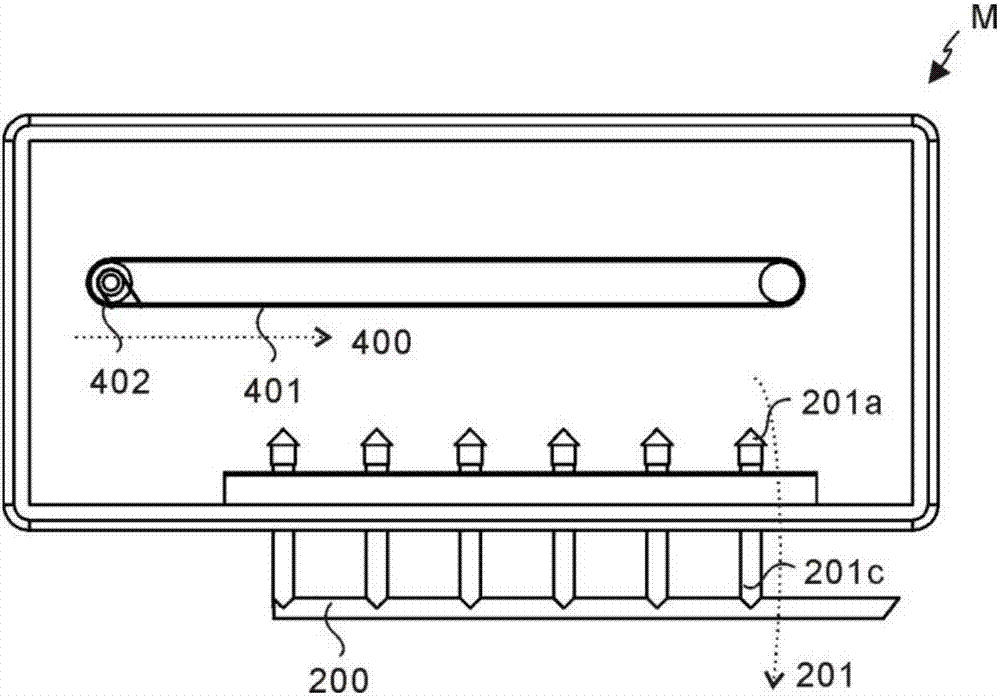

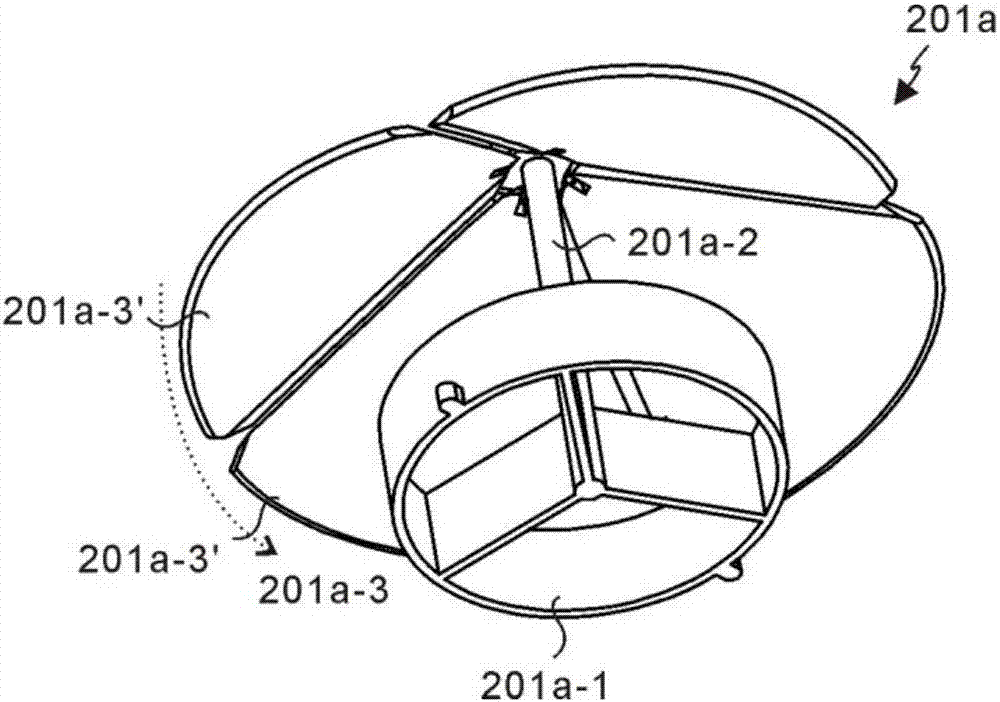

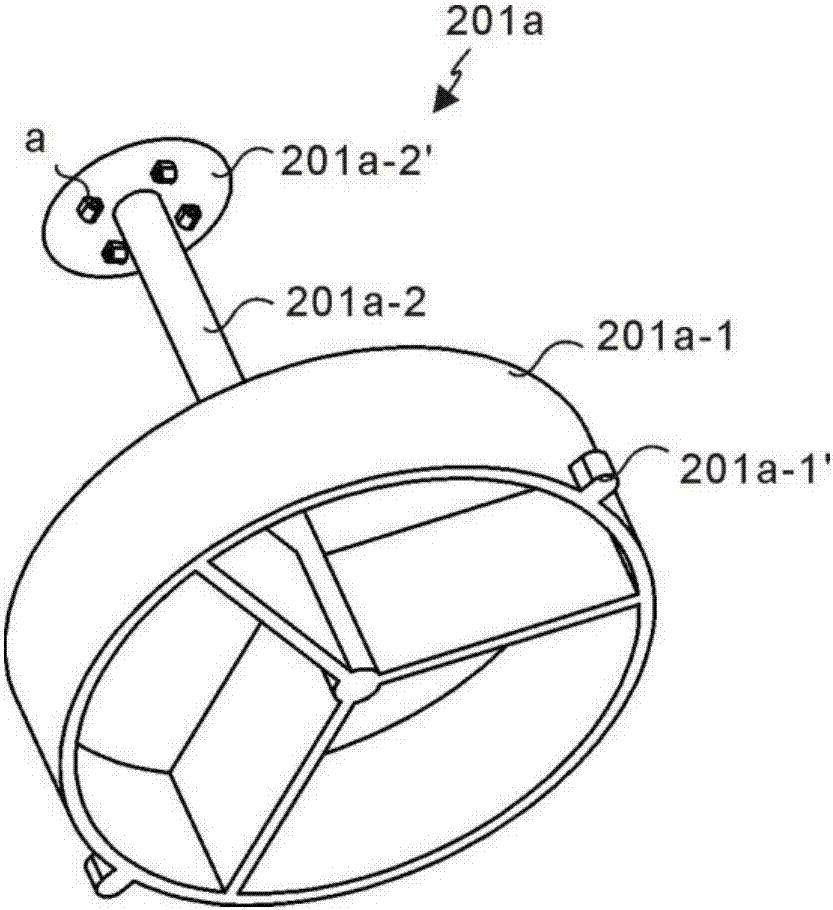

Fish meal drying and dehumidifying device

ActiveCN107036424ASuitable for drying and dehumidification requirementsEasy to installFeeding-stuffDrying gas arrangementsElectricityAssembly line

The invention discloses a fish meal drying and dehumidifying device which comprises a first independent space and an exhausting body. The first independent space comprises a conveying part which comprises a conveying piece, and materials needing to be dried and dehumidified are placed on the conveying piece. The exhausting body comprises a first exhausting piece. The first exhausting piece is connected with the lower end of the first independent space and comprises a protecting piece and a first exhausting pipe, and hot air is introduced into the first independent space through the first exhausting pipe, and dries and dehumidifies the materials on the conveying piece. According to the fish meal drying and dehumidifying device, closed circulation is adopted for carrying out dehumidifying, and exhausting of waste gas and odor is avoided in the dehumidifying process; and moreover, external heating power supply is not needed, installing is easy, the adjustment period is short, and 3.2-3.4 L of water is dehydrated per 1 KWH on average. The whole drying and dehumidifying production assembly line can treat 25-150 tons of high-moisture fish meal squeezed wet feed every day, can increase or decrease the yield according to needs of users, is free of the influence of external environment temperature and humidity, and meets the use requirement for drying and dehumidifying the fish meal in various areas.

Owner:无锡市新耀生物工程技术有限公司

Edge covering and pressing automation system for vehicle door water trimming of vehicle Body in White

PendingCN110695171AShort commissioning cycleFast production timeVehicle componentsCar doorManufacturing engineering

The invention provides an edge covering and pressing automation system for vehicle door water trimming of the vehicle Body in White. The edge covering and pressing automation system comprises two HZ-type special hydraulic cylinders, the HZ-type special hydraulic cylinders are hinged to a supporting piece and hinged to turnover plate connecting pieces through bulb matchers, and the turnover plate connecting pieces are hinged to the supporting piece and fixedly connected with a turnover plate; the two HZ-type special hydraulic cylinders are connected with a gas-liquid reinforcement cylinder, thegas-liquid reinforcement cylinder is connected with an outer high-pressure gas source, the gas-liquid reinforcement cylinder and the HZ-type special hydraulic cylinders are connected with a control unit in a main control system, and two position sensors are connected with a detection unit in the main control system. According to the edge covering and pressing automation system, signals are sent through the main control system, the HZ-type special hydraulic cylinders drive the turnover plate to rotate, and after edge covering work is finished, the edge covering and pressing automation system is restored to enter next-time circulation. The edge covering and pressing automation system has the advantages that the debugging period is short, the production speed is high, the edge covering effect is good, and less maintenance is needed in the later period.

Owner:FAW CAR CO LTD

ABS locking proof system controlling means

The invention discloses a control device of ABS locking-proof system, which comprises the following parts: signal gathering unit (100), signal processing unit (200), output control unit (300) and executing unit (400), wherein the signal gathering unit (100) gathers wheel speed signal, which generates signal according to changing line of wheel speed; the signal processing unit (200) receives the signal of signal gathering unit (100), which switches the signal into acceleration signal of wheel; the output control unit (300) receives the acceleration signal, which generates decompressing output and / or pressurized output; the executing unit (400) receives decompressing output and / or pressurized output, which adjusts braking force of wheel.

Owner:BYD CO LTD

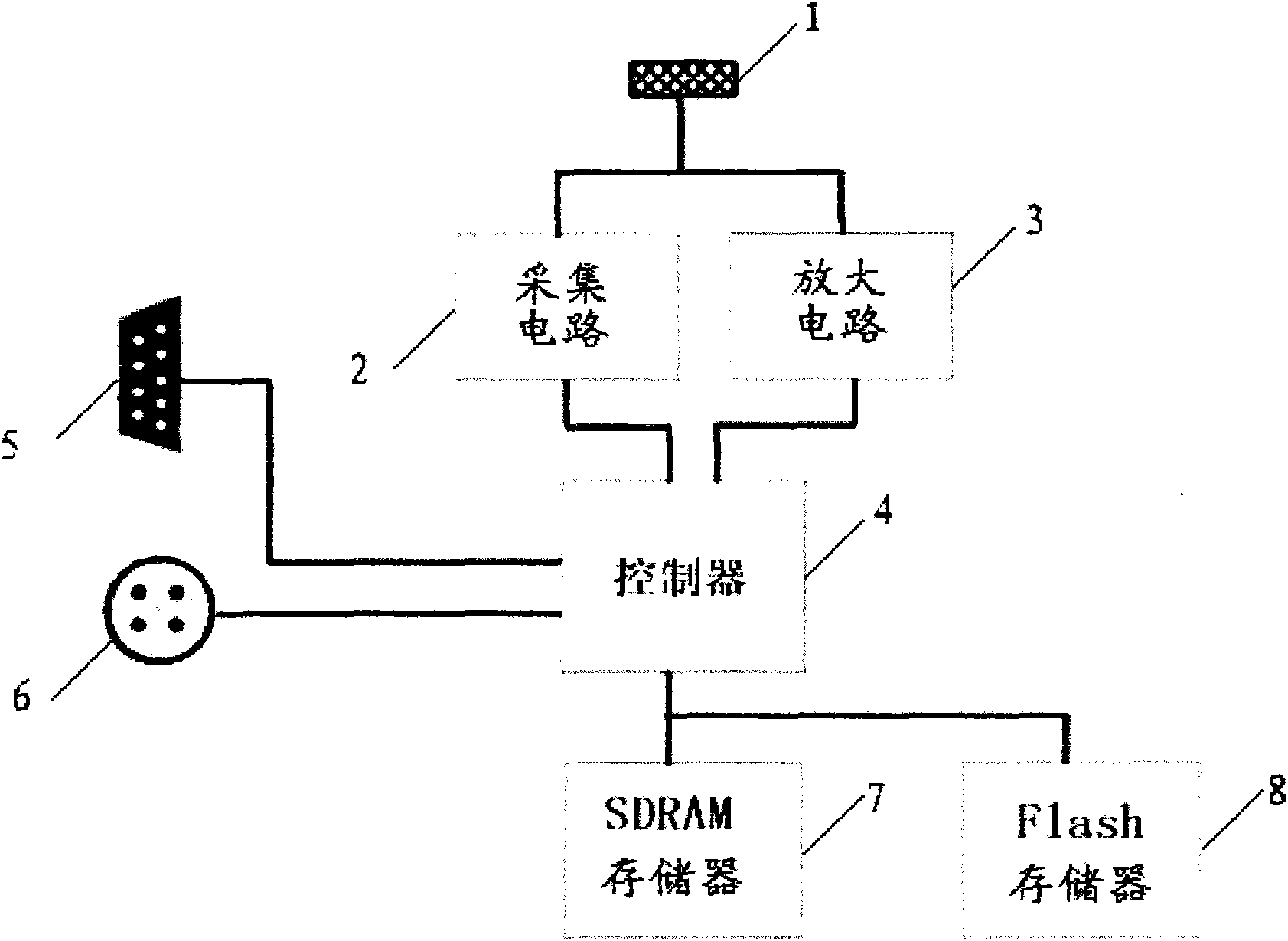

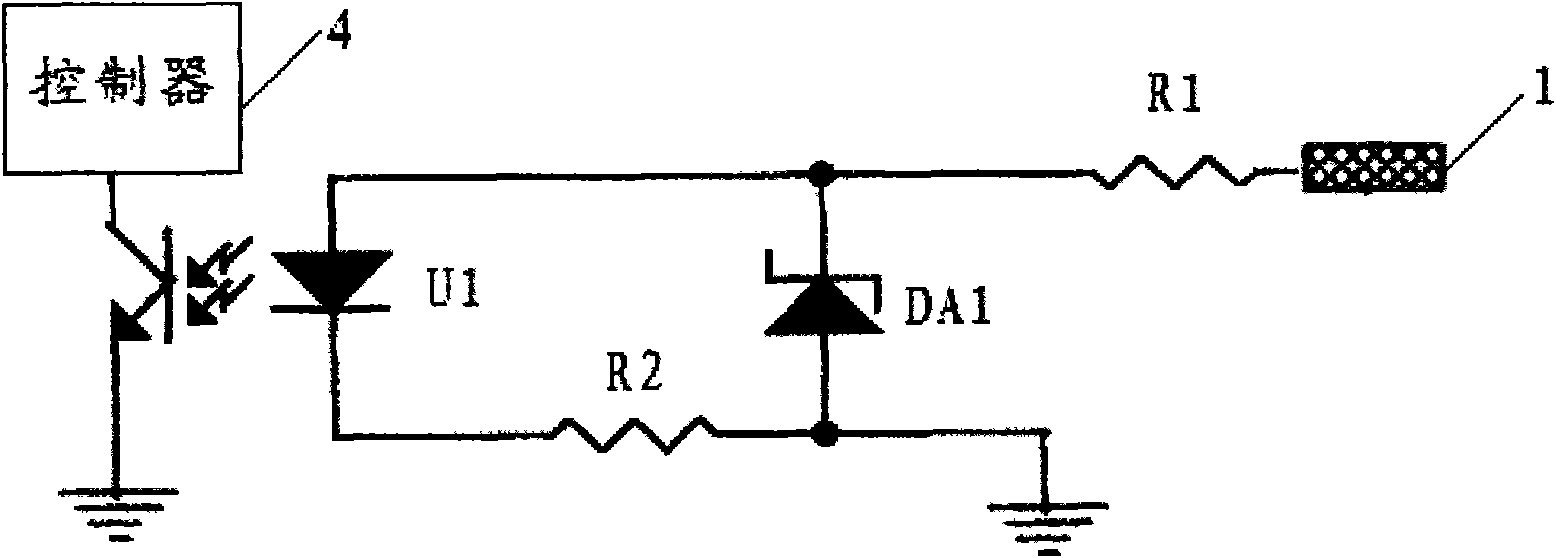

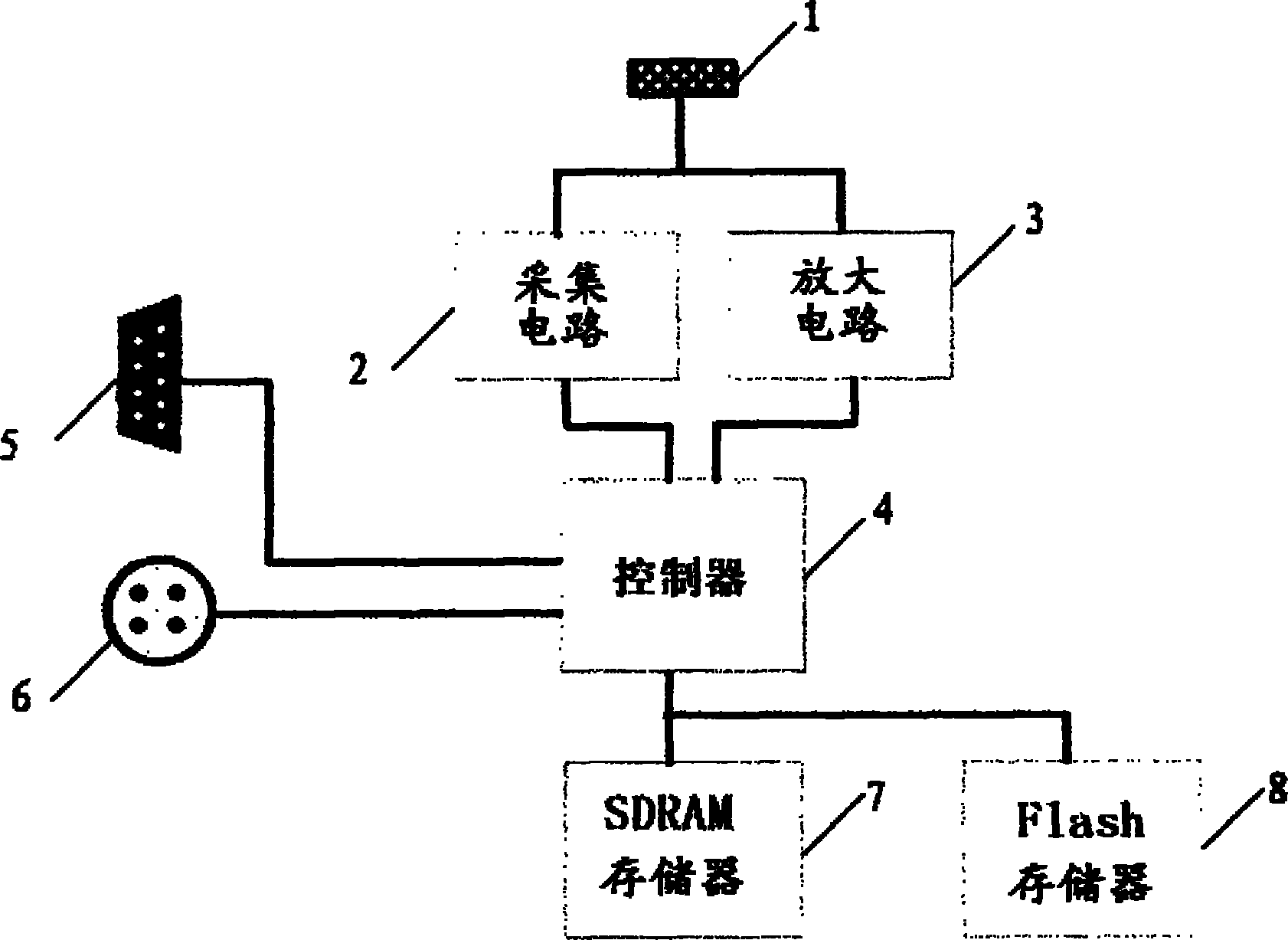

Audio acquisition and processing circuit for vehicle-mounted talkback system

InactiveCN102647652ASimple structureEasy wiringStations for two-party-line systemsTransducer circuitsRs 232 interfaceSynchronous dynamic random-access memory

The invention discloses an audio acquisition and processing circuit for a vehicle-mounted talkback system. The audio acquisition and processing circuit comprises a microphone interface, wherein the microphone interface is respectively connected with an acquisition circuit and an amplifying circuit; the acquisition circuit and the amplifying circuit are connected to a controller which is connected with an SDRAM (Synchronous Dynamic Random Access Memory) and a Flash memory and is also connected with an Ethernet interface; and further, the controller is also connected with an RS232 interface. The audio acquisition and processing circuit disclosed by the invention has the advantages of simple structure, simple wiring and short debugging period and is beneficial to the promotion and application of the vehicle-mounted talkback system.

Owner:ANNAX SUZHOU RAIL SYST

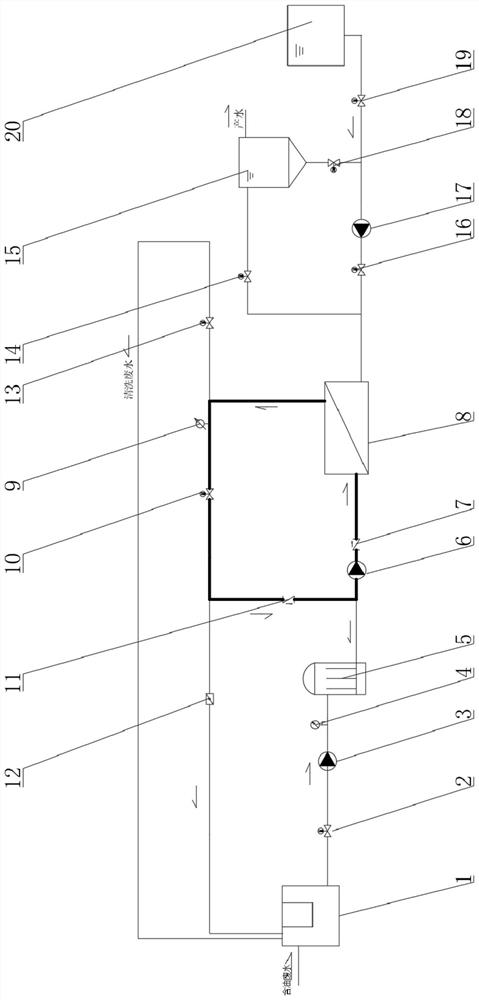

A water treatment system for decentralized sewage treatment in villages and towns

ActiveCN103253828BReduce outputRich varietyMultistage water/sewage treatmentWater treatment systemSewage

Owner:SCIMEE TECH & SCI CO LTD

Oil film removal system and method

PendingCN114249444ALow running costReduce equipment failure rateWaste water treatment from quariesFatty/oily/floating substances removal devicesWater productionCeramic membrane

The invention discloses an oil removal membrane system and method. The oil removal membrane system comprises an oil removal adjusting tank, a bag filter, a poly ceramic membrane, a water production tank and a chemical backwashing tank. According to the oil removal membrane system and method, water is produced through the flow of oily wastewater, the oil removal regulating reservoir, the poly ceramic membrane, the water production tank and water production, so that a plurality of process units are reduced, the operation cost and the equipment failure rate are reduced, the process flow is short, the debugging period is short, and the debugging time is saved. The polymer ceramic membrane is adopted and has the characteristic of high temperature resistance, the temperature of produced water is 55 DEG C, cooling treatment is not needed, the heating temperature difference of treated reinjection water is low, energy is saved, and the energy consumption of the system is reduced. A high-flow-rate filtering design is adopted, the flow rate of oily wastewater is increased, multiple times of circulating filtration are achieved, oil stains attached to the surface of an oil removal film are effectively reduced, the water production rate is kept stable, the backwashing frequency, especially the chemical backwashing frequency, is reduced, and the fluid flow loss caused by the influence of a water inlet pump on circulating circulation is effectively reduced by arranging a one-way valve on a bypass.

Owner:新疆德安环保科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com