Back door assembly assistive device

A technology of back doors and auxiliary equipment, applied in auxiliary devices, manufacturing tools, transportation and packaging, etc., can solve the problems of difficult robot debugging, unsuitable for large-scale application, and complicated maintenance in the later stage, so as to improve assembly quality and debug The effect of short cycle and simple post-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention will be further described:

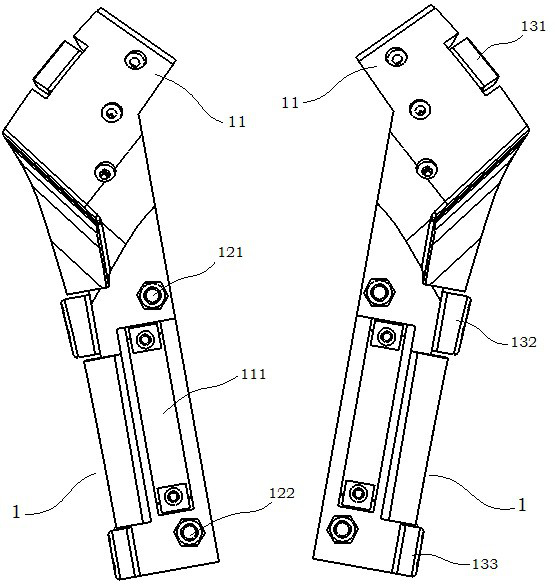

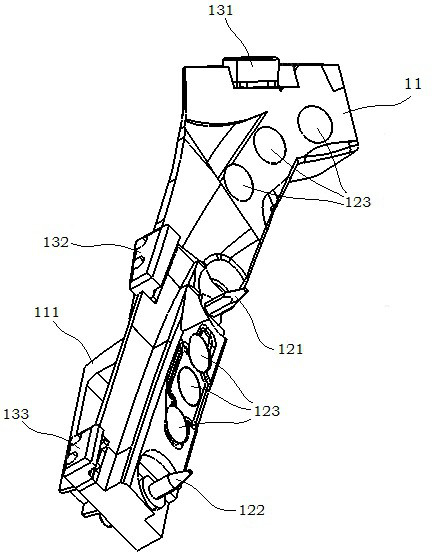

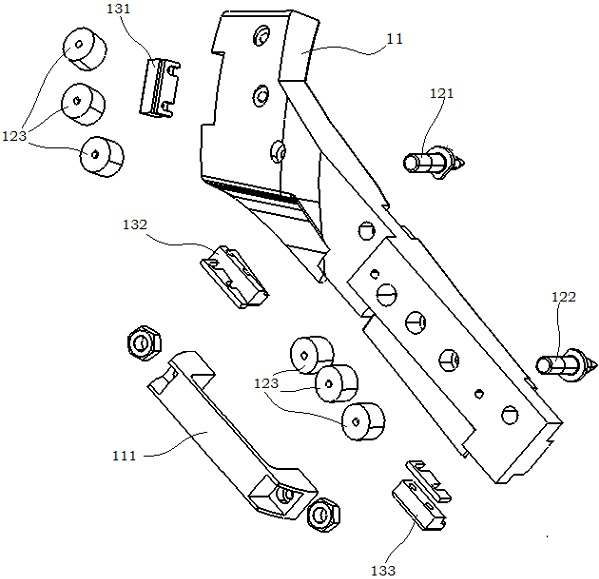

[0031] Figure 1 to Figure 5 A specific implementation manner of a rear door assembly aid of the present invention is shown. figure 1 It is a structural schematic diagram of the back door assembly aid in this embodiment; Figure 2 to Figure 3 It is a schematic structural diagram of the auxiliary assembly module in this embodiment; Figure 4 to Figure 5 It is a working diagram of the auxiliary assembly module in this embodiment.

[0032] like Figures 1 to 5 As shown, the rear door assembly aid in this embodiment includes two auxiliary assembly modules 1, and the two auxiliary assembly modules 1 are symmetrically arranged and used about the longitudinal center line of the vehicle; the auxiliary assembly module 1 includes a profiling positioning block 11 and The positioning mechanism and the assembly reference block arranged on the profiling positioning block 11, the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com