Patents

Literature

134results about How to "Improve Assembly Consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

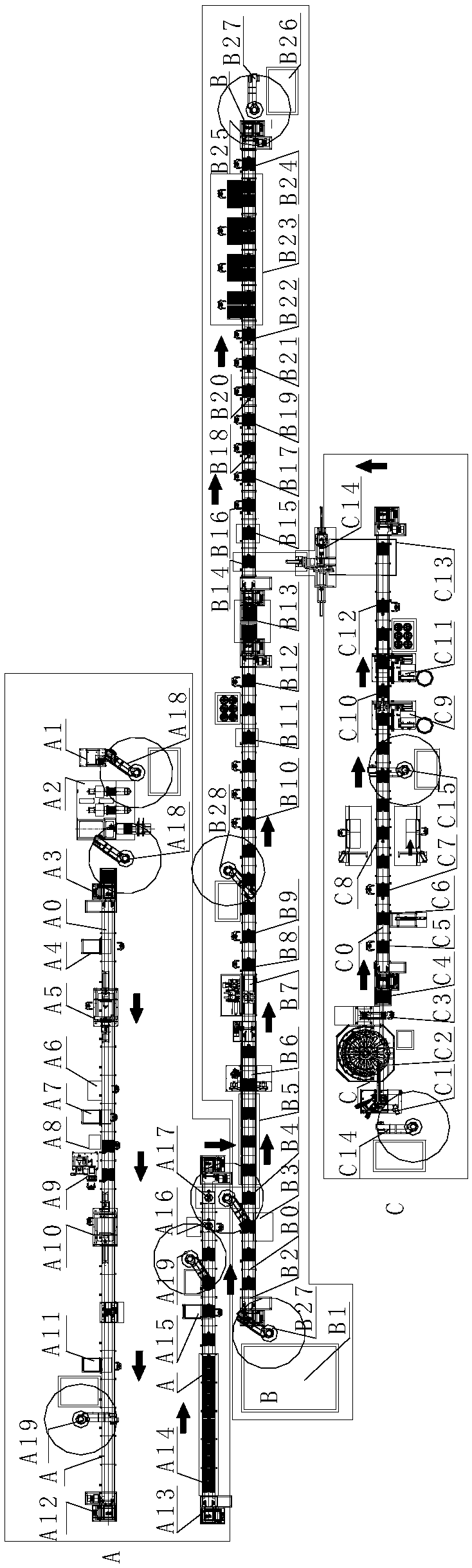

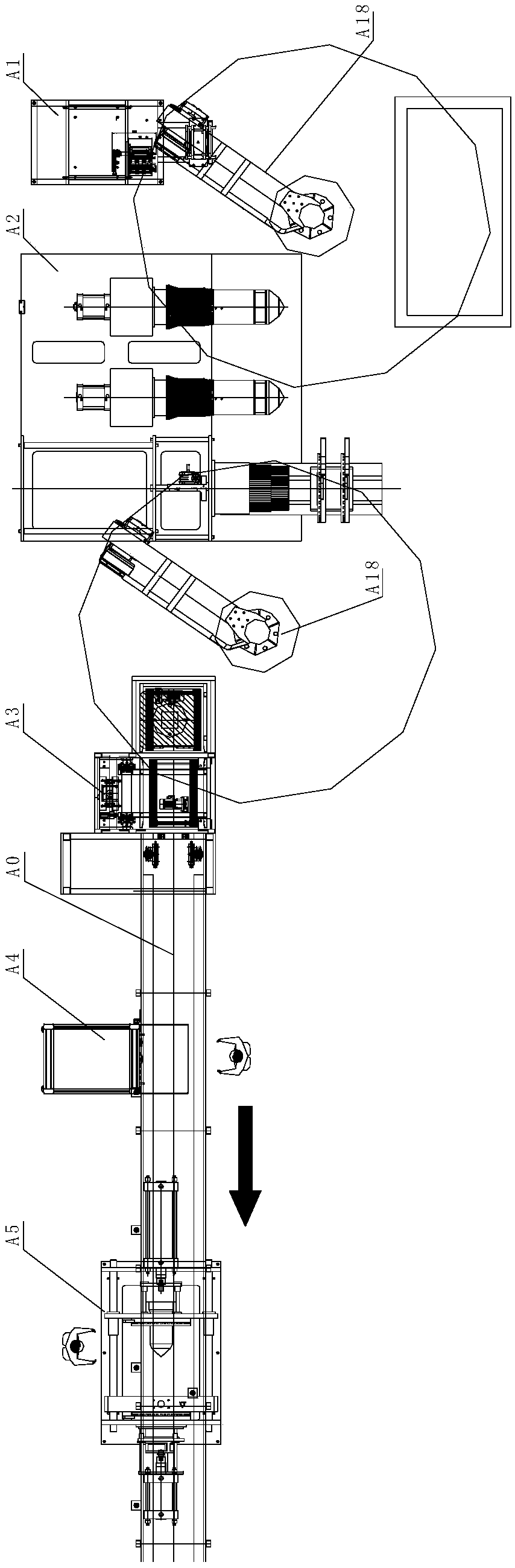

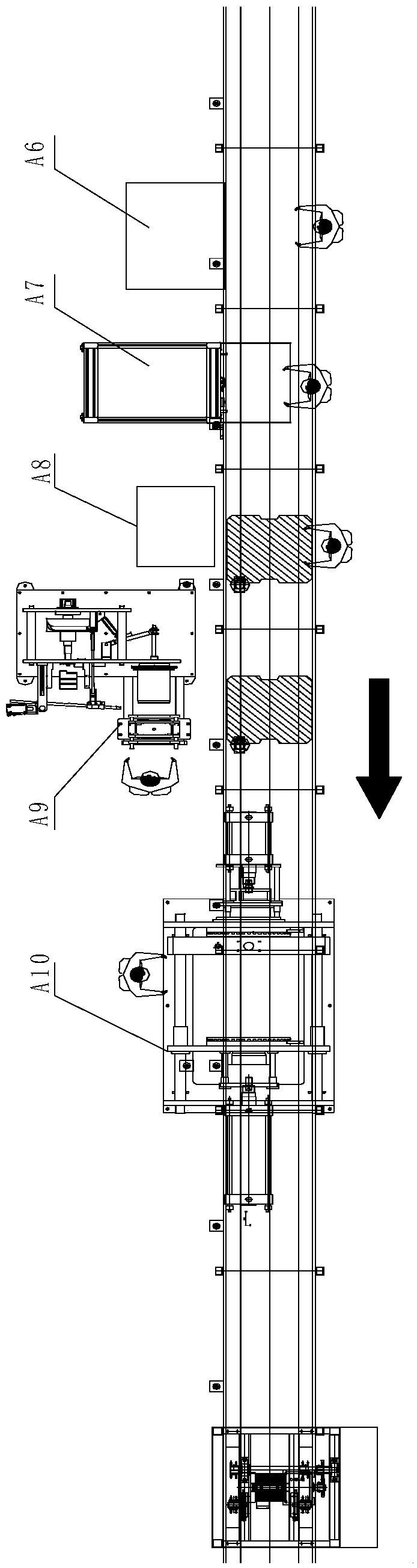

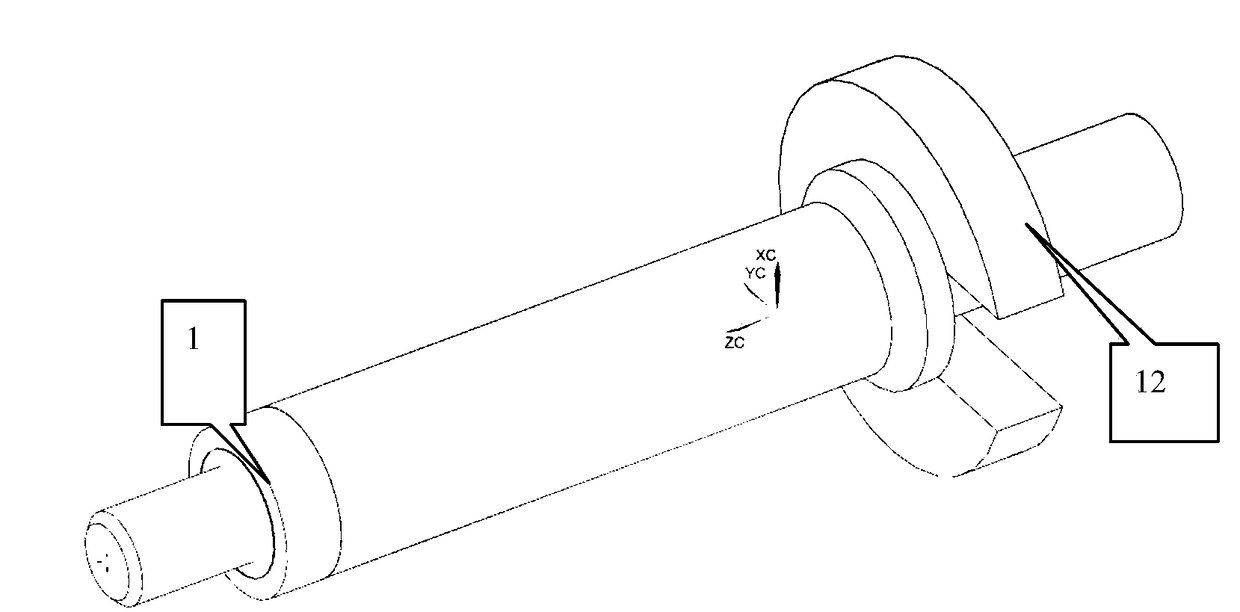

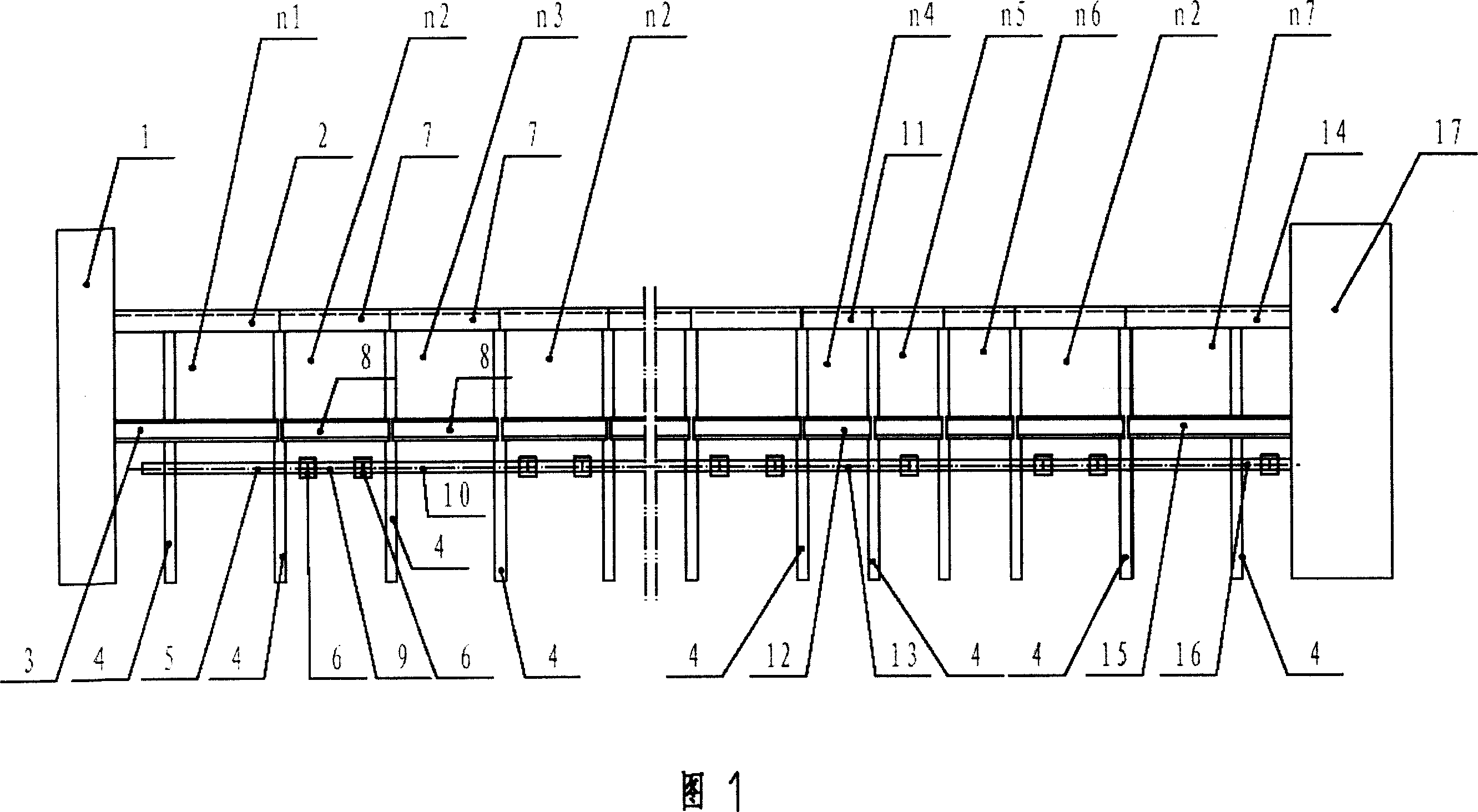

Permanent-magnet motor assembling production line

ActiveCN108880134AReduce dispatch timeAvoid wastingElectric machinesManufacturing stator/rotor bodiesProduction lineDynamic balance

The invention discloses a permanent-magnet motor assembling production line, comprising a stator assembling section, a rotor assembling section and a final assembling section. A stator assembling transmission line of the stator assembling section is sequentially provided with a stator paper inserting machine, a coil inserting and expanding integrated machine, a stator putting-in-line buffer table,a coil shaping table, a first paint stripping table, a star point extruding table, a binding table, a final shaping table, a paint dipping table, a sampling table, a stator air cooling channel, a second paint stripping table and a stator transferring preparation table along the way; The rotor assembling section comprises a rotor assembling transmission line, and the rotor assembling transmissionline is sequentially provided with an automatic magnetic steel inserting and glue dripping integrated machine, a drying machine, a rotating shaft feeding machine, a rotor putting-in-line buffer table,a nut pre-tightening table, an automatic screw cap screwing machine, a screw rod dismounting table , a dynamic balance adjusting table, a first bearing pressing machine, an automatic rotating table,a second bearing pressing machine, a rear end cover pressing table and a rotor transferring preparation table along the way. The permanent-magnet motor assembling production line has the advantages ofintegration and human-machine interaction, saving manpower and reducing costs.

Owner:浙江巨龙自动化设备股份有限公司

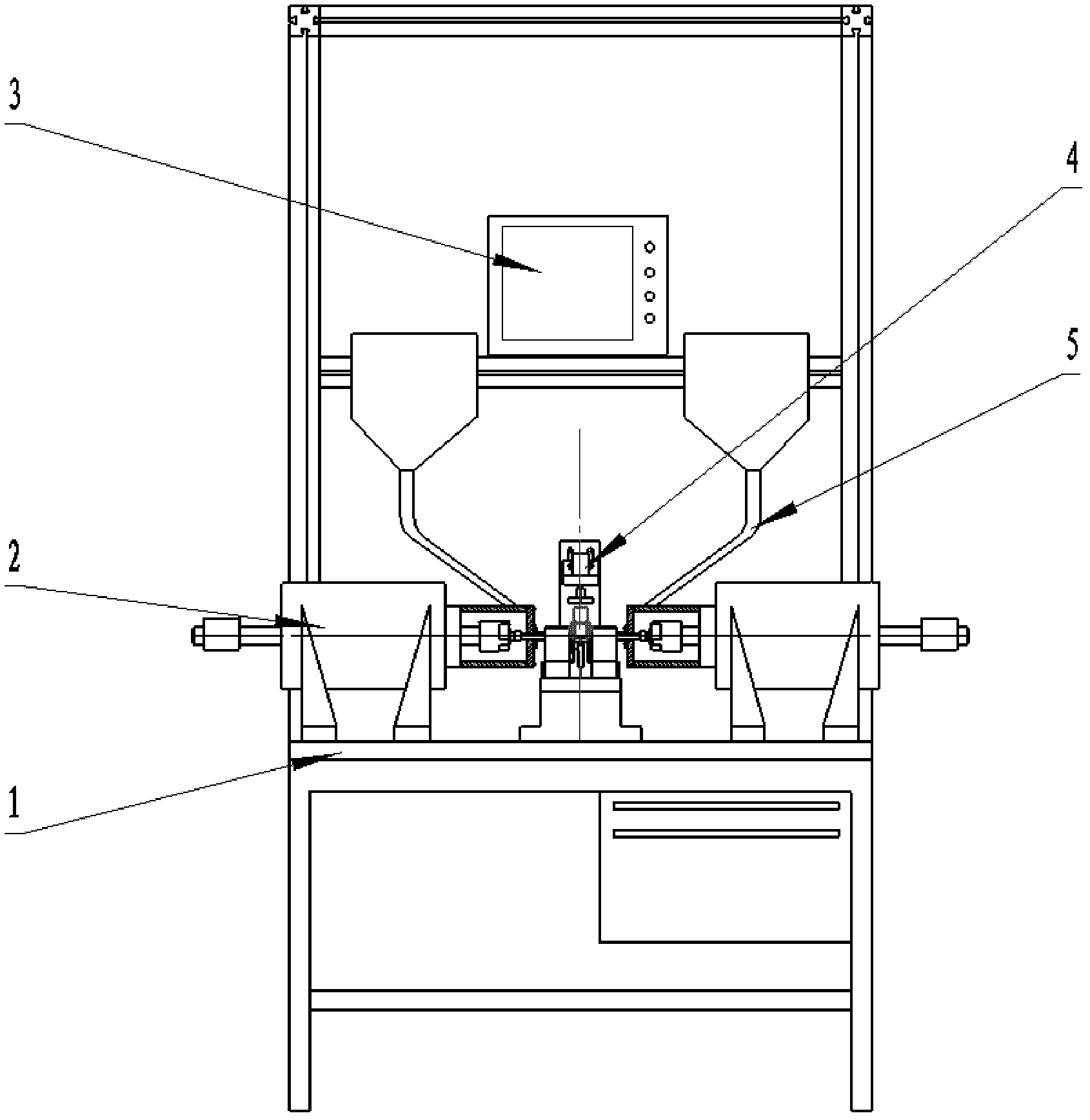

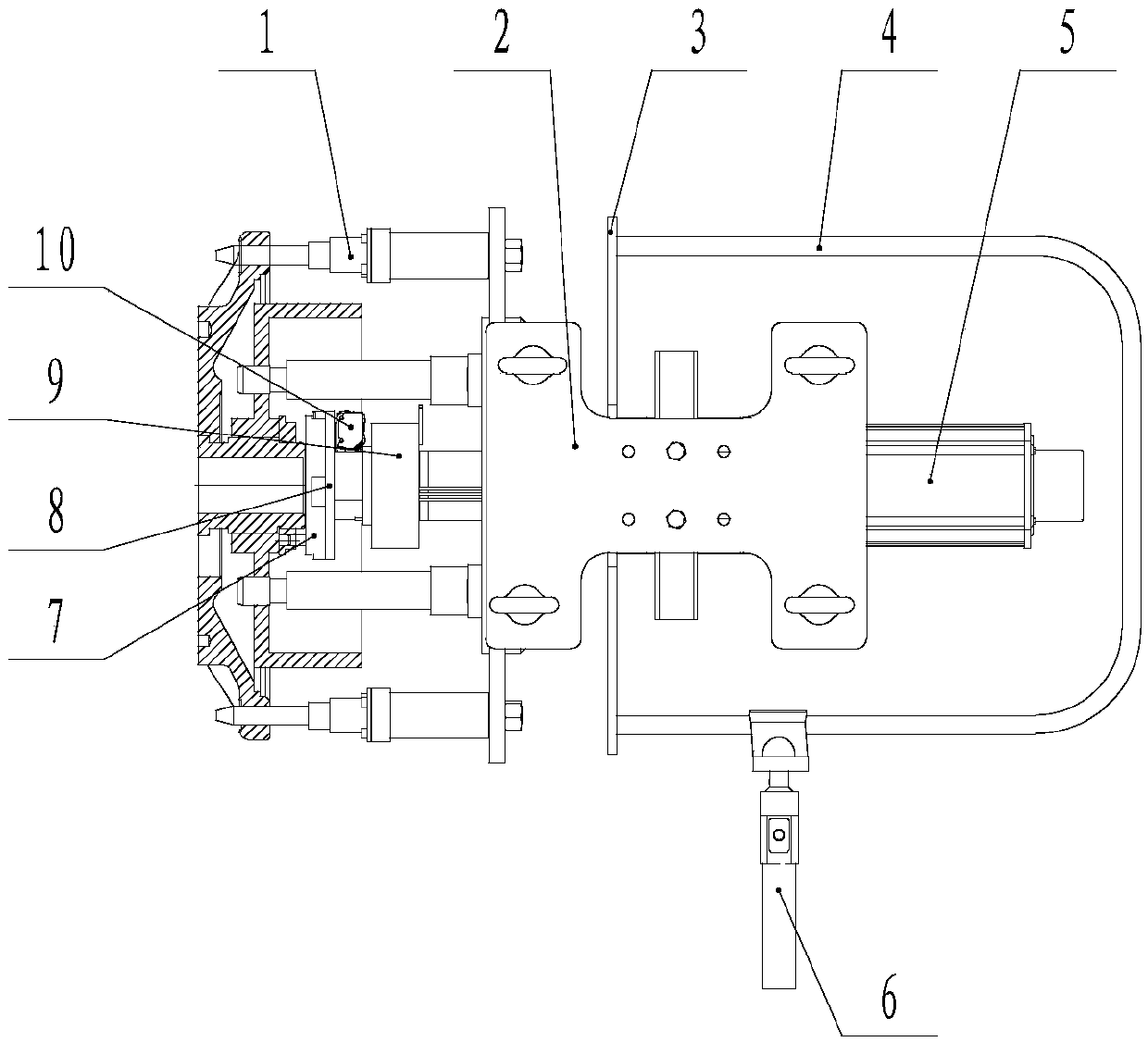

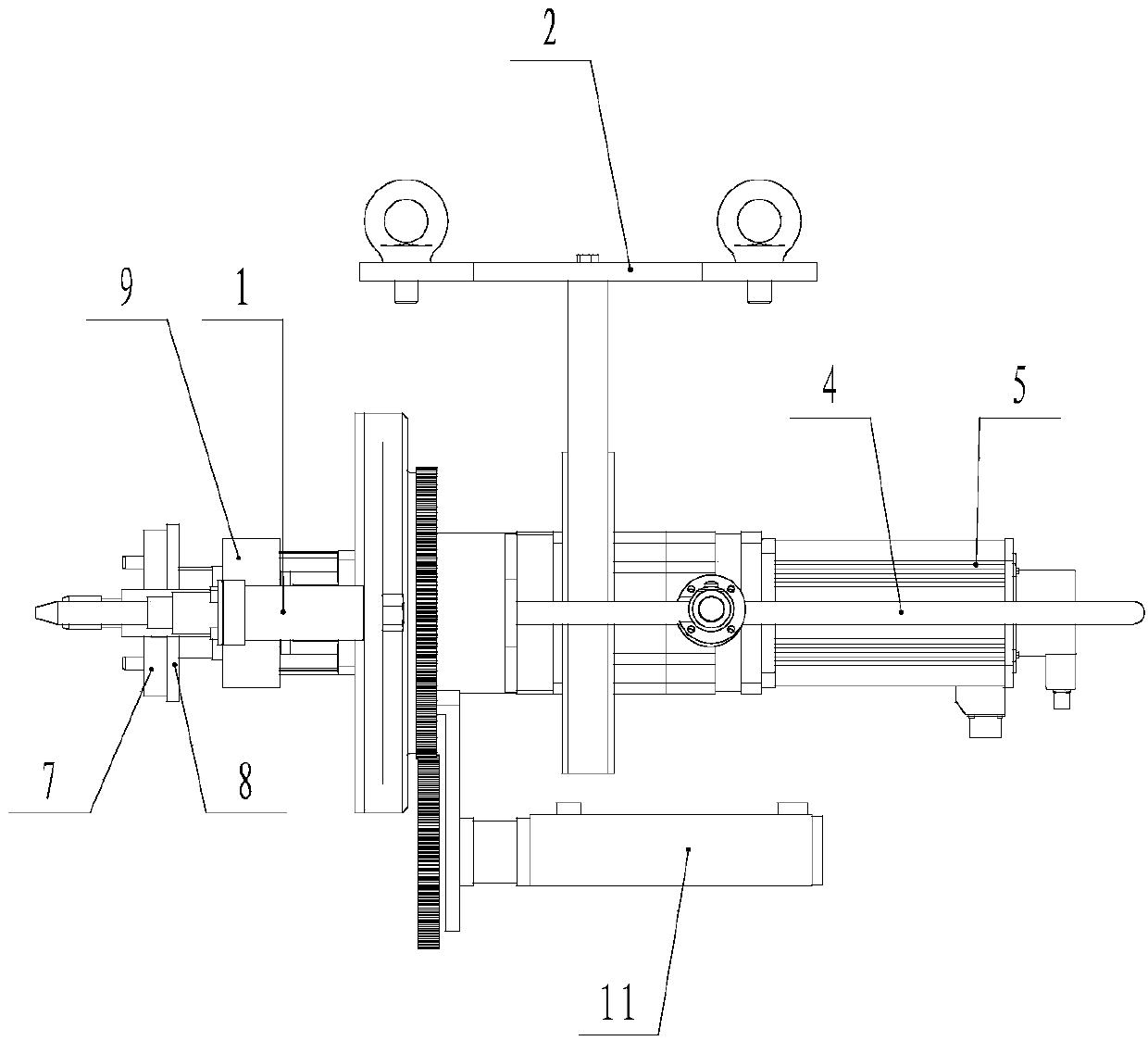

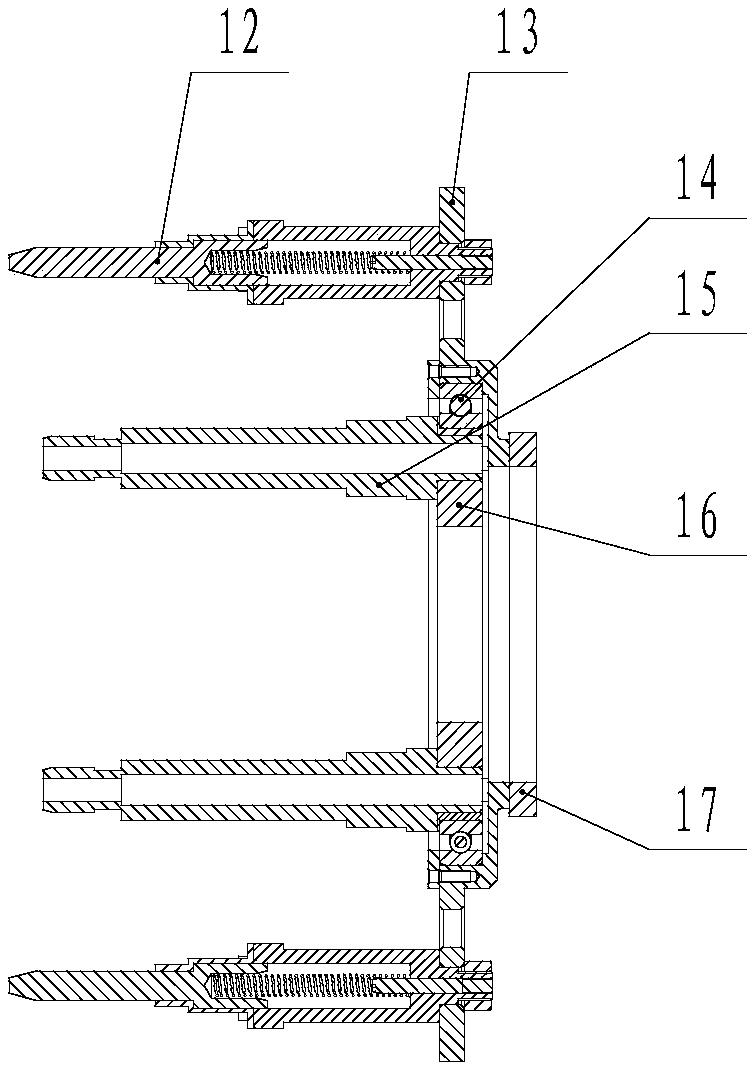

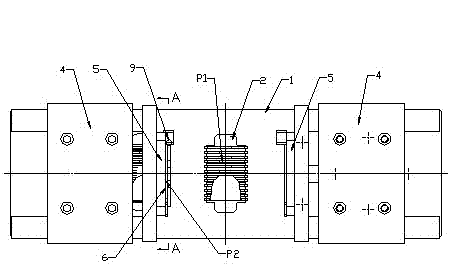

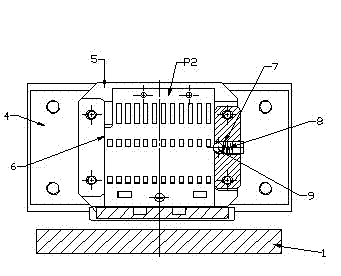

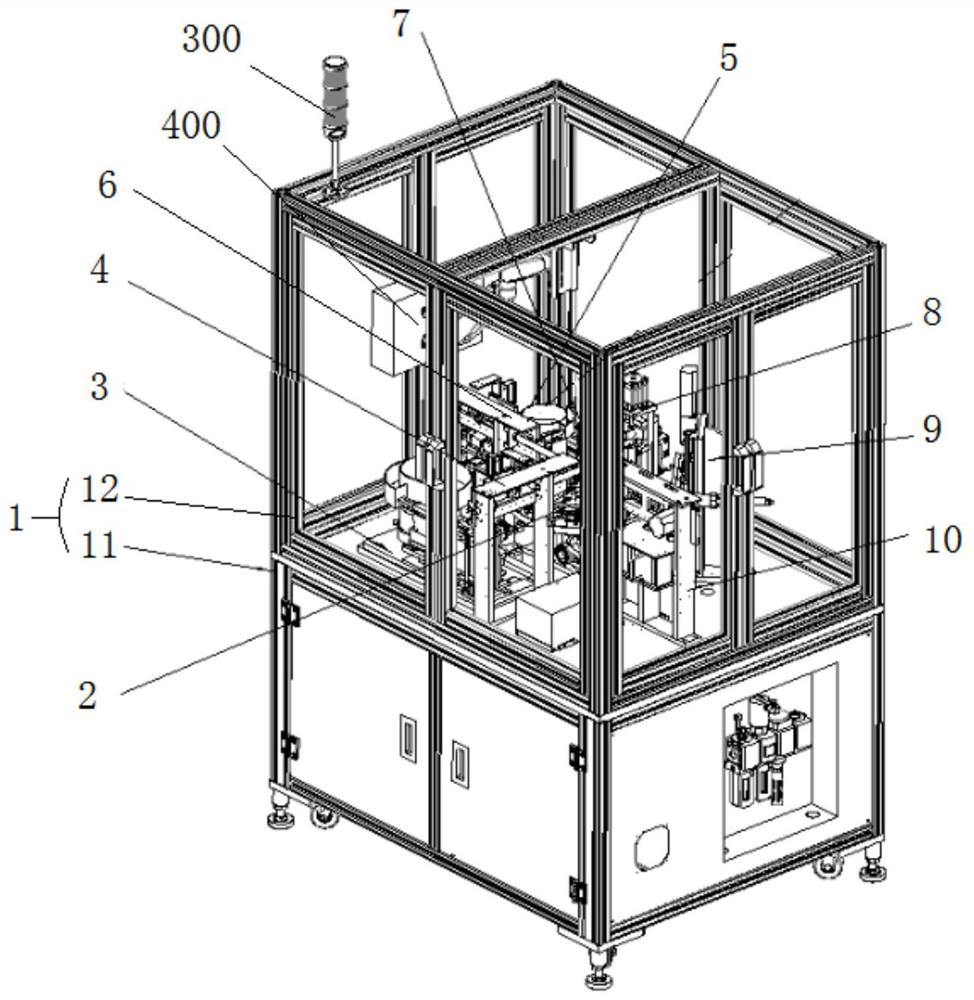

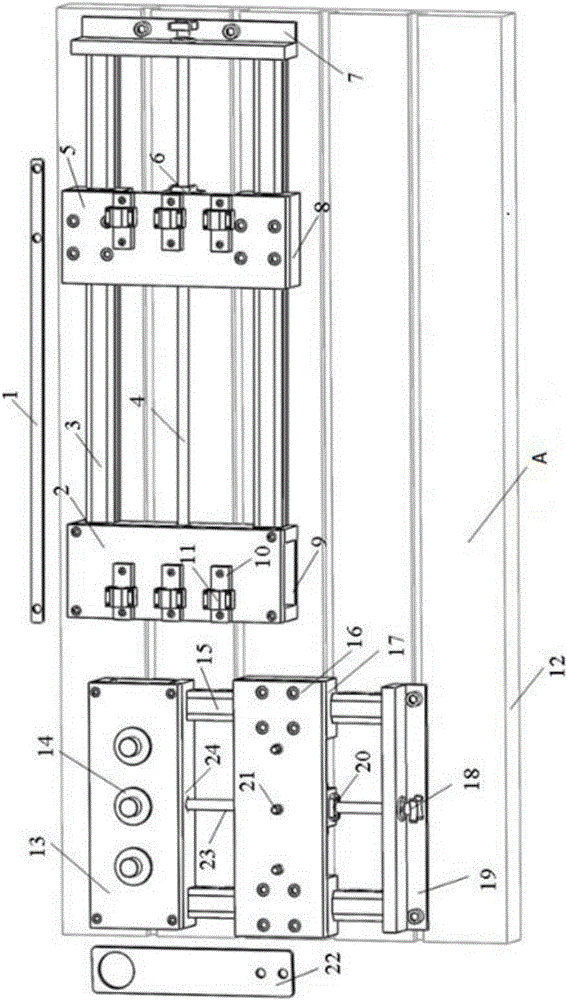

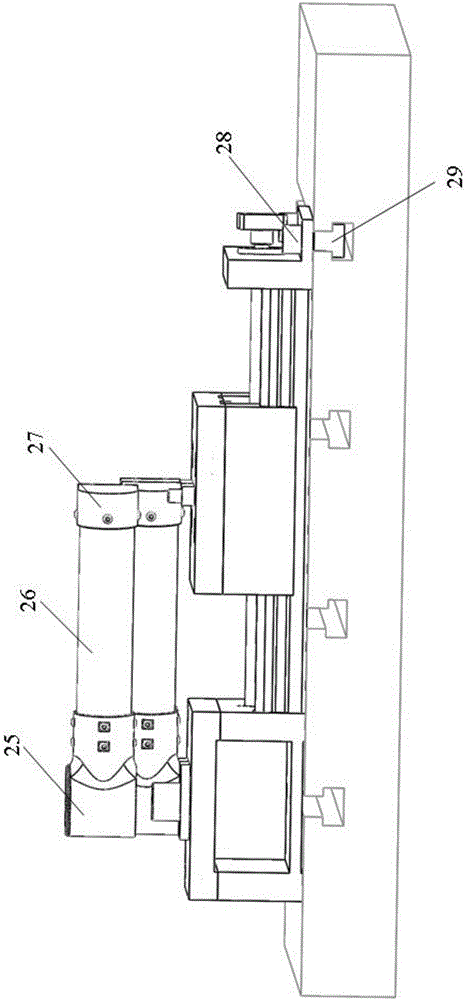

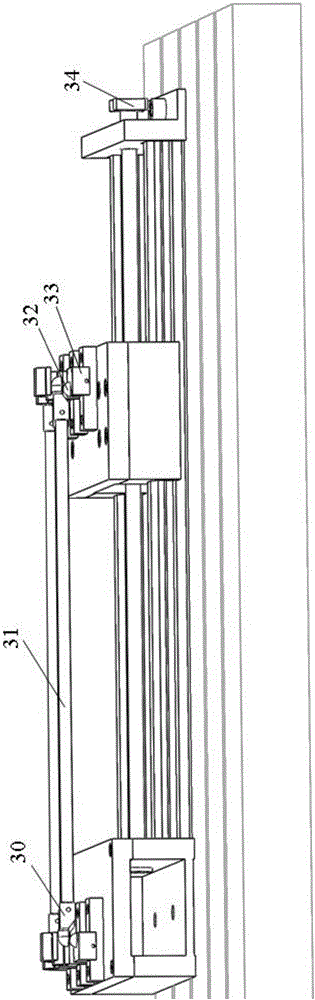

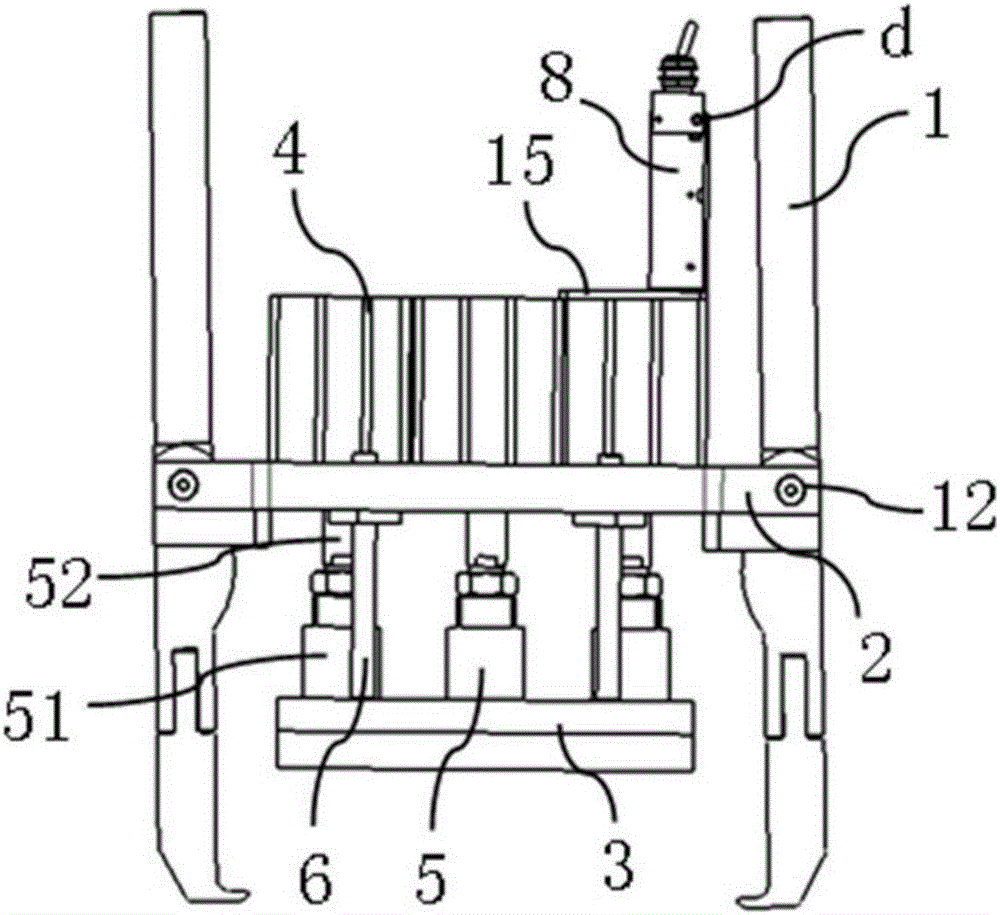

Automobile steering system cardan joint assembling device

The invention relates to an automobile steering system cardan joint assembling device which is composed of a single-fork rivet pressing dibbling machine and a double-fork rivet pressing dibbling machine. The single-fork rivet pressing dibbling machine comprises an operating platform A, actuating units A, a control, monitoring and display system A, a single-fork rivet pressing tool and feed devices. The operating platform A is provided with the single-fork rivet pressing tool. The symmetrical actuating units A are arranged on the two sides of the single-fork rivet pressing tool, the symmetrical feed devices are arranged above the single-fork rivet pressing tool, and the control, monitoring and display system A is arranged on the feed devices. The double-fork rivet pressing dibbling machine comprises an operating platform B, actuating units B, a control, monitoring and display system B and a double-fork rivet pressing tool, wherein the operating platform B is provided with the double-fork rivet pressing tool, the symmetrical actuating units B are arranged on two sides of the double-fork rivet pressing tool, and the control, monitoring and display system B is arranged above the double-fork rivet pressing tool. The automobile steering system cardan joint assembling device is capable of combining four working procedures to two working procedures, and can be finished through two kinds of operations. The device is appropriate in price and good in product assembly consistency, pressure assembling force can be monitored in an on-line mode, the automation level is high, and efficiency is high.

Owner:优立昂(上海)汽车零部件科技有限公司 +1

Bending-compression mould for processing fastener

ActiveCN102327985ACompact and ingenious structureSimplify the assembly processShaping toolsFastenerEngineering

A traditional common mould used for carrying out bending-compression assembly between two parts comprises two moulds: a transversal bending mould and a longitudinal bending mould, which has a fussy and complicated assembly process and low production efficiency. The invention provides a bending-compression mould, which comprises a lower positioning concave die and a lower punching die matched withthe lower positioning concave die for use, and is characterized in that an upper push plate and a connecting block are arranged above the lower punching die; the bottom part of the connecting block is fixedly arranged on the upper surface of the upper push plate; the lower punching die and the upper push plate are connected through a plurality of guide posts penetrating through the upper push plate; the bottom part of each guide post is fixedly connected onto the lower punching die; the top part of the guide post is provided with a stop block; a plurality of booster springs and a plurality ofpre-stressing springs are arranged between the upper push plate and the lower punching die; a plurality of transversal bending tools are fixed at the bottom part of the lower punching die; a plurality of longitudinal bending tools penetrating the lower punching die are fixed on the upper push plate; and the tool bits of the longitudinal bending tools are arranged next to the side walls of the transversal bending tools. By adopting the bending-compression mould, the process is simplified, and the production efficiency is improved.

Owner:SHANGHAI AISHIDA ROBOT CO LTD

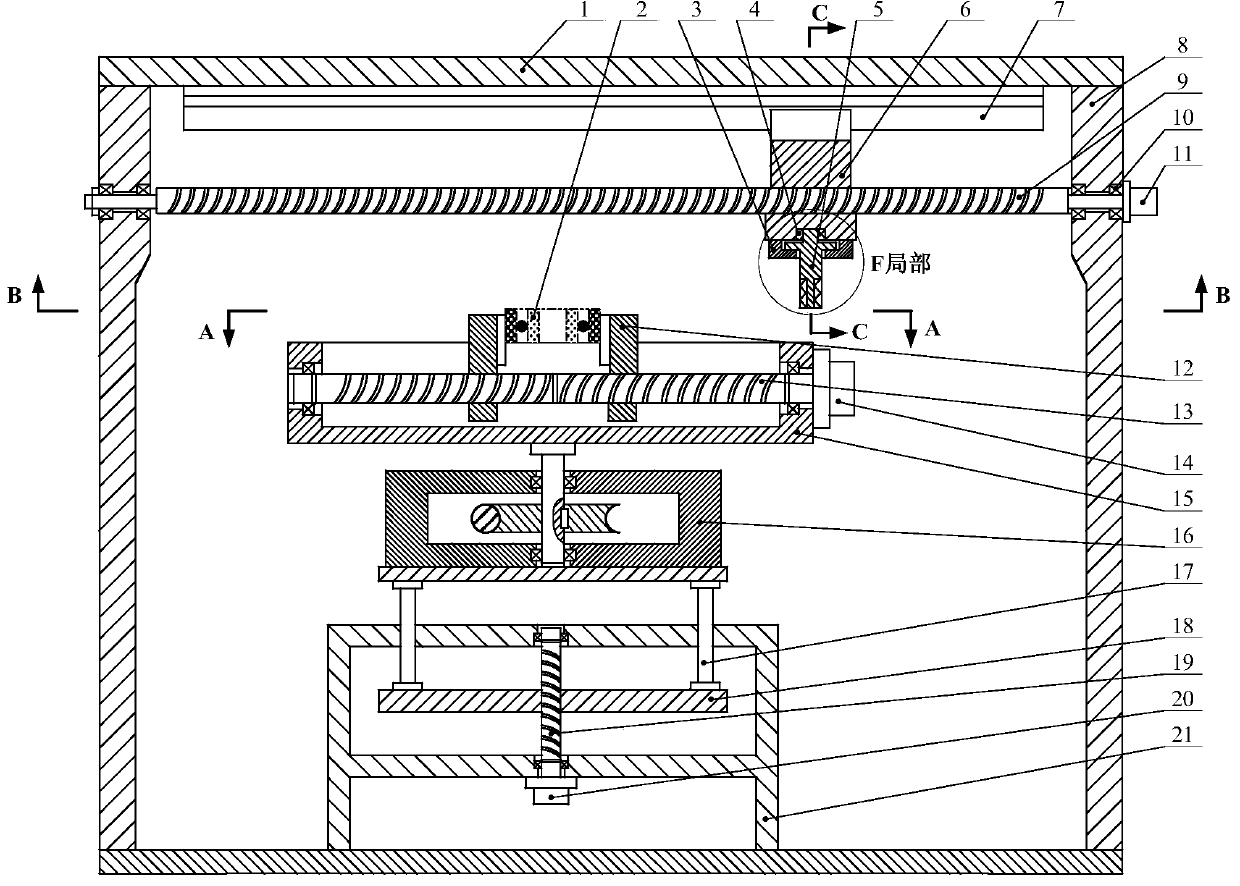

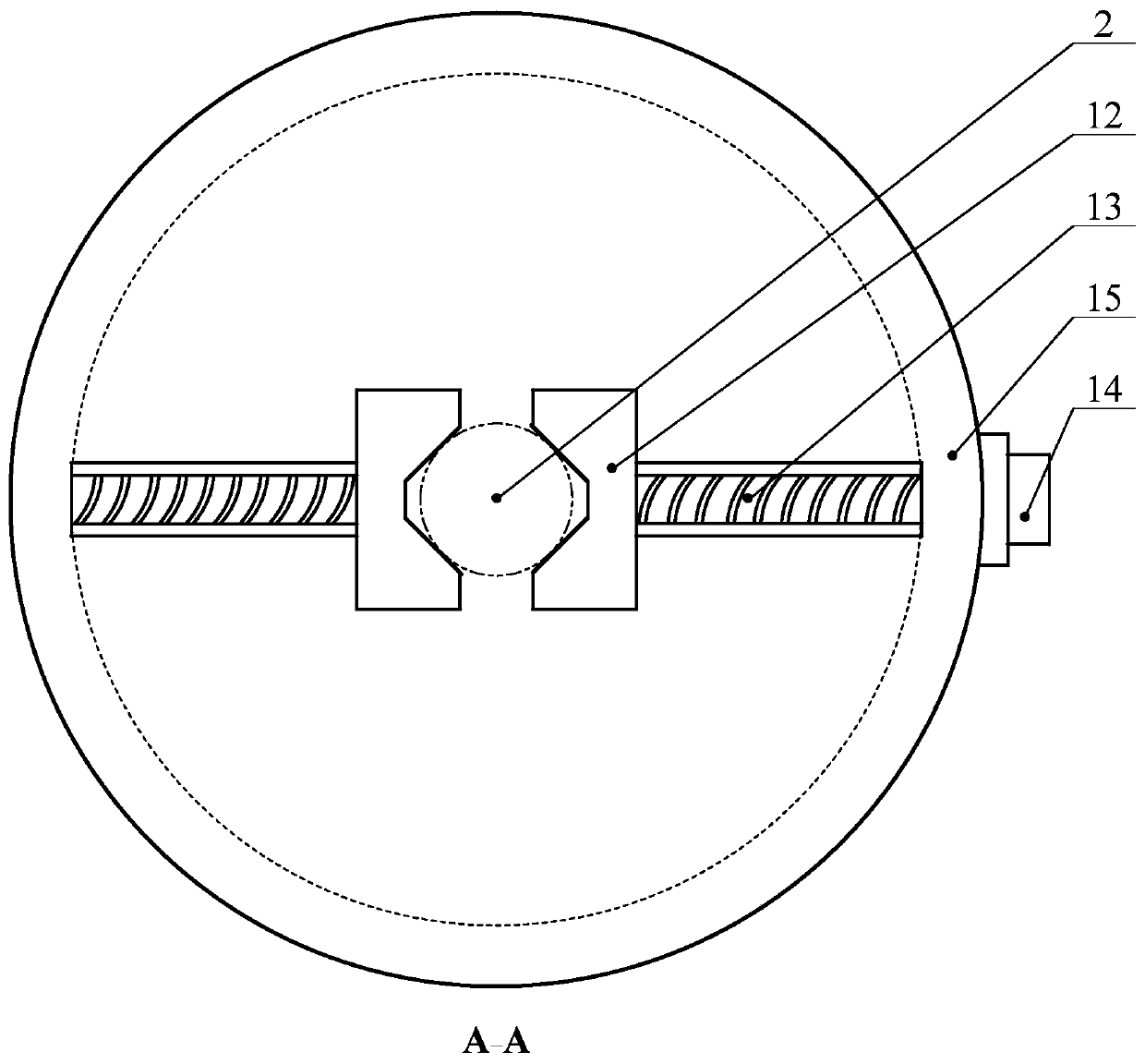

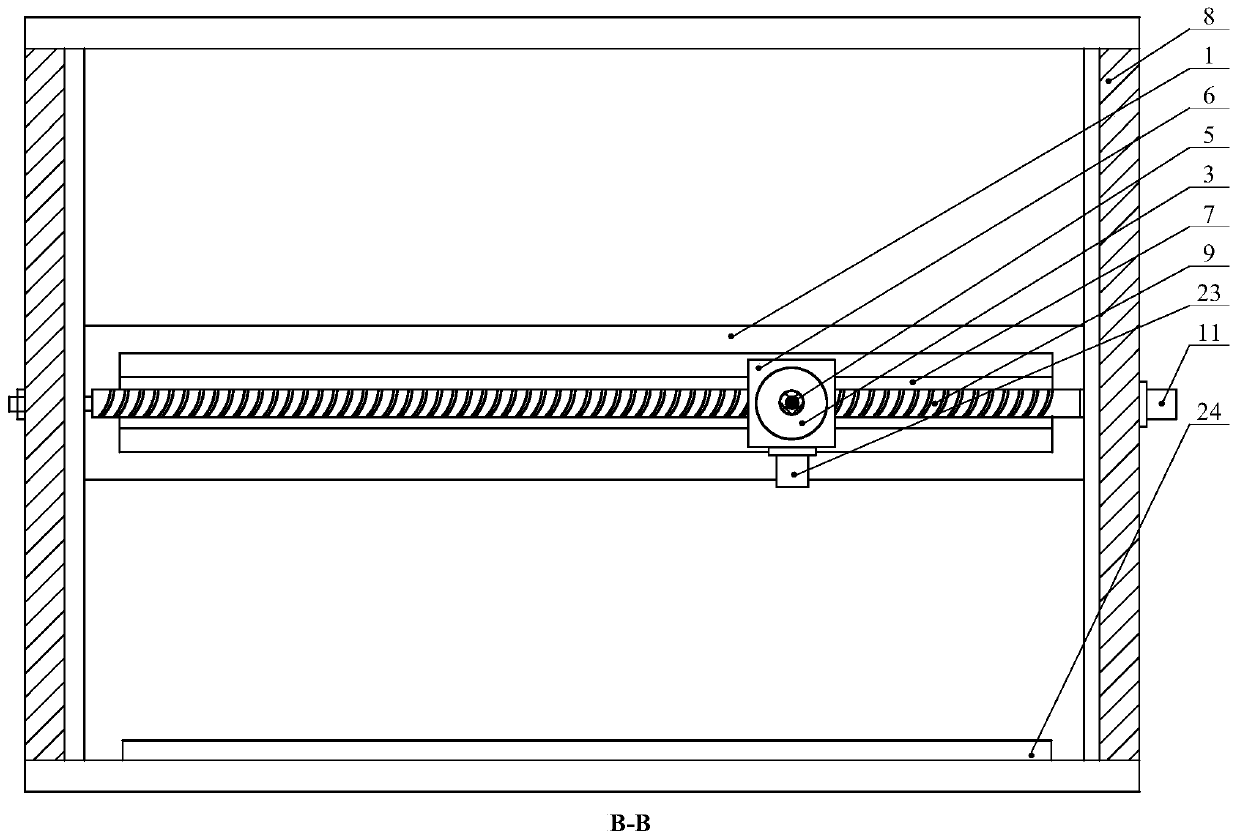

Bearing assembly clearance on-line measuring machine and clearance measuring method thereof

ActiveCN110160454ASolve online measurement problemsImprove assembly accuracyUsing optical meansGratingRolling-element bearing

The invention discloses a bearing assembly clearance on-line measuring machine and a clearance measuring method thereof. When the inner and outer rings of the bearing are assembled, the clearance canbe inconsistent or even exceed the tolerance range. The bearing assembly clearance on-line measuring machine disclosed by the invention comprises a machine body, a worktable lifting and rotating mechanism, a clamping worktable and a constant pressure measuring mechanism. The clamping worktable includes a V-shaped positioning clamping block, a clamping driving assembly, and a worktable. The constant pressure measuring mechanism includes a pressure detector, a traverse driving mechanism, a mounting block, a guide rail, a measuring slider, a scale grating, and a grating reading head. The pressuredetector includes a measuring rod seat, a pressure sensor, and a measuring rod. Two pressure sensors are arranged in a pressure detecting groove of the mounting block at intervals. The measuring rodpasses through the measuring rod seat and the top end is located between the two pressure sensors. According to the invention, by designing the constant pressure measuring mechanism and a workpiece positioning and clamping device, the online measurement problem of the clearance in the automatic assembly line of the rolling bearing can be solved.

Owner:杭州电子科技大学安吉智能制造技术研究院有限公司 +1

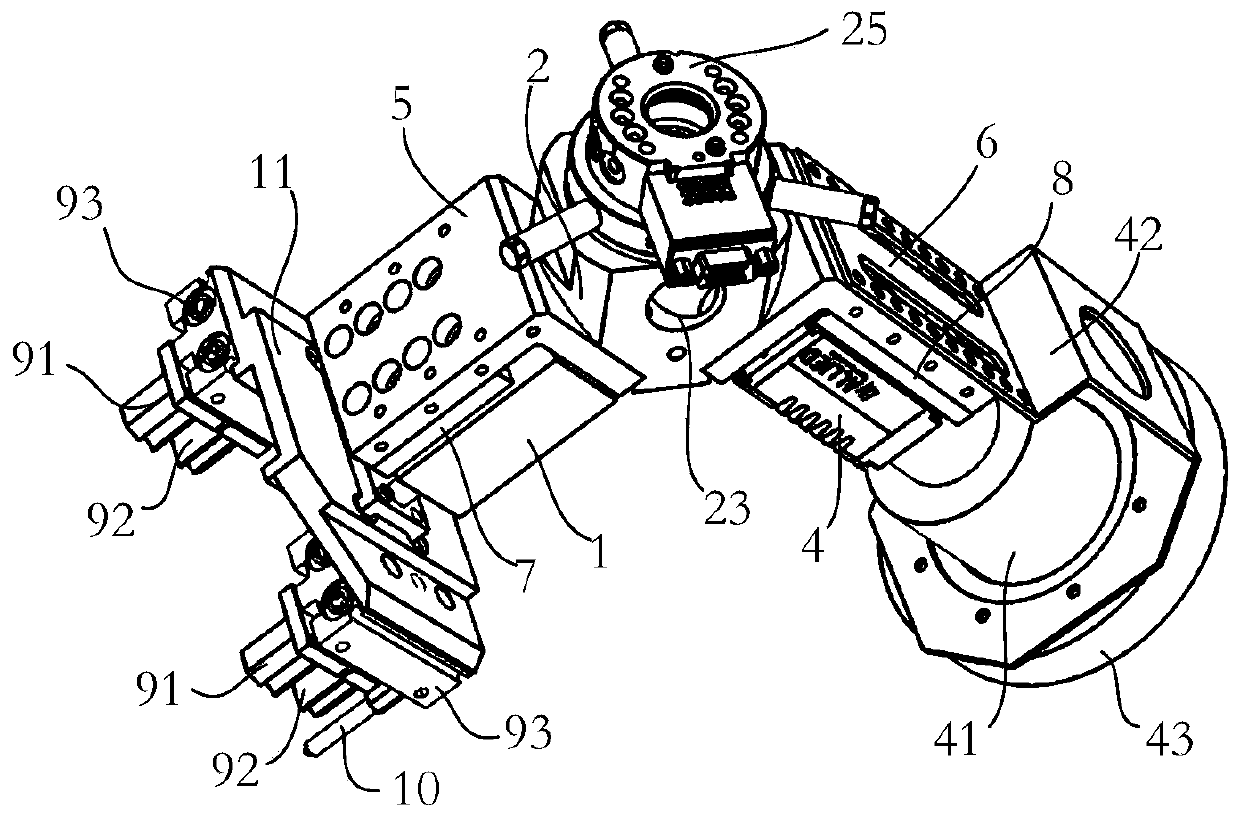

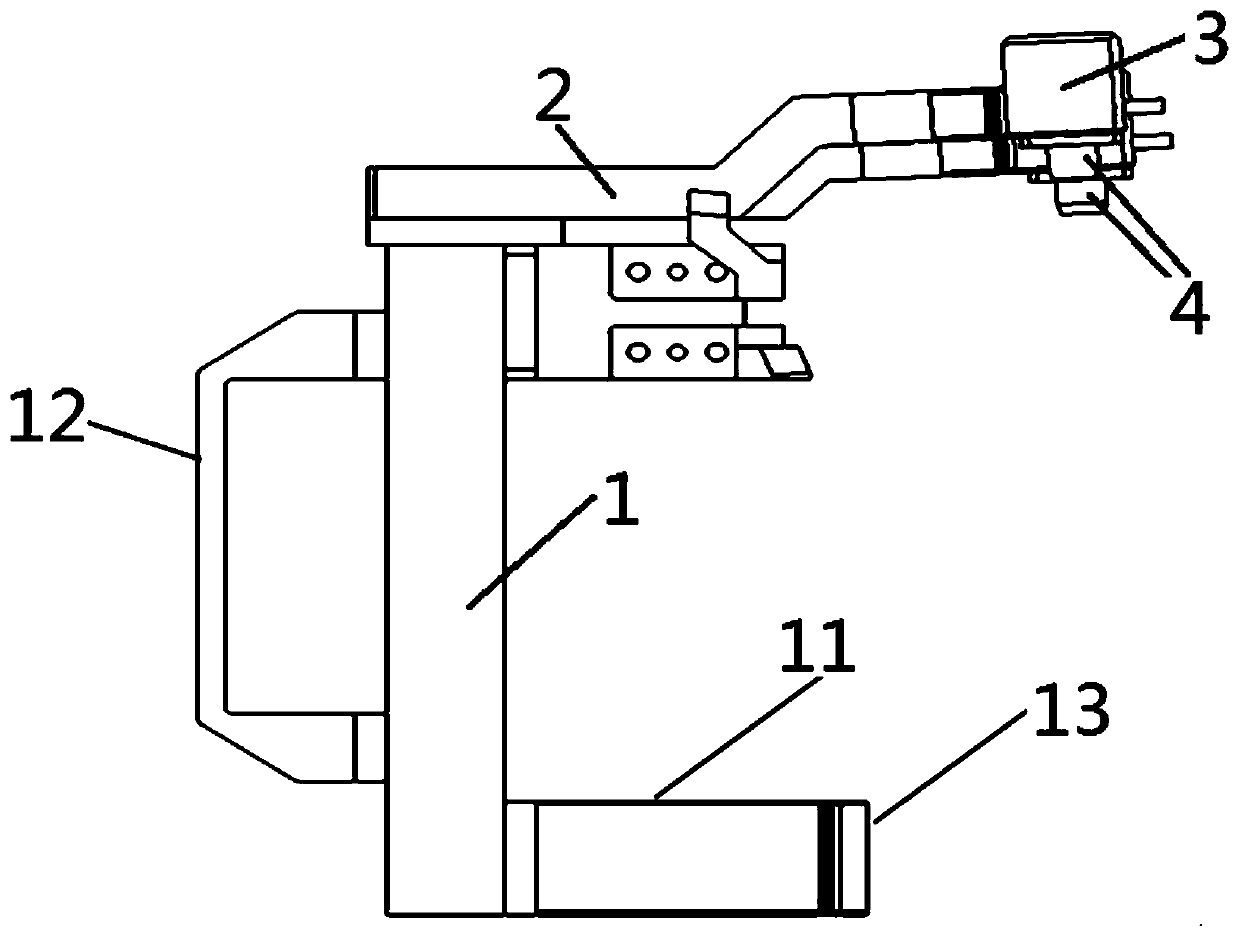

Antenna unit assembly assembling device and collecting, assembling and measuring integrated control system and method thereof

ActiveCN110328528APrecise positioningHigh precision assemblyWave based measurement systemsAssembly machinesControl systemOptical axis

The invention relates to an antenna unit assembly assembling device and a collecting, assembling and measuring integrated control system and method thereof. The assembling device comprises a mountingand dismounting air cylinder, a mounting support, an outer supporting assembly for picking or dismounting an antenna unit assembly and a camera. A first mounting face and a second mounting face whichare perpendicular are arranged on the mounting support, the mounting and dismounting air cylinder is arranged on the first mounting face, the camera is arranged on the second mounting face, the optical axis of the camera is perpendicular to the second mounting face, the driving end of the mounting and dismounting air cylinder is away from the first mounting face, and is connected with the outer supporting assembly to drive the outer supporting assembly to do reciprocated moving in the direction perpendicular to the first mounting face, the camera is used for carrying out image collecting and parameter extracting on the characteristics of the assembling position of the antenna array face, and the mounting and dismounting air cylinder can rotate to the assembling position and drive the outersupporting assembly to move to finish mounting or dismounting of the antenna unit assembly on the antenna array face. Mechanical and electrical mounting and switching of the antenna unit assembly assembling device and an industrial robot or execution mechanism can be achieved, and assembling precision needs are ensured.

Owner:BEIJING INST OF RADIO MEASUREMENT

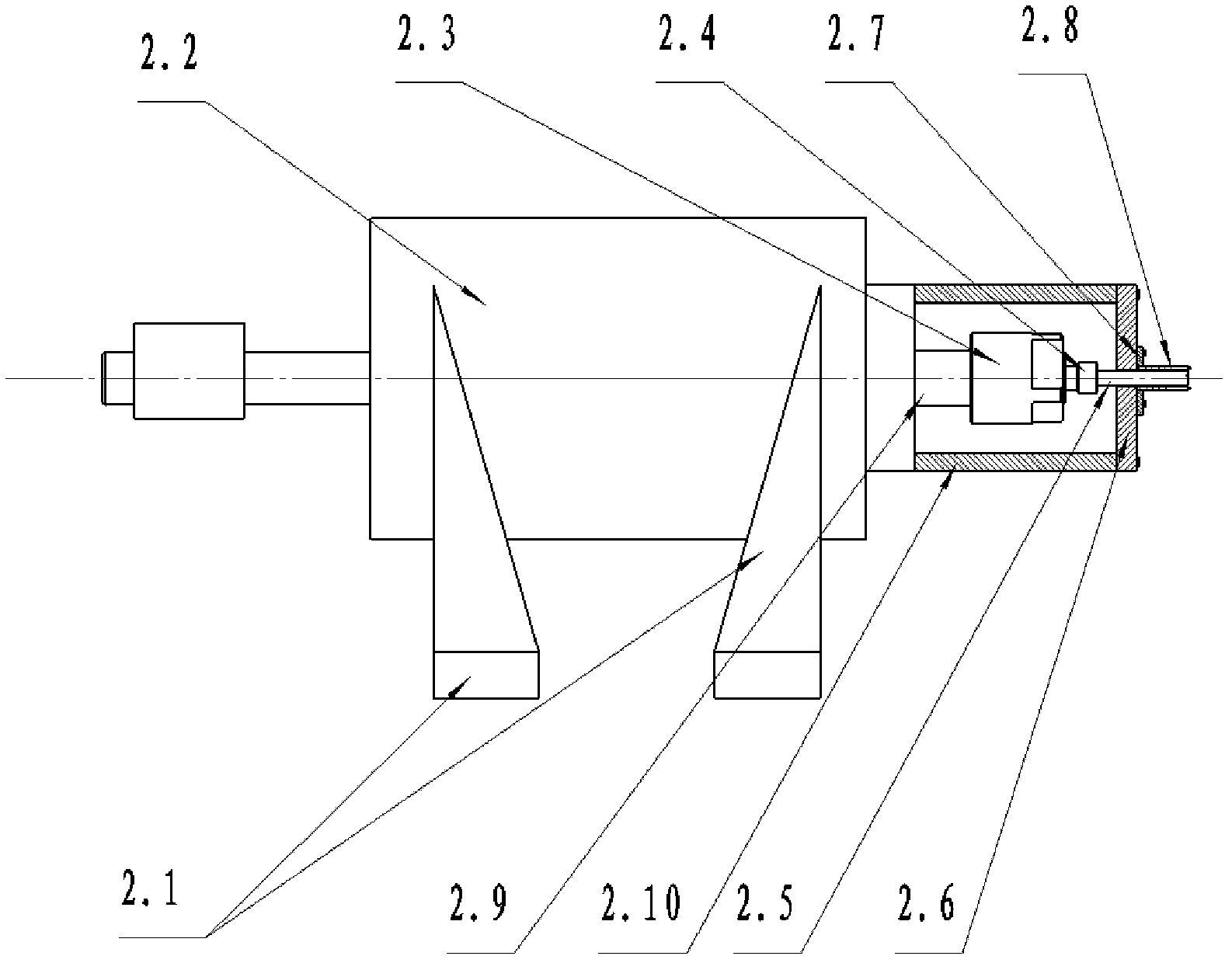

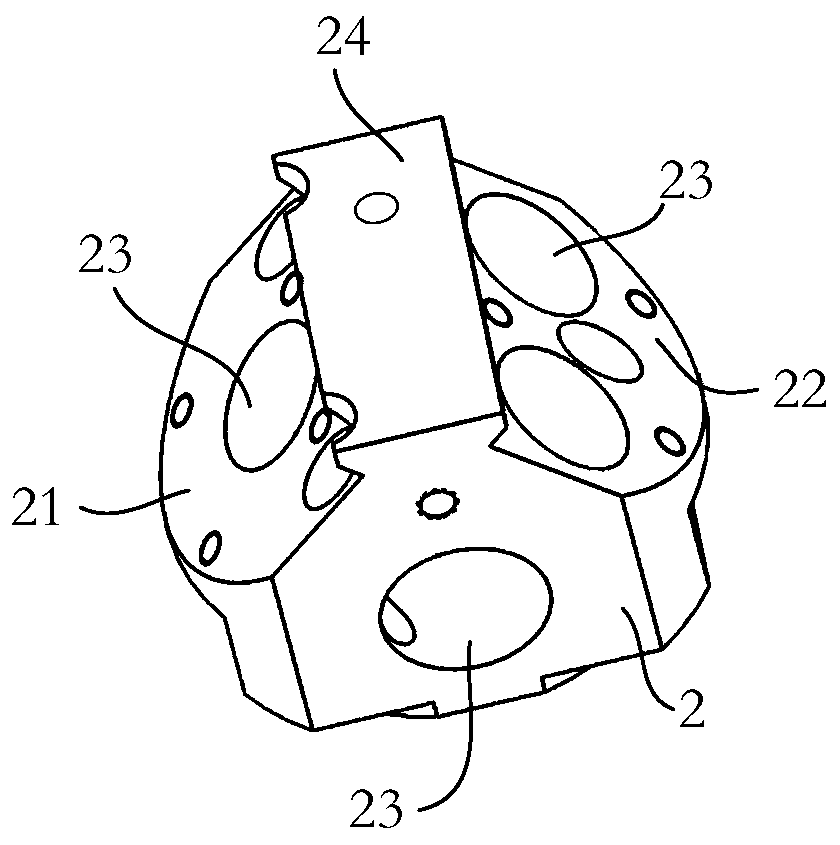

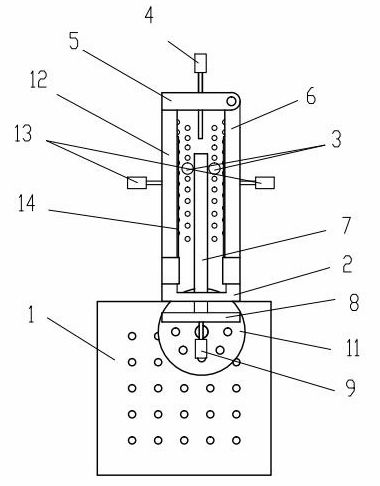

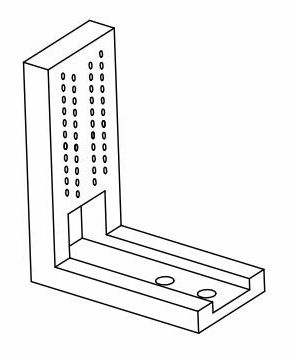

Packaging locating device of microchannel lamination laser

ActiveCN102035133ASolve the problem of pitch directivityAvoid damageLaser detailsSemiconductor lasersIndustrial engineeringLaser

The invention discloses a packaging locating device of a microchannel lamination laser, comprising a square base and a locating device for fixing a microchannel unit, and a compass and a regulating device, the compass is in a round structure which is provided with an opening at the center and is rotational, round holes are uniformly distributed at the periphery of the compass, and the compass is fixed at one side of the base by a locking screw; the locating device comprises a bottom part locating part, a top part locating part, a rear locating plate, a front locating plate, a lifting rod and the bottom surface of a lifting device, the top part locating part is articulated with the top part of the rear locating plate, the rear locating plate and the front locating plate are fixed on the bottom surface of the L-shaped bottom part locating part side by side, a round hole at the bottom part of the bottom part locating part is nested with the lifting rod, the lifting rod is fixed on the bottom surface of the lifting device, and one end of the bottom surface of the lifting device is fixed on the compass. In the invention, the assembly, inspection and fine-tuning processes of the microchannel lamination laser are integrated, the whole process is simple and easy, the assembling precision is improved, and the light beam directivity is improved.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

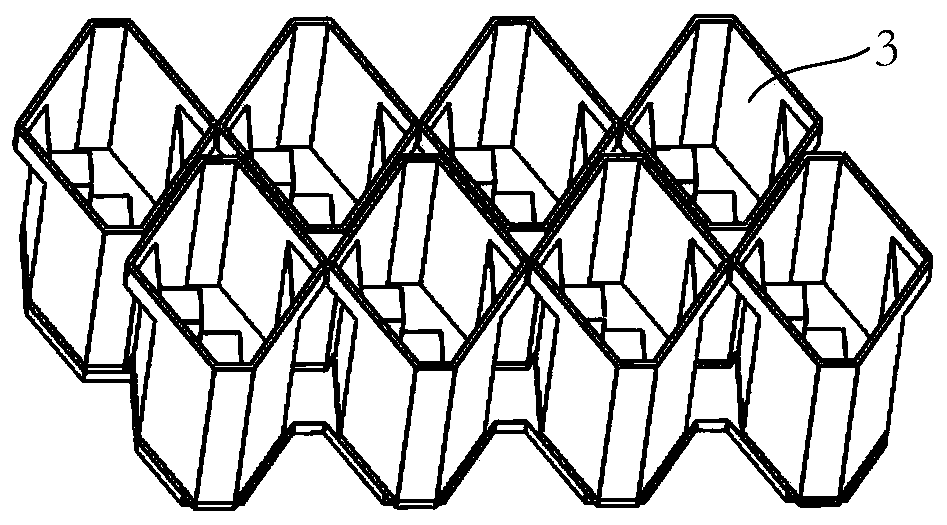

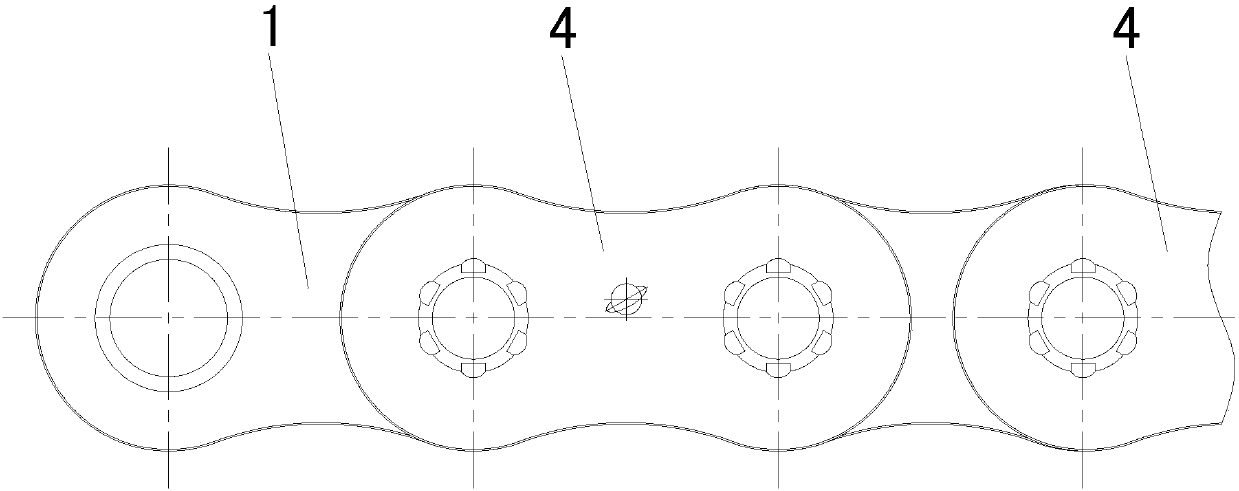

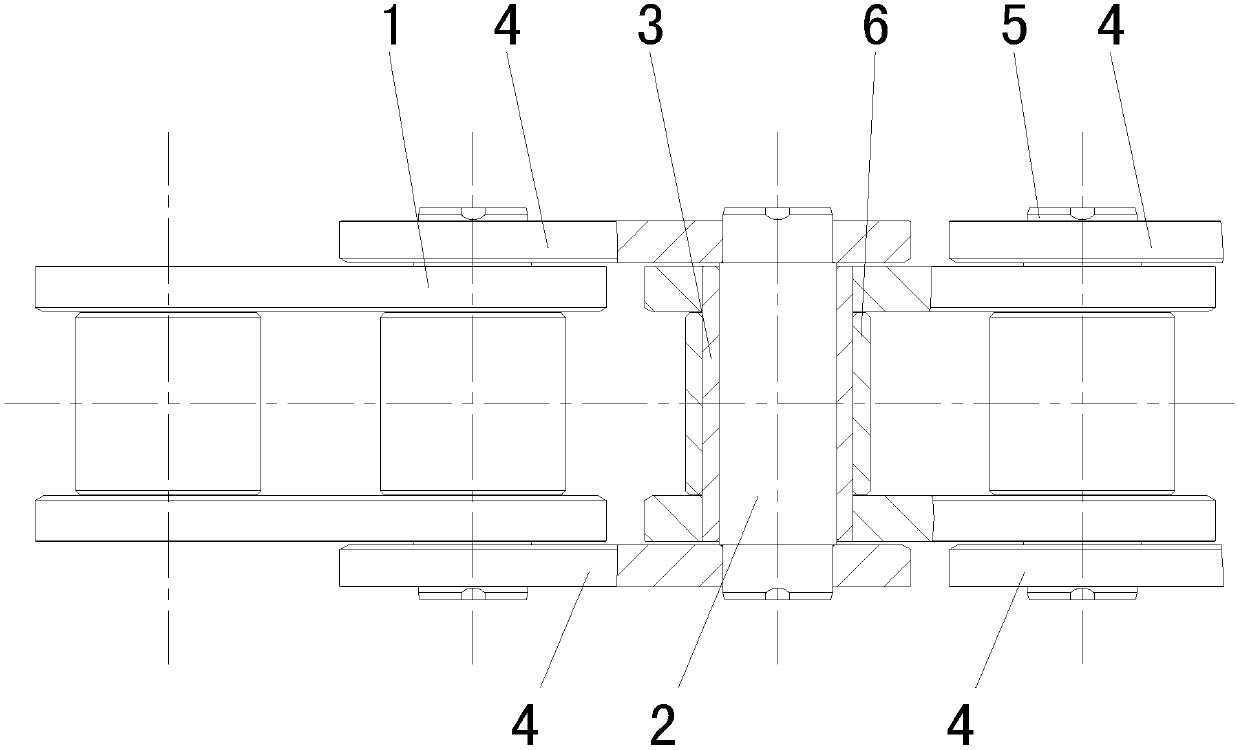

Marine chain

InactiveCN107939910APrecise assembly limitImprove mechanical propertiesChain linksDriving chainsAgricultural engineeringChain link

The invention discloses a marine chain. The marine chain is formed through a plurality of inner links sequentially connected, each inner chain segment comprises two inner chain plates; the inner chainplates are parallel and arranged at intervals, and rollers are arranged at the two ends of the inner chain plates, the rollers are clamped between the two inner chain plates; the two sides of the adjacent ends of the adjacent inner chain links are connected with outer chain plates; the two ends of the outer chain plates are provided with first through-holes; the pin shaft penetrates through the first through-holes and the inner chain plates corresponding to the two outer chain plates, and the adjacent inner chain links are connected; the rollers are arranged on the corresponding pin shafts ina sleeved mode; a sleeve is arranged between the pin shaft and the corresponding roller; sealing plugs are arranged at the two ends of the pin shafts so as to prevent the pin shaft from falling off;a step part is arranged at the joint of the pin shaft and the outer chain plate; and the inner side surface of the outer chain plate is arranged on the step part. The inner chain plates and the outerchain plates of the marine chain are long in service life, and meanwhile, the transmission of the marine chain is good in stability and low in noise.

Owner:UNIVERSAL CHUANDONG TAIZHOU

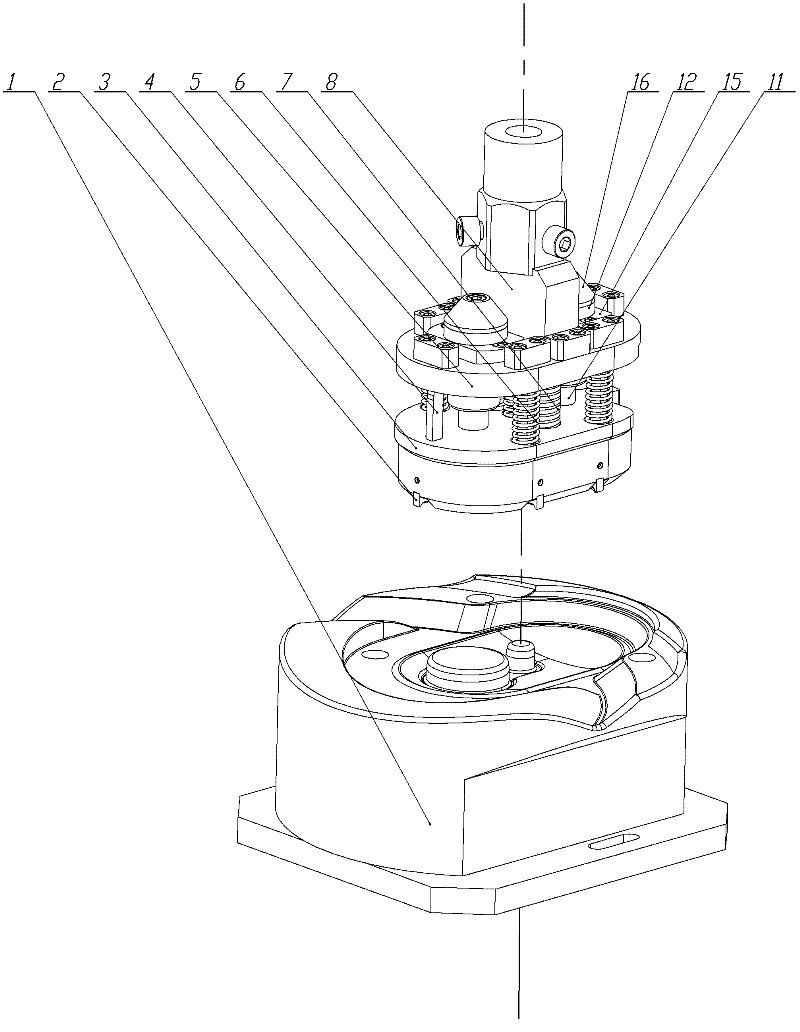

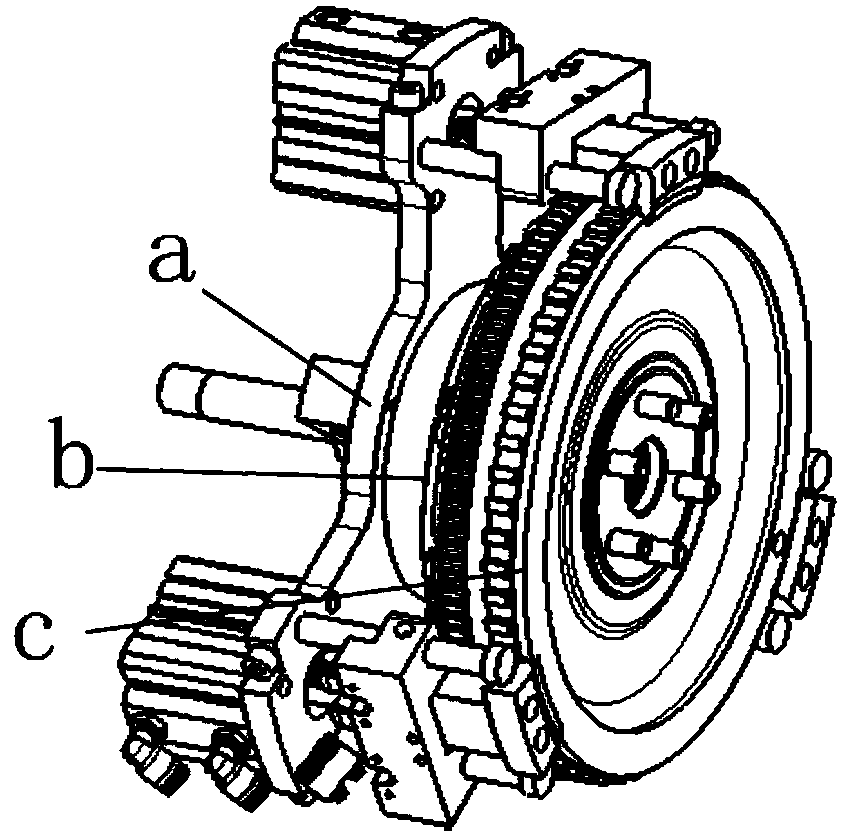

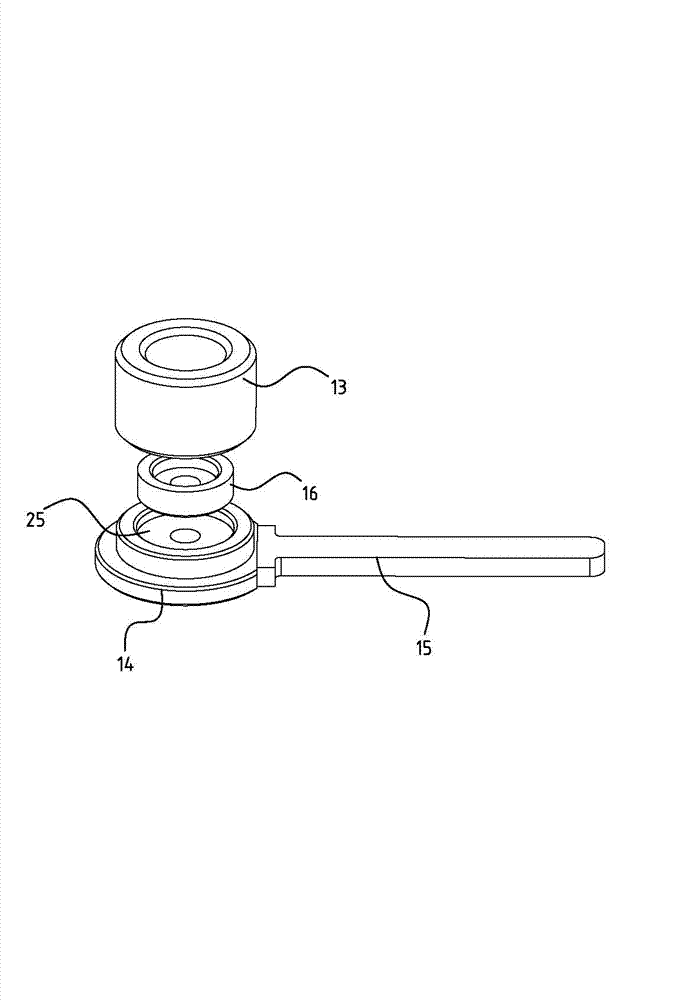

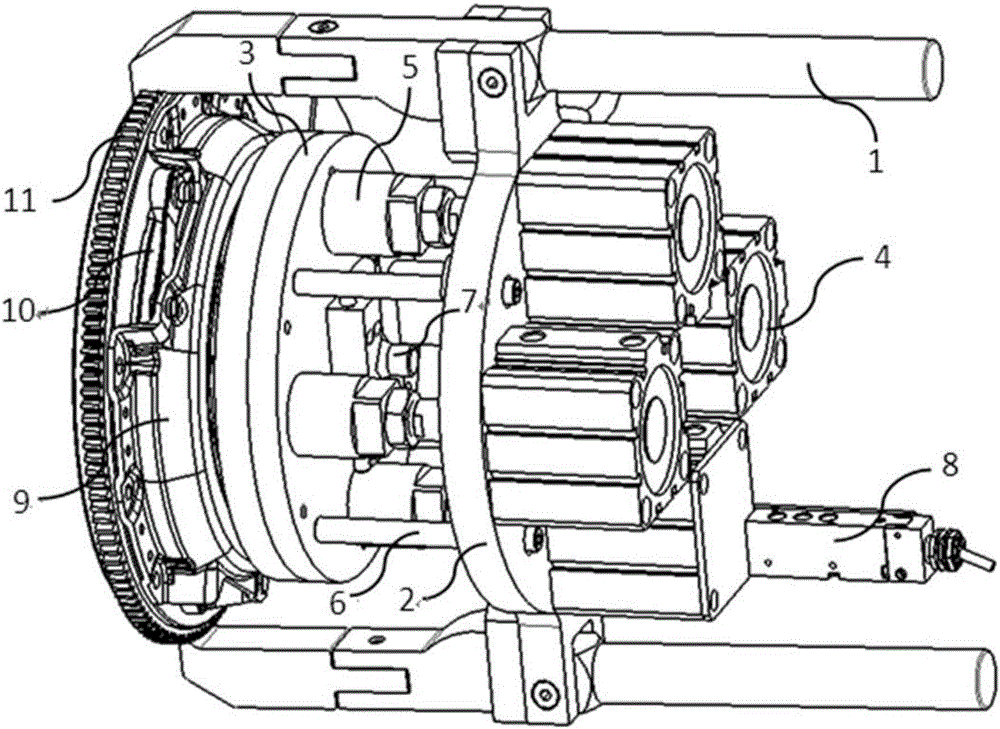

Tool for clutch assembly

ActiveCN108818417AReasonable tooling structure designImprove assembly efficiency and accuracyWork holdersMetal-working hand toolsClutchUltrasound attenuation

The invention discloses a tool for clutch assembly. The tool comprises a supporting plate and a cemtered spline shaft which is arranged on the supporting plate and used for cooperating with a hollow hole of a flywheel for locating. A set of clamping jaw mechanisms for clamping a clutch on the flywheel is arranged on the supporting plate. The tool for clutch assembly is reasonable in structural design, and assembly efficiency and precision are greatly improved. Meanwhile, stress of a mounting bolt is more even, assembly consistency is good, and the problem of torque attenuation due to uneven stress of the bolt is avoided; and the problem of shaking and abnormal sounds caused by assembling inconsistency is relieved.

Owner:CHERY AUTOMOBILE CO LTD

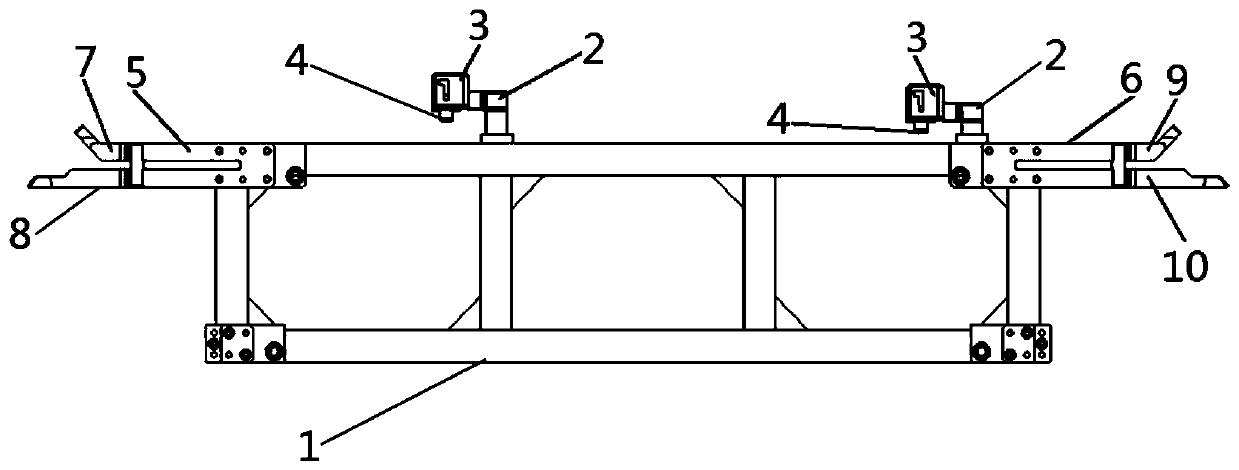

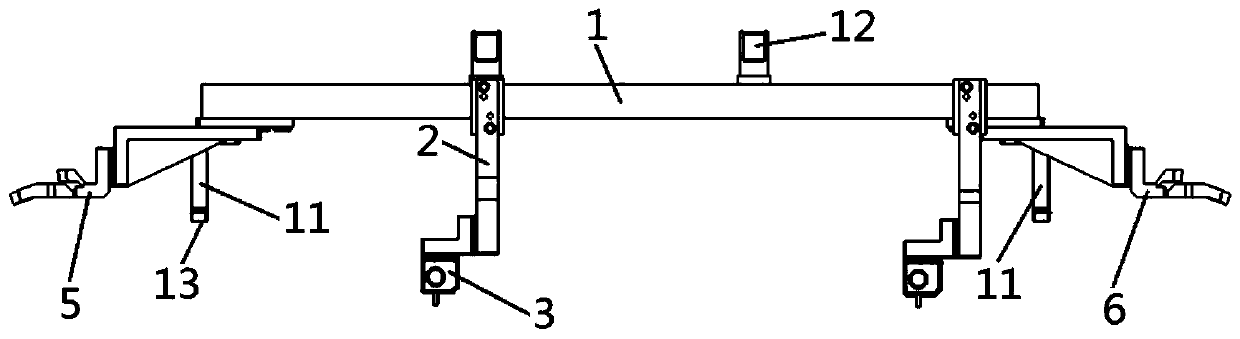

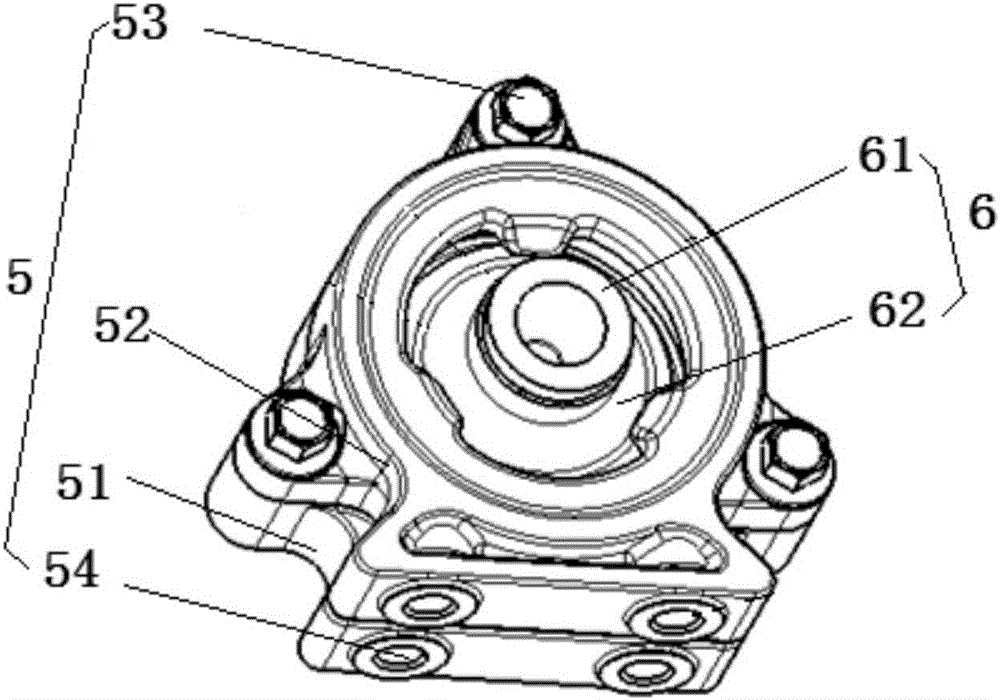

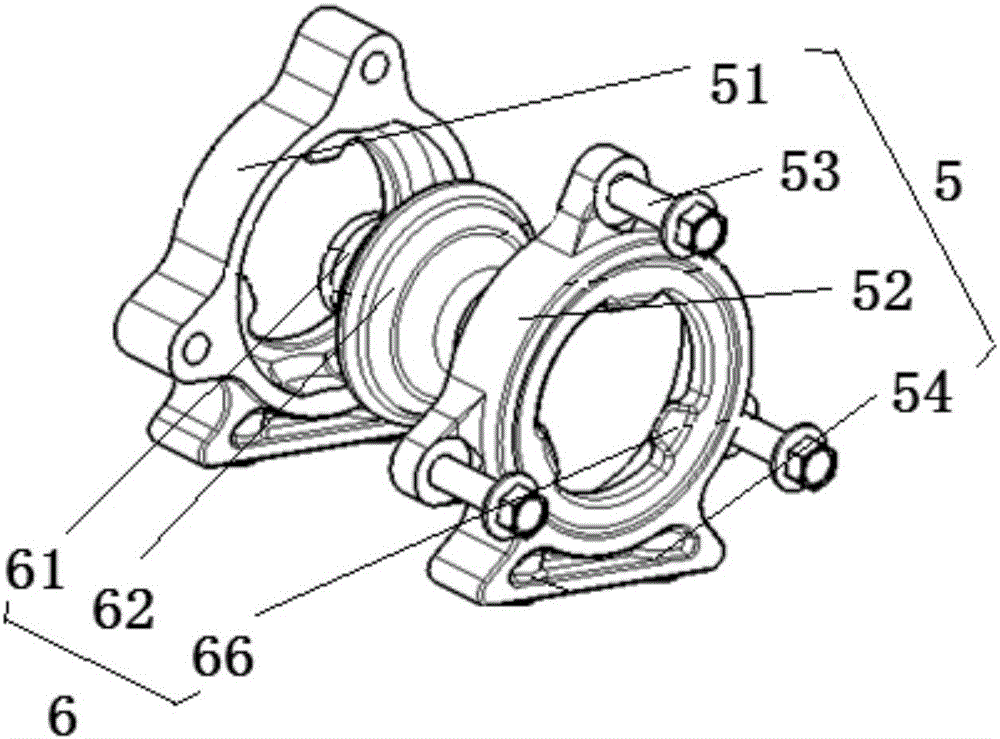

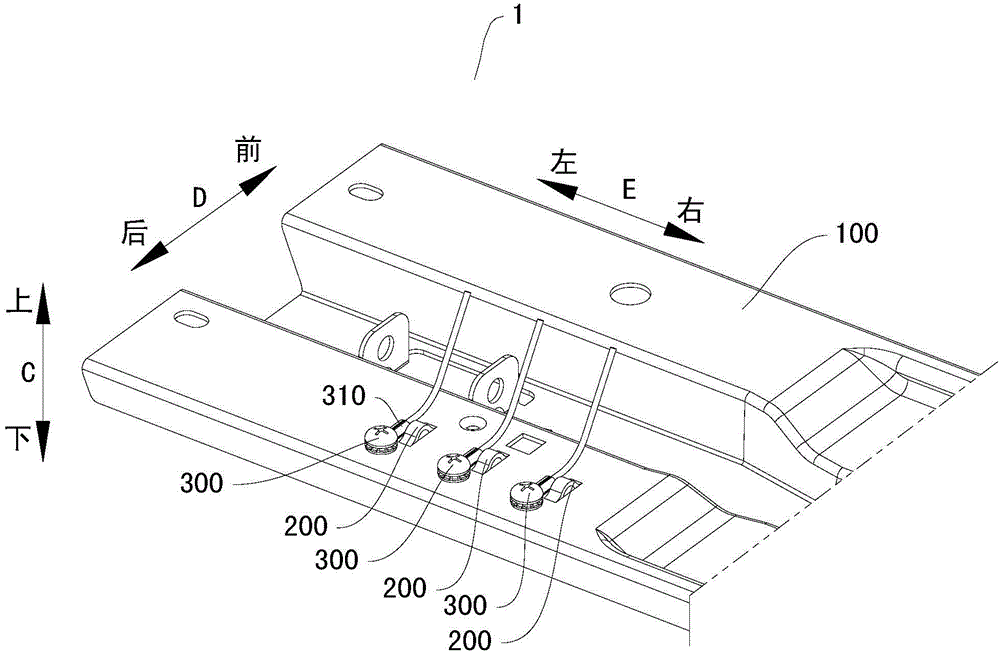

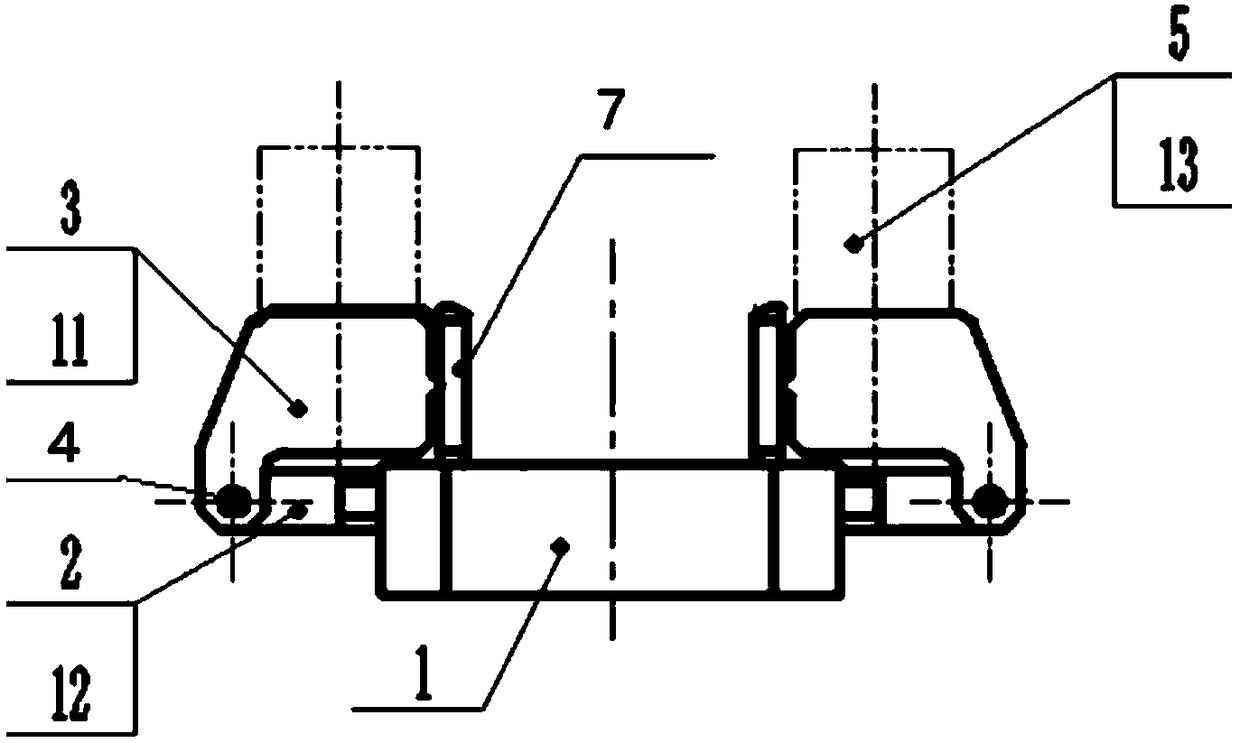

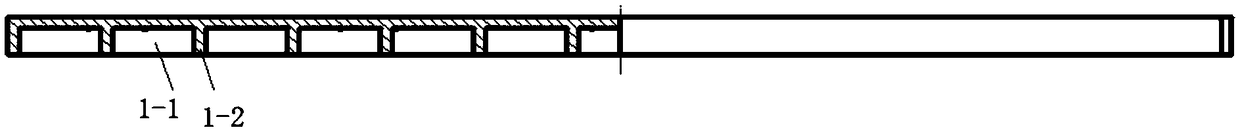

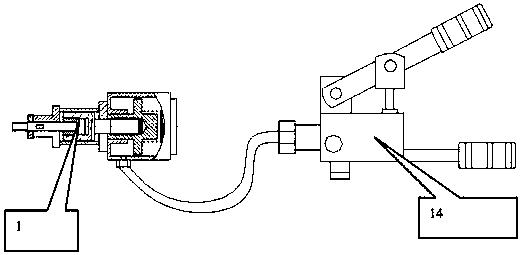

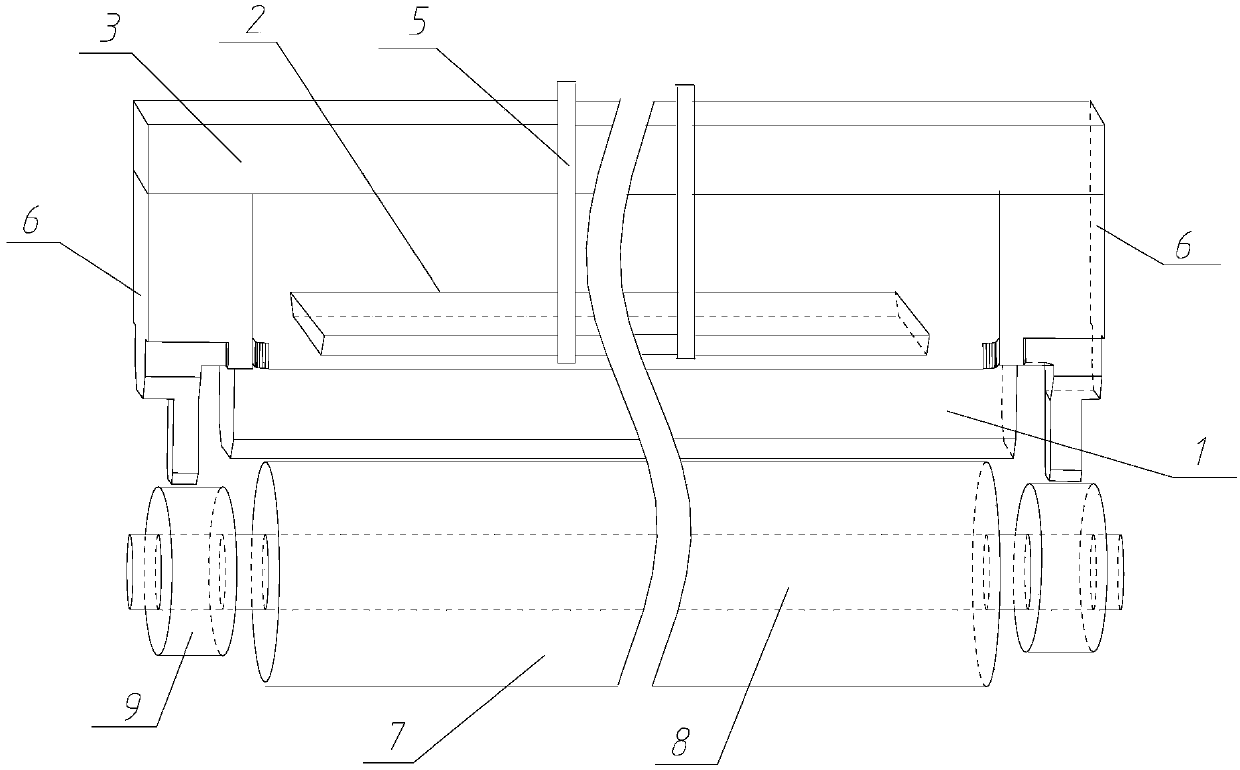

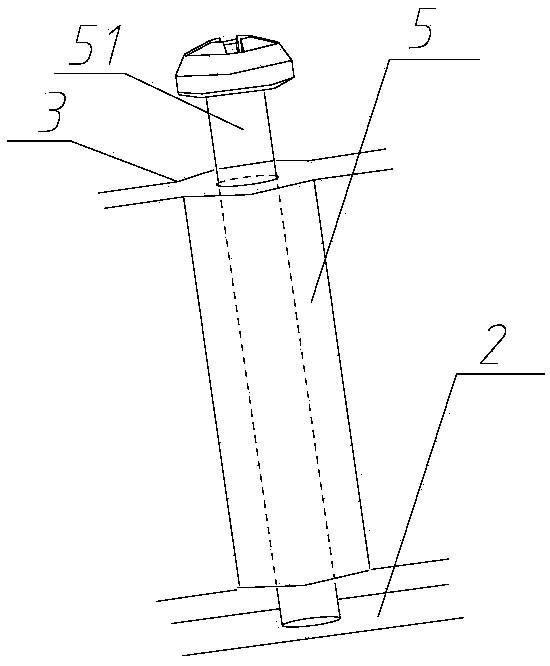

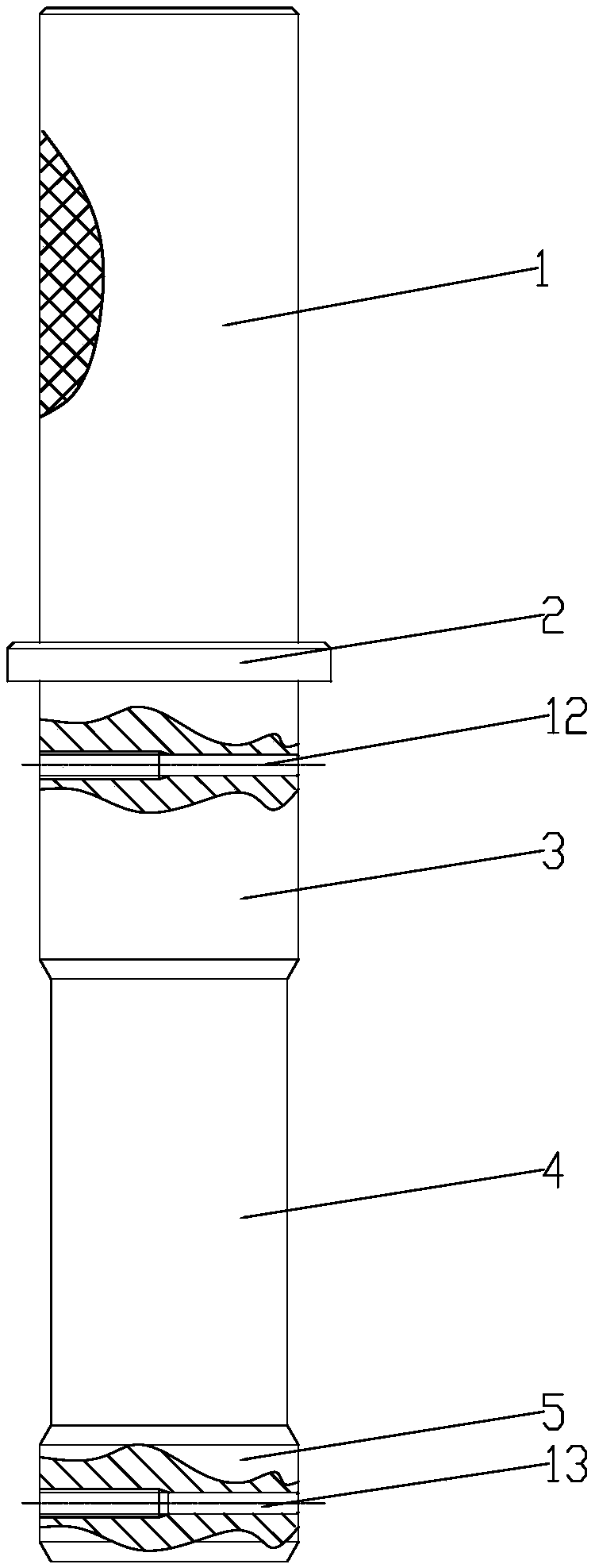

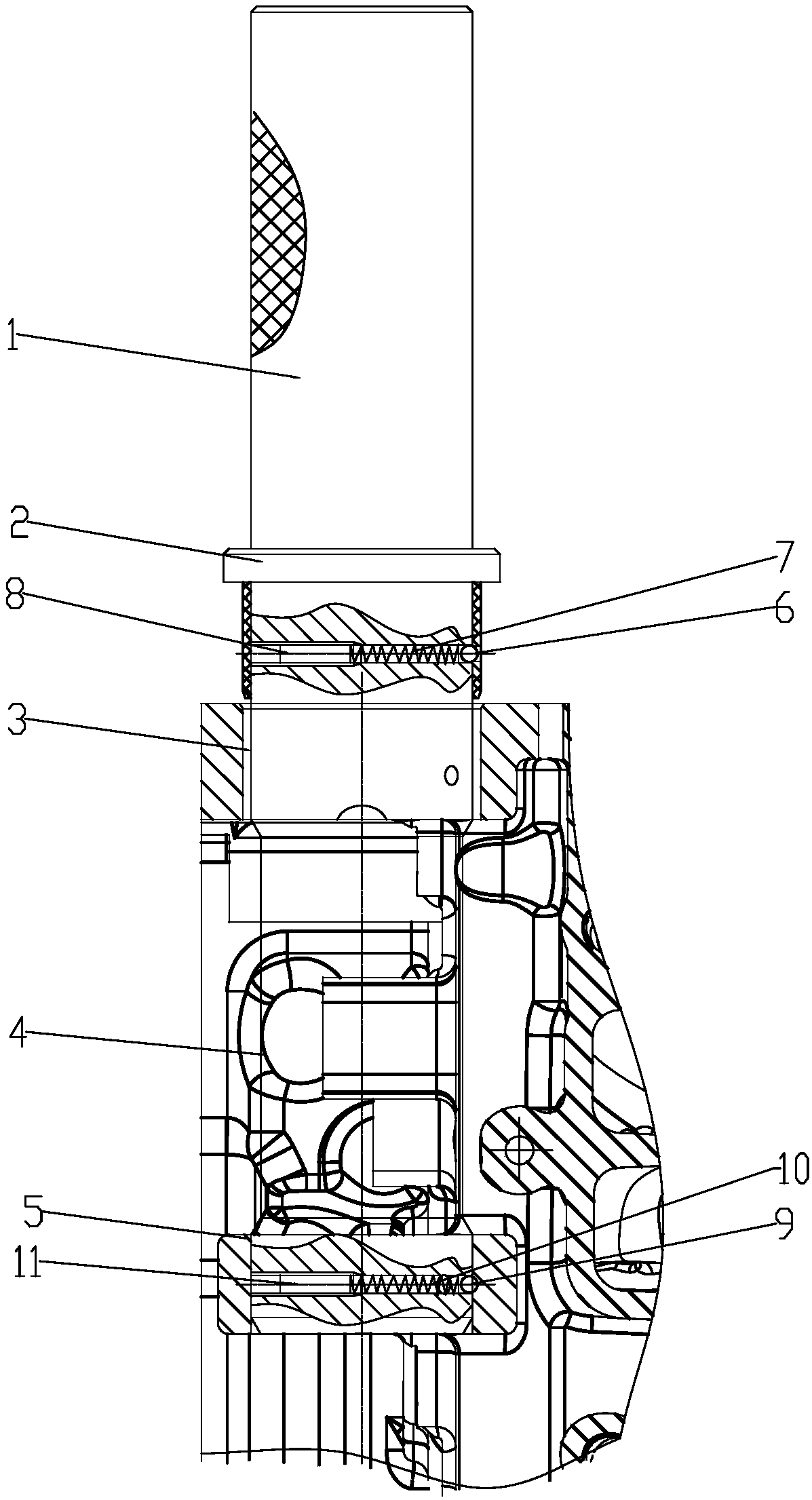

Car headlamp assembling and positioning tool

InactiveCN109823449AImprove assembly accuracyImprove Assembly ConsistencyVehiclesHeadlampEngineering

The invention provides a car headlamp assembling and positioning tool, and belongs to the technical field of car assembly auxiliary tools. Multiple connecting components (2) are arranged on the upperportion of a tool frame (1) of the car headlamp assembling and positioning tool, a car body positioning block (3) is arranged on each connecting component (2), a car body positioning pin (4) is arranged on the lower surface of each car body positioning block (3), a headlamp positioning block I (5) is arranged on one side of the tool frame (1), and a headlamp positioning block II (6) is arranged onthe other side of the tool frame (1). Car body positioning holes in one-to-one correspondence with the number and positions of the car body positioning pins (4) are arranged on the car body. The carheadlamp assembling and positioning tool is simple in structure and low in cost, and it is ensured that the space position of a car headlamp can be accurately positioned when the car headlamp is assembled, so that the assembly size consistency is good, and the labor hour is saved.

Owner:HANTENG AUTOMOBILE CO LTD

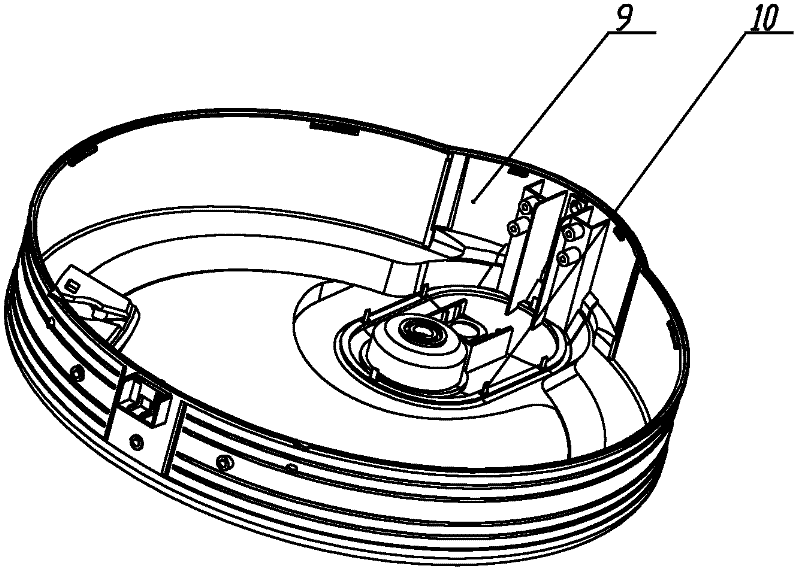

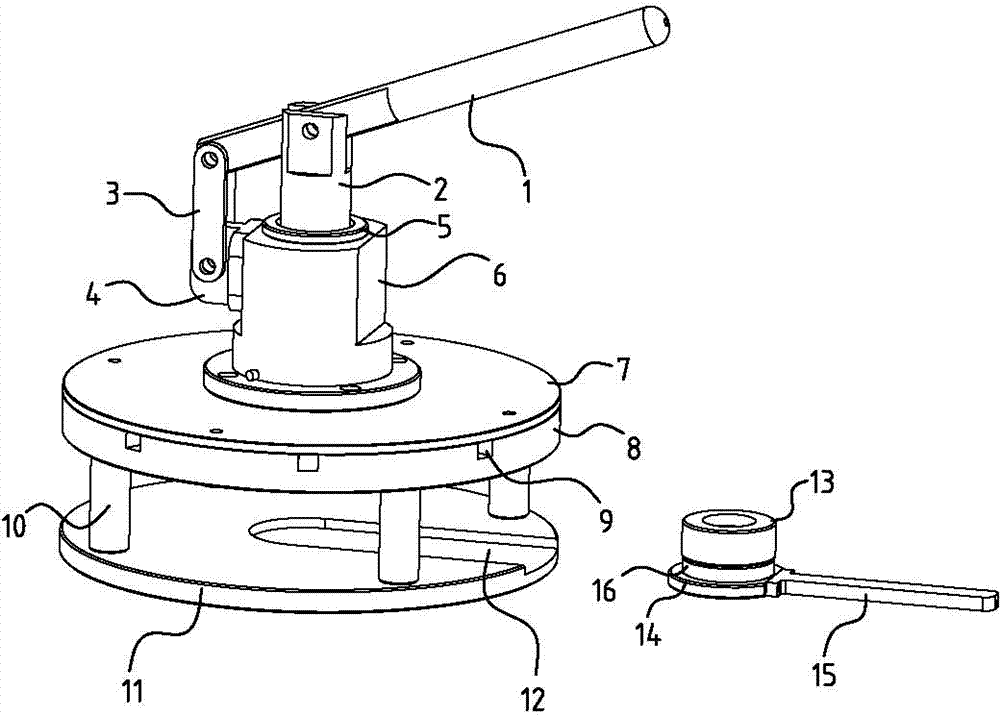

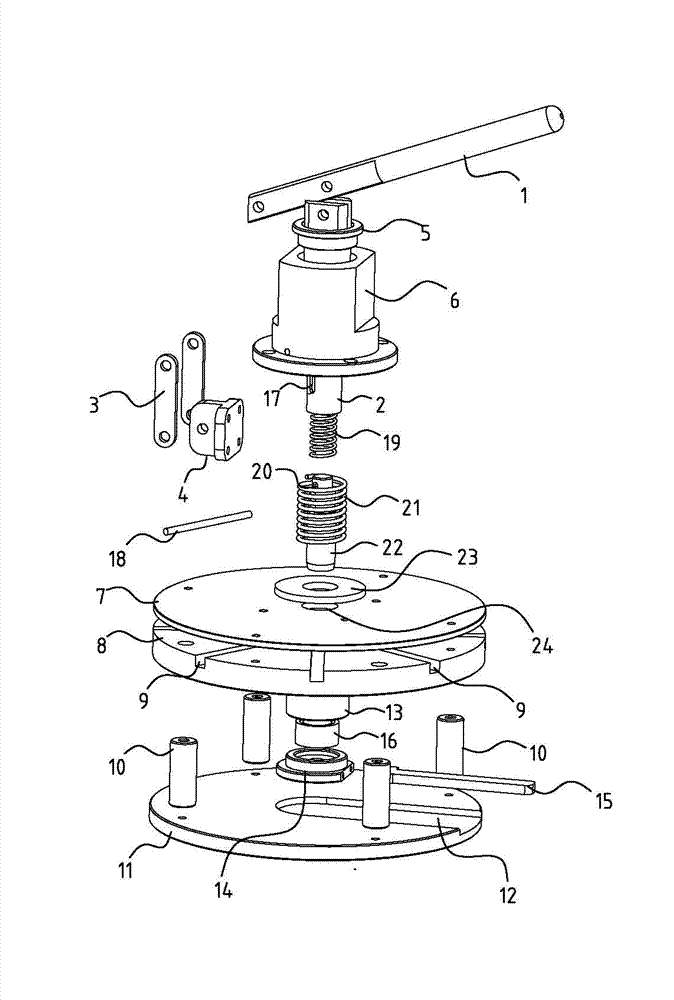

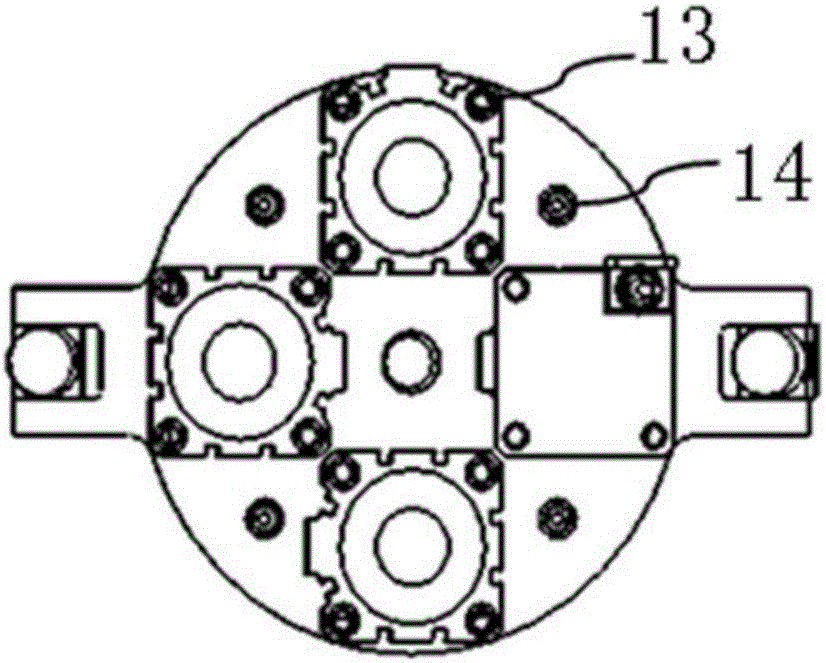

Magnetic steel assembling fixture

ActiveCN103096236AOrderly rowsGood assembly consistencyElectrical transducersArchitectural engineeringExterior space

A magnetic steel assembling fixture comprises a magnetic steel placing tray, a cover plate, a compression bar and a driving mechanism which drives the compressing bar to move up and down. A through hole is formed in middle of the magnetic steel placing tray. A plurality of grooves which are used for placing magnetic steel are formed around the through hole in the surface of the magnetic steel placing tray. One ends of the grooves are communicated with the through hole, and the other ends of the grooves are communicate with exterior space. The cover plate is arranged on the surface of the magnetic steel placing tray and a via hole is formed in the position of the through hole. The walking path of the compression bar is limited within the through hole. Containing space which is used for placing magnetic bowls is formed below the magnetic steel placing tray. The magnetic steel can be arranged on the grooves neatly. The magnetic steel which is arranged at the inner end can stretch out of the through hole. The compression mechanism is started and presses the compression bar downward, and the compression bar moves downward and penetrates through the through hole. The magnetic steel which is arranged at the inner end is taken away and pushed downward until the magnetic steel is pushed into the magnetic bowls which are below the magnetic steel placing tray, and therefore assembling of magnetic steel in the magnetic bowls is completed. The magnetic steel assembling fixture is high in assembling efficiency and safer in assembling process.

Owner:GUOGUANG ELECTRIC +1

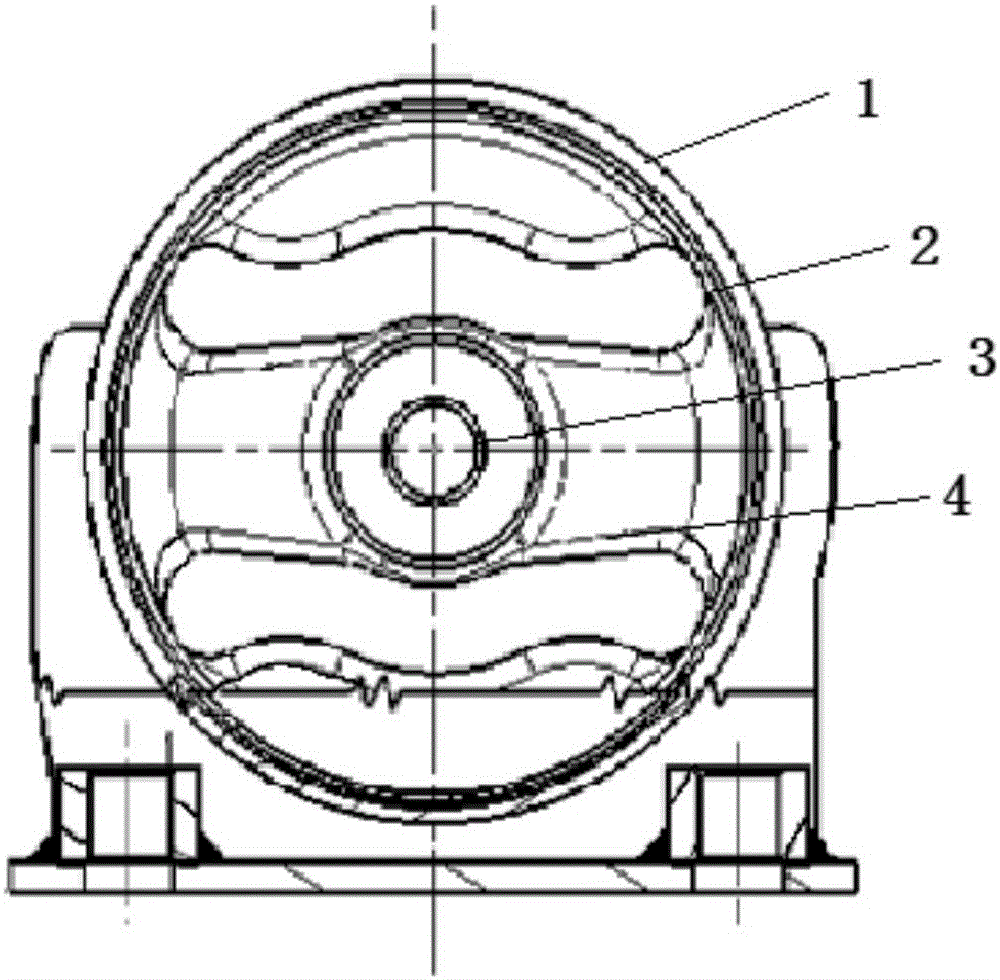

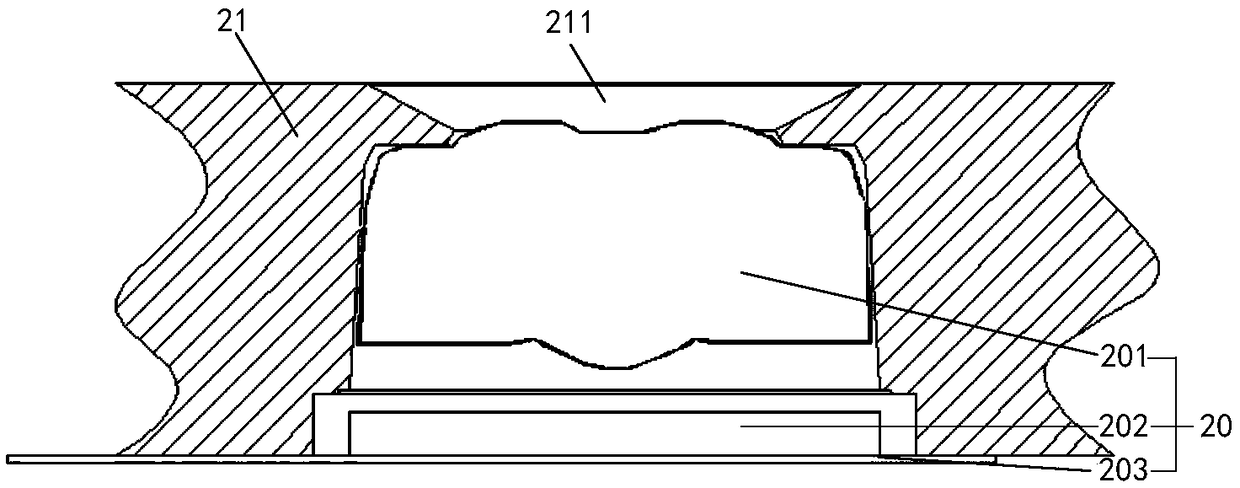

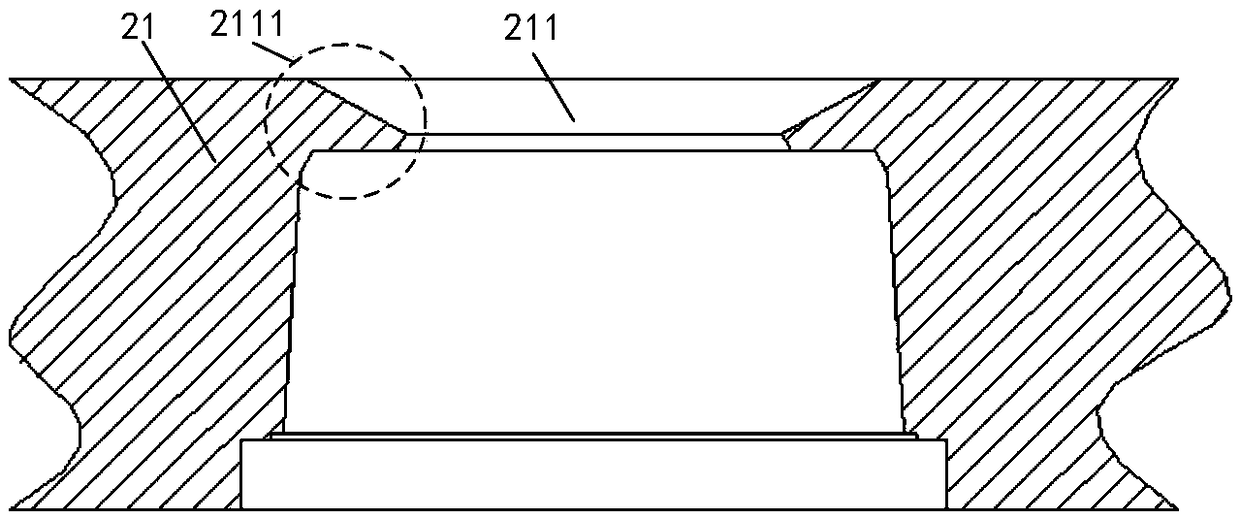

Front suspension assembly for power assembly

ActiveCN105667290ARealize motion limit effectAchieving NVH performanceNon-rotating vibration suppressionJet propulsion mountingVehicle framePowertrain

The invention provides a front suspension assembly for a power assembly, belonging to the field of vehicles. The front suspension assembly comprises a suspension bracket and an inner tube component. The suspension bracket can be fixedly connected with an auxiliary frame, the suspension bracket comprises a first bracket and a second bracket, and an accommodation space is formed between the first bracket and the second bracket; the inner tube component comprises an inner tube and a rubber mainspring, the rubber mainspring and the inner tube are vulcanized into an integrated structure, the inner tube component is arranged in the accommodation space and can move freely relative to the accommodation space, and through the matching of the inner tube component and the suspension bracket, the front suspension assembly is not stressed in the process that an engine is fully static or the engine produces incentives. By adopting the front suspension assembly for the power assembly, the front suspension assembly is not stressed in the process that the engine is fully static or the engine produces incentives, therefore the effects of reducing vibration transfer paths and eliminating over-constraints are achieved, and better NVH (Noise, Vibration and Harshness) performances can be realized.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

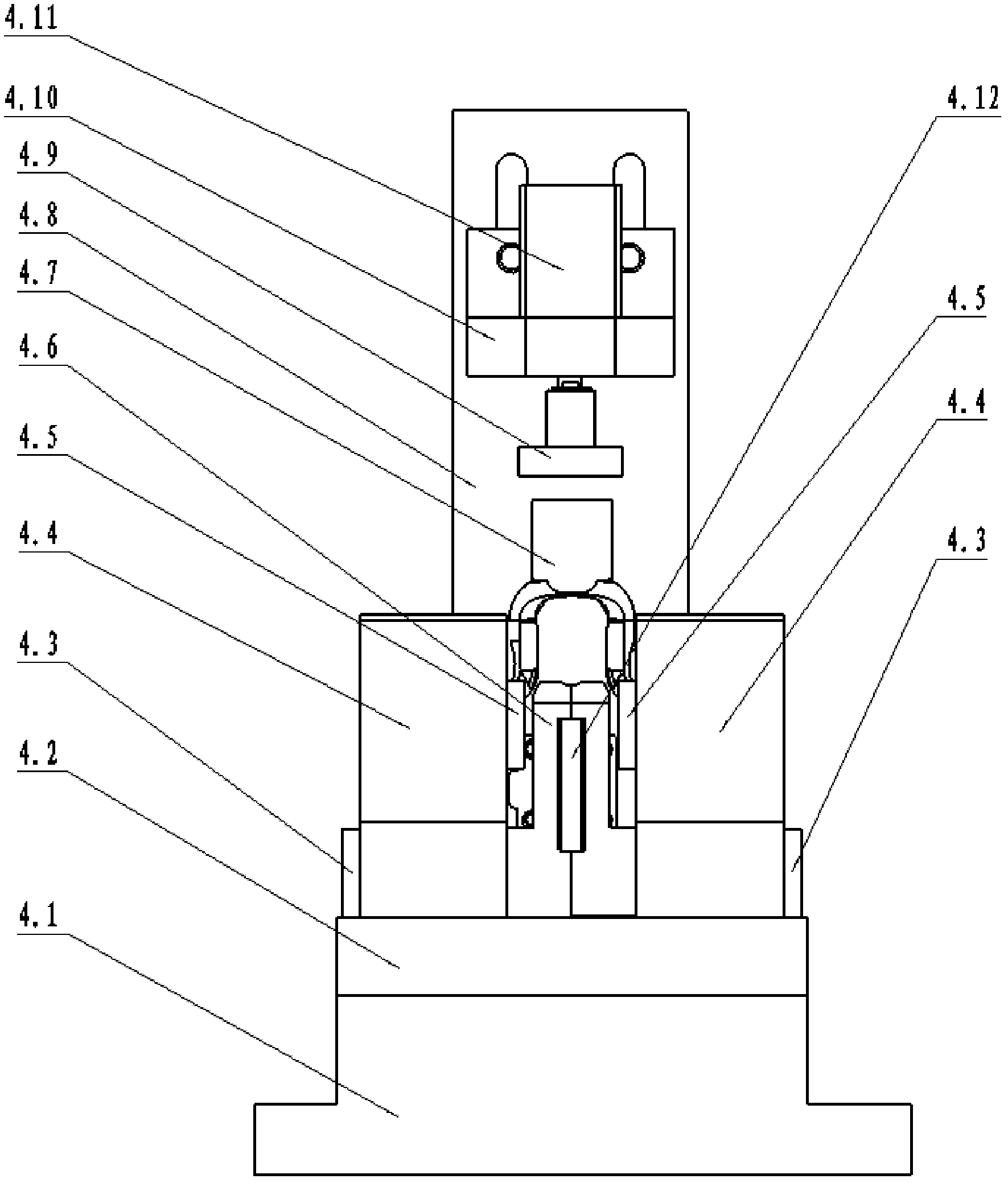

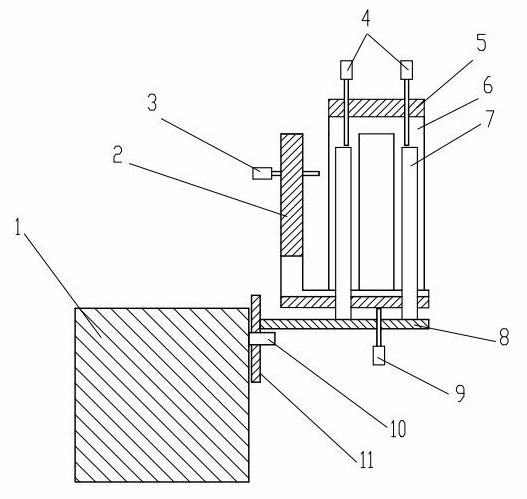

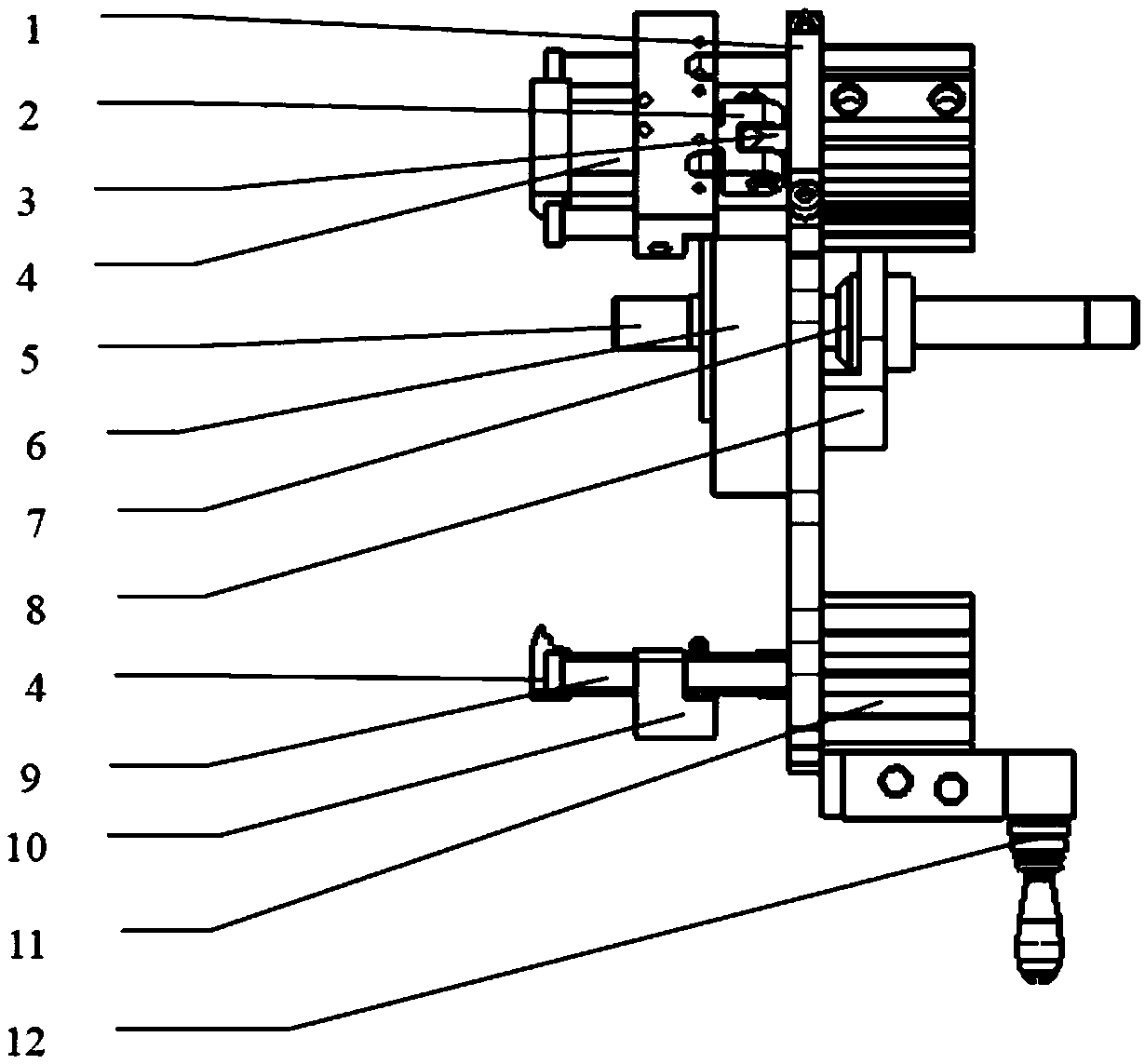

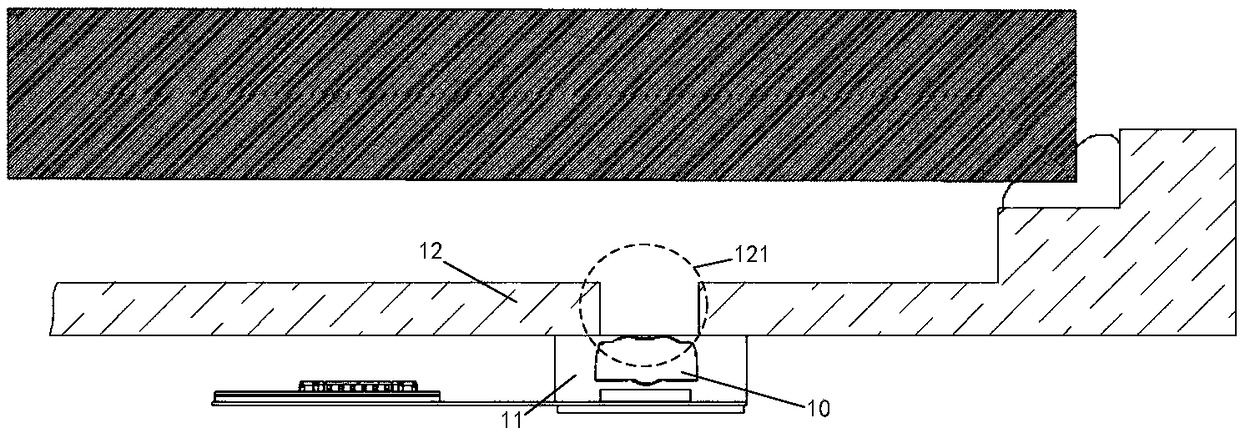

Machine for automatically tightening wheel hub adjustment nut with holes, realizing hole alignment and measuring pre-tightening force and use method of machine

ActiveCN108680299ASafe and reliable tightening operationSimple and efficient operationMeasurement of torque/twisting force while tighteningEngineeringLaser sensor

The invention discloses a machine for automatically tightening a wheel hub adjustment nut with holes, realizing hole alignment and measuring a pre-tightening force and a use method of the machine andbelongs to the engineering machinery assembly field. The machine comprises a counter-force measuring device, a nut tightening machine, a nut tightening disc, a sensor mounting disc, a laser sensor, ameasuring shaft and a PLC; the counter-force measuring device is connected with the output shaft of the nut tightening machine; the output end of the nut tightening machine is connected with the sensor mounting disc; the sensor mounting disc is connected with the nut tightening disc; the laser sensor is fixed on the sensor mounting disc; the measuring shaft is meshed with the counter-force measuring device through a gear; the PLC is connected with and controls a tightening shaft controller, a measuring shaft controller and the laser sensor. The invention also discloses a use method of the above machine. With the machine and the use method thereof of the invention adopted, the tightening of the wheel hub adjustment nut, the synchronous measurement of the pre-tightening force and the automatic alignment of the holes of the adjustment nut can be realized simultaneously; operation is automated; tightening is safe and reliable; and measurement is accurate.

Owner:SHANDONG LINGONG CONSTR MACHINERY

Arc chute sheet assembling and pressing device for circuit breaker

ActiveCN102825455ASimple structureEasy to operateMetal working apparatusLow voltage circuitsCircuit breaker

The invention relates to assembling equipment of a low-voltage circuit breaker, and particularly relates to an arc chute sheet assembling and pressing device for a circuit breaker, which is used for tightly pressing and assembling arc chute sheets arranged at intervals on a pair of flash barriers. The arc chute sheet assembling and pressing device comprises a base; a chute sheet base is arranged at the middle part of the base; vertical parallel clamping grooves are arranged on the chute sheet base; a distance between the clamping grooves is equal to a distance between the arc chute sheets to be assembled; the arc chute sheets to be assembled can be vertically placed in each clamping groove; the front and the back of the chute sheet base are respectively provided with a pressing board driven by an air cylinder; and a concave cavity matched with a flash barrier of a product to be assembled in width is arranged on the vertical face at the inner side of the pressing board. The arc chute sheet assembling and pressing device provided by the invention has the advantages of simple structure and convenience in operation; the tight pressing operation is carried out on the arc chute sheets and the flash barrier through a pair of the pressing boards driven by the air cylinder, so that the arc chute sheets and the flash barrier can be uniformly stressed, and the assembling consistence is good; and an assembling process is completed through one-step motion, so that the assembling efficiency can be improved, and the labor intensity is reduced.

Owner:JIANGSU DAQO KFINE ELECTRIC

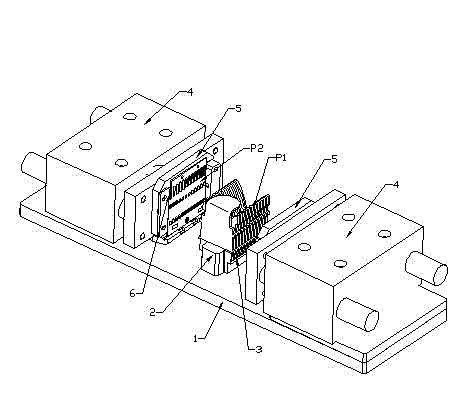

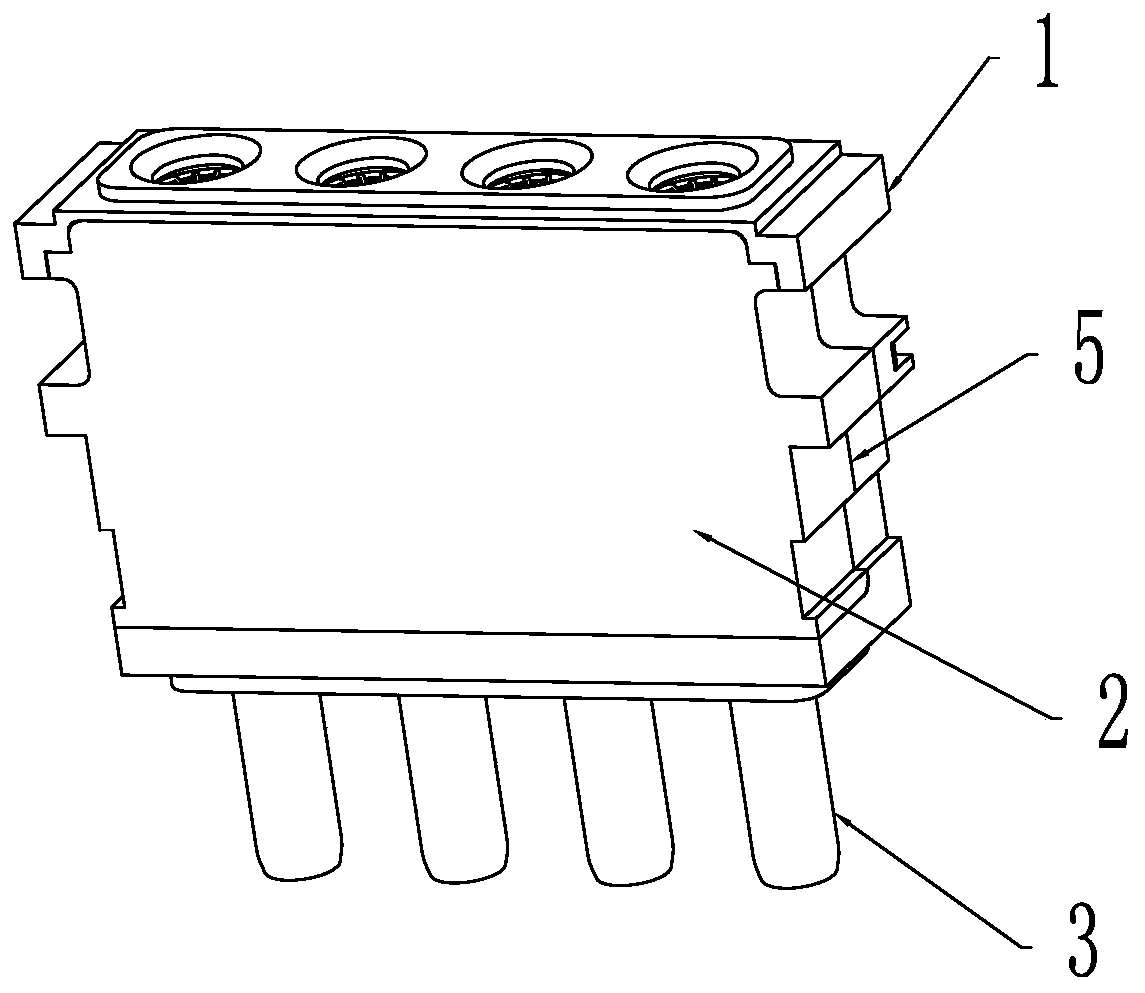

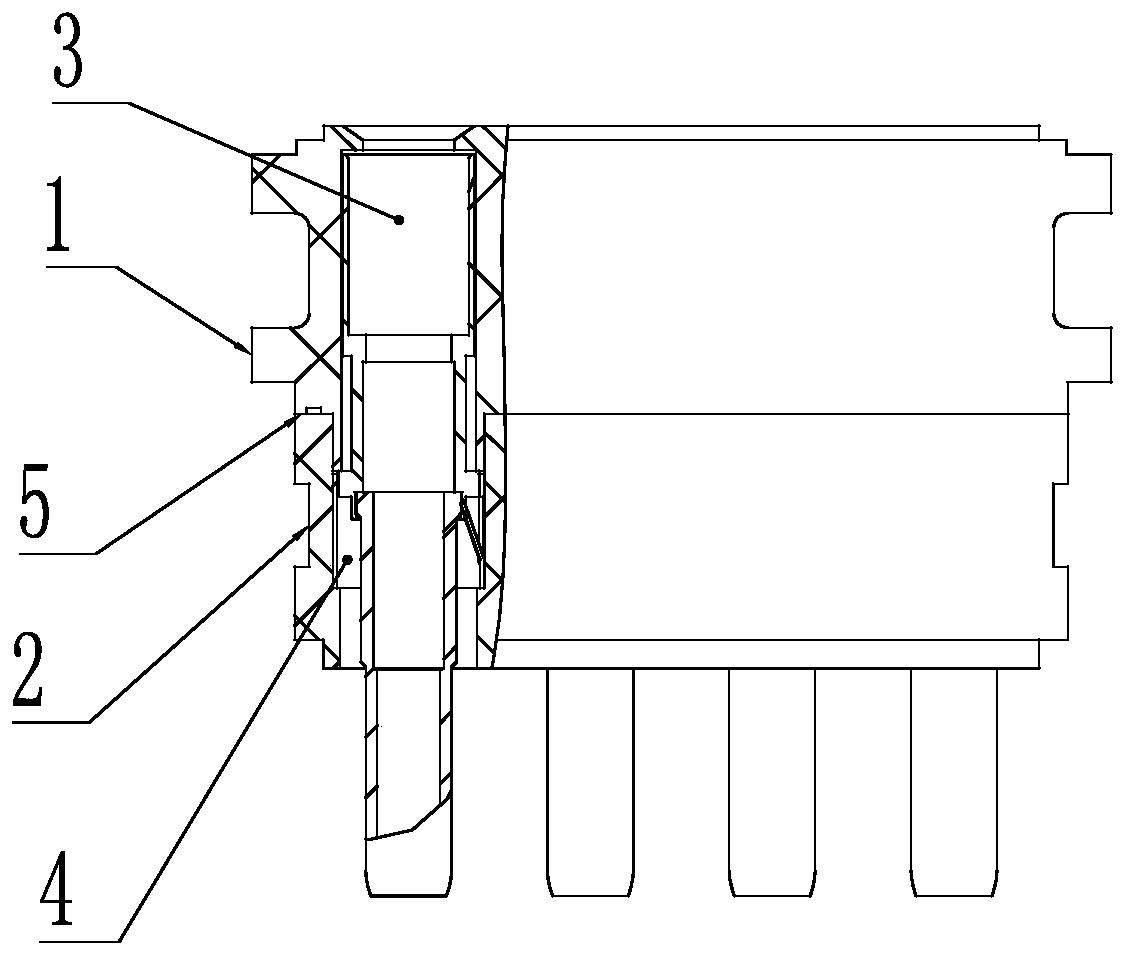

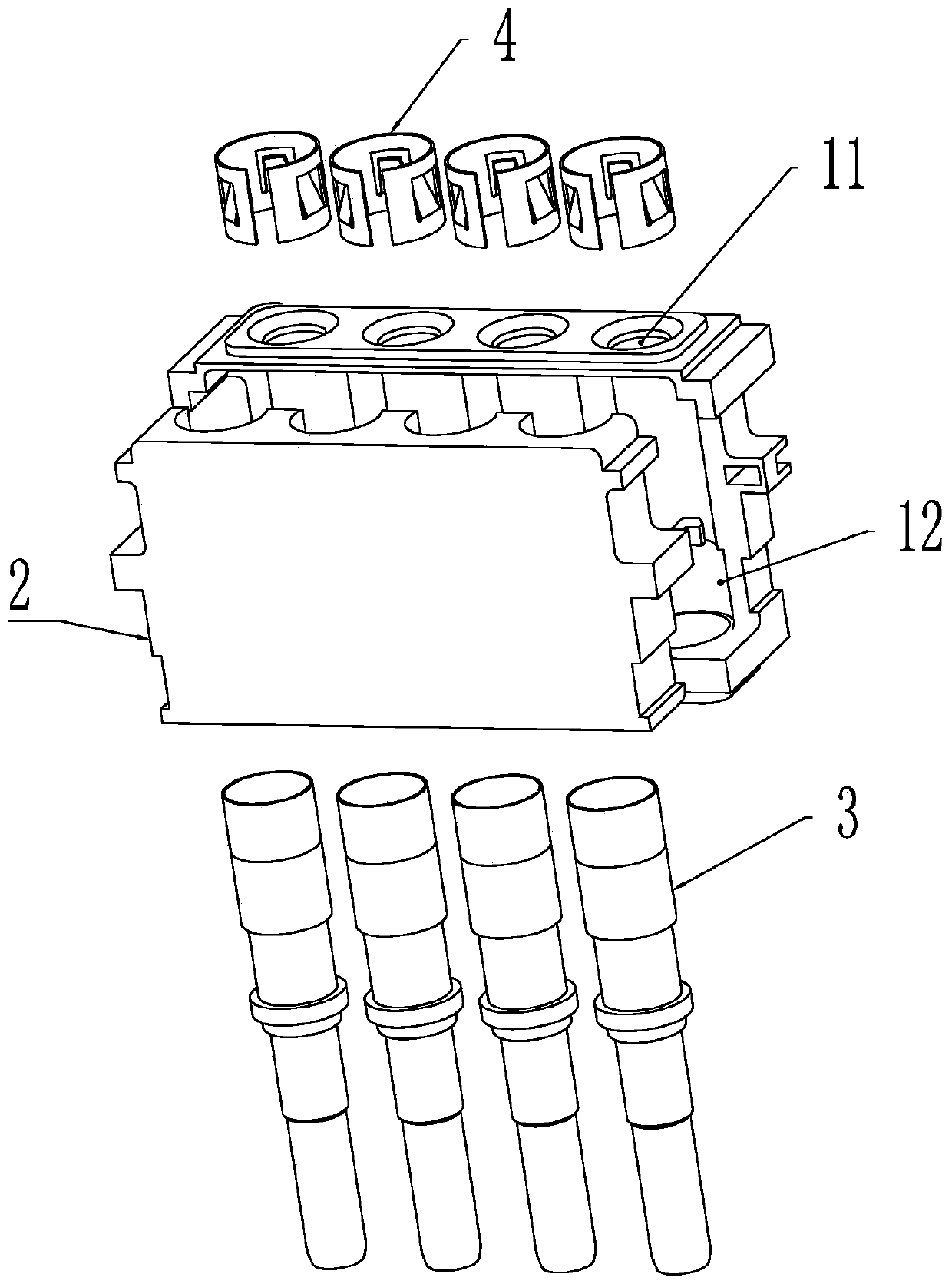

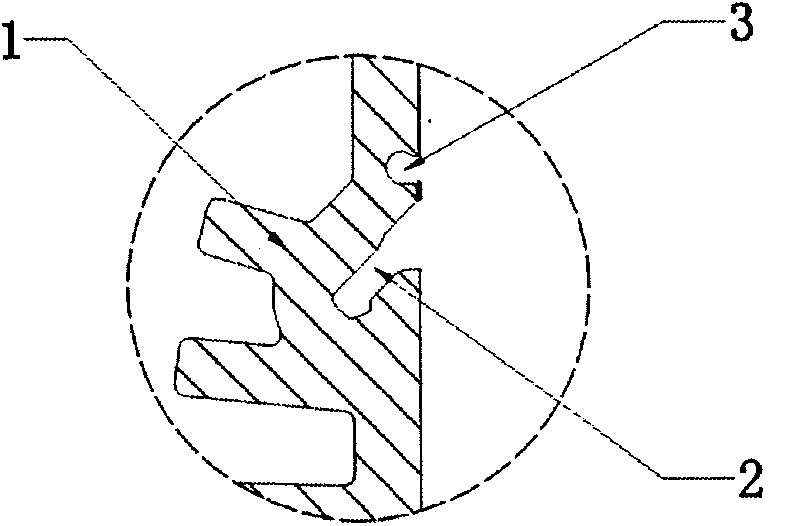

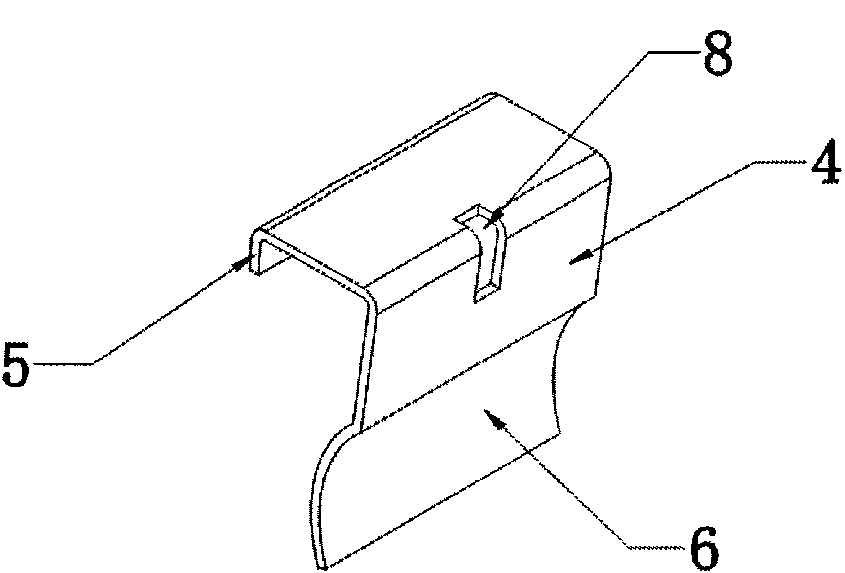

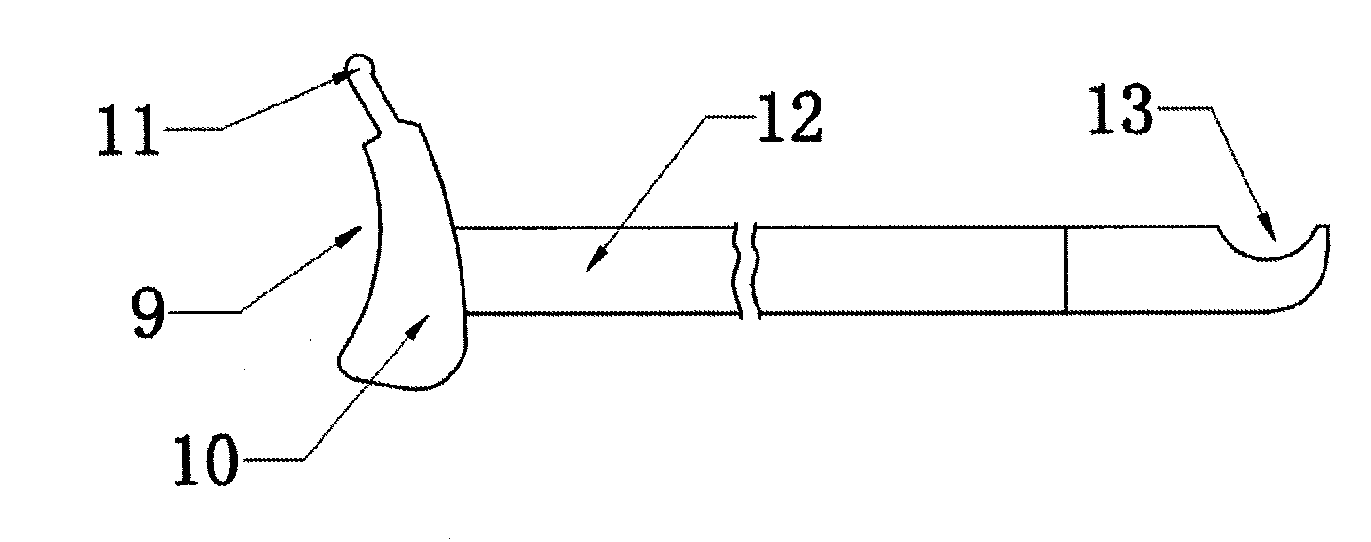

Side buckled modular connector

ActiveCN110247240AImprove Assembly ConsistencyIncrease productivityCoupling device detailsEngineeringModular connector

The invention relates to a side buckled modular connector. The side buckled modular connector includes an insulator (1), an insulation pressing plate (2) and a contact member (3) assembled in the insulator, wherein the insulation pressing plate (2) is buckled with a side surface of the insulator (1) to form a combination surface (5), and the combination surface (5) and an insertion direction of the contact member (3) are in non-perpendicular setting. The connector is advantaged in that the insulator and the insulation pressing plate are in side surface buckling matching mode, the combination surface (5) and the insertion direction of the contact member (3) are in a non-perpendicular setting mode, during operation, the combination surface bears no force, a force bearing point is on the insulator, product quality consistency and reliability of the modular connector are guaranteed, and problems of difficulty in detecting connector quality and lower production efficiency are solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Heat-dissipating fastener fixing structure and tool for demounting heat-dissipating fastener

InactiveCN103545274AReduce drillingEasy to disassembleSemiconductor/solid-state device detailsSolid-state devicesPunchingEngineering

The invention discloses a heat-dissipating fastener fixing structure and a tool for demounting a heat-dissipating fastener. The heat-dissipating fastener fixing structure comprises a chute and a heat-dissipating fastener body. The chute is formed at the back of a heat-dissipating device, and a fastening groove is formed above the chute. The heat-dissipating fastener body is a U-shaped plate with a long side and a short side. A section of inwards-recessed arc-shaped face is arranged on the long side of the heat-dissipating fastener body. The short side of the heat-dissipating fastener body can be fastened in the chute. The arc-shaped face on the long side of the heat-dissipating fastener body can be pressed on a power element at the back of the heat-dissipating device. A gap is formed between the long side of the heat-dissipating fastener body and the bottom side of the U-shaped plate. The heat-dissipating fastener fixing structure has the advantages that demounting of the heat-dissipating fastener body is facilitated, assembly efficiency is obviously improved, reliable fit of the power element and the heat-dissipating device is guaranteed, uniformity in assembly is good, process steps such as punching of the heat-dissipating device and shaping of the power element are reduced, and the heat-dissipating fastener fixing structure is simple in structure, convenient to process, high in assembly efficiency, good in uniformity and reliable in fixation.

Owner:青岛美奂电子科技有限公司

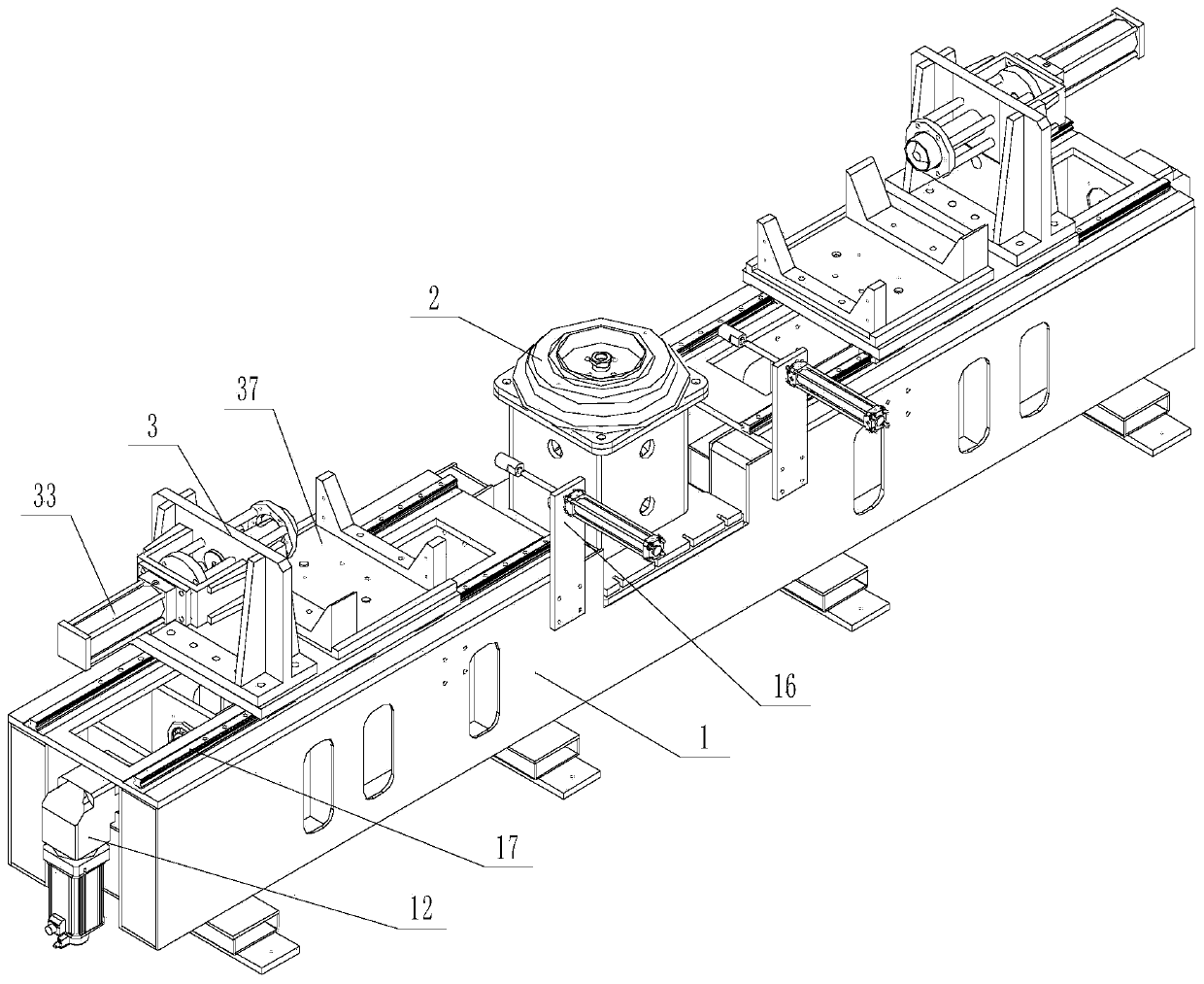

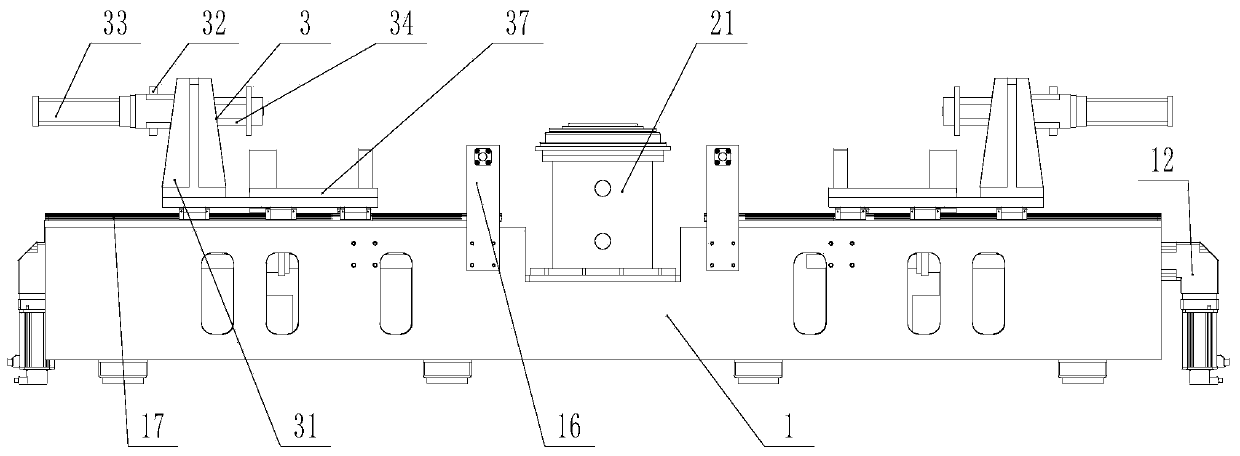

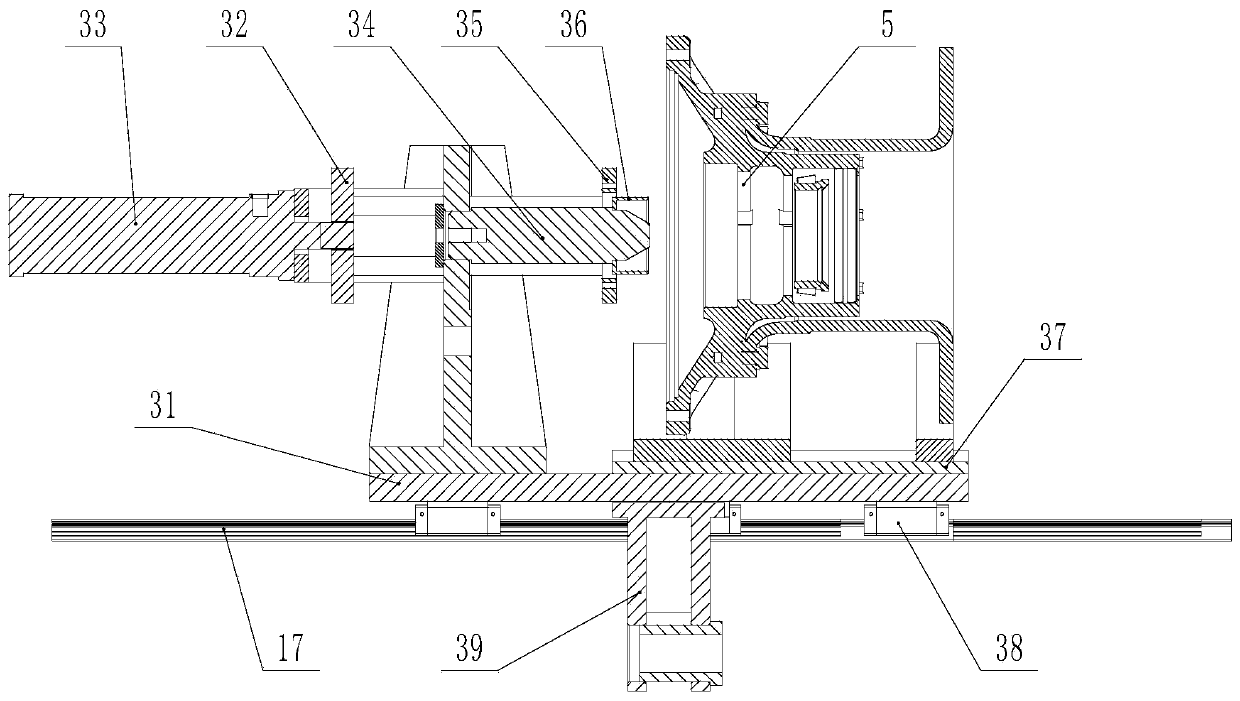

Automatic press-fitting machine for hub assemblies of drive axles

PendingCN111069882APress fit is reliableEliminates the risk of damaging hub oil sealsMetal working apparatusMachineAssembly line

The invention discloses an automatic press-fitting machine for hub assemblies of drive axles, and belongs to the technical field of axle assembly. The automatic press-fitting machine for the hub assemblies of the drive axles overcomes the defects of high labor intensity, low efficiency and difficulty in guaranteeing the quality of traditional hub assembly press-fitting in the prior art. A main structure of the automatic press-fitting machine includes a machine tool body assembly, a positioning assembly and a positioning press-fitting assembly, and the positioning assembly and the positioning press-fitting assembly are separately installed on the machine tool body assembly. The automatic press-fitting machine is mainly used for the automatic press-fitting of the hub assemblies of axle assembly lines of construction machinery loader drive axles and heavy truck drive axles.

Owner:SHANDONG LINGONG CONSTR MACHINERY

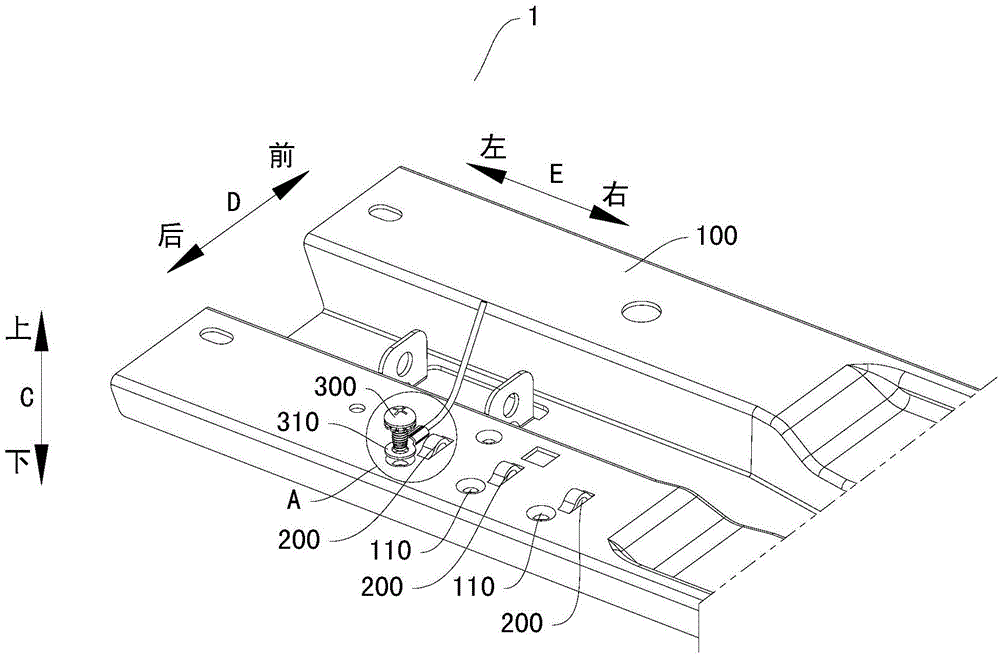

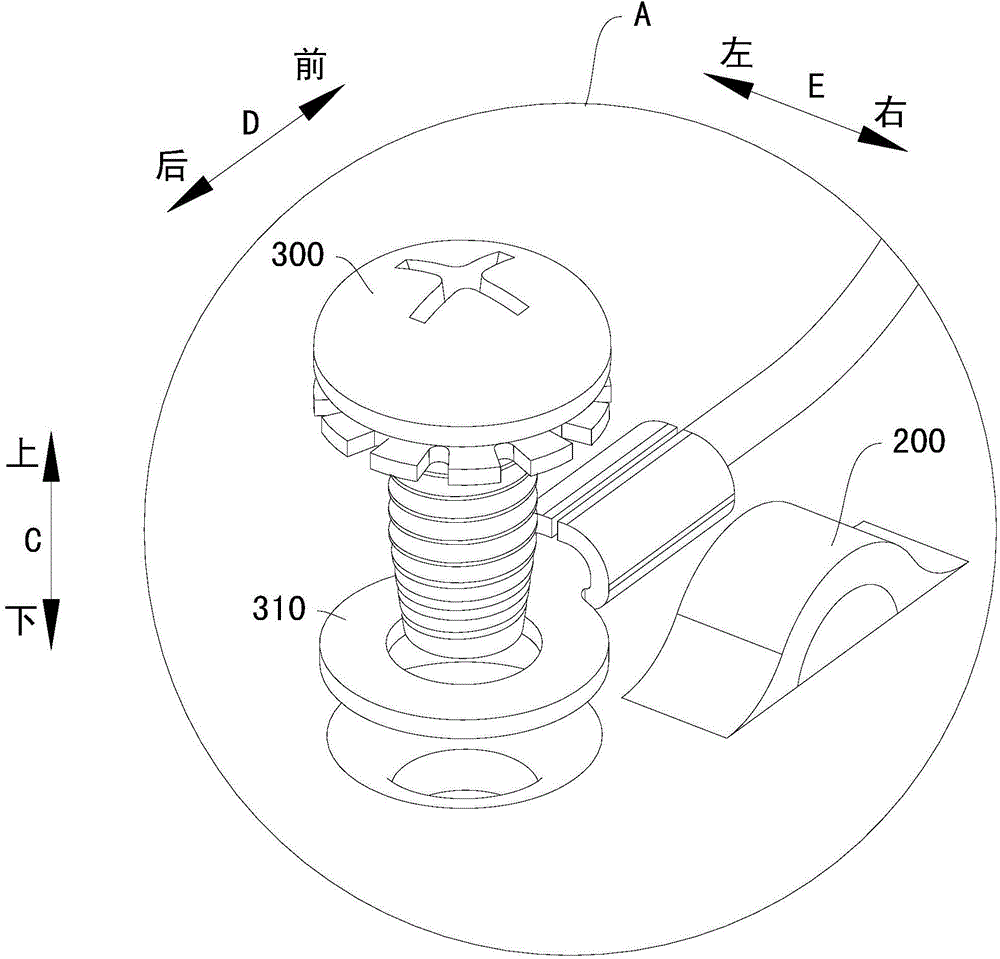

Compressor mounting plate used for refrigerator and refrigerator provided with same

InactiveCN104792099AEasy to assembleImprove Assembly ConsistencyLighting and heating apparatusRefrigeration devicesGround StrapEngineering

The invention discloses a compressor mounting plate used for a refrigerator and the refrigerator provided with the same. The compressor mounting plate used for the refrigerator comprises a plate body and ground wire positioning protrusions, wherein the plate body is provided with ground wire screw hole, the ground wire positioning protrusions are arranged on the plate body and are next to the ground wire screw holes, each ground wire screw located inside the corresponding ground wire screw hole in a matched mode is sleeved with a ground wire ground strap, and the side faces of the ground wire ground straps are stopped by the ground wire positioning protrusions. The compressor mounting plate used for the refrigerator can bring convenience to assembly, improve assembly consistence and relieve the labor intensity, and has the advantages of being high in reliability, good in safety and the like.

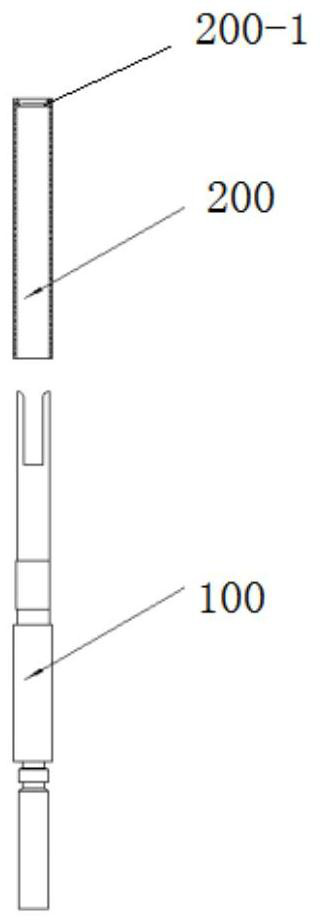

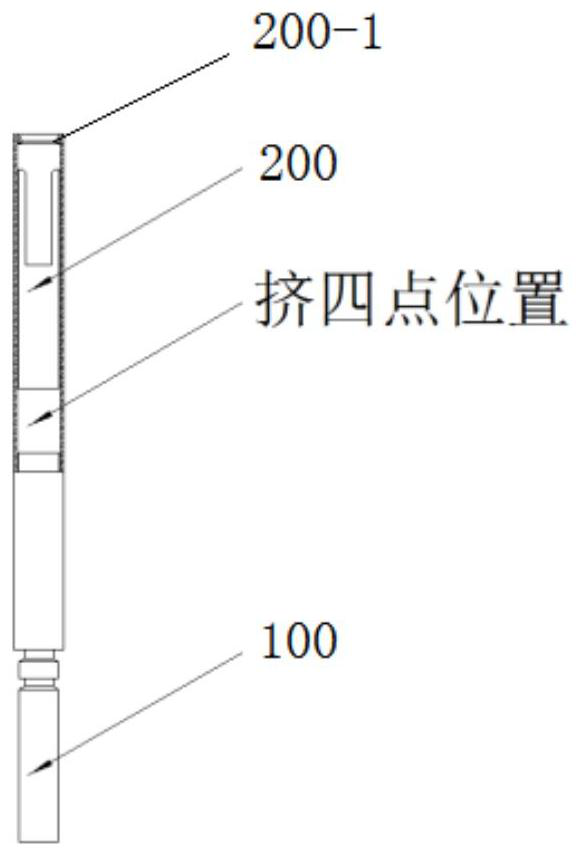

Automatic assembling equipment for riveting and extruding points of jacks and protection sleeves and assembling method thereof

PendingCN112517774AImplement automatic assemblyAchieve squeeze pointContact member assembly/disassemblyMetal-working feeding devicesProtection KITMechanical engineering

The invention provides automatic assembling equipment for riveting and extruding points of jacks and protection sleeves. The automatic assembly equipment comprises a frame assembly, a rotating tool assembly, a jack staggering and separating assembly, a jack feeding assembly, a protection sleeve detecting assembly, a protection sleeve direction selecting assembly, a protection sleeve feeding assembly, a bidirectional riveting and pressing assembly, an adjustable stroke point extruding assembly and a finished product discharging assembly. The invention further provides an assembling method of the automatic assembling equipment. The automatic assembling equipment is full-automatic equipment, can achieve automatic assembling, riveting and point extruding of jack parts and protection sleeve parts and can achieve automatic feeding and discharging; manual operation is not needed; the automatic assembling equipment is safe and stable; and the problems that the manual assembly efficiency is low, the workload is heavy, the assembling method is complex, and the requirements on the proficiency degrees of operators are high are solved. The assembling time and the consistency of the jacks and the protection sleeves are greatly improved; the quality problem is avoided; and the automatic assembling equipment has an important application value in an assembling process of the jacks and the protection sleeves.

Owner:沈阳兴华航空电器有限责任公司

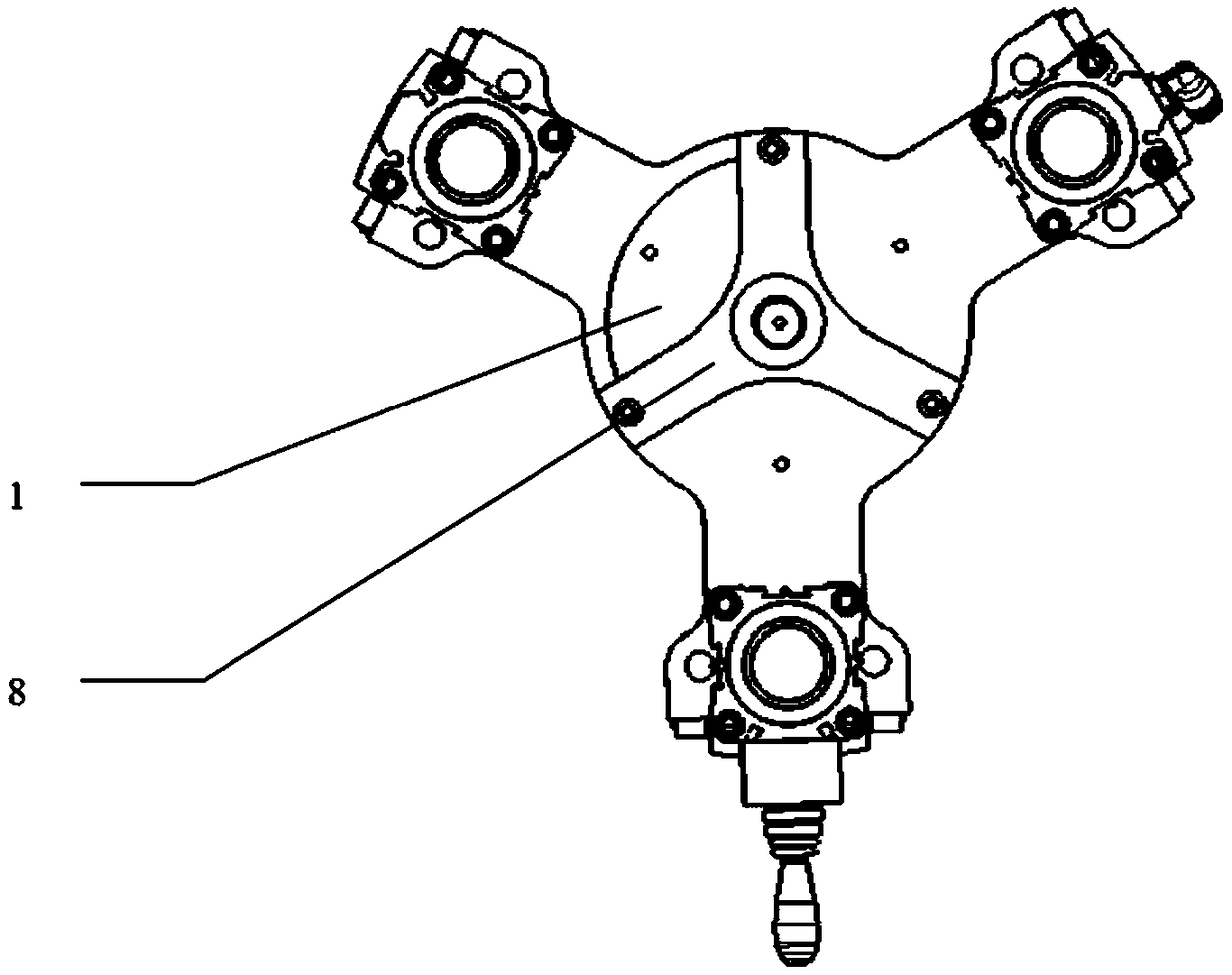

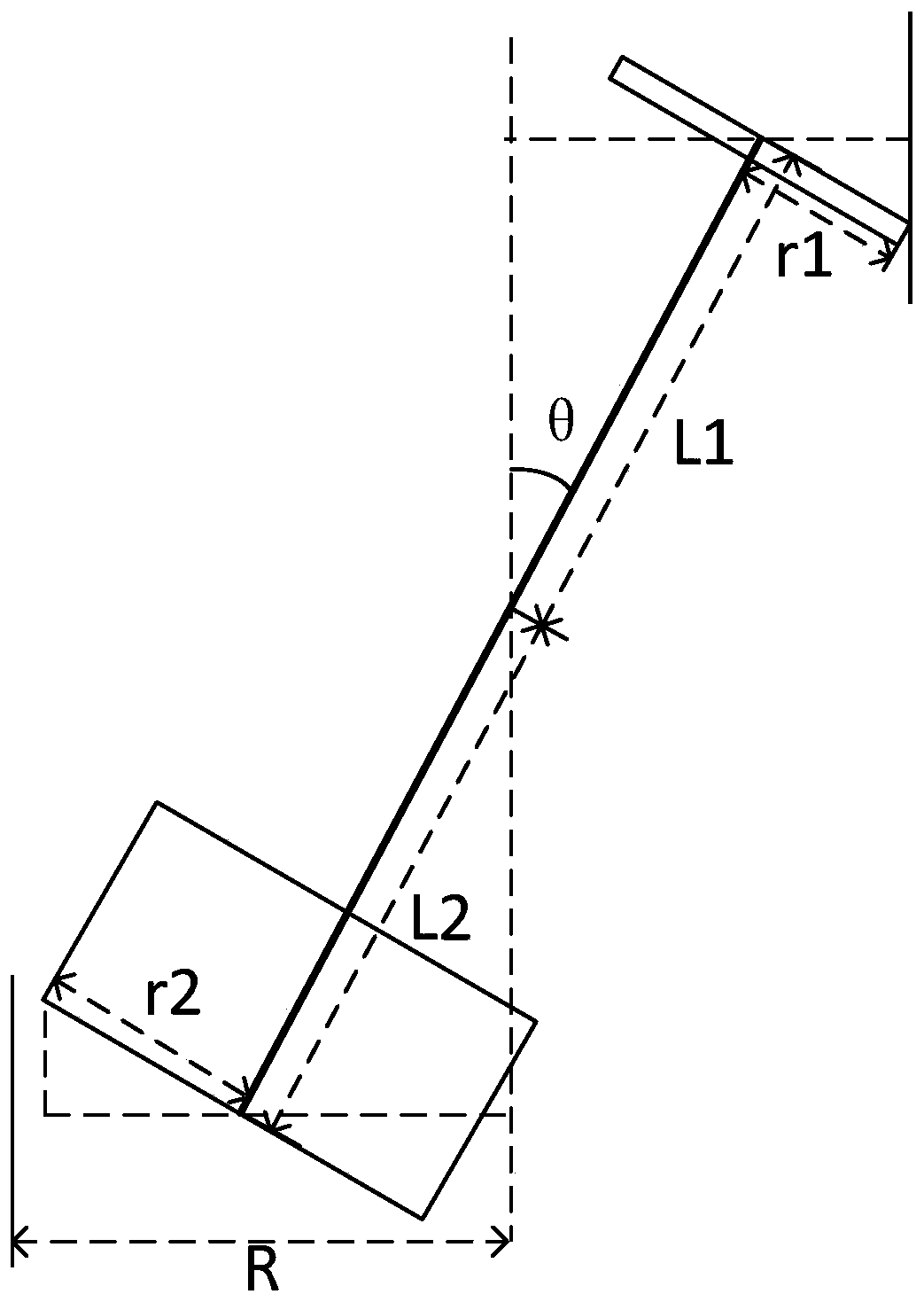

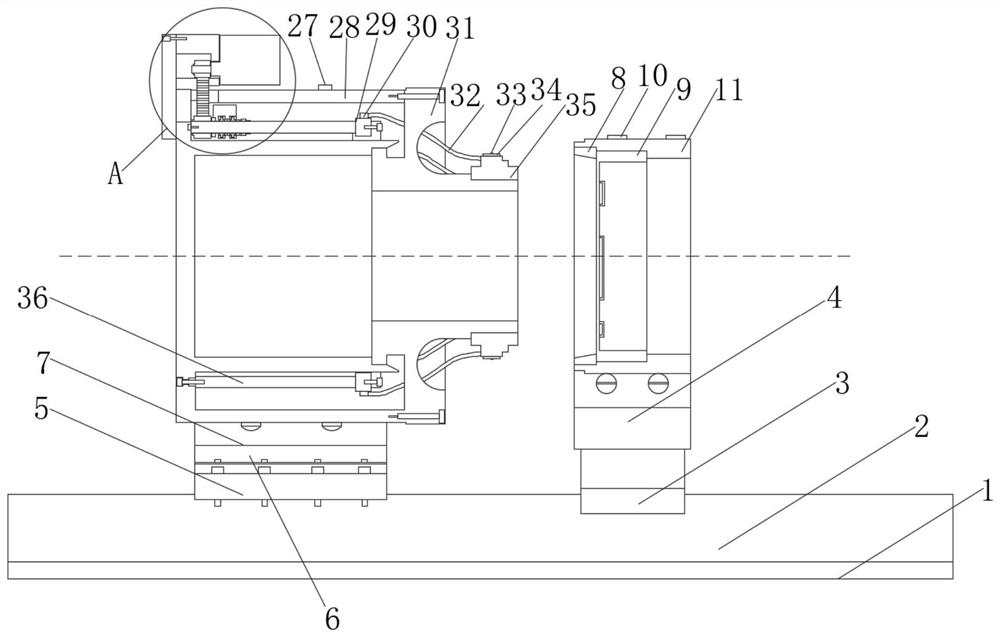

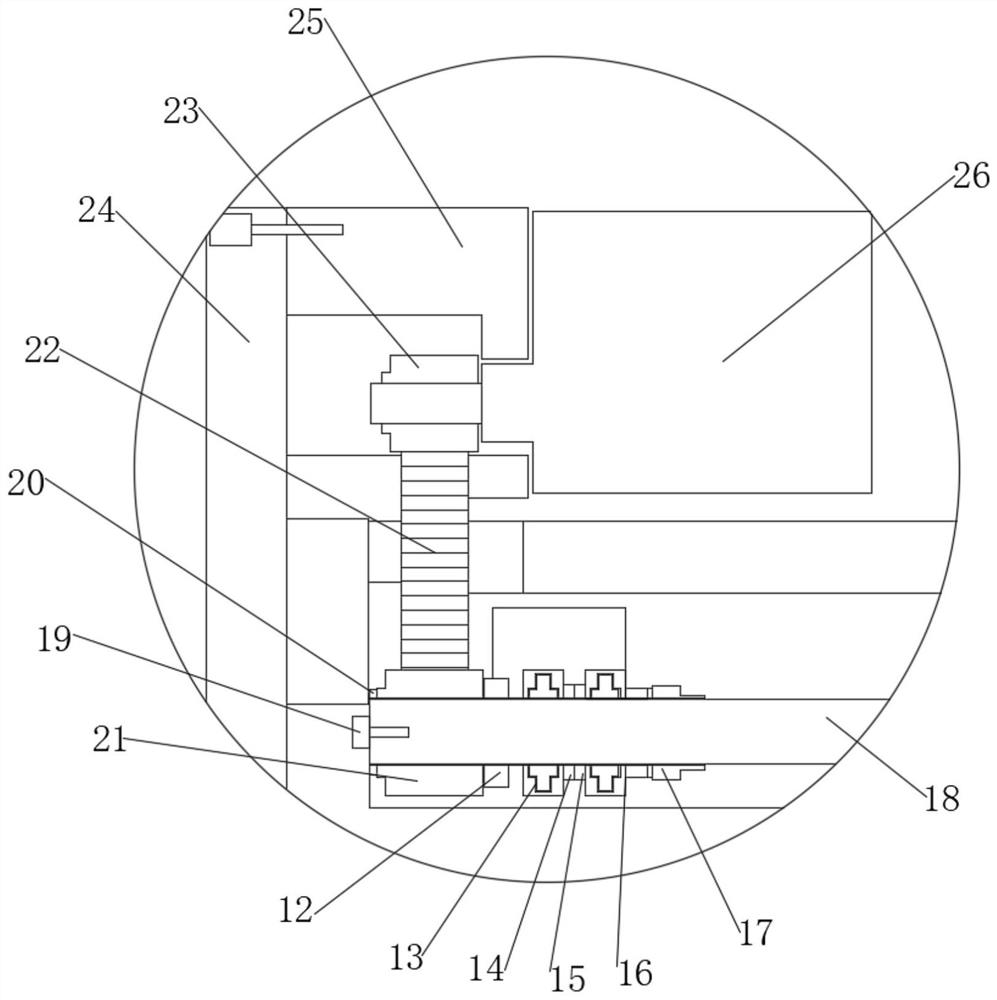

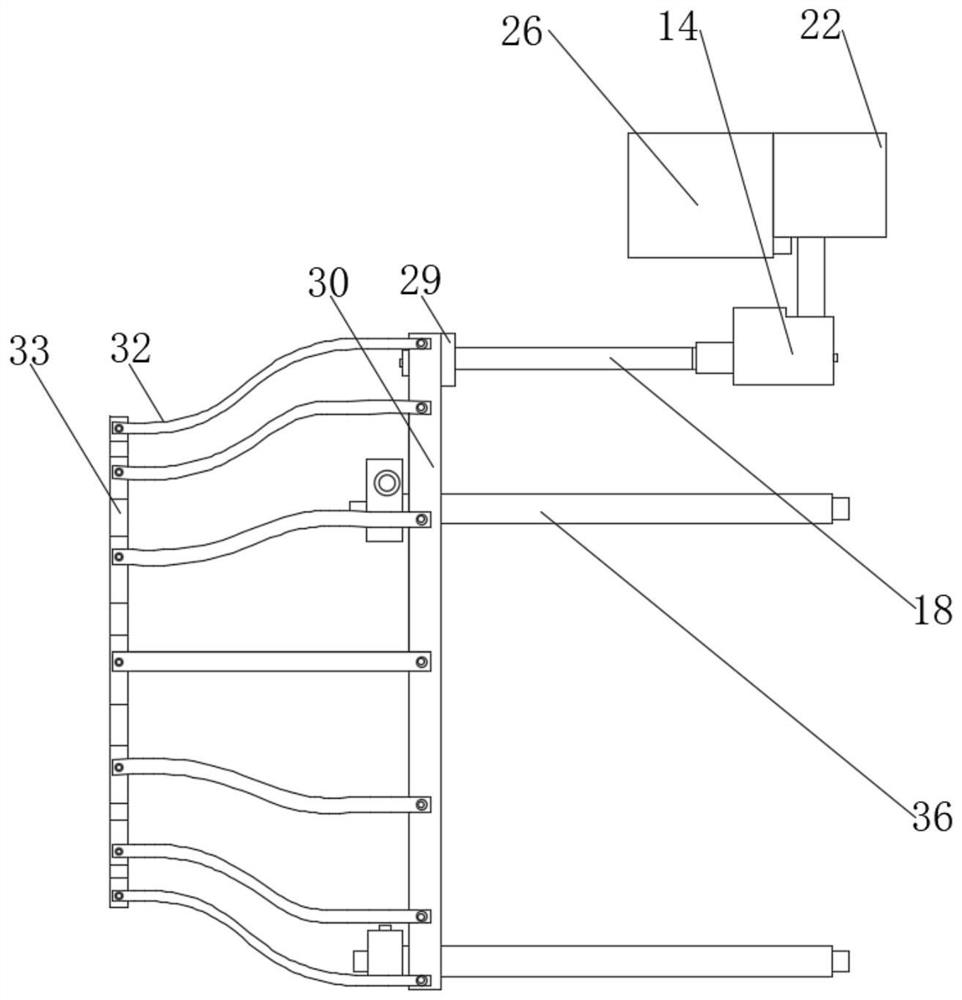

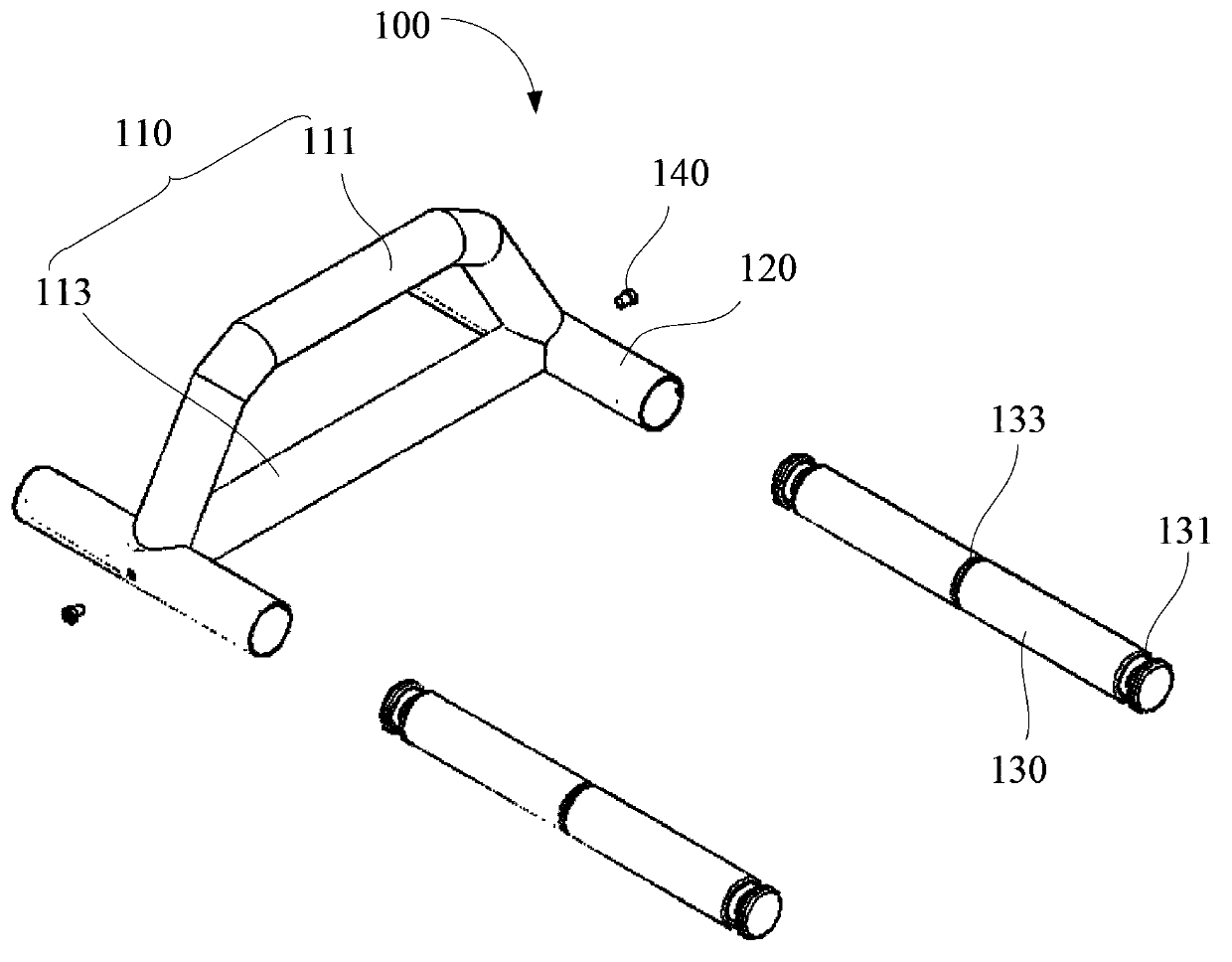

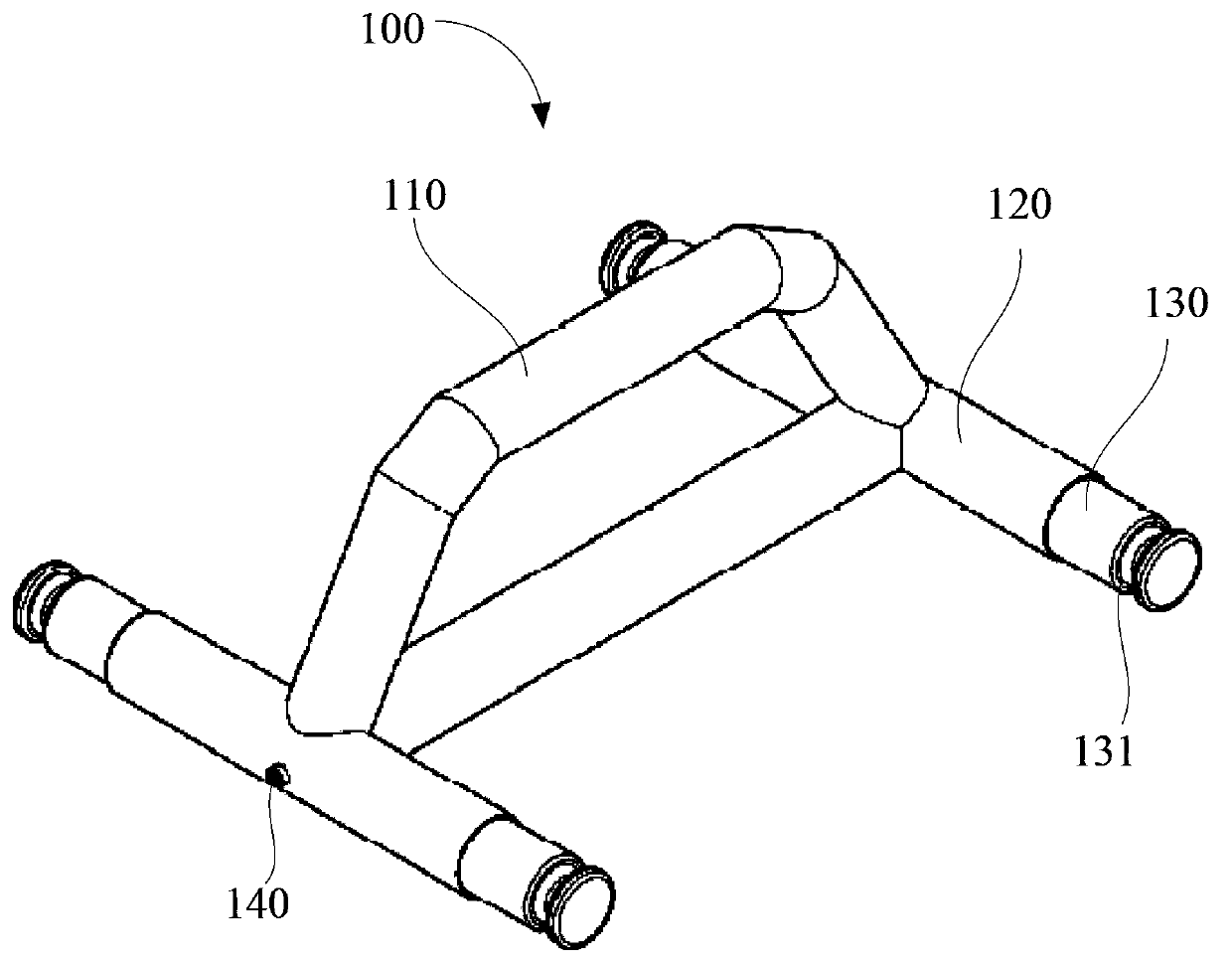

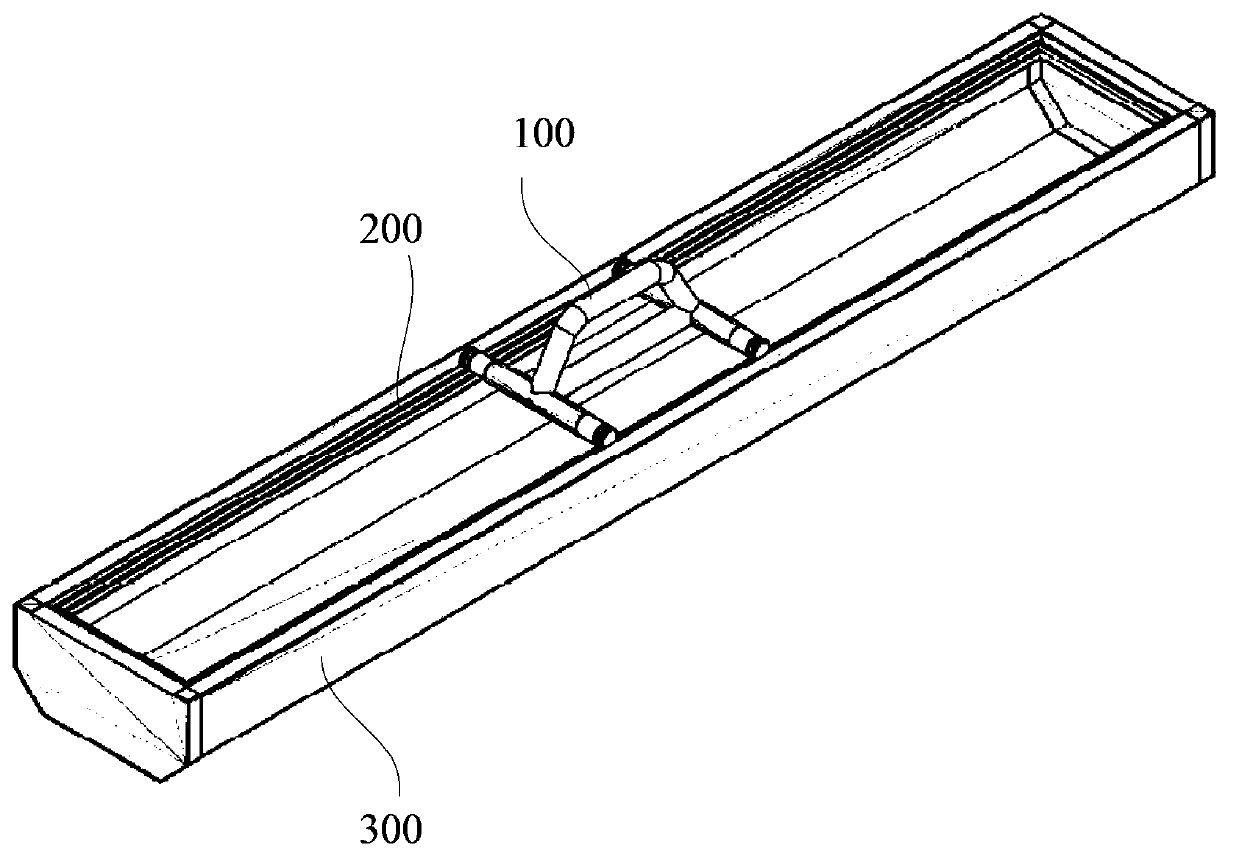

Assembling platform and assembling method thereof for high-speed parallel robot

ActiveCN106640889AImprove Assembly ConsistencyImprove assembly efficiencyMaterial gluingFiberBall screw

The invention relates to an assembling platform and an assembling method thereof for a high-speed parallel robot. The assembling platform is mainly composed of a base, stationary platform bases, stationary platforms, sliding platforms, tail boards, guide ways, sliding blocks, ball screws, scaleplates and the like. Firstly, the distances between the sliding platforms and the stationary platforms are adjusted through the scaleplates; then the two ends of carbon fiber rods are coated with AB glue, shaft end joints are slowly rotated to the two ends of the carbon fiber rods, and the shaft end joints are mounted on positioning devices of the stationary platforms and the sliding platforms; and finally, after the AB glue is solidified, a driving arm and a driven arm are taken out. The assembling platform and the assembling method thereof for the high-speed parallel robot are simple in structure, easy to operate, capable of being applied to gluing of the driving arm and the driven arm at the same time and high in assembling efficiency, and the problem of nonstandard operation in relevant industries is solved.

Owner:WUHU IROBSYS ROBOT CO LTD

Waveguide welding fixture

ActiveCN108788370AGuaranteed welding deformation requirementsWon't come offWelding/cutting auxillary devicesAuxillary welding devicesWeld seamEngineering

The invention discloses a waveguide welding fixture which comprises a supporting platform and a plurality of sets of clamping assemblies arranged in the length direction of the supporting platform. Each clamping assembly comprises two supporting bases and two swing blocks, wherein the two supporting bases are symmetrically fixed to the two ends of the supporting platform, and the two supporting bases are arranged on the two sides of the supporting platform in the width direction; each swing block comprises a swing block body and a rotating base, wherein the swing block body and the rotating base form the whole of the swing block, the lower end of the rotating base is connected with the corresponding supporting base through a rotating shaft, the lower end face of each swing block body is incontact with the upper end face of the supporting platform, and the opposite inner side faces of every two corresponding swing blocks are provided with protrusions with semicircular cross sections; and the length direction of the protrusions is the same as the length direction of the supporting platform, and the center lines of the protrusions are parallel to the upper end face of the supportingplatform. The waveguide welding fixture solves the problems that during second-time vacuum brazing of a waveguide antenna, first-time-welding welding line comes away, and the direct size accuracy is difficult to guarantee.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

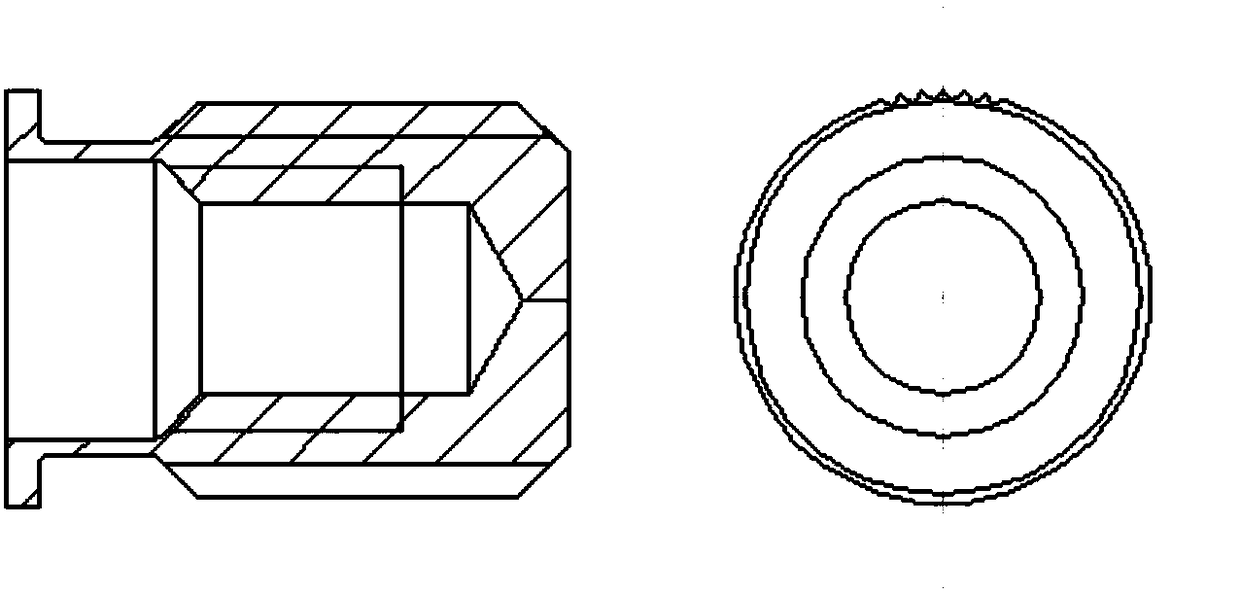

Thread bushing press fitting tool

InactiveCN108081198ANo deformationReach the goal of flexible assemblyMetal-working hand toolsKnurlingHand held

The invention discloses a thread busing press fitting tool, and belongs to the technical field of assembly. The bottleneck difficulties in the assembly process of press fitting of a thread bushing areovercome, and the problems that no special press fitting tool exists in the assembly process of press fitting of the thread busing, while deformation of an internal thread, unsteady assembly of knurling of a steel bushing, deformation of an external thread and the like are prone to being generated by using a suggested assembly tool are solved. The thread bushing press fitting tool comprises a hand press and a thread bushing pressure head. Special thread bushing pressure heads are adopted according to different specifications of thread bushings, press fitting of the thread bushing is conductedby utilizing the convenient hand press or a handheld type pressure pump, the steel bushing press fitting pressure of the press fitting tool is even and steady, the internal thread of the thread bushing can be protected when a workpiece is pressed in, and the thread bushing cannot be damaged.

Owner:BEIJING NORTH VEHICLE GROUP CORP

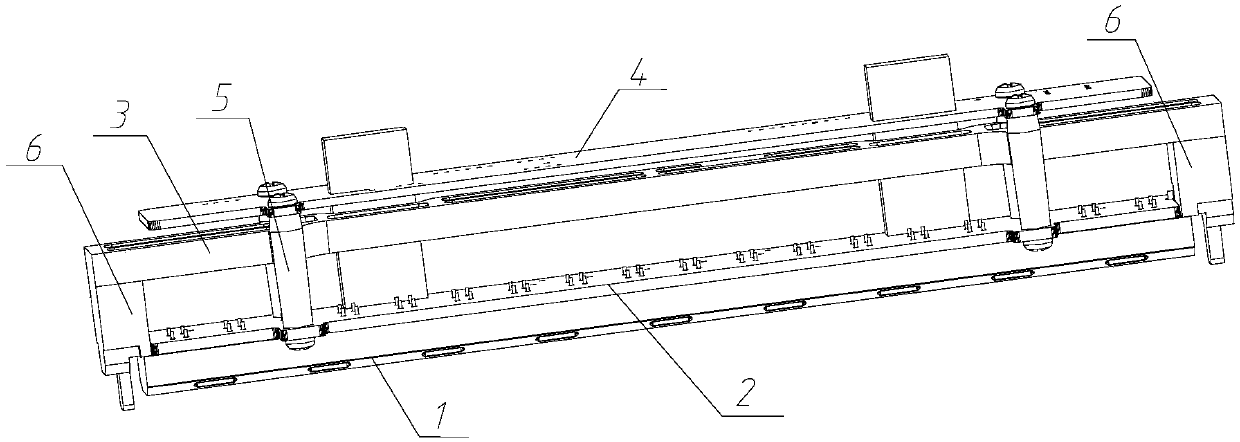

Sectional method for sectionally assembled ring spinning frame

InactiveCN1932098AGuaranteed assembly accuracyImprove Assembly ConsistencyContinuous wound-up machinesEngineeringElectrical and Electronics engineering

The assembling process of sectional ring spinning frame includes the following steps: fixing the frame head, connecting the head integral section to the frame head, fixing the middle integral section, assembling the middle spread section between the head integral section and the middle integral section, assembling the middle spread section after the middle integral section,..., connecting the first regulating section to the final middle spread section, fixing the third regulating section, assembling the second regulating section between the first regulating section and the third regulating section, fixing the tail integral section, assembling the middle spread section between the third regulating section and the tail integral section, and connecting the frame tail to the tail integral section. The assembling process has ensured assembling precision and shortened assembling period.

Owner:JINGWEI TEXTILE MASCH CO LTD

Lens module installing structure and mobile terminal

ActiveCN109151270AImprove Assembly ConsistencyEliminate fit tolerancesTelevision system detailsColor television detailsComputer terminalEngineering

The invention provides a lens module installing structure which comprises a lens assembly and a middle frame. The lens assembly comprises a lens, a chip and a circuit board, the middle frame is provided with a through hole, the lens is arranged in the through hole, the chip is installed and fixed on the circuit board and positioned in a projection area of the lens and between the lens and the circuit board, and the circuit board is fixedly connected with the middle frame. According to the lens module installing structure, the lens is embedded in the hole of the middle frame, extra use of a lens baffle part is avoided, a cooperation tolerance between a lens barrel and the lens needs not to be considered and can be eliminated, it is ensured that the lens position is reliable and accurate, and the assembling consistence of the lens module is improved.

Owner:VIVO MOBILE COMM CO LTD

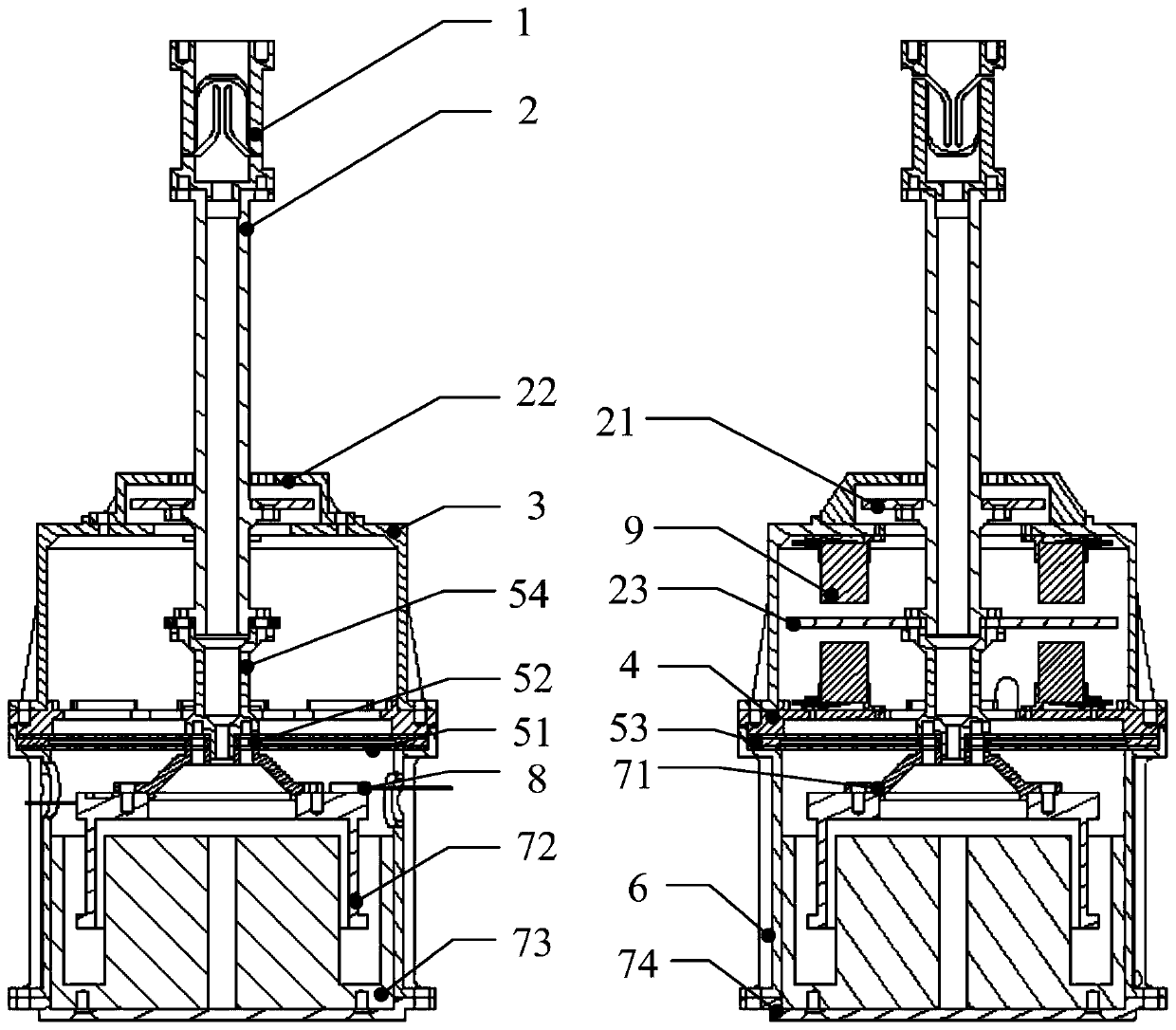

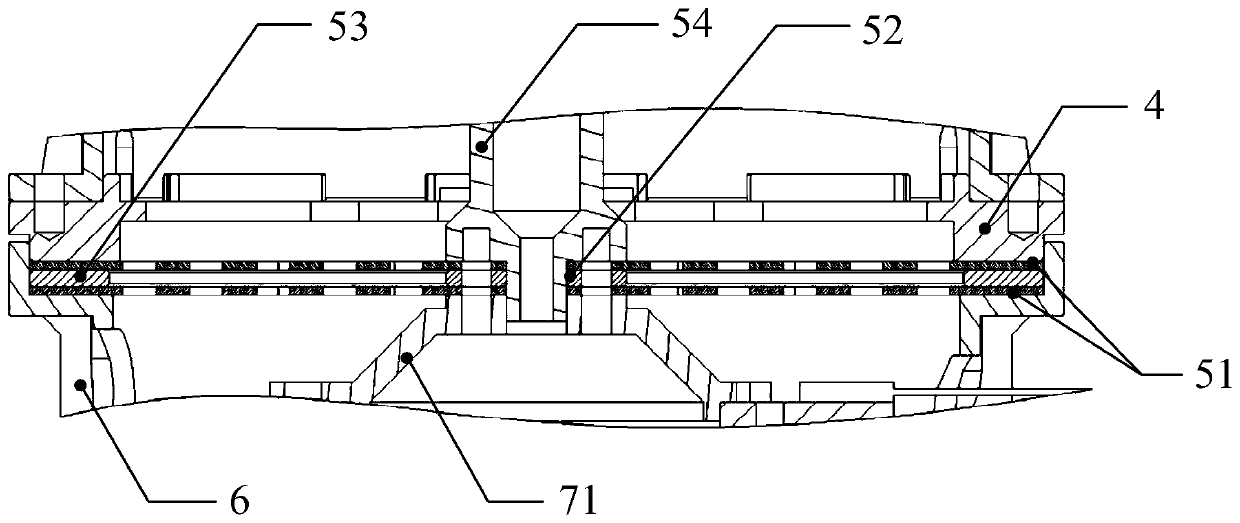

Voice coil actuator integrated with eddy current displacement sensor and assembling method

ActiveCN110417231AIncrease stiffnessImprove performance consistencyUsing electrical meansManufacturing dynamo-electric machinesSize measurementHeat conducting

The invention discloses a voice coil actuator integrated with an eddy current displacement sensor and an assembling method. The voice coil actuator comprises a flexible hinge, an actuating rod, an upper shell, an eddy disc, a flexible structure, a switching shaft, a main shell, a rotor pressure plate, a voice coil motor rotor, a voice coil motor stator, a stator pressure plate, a limiting block, alimiting disc, a measuring plate, a heat conducting rope and an eddy current displacement sensor. By using a double film spring flexible structure with inner and outer backing rings with equal thickness, the rigidity of film springs is improved effectively, moreover, a rigid replacement part with equal thickness is used for replacing the flexible structure during assembling, the problem that theassembling dimensions are difficult to measure caused by the deformation of the flexible structure is overcome, and simultaneously, accurate actuator repair dimensions can be obtained. The control accuracy and bearing capacity of the voice coil actuator can be improved, and the service life of the product is prolonged.

Owner:BEIJING INST OF CONTROL ENG

Low-pressure turbine butt-joint assembling device capable of preventing balls from falling off

PendingCN112705921AImprove assembly centering accuracyImprove Assembly ConsistencyAssembly machinesBearing componentsStructural engineeringTurbine

The invention discloses a low-pressure turbine butt-joint assembly device capable of preventing balls from falling off, and belongs to the technical field of automatic assembly. The low-pressure turbine butt-joint assembly device is characterized by comprising an aluminum base, a push rod and a guide shaft, a second V-shaped block is fixedly connected to the top of the aluminum base, and a simulation fan is fixedly connected to the inner wall of the second V-shaped block. A bearing inner ring is assembled at the tail of a low-pressure turbine shaft of an engine, a bearing outer ring is assembled at the end of a fan of the engine, a centering mechanism is assembled on a clamping tool for clamping the low-pressure turbine shaft, and the centering mechanism assists the bearing inner ring on the low-pressure turbine shaft to be matched with the bearing outer ring on the fan. The butt joint of the low-pressure turbine shaft and the fan is converted into the butt joint of the bearing inner ring and the bearing outer ring, the assembly centering precision of the low-pressure turbine shaft and the fan is greatly improved, the mode is automatic in assembly, the needed time is short, the production efficiency is high, the assembly consistency of components is good, and the centering precision is high.

Owner:上海钧工机器人有限公司

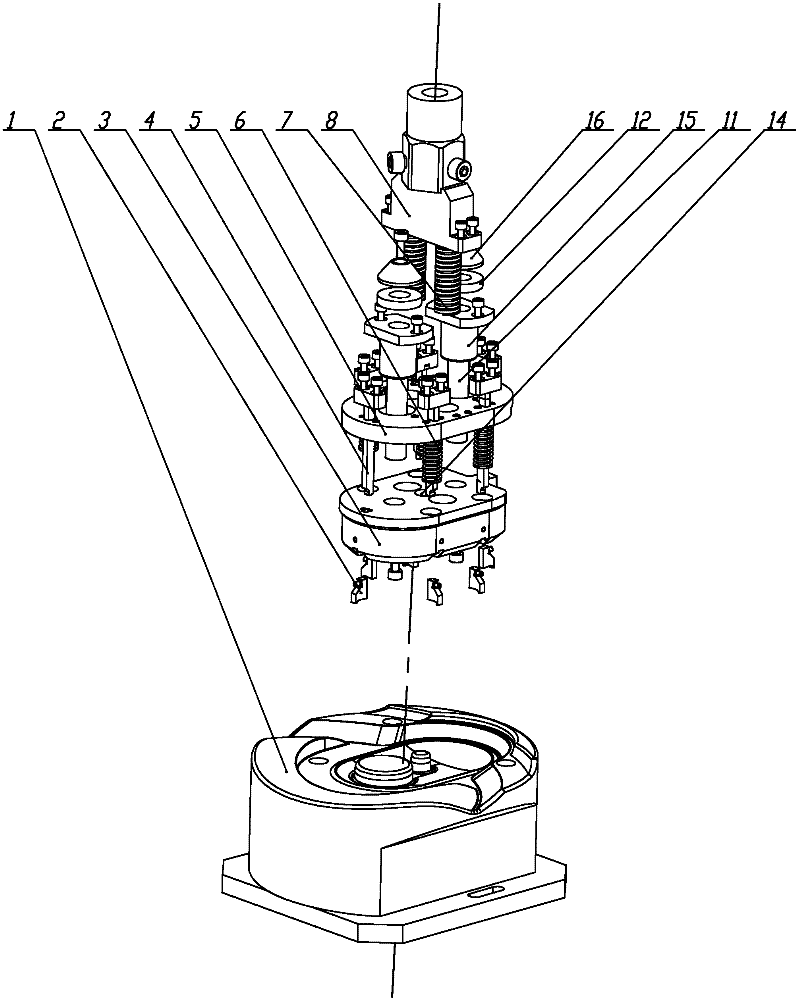

Clutch assembling tool

ActiveCN106312521AShorten the installation cycleHigh accuracy consistencyMetal working apparatusClutchCycle time

The invention relates to a clutch assembling tool which comprises a clamping jaw, a fixed disc, a working disc, a cylinder, a cylinder push rod assembly, a limiting polished rod and a regulating valve. The fixed disc is rotatably connected with the clamping jaw, the cylinder is fixed to the fixed disc, one end of the cylinder push rod assembly movably penetrates the fixed disc and then is connected with the cylinder, and the other end of the cylinder push rod assembly is fixedly connected with the working disc. The regulating valve is arranged on the cylinder. The periphery of the fixed disc is provided with a limiting polished rod through hole, one end of the limiting polished rod is fixedly connected with the working disc, and the other end of the limiting polished rod penetrates the limiting polished rod through hole. According to the technical scheme, the clutch assembling tool is high in adaptability and can be suitable for most of clutch assembly, clutch installation cycle time is shortened, clutch assembly precision and assembly consistency are greatly improved, and the problem of shaking caused by poor clutch assembly accuracy is effectively solved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Integrated long magnetic strip sensor for paper money authentic identification and positioning method

PendingCN110969756AGuaranteed accuracySimplify the assembly processPaper-money testing devicesMechanical engineeringElectrical and Electronics engineering

The invention discloses an integrated long magnetic strip sensor for paper money authentic identification and a positioning method. Two protrusions facing the same direction are fixedly arranged at the two ends of a support of the integrated long magnetic strip sensor. A long magnetic strip sensor body is arranged between the two bulges through a magnetic head plate. The magnetic head plate is connected to the support through at least two fixing columns. Moreover, the connecting line between the tops of the two projections is parallel to the bottom surface of the long magnetic stripe sensor body along the length direction. In mounting, only the top ends of the two bulges are required to be in contact with the outer rings of the two transmission shaft bearings respectively, the bottom surface of the long magnetic strip sensor body is ensured to be parallel to the side surface of the transmission bristle wheel. Therefore, the paper money is allowed to pass through the bottom surface of the long magnetic stripe sensor body in parallel, the magnetic authentic identification points on the paper money are sampled and detected, the accuracy of a reading result of magnetic induction is ensured, and the accuracy of an authentic identification result of the paper money is ensured.

Owner:SHANGHAI GOOAO ELECTRONIC TECHNOLOGY CORP

Mounting tool for camshaft bushing

InactiveCN107553393AGuarantee that the installation is qualifiedImprove installation efficiencyMetal-working hand toolsScrew threadLubricant

The invention relates to a camshaft bush installation, in particular to a camshaft bush installation tool, which belongs to the technical field of camshaft bush installation equipment. It includes a pressing rod, and the pressing rod includes a handle part, a convex shoulder part, a bush installation part, a transition part and a guide positioning part. The bush installation part is provided with a first positioning hole in the radial direction, and the first through hole section is provided with a The first positioning steel ball, the part of the first positioning steel ball can protrude from the outer surface of the bushing installation part; the internal thread of the first threaded hole section is connected to the first adjusting screw, and the first positioning steel ball and the first adjusting screw are provided with a second positioning screw. A spring, the compression degree of the first spring to the first positioning steel ball can be adjusted through the first adjusting screw. The protruding shoulder of the pressure rod of the present invention realizes the positioning of the installation depth of the bushing, and the guide part realizes the angle positioning of the oil hole of the bushing; The accurate butt joint of the holes realizes the accurate positioning of the bushing angle.

Owner:CHINA FIRST AUTOMOBILE

Sealing ring pressing-in device and sealing ring pressing-in method for lamp

InactiveCN103963003AReduce frictionPress evenlyMetal-working hand toolsHand partsStructural engineering

The invention provides a sealing ring pressing-in device which comprises a handholding frame, two fixed sleeves and two rolling shafts, wherein the handholding frame comprises a U-shaped handle part and a support rod; the two ends of the support rod are respectively and fixedlyconnectedwith the two ends of the handle part; the fixed sleeves are respectivelypositioned at the two opposite ends of the handholding frame, and arranged oppositely and parallelly; the middle part of each fixed sleeve is vertically connected with the end parts of one ends of the handle part and the support rod; the two rolling shafts respectivelypenetrate through the two fixed sleeves, and can rotate in the fixed sleeves; the two ends of the rolling shafts are exposed out of the fixed sleeves; a pressing groove is formed in each end of each rolling shaft and is matched witha sealing ring in shape;pressing groovessurround the rollingshafts for a circle in the circumferential direction of the rolling shafts. The sealing ring pressing-in device provided by the invention has the advantages as follows: the frictionbetween the sealing ring pressing-in device and the sealing rings is reduced, that the sealing rings are pressed in the sealing grooves more uniformly is ensured, the pressing-in angles are kept to be consistent, and the assembly efficiency and sealing performance of the sealing rings are improved. The invention further provides a sealing ring pressing-in method for a lamp.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

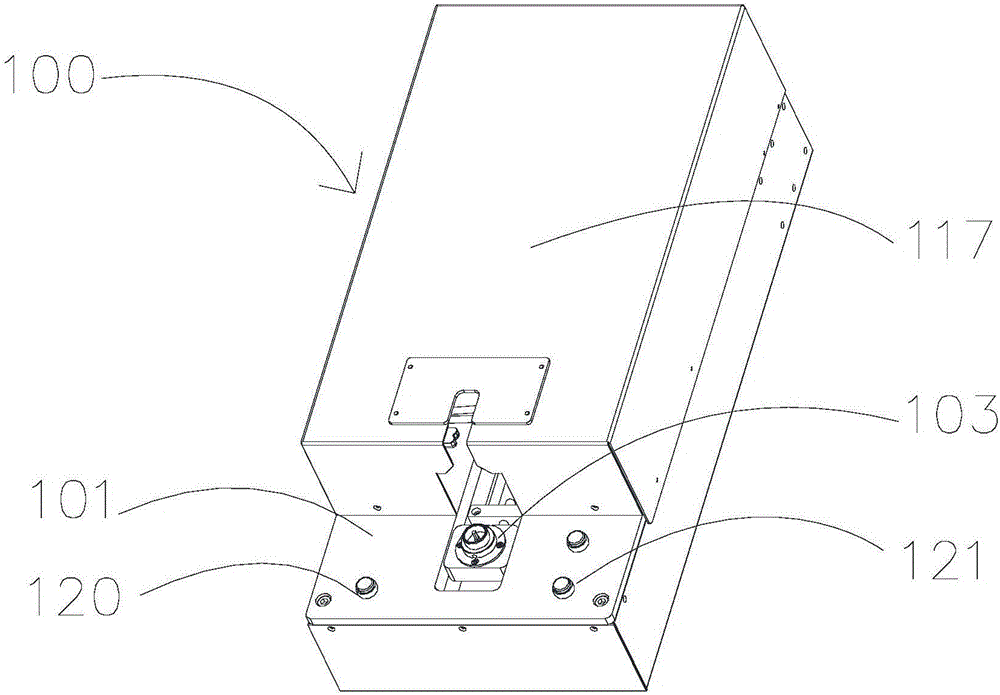

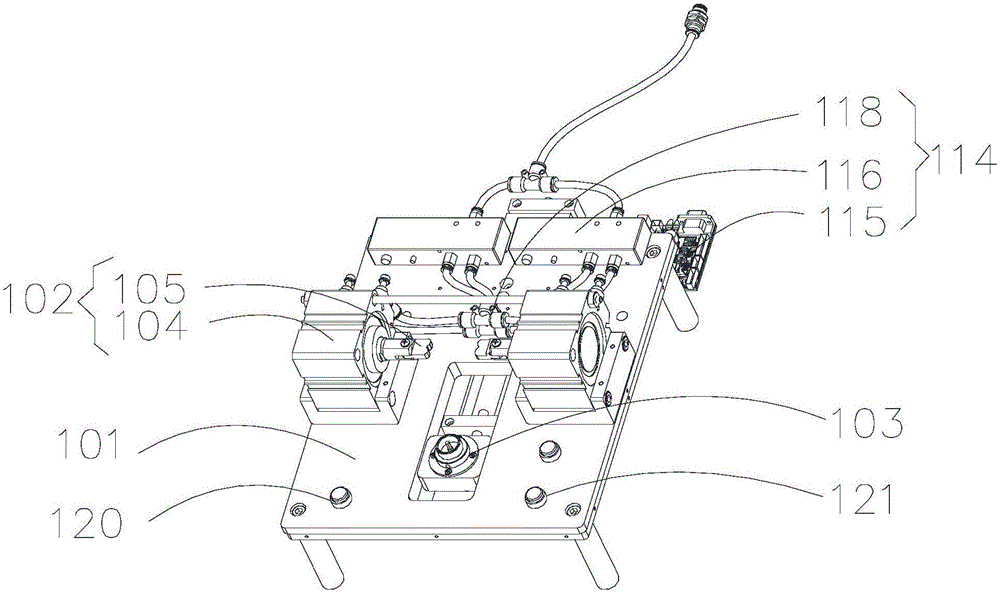

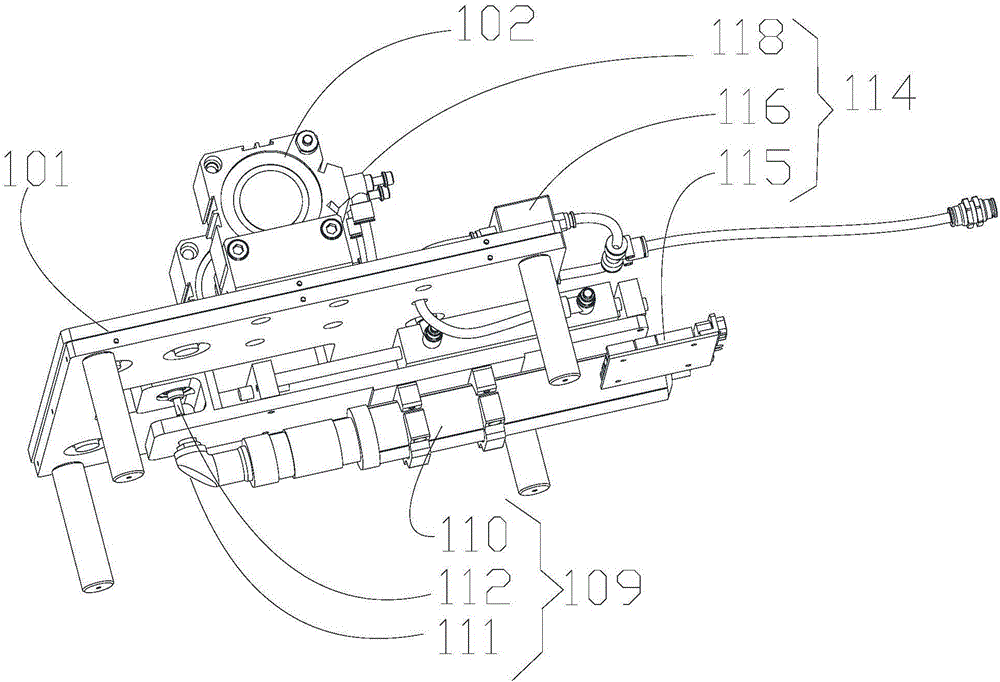

Assembly device for rotational connection

ActiveCN105965243AReduce labor intensityTorque controllableMetal working apparatusEngineeringAutomation

The invention discloses an assembly device (100) for rotational connection. The assembly device for rotational connection is used for realizing rotational connection for a first component and a second component, and comprises a base (101), a clamping component (102) arranged on the base (101) and used for clamping the first component, and a rotating component (103) arranged on the base (101) and used for longitudinally aligning the second component with the first component and tightening the second component on the first component in a rotating manner. The assembly device (100) disclosed by the invention has the characteristics of controllable rotating torque, good product assembly consistency, high automation degree, and high production efficiency.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com