Bending-compression mould for processing fastener

A buckle and mold technology, applied in the field of bending and pressing molds, can solve problems such as unsatisfactory benefits, large production space investment, increase of defective products, etc., to improve assembly consistency and assembly quality, simplify assembly procedures, and have a compact and ingenious structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

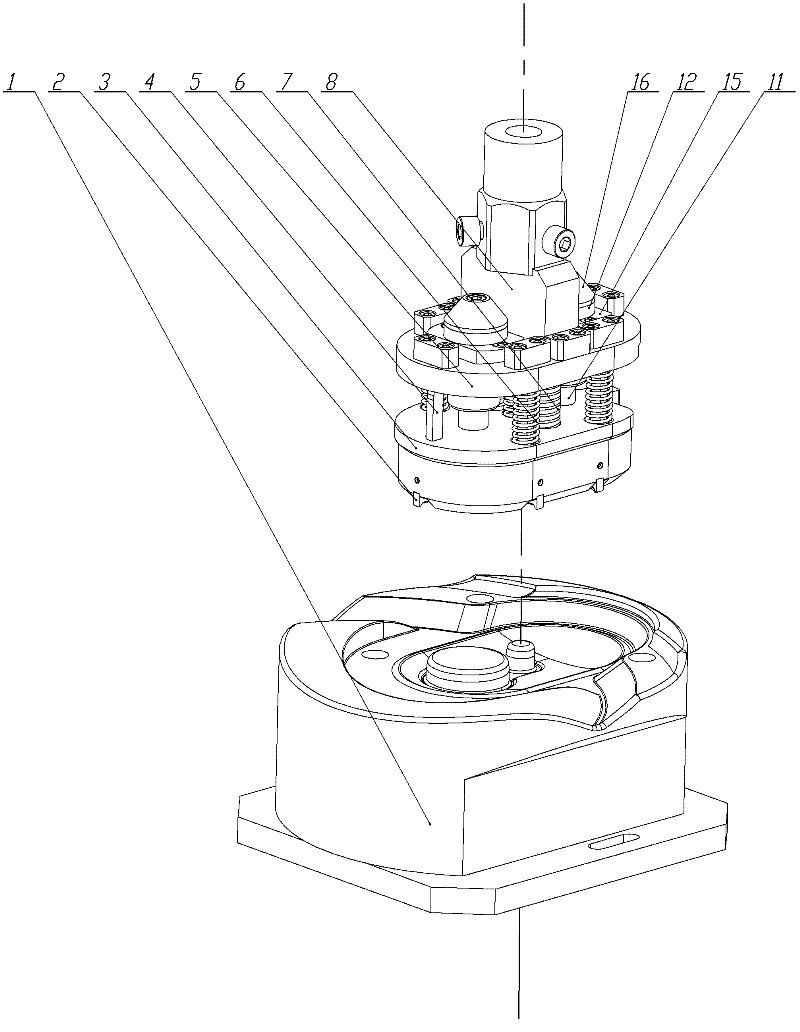

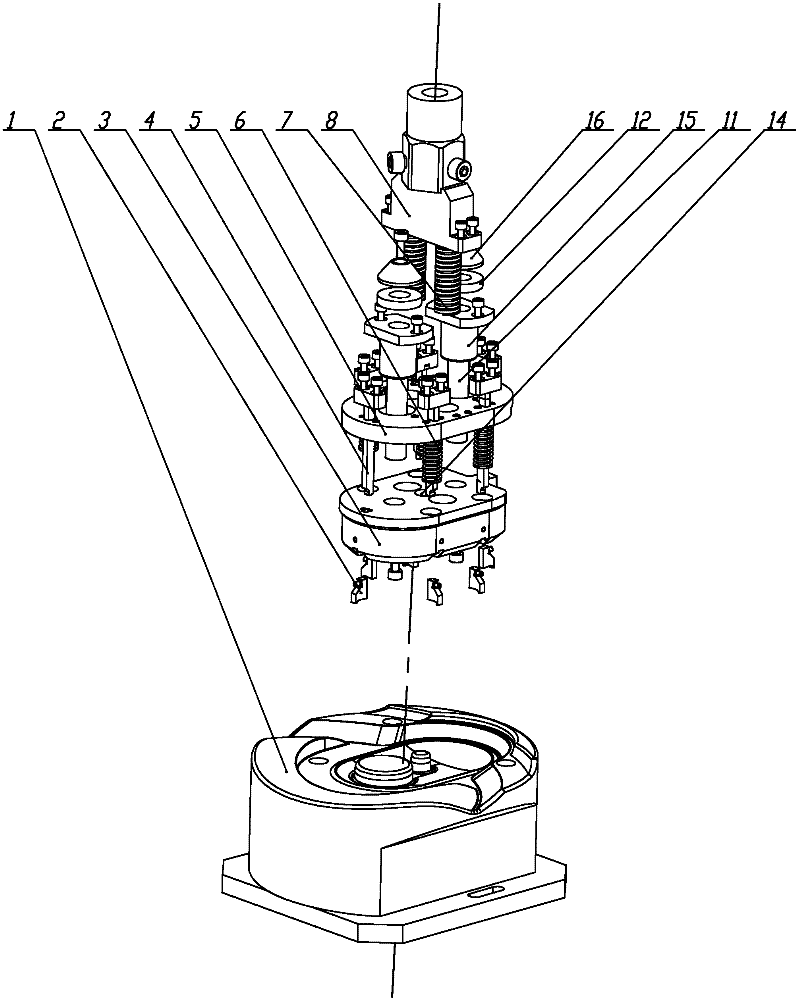

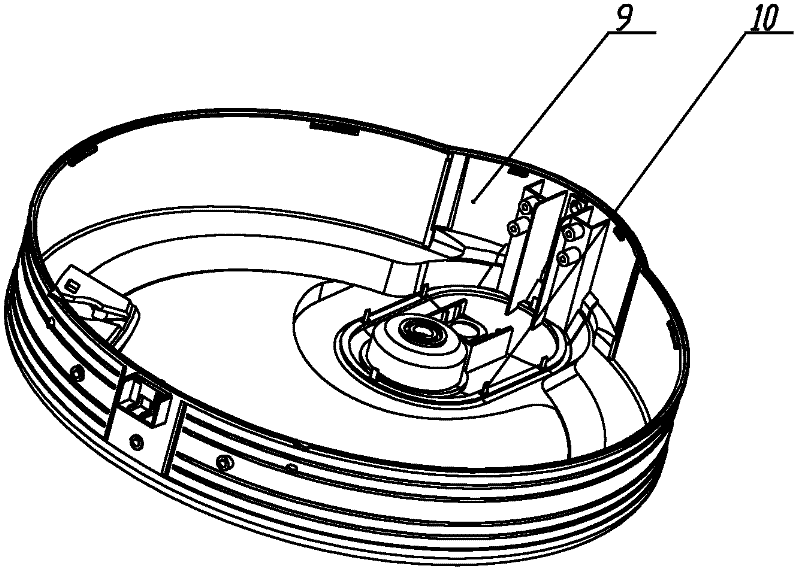

[0035] As shown in the bending die, the top of the lower punch 3 is provided with an upper push plate 5 and a connecting block 8, the bottom of the connecting block 8 is fixedly installed on the upper surface of the upper push plate 5, and the lower punch 3 and the upper push plate 5 They are connected by two guide columns 11 that pass through the upper push plate. The bottom of each guide post 11 is fixedly connected to the lower die 3 , the top is provided with a limit block 16 , and each guide post 11 is covered with a guide sleeve 15 fixed on the upper push plate 5 . Five booster springs 6 and two symmetrically arranged preload springs 7 are arranged between the upper push plate 5 and the lower die 3 .

[0036] The bottom of the lower die 3 is fixed with 6 horizontal bending knives 2, and the upper push plate 5 is fixed with 6 longitudinal bending knives 4 penetrating the lower die, which consists of a horizontal bending knife and a longitudinal bending knife. Crimping kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com