Normally closed pneumatic pipe clamp

A technology of moving tubes and cylinders, which is applied in the field of automatic control of explosives and explosives, can solve problems such as safety hazards, difficulty in determining the state of valve opening and closing, and accidents, and achieves the effects of high adaptability, ensuring installation accuracy, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

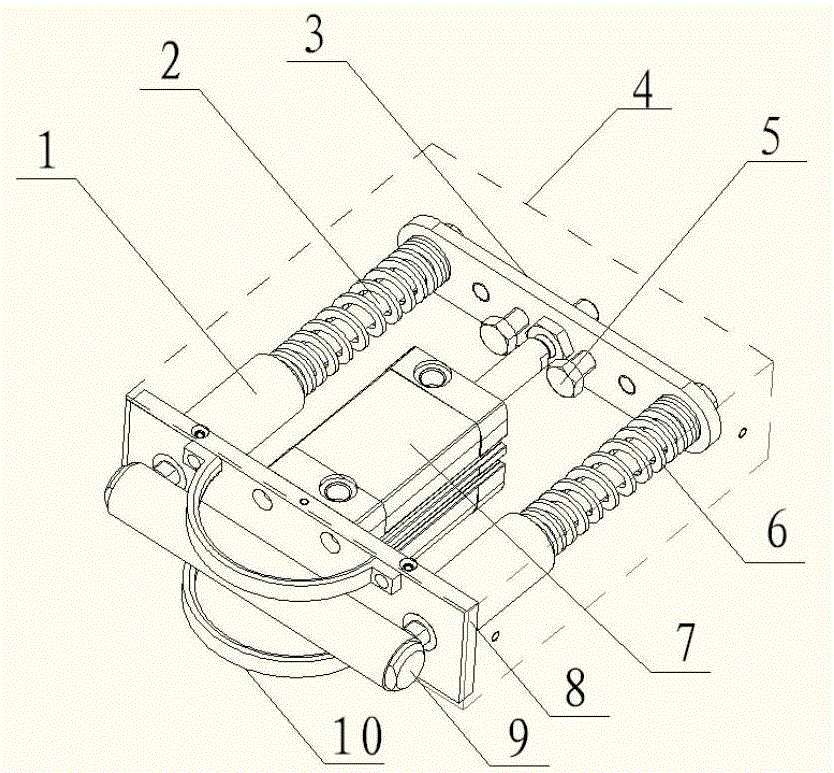

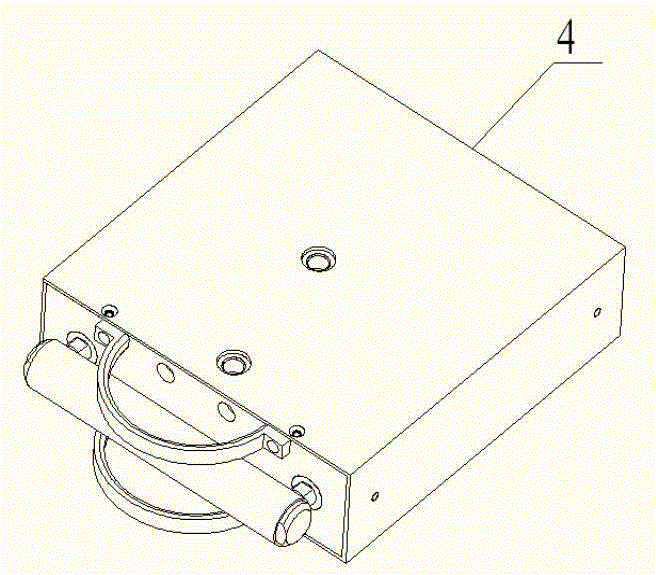

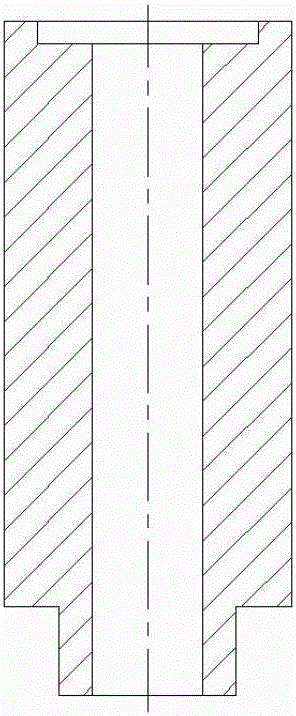

[0027] Such as figure 1 , figure 2 , a normally closed pneumatic pipe clamp is characterized in that it includes a sliding sleeve (1), a guide shaft (2), a connecting plate (3), a casing (4), an adjusting pin (5), a spring (6), a cylinder ( 7), cylinder mounting plate (8), pressure head (9), limit sleeve (10).

[0028] The cylinder 7 can be a FESTO AND series compact cylinder, which is installed on the cylinder mounting plate (8) through the side end flange without the extension rod, and the connecting plate (3) is fixed on the extension rod of the cylinder (7). One end of the guide shaft (2) is installed on the connecting plate (3), and is matched with the sliding sleeve (1) fixed on the cylinder mounting plate (8), and the pressure head (9) is connected to the other end of the guide shaft (2) Above, a gap for accommodating the hose is formed between the pressure head (9) and the cylinder mounting plate (8).

[0029] The spring (6) can be Misumi rectangular compression sp...

Embodiment 2

[0039] Such as figure 1 , figure 2 , a normally closed pneumatic pipe clamp is characterized in that it includes a sliding sleeve (1), a guide shaft (2), a connecting plate (3), a casing (4), an adjusting pin (5), a spring (6), a cylinder ( 7), cylinder mounting plate (8), pressure head (9), limit sleeve (10).

[0040] The cylinder (7) can be a FESTO AND series compact cylinder, which is installed on the cylinder mounting plate (8) through the side end flange without the extension rod, and the connecting plate (3) is fixed on the extension rod of the cylinder (7) One end of the guide shaft (2) is installed on the connecting plate (3), and is matched with the sliding sleeve (1) fixed on the cylinder mounting plate (8), and the pressure head (9) is connected to the end of the guide shaft (2). On the other end, a gap for accommodating the hose is formed between the head (9) and the cylinder mounting plate (8).

[0041] The spring (6) can be Misumi rectangular compression spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com