Round pin-inserted positioning device and tensioning and positioning round pin thereof

A positioning device and plug-in technology, used in auxiliary devices, workpiece clamping devices, bolts, etc., can solve the problems affecting the matching accuracy of positioning holes, insufficient installation accuracy of accessories, and difficulty in online adjustment, so as to reduce product quality fluctuations and ensure Positioning accuracy and stability, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below.

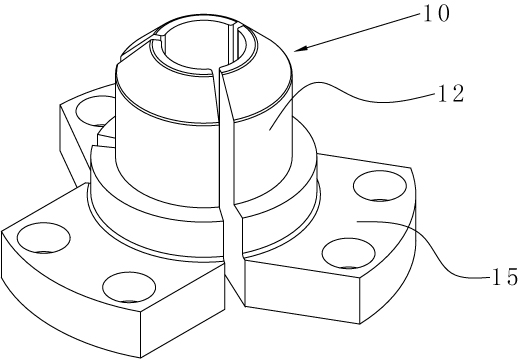

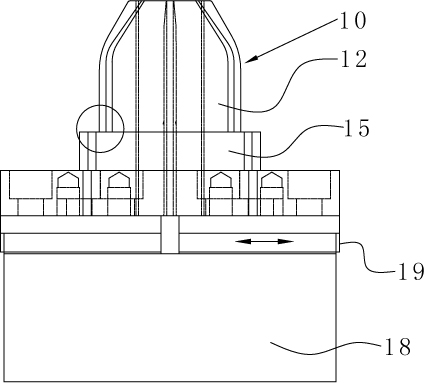

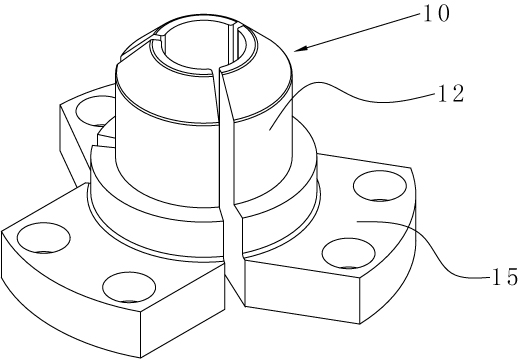

[0023] Such as figure 1 As shown, a tension positioning round pin 10 of the present invention has at least two lobes 12 separated from each other. Tension positioning round pin 10 is also called tension pin, or positioning pin. Close the pin flap 12 of the tension pin to shrink the tension pin 10, and the outer size of the tension pin 10 is smaller than the diameter of the positioning hole, so that it can be easily extended into the positioning hole, and then opened by the driving device The pin flap 12 of the tight pin makes the tension pin closely fit with the positioning hole. At this time, the outer size of the positioning pin 10 is equal to the diameter of the positioning hole, ensuring that there is no gap between the tension pin 10 and the positioning hole, improving the positioning accuracy and ensuring the fixture Positioning accuracy and stability to achieve precise positioning. Using...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com