Patents

Literature

323results about How to "Guaranteed positional stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

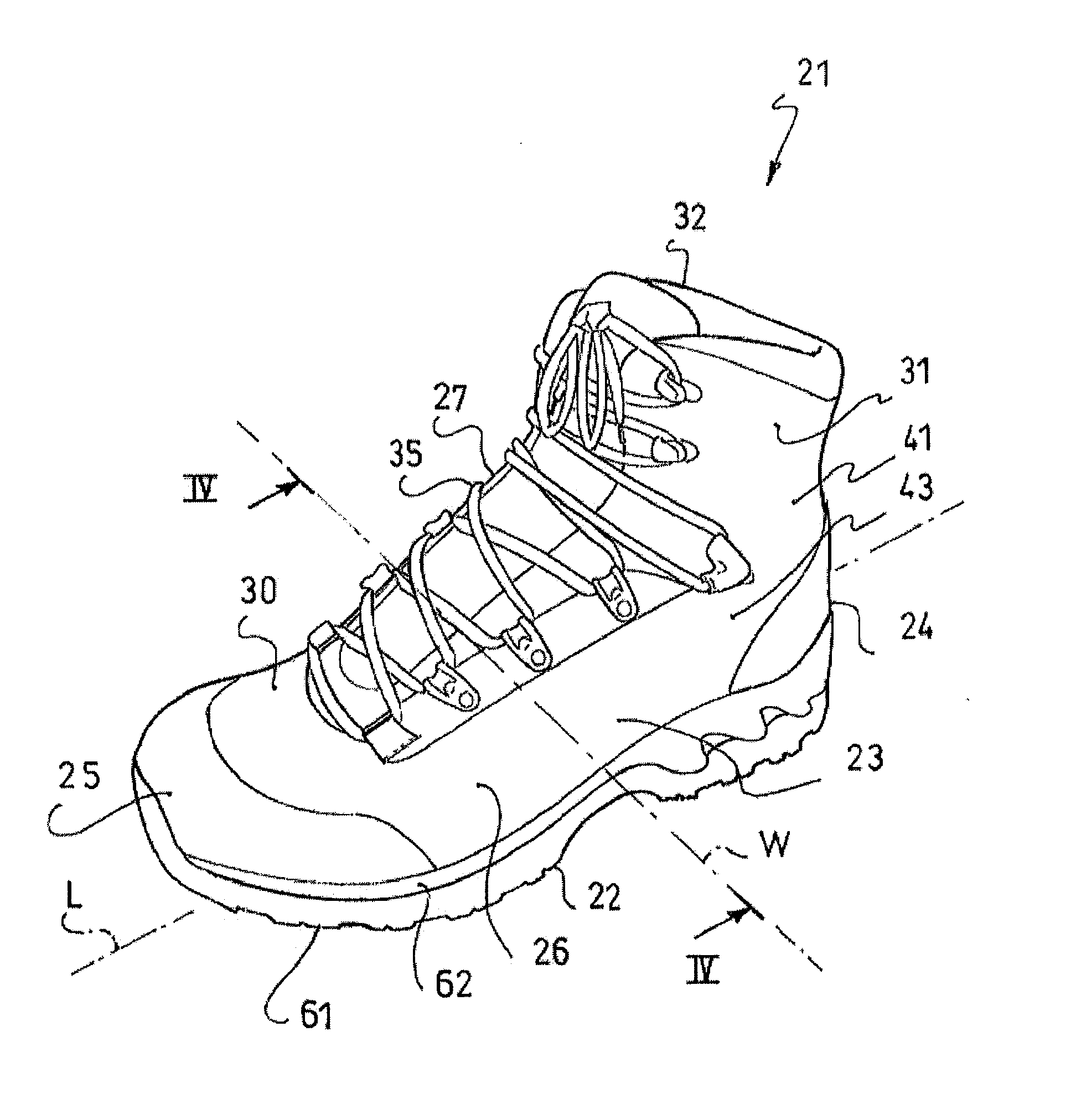

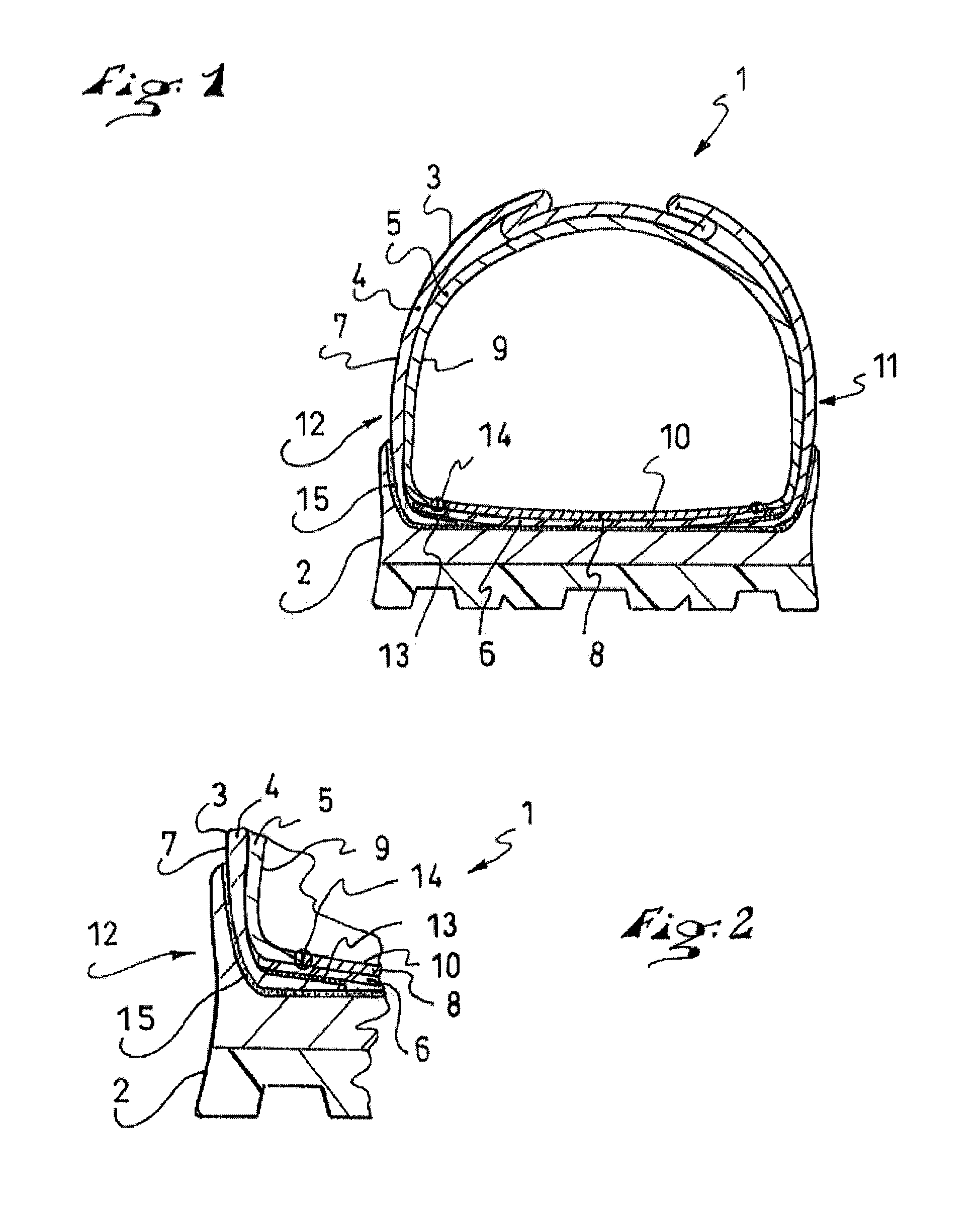

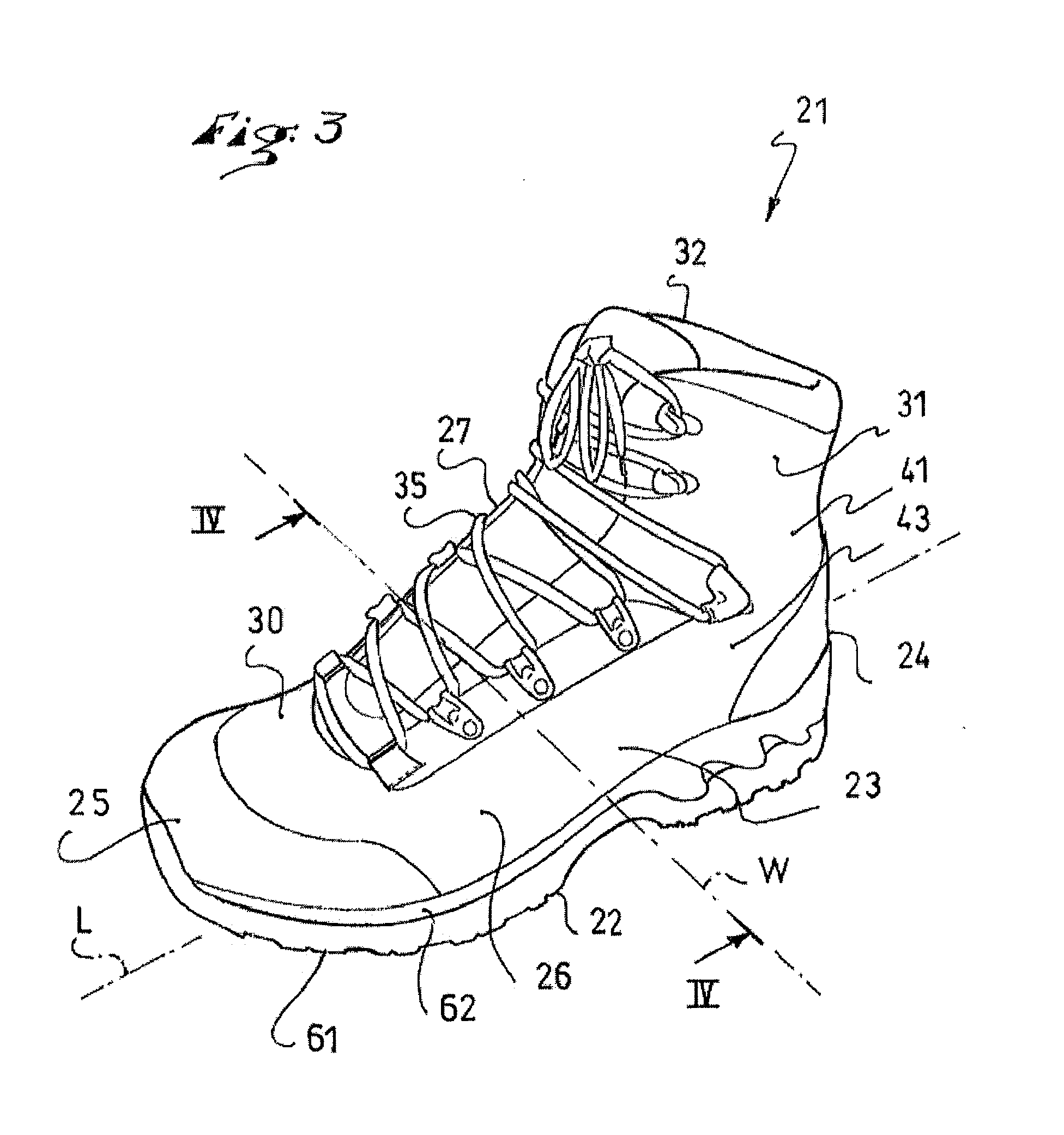

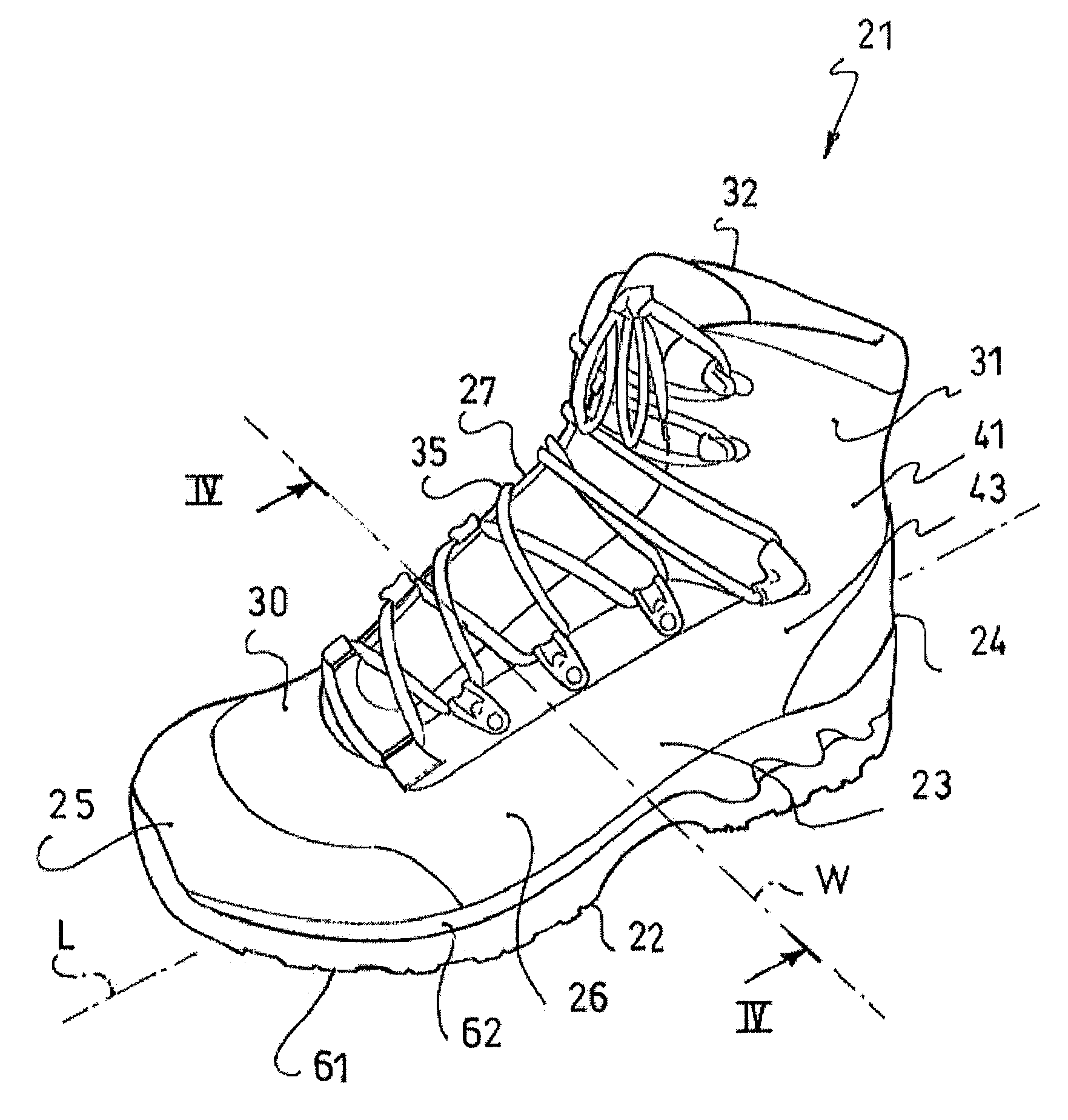

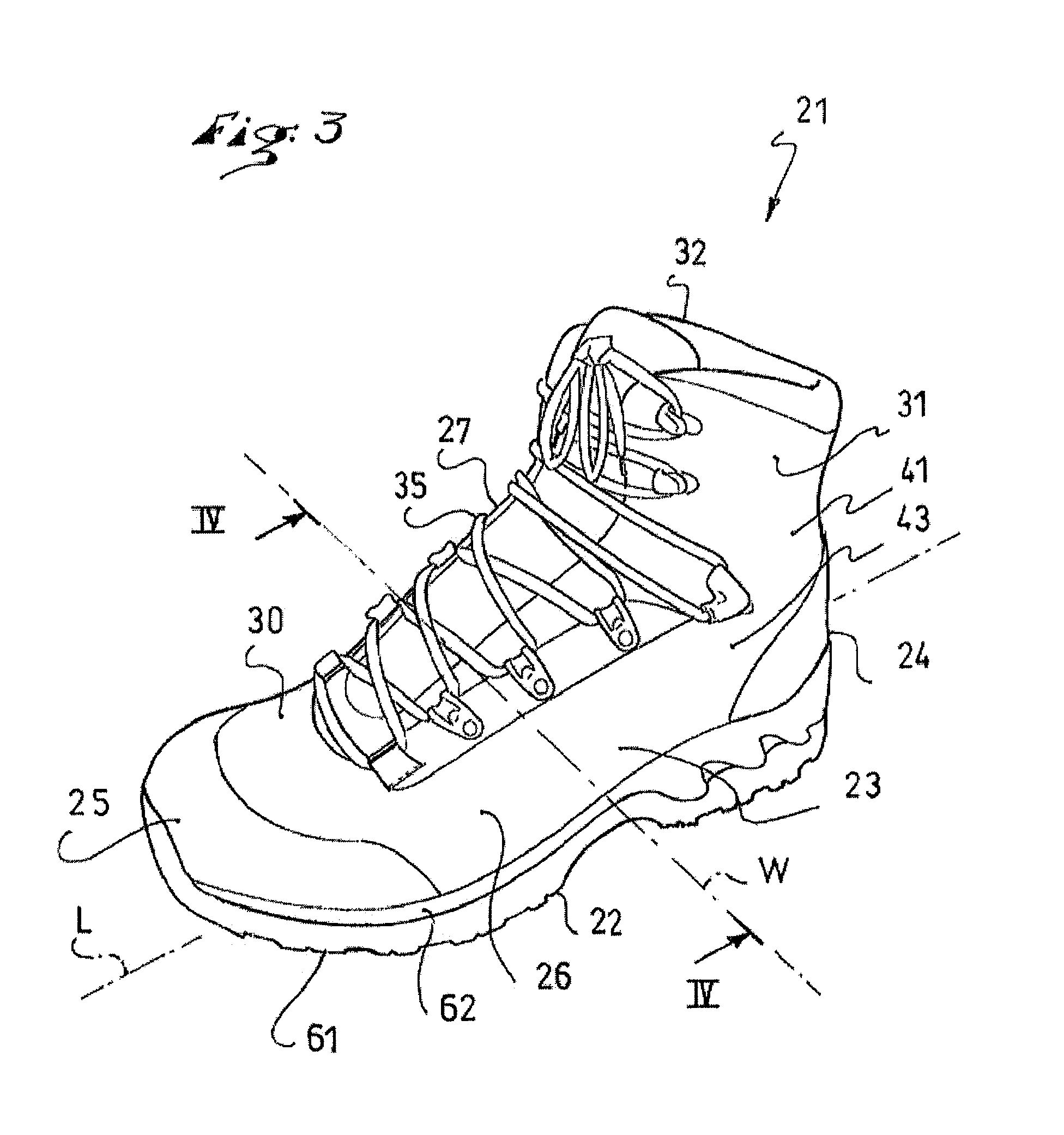

Footwear with improved sole assembly

InactiveUS20110119956A1Good flexibilityGood energy dissipationSolesDomestic footwearEngineeringMedial side

An article of footwear, including a sole assembly and an upper, the article of footwear extending lengthwise from a rear end to a front end, widthwise between a lateral side and a medial side, and heightwise from the outer sole assembly to an upper end, the article of footwear including a first fitting element as well as a second fitting element. The first fitting element includes a first envelope and a first sole of the strobel type, the first envelope being fixed to the first strobel sole at least with stitching. The second fitting element includes a second envelope and a second sole of the strobel type, the second envelope being fixed to the second strobel sole at least with stitching.

Owner:SALOMON SA

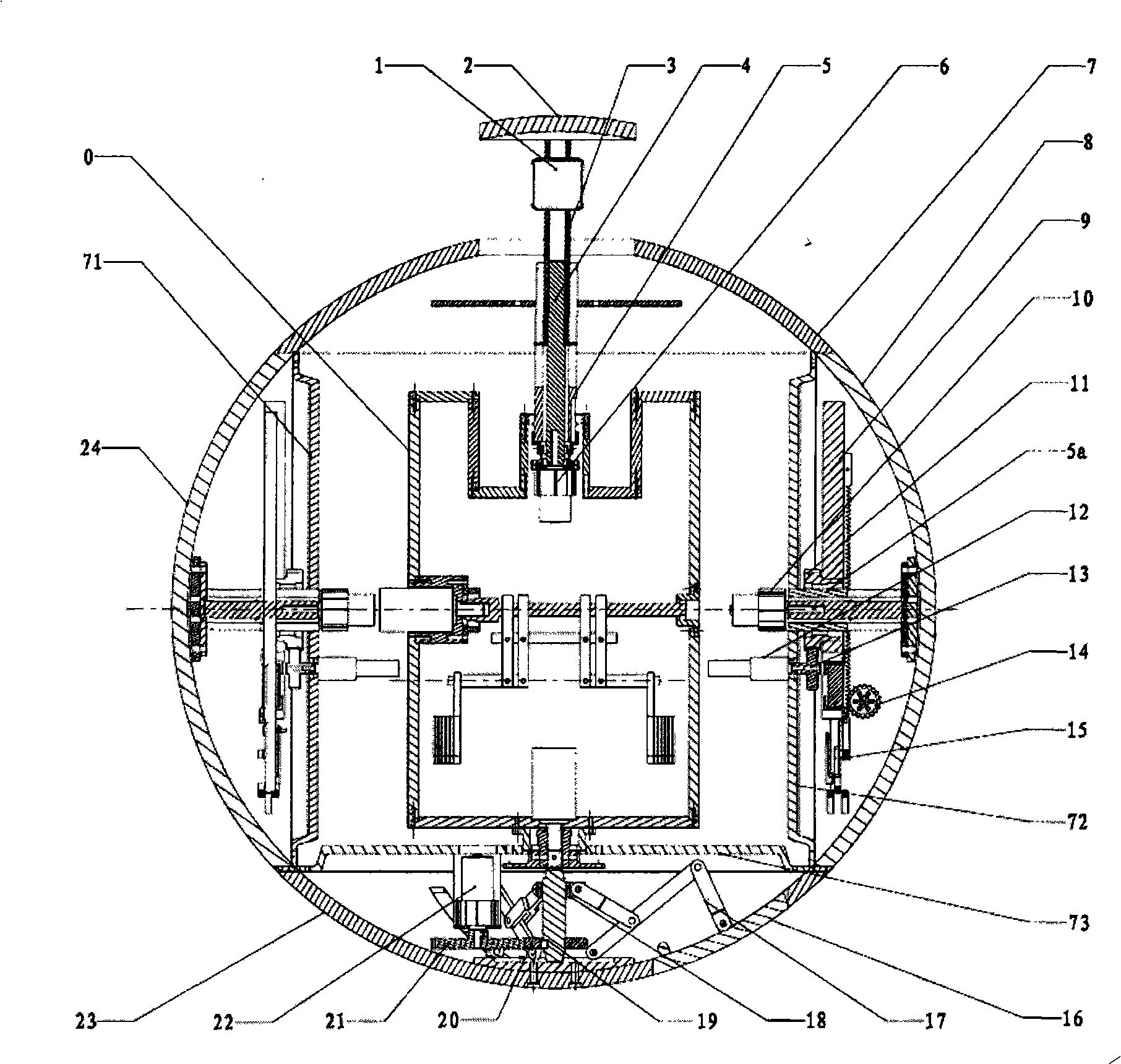

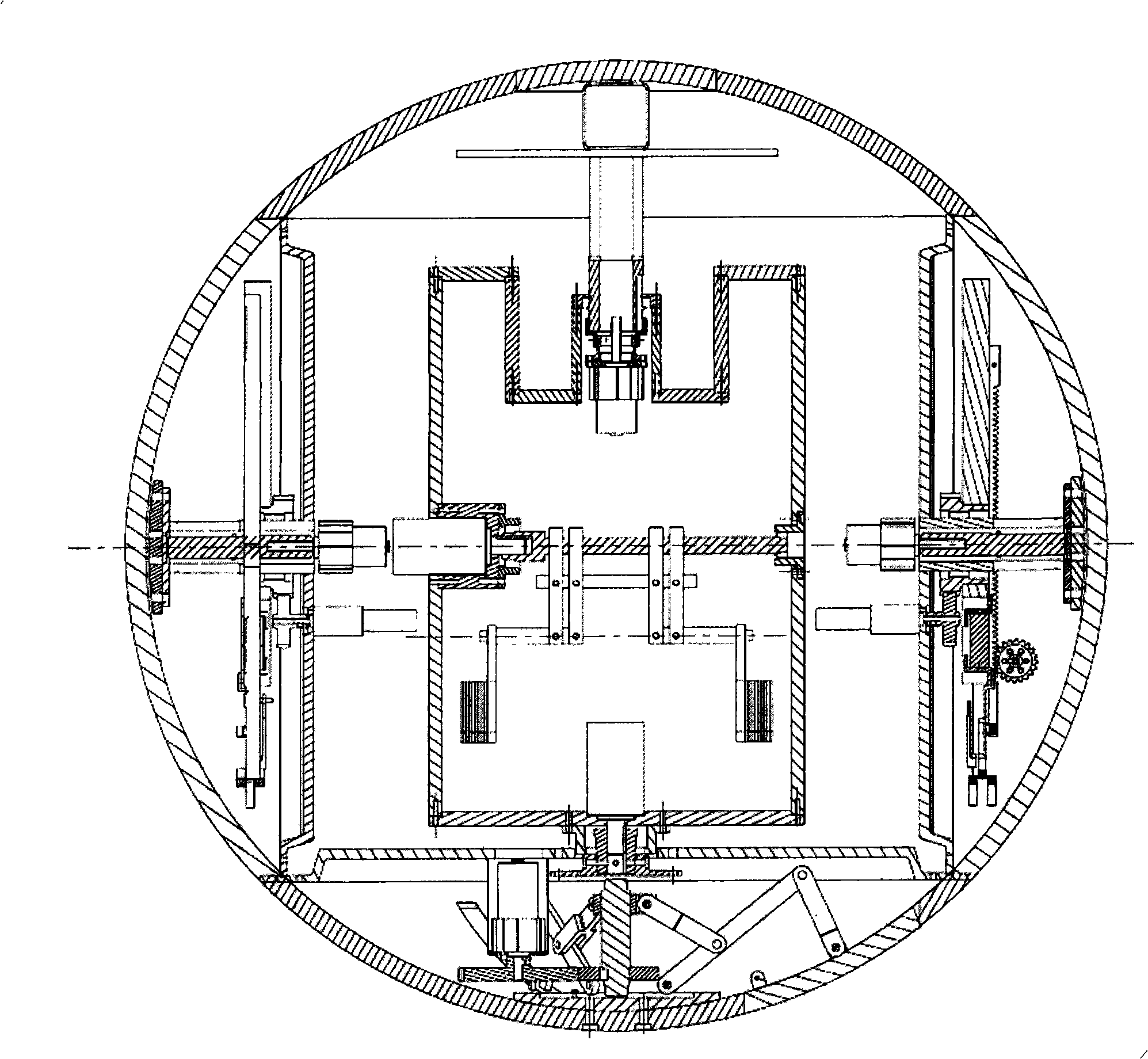

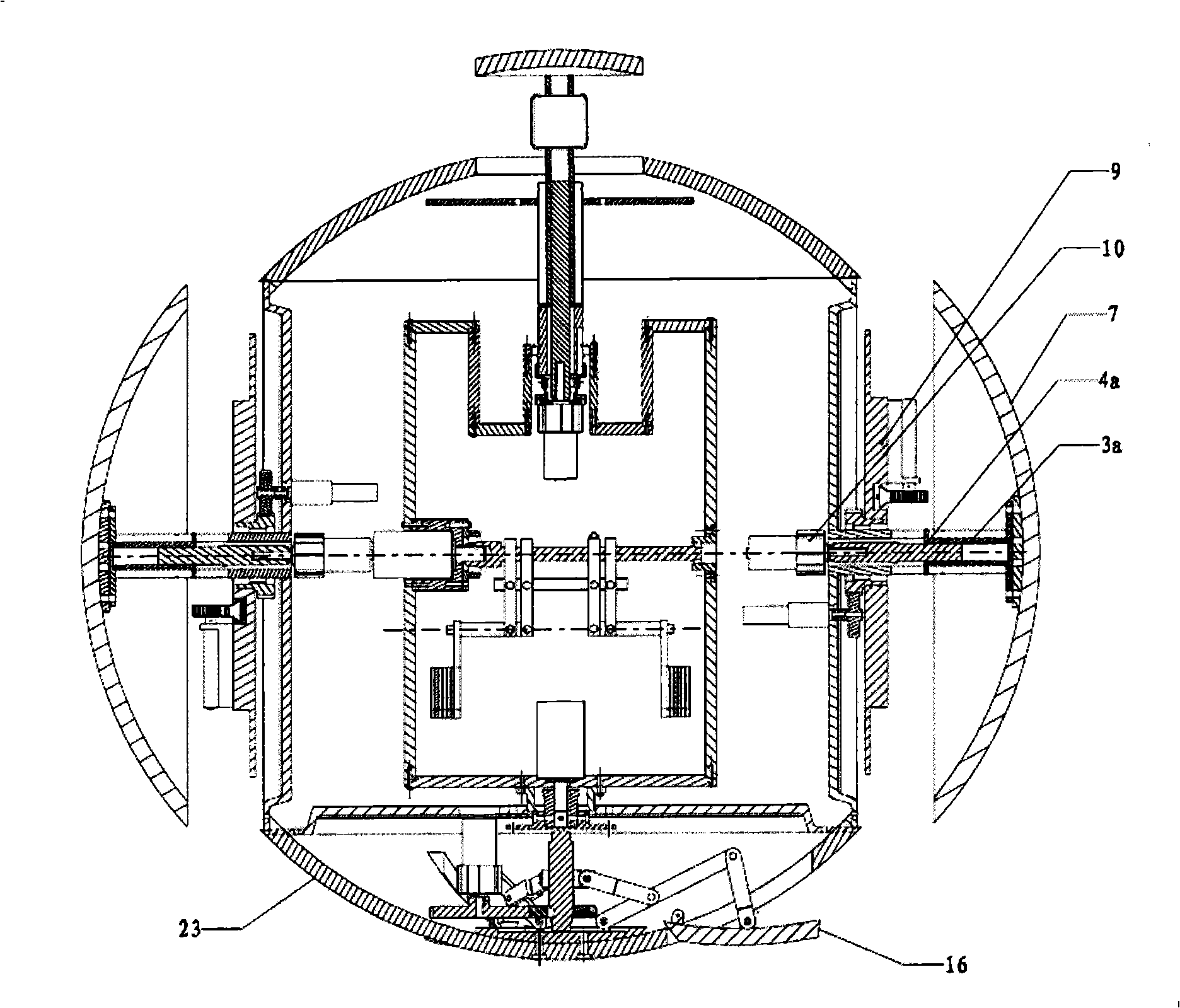

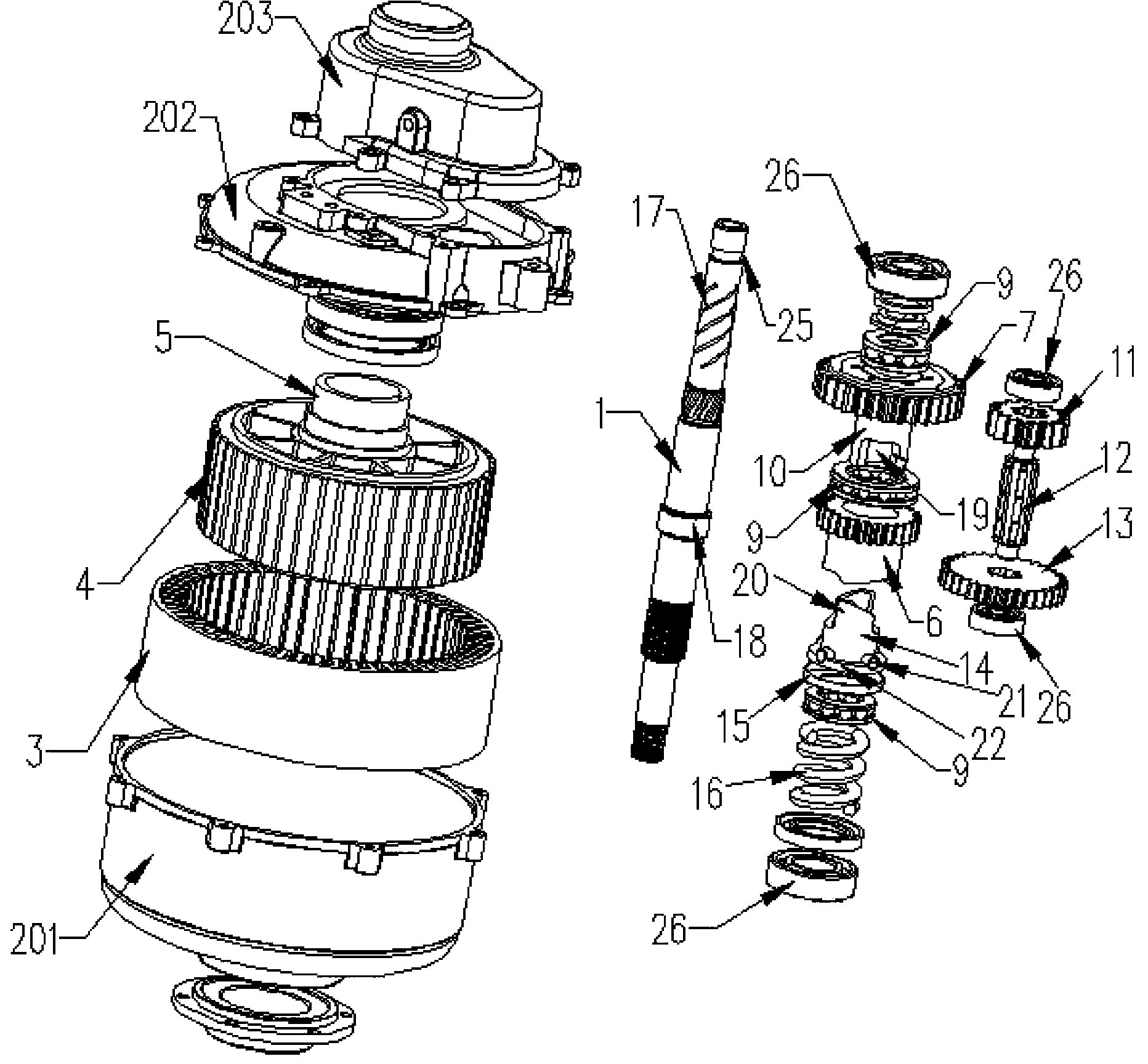

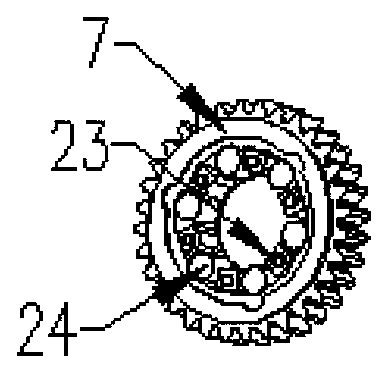

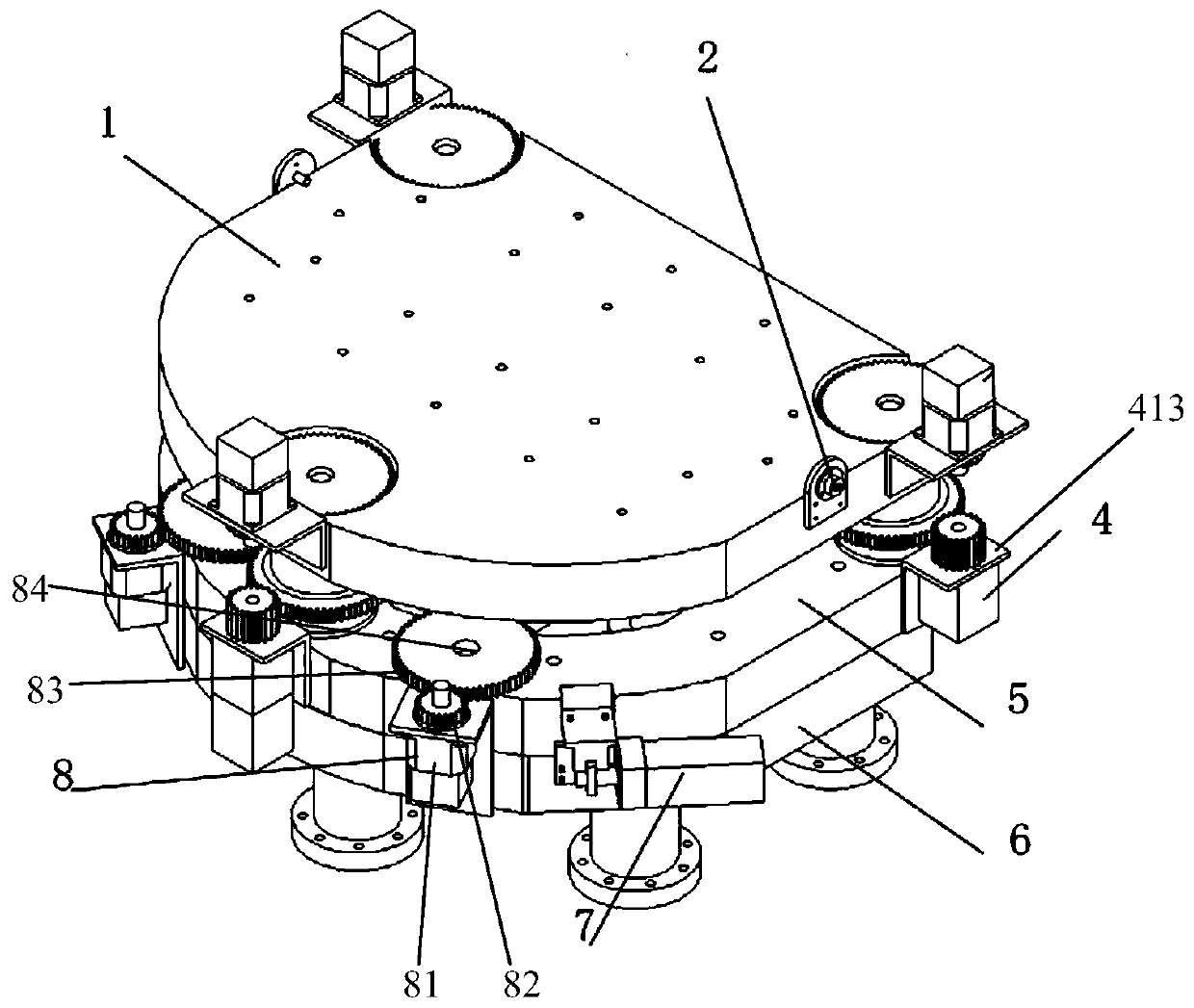

Spherical robot having visual sensation and arms on both sides

InactiveCN101314222AGuaranteed positional stabilityEasy to walkArmsVehiclesEngineeringDegrees of freedom

The invention discloses a spherical robot with vision and arms on two sides. The spherical robot comprises a spherical shell, two lateral arms, a lifting photographing device, a movement driving system and a support stabilizing mechanism, wherein, the spherical shell consists of a lifting top spherical crown, a left spherical crown, a right spherical crown, a unlifting bottom spherical crown and a middle spherical shell. The lower part of the top spherical crown is provided with the photographing device which can lift and rotate by 360 degrees in a plane; the left spherical crown and the right spherical crown on two sides of the spherical robot are respectively provided with one or a plurality of 3-DOF (degree of freedom) mechanical arms which can respectively extend out of the shell; and the bottom spherical crown is provided with a mechanism which can make a sphere stand stably. The spherical robot is a mobile robot provided with a vision sensor and can carry out complex operations and have the flexible kinetic characteristics.

Owner:BEIJING UNIV OF POSTS & TELECOMM

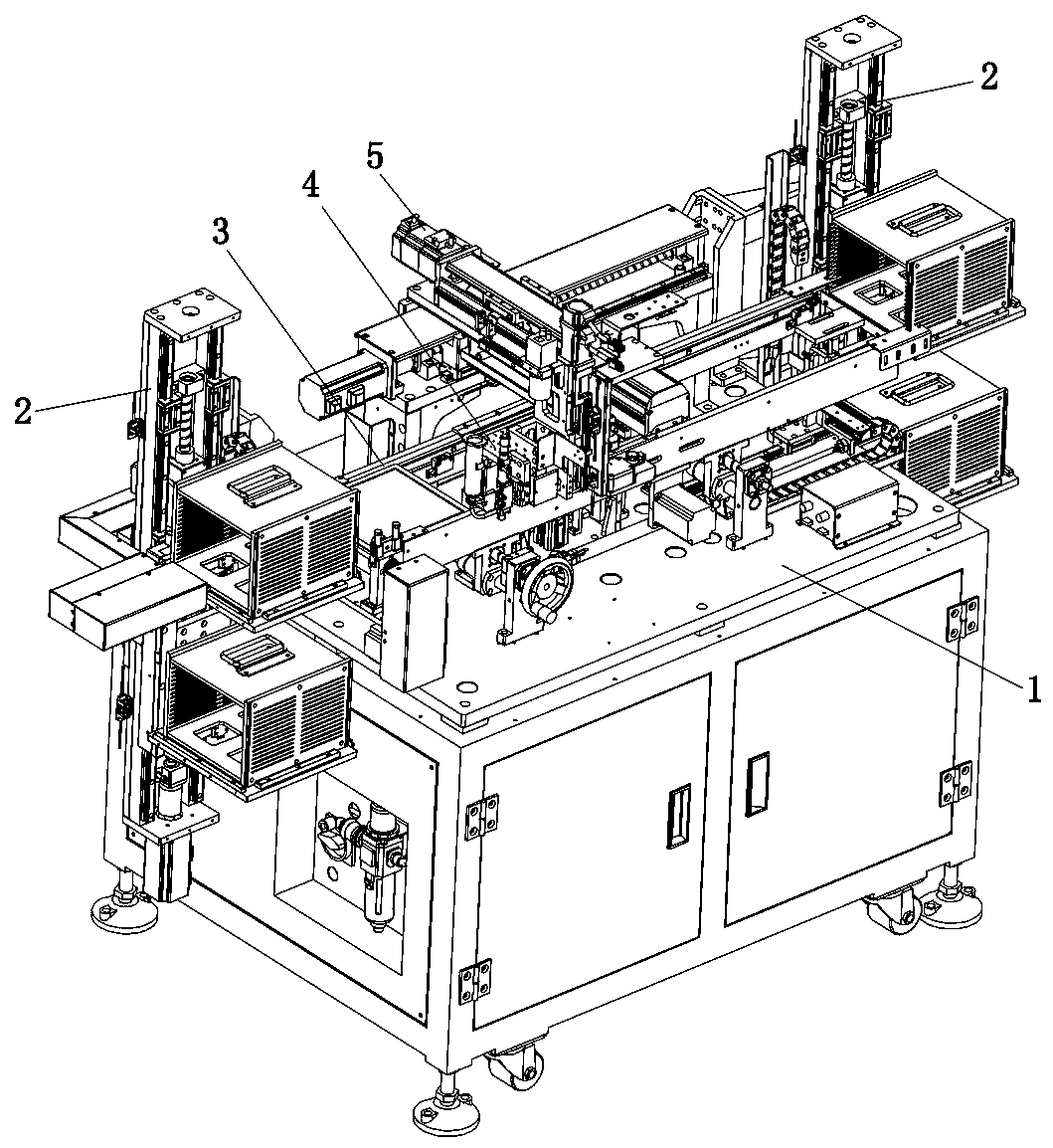

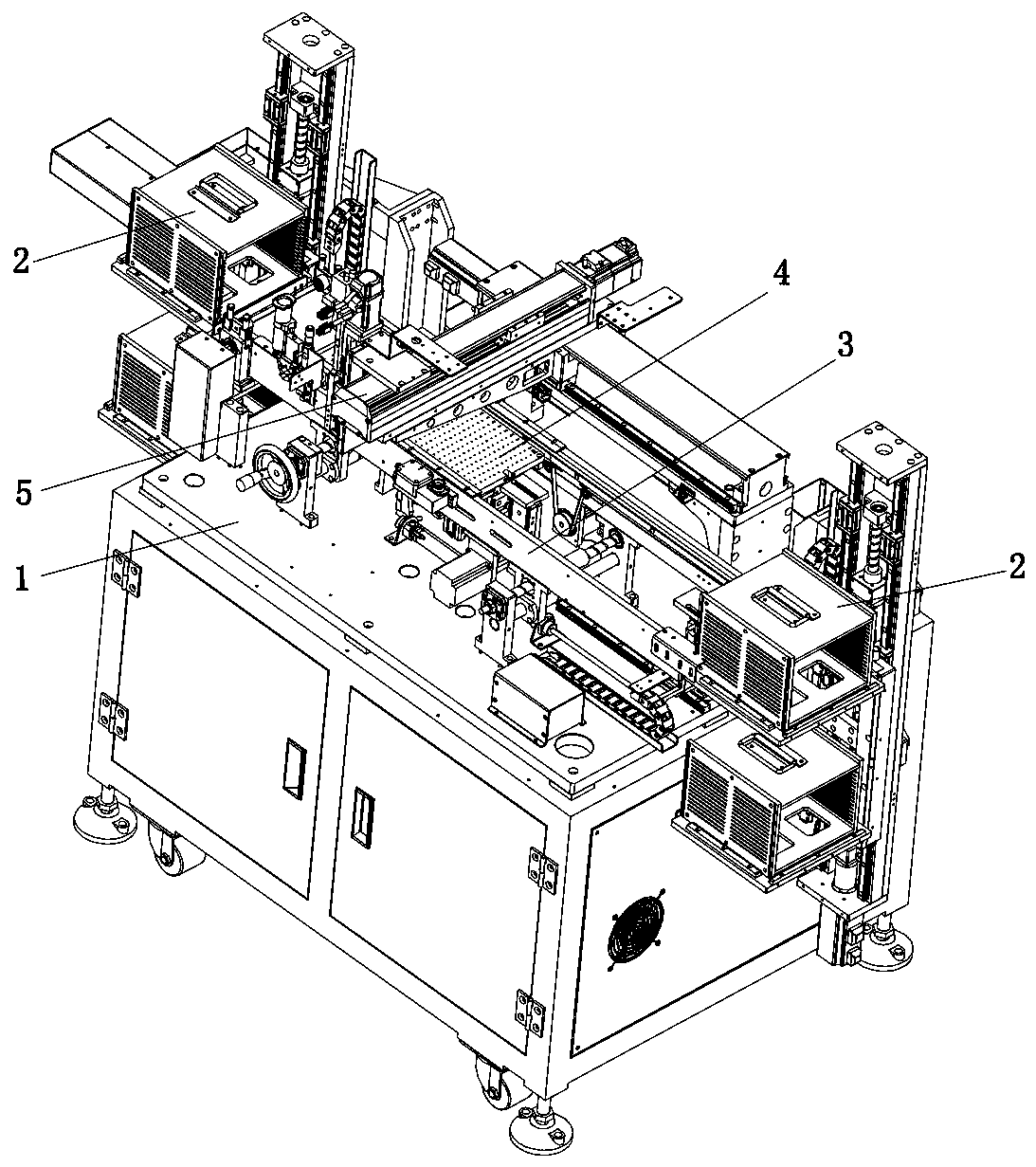

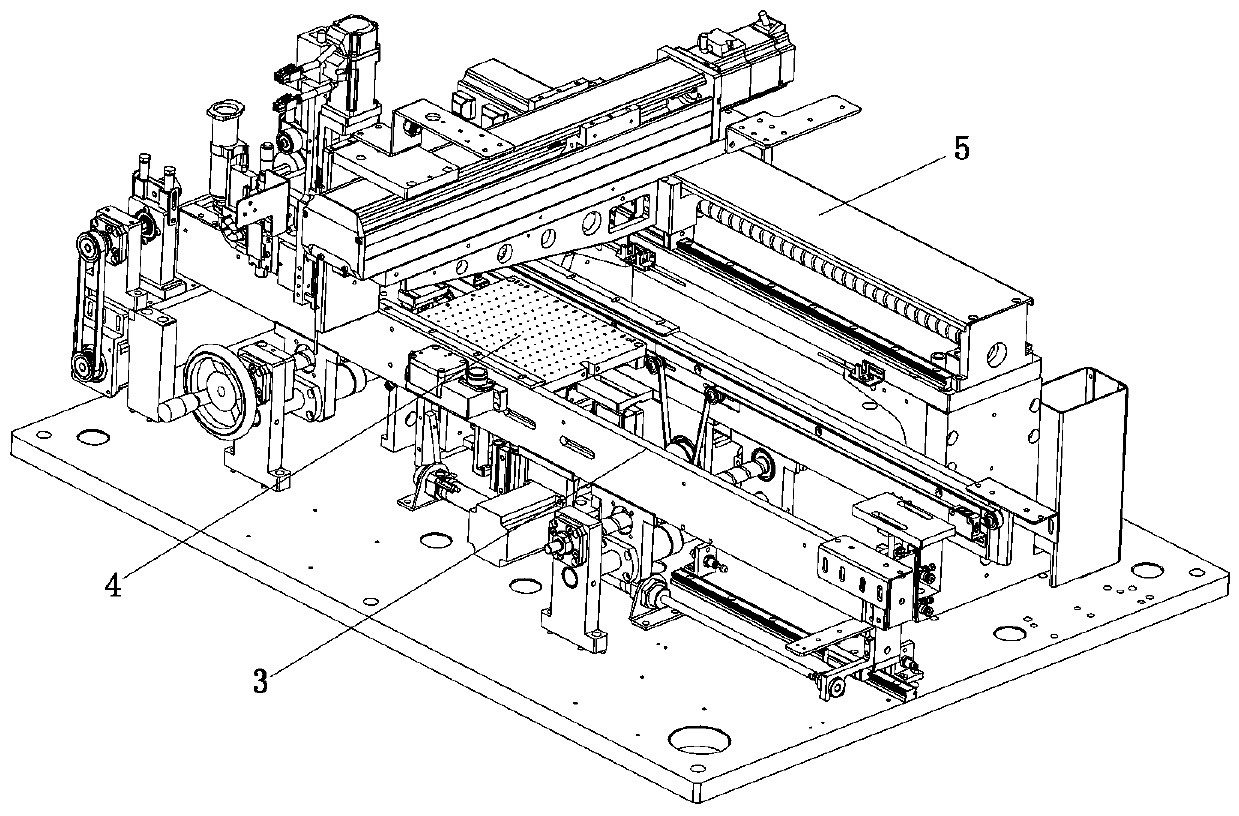

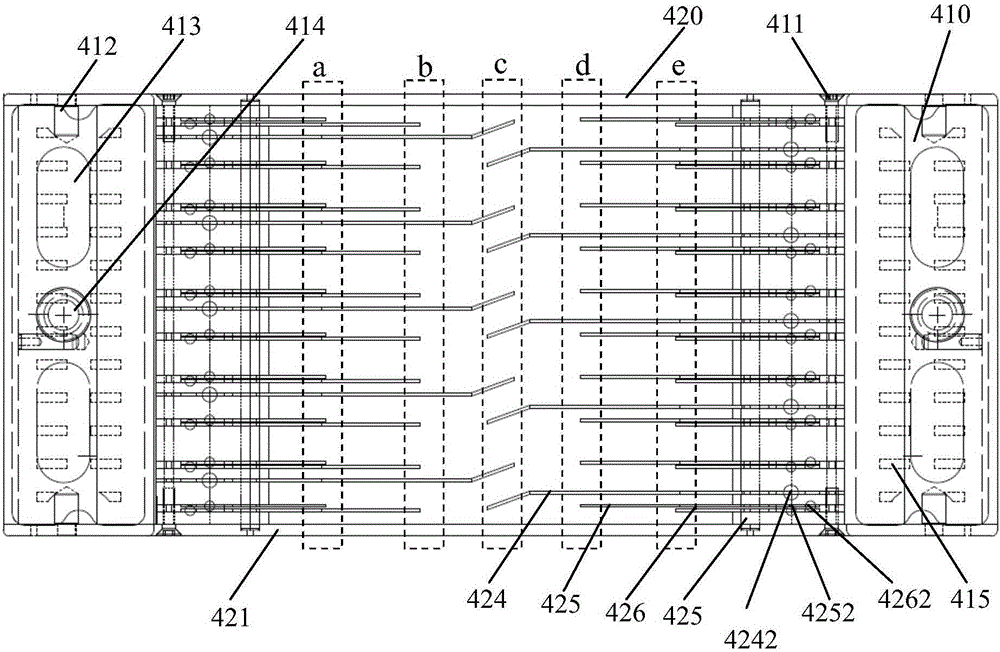

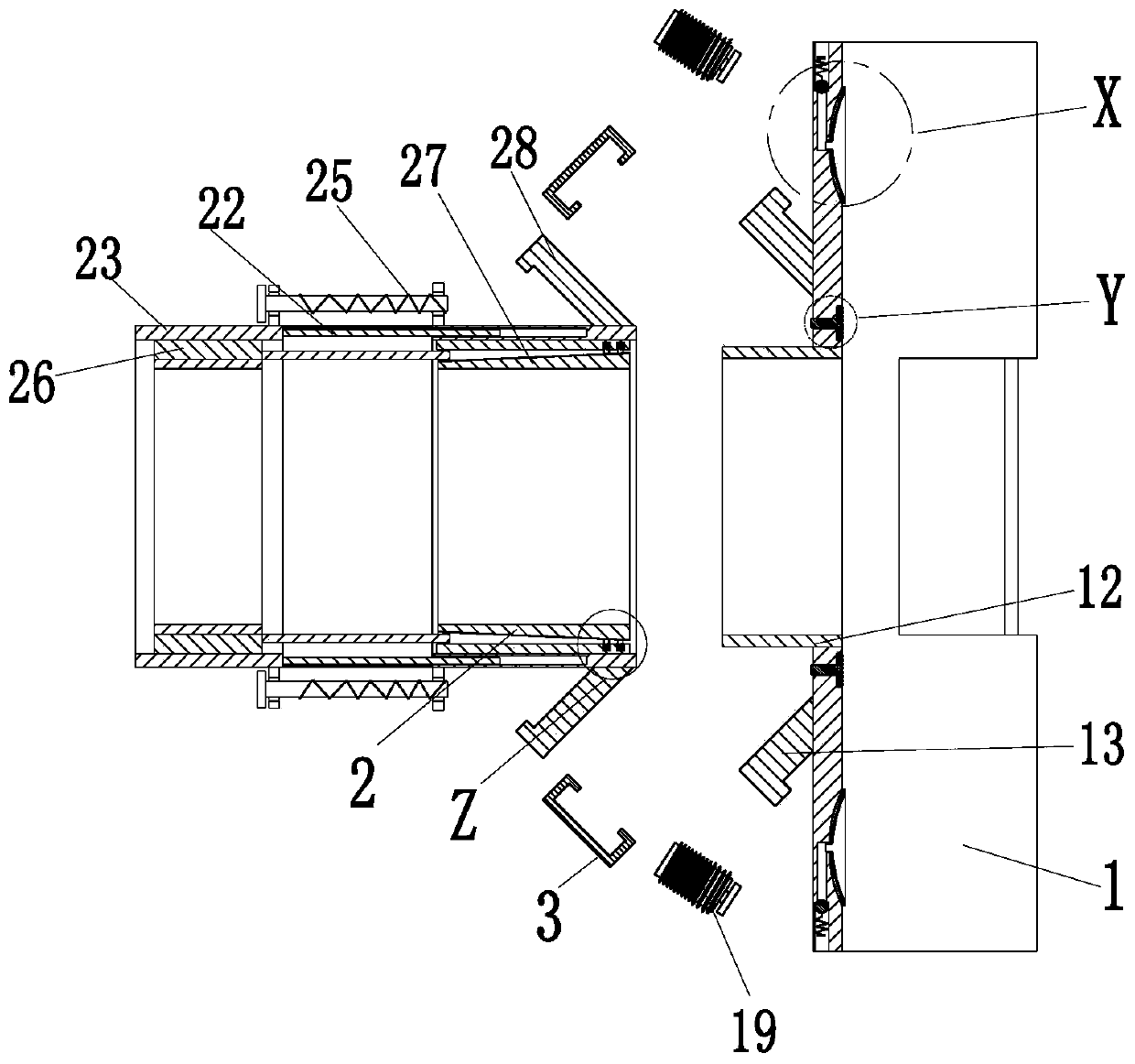

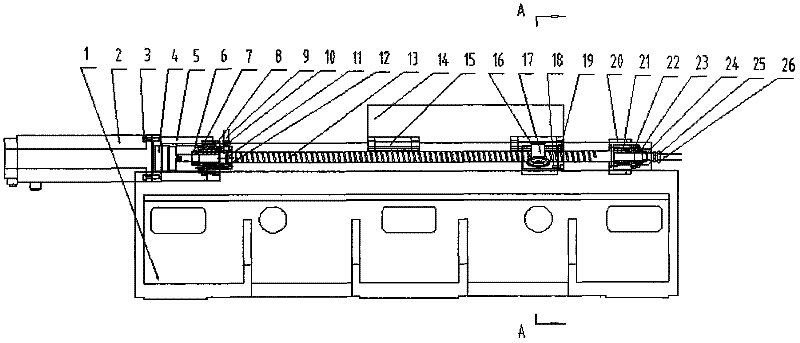

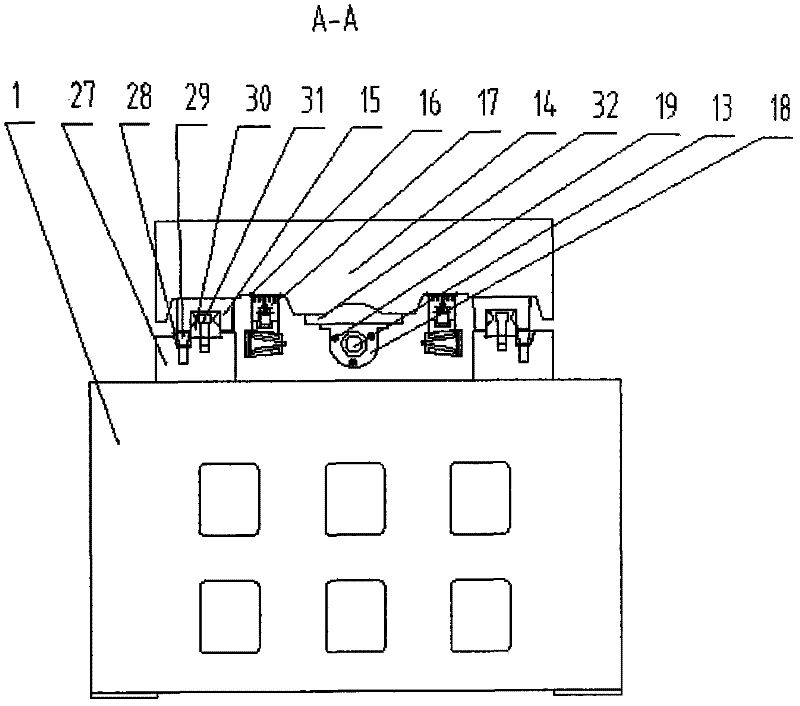

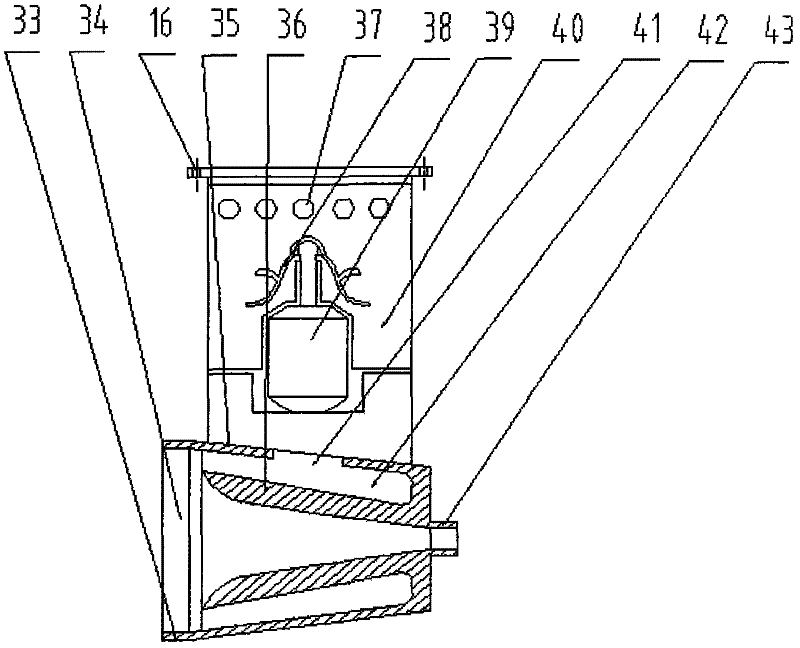

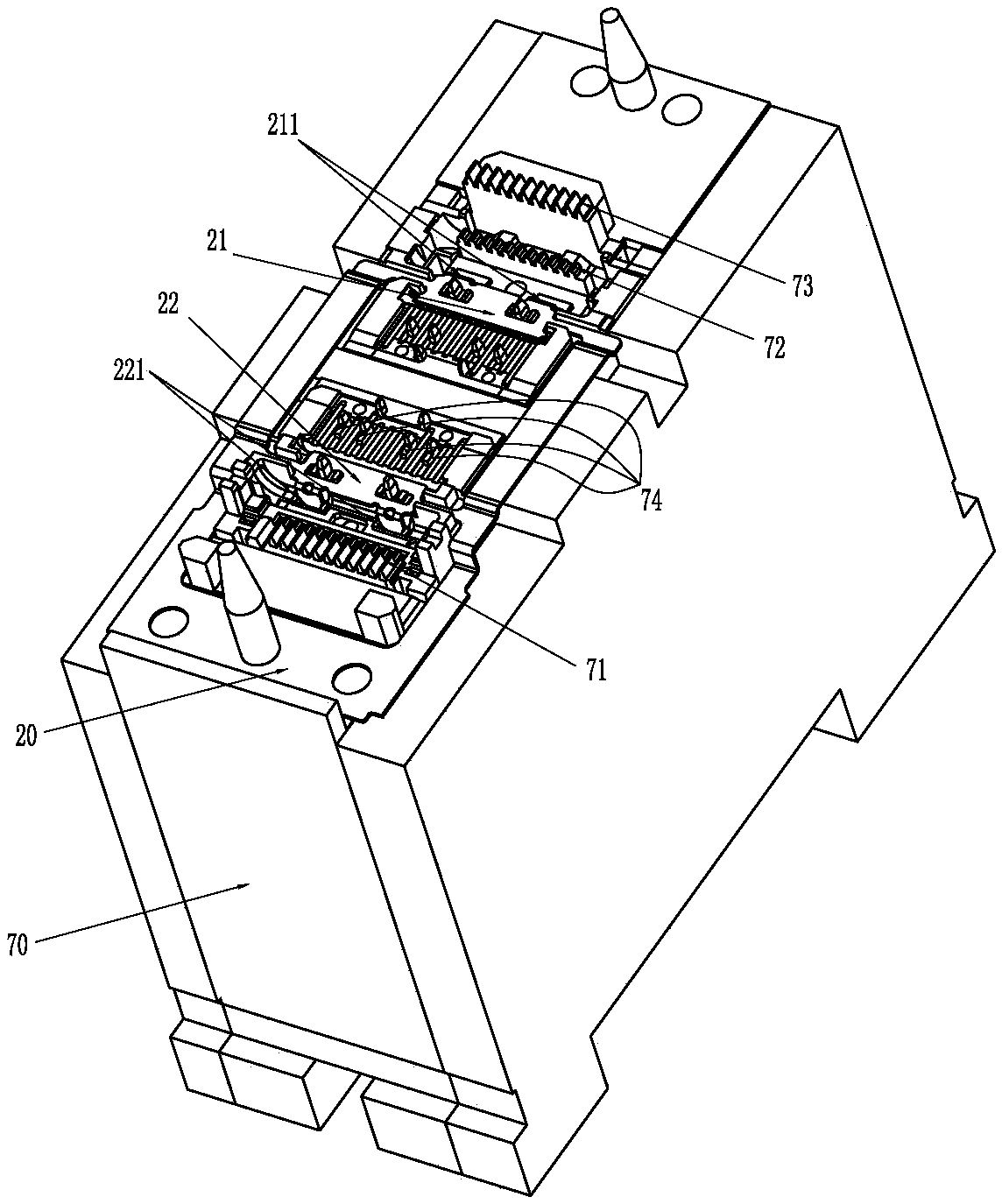

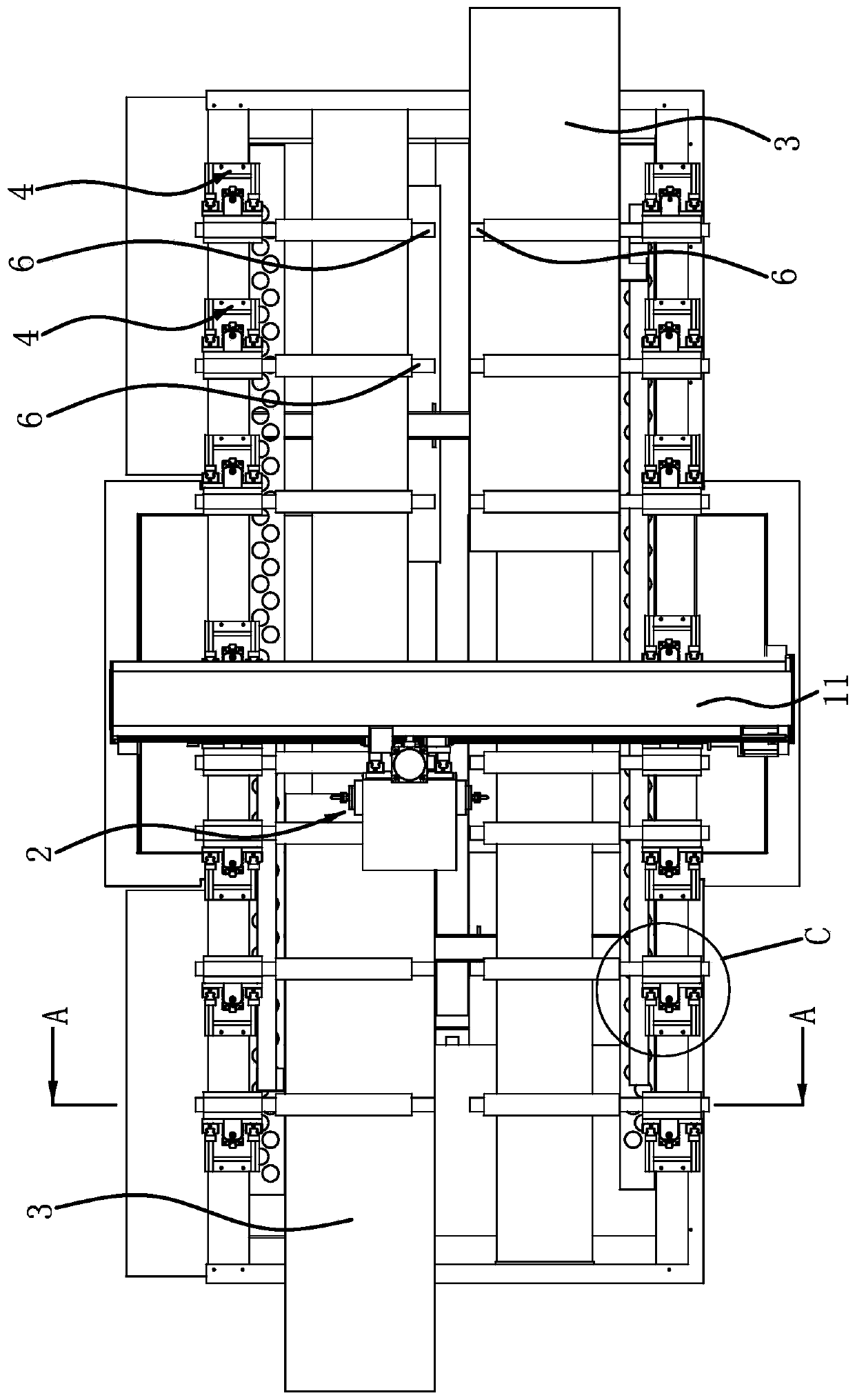

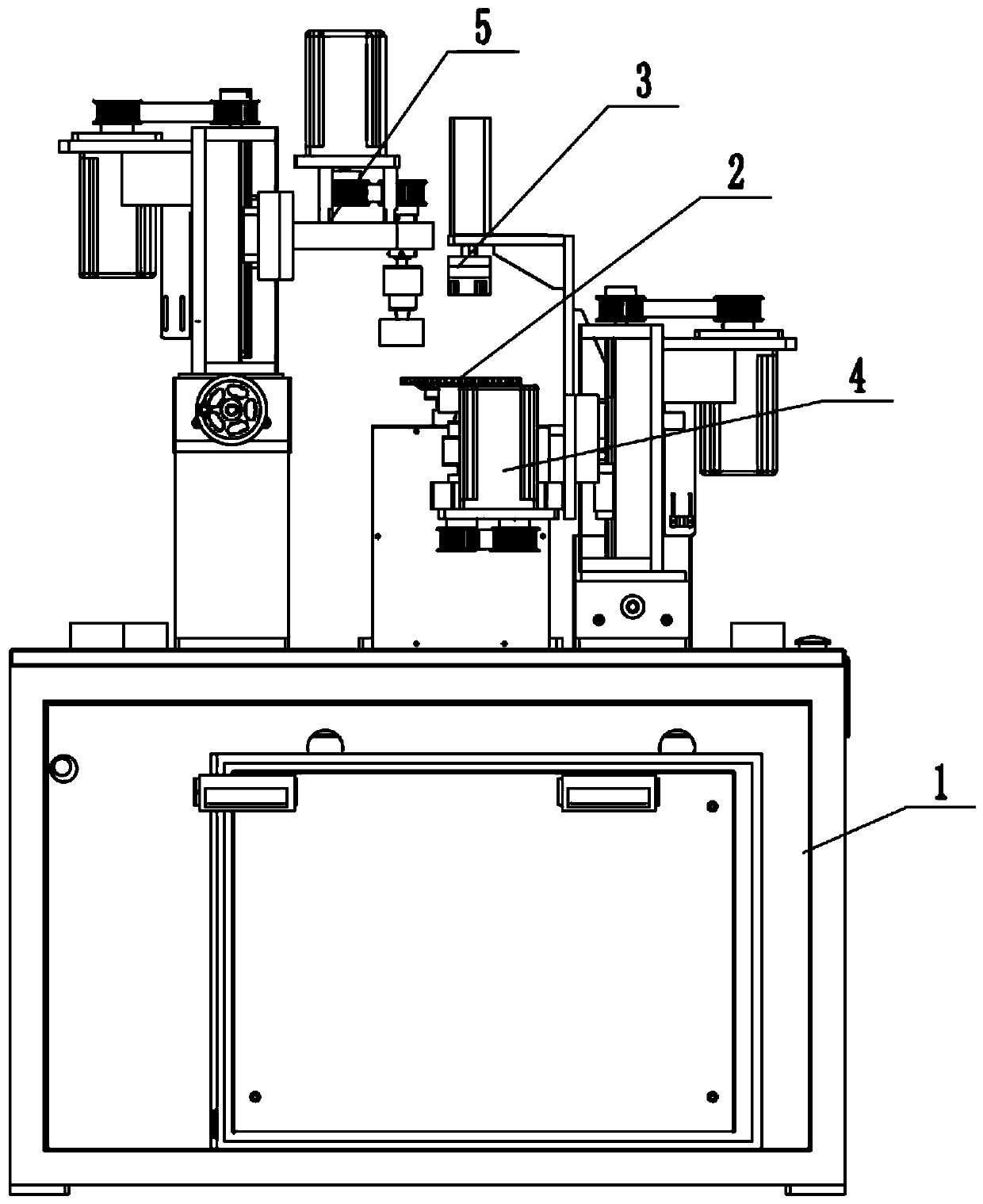

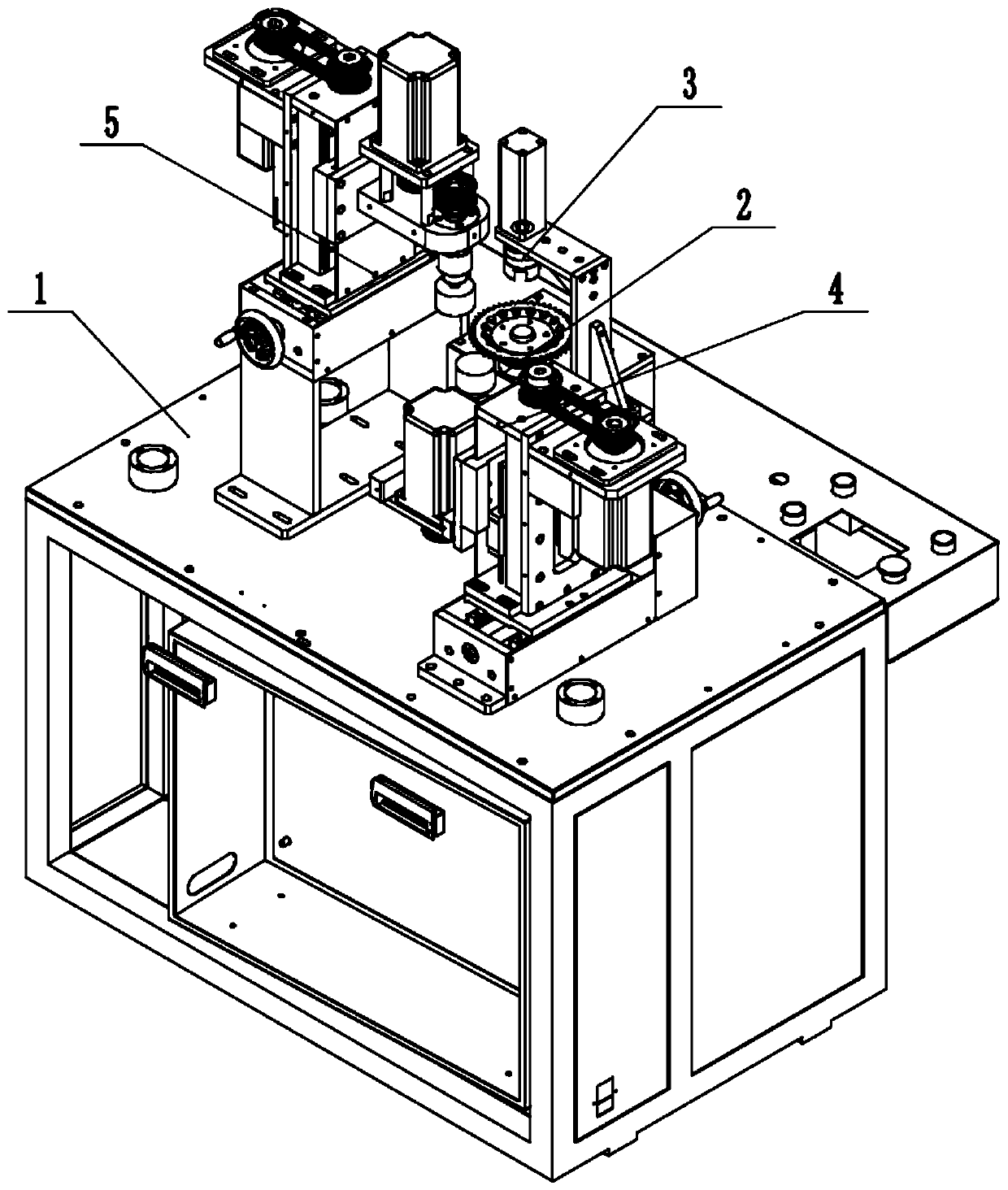

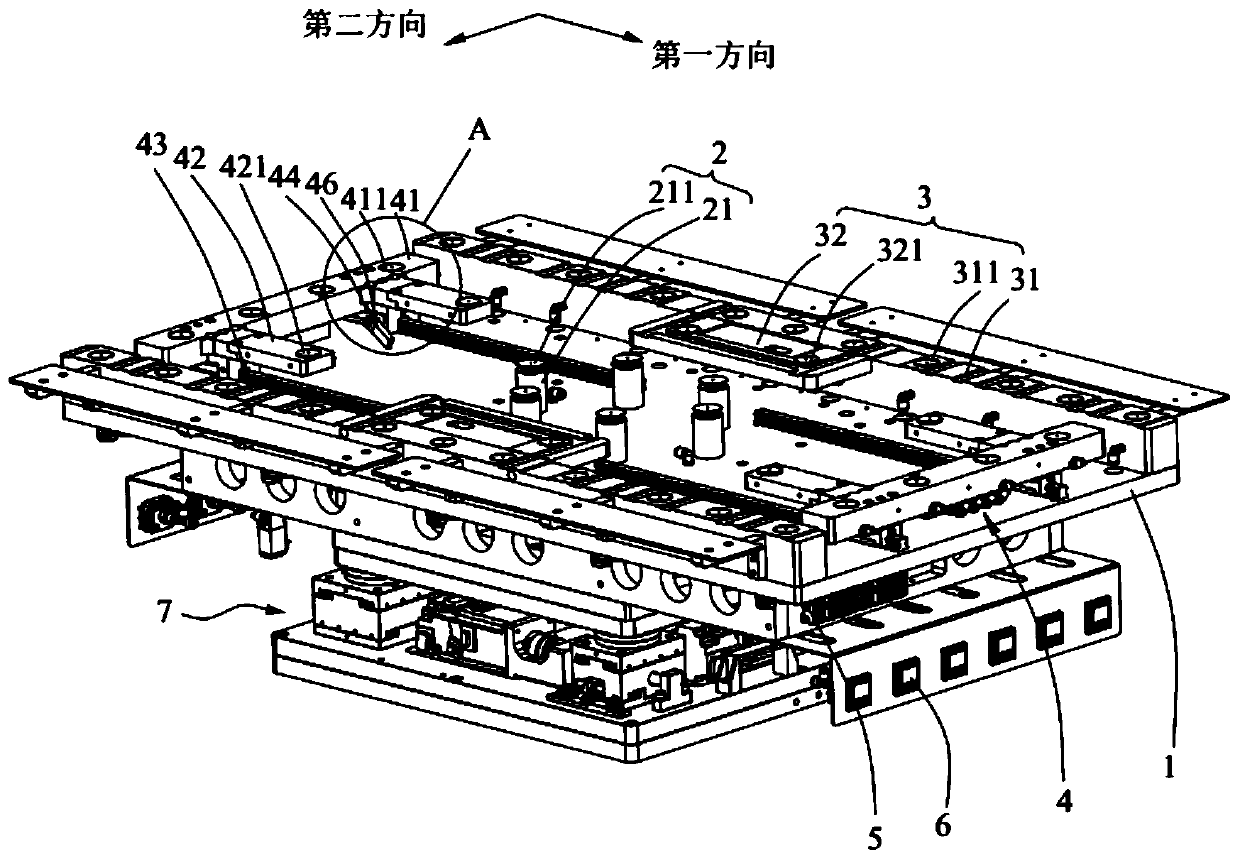

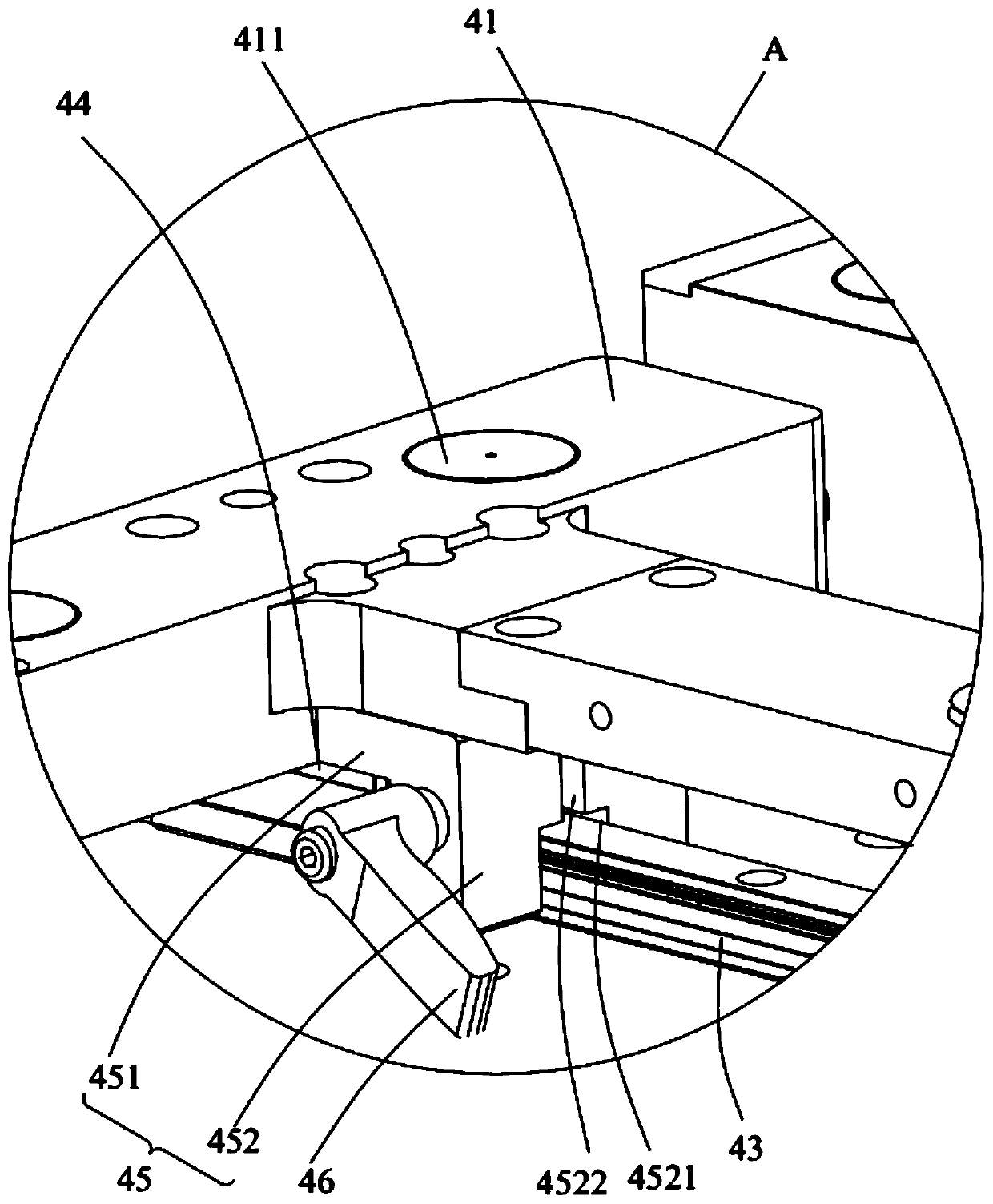

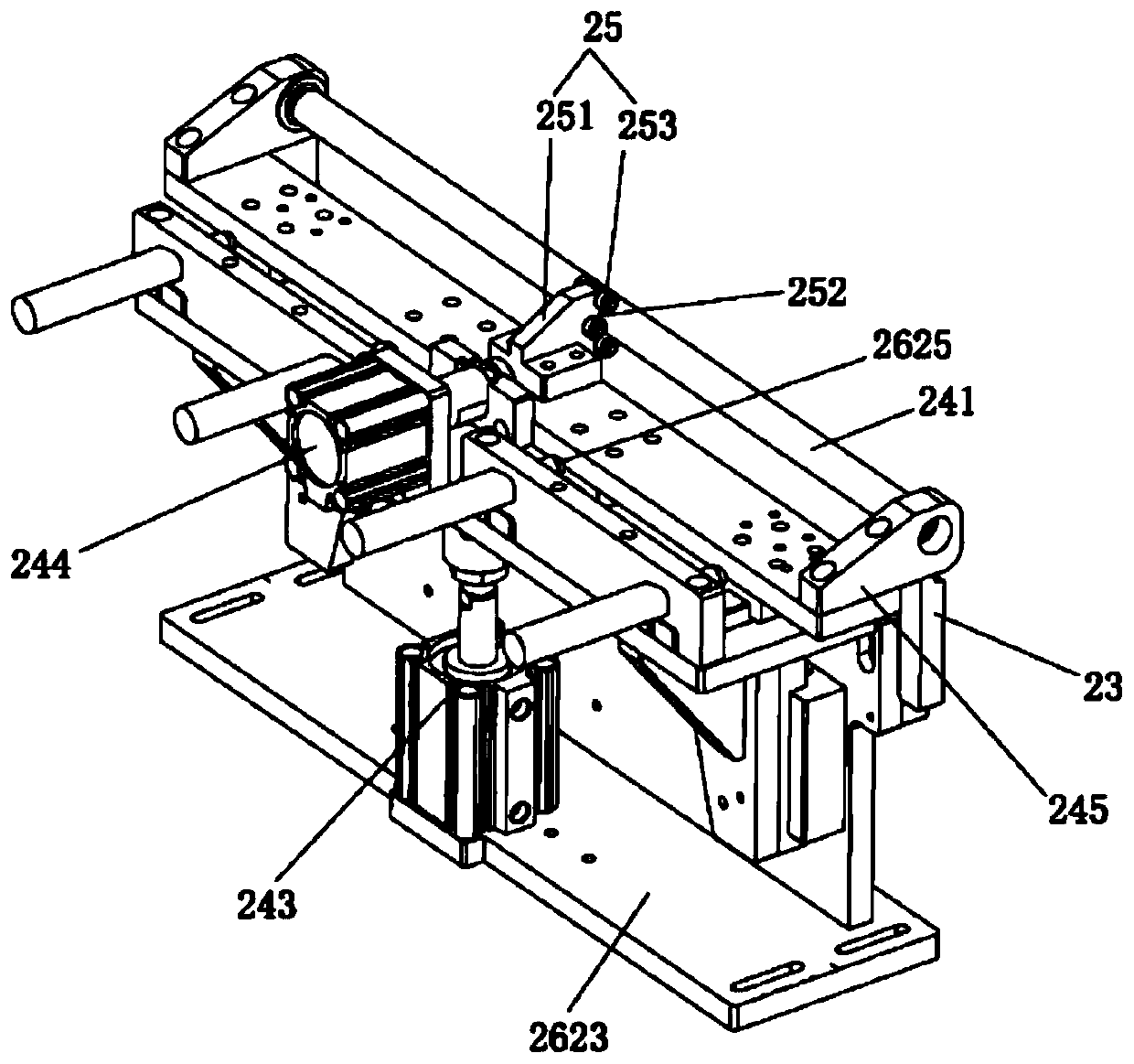

Full-automatic single-rail glue dispenser and glue dispensing process thereof

PendingCN109513578AAvoid collisions with each otherImprove adjustabilityLiquid surface applicatorsCoatingsDischarge efficiencyEngineering

The invention discloses a full-automatic single-rail glue dispenser and a glue dispensing process thereof. The full-automatic single-rail glue dispenser comprises two sets of collection and release assemblies, a conveying rail, a front pushing part, a glue dispensing platform and a glue dispensing assembly. The two collection and release assemblies are arranged on the left and right sides of a rack correspondingly symmetrically. The front pushing part is arranged on the lateral part of the collection and release assembly on the left side and pushes carrier plates in the collection and releaseassembly on the left side into the conveying rail. The conveying rail is arranged between the two collection and release assemblies. A rear pushing part of the conveying rail pushes the carrier platesinto the collection and release assembly on the right side. The glue dispensing platform is arranged between a movable support plate and a fixed support plate, conducts upward jacking and supports the carrier plates. The glue dispensing assembly is arranged above the glue dispensing platform and conducts glue dispensing on the carrier plates on the glue dispensing platform. Through the full-automatic single-rail glue dispenser and the glue dispensing process thereof, mutual friction and collision between adjacent carrier plates are avoided effectively, position stability of fingerprint modules on the carrier plates is ensured while feed and discharge efficiency is promoted in a linear pushing mode, and adjustability of the sizes of the conveying carrier plates is achieved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

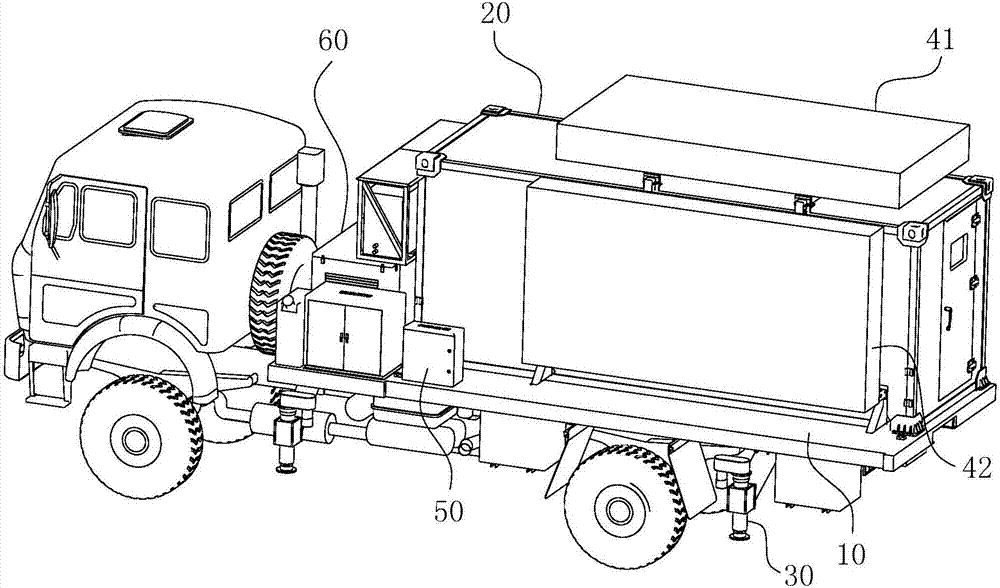

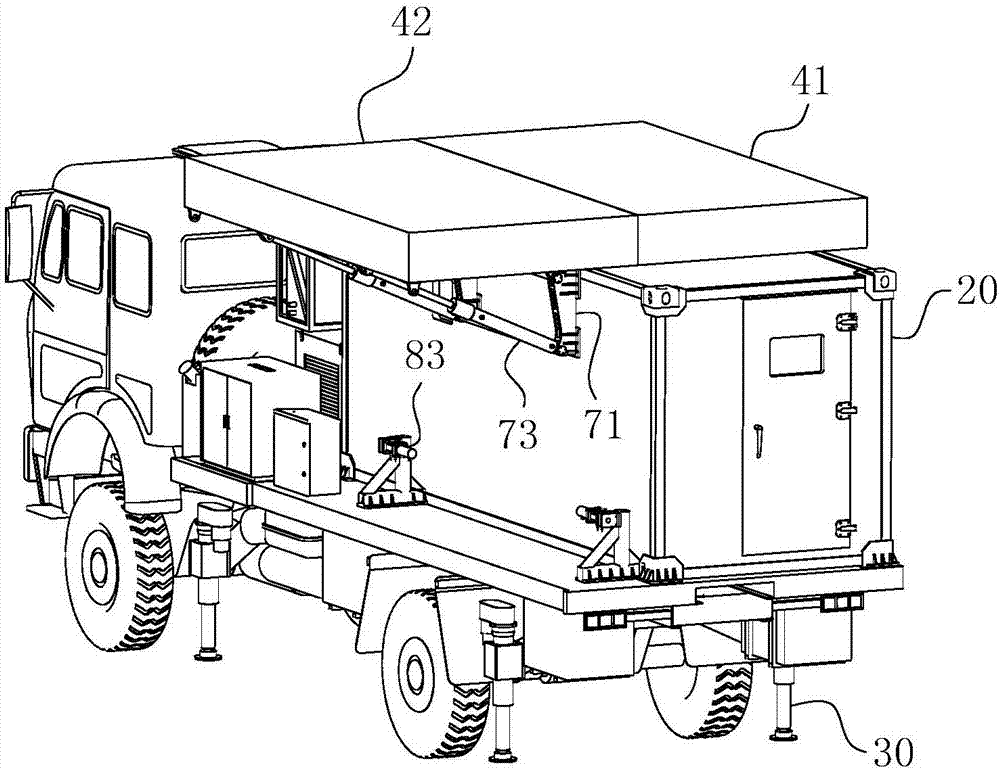

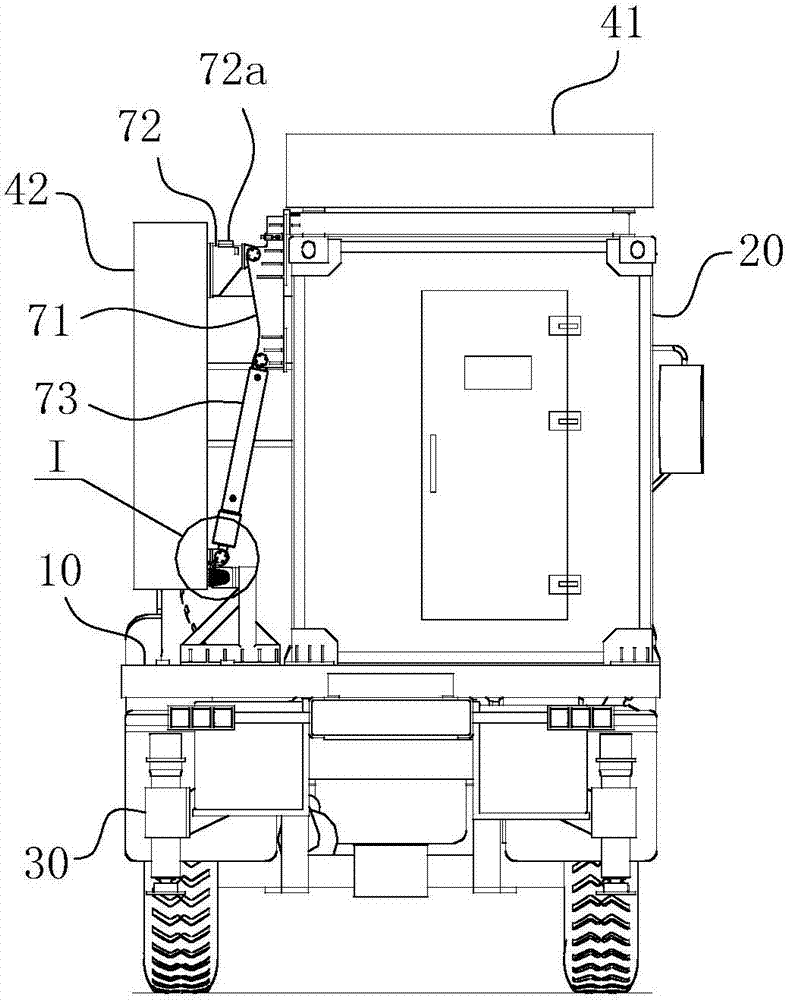

High-mobility large-scale radar vehicle

ActiveCN107097706AImprove mobilityGuaranteed mobilityCollapsable antennas meansWave based measurement systemsRadar antennasGround vehicles

The invention belongs to the technical field of vehicle-borne radars, and particularly relates to a high-mobility large-scale radar vehicle. The radar vehicle comprises an assembling platform and an electronic equipment cabin, wherein leveling supporting legs are arranged on the lower plate surface of the assembling platform; a fixed antenna and a folded antenna are arranged at the electronic equipment cabin; the folded antenna is driven by a hydraulic driving assembly, so that two position conditions of withdrawing and unfolding are generated along a vertical surface; when the folded antenna is under a withdrawing condition, the antenna plate surface of the folded antenna is vertically arranged, when the folded antenna is under an unfolding condition, the antenna plate surface of the folded antenna is horizontally arranged, and the antenna plate surface of the folded antenna and the antenna plate surface of the fixed antenna are in the same plane; and the radar vehicle also comprises a servo control system and an electric generating system. According to the high-mobility large-scale radar vehicle disclosed by the invention, the situation that the width and the height are not exceeded during the transporting of radar antennas can be guaranteed, functions of quick erecting and quick removing of an antenna array surface can also be realized, and finally, the high mobility of the ground vehicle-borne radar is guaranteed.

Owner:ANHUI SUN CREATE ELECTRONICS

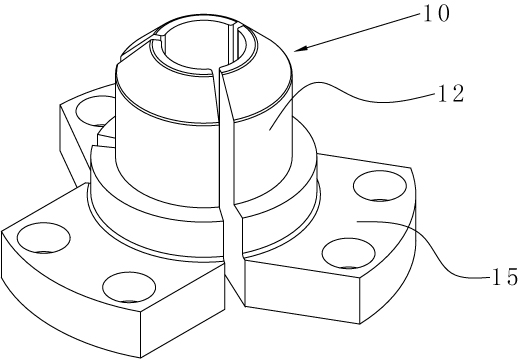

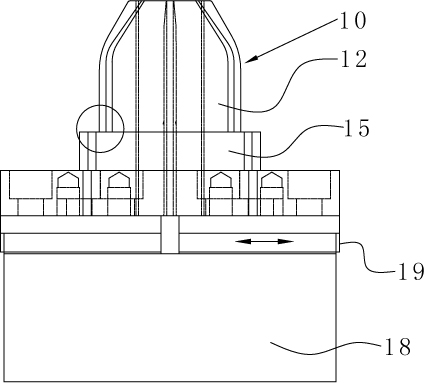

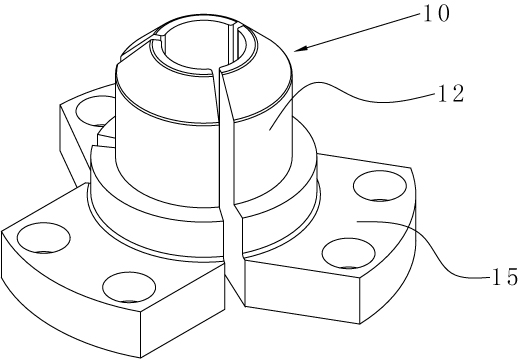

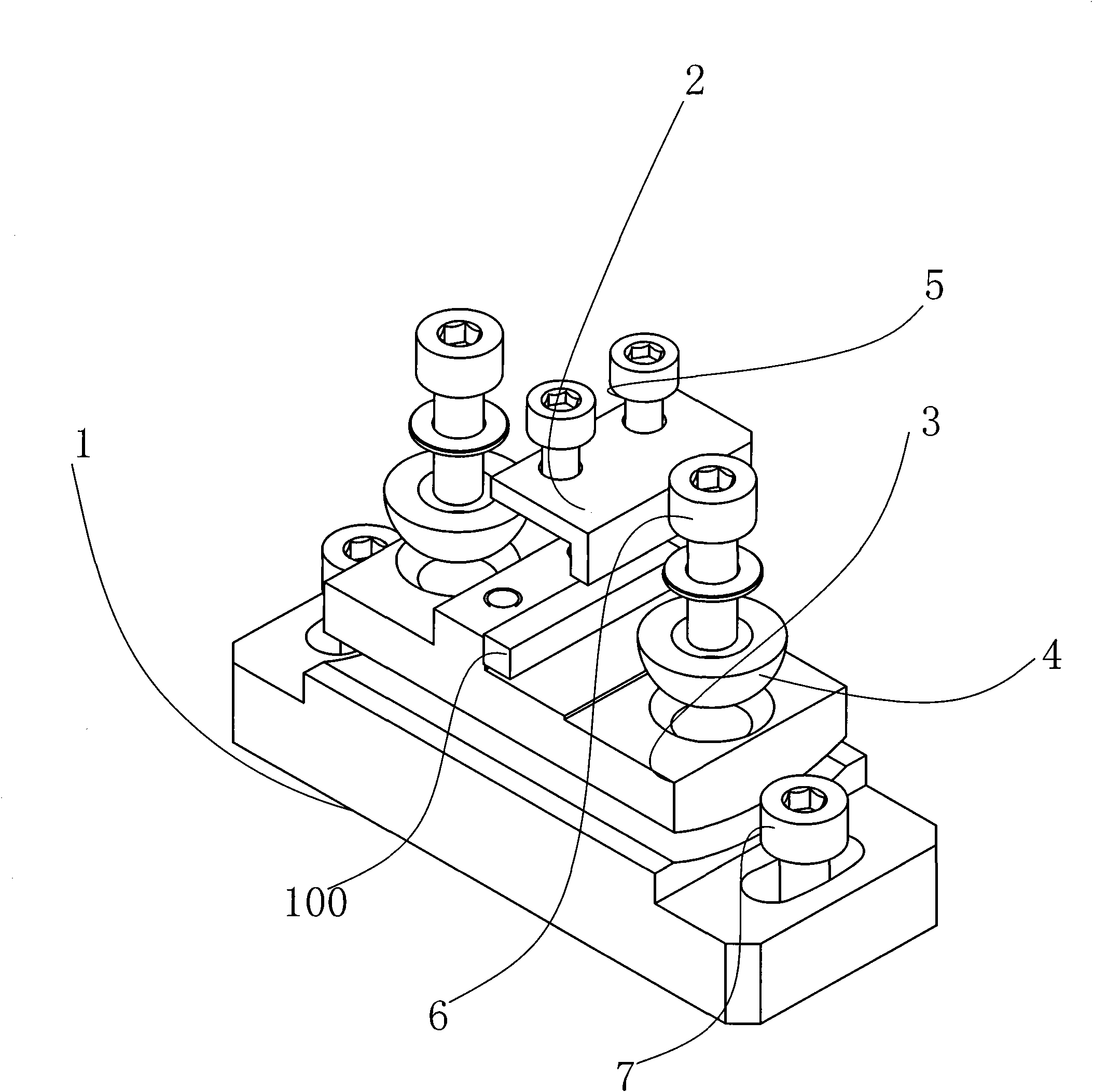

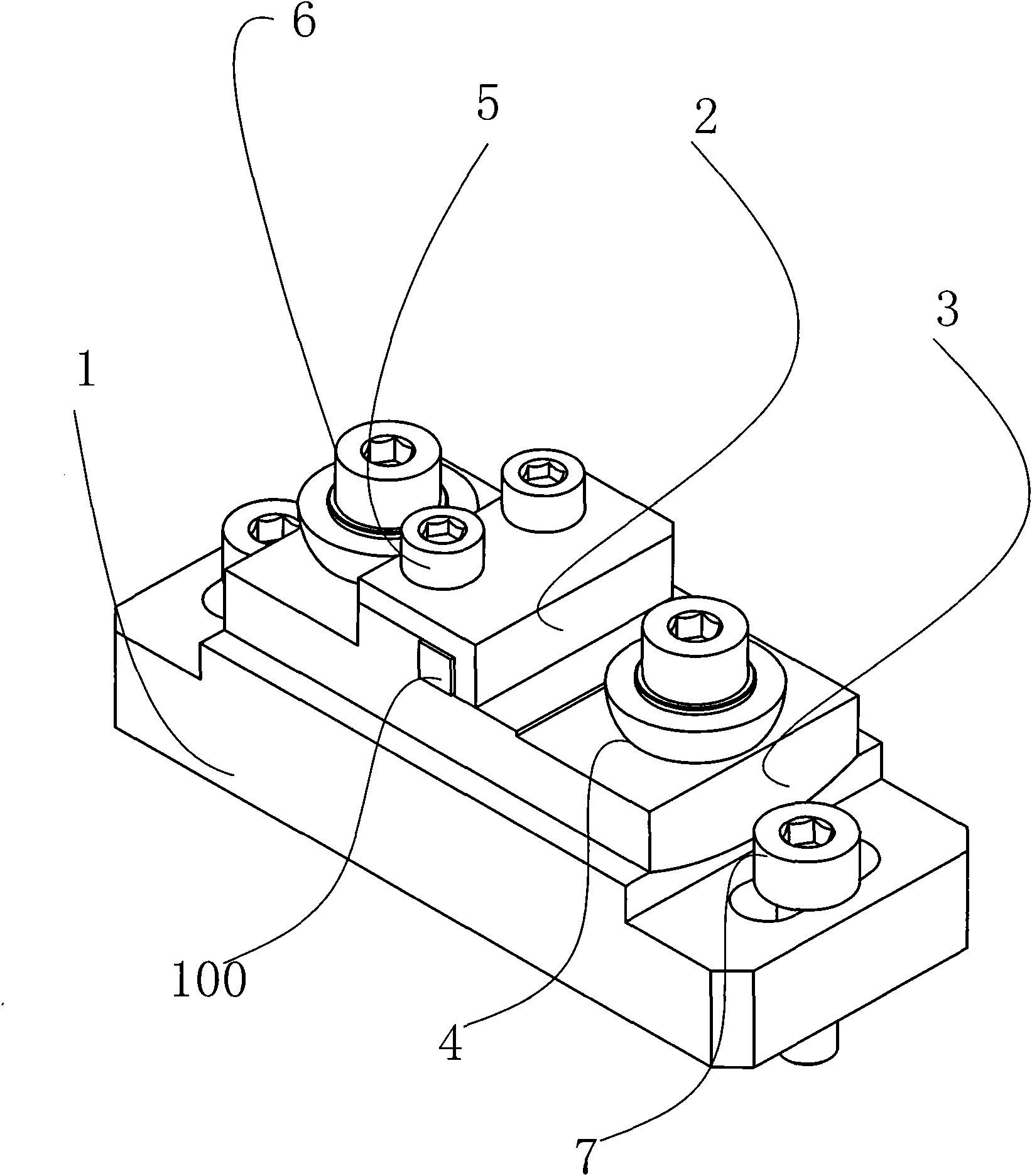

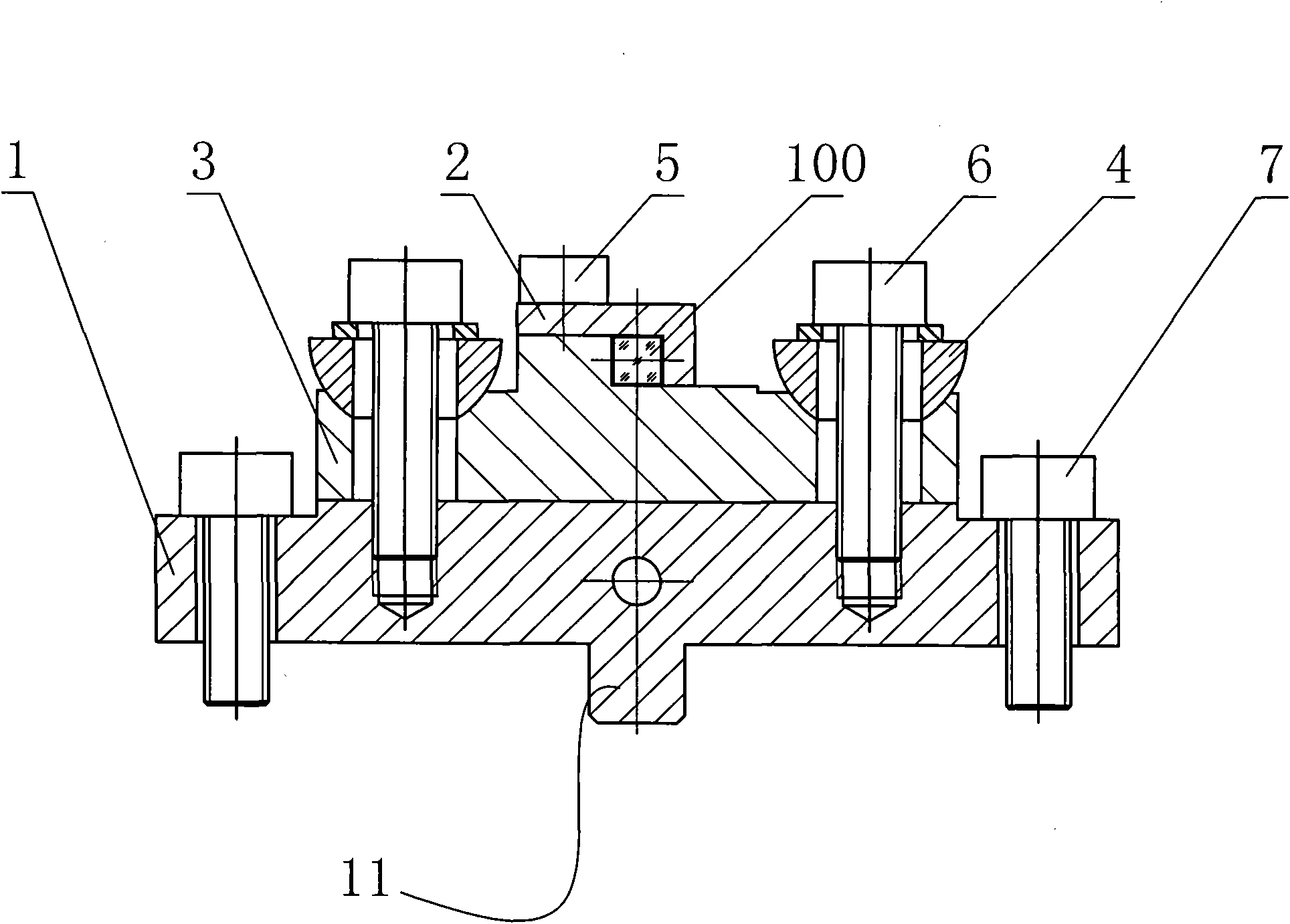

Round pin-inserted positioning device and tensioning and positioning round pin thereof

ActiveCN102121496AGuaranteed positioning accuracyGuaranteed positional stabilityWelding/cutting auxillary devicesBoltsEngineeringCar door

Owner:GUANGQI HONDA

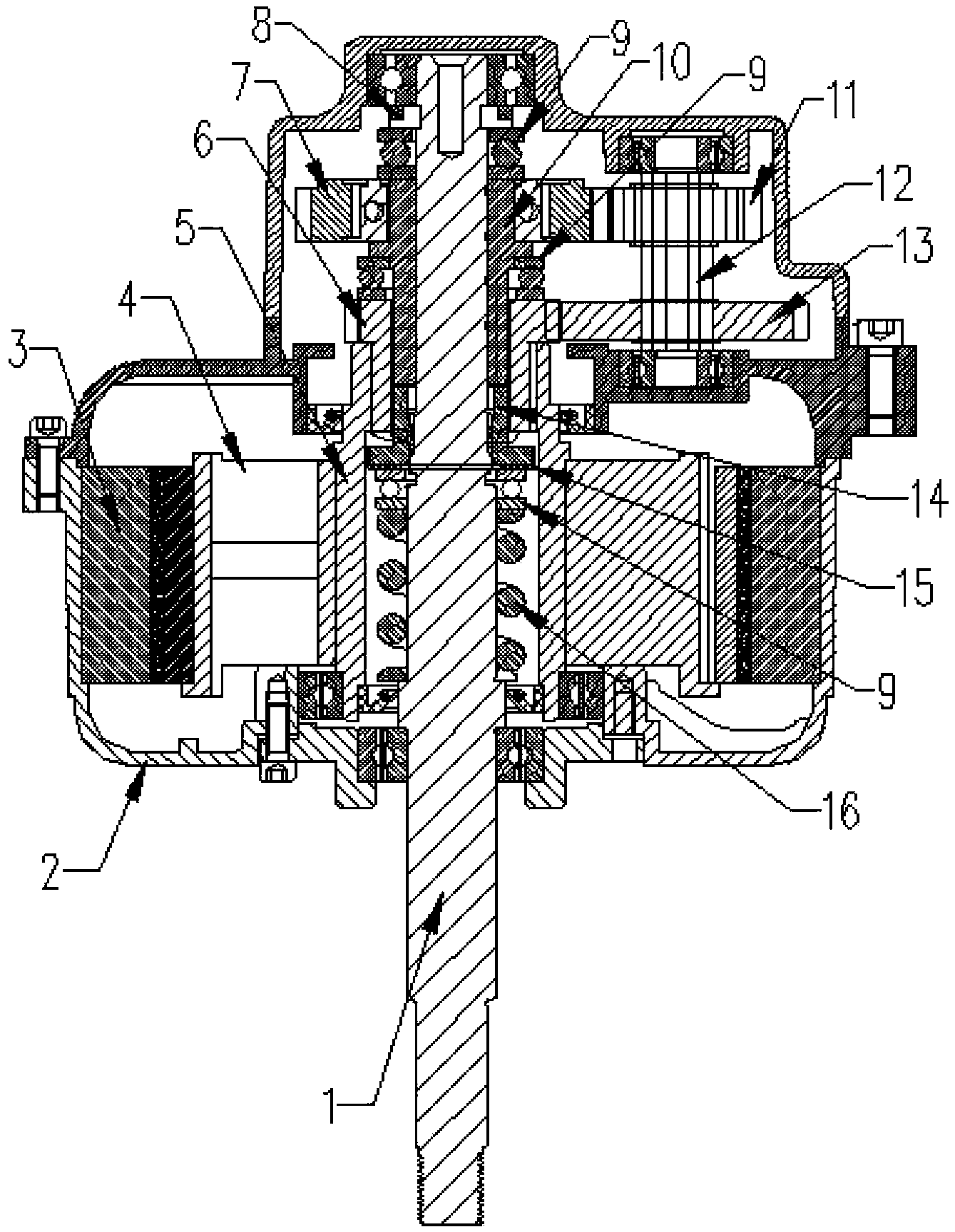

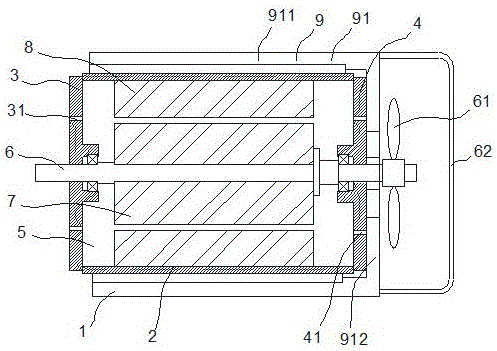

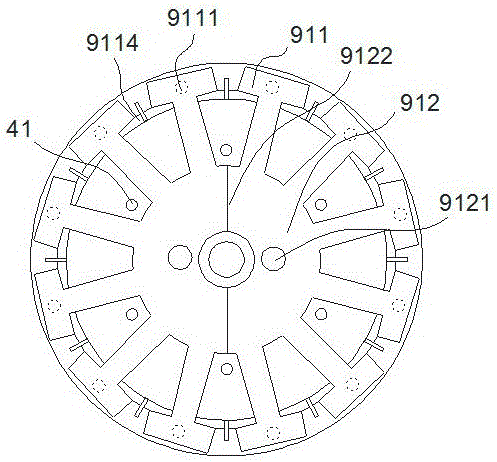

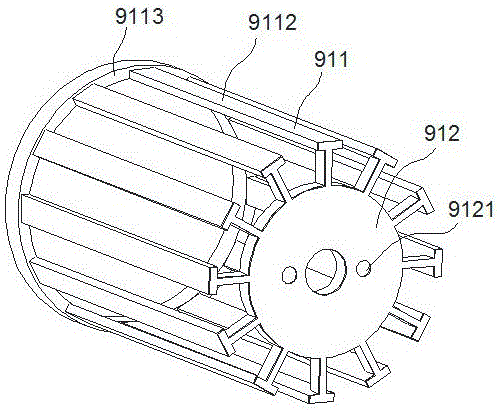

Driving motor for electric car

InactiveCN103457406ASimple structureEasy to set upElectric machinesToothed gearingsElectric carsEngineering

The invention discloses a driving motor for an electric car. The driving motor solves the problem that an existing car power mechanism is complex in structure and inconveniently applied to a car. The technical measures are that the driving motor for the electric car comprises a rotor and a stator, the stator and the rotor are coaxially arranged, and a spindle penetrates through the rotor in a gapped mode. The driving motor for the electric car is characterized in that a clutch support circumferentially and fixedly sleeves the spindle, a spring sleeving the spindle acts on one end of the clutch support, a clutch structure is arranged between the clutch support and the rotor, the clutch structure is connected with a speed reducing mechanism, an inner ring cam sleeving the spindle is connected with the clutch support, and a unidirectional structure is positioned between the inner ring cam and the speed reducing mechanism.

Owner:TAIZHOU LIMA ELECTRIC VEHICLE SCI & TECH

Improved Kalman filtering method with improved positioning precision

The invention relates to an improved Kalman filtering method with improved positioning precision, and belongs to filtering methods. The method comprises the steps of 1) tracking and synchronizing of satellite capturing; 2) data extraction; 3) calculation of the satellite speed and position; 4) least squares resolution; 5) expanded Kalman filtering measurement and establishment of a state equation;6) an expanded Kalman filtering process; and 7) adaptive adjusting. In the process of single-point positioning of a satellite navigation receiver, if instant determination of a satellite signal caused instant deterioration of a pseudo range observed quantity, the single-point positioning speed measuring precision resolved by the least squares jumps, and the method of the invention can be used eliminate the jump effectively, and the positioning stability is kept.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

Footwear with improved sole assembly

InactiveUS9072336B2Facilitates rolling movement of footImprove damping performanceSolesDomestic footwearMedial sideEngineering

An article of footwear, including a sole assembly and an upper, the article of footwear extending lengthwise from a rear end to a front end, widthwise between a lateral side and a medial side, and heightwise from the outer sole assembly to an upper end, the article of footwear including a first fitting element as well as a second fitting element. The first fitting element includes a first envelope and a first sole of the strobel type, the first envelope being fixed to the first strobel sole at least with stitching. The second fitting element includes a second envelope and a second sole of the strobel type, the second envelope being fixed to the second strobel sole at least with stitching.

Owner:SALOMON SA

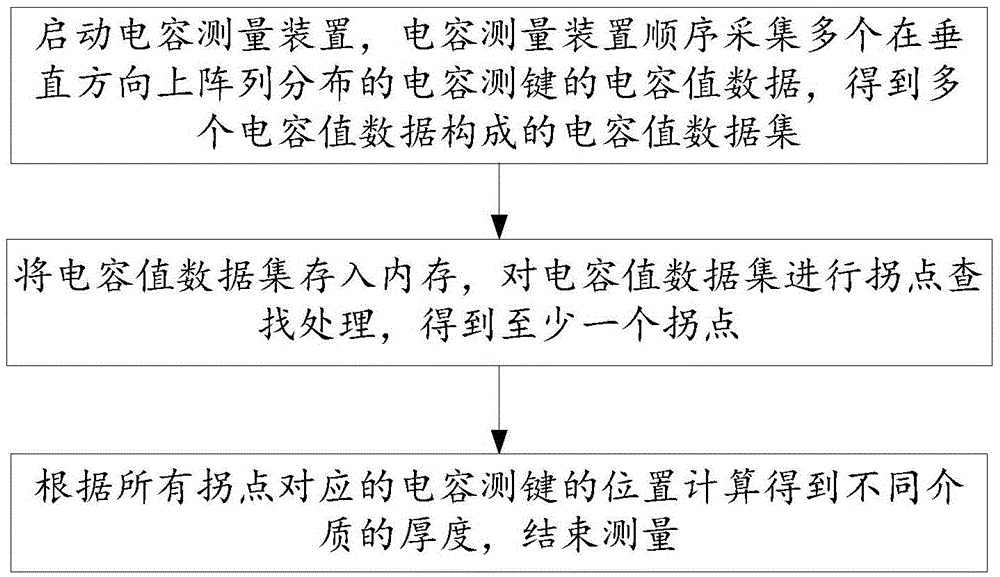

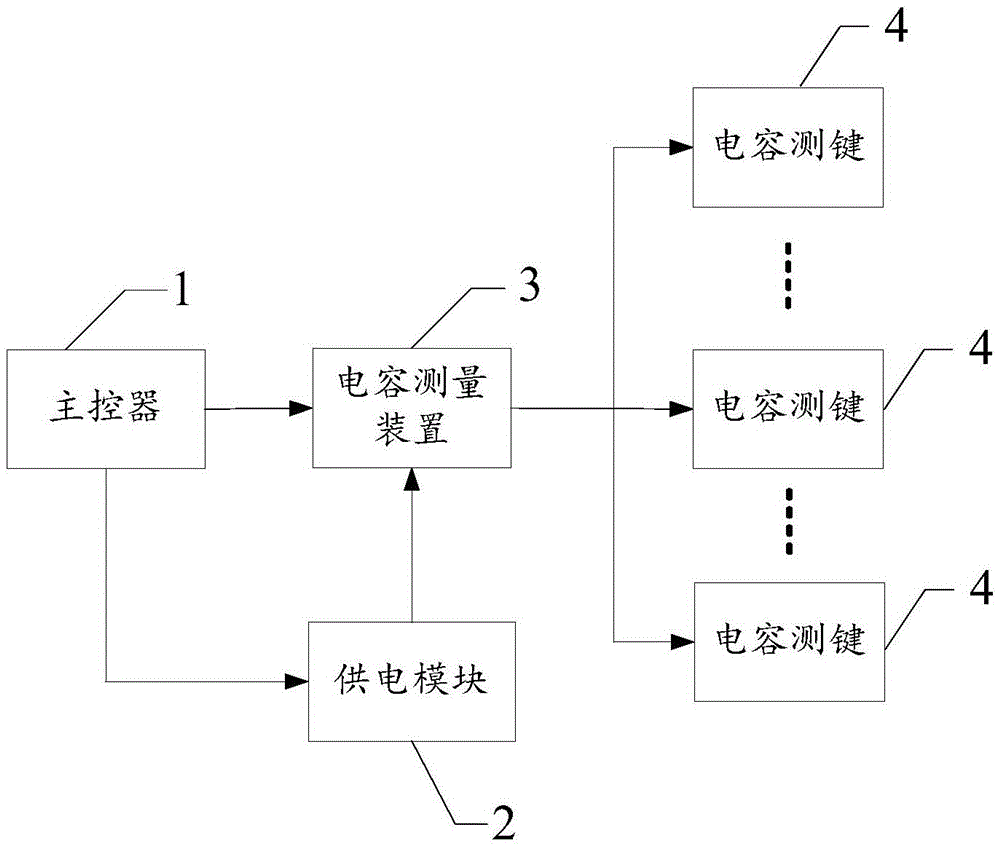

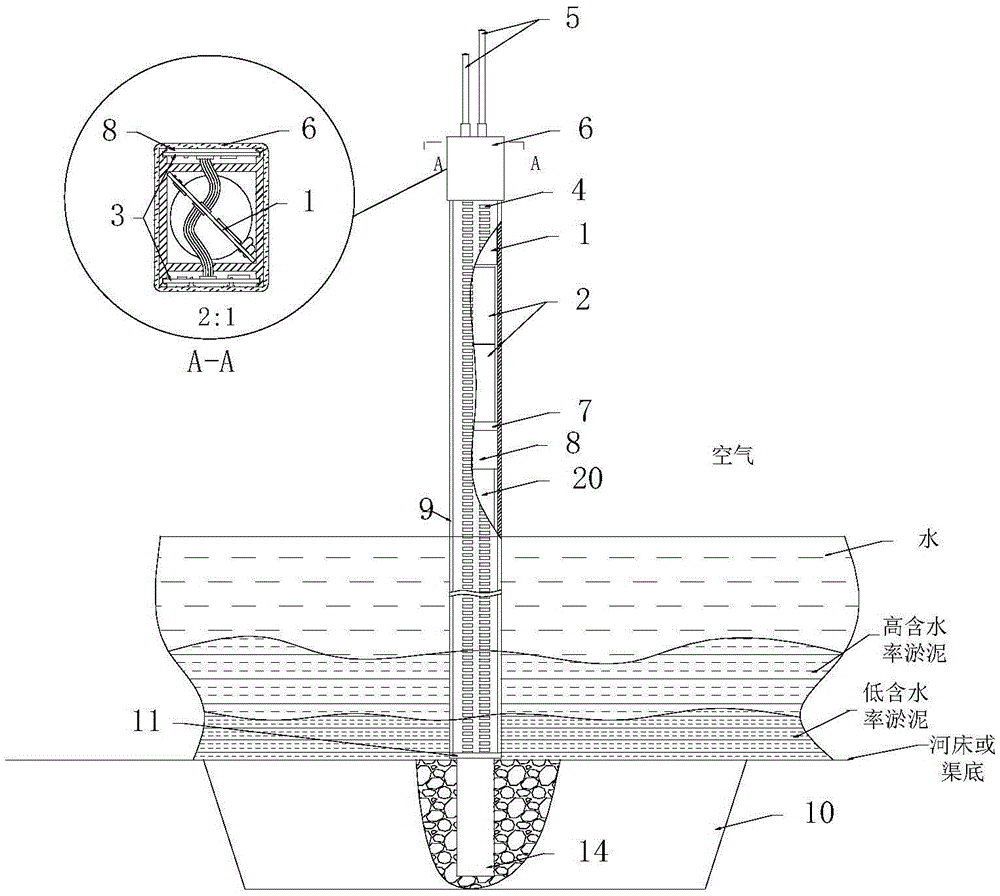

Method and device for automatically measuring thicknesses of different mediums

ActiveCN105674869AImprove accuracyStrong real-timeElectrical/magnetic thickness measurementsLevel indicators by physical variable measurementMeasurement deviceData set

The invention relates to a method and a device for automatically measuring thicknesses of different mediums. The method comprises steps: 1, a capacitance measuring device is started, capacitance value data of multiple capacitance measuring keys distributed in the vertical direction in an array mode are sequentially acquired by the capacitance measuring device, and a capacitance value data set formed by multiple capacitance value data is obtained; 2, the capacitance value data set is stored in a memory, inflection point searching and processing are carried out on the capacitance value data set to obtain at least one inflection point; and 3, according to positions of the capacitance measuring keys corresponding to all inflection points, thicknesses of different mediums are calculated and obtained, and the measurement is completed. Thus, the thickness of silt and the height of a water level can be monitored for a long time without manual intervention; the accuracy is high; the real-time performance is strong, the mounting is simple, the later maintenance workload is small, large-area extensive input is facilitated, the method and the device can be used for monitoring the thickness of the silt and the height of the water level in a water reservoir, a river way and a pipeline, and reservoir capacity calculation and water quantity measurement.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

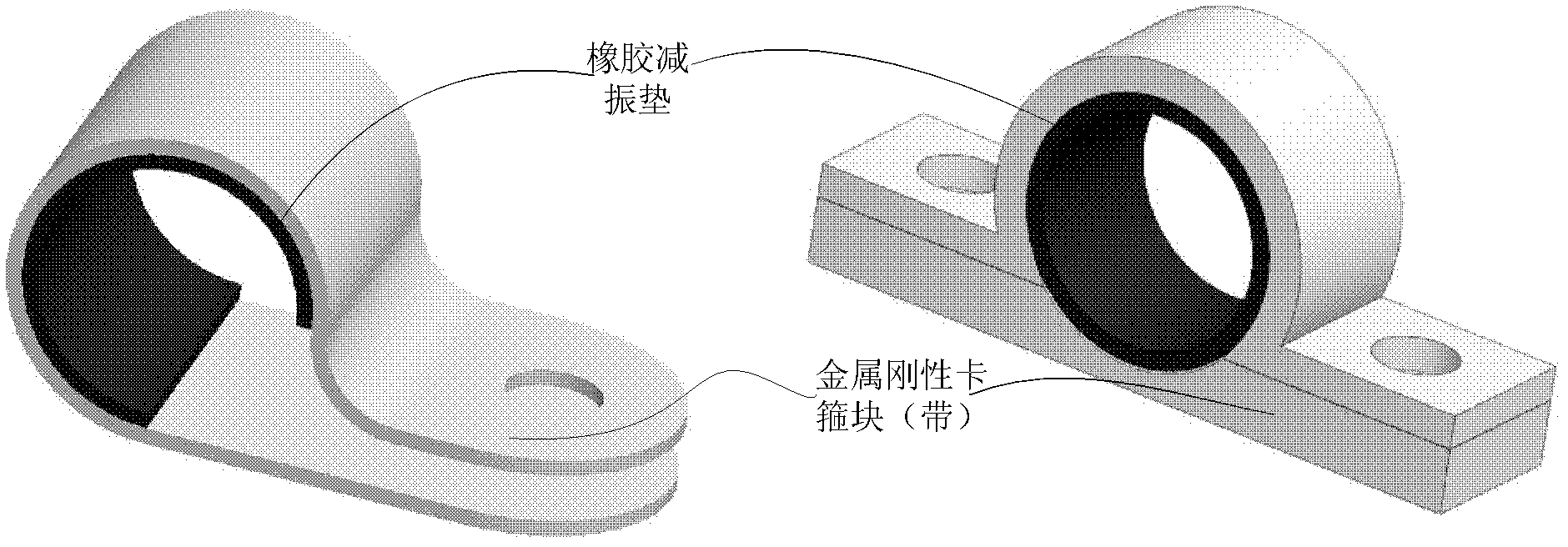

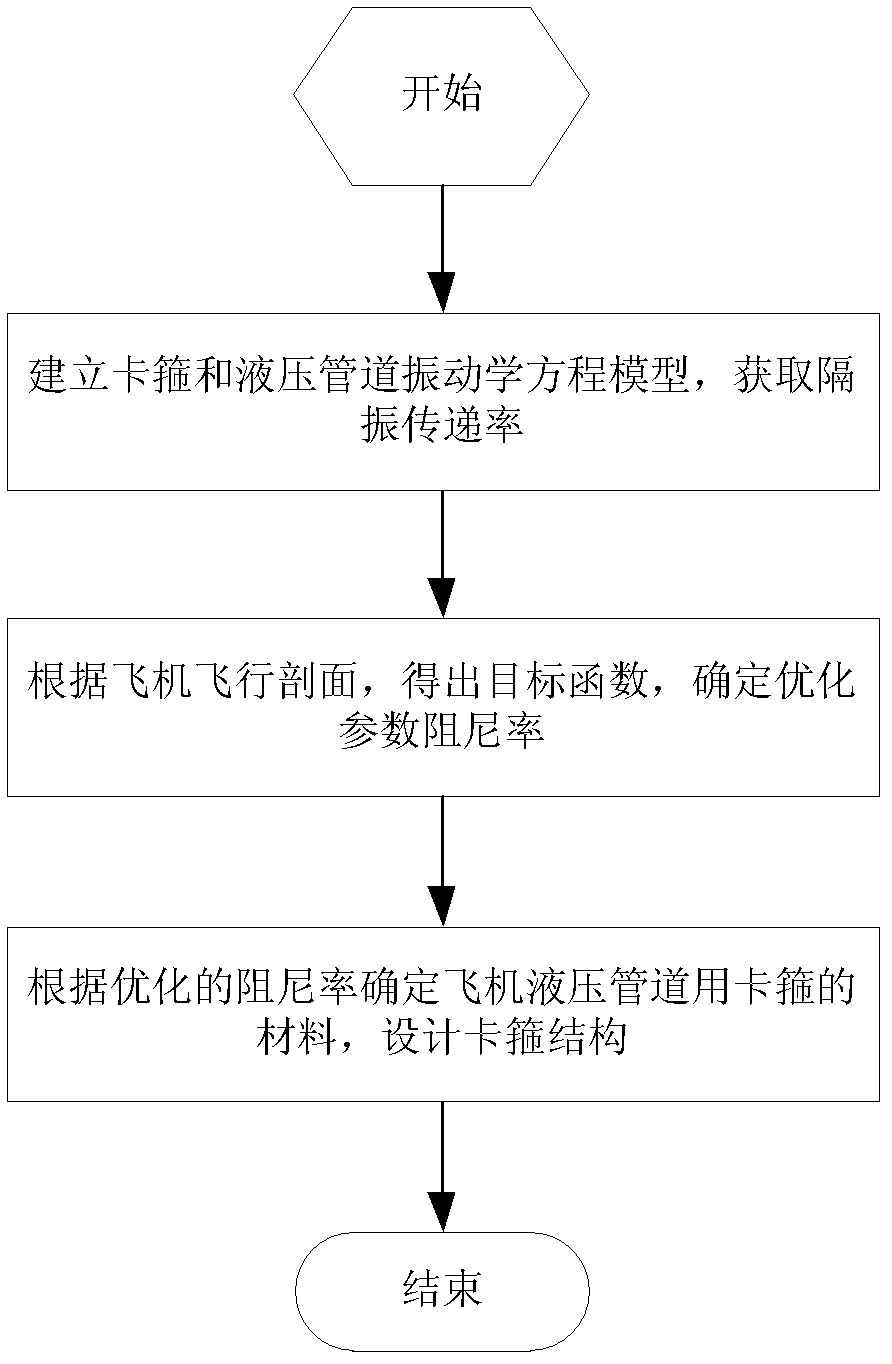

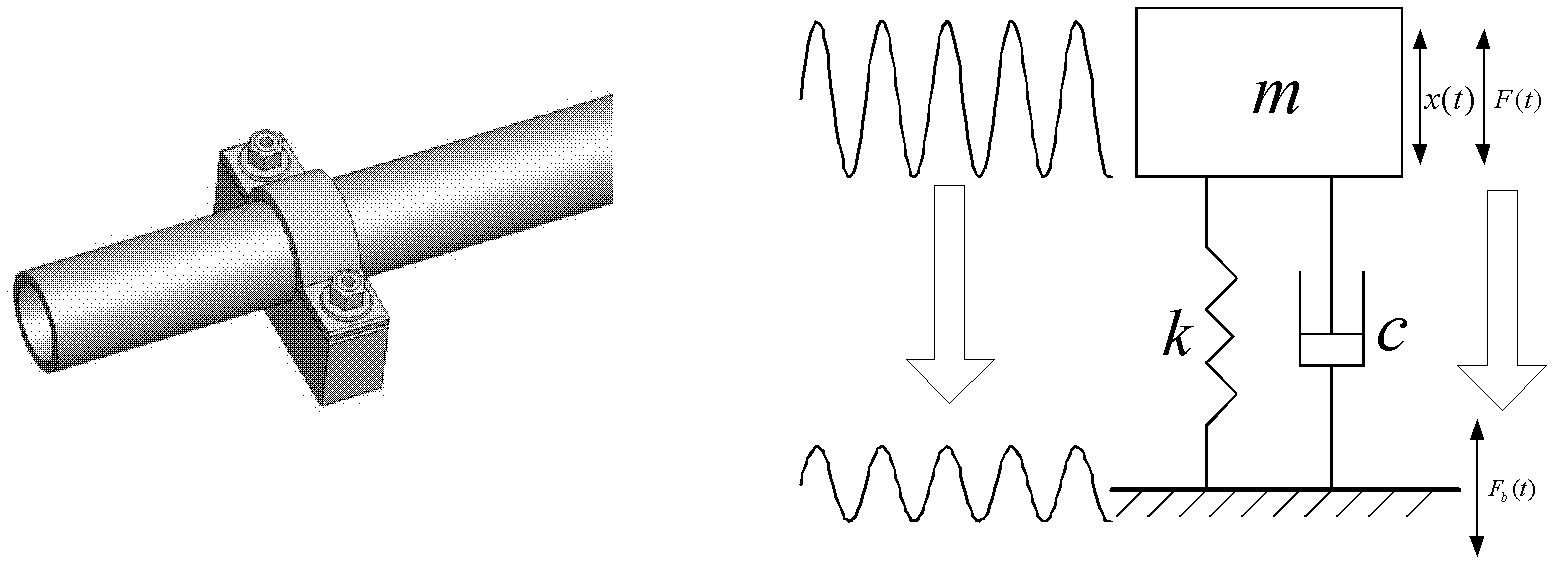

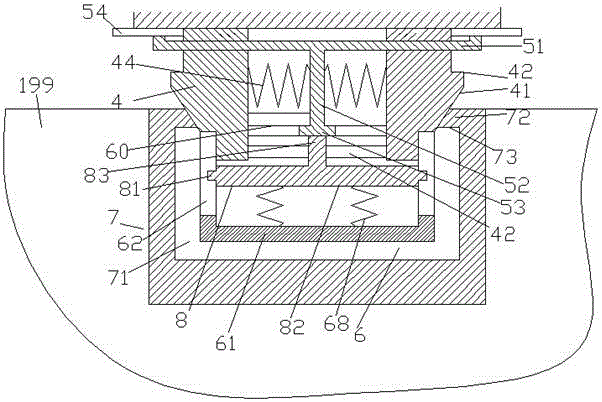

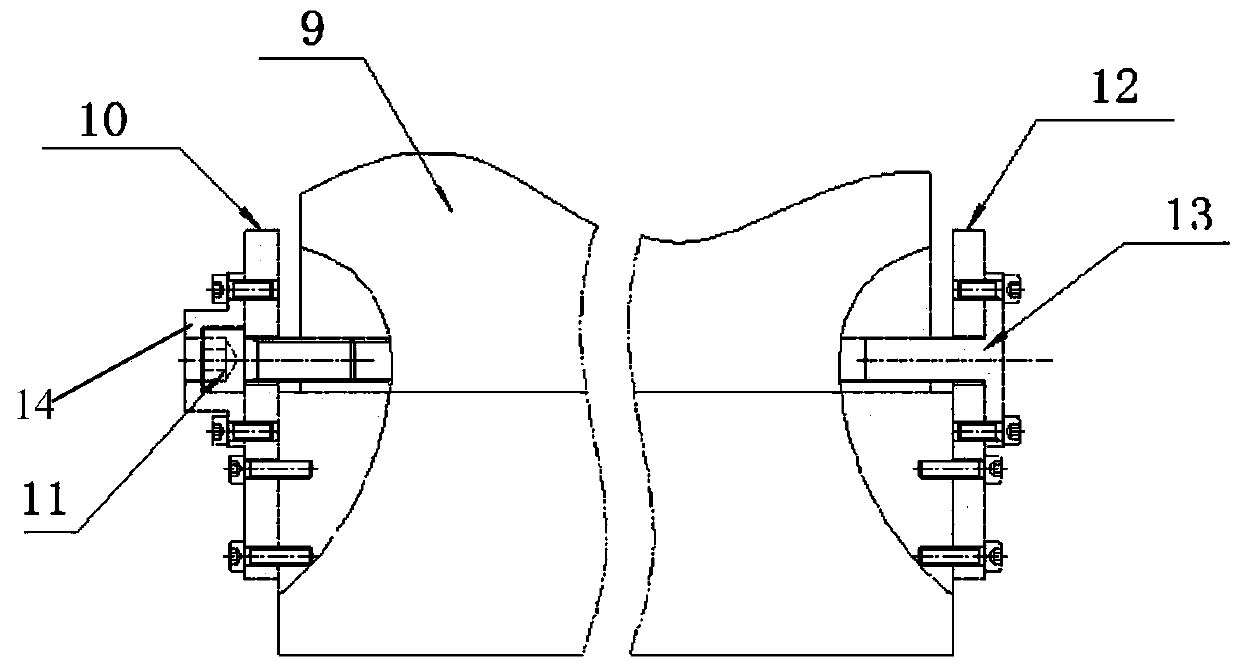

Hoop for airplane hydraulic pipeline and design method thereof

InactiveCN102494193AHigh damping characteristicsNot easy to agePipe supportsMetal rubberDamping ratio

The invention discloses a hoop for an airplane hydraulic pipeline and a design method thereof. The method comprises the steps of 1 establishing a vibration equation model of the hoop and the hydraulic pipeline and obtaining vibration isolation transmissibility; 2 according to the flight profile of an airplane, obtaining a target function and determining and optimizing damping ratio xi of parameters; and 3 determining materials used by the hoop for the airplane hydraulic pipeline according to optimized damping ratio, and designing a hoop structure. The hoop comprises fastening bolts, spring gaskets, an upper metal rubber pad block, an upper anti-lock brake system (ABS) plastic hoop block, a lower ABS plastic hoop block and a lower metal rubber pad block. The lower ABS plastic hoop block isinternally embedded in the lower metal rubber pad block, the upper ABS plastic hoop block is internally embedded in the upper metal rubber pad block, and the airplane hydraulic pipeline is located between the lower metal rubber pad block and the upper metal rubber pad block. Two fastening bolts penetrate through the upper ABS plastic hoop block and the lower ABS plastic hoop block, and the springgaskets are arranged between the two fastening bolts and the upper ABS plastic hoop block. The vibration isolation rate weighted sum corresponding to excitation source frequency points determined by the flight profile of the airplane serves as a basis of parameters for designing the hoop, and the hoop is designed according to the basis of the parameters.

Owner:BEIHANG UNIV

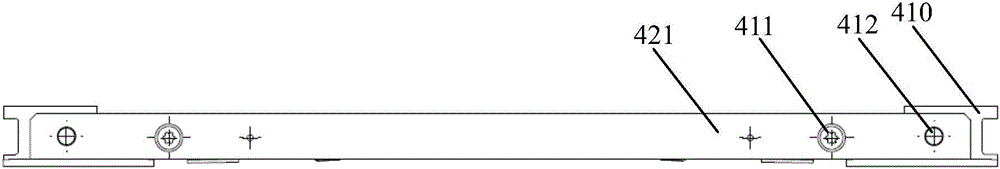

Welding belt welding, transmission and holding device for solar cell series welding machine, and series welding machine

InactiveCN106374016AGuaranteed positional stabilityNo displacementFinal product manufacturePhotovoltaic energy generationTransfer procedureEngineering

The invention provides a welding belt welding, transmission and holding device for a solar cell series welding machine. The welding belt welding, transmission and holding device for the solar cell series welding machine comprises two symmetrically arranged skirt structures and a welding belt pressing needle module connected with the skirt structures. The welding belt pressing needle module comprises a pressing-holding part of the welding belt on five pairs of cell sheets formed by a plurality of pressing needles which have three kinds of length specifications and are relatively arranged. One end of each pressing needle is arranged on an installation shaft in a sleeved mode through a slotted hole, and is jacked up through a spring by using a rotating shaft as a supporting point; the other end of each pressing needle is pressed downward on the welding belt to fix and hold the welding belt to the cell sheets. The bottom surface of the skirt structures is provided with a vacuum adsorption loop formed by a plurality of blind holes. The welding belt welding, transmission and holding device can ensure the fixing and holding of the welding belt in the transmission process, and avoid the inaccurate positioning in the transmission and the poor contact during welding which are caused by displacement.

Owner:苏州佳普硕自动化科技有限公司

Assembled building beam column connecting joint using C profile steel

ActiveCN110565804AReduce the risk of working at heightsGuaranteed stabilityBuilding constructionsButt jointEngineering

The invention relates to an assembled building beam column connecting joint using C profile steel. The assembled building beam column connecting joint comprises a wrapping frame body, four butt jointframe bodies and inserts; the four butt joint frame bodies are arranged around the wrapping frame body; and the inserts are arranged between the wrapping frame body and the butt joint frame bodies. The assembled building beam column connecting joint can solve such problems as the condition of rupture of connecting points possibly caused by long-time gravity influence after welding connection between steel beams and bearing columns, more complex process of flat grinding and welding of steel beam joints again after rupture, generation of a certain risks during aerial operation of welding or repair of the beam columns and generation of a certain economical wastes caused by difficult disassembly and recovery of the steel beams and the bearing columns in later period due to welding connection.

Owner:福建星鼎建设有限公司 +1

Hollow ball-screw gas-liquid binary cooling system

InactiveCN102398188ASolve fever problemAverage temperature dropMaintainance and safety accessoriesImpellerBall screw

The invention relates to a hollow ball-screw gas-liquid binary cooling system. The lower end face of an air generator (17) is in an oval hollow annular horn shape, the section of an air inlet is larger that that of an air outlet, the air generator (17) is internally provided with a fan (39) and an impeller (38) driven by the fan (39), the wall of an air cavity (40) for accepting lead-in air is provided with an air inlet hole (37), the wall of an annular air cavity (42) is provided with an air inlet (41), the annular air cavity (42) is provided with an exhausting crevice (44), a Coanda surface (45) is arranged at one side of the exhausting crevice (44), the wall of a central air cavity (34) is provided with an air nozzle (43), and the air injection direction of the air nozzle (43) is directed to a friction surface of a screwpair; and an oil outlet (55) of a frequency-conversion refrigerating system is connected with an oil inlet pipe (9) of a hollow ball-screw (13), an oil inlet (56) of the frequency-conversion refrigerating system is connected with an oil outlet pipe (26) of the hollow ball-screw (13), and cooling oil is transmitted through the hollow ball-screw (13).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

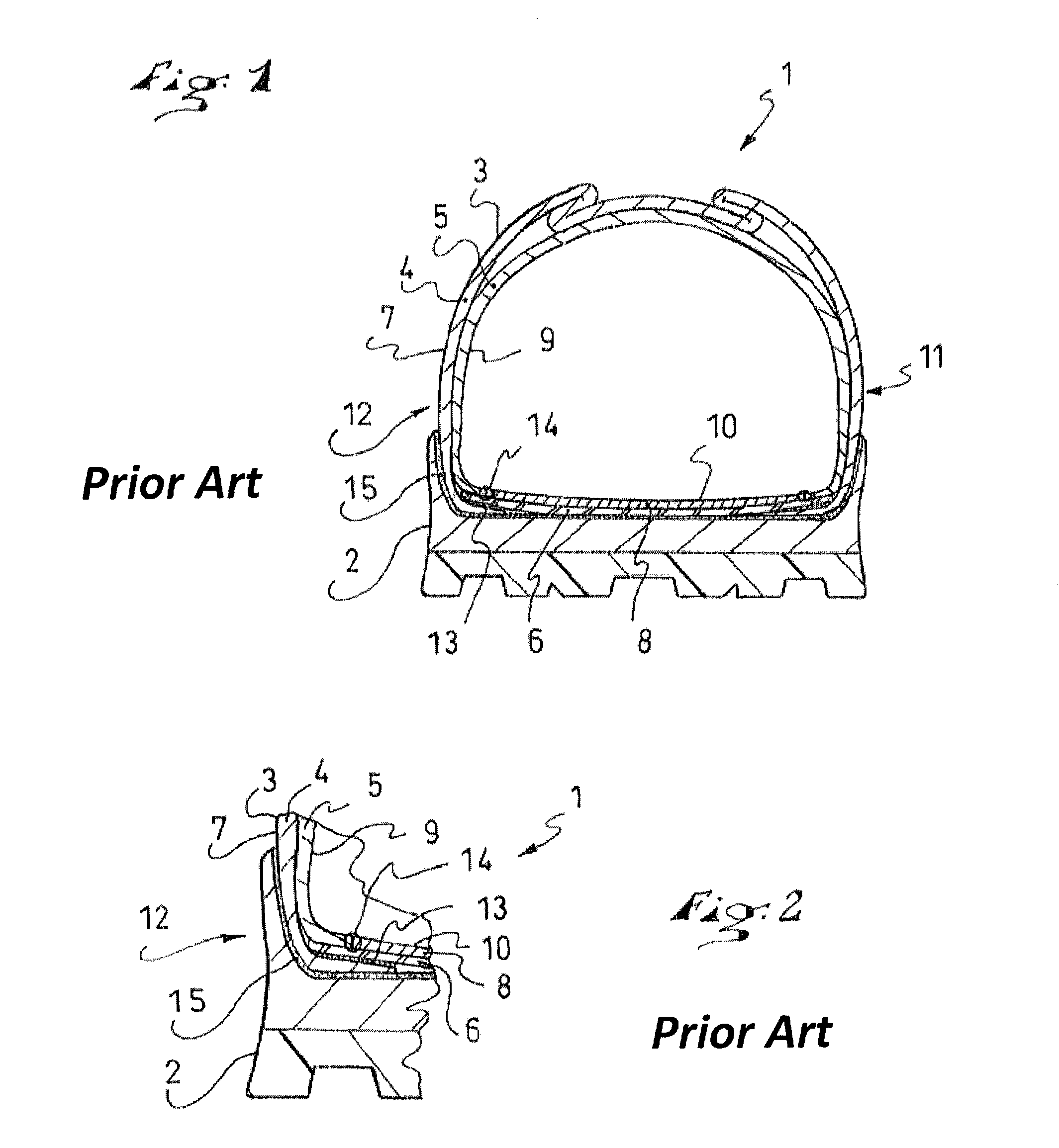

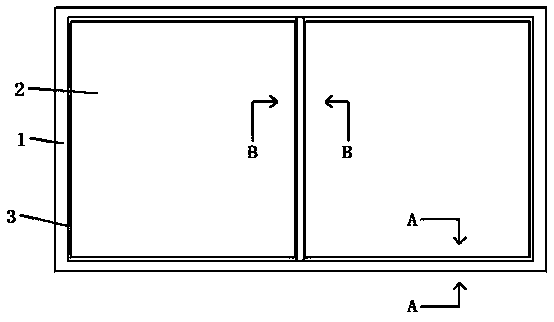

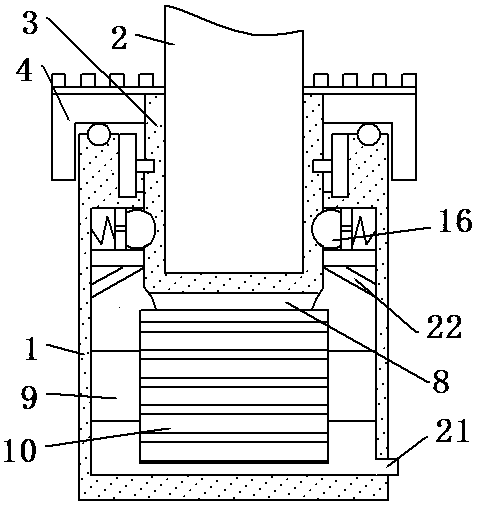

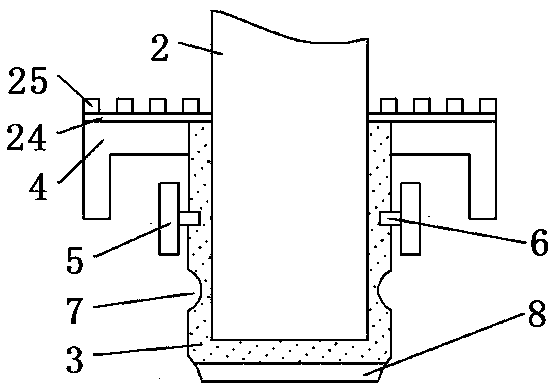

Door and window sealing structure

ActiveCN108915511AReduce shakingRealize push-pull functionCondensed water drain-offSealing arrangementsElectrical and Electronics engineering

The invention discloses a door and window sealing structure. The door and window sealing structure comprises door and window glass, an aluminum frame, a plastic frame, a first rotating shaft and firstwheels; first grooves are formed in the two ends of the plastic frame, the two ends of the top of the aluminum frame are connected with aluminum strips correspondingly, second grooves are formed in the upper portions of the inner sides of the aluminum strips, and the first wheels are located in the second grooves; second adhesive tapes are connected to the two ends in the aluminum frame correspondingly, the inner sides of the second adhesive tapes make mutual contact with the two ends of the plastic frame, the second adhesive tapes are located on the lower portions of the aluminum strips, gaps are formed between the second adhesive tapes and the aluminum strips, and the interiors of the gaps are movable connected with spacing plates through a plurality of springs; the outer side of each spacing plate is connected with a row of first balls, each spacing plate is further provided with a row of through holes, and the through holes make mutual contact with the first balls; the outer sidesof the first balls are located in the first grooves; and the interior of the aluminum frame is further connected with a row of second rotating shafts, and the second rotating shafts are in shaft connection with second wheels. According to the door and window sealing structure, the defects of the prior art can be improved, and a sealing part of the door and window sealing structure has better reliability.

Owner:唐山市林兴装饰有限公司

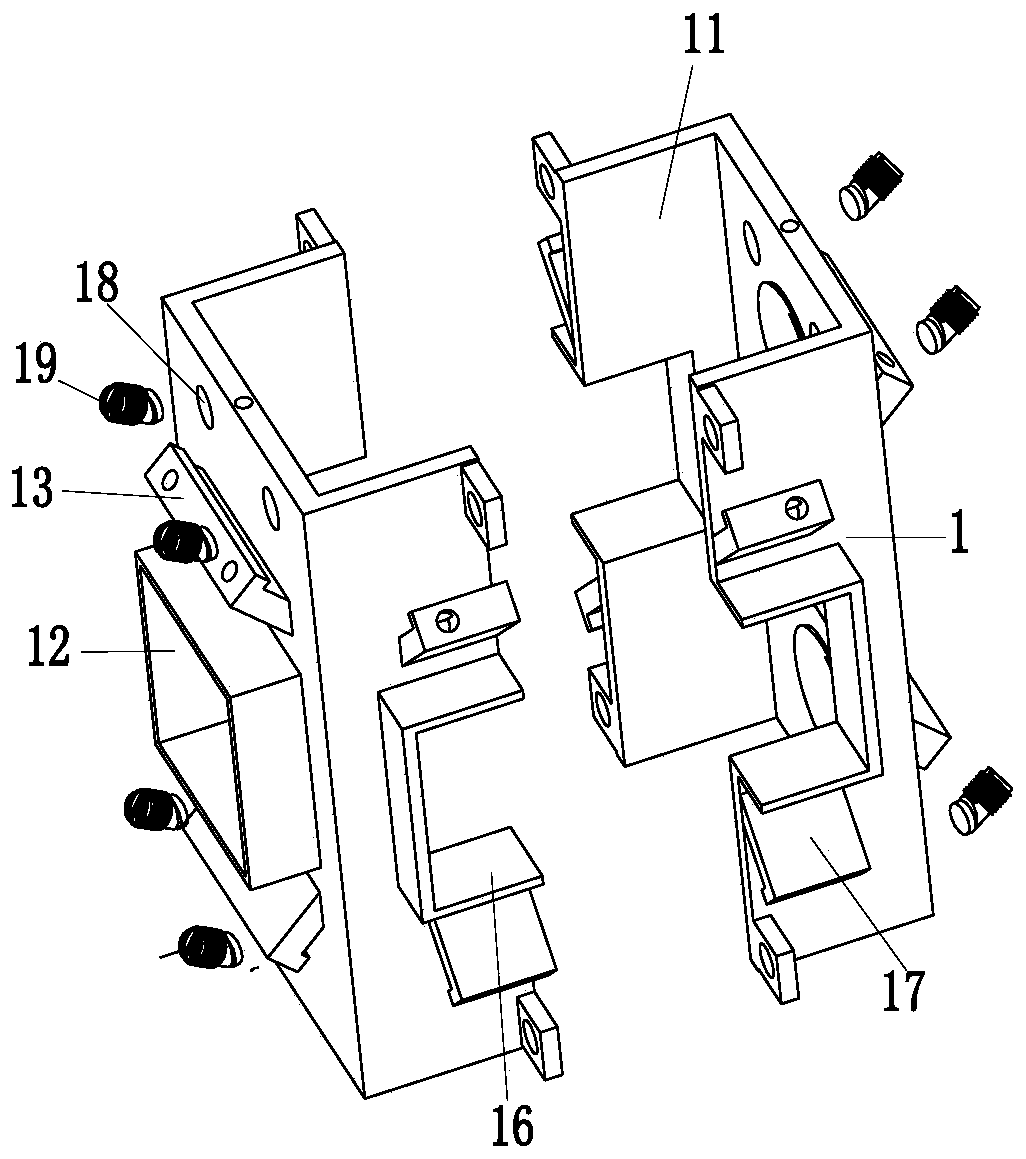

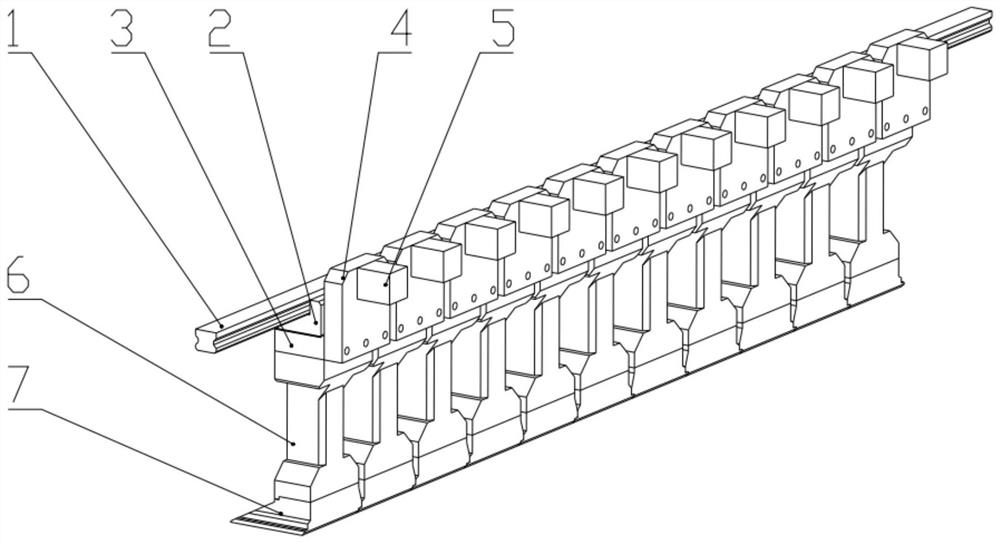

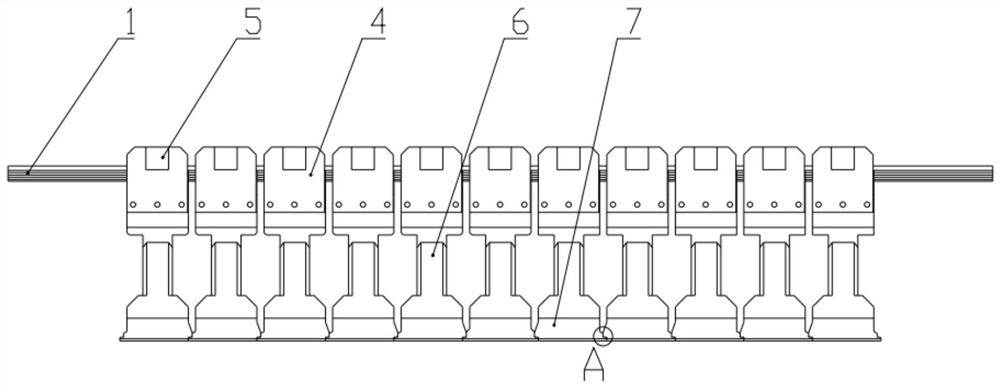

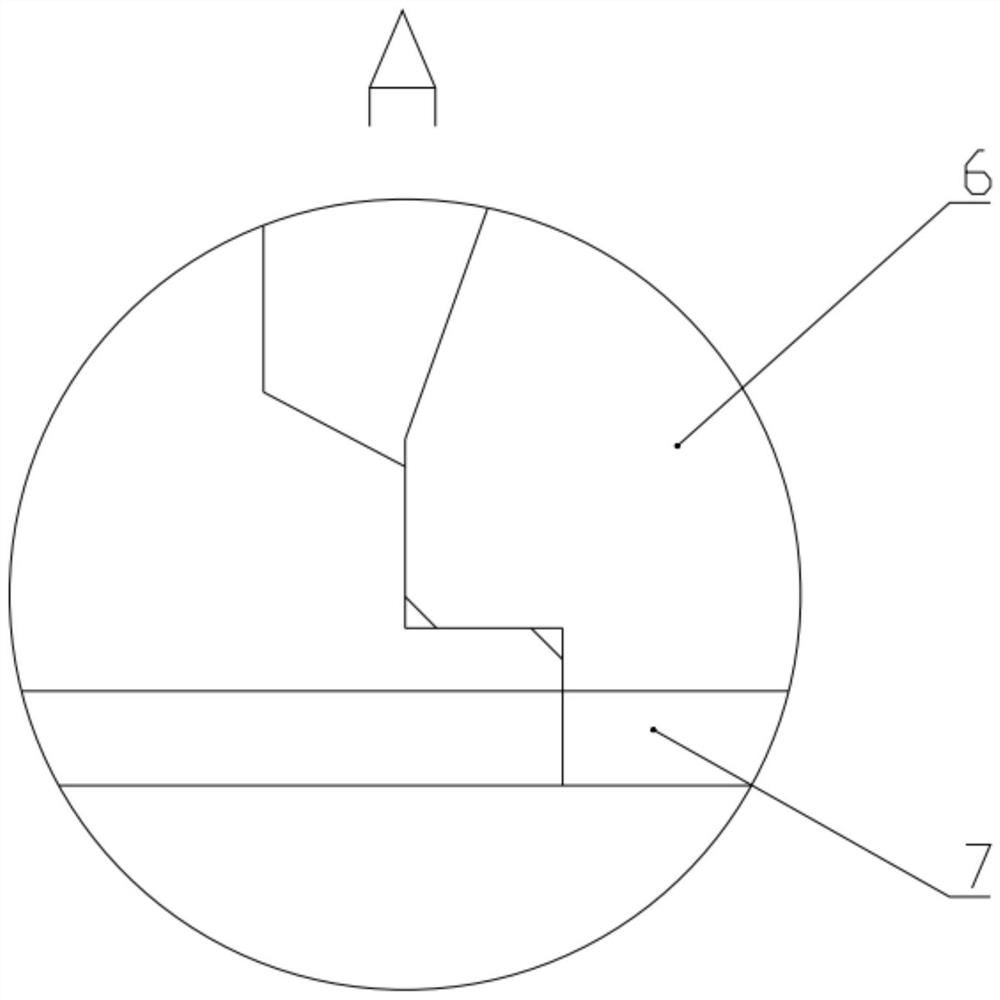

Flexible bending center pressing cutter mechanism

InactiveCN111687245AReduce wearExtended service lifeShaping toolsMechanical engineeringIndustrial engineering

The invention relates to the field of bending equipment, in particular to a flexible bending center pressing cutter mechanism. The flexible bending center pressing cutter mechanism comprises a linearguide rail, a guide rail sliding block, a sliding block base plate and pressing cutters which are sequentially connected in the longitudinal direction, the pressing cutters comprise pressing cutter upper parts and pressing cutter main bodies, the linear guide rail is fixedly connected with a positioning wallboard, one end, away from the positioning wallboard, of the sliding block base plate is fixedly connected with a limiting air cylinder block, a limiting air cylinder is installed on the limiting air cylinder block, an air cylinder jacking column of the limiting air cylinder stretches out and abuts against the positioning wallboard; and step-shaped clamping tables are arranged between every two adjacent pressing cutter main bodies. According to the flexible bending center pressing cuttermechanism, the linear sliding rail and the sliding block are adopted, so that the friction resistance is reduced, and meanwhile, the abrasion degree of the pressing cutters is reduced; automaticallylocking the pressing cutters is carried out by adopting the positioning air cylinder, the positioning accuracy and stability of the pressing cutters are guaranteed, and therefore the bending accuracyis improved; mutually stacked step-shaped clamping tables are arranged between the adjacent pressing cutters, so that the pressing cutter deflection caused by non-uniform stress of the pressing cutters at the edge of a plate is avoided; and a split type design structure is adopted, so that overall replacement of the pressing cutters is avoided, and the replacement cost is reduced.

Owner:青岛艾特智能装备有限公司

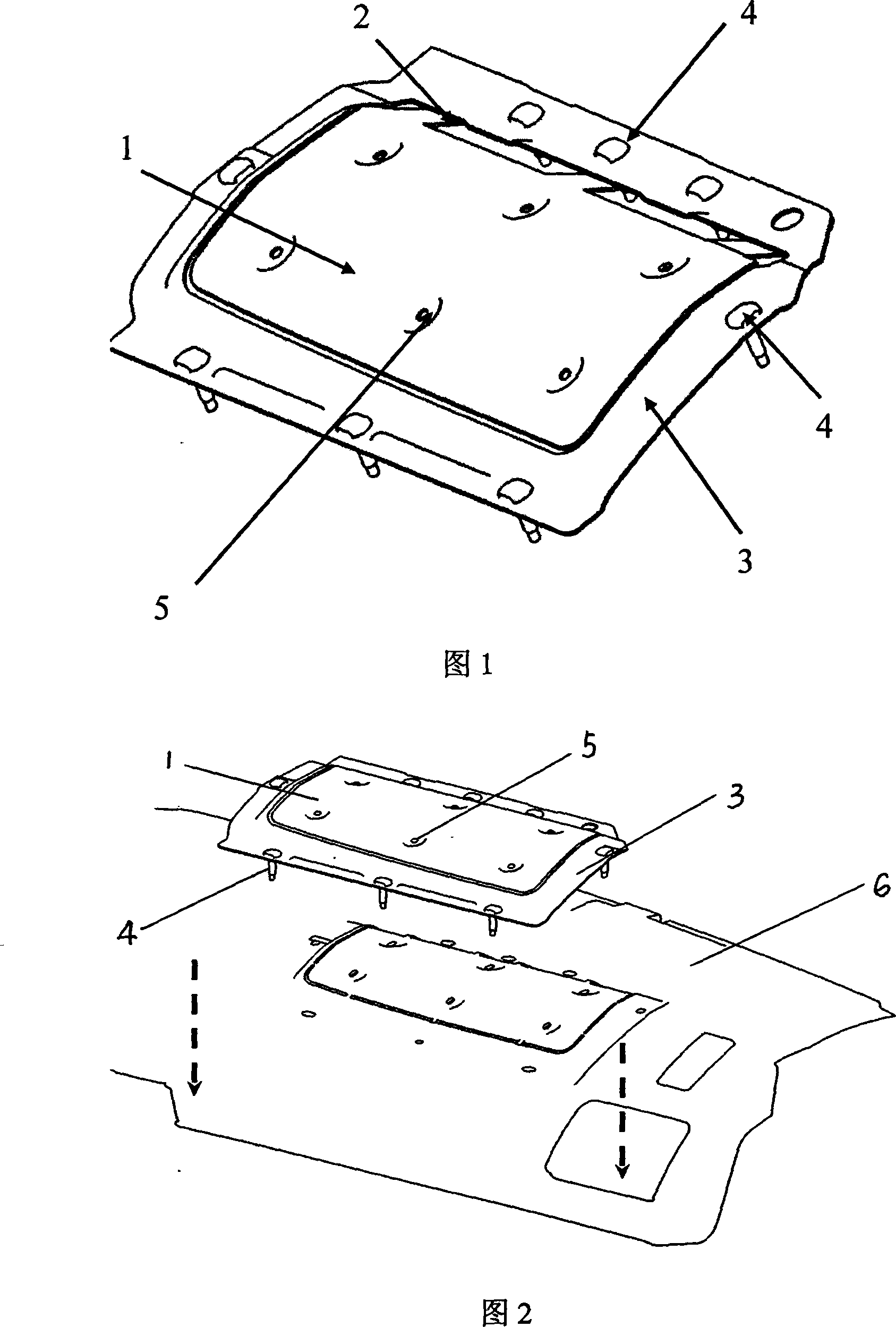

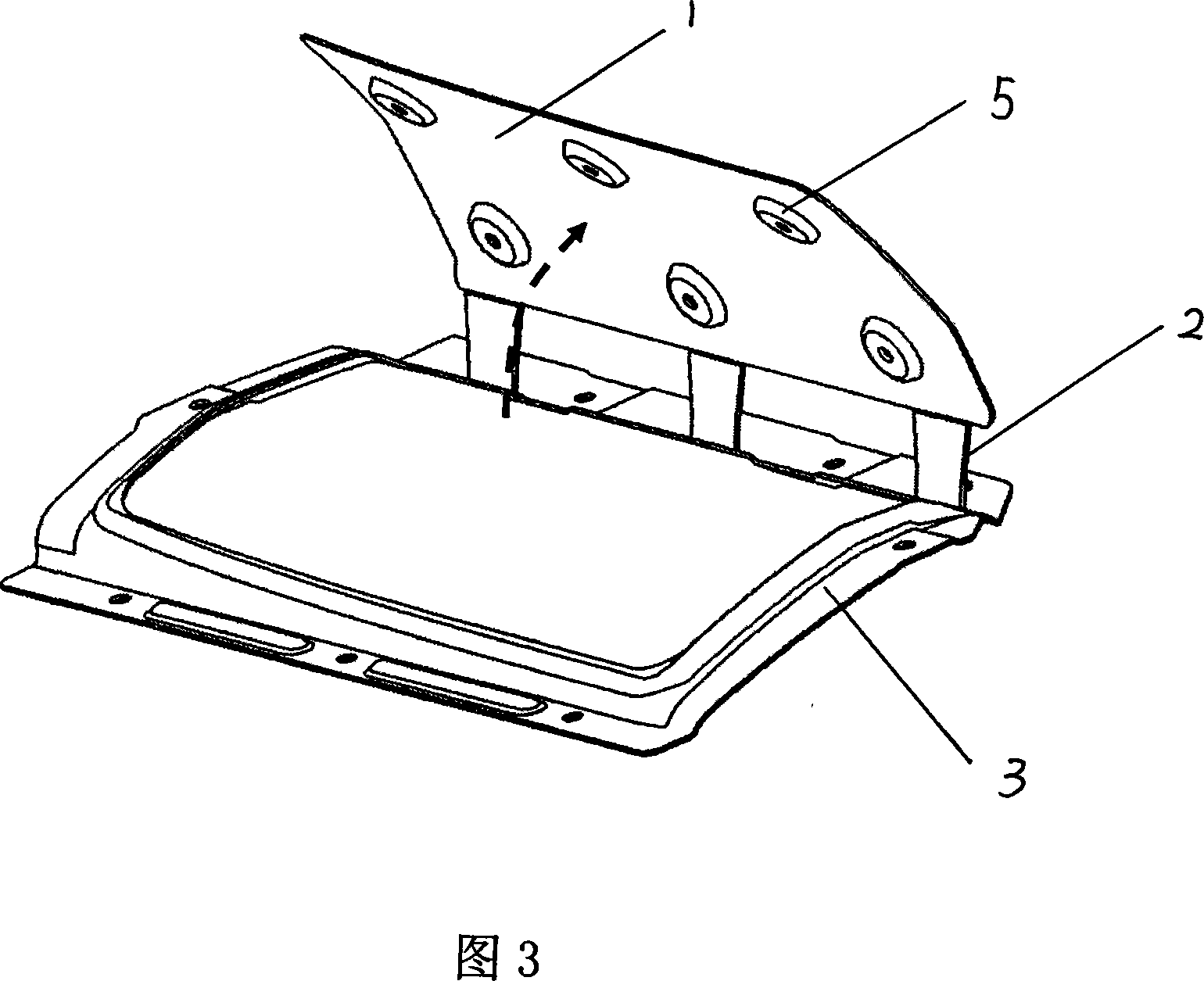

A mixed mode expansion plate of automobile safety air bag

InactiveCN101161510AGuaranteed positional stabilityGuaranteed installation reliabilityPedestrian/occupant safety arrangementComplex typeEngineering

The invention relates to a complex type unfolding plate of vehicle safety air chamber comprising a main body of unfolding plate and a frame of unfolding plate. The main body of the unfolding plate is connected with the frame of the unfolding plate by hinge. The frame of the unfolding plate is permanently connected to the position of mounting air chamber module corresponding with the main body of fascia. A counter bore is in the main body of the unfolding plate and the main body is connected with the body of the fascia by the counter bore. The counter bores are evenly dispersed on the main body of the unfolding plate to make the unfolding plate and skeleton of the fascia completely jointed with each other. The frame of the unfolding plate is permanently connected with the main body of the fascia by projection weld nut. The unfolding plate and the frame are produced by steel material. The invention uses composite plate structure of overturning hinge cooperation frame structure. The unfolding plate and the frame thereof are produced by steel material. The unfolding plate and the fascia use design of rivet joint. The structure can ensure the stability of position of the unfolding plate and the mounting reliability and strength the guiding function of the air chamber and increase the stability of guiding by the hinge.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Water cooling motor

InactiveCN106849470AGuaranteed cooling effectGuaranteed positional stabilityCooling/ventillation arrangementSupports/enclosures/casingsControl engineeringWater cooling

The invention provides a water-cooled motor, which includes a base, a housing fixed on the base, a front end cover and a rear end cover, the housing, the front end cover and the rear end cover form an inner cavity through which The front end cover and the rear end cover are provided with a rotating shaft, and a rotor is installed on the rotating shaft, and a stator is arranged around the rotor in the inner cavity, and the stator is arranged in close contact with the outer shell, and the rotor and There is a gap between the stators, and it is characterized in that: the front end cover is provided with an air inlet, the rear end cover is provided with an air outlet, and a heat dissipation device is provided, and the heat dissipation device includes a water cooling element, and the water cooling The component includes a first water-cooling part that is attached to the shell and a second water-cooling part that is in contact with the outer surface of the rear end cover, and a fan fixed on the rotating shaft is sequentially provided outward from the second water-cooling part and fan cover.

Owner:HUZHOU HONGYUAN MOTOR

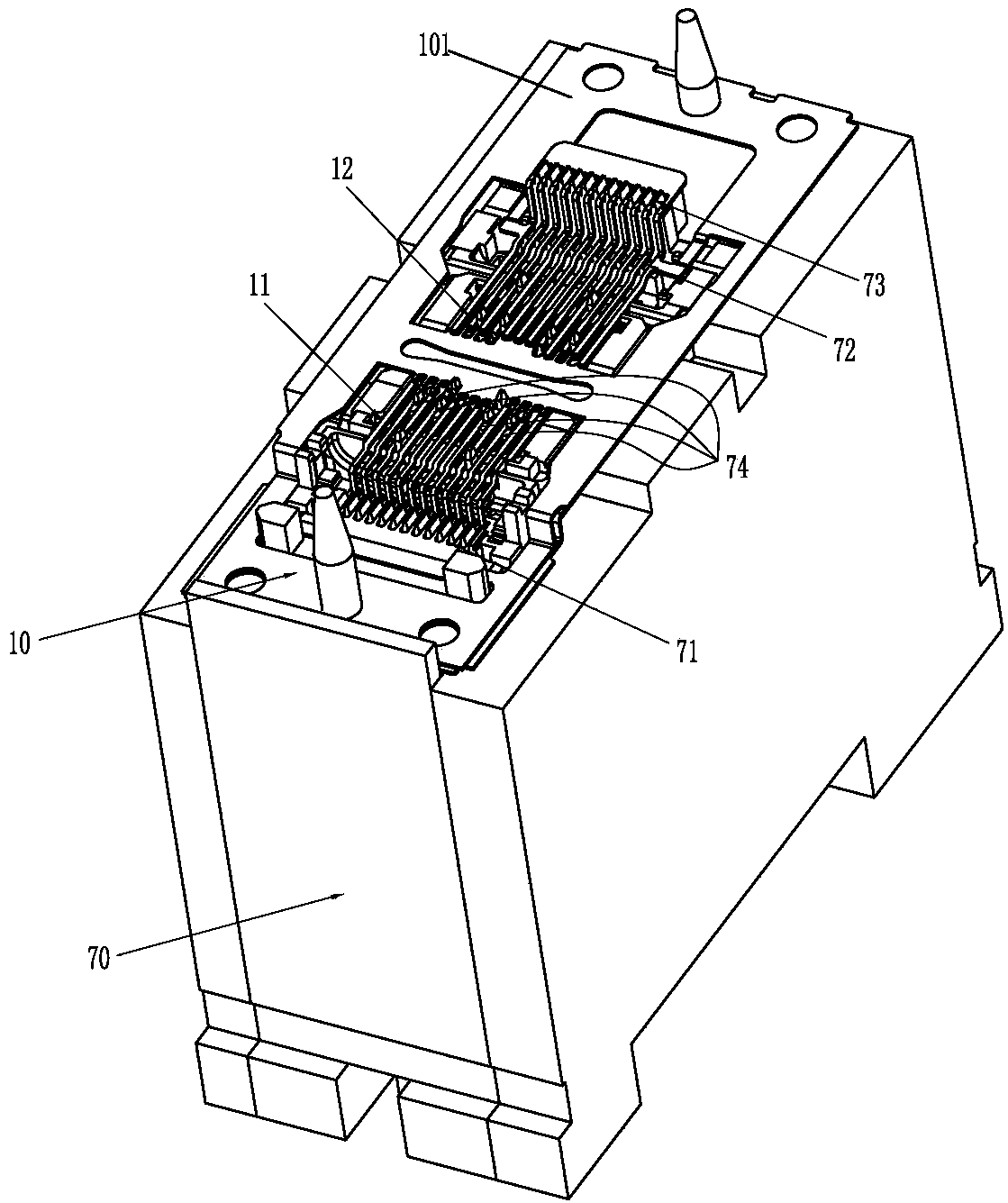

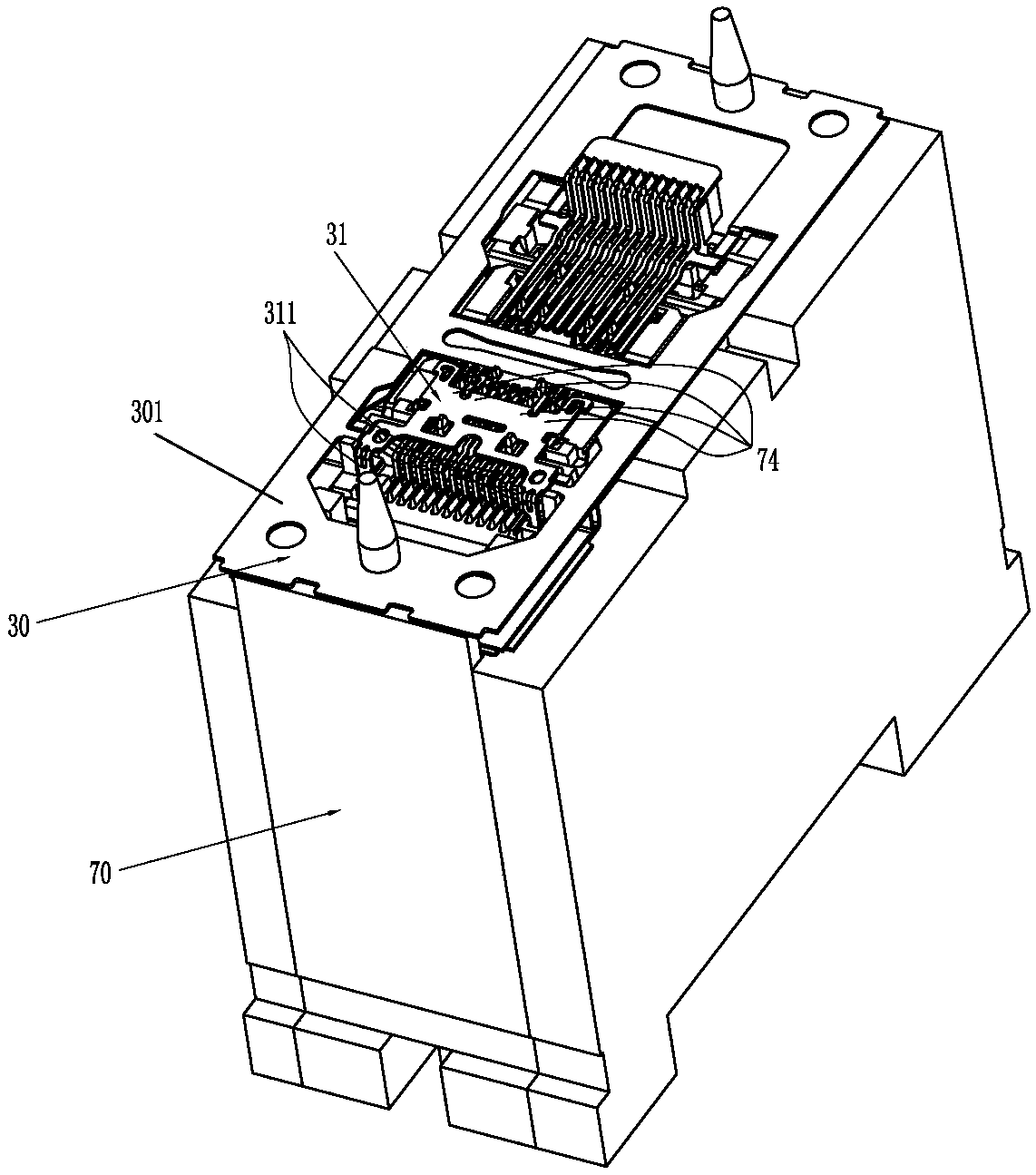

USB Type-C connector and fabrication process thereof

PendingCN108808416AGuaranteed positional stabilityReduce generationContact member manufacturingContact member assembly/disassemblyMetal stripsComputer module

The invention discloses a USB Type-C connector and a fabrication process thereof. The fabrication process comprises the steps of 1, preparing a first metal strip, a second metal strip and a third metal strip, wherein a first group of terminal and a second group of terminal are arranged on the first metal strip, a first fixed piece and a second fixed piece are arranged on the third metal strip, andan intermediate shielding piece is arranged on the third metal strip; 2, placing the three metal strips in a first injection molding die in a lamination way, and obtaining a first terminal insulationbody and a second terminal insulation body after injection molding; 3, cutting a first terminal module and a second terminal module; 4, laminating the first terminal module and the second terminal module to form a terminal core module; and 5, assembly a metal shell outside the terminal core module. By the fabrication process, the stamping process, the operation process and the injection molding die number are simplified, the production efficiency is improved, the strip waste is reduced, the resource is saved, the die design and development cost is reduced, the process of assembling an upper fixed piece, a lower fixed piece and the metal intermediate shielding piece is omitted, the manual assembly cost is reduced, the production efficiency is further improved, and meanwhile, the product quality is improved.

Owner:东莞市良拓电子科技有限公司

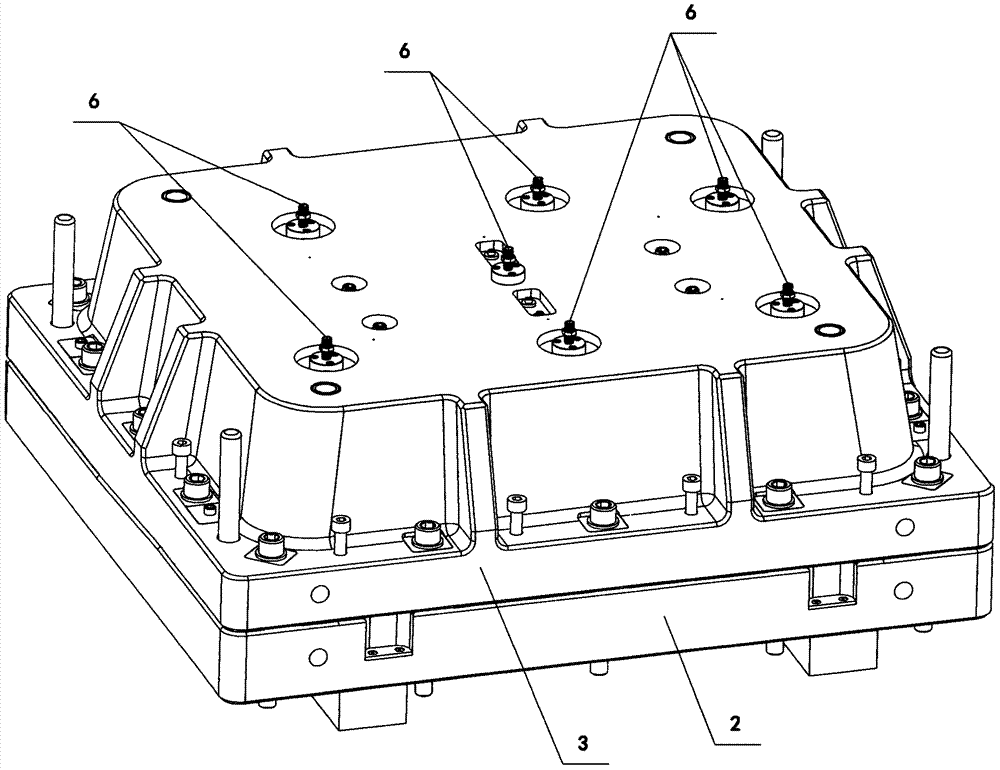

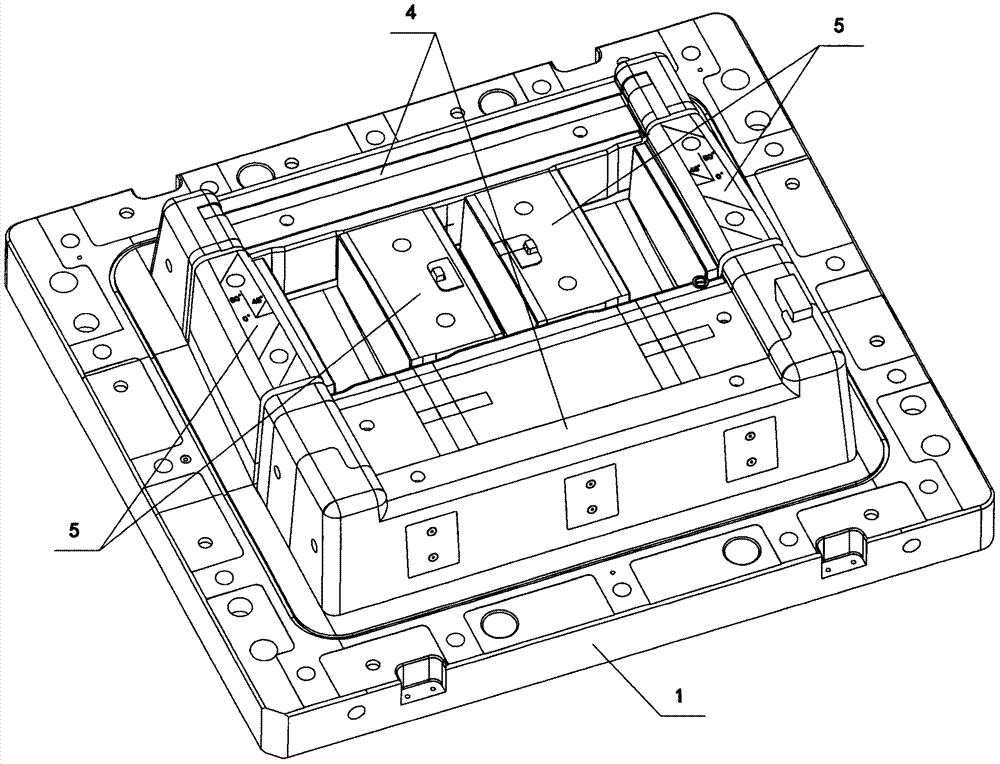

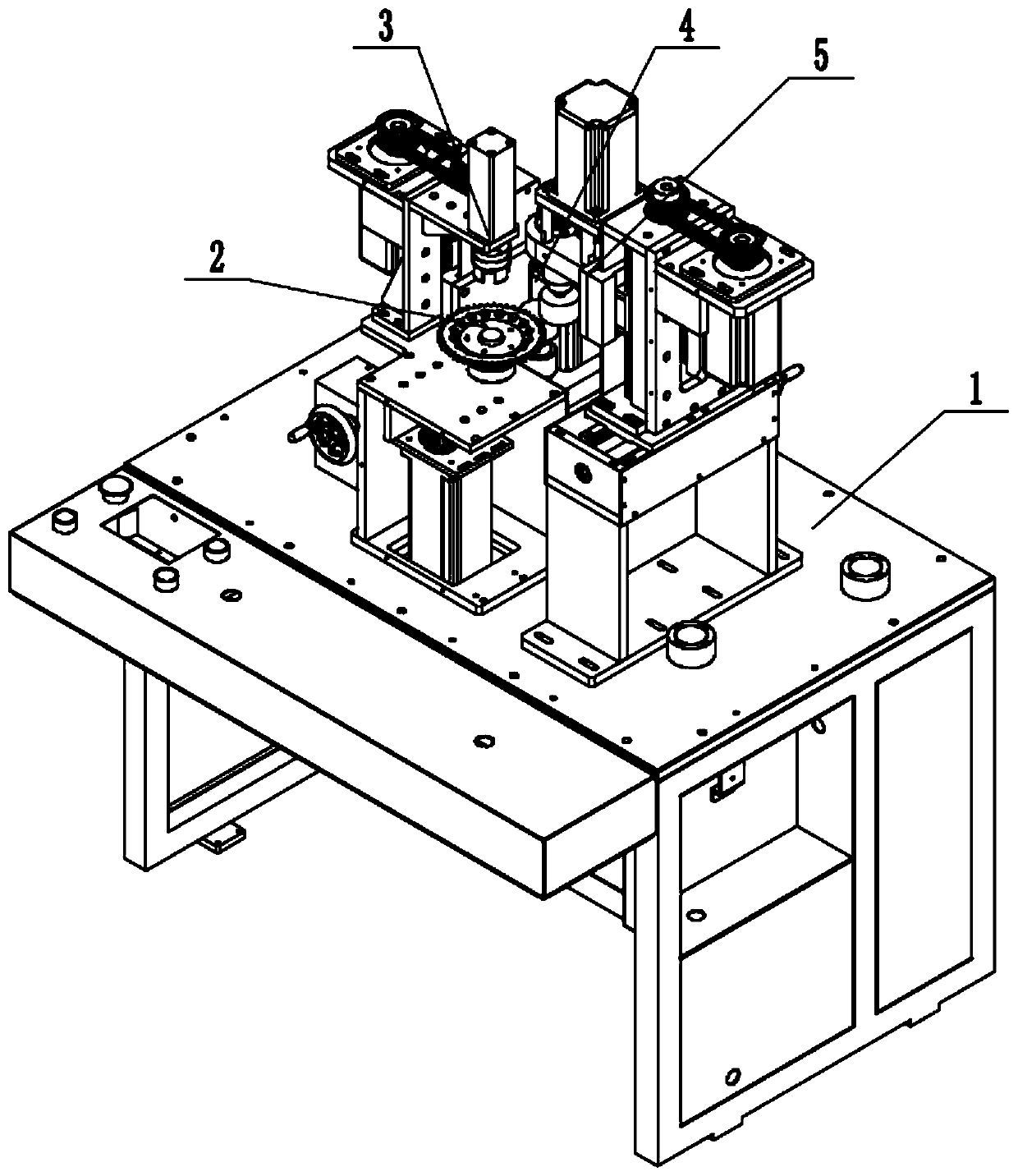

Positioning structure of carpentry machining center

ActiveCN111391038AImprove positional stabilityThere will be no phenomenon of uneven forceMulti-purpose machinesProfiling/shaping machinesMachineCarpentry

The invention provides a positioning structure of a carpentry machining center and belongs to the technical field of machining equipment. The problem that the positioning stability of irregular-shapedworkpieces by an existing carpentry machining center is poor is solved. The carpentry machining center of the positioning structure comprises a machine frame and a transverse beam which is fixed to the machine frame; a machining assembly is disposed on the transverse beam; and a machining platform is slideably disposed on the machine frame in the horizontal direction. The positioning structure comprises a plurality of installing seats which are arranged on the machine frame; positioning pressure rollers are horizontally disposed on the installing seats correspondingly; the plurality of installing seats are arranged in two rows; lifting seats are slideably connected to the installing seats in the vertical direction correspondingly; one ends of the positioning pressure rollers are connectedto the lifting seats, and the other ends of the two rows of positioning pressure rollers face the inner side of the machine frame; when the lifting seats ascend, the other ends of the two rows of positioning pressure rollers can be located above the machining platform; and each installing seat is provided with a driving part. The positioning stability of the irregular-shaped workpieces by the carpentry machining center is higher.

Owner:吴善旺

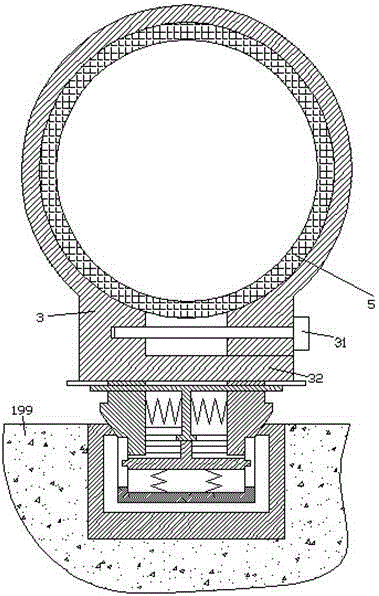

Installing and fixing device used for drainage pipe of building

InactiveCN105863178AReliable lockingGuaranteed positional stabilityRoof drainageWedge shapeCivil engineering

An installing and fixing device used for a drainage pipe of a building is used for fixedly installing the drainage pipe (5) to the building (155) and comprises a lining board (7) embedded in the building (155), an installing ring (3) for fastening the drainage pipe (5) and an elastic locking component in sliding fit with a fixedly-connected guide rod (51) on the lower side of a connecting part (32) of the installing ring (3). The right end of the installing ring (3) is a free end. The drainage pipe (5) is installed in the installing ring (3) through a bolt (31) installed at the free end. The two ends of the fixedly-connected guide rod (51) on the lower side are fixed to the connecting part (32) through connecting arms. The elastic locking component comprises two wedge-shaped locking blocks (4) which are symmetrically arranged. An ejection spring (44) is arranged between the two wedge-shaped locking blocks (4) and used for elastically expanding the two wedge-shaped locking blocks (4) open.

Owner:毛杰

Forming method for shell of airplane cover

InactiveCN107187079AGuaranteed positional stabilityQualified performanceDomestic articlesFiberVolumetric Mass Density

The invention discloses a forming method for a shell of an airplane cover. The forming method comprises the steps that (1) a special forming mould is manufactured; (2) carbon fiber cloths are laid; (3) mould compounding and glue injecting are conducted; (4) vacuumizing operation is conducted while glue is injected; (5) solidification and pressure maintaining are conducted; and (6) a product is demoulded and taken out. By adopting the method, the stability of the positions of the carbon fiber cloths is guaranteed, the density uniformity of the product is guaranteed accordingly, and it is guaranteed that performance of the finished product is qualified.

Owner:NINGBO CITY EPL MOLD & PLASTIC

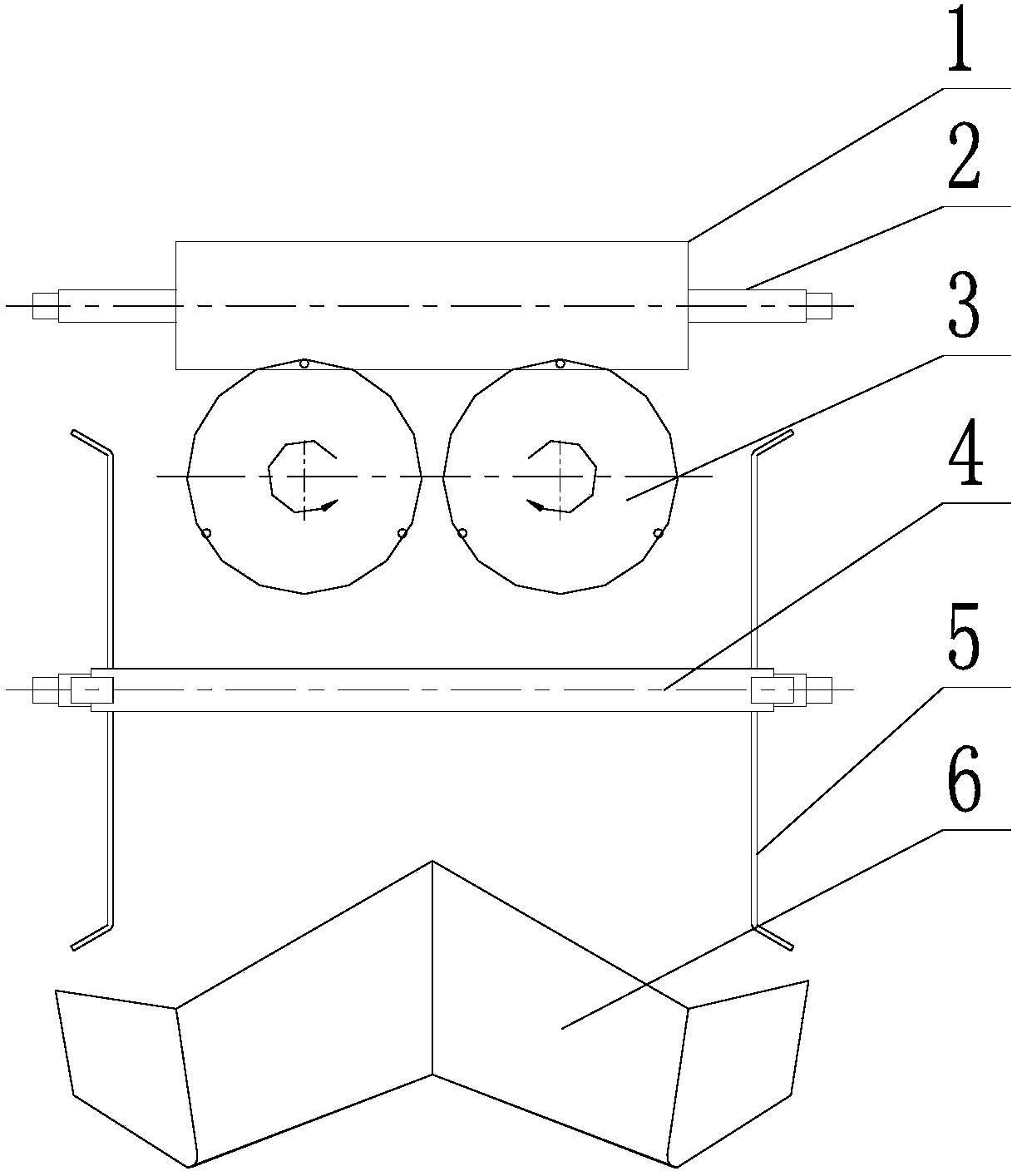

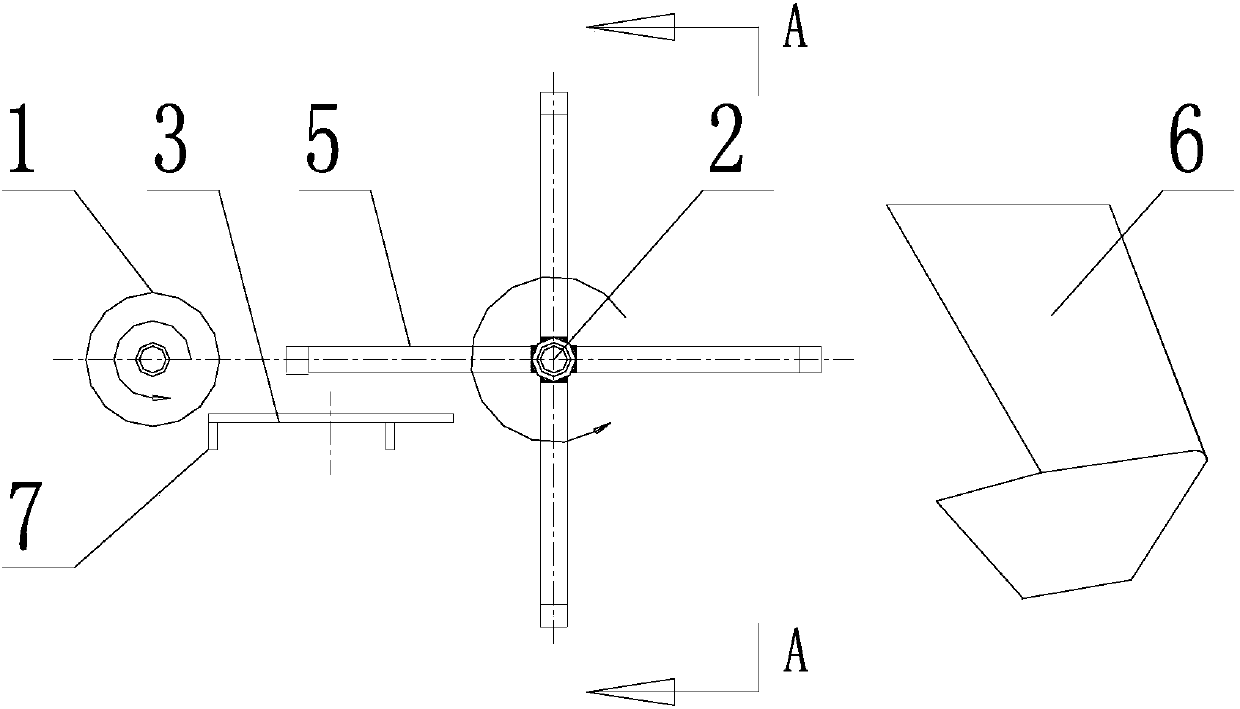

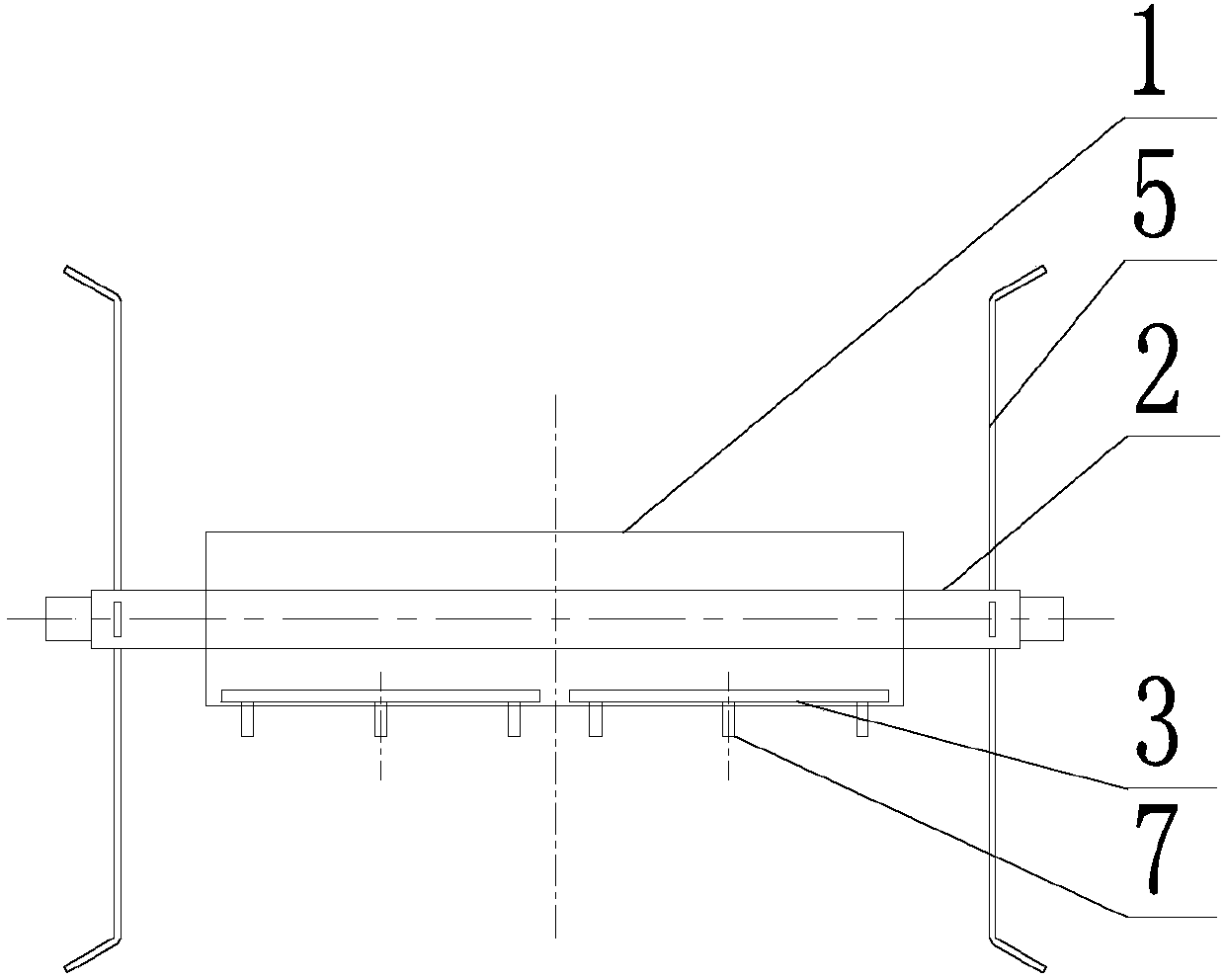

Gear double-sided deburring equipment

InactiveCN110103097AAffect the processing quality of the upper and lower surfacesGuaranteed axial length dimensional accuracyEdge grinding machinesGrinding carriagesEngineeringGrinding wheel

The invention discloses gear double-sided deburring equipment which comprises a machine frame. The equipment is characterized in that a gear rotating device, a gear pressing device, a gear lower surface deburring device and a gear upper surface deburring device are arranged on the machine frame, the gear rotating device comprises a lower mounting frame, a transmission shaft, a gear positioning seat and a first motor, the gear pressing device comprises an upper mounting frame, a gear pressure head and a pressing cylinder, the gear lower surface deburring device comprises a first X-axis adjusting mechanism, a first Z-axis adjusting mechanism, a lower grinding wheel driving mechanism and a lower grinding wheel, and the gear upper surface deburring device comprises a second X-axis adjusting mechanism, a second Z-axis adjusting mechanism, an upper grinding wheel driving mechanism and an upper grinding wheel. By means of the double-sided deburring equipment, deburring processing can be carries out on the two faces of a gear simultaneously, the production efficiency can be greatly provided, the size precision of the gear can be improved, and the subsequent assembly precision of the gear can be guaranteed.

Owner:QIJIANG COUNTY XIANGHU GEAR

Potato seedling cutting and weeding machine

ActiveCN107771496AAchieve upliftRealize distributionSoil-working equipmentsTopping machinesCircular discAgricultural engineering

The invention discloses a potato seedling cutting and weeding machine. A compression roller shaft is arranged on a central axis of a positioning compression roller of a cylinder structure. Two seedling pull-out discs are arranged at the rear positions of the bottom of the positioning compression roller. The centers of the seedling pull-out discs are connected with gear boxes through rotation shafts. A plurality of blunt teeth are evenly embedded in the outer edges of the seedling pull-out discs along the circumference. A rotary blade shaft is arranged at the rear of the seedling pull-out discs, rotary blades are arranged on the outer sidewalls of both ends of the rotary blade shaft in a 360 DEG ring shape, and herringbone scraper plates are arranged at the rear ends of the rotary blade shaft. The potato seedling cutting and weeding machine achieves the function of pulling out and arranging potato stalks into the corresponding furrows and implements the cutting and removing of potato seedlings and weeds in the furrows; the potato seedling cutting and weeding machine can simultaneously complete the works of lifting of potato seedlings, allocation and position limiting of potato seedlings, and cutting of stalks, so that a subsequent potato harvester has reduced resistance, accelerated traveling speed and reduced failure rate, thus early preparations of removing seedlings and weedsfor subsequent potato grading and bagging are performed and the harvesting efficiency of potatoes can be improved.

Owner:侯文会

Sewing process for shoe uppers and shoe soles of safety shoes

InactiveCN109832714AImprove stabilityGuaranteed stabilityNatural rubber adhesivesLaminationPunchingEngineering

The invention discloses a sewing process for shoe uppers and shoe soles of safety shoes. The sewing process for shoe uppers and shoe soles of safety shoes comprises the following steps: P1, carrying out shearing forming; P2, carrying out lining fixing; P3, carrying out edge trimming; P4, carrying out first-time bonding; P5, carrying out punching; P6, carrying out thread sewing, namely, selecting the thread with the suitable model number, and enabling the thread to sequentially pass through the punched holes for realizing the thread sewing operation; P7, carrying out second-time bonding; and P8, carrying out drying. For the sewing process for the shoe uppers and the shoe soles of the safety shoes provided by the invention, due to the placement of the linings adhered inside the shoe uppers,the comfort can be improved, punching is carried out after position fixing through the first-time bonding, so that the stability of the position can be guaranteed, the deviation dislocation can be avoided, meanwhile, filling sizing is carried out through coating of self-adhesive glue, so that the sewing stability can be guaranteed, the generation of gaps is avoided, then the stability of sewing ofthe safety shoes is greatly improved, the existing process is improved, and the use and popularization are facilitated.

Owner:저지앙하이나슈즈컴퍼니리미티드

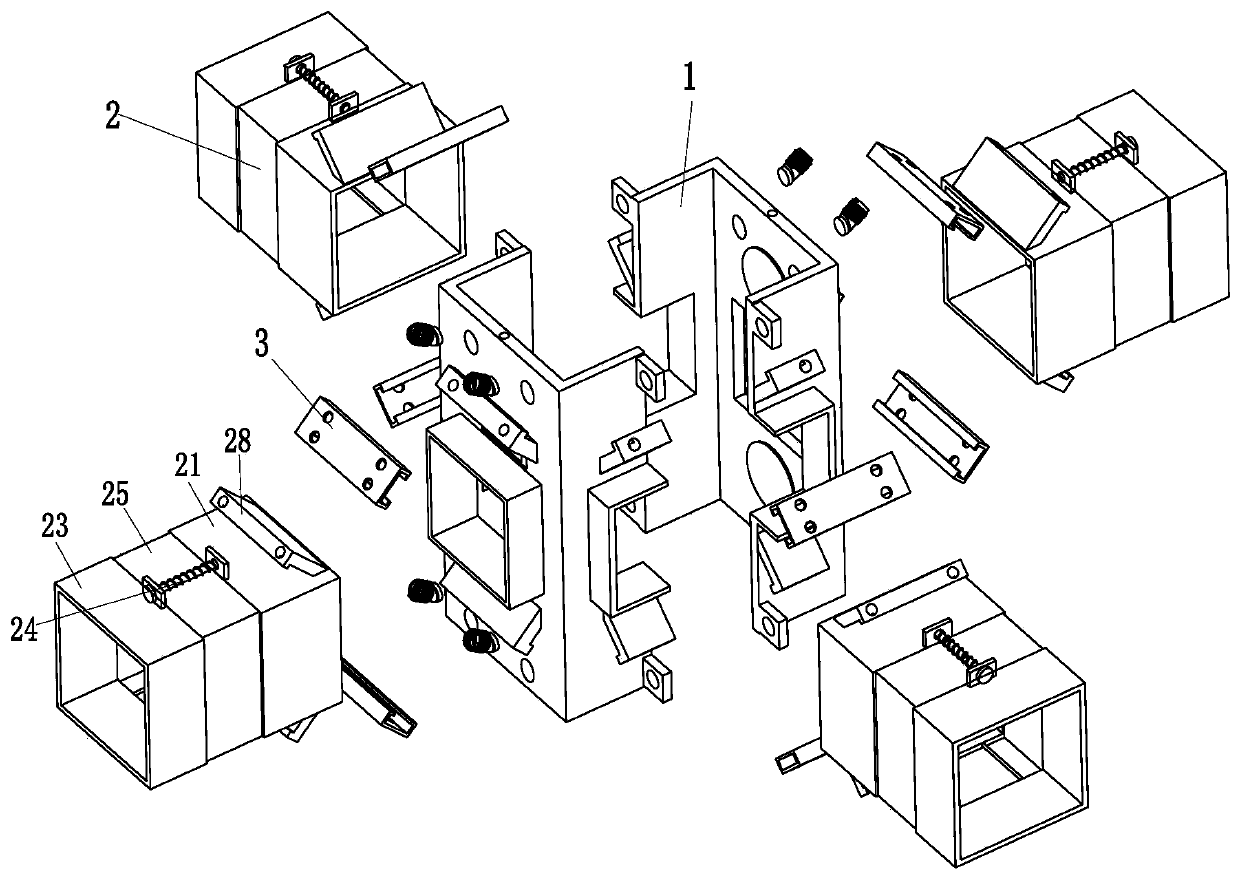

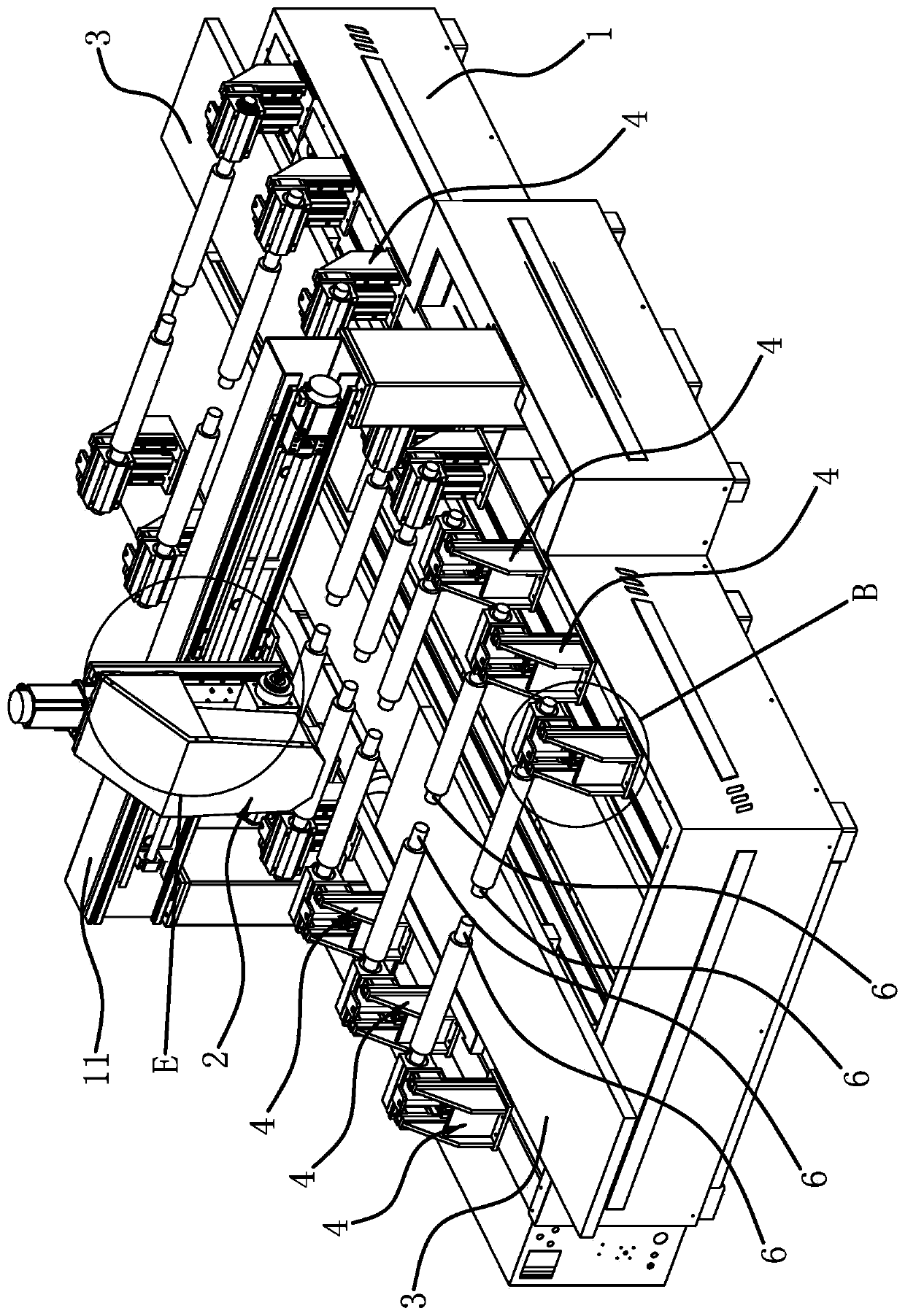

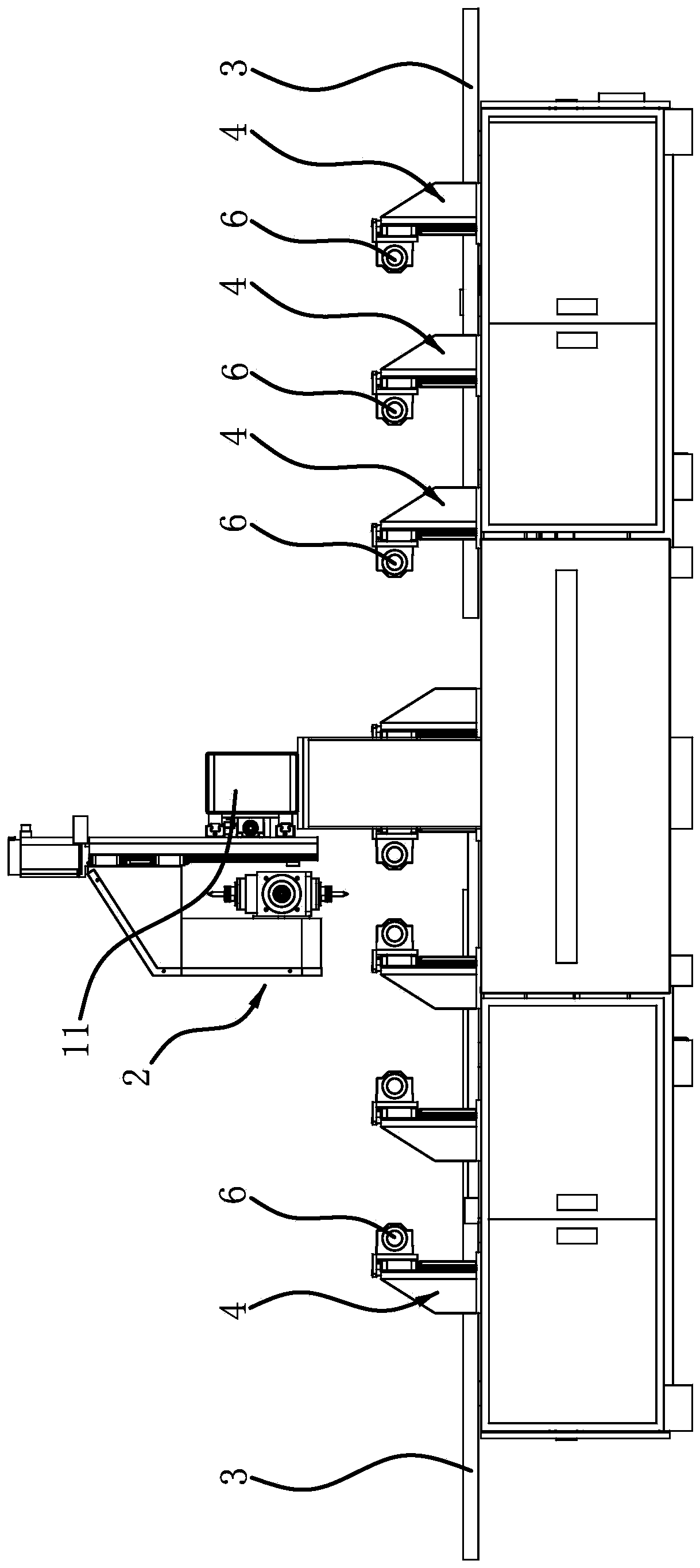

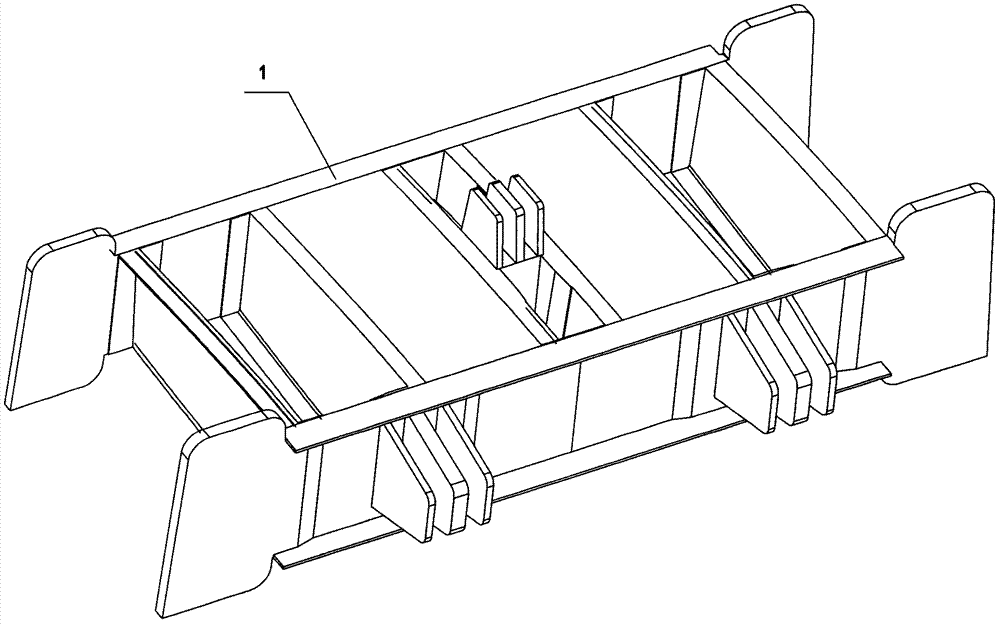

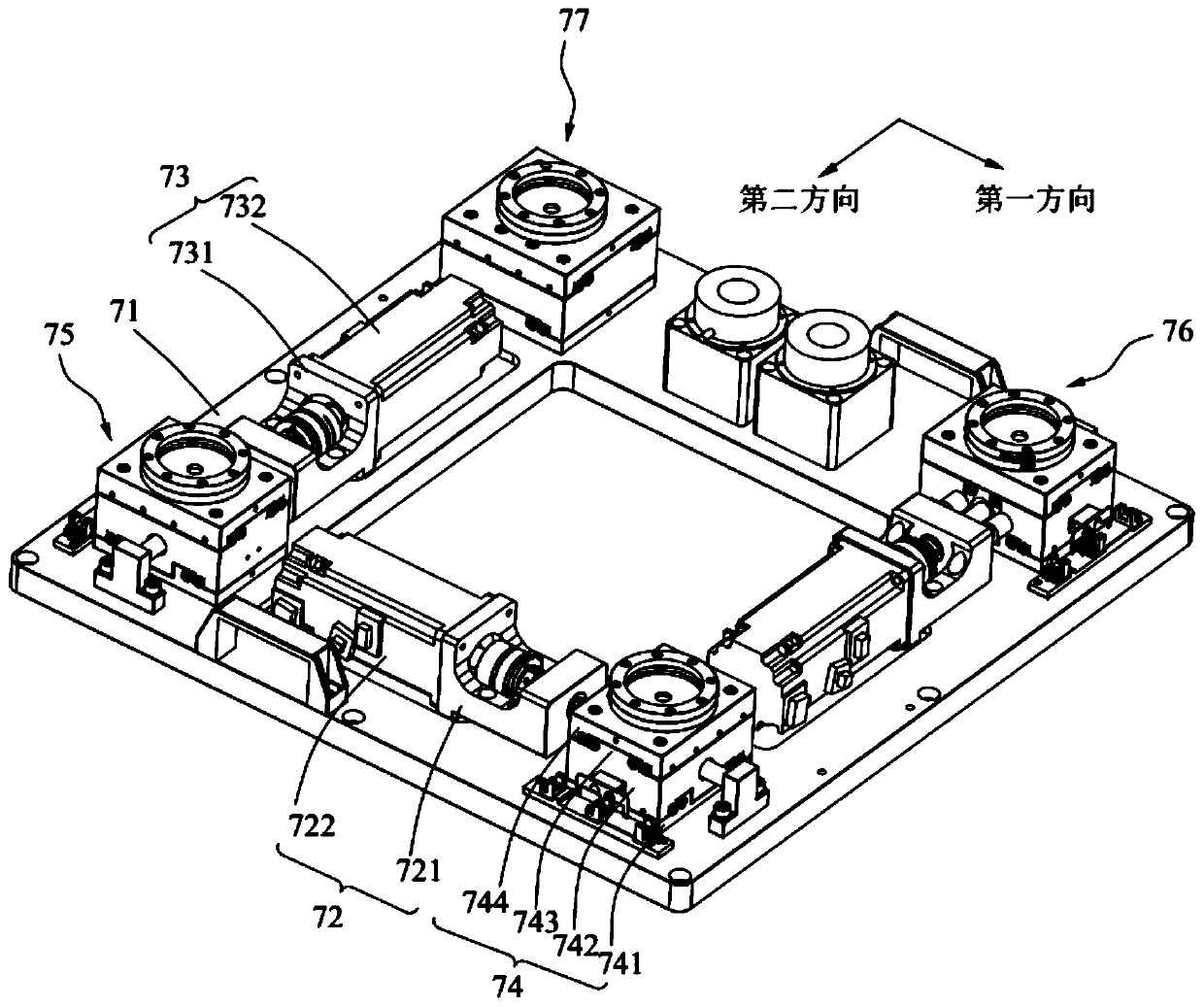

Adjusting supporting device and production line

PendingCN111135988AReduce movementGuaranteed positional stabilityLiquid surface applicatorsCoatingsProduction lineIndustrial engineering

The invention belongs to the technical field of electronic product manufacturing, and discloses an adjusting supporting device and a production line. The adjusting supporting device comprises a bearing plate, a center bearing mechanism, a fixed supporting mechanism and an adjusting supporting mechanism. The center bearing mechanism is arranged in the middle of the bearing plate and used for bearing and fixing the center area of a to-be-machined workpiece. The fixed supporting mechanism is arranged on the bearing plate in the first direction and used for bearing and fixing one set of opposite sides of the to-be-machined workpiece. The adjusting supporting mechanism is arranged on the bearing plate, and the adjusting supporting mechanism and the fixed supporting mechanism are annularly arranged around the center bearing mechanism. According to the length, in the first direction, of the to-be-machined workpiece, the adjusting supporting mechanism is configured to slide relative to the fixed supporting mechanism in the first direction so that the adjusting supporting mechanism can bear and fix the other set of opposite sides of the to-be-machined workpiece. Thus, the adjusting supporting device can adapt to to-be-machined workpieces of multiple specifications, universality is high, and bearing of to-be-machined workpieces of multiple specifications can be achieved by adopting an adjusting platform.

Owner:KUNSHAN SAMON AUTOMATION TECH

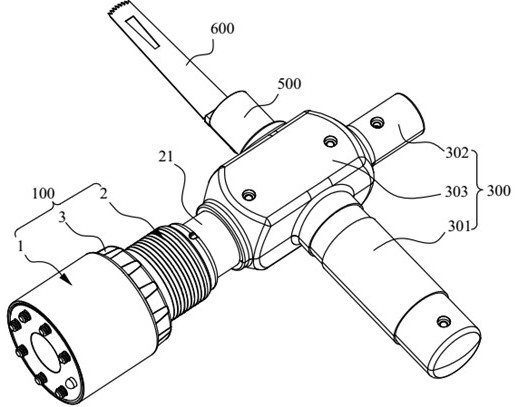

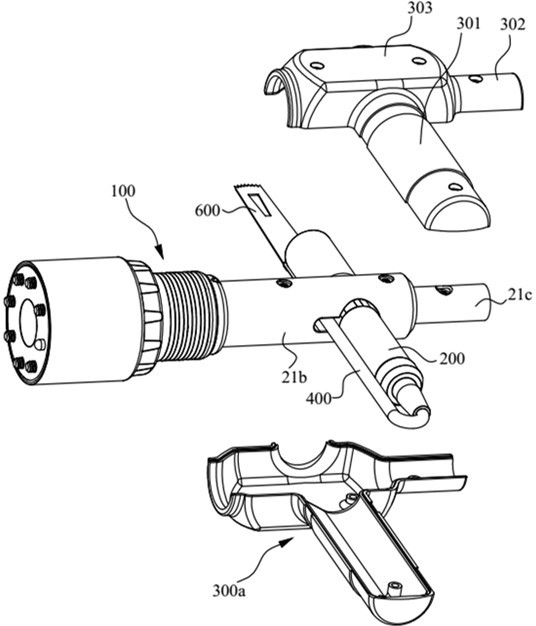

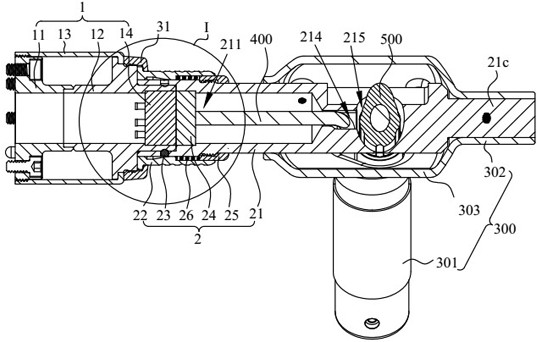

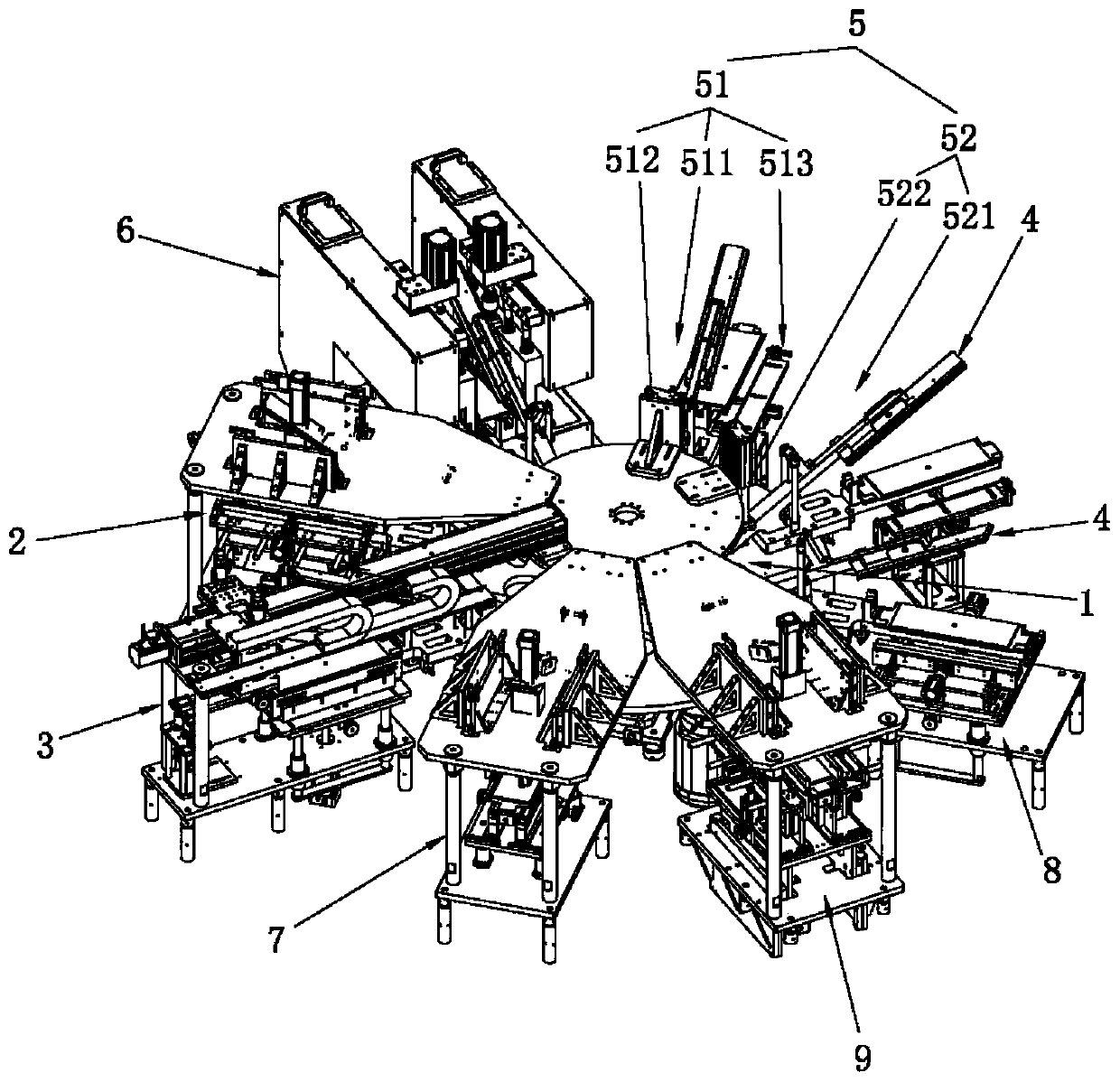

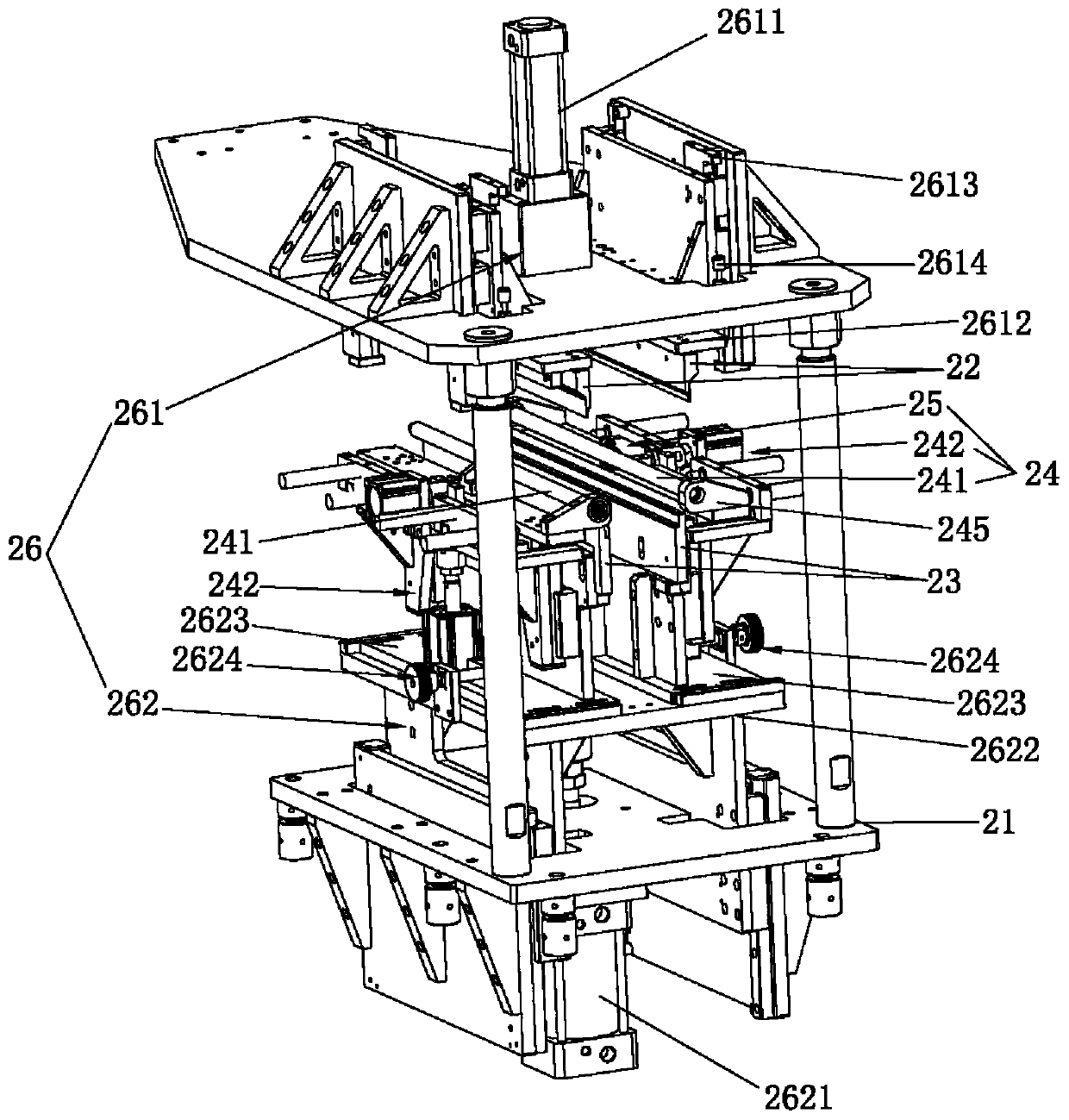

Power quick-mounting device, power device and surgical robot

ActiveCN114010325AAchieve installationAchieve disassemblyCouplings for rigid shaftsSurgical manipulatorsPower apparatusReoperative surgery

The invention belongs to the technical field of medical treatment, and particularly discloses a power quick-mounting device, a power device and a surgical robot. The power quick-mounting device comprises a quick-mounting unit, wherein the quick-mounting unit comprises a mounting main shaft, a plugging sleeve and a ball, the mounting main shaft is provided with a containing cavity and a placing hole, the plugging sleeve can slide between a first position and a second position relative to the mounting main shaft, the ball is partially contained in the placing hole, and a ball groove is formed in the inner wall of the plugging sleeve; a base unit which is provided with an inserting cylinder part, wherein an accommodating groove is formed in the outer wall of the inserting cylinder part; when the plugging sleeve slides to the first position, the ball can retreat from a containing cavity and partially enter the ball grooves, and when the plugging sleeve slides to the second position from the first position, the groove walls of the ball groove can abut against the ball and enable the ball to partially extend into the accommodating grooves. According to the power quick-mounting device, the power device and the surgical robot, the convenience of cleaning and replacing the power unit can be improved.

Owner:北京威高智慧科技有限公司

Edge folding equipment and edge folding method thereof

PendingCN111509289AGuaranteed positioning accuracyGuaranteed positional stabilityFinal product manufactureElectrolyte accumulators manufactureMechanical engineeringBattery cell

The invention relates to the technical field of battery production, in particular to edge flanging equipment and an edge flanging method thereof. The edge flanging equipment comprises a circulating conveying device, a plurality of clamping devices and a feeding and discharging device, an edge cutting device, a first edge folding device, a second edge folding device, a hot pressing device, a thirdedge folding device and a shaping device which are sequentially arranged on the periphery of the circulating conveying device. The circulating conveying device is used for conveying the multiple clamping devices to sequentially move to the feeding and discharging device, the edge shearing device, the first edge folding device, the second edge folding device, the hot pressing device, the third edgefolding device and the shaping device. According to the invention, feeding, edge cutting, 90-degree edge folding, 180-degree edge folding, hot-pressing shaping, 270-degree edge folding, shaping and discharging of the battery are automatically realized; the battery edge folding device is high in automation degree and edge folding efficiency, labor intensity and labor cost are reduced, a battery isclamped on the clamping device all the time in the whole edge folding process, the position precision and stability of the battery are guaranteed, the edge folding precision is high, the edge foldingquality is good, and the quality of the battery after edge folding is guaranteed.

Owner:DONGGUAN CHAOYE PRECISION EQUIPMENT CO LTD

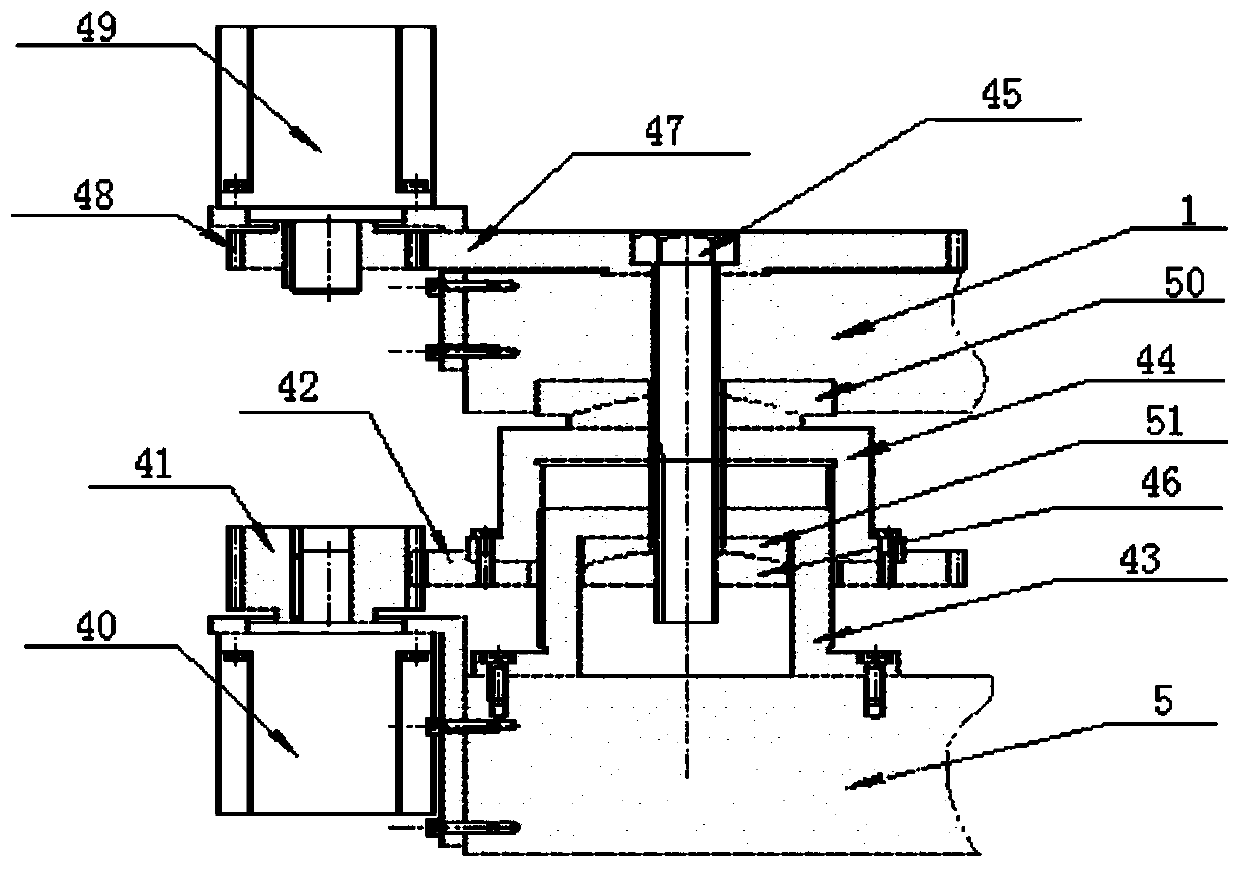

Multi-degree-of-freedom high-strength and high-precision adjusting table suitable for wind tunnel environment

PendingCN110187460AGuaranteed positioning accuracyGuaranteed positional stabilityMountingsMulti degree of freedomDegrees of freedom

The invention discloses a multi-degree-of-freedom high-strength and high-precision adjusting table suitable for a wind tunnel environment, which is used in the wind tunnel environment, has large bearing capacity, can be used for precisely adjusting optical loads of several tons, is rigidly locked and can be used under vibration or impact, the adjustment and locking of pitching, translation and height are electrically controlled and can be used under closed or severe conditions, the five-degree-of-freedom adjustment of a schlieren primary mirror is met, and the combination of pitching yawing electric adjustment and high-rigidity locking is completed. The system can ensure the position precision and stability of the adjusting table under the working conditions of vibration and wind tunnel airflow impact. The multi-degree-of-freedom high-strength and high-precision adjusting table suitable for the wind tunnel environment successfully solves the problem that the precise adjusting table works in the wind tunnel environment, and can be popularized and applied in the wind tunnel similar environment.

Owner:中国空气动力研究与发展中心超高速空气动力研究所 +1

Clamping tool

InactiveCN102468597AGuaranteed positional stabilityStable clampingLaser detailsEngineeringIndustrial engineering

The invention relates to a clamping tool. The clamping tool comprises a pedestal, a lower pressing plate, an upper pressing plate, a first fixing piece and a second fixing piece, wherein the lower pressing plate is arranged on the pedestal; the upper pressing plate is arranged on the lower pressing plate; the first fixing piece is arranged on the upper pressing plate, and the upper pressing plateis fixed on the lower pressing plate by the first fixing piece; and the second fixing piece is arranged on the lower pressing plate, and the lower pressing plate is fixed on the pedestal by the second fixing piece. The clamping tool has the advantages of high clamping stability, capacity of adjusting the pitching position of a crystal and good heat dissipation performance.

Owner:国科世纪激光技术(天津)有限公司

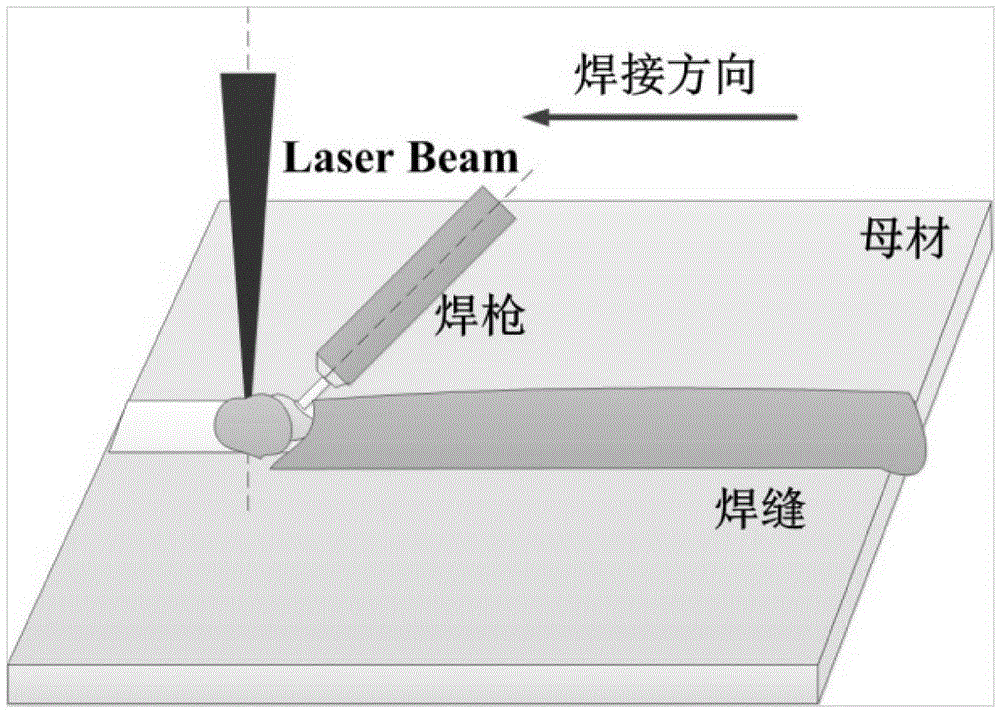

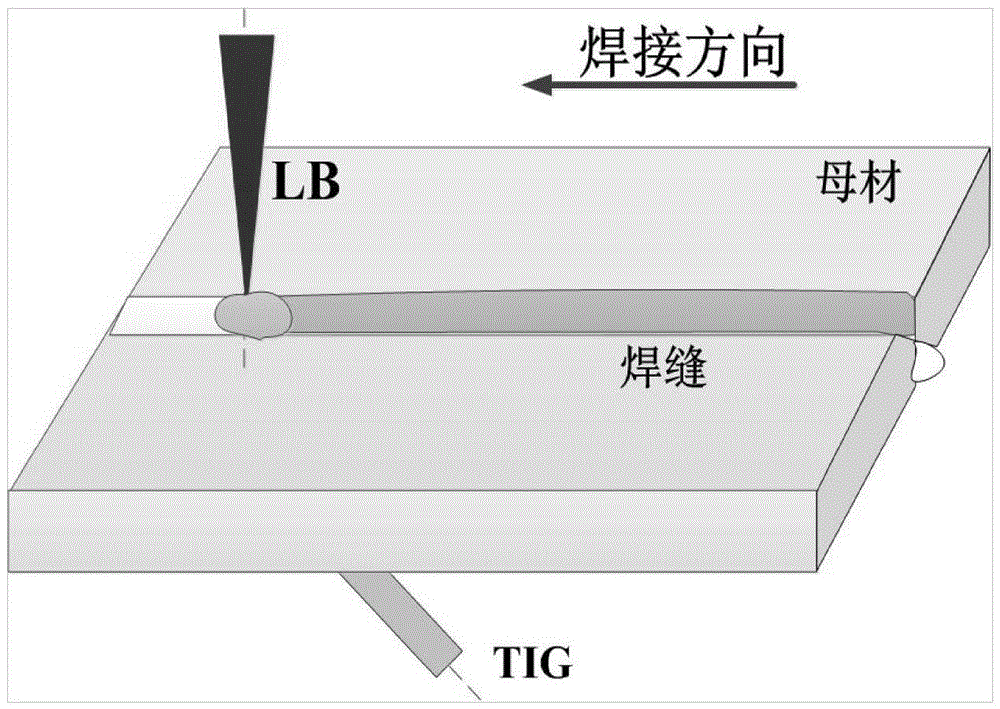

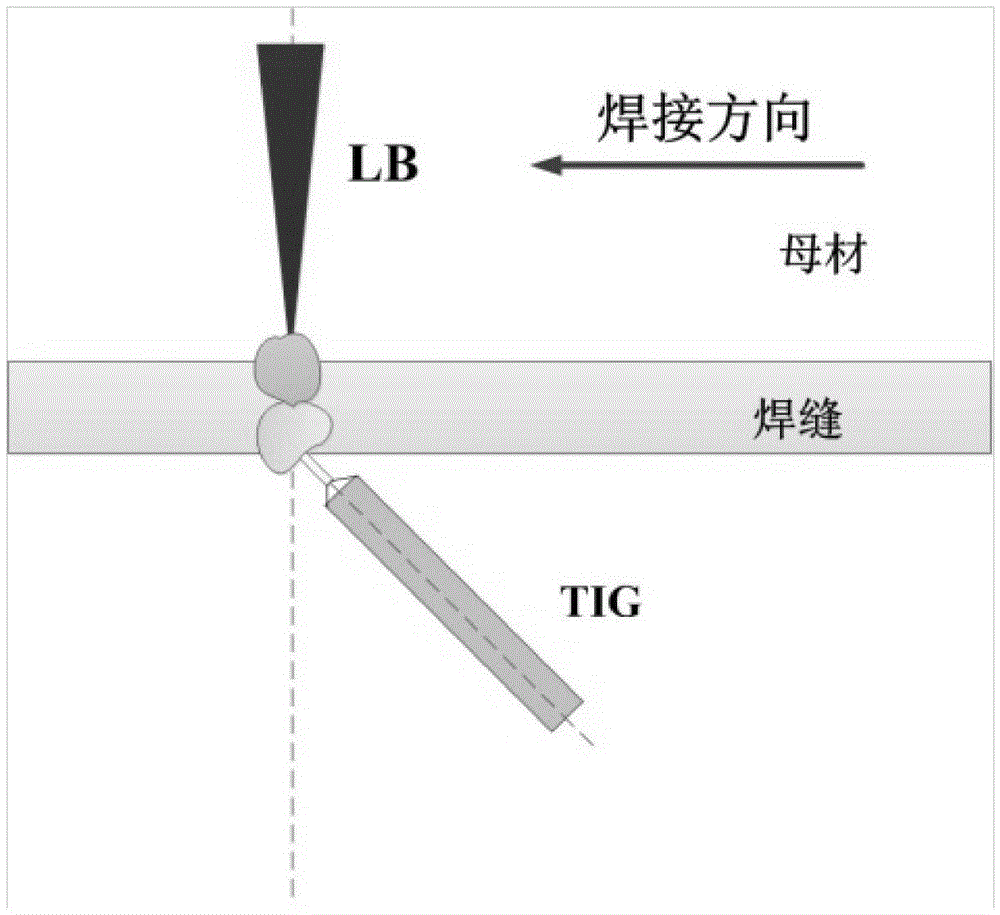

A double-sided laser-tig arc hybrid welding method

ActiveCN104400226BGuaranteed accuracyImprove accessibilityMetal working apparatusLaser beam welding apparatusEngineeringLaser beams

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com