Patents

Literature

1418results about How to "Improve loading and unloading efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

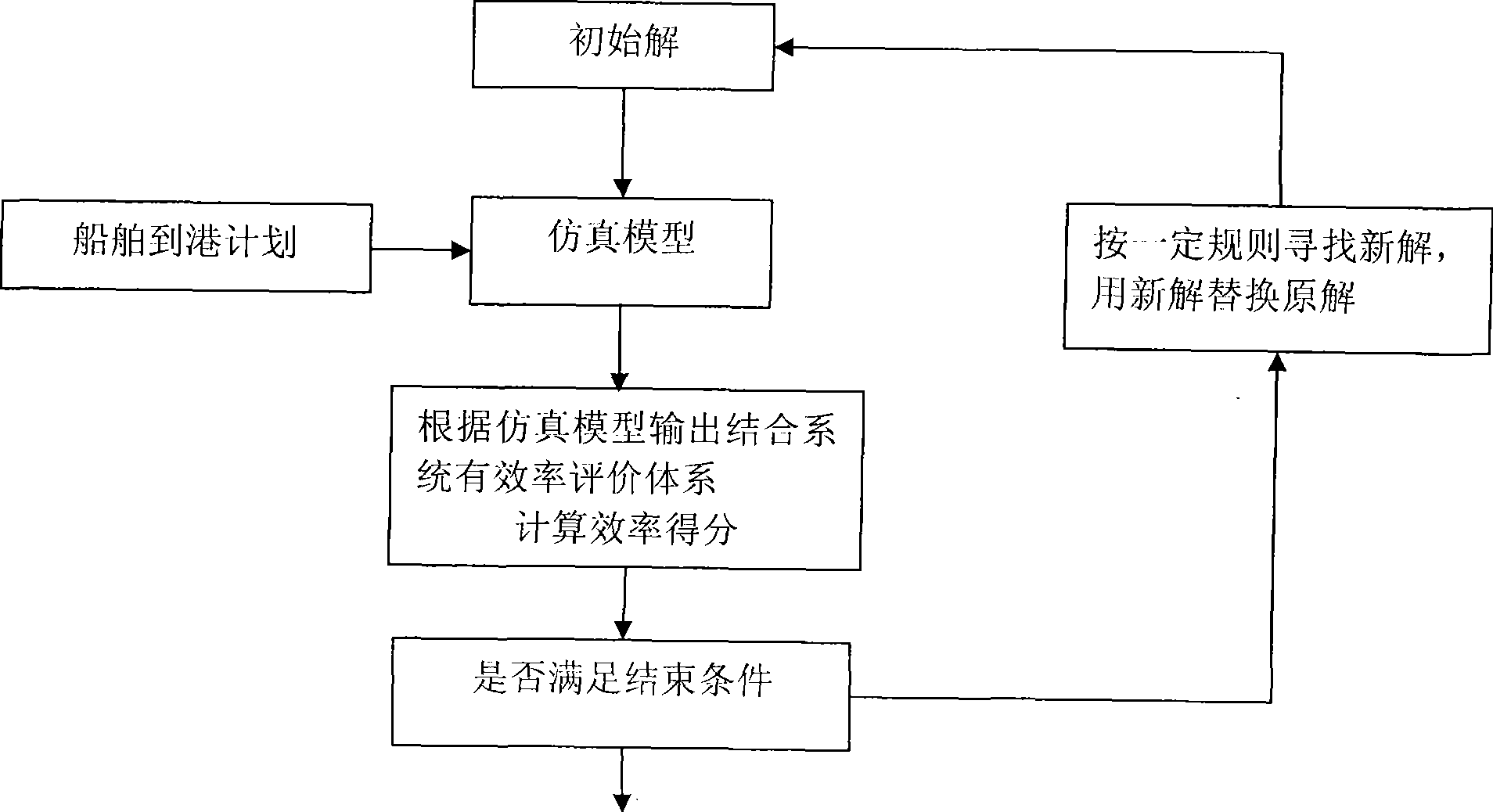

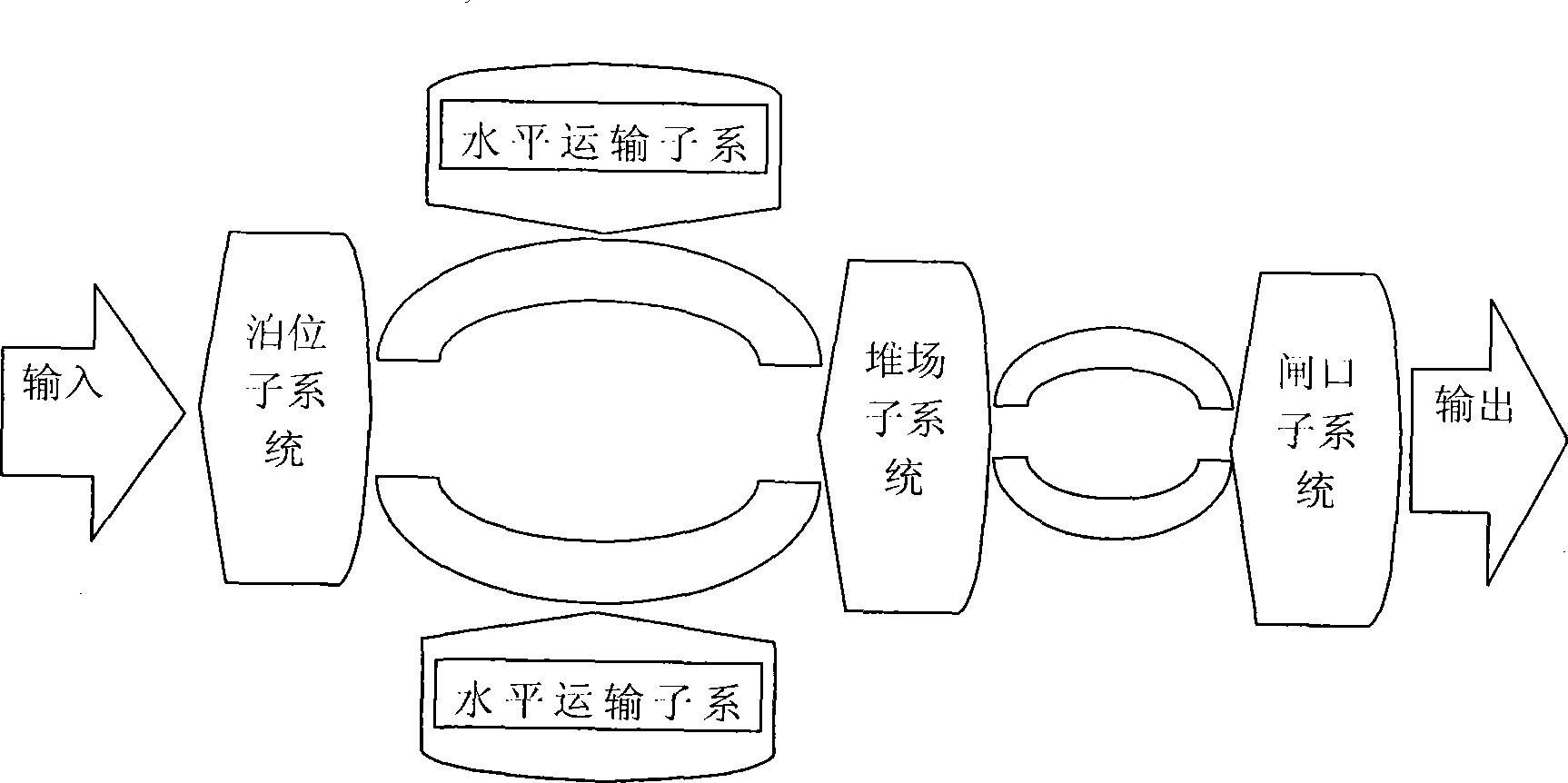

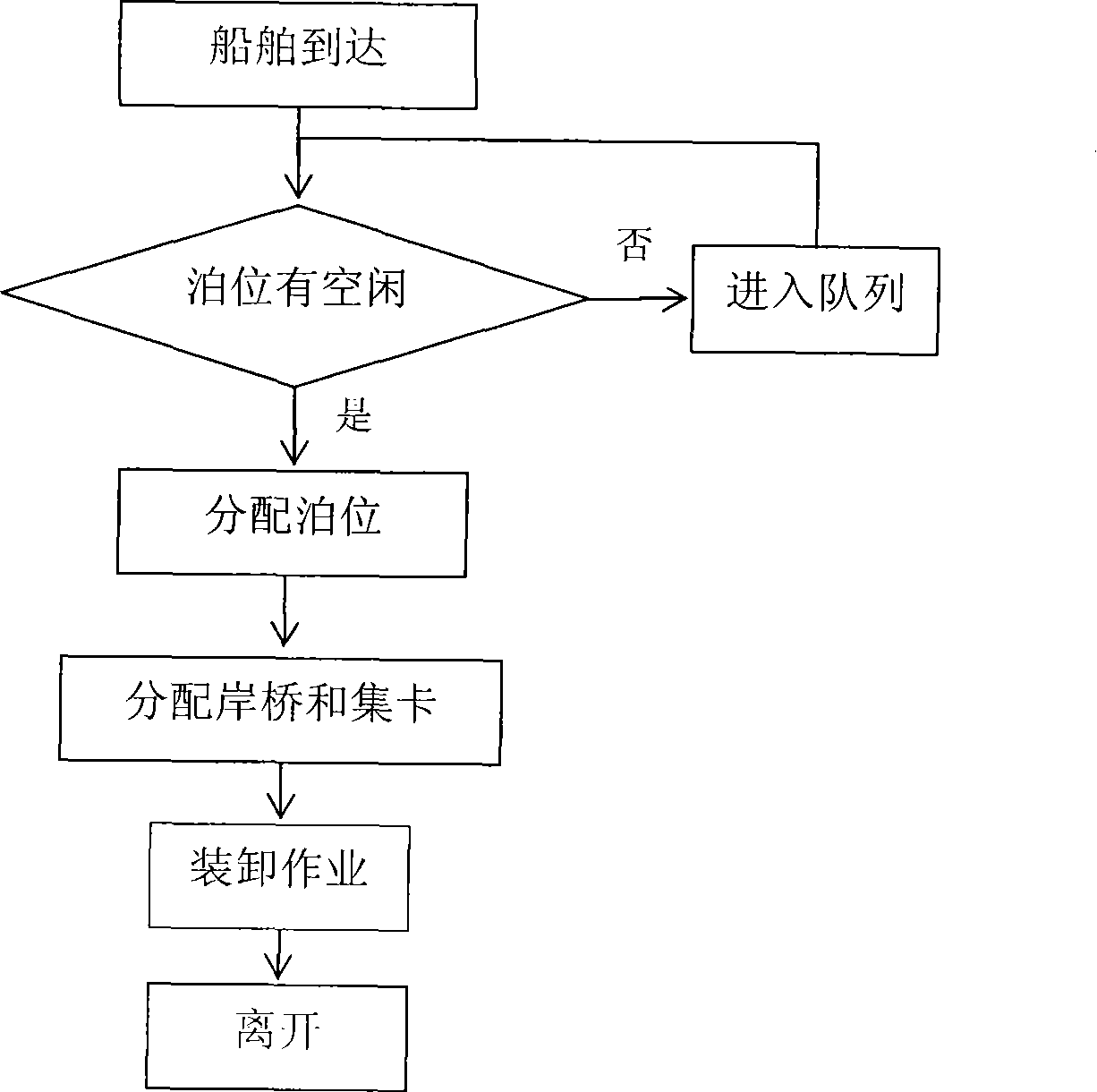

Container terminal physical distribution emulation optimizing system

InactiveCN101458788AReduce logistics costsIncreased logistics costsLogisticsDistribution controlGenetic algorithm

The invention discloses a container dock logistic simulation optimization system, which is connected with a dock logistic management system provided with a dock company logistic management data, for obtaining optimal dock resource configuration and production distribution scheme according to the ship arrival scheme. The system comprises: (1) a memory module; (2) an evaluation module for using AHP analytic hierarchy process to determine the weight value of each index, to obtain the efficiency score of a logistic system; (3) a simulation module comprising a ship arrival module, a berth distribution module, a frontier loading and unloading module, a memory operation module, a horizontal transportation module, a yard operation module, an external operation module, a lake gate check module, a distribution control module and an I / O module, building the relationship among solid properties, debugging and checking the simulation model; (4) an optimization circulation module for combining genetic algorithm and simulation technology to solve each index; (5) a simulation optimization result output module.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

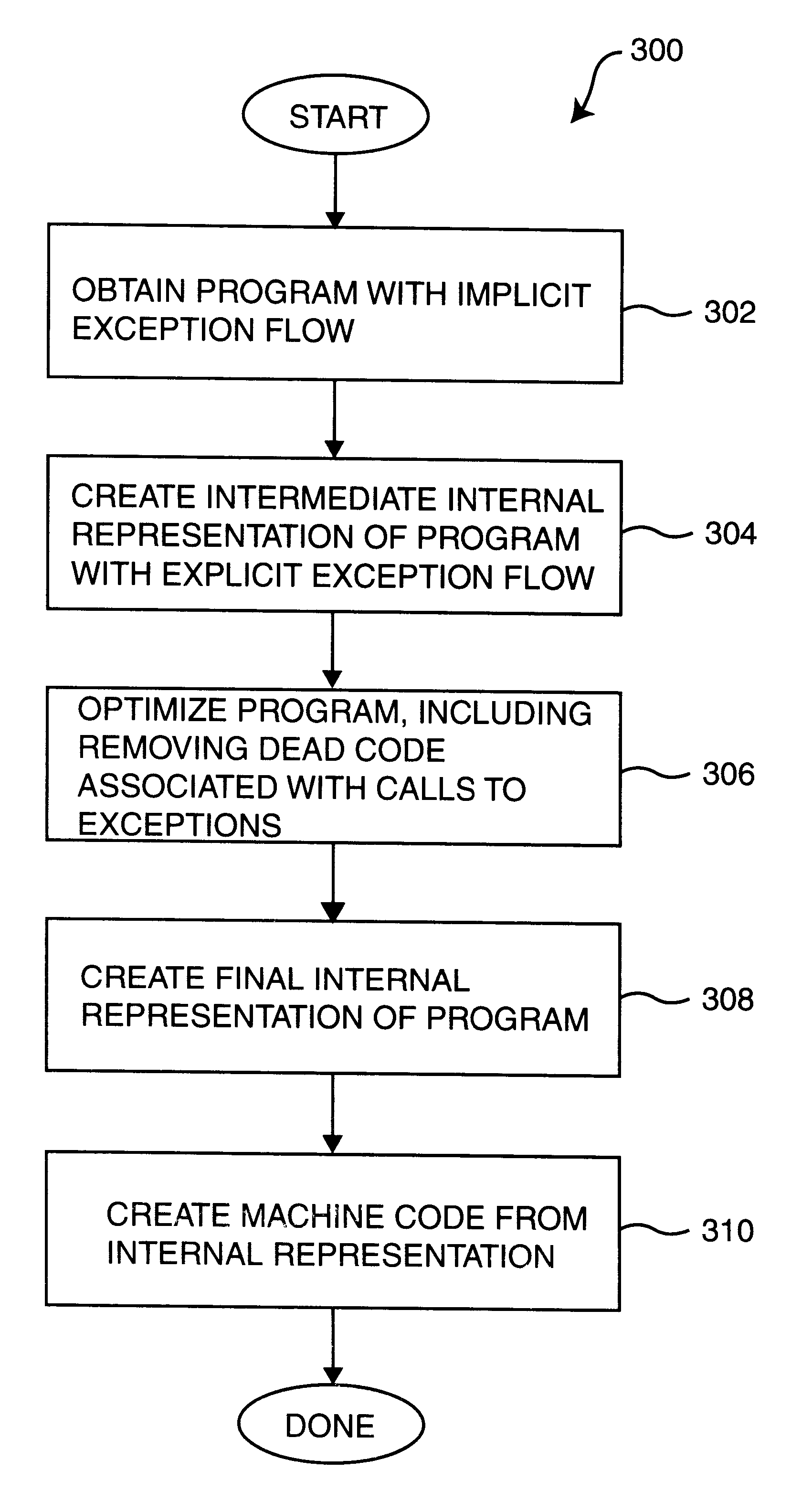

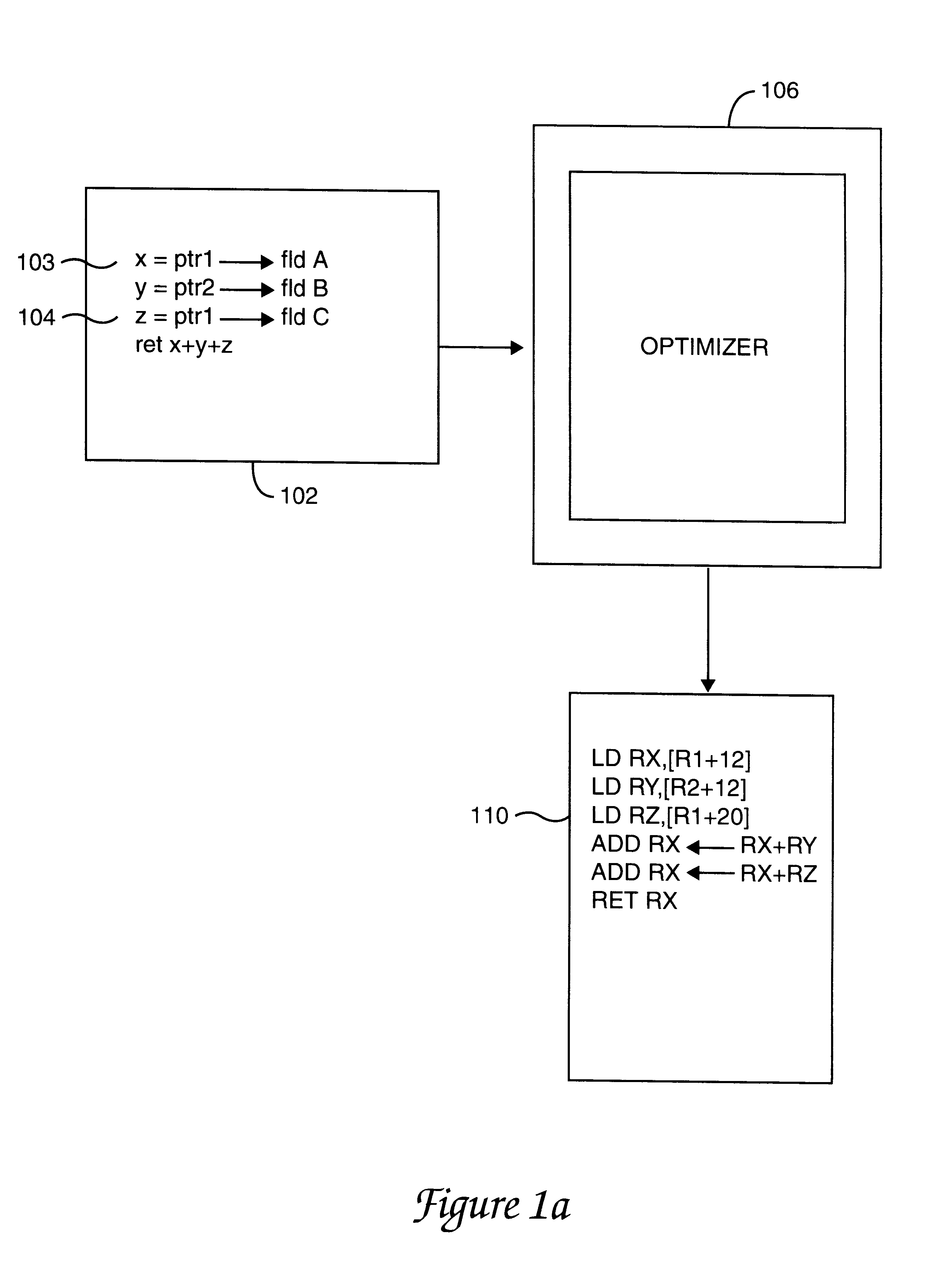

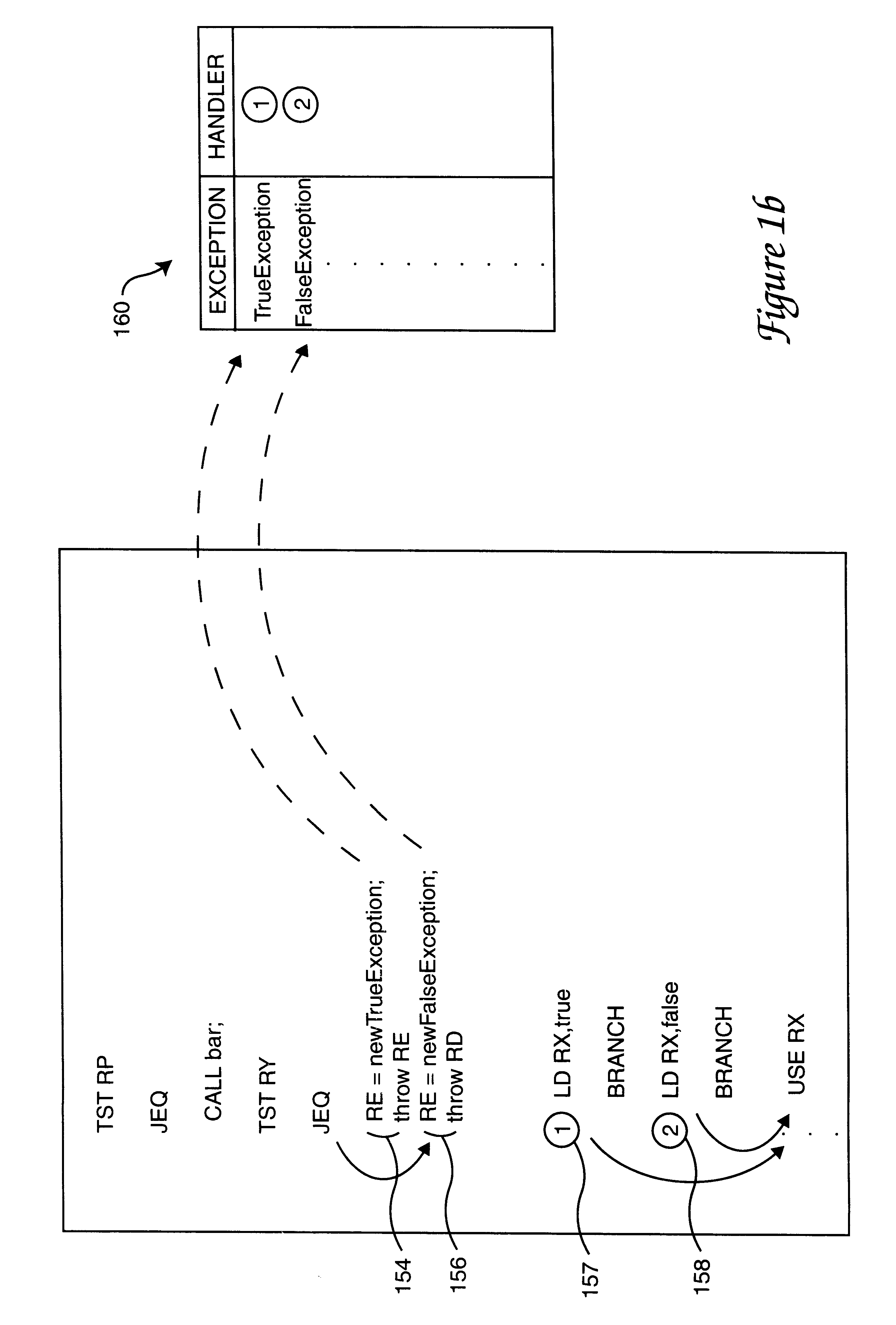

Method and apparatus for handling exceptions as normal control flow

InactiveUS6363522B1Improve loading and unloading efficiencyImprove efficiencySoftware engineeringProgram controlControl flowObject based

Methods and apparatus for handling exceptions as a part of normal program control flow are disclosed. According to one aspect of the present invention, a method for processing an exception in an object-based system includes obtaining source code that includes a code segment which is arranged to explicitly specify instructions pertaining to an exception check. The method also includes creating a final internal representation of the source code at least in part by removing a call associated with the exception check, and generating machine code associated with the final internal representation. In one embodiment, the method further includes executing the machine code. In another embodiment, creating the final internal representation of the source code includes processing the exception check as a part of a control flow associated with the source code.

Owner:ORACLE INT CORP

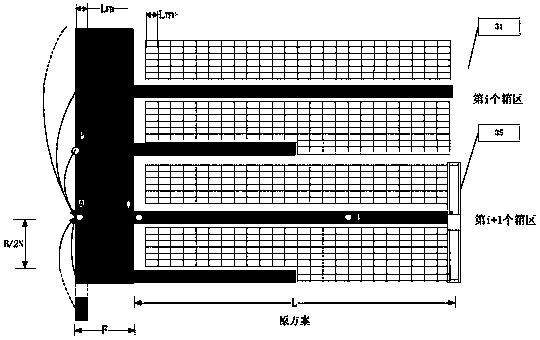

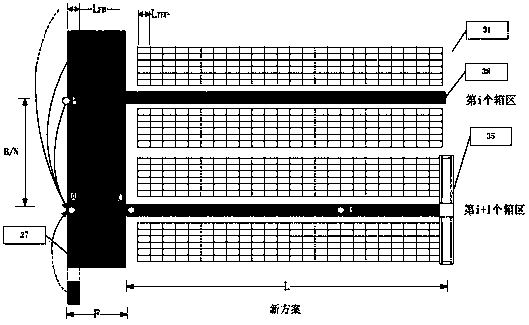

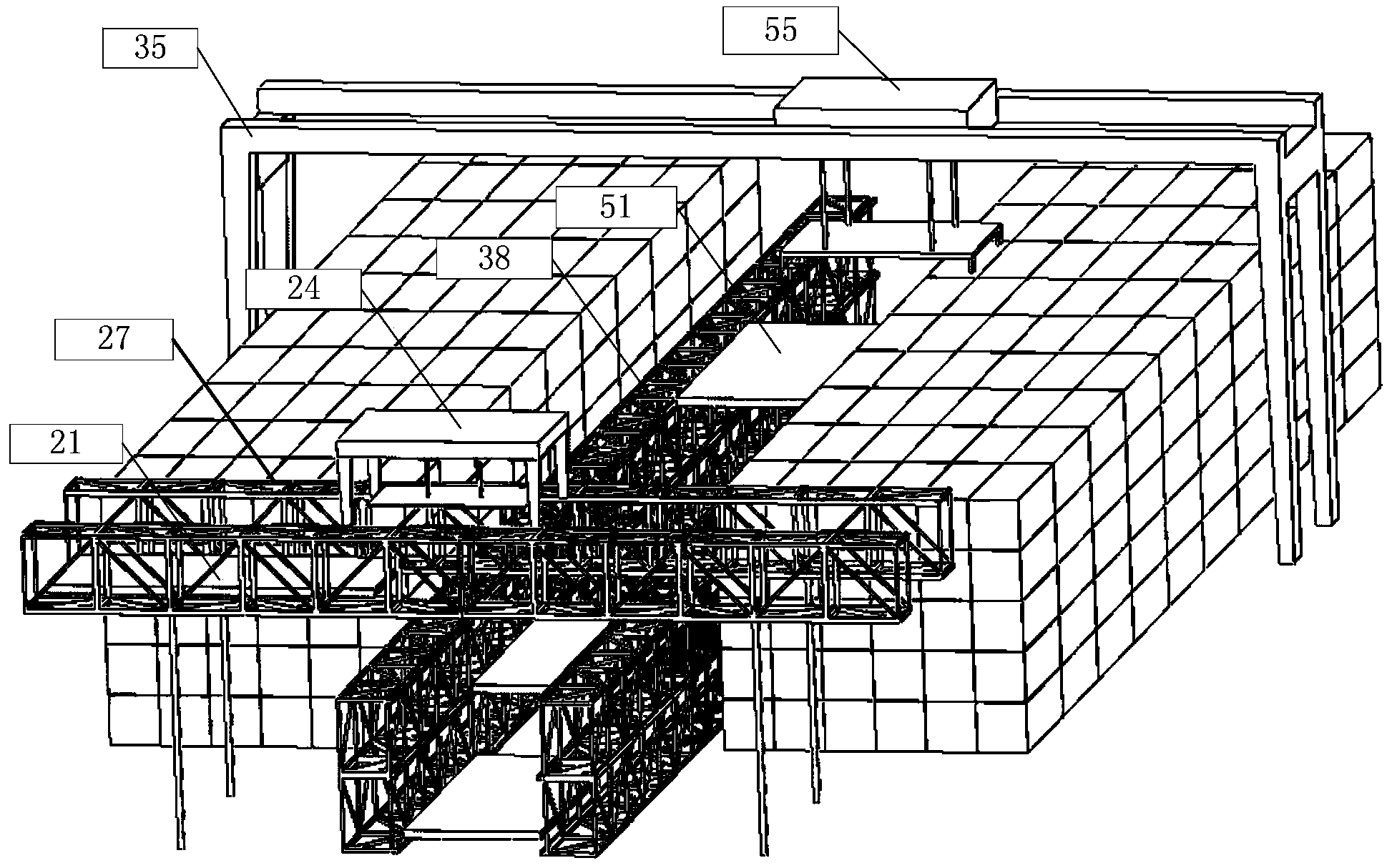

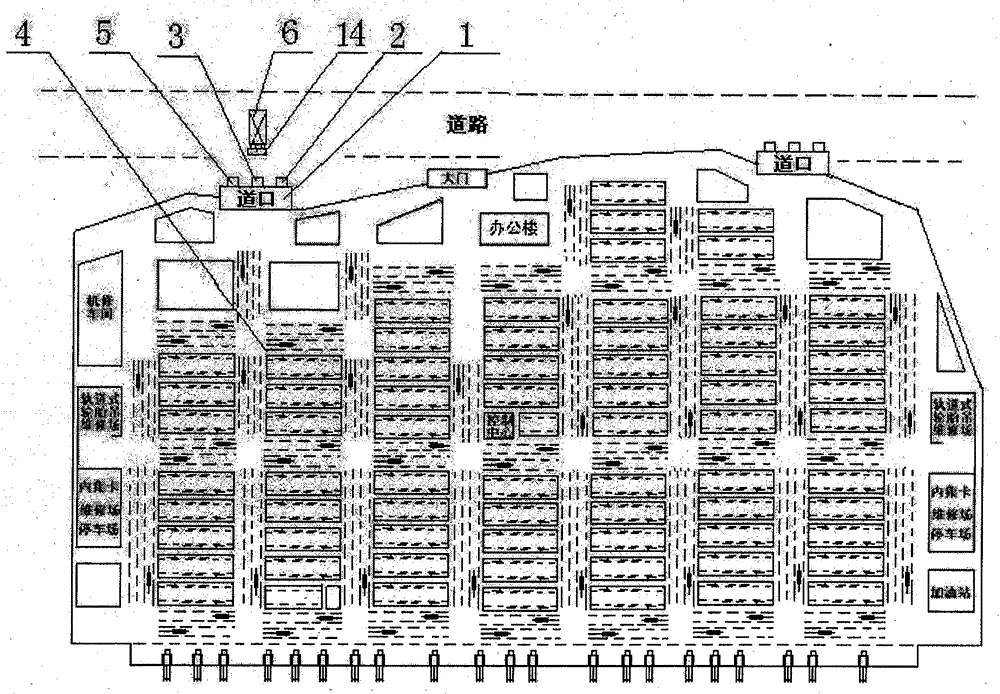

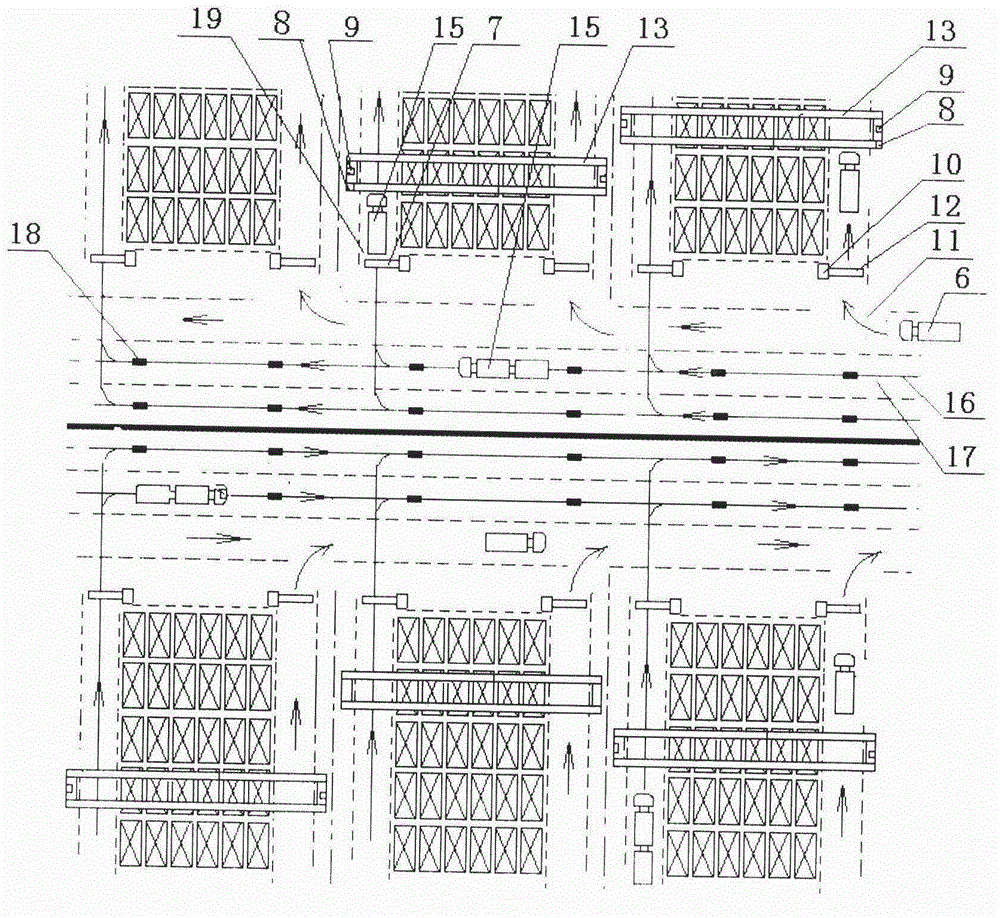

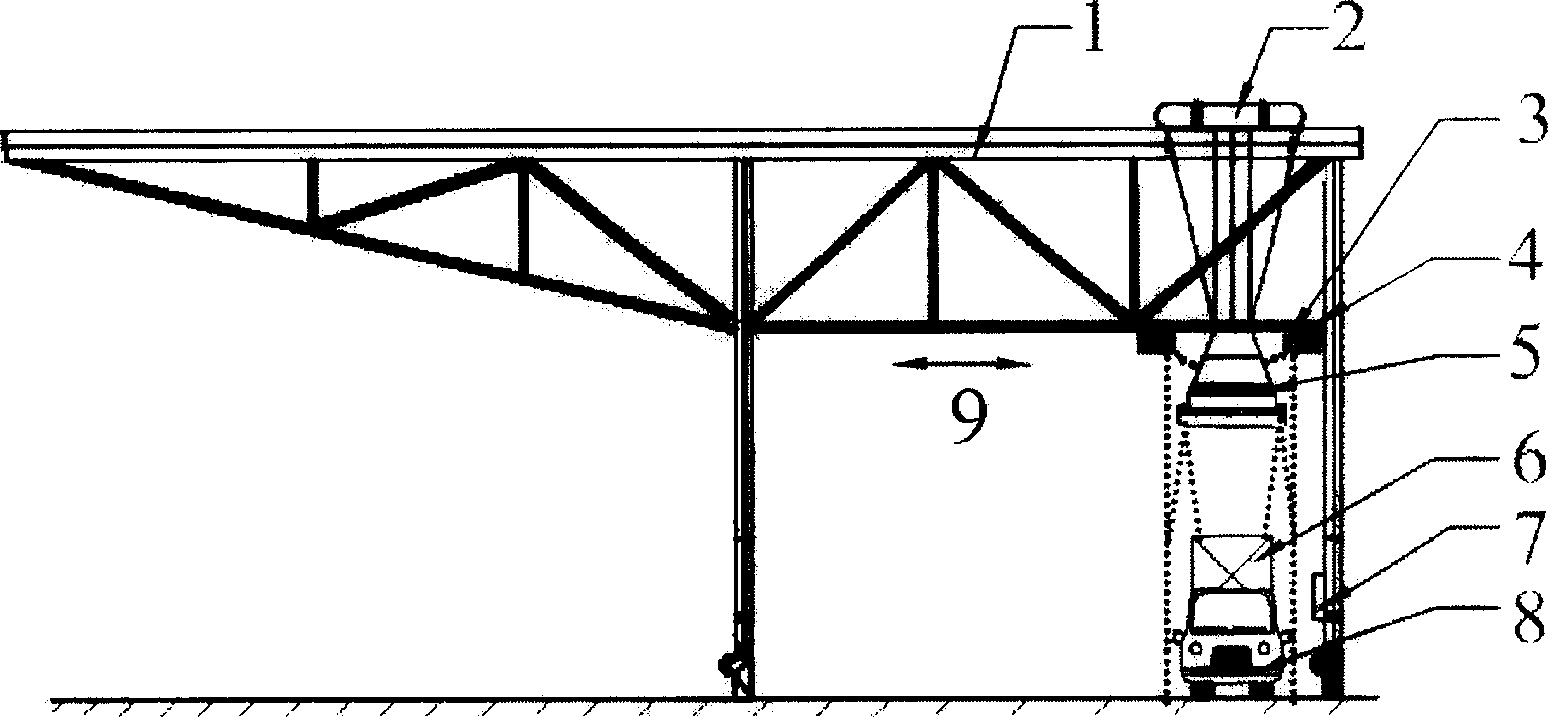

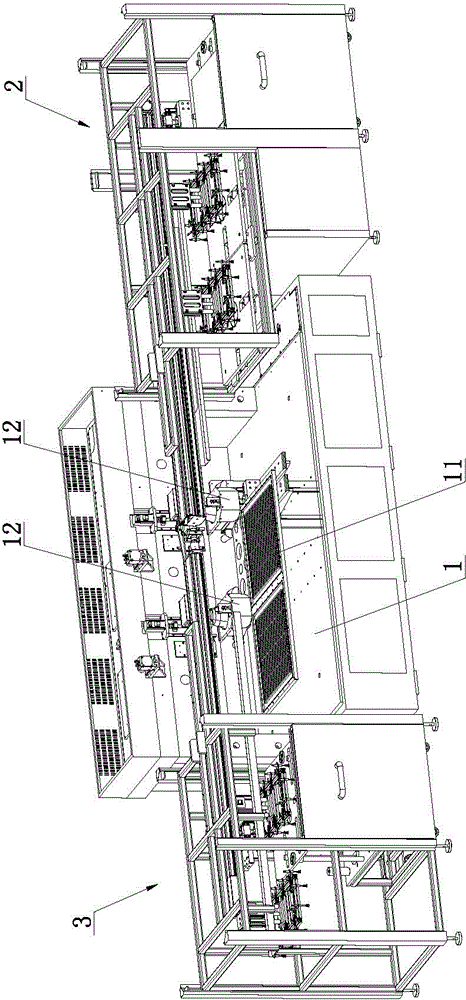

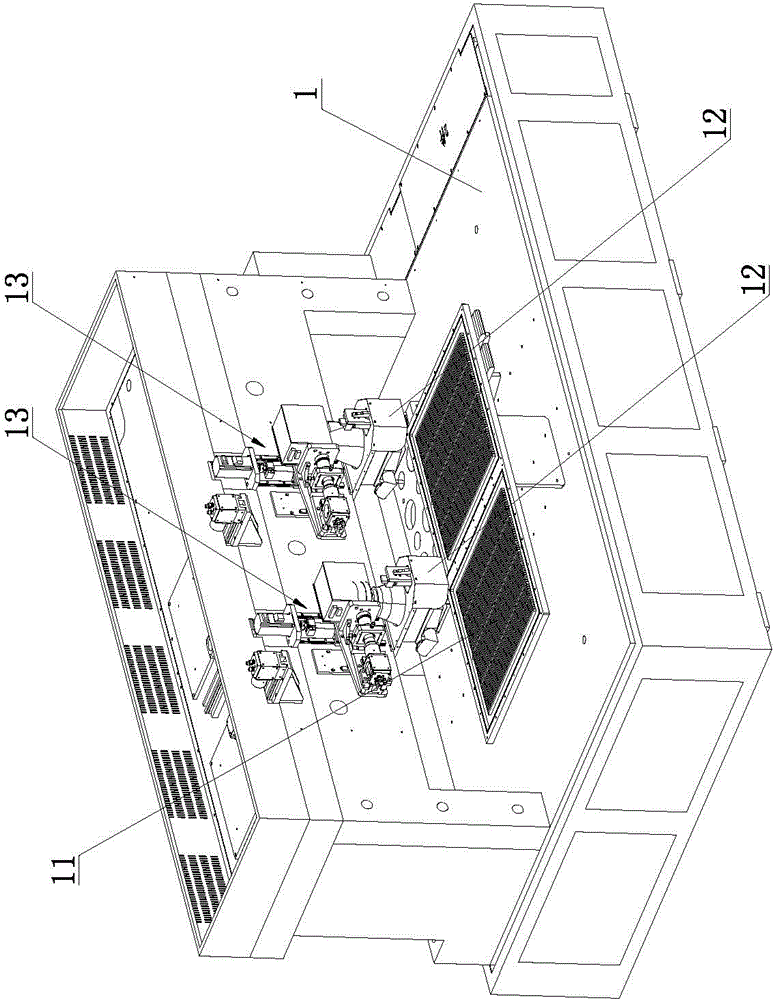

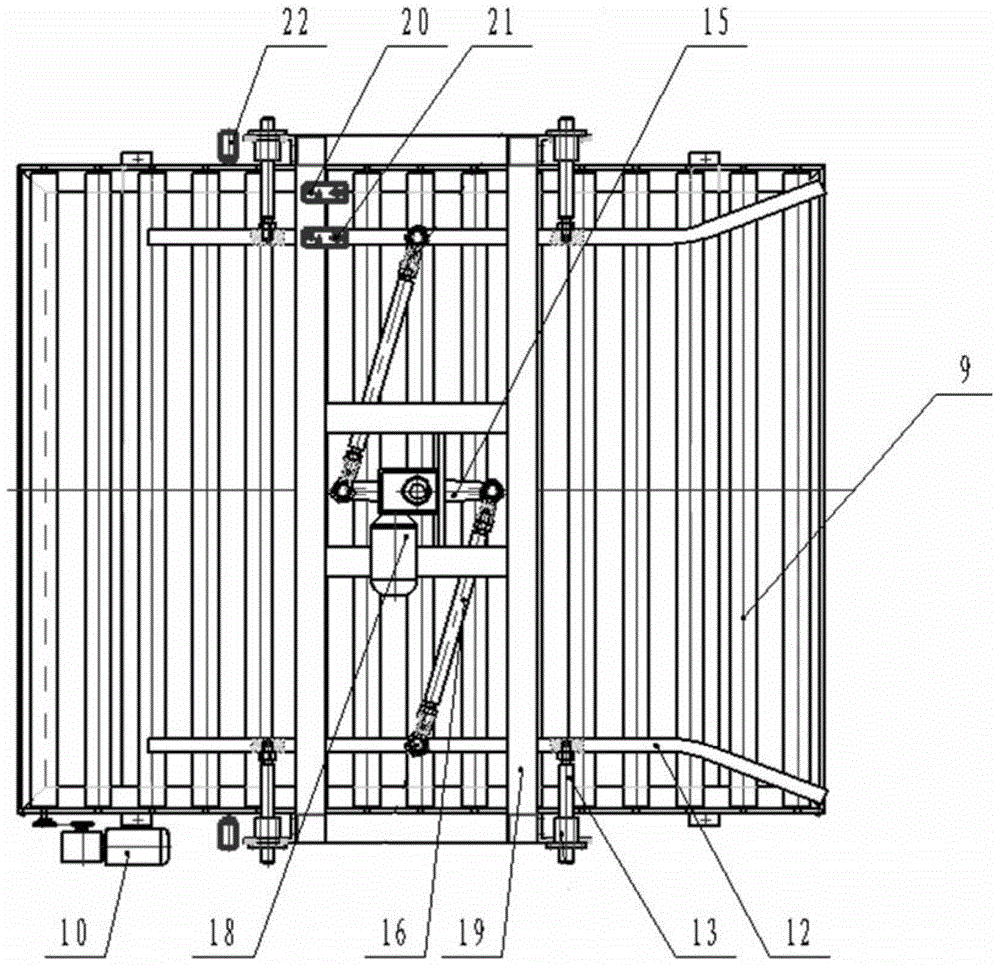

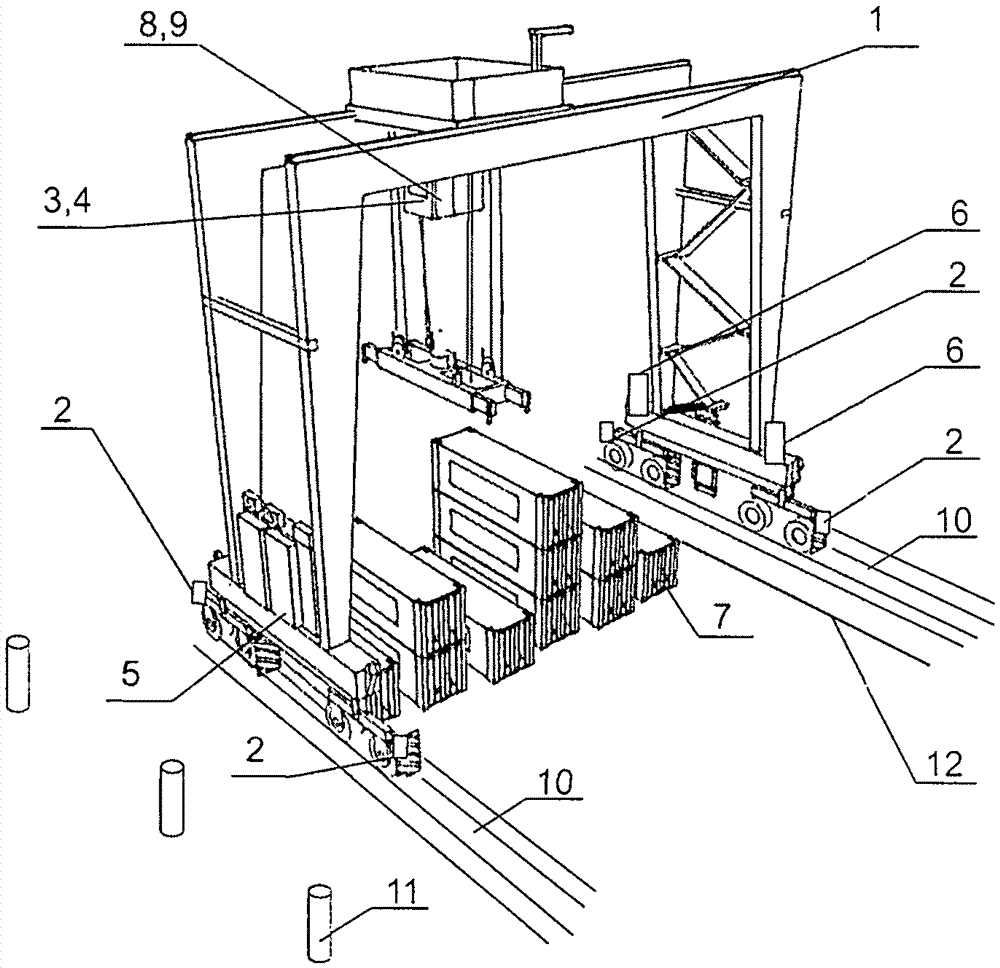

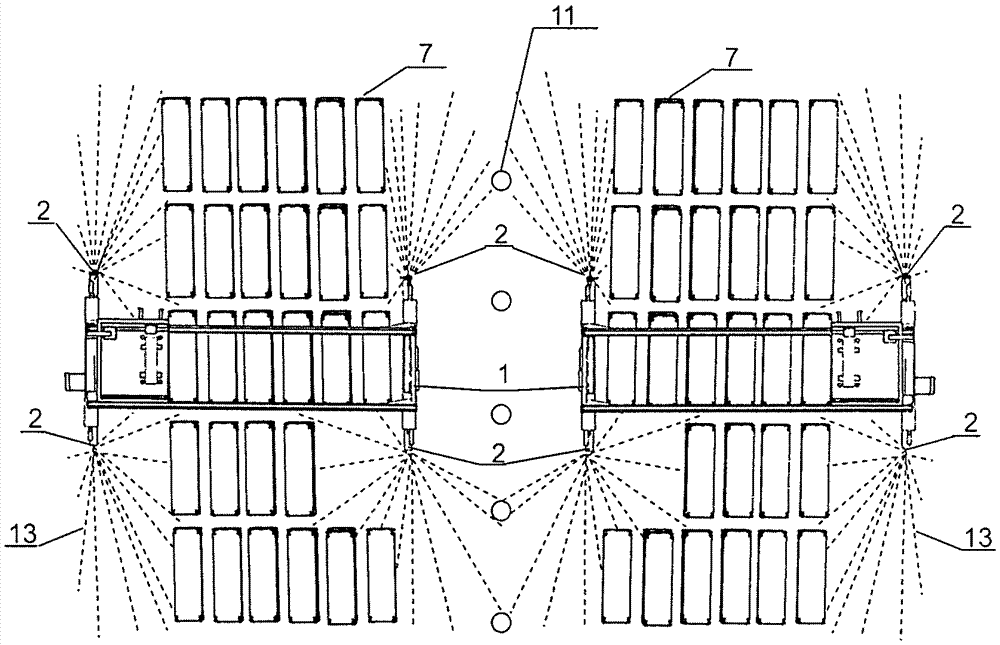

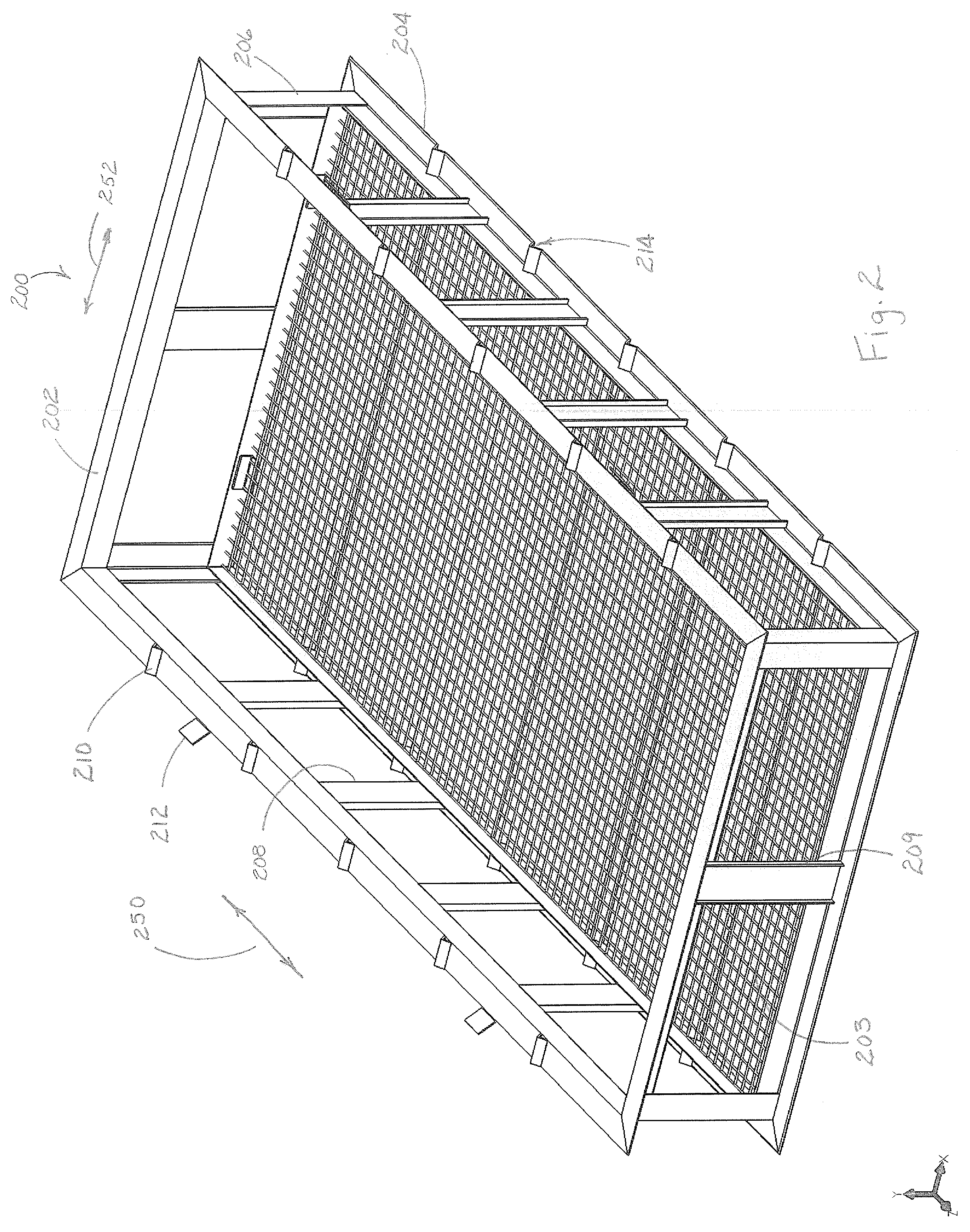

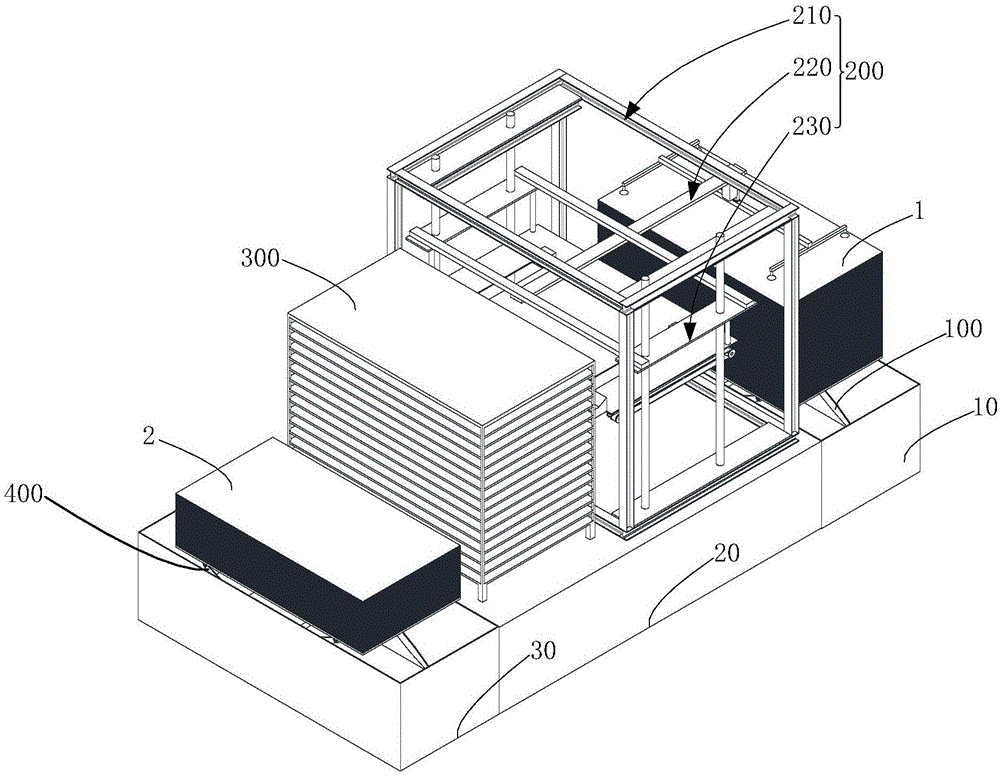

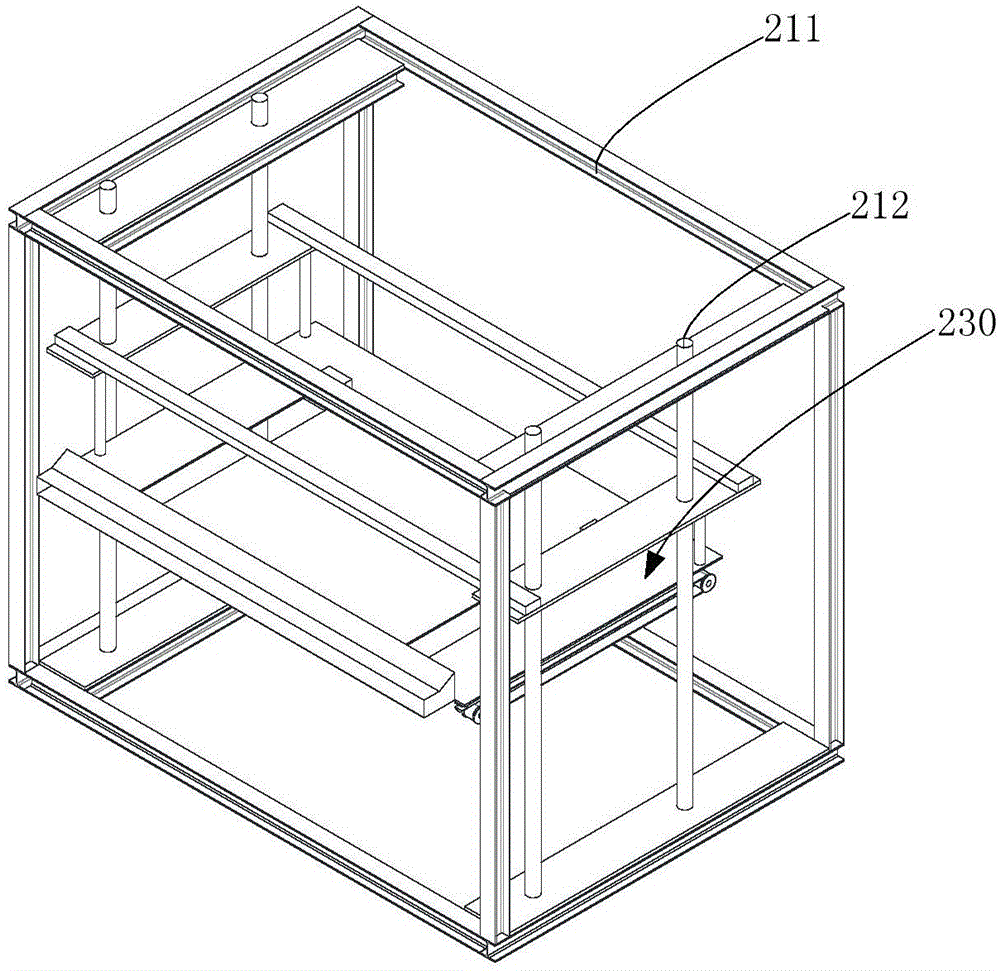

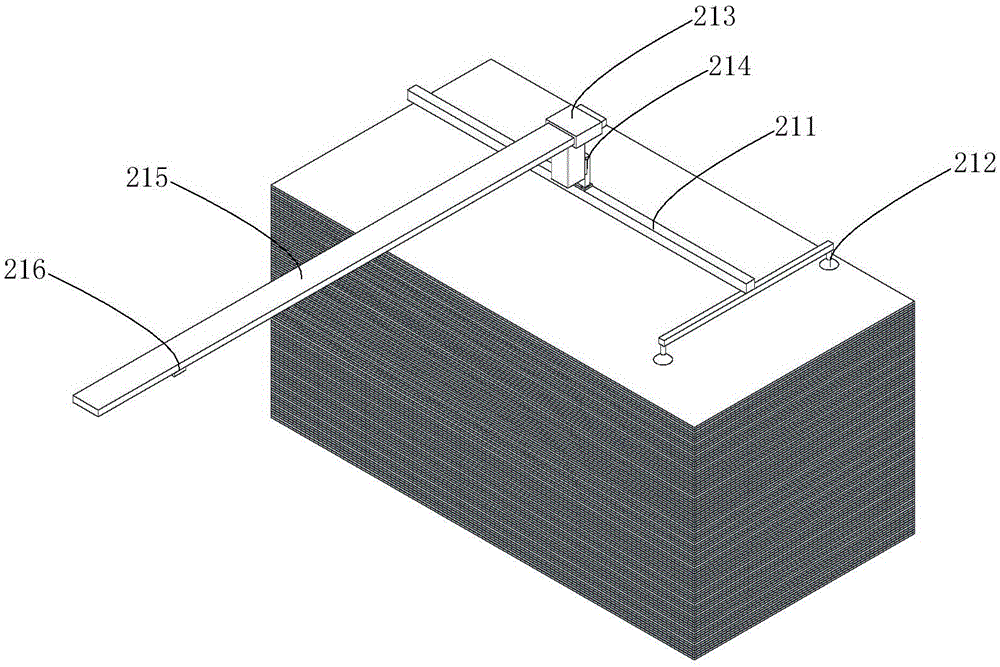

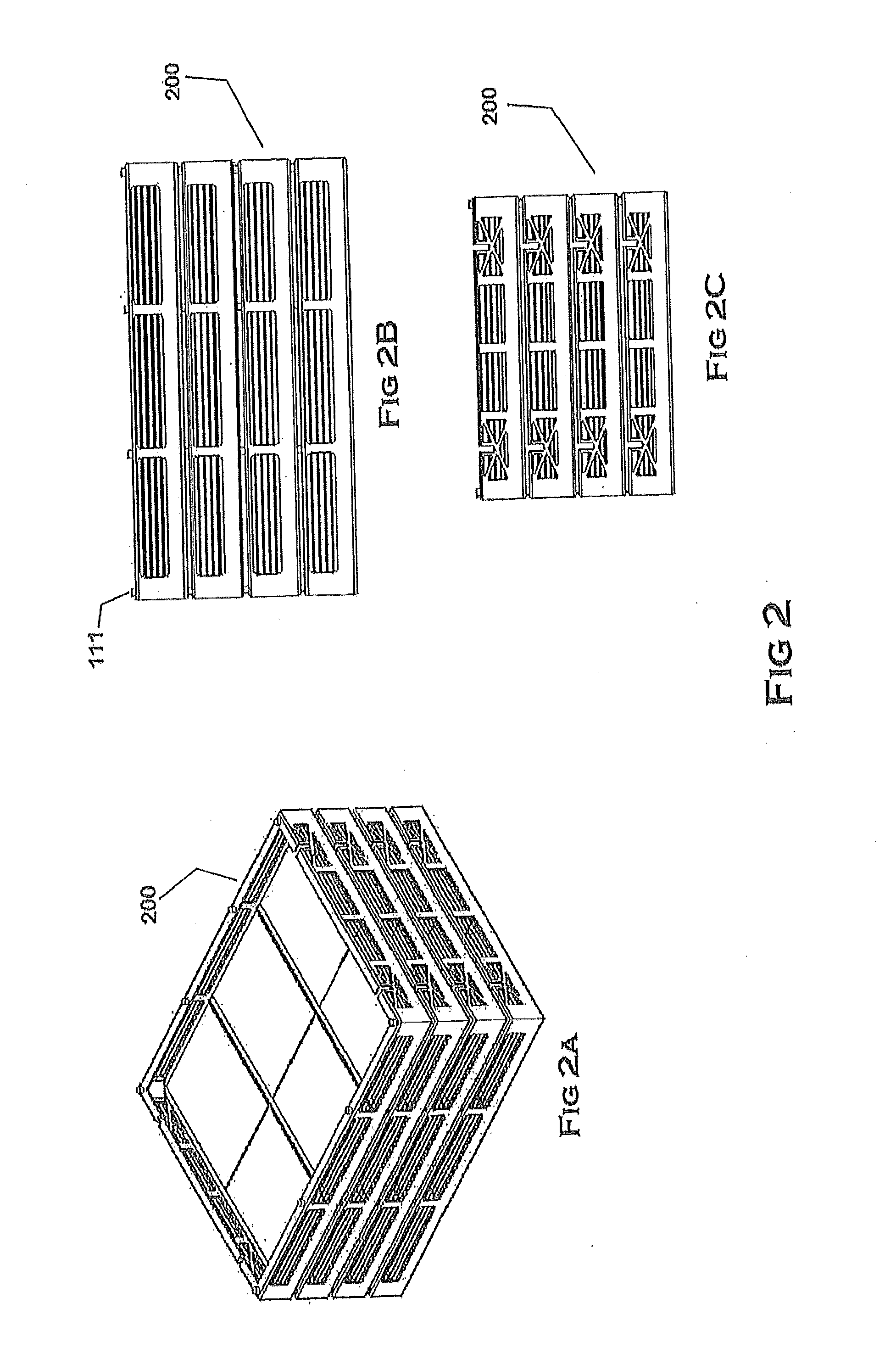

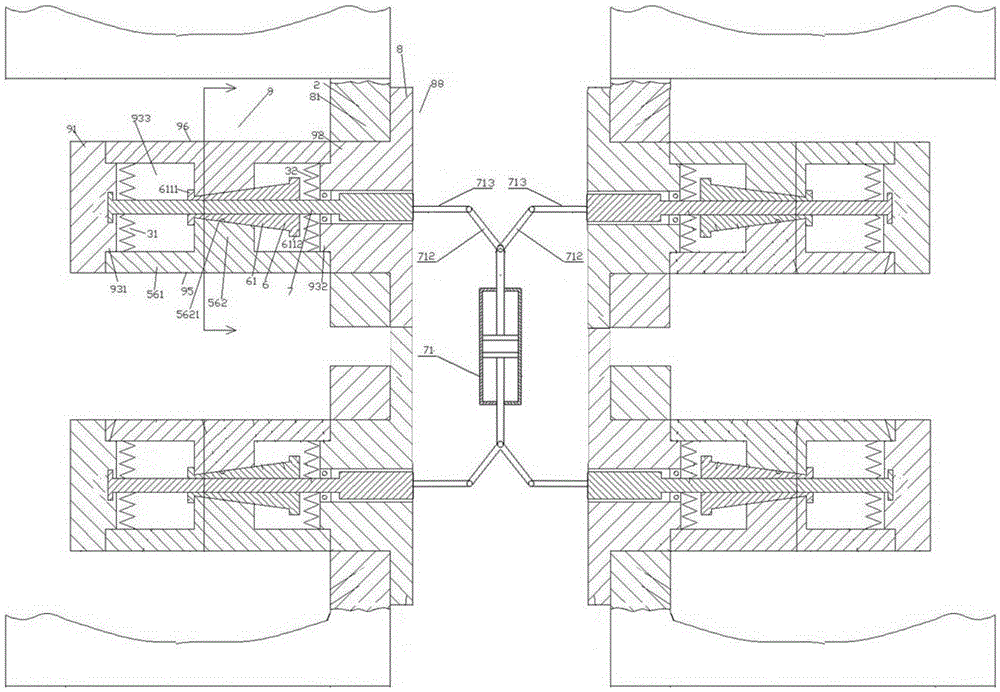

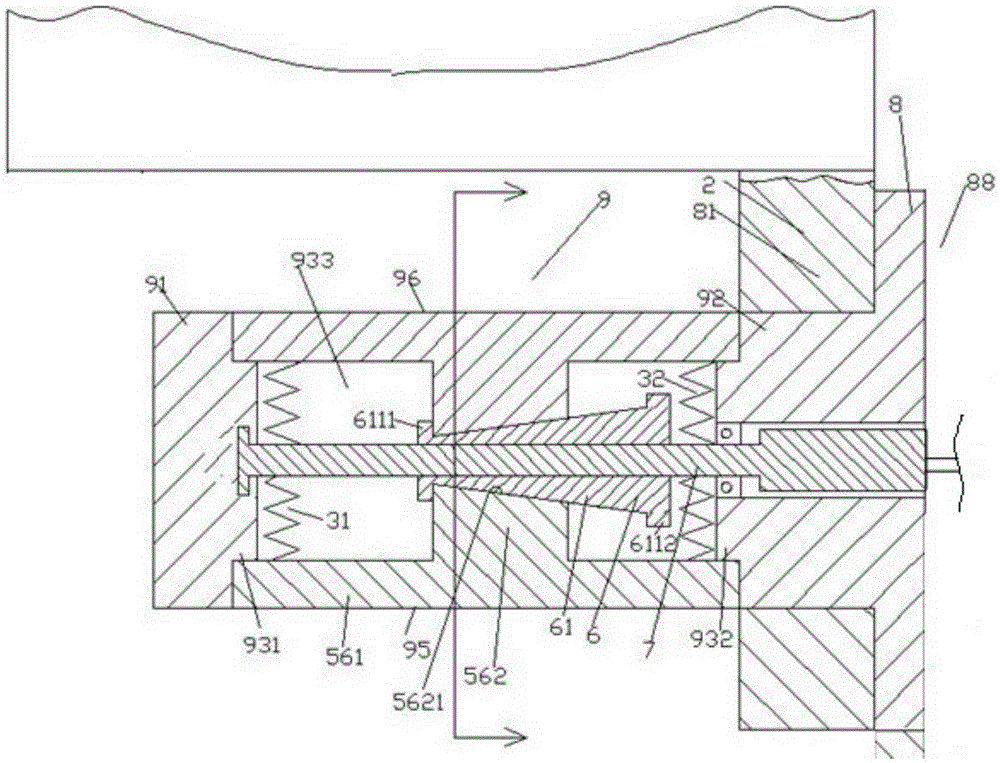

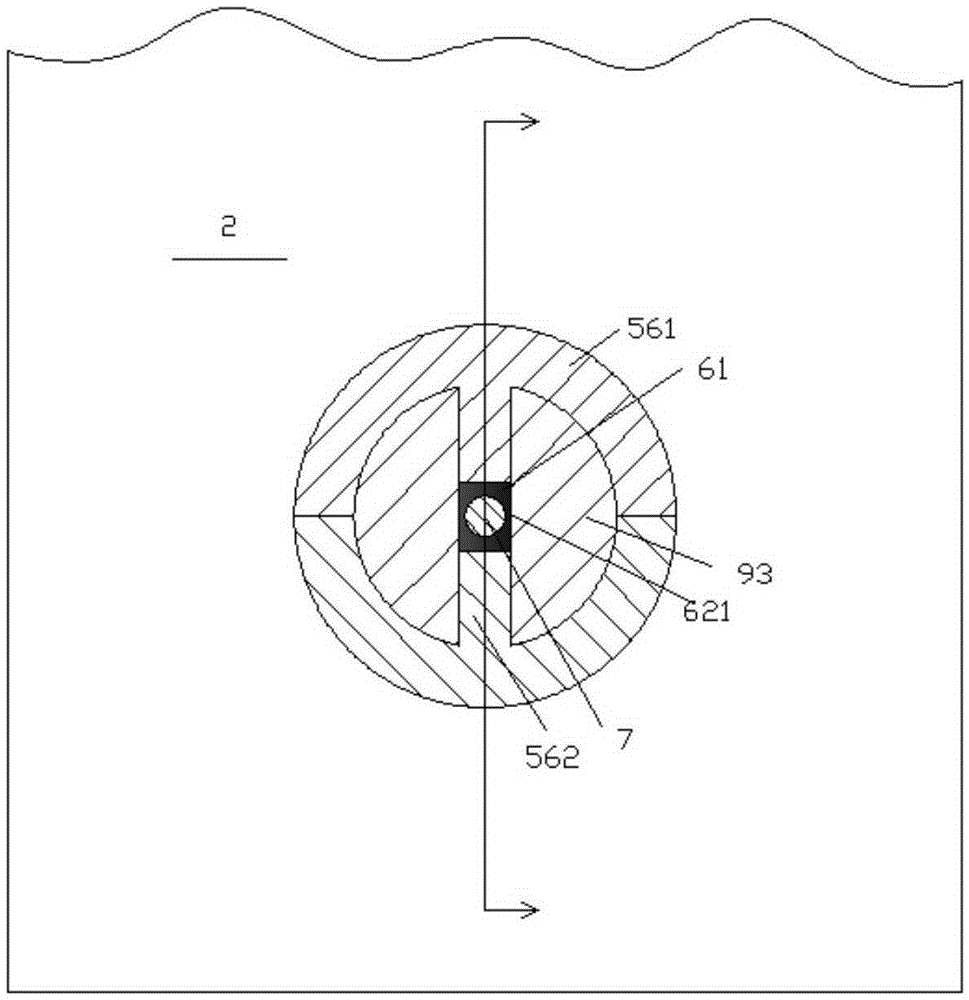

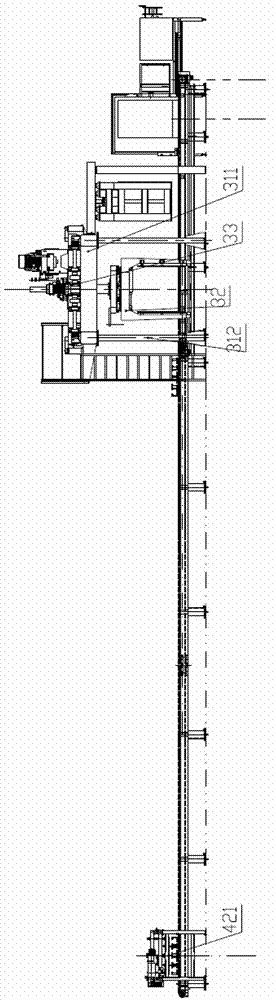

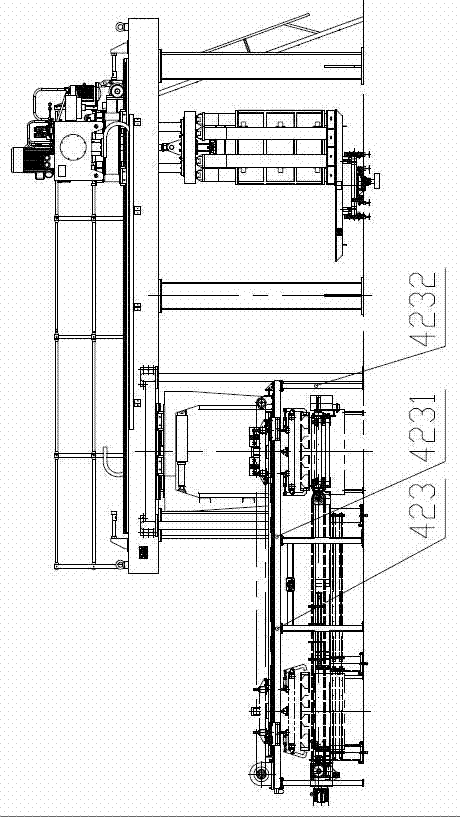

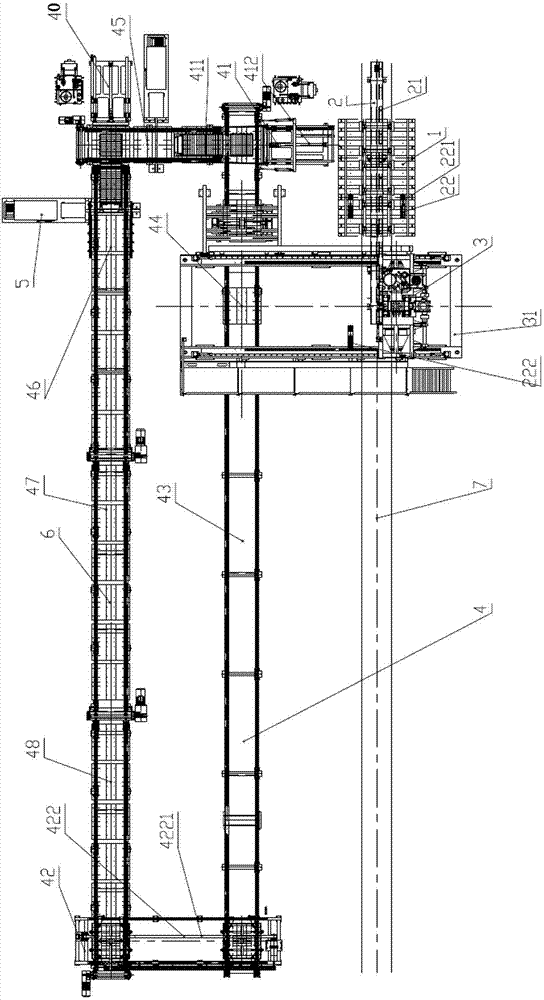

System and method for loading and unloading containers on multi-story frame type automated container yard

ActiveCN103723532AReduce movement distanceImprove loading and unloading efficiencyLoading/unloadingShoreElectricity

The invention discloses a system and method for loading and unloading containers on a multi-story frame type automated container yard. A frame bridge horizontal transportation system is adopted, the high level bridge and low level bridge matching form is adopted on bank sides, multiple stories of rail frames are also arranged inside the yard, and yard flat cars can freely move between the bank sides and the yard on the rail frames without interfering with one another. The scheme that the electric flat cars purely driven by electricity are matched with multi-storage frame type rail bridges is adopted, the containers can be rapidly conveyed between a shore bridge in front of a wharf and a yard bridge behind the wharf in a three-dimensional mode, intelligent scheduling and automation control are conveniently achieved, and the container conveying efficiency is improved. The yard flat cars which move at a high speed are used in the system, and therefore the moving distance of a transtainer is reduced, and efficiency of the ship loading and unloading, and container lifting and collecting in the yard is greatly improved. By means of the system and method for loading and unloading the containers on the multi-story frame type automated container yard, the area occupied by container areas on the wharf can be greatly reduced, and the construction cost for the wharf is reduced.

Owner:SHANGHAI MARITIME UNIVERSITY

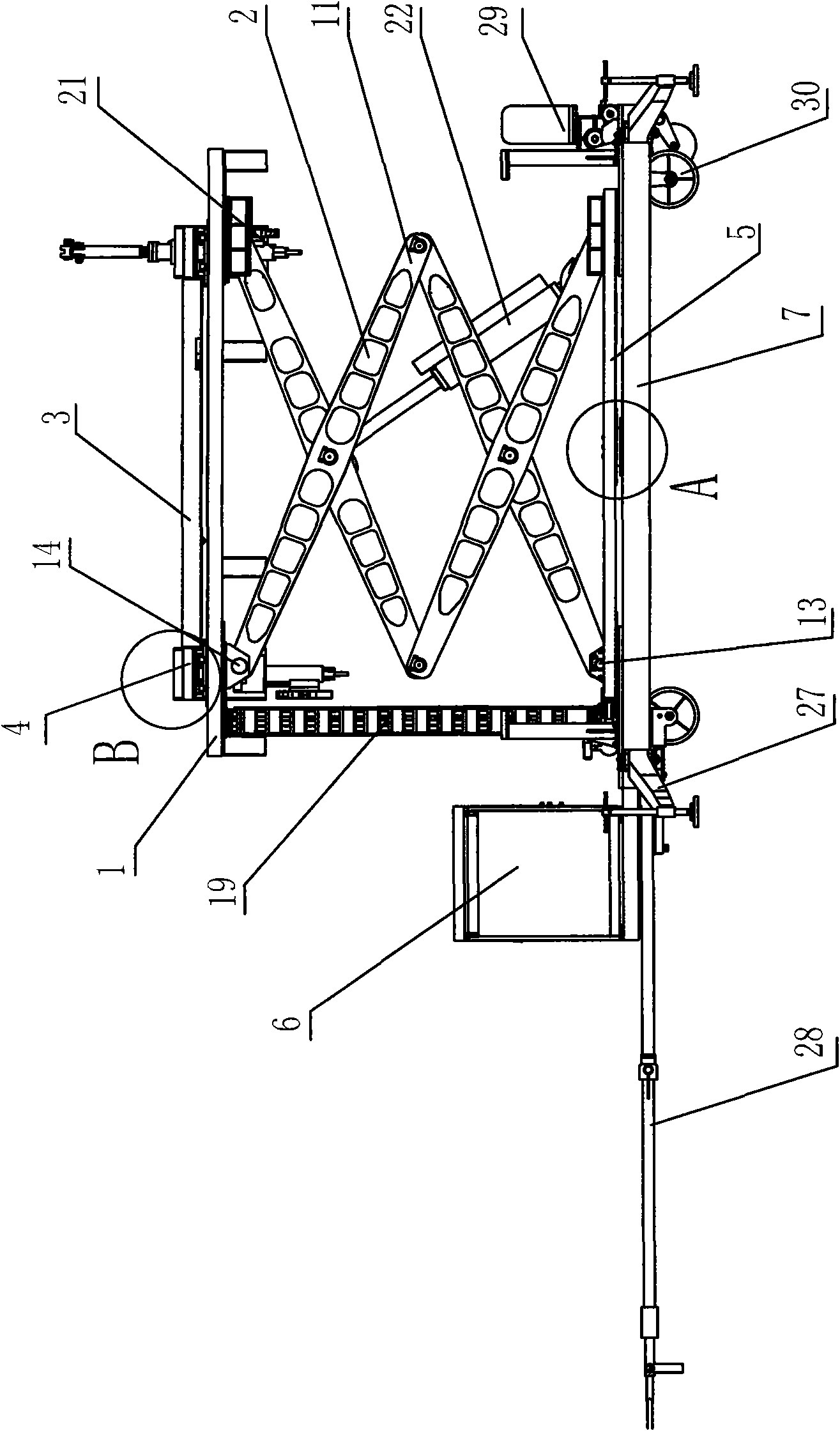

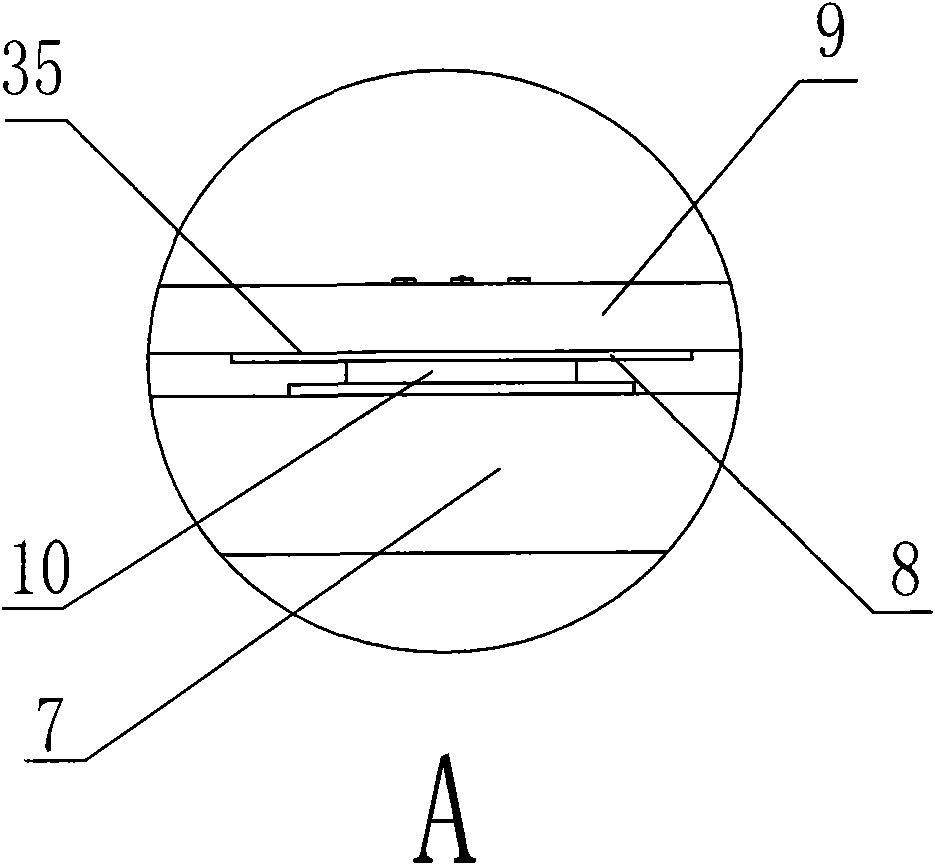

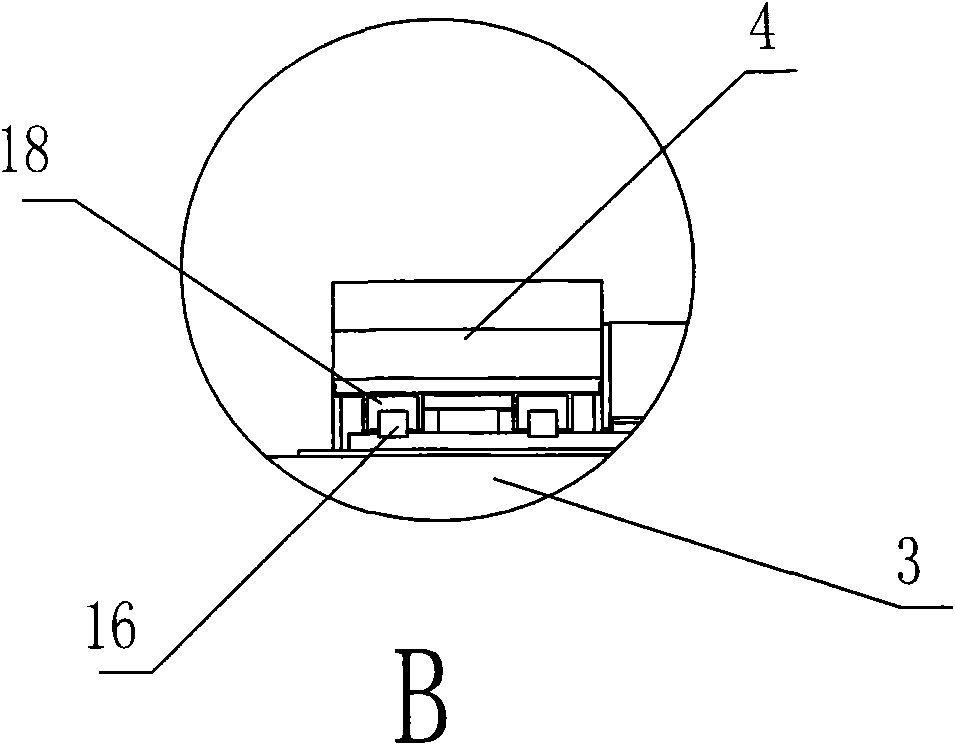

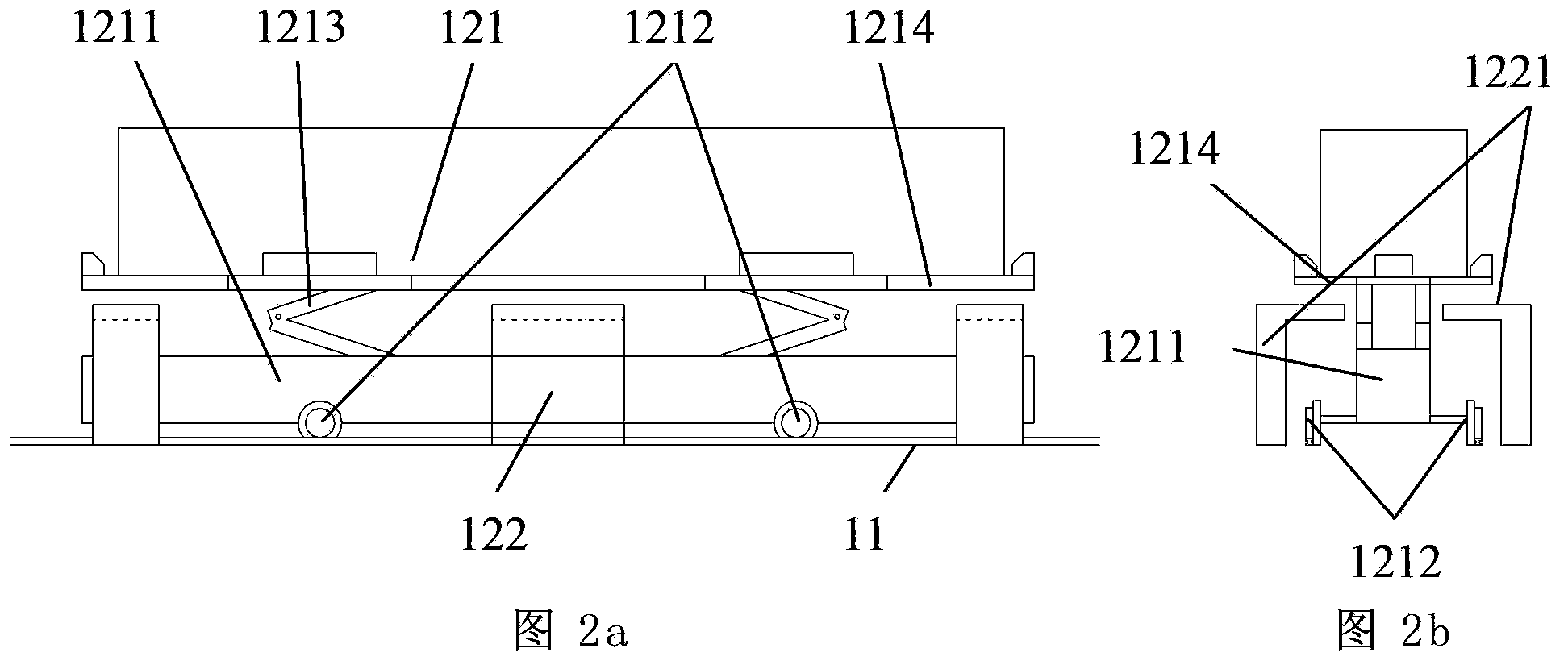

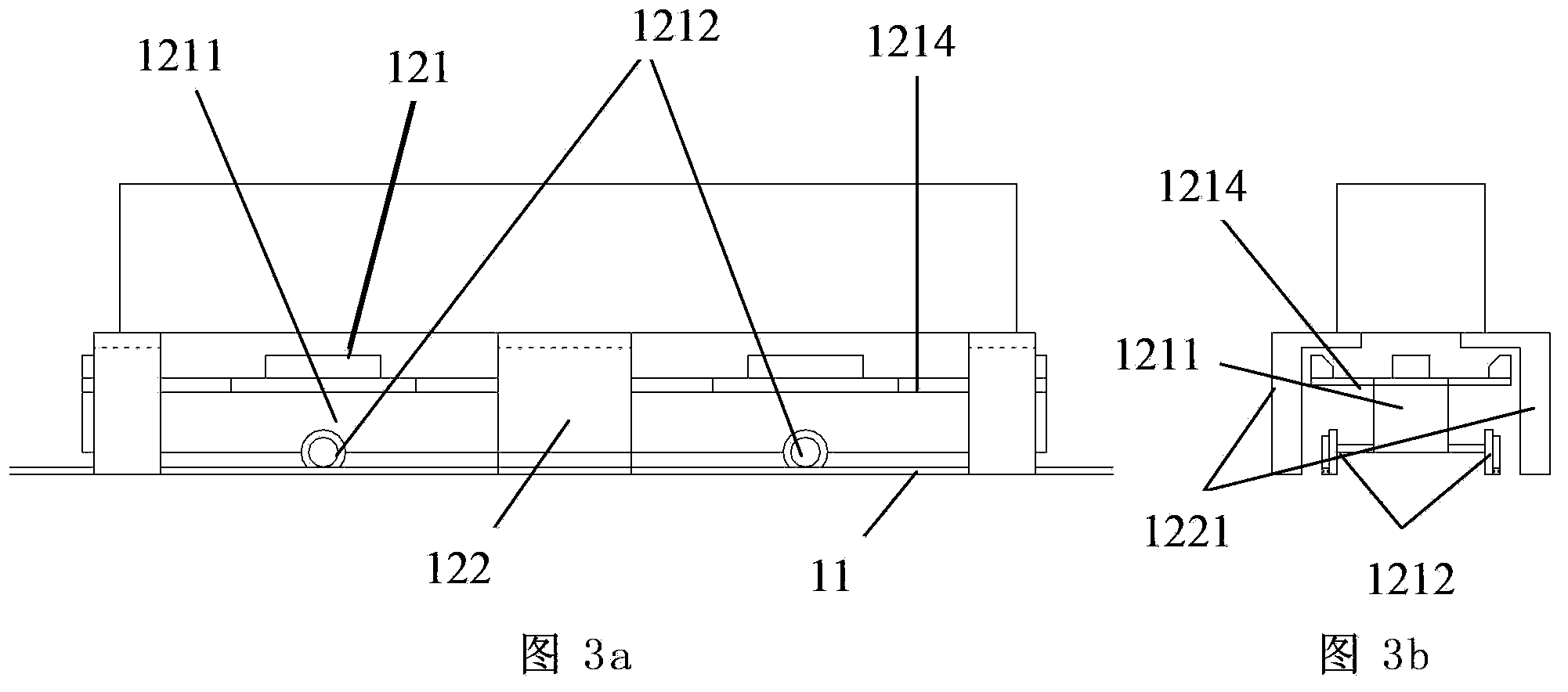

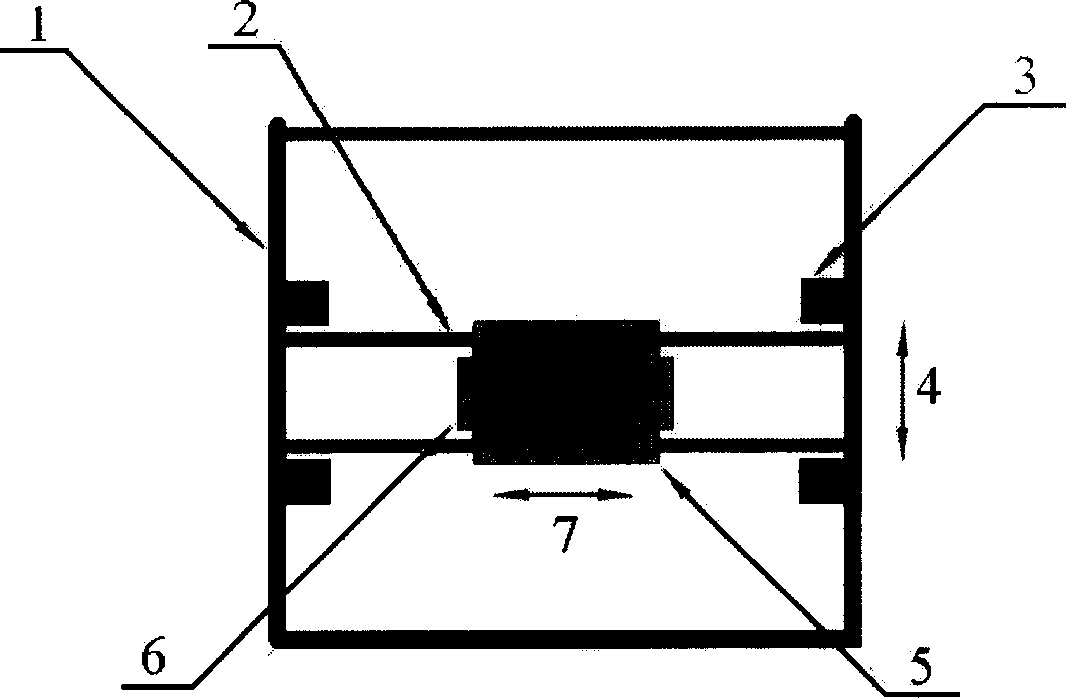

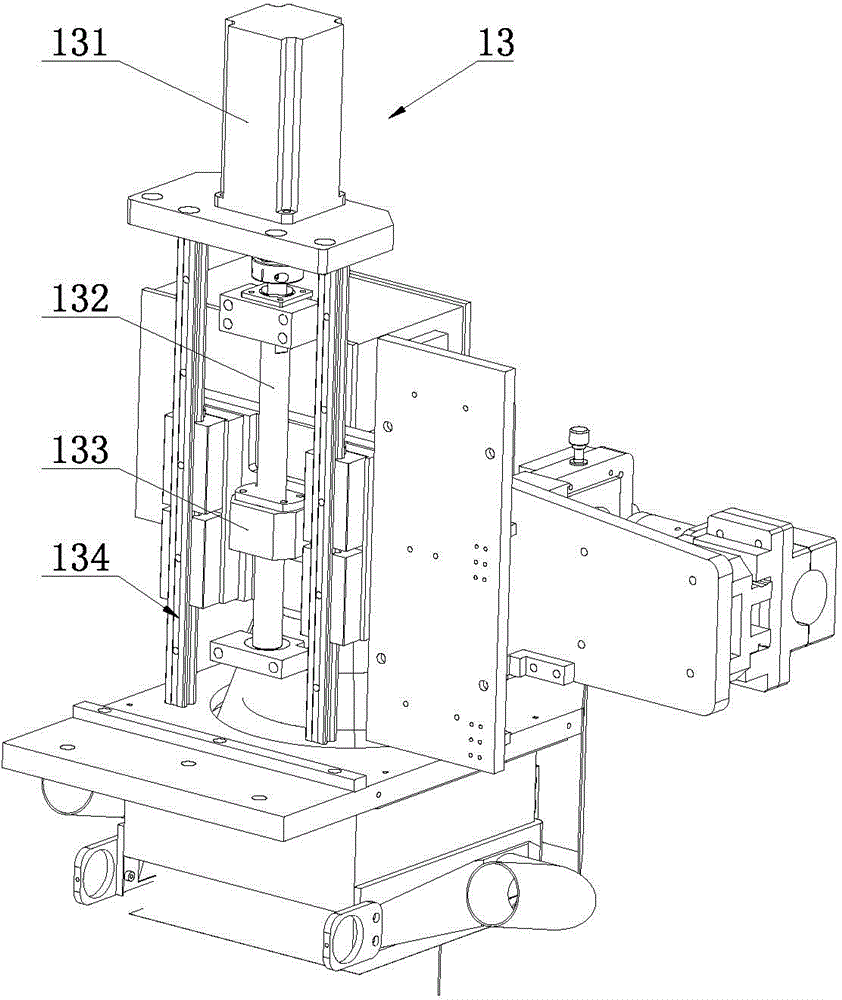

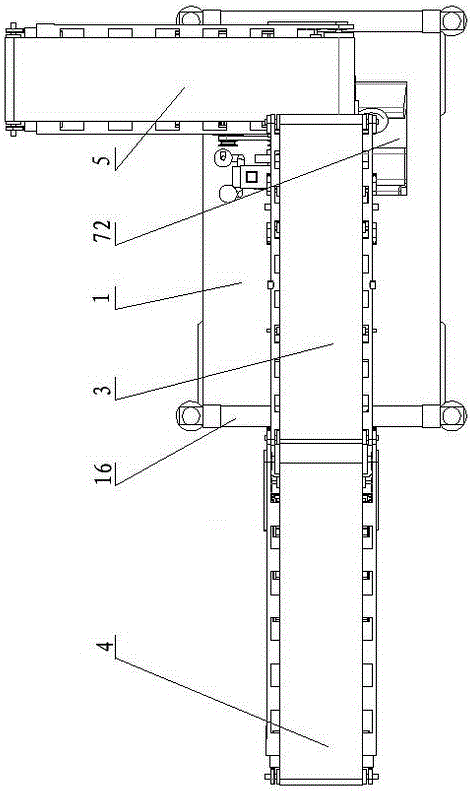

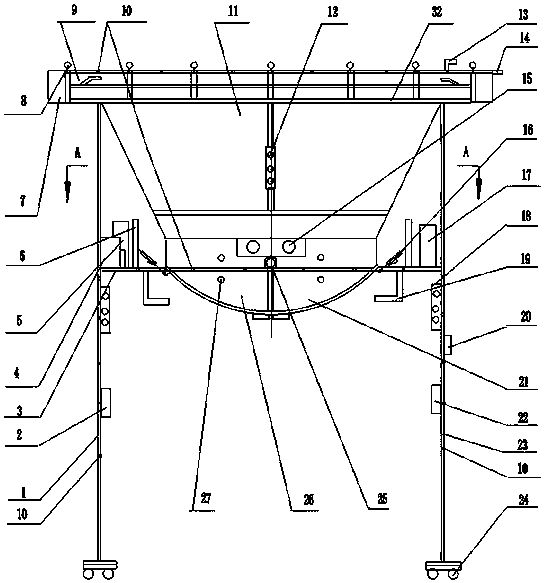

Aircraft engine mounting vehicle

InactiveCN102009340AHigh loading and unloading positioning accuracyHigh degree of automationAircraft assemblyMetal working apparatusAviationControl system

The invention discloses an aircraft engine mounting vehicle. The aircraft engine mounting vehicle comprises a lifting bracket (1), a shear type lifting mechanism (2), a back-and-forth moving frame (3), a left-right moving frame (4), a rotating disk mechanism (5), an electrohydraulic servo control system (6) and a vehicle body (7), wherein the lifting bracket (1) is provided with a longitudinal linear guide rail (15); the back-and-forth moving frame (3) is provided with a transverse linear guide rail (16) and a longitudinal slide block (17); the left-right moving frame (4) is provided with a transverse slide block (18); and the electrohydraulic servo control system (6) comprises a control unit (20) and an executing unit (21). In the aircraft engine mounting vehicle, a closed-loop servo control system consisting of the linear guide rail, a high-accuracy sensor, a high-response spaceflight servo valve, a precise servo oil cylinder and a programmable logic controller (PLC) is adopted, so 0.1mm absolute accuracy fine adjustment can be realized; and the aircraft engine mounting vehicle has the advantages of improving the aircraft engine assembling and disassembling efficiency and reducing the assembling and disassembling cost, along with high assembling, disassembling and positioning accuracy of an engine, and high automation degree and maneuverability.

Owner:成都立航科技股份有限公司

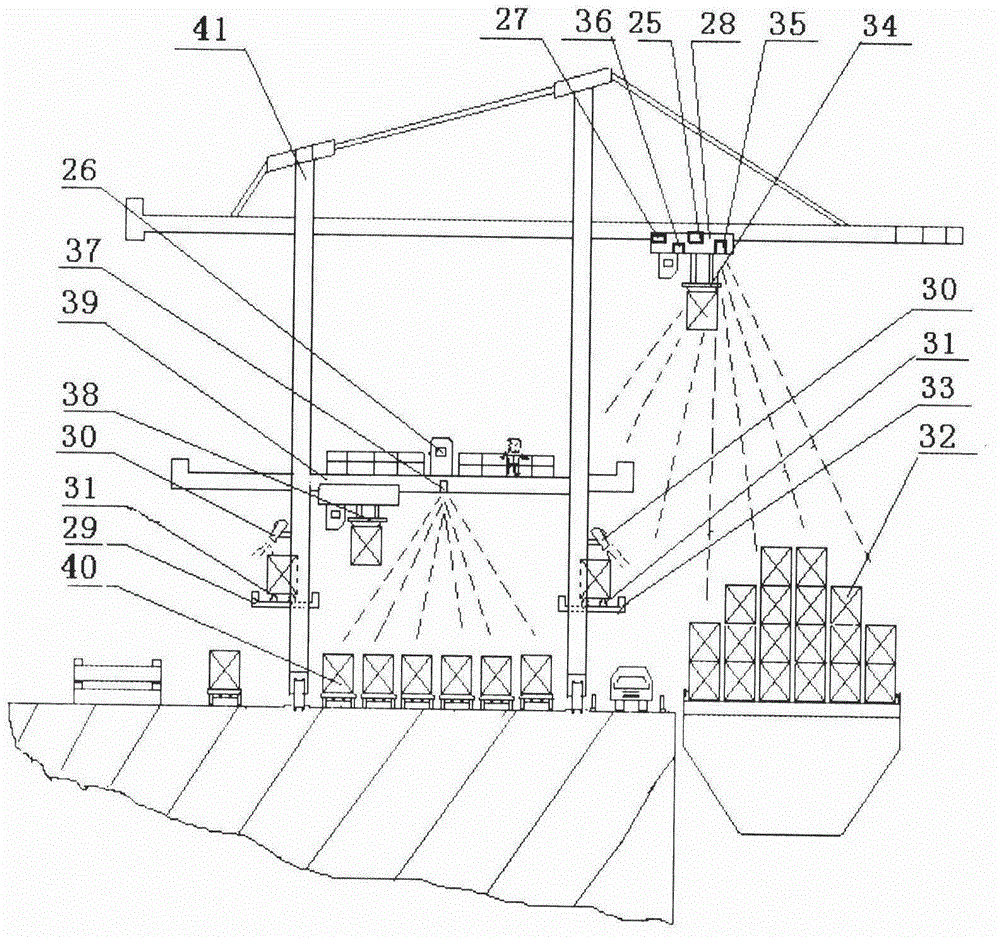

Container automated wharf loading and unloading system and method

InactiveCN104058261AAnti-collisionAvoid collisionStorage devicesPosition/course control in two dimensionsOn boardAutomated guided vehicle

The invention discloses a container automated wharf loading and unloading system and method. Containers on board are loaded or unloaded through a double-trolley and double-platform bridge crane; an automated guided vehicle refitted by a common truck, on which a metal magnetic detector, a GPS (global positioning system) reader-writer, a laser collision avoidance system and an image display system are arranged, travels along a metal enamel leading line through the metal magnetic detector; the GPS reader-writer reads radio frequency card address positions on the ground; the laser collision avoidance system and the image display system measure collision avoidance functions of people and objects; a rail tyre crane travels through rails when conveying the containers and travels through tyres during site changing; guide vehicle and outer truck lanes exist in a site and do not disturb each other; an outer truck is guided through the GPS reader-writer when entering a wharf; a common container wharf is transformed into a full-automatic container loading and unloading wharf through the equipment improvement.

Owner:NANTONG TONGLEI SOFTWARE

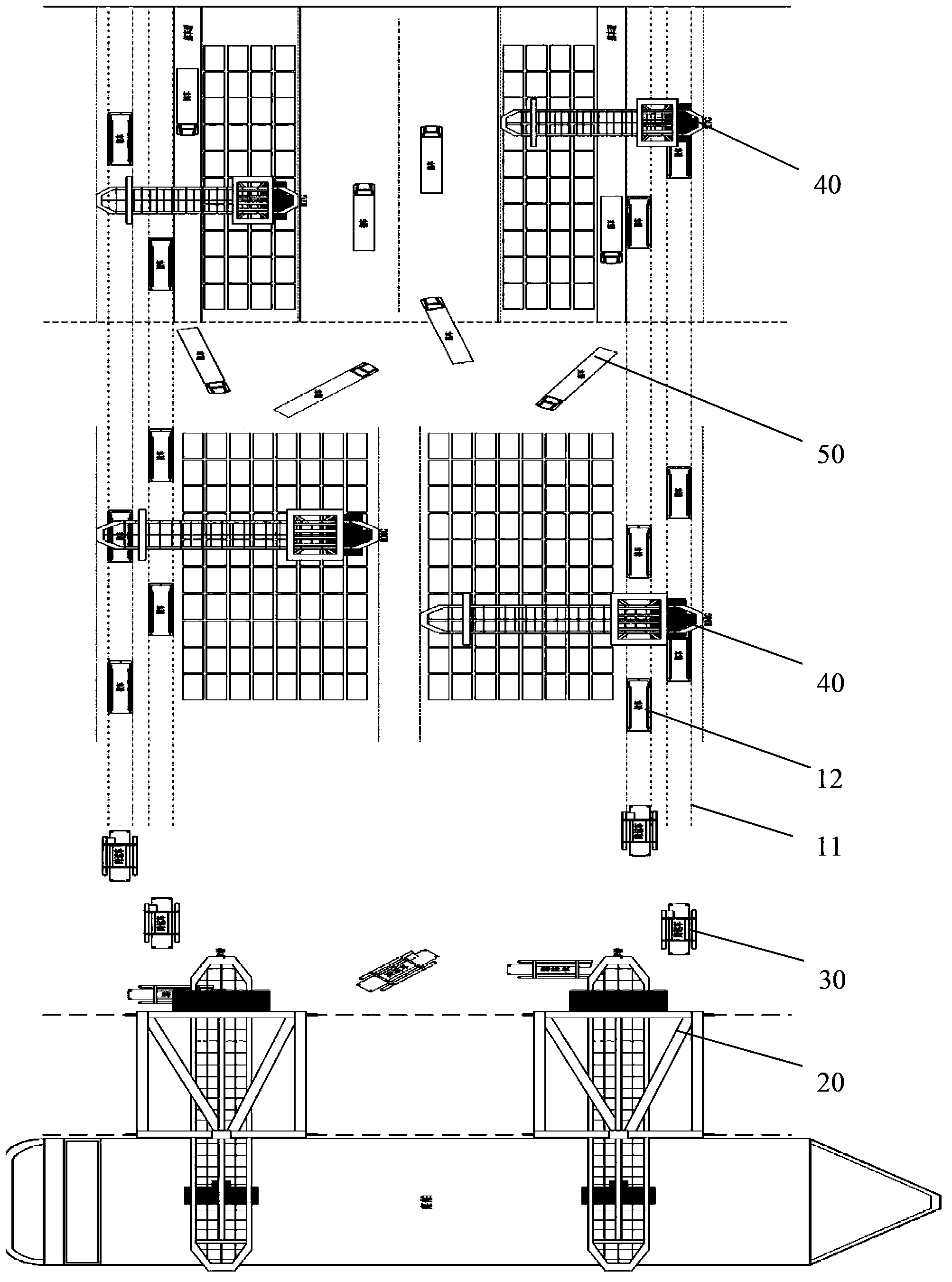

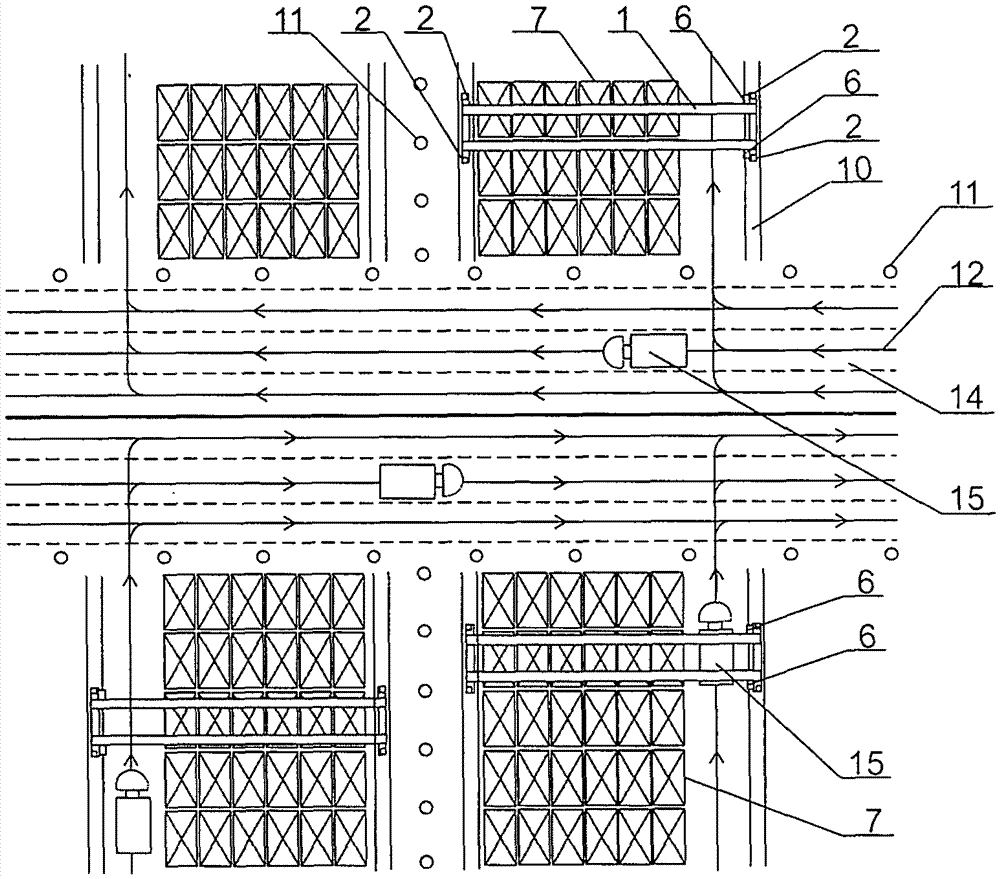

Automated container wharf handling system and handling method thereof

ActiveCN104108611AImprove loading and unloading efficiencyIncrease flexibilityLoading/unloadingStorage devicesStraddleCarrier system

The invention discloses an automated container wharf handling system and a handling method thereof. The automated container wharf handling system comprises shore bridges, straddle carriers, storage yard cranes and a shuttle carrier system. A wharf storage yard area is divided into a front storage yard and a rear storage yard along the depth direction of the wharf storage yard area. The shuttle carrier system comprises at least one set of rail and conveyors, the rails are perpendicular to the shoreline direction of a wharf and penetrate the front and rear storage yards, the conveyors are arranged on the rails and are capable of relay-conveying containers, the rails are located below the storage yard cranes, and the working radius of the storage yard crane in the front storage yard is capable of extending to a container stacking area of the rails and the front storage yard area while the working radius of the rear storage yard area is capable of extending to the container stacking area of the rails and the rear storage yard area and a traffic channel of container trucks. By means of the shuttle carrier technology, relay conveying and automated handling of the containers can be realized, energy resources are saved, and efficiency is high; the rail carriers take the place of shuttle carriers travelling for long distance, so that cost is reduced.

Owner:TIANJIN PORT (GROUP) COMPANY

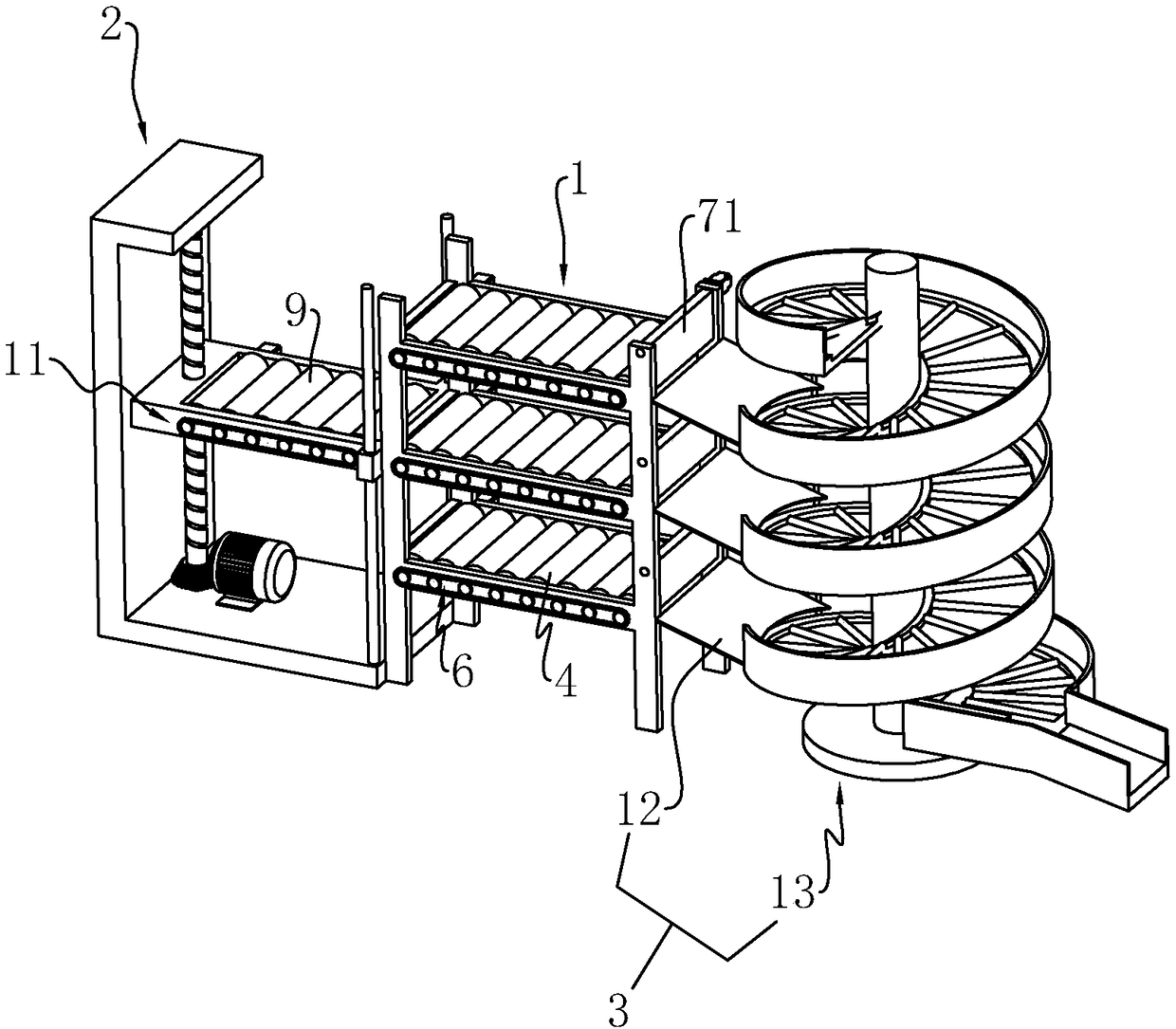

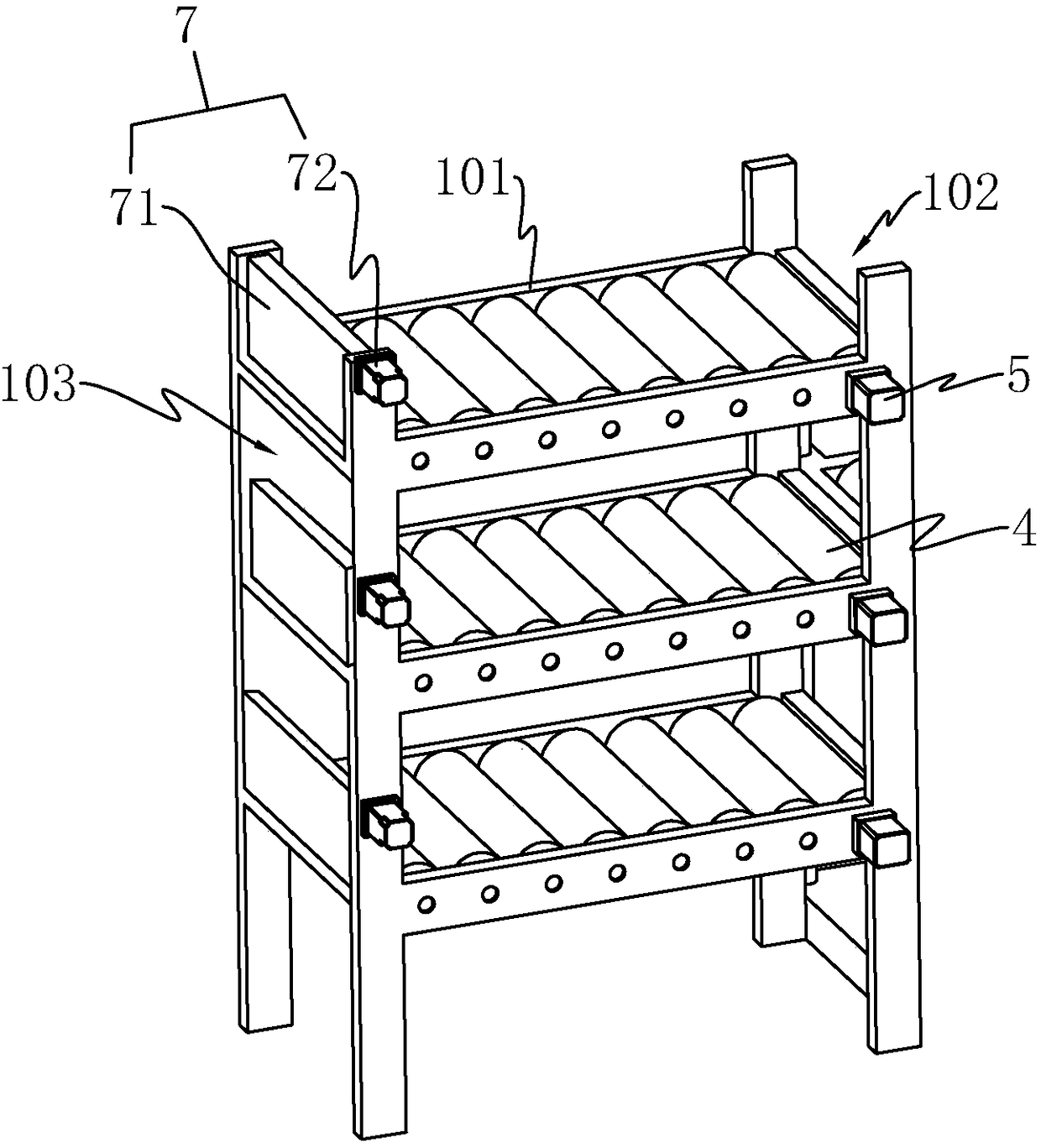

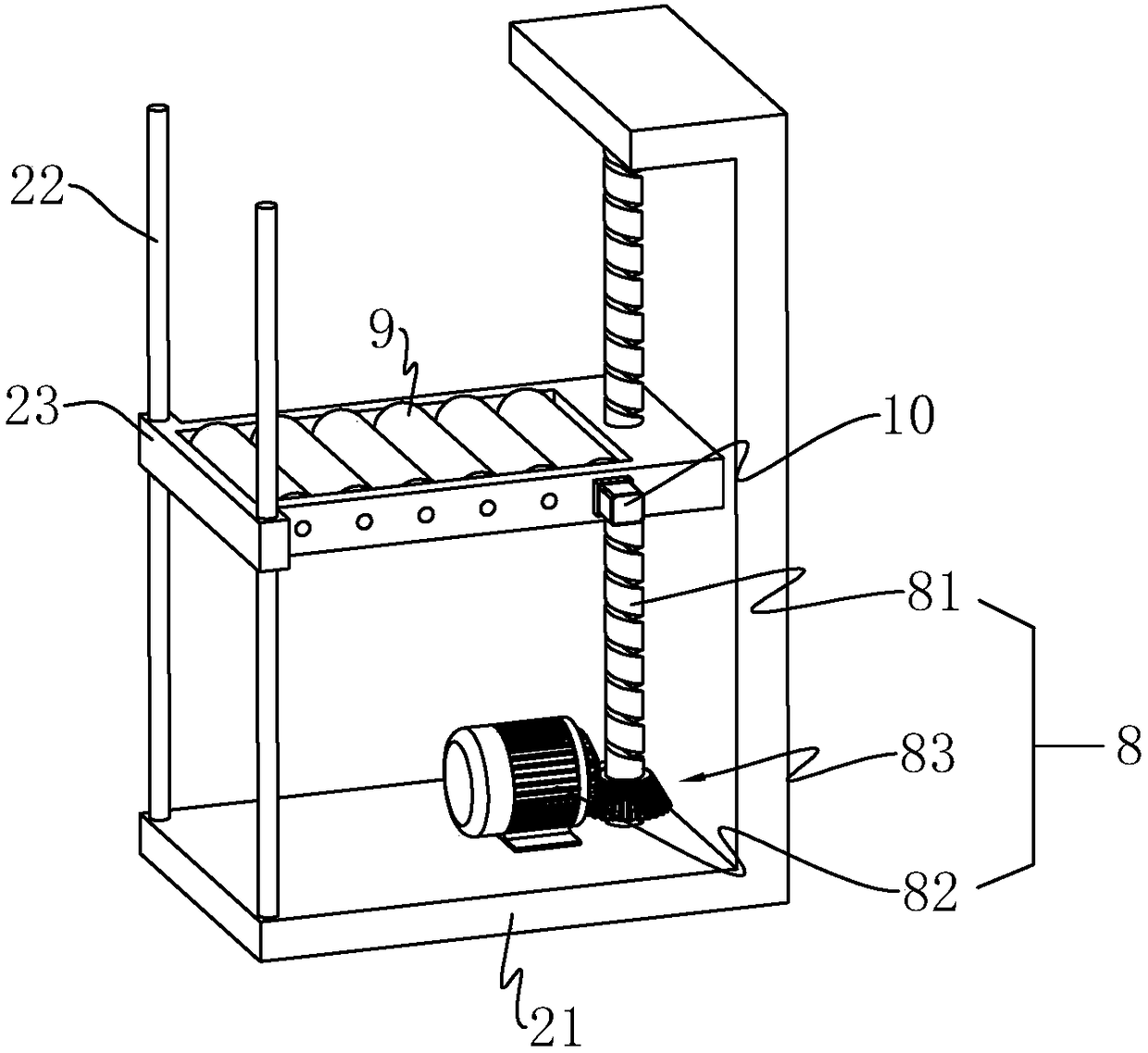

Warehouse goods storage device

InactiveCN108545389ARealize fully automatic loading and unloadingImprove loading and unloading efficiencyStorage devicesChutesLogistics managementEngineering

The invention discloses a warehouse goods storage device and relates to the field of warehouse storage logistics. The warehouse goods storage device comprises a storage rack main body which at least comprises two placing layers, wherein a goods inlet and a goods outlet are separately formed in two sides of each placing layer; the warehouse goods storage device also comprises a goods upper rack mechanism and a goods lower rack mechanism; the goods upper rack mechanism comprises a base, a placing table, a first driving assembly and a second driving assembly, and a third driving assemblies and barrier parts are arranged on the placing layers; the goods lower rack mechanism comprises a lower slideway and a bearing rack, the bearing rack comprises a central rod and a spiral slideway which is spirally arranged around the central rod from top to bottom, and a goods delivery port is formed in the lower end of the spiral slideway. The warehouse goods storage device provided by the invention isstable to work, convenient to operate and high in degree of automation, can improve the goods loading and unloading efficiency and reduce the labor intensity greatly, and meets the modern logistics development tendency.

Owner:上海诺尔国际物流有限公司

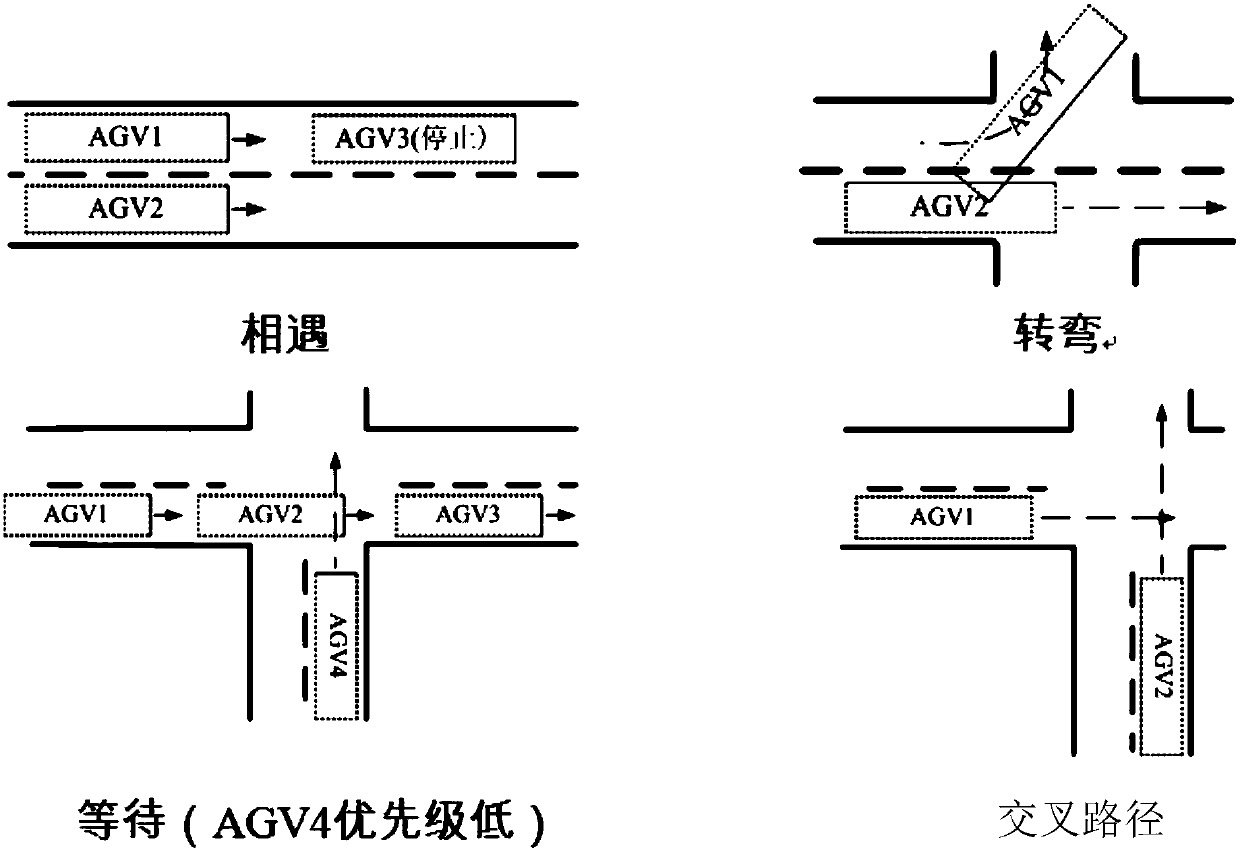

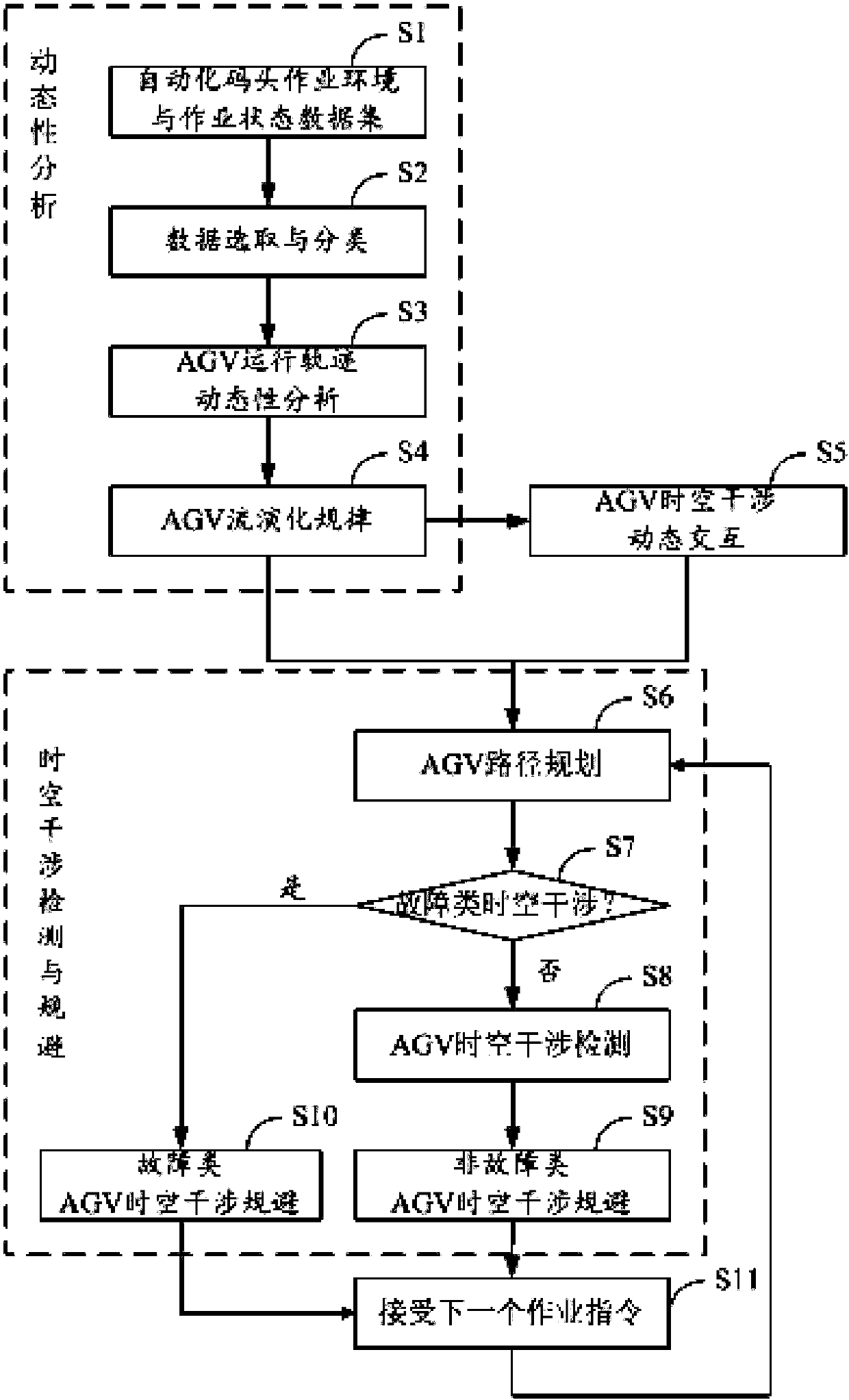

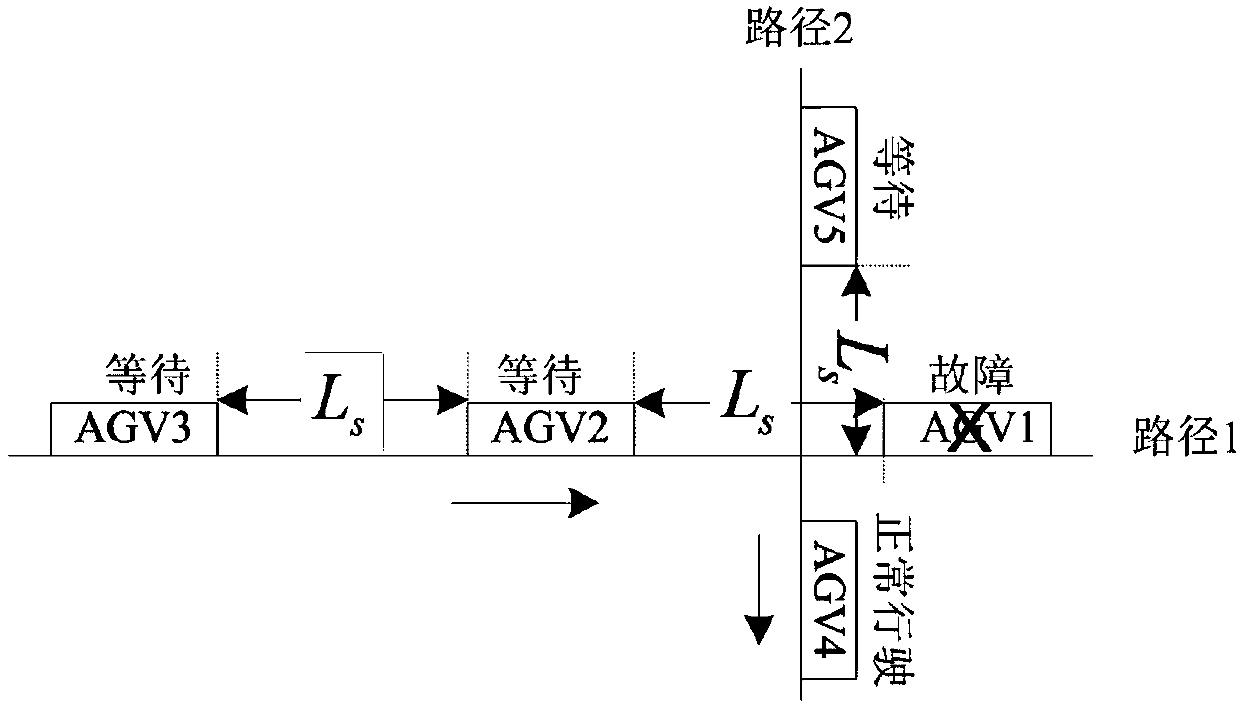

AGV (Automatic Guided Vehicle) flow space-time interference detection and avoidance method in time-varying environment

ActiveCN107816996AImprove loading and unloading efficiencyImprove securityNavigational calculation instrumentsPosition/course control in two dimensionsMarkov chainSimulation

The invention discloses an AGV (Automatic Guided Vehicle) flow space-time interference detection and avoidance method in a time-varying environment. The method comprises the following steps: researching time-varying uncertain factors and dynamic performance of an AGV time-varying moving trajectory under a conduction effect thereof; performing dynamic analysis on a terminal traffic net AGV flow byusing a Markov chain; analyzing the space-time occupancy characteristics of the AGV flow and the AGV moving trajectory path from space dimension, time dimension and business dimension; analyzing a dynamic interaction relationship between AGV space-time interference objects; researching space-time interference uncertainty and randomness; and performing dynamic detection and avoidance on the AGV space-time interference. The method disclosed by the invention has the advantages that the operating task lag problem brought by AGV space-time interference while running is solved, the operating continuity is ensured, operating wait of a gantry crane or a rail-mounted gantry crane is reduced and avoided, and reference and support can be provided for AGV path planning and transport optimization, so that the operating cost of the whole automated container terminal is reduced, and the loading and unloading efficiency and safety of the container terminal are improved.

Owner:SHANGHAI MARITIME UNIVERSITY

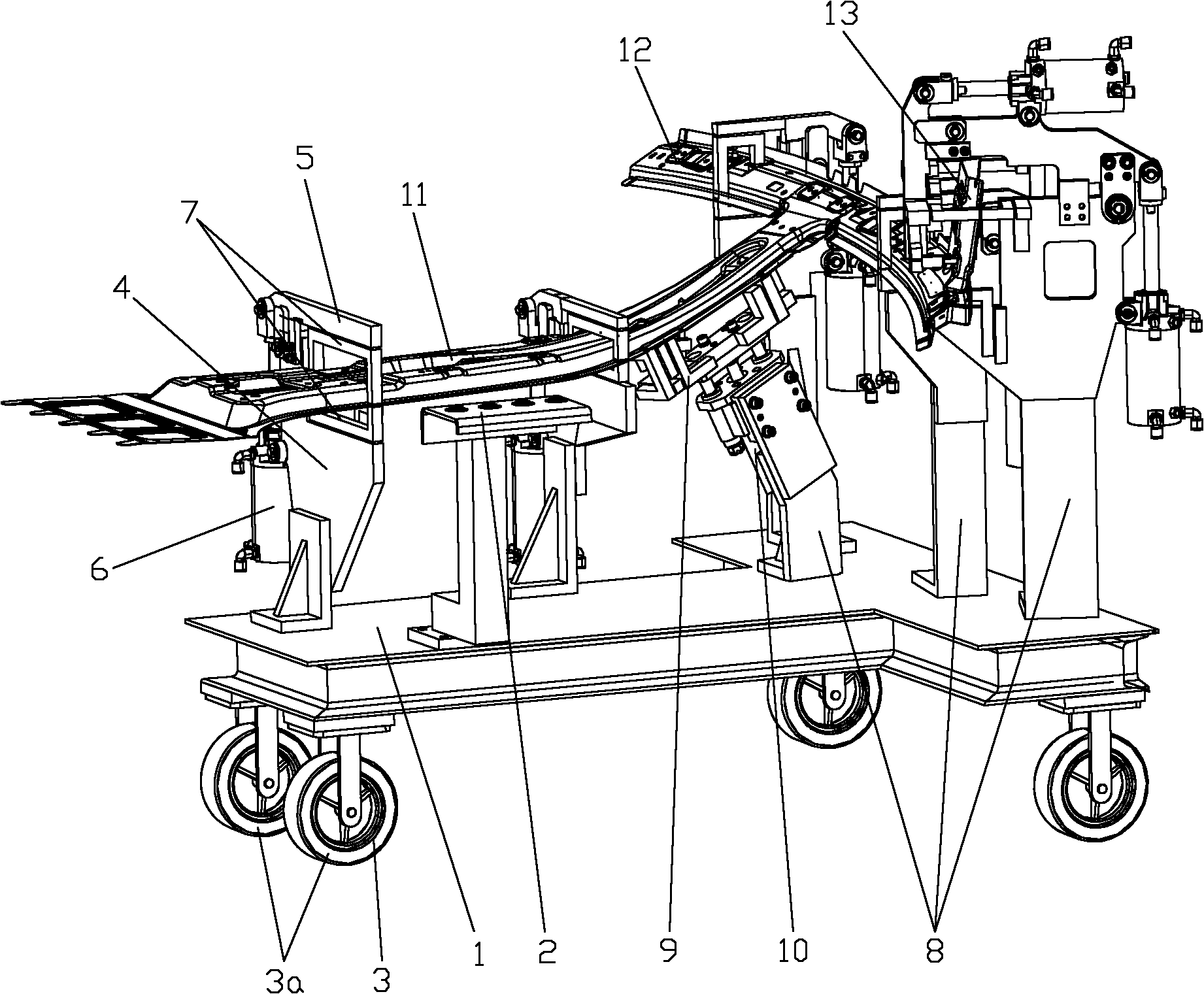

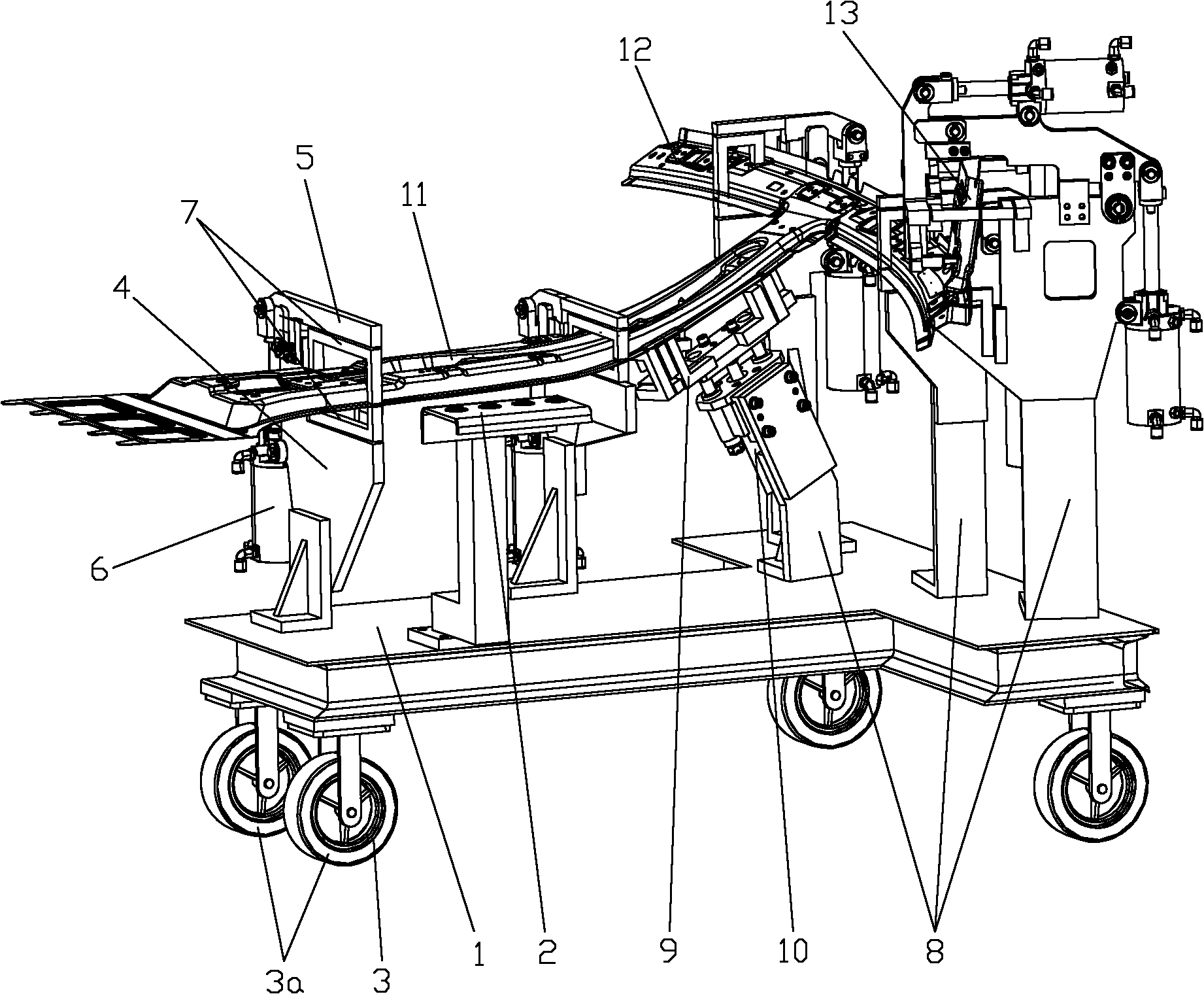

All functional glass sheet stacking and dismantling machine and glass sheet stacking and dismantling method

ActiveCN106032211AEasy to operate and maintainImprove safety and reliabilityCharge manipulationStacking articlesEngineeringGlobal function

The invention relates to the technical field of float glass and glass deep-processing, and provides an all functional glass sheet stacking and dismantling machine and a glass sheet stacking and dismantling method. The all functional glass sheet stacking and dismantling machine comprises a suction main engine and a piling bed. The suction main engine comprises a base, a pendulous device, a sucker device, and a rotating device. The pendulous device comprises a swing frame and a first rotating shaft used to drive the swing frame to swing between a glass production line and the piling bed. The rotating device comprises a second rotating shaft used to drive the sucker device to rotate. Compared with the prior art, using the global function glass sheet up-down machine, stacked glass is easy to operate and maintain. The glass sheet stacking and dismantling method comprises: according to purposes of glass, selecting a suction surface and stacking and dismantling the glass sheets, after the suction main engine is used for putting or taking down one glass sheet, a glass frame with the glass sheets moving a trip, after the glass frame is full or empty, automatically switching a vacant glass frame. Thus, efficiency of sheet up-down is greatly improved.

Owner:深圳市天圣实业有限公司

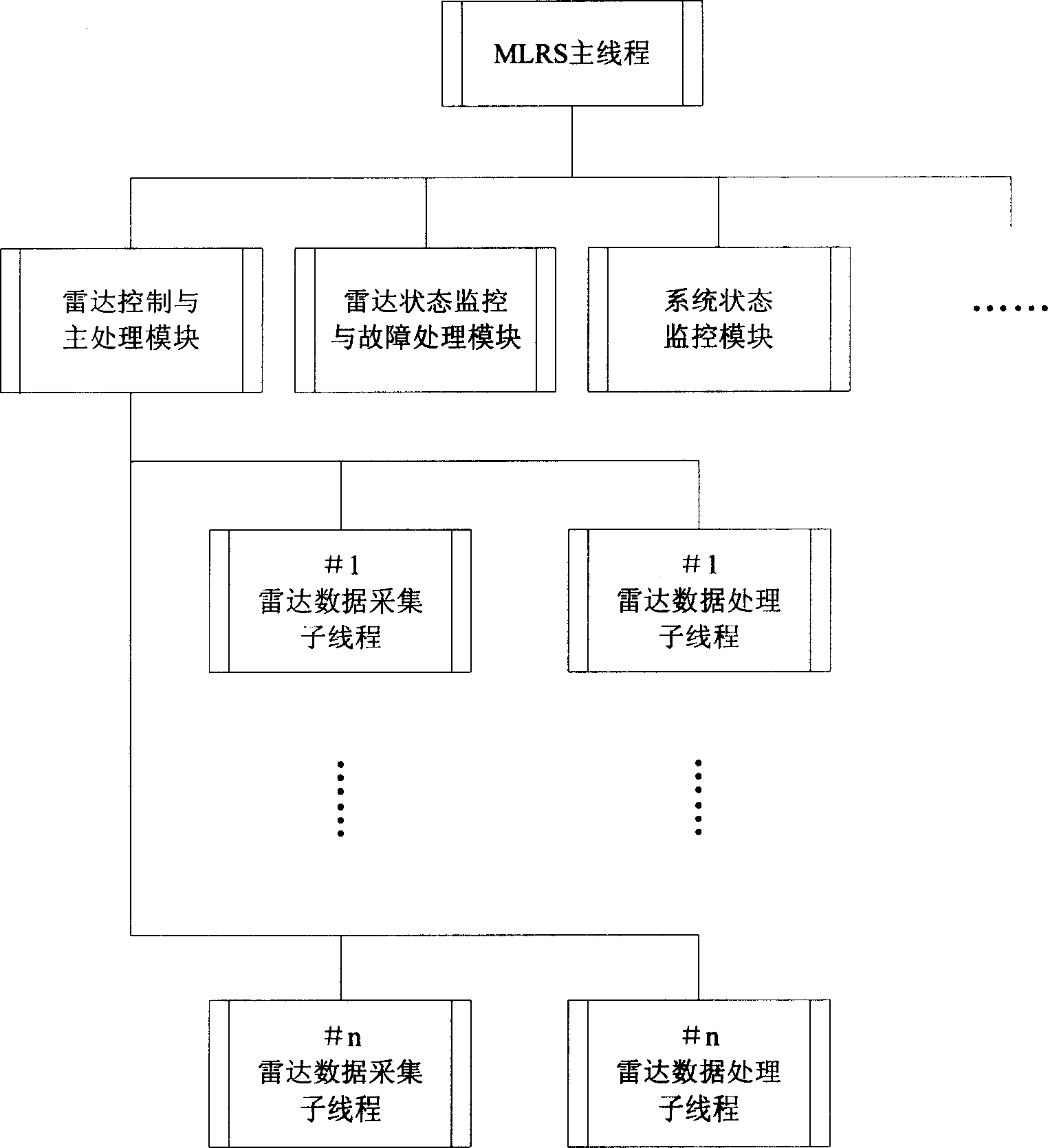

Collaborative work of multiple lidars, and dat processing method

InactiveCN1916659AImprove scanning accuracyHigh precisionElectromagnetic wave reradiationICT adaptationRadarProcess module

A method for making multilaser radar be operated coordinately includes enabling each radar to finalize object blocking scan and dynamic weighted treatment of scanning data independently under coordination control of master controlling and processing module (MCPM), carrying out effectiveness verification on data collected by each radar in real time and stopping linear grogram of the radar as well as shielding its function if certain radar is fault, feeding radar state back to system sate display module, carrying out dynamic data treatment of error compensation and coordinate matching adaptively and finalizing scan and identification task of object multiple surfaces by MCPM according to system topological structure.

Owner:SHANGHAI JIAO TONG UNIV

High-speed laser drilling machine capable of charging and discharging automatically

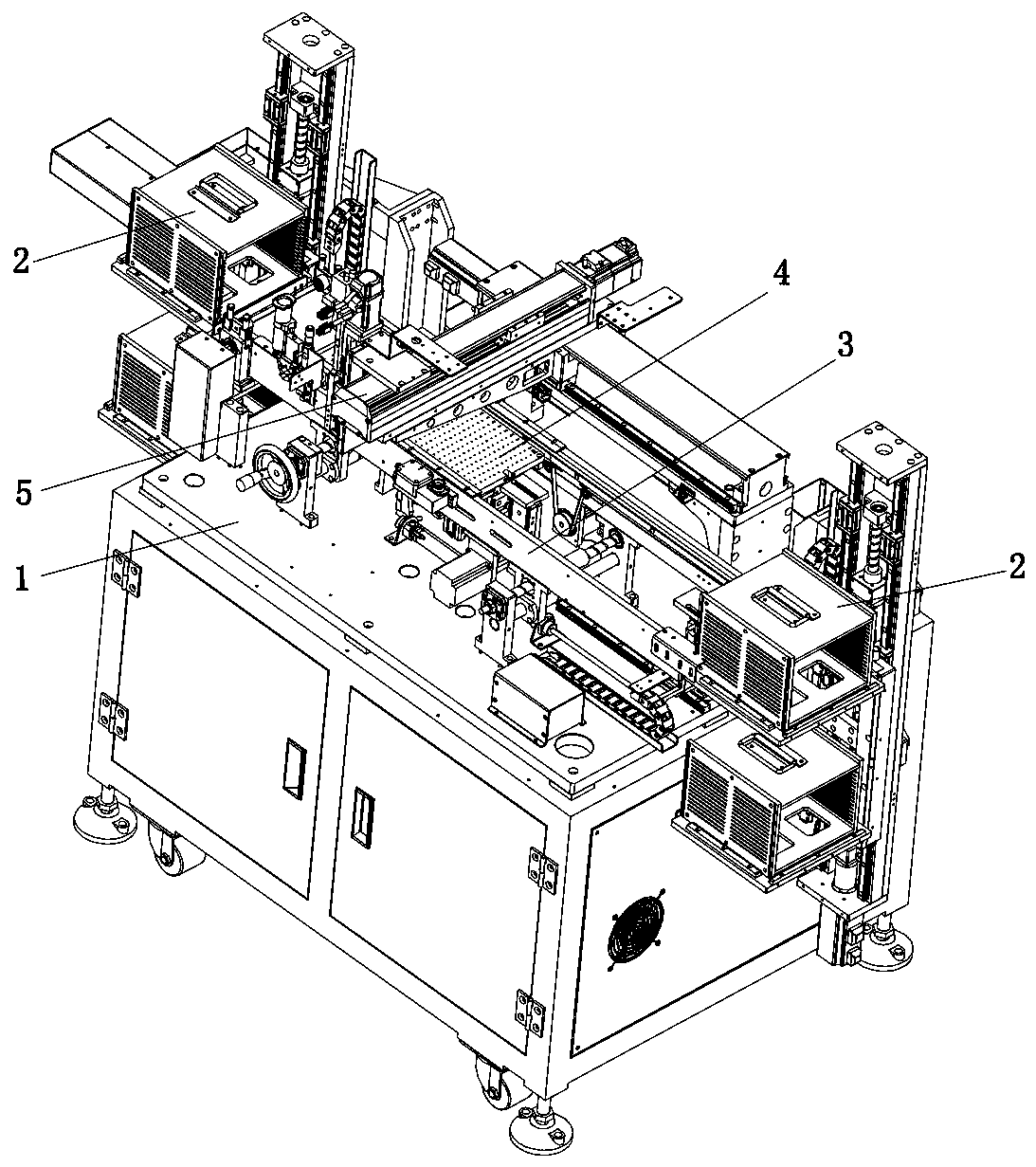

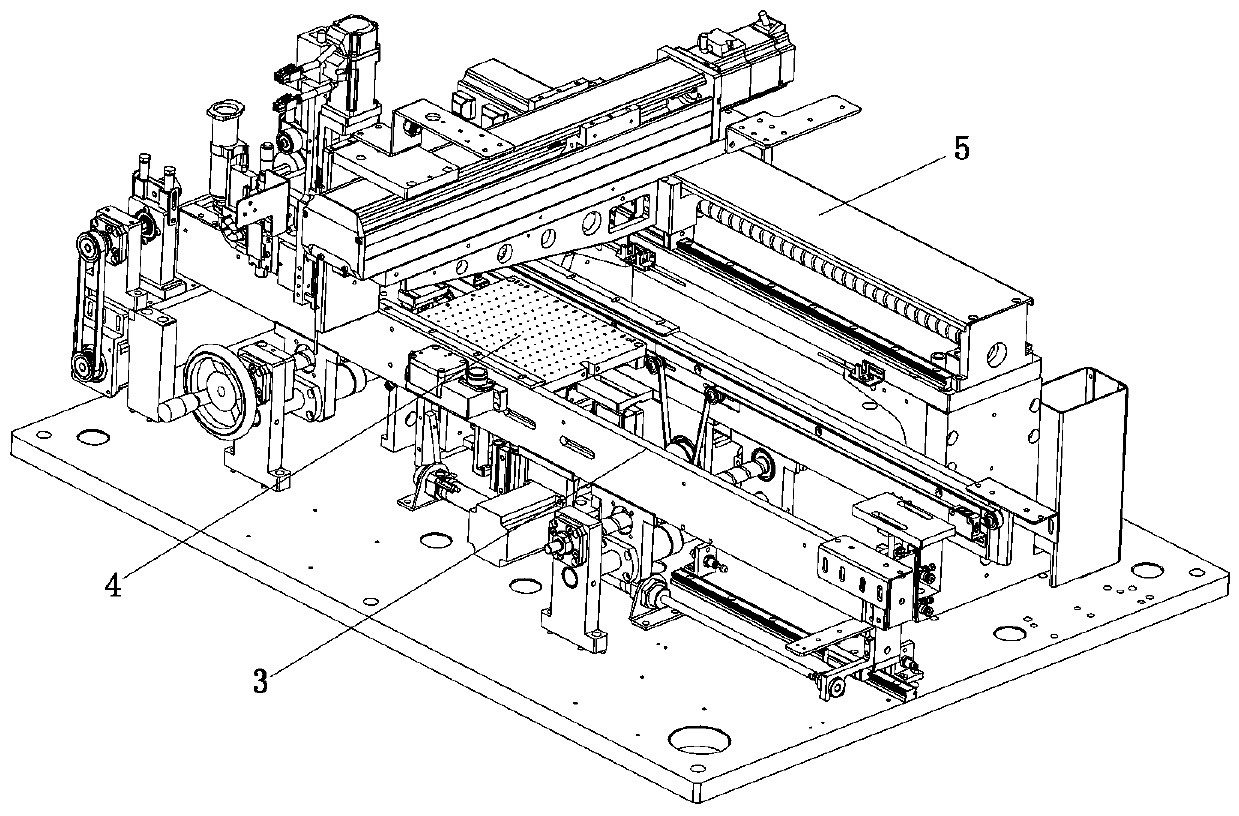

ActiveCN104551418AAvoid damageImprove loading and unloading efficiencyWelding/cutting auxillary devicesAuxillary welding devicesGalvanometerEngineering

The invention relates to the technical field of laser drilling equipment, and particularly relates to a high-speed laser drilling machine capable of charging and discharging automatically. The high-speed laser drilling machine comprises a cabinet, a charging device and a discharging device, wherein the cabinet is provided with a vacuum adsorption platform, a high-speed laser galvanometer and a drilling linear module which is used for driving the high-speed laser galvanometer to move along the z-axis direction; the charging device comprises a charging rack, a charging box, a charging component and a charging vacuum suction disc; the charging rack is provided with a charging movable plate and a charging linear module; the charging component is connected with the charging movable plate; the charging box is provided with a charging bearing plate; a charging lifting component is arranged at the rear side of the charging box; the discharging device comprises a discharging rack, a discharging box, a discharging component and a discharging vacuum suction disc; the discharging rack is provided with a discharging movable plate and a discharging linear module; the discharging component is connected with the discharging movable plate; the discharging box is internally provided with a discharging bearing plate; the discharging box is provided with a discharging lifting component. According to the high-speed laser drilling machine, the automatic charging and discharging can be realized; the charging and discharging efficiency is high; materials can be prevented from being damaged.

Owner:鞍山盛雄激光设备有限公司

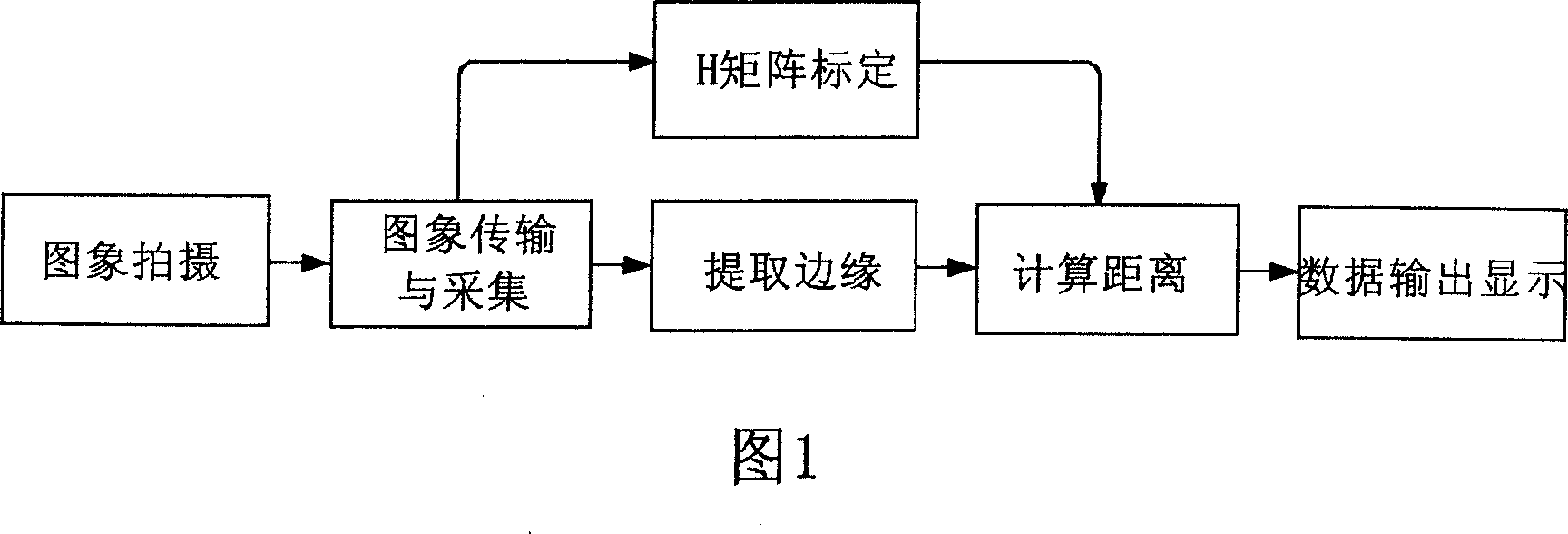

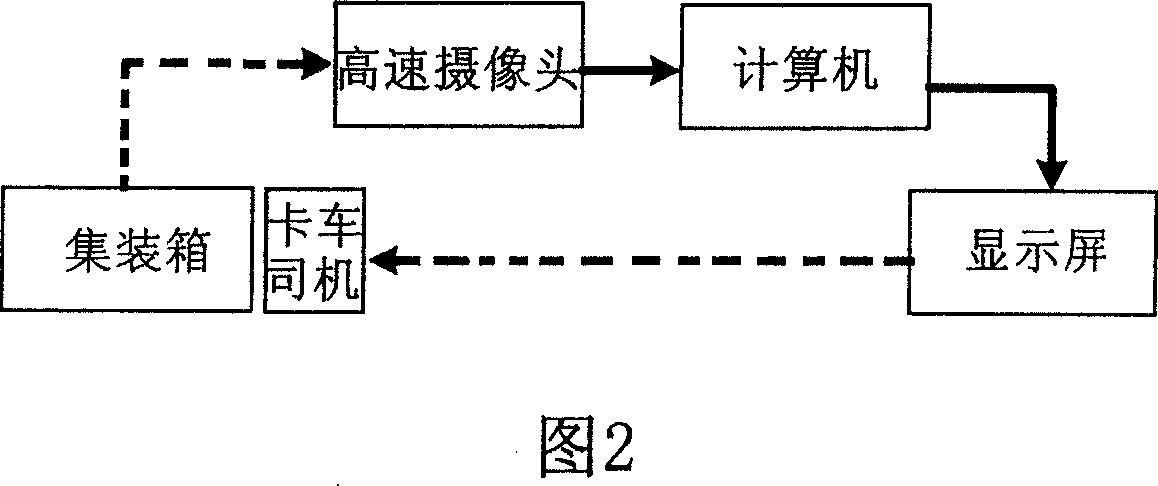

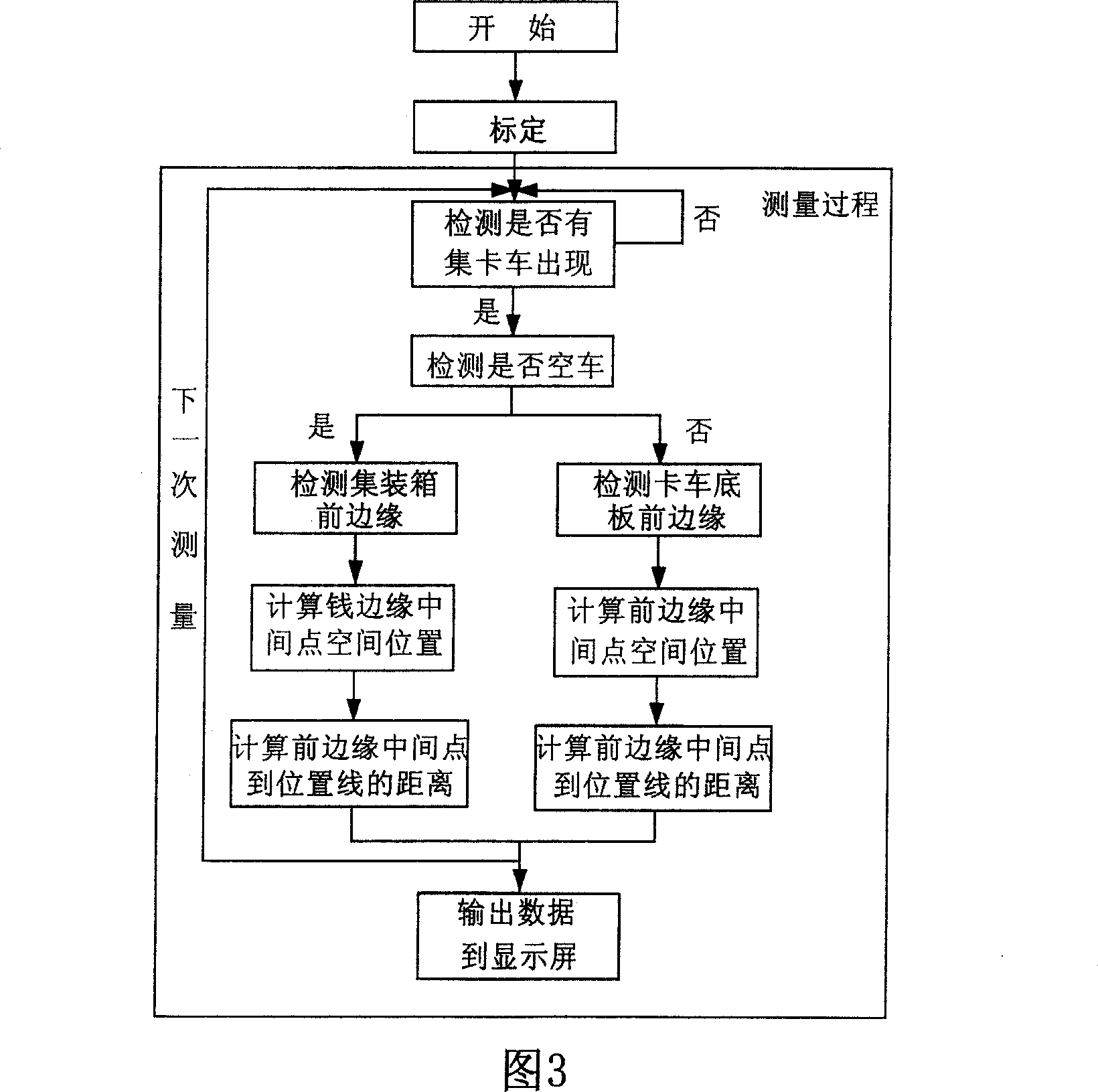

Method and device for positioning container lorry mobile in port

InactiveCN1958428AProcessing small amount of dataSimple structureLoad-engaging elementsComputer hardwareContainer crane

A locating method for the container trucks in port region includes such steps as taking image, transmitting and acquiring image, scaling in H array, extracting front edge, calculating distance, and outputting and displaying data. Its locating system is composed of high-speed camera head, computer, and electric display screen in the driver cab of container truck.

Owner:SHANGHAI MARITIME UNIVERSITY

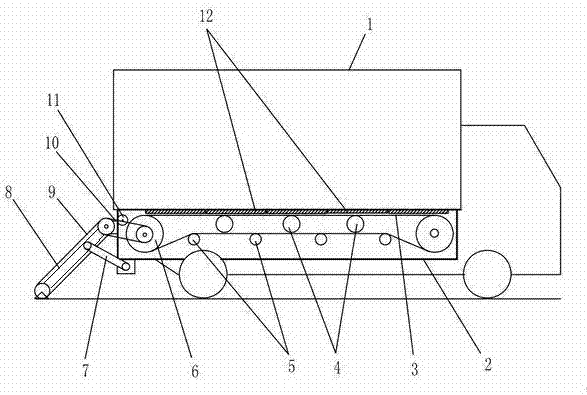

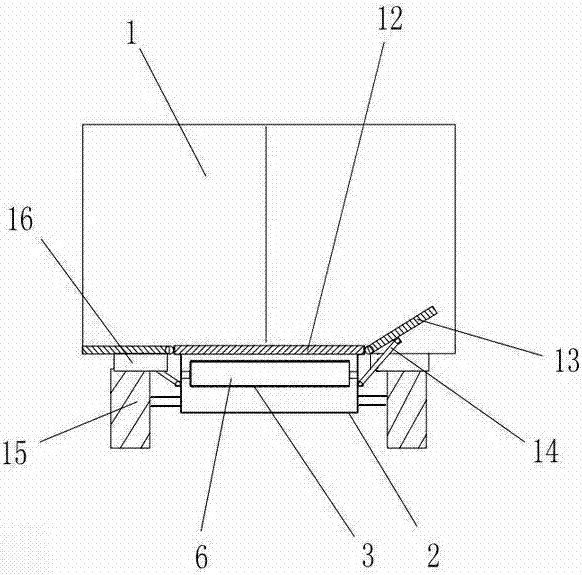

Auto-handling carriage of truck

PendingCN107244278AReduce labor intensityImprove loading and unloading efficiencyVehicle with endless chains/beltsVehicle with loading rampHydraulic cylinderDrive wheel

An auto-handling carriage of a truck is characterized in that a bottom box is mounted between the bottom of a carriage body and girders, a bottom box cover plate is arranged at the open end of the bottom box, and the girders at two ends of the bottom box cover plate are connected with movable bottom plates through hinges respectively; when the movable bottom plates on two sides are horizontal, the movable bottom plates are supported by the girders, and the bottom box cover plate and the movable bottom plates in horizontal state form a carriage body bottom plate; a conveyer belt is arranged in the bottom box in front-rear direction of the carriage body and sleeves driving wheels at front and rear ends; an auxiliary goods carrier is mounted at the rear end of the carriage body, one end of the auxiliary goods carrier is fixed to the carriage body through a rotary shaft, the other end of the auxiliary goods carrier is a free end, and the auxiliary goods carrier is connected with a goods lifting hydraulic cylinder; an auxiliary conveyer belt is arranged on the auxiliary goods carrier, and a driving shaft of the auxiliary conveyer belt is connected with the driving wheels of the conveyer belt through a transmission belt. The auto-handling carriage has the advantages that by handling goods via the conveyer belt, labor intensity of people can be greatly decreased, and handling efficiency can be greatly improved; the auto-handling carriage is novel in structure and good in goods handling convenience.

Owner:郭华

Particle packaging material storage logistics conveying system

ActiveCN104129632AReduce logistics costsLow priceStacking articlesLoading/unloadingLogistics managementControl system

The invention discloses a particle packaging material storage logistics conveying system which comprises a 90-degree turning conveyor, a guiding and leveling conveyor, a full-automatic strapping machine, a transition conveyor, a loading and conveying platform, a PLC (programmable logic control) system, a push-puller forklift truck and slide carriages. The 90-degree turning conveyor, the guiding and leveling conveyor, the full-automatic strapping machine, the transition conveyor and the loading and conveying platform are sequentially connected with one another, the PLC control system is connected with the 90-degree turning conveyor, the guiding and leveling conveyor, the full-automatic strapping machine and the transition conveyor, and the slide carriages are used with the push-puller forklift truck. The particle packaging material storage logistics conveying system has the advantages that particle packaging material stacks can be automatically strapped, stack looseness and collapse can be prevented, the high-layer stacks are good in neatness and high in quality and loading and unloading efficiency, the particle packaging material storage logistics conveying system is low in cost and high in mechanization degree and efficiency, and transition warehouses can be utilized to the greatest extent.

Owner:GUANGXI NANNING BOBST MACHINERY CO LTD

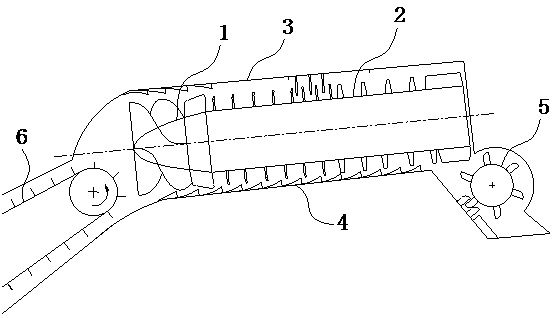

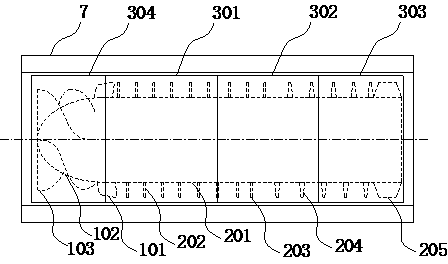

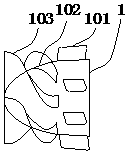

Axial-feeding type rice and wheat threshing and separating integrated device

ActiveCN103718733AShorten the lengthSimple structureCrop conditionersMowersAgricultural engineeringIntegrated devices

The invention relates to an axial-feeding type rice and wheat threshing and separating integrated device which comprises a feed head (1), a longitudinal axial-flow threshing and separating drum (2), a threshing gridded cover plate (3) and a separating concave grate (4). The feed head (1) is arranged at the front end of the longitudinal axial-flow threshing and separating drum (2), the threshing gridded cover plate (3) is arranged on the upper side of the longitudinal axial-flow threshing and separating drum (2), the separating concave grate (4) is arranged on the lower side of the longitudinal axial-flow threshing and separating drum (2), and the threshing gridded cover plate (3) and the separating concave grate (4) encircle to form a barrel capable of accommodating the longitudinal axial-flow threshing and separating drum (2). The axial-feeding type rice and wheat threshing and separating integrated device can realize high-feed harvesting of rice or wheat, and is high in harvesting efficiency and high in threshing capacity. As the length of the longitudinal axial-flow drum is reduced effectively, straws smashed by smashing and throwing mechanism are smashed effectively and thrown uniformly, and then can be returned to fields directly after harvesting.

Owner:JIANGSU UNIV

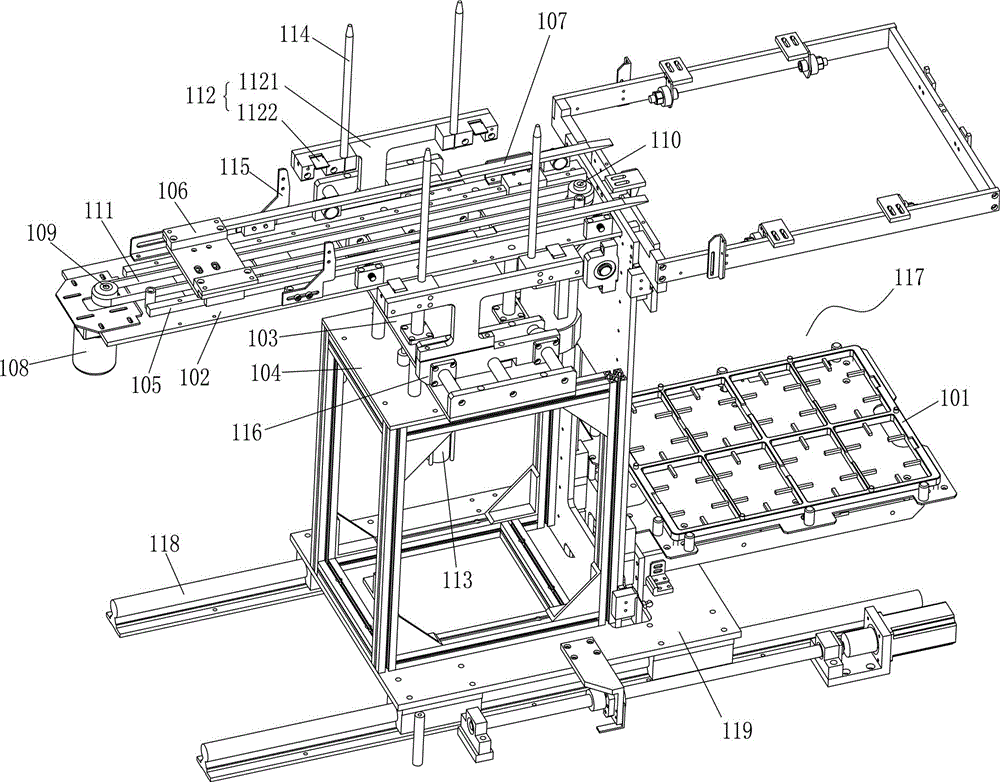

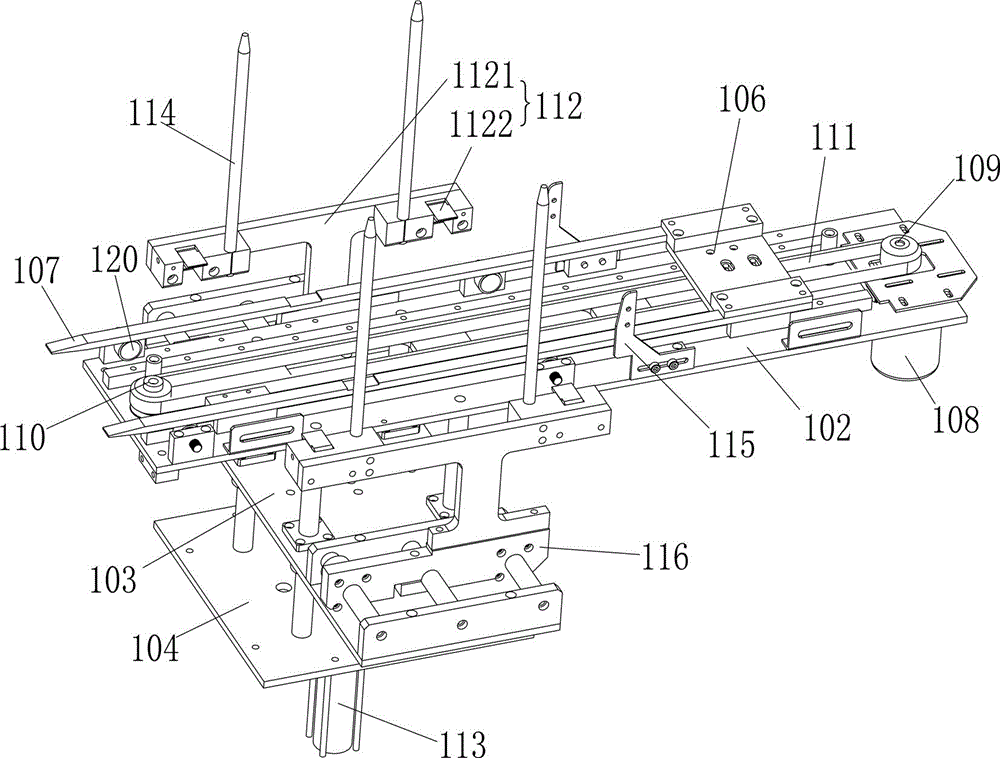

Full-automatic glass panel printing machine

InactiveCN104960326ARealize automatic stacking functionReduce usageScreen printersEngineeringPrinting press

The invention discloses a full-automatic glass panel printing machine. A feeding device and a rough positioning device are arranged at a feeding end, a discharging device is arranged at a discharging end, and a fine positioning device is arranged between the feeding end and the discharging end. A printing device is arranged above the fine positioning device. A first mechanical arm is arranged between the feeding device and the rough positioning device, a second mechanical arm is arranged between the rough positioning device and the fine positioning device, and a third mechanical arm is arranged between the fine positioning device and the discharging device. A glass panel of a material plate in the feeding device is conveyed into the rough positioning device to receive rough positioning through the first mechanical arm, the glass panel on which rough positioning is conducted is conveyed into the fine positioning device to receive fine positioning through the second mechanical arm, and the printed glass panel is conveyed onto a material plate in the discharging device through the third mechanical arm. The feeding device and the discharging device are each provided with an automatic panel changing structure and an automatic panel stacking structure.

Owner:DONGGUAN RBD TECH

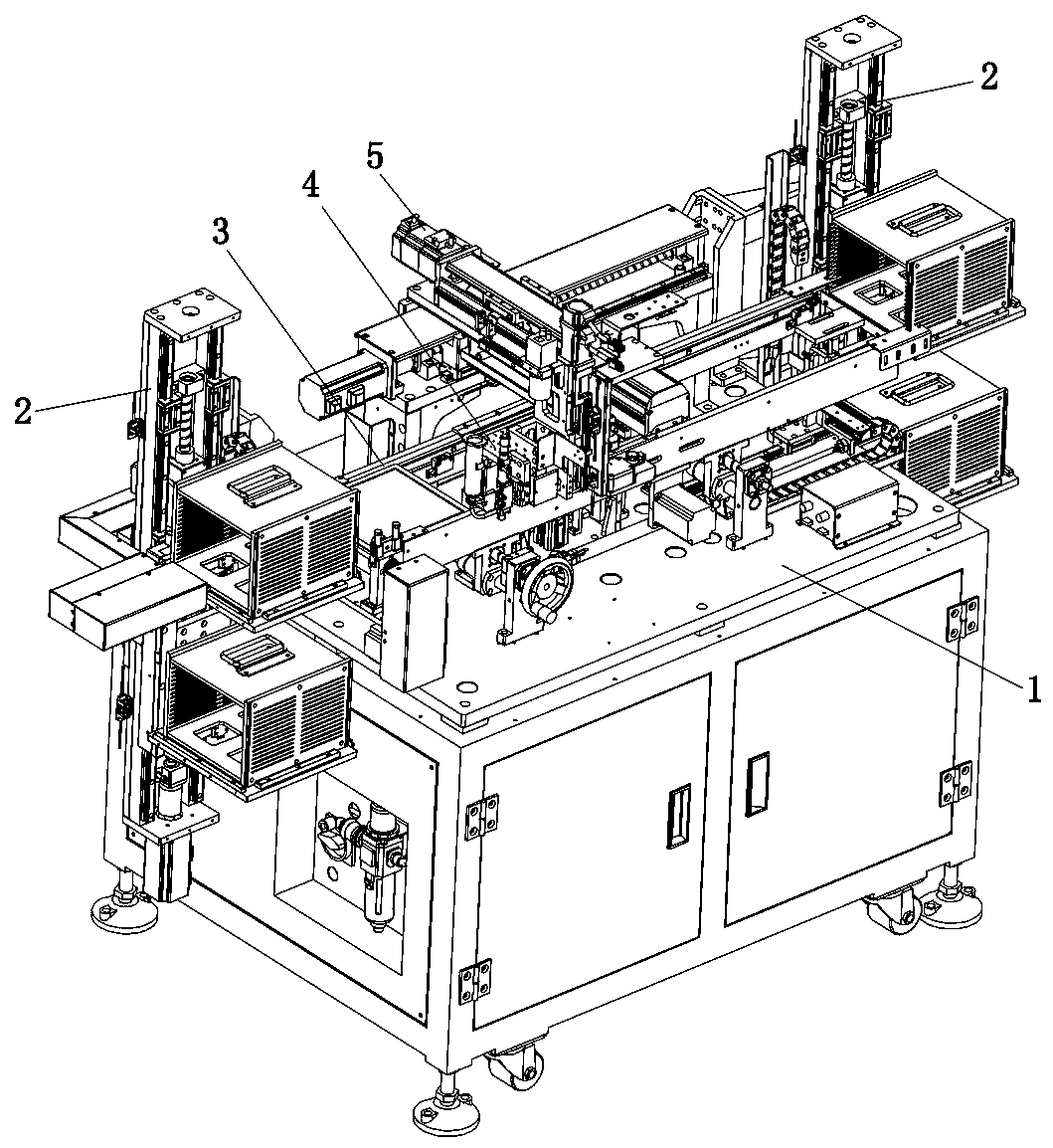

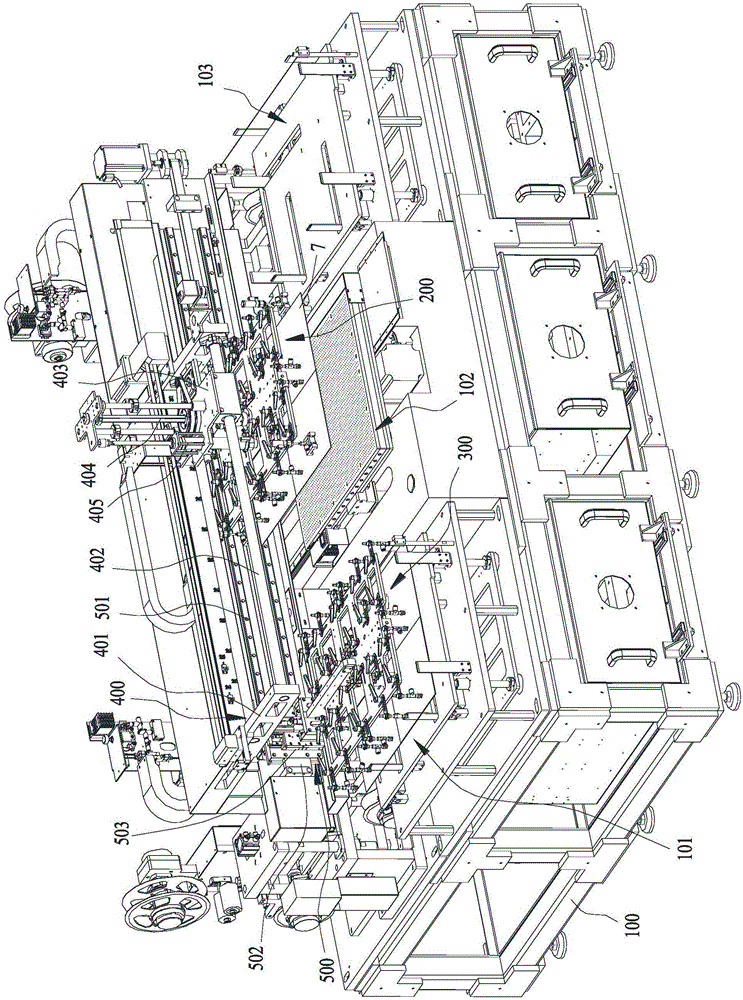

Full-automatic single-rail glue dispenser and glue dispensing process thereof

PendingCN109513578AAvoid collisions with each otherImprove adjustabilityLiquid surface applicatorsCoatingsDischarge efficiencyEngineering

The invention discloses a full-automatic single-rail glue dispenser and a glue dispensing process thereof. The full-automatic single-rail glue dispenser comprises two sets of collection and release assemblies, a conveying rail, a front pushing part, a glue dispensing platform and a glue dispensing assembly. The two collection and release assemblies are arranged on the left and right sides of a rack correspondingly symmetrically. The front pushing part is arranged on the lateral part of the collection and release assembly on the left side and pushes carrier plates in the collection and releaseassembly on the left side into the conveying rail. The conveying rail is arranged between the two collection and release assemblies. A rear pushing part of the conveying rail pushes the carrier platesinto the collection and release assembly on the right side. The glue dispensing platform is arranged between a movable support plate and a fixed support plate, conducts upward jacking and supports the carrier plates. The glue dispensing assembly is arranged above the glue dispensing platform and conducts glue dispensing on the carrier plates on the glue dispensing platform. Through the full-automatic single-rail glue dispenser and the glue dispensing process thereof, mutual friction and collision between adjacent carrier plates are avoided effectively, position stability of fingerprint modules on the carrier plates is ensured while feed and discharge efficiency is promoted in a linear pushing mode, and adjustability of the sizes of the conveying carrier plates is achieved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

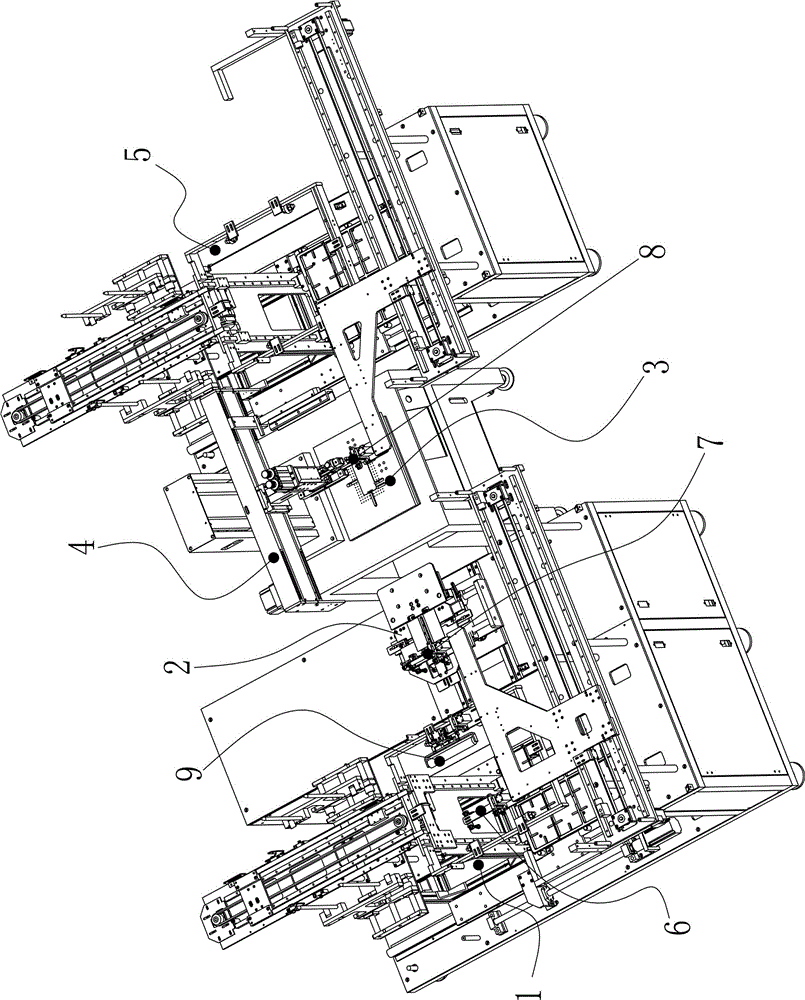

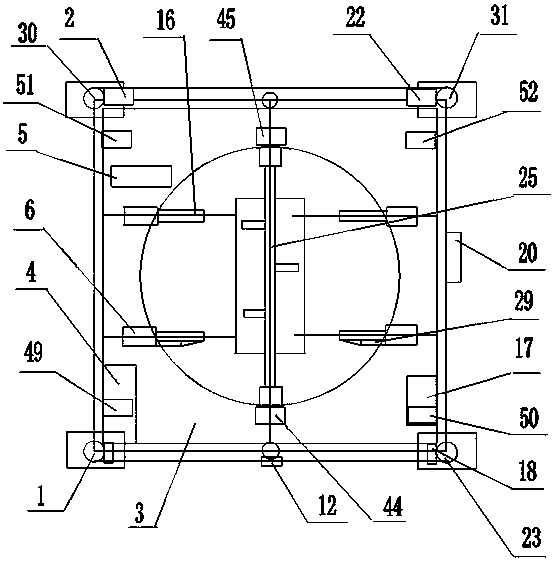

Automatic loading and unloading device

ActiveCN105072820AIncrease productivityImprove loading and unloading efficiencyPrinted circuit assemblingEngineeringMechanical engineering

The invention discloses an automatic loading and unloading device. The device includes a frame, a first sucker device for absorbing and holding flexible circuit boards, a second sucker device for absorbing and holding separator plates, a first slide assembly, and a second slide assembly. The frame is sequentially provided, in an X-axis direction, with a loading bench for loading the flexible circuit boards and the separator plates, a sheet attaching bench for attaching reinforcing sheets to the flexible circuit boards, and an unloading bench for unloading the flexible circuit boards and the separator plates. The first slide assembly and the second slide assembly are arranged on the frame and positioned in a staggered manner, wherein one slide assembly is positioned above the other slide assembly. The first sucker device is in slide fit with the frame in the X-axis direction through the first slide assembly, and the second sucker device is in slide fit with the frame in the X-axis direction through the second slide assembly. The first sucker device and the second sucker device are both positioned above the loading bench, the sheet attaching bench and the unloading bench. The automatic loading and unloading device can automatically and stably load and unload the flexible circuit boards and the separator plates.

Owner:超音速人工智能科技股份有限公司

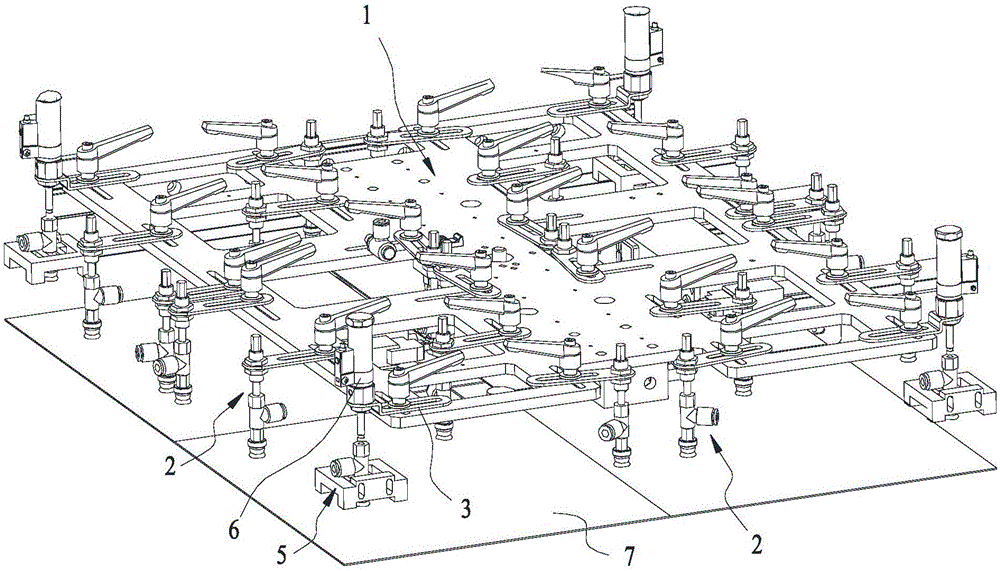

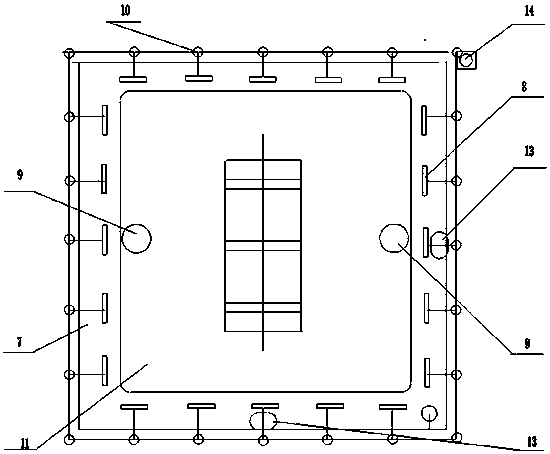

Fixture for sedan central pillar inner skin roof rail welding assembly

InactiveCN102357760AImprove loading and unloading efficiencyReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCaster

The invention discloses a fixture for a sedan central pillar inner skin roof rail welding assembly. The fixture comprises a base, and a clamping device and an operating panel which are fixedly arranged on the base, wherein the top surface of the base is a horizontal mounting plane, and the bottom of the base is provided with casters; the clamping device comprises a bracket, a compaction rack and a driving device; the bracket is fixedly connected to the base; the compaction rack is hinged to the bracket; the driving device is used for driving the clamping and releasing of the bracket and the compaction rack; a positioning pin is arranged on the bracket; and a switch for controlling the work of the driving device is arranged on the operating panel. The fixture for the sedan central pillar inner skin roof rail welding assembly can control a corresponding driving device by the switch to drive a clamping positioning part to clamp and release a workpiece, improve the assembly and disassembly efficiency of the workpiece and reduce the labor intensity of an operator, and is convenient to move.

Owner:CHONGQING HUAQING AUTOMOBILE PARTS

Container wharf flow equipment automatic walking method

InactiveCN106946049ARealize automatic walking correctionRealize automatic walkingStorage devicesImaging processingSimulation

The invention provides a container wharf flow equipment automatic walking method. Laser scanners are installed on four door leg tire front wheel brackets of a tire crane correspondingly, vertical columns are installed between the back surfaces of two tire crane lanes by a certain distance or the length of a container at intervals and are located in a straight line, the positions of the vertical columns are detected through the tire crane laser scanners, and automatic walking of the tire crane is achieved. Meanwhile, vertical columns are installed on the two sides of a road lane by a certain distance and are located in a straight line; vertical columns are installed on the inner sides of two door legs, close to the lane, of the tire crane correspondingly; and vertical columns are installed on the inner side and the outer side of each door leg of a bridge crane correspondingly. An ordinary container lorry is improved into an automatic navigation vehicle, the vertical columns higher than the top surface of the container, a camera and the laser scanners are installed on the navigation vehicle, walking datum line paint is at the center of the ground lane, the navigation vehicle shoots the walking datum line through the camera so as to conduct image processing and alignment, the positions of the vertical columns are detected through the scanners, and automatic walking of the navigation vehicle is achieved.

Owner:SHANGHAI HAILEI LASER TECH

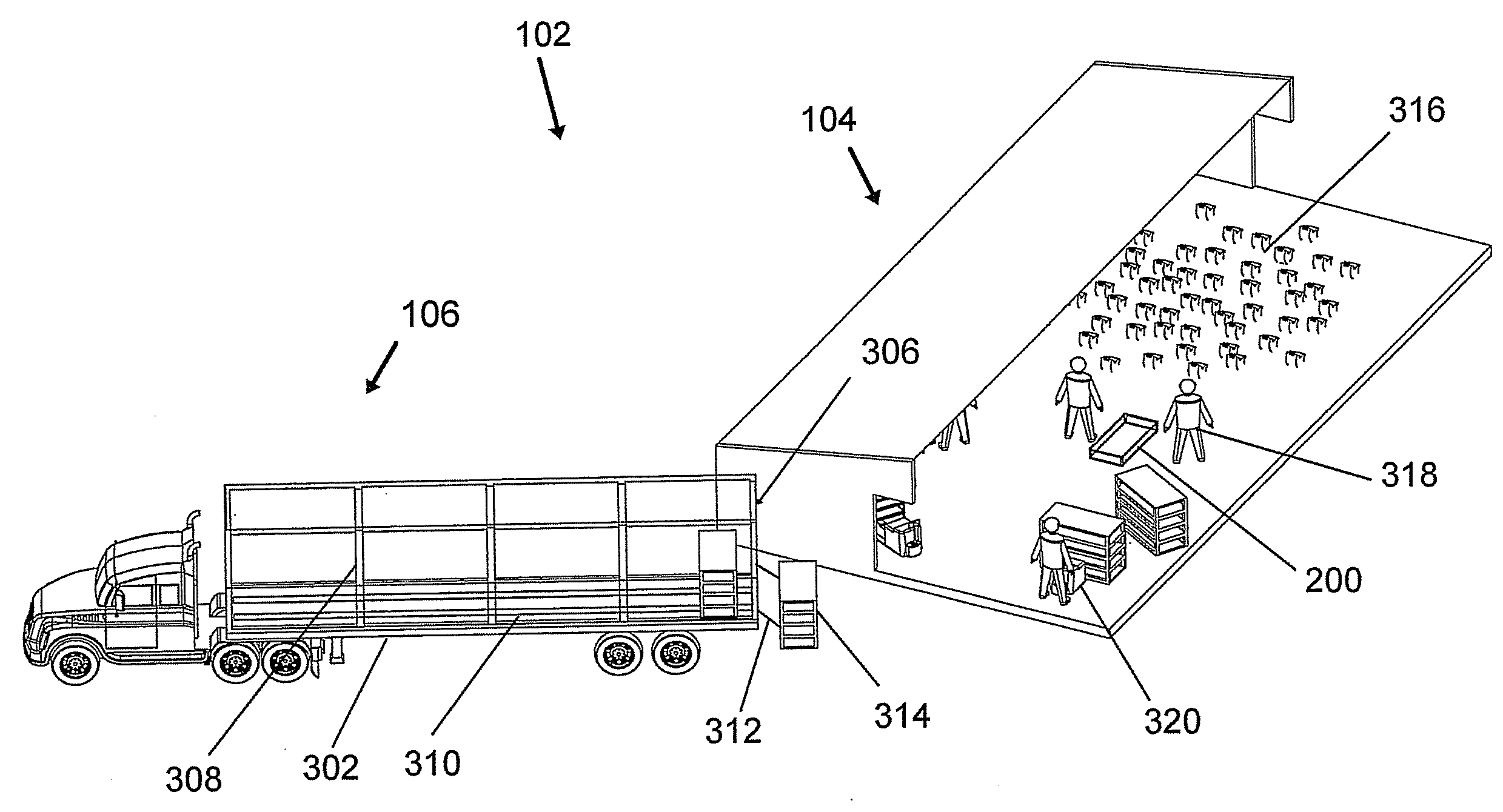

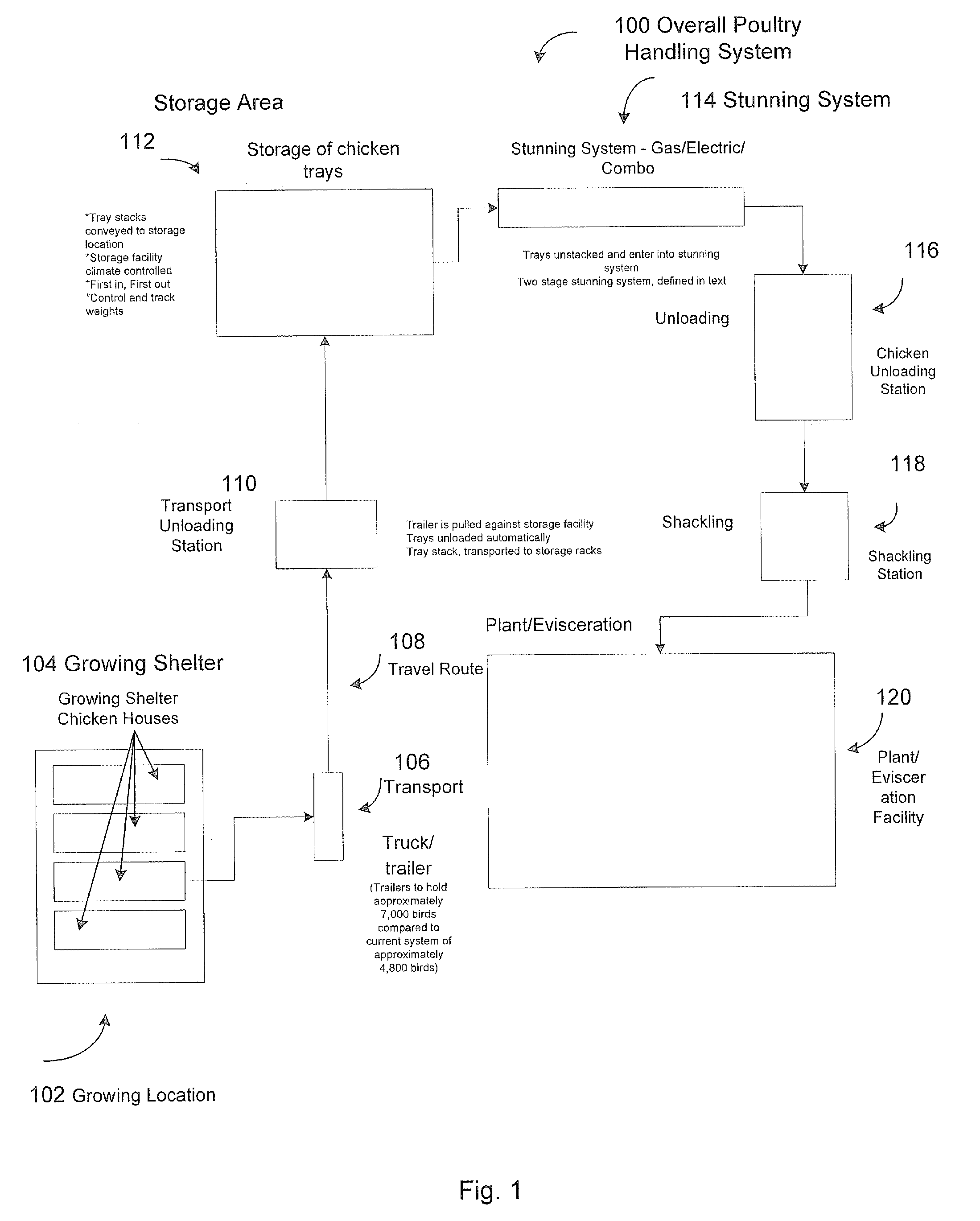

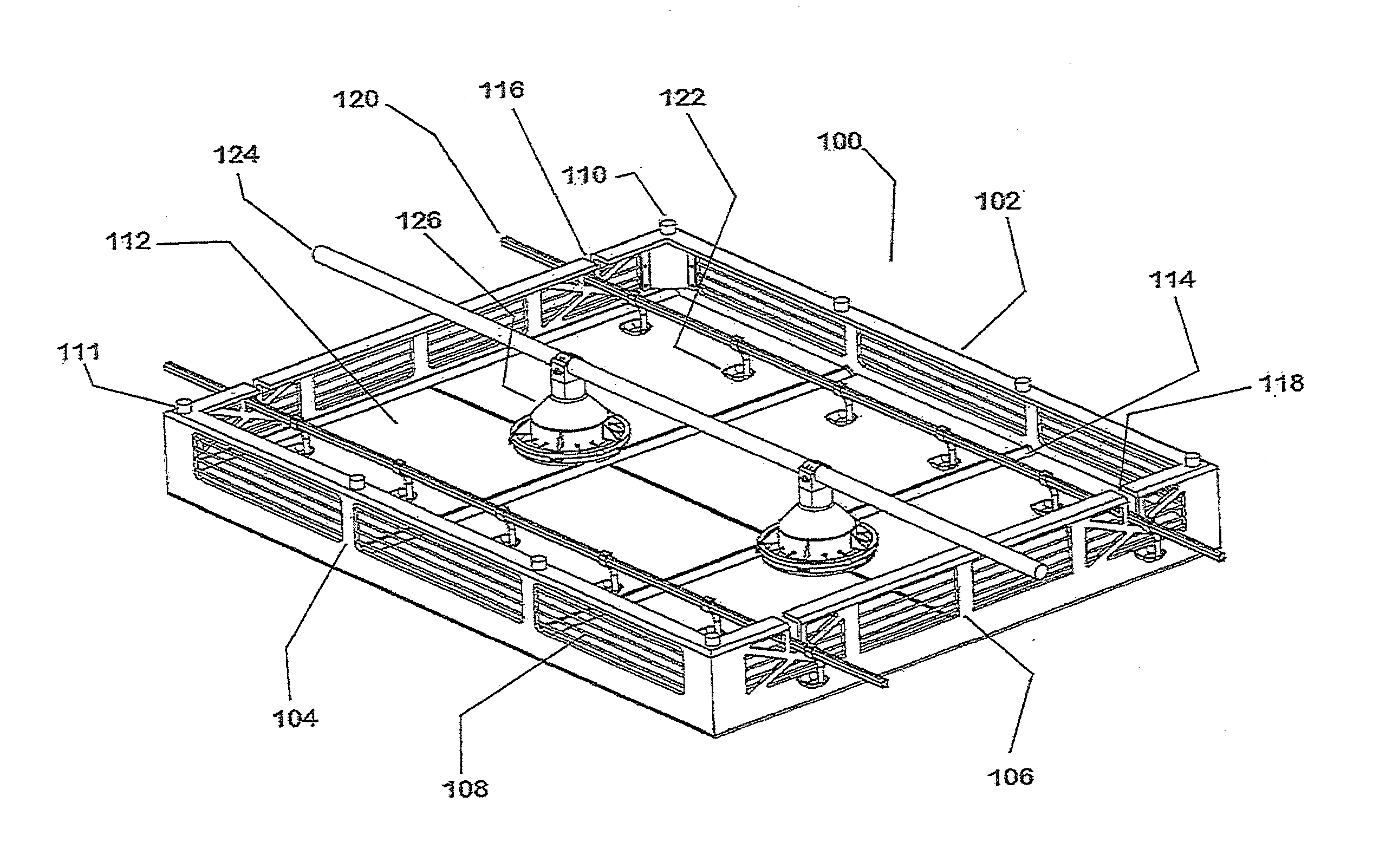

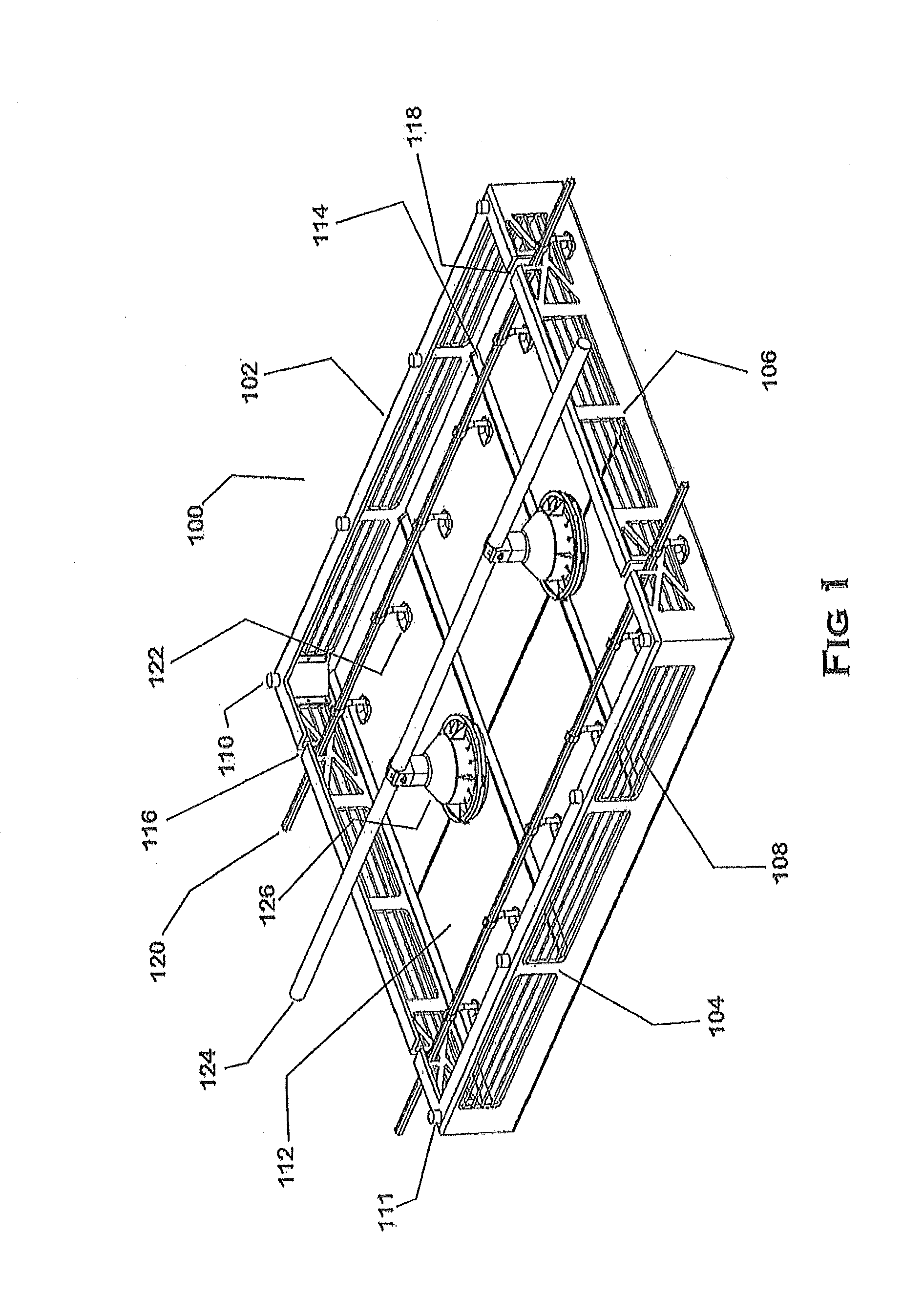

Stackable tray system and method to load, transport, stun and singulate poultry

InactiveUS20090007853A1Easy to controlSuitable environmentBlood collection/stirring apparatusGas slaughtering/stunningTransport systemEngineering

A system and method for handling poultry comprising a harvesting system, a loading system, a transport system, an unloading and storing system, a stunning system, and a singulate and hanging system. The system and method performs the steps of harvesting live poultry into stackable transport trays, stacking and loading the trays on a transport, unloading and temporarily storing the poultry for subsequent stunning and hanging. The stackable transport trays are well vented and easier for handling poultry.

Owner:TYSON FOODS

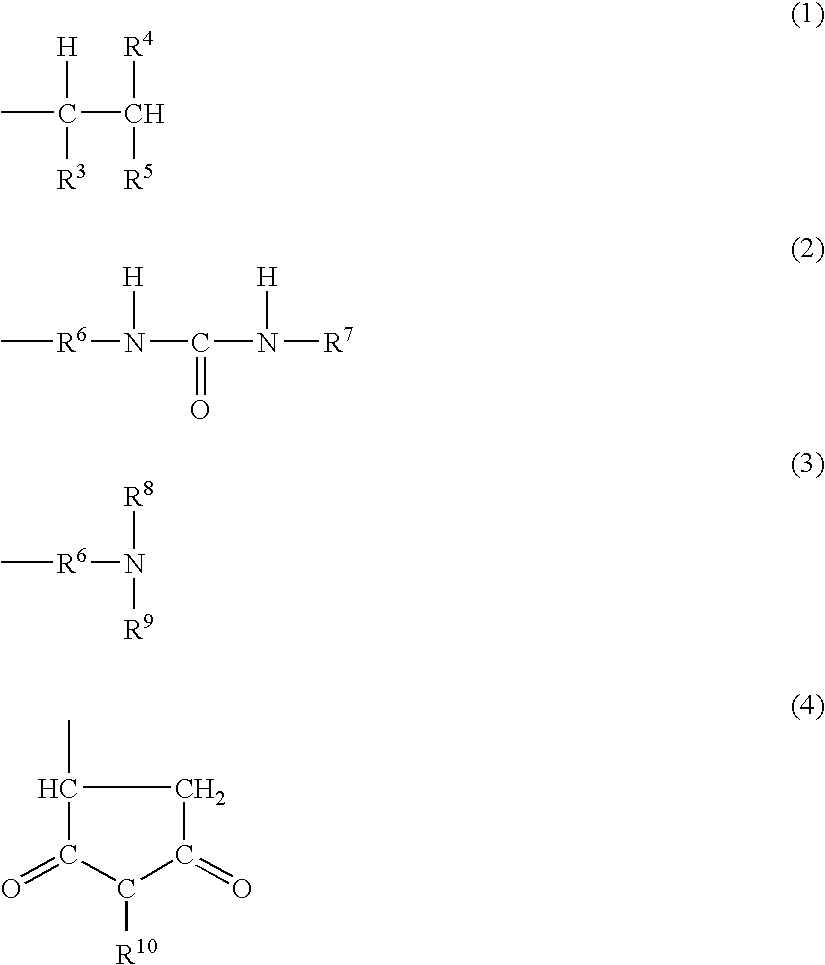

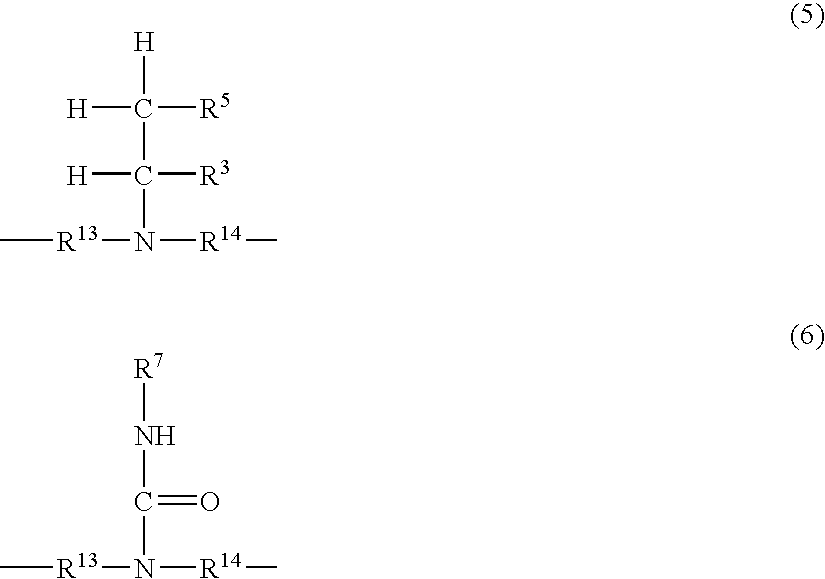

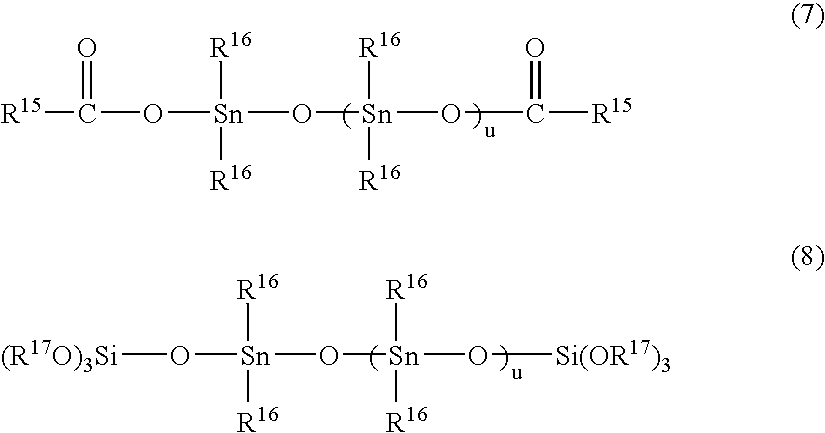

Reactive Hot-Melt Resin Composition and Reactive Hot-Melt Adhesive

InactiveUS20080312401A1Improve work efficiencyImprove efficiencyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer chemistryHot-melt adhesive

Owner:SATO SHINICHI +2

Automatic feeding and discharging system for multi-layer hot press

ActiveCN105150355AReduce labor costsImprove yieldWood working apparatusDomestic articlesManipulatorEngineering

The invention relates to the technical field of artificial board automatic machining, in particular to an automatic feeding and discharging system for a multi-layer hot press. The automatic feeding and discharging system for the multi-layer hot press comprises a control system and an automatic feeding and discharging device, connected with the control system, for multi-layer hot press. The automatic feeding and discharging device for the multi-layer hot press comprises a feeding lifting table, a plate transferring device and a discharging lifting table which are all sequentially arranged at intervals along a straight line. The multi-layer hot press is arranged between the plate transferring device and the discharging lifting table. The plate transferring device comprises a rack, a sucker type mechanical arm and a feeding and discharging tray. The rack comprises a tray lifting mechanism. The feeding and discharging tray comprises a tray base and a feeding and discharging push rod mechanism arranged on the tray base. The sucker type mechanism arm is fixed to the feeding and discharging tray or the tray lifting mechanism. By means of the automatic feeding and discharging system for the multi-layer hot press, the feeding lifting table, the plate transferring device and the discharging lifting table are controlled by the control system, automatic feeding and discharging can be achieved, and labor cost is reduced; the feeding and discharging efficiency is improved, and the plate yield is increased; and injuries caused by the hot press to human bodies in the feeding and discharging process are avoided.

Owner:深圳中智卫安机器人技术有限公司

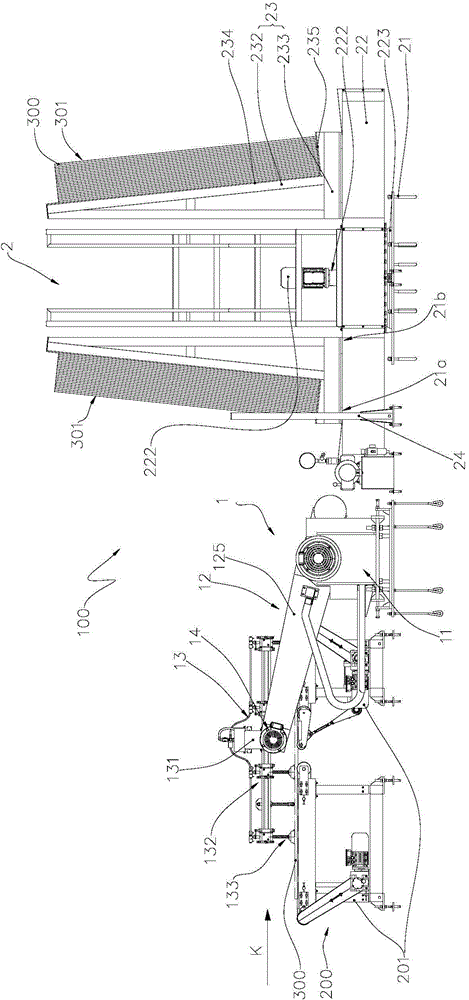

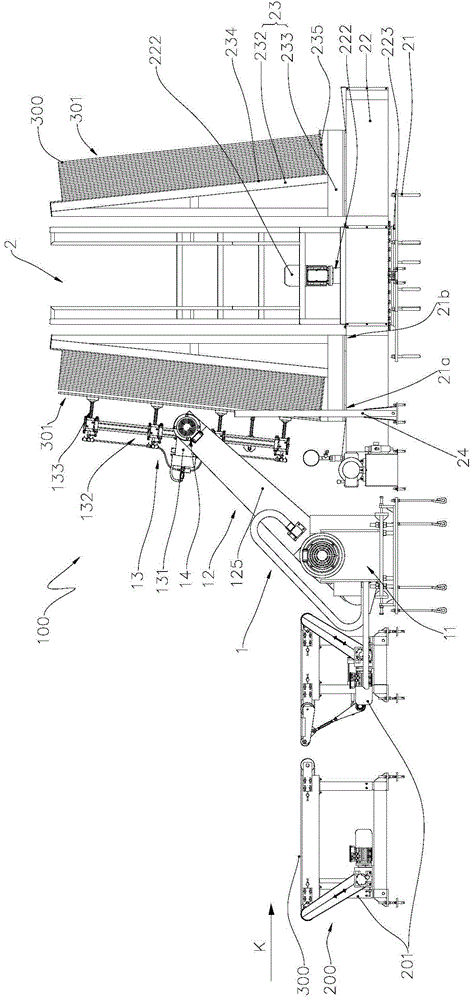

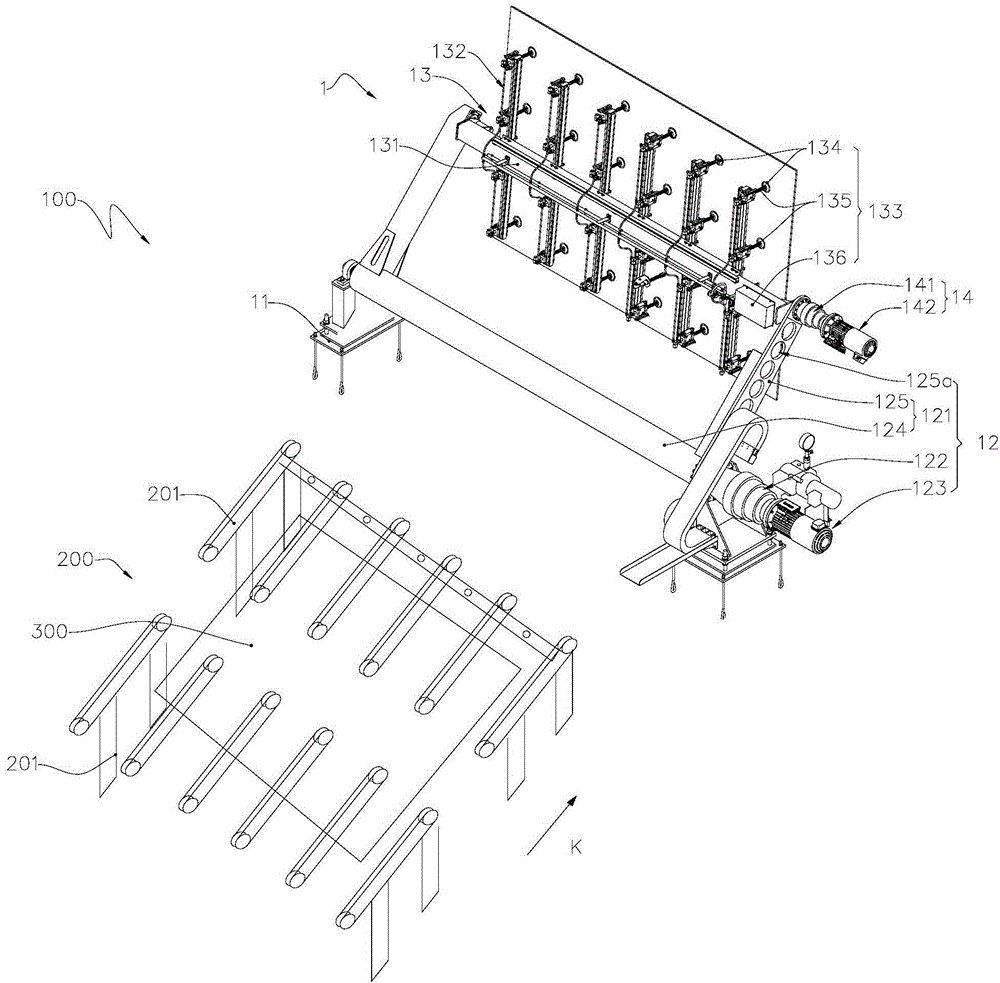

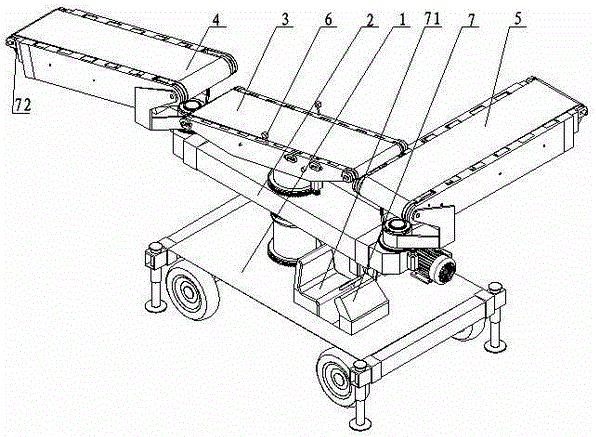

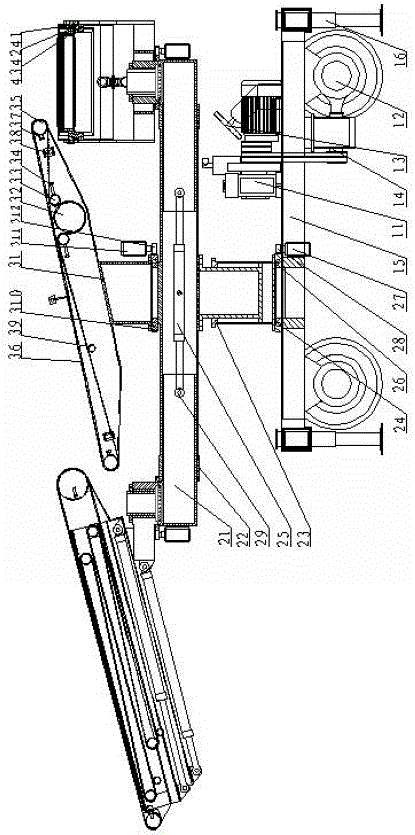

A derricking direction-changeable telescopic belt conveying bidirectional loader-unloader

InactiveCN106608551AAdjustable working heightRealize orientationConveyorsRollersControl systemStatistical analysis

The invention provides a derricking direction-changeable telescopic belt conveying bidirectional loader-unloader and relates to the field of logistics transportation cargo loading and unloading mechanical equipment. The derricking direction-changeable telescopic belt conveying bidirectional loader-unloader comprises a vehicle having bearing and walking functions, a telescopic cross arm having lifting, telescoping and swinging functions, a middle transition conveyor which has a swinging function and is capable of inclined conveying, a first belt conveyor and a second belt conveyor having derricking, swinging and telescoping functions, a metering device having metering, displaying, storing and printing functions, and an operating control system used for complete machine operation of the loader-unloader. The derricking direction-changeable telescopic belt conveying bidirectional loader-unloader has the advantages of simple structure, reliable work, convenient and rapid movement and transfer, and wide operating scope; the derricking direction-changeable telescopic belt conveying bidirectional loader-unloader can reduce manually-assisted carrying, reduce workload, shorten operating time, increase loading and unloading working efficiency, reduce the cost of loading and unloading carrying, improve working environment and work conditions, guarantee economical, rapid, convenient and safe loading and unloading and transportation, allow change of the direction of logistics conveying, and realize forward and reverse loading and unloading, automatic metering statistical analysis, and loading and unloading quantity / weight recording, displaying and storing.

Owner:襄阳忠良工程机械有限责任公司

Portable basket colony for growing and transport and method of use

ActiveUS20140299067A1Eliminate unnecessary handlingEfficient processingBird housingsTransport systemWaste management

A colony basket and method of using the same for handling poultry from DOC through the growing process and on to a production facility comprising a harvesting system, a loading system, a transport system, an unloading and storing system, hanging system and cleaning system. The system and method performs the steps of harvesting and colonizing live poultry into a singly stackable and transportable colony basket, stacking and loading the trays on a transport, unloading and temporarily storing the poultry for subsequent processing. The system and method further includes the use of a modular colony basket for interchangeable use with the described system.

Owner:TYSON FOODS

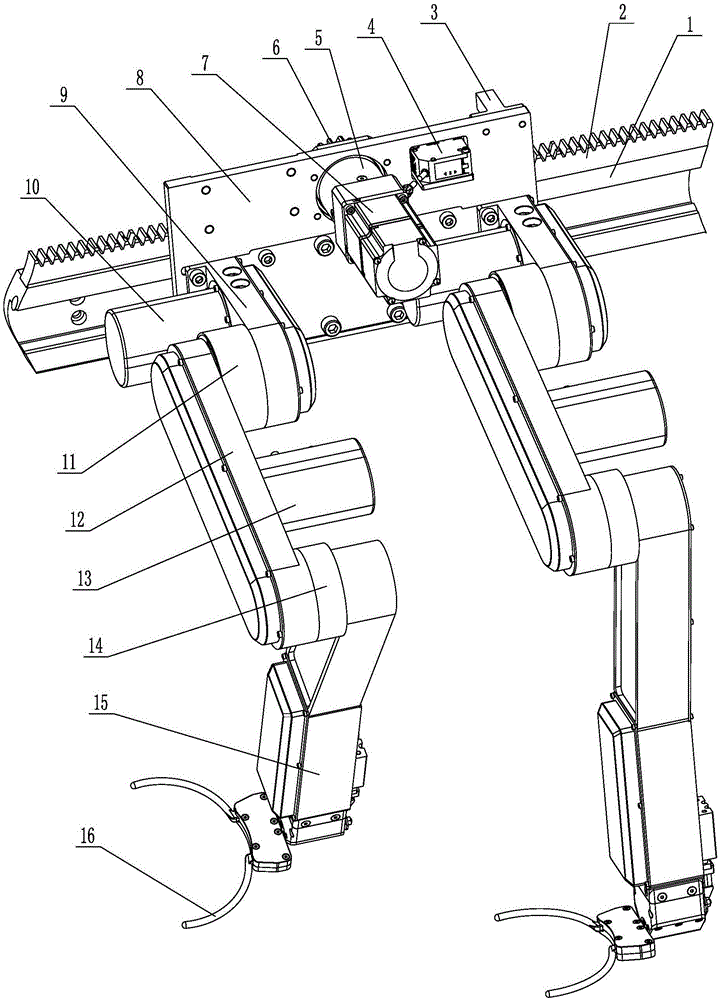

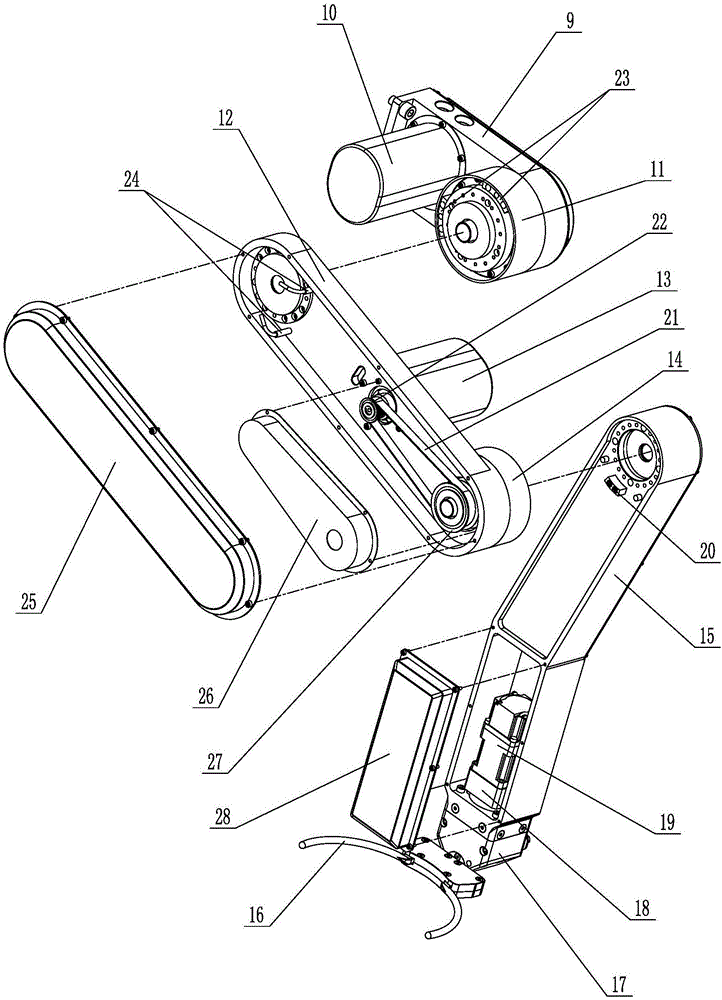

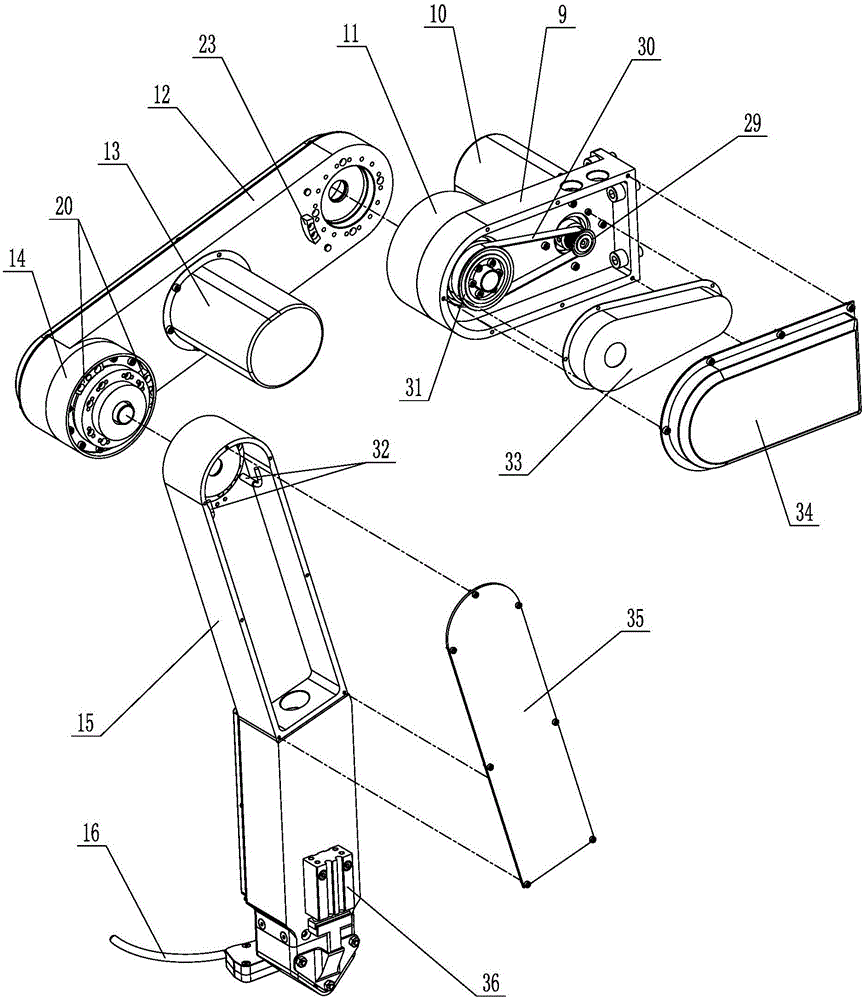

Double-arm feeding and discharging manipulator

PendingCN106625601AImprove efficiencyMovement guidance and repositioning are smoothProgramme-controlled manipulatorGripping headsGrippersManipulator

The invention provides a double-arm feeding and discharging manipulator, and belongs to a manipulator. The double-arm feeding and discharging manipulator comprises a base, wherein two manipulator bodies which are the same are arranged on the base in parallel; each manipulator body comprises a fixed arm, a first rotating arm, a second rotating arm and a manipulator gripper connected to the second rotating arm; each manipulator gripper comprises a support, a hollow rotating shaft, an upper cover plate and a lower cover plate; each support is connected with the corresponding second rotating arm; each hollow rotating shaft is rotatably connected with the corresponding support through a first oil-free lining; each upper cover plate and the corresponding lower cover plate are connected with an end of the corresponding hollow rotating shaft together; two arc-shaped clamping fingers which are clamped on side surfaces of a sheet disc-shaped workpiece are hinged to a position between each upper cover plate and the corresponding lower cover plate; each two arc-shaped clamping fingers are connected with a corresponding first driving mechanism which is used for driving the two arc-shaped clamping fingers to open and close; and each support is provided with a second driving mechanism which drives the corresponding hollow rotating shaft to rotate. In a feeding and discharging process of sheet disc-shaped workpieces, precision of the upper surfaces and the lower surfaces of the sheet disc-shaped workpieces cannot be affected, furthermore, overturning action can be finished, and feeding and discharging can be implemented simultaneously.

Owner:高维智控机器人科技(苏州)有限公司

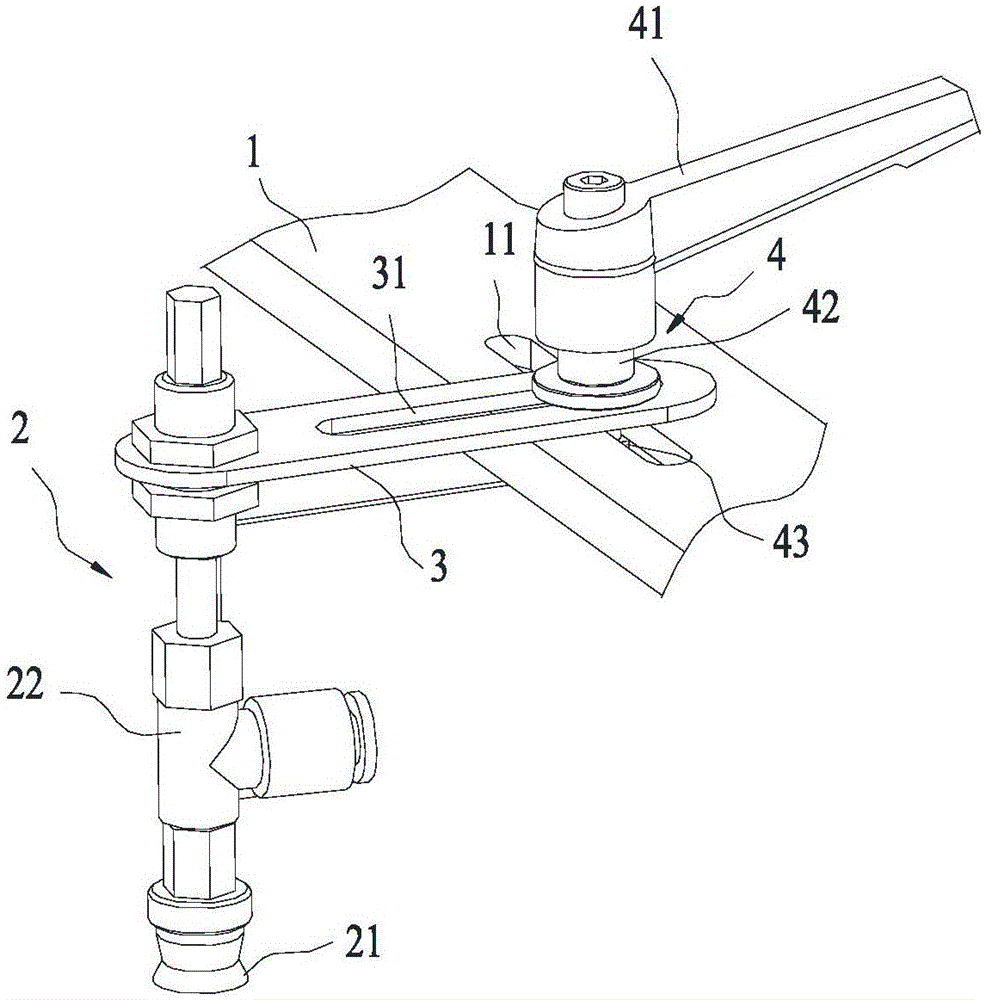

Fastening mechanism used for installation of shelves

InactiveCN105422570AImprove loading and unloading efficiencyReduce manual interventionFriction grip releasable fasteningsDowelsEngineeringMechanical engineering

The invention discloses a fastening mechanism used for installation of shelves. The fastening mechanism comprises two bodies fixedly connected with installation boards respectively; the two ends of each body comprise base parts with annular surfaces used for being combined with the back faces of supporting legs of the shelves and horizontal column parts which are integrally formed and perpendicular to the annular surfaces; each horizontal column part comprises a cylindrical inner side portion which is close to the corresponding installation board, integrally connected with the corresponding annular surface and used for being combined with a fixing hole of the supporting leg of the corresponding shelf, a cylindrical outer side portion located away from the tail end of the corresponding installation board, and a middle extending portion which is located between the cylindrical inner side portion and the cylindrical outer side portion and is cylindrical on the whole. The fastening mechanism used for installation of the shelves can also control alternate mounting and dismounting of two shelves simultaneously, when one shelf is mounted, the other shelf can be dismounted at the same time for special needs, and therefore the mounting and dismounting efficiency of the supporting legs of the shelves is improved and manual intervention is reduced.

Owner:孙莉新

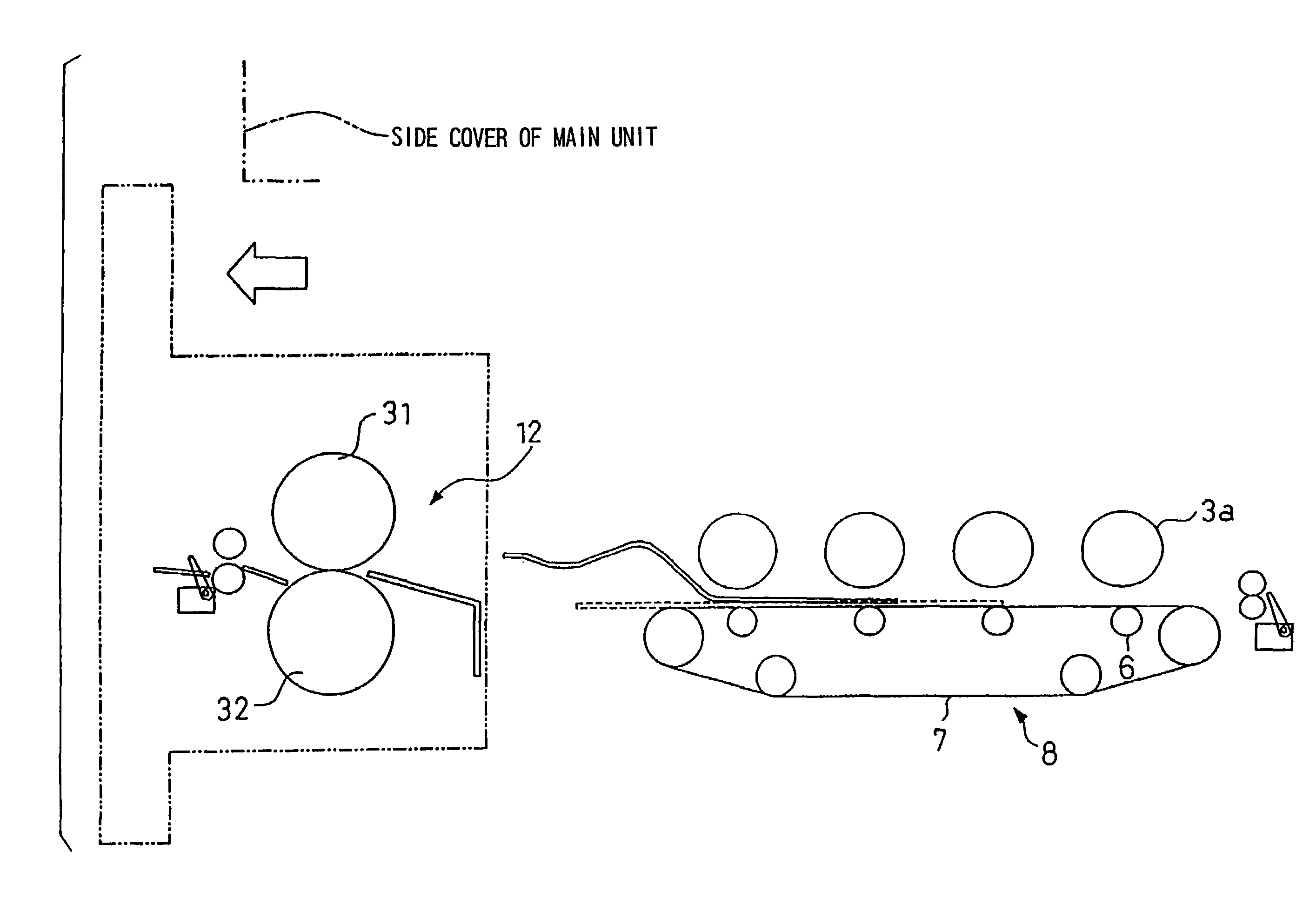

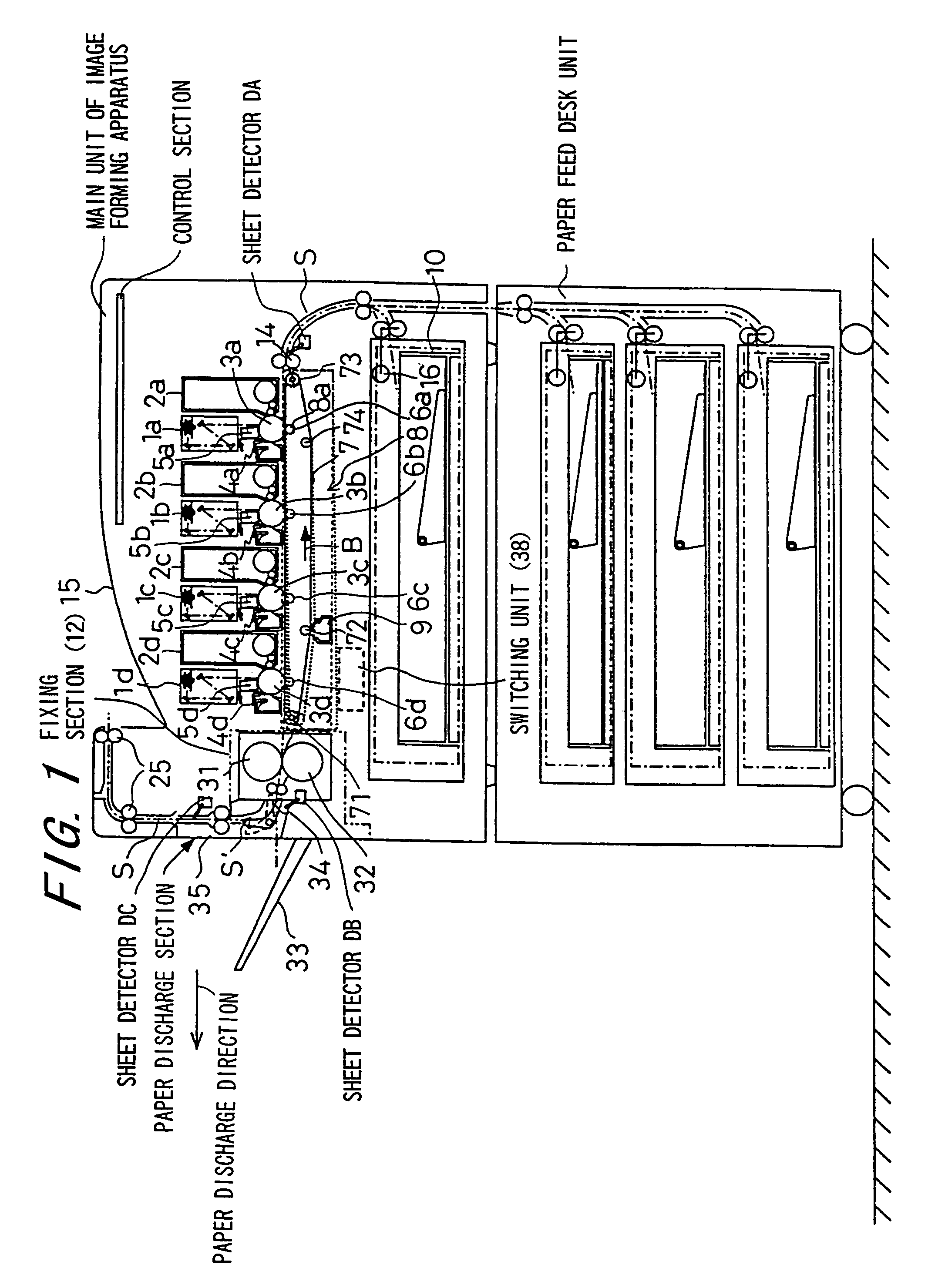

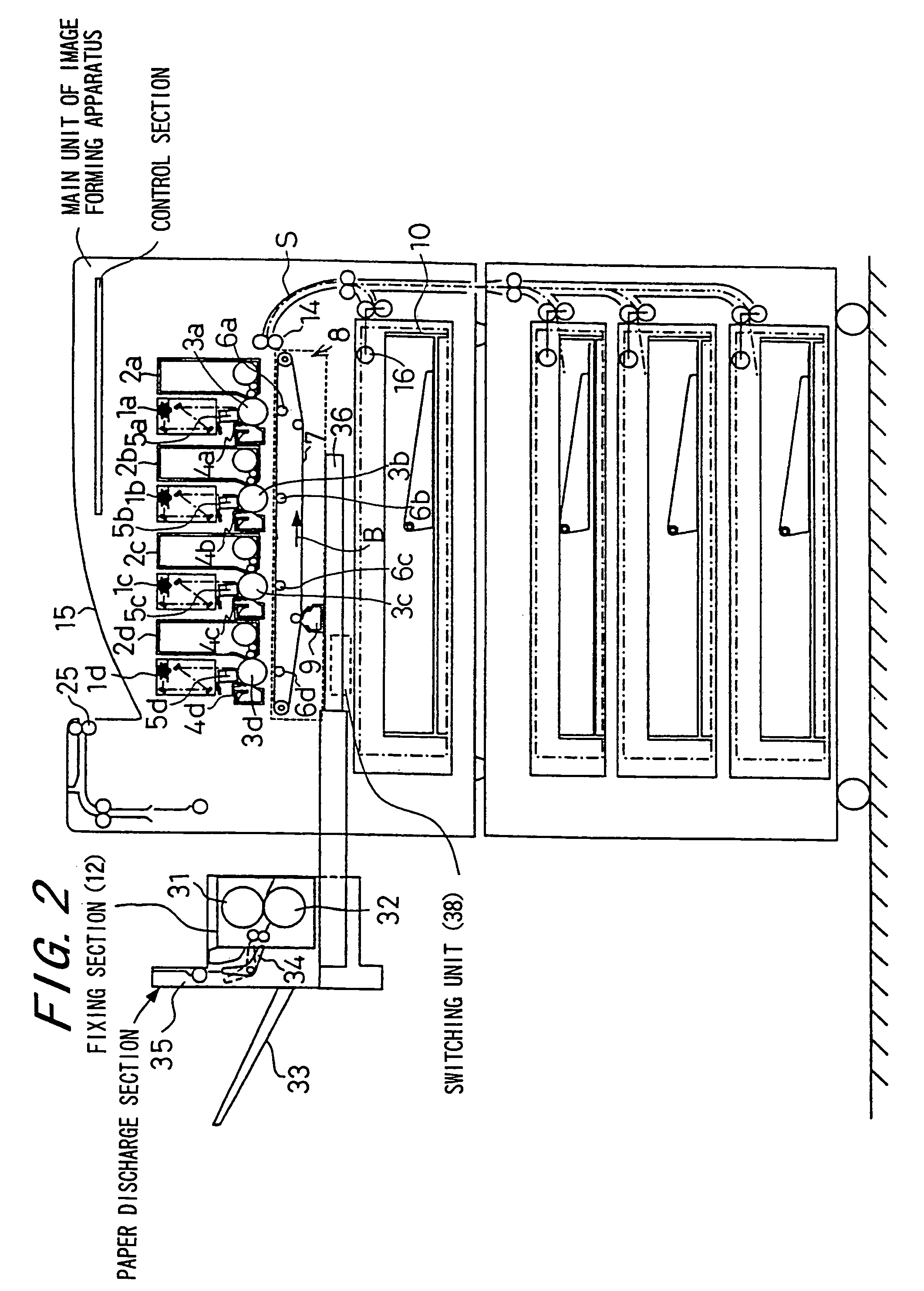

Image forming apparatus

InactiveUS7085504B2Easy to handleImprove loading and unloading efficiencyElectrographic process apparatusImage formationEngineering

An image forming apparatus transfers a toner image formed on a photoconductor drum onto a sheet-like recording member while the sheet-like recording member is transported and attracted to a transfer belt, and comprises a jam handling control unit for detecting a transport fault of the sheet-like recording member, and for stopping the transport operation when the transport fault is detected. When the transport fault is detected in a section other than a fixing section, the jam handling control unit first causes the transport operation of the fixing section, and thereafter causes the transfer belt and the transport operation on the upstream side thereof to stop, and any sheet-like recording member remaining on the transfer belt so that the transport mechanism on the upstream side thereof is transported and stopped at the position spanning between the area of the fixing section and the area of the transfer belt.

Owner:K MIZRA LLC

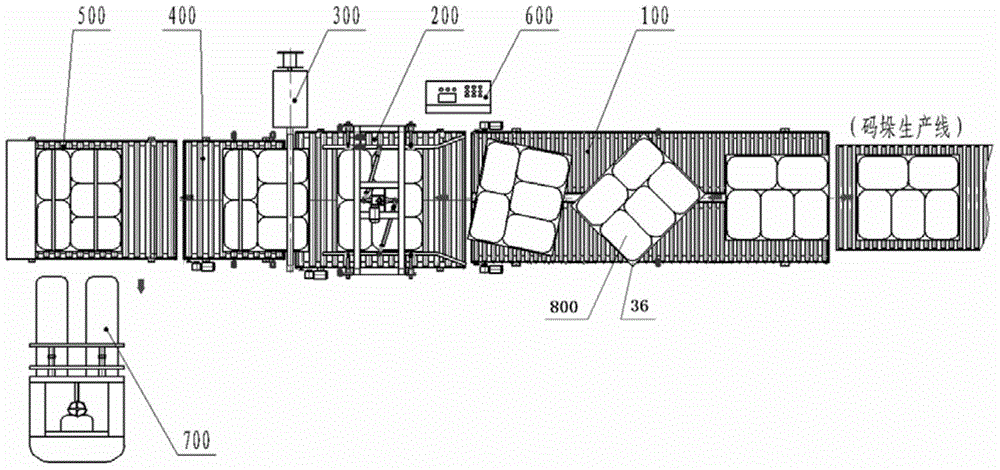

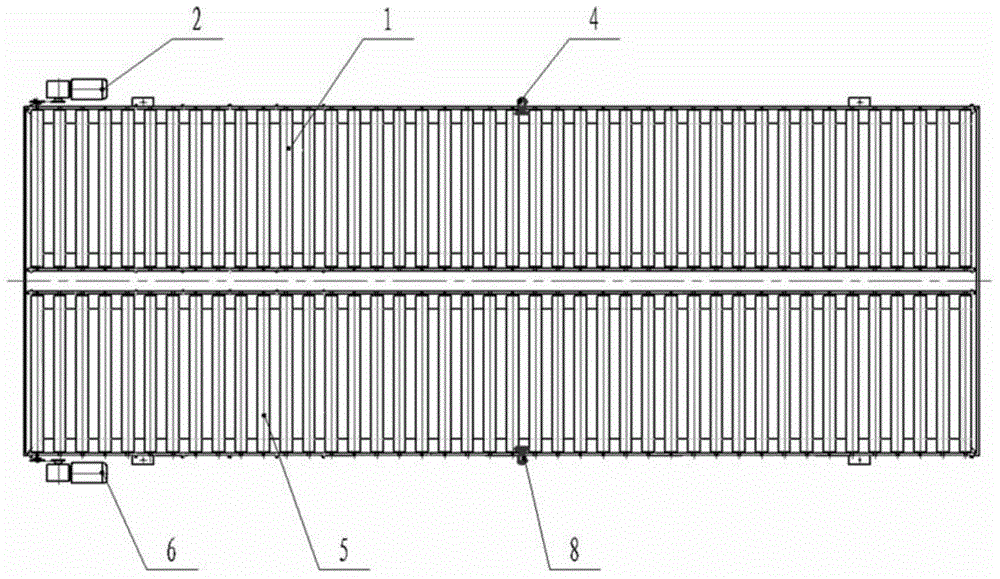

Tray-free packing method and tray-free packing device of brick stack

The invention discloses a tray-free packing method and a tray-free packing device of a brick stack. The tray-free packing device comprises a feeding machine, a clamping and transporting device, a cyclic conveying line, binding machines and a plurality of transfer trays; the feeding machine is arranged on a return track to complete the movement and positioning of a steaming-curing truck, and the return track runs through the clamping and transporting device; the cyclic conveying line is a closed rectangular annular cyclic conveying chain and comprises an empty-tray conveying chain-type conveyor belt, a secondary folding and clamping chain-type conveyor belt, an elevation and pushing mechanism, a primary binding chain-type conveyor belt, a secondary elevation and pushing mechanism, a secondary binding chain-type conveyor belt, a stack unloading chain-type conveyor belt, an empty-tray feeding chain-type conveyor belt and the a tray transportferring device; two binding machines respectively stretches across the primary binding chain-type conveyor belt and the secondary binding chain-type conveyor belt so as to bind the brick stack in the two mutually-vertical directions; and a transportferring tray is horizontally arranged on each station of the cyclic conveying line. Due to the adoption of the device, the production efficiency is greatly improved, and the labor intensity of workers is greatly alleviated.

Owner:LUOYANG ZHONGYE HEAVY IND GRP CO LTD

Bulk material discharging, storage and transportation equipment and transportation method

PendingCN108328360ARealize human-computer interactionReduce misuseConveyorsLarge containersControl systemHouse building

The invention discloses bulk material discharging, storage and transportation equipment which comprises a transportation hopper installed on the upper portion of a frame. The lower end of the transportation hopper is provided with a discharge outlet, and the discharge outlet is provided with a bin door capable of being opened and closed. The equipment further comprises a bin door opening-closing and detection system, a vehicle positioning indication human-machine interaction system, a transportation hopper material level detection and indication system, an upper spraying device and a lower spraying device which are connected with a control system, wherein the upper spraying device is installed on the upper portion of the transportation hopper, and the lower spraying device is installed onthe lower portion of the transportation hopper. Transportation vehicle automatic monitoring and reminding are achieved, a boat discharging door machine can work without interruption, the storage capacity of the transportation hopper can be displayed in real time, the bin door is automatically opened and closed for discharging, the lower portion of the transportation hopper is provided with a material weighing system, an empty vehicle weight house, a heavy vehicle weight house and a discharging, storage and transportation device are integrated into a whole, loading and weighing are completed ina one-stop mode, the automobile weight house building cost is reduced, processes are reduced, and production efficiency is improved. The invention further provides a transportation method for transporting bulk materials through the bulk material discharging, storage and transportation equipment.

Owner:RIZHAO PORT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com