All functional glass sheet stacking and dismantling machine and glass sheet stacking and dismantling method

A full-featured, glass-based technology, applied to conveyor objects, transportation and packaging, lighting and heating equipment, etc., can solve the problems of inconvenient operation and maintenance of glass, and achieve the effects of easy operation and maintenance, improved precision and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

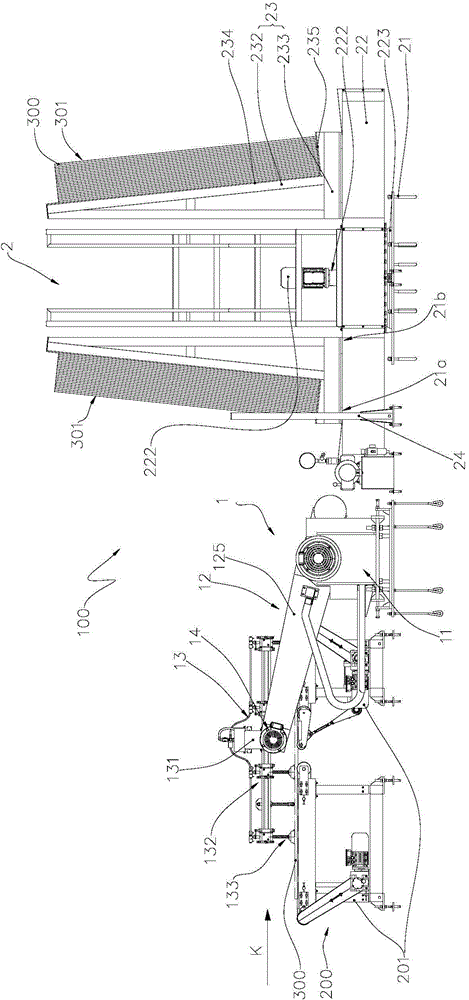

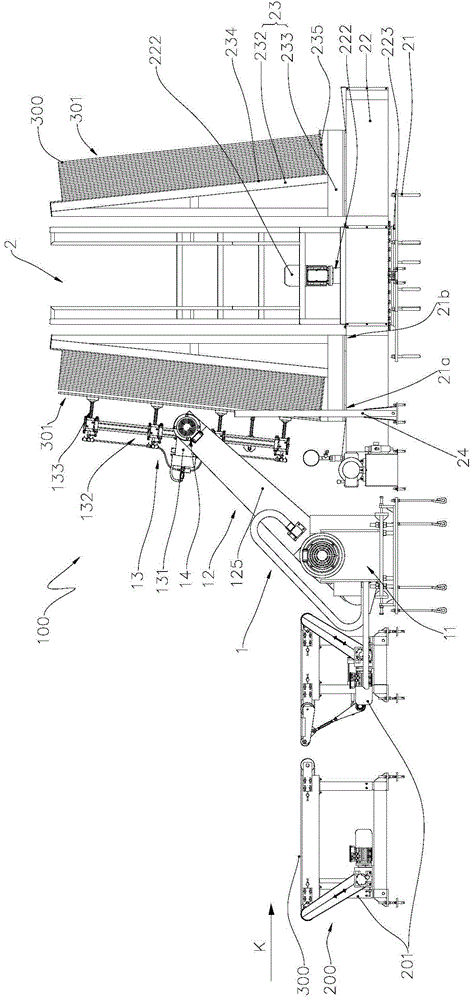

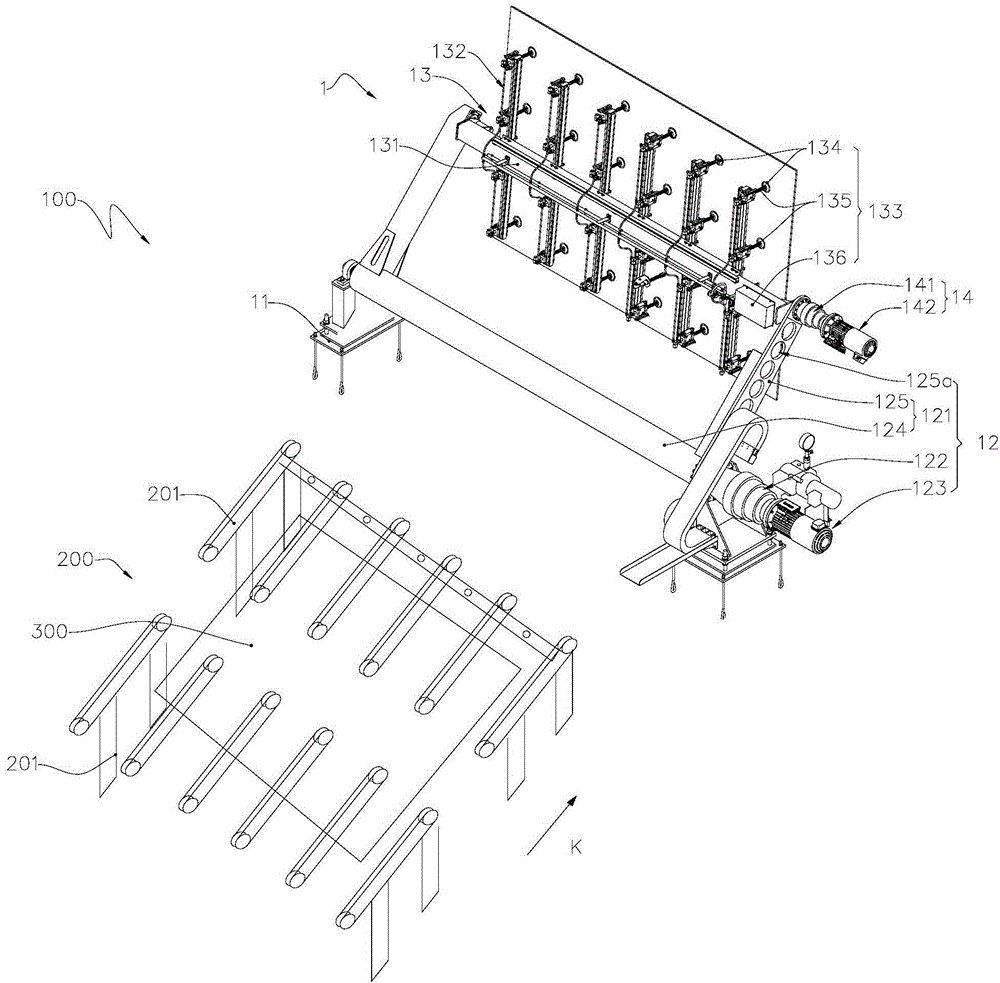

[0034] like Figure 1 to Figure 4 Shown is a preferred embodiment provided by the present invention.

[0035] The full-featured glass loading and unloading machine 100 provided by the present embodiment includes a glass plate 300 (hereinafter, for the purpose of simplification, the term is abbreviated as "glass production line 200") for the float glass production line 200 (hereinafter, for the sake of simplicity). For the sake of simplification, this term is simplified as "glass 300") suction host 1 for suction and stacking platform 2 for placing glass 300 to be sucked. The suction host 1 includes a base 11 , a swinging device 12 , a suction cup device 13 and a rotating device 14 . The swing device 12 is supported by the base 11, and the swing device 12 includes a swing frame 121, a first rotating shaft 122 fixedly connected to the side of the swing frame 121 near the base 11, and a first rotating shaft 122 for driving to rotate so that the swing frame 121 The side away from...

Embodiment 2

[0056] Combine below Figure 5 , only the differences from Embodiment 1 will be described in detail.

[0057]The walking and turning platform 25 is used for placing the sucked glass 300 horizontally. The walking overturning platform 25 includes a moving base 251 , a placing plate 252 arranged on the moving base 251 for loading and stacking the glass to be absorbed 300 , and an overturning mechanism 253 that drives the placing plate 252 to turn outward. The placing plate 252 is L-shaped, and under the action of the turning mechanism 253 , it can rotate by 90°. The right end of the placing plate 252 is pivotally connected on the moving seat 251 by a horizontal rotating shaft. The walking and turning platform 25 also includes a second roller 254 arranged at the bottom of the moving base 251 and a third power member 255 that drives the second roller 254 to move along the first direction K. The third power member 255 is a servo motor or a variable frequency motor. After the glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com