Dry-method fume gas purification method and device for synchronous desulfurization and denitrification

A desulfurization, denitrification, and flue gas purification technology, applied in the field of flue gas purification, can solve problems such as easy failure, unstable additives, and reduced practical value, and achieve the effects of strengthening mass transfer and heat transfer, and simplifying the removal system and process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A power plant uses the simultaneous desulfurization and denitrification dry flue gas purification device of the present invention for flue gas purification treatment. The generating set capacity is 200MW and the flue gas volume is 1,440,000m 3 / h, raw flue gas SO 2 The concentration is 3100mg / m 3 , raw flue gas NO x The concentration is 1100mg / m 3 , the inlet temperature of raw flue gas is 140℃, using Ca(OH) 2 As an absorbent, Ca / (S+0.5N) is 1.2, that is, the amount of absorbent used is 10.88t / h, and KMnO is selected 4 As an absorbent additive.

[0031] 1. Configure a certain concentration of additive aqueous solution and store it in the process water tank. The amount of additive added is 1% of the absorbent, that is, KMnO 4 The consumption is 0.11t / h.

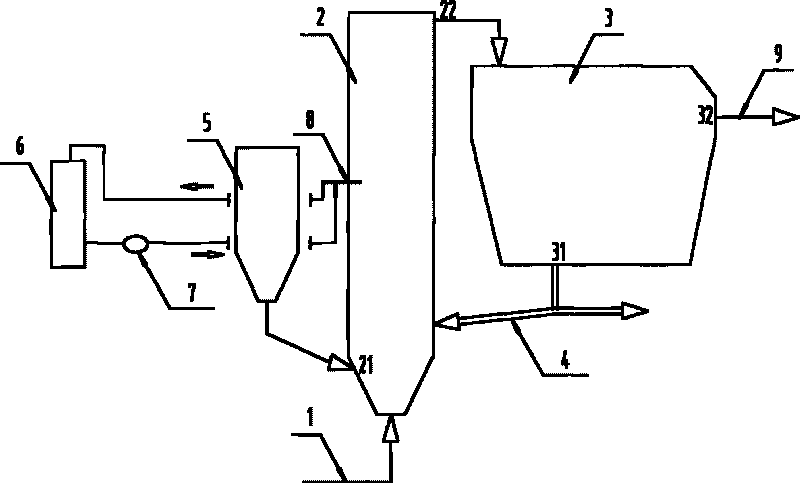

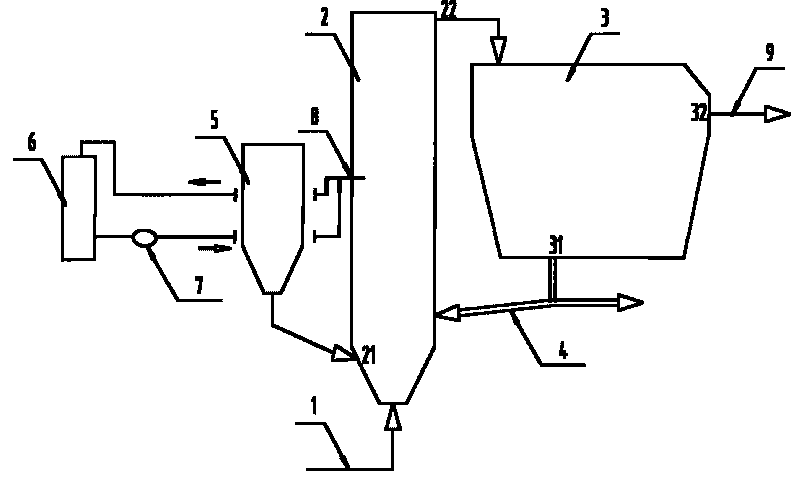

[0032] 2. The raw flue gas that needs to be purified enters the circulating fluidized bed reaction absorption tower 2 from the inlet flue 1, and is mixed with the absorbent added from the absorbent bin 5 and the r...

Embodiment 2

[0037] In Example 1, a certain power plant uses the simultaneous desulfurization and denitrification dry-process flue gas purification device of the present invention to perform flue gas purification treatment. KMnO 4 The consumption is 0.33t / h. After testing, the outlet net flue gas SO 2 The concentration is about 217mg / m 3 , the desulfurization efficiency reaches 93%; NO x The concentration is about 242mg / m 3 , The denitrification efficiency reaches 78%.

Embodiment 3

[0039] In Embodiments 1 and 2, a certain power plant uses the simultaneous desulfurization and denitrification dry flue gas purification device of the present invention to carry out flue gas purification treatment. 5%, ie KMnO 4 The consumption is 0.55t / h. After testing, the outlet net flue gas SO 2 The concentration is 155mg / m 3 , desulfurization efficiency up to 95%; NO x The concentration is 88mg / m 3 , The denitrification efficiency reaches 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com