Tetrahydrofuran preparation system and use method thereof

A technology of tetrahydrofuran and dehydration tower, which is applied in the chemical industry, can solve the problems of low THF purity, limited spandex application range, poor spandex quality, etc., and achieve the effect of reducing impurity content, facilitating subsequent processing, and less impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

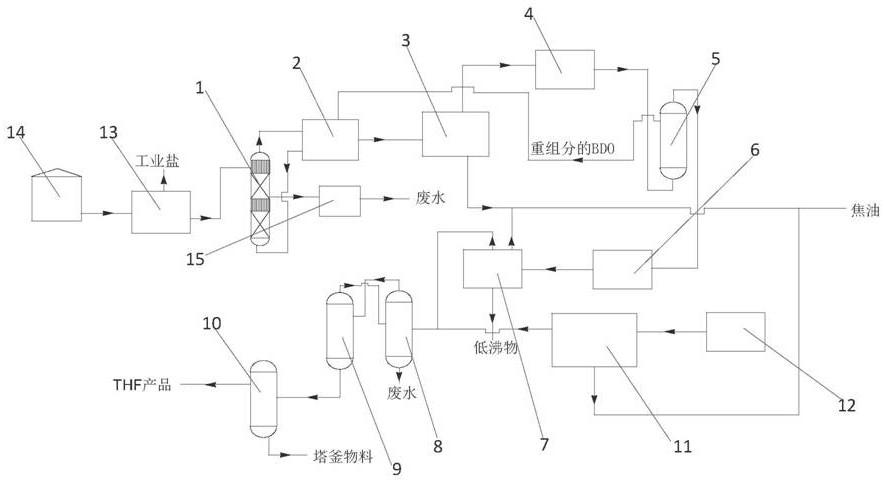

[0041] Please refer to figure 1 , figure 1 Shown is a schematic diagram of the system structure of the embodiment of the present invention.

[0042] The present invention provides a system for preparing tetrahydrofuran, comprising a BDO treatment device and a THF treatment device connected with the BDO treatment device; the THF treatment device includes a BDO reactor 7 connected with the BDO treatment device, and a THF dehydration device connected with the BDO reactor 7 Tower 8, THF pressure tower 9 connected with THF dehydration tower 8, THF decolorization tower 10 connected with THF pressure tower 9 and producing tetrahydrofuran product from the middle, and PTMEG reactor 11 connected with THF dehydration tower 10.

[0043] In this embodiment, the BDO treatment device can dehydrate and purify the tar oil, so that the obtained BDO has a higher purity, and in the subsequent preparation of THF, THF with higher purity and better quality can be obtained; The THF obtained by degr...

Embodiment 2

[0046] Please refer to figure 1 , figure 1 Shown is a schematic diagram of the system structure of the embodiment of the present invention.

[0047] The present invention provides a system for preparing tetrahydrofuran, which differs from Example 1 in that: the BDO treatment device includes a BDO dehydration tower 1, a BDO tar tank 2 connected to the top and bottom of the BDO dehydration tower 1, and a BDO tar tank 2. The BDO evaporator 3, the liquid storage tank 4 connected with the BDO evaporator 3, the BDO vacuum tower 5 connected with the liquid storage tank 4 at the bottom, and the BDO product tank 6 connected with the BDO vacuum tower 5 top and the BDO reactor 7 respectively , wherein, the middle part of the BDO vacuum tower 5 is connected with the BDO tar tank 14.

[0048] In this embodiment, the BDO dehydration tower 1 can dehydrate the recovered BDO tar, reduce the water content in the BDO tar, and facilitate subsequent processing. Its top and bottom are respectivel...

Embodiment 3

[0050] Please refer to figure 1 , figure 1 Shown is a schematic diagram of the system structure of the embodiment of the present invention.

[0051] The present invention provides a system for preparing tetrahydrofuran, which is different from Example 2 in that: the upper end of BDO dehydration tower 1 is connected with a pretreatment device.

[0052] In the present embodiment, the pretreatment device is connected with the BDO dehydration tower 1 pipeline, which collects and processes the recovered BDO tar, and can separate the salt in the BDO tar. On the one hand, the separated salt can be used after washing and decolorization. In industrial salt and deicing agent, it can improve the utilization rate, on the other hand, it can also reduce the impurities in BDO tar, which is convenient for subsequent processing, so that the final product has less impurity content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com