SCR denitration reducing agent preparation device with flue gas heating system and method

A flue gas heating and preparation device technology, applied in separation methods, chemical instruments and methods, transportation and packaging, etc., can solve problems such as complex systems and huge systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

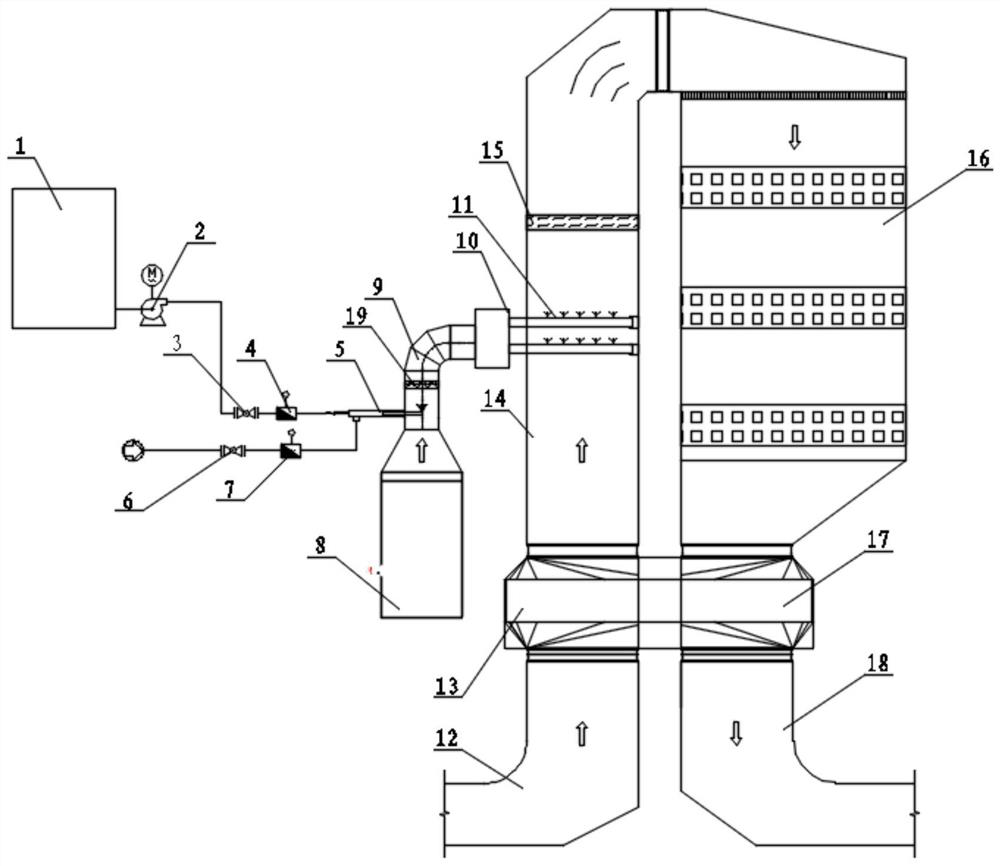

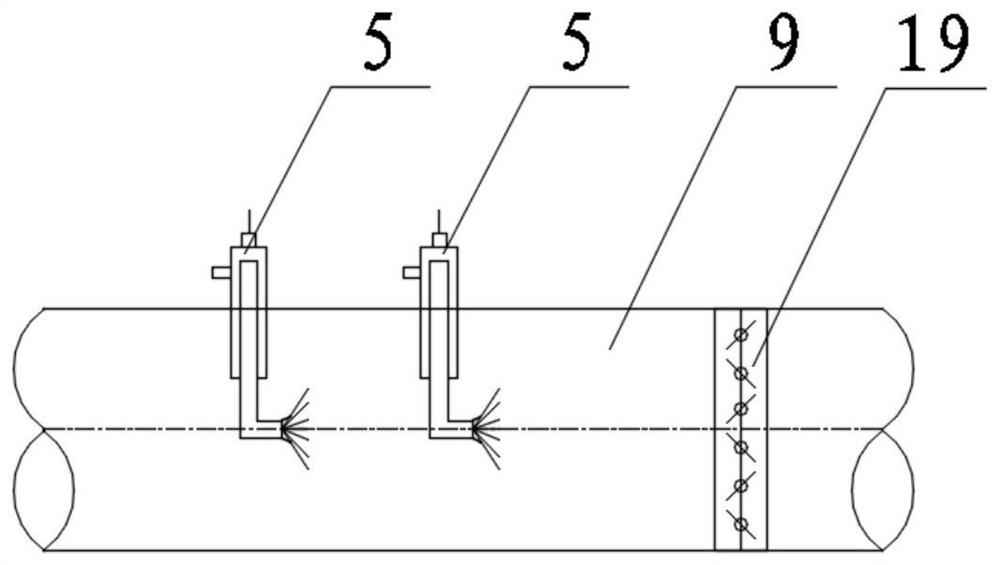

[0028] A method for preparing a SCR denitrification reducing agent with a flue gas heating system, mainly comprising: reducing agent solution storage tank 1, reducing agent solution delivery pump 2, reducing agent solution regulating valve 3, reducing agent solution flow meter 4, atomizing spray gun 5 , Compressed air regulating valve 6, Compressed air flowmeter 7, Heating furnace 8, High temperature flue gas pipe 9, Hot air bellows 10, Hot air distribution pipe 11, Denitration inlet flue 12, GGH flue gas heat exchanger raw flue gas side 13, Vertical flue 14, static mixer 15, SCR reactor 16, GGH flue gas heat exchanger net flue gas side 17, denitrification outlet flue 18, high temperature flue gas mixer (19). .

[0029] An atomizing spray gun 5 is set at the high-temperature flue gas pipeline 9 at the outlet of the heating furnace 8, and the reducing agent solution is directly sprayed into the high-temperature flue gas pipeline 9, and the high-temperature flue gas is evaporate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com