Patents

Literature

61results about How to "Increase flue gas volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

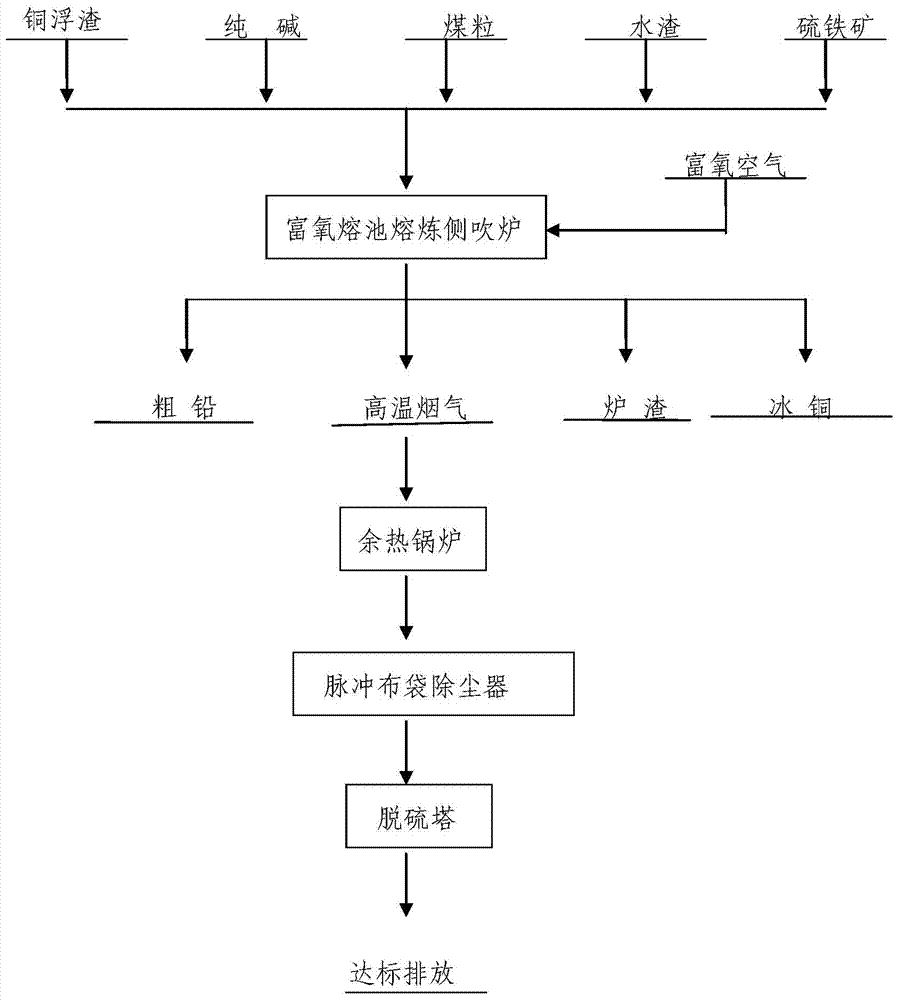

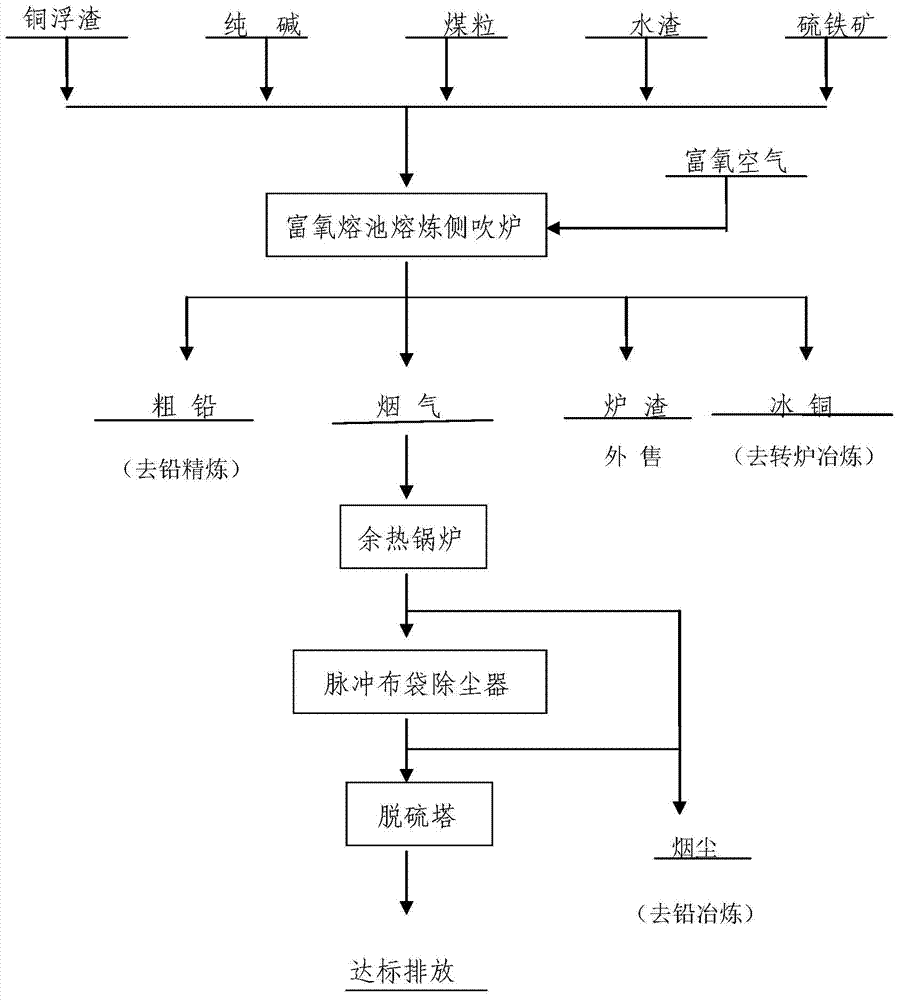

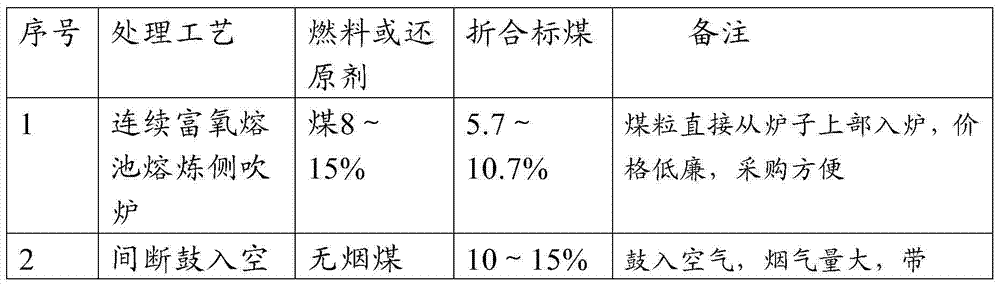

Method for treating copper dross

ActiveCN103924094AImprove melting efficiencyHigh direct metal recovery rate and recovery rateProcess efficiency improvementAutomatic controlPyrite

The invention provides a method for treating copper dross. According to the method, copper dross is treated by using an oxygen enrichment molten pool smelting side blowing furnace, coal granules are adopted as a reducing agent and fuel, copper dross, pure alkali, pyrite and water granulated slag are adopted for blending, together with the coal granules, are fed into the furnace from the feeding hole of the oxygen enrichment molten pool smelting side blowing furnace through a belt, and are blown into an oxygen enrichment air smelting pool for smelting so as to obtain crude lead, copper matte, furnace slag and high-temperature flue gas. By adopting the method provided by the invention, continuous feeding is achieved; due to adoption of a DCS automatic control technique, the working intensity of operators is low, the flushing and casting environment is good, the side blowing treatment bed is high in capacity, the efficiency of the smelting pool is high, the metal recycling rate is high, and the smelting energy consumption is low.

Owner:JIYUAN WANYANG SMELTING GROUP

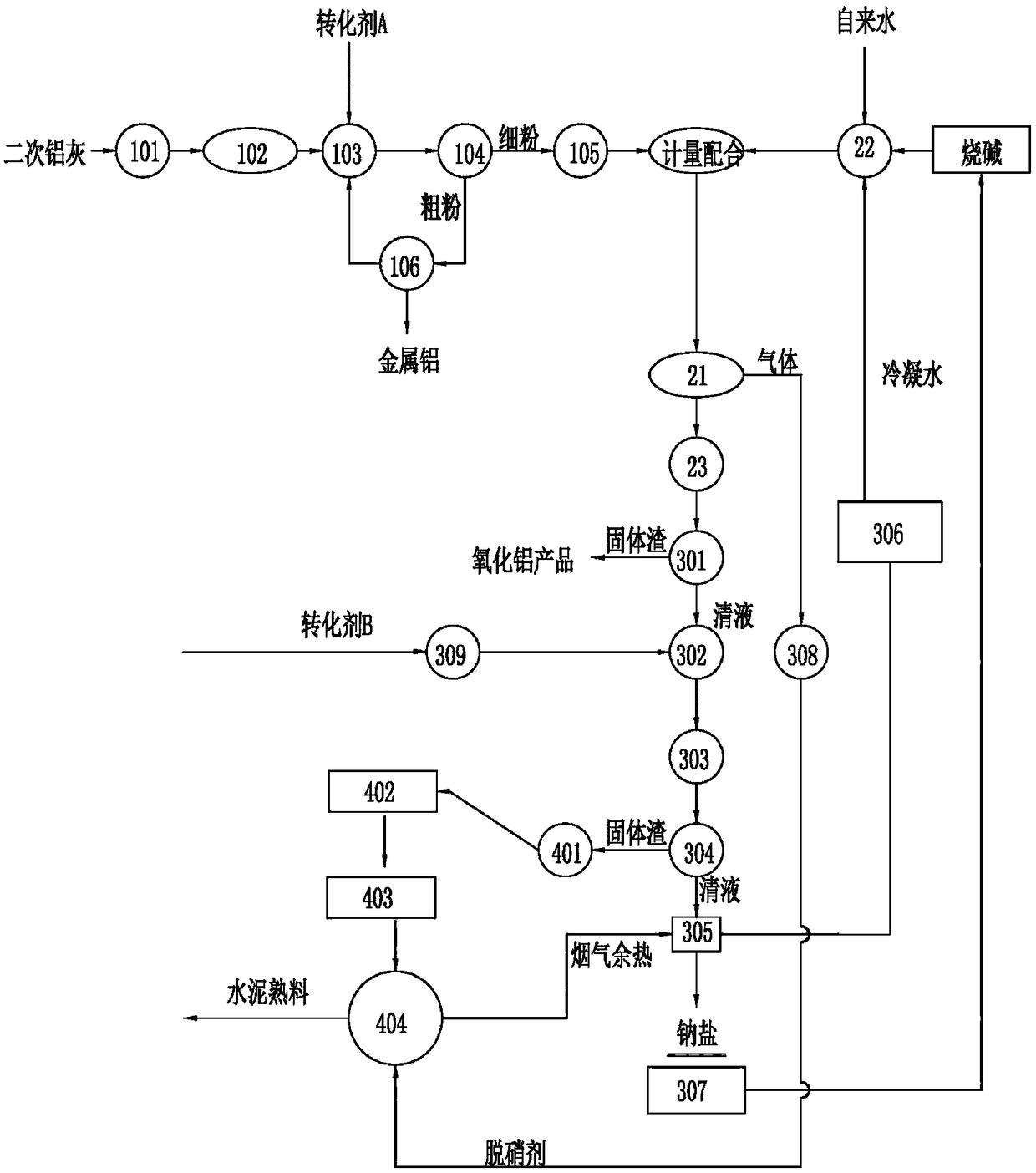

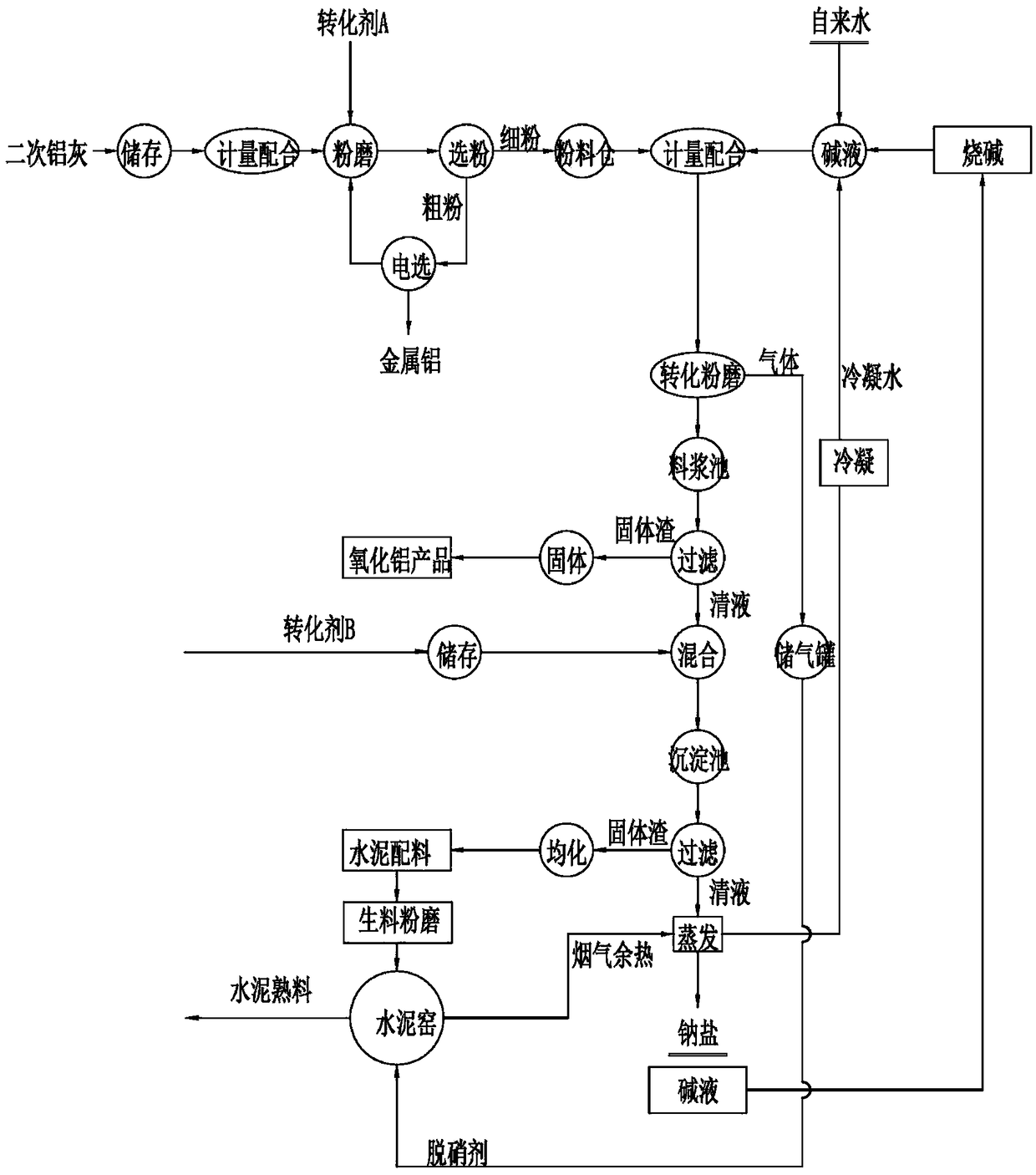

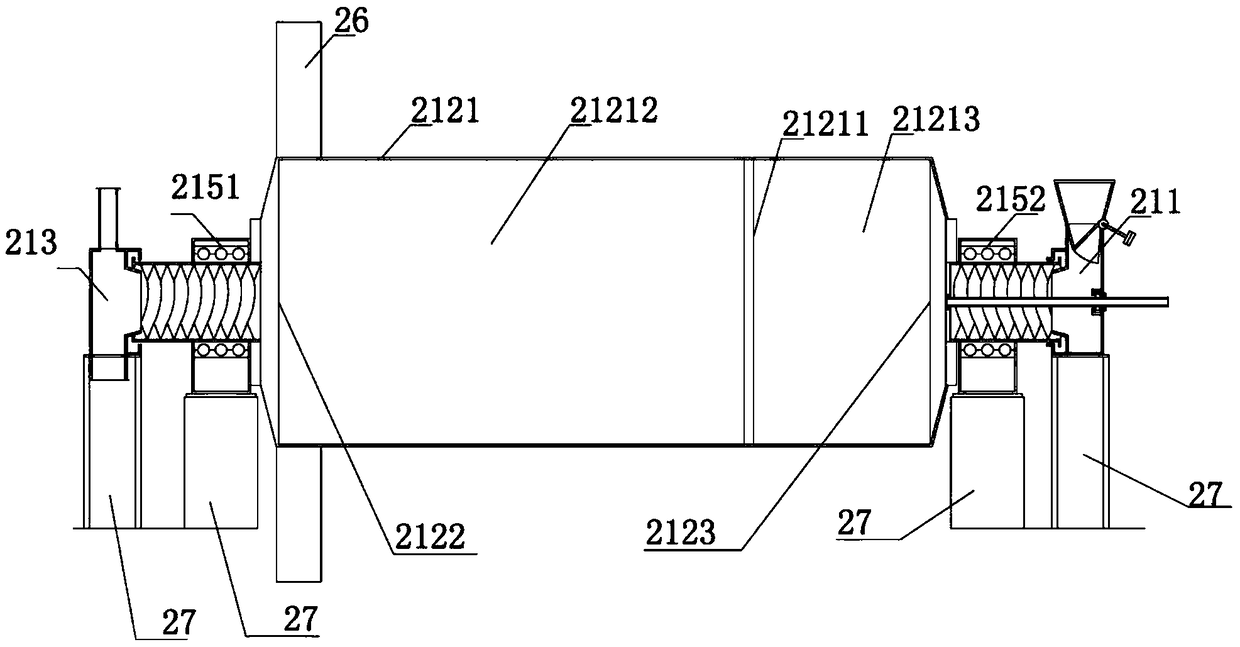

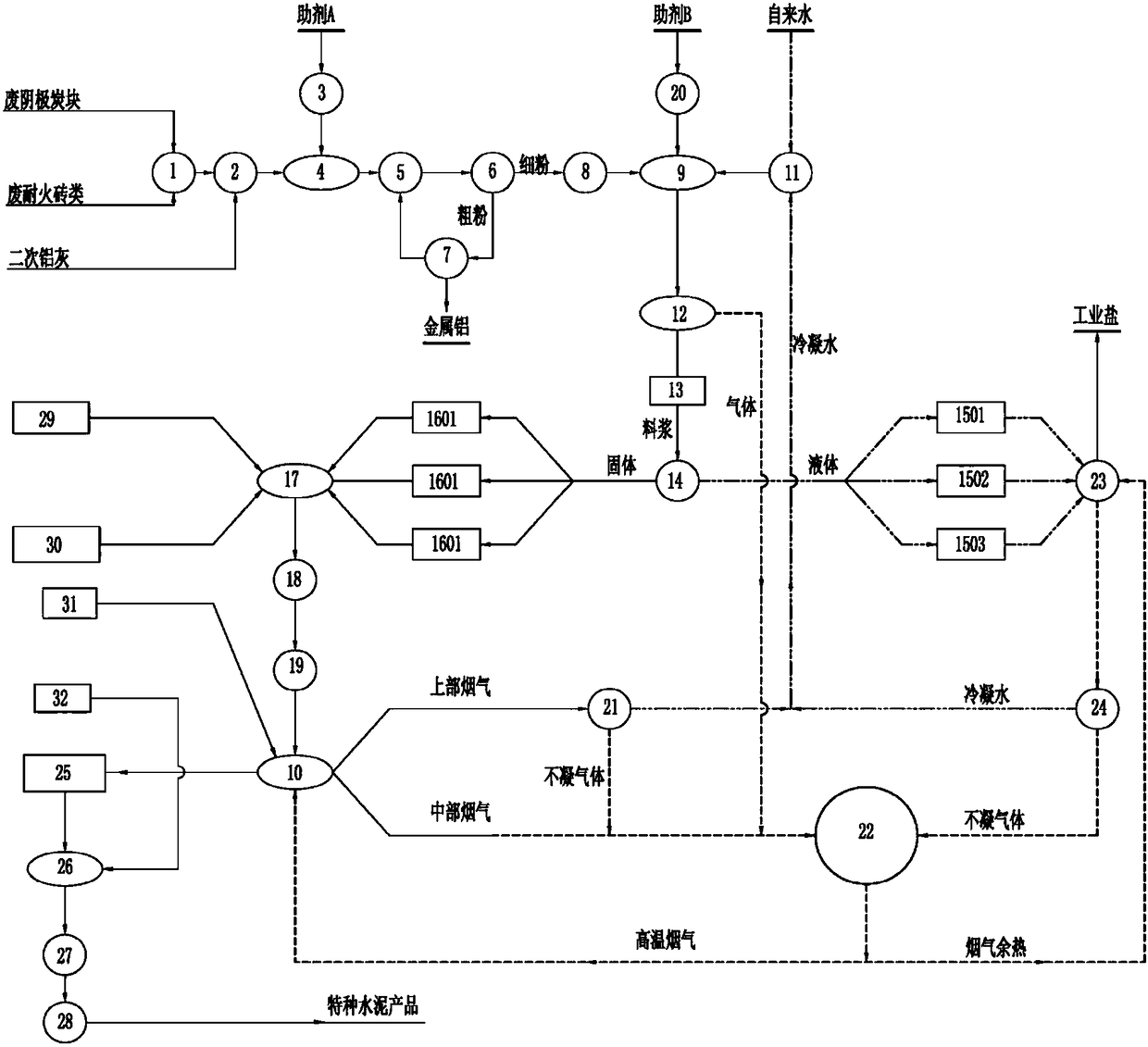

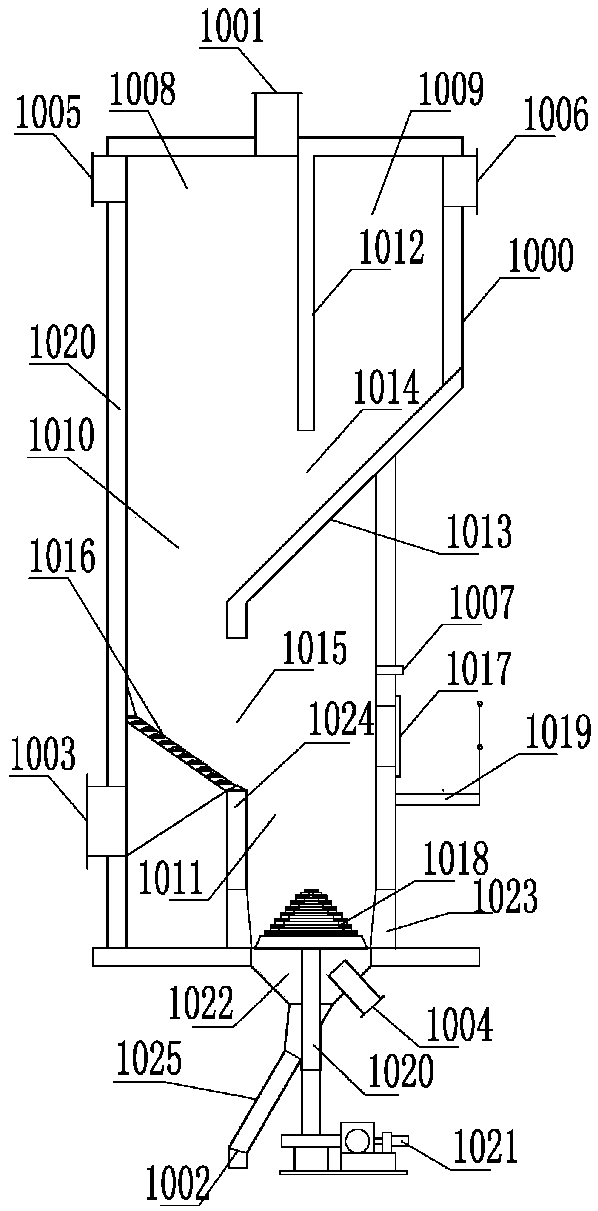

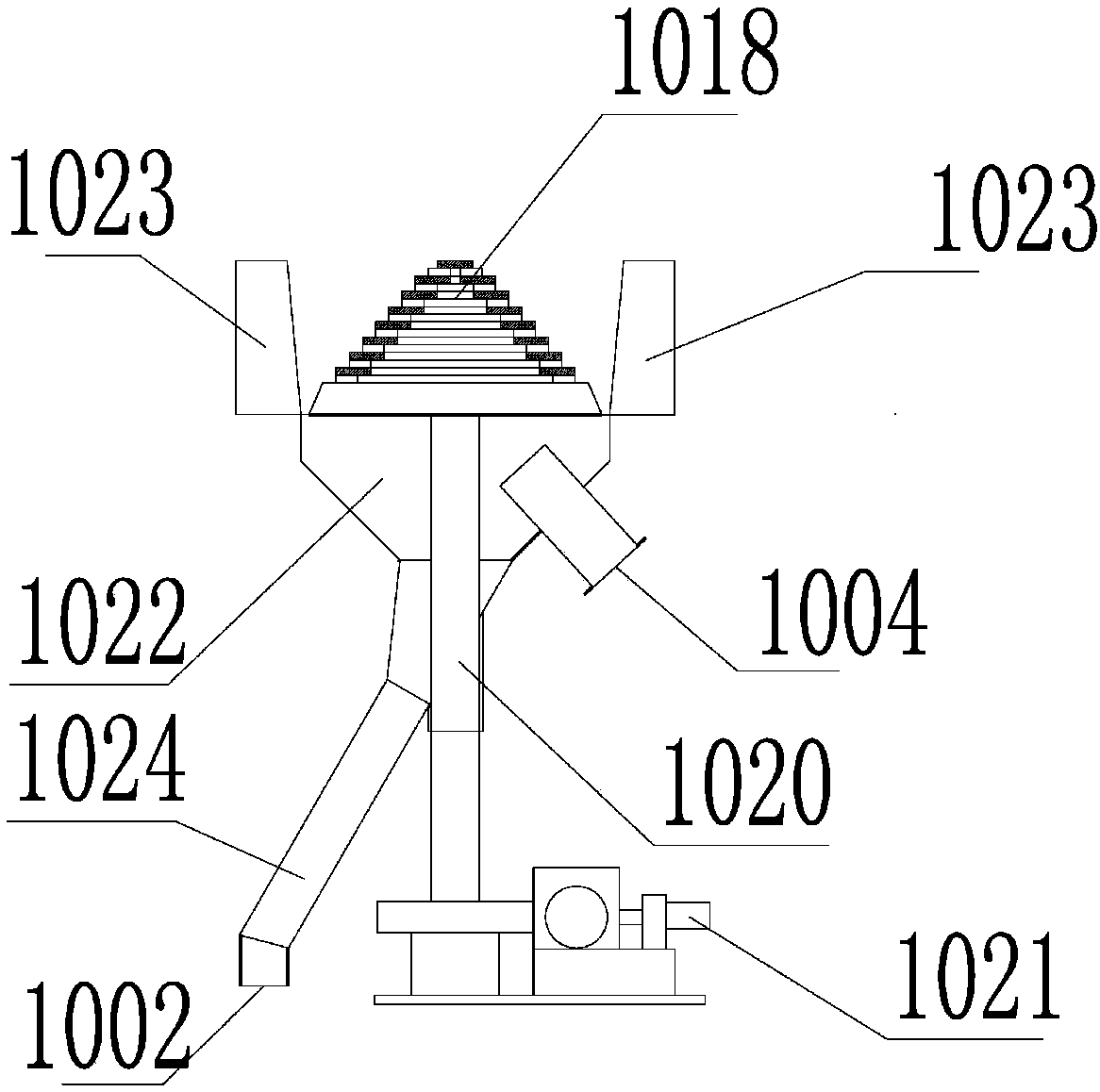

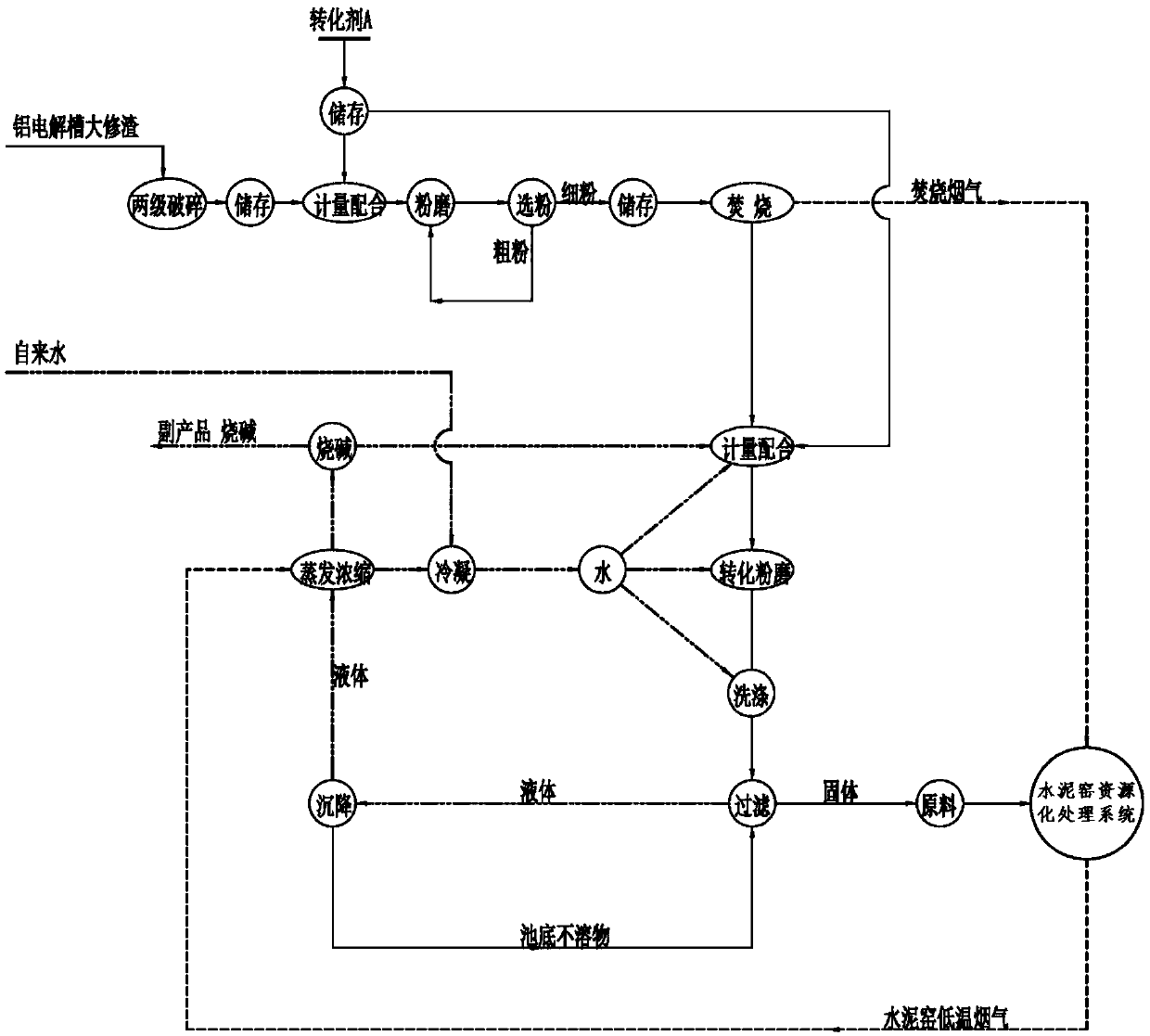

System and method for cooperatively processing secondary aluminum ash by virtue of cement kiln

PendingCN108773849AEliminate toxicityEliminate Toxic HazardsCement productionAlkali metal hydroxidesPre treatmentWet grinding

The invention provides a system and a method for cooperatively processing secondary aluminum ash by virtue of a cement kiln. The system comprises a waste residue preprocessing system, an anaerobic wet-grinding conversion system, an alkali metal salt leaching system and a cement kiln resourceful treatment system which are sequentially connected, wherein all equipment and connecting pipelines in thesystem are sealed, and a suction machine is arranged so as to generate a micro-negative pressure. The method comprises the following steps: (S1) secondary aluminum ash preprocessing, (S2) anaerobic wet-grinding conversion, (S3) alkali metal salt leaching, and (S4) cement kiln resourceful treatment. According to the system and the method, the harmless and resourceful final treatment of the secondary aluminum ash can be realized, 0.1t-0.3t of alkali metal salt, 0.02t-0.1t of caustic soda and 0.5t-0.8t of aluminum oxide byproducts can be extracted during the treatment of 1t of secondary aluminumash, and 0.2t-0.3t of cement raw materials and 0.05t-0.2t of a denitration agent can be provided for a cement plant. By utilizing an anaerobic wet-grinding conversion machine, H2 and CH4 generated inthe conversion process do not burn and explode, the disinfection and conversion of solid waste residue materials can be realized, and converted gas can be extracted.

Owner:长沙中硅环保科技有限公司

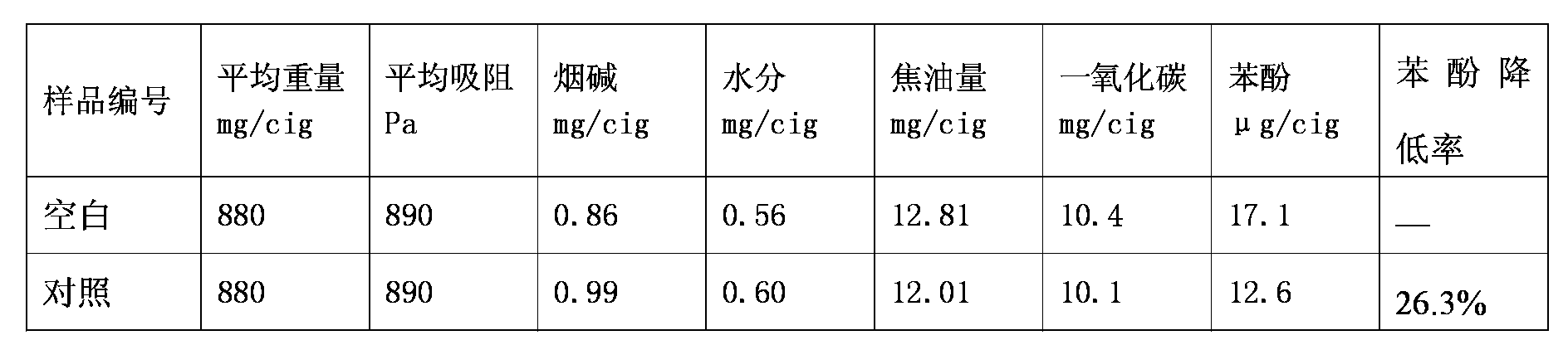

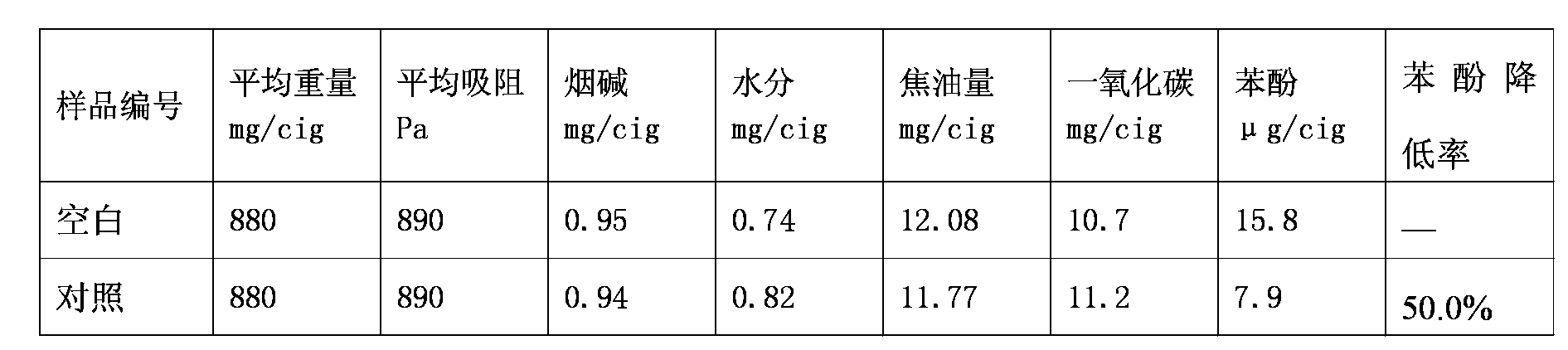

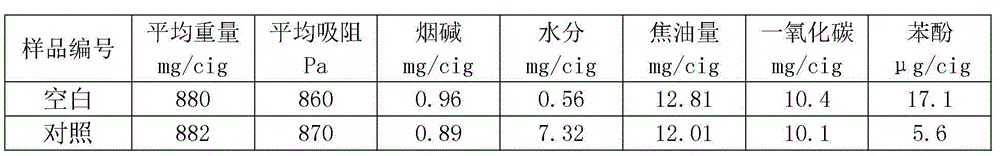

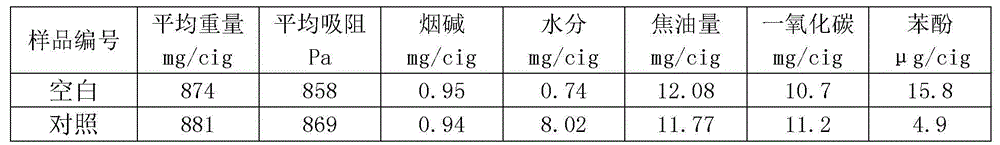

Preparation method of filter stick using cigarette harm-reducing synergistic agent containing glycerol triacetate

InactiveCN103211304ADoes not increase hardnessGuarantee the appearance qualityTobacco smoke filtersGlycerolSolvent

The invention discloses a preparation method of a filter stick using a cigarette harm-reducing synergistic agent containing glycerol triacetate. The preparation method comprises the following steps: (1) blending 60-90% mass percent of fat-soluble solvent, 5-35% mass percent of glycerol triacetate and 0.01-5% mass percent of tobacco flavor, stirring and mixing evenly to obtain the cigarette harm-reducing synergistic agent, wherein the fat-soluble solvent is food-grade fatty acid, alcohol or a grease solvent; and (2) coating the cigarette harm-reducing synergistic agent in capsules as core materials to be added into cigarette filter stick by adopting capsule addition technology of the cigarette filter stick. The method is wide in raw material source, low in cost, capable of obviously reducing the content of phenol in cigarette smoke and also endowing smoke with special aroma and taste.

Owner:HUBEI CHINA TOBACCO IND +1

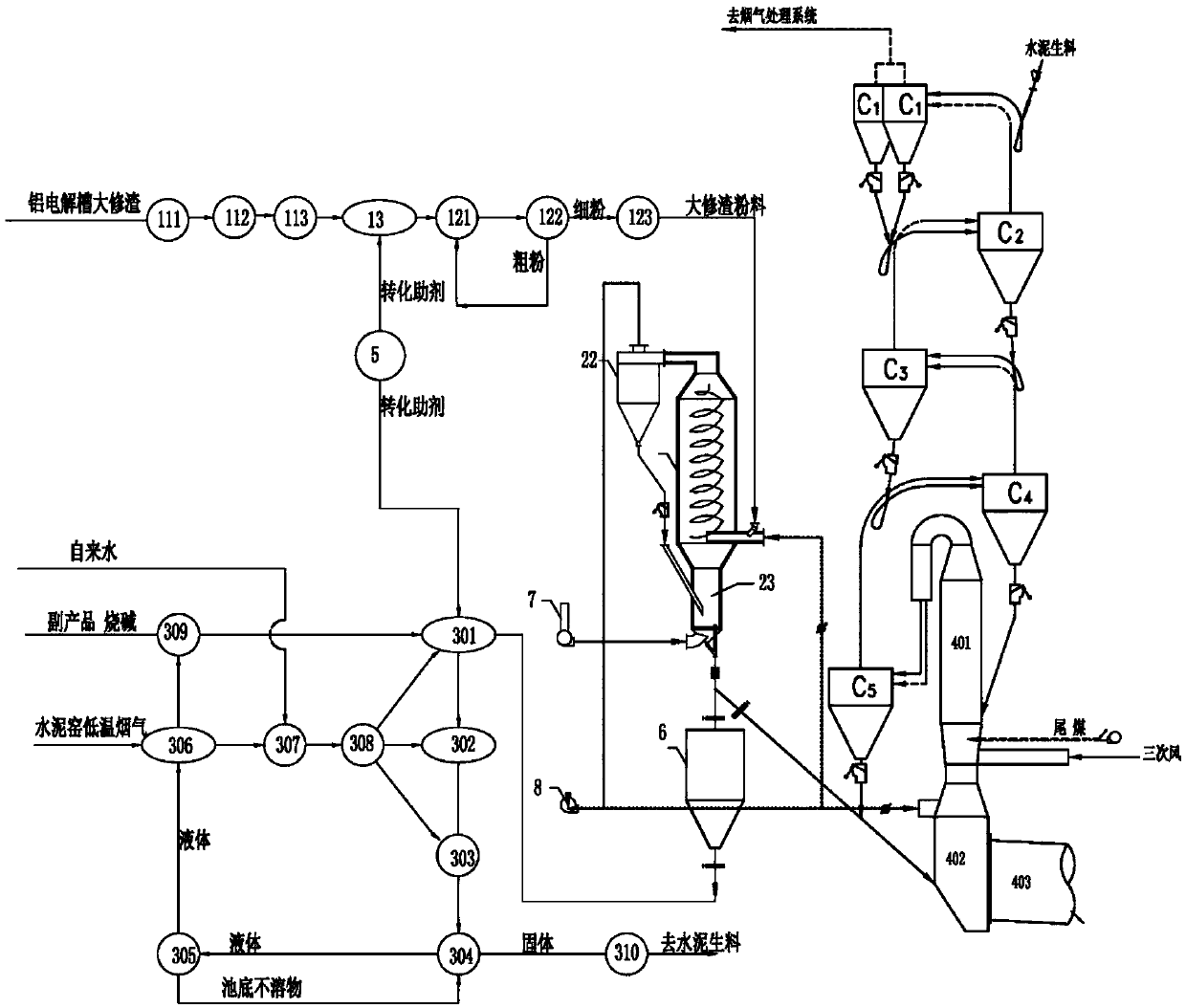

System and method to treat electrolytic aluminum waste residue and co-produce quick-setting quick-hardening cement under cooperation of cement kiln

The invention provides a system and method to treat electrolytic aluminum waste residue and co-produce quick-setting quick-hardening cement under cooperation of a cement kiln, wherein the system comprises a waste residue pretreatment system, a conversion reaction system, an alkaline metal salt extraction system and a cement kiln-based parallel production system of quick-setting quick-hardening cement, which are connected in sequence; all units in the system are hermetically connected, and a suction unit is provided to form micro negative pressure. The method comprises the steps: waste residuepretreatment; conversion reaction; extraction of alkaline metal salts and cement-kiln-based parallel production of quick-setting quick-hardening cement. The system and method herein have the advantages that electrolytic aluminum industrial waste residue can be centrally and uniformly treated at a time to eliminate its toxicity and hazard, and harmless, resourceful and final treatment of the electrolytic aluminum waste residue is achieved. The system and method are also capable of producing special quick-setting quick-hardening cement under low energy consumption and low cost, with no three wastes discharged and no secondary pollution caused.

Owner:长沙中硅环保科技有限公司 +1

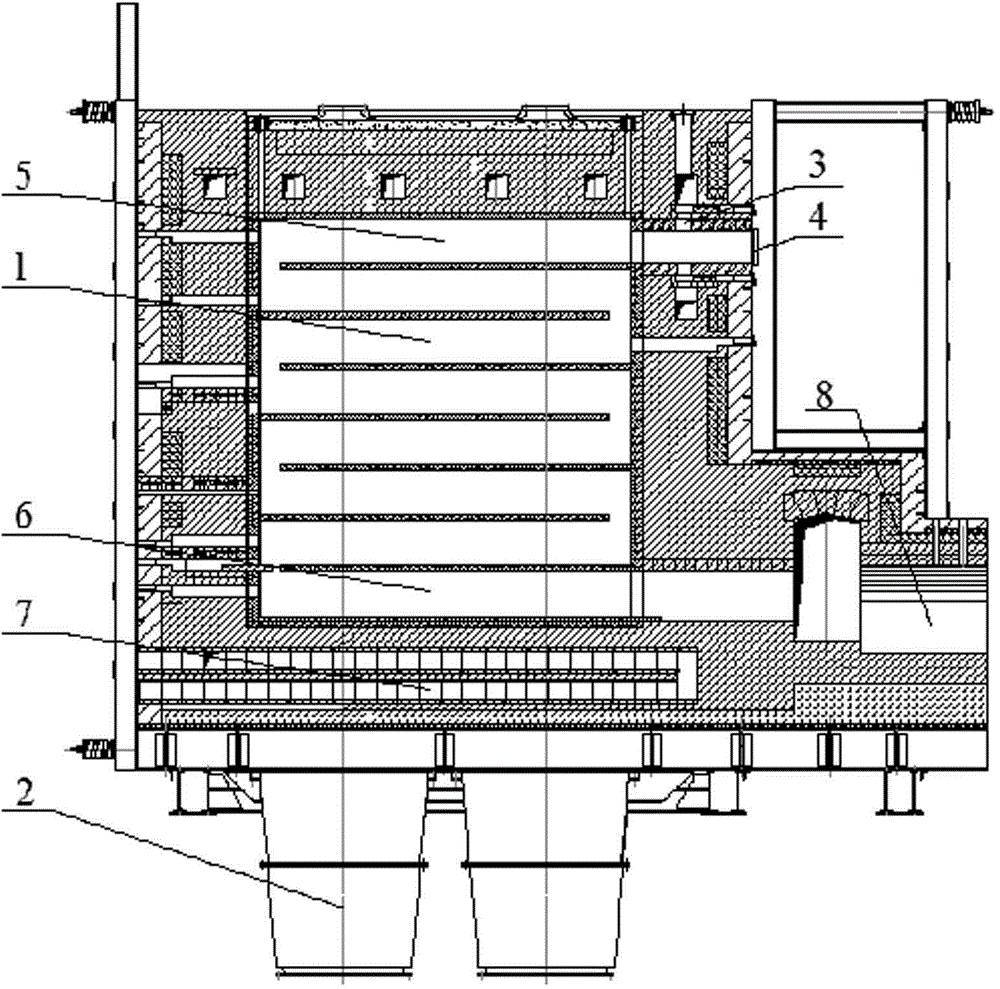

Magnetizing roasting self-heating balancing device and method for iron ore tunnel kiln

InactiveCN105091576ALower unit costIncrease profitFurnace typesWaste heat treatmentTunnel kilnCold air

The invention discloses a magnetizing roasting self-heating balancing device and method for an iron ore tunnel kiln. A heat-accumulating type heat exchanger is arranged outside a tunnel kiln heating reduction zone. A high-temperature smoke inlet of the heat-accumulating type heat exchanger is connected with a smoke exhaust port of the tunnel kiln heating reduction zone. A heating reduction zone smoke exhauster is arranged at a smoke outlet of the heat-accumulating type heat exchanger. An air blower is arranged at a cold air inlet of the heat-accumulating type heat exchanger. A hot air outlet of the heat-accumulating type heat exchanger is connected with a hot wind pass-in channel arranged on the side wall of the tunnel kiln heating reduction zone through a hot wind pipeline. According to the magnetizing roasting self-heating balancing device and method for the iron ore tunnel kiln, the ratio of the quantity of exhaust smoke exhausted out of a kiln feeding end to the quantity of exhaust smoke exhausted out of the heating reduction zone is adjusted, so that the smoke exhaust temperature at the kiln feeding end of the tunnel kiln and the heat loss due to the fact that heat is taken away by the smoke are reduced; in addition, material heating with coal as fuel is achieved when the tunnel kiln does not use externally supplied gas fuel, and the smoke exhaust temperature at the smoke outlet is reduced below 250 EDG C at the same time; the energy utilization rate is increased and unit cost of iron ore magnetizing roasting is reduced.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Hawk tea extract, preparation method thereof and application of extract in cigarette

InactiveCN104336775AGuaranteed contentImprove product qualityTobacco treatmentBiotechnologyOrganic solvent

The invention discloses hawk tea extract, a preparation method thereof, and an application of the extract in cigarette and relates to the plant extract and application thereof. The preparation method for the hawk tea extract includes steps that (1) pre-processing; (2) ultrasonic extracting; (3) purifying through ethanol; (4) membrane separation; (5) condensing. The hawk tea extract is diluted through organic solvent without toxicity and pungent smell, and the dilution ratio is 10 to 15 times; before preparing the cigarette, the hawk extract diluted liquid is sprayed to the surface of the tobacco leaf according to the mass ratio of 0.1-1%. The hawk tea extract is convenient to use and capable of greatly improving the interior quality of the cigarette, reducing the offensive odor, increasing the smoke gas amount and improving the mouth feel; the interior quality of the cigarette is greatly improved.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

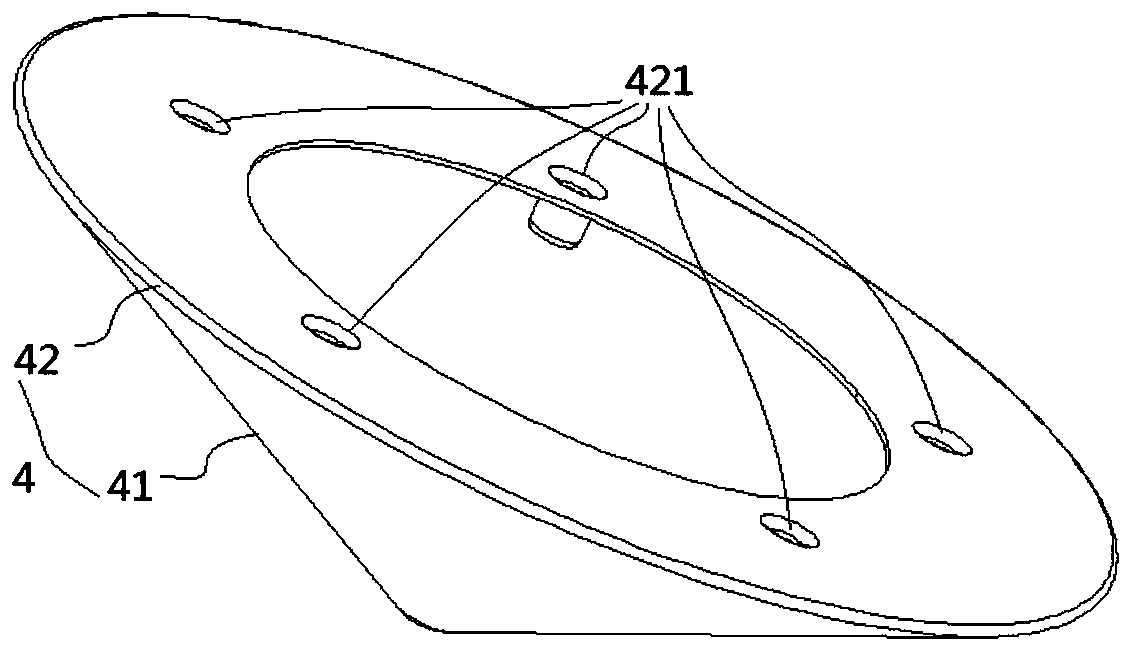

Heat-not-burn cigarette containing filter capsules

PendingCN108185511AChange styleImprove stylingTobacco treatmentCigarette manufactureHeat not burnEngineering

The invention discloses a heat-not-burn cigarette containing filter capsules. The heat-not-burn cigarette is a cylindrical sample strip, a layer of osmosis-prevention cigarette paper layer (2) is arranged at the outer layer of the sample strip, the sample strip is internally provided with one or more beaded filter capsules (4), and flaky thin sheets (1) are arranged at the sides of the filter capsules (4). By means of the heat-not-burn cigarette containing filter capsules, the smoke style and the smoke amount can be freely selected by squeezing, or not squeezing, or squeezing several filter capsules when the heat-not-burn cigarette is smoked; meanwhile, due to the advantage that smoke is generated when heating, the smoke mouthfeel can be close to that of traditional cigarettes, and multiple requirements of consumers are met.

Owner:CHINA TOBACCO YUNNAN IND

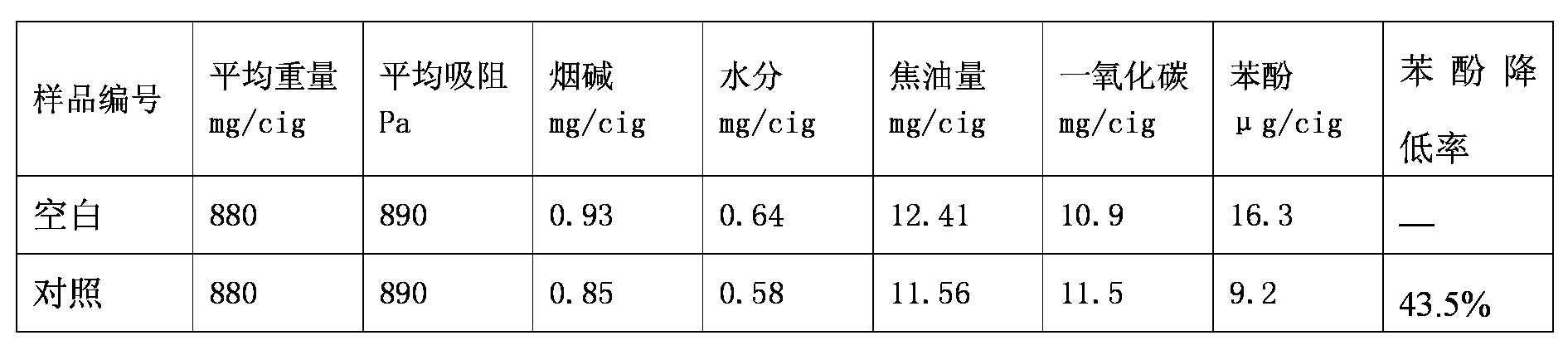

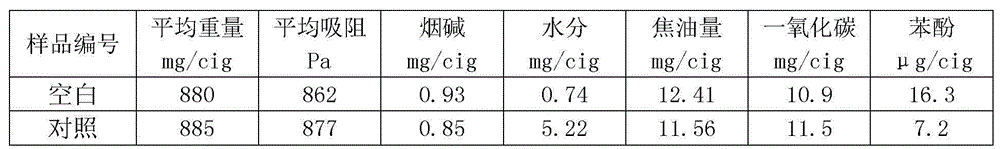

Interception agent for reducing phenol content in cigarette smoke and filter stick provided with interception agent

InactiveCN103141939AEfficient retentionIncrease moistureTobacco smoke filtersFlavorEnvironmental health

The invention discloses an interception agent for reducing the phenol content in cigarette smoke, which is prepared by blending water, glycerol and essence in a volume ratio of 2.5:(1.2-5):(0.1-0.125), stirring and evenly mixing the mixture. The invention further discloses a filter stick provided with the interception agent, which is prepared by the following steps: (1), adopting a preparation technology for an officinal capsule, taking the interception agent as the capsule core material and wrapping the agent inside the capsule; and (2), applying one or more capsules in fixed positions in a shred forming process, applying a universal filter stick forming technology , and obtaining the filter stick formed once and provided with a total addition quantity of the interception agent ranging from 0.01 mg to 0.5 mg. The interception agent and the filter stick can reduce the phenol content in the cigarette smoke remarkably, improve the cigarette smoke moisture simultaneously, enhance the moist feeling of the smoke, improve the quantity and the quality of the smoke, and endow the smoke with special aroma and smoking flavor, and have the advantages of simple formula, wide raw material source and low cost.

Owner:HUBEI CHINA TOBACCO IND +1

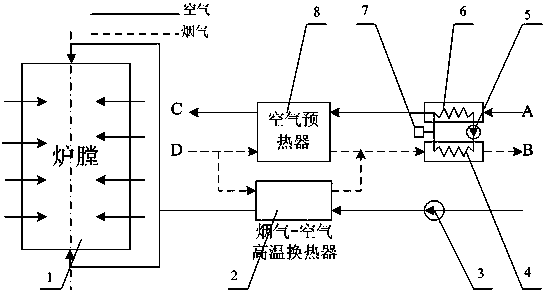

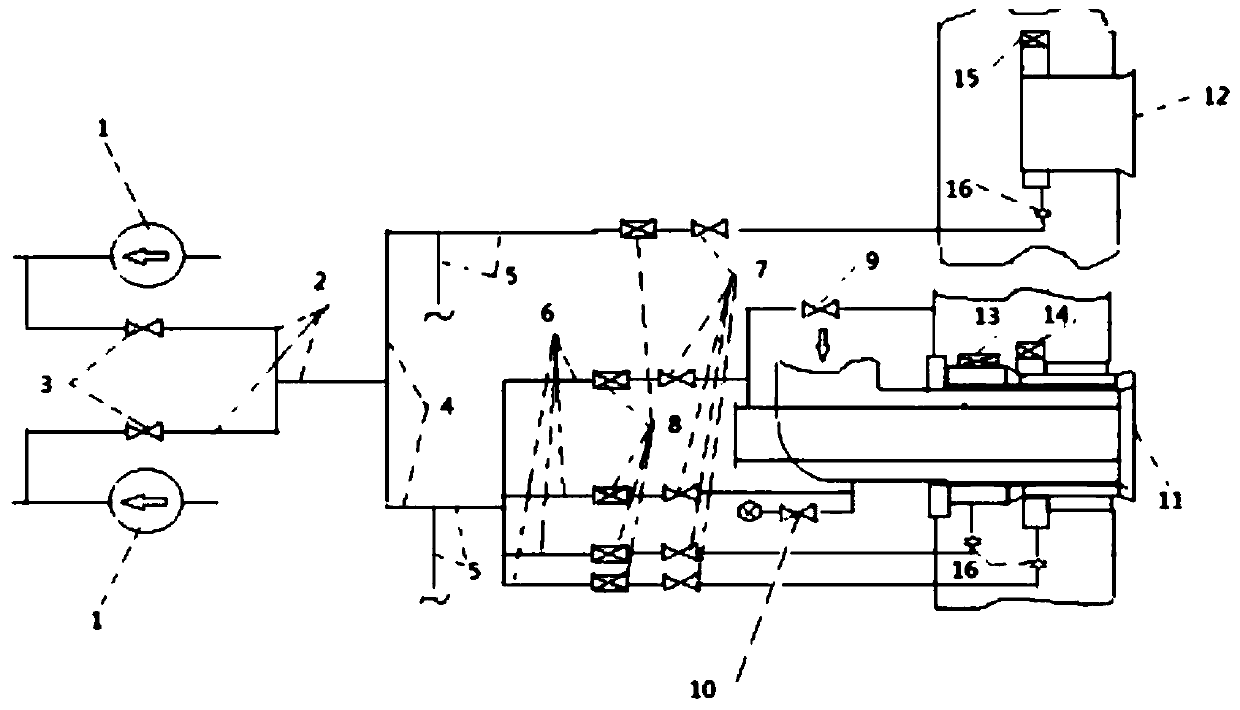

Device and method for reducing high-temperature corrosion of power station boiler by use of waste heat of flue gas

InactiveCN103776026ASimple processGuaranteed oxidizing atmosphereIndirect carbon-dioxide mitigationCombustion apparatusAir preheaterHigh-temperature corrosion

The invention discloses a device and a method for reducing high-temperature corrosion of a power station boiler by use of waste heat of flue gas. The device is additionally provided with a flue gas-air heat exchanger, an indirect-type air preheater, a Roots blower, a corresponding flue gas pipeline and a corresponding air pipeline. The method has the following flow path: one part of flue gas enters the flue gas-air heat exchanger before the flue gas enters the air preheater, the other part of the flue gas enters the air preheater to heat primary air and secondary air, the flue gas exhausted from the flue gas-air heat exchanger enters a gas flue at the outlet of the air preheater, and two flows of the flue gas are mixed and enter the indirect type air preheater; the indirect type air preheater is composed of a flue gas-air heat exchanger and an air-oil heat exchanger and utilizes conduction oil as a medium to achieve heat exchange of flue gas and air; the heated air in the flue gas-air heat exchanger, used as combustion air, enters a hearth from a side wall of a boiler burner so as to ensure that an oxidizing atmosphere is formed in a side wall combustion zone, and high temperature corrosion of a water cooled wall of the side wall is reduced or alleviated.

Owner:SOUTHEAST UNIV

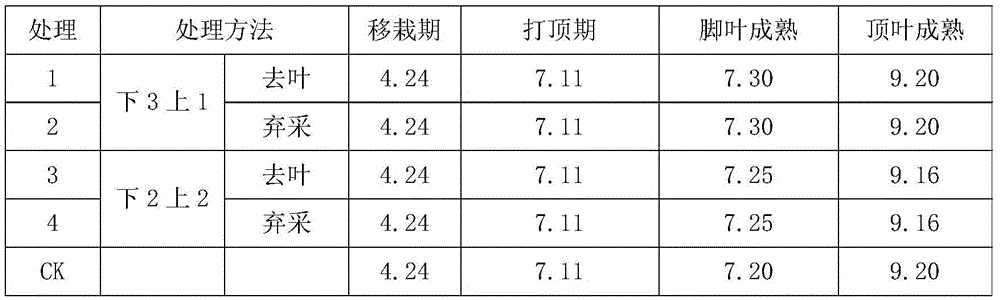

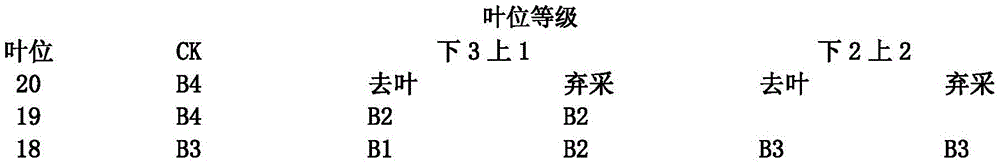

Control method for improving finished product tobacco leaf quality based on leaf position characteristics

InactiveCN105580628AAvoid unnecessary consumptionImprove sensory qualityPlant cultivationCultivating equipmentsTobacco leafManufacturing engineering

The invention discloses a control method, particularly discloses a control method for improving finished product tobacco leaf quality based on leaf position characteristics, and belongs to the technical field of tobacco cultivation technology. The control method for improving finished product tobacco leaf quality based on the leaf position characteristics controls the number of tobacco leaves to improve the finished product tobacco leaf quality in the growth process of tobacco. According to the control method, after the working procedure of topping and reserving 20 blades is executed, the finished product tobacco leaf quality is improved through the working procedure of removing part of blades at the leaf positions on the top and / or bottom again.

Owner:INST OF TOBACCO ANHUI ACADEMY OF AGRI SCI +1

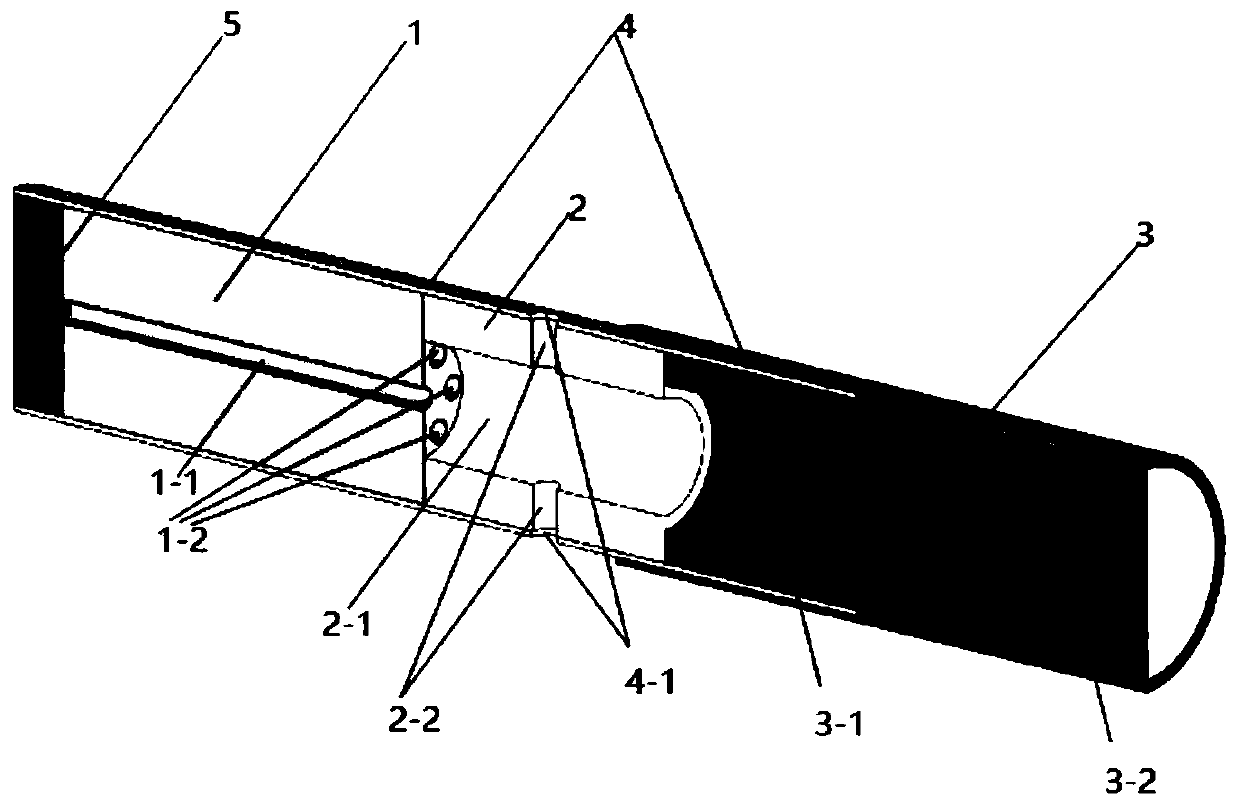

Closed heating type cigarette with smoke channel

PendingCN111567863ALower oxygen levelsFull release of aroma componentsCigar manufactureBurn cigaretteEngineering

The invention belongs to the field of heat-not-burn cigarettes, and particularly relates to a closed heating type cigarette with a smoke channel. The cigarette comprises a plug (5), a tobacco section(1), a low-suction-resistance section (2) and a functional filter tip section (3) which coaxially abut against one another in sequence from upstream to downstream, and the cigarette is wrapped with anouter wrapping piece (4). The low-suction-resistance section (2) is a pipe body provided with an axial center cavity (2-1) and at least one circumferential side wall through hole (2-2), and an axialfirst smoke channel (1-1) is formed in the axis of the tobacco section (1). According to the cigarette, a plurality of axial channels are designed in the tobacco section for the first time, and diffusion of smoke in the tobacco section is facilitated.

Owner:CHINA TOBACCO YUNNAN IND +1

Low-temperature calcining process for pot furnace

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

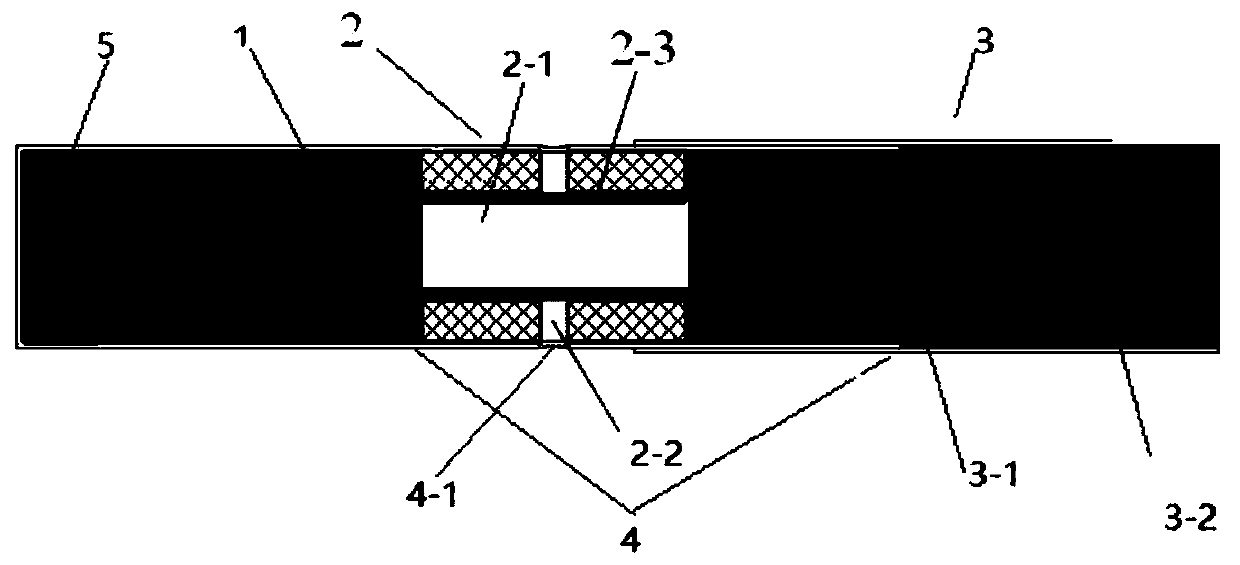

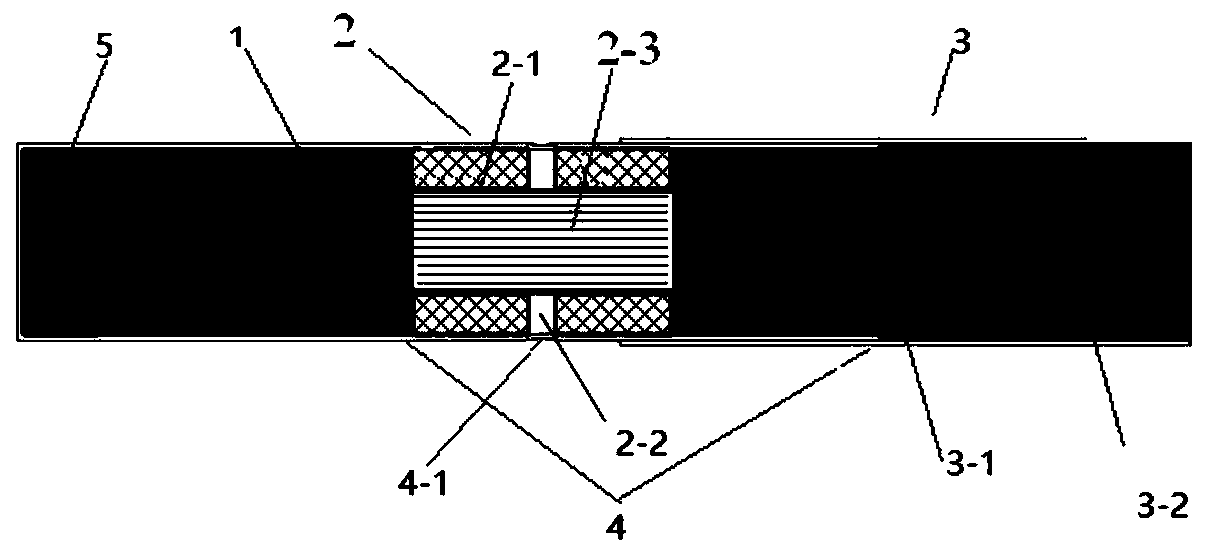

Closed heating type cigarette capable of reducing sidestream smoke

PendingCN111567862AReduce churnFull release of aroma componentsCigar manufactureEngineeringMechanical engineering

The invention belongs to the field of cigarettes, and particularly relates to a closed heating type cigarette capable of reducing sidestream smoke. The cigarette comprises a tobacco section (1), a low-suction-resistance section (2) and a functional filter tip section (3) which are sequentially and coaxially connected in an abutting mode from upstream to downstream, wherein the low-suction-resistance section (2) is a pipe body with an axial central cavity (2-1) and a circumferential side wall through hole (2-2); and the low-suction-resistance section (2) further comprises barrier layers (2-3) which are arranged on the circumferential side wall of the central cavity (2-1) and have certain air permeability. According to the cigarette, the barrier layers covering the circumferential side wallof the central cavity and the side wall through holes are arranged on the low-suction-resistance section, the cigarette has certain air permeability, and inflow of external air is not affected duringsmoking; and when the cigarette is not sucked, the smoke cannot escape through the side wall through holes, so that the smoke loss can be effectively reduced.

Owner:CHINA TOBACCO YUNNAN IND +1

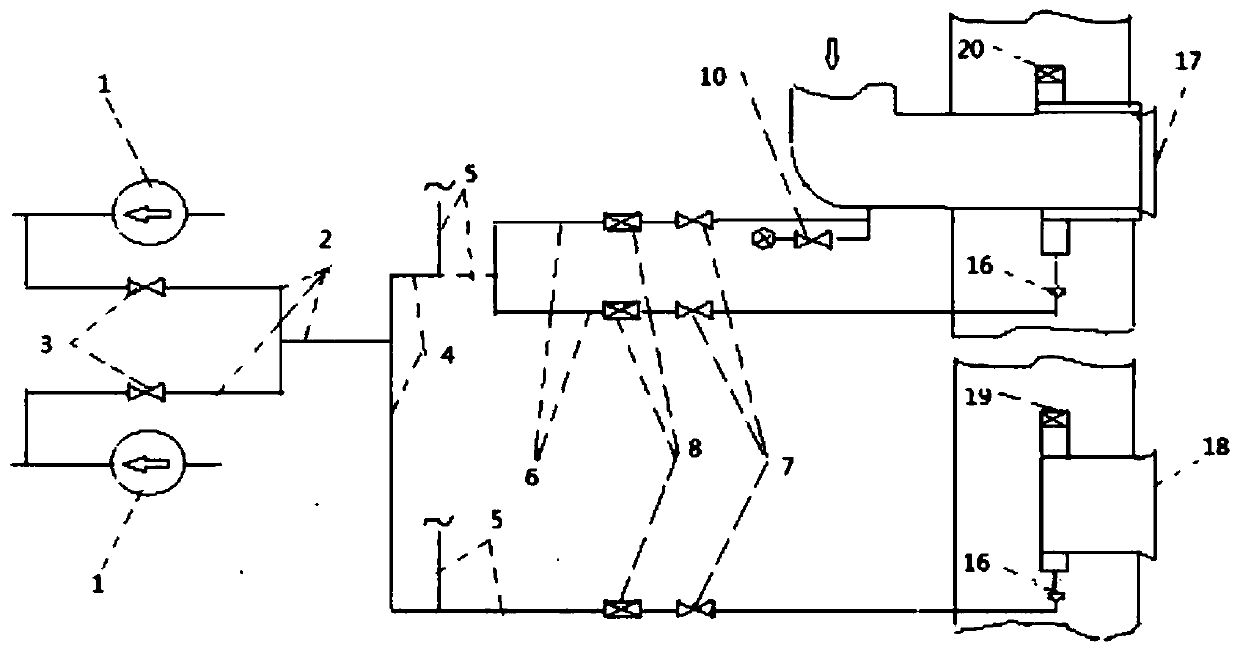

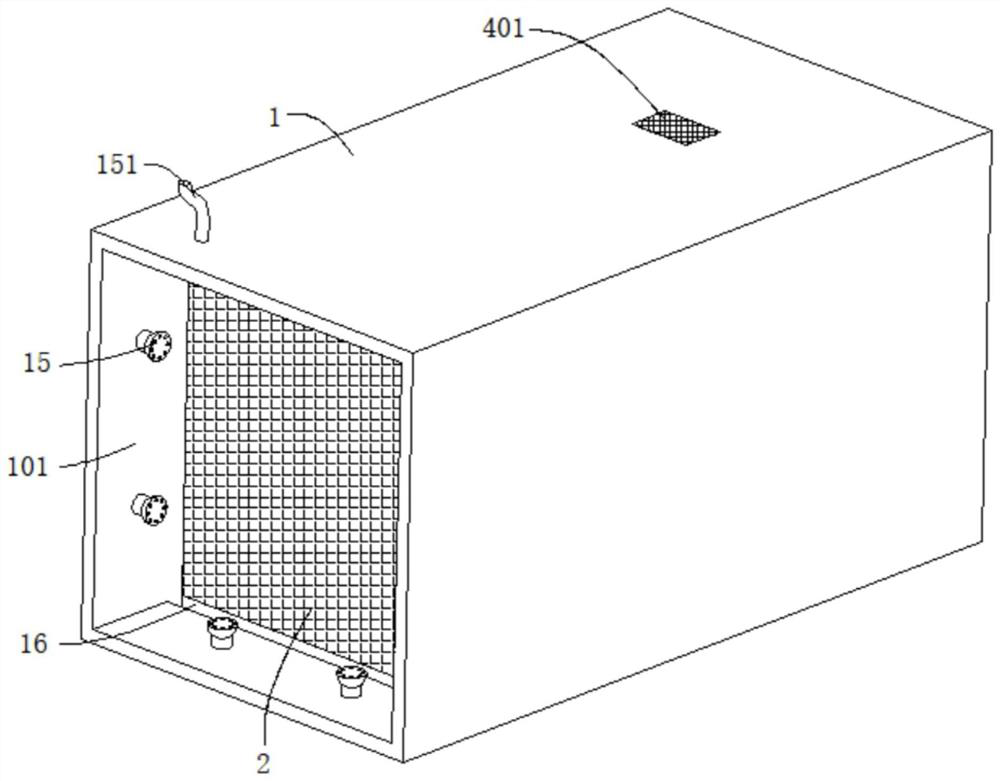

Low-temperature flue gas cooling system of shutdown combustor and parameter design method thereof

ActiveCN110287561AReduce the effects of elevatedRelieve pressureGeometric CADDesign optimisation/simulationElectricityAir volume

The invention discloses a low-temperature flue gas cooling system of a shutdown combustor and a parameter design method of the low-temperature flue gas cooling system. The low-temperature flue gas is led out from an outlet of the boiler induced draft fan, and the primary tuyere and the secondary tuyere of the standby combustor are respectively cooled by the mother pipe, the branch mother pipe, the branch pipe and the branch pipe in sequence. According to the low-temperature flue gas cooling system of the shutdown combustor and the parameter design method thereof, the low-temperature flue gas at the outlet of a boiler induced draft fan cools the shutdown combustor, so that the problems that due to the air cooling, the cooling air volume requirement is large, the boiler ash combustible matter is increased, the NOx concentration of a hearth outlet is increased, the exhaust gas temperature is increased, the fan electricity consumption is high, and a primary air nozzle is prone to burning loss, can be solved.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

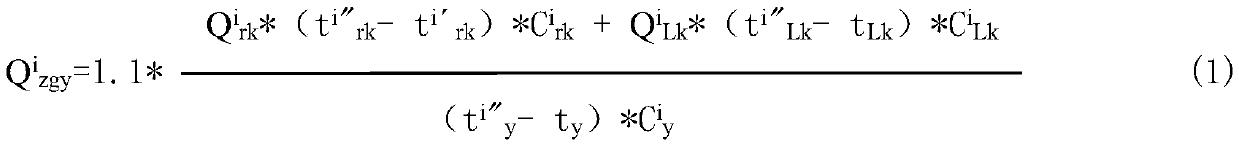

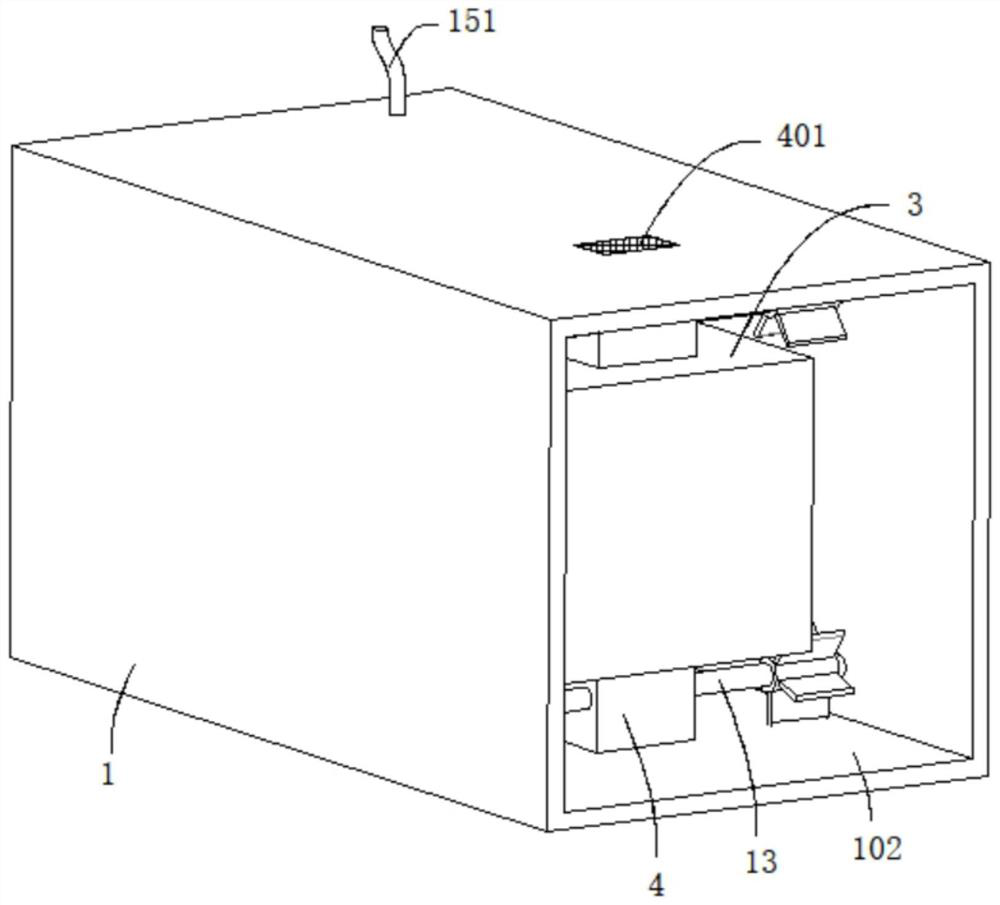

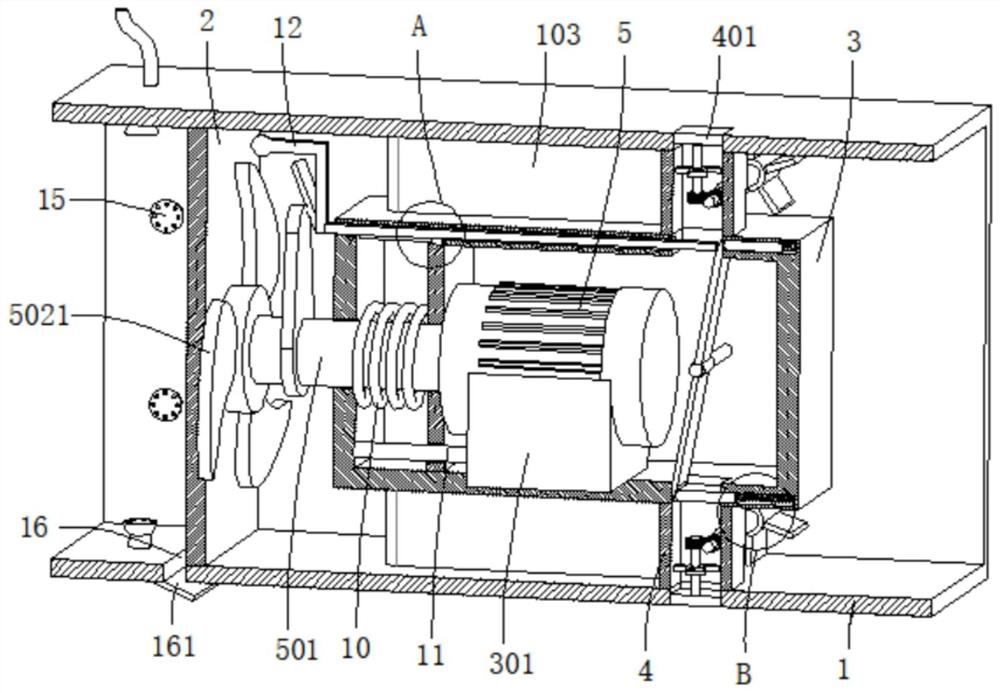

Fire-fighting smoke exhaust fan with high cooling speed and use method thereof

InactiveCN113982974AExtended service lifeImprove cooling effectDispersed particle filtrationPump componentsParticulatesThermodynamics

The invention discloses a fire-fighting smoke exhaust fan with a high cooling speed and a use method thereof, and belongs to the technical field of smoke exhaust fans. The fire-fighting smoke exhaust fan with the high cooling speed comprises a fan barrel, a smoke inlet and a smoke outlet are formed in the two ends of the fan barrel respectively, a first filter screen is arranged on the inner wall of the smoke inlet, a supporting plate is connected to the inner wall of the fan barrel, the end, away from the fan barrel, of the supporting plate is connected with an inner barrel, and a smoke exhaust assembly is arranged in the inner barrel; an exhaust mechanism used for heat dissipation is further arranged in the inner barrel, heat dissipation air channels matched with the exhaust mechanism are symmetrically connected to the two sides of the outer wall of the inner barrel in a penetrating mode, cooling mechanisms used for accelerating air flowing are arranged in the heat dissipation air channels, and the inner walls of the heat dissipation air channels are connected with second filter screens; damage of particulate matter in smoke to the smoke exhaust fan can be reduced, the heat dissipation effect and the heat dissipation rate of the inner cylinder are improved, and then the service life of the fire-fighting smoke exhaust fan is prolonged.

Owner:江苏融汇环境工程有限公司

Closed heating type cigarette with controllable suction resistance

PendingCN111588079ALower oxygen levelsReduce churnCigar manufactureBurn cigaretteMechanical engineering

The invention belongs to the field of heat-not-burn cigarettes, and particularly relates to a closed heating type cigarette with controllable smoking resistance. The cigarette comprises a tobacco section (1) with a sealed upstream end, a controllable suction resistance section (2) and a functional filter tip section (3) which are sequentially and coaxially connected in an abutting mode from upstream to downstream, and the cigarette is wrapped with an outer wrapping piece (4). The controllable suction resistance section (2) is a pipe body with an axial central cavity (2-1) and a circumferentialside wall through hole (2-2), and the controllable suction resistance section (2) further comprises a limiting flow guide element (2-3) which is arranged in the center cavity (2-1) and provided withan axial channel. According to the cigarette, a blocking layer covering the circumferential side wall of the central cavity and the side wall through holes is arranged on the controllable suction resistance section, the cigarette has certain air permeability, inflow of external air is not affected during suction, and when the smoke is not sucked, the smoke cannot escape through the side wall through holes, so that the smoke loss can be effectively reduced.

Owner:CHINA TOBACCO YUNNAN IND +1

Electronic cigarette heater and heating control method and device for ceramic heating body

PendingCN110710720AReduce the effect of temperatureClear thermal effectOhmic-resistance heating circuitsTobacco smoke filtersPower compensationElectronic cigarette

The invention discloses a non-contact electronic cigarette heater and a heating control method and device for a ceramic heating body. The ceramic heating body comprises a heating body and a heating circuit, wherein the heating body is in a columnar shape; a porous channel is formed in the heating body; and the heating circuit is arranged on the heating body to heat air passing through the porous channel. The heating control method comprises the following steps of when the non-contact electronic cigarette heater is turned on, controlling the heating circuit to perform heating work by using a first working voltage, and counting working time of the heating circuit; detecting a working current of the heating circuit; and performing voltage reduction control on the working voltage of the heating circuit according to the working time of the heating circuit and the working current of the heating circuit. By controlling the working voltage of the heating circuit, the effect of heated air required for smoking a cigarette can be achieved; dynamic power compensation does not need to be performed and the temperature does not need to be controlled; and the control complexity is reduced and thebetter control response effect is also achieved.

Owner:XIAMEN FENGTAO CERAMICS CO LTD

Electronic cigarette heater and heating control method and device for ceramic heating element

PendingCN110742315AReduce the effect of temperatureClear thermal effectOhmic-resistance heating circuitsTobacco smoke filtersPower compensationThermodynamics

The invention discloses a non-contact electronic cigarette heater and a heating control method and device for a ceramic heating element. The ceramic heating element comprises a heating body and a heating circuit, wherein the heating body is in the shape of a column, and a multihole passage is arranged in the heating body; and the heating circuit is arranged on the heating body to be used for heating air passing through the multihole passage. The method comprises the steps that when the non-contact electronic cigarette heater is started, the heating circuit is controlled to perform heating withan initial working voltage, and detect the working current of the heating circuit; according to the working current, boost control is performed on the working voltage of the heating circuit, so thatthe heating circuit can perform constant power work; and according to the working time of the heating circuit, voltage reduction control can be performed on the working voltage of the heating circuit.The working voltage of the heating circuit is controlled, so that the effect for heating air required by suction of a cigarette can be realized, dynamic power compensation is not needed, temperaturecontrol is not needed, the control complexity is simplified, and the circuit device cost can also be reduced.

Owner:XIAMEN FENGTAO CERAMICS CO LTD

Cement kiln waste heat power generation system

InactiveCN111271980AGuaranteed imported flue gas volumeGuaranteed temperatureIncreasing energy efficiencyClinker productionEngineeringSuperheater

The invention discloses a cement kiln waste heat power generation system. The cement kiln waste heat power generation system comprises a grate cooler, an ASH superheater and a kiln head AQC boiler, wherein a high-temperature exhaust pipe is arranged at a first section of the grate cooler and is connected with the ASH superheater; a medium-temperature exhaust pipe is arranged at a second section ofthe grate cooler; a first air guide pipe is arranged at the air outlet end of the ASH superheater and communicates with the medium-temperature exhaust pipe; a settling chamber is connected with the medium-temperature exhaust pipe; the air outlet end of the settling chamber is connected with the kiln head AQC boiler through a pipeline; and a steam outlet pipe is arranged on the kiln head AQC boiler and is connected with the steam inlet end of the ASH superheater. High-temperature flue gas is taken from the first section of the grate cooler and directly enters the ASH superheater to exchange heat with steam at an outlet of the kiln head AQC boiler, and an air outlet of the ASH superheater is jointed with the medium-temperature exhaust pipe through the first air guide pipe, so that flue gasquantity and temperature of the medium-temperature exhaust pipe are increased, inlet flue gas quantity and temperature of the kiln head AQC boiler are ensured, then main steam temperature of a systemis increased, high-quality stable saturated steam is provided for a steam turbine, and power generation capacity is improved.

Owner:SDIC XINDENG ZHENGZHOU CEMENT

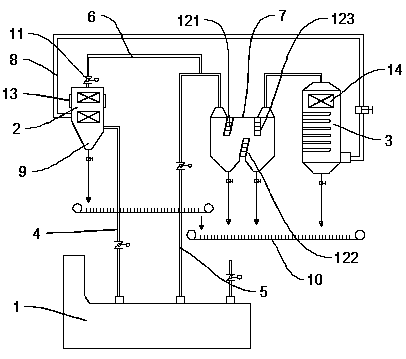

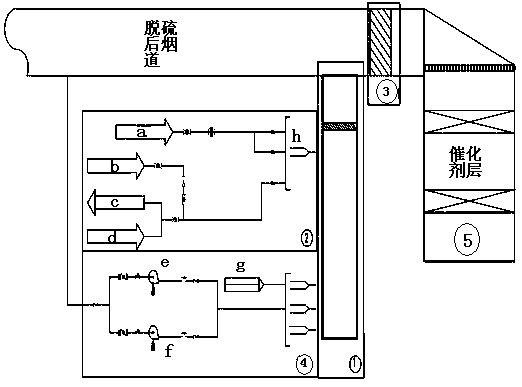

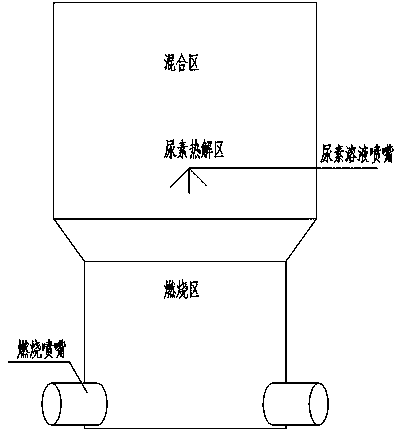

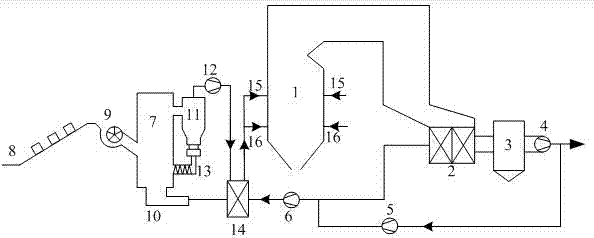

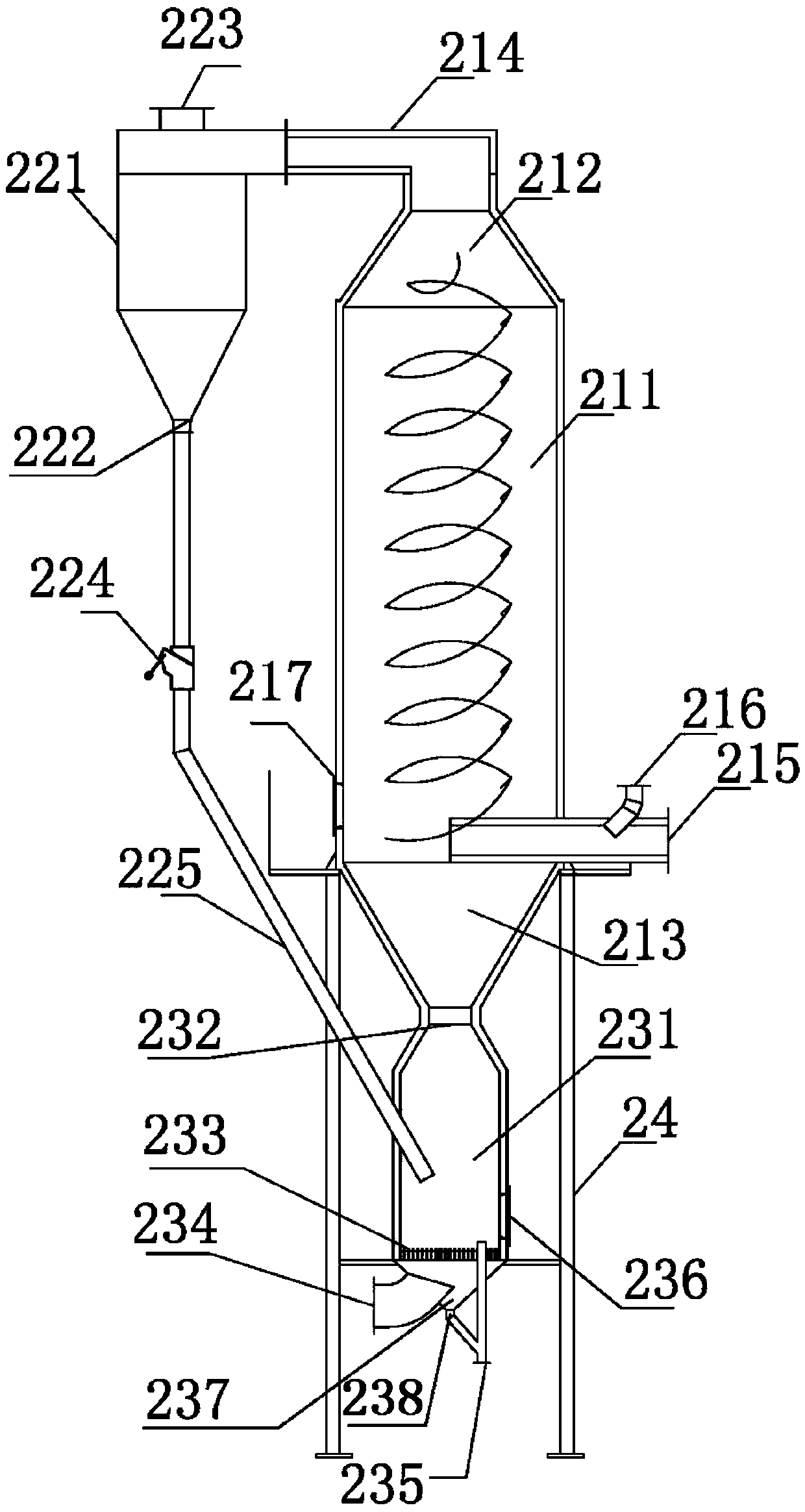

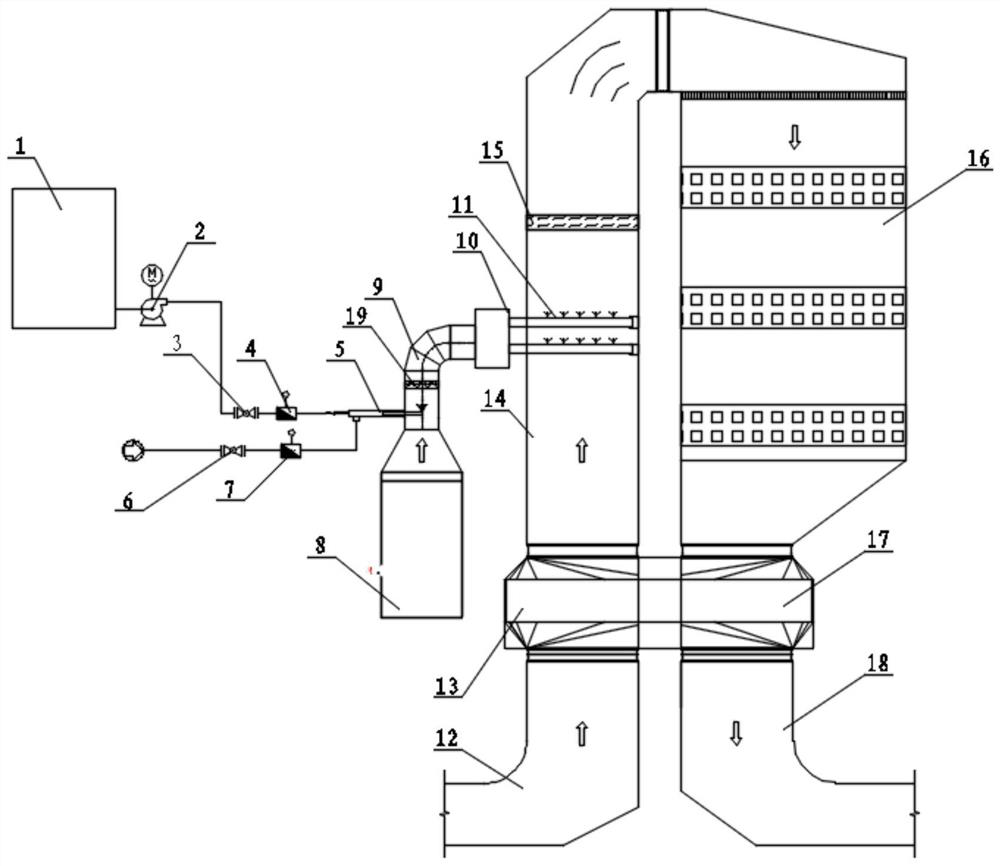

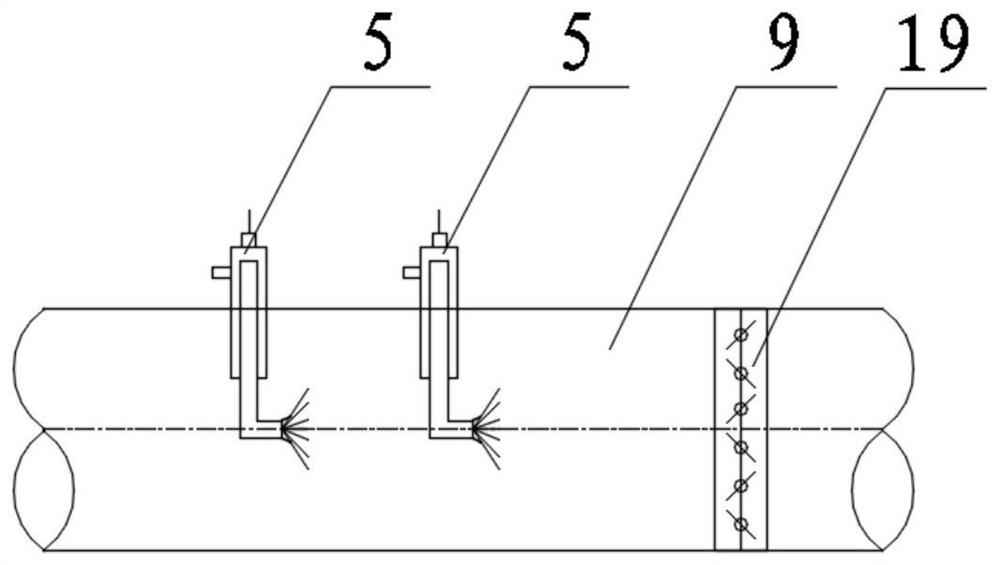

Integrated process for pyrolyzing urea for medium- and low-temperature SCR (Selective Catalytic Reduction) denitration and regenerating catalyst

InactiveCN109316962AReduce oxygen contentEasy to controlGas treatmentDispersed particle separationCombustionOxidizing agent

The invention discloses an integrated process for pyrolyzing urea for medium- and low-temperature SCR (Selective Catalytic Reduction) denitration and regenerating a catalyst. A denitration reactor isadopted for SCR denitration; the denitration reactor comprises a flue; and the pyrolyzation of the urea is carried out in high-temperature fumes generated by the combustion in a combustion furnace. The integrated process is characterized by comprising the following steps of 1), extracting partial desulfurated fumes in the flue as an oxidizing agent by utilizing a blower system to combust in an afterburner system; 2), mixing the high-temperature fumes generated by the combustion with a urea solution sprayed by an urea spraying system; and 3), after an obtained product is mixed with original fumes through a fume mixing system, using the obtained mixture as a denitration reducer to enter an SCR reactor to carry out denitration. The process is small in the quantity of devices; and the energy consumption is effectively decreased.

Owner:张扬

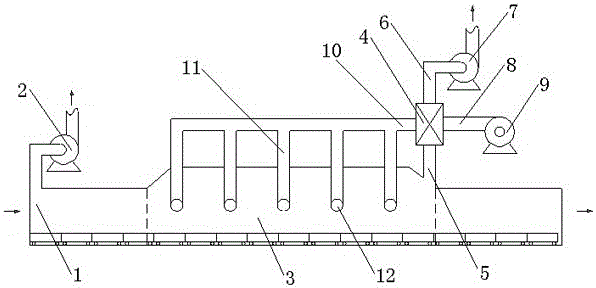

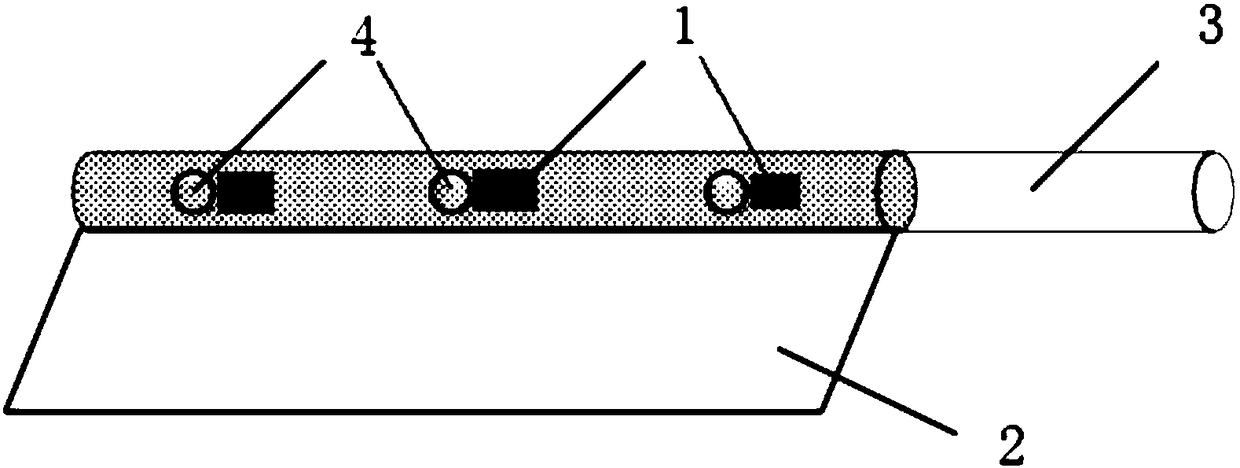

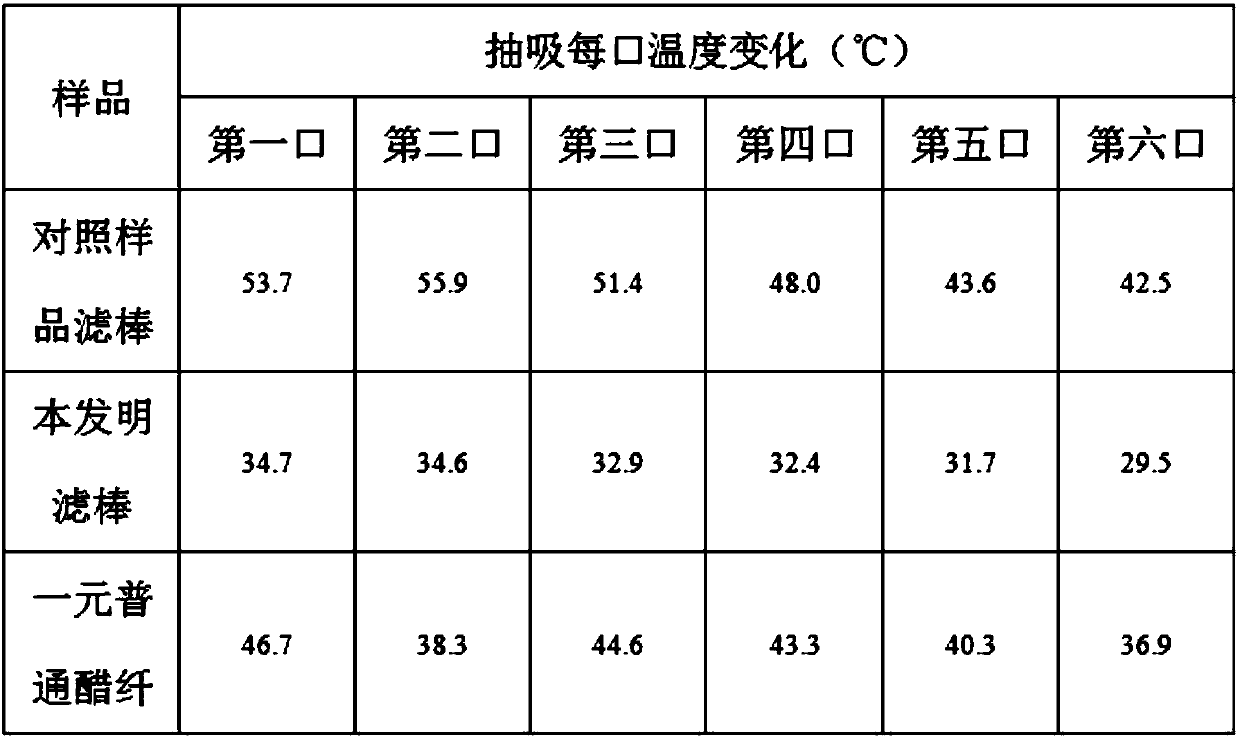

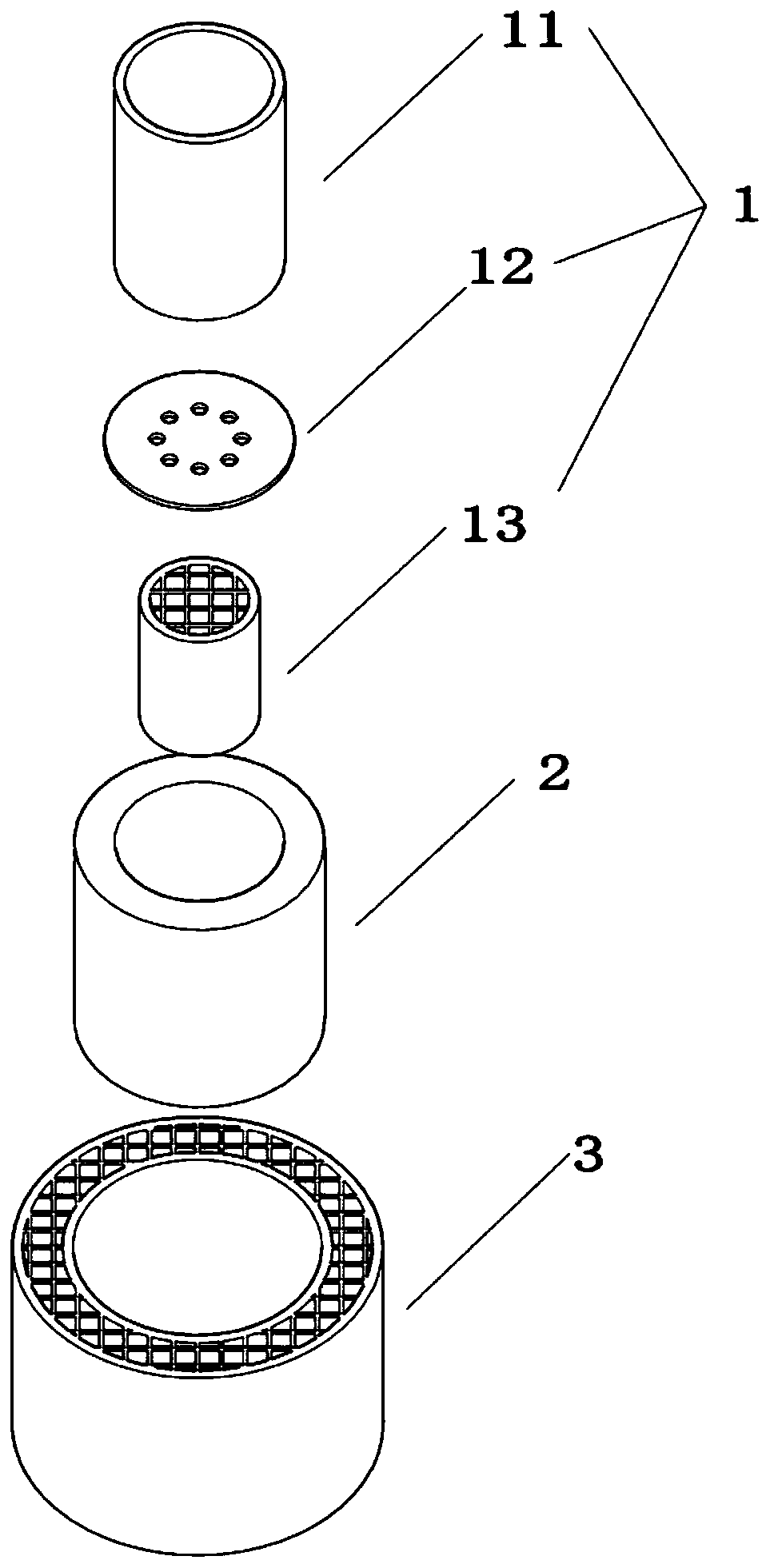

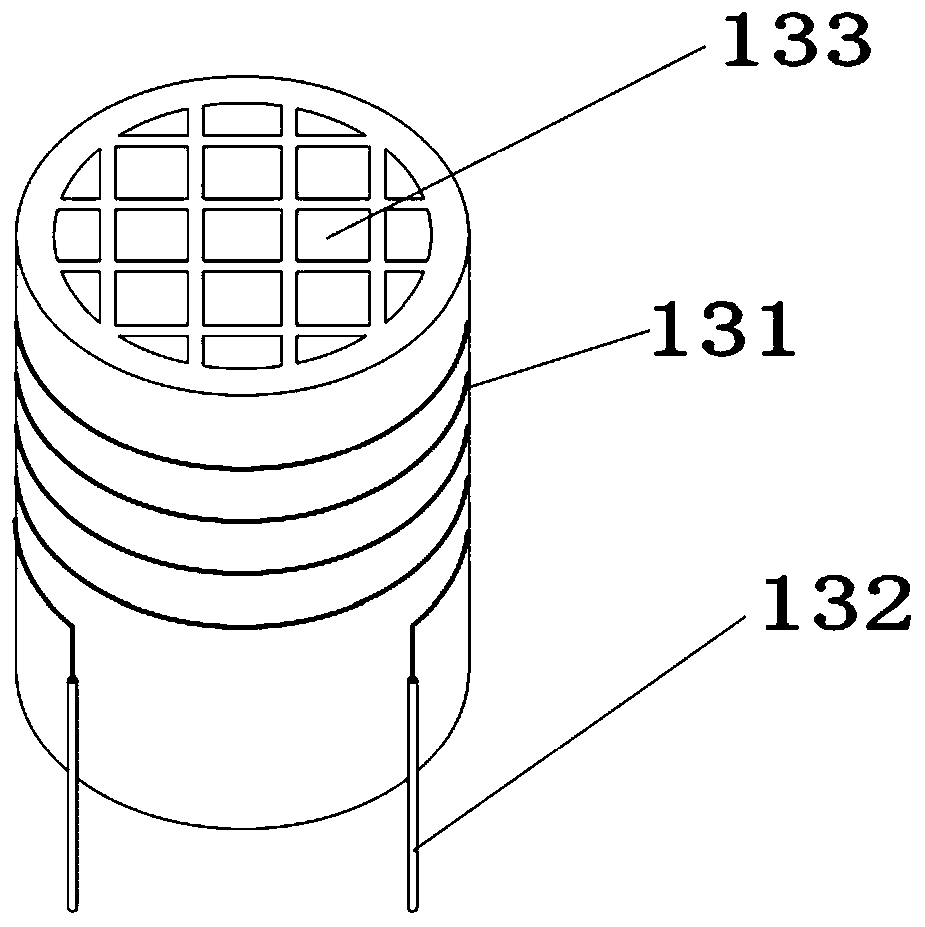

Filter stick suitable for heat-not-burn cigarette and manufacturing process of filter stick

InactiveCN110934334AReduce the temperatureIncrease flue gas volumeTobacco smoke filtersFiberPolyethylene glycol

The invention relates to a filter stick suitable for a heat-not-burn cigarette and a manufacturing process of the filter stick. The filter stick comprises a first acetate fiber section, and the firstacetate fiber section is a formed product obtained by mixing and dissolving one or more solvents of propylene glycol, glycerol, diethylene glycol, triethylene glycol, tetraethylene glycol, pentaethylene glycol, polyethylene glycol, sorbitol and xylitol with glyceryl triacetate and then adding acetate fibers. The manufacturing process comprises the following steps: 1) preparing mixed glyceride; 2)preparing a first acetate fiber section; and 3) preparing the filter stick. According to the invention, a method of adding a smoke agent and a cooling material into the acetate fiber is adopted, so when the treated filter stick is applied to the heat-not-burn cigarette, the smoke amount is obviously increased, the smoke temperature is obviously reduced, the sensory comfort is obviously increased,the requirements of the heat-not-burn filter stick are met, and the adding mode can be realized on a traditional filter stick forming machine without transformation.

Owner:CHINA TOBACCO ZHEJIANG IND

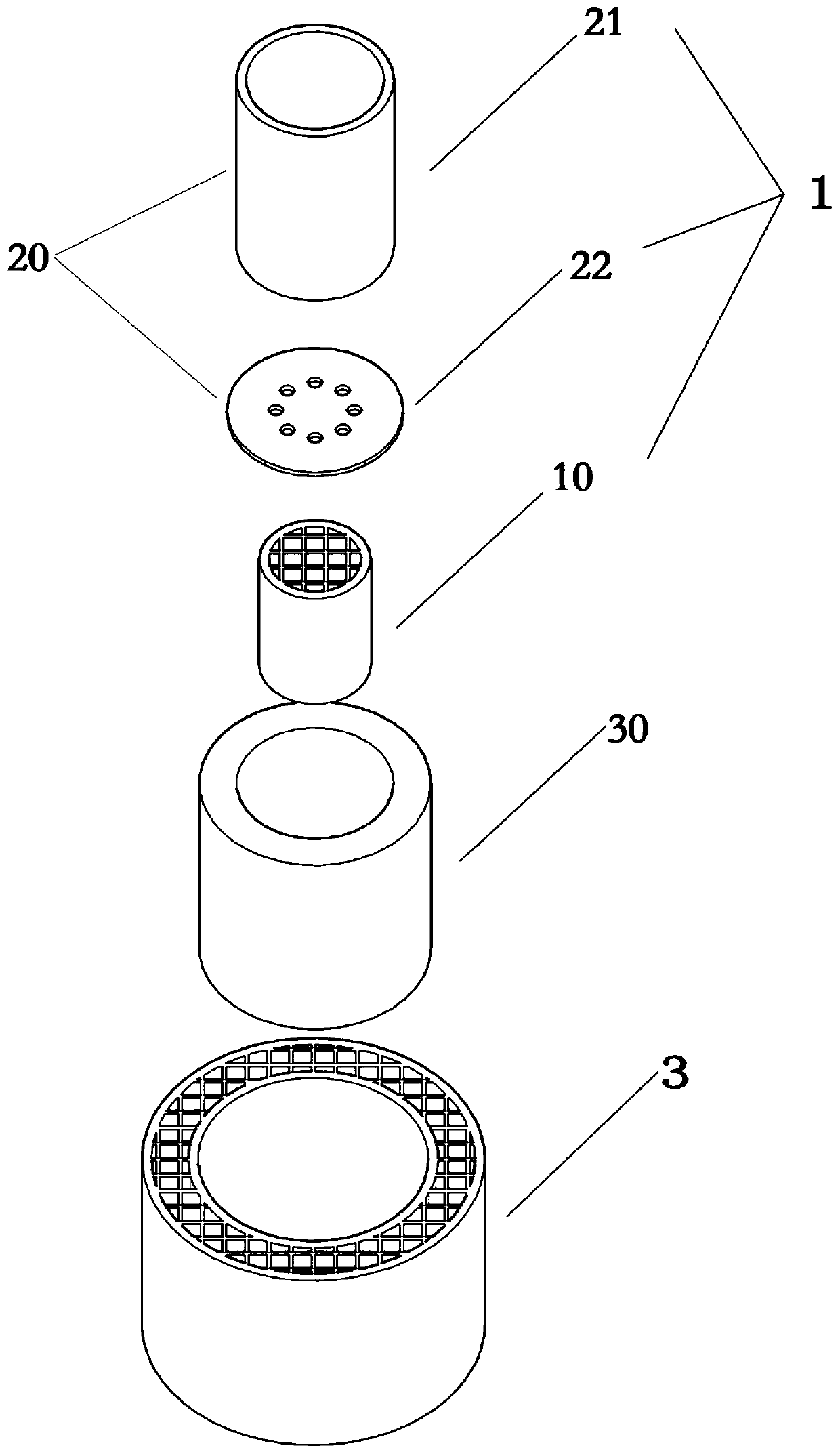

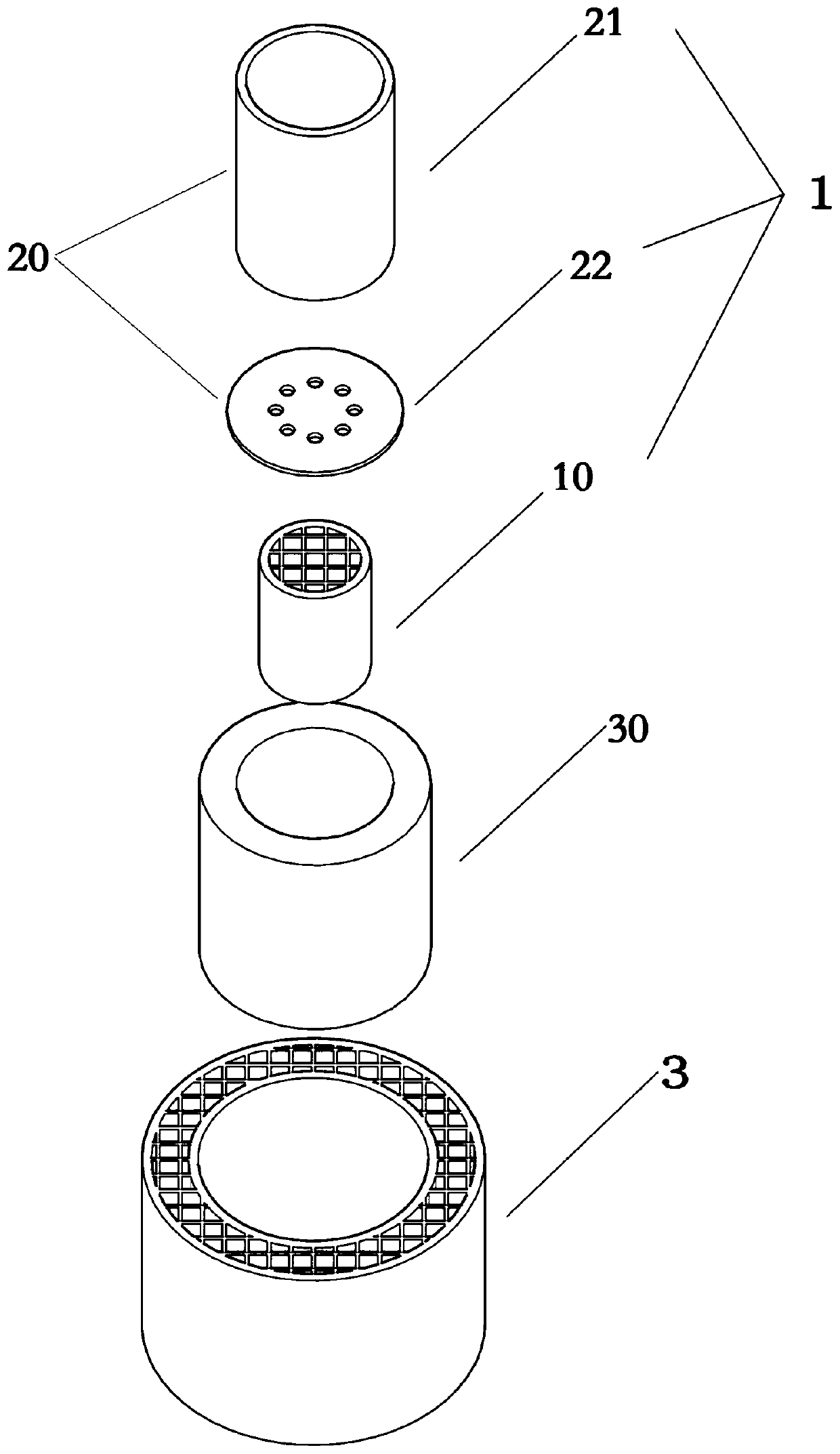

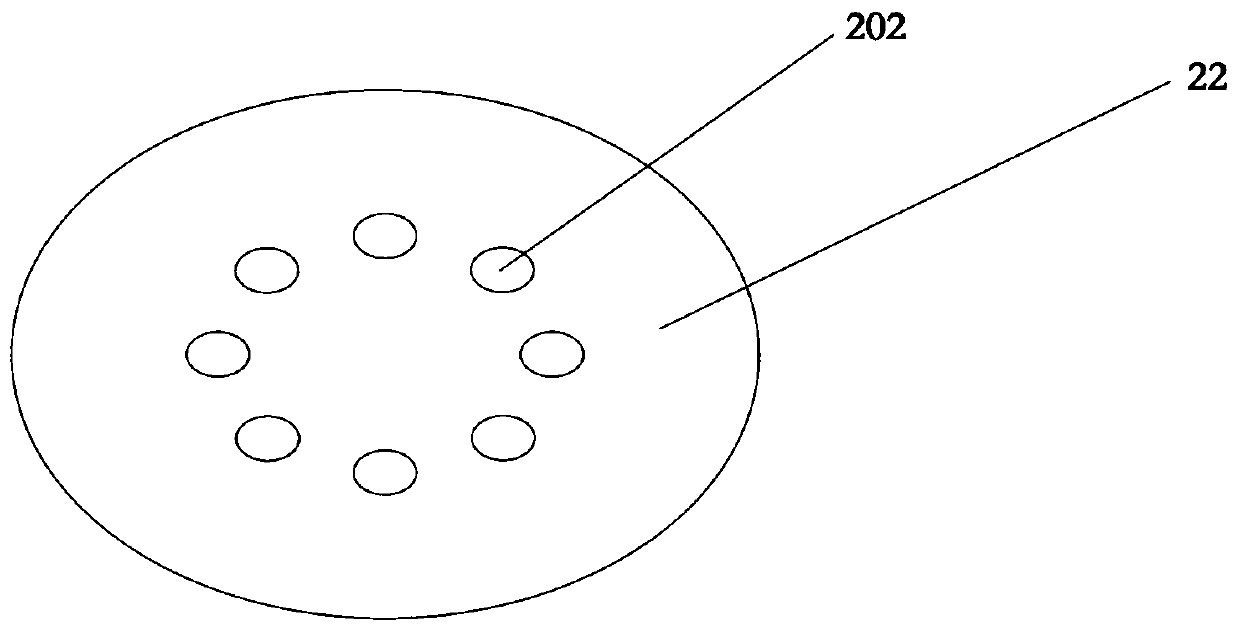

Non-contact air-heating-type electronic cigarette heater

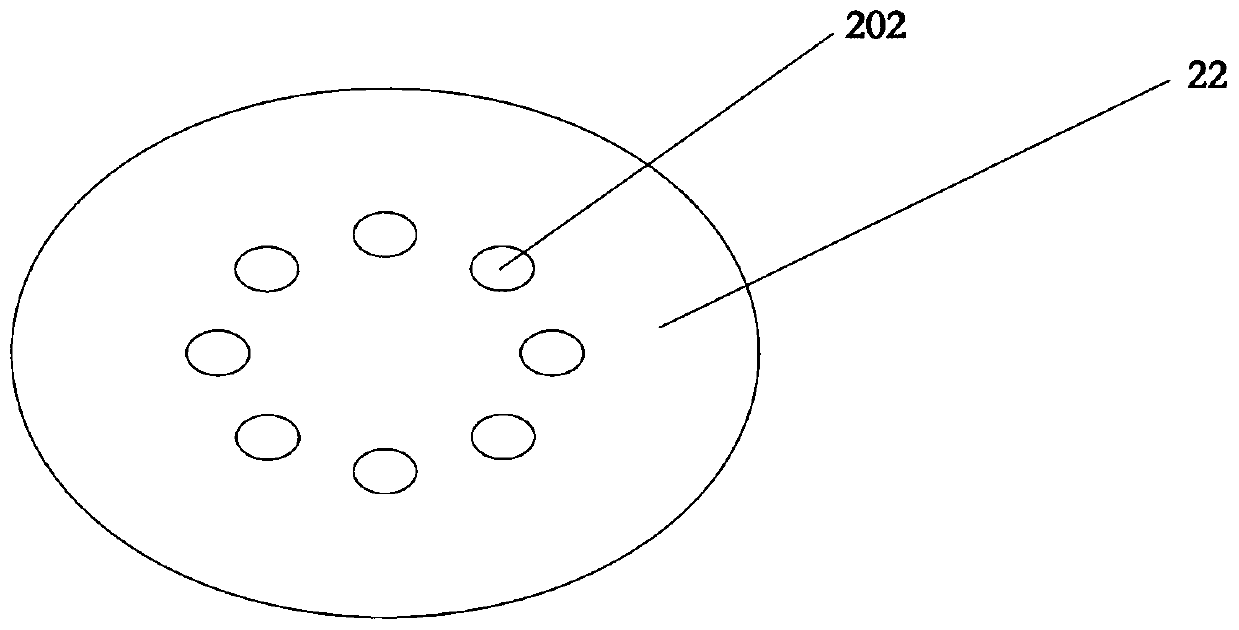

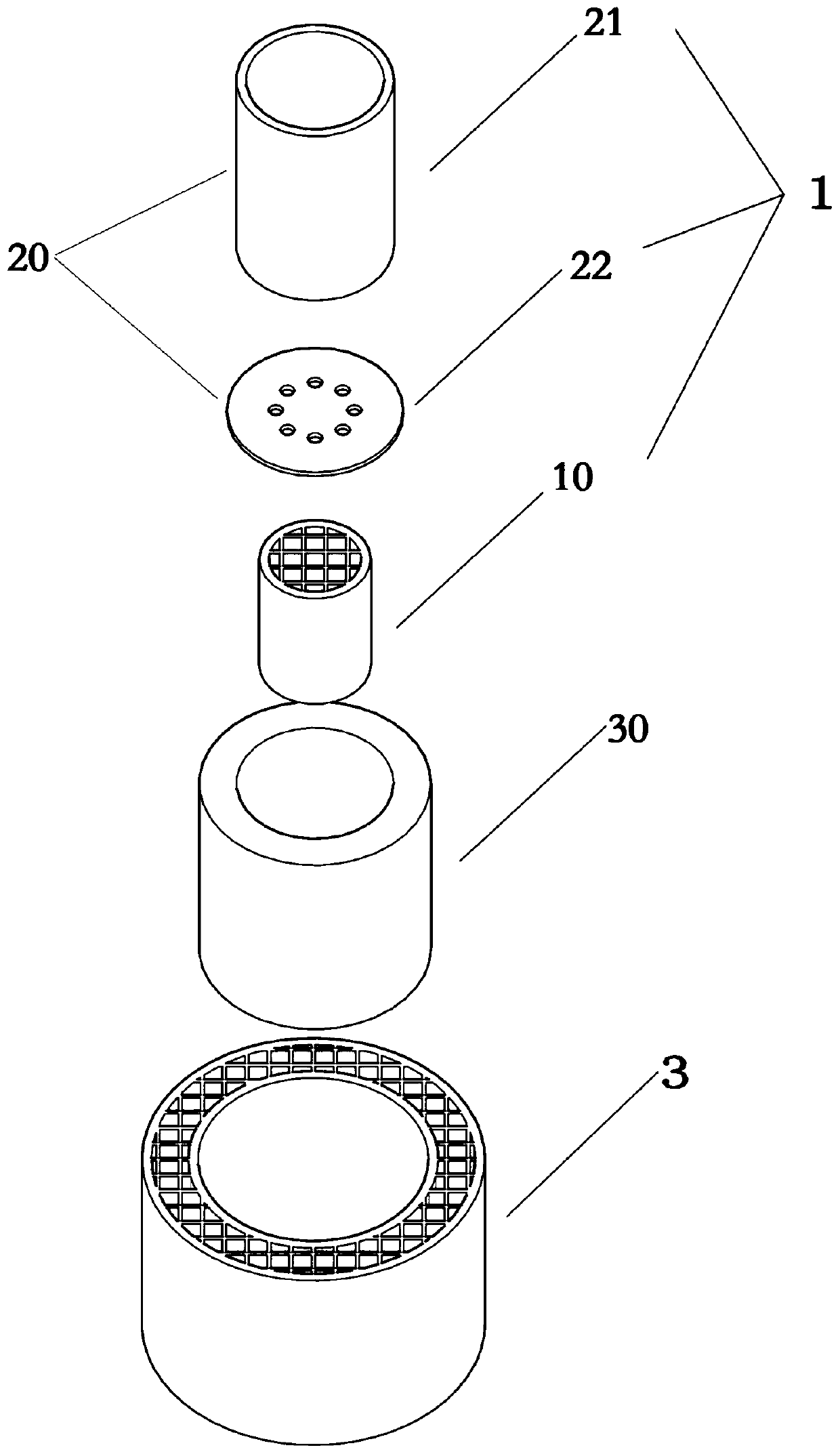

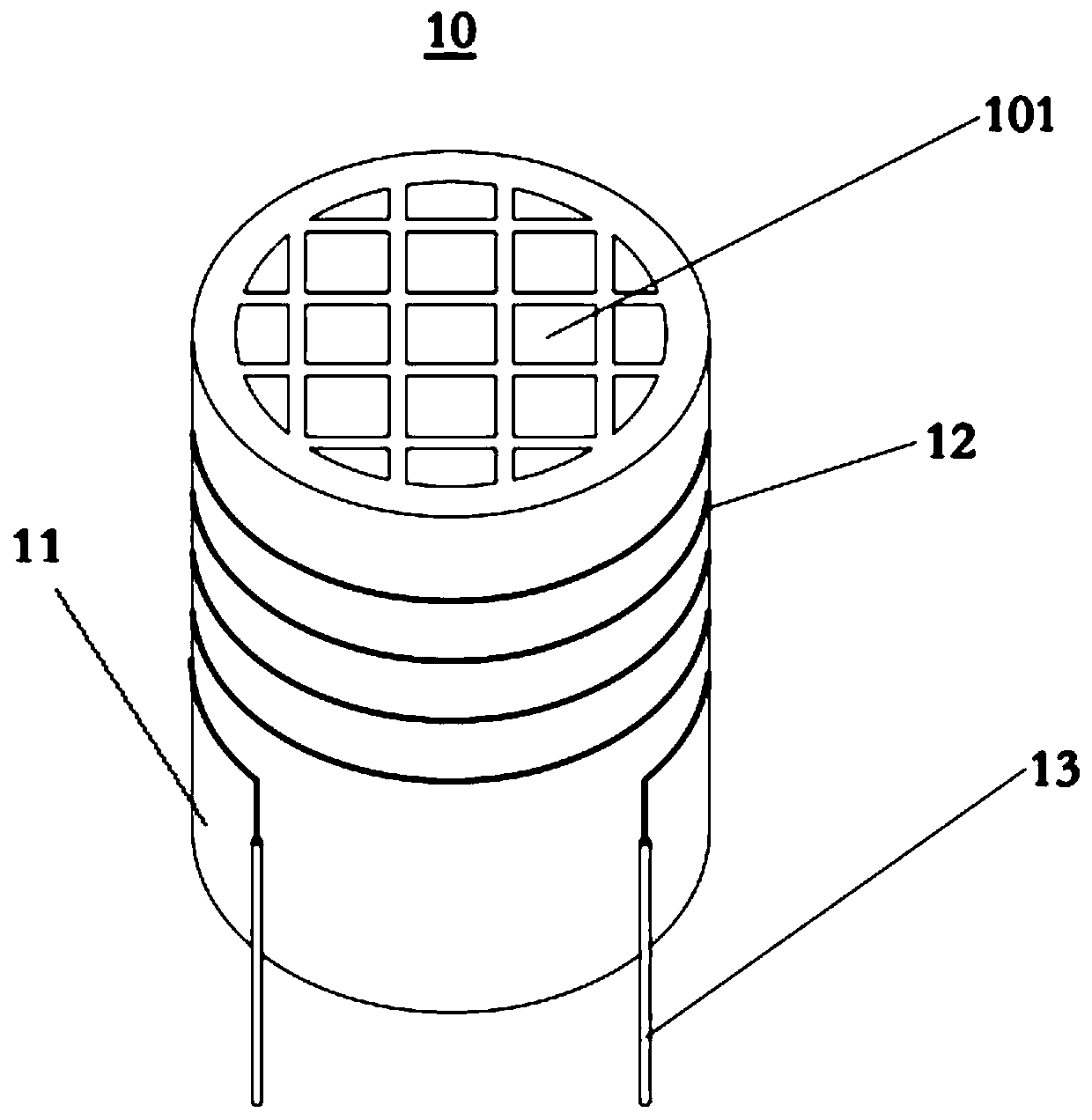

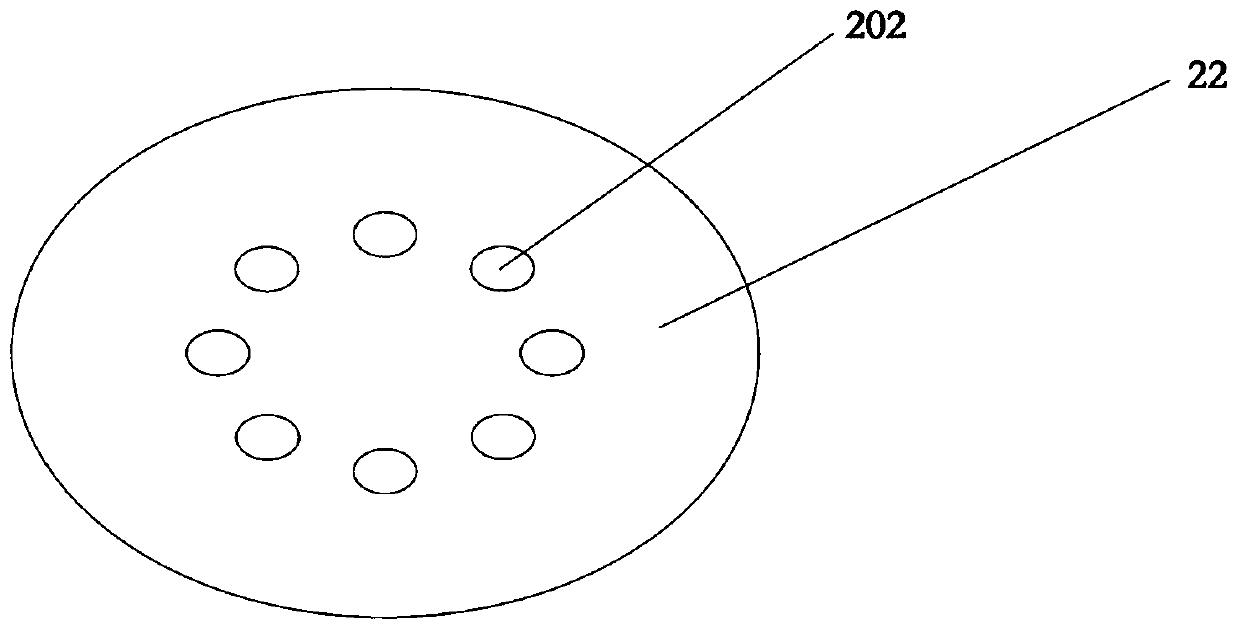

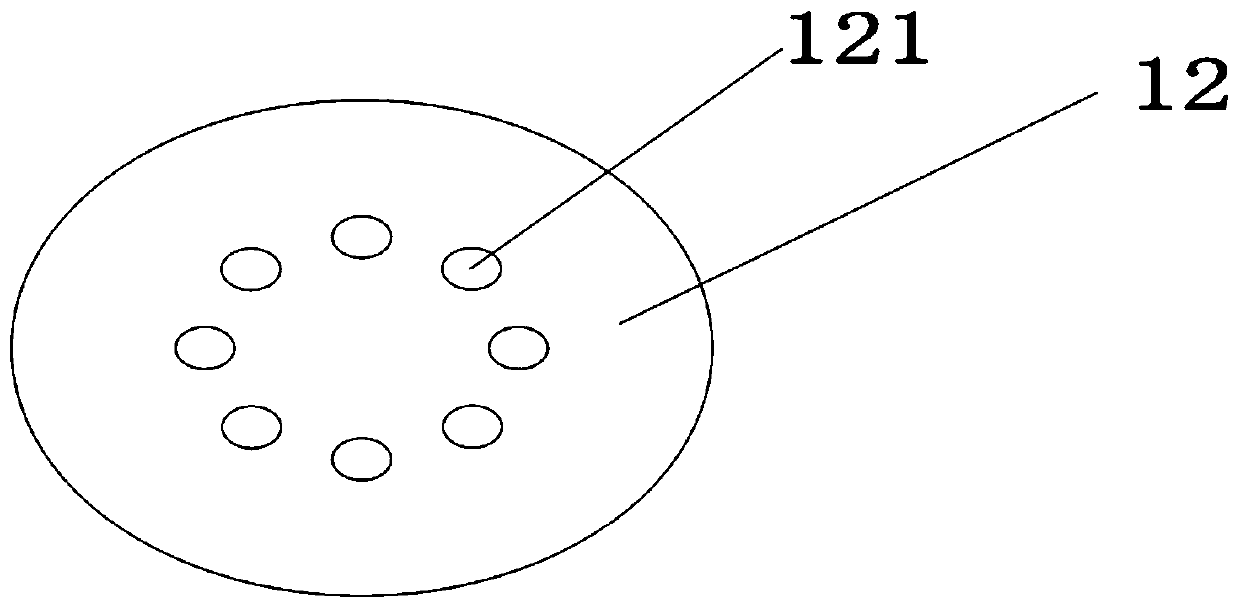

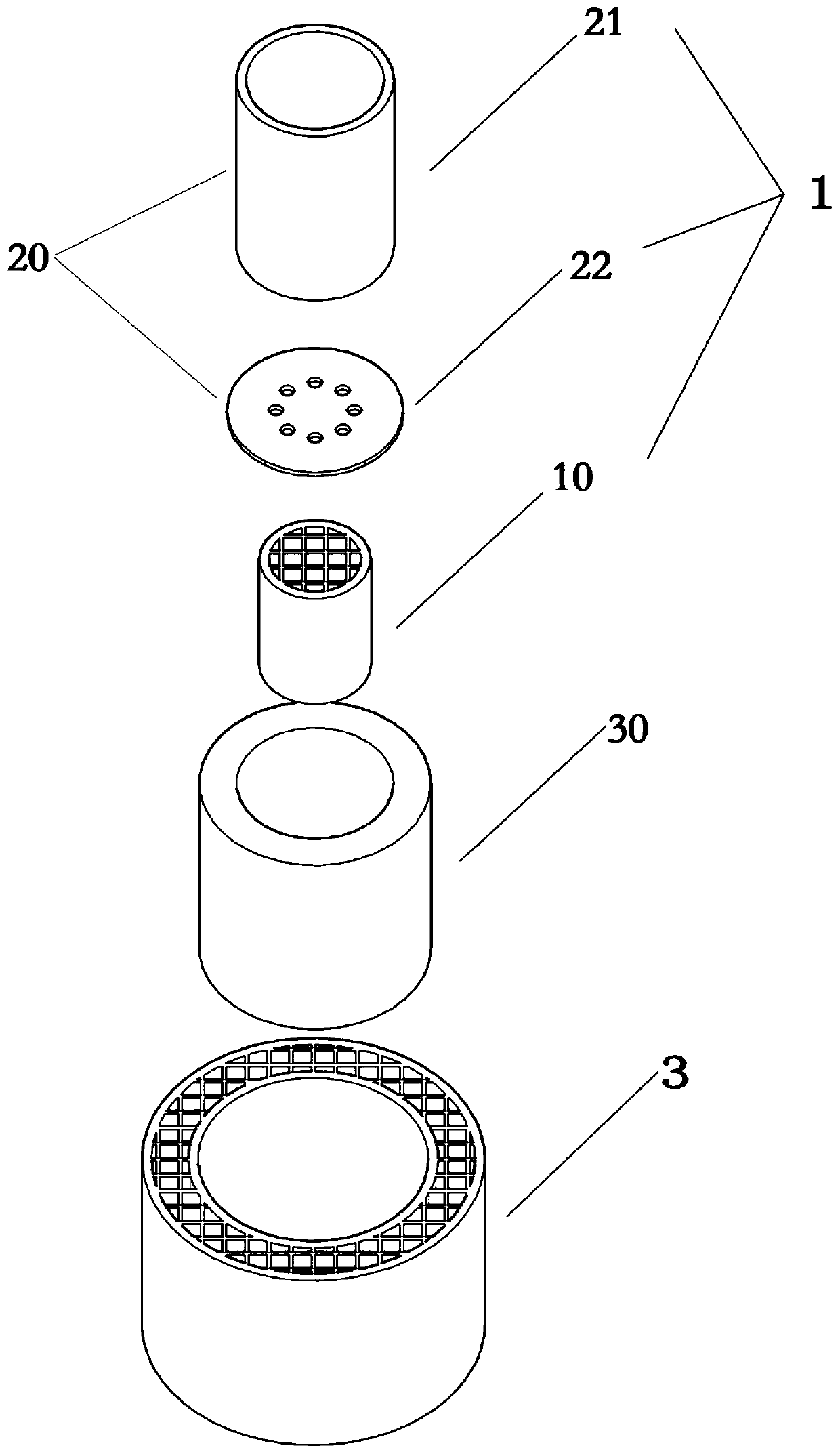

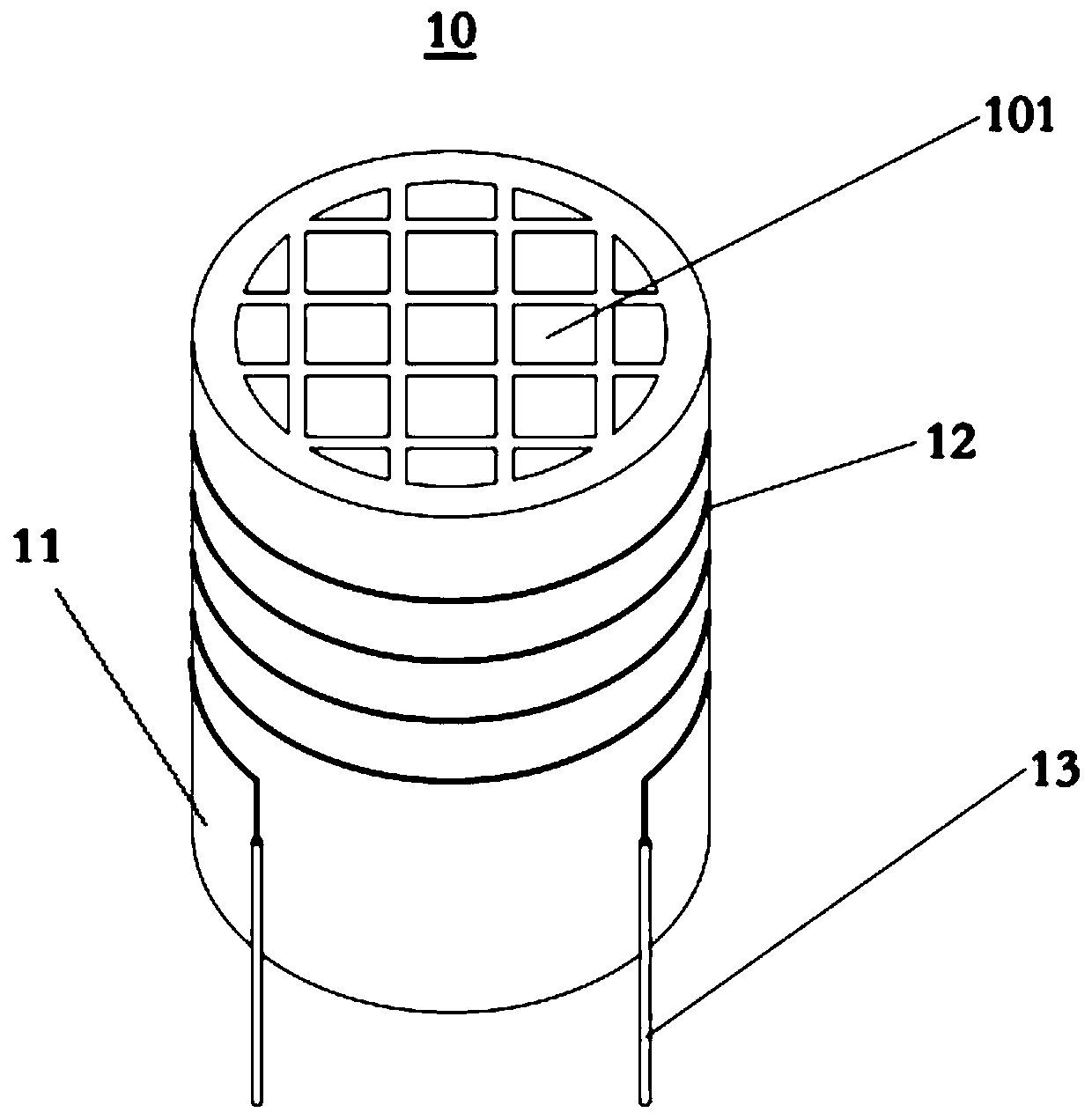

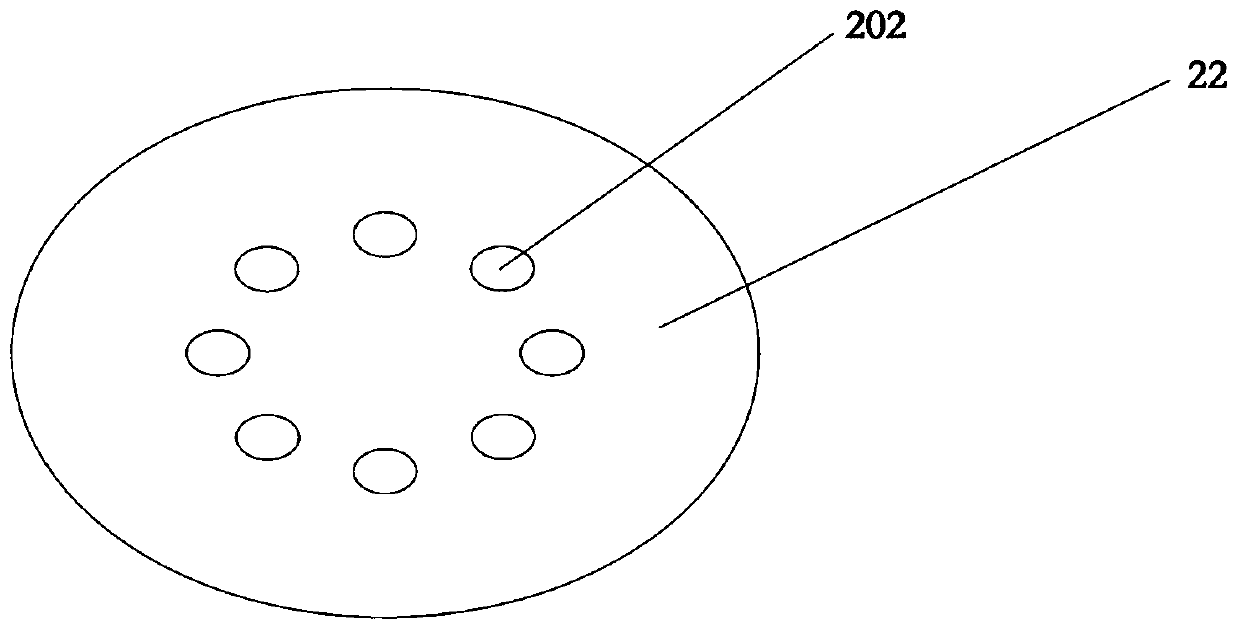

PendingCN110037352AIncrease flue gas volumeImprove compactnessTobacco devicesHoneycomb PatternEngineering

The invention discloses a non-contact air-heating-type electronic cigarette heater. The heater comprises a heating assembly, a sealing sleeve and a heat recycle device and is characterized in that a first honeycomb porous channel is formed in the side wall of the heat recycle device and divides the heat recycle device into an outer wall and an inner wall; the sealing sleeve is arranged in the inner wall of the heat recycle device, the sealing sleeve sleeves the heating assembly, and the heating assembly is connected with the heat recycle device through the sealing sleeve; a heating body is arranged in the heating assembly; a heating circuit is arranged on the heating body, a wire is arranged at an endpoint of the heating circuit, and a second honeycomb porous channel is formed in the heating body. According to the heater, air is heated through the heating assembly, so that the heated flowing air evenly roasts tobacco, and the smoke amount is increased.

Owner:XIAMEN FENGTAO CERAMICS CO LTD

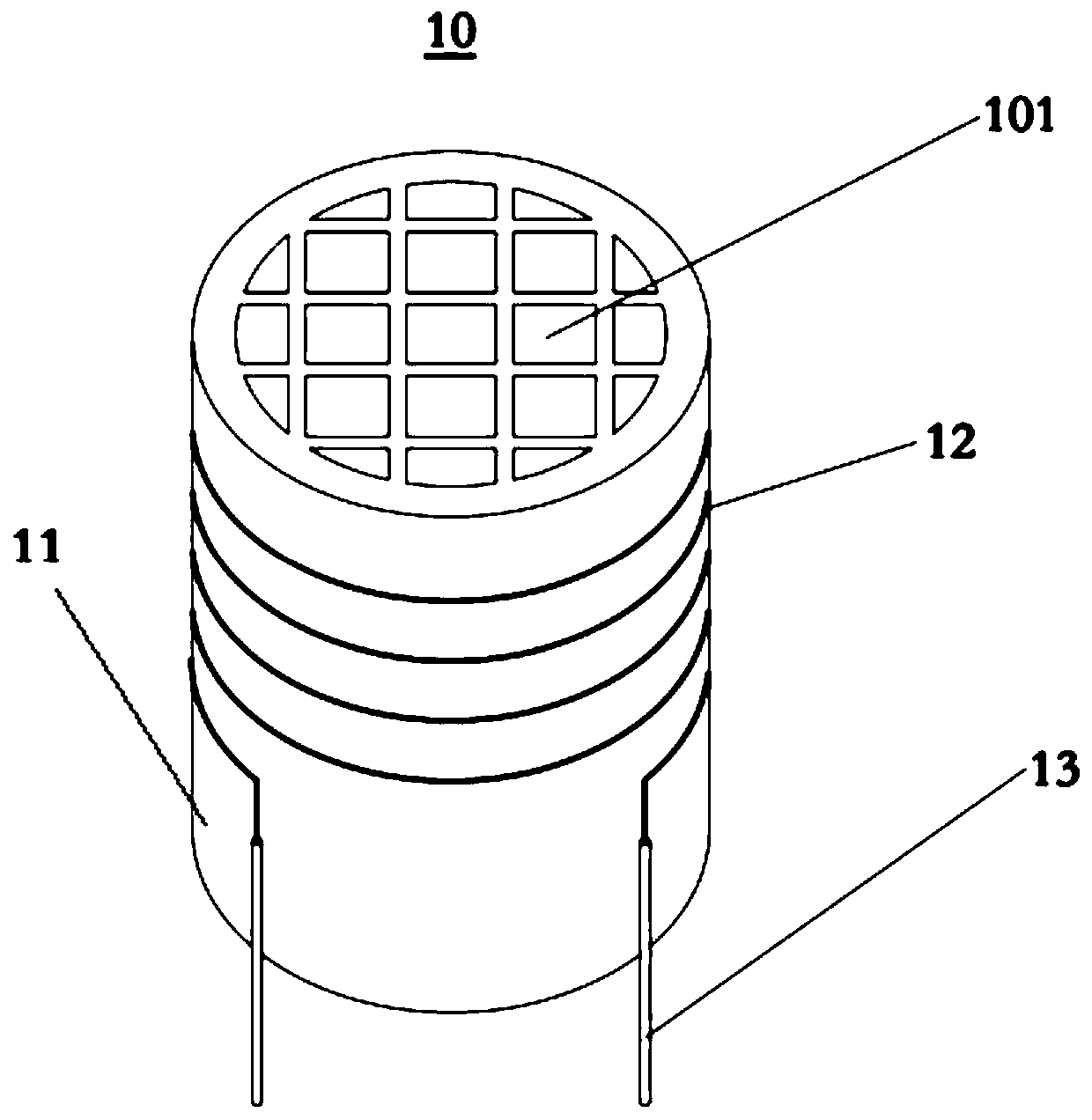

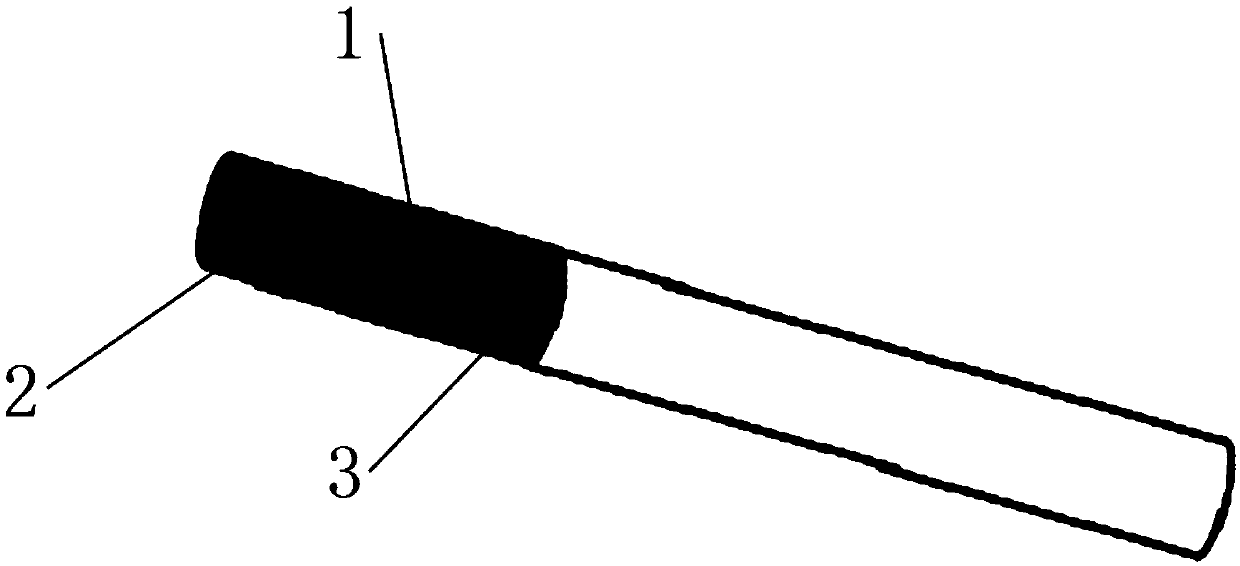

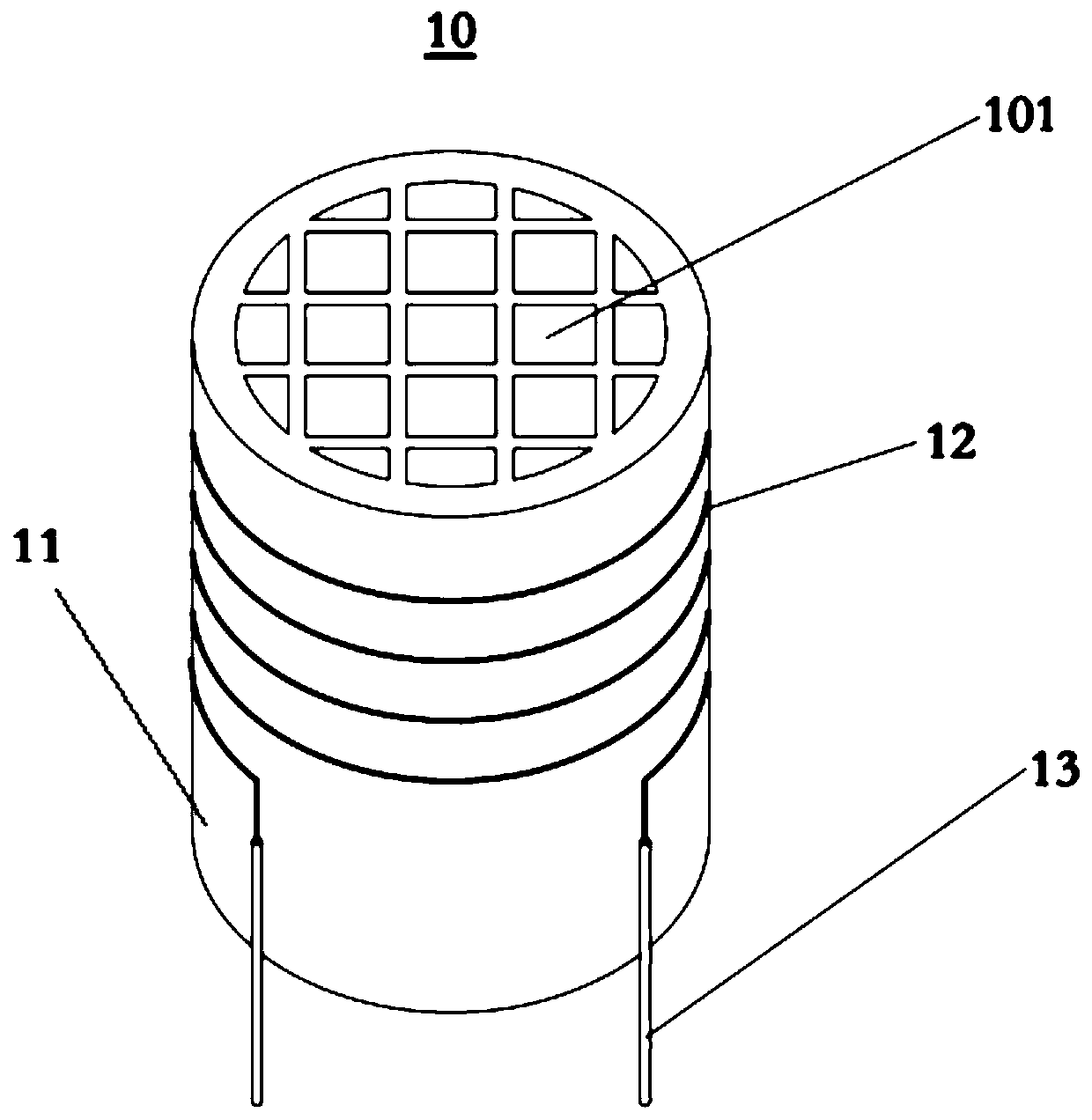

Ceramic heating element and non-contact electronic cigarette heater with ceramic heating element

PendingCN110710726AFully heatedControl flow rateOhmic-resistance heating circuitsTobacco smoke filtersElectronic cigarettePorous channel

The invention discloses a ceramic heating element. The ceramic heating element includes a heating body and a heating circuit; the heating body is columnar, and a porous channel is arranged in the heating body; and the heating circuit is arranged on the heating body to heat air passing through the porous channel. The ceramic heating element disclosed by the embodiment of the invention can increasethe contact area between the heating body and the air, and realize sufficient heating of the air, which not only has high heating efficiency and high thermal conductivity, and realizes energy saving and power saving, but also has good compactness and does not adsorb smoke particles, thereby having no abnormal odor. The invention also discloses a non-contact electronic cigarette heater with the ceramic heating element.

Owner:XIAMEN FENGTAO CERAMICS CO LTD

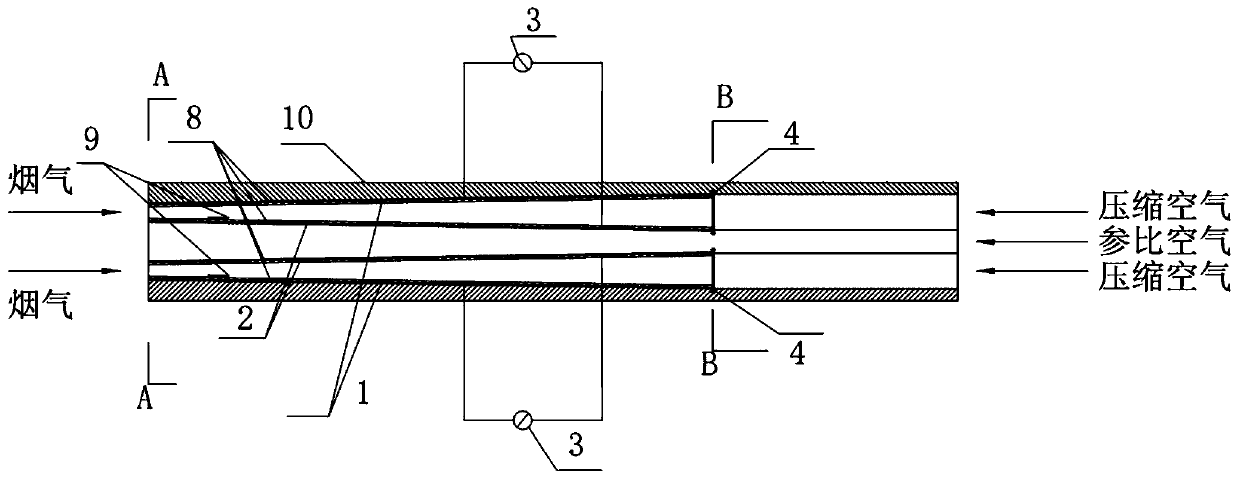

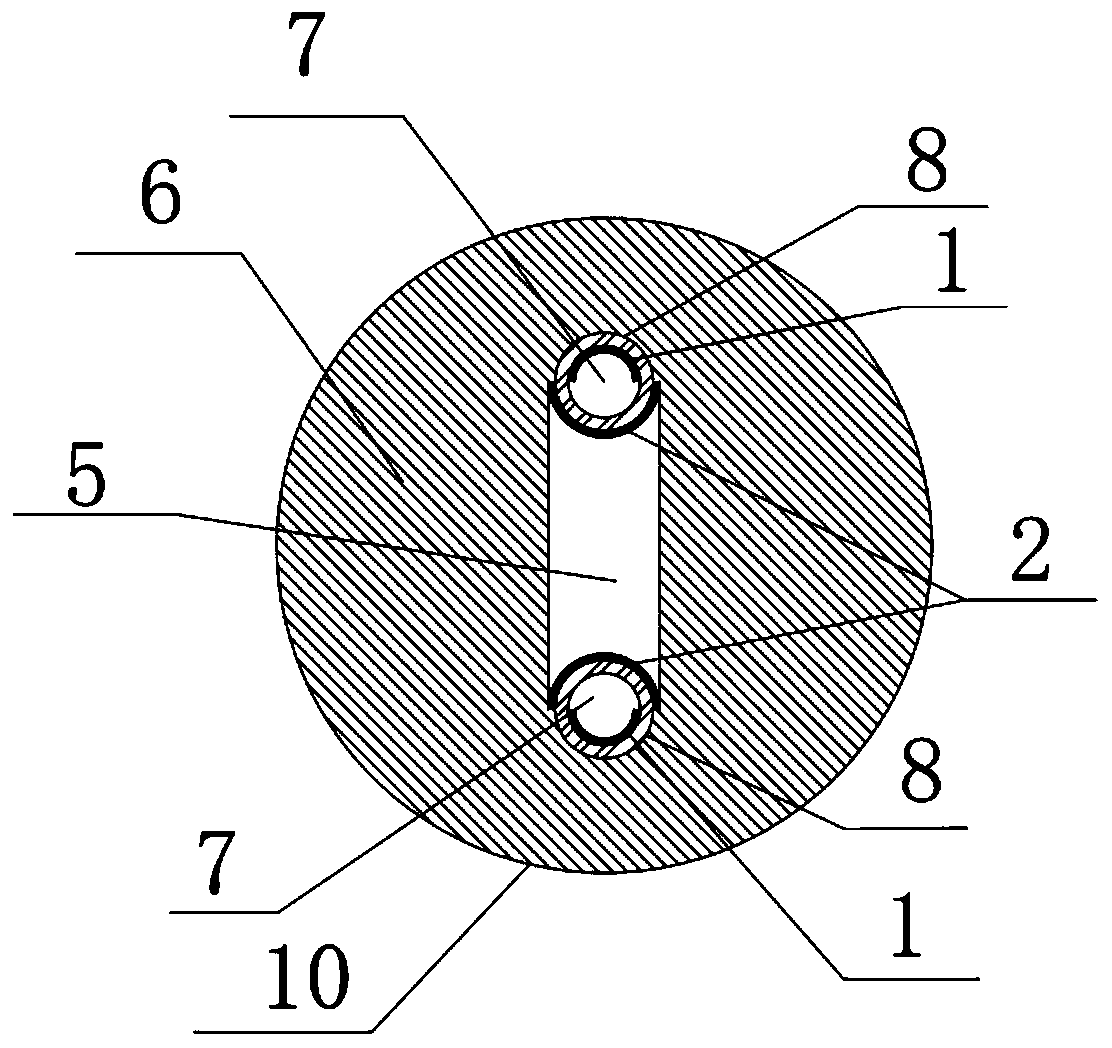

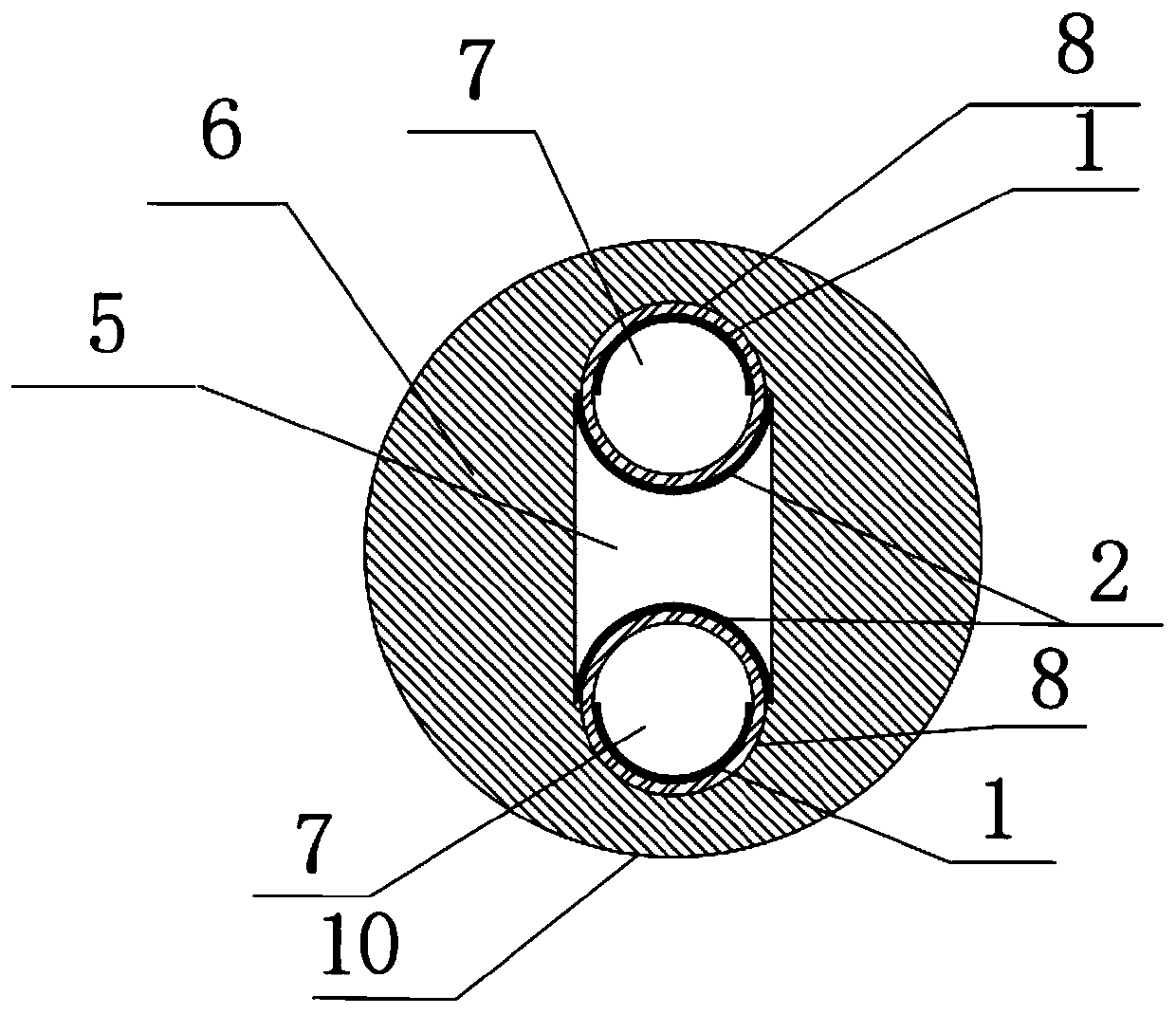

Oxygen sensor with self-calibration function

ActiveCN111537586AIncrease flue gas volumeFully contactedHollow article cleaningMaterial analysis by electric/magnetic meansOxygen sensorFlue gas

The invention discloses an oxygen sensor with a self-calibration function. The oxygen sensor comprises a sensor body, a flue gas channel and a reference air channel, wherein the flue gas channel and the reference air channel are arranged in the sensor body. Tshe flue gas channel is a zirconium oxide pipe, a flue gas side electrode is sintered and mounted on the inner side of the flue gas channel,an air side electrode is sintered and mounted on the outer side of the flue gas channel, and the potential difference between the flue gas side electrode and the air side electrode is displayed through an electromotive force measuring instrument; two ends of the flue gas channel are respectively used as a flue gas inlet end and a compressed air recoil end, and compressed air is used for reverselypurging the flue gas channel; the reference air channel is arranged on the outer side of the flue gas channel, the air side electrode is arranged in the reference air channel, and reference air is introduced into the reference air channel and used for being compared with the oxygen content of compressed air for self-calibration. According to the invention, the self-calibration function of the oxygen sensor is realized through the comparison of the backflushing compressed air and the oxygen content in the reference air in the reference air channel, and the measurement accuracy of the oxygen sensor is ensured.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

Coal-fired boiler combustion operation method and combustion operation system

PendingCN107120639APrevent dust and slaggingAvoid corrosionCombustion using gaseous and pulverulent fuelGaseous fuel feeder/distributionLower gradeProcess engineering

The invention discloses a coal-fired boiler combustion operation method and a combustion operation system. According to the combustion operation method, biomass gasified gas is injected into a hearth to assist fire coal burning. Not only can the problems of the dust deposition, scorification and corrosion be avoided, but the emission concentration of SO2 and NOx can be reduced remarkably, the carbon content of flue dust is reduced, and the high grade use of low grade biomass energy is realized.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

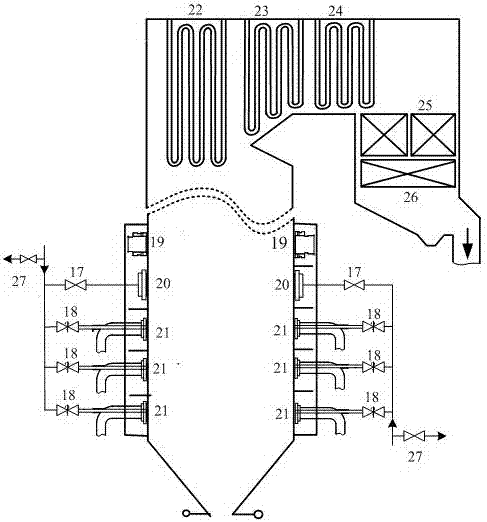

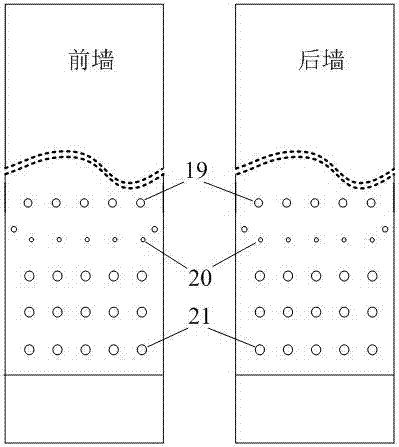

System and method for treating overhauling slag of aluminum cell by cement kiln bypass incinerating

ActiveCN108679628AEliminate the risk of secondary pollutionPromote safe productionIndirect carbon-dioxide mitigationIncinerator apparatusCyanideSlag

The invention provides a system and method for treating overhauling slag of an aluminum cell by cement kiln bypass incinerating. The system comprises an overhauling slag crushing system, a cement kilnbypass incinerating system, a conversion and dealkalizing system and a cement kiln resourceful treatment system which are sequentially connected. The method comprises the steps of S1, crushing and powdering the overhauling slag; S2, performing cement kiln bypass incinerating and disinfecting; S3, performing conversion and dealkalizing; and S4, performing resourceful treatment on a cement kiln. According to the system and the method, a suspension combined incinerating furnace is arranged at a cement kiln bypass; the crushed overhauling slag is incinerated under the conditions of high temperature, rich oxygen and long staying time, so that carbon materials in the overhauling slag can fully burn, and moreover, cyanide in the overhauling slag can be oxidized to remove the toxicity under high-temperature aerobic and alkaline conditions; the cinder obtained after incinerating of the overhauling slag is washed through alkaline liquid in order to be converted into a mineralizer containing fluorite for the cement kiln, and a caustic soda byproduct can be obtained, and as a result, the harmless, resourceful, ultimate and massive treatment of the overhauling slag of the aluminum cell can beachieved.

Owner:长沙中硅环保科技有限公司

Non-contact type electronic cigarette heater

PendingCN110710725AAvoid wastingLarge specific surface areaOhmic-resistance heating circuitsTobacco smoke filtersThermodynamicsEngineering

The invention discloses a non-contact type electronic cigarette heater. The non-contact type electronic cigarette heater comprises a ceramic heater and a smoke formation product bearing component, wherein the ceramic heater comprises a heating body and a heating circuit; the heating body is columnar in shape, and a porous channel is arranged in the heating body; the heating circuit is arranged onthe heating body for heating air passing through the porous channel; the smoke formation product bearing component comprises a preheating pipe and baffles; the baffles are arranged in a cavity definedby the preheating pipe to divide the cavity into a first cavity and a second cavity; the first cavity is applicable to holding smoke formation products and preheating the smoke formation products; the second cavity is applicable to holding at least one part of the ceramic heater. According to the non-contact type electronic cigarette heater, at least one part of the ceramic heater is arranged inthe cavity defined by the preheating pipe, so that the effect of preheating the cavity can be achieved, heating efficiency can be improved, the heated flowing air can uniformly bake the smoke formation products, the waste of cut tobacco of the smoke formation products can be avoided, and the amount of smoke also can be improved.

Owner:XIAMEN FENGTAO CERAMICS CO LTD

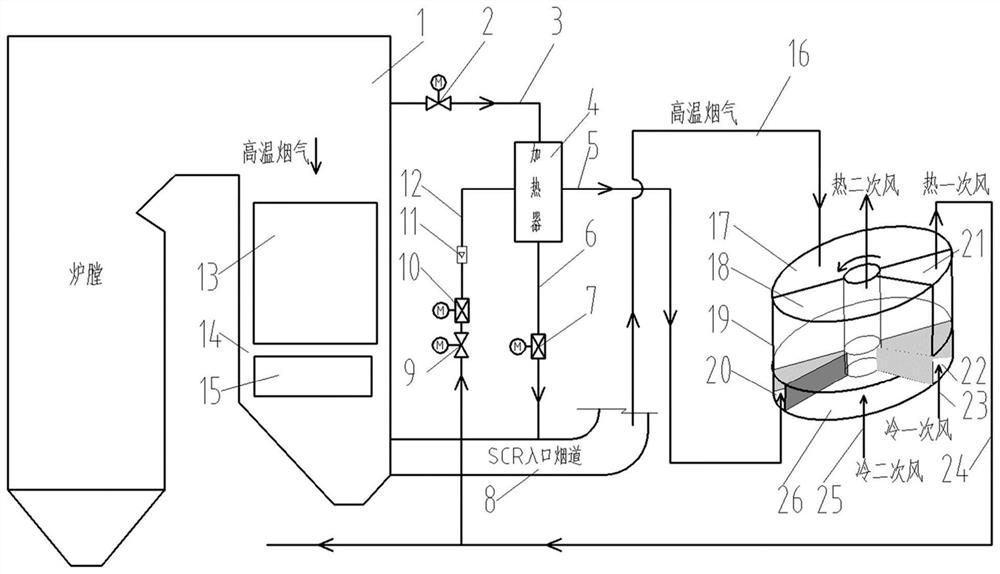

SCR denitration reducing agent preparation device with flue gas heating system and method

PendingCN112774436ASave spacePrevent leakageTransportation and packagingDispersed particle separationFlueChemistry

The invention discloses an SCR denitration reducing agent preparation device with a flue gas heating system and a method. The preparation of an SCR denitration reducing agent is completed by utilizing the flue gas heating system. A reducing agent solution is directly sprayed into a high-temperature flue of a flue gas heating system, ammonia gas evaporated from high-temperature flue gas is mixed with the high-temperature flue gas and then fed into an original flue gas flue through the high-temperature flue to be mixed with original flue gas, a reducing agent required by denitration is provided, and the reducing agent solution can be ammonia water or a urea solution. Compared with a traditional SCR denitration reducing agent preparation system, an evaporator, an ammonia-air mixer, a dilution fan, a dilution air heating device, an ammonia spraying grid and the like do not need to be arranged, and the system has the advantages of being simple, easy to control, small in investment and the like.

Owner:BEIJING SHOUGANG INT ENG TECH

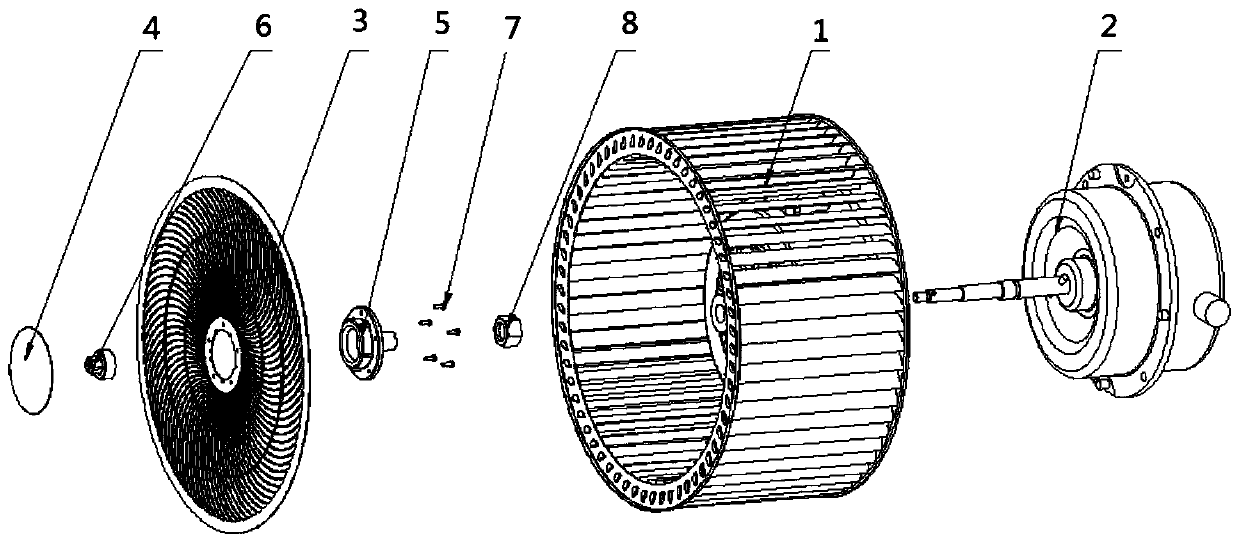

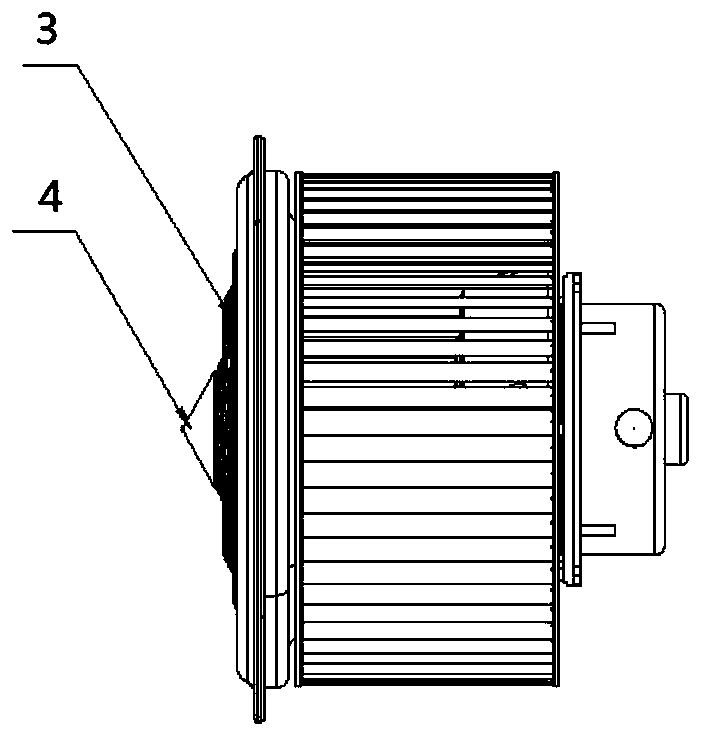

Fan assembly and range hood

PendingCN110332133AReduce or virtually eliminate filtrationIncrease centrifugal forceDomestic stoves or rangesPump componentsImpellerCentrifugal force

The invention provides a fan assembly and a range hood. The fan assembly comprises an impeller, a motor and a rotary filter screen arranged at an air inlet, and further comprises an oil guiding piece,wherein the oil guiding piece is arranged on one end face, far away from the impeller, of the rotary filter screen, at least one part of the oil guiding piece is arranged to close to the circle center part of the rotary filter screen, the oil guiding piece is provided with an oil guiding part in contact with lampblack, and at least a part of the oil guiding part protrudes towards the air inlet direction. Under the action of the impeller, the lampblack at the rotary filter screen flows in an oil drop state in the adsorption process, and is guided to be away from the center of the rotary filterscreen at the oil guiding piece, oil drops far away from the center of the rotary filter screen are large in centrifugal force, the oil drops can be well thrown out to the periphery, and the better lampblack separation effect is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

Ash blocking prevention system of reheating primary air recirculation rotary air preheater

PendingCN112283739AImprove the heating effectThe heating effect is sufficientHeat storage plantsCombustion processAir preheaterFlue gas

The invention discloses an ash blocking prevention system of a reheating primary air recirculation rotary air preheater and aims at solving the problem of rotary air preheater ash blocking generally existing in an existing thermal generator set. The ash blocking prevention system comprises a primary air heater, an original primary air duct, a first flue, a second flue, a first air duct and a second air duct, and the first flue, the second flue, the first air duct and the second air duct are connected with the primary air heater. An inlet of the first flue is connected with a boiler rear vertical shaft flue, an outlet of the first flue is connected with a flue gas inlet end of the primary air heater, an inlet of the second flue is connected with the flue gas outlet end of the primary air heater, an outlet of the second flue is connected with a boiler SCR system inlet flue, and an inlet of the first flue is connected with the original primary air duct. An outlet of the first air duct isconnected with the air inlet end of the primary air heater, the air outlet end of the primary air heater is connected with an inlet of the second air duct, and an outlet of the second air duct is connected with a reheating primary air inlet of the air preheater.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com