Fan assembly and range hood

A component and fan technology, applied in the direction of removing oil fumes, machines/engines, pump components, etc., can solve the problems of reducing the separation degree of grease in the rotary filter, small centrifugal force, and affecting the cleaning effect, etc., to achieve increased smoke volume, large centrifugal force, Good oil fume separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

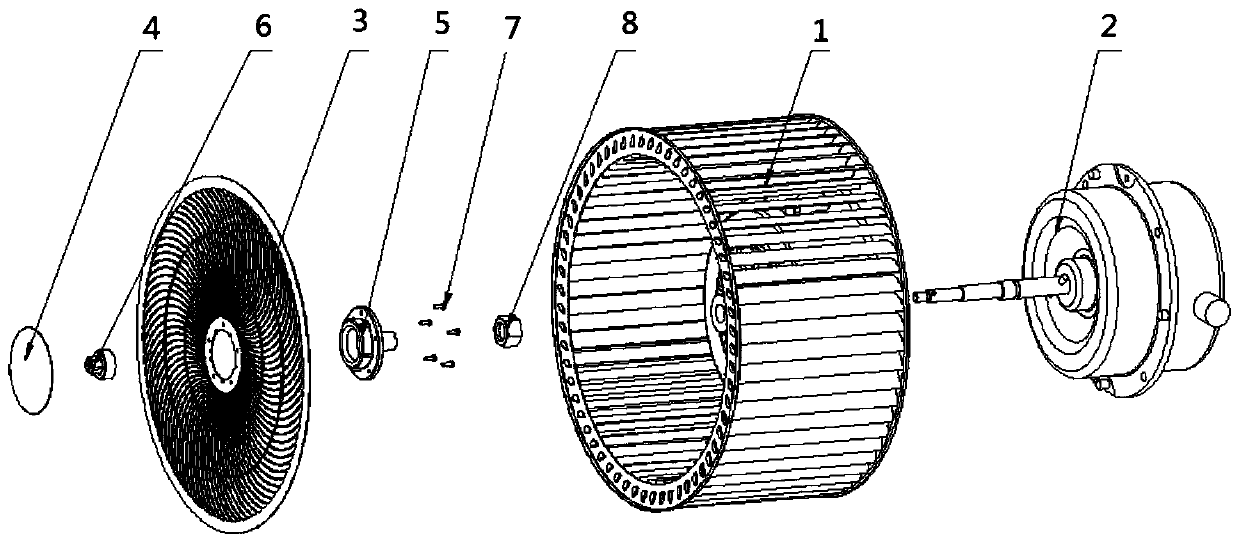

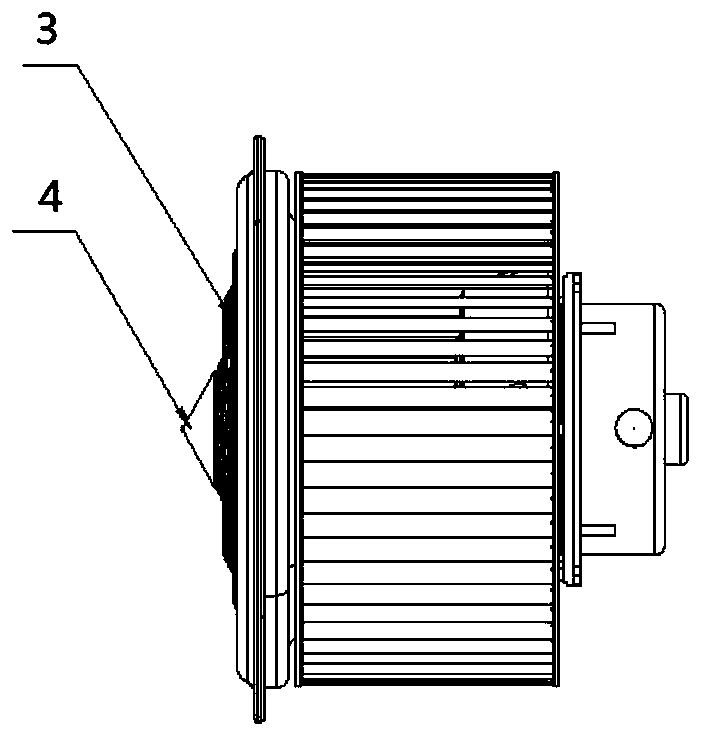

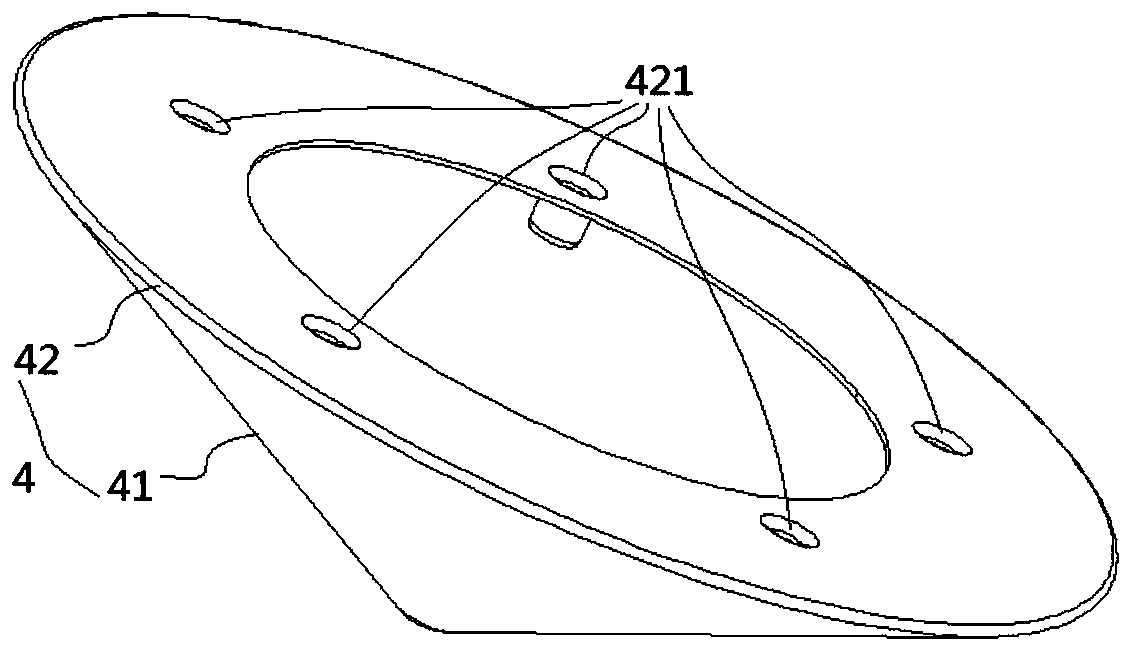

[0041] Figure 1 to Figure 2 As shown, a fan assembly provided in this embodiment includes an impeller 1, a motor 2 and a rotating filter screen 3 arranged on the motor 2, and also includes: an oil guide 4 arranged near the rotating filter screen 3 One end of the air inlet, at least a part of the oil guide 4 is set close to the center of the rotary screen 3, and the oil guide 4 has an oil guide 41 in contact with the oil fume, and the oil guide 41 At least a part of it protrudes toward the wind inlet direction.

[0042] It should be noted that the fan assembly in this embodiment is applied to a range hood, and it includes a turbofan. The above-mentioned turbofan has an air inlet, the above-mentioned impeller 1 is installed on the inner peripheral wall of the air inlet, and the motor 2 is installed on the air inlet. Axially, it is arranged close to one end, and the impeller 1 is fixed on the motor shaft of the motor 2 through the impeller nut 8, and rotates together with the m...

Embodiment 2

[0051] This embodiment provides a range hood, which includes the fan assembly in Embodiment 1, and has all its technical advantages, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com