Integrated process for pyrolyzing urea for medium- and low-temperature SCR (Selective Catalytic Reduction) denitration and regenerating catalyst

A catalyst and denitrification technology, which is applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems that the system needs to be shut down for processing, affects the system production, and requires a large site, so as to reduce the oxygen content in the flue gas, increase the Equipment capacity, beneficial effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

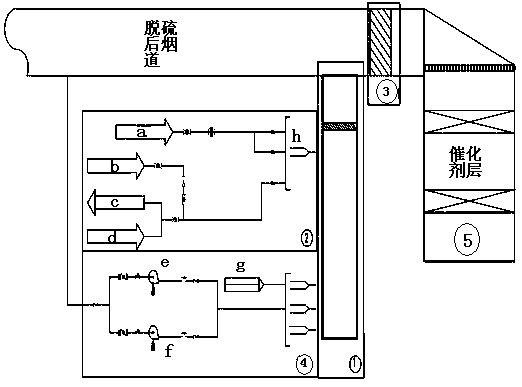

[0025] The integrated process of urea pyrolysis and catalyst regeneration for medium and low temperature SCR denitrification in this embodiment, the SCR denitrification adopts a denitrification reactor, and the denitrification reactor includes a flue, and the urea pyrolysis is burned in a combustion furnace to generate high-temperature flue gas proceed, see figure 1 shown, including the following steps:

[0026] 1) Use the blower system 4 to extract the desulfurized flue gas in the flue as an oxidant and burn it in the afterburner system 1;

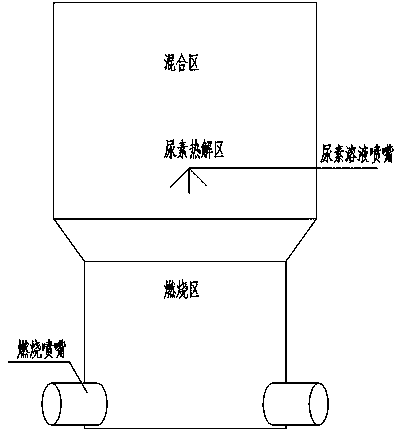

[0027] 2) Mix the high-temperature flue gas generated by combustion with the urea solution sprayed by the urea injection system 2;

[0028] 3) After being mixed with the original flue gas through the flue gas mixing system 3, it enters the SCR reactor as a denitration reducing agent for denitrification.

[0029] The blower system 4 uses the first booster fan e and the second booster fan f to send blast furnace gas or coke oven gas g int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com