Preparation method of fine-particle spherical titanium powder for three-dimensional (3D) printing

A spherical titanium powder, 3D printing technology, applied in the field of metal powder preparation, can solve the problems of coarse particle size, high cost, wide distribution range, etc., and achieve the effects of high fluidity, high sphericity, and low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

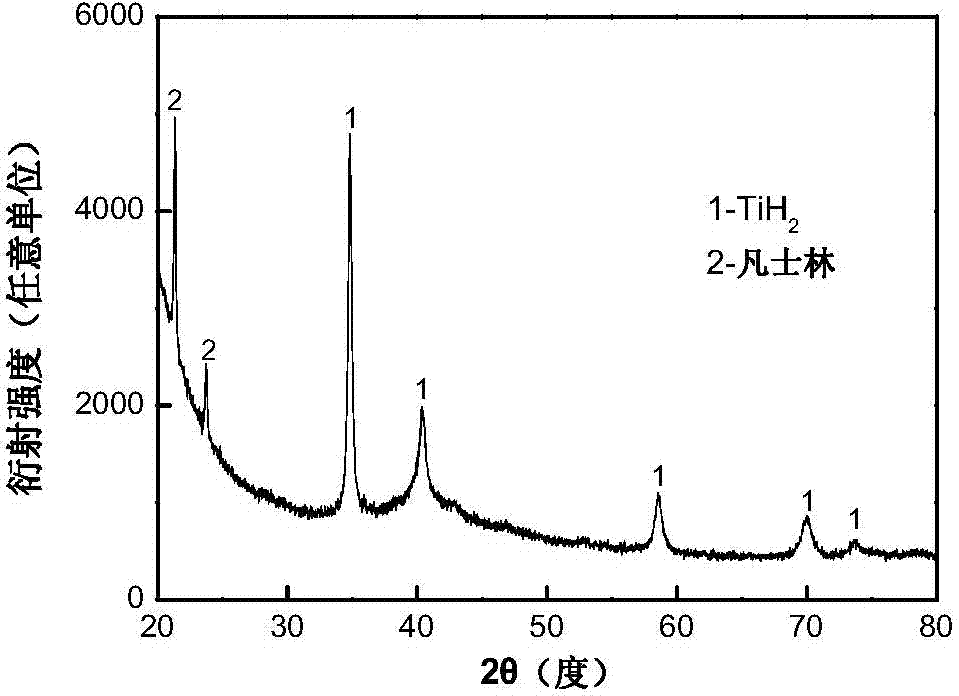

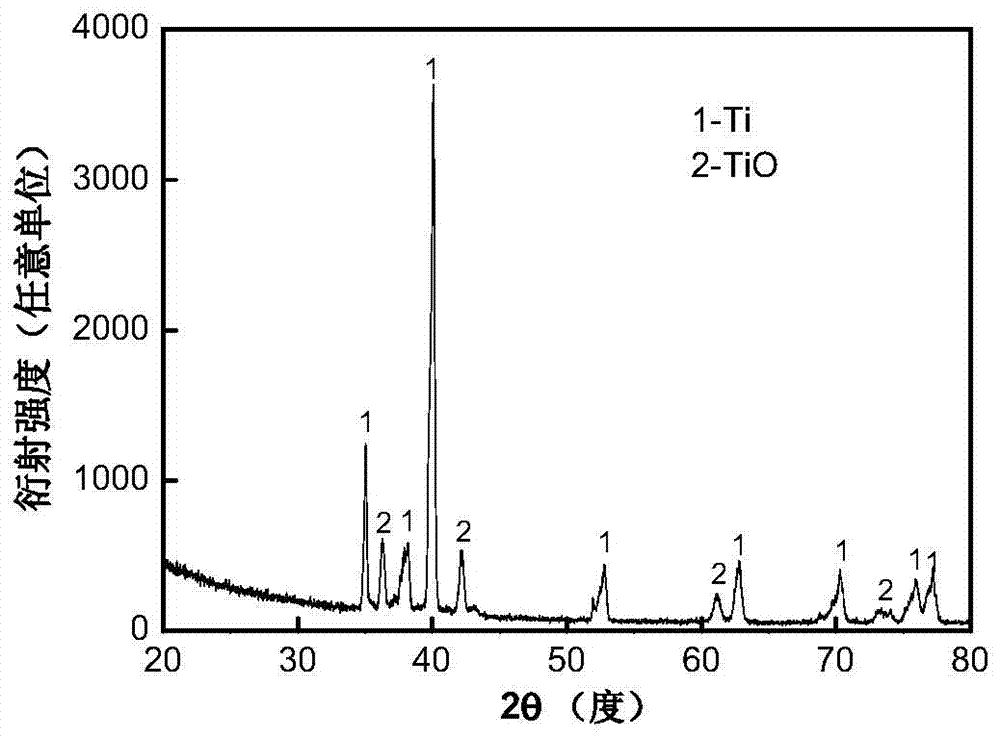

[0017] Example 1. Using the raw material high-purity titanium block (purity 99.99wt%) as the anode, in an inert gas argon environment, a high-intensity arc is formed by discharge, the arcing current is 100A, the arc voltage is 10V, and then hydrogen is introduced , the ratio of hydrogen to inert gas is 1:1, and titanium hydride (TiH 2 ), form solid titanium hydride nanoparticles after condensation, such as figure 1 ; Polyvinyl alcohol, polyethylene glycol, deionized water and titanium hydride nanoparticles were prepared into a suspension liquid slurry, and the centrifugal atomization drying method was used for agglomeration and granulation to obtain 20 μm spherical titanium hydride particles; The tubular furnace heat-treated the granulated titanium hydride powder. The heat treatment temperature of the first stage was 230°C, and the holding time was 120 minutes; the heat treatment temperature of the second stage was 700°C, and the holding time was 180 minutes; the heat treatmen...

example 2

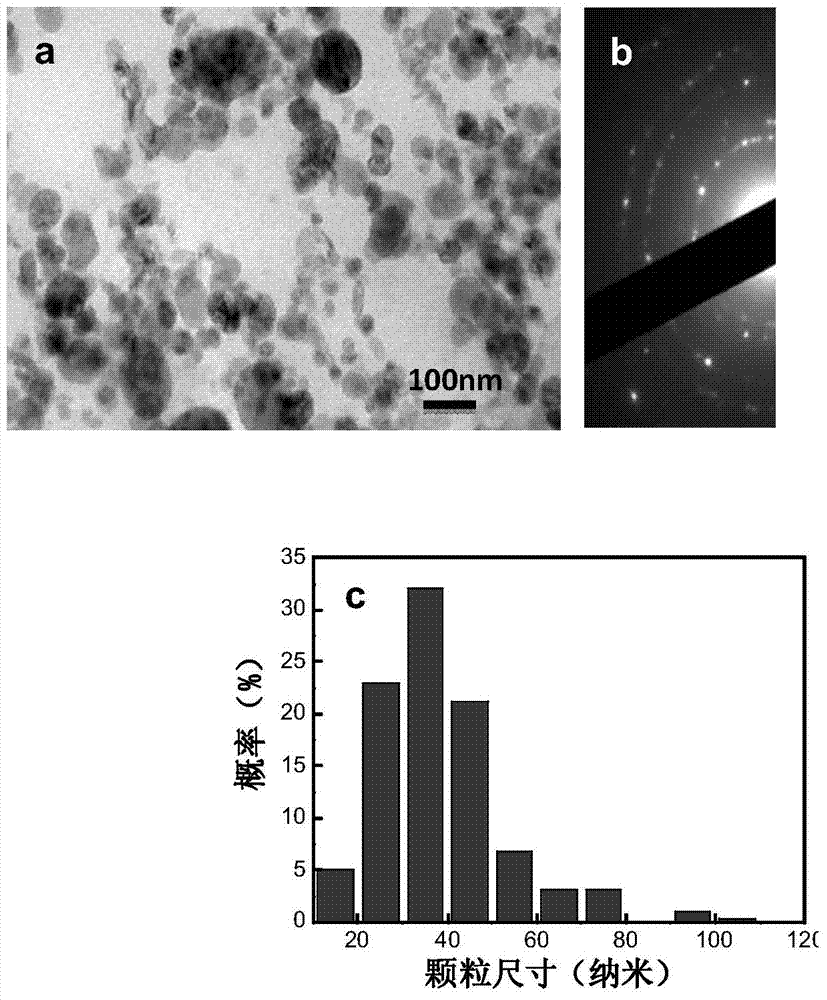

[0018] Example 2. Using the raw material high-purity titanium block (purity 99.99wt%) as the anode, in an inert gas helium environment, a high-intensity arc is formed by discharge, the arc starting current is 250A, the arc voltage is 30V, and then hydrogen is introduced , the ratio of hydrogen to inert gas is 1:3, and titanium hydride (TiH 2 ), solid titanium hydride nanoparticles are formed after condensation, and its micromorphology and particle size distribution are as follows figure 2 ; Polyvinyl alcohol, polyethylene glycol, deionized water and titanium hydride nanoparticles were prepared into a suspension liquid slurry, and the centrifugal atomization drying method was used for agglomeration and granulation to obtain spherical titanium hydride particles of 50 μm; argon-protected The tubular furnace heat-treated the granulated titanium hydride powder. The heat treatment temperature of the first stage was 280°C, and the holding time was 90 minutes; the heat treatment temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com