Patents

Literature

446results about How to "Improve styling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Distiller yeast, preparation process of distiller yeast and process for preparing health care liquor by utilizing distiller yeast

ActiveCN103421646AHarmonizeQuality improvementAlcoholic beverage preparationHordeum vulgareChinese liquor

The invention relates to alcohol products, in particular to distiller yeast for manufacturing liquor and a process for preparing the distiller yeast, and further relates to a process for preparing health care liquor by utilizing the distiller yeast. A mixture of wheat, barley and peas is used as a raw materials formula, and the wheat, the barley and the peas are mixed, wherein the weight ratio of the wheat to the barley to the peas is 4:5:1. The raw material formula further comprises bighead atractylodes rhizome which, by weight, accounts for 0.5% of the mixture of the wheat, the barley and the peas, pericarpium citri reticulatae which, by weight, accounts for 0.3% of the mixture of the wheat, the barley and the peas, red jujube which, by weight, accounts for 0.2% of the mixture of the wheat, the barley and the peas, liquorice which, by weight, accounts for 0.3% of the mixture of the wheat, the barley and the peas and folium mori which, by weight, accounts for 0.3% of the mixture of the wheat, the barley and the peas. According to the distiller yeast and the process for preparing the distiller yeast, beneficial microorganisms in the yeast for making hard liquor are fully bred, the quality of the distiller yeast is improved, and a role in restraining infectious microbes is played by adding Chinese herbal medicine. The invention further provides the process for preparing the health care liquor, according to the process, the style characteristics of traditional Chinese liquor are kept, and the health care liquor has the effects of body building, fitness and disease treatment.

Owner:河南尧香酒业有限公司

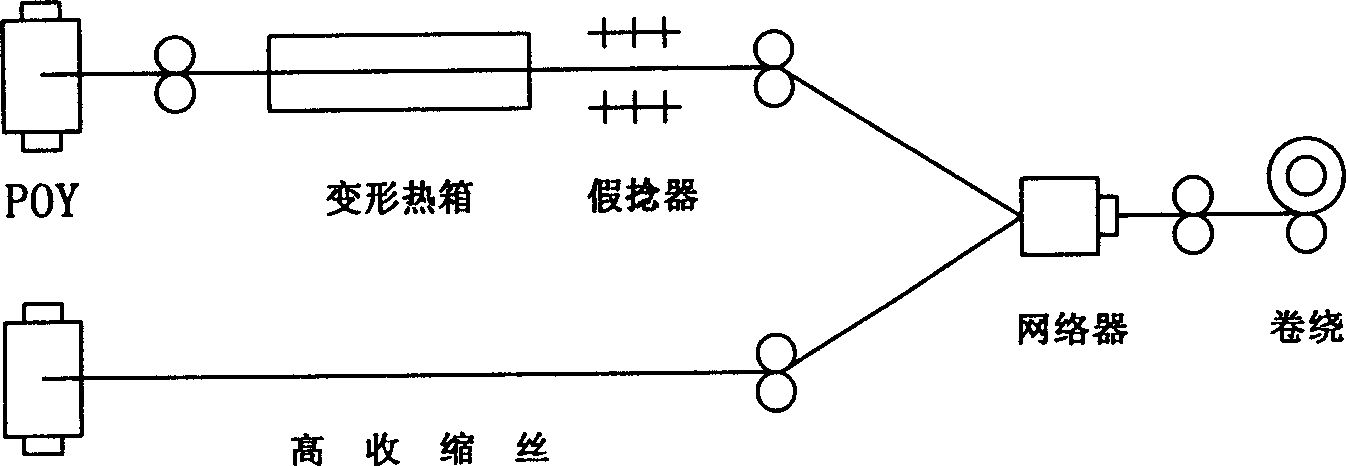

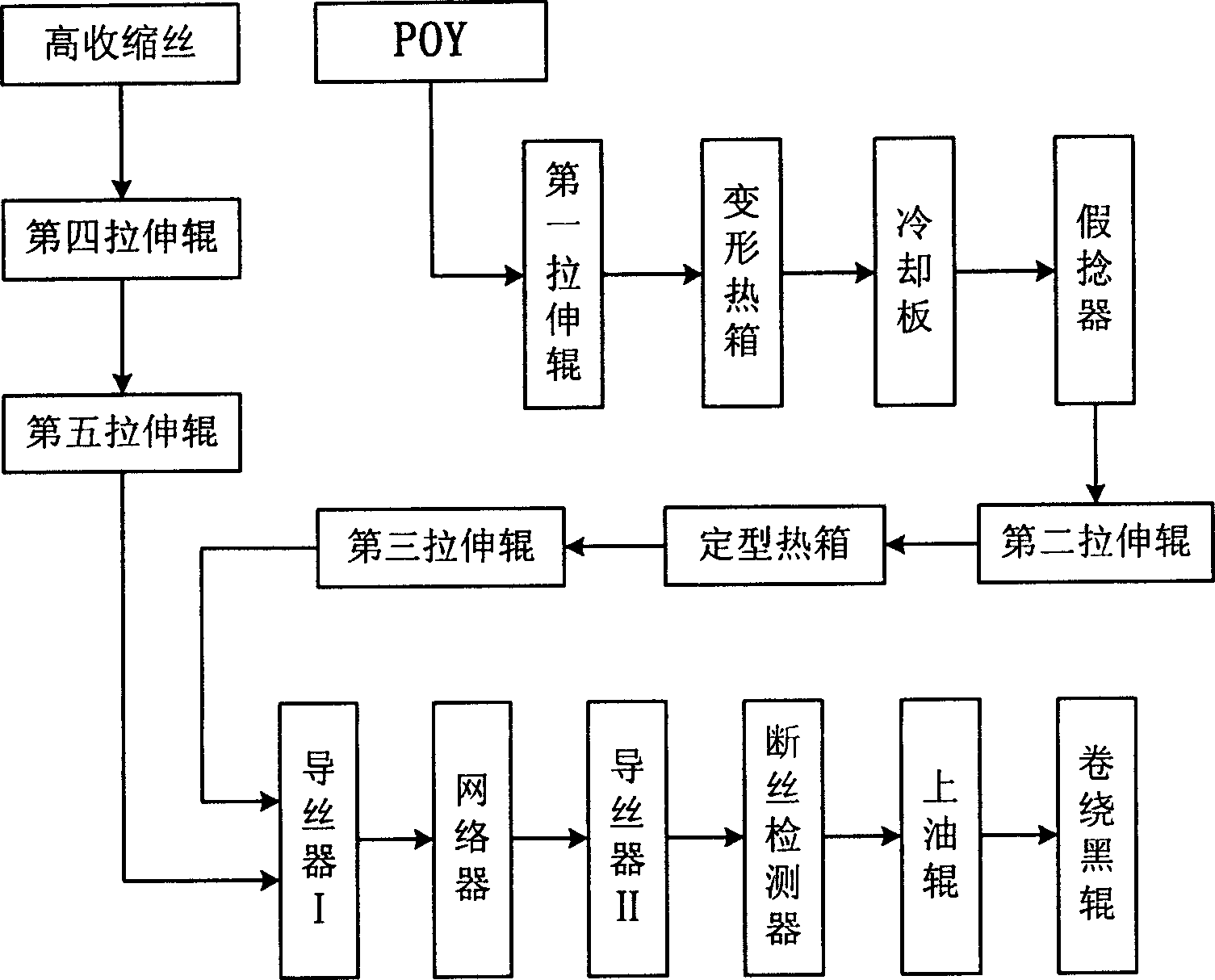

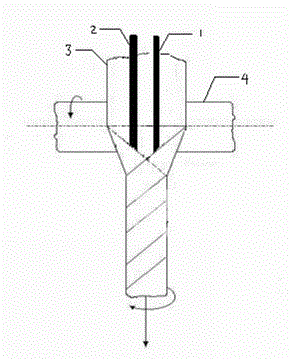

Process for preparing plied yarn by one-step process using textured yarn and highly retractable yarn

The invention relates to a process for preparing plied yarn by one-step process using textured yarn and highly retractable yarn, comprising: having the draw texturising machine as main processing device, drawing and deforming the pre-oriented yarn POY, heating moulding the produced deforming yarn by the heat moulding box and the third drawing roll; meanwhile, setting the fourth and fifth drawing roll on the draw texturising machine, feeding and drawing the highly retractable yarn, sending into network device for combining with the deformation yarn, detecting and oiling by guide, detector and oiling roll, finally winding to obtain the resultant yarn. The invention increases the moulding procedure of the deformation yarn, solves the problem the moulding the yarn combining in a single step. The resultant yarn has a good fastness and uniformity of the network degree, little yarn breakage which can be used to produce the material like wool fabrics, polyester peach skin, suede nap.

Owner:中国石化仪征化纤股份有限公司

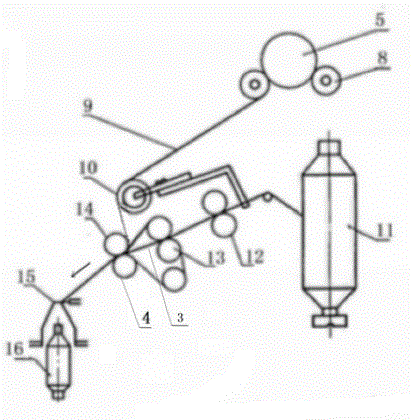

Polyester drawn textured yarn and production process thereof

The invention discloses a polyester drawn textured yarn, which is continuously produced by polyester. The polyester drawn textured yarn is characterized in that the specification is 75D / 288F, and a product has excellent performance. The invention also discloses production process thereof, which comprises the following steps of: performing esterification reaction on pure terephthalic acid and glycol serving as raw materials; then performing pre-polycondensation and final polycondensation to prepare polyester melt for direct spinning; and adopting a POY-DTY circular blast cooling process route, wherein the viscosity of the prepared polyester melt is 0.650. The production process has the advantages of reasonable process, good fiber spinnability, excellent physical indexes, few broken filaments and broken ends, high switching success ratio, 95 percent of full-package rate, smooth subsequent processing, light and soft texture and good style of woven fabrics, and application in fabrics and linings of high-grade down jackets and fabrics of sportswear and casual wear.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

Method for preparing meaty paste essence by controlling natural amino acids and obtained product

The invention discloses a method for preparing meaty paste essence by controlling natural amino acids and an obtained product. The method is characterized by preparing the meaty paste essence through the natural amino acid control technology, and preparing the natural paste essence by combining the amino acids from natural animals with other auxiliary materials through the Maillard reaction technology. The obtained product belongs to the purely natural food condiments without toxic or side effects. The meaty paste essence not only has aroma close to the natural aroma, attractive flavor and good taste, but also has higher nitrogen content, rich nutrition, good safety performance and stable product property.

Owner:TIANNING FLAVOR JIANGSU

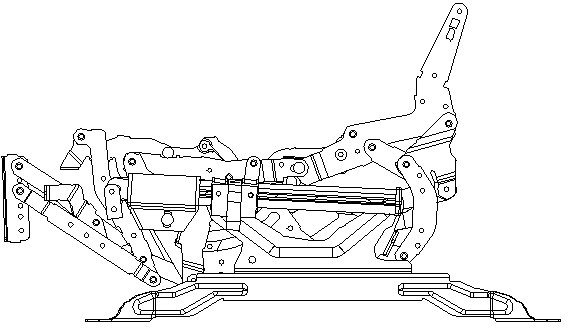

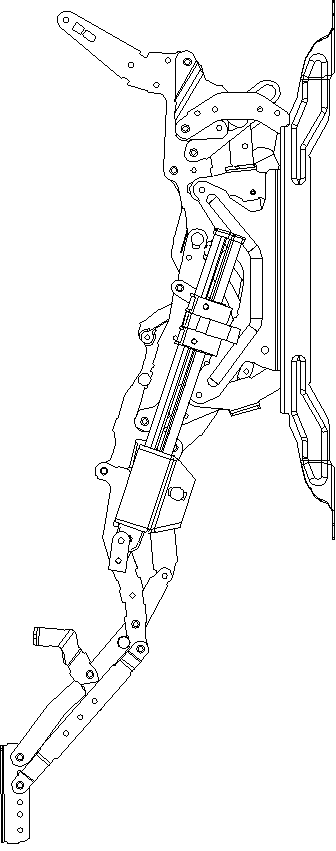

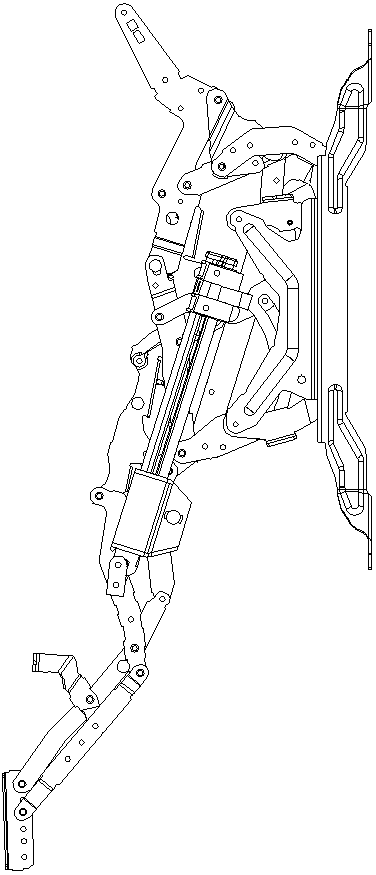

Mechanical stretching device for electric rocking chair of movable sofa

ActiveCN103445558ARealize electric functionImprove comfortSofasCouchesMechanical stretchingElectric machinery

The invention relates to a mechanical stretching device for an electric rocking chair of a movable sofa. The mechanical stretching device comprises a left-side member, a right-side member and an electric device, wherein the electric device comprises a motor, a motor fixing bracket, a guide rail bracket, a motor fixing tube, a motor moving sliding block and a motor guide rail, the motor fixing tube is mounted on the motor fixing bracket, the motor fixing bracket is rotatably connected with a transmission connecting member, and the transmission connecting member is rotatably connected with the guide rail bracket through a third rotating shaft; a first guide rail is arranged on the guide rail bracket and is in an circular arc shape; the third rotation shaft is arranged in the first guide rail; one end of the motor is connected with the motor moving sliding block, the other end of the motor is rotatably connected with a leg square tube, and the motor is mounted on the motor guide rail; the motor moving sliding block is fixed on the motor fixing tube and is in sliding connection with the motor guide rail. According to the mechanical stretching device, the motor fixing tube is provided with a sunken part, and the motor moving sliding block is fixed in the sunken part. As the electric rocking chair is endowed with an electric function, the automatic degree and the comfort of the sofa are improved.

Owner:REMACRO MASCH & TECH (WUJIANG) CO LTD

Two-core covering yarn made by ring spinning and production method thereof

Provided are a two-core covering yarn made by ring spinning and a production method thereof. The two-core covering yarn comprises an inner-layer yarn core and an outer wrapping fiber. The inner-layer yarn core is composed of a first centre yarn and a second centre yarn. The first centre yarn and the second centre yarn are arranged in parallel. The inner-layer yarn core is wrapped in a spiral form by the outer wrapping fiber. The first centre yarn is made by a polyurethane filament with weight percentage of 8.4. The second centre yarn is made by a polyester filament with weight percentage of 15.8%. The outer wrapping fiber is made by a cotton fiber with weight percentage of 75.8. The two-core covering yarn is of 36 Tex. A doubling long yarn passes behind a front leather roller of a spinning machine and is fed with an outer wrapping thick yarn into a twisting rectangular area composed of a front leather roller and a front roller. The outer wrapping thick yarn is stretched by a back roller and a middle roller. Two filaments are complementary in performance and featured by being high in elasticity and strength without broken filaments. Especially for a parallelly-arraying two-core yarn structure, fine wrapping performance is obtained and soft handfeel is achieved. Defects of utilizing air vortex spinning to make a two-core covering yarn are overcome.

Owner:JIHUA 3542 TEXTILE CO LTD

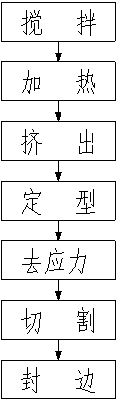

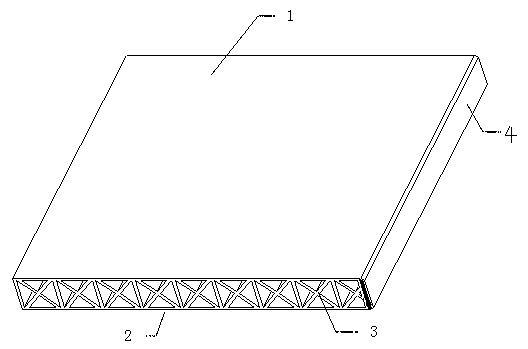

Process for molding hollow plastic building template

The invention discloses a process for molding a hollow plastic building template. The process comprises the following steps: stirring, heating, extruding, setting, performing stress removal treatment, cutting and sealing. The template subjected to extrusion molding is subjected to quick heating and cooling treatment, the internal residual stress is removed, and the setting effect of the template is improved and service life of the template is prolonged; and a notch of the template is subjected to grinding, coating, final pressing and other process steps through a sealing machine, and a sealing strip is adhered to the cut side, so that the cement mortar can be effectively prevented from being poured into the template through the hollow part in the template using process, the service life is prolonged, and due to the test, compared with the non-sealed hollow plastic building template, the sealed hollow plastic building template has the advantages that the strength is improved by three times, and the service life is prolonged by five times under the condition of the same workload, and the practical effect is obvious.

Owner:张浩

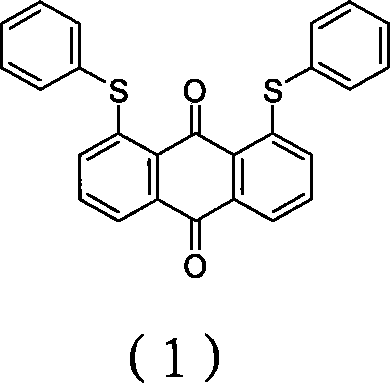

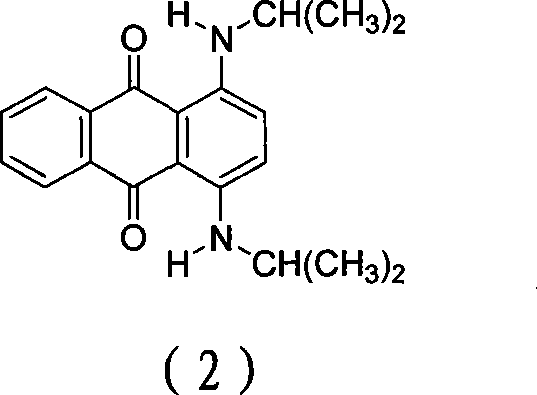

Dyeing method suitable for dacron fabric and application thereof

The invention discloses a polyester fiber fabric coloring method and the fabric adopting the method and manufactured by using the method. The method is a method which combines pretreatment and coloring to carry out one bath one step coloring. The dosage of alkali is 0.3 to 30g / l, and the bath ratio is 1:3 to 1:40 under the strong alkalinity condition that the pH of a dye bath is equal to or more than 10.6 and is equal to or less than 14. An alkali resistance dispersing dye is used for carrying out the one bath one step coloring on the polyester fiber and a fabric thereof under the condition of having a pretreatment addition agent or having no pretreatment addition agent. The invention carries out the one bath one step coloring under the strong alkalinity condition. The alkalinity condition can effectively remove the slurry and oil agent on a polyester fabric, overcome the defects of generating a plurality of dye defects caused by the precipitation of other decomposing products such as polyester oligomer in an acid bath and simultaneously bring the effect of neat fabric surface and good fabric style which can meet the requirement of fastness that usually needs no reduction and cleaning. The amount reducing effect of the alkali can also lead the fabric to be smooth and the hand feeling to be better. The method simplifies the coloring technique, reduces the waste water of pretreatment, saves energy, reduces the manufacture cost and improves the labor production efficiency.

Owner:浙江昱泰染化科技有限公司

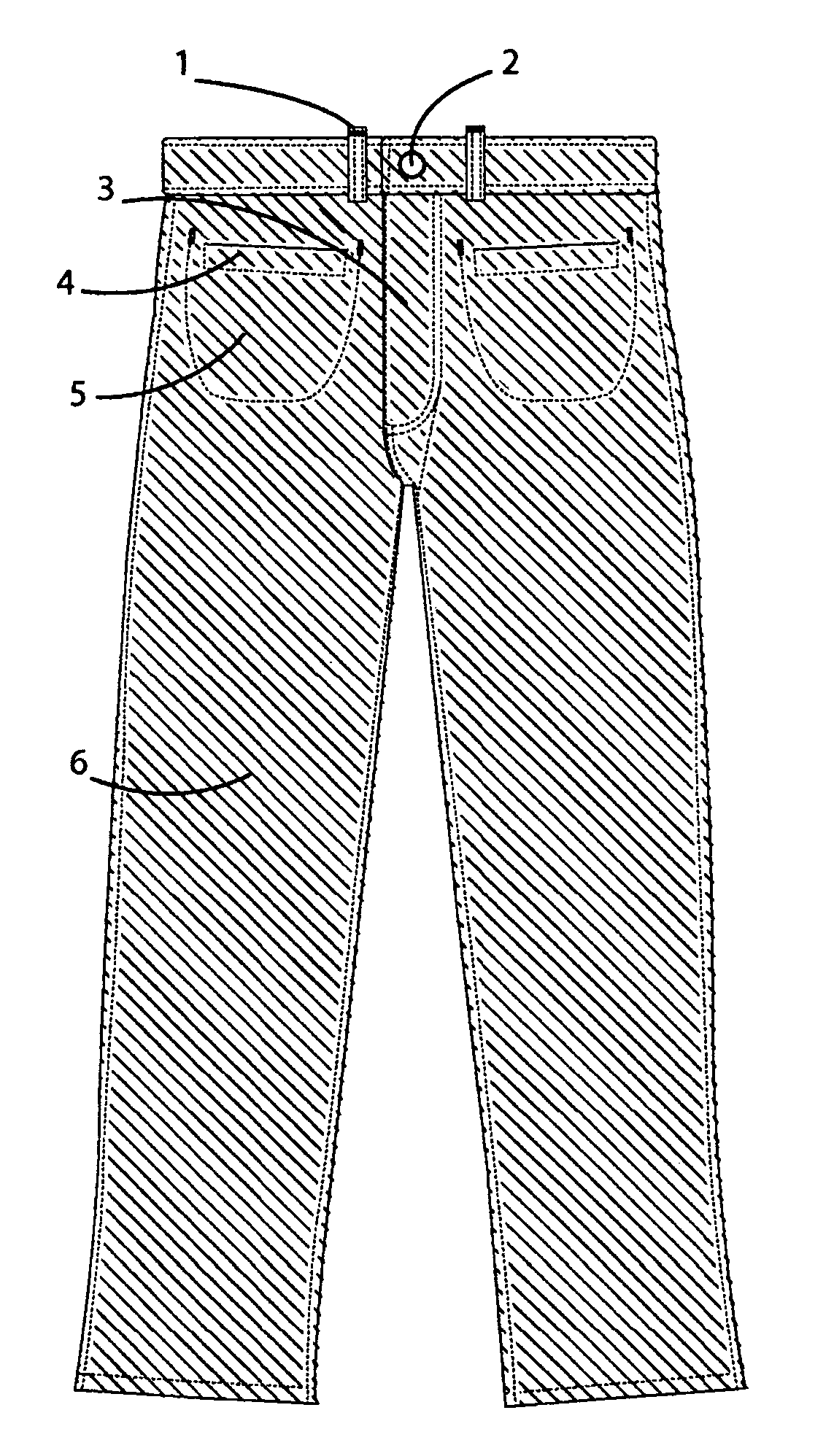

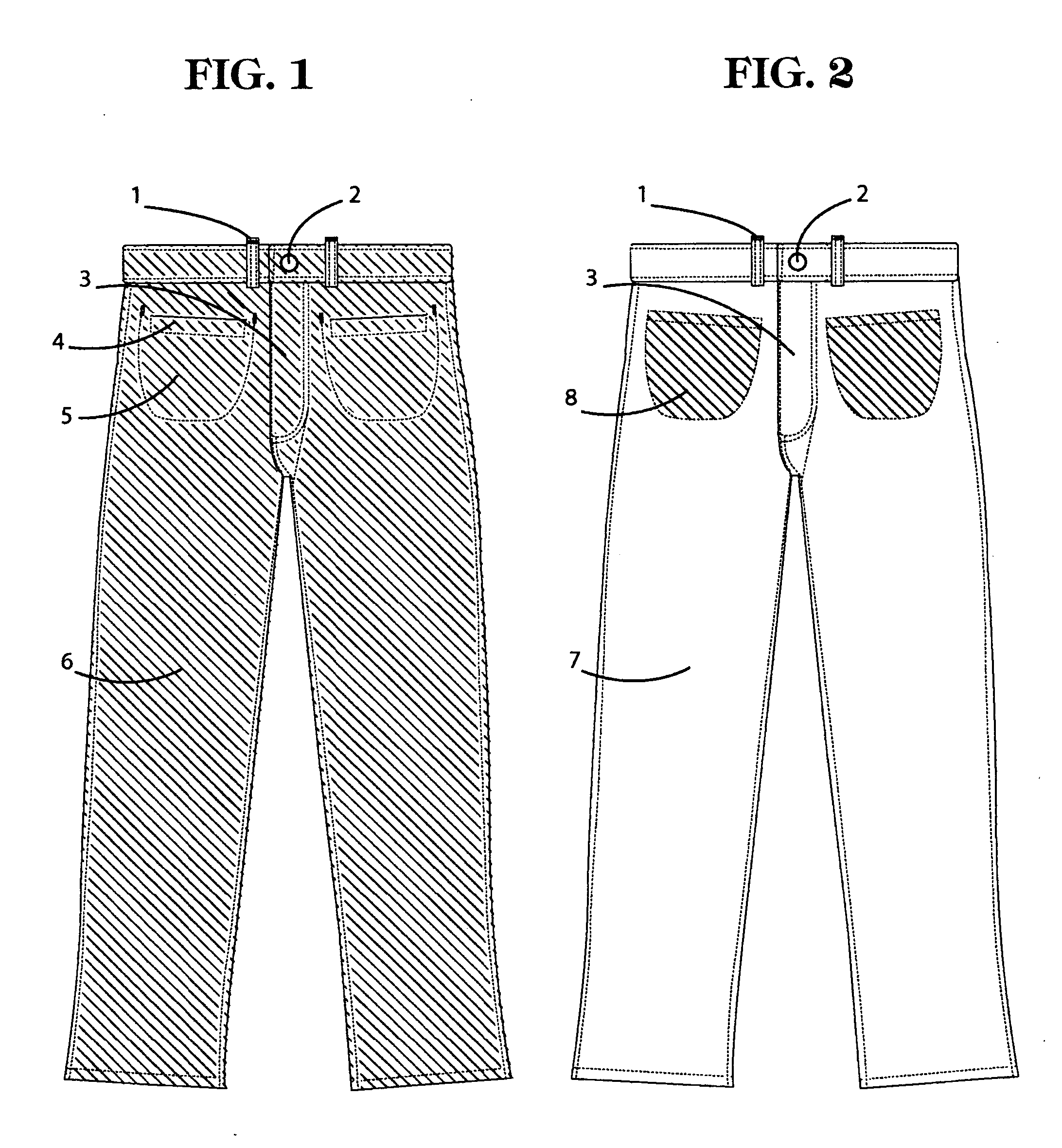

Reversible jeans for men and women

InactiveUS20060107441A1Reduce volumeImprove stylingConvertible garmentTrousersNatural resourceUpper thigh

A reversible garment comprising of a bottom portion for covering the bottom portion of at least the waist and upper thighs of the wearer. The garment further includes a first side that is configured to have a first design and a second side that is opposite and is configured to have a second design. The inventive reversible jeans are lightweight and versatile, which make them convenient and compact for travel, ideal for today's on-the-go traveler. Having one pair of reversible jeans, as opposed to having two separate pairs of traditional jeans, has a significant impact on the conservation of natural resources, and significantly reduces pollution on a worldwide scale. The manufacturing of jeans takes a detrimental toll on the environment. Reversible jeans for men and women not only reduce pollution, but make the wearer environment conscience.

Owner:HOUDROGE WALEED M

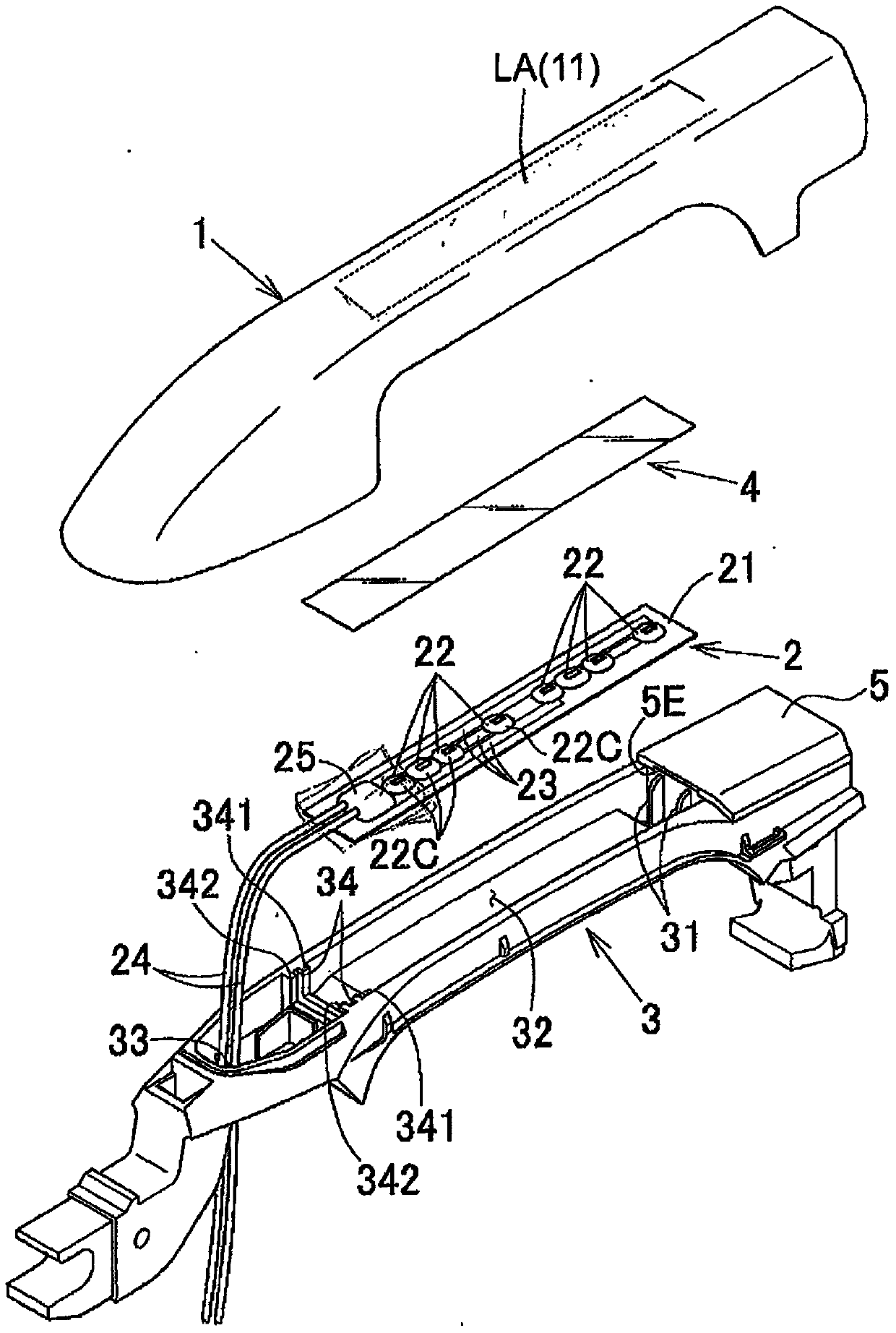

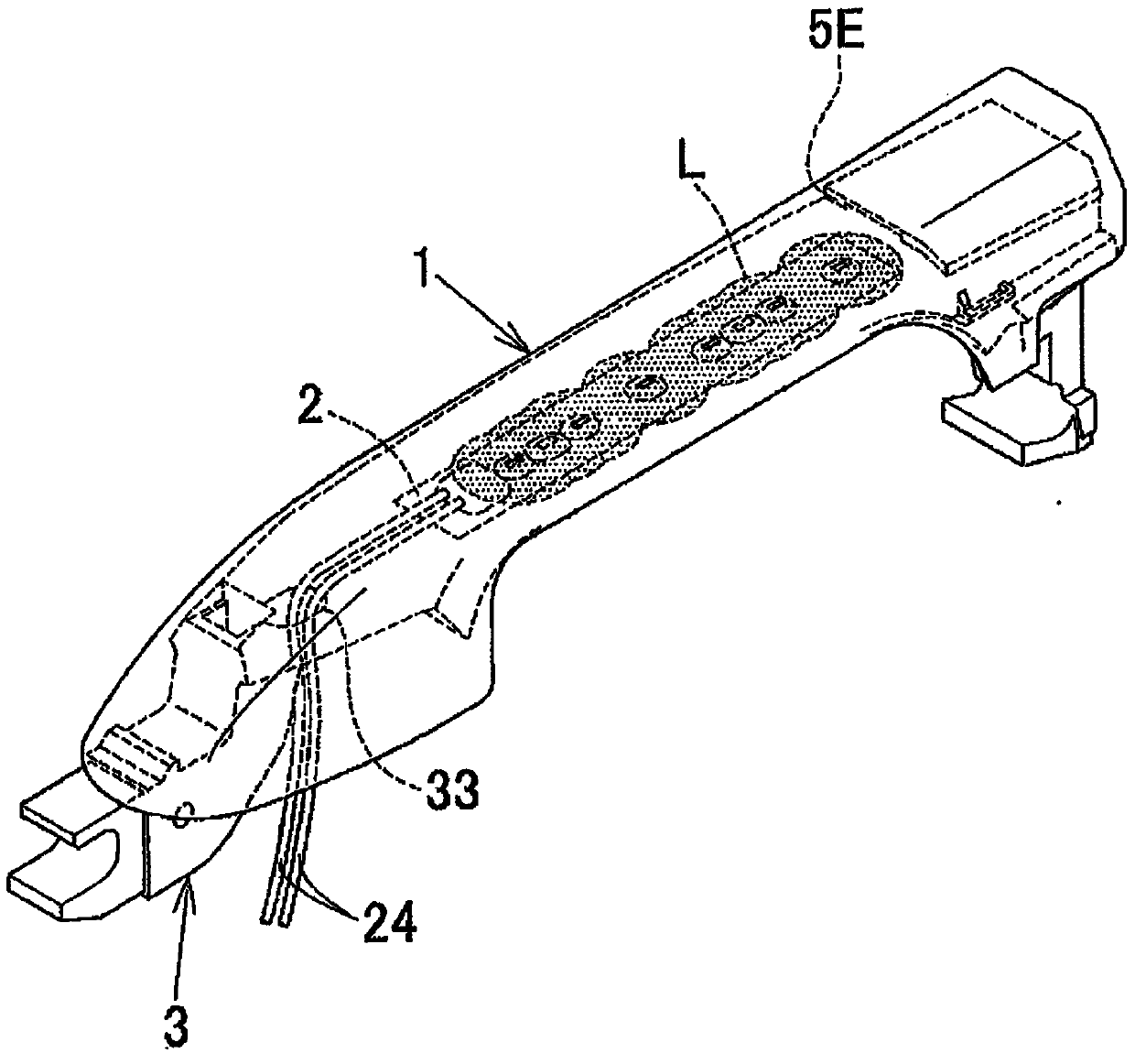

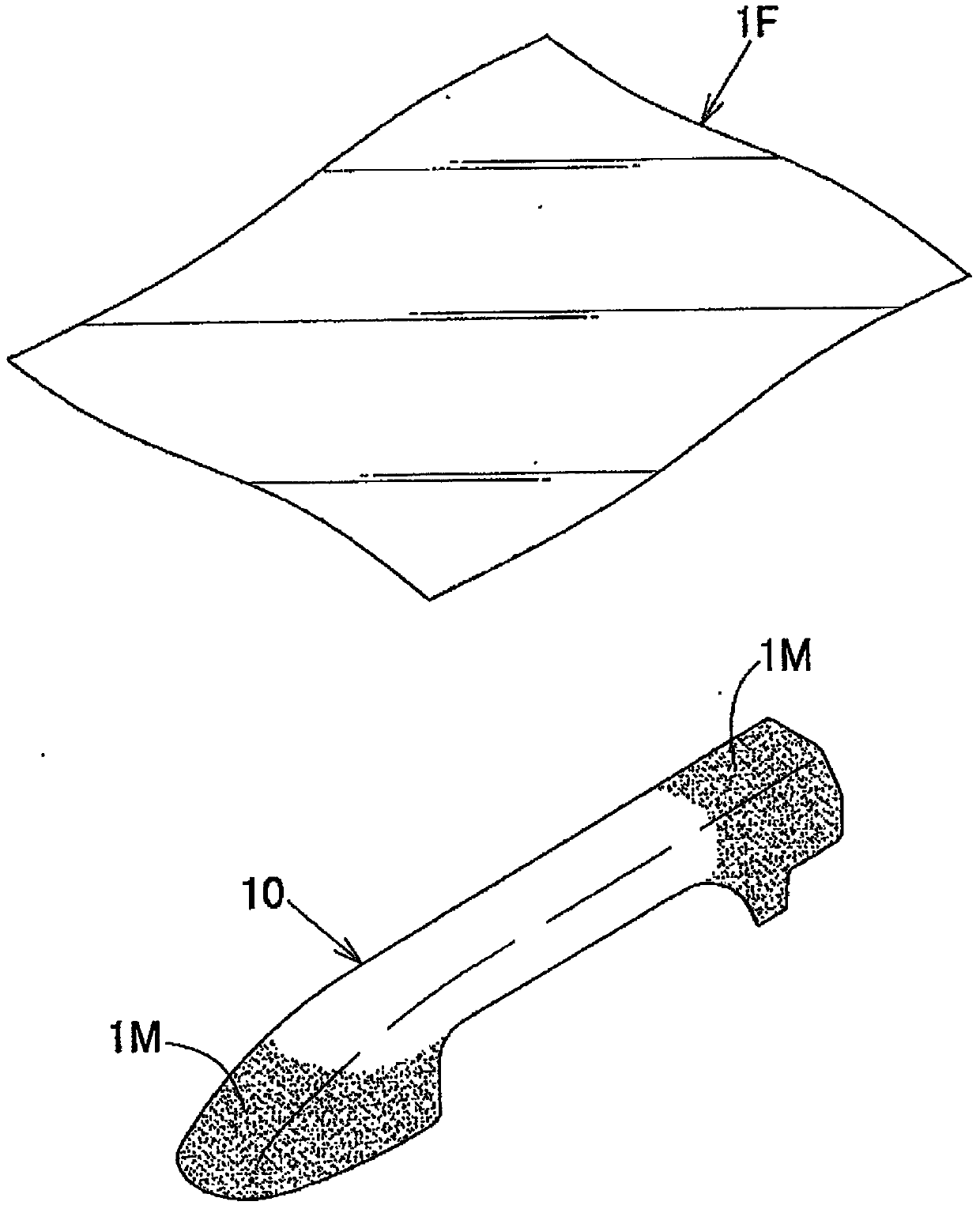

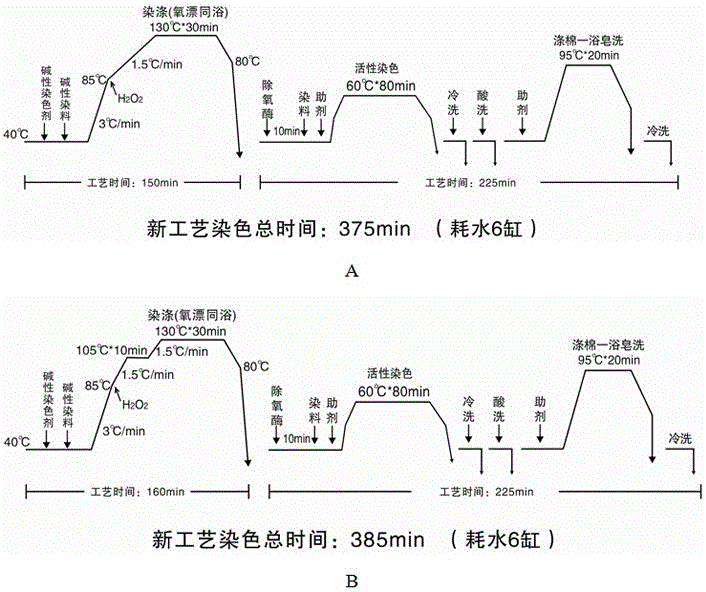

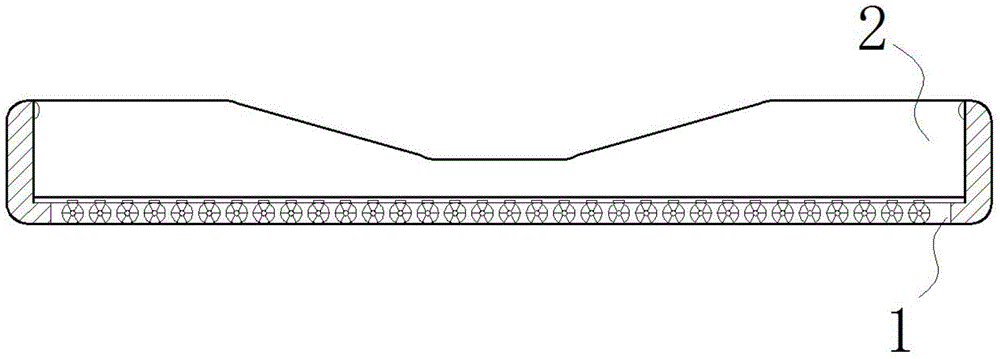

Vehicle functional component

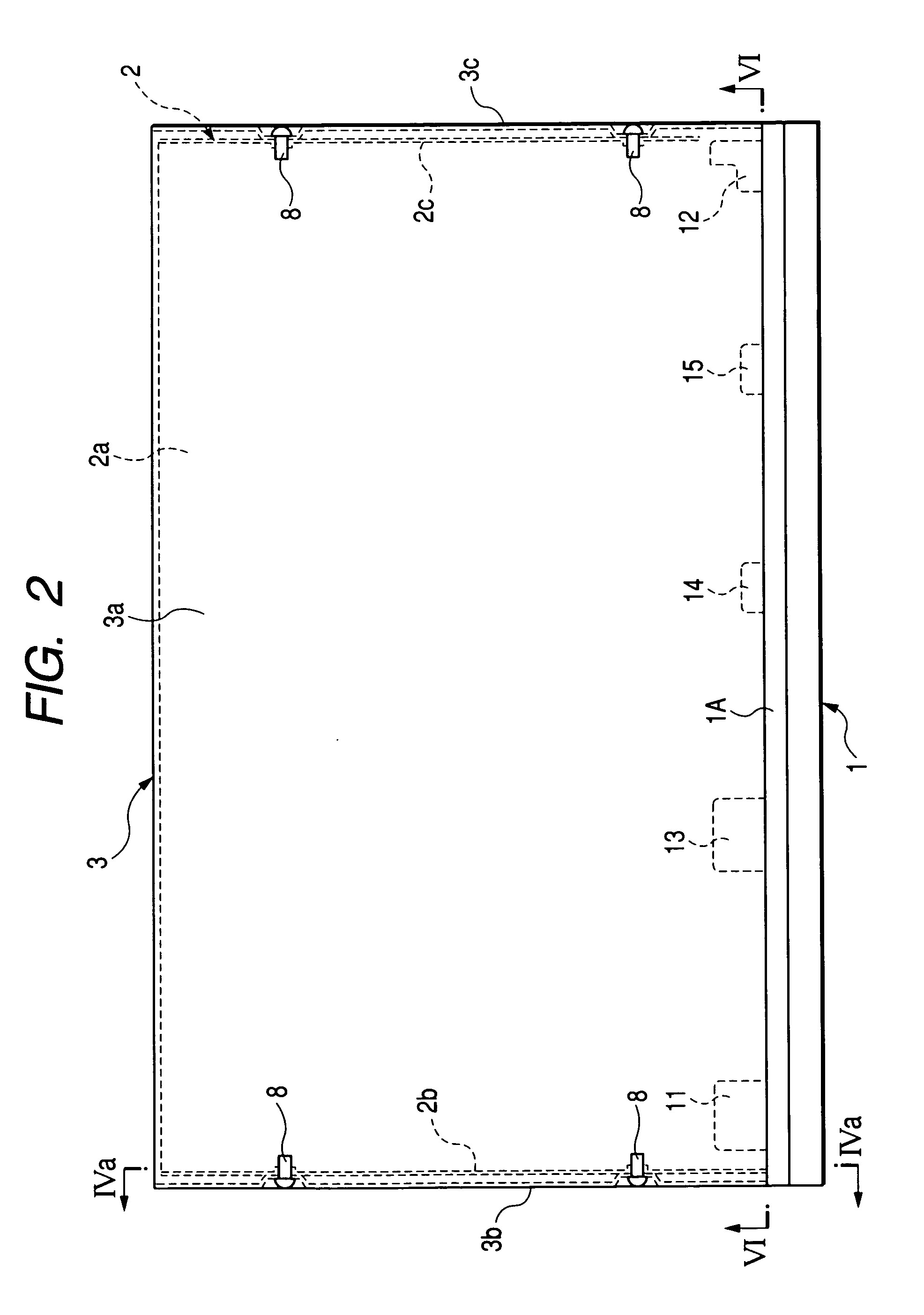

The invention aims to obtain a light-emitting function of a vehicle functional component with a relatively simple structure and in a relatively compact form. In addition, provided is a vehicle functional component excellent in sense of beauty and appearance without impairing the designability of the vehicle functional component itself. The vehicle component is characterized by comprising: a molded cover (1) molded into a surface shape of a component to be attached to a vehicle; and a surface light-emitting element (2) fixed by being bonded or fitted into along the back surface of the molded cover (1). In the vehicle component, the molded cover (1) is formed by decorating and molding a translucent resin mold material with a translucent film, and light from the surface light-emitting element (2) transmits the molded cover (1) and emerges in a predetermined light-emitting region which is a part of the surface of the vehicle component.

Owner:FU SE VACUUM FORMING +1

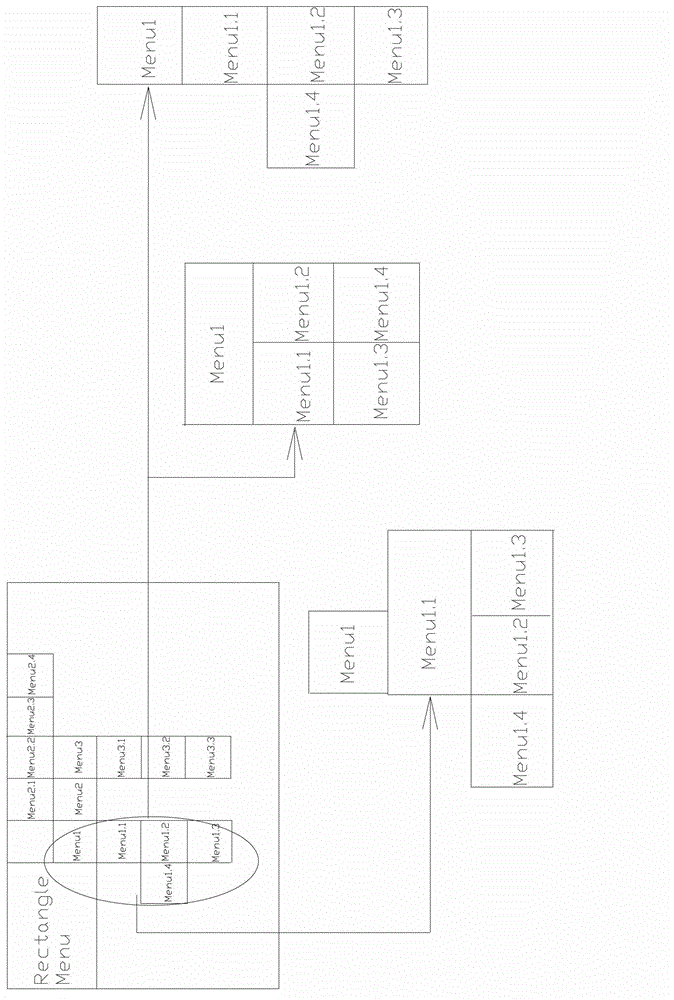

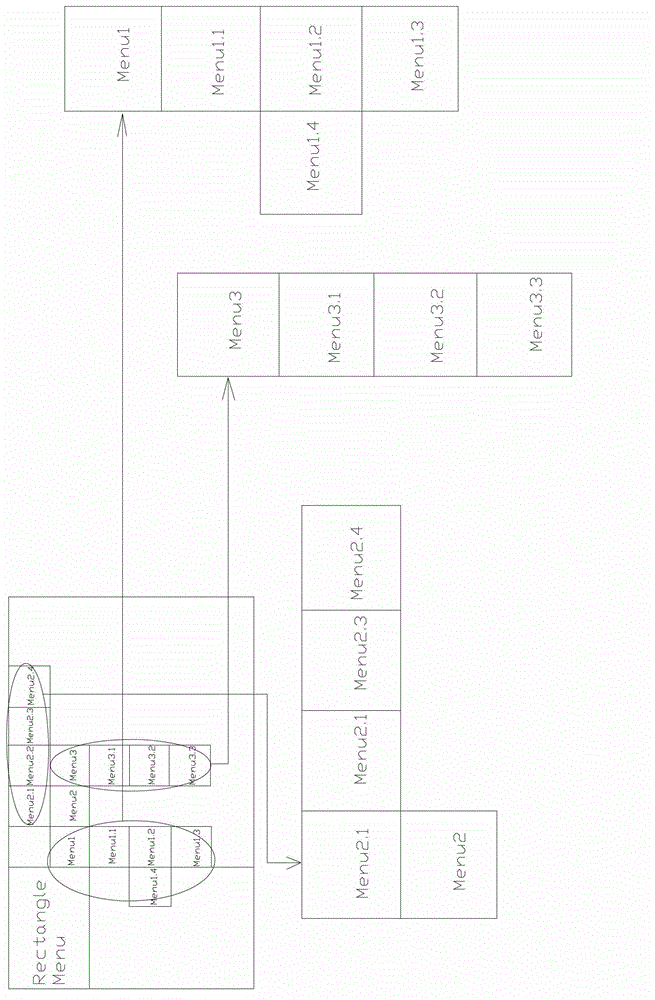

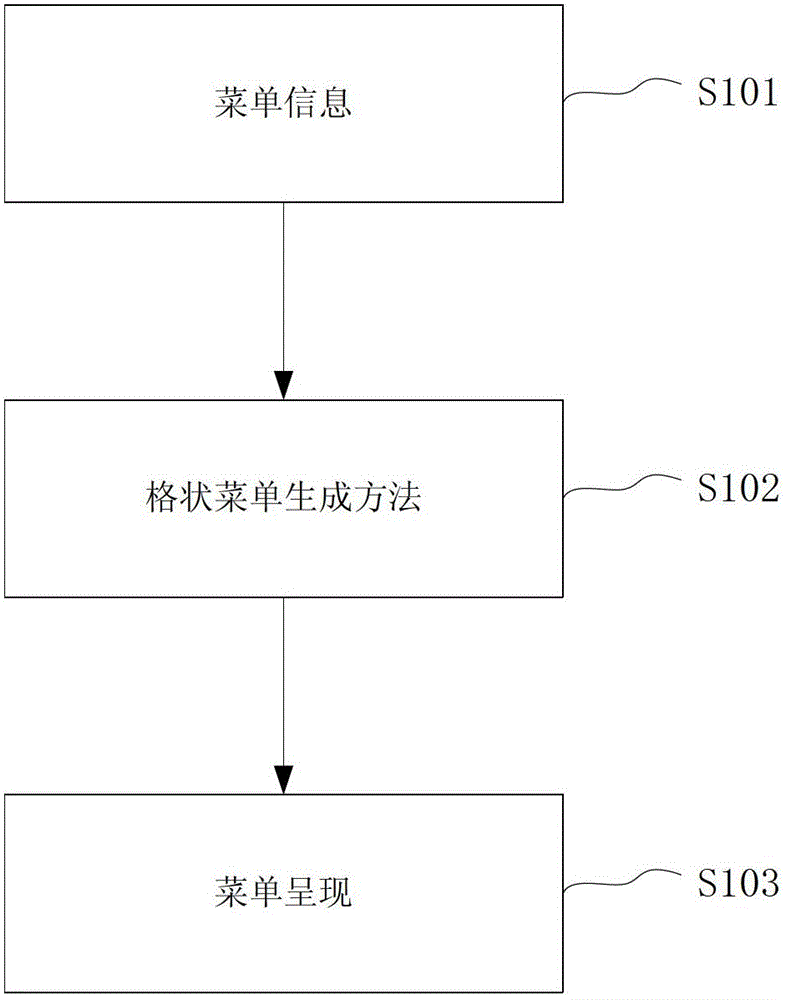

Method for generating case dynamic variety menu

ActiveCN103150158AFind quicklySingle styleSpecific program execution arrangementsComputer terminalHuman–computer interaction

The invention provides a method for generating a case dynamic variety menu. The method comprises the steps of: storing menu information, wherein the menu information comprises a menu hierarchical structure or menu style; secondly, processing the menu information through a menu generating method; and finally, showing the processed menu on a terminal screen, and interacting the menu shown on the terminal screen with a user. The invention solves the problems of the unreasonable layout space arrangement of the existing menu and the limit to display of a terminal with a smaller screen, and has the advantages of generality, self growth, space reasonableness, good interaction and the like.

Owner:广州方铭交互信息科技有限公司

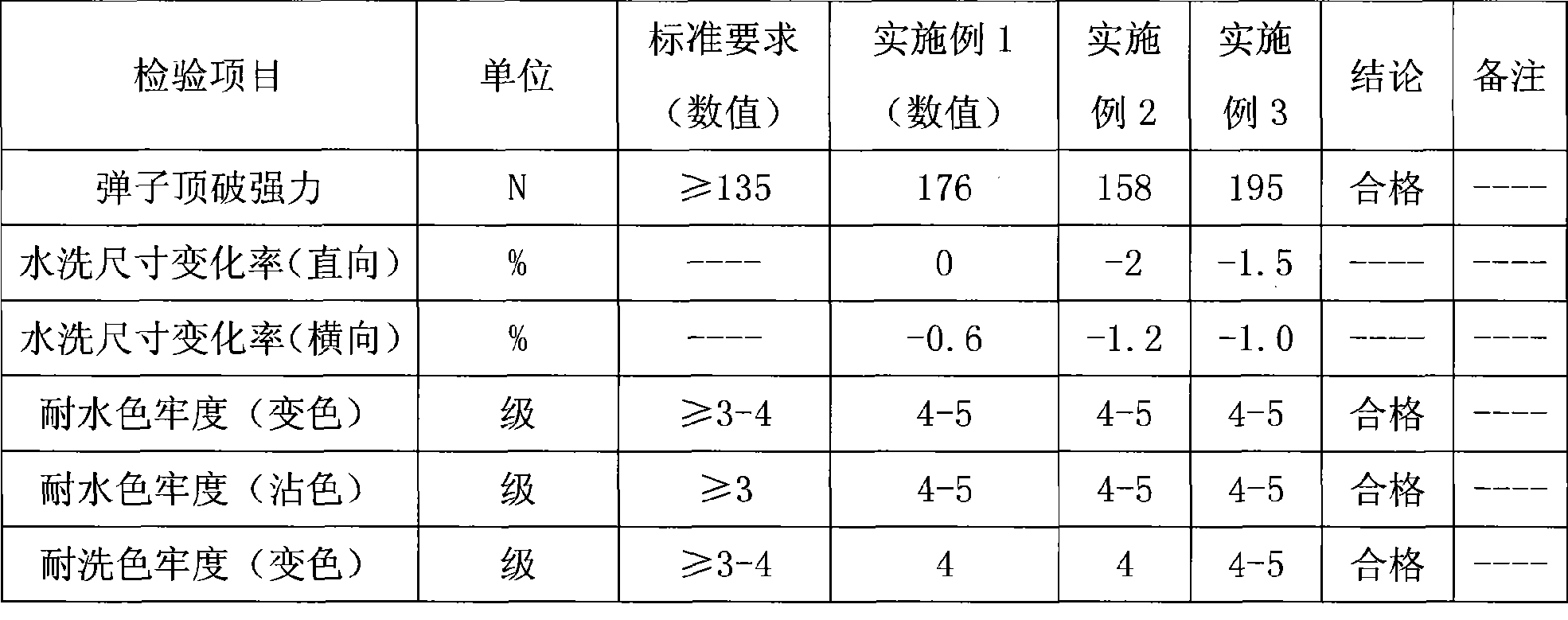

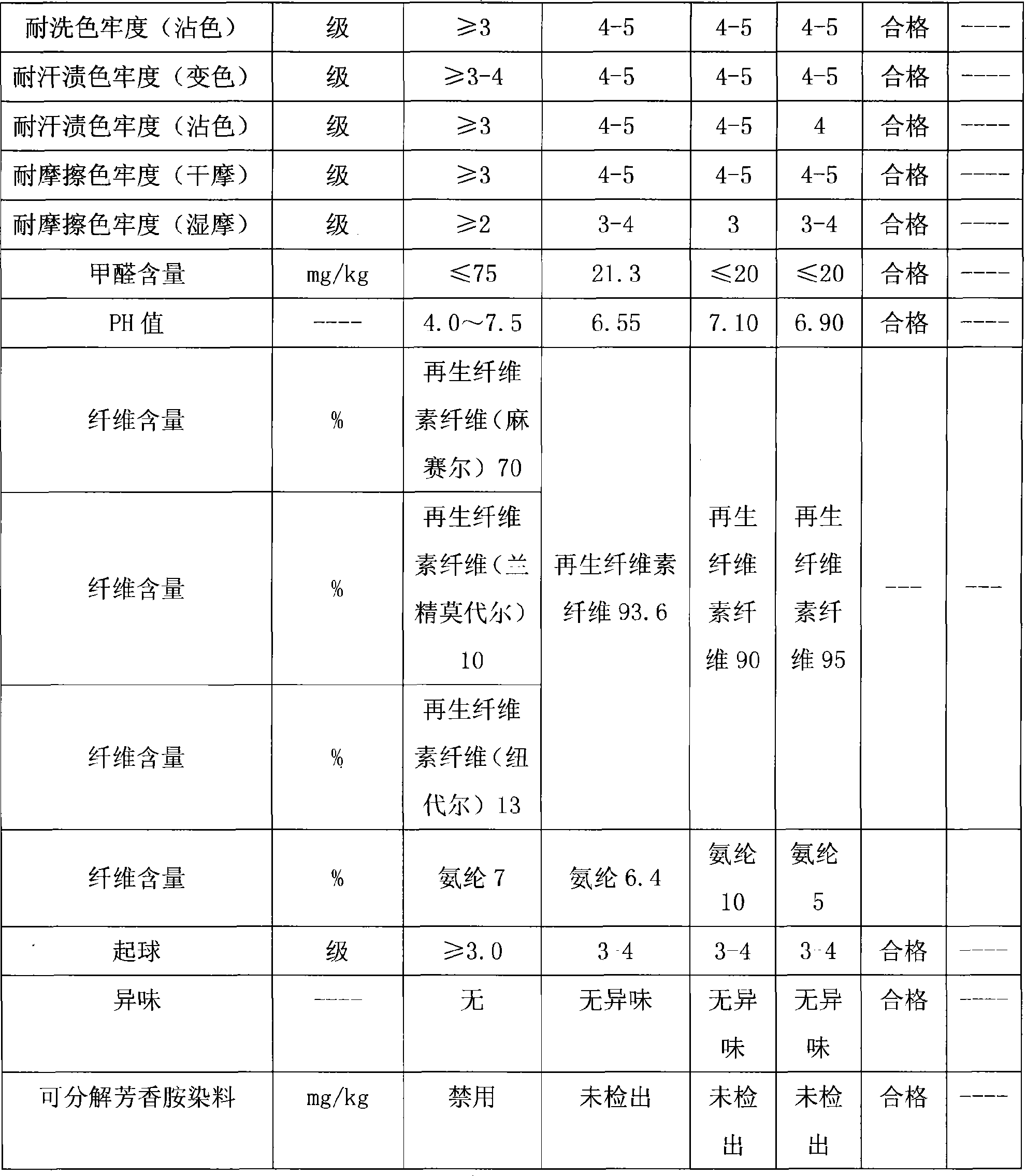

Jutecell underwear fabric and manufacture method thereof

The invention discloses a Jutecell underwear fabric and a manufacture method thereof, belonging to the technical field of textiles. The Jutecell underwear fabric is characterized by comprising the following components based on part by weight: 50 to 70 parts of Jutecell, 10 to 20 parts of Modal, 10 to 20 parts of Newdal, and 5 to 10 parts of polyurethane elastic fibers. The manufacture method comprises the following steps that: the Jutecell, the Modal and the Newdal are spun into compact spinning blended yarns; the compact spinning blended yarns are interwoven with the polyurethane elastic fibers to form a knitted underwear fabric; and the knitted underwear fabric is subjected to preshaping, dyeing, drying and shaping treatment. The fabric not only has good skin-friendly property, low pilling tendency and comfortable elasticity, but also sufficiently reflects itching feel, bactericidal and antifungal activity, moisture absorption and fast dryness; and Modal has soft hand feeling, bright color, the Newdal is smooth and has good drapability, and the polyurethane elastic fiber has excellent performance of stretching and extending. The fabric adopts a unique textile structure to lead the appearance of the fabric to be more unique.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV

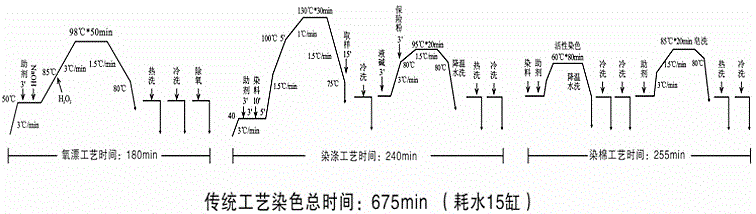

Dyeing method of polyester-cotton blended knitting fabric

ActiveCN106012610AAvoid scratchesAvoid rubbingBleaching apparatusDyeing processPolyesterPulp and paper industry

The invention discloses a dyeing method of polyester-cotton blended knitting fabric. The dyeing method comprises the steps of pre-treatment, dyeing of a polyester part and oxygen bleaching of a cotton part, dyeing of the cotton part and after-treatment. According to the dyeing method disclosed by the invention, dyeing is carried out by adopting a special alkaline polyester-cotton dyeing agent, the technologies of the oxygen bleaching of the cotton part and the dyeing of the polyester part are combined into one, washing of the polyester part can be omitted, and washing can be carried out only after the dyeing of the cotton part. Compared with traditional craftwork, the dyeing method disclosed by the invention has the advantages that the technological process is greatly simplified, the dyeing time is greatly shortened, the use of water, electricity and steam can be obviously reduced, the production cost is obviously reduced, and the pollution to the ecological environment, particularly the water resource, is reduced.

Owner:石狮市瑞鹰纺织科技有限公司

Mould using for organic binder, molding sand composition and mould

ActiveCN101104194AIncrease the number of casting shapesImprove productivityFoundry mouldsFoundry coresCarbamateOrganic solvent

The invention provides an organic adhesive used in casting which can assure excellent casting intensity when phenolic aldehyde carbamate is cast, and can solve or reduce the sand-sticking problem that the sclerosis molding sand composition sticks on the surface of a mould. The organic adhesive of the invention is used in the gas sclerosis casting and the molding of the self- sclerosis casting of the phenolic aldehyde carbamate. The invention is characterized in that: the organic adhesive adopts a condensation product of unsaturated fatty acid with alcoholic hydroxyl, phenol formaldehyde resin, polyisocyanate compound, and organic solvent as the essential components.

Owner:ASAHI YUKIZAI KOGYO CO LTD

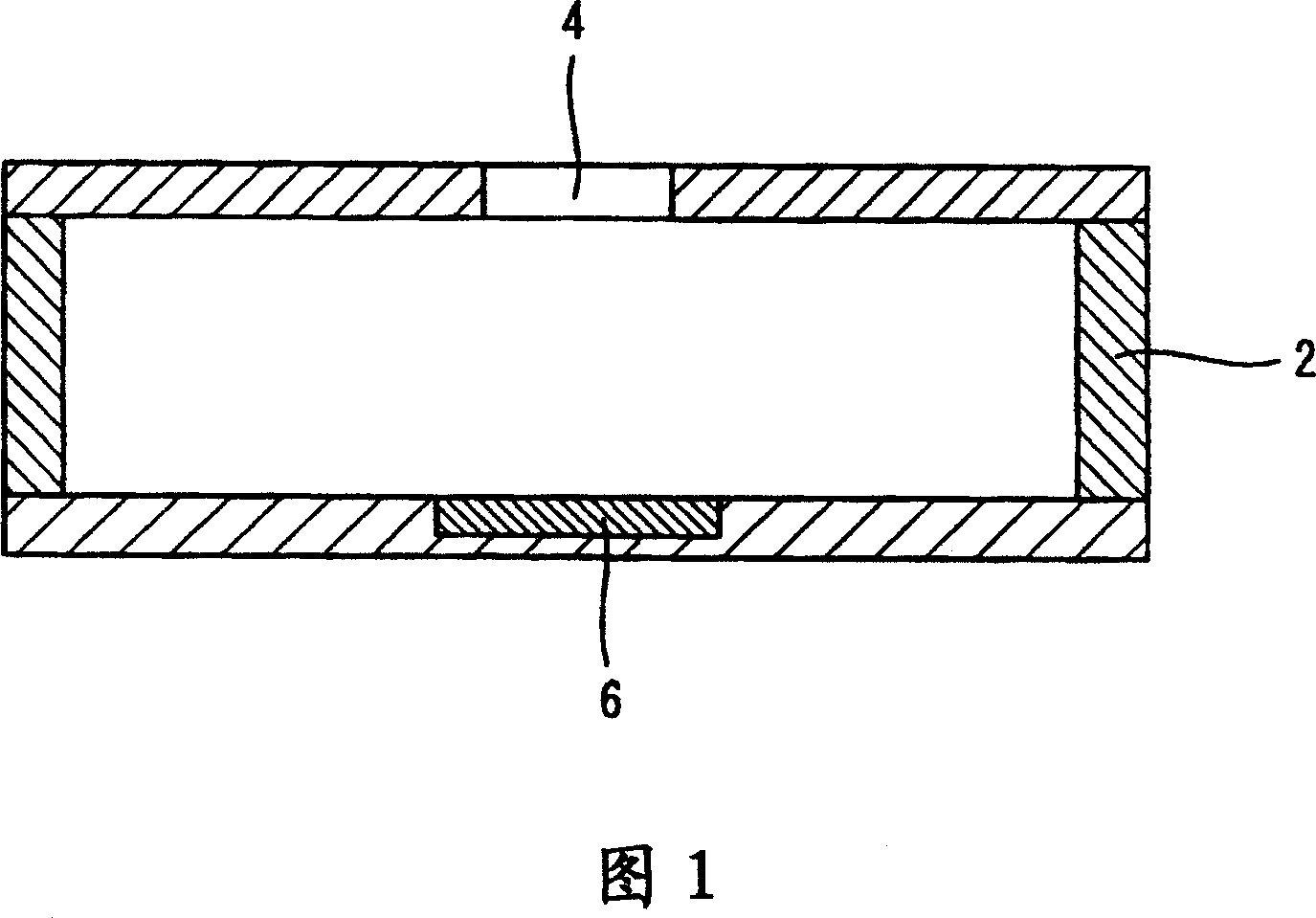

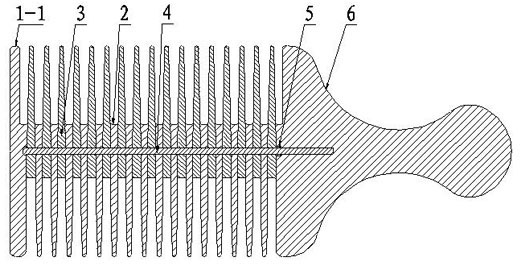

Comb

InactiveCN101912191AFunction increaseImprove stylingCurling devicesHair combsWhole bodyAdhesive glue

The invention discloses a comb, which comprises an auxiliary tooth and a plurality of comb teeth, wherein spacers are arranged between the auxiliary tooth and the comb teeth and between the comb teeth; the auxiliary tooth, the comb teeth and the spacers are connected in series by connecting ribs to form a whole body; gaps formed between the auxiliary tooth and the spacers and between the spacers and the comb teeth on the connecting ribs are glued; and the parts, glued with the comb teeth, of the spacers form a comb back. In the invention, all scattered raw materials can be rationally used, so that resource waste is avoided, and the production cost of an enterprise is reduced; meanwhile, the hair is protected in a combing process.

Owner:刘燕西

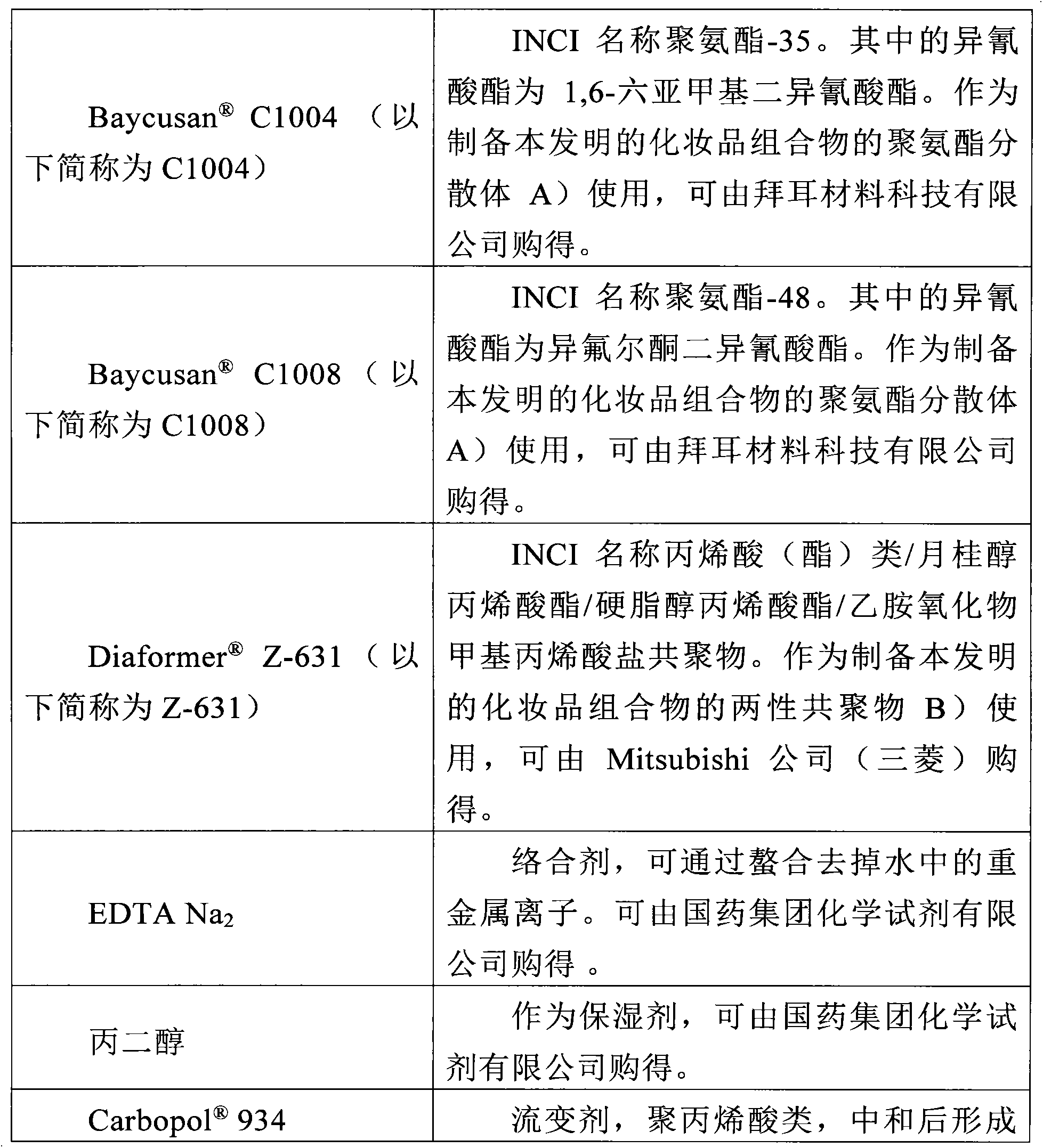

Cosmetic composition

InactiveCN104042453ALong-lasting stylingExcellent water vapor resistanceCosmetic preparationsHair cosmeticsHigh humidityMedicine

The invention relates to a cosmetic composition, and especially relates to a hair fixing composition, its application in hair fixing, and its use method. The composition includes special polyurethane and an amphoteric copolymer. Compared with cosmetic compositions in the prior art, the cosmetic composition provided by the invention has the advantages of curling maintenance under high humidity, high elasticity, easy washing and comfortable hair feeling.

Owner:COVESTRO DEUTSCHLAND AG

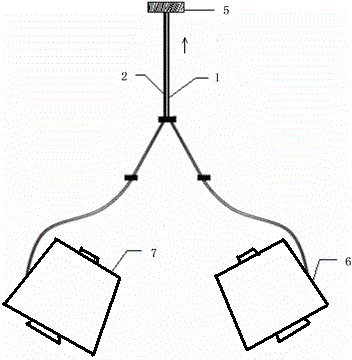

Full-drawn yarn of super fine polyester and manufacturing process thereof

InactiveCN101724923AImprove spinnabilityImprove stylingArtificial filament heat treatmentMelt spinning methodsYarnAdditional values

The invention relates to a full-drawn yarn of super fine polyester manufactured by using polyester continuously. The full-drawn yarn of super fine polyester with a specification of 75D / 192F is manufactured by a one-step process route of circular blowing, cooling and spinning, and the yarn has good performance. The manufacturing process of the full-drawn yarn of super fine polyester comprises the following steps of: esterifying phthalic acid and glycol by using the refined raw material, preparing the melted polyester by the prepolycondensation and the final polycondensation, and directly spinning the melted polyester. The manufacturing process route comprises melted polyester, conveying the melted polyester, a spinning box, a metering pump, a member, circular blowing cooling, bundling and oiling, a paved path, a first hot roller, an interlacer, a second hot roller and winding. The invention has advantages of reasonable manufacturing processing, good fibre spinnabilitty, smooth weaving, light, flexible quality of the fabric and good style of the fabric, thereby meeting weaving request of fabric and lining of high-grade clothes and improving the grade and the additional value of products.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

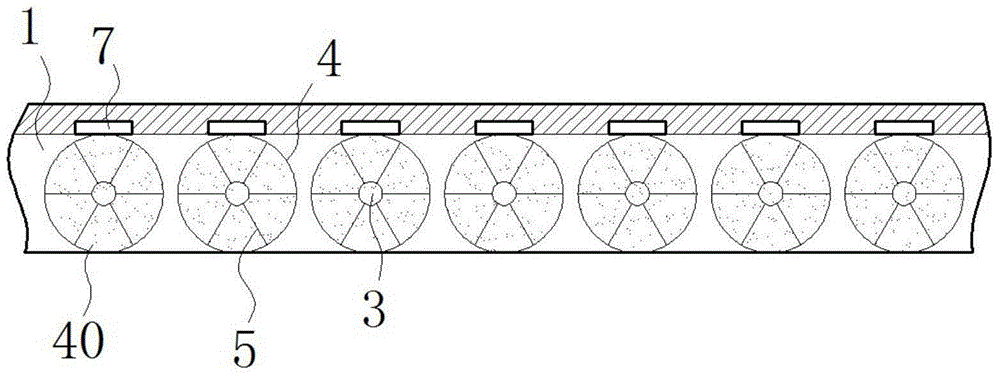

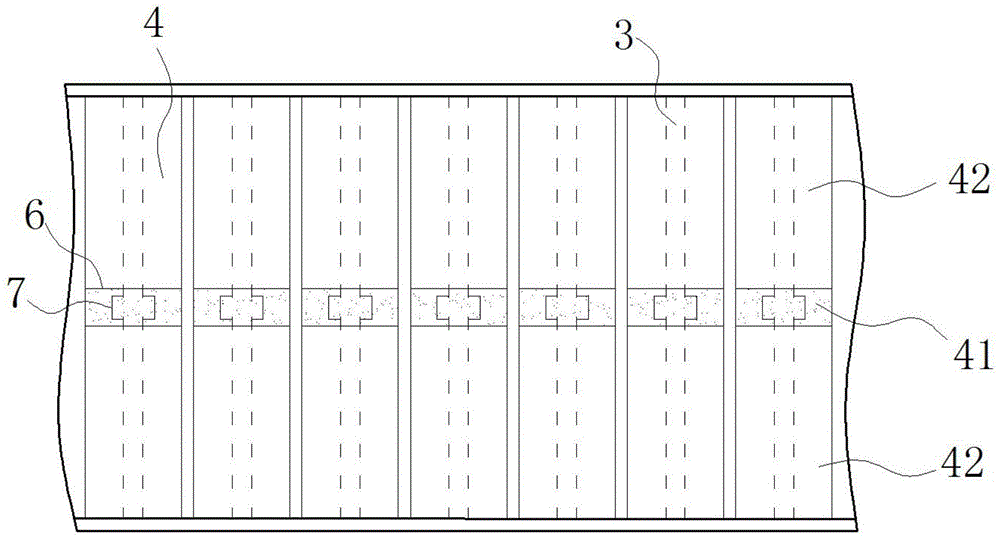

Mobile phone shell capable of dissipating heat

ActiveCN104935703ASmall coverageFast absorptionTelephone set constructionsCooling/ventilation/heating modificationsEngineeringMobile phone

The invention relates to a mobile phone shell capable of dissipating heat. The mobile phone shell capable of dissipating heat comprises a hollow backboard and side frames; rotary shafts are equidistantly arranged in the backboard in parallel and closed heat dissipating sleeves are sleeved on the rotary shafts; baffles are equidistantly arranged at circumference among the heat dissipating sleeves and the rotary shafts; two partitioning areas vertical to the rotary shafts are arranged in each heat dissipating sleeve; magnetofluid is filled in a driving field; radiating liquid is filled in a heat dissipating field; small magnetic sheets opposite to the driving field are equidistantly arranged at one surface of the backboard adjacent to a mobile phone. The mobile phone shell could be used for effectively dissipating heat while effectively protecting the mobile phone, and will not influence the transmission of mobile phone signals, thereby having relative high ornamental value.

Owner:新沂市掌尚电子信息技术有限公司

Plastic woven bag edgefold shaping machine and method

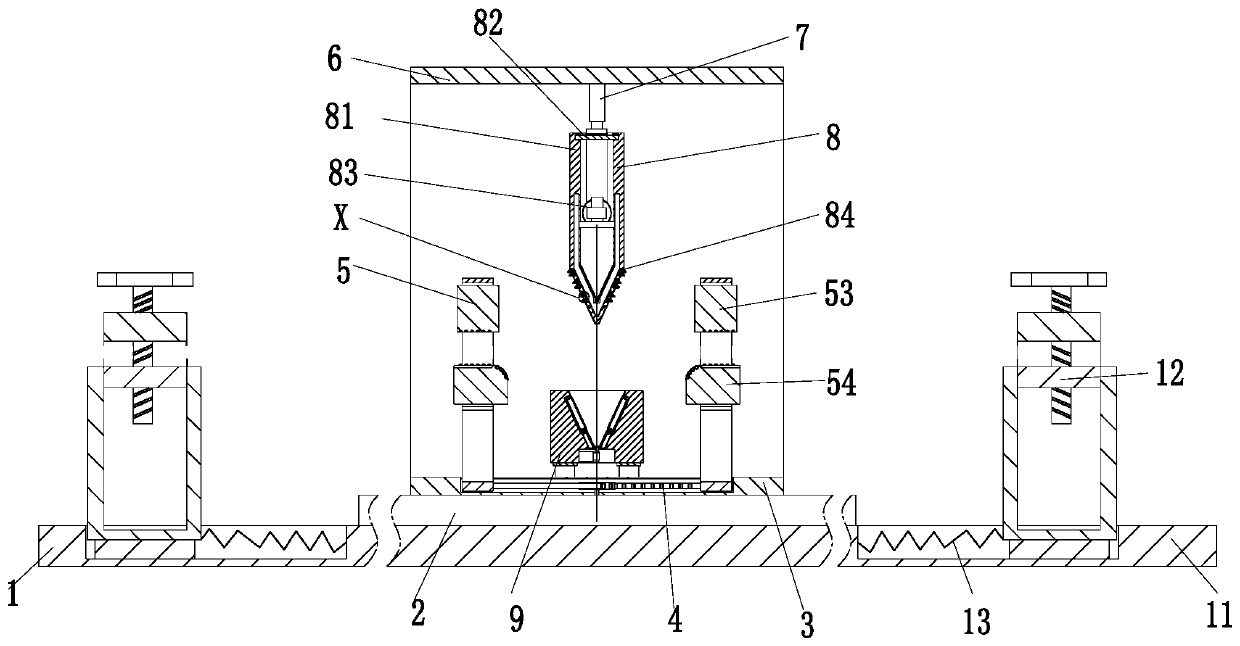

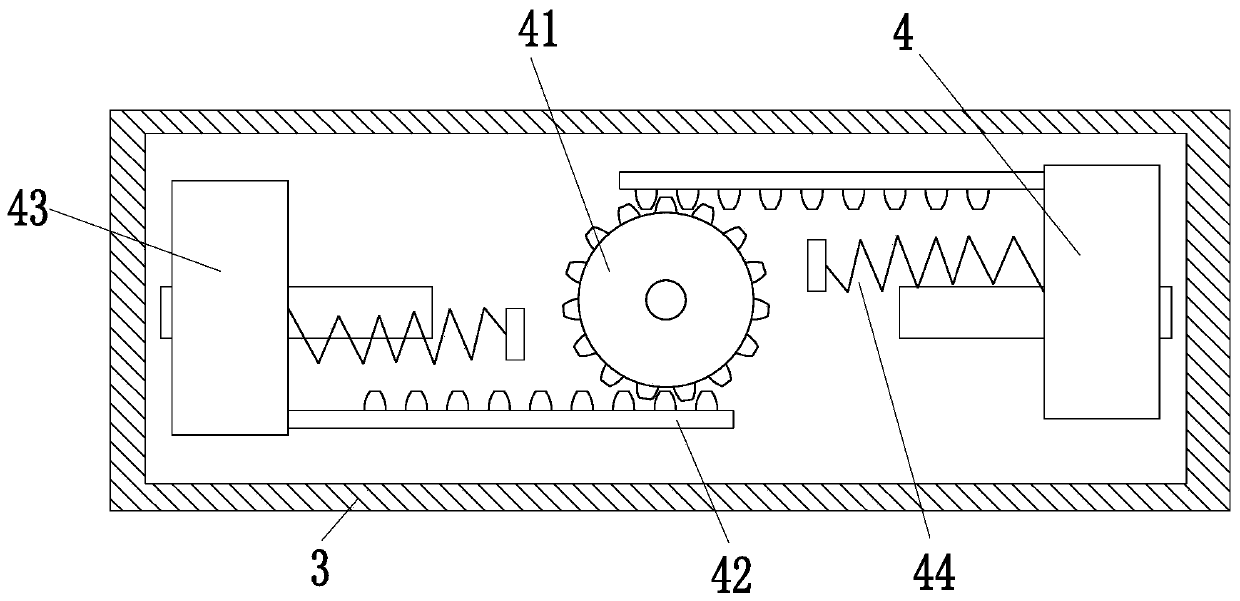

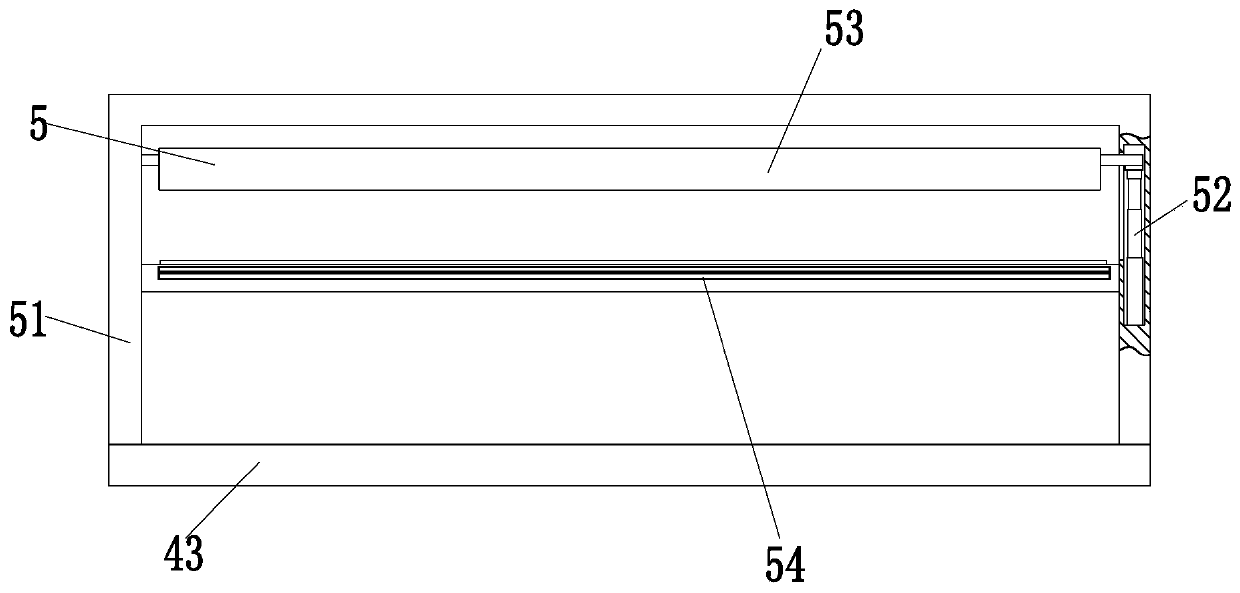

InactiveCN110497653AReduces accidental creasingImprove hemming effectBag making operationsPaper-makingEngineeringPortal frame

The invention relates to a plastic woven bag edgefold shaping machine and a method. The machine comprises a clamping base, a working electric sliding block, a displacement frame, a synchronizing device, two positioning clamps, a portal frame, a driving cylinder, a pressing device and a mark ironing device. The working electric sliding block is mounted on the clamping base. The displacement frame is arranged on the working electric sliding block. The synchronizing device is mounted in the middle of the displacement frame. The two positioning clamps are mounted at the left and right ends of thesynchronizing device. The mark ironing device is mounted in the middle of the displacement frame. The portal frame is mounted on the displacement frame. The upper end of the portal frame is connectedwith the pressing device through the driving cylinder. By means of the plastic woven bag edgefold shaping machine and the method, the problems that an existing edgefold machine commonly adopts rigid pressing for woven fabric, two pressing dies are adopted for pressing the woven fabric repeatedly, clear folding marks can only be obtained through repeated pressing since the woven fabric is flexiblefabric, and the edgefold shaping effect is poor can be solved.

Owner:台州市伟鸿家居用品有限公司

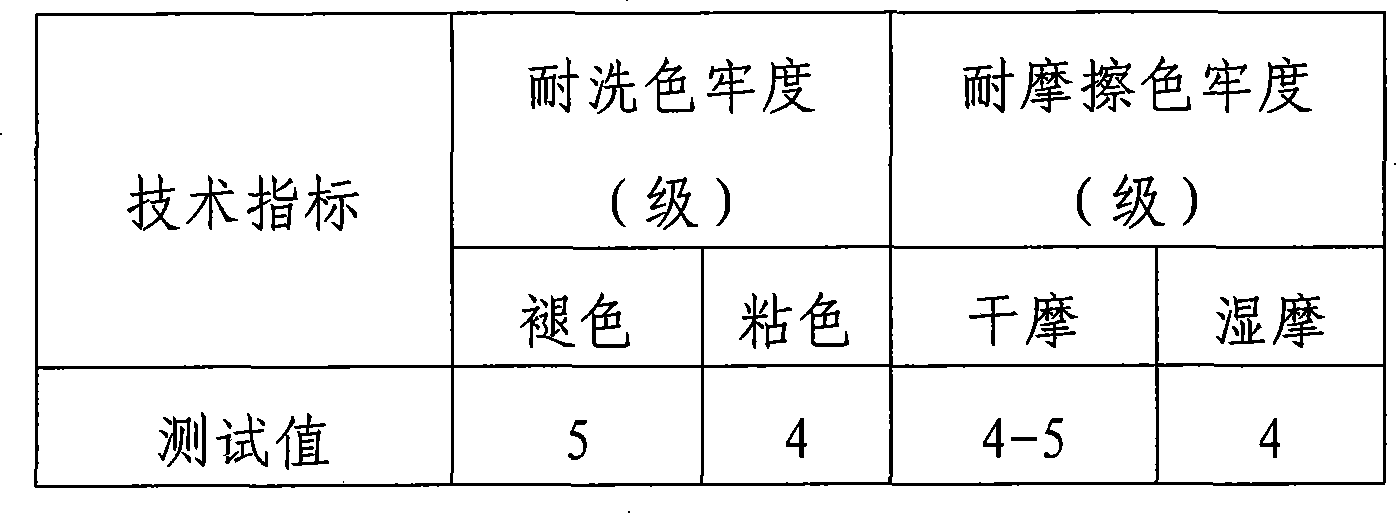

Production process of wool terylene blended smooth double-faced woolen goods

ActiveCN108456965AEasy to organizeHair to smoothLiquid/gas/vapor treatment of propelled fabricsDyeing processYarnPulp and paper industry

The invention provides a production process of wool terylene blended smooth double-faced woolen goods. The production process of the smooth double-faced woolen goods includes the steps: sufficiently mixing wool fibers and terylene fibers; spinning the mixed wool fibers and terylene fibers into yarns of 13 / 1 metric number by an open-end spinning frame; weaving the spun yarns on a rapier loom; performing edge sewing, fulling, scouring, dewatering, drying, decating, teasel raising, drying, anti-shrinking finishing, dyeing, softening finishing, scalding, cutting, decating and the like on a woven gray fabric to prepare a finished product. The total number of warp yarns is 6100-6300, the acting reed width is 195-200cm, porter / permeating number is 35 / 9, weft density is 285-290 yarns / 10cm, and theweight of a fabric billet is 930-950g / m<2>. The fabric is fine, smooth and soft in hand feeling, compact in texture, bright in color and high in color fastness and does not easily felt after being washed with water.

Owner:江阴市长泾花园毛纺织有限公司

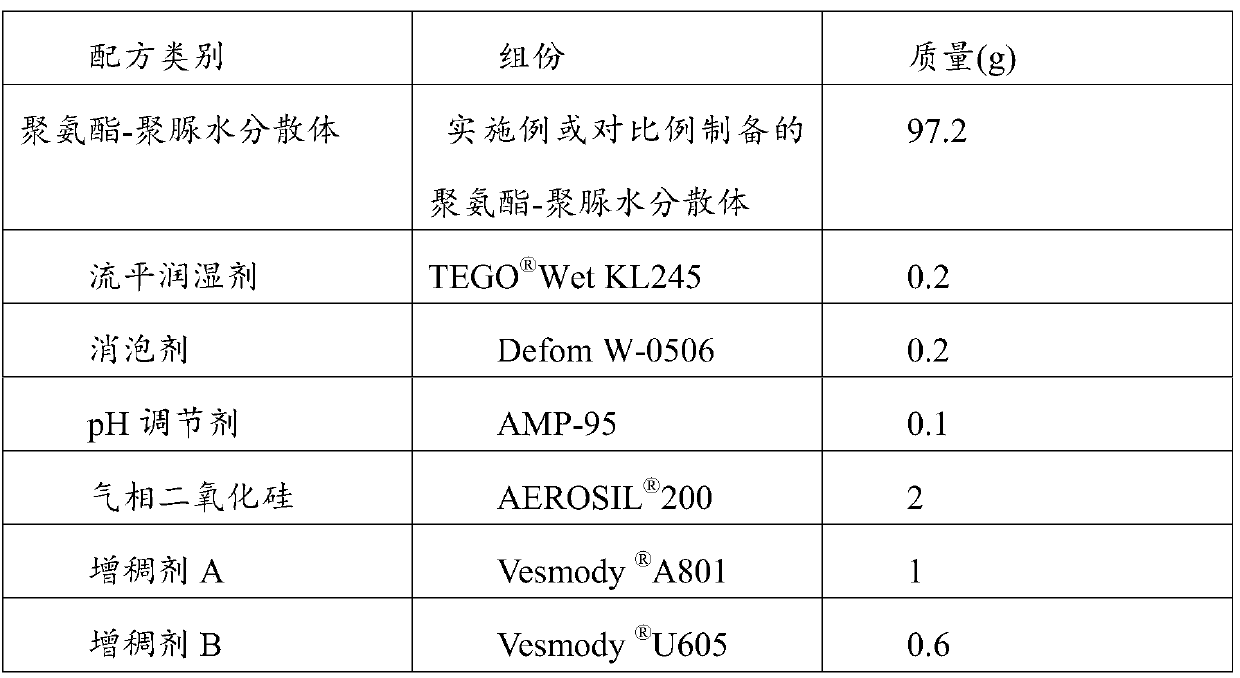

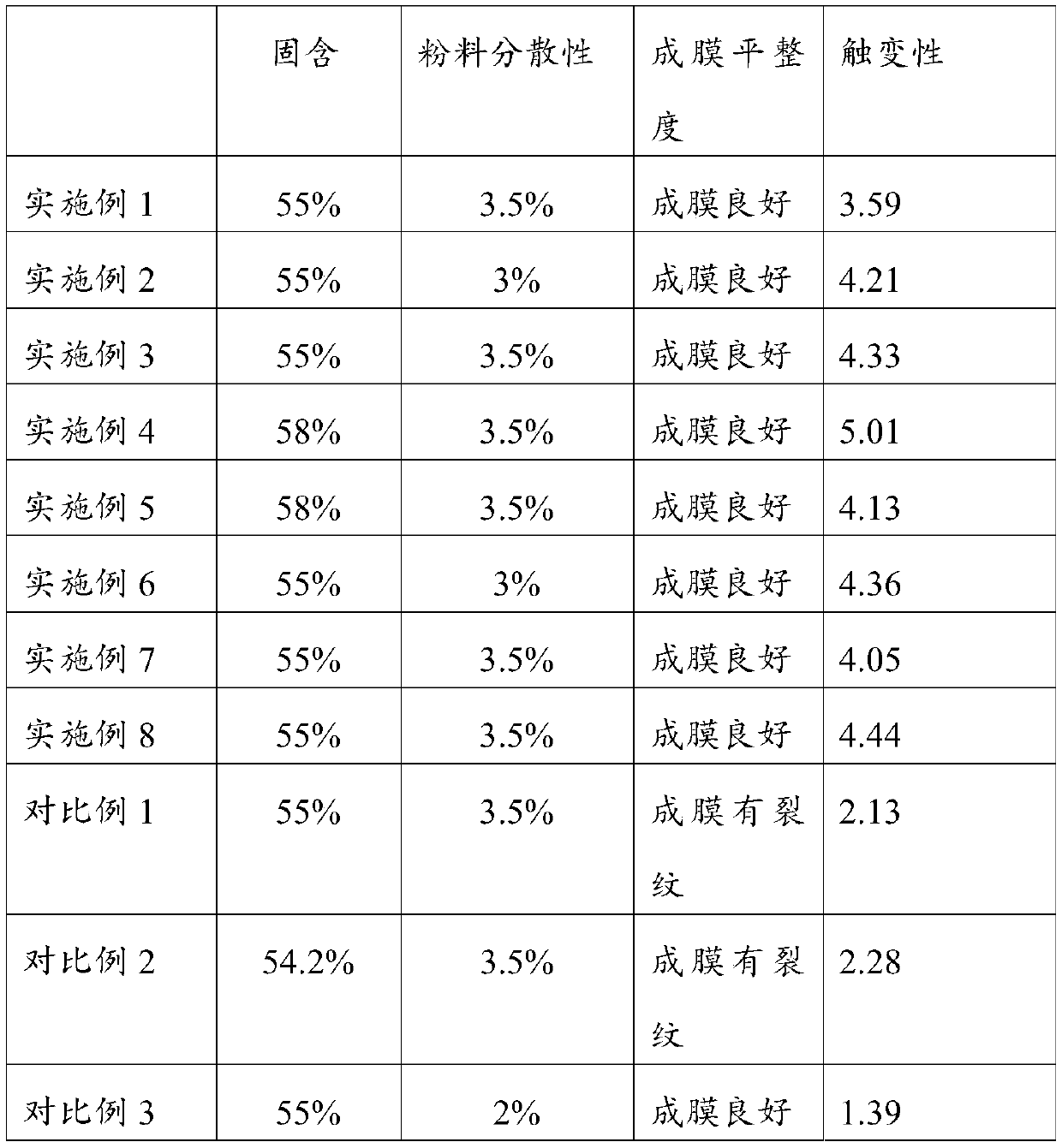

Polyurethane-polyurea aqueous dispersion as well as preparation method and application thereof

ActiveCN109679059AExcellent Shear ViscosityImprove stylingTextiles and paperTextile printerPolymer science

The invention discloses a polyurethane-polyurea aqueous dispersion as well as a preparation method and an application thereof. The polyurethane-polyurea aqueous dispersion contains one or more tertiary amine compounds, one or more polyols with functionality degree of 2-4, one or more polyisocyanates and the like. The polyurethane-polyurea aqueous dispersion has excellent powder dispersity and filmforming performance, and printing paste with the polyurethane-polyurea aqueous dispersion as a matrix has excellent thixotropy, workability and printing flatness and is applicable to the fields of spinning, printing or synthetic leather.

Owner:WANHUA CHEM GRP CO LTD +1

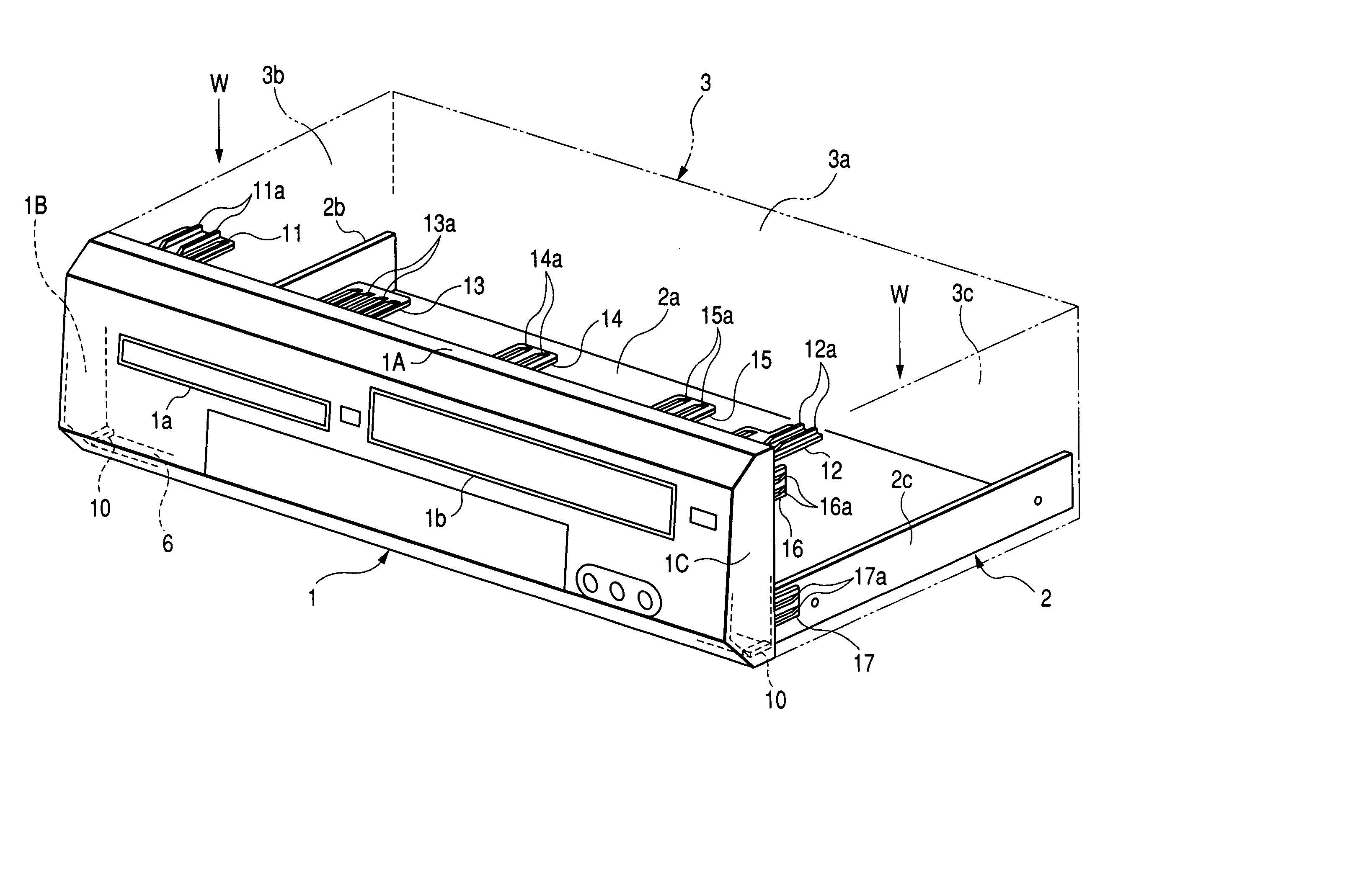

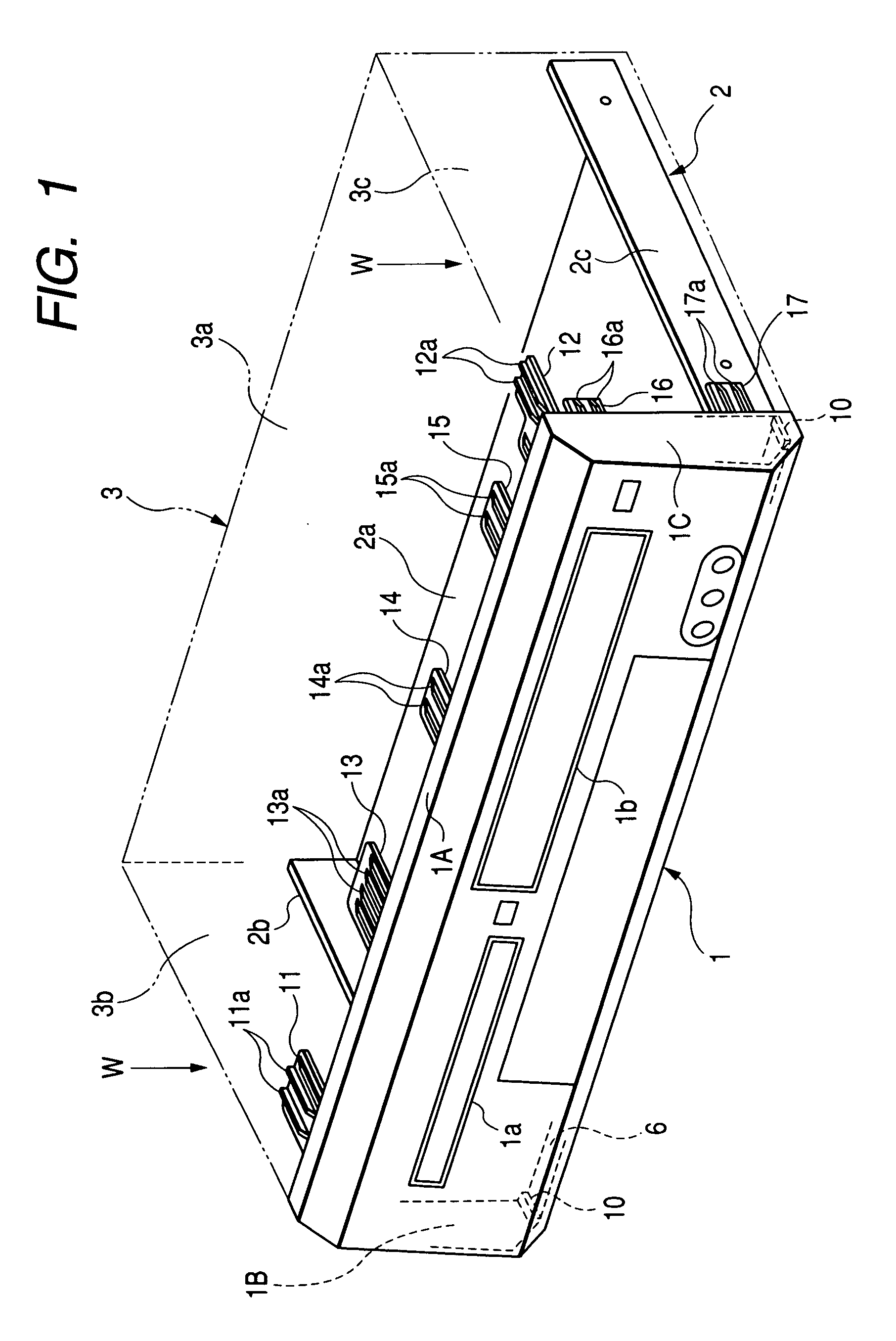

Outer casing of electric equipment

InactiveUS6903937B2Improve stylingDigital data processing detailsCoupling device detailsEngineeringElectric equipment

An outer casing of an electric equipment including: a front panel; a base case having a bottom plate portion and a pair of side plate portions; a top case having a roof portion, a pair of side plate portions, a roof portion protruding piece, and a pair of side plate protruding pieces; and a fixing member. A longitudinal width of each of side plate protruding pieces is set smaller than a longitudinal width of the recess portion for a predetermined length. The outer casing further includes a pair of pedestals integrally formed at both end portions of a bottom face of the recess portion with height thereof being set substantially the same as the predetermined length.

Owner:FUNAI ELECTRIC CO LTD

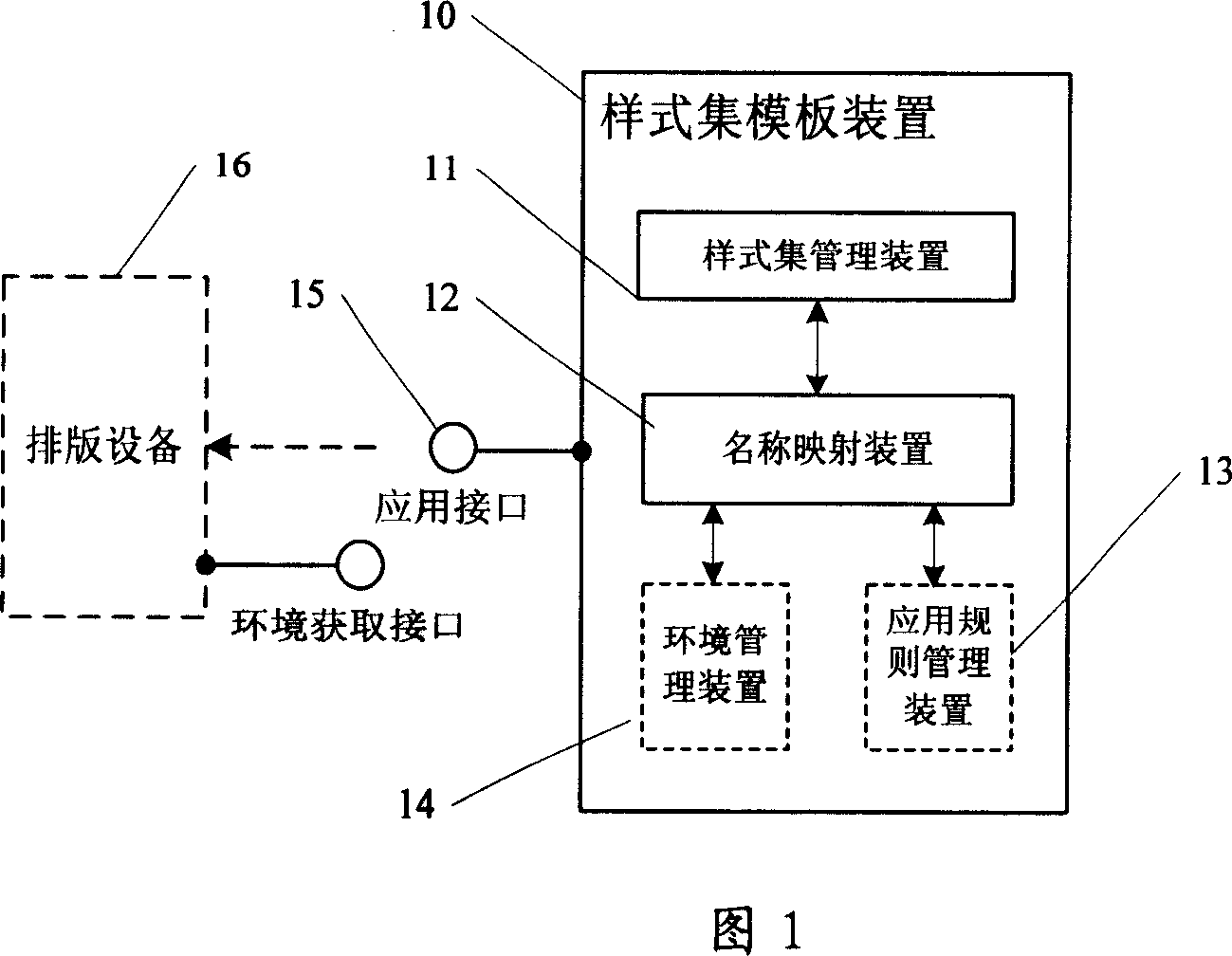

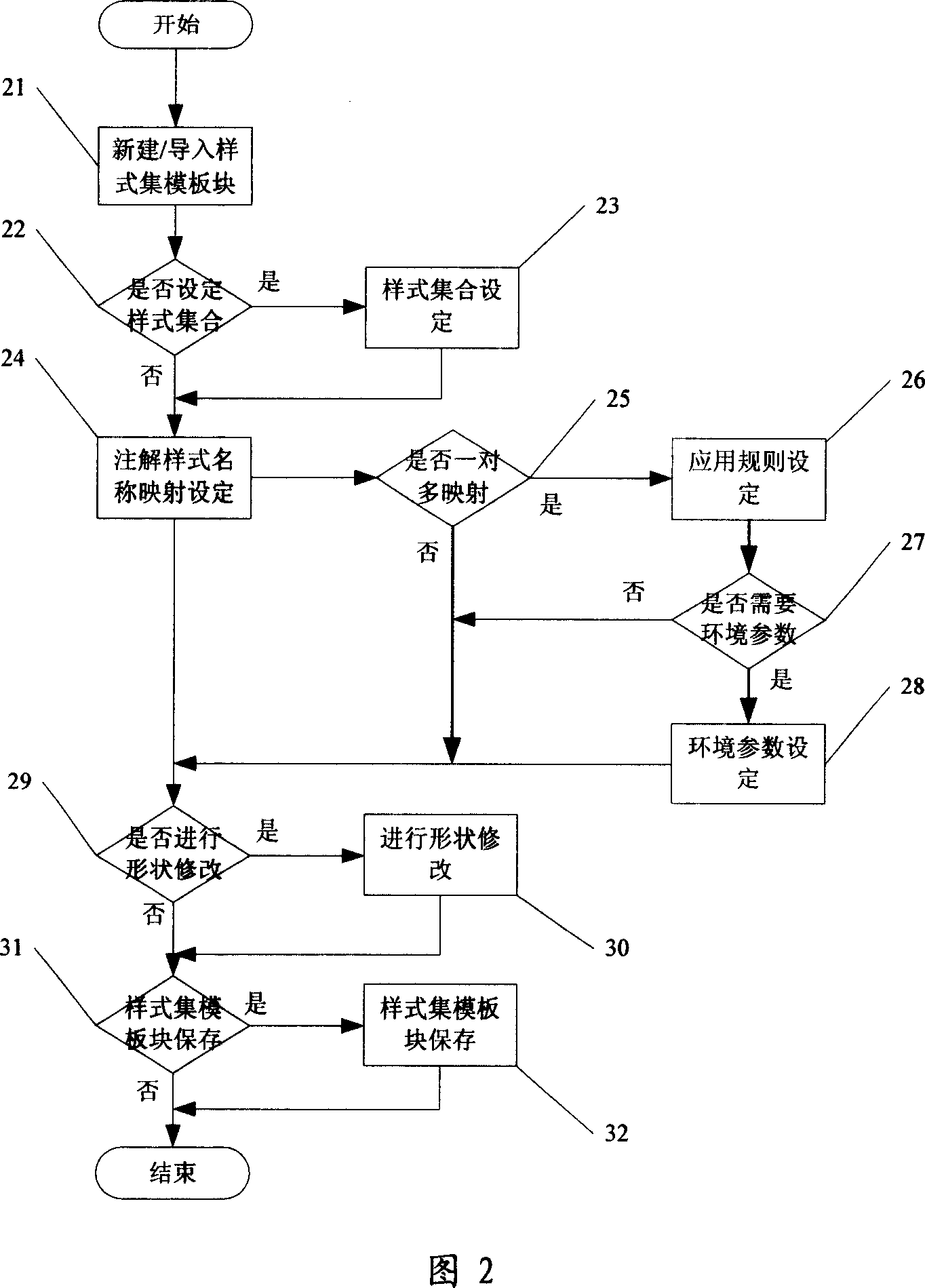

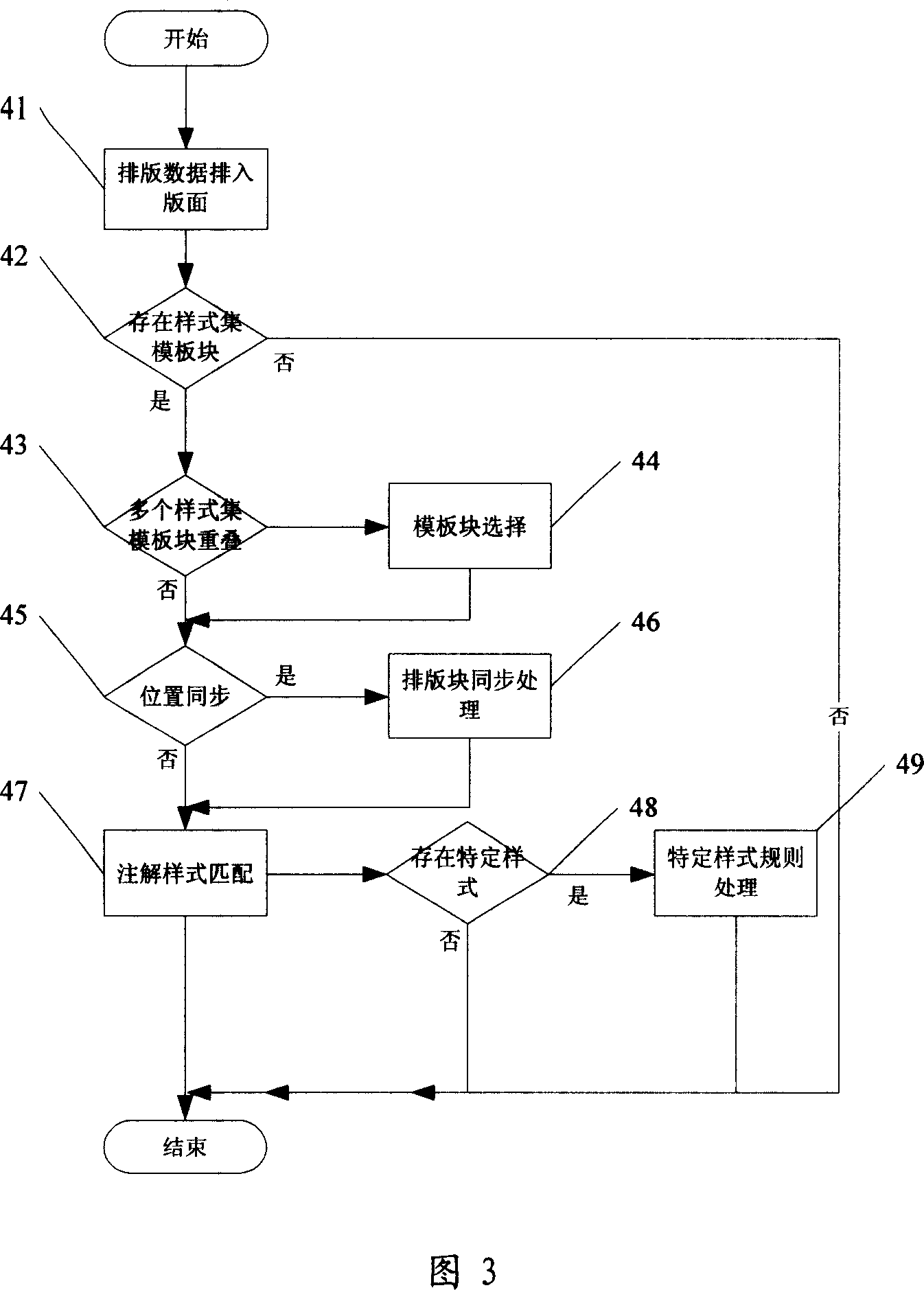

Template device of style set for quick formatting layout, and implement method

ActiveCN101004736AImprove reuseImprove typesetting efficiencySpecial data processing applicationsData formatApplication Context

Owner:方正国际软件(北京)有限公司 +1

Polyvinylidene chloride composition and its prepn

PURPOSE: A polyvinylidene chloride-based resin composition, its preparation method and a film prepared from the resin composition are provided, to improve the processability, the heat stability, the color tone, the dispersibility of a pigment, and the gas barrier properties. CONSTITUTION: The polyvinylidene chloride-based resin composition comprises 100 parts by weight of a polyvinylidene chloride-based resin; a heat stabilizer comprising 0.1-5 parts by weight of at least one epoxy compound selected from the group consisting of an epoxylated vegetable oil, an epoxylated animal oil, an epoxylated fatty acid ester and an epoxylated resin prepolymer, and 0.3-5 parts by weight of a glycidyl group-containing (meth)acryl-based resin; and optionally a pigment. Preferably the glycidyl group-containing (meth)acryl-based resin is a copolymer of 10-50 wt% of the glycidyl ester of an unsaturated organic acid capable of vinyl polymerization and 50-90 wt% of at least one kind of vinyl monomer capable of copolymerizing with the glycidyl ester.

Owner:KUREHA KAGAKU KOGYO KK

Floor tile

The invention discloses a floor tile which comprises a cement tile layer and a plastic layer. The plastic layer is bonded on the cement tile layer. The contact face of the plastic layer in contact with the cement tile layer is uneven. The plastic layer is added on a traditional cement tile, and the face of the plastic layer fixed with the cement tile layer is uneven, so that the figurability of the plastic tile is improved, and the plastic bonding performance is also improved.

Owner:WUXI CITY UNITE PETRO CHEM EQUIP

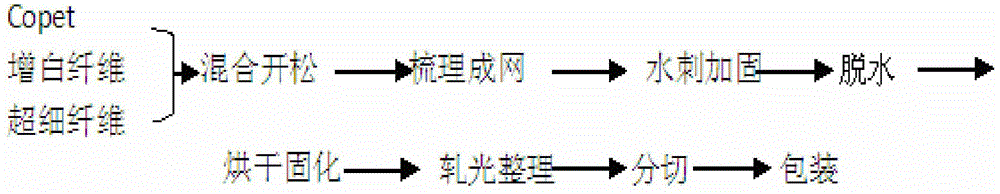

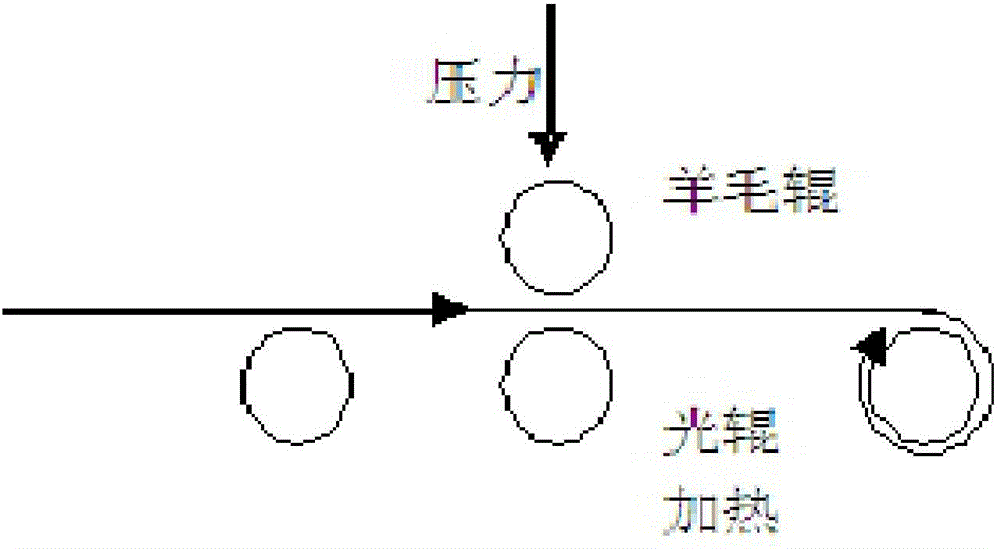

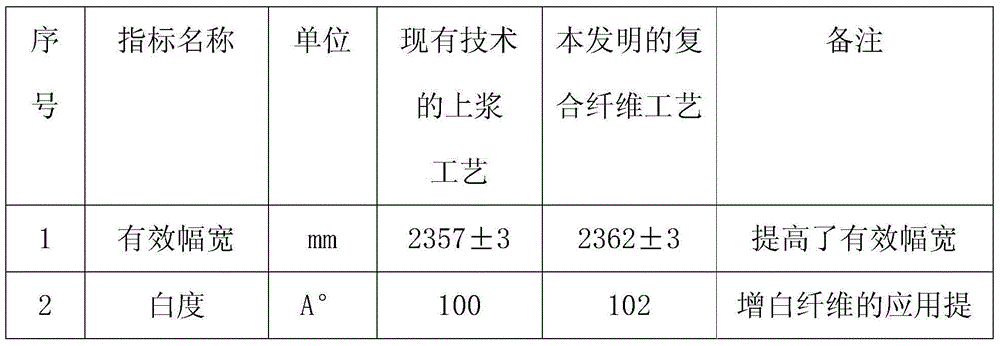

Spunlaced nonwovens and machining method for composite fiber curtain filtration

The invention discloses spunlaced nonwovens and a machining method for composite fiber curtain filtration. According to the method, copet composite fiber, whitening polyester fiber and superfine polyester fiber in the weight proportion 1.5: 2.5:1 are subjected to the following steps to form the spunlaced nonwovens, 1, the copet composite fiber, the whitening polyester fiber and the superfine polyester fiber are mixed in the weight proportion 1.5: 2.5:1; 2, the mixed material is conveyed to an air pressure cotton box carding machine through a draught fan after being subjected to mixing opening; 3, the mixed fiber is subjected to carding to form a mesh, and the mesh is conveyed to a spunlace machine; 4, spunlace machining is conducted on the mixed fiber on a spunlace machine; 5, dehydration treatment is conducted; 6, the mixed fiber is transferred to a dryer to be subjected to continuous drying solidification after the spunlace machining, the solidification temperature of a first drying oven is 160+-3 DEG C, the solidification temperature of a second drying oven is 170+-3 DEG C, and the speed is 45-50 m / min; 7, calendering finish is conducted; 8, the working procedures of slitting and packaging are conducted. The spunlaced nonwovens and machining method for the composite fiber curtain filtration has the advantages that the effects of printing and dyeing, bending and polishing are achieved, no sizing agent exists, and the cost is low.

Owner:SHANDONG PROVINCE WINSON NON WOVEN MATERIALS

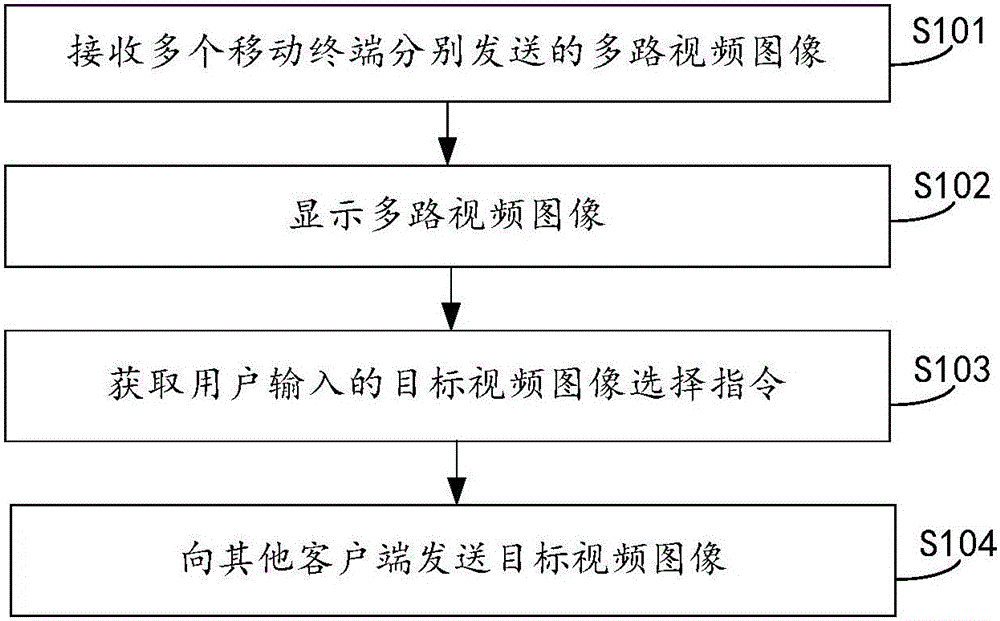

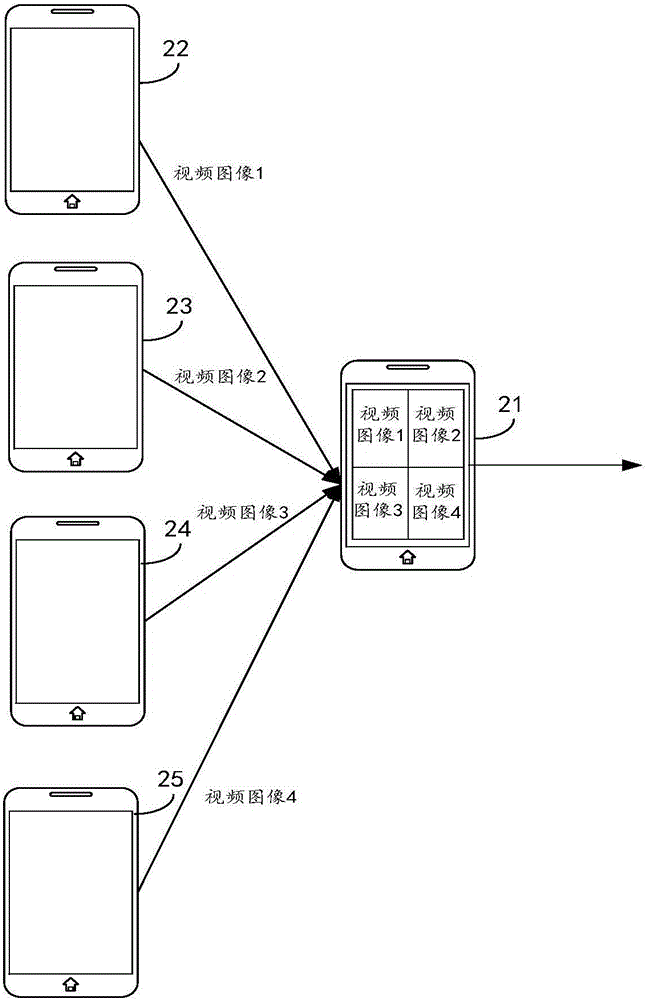

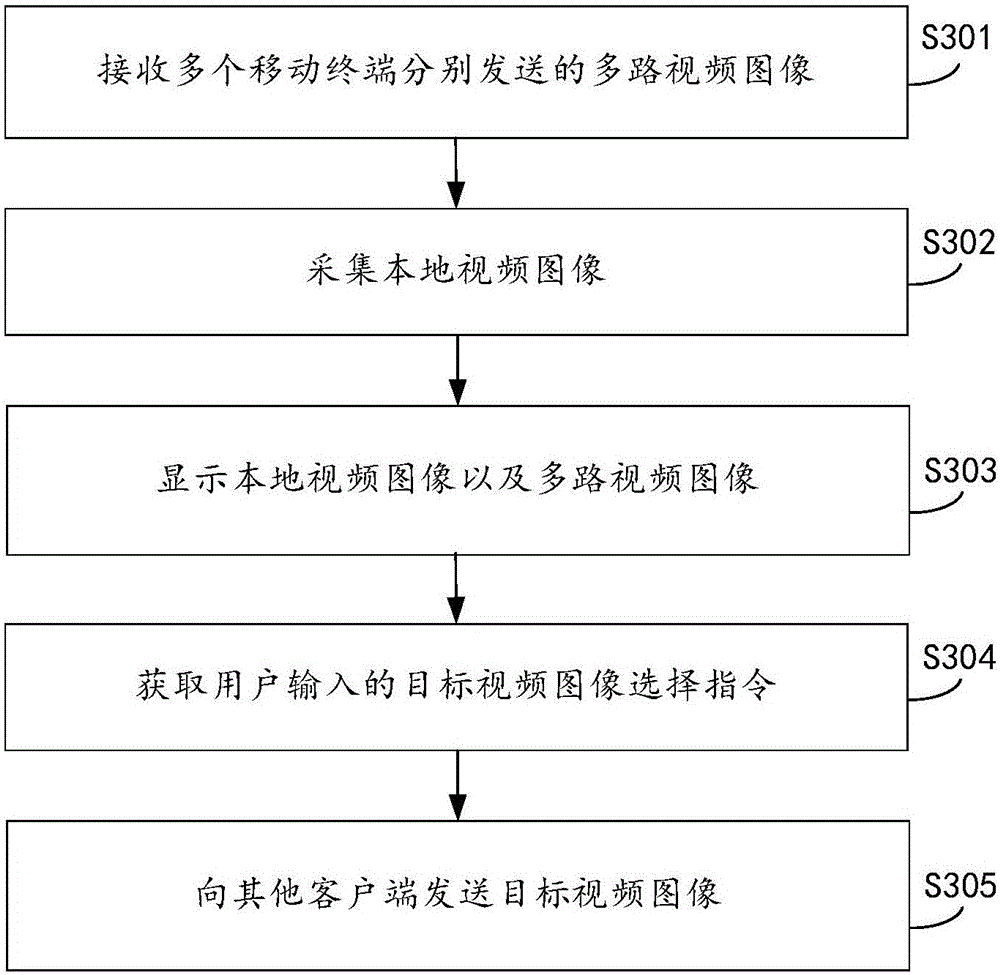

Video processing method and device

ActiveCN105828201AImprove experienceRich live video contentTelevision system detailsTransmissionUser inputVideo processing

The invention discloses a video processing method and device. The video processing method includes the following steps that: a plurality of paths of video images sent by a plurality of mobile terminals respectively are received; the plurality of paths of video images are displayed; a target video image selection instruction inputted by a user is obtained, wherein the target video image selection instruction carries the identifiers of target video images, wherein the target video images are at least one of the plurality of paths of video images; and the target video images are sent to other clients. With the video processing method and device provided by the embodiments of the invention adopted, any video images selected from the plurality of paths of displayed video images can be adopted as the target video images for direct broadcast, and the content of the video direct broadcast can be rich, and user experience can be greatly improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

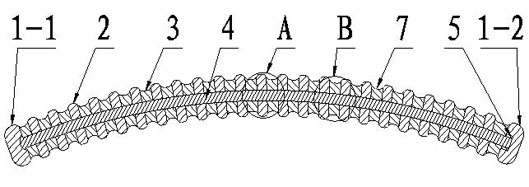

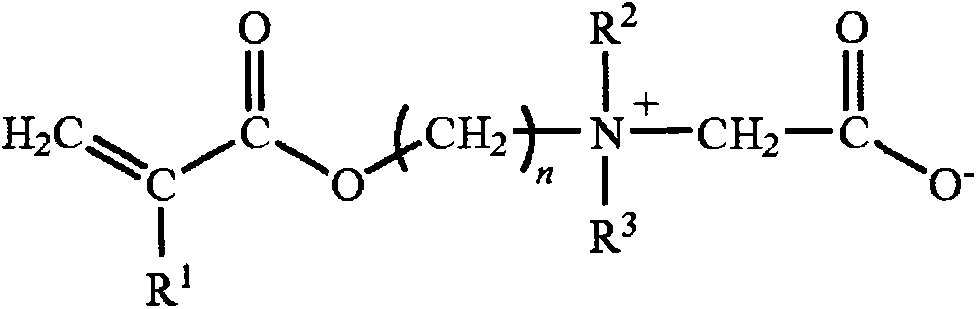

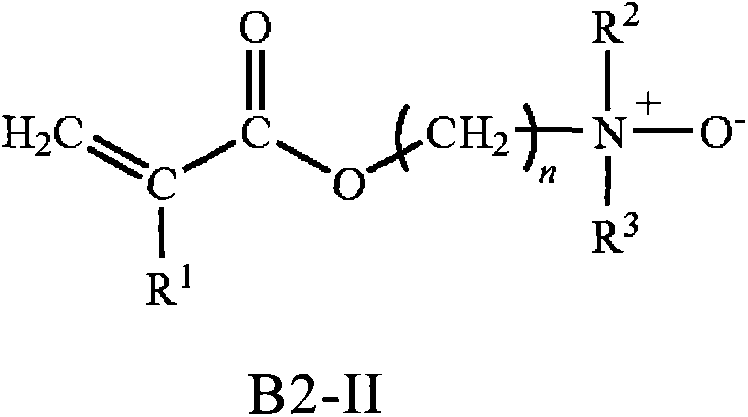

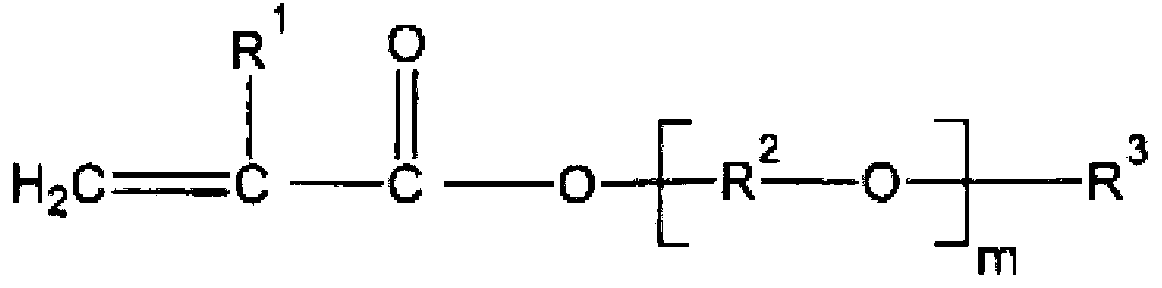

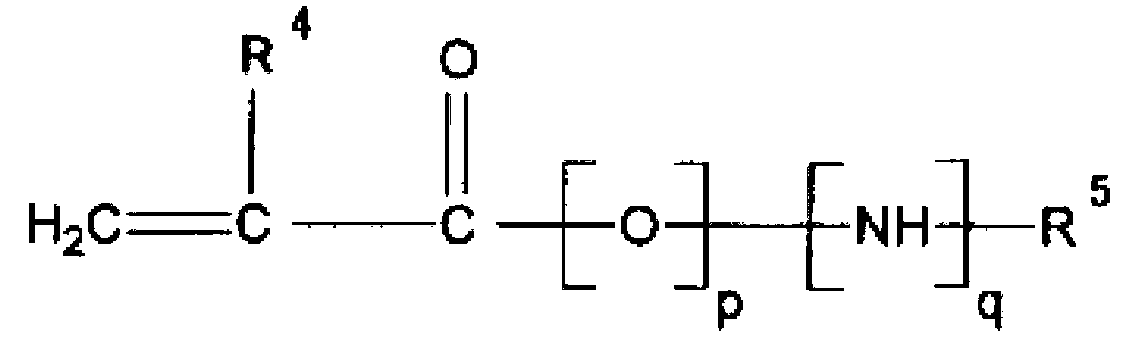

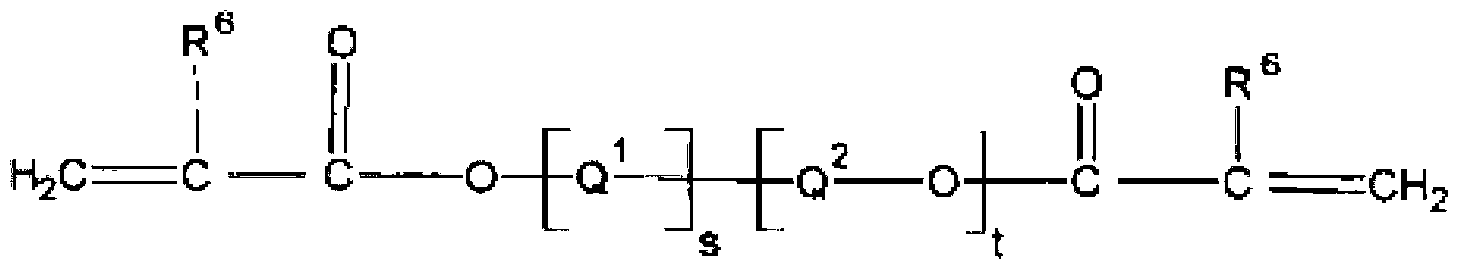

Copolymer and cosmetic material composition

InactiveCN103189404AImprove stylingBroad Formulation FreedomCosmetic preparationsHair cosmeticsWaxHydrogen atom

The objective of the present invention is to provide: a copolymer having a wide degree of freedom of formulation as a spray, mist, wax, and the like, while having high setting properties and hair styling performance; and a cosmetic material composition containing the copolymer. The present invention relates to: a copolymer that has an endothermic start point between -25 DEG C and 40 DEG C, does not dissolve in water under 30 DEG C, and contains a constituent unit corresponding to the vinyl monomer (A) represented by general formula (1), and a constituent unit corresponding to the vinyl monomer (B) represented by general formula (2). (In general formula (1), R1 represents a hydrogen atom or a methyl group, R2 represents an alkylene group having 2-4 carbon atoms, R3 represents a hydrogen atom or an alkyl group having 1-3 carbon atoms, and m represents an integer from 15 to 50. In general formula (2), R4 represents an hydrogen atom or a methyl group, R5 represents an alkyl group having 2-10 carbon atoms, p and q each represent the integer 0 or 1, and p+q=1.)

Owner:MITSUBISHI CHEM CORP

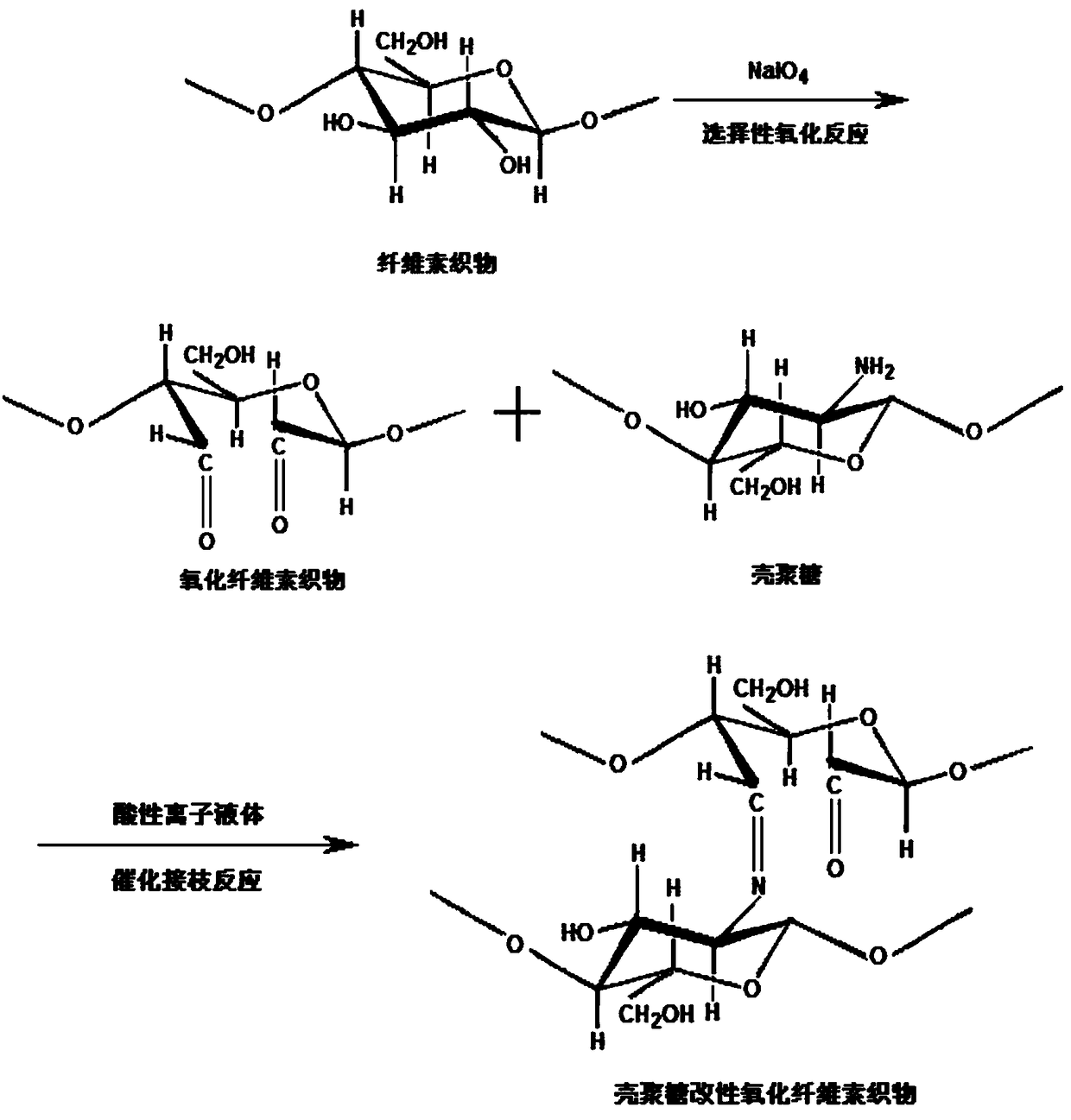

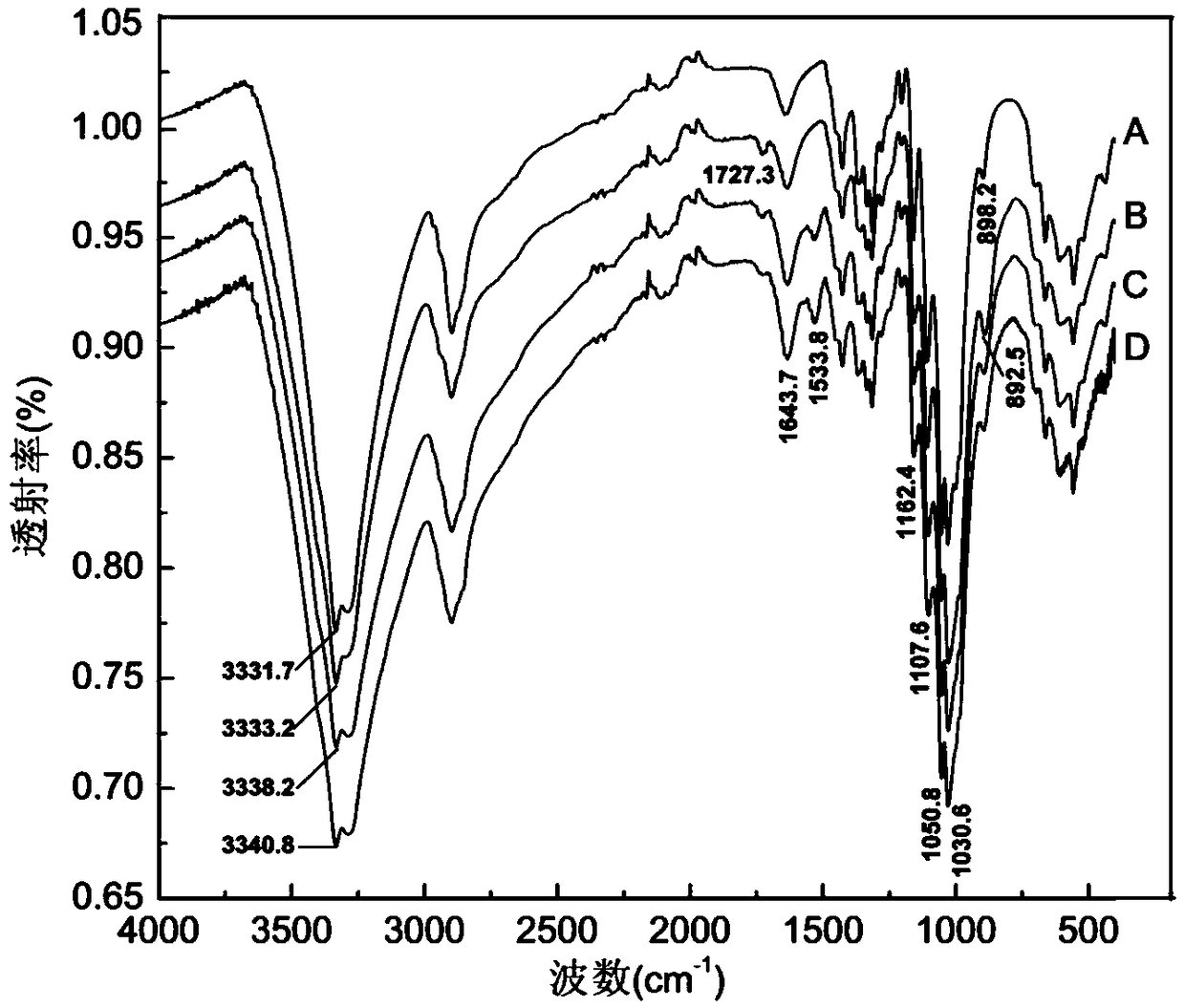

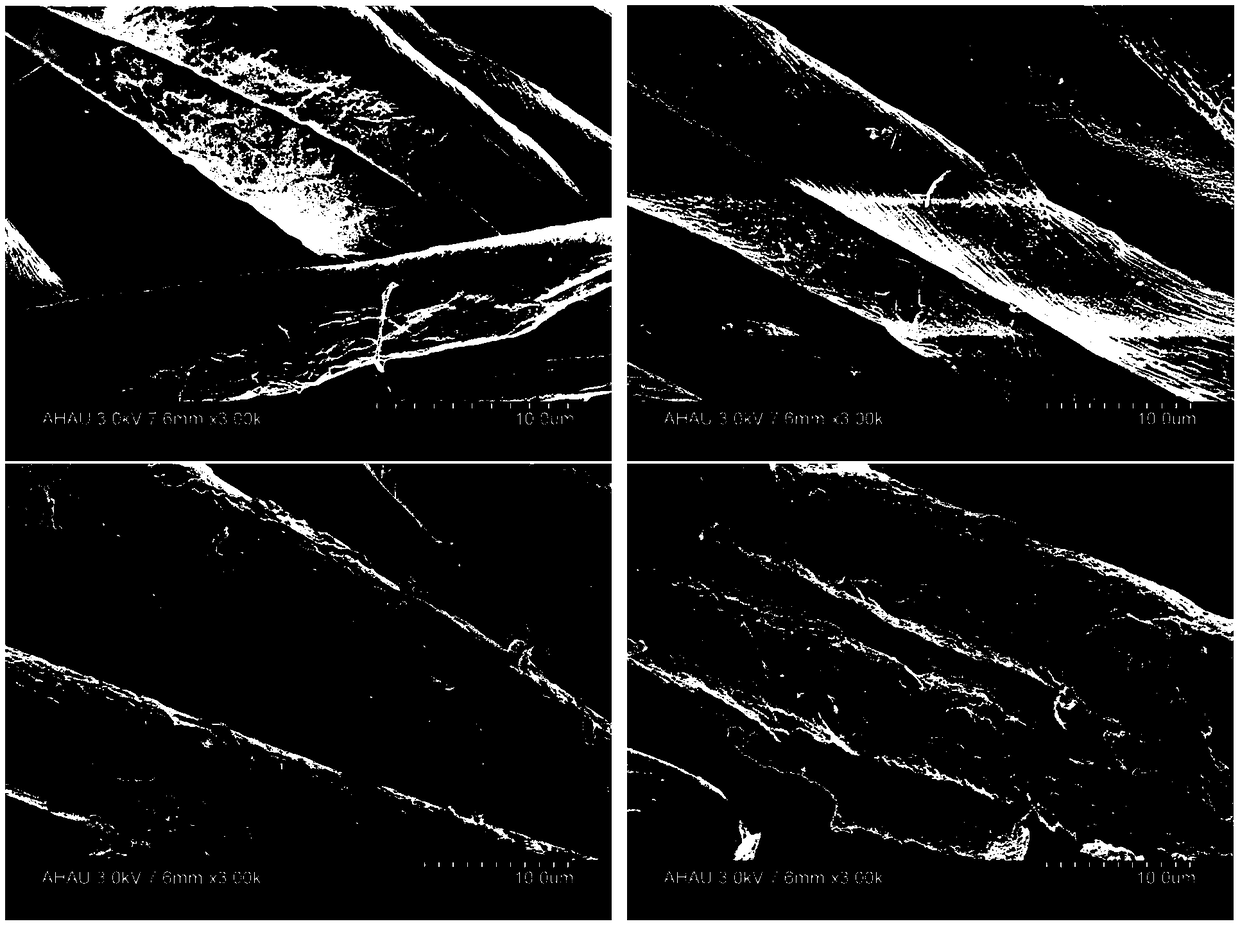

Long-lasting antibacterial chitosan modified oxidized cellulose fabric and preparation method thereof

InactiveCN109295719AImprove skinAnti-wrinkle moisture absorptionPhysical treatmentVegetal fibresAntibacterial activityOxidised cellulose

The invention discloses a long-lasting antibacterial chitosan modified oxidized cellulose fabric and a preparation method thereof. The long-lasting antibacterial chitosan modified oxidized cellulose fabric is obtained through a nucleophilic addition reaction of an amino group in a chitosan molecule and an aldehyde group in a selectively oxidized cellulose fabric. The chitosan modified oxidized cellulose fabric prepared in the invention has long-lasting and efficient antibacterial activity and good wearability, has good affinity to human bodies, is safe and hygienic, and overcomes the negativeinfluences of a chemical cross-linking agent used in conventional chitosan modification on the excellent properties of cellulosic fabric and the health of the human bodies, so the long-lasting antibacterial chitosan modified oxidized cellulose fabric has an actual application prospect.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Preparation method and application of ecological finishing agent used for cellulose and protein fiber fabrics

InactiveCN103603195AImprove stabilityInhibition of agglomerationVegetal fibresAnimal fibresCelluloseNatural fiber

The invention relates to a preparation method and application of a deacetylated chitosan ecological finishing agent used for finishing natural fibers and regenerated natural fiber fabrics. The invention aims to solve the technical problems of a crosslinking problem, size and uniformity of chitosan acetic acid sol particles and stability of the finishing agent. The method is technically characterized by comprising the following steps: mixing chitosan and lacial acetic acid to form an acetic acid aqueous solution with the acetic acid concentration of 1.5-3 percent, dripping a 10g / L of ion stabilizer agar solution, regulating the size of the chitosan colloid particles to be in a distribution range of 60-100nm, forming a uniform and stable acetic acid-chitosan colloid solution of which the colloid size is in a nanoscale, controlling the pH value to be 4-7, wherein the viscosity of the colloid solution is 2-60mPa.s. The method has good chitosan fixation effect, does not have harmful or chemical residues and is environment-friendly, high-efficiency, harmless to human bodies and rich in raw material source.

Owner:安徽甲特生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com