Two-core covering yarn made by ring spinning and production method thereof

A ring spinning, core yarn technology, applied in the field of double core core yarn, can solve the problems of expensive eddy current spinning equipment, reduce the high elasticity of the yarn core, poor hand feeling, etc., and achieve excellent style and comfort performance, good covering performance, The effect of soft touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

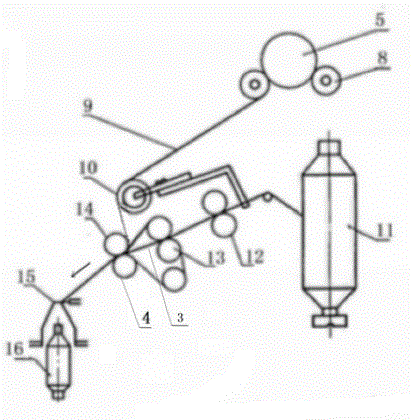

Method used

Image

Examples

Embodiment Construction

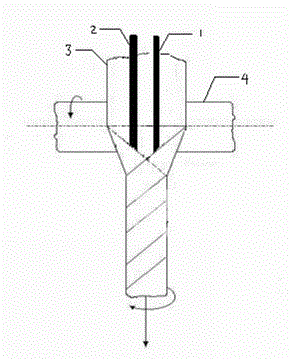

[0013] Such as figure 1 As shown, the present invention includes inner layer yarn core and outsourcing fiber 3, and described inner layer yarn core is made of center core wire one 1, center core wire two 2, and center core wire one 1, center core wire two 2 are parallel and juxtaposed; The outer covering fiber 3 wraps the inner layer yarn core in a helical form, and is spun on the front roller 4 by ring spinning; the central core thread one 1 is spandex filament, and the central core thread two 2 is polyester filament, and the outer covering Fiber 3 is cotton fiber.

[0014] The first central core thread 1 is spandex filament of 40 denier, and the second central core thread 2 is T400 elastic filament of 75 denier.

[0015] The weight percentage of the central core wire 1 is 8.4%, the weight percentage of the central core wire 2 2 is 15.8%, the weight percentage of the outer fiber 3 is 75.8%, and the number of the double-core core-spun yarn is 36 tex .

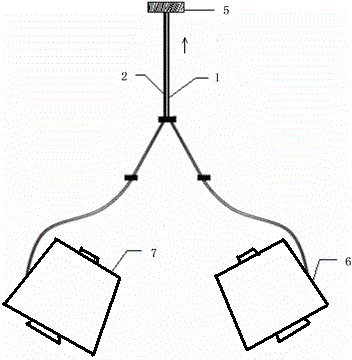

[0016] Such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com