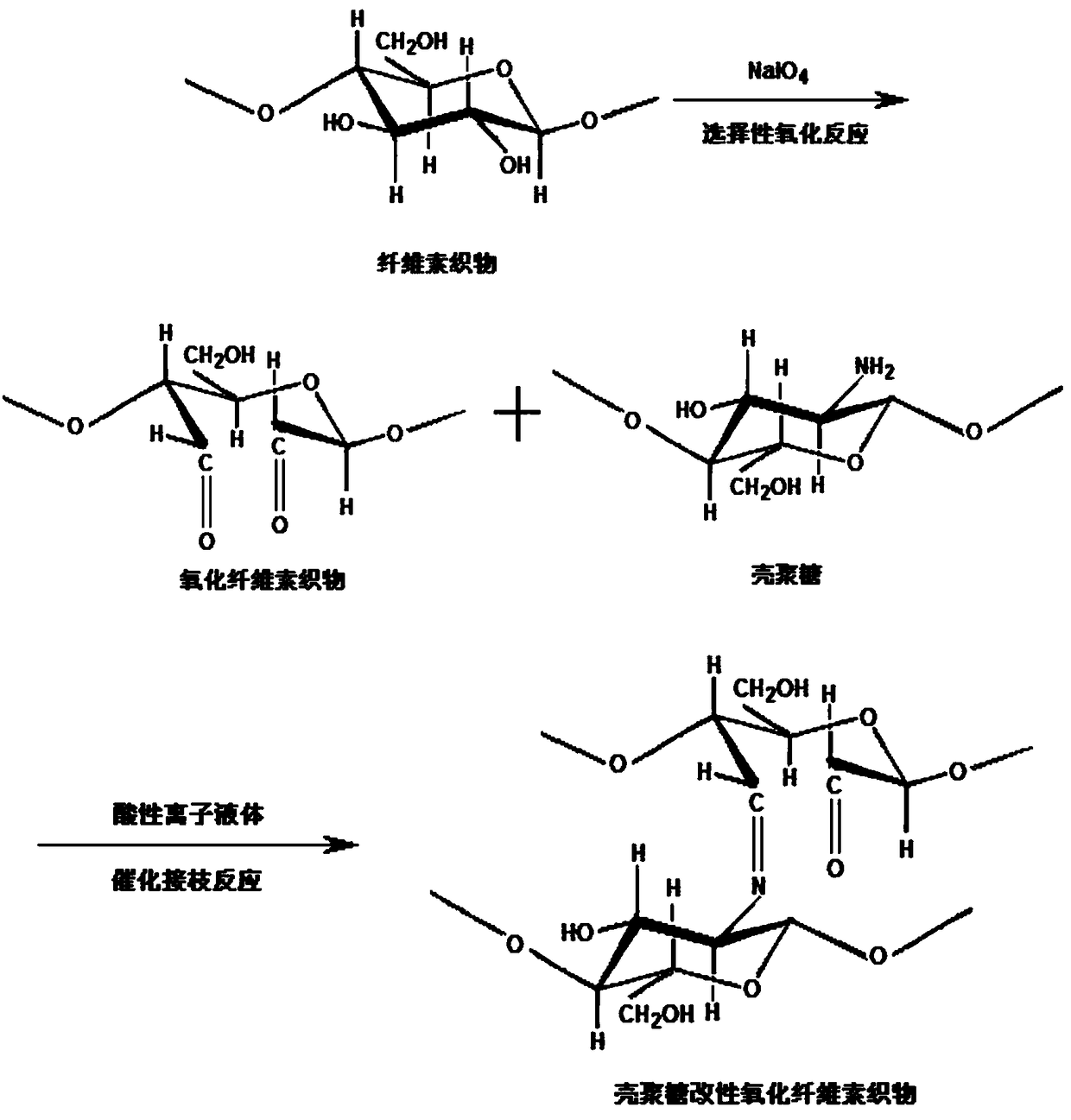

Long-lasting antibacterial chitosan modified oxidized cellulose fabric and preparation method thereof

A technology for modifying oxidized cellulose and chitosan, which is applied in fiber treatment, plant fiber, physical treatment, etc. It can solve the problems of high requirements for process equipment, complicated preparation of finishing agents, and various components of finishing liquid, and achieves washing resistance Good performance, easy to recycle and reuse, and the effect of accelerating the speed of heat movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

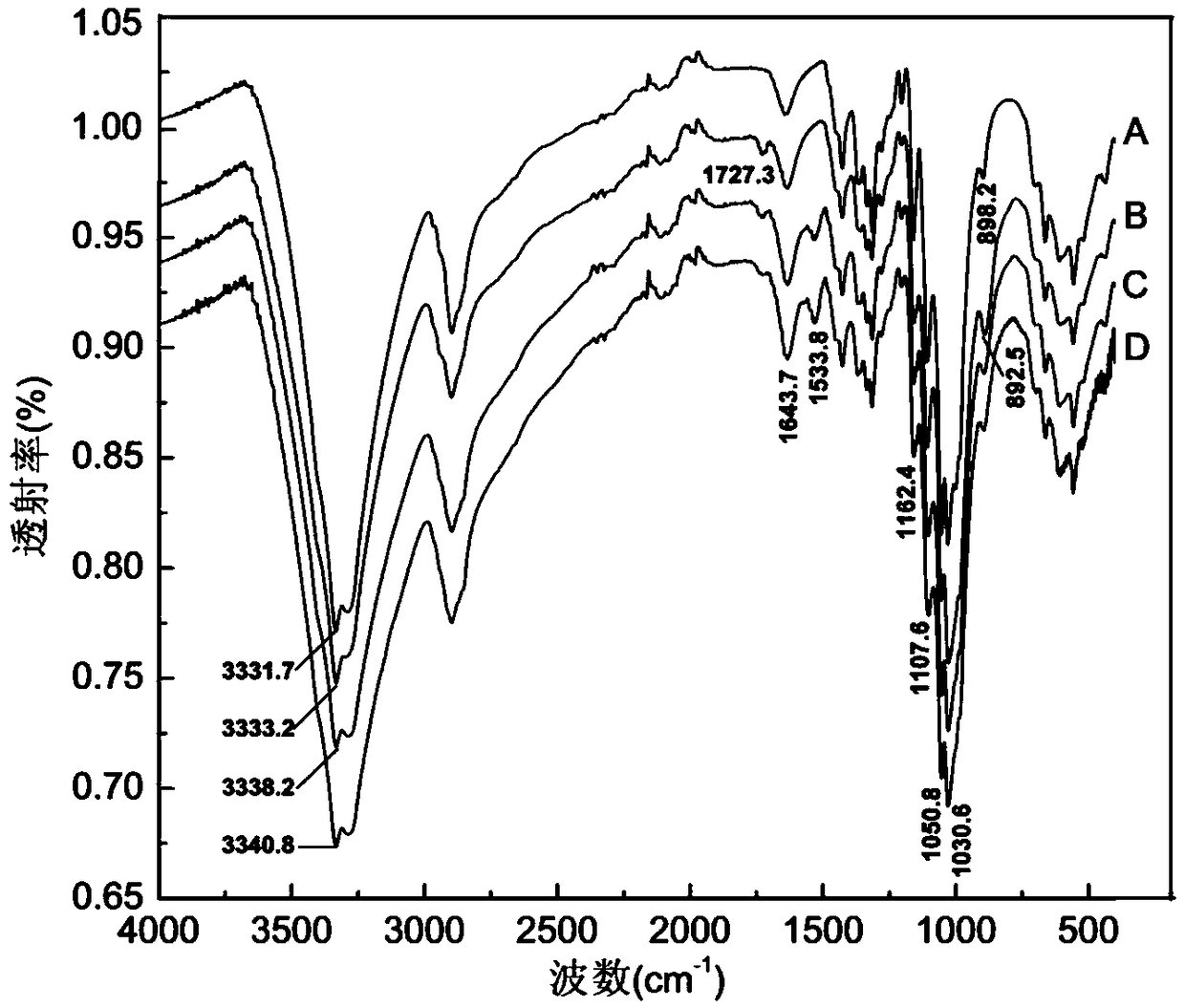

Method used

Image

Examples

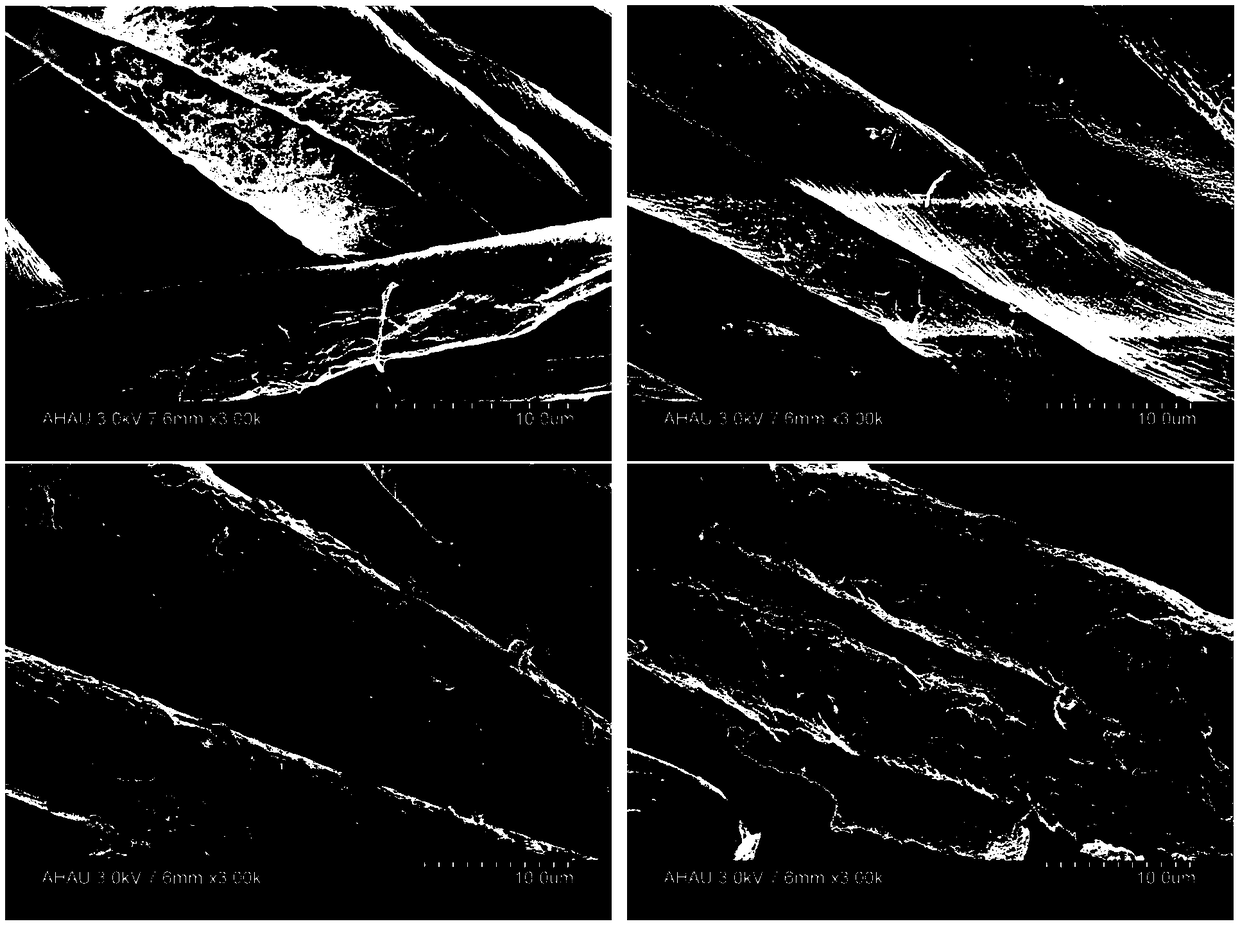

Embodiment 1

[0031] (1) Dry chitosan with a viscosity-average molecular weight of 300,000 and a deacetylation degree of 92.4% at 85°C for 3 hours, then add it to 1-allyl-3-methylimidazolium chloride salt ionic liquid and continue at 100°C Stir for 3 hours to dissolve the chitosan, and obtain a chitosan / 1-allyl-3-methylimidazolium chloride ionic liquid solution with a mass concentration of 0.8%;

[0032] (2) Immerse the desizing and scouring cotton fabric at room temperature into a NaOH solution with a mass concentration of 9%, microwave-assisted treatment for 2min (microwave power is 156W), and then wash with deionized water to neutrality to obtain The cotton fabric of microwave synergistic alkali pretreatment; Press bath ratio 1:50, add the cotton fabric of microwave synergistic alkali treatment in the sodium periodate solution of 1g / L, continue dripping ethylene glycol simultaneously (make ethylene glycol at high The mass concentration in sodium iodate solution is 10%), carry out selecti...

Embodiment 2

[0035] (1) Dry chitosan with a viscosity-average molecular weight of 300,000 and a degree of deacetylation of 92.4% at 90°C for 2 hours, then add it to 1-ethyl-3-methylimidazolium acetate ionic liquid, and dry it at 95°C Continue stirring for 2 hours to dissolve the chitosan, and obtain a chitosan / 1-ethyl-3-methylimidazolium acetate ionic liquid solution with a mass concentration of 1.2%;

[0036] (2) Immerse the desizing and scouring cotton fabric at room temperature into a NaOH solution with a mass concentration of 12%, microwave-assisted treatment for 2min (microwave power is 212W), and then wash with deionized water to neutrality to obtain The cotton fabric of microwave synergistic alkali pretreatment; Press bath ratio 1:50, add the cotton fabric of microwave synergistic alkali treatment in the sodium periodate solution of 2g / L, continue dripping glycerol simultaneously (make glycerol at high The mass concentration in sodium iodate solution is 12%), carry out selective oxi...

Embodiment 3

[0039] (1) Dry chitosan with a viscosity-average molecular weight of 300,000 and a degree of deacetylation of 92.4% at 95°C for 2 hours, then add it to 1-butyl-3-methylimidazolium acetate ionic liquid, and dry it at 100°C Continue stirring for 2 hours to dissolve the chitosan, and obtain a chitosan / 1-butyl-3-methylimidazole acetate ionic liquid solution with a mass concentration of 1%.

[0040] (2) Immerse the viscose fabric through desizing and scouring at room temperature into a NaOH solution with a mass concentration of 10%, microwave-assisted treatment for 2min (microwave power is 128W), and then wash to neutral with deionized water to prepare Obtain the viscose fabric of microwave synergistic alkali pretreatment; Press bath ratio 1:50, add the viscose fabric of microwave synergistic alkali treatment in the sodium periodate solution of 1.5g / L, continue dripping propylene glycol simultaneously (make propylene glycol at high The mass concentration in the sodium iodate soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com