Patents

Literature

214 results about "Sodium laurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium laurate is a chemical compound with formula CH₃(CH₂)₁₀CO₂Na. As the sodium salt of a fatty acid (lauric acid), it is classified as a soap. It is a white solid.

Stable multi-phased personal care composition

InactiveUS20060079418A1Increase depositionExcellent skin conditioningCosmetic preparationsHair cosmeticsPersonal careSodium laurate

A stable multi-phase personal care composition is described. The stable multi-phase composition comprises least two visually distinct phases; wherein at least one visually distinct phase comprises a cleansing phase comprising a surfactant component. The surfactant component comprises at least one anionic surfactant selected from the group consisting of ammonium lauryl sulfate, ammonium laureth sulfate, sodium lauryl sulfate, sodium laureth sulfate, sodium cocoyl sulfate, sodium laurate, sodium cocoyl isethionate, monomethyl branched surfactants and mixtures thereof. The visually distinct phases of the stable multi-phase personal care composition form a pattern.

Owner:THE PROCTER & GAMBLE COMPANY

Germicidal antiviral composite containing chlorine dioxide

InactiveCN101669518AStable active ingredientsControl release speedBiocideDisinfectantsSodium laurateCarboxymethyl cellulose

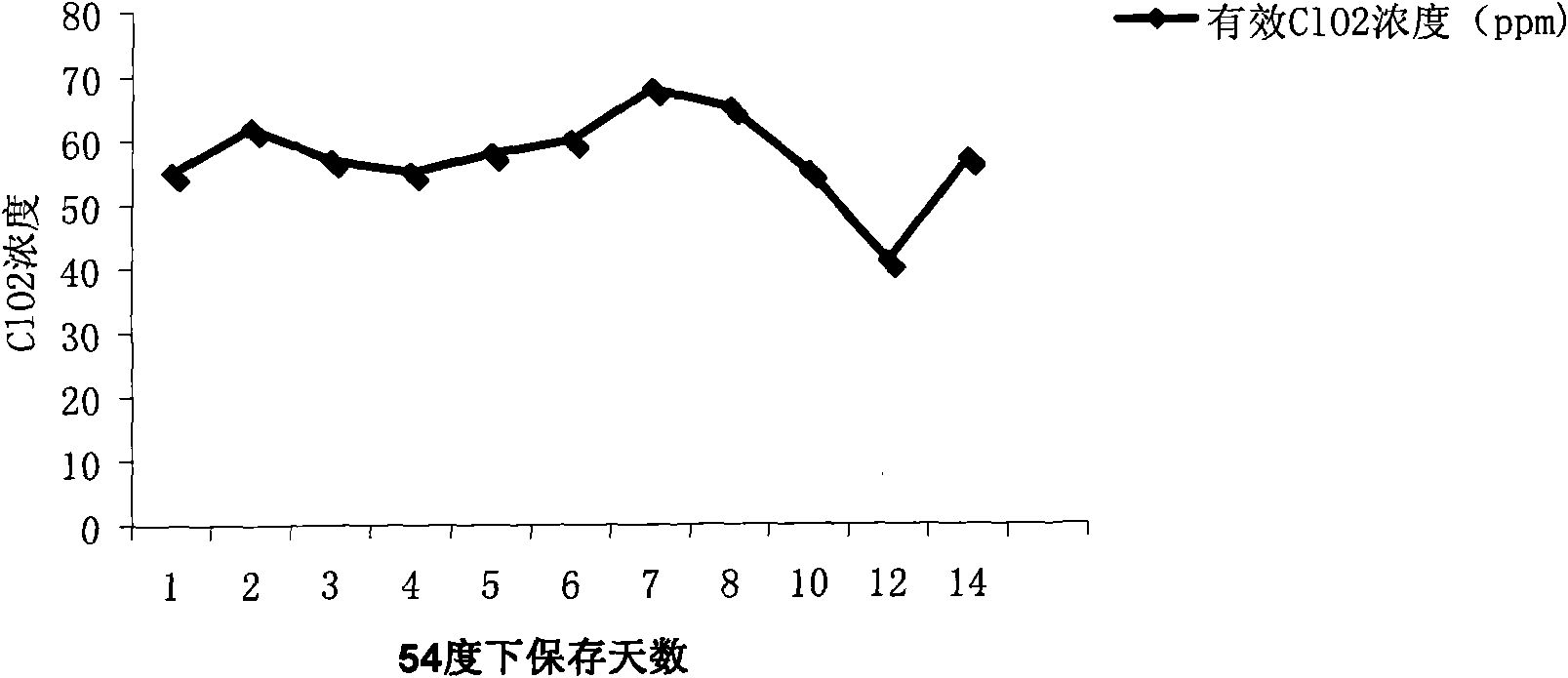

The invention discloses a germicidal antiviral composite containing chlorine dioxide. The composite comprises a functional composition that can provide chlorine dioxide and a stabilizing agent, wherein the stabilizing agent is a compound that can cause the functional composition capable of providing the chlorine dioxide to stably exist in a solvent or a carrier and comprises one or more of EDTA, carboxymethyl cellulose, sodium laurate, polyethylene glycol, cyclodextrin, glucan, chitin, and mucopolysaccharide and the like. The technical means adopted in the invention solves the difficulty thatthe chlorine dioxide is instable in products or a complicated stabilizing and releasing technical means is needed in application of products, thus expanding the production and application range of products.

Owner:BEIJING OKEANOS TECH

Cutting fluid containing waste engine oil and preparation method therefor

InactiveCN103710127AImprove the lubrication effectGood extreme pressure and anti-wear propertiesAdditivesBase-materialsDiethylene glycol monobutyl etherPhytic acid

Provided is a cutting fluid containing waste engine oil. The cutting fluid is prepared from the following raw materials, by weight, 12-14 parts of waste engine oil, 1-2 parts of triethanolamine, 4-6 parts of amino-acid ester, 2-3 parts of phytic acid, 2-3 parts of dodecyl dimethyl benzyl ammonium chloride, 1-2 parts of nanoscale graphite micropowder, 14-16 parts of diethylene glycol monobutyl ether, 5-8 parts of propylene glycol, 1-2 parts of sodium laurate, 6-8 parts of auxiliary agents and 200 parts of water. Through application of nanoscale graphite micropowder, the cutting fluid has excellent lubricating property and extreme pressure resistance. Through application of waste engine oil, the cost is lowered. The cutting fluid has good antirust performances, contains no substances of sodium salt, phenol, chlorinated paraffin, mineral oil and the like, has no damage to human body, and is a environmentally friendly and green product.

Owner:MAANSHAN HENGYI MACHINERY MFG

Nano composite pesticides new formulation and preparation method thereof

InactiveCN101288397AReduce spraying costsImprove adhesionBiocideAnimal repellantsSodium laurateUltimate tensile strength

The invention discloses a new dosage form of nanometer compound pesticide and a preparation method thereof, which is prepared by adopting modified nanometer TiO2, chitosan and technical product of pesticides as the raw materials, wherein, the modified nanometer TiO2 has improved mechanical property which is modified through sodium laurate. By utilizing the property of film build of chitosan, the chitosan and the technical product of pesticides react fully, a layer of film is formed on the surface of a spraying object, the film can reduce loss of liquid medicine, ensure more pesticide to be attached on crops, facilitate penetration of systemic pesticide and increase the safety for the operators of spraying and environment; the added modified nanometer TiO2 helps the film have certain intension and tenacity, thus achieving slow release and long effect of pesticide; meanwhile, by utilizing the antibacterial property of chitosan and nanometer TiO2, the effects of antibacterial property and getting rid of pests of pesticide are increased. The nanometer compound pesticide is a new dosage form of pesticide with the characters of long effect, safety, innocuity, economy and convenience.

Owner:GUIZHOU UNIV

Low foam laundry liquid

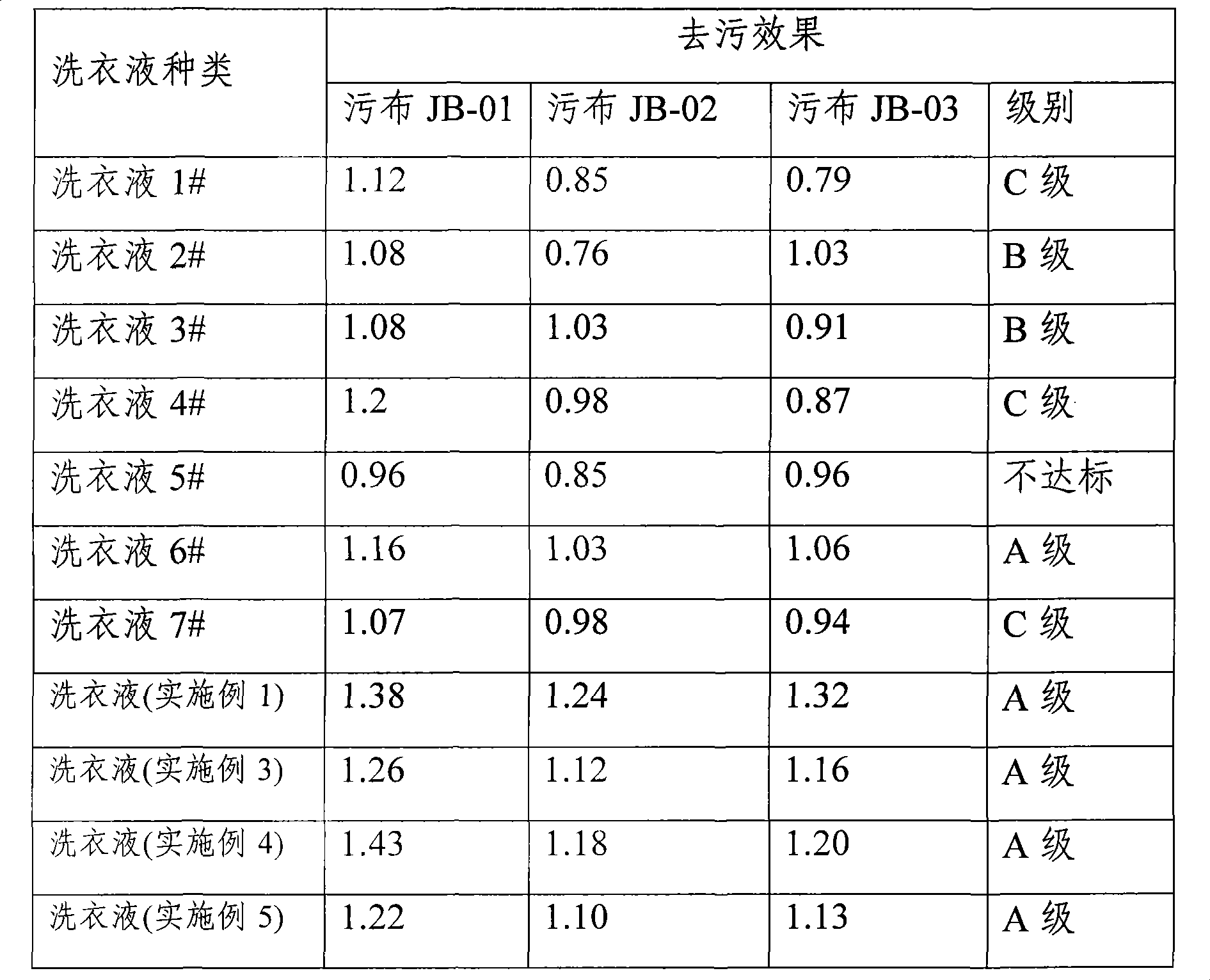

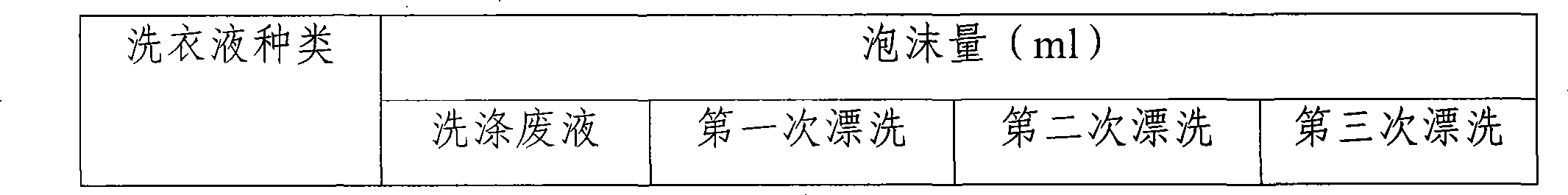

ActiveCN101372648AImprove cleanlinessEasy to rinseNon-ionic surface-active compoundsWater savingSodium laurate

The invention relates to a detergent. The invention discloses a low-foam fabric cleaner; the main active ingredients of the cleaner and the parts by weight thereof are as follows: 1-9 part(s) of sodium laurate, 1-11 part(s) of polyoxyethylene carboxylate fatty acid ester, 10-25 parts of surface active agent, 0.1-1 part of chelating agent and 0.5-5 part(s) of thickening agent. The complex formulation of sodium laurate and polyoxyethylene carboxylate fatty acid ester can lower the foaming power of other surface active agents, thus achieving the function of reducing foam. The low-foam fabric cleaner is easy to rinse, water-saving and energy-saving, and has strong detergency.

Owner:BEIJING REWARD HOME CARE CHEM

Nano silver facial perfuming soap

PendingCN101130719AGuaranteed healthy skinGood effectInorganic/elemental detergent compounding agentsSodium laurateSodium stearate

The invention discloses a beauty soap of nanometer silver, which comprises the following steps: 1. 5-2. 5% nanometer colloid silver, 2. 0-3. 0% pure embryo element, 0. 05-0. 15% collagen, 0. 05-0. 15% ursin, 6. 0-8. 0% deep sea, 7. 0wt% coagulant, 12. 0-14. 0% water, 21. 5-22. 5% glycerin, 8. 0-9. 0% sodium oleate, 21. 0-23. 0% sodium stearate, 11. 0-13. 0% sodium laurate and 3. 0-4. 0 essence. The invention not only has strong detergency, but also possesses the function of antibiotic and disinfection to maintain the oil-water balance of skin, prevent skin from aging with skin beauty.

Owner:全昌均 +1

Composite active carbon desulfurizer and preparation method thereof

InactiveCN103736391AReduce dosageImprove desulfurizationDispersed particle separationEnvironmental resistanceSodium bicarbonate

A composite active carbon desulfurizer is prepared from the following raw materials by weight: 100-120 parts of bamboo charcoal, 30-34 parts of quicklime, 10-12 parts of weathered coal, 3-4 parts of sodium hydroxide, 12-14 parts of sodium bicarbonate, 10-12 parts of ammonium bicarbonate, 30-35 parts of gypsum, 40-45 parts of fresh reed roots, 35-39 parts of zeolite, 5-6 parts of sodium tripolyphosphate, 4-5 parts of carboxymethylcellulose sodium, 2-3 parts of sodium laurate, 4-5 parts of auxiliary agents, and a proper amount of water. By using zeolite, fresh reed roots, weathered coal, gypsum and the like, after high temperature carbonization, the desulfurizer of the invention not only has adsorption and ion exchange effects, but also has antibacterial effect, saves the using amount of bamboo charcoal, and improves economic benefits and environmental protection benefits; by using a plurality of alkaline compounds, rapid and thorough desulfurization is realized; the desulfurizer of the invention can adsorb SO2, SO3, H2S, organic sulfur, n-butyl sulfur of waste gas and waste water, is wide in application, and causes no secondary pollution.

Owner:WUHU ZHONGLU IND

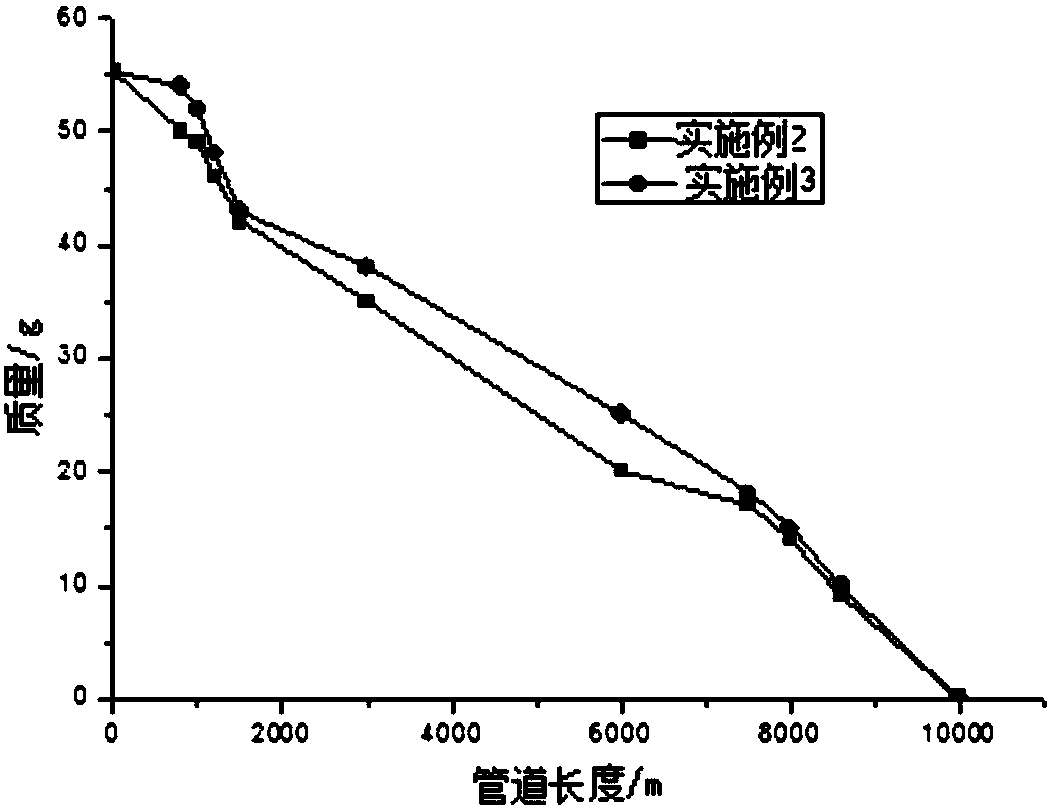

Soluble chemical paraffin removal ball and preparation method and use method of soluble chemical paraffin removal ball

ActiveCN108559675APrevent redepositionPlay the role of physical wax removalCationic surface-active compoundsDetergent mixture composition preparationSodium stearateOctadecyltrimethylammonium bromide

The invention provides a soluble chemical paraffin removal ball and a preparation method and a use method of the soluble chemical paraffin removal ball. The soluble chemical paraffin removal ball comprises the following raw materials: 60-104 parts of a surfactant and 7-27 parts of a thickener; the surfactant is one or more of sodium stearate, hexadecyl trimethyl ammonium chloride, hexadecyl trimethyl ammonium bromide, sodium laurate, octadecyl trimethyl ammonium chloride, and octadecy trimethyl ammonium bromide; the thickener comprises 2-10 parts of sodium carboxymethylcellulose, 2-10 parts ofpolyacrylamide and 2-7 parts of sodium polyphosphate. The raw materials are proportionally added into absolute ethyl alcohol, stirred evenly, formed through a mould, and dried to obtain the soluble chemical paraffin removal ball. The paraffin removal ball is added according to the conditions of the pipeline length and the paraffin precipitation. The chemical paraffin removal ball has double effects of physically removing paraffin and chemically preventing paraffin, and the problem of paraffin precipitation in a transportation pipeline of the crude oil is solved.

Owner:XI'AN PETROLEUM UNIVERSITY

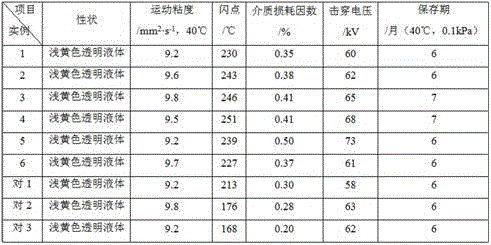

Nano-modified transformer oil and preparation method thereof

ActiveCN106544143AHigh thermal conductivityImprove insulation performanceLubricant compositionWater bathsHeat conducting

The invention belongs to the technical field of electricity, and particularly relates to nano-modified transformer oil and a preparation method thereof. The transformer oil is prepared from 0.15 to 0.8% of modified aluminium nitride nano-particles and 0.2 to 1.0% of modified alpha-Al2O3 nano-particles in percentage by weight. The nano-modified transformer oil is prepared by the following steps: adding aluminium nitride nano-particles and a silane coupling agent into an organic solvent to carry out sonic oscillation for 1 to 2h, then adding methyl methacrylate, carrying out water bath reaction at 60 to 80 DEG C for 10 to 12h, ball-milling, carrying out rotary evaporation for removing the organic solvent, drying, obtaining powder, then carrying out Soxhlet extraction with methylbenzene, and then carrying out devolatilization, thus obtaining the modified aluminium nitride nano-particles; modifying alpha-Al2O3 nano-particles with a sodium laurate solution to obtain the modified alpha-Al2O3 nano-particles; adding the modified nano-particles into base oil, then adding a molecular sieve for adsorption, and filtering. The nano-modified transformer oil prepared by the method has excellent heat-conducting property and electrical performance.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

Odor-eliminating eider down caring agent and preparation method thereof

InactiveCN103351963AMothproofMildew proofFibre treatmentSurface-active non-soap compounds and soap mixture detergentsCross-linkFatty alcohol

An odor-eliminating eider down caring agent is characterized by being composed of following components in parts by weight: 2 to 3 parts of permethrin, 3 to 4 parts of propylene glycol, 4 to 5 parts of sodium laurate, 1 to 2 parts of sodium citrate, 1 to 2 parts of oleic acid, 0.3 to 0.5 part of rose essential oil, 2 to 3 parts of fatty alcohol polyoxyethylene ether, 1 to 2 parts of DMDHEU, 1 to 2 parts of sodium persulfate, 1 to 2 parts of EBST, 0.1 to 0.3 part of anti-ultraviolet agent, 1 to 2 parts of cross-linking agent TAIC, 3 to 4 parts of softener, and 200 parts of water. The odor-eliminating eider down caring agent has the advantages of integration of moth resistance, mildew resistance, anti-bacterium and odor-eliminating functions, small usage amount, and good effects on anti-bacterium, mildew resistance, moth resistance and odor-eliminating.

Owner:安徽华强羽绒有限公司

Down feather detergent

InactiveCN104312762AGood conditionConvenient careSurface-active detergent compositionsFibre treatmentSodium bicarbonateMorpholine

The invention discloses a down feather detergent which comprises the following components in parts by weight: 100 parts of water, 3-4 parts of triethanolamine, 2-3 parts of octadecanol polyoxyethylene ether, 1-2 parts of abietic acid polyoxyethylene ester, 1-2 parts of polyglycerol monostearate, 1-2 parts of hydroxypropyl methyl cellulose, 3-4 parts of sodium laurate, 1-2 parts of dodecyl trimethyl ammonium sulfate, 1-2 parts of sodium persulfate, 1-2 parts of N-octyl isothiazolinone, 1-2 parts of phenyl silicon oil, 2-3 parts of aminomethyl propanol, 2-3 parts of morpholine, 1-2 parts of sodium bicarbonate, 1-2 parts of tea polyphenol, 2-3 parts of vinyl trimethoxy silane, 1-2 parts of polyisobutene, 3-4 parts of polyvinylpyrrolidone, 1-2 parts of dimer acid and 2-3 parts of maleic anhydride modified polyethylene. The down feather detergent disclosed by the invention can effectively remove stain on down feather and has a relatively good conditioning and caring function on down feather.

Owner:常熟市奥琪特服饰有限公司

Preparation method of TOPCon structure battery

ActiveCN110416359AFree from corrosionReduced diffusion rateFinal product manufactureSemiconductor devicesProduction lineSodium laurate

The invention discloses a preparation method of a TOPCon structure battery, and the method comprises the following steps: before a step of removing polycrystalline silicon winding plating, reserving aBSG on the front surface of a silicon wafer; in the step of removing the polycrystalline silicon winding plating, removing the polycrystalline silicon on the front surface of the silicon wafer by adding an alkaline solution of an additive, wherein the additive comprises the following components in percentage by mass: 2%-5% of glyceryl monostearate, 1%-2.5% of diethylene glycol, 1%-2.5% of sodiumlaurate and 1%-2% of beta-cyclodextrin and the balance of deionized water, and the alkaline solution is a KOH solution or a NaOH solution. According to the method, the polycrystalline silicon windingplating is removed by adding the alkaline solution of the additive, so that the BSG can be protected from being corroded by the alkaline solution, and furthermore, alkali cannot corrode a phosphorus diffusion part and a boron diffusion part. The process window is wider, the efficiency is more stable, the diffusion capacity can be improved, a groove type machine and a chain type machine can be applied, and a production line can conveniently use an existing machine table to achieve mass production.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

Down washing agent and preparation method thereof

InactiveCN103451954AEfficient removalGood conditionFibre treatmentAmpholytes/electroneutral surface-active compoundsSodium bicarbonateSodium laurate

The invention provides a down washing agent which is characterized by being prepared from the following raw materials in parts by weight: 1-2 parts of polyoxyethylene octadecanol ether, 3-4 parts of rosin-polythylene oxide ester, 3-4 parts of betaine, 1-2 parts of sodium laurate, 2-3 parts of dimer acid, 1-2 parts of sodium bicarbonate, 2-3 parts of polyisobutylene, 4-5 parts of 2-amino-2-methyl-1-propanol, 3-4 parts of softening agent and 150 parts of water. The down washing agent is capable of effectively removing dirt on down, recovering the original elasticity and bulkiness of the down and keeping the original warmth retention property, better in conditioning and nursing effects for the down, strong in detersive power, good in stability, suitable for both hot water and cold water and free of hand injury because of being neutral.

Owner:安徽华强羽绒有限公司

Preparation method of wetting selective oil-water separation membrane separated according to requirements

ActiveCN108837707ACause harmLow costMembranesSemi-permeable membranesAluminum IonEnvironmental resistance

The invention belongs to the technical field of chemical separation and relates to a preparation method of a wetting selective oil-water separation membrane separated according to requirements. The preparation method comprises the following steps: firstly, mixing an aluminate precursor and a pH regulator to form a solution, adding 8 to 12 ml of aluminum ion pH regulator mixed solution according toa porous basement membrane per square centimeter, carrying out hydrothermal reaction at the temperature of 150 to 200 DEG C for 12 to 24 hours, taking out a reactant, washing and carrying out vacuumdrying to obtain a precursor separation membrane with a hierarchical structure; carrying out high-temperature calcining to obtain a superhydrophilic / underwater super-oleophobic separation membrane with a hierarchical structure; then adding the superhydrophilic / underwater super-oleophobic separation membrane into a sodium laurate solution and carrying out modification reaction at the temperature of40 to 70 DEG C for 5 to 9 hours, and carrying out high-temperature calcining to obtain the superhydrophilic / underwater super-oleophobic separation membrane with the hierarchical structure; and carrying out repeated calcining and surface modification to obtain the wetting selective membrane according to the requirements. The preparation method disclosed by the invention has the advantages of simple process and low cost, solves the problems of poor selectivity, high possibility of pollution, low separation efficiency and the like of a traditional oil-water separation membrane are solved by utilizing surface superhydrophilic and super-hydrophobic characteristics under different conditions, and has a great application value in the fields of environment friendliness, chemical engineering and the like.

Owner:JIANGSU SAFELY ENVIRONMENT ENG

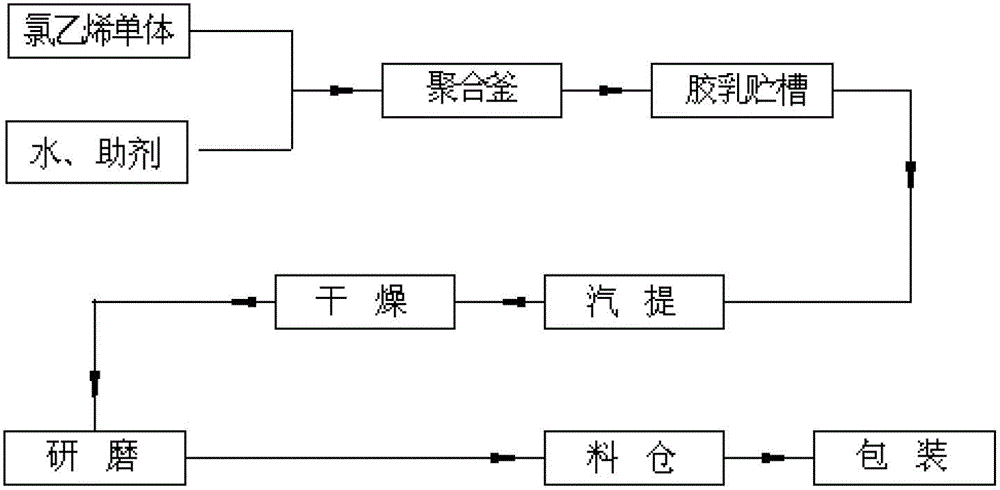

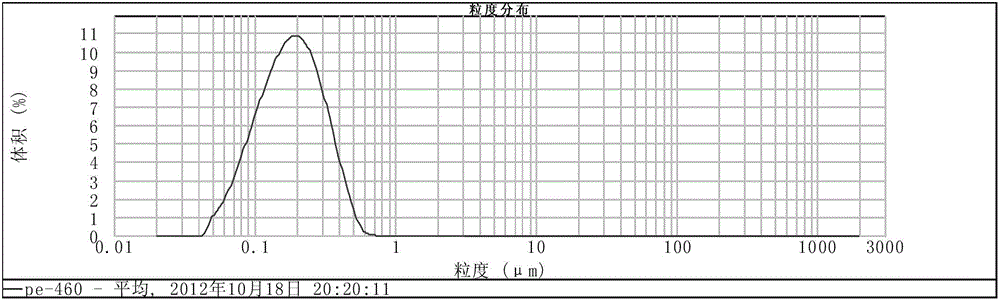

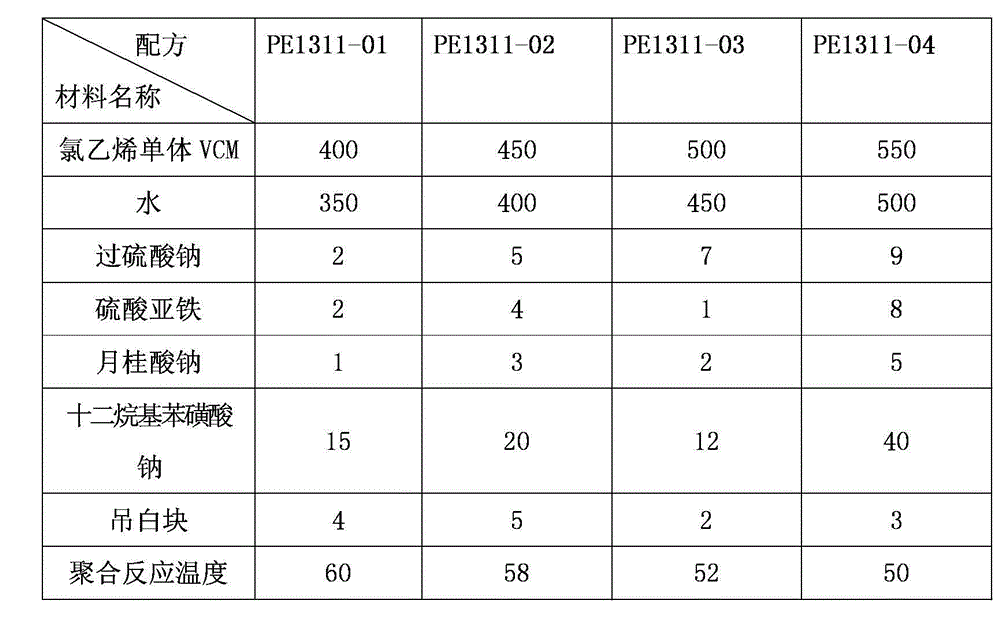

High viscosity polyvinyl chloride paste resin PE1311 and preparation method thereof

Owner:ANHUI TIANCHEN CHEM

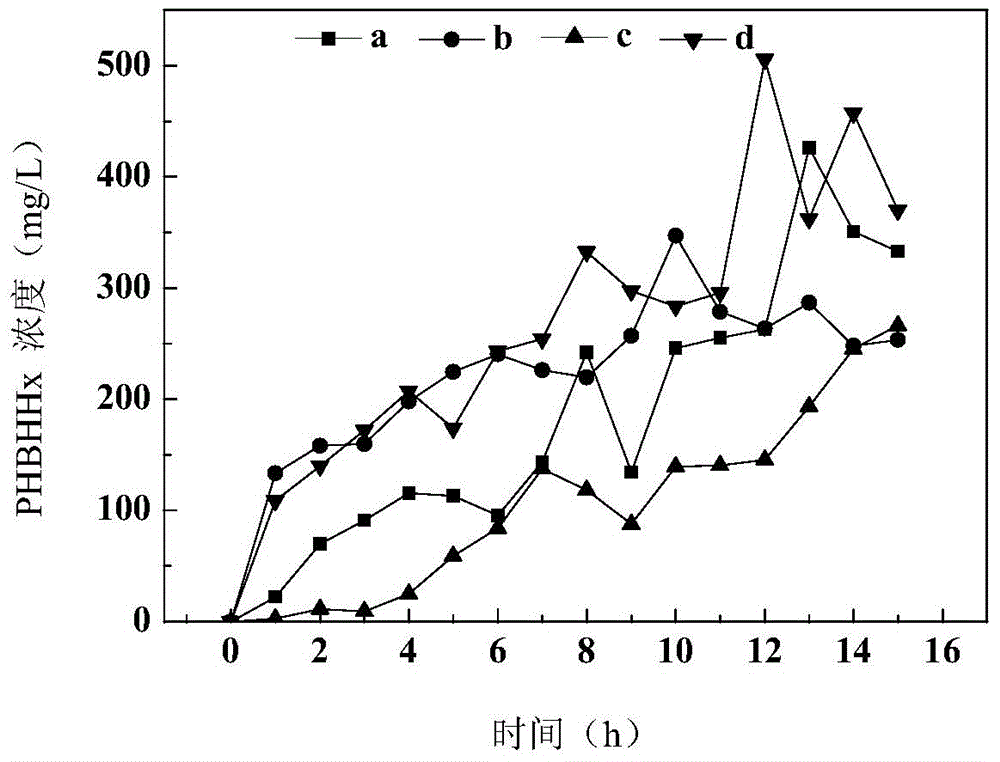

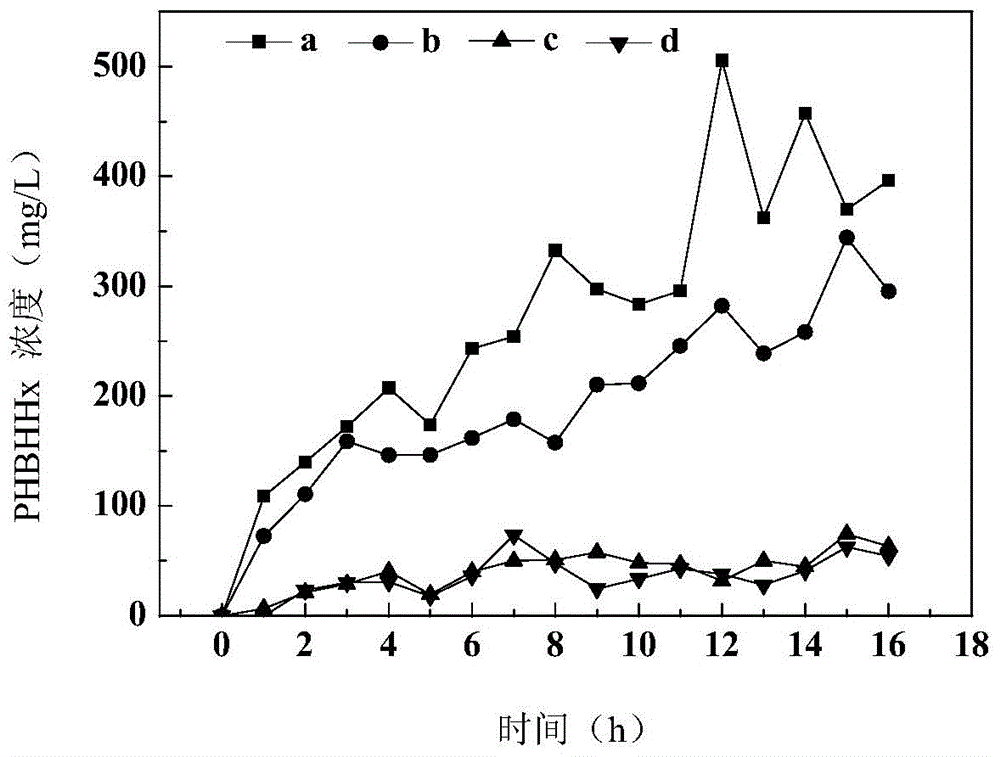

Method for producing medium-chain-length polyhydroxyalkanoates by virtue of excess activated sludge

The invention discloses a method for producing medium-chain-length polyhydroxyalkanoates by virtue of excess activated sludge, and relates to polyhydroxyalkanoates. The method comprises the following steps: using sodium laurate as a unique substrate carbon source for domesticating original sludge, and synthesising poly-3-hydroxybutyrate-co-3-hydroxyhexanoate by virtue of the stably-domesticated activated sludge, wherein 1.5g / L sodium laurate is uniformly poured for three times while being used as the unique substrate, and the highest concentration of cumulative PHBHHx of the sludge is 505.5mg / L under a continuous aeration condition and in case of nitrogen deficiency and phosphorus deficiency; the PHBHHx are synthesised by virtue of activated sludge mixed micro-organisms for the first time, and an infrared absorption spectrum and thermogravimetric analysis proves that PHBHHx samples have chemical structures and physical properties similar to those of PHBHHx standard substances synthesised from pure strains. The method is simple in equipment, easy to operate, free from a sterile working condition and rich in excess sludge source, and therefore has a great application prospect in the aspect of producing plastic products needed in the industry and the agriculture.

Owner:XIAMEN UNIV

Preparation method for liquid laundry detergent possessing plant sterilization function

InactiveCN104479892AGood antibacterial effectGood removal effectNon-ionic surface-active compoundsDetergent compounding agentsSodium laurateLiquid laundry detergent

A provided liquid laundry detergent possessing plant sterilization function comprises the following compositions in percent by mass: 5-15% of polyoxyethylene fatty acid, 10-20% of sodium laurate, 0.5-5% of a viola philippica extraction liquid, 0.5-3% of a raw ginger extraction liquid, 1.5-5% of a thickening agent, 0.1-0.5% of sodium citrate, and the balance water. Substantial synergic effect is generated through combined usage of a surfactant and plant extractives. The liquid laundry detergent shows extremely good decontamination capability, also has good antibacterial sterilization performances, is mild, free of stimulation and good in biological degradability, is an environment-friendly safe nontoxic detergent, and is especially applicable to cleaning of children clothes and pregnant woman underwear and clothes next to the skin.

Owner:王越

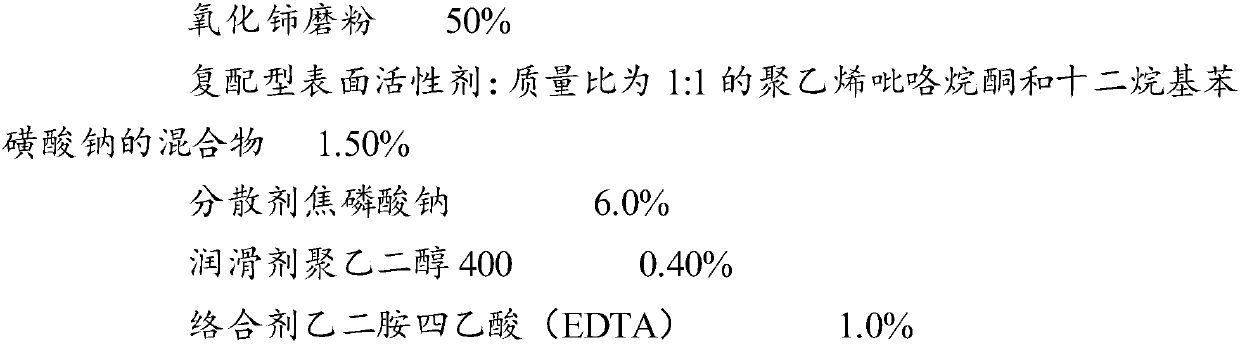

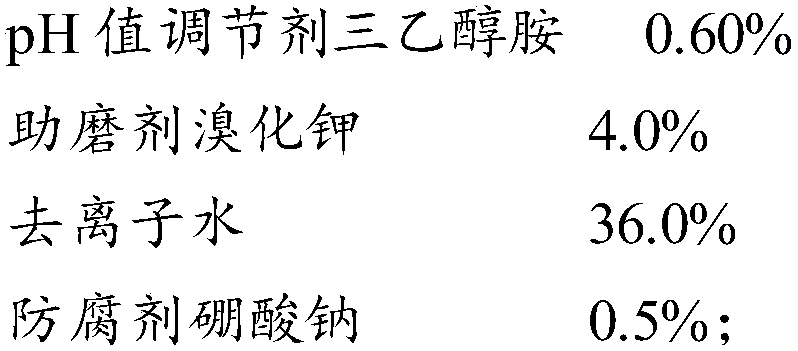

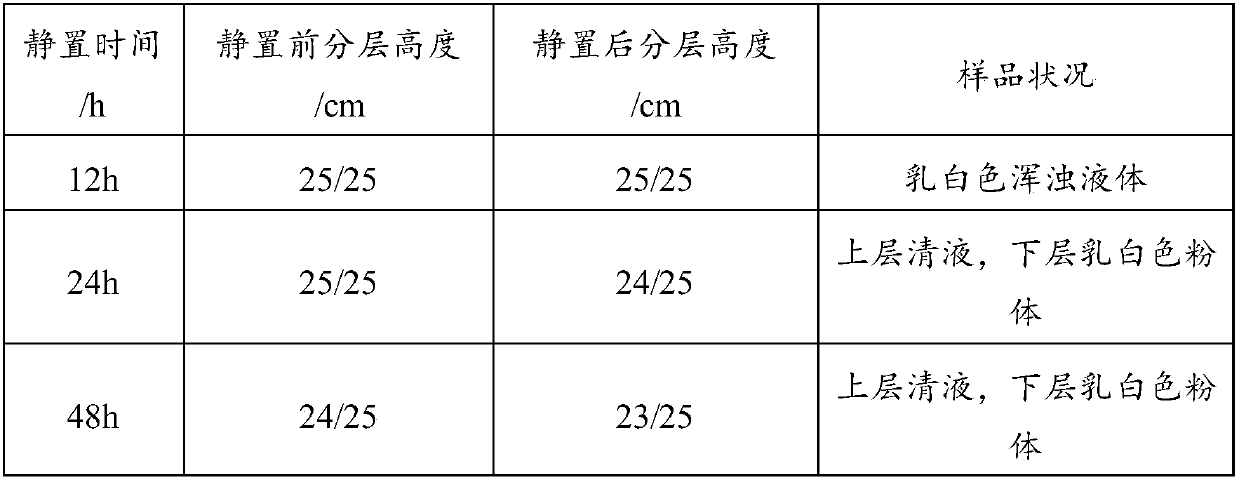

Water-based cerium oxide polishing solution for polishing glass, and preparation method thereof

InactiveCN109929460AGood dispersion and suspensionImprove yieldPolishing compositions with abrasivesWater basedSodium stearate

The invention provides a water-based cerium oxide polishing solution for polishing glass, and a preparation method thereof. The polishing solution comprises 20-55% of ground cerium oxide, 0.1-3% of acompound surfactant, 1-8% of a dispersant, 0.1-2% of a lubricant, 0.01-3% of a complexing agent, 0.01-5% of a grinding aid, 0.01-1% of a pH regulator, 0.01-2% of a preservative, and the balance of water, wherein the compound surfactant is a compound of a nonionic surfactant and an anionic surfactant; the nonionic surfactant is one or more of polyvinylpyrrolidone, alkylphenol polyoxyethylene ether,fatty alcohol polyoxyethylene ether and fatty acid glyceride; the anionic surfactant is one or more of sodium dodecylbenzenesulfonate, sodium laurate, sodium stearate and sodium succinate; and the dispersant is one or more of sodium oxalate, sodium hexametaphosphate, sodium pyrophosphate, sodium nitrate, sodium polyacrylate and sodium lauryl sulfate. The polishing solution has a good suspending dispersibility, and products polished with the polishing solution have a high yield.

Owner:LENS TECH CHANGSHA

Soilless cultivation matrix of paeonia lactiflora and manufacturing method thereof

InactiveCN103503750AStrong water absorptionImprove the bactericidal effectAgriculture gas emission reductionCultivating equipmentsSodium BentonitePeat

The invention relates a soilless cultivation matrix of paeonia lactiflora. The soilless cultivation matrix comprises, by volume, 20-30 parts of peat, 10-15 parts of feculae bombycis, 10-12 parts of weathered coal, 15-20 parts of vinasse and 5-10 parts of modified plant ash. By weight, 3%-4% of bentonite, 1%-2% of gamma-methacryloxy propyl trimethoxyl silane, 1%-2% of canola oil, 0.8%-1.5% of sodium laurate, 3%-4% of tea saponin, 0.2%-0.5% of moringa oleifera seeds, 3%-4% of chitosan liquid, of the plant ash and moderate water are added into the plant ash. The solution is fully stirred for 1-2 hours at the revolving speed of 600-800rpm, granulated and dried. The cultivation matrix of the formula is used for soilless cultivation of the paeonia lactiflora, flower seedlings grow fast, branches and leaves are flourishing, the overall integration rate is high and can reach 78%, and the diameter of a flower is large and can reach more than 75mm.

Owner:合肥市天丰菌业科技有限公司

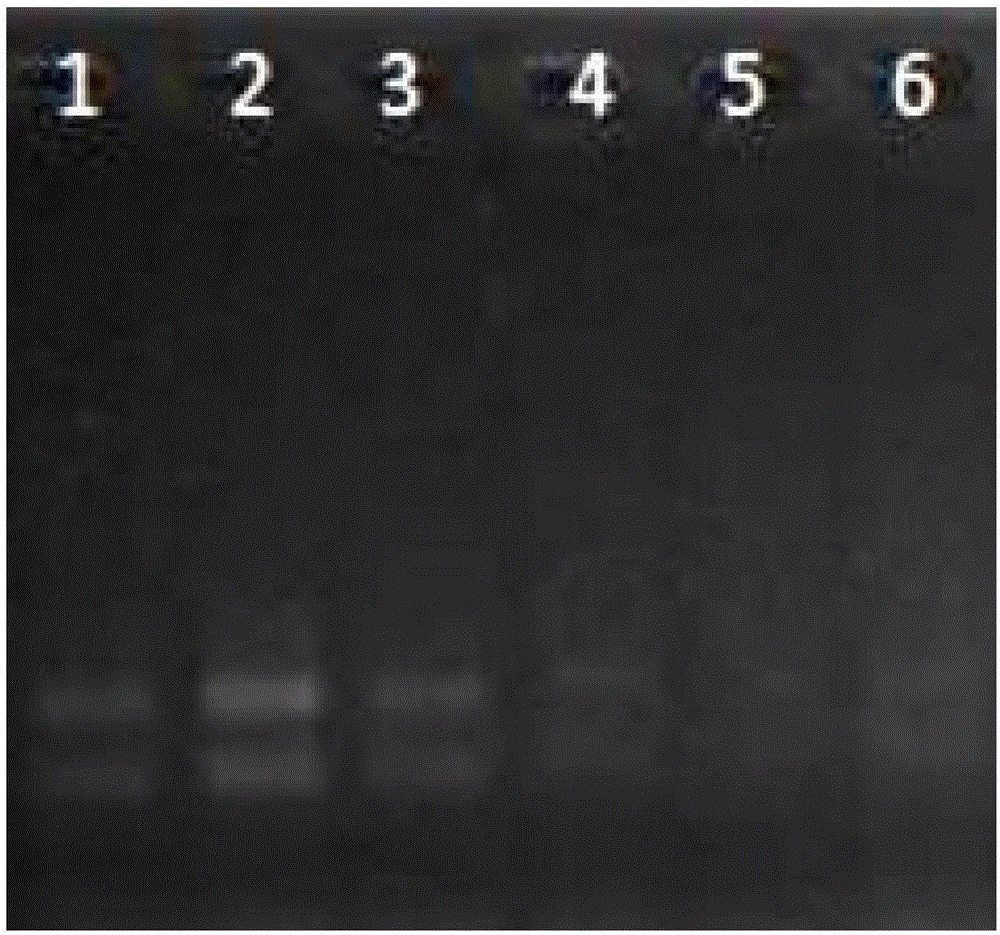

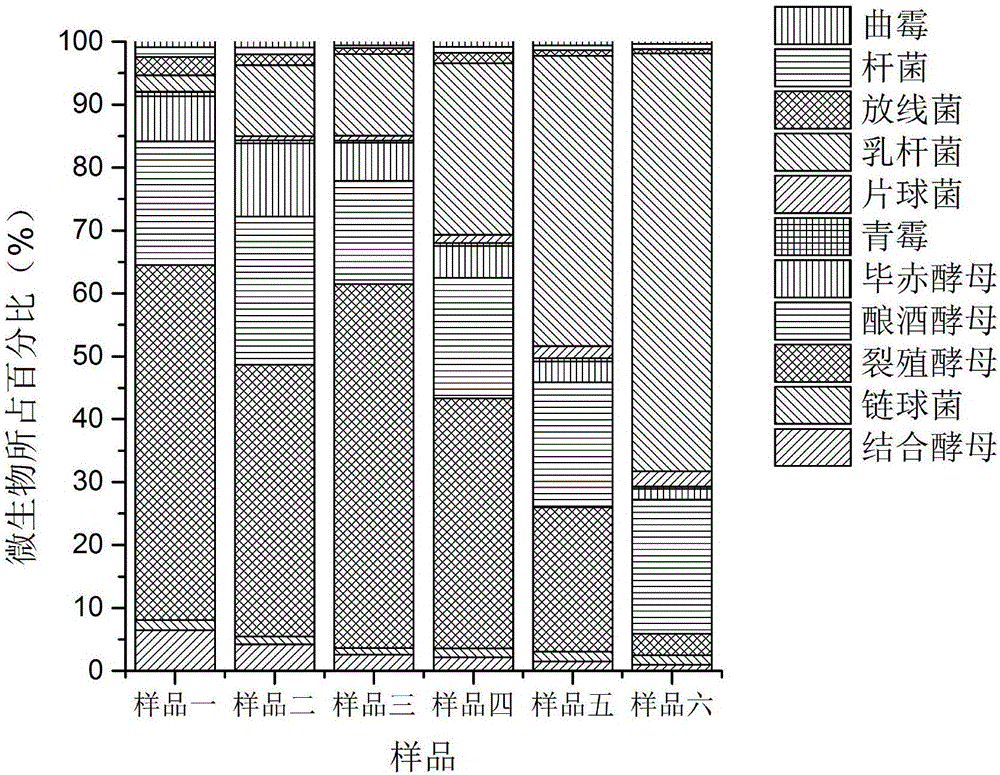

Method for extracting total RNA from fermented grains used for Chinese liquor fermentation

The invention discloses a method for extracting total RNA from fermented grains used for Chinese liquor fermentation, and belongs to the biotechnical field. The total DNA is rapidly extracted from microbial communities in 2h against the particularity of a Chinese liquor fermented grain sample through combining a sodium laurate extraction technology and a guanidinium isothiocyanate-phenol-chloroform extraction technology. The microbial total RNA extracted through using the method has the advantages of high output, good integrity, good purity, and effective extraction of eukaryotic and prokaryotic microbes from the sample.

Owner:JIANGNAN UNIV

Metal surface cleaning agent capable of strongly removing scales and preparation method thereof

The invention discloses a metal surface cleaning agent capable of strongly removing scales. The cleaning agent is characterized by being composed of the following raw materials in parts by weight: 3 to 5 parts of sodium dodecyl sulfate, 2 to 4 parts of N-acyl monosodium glutamate, 4 to 6 parts of illite powder, 1 to 2 parts of zeolite powder, 2 to 4 parts of calcite powder, 0.5 to 1 part of aluminum hydroxide, 3 to 5 parts of triethanolamine, 0.1 to 0.2 part of sodium laurate, 2 to 4 parts of sodium citrate, 1 to 2 parts of calcium citrate, 0.3 to 0.5 part of inositol hexaphosphate, 0.1 to 0.2 part of phosphatidylcholine, 0.1 to 0.2 part of calcium gluconate, 3 to 5 parts of auxiliary agent, and 40 to 50 parts of water. The invention has the function of strongly removing scales, and can effectively remove the water scales and high-temperature oxide scales on the metal surface so as to polish the metal surface. The washing time is short, the washing temperature is low, and the cleaning agent is suitable for scale removing treatment on surfaces of different metal materials and metal workpiece.

Owner:HEFEI DAAN PRINTING

Water-based antirust semisynthesis cutting fluid and preparation method therefor

InactiveCN103710120AImprove the lubrication effectImprove cooling effectLubricant compositionDispersion stabilityWater based

Provided is a water-based antirust semisynthesis cutting fluid. The cutting fluid is prepared from the following raw materials, by weight, 1-2 parts of triethanolamine, 3-4 parts of boric acid ester, 12-14 parts of polyethylene glycol, 3-4 parts of stearic acid, 1-2 parts of 4-methyl salicylic acid, 1-2 parts of 2-aminoethyl heptadecenyl imidazoline, 1-2 parts of triethanolamine, 10-12 parts of white oil, 1-2 parts of sodium laurate, 6-8 parts of auxiliary agents and 200 parts of water. The cutting fluid has good lubricating effect, cooling effect and cleaning effect, has dispersion stability characteristics, has good extreme pressure wear resistance, has excellent anti-oxidation, anti-corrosion and antirust effects, can form a protection film on a metal surface, decreases corrosion and rusting of machine tools, workpieces and cutters, raises the finished product rate, and lowers production cost.

Owner:MAANSHAN HENGYI MACHINERY MFG

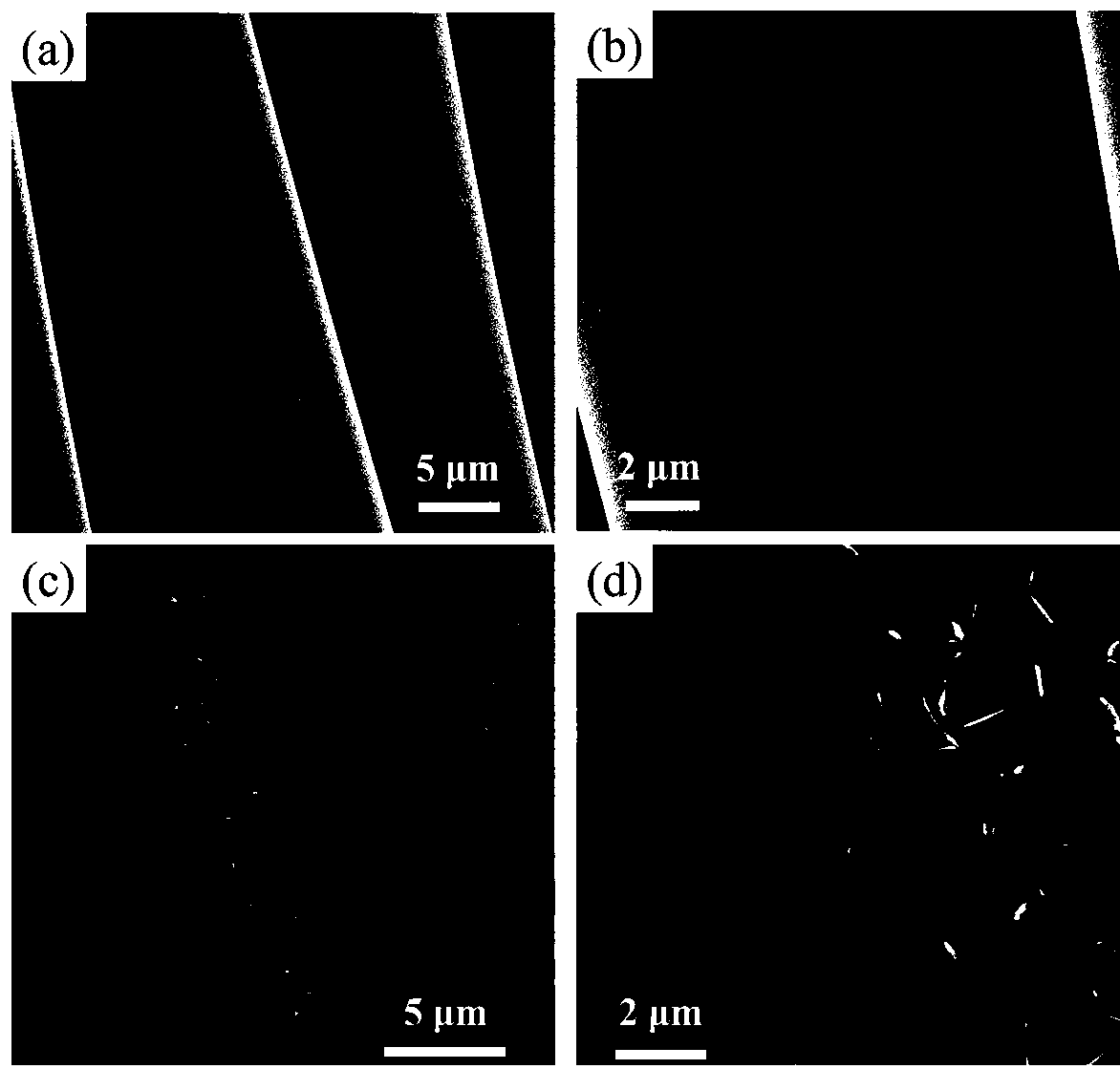

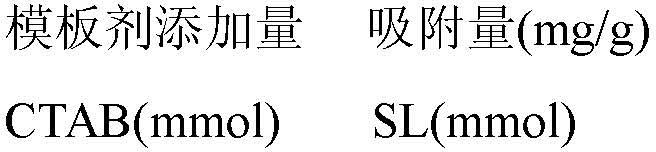

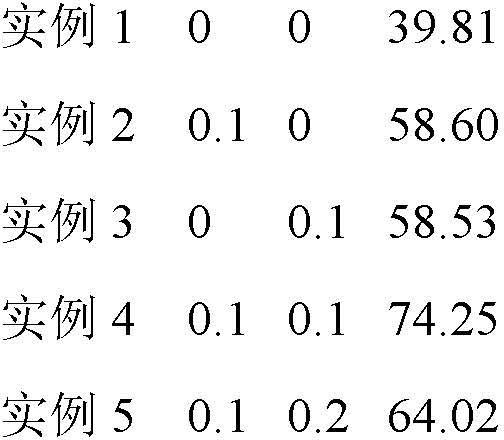

Preparation of modified magnetic zeolite imidazole framework material and adsorption of trace ceftazidime in water

InactiveCN111889077AFlat surfaceUniform sizeOther chemical processesWater contaminantsAdsorption effectMethyl palmoxirate

The invention discloses a preparation method of a pore-channel-modified magnetic zeolite imidazole framework material adsorbent (ZIF-8@SiO2-Fe3O4). According to the method, zinc nitrate hexahydrate isused as a metal source, 2-methylimidazole is used as an organic ligand, methanol is used as a reaction solvent, cetyltrimethylammonium bromide (CTAB) and sodium laurate (SL) are used as template agents, and SiO2@Fe3O4 is used as a magnetic particle. After the template agents are added to adjust a pore diameter, the optimal adsorption pore diameter is 6.27 nm. As the influence of adsorption temperature, the initial pH value of a solution, ion strength and a humic acid concentration on the adsorption effect is taken into consideration, adsorption conditions after optimization are that the adsorption temperature is 294.62 K, the initial pH value is 6.27 and the ion strength is 0.37 g.L<-1>; and under the conditions, optimal adsorption effect is obtained, and the adsorption quantity of a ceftazidime solution reaches 96.84 mg.g<-1>. Repeated regeneration experiments also show that the ZIF-8@SiO2@Fe3O4 has good cyclic utilization, and the utilization rate of the ZIF-8@SiO2@Fe3O4 after fivecycles still reaches 90% or above. The adsorbent is prepared through a room-temperature stirring method, and the template agents are removed through calcination, so the method is simple; and the adsorbent is good in cyclic utilization and can serve as an adsorbent with excellent properties.

Owner:BEIJING UNIV OF CHEM TECH

Novel desizing agent and preparation method thereof

ActiveCN108505318AWith desizing effectImprove desizing effectDry-cleaning apparatus for textilesGrip property fibresEthylhexyl palmitatePotassium

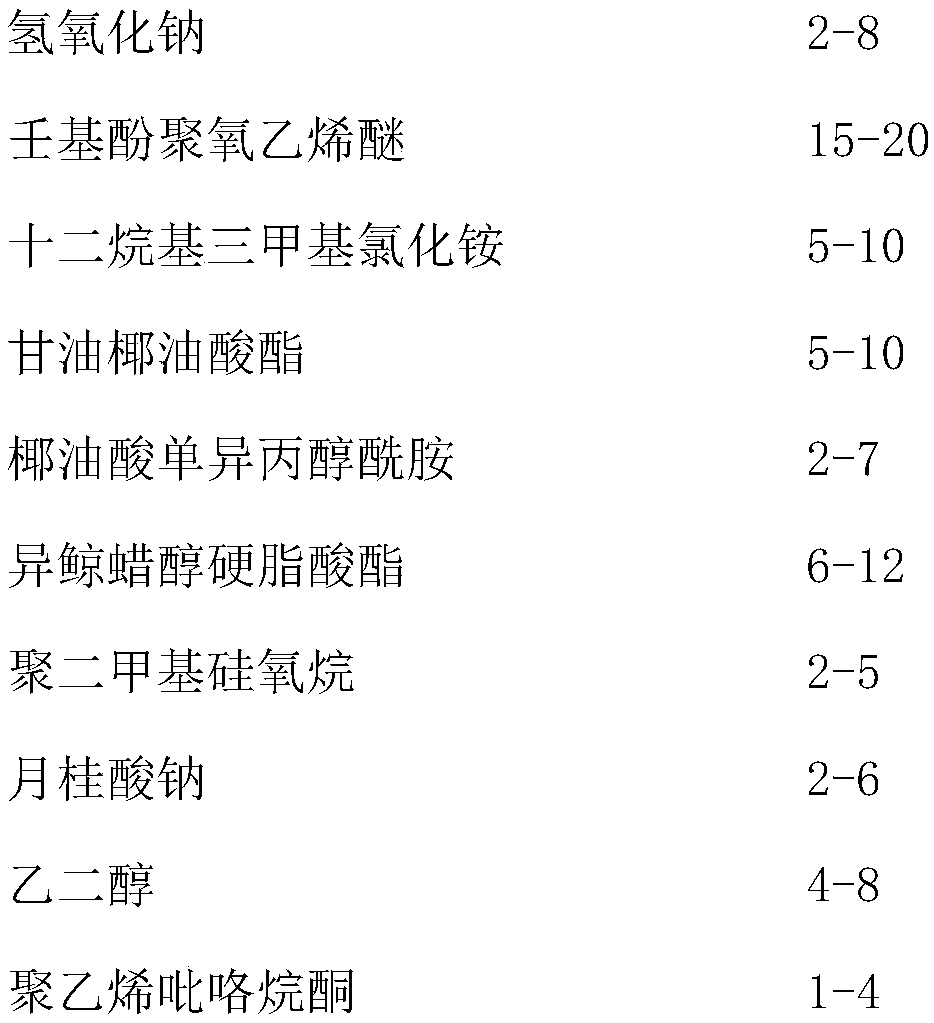

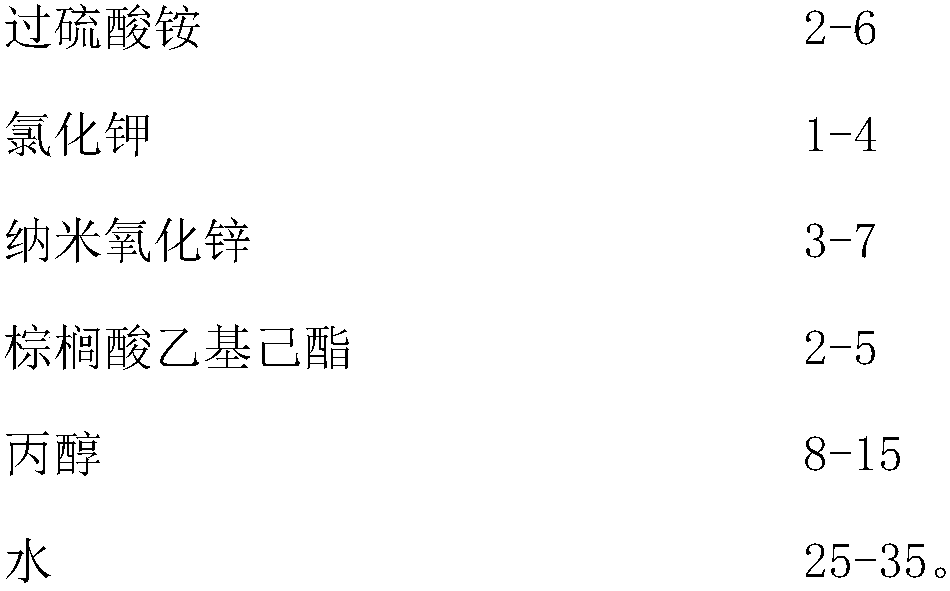

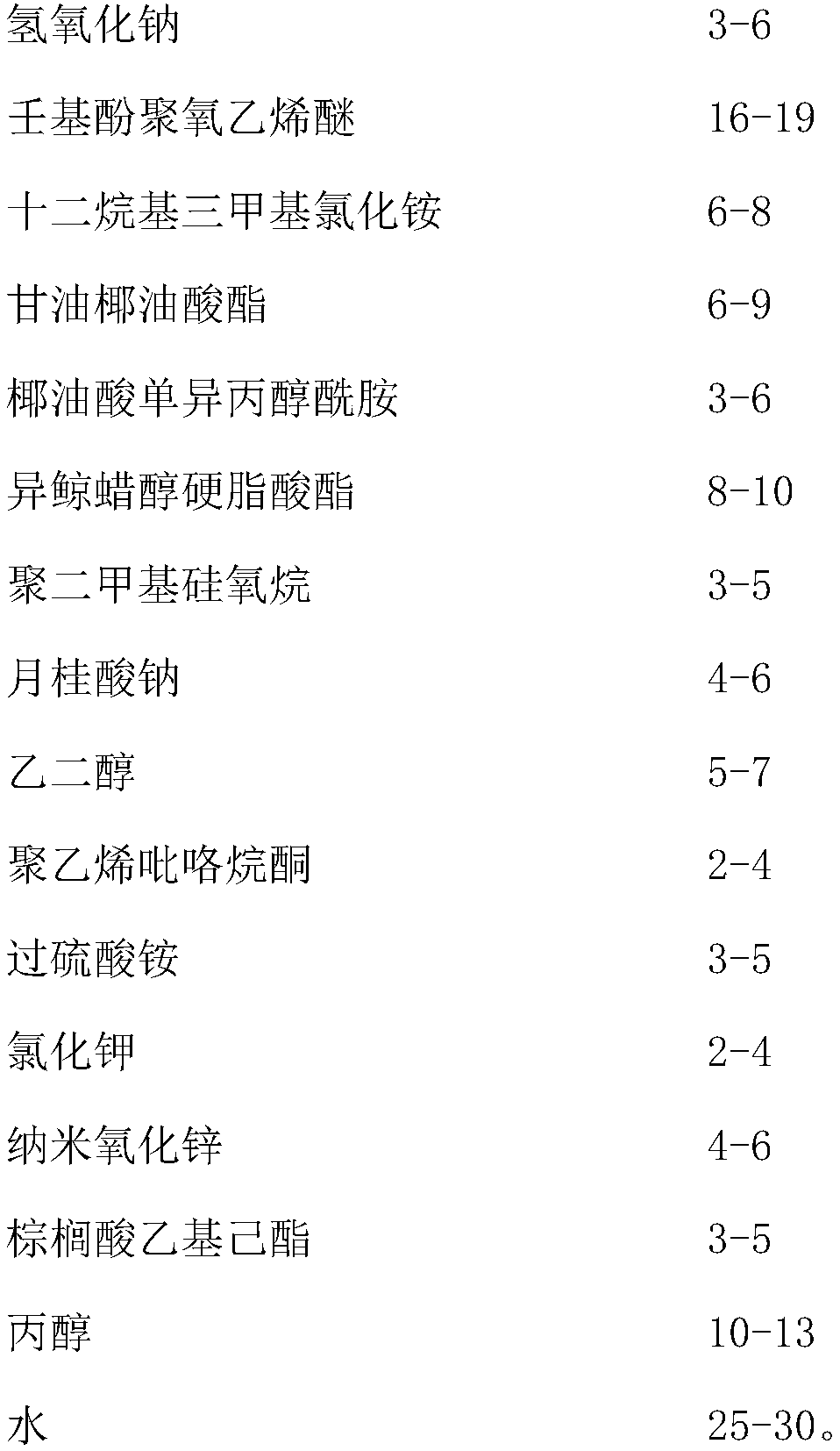

The invention aims at overcoming the defects in the prior art, and provides a desizing agent with the advantages that the desizing effect is good; the damage on fabrics is small; the treated fabrics have a good wool effect, hand feeling and whiteness; in addition, the seepage performance and the dispersion performance are good; the refining effect is achieved. The invention provides the desizing agent, which is prepared from the following ingredients in parts by weight: 2 to 8 parts of sodium hydroxide, 15 to 20 parts of nonylphenol polyoxyethylene ether, 5 to 10 parts of dodecyl trimethyl ammonium chloride, 5 to 10 parts of glyceryl cocoate, 2 to 7 parts of coconut acid monoisopropanolamide, 6 to 12 parts of isocetyl stearate, 1 to 3 parts of polydimethylsiloxane, 2 to 6 parts of sodium laurate, 4 to 8 parts of glycol, 1 to 4 parts of polyvinylpyrrolidone, 2 to 6 parts of ammonium persulfate, 1 to 4 parts of potassium chloride, 1 to 4 parts of nano-zinc oxide, 2 to 5 parts of ethylhexyl palmitate, 8 to 15 parts of propyl alcohol and 25 to 35 parts of water. The desizing rate of the fabrics treated by the desizing agent provided by the invention is 96.1 percent or higher; in addition, the fabrics cannot be damaged.

Owner:多恩生物科技有限公司

Preparation method of nano calcium carbonate for odorless oxime-removed silicone adhesive

ActiveCN108912740AGood dispersionImprove mechanical propertiesPigment treatment with non-polymer organic compoundsDispersitySodium stearate

The invention discloses a preparation method of nano calcium carbonate for an odorless oxime-removed silicone adhesive. The preparation method comprises the following steps: calcining limestone and digesting quick lime and diluting to obtain lime slurry with the solid content of 10 to 13 percent; carrying out carbonization reaction on the lime slurry, so as to obtain nano calcium carbonate suspension; conveying the nano calcium carbonate suspension to a surface treatment device adding a compound surfactant composed of sodium stearate and sodium laurate under a high-speed heating condition; stirring and carrying out surface modification; then adding aluminum silicate and iron oxide and continually stirring for 30 to 90min to finish surface treatment, so as to obtain modified calcium carbonate slurry; dehydrating, drying and crushing the modified calcium carbonate slurry to obtain the product. According to a modification method of the calcium carbonate, the dispersity of the calcium carbonate in the silicone adhesive can be effectively improved, and the nano calcium carbonate also can be used for extremely reducing the release of oxime in a curing process of the filled silicone adhesive under the cooperative effect of physical adsorption of the aluminum silicate and reduction reaction of iron oxide powder, and the odor-removal effect is remarkable.

Owner:ANHUI PROVINCE XUNCHENG CITY HUANA NEW MATERIAL TECH CO LTD

Flame-retardant wear-resisting modified acrylic resin coating

InactiveCN104449136AInhibitionEvenly dispersedFireproof paintsPolyurea/polyurethane coatingsEpoxyAcrylic resin

The invention discloses a flame-retardant wear-resisting modified acrylic resin coating which comprises the following raw materials in parts by weight: 68-71 parts of acrylic resin, 12-15 parts of polyurethane resin, 16-19 parts of aldehyde ketone resin, 7-10 parts of powdery ethylene propylene diene monomer, 6-9 parts of hollow glass beads, 5-7 parts of organic bentonite, 3-5 parts of talcum powder, 7-9 parts of zeolite powder, 12-15 parts of modified yttrium oxide, 5-7 parts of mica powder, 2.5-3 parts of diisononyl phthalate, 5-8 parts of epoxy xanthium sibiricum butyl oleate, 3-6 parts of sodium laurate, 3-5 parts of (1,3-dichloro-2-propyl) phosphotriester, 13-16 parts of nano-magnesium hydroxide, 4-6 parts of antimony trioxide, 8-11 parts of a drying catalyst, 12-15 parts of a pigment, 3-4 parts of a toughening agent, 1.5-2 parts of an antifoaming agent, 2-3 parts of a leveling agent and 1-2 parts of a mould inhibitor. The flame-retardant wear-resisting modified acrylic resin coating has excellent flame retardancy and wear resistance and high curing speed.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

High-strength alkali-resistant brush wires and production process thereof

InactiveCN105544012AGood alkali resistanceExtended service lifeConjugated synthetic polymer artificial filamentsArtifical filament manufactureFiberAntioxidant

The invention discloses high-strength alkali-resistant brush wires and a production process thereof, wherein the high-strength alkali-resistant brush wires are composed of the following raw materials in parts by weight: 40-45 parts of polyurethane, 10-20 parts of trimethyl ammonium methyl sulfate, 10-20 parts of a coupling agent, 30-35 parts of fatty alcohol polyoxyethylene ether, 18-20 parts of sodium laurate, 4-5 parts of phosphoric acid, 2-4 parts of monoethanolamine, 6-8 parts of a glass fiber, 3-5 parts of organic alcohol amine, 2-4 parts of azodiisobutyronitrile, 6-8 parts of amino-2-methyl-1-propanol, 12-15 parts of silica, 1-4 parts of polyethylene glycol 4000, 1-3 parts of an accelerator, 10-20 parts of a curing agent, 5-8 parts of an alkali absorption agent, and 2-3 parts of an antioxidant. Compared with the prior art, the alkali absorption agent and the antioxidant are added into abrasive wires, so that the alkali resistance of the abrasive wires and the service life of the abrasive wires in a strong alkali environment are greatly improved. At the same time, the production process is simple, special processing is not required, and the processing cost is low.

Owner:安徽天瑞塑业股份有限公司

Starch binder

InactiveCN103102827AImprove performanceAvoid damageNon-macromolecular adhesive additivesStarch adhesivesSodium bicarbonatePolyethylene glycol

The invention discloses a starch binder consisting of the following raw materials: lignosulfonate, styrene, nano diatomite, epoxidized soybean oil, acrylic ester, acrylic acid, sodium persulfate, sodium allyloxy hydroxypropyl sulphonate, starch, sodium hydroxide, borax, modified wood ash, and water; as well as water-soluble nanoscale silica sol, ammonium polyacrylate, polyethylene glycol, zinc powder, waterborne polyurethane, sodium laurate, sodium bicarbonate and water. The starch binder is stable in quality, strong in binding power, good in tensile force, fast to dry without foaming, and capable of comprehensively improving all properties of a corrugated carton; as the modified wood ash is added, the damage of water molecules to the binder is effectively decreased, and the water resisting property of the binder is greatly increased; and as the hydrophilic performance of the binder is decreased, the binder has a good characteristic of being fast to dry, thereby being beneficial to use on a high-speed production line of the corrugated carton.

Owner:TONGLING SONGMA FOOD PACKAGE MACHINERY MFG

Papermaking auxiliary agent mixture

InactiveCN104695258AEasy to manufactureImprove stabilityCellulose material pulpingQuinoneAlkylphenol

The invention discloses a papermaking auxiliary agent mixture. The papermaking auxiliary agent mixture is composed of following raw materials, by mass, 100 to 200 parts of terphenyl quinone, 100 to 200 parts of isopentene naphthoquinone, 100 to 200 parts of anthranol, 100 to 200 parts of anthracene cyclic ketone, 20 to 50 parts of octaphenyl polyoxyethyiene, 20 to 50 parts of bisphenol A polyethenoxy ether, 20 to 50 parts of polyoxyethylene lauryl ether, 20 to 50 parts of alkylphenol polyoxyethylene, 50 to 80 parts of calcium dodecyl benzene sulfonate, 50 to 80 parts of sodium tripolyphosphate, 50 to 80 parts of sodium laurate, 10 to 20 parts of organosilicon waterproofing agent, and 10 to 20 parts of a stabilizing agent. The papermaking auxiliary agent mixture is convenient to prepare, is high in stability, is nontoxic, possesses no corrosivity, is easy to store, is convenient to be mixed with alkali liquor uniformly, and is low in foamability. The papermaking auxiliary agent mixture can be uniformly mixed with alkali liquor; boiling time is shorter than that of conventional auxiliary agents; yield is higher; slurry uniformity is higher; foam generated in production processes is less; and operation is convenient.

Owner:郑辉安

High-efficiency cleaning agent for down feathers

InactiveCN108034528AStay flexibleGuaranteed volumeInorganic/elemental detergent compounding agentsAmpholytes/electroneutral surface-active compoundsPelargonium x hortorumBetaine

The invention relates to the technical field of down feather processing, and in particular relates to a high-efficiency cleaning agent for down feathers. The high-efficiency cleaning agent for the down feathers provided by the invention comprises the following raw materials in parts by weight: 12-15 parts of an LAS-ammonium salt, 6-12 parts of fatty alcohol polyoxyethylene ether, 6-10 parts of pelargonium hortorum, 6-10 parts of ethyl acetate, 3-7 parts of sodium dodecyl benzene sulfonate, 3-7 parts of citric acid, 4-8 parts of sophorolipid, 2-4 parts of trichloro ethylene, 4-6 parts of betaine, 2-3 parts of sodium laurate, 8-12 parts of citric acid thatch, 4-8 parts of cinnamomum porrectum leaves, 2-6 parts of cassia twig, 2-4 parts of gleditsia sinensis fruits, and 6-10 parts of a defoaming agent. The high-efficiency cleaning agent for the down feathers provided by the invention has good cleaning effects and thorough odor removal, does not damage the down feathers while cleaning andremoving odor, and can reduce breeding of bacteria after the down feathers are cleaned.

Owner:安徽羽洁家纺有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com