Patents

Literature

102results about How to "Good dispersion and suspension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High performance alkali swelling thickener and preparation method thereof

InactiveCN103204968AGood value for moneySmall smellCosmetic preparationsToilet preparationsFunctional monomerWell drilling

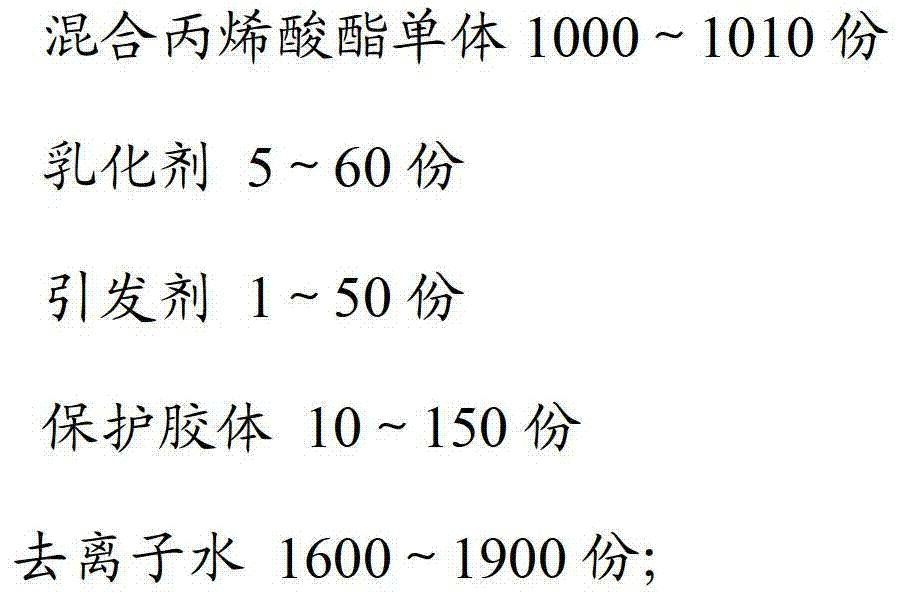

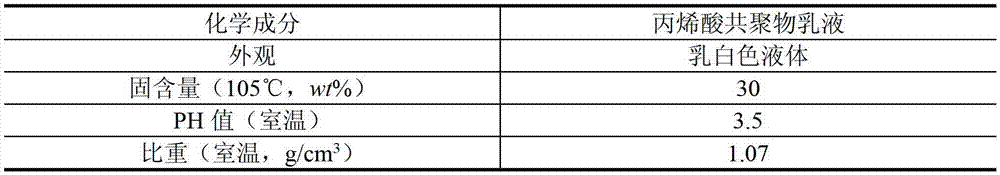

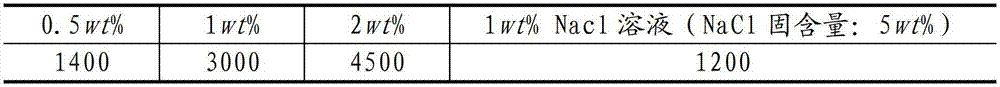

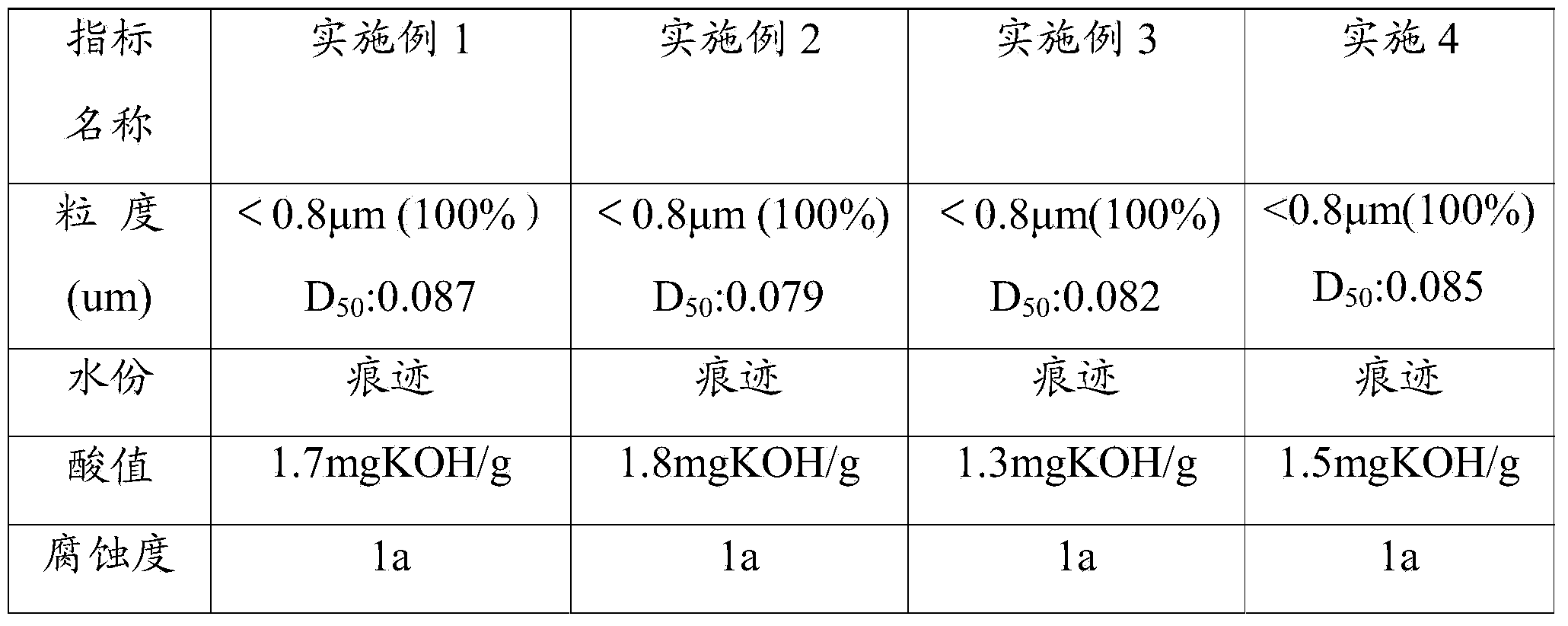

The invention discloses a high performance alkali swelling thickener which is characterized by comprising the components in parts by weight as follows: 1000-1010 parts of mixed acrylate monomer, 5-60 parts of emulsifier, 1-50 parts of initiator, 10-150 parts of protective colloid and 1600-1900 parts of deionized water. The mixed acrylate monomer is a mixture of soft monomer, a hard monomer and a crosslinking functional monomer. The invention further discloses a preparation method of the high performance alkali swelling thickener. The high performance alkali swelling thickener provided by the invention has the advantages of high swelling performance, high viscosity and high transparency, and is high temperature and low temperature resisting. The thickener is not only suitable for daily cosmetic and home nursing products and bonders, but also suitable for the field of well drilling in oil fields.

Owner:ZHONGSHAN POLYTECHNIC

Graphene-containing frictional regulator and preparation method thereof

ActiveCN104342236AImprove thermal conductivityImprove the lubrication effectAdditivesColloidOil phase

The invention discloses a graphene-containing frictional regulator and a preparation method thereof. The graphene-containing frictional regulator comprises the following components in percentage by mass: 0.3-1.2% of nano graphene, 3-8% of nano graphite particles, 1-6% of polymer protective colloid, 0.5-5% of dispersing agent, and the balance of base oil. Through the frictional regulator, the lubrication between metal pieces on the surface of a friction pair can be greatly promoted, and the wear is reduced; the anti-wear, lubrication, remediation and sealing properties can be increased to form synergistic effect, antiwear and lubrication effects of an engine on the severe wear when the engine is in cold starting can be enhanced, and the service life of the engine can be prolonged. The system has excellent dispersion and suspension properties as well as has no precipitation through an oil phase dispersion technology, and the frictional regulator is stable in the performances of the colloid.

Owner:GUANGDONG DONGGUAN TEAMRUN ELECTRONICS MATERIAL

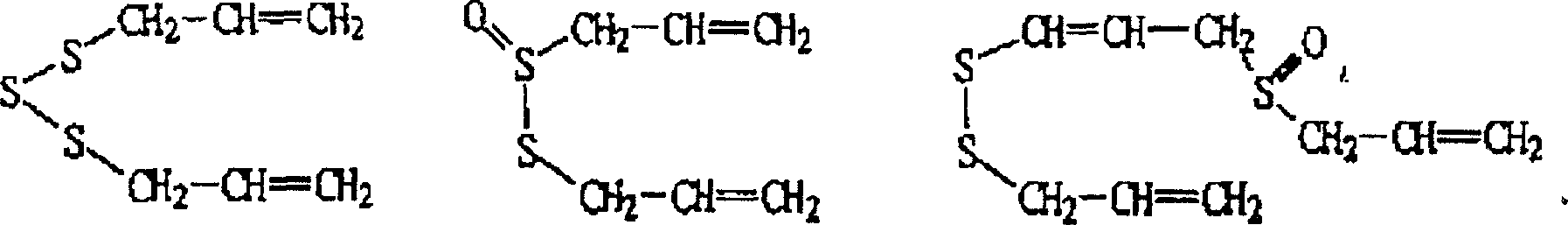

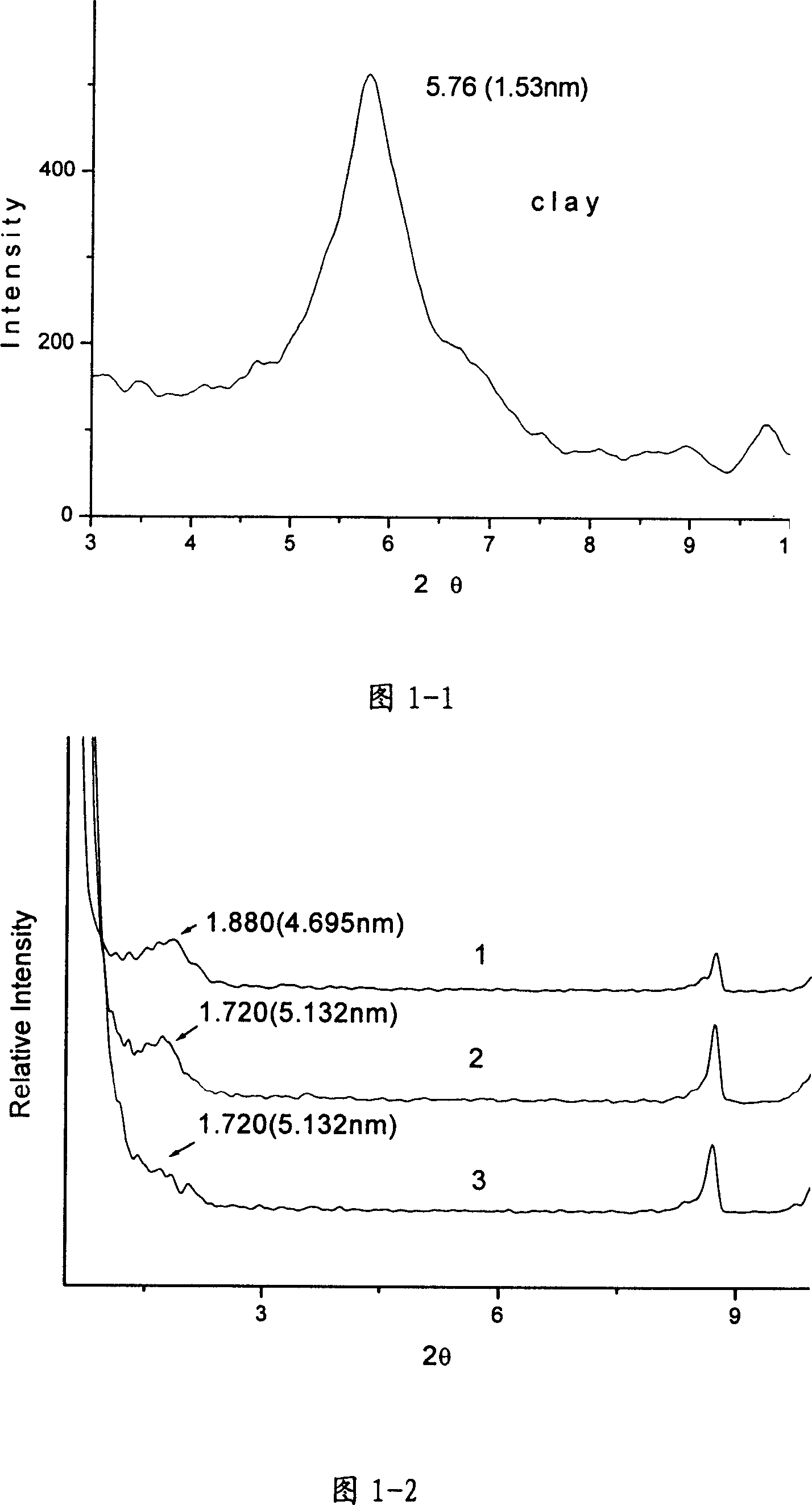

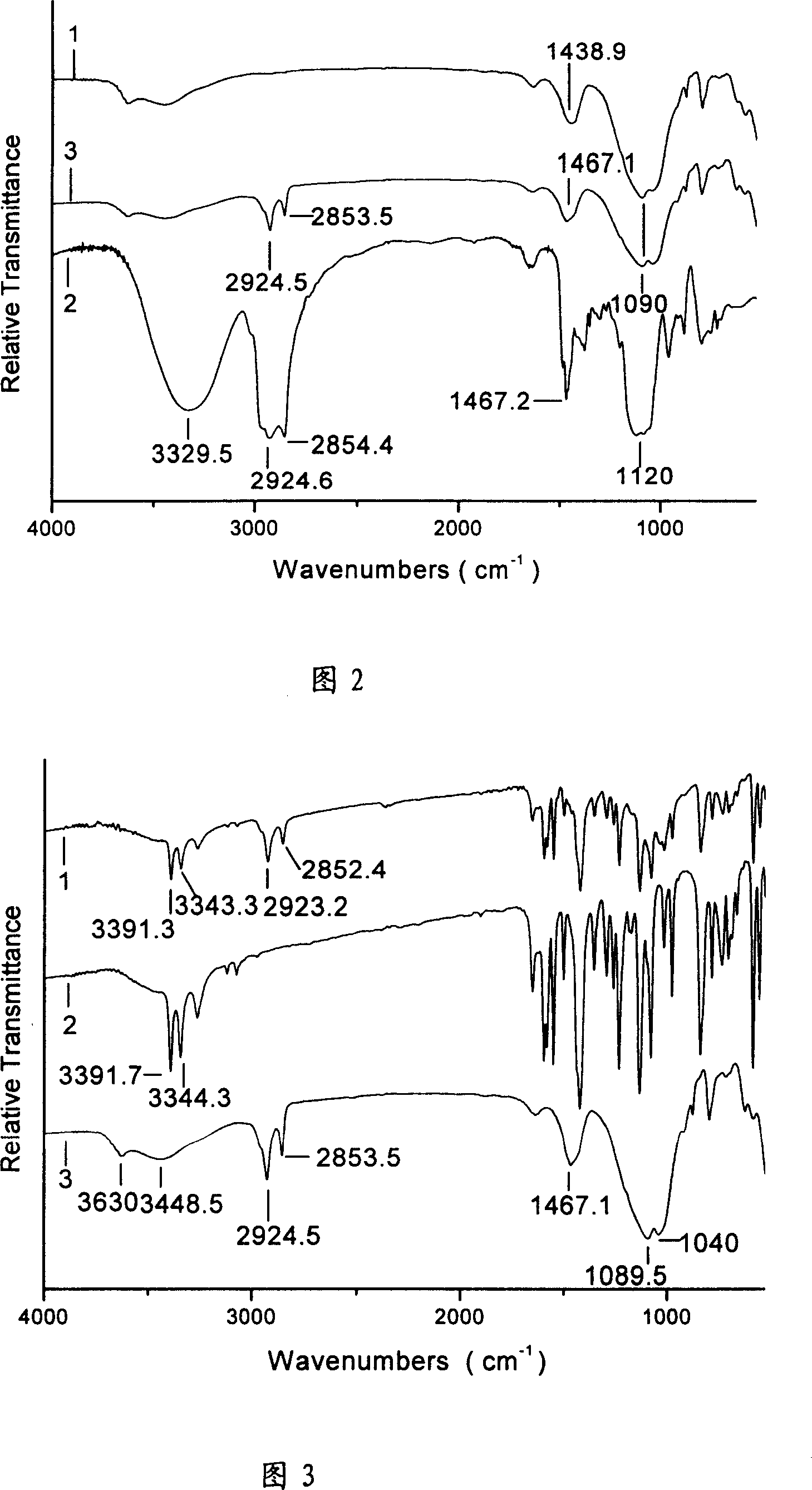

Polymer/montmorillonite-gallicin nano-antibacterial composite material and its preparation method

InactiveCN1948394AGood sustained release effectImprove antibacterial propertiesBiocideAnimal repellantsPolymer sciencePolyolefin

This invention is a polymer / montmorillonite-garlicin nanometer antibiosis composite. Its raw materials and weight amount is that polymer 100, montmorillonite-garlicin 0.1-10, disperse medium 0-400, cross linking agent, accelerator 0-1. The polymer is composed by silicone rubber gum which is chosen from methylsilicone, pyro-methylsilicone and additive type methylsilicone, polyurethane which is chosen from PE, PVC and PP, or the polymer of two compounds. The functional intercalator of montmorillonite-garlicin is garlicin. The invention slows down the release of garlicin, so it can extend its antibiosis function outstandingly with its good slow-release nature. Except the preparation of high performance montmorillonite-garlicin materials, it can also boost the mechanic function, heat resistance, mediator resistance of the polymer basal body.

Owner:NANJING NORMAL UNIVERSITY

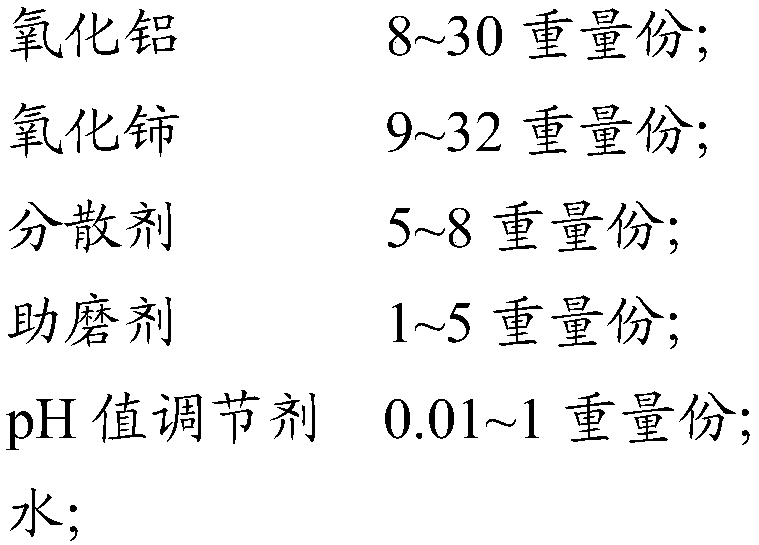

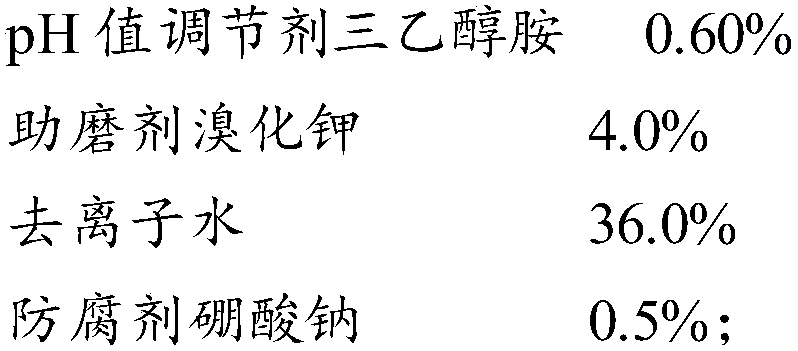

Polishing solution for glass and preparation method of polishing solution

ActiveCN109135580AGood dispersion and suspensionGood suspensionPolishing compositions with abrasivesIonChemistry

The invention provides a polishing solution for glass. The polishing solution is prepared from 8 to 30 parts by weight of aluminum oxide, 9 to 32 parts by weight of cerium oxide, 5 to 8 parts by weight of dispersing agent, 1 to 5 parts by weight of grinding aid, 0.01 to 1 part by weight of pH modifier and proper amount of water. The water enables the total amount of the polishing solution to be 100 weight parts. The particle size of the aluminum oxide is 100 to 500 nm and the particle size of the cerium oxide is 600 to 1200 nm. Compared with the prior art, the polishing solution disclosed by the invention has the advantages that the cerium oxide and the aluminum oxide are compounded to serve as an abrasive; the aluminum oxide can effectively improve the polishing rate; the cerium oxide canreduce the surface roughness of machining parts and improve the strength of the glass; meanwhile, elements such as F and O in the dispersing agent can be complexed with metal ions in abrasive particles, so that the suspension property of the polishing solution is improved; by combined action of all the components, the polishing solution has better polishing efficiency as well as better suspensiondispersion and high stability; the polished product has the advantages of high strength, low roughness and higher apparent yield.

Owner:LENS TECH CHANGSHA

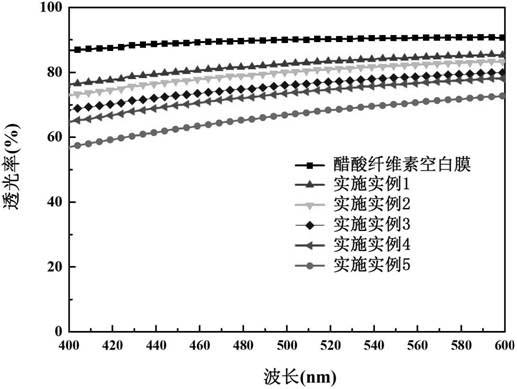

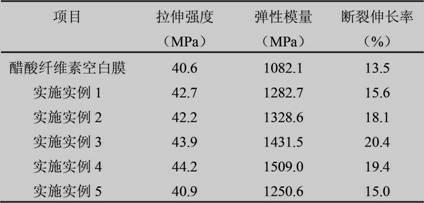

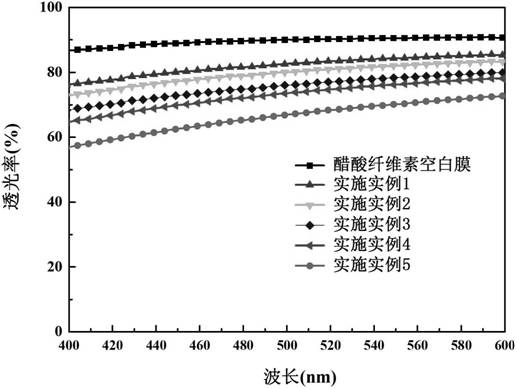

Method for improving mechanical property of cellulose acetate

ActiveCN102660050AImprove mechanical propertiesGood dispersion and suspensionComposite filmAcetic anhydride

The invention relates to a method for improving the mechanical property of cellulose acetate and belongs to the field of preparation and application of high polymer materials. The method comprises the following specific steps of: preparing nano cellulose whisker slurry; uniformly mixing slurry B and glacial acetic acid to obtain slurry C; adding a mixed solution of sulfuric acid, acetic anhydride and the glacial acetic acid into the cooled slurry C to obtain a mixed solution D; stirring the mixed solution D at room temperature, slowly heating to 35 to 55 DEG C, and reacting at the temperature of between 35 and 55 DEG C to obtain reactant E; cooling the reactant E to room temperature, and washing slurry at the bottom by using ethanol and acetone sequentially, and performing suction-filtering to obtain a filter cake F; placing the filter cake F in acetone and performing ultrasonic dispersion to obtain acetic acid esterification nano cellulose suspension G which can suspend stably in acetone; and dissolving cellulose acetate in the suspension G and casting to form a cellulose acetate composite film. According to the method, on the premise of not reducing the light transmittance of the cellulose acetate obviously, the tensile strength, the elastic modulus and the breaking elongation of the cellulose acetate are improved comprehensively.

Owner:山东赫达集团股份有限公司

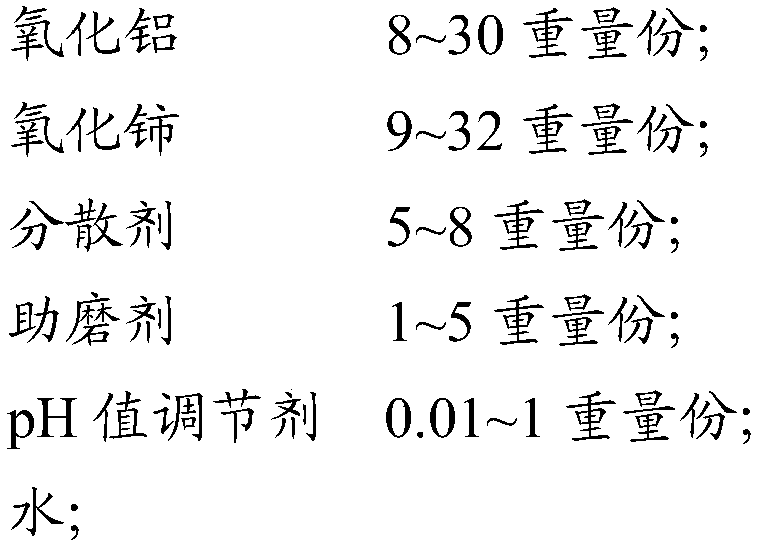

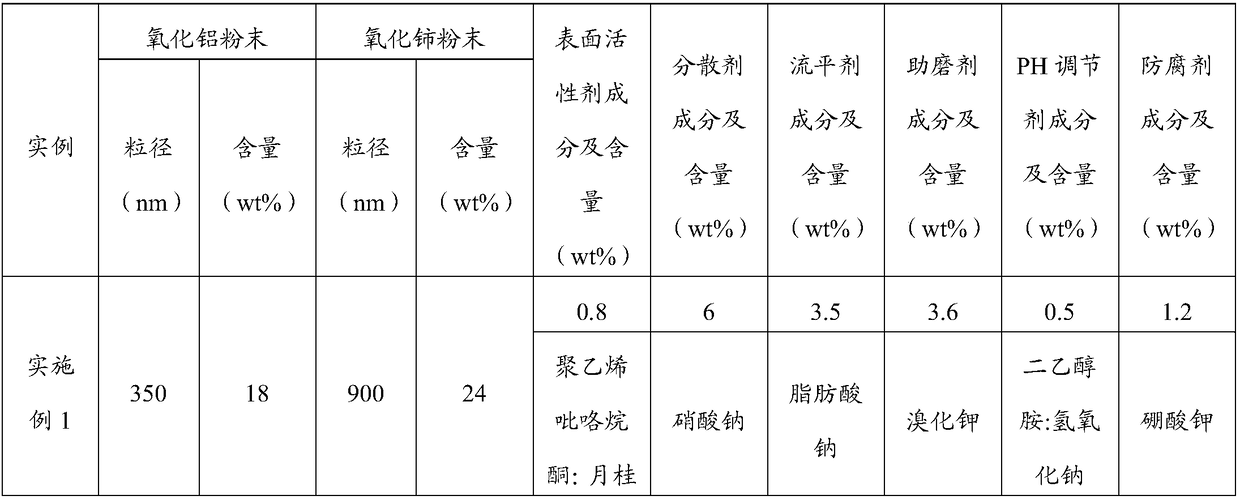

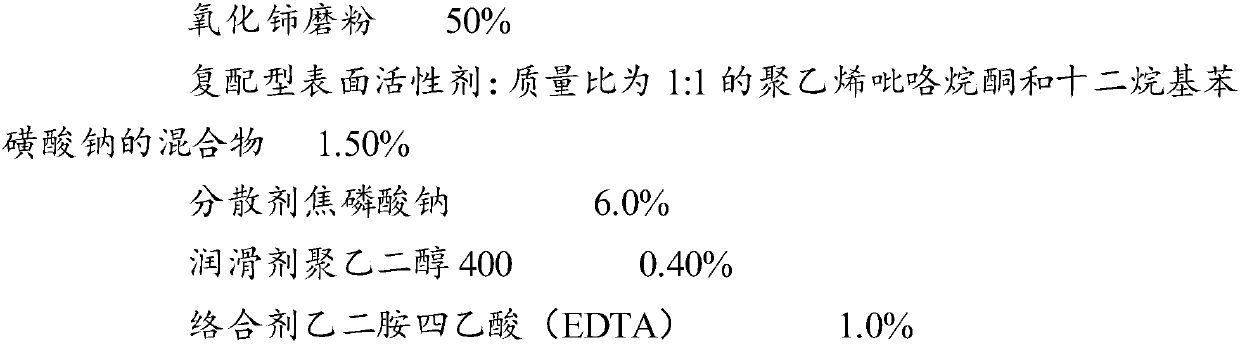

Water-based cerium oxide polishing solution for polishing glass, and preparation method thereof

InactiveCN109929460AGood dispersion and suspensionImprove yieldPolishing compositions with abrasivesWater basedSodium stearate

The invention provides a water-based cerium oxide polishing solution for polishing glass, and a preparation method thereof. The polishing solution comprises 20-55% of ground cerium oxide, 0.1-3% of acompound surfactant, 1-8% of a dispersant, 0.1-2% of a lubricant, 0.01-3% of a complexing agent, 0.01-5% of a grinding aid, 0.01-1% of a pH regulator, 0.01-2% of a preservative, and the balance of water, wherein the compound surfactant is a compound of a nonionic surfactant and an anionic surfactant; the nonionic surfactant is one or more of polyvinylpyrrolidone, alkylphenol polyoxyethylene ether,fatty alcohol polyoxyethylene ether and fatty acid glyceride; the anionic surfactant is one or more of sodium dodecylbenzenesulfonate, sodium laurate, sodium stearate and sodium succinate; and the dispersant is one or more of sodium oxalate, sodium hexametaphosphate, sodium pyrophosphate, sodium nitrate, sodium polyacrylate and sodium lauryl sulfate. The polishing solution has a good suspending dispersibility, and products polished with the polishing solution have a high yield.

Owner:LENS TECH CHANGSHA

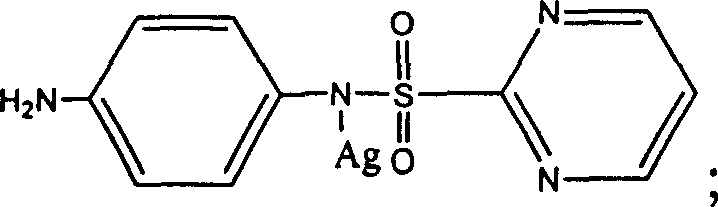

Polymer/ montorillonite clay- organosilicon antibacterial agent -sulfadiazine silver nano antibacterial composite material and its preparation method

InactiveCN1970634AAntimicrobial boostImprove performanceBiocideDisinfectantsDielectricPolymer science

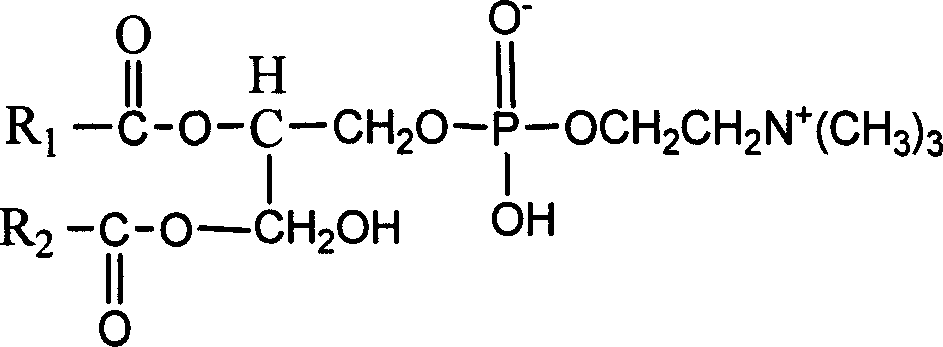

The invention discloses a nanometer antibiotic composite material of polymer / montmorillonite-soya bean lecithin-silvadene, which comprises the following parts: 100g polymer, 0.1-10g montmorillonite-soya bean lecithin-silvadene composition, 0-400g dispersing dielectric, 0-10g crosslinking agent and 0-1g accelerant, wherein the polymer is composed of raw rubber of silicon rubber, polyurethane or two copolymer or polyolefin material; the raw rubber of silicon rubber is selected from indoor-temperature silicon rubber, high-temperature silicon rubber, addition-typed silicon rubber; the polyolefin material can be PE, PVC, PP; the ion exchange content of montmorillonite is 70-120mmol / 100g.

Owner:NANJING NORMAL UNIVERSITY

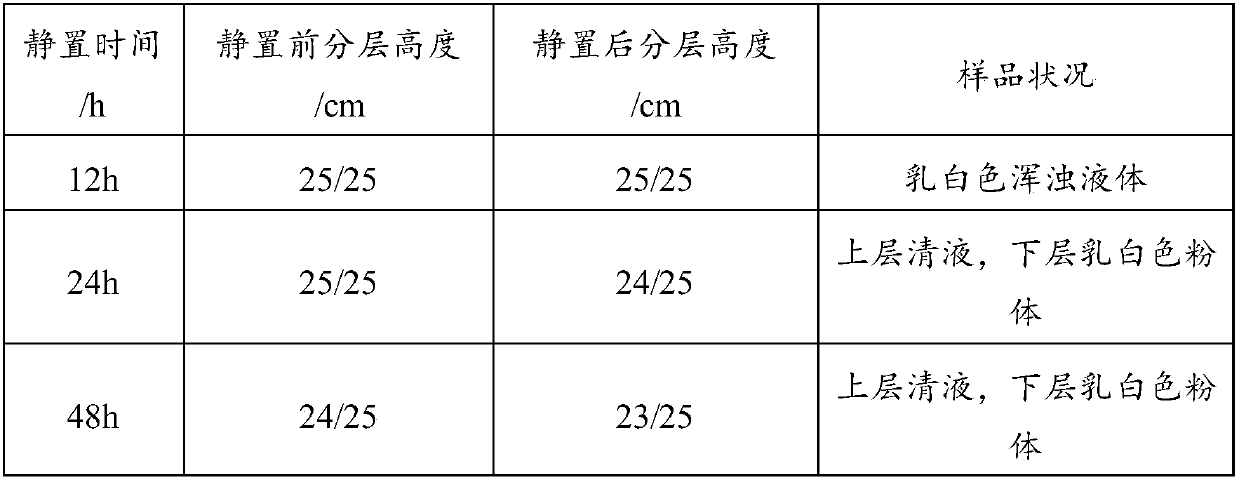

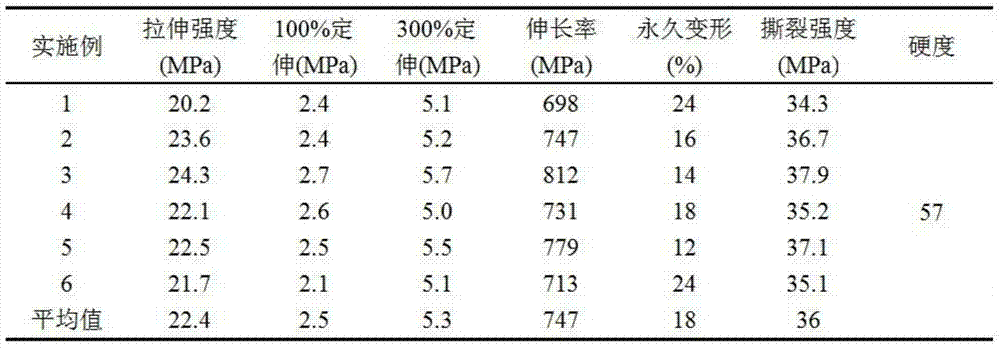

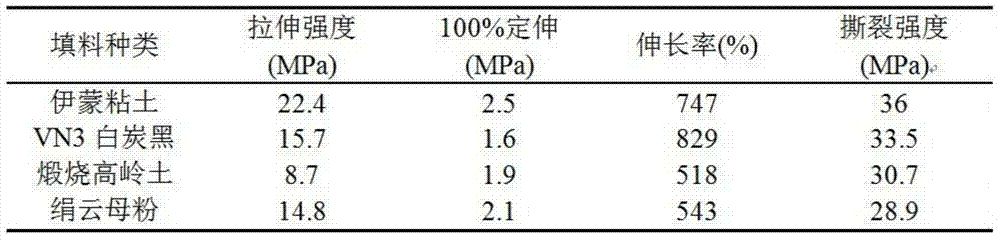

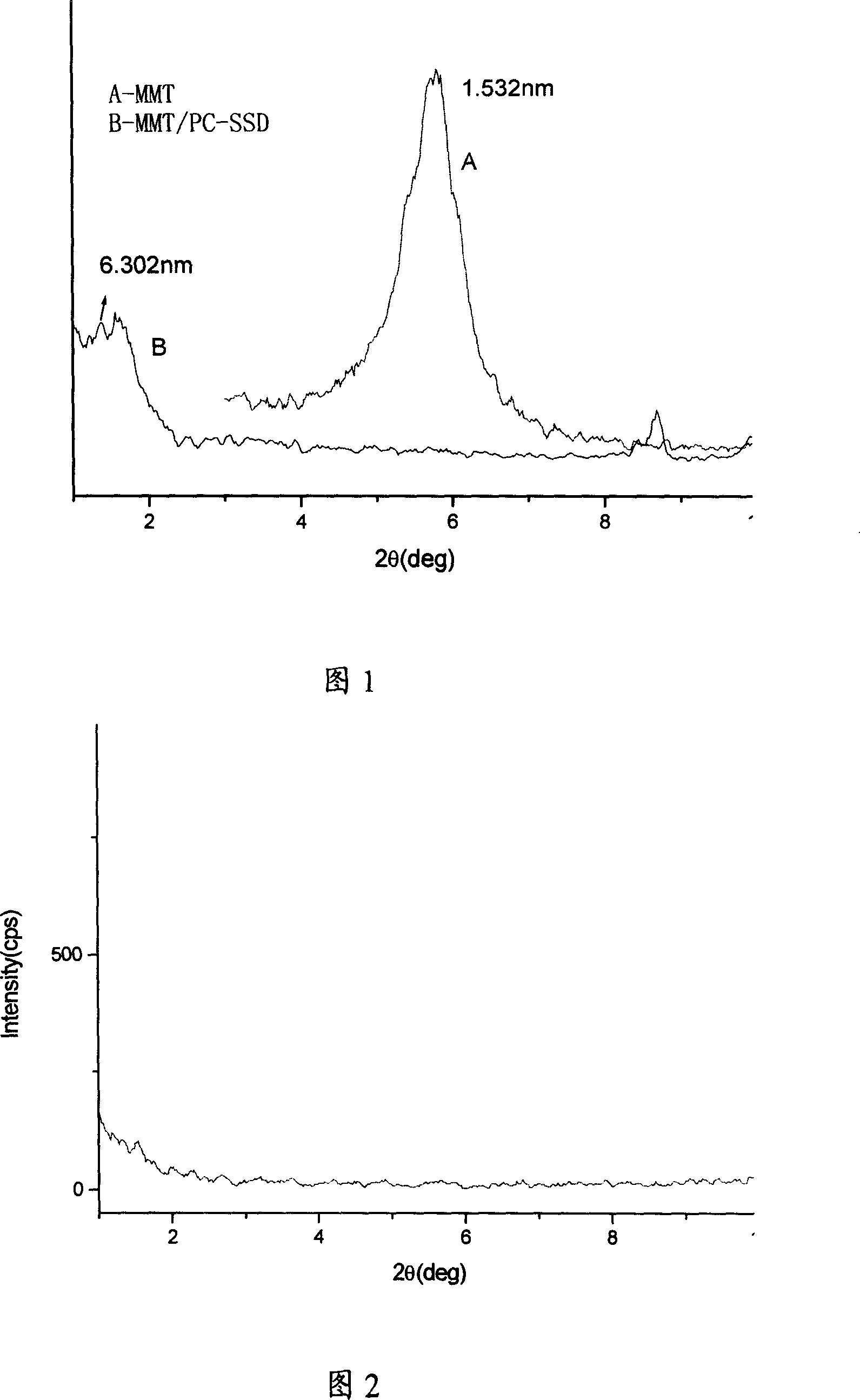

Preparation method of illite/montmorillonite mixed-layer clay/natural rubber compounded rubber

The invention discloses a preparation method of illite / montmorillonite mixed-layer clay / natural rubber compounded rubber and belongs to the technical field of the performance improvement of the compounded rubber. The preparation method comprises the following steps: (1) breaking, dispersing and sieving natural illite / montmorillonite mixed-layer clay so as to obtain slurry; (2) chemically bleaching the slurry; (3) grinding the bleached slurry so as to obtain nanometer slurry; (4) mixing natural latex and water so as to obtain natural latex turbid liquid; (5) mixing the nanometer slurry and the natural latex turbid liquid so as to obtain illite / montmorillonite mixed-layer clay / natural rubber turbid liquid; (6) flocculating the illite / montmorillonite mixed-layer clay / natural rubber turbid liquid and pelleting so as to obtain illite / montmorillonite mixed-layer clay / natural rubber compounded colloidal particles; and (7) drying the colloidal particles so as to obtain the illite / montmorillonite mixed-layer clay / natural rubber compounded rubber. The preparation method is simple in technological process; the production cost is reduced; the emission of dust is reduced; and the illite / montmorillonite mixed-layer clay / natural rubber compounded rubber prepared by the method has relatively strong mechanical property.

Owner:中科纳达新材料(广西)有限公司

Polymer/ montorillonite clay- soy bean lecithin-sulfadiazine silver nano antibacterial composite material and its preparation method

InactiveCN1970633AImprove antibacterial propertiesImprove mechanical propertiesBiocideDisinfectantsChemistryLecithin

The invention discloses a nanometer antibiotic composite material of polymer / montmorillonite-soya bean lecithin-silvadene, which comprises the following parts: 100g polymer, 0.1-10g montmorillonite-soya bean lecithin-silvadene composition, 0-400g dispersing dielectric, 0-10g crosslinking agent and 0-1g accelerant, wherein the polymer is composed of raw rubber of silicon rubber, polyurethane or two copolymer or polyolefin material; the raw rubber of silicon rubber is selected from indoor-temperature silicon rubber, high-temperature silicon rubber, addition-typed silicon rubber; the polyolefin material can be PE, PVC, PP. The invention improves stretching strength by 370%, which increases fracture extending rate by 480%.

Owner:NANJING NORMAL UNIVERSITY

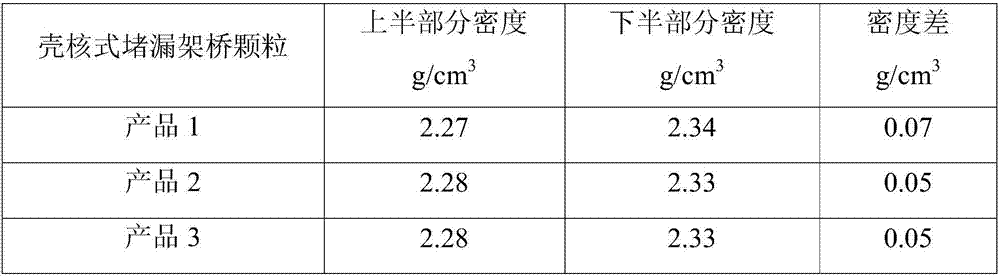

Core-shell type oil-based drilling fluid plugging and bridging particle and preparation method thereof

The invention discloses a core-shell type oil-based drilling fluid plugging and bridging particle and a preparation method thereof. The bridging particle adopts a core-shell structure particle formedby coating an oleophilic polymer layer on the surface of calcium carbonate particles, wherein the oleophilic polymer is a macromolecular copolymer of butyl acrylate, styrene and octadecyl methacrylate. According to the core-shell type oil-based drilling fluid plugging and bridging particle, an oleophilic polymer film layer is attached onto the surface of the original plugging and bridging particle, so that embrittlement of the original plugging and bridging particle is reduced, the pressure-bearing capacity of the original plugging and bridging particle in drilling fluid plugging slurry reaches 5MPa or higher, the density of the original plugging and bridging particle is reduced, the suspension property of the particle in the oil-based drilling fluid is increased, and by enhancing lipophilic property of the original plugging and bridging particle, the aims of improving the suspension dispersity of the plugging and bridging particle in the oil-based drilling fluid and improving the pressure-bearing ability of the whole oil-based drilling fluid plugging formula are achieved. In addition, the bridging particle is simple and feasible in preparation method and has excellent market popularization value.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

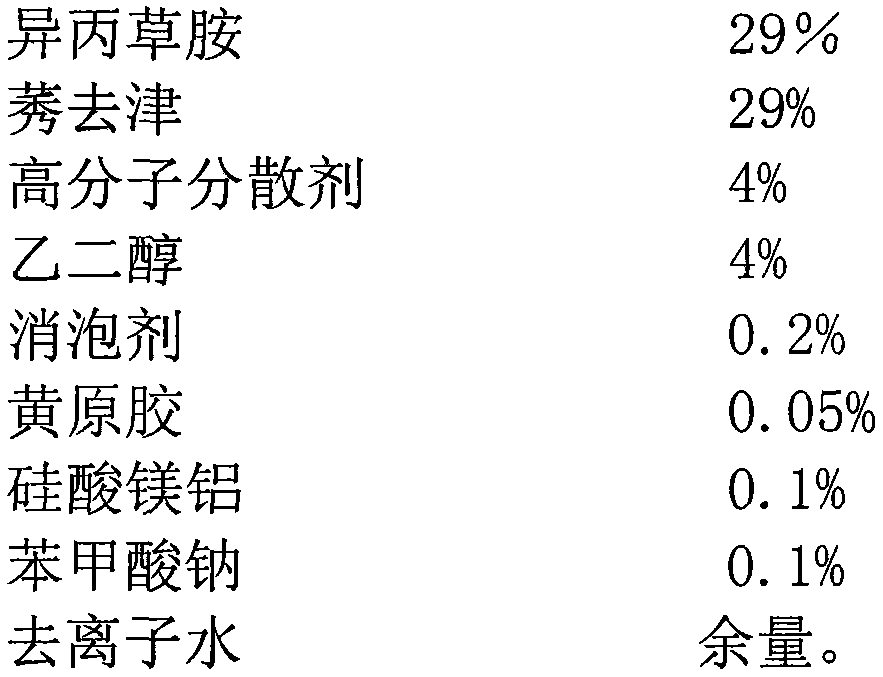

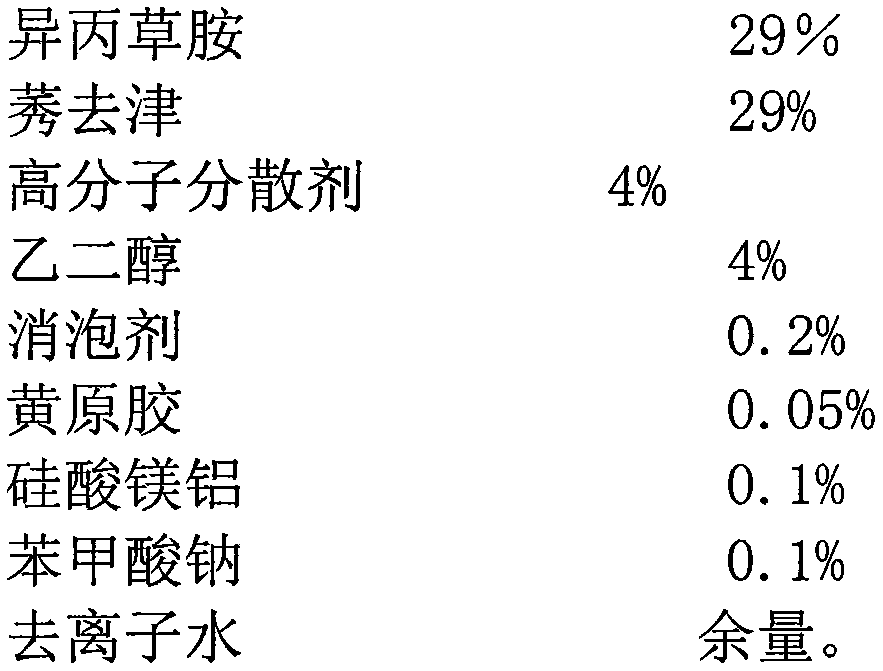

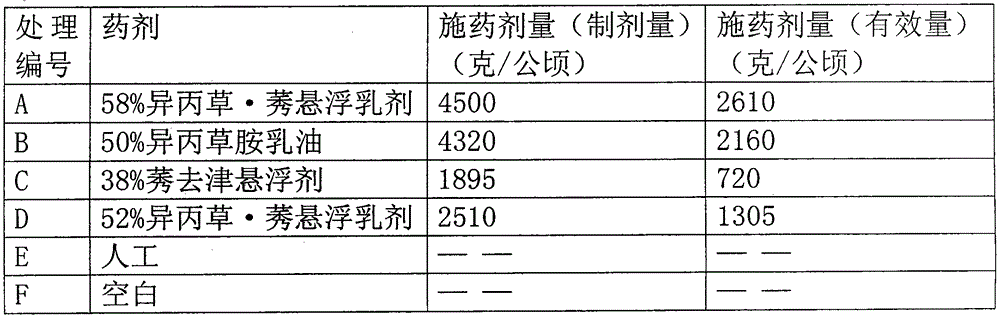

Herbicide composition containing propisochlor and atrazine and preparation method thereof

InactiveCN104982431AIncrease contentImprove weed control effectBiocideAnimal repellantsSodium benzoateXanthan gum

The invention provides a polymeric dispersant which comprises a block polymer of methyl methacrylate, butyl acrylate and acrylamide. A herbicide composition which is prepared from the polymeric dispersant and contains propisochlor and atrazine and a preparation method thereof are provided. The herbicide composition comprises, by weight, 29% of the propisochlor, 29% of the atrazine, 4% of the polymeric dispersant, 4% of ethanediol, 0.2% of defoamer, 0.05% of xanthan gum, 0.1% of aluminium-magnesium silicate, 0.1% of sodium benzoate and the balance deionized water. The herbicide composition containing the propisochlor and the atrazine and the preparation method thereof have the advantages of being high in content and good in weeding effect.

Owner:天津市华宇农药有限公司

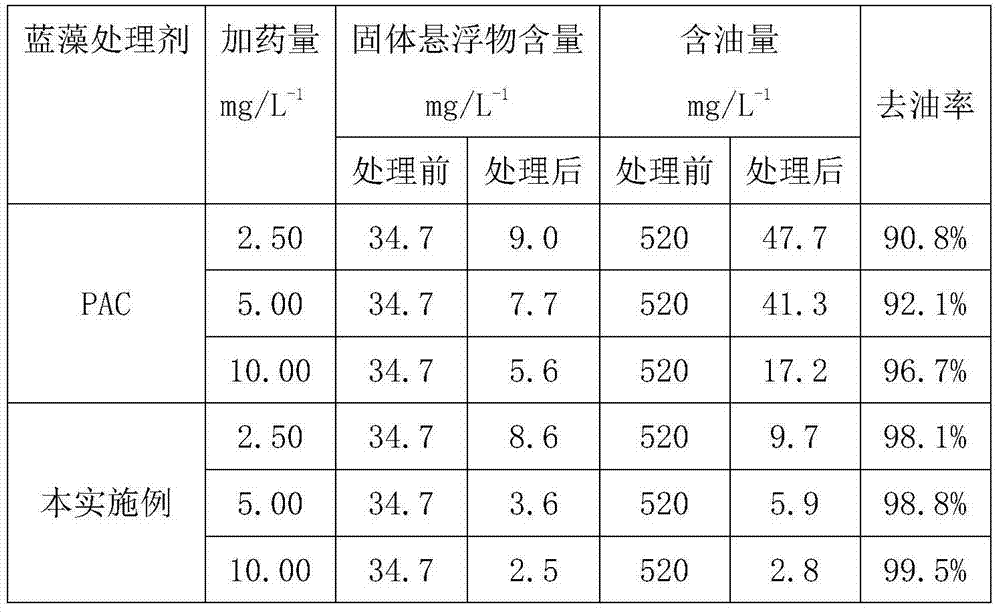

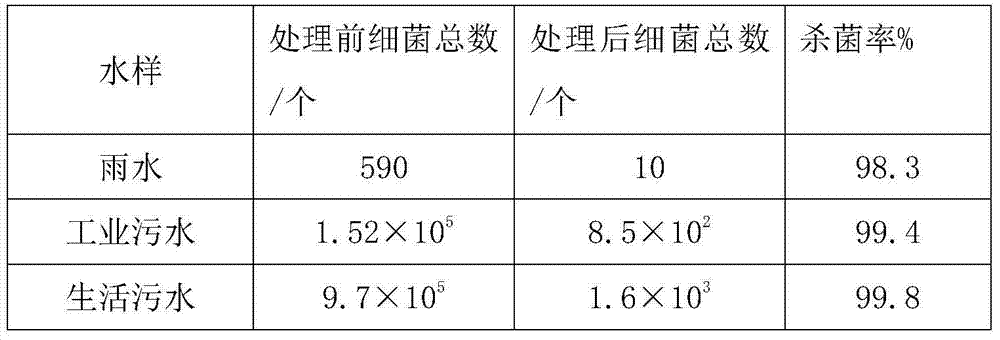

Sodium bentonite processing agent for blue-green algae and preparation method thereof

A sodium bentonite processing agent for blue-green algae is prepared from the following raw materials in parts by weight: 10-20 parts of serpentine, 40-45 parts of sodium-base bentonite, 2-3 parts of magnesium chloride, 8-13 parts of calcium chloride, 15-20 parts of potassium ferrate(VI), 12-16 parts of equisetum hyemale, 13-16 parts of pericarpium granati, 3-5 parts of polymaleic acid, 3-4 parts of sodium pyrophosphate, 2-3 parts of urea, 3-5 parts of anhydrous sodium sulfate, 3-5 parts of boric acid, 4-6 parts of polyvinyl alcohol, proper amount of water, and 3-4 parts of an adsorption auxiliary agent. By adding potassium ferrate(VI), the processing agent for blue-green algae has synergic effects of oxidation, adsorption, flocculating, precipitation, sterilization, disinfection, decoloring and deodoring, also does not generate any toxic and harmful substances, is capable of increasing water dissolved-oxygen content, has good removal effects on ammonia nitrogen, nitrites and algae in water, and is used to remove fulvic acid and suspensions in water and eutrophication phenomenon in fresh water. The processing agent for blue-green algae is good in dispersing suspending property and good in adsorption property, and can help to rapidly aggregate and salvage blue-green algae.

Owner:WUHU XIANGRONG FOOD

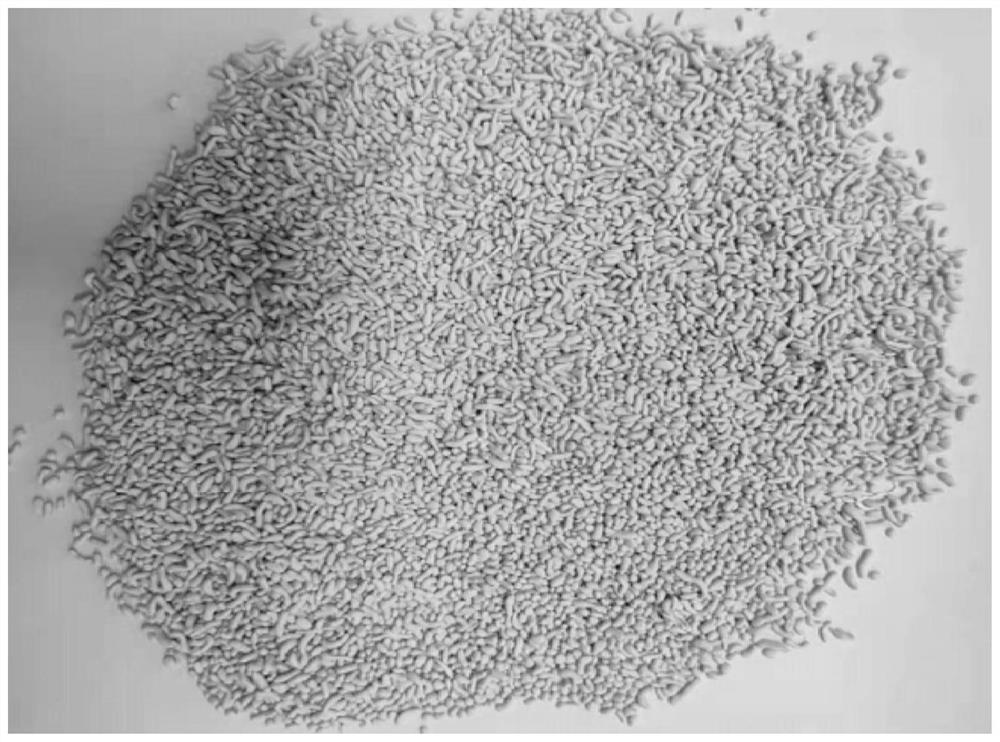

Preparation method of granular titanium-based lithium ion sieve adsorbent with high adsorption capacity

ActiveCN114345291AImprove hydrophilicityHigh porosityOther chemical processesProcess efficiency improvementAdhesivePhysical chemistry

The invention relates to a preparation method of a high-adsorption-capacity granular titanium-based lithium ion sieve adsorbent. The method comprises the following steps: step 1, preparing titanium-based lithium ion sieve precursor powder; step 2, preparation of the high-adsorption-capacity granular titanium-based lithium ion sieve adsorbent: 1) pretreatment of precursor powder; 2) preparing a composite adhesive; (3) doping, blending and homogenizing; (4) molding and granulating; and 5) eluting and replacing. The prepared granular adsorbent has relatively high porosity, shows good suspension property when being used for extracting lithium from salt lake brine or simulated brine, and is high in adsorption and desorption rate and high in lithium extraction activity, and the lithium ion selectivity and the elution rate can reach 95% or above; the granular adsorbent is stable in structure, low in solution loss and long in cycle service life; the forming and granulating process of the granular adsorbent is simple and easy to control, and industrialization is easy to realize.

Owner:CHENGDU CHEMPHYS CHEM IND +1

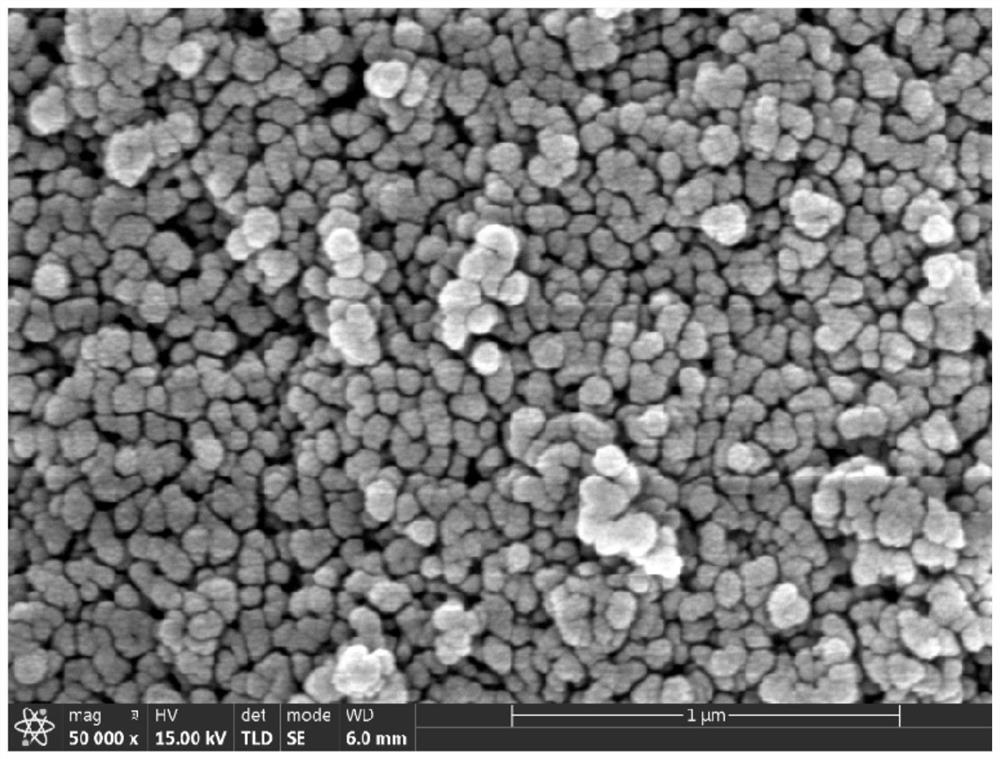

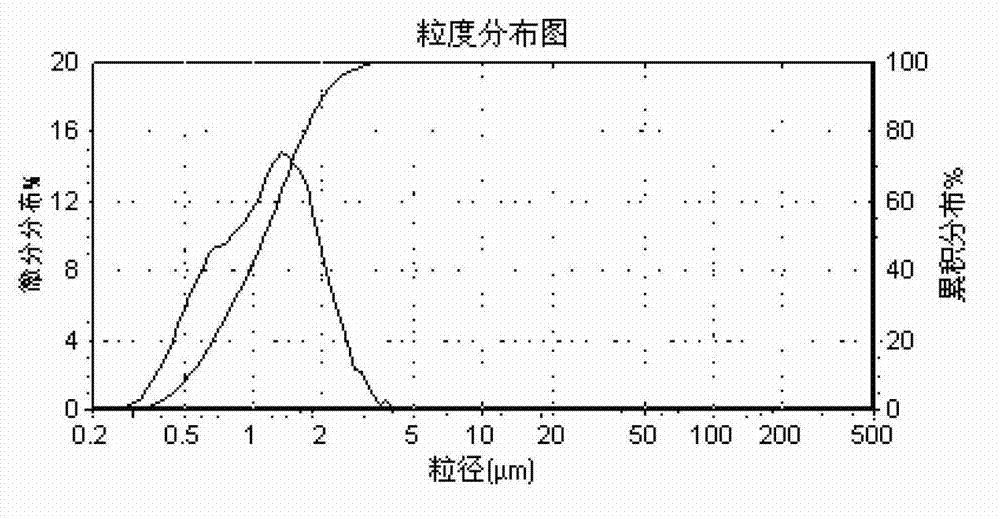

Preparation method for polishing powder used for high performance devices such as liquid crystal display

InactiveCN104031561AUniform particle size distributionGood dispersion and suspensionPolishing compositions with abrasivesMicroscopic morphologyLanthanum

The invention discloses a preparation method for polishing powder used for high performance devices such as liquid crystal display, which is characterized in that polishing powder microscopic morphology is polyhedral spherical shape, the corner angle of the particle with the above morphology is standard and uniform, scratch is not generated during a polishing process, the polyhedral structural powder has controllable morphology; the particle size distribution is uniform, average volume particle size D50 by a laser diffraction method is 0.7-2.0mum, specific surface area is 1.0-3.5m<2> / g; the dispersibility and suspensibility are good, potential of Zeta is -47mV, the polished surface is shine and neat, no scratch is generated on the surface; the cleaning performance and grinding speed of the product are better than that of certain product on market; the method comprises the following steps: adding cerous carbonate, lanthanum cerium carbonate or lanthanum cerium carbonate praseodymium in a hydrochloric acid solution for dissolving, adjusting pH value to 4-4.5, generating a cerium chloride, lanthanum chloride cerium or lanthanum chloride cerium praseodymium solution, taking the solution as a stock solution, adding a saturated ammonium bicarbonate precipitant with pH value at 8-9 to prepare the rare earth oxide polishing powder, and adding a chemical auxiliary agent in a chlorination rare earth solution or a precipitating agent solution for improving the powder performance before a precipitation reaction process.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

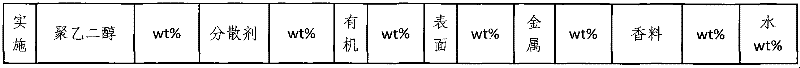

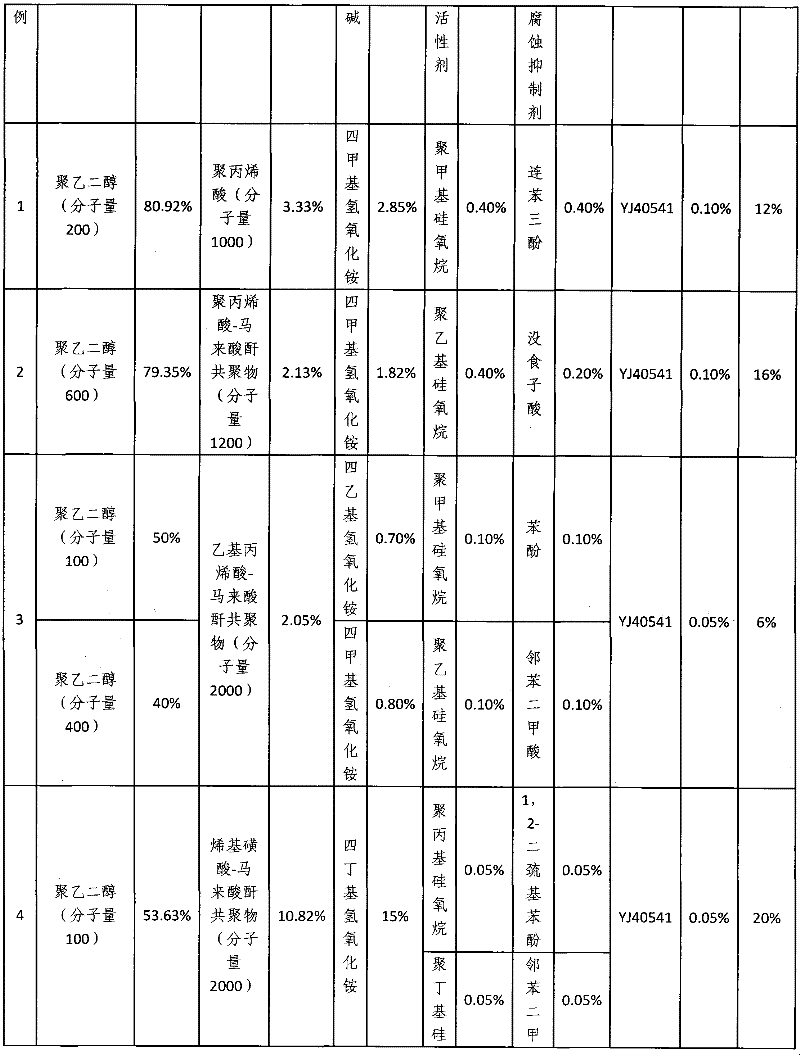

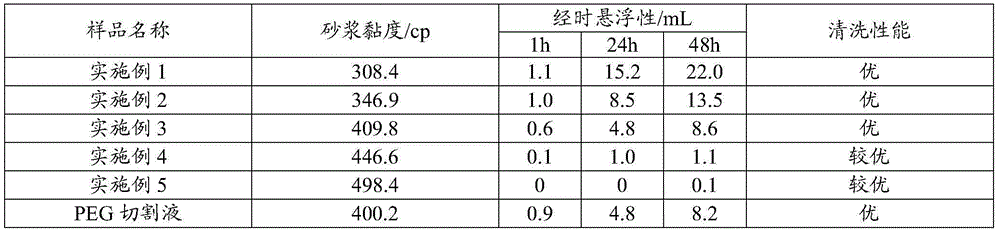

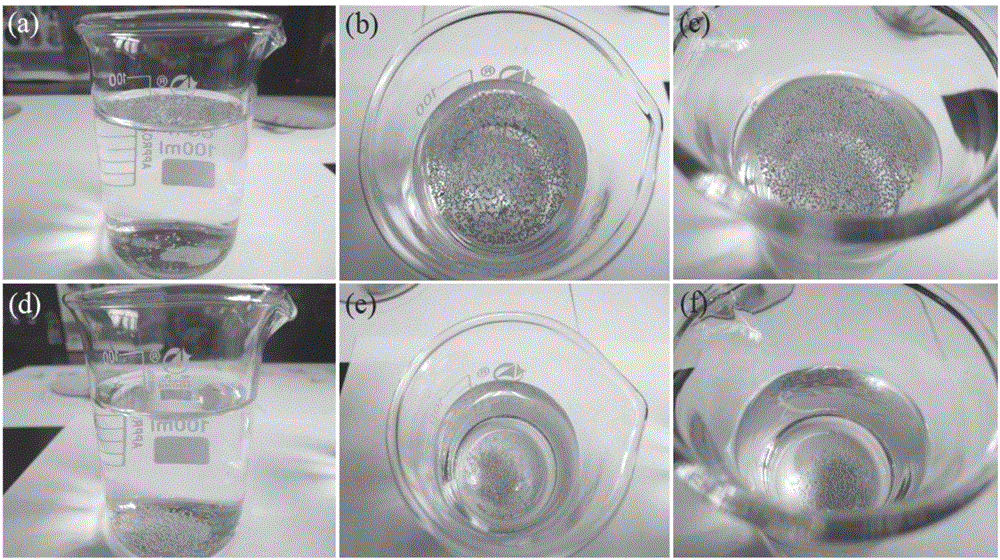

A water-based wire cutting fluid for silicon wafers

InactiveCN102260582ALow costGood dispersion and suspensionLubricant compositionPolyvinyl alcoholWire cutting

The invention provides a water-based cutting fluid for silicon wafers, which consists of the following raw materials in proportions by mass: polyvinyl alcohol, 2-10 parts, benzotriazole, 0.05 parts, deionized water, 89.95-98 servings. The water-based cutting fluid is characterized by low cost and environmental friendliness. Due to the good viscosity and dispersibility of the polyvinyl alcohol aqueous solution, the dispersibility of the blade in this cutting fluid is good, especially after settling, it is easier to redisperse. Using the water-based cutting fluid of the invention has a high qualified rate of finished products, and the silicon wafers after cutting are easier to clean.

Owner:CHANGZHOU UNIV

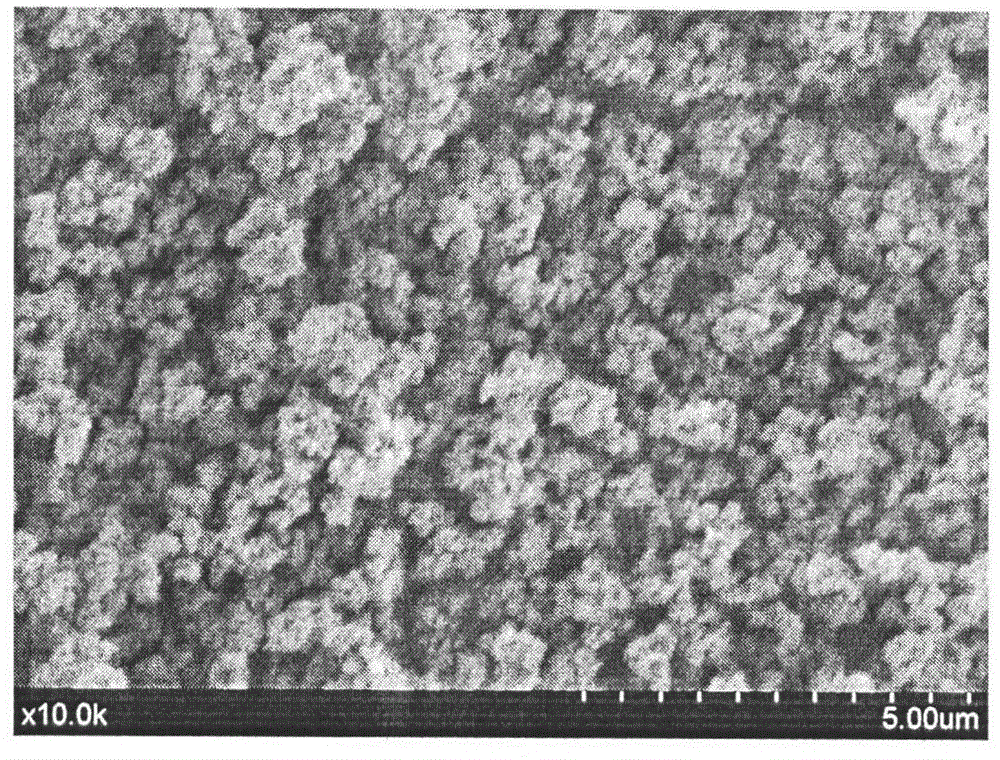

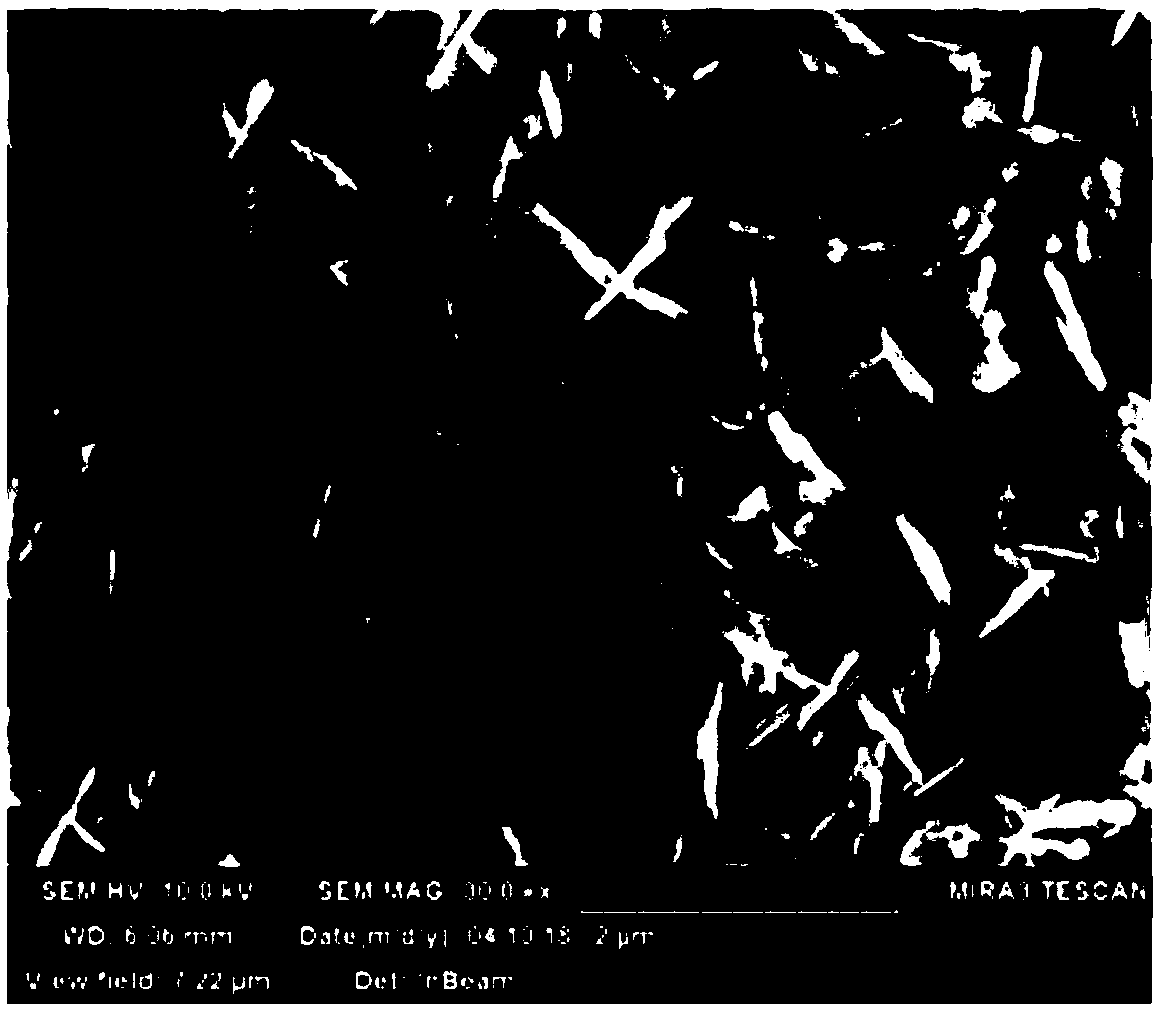

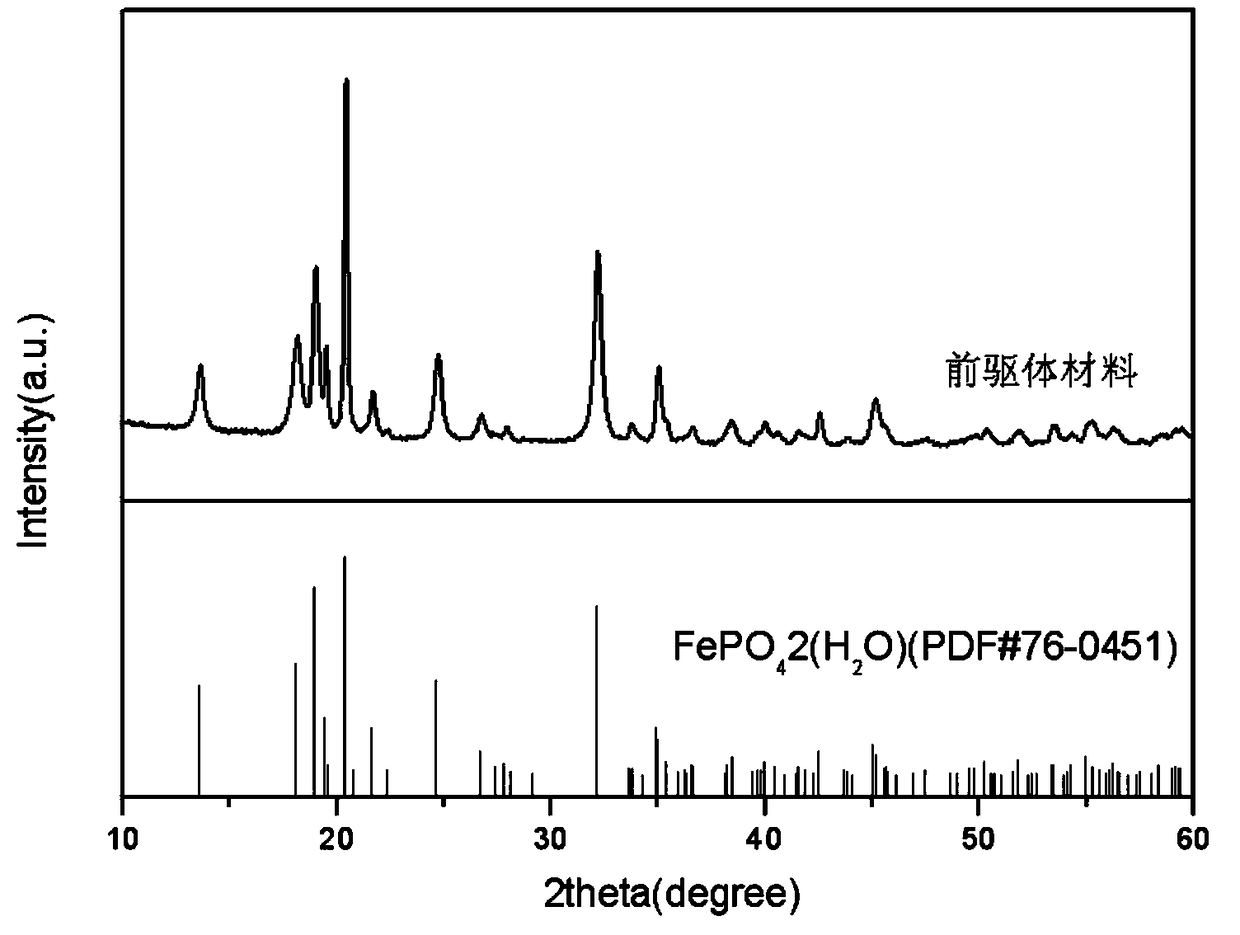

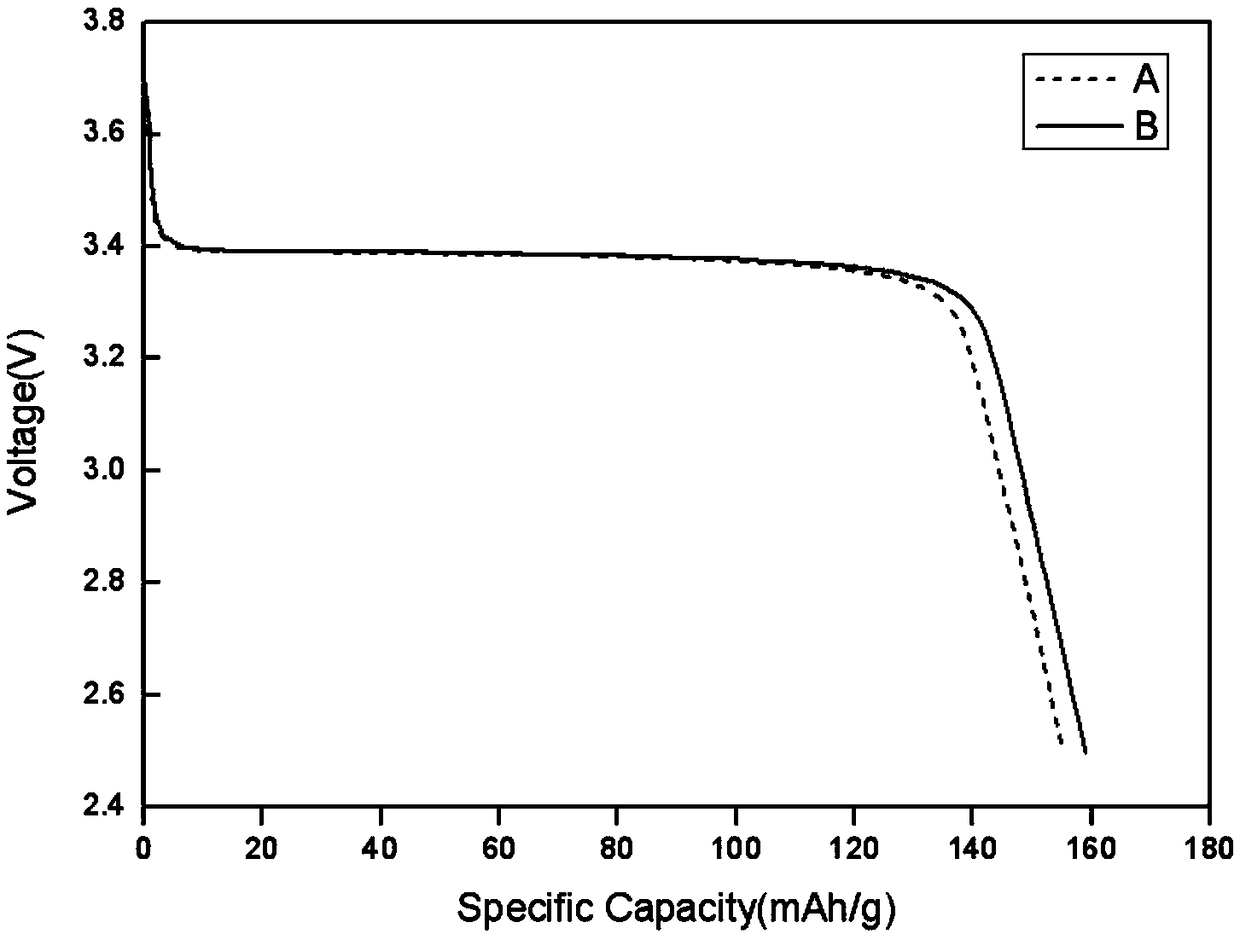

Preparation method for lithium iron phosphate precursor without wastewater discharge

ActiveCN109461931AGood dispersion and suspensionImprove electrochemical performanceCell electrodesSecondary cellsCarbon nanotubePhosphoric acid

The invention provides a preparation method for a lithium iron phosphate precursor without wastewater discharge. The preparation method comprises the steps of diluting concentrated phosphoric acid with deionized water, mixing with pre-activated Fe2O3, or further adding a carbon nanotube to obtain a mixed liquid; performing wet grinding after ultrasonic dispersion on the mixed liquid, performing sieving, and adding a dispersing agent for heating, stirring and dispersing; performing heating reaction on the dispersed paste under an N2 environment, and obtaining a precipitant and a solution aftercooling; and performing high-speed separation on the precipitant and the solution, and drying the precipitant, thereby obtaining an iron phosphate (or iron phosphate / carbon nanotube) precursor. The Fe2O3 and phosphoric acid are used as raw materials, the carbon nanotube can be combined, the lithium iron phosphate precursor is prepared by a hydrothermal method, the preparation process is simple, isshort in time and low in energy consumption and cost, no wastewater is discharged, no other side product and impurity ions are introduced, the iron phosphate product is pure, the product is high in purity, and the improvement of the performance and the quality of the lithium iron phosphate battery are facilitated.

Owner:SHENZHEN QINGYAN EQUIP TECH CO LTD

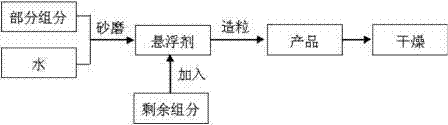

Quickly disintegrated imidacloprid and emamectin benzoate water dispersible granules and preparation method thereof

ActiveCN102763671ASmall particle sizeHigh dispersion suspension rateBiocideAnimal repellantsEmamectin benzoateSuspending Agents

The invention belongs to the technical field of pesticides, and relates to quickly disintegrated imidacloprid and emamectin benzoate water dispersible granules and a preparation method thereof. A formula comprises the following components: imidacloprid and emamectin benzoate in a mass ratio of 9:1, 3.0 to 20.0 percent of dispersant, 1.0 to 5.0 percent of wetting agent, 0 to 20.0 percent of disintegrating agent and the balance of filler. The preparation method comprises the following steps of: changing a part of components in the formula into water, grinding to obtain a suspending agent, adding the changed components into the suspension, stirring uniformly, granulating with a 'dry method', and drying, thus obtaining the water dispersible granules. According to the technology, the conventional equipment is integrated, and production can be carried out without adding expensive equipment; and due to small granule diameter and low requirement for the dispersion wetting agent, the prepared water dispersible granules have the characteristics of small granule diameter, quick dispersion and disintegration in water and good dispersion and suspension properties.

Owner:中化化工科学技术研究总院有限公司 +1

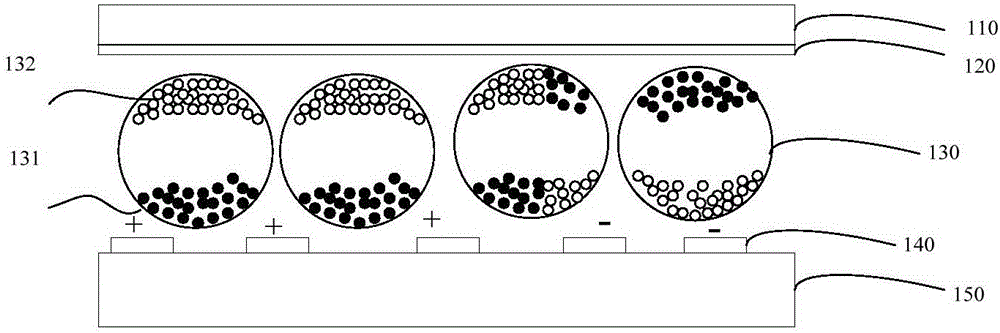

High-performance electrophoretic particle and electrophoretic disclosing solution

InactiveCN104073023AGood dispersion and suspensionGood dispersionOrganic dyesPigment treatment with macromolecular organic compoundsOrganic solventElectrophoresis

The invention discloses a high-performance electrophoretic particle. The high-performance electrophoretic particle comprises a plurality of pigment particles, wherein the surfaces of the pigment particles are coated by a high-molecular polymer via a surface modifying agent. The high-performance electrophoretic particle is prepared through the following steps: A, mixing: a step of dissolving the surface modifying agent with an anhydrous organic solvent and dispersing to-be-treated pigment powder in the obtained solution so as to obtain a mixed solution A; B, nanometer grinding: a step of treating the mixed solution A by using nanometer fine grinding technology so as to obtain a mixed solution B; C, cleaning: a step of cleaning the mixed solution B so as to obtain a pigment mixture; and D, high-molecular coating: a step of treating the pigment mixture by using high-molecular coating technology so as to obtain the high-performance electrophoretic particle. The invention further discloses an electrophoretic disclosing solution. The high-performance electrophoretic particle provided by the invention has good suspension dispersibility and realizes no settlement and layering in 15 d without stirring. The electrophoretic disclosing solution has good dispersibility, stability and photoelectric performance.

Owner:GUANGZHOU OED TECH INC

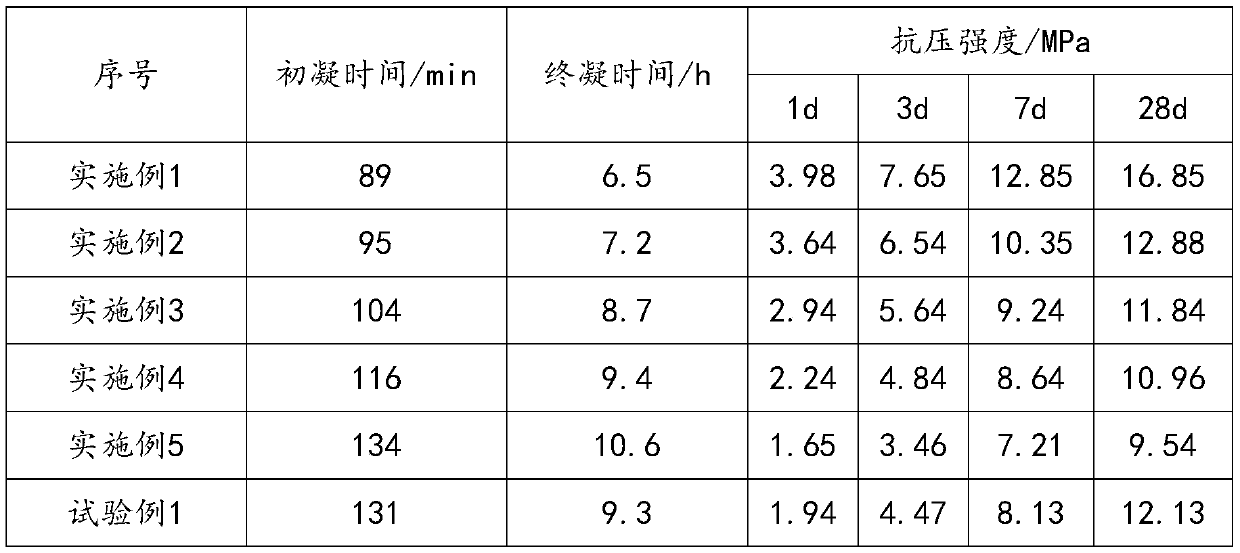

Hemihydrate phosphogypsum-based filling material and preparation method and application thereof

The invention relates to the technical field of mine filling materials, in particular to a hemihydrate phosphogypsum-based filling material and a preparation method and application thereof. The material is prepared from, by weight, 50-150 parts of hemihydrate phosphogypsum, 10-20 parts of an auxiliary gel material, 2-5 parts of a coagulant, 2-5 parts of an adsorption dispersant, 2-5 parts of a water-retaining agent and 0.5-1.5 parts of a water reducing agent; the auxiliary gel material is prepared from, by weight, 60-80 parts of high-calcium fly ash, 15-30 parts of wet-discharged fly-ash and 5-10 parts of cement. Accordingly, the hemihydrate phosphogypsum serves as a main gel material, the high-calcium fly ash is combined to serve as the auxiliary gel material, the activity of the gel material is stimulated through the composite coagulant, one or multiple admixtures are blended, and the mine filling material which is high in concretion strength, good in fluidity, good in water retention, good in suspension and dispersion, easy to transport, low in cost, environmentally friendly and capable of saving energy is prepared.

Owner:山东塔罗斯智能装备有限公司

Compound immune magnetic beads for separation and purification of hepatic stellate cells and preparation method of compound immune magnetic beads

The invention relates to the technical field of cell separation and purification materials and particularly relates to compound immune magnetic beads for separation and purification of hepatic stellate cells and a preparation method of the compound immune magnetic beads. The compound immune magnetic beads are prepared by grafting antibodies on magnetic bead granules of which the granule sizes are50-1500nm, wherein the antibodies include CD11b and CD146 antibodies, and the inner cores of the magnetic bead granules are Fe3O4 micro-spheres including carboxylated graphene layers, modified chitosan layers and sodium alginate layers from inside to outside. The antibodies are grafted on the magnetic bead granules to obtain the compound immune magnetic beads; the magnetic bead granules contain more carboxyl functional groups, have good dispersion properties in solutions and can not aggregate easily; the antibodies have a higher grafting ratio on the magnetic bead granules and have higher binding stability; and the compound immune magnetic beads can be used for separation and purification of hepatic stellate cells so as to obtain hepatic stellate cells with higher purity and better activity.

Owner:ARMY MEDICAL UNIV

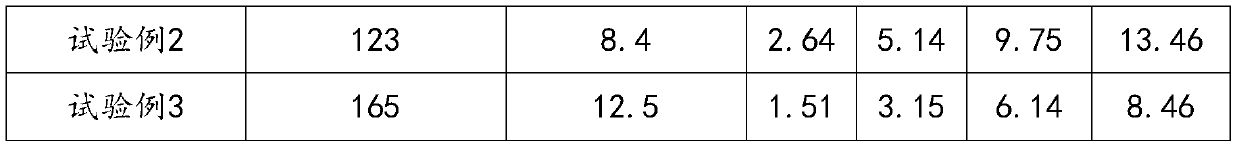

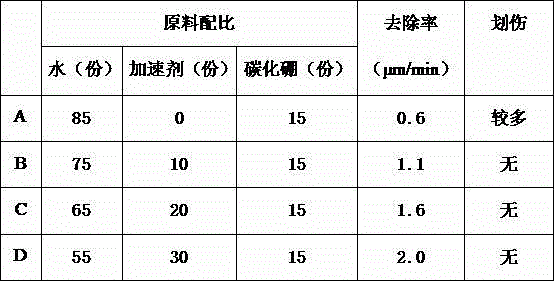

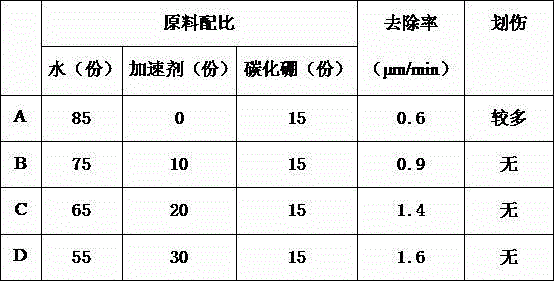

Accelerator used in grinding hard material

ActiveCN104592935AImprove mechanical frictionStop scratchesOther chemical processesChemistryAcrylate polymer

The invention discloses an accelerator used in grinding a hard material. The accelerator comprises the following components in parts by weight: 4-16 parts of an alcohol amine compound, 4-40 parts of an alcohol compound, 1-10 parts of polyacrylate, 10-50 parts of an acrylate polymer, 3-17 parts of a surfactant, 1-15 parts of a cellulosic polymer and 2-27 parts of water and has a pH value of 7-13. The accelerator has better suspension dispersion effect on a large-particle friction agent so that the prepared grinding fluid is difficult to deposit to the bottom of the machine during the circular processing, the chemical interaction between the grinding fluid and sapphire wafers can be enhanced, the hydration of the surface of the wafer is effectively promoted, the interfacial damage layer caused by the purely mechanical effect of the wafer is reduced and thus the grinding removal rate is greatly improved and the production efficiency is significantly increased.

Owner:JIANGSU SINO KRYSTALS OPTROINCS

Cutting fluid for cutting of scroll saw

InactiveCN102344776AGood dispersion and suspensionGood lubricity and coolingOther chemical processesFine working devicesBiomedical engineeringCutting fluid

The invention discloses a cutting fluid for cutting of a scroll saw. The cutting fluid disclosed by the invention has the advantages of low cost and favorable dispersibility, suspension property, lubricity, cooling property and favorable stability, and thereby the cutting yield is improved. In addition, the cutting fluid disclosed by the invention is environment-friendly and is convenient to recover.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

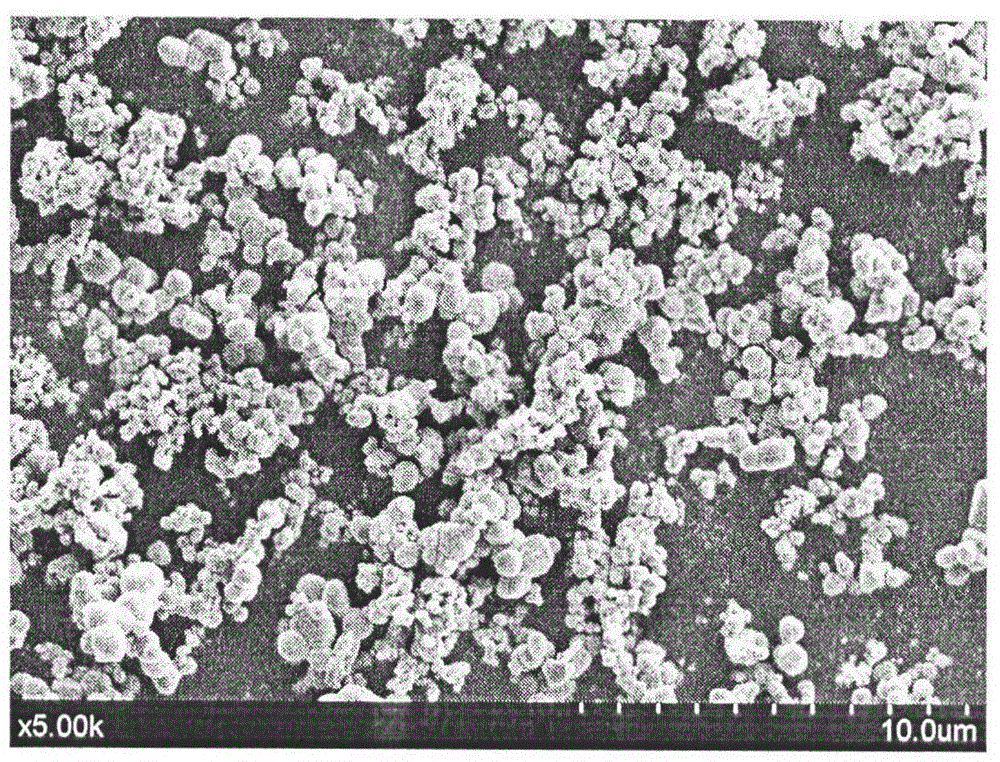

Graphene-grafted modified calcium carbonate powder and preparation method thereof

InactiveCN106590043AImprove filling modification effectImprove performancePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSurface reactionDispersity

The invention discloses graphene-grafted modified calcium carbonate powder. According to the graphene-grafted modified calcium carbonate powder, calcium carbonate is subjected to wet ball milling pretreatment through a titanate coupling agent / ethanol solution at first, the dispersity of the calcium carbonate is improved, and the surface reaction activity is improved; then, a graphene-polyethyleneimine thin film is grafted on the surface of the calcium carbonate, and the advantages of graphene are introduced; and meanwhile, the powder has amphipathy and has a good suspension dispersion effect in a water system and an oil system, so that the filling modification effect of the calcium carbonate powder is effectively improved, and a product with better performance is obtained.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

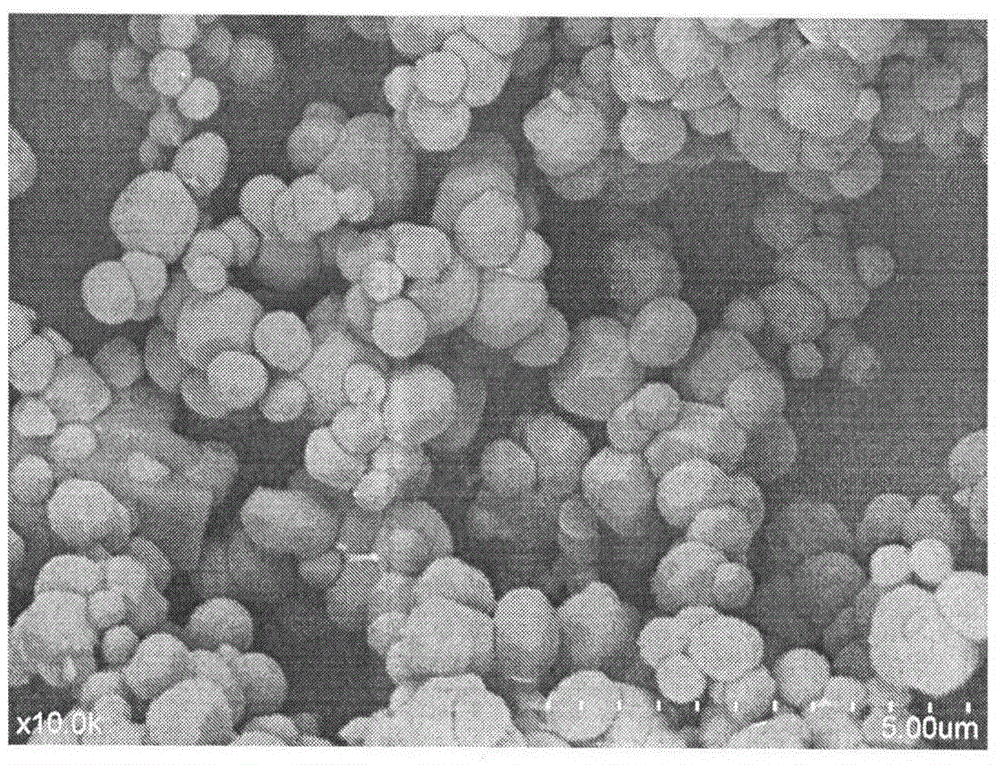

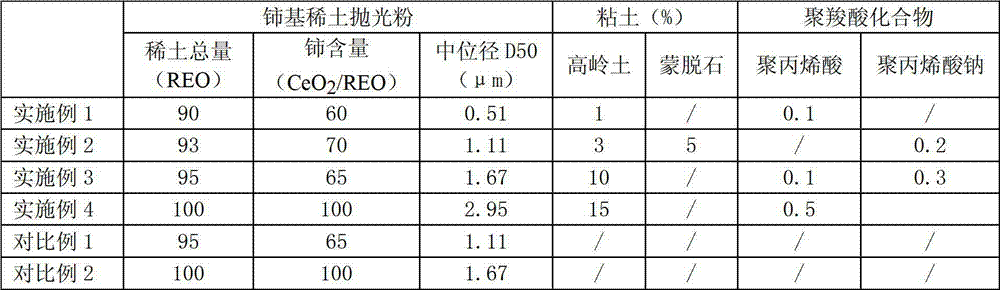

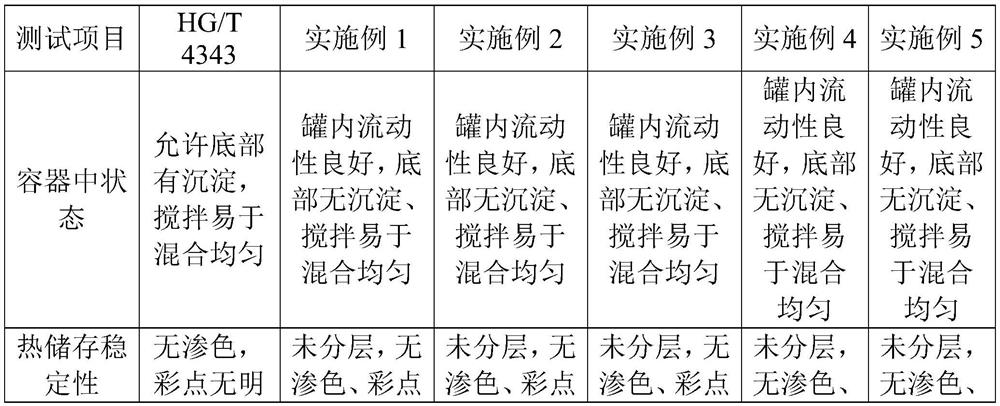

Cerium-based mischmetal polishing material and preparation method thereof

InactiveCN102898953AInhibition of reunion tendenciesGood dispersion and suspensionPolishing compositions with abrasivesCeriumCarboxylic acid

The invention aims to disclose a cerium-based mischmetal polishing material and a preparation method thereof. The material comprises the following components in percentage by weight: 83 to 99 percent of cerium-based mischmetal polishing powder, 1 to 15 percent of clay and 0.1 to 0.5 percent of polycarboxylic acid compound. Compared with the prior art, the material has the advantages that the aggregative trend of the polishing powder is restrained, suspending and dispersing properties of the polishing powder during use are effectively improved, specific gravity of the polishing powder is reduced, and the polishing powder is high in suspending property and universality, easy to clean after polishing, high in polishing efficiency and the like, so that the aim of the invention is fulfilled.

Owner:上海华明高纳稀土新材料有限公司

Self-thickening multicolor paint and application thereof

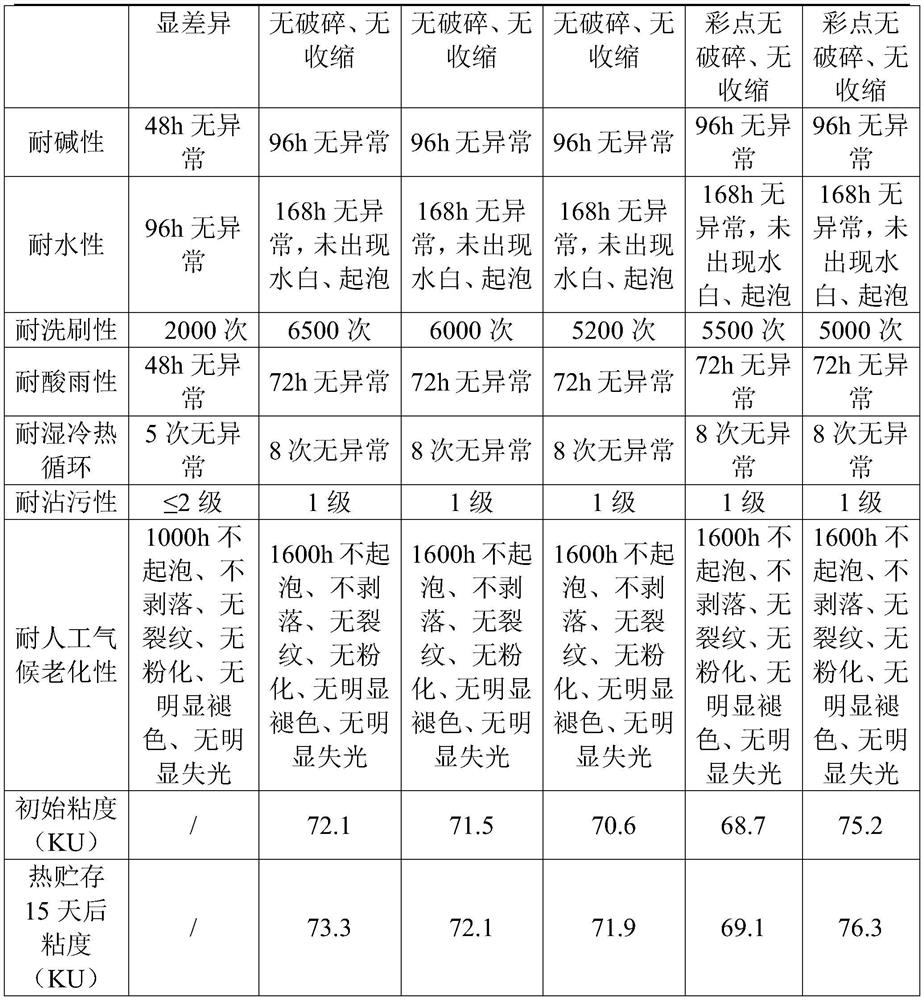

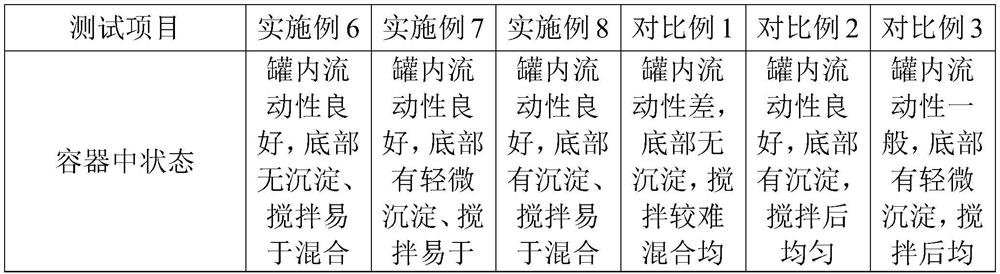

ActiveCN114085583AImprove water resistanceViscosity is easy to controlMulticolor effect coatingsPolymer scienceEmulsion

The invention relates to self-thickening multicolor coating and application thereof. The self-thickening multicolor paint comprises base paint, a granulation liquid, a self-thickening continuous phase and a non-active continuous phase according to a specific component ratio, color points prepared from the base paint and the granulation liquid are mixed with the self-thickening continuous phase and the non-active continuous phase step by step, protective glue and the continuous phase can be subjected to a directional controllable self-thickening reaction, the viscosity of the paint is controllable, and the storage stability is relatively good. Matting powder and talcum powder in the self-thickening continuous phase and the non-active continuous phase have relatively good dispersion suspension property and can play a synergistic role with an emulsion in a coating system, so that the storage stability of the coating is improved, and the problems of storage layering, construction sagging and the like of the multi-color coating are solved. According to the self-thickening multi-color paint, an alkali swelling thickening agent is not used, so that the paint is good in water resistance, and is not easy to whiten and blister when meeting water.

Owner:安徽嘉宝莉科技材料有限公司

Preparation method of casting coating

InactiveCN109894571AHigh modulus of elasticityImprove thermal shock resistanceFoundry mouldsFoundry coresDispersityPolyvinyl alcohol

The invention discloses a preparation method of casting coating, and belongs to the technical field of coating preparation. Firstly, rice hulls serve as raw materials, the rice hulls are smashed, ricehull smashed materials are obtained, the rice hull smashed materials react at high temperature, silicon carbide does not easily suffer from an oxidization reaction, and the burning-on defect generated due to metal penetration of the casting coating prepared with the method can be effectively avoided; glass fibers serve as raw materials, the surfaces of the glass fibers also contain silanol groups, the surface tension of the silicon carbide is reduced, the surface energy of the silicon carbide is reduced, and the suspension dispersity is improved; kaolin and quartz stones serve as raw materials, the high temperature resistance of the kaolin and the quartz stones is extremely good, and the abrasion resistance of the kaolin and the quartz stones is good; sardine bones serve as raw materials,the sardine bones contain a large amount of fluorine, fluorine is bound on the surface of modified inorganic matter through a fermentation effect, and the suspension dispersity of the casting coatingprepared with the method is further improved; and polyvinyl alcohol is strong organic adhesive, the strength of the casting coating can be improved, and broad application prospects are achieved.

Owner:谭建平

Aqueous dissociating abrasive cutting fluid used for making solar silicon wafer and its preparation method

InactiveCN103952224AImprove yieldImprove extrusion resistanceLubricant compositionHigh rateAgricultural engineering

The invention discloses an aqueous dissociating abrasive cutting fluid used for making a solar silicon wafer and its preparation method; the cutting fluid comprises an acrylic thickener, triethanolamine, a defoaming agent, triethanolamine oleate soap and deionized water; on the one hand the triethanolamine oleate soap can improve crumpling resistance and lubricating property of the cutting fluid, and on the other hand, the triethanolamine oleate soap is anticorrosive, and can prolong the shelf life of the cutting fluid and enhance the cutting fluid stability. At the same time, the cutting fluid contains a large amount of the deionized water, and the water is large in specific heat capacity, so that the cutting fluid has good cooling property, and the water solution is easy to wash. In addition, the large amount of deionized water in the components can greatly reduce the cutting fluid production cost and reduce environmental pollution, the cut wafer is easy to clean, dirty wafer is less, and the rate of finished silicon wafer is high. Finally, the aqueous dissociating abrasive cutting fluid has the advantages of simple preparation, easy operation, low production cost, high rate of finished cut silicon wafer, easy subsequent cleaning, no pollution to the equipment and the like.

Owner:西安通鑫半导体辅料有限公司

Novel method for preparing self-suspension ceramsite

InactiveCN106281298AAvoid cloggingSimple preparation processFluid removalDrilling compositionOctadecyltrichlorosilaneMass ratio

The invention discloses a novel method for preparing self-suspension ceramsite. The novel method comprises the following steps: (1), xylene, acetone, octadecanol and butyl acetate in a certain mass ratio are added into a first reactor in which a stirrer and a thermometer are loaded; (2), under an ice-bath condition, dodecyl trimethylsilane, octadecyl trichlorosilane and stearic acid are slowly added into a second reactor in which a stirrer and a thermometer are loaded, and stirring for reaction for a period of time at a constant speed is performed under the condition of 78-80 DEG C, so as to obtain a head product A; (3), deionized water, alkylphenol polyoxyethylene, span 60 and ethyl alcohol in a certain mass ratio are added into the second reactor in which the stirrer and the thermometer are loaded, then the head product A is added, stirring for dispersing at a high speed for a period of time is performed, a certain mass of ceramsite is added, the reaction continues for a period of time, and ethyl alcohol is used for washing for two times, and then sample collecting is performed. The ceramsite prepared by adopting the method for preparing self-suspension ceramsite can be dispersed in water in a suspending manner, and as a fracturing propping agent, the ceramsite can ensure that high flow conductivity is kept at cracks and crack blockage are prevented.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

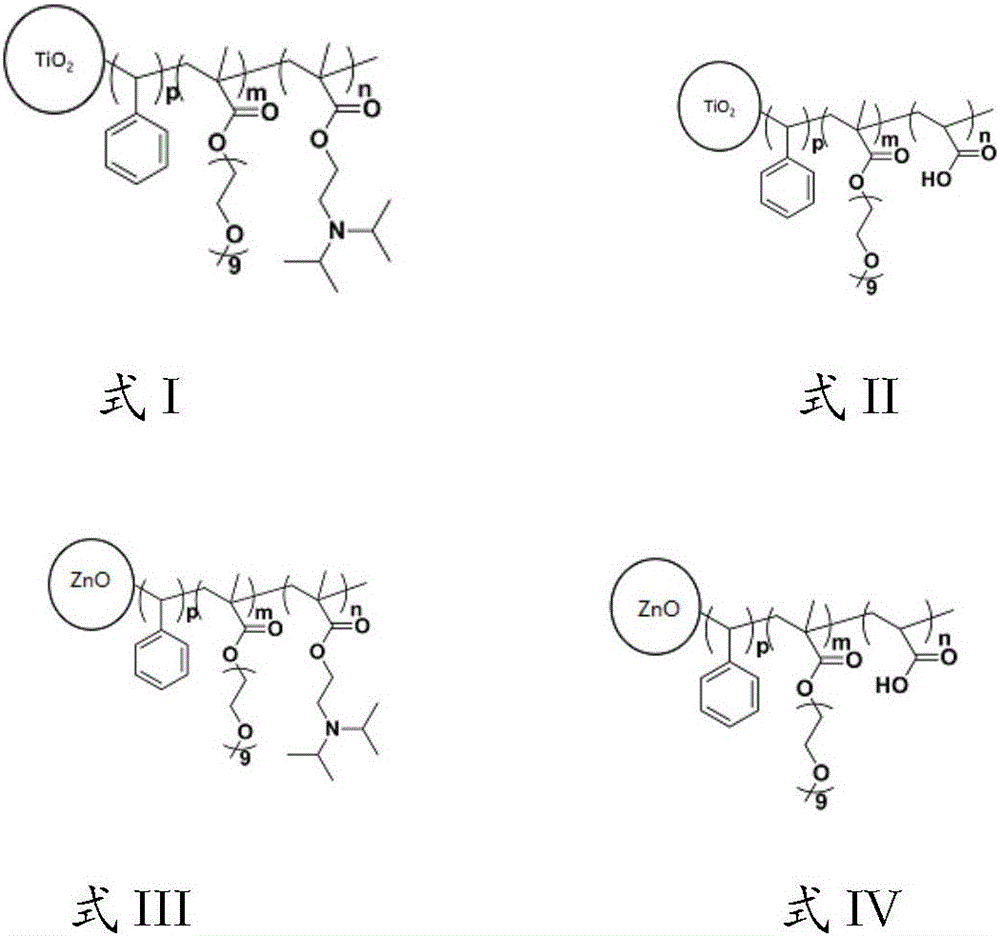

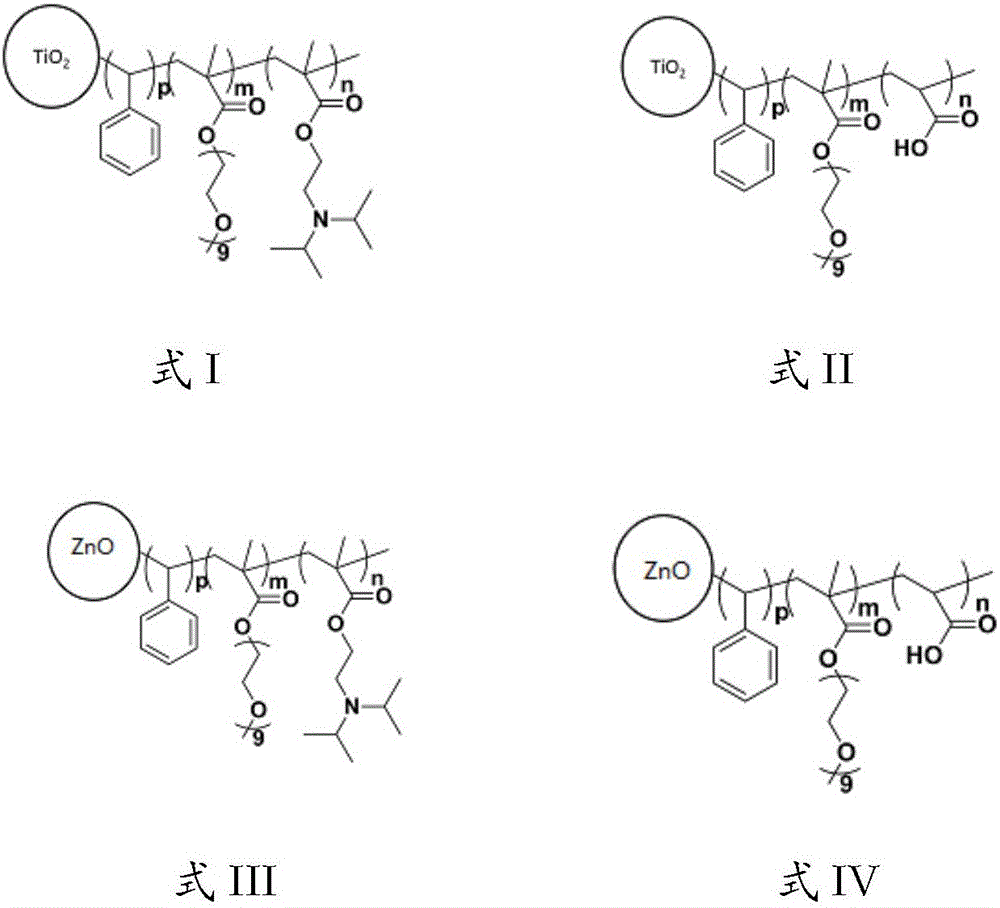

Electrophoretic particle and preparation method thereof, microcapsule and electronic ink screen

The invention discloses an electrophoretic particle and a preparation method thereof, a microcapsule and an electronic ink screen. According to the invention, the electrophoretic particle is a nanoparticle with a core-shell structure, wherein the core is TiO2 or ZnO; the shell is a macromolecular polymer modified on the core; and the macromolecular polymer comprises a hydrophobic segment and a hydrophilic segment. According to the invention, the preparation method of the electrophoretic particle comprises the steps: modifying a chain transfer agent; modifying polystyrene; modifying poly-oligo polyethylene glycol methyl ether methyl acrylate; and modifying polyelectrolyte. According to the invention, the microcapsule comprises the electrophoretic particle provided by the invention. According to the invention, the electronic ink screen comprises the microcapsule provided by the invention.

Owner:BOE TECH GRP CO LTD +1

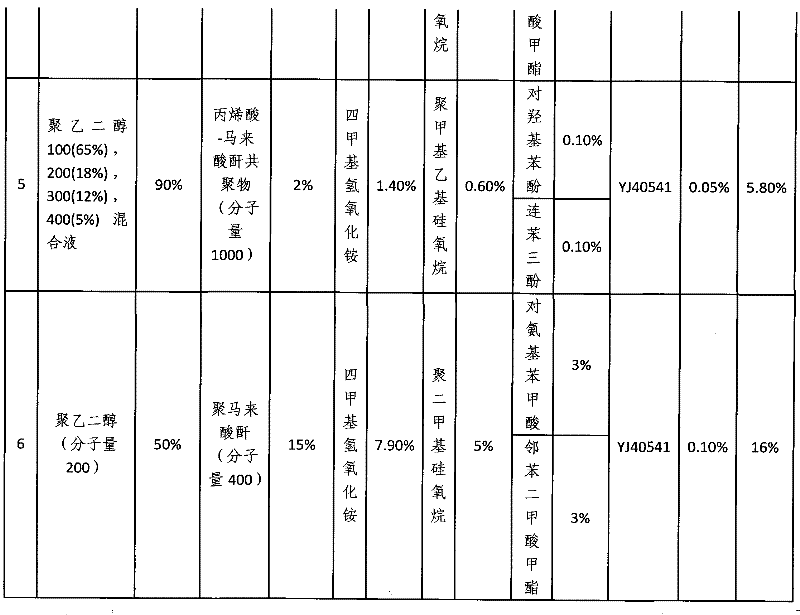

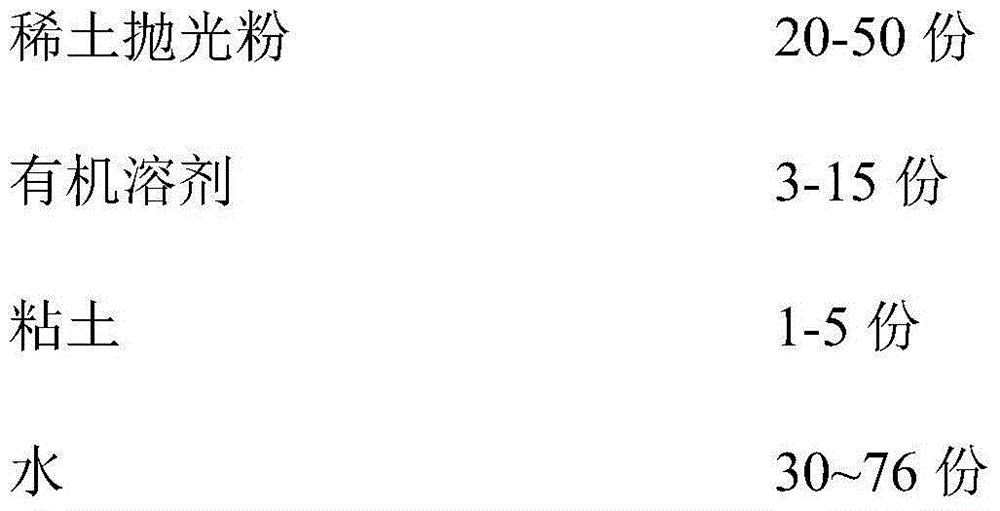

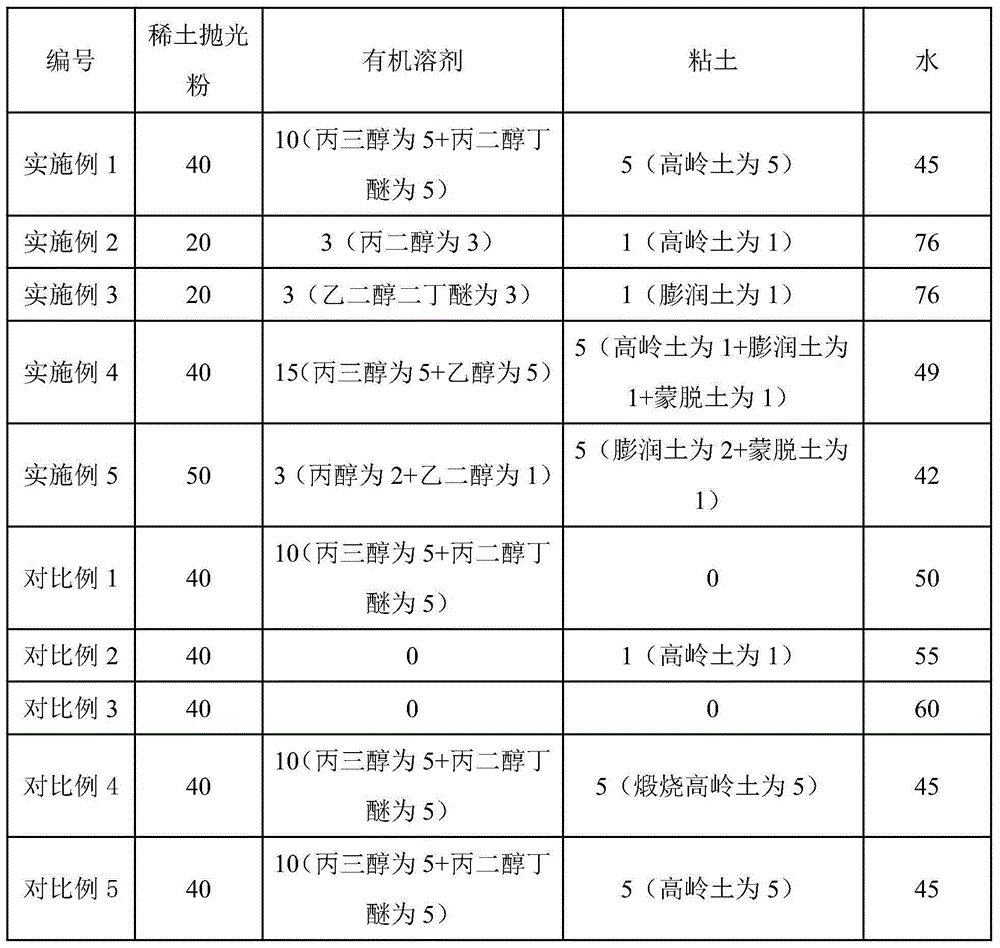

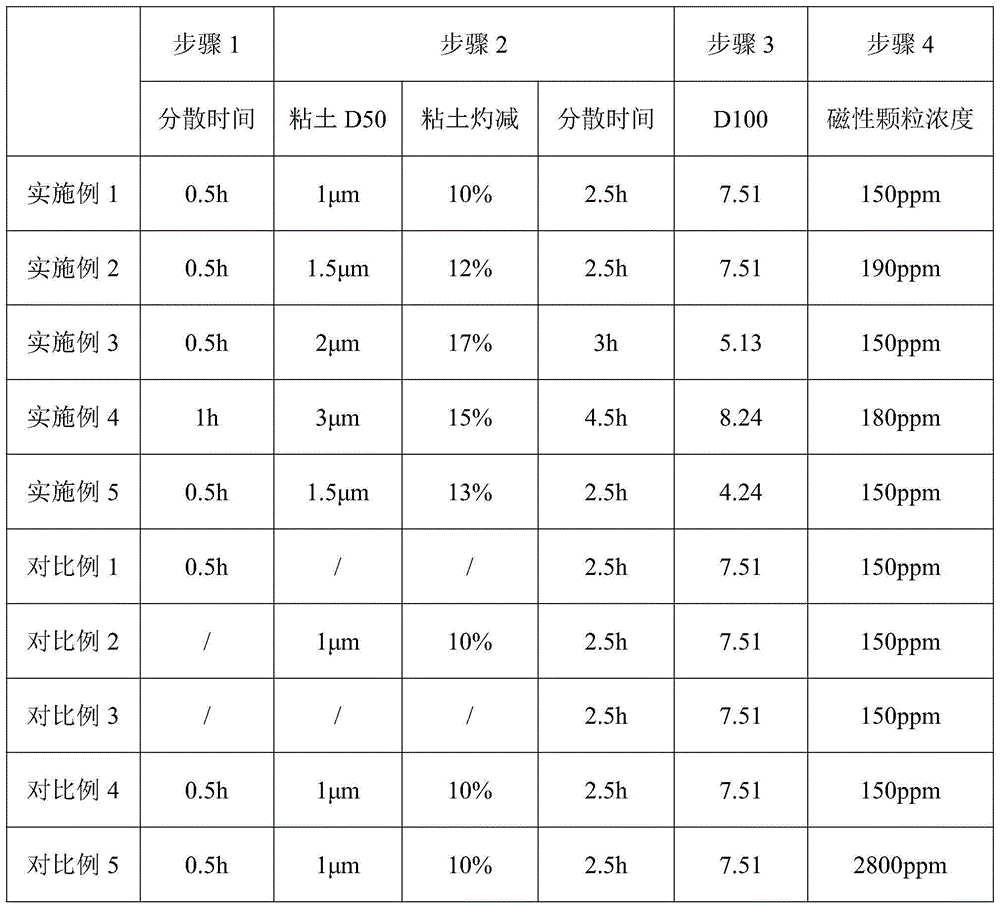

Rare earth polishing liquid and preparation method thereof

ActiveCN104479555AEasy to prepareSolve the ease of cleaningPolishing compositions with abrasivesOrganic solventRare earth

The invention provides a rare earth polishing liquid and a preparation method thereof; the rare earth polishing liquid comprises the following components in parts by weight: 20-50 parts of a rare earth polishing powder, 3-15 parts of an organic solvent, 1-5 parts of clay, and 30-76 parts of water. The rare earth polishing liquid solves the problem of suspension dispersion of a polishing powder in water, overcomes the bonding problem of the polishing liquid in preparation and storage processes and good cleaning problem of the polishing liquid in a use process at present, and has the characteristics of good suspension dispersibility, fast polishing speed, high polishing precision, excellent cleaning performance of polished products and the like. The rare earth polishing liquid is suitable for surface polishing processing of integrated circuits, flat panel display, optical glass and other electronic information industry precision devices, and meets polishing yield rate requirements of increasingly-strict business on polishing materials in accuracy, polishing corrosion amount, easy cleaning and the like.

Owner:NUOXUAN CHEM TECH SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com