Preparation method for polishing powder used for high performance devices such as liquid crystal display

A liquid crystal display, polishing powder technology, applied in the direction of polishing compositions containing abrasives, etc., to achieve the effect of bright and clean polishing surface, uniform particle size distribution, good dispersion and suspension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

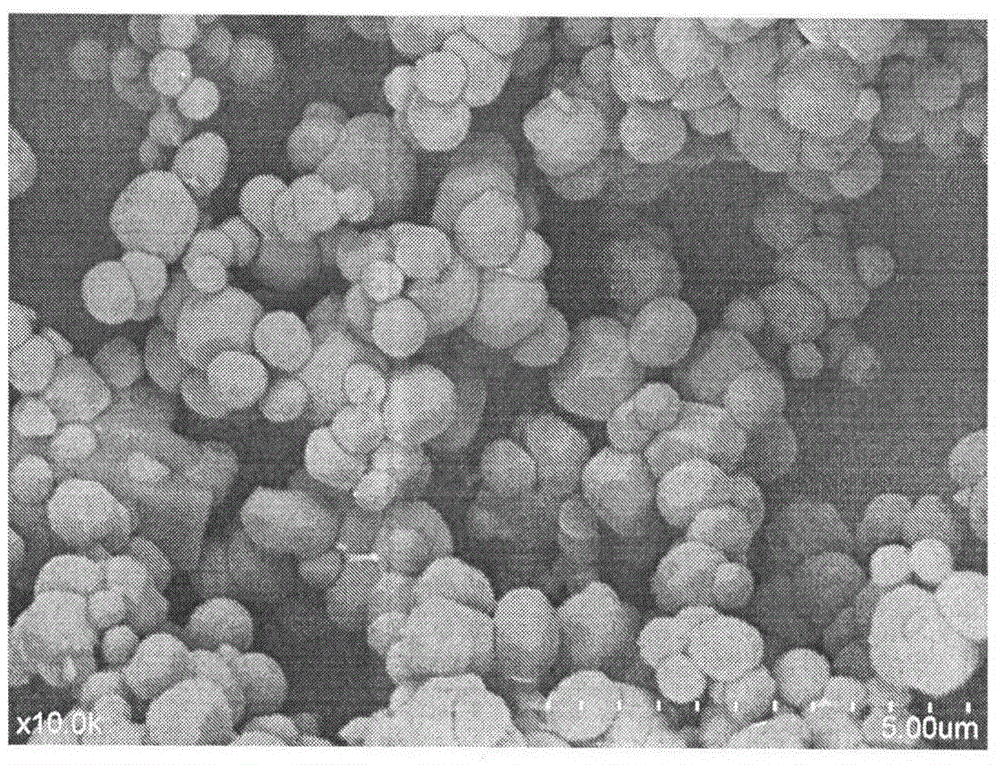

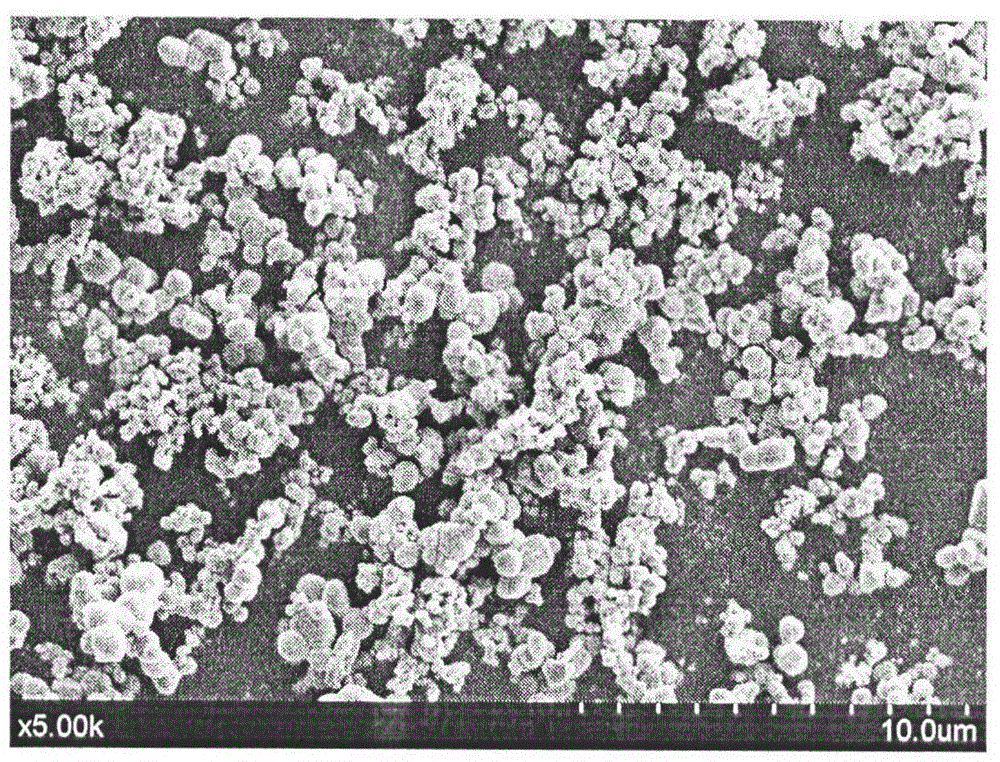

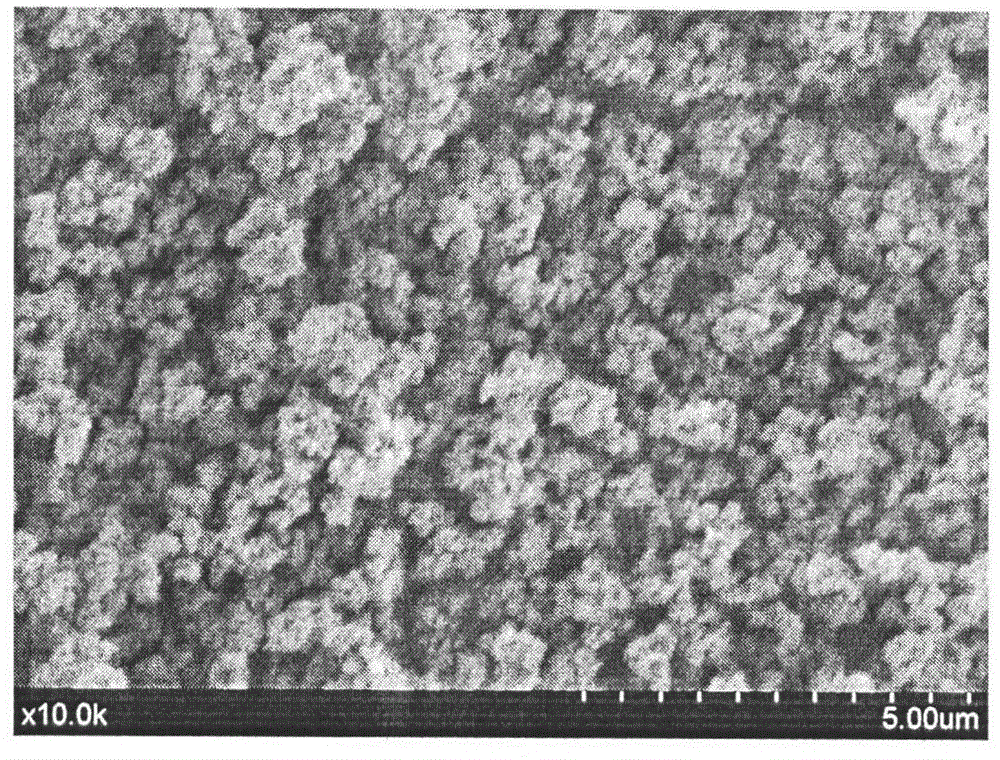

Image

Examples

Embodiment 1

[0029] (1) Raw material preparation: weigh 1 kg of lanthanum cerium carbonate and add hydrochloric acid to prepare a 0.5 mol / L cerium chloride solution, and adjust the pH of the solution to 4-4.5 with hydrochloric acid and rare earth carbonate. Weigh 0.305 kg of ammonium bicarbonate to prepare a saturated ammonium bicarbonate solution as a precipitant, and adjust the pH to 8-9 with ammonia water. Prepare 2mol / L potassium chloride solution, weigh the content to account for 30% of the mass percentage of the rare earth oxide powder, prepare 30% polyethylene glycol 20000 solution, weigh the content to account for 2% of the mass percentage of the rare earth oxide powder, Add to the lanthanum cerium chloride solution simultaneously and stir evenly;

[0030] (2) Fluorination: Weigh fluosilicic acid with a weight concentration of 30%, add it into the lanthanum cerium chloride solution at a constant speed under normal temperature stirring conditions, the mass ratio of fluosilicic acid ...

Embodiment 2

[0035] (1) Raw material preparation: Weigh 0.6 kg of cerium carbonate and add hydrochloric acid to prepare a 0.4 mol / L cerium chloride solution, and adjust the pH of the solution to 4-4.5 with hydrochloric acid and rare earth carbonate. Weigh 0.184g of ammonium bicarbonate to prepare a saturated ammonium bicarbonate solution as a precipitant, and adjust the pH to 8-9 with ammonia water. Prepare 2mol / L sodium chloride solution, weigh 18% of the mass percentage of the rare earth oxide powder, prepare 30% sodium polyacrylate solution, weigh 1% of the rare earth oxide powder, and add Into the cerium chloride solution, stir evenly;

[0036] (2) Fluorination: Weigh fluosilicic acid with a weight concentration of 30%, add it to the cerium chloride solution at a constant speed under stirring at room temperature, the mass ratio of fluosilicic acid to cerium oxide is 7%, and continue stirring for 10 minutes;

[0037] (3) Precipitation: Warm up the fluorinated cerium chloride solution t...

Embodiment 3

[0041] (1) Preparation of raw materials: Weigh 0.8 kg of cerium carbonate and add hydrochloric acid to prepare a 0.8 mol / L cerium chloride solution, and adjust the pH of the solution to 4-4.5 with hydrochloric acid and rare earth carbonate. Weigh 0.245 g of ammonium bicarbonate to prepare a saturated ammonium bicarbonate solution as a precipitant, and adjust the pH to 8-9 with ammonia water. Prepare 2mol / L magnesium chloride solution, weigh the content to account for 25% of the mass percentage of rare earth oxide powder, prepare 30% dispersant LBD-1 solution, weigh the content to account for 5% of the mass percentage of rare earth oxide powder, and add Into the cerium chloride solution, stir evenly;

[0042] (2) Fluorination: Weigh fluosilicic acid with a weight concentration of 30%, add it to the cerium chloride solution at a constant speed under stirring at room temperature, the mass ratio of fluosilicic acid to cerium oxide is 8%, and continue stirring for 15 minutes;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com