High performance alkali swelling thickener and preparation method thereof

An alkali swelling and thickening agent technology, applied in chemical instruments and methods, polymer adhesive additives, pharmaceutical formulations, etc. Strong plasticity, increased viscosity, and excellent emulsifying properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

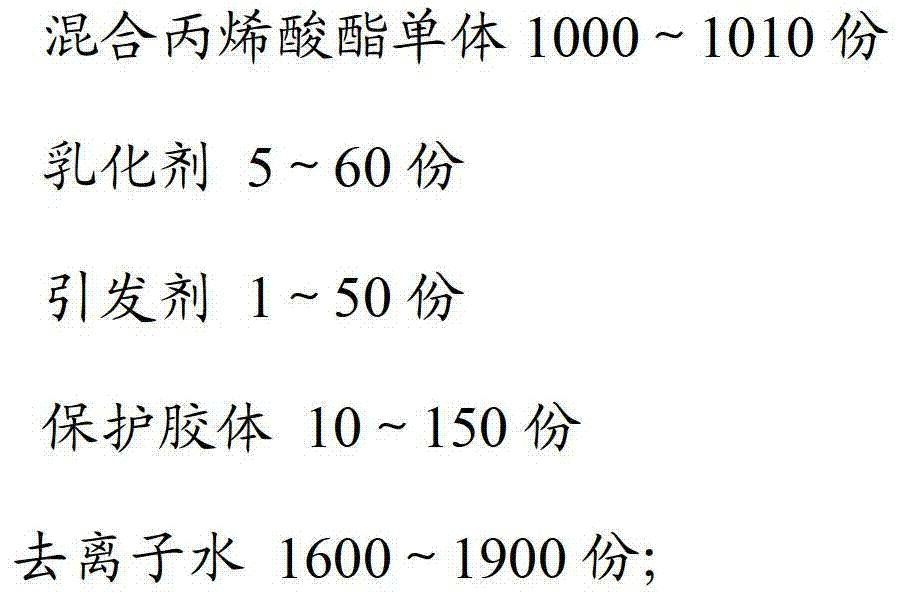

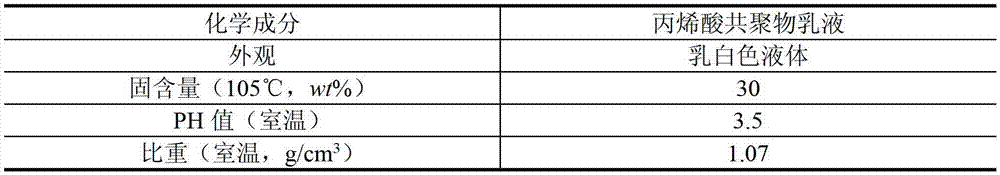

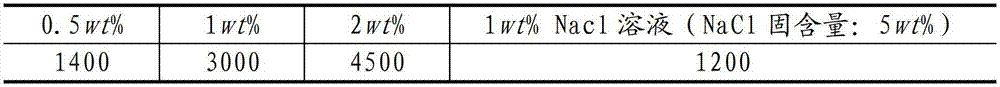

[0033] A high-performance alkali-swellable thickener whose production formula (in kg) is:

[0034] (1) Methyl methacrylate: 400

[0035] (2) Butyl acrylate: 200

[0036] (3) Styrene: 150

[0037] (4) Ethylene acetate: 200

[0038] (5) Acrylic: 50

[0039] (6) AEO-9:10

[0040] (7) Ammonium persulfate: 2

[0041] (8) Polyvinyl alcohol: 10

[0042] (9) Deionized water: 1900.

[0043] Production Process:

[0044] (1) Pre-emulsification and batching: Add 1500kg deionized water, 10kg emulsifier AEO-9, 400kg methyl methacrylate, 200kg butyl acrylate, 150kg styrene, 200kg ethylene acetate and 50kg acrylic acid into the pre-emulsification kettle , and then vigorously stir for pre-emulsification until a stable pre-emulsion is obtained.

[0045] (2) Add 2kg of ammonium persulfate to 98kg of deionized water to make an initiator solution for later use.

[0046] (3) Add 10kg of polyvinyl alcohol to 90kg of deionized water to prepare a protective colloid solution for later use.

...

Embodiment 2

[0055] A high-performance alkali-swellable thickener whose production formula (in kg) is:

[0056] (1) Isooctyl acrylate: 300

[0057] (2) Butyl acrylate: 300

[0058](3) Methyl methacrylate: 100

[0059] (4) Styrene: 300

[0060] (5) Hydroxyethyl methacrylate: 50

[0061] (6) Tween-80: 10

[0062] (7) Potassium persulfate: 2

[0063] (8) Sodium carboxymethylcellulose (CMC): 10

[0064] (9) Deionized water: 1800.

[0065] Production Process:

[0066] (1) Pre-emulsification and batching: Add 1500kg of deionized water, Tween-80, and isooctyl acrylate, butyl acrylate, methyl methacrylate, styrene, and hydroxyethyl methacrylate into the pre-emulsification kettle for pre-emulsification , to obtain a stable pre-emulsion.

[0067] (2) Add 2kg of potassium persulfate to 98kg of deionized water to make an initiator solution for later use.

[0068] (3) Add 10kg sodium carboxymethyl cellulose to 90kg deionized water to prepare a protective colloid solution for later use.

[00...

Embodiment 3

[0074] A high-performance alkali-swellable thickener whose production formula (in kg) is:

[0075] (1) Ethyl methacrylate: 360

[0076] (2) Butyl acrylate: 280

[0077] (3) Methyl methacrylate: 120

[0078] (4) Methyl acrylate: 180

[0079] (5) N,N-methylenebisacrylamide: 70

[0080] (6) Sodium lauryl sulfate: 10

[0081] (7) Potassium persulfate: 2

[0082] (8) Sodium polymethacrylate: 10

[0083] (9) Deionized water: 1600.

[0084] Production Process:

[0085] (1) Pre-emulsification and batching: Add 1200kg of deionized water, sodium lauryl sulfate, and ethyl methacrylate, butyl acrylate, methyl methacrylate, methyl acrylate, N,N to the pre-emulsification kettle - Methylenebisacrylamide, pre-emulsified to obtain a pre-emulsion.

[0086] (2) Add 2kg of potassium persulfate to 98kg of deionized water to make an initiator solution for later use.

[0087] (3) Add 10kg of sodium polymethacrylate to 90kg of deionized water to prepare a protective colloid solution for lat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com