Tableware detergent with enzyme and preparation method thereof

A tableware detergent and enzyme preparation technology, which is applied in the direction of detergent compounding agent, detergent composition, surface active detergent composition, etc., can solve the problems of poor enzyme stability and weak decontamination ability, and achieve high cost performance, Good effect on stubborn stains and stains, good product flow and high and low temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

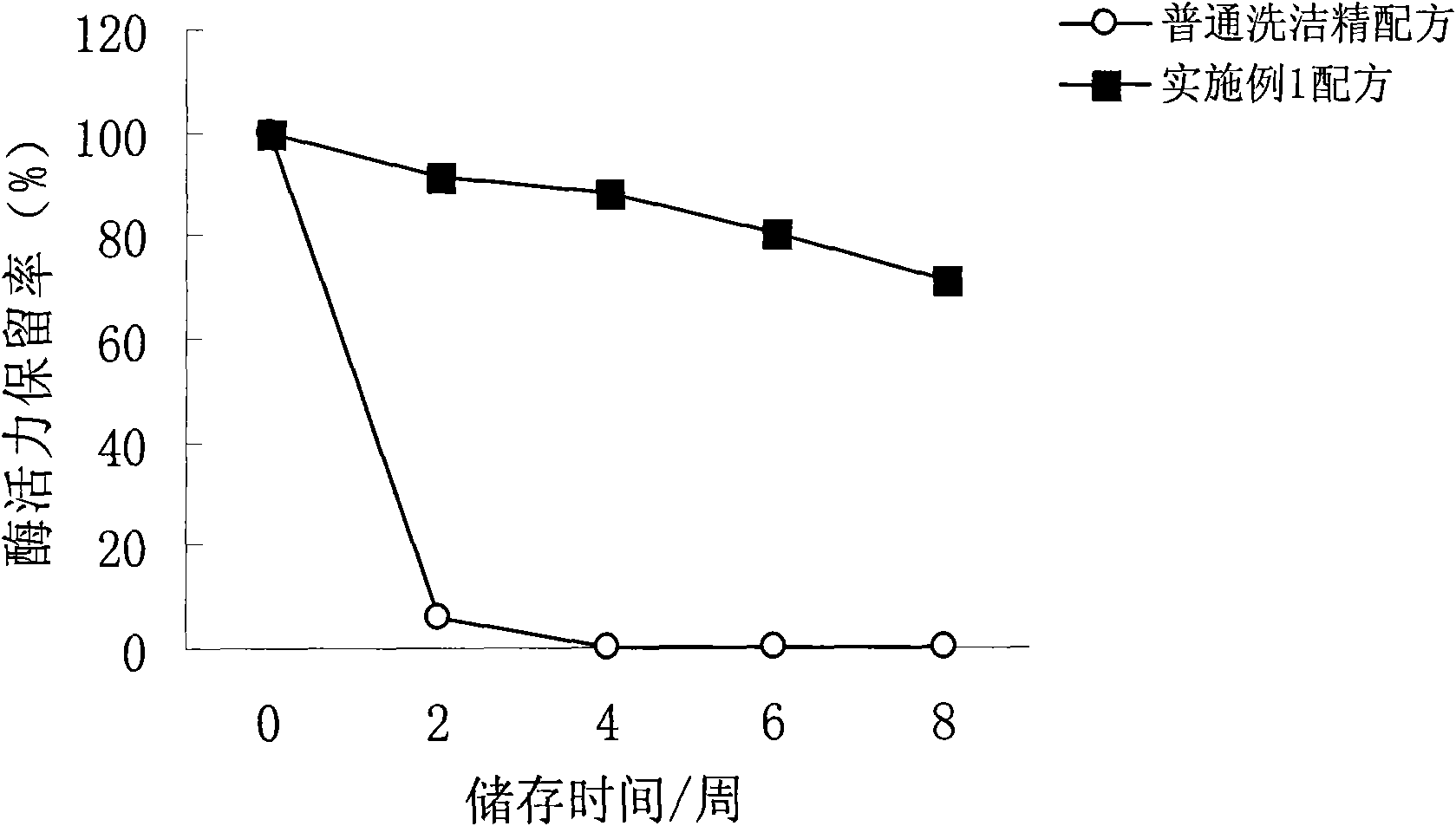

Embodiment 1

[0037] (1) Invention formula:

[0038] Raw material name weight percentage (%)

[0039] Sodium fatty alcohol polyoxyethylene ether sulfate 22.0

[0040] Alkanolamide 1.0

[0041] Fatty alcohol polyoxyethylene ether succinate disodium 2.0

[0042] Sodium citrate 1.0

[0043] Calcium chloride dihydrate 0.05

[0044] Propylene Glycol 5.0

[0046] Isothiazolinone 0.06

[0047] Fragrance 0.1

[0048] Amylase 0.3

[0049] Soft water balance

[0050] (2) The production process is as follows:

[0051]Put soft water with 70% of the total weight of raw material water into the batching pot first; then put in fatty alcohol polyoxyethylene ether sodium sulfate and stir until completely dissolved; put in alkanolamide and stir until completely dissolved; put in sodium citrate and stir until completely dissolved Put in the remaining amount of soft water, measure the pH value, and adjust the pH to 7-8.5 by adding an appropriate amount of citric acid acco...

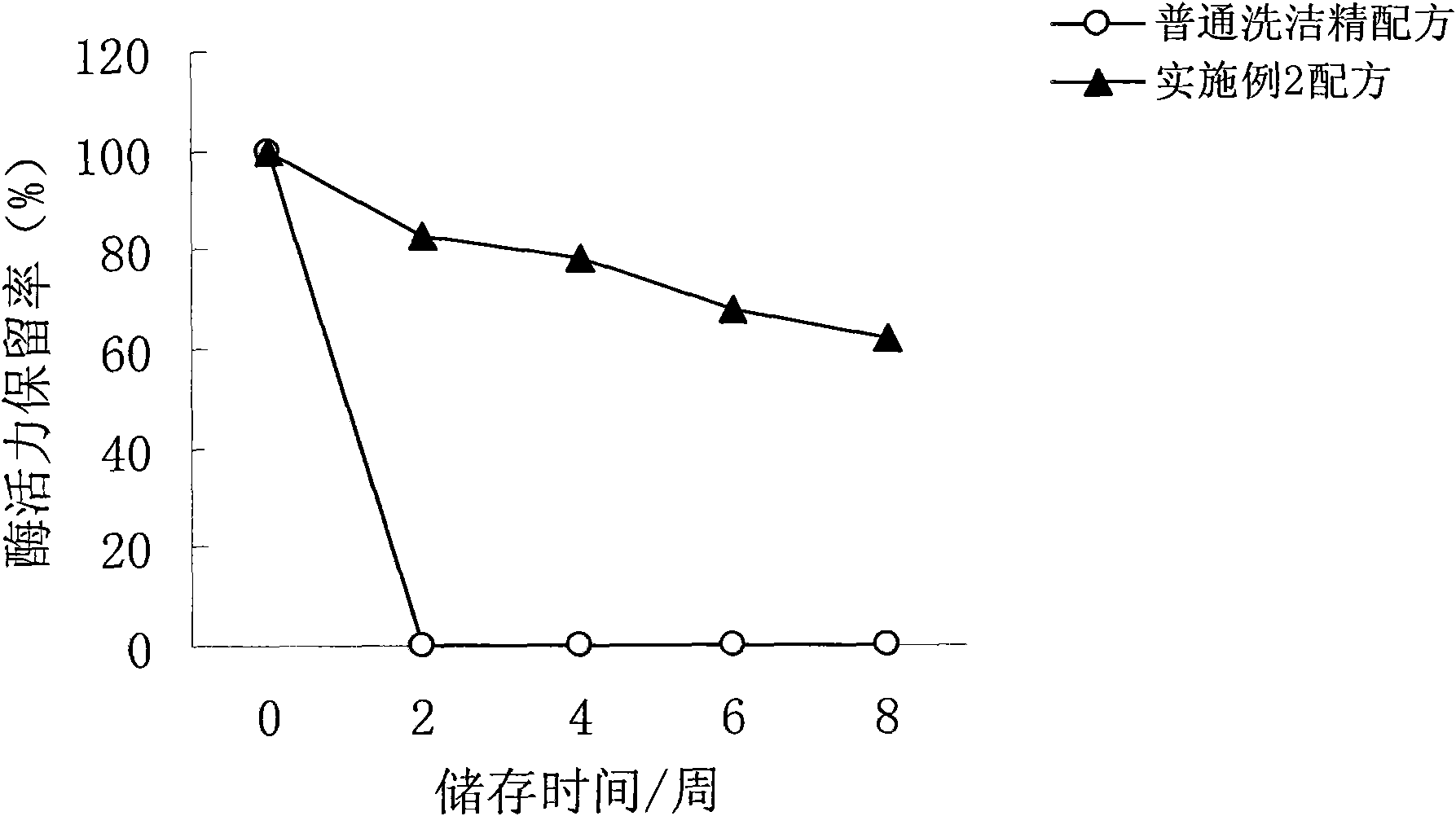

Embodiment 2

[0055] (1) Invention formula:

[0056] Raw material name weight percentage (%)

[0057] Sodium fatty alcohol polyoxyethylene ether sulfate 6.8

[0058] Fatty alcohol polyoxyethylene ether-7 3.0

[0059] Alkanolamide 1.0

[0060] APG 5.0

[0061] Sodium fatty acid methyl ester sulfonate 4.0

[0062] Calcium chloride dihydrate 0.05

[0063] Propylene Glycol 5

[0064] Sodium chloride 1.5

[0065] Isothiazolinone 0.06

[0066] Sodium citrate 0.3

[0067] Fragrance 0.1

[0068] Protease 0.3

[0069] Soft water balance

[0070] (2) The production process is as follows:

[0071] Put soft water with 70% of the total weight of raw material water into the batching pot first; then put in fatty alcohol polyoxyethylene ether sodium sulfate, stir until completely dissolved; put in fatty acid methyl ester sodium sulfonate, stir until completely dissolved; put in fatty alcohol polyoxyethylene Ether-7, stirred until completely dissolved; put in alkanolamide and APG, stirred until...

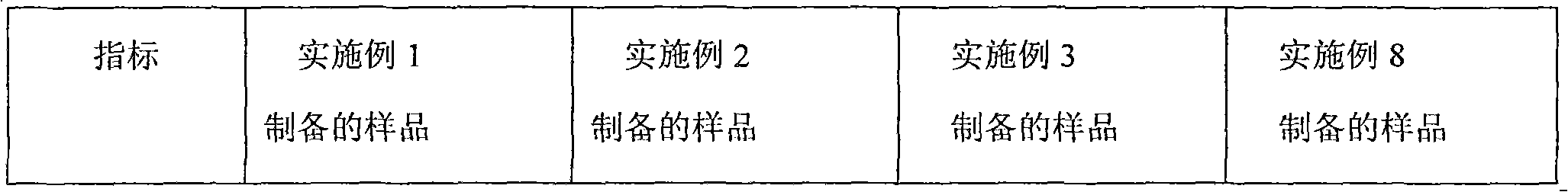

Embodiment 3

[0075] (1) Invention formula:

[0076] Raw material name weight percentage (%)

[0077] Sodium fatty alcohol polyoxyethylene ether sulfate 26

[0078] Fatty alcohol polyoxyethylene ether succinate disodium 3.0

[0079] Sodium fatty alcohol polyoxyethylene ether carboxylate 14.0

[0080] Alkanolamide 3.0

[0081] Borax 2.0

[0082] Sodium chloride 1.0

[0083] Polyacrylate 0.7

[0084] Isothiazolinone 0.06

[0085] Sodium citrate 0.5

[0086] Fragrance 0.1

[0087] Protease 0.5

[0088] Soft water balance

[0089] (2) The production process is as follows:

[0090] Put soft water of 70% of the total weight of raw material water into the batching pot first; then put in polyacrylate, stir until completely dissolved; put in fatty alcohol polyoxyethylene ether sodium sulfate, stir until completely dissolved; put in fatty alcohol polyoxyethylene ether carboxylic acid Sodium, stir until completely dissolved; put in alkanolamide, stir until completely dissolved; put in sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com