Cutting fluid for cutting of scroll saw

A cutting fluid and wire saw technology, applied in the field of cutting fluid, can solve the problems of poor redispersion ability, wide knife edge, silicon carbide deposition, etc., and achieve good dispersion and suspension, good lubricity and cooling, and good dispersion. and the effect of suspension

Inactive Publication Date: 2012-02-08

ANJI MICROELECTRONICS (SHANGHAI) CO LTD

View PDF2 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Its disadvantages are: large damage on the surface of the wafer; wide knife edge, large material loss; low productivity; therefore, the internal circle cutting is far from meeting the current production needs in terms of output and capacity, especially the rapid development of large-scale integrated circuits and solar cells. , the demand for wafers increased sharply, and people began to consider adopting more efficient cutting equipment, and the wire saw came into being

[0005] The existing cutting fluids at home and abroad all have the weakness of poor redispersibility. After a long time of storage, silicon carbide will deposit and agglomerate. If you stir again, the silicon carbide cannot be dispersed in the cutting fluid again.

high cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

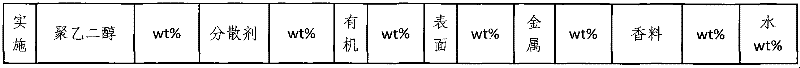

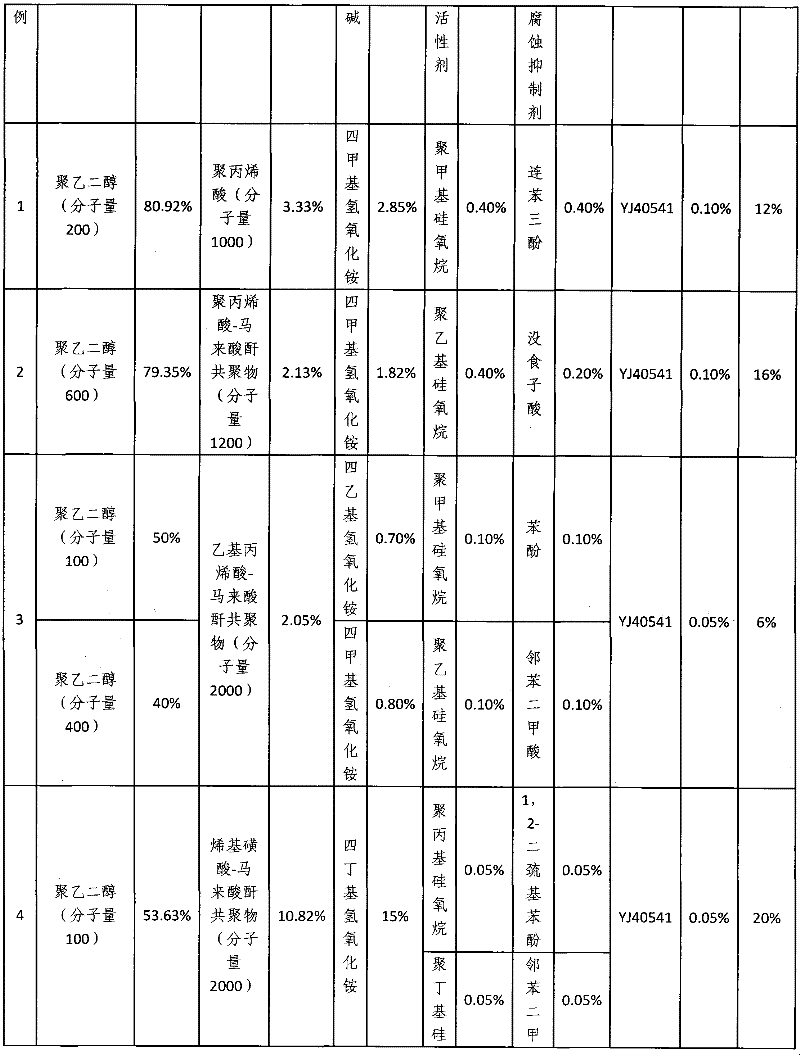

preparation Embodiment 1~6

[0025]

[0026]

[0027]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a cutting fluid for cutting of a scroll saw. The cutting fluid disclosed by the invention has the advantages of low cost and favorable dispersibility, suspension property, lubricity, cooling property and favorable stability, and thereby the cutting yield is improved. In addition, the cutting fluid disclosed by the invention is environment-friendly and is convenient to recover.

Description

technical field [0001] The invention relates to a cutting fluid, in particular to a cutting fluid for wire saw cutting. Background technique [0002] With the rapid development of the electronics industry, wafers are more and more widely used in integrated circuits, solar cells, LED lighting and other industries, and wire saw cutting of wafers has also received more and more attention. The cutting materials are mainly silicon, germanium, gallium arsenide, sapphire (aluminum oxide) and other hard materials. [0003] The earliest use in the field of wafer processing is the outer circle cutting technology. This cutting method achieves the purpose of cutting by grinding the material to be cut by the diamond sheet grinding wheel clamped on the high-speed rotating spindle. With the development of material preparation technology and the increase of cutting diameter, the rigidity of the outer circular blade is poor, and the problem that the swing amount of the blade is difficult t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09K3/14B28D5/04

Inventor 于昊宫勇

Owner ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com