Rare earth polishing liquid and preparation method thereof

A technology of rare earth polishing and rare earth polishing powder, which is applied to polishing compositions containing abrasives, etc., can solve the problems of inability to maintain dispersion maintenance, inability to improve dispersion maintenance, and low particle dispersion, and to reduce product scratches. damage, solve the effect of easy cleaning, and improve the amount of erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

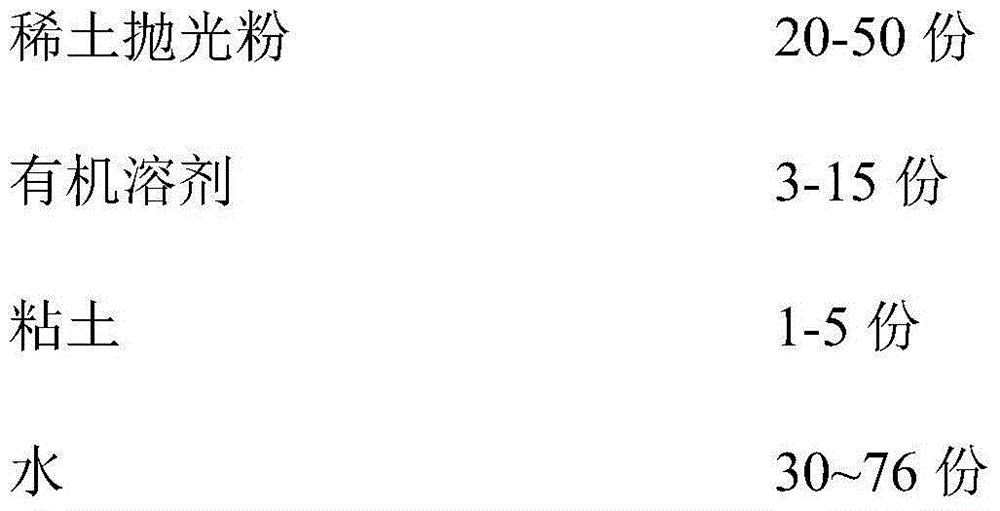

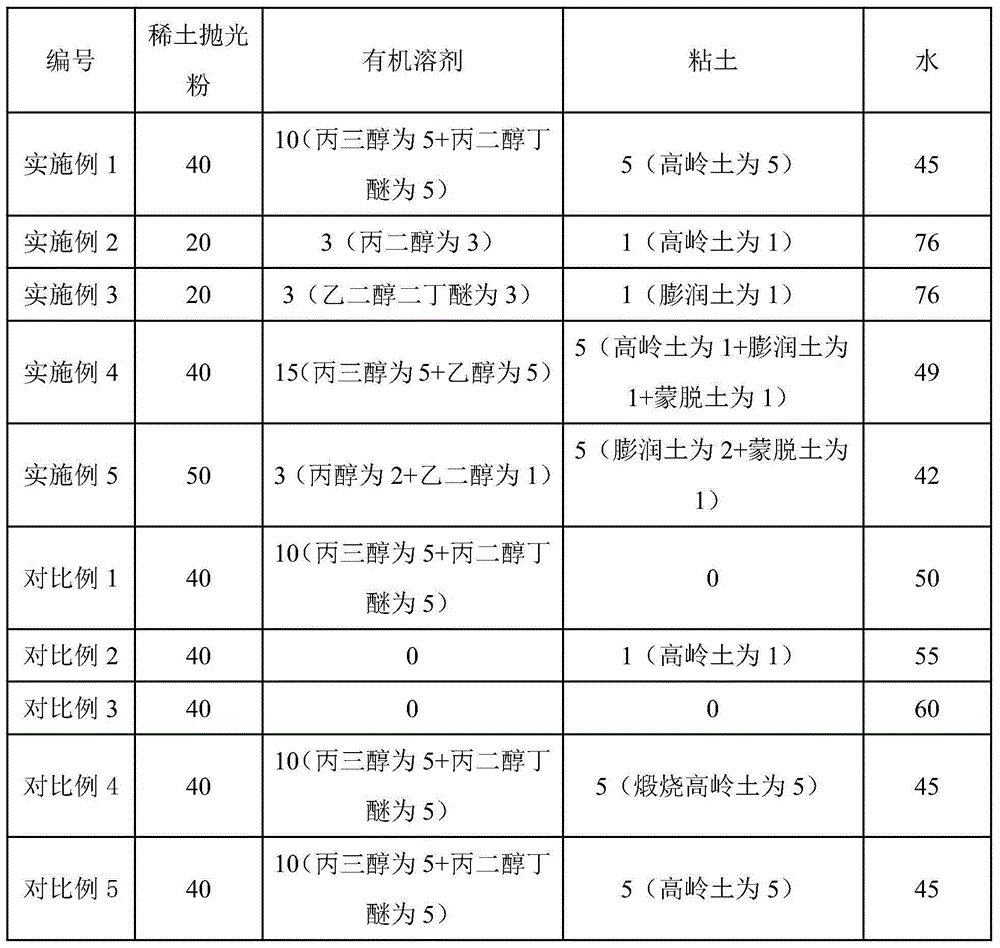

Examples

Embodiment 1

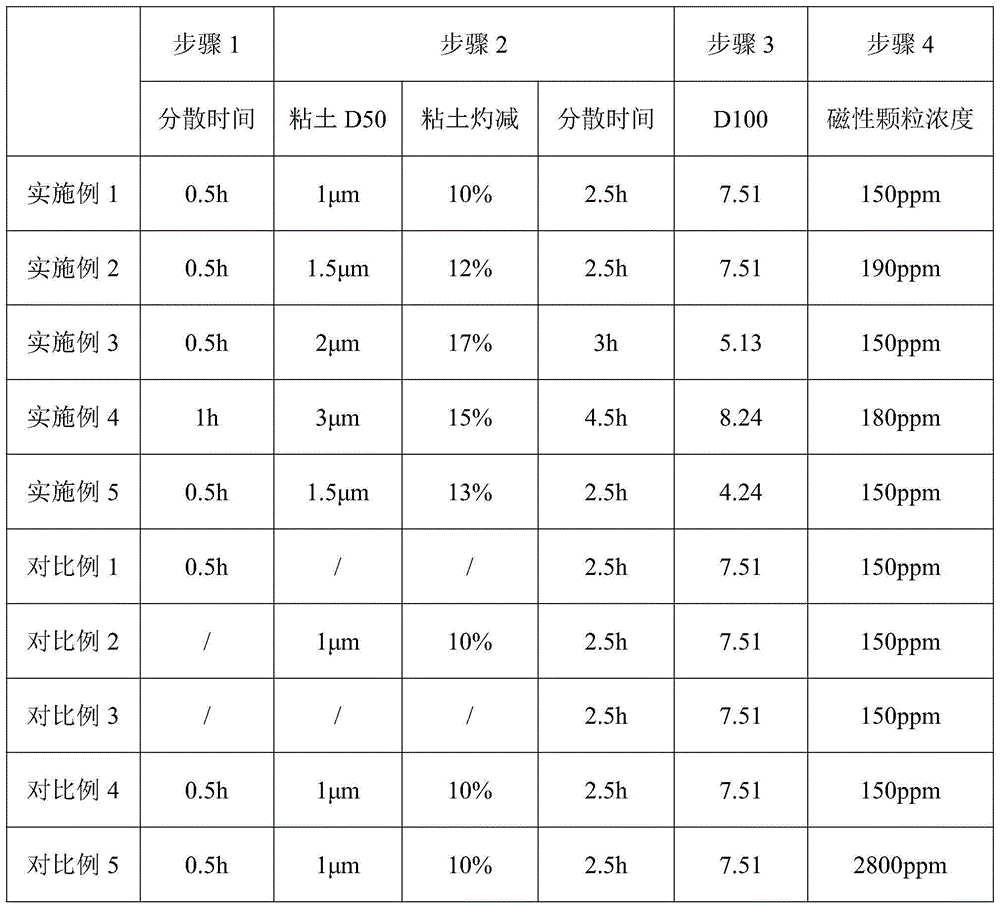

[0043] (1) Dispersion of the organic solution: Add 5kg of glycerol and 5kg of propylene glycol butyl ether into 45kg of water with a conductivity of 10us / cm, and shear and disperse for 0.5h to obtain solution A;

[0044] (2) Dispersion of clay: add 5kg D50 of 1 μm kaolin (10% weight loss on ignition) into solution A, beat with water, shear and disperse for 2.5 hours, and sieve through 500 mesh wet method to obtain slurry B;

[0045] (3) Preparation of polishing liquid: Add 40kg of rare earth polishing powder into slurry B under stirring conditions, and wet ball mill until the largest particle D100≤10μm;

[0046] (4) Control of magnetic substances: the slurry after ball milling is passed through a magnetic separator made of magnetic materials magnetized by excitation, and the concentration of magnetic particles is controlled to be no more than 200ppm by weight.

[0047] The magnetic separator is a fluid pipeline demagnetizer;

[0048] In Example 2-5 and Comparative Example 1-4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com