Patents

Literature

44results about How to "Solve the glue problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

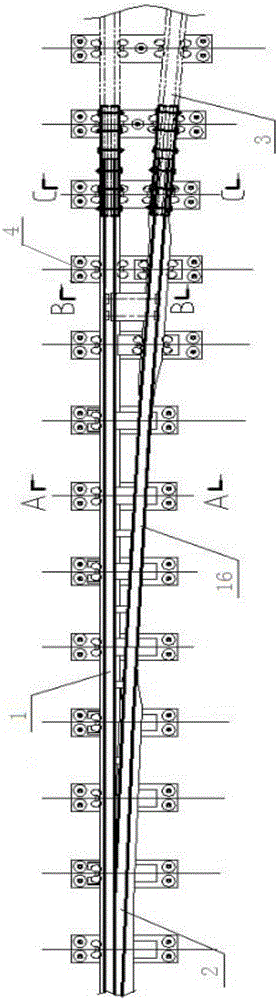

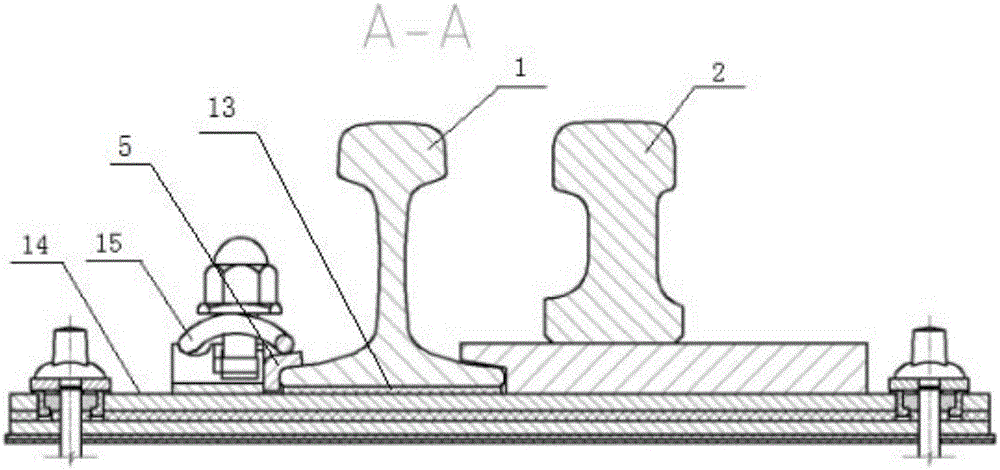

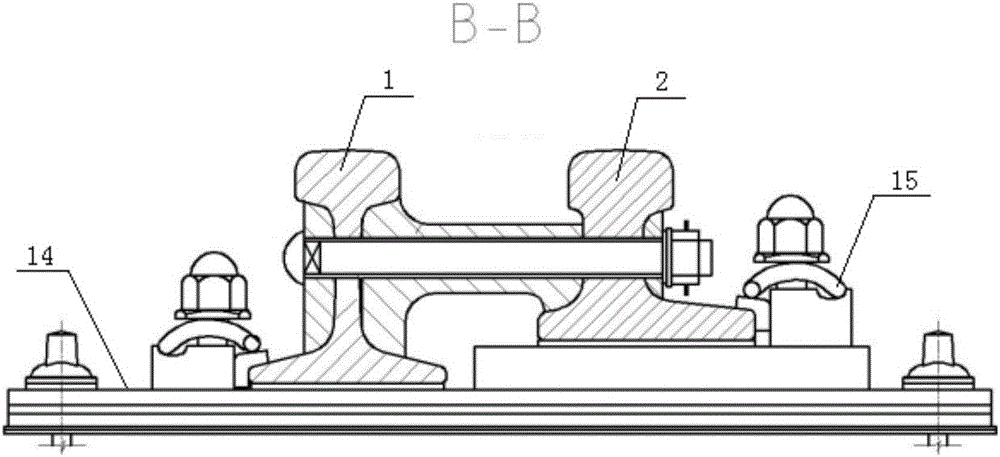

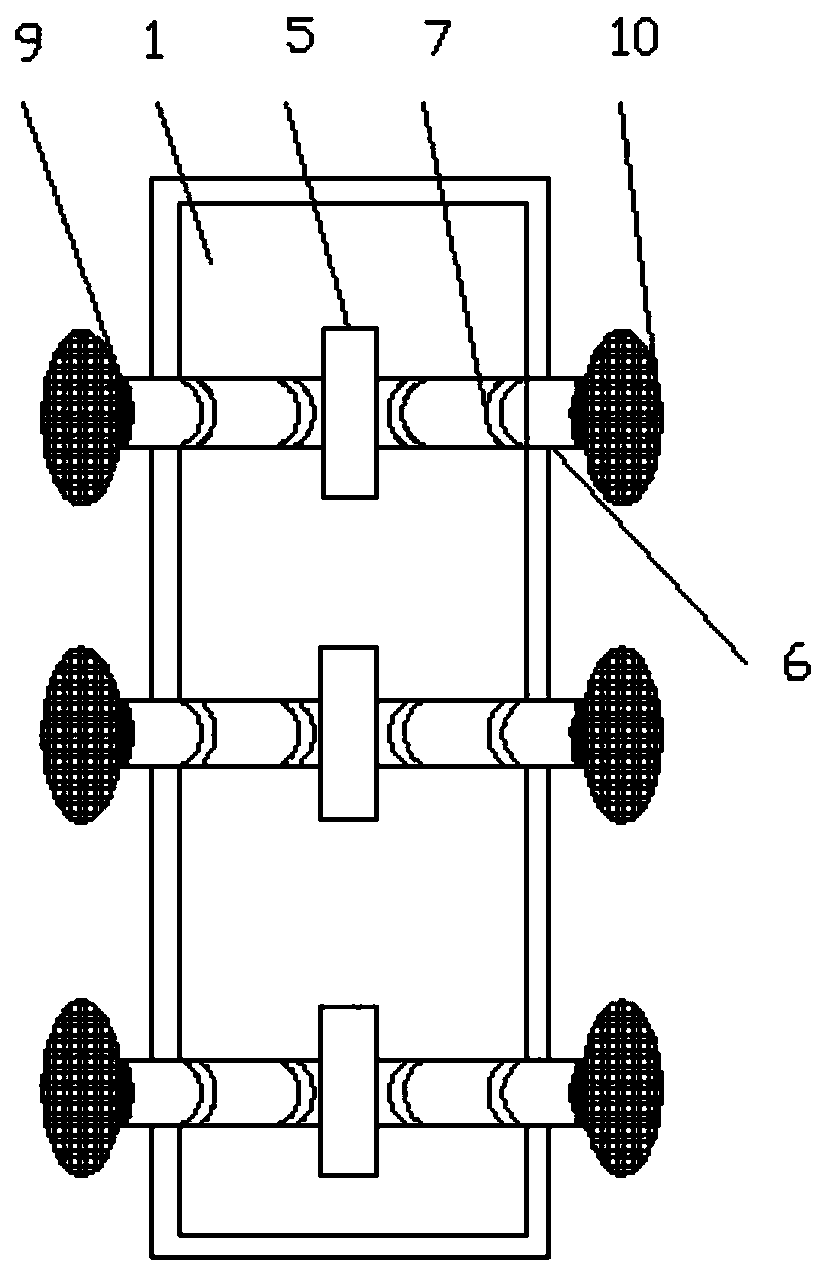

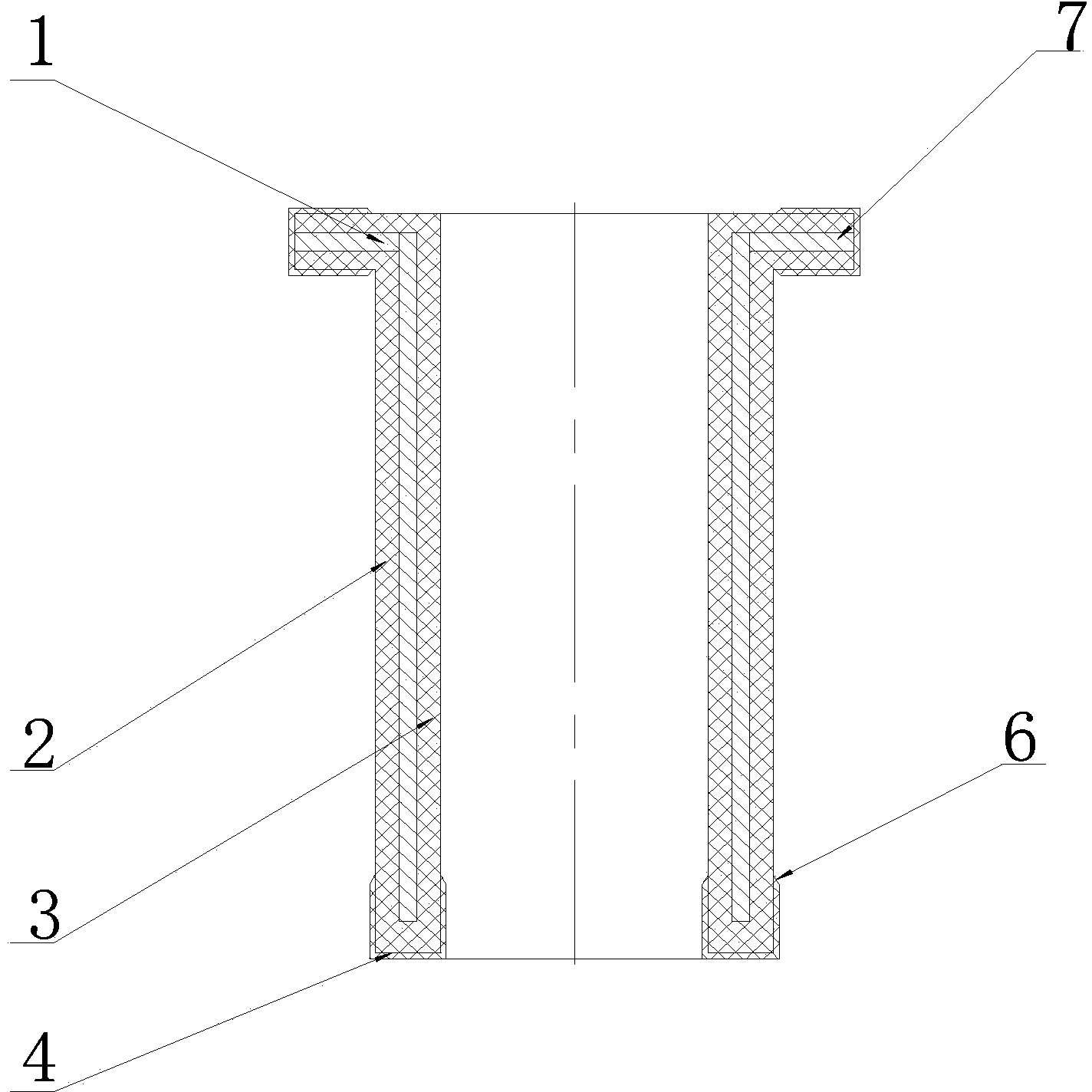

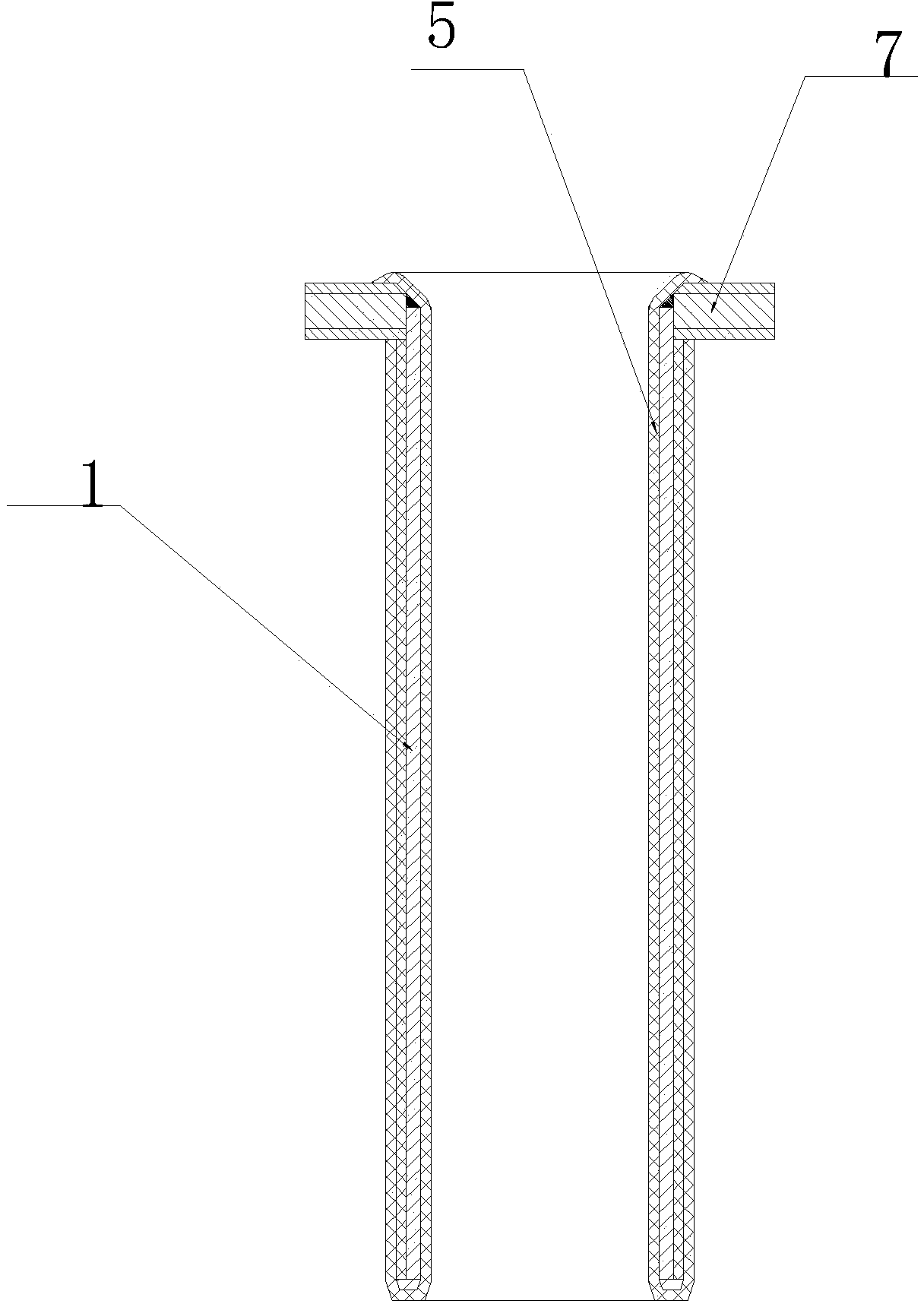

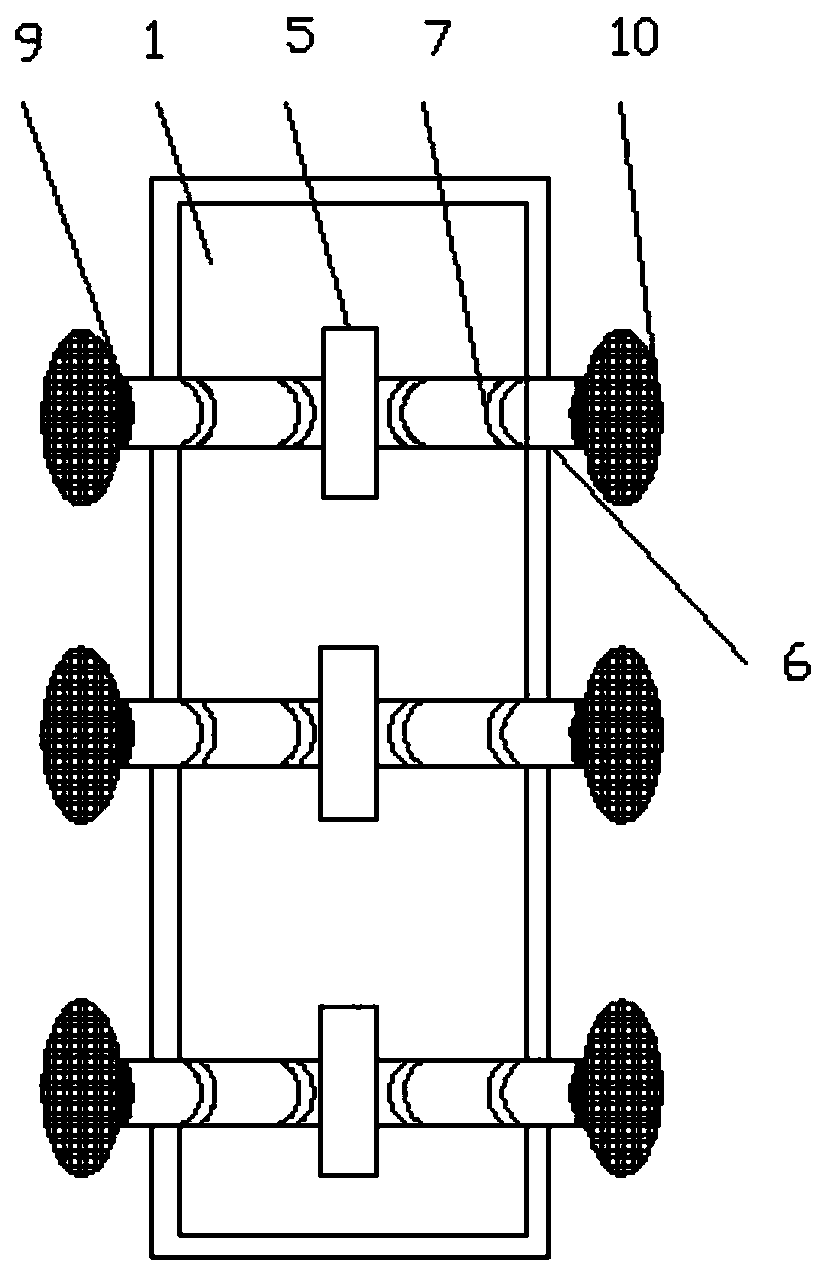

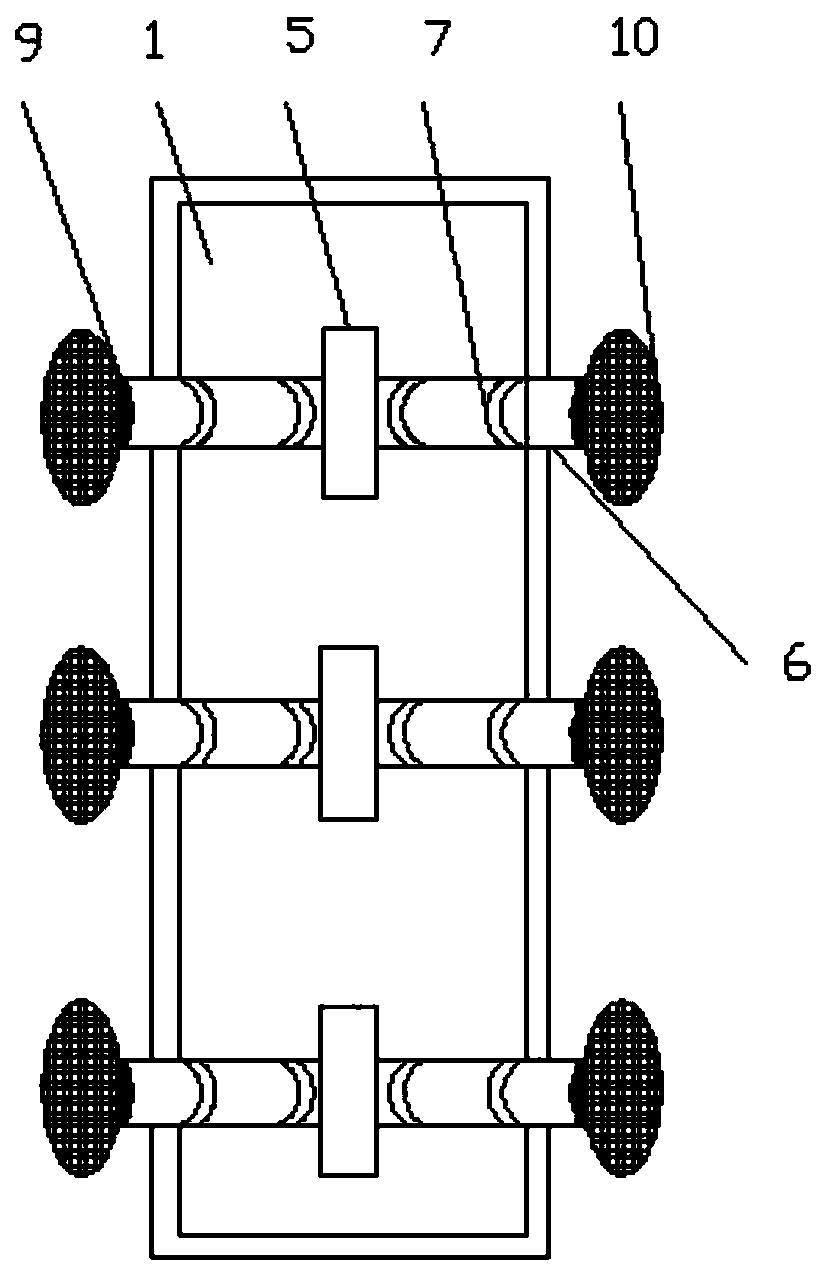

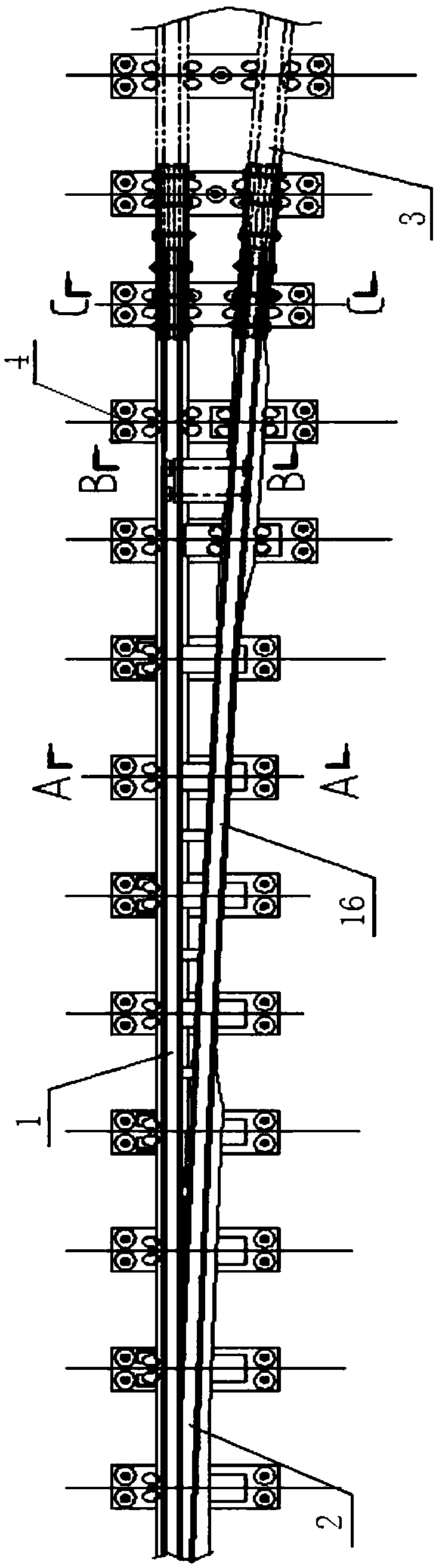

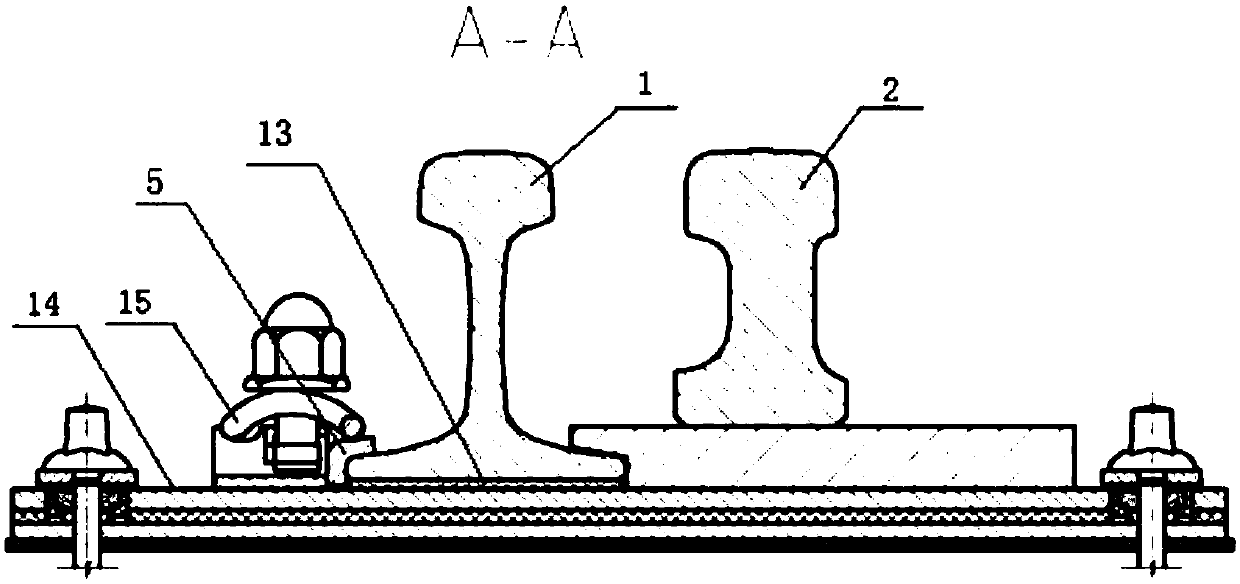

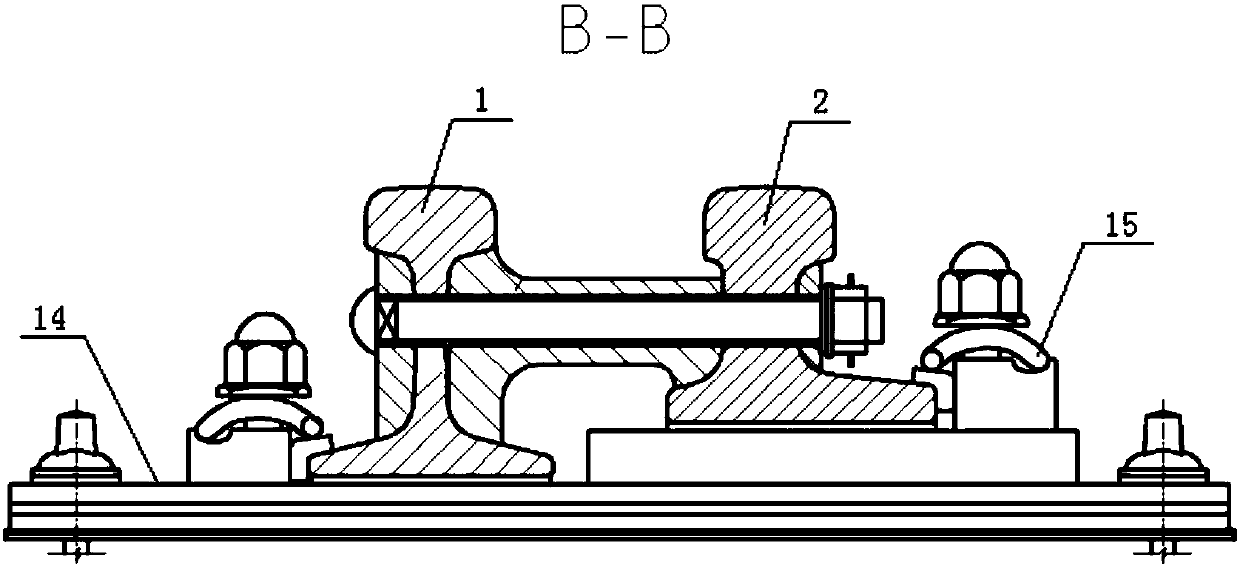

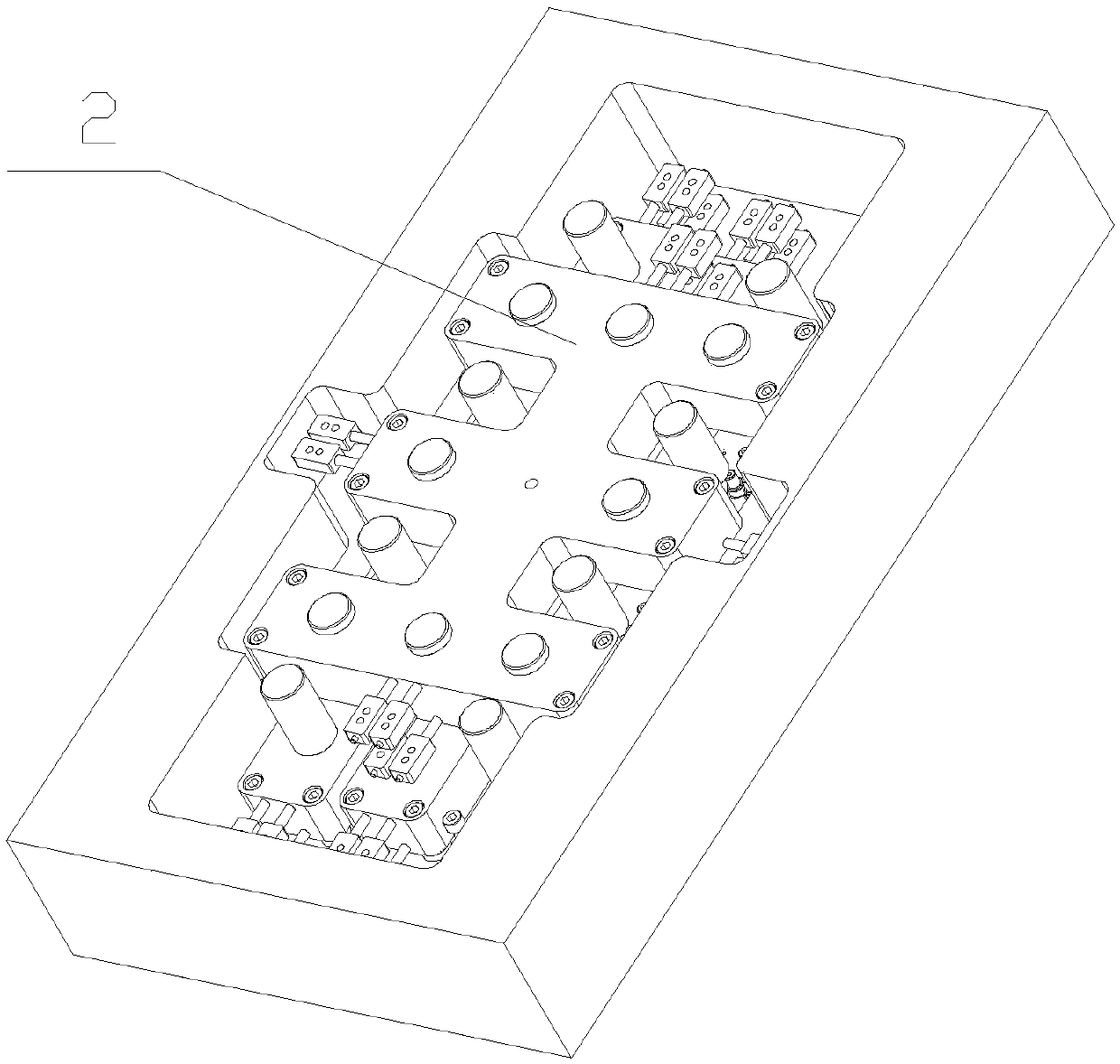

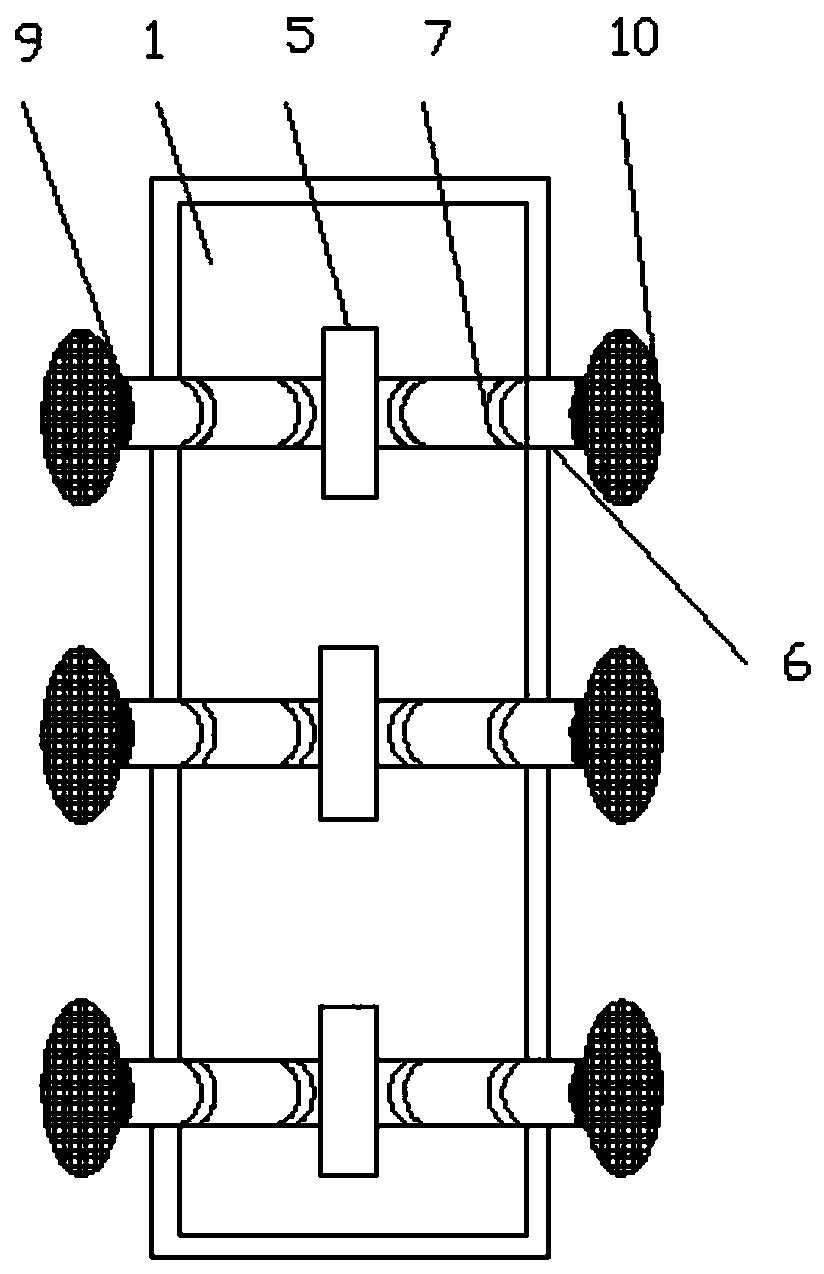

Urban railway transport vibration attenuation turnout structure

ActiveCN105862522AImprove pullout resistanceIncrease the installation heightRail switchesVibration attenuationEngineering

Disclosed is an urban railway transport vibration attenuation turnout structure. The urban railway transport vibration attenuation turnout structure comprises stock rails, switch rails and guide rails. The stock rails, the switch rails and the guide rails are mounted on a track bed through vibration attenuation fastener systems; the heel ends of the switch rails are provided with elastic bendable sections; the width of rail limbs of the working sides of the elastic bendable section is smaller than that of rail limbs of the working sides of the other sections of the switch rails; the stock rails, the heel ends of the switch rails and joints of the guide rails are connected through vibration attenuation joint clamping plates and common joint clamping plates, the vibration attenuation joint clamping plates are mounted on the non-working sides, and the common joint clamping plates are disposed on the working sides; and the top end faces of the vibration attenuation joint clamping plates are higher than the rail top faces of connected steel rails, and the top end faces of the vibration attenuation joint clamping plates have inclination consistent with that of wheel treads, so that the wheel treads operate on the top end faces of the vibration attenuation clamping plates when a train passes through joints. By means of the urban railway transport vibration attenuation turnout structure, vibration and noise caused by mutual impact of wheels and rails are reduced, the service life of turnout parts is prolonged, moreover, turnout construction is convenient, and less daily maintaining is needed.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP +1

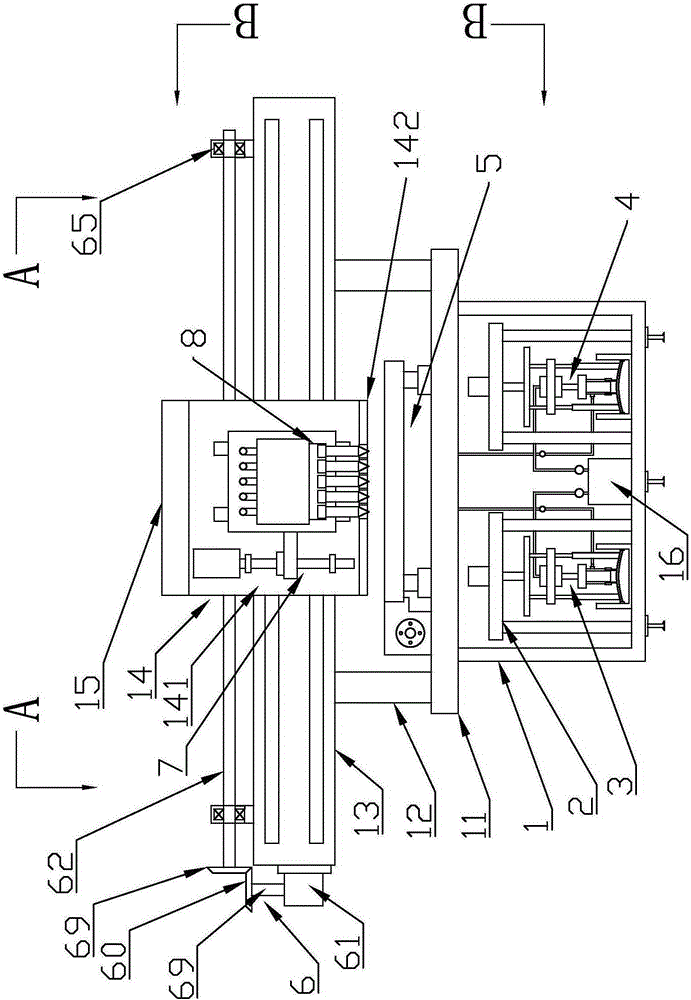

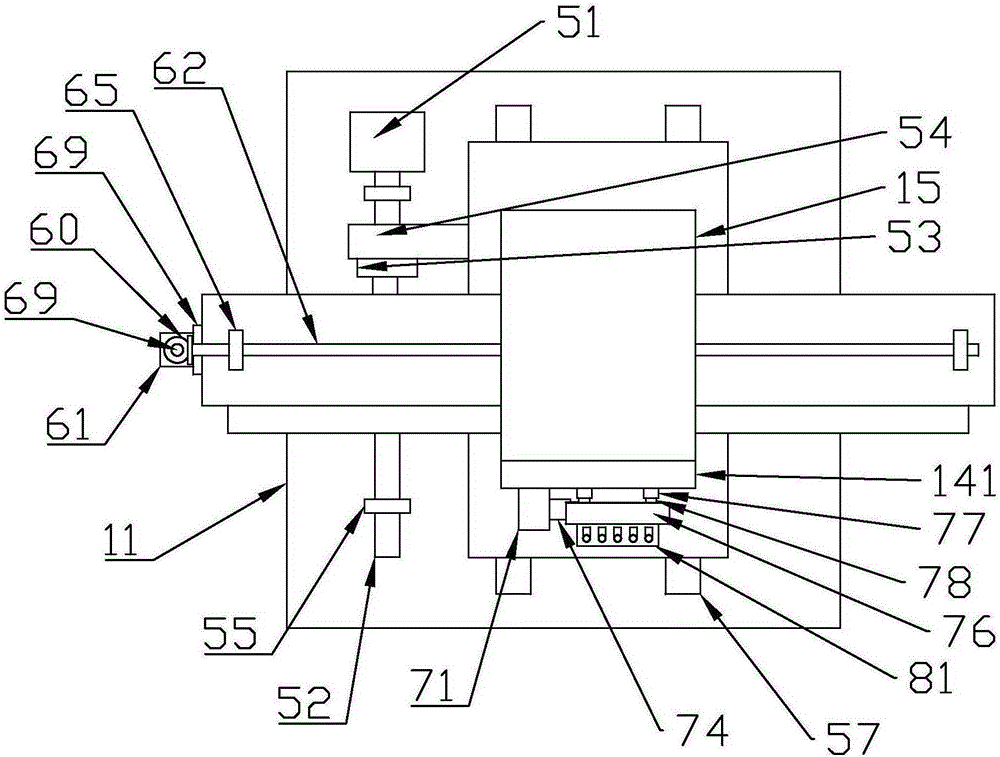

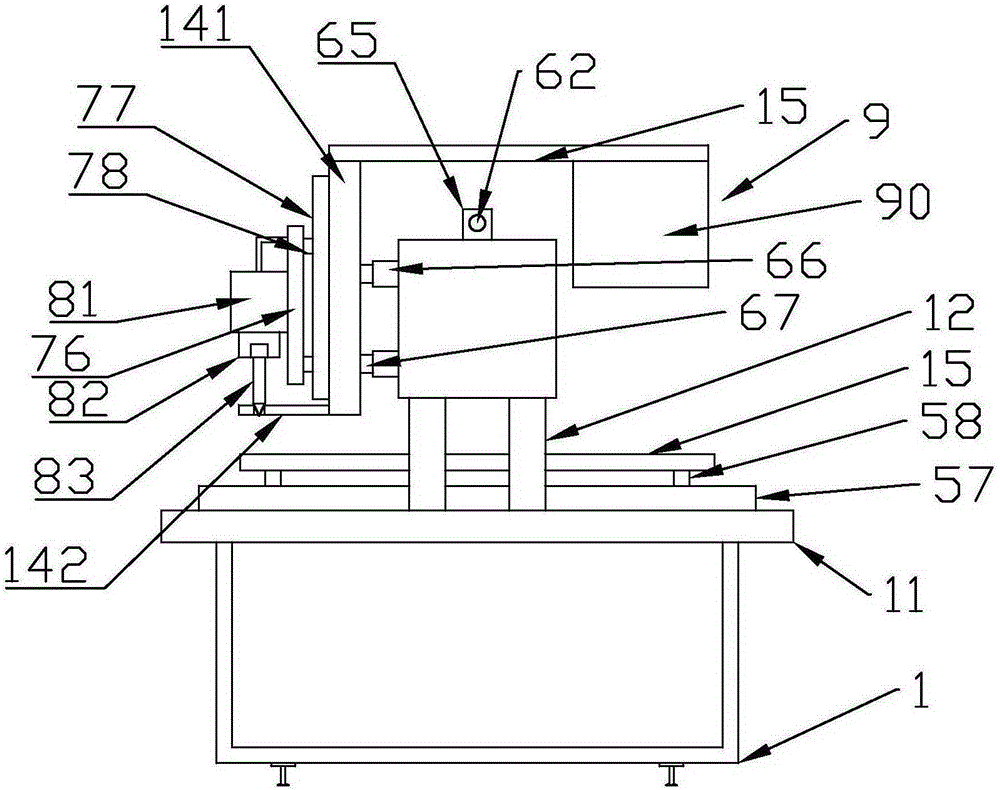

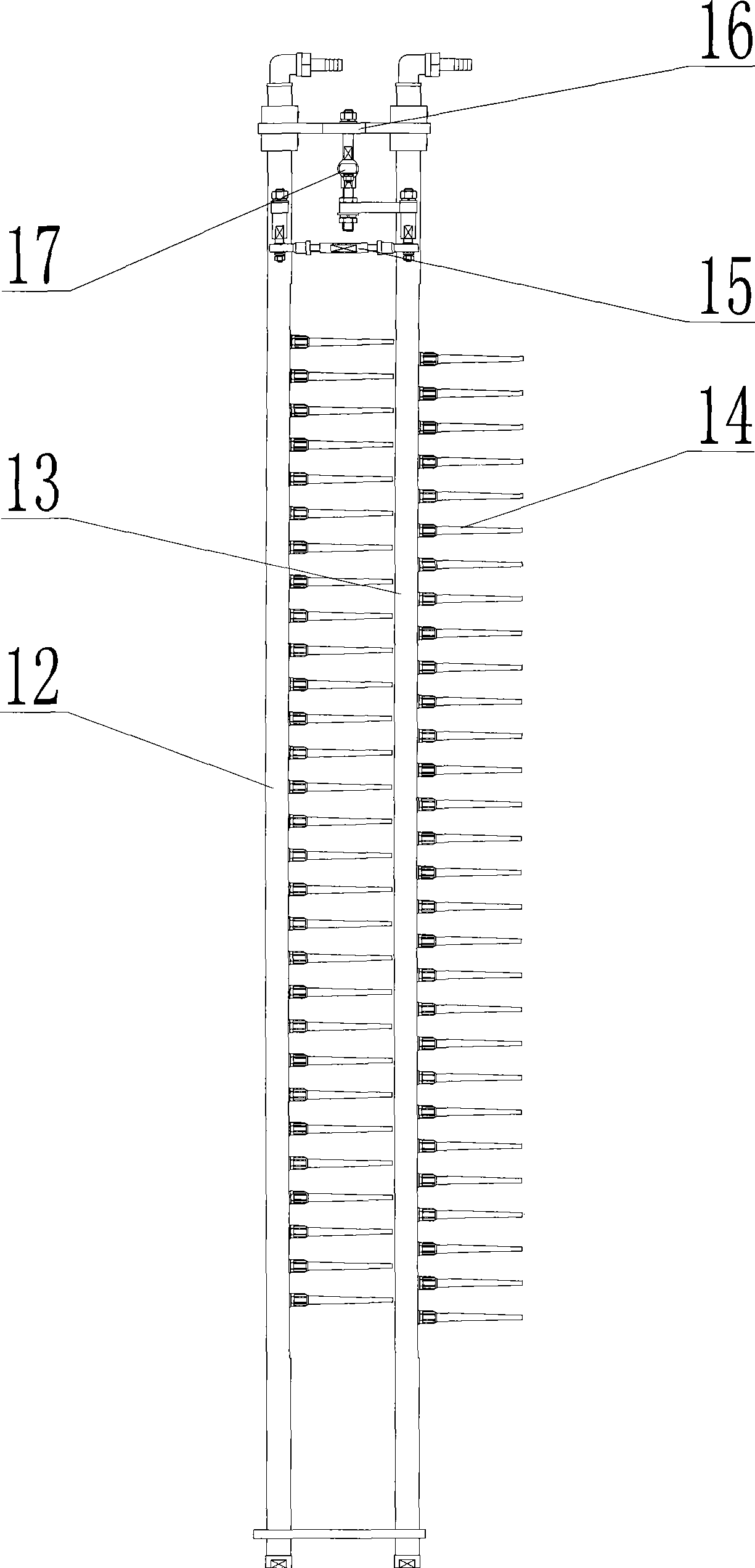

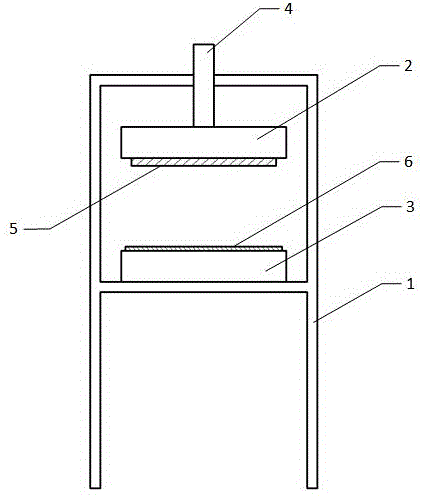

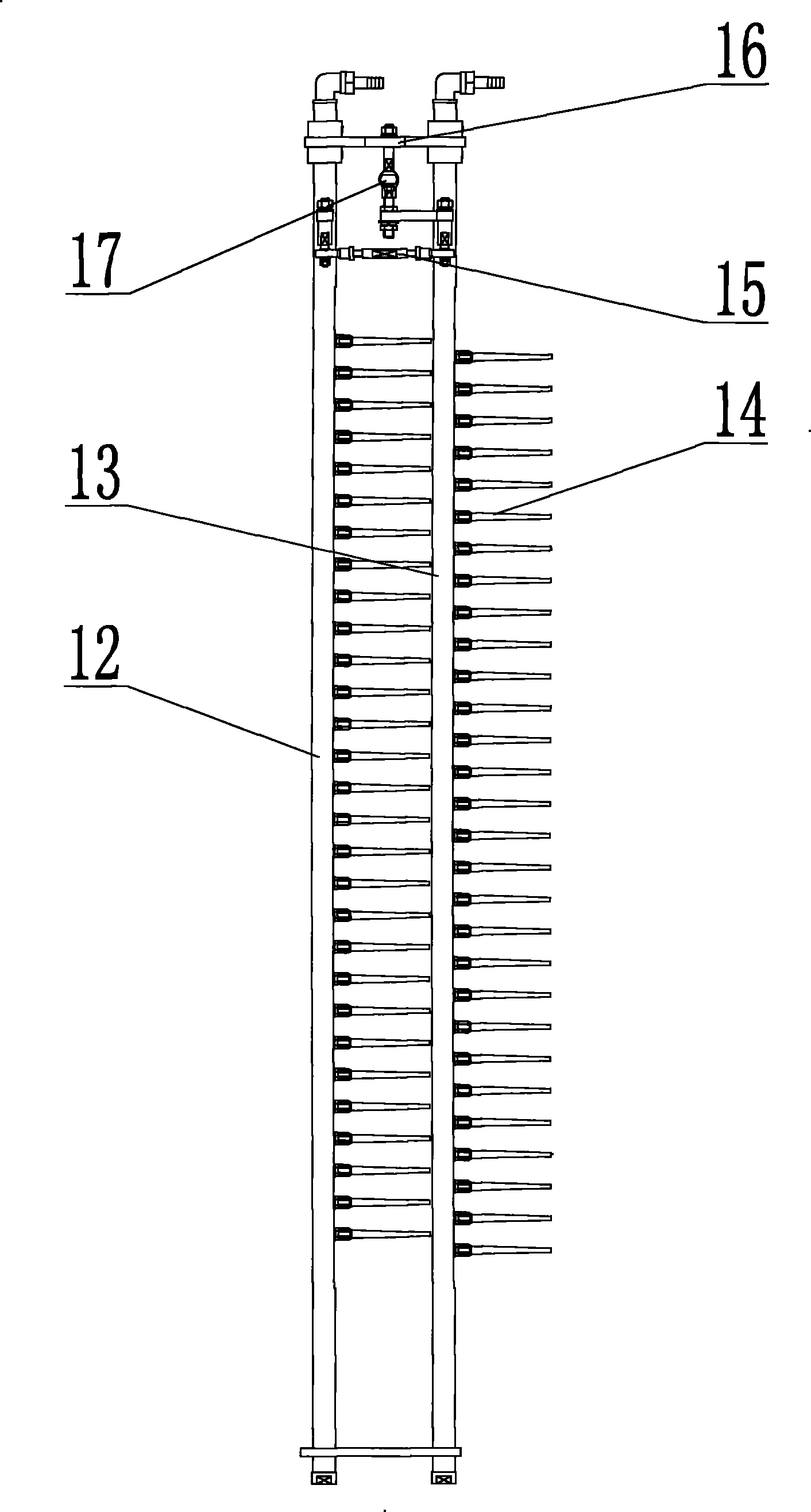

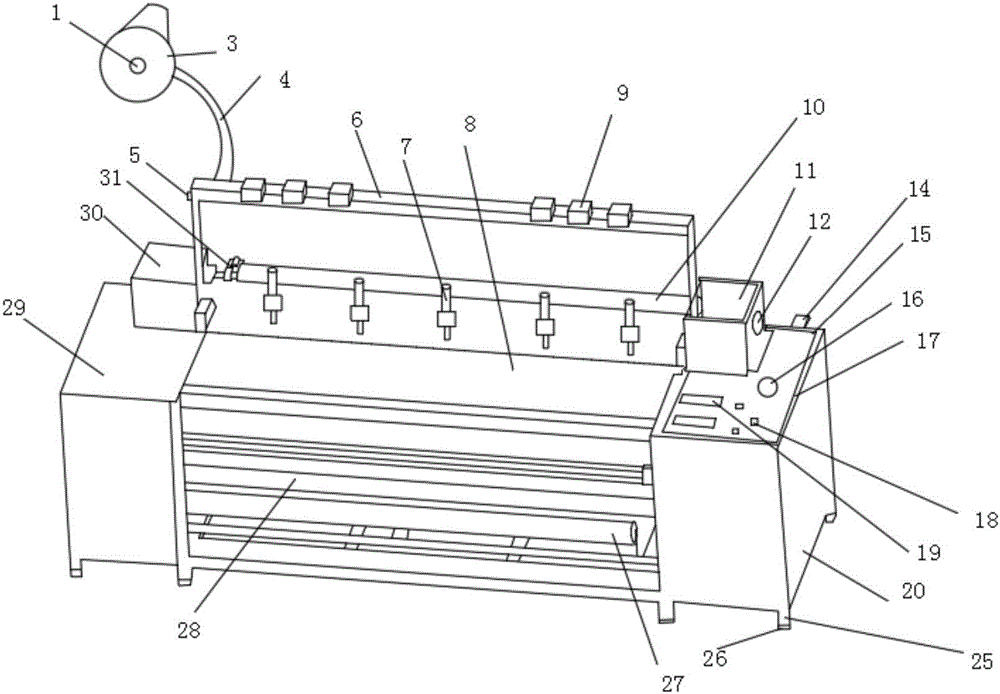

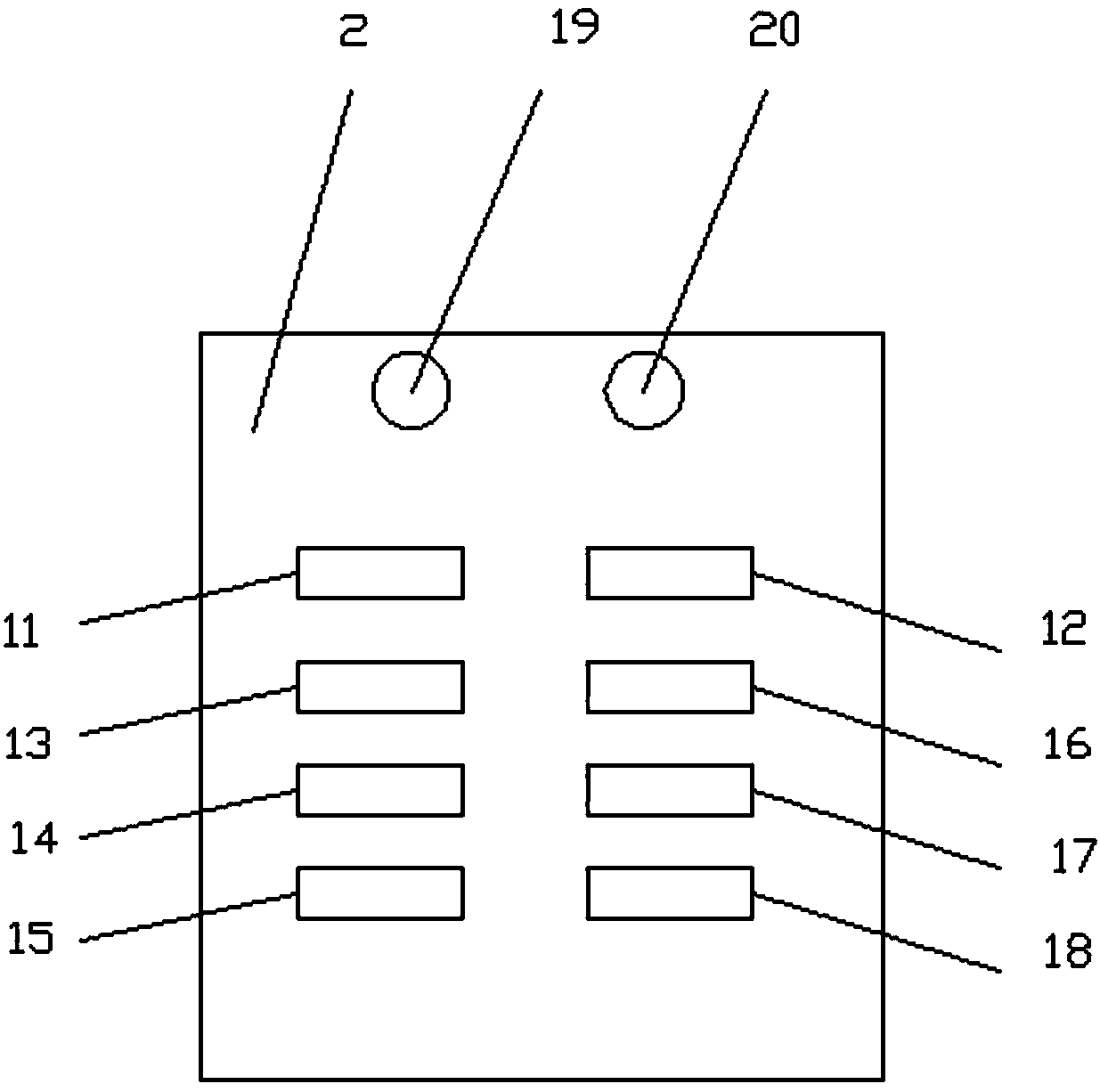

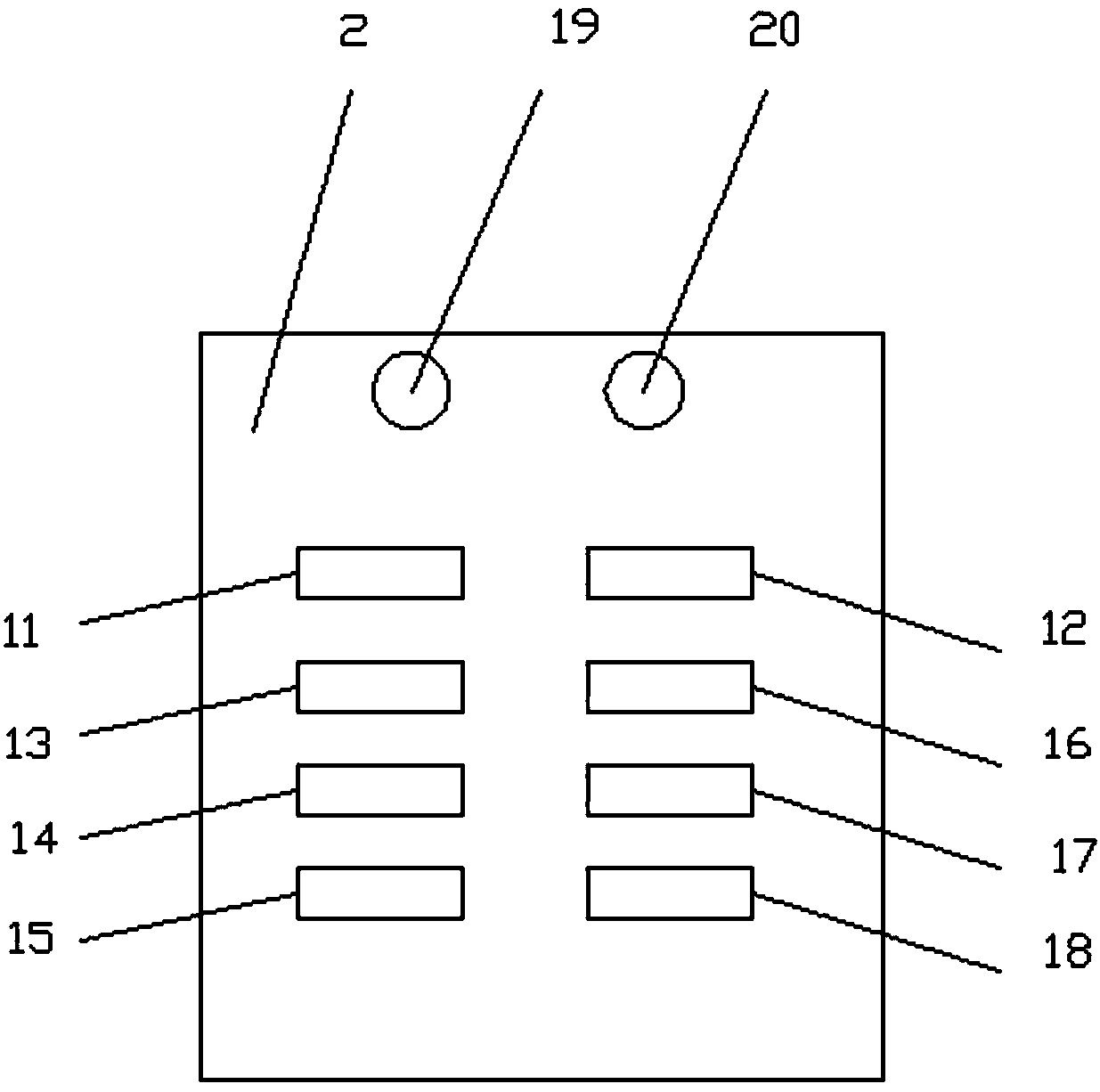

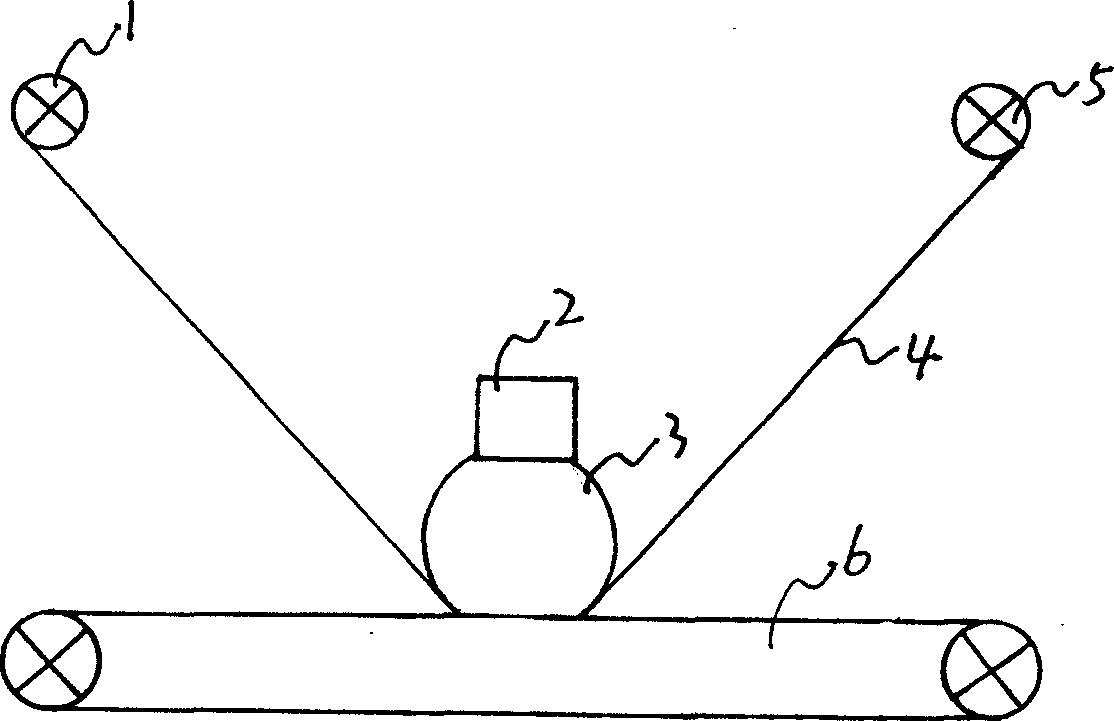

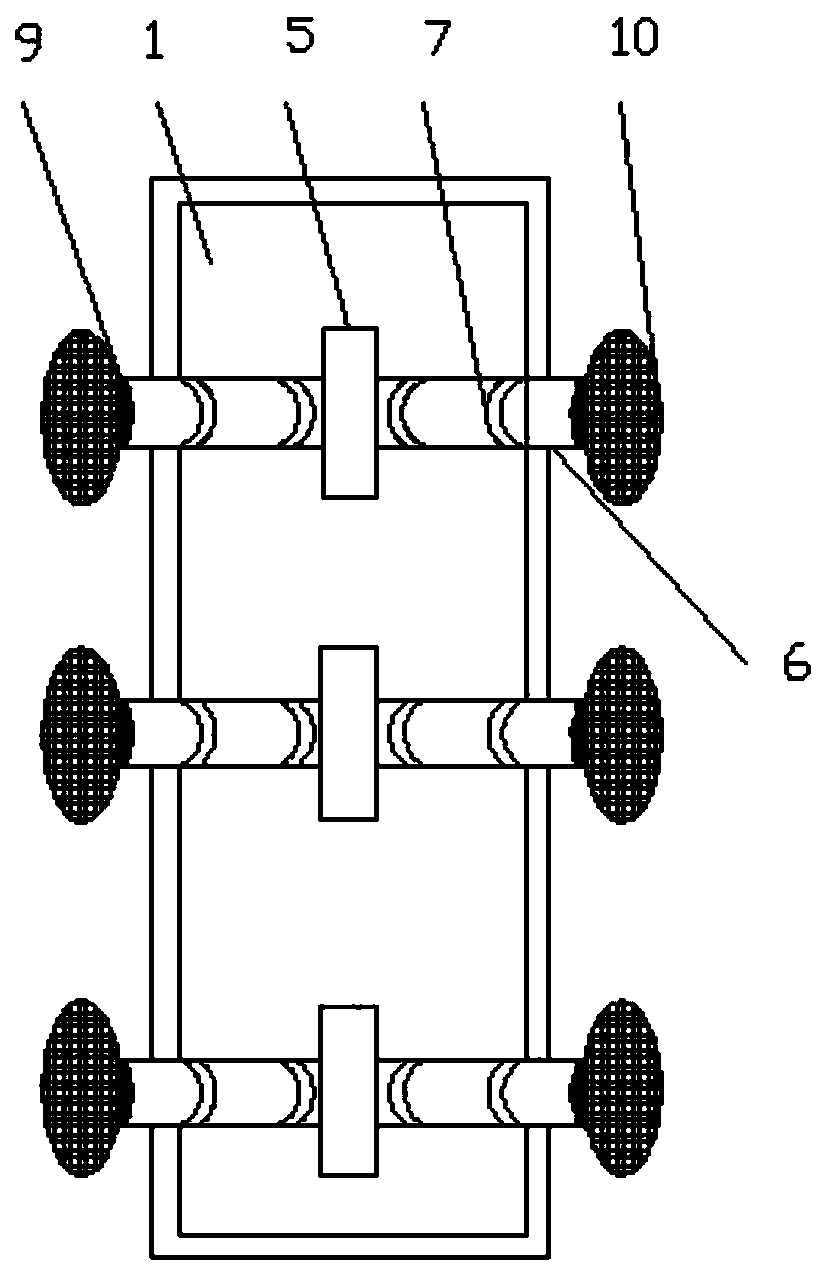

Double-component glue spreading machine applied to hollow glass production

InactiveCN105195379ASolve the glue problemSimple structureLiquid surface applicatorsCoatingsAgricultural engineeringGlass production

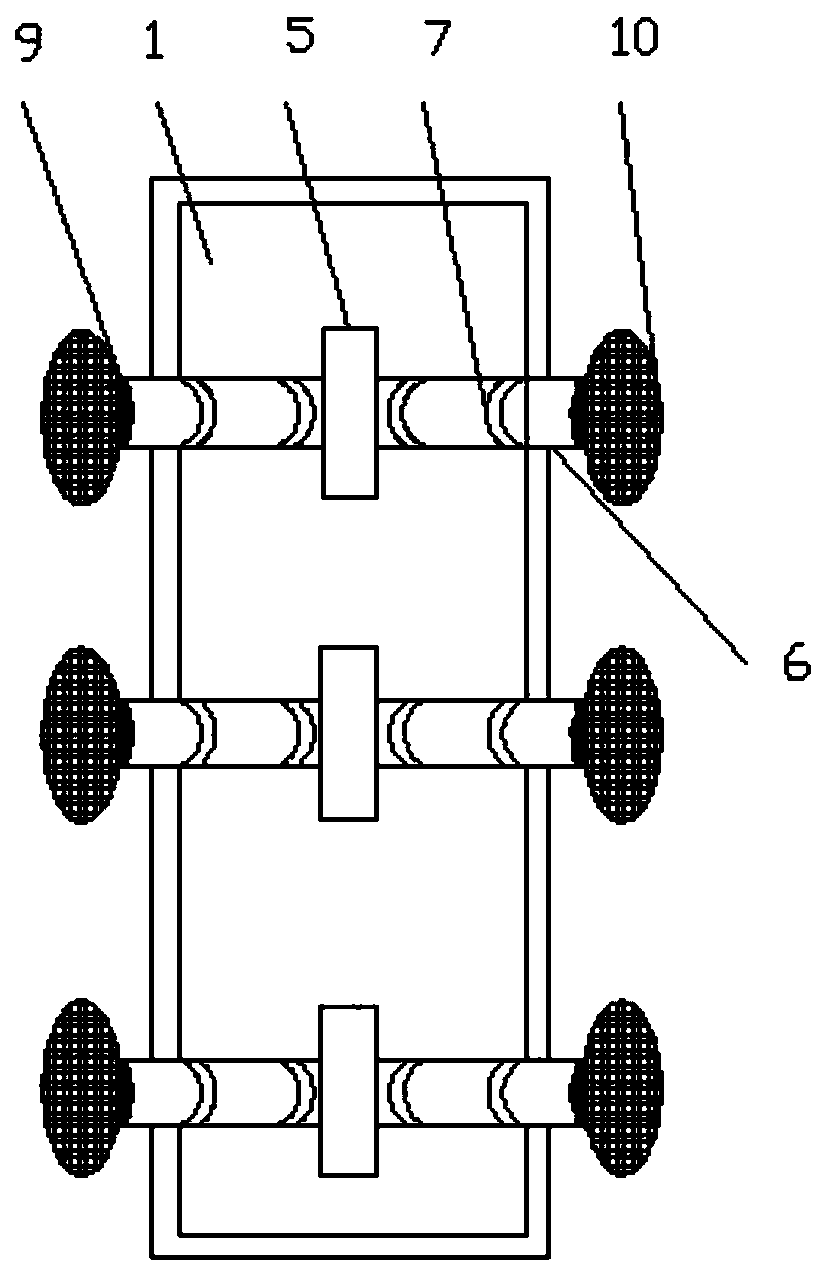

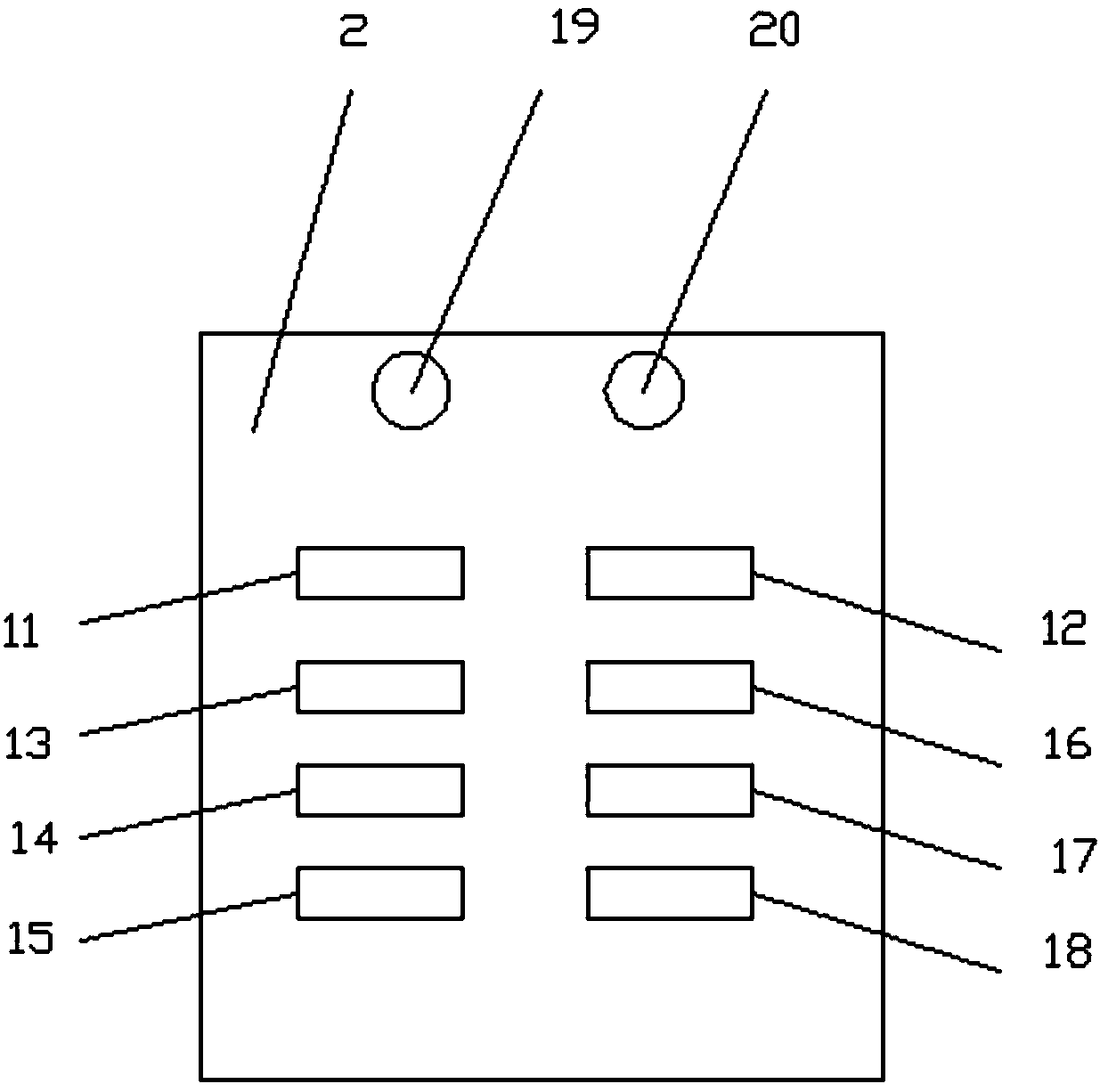

The invention discloses a double-component glue spreading machine applied to hollow glass production. The double-component glue spreading machine comprises a frame and a middle workbench, wherein the middle workbench is located on the frame and provided with a support frame and a Y-direction conveying device, a crossbeam is disposed on the support frame, an X-direction moving device is disposed at the front end of the crossbeam and connected with a glue spreading trolley, the glue spreading trolley comprises a vertical connecting seat and a horizontal baffle, the vertical connecting seat is connected with the horizontal baffle, a Z-direction moving device and a glue spreading device are disposed on the vertical connecting seat, a connecting plate is disposed at the upper end of the vertical connecting seat and connected with a glue mixing device, the glue mixing device is connected with an A-type glue supply device and a B-type glue supply device, an air inlet system is disposed at the bottom of the frame, the left side of the air inlet system is connected with the A-type glue supply device, and the right side of the air inlet system is connected with the B-type glue supply device. The double-component glue spreading machine is simple in structure, scientific and convenient, high in pertinence, high in automation level and capable of well solving the glue spreading problems of hollow glass.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

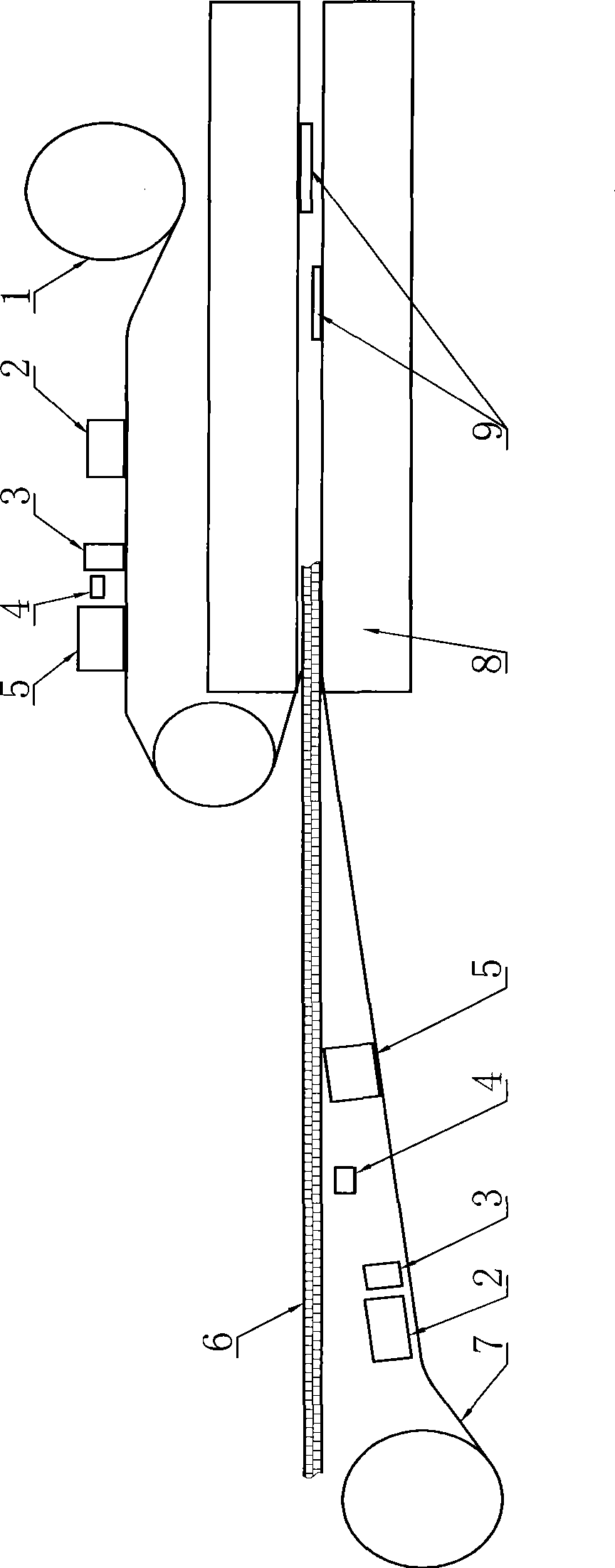

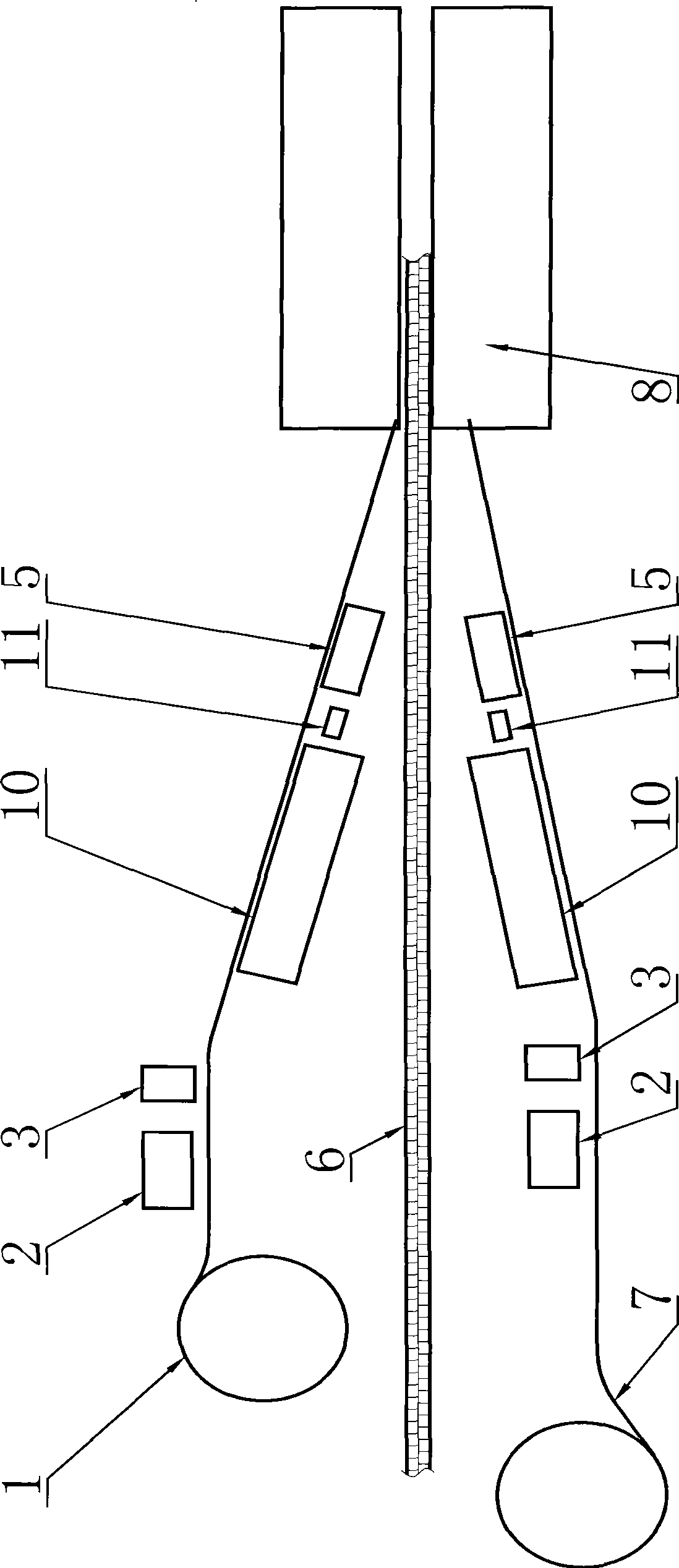

Manufacturing process for metal thermo-insulation sandwich board

ActiveCN101367288AHigh strengthHigh composite strengthLamination ancillary operationsLaminationComposite strengthSheet steel

The invention relates to a process for manufacturing an insulated metal laminboard. The process is characterized in that a method comprises the following steps: a glue coating device for a steel plate is arranged on an insulated metal laminboard compounding machine set; firstly, an upper steel plate and a lower steel plate are subjected to cold rolling and molding by a cold rolling machine; secondly, glue is coated on the upper steel plate and the lower steel plate by the glue coating device for the steel plate of the insulated metal laminboard compounding machine set; and finally the upper steel plate and the lower steel plate are compounded with a heat insulation core material by the insulated metal laminboard compounding machine set to form the laminboard. The process has the advantages of improving the strength of the steel plate and the composite strength of the laminboard after the final molding, the sealing performance of a joint when the laminboards are spliced and the heat insulation performance of a color steel laminboard.

Owner:SHANGHAI YONGMING MACHINERY MFG

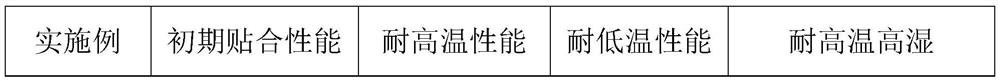

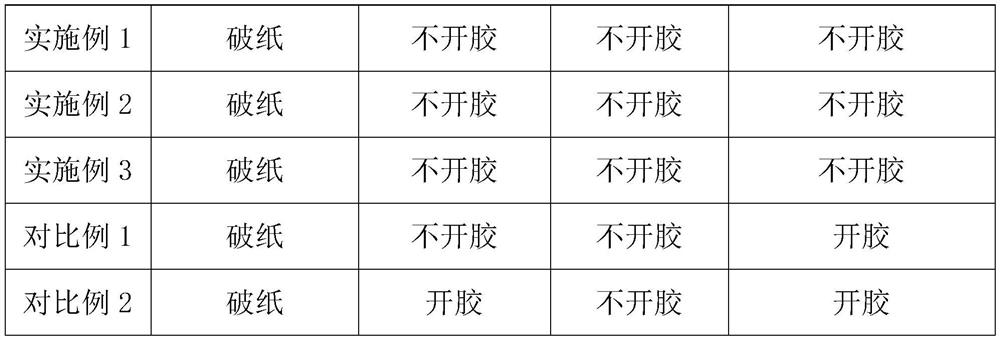

High-temperature-resistant and high-humidity-resistant water-based box pasting adhesive and preparation method thereof

InactiveCN112409960AIncrease the degree of cross-linkingSolve the glue problemMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention discloses a high-temperature and high-humidity-resistant water-based box pasting adhesive, which comprises the following components in parts by weight: 60-90 parts of water-based polymer, 10-40 parts of water-based tackifying resin, 0.5-4 part of a water-based single-component cross-linking agent, 0.05-0.3 part of a defoaming agent, 0.1-0.5 part of a wetting agent, 0.05-0.2 part of apreservative and 0.05-0.8 part of a thickening agent, wherein the water-based polymer is a mixture of polyacrylate emulsion, carboxylic butadiene-styrene latex and vinyl acetate-ethylene copolymer emulsion. Compared with an existing water-based box pasting adhesive, the cross-linking degree between polymer molecular chains is improved by combining different water-based polymers and adding the single-component cross-linking agent, the high and low temperature resistance and high temperature and high humidity resistance can be met at the same time, and the adhesive failure problem of a packaging box in the transportation process is prevented.

Owner:东莞海丽化学材料有限公司

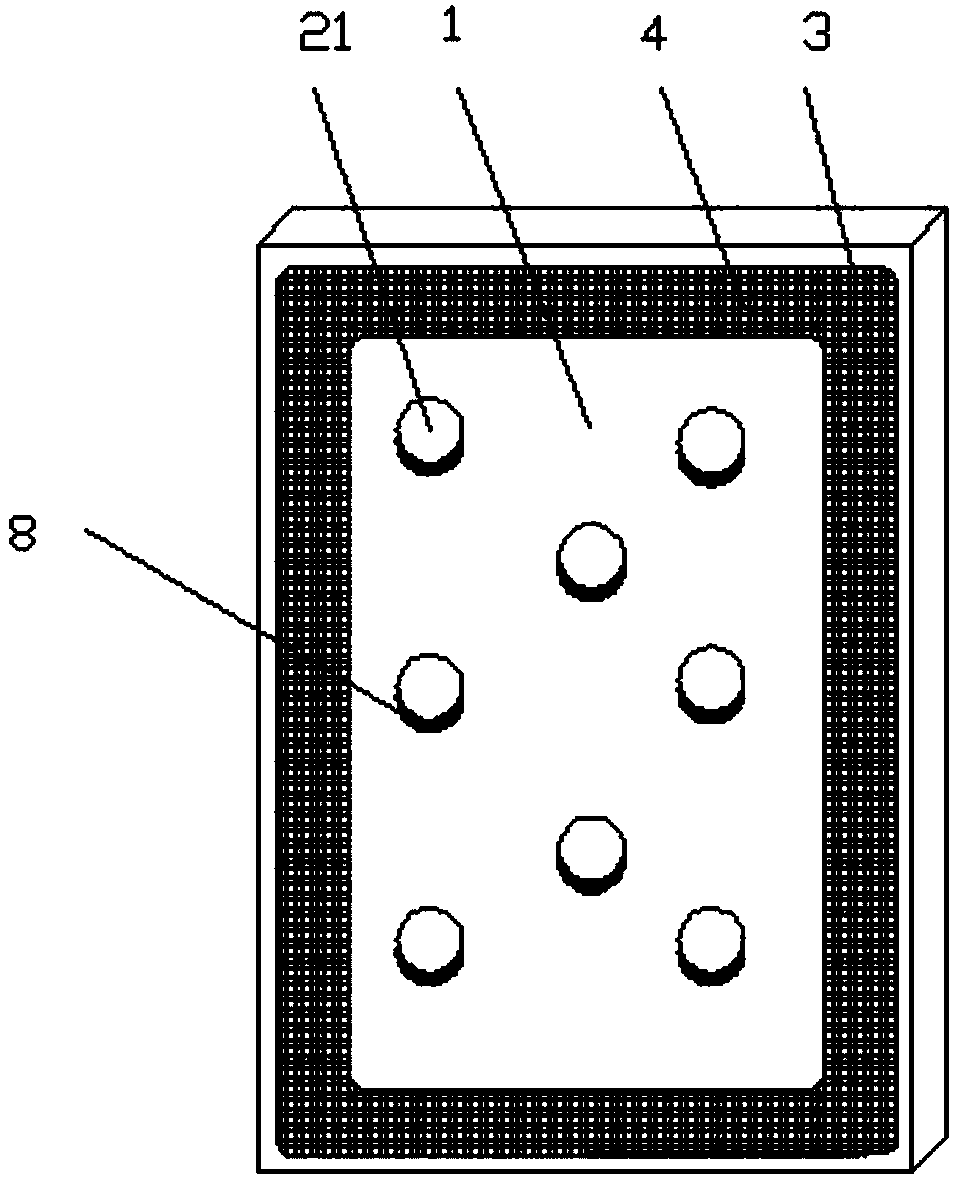

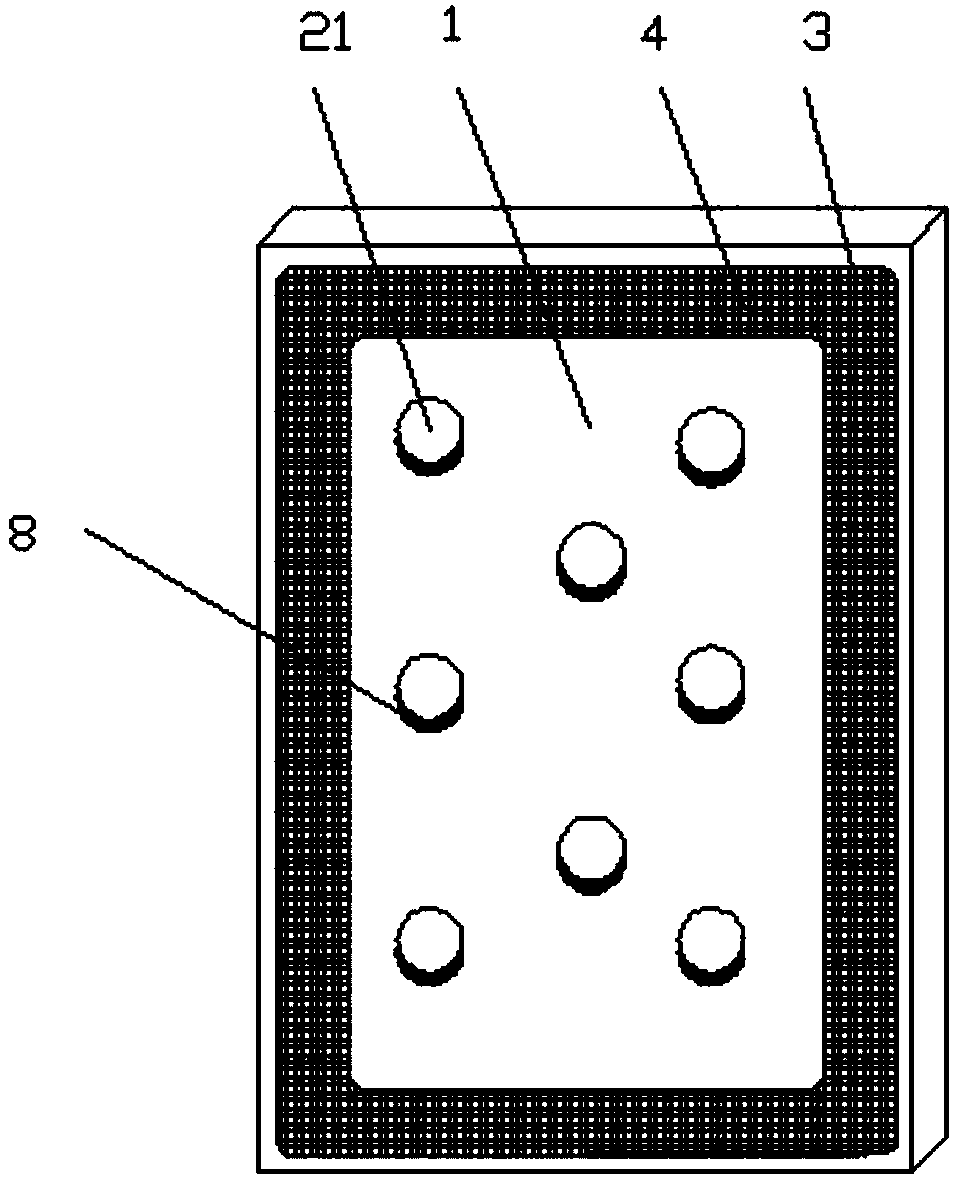

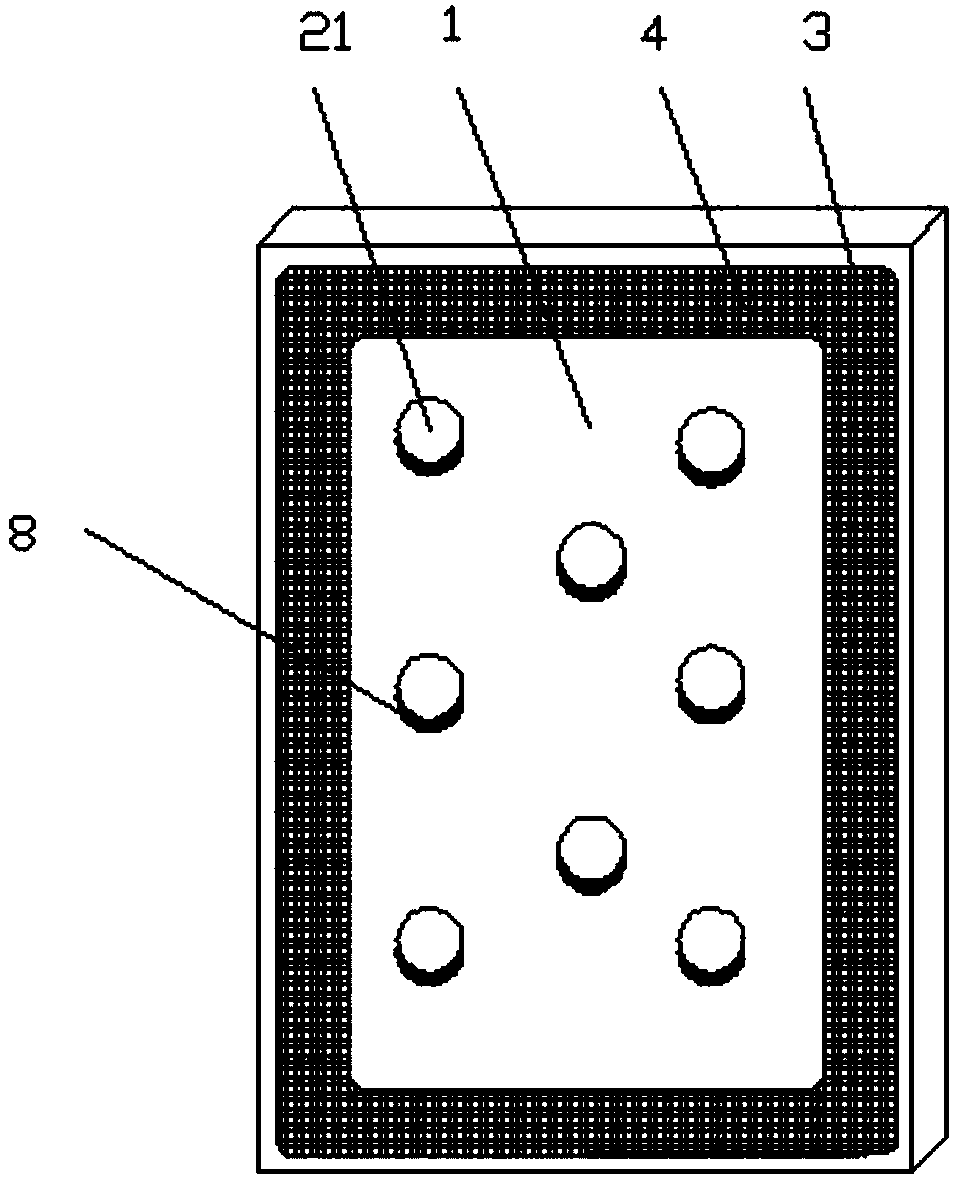

Vacuum attaching device and display mother board attaching method

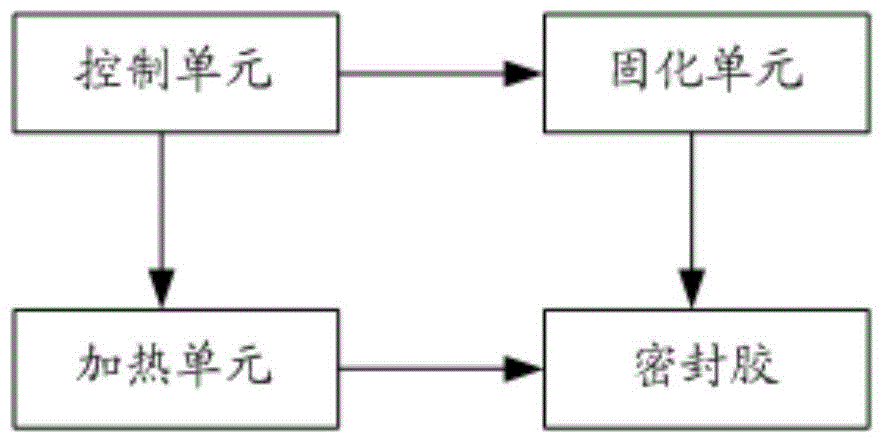

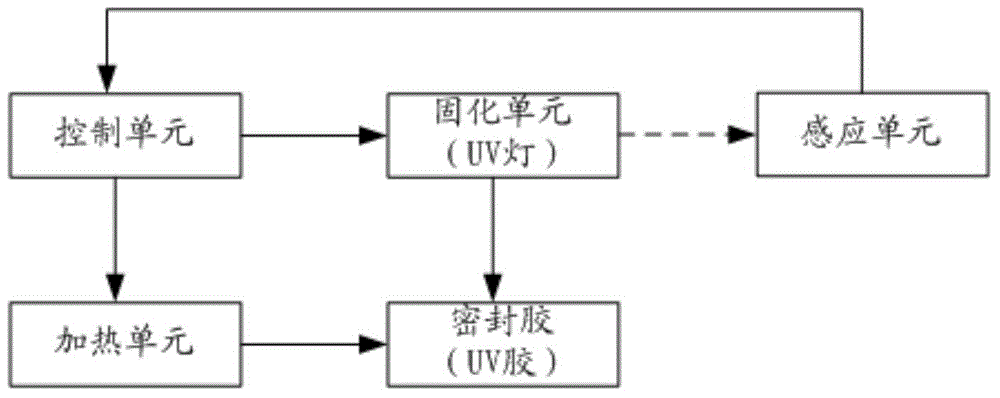

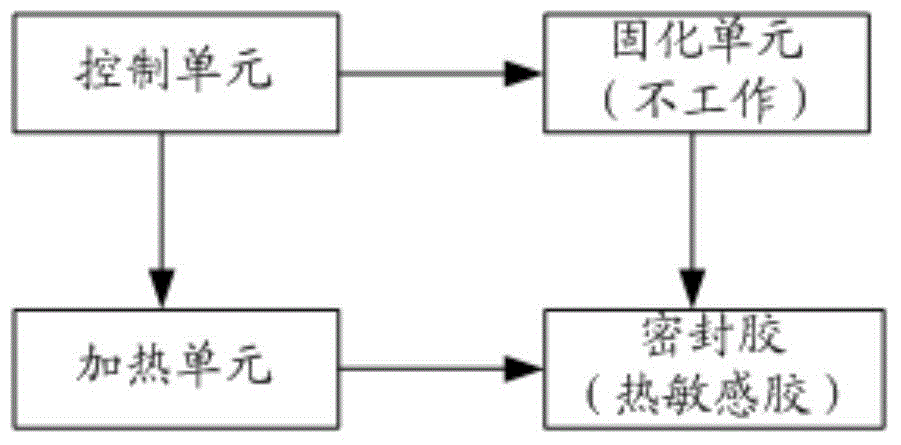

InactiveCN104865753AFit tightlySolve misalignmentPrinted circuits structural associationsNon-linear opticsEngineeringControl unit

The invention provides a vacuum attaching device and display mother board attaching method, and belongs to the technical field of attaching processes of display panels. The vacuum attaching device comprises a control unit, a first bearing table, a second bearing table, a curing unit and a heating unit, the first bearing table is opposite to the second bearing table, the curing unit is arranged on the peripheral area of the first bearing table or the second bearing table, the first bearing table is used for bearing a first mother board, the second bearing table is used for bearing a second mother board, sealing gum is coated on the peripheral area of the first mother board or the second mother board, the curing unit is used for curing the sealing gum, the control unit is used for controlling the curing unit to work or not, and the heating unit is used for heating the sealing gum under control of the control unit. The vacuum attaching device can solve the problems that the first mother board and the second mother board cannot be firmly attached by an existing attaching device, consequently, the first mother board and the second mother board are misplaced in the carrying process, and the display mother boards are poor.

Owner:BOE TECH GRP CO LTD +1

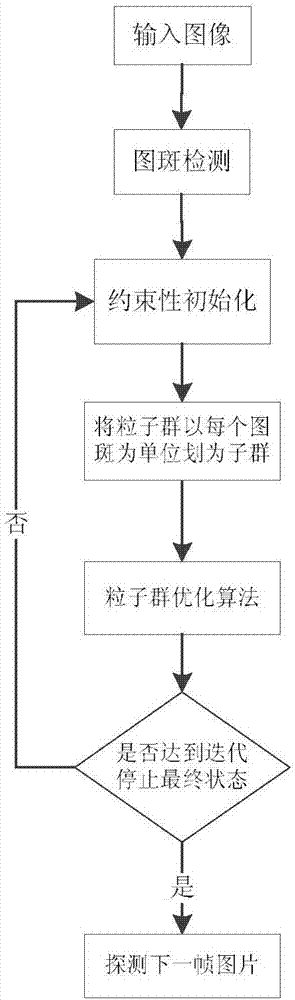

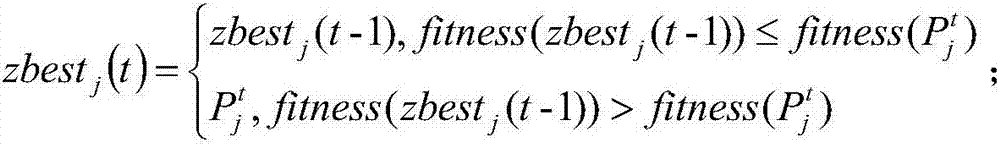

Particle swarm optimization algorithm-based tracking and locating method for multiple moving targets in video

InactiveCN107169990ASolve the problem that some moving targets cannot be locatedSolve the glue problemImage enhancementImage analysisPattern recognitionComputer vision

The invention discloses a particle swarm optimization algorithm-based tracking and locating method for multiple moving targets in a video. The method comprises the steps of firstly performing image spot detection through a background difference method; and then dividing a particle swarm into particle sub-swarms by taking image spots as units, and using a particle swarm optimization algorithm in each sub-swarm to achieve the purpose of locating the multiple moving targets. According to the method, the problem of multi-target detection and the problem of difficult detection caused by object adhesion and picture darkness can be solved.

Owner:NANJING UNIV OF POSTS & TELECOMM

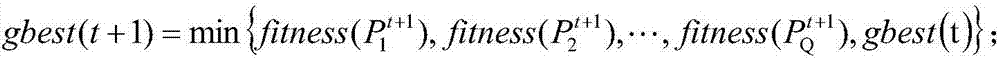

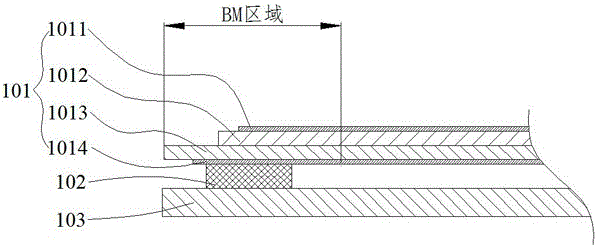

Liquid crystal display device

ActiveCN106292034ANo cracking phenomenonGuaranteed stabilityNon-linear opticsLiquid-crystal displayWorking temperature

The invention provides a liquid crystal display device which comprises a panel, an adhesive layer and an adhesive medium, wherein the panel comprises a glass layer and a lower polarizing film; the lower polarizing film is bonded and fixed to the lower surface of the glass layer; the surface area of the lower polarizing film is smaller than that of the glass layer; the adhesive layer is arranged on the lower surface of the glass layer along an outer contour edge of the lower polarizing film; the lower surface of the glass layer is fixedly bonded to the surface of the adhesion medium through the adhesive layer. For the fixation of the panel and the adhesive medium, the glass layer and the adhesive medium are fixedly bonded through the adhesive layer in the invention; when a working temperature of the liquid crystal display device changes, the deformation quantity generated by the glass layer under the change of temperature is insufficient to deform or crack the panel, so as to avoid the occurrence of panel cracking phenomenon due to excess deformation quantity of the lower polarizing film, to ensure the panel working stability, and to be beneficial to the frameless design of the liquid crystal display device.

Owner:HISENSE VISUAL TECH CO LTD

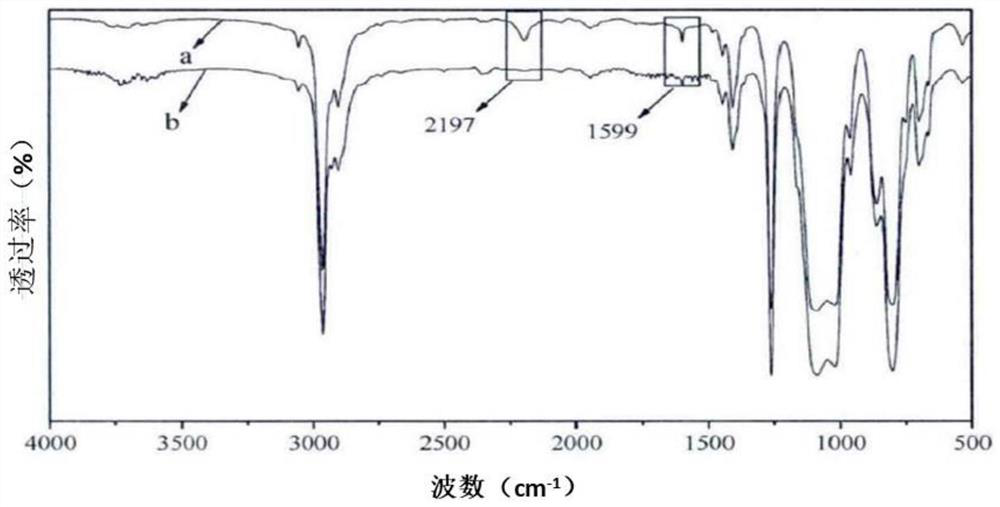

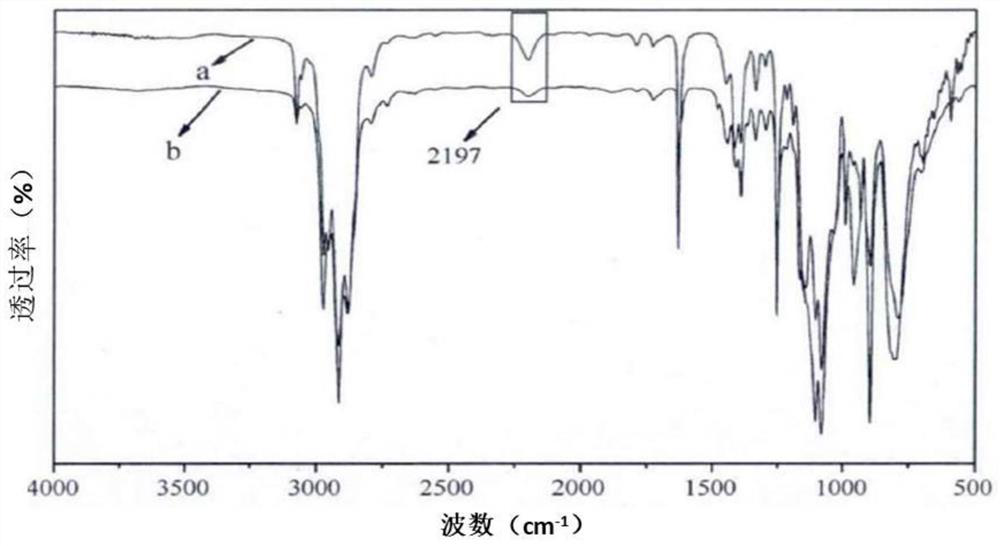

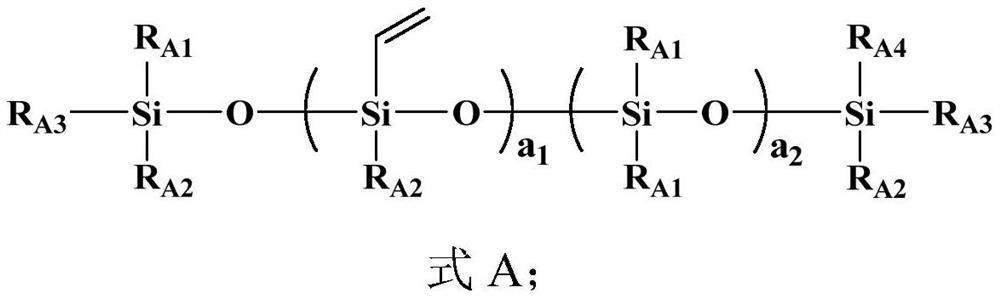

Liquid organic silicon optical adhesive as well as preparation method and application thereof

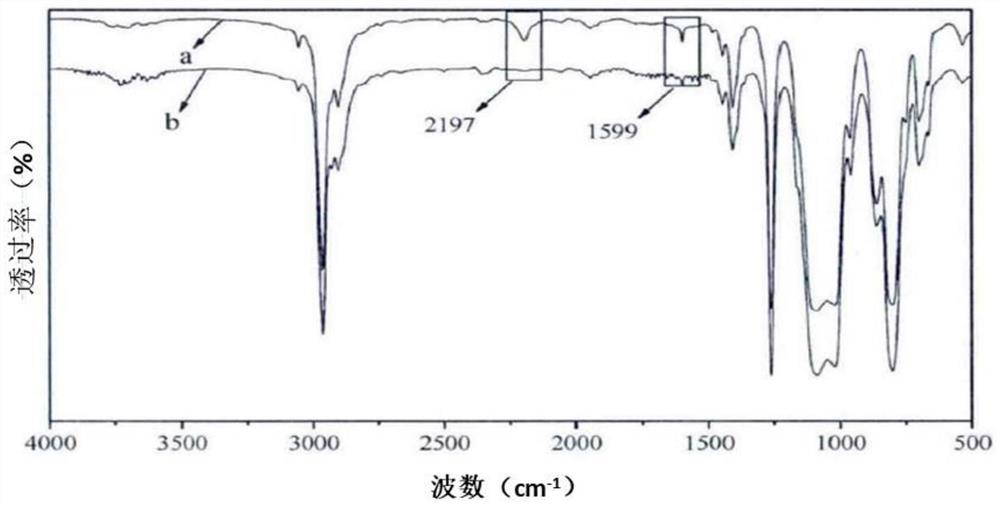

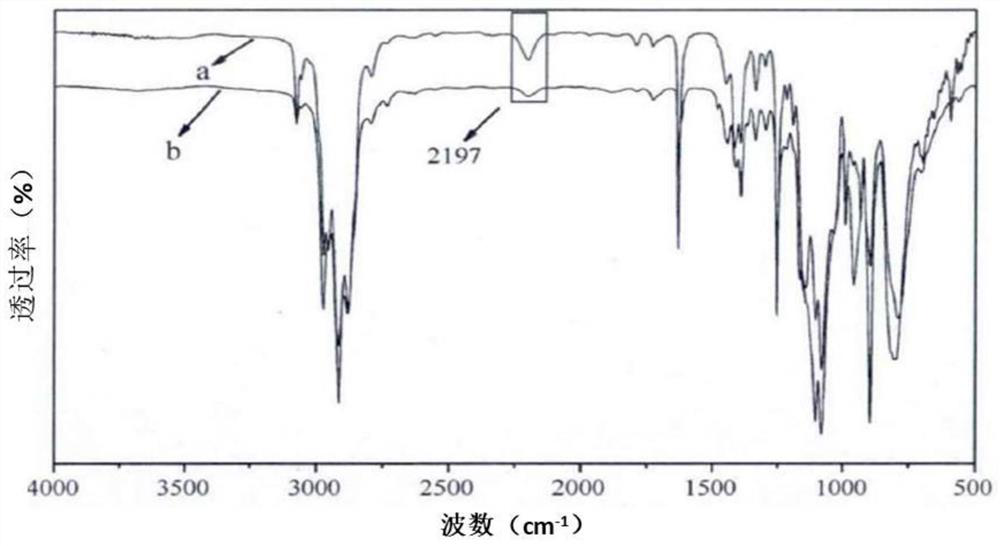

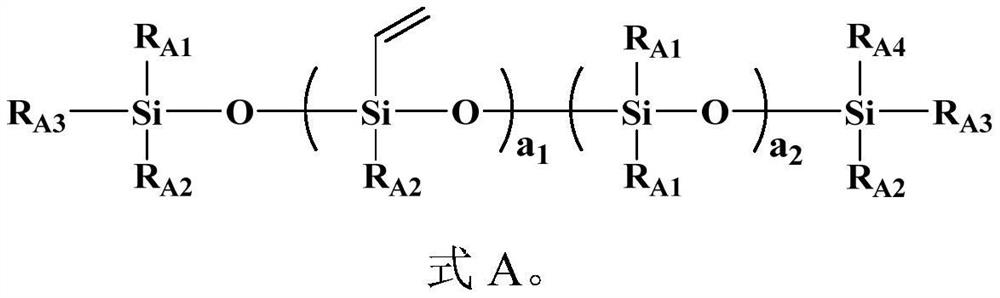

ActiveCN112280527AImprove cohesive strengthImprove mechanical propertiesAdhesive processesNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention provides a liquid organic silicon optical adhesive and a preparation method and application thereof, the liquid organic silicon optical adhesive comprises a component A and a component B, the component A comprises vinyl polysiloxane, and the component B comprises hydrogen-containing polysiloxane and a macromolecular modified silane coupling agent, wherein the macromolecular modifiedsilane coupling agent is selected from any one or a combination of at least two of an acrylate modified silane coupling agent, a vinyl siloxane modified silane coupling agent, an epoxy cyclohexyl modified silane coupling agent or a hyperbranched silane coupling agent. According to the liquid organic silicon optical adhesive, through screening and compounding of components, especially introductionof the macromolecular modified silane coupling agent, stronger physical and chemical interaction is formed in a polymer matrix, and the interface adhesion and mechanical properties of an adhesive filmare remarkably improved on the premise of not influencing a bonding effect and a repairing effect; and the problem of bubble reversion or glue failure of a large-size full-lamination laminated product under low air pressure is solved.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

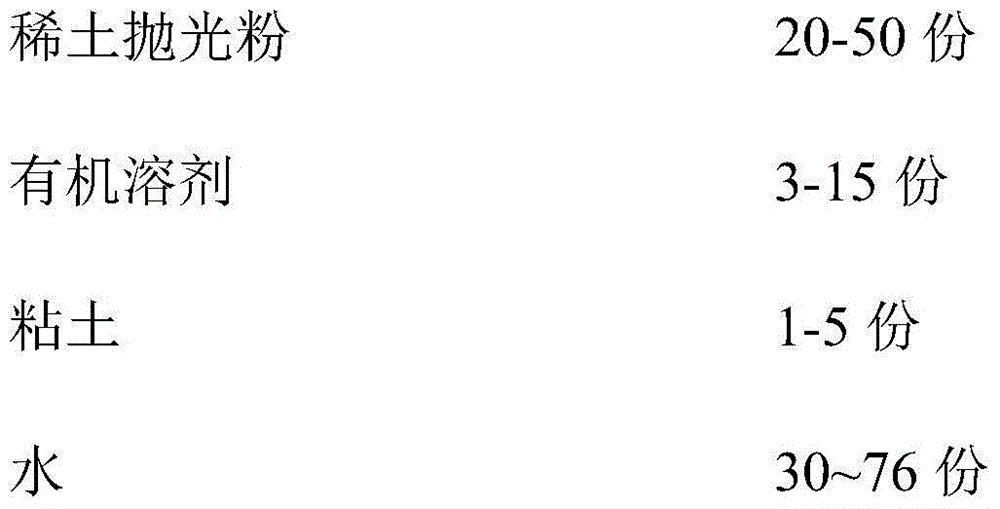

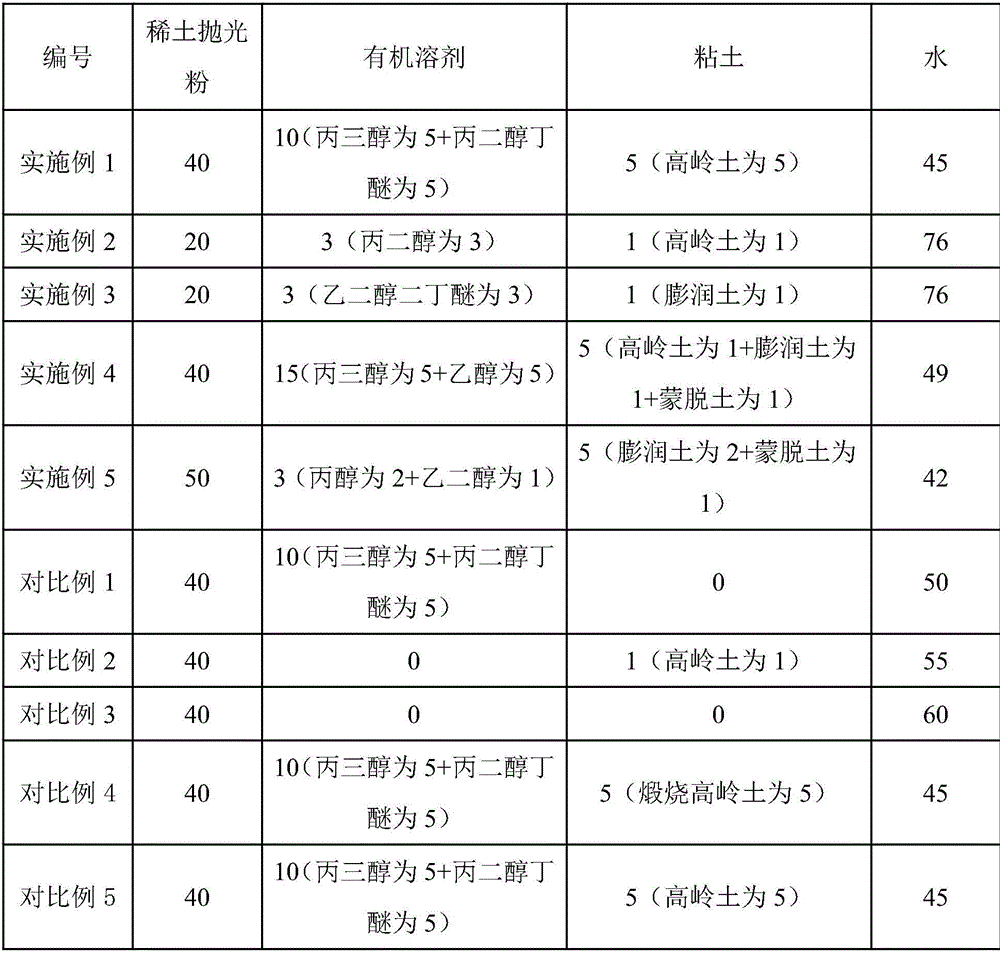

Rare earth polishing liquid and preparation method thereof

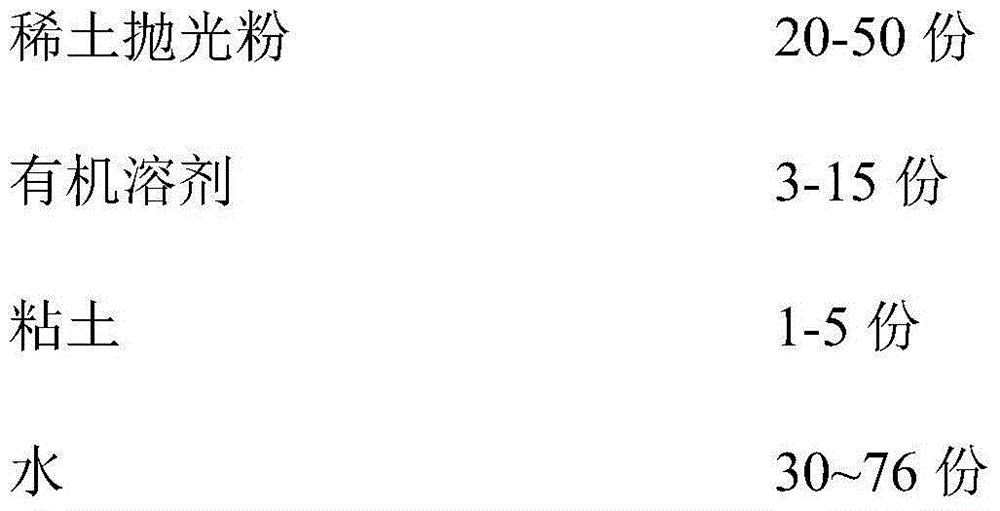

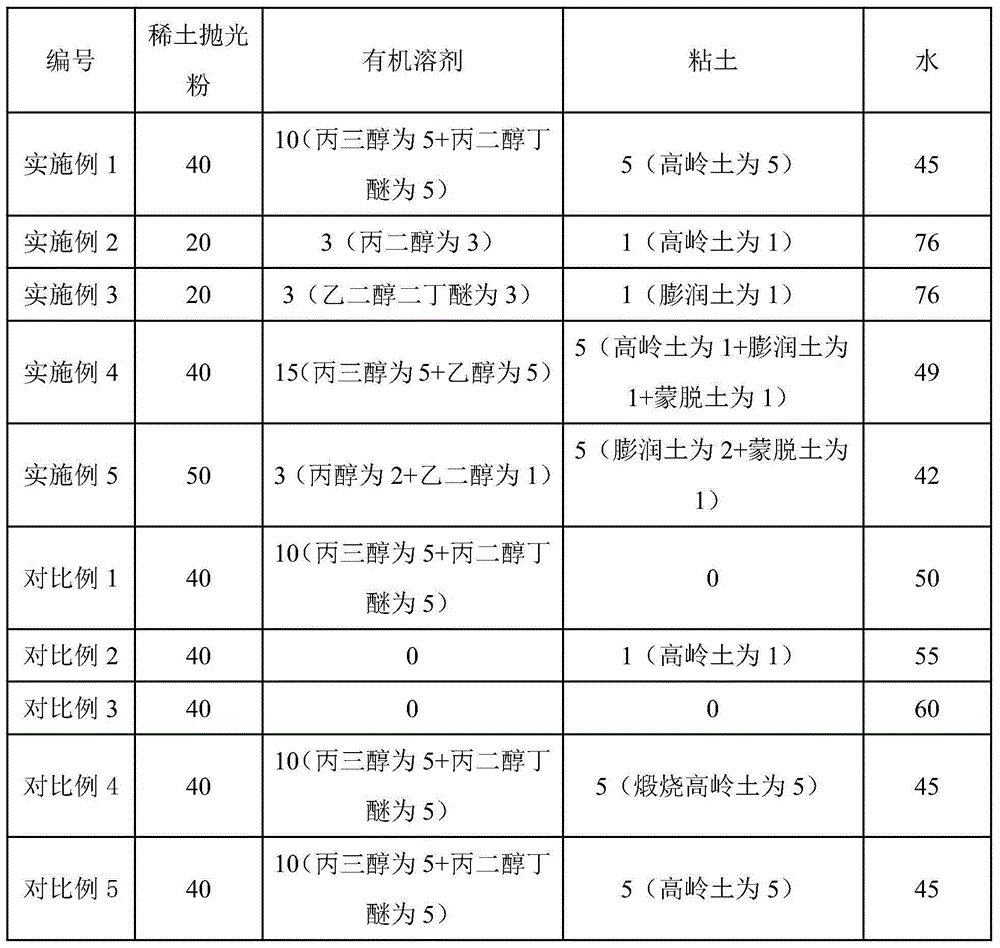

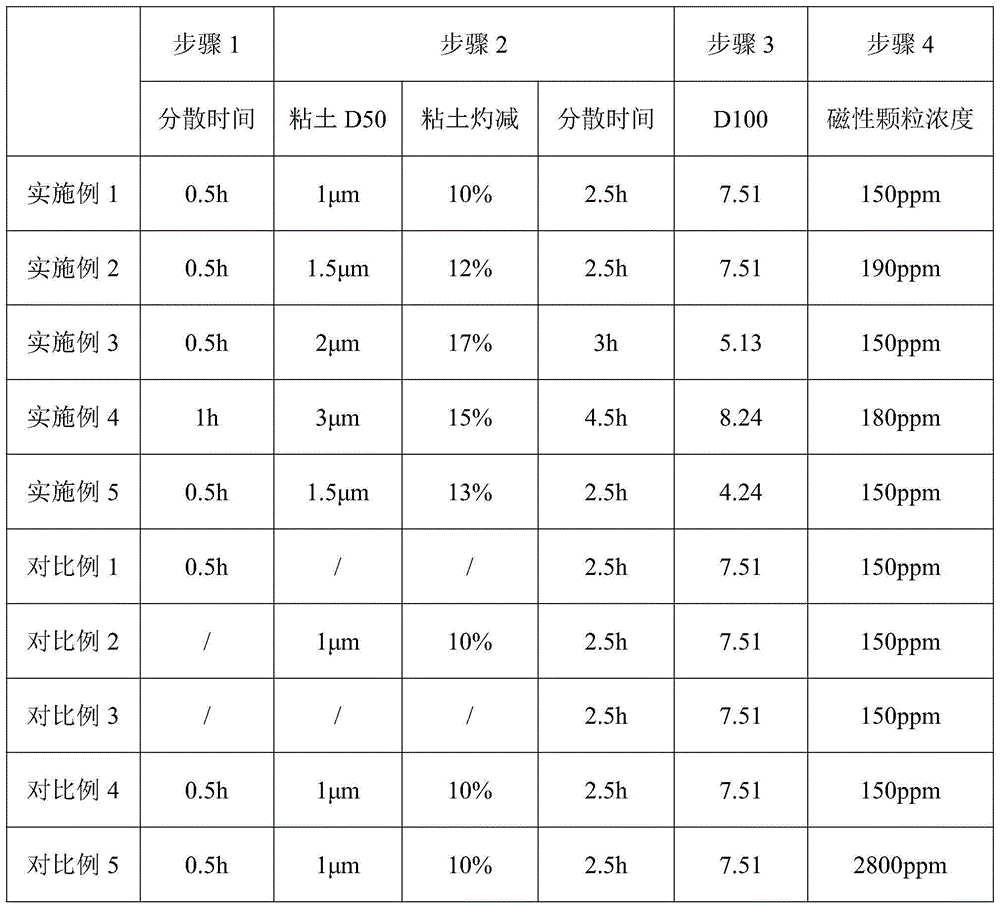

ActiveCN104479555AEasy to prepareSolve the ease of cleaningPolishing compositions with abrasivesOrganic solventRare earth

The invention provides a rare earth polishing liquid and a preparation method thereof; the rare earth polishing liquid comprises the following components in parts by weight: 20-50 parts of a rare earth polishing powder, 3-15 parts of an organic solvent, 1-5 parts of clay, and 30-76 parts of water. The rare earth polishing liquid solves the problem of suspension dispersion of a polishing powder in water, overcomes the bonding problem of the polishing liquid in preparation and storage processes and good cleaning problem of the polishing liquid in a use process at present, and has the characteristics of good suspension dispersibility, fast polishing speed, high polishing precision, excellent cleaning performance of polished products and the like. The rare earth polishing liquid is suitable for surface polishing processing of integrated circuits, flat panel display, optical glass and other electronic information industry precision devices, and meets polishing yield rate requirements of increasingly-strict business on polishing materials in accuracy, polishing corrosion amount, easy cleaning and the like.

Owner:NUOXUAN CHEM TECH SHANGHAI

Spare tire cover plate production method, and composite tool with heating function

The invention relates to a spare tire cover plate production method and a composite tool. In the production process, a base plate is arranged on an upper die, a facing material is paved on a lower die, an extractable radiation heating plate is adopted to heat glue on the facing material to solve the problems of easy cooling and hand sticking caused by preheating of the facing material in the prior art, and the lower die is introduced with cooling water to solve the tackless problem caused by untimely cooling and low initial viscosity after compounding completed through a lower die heating scheme in the prior art.

Owner:YANTAI ZHENGHAI HIGH TECH

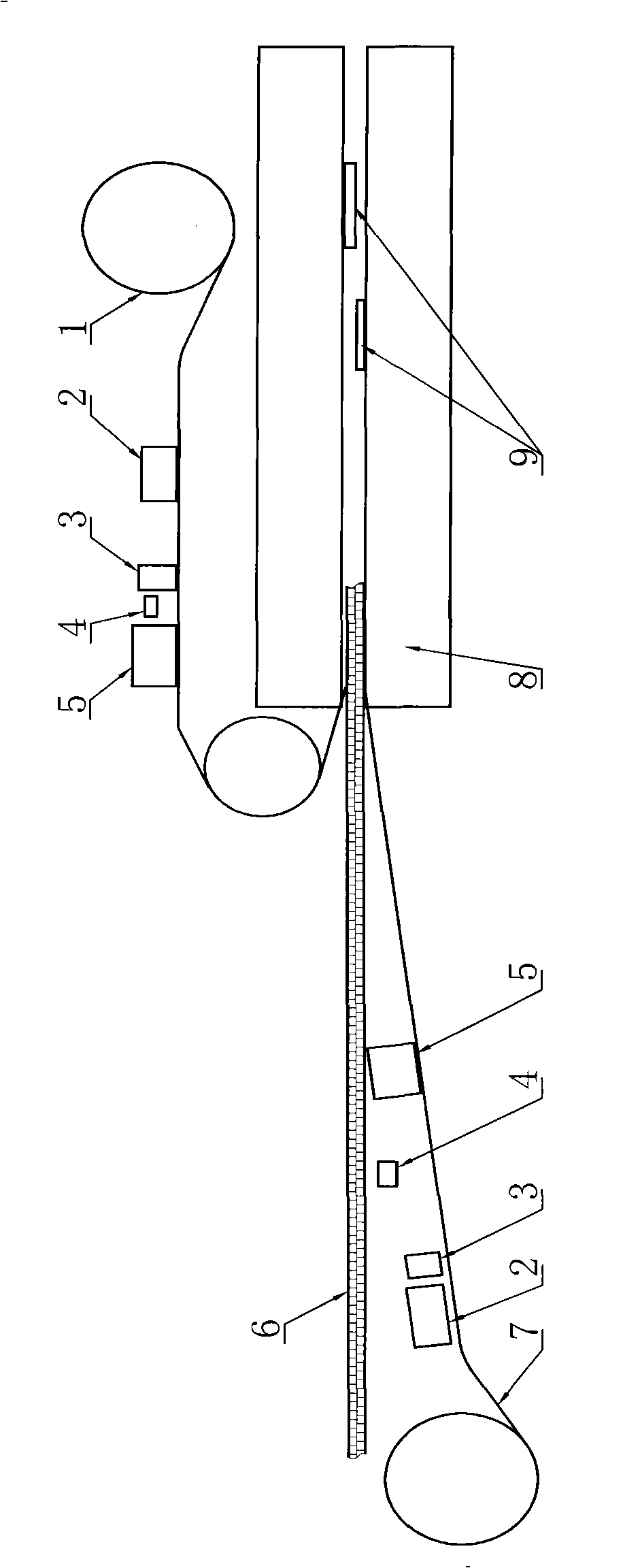

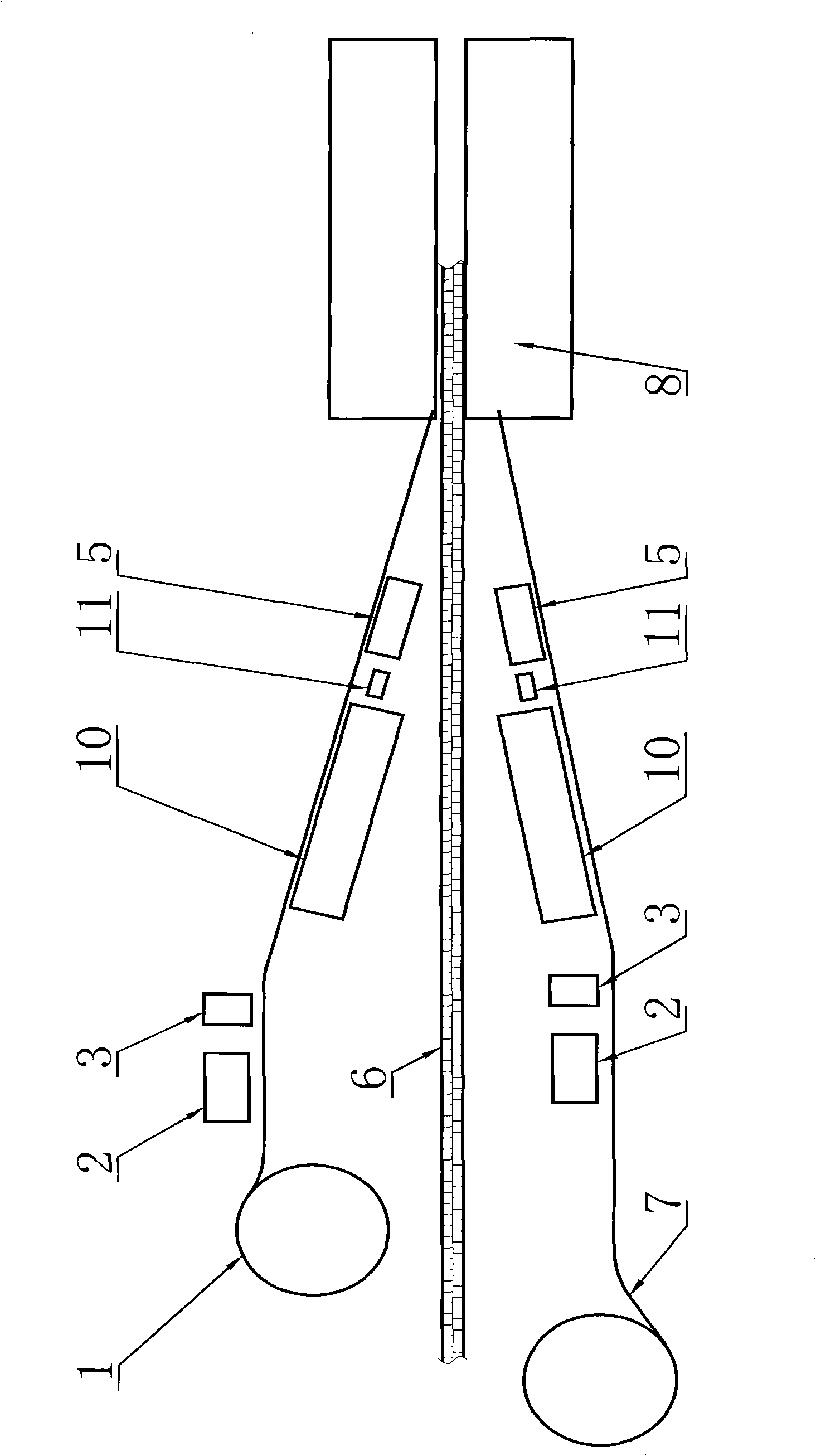

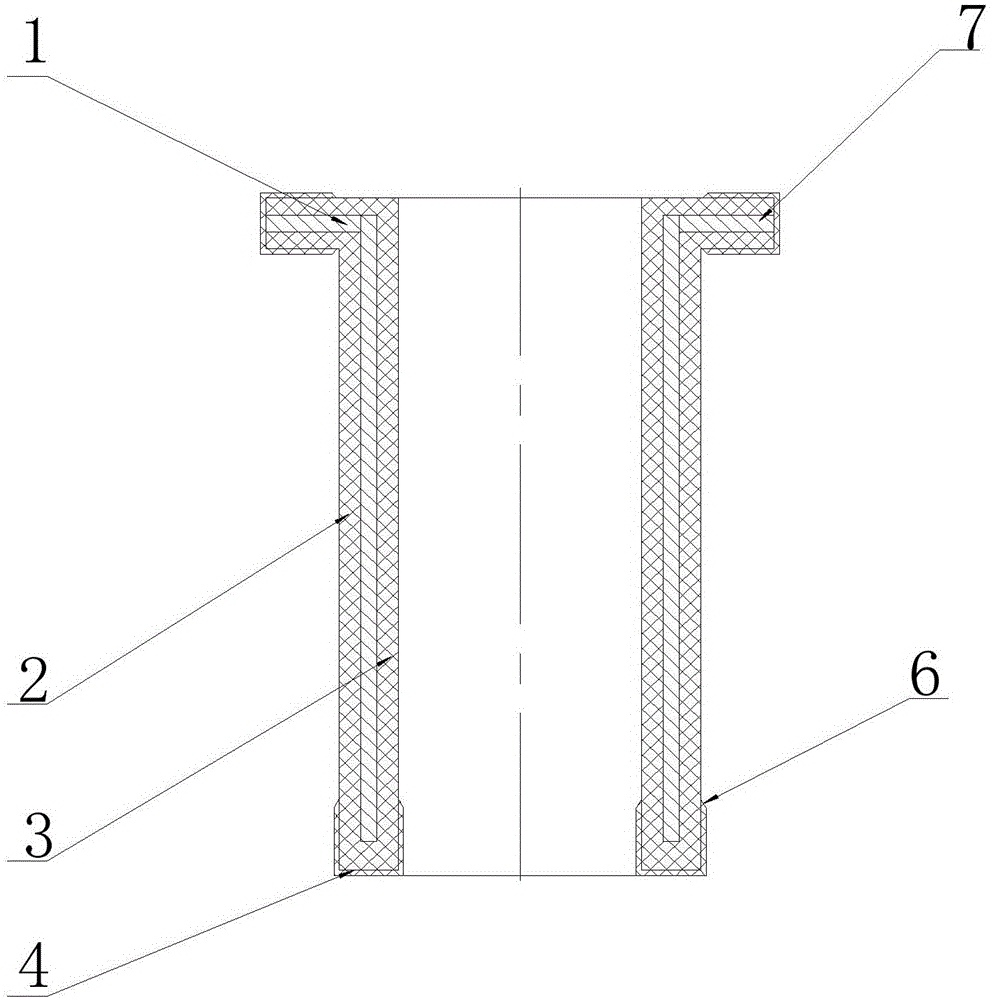

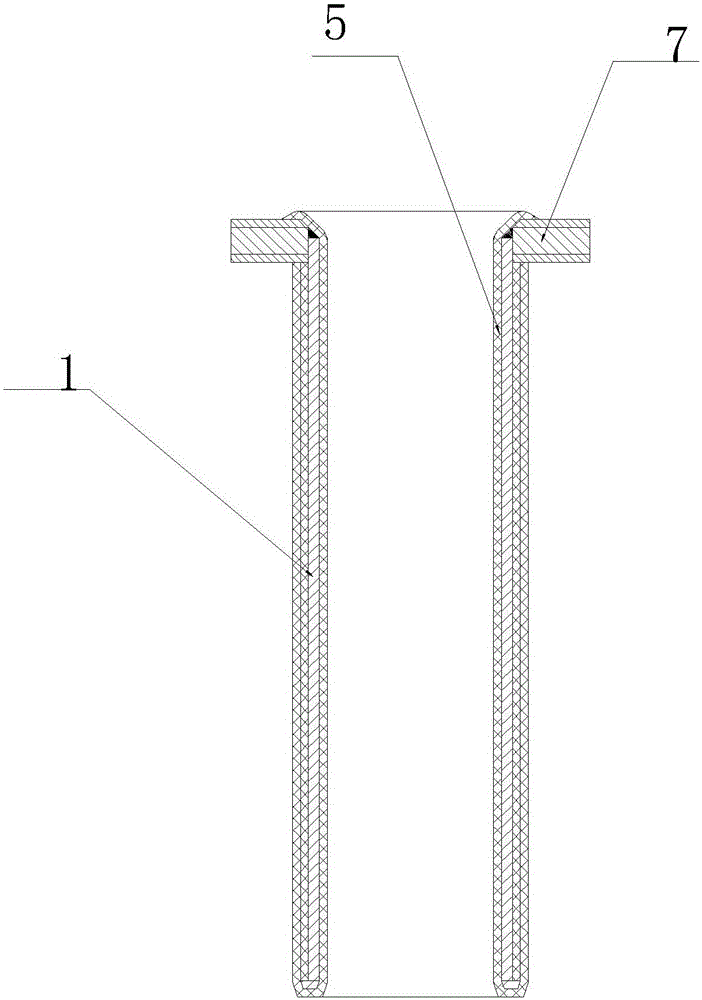

Manufacturing process for metal thermo-insulation sandwich board

ActiveCN101367288BSolve the glue problemHigh strengthLamination ancillary operationsLaminationComposite strengthSandwich board

The invention relates to a process for manufacturing an insulated metal laminboard. The process is characterized in that a method comprises the following steps: a glue coating device for a steel plate is arranged on an insulated metal laminboard compounding machine set; firstly, an upper steel plate and a lower steel plate are subjected to cold rolling and molding by a cold rolling machine; secondly, polyurethane two component glue continues to flow out through a first feed pipe and a second feed pipe on the upper steel plate and the lower steel plate by the glue coating device for the steel plate of the insulated metal laminboard compounding machine set; a steering equipment is pushed by a cylinder to drive the first feed pipe and the second pipe, so that a glue discharging pipe on the feed pipes is tightly attached to the steel plate and finally the upper steel plate and the lower steel plate are compounded with a heat insulation core material by the insulated metal laminboard compounding machine set to form the laminboard. The process has the advantages of improving the strength of the steel plate and the composite strength of the laminboard after the final molding, the sealing performance of a joint when the laminboards are spliced as well as the heat insulation performance of a color steel laminboard.

Owner:SHANGHAI YONGMING MACHINERY MFG

A kind of liquid organosilicon optical glue and its preparation method and application

ActiveCN112280527BImprove cohesive strengthImprove mechanical propertiesAdhesive processesNon-macromolecular adhesive additivesEpoxyPolymer science

The invention provides a liquid organic silicon optical adhesive and its preparation method and application. The liquid organic silicon optical adhesive includes A component and B component, the A component includes vinyl polysiloxane, and the B component The components include hydrogen-containing polysiloxane and macromolecular modified silane coupling agent; the macromolecular modified silane coupling agent is selected from acrylate modified silane coupling agent, vinyl siloxane modified silane coupling agent Any one or a combination of at least two of coupling agents, epoxycyclohexyl modified silane coupling agents or hyperbranched silane coupling agents. Through the screening and compounding of components, especially the introduction of macromolecular modified silane coupling agent, the liquid organic silicon optical adhesive can form stronger physical and chemical interactions inside the polymer matrix without affecting the bonding effect. And under the premise of the repair effect, the interface adhesion and mechanical properties of the adhesive film are significantly improved, and the problem of anti-foaming or glue opening of the large-size fully-fitted products under low air pressure is overcome.

Owner:广东派乐玛新材料技术有限公司

Laser slitting machine

ActiveCN107520542AEasy to removeEasy to cleanWelding/soldering/cutting articlesLaser beam welding apparatusEngineeringLED lamp

The invention discloses a laser slitting machine. The laser slitting machine comprises an LED lamp, a fixed hose and a silencer; a lamp holder is arranged at one end of the LED lamp; a connecting support is arranged at one end of the fixed hose; a lamp switch is arranged on one side of the connecting support; an execution table is arranged below cutters; a prompt lamp is arranged on one side of a CO2 laser; an electric box is arranged under an emergency stop button; the silencer is fixedly connected to the electric box; nuts are arranged at one ends of fixing blocks; supporting legs are arranged under the electric box; and a machine frame is arranged on one side of a movable shaft. According to the laser slitting machine, a net cover is fixedly connected to the electric box through the nuts so that the net cover can be conveniently taken down from the electric box, station trackers are combined with the CO2 laser so that the blank that a laser is used for umbrella cloth slitting can be filled, and therefore the defect of a cold cutting knife technology can be really and fundamentally overcome, the industry level can be improved, the quality can be improved, and the problems of broken filaments and glue residues at a selvedge of an existing slitting machine can be solved.

Owner:浙江天玮雨具有限公司

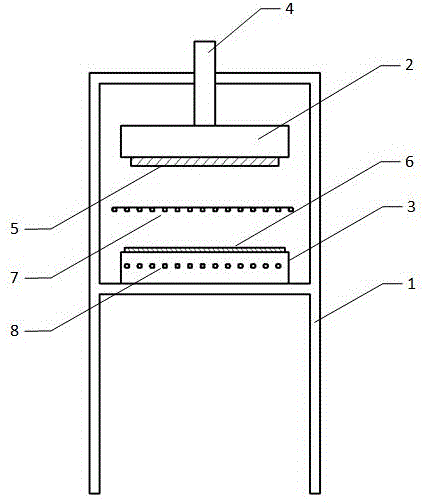

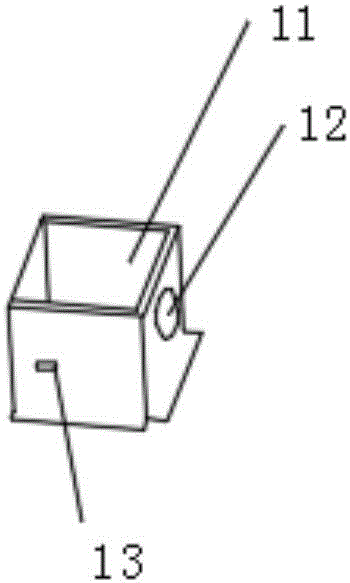

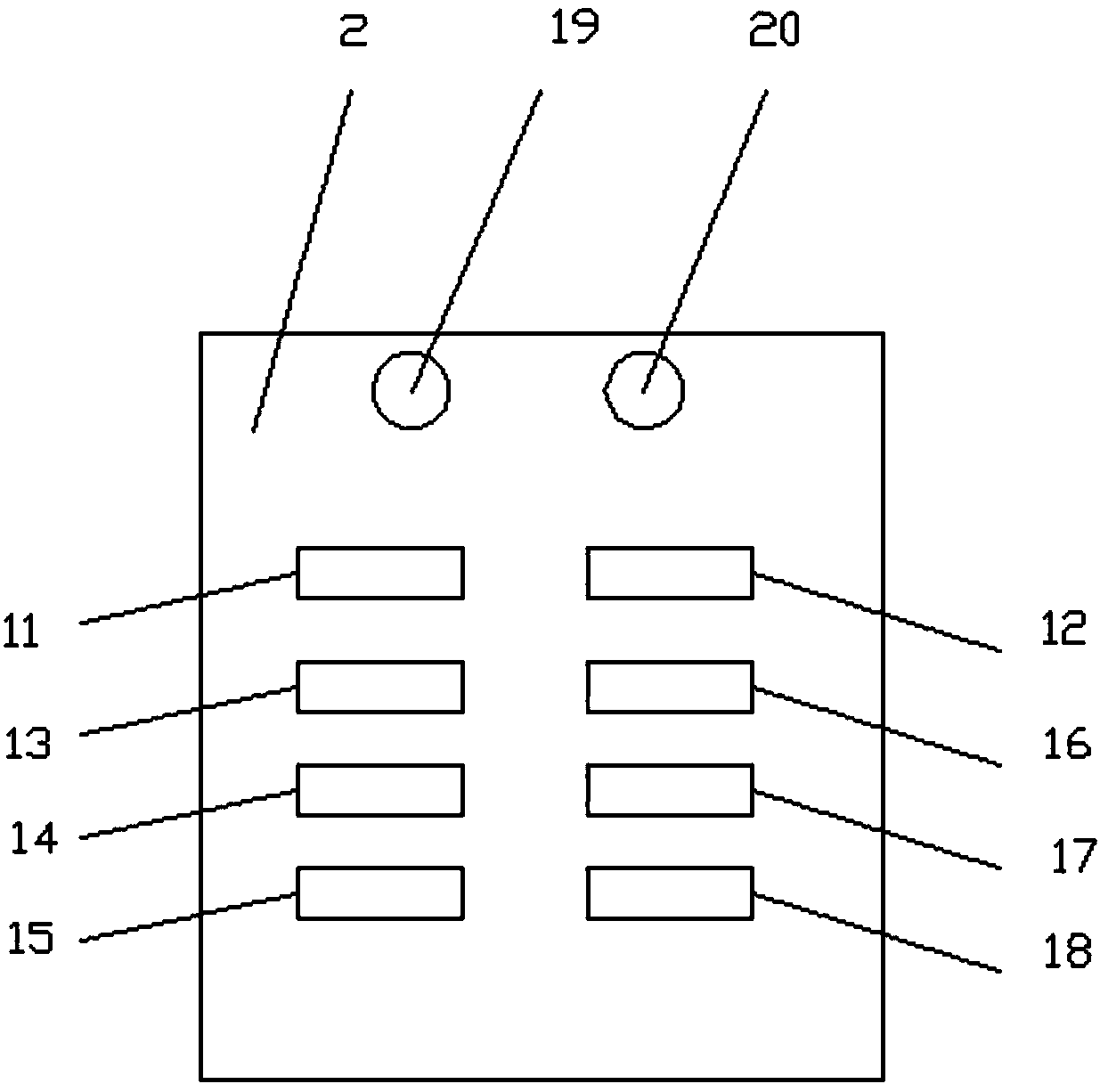

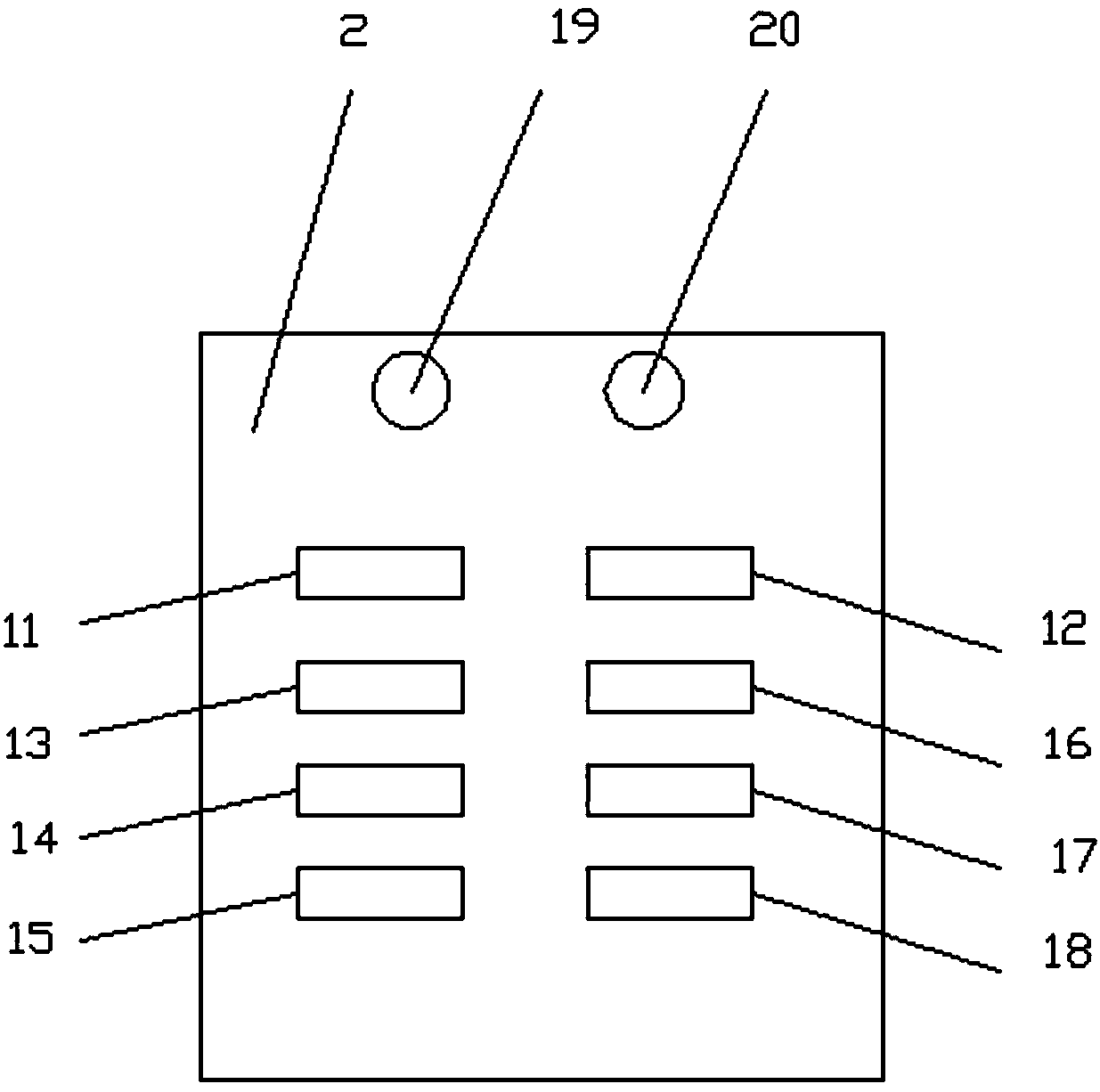

Dispensing time control device

InactiveCN111617935AImprove product capacitySolve the glue problemLiquid surface applicatorsCoatingsBackplaneWorkbench

The invention discloses a dispensing time control device. The dispensing time control device comprises a bottom plate and supporting plates distributed on the periphery of the bottom plate. A workbench plate is fixedly connected to the supporting plates. A photoelectric sensor is arranged on the workbench plate. When a product is placed on the workbench plate, the photoelectric sensor sends a sensed signal to a timer, and the timer starts timing after receiving the signal. When the product is taken away at the set time, the photoelectric sensor sends a time zero clearing signal to the timer, the time on the timer is cleared, and meanwhile the next time of product timing is started. When the product is not taken away at the set time, the timer sends a signal to a vacuum module and a buzzer.After the vacuum module and the buzzer receive the signals, the buzzer gives an alarm, a vacuum die locks the product, and the product cannot be taken out by the next station. The problem that due tothe fact that the idle time of the product after dispensing is too long, product press fit is poor or glue failure occurs is solved, and the idle time of the product does not need to be calculated manually.

Owner:安徽英力电子科技股份有限公司

Sunroom skylight system and manufacturing method thereof

ActiveCN105649280BAvoid enteringImprove insulation effectDoors/windowsSky-lights/domesThermal insulationAgricultural engineering

Owner:VIEWMAX DOORS & WINDOWS CO LTD

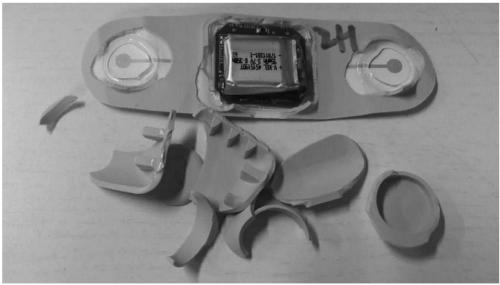

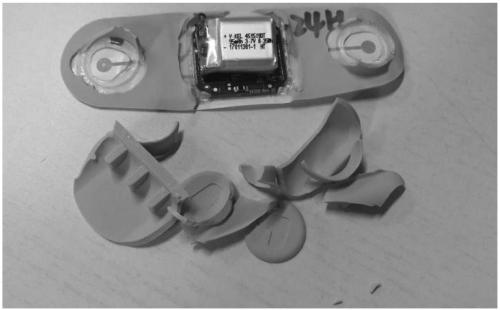

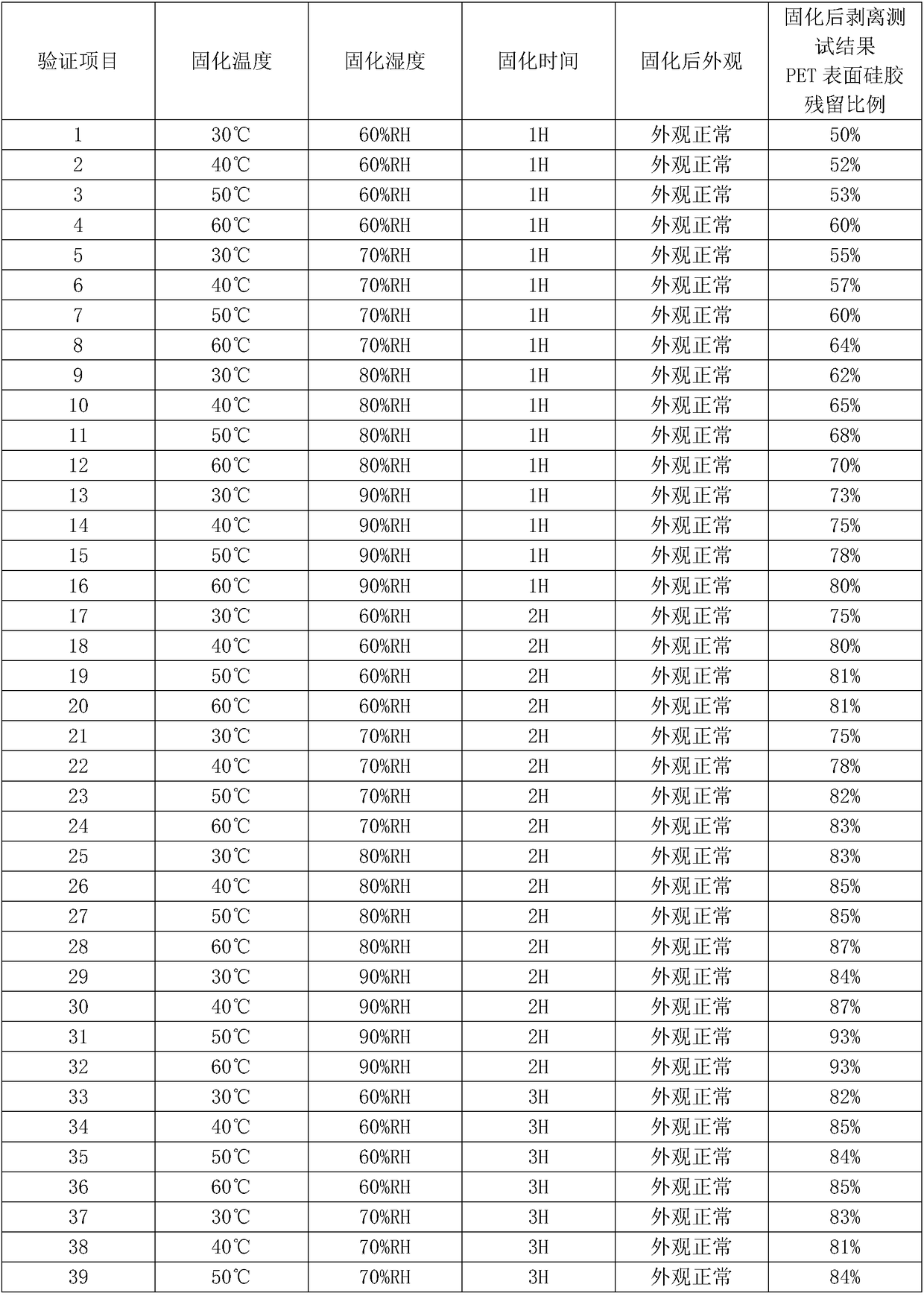

Fast bonding process of silica gel and PET

InactiveCN109401646AReduce inertia factorInert factor improvementAdhesive processes with surface pretreatmentHigh humidityBonding process

The invention discloses a fast bonding process of silica gel and PET. The fast bonding process comprises the steps: the silica gel is prepared, specifically, the silica gel is provided, the binding surface of the silica gel is sequentially subjected to ultrasonic cleaning, laser treatment and plasma treatment, and then pretreated silica gel is obtained; the PET is prepared, specifically, the PET is provided and subjected to surface plasma treatment; and bonding is conducted, specifically, glue is smeared on the binding surface of the pretreated silica gel, then the binding surface of the PET and the binding surface of the pretreated silica gel are bonded, then the pressure is maintained through a pressure maintaining jig, the pressure maintaining jig is placed into a high-temperature and high-humidity box, then curing is started, the temperature is controlled to be 30-60 DEG C, the humidity is controlled to be 60-90%, the curing time is controlled to be 1-3 H, and after curing, the silica gel and PET bonding structure is obtained. According to the bonding process, inert factors on the surface of the silica gel are improved, the bonding strength between the silica gel and the PET isgreatly enhanced, and the problem of a glue failure between the silica gel and the PET is solved; and meanwhile, under the premise of ensuring the production quality, rapid curing can be achieved, and the production efficiency is improved.

Owner:维灵(杭州)信息技术有限公司

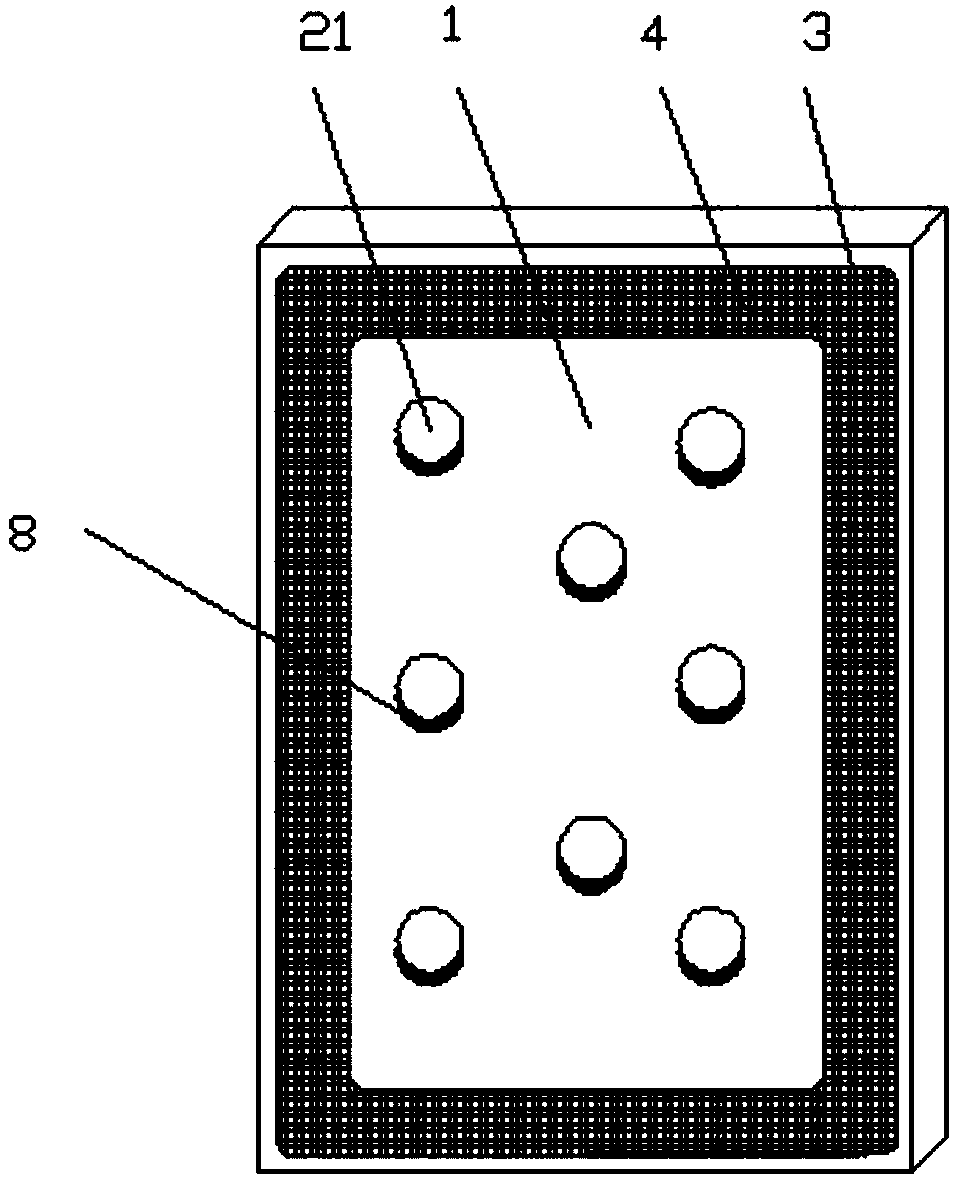

Intelligent safety fireproof door and detection system based on internet of things technology

InactiveCN109869078AStop the spread of firePrevent the spread of fireFireproof doorsClosed circuit television systemsInternet of ThingsMagnesium

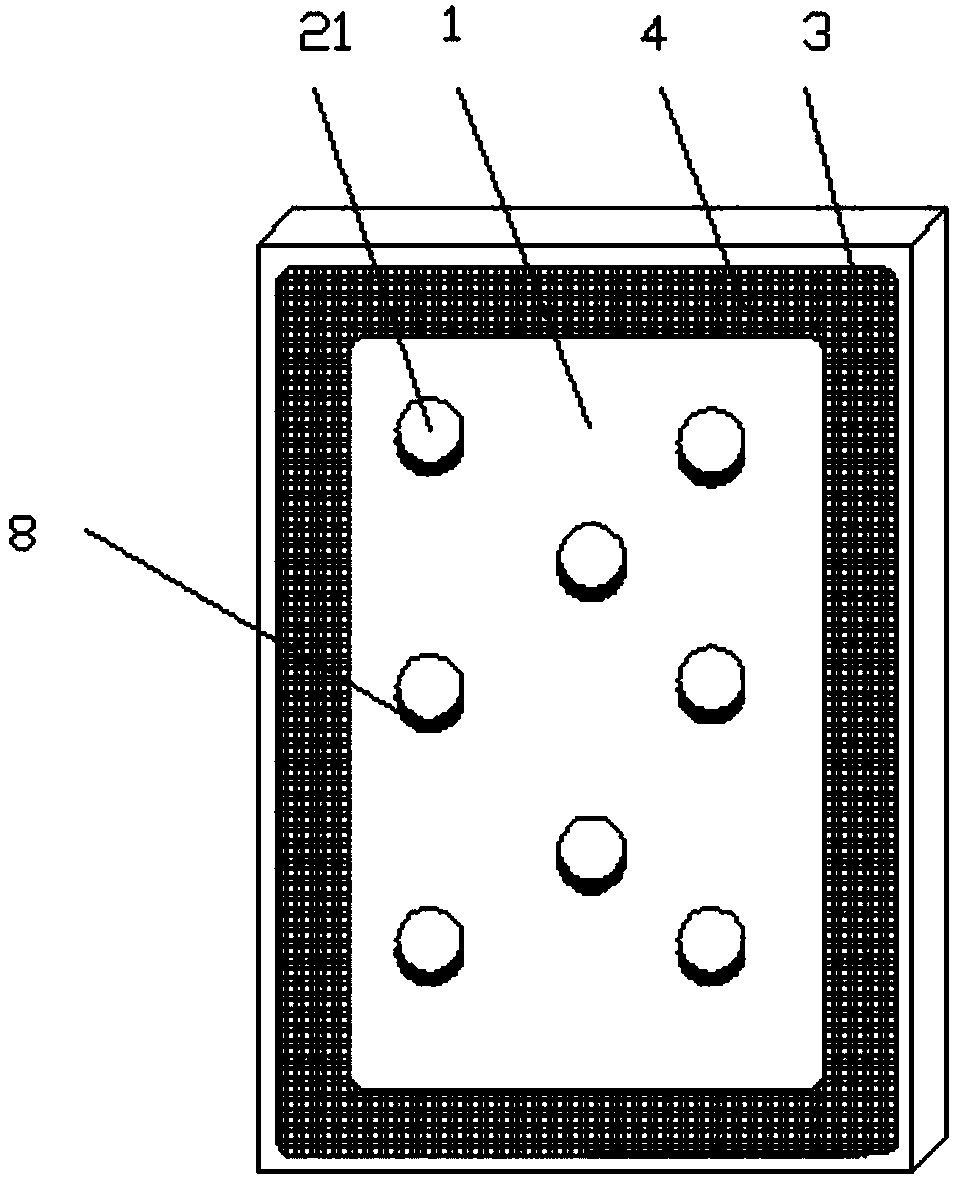

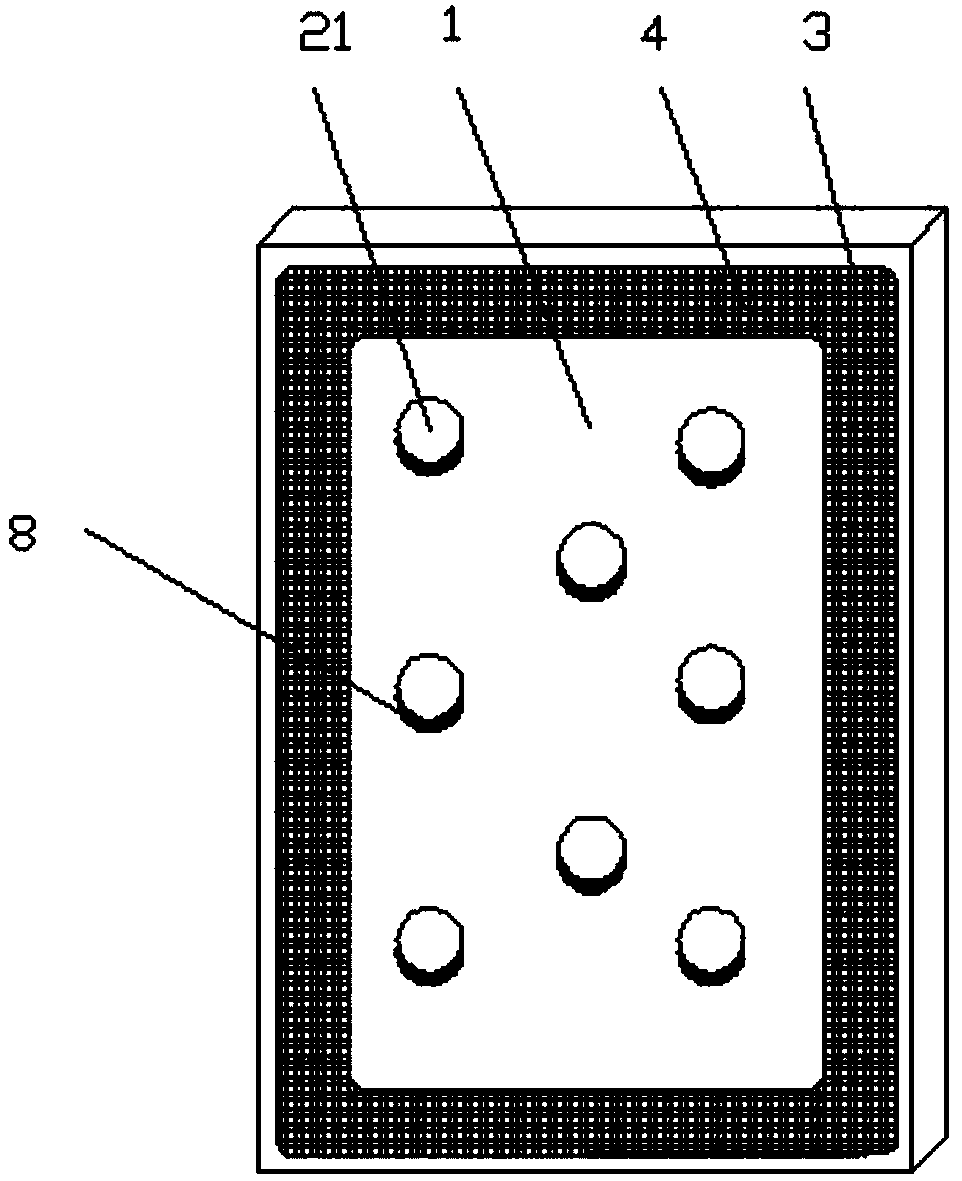

The invention discloses an intelligent safety fireproof door and detection system based on internet of things technology. The intelligent safety fireproof door and detection system comprise a fireproof door body and a monitoring control system. A groove is formed in the periphery of the fireproof door body, a fire extinguisher is embedded into the groove, a plurality of pipelines are arranged in the fireproof door body, a plurality of through holes are formed in the surface of the fireproof door body, telescopic pipes are embedded into the through holes, one end of each telescopic pipe is connected with a switch, and a sprayer is arranged on one side of each switch. A heat-resistance net layer and a mineral glass-magnesium fireproof layer are arranged in the fireproof door, the fireproof door body is a member made of PVC mold-pressed plastic-uptake materials, due to the fact that four sides of a door plate can be sealed into a whole after plastic-uptaking, the problem that sealing edges are prone to glue failure after long time is solved, spreading of fires is prevented, and personal safety and property safety are guaranteed to the higher extent.

Owner:周超超

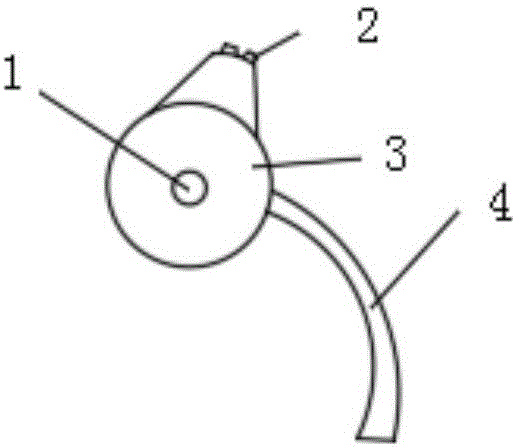

Swirler overflow tube gluing technology

ActiveCN103624982ASolve the glue problemSolve wear and tearManufacturing technologyEconomic benefits

The invention relates to a swirler overflow tube gluing technology. The technology comprises the following steps: step (1), a rubber long barrel is manufactured, wherein the length of the rubber long barrel is the sum of the length of a rubber layer, required to be glued, of the inner surface and the outer surface of a metal circular tube; step (2), the rubber long barrel is glued on the inner surface of the metal circular tube firstly, and the long barrel rubber extending out of the bottom of the metal circular tube is flanged outwards; step (3), after glue water is brushed on the outer surface of the metal circular tube, the long barrel rubber outwards flanged is dragged towards one end with a flange, and the rubber layer is glued on the outer surface of the metal circular tube. As the inner surface and the outer surface of the metal circular tube is glued integrally through the long barrel rubber, the bottom of the metal circular tube is without gluing gaps, so that the problem of glue failure is solved thoroughly. The problem of abrasion due to the glue failure when a swirler is in use is solved by changing the manufacturing technology, so that the economic benefit is obviously improved.

Owner:YANTAI XINHAI MINING MACHINERY

Smoke-insulation fireproof door

InactiveCN110485891AAvoid spreadingEnsure safetyFireproof doorsFire rescueCompression moldingControl system

The invention discloses a smoke-insulation fireproof door which comprises a fireproof door body and a monitoring control system, wherein a groove is arranged around the fireproof door body; a fire extinguisher is embedded in the groove; a plurality of pipelines are arranged inside the fireproof door body; a plurality of through holes are arranged in the surface of the fireproof door body; telescopic pipes are embedded in the through holes; one end of each telescopic pipe is connected with a switch; and one side of each switch is provided with a nozzle. The smoke-insulation fireproof door internally comprises a heat-resistant net layer and a mineral magnesium oxide fireproof layer, and the fireproof door body is a component made of PVC compression molding and suction molding materials; fouredges of a door panel can be sealed into a whole after suction molding so that the problem that the sealed edges may be unglued after a long time can be solved; and in addition, the spread of fire isprevented and the personnel safety and property safety can be protected to a greater extent.

Owner:何腾

Automatic fire door insert bolt structure

InactiveCN109882046AAvoid spreadingEnsure safetyFireproof doorsFire rescueControl systemFire extinguisher

The invention discloses an automatic fire door insert bolt structure. The automatic fire door insert bolt structure comprises a fire door body and a monitoring control system. A groove is formed in the periphery of the fire door body, and a fire extinguisher is embedded in the groove. The fire door body is internally provided with a plurality of pipelines, a plurality of through holes are formed in the surface of the fire door body, telescopic tubes are embedded in the through holes, switches are connected to one ends of the telescopic tubes, and nozzles are arranged on one sides of the switches. According to the automatic fire door insert bolt structure, a heat-resistant mesh layer and a mineral glass-magnesium fire-retardant layer are arranged in the fire door, a fire door body is a member made of a PVC mold pressing blister material, the four sides of a door panel are sealed into one body after blister is performed, the problem that glue failure possibly occur after long-term side sealing is solved, the spread of fire is prevented, and the safety of personnel and property safety are guaranteed to a greater extent.

Owner:周涛

Fire door

InactiveCN109838182AAvoid spreadingEnsure safetyFireproof doorsDoor leavesControl systemFire extinguisher

The invention discloses a fire door. The fire door includes a fire door body and a monitoring control system; the periphery of the fire door is provided with a groove; a fire extinguisher is embeddedin the groove; the internal of the fire door body is provided with multiple pipelines; the surface of the fire door body is provided multiple through holes; telescoping tubes are embedded in the through holes; one ends of the telescoping tubes are connected to switches; and one sides of the switches are provided with nozzles. The internal of the fire door includes a heat resistant mesh layer and amineral glass magnesium fireproof layer; the fire door body is a component made of a PVC molded vacuum forming material; and as the four sides of a door plate can be sealed into one body after vacuumforming, the tackless problem after long-time edge sealing can be solved, the spreading of fire can be prevented, and personnel safety and property safety can be guaranteed to a greater extent.

Owner:宋贤露

A kind of gluing process for cyclone overflow pipe

Owner:YANTAI XINHAI MINING MACHINERY

Vibration-reducing turnout structure for urban rail transit

ActiveCN105862522BImprove pullout resistanceIncrease the installation heightRail switchesVibration attenuationEngineering

Disclosed is an urban railway transport vibration attenuation turnout structure. The urban railway transport vibration attenuation turnout structure comprises stock rails, switch rails and guide rails. The stock rails, the switch rails and the guide rails are mounted on a track bed through vibration attenuation fastener systems; the heel ends of the switch rails are provided with elastic bendable sections; the width of rail limbs of the working sides of the elastic bendable section is smaller than that of rail limbs of the working sides of the other sections of the switch rails; the stock rails, the heel ends of the switch rails and joints of the guide rails are connected through vibration attenuation joint clamping plates and common joint clamping plates, the vibration attenuation joint clamping plates are mounted on the non-working sides, and the common joint clamping plates are disposed on the working sides; and the top end faces of the vibration attenuation joint clamping plates are higher than the rail top faces of connected steel rails, and the top end faces of the vibration attenuation joint clamping plates have inclination consistent with that of wheel treads, so that the wheel treads operate on the top end faces of the vibration attenuation clamping plates when a train passes through joints. By means of the urban railway transport vibration attenuation turnout structure, vibration and noise caused by mutual impact of wheels and rails are reduced, the service life of turnout parts is prolonged, moreover, turnout construction is convenient, and less daily maintaining is needed.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP +1

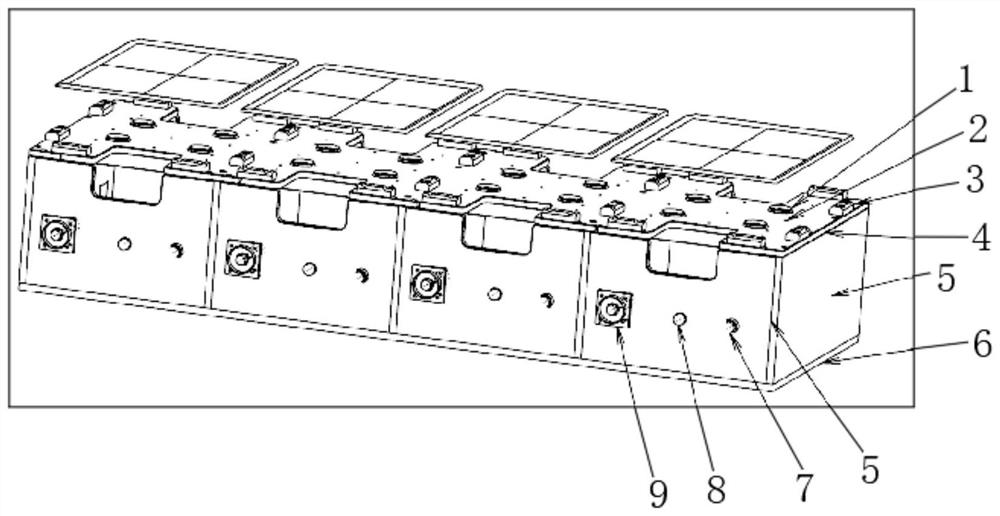

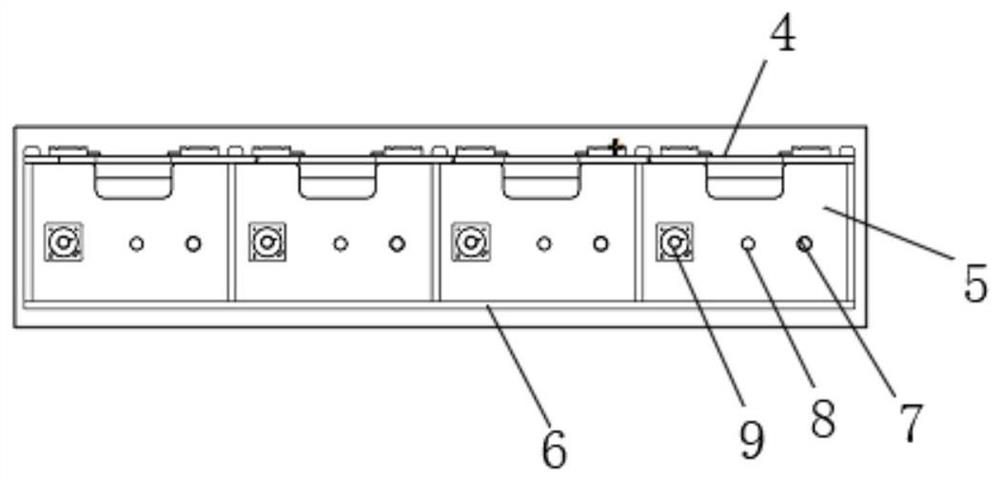

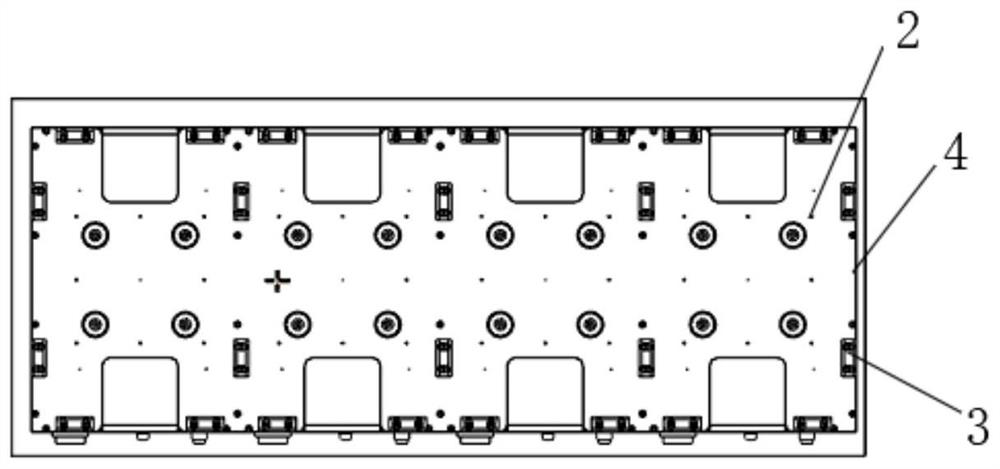

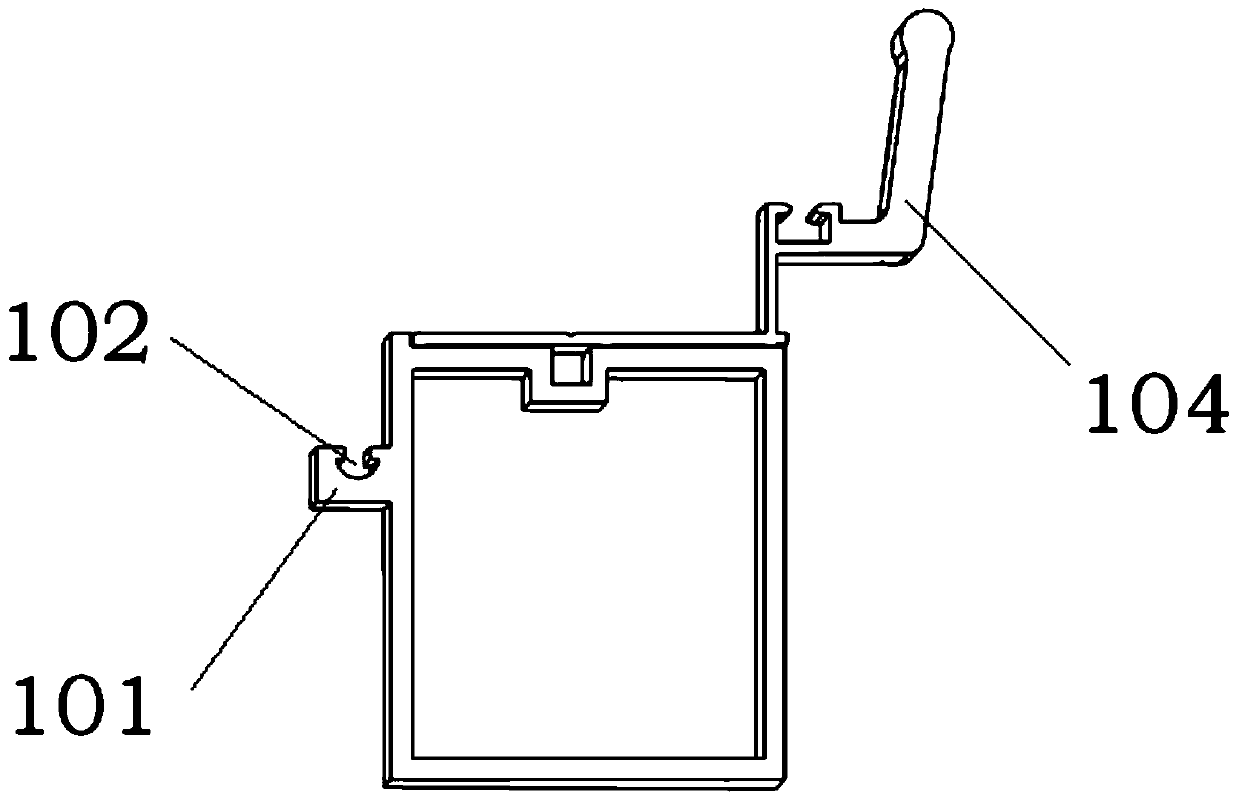

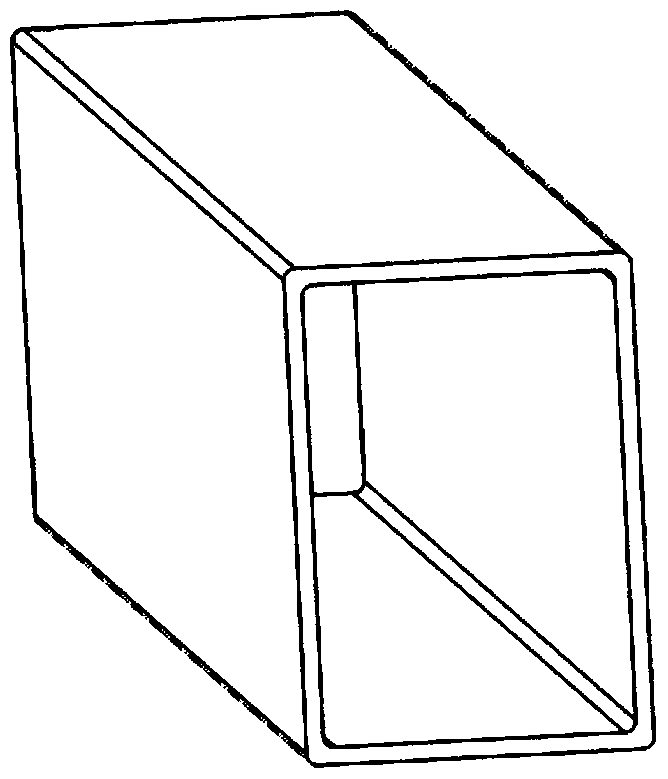

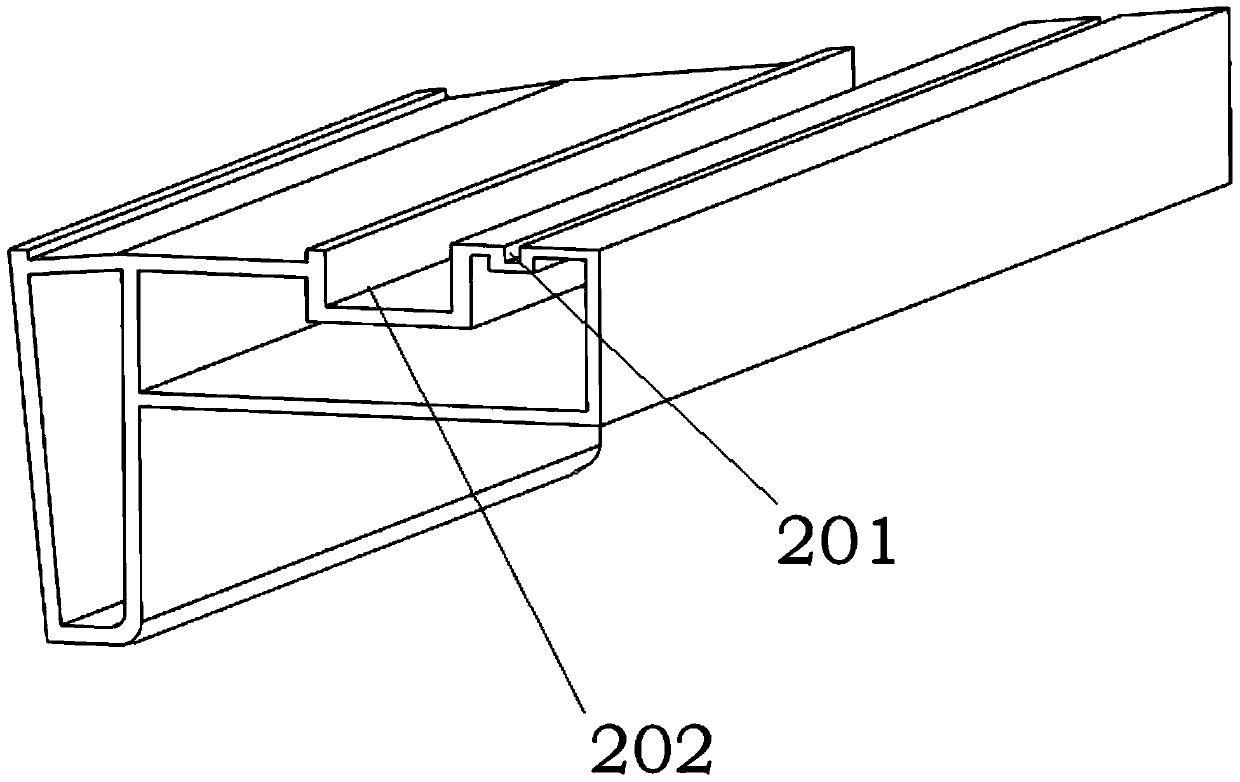

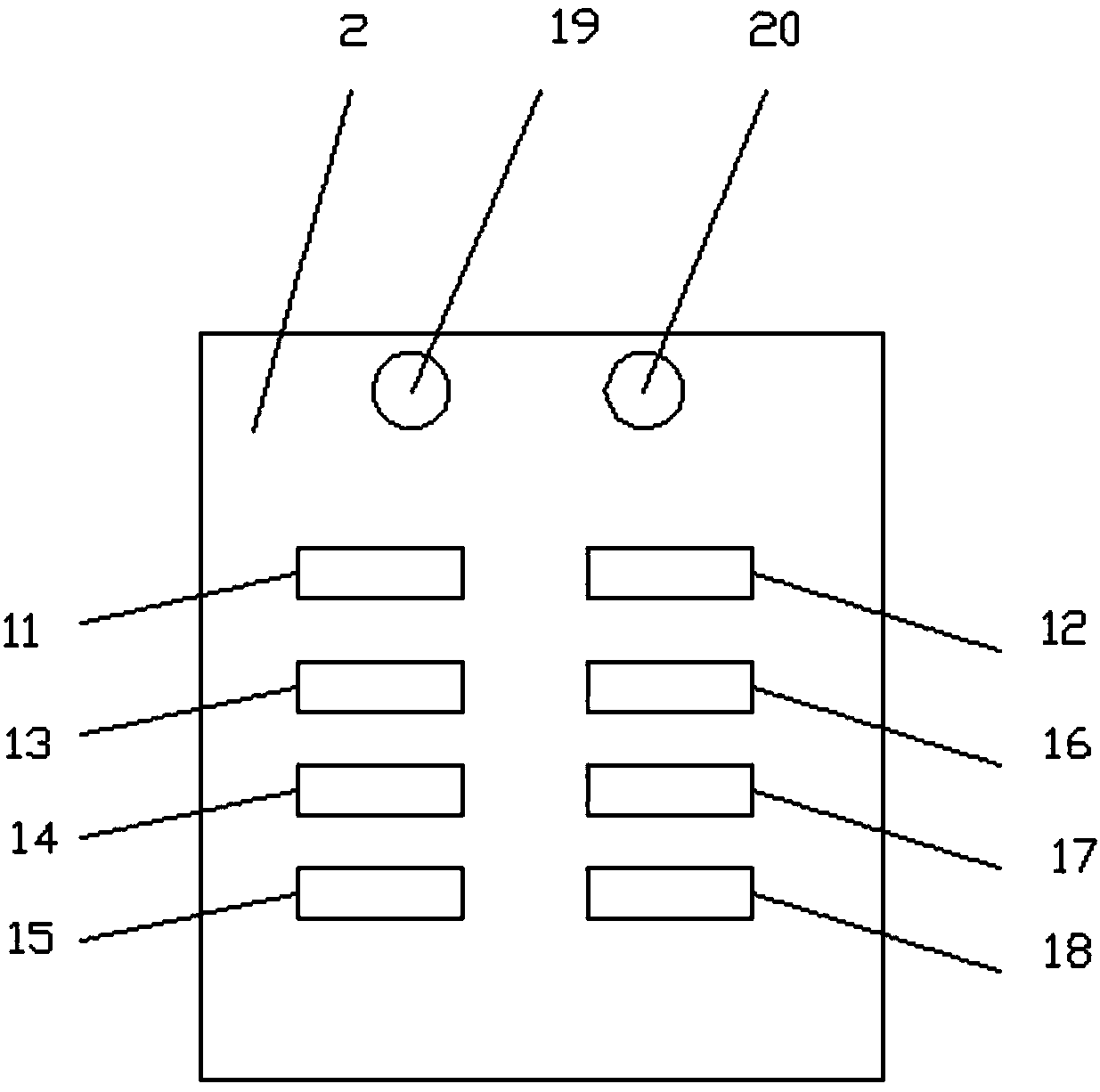

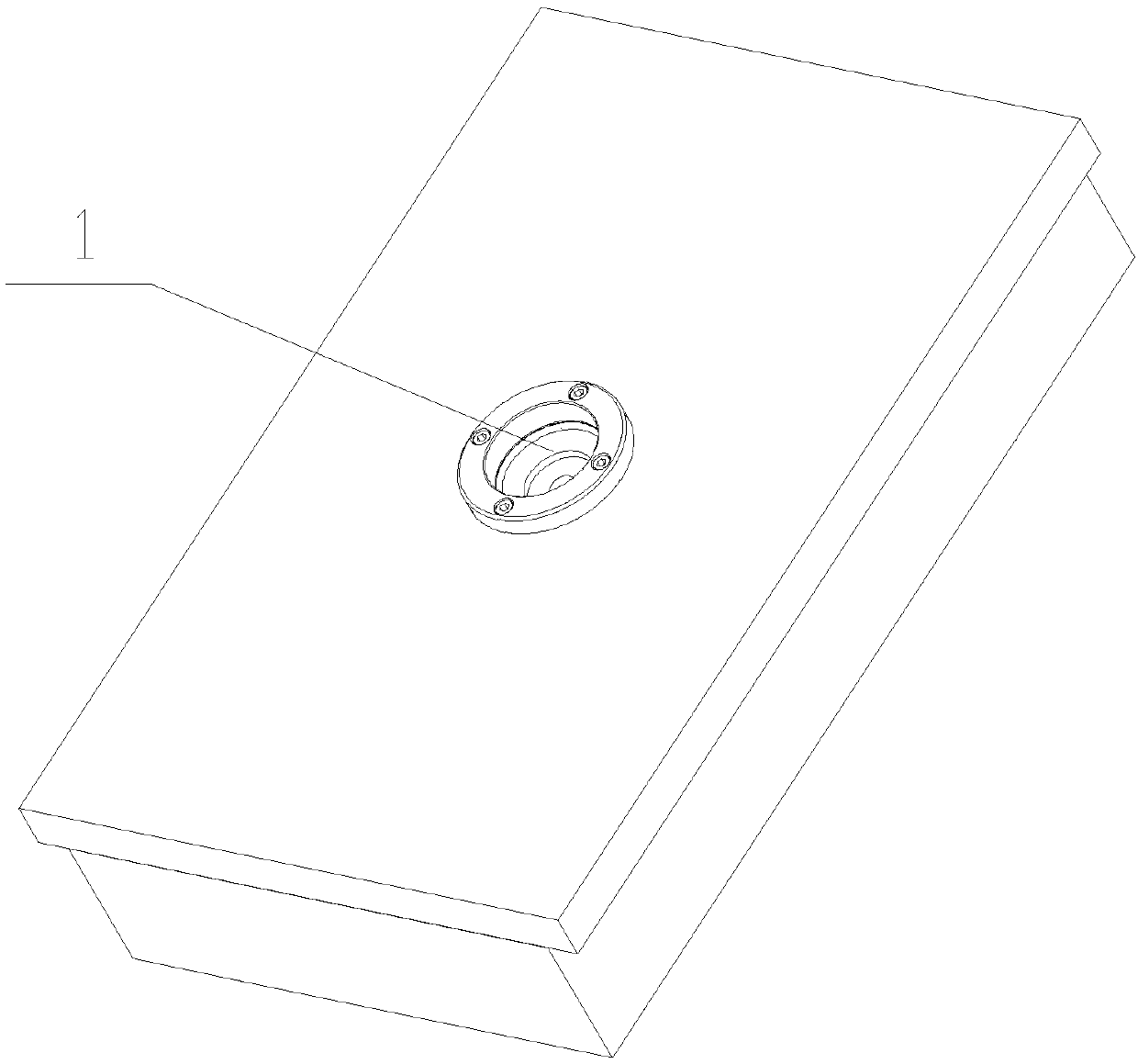

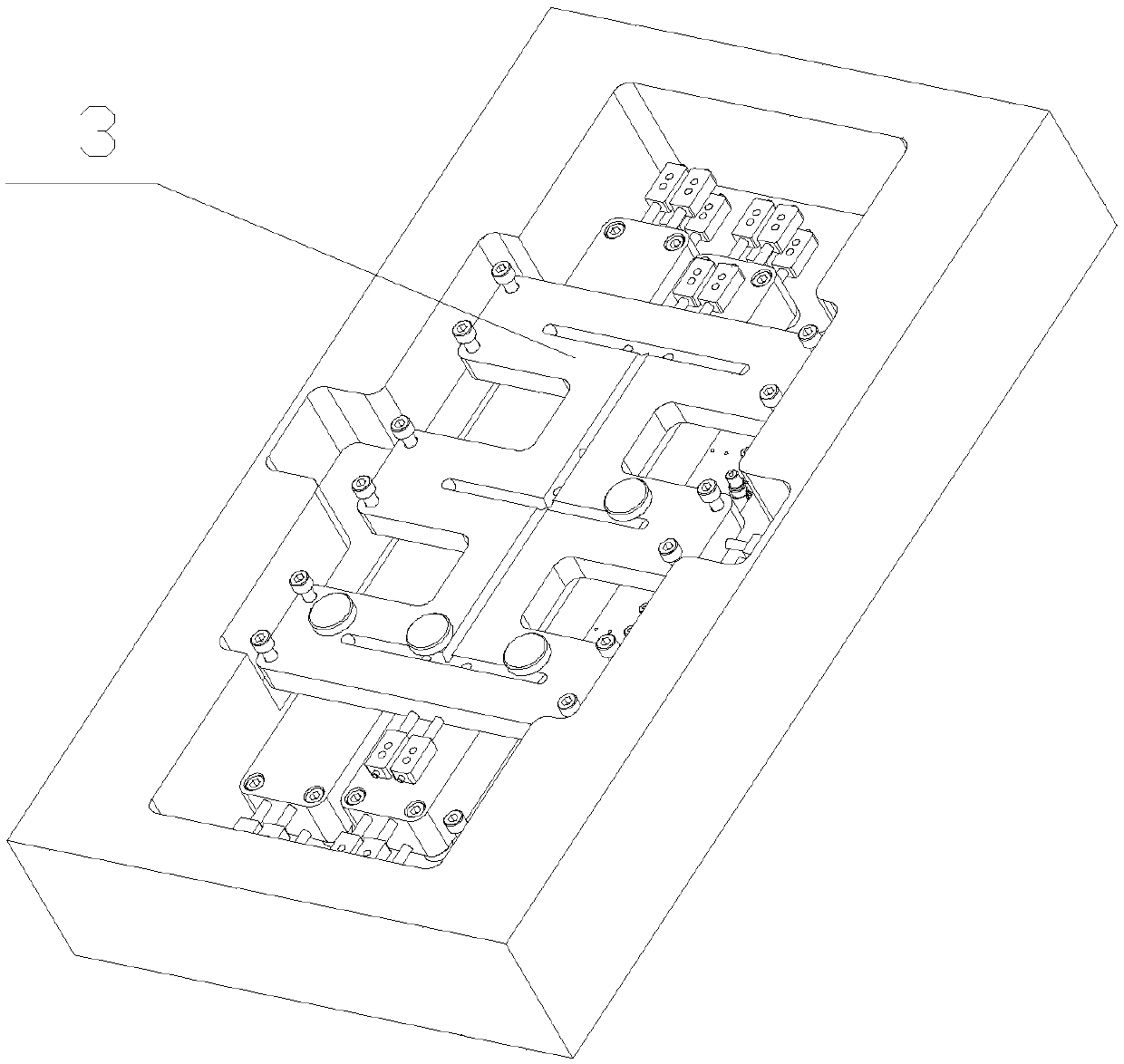

Multi-cavity small-product small-nozzle hot runner

The invention discloses a multi-cavity small-product small-nozzle hot runner. The multi-cavity small-product small-nozzle hot runner comprises a sprue, a bridging upper plate, a bridging lower plate,a runner upper plate, a runner lower plate, nozzle cores and a front mold core, wherein the runner upper plate is provided with a semicircular runner, the runner lower plate is provided with a semicircular runner, and after the runner upper plate and the runner lower plate are locked through screws, the two semicircular runners form a whole runner; the upper bridging plate is provided with a semicircular runner, the lower bridging plate is provided with a semicircular runner, and after the upper bridging plate and the lower bridging plate are locked through screws, the two semicircular runnersform a whole runner; and the nozzle cores are in communication with a product cavity through the runner of the front mold core. The multi-cavity small-product small-nozzle hot runner has the beneficial effects that heating wires are arranged on the bridging plates and the runner plates, and the nozzle cores are arranged on the runner plates, so that the problem of waste of water gap material at amain runner can be solved; and the nozzle cores are arranged to pass through the runner of the front mold core to pour a product so that the problems of glue feeding of appearance products and the waste of the water gap material in the cavity can be solved.

Owner:深圳市凯尔斯特热流道技术有限公司

Indoor wood splicing pain-drying fire-proof door

InactiveCN109882048AAvoid spreadingEnsure safetyProgramme controlComputer controlControl systemFire - disasters

The invention discloses an indoor wood splicing pain-drying fire-proof door. The indoor wood splicing pain-drying fire-proof door comprises a fire-proof door body and a monitoring control system, a groove is formed in the periphery of the fire-proof door body, a fire extinguisher is arranged in the groove in an embedded mode, a plurality of pipelines are arranged in the fire-proof door body, and aplurality of through holes are formed in the surface of the fire-proof door body; and telescopic pipes are arranged in the through holes in an embedded mode, switches are connected to one ends of thetelescopic pipes, and nozzles are arranged on one sides of the switches. According to the indoor wood splicing pain-drying fire-proof door, the interior of a fire-proof door comprises a thermal resisting net layer and a mineral glass magnesium fire-proof layer, the fire-proof door body is a component of a PVC mold pressing and blister material, due to the fact that four edges of a door board canbe sealed into an integrity after blister, the problem that glue failure can possibly occur to the sealing edges after a long period of time is solved, spreading of a fire disaster is prevented, and personnel security and property security are guaranteed to a larger extent.

Owner:周涛

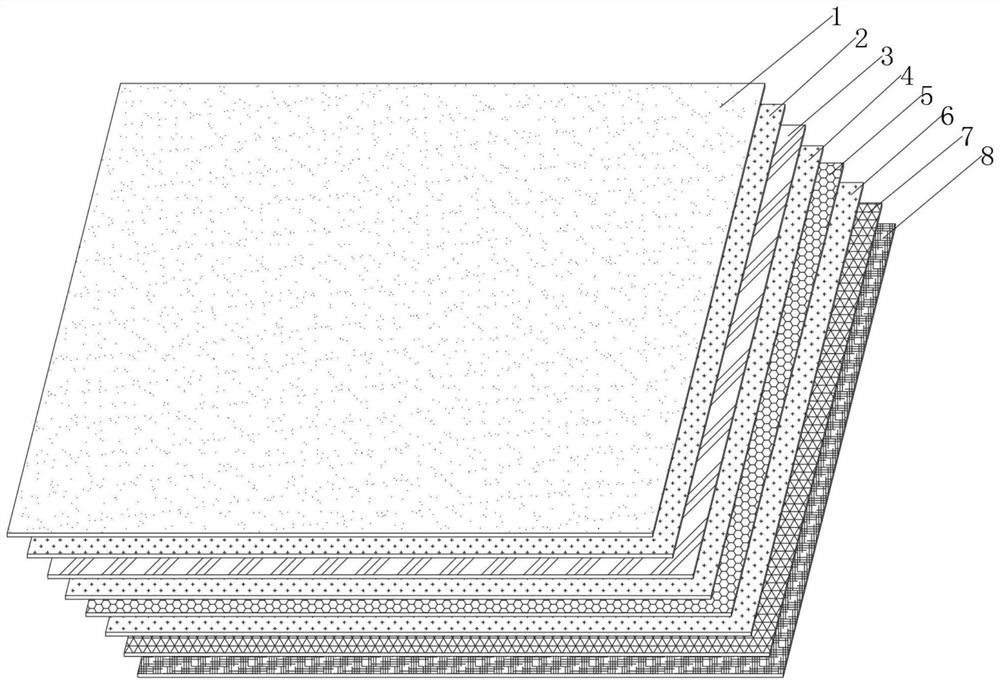

Solar canvas and preparation method thereof

PendingCN111805985AAvoid damageImprove integritySynthetic resin layered productsLaminationForeign object damageWeather resistance

The invention provides solar canvas and a preparation method thereof, relates to the technical field of solar energy, and solves the technical problems in the prior art that a solar cell module is noteasily and effectively combined with canvas, and the combination integrity of the solar cell module and the canvas is poor. The solar canvas comprises a protective film layer, a first film clamping layer, a water blocking film layer, a second film clamping layer, a solar chip layer, a third film clamping layer, a back plate layer and a canvas layer which are laminated in sequence, namely, all thelayers are laminated and compounded to form a firm whole body; the solar chip layer is firmly bonded and internally arranged between the second film clamping layer and the third film clamping layer so as to avoid foreign object damage and greatly improve integrity and weather resistance of the assembly. The integrity and weather resistance of the assembly are greatly improved, the characteristicthat the whole assembly is light, thin and soft is guaranteed, glue failure is avoided in a laminating mode, the weather resistance is higher, the binding performance of the cloth and the solar assembly is better. The invention also provides the preparation method of the solar canvas. The solar canvas is used for enabling a solar chip to be more convenient to use.

Owner:光能动力(北京)科技有限责任公司

Broad band oscillatory type abrasive belt grinding head and grinding method

The present invention relates to wide belt vibrating grinding head and grinding method for sander and belongs to the field of sander assembly manufacturing. The ground workpiece is made to contact with the sanding surface of sand belt in the sand belt delivering and withdrawing mechanism and the wide belt vibrating grinding head in the back side of the sanding surface is started to grind the workpiece. The present invention has the advantages of greatly raised workpiece surface grinding precision, no trouble of sand belt junction and low power consumption.

Owner:陈勇奇

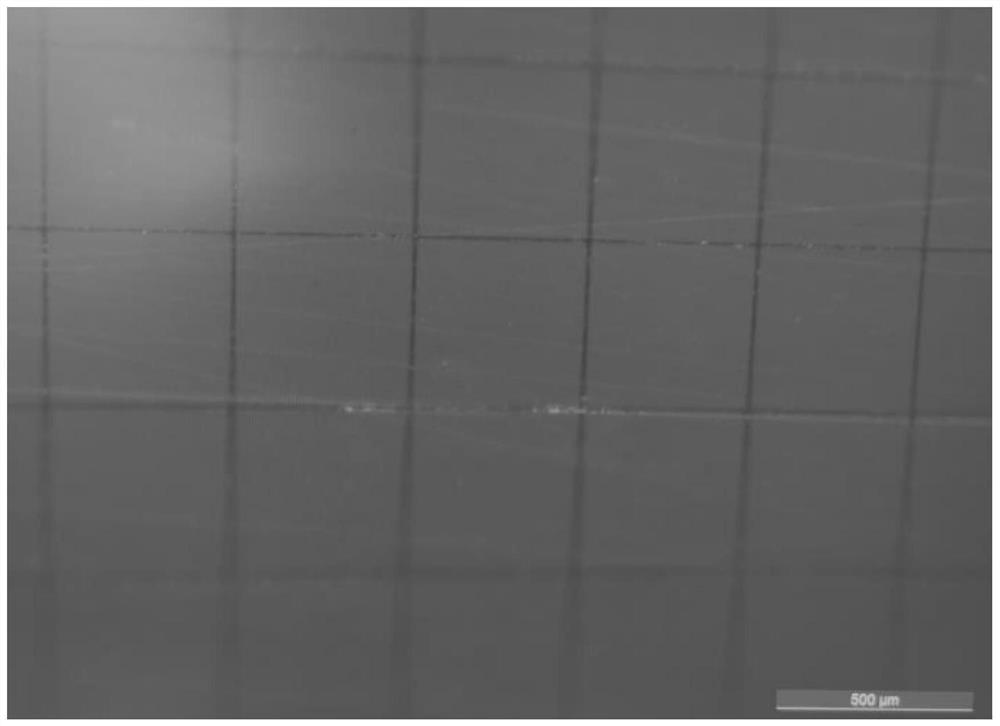

Manufacturing method of concave metal mesh of fairing

PendingCN114051372AIncrease flexibilityReduce manufacturing costMagnetic/electric field screeningStructural engineeringChromium coating

The invention provides a manufacturing method of a concave metal mesh of a fairing. The technical problems that an existing concave metal mesh of the fairing is complex in process, high in equipment cost, difficult in process parameter control, difficult in spherical surface uniformity guarantee and difficult in gluing and exposure are solved. Comprising the following steps: 1) soaking degreased cotton with a mixed solution of alcohol and diethyl ether to clean the concave surface of the fairing; (2) fixing a fairing on a rotary gluing machine, dripping the positive photoresist on the concave surface of the fairing by using a dropper, manually rotating the fairing, and then starting the rotary gluing machine for spin coating; (3) putting the fairing into a baking oven to be baked and then taking out; (4) installing the fairing on concentric scanning laser direct writing exposure equipment, starting centering, and starting longitude and latitude scribing; (5) immersing the fairing in a developing solution to be developed for 50-60 S; (6) placing the fairing in a vacuum chamber, and after the fairing is bombarded with an ion source, evaporating a chromium layer and a gold layer sequentially; and (7) dripping acetone to the concave face of the fairing, scrubbing the fairing, and obtaining the fairing concave face metal mesh.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

Fire-proof door

InactiveCN110485882AAvoid spreadingEnsure safetyFireproof doorsFire rescueControl systemFire extinguisher

The invention discloses a fireproof door. The fireproof door comprises a fireproof door body and a monitoring control system; grooves are formed at the periphery of the fireproof door body; fire extinguishers are embedded in the grooves; a plurality of pipelines are arranged in the fireproof door body; a plurality of through holes are formed in the surface of the fireproof door body; telescopic pipes are embedded in the through holes; one ends of the telescopic pipes are connected with switches; and spray heads are arranged on one sides of the switches. The fireproof door comprises a heat-resistant net layer and a mineral glass magnesium fireproof layer inside, and the fireproof door body is a component made of PVC molded plastic uptake materials. Since the four edges of a door panel can be sealed into a whole after plastic uptake, the problem that glue may be opened after the edges are sealed for a long time is solved, the spread of fire is prevented, and the safety of personnel and property is ensured to a greater extent.

Rare earth polishing liquid and preparation method thereof

ActiveCN104479555BEasy to prepareSolve the ease of cleaningPolishing compositions with abrasivesOrganic solventRare earth

The invention provides a rare earth polishing liquid and a preparation method thereof; the rare earth polishing liquid comprises the following components in parts by weight: 20-50 parts of a rare earth polishing powder, 3-15 parts of an organic solvent, 1-5 parts of clay, and 30-76 parts of water. The rare earth polishing liquid solves the problem of suspension dispersion of a polishing powder in water, overcomes the bonding problem of the polishing liquid in preparation and storage processes and good cleaning problem of the polishing liquid in a use process at present, and has the characteristics of good suspension dispersibility, fast polishing speed, high polishing precision, excellent cleaning performance of polished products and the like. The rare earth polishing liquid is suitable for surface polishing processing of integrated circuits, flat panel display, optical glass and other electronic information industry precision devices, and meets polishing yield rate requirements of increasingly-strict business on polishing materials in accuracy, polishing corrosion amount, easy cleaning and the like.

Owner:NUOXUAN CHEM TECH SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com